Measurement machine of external dimension of bearing

A technology of appearance size and detection machine, applied in the direction of measuring device, material analysis by optical means, instrument, etc., can solve the problems of low detection efficiency, single function, limited detection range, etc., to reduce labor intensity, improve detection efficiency, Good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

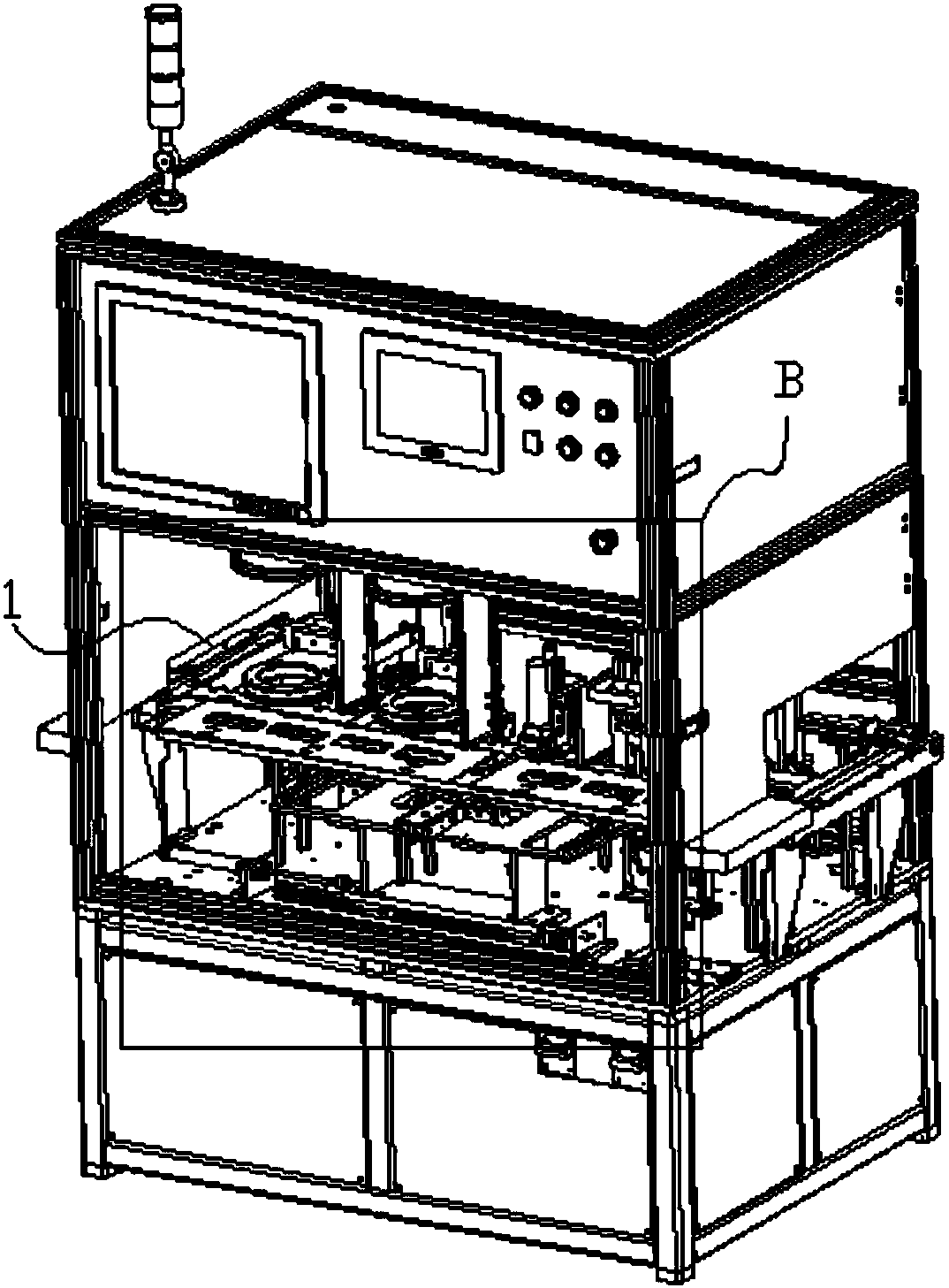

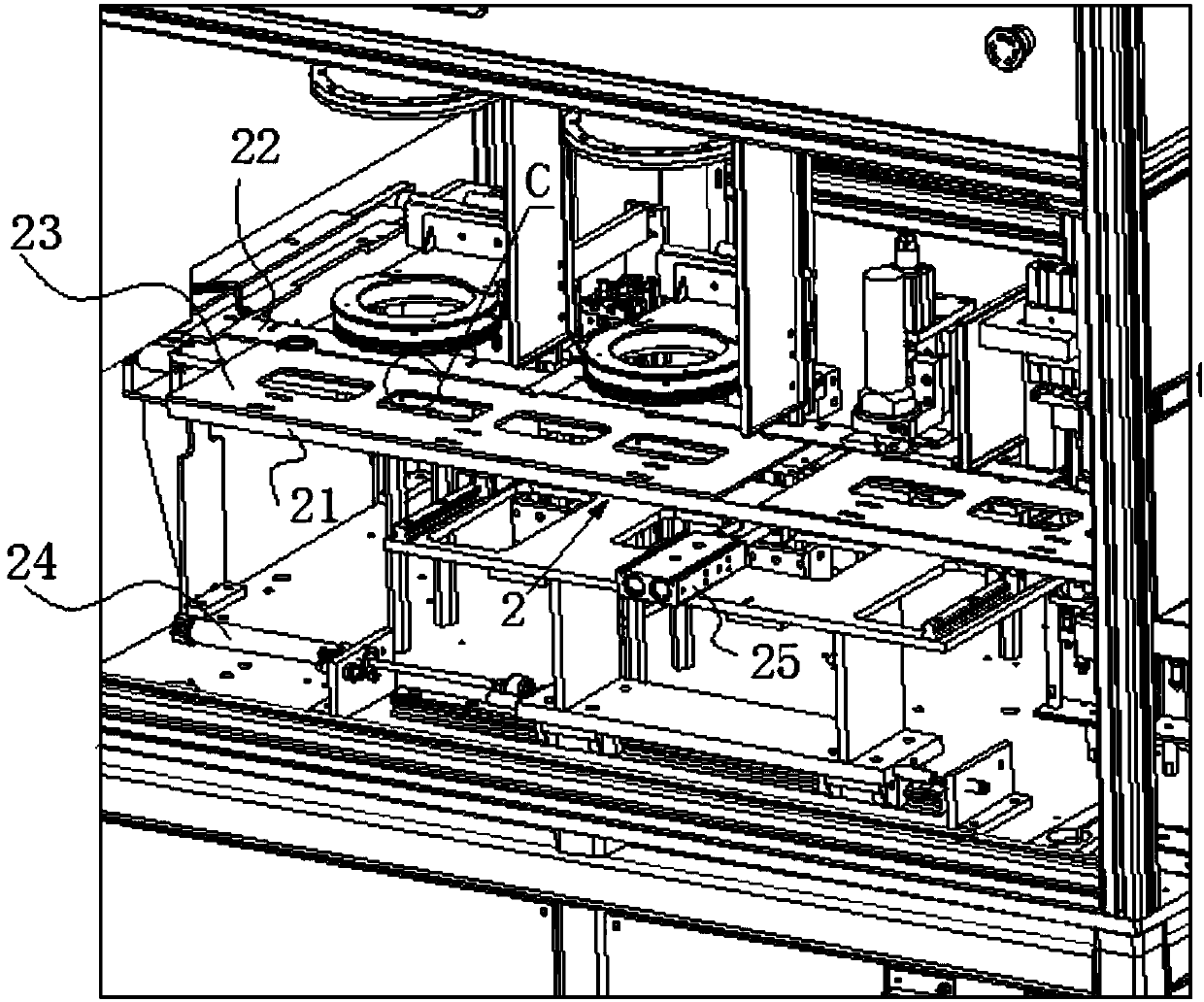

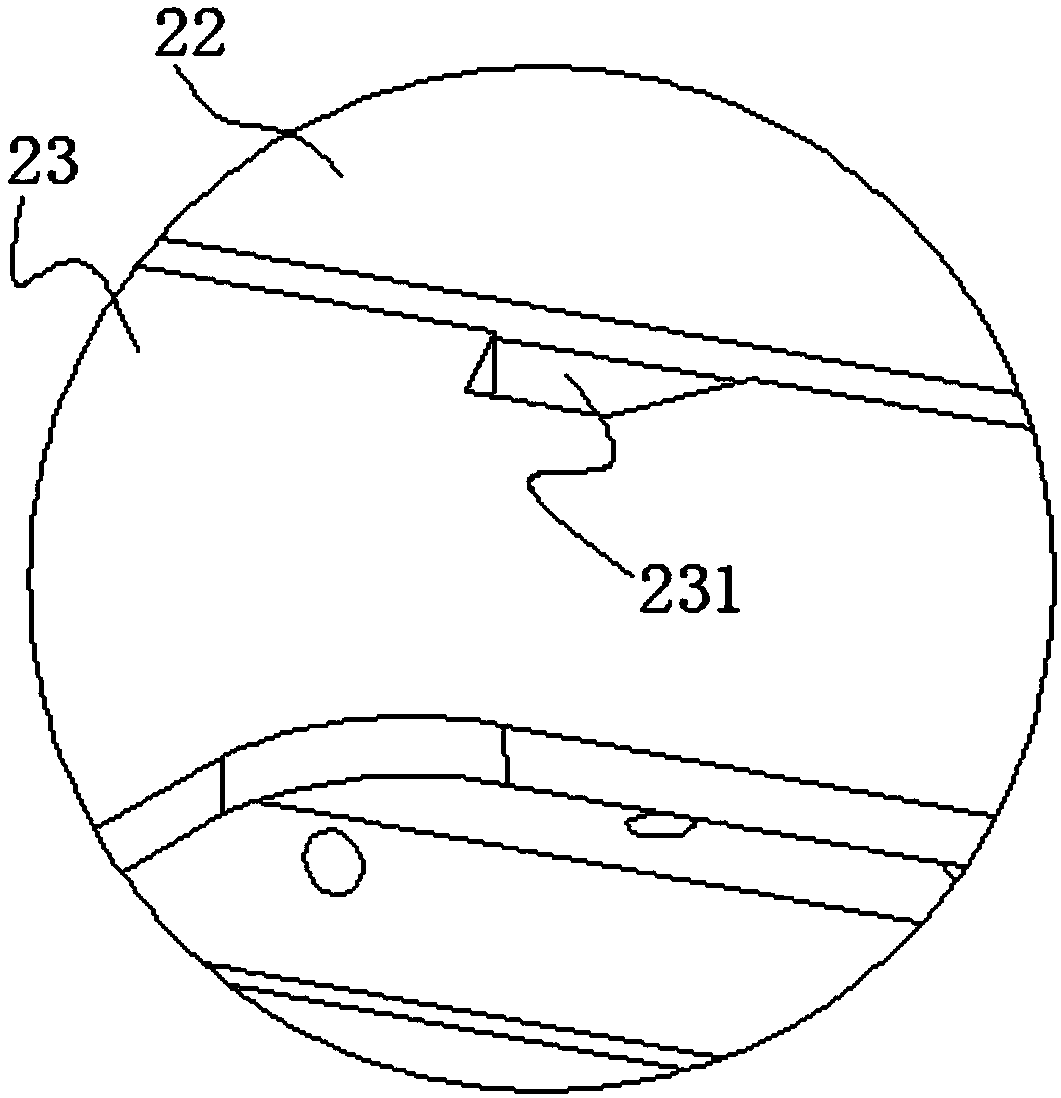

[0038] Embodiment: a kind of bearing exterior dimension inspection machine, such as Figure 1 to Figure 11 As shown, it includes a feeding mechanism 1, a conveying mechanism 2, a detection mechanism and a blanking mechanism 8, the detection mechanism is positioned at the downstream of the loading mechanism, the blanking mechanism is positioned at the downstream of the detection mechanism, and the detection mechanism is located at the downstream of the detection mechanism. The mechanism includes a bearing upper end surface detection mechanism 3, a bearing lower end surface detection mechanism 5, a bearing inner hole diameter detection mechanism 6 and a bearing side surface detection mechanism 7, and the bearing upper end surface detection mechanism 3 and the bearing lower end surface detection mechanism 5 are provided. There is a bearing turning mechanism 4;

[0039] A control system is also provided, the feeding mechanism, the conveying mechanism, the bearing upper end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com