Patents

Literature

41results about How to "Large amount of grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

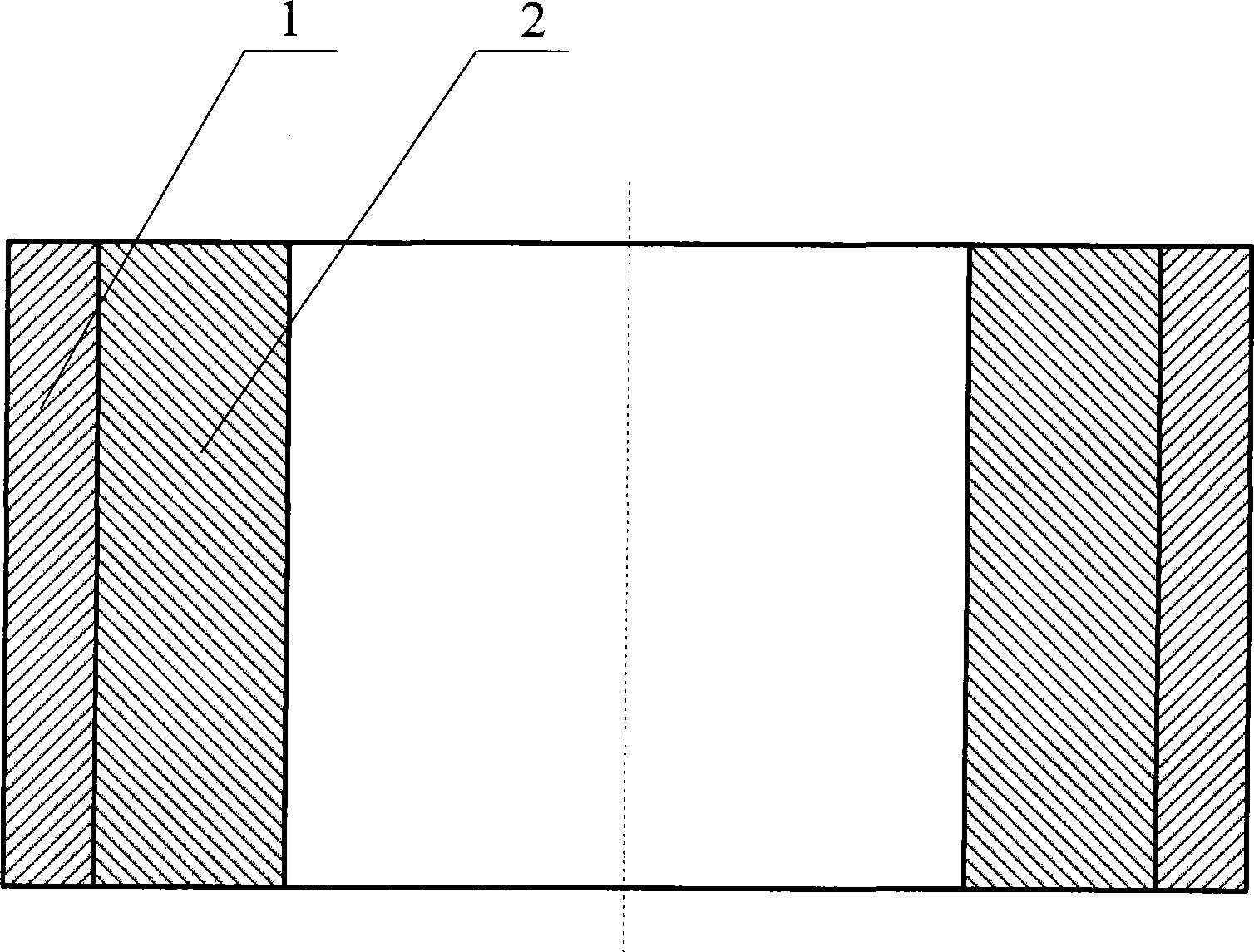

Abrasion-proof cast iron roll collar for straightening steel rail and preparation method thereof

InactiveCN101412050AEliminate high temperature heat treatmentShorten the production cycleRollsProcess efficiency improvementCompound aWear resistant

The invention provides a wear resistant cast iron roll collar used for aligning a steel rail and a preparation method, which belong to the technical field of steel rail processing. The prior wear resistant cast iron roll collar used for aligning the steel rail has the defects of easy occurrence of cracks, complicated manufacture process and the like in quenching process. The method is to compound a wear resistant outer layer with a magnesium iron inner layer into an integral roll collar by centrifuge casting, wherein the wear resistant outer layer comprises the following ingredients in weight percentage: 3.0 to 3.4 percent of C, 1.5 to 2.0 percent of Si, 1.2 to 1.6 percent of Mn, 0.2 to 0.4 percent of Nb, 0.03 to 0.06 percent of RE, 0.03 to 0.06 percent of Mg, 2.5 to 3.0 percent of Ni, 0.4 to 0.6 percent of Mo, 0.8 to 1.2 percent of Cu, 1.5 to 1.8 percent of Cr, 1.0 to 1.4 percent of V, 0.03 to 0.08 percent of B, 0.002 to 0.005 percent of Te, 0.01 to 0.03 percent of Ba, less than or equal to 0.06 percent of P, less than 0.03 percent of S, and the balancing being Fe. The invention has the advantages of high hardness of the roll collar, good wear resistance, simple production process and low production cost.

Owner:BEIJING UNIV OF TECH

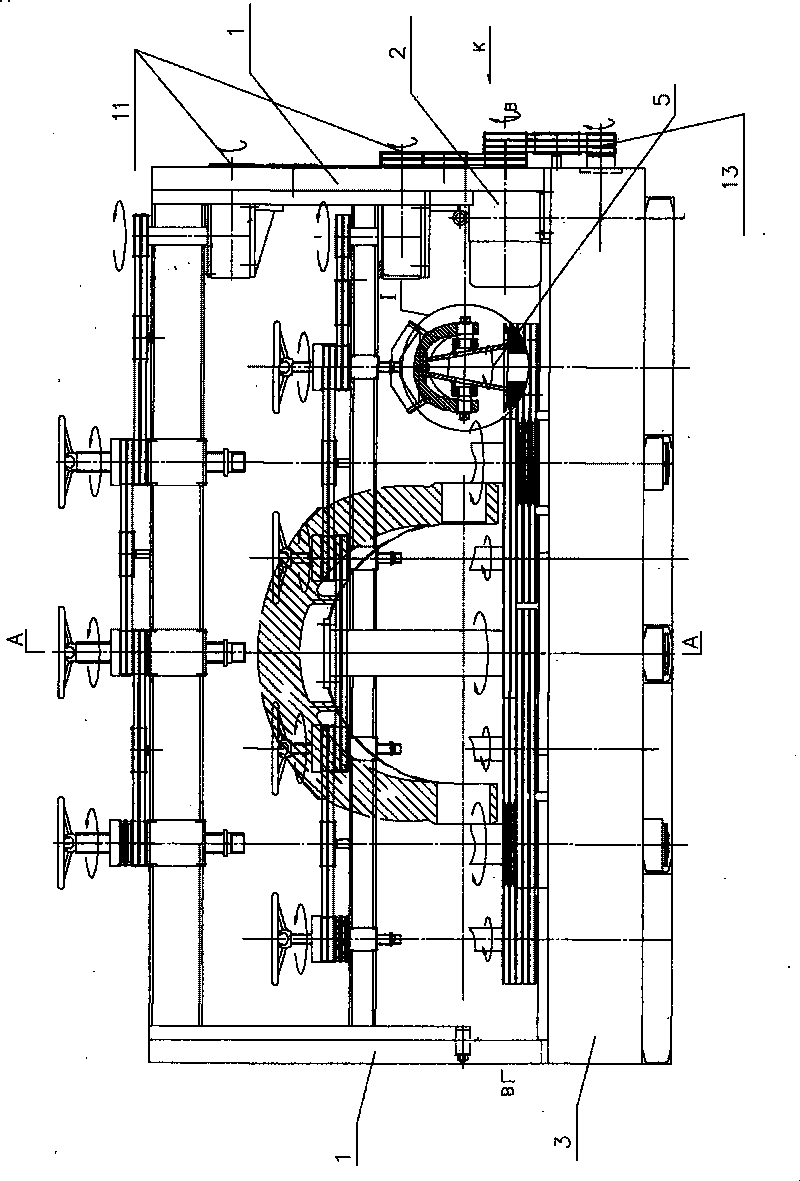

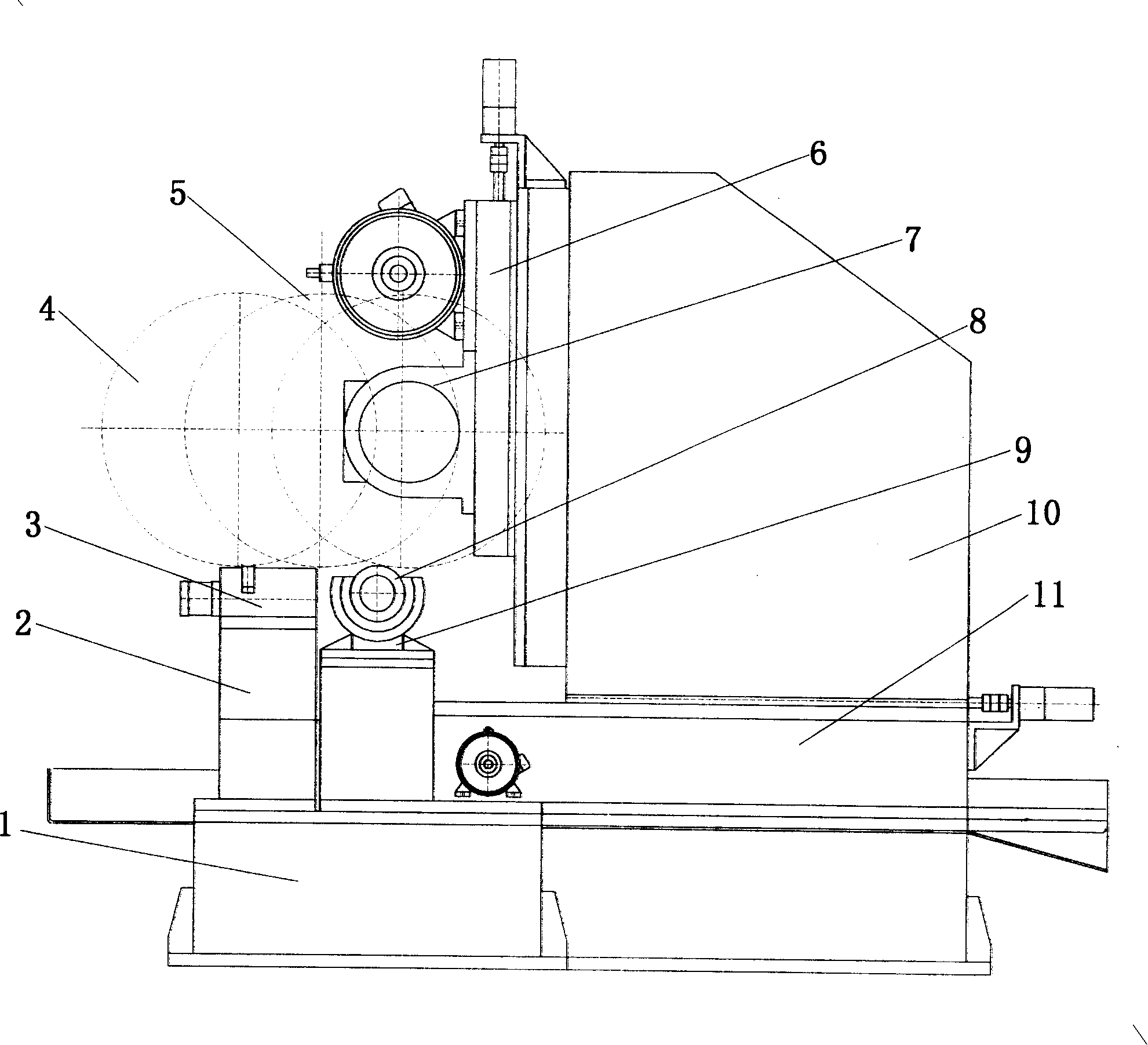

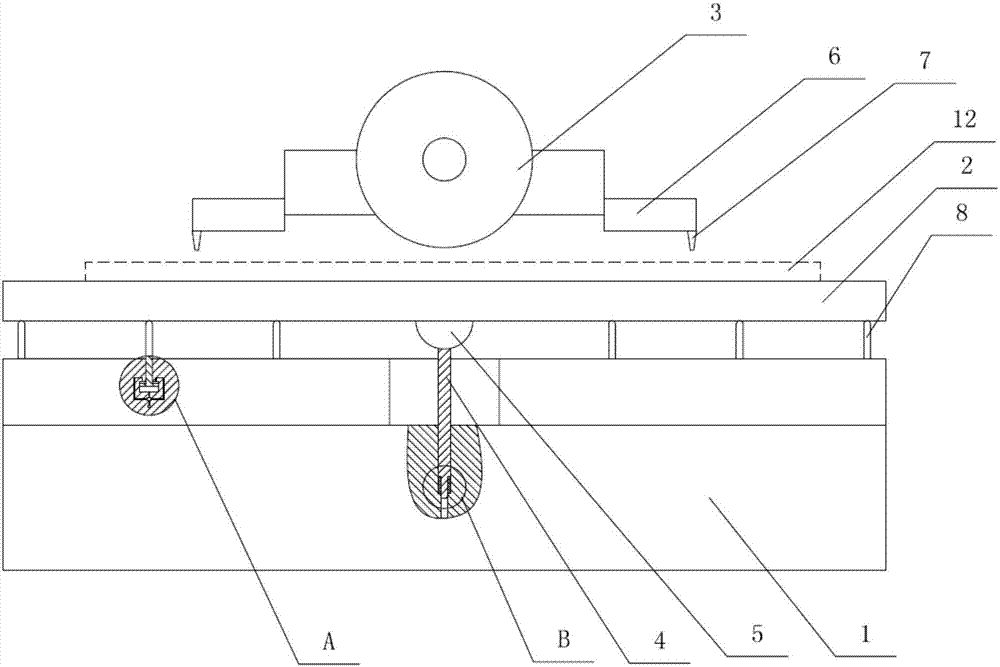

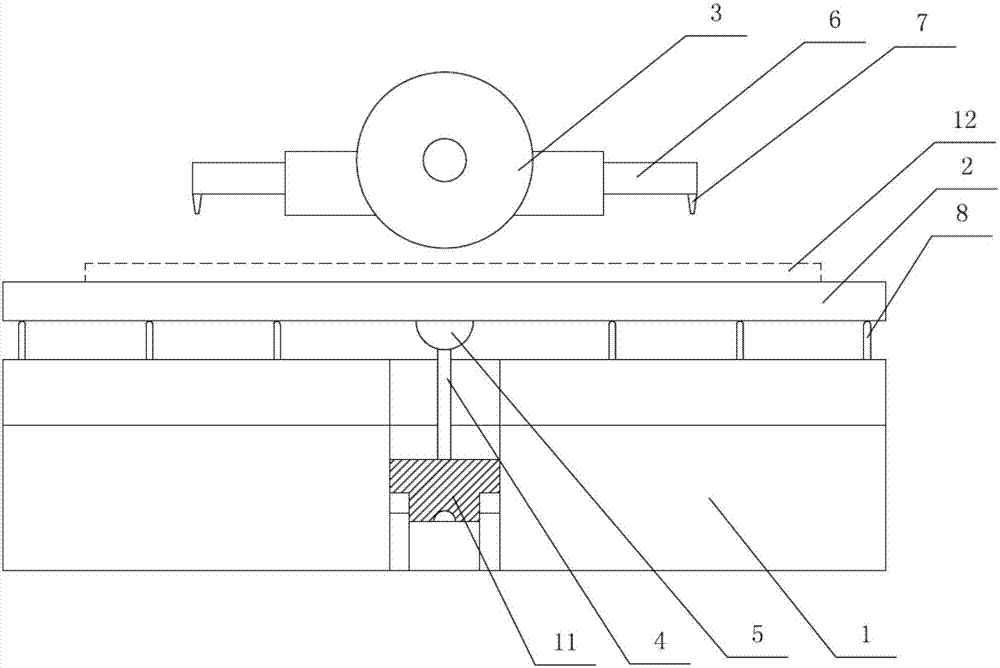

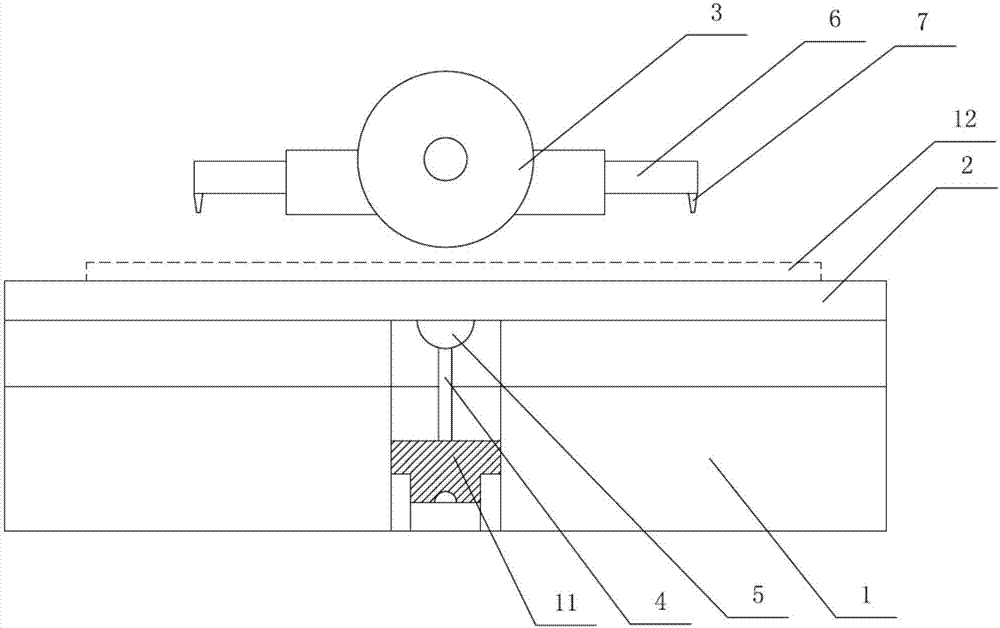

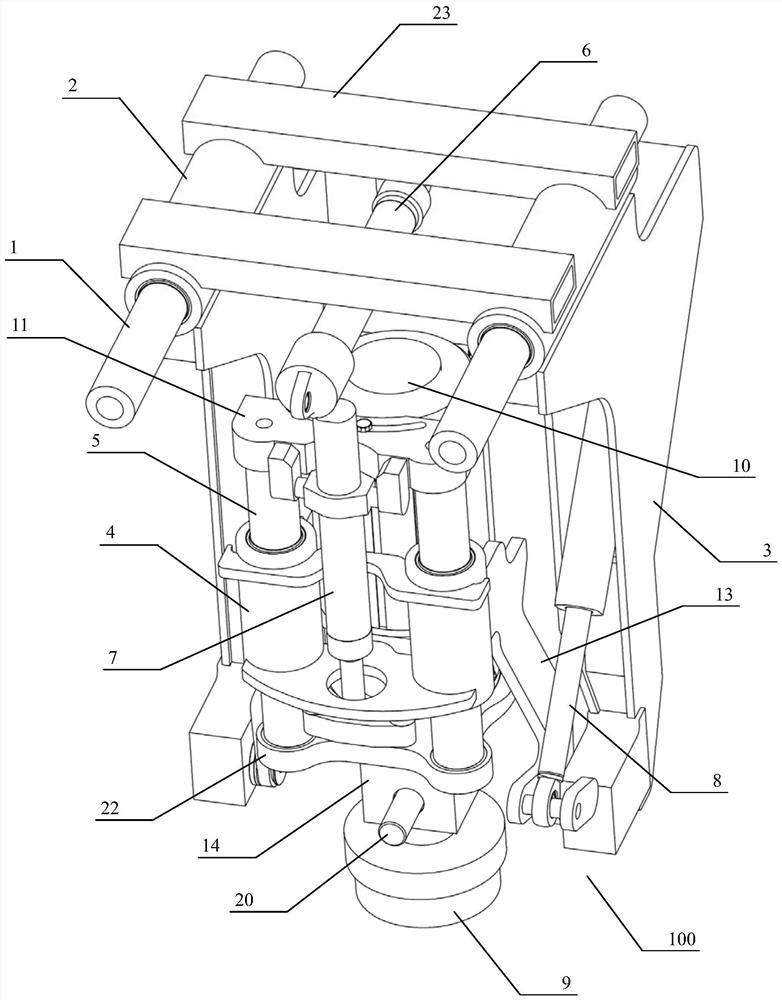

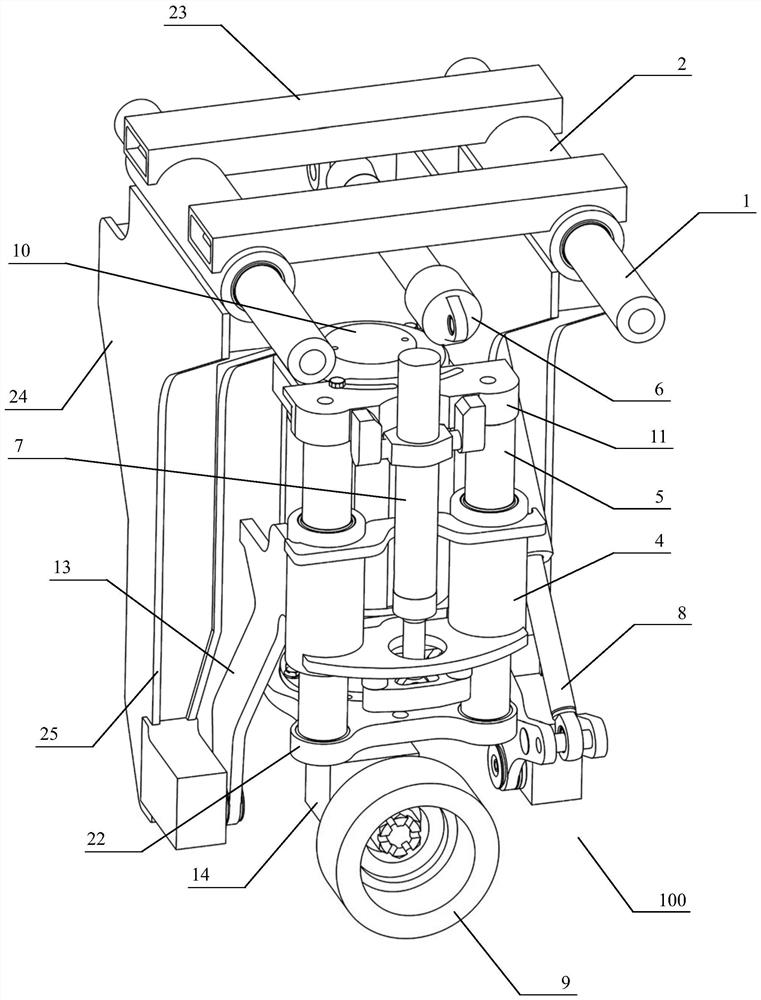

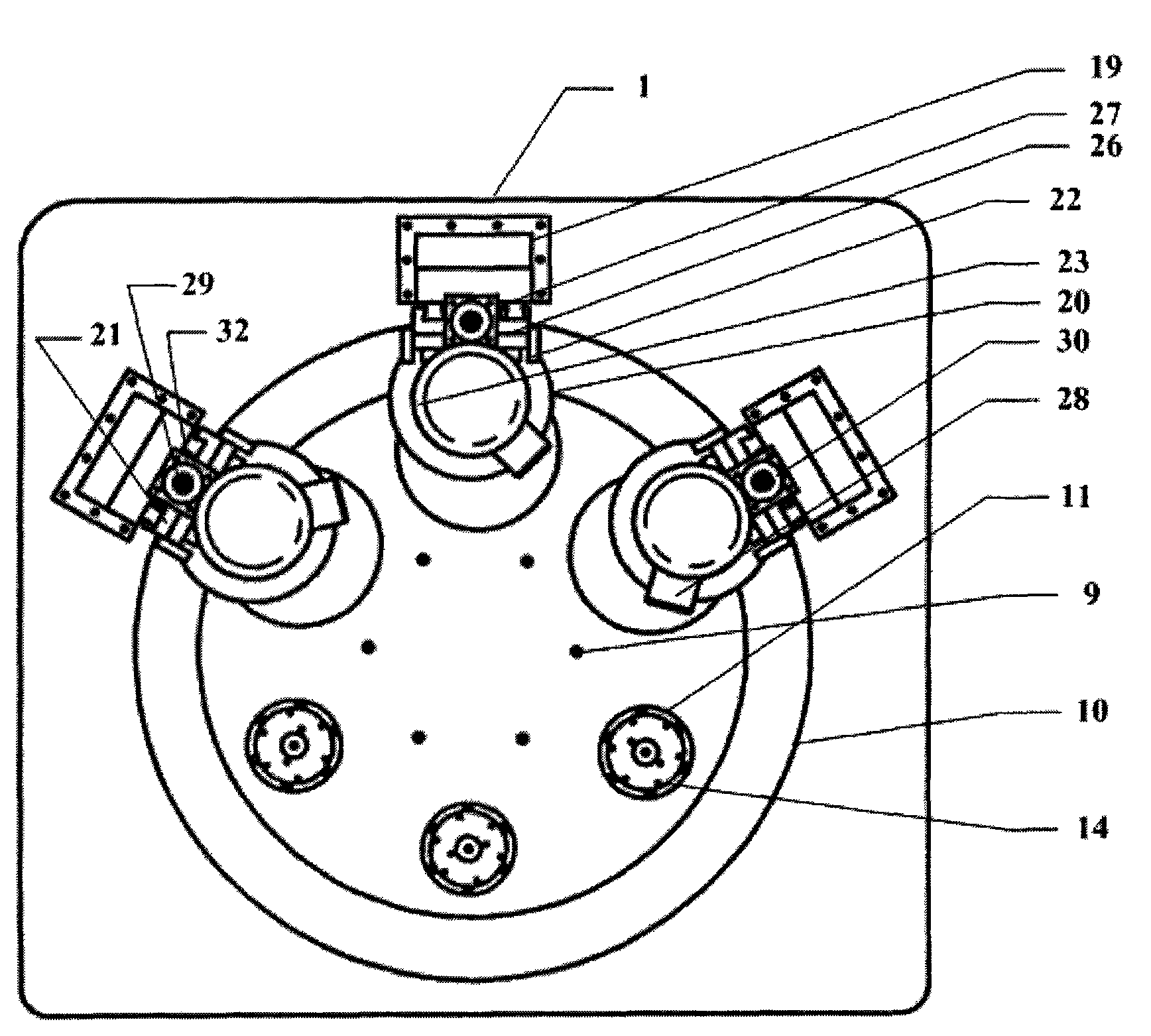

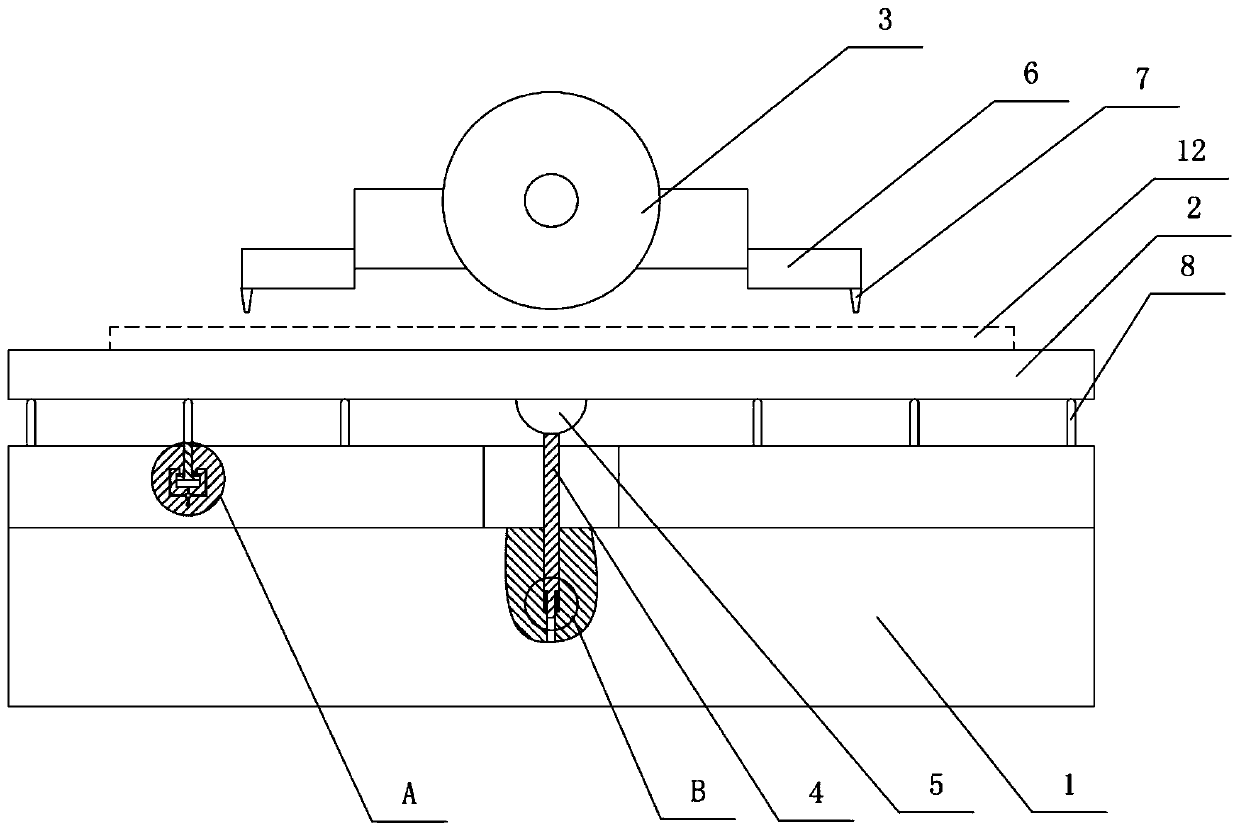

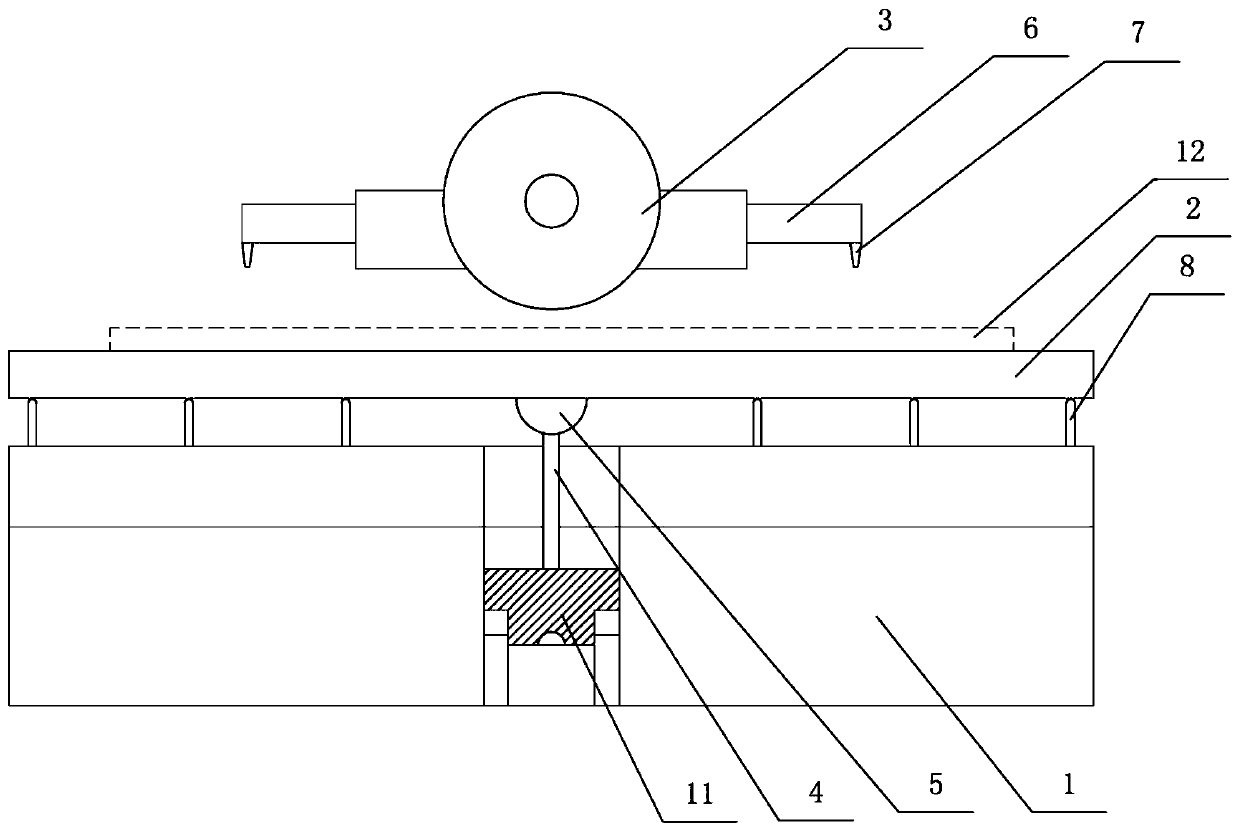

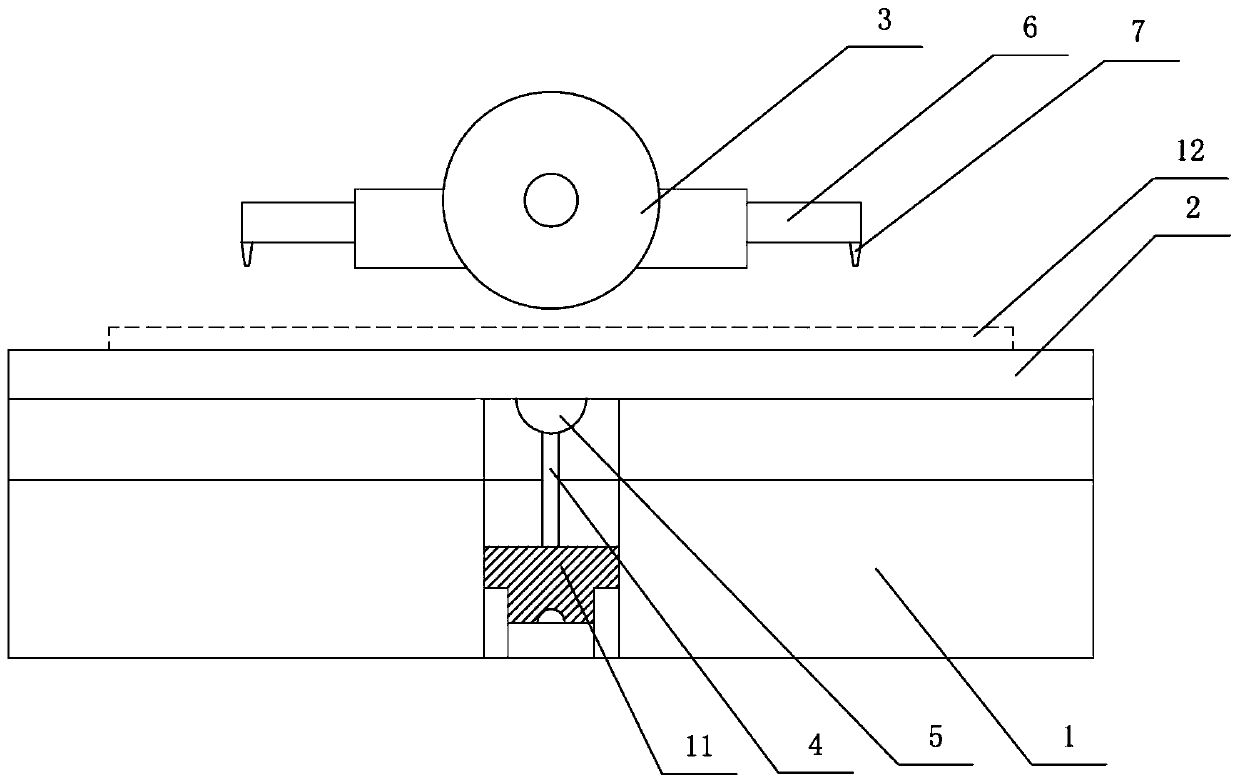

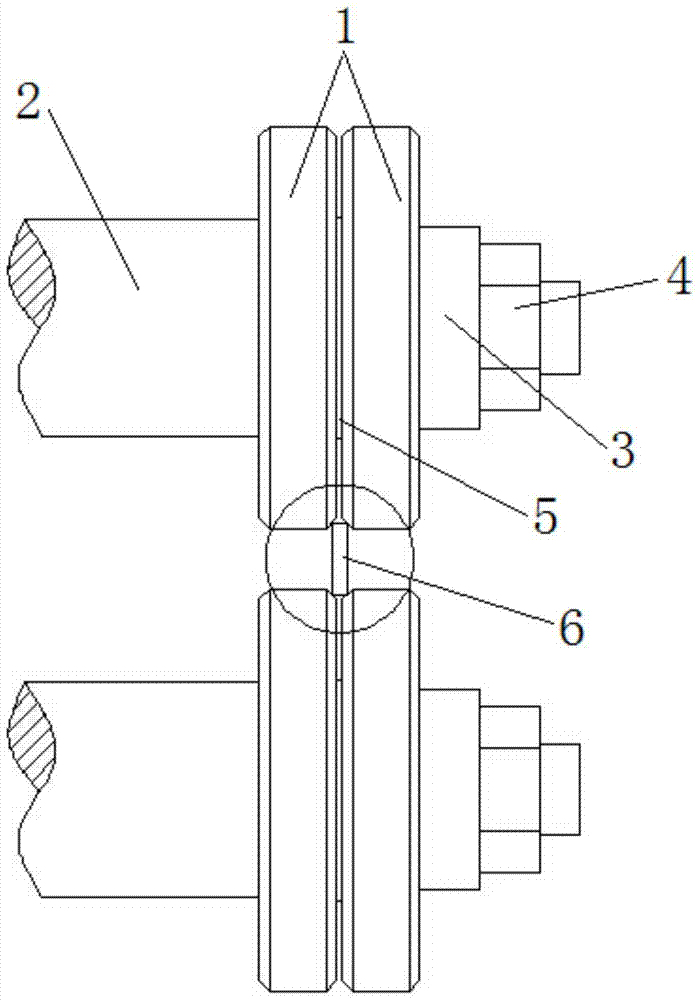

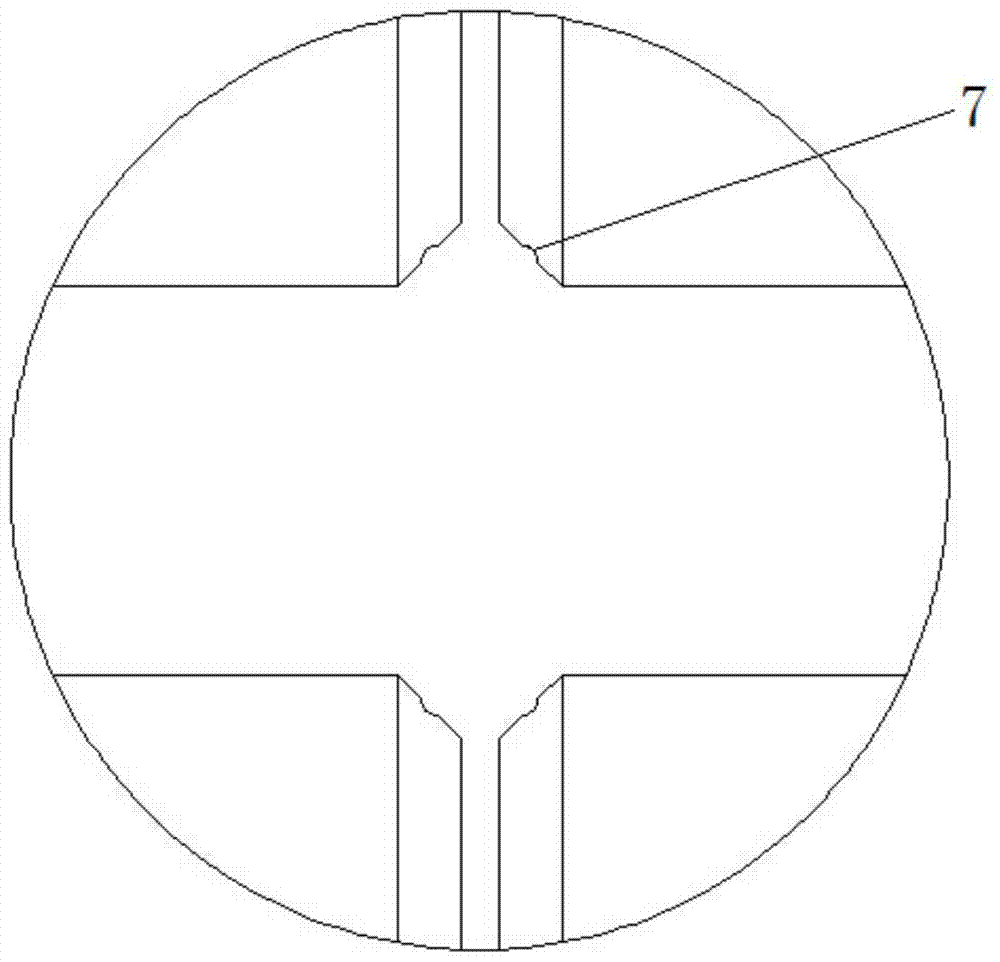

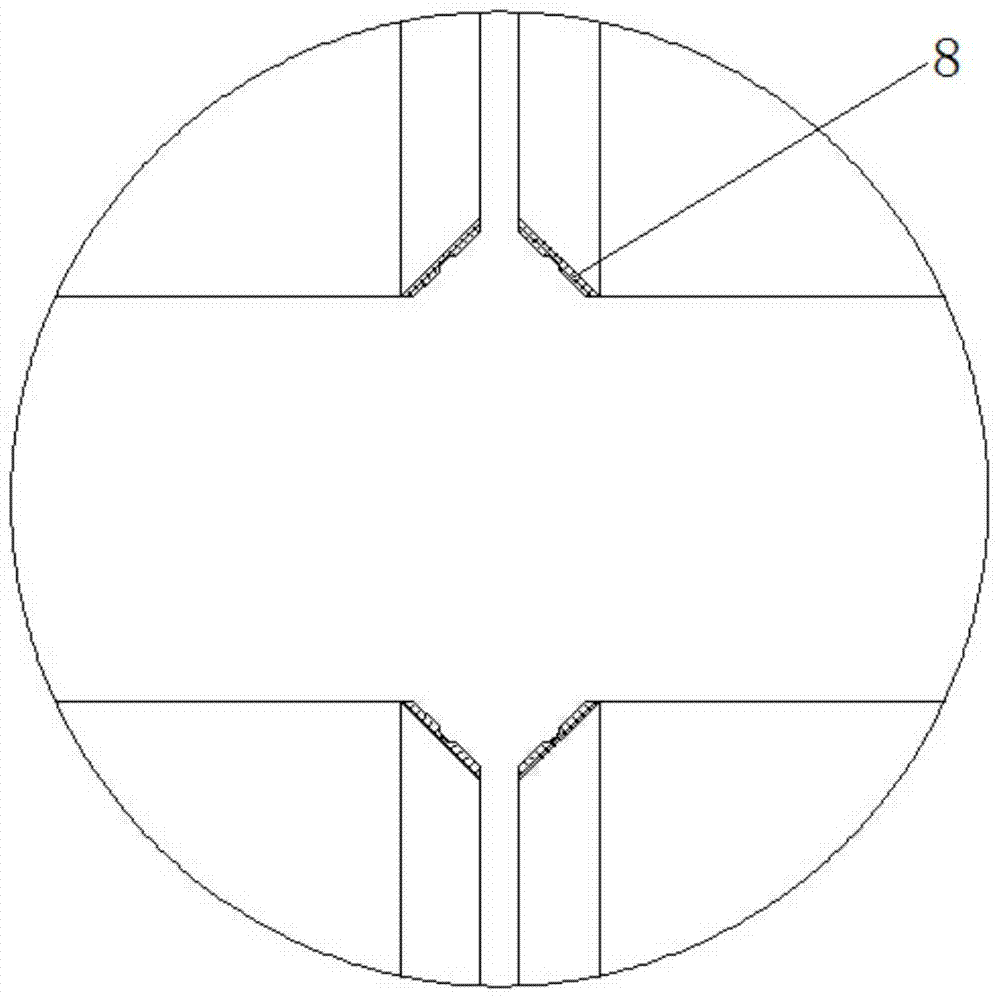

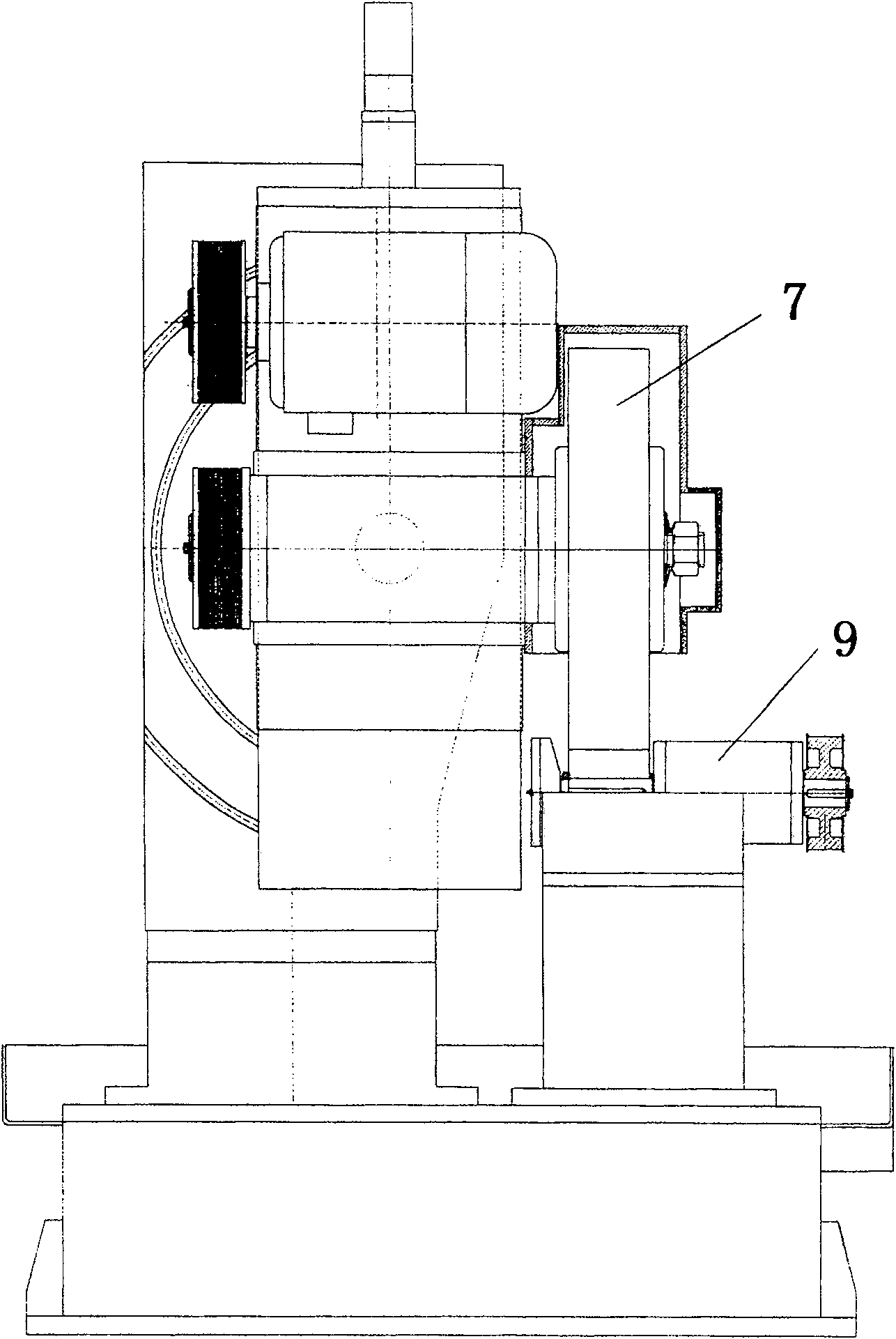

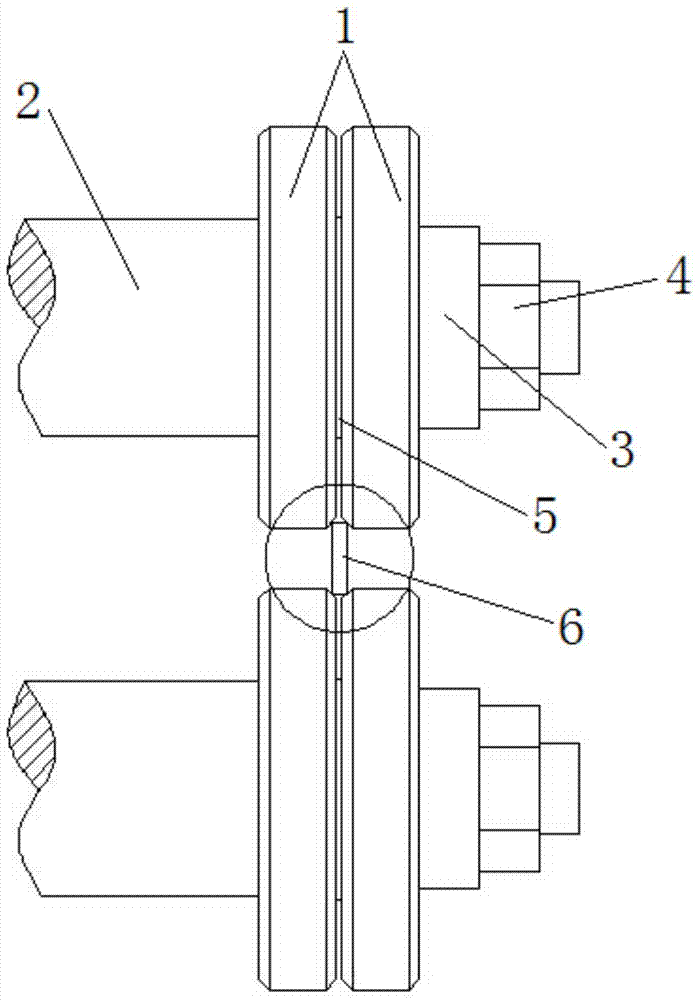

Valve clack sphere grinding machine of double eccentric semi-ball valve

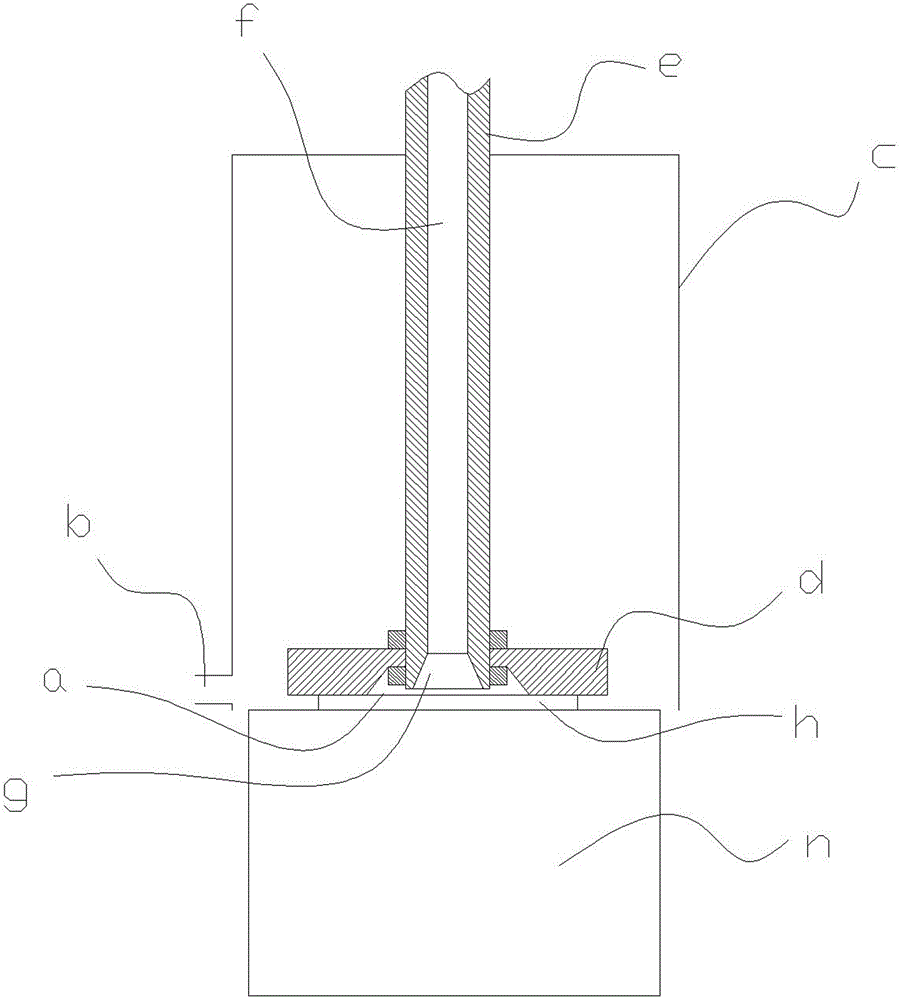

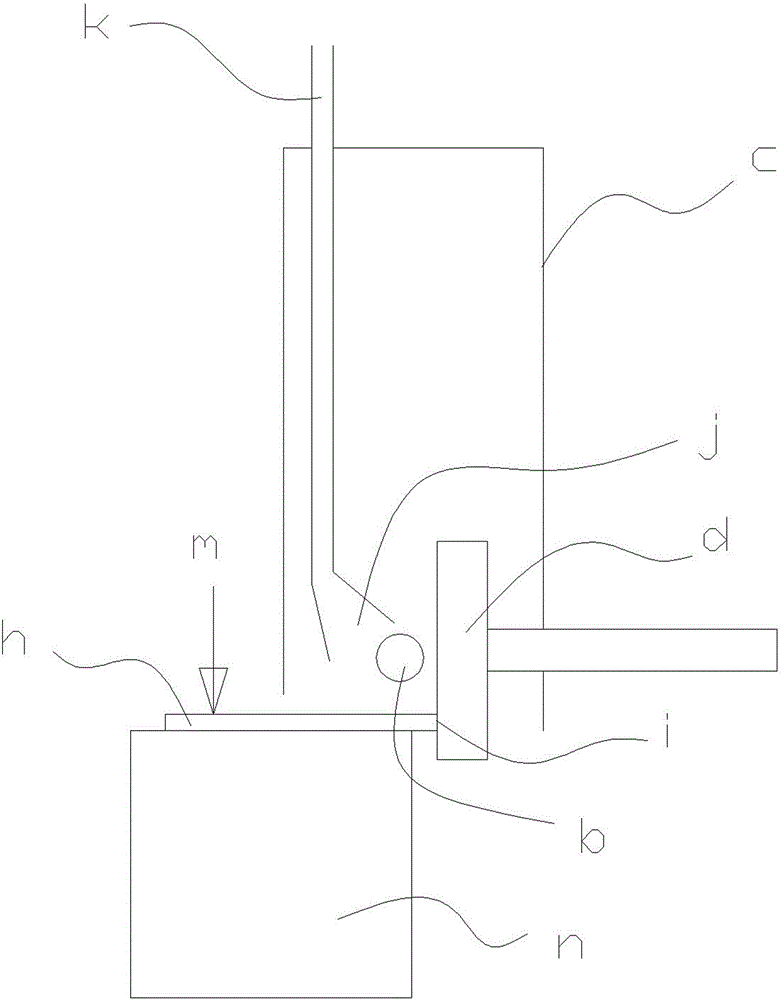

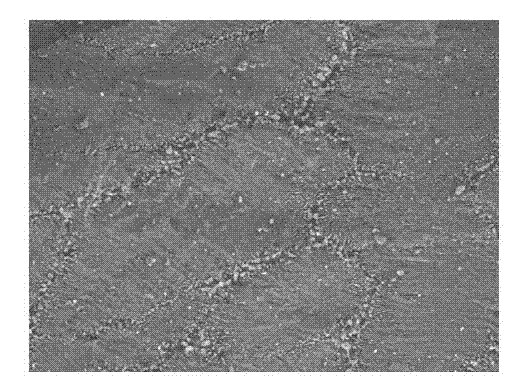

InactiveCN101722455ARealize automatic grindingGuaranteed grinding qualitySpherical surface grinding machinesEngineeringUniform rotation

The invention discloses a valve clack sphere grinding machine of a double eccentric semi-ball valve. A frame (1), a motor (2), a loading workpiece rotating main shaft (4) and a tool (5) are arranged on an engine base (3), wherein the frame is arranged on the upper part of the engine base and provided with an angle adjustment frame (6) with adjustable angles; a rotating auxiliary shaft (7) is fixedly connected to the angle adjustment shaft; a grinder clamping mechanism (8) is arranged on the rotating auxiliary shaft, and a semispherical grinder body (9) is fixedly connected to the grinder clamping mechanism; the lower part of the engine base corresponding to the rotating auxiliary shaft (7) is provided with the loading workpiece rotating main shaft which simultaneously rotates with the rotating auxiliary shaft and has opposite direction to the rotating auxiliary shaft, and the tool used for fixing a semi-sphere is arranged on the loading workpiece rotating main shaft; and the upper end of the tool is a semispherical positioning disk eccentrically arranged on the loading workpiece rotating main shaft. Through the adjustment of the angle adjustment frame, the grinder rotates on a semi-ball valve clack at a uniform speed so as to form mutually crossed reticular tracks and achieve an ideal ball grinding surface.

Owner:HENAN SHANGDIE VALVE CO LTD

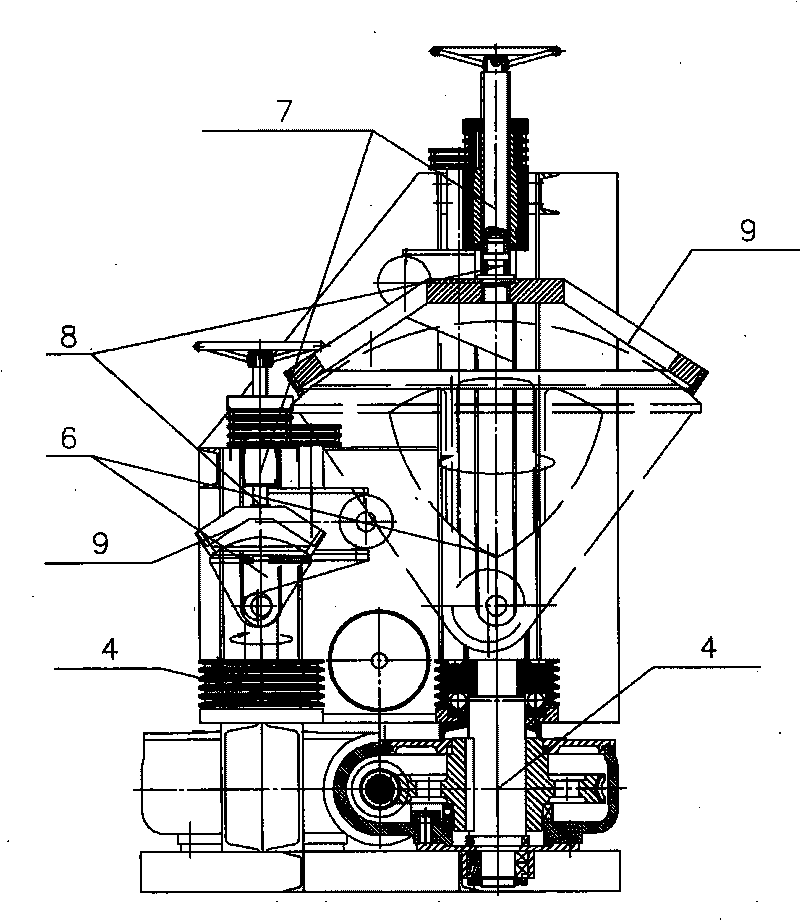

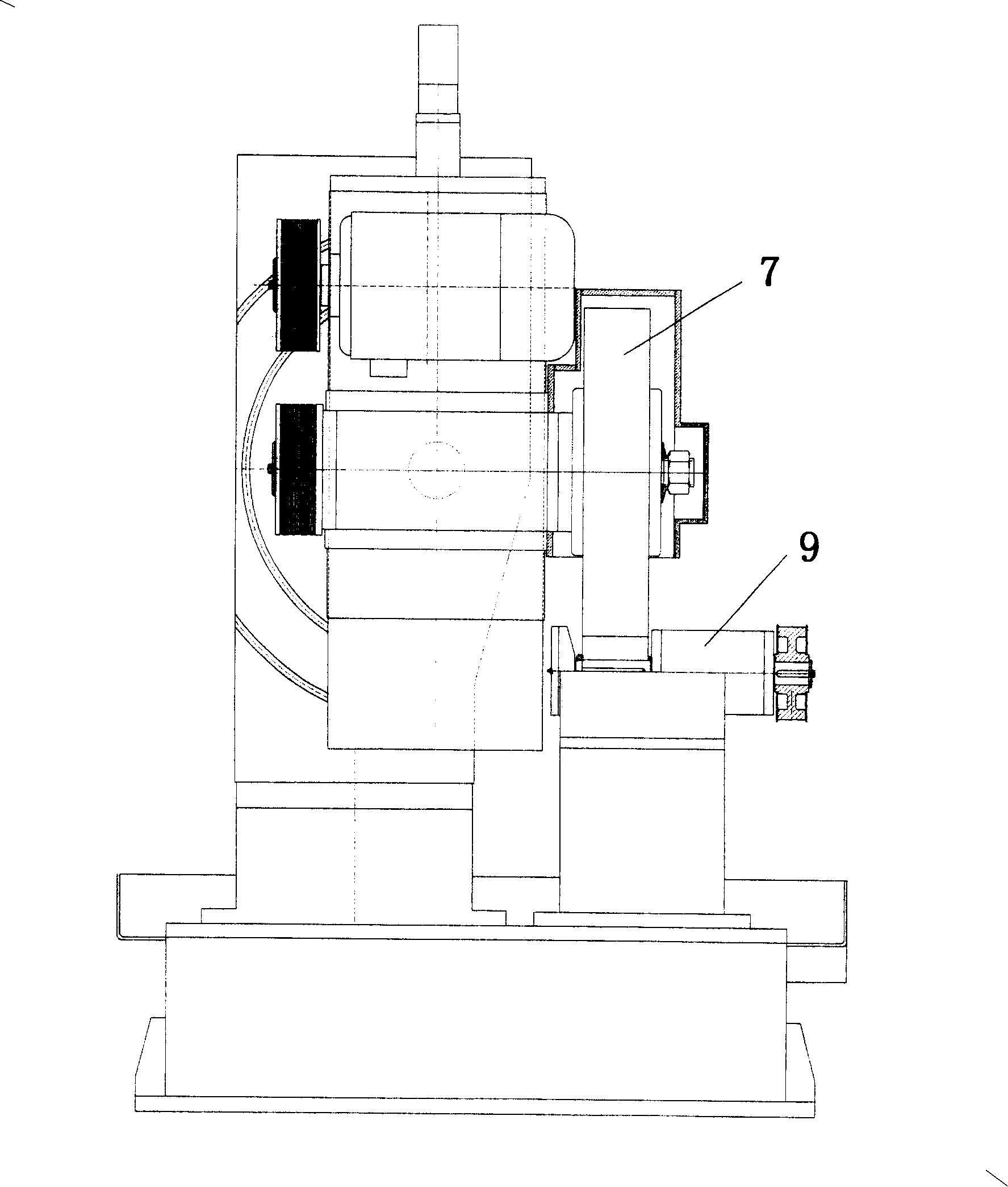

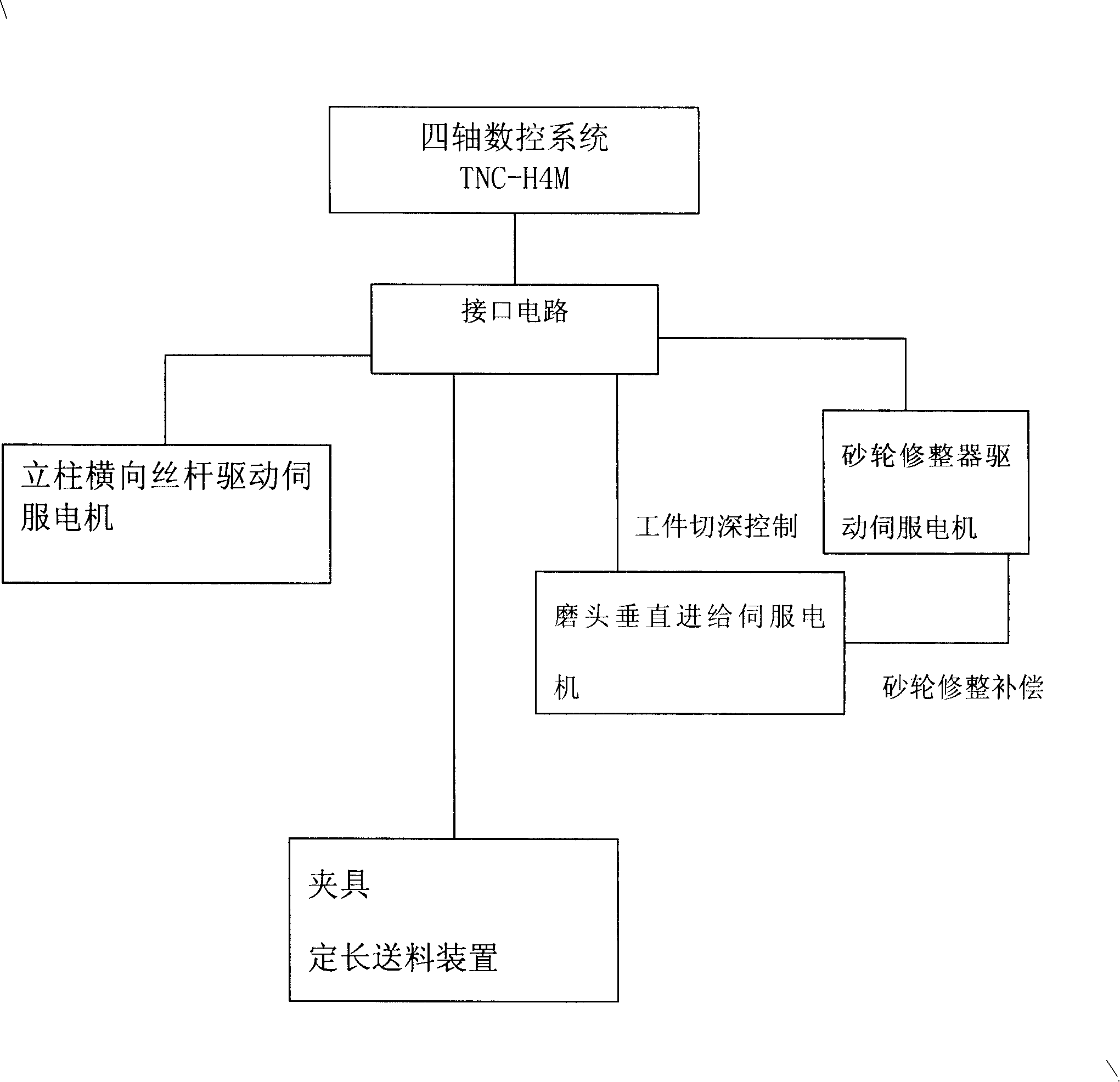

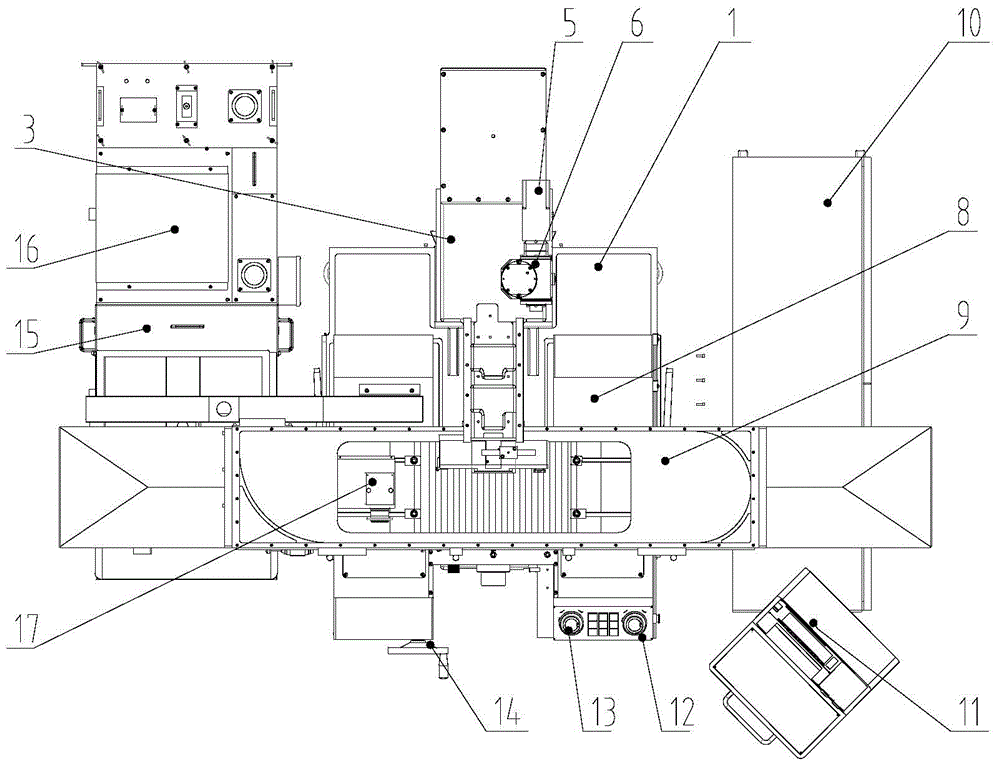

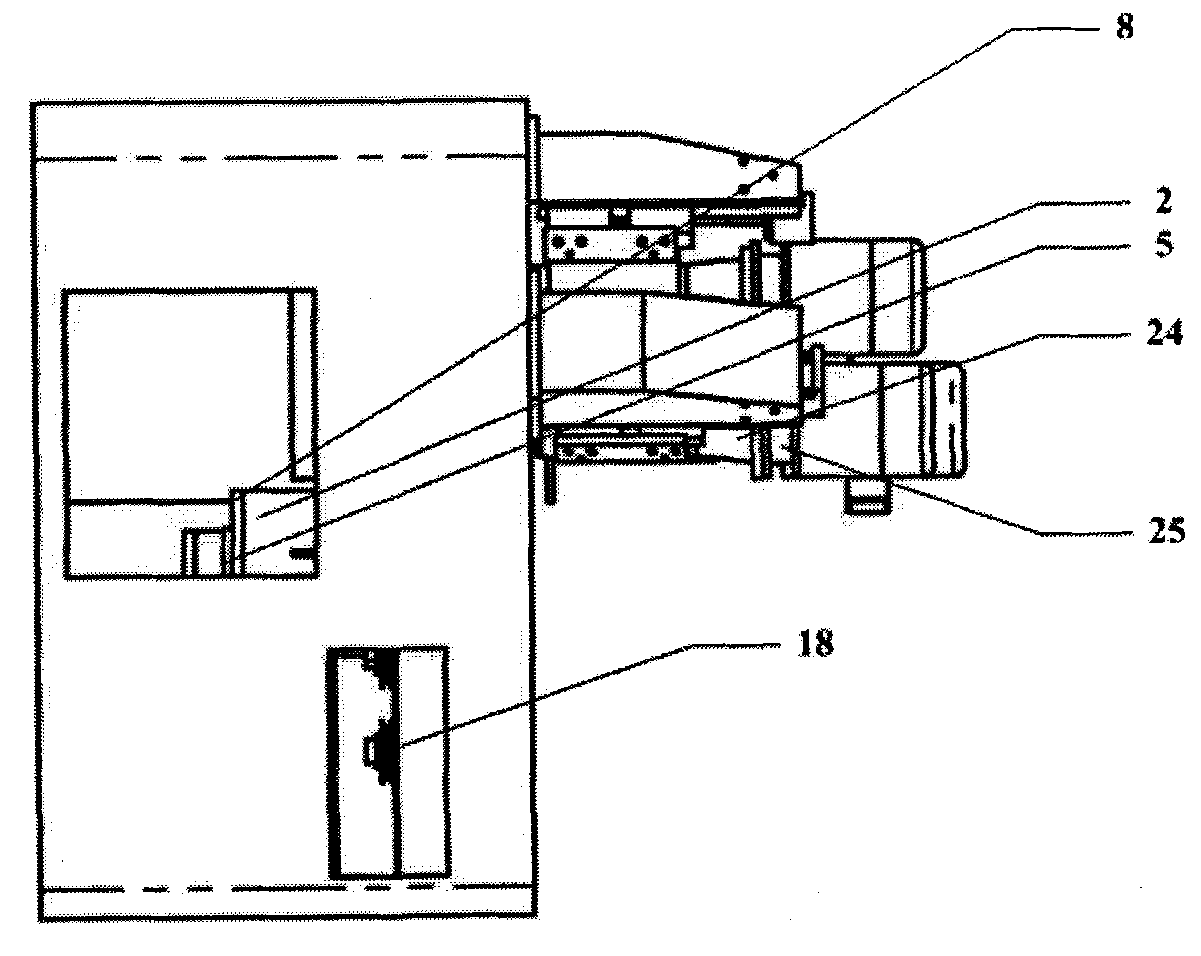

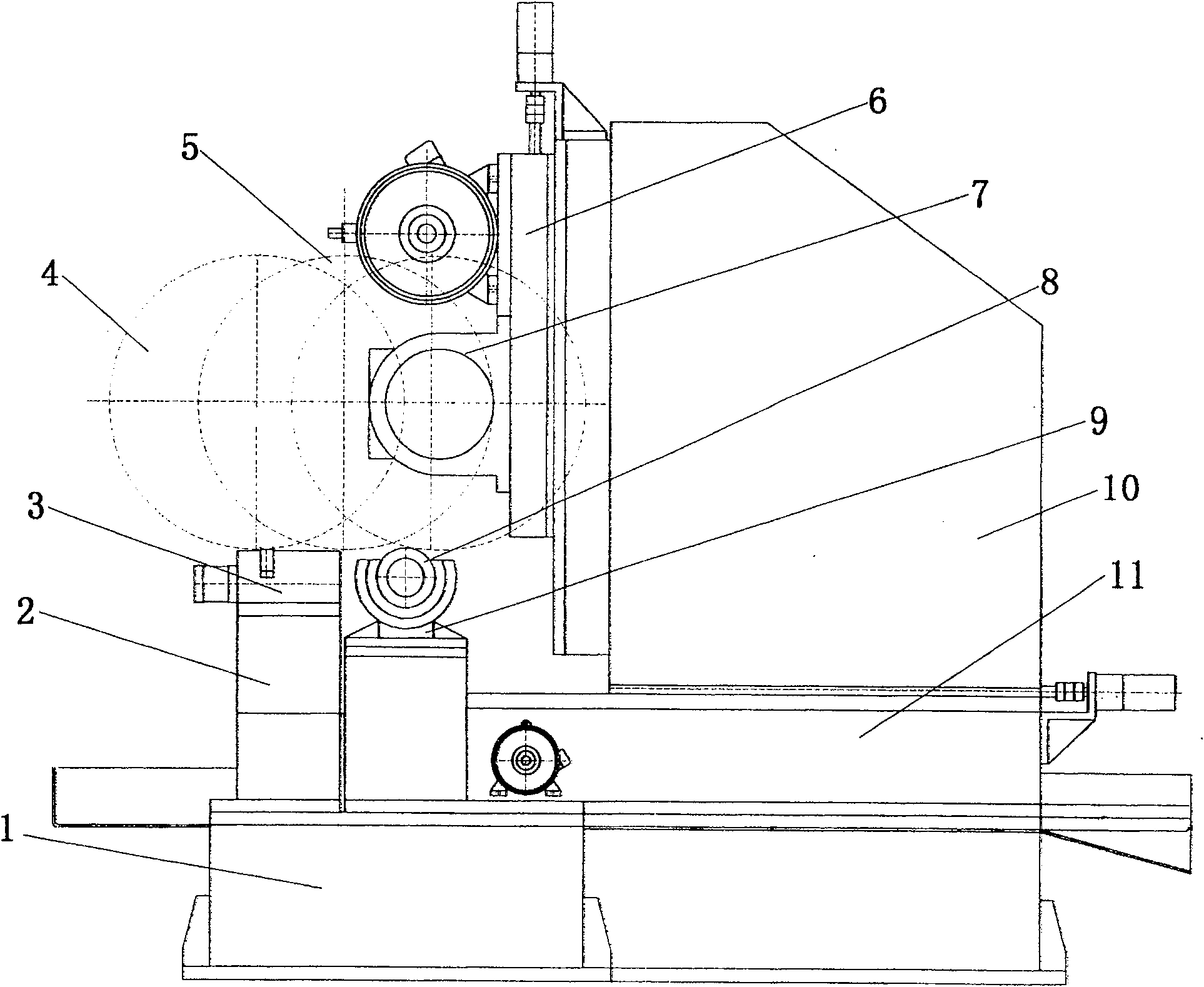

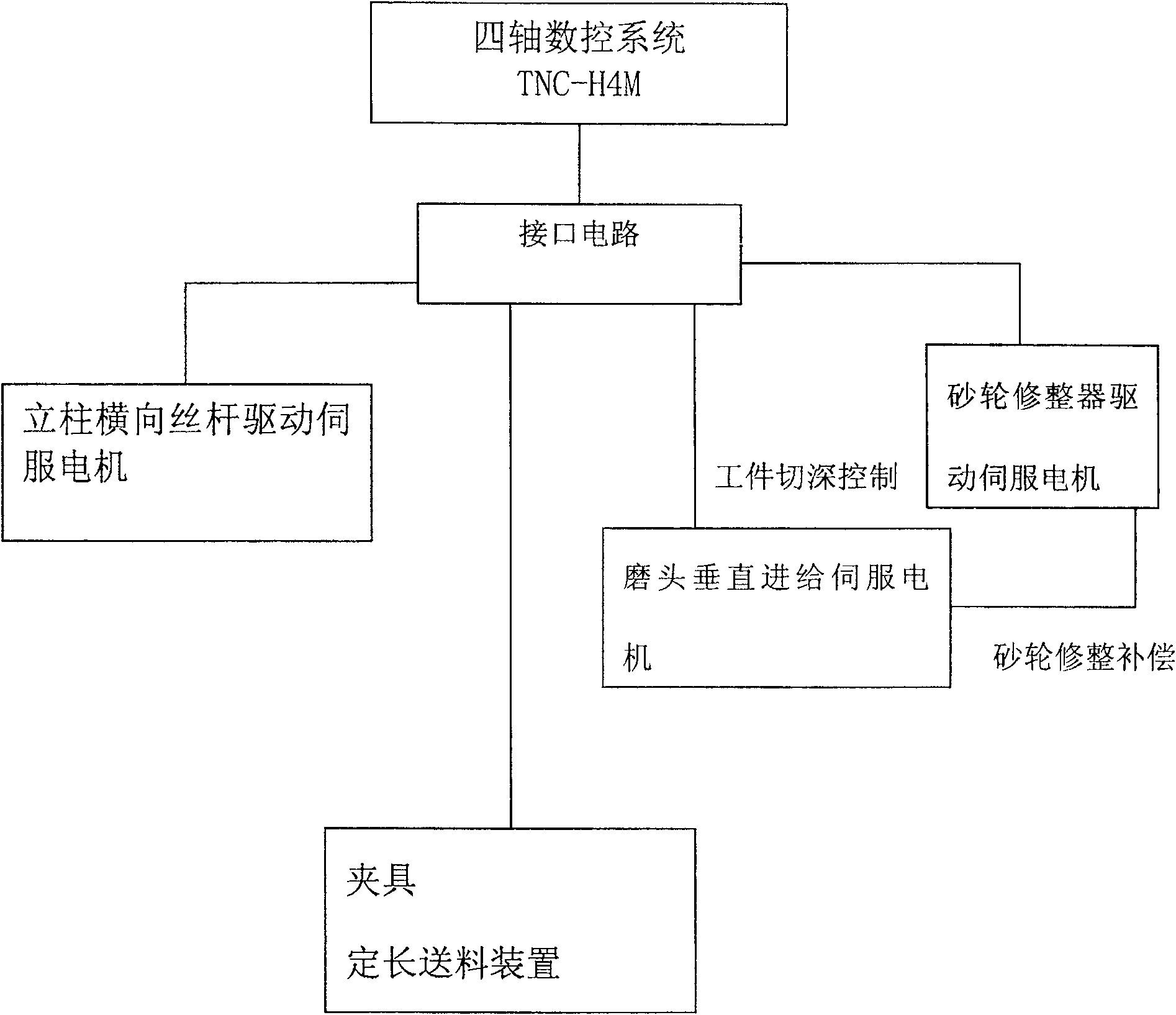

Numerical control automatic tooth profile strength forming grinder

InactiveCN101200046AImprove the finishExtended service lifeAbrasive surface conditioning devicesGrinding machinesStopped workEngineering

The invention discloses a numerical control full-automatic tooth-profile strength molding grinder, which comprise a grinder body, a working table, a grinding head, a grinding wheel dresser, an automatic feeding mechanism, a grinding head transverse feeding mechanism, a grinding head vertical feeding mechanism, a clamp, a work piece fixed-length feeding device, a medium pressure and large flow cooling and lubricating and high pressure washing pumping station, a precise filter and a numerical control system. In the invention, the grinding wheel dresser is arranged at the back of the working table; when a machine tool is arranged at the position of stop working, the grinding wheel is positioned between the working table and the grinding wheel dresser, and does not touch the work piece and the dresser; when the machine tool is grinding, the grinding wheel moves in working feed forward, and grinds the work piece in strength molding; when the grinding wheel needs dressing, the grinding wheel moves backward and passes through the grinding wheel dresser to finish the dressing and the depth control of the machining dimension, therefore the dimension of the grinding wheel changed by the dressing will not influence the machining precision. The machine tool can finish a full-automatic cycle movement through a four or five-axis numerical control system.

Owner:徐震 +1

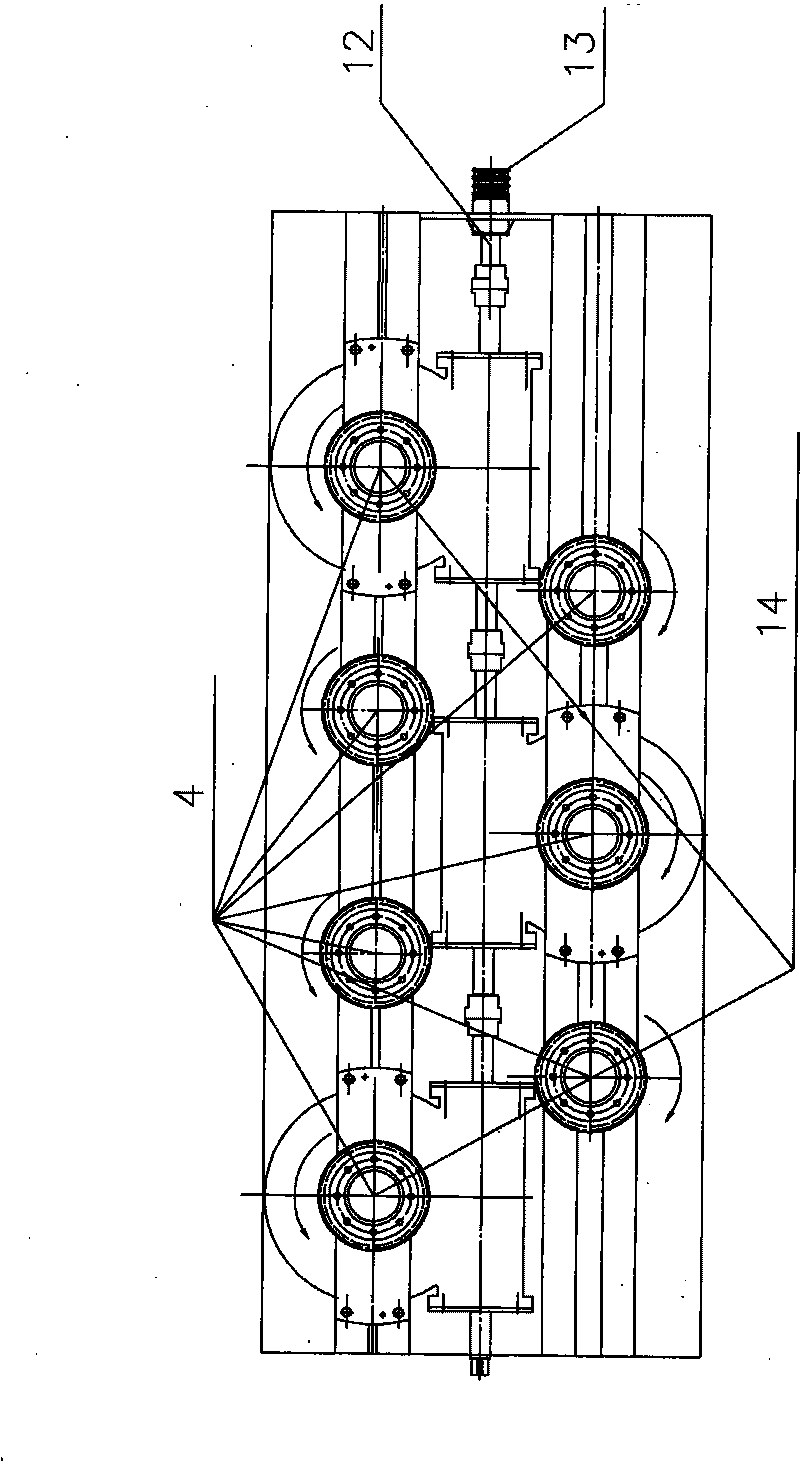

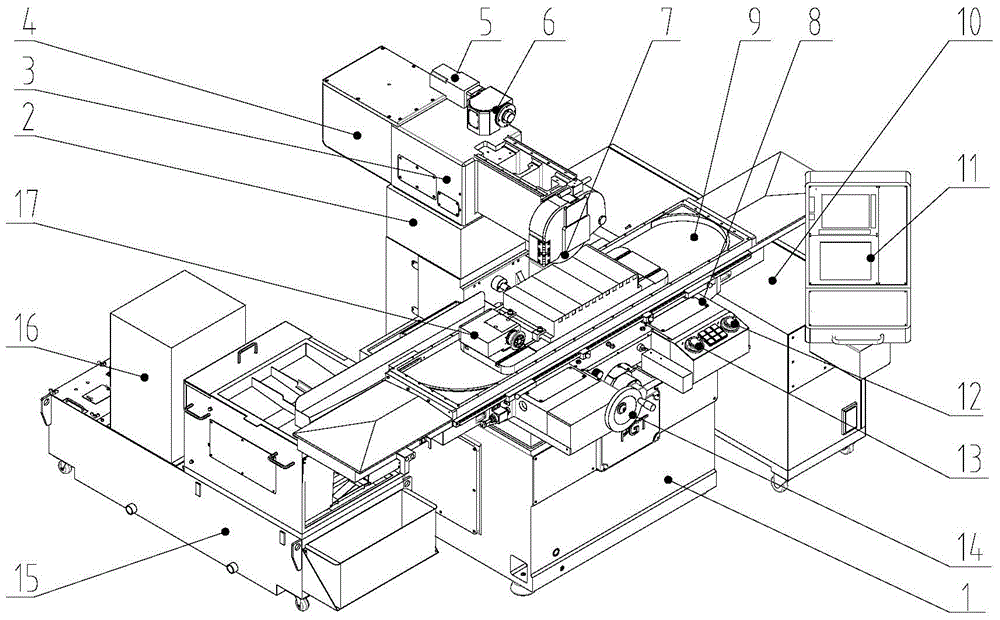

Small and medium-sized plane form grinding machine tool

InactiveCN104476345AImprove rigidityImprove stabilityGrinding drivesAbrasive surface conditioning devicesDisplay deviceReducer

The invention discloses a small and medium-sized plane form grinding machine tool. A vertical shaft upright column is mounted at the rear part of a tool body; a water cooler is mounted behind a water tank; a display is mounted in front of the upper part of an electric cabinet; a grinding head is mounted at the upper end of the vertical shaft upright column; a Y-axis lead screw is mounted inside the vertical shaft upright column; a spindle motor is mounted inside the grinding head; a counter weight is mounted at the rear end of the grinding head; a Y-axis speed reducer matched with the Y-axis lead screw is mounted at the upper part of the grinding head; a Y-axis servo motor matched with the Y-axis speed reducer is mounted at the front end of the Y-axis speed reducer; an abrasive wheel is mounted at the front end of the grinding head; a Z-axis lead screw, a Z-axis servo motor and a Z-axis speed reducer are mounted inside the tool body; according to the grinding head and the vertical shaft upright column of the machine tool, overall vertical movement feeding is realized, and the rigidity and the accuracy stability are high; the grinding capacity of the plane form grinding machine tool is greatly improved, the grinding amount is large, and the accuracy retention is high; the machining stability of a plane grinder is improved. The grinding range of the plane grinder is expanded, and the machine tool is high in accuracy, high in steady mobility and long in service life.

Owner:XIAN PGT PRECISION MACHINERY

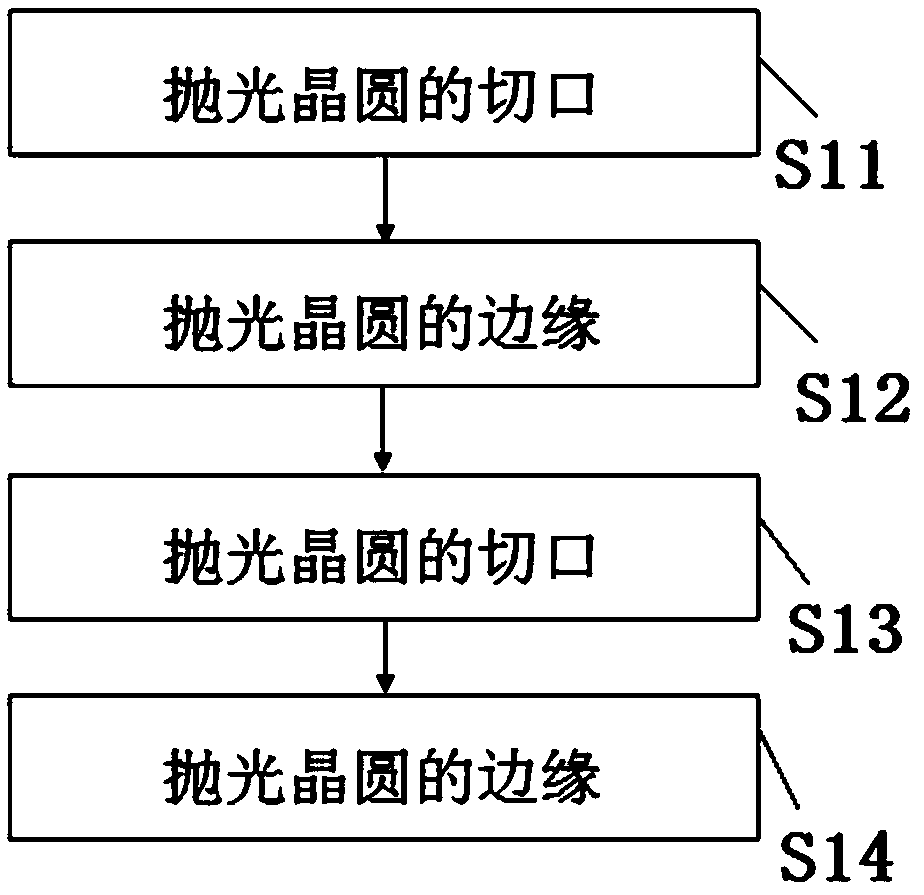

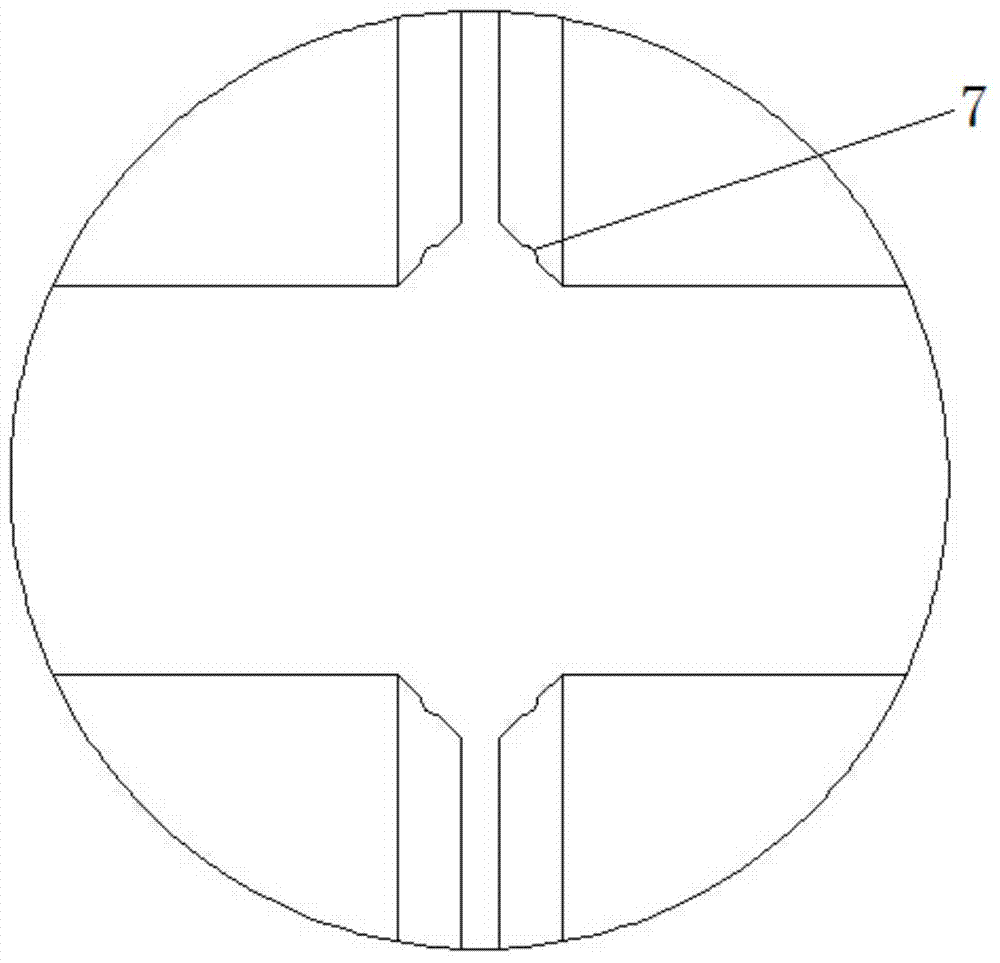

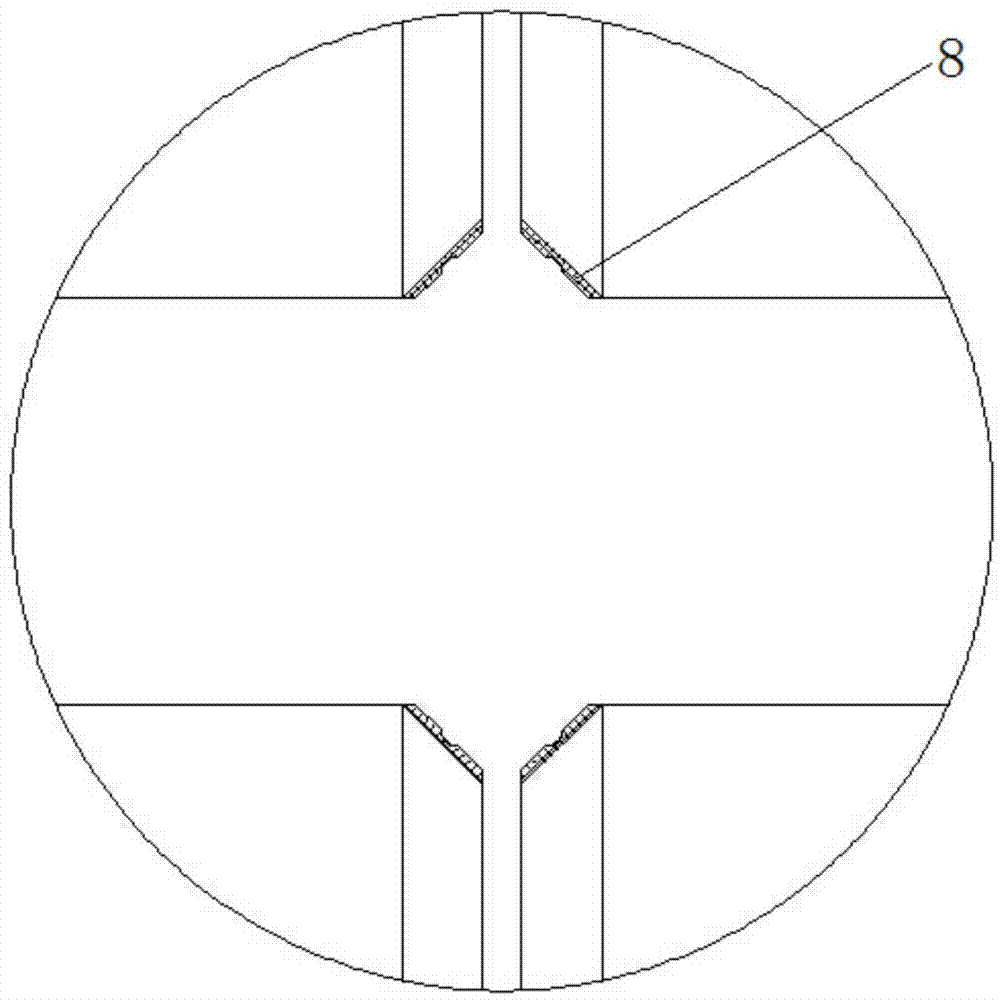

Wafer processing method and device

InactiveCN109605207AImprove grinding qualityGuaranteed grinding qualityLapping machinesRe operationsEngineering

The invention provides a wafer processing method and device. The wafer processing method comprises the following steps that a notch of a wafer is polished; the edge of the wafer is polished; and the notch and the edge of the wafer are polished repeatedly and alternately till polishing of the edge of the wafer is finished. According to the wafer processing method, by repeatedly and alternately polishing the notch and the edge of the wafer and finishing the polishing of the edge of the wafer, the removal rate of protrusions nearby the notch corner is improved, the notch grinding quality is improved, the influence of particles falling on the edge area to the subsequent working procedure is reduced, the capacity is not reduced by processing the wafer through the method, the overall grinding amount of the edge face is increased so that the defects caused by not grinding of the edge can be reduced, the re-operation rate is reduced, and the wafer edge grinding effect is enhanced. The method can be achieved through the wafer processing device, and the wafer grinding quality is ensured.

Owner:XIAN ESWIN SILICON WAFER TECH CO LTD

Technology for machining roller bearing outer ring for drafting system of textile machine

InactiveCN103231290APrecise positioningImprove rotation performanceRevolution surface grinding machinesPlane surface grinding machinesCylindrical grindingMachining process

A technology for machining a roller bearing outer ring for a drafting system of a textile machine comprises the machining steps of blank turning, heat treatment, rough grinding of an outer circle, rough grinding of end faces, fine grinding of the outer circle, fine grinding of end faces, final grinding of the outer circle, final grinding of end faces, supergrinding of the outer circle, grinding of a trench, fine grinding of the trench, washing and assembly. According to the technology for machining the roller bearing outer ring for the drafting system of the textile machine, bold exploration and renovation of the process and the structural improvement of a fixture are performed, the optimum technological parameter is selected, and 97% control rate of products can be achieved under the condition that the technological requirement of full-height inner end faces for the external circle perpendicular error is up to 0.005mm.

Owner:NINGBO ZHENHAI SILVER BALL BEARING CO LTD

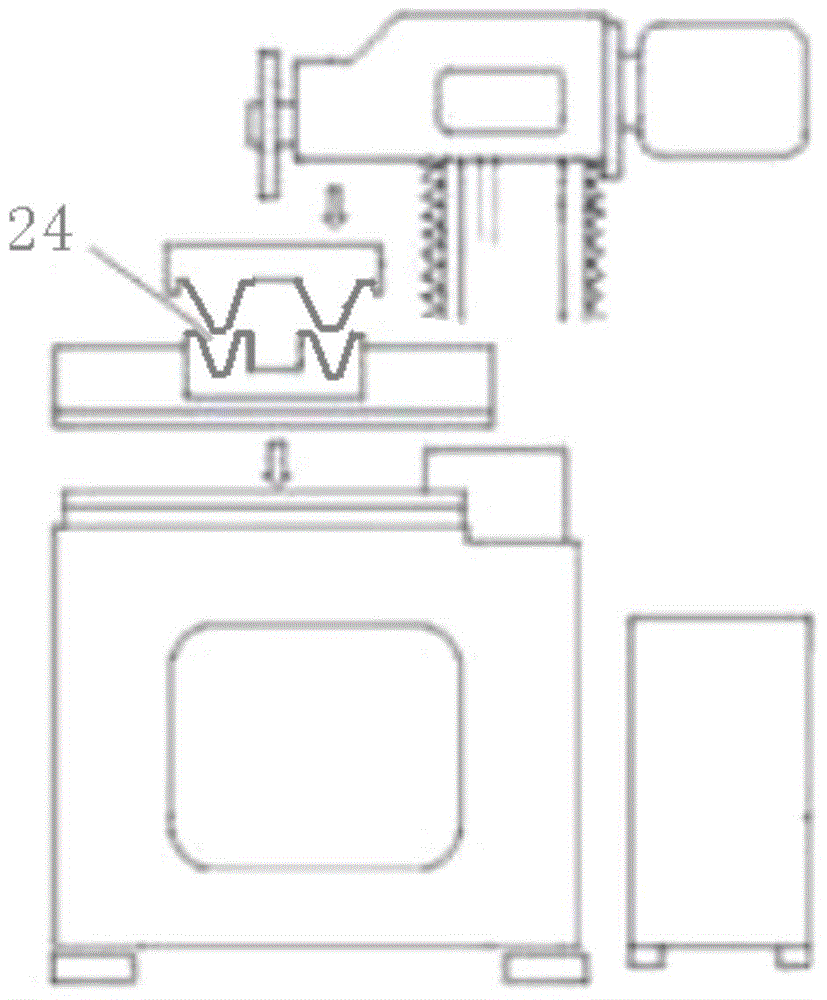

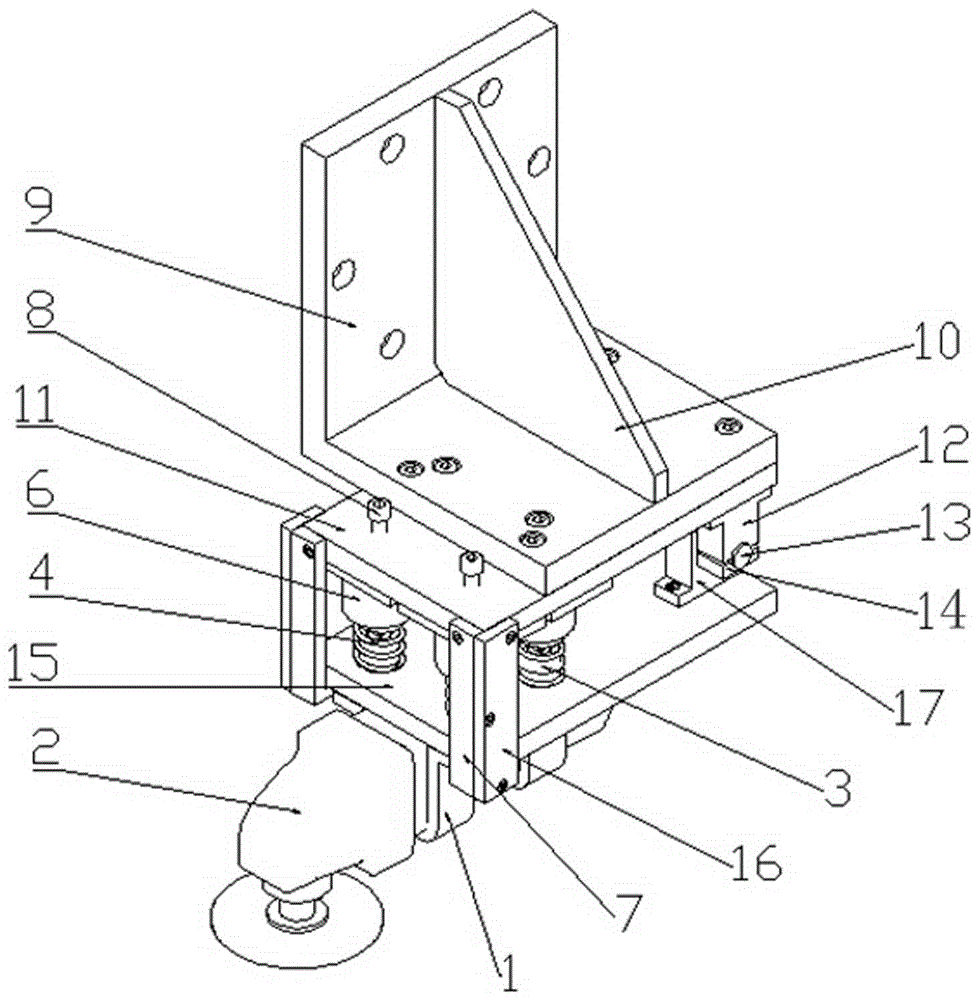

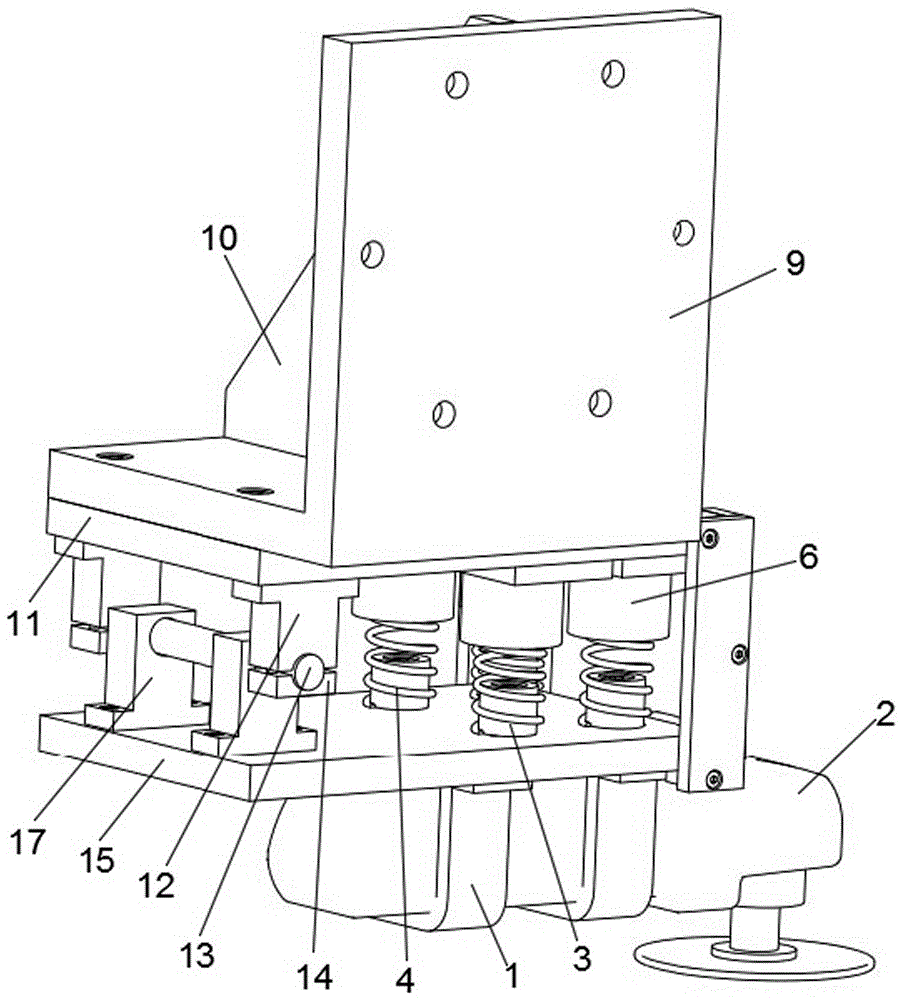

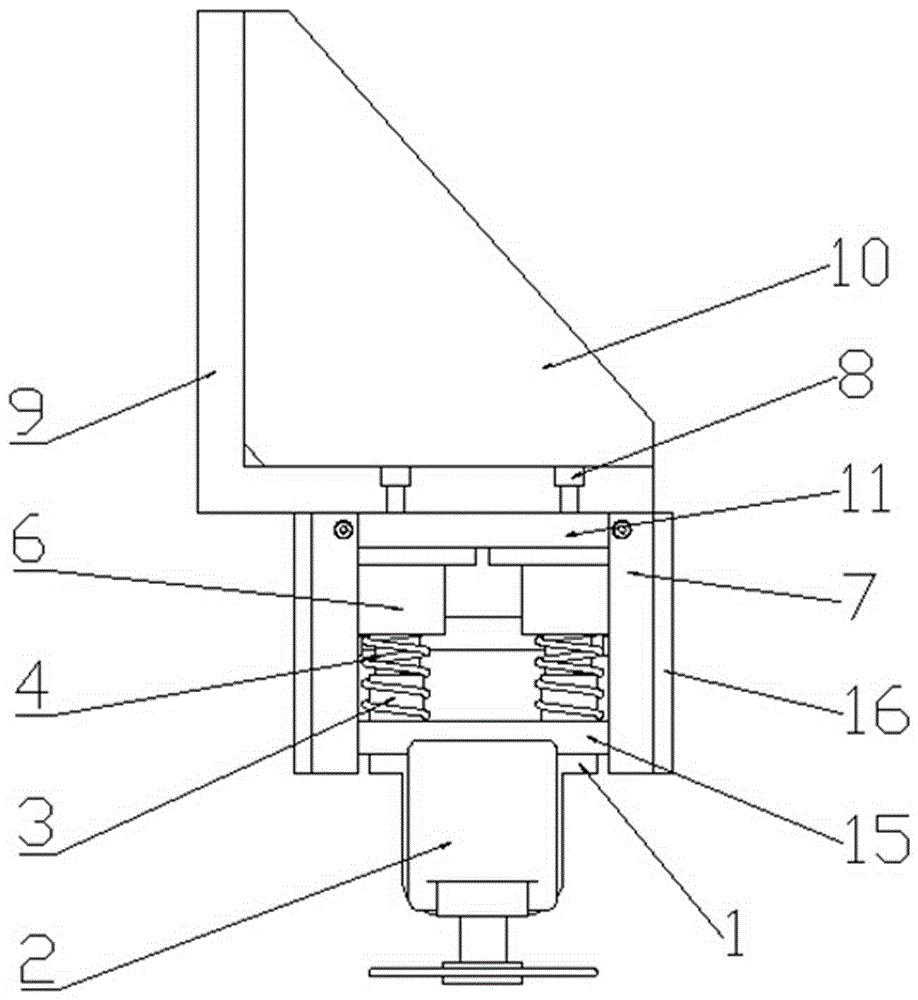

Pressure-adjustable floating polishing device

PendingCN105690198ASolve the problem of stuck and burnedRelieve great pressureGrinding carriagesGrinding bedsPolishingMachine

The invention provides a pressure-adjustable floating polishing device. The pressure-adjustable floating polishing device comprises a polishing machine and further comprises polishing machine connection plates, the polishing machine connection plates comprise the upper polishing machine connection plate and the lower polishing machine connection plate, and the polishing machine is fixed to the lower side of the lower polishing machine connection plate. A rotary mechanism and a floating mechanism are disposed between the upper polishing machine connection plate and the lower polishing machine connection plate. By means of the arrangement of the floating mechanism, huge pressure caused by uneven workpiece surfaces can be relieved when the polishing device works, and the problem that during polishing, a polishing machine is stuck and burnt out due to small difference is solved. The grinding speed of the floating polishing device is high, the grinding amount is large, the plane grinding effect is good, and the floating polishing device is more stable and safer compared with the electric spindle polishing mode and the mode that a robot directly clamps the polishing machine for polishing.

Owner:SHANDONG ROBOT INTELLIGENT TECH

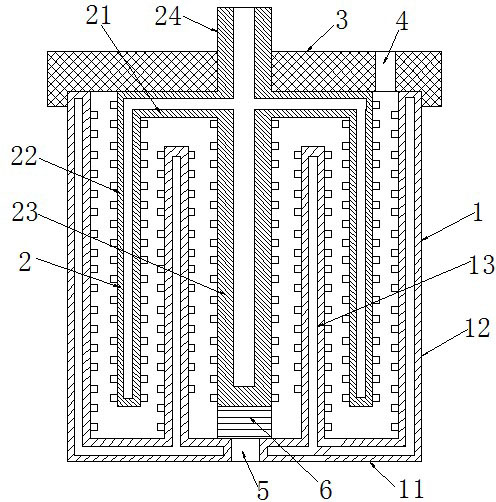

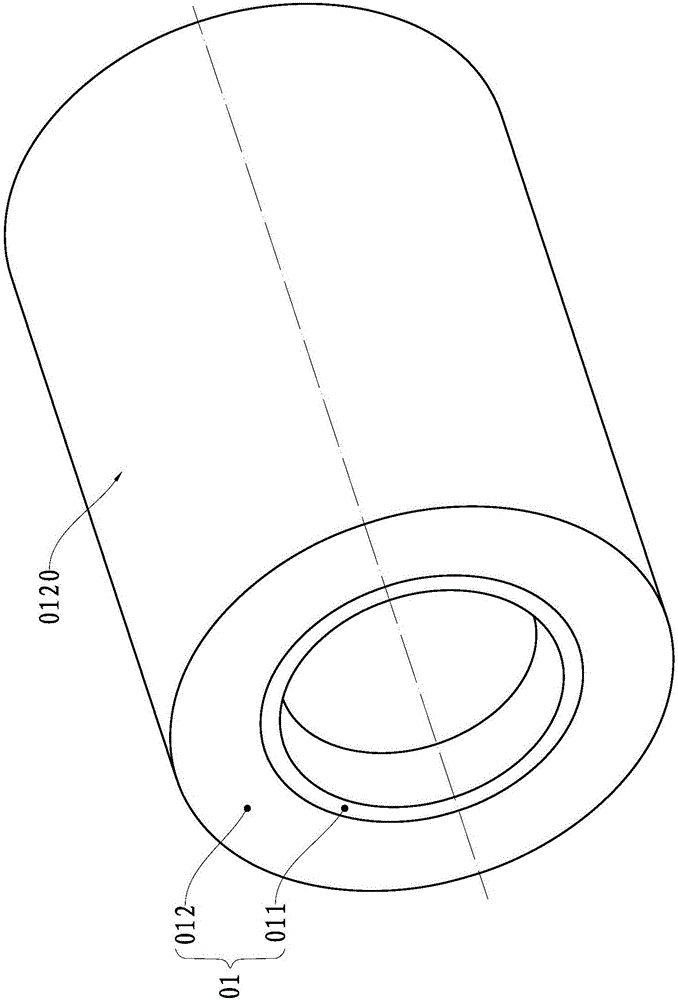

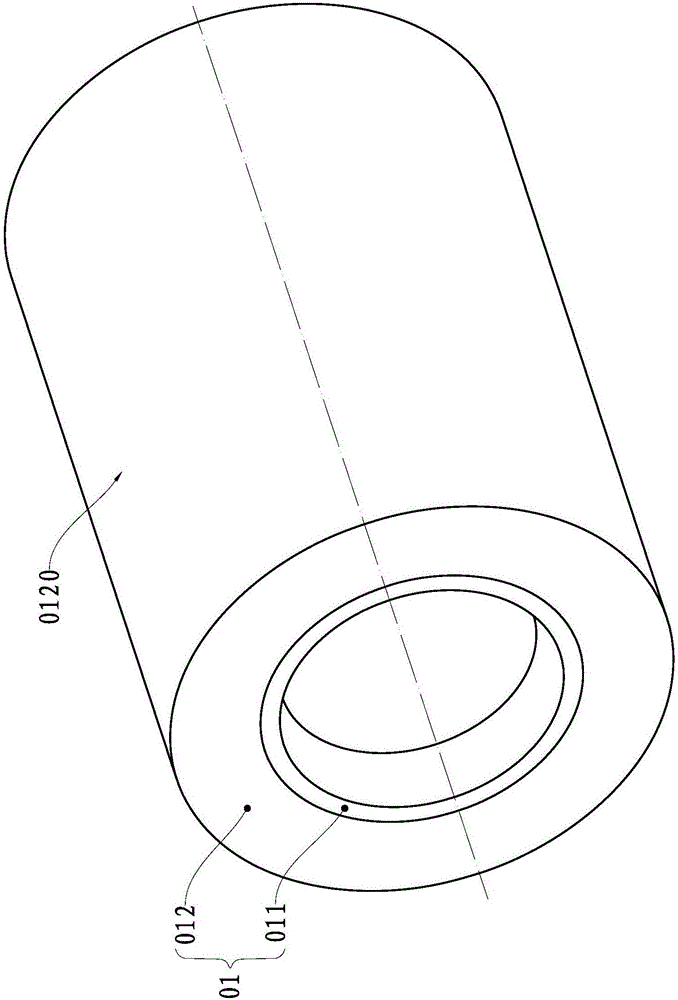

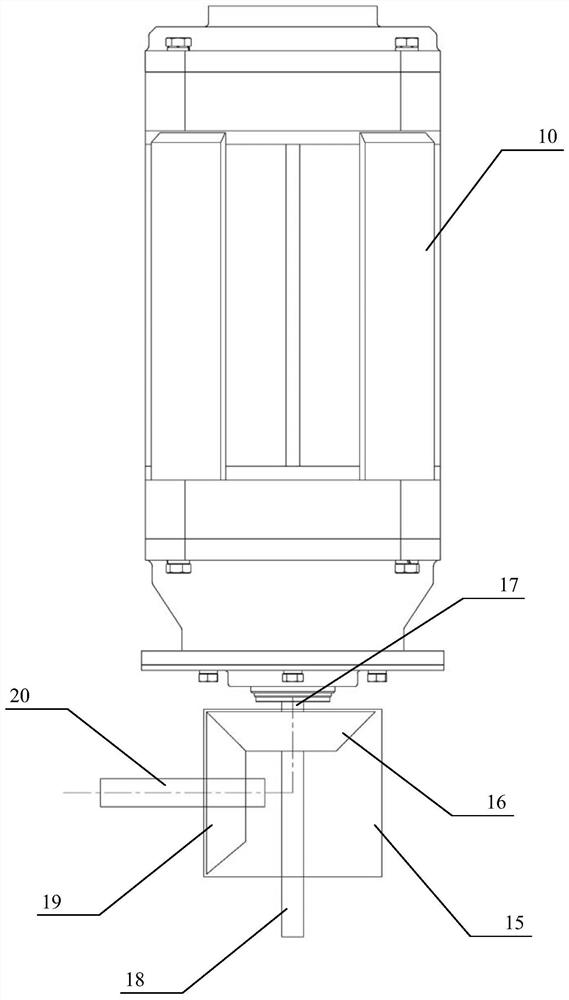

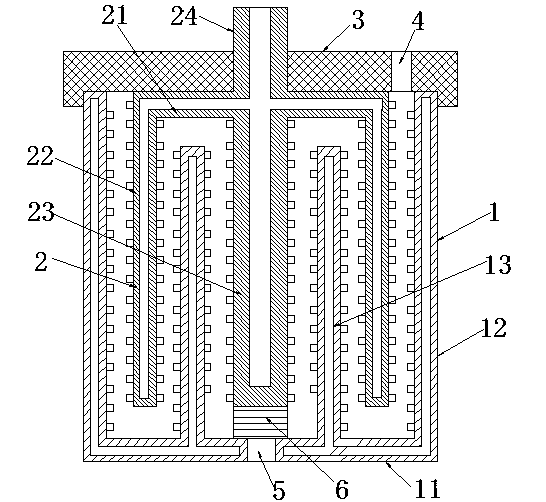

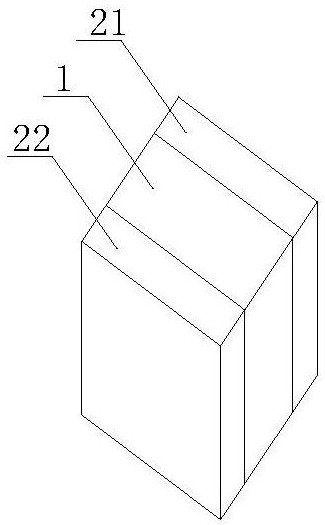

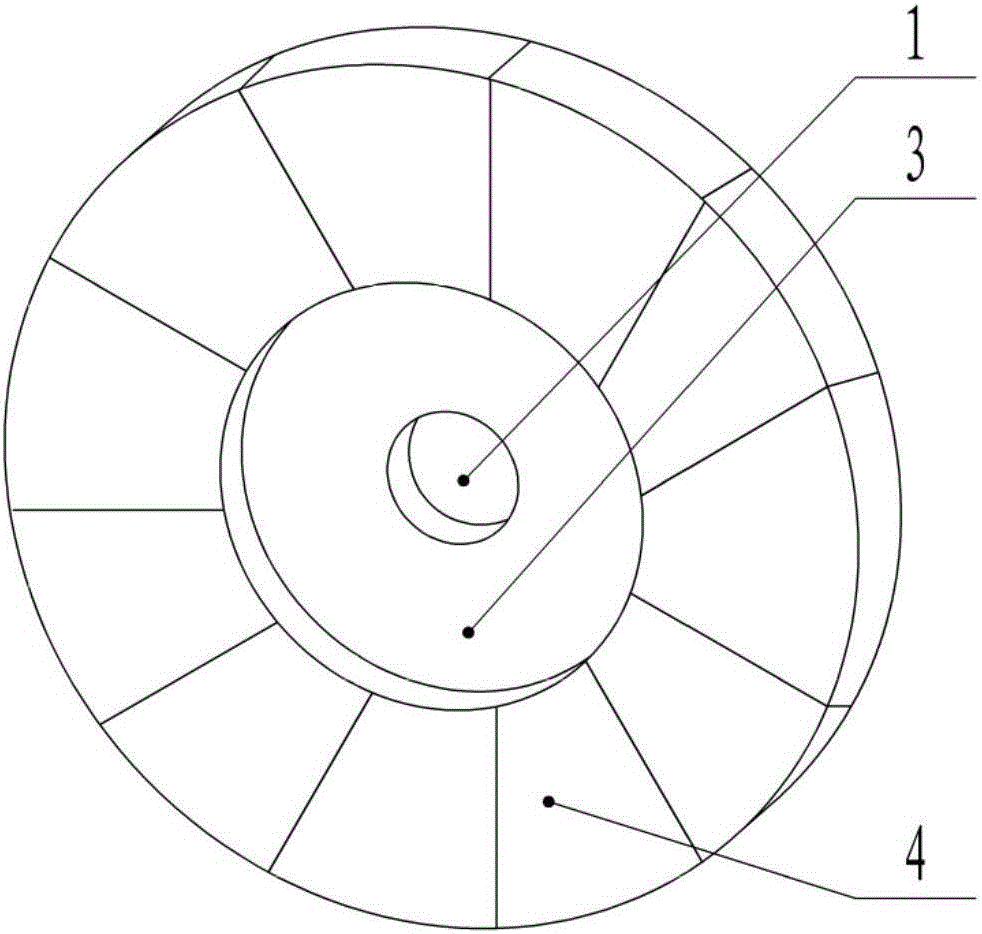

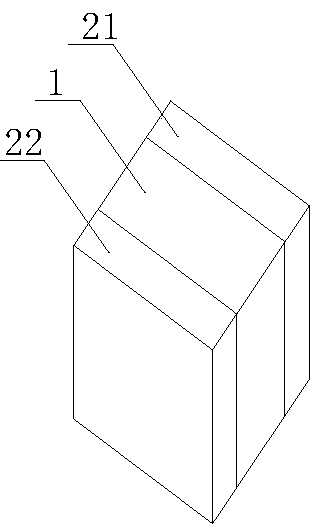

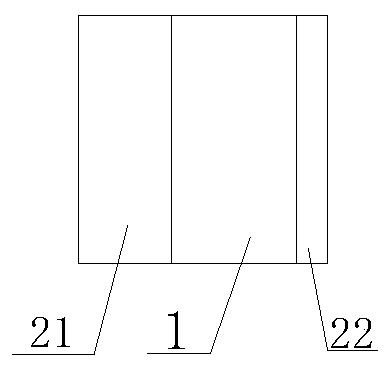

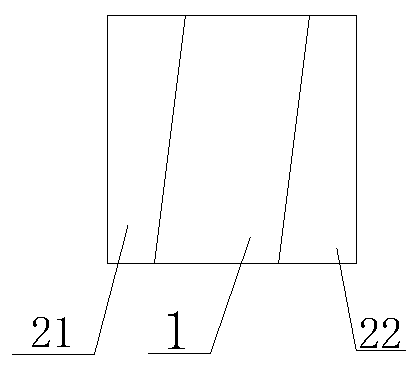

Ball mill

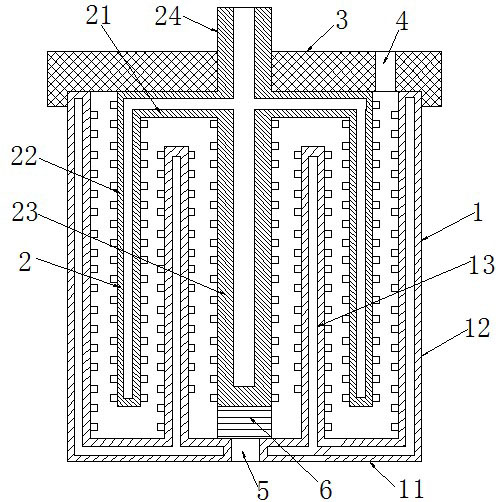

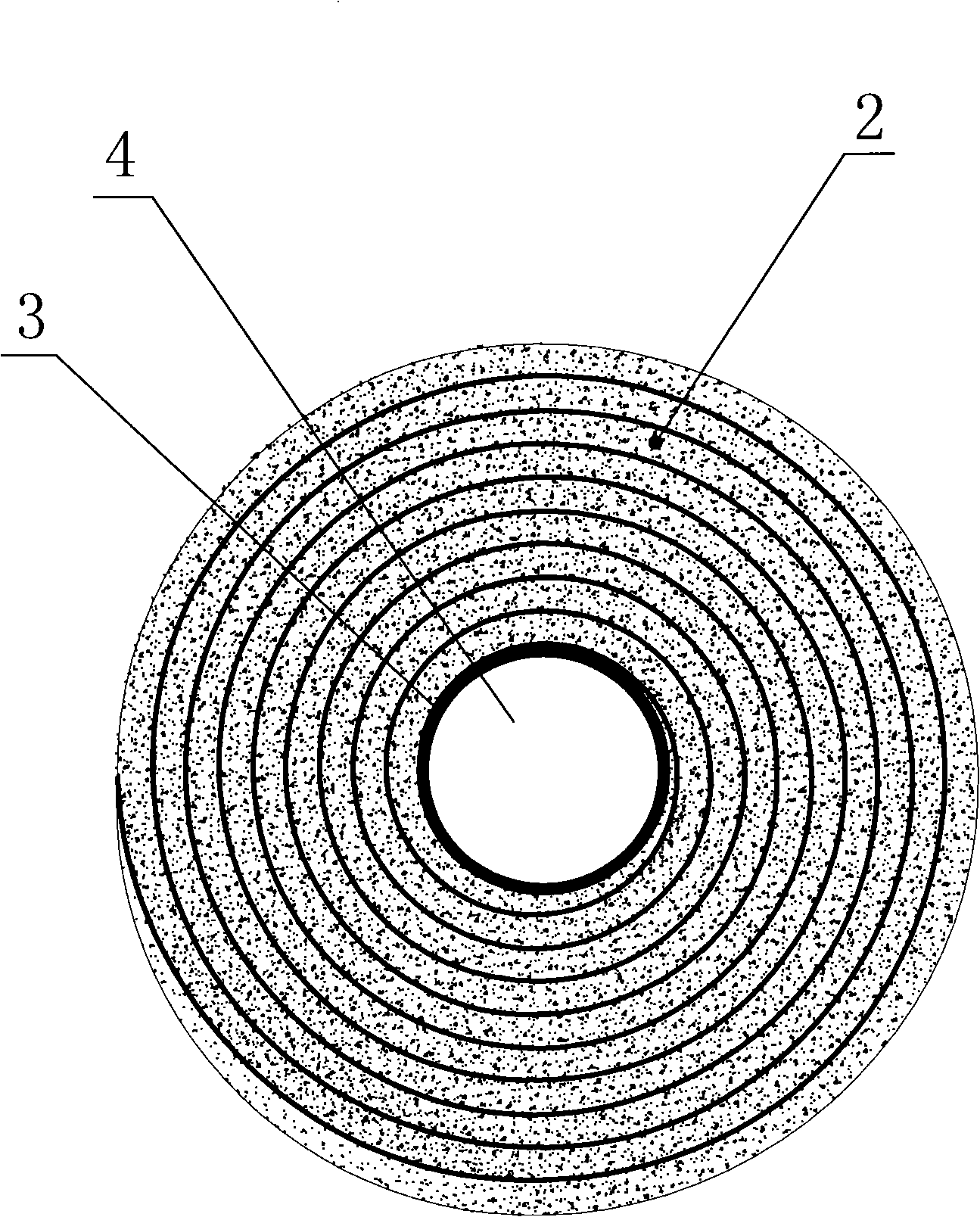

InactiveCN102688793ALarge amount of grindingImprove grinding efficiencyGrain treatmentsBall millStator

The invention discloses a ball mill which comprises a stator cylinder body consisting of a bottom surface, an outer-circle cylinder wall and an inner-circle cylinder wall and a rotor cylinder body consisting of a top surface, a rotor cylinder wall, a central post and a connecting shaft, wherein the rotor cylinder wall is arranged between the outer-circle cylinder wall and the inner-circle cylinder wall, the central post is arranged in the inner-circle cylinder wall, an outer-circle grinding cavity is formed between the outer-circle cylinder wall and the rotor cylinder wall, a middle-circle grinding cavity is formed between the rotor cylinder wall and the inner-circle cylinder wall, and an inner-circle grinding cavity is formed between the inner-circle cylinder wall and the central post, so that the ball mill disclosed by the invention is provided with three grinding cavities, and the material enters from a material inlet, and is sequentially ground by the outer-circle grinding cavity, the middle-circle grinding cavity and the inner-circle grinding cavity, screened by a screening device, and discharged outside a material outlet, therefore, compared with the ball mill which is provided with only one grinding cavity, the ball mill is higher in grinding quantity, and higher in grinding efficiency.

Owner:苏州聚贝机械设计有限公司

Tile grinding cooling method and device

InactiveCN105108653AConserve waterReduce pollutionGrinding/polishing safety devicesDrive shaftEngineering

The invention provides a tile grinding cooling method and device. Grinding is conducted in a dustproof cover, in the grinding process, cooling gas flows out of the outlet of the bottom end of a transmission shaft in the middle of a grinding wheel, flows out of the grinding wheel along the space between the grinding wheel and a tile surface from the middle of the grinding wheel in a radial mode, and then converges and flows out of an exhaust opening of the lower portion of the dustproof cover; or, the cooling gas flows out from an inner cavity of the dustproof cover to the position, for grinding a tile, of the grinding wheel, and then converges and flows out of the exhaust opening of the lower portion of the dustproof cover after cooling the grinding face of the grinding wheel. Compared with the prior art, the tile grinding cooling method and device have the advantages that the grinding tool does not need to exert large pressure on the tile, the temperature of the grinding tool during grinding can be effectively decreased, and burn marks and scratches are avoided.

Owner:GUANGDONG SINID TECH

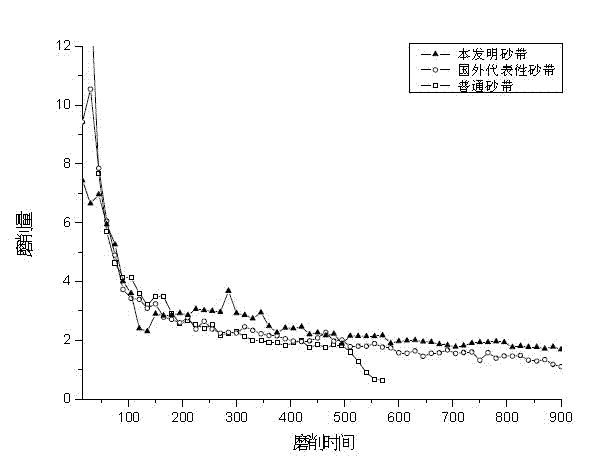

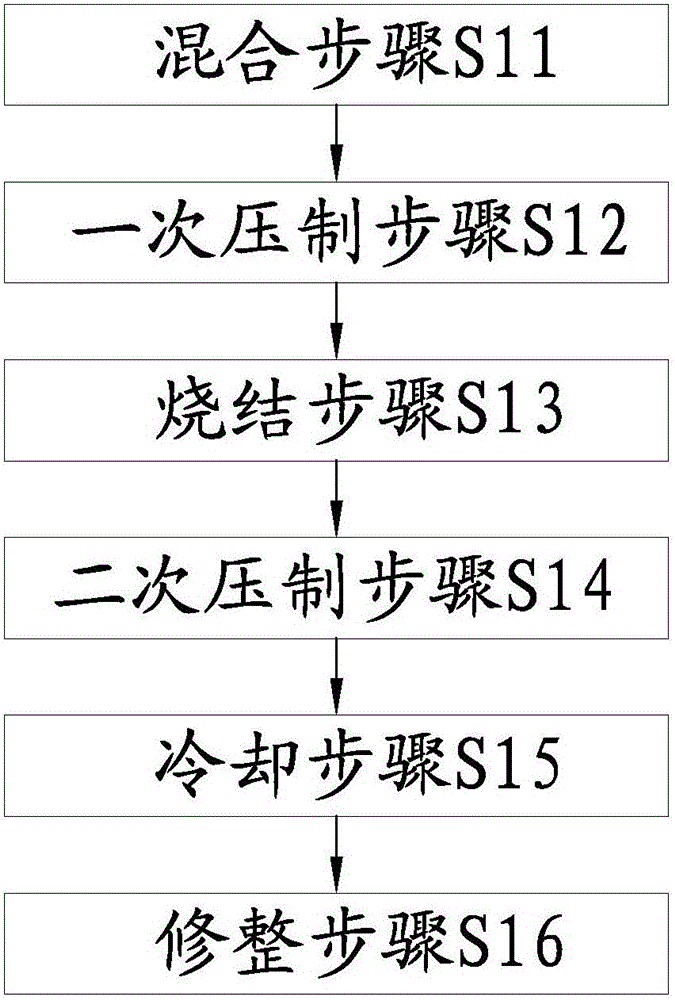

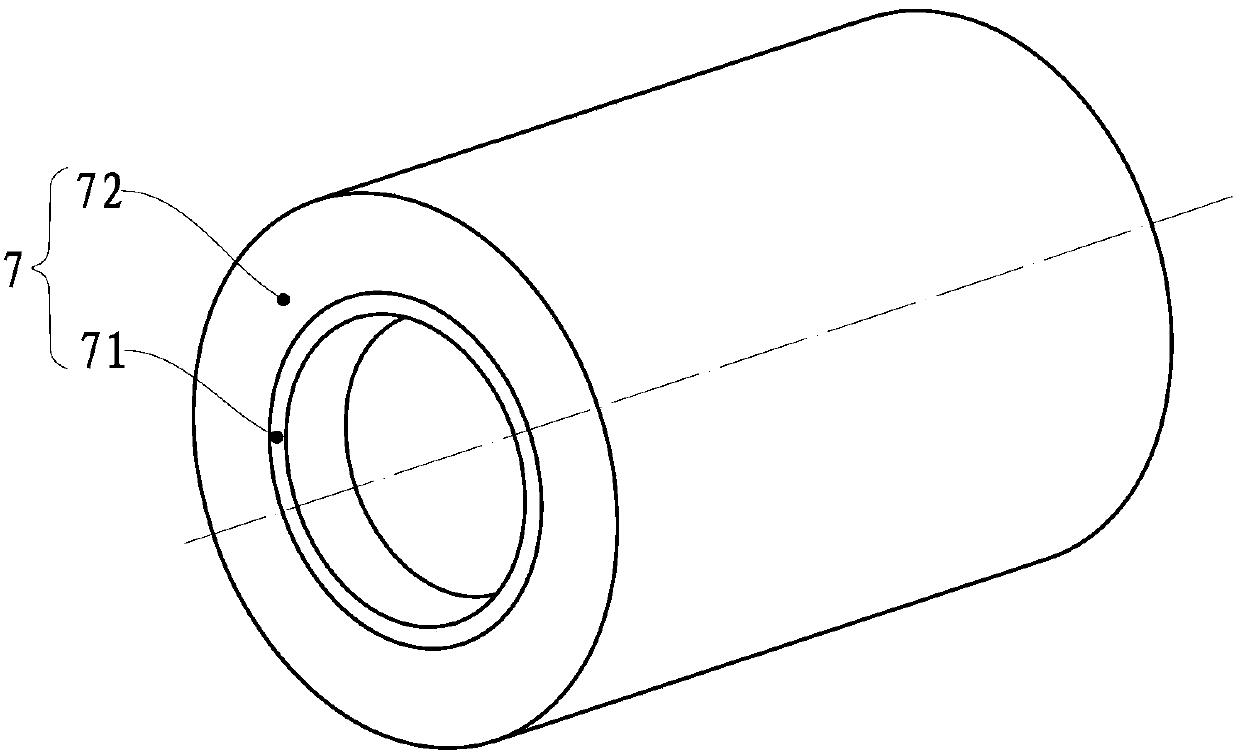

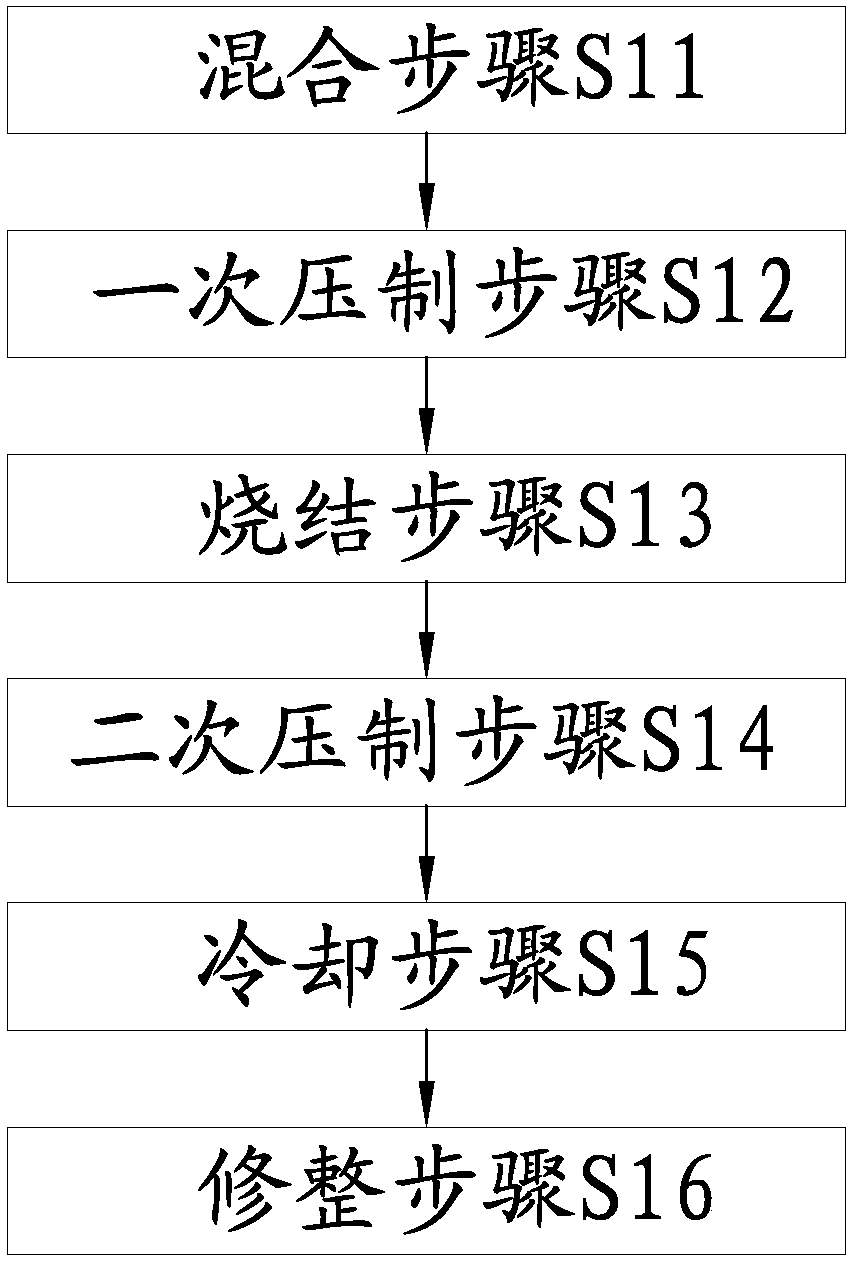

Sintering method of abrasion resisting abrasive particles

The invention relates to a sintering method of abrasion resisting abrasive particles, and belongs to the technical field of preparation of coated abrasive tools. The method comprises the following steps of: mixing 5-15 parts of mineral polymeric material bonder, 1-10 parts of alkali compound, 10-30 parts of stuffing and 60-100 parts of abrasive material; dissolving the components in glycol ether; adding 2-5 parts of catalyst; heating and mixing at a constant temperature within 30-50 DEG C; mixing to a semi-gel state, adding 0.5-1 parts of template to sinter, wherein the sintering temperature is 300-400 DEG C and the sintering time is 6-9 hours, quickly annealing and cooling, smashing, sieving and separating abrasive particles in same size. The abrasive particles prepared by the method provided by the invention are abrasion resistive and anti-blocking, and workpieces are not burned in long time grinding.

Owner:ZIBO RIKEN MT COATED ABRASIVES

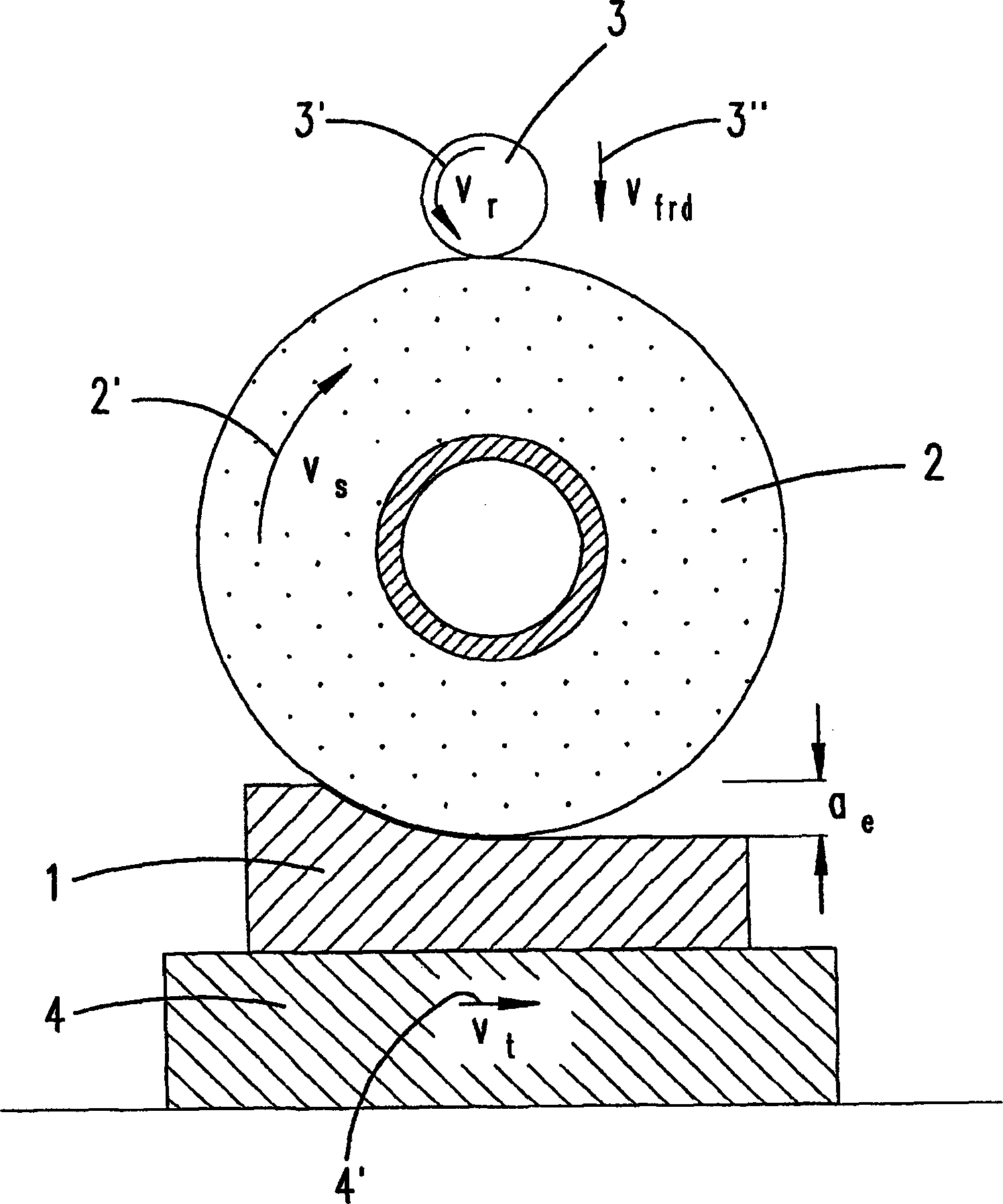

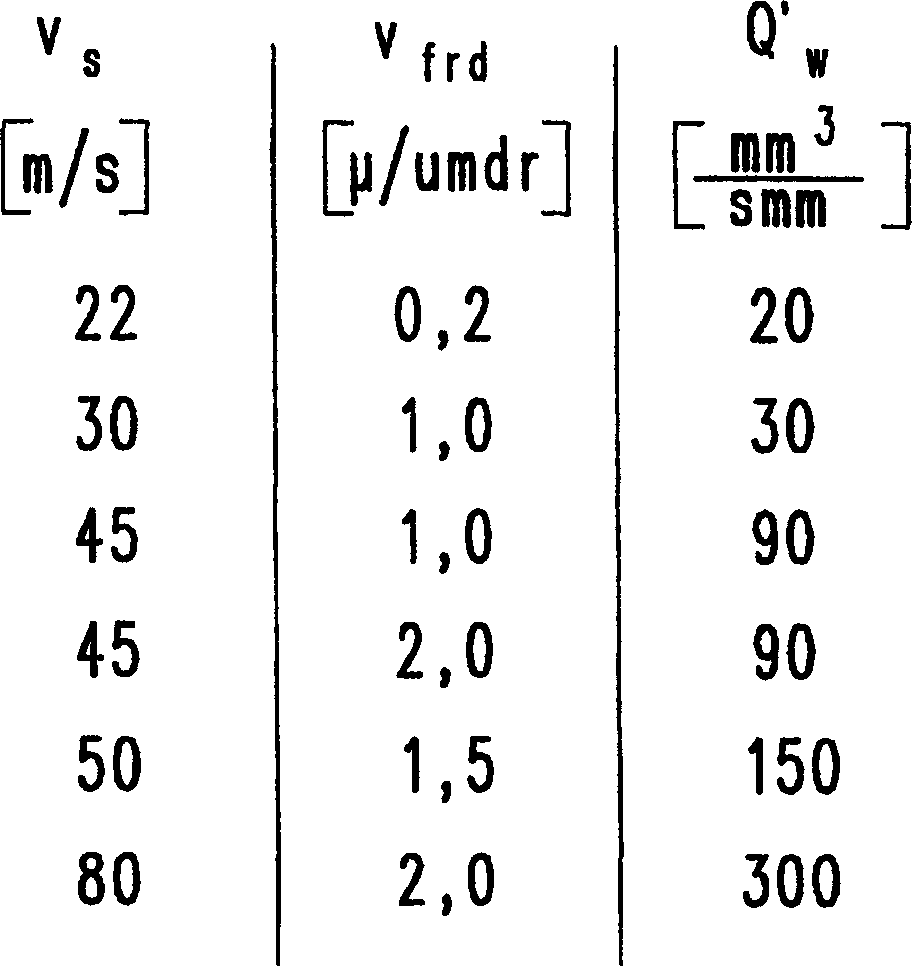

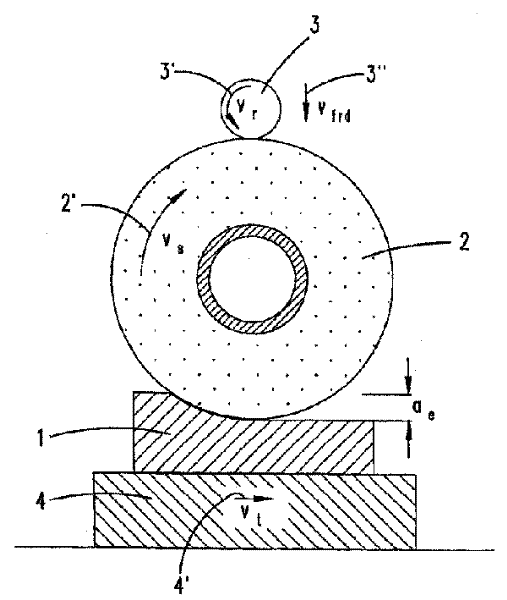

Method for grinding metallic workpieces containing, in particular nickel

InactiveCN1430546AHigh removal rateIncrease sharpnessBonded abrasive wheelsAbrasive surface conditioning devicesGrinding wheelMetallic Nickel

The invention relates to a method for grinding metallic workpieces containing, in particular, nickel, whereby a rotationally driven grinding wheel (2) is continuously dressed by a rotationally driven dressing wheel (3) during the grinding of the workpiece (1) by the continual advance (vfrd) of the dressing wheel. In order to increase the grinding capacity, the invention provides that with a dressing advance velocity of 1 to 2 mum per rotation of the grinding wheel and with a circumferential velocity of the grinding wheel (vs) of at least 45 m / s, the advance (table velocity vt) is set such that the rate of metal removal is at least 90 mm<3> / mms.

Owner:蒂罗利特研磨剂工厂斯瓦罗夫斯基两合公司

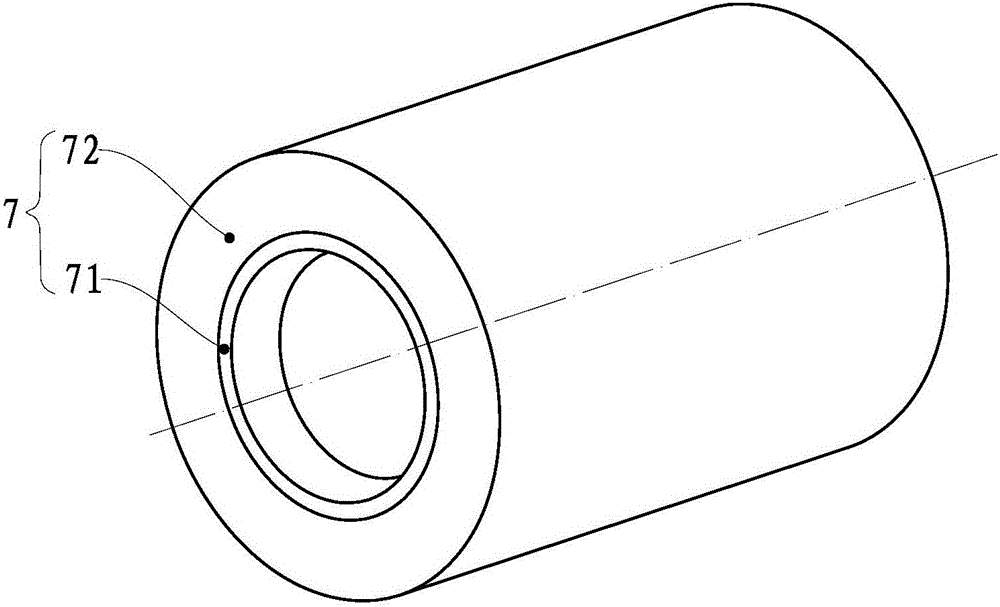

Ceramic metal bonding agent grinding tool and manufacturing method thereof

ActiveCN105751087AReduce manufacturing costImprove cooling effectBonded abrasive wheelsGrinding devicesCeramic metalRaw material

The invention provides a ceramic metal bonding agent grinding tool and a manufacturing method thereof and belongs to the technical field of processing equipment. The ceramic metal bonding agent grinding tool comprises a grinding layer; the grinding layer is made of a raw material containing a metal bonding agent raw material, a temporary bonding agent, abrasive particles and Ti3AlC2. The ceramic metal bonding agent grinding tool provided by the invention has good grinding performance.

Owner:ZHUHAI JUHAI TECH

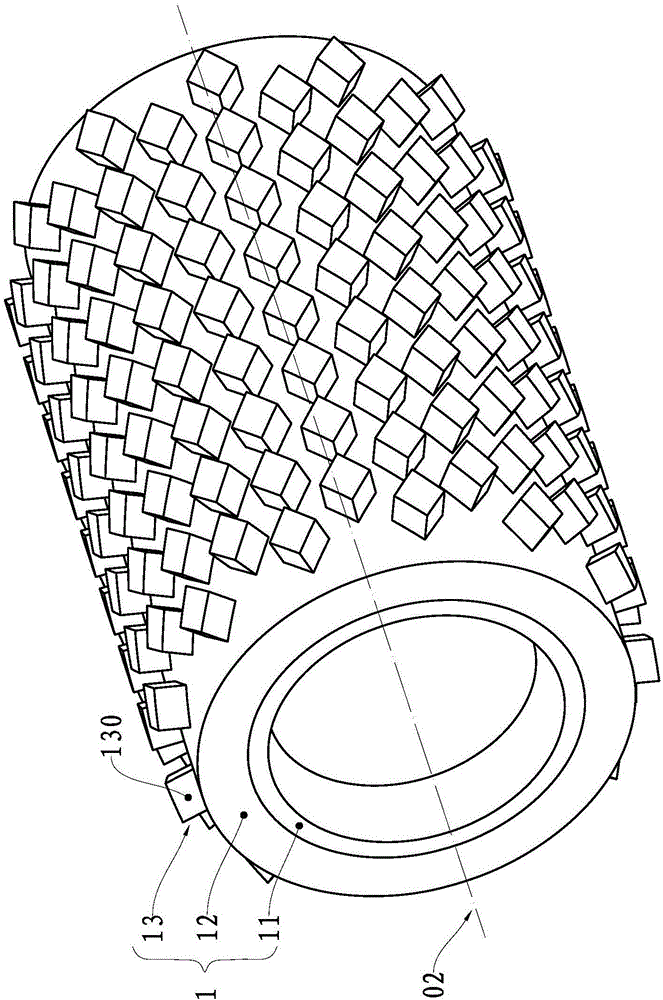

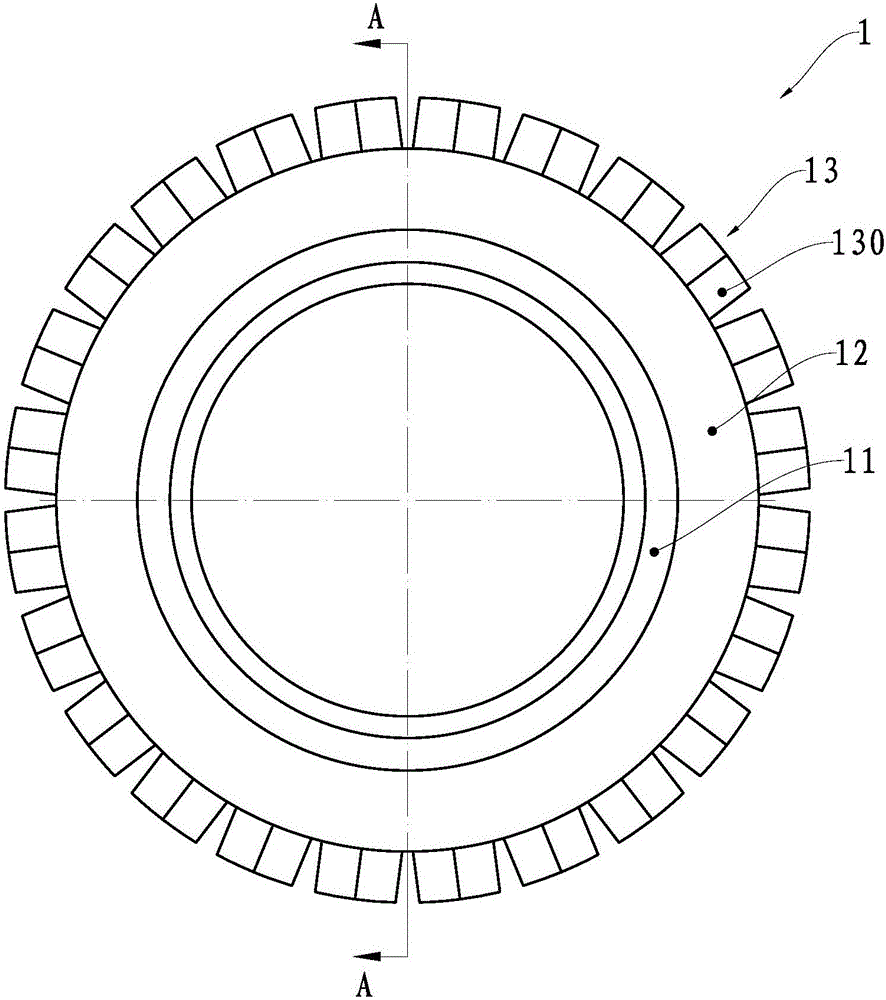

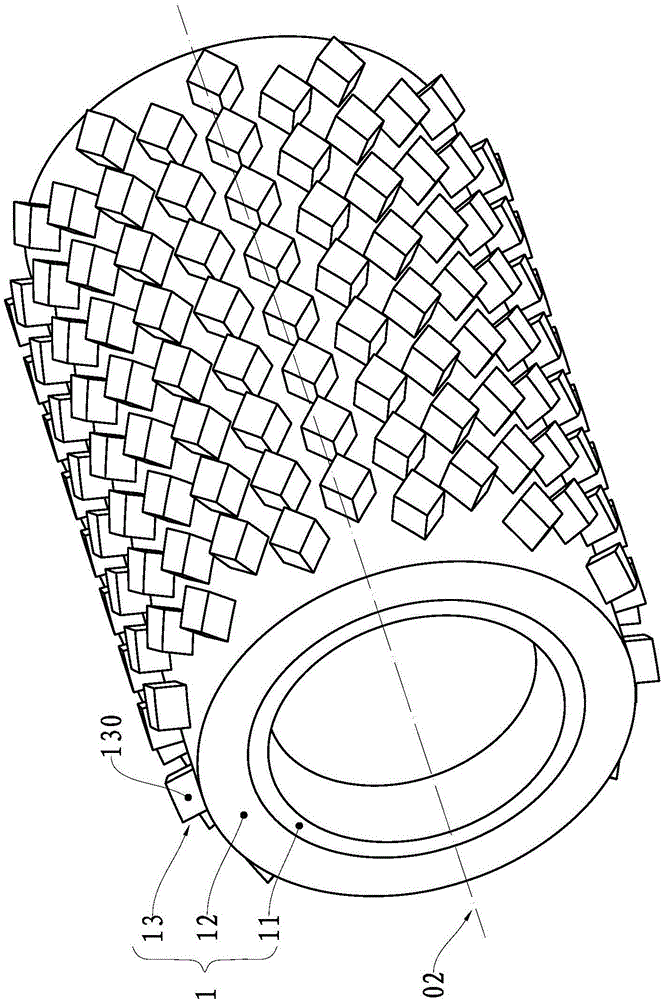

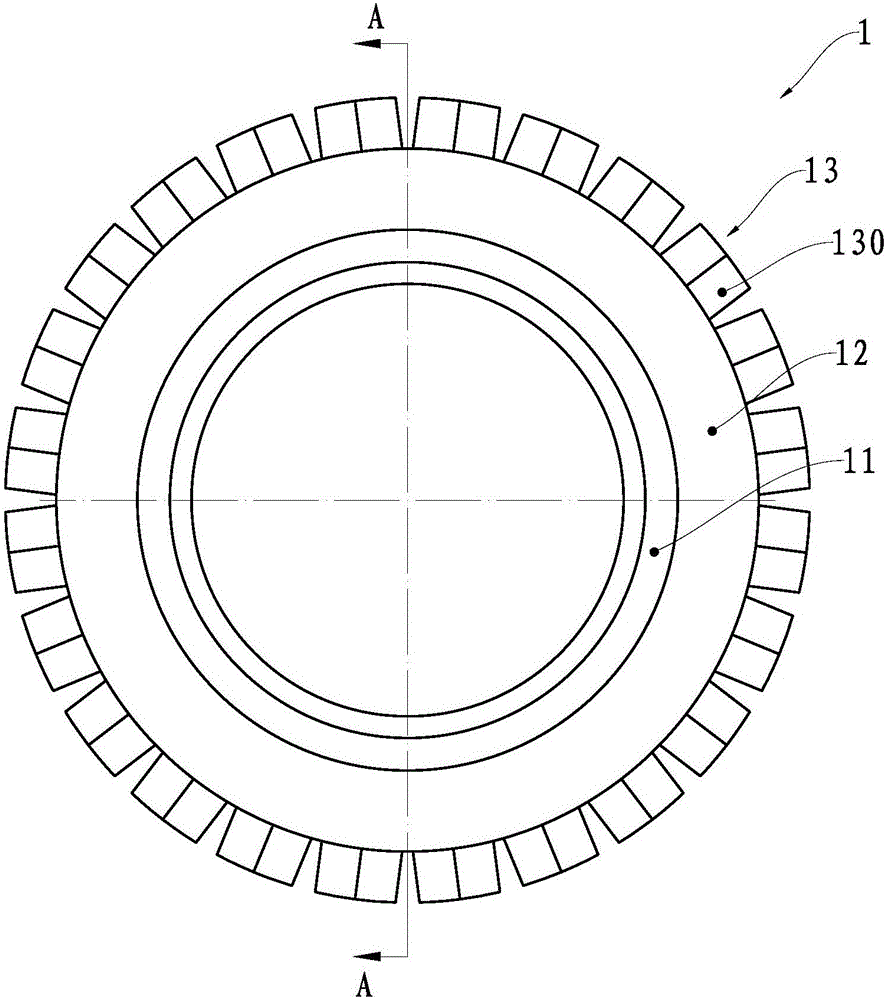

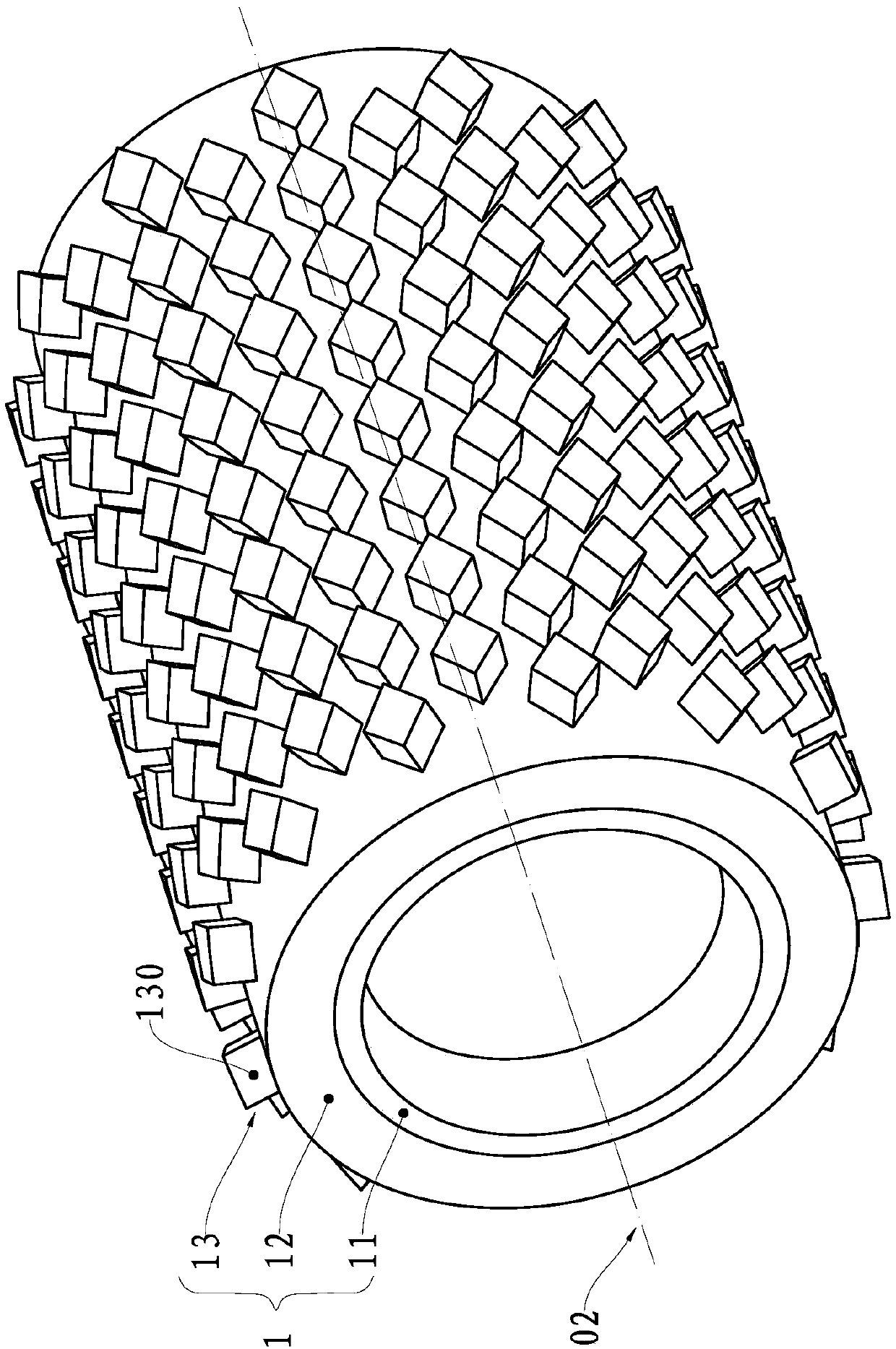

Grinding wheel for polishing and grinding ceramic tile biscuit, manufacturing method of grinding wheel and polishing and grinding apparatus and polishing and grinding method for ceramic tile biscuit

InactiveCN105729318AReduce manufacturing costImprove cooling effectBonded abrasive wheelsGrinding devicesGrinding wheelMachining

The invention relates to a grinding wheel for polishing ceramic tile blanks, a manufacturing method, a polishing device and a polishing method, and belongs to the technical field of ceramic tile processing. Wherein, the grinding wheel includes a mandrel, an elastic layer and a grinding layer. In the radial direction of the grinding wheel, the elastic layer is fixed between the mandrel and the grinding layer. The grinding layer consists of grinding blocks. By arranging an elastic layer between the grinding block and the mandrel, the missing throwing rate can be effectively reduced.

Owner:ZHUHAI JUHAI TECH

Resin binder grinding tool and manufacturing method thereof

InactiveCN105945738AReduce missed throw rateQuick polishingBonded abrasive wheelsGrinding devicesSodium carbonateGypsum

The invention provides a resin binder grinding tool and a manufacturing method thereof, and belongs to the technical field of machining equipment. The resin binder grinding tool comprises a substrate and a grinding layer. Raw materials of the grinding layer comprise, by weight, 61-66 parts of phenolic resin powder, 0-8 parts of zinc oxide, 0-5 parts of barium sulfate, 0-4 parts of sodium carbonate, 5-9 parts of semi-hydrated gypsum powder, 3-4 parts of white carbon black, 5-10 parts of poly-butyraldehyde, 3-6 parts of zinc stearate, 0-6 parts of zirconium oxide and 4.5-5 parts of diamond. The resin binder grinding tool made from the raw materials is suitable for accurate grinding of tile biscuits.

Owner:ZHUHAI JUHAI TECH

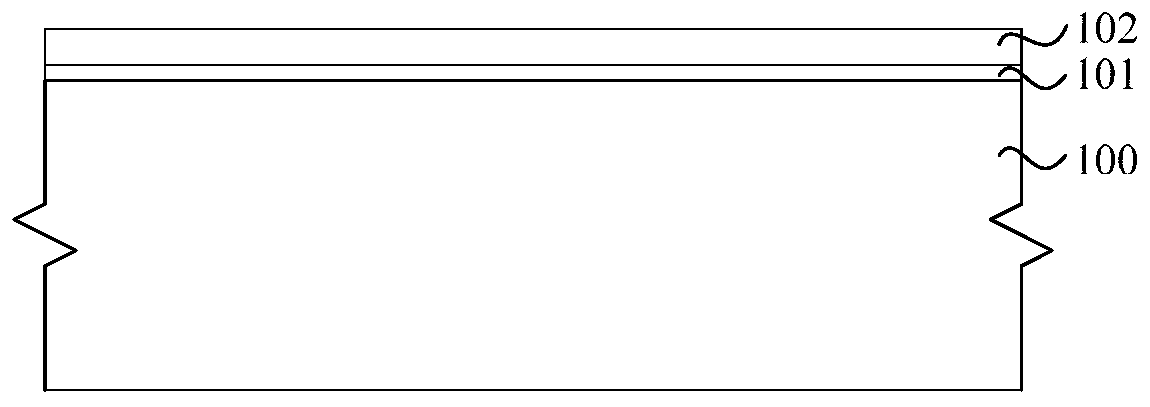

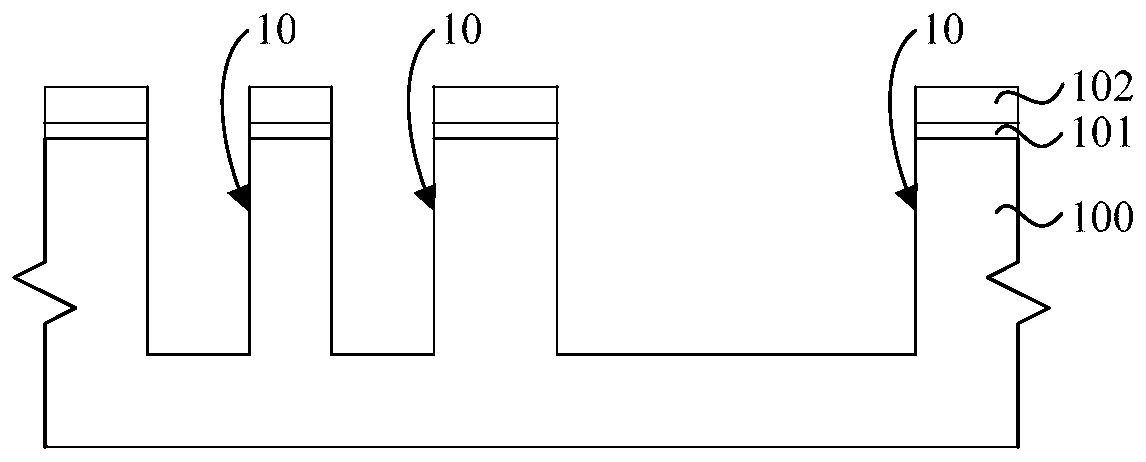

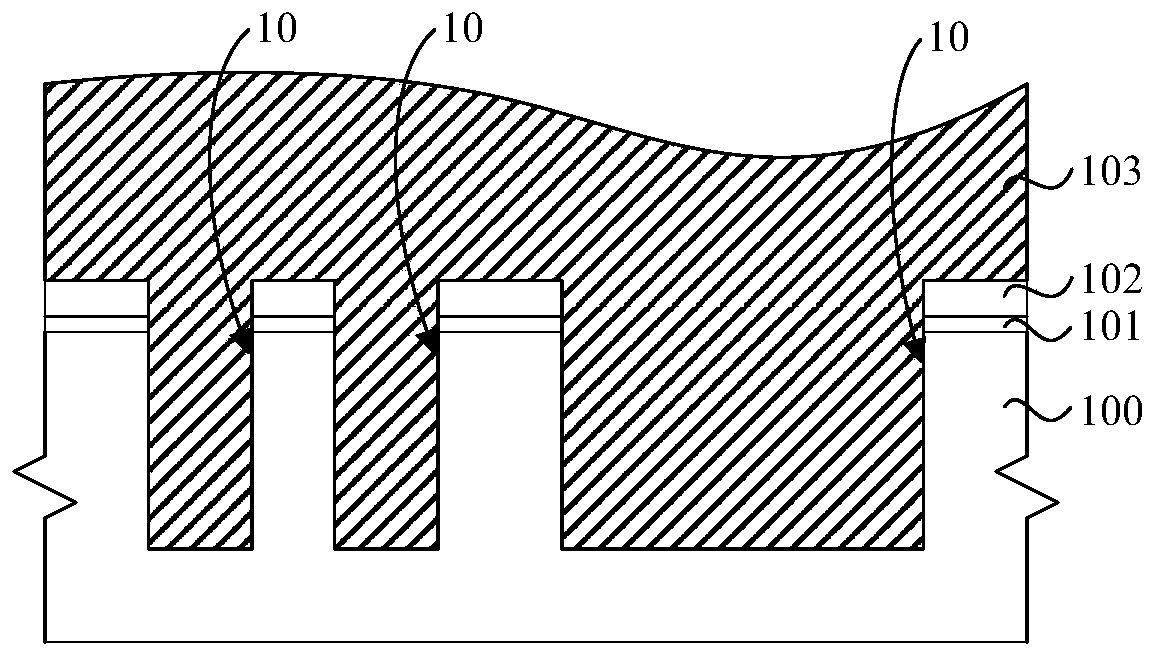

Semiconductor structure and forming method thereof

PendingCN111584616ALarge amount of grindingNot prone to dentsSemiconductor/solid-state device manufacturingSemiconductor devicesCrystallographyEtching

The invention provides a semiconductor structure and a forming method thereof. The forming method comprises the following steps: before filling a first groove on a pretreatment substrate by using a filling material, forming an auxiliary layer covering the inner surface of the first groove; forming a first filling medium and carrying out back etching, wherein the upper surface of the obtained firstfilling medium is higher than the upper surface of the pretreatment substrate; and then forming a second filling medium and executing a second planarization process. Since the grinding amount of thefirst groove region is greater than that of the surrounding region, the first groove region is not easy to sink after the second planarization process is completed; the process of filling the first groove does not need to adopt a photoresist and an exposure process, so that implementation is convenient, and the cost is lower; and according to the semiconductor structure formed by the forming method, the surface with better flatness can be obtained, so that the quality is higher.

Owner:NEXCHIP SEMICON CO LTD

Numerical control grinding machine

InactiveCN107378668ALarge amount of grindingGrinding feedersGrinding work supportsNumerical controlEngineering

The invention discloses a numerical control grinding machine. The numerical control grinding machine comprises a machine tool body, a carrying table and a grinding wheel assembly, wherein the carrying table is arranged on the machine tool body, and the grinding wheel assembly is arranged above the carrying table and is used for grinding a workpiece on the carrying table. The numerical control grinding machine is characterized in that the carrying table is in rotating fit with the machine tool body, an adjusting device is arranged on the machine tool body and is used for adjusting the dip angle between the upper end surface of the carrying table and the horizontal plane, and when the carrying table is adjusted to a set position, the carrying table is fixed relative to the position of the machine tool body. The numerical control grinding machine has the advantages that only the surface, to be machined, of the workpiece can be ground, the influence on the thickness of the workpiece is small, and therefore the grinding amount is small, and the efficiency is high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Inner surface grinding equipment for special-shaped casting

InactiveCN114850991AReduce forceIncrease forceRevolution surface grinding machinesGrinding/polishing safety devicesPolishingEngineering

The invention relates to the field of grinding machining, in particular to special-shaped casting inner surface grinding equipment which comprises a center shaft, a grinding mechanism and an adjusting mechanism, the center shaft extends in the left-right direction, and the center shaft is driven by an external driving element to rotate and feed from right to left; each polishing mechanism comprises two polishing units, when the polishing units rotate along with the center shaft and the diameters of the inner surfaces of the castings are different, the swing amplitudes of swing arms of the two polishing units are different, the adjusting mechanisms enable the mass centers of the polishing units with the large swing amplitudes to be closer to the center shaft, and the acting force of the polishing units on the inner surfaces of the castings is reduced by reducing the centrifugal force of the polishing units. Therefore, the grinding amount of the grinding unit on the inner surface of the casting is reduced; and the adjusting mechanism enables the mass center of the polishing unit with the small swing amplitude to be farther away from the center shaft, the acting force of the polishing unit on the inner surface of the casting is increased by increasing the centrifugal force of the polishing unit, and therefore the grinding amount of the polishing unit on the inner surface of the casting is increased, and the deformation degree of the inner surface of the casting is overall reduced.

Owner:泗洪晶隆机械制造有限公司

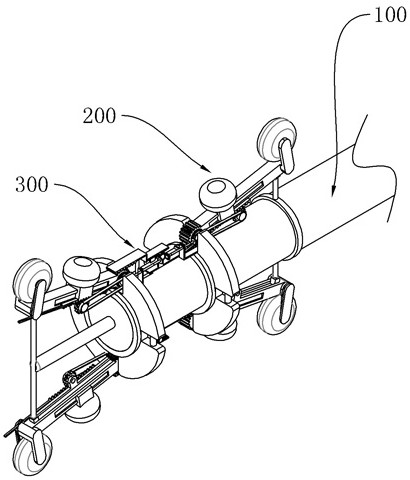

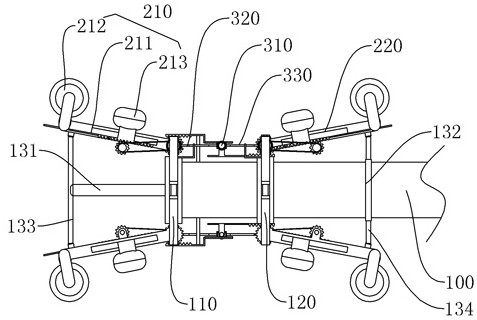

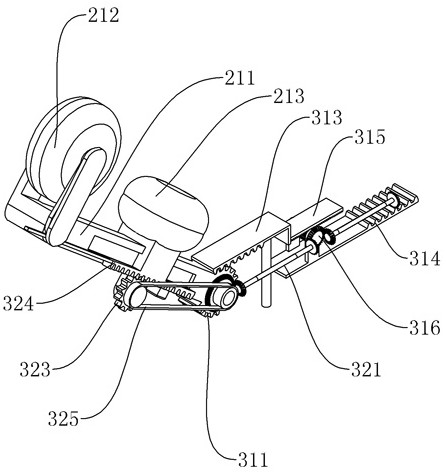

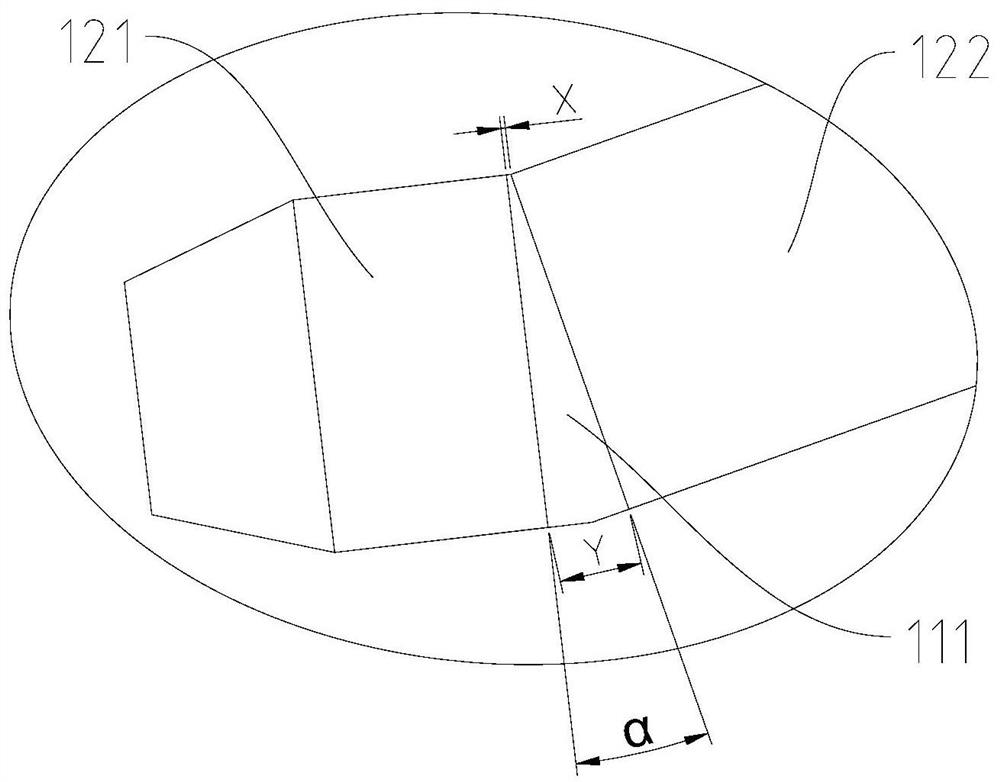

Steel rail fat edge grinding device and steel rail grinding wagon

PendingCN113152177AFlexible polishing strategyImprove work efficiencyRailway track constructionVehicle frameSurface grinding

The invention discloses a steel rail fat edge grinding device and a steel rail grinding wagon. The grinding device comprises a frame arranged at the bottom of the steel rail grinding wagon, a traction mechanism mounted between the frame and the bottom of the steel rail grinding wagonfor transmitting traction force and driving the steel rail grinding unit to perform grinding operation along a rail, and a steel rail polishing unit mounted on the frame and configured into an end face polishing unit or a cambered surface polishing unit. The end face grinding unit is used for conducting targeted grinding on the fat edge of the inner side of the steel rail, and the cambered surface grinding unit is used for conducting profile enveloping grinding on the steel rail. The technical problems that an existing grinding device is single in strategy, the grinding mode cannot be adjusted according to actual needs, the requirement for large grinding amount cannot be met at the same time, plastic fat edges of the steel rail cannot be removed, and what can be guaranteed is that the profile and the surface roughness of the ground steel rail meet the requirements can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

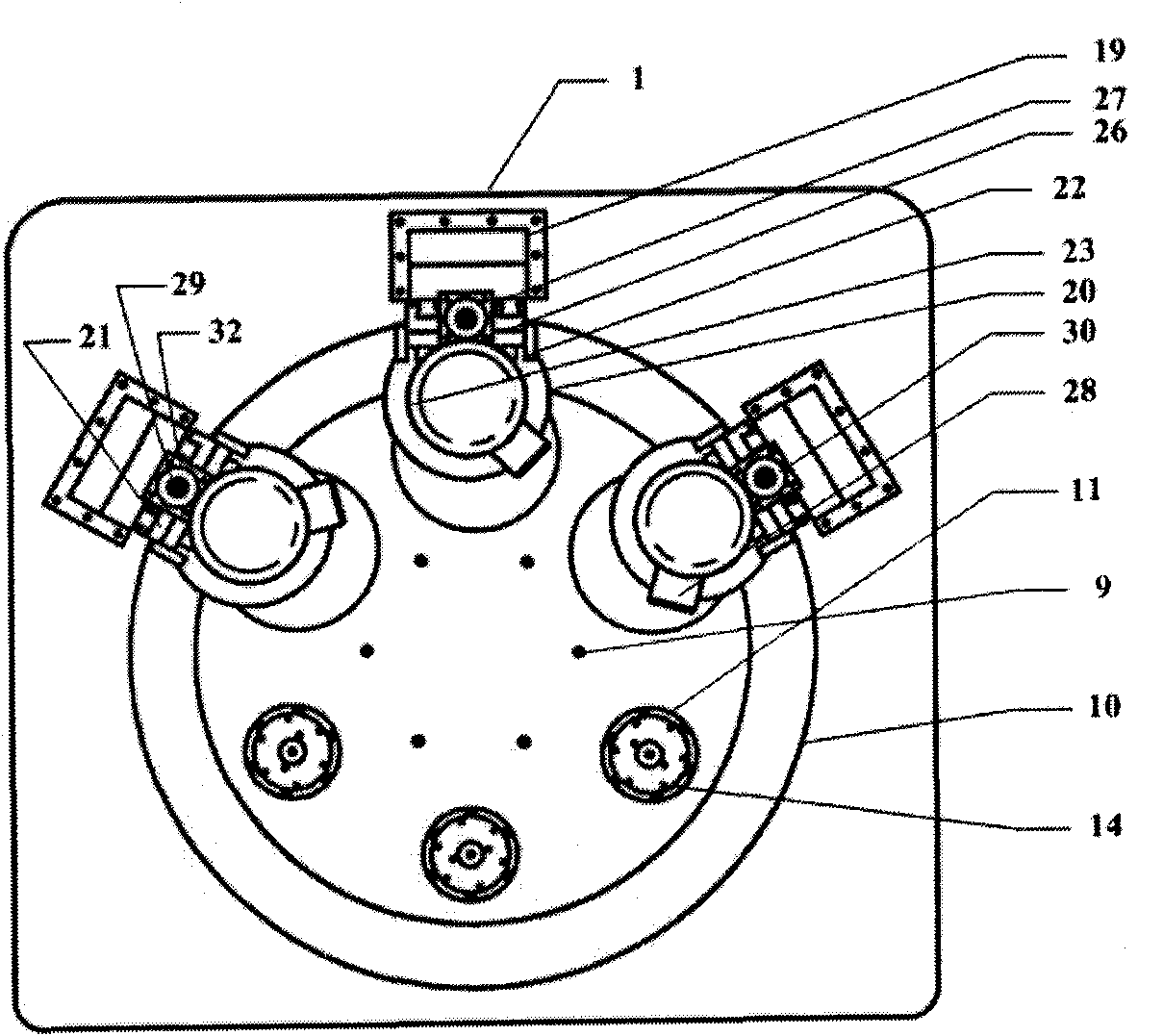

Multi-head high-speed grinder

InactiveCN101927452AEasy to assemble and disassembleReasonable design structureLapping machinesLapping toolsSuperhard materialElectric machinery

The invention relates to a multi-head high-speed grinder comprising a transmission part, an upper grinding disk part and a lower grinding disk part, wherein the transmission part is arranged in a stand and consists of an upper grinding head main motor, a lower disk motor and an upper grinding head servo motor; upper grinding heads in the upper grinding disk part are connected with the upper grinding head main motor; and the upper grinding heads are also provided with grinding head shaft grinding wheels. In the invention, the design structure is reasonable and compact, the upper grinding heads are directly connected with a high-speed motor, therefore, the rotating speed of the upper grinding heads reaches 2900 turns / minute, and the grinding amount is larger; the feed amount of the upper grinding heads is set to be 0.001mm, therefore, the grinding accuracy is greatly improved, and the grinding amount, the planeness and the parallel degree can also be increased; and in addition, the number of the upper grinding heads is set to be three, and three grinding modes, i.e. coarse grinding, medium grinding and fine grinding can be carried out on workpieces when upper grinding heads are rotated per turn; and the multi-head high-speed grinder is more suitable for grinding superhard materials to meet the requirements of customers.

Owner:深圳市方达研磨技术有限公司

A CNC grinding machine

InactiveCN107378668BLarge amount of grindingGrinding feedersGrinding work supportsNumerical controlEngineering

The invention discloses a numerical control grinding machine. The numerical control grinding machine comprises a machine tool body, a carrying table and a grinding wheel assembly, wherein the carrying table is arranged on the machine tool body, and the grinding wheel assembly is arranged above the carrying table and is used for grinding a workpiece on the carrying table. The numerical control grinding machine is characterized in that the carrying table is in rotating fit with the machine tool body, an adjusting device is arranged on the machine tool body and is used for adjusting the dip angle between the upper end surface of the carrying table and the horizontal plane, and when the carrying table is adjusted to a set position, the carrying table is fixed relative to the position of the machine tool body. The numerical control grinding machine has the advantages that only the surface, to be machined, of the workpiece can be ground, the influence on the thickness of the workpiece is small, and therefore the grinding amount is small, and the efficiency is high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Ball mill

InactiveCN102688793BLarge amount of grindingImprove grinding efficiencyGrain treatmentsEngineeringBall mill

The invention discloses a ball mill which comprises a stator cylinder body consisting of a bottom surface, an outer-circle cylinder wall and an inner-circle cylinder wall and a rotor cylinder body consisting of a top surface, a rotor cylinder wall, a central post and a connecting shaft, wherein the rotor cylinder wall is arranged between the outer-circle cylinder wall and the inner-circle cylinder wall, the central post is arranged in the inner-circle cylinder wall, an outer-circle grinding cavity is formed between the outer-circle cylinder wall and the rotor cylinder wall, a middle-circle grinding cavity is formed between the rotor cylinder wall and the inner-circle cylinder wall, and an inner-circle grinding cavity is formed between the inner-circle cylinder wall and the central post, so that the ball mill disclosed by the invention is provided with three grinding cavities, and the material enters from a material inlet, and is sequentially ground by the outer-circle grinding cavity, the middle-circle grinding cavity and the inner-circle grinding cavity, screened by a screening device, and discharged outside a material outlet, therefore, compared with the ball mill which is provided with only one grinding cavity, the ball mill is higher in grinding quantity, and higher in grinding efficiency.

Owner:苏州聚贝机械设计有限公司

Equal channel angular extrusion method

The invention discloses an equal channel corner extrusion method. The channel angular extrusion method includes steps: (1) extruding the green body: putting the green body into the extrusion section of the L channel and being extruded to the forming section; (2) pushing out the green body: putting the granular material into Squeeze in the extrusion section so that the green body is pushed out of the discharge port of the forming section; (3) Take out the granular material. First of all, the extruded particles can be hollowed out by extending the strips into the forming section without forming back pressure, that is, when the green body is extruded each time, there is no residue of the last extrusion in the L channel, so that The green body is always the first to be extruded, and the shape of the obtained green body is not a parallelogram or a rhombus, but a regular cuboid shape, which will not cause waste of materials, and can reduce the grinding time when performing multi-pass extrusion. Secondly, the loading force required for the extrusion of granular materials is significantly smaller than the extrusion force of the back pressure method, which can significantly save energy consumption.

Owner:SOUTHWEST JIAOTONG UNIV

Grinding method for roll groove profile of chain riveting head machine

The invention discloses a grinding method for the roller groove profiles of a chain riveting machine and belongs to the technical field of grinding. The grinding method comprises the steps of (a) driving upper and lower two groups of rollers to rotate by a driving main shaft, (b) selecting an electric grinding machine on which a thin grinding wheel and turning on the electric grinding machine for running, (c) putting the grinding wheel rotating at a high speed to the V-shaped groove of one roller from the left side or the right side of the roller and adjusting the grinding wheel to be flush with one side of the V-shaped groove for grinding according to the angle of the V-shaped groove, and grinding the groove on the other side of the V-shaped groove by use of the same method, (d) repeating the step (c) to grind the V-shaped grooves of the upper and lower two groups of rollers, and (e) fine adjusting the space between the upper and lower two groups of rollers to compensate the quantity of grinding of the roller groove profiles. The grinding method for the roller groove profiles of the chain riveting machine is capable of realizing quick grinding of the roller groove profiles without demounting the rollers, and is good in grinding quality, and meanwhile, simple and easy to operate, and low in quantity of grinding on the rollers; the rollers are durable and a matching error generated by re-mounting after turning removal is avoided.

Owner:溧阳市超强链条制造有限公司

Numerical control automatic tooth profile strength forming grinder

InactiveCN100566936CImprove the finishExtended service lifeAbrasive surface conditioning devicesGrinding machinesStopped workHigh pressure

The invention discloses a numerical control full-automatic tooth-profile strength molding grinder, which comprise a grinder body, a working table, a grinding head, a grinding wheel dresser, an automatic feeding mechanism, a grinding head transverse feeding mechanism, a grinding head vertical feeding mechanism, a clamp, a work piece fixed-length feeding device, a medium pressure and large flow cooling and lubricating and high pressure washing pumping station, a precise filter and a numerical control system. In the invention, the grinding wheel dresser is arranged at the back of the working table; when a machine tool is arranged at the position of stop working, the grinding wheel is positioned between the working table and the grinding wheel dresser, and does not touch the work piece and the dresser; when the machine tool is grinding, the grinding wheel moves in working feed forward, and grinds the work piece in strength molding; when the grinding wheel needs dressing, the grinding wheel moves backward and passes through the grinding wheel dresser to finish the dressing and the depth control of the machining dimension, therefore the dimension of the grinding wheel changed by the dressing will not influence the machining precision. The machine tool can finish a full-automatic cycle movement through a four or five-axis numerical control system.

Owner:徐震 +1

Automobile part grinding sheet

The invention discloses an automobile part grinding sheet which comprises a grinding sheet body and a base layer. The automobile part grinding sheet is characterized in that the grinding sheet body is located on the outer side of the base layer which is provided with a round groove, a shaft hole is formed in the center of the base layer, the axis of the shaft hole is identical to that of the round groove of the base layer, and a plurality of grinding racks are arranged on the periphery of the grinding sheet body in an embedded fit mode. The thickness of the grinding sheet body ranges from 12mm to 18 mm. The automobile part grinding sheet provided by the invention is convenient to install, low in cost and large in grinding amount, the working efficiency is improved, and noise is lowered; and by the adoption of the grinding racks made of brown aluminum oxide, the service life is greatly prolonged, and the surface finish-machining effect is excellent.

Owner:TIANJIN ZHONGDA PRECISION MACHINERY

Equal-channel angular pressing method

The invention discloses an equal-channel angular pressing method. The equal-channel angular pressing method comprises the steps of (1) billet extruding: a billet is placed into an extruding segment ofan L channel and extruded to a molding segment; (2) billet pushing: a particle material is placed into an extruding segment to be extruded so as to make the billet be pushed out of a discharging opening of the molding segment; and (3) particle material taking out. Firstly, a strip-shaped object can be used to stretch into the molding segment to take the extruded particles out, back pressure cannot be formed, namely, when the billet is extruded each time, the residue extruded at the last time does not exist in the L channel, so that the billet is always the first to be extruded out, the shapeof the obtained billet is not parallelogram or diamond, while the regular cuboid shape is retained, the waste of the material cannot be caused, and the polishing time can be reduced during multi-passextruding; and secondly, the loading force required by adopting the particle material extruding is significantly lower than the extruding force by adopting the back pressure manner, and the energy consumption can be significantly reduced.

Owner:SOUTHWEST JIAOTONG UNIV

Grinding method for roller groove profiles of chain riveting machine

The invention discloses a grinding method for the roller groove profiles of a chain riveting machine and belongs to the technical field of grinding. The grinding method comprises the steps of (a) driving upper and lower two groups of rollers to rotate by a driving main shaft, (b) selecting an electric grinding machine on which a thin grinding wheel and turning on the electric grinding machine for running, (c) putting the grinding wheel rotating at a high speed to the V-shaped groove of one roller from the left side or the right side of the roller and adjusting the grinding wheel to be flush with one side of the V-shaped groove for grinding according to the angle of the V-shaped groove, and grinding the groove on the other side of the V-shaped groove by use of the same method, (d) repeating the step (c) to grind the V-shaped grooves of the upper and lower two groups of rollers, and (e) fine adjusting the space between the upper and lower two groups of rollers to compensate the quantity of grinding of the roller groove profiles. The grinding method for the roller groove profiles of the chain riveting machine is capable of realizing quick grinding of the roller groove profiles without demounting the rollers, and is good in grinding quality, and meanwhile, simple and easy to operate, and low in quantity of grinding on the rollers; the rollers are durable and a matching error generated by re-mounting after turning removal is avoided.

Owner:溧阳市超强链条制造有限公司

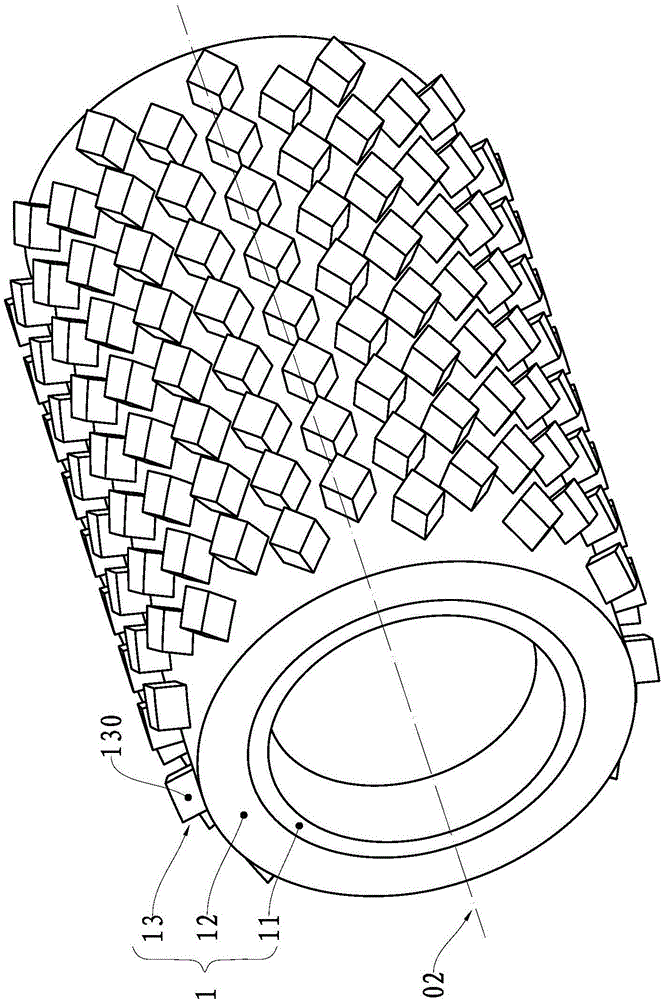

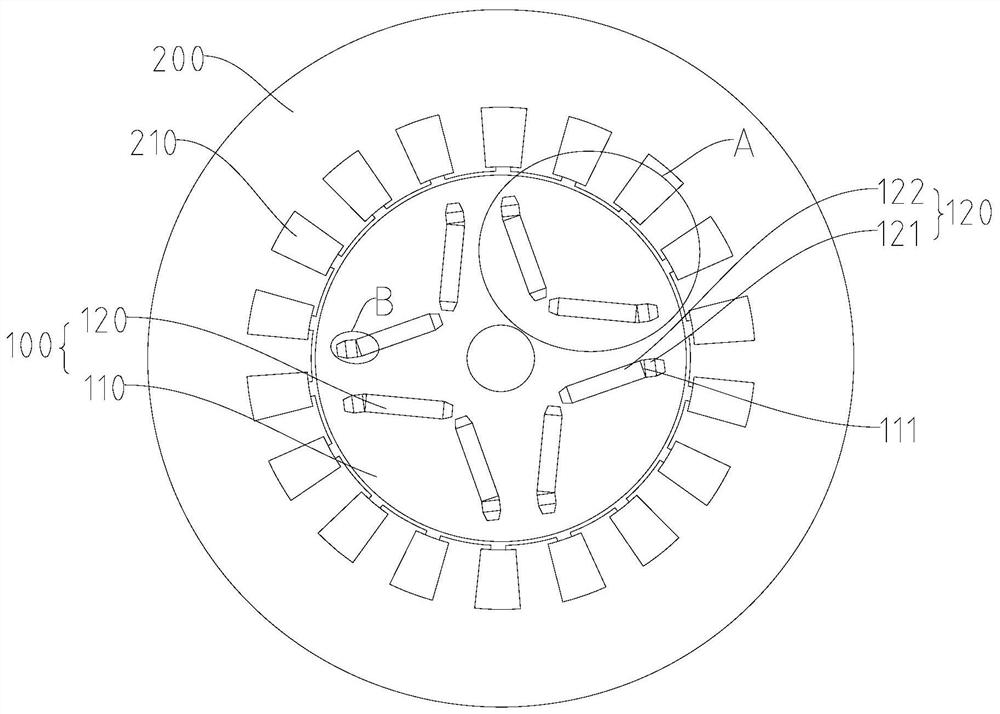

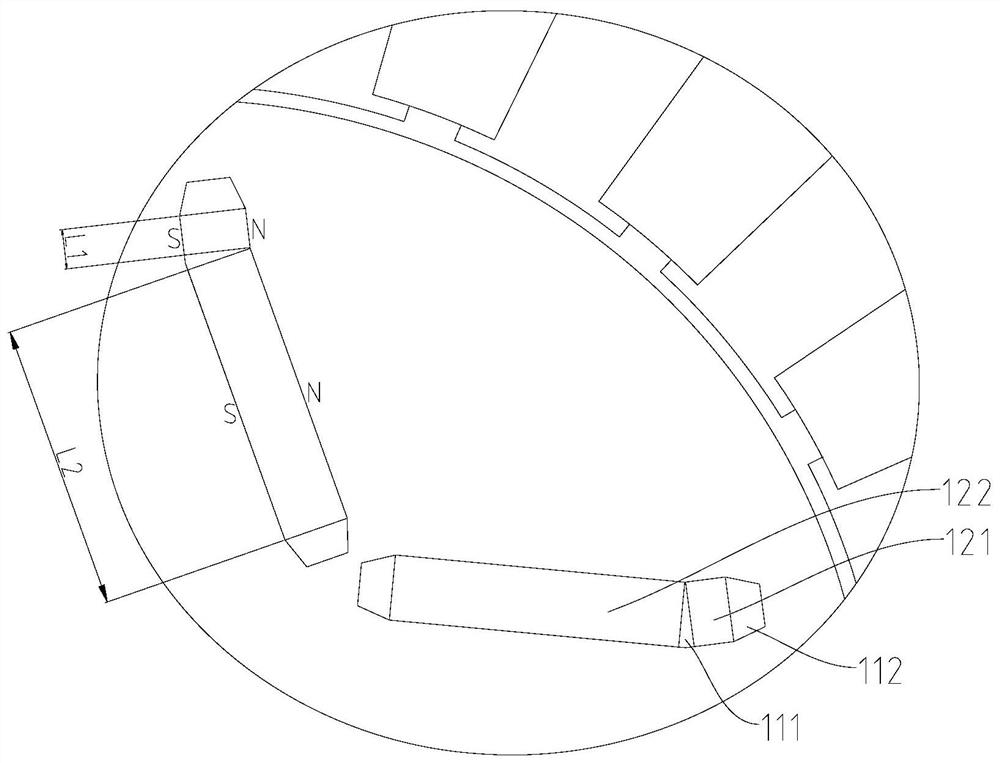

Motor rotor and IPM motor

ActiveCN113644768ALarge amount of grindingResistance to demagnetizing fieldMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsElectric machineEngineering

The present disclosure relates to a motor rotor and an IPM motor. The motor rotor comprises an iron core (110), mounting grooves (111) recessed from the end face of the iron core (110) and magnets (120) embedded in the mounting groove, wherein the mounting groove extends in a direction from the middle portion of the iron core to an outer peripheral surface, the magnets comprise first magnets and second magnets which are arranged at intervals in the extending directions of the mounting grooves, the magnetizing direction of the first magnets is perpendicular to the extending directions of the mounting grooves, the first magnets are fixed to the radial outer sides of the second magnets, and the coercive force of the first magnets is larger than that of the second magnets. According to the invention, the first magnets and the second magnets are arranged at intervals, the mode that the first magnets and the second magnets are combined into a whole through a complex bonding technology with higher cost does not need to be considered, and the problem that the two kinds of magnets combined into a whole are separated due to the fact that a binding agent is softened due to temperature rise in the working process is fundamentally eradicated.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Vitrified metal bond abrasive tool and manufacturing method thereof

ActiveCN105751087BReduce manufacturing costImprove cooling effectBonded abrasive wheelsGrinding devicesCeramic metalMetal binding

The invention provides a ceramic metal bonding agent grinding tool and a manufacturing method thereof and belongs to the technical field of processing equipment. The ceramic metal bonding agent grinding tool comprises a grinding layer; the grinding layer is made of a raw material containing a metal bonding agent raw material, a temporary bonding agent, abrasive particles and Ti3AlC2. The ceramic metal bonding agent grinding tool provided by the invention has good grinding performance.

Owner:ZHUHAI JUHAI TECH

Flexible abrasive wheel and wheel blank of flexible abrasive wheel

InactiveCN101342684AAvoid fragmentationImprove grinding efficiencyFlexible-parts wheelsEngineeringGrinding wheel

The present invention discloses a soft grinding wheel blank and a soft grinding wheel. The soft grinding wheel comprises an installing sleeve and a grinding wheel body. The grinding wheel body consists of bar sand-planted cloth wrapped around the installing sleeve. The adjacent sand-planted cloth is bonded as a whole by bond. The bar sand-planted cloth is molded sand-planted cloth which is made from soft bar cloth material as a substrate, and a single surface is planted with sands. The grinding wheel body of the present invention is made by wrapping the sand-planted cloth, and each layer is bonded with each other, so the soft grinding wheel has good integrity and also has certain flexibility, thereby avoiding the problem of grinding wheel cataclasm, preventing the potential safety hazard caused by the cataclasm, improving the grinding force and the grinding tolerance of the grinding wheel and greatly improving the grinding efficiency of the grinding wheel.

Owner:张占发

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com