Device for automatically reversing generator shell

An automatic turning and generator technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of being easily affected by operators, prone to deviation, and unfavorable production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

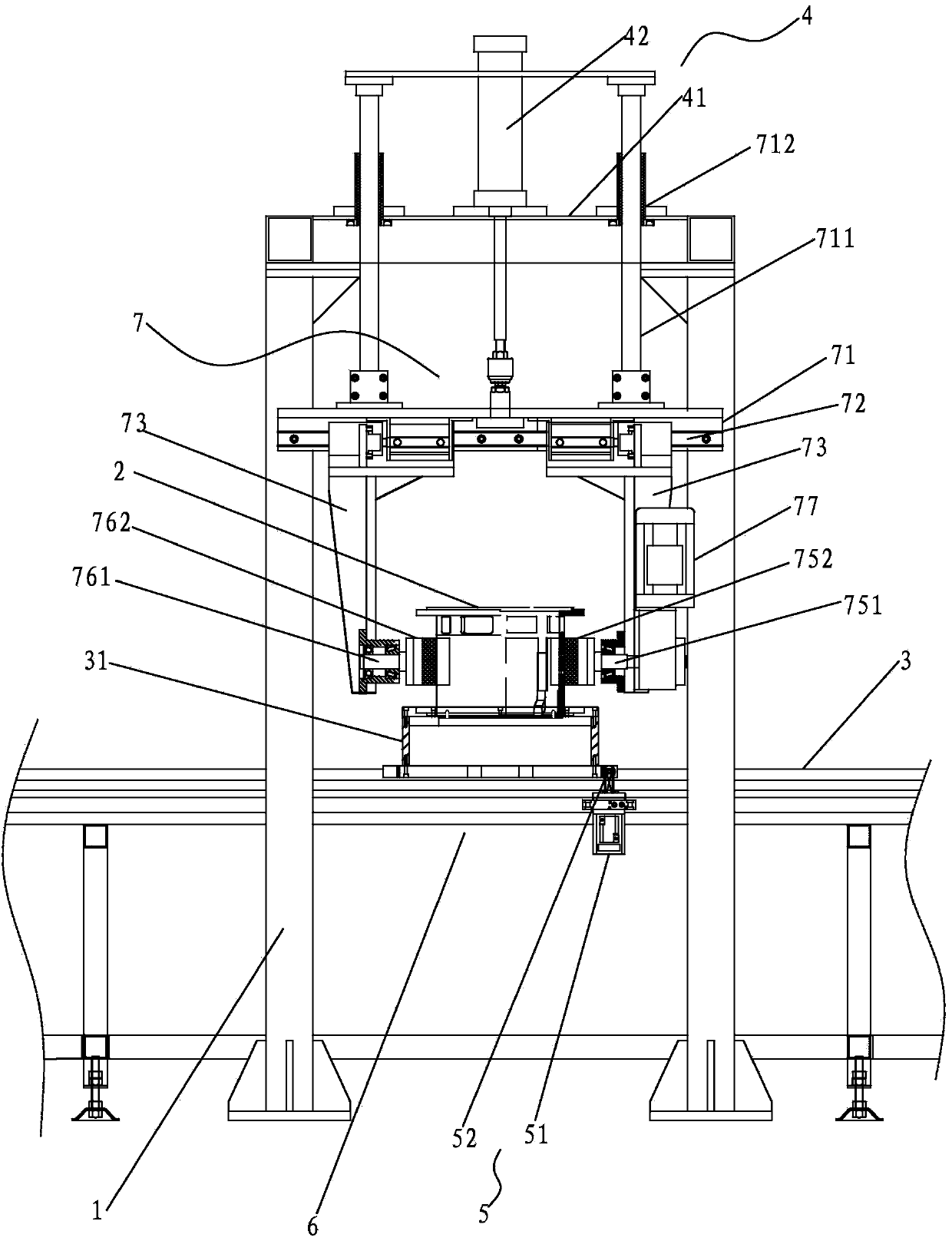

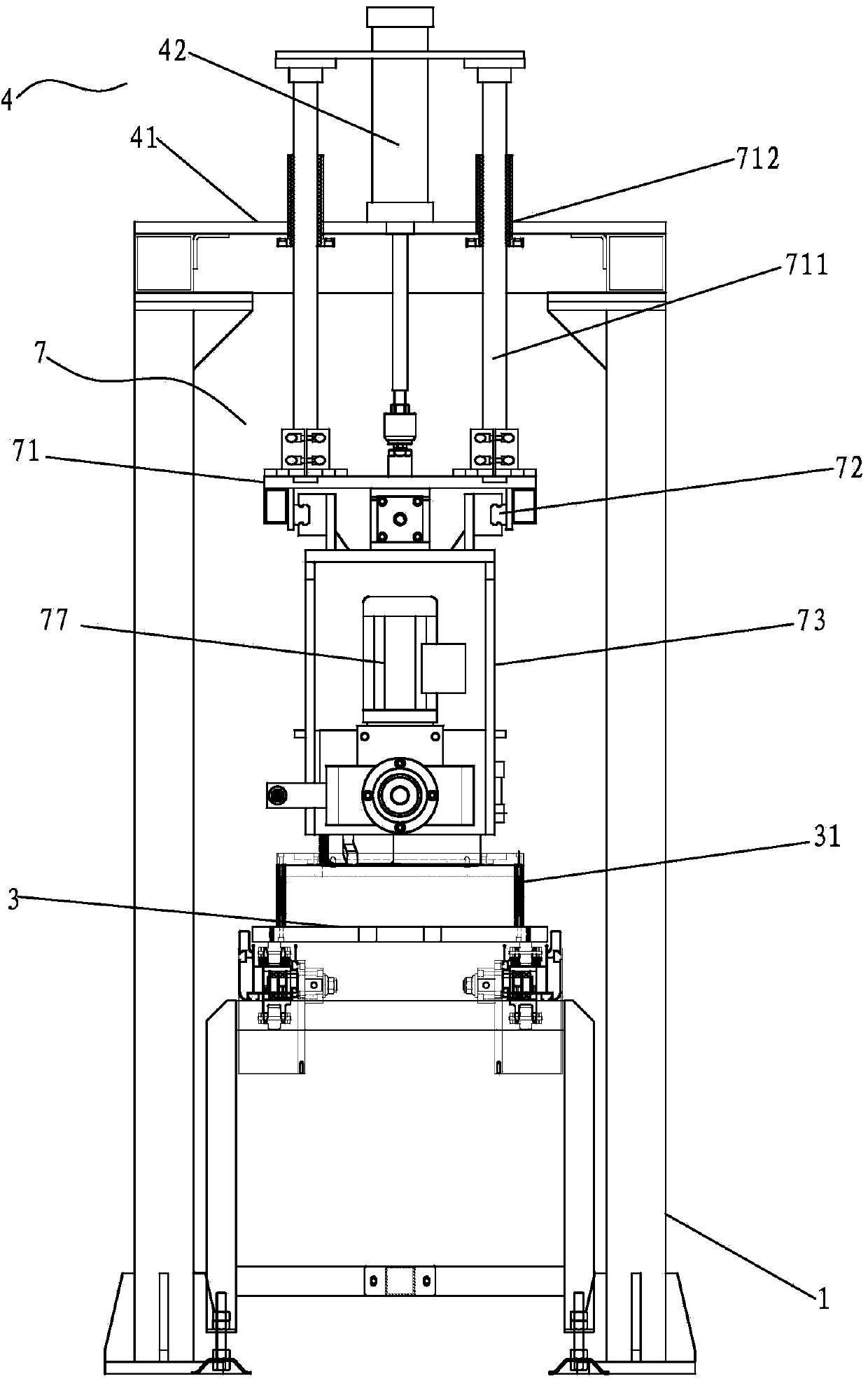

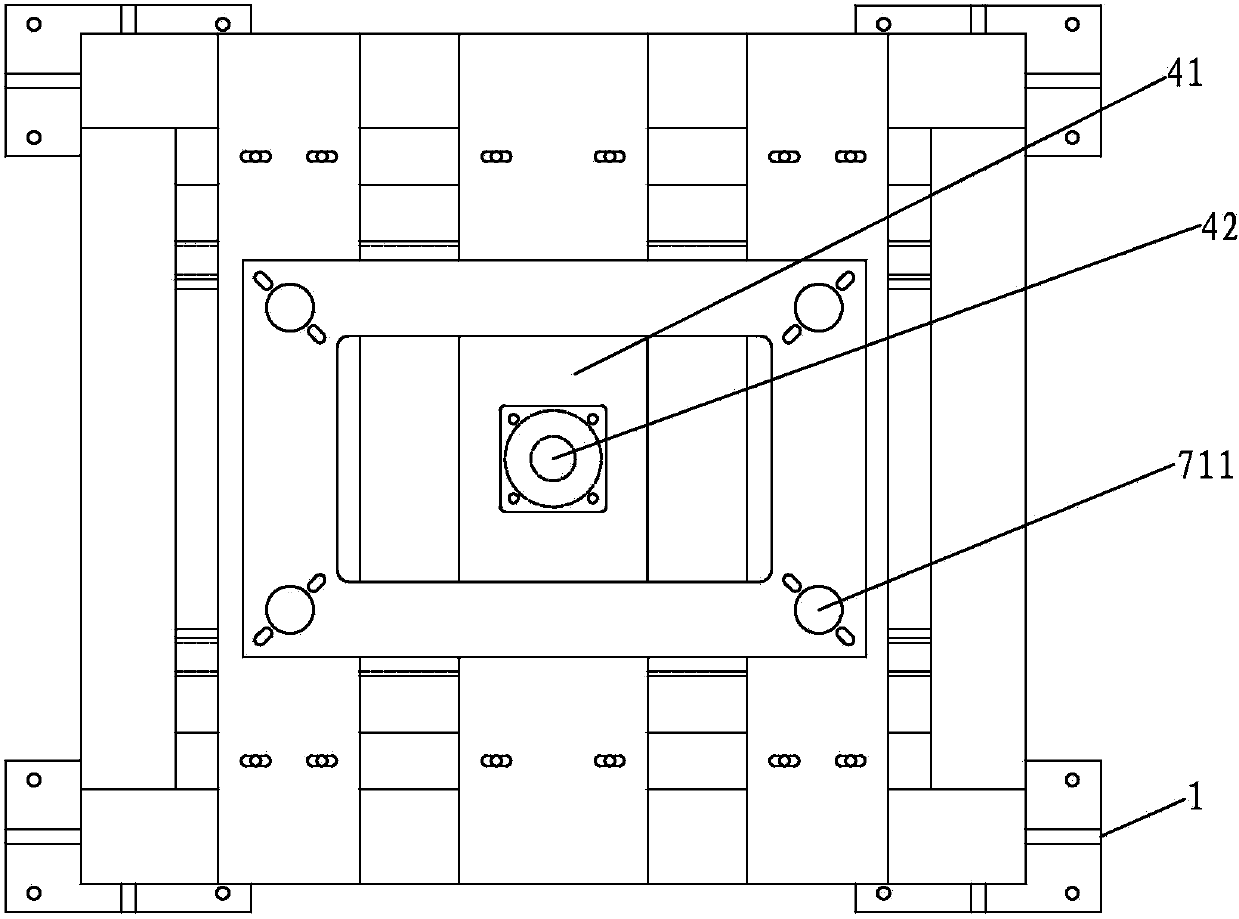

[0019] The present invention is a device for automatically turning over the generator shell, comprising a frame 1 and a conveying track 3 for transporting the generator shell 2, the conveying track 3 is provided with a tooling fixture 31 for carrying and transporting the generator shell 2, and the conveying track 3. Transport the generator casing 2 to the overturning station 6. The overturning station 6 is provided with a positioning mechanism 5. The positioning mechanism 5 includes a positioning cylinder 51 fixedly connected to the conveying track 3 and a tooling fixture 31 used to stop the positioning during the overturning. The positioning catch 52 on the station 6, the output end of the positioning cylinder 51 is connected with the positioning catch 52, and the clamping turning mechanism 7 and the drive mechanism 4 that drives the clamping turning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com