Fabric wrinkle recoverability testing device and application thereof

A technology for testing devices and fabrics, applied in the directions of measuring devices, using mechanical devices, analyzing materials, etc., can solve the problems of poor testing stability, large dispersion, and long testing time, and achieve the effect of improving stability and eliminating experimental errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Sample fabric parameters: raw material 100% cotton, plain weave, warp yarn density 41.6tex, weft yarn density 58.3tex, warp density 350, weft density 280.

[0023] The steps of testing the sample fabric with the fabric wrinkle recovery performance device of the present invention are as follows:

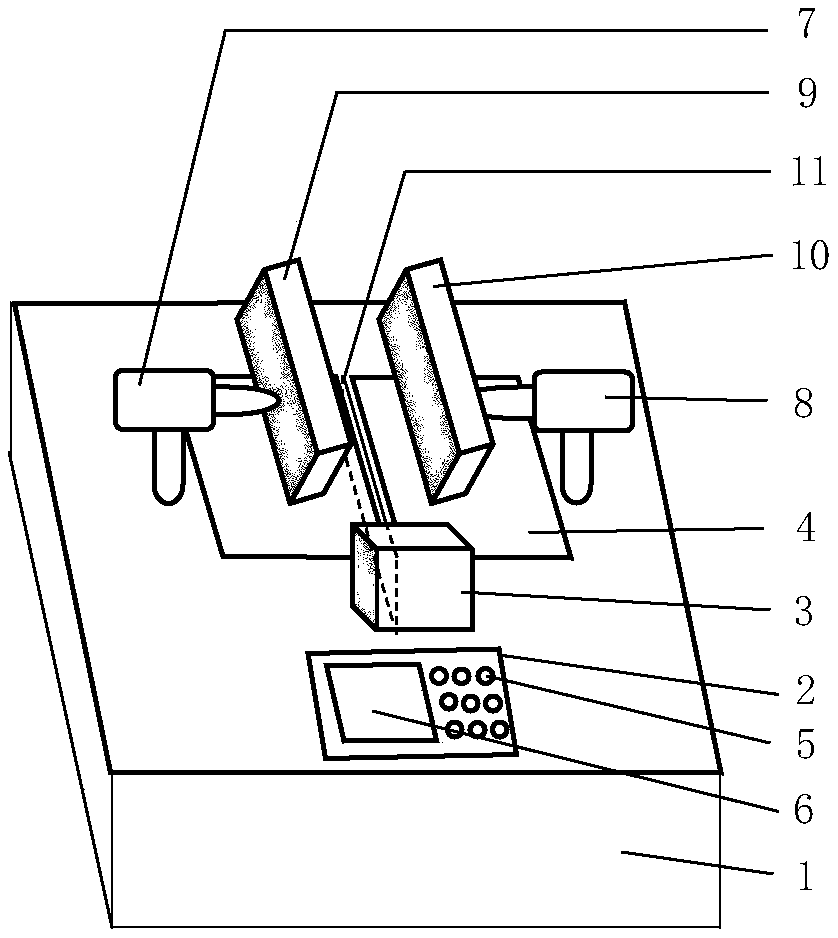

[0024] Step 1: Select the fabric to be tested with a size of 380mm×380mm, and place the fabric to be tested horizontally on the sample table 4;

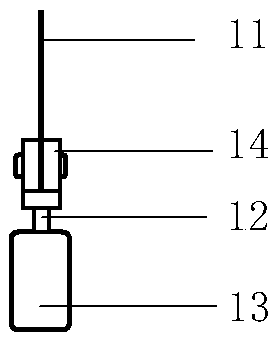

[0025] Step 2: Start the lifter 12, lift the fabric to be tested by 80mm at a rising speed of 0.02m / s through the sheet 11, so that part of the fabric to be tested enters between the left press block 9 and the right press block 10, and passes through the left cylinder 7 And the right cylinder 8 makes the left pressing block 9 and the right pressing block 10 move toward each other at a speed of 0.02m / s, and after contacting the fabric to be tested, apply a pressure of 20N, pressurize for 1min, and then control the left pressing block 9...

Embodiment 2

[0028] Sample fabric parameters: raw material 65% cotton / 35% polyester, two up and one down left twill weave, warp yarn density 58.3tex, weft yarn density 58.3tex, warp density 320, weft density 250.

[0029] The steps of testing the sample fabric with the fabric wrinkle recovery performance device of the present invention are as follows:

[0030] Step 1: Select the fabric to be tested with a size of 380mm×380mm, and place the fabric to be tested horizontally on the sample table 4;

[0031] Step 2: Start the lifter 12, lift the fabric to be tested by 80mm at a rising speed of 0.02m / s through the sheet 11, so that part of the fabric to be tested enters between the left press block 9 and the right press block 10, and passes through the left cylinder 7 And the right cylinder 8 makes the left pressing block 9 and the right pressing block 10 move toward each other at a speed of 0.02m / s, and after contacting the fabric to be tested, apply a pressure of 20N, pressurize for 1min, and ...

Embodiment 3

[0034] Sample fabric parameters: raw material 100% wool, two upper and two lower left twill weaves, warp yarn density 16.6tex, weft yarn density 14.6tex, warp density 345, weft density 300.

[0035] The steps of testing the sample fabric with the fabric wrinkle recovery performance device of the present invention are as follows:

[0036] Step 1: Select the fabric to be tested with a size of 380mm×380mm, and place the fabric to be tested horizontally on the sample table 4;

[0037]Step 2: Start the elevator 12, lift the fabric to be tested by 90mm at a rising speed of 0.02m / s through the sheet 11, so that part of the fabric to be tested enters between the left press block 9 and the right press block 10, and passes through the left cylinder 7 And the right cylinder 8 makes the left pressing block 9 and the right pressing block 10 move towards each other at a speed of 0.02m / s, and after contacting the fabric to be tested, apply a pressure of 25N, pressurize for 1min, and then con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com