Automatic seasoning production process

A production process and condiment technology, which is applied in the field of automatic production process of condiments, can solve the problems of reducing the difficulty of grinding and manual smashing, and achieve the effect of reducing the difficulty of grinding and realizing automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

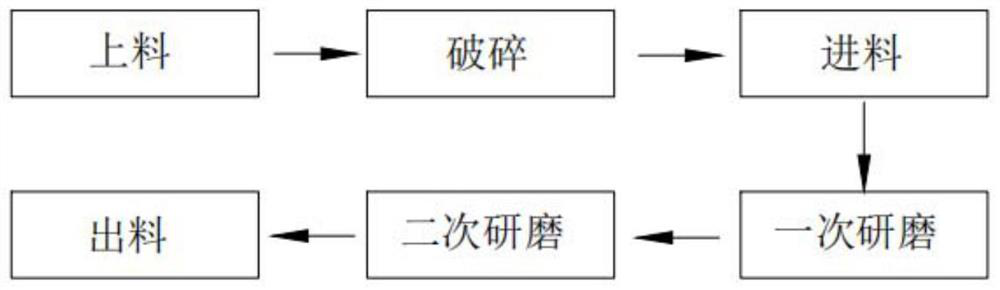

[0092] like figure 1 Shown, a kind of flavoring automatic production technology, it comprises the following steps:

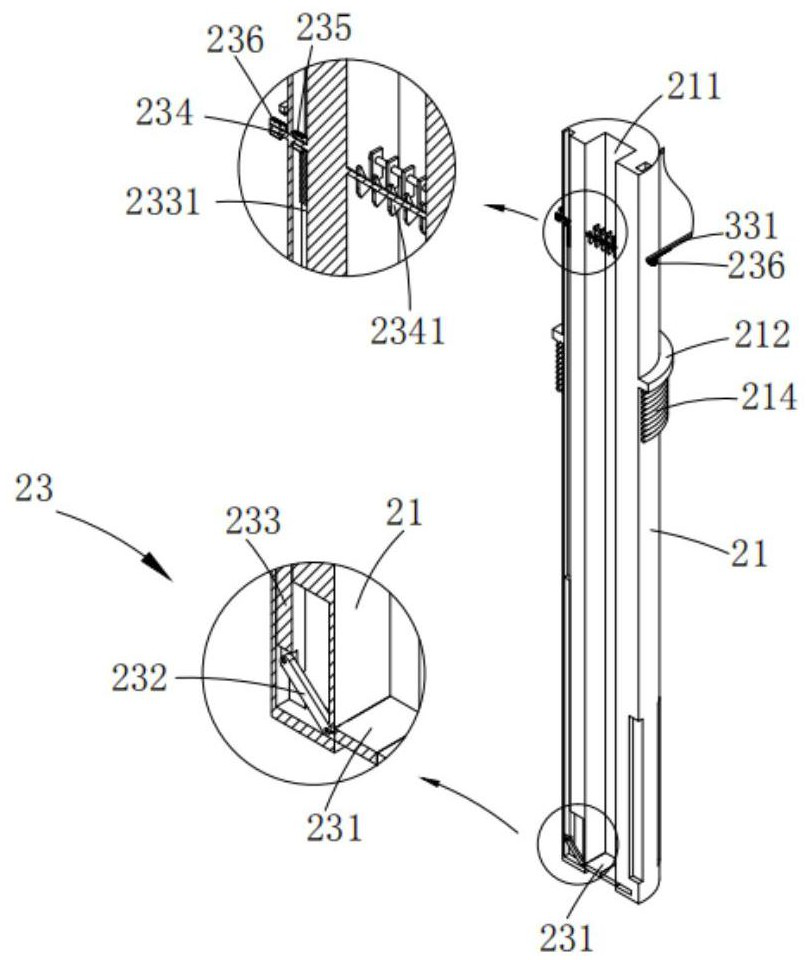

[0093] Step 1, the feeding process, the first cylinder 32 pushes the pusher 33 to move forward, and the pusher 33 squeezes out the material in the storage bin 31, so that the material falls to the grinding shaft 21 through the first discharge port 311 Inside the second through hole 211;

[0094] Step 2, the crushing process, is synchronized with step 1. While the first cylinder 32 is moving, the second rack 331 on the pusher 33 is engaged with the second gear 236, and the second gear 236 rotates to drive the second rotating shaft 234 to synchronize Rotate, the cutters 2341 on the two second rotating shafts 234 rotate relative to each other to initially crush the falling materials;

[0095] Step three, the feeding process, is synchronized with step two, the second rotating shaft 234 rotates to drive the first gear 235 to rotate, and since the first gear 235 is ...

Embodiment 2

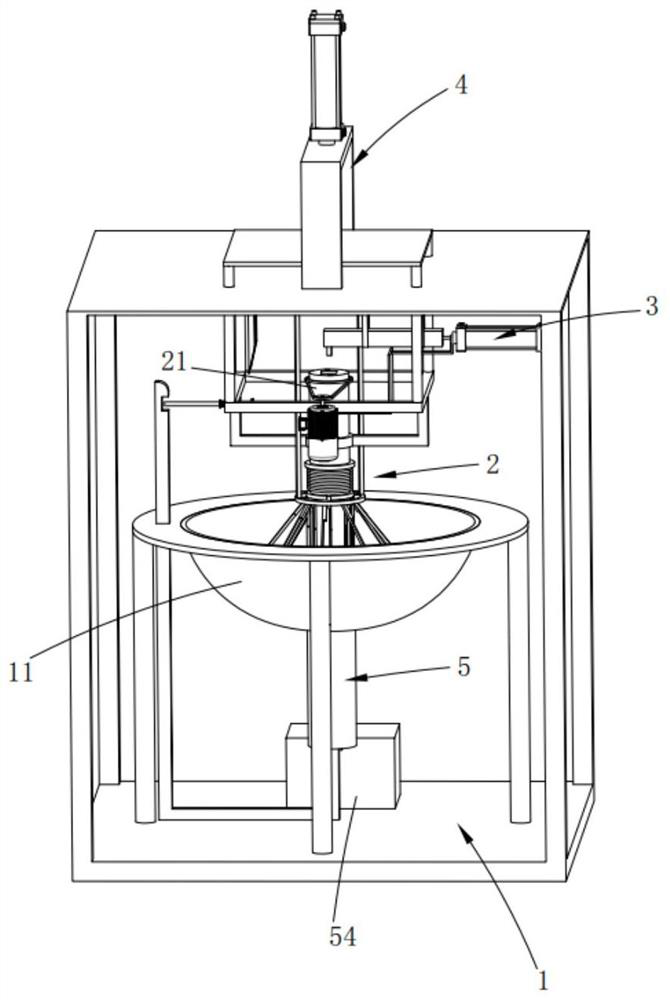

[0108] like figure 2 and 9 Shown, a kind of condiment automatic production technology, it comprises:

[0109] The first base 1, the first base 1 is provided with a second base 11, and the bottom of the second base 11 is provided with a first through hole 12;

[0110] A grinding mechanism 2, the grinding mechanism 2 is located above the second base 11, the grinding mechanism 2 includes a grinding shaft 21 and a grinding assembly 22, the grinding shaft 21 is coaxially arranged with the first through hole 12, The grinding shaft 21 runs through the grinding shaft 21 along its axial direction to form a second through hole 211, and the middle part of the grinding shaft 21 is provided with a first bump 212 and a slider 213, and the slider 213 is arranged along the grinding shaft. 21 is slidably arranged under the first bump 212 in the axial direction, the slider 213 is connected to the first bump 212 through the first spring 214, and the lower end of the grinding shaft 21 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com