Automatic detection device for magnetic loop image

An automatic detection device and image detection technology, applied in the direction of measurement device, optical device, testing moving board, etc., can solve the problems of long production line, waste of personnel, etc., to achieve automatic production, reduce labor costs, and reduce inspection time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred embodiment of the present invention is described in detail as follows:

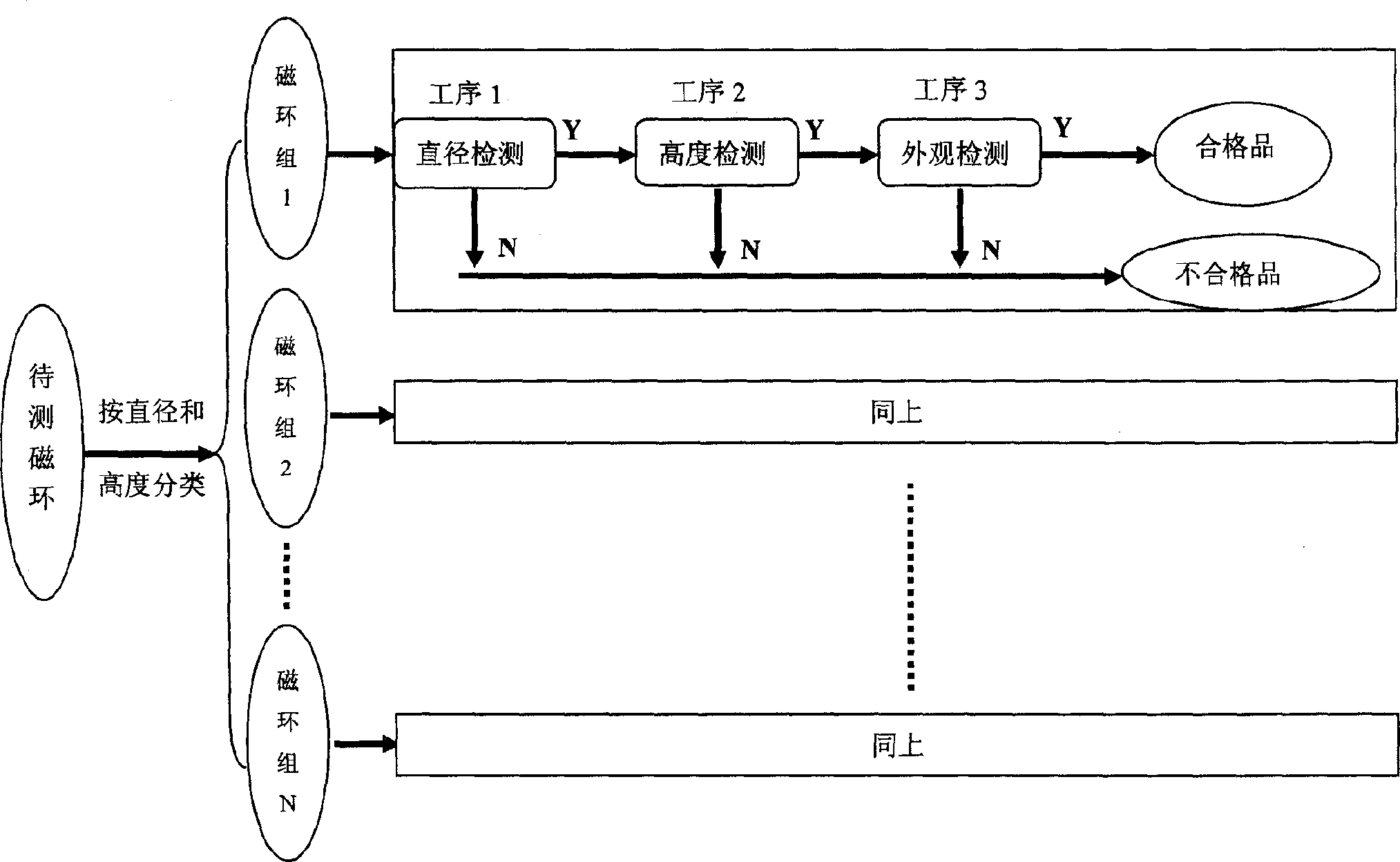

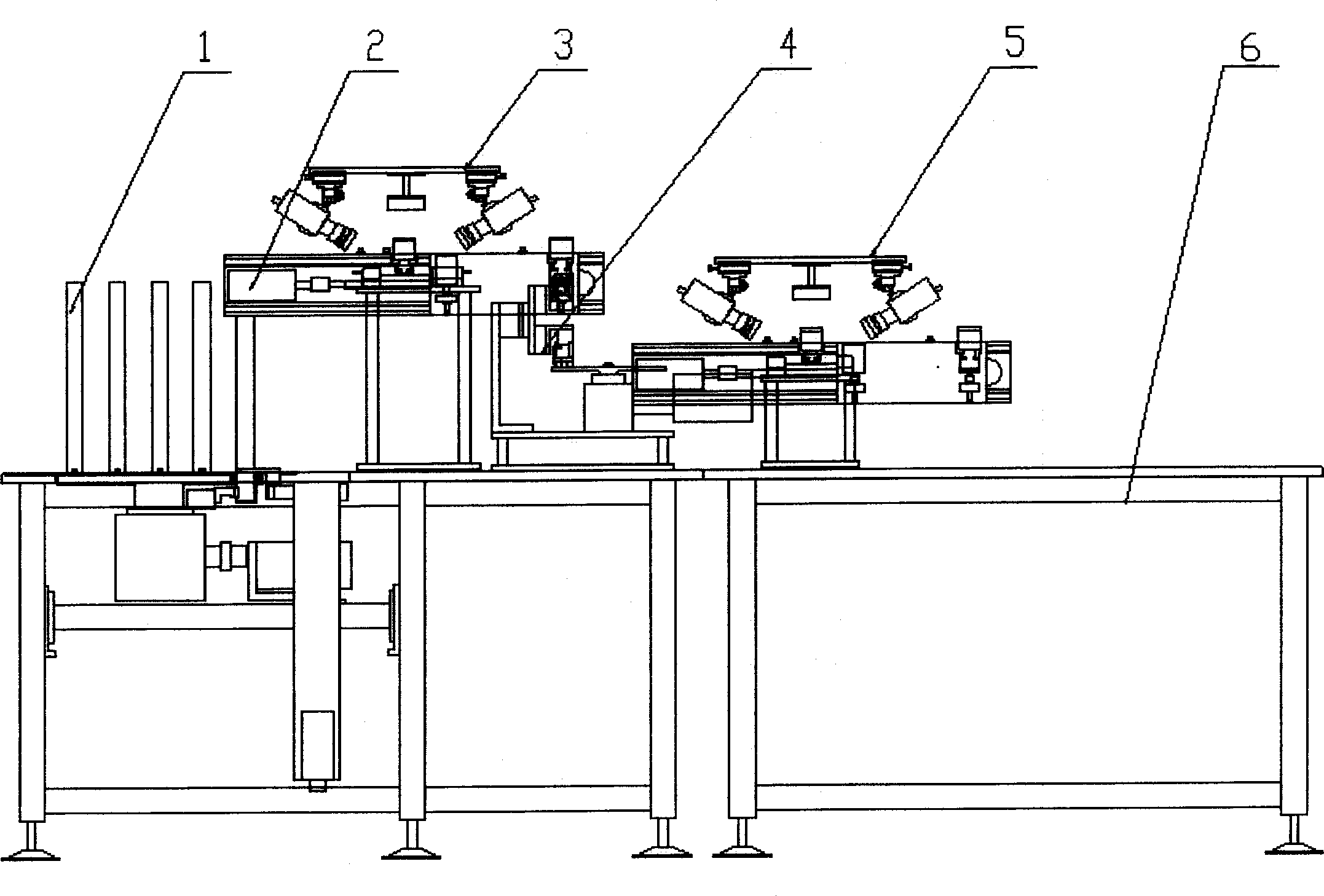

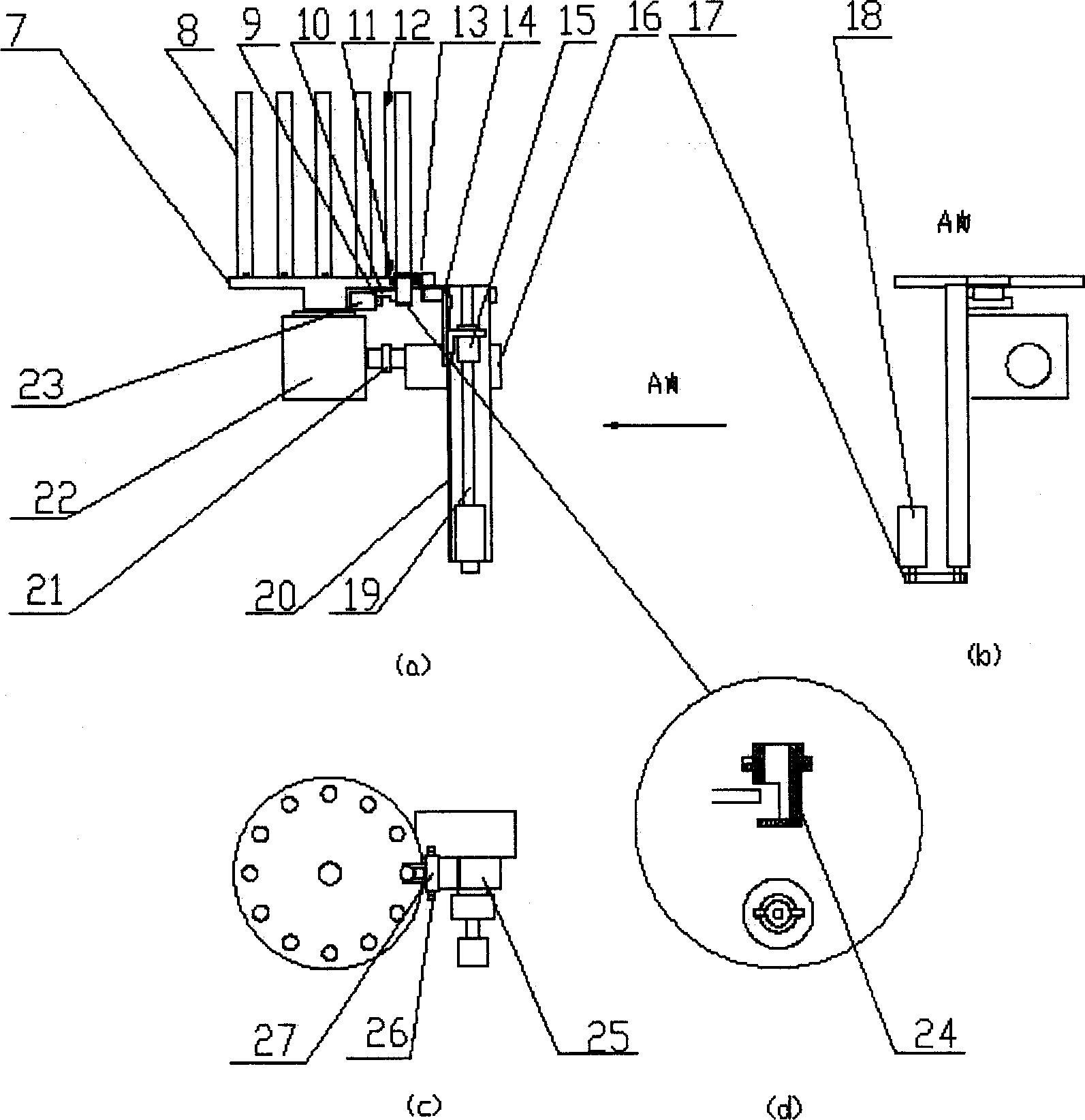

[0025] see figure 2 , the magnetic ring image automatic detection device includes a frame 6, on the frame 6 table tops, a magnetic ring automatic feeding tray 1 is installed on the front part and the first set of double-head transfer manipulator device 2 is installed on the front of the frame. A first image detection platform 3 is installed on the first set of double-head transfer manipulator device 2, and a second set of double-head transfer manipulator device and a magnetic ring flipping device 4 are installed on the rear side of the first set of double-head transfer manipulator device 2. A second image detection platform 5 is installed on the rear side of the device 4; the magnetic ring is sent to the first image detection platform 3 by the first set of double-head transfer manipulator device 2 on the magnetic ring automatic feeding tray 1 to determine the diameter of the magnetic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com