Patents

Literature

718results about How to "Realize unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

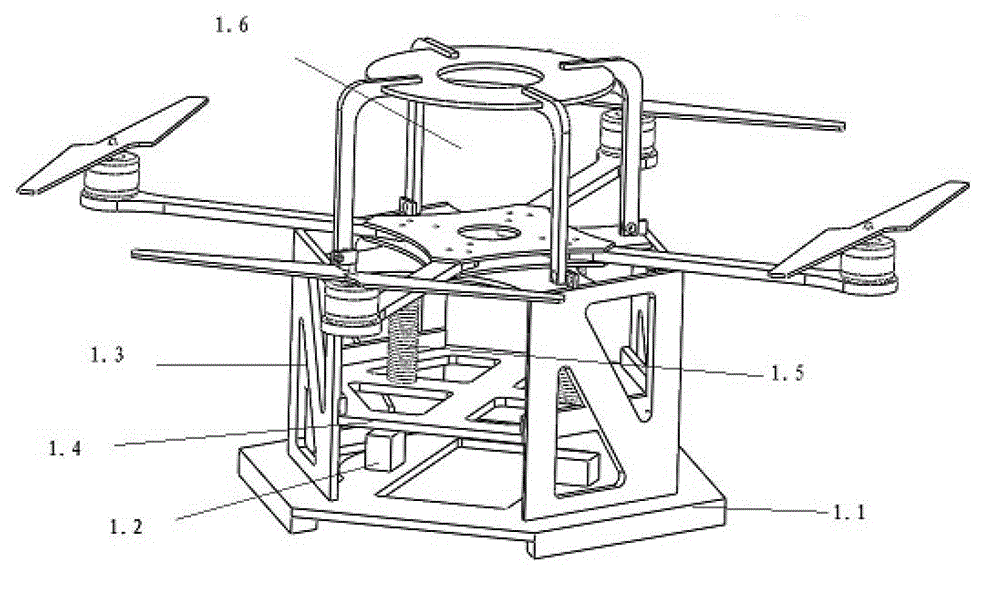

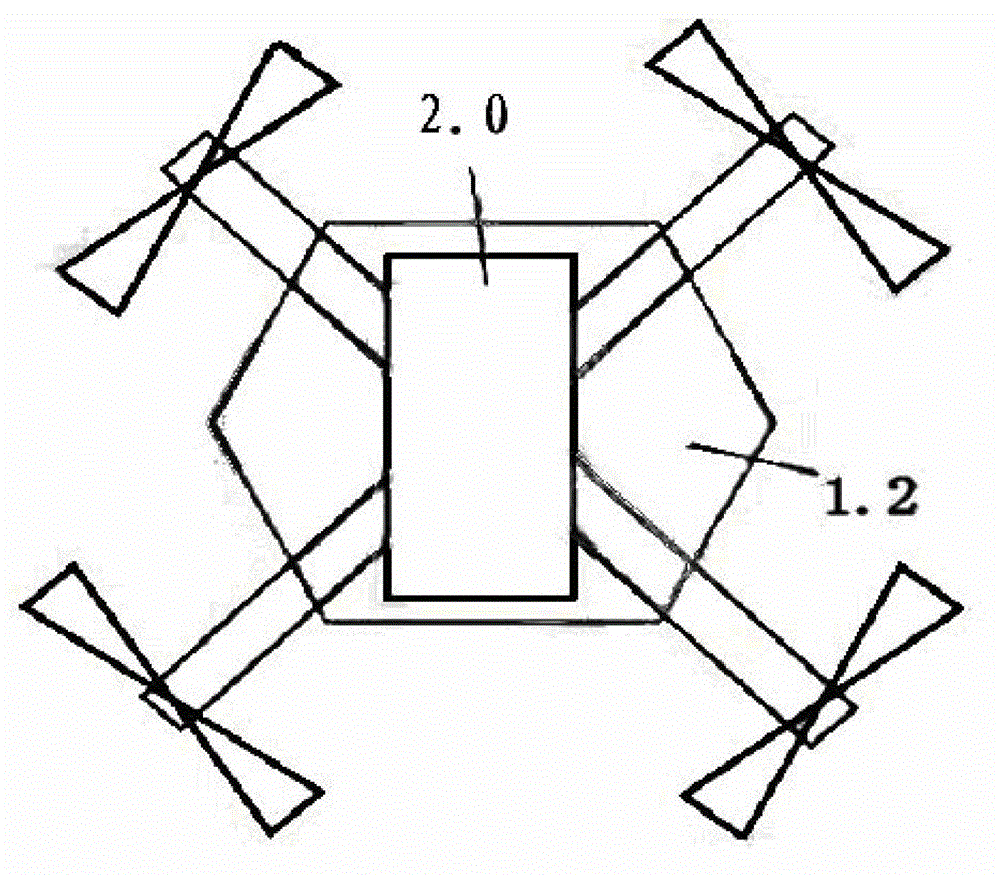

Battery automatic replacement system of small-sized multi-rotor-wing unmanned aerial vehicle

ActiveCN102909540AEasy to installImprove efficiencyProgramme-controlled manipulatorMetal working apparatusManipulatorBattery storage

The invention discloses a battery automatic replacement system of a small-sized multi-rotor-wing unmanned aerial vehicle. The battery automatic replacement system comprises a multi-track trolley, a battery storage disk, an unmanned aerial vehicle landing gear, a landing gear fixing plate, a landing gear fixing plate support, a battery storage disk support and a mechanical arm, wherein the landing gear fixing plate is arranged above the multi-track trolley, and is fixedly connected with the multi-track trolley through the landing gear fixing plate support; the unmanned aerial vehicle landing gear is arranged above the landing gear fixing plate; a battery inlet matched with the size of a battery is formed in the center of the fixing plate; the battery storage disk is arranged below the landing gear fixing plate, and is fixedly connected with the multi-track trolley through the battery storage disk support; and the mechanical arm is arranged below the battery storage disk. The battery automatic replacement system adopts a turntable type battery storage bin, so that five times of battery replacement can be performed at most through one step; and the battery automatic replacement system adopts a blind plugging type battery installation mode to achieve effects of convenience, fastness and high efficiency.

Owner:徐州新电高科电气有限公司

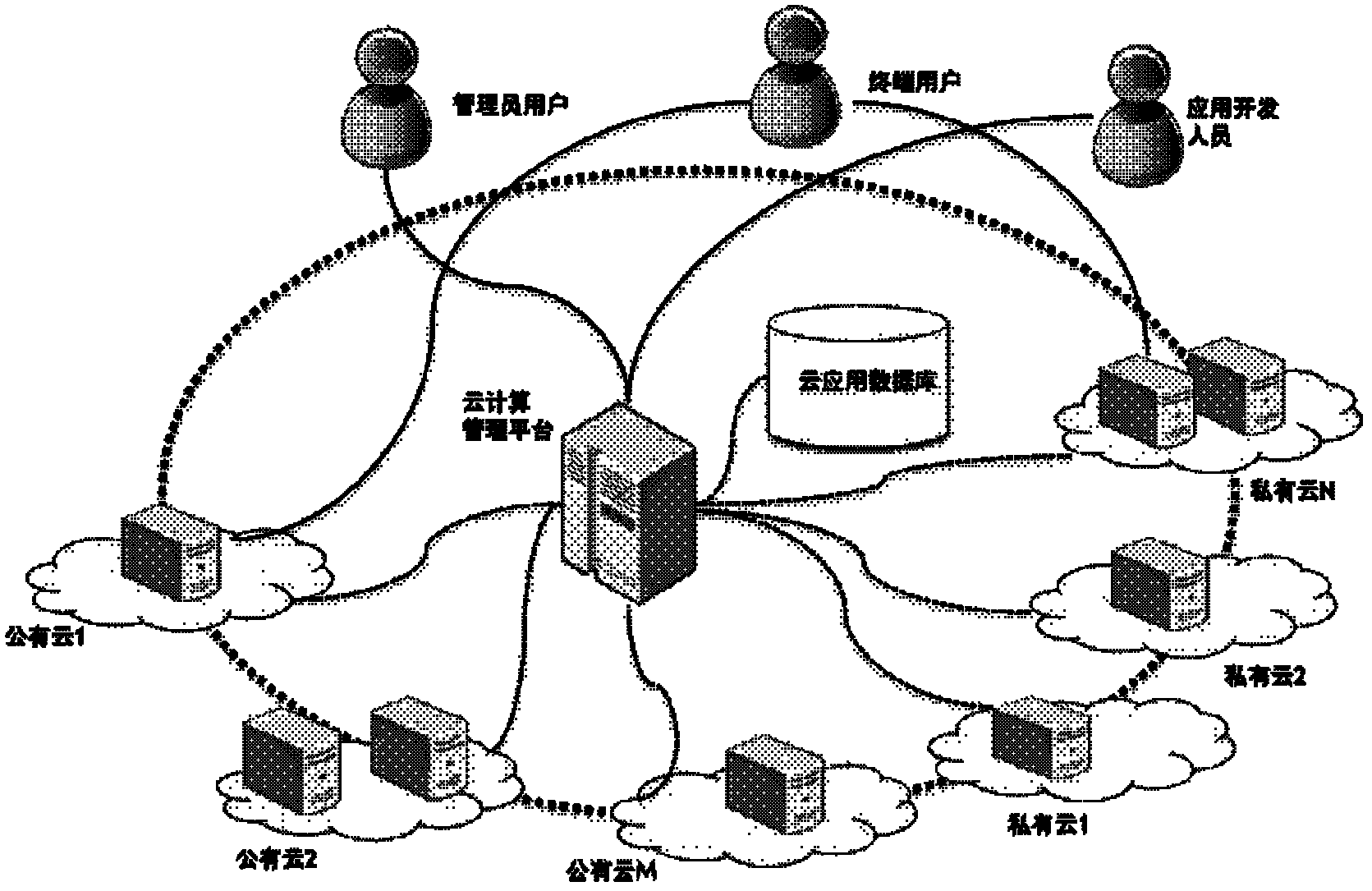

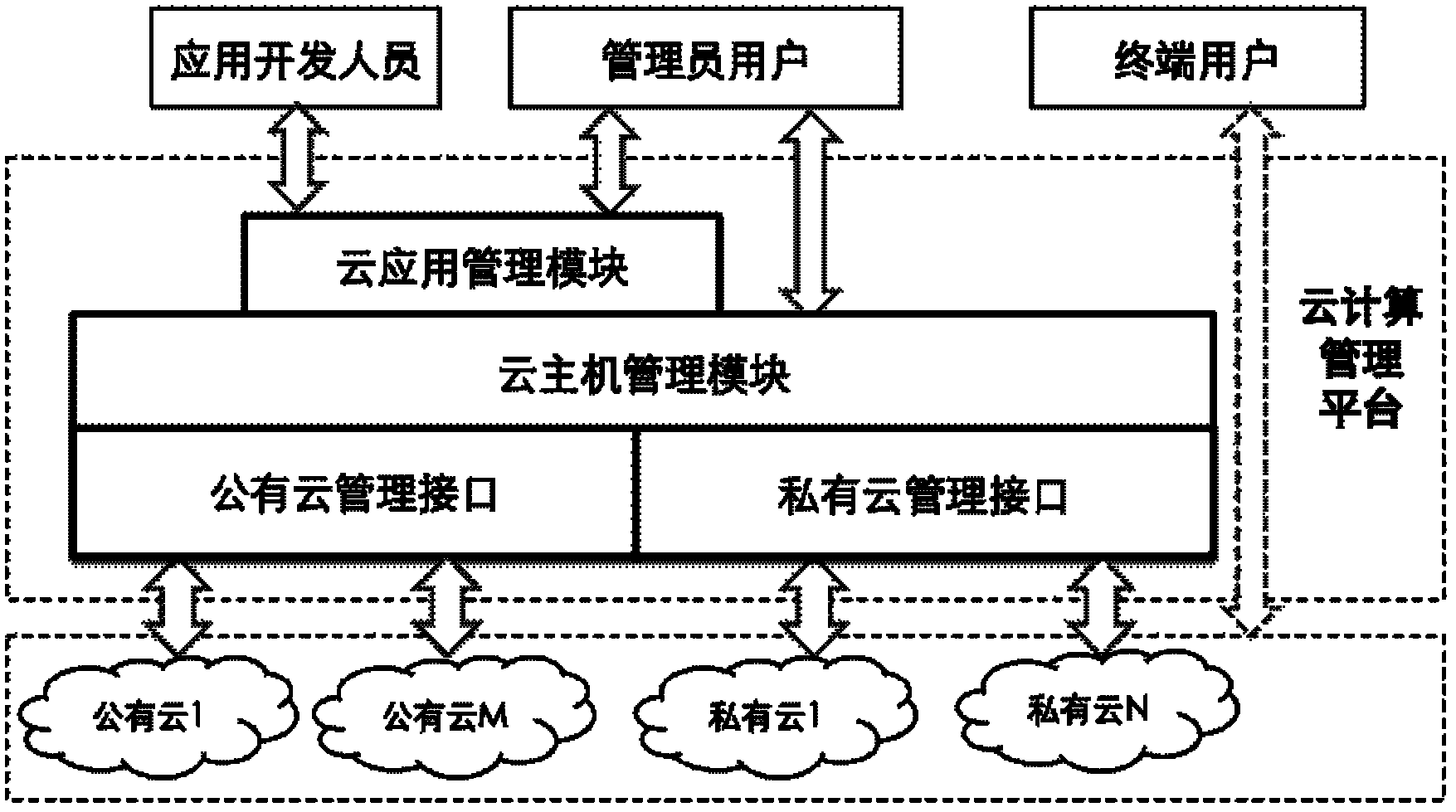

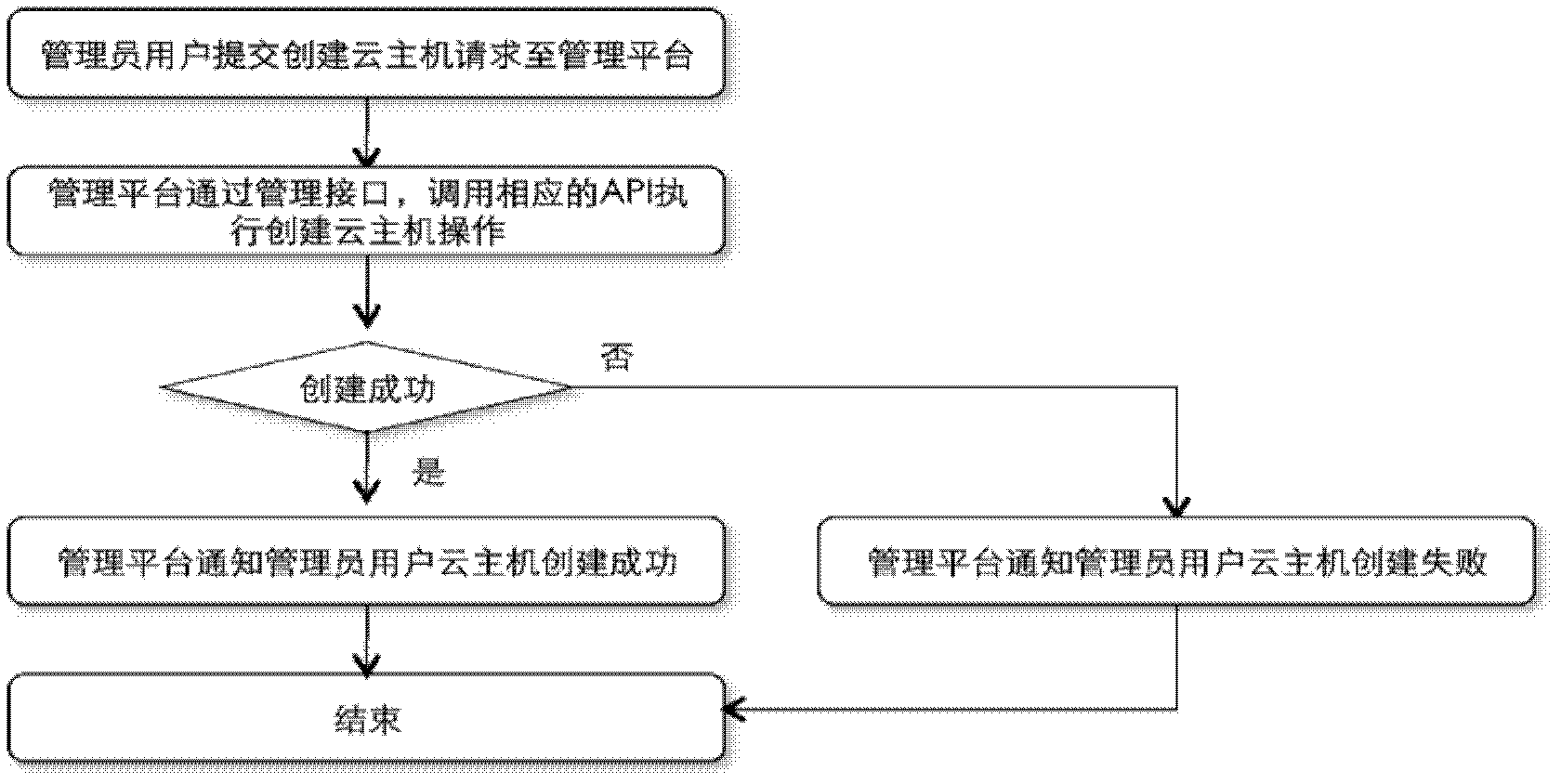

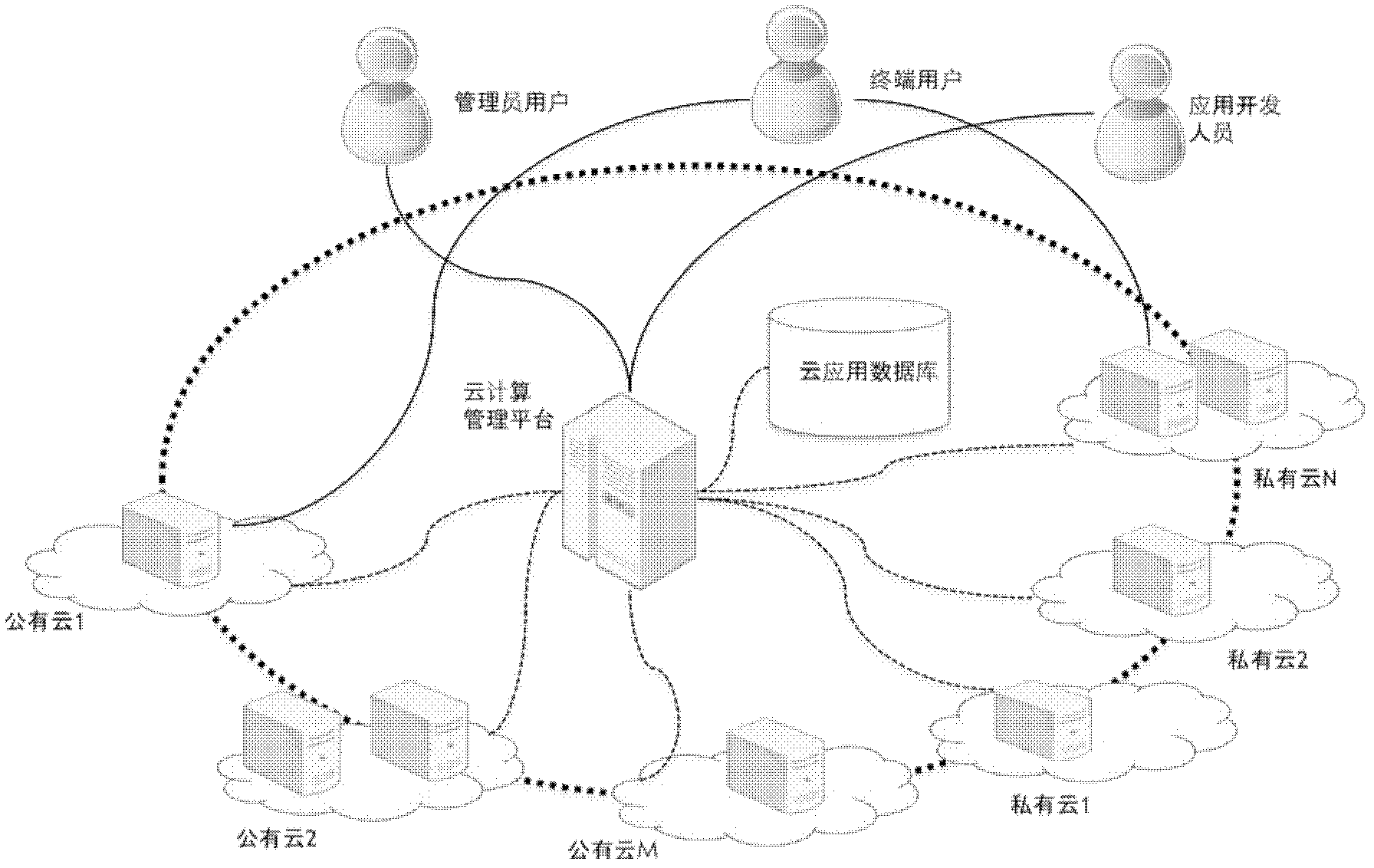

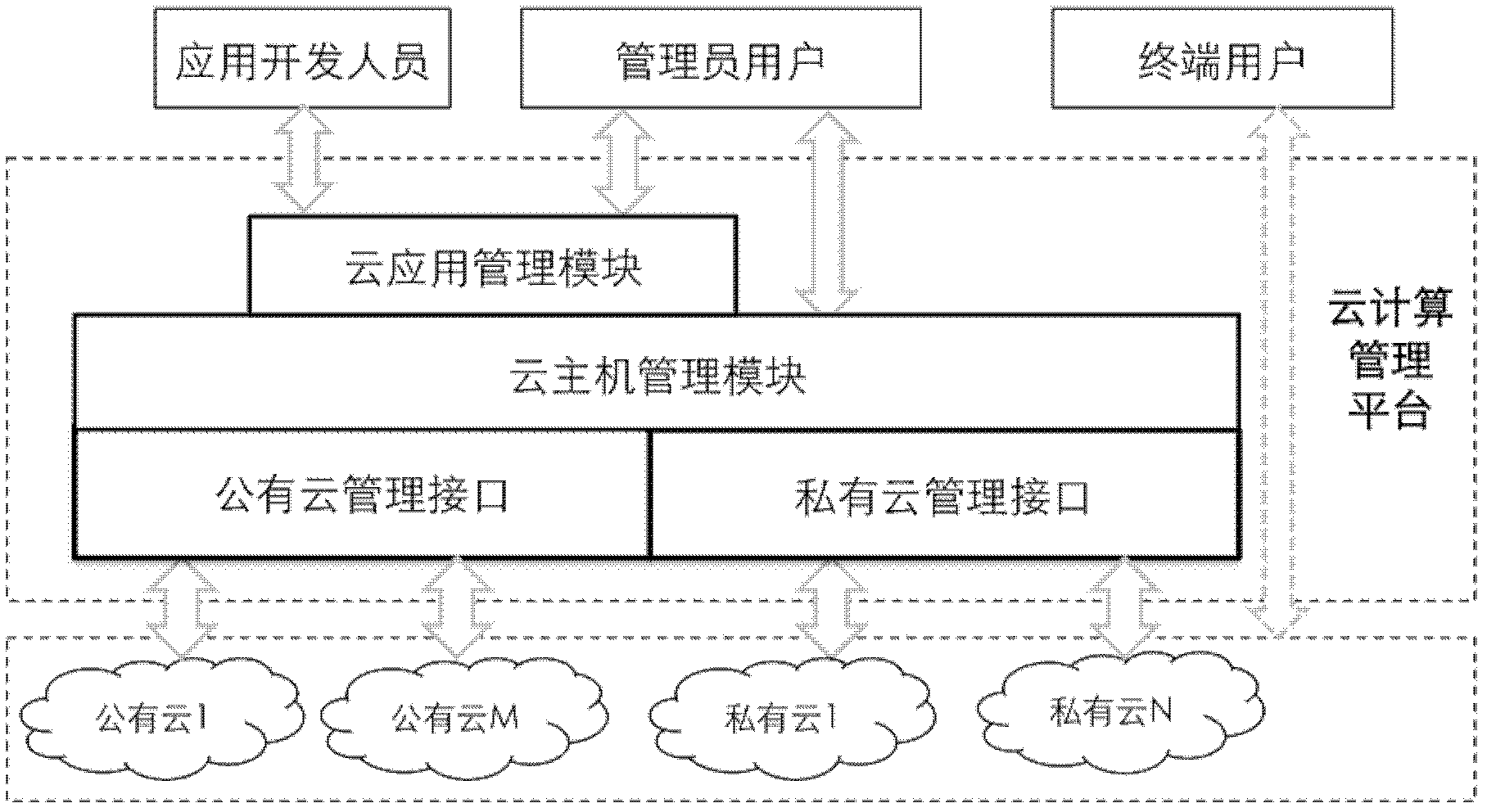

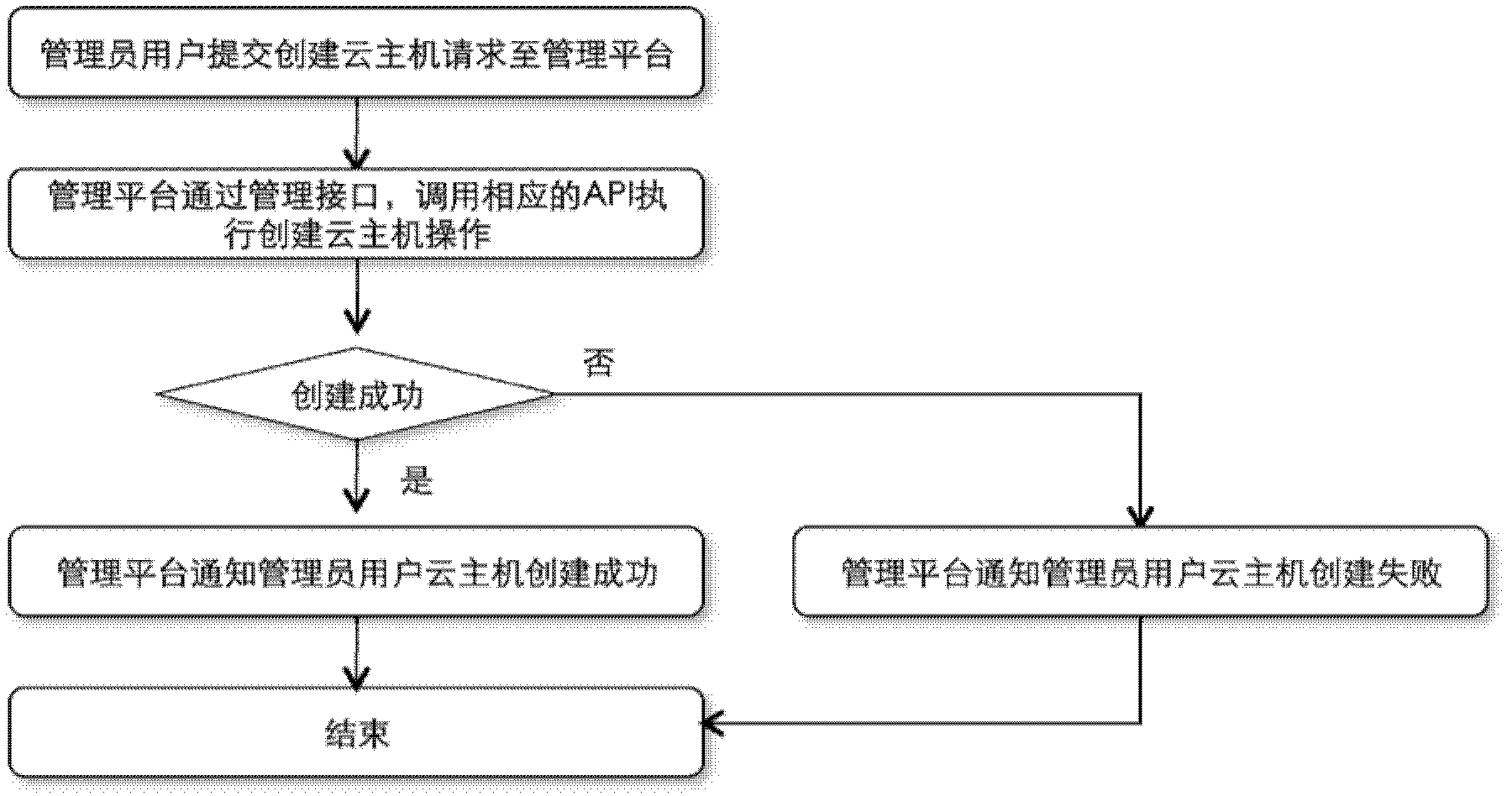

System for managing cloud computing service and cloud computing management method

ActiveCN102427481ARealize unified managementAutomate deploymentTransmissionManagement systemCloud management

The invention discloses a system for managing cloud computing service, which comprises a cloud computing management platform and a cloud application database, wherein the cloud application database is connected with the cloud computing management platform, and the cloud computing management platform is connected with public clouds or private clouds through a network; and the cloud application database comprises all installation packages for cloud application; and the cloud computing management platform is used for helping customers to realize managing a cloud host in the public clouds or private clouds and cloud application in the cloud host. The cloud computing management system provided by the invention realizes the unified management of multiple public clouds and multiple private clouds through a public cloud management interface and a private cloud management interface, so that great convenience is provided for users.

Owner:EAYUN INC

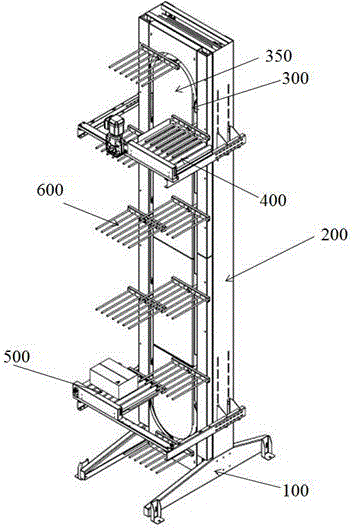

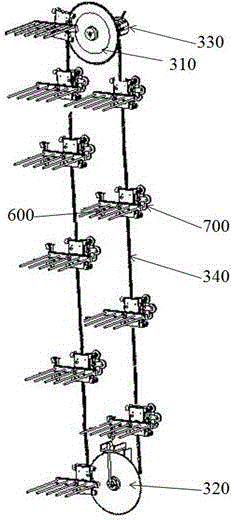

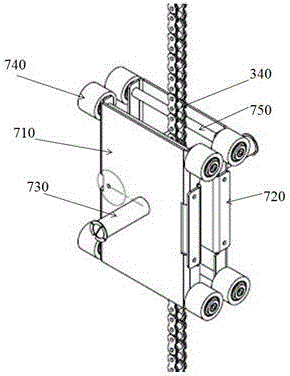

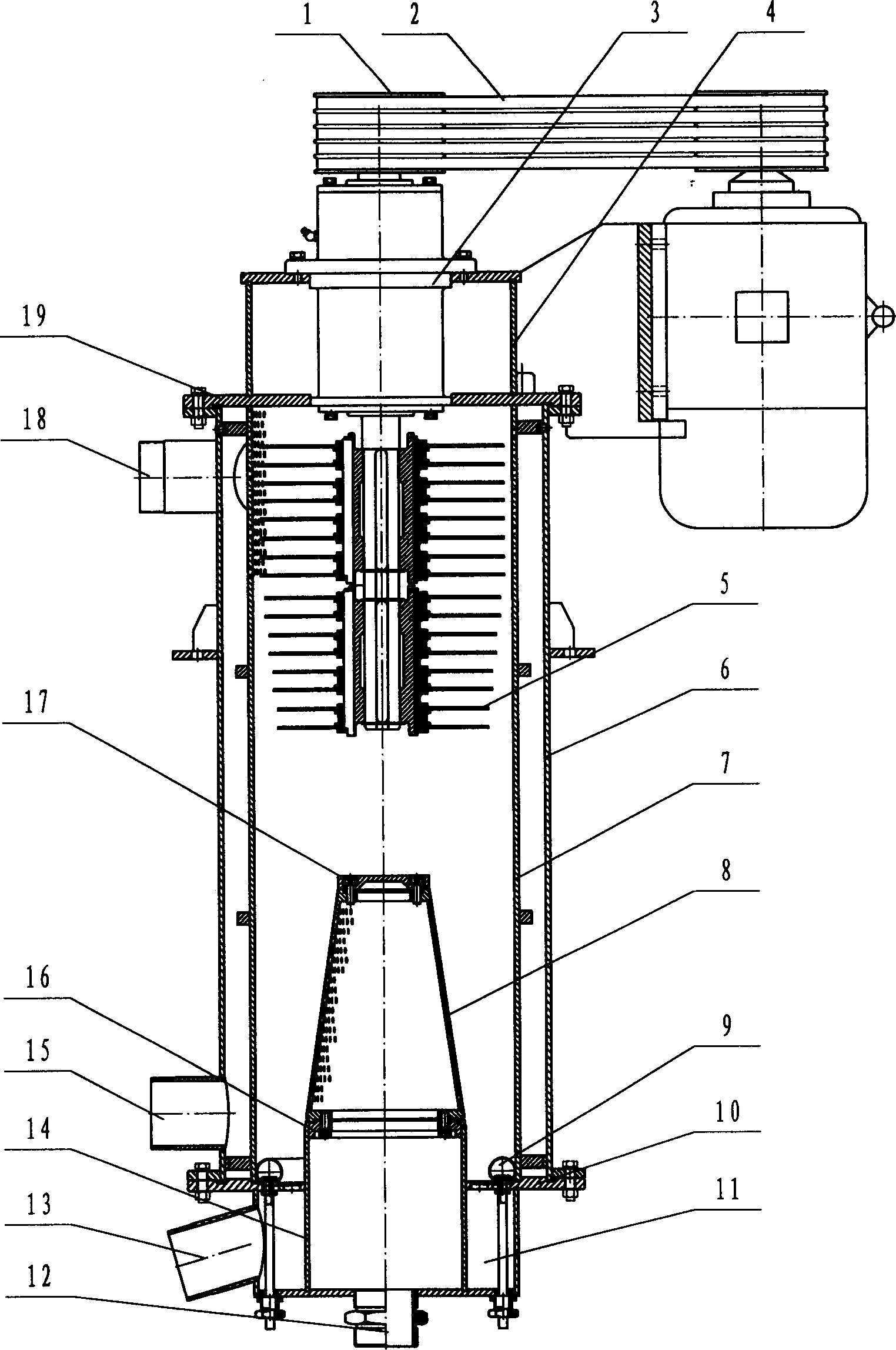

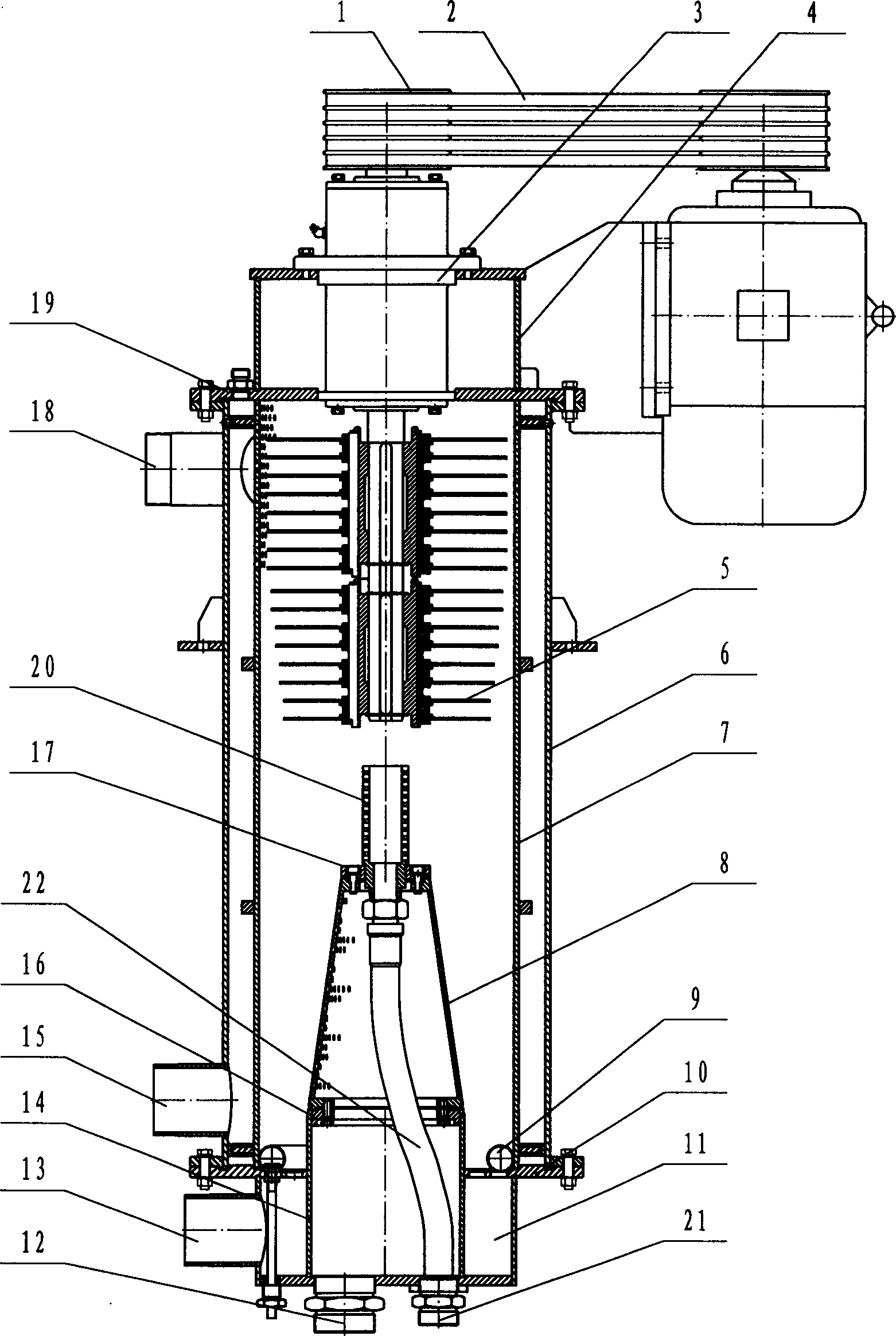

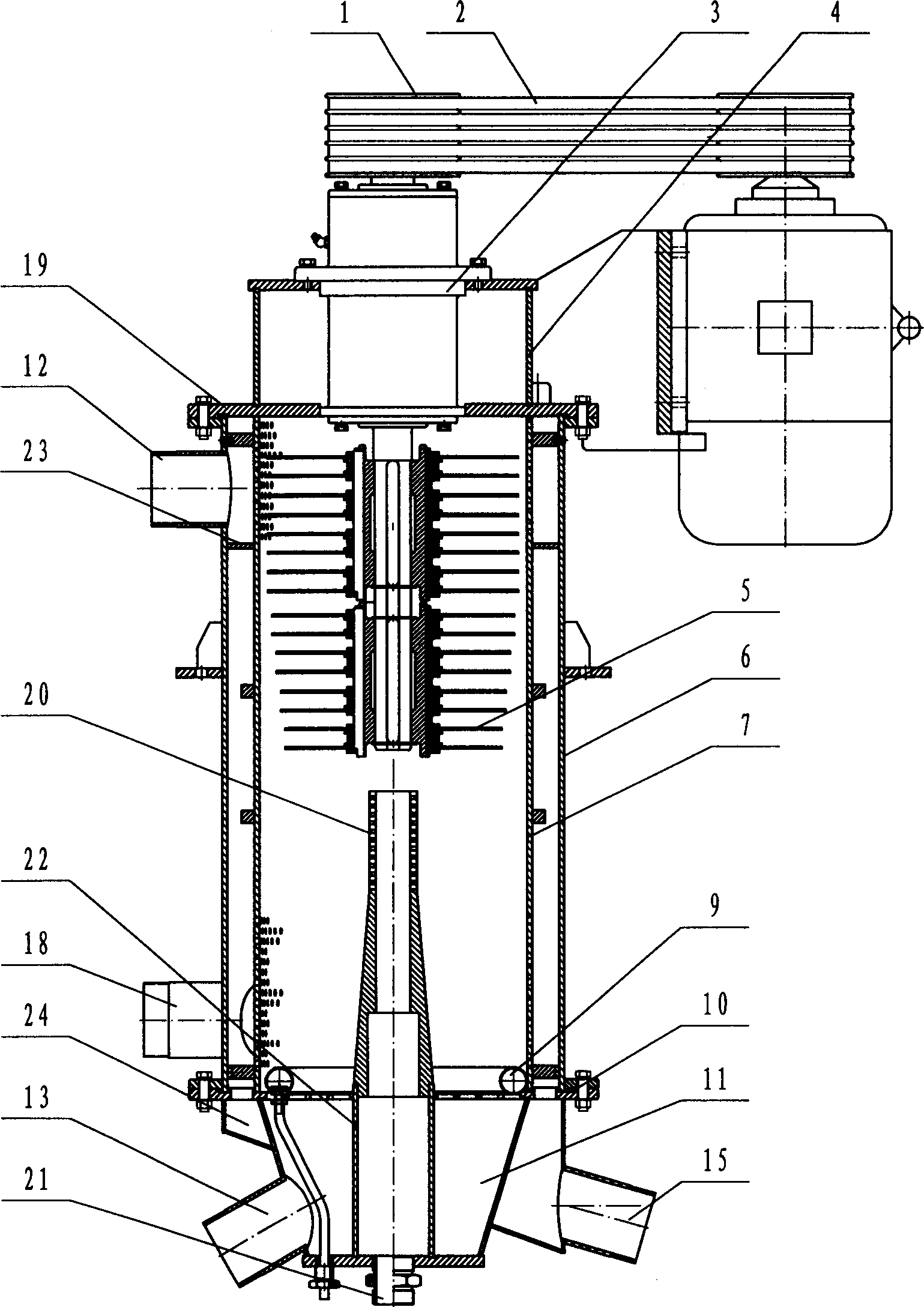

Circulating vertical conveyer

InactiveCN106697750ACompact structureSmall footprintConveyorsConveyor partsDrive motorSmall footprint

The invention provides a circulating vertical conveyer comprising bases, a rack, a driving gear, a driven gear, a feeding and conveying device, a discharging and conveying device, a plurality of moving retainers and fork rods; the rack is fixedly arranged on the bases and is provided with a guide rail; the driving gear is mounted on the guide rail, and the rear of the driving gear is provided with a driving motor; the driven gear is mounted on the guide rail and is connected with the driving gear by a driving chain; the feeding and conveying device is mounted at the upper end of the guide rail; the discharging and conveying device is fixedly arranged at the lower end of the guide rail; the plurality of moving retainers are uniformly and fixedly arranged on the driving chain at intervals; and the fork rods are fixedly arranged on shaft sleeves of the moving retainers. The circulating vertical conveyer is compact in structure, small in floor area, high in circulating speed, capable of realizing automatic feeding and discharging, keeping the stability of goods in a moving process and preventing the goods from shaking or dropping in the moving process and particularly suitable for the situations that the plant layout is urgent, the production speed is high, and a product is required to be vertically conveyed from a high position to a low position or is vertically lifted from the low position to the high position.

Owner:广州市烨兴融集团有限公司

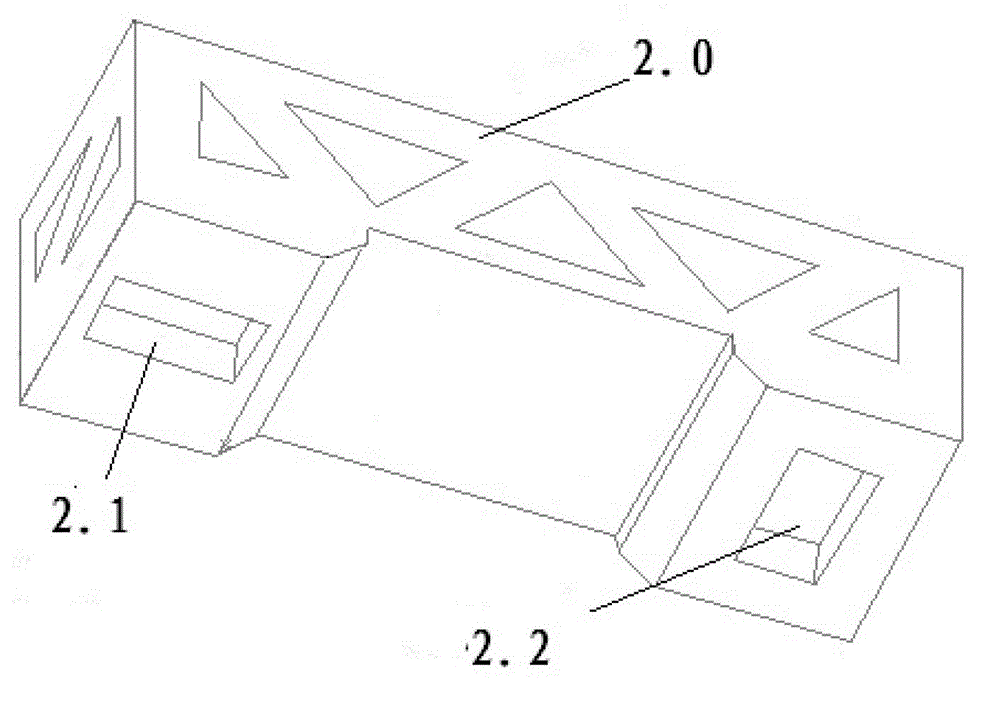

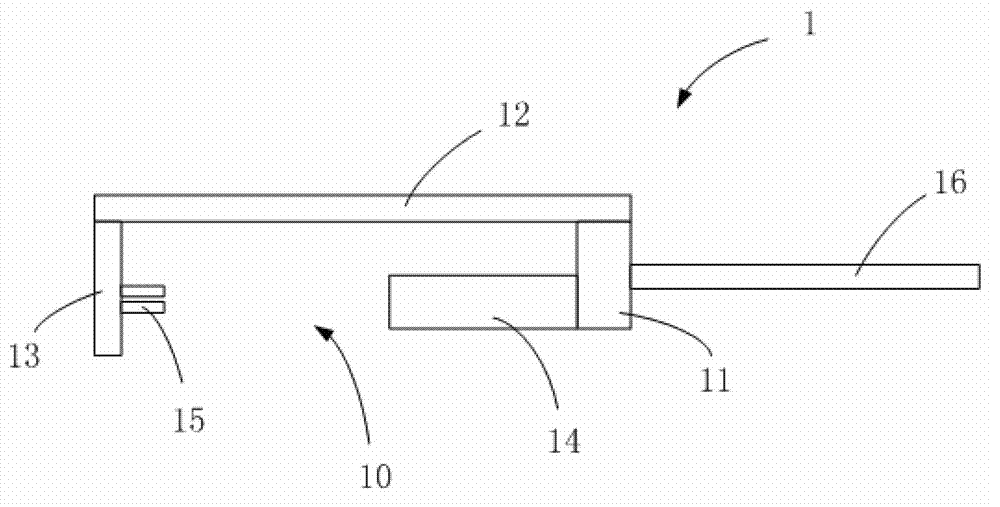

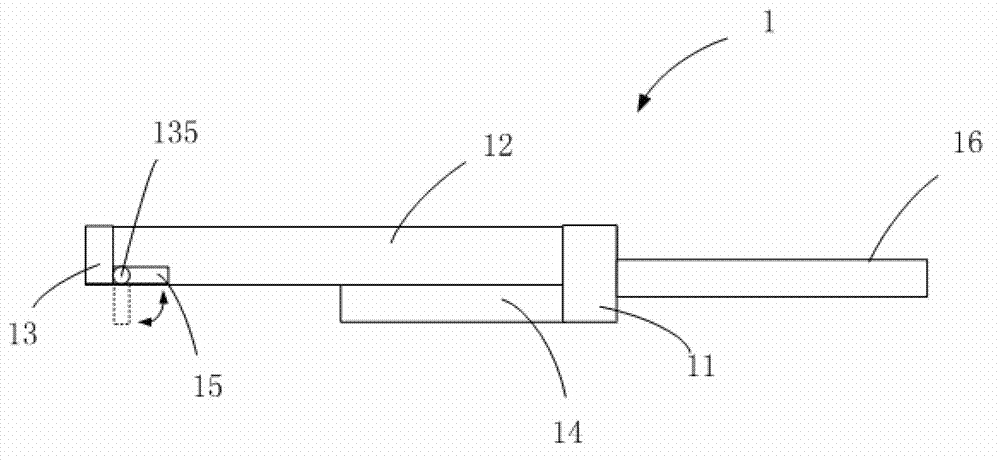

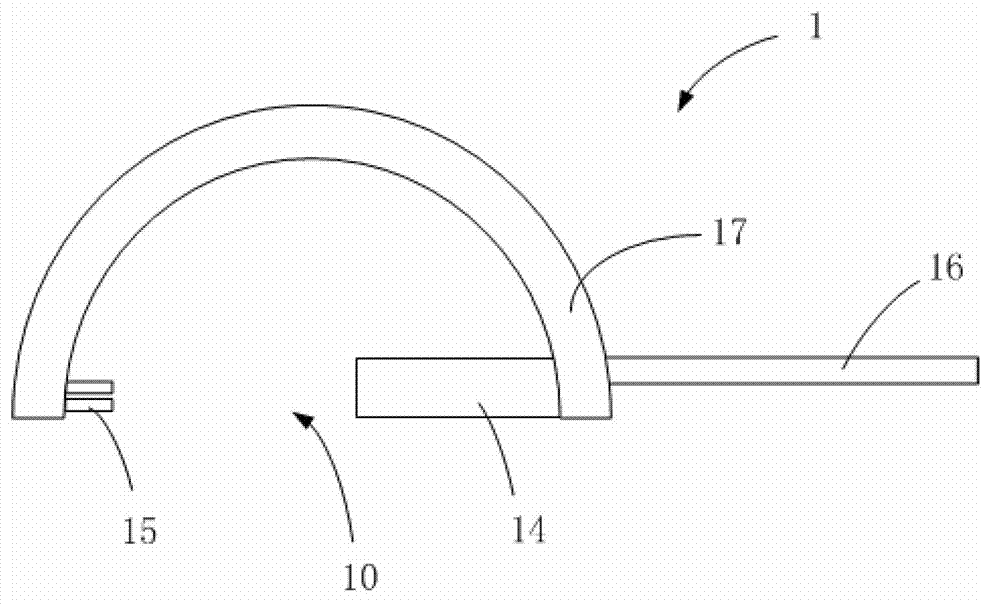

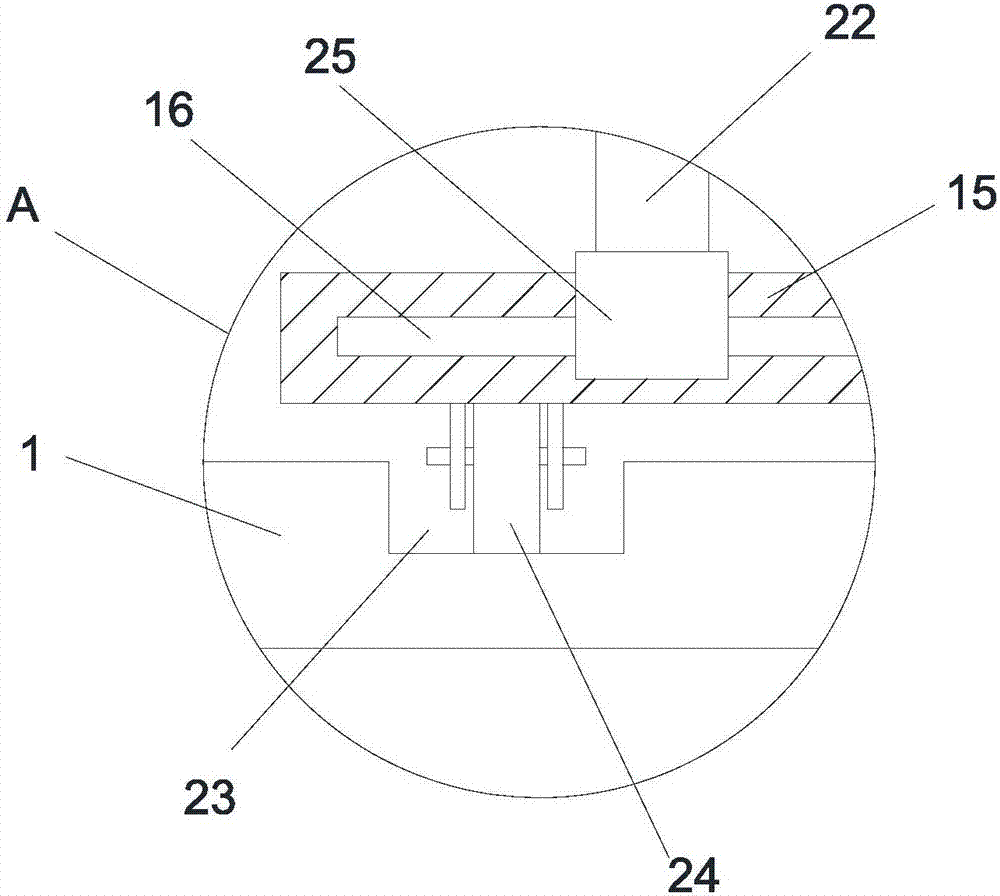

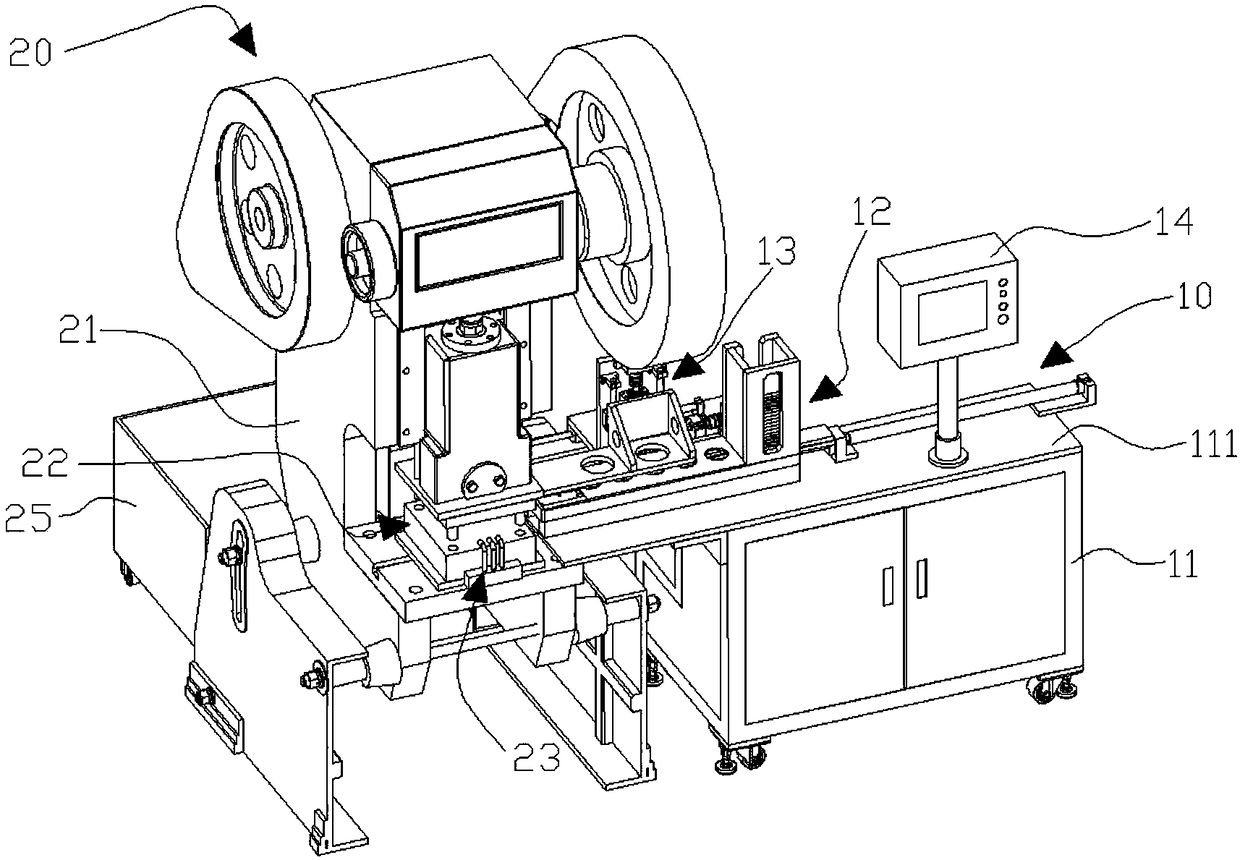

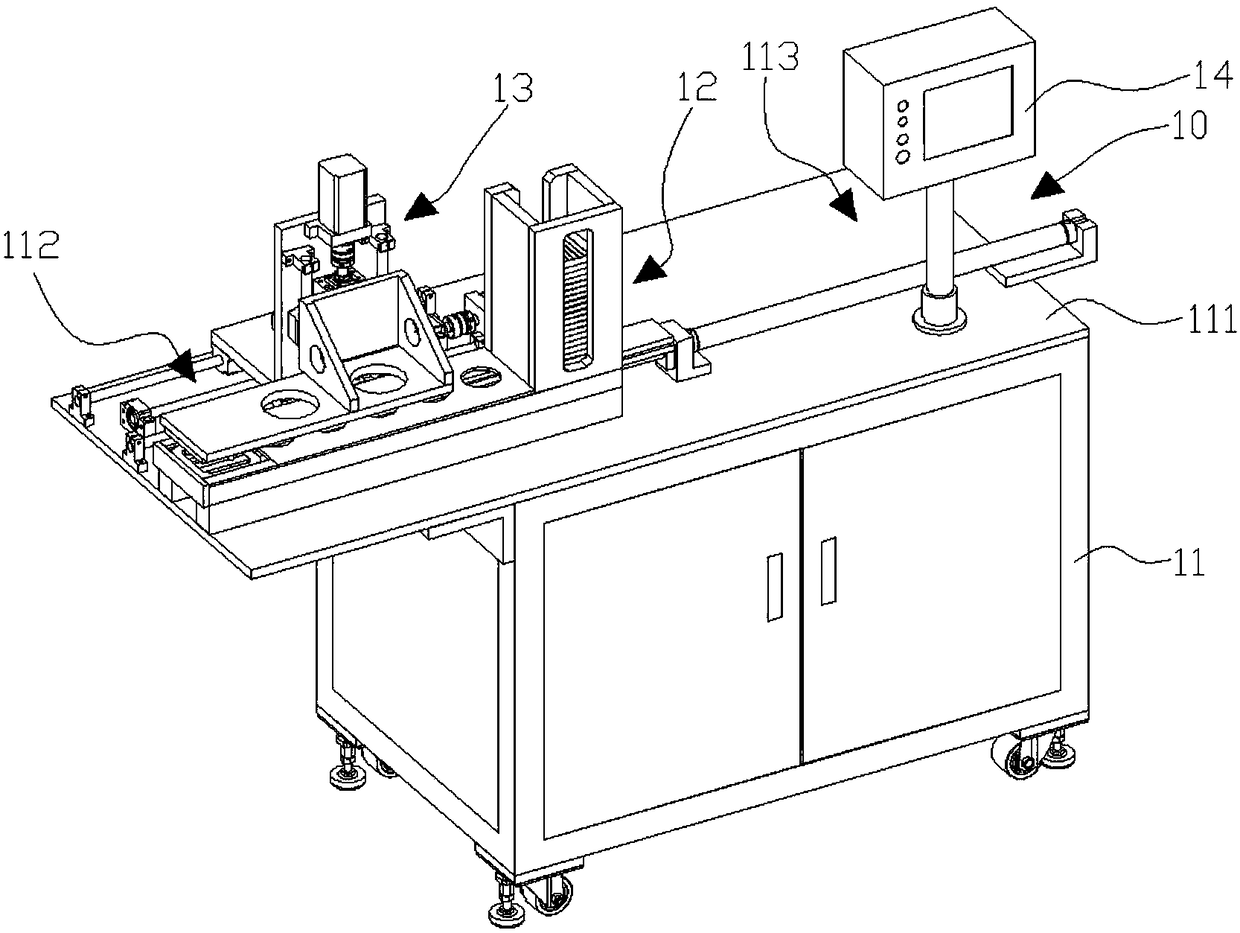

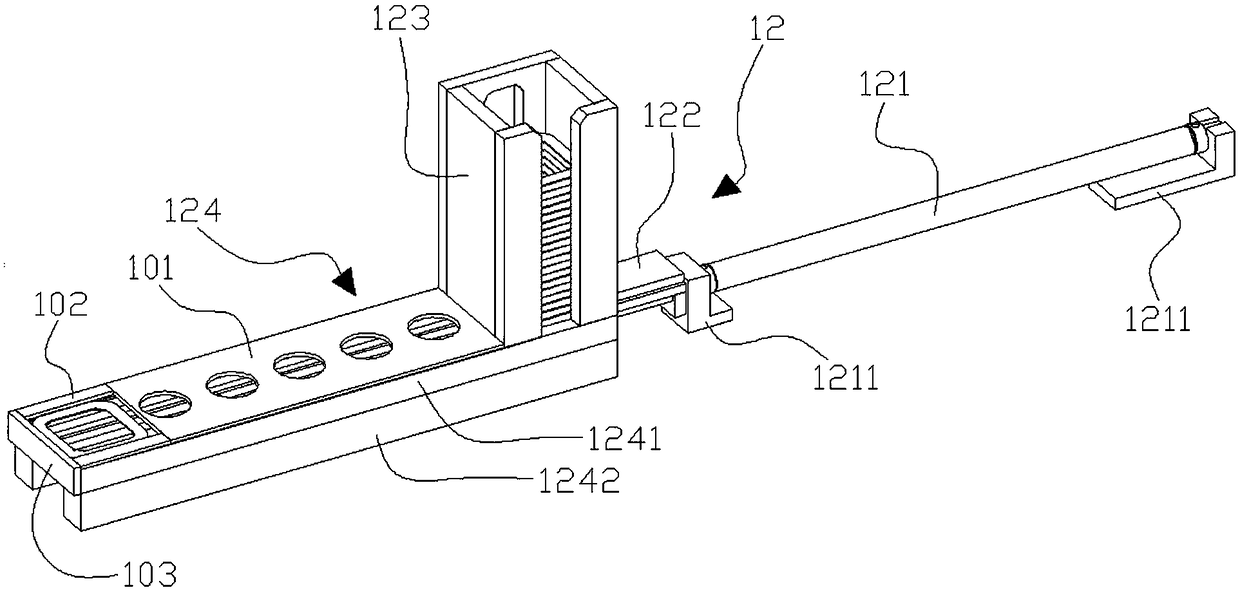

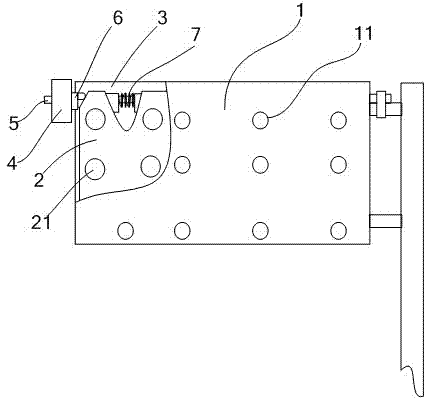

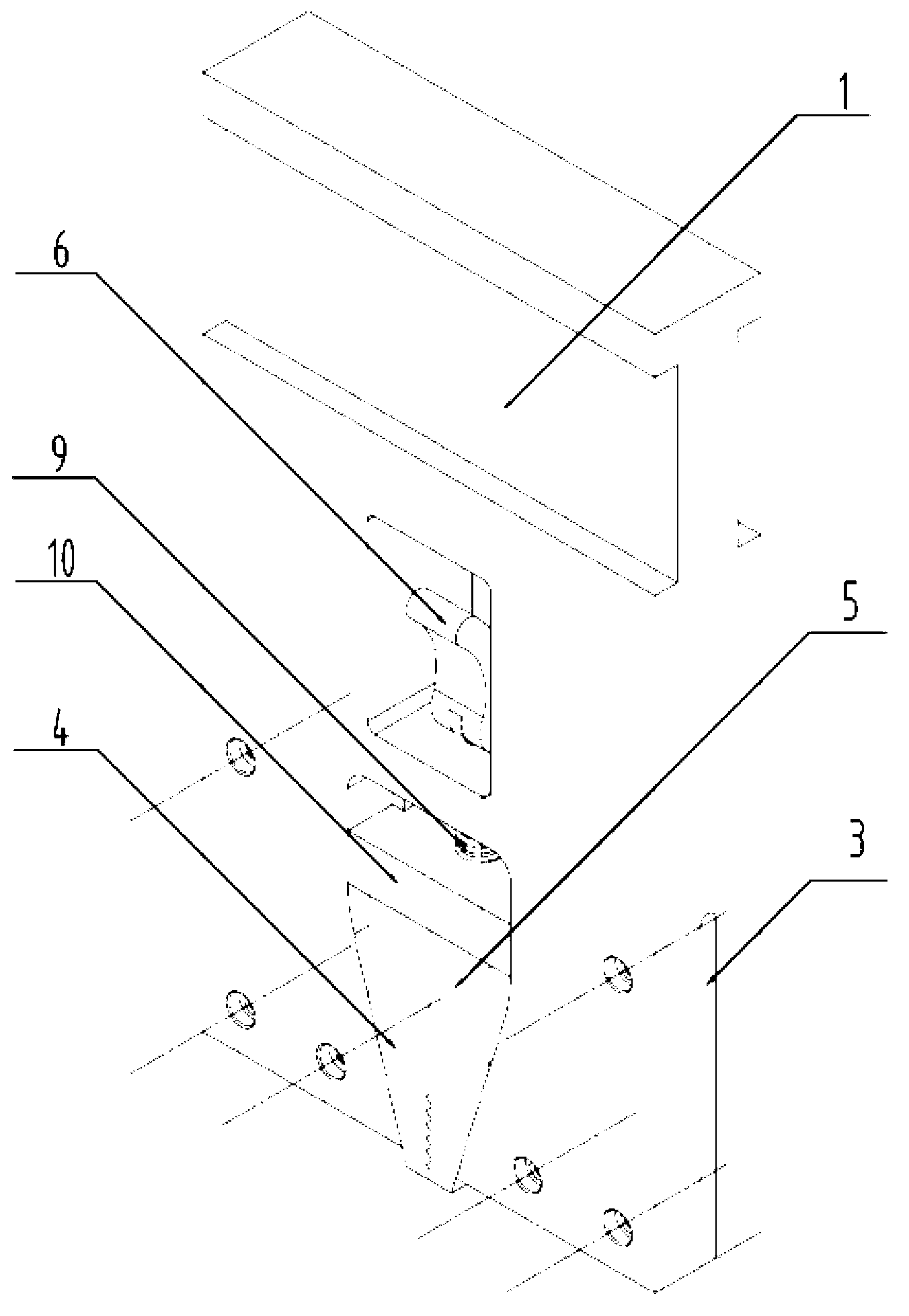

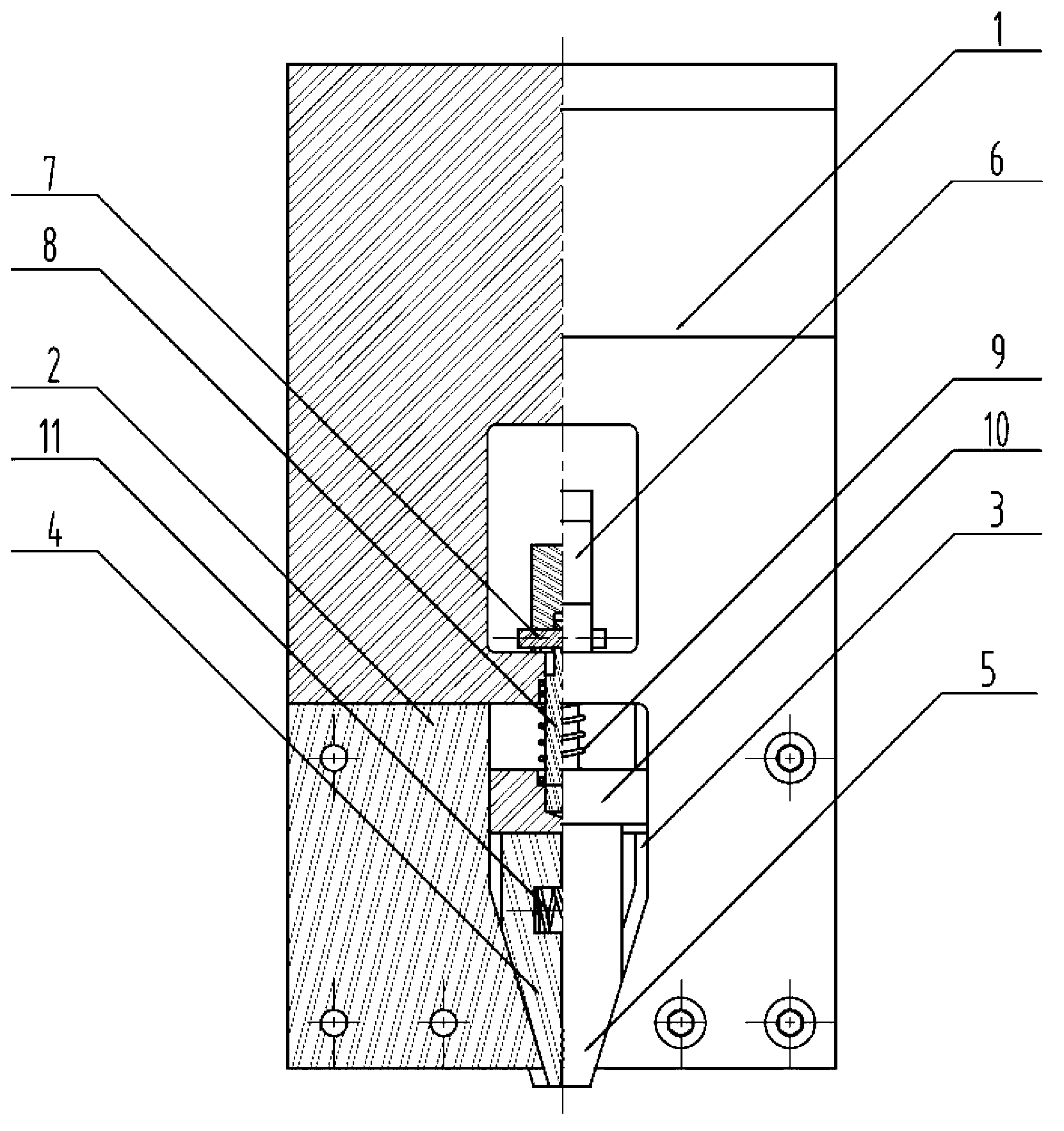

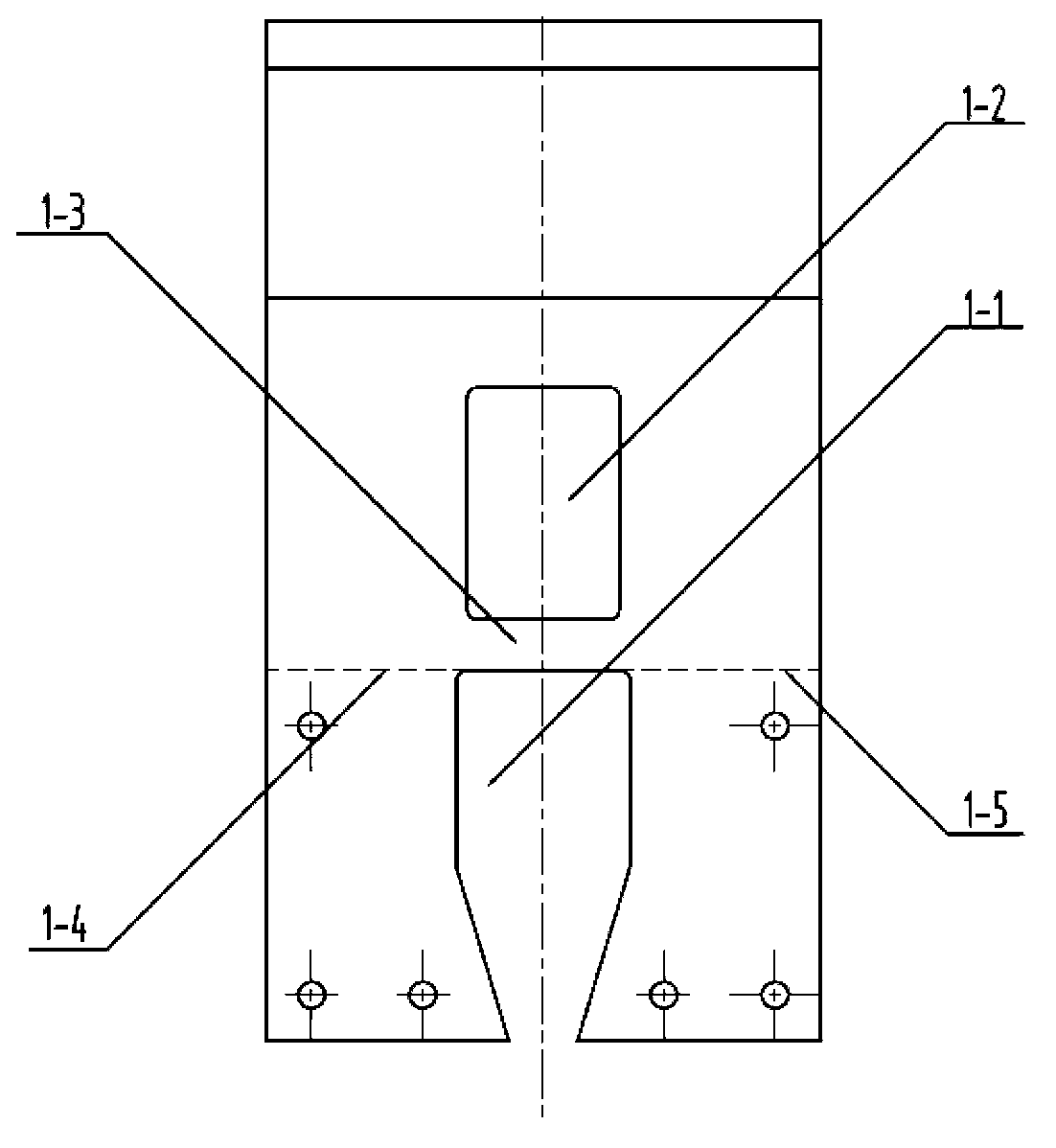

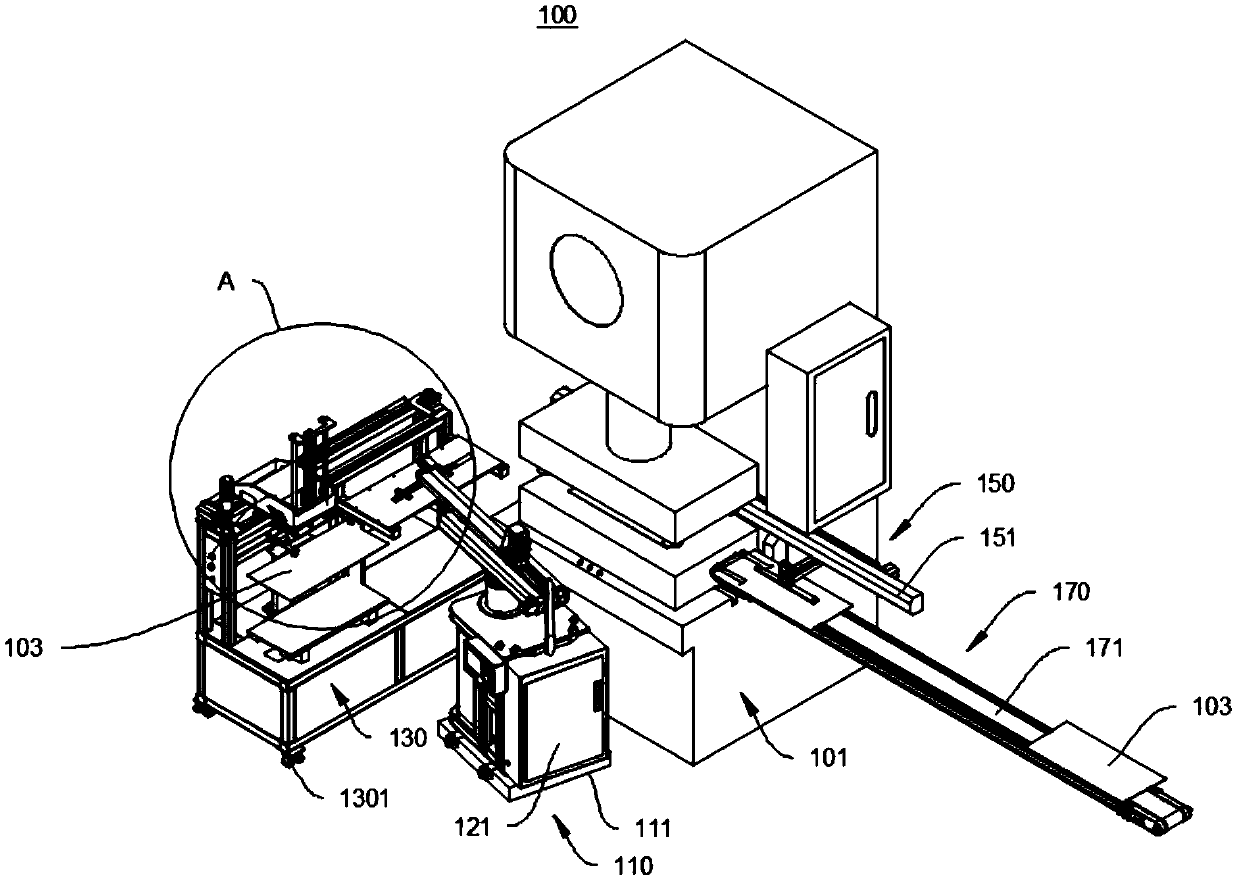

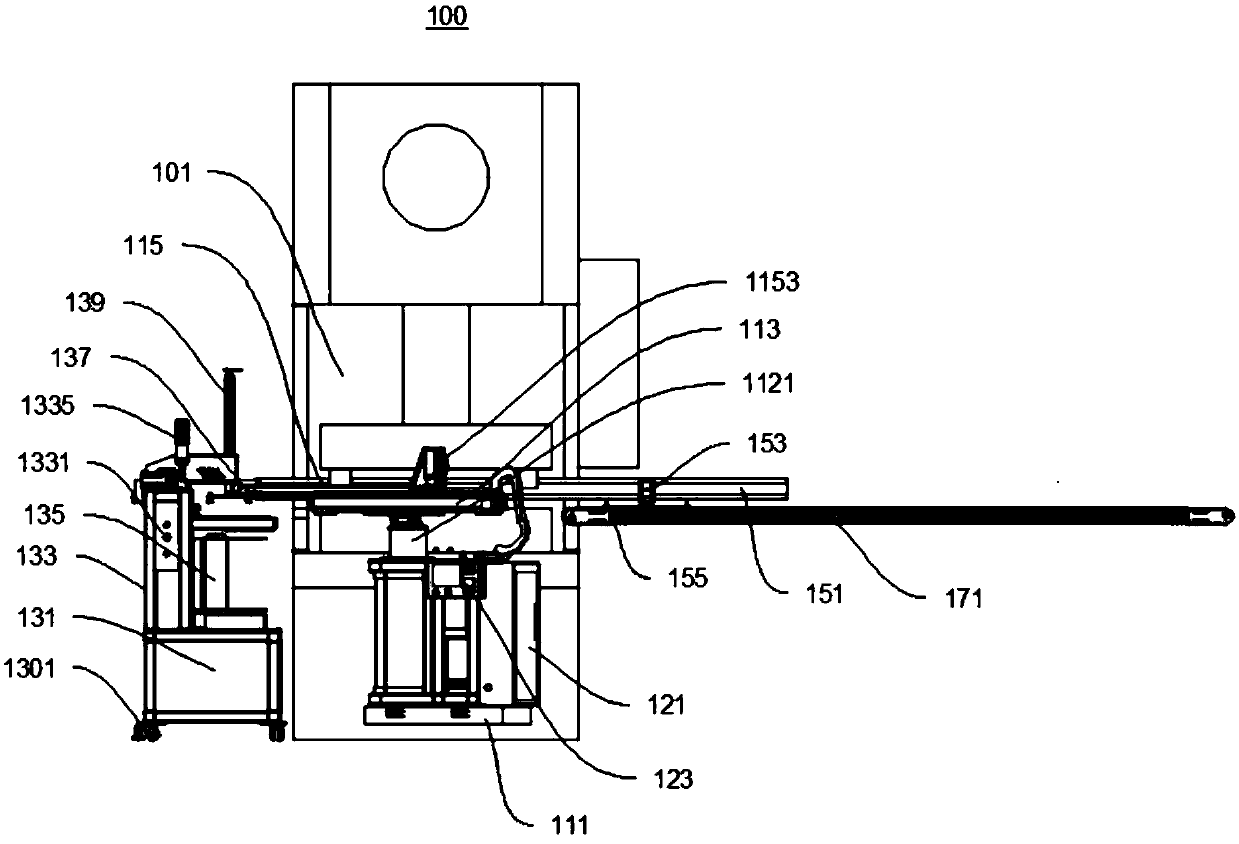

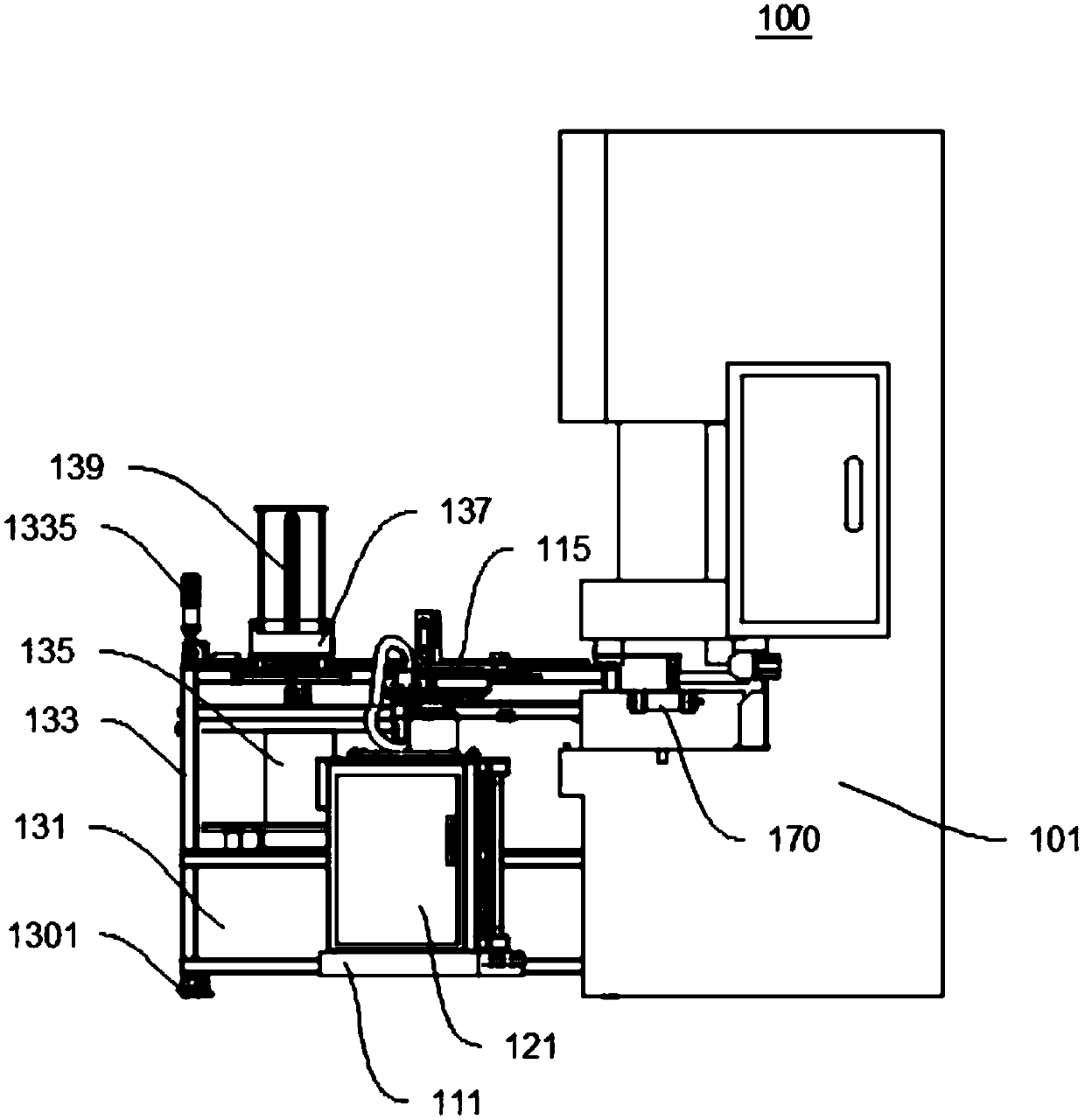

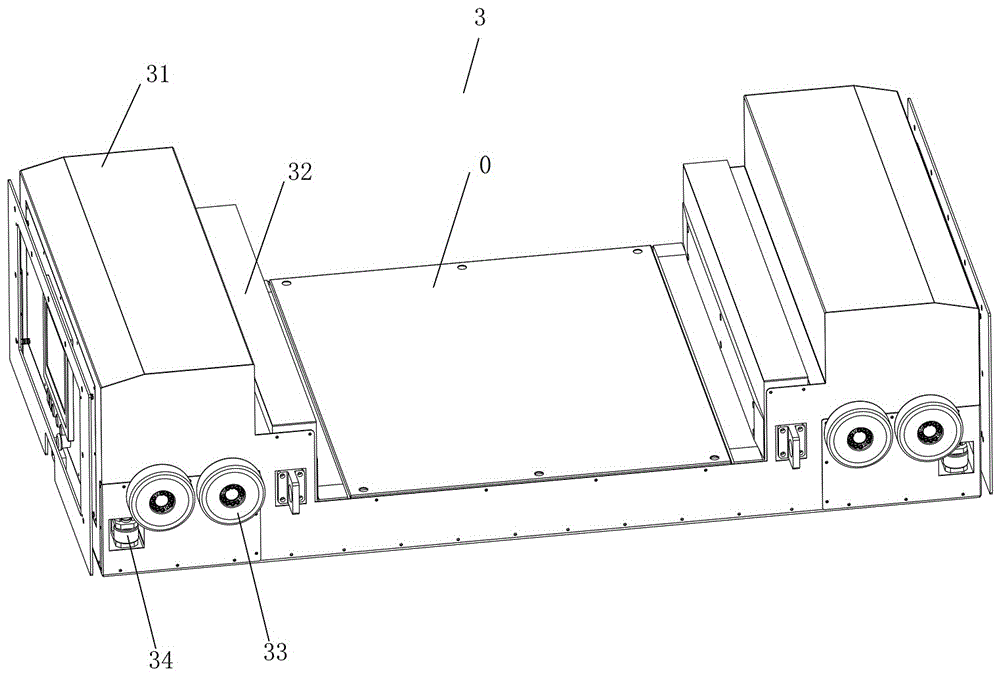

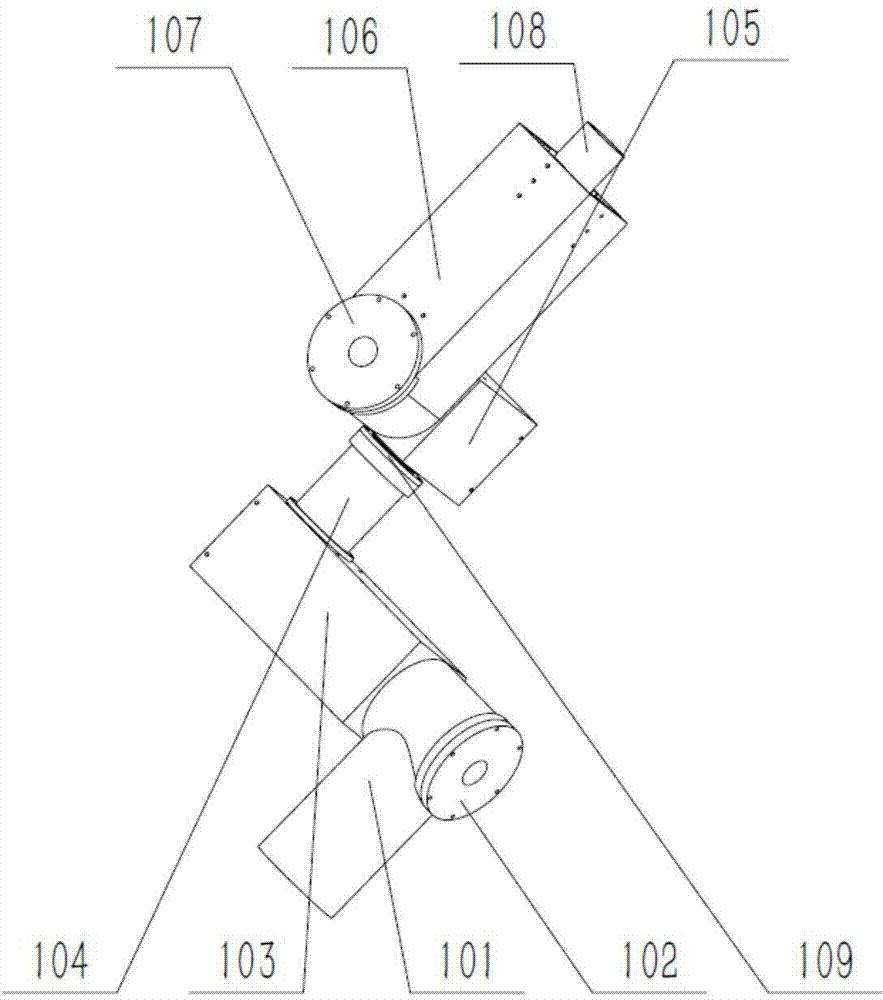

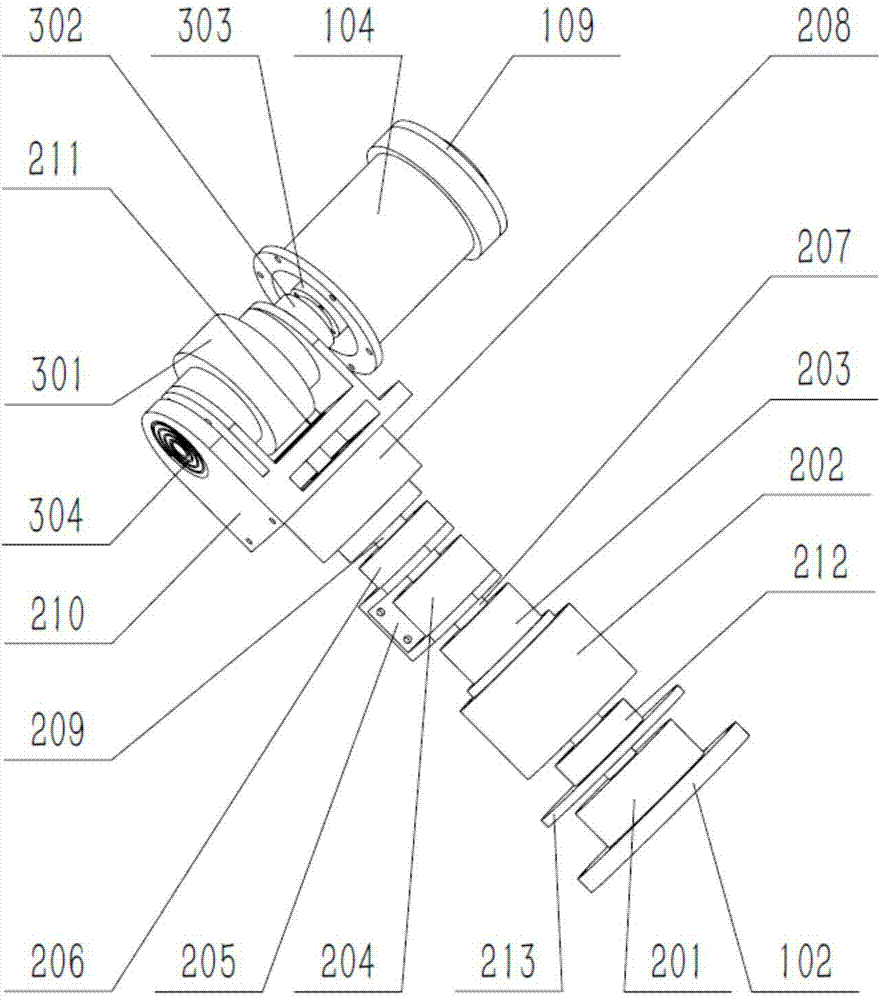

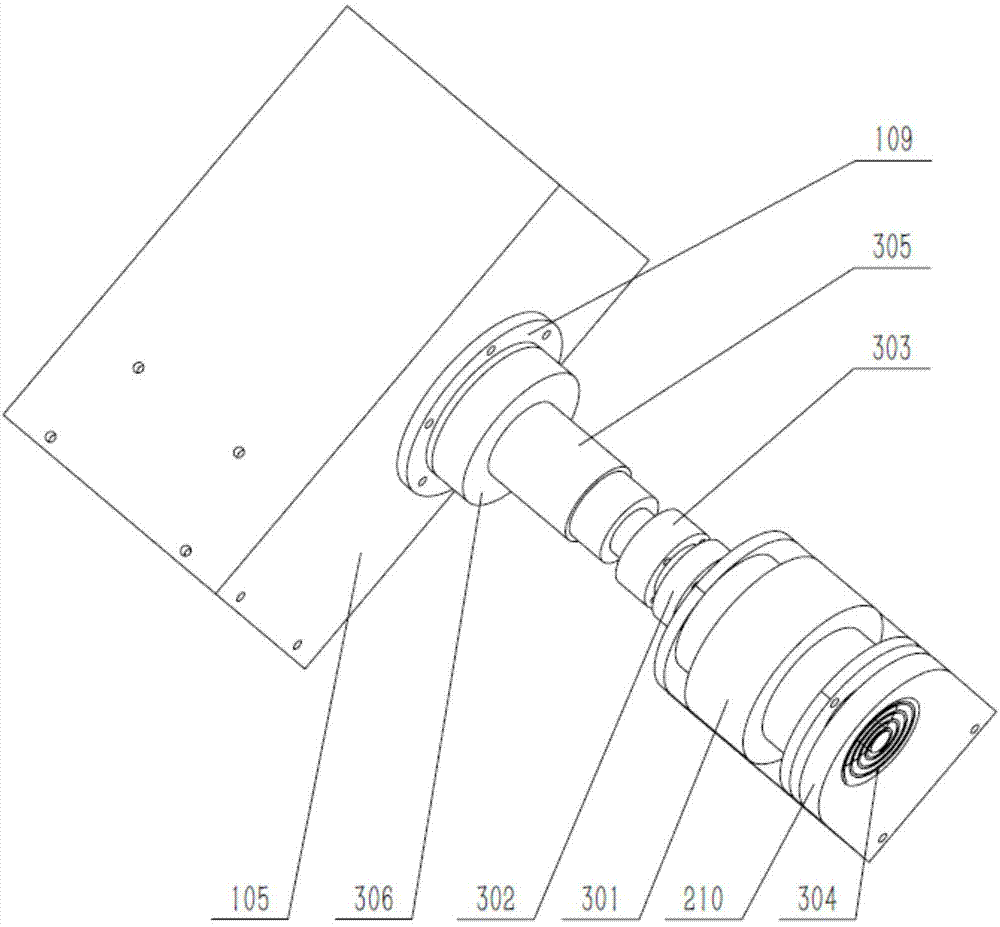

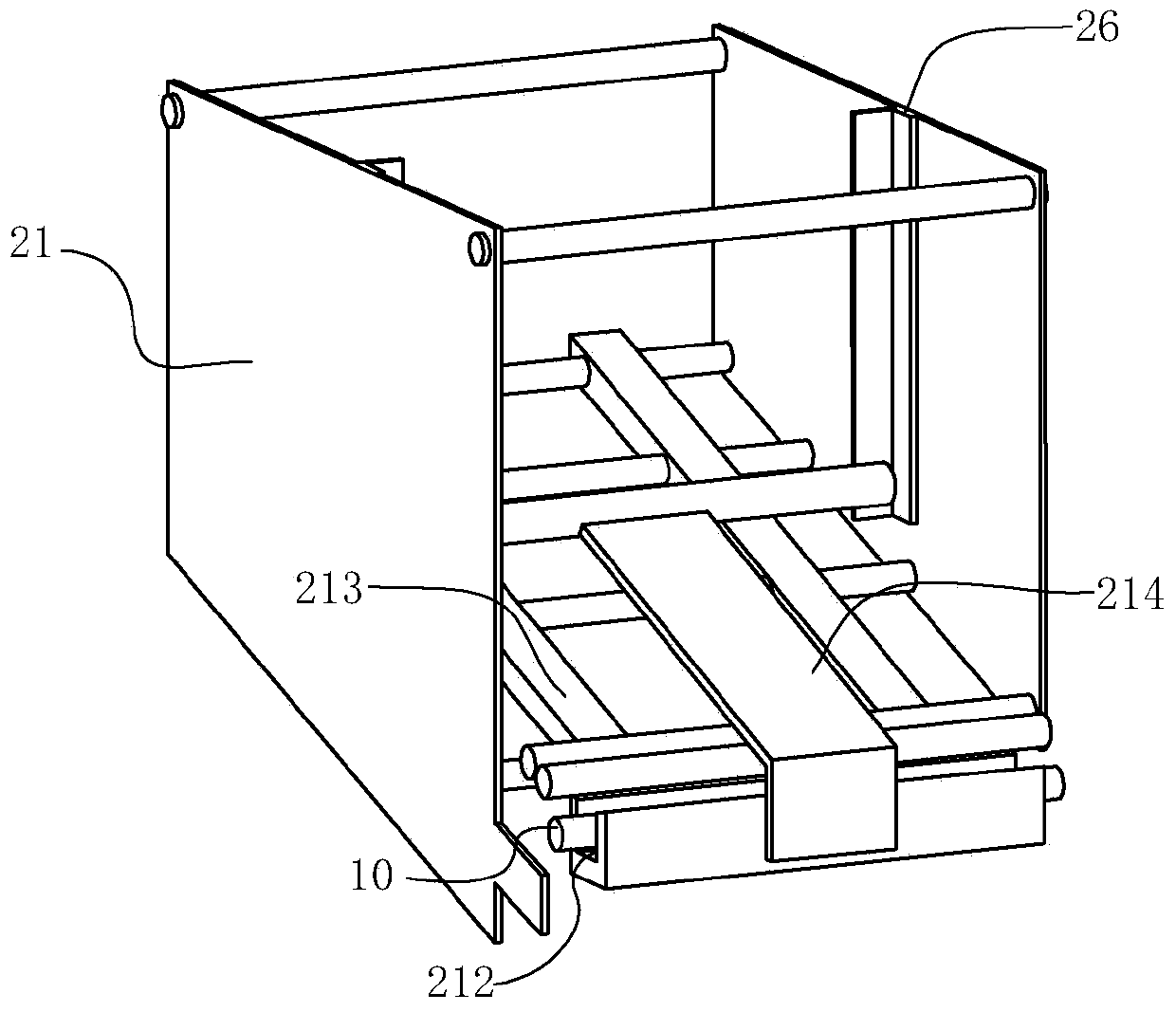

Mechanical arm, automatic loading and unloading system of slide, and digital pathological section scanner

ActiveCN102922525ASimple structural designAchieve loadingGripping headsMaterial analysis by optical meansEngineeringManipulator

The invention provides a mechanical arm, an automatic loading and unloading system of a slide, and a digital pathological section scanner. The mechanical arm, provided by the invention, comprises a loading and unloading frame, wherein a containing space is formed by the loading and unloading frame in a surrounding manner, a horizontal pushing piece is arranged on the loading and unloading frame on one side of the containing space, and a clamping rod is arranged on the loading and unloading frame on the other side of the containing space. According to the mechanical arm provided by the invention, the structural design is simple, and the subsequent loading and unloading of the slide can be realized by virtue of the cooperation between the horizontal pushing piece and the clamping rod; and the operation is convenient and less error-prone, and the cost is lowered when the efficiency is improved.

Owner:KONFOONG BIOTECH INT

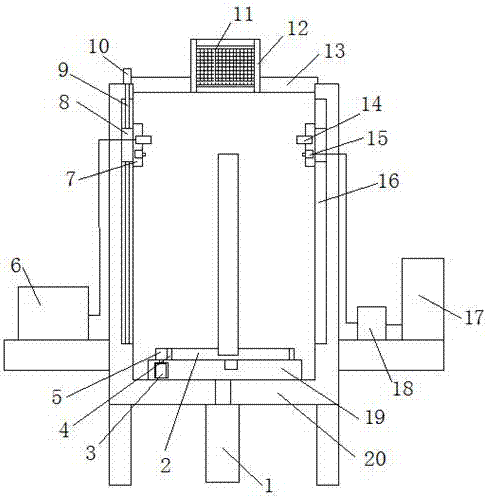

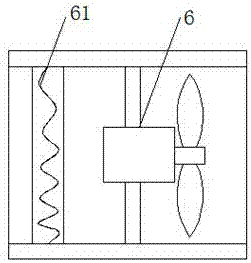

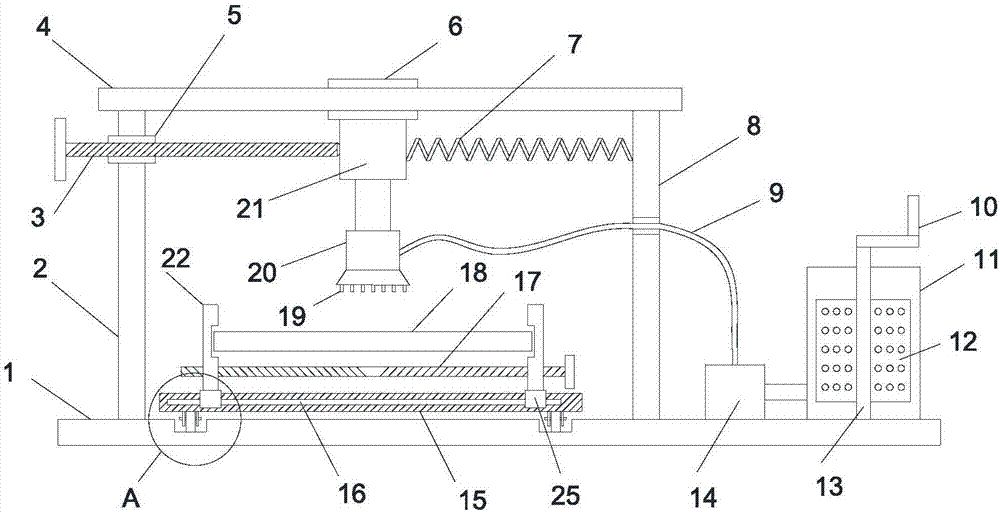

Automatic paint spraying device for metal castings

PendingCN107214035AEasy to installEasy to unloadLiquid surface applicatorsLiquid spraying apparatusPiston rodSpray painting

The invention discloses an automatic paint spraying device for metal castings. The automatic paint spraying device comprises a paint spraying barrel with an opening in the top end. Support columns are correspondingly mounted on the four corners of the bottom end of the paint spraying barrel. An air cylinder vertically arranged is fixedly arranged on the side wall of the bottom end of the paint spraying barrel through bolts. A movable plate is welded to a piston rod of the air cylinder. The movable plate is located on the inner wall of the bottom end of the paint spraying barrel. The top end of the movable plate is rotationally connected with a mounting plate horizontally arranged. A first electric motor is embedded into the movable plate. An output shaft of the first electric motor is connected with a gear. The gear is located on one side of the mounting plate. Tooth mouths distributed in an array manner are mounted on the side walls of the periphery of the mounting plate. The tooth mouths are engaged with the gear. A fixing ring is slidably connected into the paint spraying barrel. An annular air outlet pipe and a liquid spraying pipe are mounted on the inner wall of the fixing ring. The air outlet pipe is located above the liquid spraying pipe. By the adoption of the automatic paint spraying device, the multi-angle paint spraying of the metal castings can be achieved, the paint spraying effect is good, the quick mounting and discharging of the metal castings are achieved, and the air pollution is reduced.

Owner:JIANGSU SUGAO FLUID MACHINERY

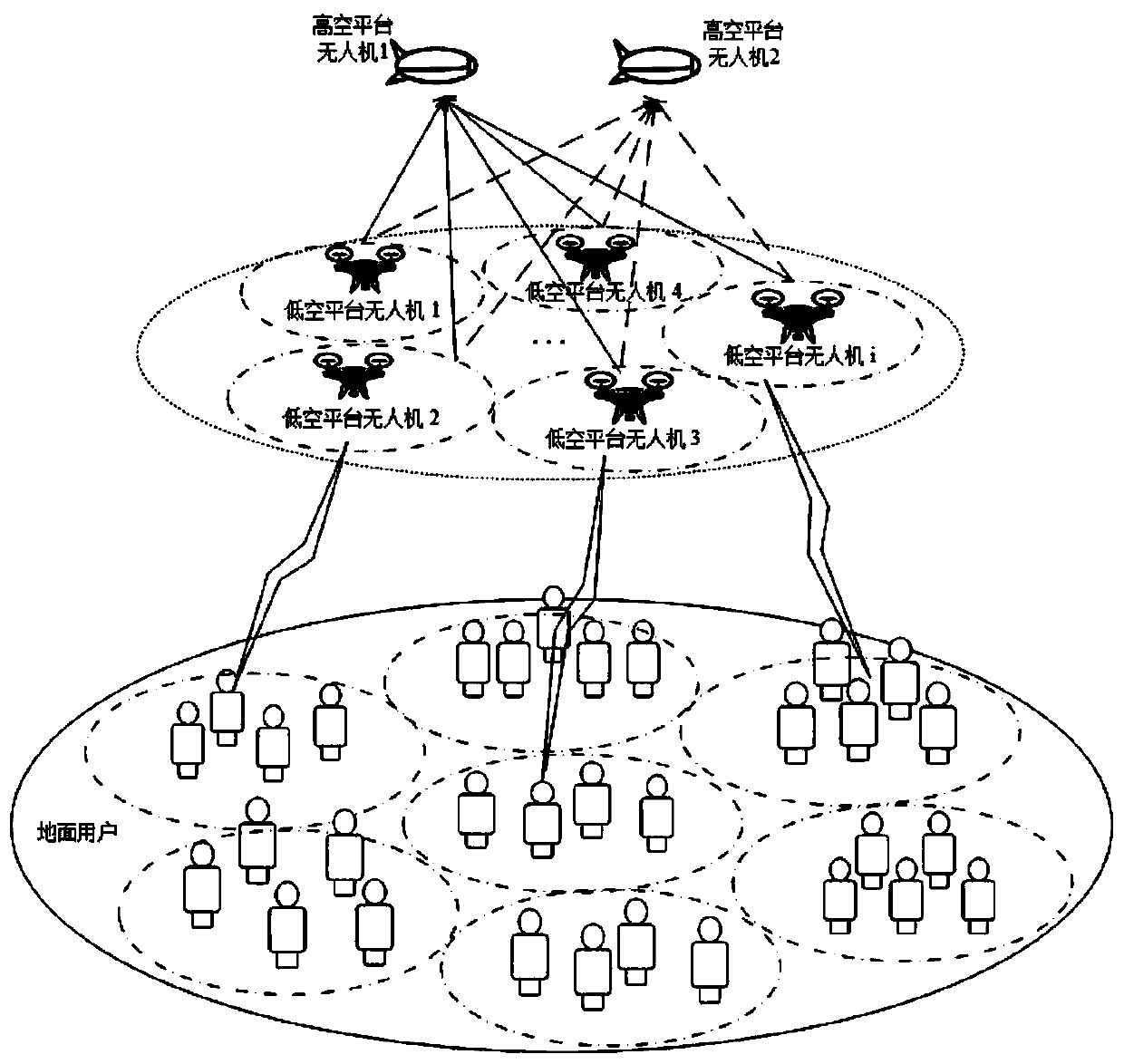

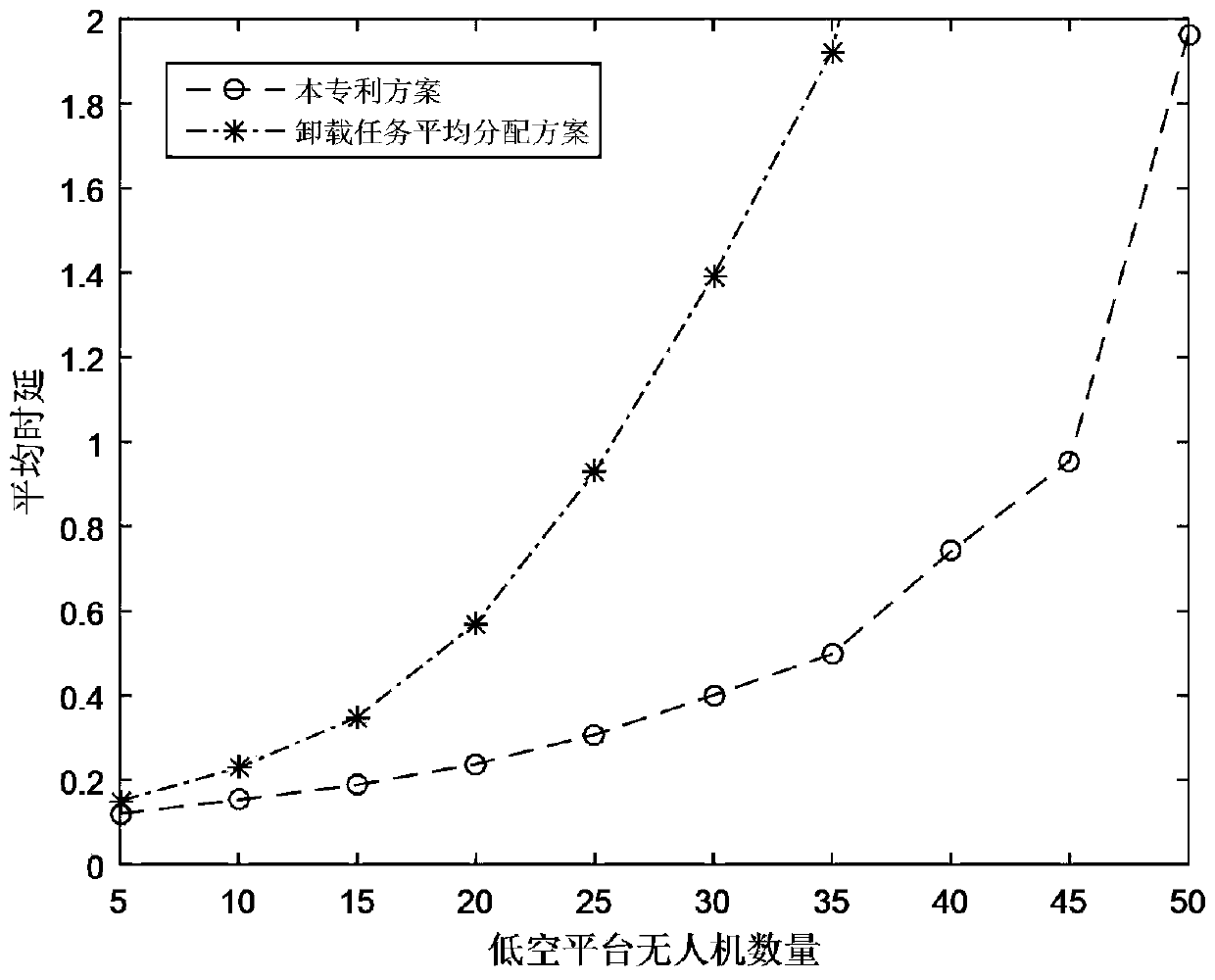

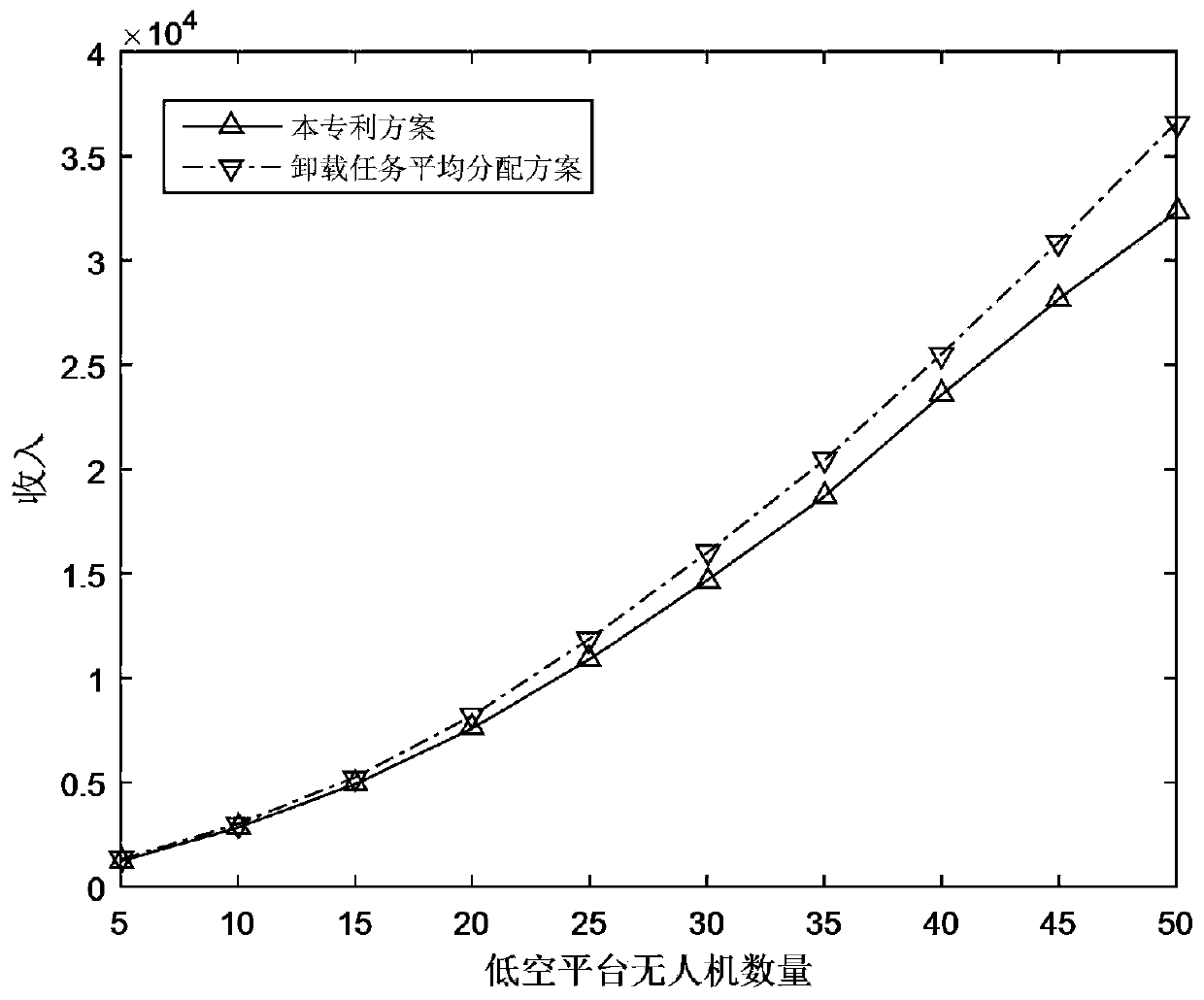

Unloading task allocation method of mobile edge computing system based on double-layer unmanned aerial vehicle

ActiveCN110336861ARealize unloadingReduce complexityData switching networksOptimization problemDelay sensitive

The invention discloses an unloading task allocation method of a mobile edge computing system based on a double-layer unmanned aerial vehicle. The mobile edge computing system comprises two high-altitude platform unmanned aerial vehicles provided with mobile edge computing servers and a plurality of low-altitude platform unmanned aerial vehicles, and the two high-altitude platform unmanned aerialvehicles are used for executing computing tasks unloaded by the low-altitude platform unmanned aerial vehicles; the unloading task allocation method comprises the following steps: modeling calculationtask unloading allocation problems of the low-altitude platform unmanned aerial vehicle and the high-altitude platform unmanned aerial vehicle through a game, and establishing a utility function of the upper-layer high-altitude unmanned aerial vehicle and a cost function of the lower-layer low-altitude platform unmanned aerial vehicle based on the price; and solving an equilibrium planning problem with equilibrium constraints obtained after modeling: on the basis of a strategy of fixing an upper-layer leader, firstly solving an equilibrium solution of an optimization problem of a plurality ofusers at a lower layer of the game, and then solving an equilibrium solution of a plurality of unmanned aerial vehicle base stations at an upper layer. The problems existing when an existing unmannedaerial vehicle executes calculation-intensive and delay-sensitive tasks are solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Automatic feeding device

InactiveCN102029330ARealize automatic feedingRealize stampingMetal-working feeding devicesPositioning devicesEngineeringUltimate tensile strength

The invention relates to an automatic feeding device which comprises a base, a feeding box and a feeding cylinder, wherein the feeding box is vertically arranged on the upper surface of the base, a longitudinal feeding groove is arranged inside the feeding box, a horizontal channel communicated with the feeding groove is formed between the lower bottom surface of the feeding box and the base, the upper surface of the base at one side of the feeding box is provided with the feeding cylinder, the front end of the feeding cylinder is provided with a horizontal push plate moving in the horizontal channel of the feeding box, and the base at the other side of the feeding box is provided with a processing table. The automatic feeding device is a feeding machine with simple structure, simple operation and high automation, can realize automatic feeding and discharging, greatly improves the production efficiency, lowers the labor intensity of workers, and is suitable for being popularized and used in musical instrument industry or other industries.

Owner:TIANJIN JINBAO MUSICAL INSTR

Cloud computing management system and cloud computing management method

InactiveCN102882908ARealize unified managementImprove efficiencyData switching networksCloud managementManagement system

The invention discloses a cloud computing management system. The system comprises a cloud computing management platform and a cloud application database, wherein the cloud application database is connected to the cloud computing management platform; the cloud computing management platform is connected with public clouds or private clouds through networks; the cloud application database comprises installation packages of all cloud applications; and the cloud computing management platform is used for helping a client to manage cloud hosts in the public clouds or private clouds and the cloud applications in the cloud hosts. By the cloud computing management system, various public clouds or private clouds are managed in a unified mode through a public cloud management interface and a private cloud management interface, and great convenience is brought to a user.

Owner:EAYUN INC

Platy workpiece paint spraying device for machining

The invention discloses a paint spraying device for a plate-shaped workpiece for machining, comprising a bottom plate, a left column and a right column are vertically fixed on the bottom plate, a threaded sleeve is arranged on the left column, and a threaded sleeve is horizontally provided with a thread through a thread fit. The first screw rod, the top plate is fixed horizontally on the left column and the right column, the sliding sleeve on the top plate is provided with a sliding sleeve, the rotating shaft is fixedly installed with a stirring plate, and the inlet end of the conveying pump is connected with the paint bucket through a pipeline; above the bottom plate A sliding plate is arranged horizontally, a chute is horizontally and horizontally opened on the side of the sliding plate, and two limit sliders are matched and connected to the chute, and a splint is vertically fixed on each of the limit sliders, and the splint is horizontally and horizontally installed. A second screw rod is threadedly connected, and the left half and the right half of the second screw rod have opposite screw threads; the invention is simple and convenient to adjust, and has strong practicability and operability, so that the surface of the plate-shaped workpiece can achieve a uniform painting effect and improve the the quality of the spray paint.

Owner:深圳市海帮国际商务服务有限公司

Settling centrifuger with internal rotor

InactiveCN1383926ADiffusion evenly distributedEasy to separateWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSlurrySewage treatment

The present invention relates to the technology of centrifugal separation of mixed liquid. The centrifuge incldues transmission mechanism, pin wheel rotor with extending area covering at least partial centrifugal cavity space, slurry intake, casing and filtering cylinder assembly, aerator, slurry outlet filter and light phase skimming out device. The centrifugal cavity has several modes and several slurry and material discharge combinations. The material in slurry discharge filter is eliminated by centrifugal vortex and gravity. The present invention is used in solid-solid, liquid-liquid and solid-liquid-liquid separation, mass-transferring reaction and sewage treatment.

Owner:高根树

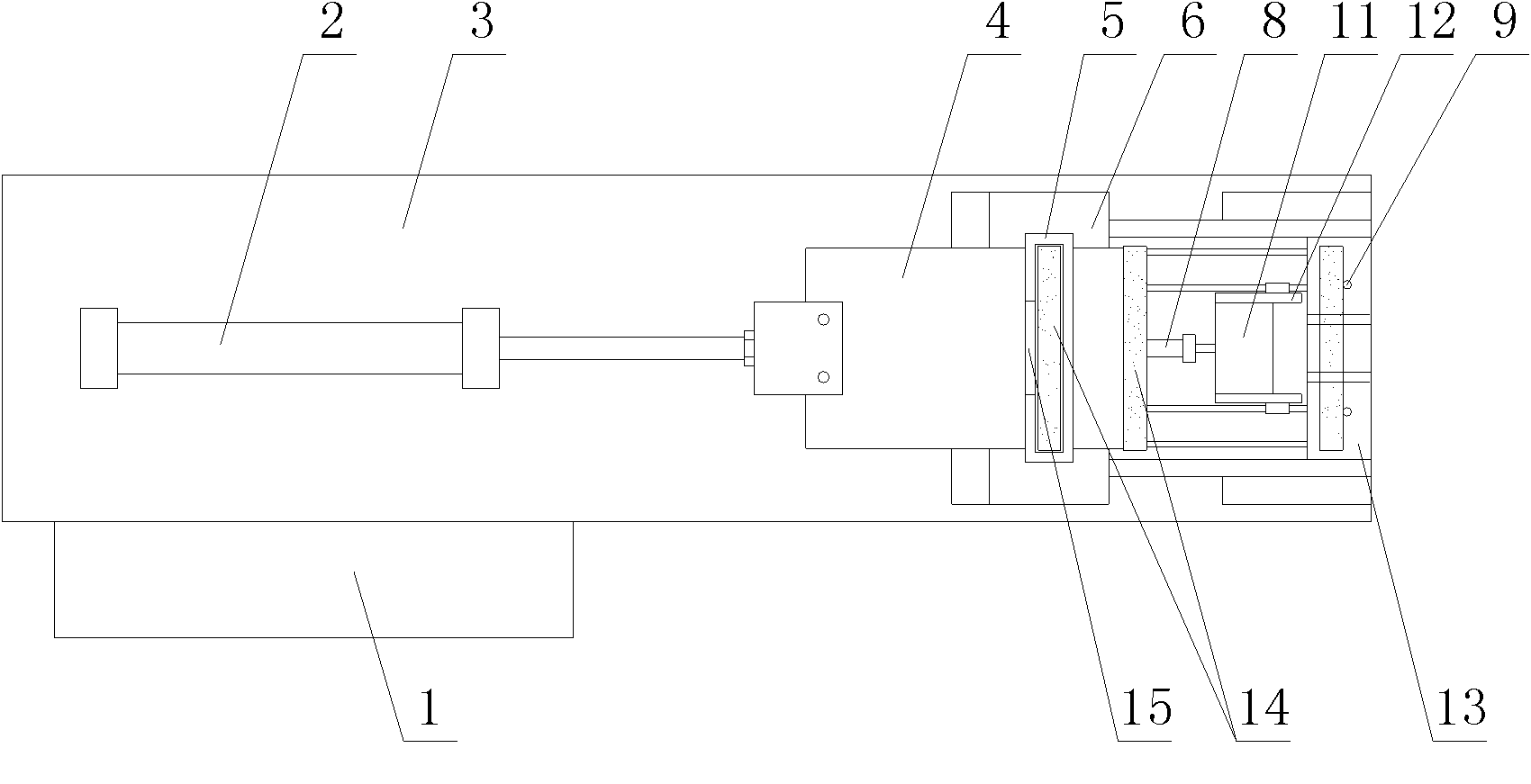

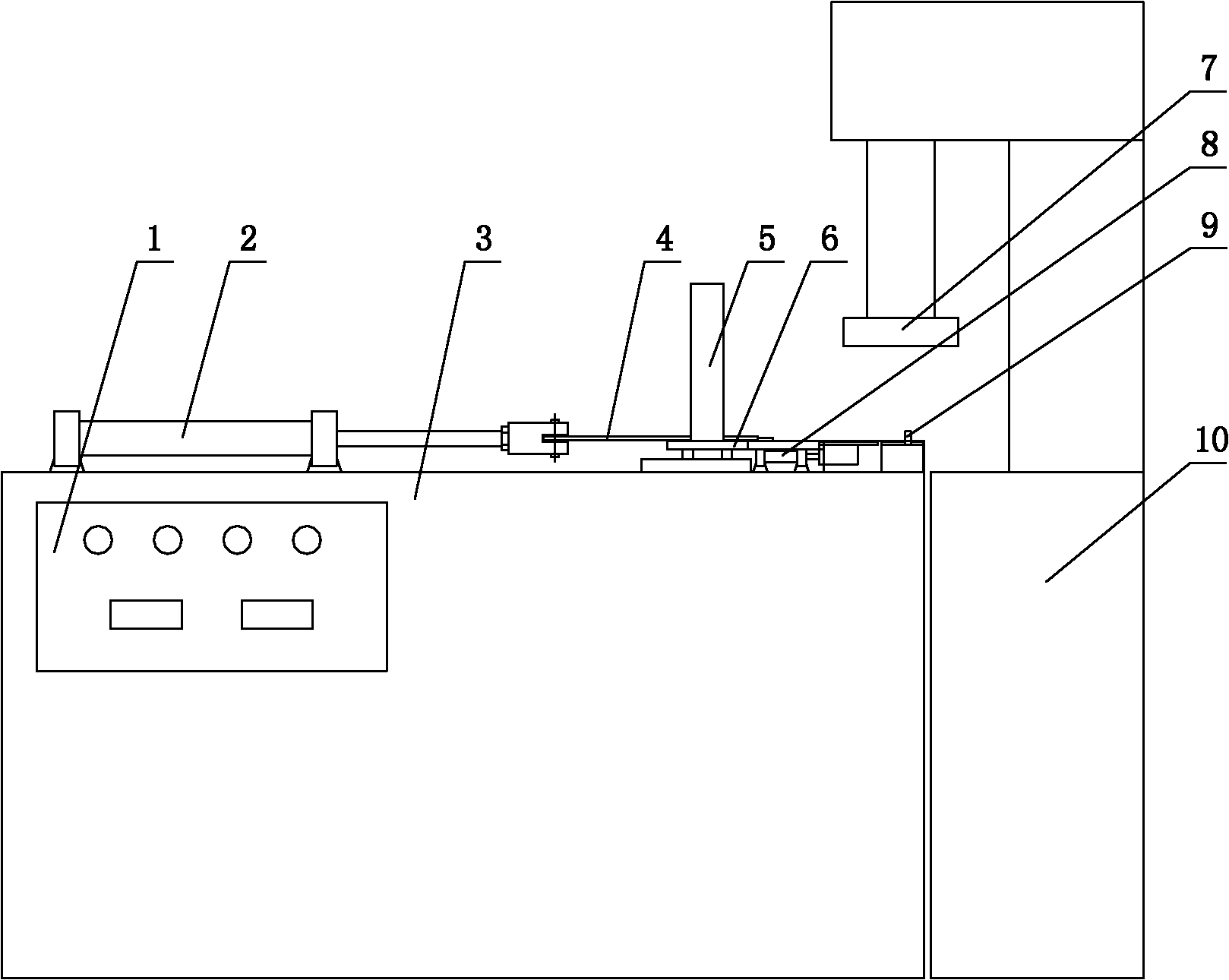

Punching device for automatic loading and unloading

The invention discloses a punching device for automatic loading and unloading. The punching device comprises an automatic loading mechanism and an automatic unloading and punching mechanism; the automatic loading mechanism is used for conveying metal sheets to the automatic unloading and punching mechanism, and comprises a mounting base, a pushing structure and a feeding structure; the pushing structure is mounted at the front end of the top surface of a mounting plate, and comprises a pushing cylinder, a push plate, a storage box and a pushing guide rail; the pushing cylinder, the push plate,the storage box and the pushing guide rail are arranged on the same straight line; the pushing cylinder and the push plate push the metal sheets, positioned at the bottommost part in the storage box,into the pushing guide rail to convey from the end near the pushing cylinder to the other end; the feeding structure is arranged at the back end of the top surface of the mounting plate, and is usedfor conveying the metal sheets, conveyed to the end far from the pushing cylinder of the pushing guide rail, from the pushing structure to the automatic unloading and punching mechanism; and the automatic unloading and punching mechanism is used for punching and automatically unloading the metal sheets. The punching device realizes automatic loading and unloading.

Owner:HONORFAITH FURNITURE

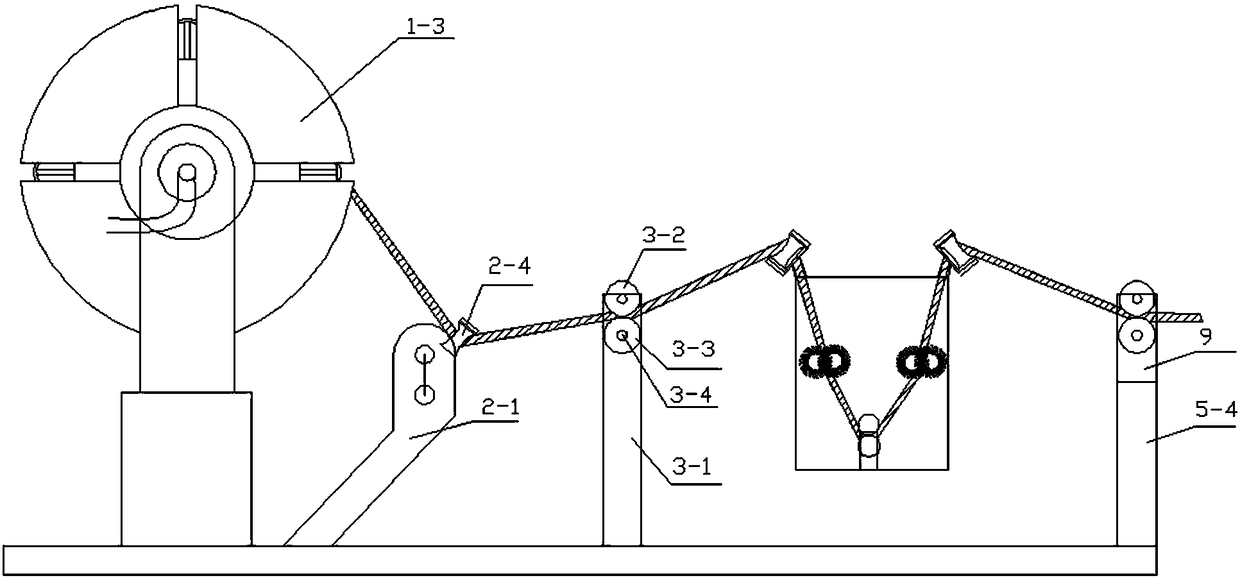

Cable winding and unwinding device and using method thereof

ActiveCN108313836AUniform and accurate retractionReduce labor wasteCable transmissionInteraction interface

The invention provides a cable winding and unwinding device and a using method thereof. The cable winding and unwinding device comprises a traction device, a cleaning device, a counting device, a cable discharging device, a reel body, a controller and a human-computer interaction interface. Cable parameters are input through the human-computer interaction interface and the cable winding and unwinding device is started, and cables are pulled to the cleaning device through the traction device. The cleaning device cleans the cables, the counting device counts the cables, and finally uniform winding is achieved. Speed data of a counting device encoder and a cable discharging motor is fed back to the controller, and determined reel motor rotational speed by calculation is compared and adjustedwith actual reel motor rotational speed to ensure the consistency of the cable discharging speed, the cable transmission speed and the reel winding speed, so that the winding quality is improved. Whenthe winding is completed, the coil discharging can be performed or the reel can be carried as required, so that the operation is simplified and the work efficiency is improved.

Owner:国网山东省电力公司嘉祥县供电公司 +1

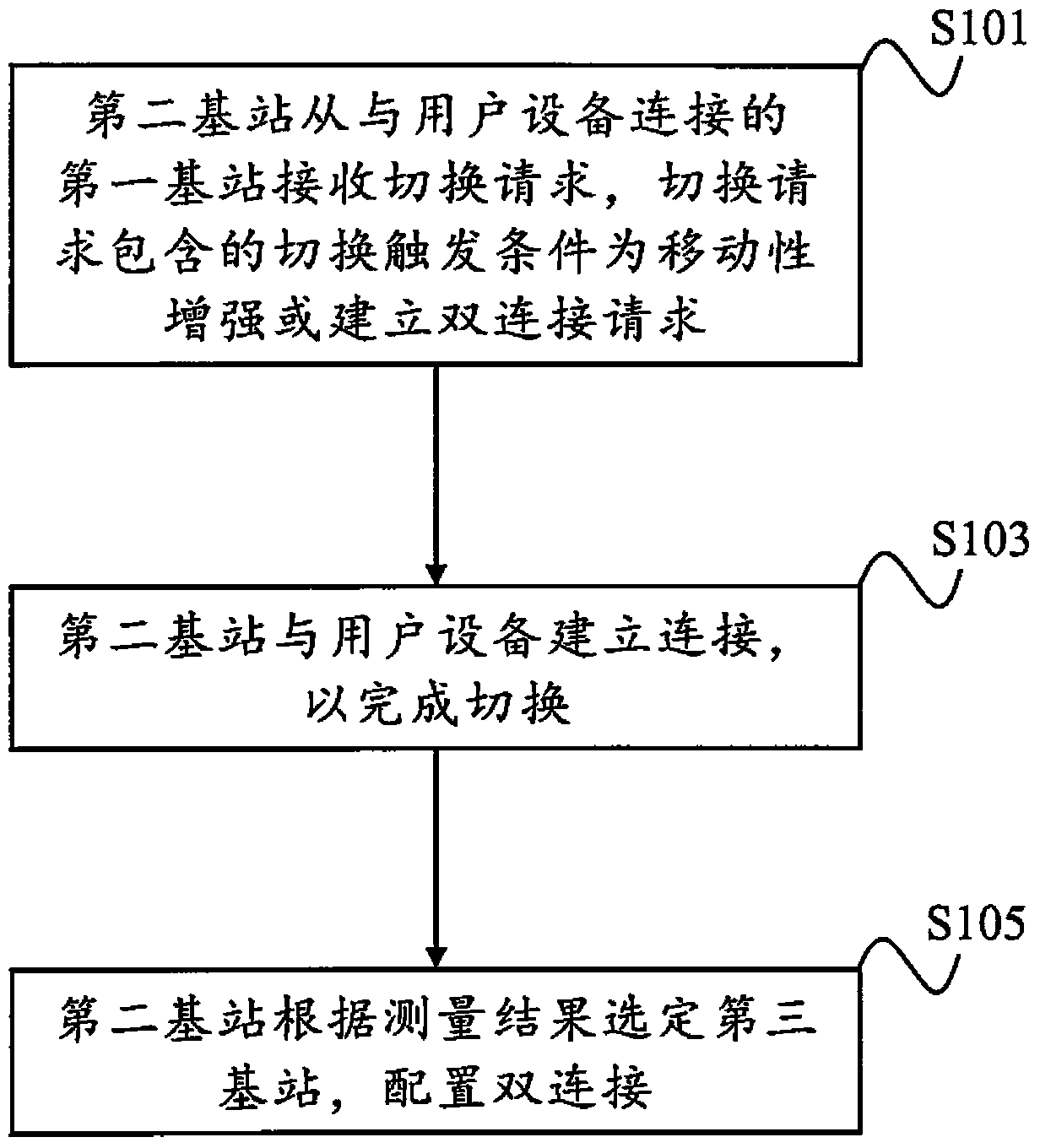

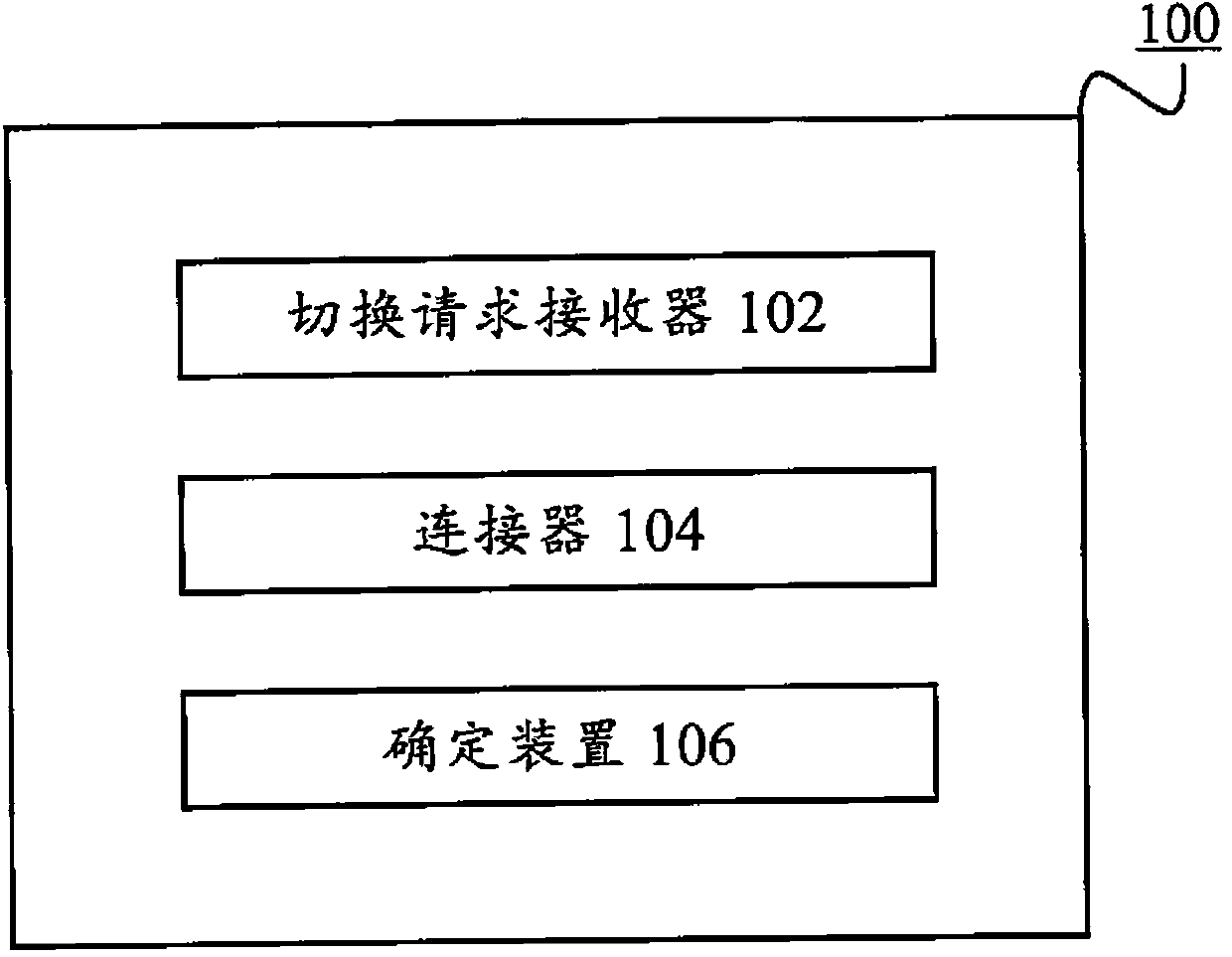

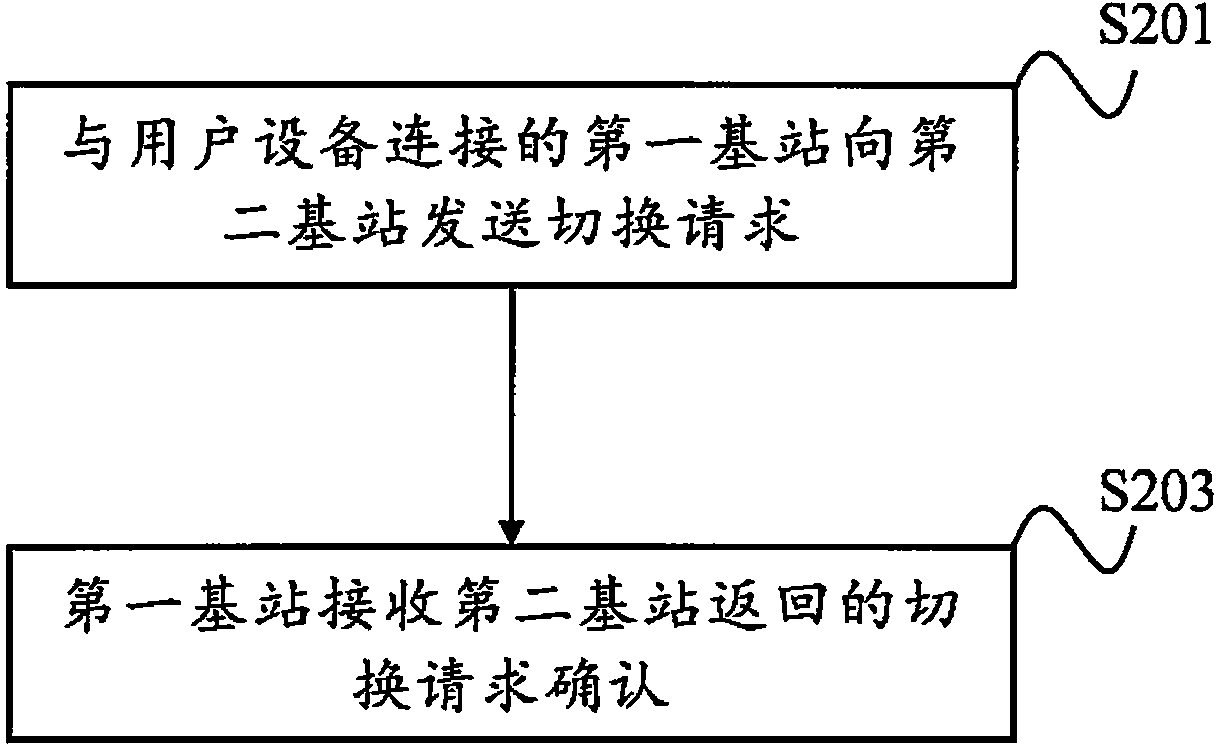

Switching method used for double-connection, user equipment, and base stations

ActiveCN105517086ARealize unloadingReduce handover failure rateWireless communicationCommunications systemUser equipment

The invention discloses a method used for establishing double-connection in a communication system. The method is characterized in that a second base station is used to receive a switching request from a first base station connected with the user equipment; the second base station is used to respond to the switching request, and is used to establish the connection with the user equipment; the second base station can be used to determine a third base station according to the received measurement results, and the establishing of the connection between the third base station and the user equipment can be facilitated, and therefore the double-connection can be provided for the user equipment. The switching trigger condition of the switching request comprises the mobility enhancement or the establishing of the double-connection request. The invention also provides the corresponding base stations and the user equipment.

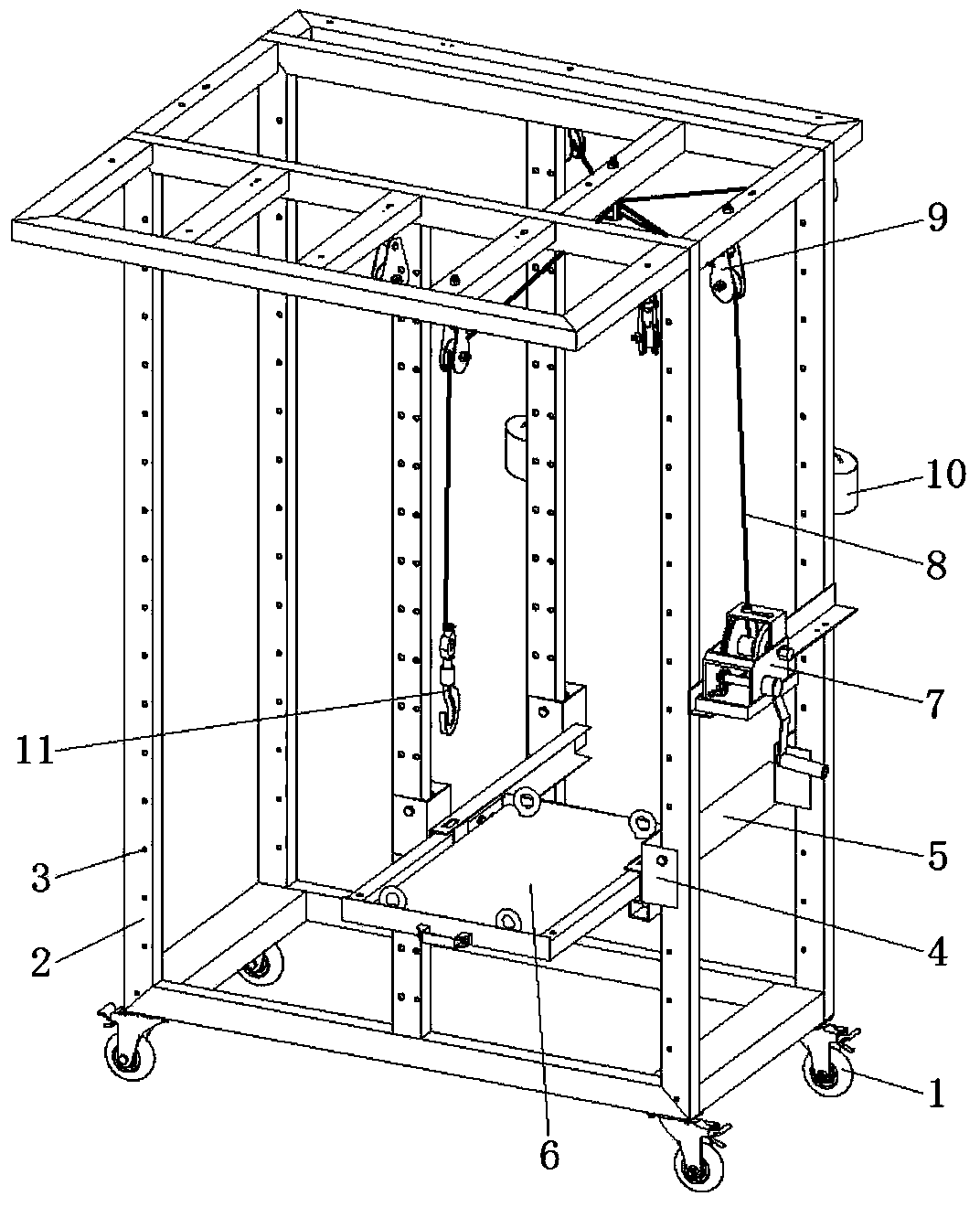

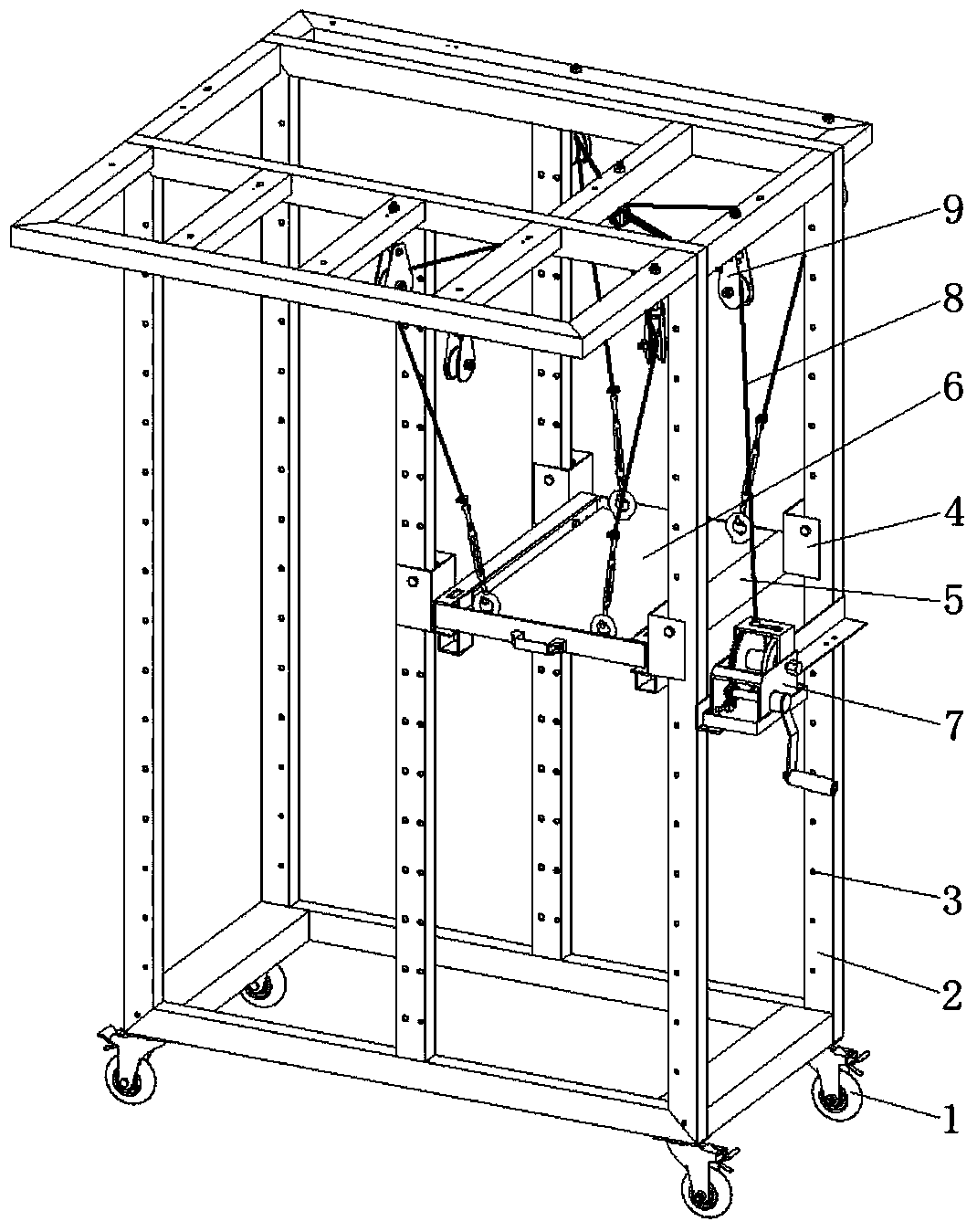

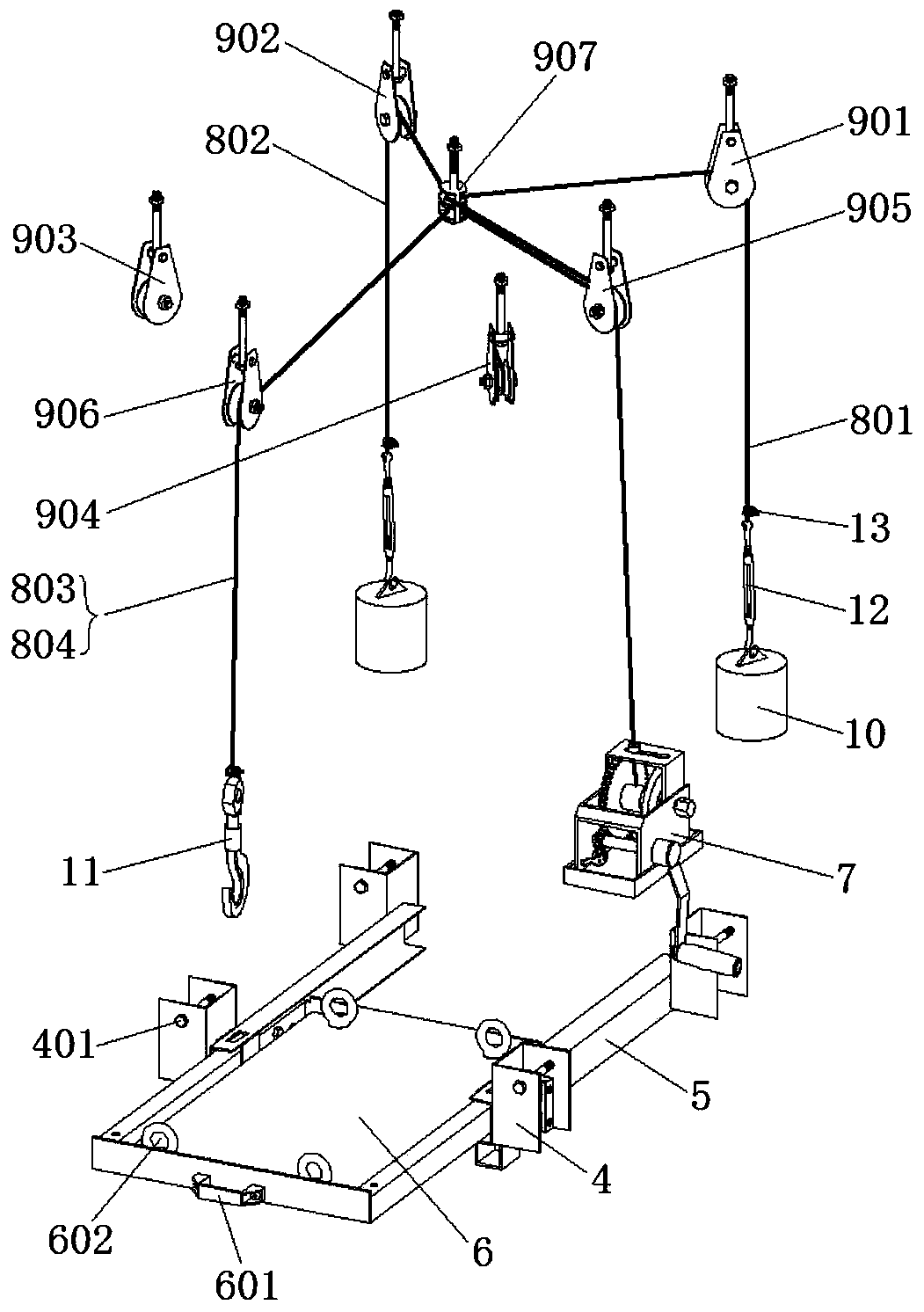

Self-loading and unloading heavy-load shelf with adjustable layer interval

ActiveCN104210796ARealize spacing adjustmentAchieve mechanical propertiesWinding mechanismsStorage devicesBlock and tackleWinch

The invention discloses a self-loading and unloading heavy-load shelf with an adjustable layer interval, and belongs to the field of shelves. The self-loading and unloading heavy-load shelf comprises a main framework, a layered frame, a manual winch, steel wire ropes, a pulley block, a heavy object and a lifting hook, wherein the layered frame comprises rolling lifting sliding sleeves, heavy-load slide rails and a tray; the heavy-load slide rails are arranged on both sides of the tray, and are arranged on vertical columns of the main framework through the rolling lifting sliding sleeves arranged at the two ends of the heavy-load slide rails; the manual winch is fixed on one side of the main framework, and four steel wire ropes are led out of the manual winch; after the steel wire ropes pass through the pulley block on the top of the main framework, two of the steel wire ropes are combined together and are connected with the hoisting hook, and the other two steel wire ropes are connected with the heavy object; hoisting rings are arranged on the four corners of the tray respectively and are correspondingly connected with the four steel wire ropes, and the tray is lifted or lowered through the manual winch. By adopting the self-loading and unloading heavy-load shelf, the height of a laminate can be adjusted under the condition that the laminate is under load; moreover, loading and unloading of heavy goods can be realized, and the self-loading and unloading heavy-load shelf is particularly suitable for storing heavy goods.

Owner:常州东吉路国际贸易有限公司

Windproof sign

InactiveCN104504997AOvercoming unclear situationsTo achieve the purpose of unloadingTraffic signalsRoad signsEngineeringCam

The invention relates to the field of the manufacturing of a traffic hardware device, and particularly relates to a windproof sign. The windproof sign comprises an indication panel, a rotating plate and a crossbar, wherein the indication panel consists of an installation surface and an indication surface, the installation surface and the indication surface form a cavity, a baffle plate is embedded in the cavity, a through hole is respectively formed in the indication surface and the installation surface in a penetrating manner, a transitional hole which is staggered to the through hole in the installation surface is formed in the baffle plate, the upper end of the baffle plate sleeves the crossbar, the upper end of the rotating plate is connected with a cam bearing, a torsion spring is arranged between the rotating plate and the crossbar, the cam bearing abuts and contacts the baffle plate, and a return spring is arranged between the baffle plate and the crossbar. The windproof sign has beneficial effects that the situation that the character is unclear due to direct perforation can be overcome, and the windproof purpose can be achieved.

Owner:重庆攸亮科技股份有限公司

Tensile fixture

The invention provides a tensile fixture, which belongs to the field of fixtures. The tensile fixture overcomes the problems that a conventional fixture cannot reliably clamp a tiny sample and becomes slack at high temperature and is especially applicable to tensile test of tiny samples under the conditions of normal temperature and high temperature. According to the invention, an elastic force released by a longitudinal spring exerts a continuous pretightening effect on a sample, the pretightening effect is more continuous and stable compared with a pretightening effect of a screw, and operation in the invention is simpler; in the process of drawing, the clamp force of a chuck increases with increase of a tensile force, a pretightening force can be continuously maintained at the same time, so relaxation of a material caused by thermal expansion can be effectively compensated, which guarantees that the sample is stably clamped and prevented from slipping in the process of drawing; and thus, the problems of slipping of a tiny sample caused by thermal expansion, a small size and the like in the process of drawing, inconvenient clamping and the like are effectively overcome.

Owner:HUAZHONG UNIV OF SCI & TECH

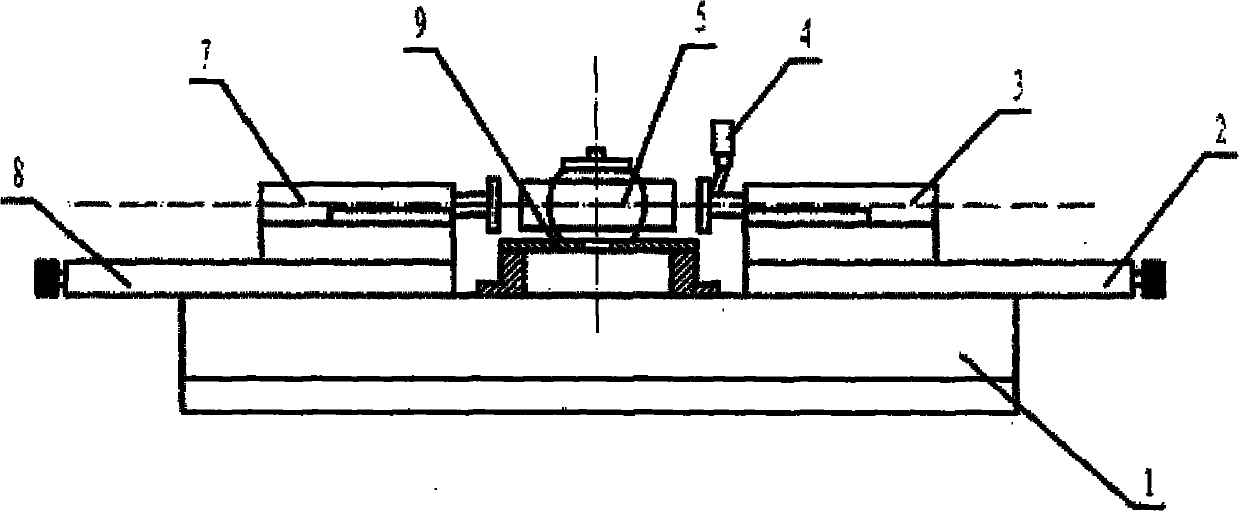

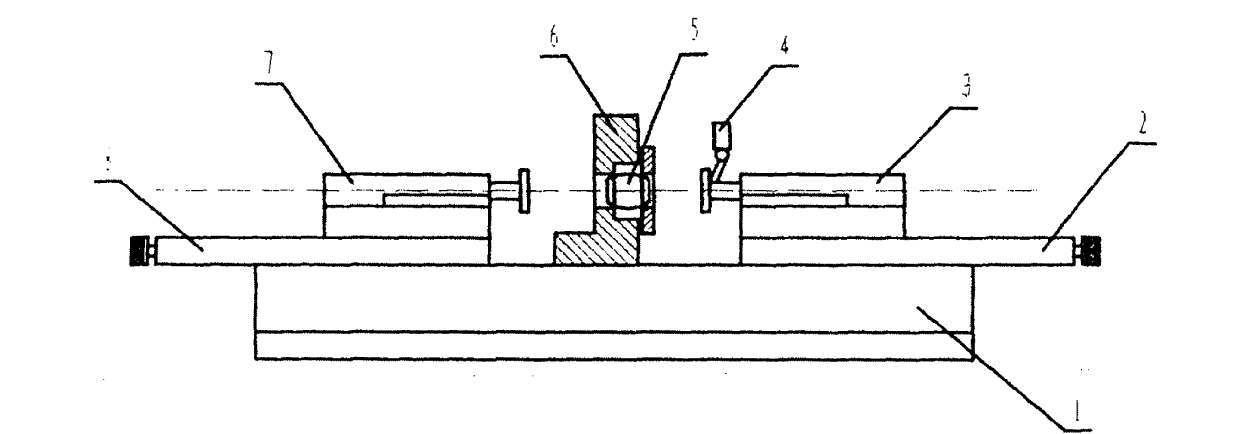

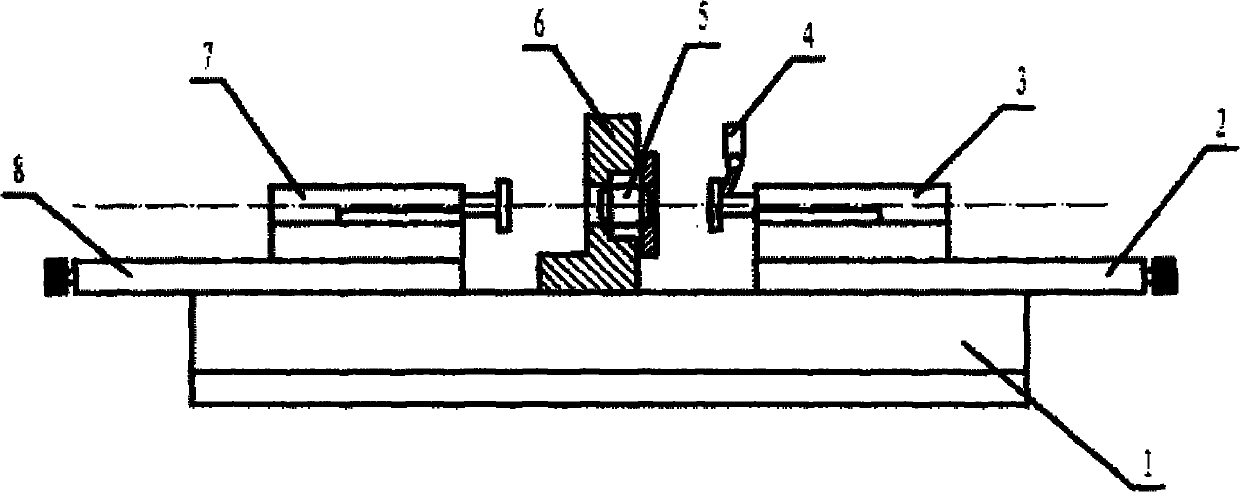

Device for detecting axial clearance and radial clearance of joint bearing

The invention provides a device for detecting an axial clearance and a radial clearance of a joint bearing. The device consists of dynamometers, a clearance measuring meter, a loading slipway, an unloading slipway, a bearing clamp and a rack. The joint bearing is mounted between the two dynamometers through the bearing clamp; the dynamometers are mounted on the loading / unloading slipway; the loading / unloading slipway is mounted on the rack; and the clearance measuring meter is fixed on the rack. The device can detect the axial clearance and the radial clearance of the joint bearing, and the axial clearance and the radial clearance of the joint bearing can be measured by exchanging different bearing clamps. By the invention, the loading and unloading of different loads in the measurement can be realized.

Owner:YANSHAN UNIV

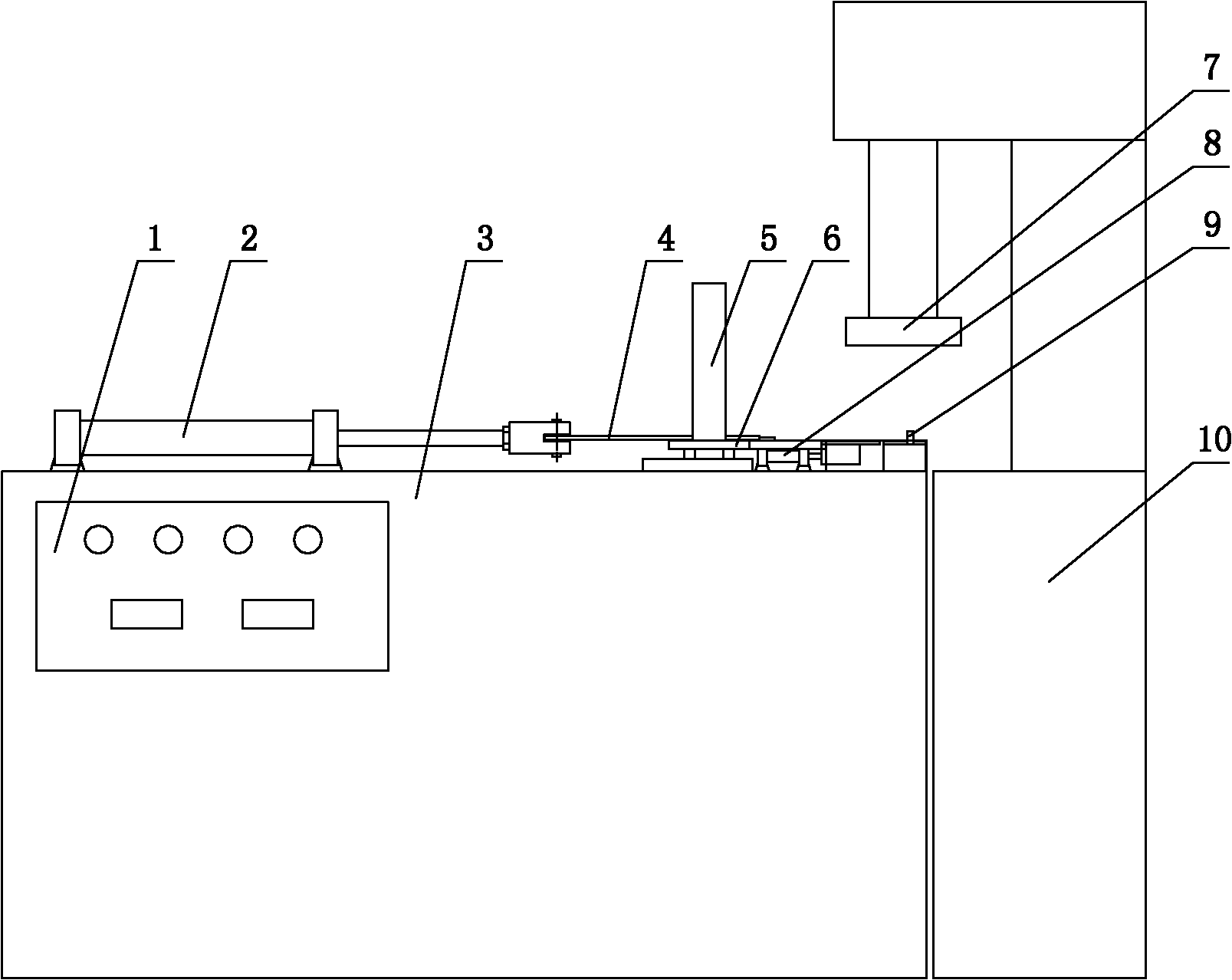

Automatic feeding and discharging mechanical arm of punching machine

ActiveCN107900245ARealize dynamic adjustmentEasy to operateMetal-working feeding devicesPositioning devicesDischarge efficiencyPunch press

The invention provides an automatic feeding and discharging mechanical arm of a punching machine and relates to the technical field of mechanical automation. The automatic feeding and discharging mechanical arm of the punching machine comprises a feeding platform, a feeding mechanical arm and a horizontal auxiliary arm. The feeding mechanical arm body conveys a product to a punching platform. Thehorizontal auxiliary arm moves the product out from the punching platform. The feeding mechanical arm comprises a first operation platform, a servo motion module, a control system, a manipulator arm and a manipulator hand, wherein the servo motion module, the control system, the manipulator arm and the manipulator hand are installed on the first operation platform. The servo motion module is electrically connected with the control system. The servo motion module is connected with the manipulator arm. The manipulator arm is connected with the manipulator hand. The horizontal auxiliary arm comprises a horizontal beam, a first transmission assembly, a support and a grabbing assembly. The horizontal beam is installed on the punching platform. The first transmission assembly is installed on thehorizontal beam. The support is connected with the first transmission assembly. The grabbing assembly is connected with the support. The automatic feeding and discharging mechanical arm of the punching machine is convenient to manipulate, high in feeding and discharging efficiency, high in control precision, safe and reliable.

Owner:绵阳海迪机器人科技有限公司

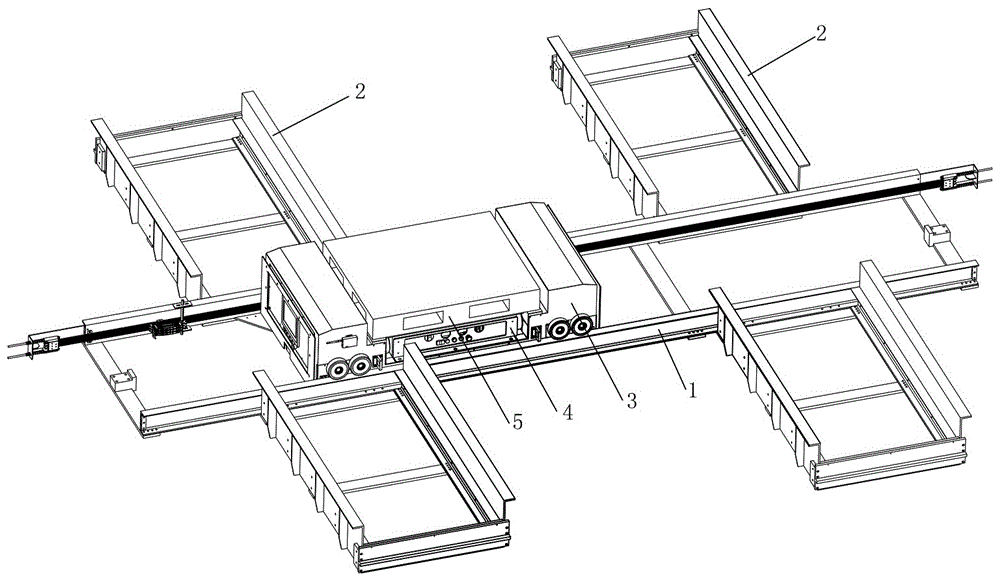

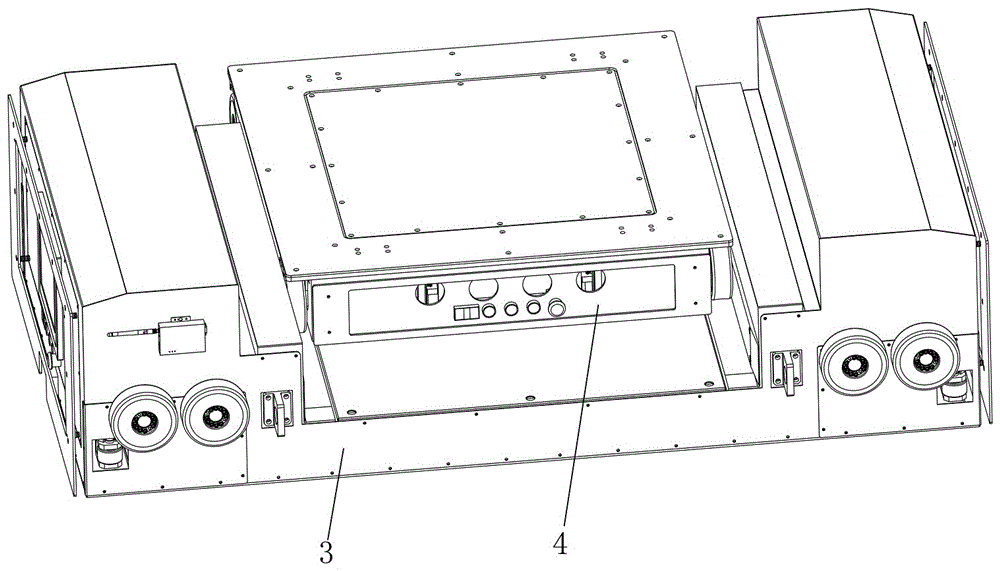

Shuttle child-mother vehicle for automatically carrying materials in and out from warehouse

InactiveCN106429156AImprove carrying capacityGuaranteed stabilityStorage devicesAutomotive engineering

The invention discloses a shuttle child-mother vehicle for automatically carrying materials in and out from a warehouse. The shuttle child-mother vehicle comprises at least two lanes spaced in parallel, and rails vertically connected to two sides of the lanes; and the lanes and the rails form material transportation rails. The shuttle child-mother vehicle further comprises a mother vehicle, and a child vehicle slidingly arranged on the mother vehicle; the mother vehicle is arranged on the lanes, and linearly slides along the lanes in a reciprocating manner; a child vehicle groove inwards recessed is formed in the middle part of the mother vehicle; slide ways are respectively formed in two sides of the child vehicle groove; the child vehicle is arranged in the child vehicle groove; child wheels on two sides of the child vehicle are put on the slide ways for supporting the child vehicle; a walking module and an ejecting module are arranged in the child vehicle, and adopt independent driving mechanisms; the walking module drives the child vehicle to linearly slide on the slide ways or the rails; and the ejecting module drives an object carrying plate to lift in the vertical direction. The shuttle child-mother vehicle matches the mother vehicle with the child vehicle to realize full-automatic material carrying, effectively promotes the carrying efficiency, and reduces the carrying cost.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

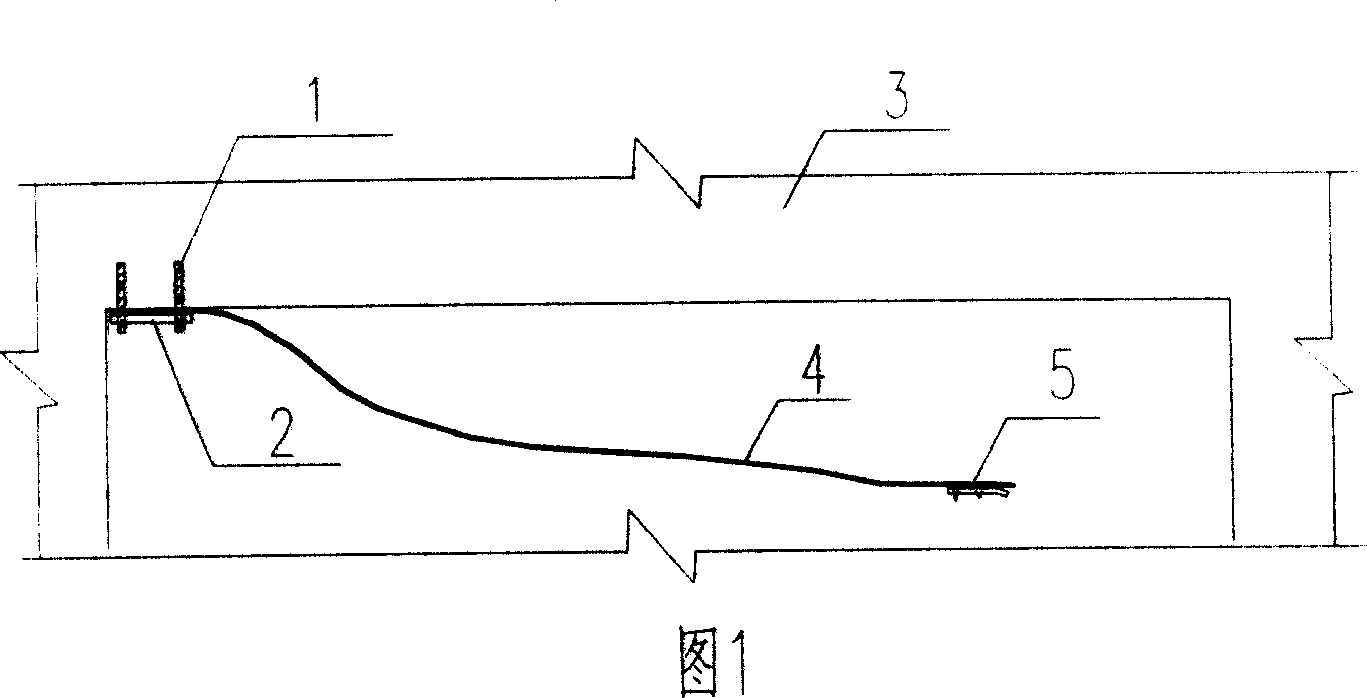

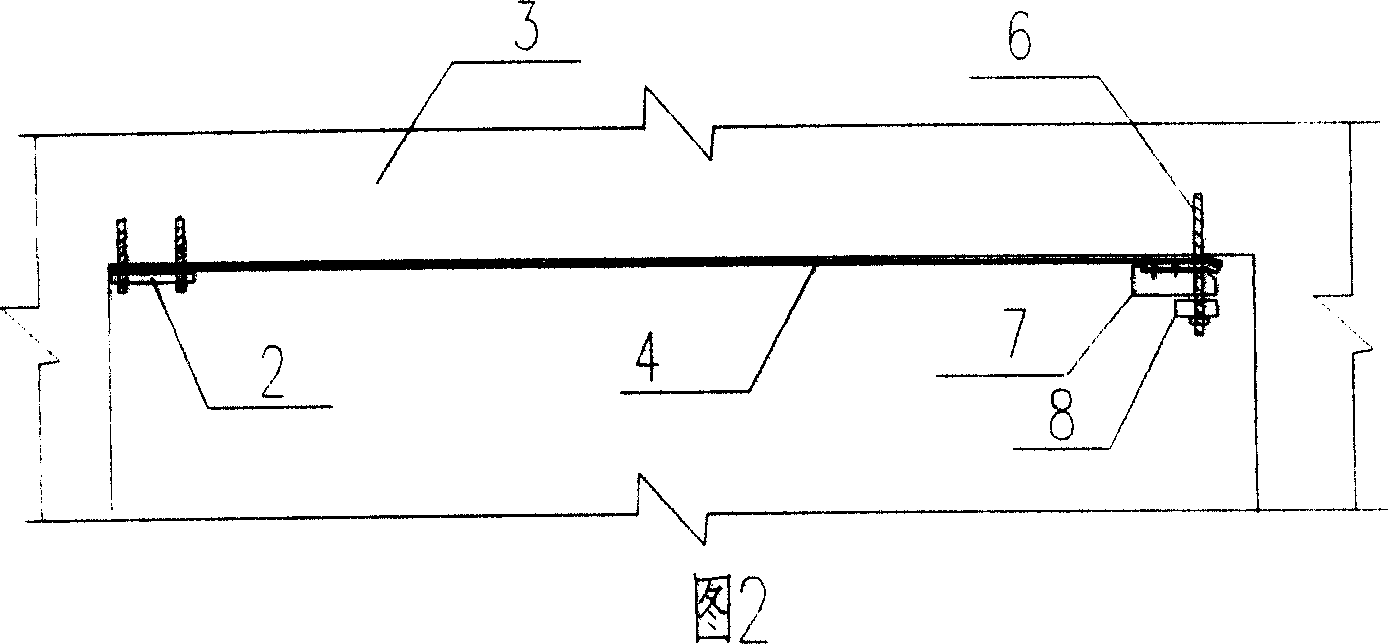

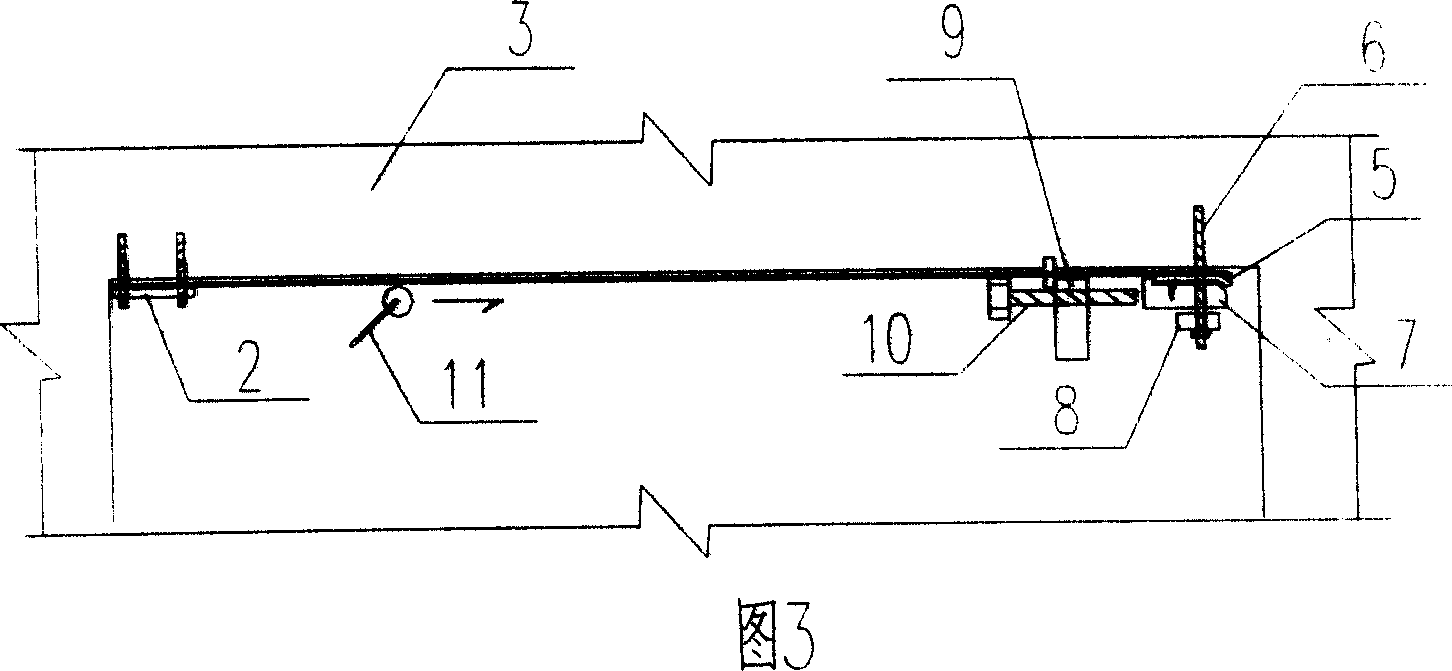

Method for rein forcing concrete structure by top push type prestress carbon fibre cloth and use

The present invention relates to method of reinforcing concrete structure with top pushed pre-stressed carbon fiber cloth and its application. The method includes the following steps: fixing one end of the carbon fiber cloth to the concrete structure and adhering the other end to anchor plate and fixing to the pushing board to form the stretching end; brushing special glue to the surface of concrete structure, controlling the interval between the stretching end and the concrete structure with the limiting board, and pushing the stretching end forward with the pushing device the stretch the carbon fiber cloth; reaching the stress and regulating the limiting board to make the stretching end adhering the surface of the concrete structure; and disassembling the pushing device, the limiting board and the pushing board after curing. The present invention can reach excellent reinforcing effect.

Owner:葛培中

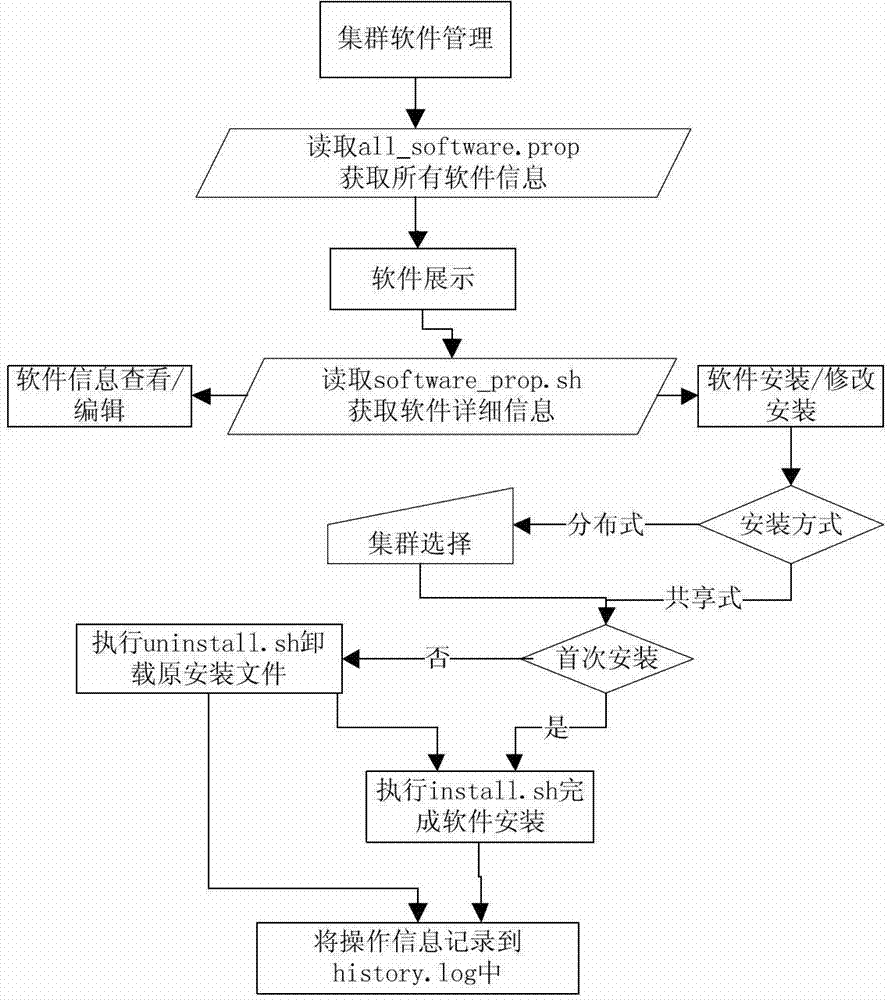

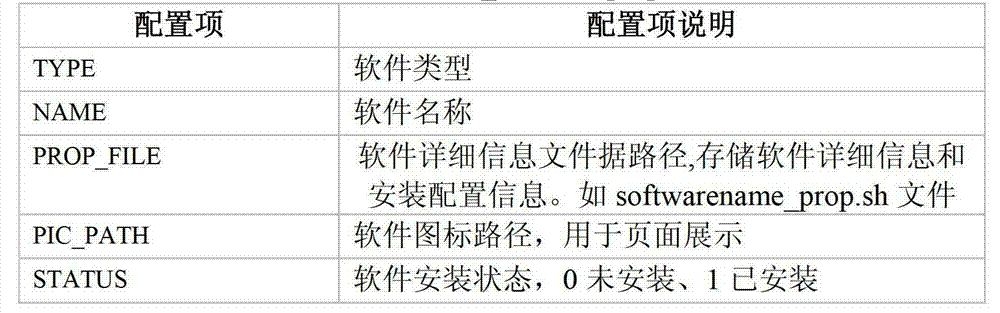

Method and system for managing Linux cluster software

InactiveCN102880935AEasy installation referenceAchieve installationProgram loading/initiatingResourcesLogfileManagement system

The invention relates to a method and a system for managing Linux cluster software. The method comprises the following steps of: (1) acquiring the software information of the Linux cluster software; (2) acquiring the check and edit implementation information and installation configuration information of the Linux cluster software; (3) maintaining the name, a software version, a software description file and a software installation file of the Linux cluster software; (4) installing the Linux cluster software; (5) judging whether the Linux cluster software is installed for the first time; and (6) recording the installation operation information of the Linux cluster software into an installation log file. By the invention, the problem that a monitoring management system cannot perform integrated unified management on operation of the whole cluster such as software installation, updating and uninstalling are solved, and the one-click installation and batch installation of the Linux cluster software are realized.

Owner:DAWNING INFORMATION IND BEIJING

Soft contact joint based on motion and static blocks

The invention relates to a space robot structure, in particular to a soft contact joint based on motion and static blocks. The soft contact joint comprises a driving and transmission mechanism, a damping component and a sensing unit, wherein the driving and transmission mechanism mainly comprises a motor driving unit, a controller, an inner shell, an outer shell, a sliding block and a sliding rail, the damping component mainly comprises a linear magneto-rheological damper, a clutch, a rotary magneto-rheological damper, a spring mechanism and a torsion spring mechanism, and the sensing unit comprises an encoder and a linear displacement sensor. The overall flexibility of the mechanical arm joint is mainly controlled by the clutch and the magneto-rheological dampers in the damping component, pitching and yaw two-degree-of-freedom rigid driving and spatial six-dimensional momentum discharge interconversion can be achieved according to an operation task, and then soft contact of spatial operation is achieved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

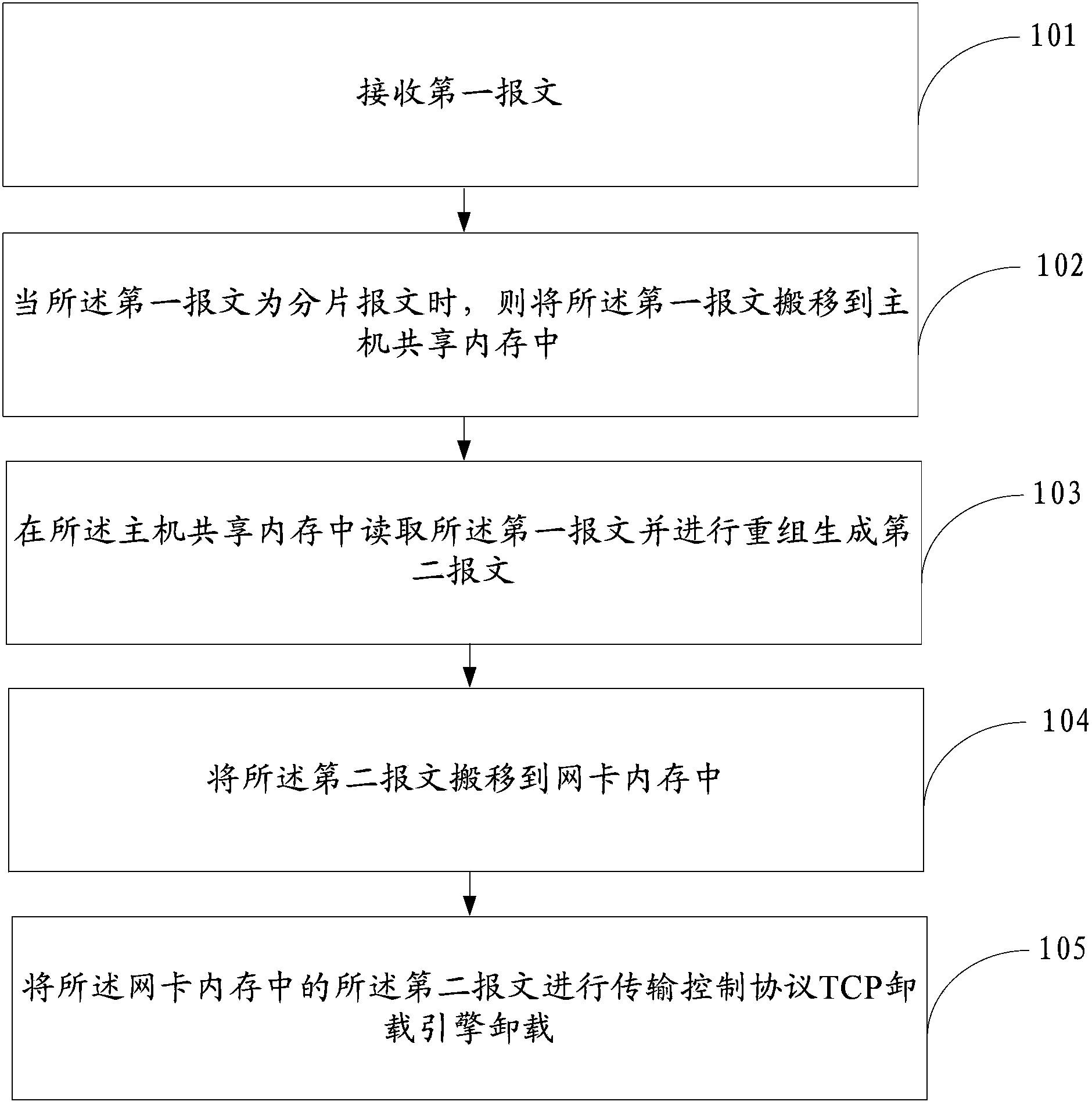

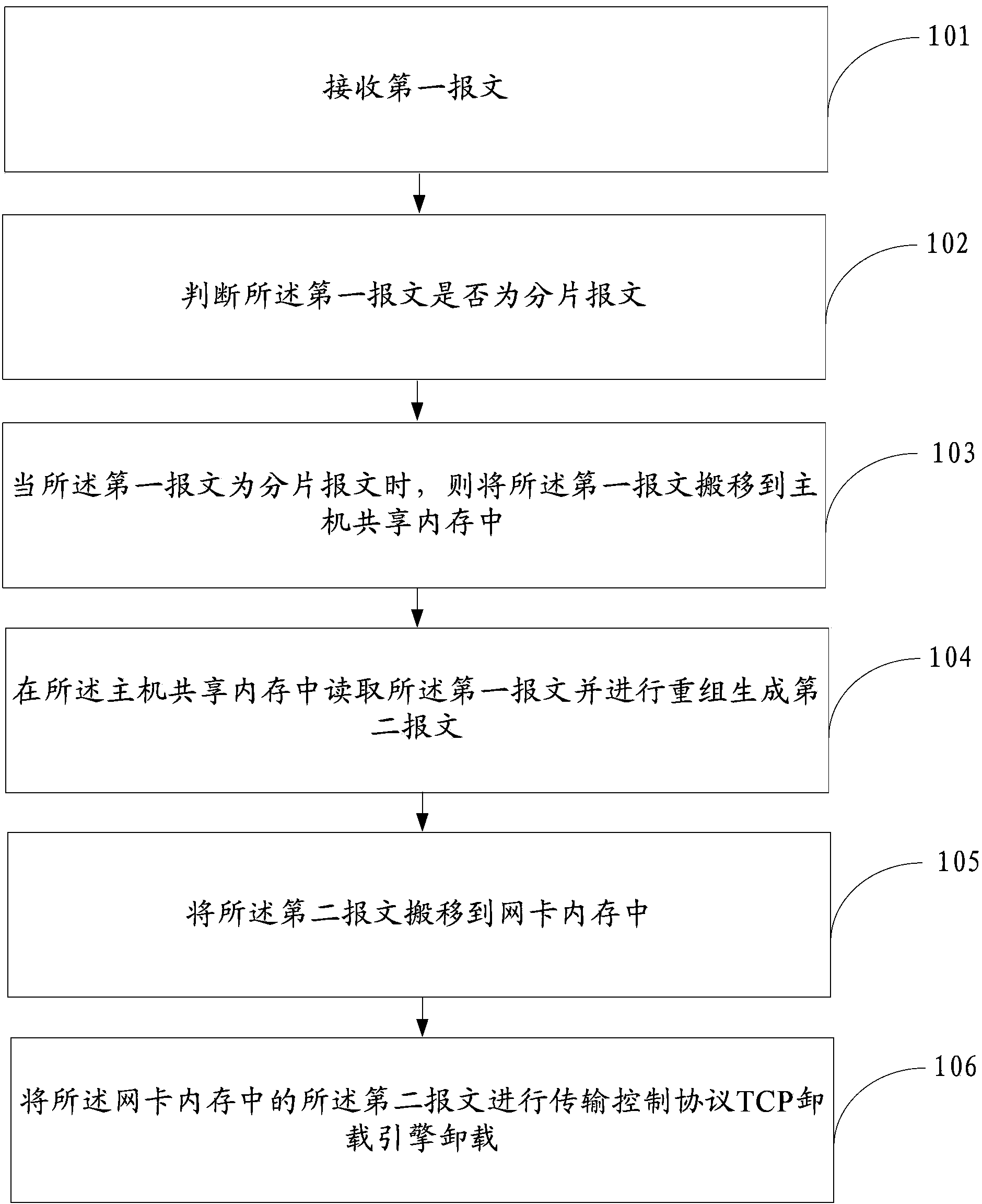

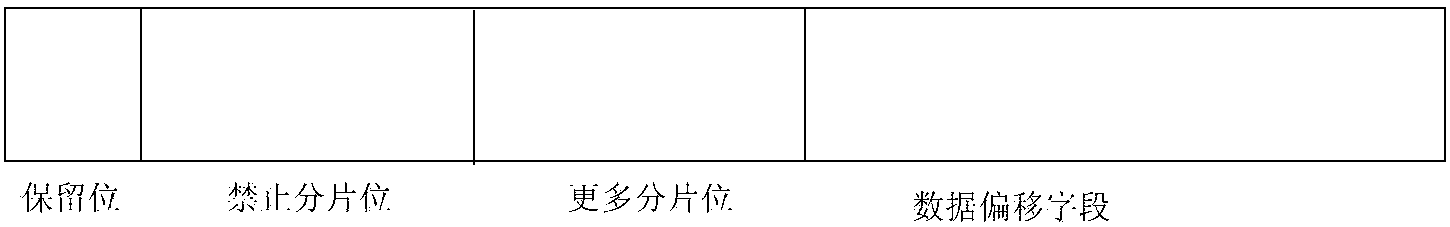

Method, device and equipment for processing messages

ActiveCN103414714ARealize unloadingImprove responsivenessTransmissionIP fragmentationMessage processing

The invention provides a method, device and equipment for processing messages, and relates to the field of computers. The method, device and equipment for processing the messages can enable a TOE network card to support the processing to IP fragmentation messages and achieve the hardware TOE uninstall of the fragmentation messages, and improve the response performance and the transmission performance of a network. The method comprises the steps that firstly, the TOE network card of a TCP uninstall engine receives a first message, if the first message is a fragmentation message, the first message is moved to a mainframe shared memory, the first message is then reassembled through a TOE drive to generate a second message, the second message is moved to a TOE network memory, TOE uninstall is then carried out on the second message, and lastly, data after the TOE uninstall are handed to a system upper layer unit for processing. The method, device and equipment for processing the messages is used for message processing.

Owner:XFUSION DIGITAL TECH CO LTD

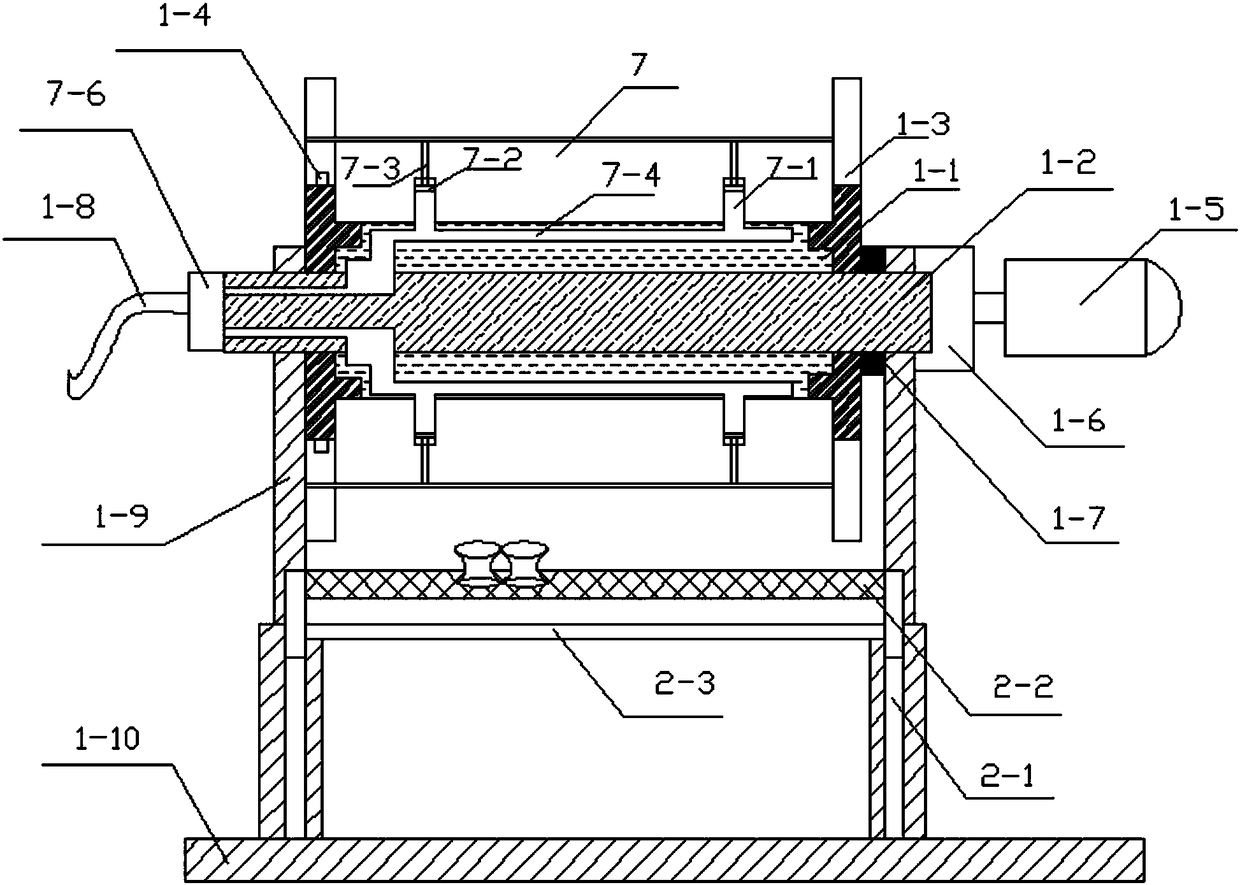

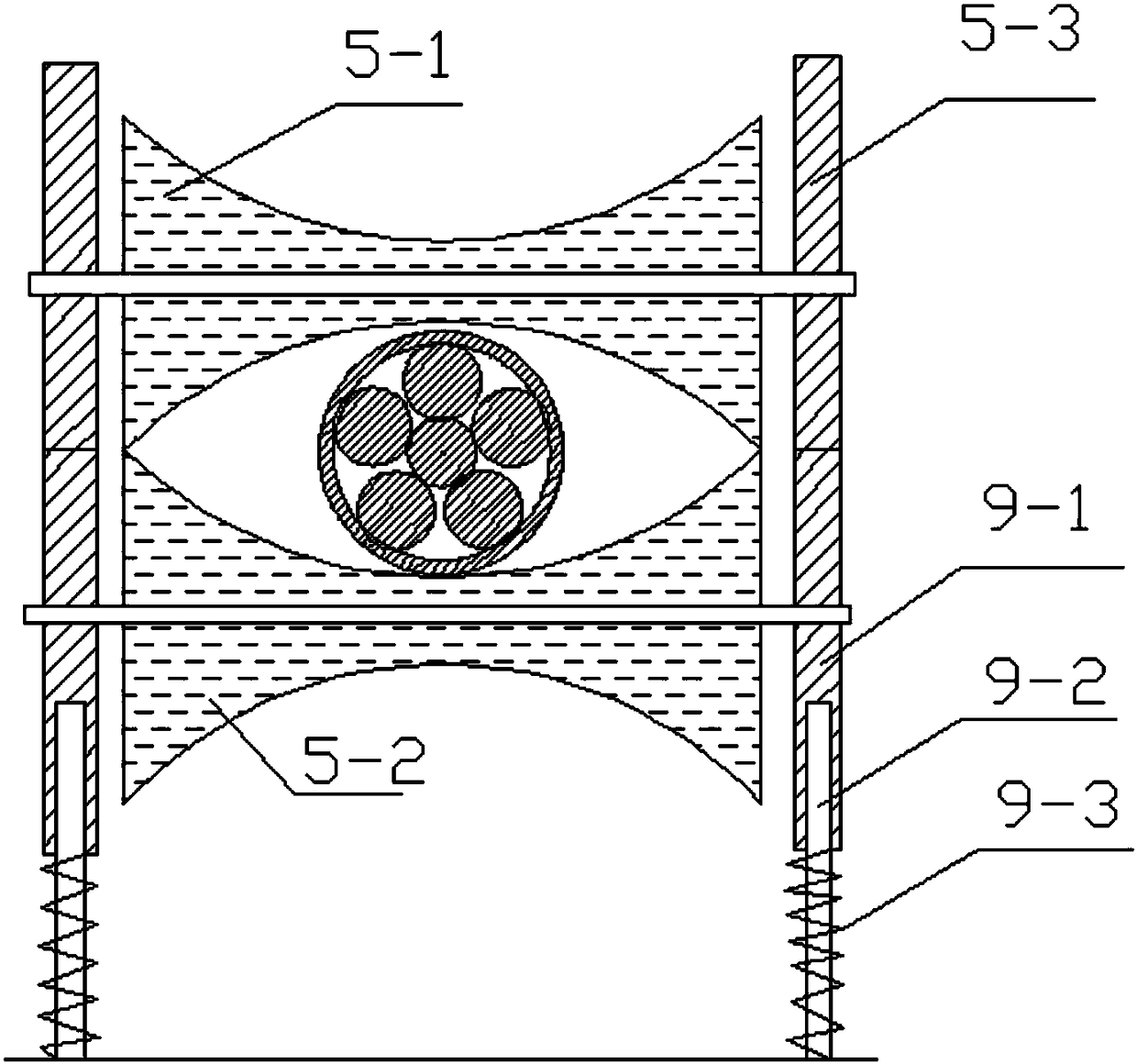

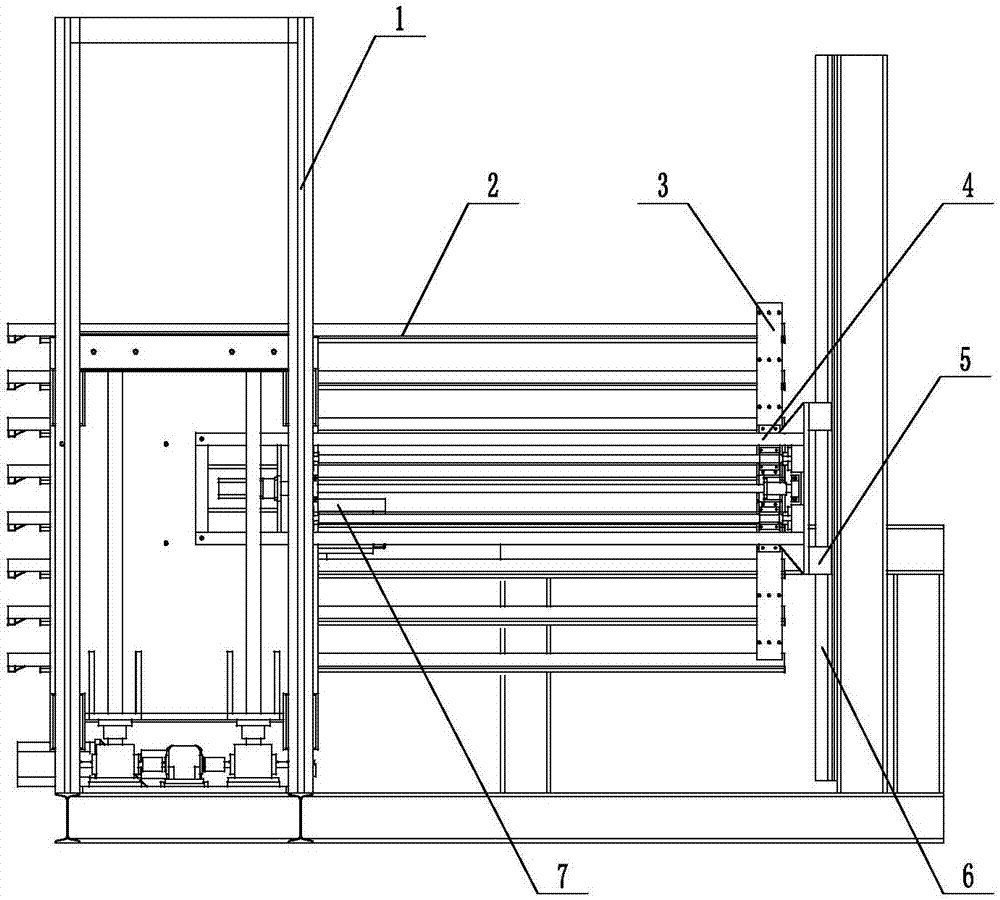

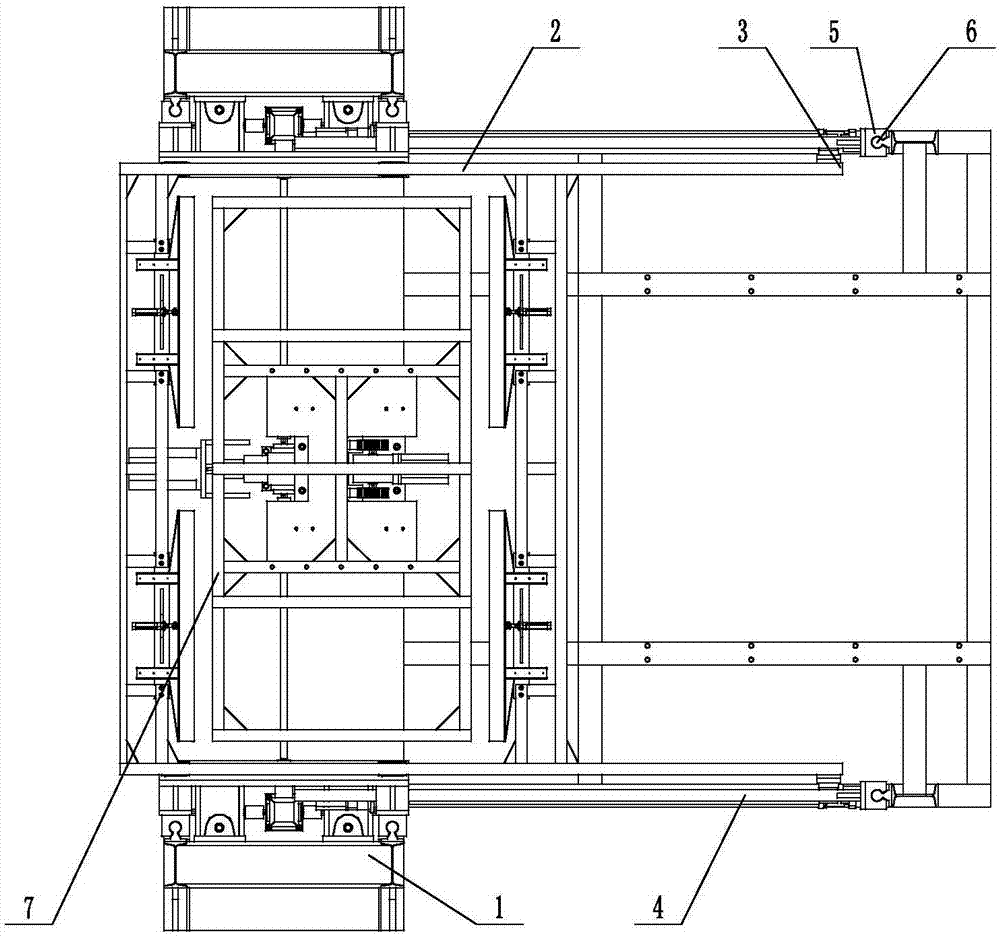

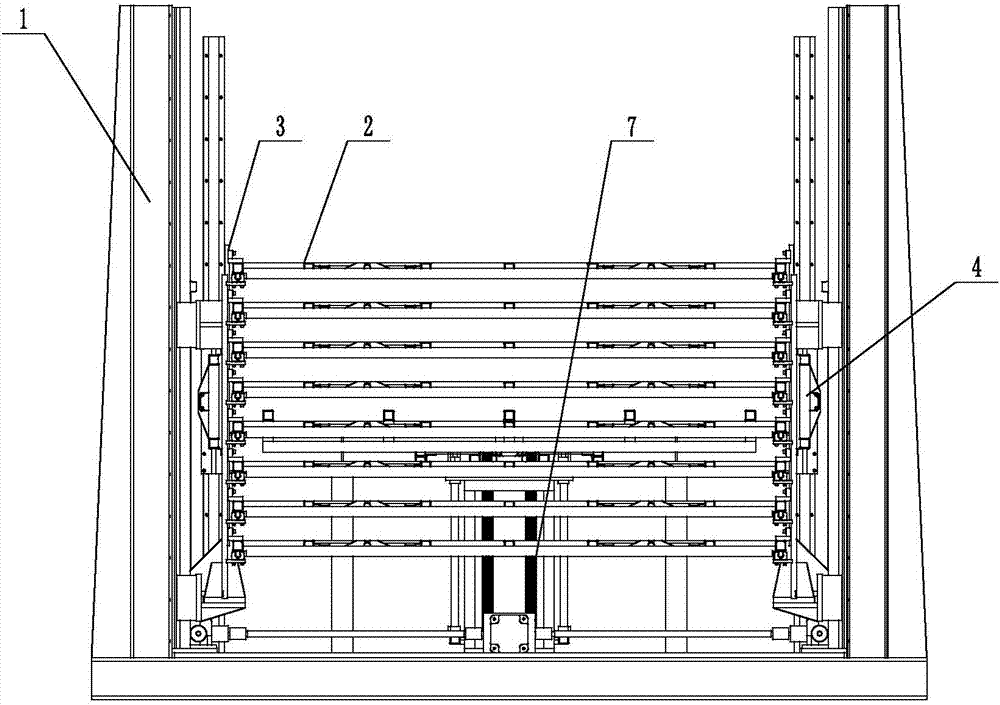

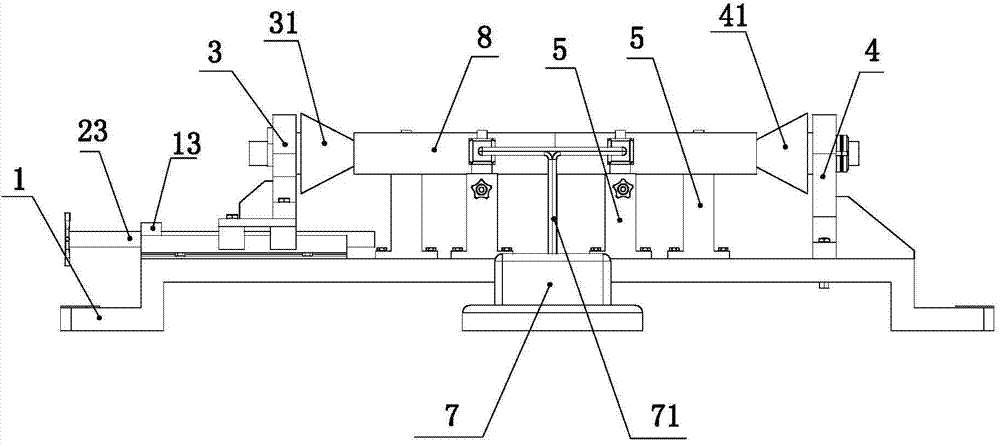

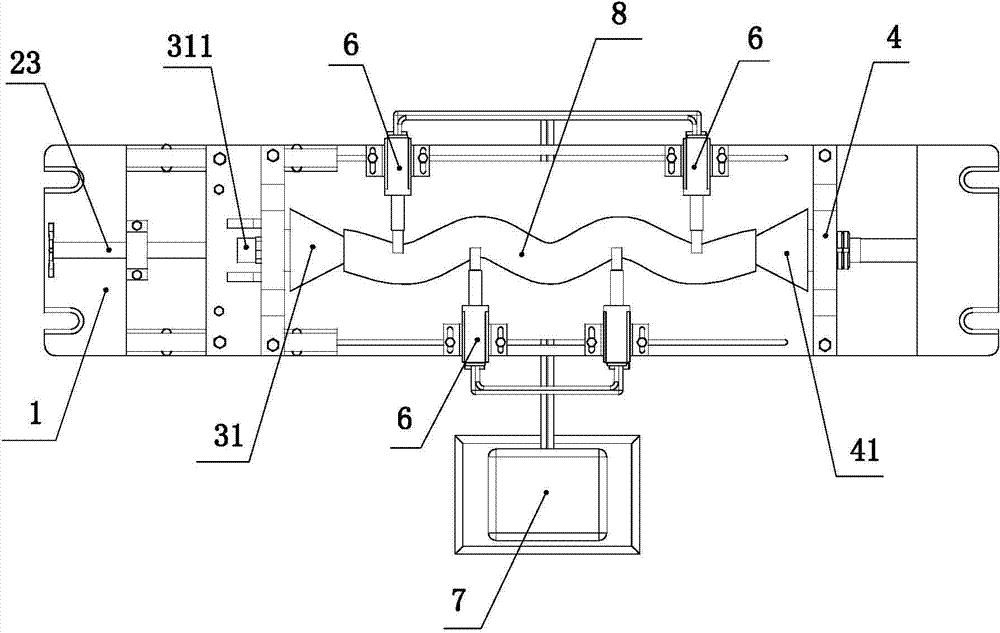

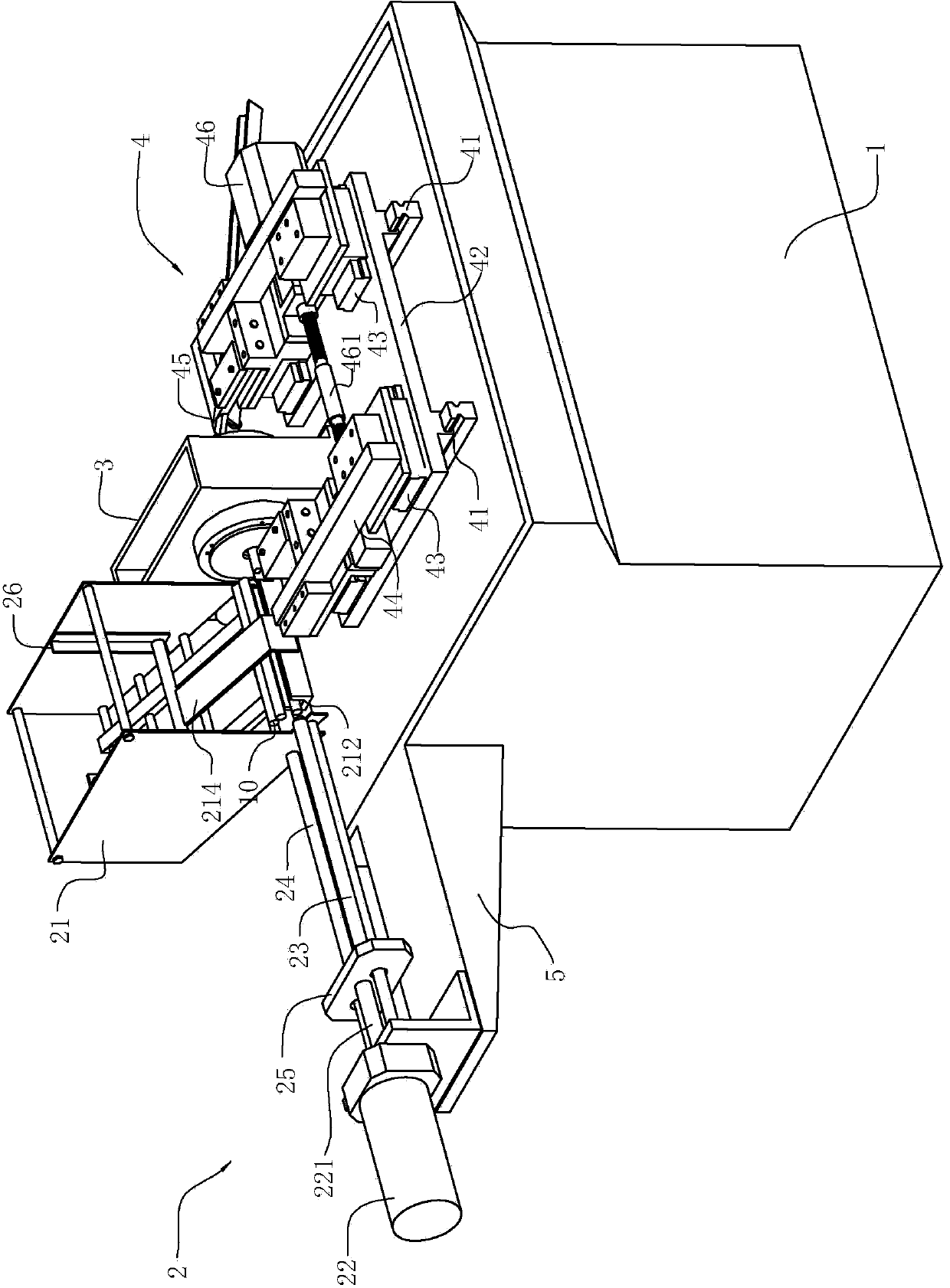

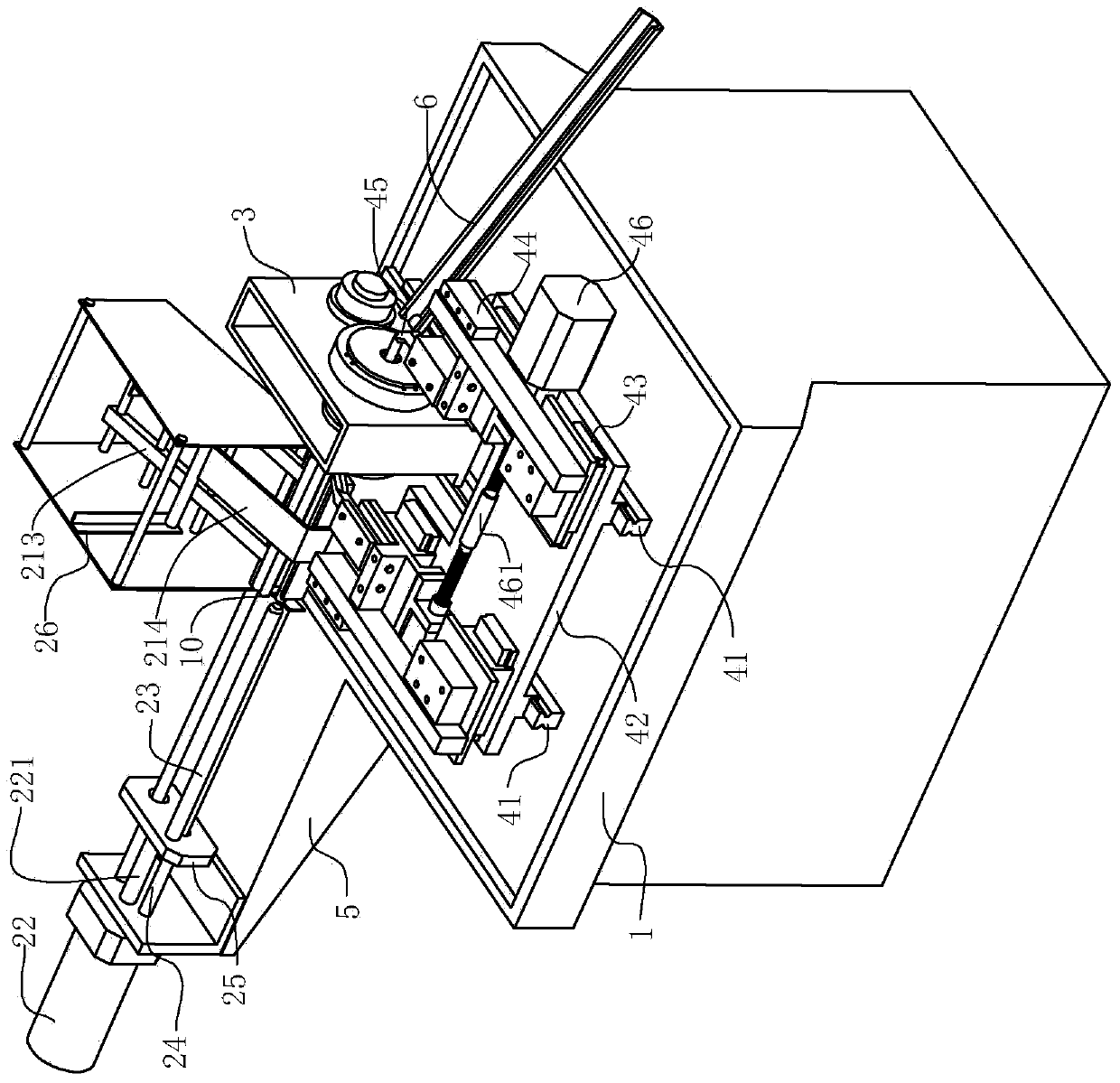

Wood board loading and unloading lifting assembly

ActiveCN107139280AHigh degree of automationReduce manpower consumptionPlywood pressesLaminationEngineeringMechanical engineering

The invention discloses a wood board loading and unloading lifting assembly which comprises a lifting mechanism (1), a jacking mechanism (7), a push mechanism (4) and a plurality of bearing and connecting mechanisms (2). The wood board loading and unloading lifting assembly has the advantages that working efficiency is high, energy consumption is reduced, manpower is saved, conveying precision is high, and a hot press can conduct hot pressing on the two faces simultaneously.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

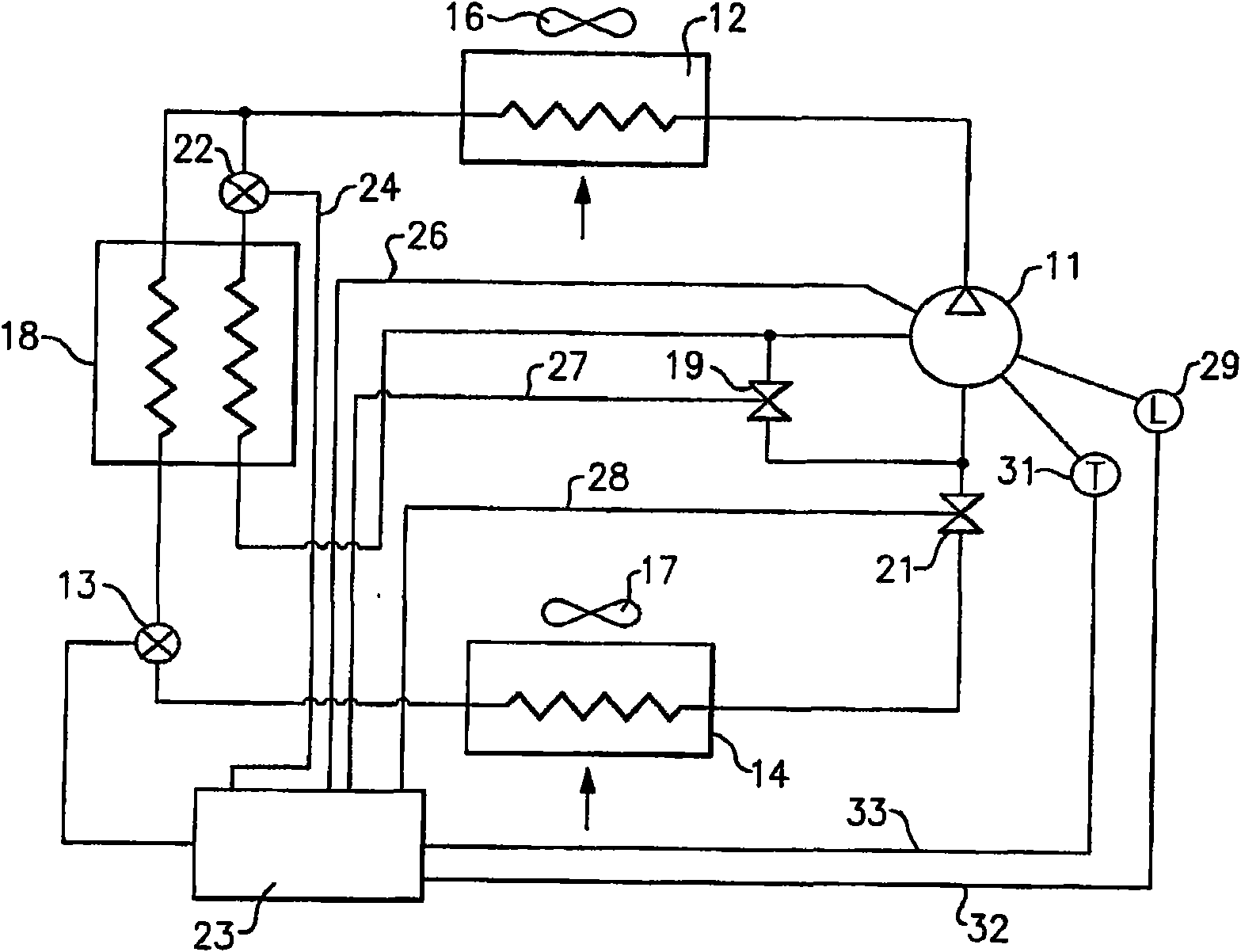

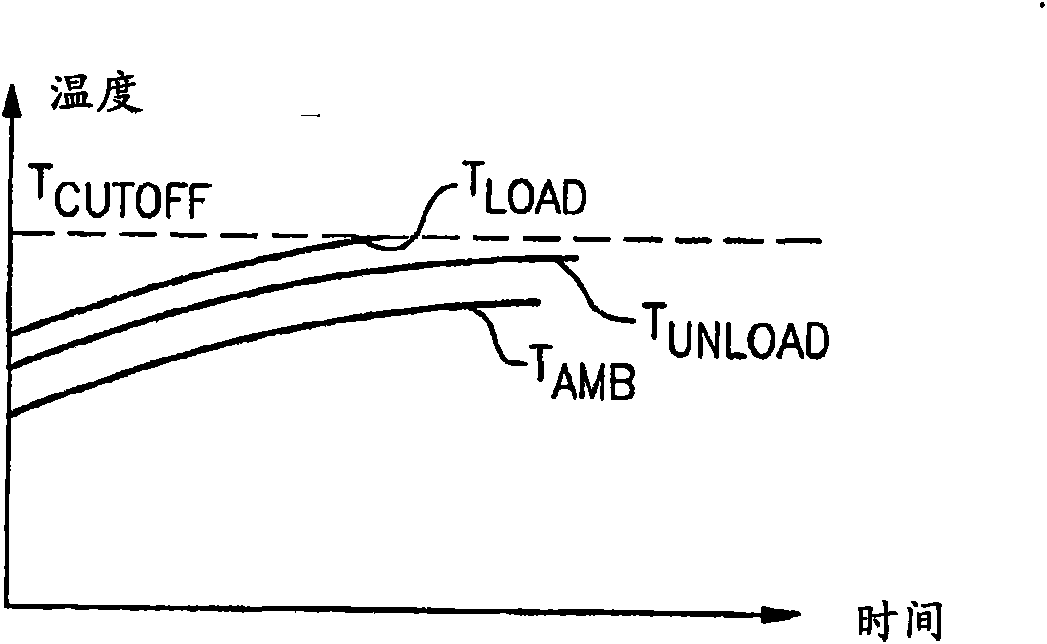

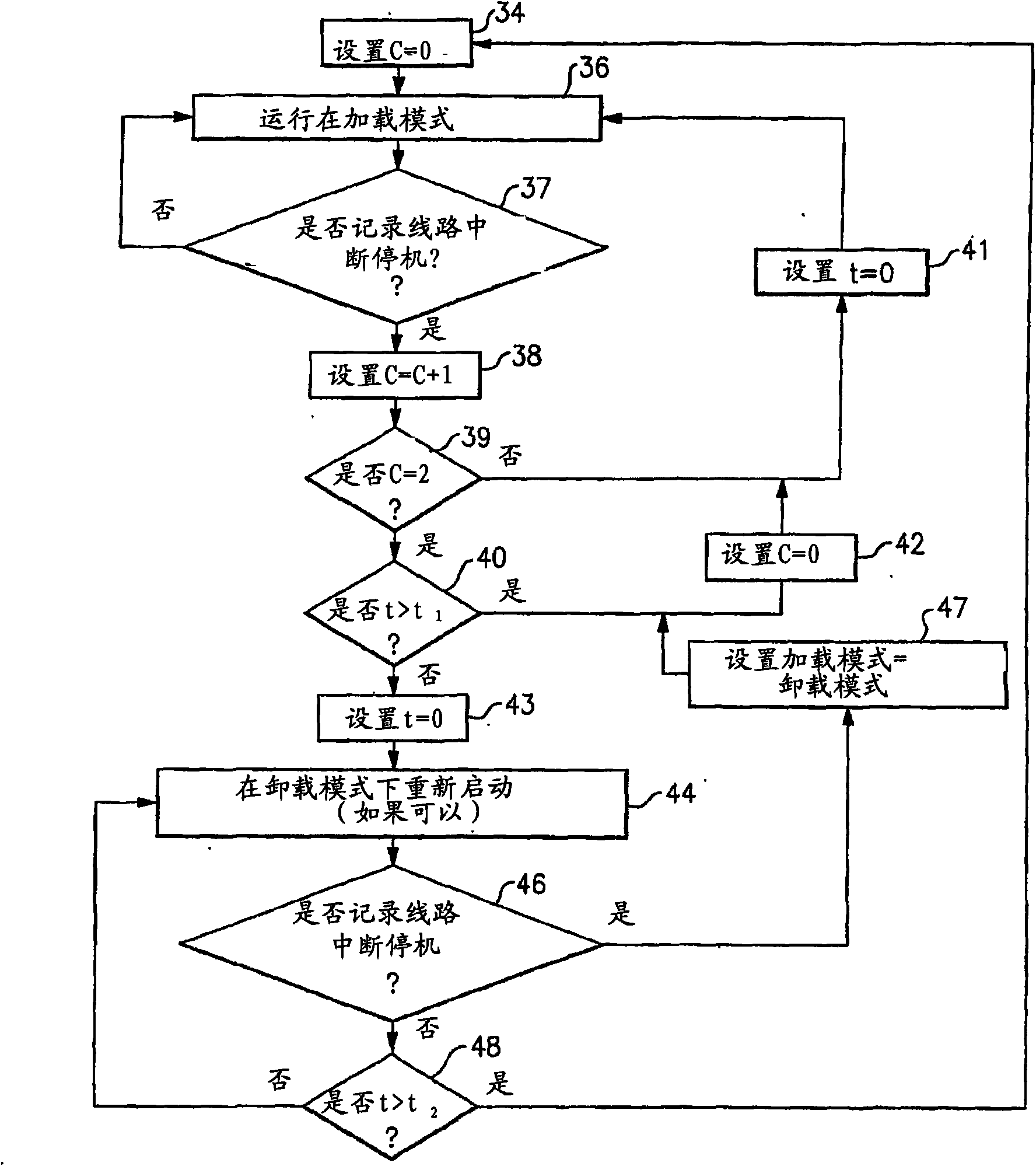

Compressor motor control

InactiveCN101688714ARealize unloadingMechanical apparatusCompression machines with non-reversible cycleMotor controlEngineering

Owner:CARRIER CORP

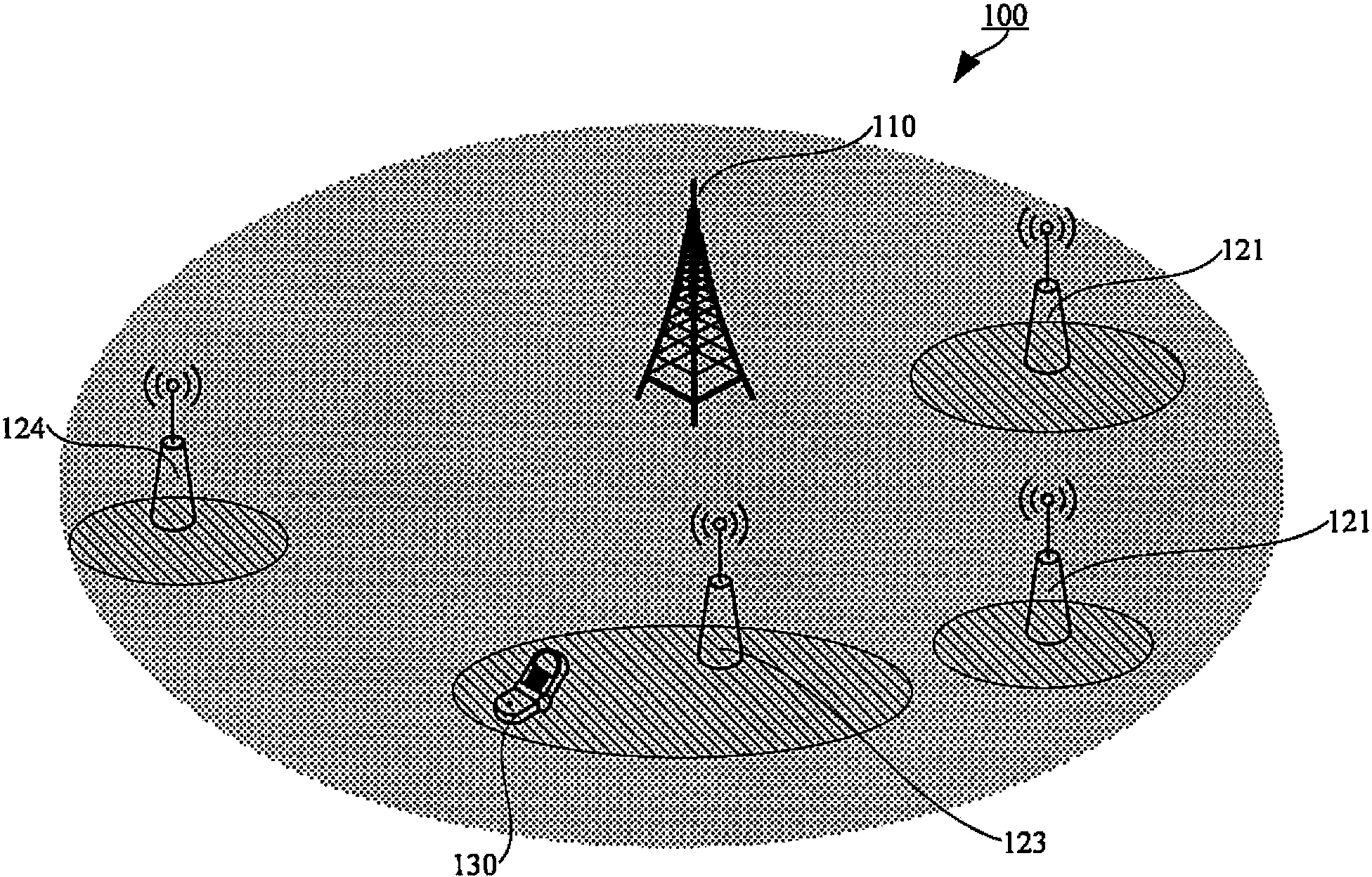

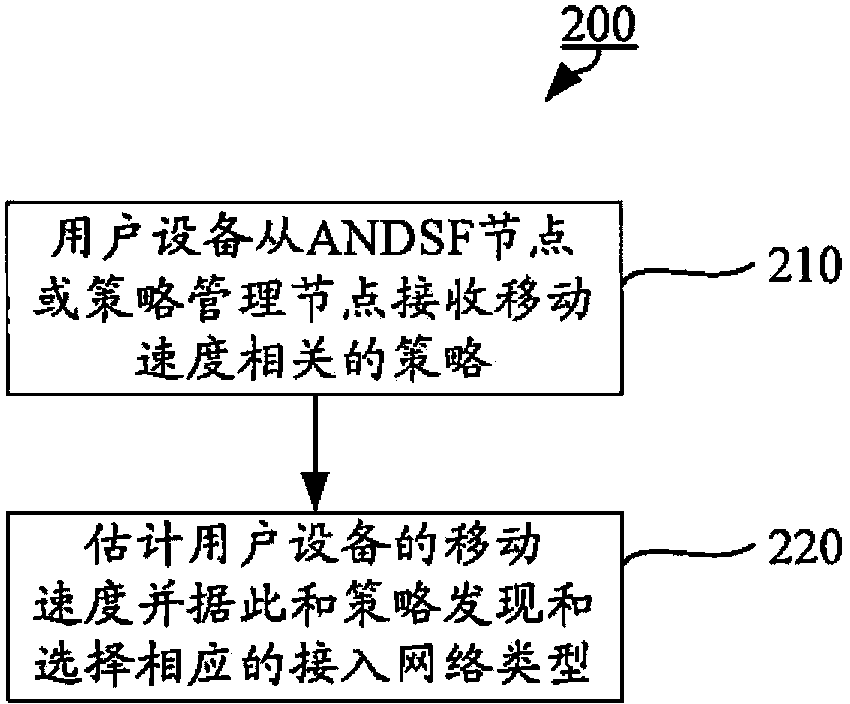

Method for configuring user equipment for discovery and selection of access network type

InactiveCN103906193AImprove network experienceRealize unloadingNetwork traffic/resource managementAssess restrictionMoving speedAccess network discovery and selection function

The invention relates to a method for configuring user equipment for discovery and selection of an access network type in a wireless communication network. The method includes the following steps: the user equipment discovers and selects a function node or strategic management node from an access network to receive a static or a semi-static strategy related with a movement speed; and the movement speed of the user equipment is estimated and a corresponding access network type is discovered and selected according to the movement speed and the strategy. According to the method in the invention, the movement speed of the user equipment is taken into consideration of access network discovery and selection functions, and thus a preferable access network can be selected reasonably according to the speed of the user equipment. Thus, one the one hand, network load balance and network unloading can be realized efficiently by means of the wireless communication network provided by a WLAN or a micro base station; and on the other hand, a network experience effect of a user can be greatly improved.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD +1

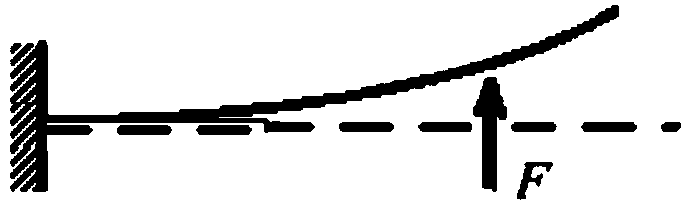

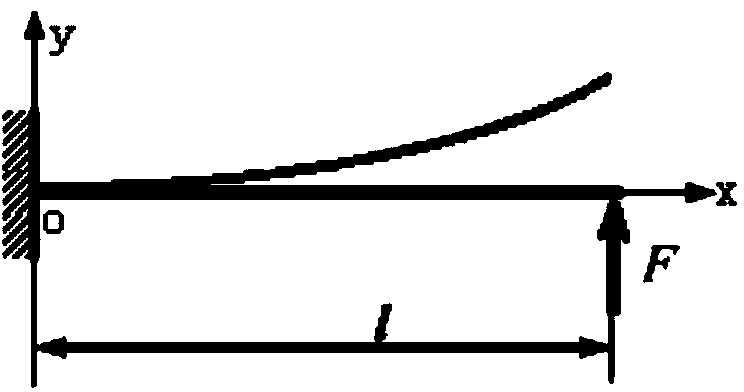

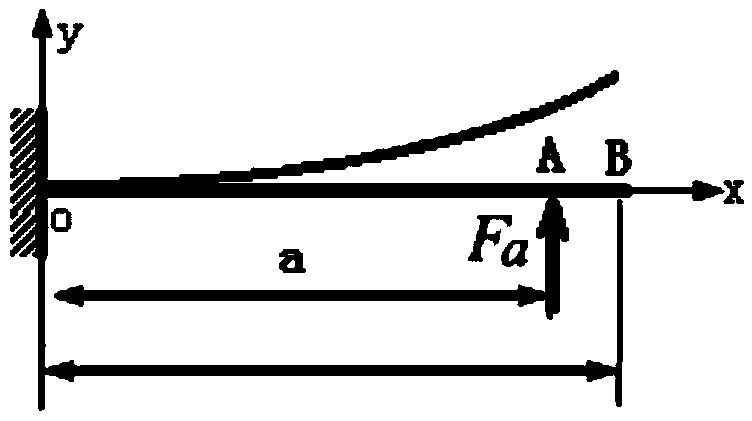

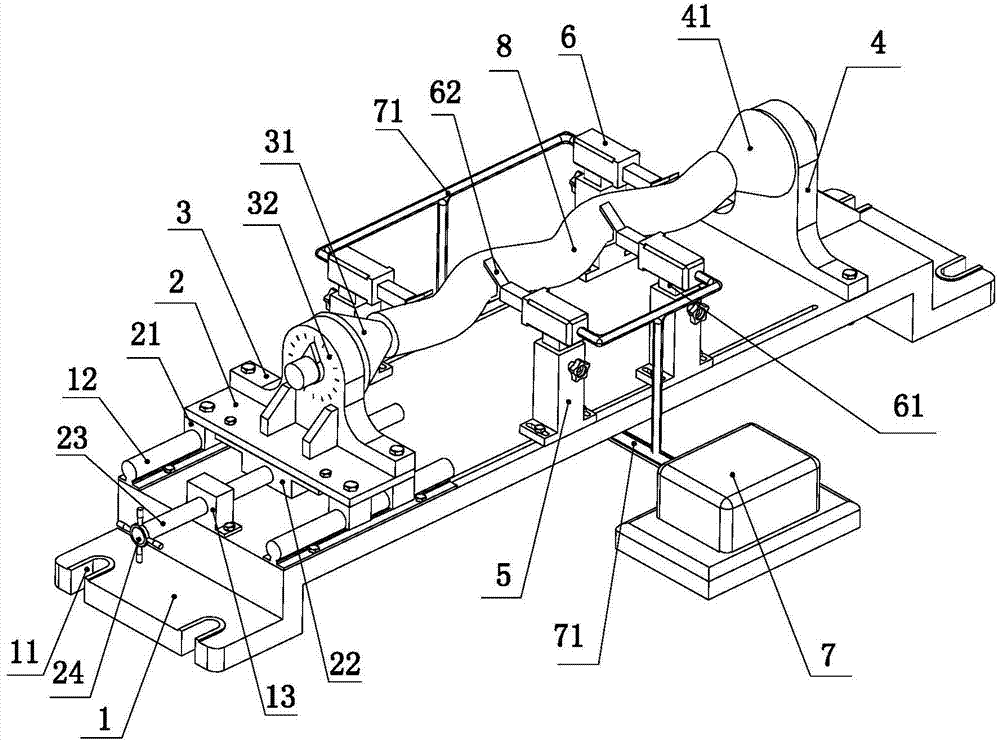

Method and system for measuring contact force of satellite-borne slip ring based on cantilever beam theory

InactiveCN103837280AEasy to analyzeRealize precise measurementApparatus for force/torque/work measurementSatelliteLeast squares

The invention discloses a method and system for measuring the contact force of a satellite-borne slip ring based on the cantilever beam theory. According to the method, the contact force of the satellite-borne slip ring is indirectly and accurately measured, namely, a measuring point is set near a contact point between an electric brush wire and the electric conductive slip ring, a relational expression between the initial measuring force exerted on the measuring point and the contact pressure at the contact point is elicited according to a deflection curve equation of a uniform-section straight girder, monadic regressive analysis is conducted on data measured at the measuring point through the least square method according to the linear rule of deformation, so that the accurate initial measuring force is obtained, the contact force is obtained, and the measuring accuracy is high. The system for measuring the contact force is composed of the electric conductive slip ring, the electric brush wire, a loading lifting hook, a force sensor, a displacement sensor, a connecting board, an accurate electric control motion table, a motor driver, a motor control card, a multichannel data acquisition card, a current sensor, an industrial personal computer and a displayer. Design is ingenious, operation is convenient and measurement is accurate.

Owner:ZHONGWEI ELECTRONICS INSTR FACTORY ZHANGZHOU CITY

Flexible clamping device of bent pipe

ActiveCN104722619AStable clampingRealize the clamping effectMetal-working feeding devicesPositioning devicesEngineeringMachining

A flexible clamping device of a bent pipe is applied to indexing hole machining of the bent pipe and used for solving the problem that the bent pipe is not convenient to clamp or fix. A movable platform is arranged on the top of a rack in a sliding mode, a movable support is arranged on the movable platform, and a movable thrusting piece is movably installed at the upper portion of the movable support through a rotating shaft. A fixed support corresponding to the movable support is arranged at the other end of the top of the rack, a fixed thrusting piece is rotationally installed at the upper portion of the fixed support through a rotating shaft, and the pipe is clamped through the cooperation of the fixed thrusting piece and the movable thrusting piece. Oil cylinders are arranged on the front side and the rear side of the part, between the fixed support and the movable support, of the rack respectively, piston rods of the oil cylinders are provided with chucks, and the bent pipe is clamped in a horizontal plane through the cooperation of the chucks on the front side and the rear side. According to the clamping device, the bent pipe can be firmly clamped, the bent pipe can be rotated without dismounting the pipe, an indexing hole can be conveniently machined, and the machining precision is guaranteed.

Owner:山东深图智能科技有限公司

Gearbox gear shaft chamfering and forming device

ActiveCN104174875ARealize unloadingRealize the processing effectPositioning apparatusTurning machinesEngineeringMechanical engineering

A gearbox gear shaft chamfering and forming device comprises a base, a feed device, a clamp and a cutting device, wherein the feed device, the clamp and the cutting device are fixed on the base. The feed device is capable of automatically inserting gear shafts to be processed into the clamp, the clamp drives the gear shafts to be processed to rotate and clamps the same during rotating, two ends of the gear shafts are exposed out of the clamp and correspond to two cutters on the cutting device, and the cutting device can drive the cutters to move on the horizontal plane and align to ends of the gear shafts. By the gearbox gear shaft chamfering and forming device, the gear shafts can be clamped tightly during cutting and can be unclamped after cutting, thus, automatic feed and discharge of the gear shafts can be realized, and production efficiency is greatly improved. Further, the gear shafts of different sizes can be clamped, and usage range of the gearbox gear shaft chamfering and forming device is broadened.

Owner:浙江祥晋汽车零部件股份有限公司

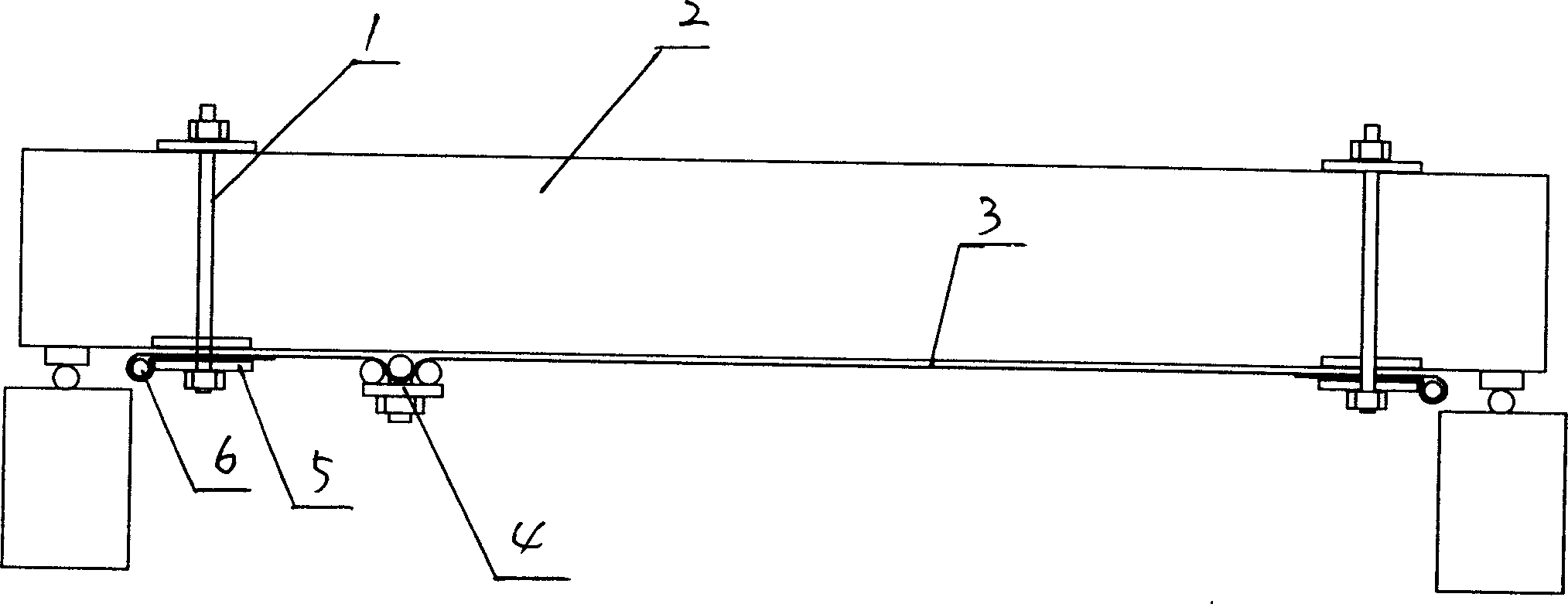

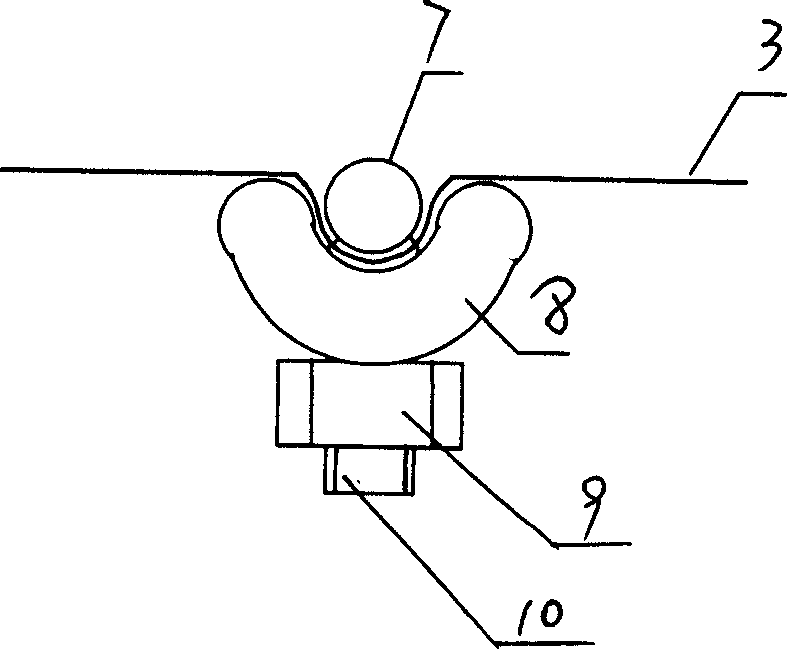

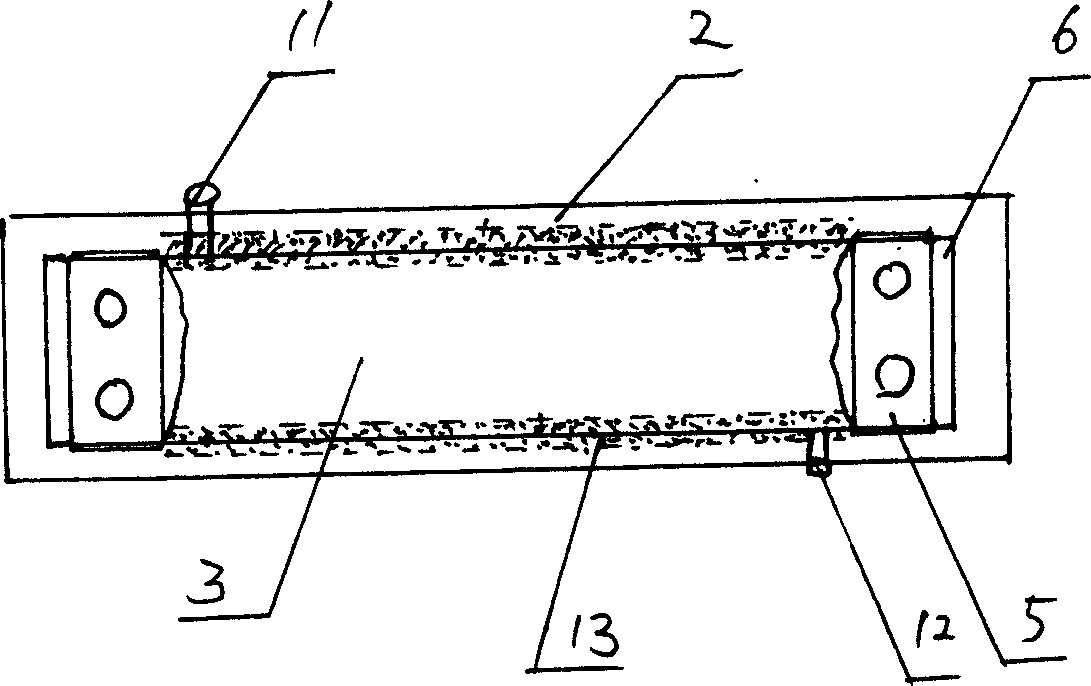

Method for strengthening construction unit using high strength fibre cloth

InactiveCN1693623ADisadvantages of changing reinforcementRealize unloadingBuilding reinforcementsFiberSheet steel

This invention discloses is a method of using high intensity fiber cloth for strengthening member. The cloth is anchored to the two ends of member after it is flattened. Then horizontal strain is done through horizontal stretching equipment between the two anchor ends. The anchor method is that the end of the cloth is rolled through a steel roller and then retraced, and it is nipped between two steel boards with the cloth, then they are fixed at end of consolidated pieces through high tensile bolt. Binding coat can be painted on member surface, then anchor and stretching is done before the glue of the binding coat doesn't solidify. Also using rubber belt to seal fiber cloth edge and member after anchor and stretching is done, compound lining hole is set at one end, and vent hole is set at the other end, structure glue is injected between fiber cloth and members through the hole. Stiffness and ultimate strength of the consolidated structure member can be increased by using the method in this invention, and the deformation in application stage can be recovered or part recovered and crack width of structure members can be reduced.

Owner:田安国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com