Full-automatic base plate size detection equipment and base plate detection line and detection method of base plate detection line

A fully automatic technology for detecting substrates, applied in semiconductor/solid-state device testing/measurement, measuring devices, instruments, etc., can solve problems such as unguaranteed dimensional accuracy, and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

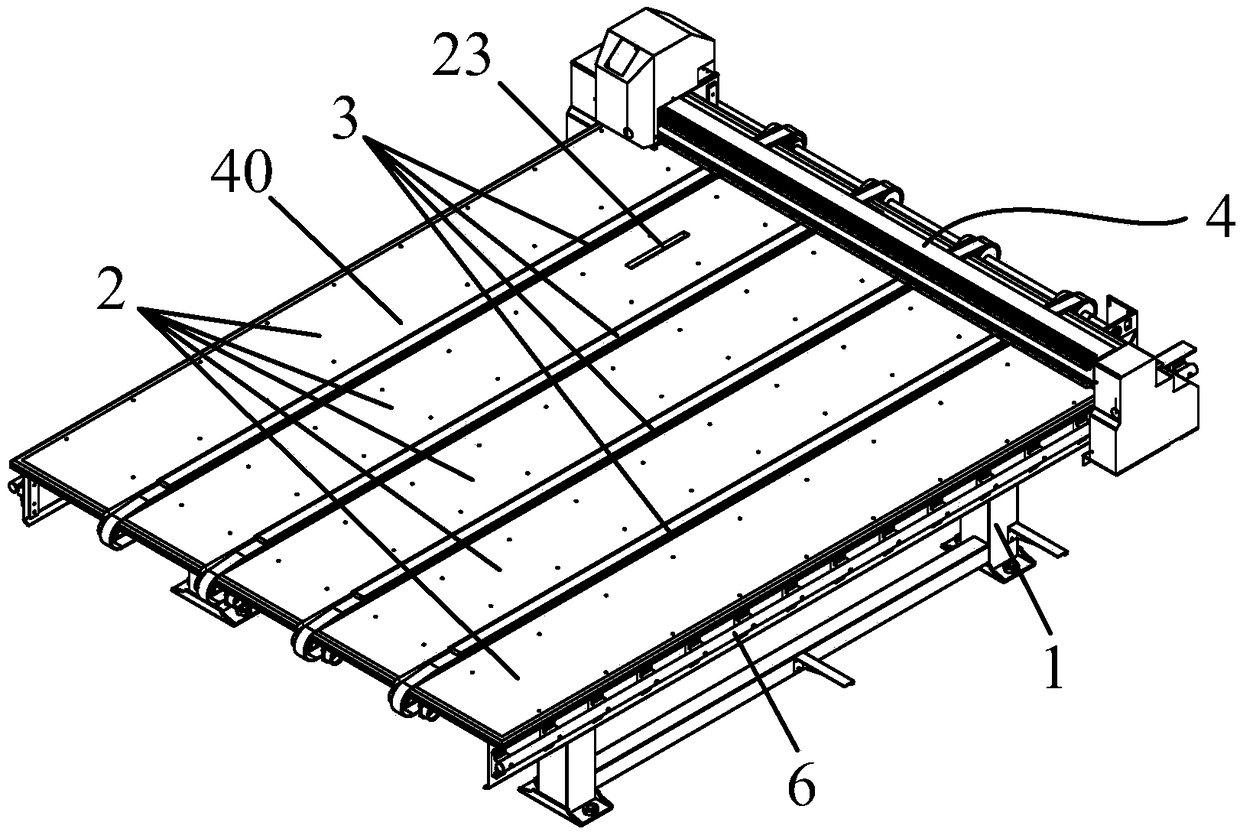

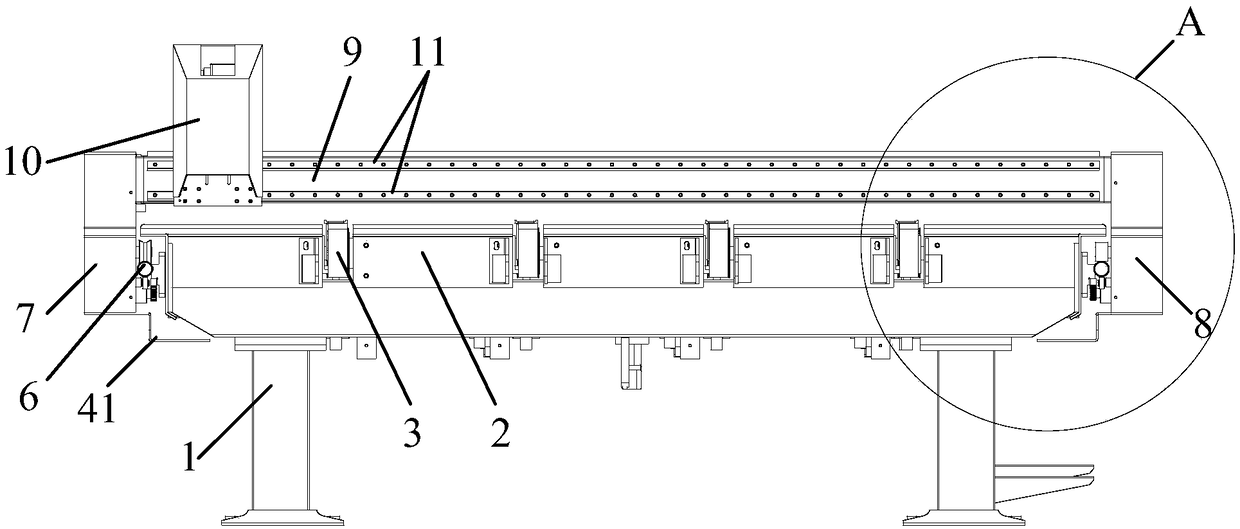

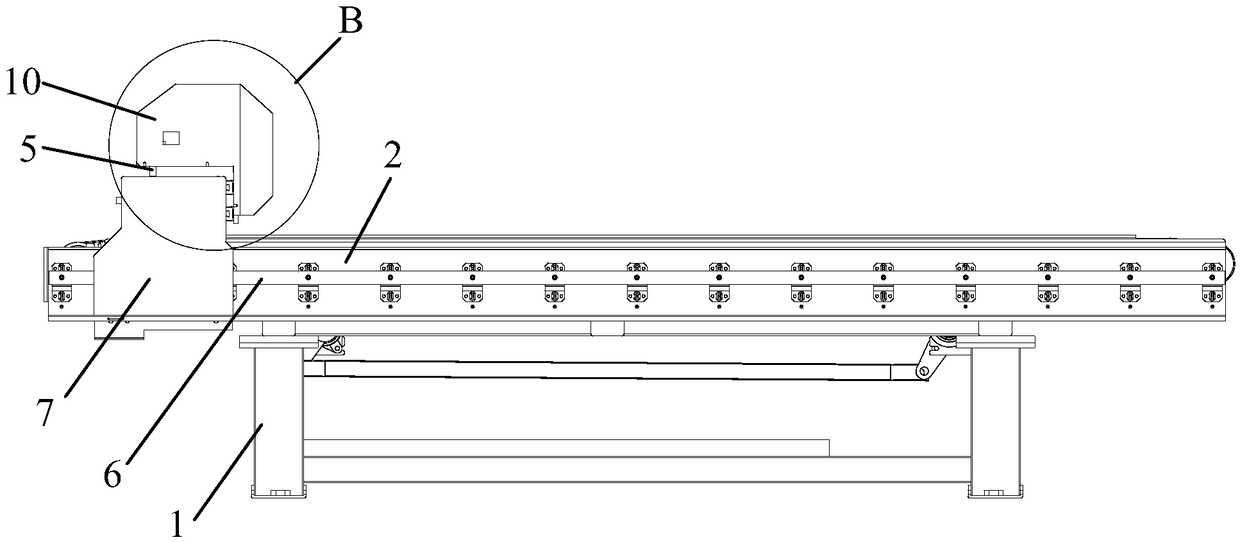

[0034] Embodiments of the present invention: as figure 1 with image 3 As shown, a fully automatic substrate size detection equipment includes a main frame 1, a carrying plate 2, a conveyor belt 3, a door-type traveling mechanism 4 and a laser sensor 5, and there are multiple carrying plates 2 fixed on the main frame 1 at equal intervals. A conveyor belt 3 is arranged between two adjacent load plates 2, and the transmission direction of the conveyor belt 3 is parallel to the length direction of the load plate; the load plate 2 on both sides is provided with a walking track 6 arranged along its length direction, The portal traveling mechanism 4 is installed on the walking track 6, and the laser sensor 5 is installed on the portal traveling mechanism 4 through the third traveling mechanism 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com