Full-automatic aluminum pipe filling and tail folding and sealing machine

A fully automatic sealing machine technology, applied in packaging and other directions, can solve the problems of rough tail folding, poor effect, poor quality, etc., and achieve the effect of thorough sealing, better effect and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

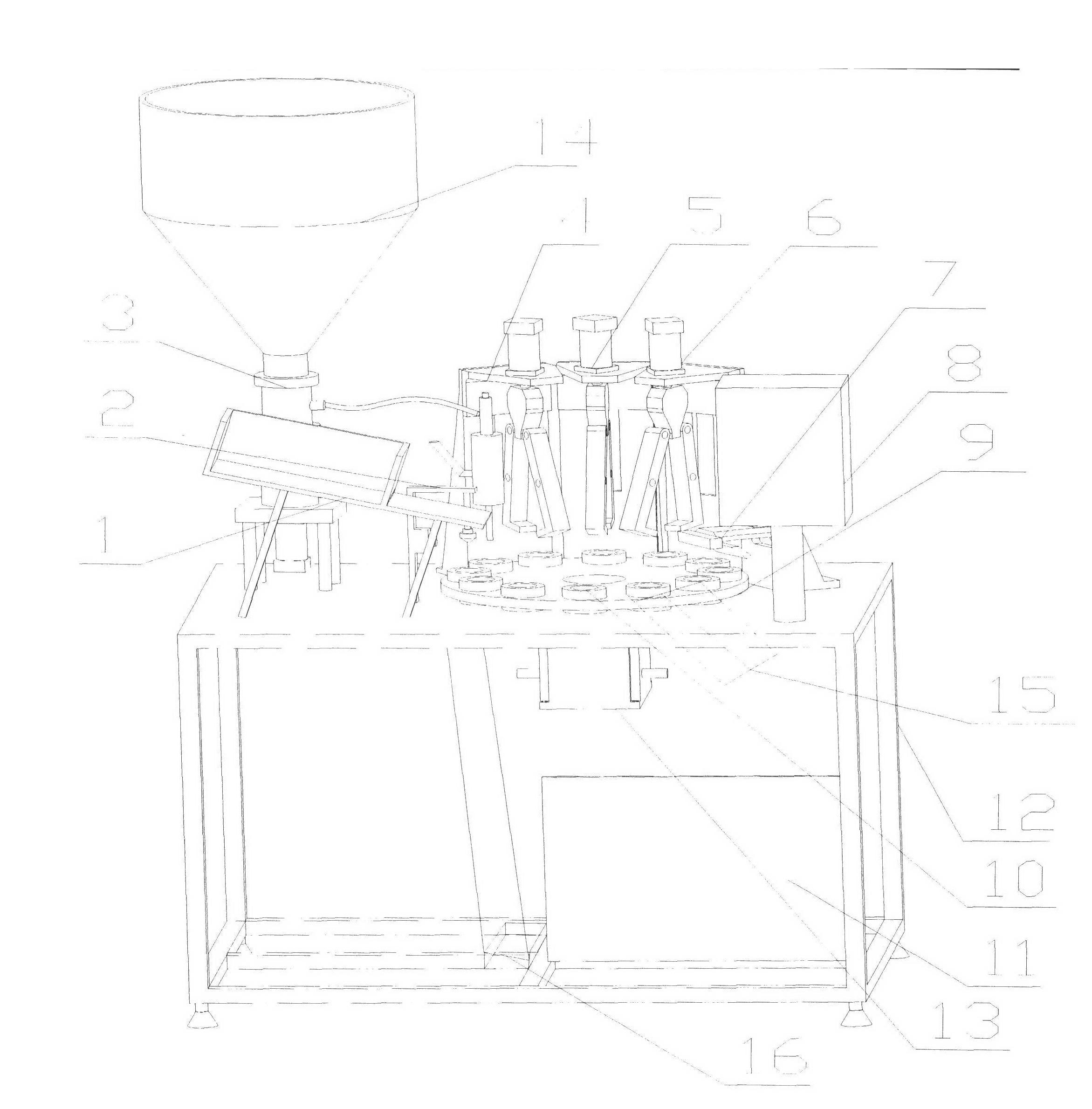

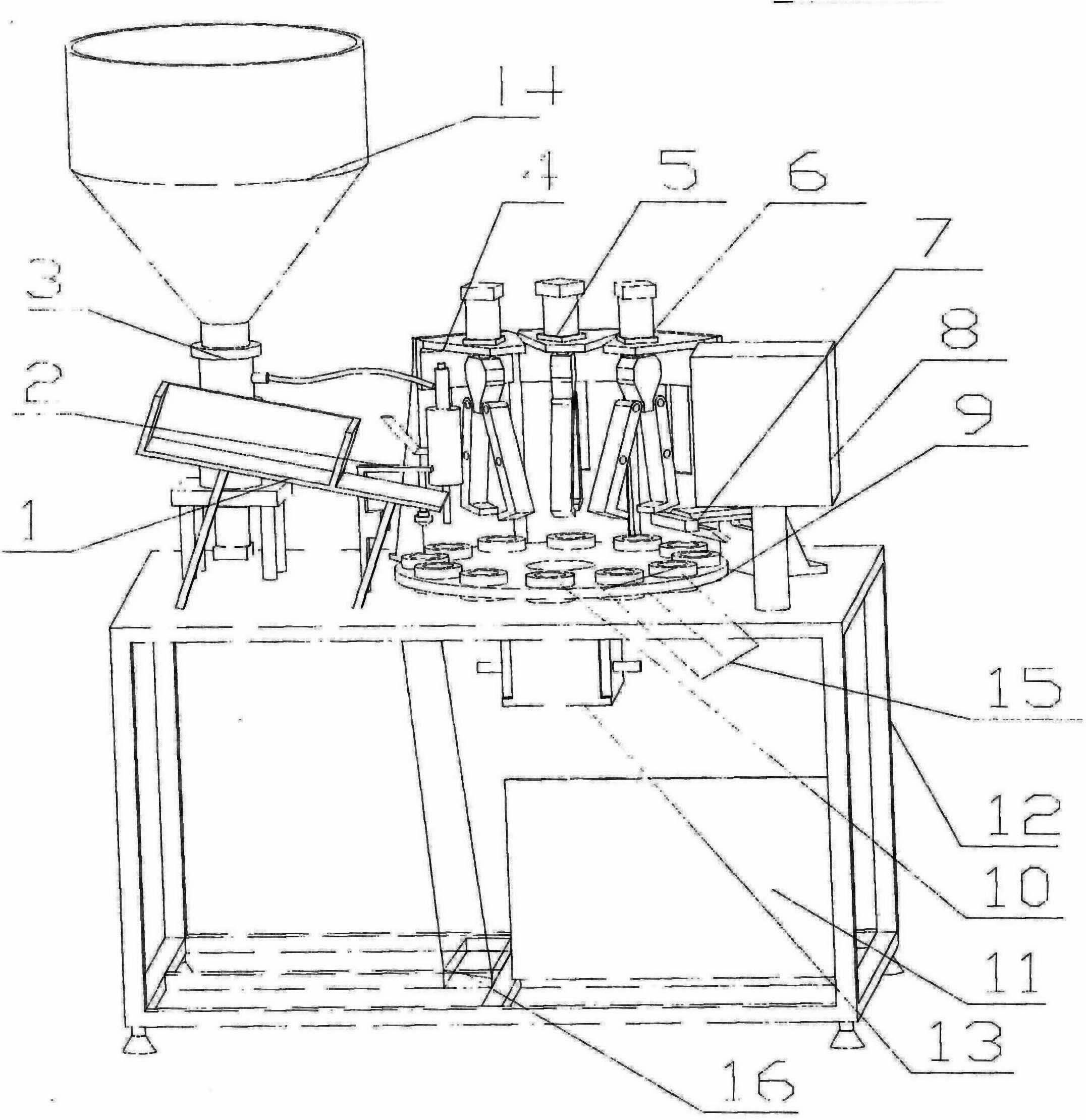

[0011] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, a fully automatic aluminum tube filling, folding and sealing machine according to the present invention includes a workbench installed on the frame 12 and an electric control box 8 installed on one side of the frame 12, and also includes a The circular turntable mechanism 9 on the workbench is provided with several material cups 10 on the circular turntable mechanism 9, and an automatic tube loading device 1, a detection device 2, and a filling device 3 are arranged in sequence around the material cups 10 , Tail flattening device 4, a hemming mechanism 5, a second hemming mechanism 6, a tail pressing device 7 and an automatic lowering device 15. The circular turntable mechanism 9 is driven by the main drive motor 13 at the bottom of the frame 12 . A rotatable tray is provided at the outlet of the automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com