Patents

Literature

222results about How to "Realize automatic loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

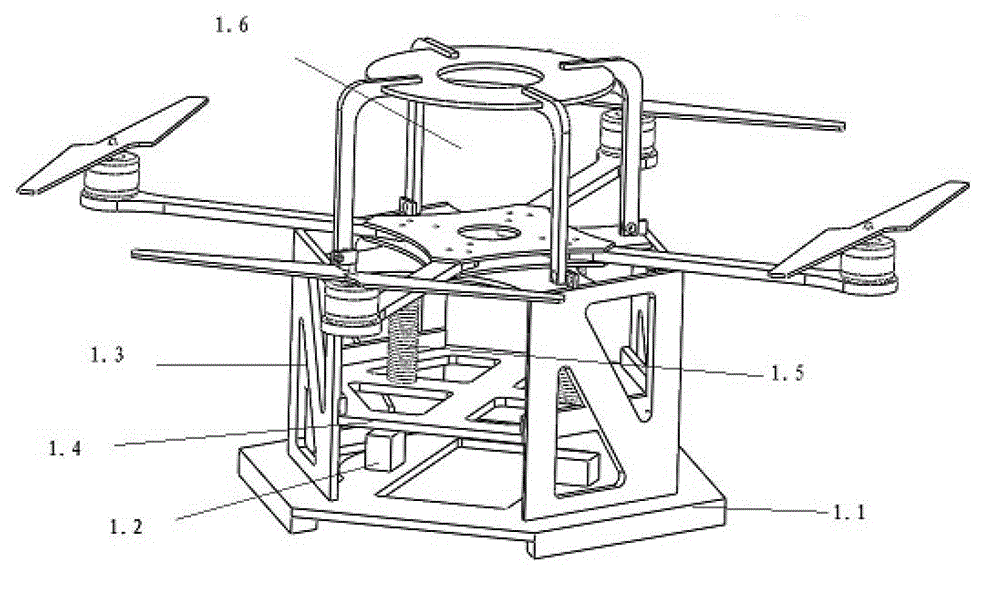

Battery automatic replacement system of small-sized multi-rotor-wing unmanned aerial vehicle

ActiveCN102909540AEasy to installImprove efficiencyProgramme-controlled manipulatorMetal working apparatusManipulatorBattery storage

The invention discloses a battery automatic replacement system of a small-sized multi-rotor-wing unmanned aerial vehicle. The battery automatic replacement system comprises a multi-track trolley, a battery storage disk, an unmanned aerial vehicle landing gear, a landing gear fixing plate, a landing gear fixing plate support, a battery storage disk support and a mechanical arm, wherein the landing gear fixing plate is arranged above the multi-track trolley, and is fixedly connected with the multi-track trolley through the landing gear fixing plate support; the unmanned aerial vehicle landing gear is arranged above the landing gear fixing plate; a battery inlet matched with the size of a battery is formed in the center of the fixing plate; the battery storage disk is arranged below the landing gear fixing plate, and is fixedly connected with the multi-track trolley through the battery storage disk support; and the mechanical arm is arranged below the battery storage disk. The battery automatic replacement system adopts a turntable type battery storage bin, so that five times of battery replacement can be performed at most through one step; and the battery automatic replacement system adopts a blind plugging type battery installation mode to achieve effects of convenience, fastness and high efficiency.

Owner:徐州新电高科电气有限公司

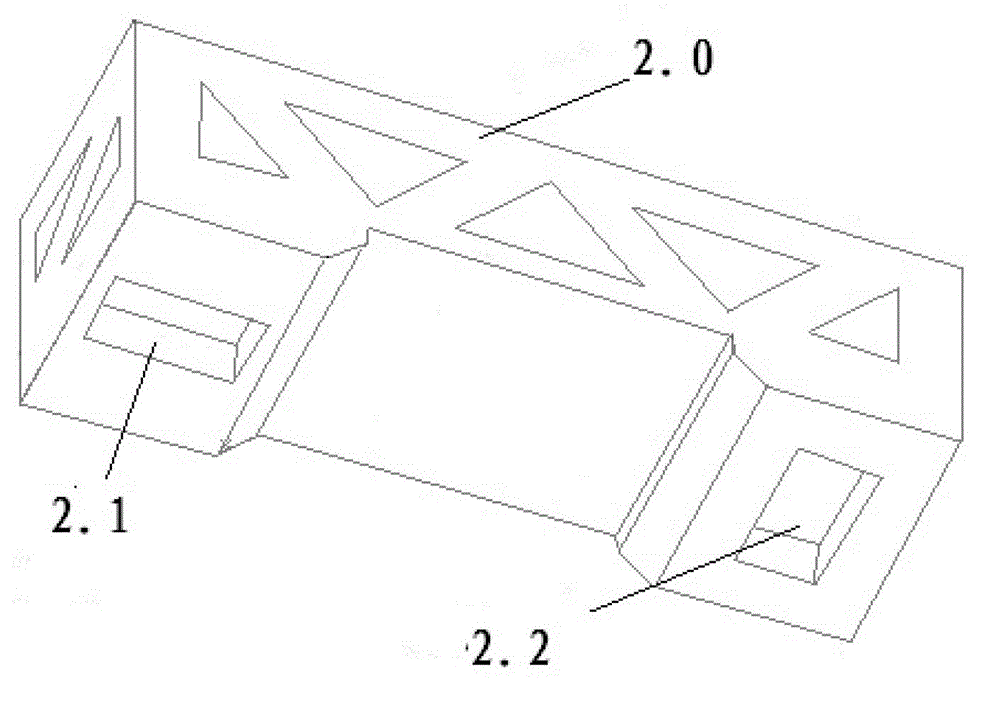

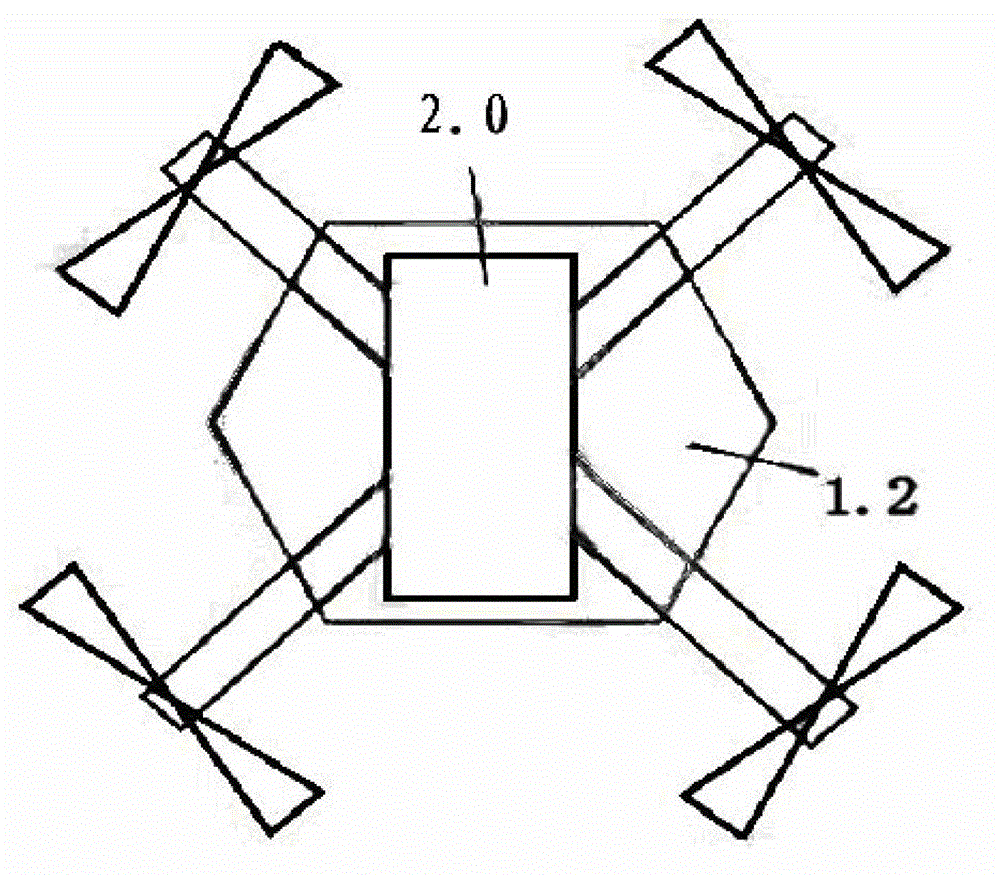

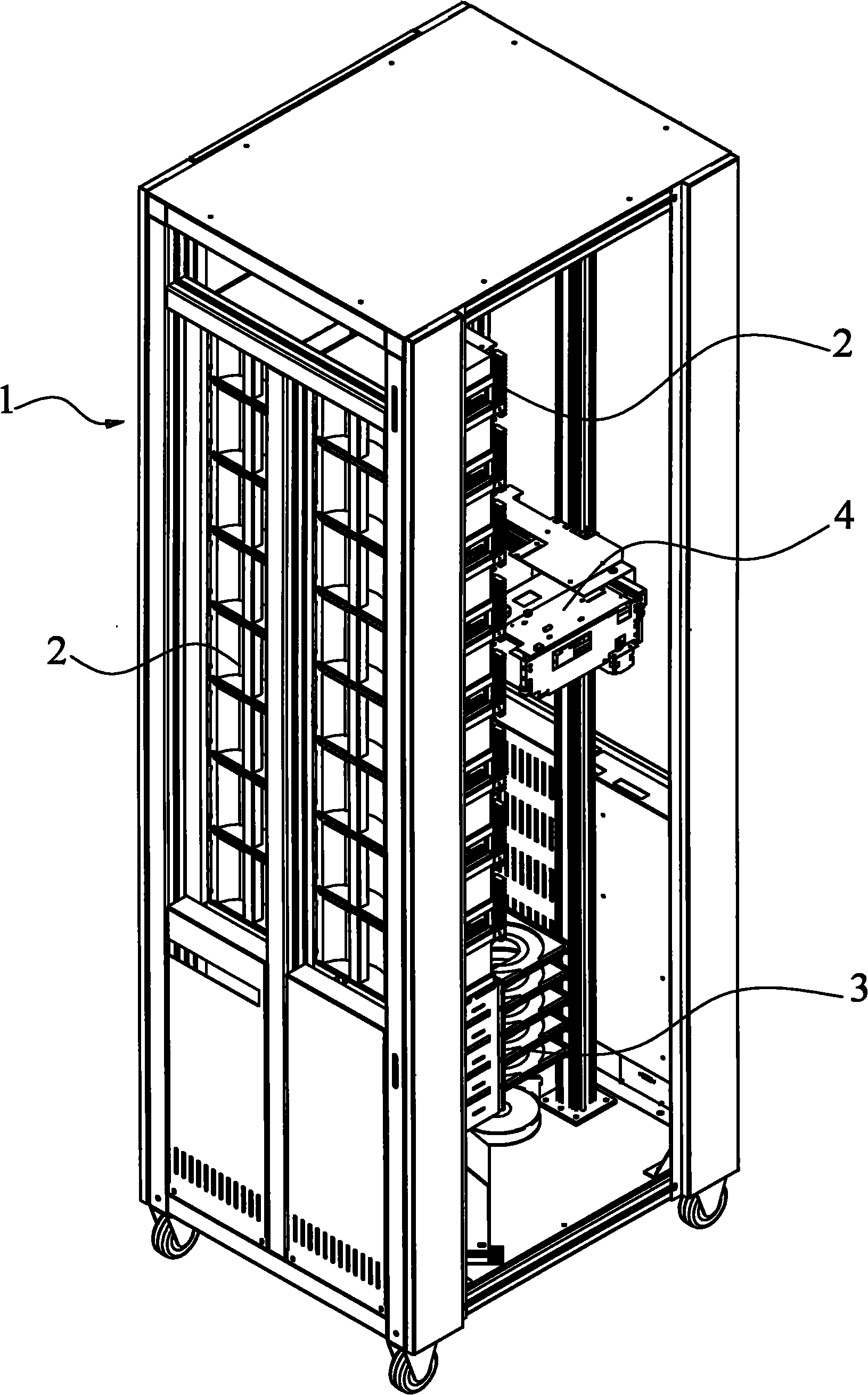

Automatic container system

The invention discloses an automatic container system. The system comprises a rail frame, a plurality of containers, at least one container moving device, a connecting device, a movement device drive unit, a connecting device drive unit and a control unit, wherein the plurality of containers are movably arranged on the rail frame, at least one space which is used for moving and switching the container and is not less than the size of the container is left; the connecting device is used for connecting the container moving device with the container and drives the container to move. According to the automatic container system provided by the invention, the intensive arrangement of a plurality of rows of the containers without space can be realized by switching the positions of the containers, so that half of storage content can be promoted in comparison with a traditional technology; the automatic container system is matched up with an unloader so as to move out or in goods in any cell of any container, so that automatic goods entry and exit and refined goods management can be realized; and the containers and the rail frame can be freely spliced and assembled by adopting a standard cell design, so that the layout is flexible. The automatic container system is suitable for intensive storage centers, automatic storage racks in supermarkets, automatic storage cabinets, three-dimensional parking buildings, automatic container trucks, vending machines, automatic post cabinets and the like.

Owner:潘玉坤 +1

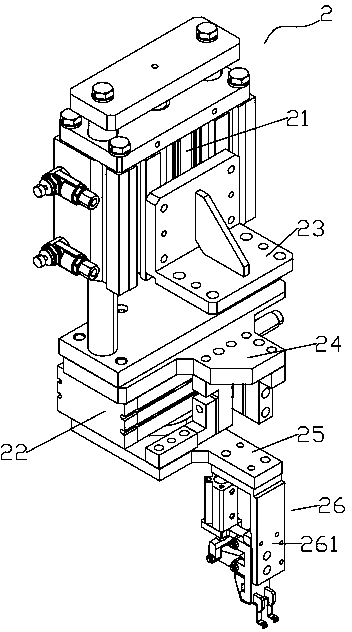

Automatic control method of workpiece-carrying injection molding and robot handling system

The invention discloses an automatic control method of workpiece-carrying injection molding. Automatic control of workpiece-carrying injection molding is completed through a rotor handling system, wherein a robot arm handling system is arranged near the side of an injection molding machine in a hanging manner, and automatic feeding of an embedded member of the injection molding machine and procedures of automatic grabbing and automatic placing of a finished injection molding workpiece are realized through a pneumatic control system and a program control system, wherein the robot arm handling system is provided with a grabbing mechanism which is composed of an air cylinder-controlled horizontal extending mechanism, and an air cylinder-controlled finished injection molding workpiece grabber mechanism, a small air cylinder-controlled embedded member compacting mechanism and a small air cylinder-controlled embedded member extending and compacting mechanism. The invention further discloses a robot handling system. The robot handling system is an automatic system which is high in automation degree, high in production efficiency and strong in universality, and is capable of lightening the labor intensity of manual operation, and realizing the automatic feeding of the embedded member of the injection molding machine and automatic grabbing and automatic placing of the finished injection molding workpiece.

Owner:GUANGZHOU RUISONG INTELLIGENT TECH CO LTD

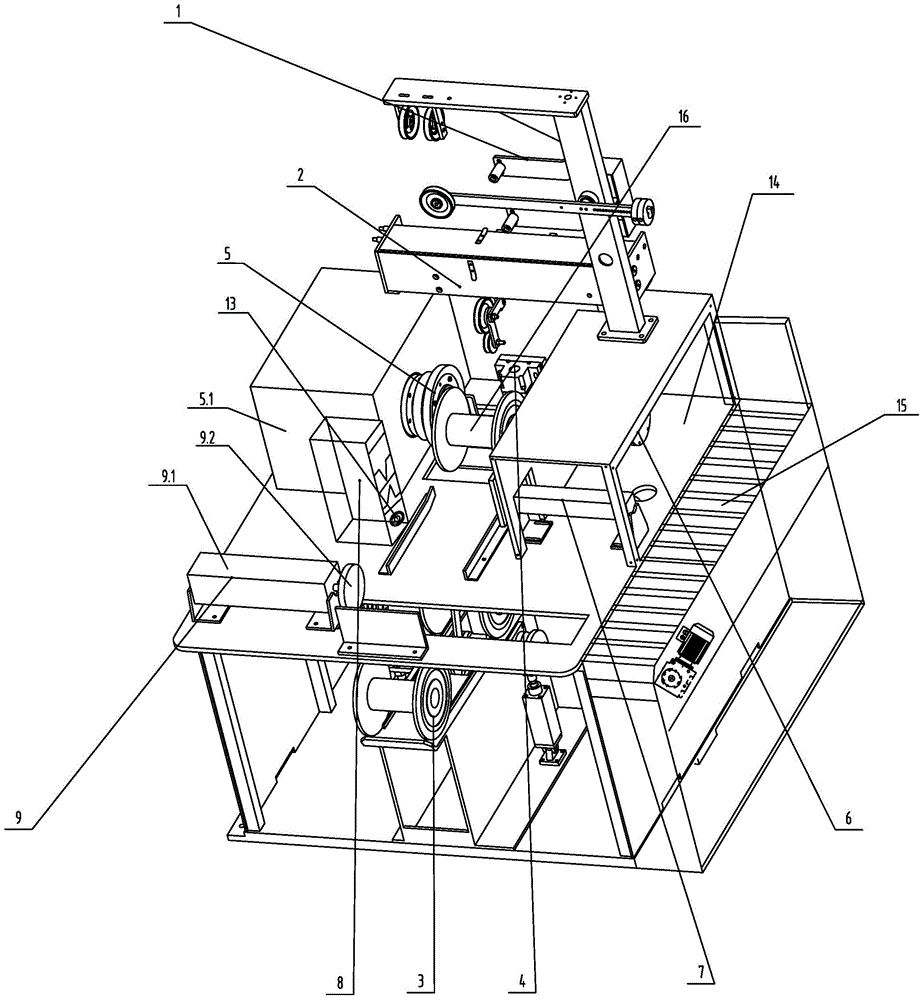

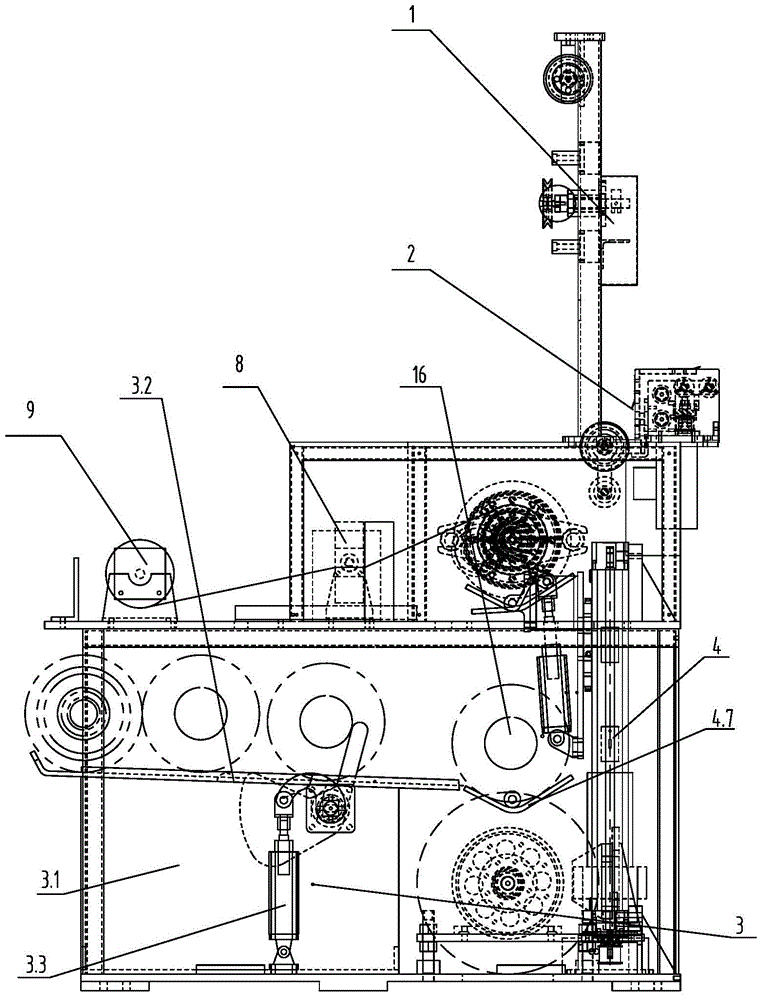

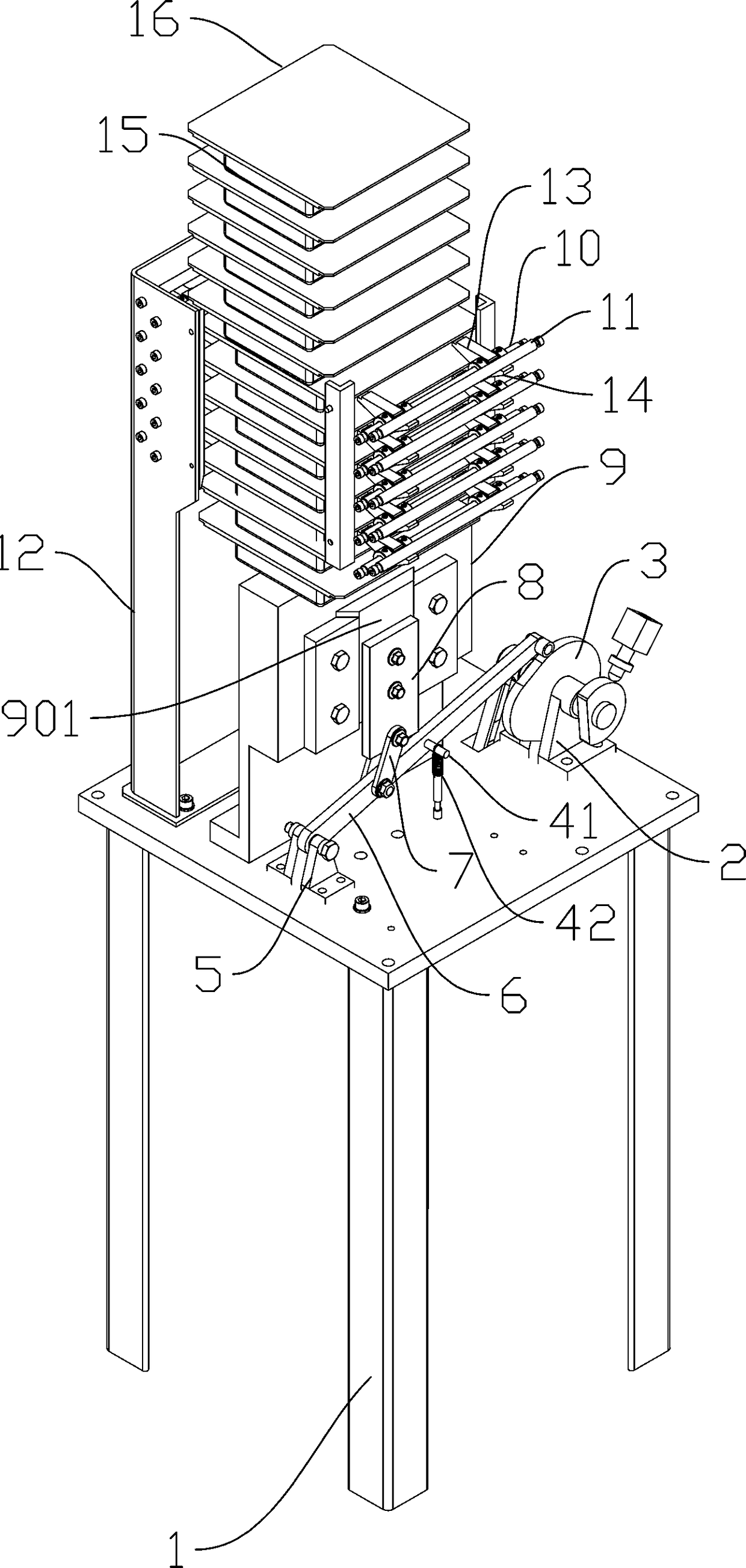

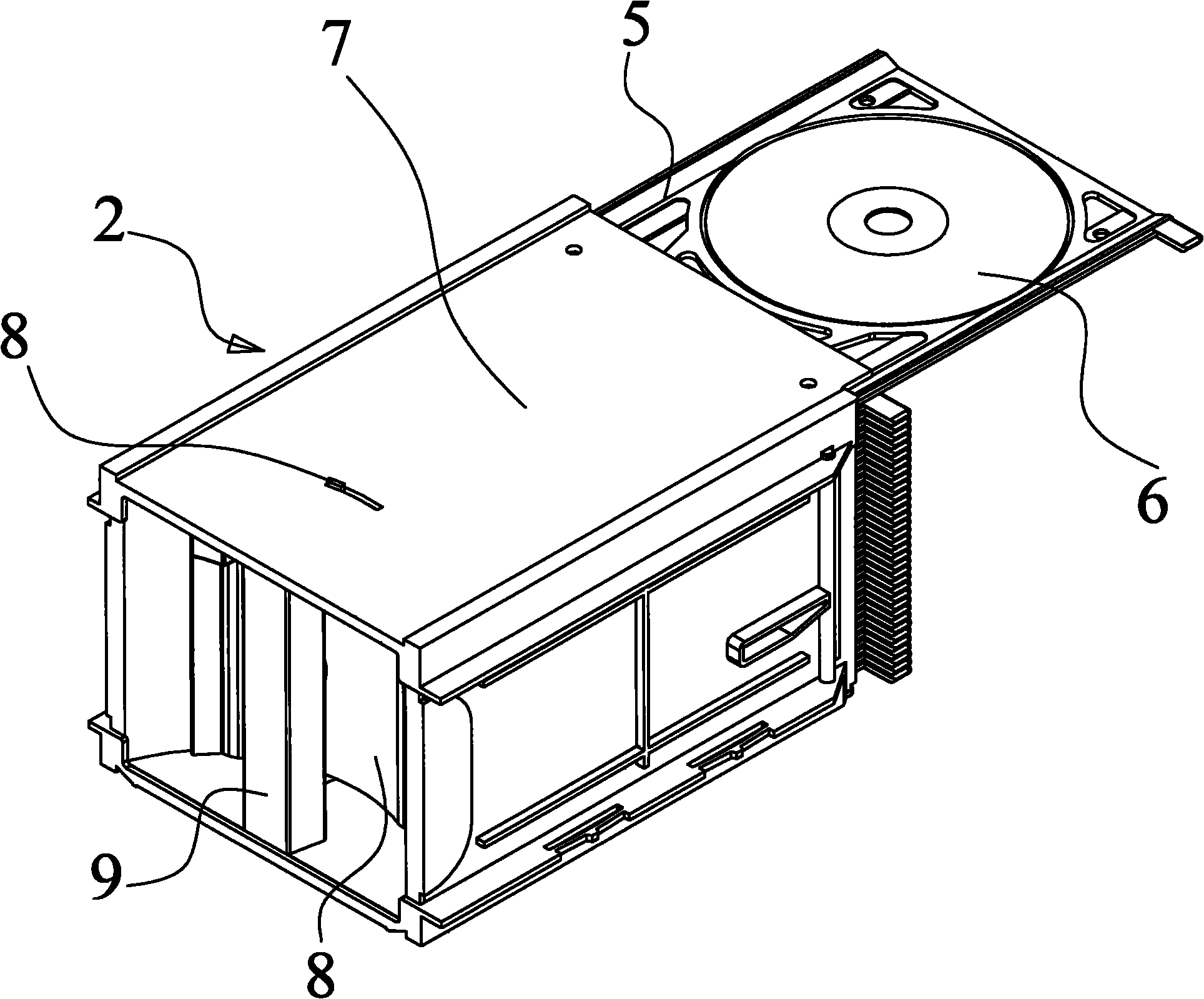

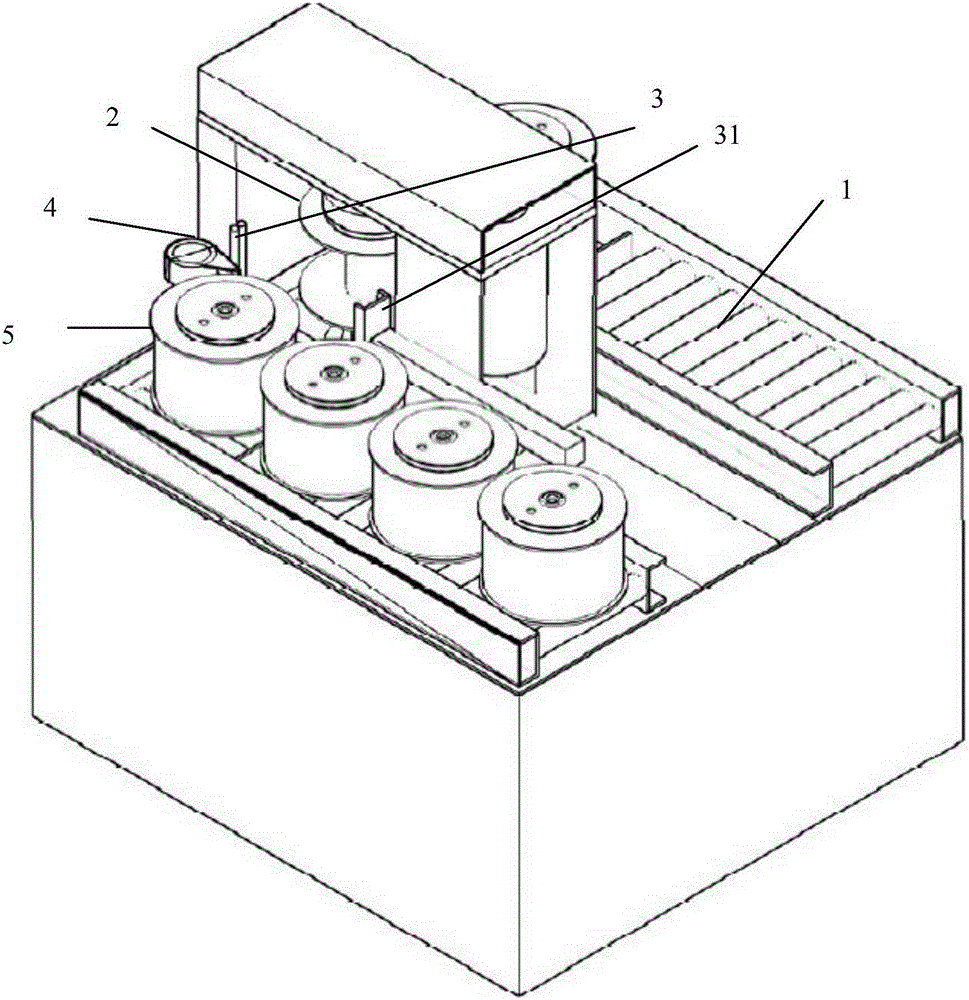

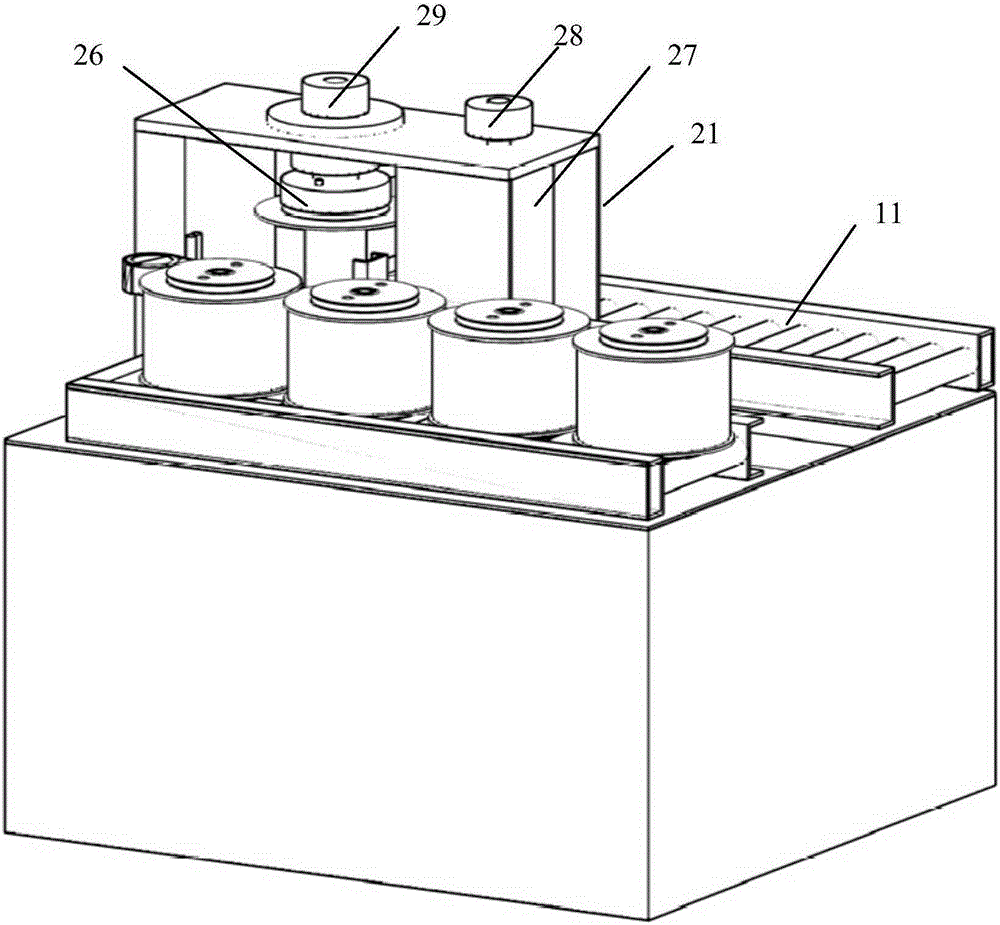

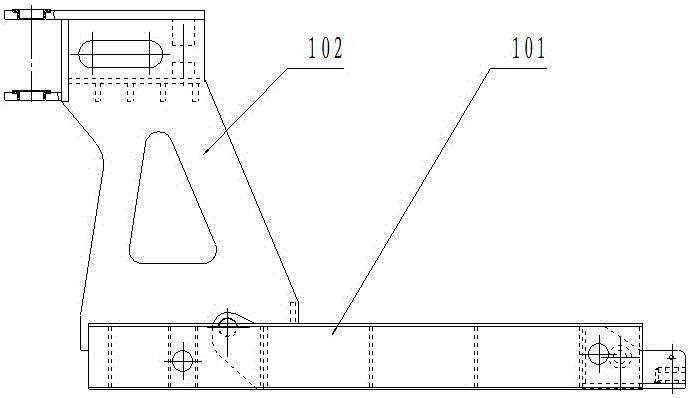

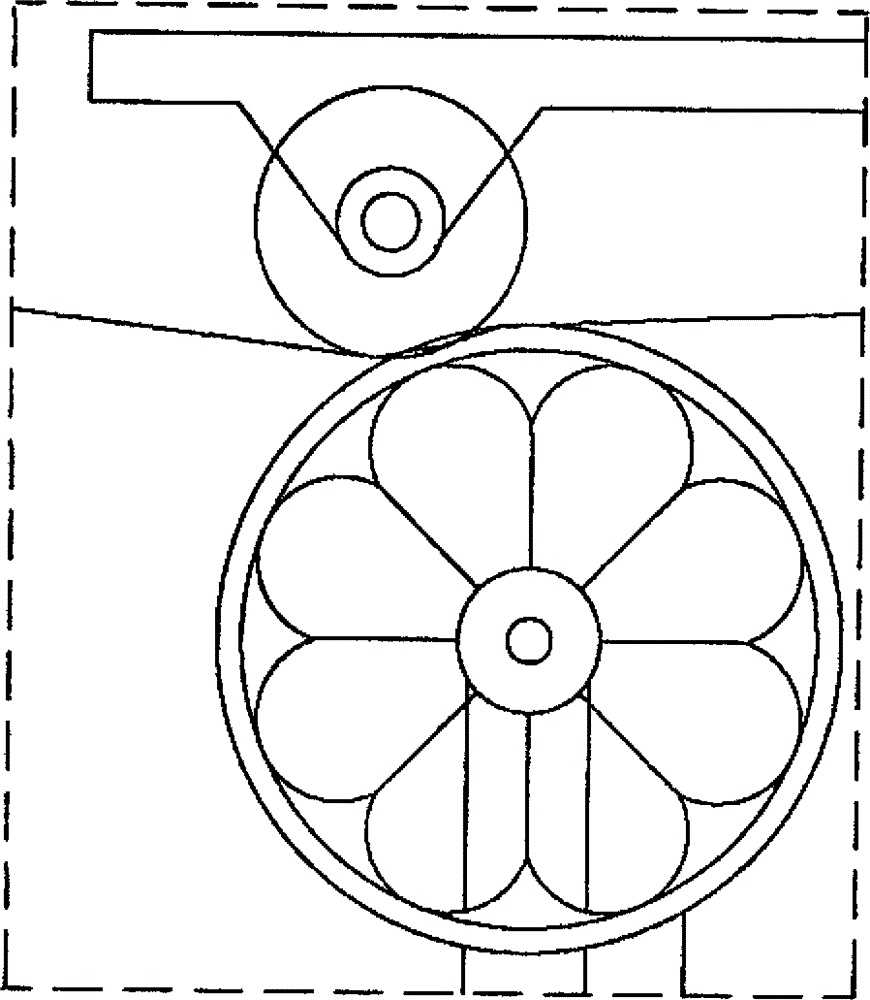

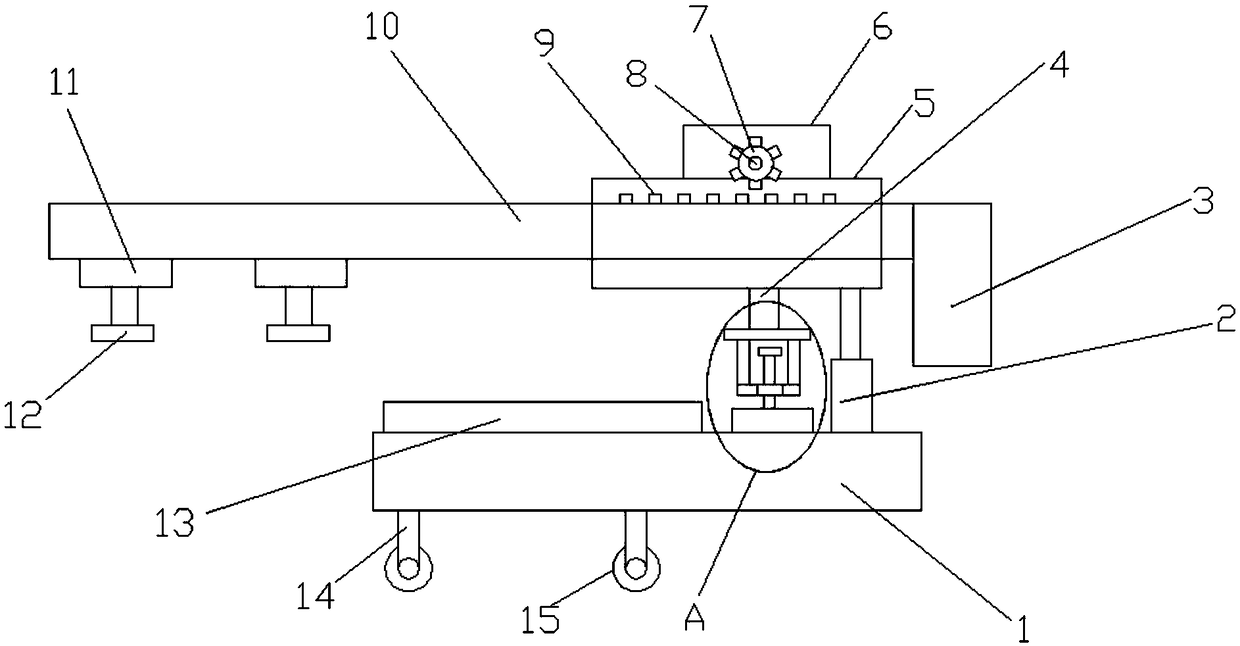

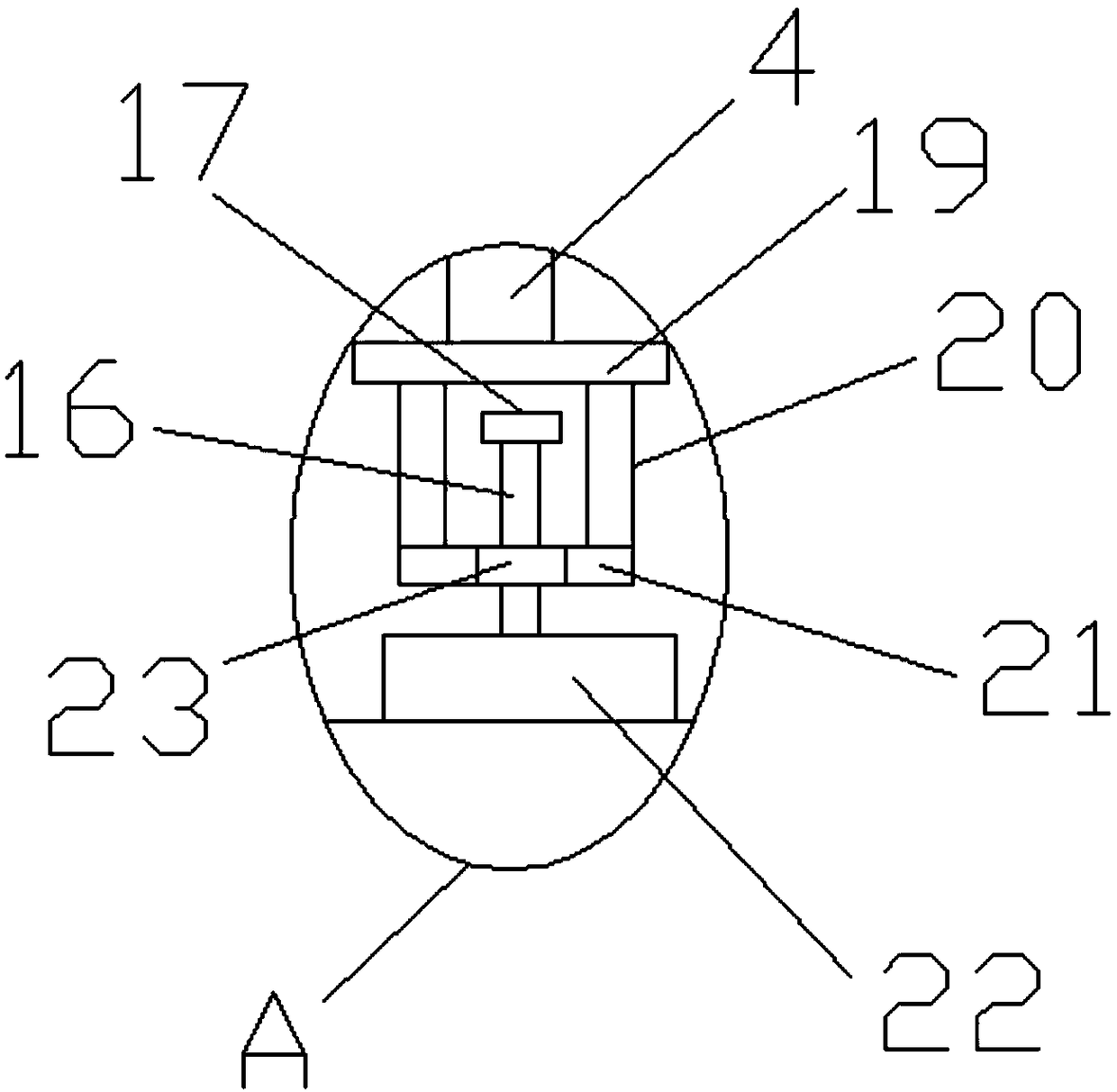

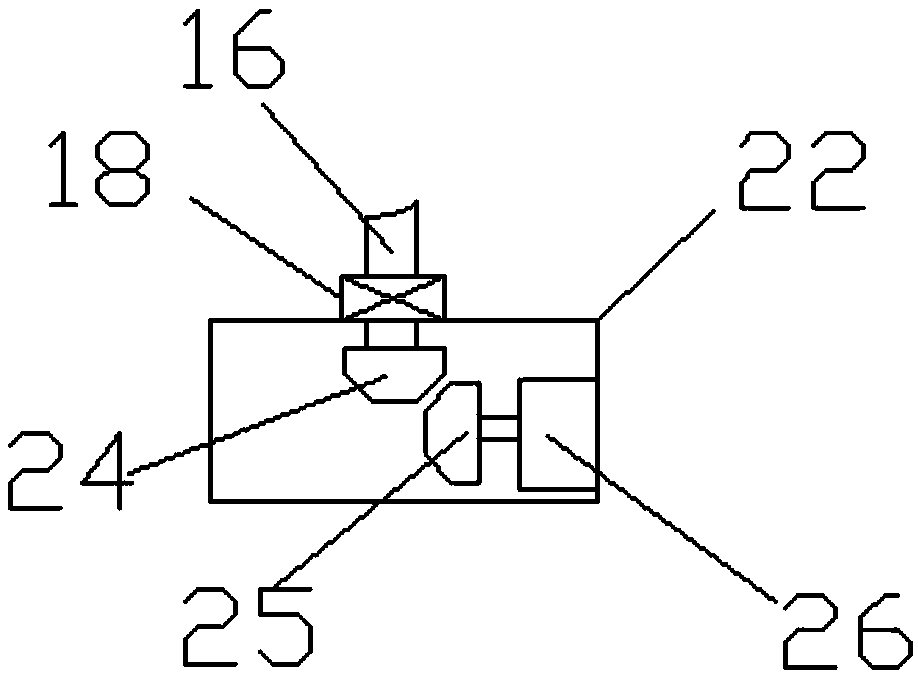

Steel wire rod take-up device

ActiveCN104944214ARealize automatic loadingHigh degree of automationFilament handlingAutomationWire rod

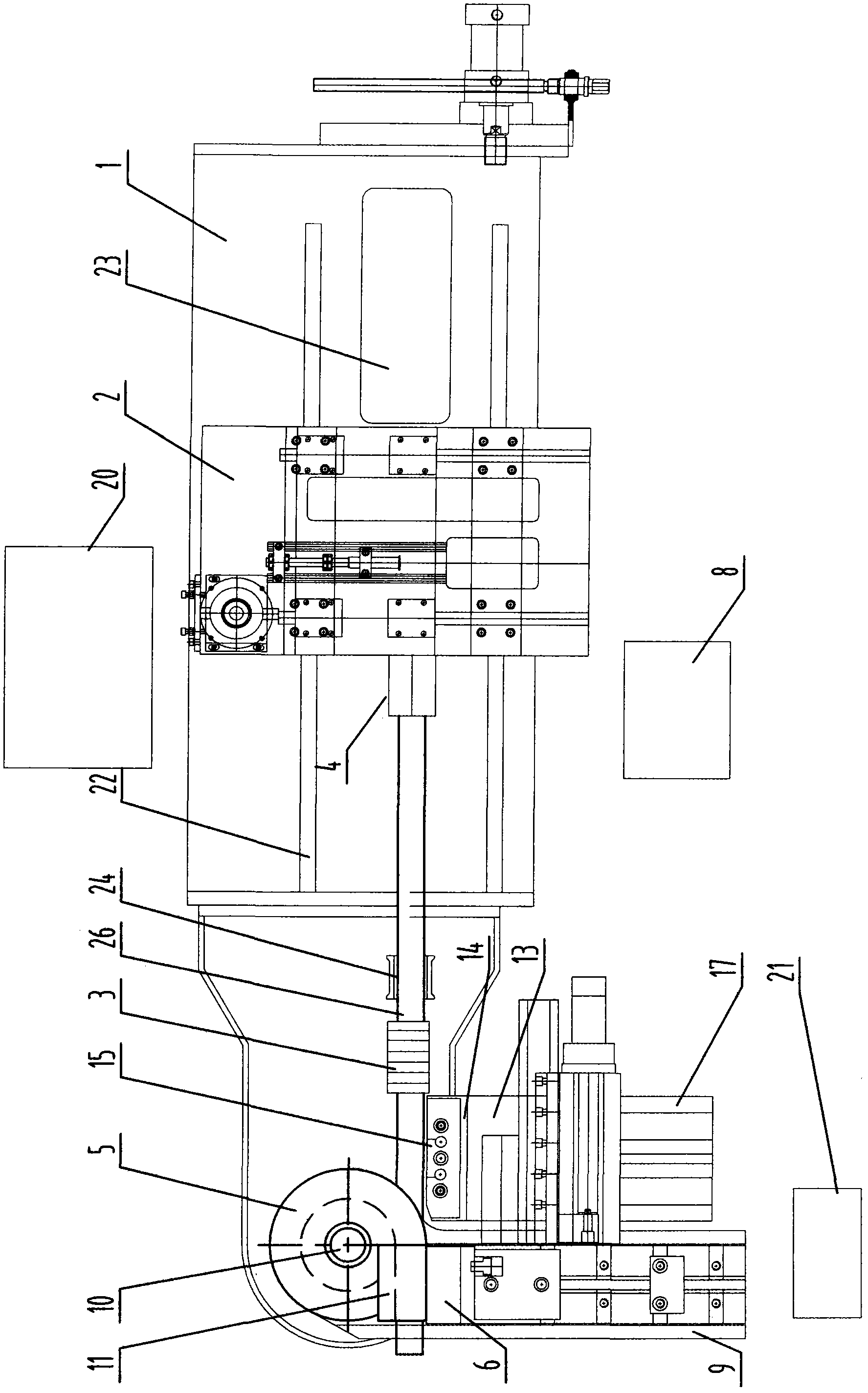

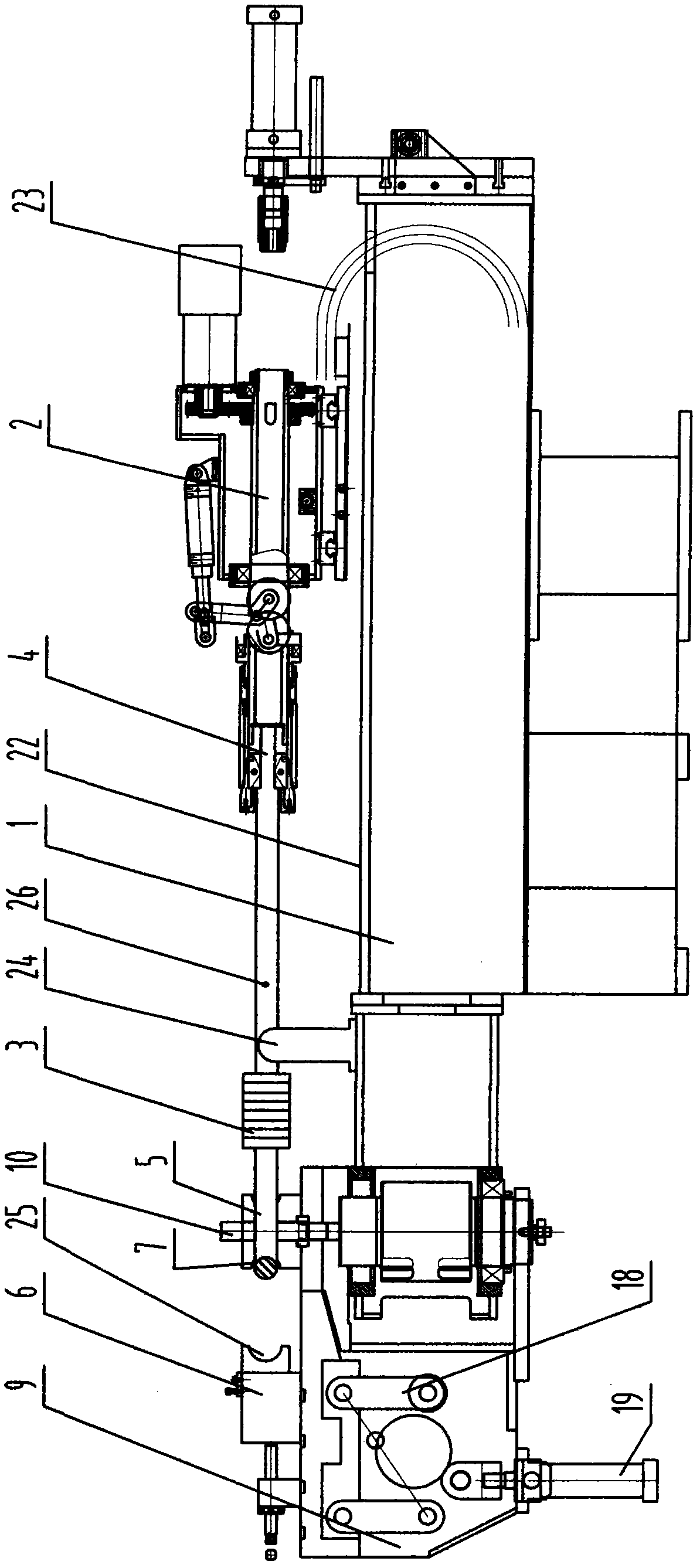

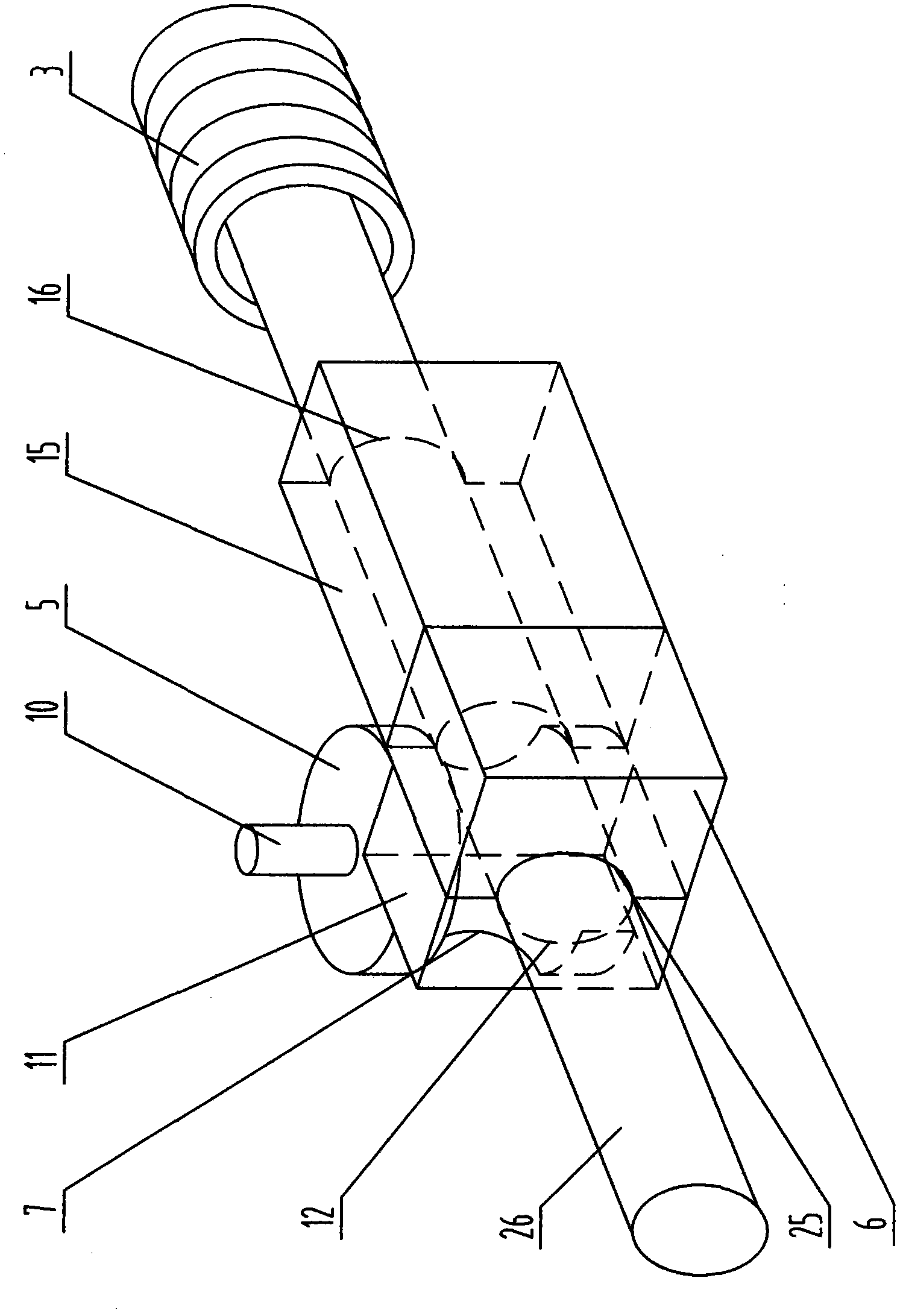

The invention discloses a steel wire rod take-up device which comprises a rack and a wire arranging assembly. An automatic wire clamping and wheel discharging assembly used for clamping a spool and a spool ejecting assembly are arranged on one side below the wire arranging assembly, wherein the automatic wire clamping and wheel discharging assembly and the spool ejecting assembly are fixed to the rack respectively, an automatic disc feeding and discharging assembly located between the automatic wire clamping and wheel discharging assembly and the spool ejecting assembly is arranged below a wire arranging wheel set, a wire pushing and locating assembly and an automatic fusing assembly are oppositely arranged on one side of the automatic wire clamping and wheel discharging assembly and one side of the spool ejecting assembly, the distance between the wire pushing and locating assembly and the automatic fusing assembly is larger than the axis length of the spool, a steel wire locating clamp is arranged on the automatic fusing assembly, and the signal input end of the wire arranging assembly, the signal input end of the automatic wire clamping and wheel discharging assembly, the signal input end of the spool ejecting assembly, the signal input end of the automatic disc feeding and discharging assembly, the signal input end of the wire pushing and locating assembly and the signal input end of the automatic fusing assembly are all connected with the signal output end of a PLC. The steel wire rod take-up device is high in automation degree, high in production efficiency, low in manual labor intensity, and suitable for being widely applied to cable devices.

Owner:湖北三江航天江北机械工程有限公司

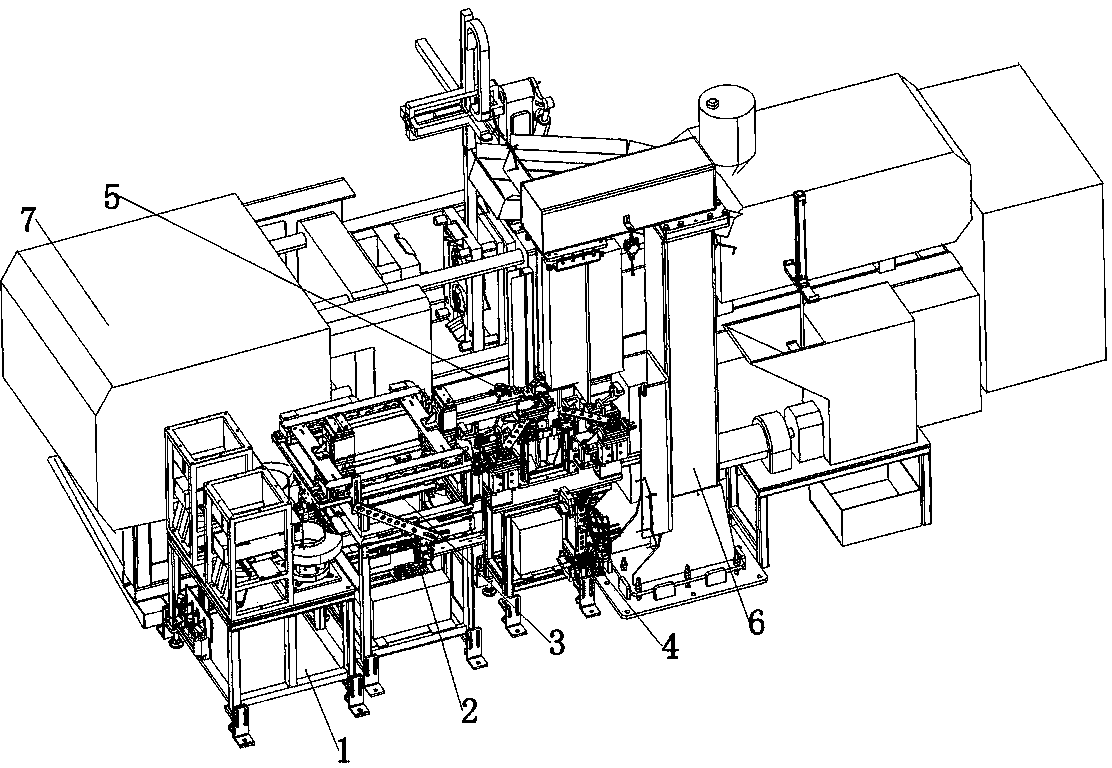

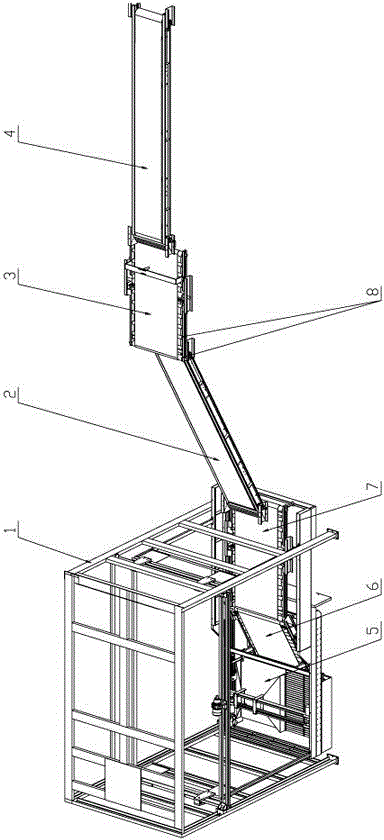

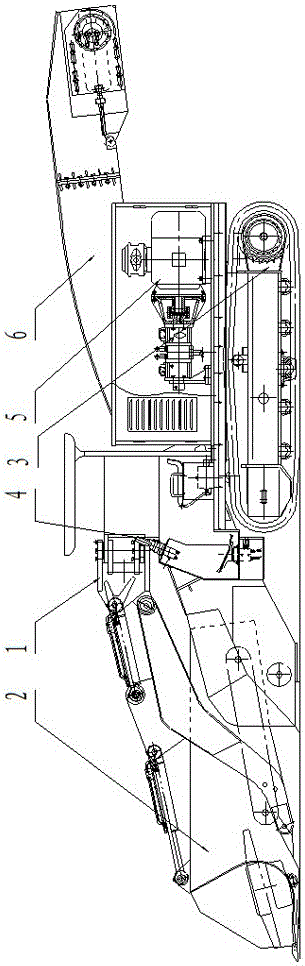

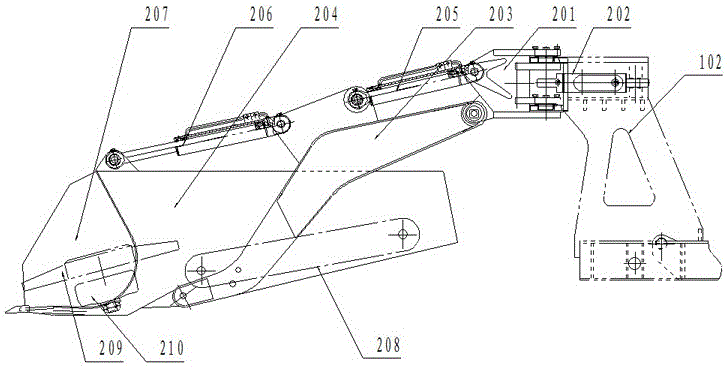

Automatic pipe bending device and pipe bending process thereof

The invention discloses an automatic pipe bending device and a pipe bending process thereof, belonging to the technical field of mechanical processing and manufacturing. The technical scheme adopted by the invention is as follows: under the automatic control of an automatic control platform, a loading claw of a pipe loading machine firstly shifts a single pipe into a rotating fixture of a pinch device, the pinch device drives the pipe to move forward through a heater, the heater heats a bent part of the pipe to 1200-1350 DEG C, the bent part is moved to a bending mold, a follower plate and a movable jaw clamp the pipe, the movable jaw and the bending mold rotate to a bending angle around a rotating shaft, the follower plate and the movable jaw are reset after the pipe is released, the above process is repeated until the bending of the whole pipe is finished, and an unloading manipulator carries out unloading operation, thus finishing the bending process. The system can automatically finish pipe operations such as loading, feeding, heating, rotating, bending, unloading and the like, so that the pipe can be automatically bent and molded, the molding process is more accurate, and theyield is high; and the number of times for transporting the pipe in the processing process is reduced, and the productivity is improved.

Owner:西安德卡汽车系统有限公司

Classification logistics box automatic loading device

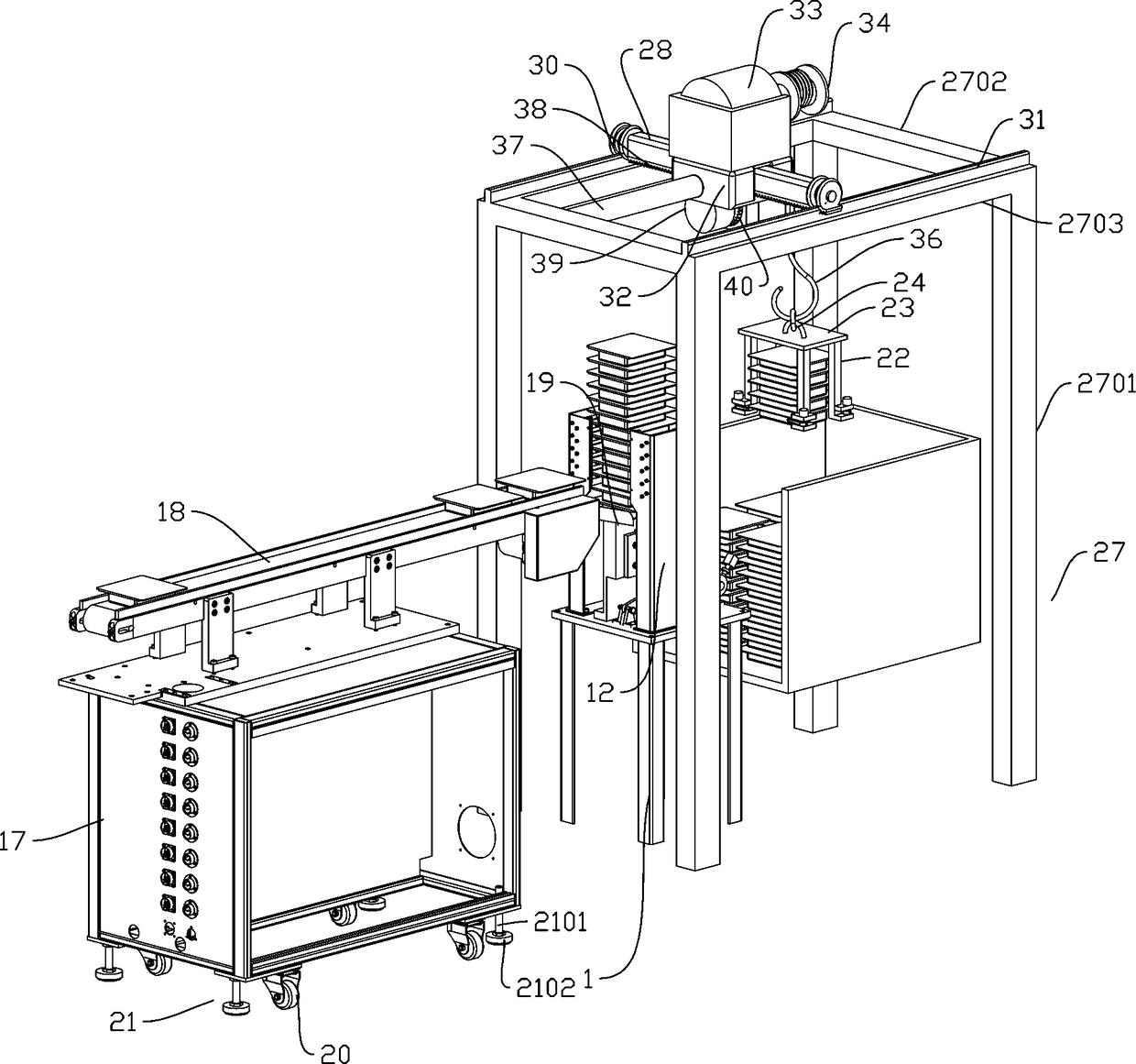

InactiveCN108792634ARealize automatic loadingRealize handlingConveyorsStacking articlesLogistics managementEngineering

The invention provides a classification logistics box automatic loading device. The classification logistics box automatic loading device comprises a stacking device. The stacking device comprises a supporting seat. A cam frame is arranged on the upper side of the cam frame. A rotary shaft of a cam is rotatably mounted on the cam frame and is driven through a first motor. A hinge support is arranged on the supporting seat. One end of a connecting rod is hinged to the hinge support, and the other end of the connecting rod abuts against the cam. The connecting rod is hinged to a lifting connecting rod. The upper end of lifting connecting rod is hinged to a lifting plate. The lifting plate is slidably mounted in a sliding groove of a blanking platform. A multi-layer supporting mechanism is arranged above the blanking platform. The supporting mechanism comprises rotary shafts and limiting rods, and the rotary shafts and the limiting rods are symmetrically arranged on the two sides above the blanking platform. The two ends of the rotary shafts and the two ends of the limiting rods are mounted on a support. The support is fixed to the supporting seat. Supporting jaws are rotatably mounted on the rotary shafts. The sides, far away from logistics boxes, of the supporting jaws are provided with limiting jaws. The limiting rods limit the limiting jaws to rotate upwards. Through the classification logistics box automatic loading device, automatic stacking of the logistics boxes is realized, the labor intensity is relieved, the logistics efficiency is improved, and the logistics company image is promoted.

Owner:CHINA THREE GORGES UNIV

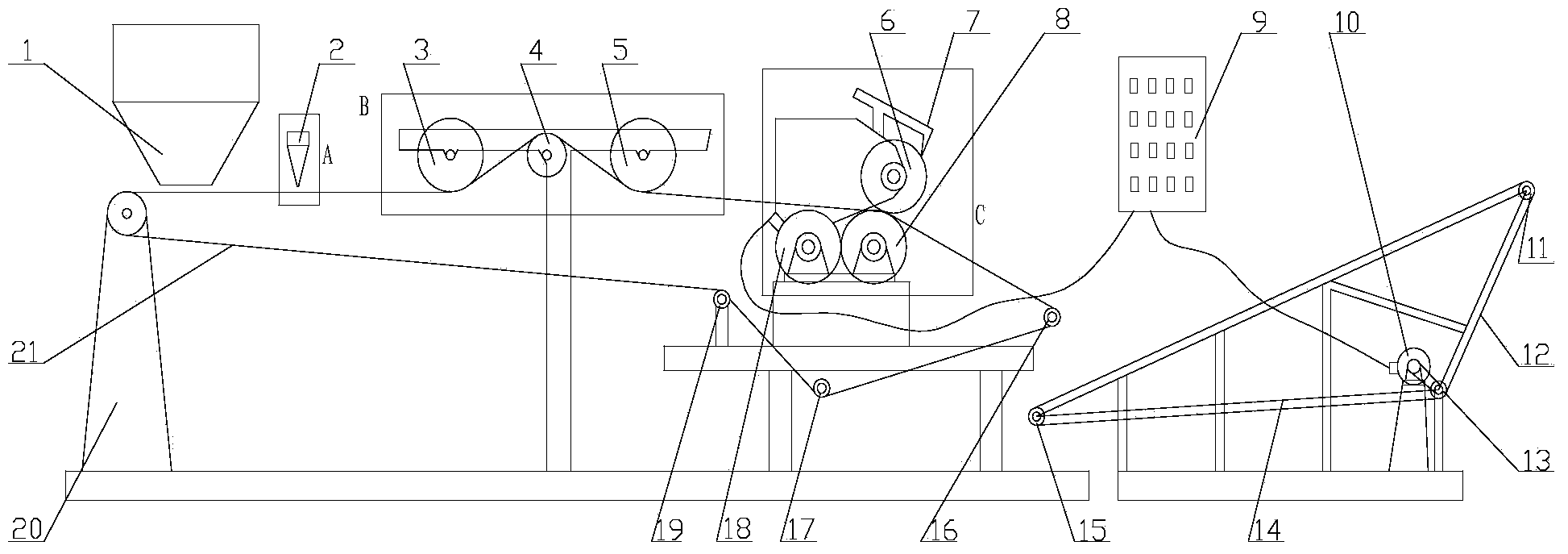

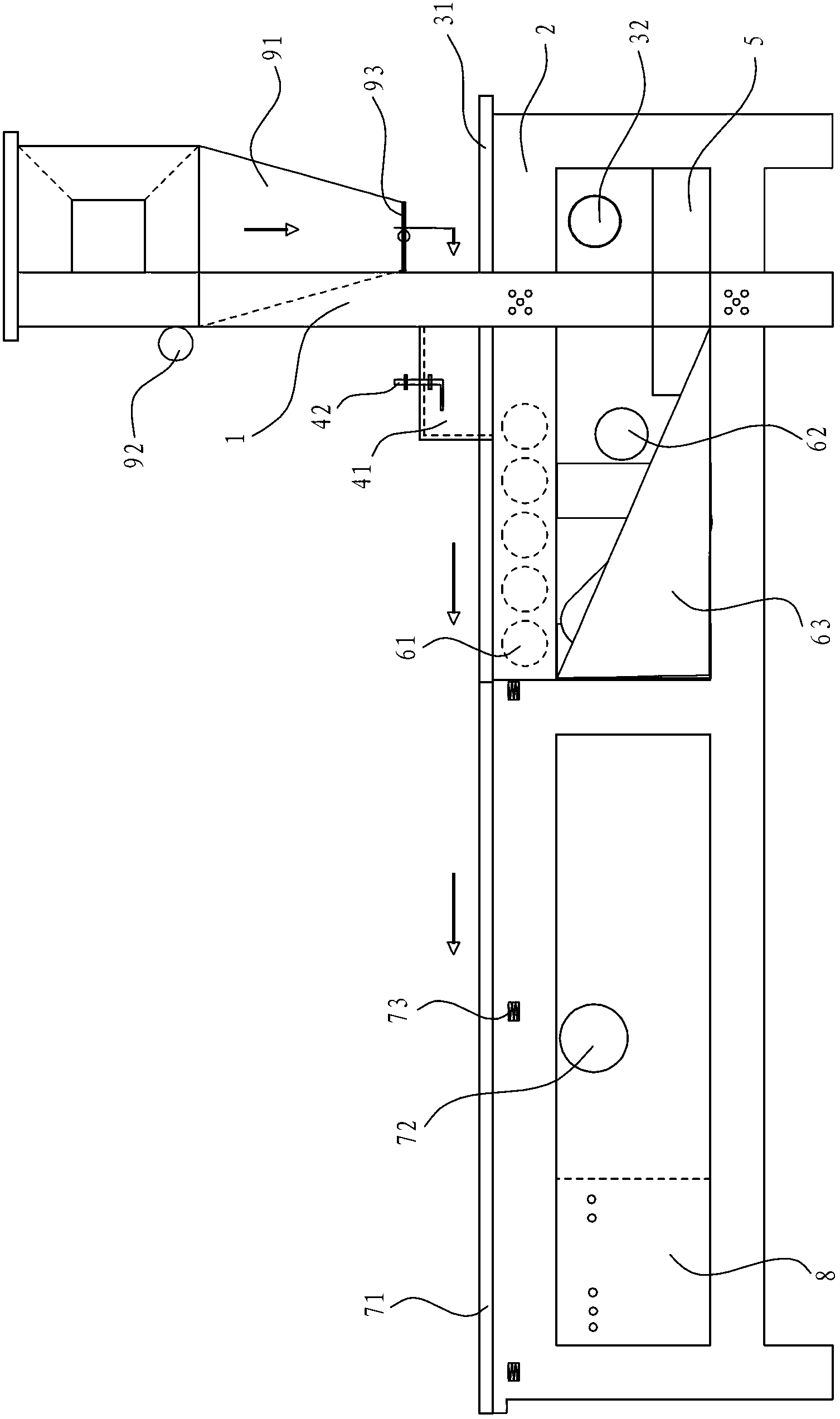

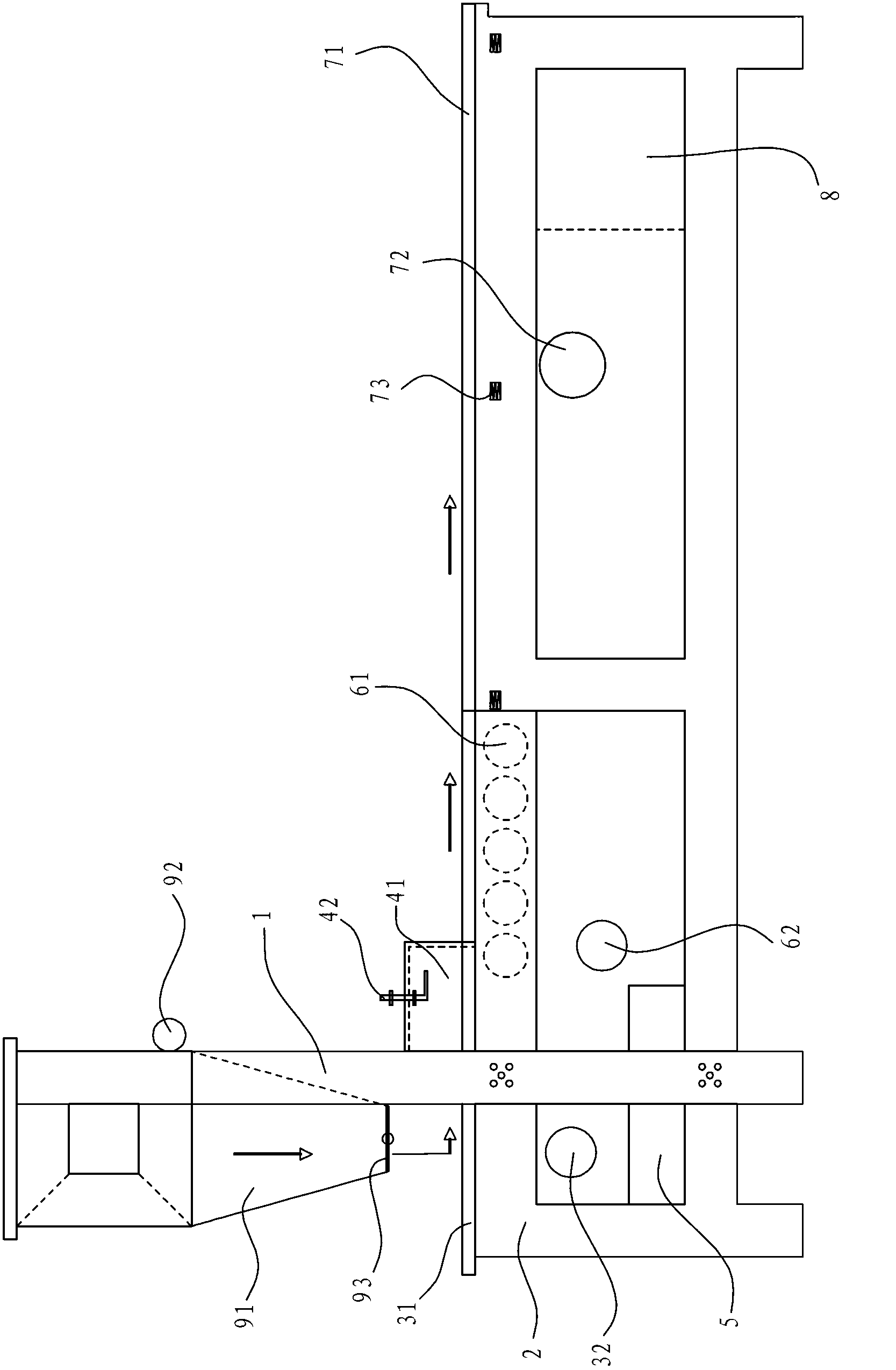

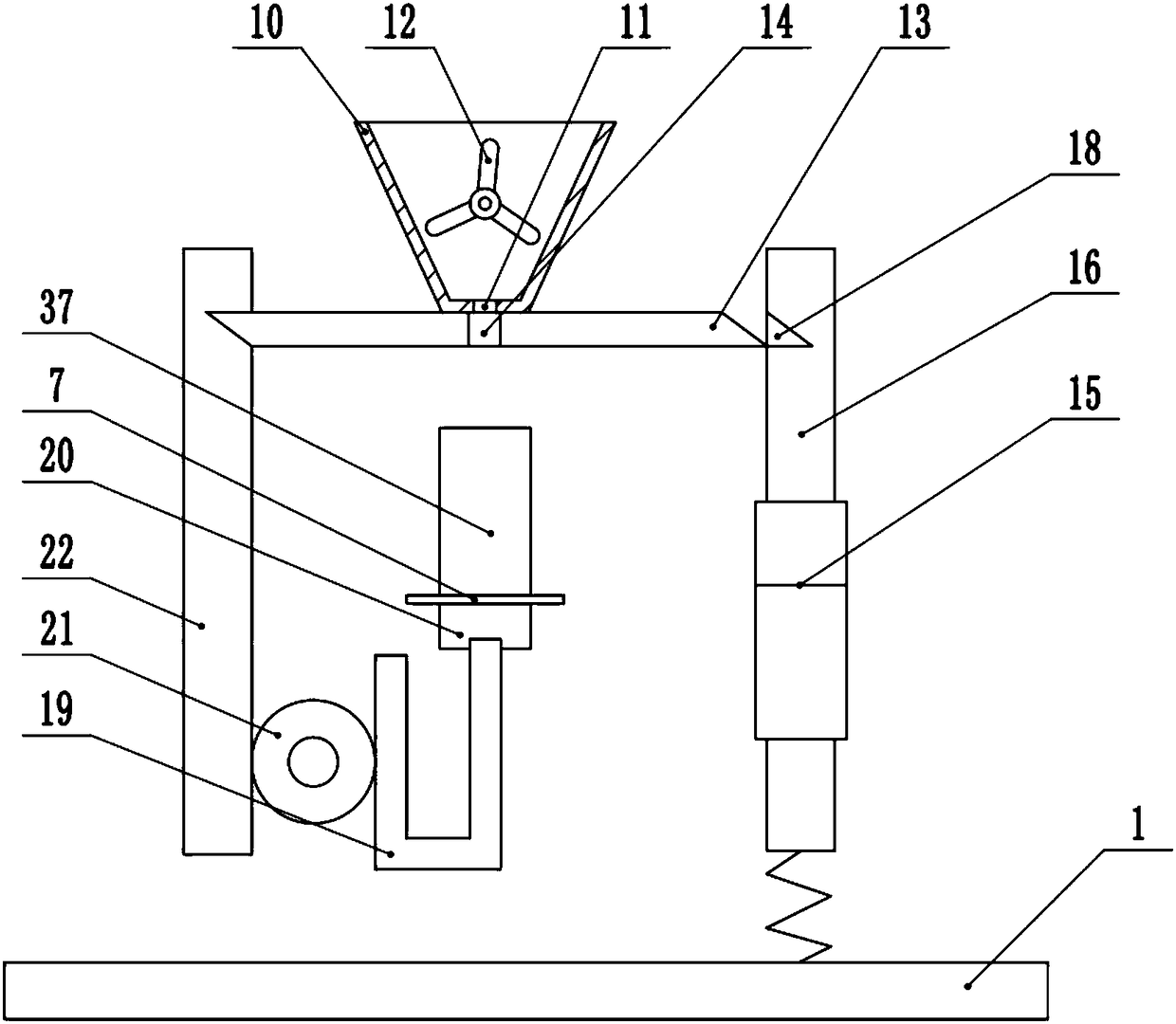

Automatic stacking and loading machine for bagged cement

ActiveCN104670925AReduce labor intensityImprove working environmentLoading/unloadingMaster controllerWorking environment

The invention relates to an automatic stacking and loading machine for bagged cement, characterized by comprising a receiver, a transfer device, a lifting coordinator, a grouping device, a slide carriage device, a stacking device, a lifting device and a master controller. The receiver is abutted to one end of the transfer device. The other end of the transfer device is rotatably connected with the upper end of the lifting coordinator. The lower end of the lifting coordinator is movably connected with the front end of the grouping device. The rear end of the grouping device is connected with the slide carriage device. The lower end of the slide carriage device is flush with the stacking device. The grouping device, the slide carriage device and the stacking device are lifted up and down together by the lifting device. The receiver, the transfer device, the grouping device, the stacking device and the lifting device are all connected with the master controller. The automatic stacking and loading machine has the advantages that cement bags from the machine can be directly grouped and stacked, automatic loading of the bagged cement is achieved, labor intensity is reduced for workers, work environment is improved, and efficiency is greatly improved.

Owner:HUBEI HAFU CEMENT MACHINE

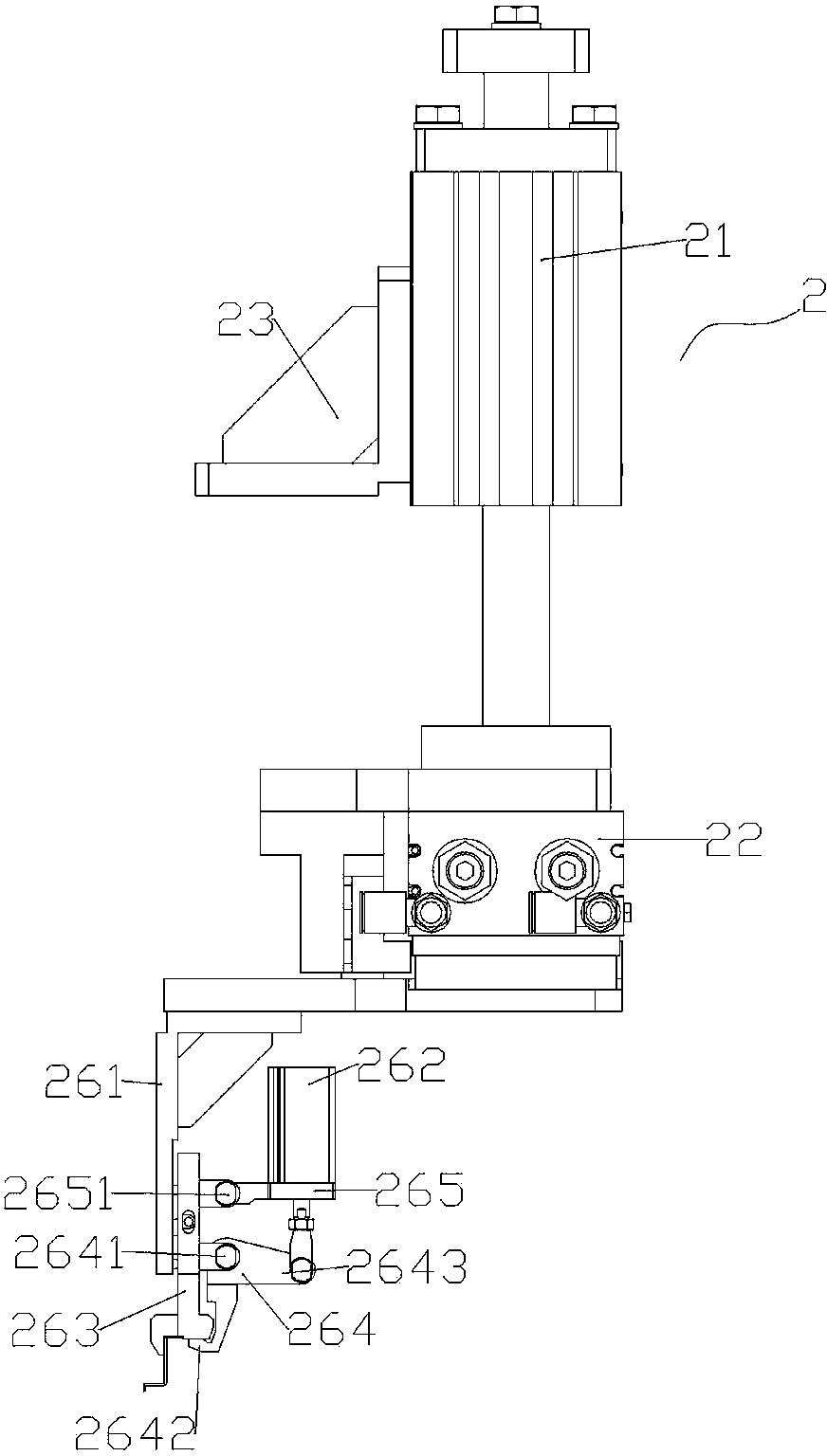

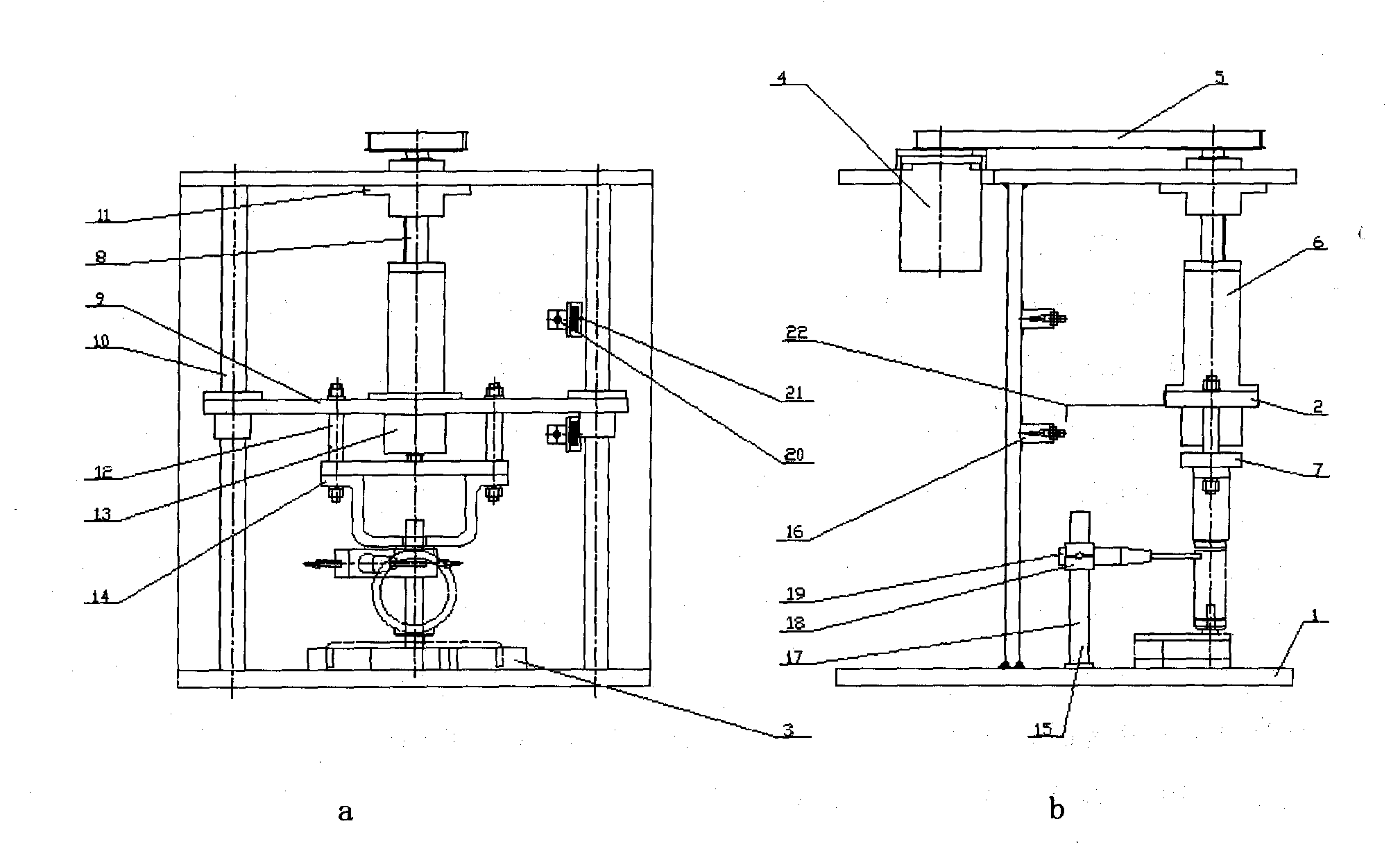

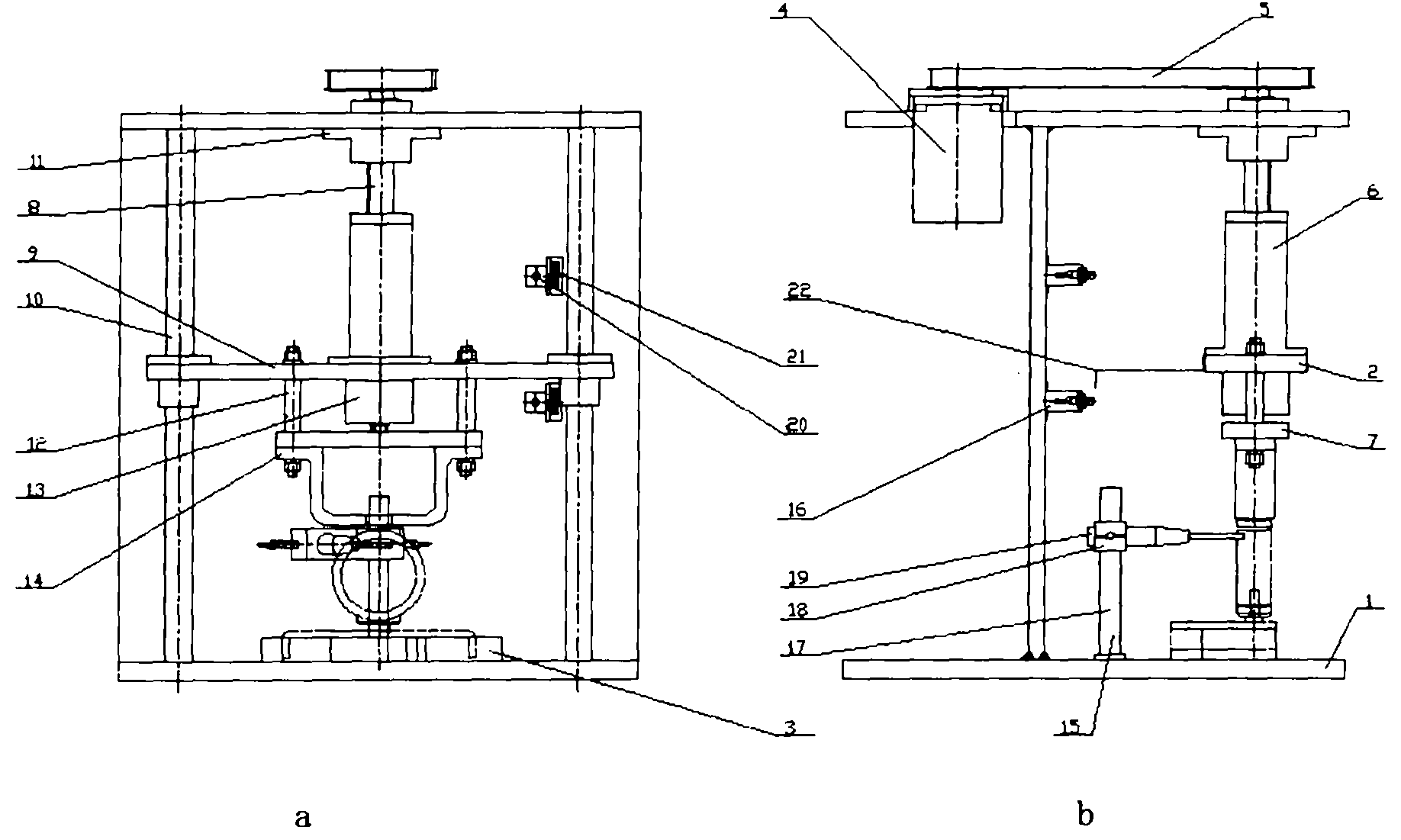

Automatic loading device of stress ring

InactiveCN101793653ARealize automatic loadingMeet loading needsInvestigating abrasion/wear resistanceEngineeringCorrosion

The invention relates to an automatic loading device of a stress ring for a hydrogen sulfide resistant stress corrosion test, belonging to the technical field of mechanical tests. The automatic loading device comprises a stand, a transmission pressurization mechanism and a stress ring positioning board, wherein the stress ring positioning board is horizontally arranged at the bottom of the stand, and the transmission pressurization mechanism is positioned in the stand and is vertically arranged above the stress ring positioning board. The transmission pressurization mechanism comprises a stepping motor, a synchronous belt transmission mechanism, a vertical driving mechanism and a connection pressurization mechanism, wherein the stepping motor is fixedly arranged at the upper part of the stand and is connected with one end of the synchronous belt transmission mechanism; the other end of the synchronous belt transmission mechanism is connected with the vertical driving mechanism; the vertical driving mechanism is rotatablely arranged at the upper part of the stand vertically; and the connection pressurization mechanism is fixedly arranged at the lower end of the vertical driving mechanism and is in contact with the stress ring to be measured. The invention realizes the purpose of loading the load of which the loading force is 0.1-40KN through a compact structure.

Owner:SHANGHAI JIAO TONG UNIV

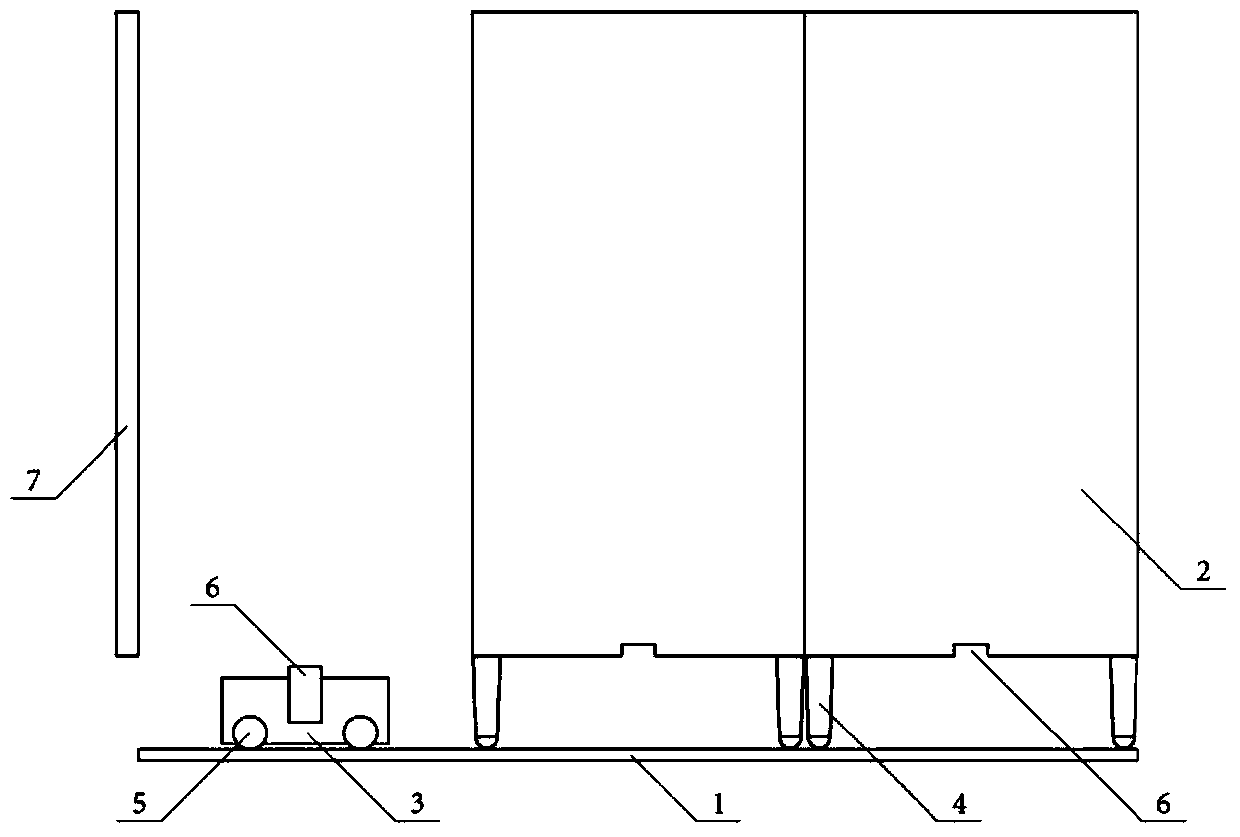

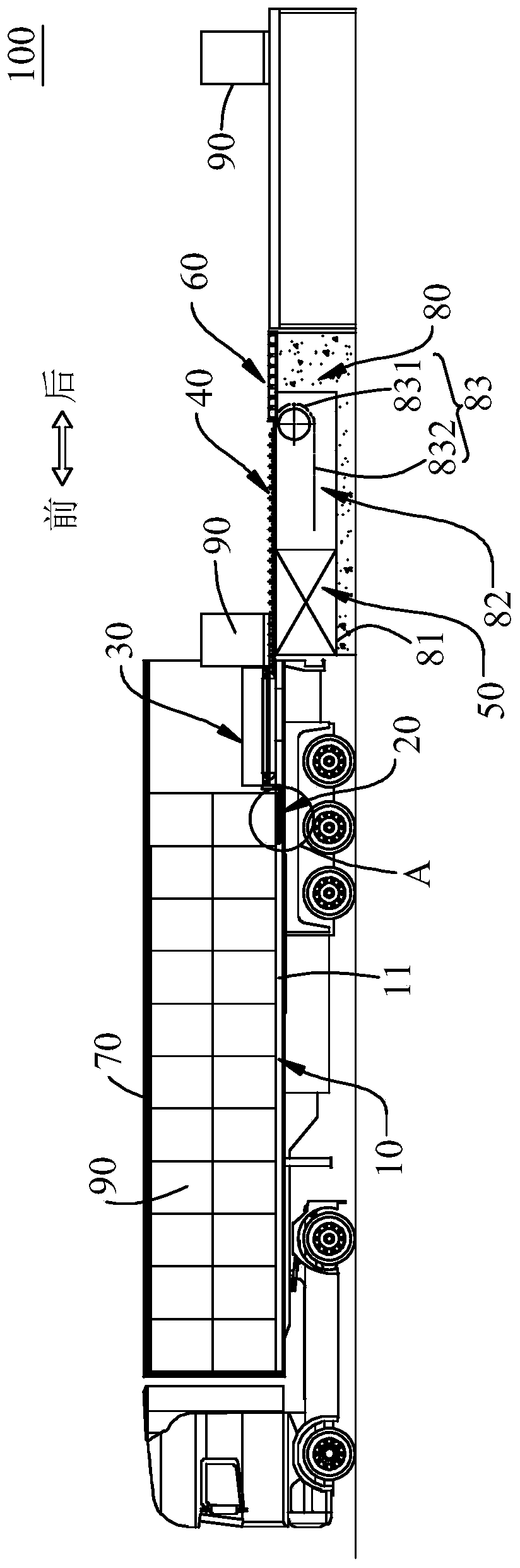

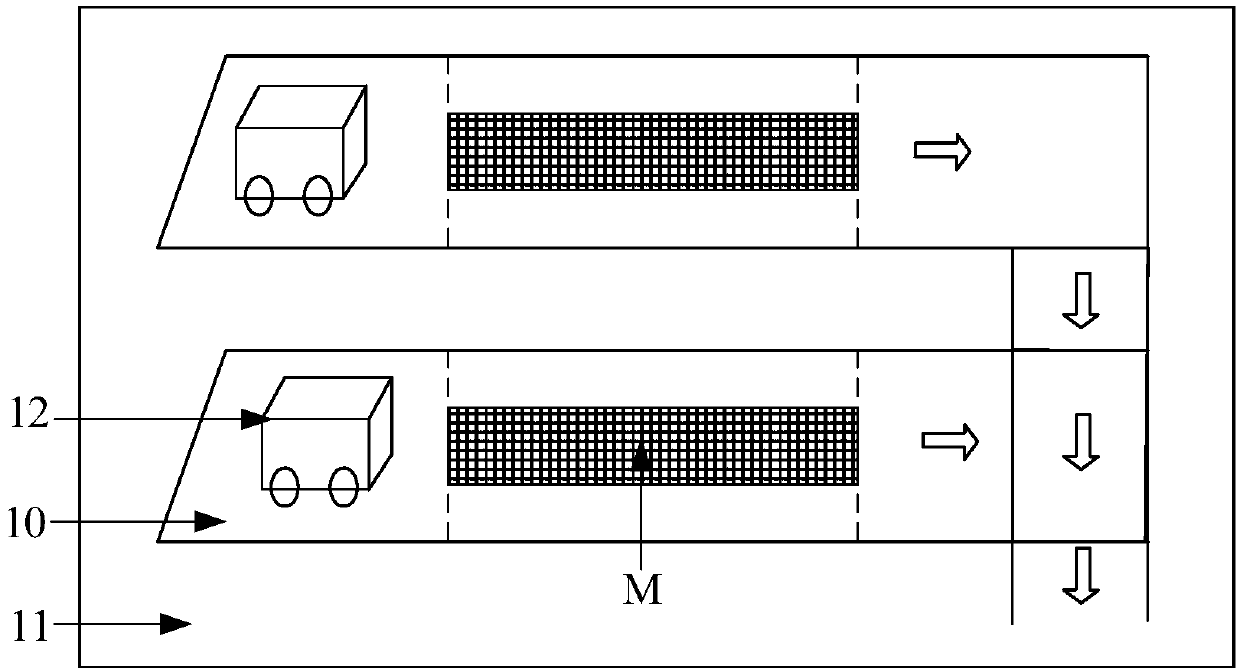

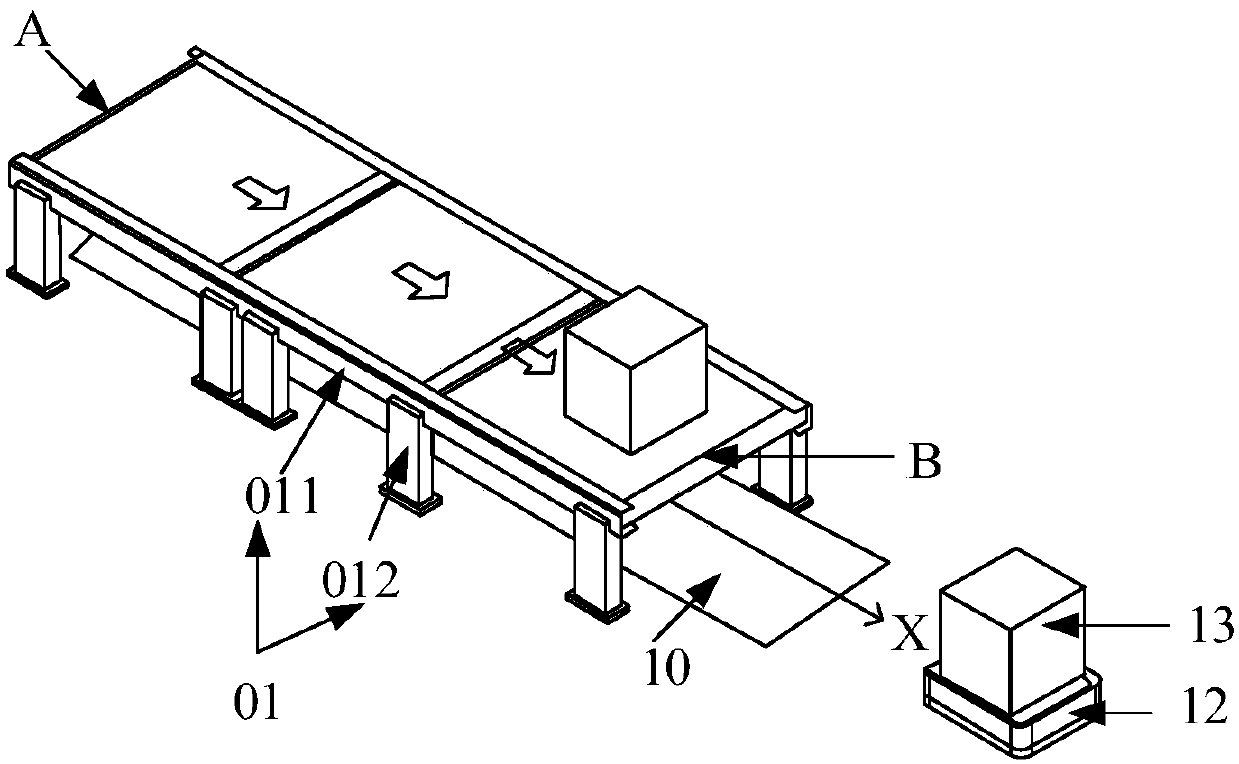

Automatic loading and unloading system, automatic loading method and automatic unloading method

PendingCN111573316ARealize automatic loadingImprove loading efficiencyLoading/unloadingLogistics managementTruck

The invention relates to an automatic loading and unloading system, an automatic loading method and an automatic unloading method, and belongs to the technical field of logistics systems. The automatic loading and unloading system involves a cargo bearing plate, submerged transferring devices, a traction loading and unloading operation device and a flexible conveying line, wherein the cargo bearing plate is used for being laid on a bottom plate of a truck carriage, the traction loading and unloading operation device is located between the submerged transferring devices and the flexible conveying line, the traction loading and unloading operation device is connected with the submerged transferring devices and the front end of the flexible conveying line, the traction loading and unloading operation device can drag the submerged transferring devices and the flexible conveying line to move in the front-back direction, and the submerged transferring devices, the traction loading and unloading operation device and the flexible conveying line can achieve cargo transferring. According to the automatic loading and unloading system, automatic loading and unloading on cargo can be achieved,labor and time are saved, and the logistics cost is reduced.

Owner:JIANGSU GUANCHAO LOGISTICS TECH CO LTD

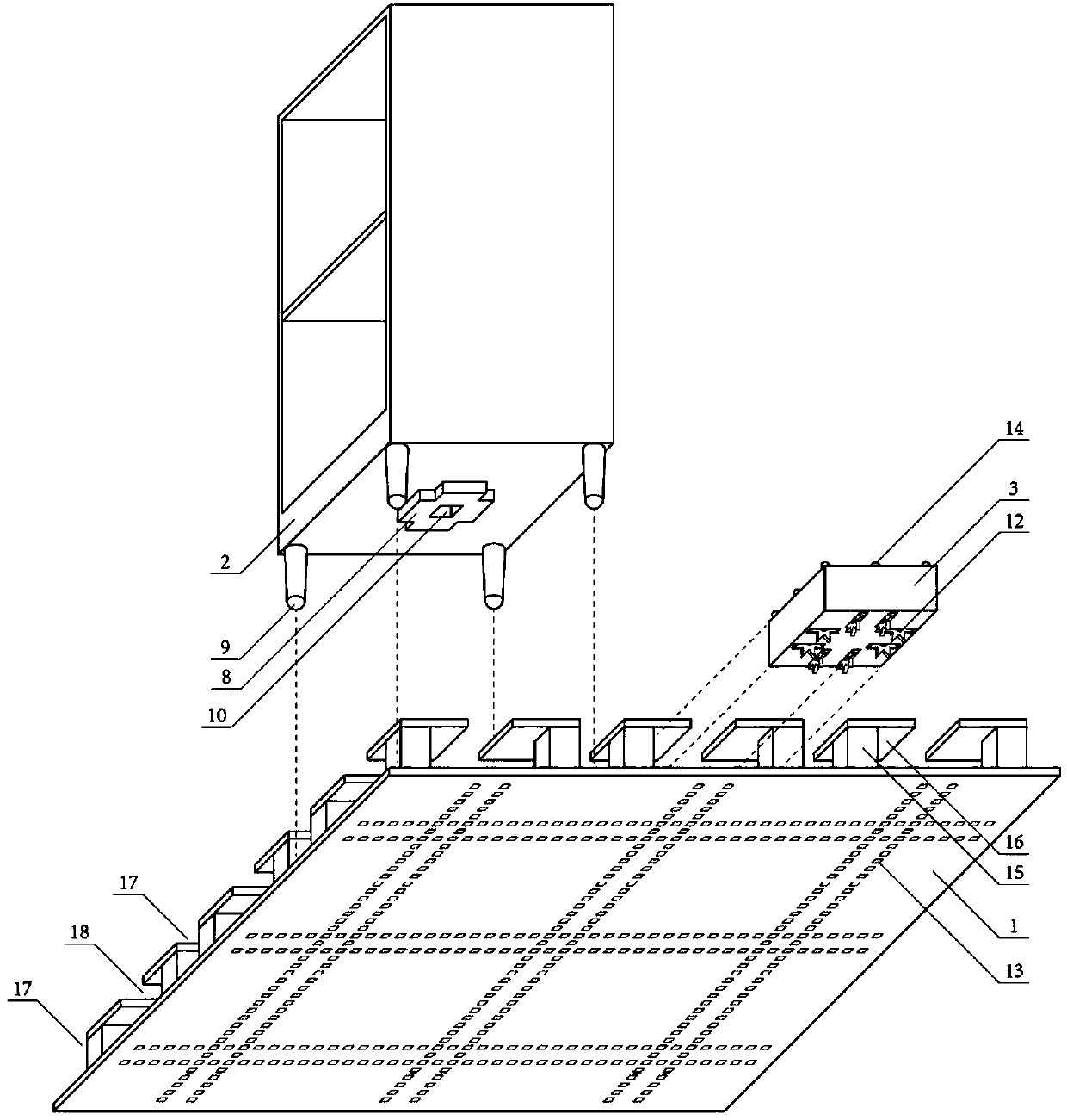

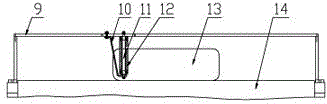

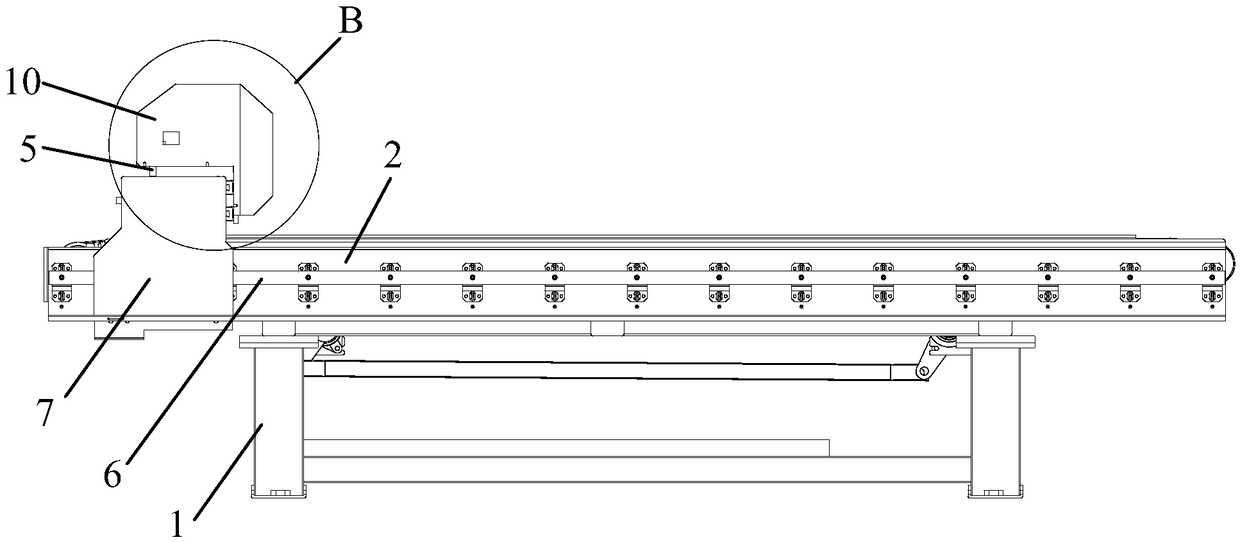

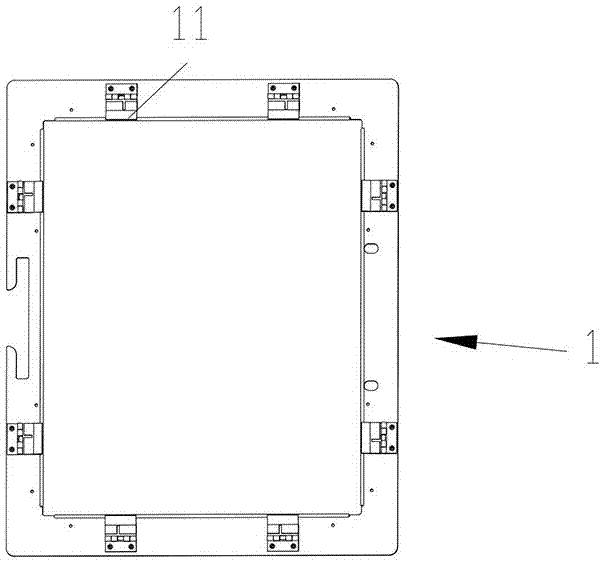

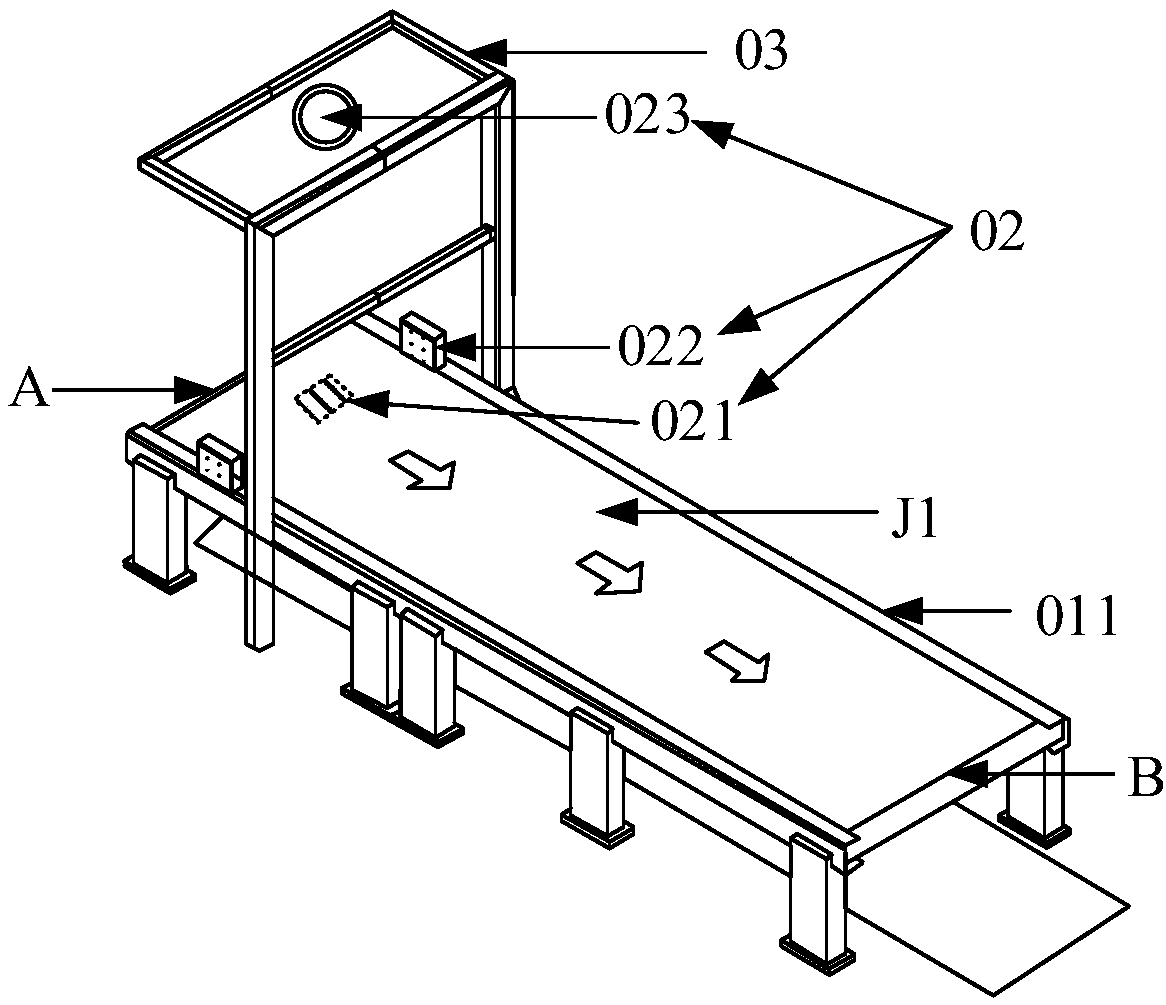

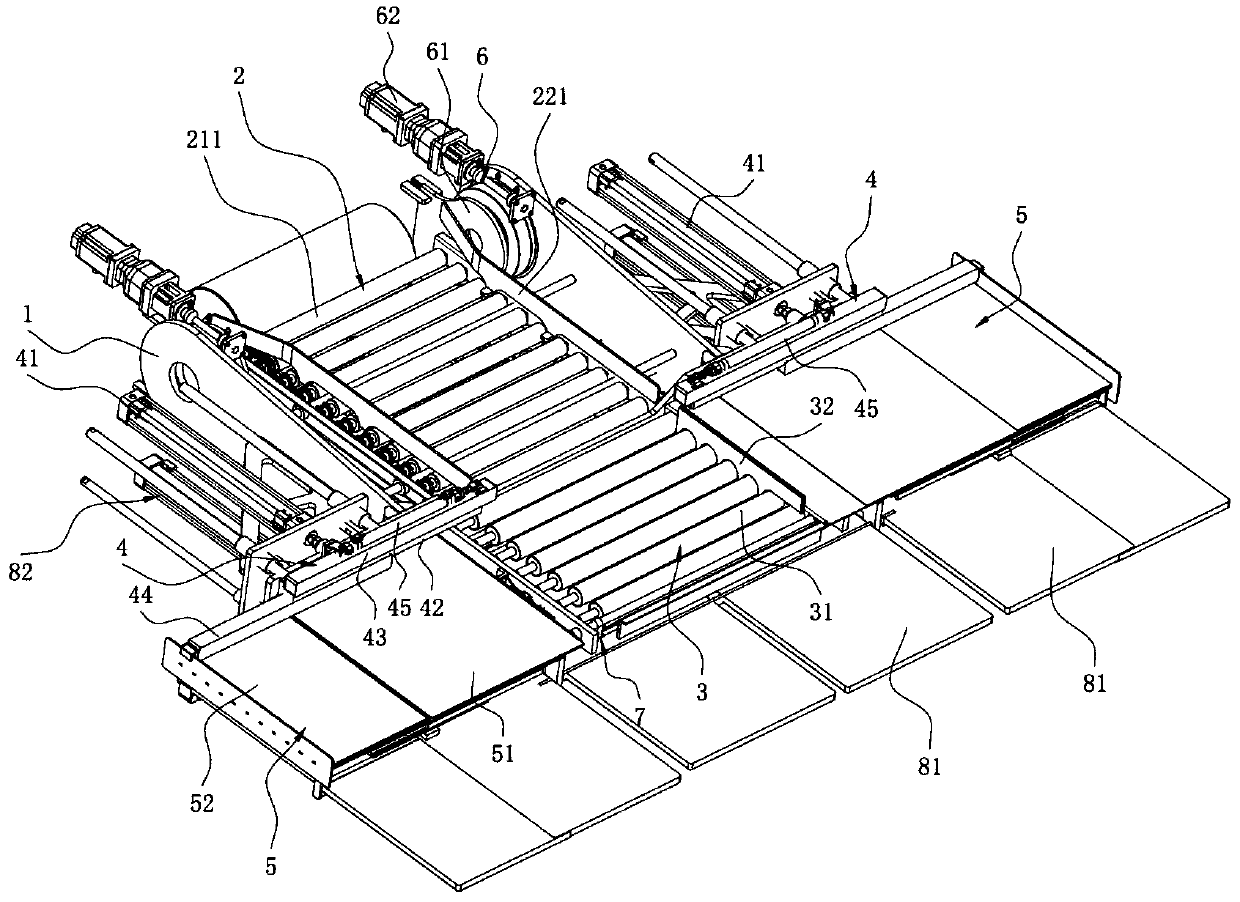

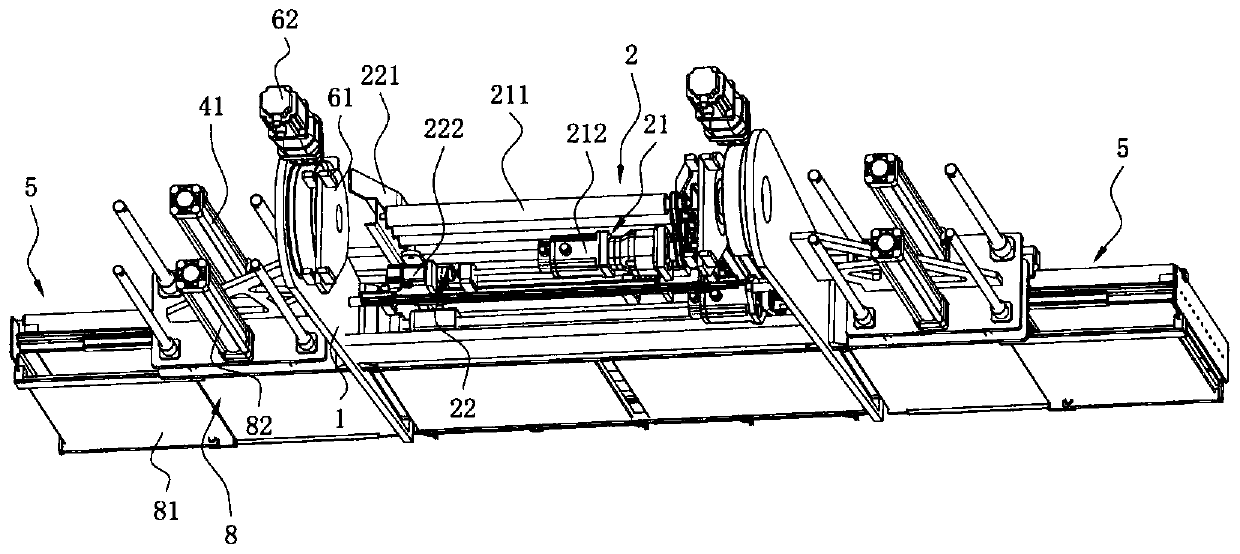

Full-automatic base plate size detection equipment and base plate detection line and detection method of base plate detection line

InactiveCN108057636AQuality improvementEffectiveSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTesting equipmentEngineering

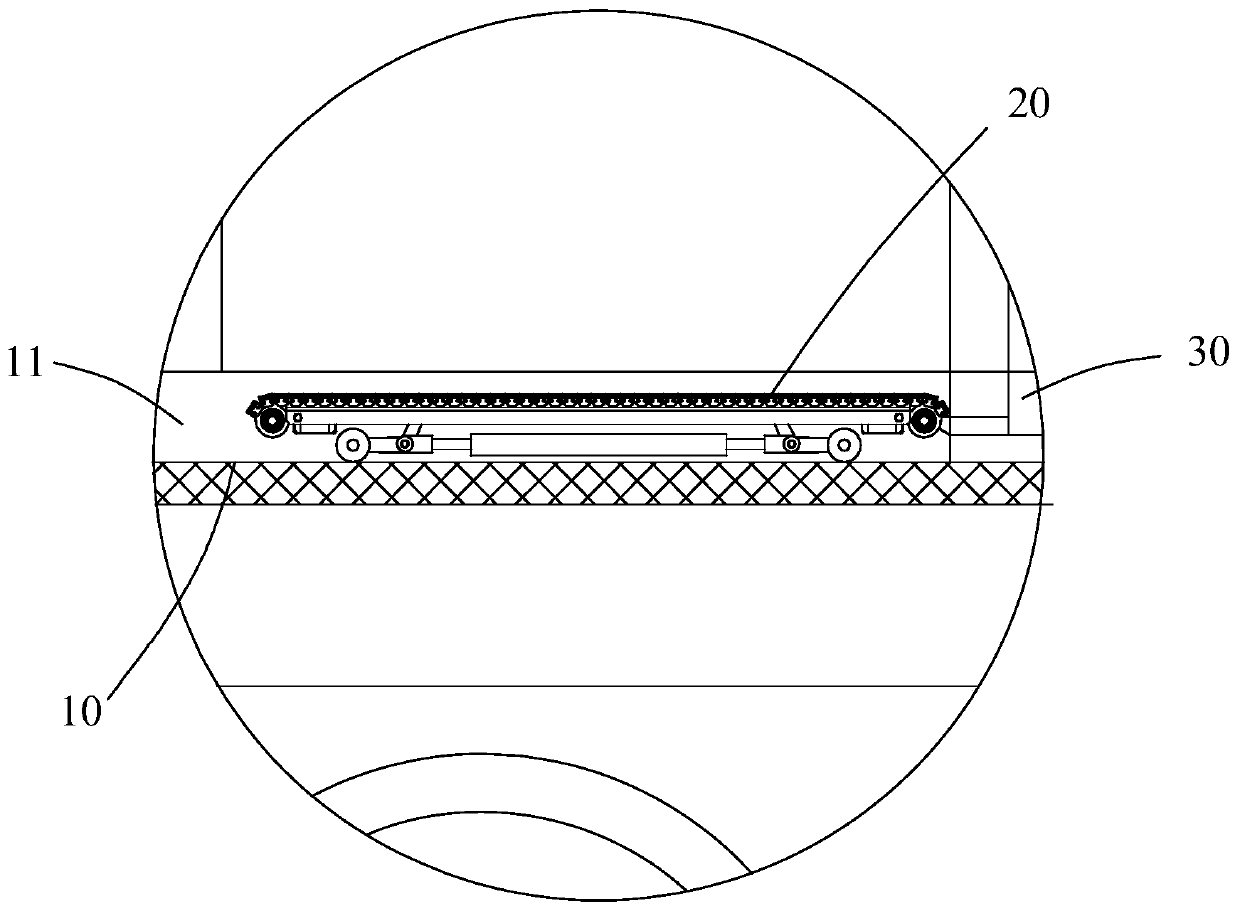

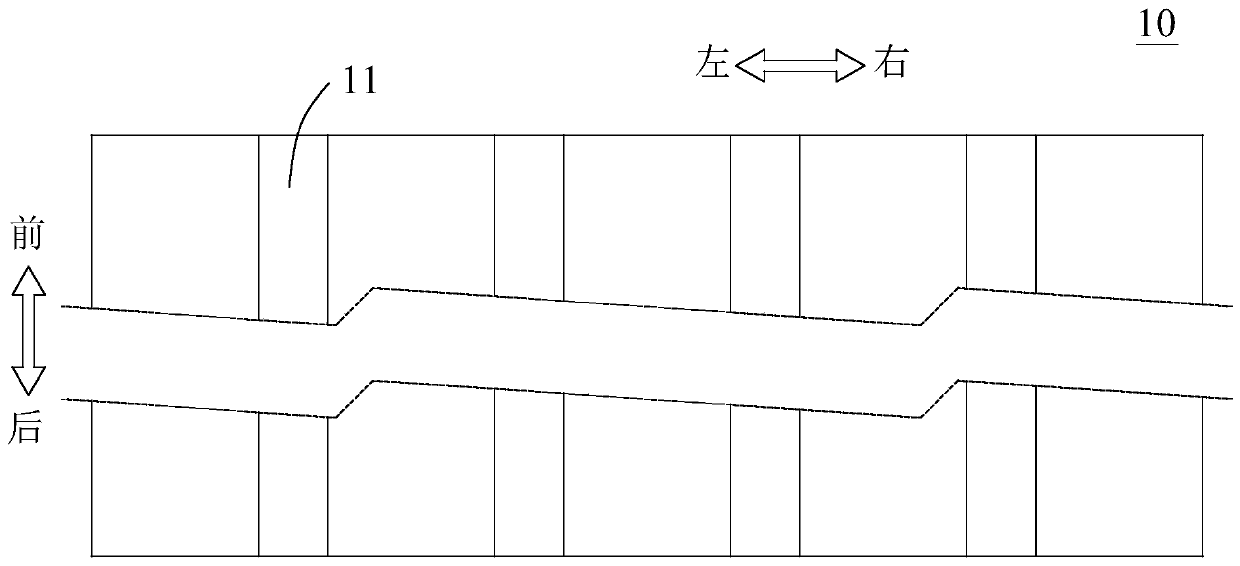

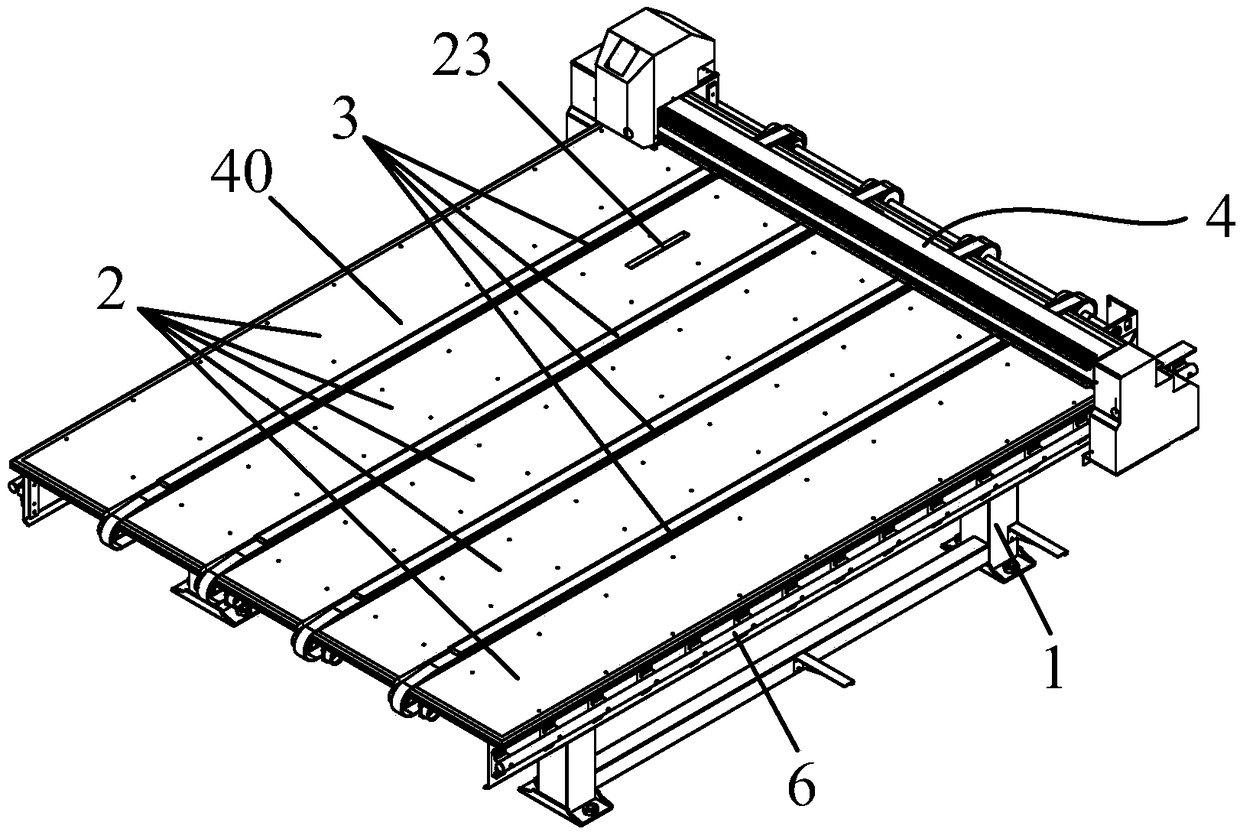

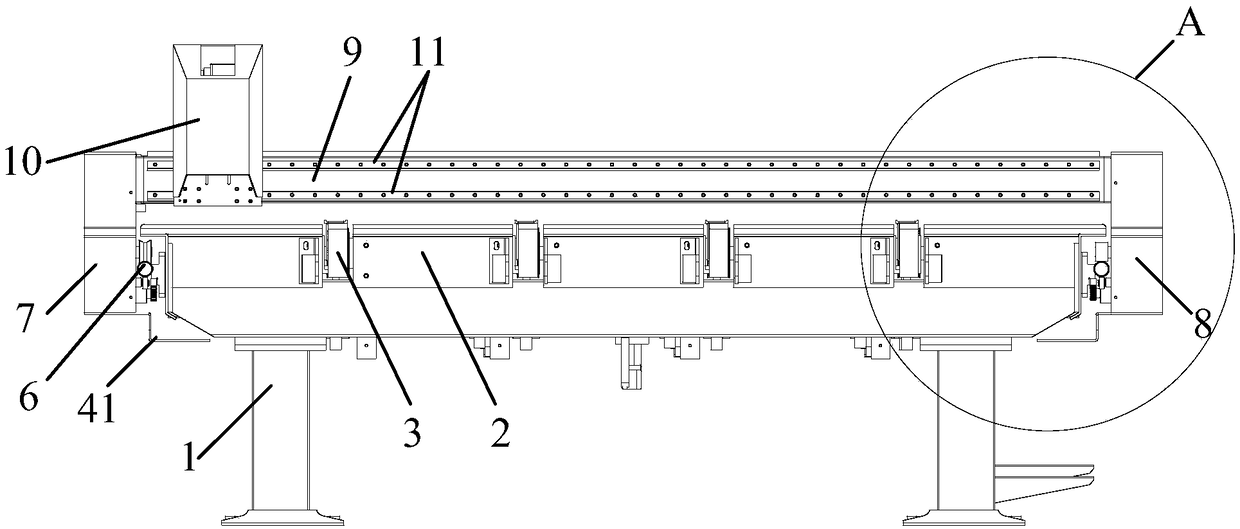

The invention discloses full-automatic base plate size detection equipment, a base plate detection line and a detection method of the base plate detection line. The full-automatic base plate size detection equipment comprises a main rack, a plurality of loading plates, conveying belts, a gate-type travelling mechanism and a laser sensor, wherein the plurality of loading plates are fixed to the main rack at equal intervals; one conveying belt is arranged between the two adjacent loading plates; travelling tracks are arranged on the loading plates located at the two sides along the length directions of the loading plates; the gate-type travelling mechanism is arranged on the traveling tracks; and the laser sensor is arranged on the gate-type travelling mechanism through a third travelling mechanism. The base plate detection line comprises an automatic feeding device, base plate size detection equipment and an unloading output table which are connected in sequence; and the base plate sizedetection equipment adopted by the base plate detection line is the full-automatic base plate size detection equipment. The full-automatic base plate size detection equipment can automatically detectthe size of a base plate to replace manual work and has the advantages of fast detection speed and high detection accuracy.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

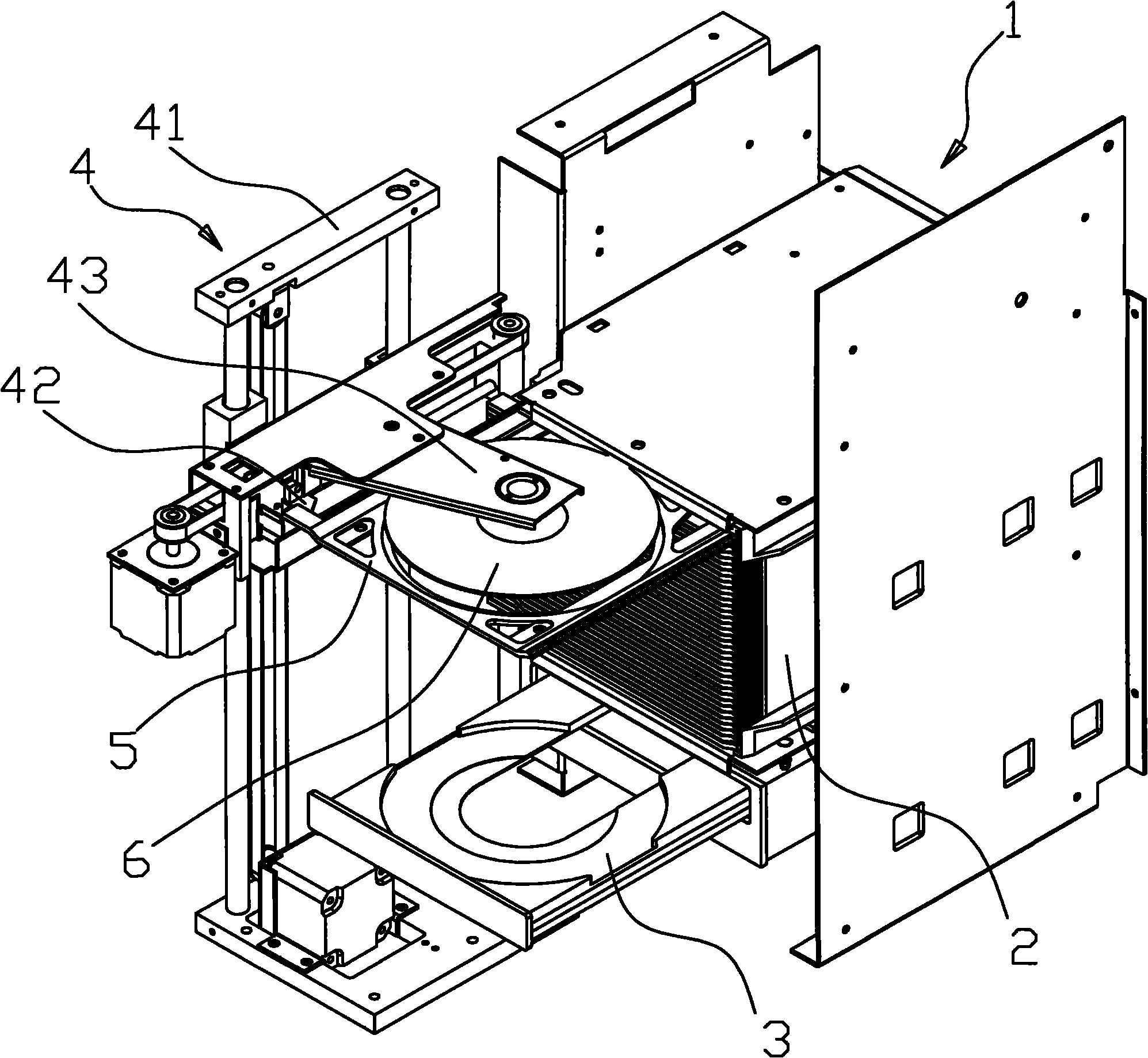

Method for automatically loading barreled CDs to CD cassette of MO jukebox

InactiveCN101794605AShorten the timeRealize automatic loadingRecord information storageEngineeringManipulator

The invention discloses method for automatically loading barreled CDs to a CD cassette of a MO jukebox. The method comprises the following steps: 1) placing a barreled CD cassette filled with the barreled CDs at a corresponding position on the MO jukebox; 2) driving a manipulator CD withdrawer and a manipulator CD gripper to lift to a vertical position corresponding to the barreled CD cassette by a manipulator lift; 3) withdrawing a tray of the barreled CDs from a cassette box of the barreled CD cassette to an open position by the manipulator CD withdrawer; 4) gripping the topmost CD on the tray of the barreled CDs by the manipulator CD gripper; and 5) lifting the manipulator CD withdrawer and the manipulator CD gripper to the position where a target unit is positioned by the manipulator lift, opening the target unit, and putting the CD on the manipulator CD gripper into the target unit. By using the method, the barreled CDs can be transferred into the CD cassette of the MO juke box automatically one by one and the MO jukebox dose not need stopping and is operated by people, and the CDs are not easily damaged.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

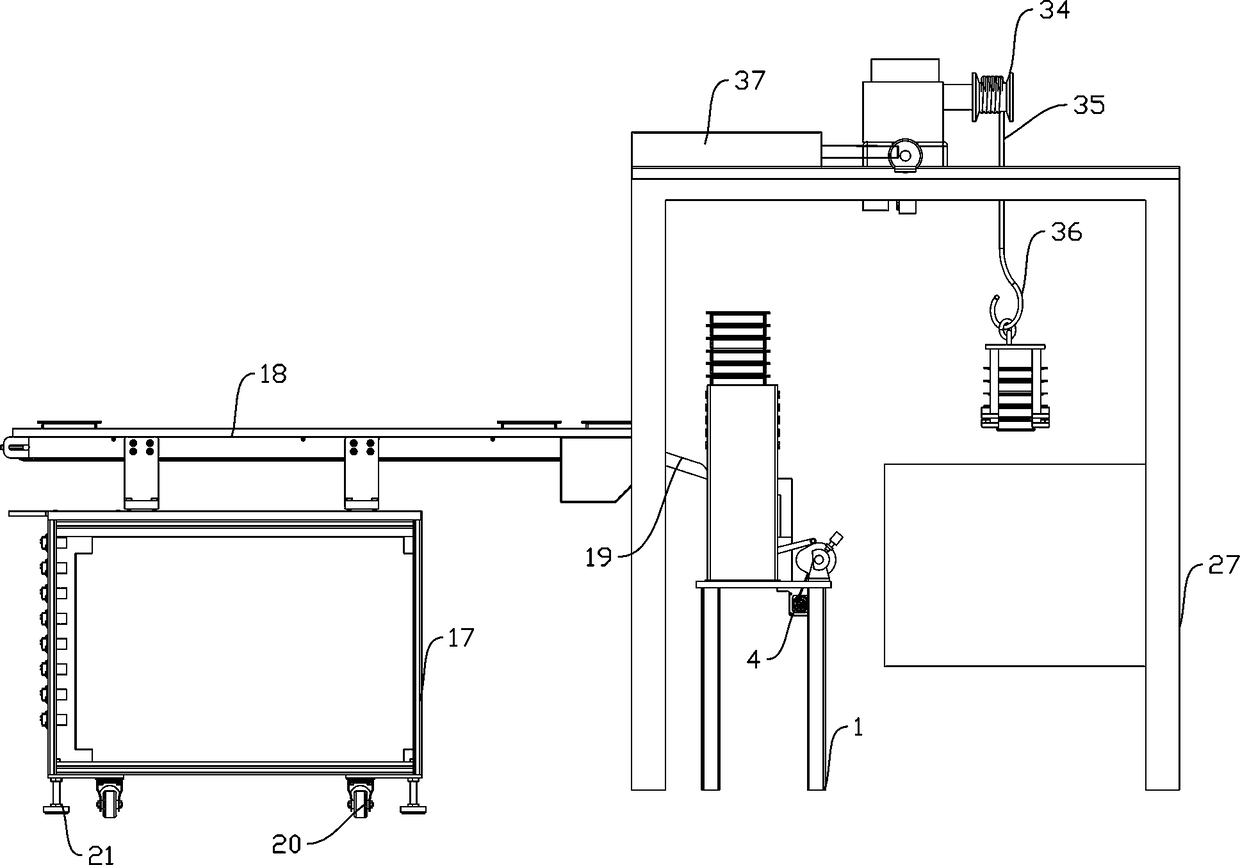

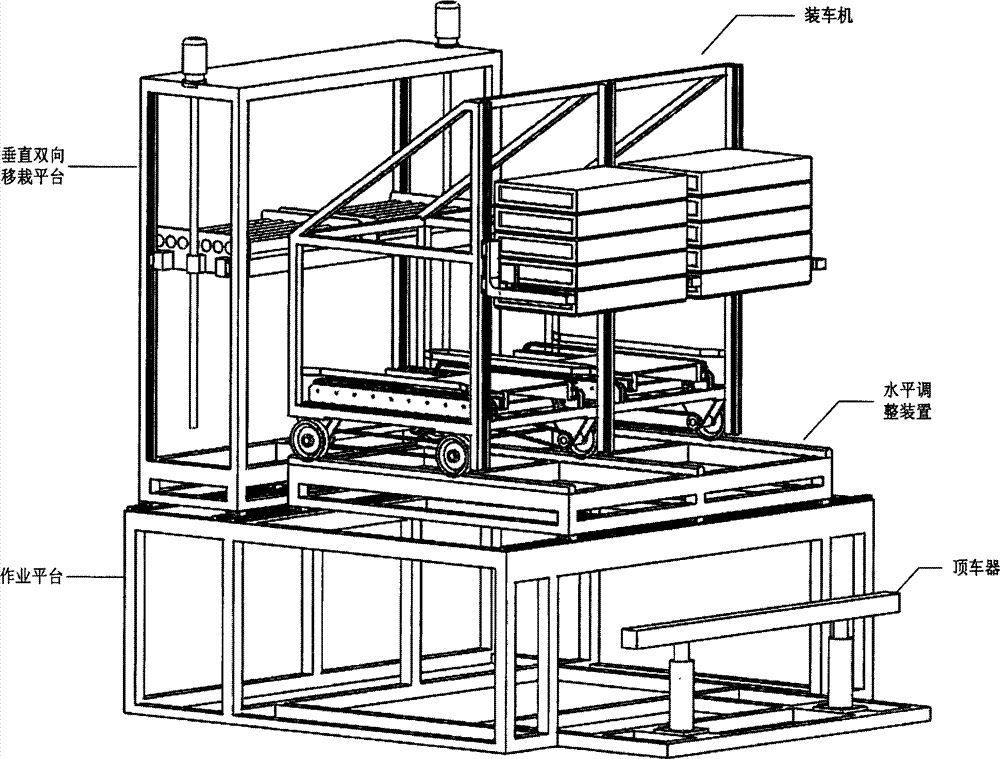

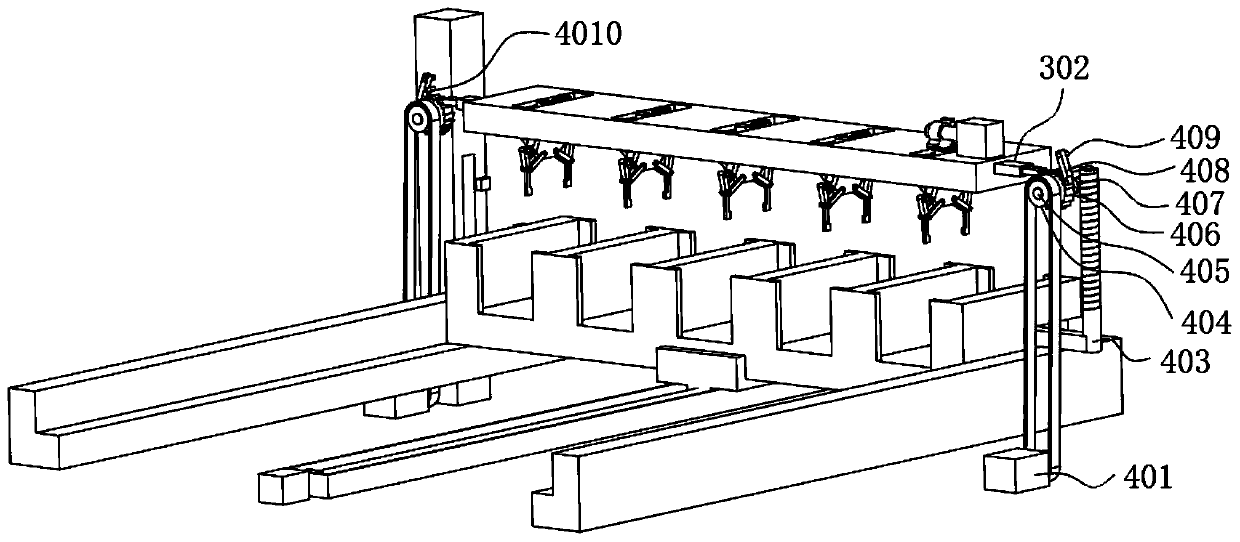

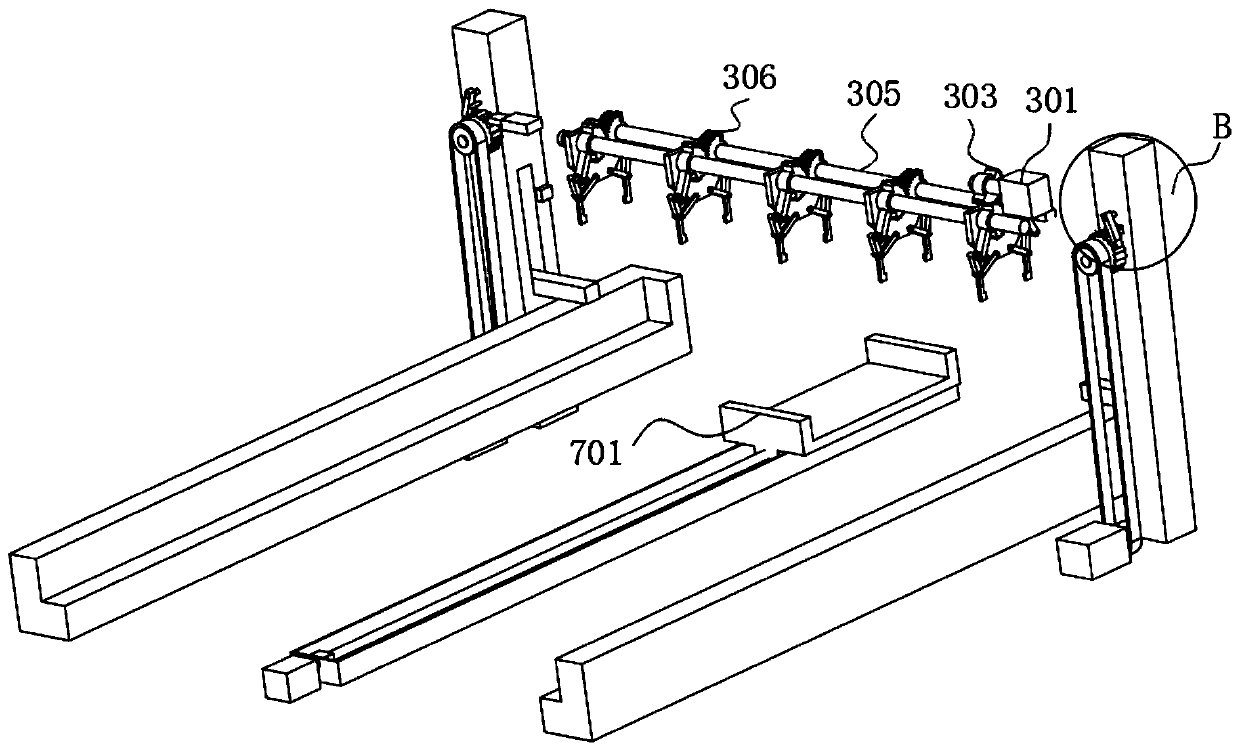

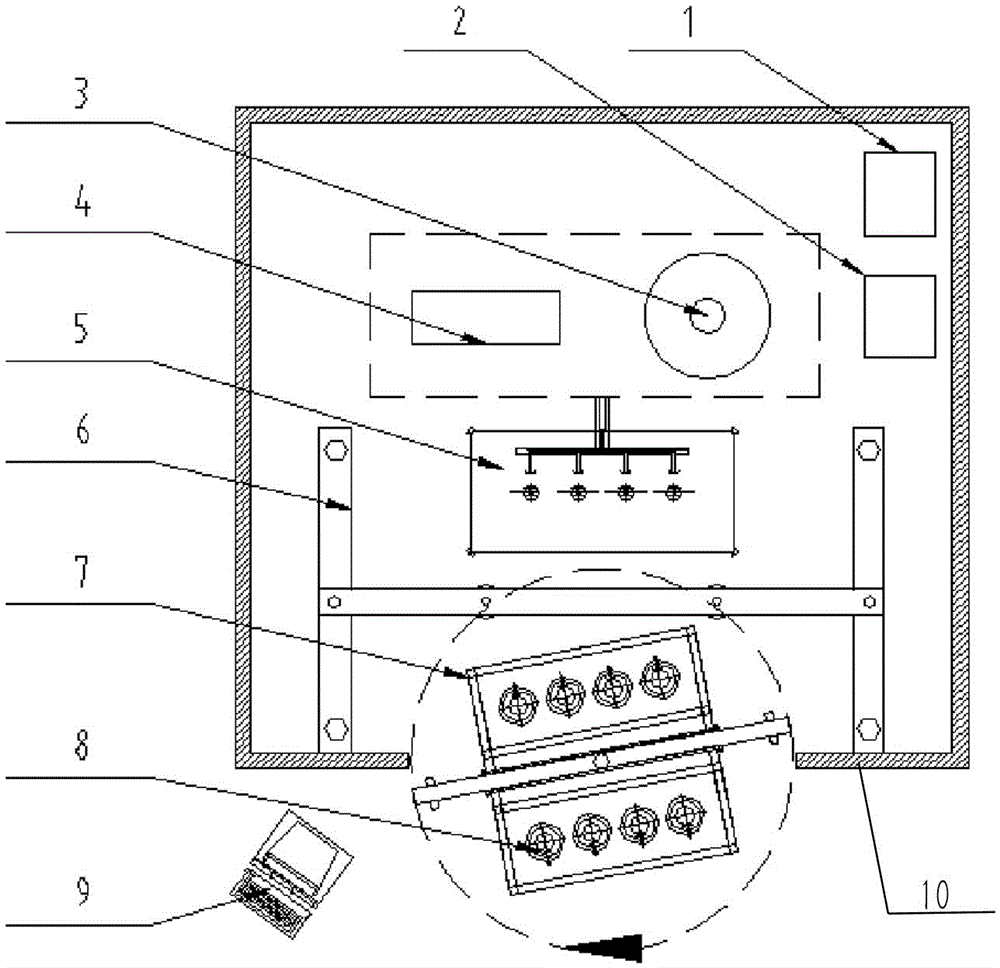

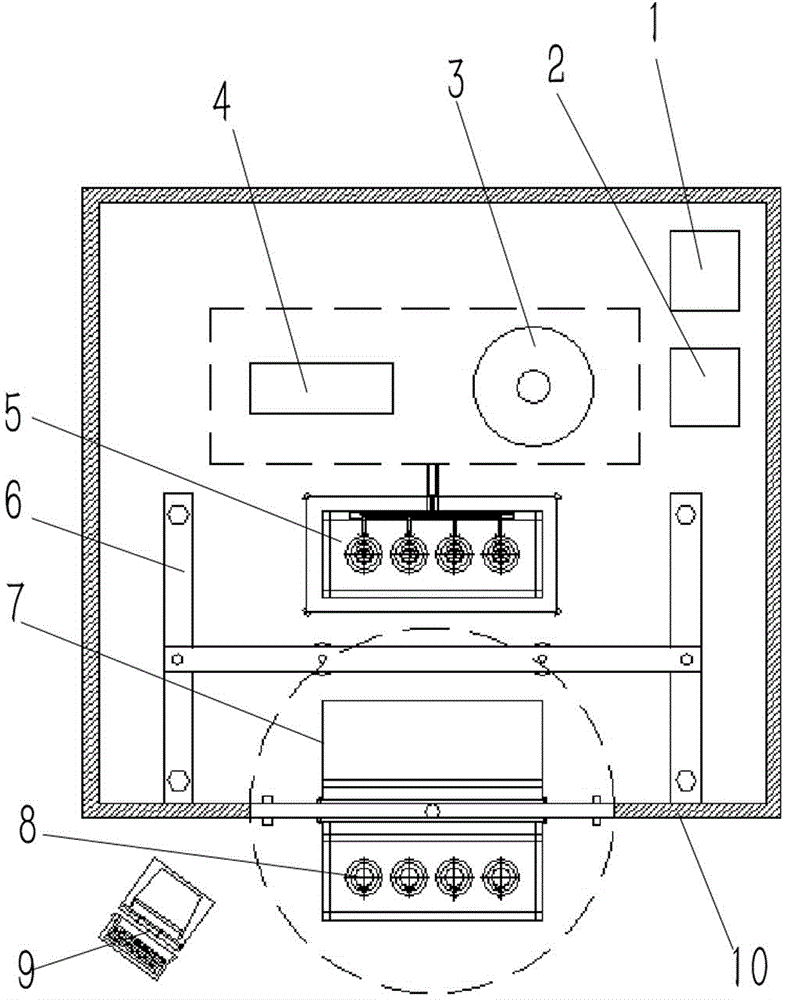

Automatic electricity meter turnover box loading system

InactiveCN103359490ARealize automatic loadingStacking articlesLoading/unloadingElectricityStopped work

The invention provides an automatic electricity meter turnover box loading system by which automatic loading of electricity meters from a stereoscopic warehouse to a truck. The system is composed of a connecting system, an automatic carrying and stacking robot and a backing induction system and connected with a stereoscopic warehouse conveying line and a truck compartment, and is in communication with an upper-layer control platform. After the system is successfully connected with the stereoscopic warehouse conveying line, the truck compartment and the upper-layer control platform, the system starts to check out-of-warehouse information and order information at a warehouse outlet in real time, if the out-of-warehouse information is not coincident with the order information, the system stops working and gives an alarm, and restarts working after the alarm is eliminated; if the out-of-warehouse information is coincident with the order information, a turnover box is conveyed to a vertical two-way transplanting platform of the system by the conveying line and then conveyed onto a loading machine, and the loading machine grabs two stacks of the electricity meters, moves along rails to corresponding positions in the truck compartment for stacking and then returns to an operating platform to receive next two stacks of the electricity meters. On-site actual working tests show that the automatic electricity meter turnover box loading system is good in effect, so that the problem that existing electricity meter loading is high in intensity and low in efficiency.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY

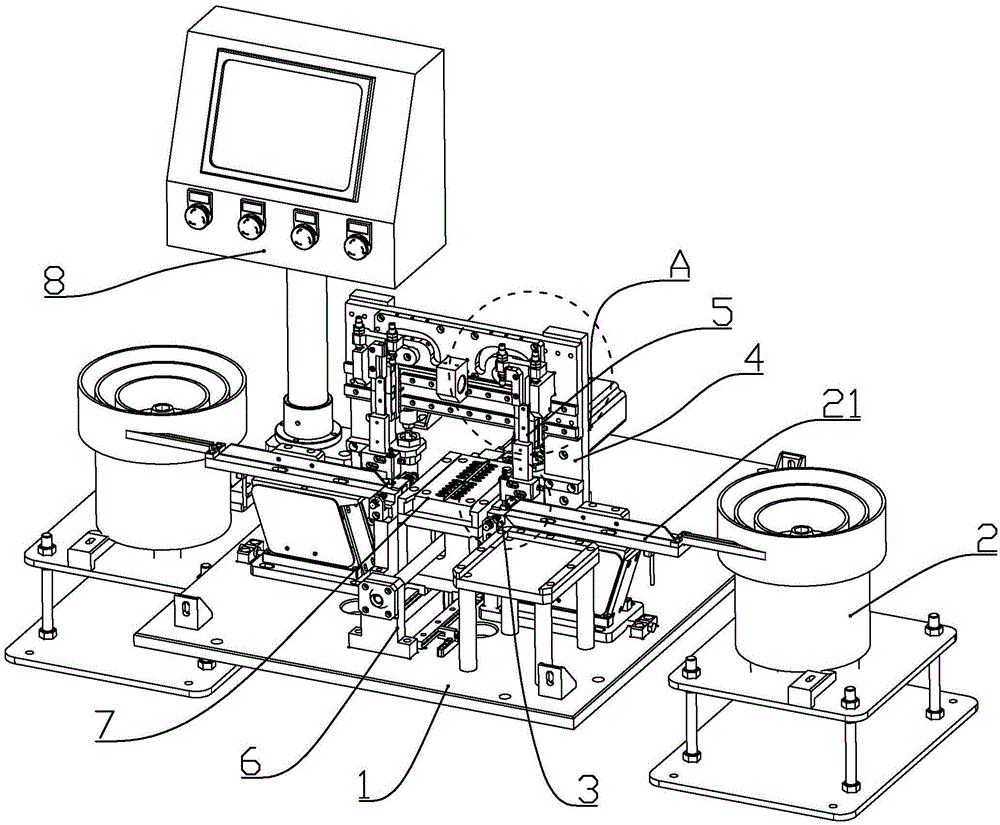

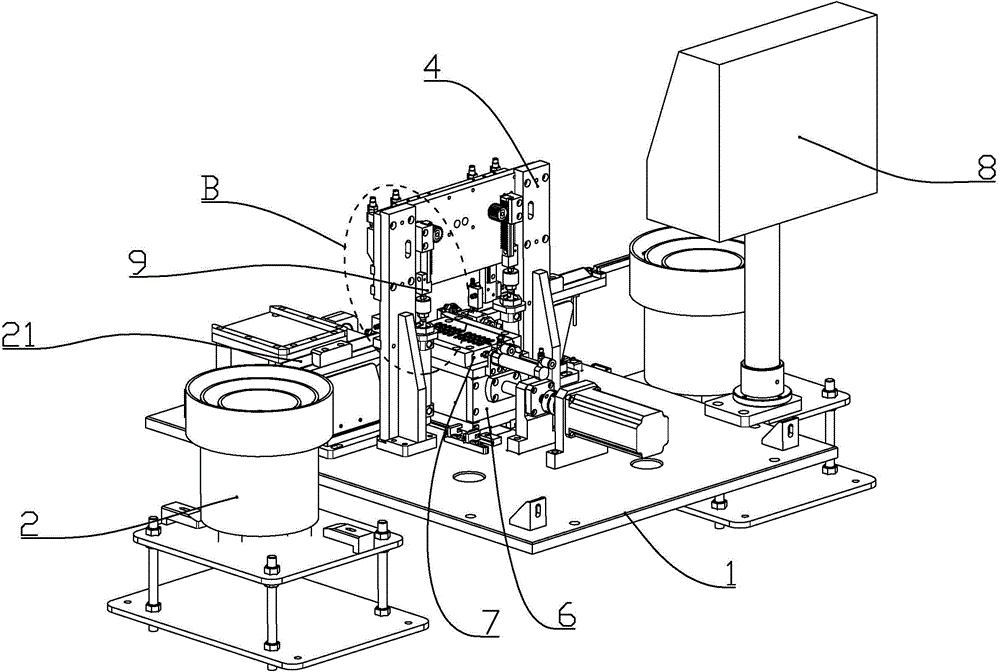

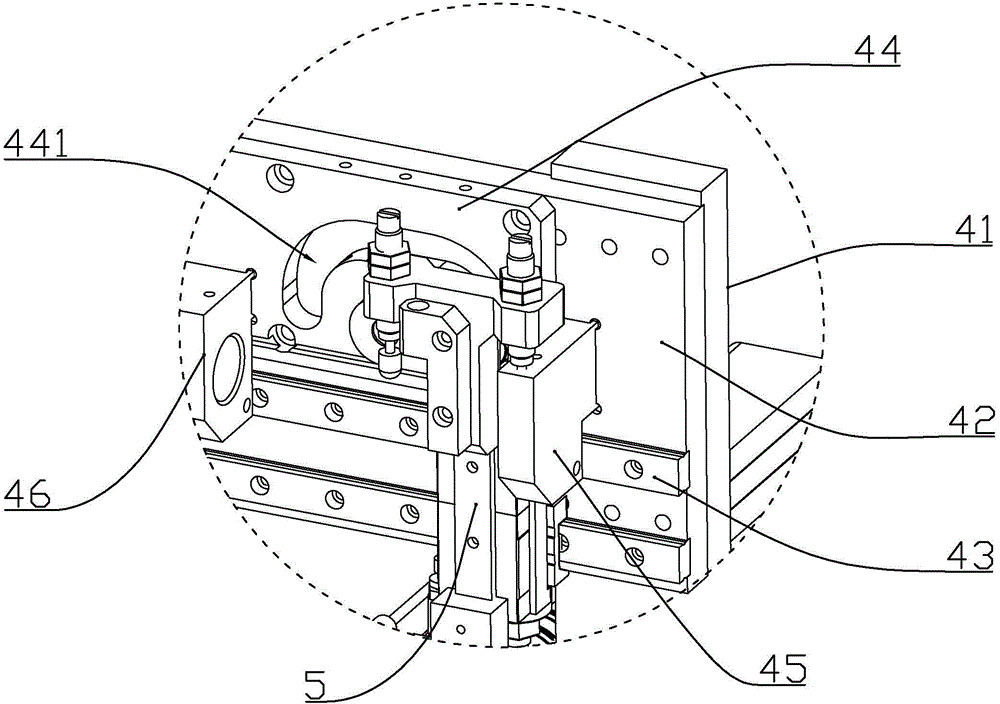

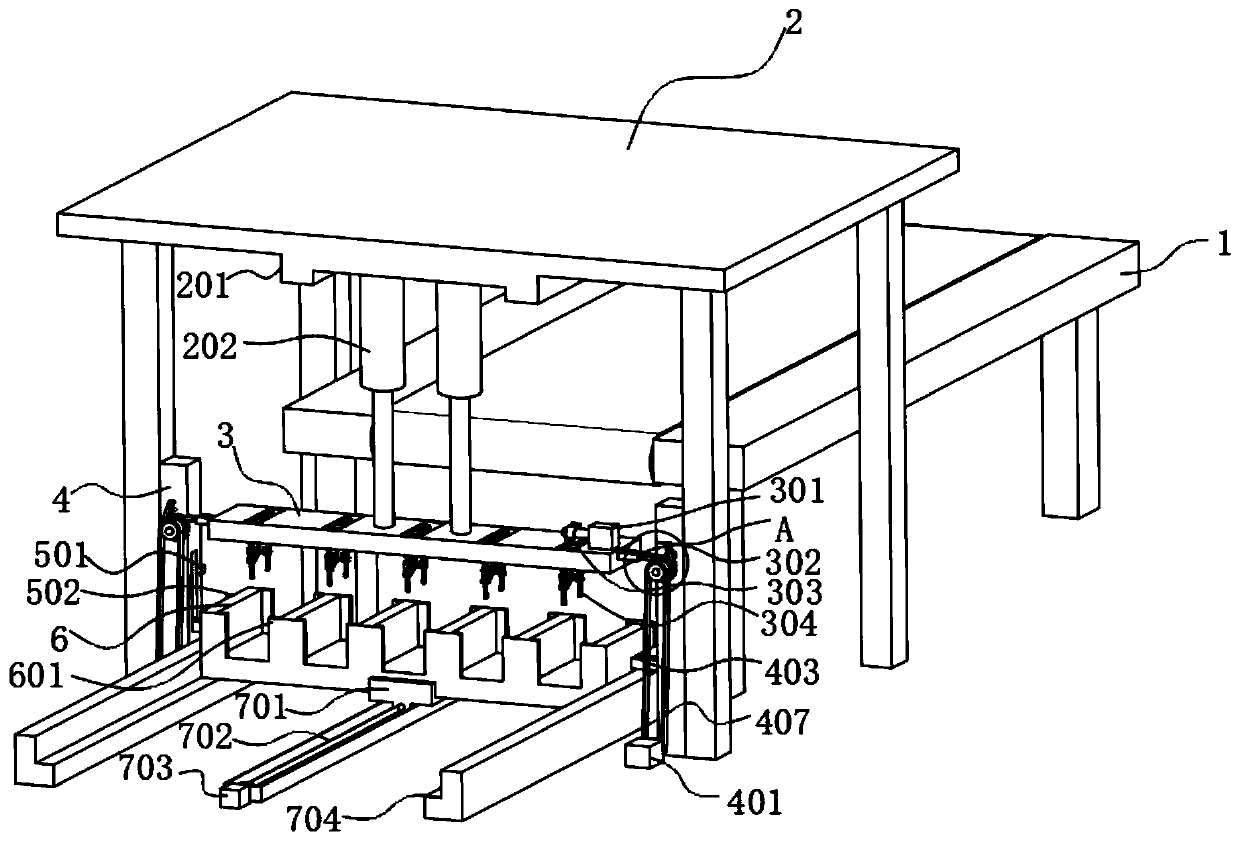

Device for automatically loading nose pad insert of glasses

The invention discloses a device for automatically loading a nose pad insert of a pair of glasses. The device for automatically loading the nose pad insert of the pair of glasses comprises a base, a mould moving mechanism which is arranged on the base and used for fixing a mould and horizontally conveying the mould, a feeding mechanism which is arranged on the base and is arranged at the two sides of the mould moving mechanism, a vibration feeding mechanism which is arranged on the base and is connected with a feeding end of the feeding mechanism, a material moving frame which is arranged on the base and is perpendicular to a moving direction of the mould, a material moving mechanism which is arranged on the material moving frame and used for carrying an insert to the mould from the feeding mechanism and a driving mechanism which is arranged on the material moving mechanism and used for driving the material moving mechanism to move. The device for automatically loading the nose pad insert of the pair of glasses has the advantages that the insert is conveyed to the feeding mechanism by virtue of the vibration feeding mechanism, then the insert is carried and loaded onto the mould by driving the material moving mechanism by virtue of the driving mechanism, automatic loading of the insert is realized, production efficiency is greatly improved, and production cost is reduced.

Owner:TAIZHOU LUQIAO QIPING GLASS FITTINGS

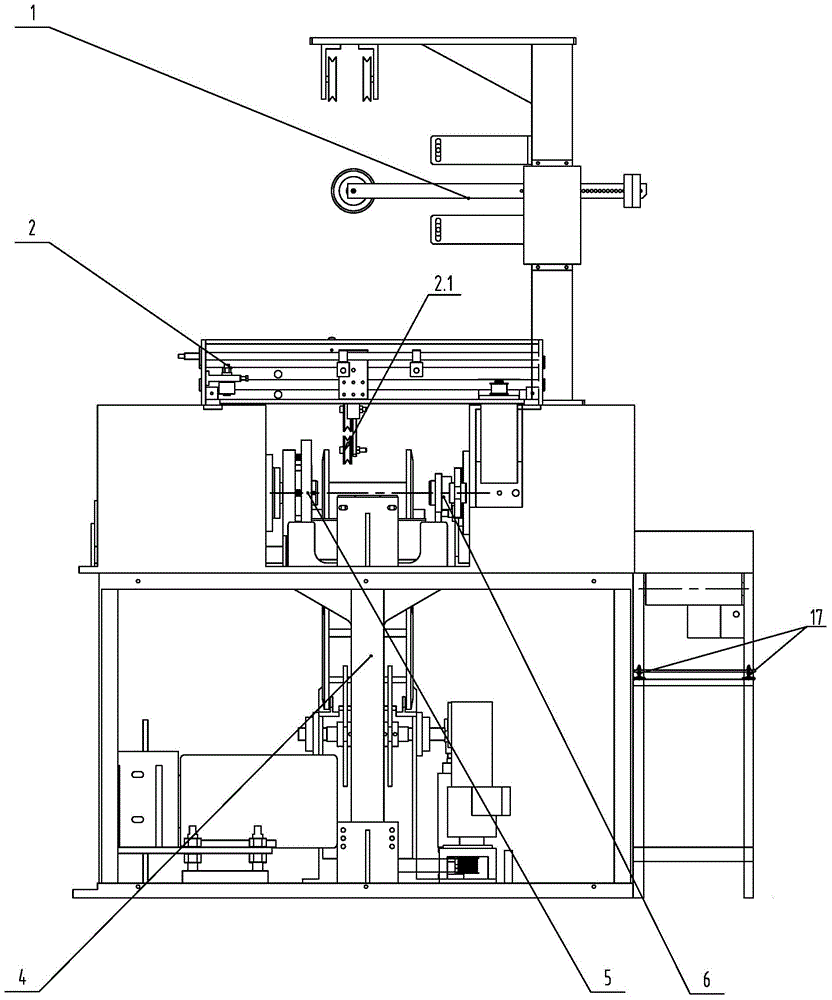

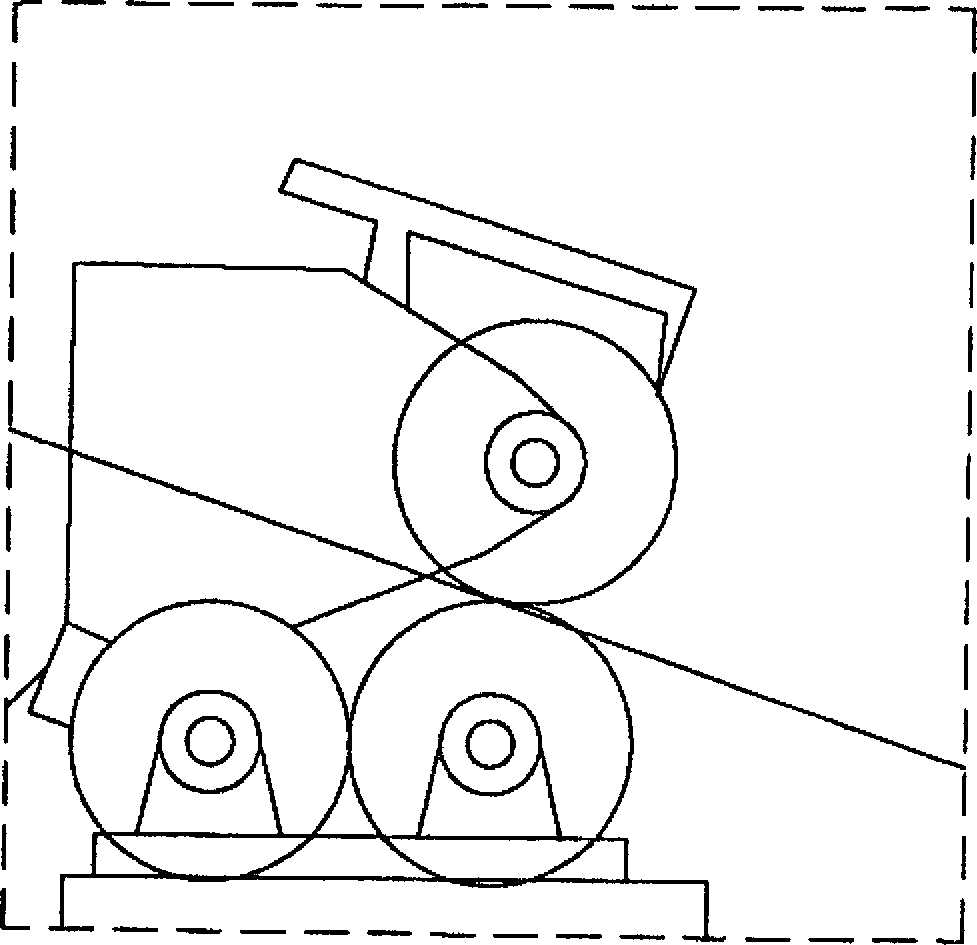

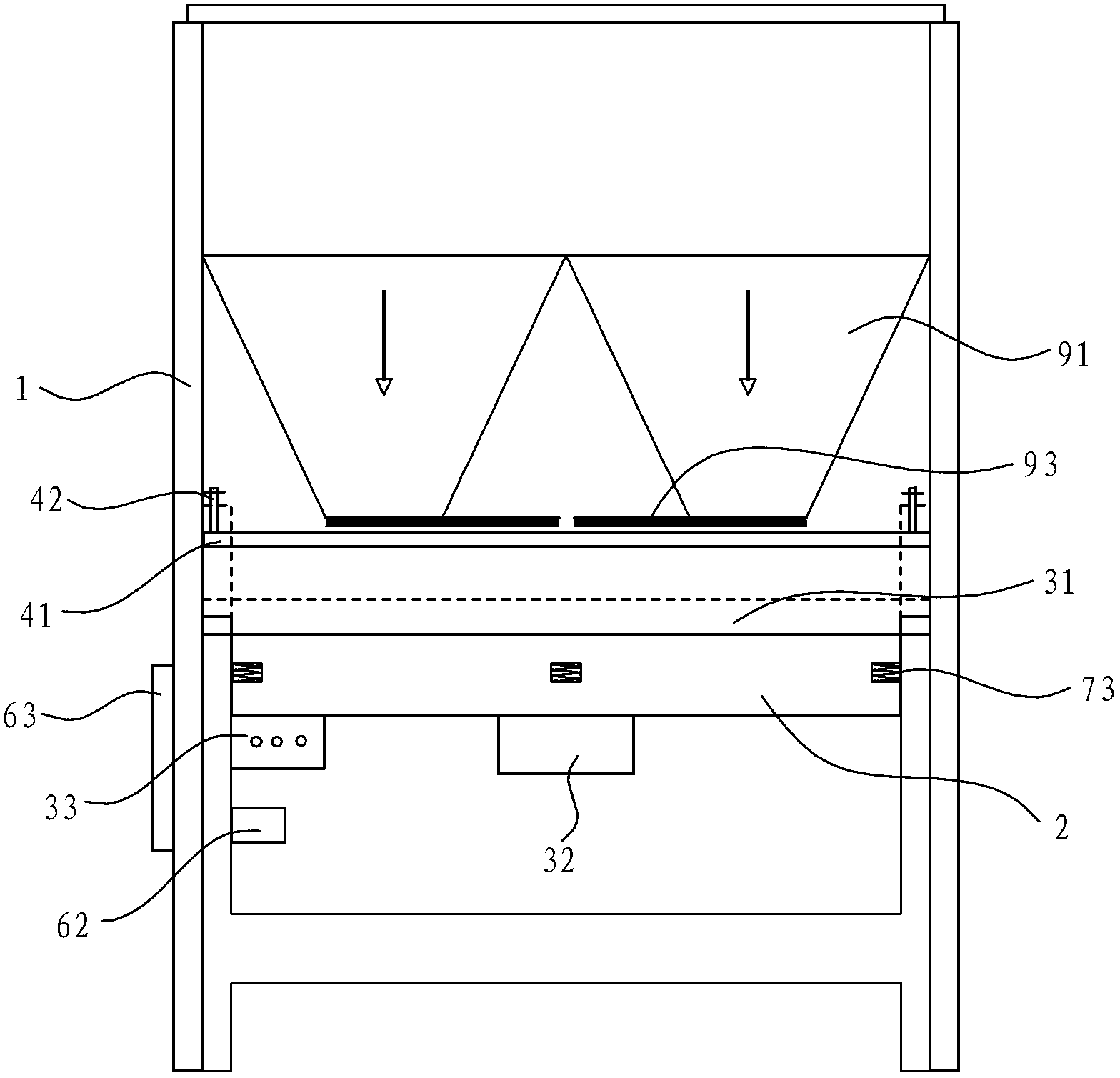

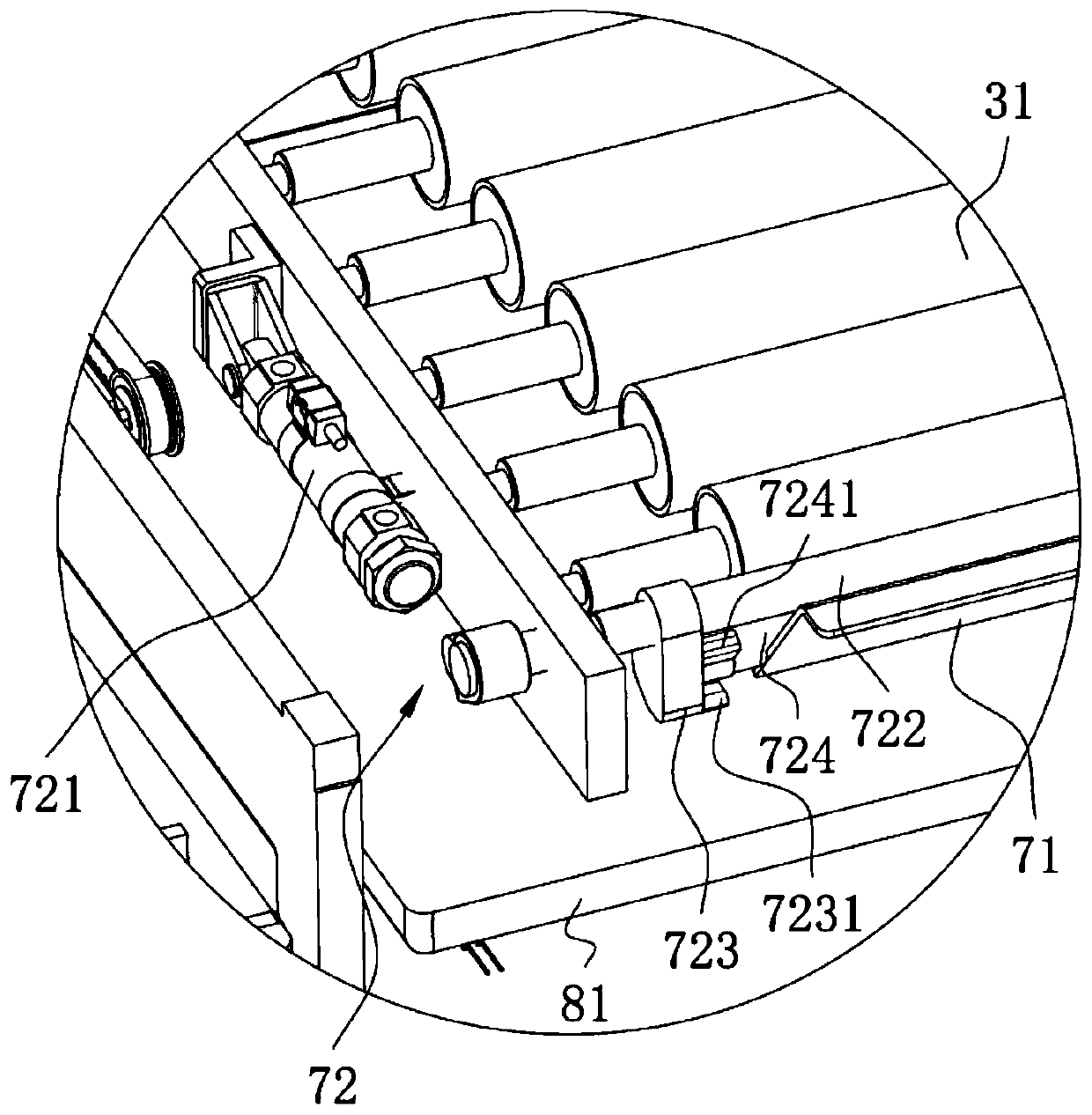

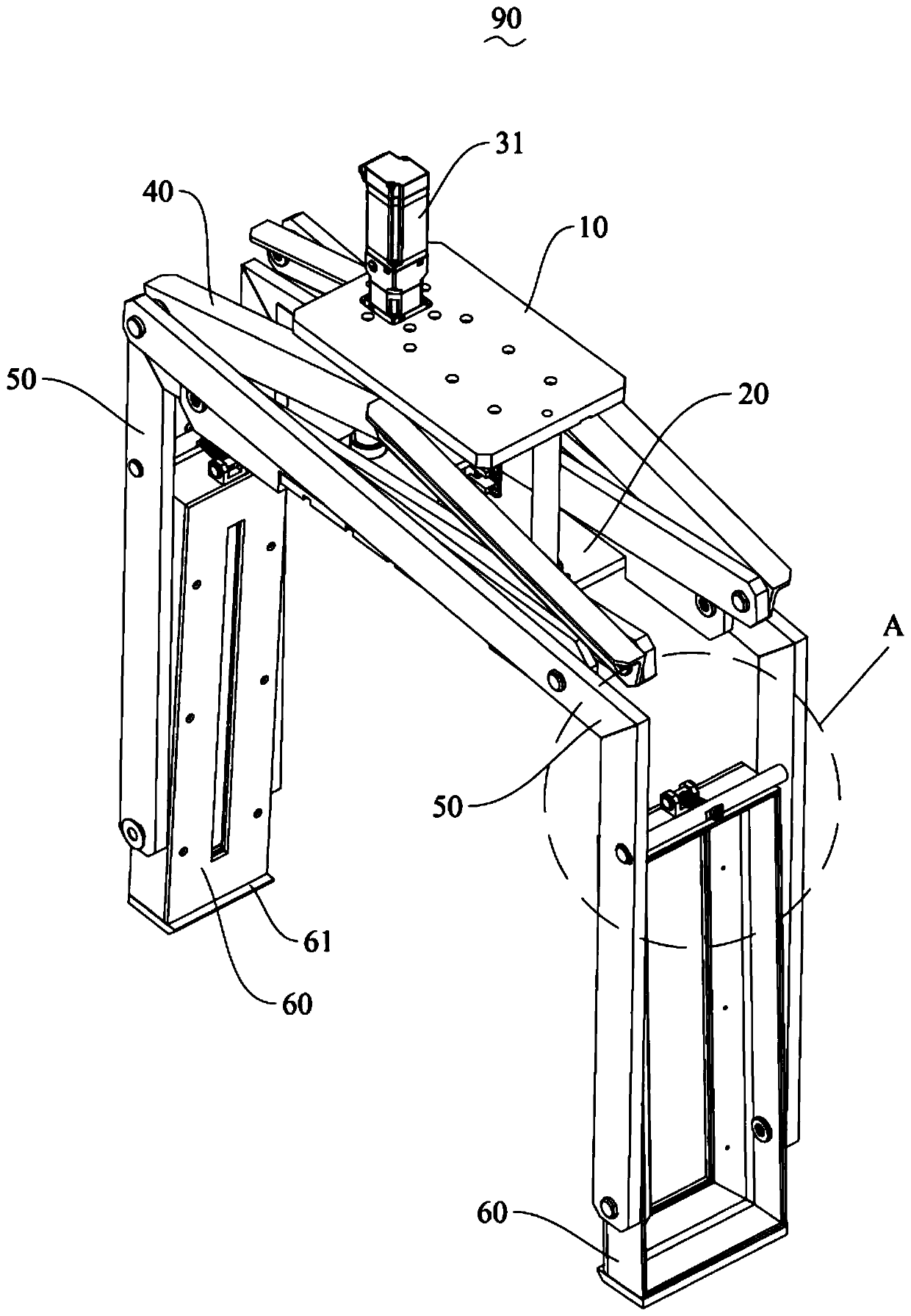

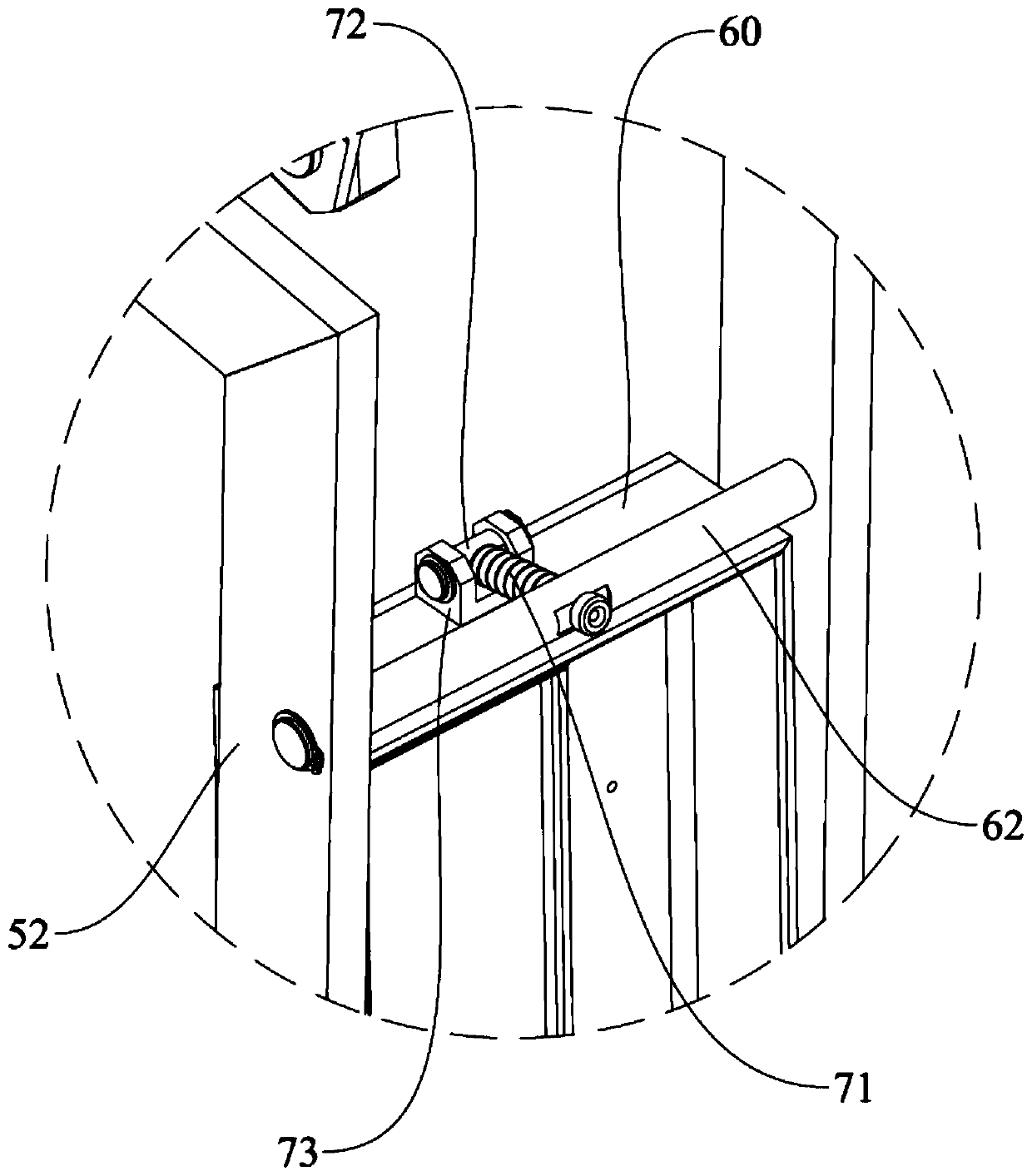

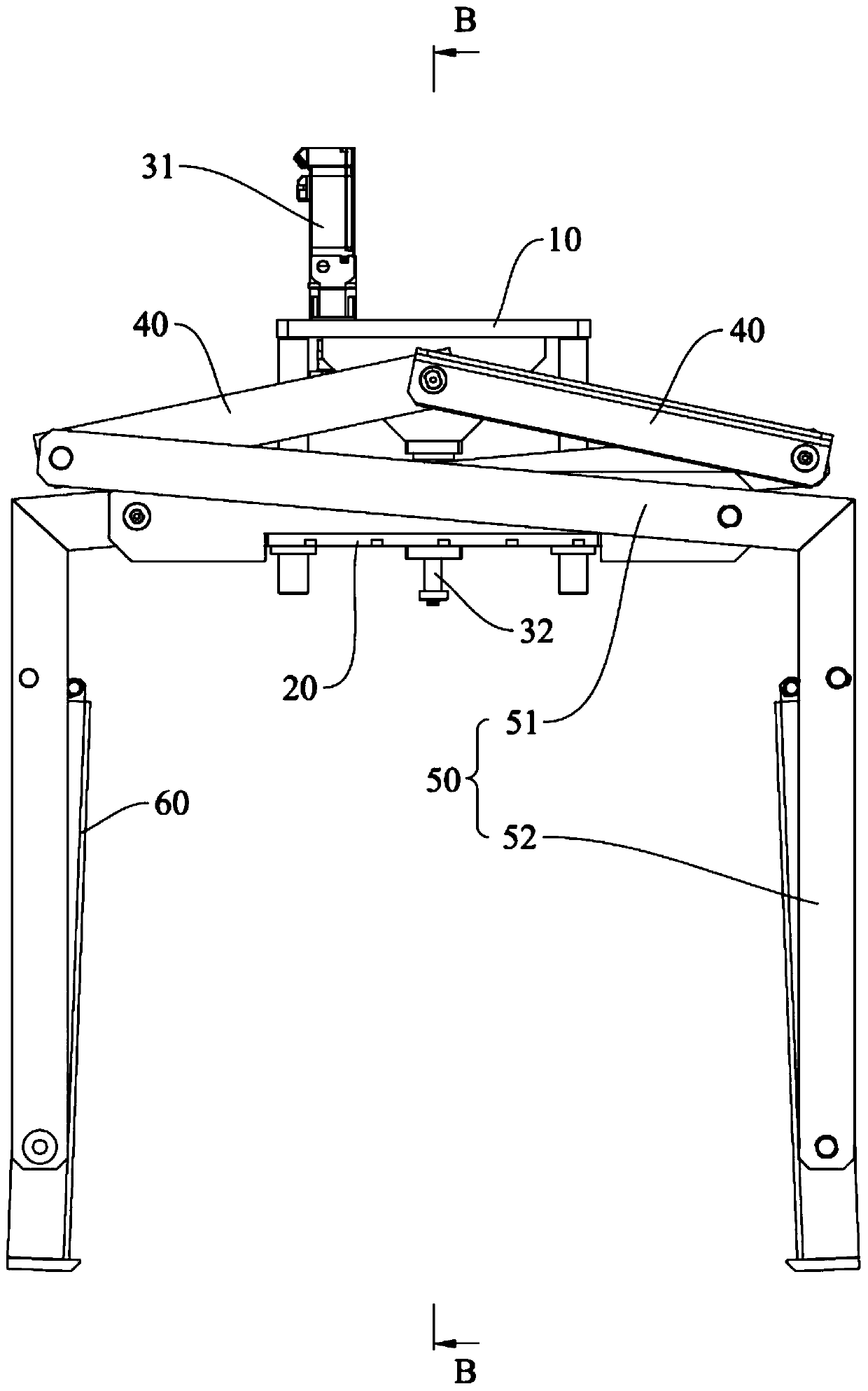

Automatic wheel replacing take-up machine

InactiveCN105253712AAvoid many problems such as scroll offsetImprove stabilityFilament handlingButt jointWorkload

The invention discloses an automatic wheel replacing take-up machine which comprises a conveying device and a winding device. I-shaped wheels used for winding are placed vertically, in this way, the problems of rolling, off-tracking and the like during conveying of the I-shaped wheels are solved, and the stability during conveying is improved. According to the automatic wheel replacing take-up machine, an automatic guided vehicle (AGV) can be in seamless butt joint with the conveying device directly, the purposes of automatic wheel mounting, automatic wheel dismounting and transferring are achieved, the workload is reduced, and the working efficiency is improved. By arranging a lifting air cylinder, a lower ejector pin is driven to make the I-shaped wheels to ascend and descend, each I-shaped wheel full of wires can be descended onto the conveying device along with the lower ejector pin, the damage to the machine caused when the I-shaped wheels are dismounted after the I-shaped wheels are full of wires is avoided, the service life of the machine is prolonged, the reliability of the machine is improved, long-term stable operation at an industry scene can be achieved, and automation of the industry is achieved in a real sense. In addition, by arranging a sticking device, a tail wire can be fixed automatically, transportation is convenient, manual participation is not needed in the whole process, and the automation degree is high.

Owner:王波

Badminton detection machine

ActiveCN111054645AImprove detection efficiencyImprove detection qualitySortingLight sourceReal-time computing

The invention discloses a badminton detection machine. The badminton detection machine comprises a frame body, a controller, a badminton feeding mechanism, a detection mechanism and a badminton discharging mechanism, wherein the badminton feeding mechanism, the detection mechanism and the badminton discharging mechanism are in signal connection with the controller; the detection mechanism comprises a rotating disc, rotating stations, an upper camera, a side camera and a light source, wherein the rotating stations are evenly distributed on the rotating disc and can keep a rotating state relative to the rotating disc; and the upper camera and the side camera correspond to the tops and the side faces of the rotating stations on detection positions at the same time, and the badminton feeding mechanism and the badminton discharging mechanism correspond to the rotating stations correspondingly. The structure of the badminton detection machine achieves automatic badminton feeding and detection and automatic sorting after detection, greatly improves the detection efficiency, improves the detection quality, is high in sorting precision and good in stability, and can be used in cooperation with all kinds of automatic badminton production equipment.

Owner:林先明

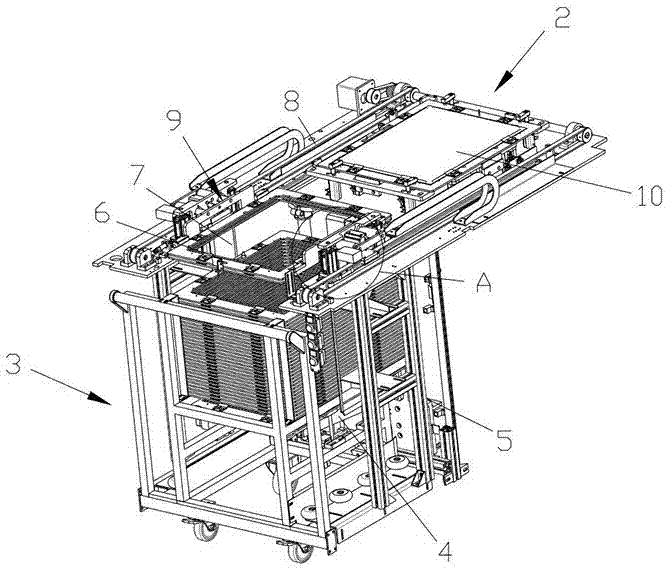

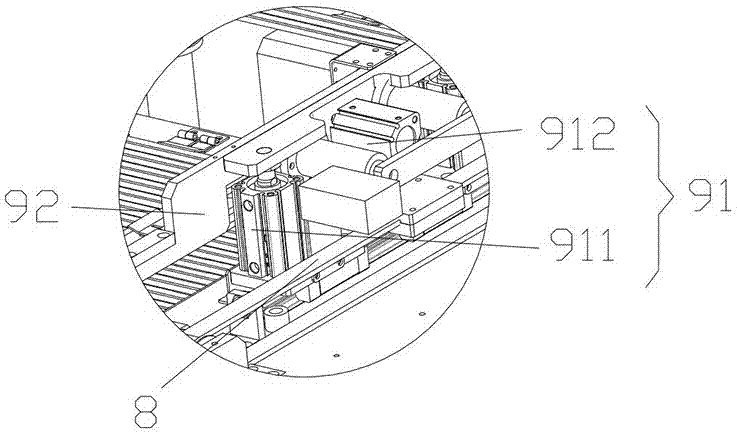

Tray transferring mechanism

PendingCN107128675ARealize automatic loadingAchieve separationConveyorsStacking articlesEngineeringTransfer mechanism

The invention relates to the technical field of circuit board processing production, in particular to a tray transferring mechanism which comprises a tray storage vehicle used for storing a tray, a transferring table used for bearing the tray and a transferring assembly used for conveying the tray between the transferring table and the tray storage vehicle. The transferring assembly is provided with two first guide rails and two tray clamping parts movably connected to the two first guide rails correspondingly. The two tray clamping parts are used for clamping the two sides of the tray. The tray transferring mechanism has the beneficial effects that the tray transferring mechanism is reasonable in structural design, automatic loading or separation of a circuit board and the tray is achieved, automatic feeding and discharging of the tray are achieved, production efficiency is improved, and production cost is reduced.

Owner:XUNDE MACHINERY DONGGUAN CO LTD

Automatic crawler-type loading shovel

InactiveCN106284453AReduce labor intensityIncrease the speed of excavationMechanical machines/dredgersSmall footprintShovel

The invention discloses an automatic crawler-type loading shovel. The automatic crawler-type loading shovel comprises a rack assembly, a loading shoveling mechanism arranged in front of the rack assembly, walking mechanisms arranged on the two sides of the rack assembly, a control mechanism which is arranged above the left side of the rack assembly to control the whole loading shovel to work, a power mechanism for providing power for the automatic crawler-type loading shovel and a transport mechanism arranged on the rack assembly; the automatic crawler-type loading shovel is a novel efficient deslagging transport device for underground mine tunneling, the loading shovel is used for tunneling of a small section, a medium section and a large section, the automatic crawler-type loading shovel works on the tunneling face, and the heavy deslagging and transporting tasks are completed. According to the scheme, the shovel has the automatic functions of slagging off and slag removal, and is easy and convenient to operate, low in labor intensity of operators, flexible, small in occupied area, good in site adaptation, safe, stable, reliable and capable of greatly increasing the engineering tunneling speed.

Owner:安徽宏昌机电装备制造有限公司

Cargo loading device of automatic guided vehicle, control method of cargo loading device and control system of cargo loading

PendingCN109720830AImprove efficiencyRealize automatic loadingControl devices for conveyorsSortingEngineeringMechanical engineering

The invention relates to a cargo loading device of an automatic guided vehicle, a control method of the cargo loading device and a control system of the cargo loading, and belongs to the field of logistics. The cargo loading device comprises a cargo loading conveying table and a control assembly, the cargo loading conveying table further comprises a cargo supporting platform and a driver for driving the cargo supporting table to move, the cargo supporting platform is provided with a cargo inlet and a cargo outlet, the control assembly can control the cargo supporting platform to convey cargoesfrom the cargo inlet to the cargo outlet through the driver, and the cargoes are conveyed to a carrying vehicle through the cargo outlet. According to the cargo loading device, automatic loading of the cargos is realized, and the loading efficiency and accuracy of the cargos are improved; and the cargo loading device, the control method and the control method are used for loading the cargos in logistics transportation.

Owner:HANGZHOU HIKROBOT TECH CO LTD

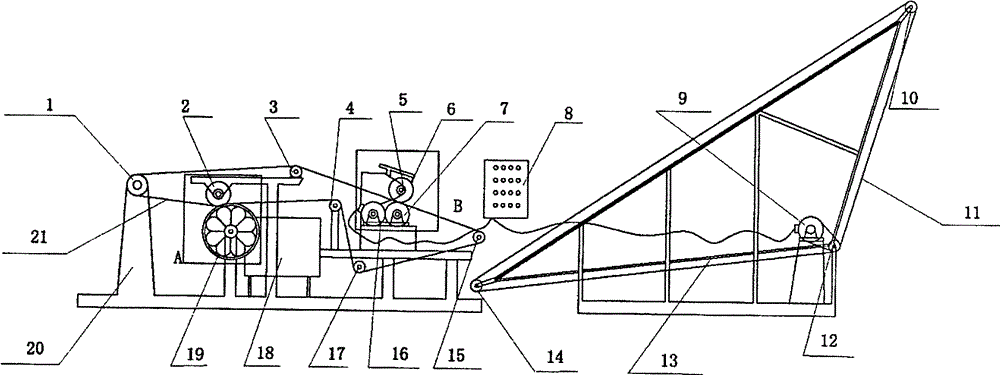

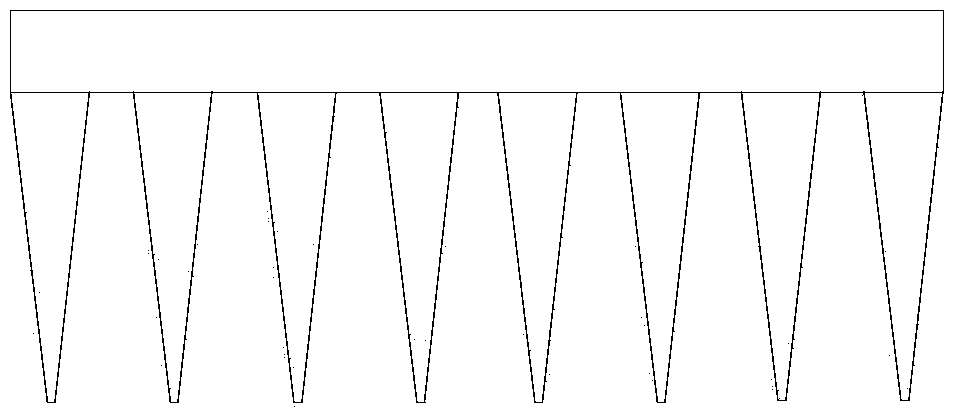

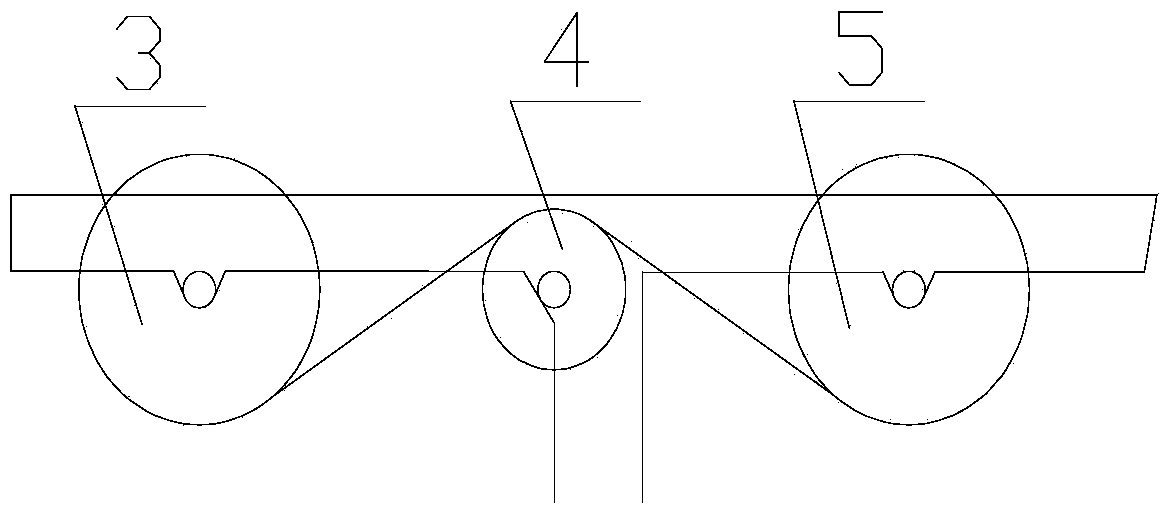

Belt filter press for manioc waste

InactiveCN103055580ARealize automatic loadingSqueeze fullyMoving filtering element filtersHigh energyFiltration

The invention relates to a belt filter press of manioc waste. The belt filter press comprises a rack, a motor, a container slot, a large roller, a middle roller group, a small roller group, a conveying belt, a scraper, a controller, a load conveying rack, a load motor, a load conveying belt and a load roller group, wherein the motor, the container slot, the large roller, the middle roller group and the small roller group are fixedly arranged on the rack; a conveying mechanism is formed by the conveying belt, the large roller, the middle roller group, the small roller group and the motor; the middle roller group is formed by a first middle roller, a second middle roller, a third middle roller and a fourth middle roller, the large roller is in counter-rolling contact with the first middle roller, and the second middle roller is in counter-rolling contact with the third middle roller; the motor is controlled by the controller; and a load conveying mechanism is formed by the load conveying belt, the load roller group and the load motor. Compared with an existing dehydration technology, such as vacuum roller rotation and plate-frame pressure filtration, the belt filter press provided by the invention has the advantages of small size, simple structure and high energy efficiency. The belt filter press can be applied to dehydration processing of waste liquid materials of opacified microparticle materials in industries of manioc processing, sewage treatment, paper making and the like.

Owner:GUANGXI UNIV

Barbell type manioc waste belt pressure filter with mud carding device

InactiveCN103623633ARealize automatic loadingSqueeze fullyMoving filtering element filtersEmulsionPapermaking

The invention discloses a barbell type manioc waste belt pressure filter with a mud carding device. The barbell type manioc waste belt pressure filter comprises a rack, a motor, a feeding groove, the mud carding device, a pressure filter roller group, an auxiliary roller group, a conveying belt, a scraper, a controller, a loading conveying rack, a loading motor, a loading conveying belt and a loading roller group, wherein the motor, the feeding groove, the mud carding device, the pressure filter roller group, the auxiliary roller group and the motor are fixedly arranged on the rack. The barbell type manioc waste belt pressure filter has the advantages that a dehydration link is added; the dehydration efficiency is improved. The barbell type manioc waste belt pressure filter can be applied to dehydration treatment of micro-particle emulsion waste liquor materials in the industries of manioc processing, sewage treatment, papermaking and the like.

Owner:GUANGXI UNIV

Soundbox spraying equipment capable of automatically feeding

ActiveCN111375511AEnsure consistencyRealize automatic loadingSpraying apparatusEngineeringPersonnel safety

The invention discloses soundbox spraying equipment capable of automatically feeding and belongs to the technical field of soundbox spraying. The soundbox spraying equipment capable of automatically feeding comprises a conveying device, a translation platform, a clamping device, a lifting column and a material placing basket; the translation platform is arranged above the front end of the conveying device; a sliding device is arranged on a lower surface of the translation platform; a lower surface of the sliding device is fixedly connected with a telescopic cylinder; and a clamping device is fixedly connected below the telescopic cylinder. Automatic feeding is realized by a transmission device, a clamping jaw device, the translation platform and the conveying device, so that manual work isreduced and personnel safety is guaranteed; manual feeding is not adopted, many workpieces can be placed in the material placing basket at one time and five workpieces can be clamped by the clampingdevice at each time, so that working efficiency is improved; the workpiece grabbing and placing positions are unchanged at each time, so the influence on the spraying effect caused by position changeof the workpieces is reduced; and a conveying mechanism is arranged below the material placing basket and the material placing basket can move back and forth, so that injury caused by that people approaches the spraying position is reduced.

Owner:西安启界海图信息科技有限责任公司

Load shifting device and vacuum arc-extinguishing chamber aging device using load shifting device

ActiveCN104576123ARealize automatic loadingPrevent leakageHigh-tension/heavy-dress switchesAir-break switchesEngineeringRadiation resistance

The invention discloses a load shifting device and a vacuum arc-extinguishing chamber aging device using the load shifting device. A load shifting port is formed in the wall of an aging lead room; the load shifting device which consists of a fixed seat, a support seat and a bearing unit is assembled in the load shifting port; a shifting device which is used for shifting the bearing unit with an arc-extinguishing chambers to be detected between an aging platform and the support seat is assembled in the aging lead room. During the use, the arc-extinguishing chambers to be detected shifts indoors and the detected arc-extinguishing chambers shift outdoors through the rotation of the support seat in the load shifting device on the fixed seat; after the arc-extinguishing chambers to be detected shift indoors, the load shifting port of the aging lead room is blocked by the support seat to prevent the harmful rays generated in the aging process from escaping, so that the automatic loading of the arc-extinguishing chamber aging operation is realized when the radiation resistance in the aging process is ensured and then the arc-extinguishing chamber aging efficiency is accelerated.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC

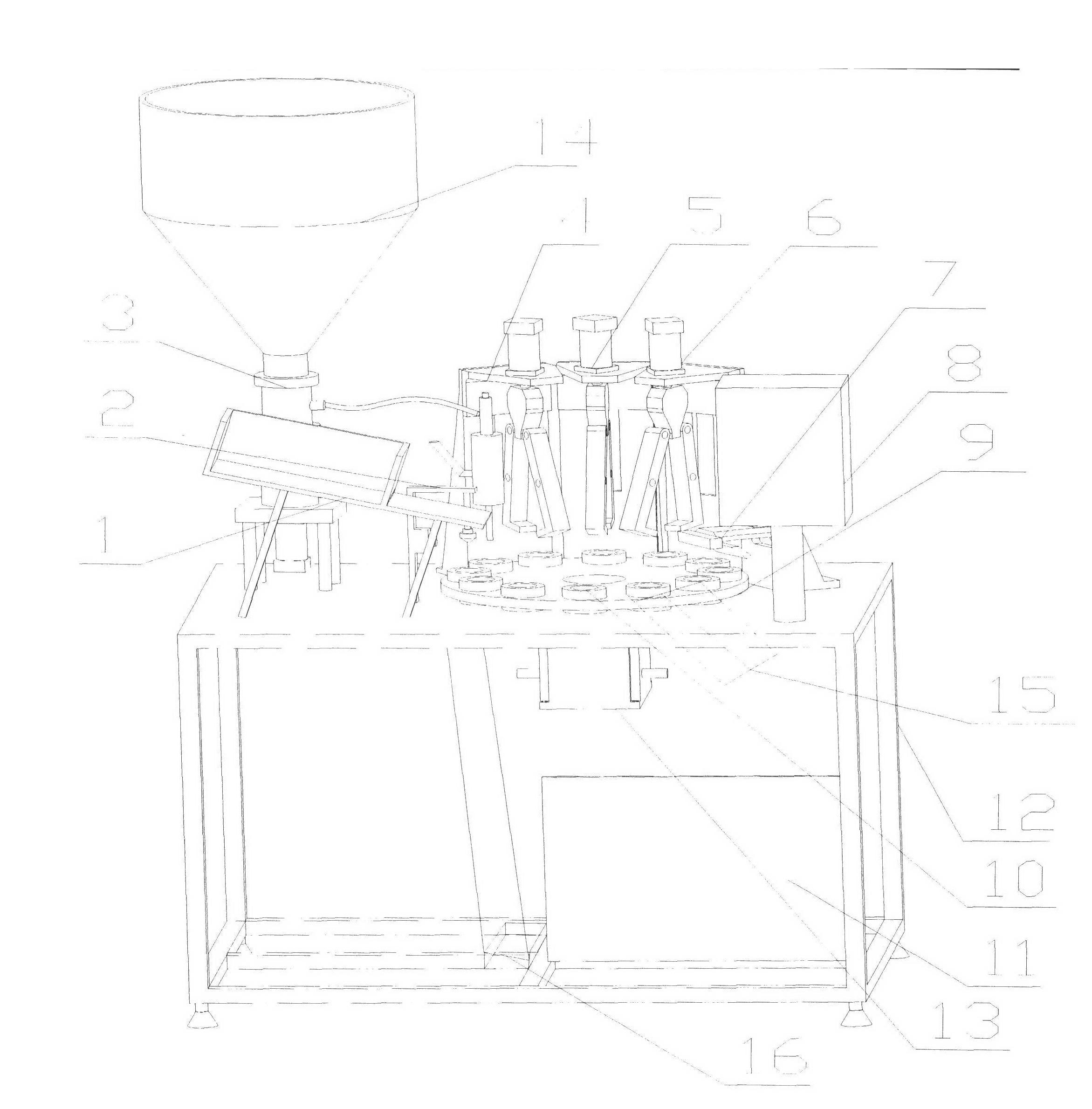

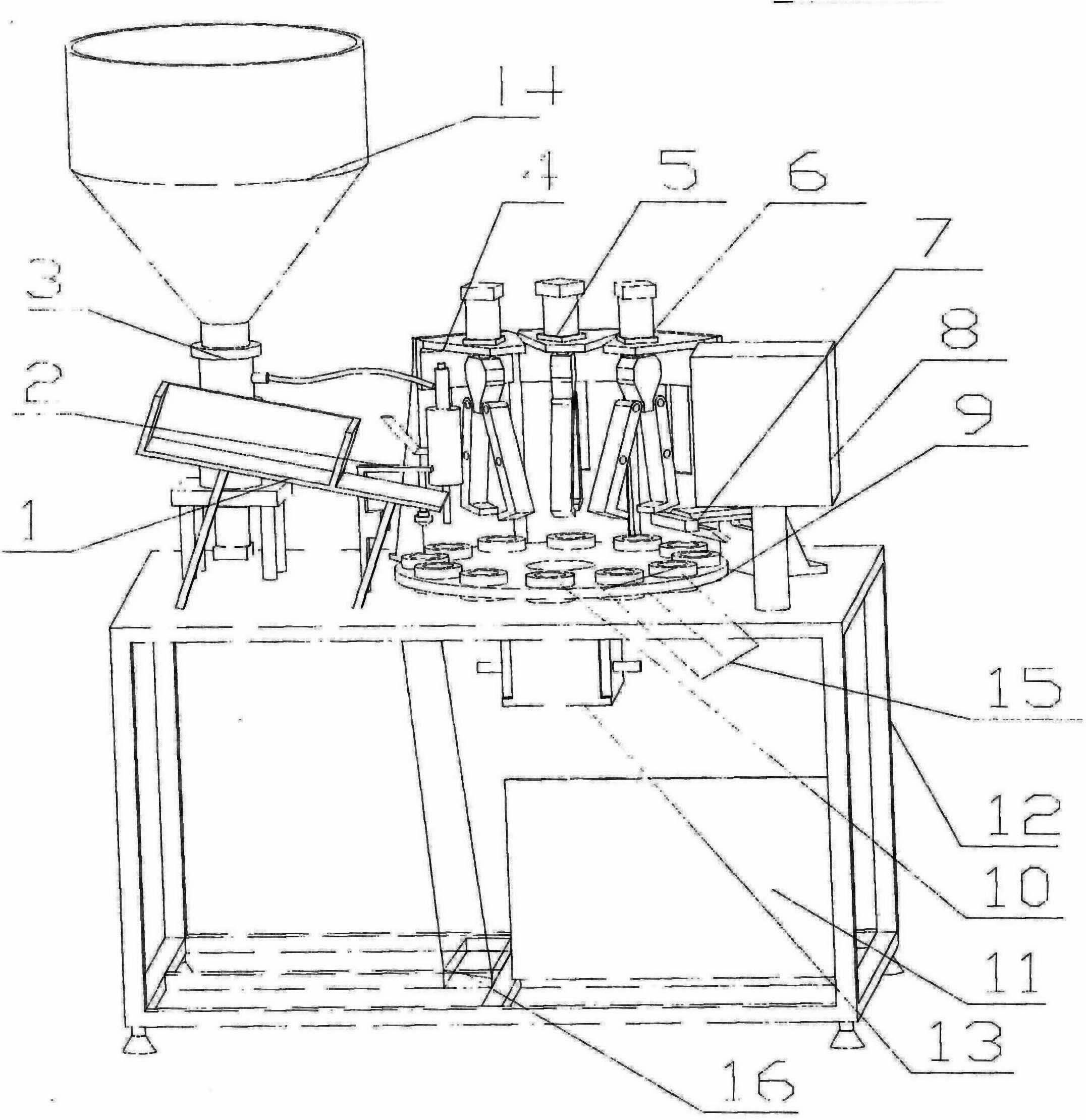

Multifunctional paving brick pouring and tamping machine

InactiveCN102699980AHigh degree of automationAdvanced technologyCeramic shaping apparatusBrickUltimate tensile strength

The invention relates to a multifunctional paving brick pouring and tamping machine. The machine comprises a frame and a worktable arranged on the frame, and is characterized by also comprising a feeding mechanism for feeding a material into a cavity of a die box, a vibrating mechanism for vibrating the material in the cavity of the die box, a scraping mechanism for scraping the material in the cavity of the die box, and a compacting mechanism, wherein the die box scraped by the scraping mechanism is conveyed to the compacting mechanism through a transmission mechanism. Compared with the prior art, the multifunctional paving brick pouring and tamping machine has the advantages that the feeding mechanism, the vibrating mechanism, the scraping mechanism, the die box transmission mechanism and the compacting mechanism are integrated, the material from the feeding mechanism is put into the die box and then vibrated, scraped, conveyed and compacted in sequence, and automatic loading can be realized, so that the pouring and tamping machine is high in automation degree, the process is relatively advanced, the labor intensity of workers can be effectively reduced, and labor efficiency is improved.

Owner:姚茂国

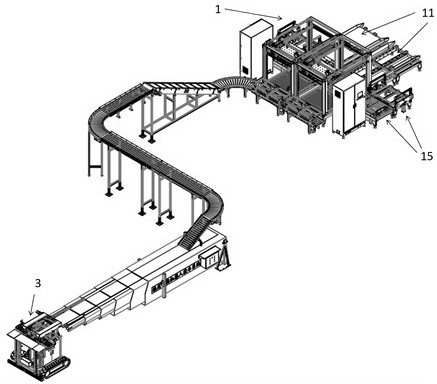

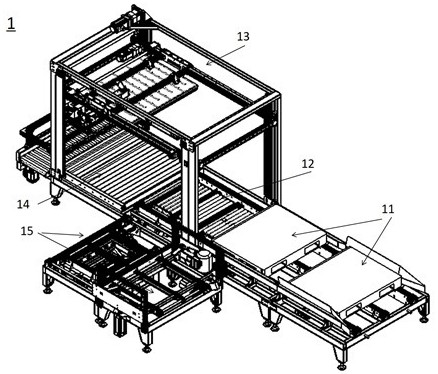

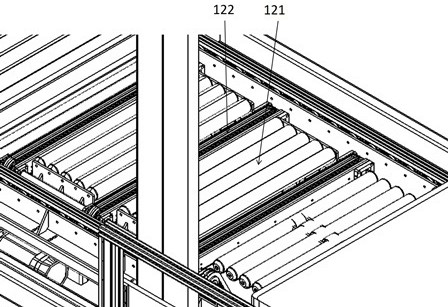

Automatic loading system

ActiveCN112573239ALow costLower requirementArticle unpackingLoading/unloadingLogistics managementProcess engineering

The embodiment of the invention relates to the field of logistics industry truck loading, and discloses an automatic loading system. The automatic loading system comprises a tray disassembling devicefor disassembling products, a conveying belt for receiving the products output by the tray disassembling device and conveying the products, and a loading part for receiving, arranging and placing theproducts. The loading part comprises an accelerating unit, an integrating unit connected with the accelerating unit, and a placing unit. According to the automatic loading system, full-automatic loading can be achieved, dependence on manpower is avoided, the occupied space of the system is reduced, the safety of products is guaranteed, the automatic loading system can adapt to vehicle bodies of different sizes, the applicability of the system is improved, the cost of the system is reduced, and the loading efficiency is improved.

Owner:苏州澳昆智能机器人技术有限公司

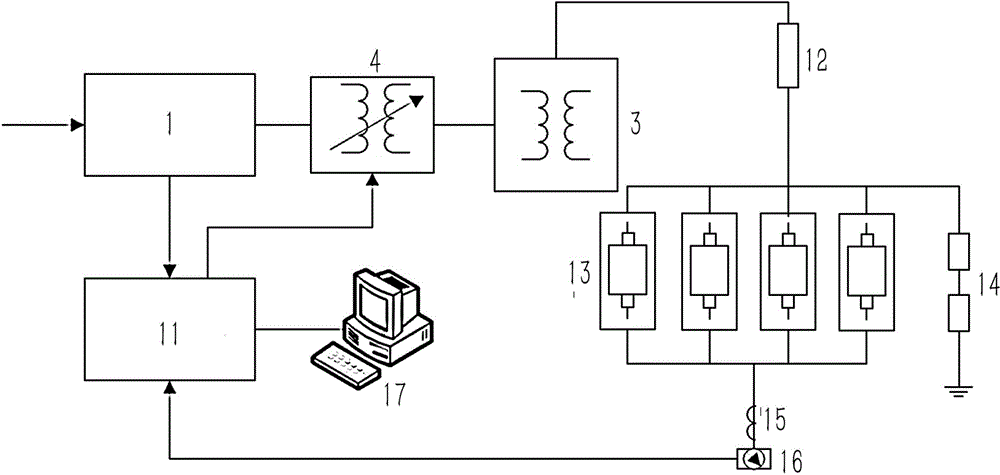

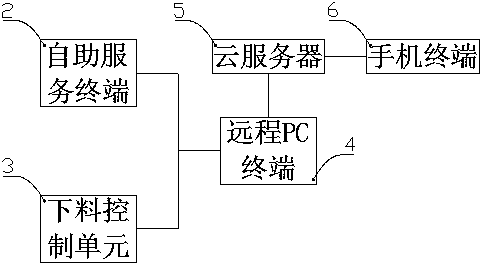

Silo feeding control system

ActiveCN108116907ARealize automatic loadingImprove loading efficiencyControl devices for conveyorsLoading/unloadingMicrocontrollerRadio frequency

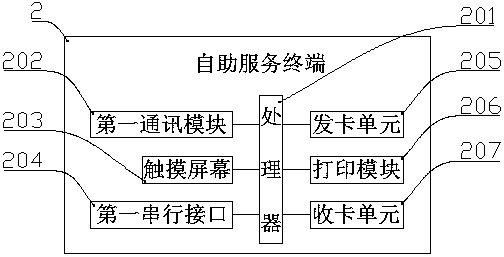

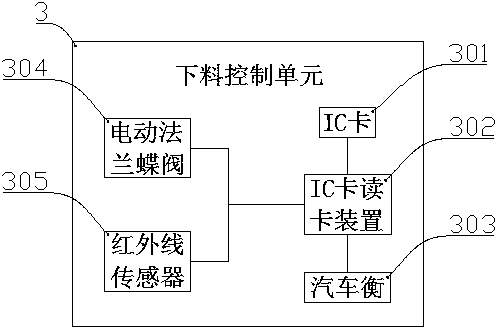

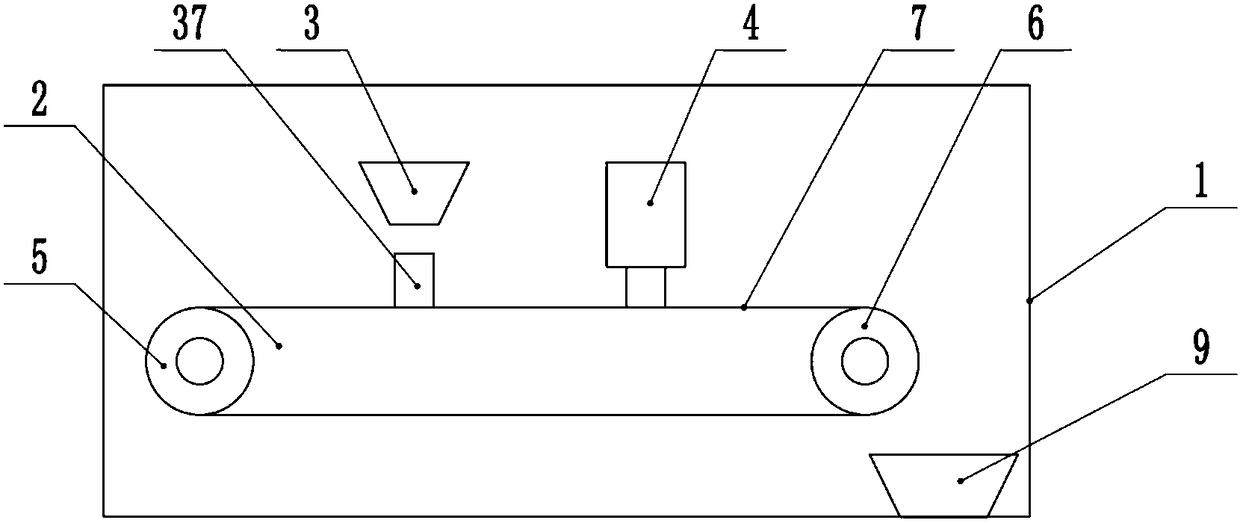

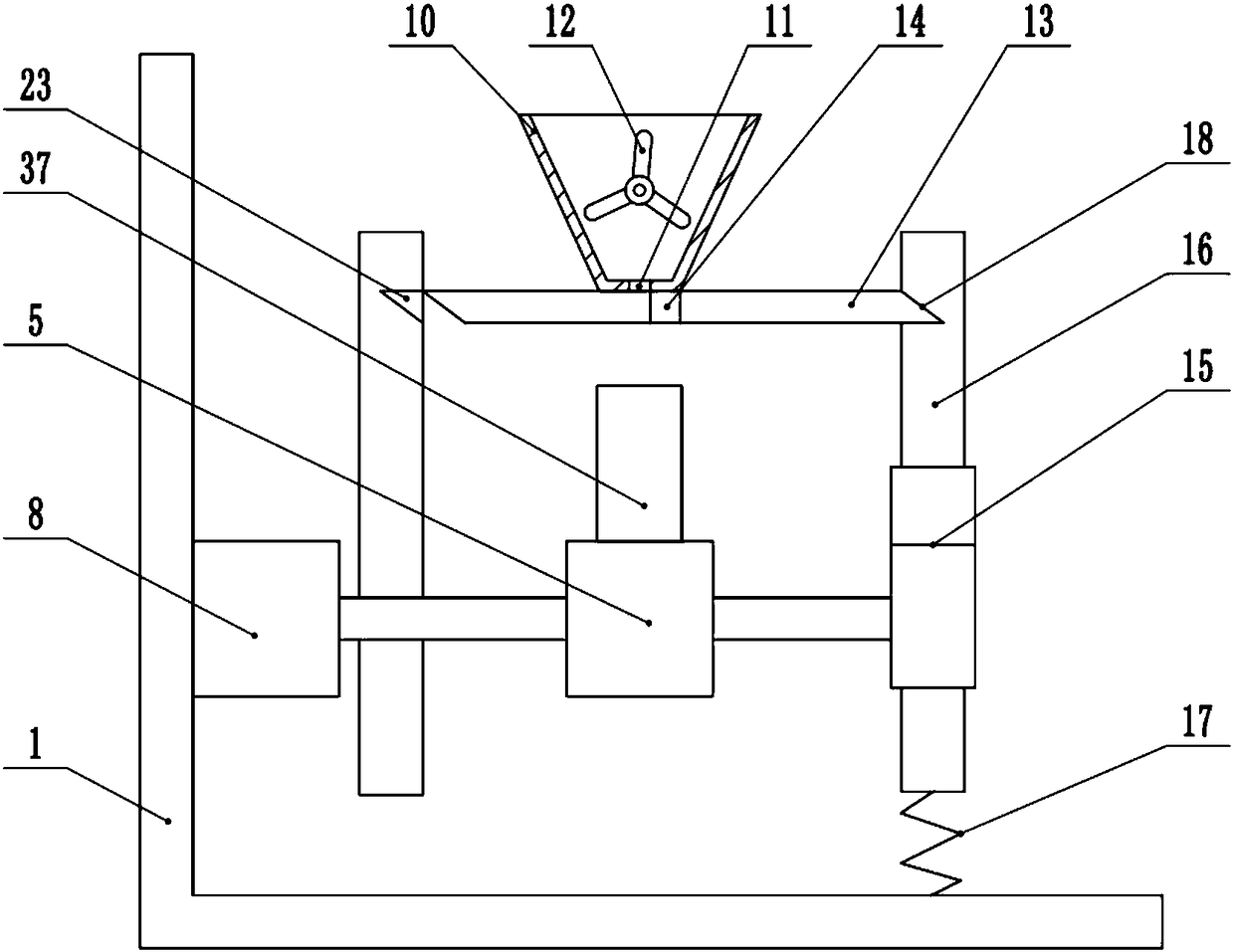

The invention discloses a silo feeding control system. The silo feeding control system comprises a silo, a self-service terminal, a feeding control unit, a remote PC (personal computer) terminal, a cloud server and a mobile phone terminal, wherein the self-service terminal comprises a processor, a first communication module, a touch screen, a first serial interface, a card issuing unit, a printingmodule and a card receiving unit; the feeding control unit comprises an IC (integrated circuit) reading device, which is connected with an IC card, a vehicle scale, an electric flange butterfly valveand an infrared sensor; the IC card reading device comprises a singlechip microcomputer, which is connected with a second communication module, a second serial interface, a radio frequency identification module and a voice module. The silo feeding control system has the advantages of being accurate in positioning, accurate and controllable in material loading amount, automated in material loadingand capable of saving labor investment.

Owner:ZHENGZHOU JINHENG ELECTRONICS TECH CO LTD

Seed inner package charging machine

PendingCN108583948ARealize automatic openingAchieve automatic shutdownWrapper twisting/gatheringSolid materialDrive wheelGear wheel

The invention relates to the technical field of seed packaging, and discloses a seed inner package charging machine. The seed inner package charging machine comprises a rack. A conveying mechanism, acharging mechanism and a sealing mechanism are arranged on the rack. The conveying mechanism comprises a driving wheel. The charging mechanism comprises a charging box, and a discharging opening is formed on the charging box. A baffle is in sliding connection to the rack and provided with a through hole. The driving wheel is coaxially connected with a sector gear. A first gear rack used for beingengaged with the sector gear is in sliding connection to the rack. A first spring is connected between the first gear rack and the rack. A first wedge groove allowing the baffle to be inserted is formed on the first gear rack. A first transmission rod is in sliding connection to the rack. A supporting plate is arranged on the first transmission rod. Gear teeth are formed on the first transmissionrod. The first transmission rod is engaged with a gear through the gear teeth. A second gear rack is engaged to the gear. A second wedge groove allowing the baffle to be inserted is formed on the second gear rack. The seed inner package charging machine solves the problem that in a seed packaging device in the prior art, the packaging percent of pass is reduced due to the fact that the bagging quantity cannot be controlled is solved.

Owner:重庆市飞龙种业有限责任公司

Intelligent glass handling device

InactiveCN108689162ARealize automatic loadingRealize unloadingConveyor partsHand carts with multiple axesVehicle frameGear wheel

The invention discloses an intelligent glass handling device. The intelligent glass handling device comprises a frame, wherein a traveling mechanism is arranged at the bottom of the frame; a bracket for placing glass is arranged at the top of the frame; a vertical support is fixedly arranged at the right side of the bracket at the top of the frame; a lifting mechanism is arranged at the bottom endof the vertical support; the vertical support is supported on the frame through the lifting mechanism; a transverse sleeve is arranged at the top end of the vertical support; a transverse slide bar is mounted in the transverse sleeve in a sleeved manner; a transverse toothed rail is arranged on the upper side of the top of the transverse slide bar; a first engine room is fixedly arranged at the top end of the vertical support; the bottom of the first engine room communicates with the transverse sleeve; and a movable gear is arranged in the first engine room and mounted on a gear shaft in thefirst engine room in a sleeving manner. The intelligent glass handling device is skillful in structural setting and reasonable in arrangement and realizes automatic loading and unloading of glass, theglass handling efficiency is greatly improved, and the intelligent glass handling device is stable in running, guarantees the handling safety and realizes intelligent handling.

Owner:FOSHAN LINGXIN INFORMATION TECH CO LTD

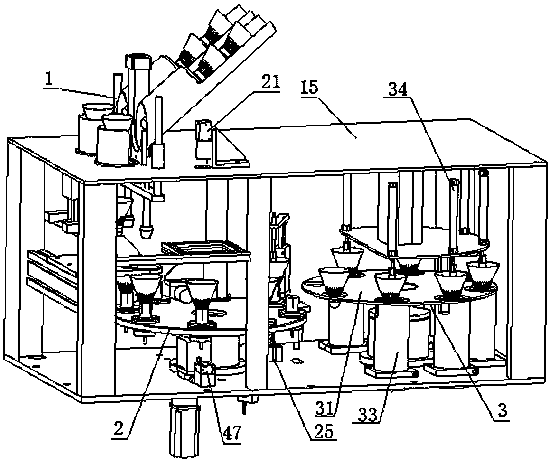

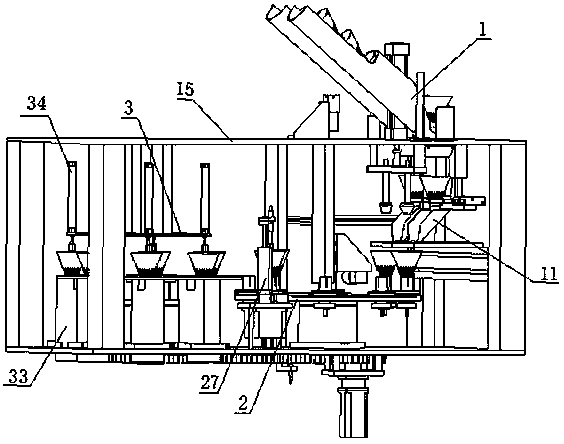

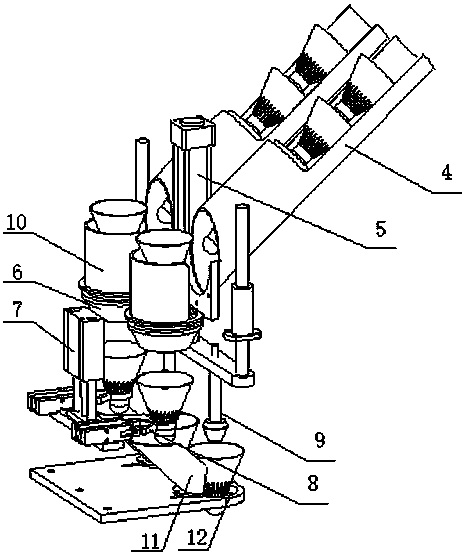

Full-automatic aluminum pipe filling and tail folding and sealing machine

The invention provides a full-automatic aluminum pipe filling and tail folding and sealing machine, which comprises a workbench on a framework and an electric control box mounted on one side of the framework. The full-automatic aluminum pipe filling and tail folding and sealing machine is characterized by further comprising a circular turntable structure mounted on the workbench, a plurality of feed cups are arranged on the circular turntable structure, an automatic pipe feeding device, a detection device, a filling device, a tail flattening device, a primary folding mechanism, a secondary folding mechanism, a tail pressing device and an automatic pipe discharging device are sequentially arranged around the feed cups. The full-automatic aluminum pipe filling and tail folding and sealing machine has the advantages of low noise, power consumption and cost, easiness in maintenance, no hurt to human bodies and the like, realizes full automatic filling and tail sealing, realizes automatic pipe feeding, filling and discharging and can run continuously. By the double folding technology, tails of aluminum pipes can be sealed more completely, so that sealing effect is better.

Owner:NANTONG BAOTIAN PACKING MACHINERY

Stacking tool for loading

InactiveCN110422645ANeat one-time palletizingImprove palletizing efficiencyStacking articlesDe-stacking articlesMechanical engineeringEngineering

The invention relates to the technical field of carriage stacking, in particular to a stacking tool for loading. The stacking tool for loading comprises a mounting frame, a feeding mechanism, a distribution mechanism, pushing mechanisms and supporting plate mechanisms, wherein the mounting frame is connected with a variable-amplitude mechanism for driving the installation frame to swing; the feeding mechanism is mounted on the mounting frame; the feeding mechanism forms a delivery channel allowing goods to pass through; the distribution mechanism is provided with a distribution station arranged at an outlet of the delivery channel; and two sides of the distribution station are separately provided with the supporting plate mechanisms, when the goods move from the delivery channel to the distribution station, the distribution mechanism moves the goods to the supporting plate mechanisms, and the pushing mechanisms are arranged at one sides of the supporting plate mechanisms and used for moving the goods on the supporting plate mechanisms out of the supporting plate mechanisms for stacking. According to the stacking tool for loading, automatic loading of the goods is facilitated, and the tidiness degree of the stacked goods and the stability of placing the stacked goods are improved.

Owner:GUAGNZHOU SYL AUTOMATIC CONTROL TECH CO LTD

Carrying manipulator and carrying robot

The invention discloses a carrying manipulator and a carrying robot. The carrying manipulator comprises a fixing seat, a driving mechanism, a movable piece and a clamping mechanism, wherein the driving mechanism is arranged on the fixing seat; the movable piece is connected with the output end of the driving mechanism, and the driving mechanism can drive the movable piece to ascend and descend; and the clamping mechanism comprises two clamping arms and two connecting arms, one end of each connecting arm is hinged to the fixing seat, each clamping arm comprises a first arm and a second arm which are connected and form a certain included angle, the first arms of the two clamping arms are arranged in a crossed mode, one ends of the first arms are hinged to the other ends of the connecting arms, the other ends of the first arms are hinged to the movable piece, and the second arms of the two clamping arms are oppositely arranged and can get close or away from each other along with the lifting of the movable piece, so that a piece to be clamped is clamped or released. When the driving mechanism of the carrying manipulator drives the movable piece to ascend, the second arms of the two clamping arms get close to each other to clamp the piece to be clamped. When the whole carrying manipulator is lifted, the gravity of the to-be-clamped piece enables the two second arms to further get close, and clamping reliability and clamping force are increased.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com