Patents

Literature

185results about How to "Realize automatic grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

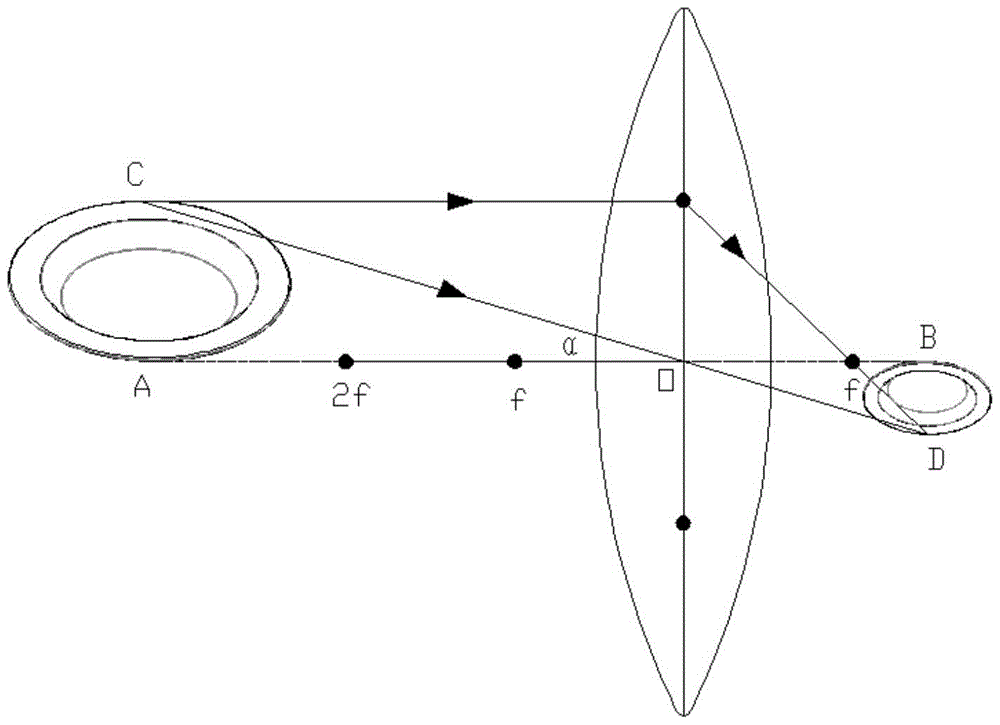

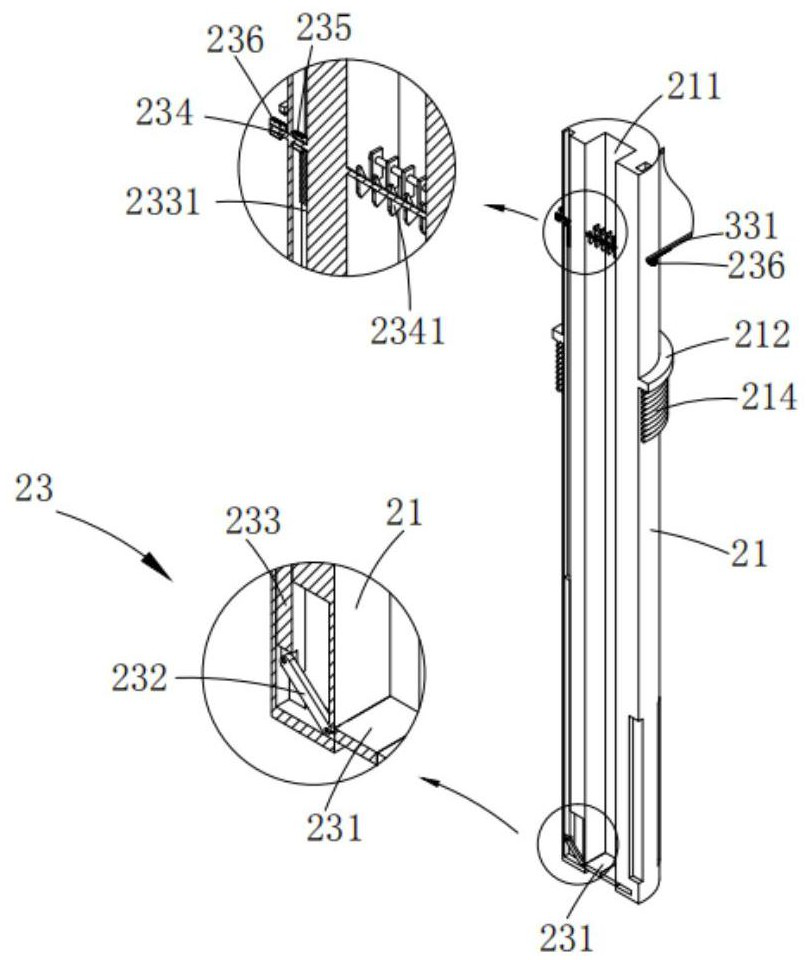

Preparation method, grinding method and device for microsection sample

ActiveCN103076216ARealize automatic grindingImprove grinding efficiencyPreparing sample for investigationColloidMaterials science

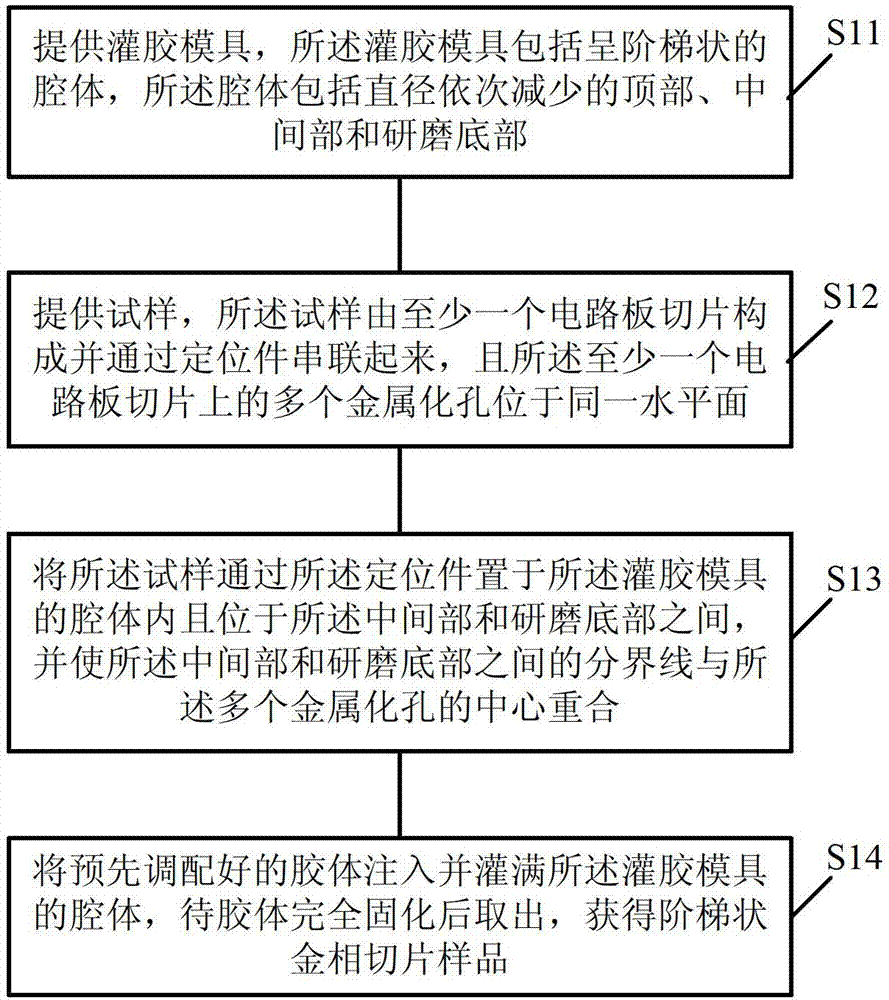

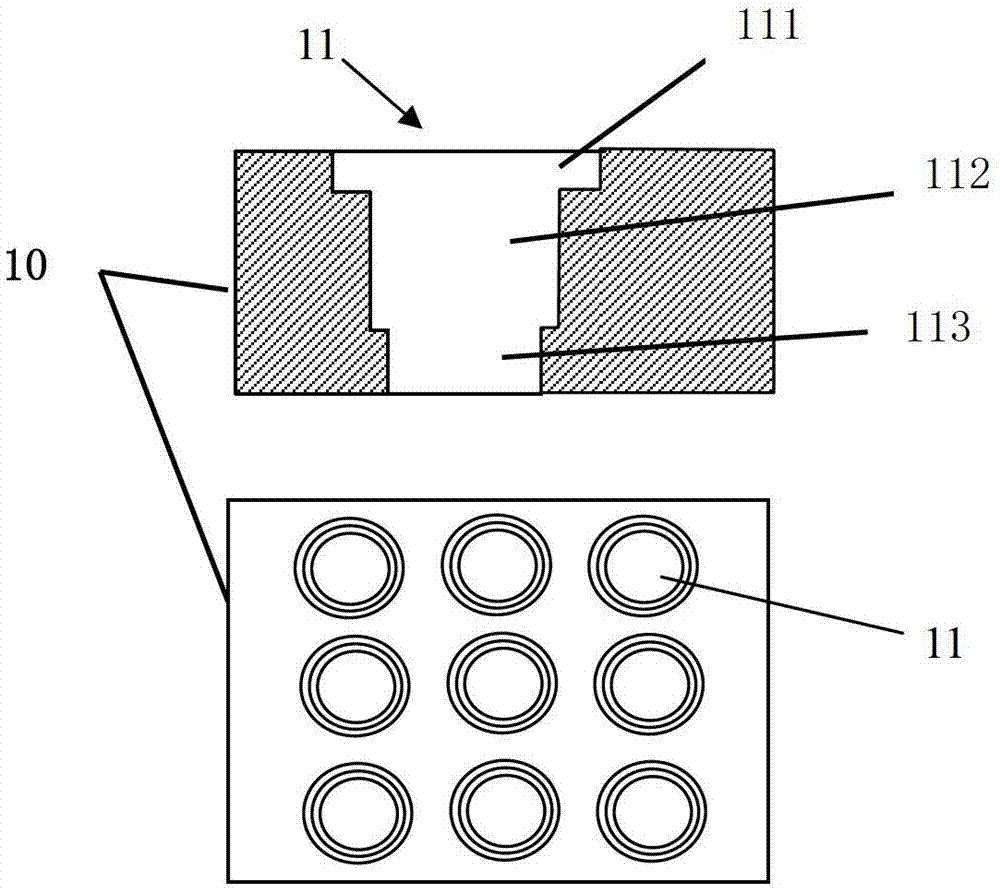

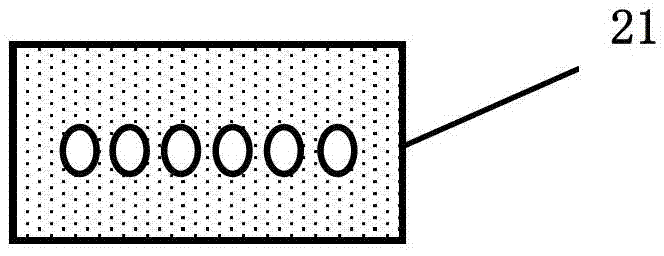

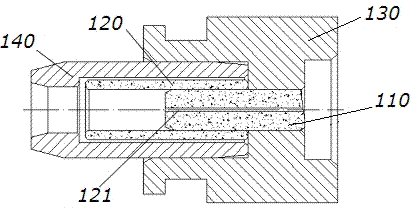

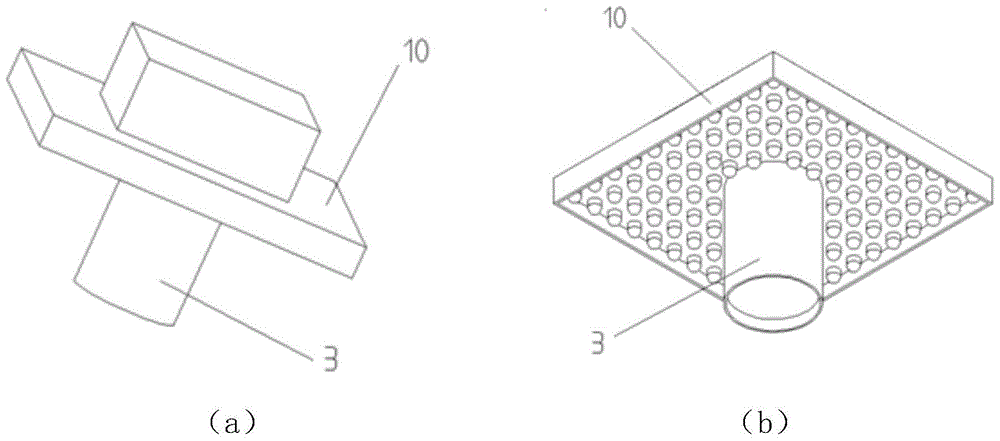

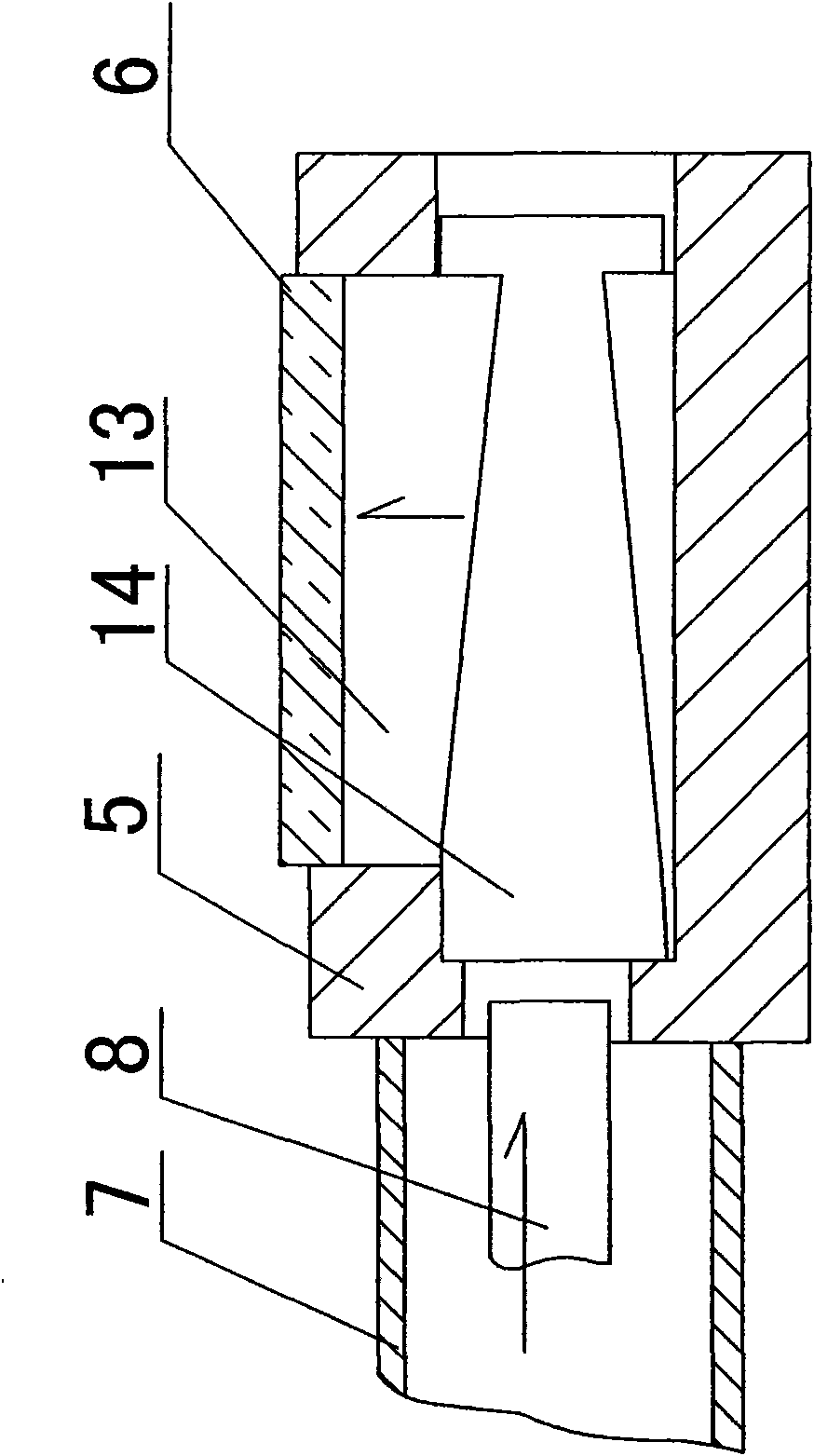

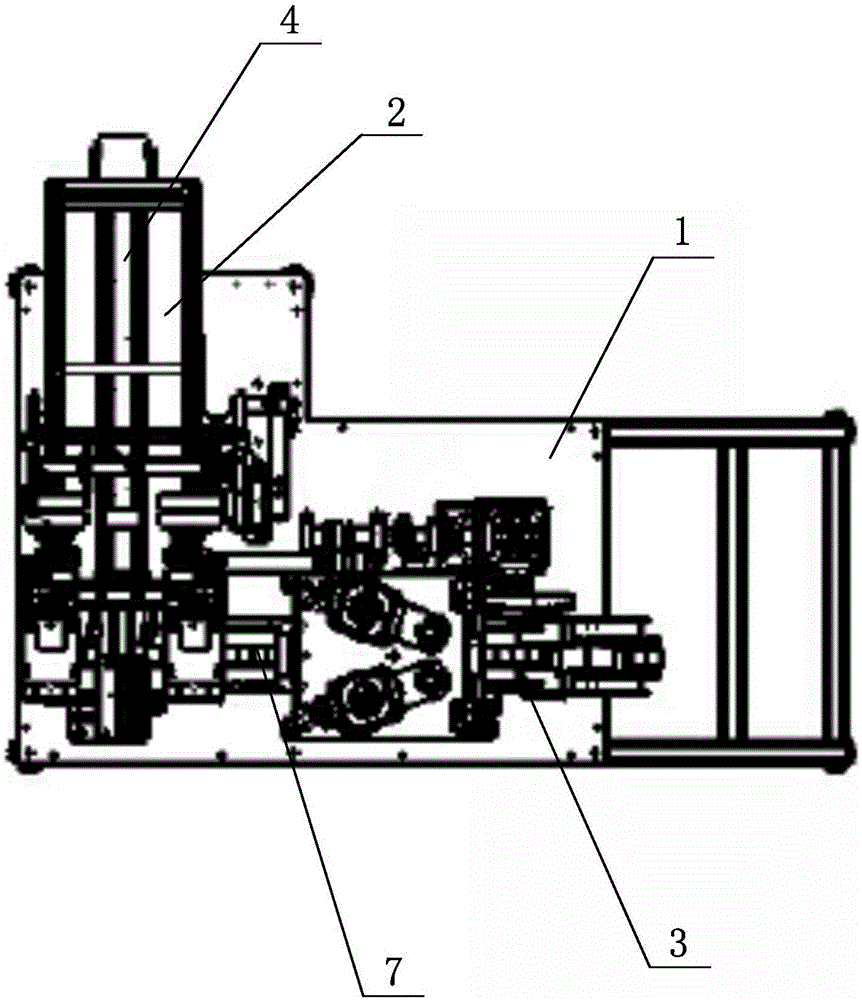

The invention discloses a preparation method for a microsection sample. The method comprises the following steps: providing a glue-pouring mould, wherein the glue-pouring mould comprises a step-shaped cavity, and the cavity consists a top part, a middle part and a bottom part, of which the diameters are sequentially reduced; providing a sample to be detected, wherein the sample to be detected comprises at least one circuit board slice connected in series through a positioning member, and a plurality of metalized holes in at least one circuit board slice are located in the same horizontal plane; placing the sample to be detected in the cavity of the glue-pouring mould through the positioning member and between the middle part and the bottom part of the cavity, and ensuring that a dividing line of the middle part and the bottom part is coincided with the center of the metalized holes; and pouring and filling pre-blended colloid into the cavity of the glue-pouring mould, and taking out the colloid after being completely cured to obtain the step-shaped microsection sample. The invention further discloses a grinding method and a device for a microsection.

Owner:GCI SCI & TECH

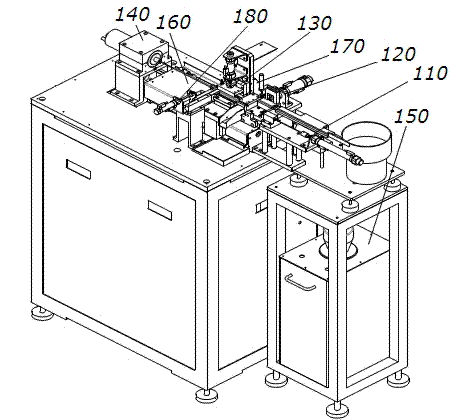

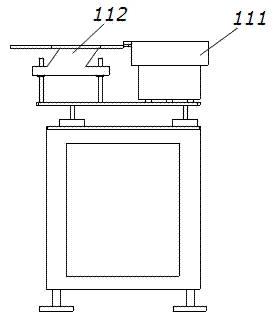

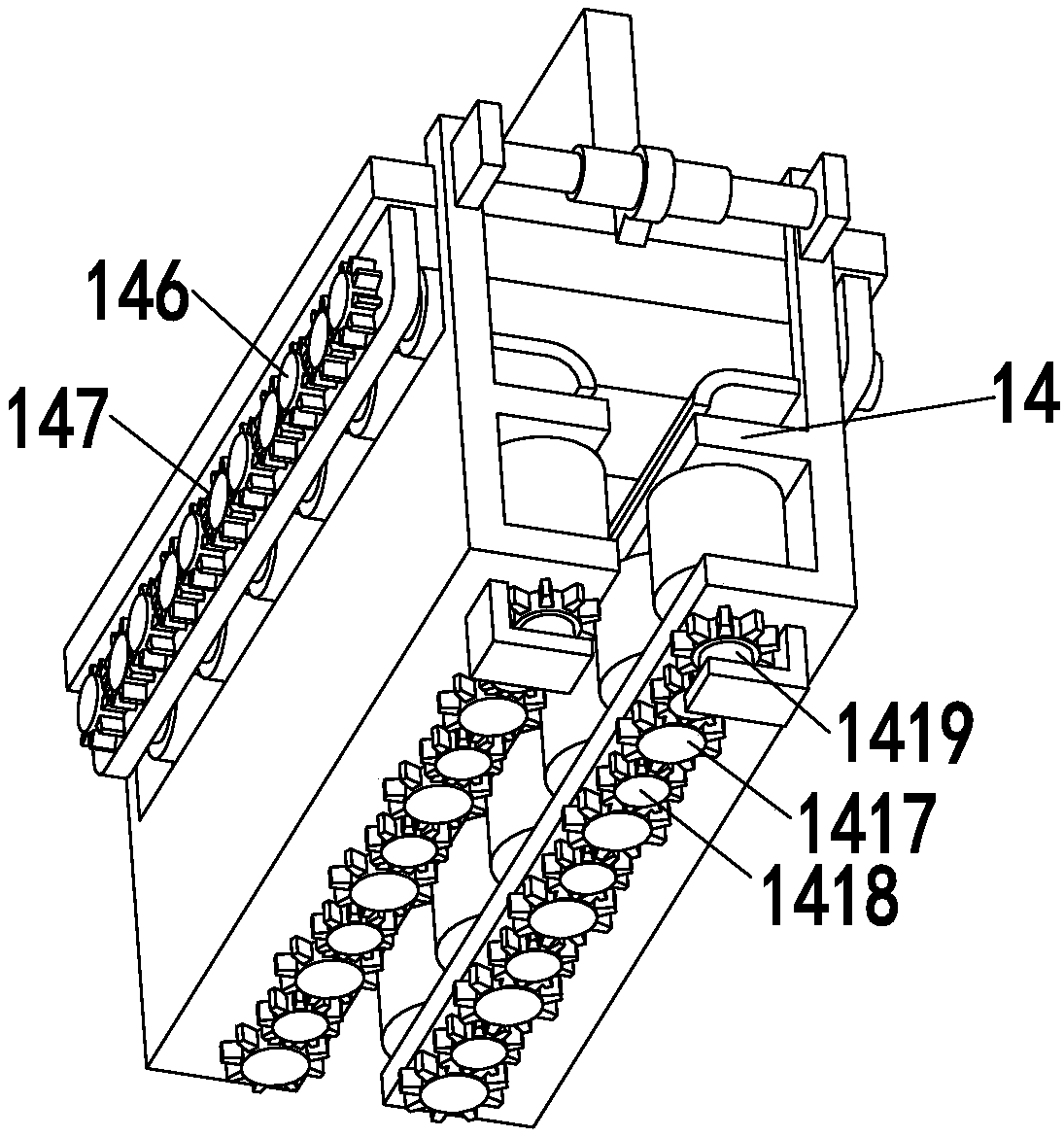

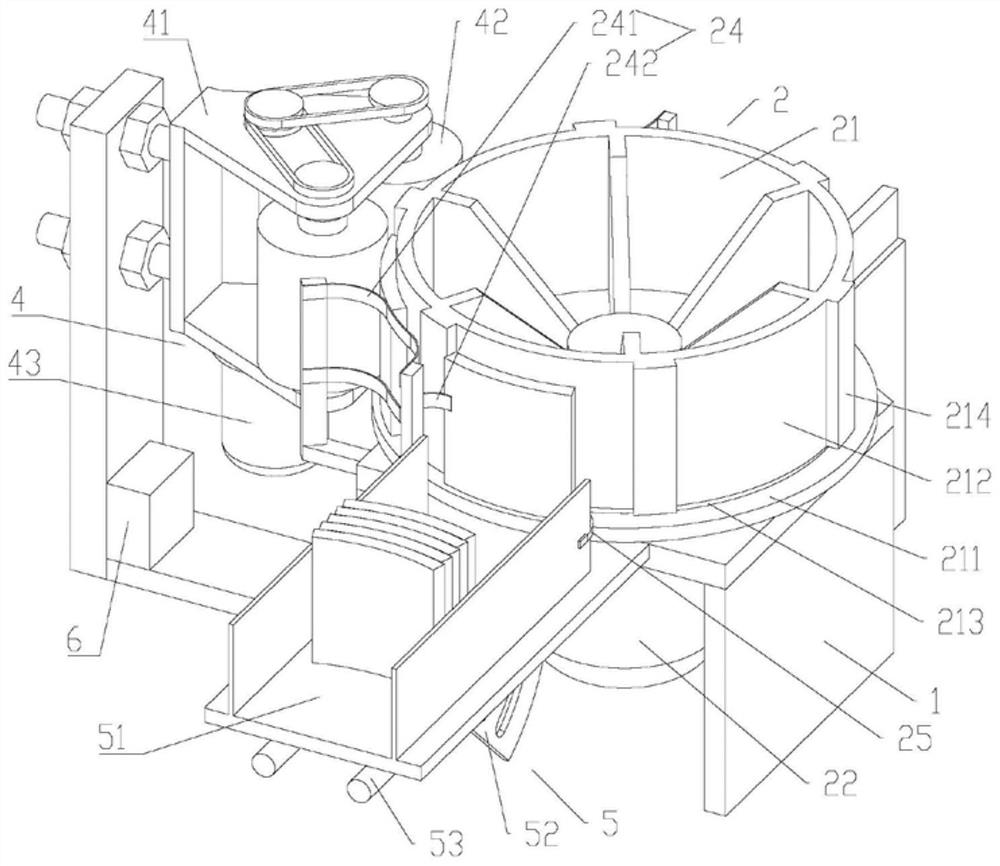

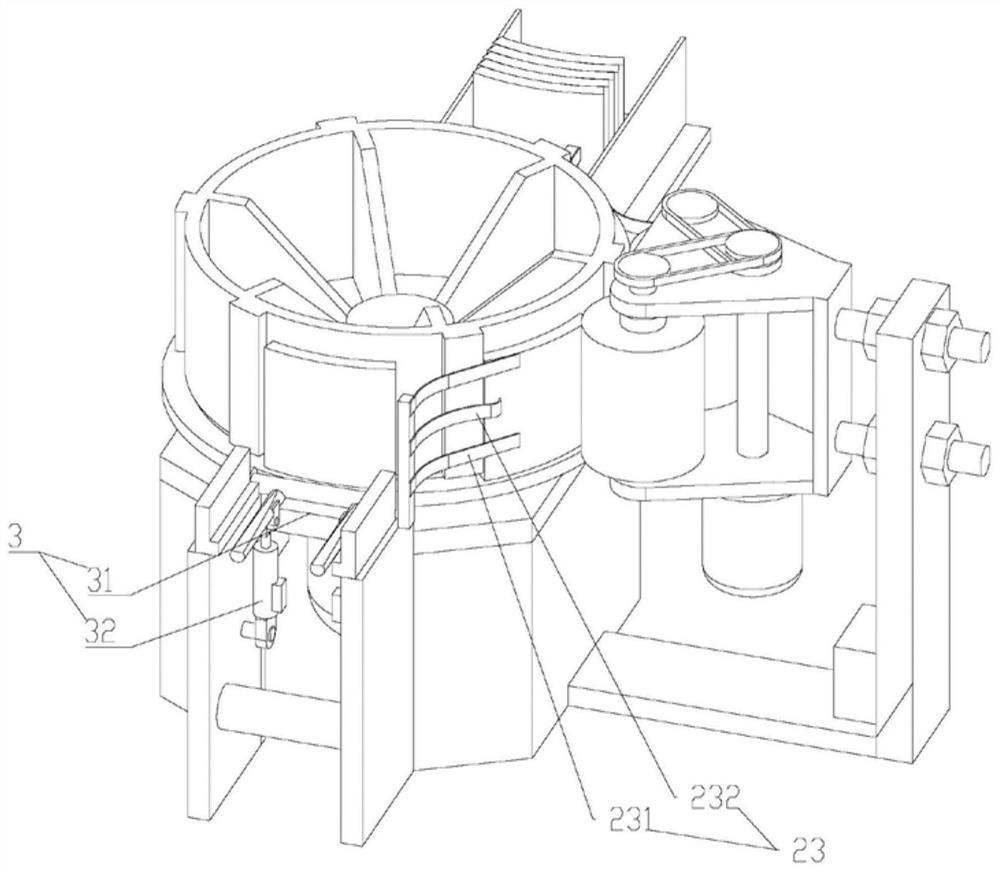

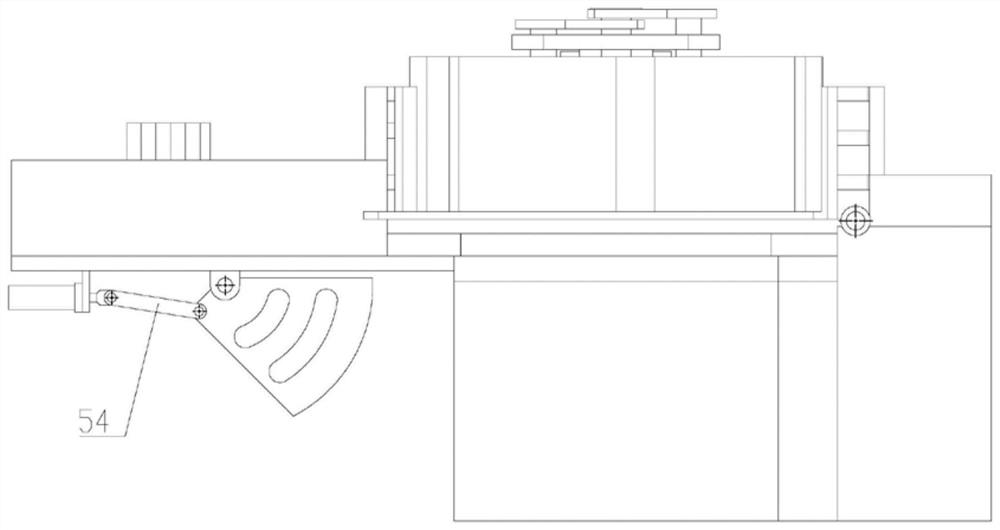

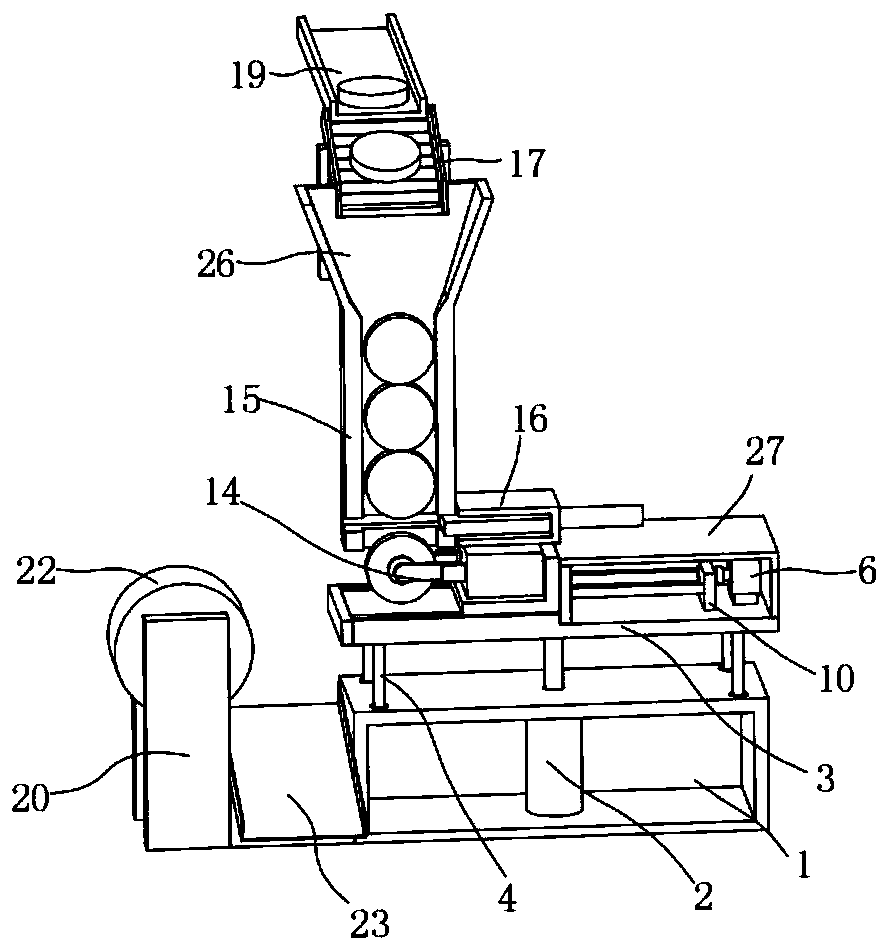

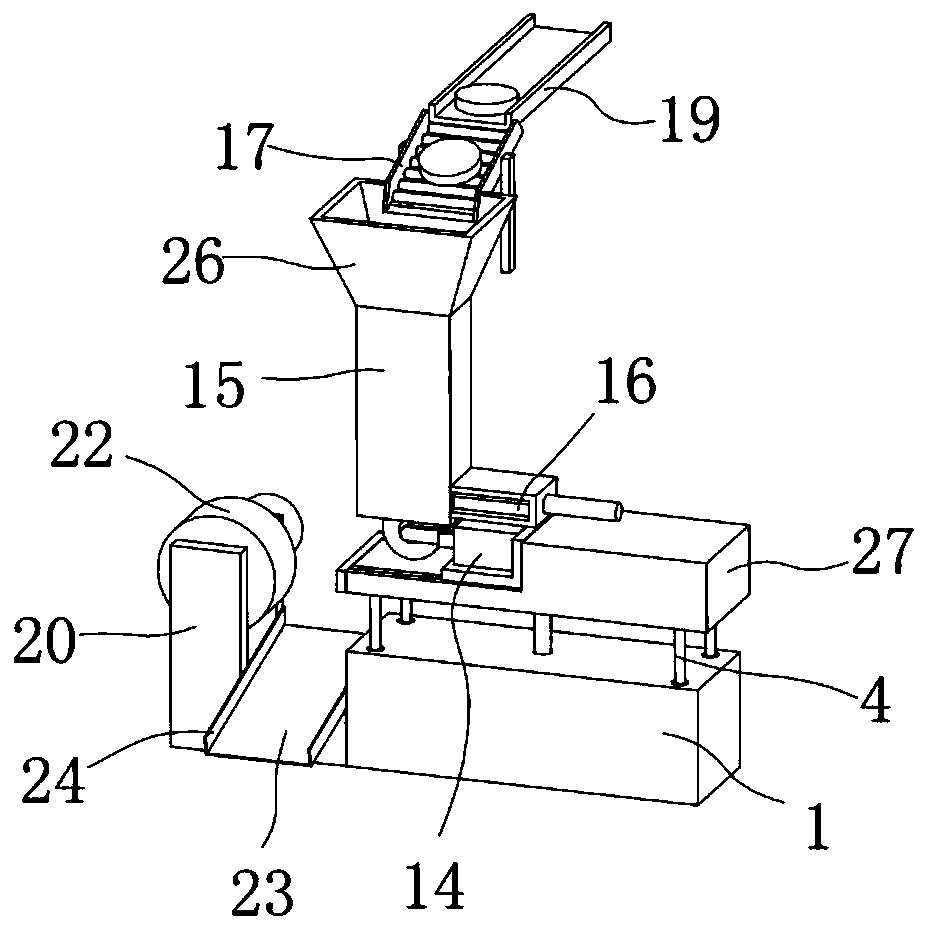

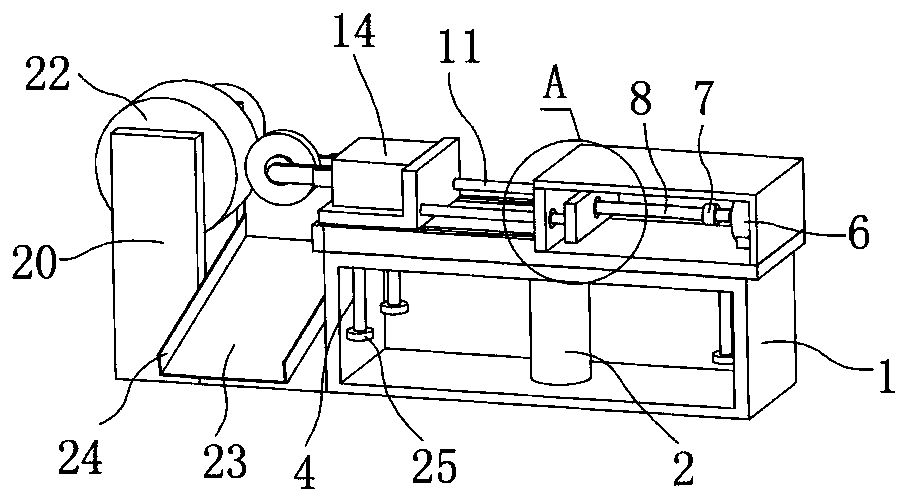

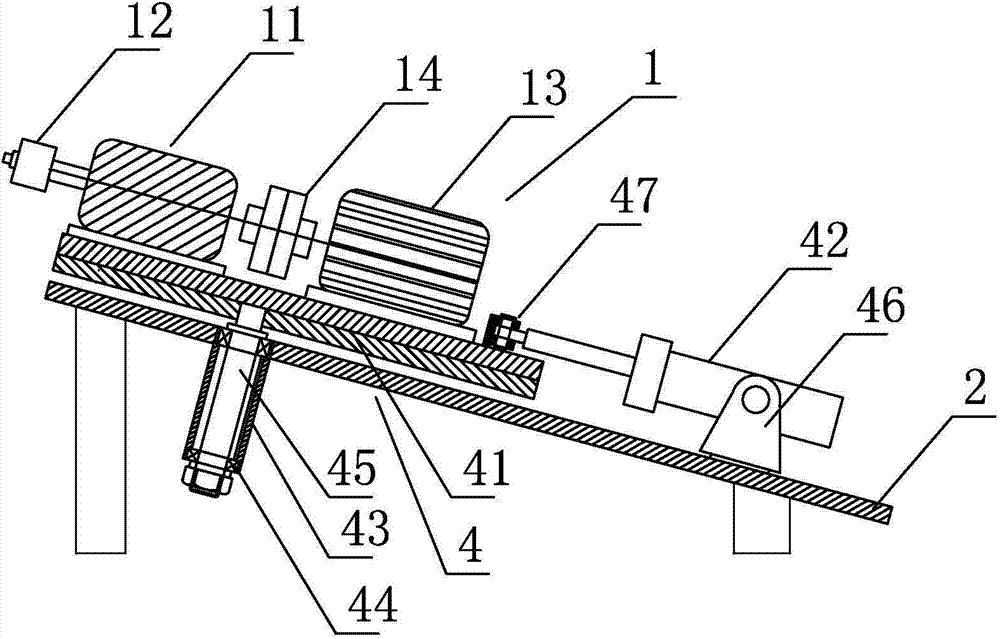

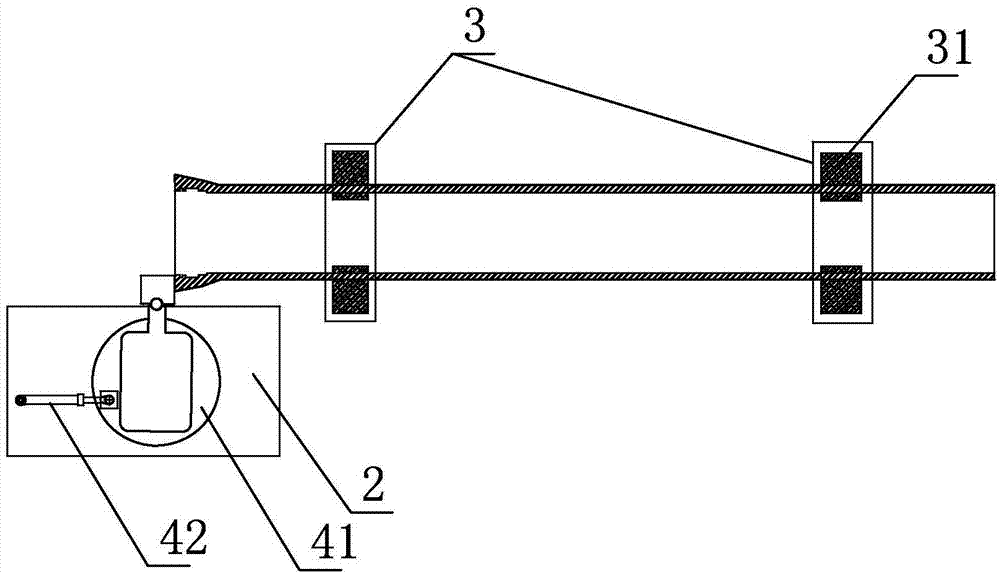

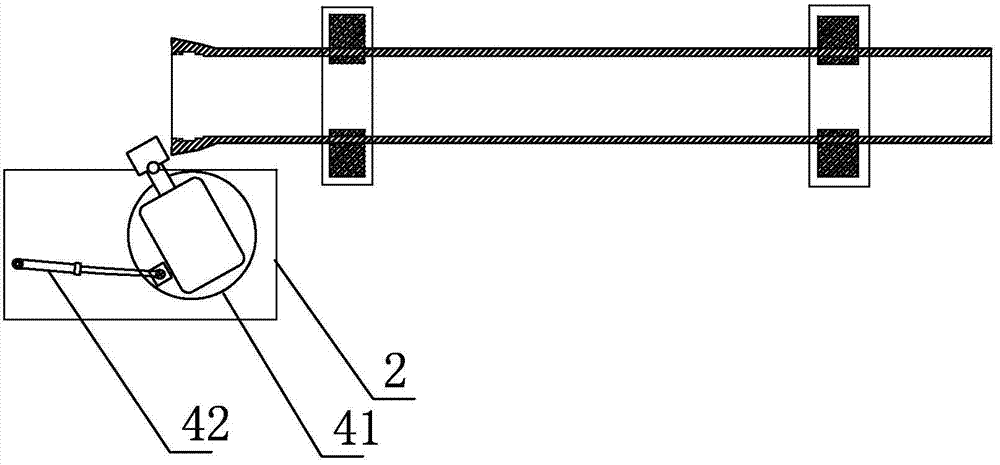

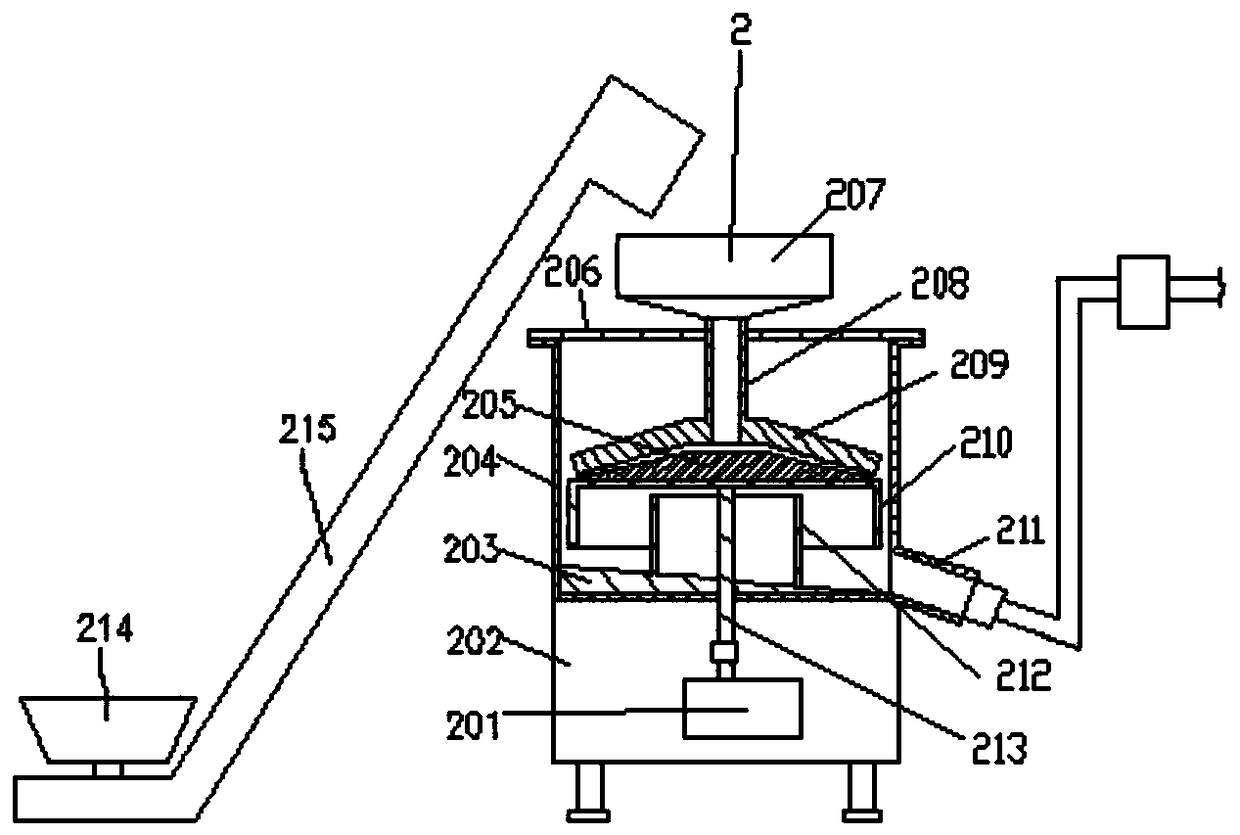

Inner bore lapping machine for ceramic bushing used for optical fiber ceramic inserted core metal assembly

ActiveCN102814728ARealize automatic grindingLower quality requirementsLapping machinesGrinding/polishing safety devicesProcessing costDislocation

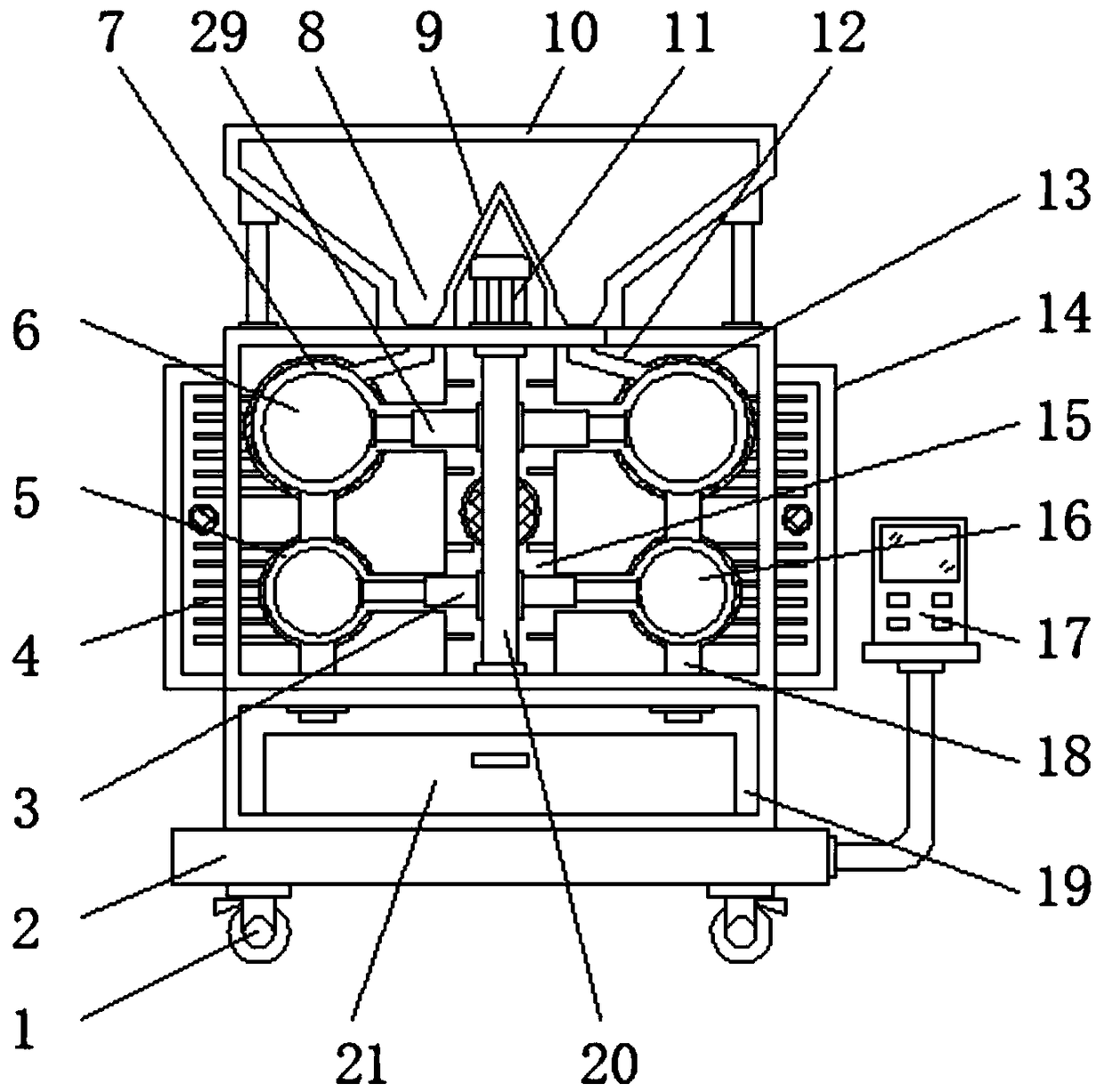

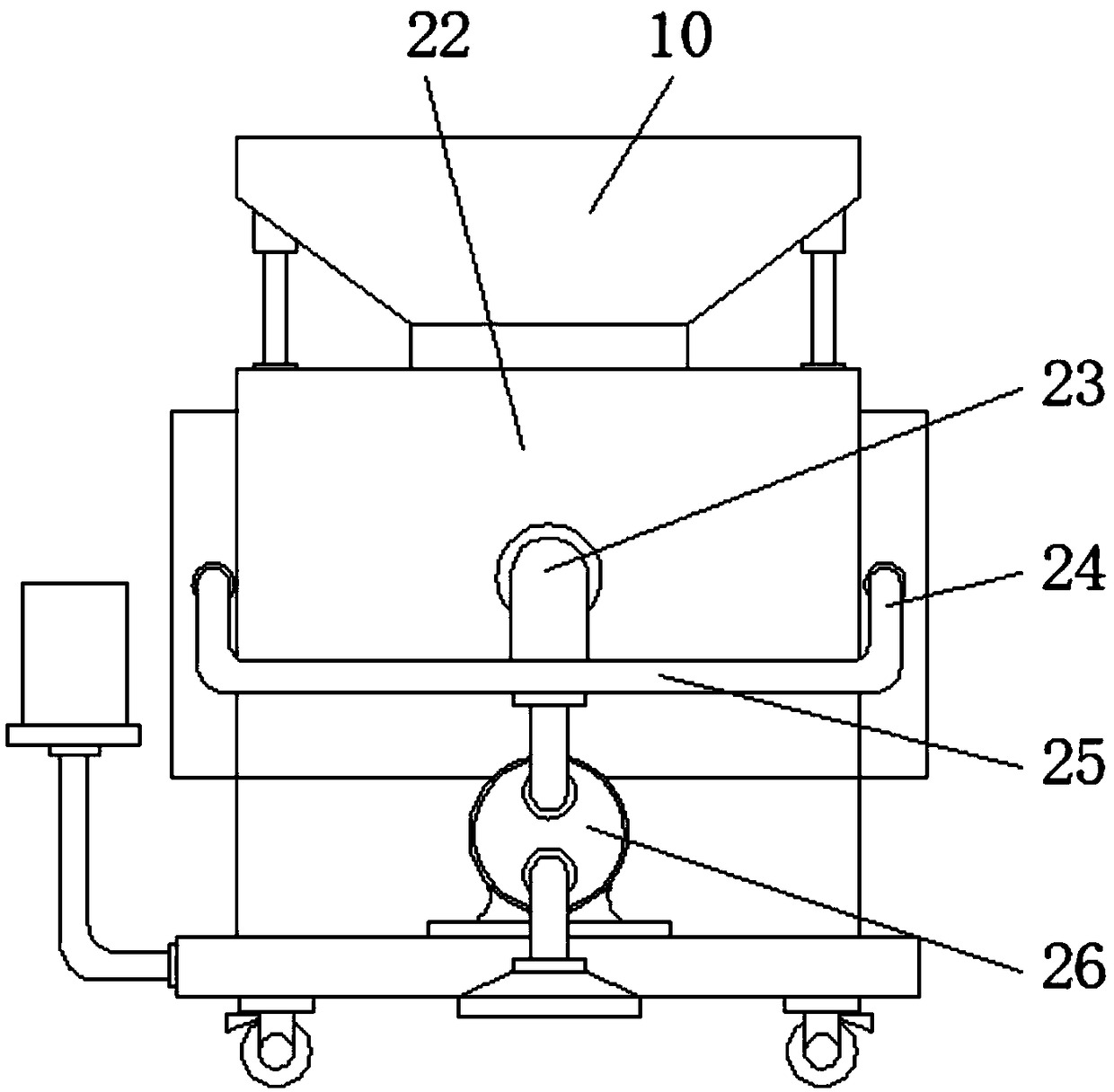

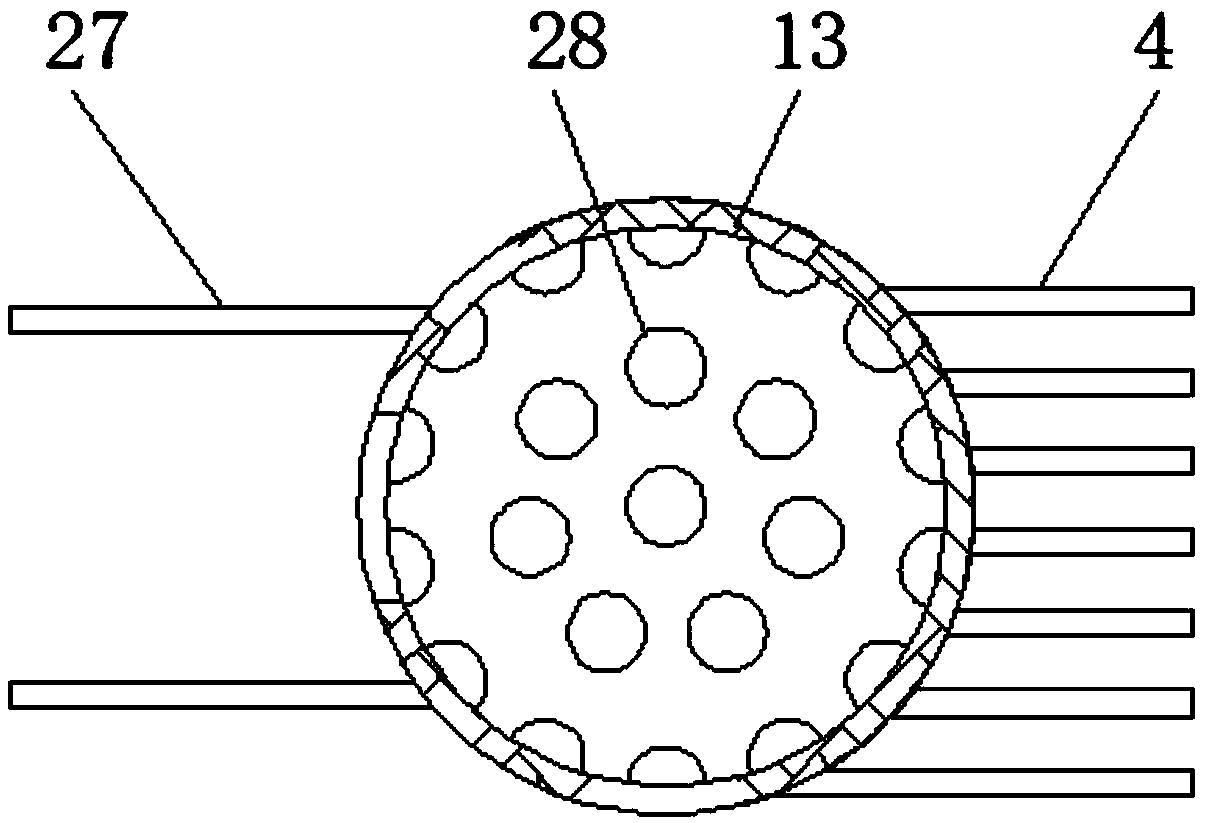

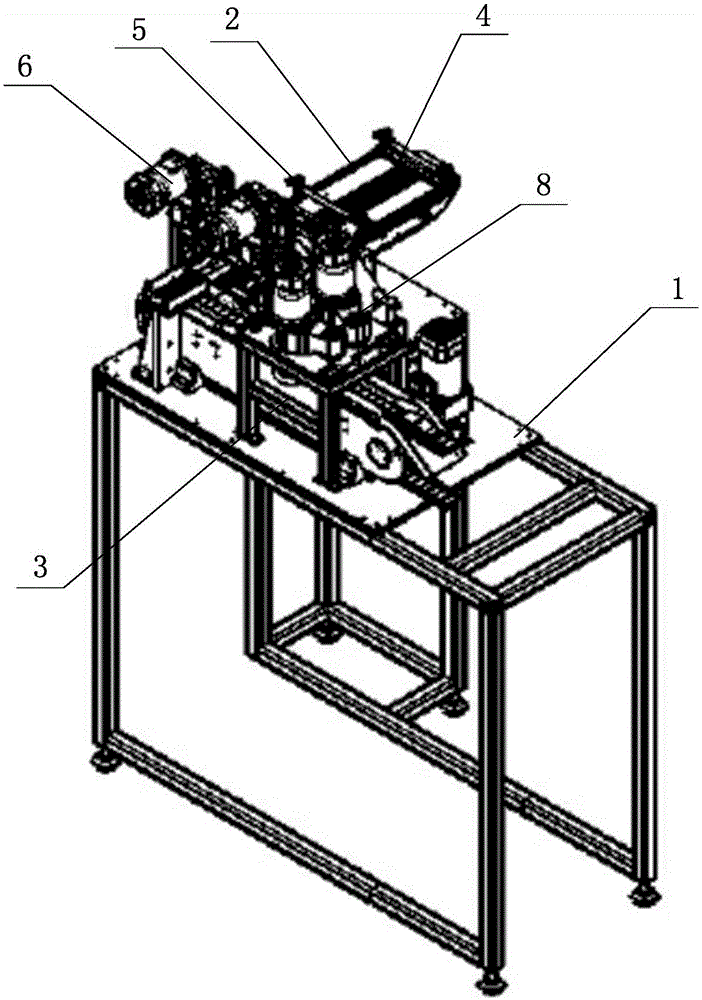

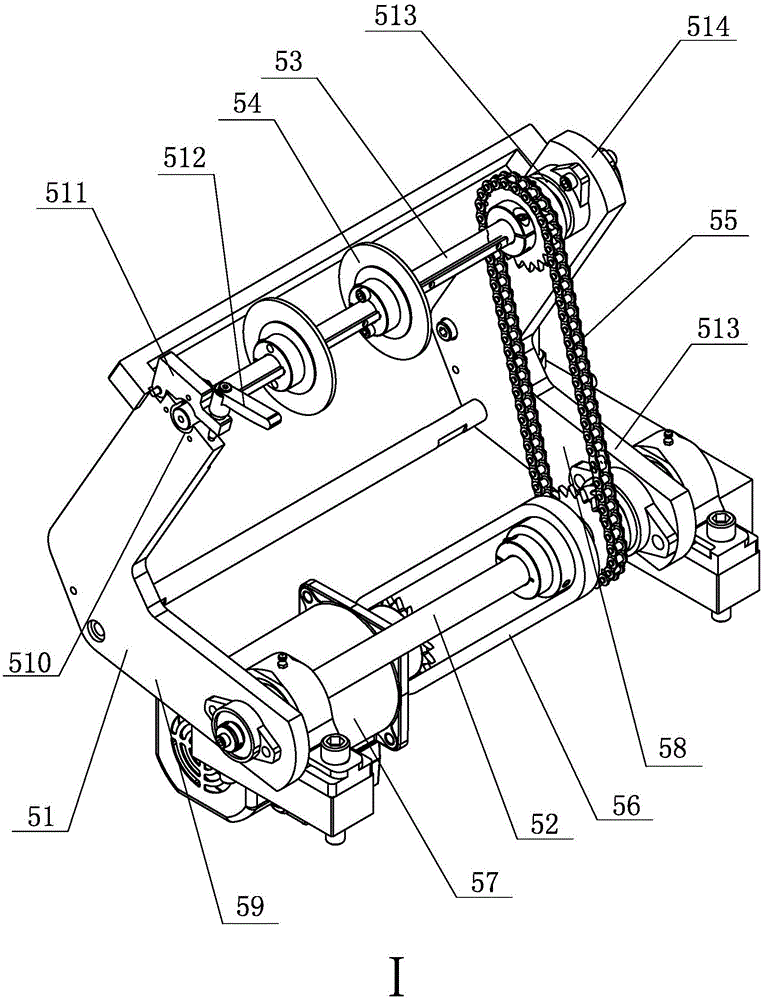

The invention discloses an inner bore lapping machine for a ceramic bushing used for an optical fiber ceramic inserted core metal assembly. The inner bore lapping machine comprises a vibration sorted material feeding unit, a dislocation material pushing unit, a sleeve pipe compacting unit, a main shaft rotating unit, a grinding circulating feeding unit and an automatic material discharging unit, wherein the dislocation material pushing unit comprises a material pushing cylinder and a dislocation cylinder which are arranged in an orthogonality mode, the sleeve pipe compacting unit is arranged on a sliding block of the grinding circulating feeding unit, and the automatic material discharging unit comprises a material discharging cylinder. Because the dislocation cylinder, the sleeve pipe compacting unit which is arranged on the sliding block and the material discharging cylinder are used, the ceramic sleeve pipe compacted in a grinding tool is driven by the sliding block to move back and forth on a grinding steel needle rotating at a high speed, the small optical fiber parts can be automatically ground at a lower cost, the production efficiency and the product quality are greatly improved, the processing cost of a product is reduced, the quality requirement on an operator is reduced, the contact between a person and a machine is reduced, and at the same time potential safety hazards are greatly reduced.

Owner:SHENZHEN XIANGTONG PHOTOELECTRIC TECH

Edging device and method based on visual control

ActiveCN105729267ARealize automatic grindingExtended service lifeEdge grinding machinesImage enhancementImaging processingControl system

The invention discloses an edging device and method based on visual control. A conveying unit is used for conveying to-be-edged workpieces; image acquisition modules of visual control units are used for acquiring image data of the to-be-edged workpieces and send the image data to an image processing module, and the image processing module acquires contour features reflecting edges of the workpieces on the basis of the image data and acquires G codes for processing by a numerical control system according to the contour features; and finally, edging units are used for edging the to-be-edged workpieces efficiently according to the G codes under control of the control system. The edging device and method adopt the visual control manner so that edges of tableware trays are ground automatically, the visual control units and the edging units located at different stations are used for realizing high-precision acquisition of tableware contour images and high-precision grinding of the tableware edges, and the edging device and method have the advantages of high edging precision, high efficiency, easy operation, convenient maintenance and the like.

Owner:HUAZHONG UNIV OF SCI & TECH +1

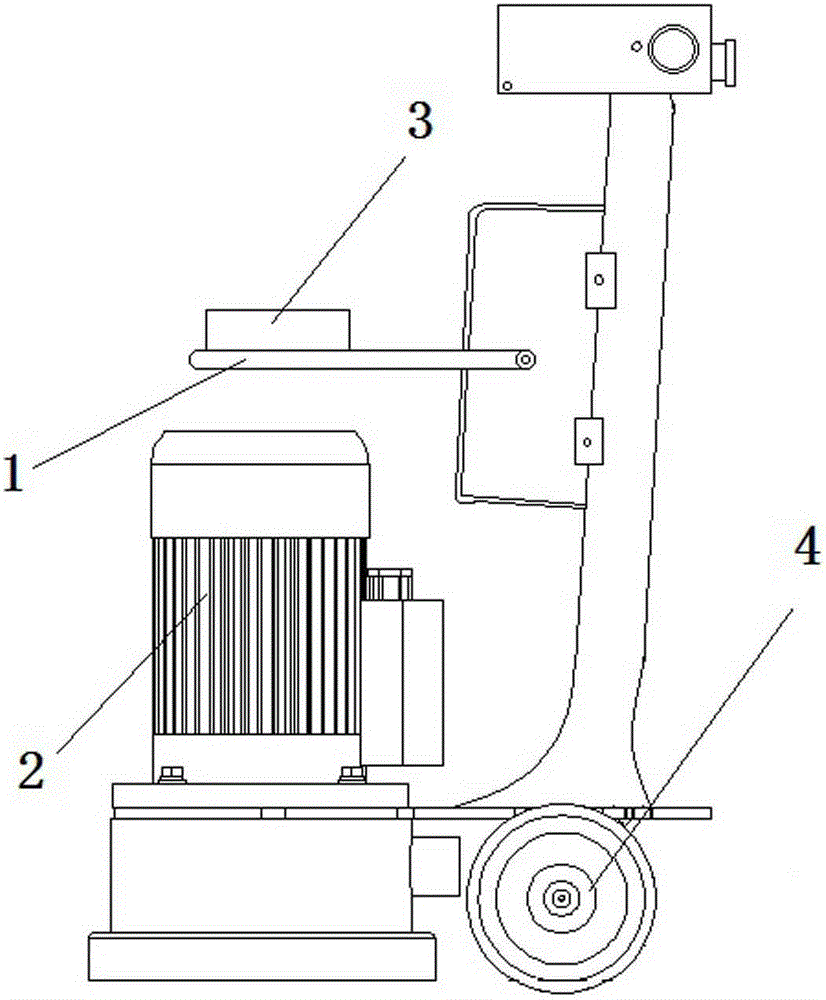

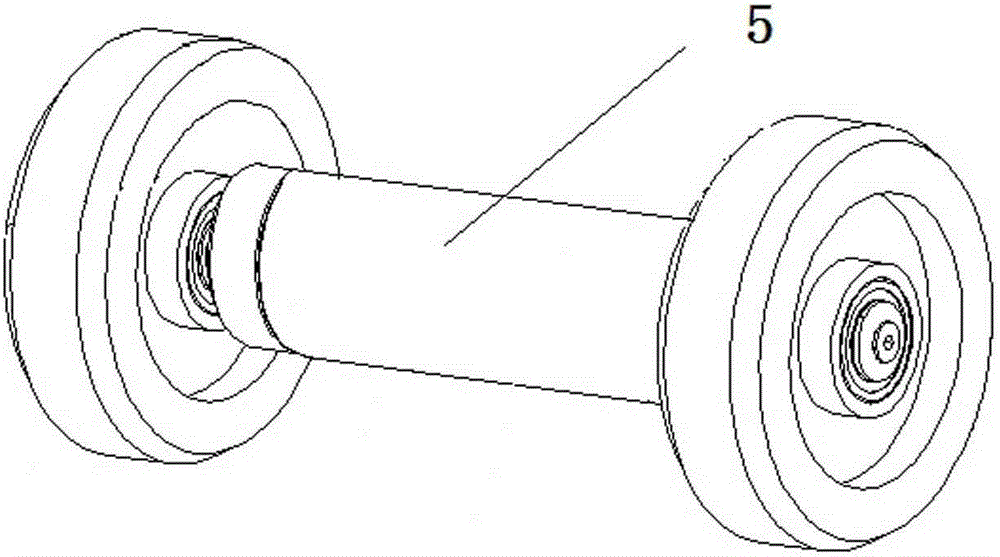

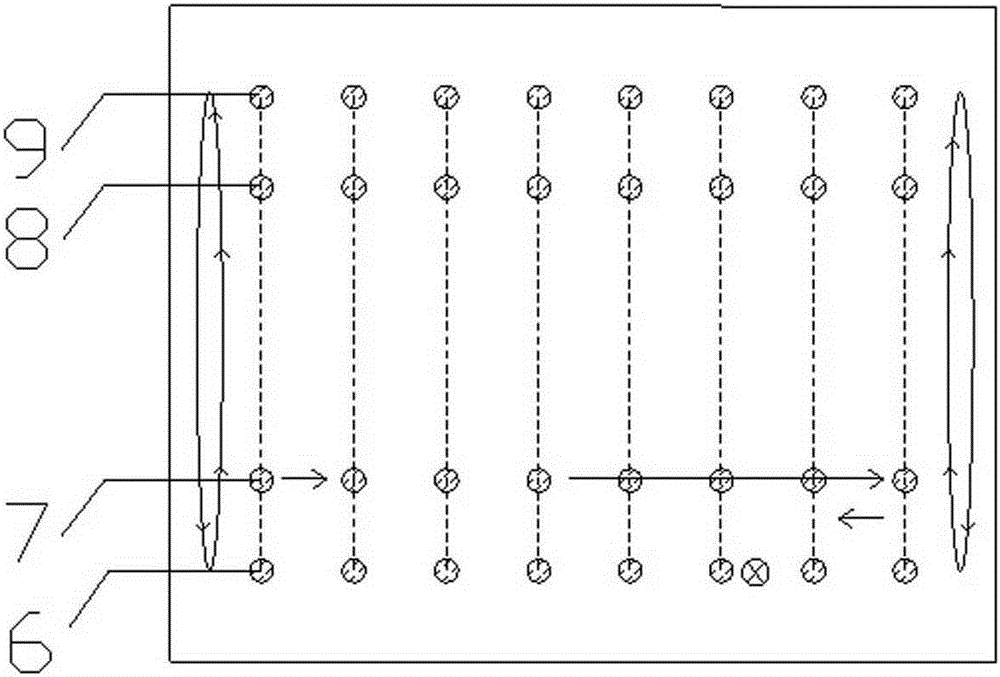

Control system and method for intelligent terrace grinding machine

ActiveCN105252363ARealize automatic grindingReduce the impact of damageGrinding drivesPlane surface grinding machinesDrive wheelControl system

The invention relates to a control system and method for an intelligent terrace grinding machine. The system comprises a positioning control device which is arranged over a drive motor of a grinding disc, and an indoor positioning module. The positioning control device comprises a first micro-control processing module, a moving end positioning module and a first communication module. The first micro-control processing module rotates with a driving wheel and is connected with a driving device of a grinding disc driving motor. A moving control terminal comprises a second micro-control processing module, an electronic map module, a touch display module and a second communication module. The method includes the steps that the running path of the terrace grinding machine is determined through an indoor Bluetooth base station; and after a positioning control module is started, the terrace grinding machine begins grinding according to the running path. According to the control system and method for the intelligent terrace grinding machine, the indoor terrace can be automatically ground effectively, and consumed labor cost is reduced.

Owner:JINJIANG XINGYI POLISHING MACHINERY

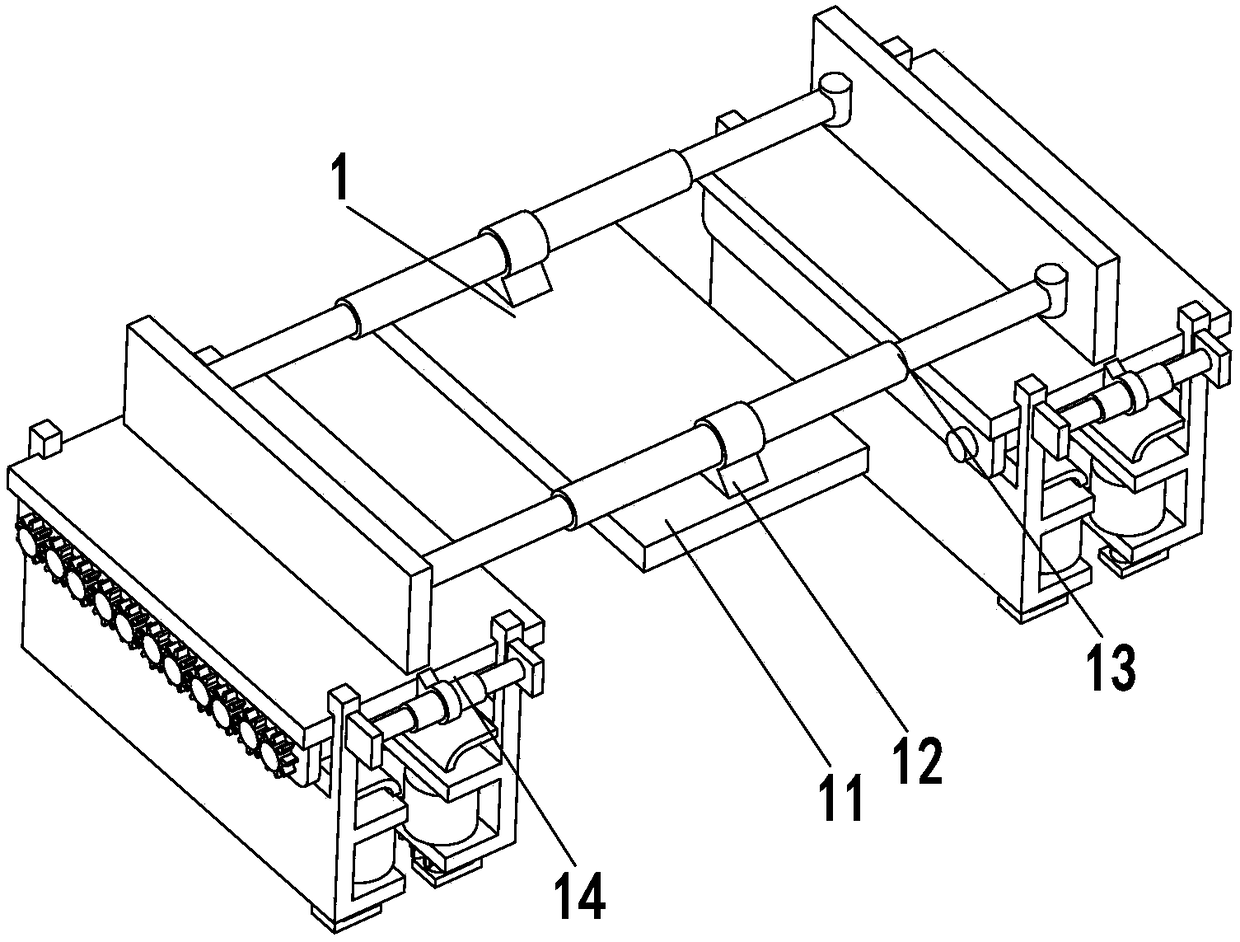

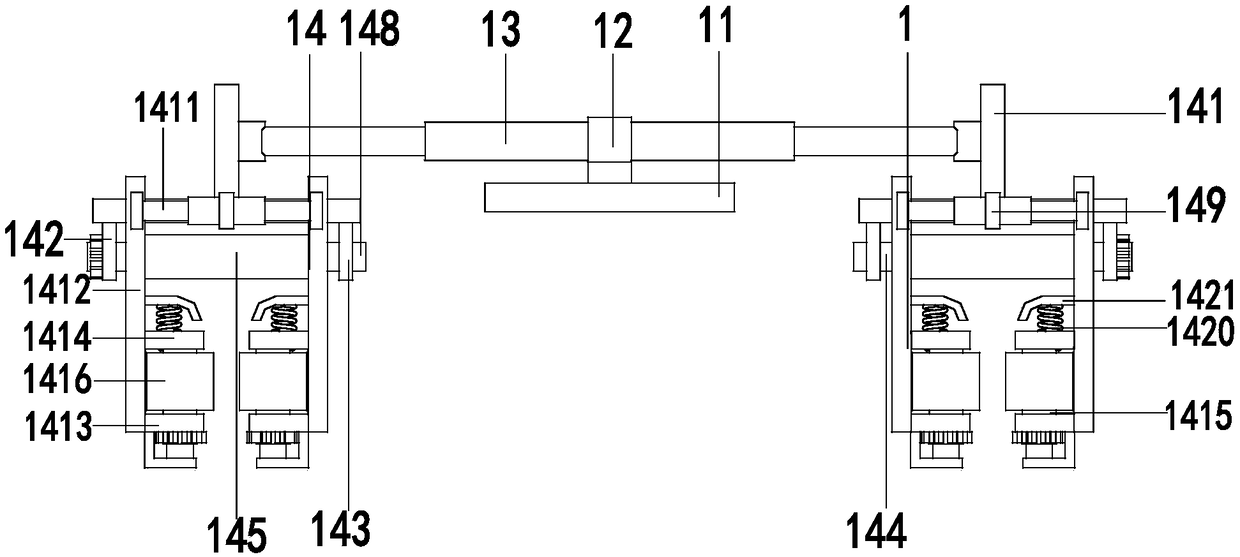

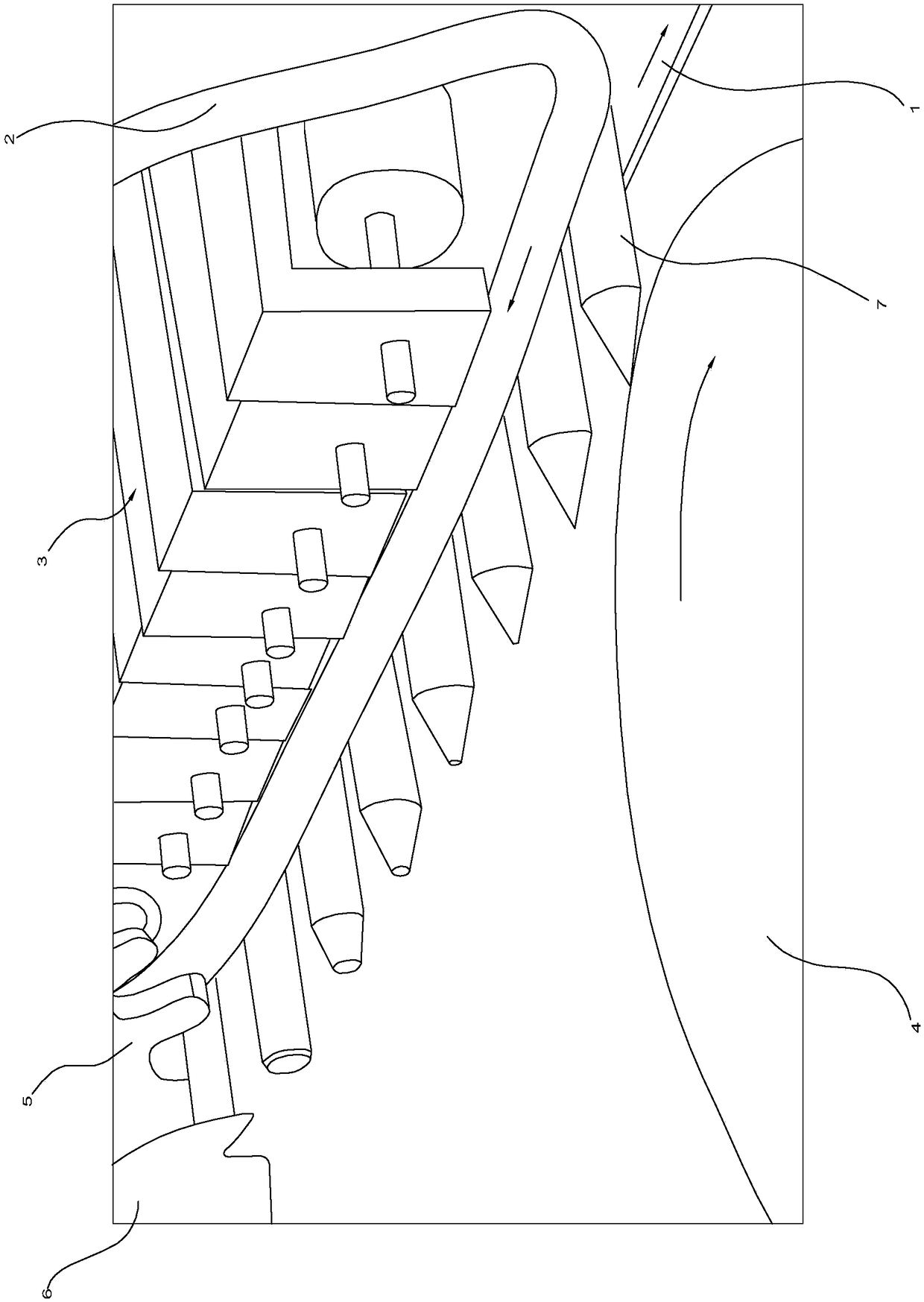

An automatic grinding system for maintenance of high speed rail, power train and metro rail

ActiveCN109056435ASolve the costSolve efficiency problemsRailway track constructionElectric machineEngineering

A method and apparatus for high-speed rail, Automatic grinding system for rail maintenance on power cars and metro lines, include a polishing device, the polishing device comprises a mounting plate, amounting base for adjusting the cylinder and the grinding mechanism, A left and right end of that mounting plate are symmetrically mount with mounting bases, A regulating cylinder is installed in themounting base, the adjusting cylinder is two-way telescopic structure, A grinding mechanism is installed at the front and rear ends of the adjusting cylinder, The grinding mechanism comprises a workframe, a No. 1 fixed plate, a No. 2 fixed plate, a rotating shaft, a rotating grinding wheel, a rotating gear, a transition gear, a rotating electric machine, a fixed seat, an adjusting electric pushrod, an adjusting frame, a No. 1 working plate, a No. 2 working plate, a rotating shaft, a rotating grinding wheel, a rotating gear, a connecting gear, a rotating electric machine, an auxiliary springand a guide plate. The invention can solve the problems of high labor cost, low working efficiency, inconvenient adjustment, small use range and the like existing in the existing rail maintenance andpolishing process, and can realize the function of automatic polishing of the rail.

Owner:JIANGSU JINYANG MACHINERY

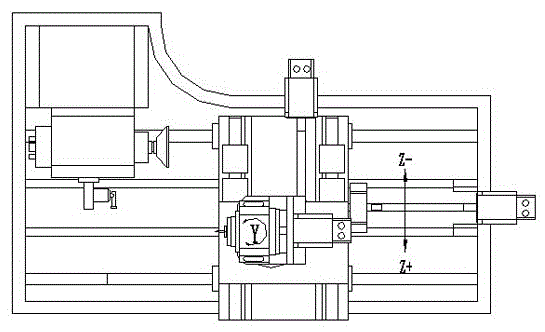

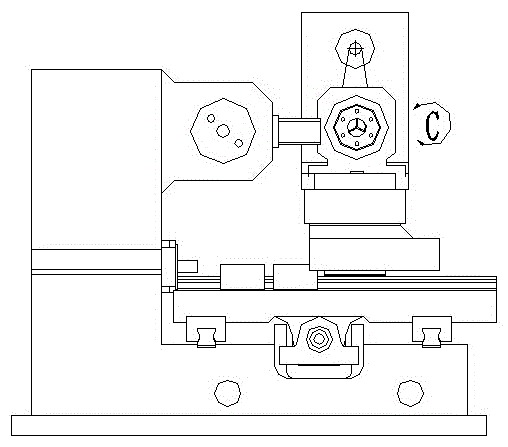

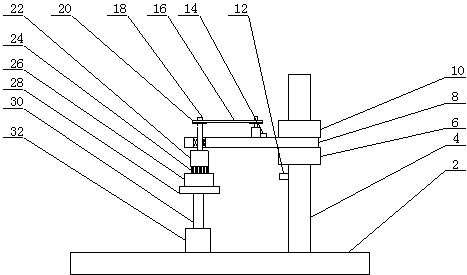

Four-axis numerical control polishing device special for graver

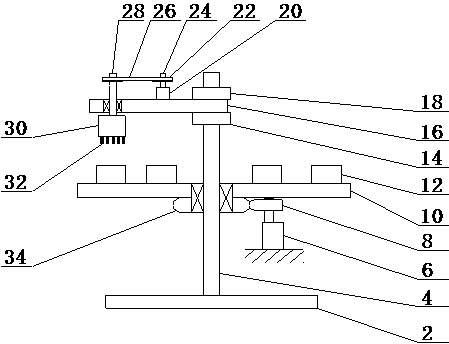

InactiveCN105014486ARealize automatic grindingImprove grinding accuracyGrinding carriagesGrinding drivesNumerical controlGrinding wheel

The invention discloses a four-axis numerical control polishing device special for a graver. The four-axis numerical control polishing device comprises a numerical control device and a base. A shaft base is arranged on the left end of the base. A grinding wheel which extends to the right side of the shaft base and can axially rotate is transversely arranged on the shaft base. An X-axis transverse movement mechanism extending in a left-and-right manner is arranged at the portion, on the right side of the shaft base, of the base. A Z-axis transverse movement mechanism extending in a front-and-back manner is arranged on the X-axis transverse movement mechanism. A rotating base capable of rotating around the vertical center axis of the Z-axis transverse movement mechanism is vertically arranged on the Z-axis transverse movement mechanism. A clamp capable of rotating around the transverse center axis of the rotating base is transversely arranged on the rotating base. The to-be-polished graver capable of being in contact with the grinding wheel is clamped in the center of the left side of the clamp. The four-axis numerical control polishing device has the beneficial effects that automatic polishing of the graver is achieved, manual operation is not required any more, labor is saved, the polishing efficiency is greatly improved, and the graver polishing accuracy and the graver polishing consistency are also improved.

Owner:SHANDONG YUNFENG CNC TECH CO LTD

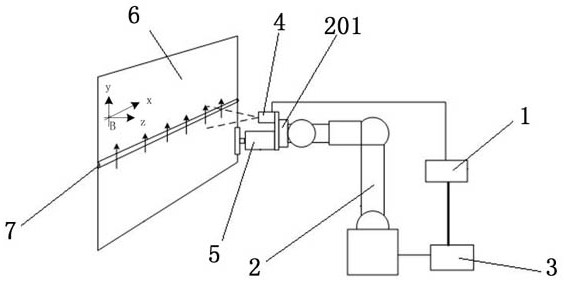

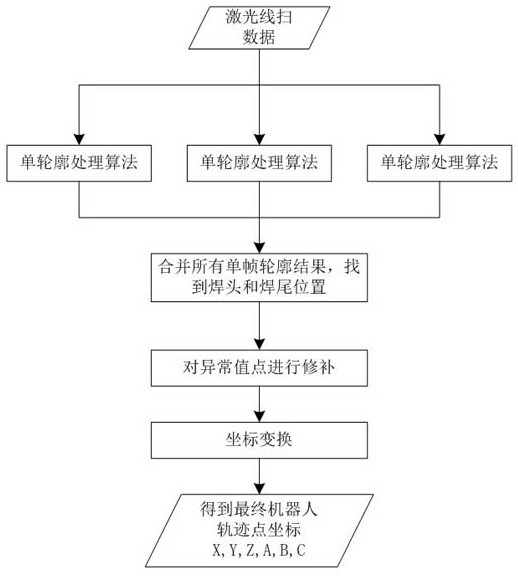

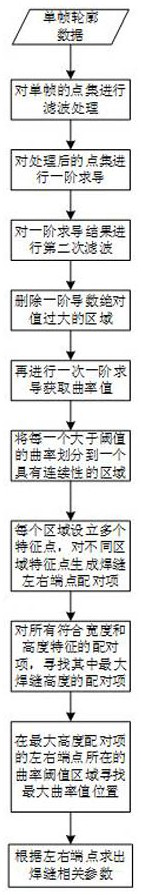

Weld joint recognizing and positioning method and device for weld joint grinding

ActiveCN111993200ARealize automatic grindingSolve the problem of being low, short, easily disturbed by welding slag, and affecting the grinding effectEdge grinding machinesGrinding feed controlPhysicsGrinding

The invention relates to a weld joint recognizing and positioning device for weld joint grinding. The device comprises a linear scanning laser sensor and a grinding head assembly which are fixedly connected to a tail end clamp of a robot, a controller is connected with the robot through a control line, and an industrial personal computer is connected with the linear scanning laser sensor and the controller through data lines. A weld joint recognizing and positioning method achieved by means of the device is characterized in that the robot drives the linear scanning laser sensor to conduct constant-speed linear scanning on the weld joint position of a vehicle body, multiple frames of weld joint contour data are obtained, the industrial personal computer calculates weld joint and base metaldata, the position posture is converted into 6DOF coordinates, the robot calculates and generates a grinding machining track according to the 6DOF coordinates, the grinding head assembly is driven toexecute the machining track, and weld joint grinding is carried out. According to the device and the method, the requirement for welding joint recognition and positioning in grinding application is met, automatic welding joint grinding is achieved, the problems that a vehicle body skin welding joint is relatively low and short and is prone to being interfered by welding slag, and consequently, thegrinding effect is affected are solved, and the recognition accuracy and the grinding precision are improved.

Owner:SHANGHAI RO INTELLIGENT SYST

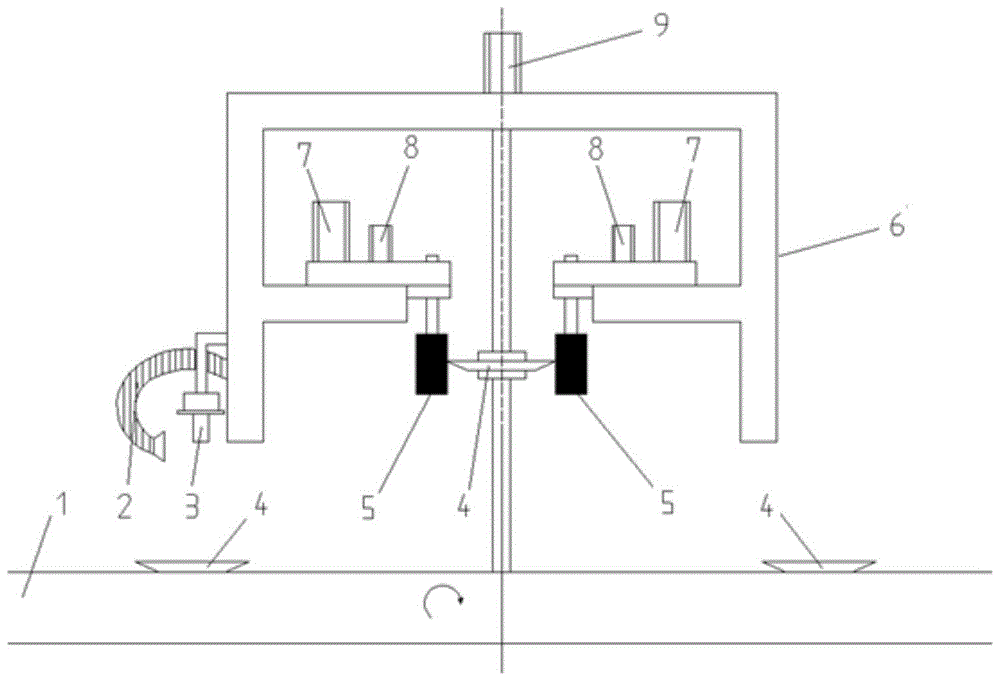

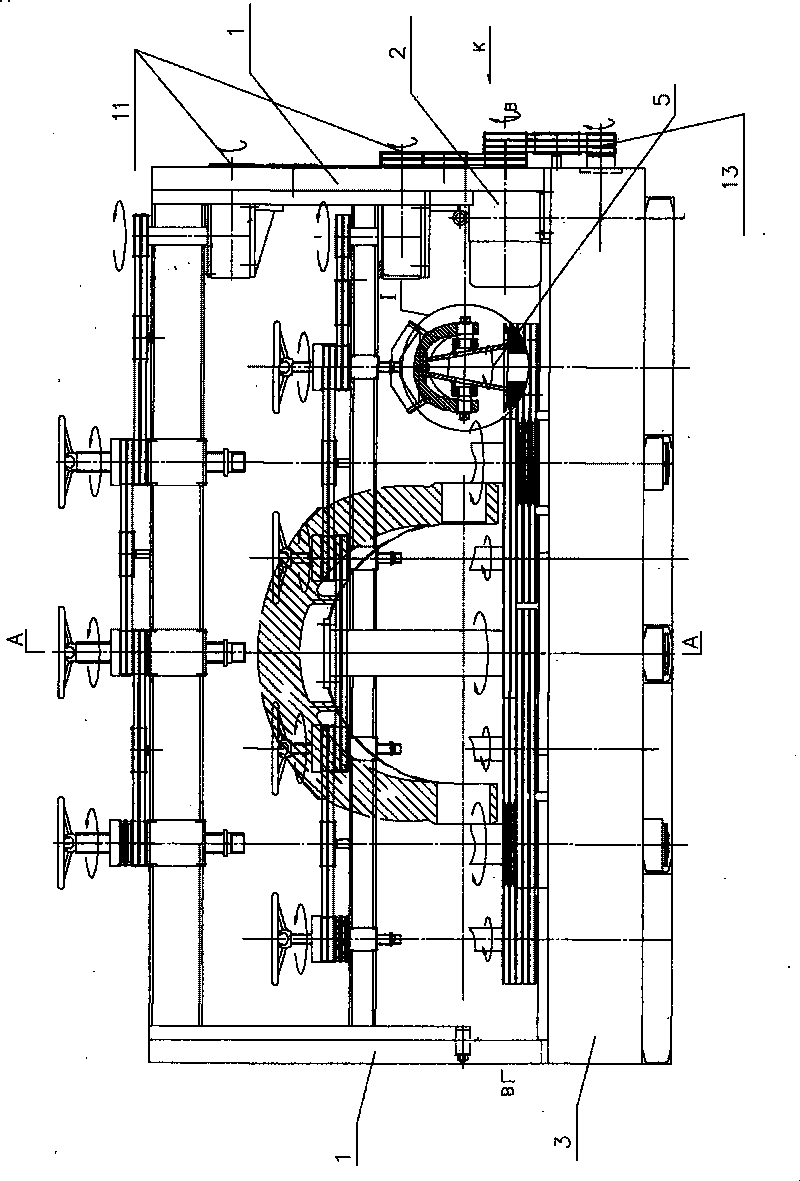

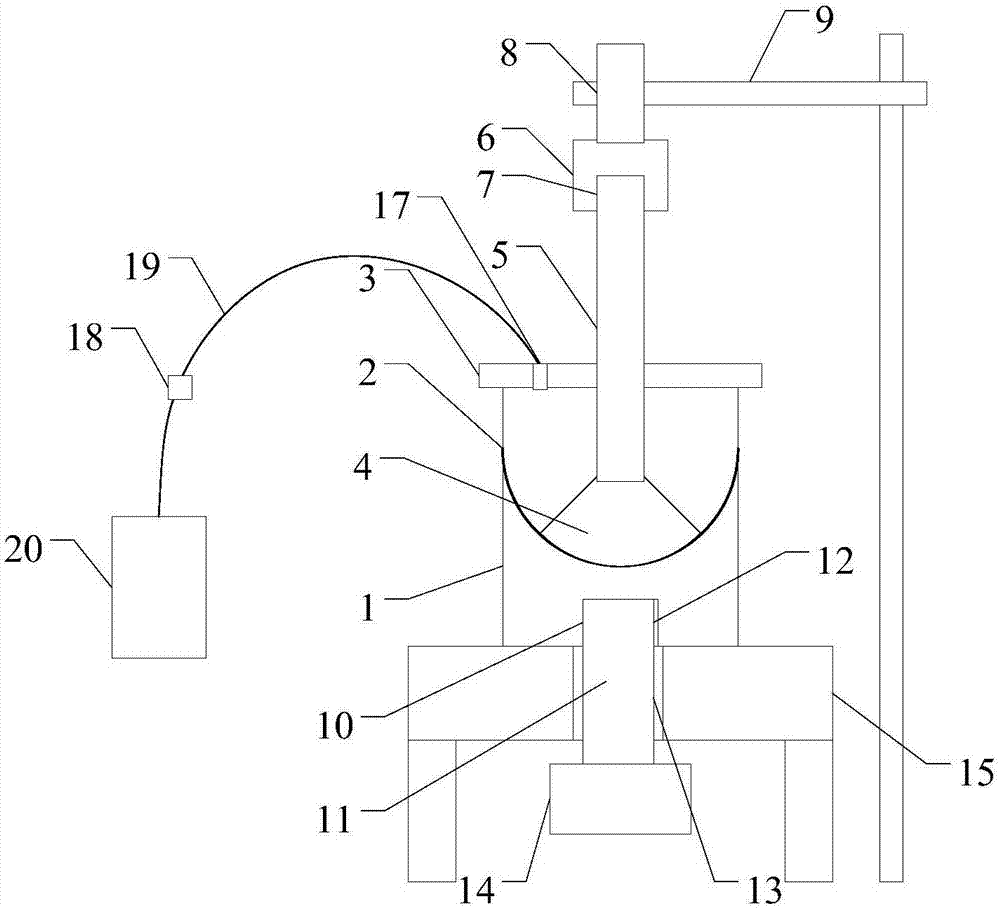

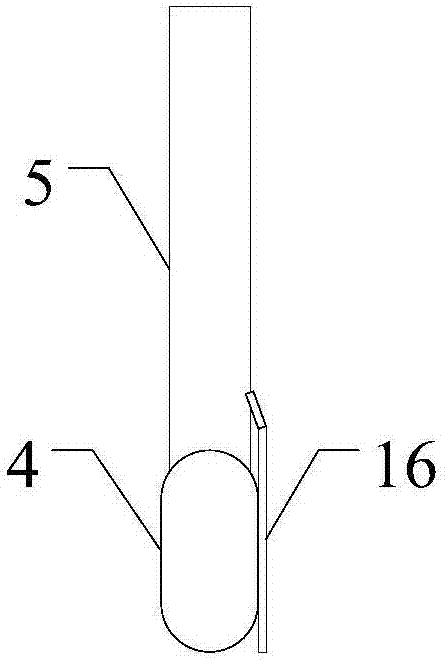

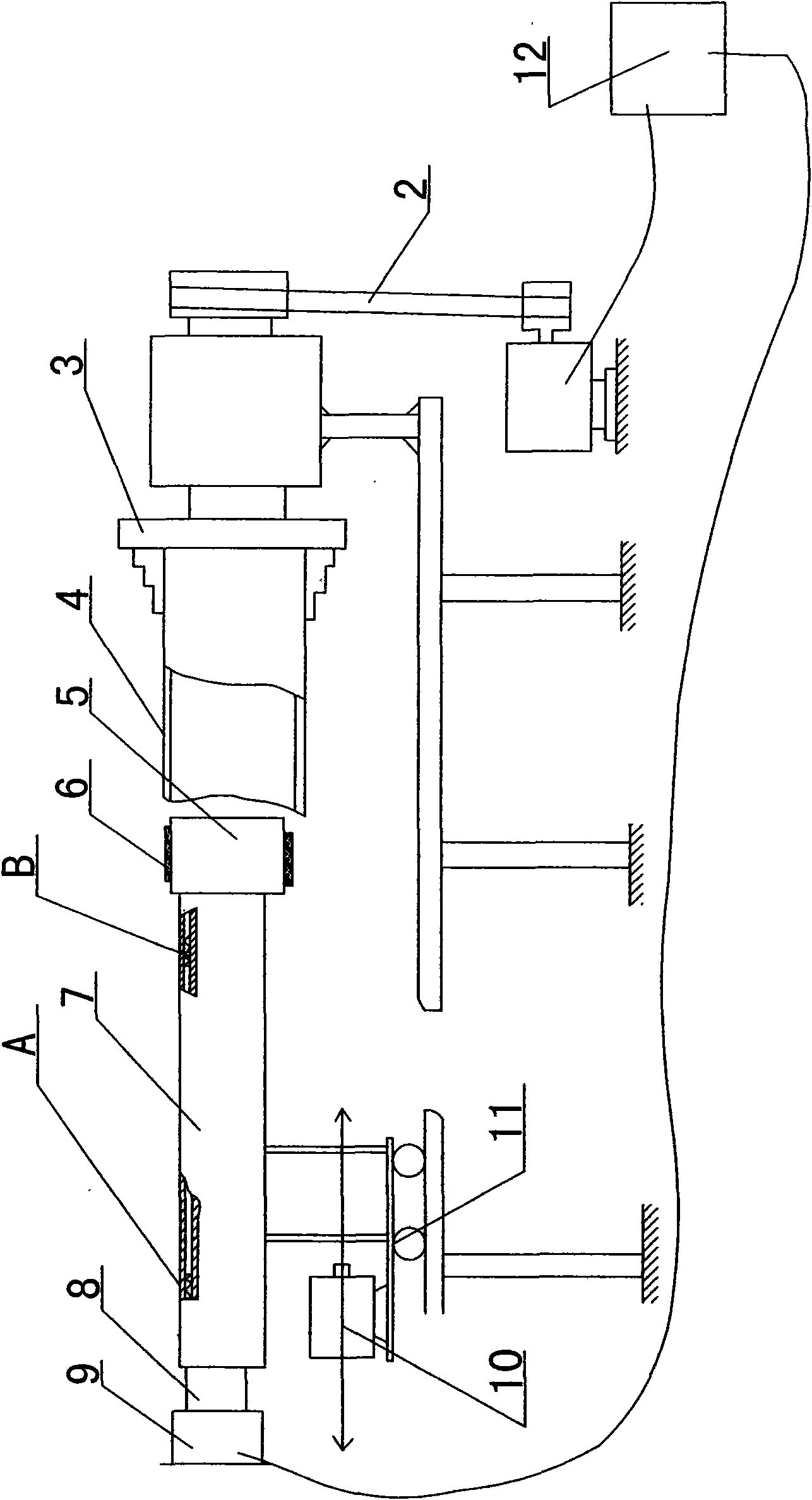

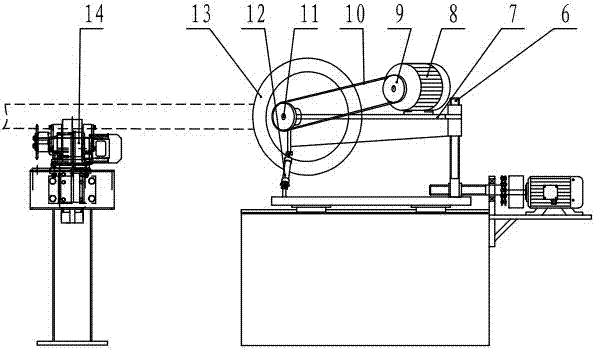

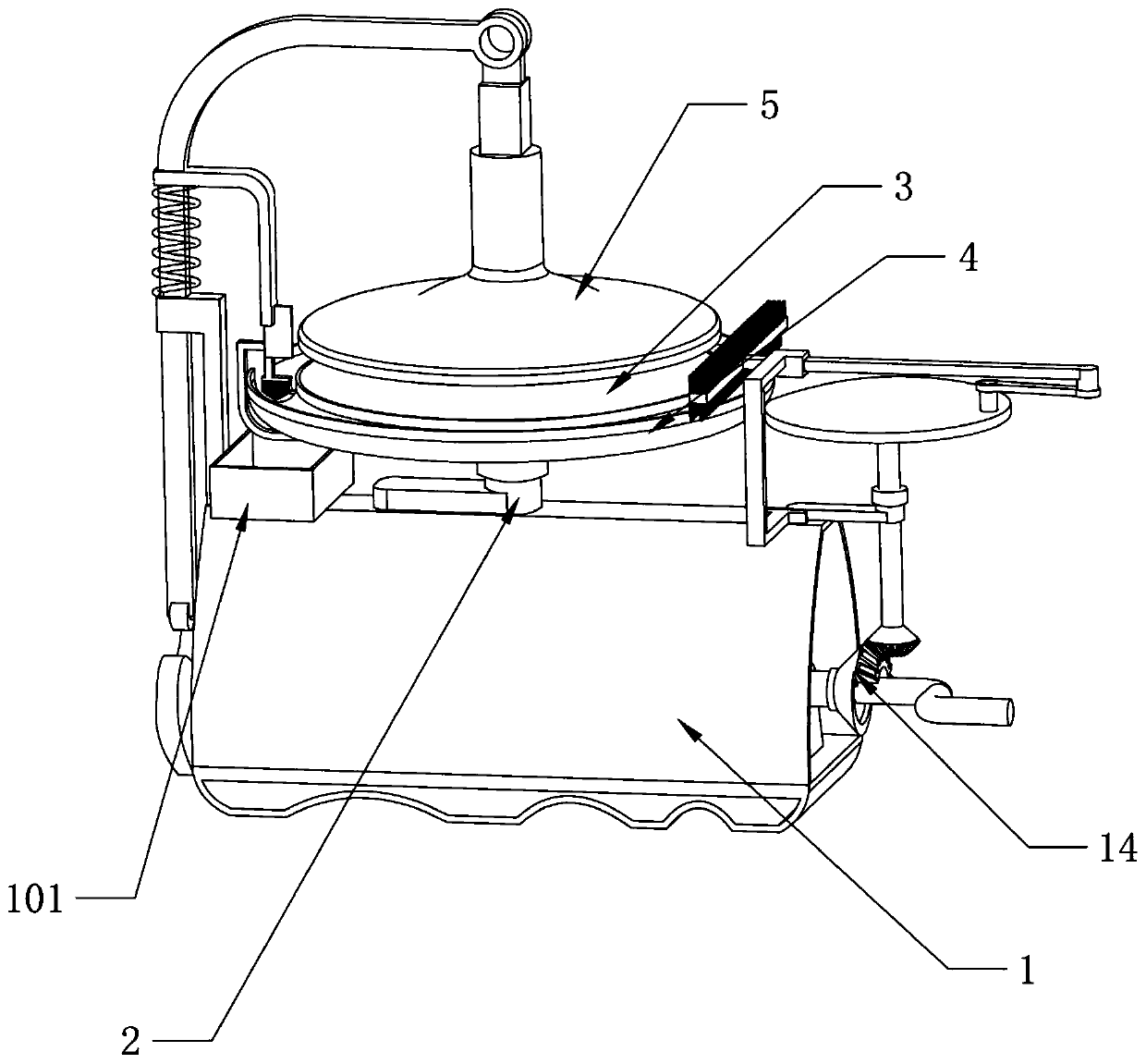

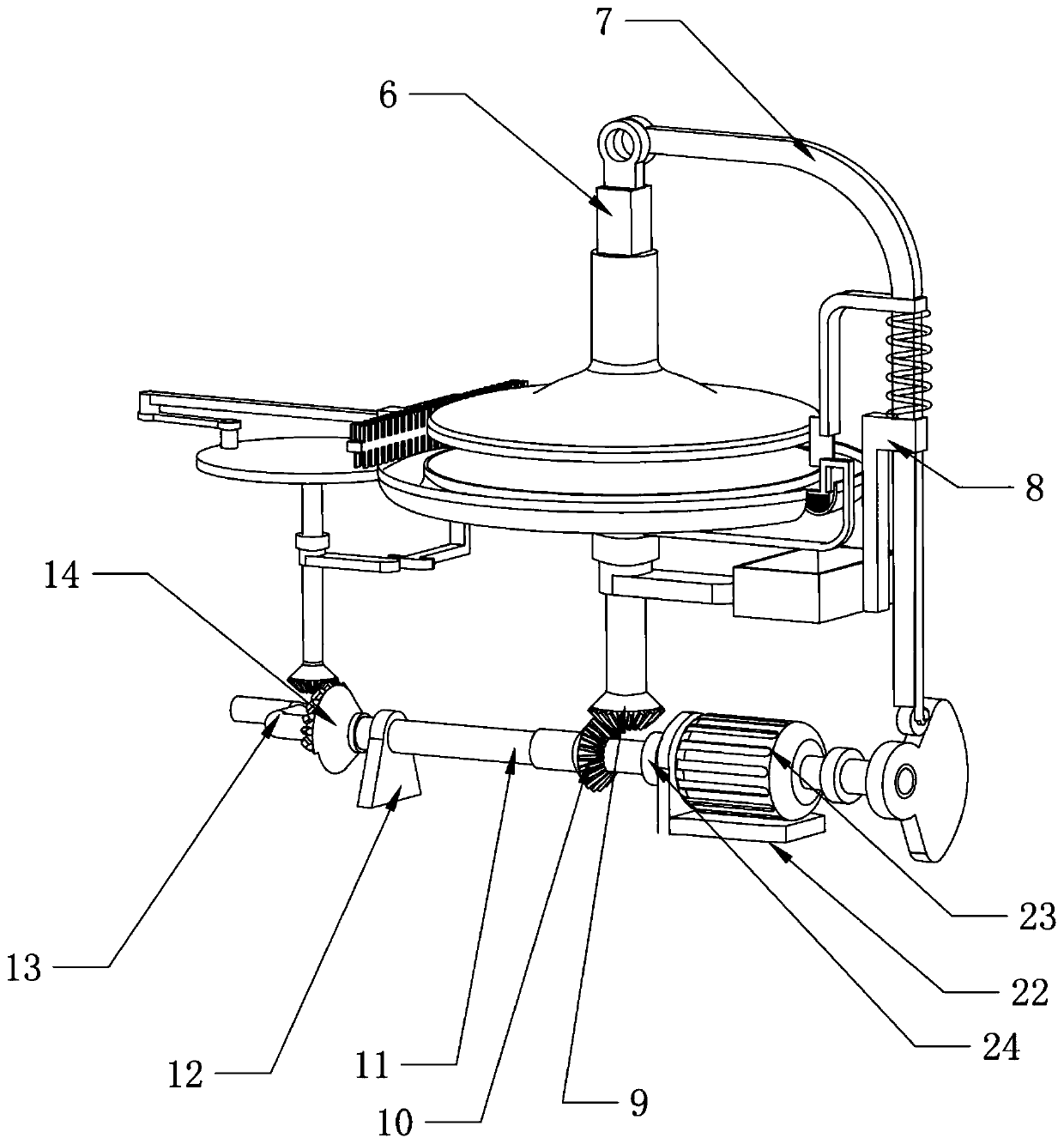

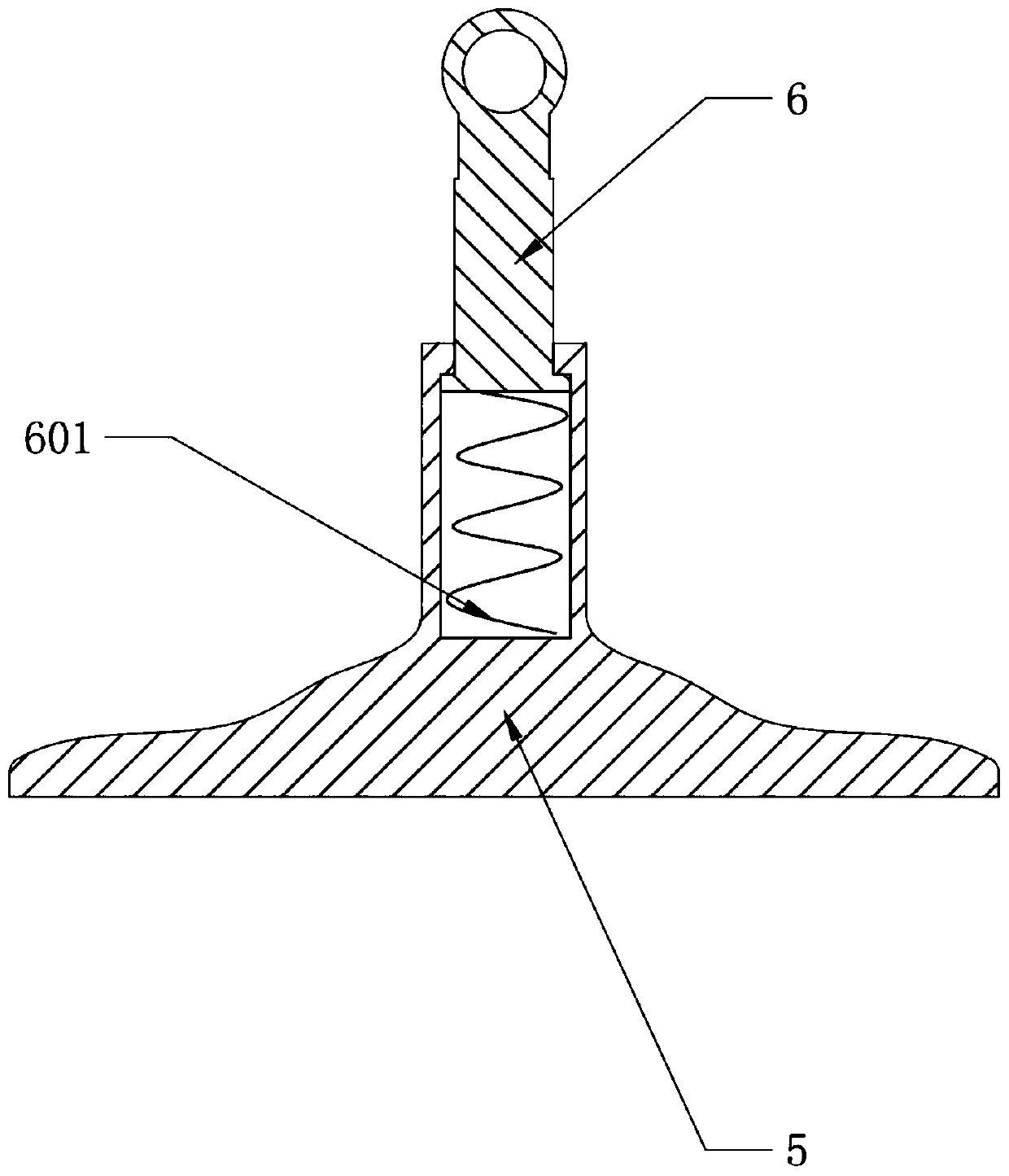

Valve clack sphere grinding machine of double eccentric semi-ball valve

InactiveCN101722455ARealize automatic grindingGuaranteed grinding qualitySpherical surface grinding machinesEngineeringUniform rotation

The invention discloses a valve clack sphere grinding machine of a double eccentric semi-ball valve. A frame (1), a motor (2), a loading workpiece rotating main shaft (4) and a tool (5) are arranged on an engine base (3), wherein the frame is arranged on the upper part of the engine base and provided with an angle adjustment frame (6) with adjustable angles; a rotating auxiliary shaft (7) is fixedly connected to the angle adjustment shaft; a grinder clamping mechanism (8) is arranged on the rotating auxiliary shaft, and a semispherical grinder body (9) is fixedly connected to the grinder clamping mechanism; the lower part of the engine base corresponding to the rotating auxiliary shaft (7) is provided with the loading workpiece rotating main shaft which simultaneously rotates with the rotating auxiliary shaft and has opposite direction to the rotating auxiliary shaft, and the tool used for fixing a semi-sphere is arranged on the loading workpiece rotating main shaft; and the upper end of the tool is a semispherical positioning disk eccentrically arranged on the loading workpiece rotating main shaft. Through the adjustment of the angle adjustment frame, the grinder rotates on a semi-ball valve clack at a uniform speed so as to form mutually crossed reticular tracks and achieve an ideal ball grinding surface.

Owner:HENAN SHANGDIE VALVE CO LTD

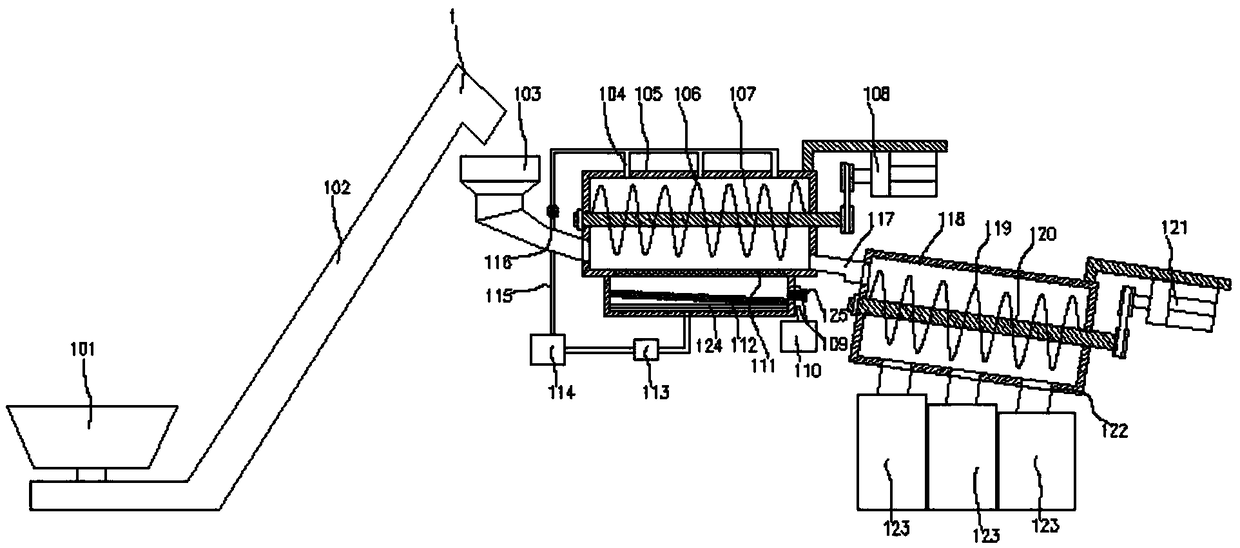

Powder metallurgy chip removing machine tool

InactiveCN103481147ARealize automatic grindingContinuous productionEdge grinding machinesGrinding drivesSufficient timeEngineering

The invention discloses a powder metallurgy chip removing machine tool, comprising a rack and a liftable first workbench which is horizontally arranged on the rack, wherein a brush head which is driven by a rotating device to rotate is arranged on the first workbench; a plurality of brush wires are fixedly arranged on the lower end of the brush head; a rotatable second workbench is also arranged on the rack; the second workbench is located below the first workbench; a plurality of fixing seats which are used for fixing workpieces are also arranged on the upper surface of the second workbench. The powder metallurgy chip removing machine tool is characterized in that a drive gear which is concentric with the second workbench is also fixedly connected to the lower part of the second workbench; the drive gear is meshed with an incomplete gear which is driven by a power device to rotate. The workpieces are placed on the fixing seats, the second workbench rotates intermittently, the workpieces are intermittently transmitted to a position below the brush head, and are ground, and burrs are removed; due to the adoption of the mode, enough time is reserved for the clamping and the grinding of the workpieces; manual halt is not needed to be carried out by an operator; automatic grinding of the workpiece and continuous production are realized; production efficiency is improved.

Owner:SUZHOU MIMO METAL SCI & TECH

Method and equipment for polishing EVA foamed sole

ActiveCN110051083AReduce manual operationsWide range of applicationsEdge grinding machinesShoemaking devicesEngineeringBinoculars

The invention belongs to the technical field of sole polishing, and particularly relates to a method and equipment for polishing an EVA foamed sole, wherein the method comprises the following steps: feeding, fixing an EVA sole on a tooling plate, and conveying the tooling plate to move; taking a picture, taking a picture of the EVA sole by using a 3D structured light binocular camera; after obtaining point cloud data, automatically generating a side polishing track and a bottom polishing track, and respectively outputting side polishing track coordinates and bottom polishing track coordinatesto an industrial robot; side polishing, receiving the side polishing track coordinates through the industrial robot, and polishing the side of the EVA sole according to the side polishing track; polishing the bottom, receiving the bottom polishing track coordinates through the industrial robot, and polishing the bottom of the EVA sole according to the bottom polishing tracks. The method and equipment for polishing the EVA foamed sole can be suitable for automatically polishing various EVA soles with different shapes and irregular shapes, and are very wide in application range.

Owner:GUANGDONG GONGYE TECH CO LTD

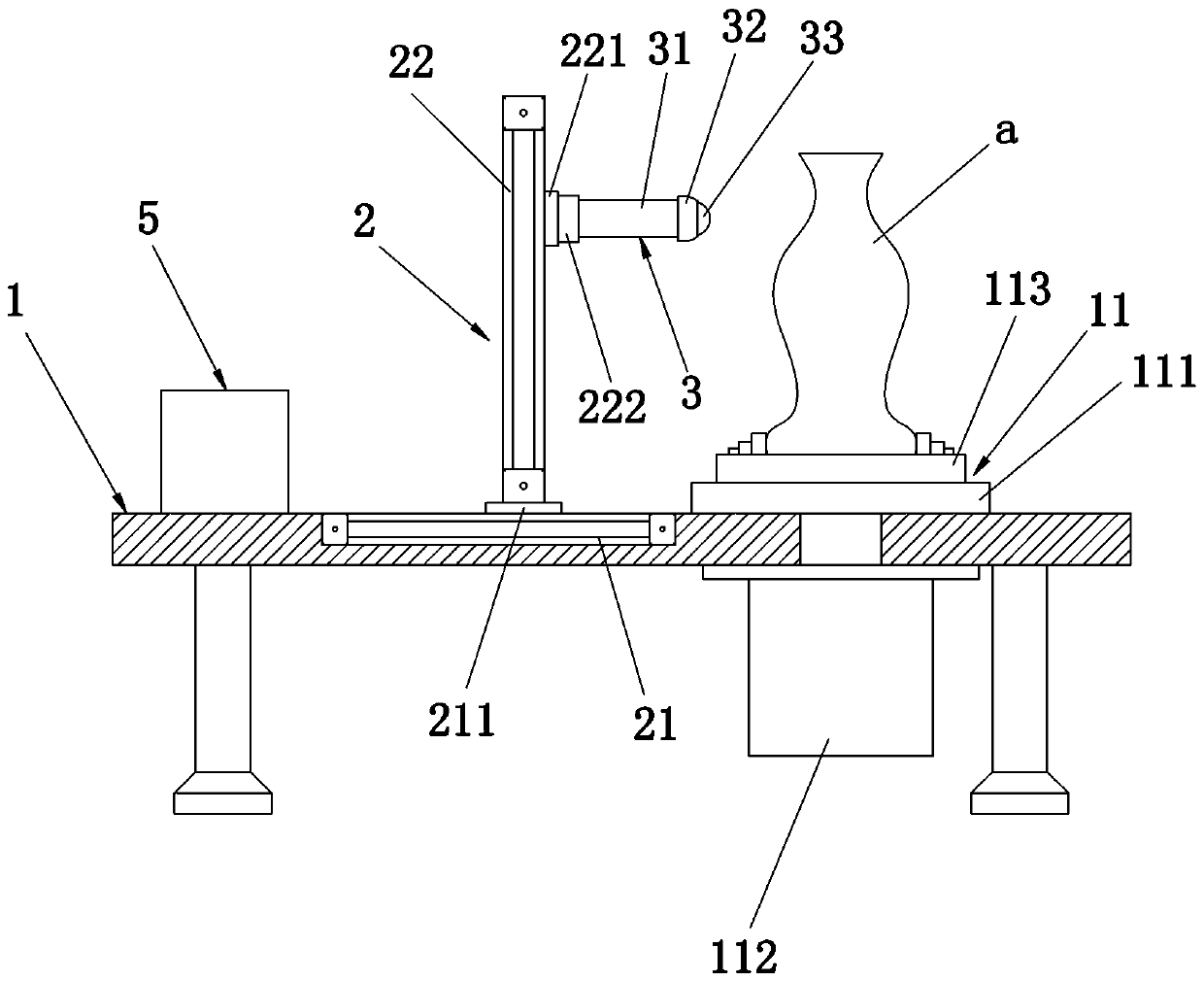

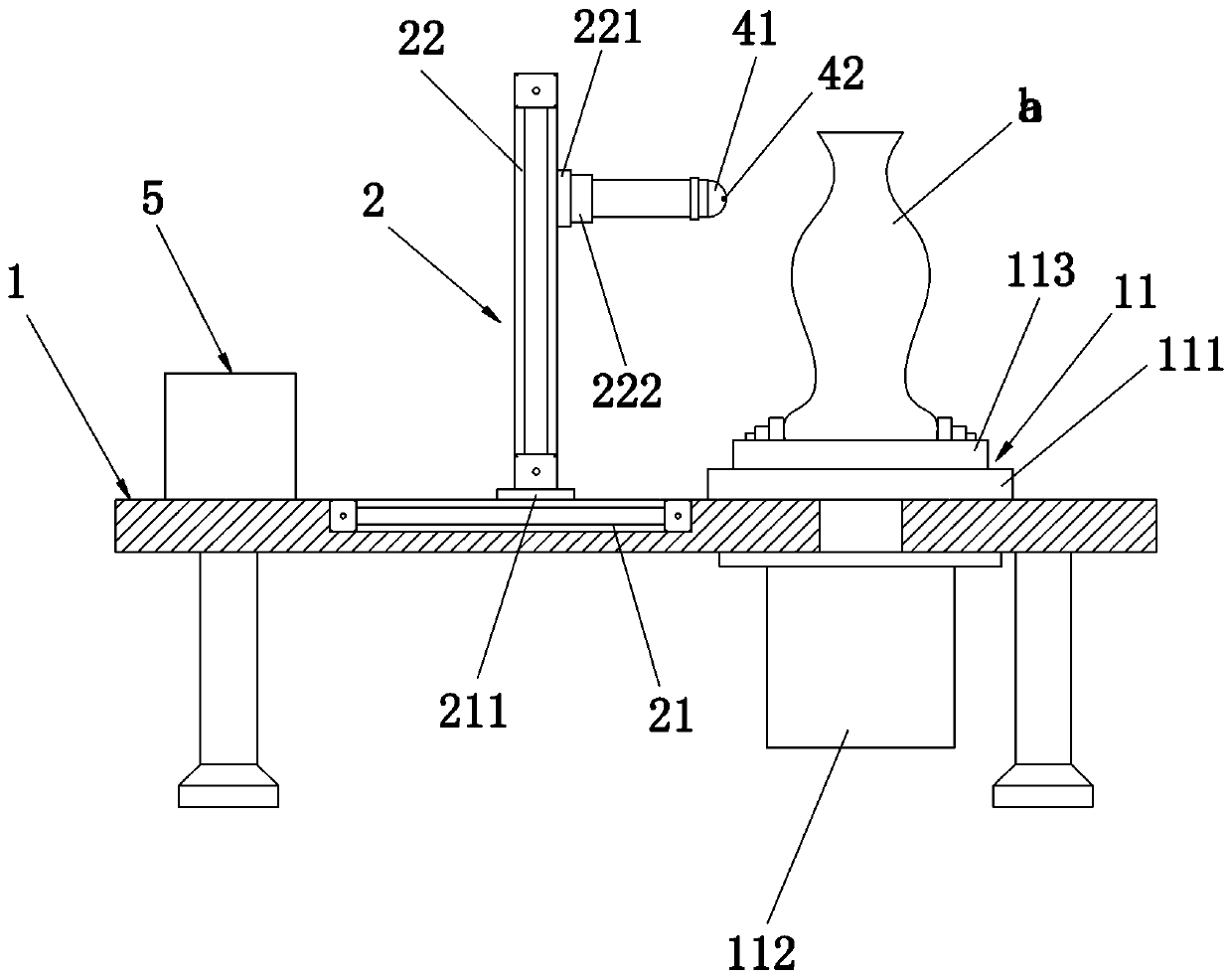

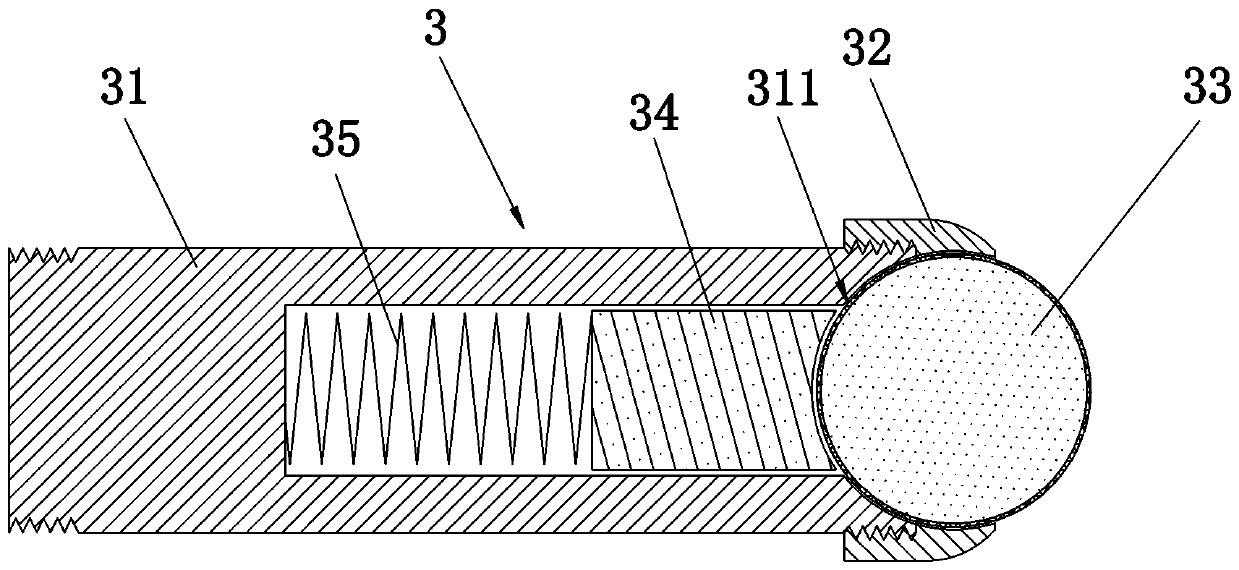

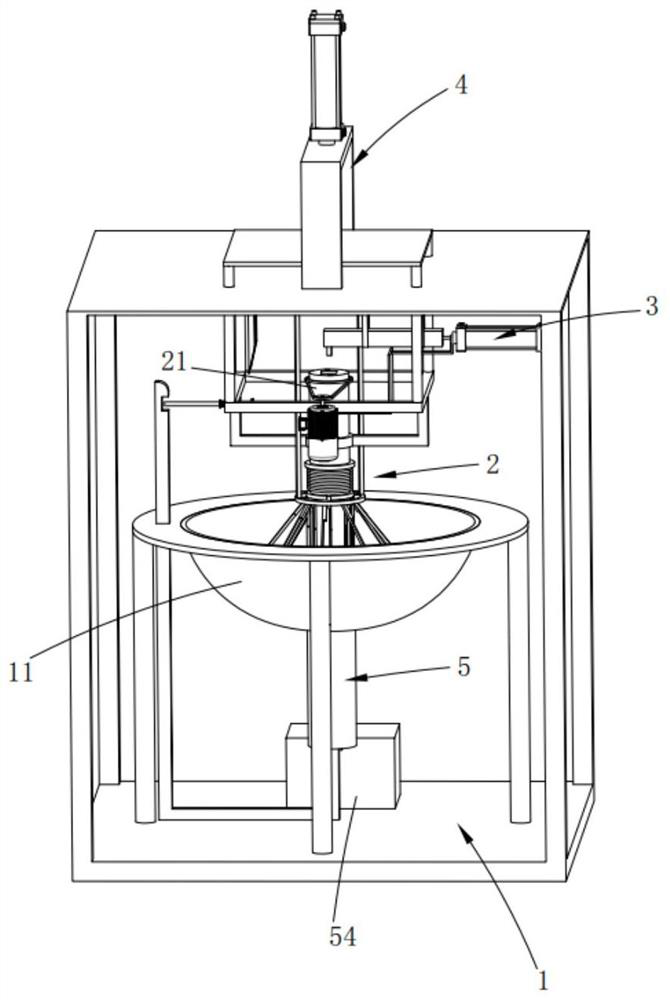

Ceramic blank automatic polishing machine

ActiveCN110860971ARealize automatic grinding processImprove sanding effectGrinding carriagesCeramic shaping apparatusPolishingWorkbench

The invention discloses a ceramic blank automatic polishing machine, and relates to the field of ceramic production equipment. The ceramic blank automatic polishing machine comprises a workbench, a sandbag polishing head and a driving device; the workbench is rotatably provided with a fixing seat where a ceramic blank can be placed; the sandbag polishing head is arranged on the upper portion of the workbench and driven to move up and down on the outer surface of the ceramic blank under action of the driving device, and polishing of the ceramic blank can be achieved. The ceramic blank automaticpolishing machine can achieve automatic polishing of the ceramic blank, the polishing effect and the polishing efficiency of the ceramic blank are improved advantageously, and the problems that the traditional ceramic polishing procedure relies on the manpower mode, the production efficiency is low, and the product quality is variable are solved. In addition, it is a large breakthrough to adopt the sandbag polishing head to polish the ceramic blank, the shape of the sandbag polishing head can be automatically changed along with changing of the outline of the ceramic blank in the polishing process, thus, unnecessary abrasion to the ceramic blank can be avoided, and in addition, precision polishing of the ceramic blank can be achieved.

Owner:FUJIAN JIAMEI GRP

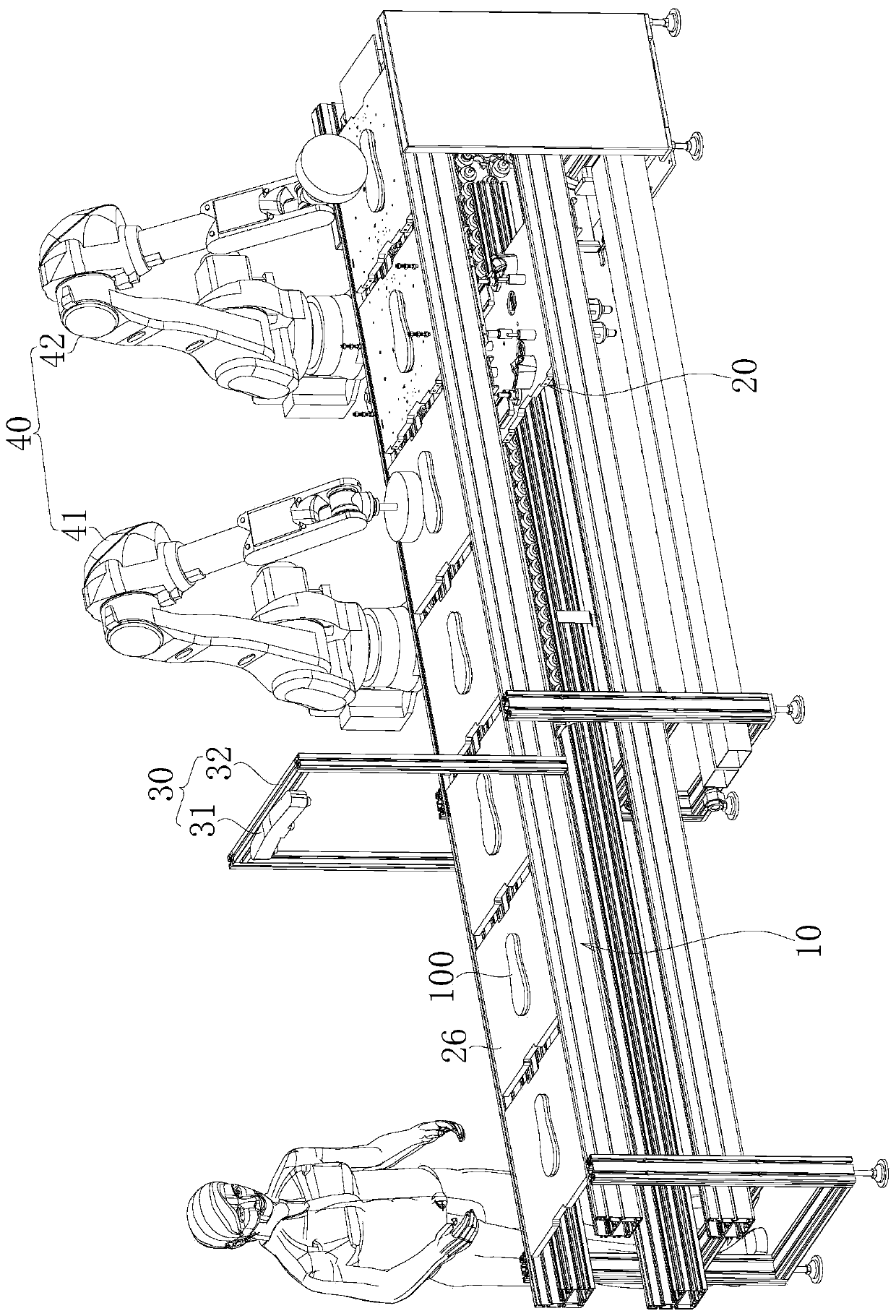

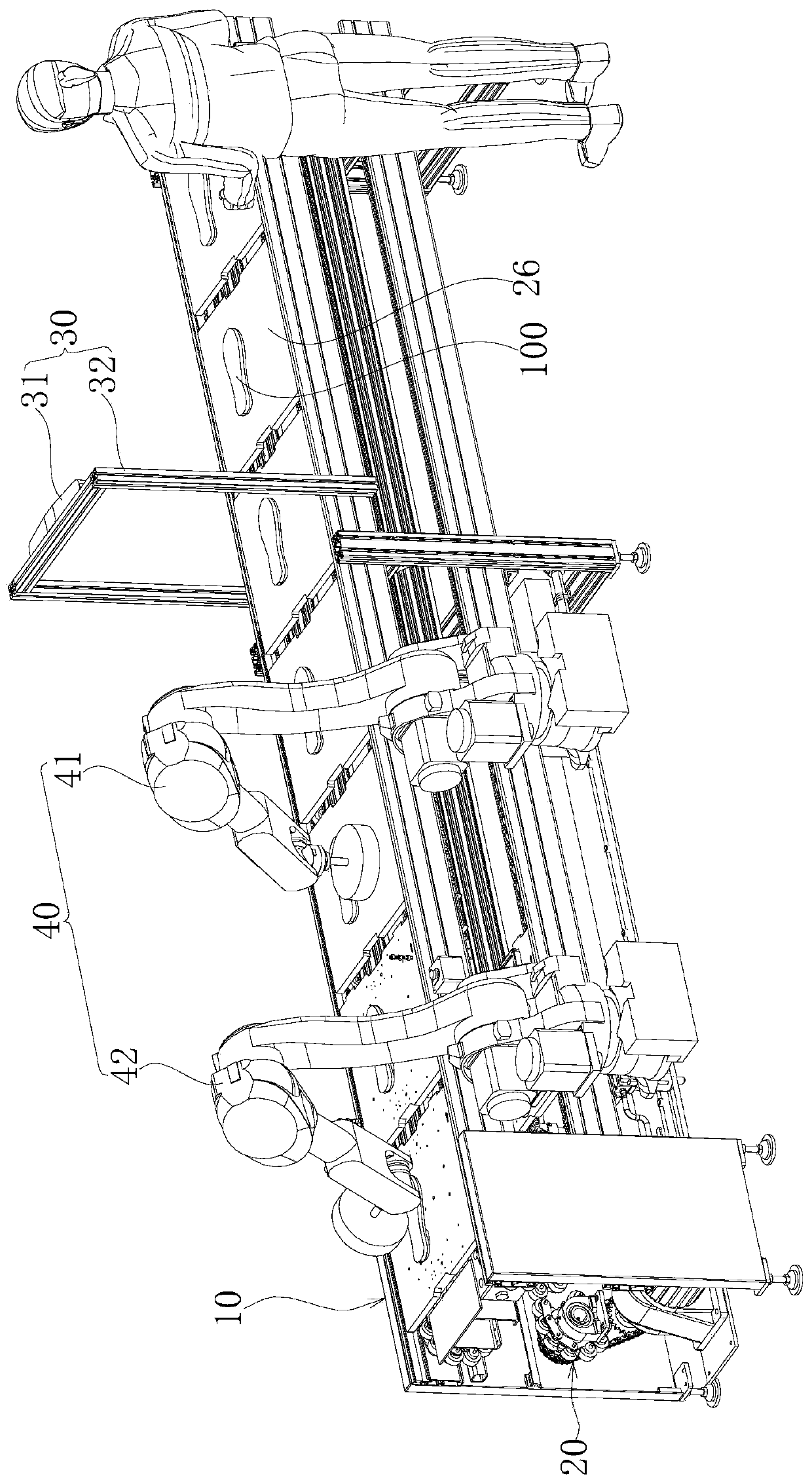

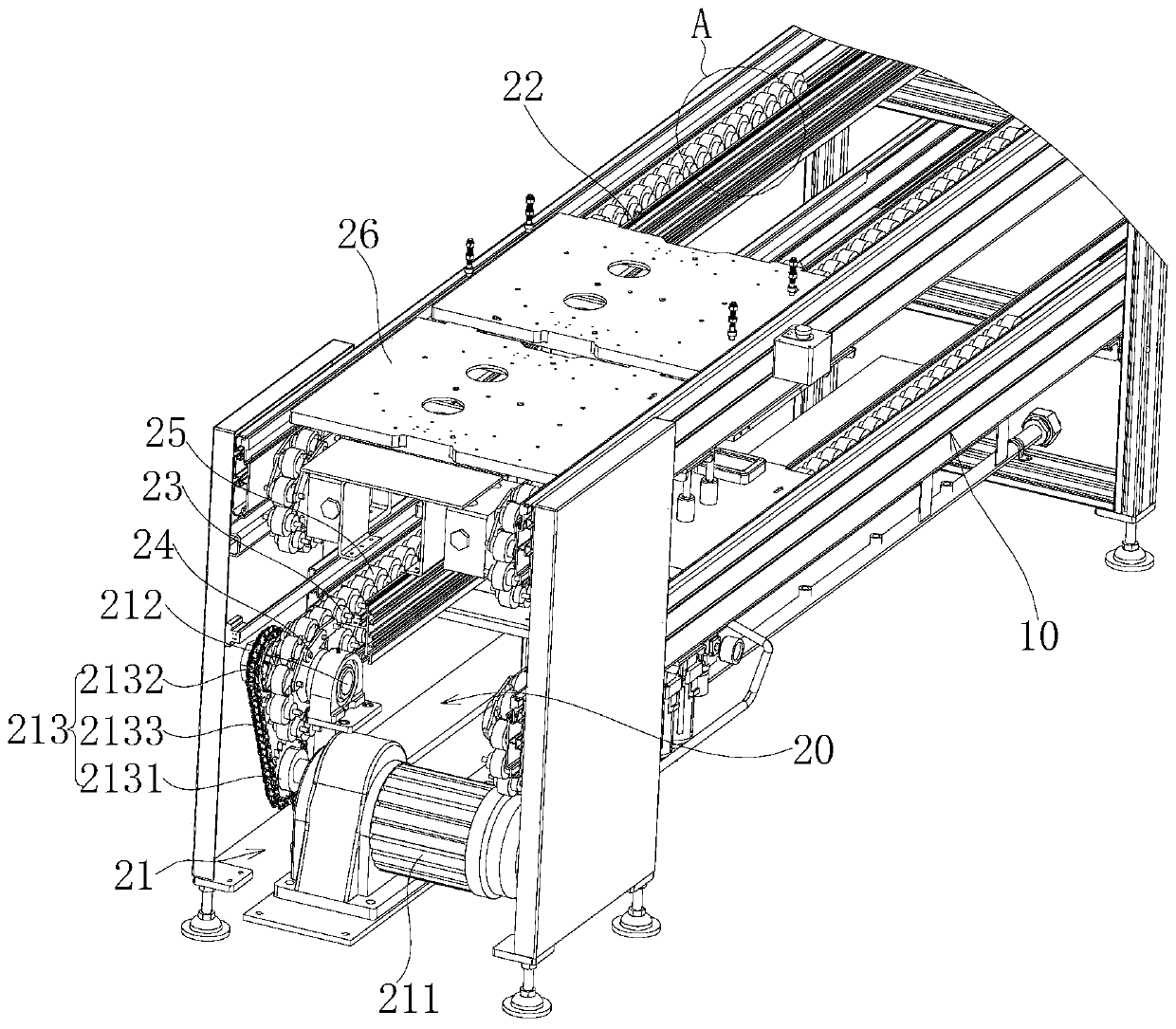

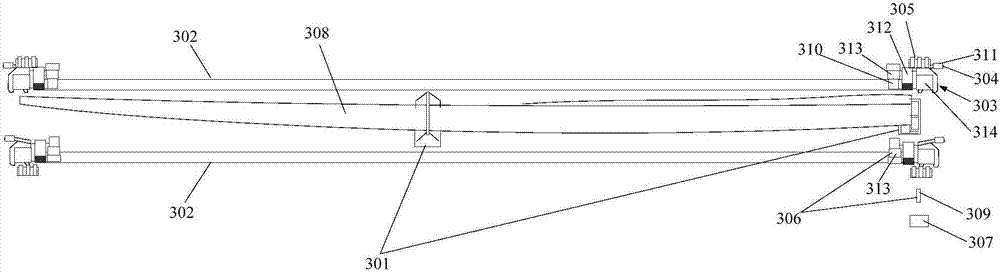

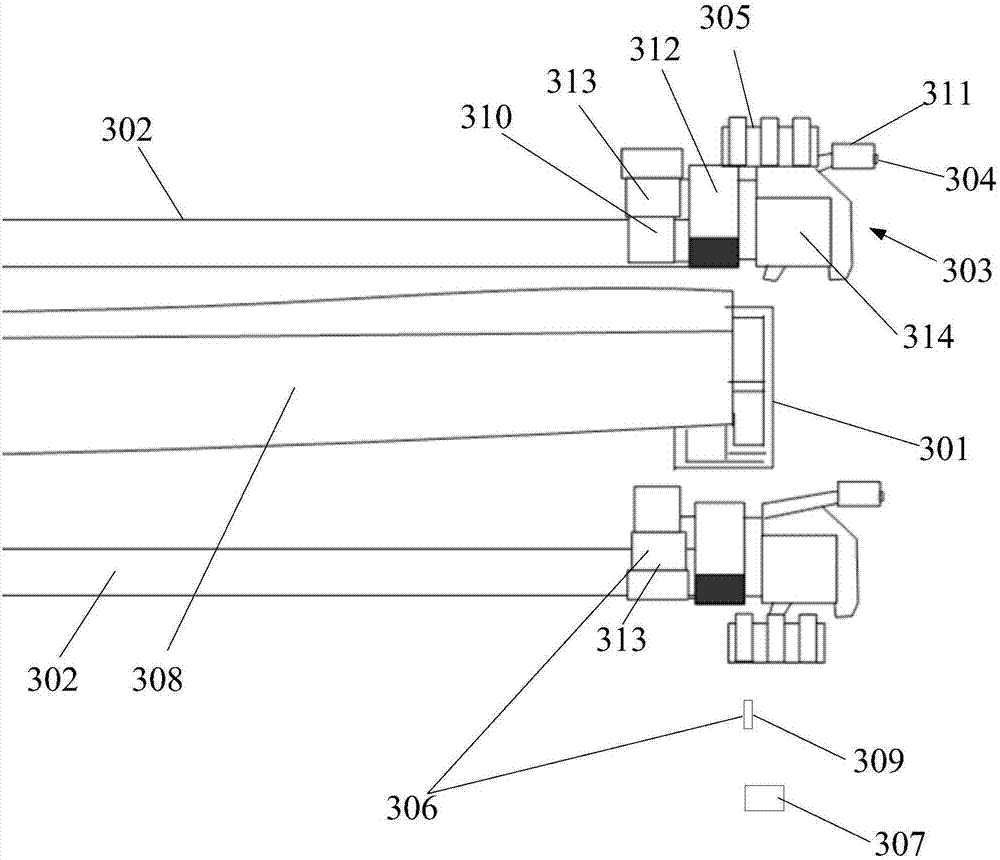

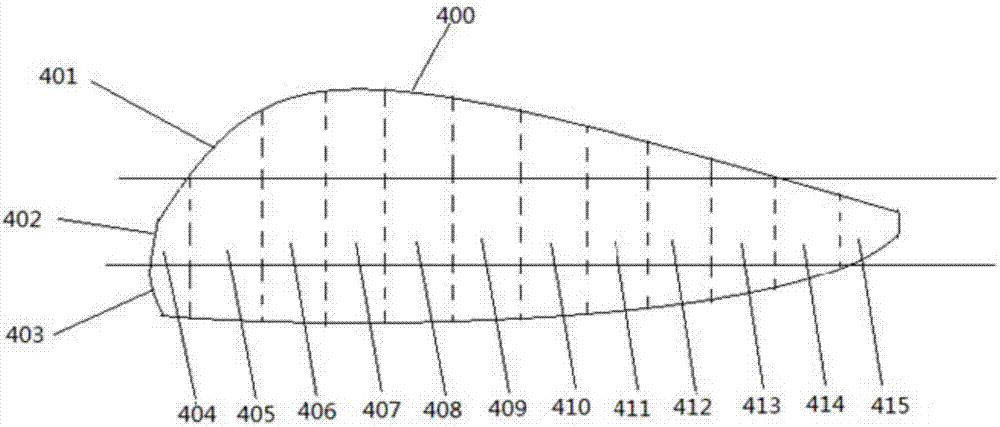

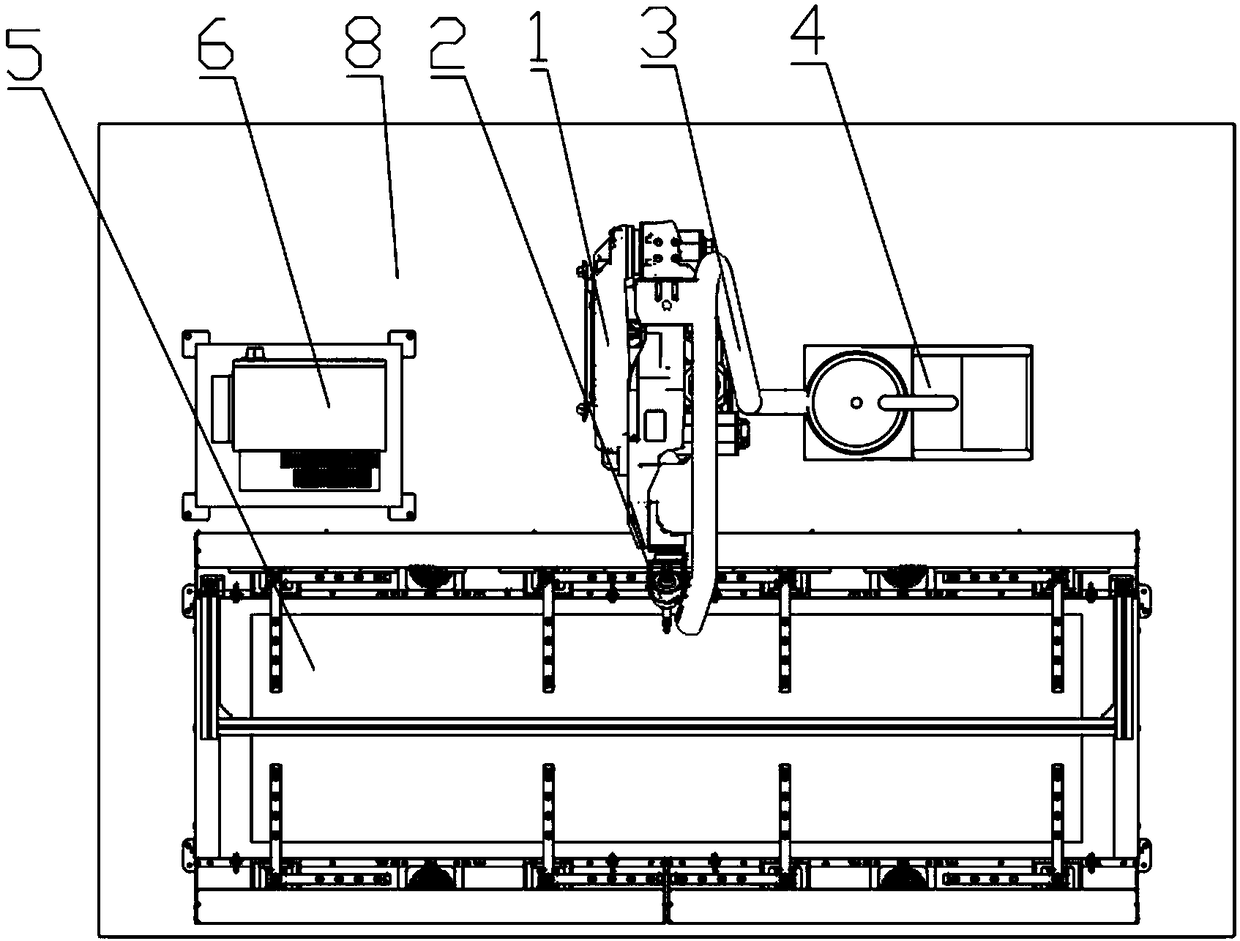

Large blade type workpiece robot collaborative grinding system and method

PendingCN107263255AGuarantee processing quality and consistencyHigh degree of automationGrinding feed controlAutomatic grinding controlCorner angleControl theory

The invention provides a large blade type workpiece robot collaborative grinding system. The large blade type workpiece robot collaborative grinding system comprises a blade turnover clamping module, horizontal guide rails, N robot grinding units, N measuring modules corresponding to the robot grinding units, a control module and an upper computer module, wherein the control module comprises a tool control submodule and N robot grinding unit control submodules; the blade turnover clamping module is used for mounting and clamping blades to be ground; the two horizontal guide rails are arranged on the two sides of the blades in the long axis direction of the blades, and each horizontal guide rail is at least provided with one robot grinding unit; each robot grinding unit comprises a robot, a matched robot controller and a grinding device; each grinding device is mounted at the tail end of the robot corresponding to the grinding device, and each measuring module is mounted at the tail end of the corresponding robot; and the tool control submodules are connected with the blade turnover clamping module and control the turnover direction, turning angles and clamping operation of the blades. The large blade type workpiece robot collaborative grinding system can improve the grinding efficiency and quality of the blades.

Owner:无锡中车时代智能装备研究院有限公司

Extraction mortar for botanical experiment

PendingCN107952561ARealize automatic grindingReduce the difficulty of operationGrain treatmentsAgricultural engineeringStructural engineering

The invention discloses an extraction mortar for a botanical experiment. The extraction mortar comprises a fixed seat, a rotating shaft, a base, a mortar body, a mortar cover, a grinding hammer and apressure applying mechanism, the middle position of the fixed base is provided with a rotating shaft hole, and the rotating shaft is rotatably arranged in the rotating shaft hole in a penetrating mode; the lower end of the rotating shaft is connected to a driving motor, the base is provided with a clamping groove, the base is placed on the fixed seat, and the rotating shaft is detachably clamped into the clamping groove; the mortar body is arranged on the base, the mortar cover is arranged on the mortar body, the middle of the mortar cover is provided with a through hole, and the mortar coveris made of a transparent material; the grinding hammer penetrates through the through hole, and a hammer head of the grinding hammer is located in the mortar body; and the pressure applying mechanismcomprises a bracket, a pressing block and a lifting mechanism, and the pressing block is arranged on the bracket in the mode of being capable of moving in the vertical direction, the lifting mechanismis connected to the pressing block to drive the pressing block to move downwards, and the pressing block abuts against the upper end of a hammer handle of the grinding hammer, so that the hammer headof the grinding hammer abuts against the bottom of the mortar body in a pressing mode. The extraction mortar for the botanical experiment reduces the operation difficulty of experimenters and avoidsharm to bodies of the experimenters.

Owner:广西壮族自治区环境监测中心站

Grinding machine tool for outer arc surface of drum brake pad

PendingCN111660175ARealize automatic grindingEdge grinding machinesGrinding carriagesCircular discElectric machinery

The invention relates to the technical field of grinding machines, and in particular to a grinding machine tool for an outer arc surface of a drum brake pad. The grinding machine tool comprises a rack, wherein the rack is provided with a clamping mechanism, a feeding device, a grinding device and a stacking device, the clamping mechanism comprises a grinding disc and a rotating motor, the grindingdisc comprises a disc bottom and a cylindrical disc ring, the connection between the disc ring and the disc bottom is provided with a groove surrounding a circle of the disc ring, a plurality of stopping plates along an axis direction of the disc ring are uniformly distributed on the outer circumference of the disc ring, and the outer side of the grinding disc is provided with a left compressingdevice and a right compressing device which resist a brake pad so as to fit the disc ring, and crow plate for separating the brake pad from the grinding disc. According to the invention, the brake padis automatically fitted with the disc ring through the feeding device, the outer arc surface of the brake pad is grinded by the rotation of the grinding disc and the grinding device, and the grindingbrake pad is restacked by the stacking device, so as to realize the automatic grinding of the outer arc surface of the brake pad.

Owner:湖北龙运汽车配件有限公司

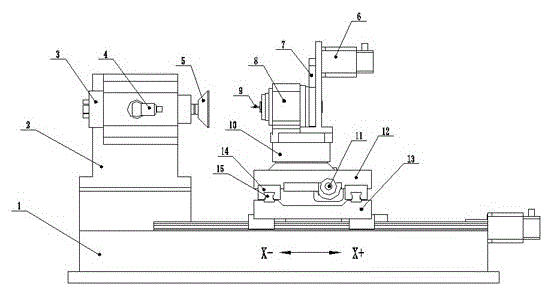

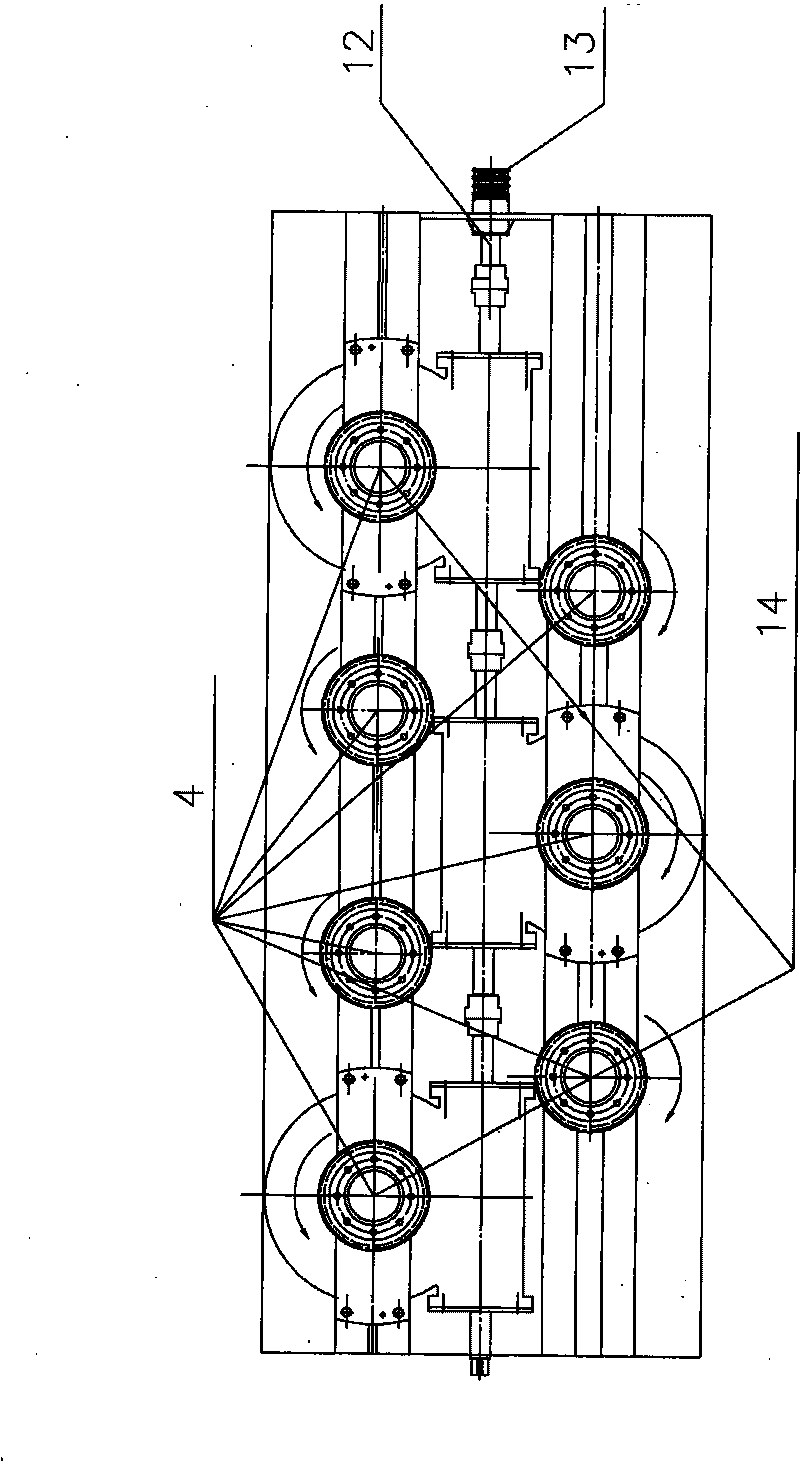

Digital control horizontal honing machine and honing method for realizing control of grinding force

InactiveCN101559577AIntuitive screen displayEasy to operateHoning machinesAutomatic controlElectric machinery

The invention belongs to the field of pipe fitting process equipment, and more particularly relates to a horizontal honing machine provided with an automatic control device and a honing method for realizing control of grinding force. The horizontal honing machine is characterized in that a screw rod provided with a core bar connected with a grinding rod of a honing head is arranged at one side close to the honing head; a signal input end of a computer input control unit is connected with a workpiece driving motor, and a signal output end of the computer input control unit is connected with a core bar driving device. In the method, the screw rod provided with the core bar connected with the grinding rod of the honing head is arranged at one side close to the honing head, one end of the computer input control unit is connected with the workpiece driving motor, and the other end thereof is connected with the core bar driving device. The invention aims at solving the problems that the existing honing machine can not realize the automatic control of the grinding force, has poor correction capability for non-circular pipe fittings, etc.

Owner:于伟忱

Grinding equipment for pharmaceutical engineering

InactiveCN108772179AImprove grinding efficiencyGuaranteed grinding qualityGrain treatmentsEngineeringPharmaceutical engineering

The invention discloses grinding equipment for pharmaceutical engineering. The grinding equipment comprises a bottom plate, an equipment body, first grinding cavities and second grinding cavities. Thefirst grinding cavities and the second grinding cavities are annularly formed at the edge inside the equipment body sequentially from top to bottom. Heat-conducting abrasion-resistant plates are arranged on the inner side walls of the first grinding cavities and the second grinding cavities correspondingly, and first fin sheets and second fin sheets are evenly fixed to the two sides of the heat-conducting abrasion-resistant plates correspondingly. The ends, away from the heat-conducting abrasion-resistant plates, of the first fin sheets all extend into a heat dissipating cavity, and the ends,away from the heat-conducting abrasion-resistant plates, of the second fin sheets all extend into a heat dissipating box. An air pump is mounted at the position, on one side of the equipment body, ofthe top of the bottom plate through a bolt, and the input end of the air pump is fixedly connected with a distributing pipe. According to the grinding equipment, by forming the first grinding cavities and the second grinding cavities, materials are simply crushed through the first grinding cavities firstly and then enter the second grinding cavities to be ground, thus material grinding is quicker, and the grinding effect is better.

Owner:许兰兰

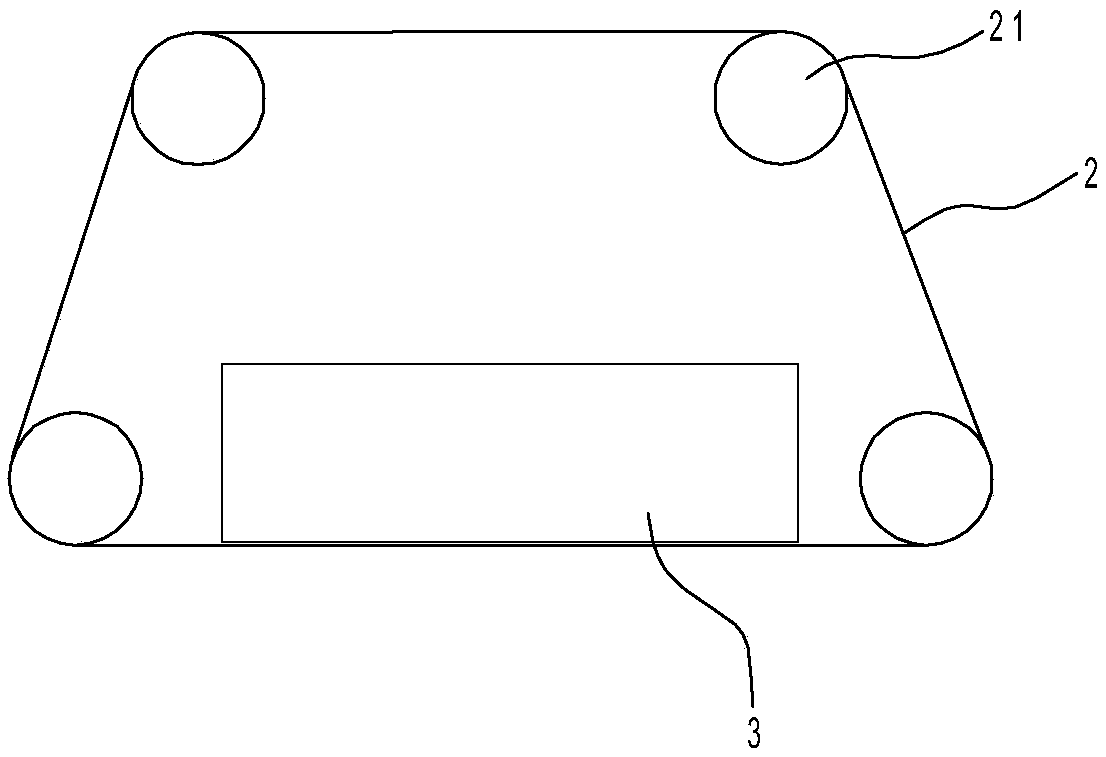

Grinding machine for burrs of brake pad

ActiveCN105127859AAchieve grindingRealize automatic grindingEdge grinding machinesGrinding carriagesEngineeringBrake pad

The invention discloses a grinding machine for burrs of a brake pad. The grinding machine is characterized by comprises a rack, a first grinding mechanism and a second grinding mechanism, wherein the first grinding mechanism and the second grinding mechanism are arranged on the rack and are perpendicular to each other; the first grinding mechanism comprises a conveying chain, a groove grinding mechanism arranged above the conveying chain, and a top edge grinding mechanism, the groove grinding mechanism is arranged above the middle of the conveying chain, and the top edge grinding mechanism is close to the second grinding mechanism; and the second grinding mechanism comprises a conveying belt and a side edge grinding mechanism arranged above the conveying belt, a plurality of magnets are attracted to the conveying belt and are in contact, and the side edge grinding mechanism is arranged at the tail end of the conveying belt. The grinding machine can automatically grind the burrs of the brake pad.

Owner:苏州隆士丹自动化技术有限公司

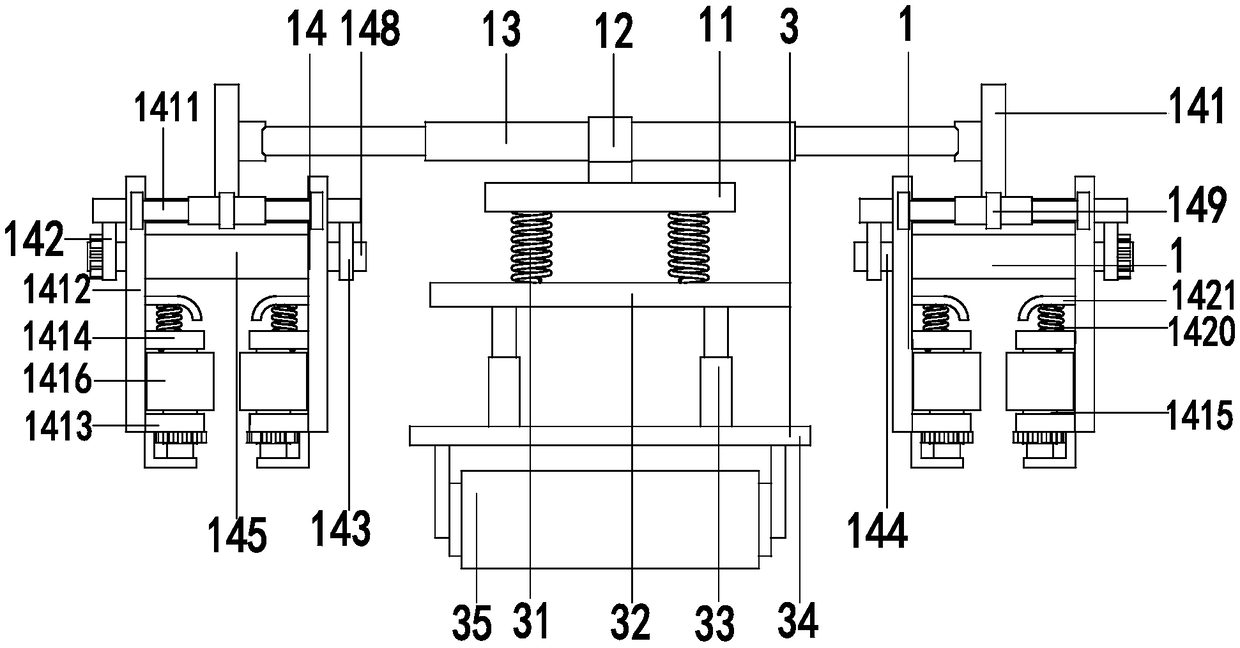

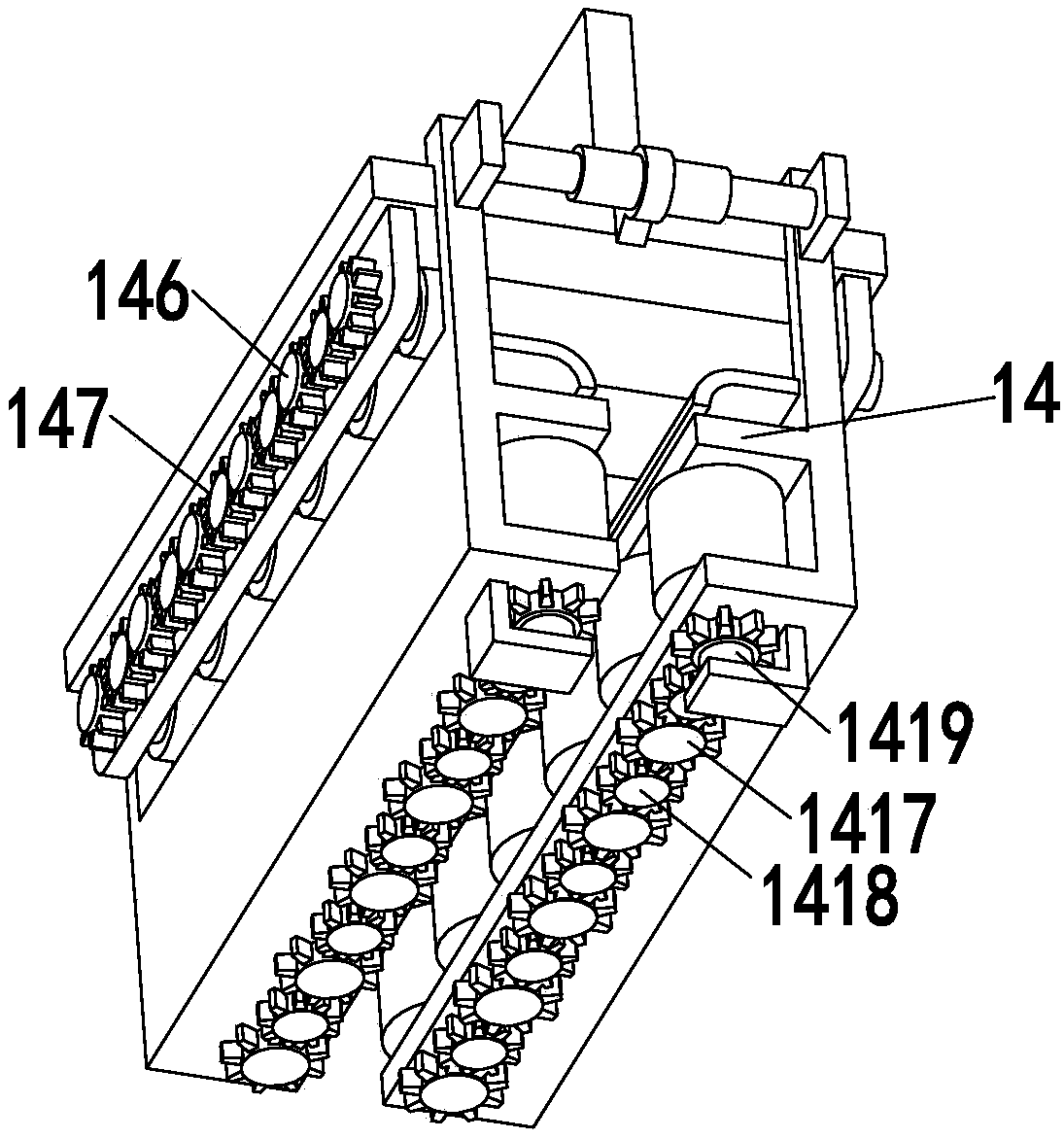

An automatic grinding robot for rail maintenance

ActiveCN108978376APlay a shock absorbing roleImprove stabilityRailway track constructionFuel tankEngineering

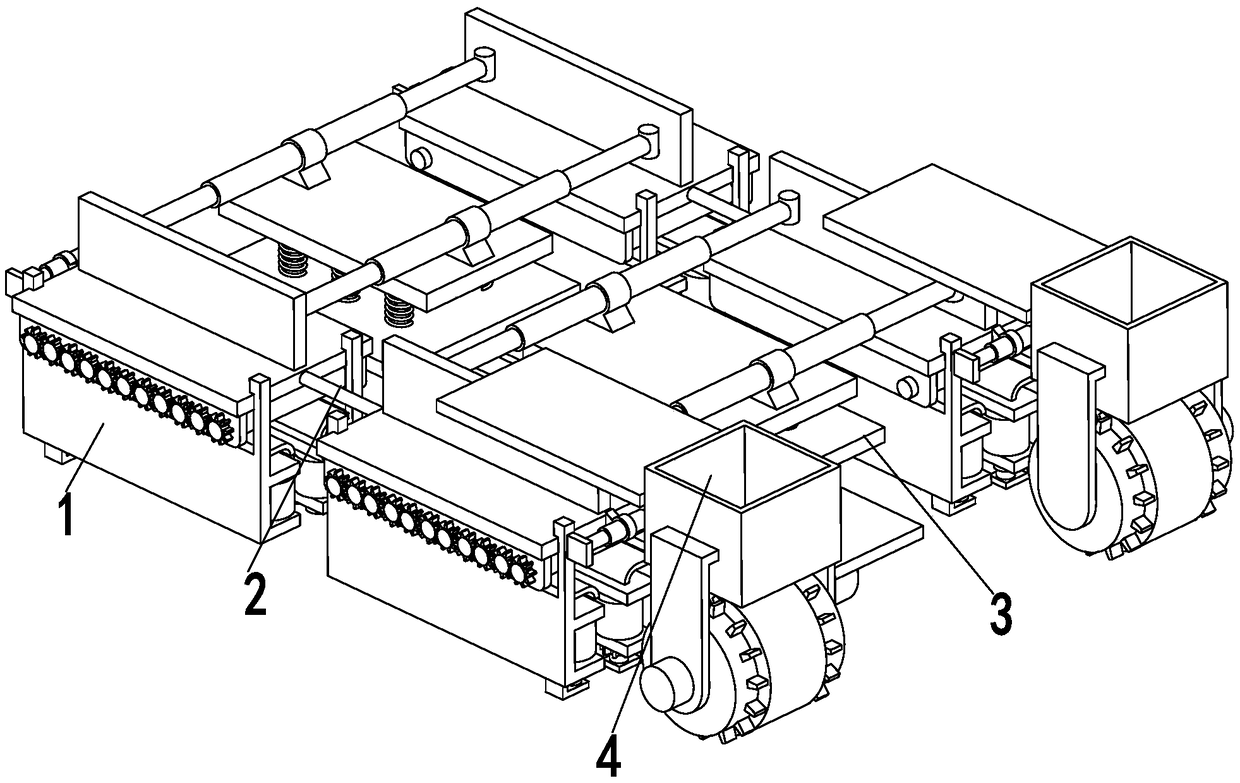

The invention relates to an automatic grinding robot for rail maintenance, including two polishing devices, a connecting chain, walking devices and an oiling device, The two grinding devices are symmetrically arranged left and right, and the two grinding devices are connected with each other through a connecting chain, Low ends of the polishing device are provided with walking devices, The polishing devices comprise mounting plates, mounting seats, adjusting cylinders and polishing mechanisms; the walking devices comprises buffer springs, supporting plates, adjusting height cylinders, base plates and traveling wheels; and the oiling device comprises a horizontal plate, an oil storage tank, an oil extraction roller, an oiling roller, a connecting frame and a working motor. The invention cansolve the problems of high labor cost, low working efficiency, inconvenient adjustment, small use range and the like existing in the existing rail maintenance and polishing process, and can realize the functions of automatic polishing and oiling of the rail.

Owner:海安苏博机器人科技有限公司

Pencil production grinding device

ActiveCN109080315AAchieve pin tipRealize automatic grindingSharpenersGrinding drivesSurface roughnessEngineering

The invention discloses a pencil production grinding device. The pencil production grinding device comprises a conveyor belt, and is characterized in that a pressing belt is arranged above the conveyor belt, a pressure regulating unit is arranged on the inner side the pressure belt, and the pressure regulating unit comprises a plurality of pressure regulating assemblies arranged in parallel; eachpressure regulating assembly comprises a fixing bracket, a rotating shaft and a columnar cam; the fixing brackets are opened downwardly to for opening portions; the two ends of the rotating shafts aredisposed on the opposite side walls of the opening portions, and the columnar cams are disposed on the rotating shafts; the distances between the axes of the columnar cams of the pressure regulatingassemblies and the corresponding axes of the rotating shafts are not equal; a grinding roller set is rotatably arranged on the outer side of the conveyor belt, the grinding roller set includes a center roller and a plurality of grinding rings arranged above the outer wall of the center roller in parallel in a sleeving mode, and the grinding rings have different surface roughness. The pencil production grinding device realizes automatic grinding of a pencil tip in the pencil production process, improves the grinding quality, and improves the production efficiency at the same time.

Owner:SUZHOU CHUANGMING SOFTWARE TECH CO LTD

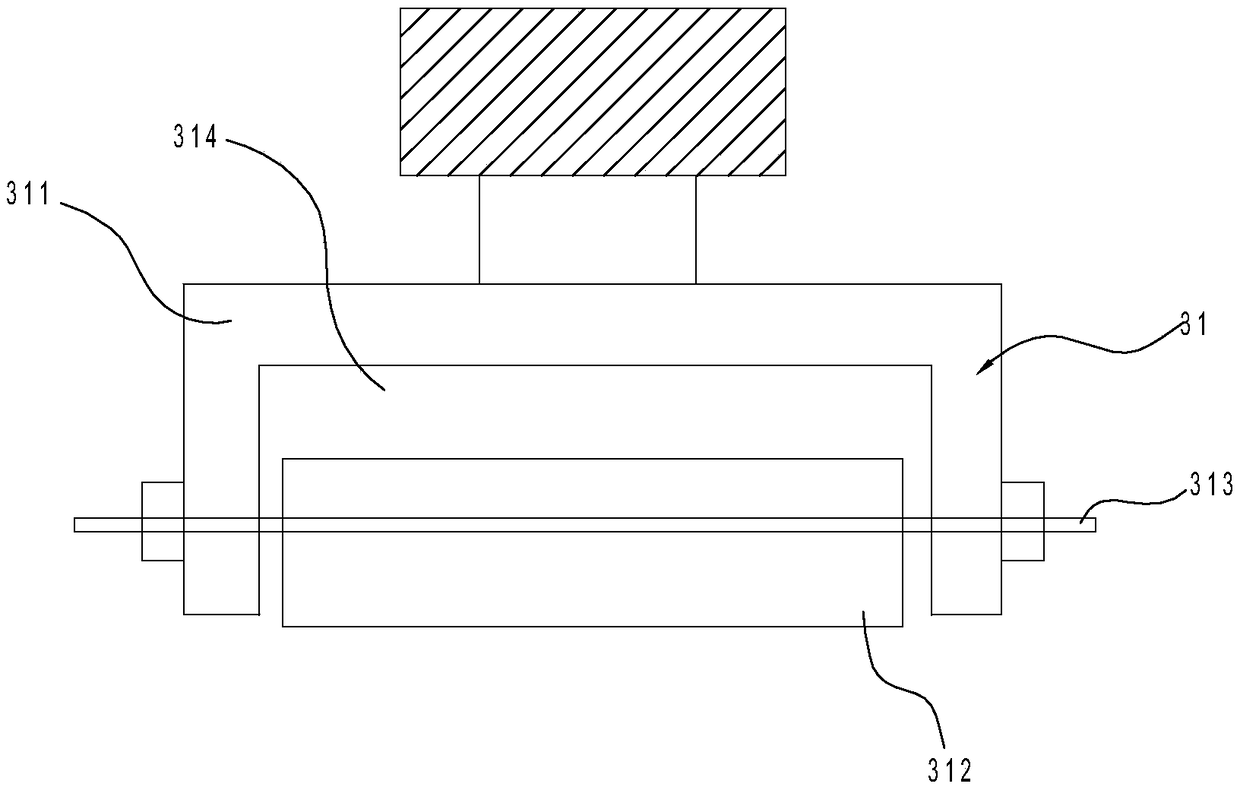

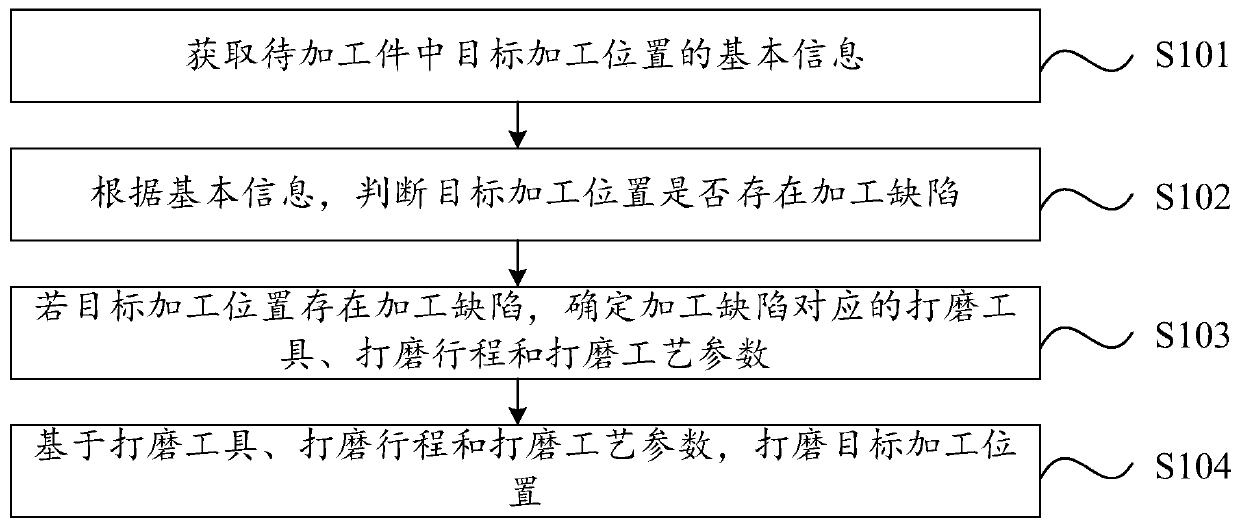

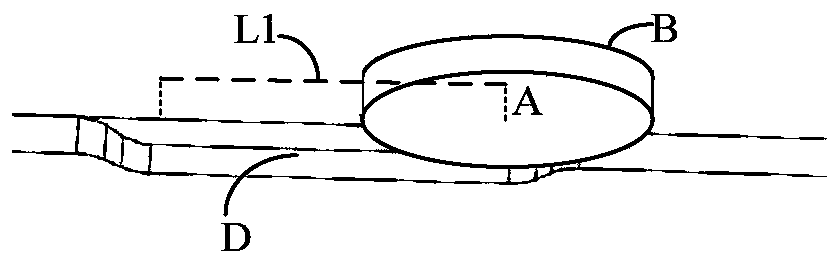

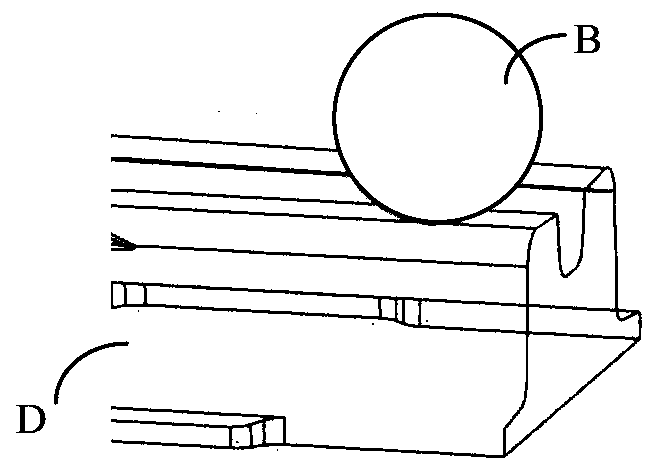

Automatic grinding method, device and equipment

ActiveCN110170922ANo harm to physical and mental healthRealize automatic grindingEdge grinding machinesGrinding feed controlRisk strokePsychological health

The invention relates to an automatic grinding method, device and equipment. The method comprises the following steps of acquiring basic information of a target machining position in a workpiece to bemachined; judging whether machining defects exist in the target machining position according to the basic information; determining a grinding tool, a grinding stroke and a grinding process parametercorresponding to the machining defects if the machining defects exist in the target machining position; grinding the target machining position on the basis of the grinding tool, the grinding stroke and the grinding process parameter. According to the automatic grinding method, device and equipment, the targeted grinding tool, the grinding stroke and the grinding process parameter are determined through different target machining positions, automatic grinding of complex positions in a turnout groove is realized, manual grinding is not needed, manpower is liberated, the physical and psychological health of constructors is not harmed, and the grinding quality and the grinding efficiency are improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Grinding device for optical lens producing and production

ActiveCN111015433AAchieve grindingNo manualOptical surface grinding machinesGrinding drivesEngineeringOptic lens

The invention discloses a grinding device for optical lens producing and production. The grinding device comprises a mounting box. A first cylinder is fixed in the mounting box. A fixed block is fixedto a piston rod of the first cylinder. A first servo motor is fixed to the fixed block. A lead screw is fixed to an output shaft of the first servo motor. The lead screw is in threaded transmission connection with a transmission nut. The transmission nut is embedded in a push plate. A second guiding rod is fixed to the push plate. A material clamping mechanism is fixed to the second guiding rod.A feeding box is arranged on the material clamping device. A locking mechanism is arranged at the lower end of the feeding box. A mounting plate is arranged at the upper end of the feeding box. A material sliding roller is rotatably connected to the mounting plate. A material conveying belt is connected to the upper end of the mounting plate. A grinding wheel is arranged on one side of the mounting box. An optical lens is automatically ground through the structure, the automation degree is high, manpower is saved, the working efficiency is high, and the product processing quality is good.

Owner:上饶市东昇光学仪器有限公司

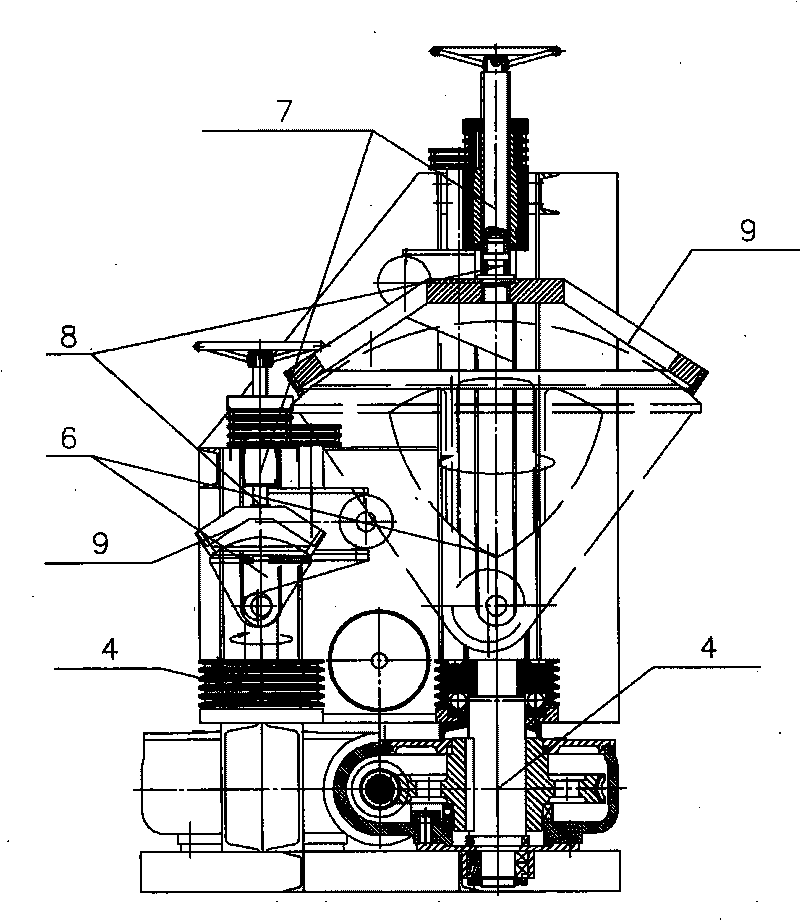

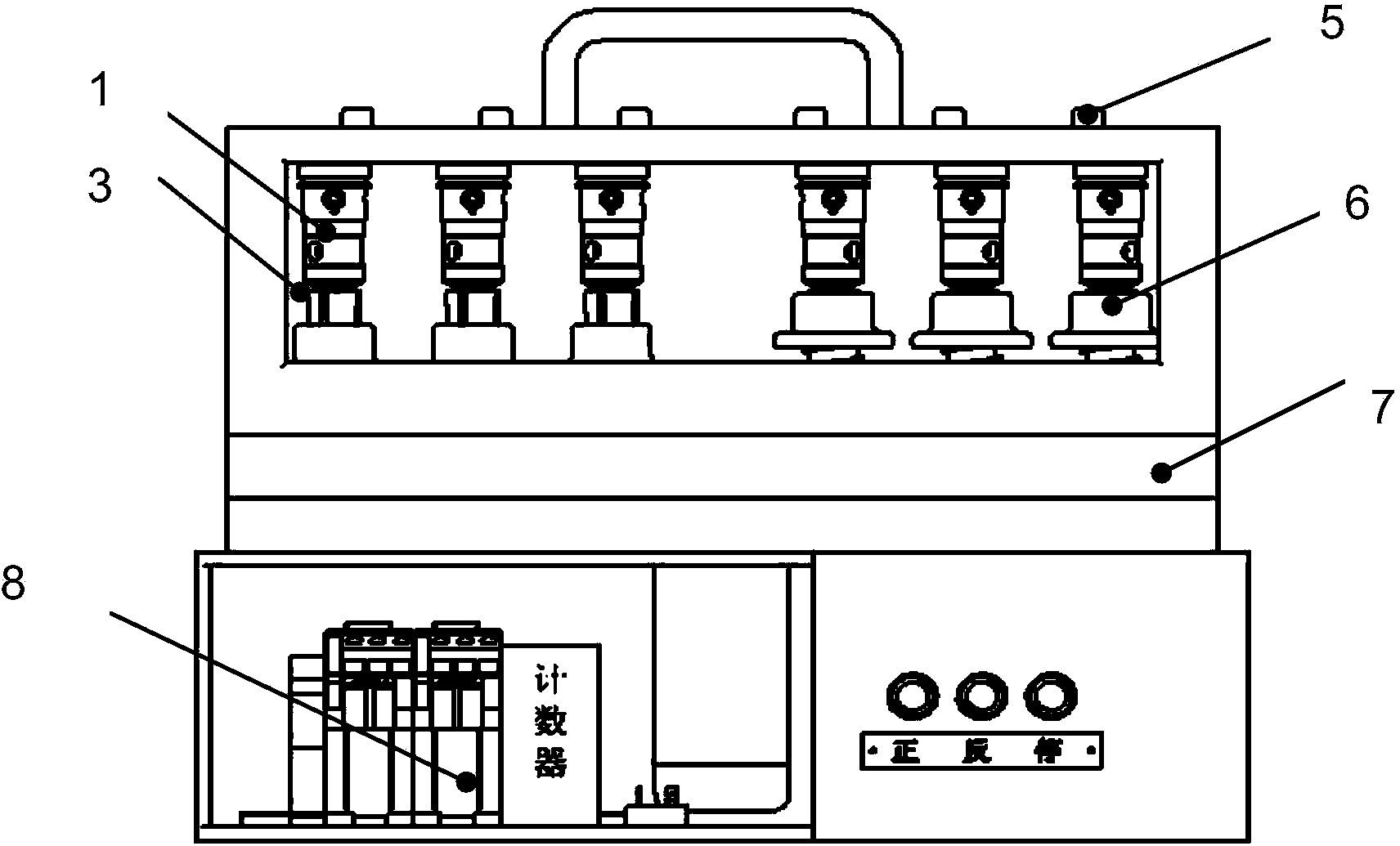

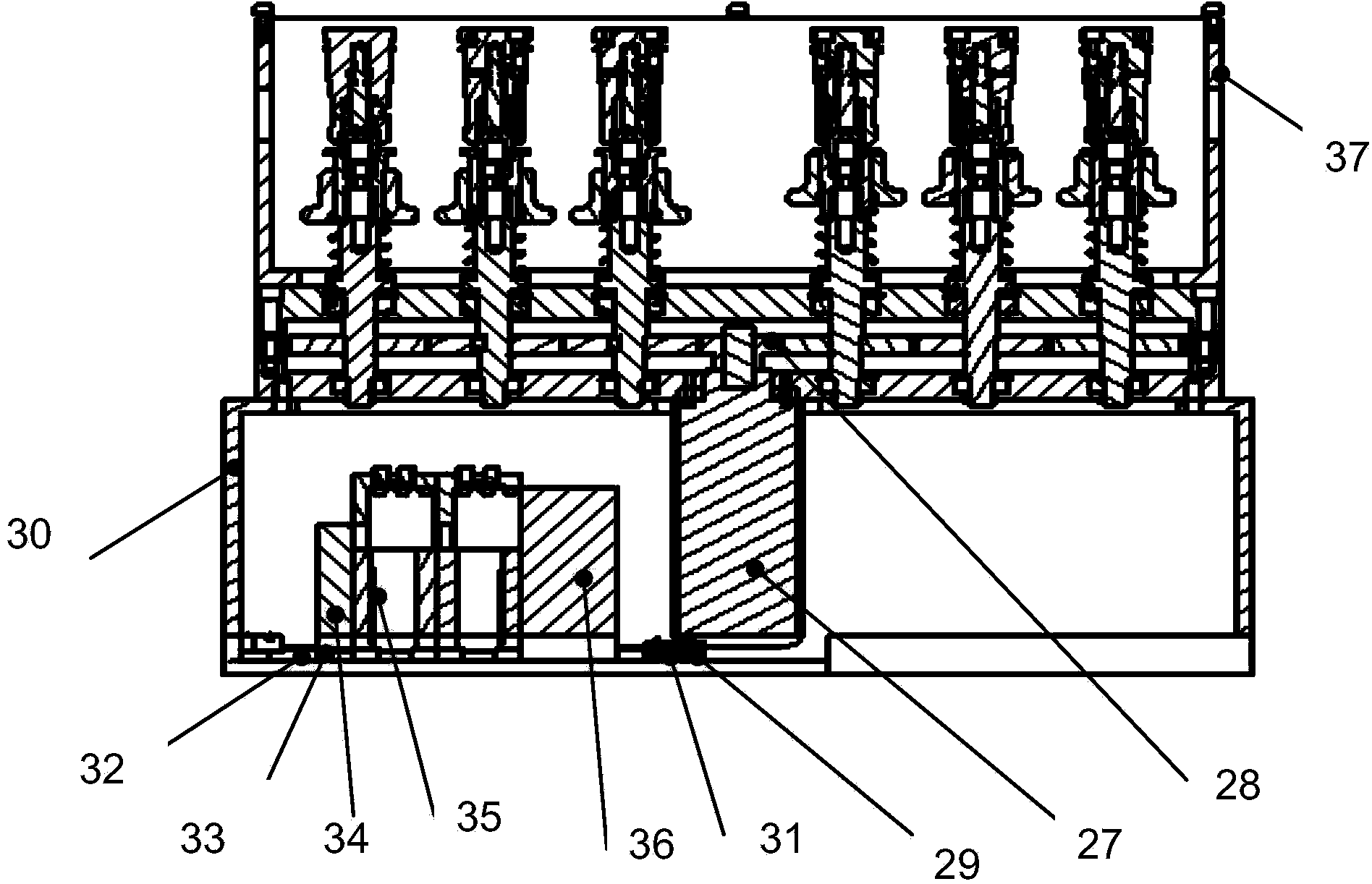

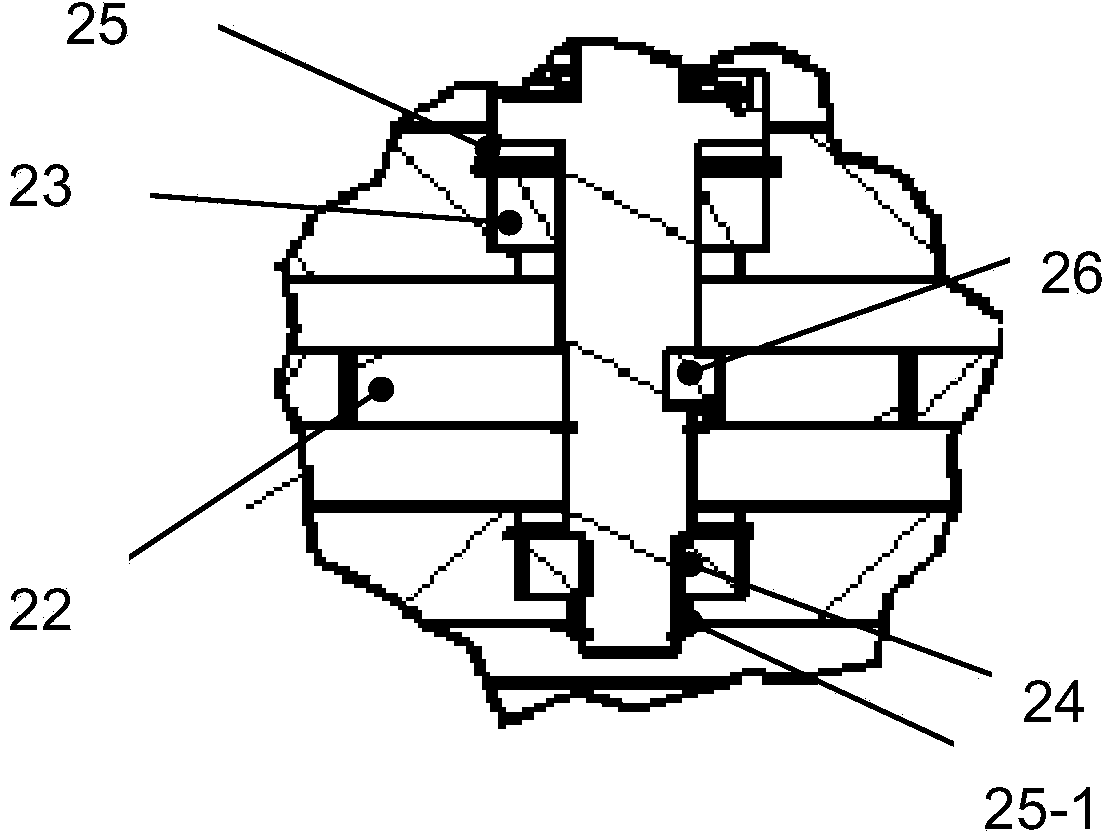

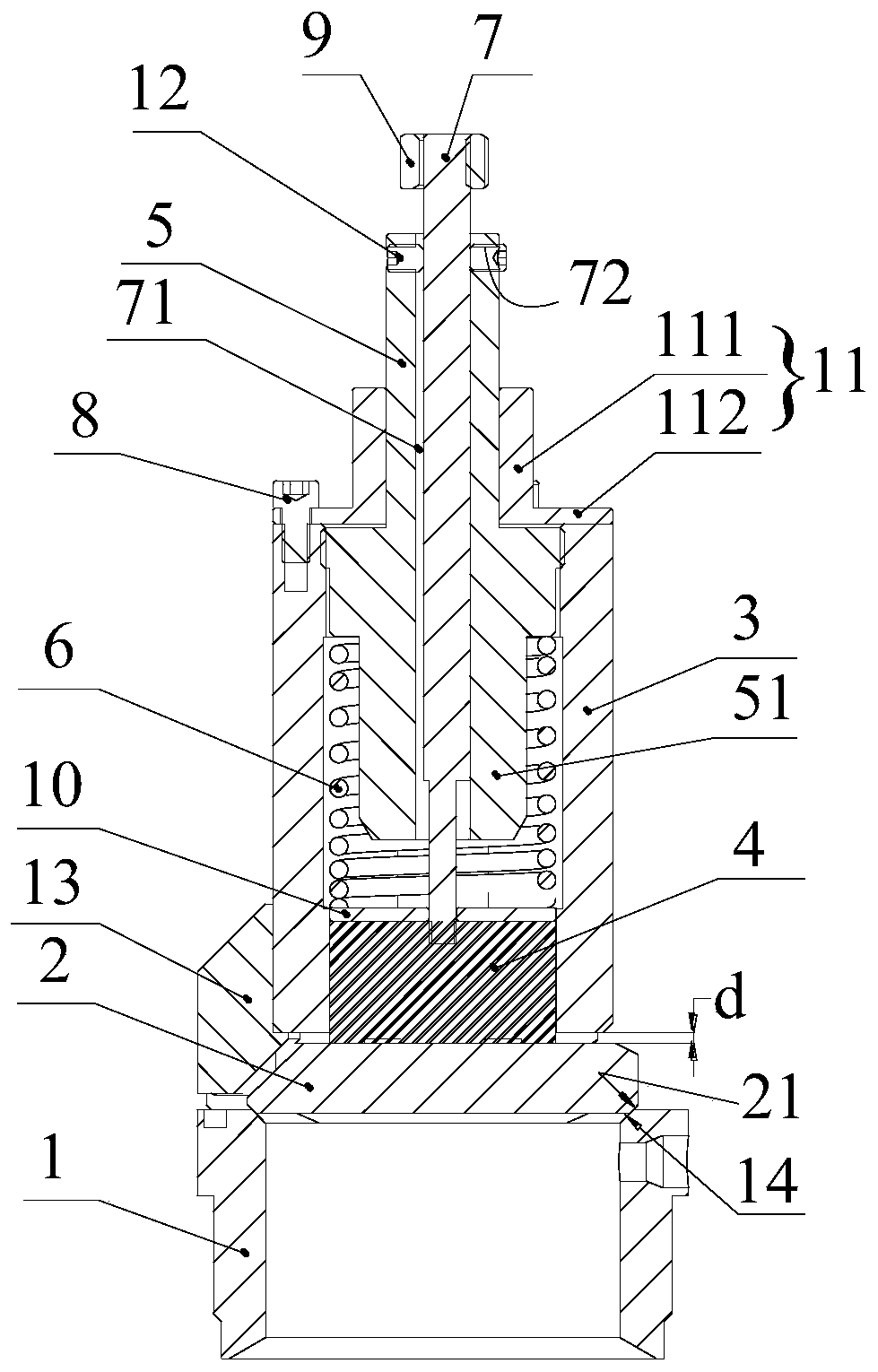

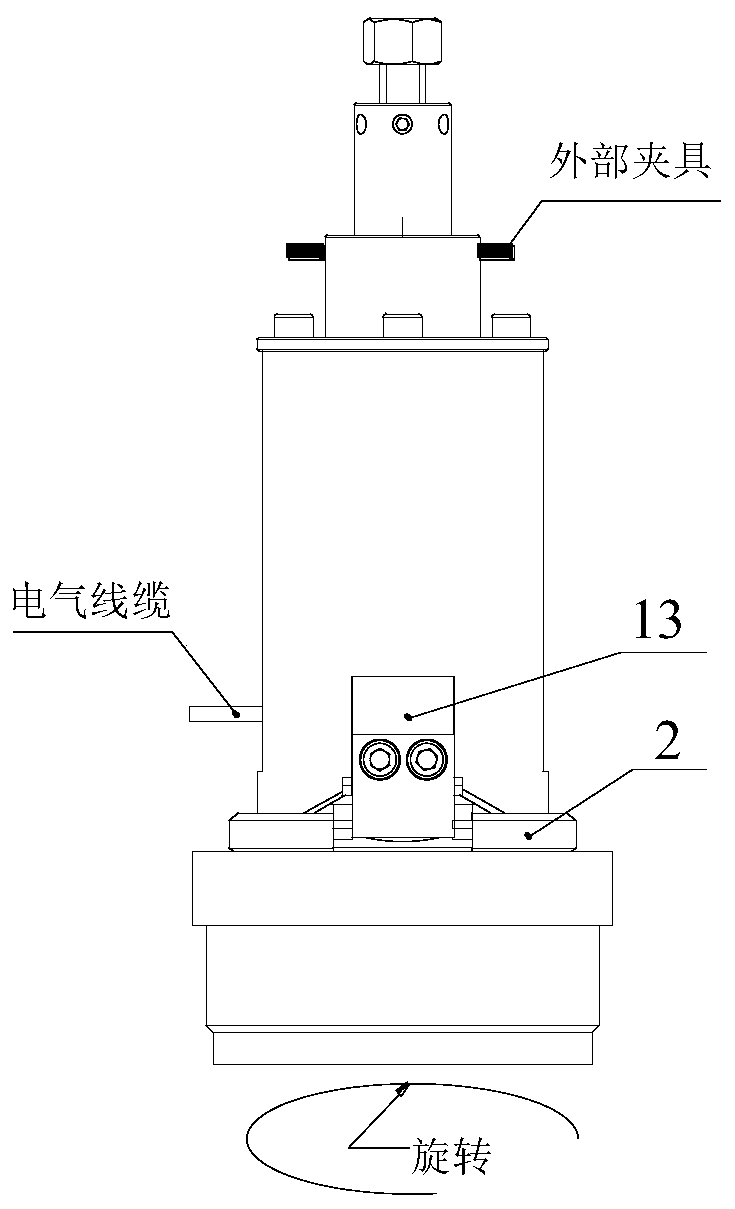

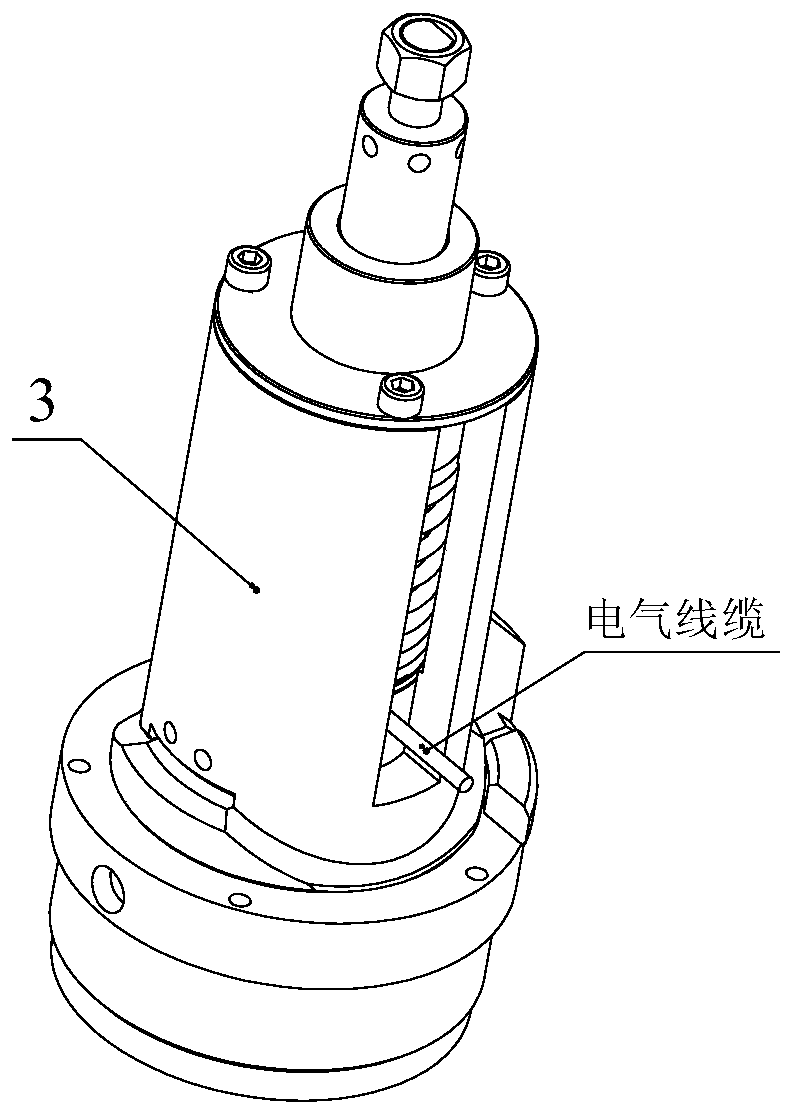

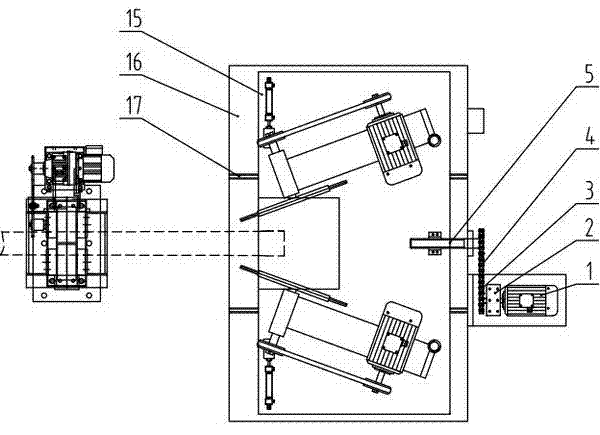

Hydraulic-spring mechanism reversing-valve valve spool and valve bush running-in device

ActiveCN103481182AGuaranteed tightnessImprove efficiencyLapping machinesWork carriersEngineeringAutomation

The invention discloses a hydraulic-spring mechanism reversing-valve valve spool and valve bush running-in device comprising a grinding box body. A control mechanism is arranged in a lower box body of the grinding box body, a reducing mechanism is arranged in an upper box body of the grinding box body, a grinding mechanism is arranged on the reducing mechanism, and a guide mechanism is arranged on a box cover of the upper box body above the grinding mechanism. The grinding mechanism at least comprises a valve spool clamped by a set of clamping mechanism and a valve bush sleeved on the valve spool. The control mechanism is connected with the reducing mechanism through a motor to drive the valve spools in the grinding mechanism to rotate relatively to the valve bush, so that grinding of the valve spools under the action of the positioning valve bushes of the guide mechanism can be realized. The hydraulic-spring mechanism reversing-valve valve spool and valve bush running-in device is compact in design, simple in structure, easy to operate and applicable to grinding of hard-sealed parts in other industries. Conventional manual grinding technology can be replaced by the grinding device, so that grinding automation is realized.

Owner:CHINA XD ELECTRIC CO LTD +1

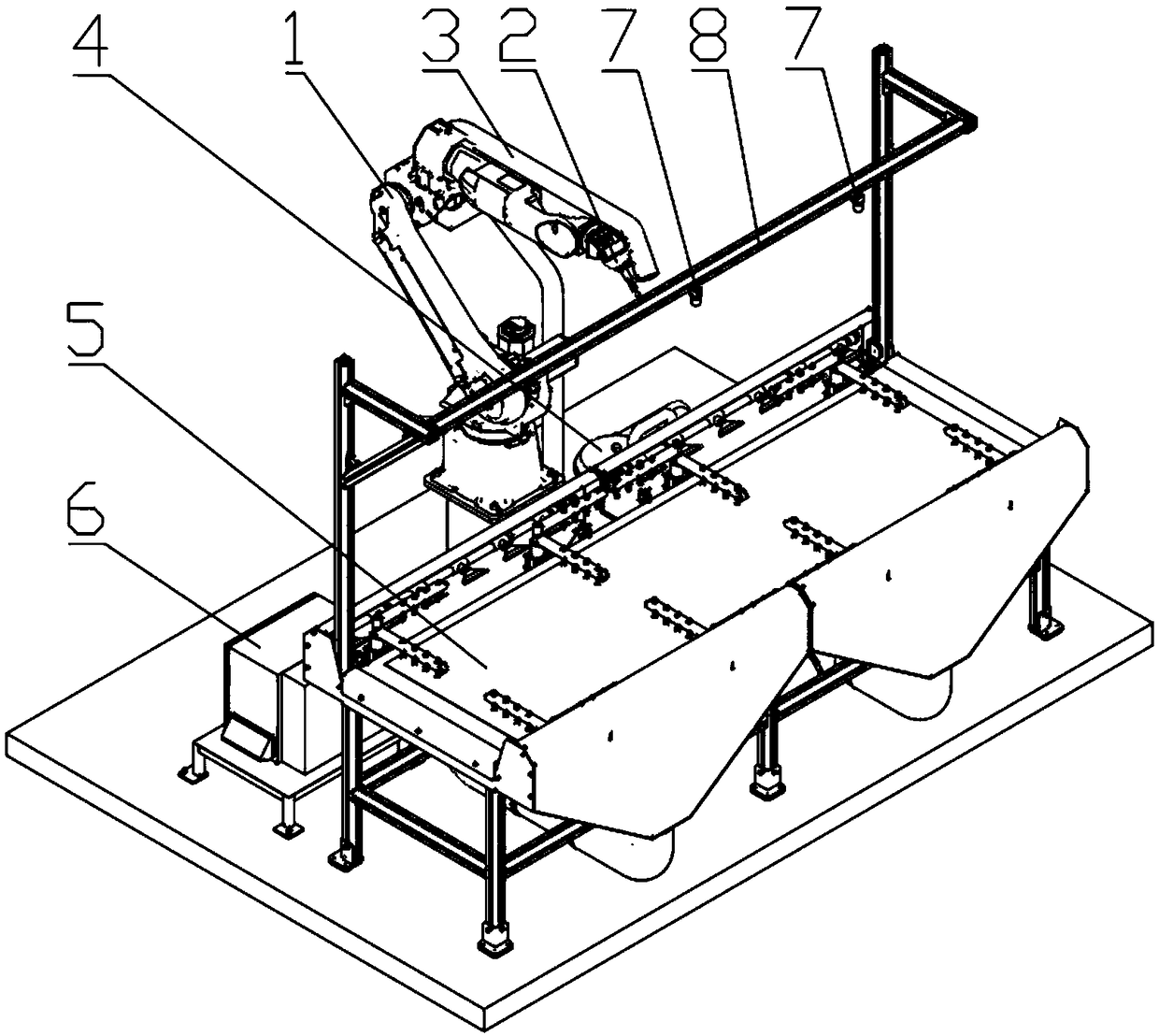

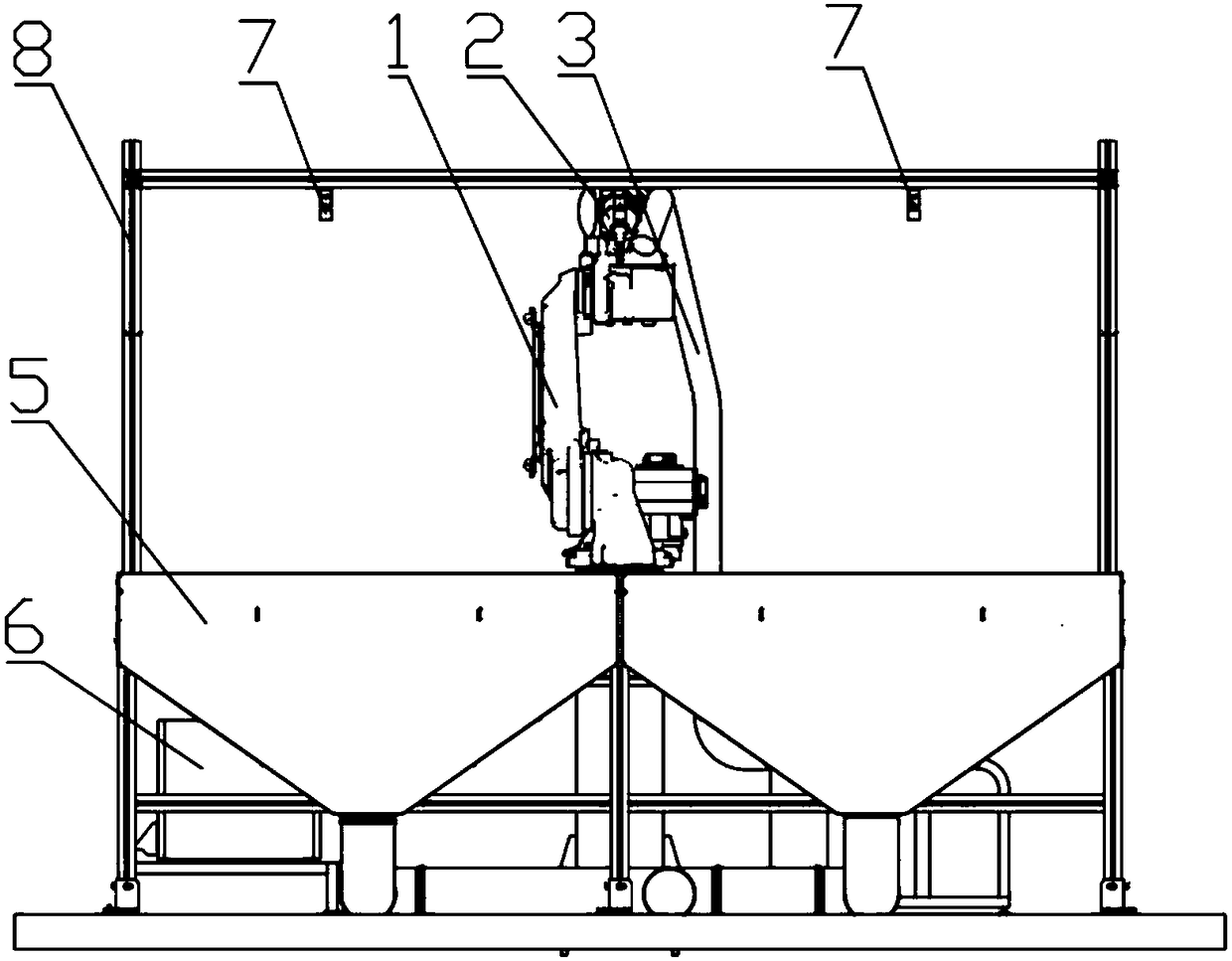

Wood veneer flaw visual identification and automatic polishing workstation

PendingCN109079652AEnsure consistencyRealize automatic grinding processGrinding feed controlGrinding feedersWood veneerEngineering

The invention discloses a wood veneer flaw visual identification and automatic polishing workstation. The wood veneer flaw visual identification and automatic polishing workstation comprises a controlcabinet, a frame and a mechanical hand arranged at one side of the frame, wherein a polishing table is fixedly arranged at the middle part of the frame in a horizontal direction; dust removal protective shields are fixedly arranged on the frame of the front side and rear side of the polishing table; a clamping device and a blowing device are also arranged at the front side and rear side of the polishing table; multiple vision cameras are arranged at the upper part of the polishing table; a floating polishing head is arranged at the tail end of the mechanical hand; and the mechanical hand, theclamping device, the blowing device and the vision cameras are electrically connected to the control cabinet. The wood veneer flaw visual identification and automatic polishing workstation has the beneficial effects that the vision cameras are used for precisely identifying veneer flaws, and the control cabinet controls the motion of the mechanical hand so as to precisely polish a flaw position;the full-automatic operation in the whole polishing process is realized, and thus, the polishing efficiency is improved; and the polishing pressure is effectively controlled through procedures, and thus, the consistency of polishing quality is ensured.

Owner:YANTAI WALU ROBOT AUTOMATION CO LTD

Grinding repair device for sealing surface of safety valve

ActiveCN109719589ASimple structureLow costSeat surface grinding machinesLapping machinesEngineeringSafety valve

The invention discloses a grinding repair device for a sealing surface of a safety valve and belongs to the technical field of manufacture of safety valves for oil-gas wells. The grinding repair device comprises a fixing mechanism for fixing a valve plate, wherein the fixing mechanism comprises an outer barrel and a spigot shaft arranged in the outer barrel in a penetrating manner; the spigot shaft is screwed on the outer barrel through threads; and a magnet for attracting the valve plate is connected to the end part of the spigot shaft. The novel grinding repair device provided by the embodiment of the invention is simple in structure and low in cost, and realizes automatic grinding, the grinding cost is lowered, and the grinding efficiency is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Edge grinding chamfering device and method for pipe fitting socket

InactiveCN104759961ARealize free adjustmentRealize automatic grindingEdge grinding machinesGrinding drivesPipe fittingEngineering

The invention provides an edge grinding chamfering device for a pipe fitting socket. The device comprises repair grinding device, a supporting seat for mounting the repair grinding device, and a supporting frame for supporting a pipe fitting; a rotating device comprises a rotating seat mounted on the supporting seat, and an oil cylinder for driving the rotating seat to rotate; the repair grinding device is fixedly mounted on the rotating seat; the oil cylinder is mounted above the supporting seat and drives the repair grinding device to rotate to repair and grind the pipe fitting through the rotating seat; the repair grinding device and the oil cylinder are connected with a PLC system. According to the device, the whole grinding process is automatically controlled through the PLC system, so that manual grinding is avoided, and as a result, the grinding efficiency and the grinding precision can be greatly increased.

Owner:XINXING DUCTILE IRON PIPES CO LTD

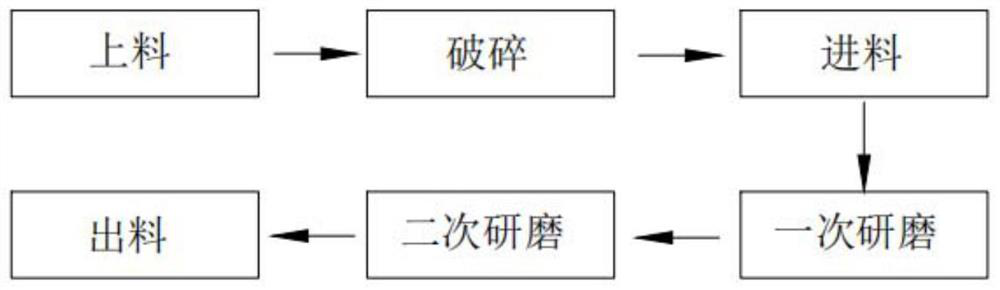

Automatic seasoning production process

InactiveCN112246313ARealize automated productionReduce the difficulty of grindingGrain treatmentsProcess engineeringCrushing procedure

The invention relates to the technical field of seasoning production equipment, in particular to an automatic seasoning production process. The automatic seasoning production process comprises the following steps: step 1, a feeding procedure; step 2, a crushing procedure which is carried out synchronously with the step 1; step 3, a feeding procedure which is synchronously carried out with the step2; step 4, a primary grinding procedure; step 5, a secondary grinding procedure which is synchronously carried out with the step 4; and step 6, a discharging procedure. A grinding shaft is driven bya driving mechanism to slide up and down, materials are driven to enter a second base for secondary grinding after being subjected to primary grinding in a first through hole, meanwhile, the materialsin the grinding shaft are driven to be crushed and fed at the same time through pushing of a first air cylinder, grinding is conducted after crushing, the grinding difficulty is reduced, automatic production of seasonings is achieved, and manual feeding and mashing are not needed.

Owner:ANHUI FUYANG FOREFRONT FOOD CO LTD

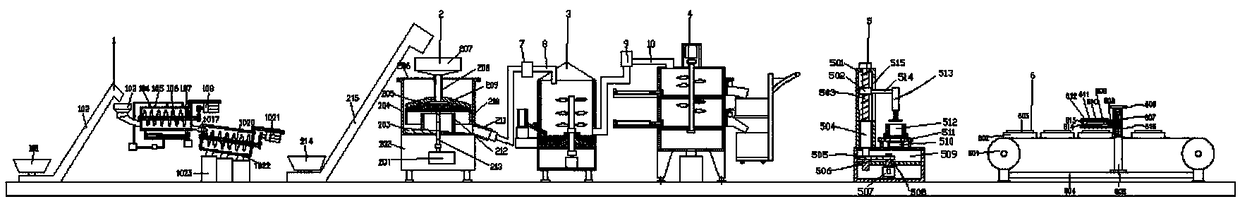

Manufacturing process and production line of dried tofu

InactiveCN109169952AFull of nutritionIncrease elasticityCheese manufactureFood sciencePulp and paper industryGypsum

The invention discloses a manufacturing process and a production line of dried tofu. The production line comprises a clearing and soaking device, a pulping device, a pulping boiling and curding device, a pulp filtering device, a pressing device and a slicing device; and the pulping device communicates with the pulping boiling and curding device by a first pipe, a first pump is arranged on the first pipe, the pulping boiling and curding device communicates with the pulp filtering device by a second pipe, and a second pump is arranged on the second pipe. The invention provides the manufacturingprocess and the production line of the dried tofu. The dried tofu is rich in nutrients, has a tender, smooth and elastic mouth feel, has a long shelf life, does not contain gypsum, and is good for thebody.

Owner:湖南省富田桥游浆豆制品发展有限公司

Novel powder metallurgy deburring machine tool

InactiveCN103481146ARealize automatic grindingContinuous productionEdge grinding machinesGrinding drivesEngineeringMachine tool

The invention discloses a novel powder metallurgy deburring machine tool, comprising a rack and a workbench which is horizontally arranged on the rack and is capable of rising and falling, wherein the workbench is provided with a brush head which is driven by a rotating device for rotating, and the lower end of the brush head is fixedly provided with a plurality of brush wires. The machine tool is characterized in that a fixing seat for fixing a workpiece is arranged under the brush head, the bottom of the fixing seat is connected to an air cylinder arm of an air cylinder, and the air cylinder is used for pushing the fixing seat to rise and fall. When in use, the workpiece is placed on the fixing seat, the air cylinder works, the air cylinder arm upwards moves to upwards push the fixing seat to be contacted with the brush wires, and the brush wires rotate to polish the workpiece and deburr, after the manner is adopted, automatic polishing of the workpiece can be realized without manually stopping the machine by operators, and continuous production is realized, so that the production efficiency is improved.

Owner:SUZHOU MIMO METAL SCI & TECH

External transition belt grinding device for end upsetting of steel pipe

InactiveCN102962750ASave sanding timeImprove stabilityGrinding machinesGrinding/polishing safety devicesHigh volume manufacturingEngineering

The invention discloses an external transition belt grinding device for end upsetting of a steel pipe, belonging to the field of drilling equipment. The external transition belt grinding device comprises a lifting rotation roll, a grinding device, an adjusting device, guiderails and a dust collection box, wherein the dust collection box is an open box body, the adjusting device is fixedly arranged on the side surface of the dust collection box, the lifting rotation roll which is isolated from the dust collection box is arranged on the other side of the dust collection box opposite to the adjusting device, the guiderails are arranged on the upper surfaces of another two side walls of the dust collection box and provided with the grinding device. In use, the external transition belt grinding device is fast in grinding speed, high in production efficiency, simple and effect in structure, convenient to operate, safe and reliable to use, stable to run, excellent in performance, convenient to maintain, suitable for large-batch production and grinding, and long in service life.

Owner:CNPC BOHAI EQUIP MFG +1

Medicinal herb grinding device for preventing medicine adhesion

ActiveCN110898917ARealize automatic grindingOvercome the defect of easily attaching drug powder to the grinding deviceCocoaCleaning using toolsPharmacy medicineEngineering

The invention relates to a grinding device, in particular to a medicinal herb grinding device for preventing medicine adhesion. The medicinal herb grinding device for preventing medicine adhesion canbe used for automatically grinding medicines and automatically collecting the medicines on the grinding device after grinding. The medicinal herb grinding device for preventing medicine adhesion comprises a bottom plate, a collecting box, a rotating fixing base, a lower grinding disc, a material containing pool, an upper grinding disc and the like; and the bottom plate is provided with the collecting box, and the bottom plate is fixedly connected with the rotating fixing base. The defect that medicine powder is easily attached to the grinding device due to manual grinding is overcome, the powder is swept out from the grinding device through dual functions of a double-sided steel brush and a brush, the powder directly falls into the collection box and does not need to be further collected,and therefore the productivity is improved. Besides, automatic grinding of the medicines is achieved through a double-shaft motor, manual operation is not needed, and the production efficiency is improved.

Owner:JIANGXI JUWANG PHARMA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com