Bearing production detecting system based on MES

A detection system, a technology for bearing production, applied in grinding machine parts, optical testing for flaws/defects, control of workpiece feed motion, etc. Insufficient and other problems, to achieve the effect of reducing management costs, saving labor, and realizing comprehensive informatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

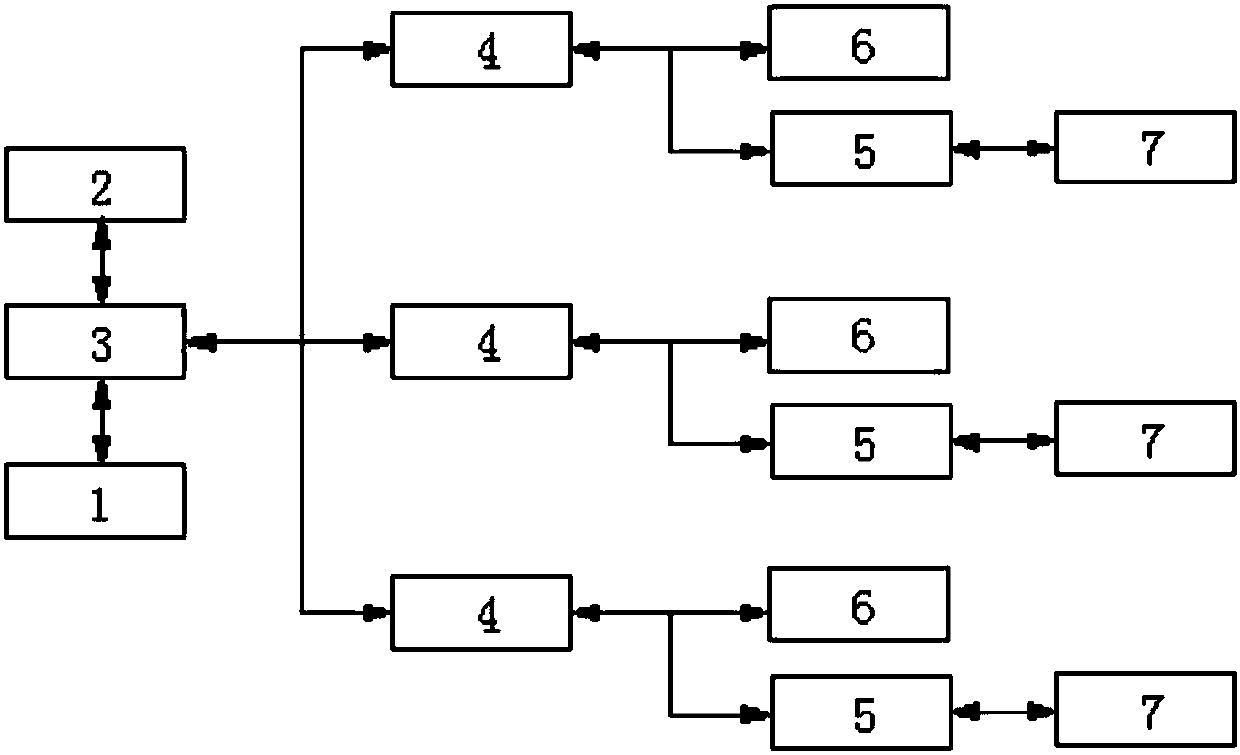

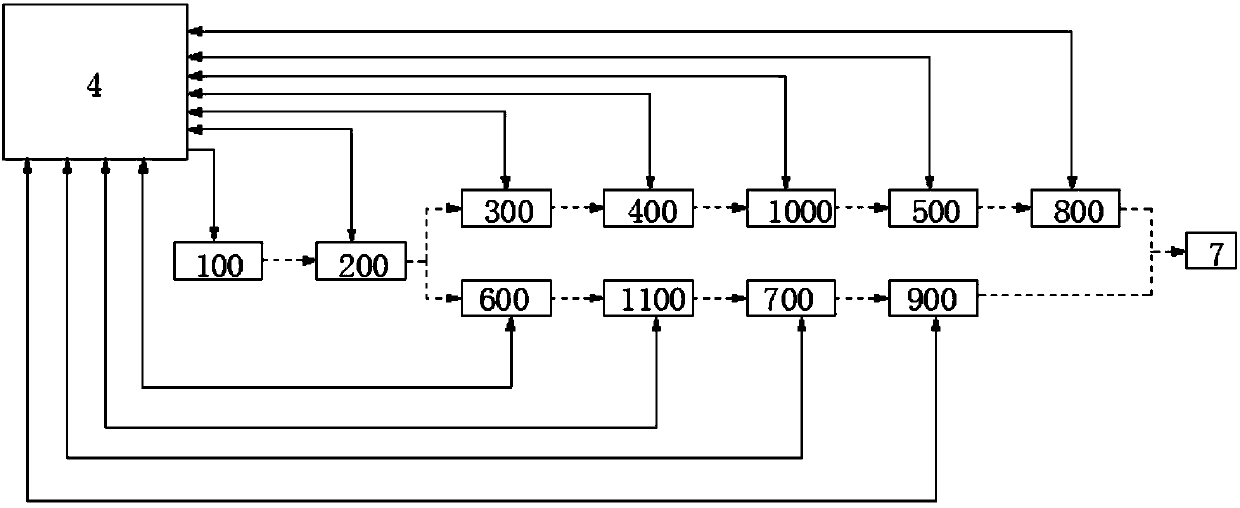

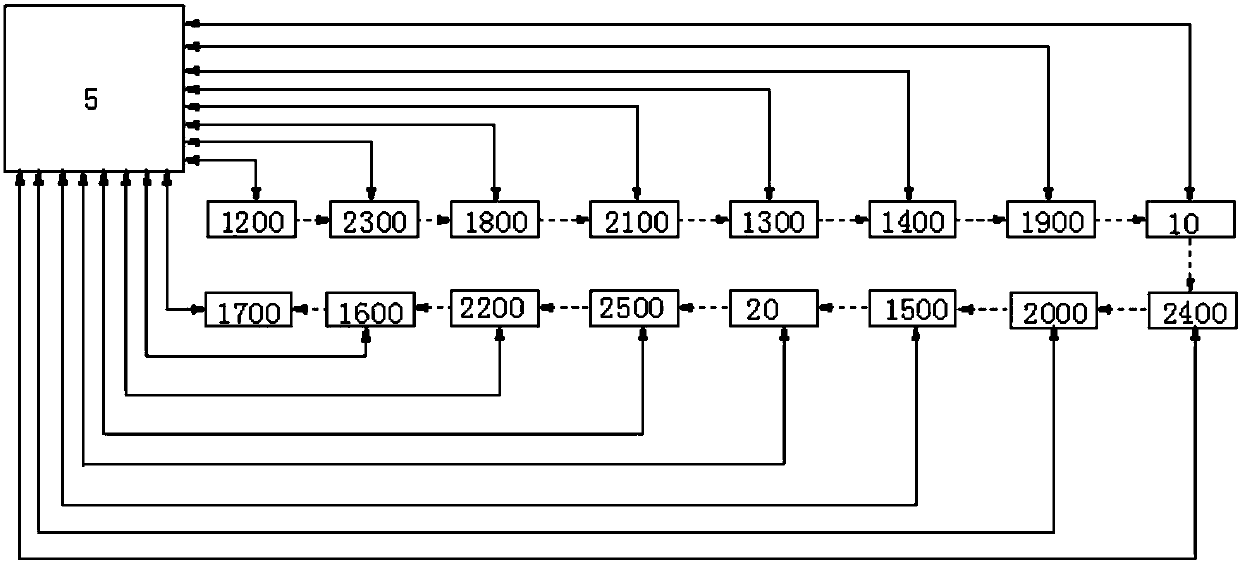

[0058] Embodiment 1: A bearing production inspection system based on MES, such as Figure 1.1 to Figure 1.3 As shown, the MES includes an MES server 1, a database server 2 and a switch, and the MES server and the database server are respectively connected to the switch by signals;

[0059] The bearing production inspection system includes at least one production line, each production line includes a grinding line 6 and an assembly line 7, the grinding line is located upstream of the assembly line, and the grinding line includes a grinding machine, a first testing machine and a second A washing machine, each of the assembly lines includes an inner and outer ring storage and feeding machine 1200, a second washing machine, a second testing machine, a set assembly machine 1300, a cage riveting machine 1400, a grease injection and capping machine 1500, a mist antirust machine 1600 and packaging machine 1700, the grinder, the first detector, the first cleaning machine, the inner and...

Embodiment 2

[0095] Embodiment 2: the MES further includes a router and a firewall, and the MES server, the database server, the switch and the firewall are all connected to the router through a network signal.

[0096] Embodiment 1 is applicable to the situation that the enterprise uses a local area network, and embodiment 2 is applicable to the situation that the enterprise does not use a local area network.

[0097] Work process and working principle of the present invention are as follows:

[0098] Control the production and testing equipment in the bearing production testing system of the bearing production testing system through MES, provide data support and analysis for production management, equipment management and quality management, improve production efficiency and reduce management costs;

[0099] Using MES, the product quality data of each equipment in the bearing production testing system, the operation status of the production equipment, and faults are transmitted to the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com