Silo feeding control system

A control system and silo technology, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of inaccurate detection of truck scales, reduced efficiency of loading materials, and increased personnel input, so as to achieve real-time sharing. , The effect of improving loading efficiency and saving personnel input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

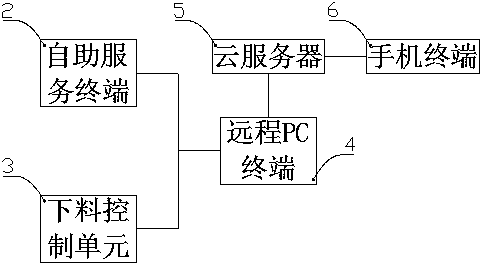

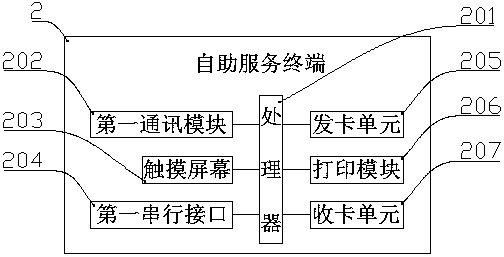

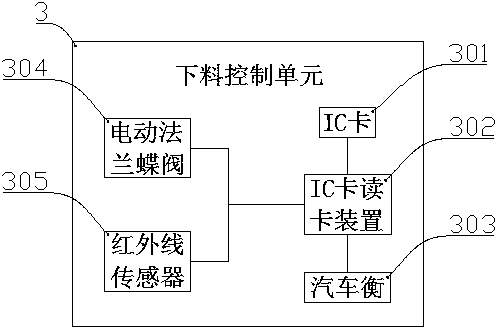

[0036] according to Figure 1-5 As shown, a silo unloading control system includes a silo 1 containing materials, a self-service terminal 2 for sending and receiving IC cards 301, a unloading control unit 3 for controlling material loading, and an information management remote PC terminal 4, a cloud server 5 for information storage and sharing, and a mobile phone terminal 6 for remote information inquiry; the self-service terminal 2 includes a processor 201, a first communication module 202, a touch screen 203, a first Serial interface 204, card issuing unit 205, printing module 206 and card receiving unit 207, described processor 201 communicates with first communication module 202, touch screen 203, first serial interface 204, card issuing unit 205, printing module through signal line 206 is connected with the card collection unit 207, and the first communication module 202 is used to realize the connection between the self-service terminal 2 and the remote PC terminal 4; th...

Embodiment 2

[0039] according to Figure 6 As shown, the blanking control method of the described silo blanking control system comprises the following steps:

[0040] S1. Before entering the field, get the IC card bound with the information of the material truck and the information of the pre-installed materials at the self-service terminal;

[0041] S2. The feed truck drives to the truck scale below the silo;

[0042] S3. The infrared sensor detects whether the positions of the material receiving port and the discharging port of the material truck correspond, and gives a voice prompt;

[0043] S4. The vehicle is parked in place, and the IC card is swiped on the IC card reader device, and the electric flange butterfly valve is opened to feed the material into the feeder;

[0044] S5. During the feeding process, the truck scale detects the weight change of the feeding truck, and the infrared sensor detects whether the material added in the feeding truck is about to reach the feeding port; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com