Patents

Literature

174results about How to "Realize fully automatic detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enzyme-linked immune analysis method and fully-automatic enzyme-linked immune analyzer

ActiveCN102116771AUnique structural shapeNo wasteMaterial analysis by optical meansBiological testingTemperature controlControl system

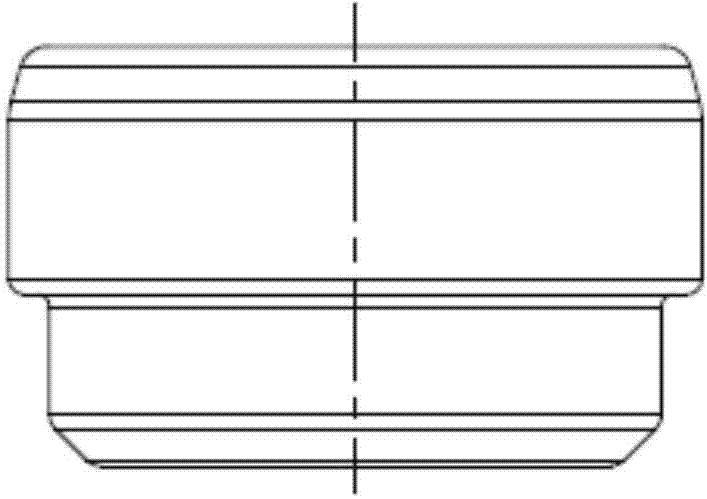

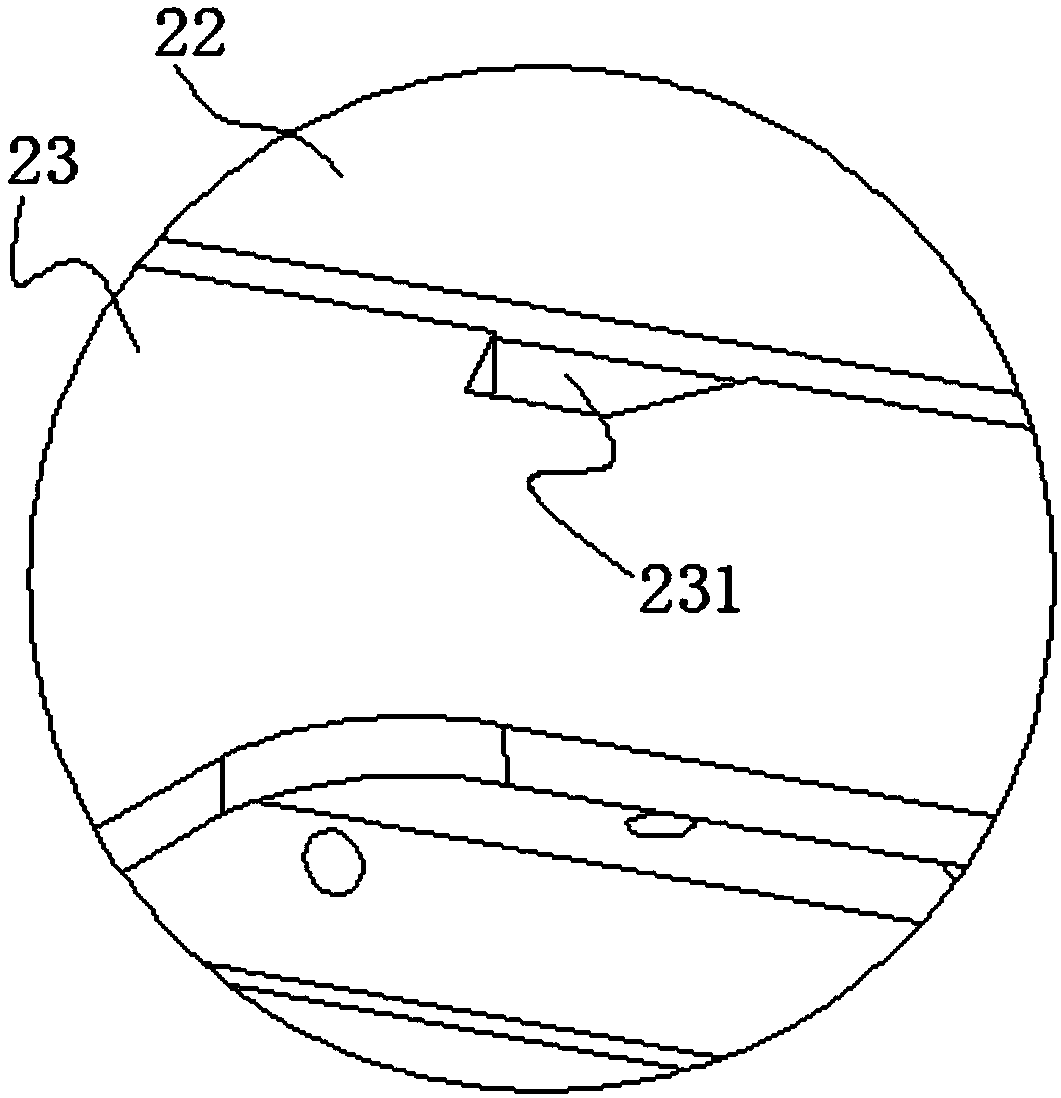

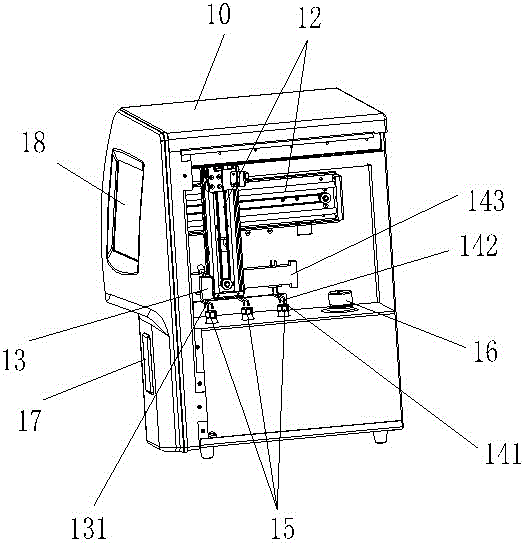

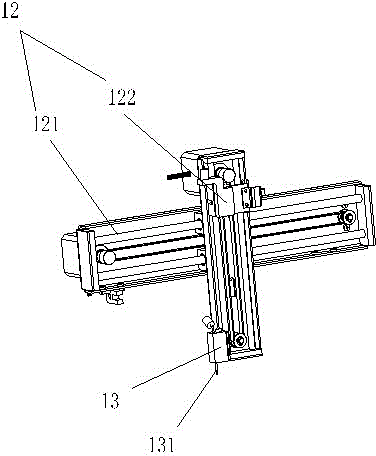

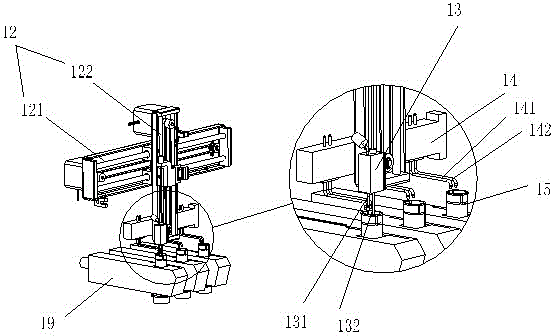

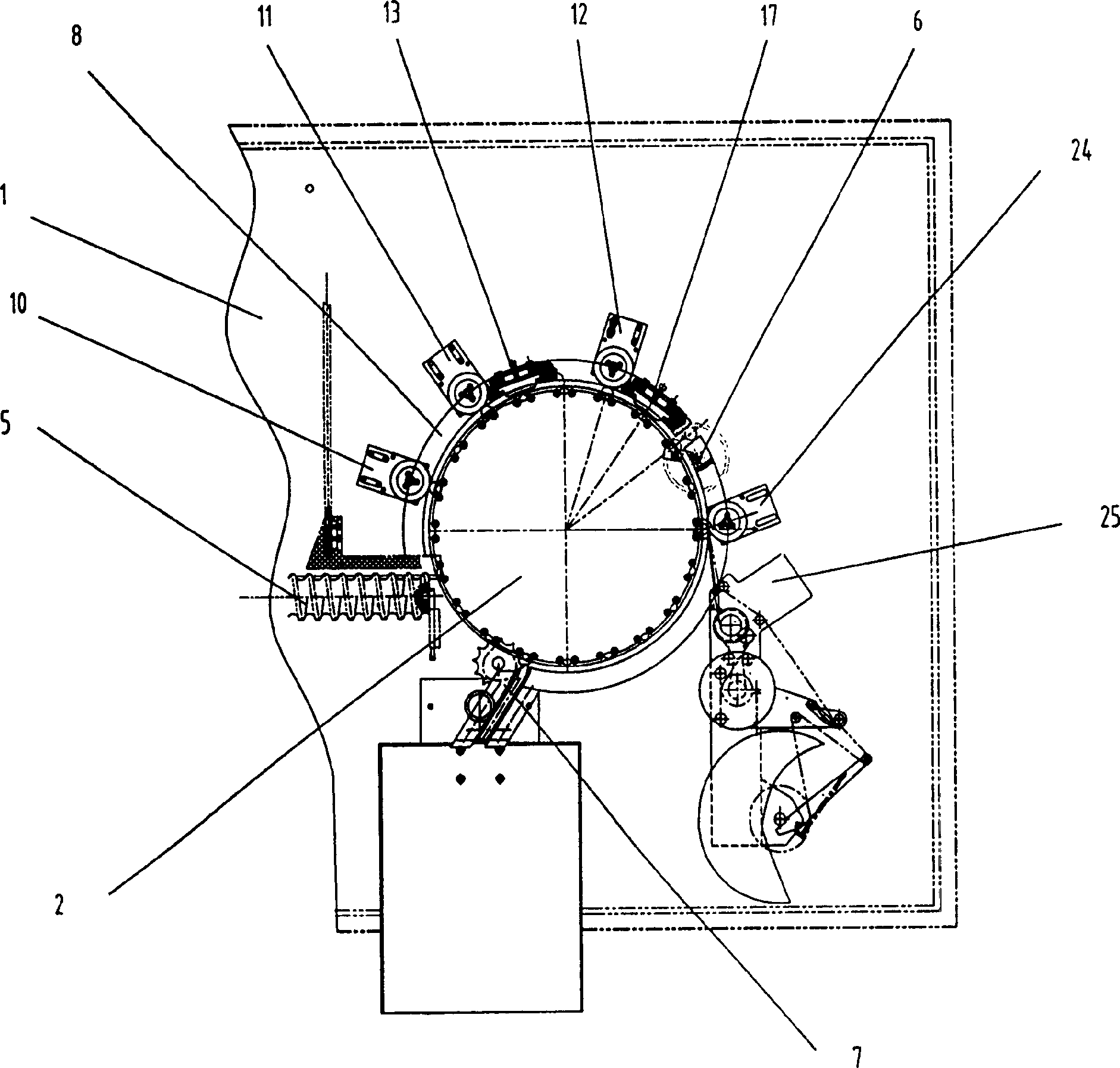

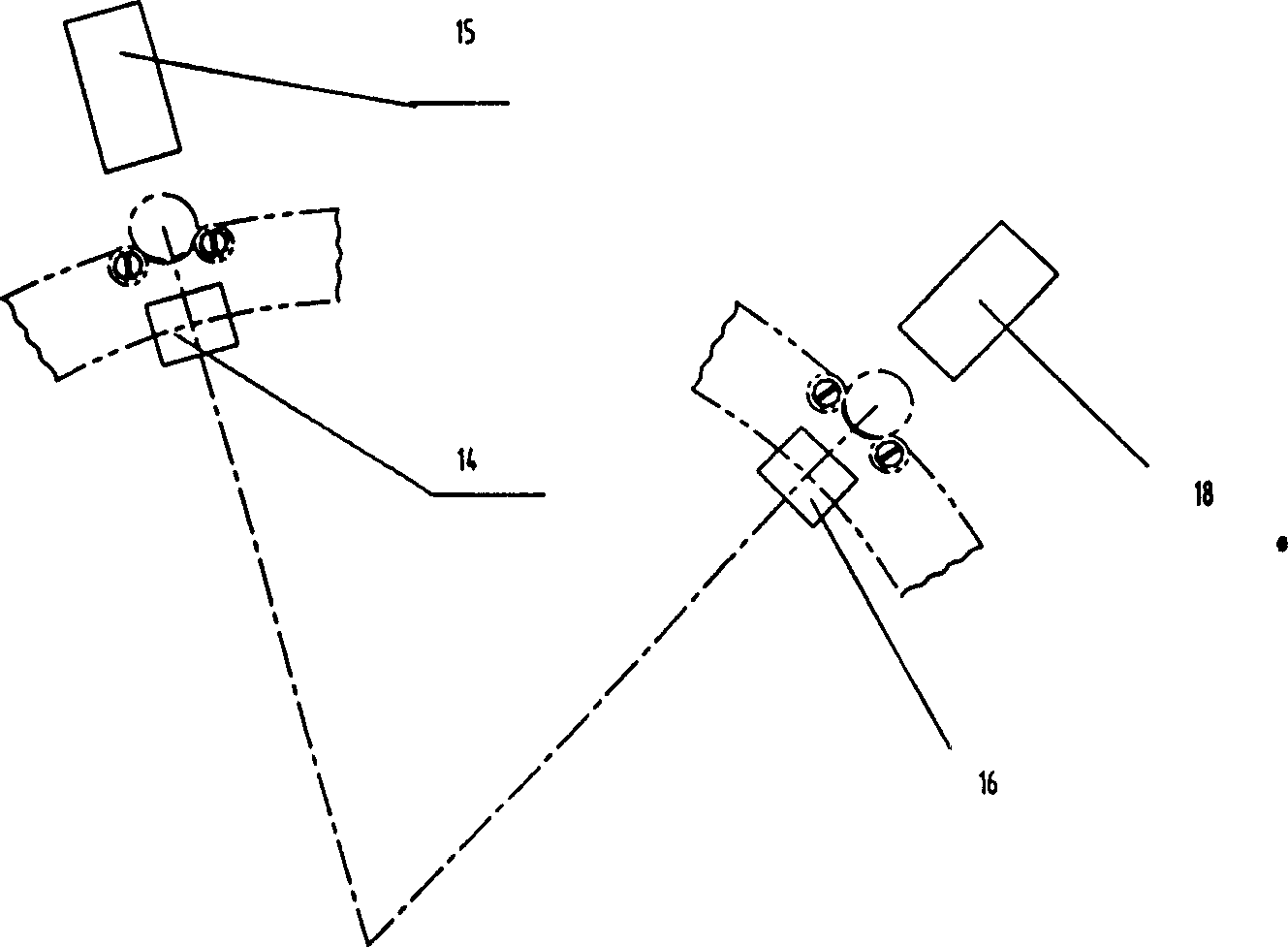

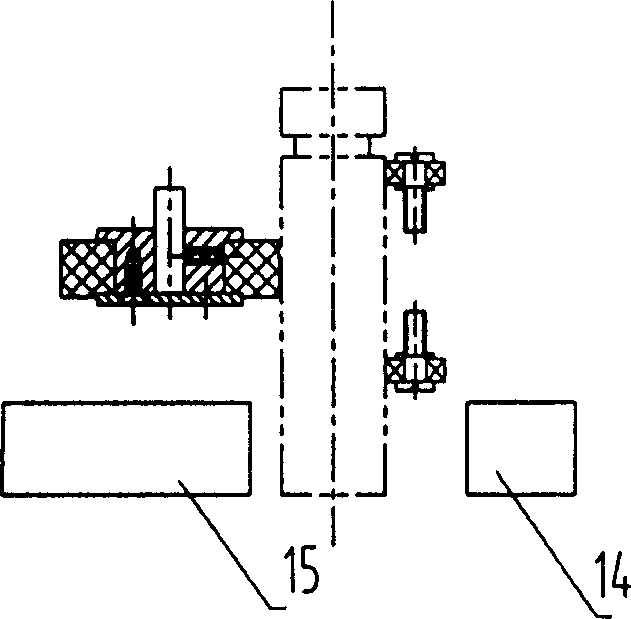

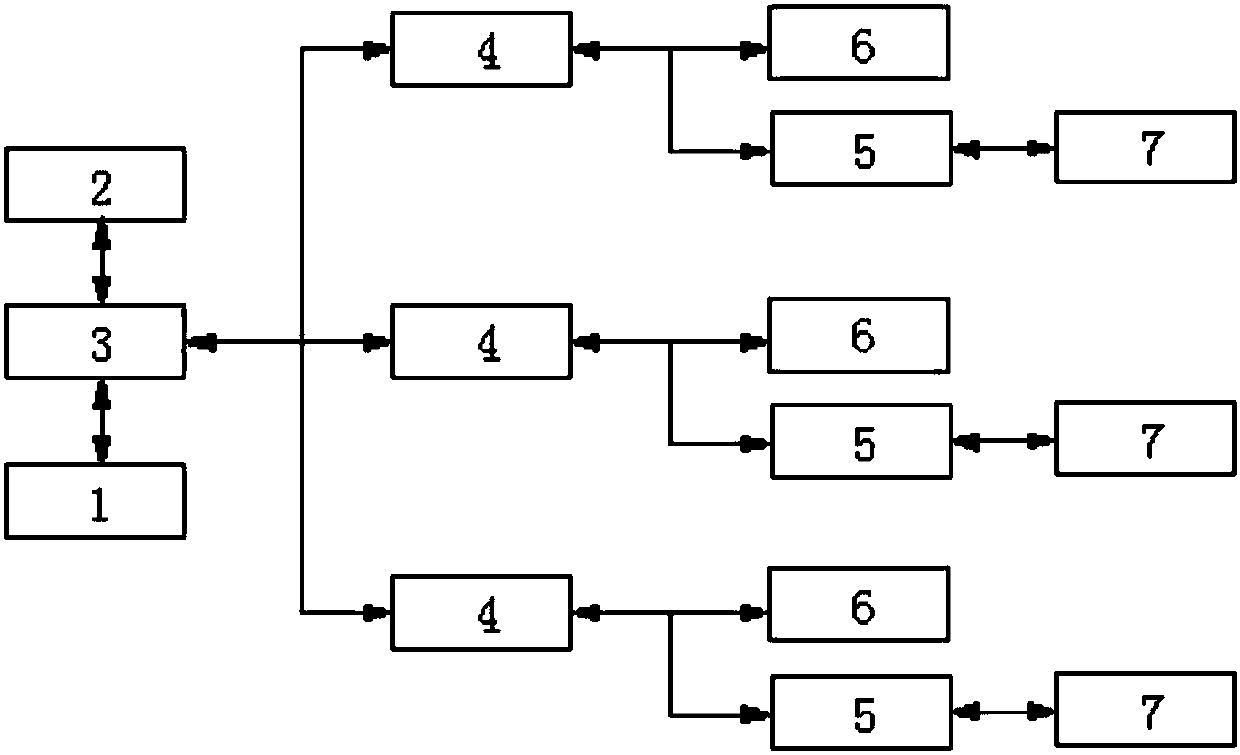

The invention relates to an enzyme-linked immune analysis method and a fully-automatic enzyme-linked immune analyzer. The analyzer comprises a rack component, a washing component, a sample adding / reagent adding component, a heating and temperature control component, a fluid path system, an input and output device, an optical measurement component and a control system, wherein the rack component comprises a rack soleplate; a pillar is arranged on the rack soleplate; a lower fixed plate and an upper fixed plate are arranged on the pillar from bottom to top in sequence; a circular reaction plate is arranged between the lower fixed plate and the upper fixed plate; the circular reaction plate is connected with the upper fixed plate and the lower fixed plate through a central shaft; a first motor is fixedly arranged at the lower part of the lower fixed plate; and the first motor is used for driving the circular reaction plate to rotate through a first transmission mechanism. When in use, the enzyme-linked immune analysis method and the fully-automatic enzyme-linked immune analyzer can carry out the detection of corresponding projects without wasting reagent through only one sample; and detection reagents need not to be respectively contained in different reagent bottles, so that the operation is very convenient, and the operation error is not easily caused, thereby ensuring the accuracy of the detection results.

Owner:SHENZHEN YHLO BIOTECH

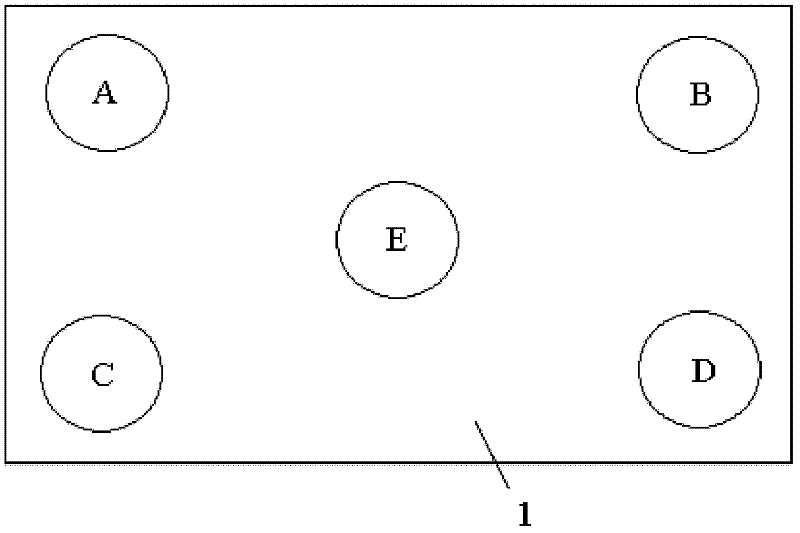

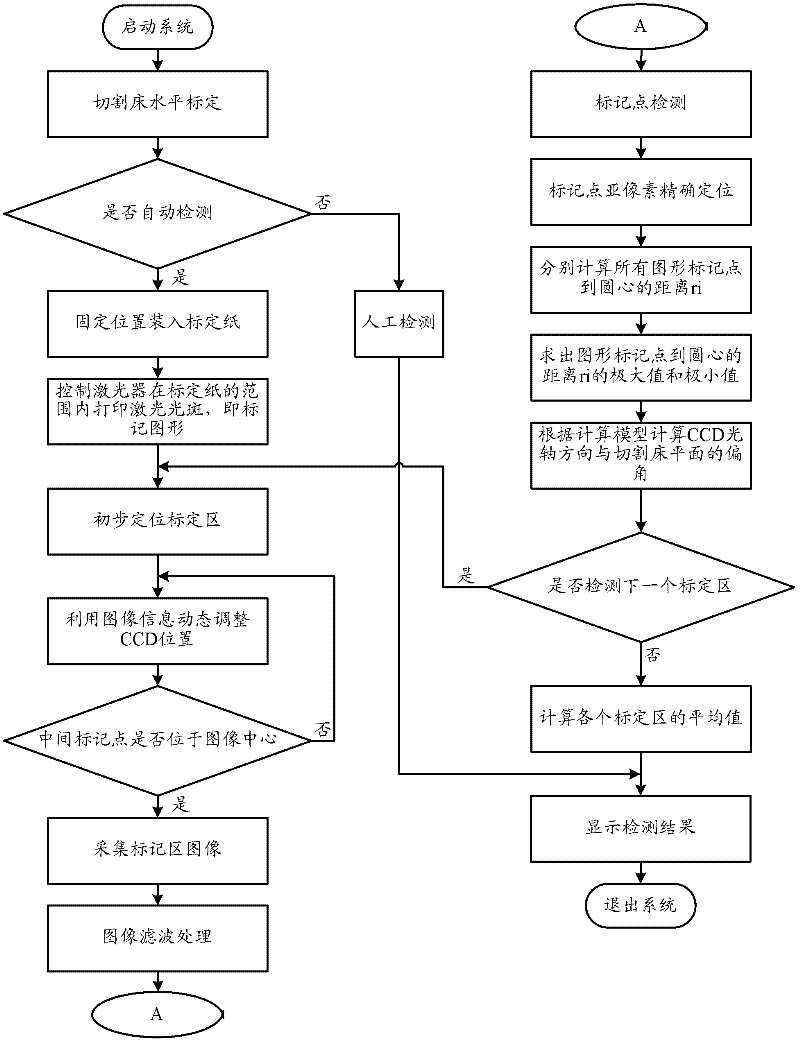

Method and system for detection of verticality of CCD installation of laser cutting machine with automatically edge searching performance

InactiveCN102353346AHigh precisionIncrease the level of automationUsing optical meansImaging processingOptical axis

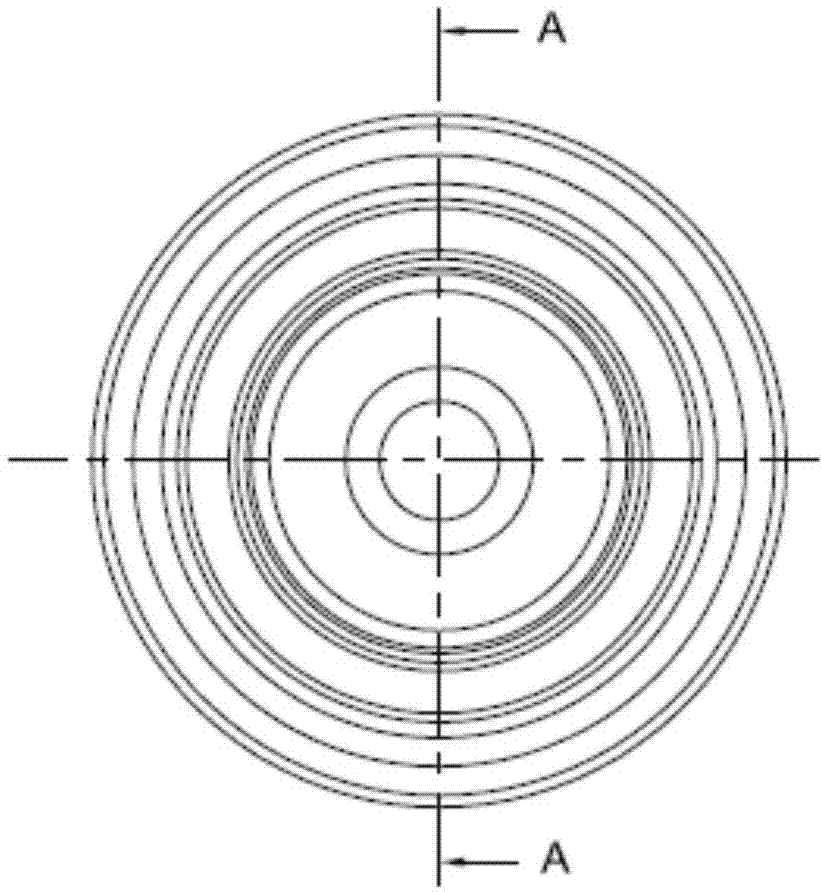

The invention relates to a method and a system for detection of a verticality of CCD installation of a laser cutting machine with an automatically edge searching performance. The method comprises the following steps that: a laser head of a laser cutting machine is directly utilized; a circle and a center of circle mark patterns that are formed by laser light spots are typed on calibration papers,which are paved fixedly at five different areas at a working plane of a cutting bed; marked images at the five different areas are shot through a CCD; an image processing technology is utilized and circumference point coordinates and center point coordinates of the marked images are respectively extracted; and an extreme values of distance of from the center point to all the circumference points are calculated and a verticality between a CCD shaft and the cutting bed is calculated by a calculation model. In addition, the invention also relates to a detection system for a verticality of CCD installation of a laser cutting machine with an automatical edge searching performance. And the detection system mainly comprises three software modules: a control module, an image processing module, and a data processing module. According to the invention, problems on slow detection speed, low efficiency and poor precision and the like during detection on a verticality of CCD installation of a laser cutting machine with an automatically edge searching performance are solved and an automatic capability of the system is also improved.

Owner:DONGHUA UNIV

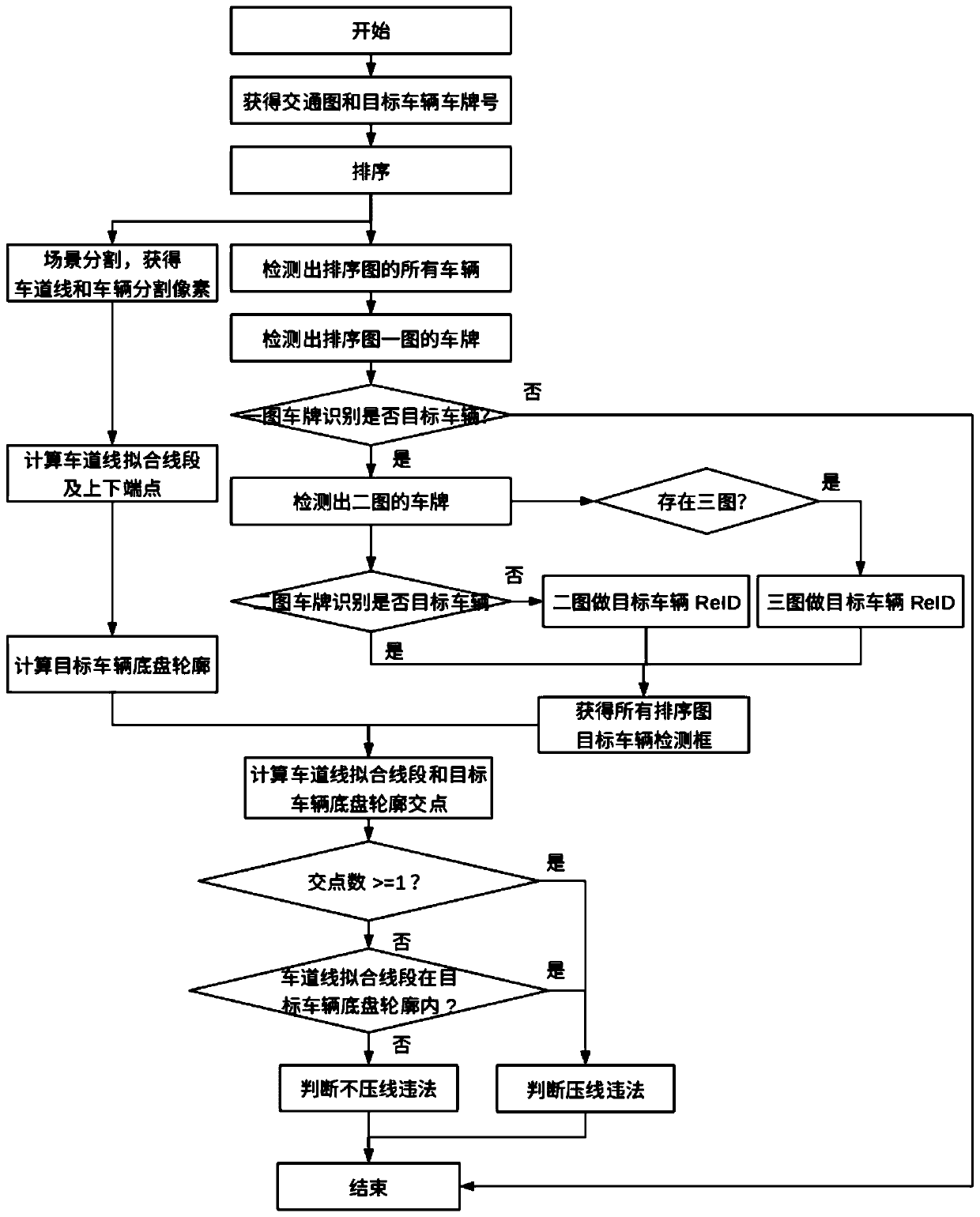

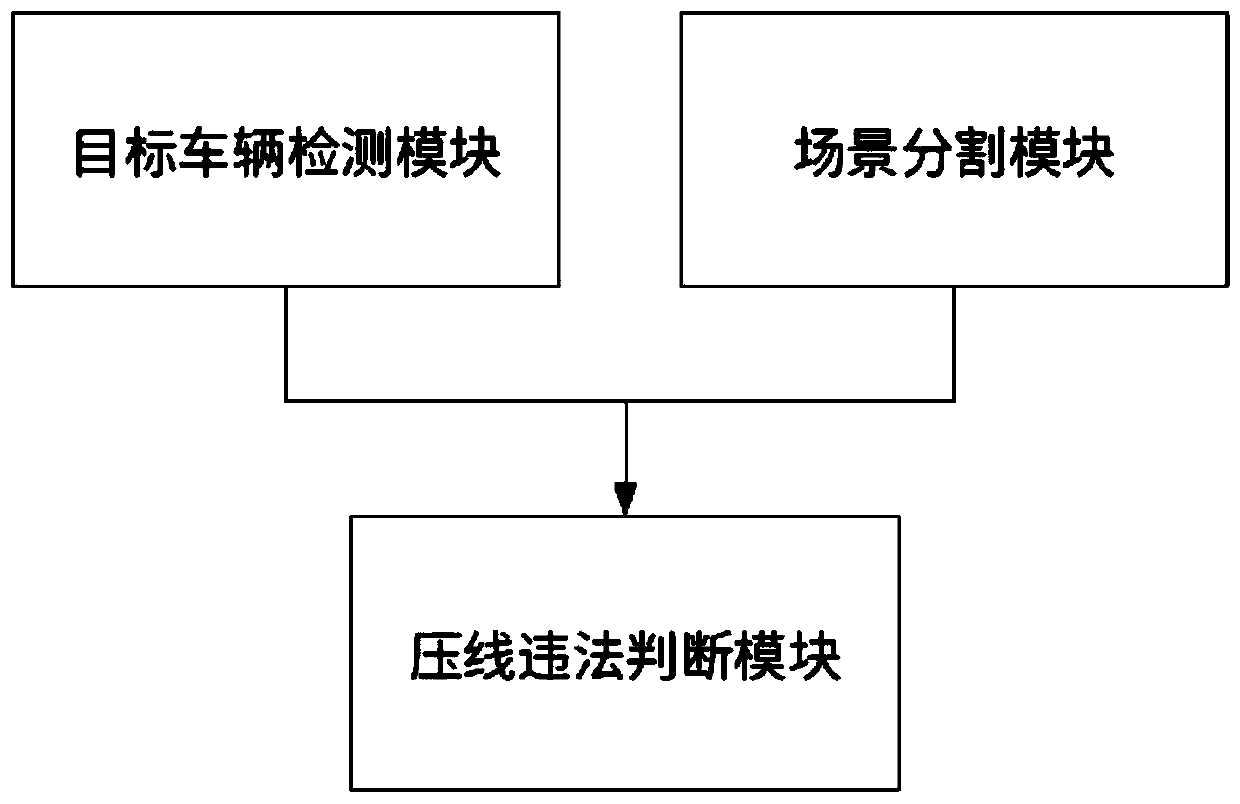

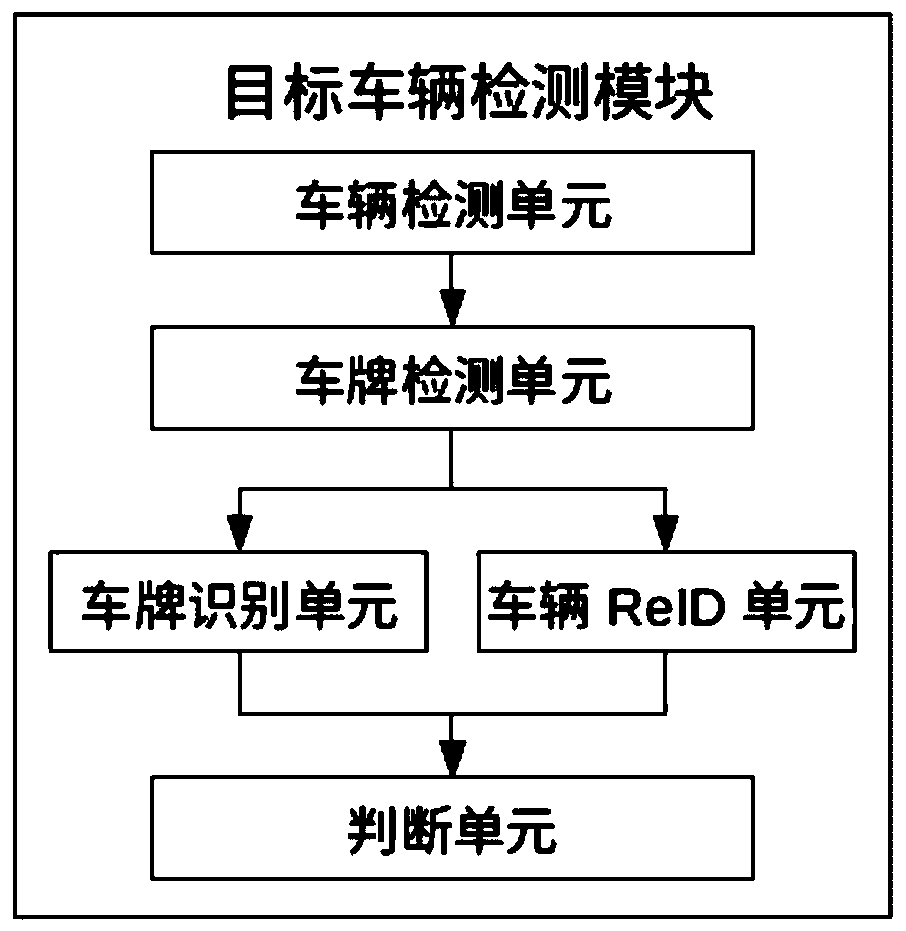

Deep learning based automatic checking method against vehicle lane-pressing illegal behavior

ActiveCN109949578AMeet the characteristicsRealize fully automatic detectionRoad vehicles traffic controlCharacter and pattern recognitionLearning basedComputer graphics (images)

The invention discloses a deep learning based automatic checking method against a vehicle lane-pressing illegal behavior. The method comprises the following steps that a snapshot picture of a camera is obtained, cut and ordered; the license plate number of a target vehicle is obtained; a deep learning based target vehicle detection module is used to detect the target vehicle in different ordered images, and a target vehicle detection frame is obtained; scene cutting is carried out on the ordered image by means of deep learning based scene cutting module, and segmented solid line pixels are obtained; in each ordered image, a vehicle lane pressing illegal behavior determining module determines whether there is an intersection point between a solid line fitting straight line and a straight line of a lower frame of the target vehicle detection frame by calculation; and whether the target vehicle in the group of ordered images has a lane pressing illegal behavior is determined according toposition of the intersection point. Thus, the method is suitable for illegal behavior checking via the pictures shot by traffic cameras in the real scene.

Owner:上海眼控科技股份有限公司

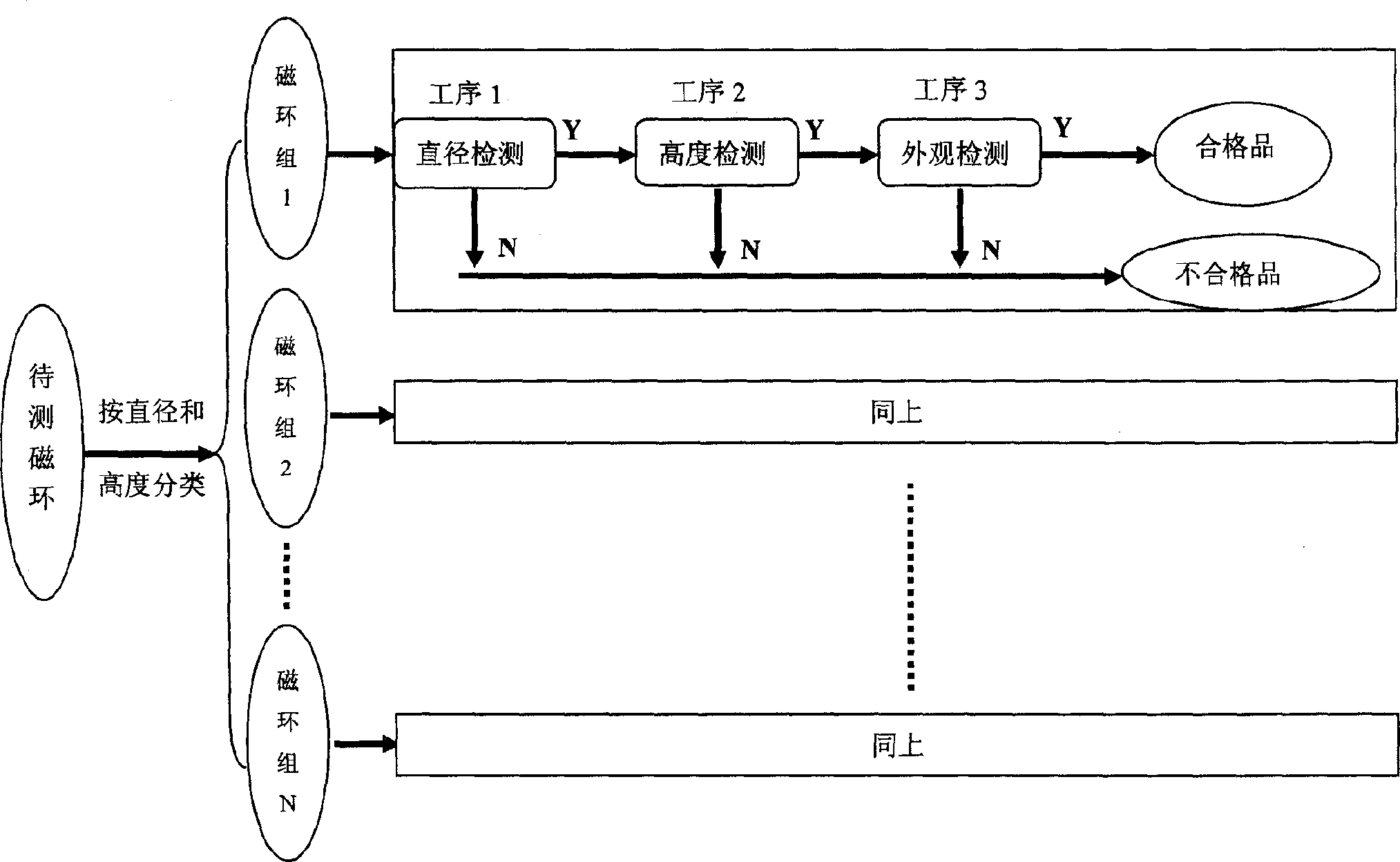

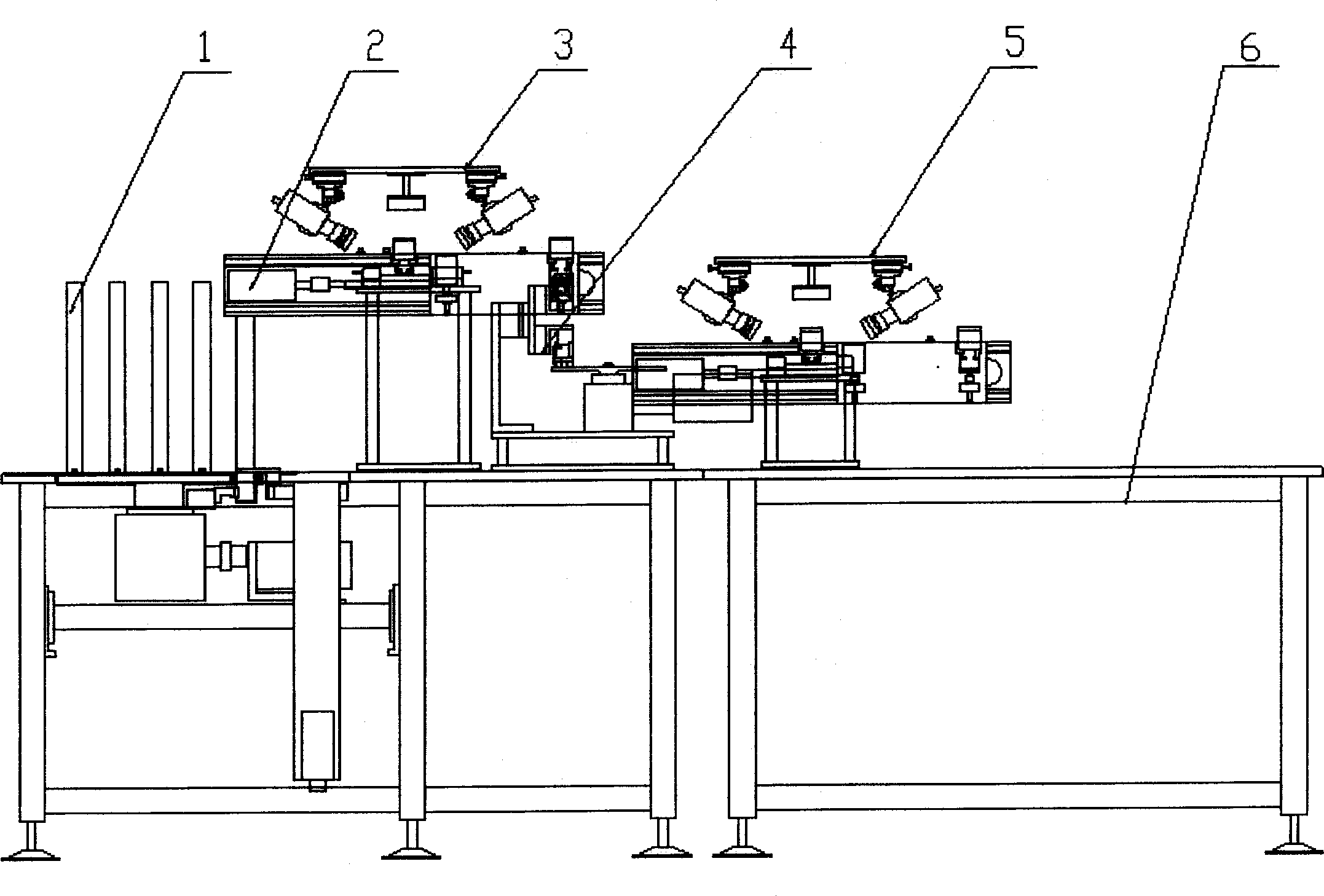

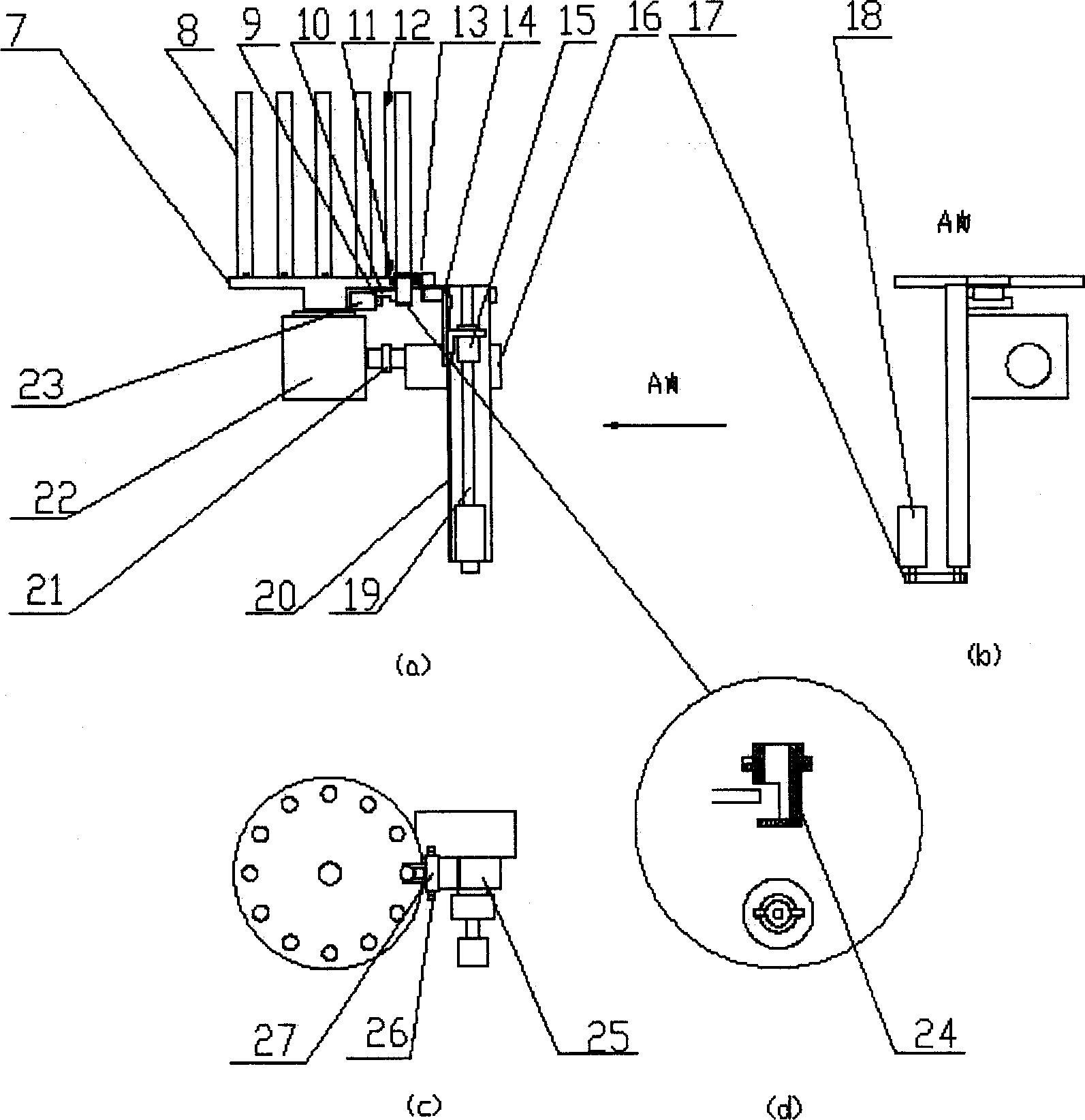

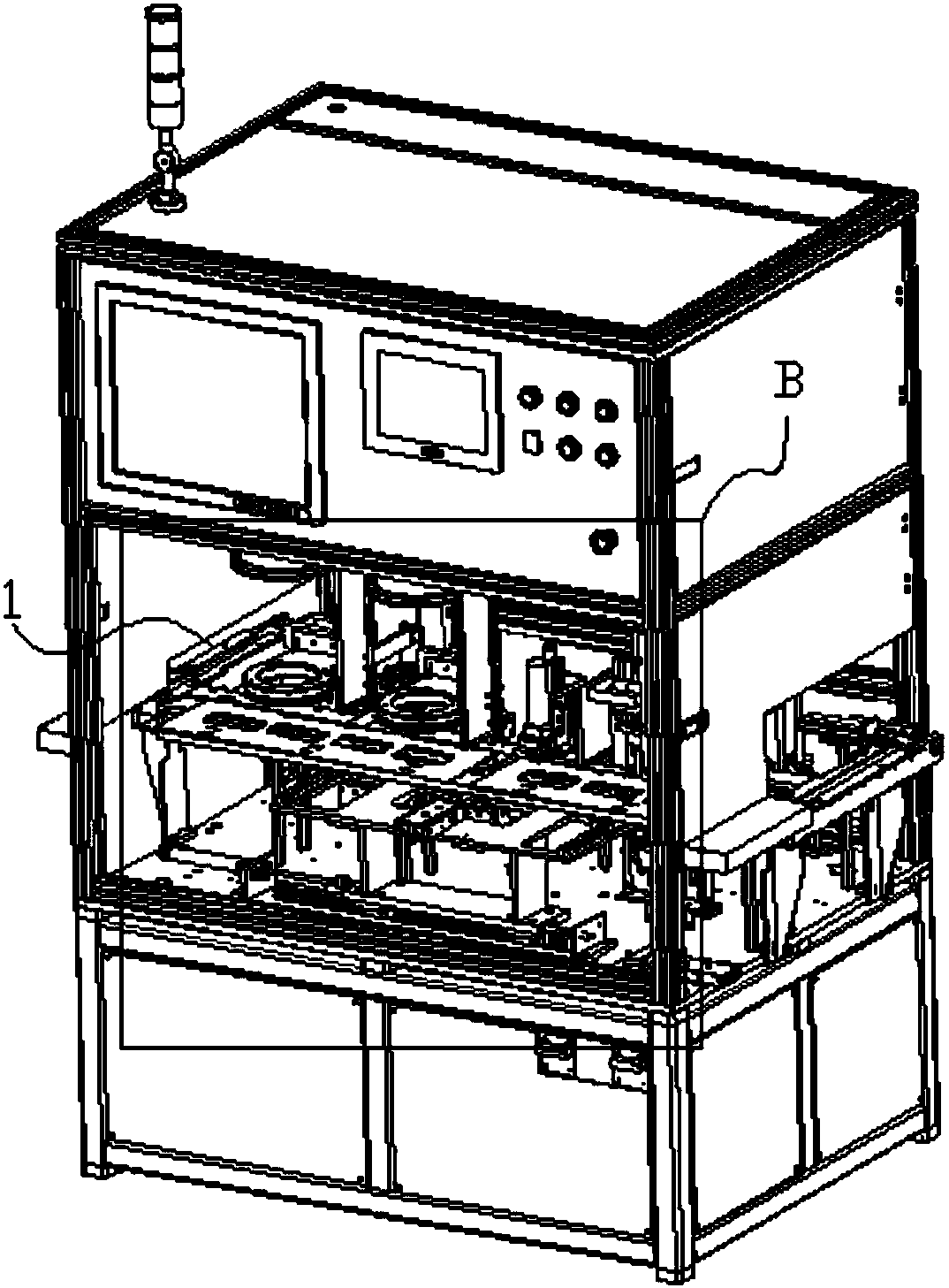

Automatic detection device for magnetic loop image

InactiveCN1865948ARealize fully automatic detectionRealize automated productionInvestigating moving sheetsOptically investigating flaws/contaminationImage detectionManipulator

The related natural detection device for magnet ring image comprises: a frame with an auto feeding pan for magnet ring on front and a first dual-head mobile manipulator on back; arranging a first image detection platform on the manipulator and a second manipulator as well as a ring turning device on back side of the platform; using the first manipulator and platform to detect diameter and top surface, and the second device to detect target thickness and bottom surface. This invention reduces time and cost.

Owner:SHANGHAI UNIV

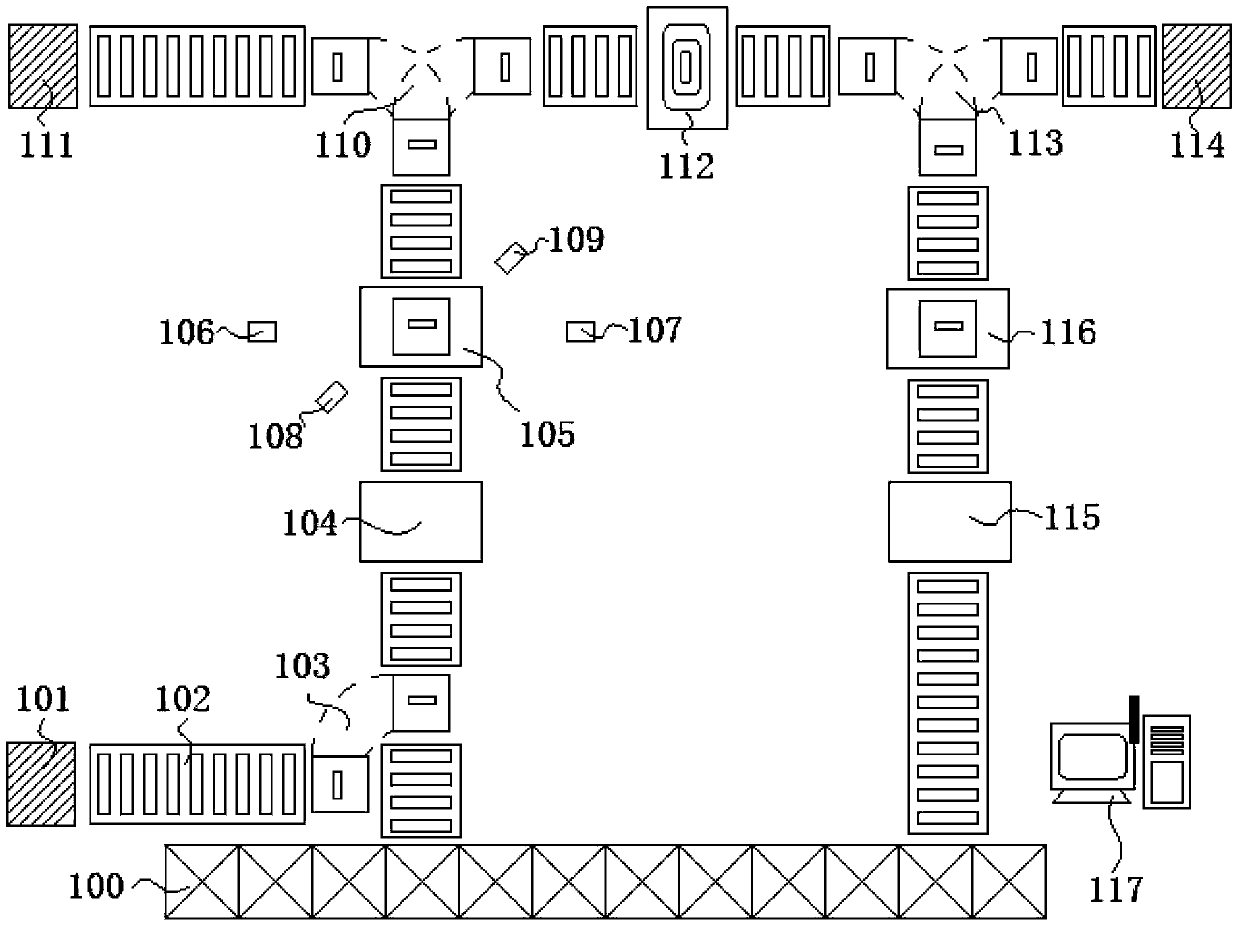

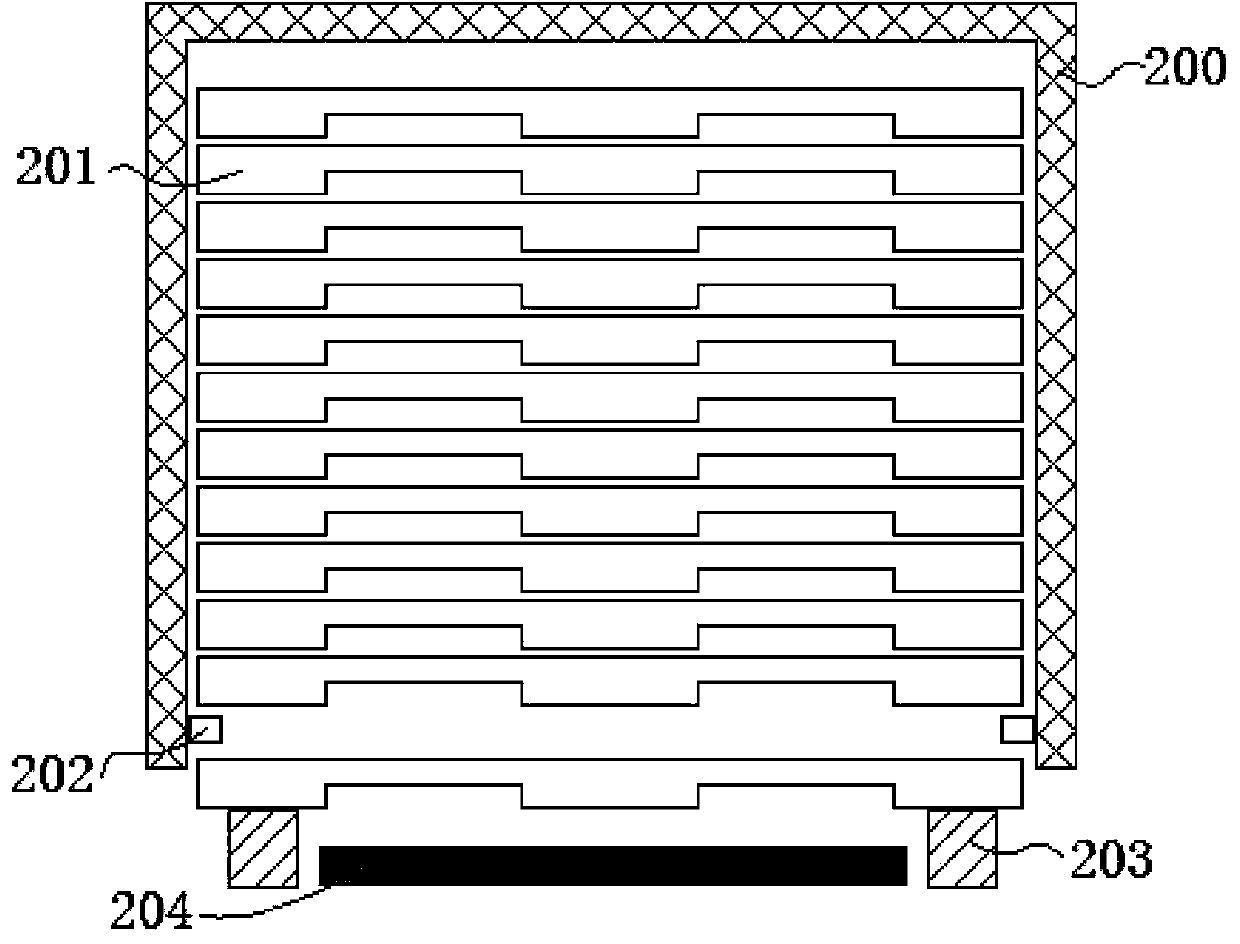

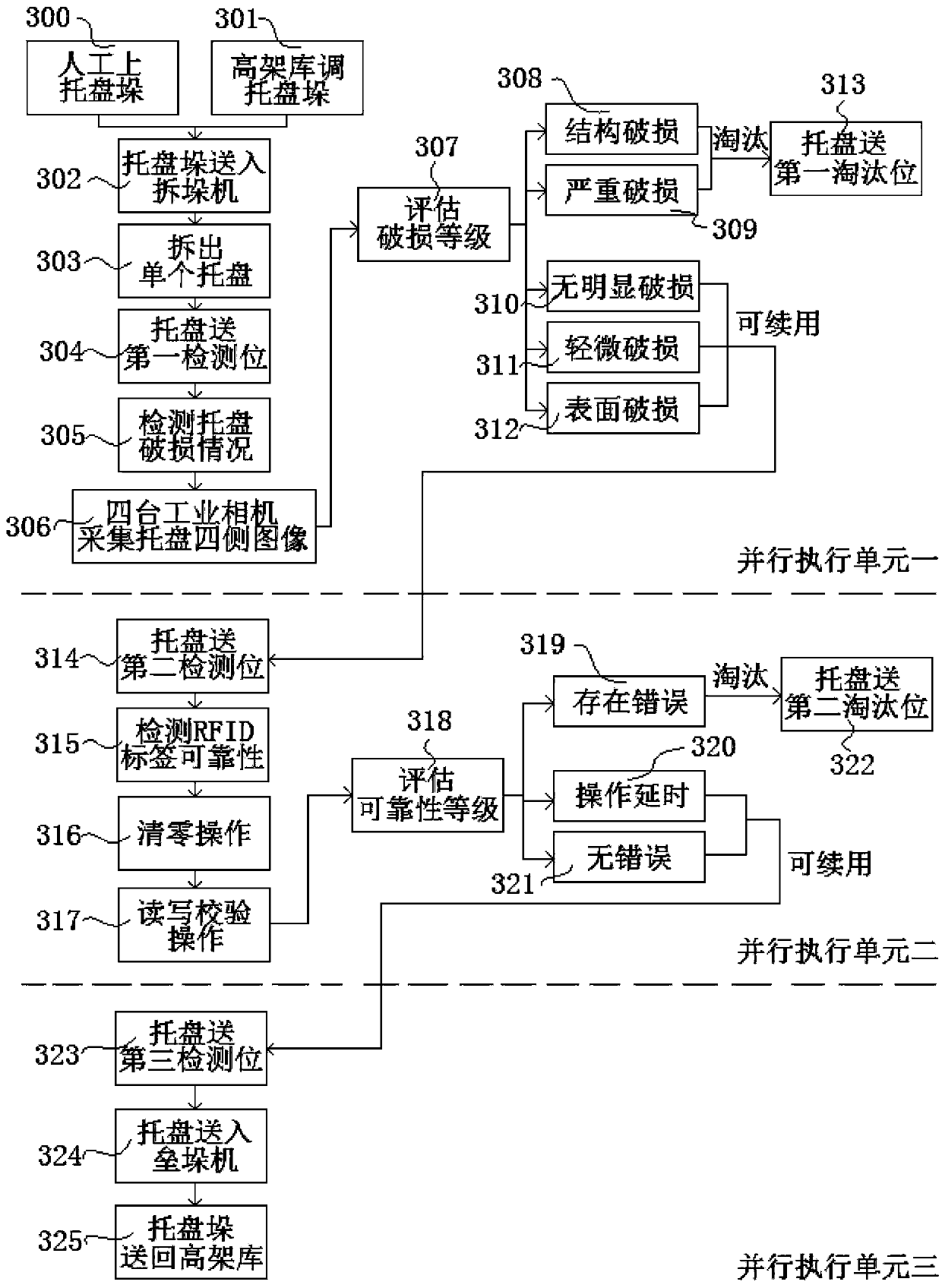

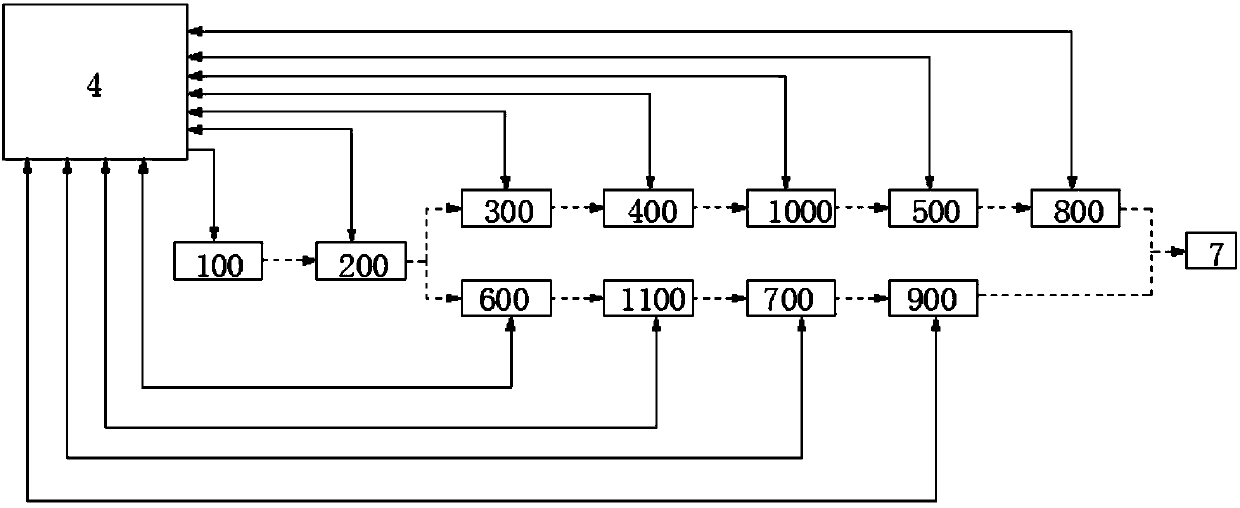

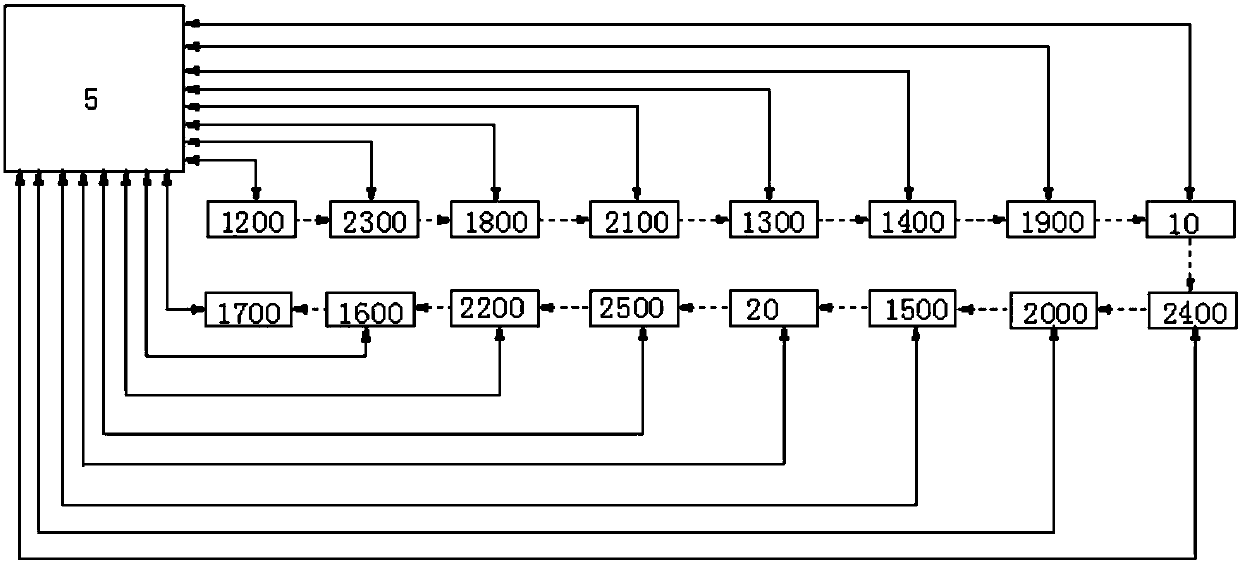

Full-automatic detection system and full-automatic detection method for sustainability of RFID (radio frequency identification device) logistic flat trays

ActiveCN103472066AReduce the average detection cycleImprove detection efficiencyOptically investigating flaws/contaminationMachine visionStack machine

The invention relates to a full-automatic detection system and a full-automatic detection method for sustainability of RFID (radio frequency identification device) logistic flat trays. The system comprises a full-automatic elevated three-dimensional warehouse, a manual stacking position, an unstacking machine, a first detection position, a first bidirectional 90-degree rotation conveying belt, a first elimination position, a second detection position, a second bidirectional 90-degree rotation conveying belt, a second elimination position, a stacking machine, an extendable detection position and a tray detection management system. According to the system and the method, the full-automatic detection of the RFID logistic combined transportation flat trays is achieved, and both the starting and stopping points of a detection assembly line can be connected to the full-automatic elevated three-dimensional warehouse, so that the manual intervention is alleviated; the trays are stacked by the unstacking machine and the stacking machine, so that the tray storage space is narrowed; the tray breakage degree is detected by adopting a machine vision method, so that the speed is quick and the accuracy is high; the reliability of the built-in RFID label data of the trays is detected by adopting reset and read-write check methods; detection items are scheduled in a unified way according to a detection management system and are parallelized.

Owner:CHINA TOBACCO ZHEJIANG IND

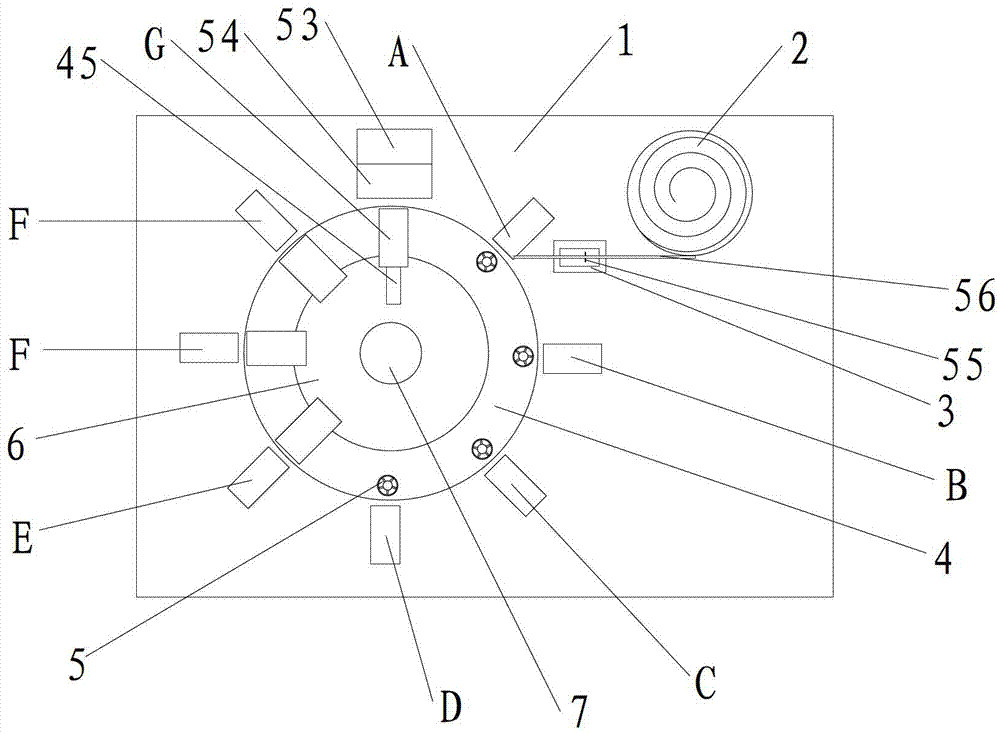

Method and equipment for fully-automatically detecting motor commutator

InactiveCN102735287AReduce collisionProtect the motor commutatorTesting dielectric strengthResistance/reactance/impedenceAutomatic controlTransfer mechanism

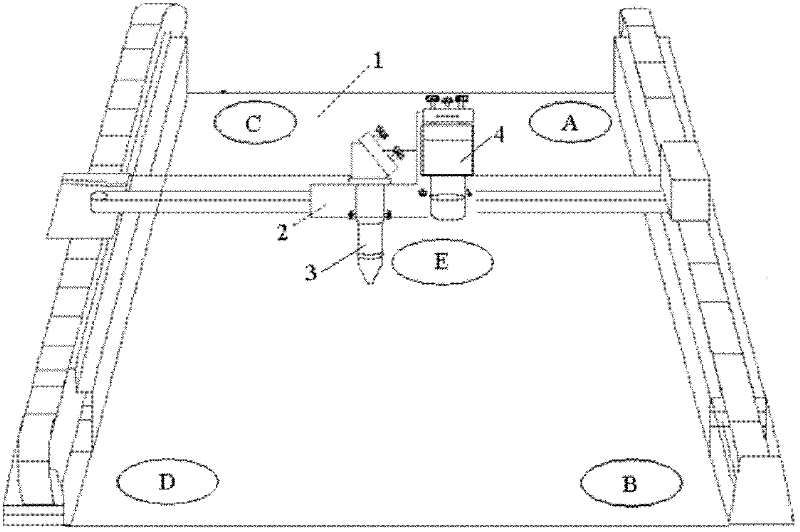

The invention discloses a method for fully-automatically detecting a motor commutator. The method is implemented by equipment for fully-automatically detecting the motor commutator. The invention also discloses the equipment for fully-automatically detecting the motor commutator. The equipment comprises a worktable, a feeding tray, a linear vibration feeding machine, a rotary table, a jig and an automatic control mechanism, wherein the jig is arranged in a jig hole formed in a part of the rotary table, which corresponds to a station; a product transferring mechanism A, a height detection mechanism B, a quality flaw detection mechanism C, an inner diameter detection mechanism D, a mechanism E for detecting medium intensity between the inner diameter and metal sheets, a mechanism F for detecting medium intensity between two metal sheets and a discharging mechanism G which is fixed on the worktable and penetrates through a fixed tray fixedly connected with the upper end of a connecting shaft in the center of the rotary table are fixedly arranged on the worktable along the clockwise direction of the rotary table from a linear guide rail position of the linear vibration feeding machine. By utilizing the method and the equipment, the motor commutator can be fully-automatically detected, the working efficiency is greatly improved, and the production cost is reduced.

Owner:周仲华

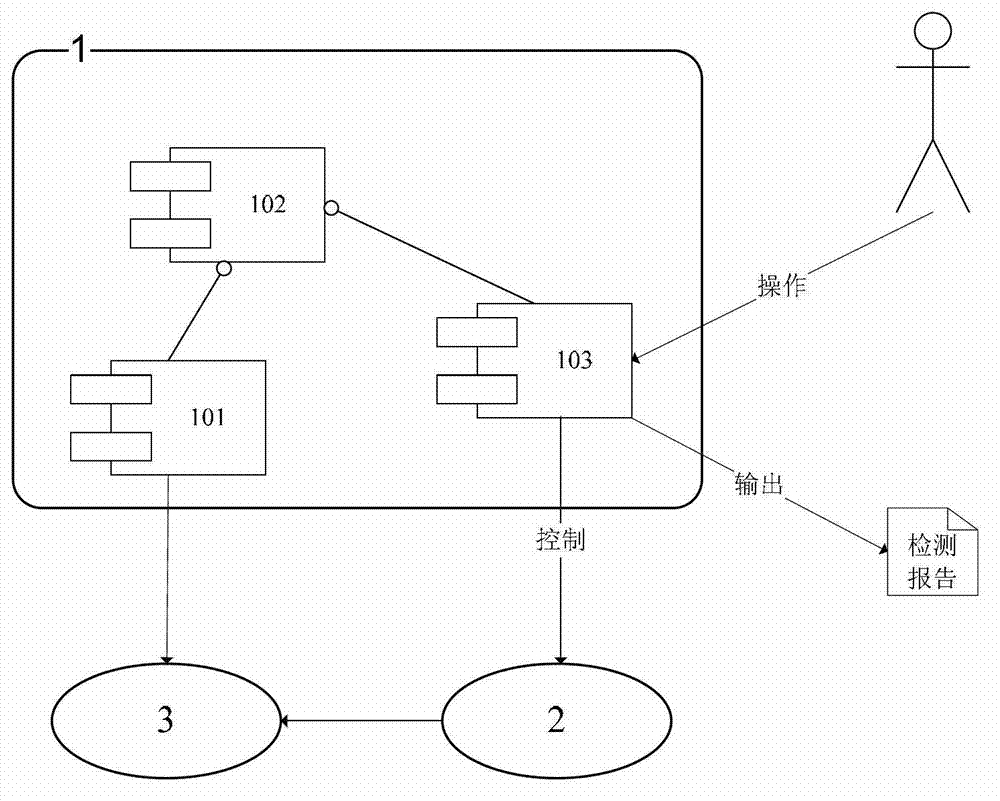

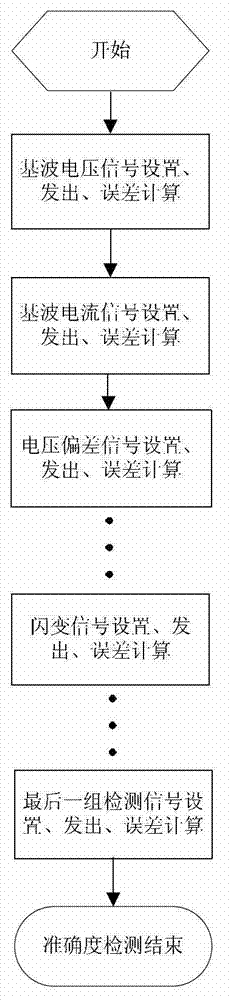

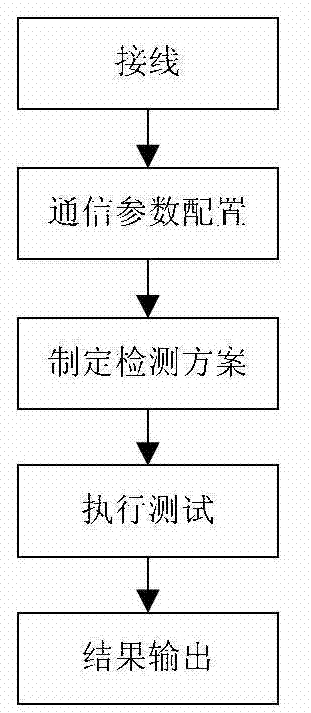

Full-automatic detecting system for power quality monitoring devices

InactiveCN103116095ARealize fully automatic detectionAvoid introducingElectrical testingPower qualityGeneral purpose

A full-automatic detecting system for power quality monitoring devices comprises an upper computer detecting system and a standard source. The upper computer detecting system comprises a data acquisition module, a data storage module and a detecting control module, a detected monitoring device is connected with the standard source by a testing signal line and is connected with the upper computer detecting system by an Ethernet, and the standard source and the upper computer detecting system are connected with each other by a GPIB (general purpose interface bus) to form a closed-loop control system. The power quality monitoring device can be fully automatically detected by means of simple connection and configuration during detection. The full-automatic detecting system has the advantages that the detection time is shortened, the detection efficiency is improved, errors caused by human factors are prevented, the extension compatibility is sufficiently considered in order to gain support of detection specifications in different regions, different standard sources and the detected monitoring devices, and novel standard sources and novel detected monitoring devices can be quickly connected into the full-automatic detecting system on the basis of a detection scheme template and the UAPI (uniform application program interface) technology.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

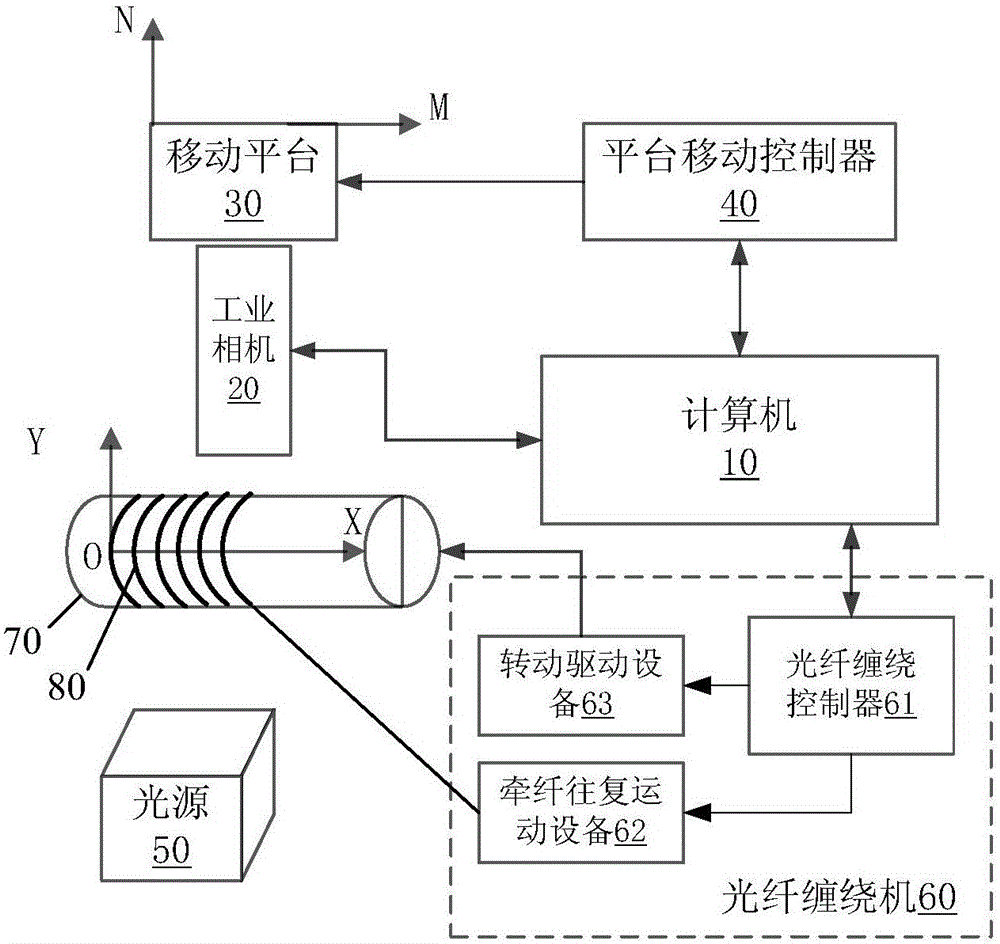

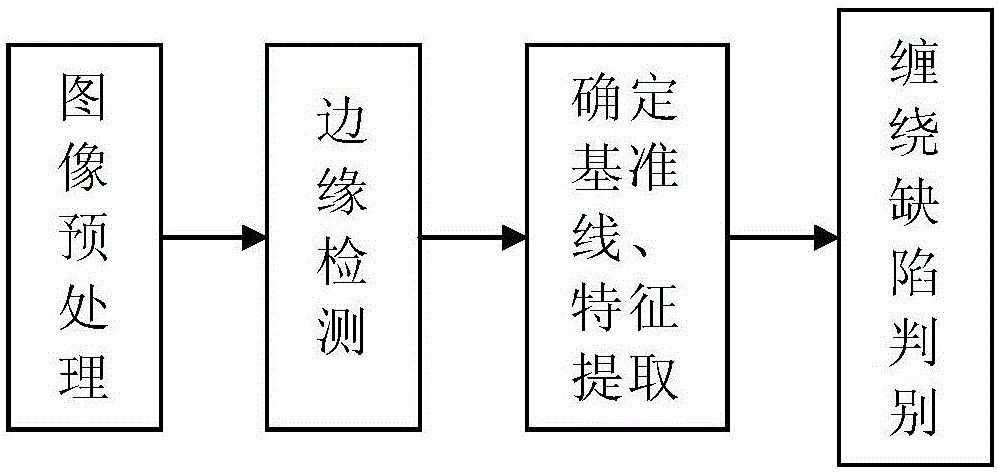

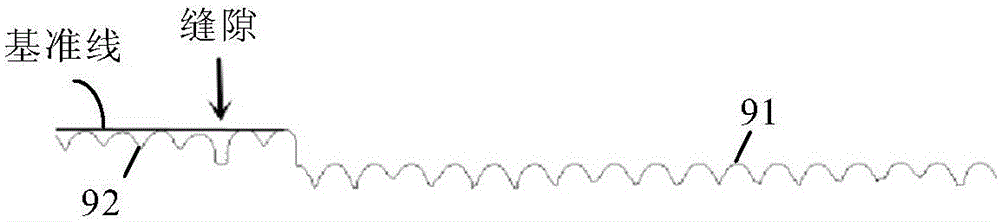

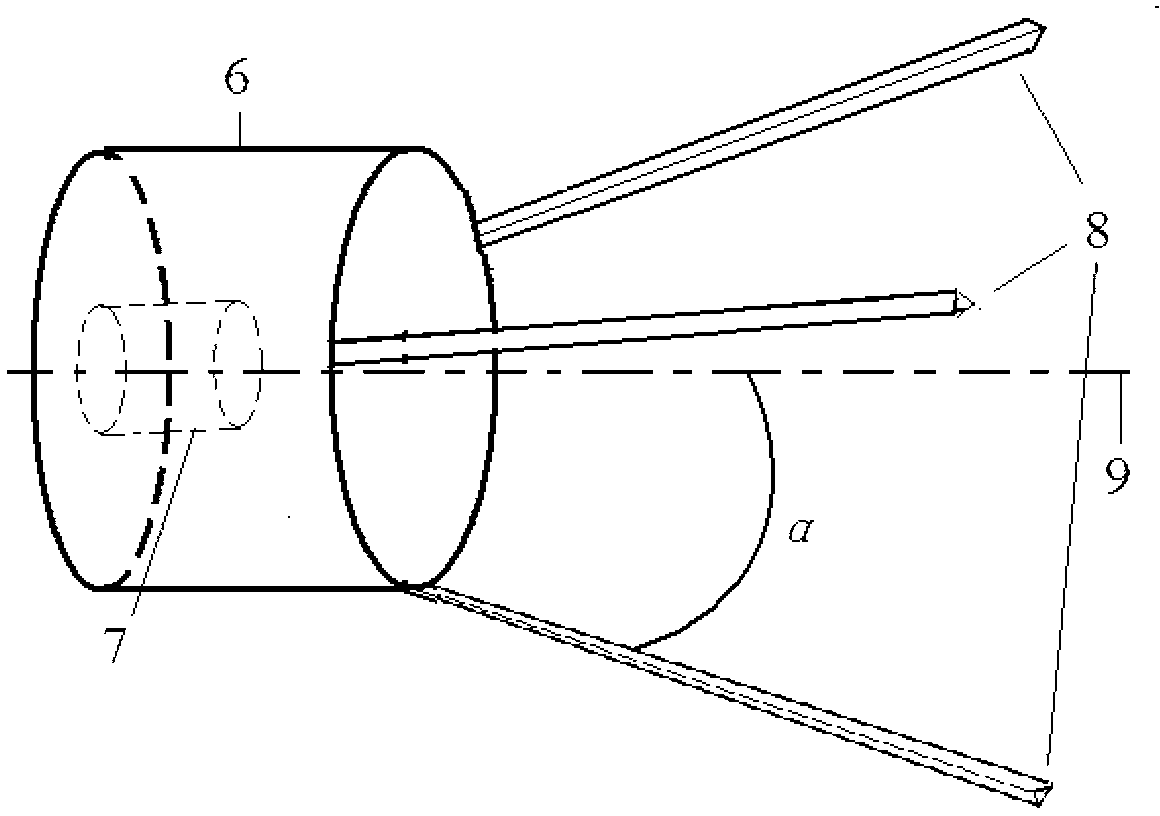

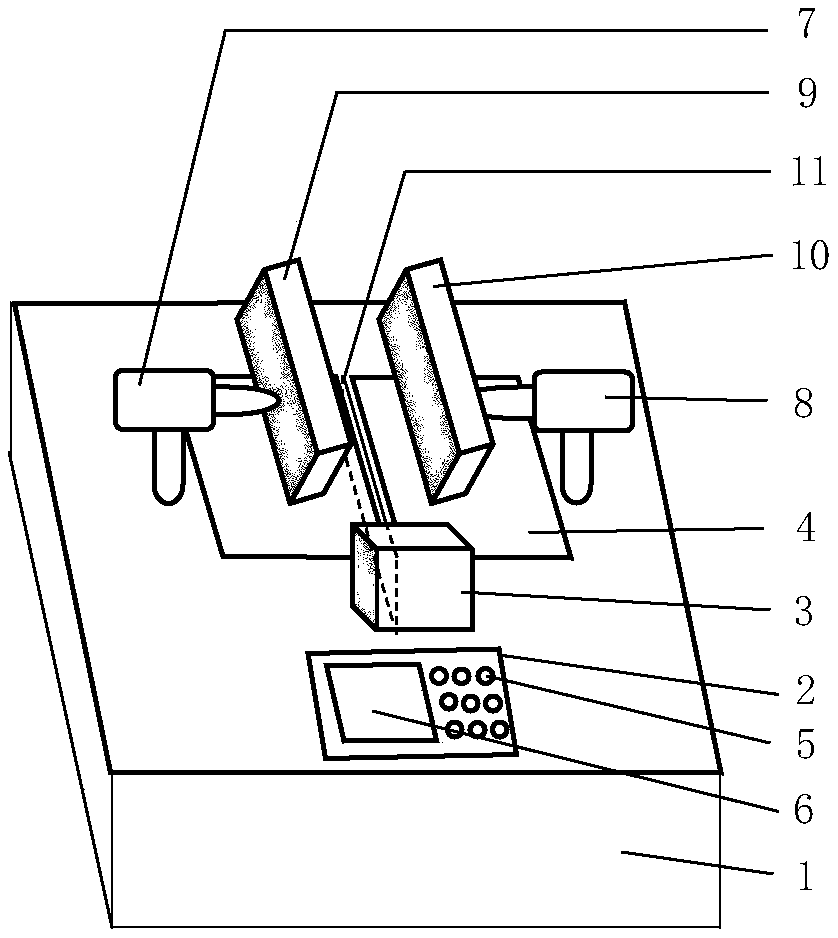

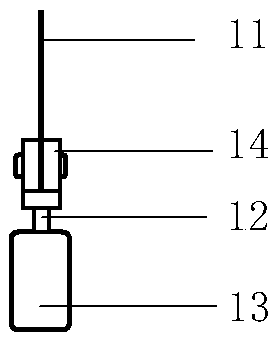

Full-automatic optical fiber winding defect detection system and method and optical fiber winding method

InactiveCN105115981ARealize real-time automatic detection functionGuarantee the quality of windingMaterial analysis by optical meansWinding machineEngineering

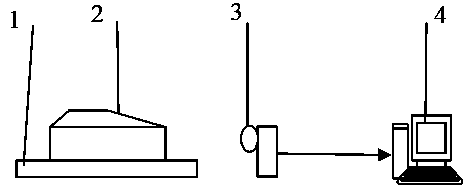

The invention discloses a full-automatic optical fiber winding defect detection system and method and an optical fiber winding method. The full-automatic optical fiber winding defect detection system comprises an industrial camera provided with an industrial lens, a light source, a moving platform, a platform moving controller and a computer, the industrial camera and the light source are arranged on two sides of a rotating shaft wound by an optical fiber respectively, rotating of the rotating shaft is controlled by an optical fiber winding machine, the industrial camera is mounted on the moving platform which is connected with the platform moving controller, and the platform moving controller, the industrial camera and the optical fiber winding machine are all connected with the computer. The full-automatic optical fiber winding defect detection system and method realizes a function of realtime and automatic detection of defects in the process of winding the optical fiber. The optical fiber winding method coordinates and cooperates with the optical fiber winding machine, full automation in winding the optical fiber can be realized, and production efficiency is high.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

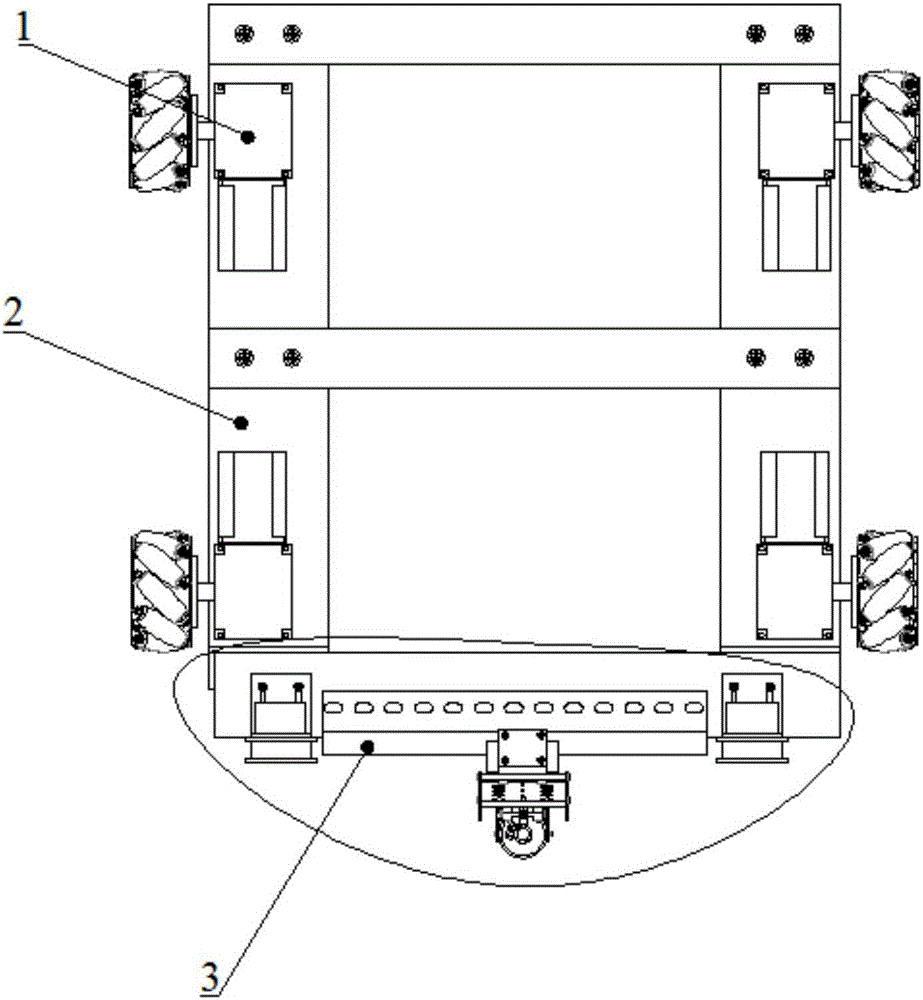

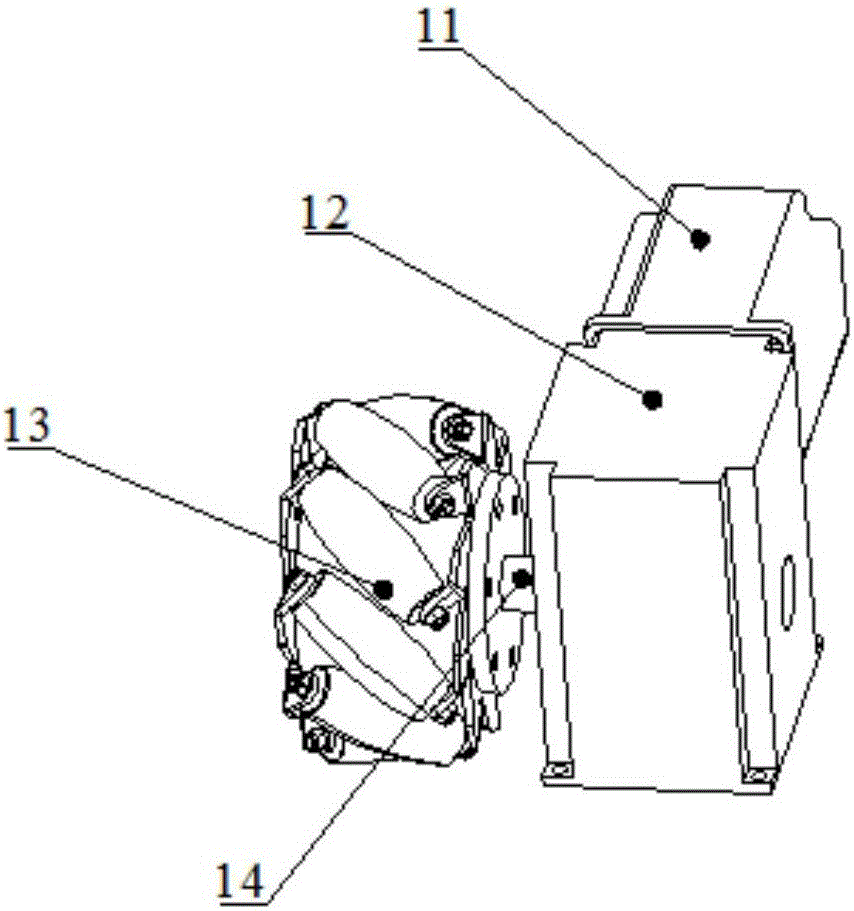

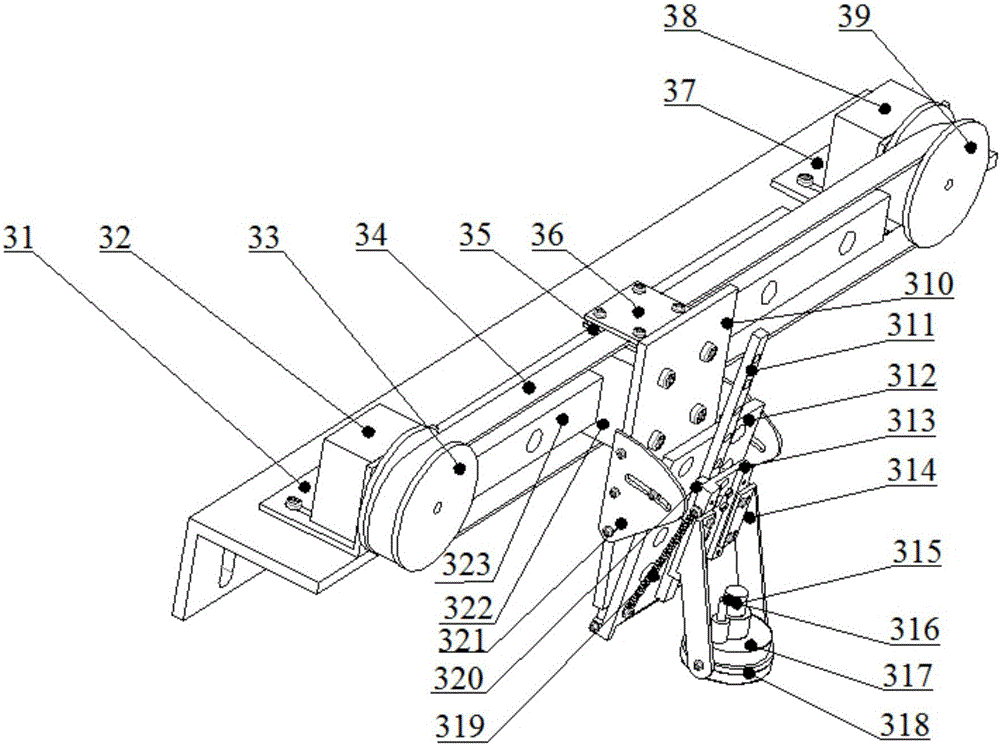

Robot for all-bearing defect detection of large-capacity flat-bottom container bottom plate and detection method

InactiveCN105973986AFacilitate all-round defect location detectionEasy to detect all-round defect position detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesIndependent motionLocation detection

The invention discloses a robot for all-bearing defect detection of a large-capacity flat-bottom container bottom plate and a detection method. The robot comprises a robot body, wherein a walking device and a detection device are arranged under the robot body, and the detection device is arranged at one end of the robot body; the walking device consists of four independent Mecanum wheel mechanisms which are arranged on the robot body; the detection device mainly consists of an ultrasonic probe and an ultrasonic probe adjusting mechanism, and the ultrasonic probe is connected with an ultrasonic generator; the ultrasonic probe adjusting mechanism comprises a first adjusting mechanism and a second adjusting mechanism; the first adjusting mechanism is used for driving the ultrasonic probe to move left and right along the horizontal direction; the second adjusting mechanism is used for adjusting the height of the ultrasonic probe, so that the ultrasonic probe is attached with the surface of the to-be-detected container bottom plate to be detected. The robot has the advantages that the all-bearing defect position detection can be performed on the detected container, the missed detection due to low feedback signal intensity caused by inverticality between ultrasonic direction and defect direction is avoided, and the detection accuracy is improved.

Owner:SICHUAN UNIV

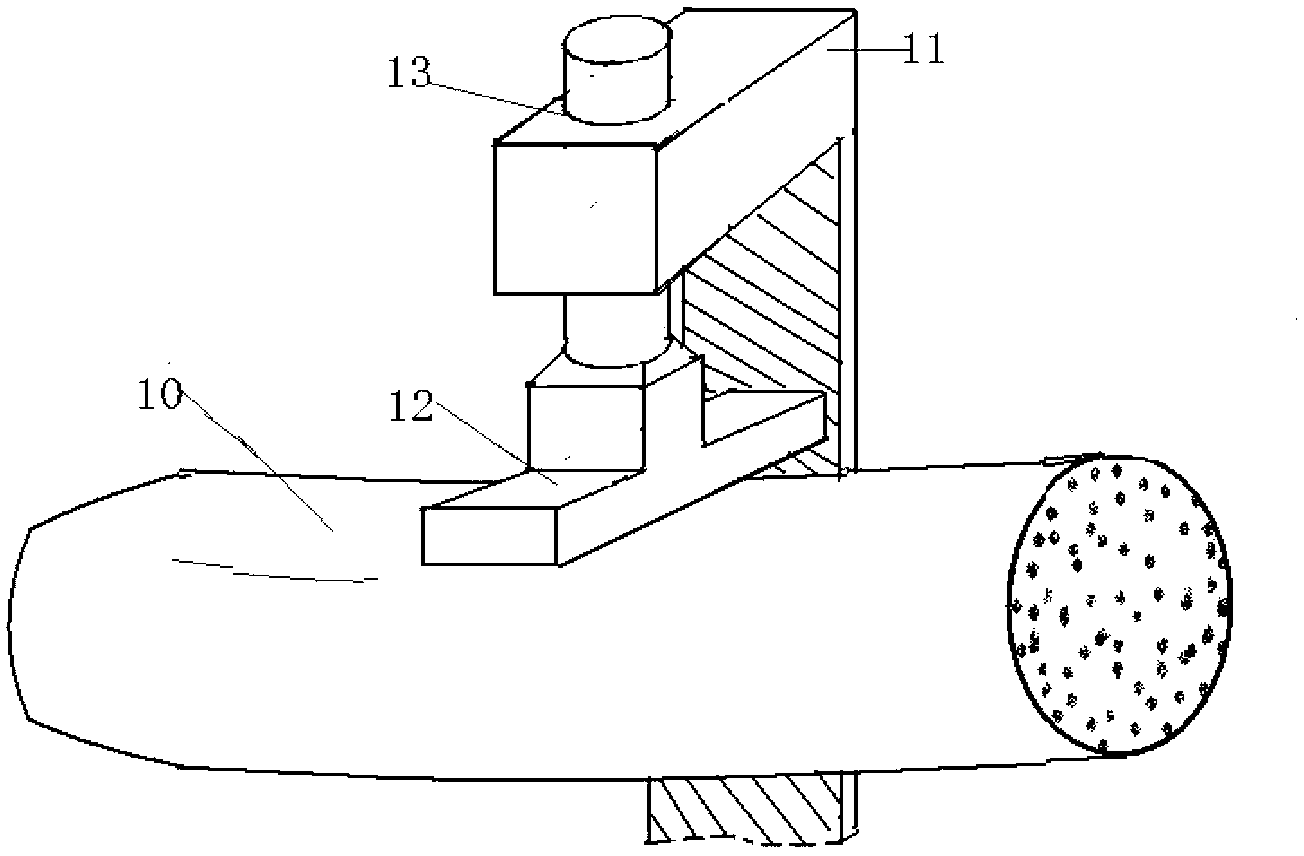

Synchronous measurement device for perimeter and maximum center axis offset of cigar and detection method

ActiveCN103234501AReplace at any timeRealize synchronized measurementsUsing optical meansNon destructiveMeasurement device

The invention discloses a synchronous measurement device for perimeters and maximum center axis offset of cigars. The synchronous measurement device comprises a U-shaped support. Two opposite cigar clamping systems are arranged on the U-shaped support and connected with a power system. A measuring system is arranged on the bottom surface of the U-shaped support, and the power system and the measuring system are both connected with a control system. Meanwhile, the invention discloses a detection method utilizing the synchronous measurement device. With the synchronous measurement device and the detection method, detection accuracy and check efficiency can be effectively improved, nondestructive detection can be achieved, and cigar image can be greatly promoted.

Owner:CHINA TOBACCO SHANDONG IND

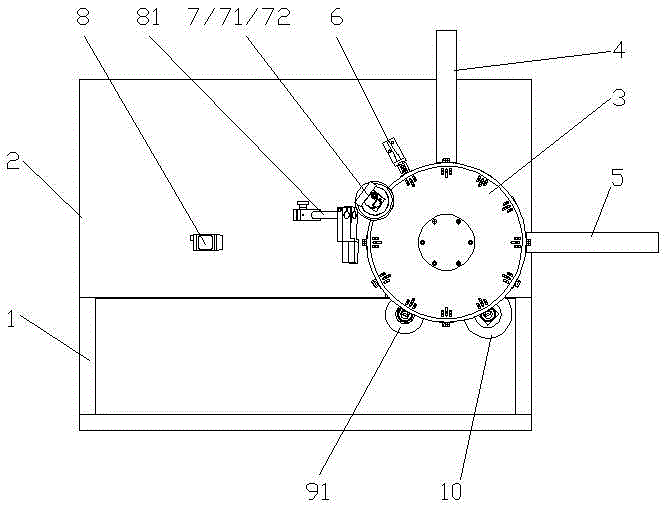

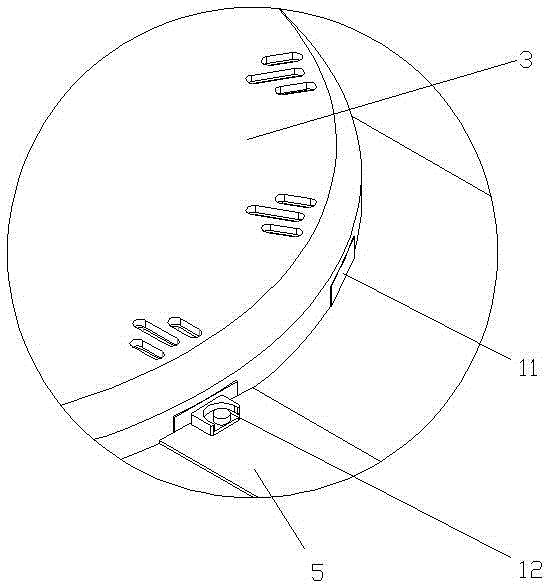

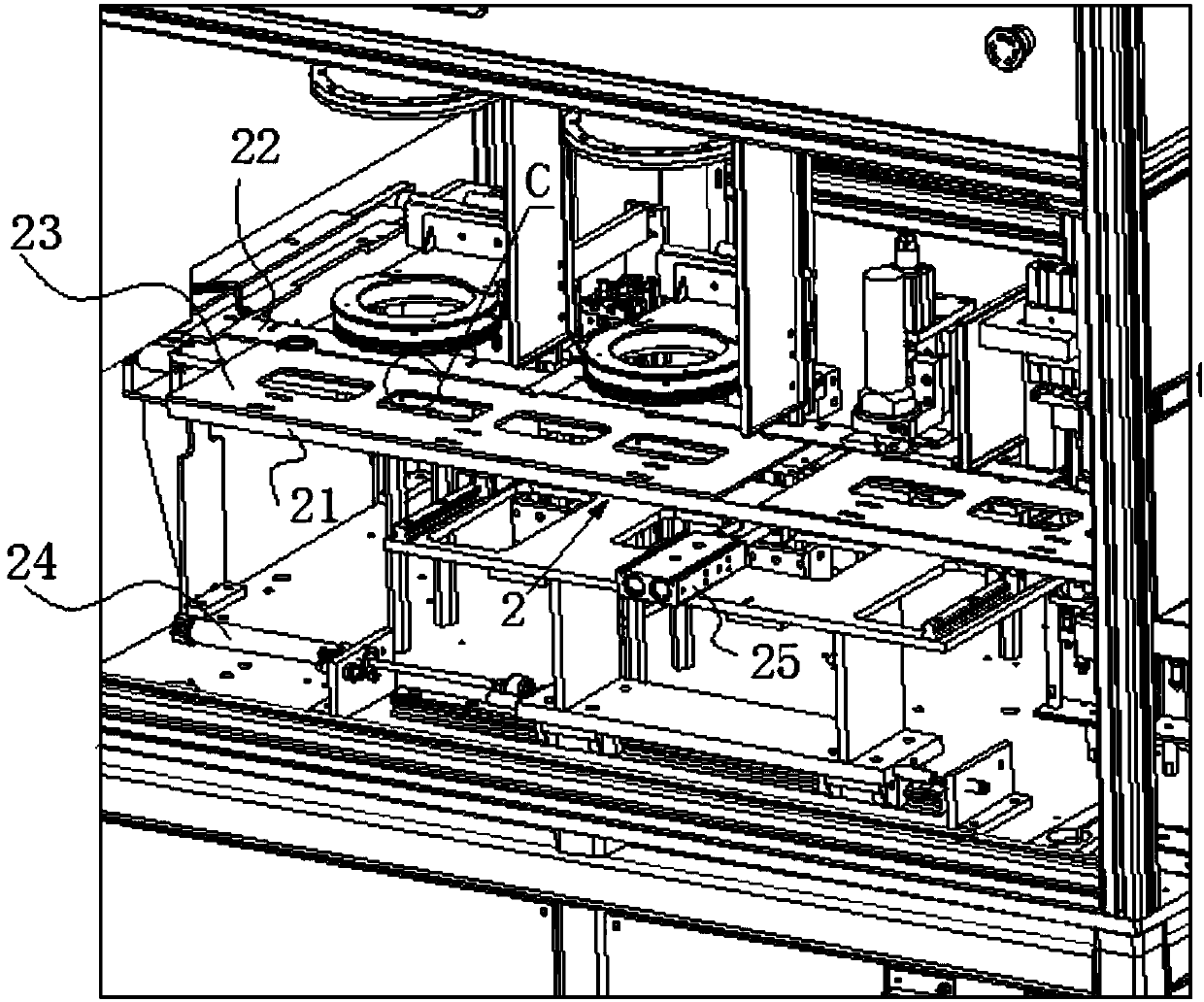

Multi-station conveying shooting mechanism for automatic detection of soft-magnetic magnetic core

InactiveCN105352967ARealize fully automatic detectionSimple structureOptically investigating flaws/contaminationEngineeringMechanical engineering

A related multi-station conveying shooting mechanism for automatic detection of soft-magnetic magnetic core comprises a machine frame, an installation platform, a rotation disc, a charging conveying belt, a discharging conveying belt, a visual image shooting group and a PLC; the lateral side of the rotation disc is provided with a plurality of stations at equal intervals, and the stations are used for holding workpieces, and the rotation disc is capable of uniformly intermittently rotating; one side of the rotation disc is provided with a workpiece calibration device; the visual image shooting group is distributed at the periphery of the rotation disc and is used for shooting visual images of all surfaces of the workpice; and the PLC is used to control the rotation disc, the charging conveying belt, the discharging conveying belt, the workpiece calibration device and the visual image shooting group to have coordinated consistent motion. The mechanism is reasonable and simple in structure, is capable of realizing full-automatic detection on soft-magnetic magnetic core, is high in detection efficiency and low in false drop rate, and is capable of substantially reducing labors at the magnetic core detection link, thereby substantially saving production cost.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

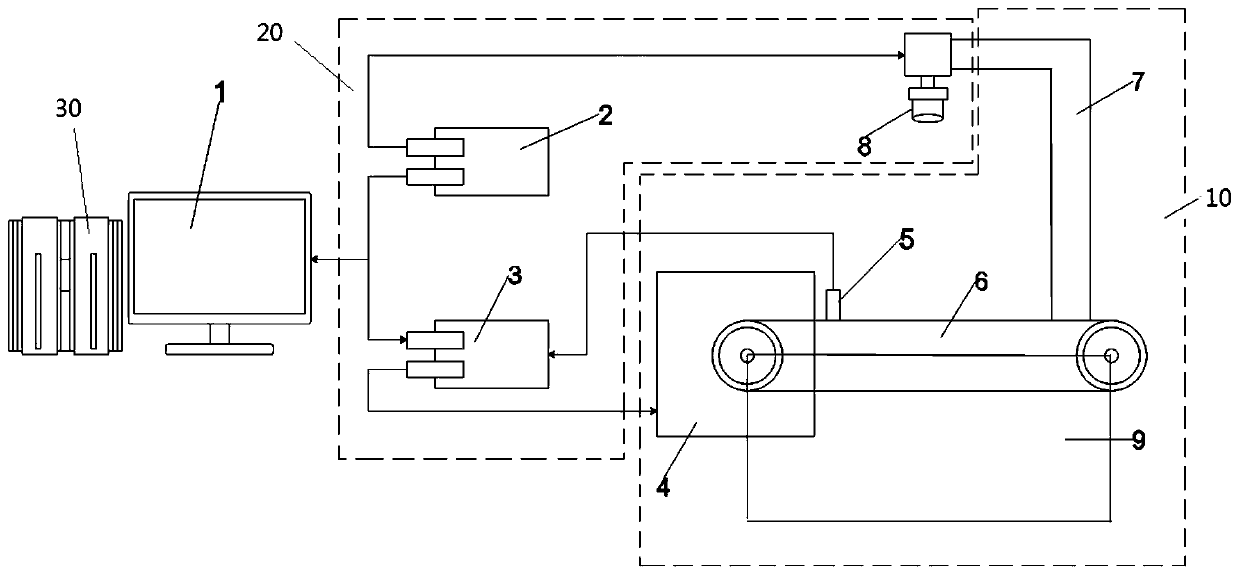

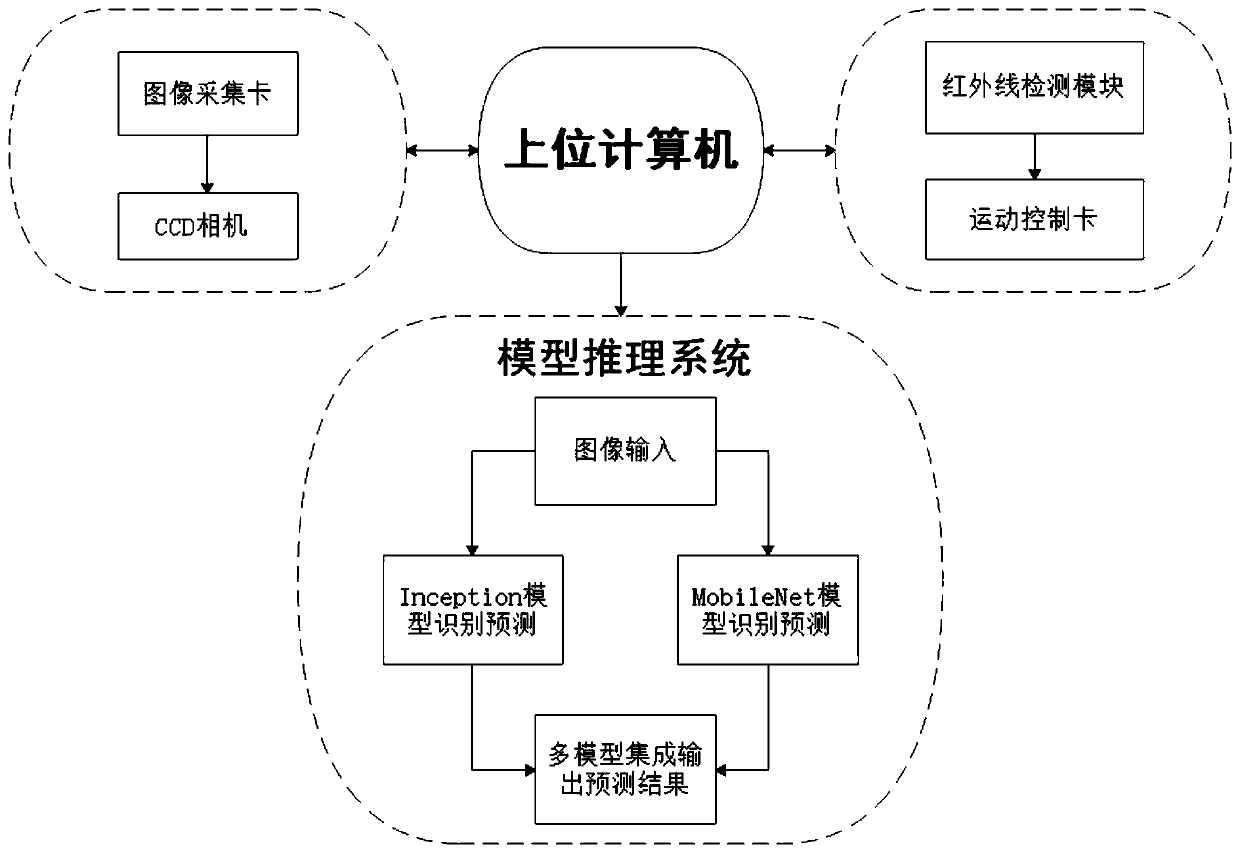

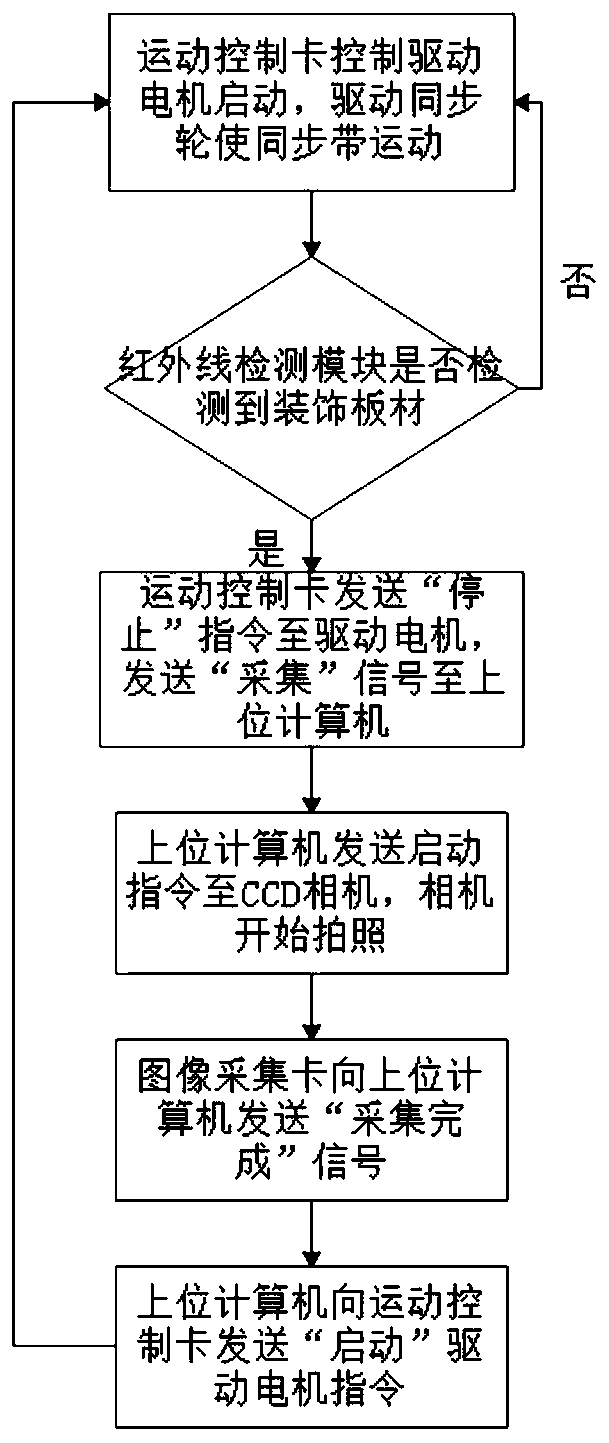

Defect detection and recognition device and method based on deep learning algorithm

ActiveCN109724984AReduce missed detection rateReduce manual workloadOptically investigating flaws/contaminationNetwork modelReasoning system

The invention discloses a defect detection and recognition device based on a deep learning algorithm, which relates to the field of defect detection and identification. The device comprises a test bench, a detection system, a model-based reasoning system, The detection system is connected to the test bench, and the model-based reasoning system operates in the detecting system. The defect detectionand recognition device and method based on deep learning algorithm trains an effective neural network model to detect and recognize the processing defect image to be defected under the condition thatthe actual processing defect data sample is insufficient, and uses the deep learning algorithm to reduce the misdetection probability, and realizes the automatic detection of the decorative sheet tobe detected, and reduces the amount of manual work.

Owner:SHANGHAI JIAO TONG UNIV

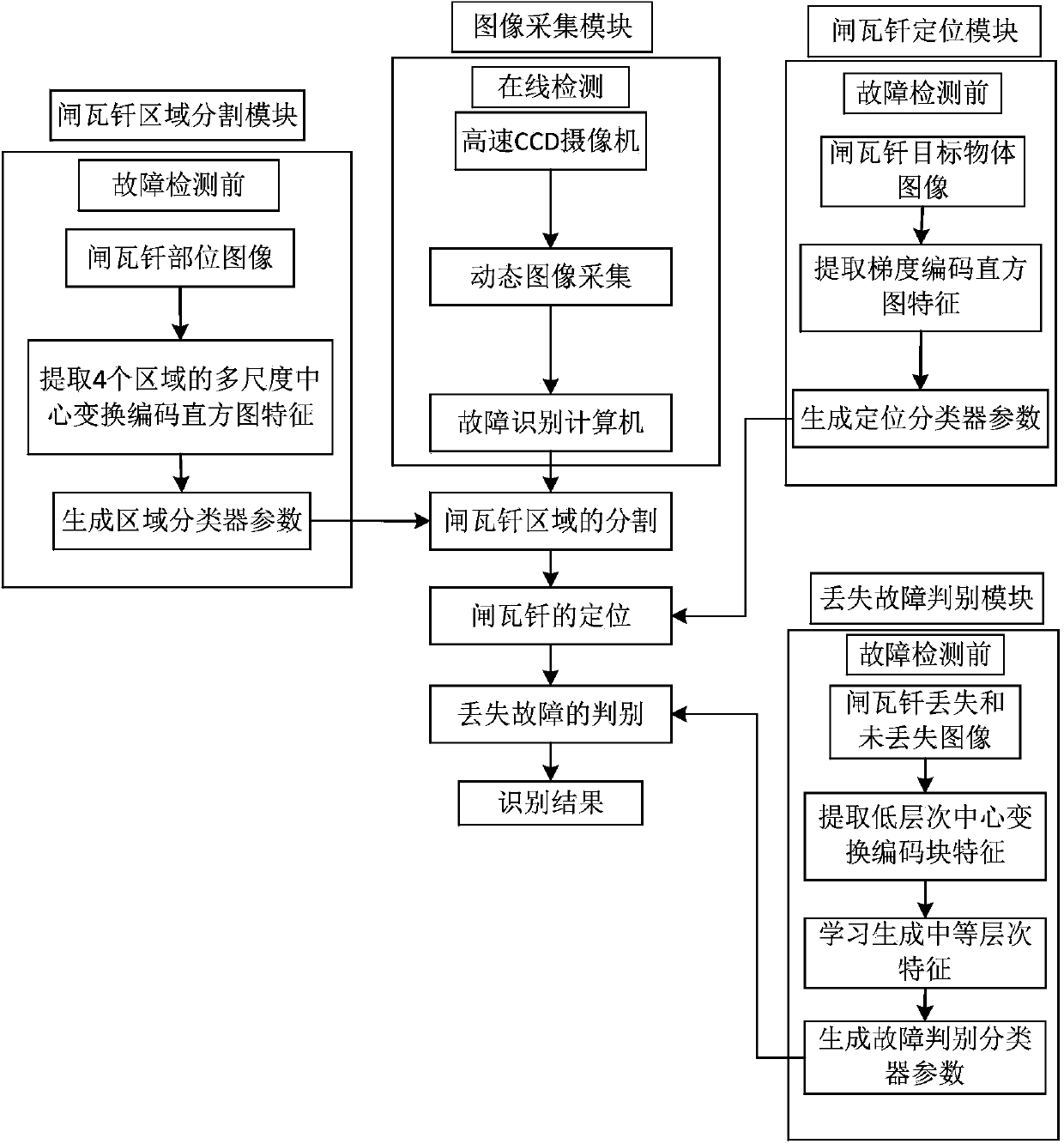

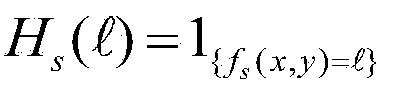

Automatic detection method for brake shoe borer loss fault of railway wagon

ActiveCN104268588ASmall amount of calculationReduce the possibility of false detectionImage analysisCharacter and pattern recognitionFault detection rateTruck

The invention provides an automatic detection method for a brake shoe borer loss fault of a railway wagon. Firstly, an area classifier, a positioning classifier and a fault judgment classifier are trained firstly; a brake shoe borer image to be tested is segmented through the area classifier, in the areas obtained after segmentation, a multi-level multiple-cascade-connection detection concept is adopted, a brake shoe borer is positioned through the positioning classifier, whether the brake shoe borer is lost or not is judged through the fault judgment classifier, and fully automatic detection on the brake shoe borer loss fault of the railway wagon is realized. By means of the automatic detection method for the brake shoe borer loss fault of the railway wagon, the fault detection rate reaches 99 percent, the detection speed reaches five frames / second, and the actual application requirement is met.

Owner:江阴智产汇知识产权运营有限公司

Method for testing tightness of soft-packaging lithium battery

InactiveCN107631844AAvoid bloatingWon't breakDetection of fluid at leakage pointEngineeringLithium-ion battery

The invention, which relates to the field of lithium ion battery preparation, discloses a method for testing the tightness of a soft-packaging lithium battery. The method comprises: (1), electrolyte injection into the battery is carried out; to be specific, an electrolyte is poured into a battery electric core; (2), evacuation is carried out; to be specific, the battery is vacuumized in a vacuum cabin after electrolyte injection; (3), helium gas injection is carried out; to be specific, helium gas is injected into the vacuum cabin and thus the battery core is filled with the helium gas, and then the electric core is sealed; and (4), evacuation and helium detection are carried out; to be specific, the battery is transferred to another vacuum cabin, the battery core is clamped by a clamp tocarry out pressurization, and then vacuumization is carried out to detect the helium content in the vacuum cabin. According to the method disclosed by the invention, the battery is protected from being damaged; one hundred percent of full detection is realized; and the detection accuracy is high and the cost is low.

Owner:WANXIANG 123 CO LTD +1

Full-automatic base plate size detection equipment and base plate detection line and detection method of base plate detection line

InactiveCN108057636AQuality improvementEffectiveSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTesting equipmentEngineering

The invention discloses full-automatic base plate size detection equipment, a base plate detection line and a detection method of the base plate detection line. The full-automatic base plate size detection equipment comprises a main rack, a plurality of loading plates, conveying belts, a gate-type travelling mechanism and a laser sensor, wherein the plurality of loading plates are fixed to the main rack at equal intervals; one conveying belt is arranged between the two adjacent loading plates; travelling tracks are arranged on the loading plates located at the two sides along the length directions of the loading plates; the gate-type travelling mechanism is arranged on the traveling tracks; and the laser sensor is arranged on the gate-type travelling mechanism through a third travelling mechanism. The base plate detection line comprises an automatic feeding device, base plate size detection equipment and an unloading output table which are connected in sequence; and the base plate sizedetection equipment adopted by the base plate detection line is the full-automatic base plate size detection equipment. The full-automatic base plate size detection equipment can automatically detectthe size of a base plate to replace manual work and has the advantages of fast detection speed and high detection accuracy.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

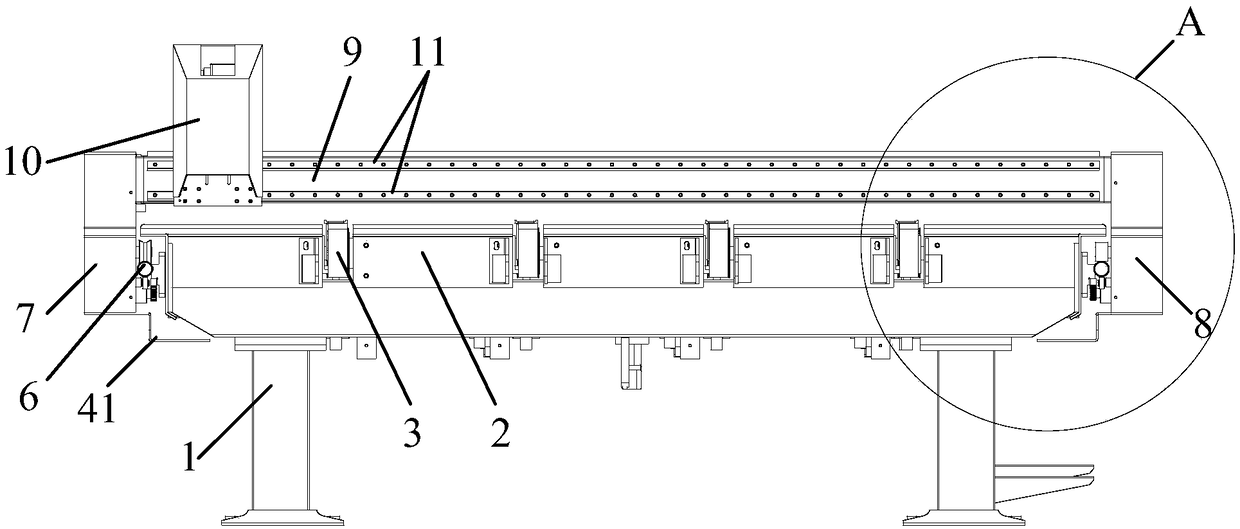

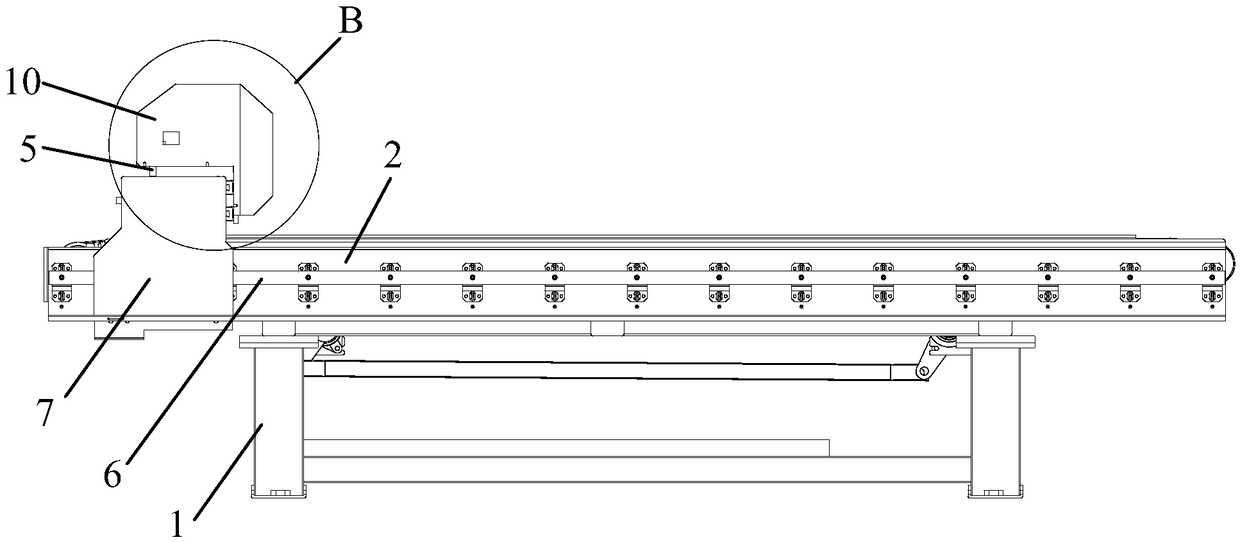

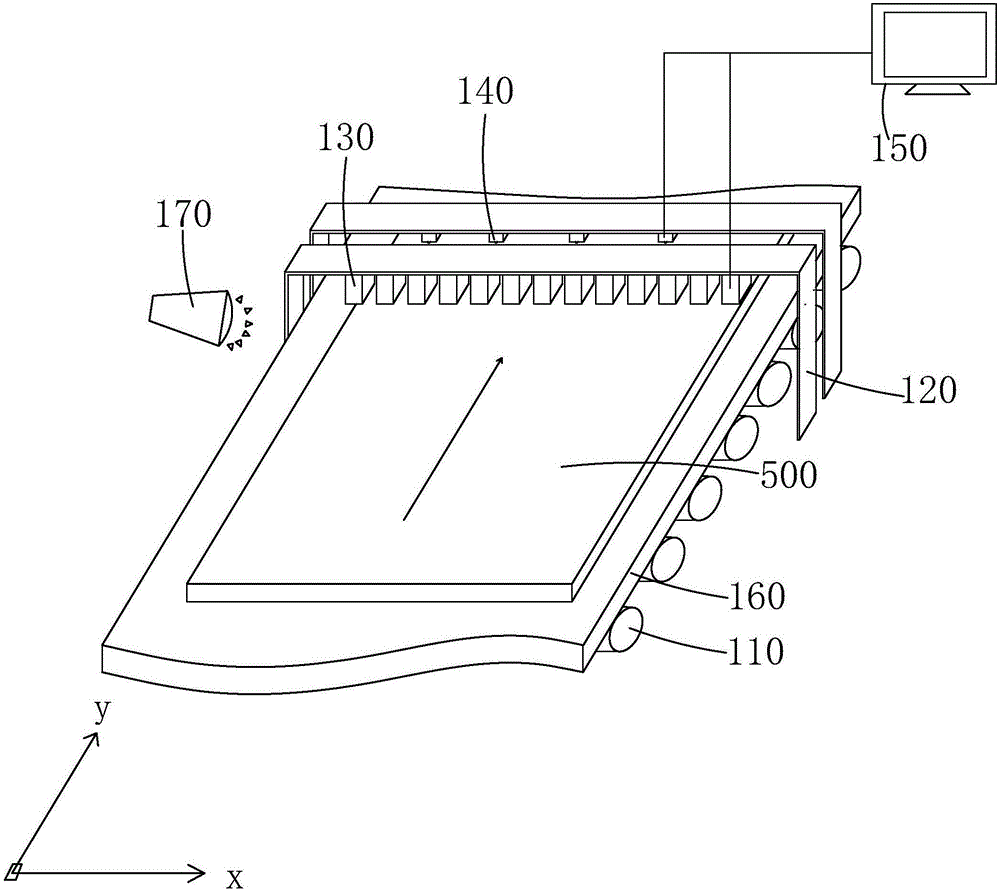

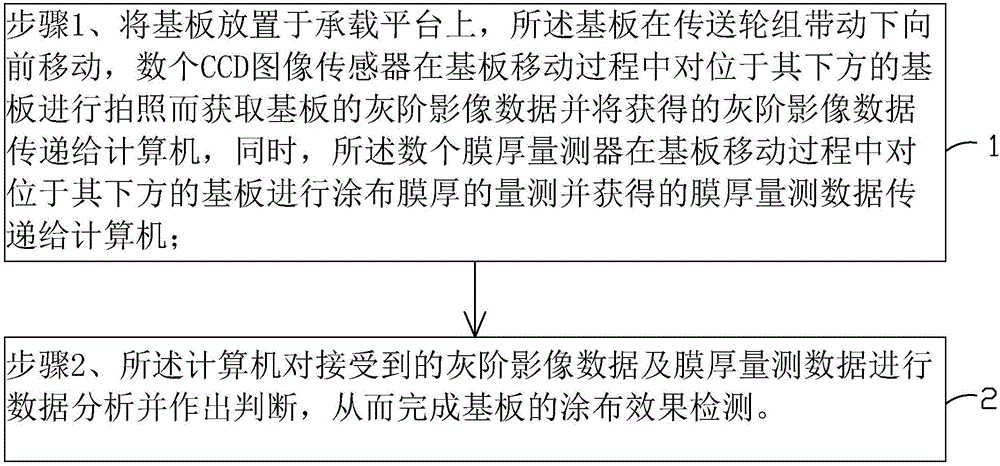

Coating detecting device

InactiveCN106597712AIncrease setup densityImprove AOI detection functionNon-linear opticsForeign matterData treatment

The invention provides a coating detecting device and method. The coating detecting device comprises a bearing platform, a conveying wheel set, a fixing support, a plurality of CCD image sensors, a plurality of film thickness measurers and a computer for processing data. The coating detecting device has the advantages that the row of CCD image sensors are arranged above the conveying wheel set, the arranging density of the CCD image sensors is increased, a high-precision AOI detecting function is achieved, coating defects such as foreign matter, bubbles, color halo, scratches and printing skewing can be detected effectively, extra spot checking is not needed later to perform macroscopic and microcosmic detection, operators does not need to remotely sense the back and forth movement of the CCD image sensors, the coating effect of a substrate can be detected in a full-automatic manner, productivity can be increased effectively, a film thickness measuring function is achieved by the film thickness measurers, and comprehensive detecting of the coating effect of the substrate is achieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

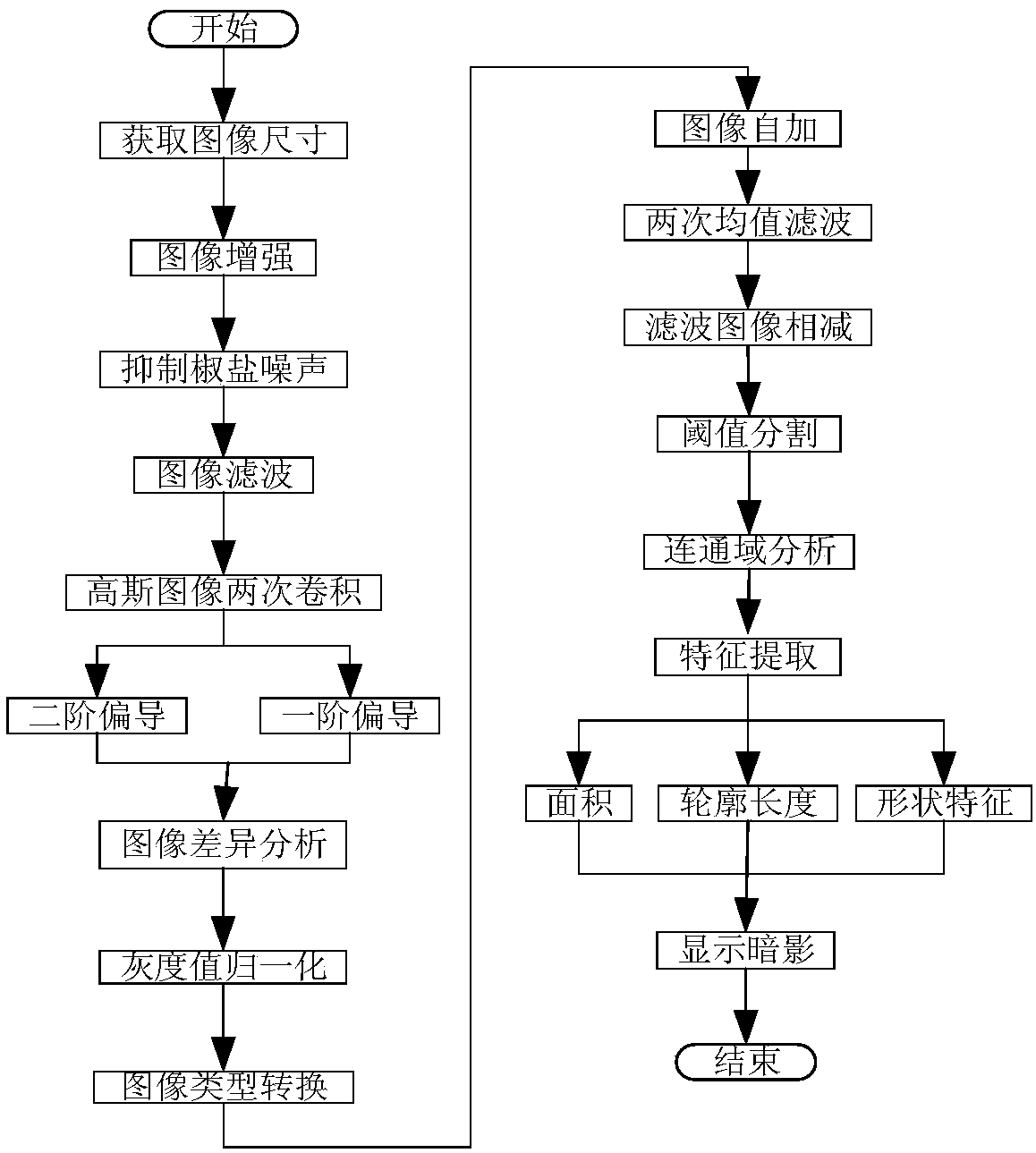

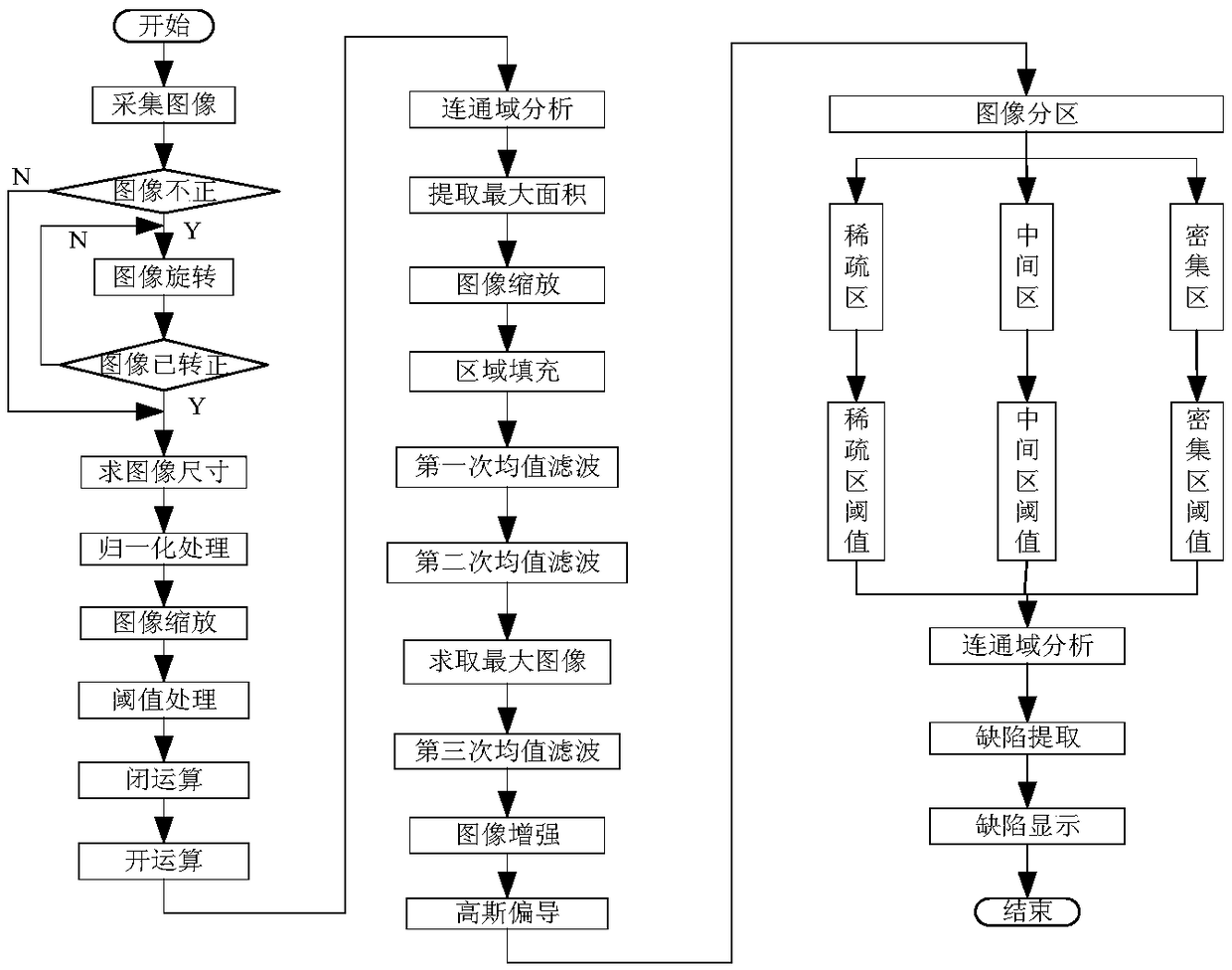

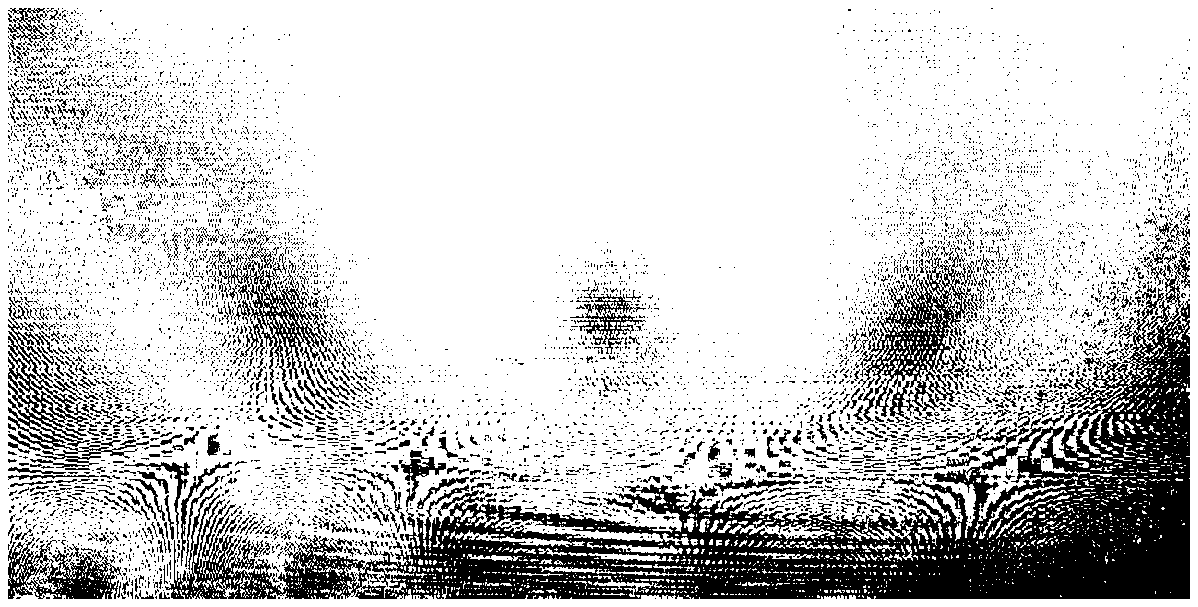

Detection method of shadow defect of light guide plate (LGP)

ActiveCN108876768AReduce complexityImplement automatic detectionImage enhancementImage analysisPattern recognitionLight guide

The invention provides a detection method of a shadow defect of a light guiding plate. Contrast is enhanced, salt and pepper noises are suppressed, filtering is carried out, two times of convolution are carried out, normalization of grayscale values is carried out, then two times of mean filtering are carried out, threshold segmentation processing is carried out, a connected domain of a foregroundimage is extracted, a connected-domain feature is processed, then the shadow defect is obtained, and the extracted shadow defect is displayed. According to the self-adaptive detection method of the light guide plate provided by the invention, complexity is relatively low, and automatic detection and extraction on a shadow of the light guide plate can be realized. An experiment result shows that detection accuracy and detection efficiency of the algorithm are higher, stability is higher, and the shadow can be detected in real time.

Owner:金名山光电(吴江)有限公司

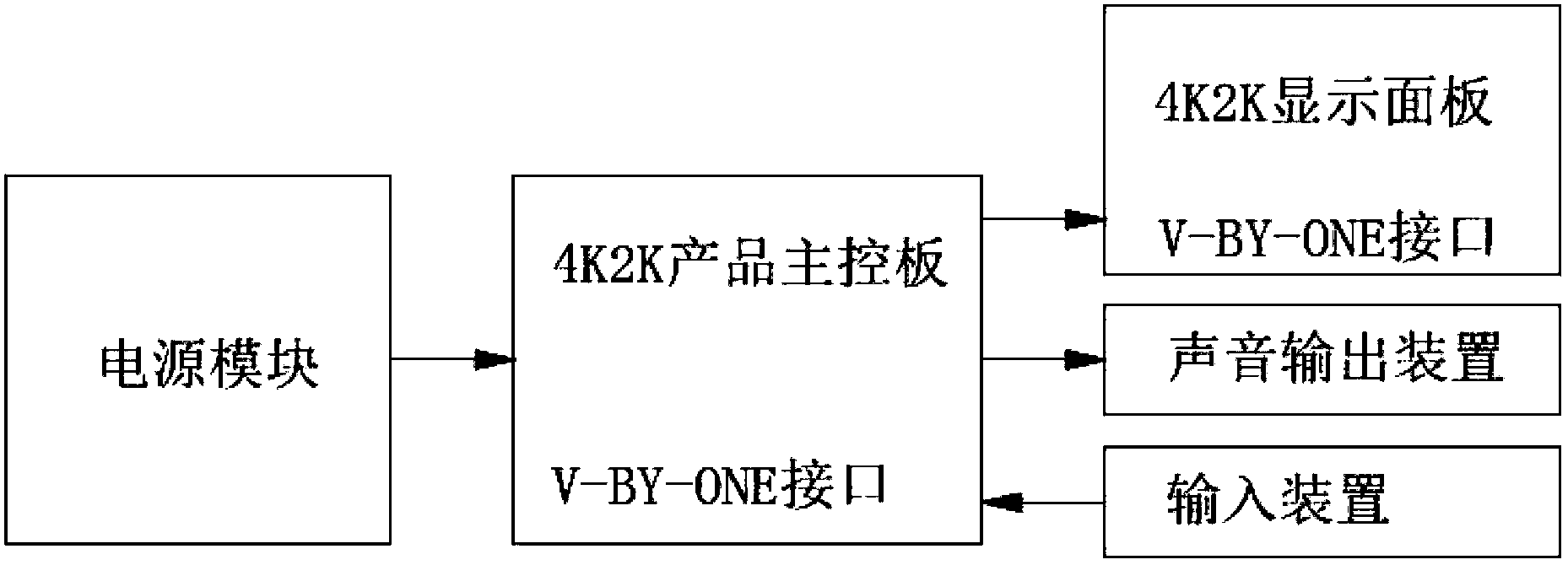

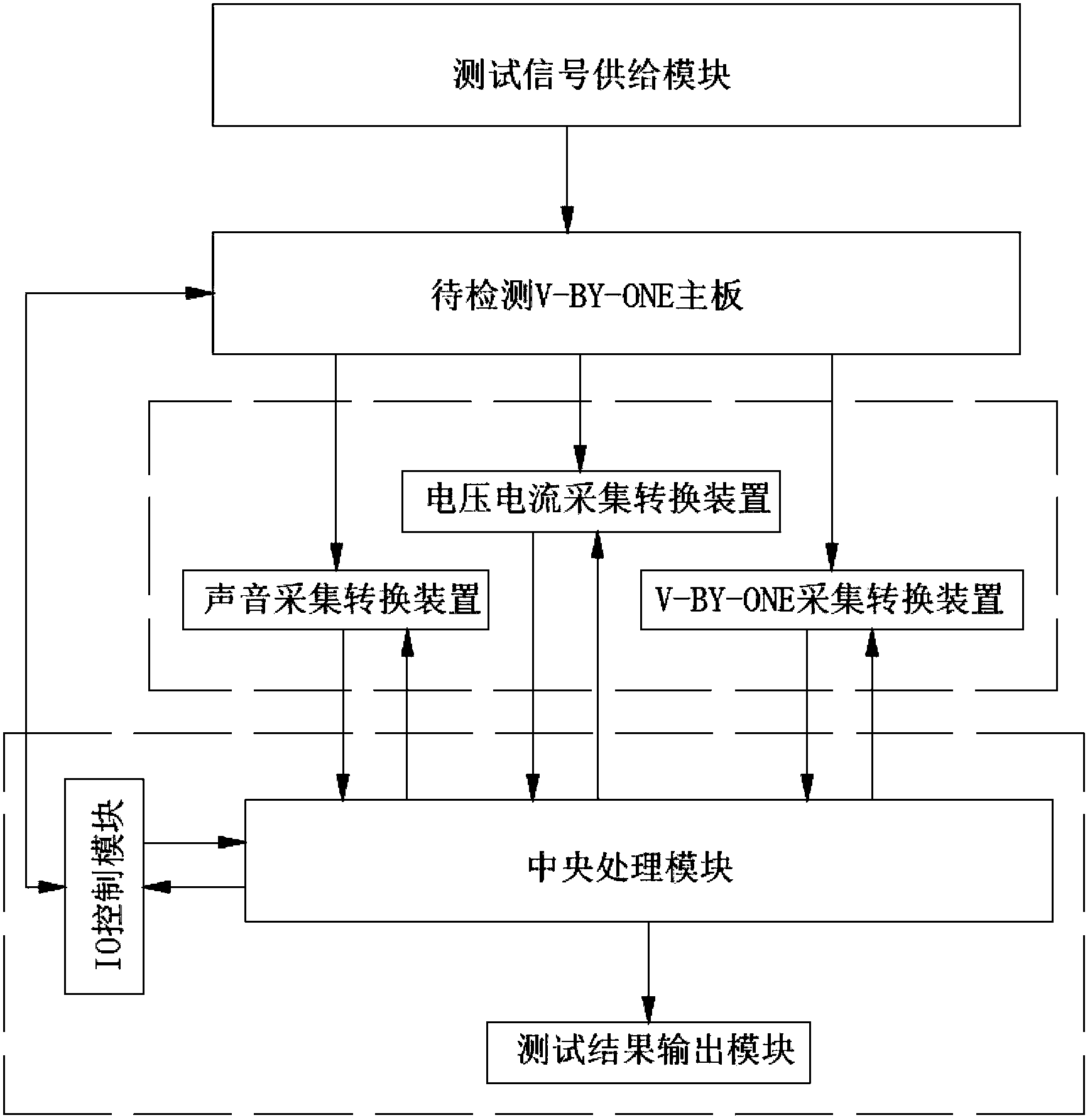

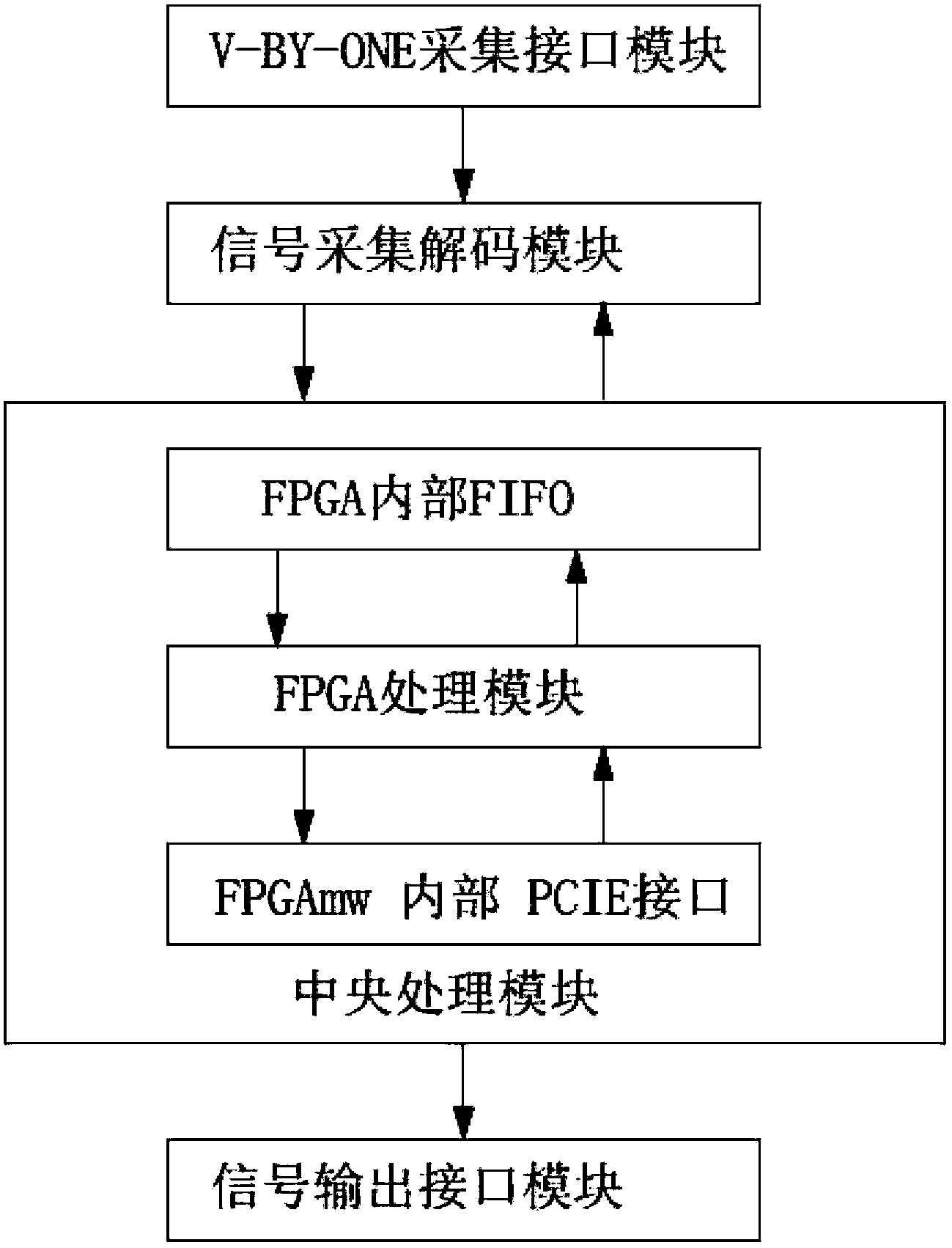

Method and device for automatically detecting 4K2K product main control board

ActiveCN103376401ASimple structureImprove detection efficiencyElectronic circuit testingVoltageComputer hardware

The invention discloses a method and device for automatically detecting a 4K2K product main control board. The method comprises the steps that a V-BY-ONE collection and conversion device collects a V-BY-ONE signal of the 4K2K main control board to be detected, coverts the signal into an RGB image signal, and transmits the RGB image signal to a central processing module, the automatic detection and the judgment of the image signal of the 4K2K main control board to be detected are completed, a voice collection and conversion device collects a board card voice signal of the 4K2K main control board to be detected, and the detection and the judgment of the board card voice signal are completed; a voltage and current collection and conversion device collects board card voltage and current signals of the 4K2K main control board to be detected, so that the detection and the judgment of the board card voltage and current are completed; the central processing module outputs the final judgment result to a test result output module, and the detection process is in the full-automatic detection. The method and device achieve full-automatic detection on the main control board to be detected, and is high in detection efficiency, high in accuracy rate, and stable and reliable in detection result.

Owner:广东中科芯联智能技术有限公司

Display screen detection equipment

PendingCN107884342ARealize automatic feeding and dischargingEfficient detectionMaterial analysis by optical meansComputer scienceComputer engineering

The invention discloses display screen detection equipment which comprises a controller, an automatic alignment fixture, a locating camera, a detection assembly and a manipulator, wherein the automatic alignment fixture is capable of adjusting a display screen placed on the fixture to a target position according to received adjustment parameters; the locating camera is capable of shooting the display screen placed on the automatic alignment fixture, the controller can calculate the offset direction, distance and angle of the display screen according to the shot image of the locating camera, and the offset direction, distance and angle of the display screen are taken as the adjustment parameters to be transmitted to the automatic alignment fixture; the detection assembly is capable of shooting the display screen positioned at the target position on the automatic alignment fixture, and the controller can analyze the defects of the display screen and generate detection results according to the shot image of the detection assembly; and the manipulator is capable of conveying a to-be-detected display screen onto the automatic alignment fixture from a take-out position and conveying thedetected display screen on the automatic alignment fixture to a discharging position. The display screen detection equipment can effectively solve the problems that the display screen detection efficiency is low and the degree of automation is low.

Owner:DONGGUAN SUMIDA AUTOMATION CO LTD

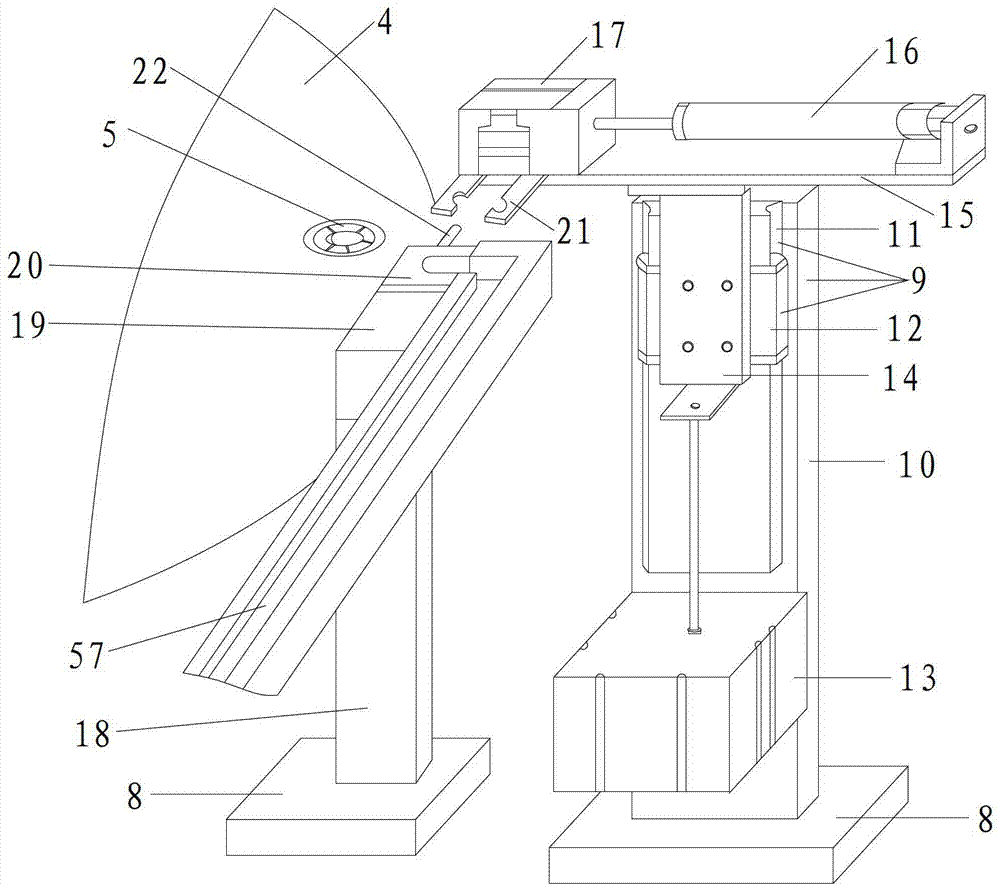

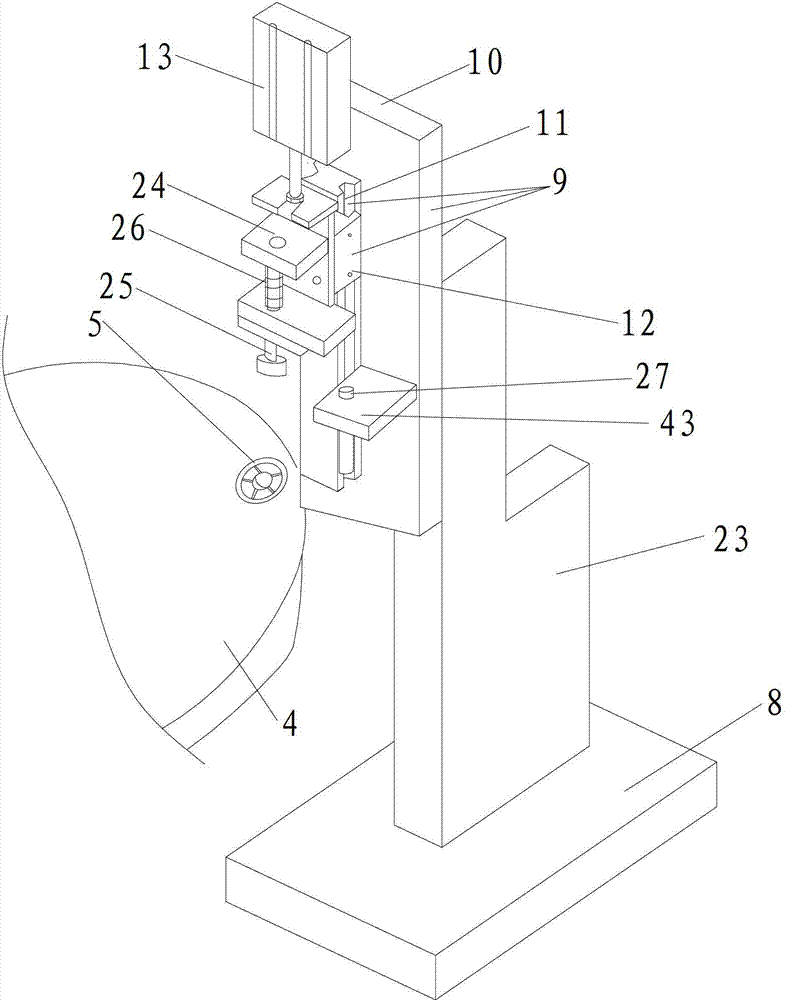

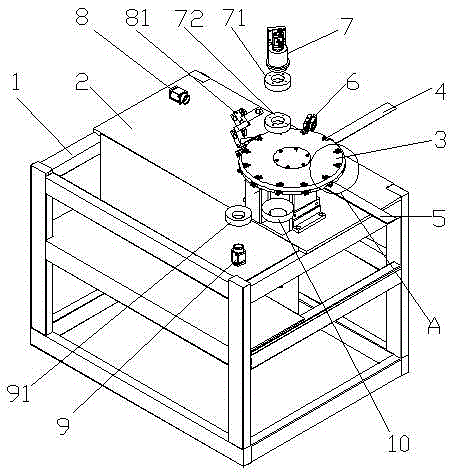

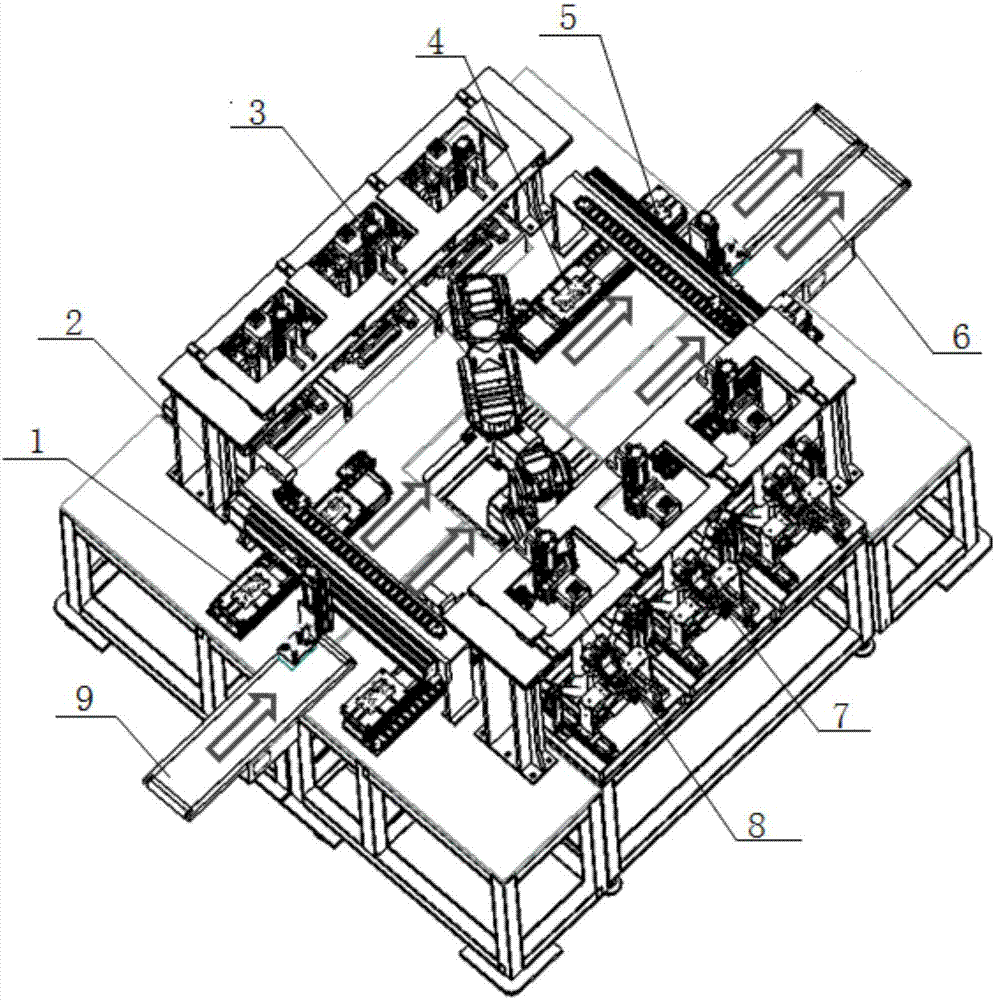

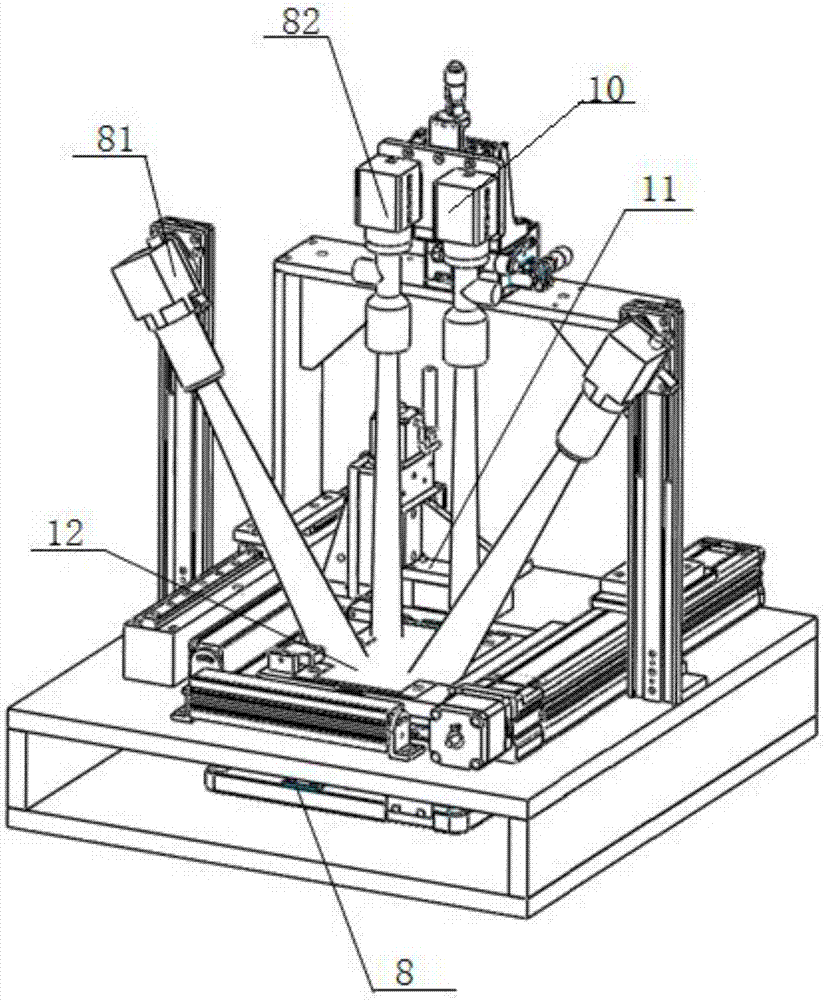

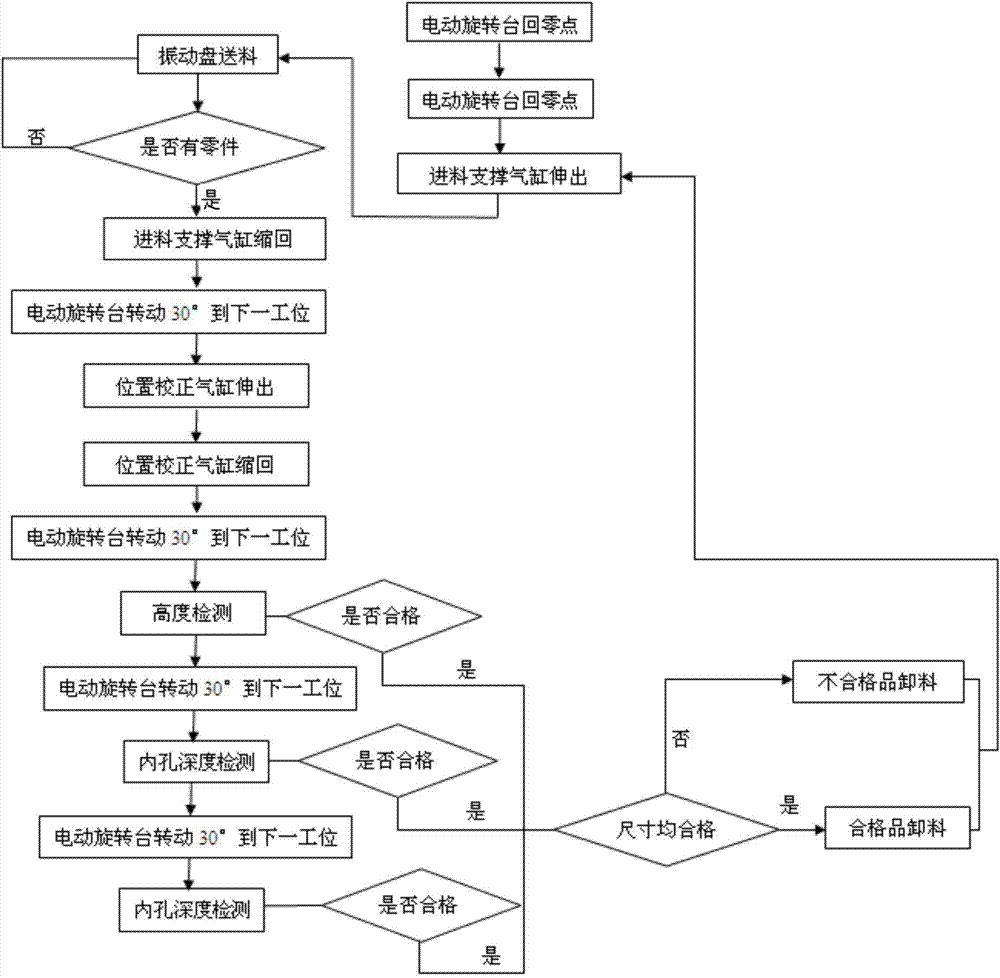

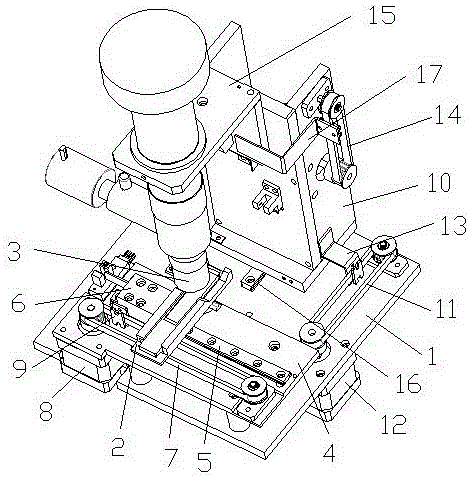

Full-automatic detection device and method for height and inner hole depth of pilot valve seat

ActiveCN103962310ARealize fully automatic detectionImprove efficiencySortingRotary stageProgrammable logic controller

The invention relates to a full-automatic detection device and method for the height and inner hole depth of a pilot valve seat. The device comprises a spiral vibration plate, wherein a discharging opening of the spiral vibration plate extends to a feeding position of an electric rotation table along a horizontal rail; a feeding support cylinder and a feeding optical fiber sensor are arranged in the feeding position of the electric rotation table; a position correction cylinder is also arranged near the feeding position of the electric rotation table; a height detector and an inner hole depth detector are arranged in a detection station of the electric rotation table; an unaccepted product unloading mechanism, an unaccepted product receiving mechanism, an accepted product unloading mechanism and an accepted product receiving mechanism are arranged in a discharging station of the electric rotation table; a discharging optical fiber sensor is also arranged in the position behind the discharging station of the electric rotation table; the device also comprises a PLC (Programmable Logic Controller). The device is capable of improving the detection efficiency and improving the stability of a detection result. Meanwhile, the optical fiber sensors are arranged in the feeding and discharging stations, so that the safety and the reliability in the full-automatic production process are guaranteed.

Owner:LX PRECISION SHANGHAI CO LTD

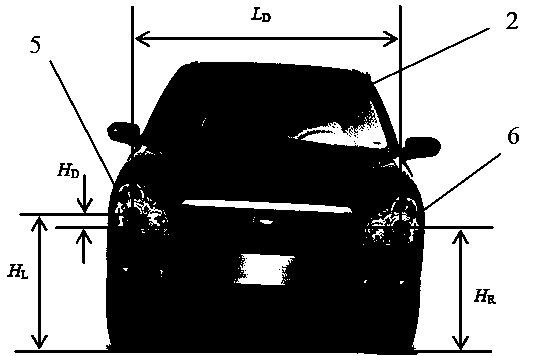

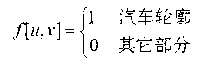

Automobile body inclination degree measurement method of small automobile

InactiveCN103411565ARealize fully automatic detectionSimple hardware structureUsing optical meansExtensibilityImage segmentation

The invention provides an automobile body inclination degree measurement method of a small automobile. The automobile body inclination degree measurement method is mainly suitable for appearance inspection and performance detection of the small automobile. A measurement system comprises a computer, an automobile straightening device and a camera installed right in front of the to-be-detected automobile. The camera and the to-be-detected automobile are aligned through calibrating of a video camera, and an image of the front end face of the automobile is shot and transmitted to the computer. A front license plate area of the automobile is pre-estimated. A front license plate profile of the automobile is extracted based on Hough conversion restricted by a length-to-width ratio and a front license plate is accurately positioned. According to the relative position relationship of the front license plate and head lamps of the automobile, detection areas of the head lamps of the automobile are pre-estimated, image division is carried out on the pre-estimated detection areas, the profiles of the head lamps are extracted, the center, namely the horizontally symmetric point, of the left head lamp area and the right head lamp area is obtained in a centroid method, and accordingly the automobile body inclination degree is obtained. The method is a non-contact measurement method, the automobile body inclination degree of a small automobile can be automatically detected, and the method can be integrated with other detection items easily, and has good extensibility.

Owner:LINYI UNIVERSITY

Large-visual-field microscopic examination device and method for full-automatic immunohistochemistry

InactiveCN105092582ARealize fully automatic detectionImprove detection efficiencyMaterial analysis by optical meansCamera lensCcd camera

The invention discloses a large-visual-field microscopic examination device for full-automatic immunohistochemistry. The large-visual-field microscopic examination device comprises a base. A section objective table capable of horizontally moving relative to the base is arranged on the base. A microscope lens capable of horizontally and longitudinally moving relative to the base is arranged above the base. The horizontal motion direction of the microscope lens is perpendicular to the moving direction of the section object table. A CCD camera is arranged above the microscope lens. The invention further discloses a large-visual-field microscopic examination method for full-automatic immunohistochemistry. The microscope lens and the CCD camera are arranged to be of the structure with the adjustable position, a complete section image is obtained by means of an image capture and splicing method, the section image and a database are compared to obtain a result, and full-automatic detection is achieved.

Owner:苏州合惠生物科技有限公司

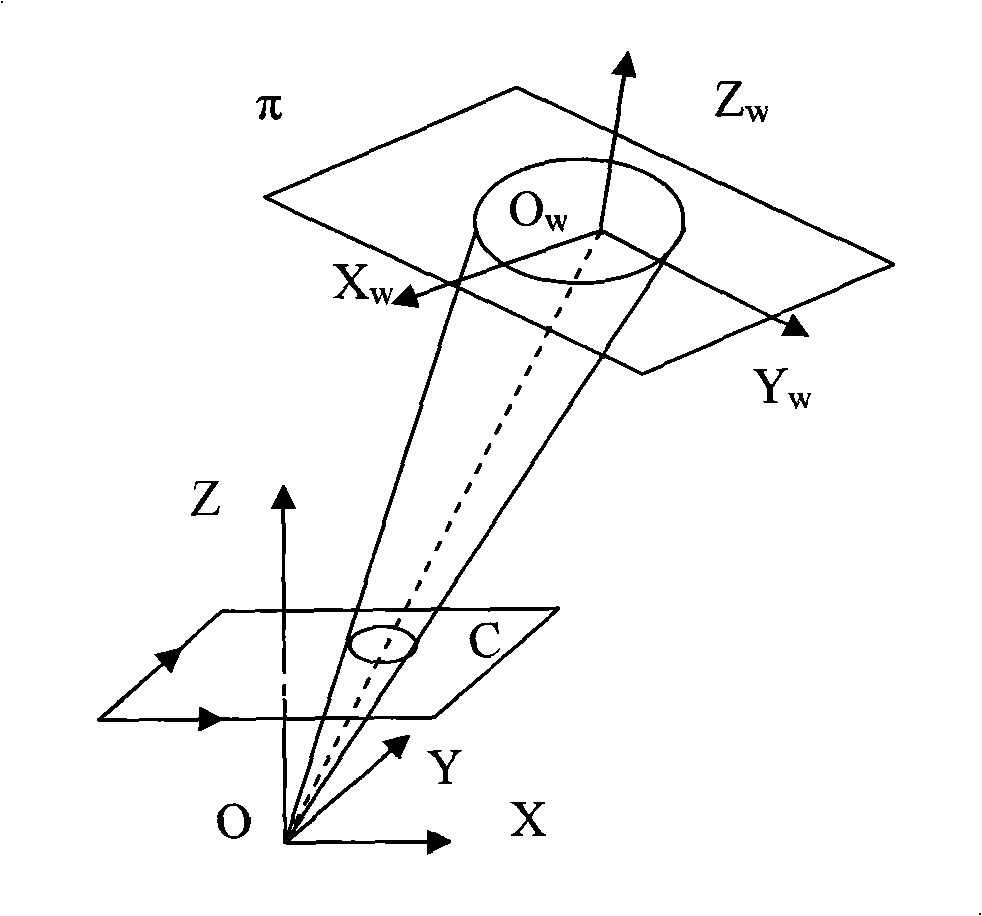

Method for correcting automobile headlamp detecting light bundle shining direction deviation

InactiveCN103344418AHigh measurement accuracyGood repeatabilityTesting alignment of vehicle headlampsIn vehicleLight beam

The invention discloses a method for conducting error correcting on measuring data of light bundle shining directions of an automobile headlamp detecting instrument in vehicle detecting. The method is mainly applicable to the full-automatic detecting process of an automobile headlamp. A system is composed of a camera installed right above a vehicle to be tested, a computer, and the automobile headlamp detecting instrument. A light bundle shining direction measurement error is formed by the offset angle between an image plane and a detecting site, and the automobile lengthwise axis offset angle of an image. A rotary matrix between an image coordinate system and a world coordinate system is obtained through camera calibration, and then the image offset angle is obtained. The automobile lengthwise axis offset angle of the image is obtained based on a quick realizing method of a largest second order central moment algorithm. According to the method, the measurement data of the headlamp detecting instrument can be corrected automatically, the accuracy rate and the repeatability of a headlamp bundle shining direction detecting result are effectively improved, and guarantee is provided for safety running of an automobile at night.

Owner:LINYI UNIVERSITY

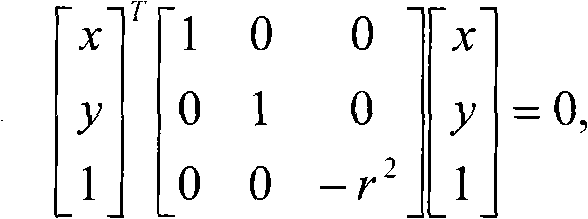

Measuring method for spacing circle geometric parameter based on monocular vision technology

InactiveCN101344376AReduce measurement errorHigh application valueUsing optical meansDistortion correctionSpatial Orientations

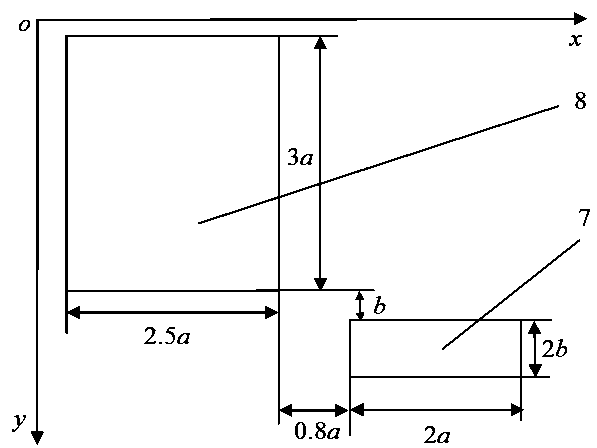

The invention relates to a measurement method of geometric parameters of a spatial circle which is based on the monocular vision technology, which comprises the following steps: internal parameters of a camera and one order radial distortion parameters are firstly determined; an image containing an oval image of the spatial circle is obtained by utilizing the camera for shooting, and the distortion correction thereof is carried out; all the geometric parameters of the spatial circle can be directly linearly calculated by fitting the oval image of the image plane after the distortion correction, and the geometric parameters comprise a spatial coordinate of the circle center of the spatial circle and the spatial orientation of the plane which is located by the spatial circle. The measurement method of the invention can accurately measure all the geometric parameters of the spatial circle at one time, realize the full automatic detection and reduce the measurement errors caused by manual intervention, thereby being particularly applicable to non-contact industrial detection and vision-based autonomous navigation systems.

Owner:SHANGHAI JIAO TONG UNIV

Measurement machine of external dimension of bearing

PendingCN107860779ARealize fully automatic detectionReduce labor intensityMaterial analysis by optical meansControl systemEngineering

The invention discloses a measurement machine of the external dimension of a bearing. The measurement machine comprises a feeding mechanism, a carrying mechanism, a measurement mechanism and a discharging mechanism. The measurement mechanism is located on the down stream of the feeding mechanism, and the discharging mechanism is located on the down stream of the measurement mechanism which comprises a bearing upper end surface measurement mechanism, a bearing lower end surface measurement mechanism, a bearing inner hole diameter measurement mechanism and a bearing side surface measurement mechanism, wherein a bearing turnover mechanism is arranged between the bearing upper end surface measurement mechanism and the bearing lower end surface measurement mechanism. The measurement machine isfurther provided with a control system, the feeding mechanism, the carrying mechanism, the bearing upper end surface measurement mechanism, the bearing turnover mechanism, the bearing lower end surface measurement mechanism, the bearing inner hole diameter measurement mechanism, the bearing side surface measurement mechanism and the discharging mechanism are electrically connected with the controlsystem. The measurement machine takes the place of the human eyes to achieve automatic detection of the bearing, the eyes of workers are liberated, and the labor intensity of the workers is reduced.Meanwhile, the measurement efficiency of the bearing can be effectively improved, the measurement precision is high, and the practicability is high.

Owner:KUNSHAN MINCHTECH AUTOMATION CO LTD

Immune scatter turbidimetry based full-automatic detection device and method thereof

InactiveCN104535776ARealize fully automatic detectionImprove efficiencyMaterial analysisMiniaturizationTurbidimetry

The invention discloses an immune scatter turbidimetry based full-automatic detection device and a method thereof. By means of a sampling needle and two reagent needles, individual loading of a sample and double reagent needles can be realized, cross contamination between liquid reagents can be avoided, and the detection accuracy can be improved. The sample adding and cleaning between channels are independent to each other, thus greatly improving the efficiency of the detection device. The reaction cup can be used repeatedly, not only saves cost, but also realizes miniaturization and intelligentization of immune scatter turbidimetry full-automatic detection equipment, thus being better suitable for the detection needs of hospitals and small clinics. At the same time, a magnetic field transformation bottom spiral eddy current mixing and cleaning technology is adopted to achieve good stirring and cleaning effects of the reaction cup.

Owner:SHENZHEN LIFOTRONIC TECH

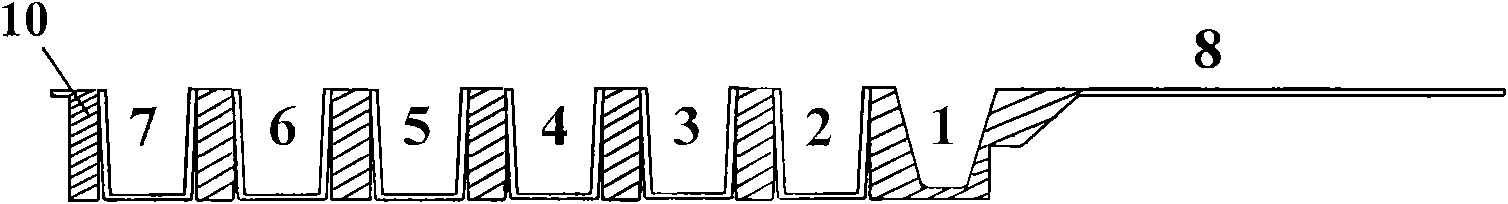

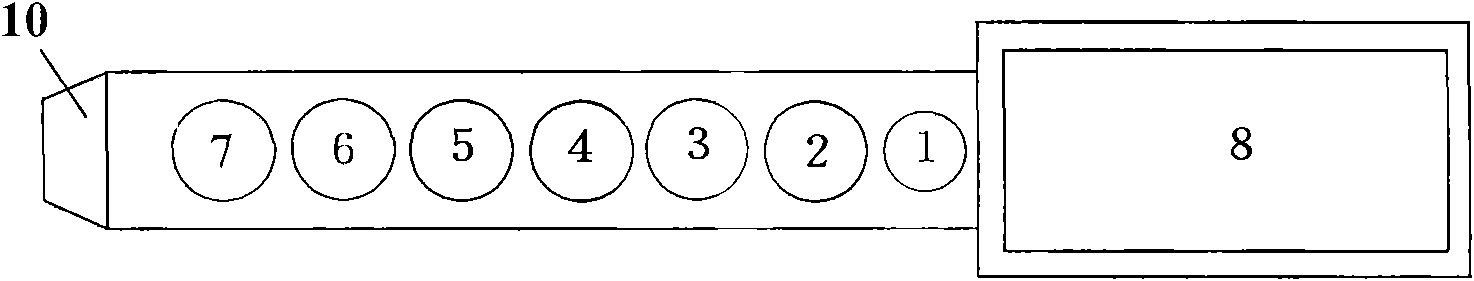

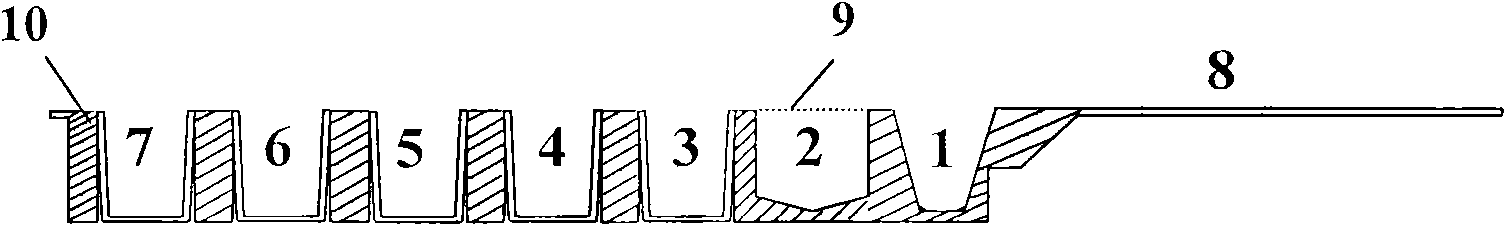

Oral liquid full automatic lamp detecting machine

InactiveCN1619298AQuality assuranceImprove detection accuracyOptically investigating flaws/contaminationSortingIntermittent motionEngineering

The present invention disclosed a full-automatic light inspection machine for oral solution. It includes machine frame, graduated disk, pulley, bottle-feeding mechanism, rejection mechanism, labelling mechanism, light source, CCD camera, quick stopping mechanism and bottle-discharging mechanism, etc.

Owner:长沙正中药机厂

Bearing production detecting system based on MES

PendingCN107932333AFully automatedRealize intelligenceGrinding feed controlOptically investigating flaws/contaminationNetwork managementAssembly line

The invention discloses a bearing production detecting system based on an MES. The MES comprises an MES server, a database server and a switch. The MES server and the database server are in signal connection with the switch. The bearing production detecting system comprises grinding lines and assembling lines. Each grinding line is located on the upstream of the corresponding assembling line. Eachgrinding line comprises a grinding machine, a first detecting machine and a first washing machine. Each assembling line comprises an inner and outer ring storing feeding machine, a second washing machine, a second detecting machine, a sleeve combining assembling machine, a holding frame squeeze riveter, a grease injection pressure cover machine, an atomizing rust prevention machine and a packaging machine. A respective control unit is installed on each machine and is in signal connection with the switch of the MES. According to the system, management functions of production dispatching, product tracking, quality control, equipment fault analysis, network report form and the like are integrated on a unified platform, the system helps an enterprise to set up an integrated real-time MES information system, and automation, intelligence and continuity of a bearing production line are achieved.

Owner:KUNSHAN MINCHTECH AUTOMATION CO LTD

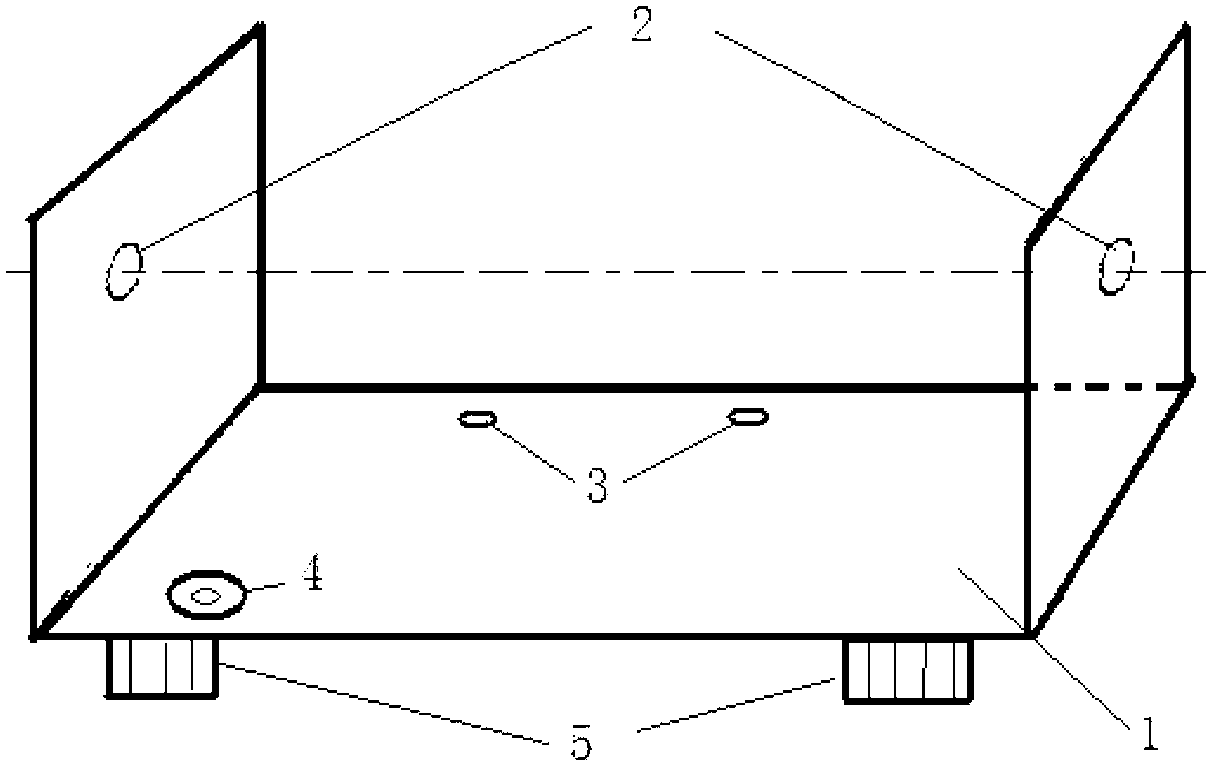

Fabric wrinkle recoverability testing device and application thereof

ActiveCN108872061ARealize fully automatic detectionRealize intelligent analysis and evaluationUsing mechanical meansMaterial analysisWrinkle skinEngineering

The invention relates to a fabric wrinkle recoverability testing device and application thereof. The device comprises a device tank; the device tank is sequentially provided with a console, a camera and a fabric clamping device from front to back; the console controls running of the camera and the fabric clamping device and comprises control buttons and a display screen; the fabric clamping devicecomprises a sample table, a left cylinder, a right cylinder, a left pressure block, a right pressure block and a thin sheet; the thin sheet is arranged at the middle part and is parallel to the leftside surface; the upper end of the thin sheet is flush with the upper plane, and the lower end is connected with a lifter; the lifter controls the thin sheet to penetrate through the upper plane to perform up-and-down vertical movement; the left cylinder and the right cylinder are symmetrically arranged on the left side and the right side of the thin sheet; the left pressure block and the right pressure block are fixedly arranged on the inner sides of the left cylinder and the right cylinder symmetrically and are parallel to the thin sheet; the left cylinder and the right cylinder control theleft pressure block and the right pressure block to perform left-and-right parallel movement respectively; and the camera is arranged at the middle part of the device tank and is perpendicular to thethin sheet, and a lens of the camera faces the thin sheet. The device has the advantages of high testing stability and high efficiency.

Owner:JIANGNAN UNIV

A method for detecting white dot defect of light guide plate

ActiveCN109272525AAccurate judgmentImprove detection accuracyImage enhancementImage analysisLight guideWhite point

A method for detecting white point defect of light guide plate. A light guide plate is partitioned according to the density of light point, different parameters are adopted for different area processing algorithm, and adjustment parameters such as area and eccentricity are set, so that white point defect required by manufacturer can be detected automatically and the adaptability is strong. The invention not only can detect the sparse area in the light guide plate, but also can accurately judge the small white dots in the dense area, and the detection accuracy is high. The algorithm of the invention can detect different types of light guide plates, and has good stability and wide application range. The invention has the advantages of simple algorithm, high efficiency, short processing timeof the light guide plate image, and conforms to the actual requirements of enterprises. In addition, the invention can realize full automatic detection only by properly adjusting a few parameters, andis convenient to operate and maintain.

Owner:HANGZHOU HUICUI INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com