Patents

Literature

62results about How to "To achieve the purpose of unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

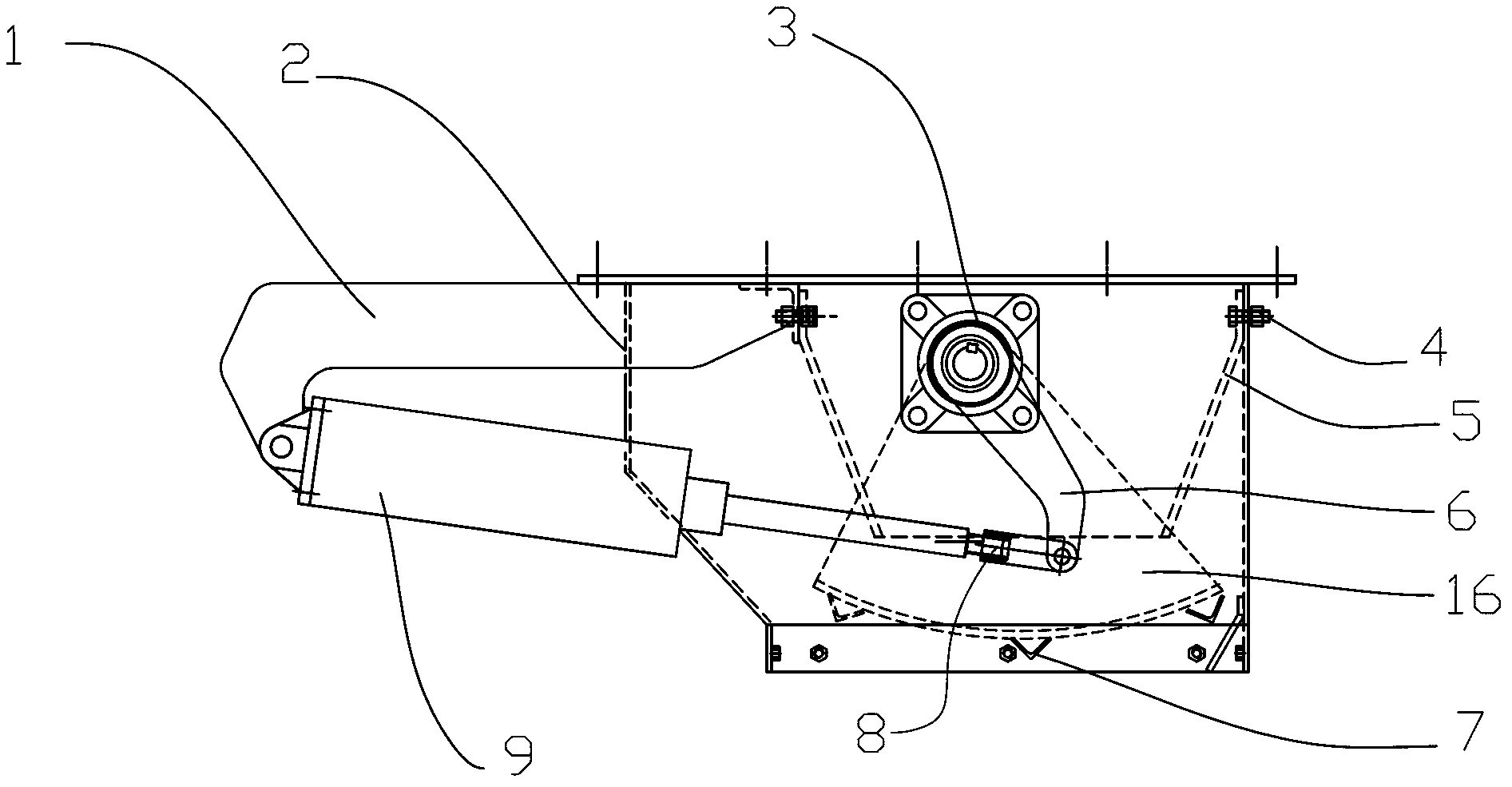

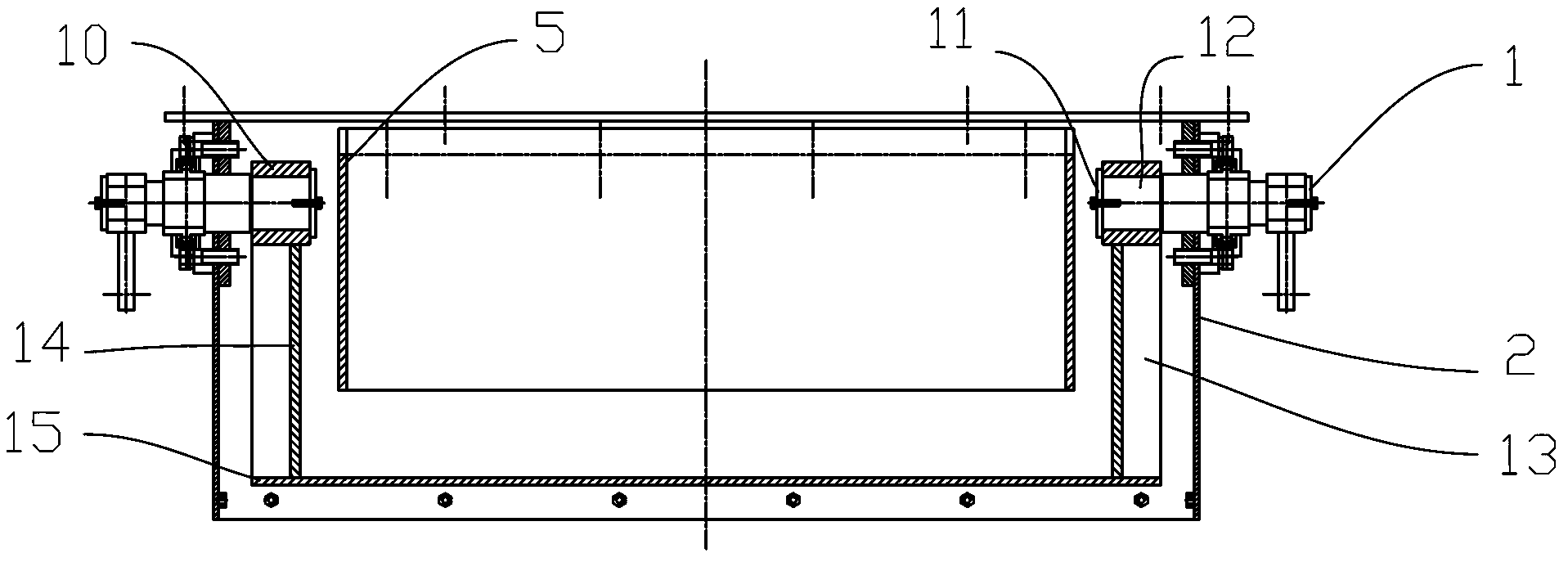

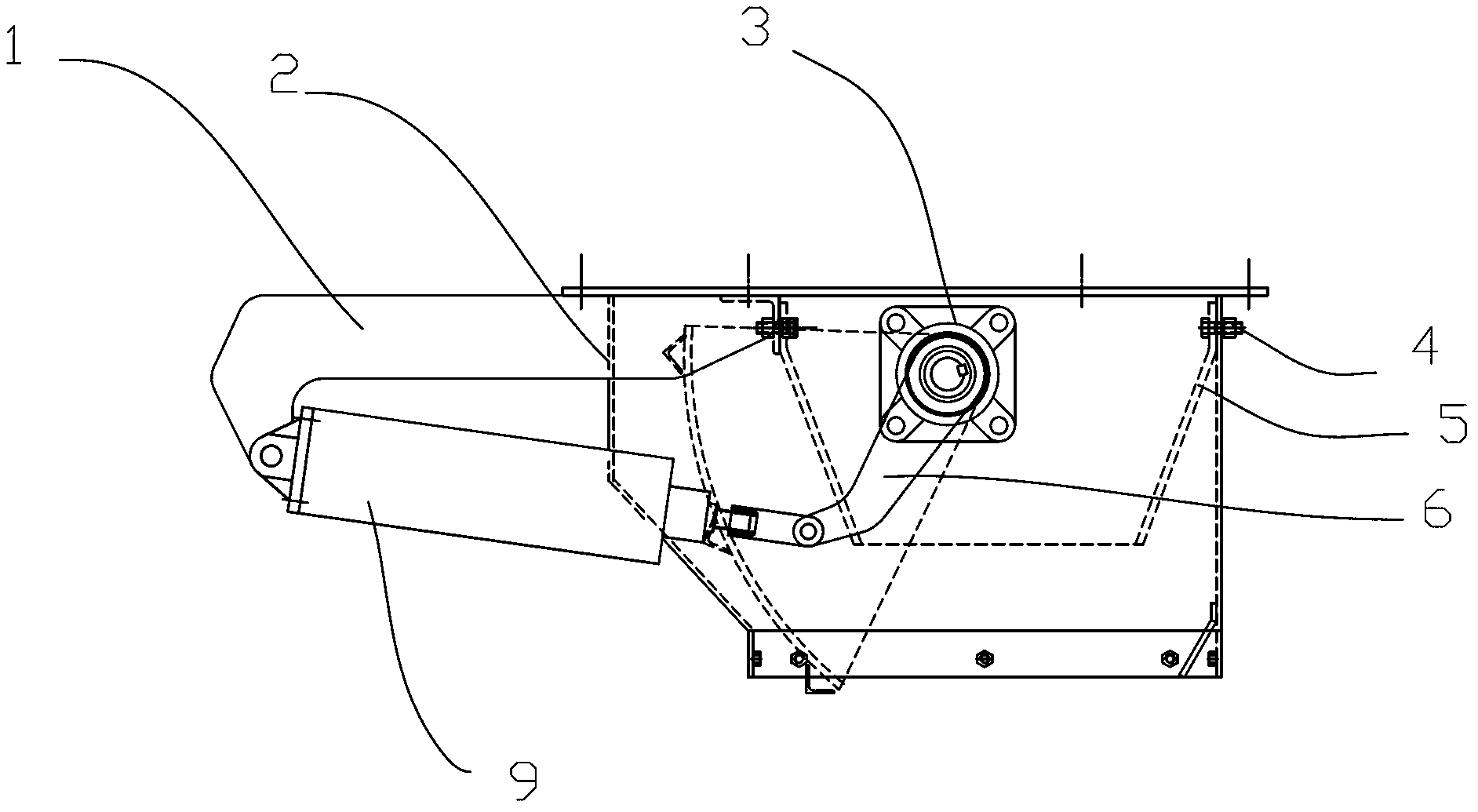

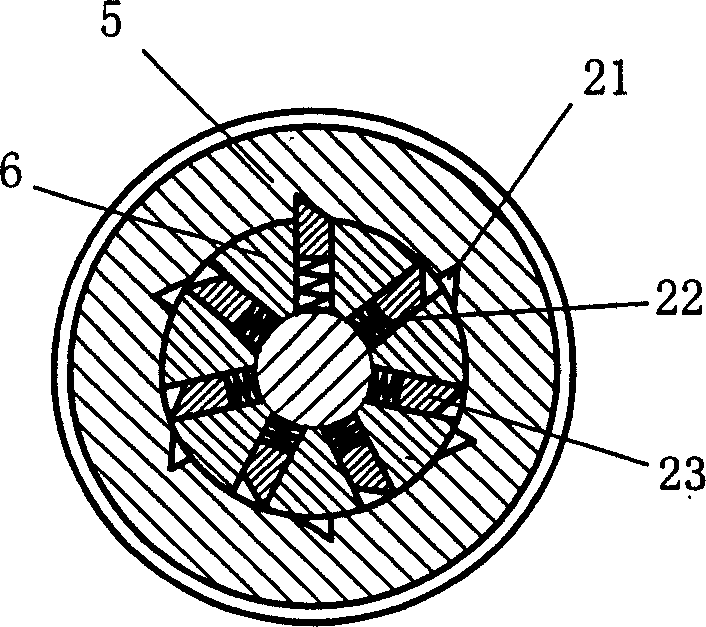

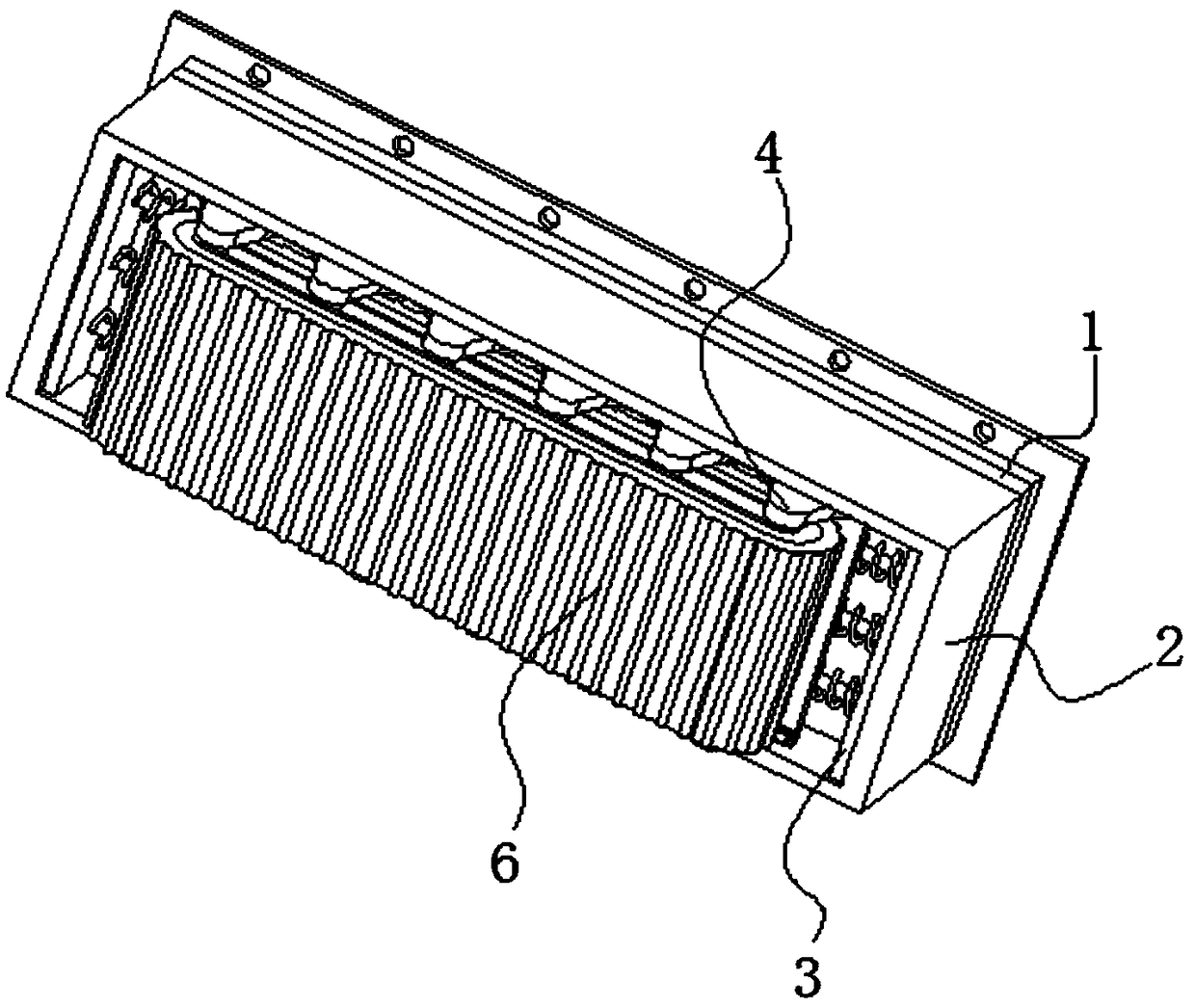

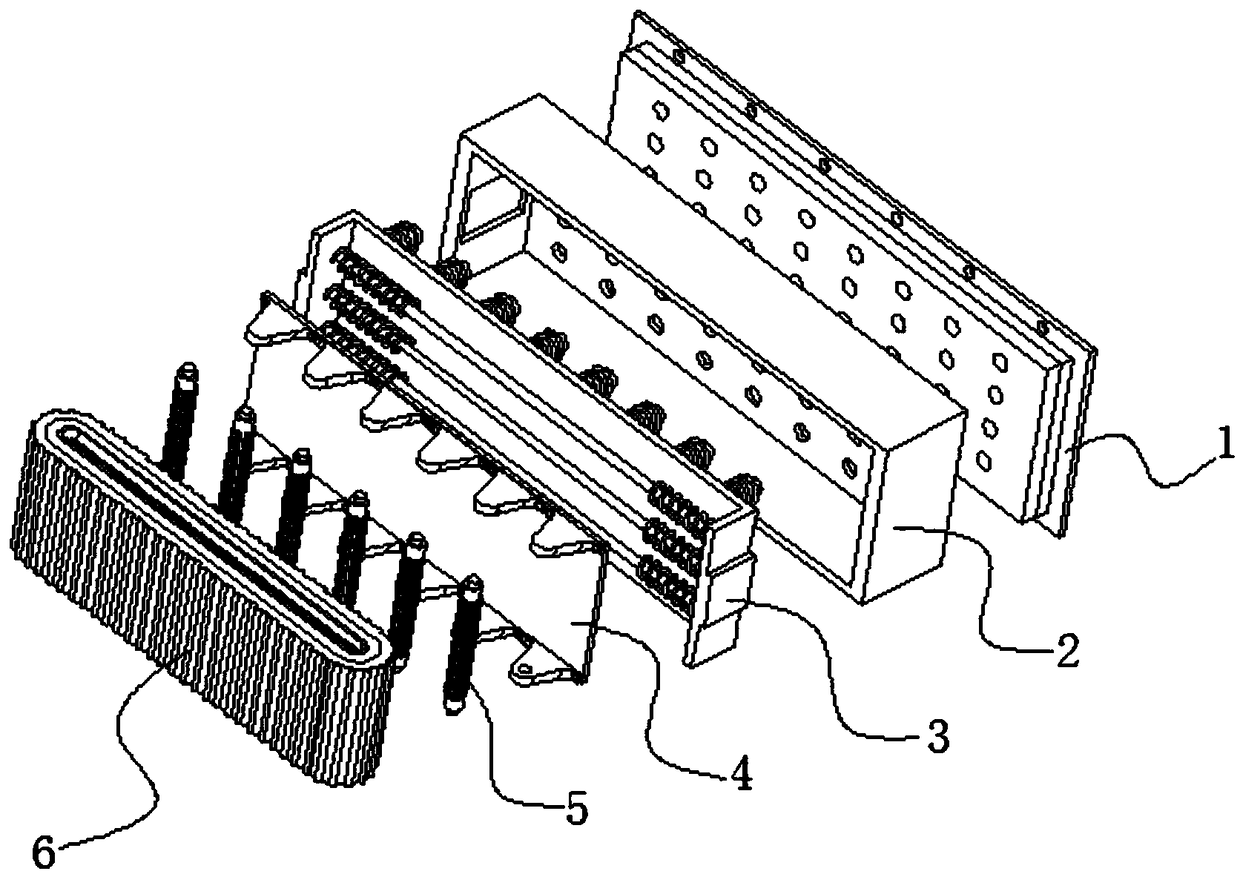

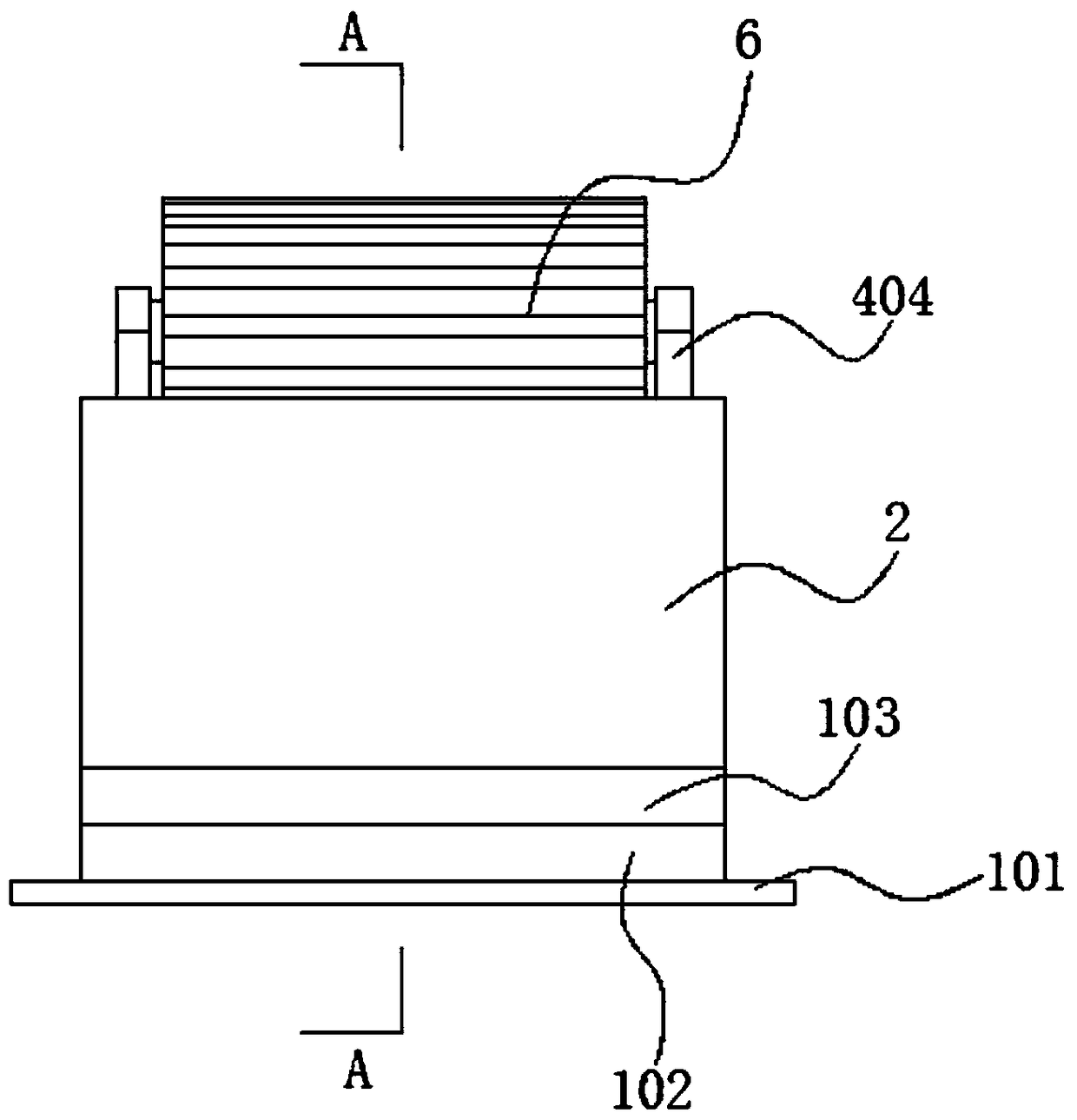

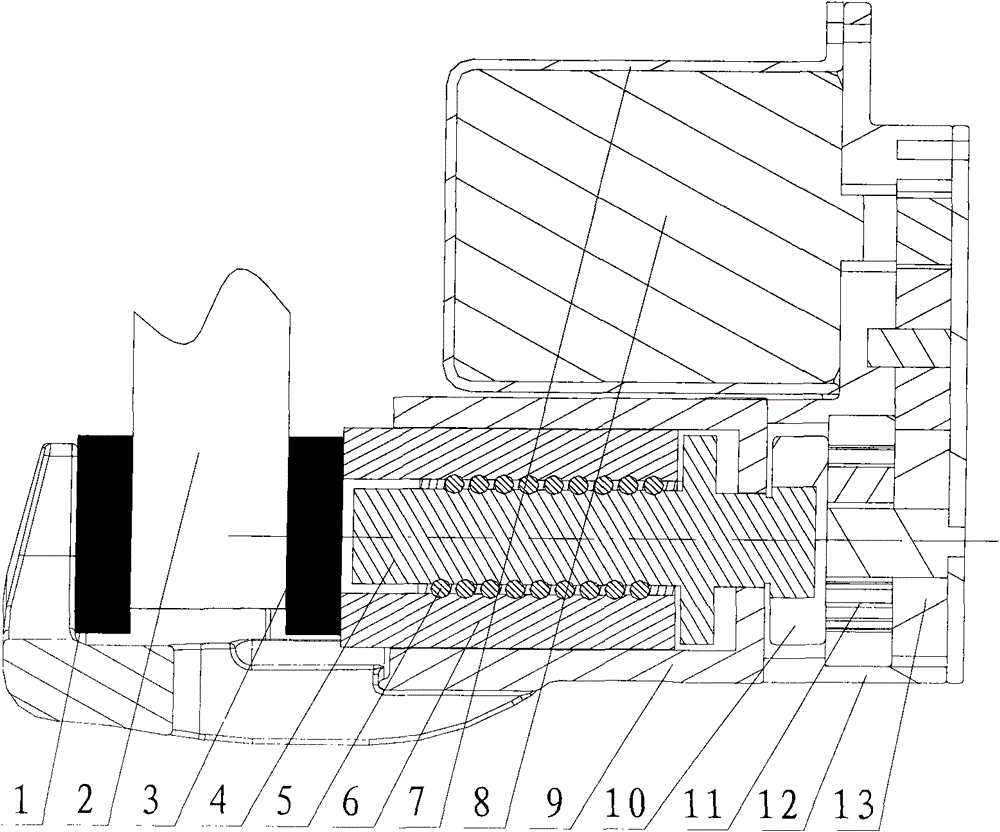

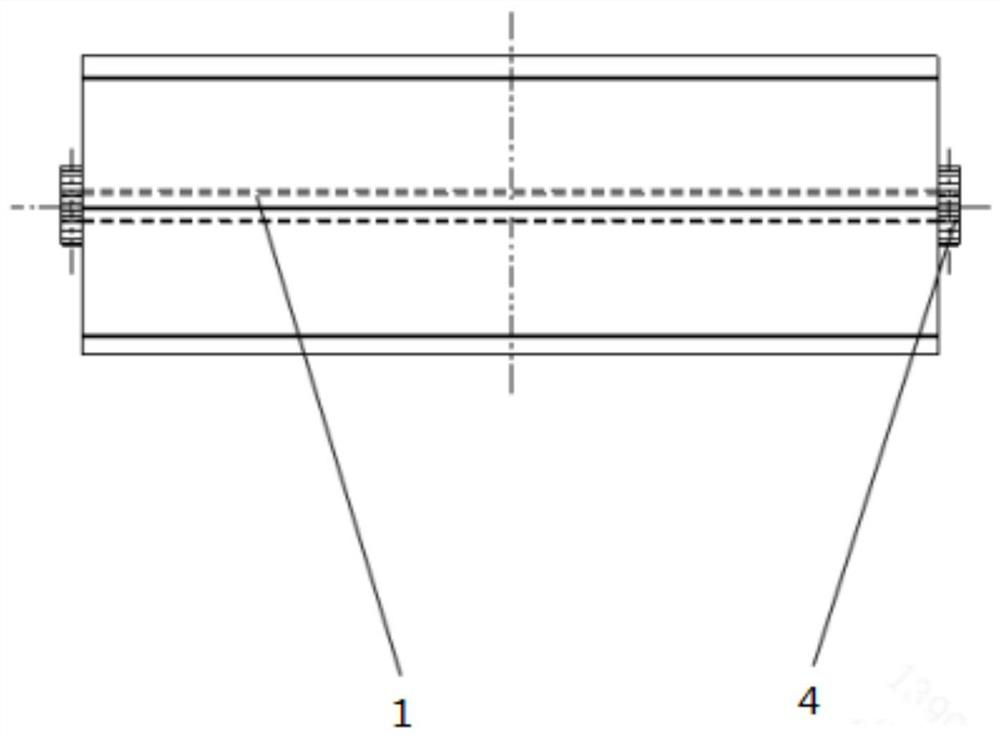

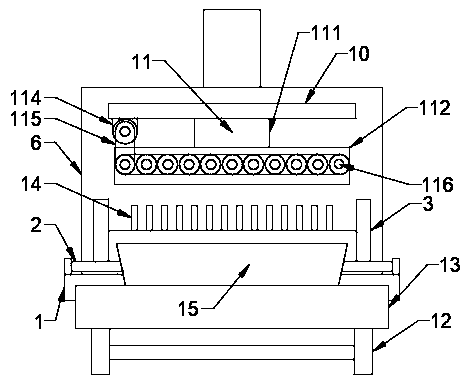

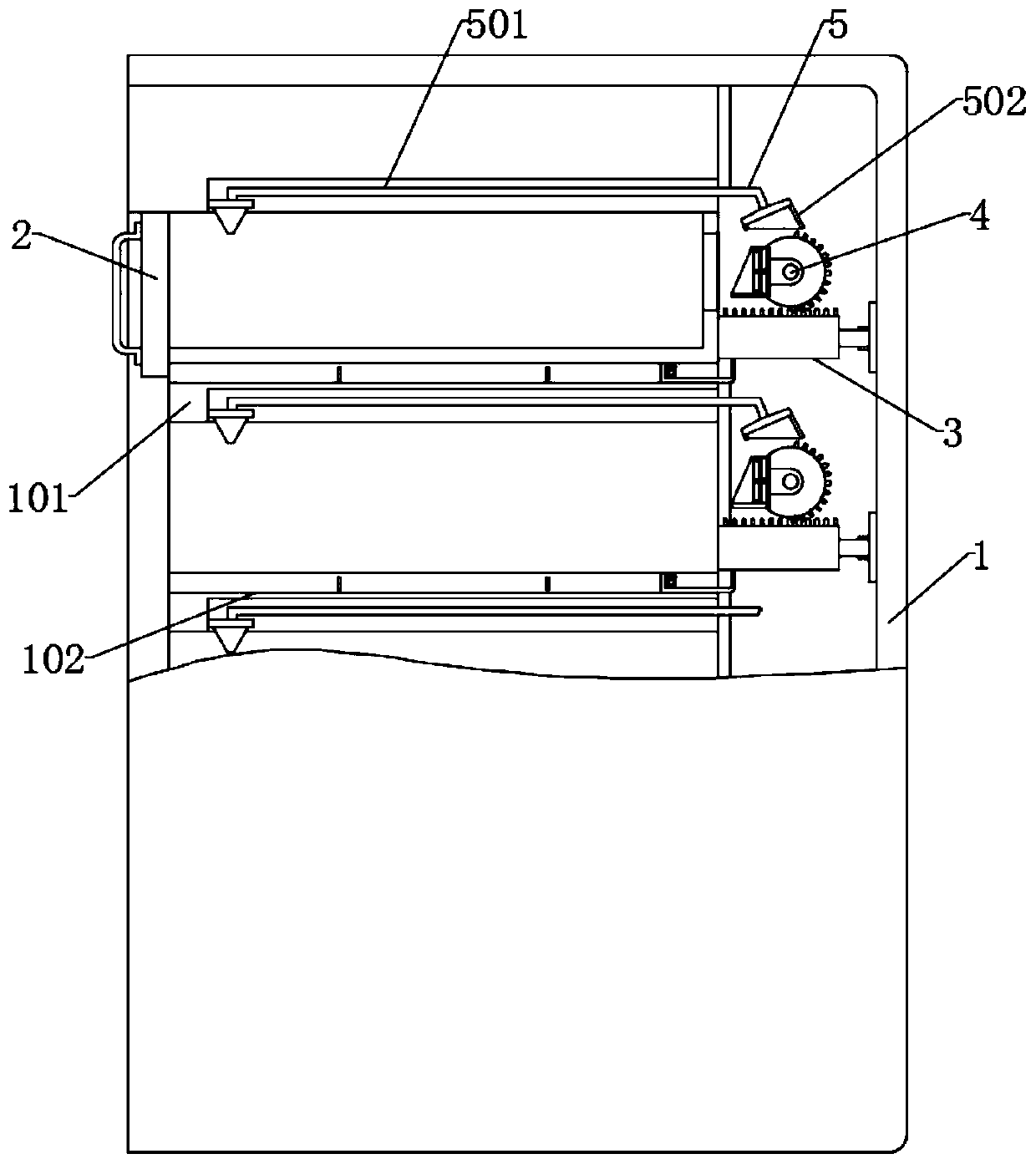

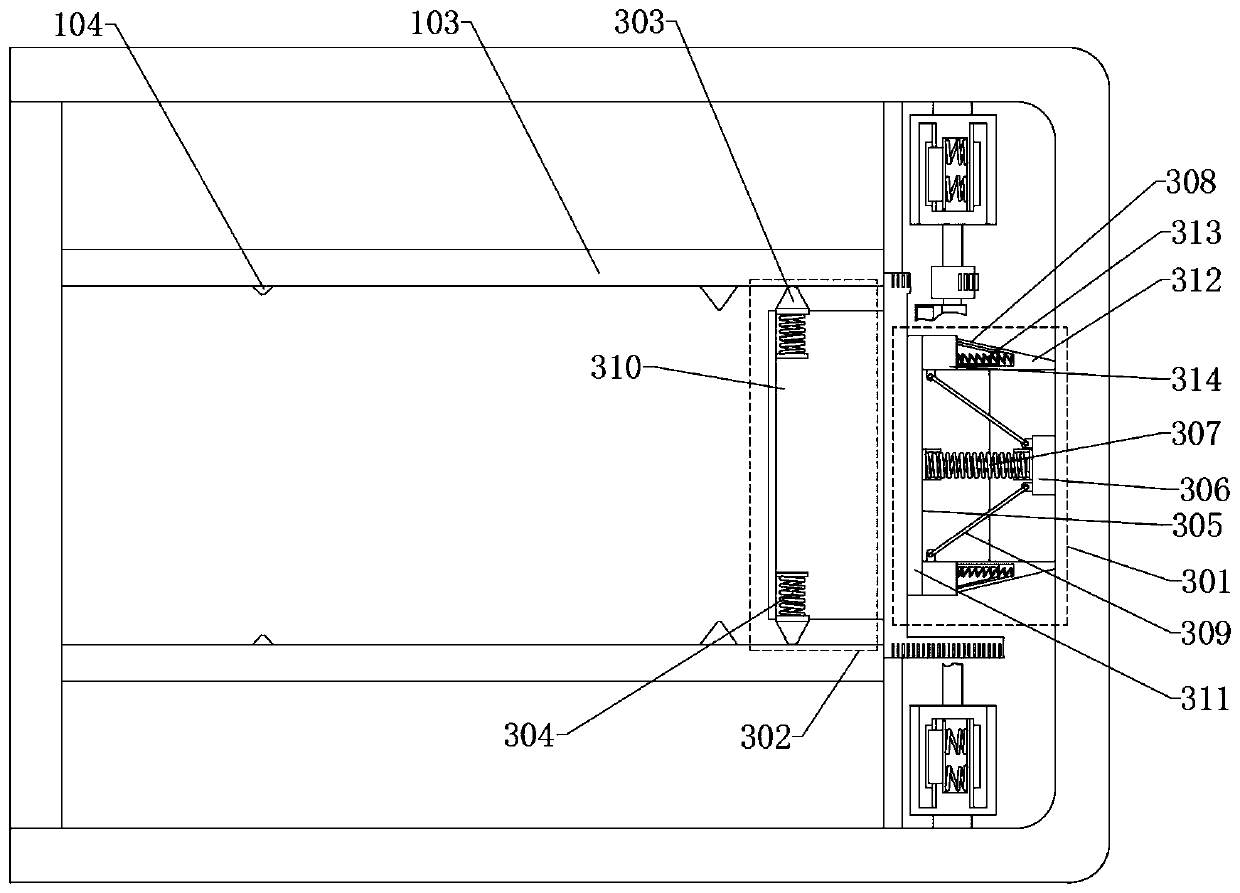

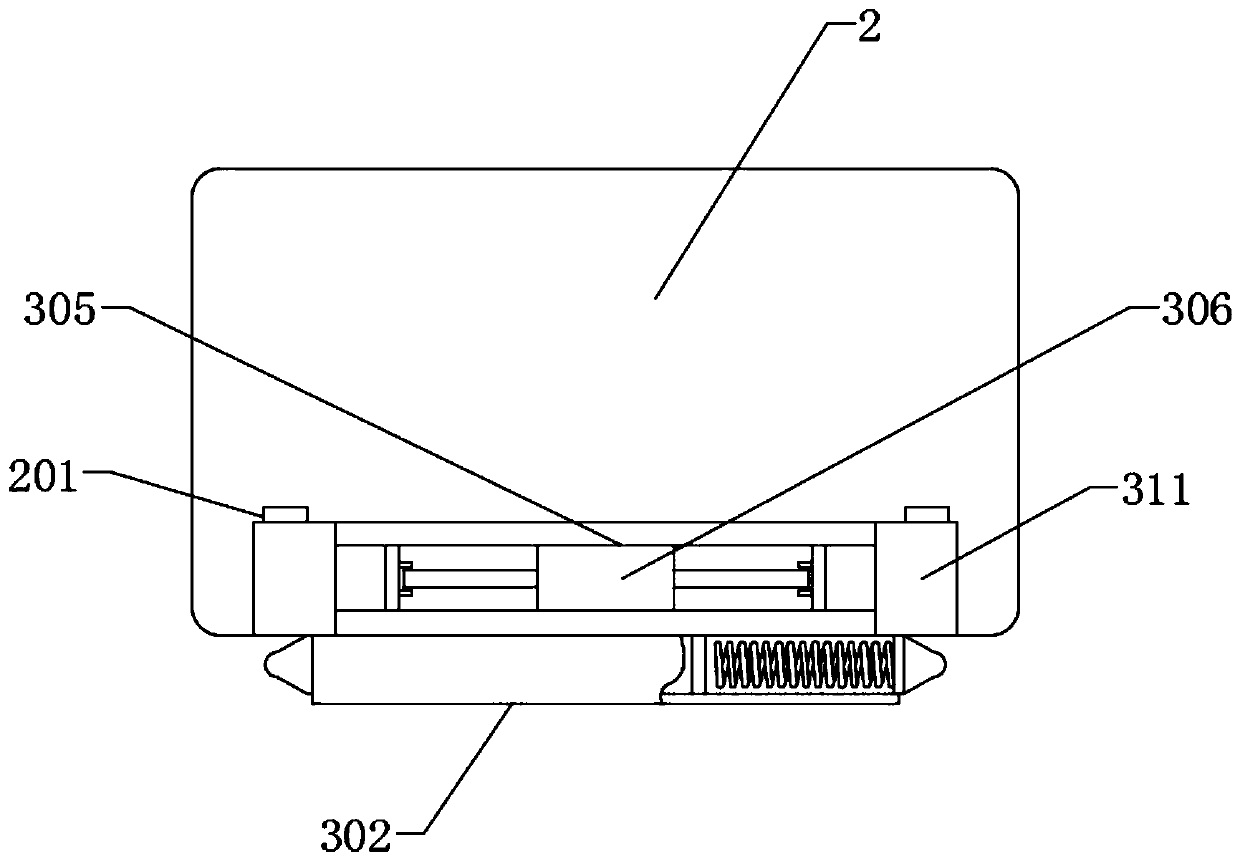

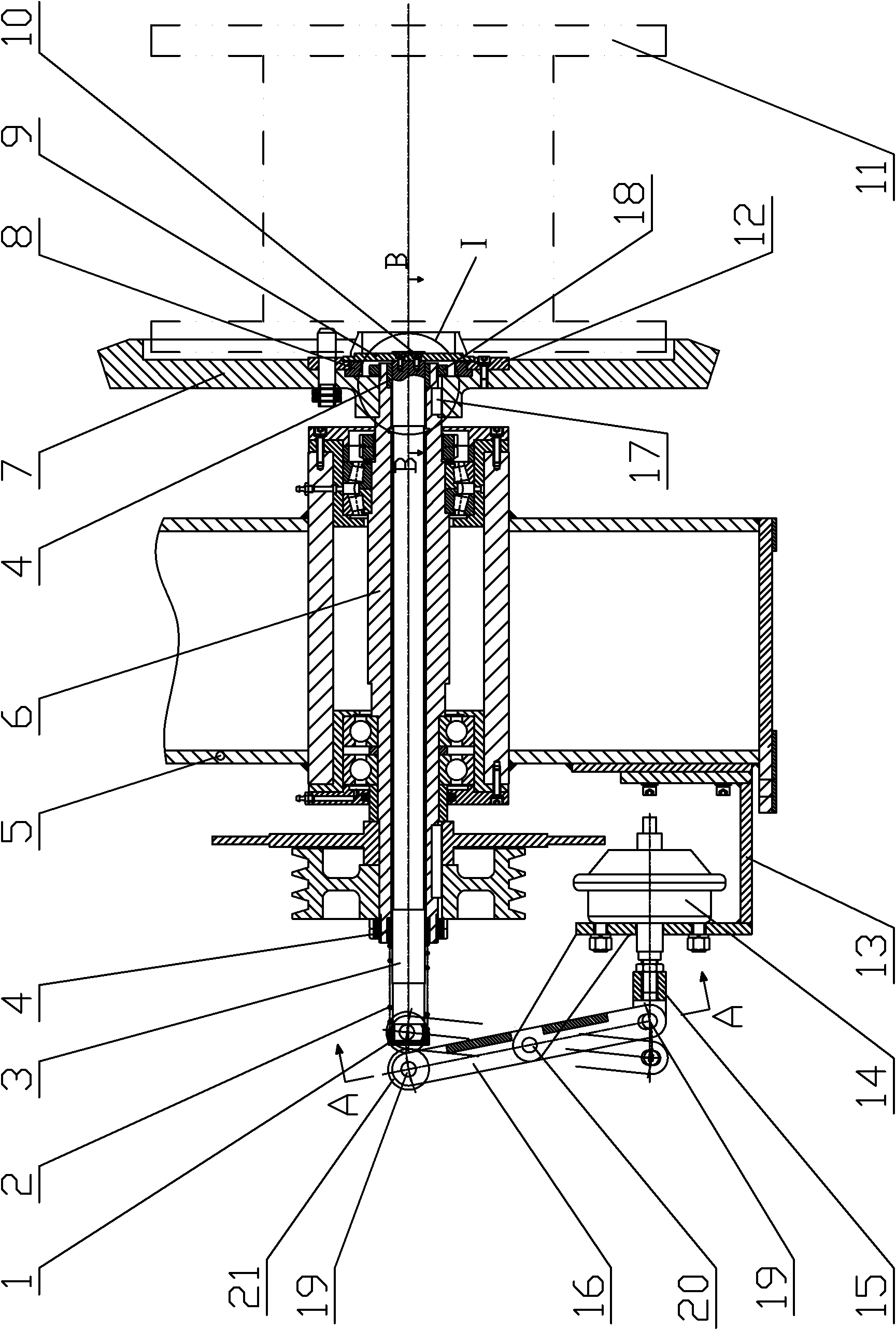

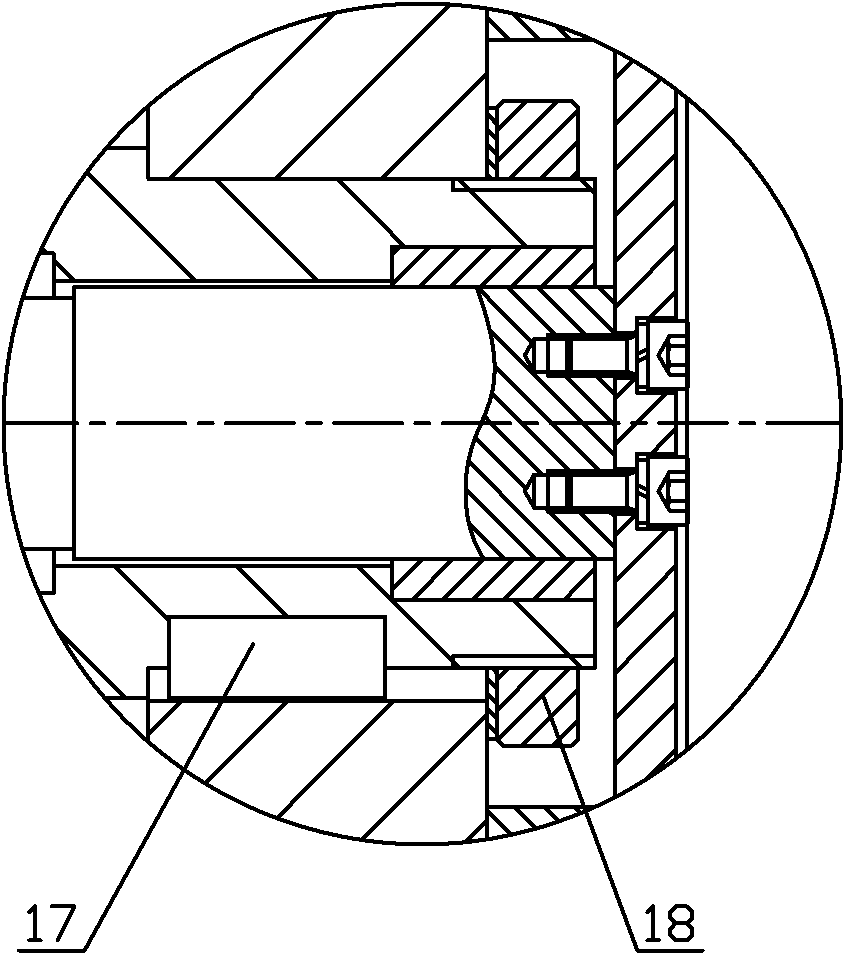

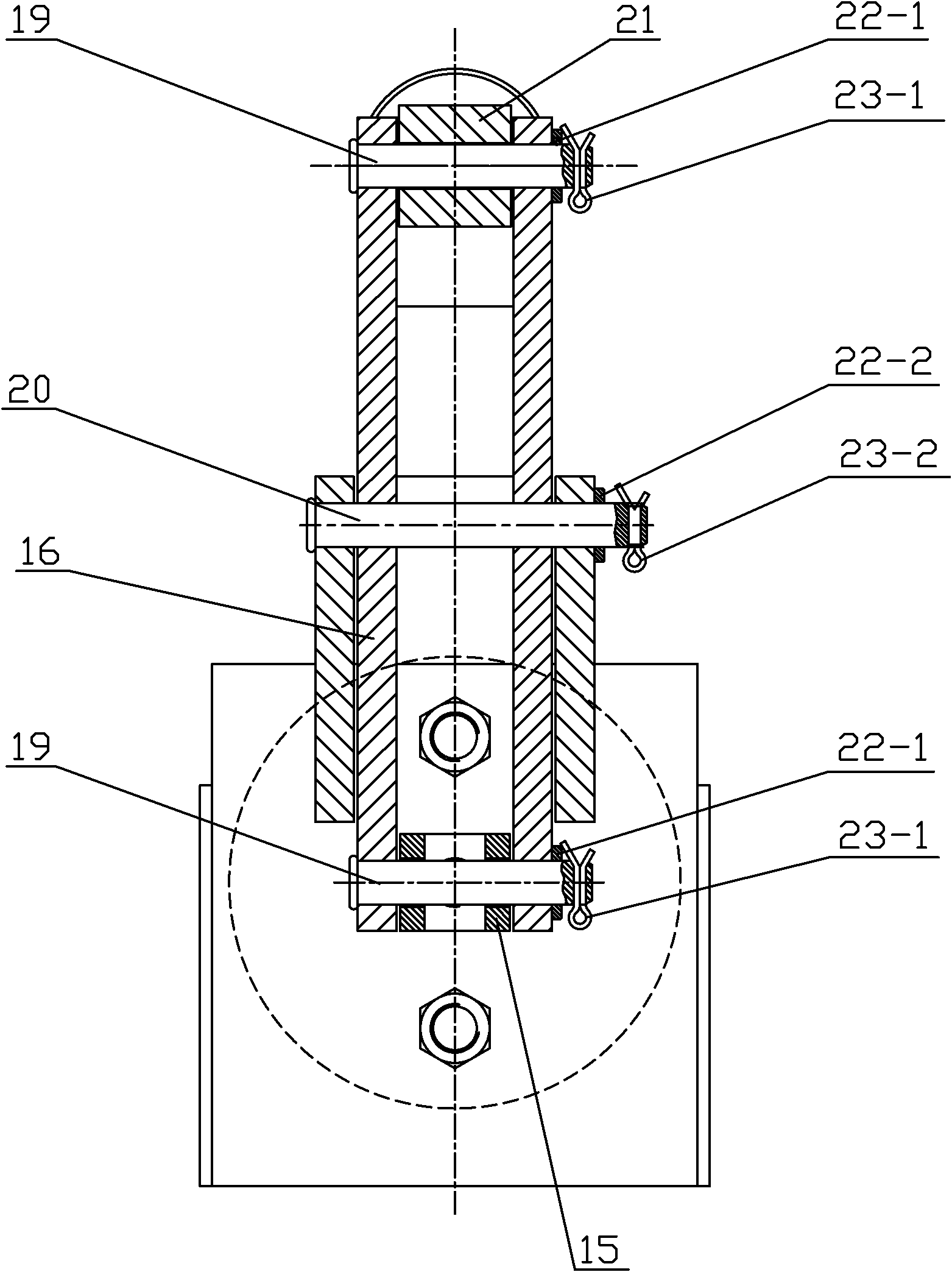

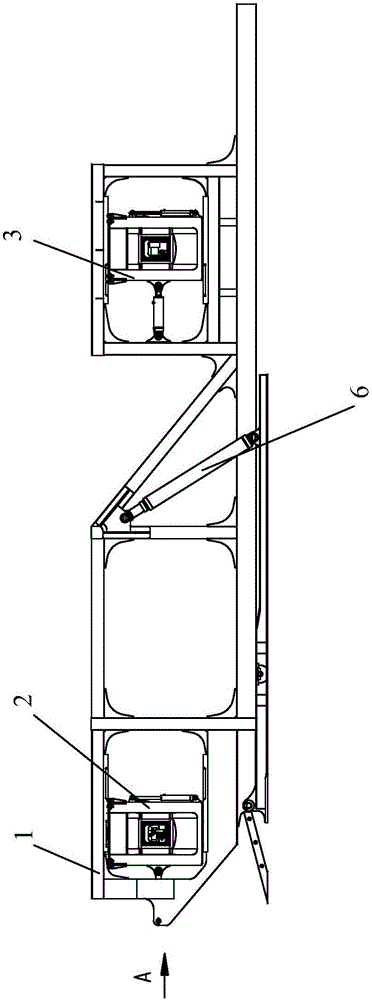

Press moveable platform for elastic element unloading

ActiveCN101244638AReduce distortionTo achieve the purpose of unloadingPressesHydraulic cylinderGlass fiber

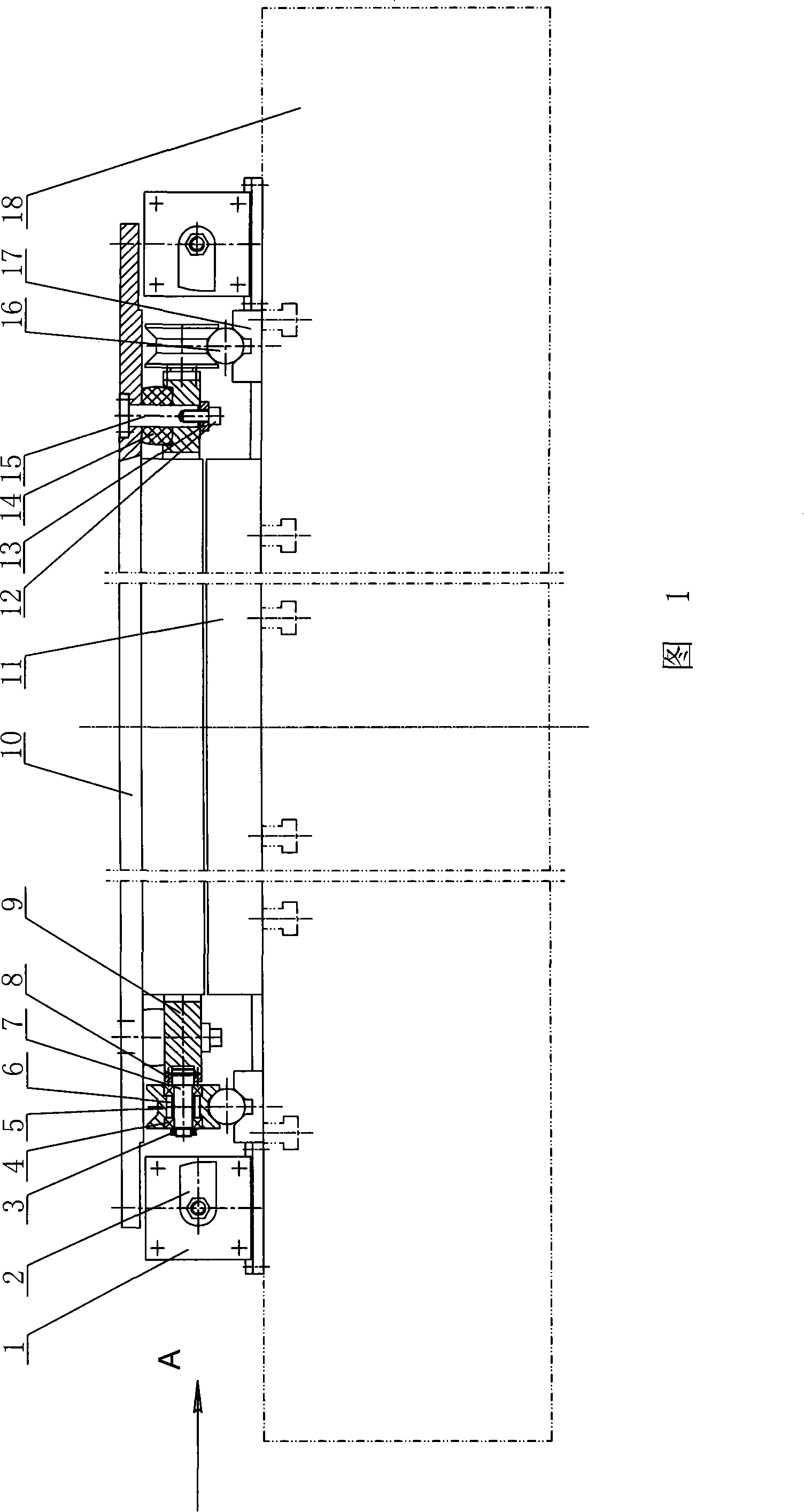

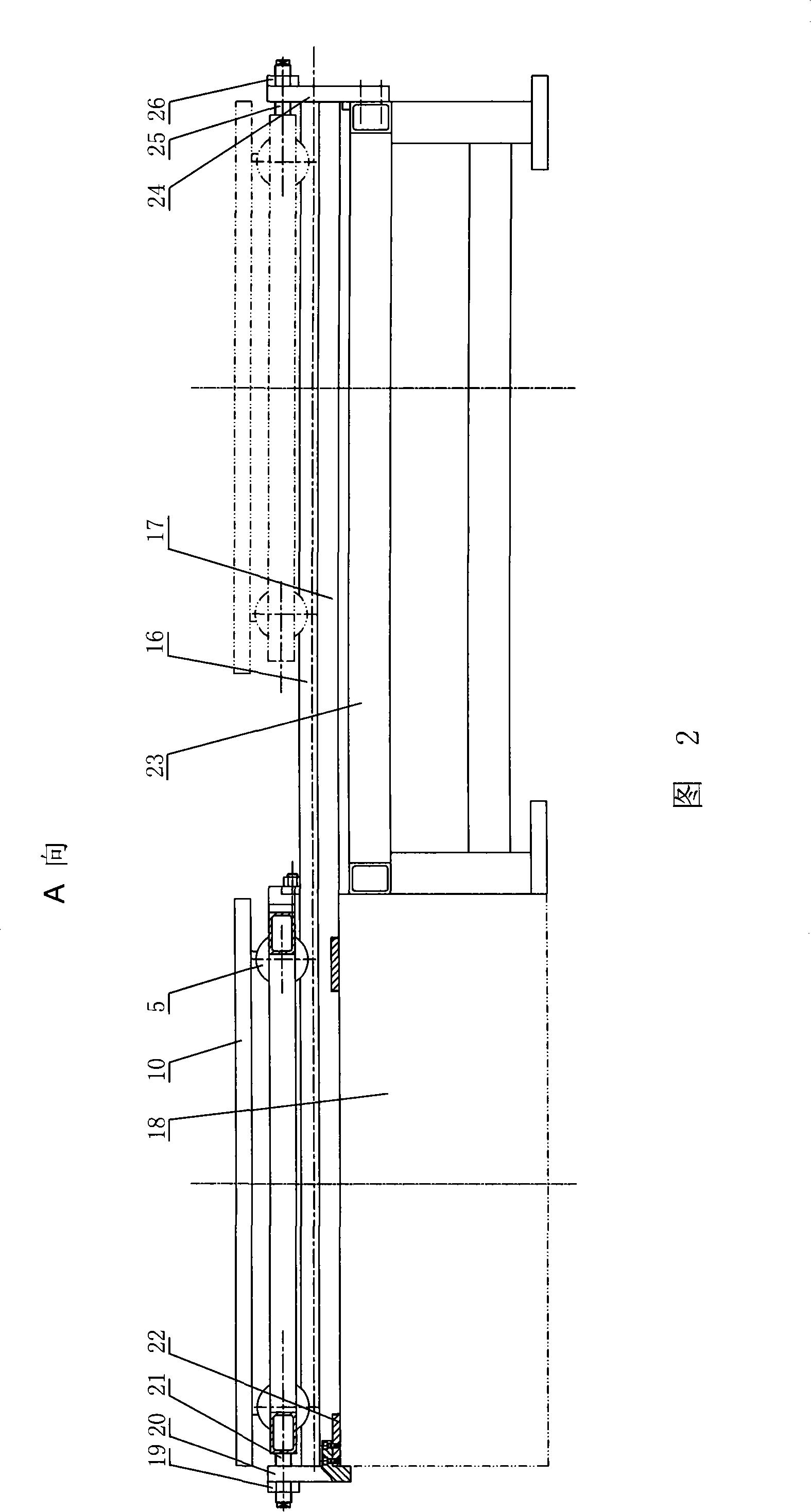

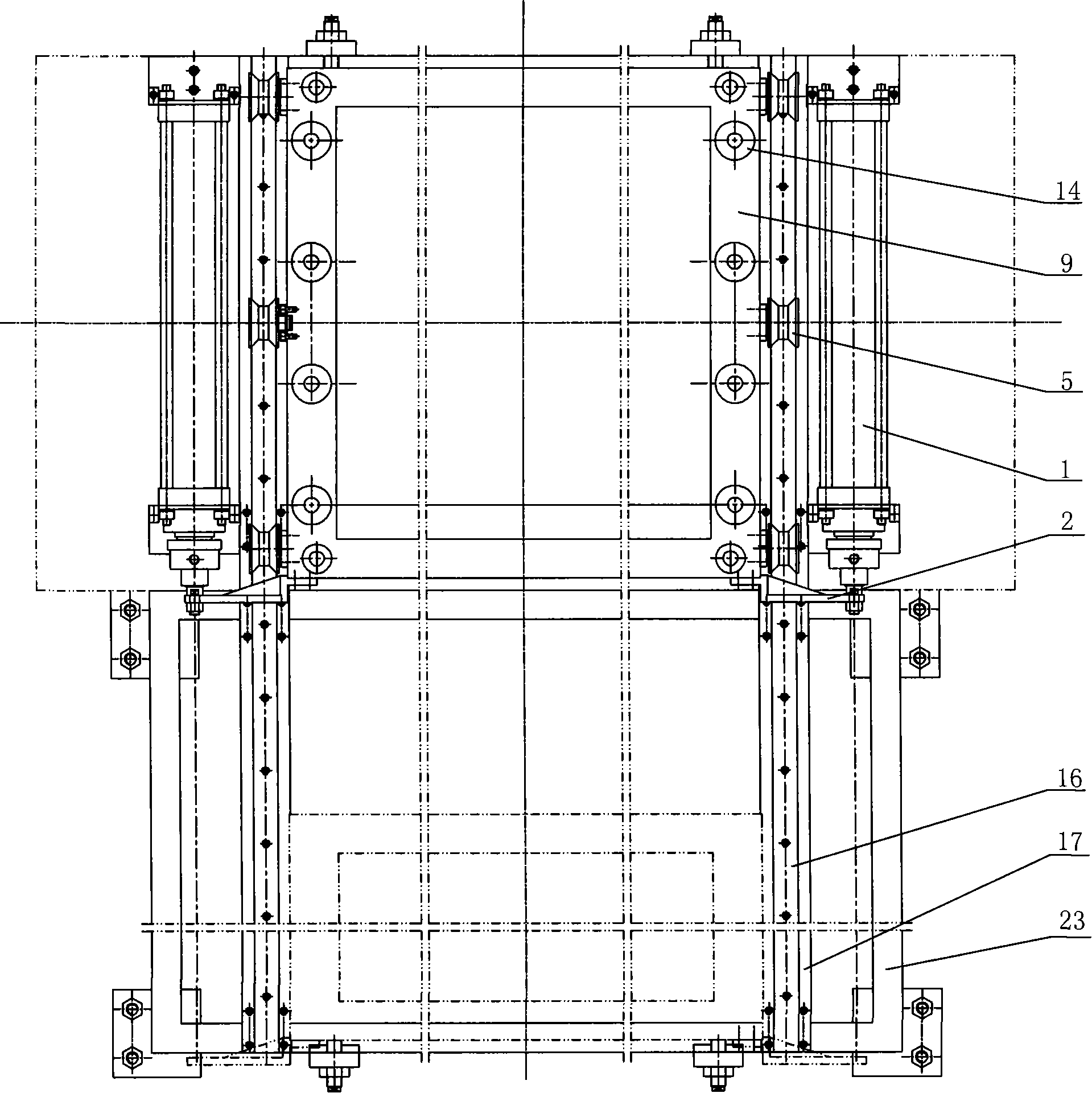

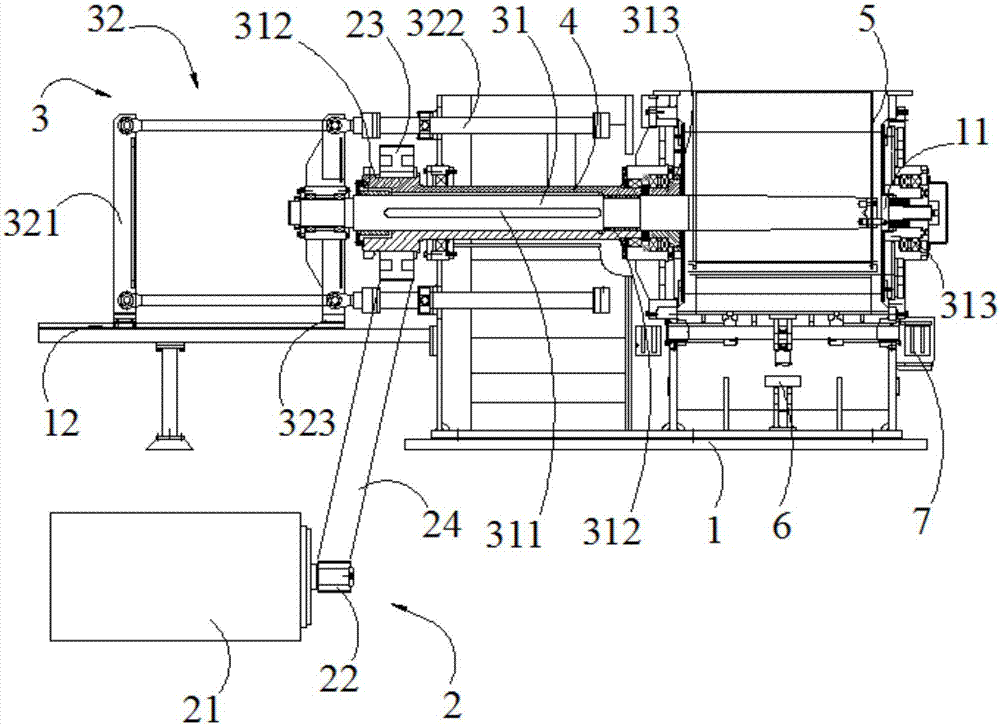

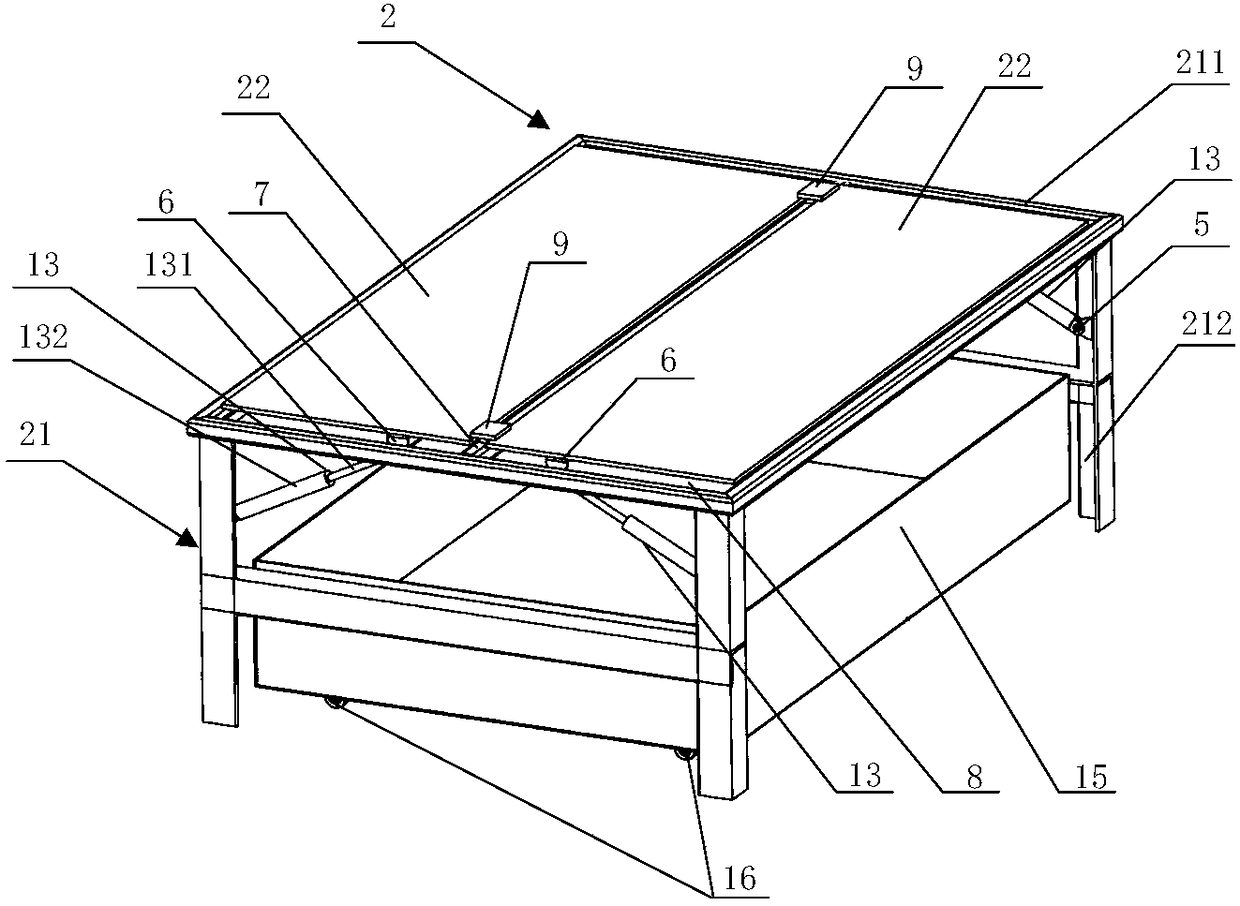

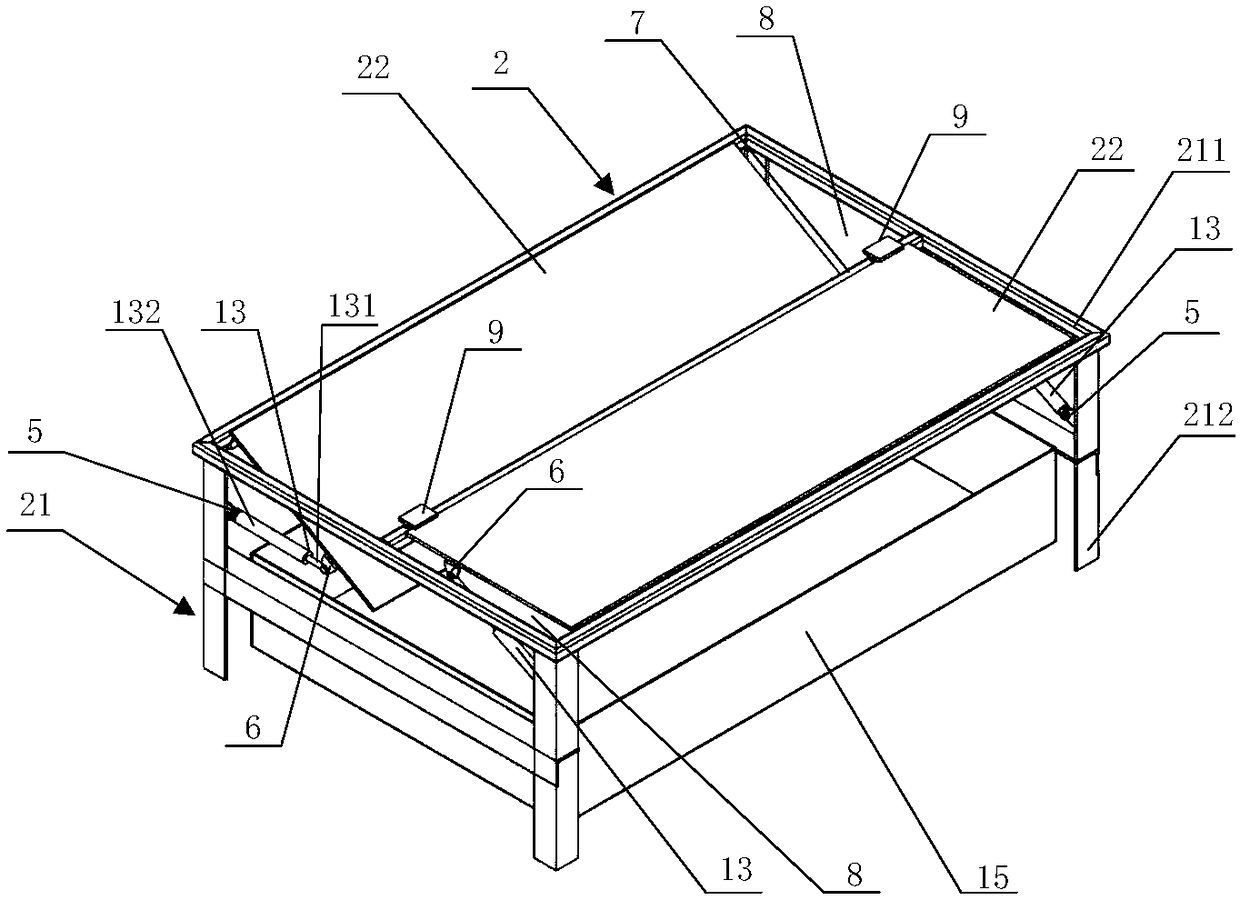

The invention discloses a moving worktable of the pressing machine of the elastic element unloading in the pressing machine field, which comprises a working plate, and a moving supporting bracket is arranged under the working plate. A leader is used to guide between the working plate and the moving supporting bracket, a pre-compressing elastic element is sleeved on the leader, and the upper and lower ends of the elastic element are respectively propped on the working plate and the moving supporting bracket. Rollers are arranged at two sides of the moving supporting bracket, and the rollers are supporting on the linear guide of the circular cross-section. Cylinders or hydraulic cylinders are respectively arranged at two sides of the moving supporting bracket, and the cylinder bodies of the cylinders or the hydraulic cylinders are fixed with the bed, and the piston extending end of the cylinder or the hydraulic cylinder is fixed with the moving supporting bracket. A padding plate is arranged under the working plate, and an obligated clearance is arranged between the two. When the worktable endures the function of the clamping force, the elastic element is compressed, and the working plate is pressed on the padding plate directly. The moving worktable of the pressing machine has the advantages of enabling the molds to move between two stations and locate automatically, supporting a certain clamping force, and satisfying the reinforcing reaction for injection forming of the long glass fiber of the automobile ornament.

Owner:扬州市邗江扬子汽车内饰件有限公司

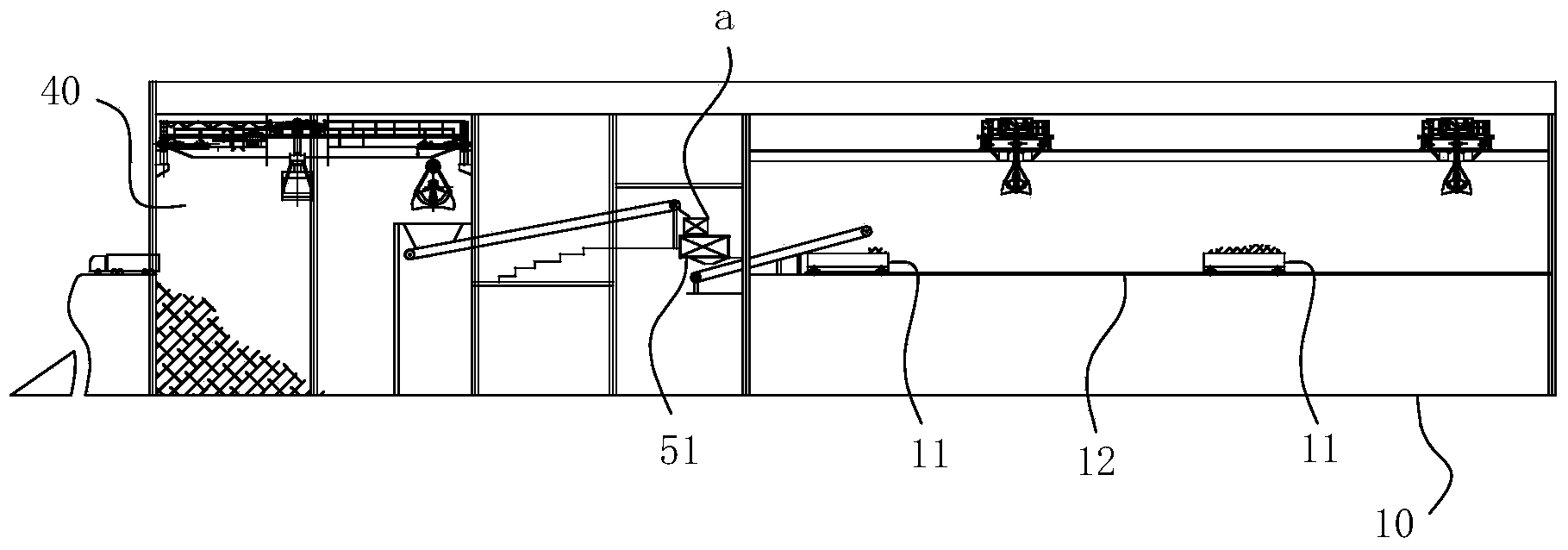

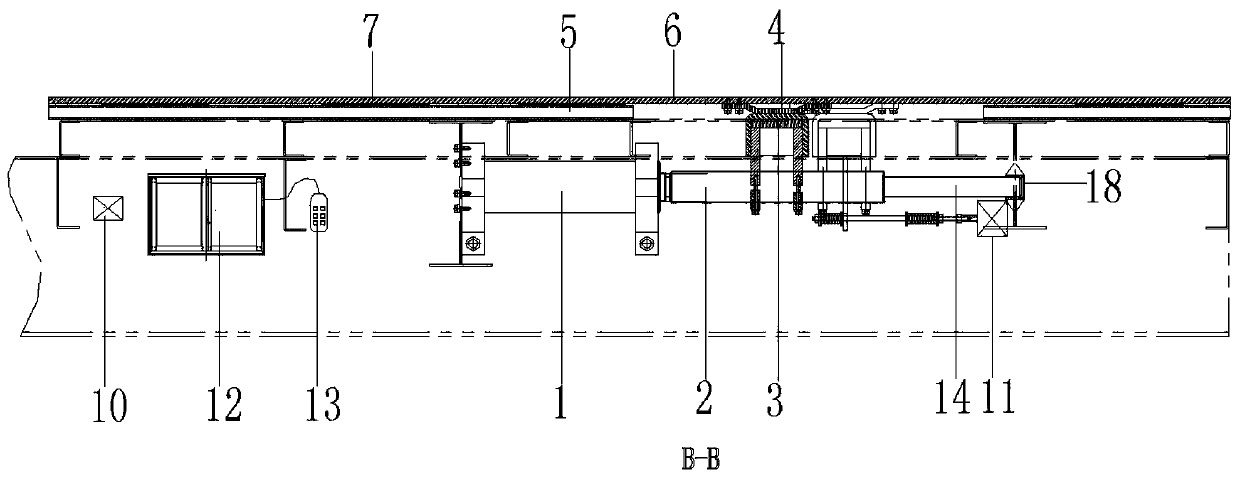

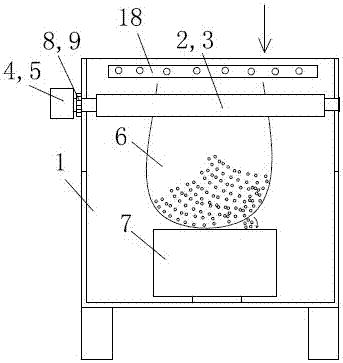

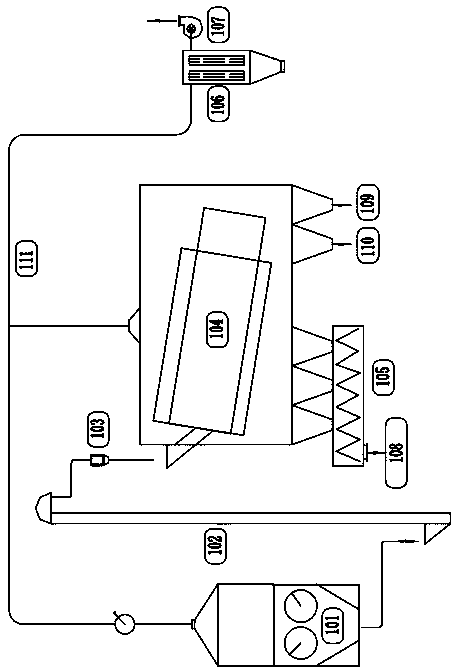

Mixed waste disposal system

InactiveCN103759273AReduce moisture contentHigh calorific valueSolid waste disposalIncinerator apparatusMixed wasteMunicipal solid waste

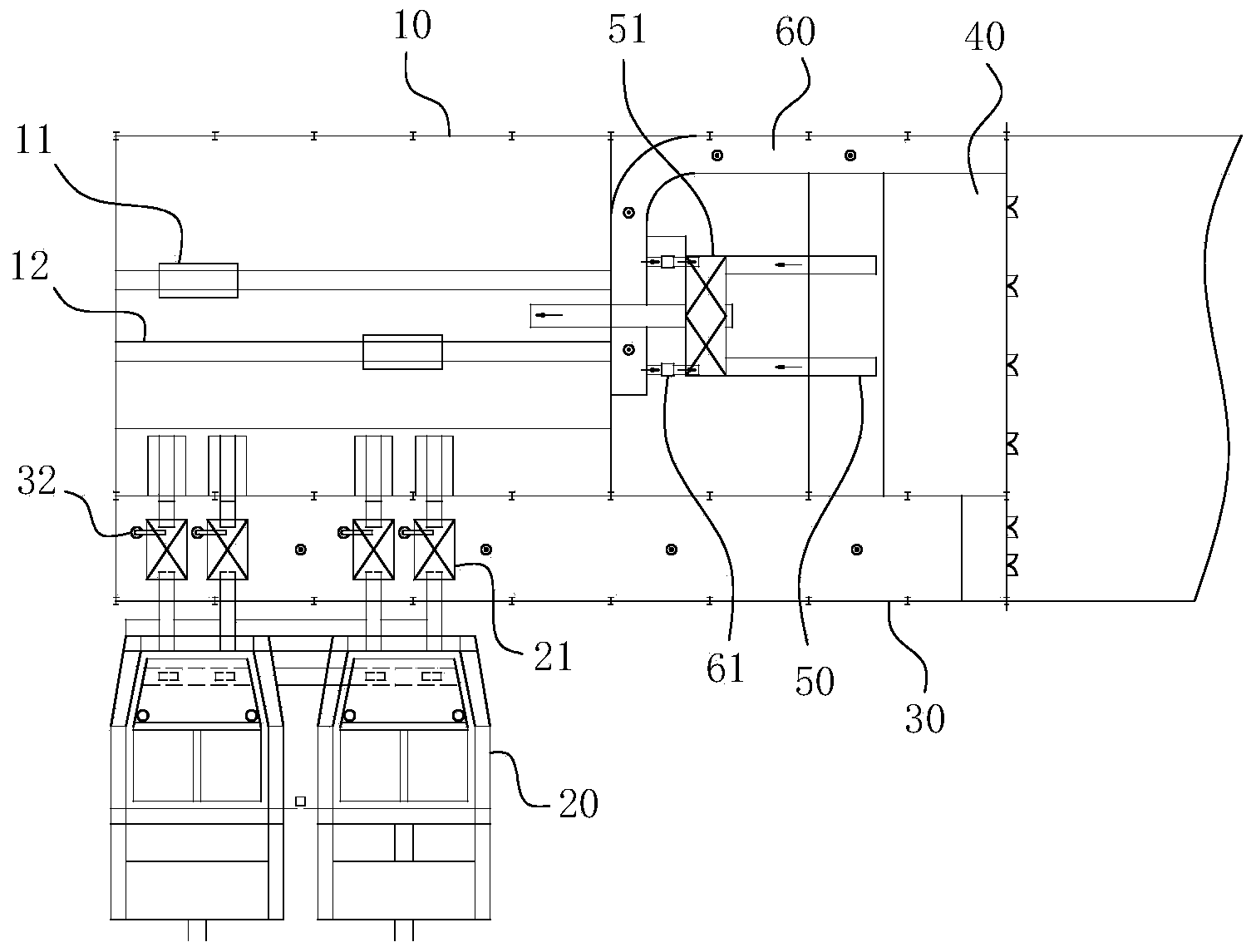

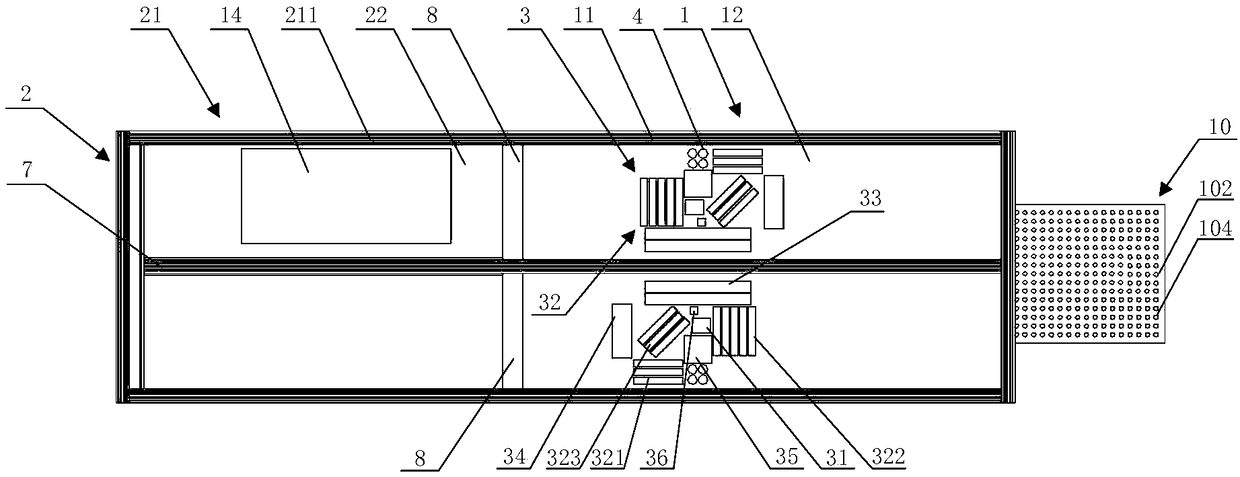

The invention belongs to the field of municipal solid waste disposal and particularly relates to mixed waste disposal system. The mixed waste disposal system at least comprises a waste pile-up unit used for waste pile-up fermentation and a waste incineration unit used for waste incineration. The mixed waste disposal system further comprises a sludge storage disposal pool, a material sliding ramp used for conveying materials is arranged in the sludge storage disposal pool, and the material sliding ramp is in the shape of an inclined face or a step-shaped structure becoming lower gradually. A sludge feeding end is arranged at the higher end of the material sliding ramp, and the lower end of the material sliding ramp forms a sludge discharging end. The time for sludge to flow from the sludge feeding end to the sludge discharging end along the material sliding ramp is longer than or equal to the number of days for the sludge to undergo set pile-up and warm-up fermentation and aerobic reaction. Both the waste pile-up unit and the discharging end of the sludge storage disposal pool are communicated with the feeding end of the waste incineration unit. Due to the simple and practical structure, mixed incineration disposal effect on municipal sludge and household waste can be achieved efficiently.

Owner:南京溧水石湫机场科技工业园开发有限公司

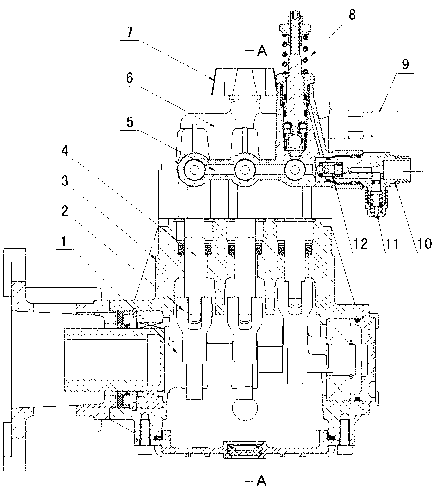

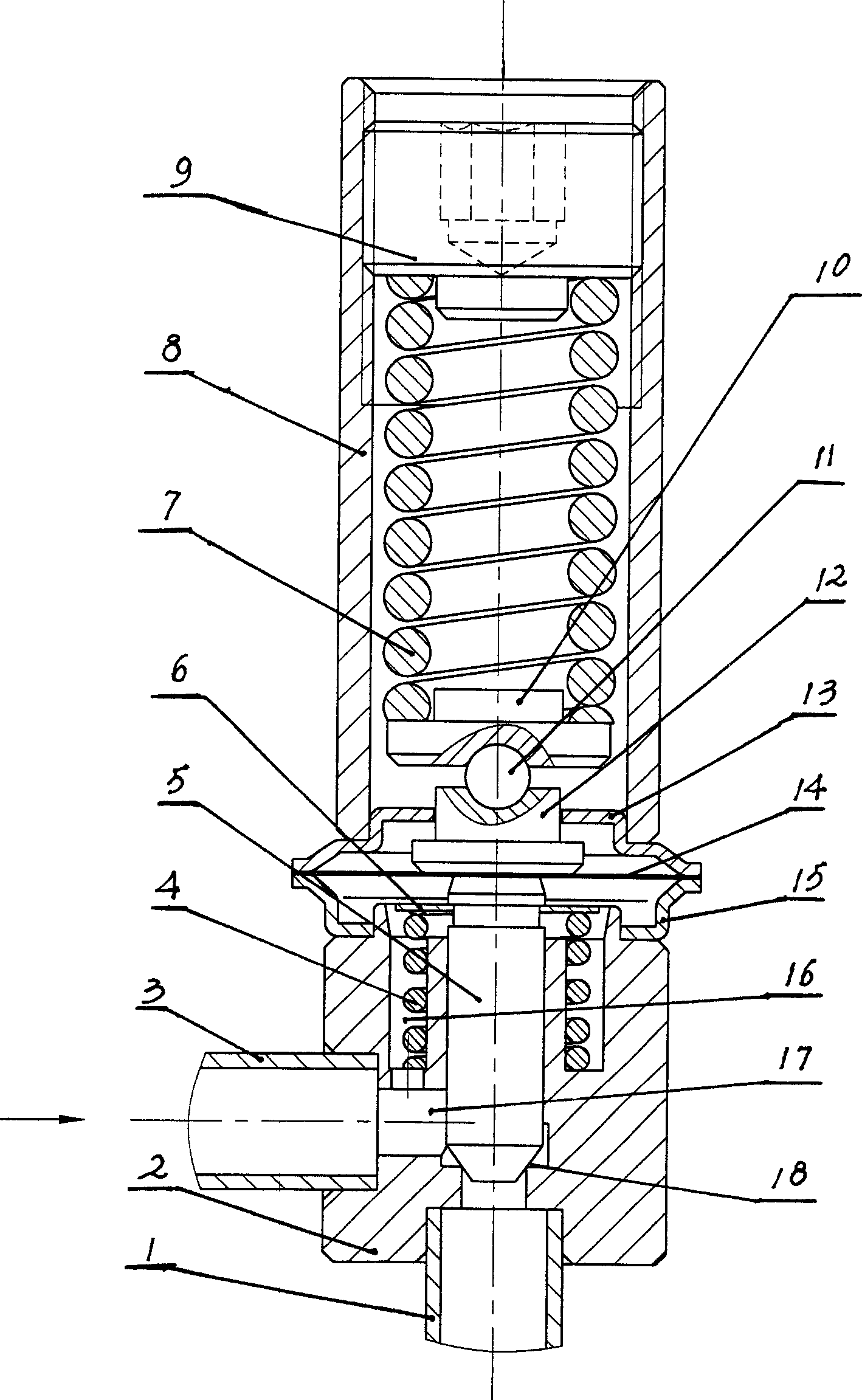

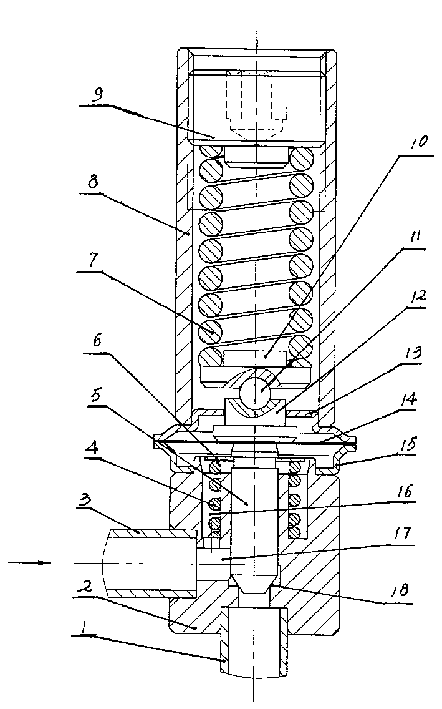

Crankshaft type high-pressure cleaning pump

InactiveCN102797657ATo achieve the purpose of unloadingUnloading sensitivePositive-displacement liquid enginesMulti-cylinder pumpsEngineeringHigh pressure water

The invention discloses a crankshaft type high-pressure cleaning pump. The crankshaft type high-pressure cleaning pump comprises a box body (3), a crankshaft (1) connected with a power, a connecting rod (2), a plunger piston (4), a pump body (6), a water supply connector (7), a pressure regulating unloading valve (8) and a high-pressure water discharging connector (10), wherein a low-pressure cavity (15), an exchange cavity (13) and a high-pressure cavity (5) are arranged in the pump body (6), the plunger piston (4) is connected on an exchange cavity (13), the water supply connector (7) is connected on the low-pressure cavity (15), a water supply check valve (14) is installed between the low-pressure cavity (15) and the exchange cavity (13), a water discharging check valve (16) is installed between the exchange cavity (13) and the high-pressure cavity (6), the high-pressure water discharging connector (10) is connected on a water outlet of the high-pressure cavity (5), a check valve (12) corresponding to a water outlet of the high-pressure cavity (5) is arranged on the high-pressure water discharging connector (10), and the pressure regulating unloading valve (8) is arranged on the high-pressure cavity (5) of the pump body (6). Due to the adoption of the structure, the crankshaft type high-pressure cleaning pump has the advantages that the structure is simple and reasonable, the operation and the use are convenient, the pressure regulation is stable, the pressure is stable, the unloading is flexible, the cleaning pump is used by limiting the pressure, and the service life is long, and the like.

Owner:浙江驰江工贸有限公司

Fully-sealed discharge door of intermediate storage bin

InactiveCN103231452AChange structureMeet the requirements of the mixing processDischarging apparatusIntermediate storageSerial port

The invention discloses a fully-sealed discharge door of an intermediate storage bin, and belongs to discharge doors. The discharge door structurally comprises a shield, a material port, an arc material door and an arc material door switch driving device, wherein the material port and the arc material door are respectively formed in the shield; openings are formed in the upper end and the lower end of the shield; the upper end of the shield is connected with the intermediate storage bin; the lower end of the shield is connected with a feed port of an agitator; the arc material door comprises an arc plate and end plates arranged on the front side and the rear side of the material port; the arc plate is arranged at the lower part of the material port; the two sides of the arc plate are connected with the lower parts of the end plates; and the arc material door switch driving device is connected with the end plates. Compared with the prior art, the fully-sealed discharge door of the intermediate storage bin has the characteristics that the fully-sealed discharge door solves the problems that material spreading and leaking is caused due to the fact that an existing discharge door cannot be closed tightly, the existing discharge door can be opened automatically due to the gravity of the feeding material if an air cylinder breaks down, repeated feeding happens and the like, so that the fully-sealed discharge door has good popularization and application values.

Owner:SHANTUI JANEOO MACHINERY

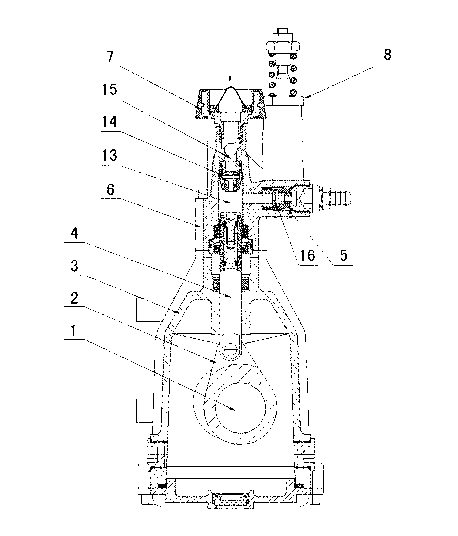

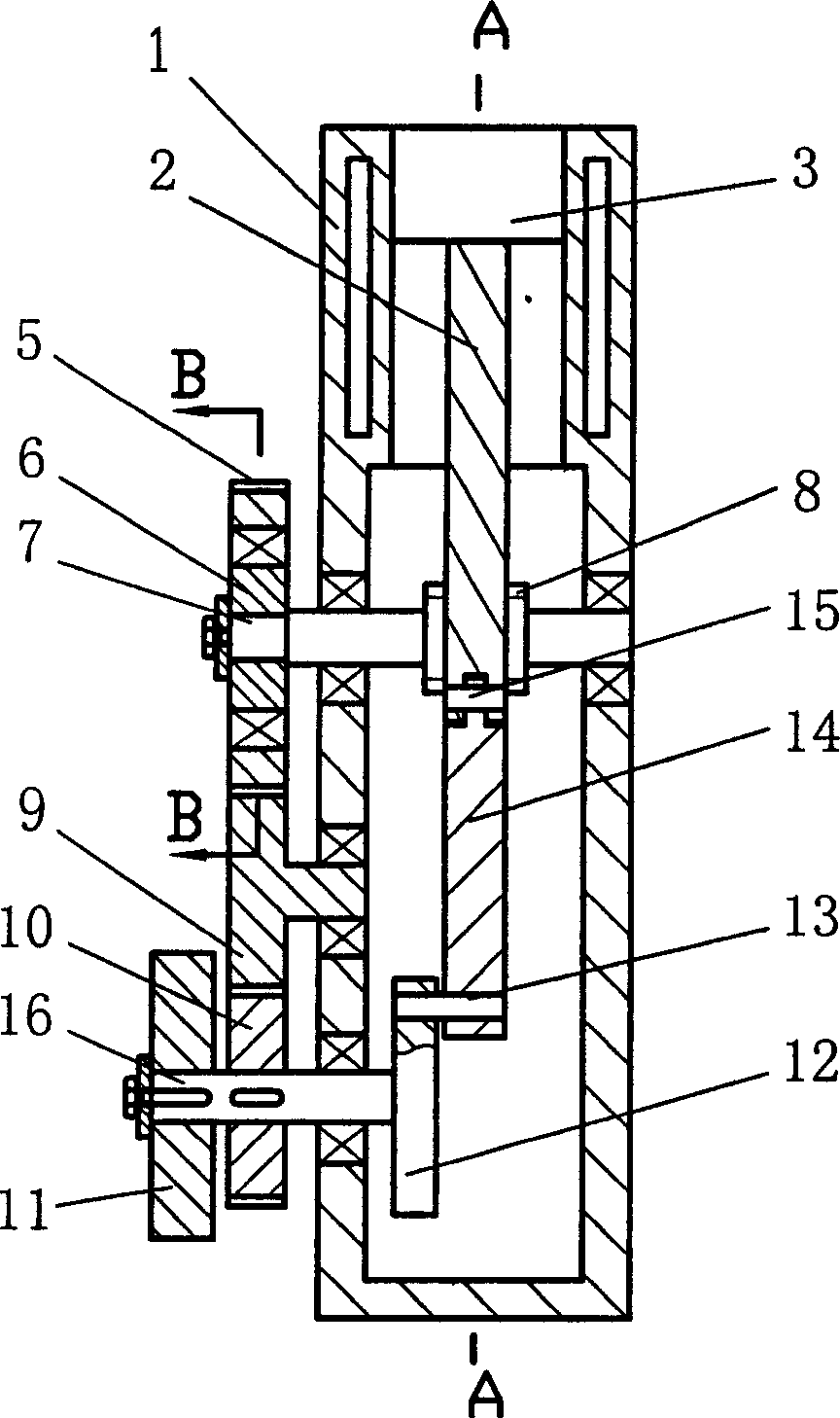

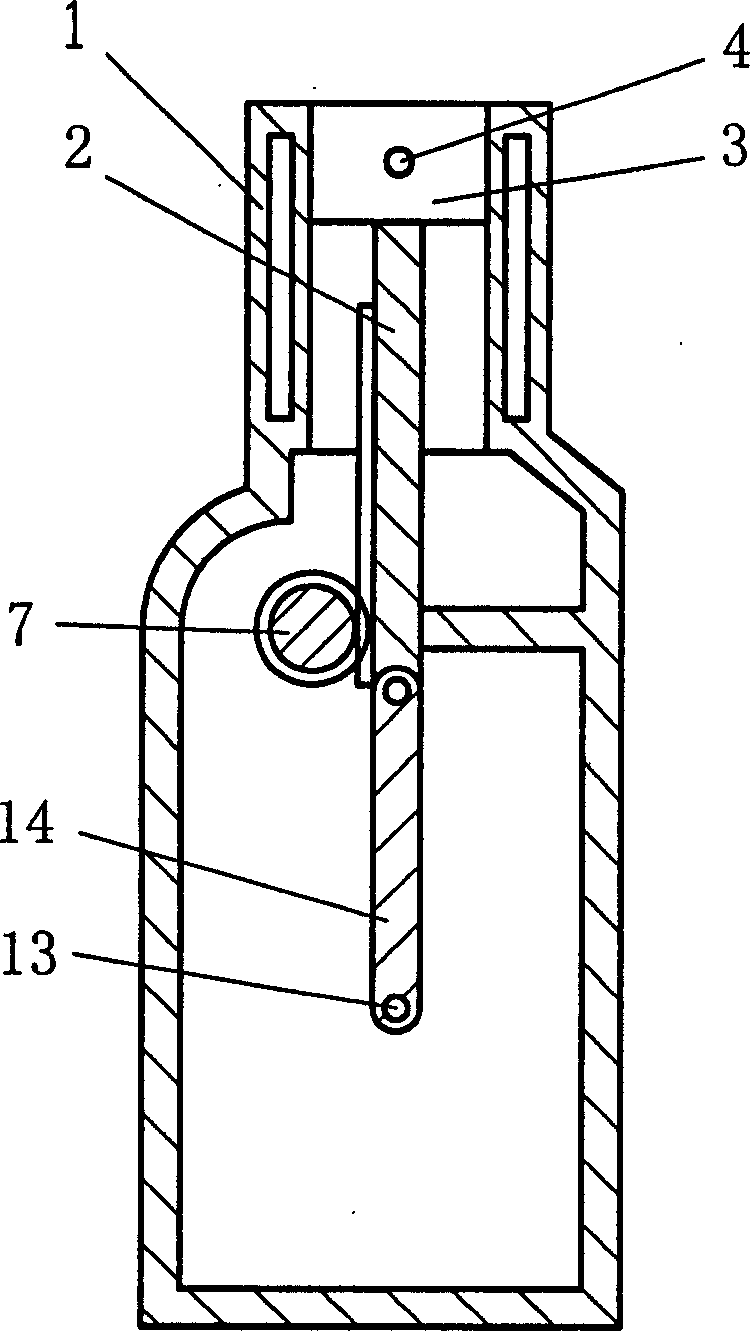

Pressure regulation relief valve for air conditioner

InactiveCN1504710ALarge fluid forceReduce frequent startupEqualizing valvesSafety valvesEngineeringRelief valve

An air-conditioner pressure adjustment unloading valve comprises a valve body, connected to an induction pipe and an outlet pipe, a spool is arranged in the valve body, which accommodates an auxiliary spring, the valve body is connected with a film retaining bracket for mounting the films, the film retaining bracket is connected with an adjustment barrel in which an pressure regulating spring is arranged.

Owner:周纪昌

Rolling type internal combustion engine

InactiveCN1793628ALarge torqueHigh energy conversion rateMachines/enginesFreewheelReciprocating motion

The invention is a novel twisting internal combustion engine, on the basis of an original reciprocating internal combustion engine, adding ratchet wheel shaft, inner wheel, ratchet mechanism, ratchet wheel, transition gear shaft, force release disc drive gear, force release disc shaft, link rod, and fly wheel, and changing the original link rod into a push rod provided with a rack on the side surface, where the rack engages with the gear on the ratchet wheel shaft; in the word doing course, piston and the push rod go down to push the ratchet wheel to rotate, the moving direction of the piston is always kept to be the tangential direction of the circumference of the ratchet wheel so that the moment is large, and the remaining travel is implemented by depending on fly wheel inertia to make the push rod reciprocate through the force release disc shaft and the link rod, therefore the energy conversion ratio is high, achieving unloading purpose. By setting the ratchet mechanism to be a reduced tooth or pawl mechanism, it can largely reduce clearance joints.

Owner:何荣灿

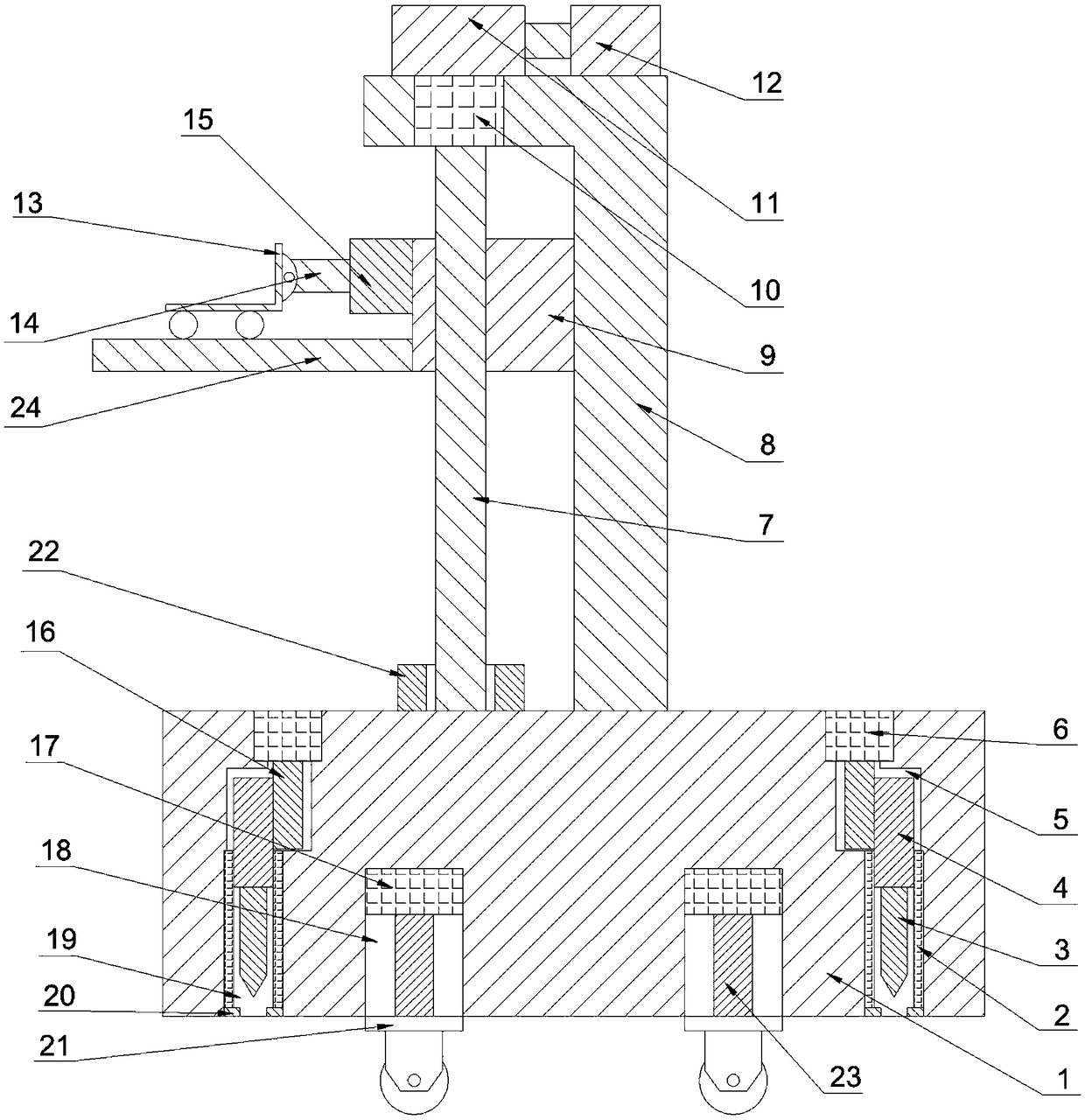

Building construction material transport apparatus for sludge ground

InactiveCN109131484AIncrease contact areaNot easy to slideCastorsBuilding material handlingSludgeEngineering

The invention relates to the technical field of building construction, and disclosed is a building construction material transport apparatus for a sludge ground, comprising a base, a plurality of universal wheels for supporting and sliding are arranged on the lower surface of the base, a telescoping mechanism for telescoping the universal wheels into the base is arranged in the base opposite to the universal wheels, two sides of the base are provided with fixing mechanisms for connecting the base and the soft mud floor, and an elevating mechanism for transporting materials is arranged on theupper surface of the base. The invention solves the problem that the wheels will sink into the soft mud ground due to the pressure of the materials in the use process of the existing material transportation equipment, which causes the material transportation process to be unstable, easy to roll over, and causes the injury of the construction personnel.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

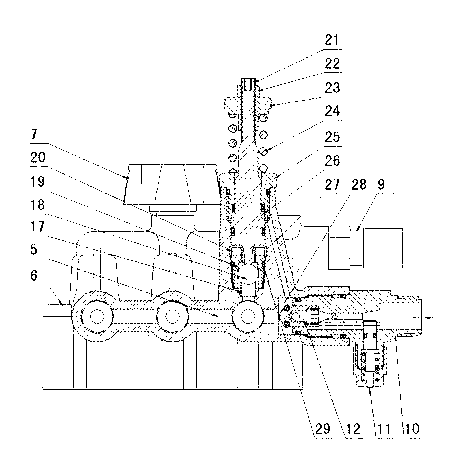

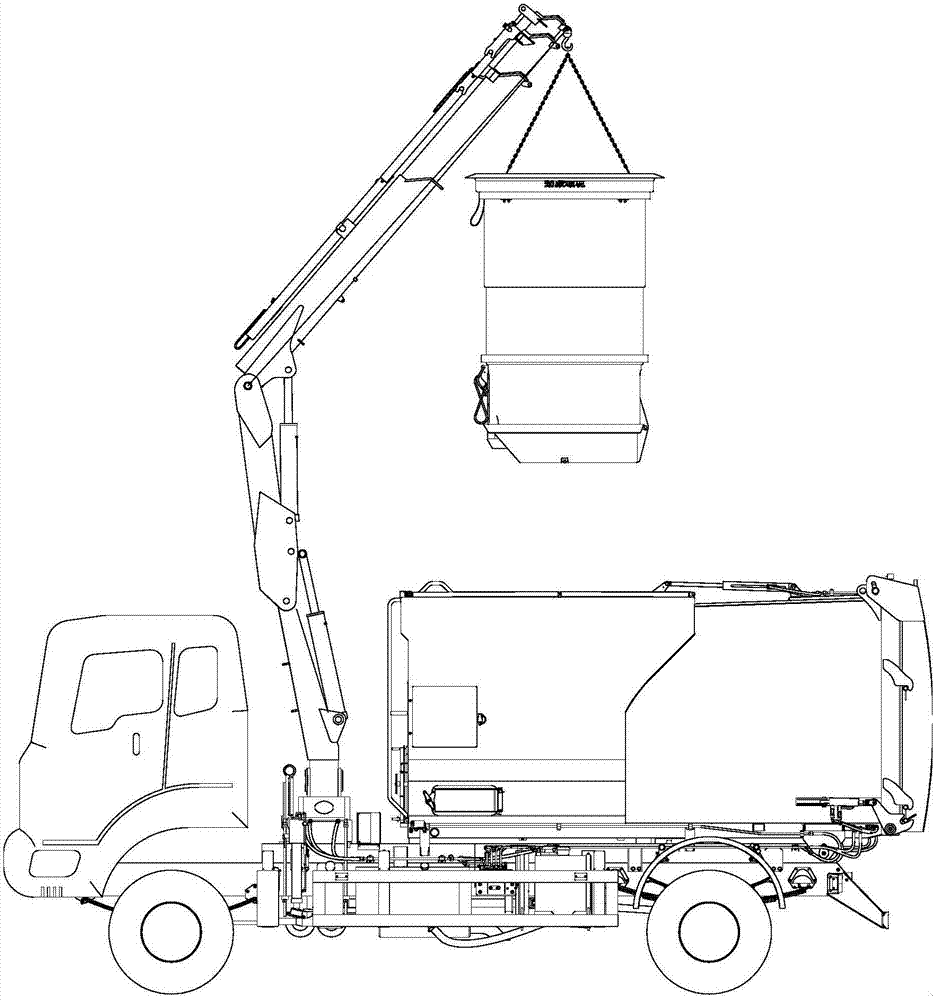

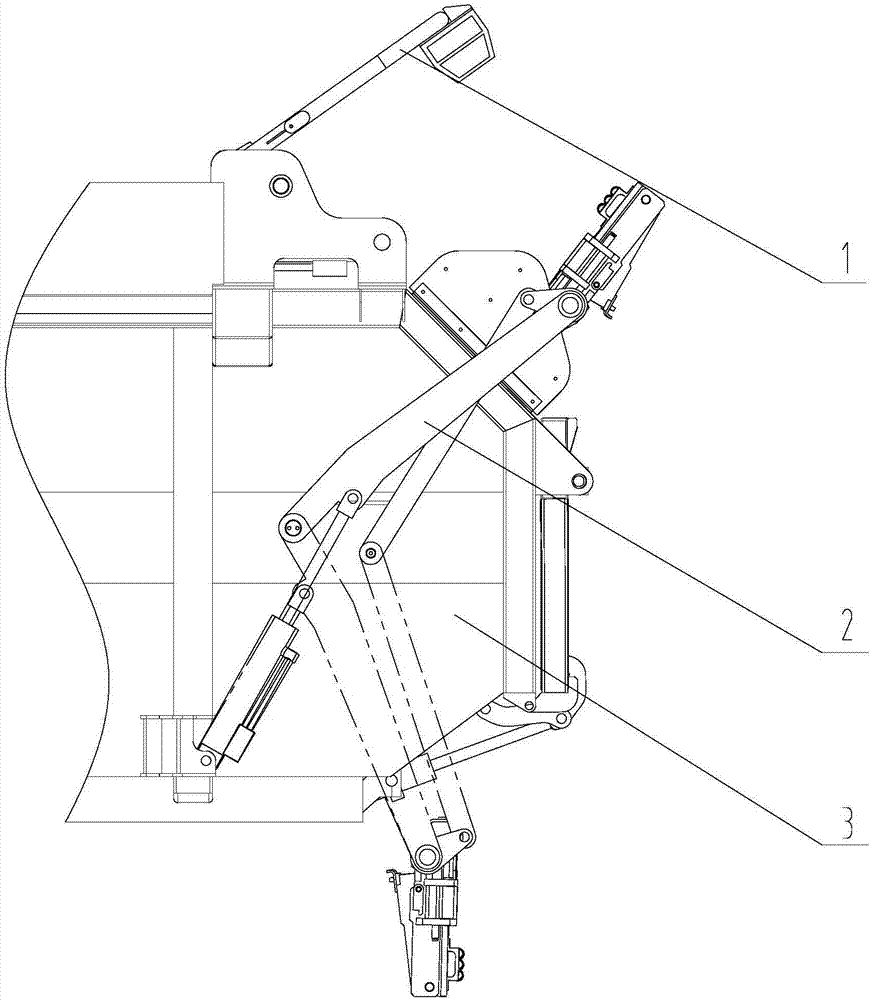

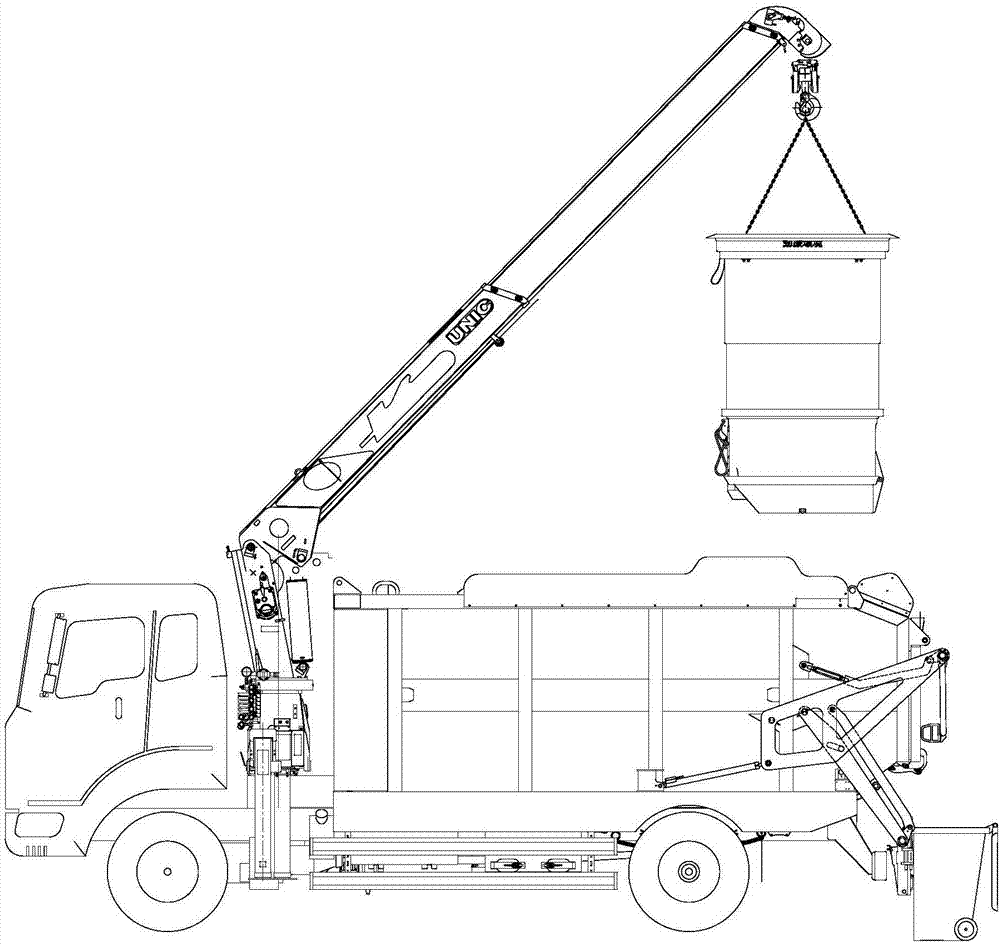

Bucket overturning and bucket stopping linkage mechanism for straight arm bucket hoisting vehicle

InactiveCN107539687AReach the barrelTo achieve the purpose of unloadingRefuse vehiclesAutomotive engineering

Owner:JINLV ENVIRONMENT TECH

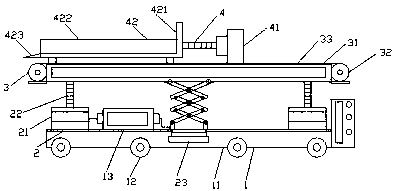

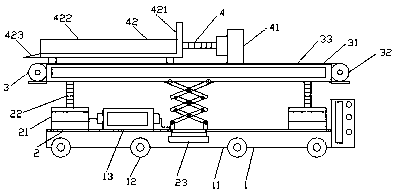

Mechanically automatic unloading device

InactiveCN109835733AIncrease flexibilityImprove securityLoading/unloadingHydraulic cylinderEngineering

The invention relates to a mechanically automatic unloading device. The mechanically automatic unloading device comprises a moving device, a lifter, a conveying device and an unloader, wherein the moving device is arranged at a lowermost side of the mechanically automatic unloading device body and the upper side of the moving device is provided with the lifter; the upper side of the lifter is connected to the conveying device; and the upper side of the conveying device is provided with the unloader. The flexibility of the mechanically automatic unloading device is improved by arranging the moving device; the height of the mechanically automatic unloading device is adjusted by arranging the lifting device; the supporting function is achieved by folding a telescopic rod, so that the safety of the device during operation is improved; the unloader at the upper side of the conveying device is conveyed by setting the conveying device, so that the mechanization degree of the device is improved; a piston is pushed to move by a hydraulic cylinder on a hydraulic pusher, so that a shovel plate is pushed by a hydraulic rod; and finally, the goods are shoveled by the shovel plate, so that the unloading is achieved.

Owner:江苏吉意信息技术有限公司

Dried tofu pressing-cutting and packaging device

ActiveCN106697367AReduce oxidationSlow down the rate of deteriorationWrappingPackaging foodstuffsEngineeringFood processing

The invention relates to the field of food processing equipment, in particular to a dried tofu pressing-cutting and packaging device. The dried tofu pressing-cutting and packaging device comprises a conveying belt, a hollow shaft, a forming roller, a packaging table flush with the conveying belt and a film pressing machine arranged above the packaging table; the forming roller is fixed on the hollow shaft; a cavity of the hollow shaft forms an air channel; a plurality of strip-shaped grooves are uniformly distributed in the outer circle surface of the forming roller in the axial direction of the forming roller; a plurality of partition plates perpendicular to the hollow shaft are arranged in the strip-shaped grooves and divide the strip-shaped grooves into a plurality of square grids; the edge of the side, facing the surface of the forming roller, of each partition plate is in a sawtooth shape; air pipes are arranged inside the forming roller in the radial direction of the forming roller; one ends of the air pipes communicate with the air channel, and the other ends of the air pipes communicate with the strip-shaped grooves; and pressing-cutting blades are welded to the inner walls of the strip-shaped grooves. According to the dried tofu pressing-cutting and packaging device, the square grids on the forming roller are used for cutting the dried tofu, and the shape of the square grids is fixed, so that the pressed-cut dried tofu is uniform in shape and does not need to be separately screened; and the dried tofu is discharged out of the square grids and then is subjected to film pressing and packaging immediately, long-time retention is avoided and therefore breeding of bacteria on dried tofu can be prevented.

Owner:CHONGQING YUPAI AGRI PROD DEV

Split type horizontal moving dump carriage and dump truck with same

PendingCN110576782ANo rolloverNo back flipVehicle with pusher plateTransportation itemsSlide plateThrough transmission

The invention discloses a split type horizontal moving dump carriage and belongs to the field of transportation equipment. The split type horizontal moving dump carriage comprises a cargo unloading platform. The cargo unloading platform comprises multiple sets of sliding bodies connected through buckles. Each set of sliding body comprises a plurality of sliding plate grooves connected mutually through buckles, a guide track matched with the corresponding sliding plate groove is formed below each sliding plate groove, and a power device driving the corresponding sliding plate groove to move onthe corresponding guide track is further arranged on the lower portion of each sliding plate groove. Each power device comprises cylinder bodies installed on a fixing plate and piston rods connected with the power output ends of the cylinder bodies, the piston rods are connected with guide shafts, the tail ends of the guide shafts are fixed to bearing blocks, and a transmission beam is fixedly connected to the upper portions of the piston rods, and the upper portion of the transmission beam is connected with the corresponding sliding plate groove through transmission connecting fixing pieces.The split type horizontal moving dump carriage completes unloading through the relative movement of the guide tracks and the sliding plate grooves and assistance of push shovels.

Owner:山东永柱汽车制造有限公司

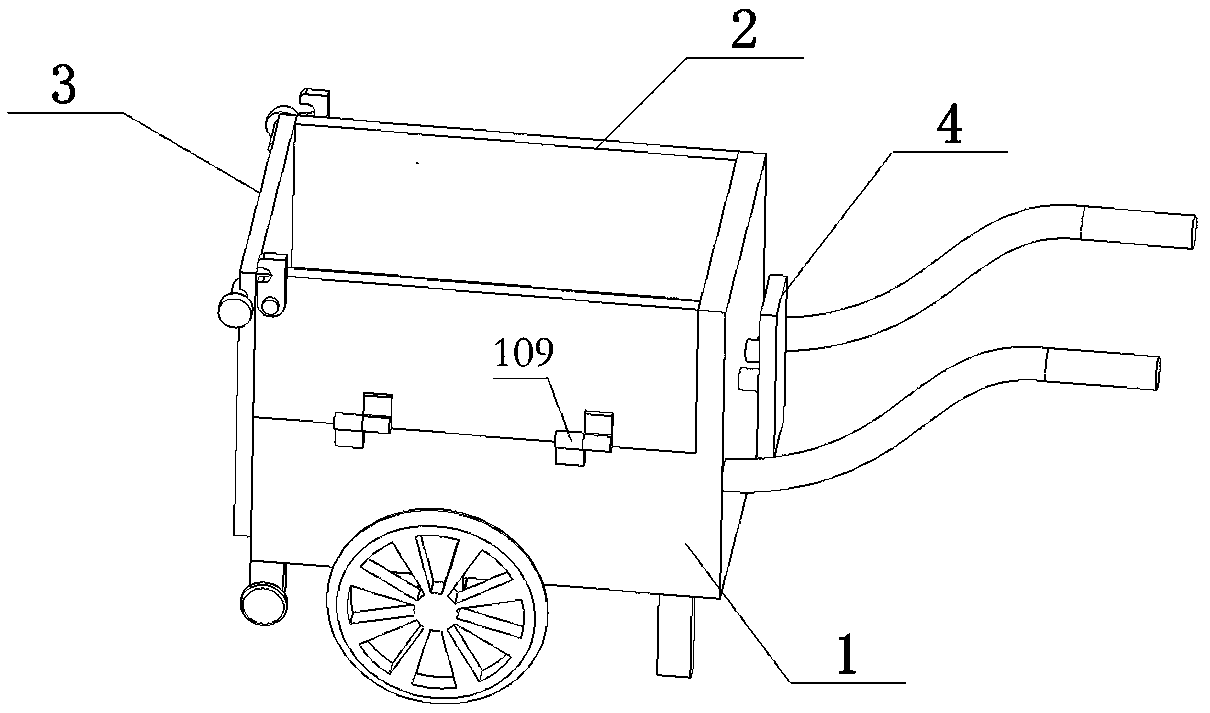

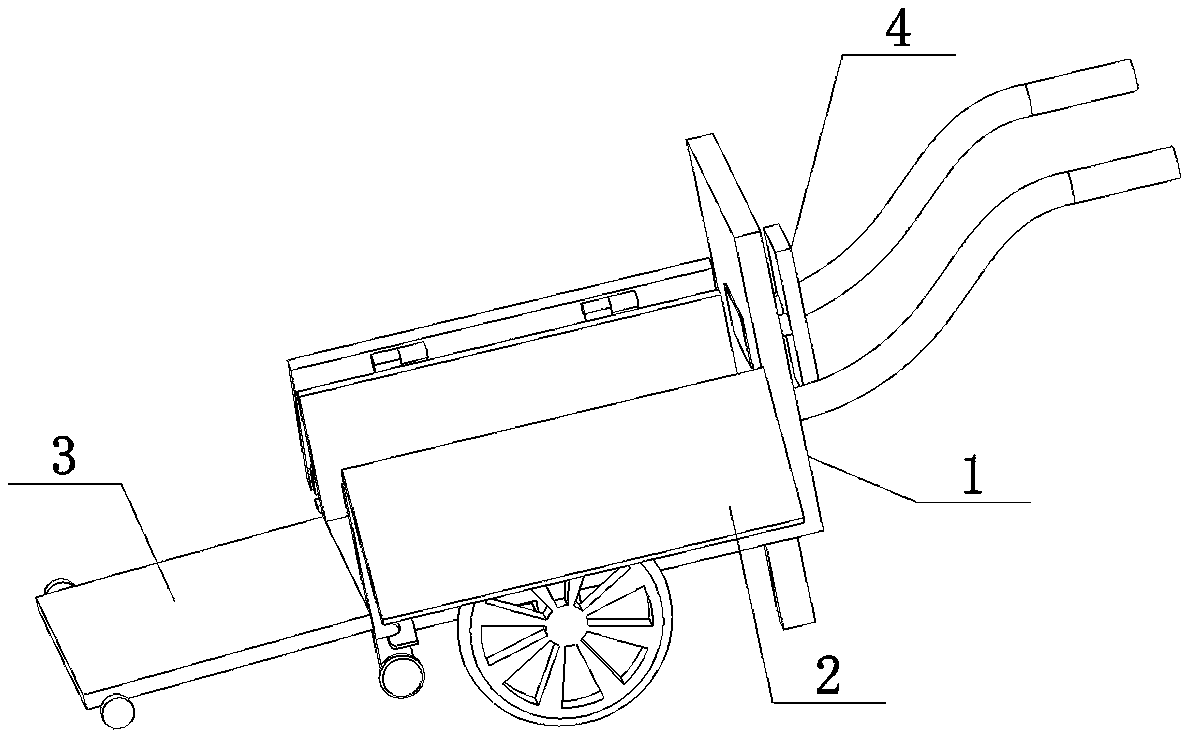

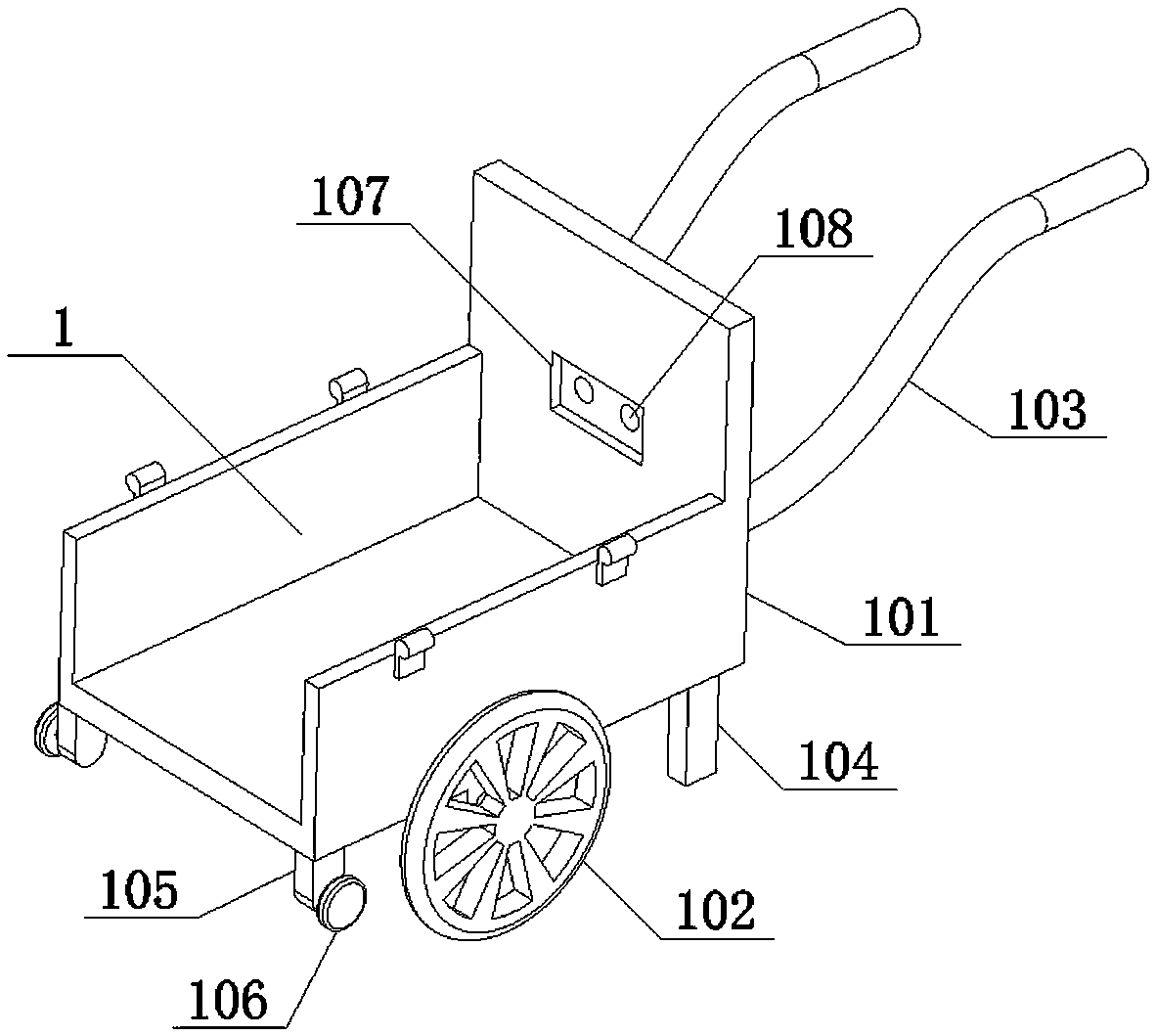

Aerated block carrying device for constructional engineering construction

InactiveCN111055893ATo achieve the purpose of unloadingSave human effortHand carts with one axisHand cart accessoriesArchitectural engineeringCarriage

The invention discloses an aerated block carrying device for constructional engineering construction. The device comprises a conveying mechanism, heightening mechanisms, a sealing mechanism and a discharging mechanism, the heightening mechanisms are movably connected to the two sides of the conveying mechanism, the sealing mechanism is movably connected to one side of the conveying mechanism, andthe discharging mechanism is movably connected to the side, away from the sealing mechanism, of the conveying mechanism. According to the aerated block carrying device for constructional engineering construction, a door plate is opened to incline an carriage to enable an aerated block in the carriage to slide down, the aerated block is unloaded, and manpower is saved; a limiting rods and rolling wheels limit the inclination angle of the carriage, the problems that the inclination angle of the carriage is too large and the aerated block directly falls off and is damaged are avoided, and the aerated block is protected; the heightening mechanisms increase the amount of aerated blocks transported each time, improves the carrying efficiency, is opened to reduce the height of the carrying device, and facilitates truck loading; and when the aerated block is clamped in the carriage, the aerated block is pushed out by using the discharging mechanism , so that the practicability is improved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Bridge anti-collision structure with bridge pier protection function

ActiveCN108914885AReduce impactProtection stabilityClimate change adaptationShipping equipmentPull forceEngineering

The invention discloses a bridge anti-collision structure with a bridge pier protection function, and relates to the technical field of bridge protection. The bridge anti-collision structure with thebridge pier protection function comprises an installation seat, a buffer box, a buffer frame, a support frame, six transmission rolls and a buffer belt, wherein the buffer frame is of a U-shaped platestructure; thirty-two slide columns are fixed to one surface of the buffer frame; thirty-two first springs are fixed between the buffer frame and one inner wall of the buffer box; and the first springs are arranged on the outer surfaces of the slide columns in a surrounding manner. According to the bridge anti-collision structure with the bridge pier protection function, the buffer belt is drivento transmit around the transmission roll to relieve a force through friction between a filling bag and a ship, first-time buffer is carried out through co-use for a filler in the filling bag and gasin the filling bag, second-time buffer is carried out through an elastic force and a pull force which are provided by second springs, third-time buffer is carried out through that the first springs are extruded to generate an elastic force, and fourth-time buffer is carried out through co-use for a rubber plate and a closed-pore foamed aluminum plate, so that the problem of poor protection effectfor an existing bridge anti-collision structure is solved.

Owner:FOSHAN UNIVERSITY

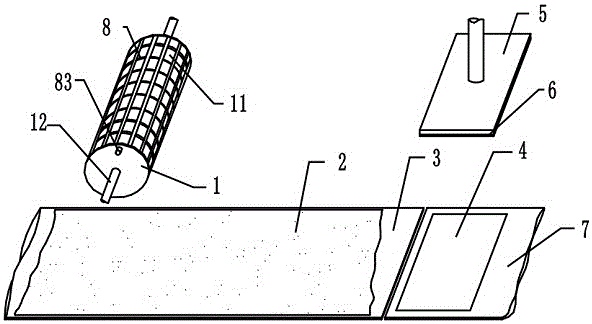

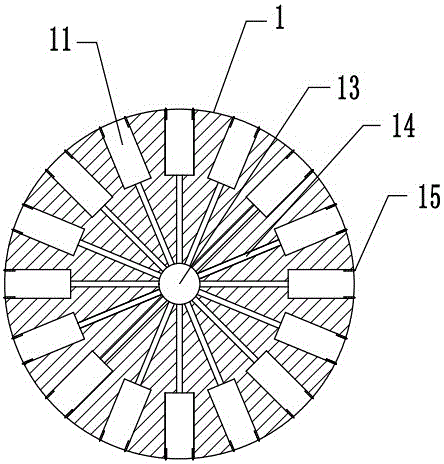

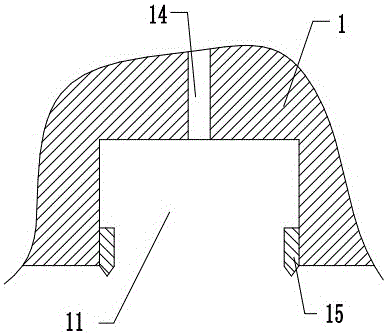

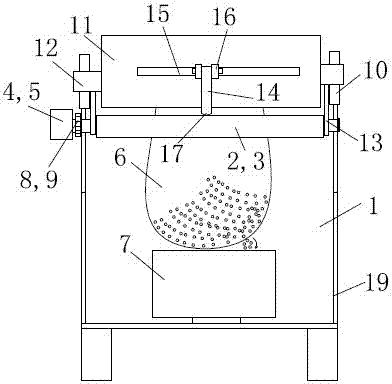

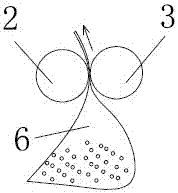

Small particle material squeezing material-unloading machine

The invention discloses a small particle material squeezing material-unloading machine. The small particle material squeezing material-unloading machine comprises an open-type box body, a first squeezing roller and a second squeezing roller, wherein the first squeezing roller and the second squeezing roller are arranged at a top position of the open-type box body, one of the first squeezing rollerand the second squeezing roller is connected with a rotating hand shank or a rotating power source or both of the first squeezing roller and the second squeezing roller are simultaneously connected with the rotating hand shank or the rotating power source, a flexible bag loaded small particle materials is hung on the first squeezing roller or the second squeezing roller, the small particle materials inside the flexible bag are squeezed and unloaded by the two squeezing rollers, and the bottom of the open-type box body is provided with a detachable collecting device. According to the small particle material squeezing machine, the top position of the open-type box body is provided with the pressurizing pair rollers, the flexible bag loaded the small particle materials is hung on the first squeezing roller or the second squeezing roller, one of the rotatable squeezing rollers is swung, then the material unloaded part of the flexible bag is driven to rotate and finally rotate to the material loaded part slowly, then the squeezing is performed slowly, the materials are squeezed out of the bag, and the purpose of material unloading is achieved.

Owner:广德博亚新星电子科技有限公司

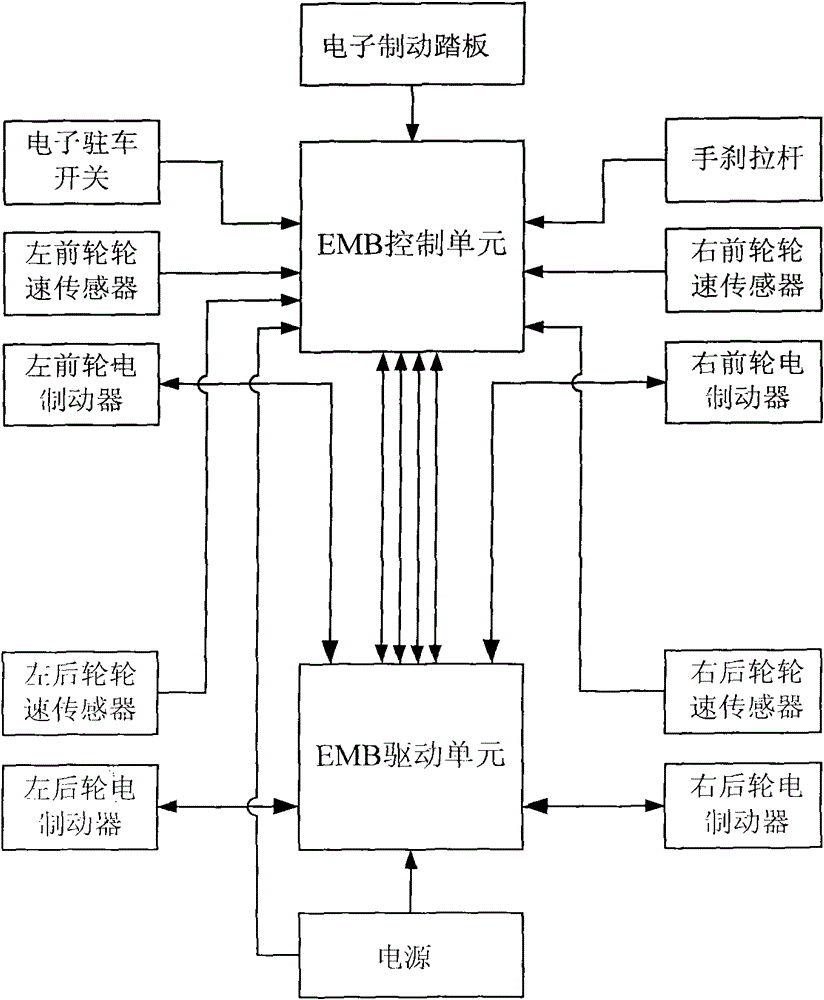

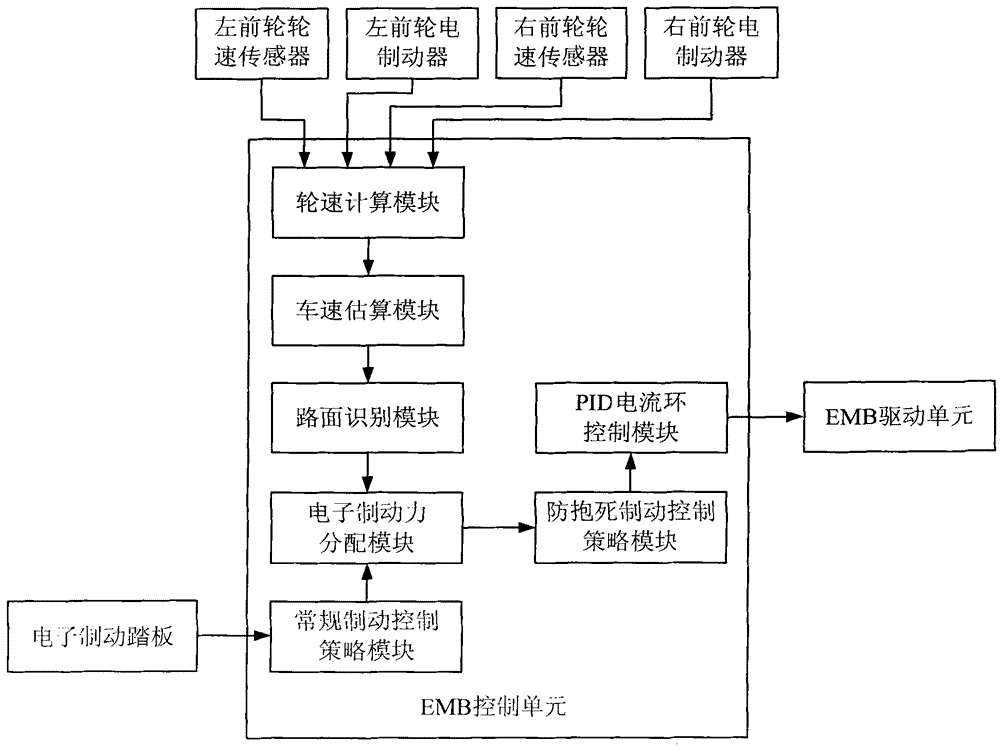

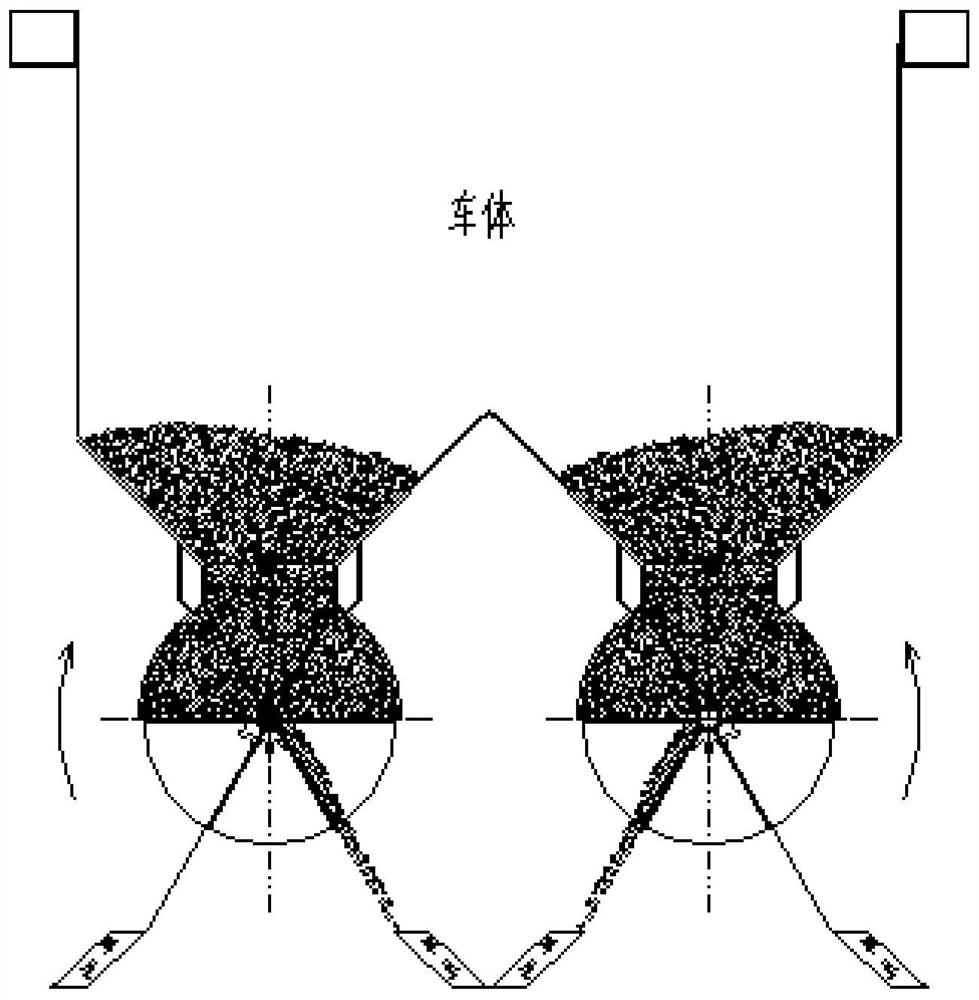

Electronic mechanical brake system and automobile adopting same

The invention provides an electronic mechanical brake system which comprises a brake signal inputting unit, an EMB (electromechanical brake system) control unit, an EMB drive unit, and a plurality of electric brakes corresponding to a plurality of wheels respectively, wherein the signal inputting unit is used for generating brake signals and outputting the brake signals to the EMB control unit in real time; the EMB control unit is used for receiving the brake signals and outputting a plurality of paths of duty ratio signals to the EMB drive unit; the path number of the duty ratio signals is equal to that of the electric brakes; the EMB drive unit is used for receiving the duty ratio signals in real time and driving and controlling the plurality of electric brakes according to the duty ratio signals; and the plurality of electric brakes are respectively used for braking the corresponding wheels. Correspondingly, an automobile adopting the braking system is provided. The electronic mechanical brake system has the advantages of simple structure, small volume, convenience in installation, low cost, fast braking response, good braking stability, no pollution, and the like.

Owner:CHERY AUTOMOBILE CO LTD

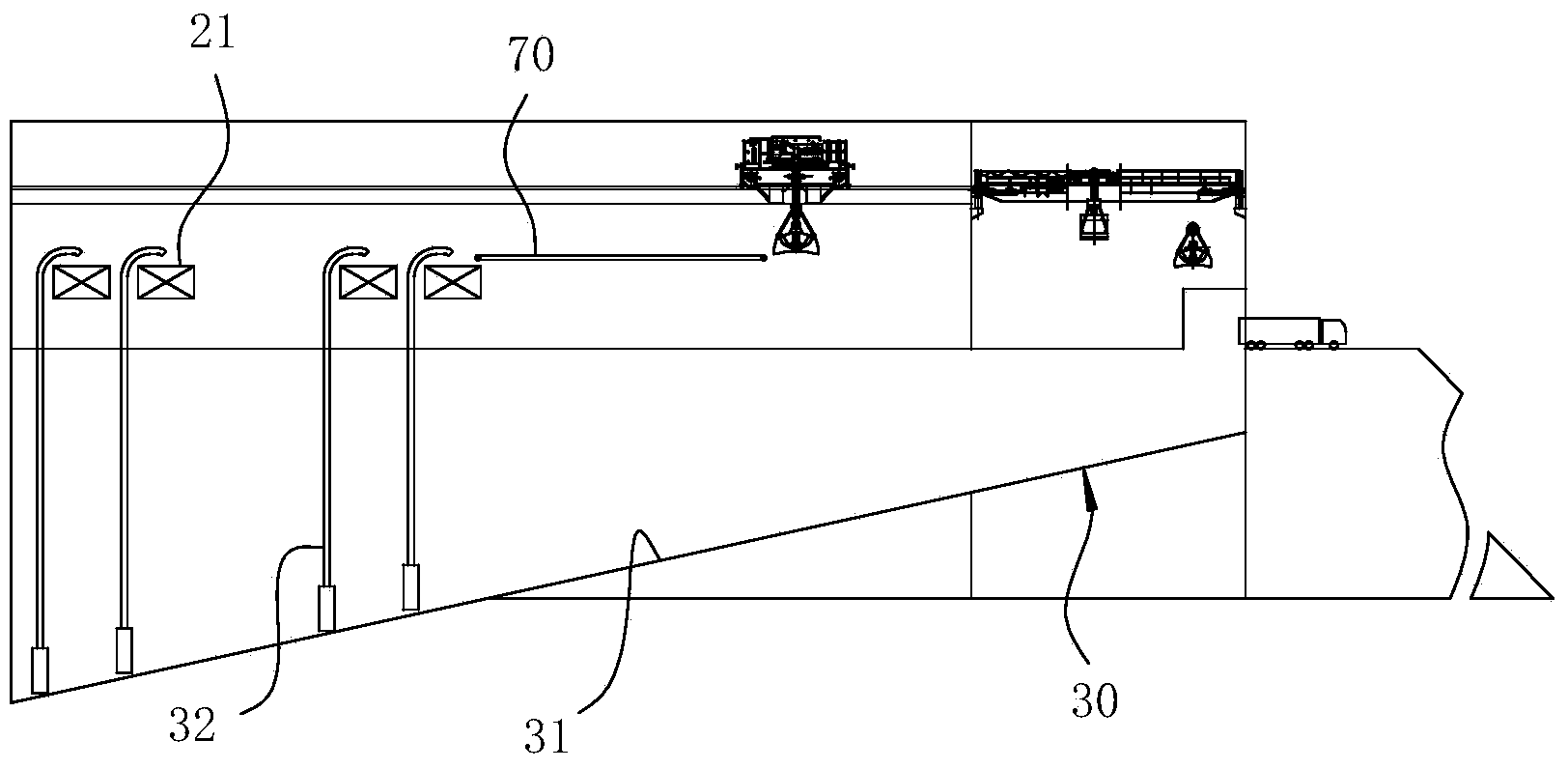

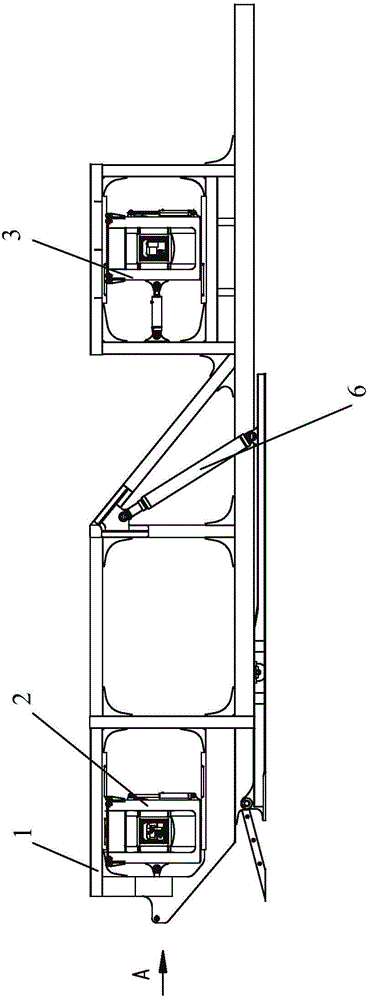

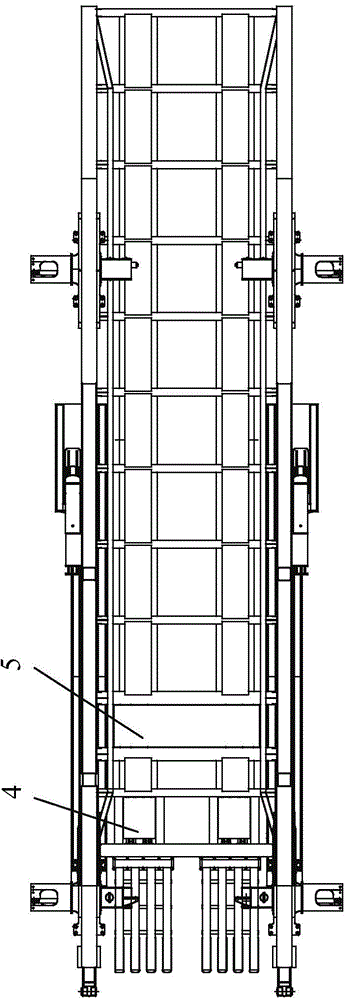

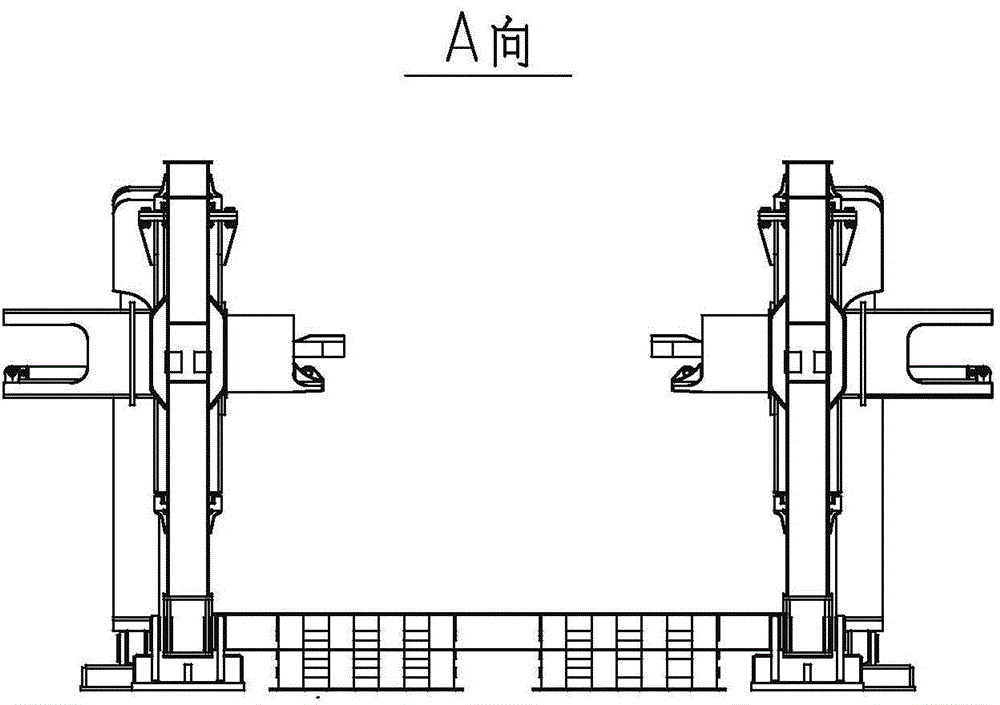

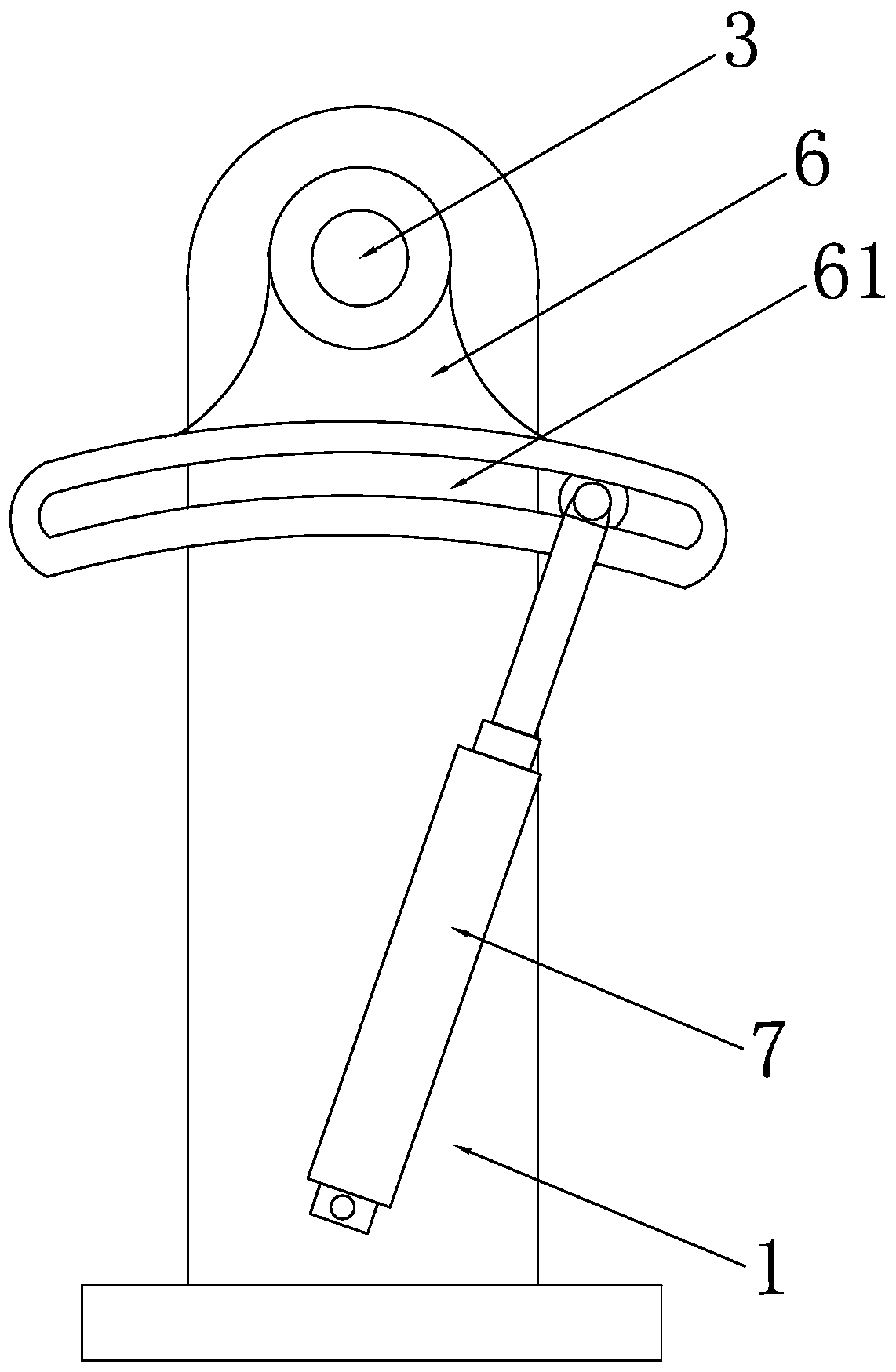

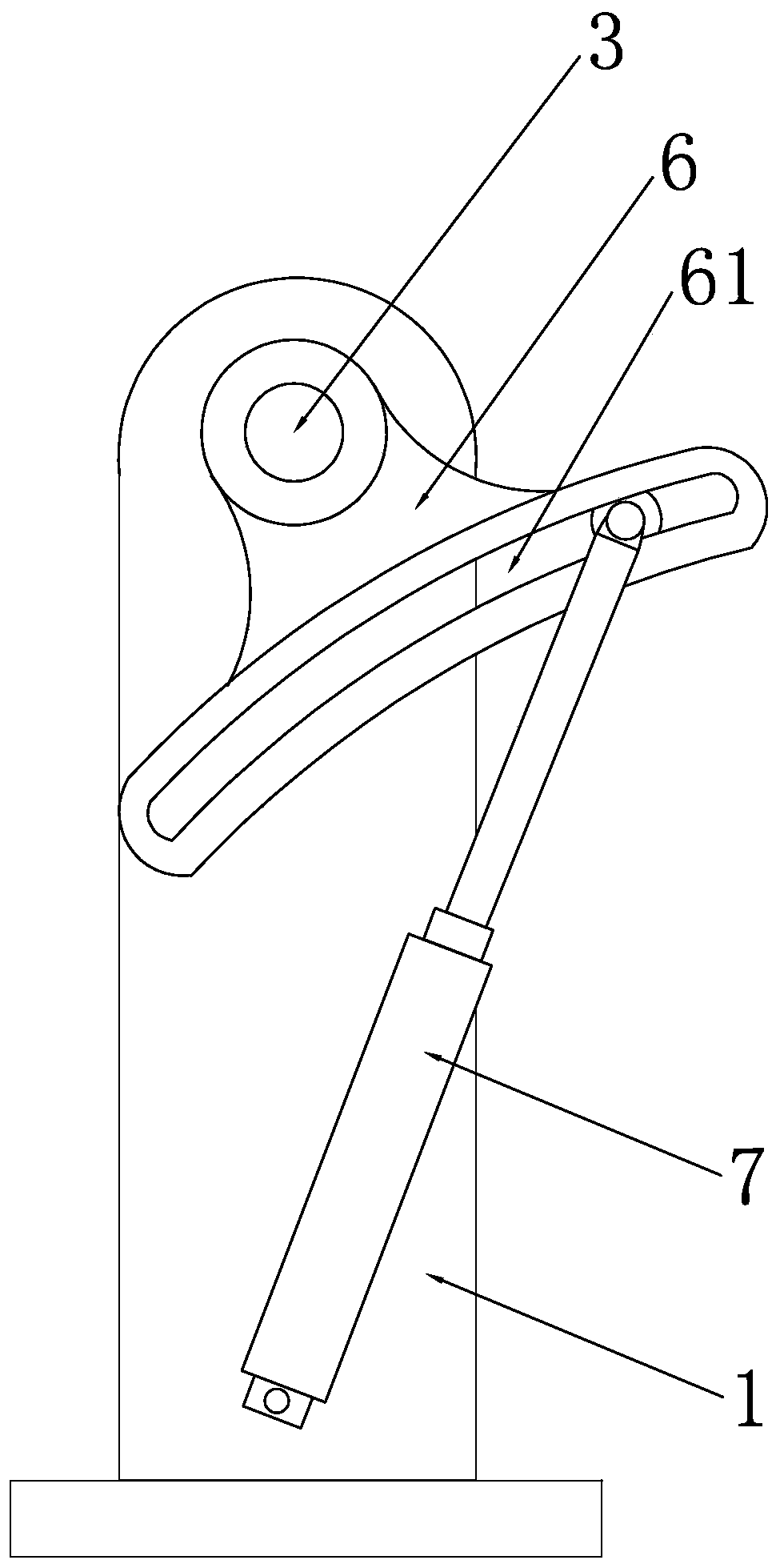

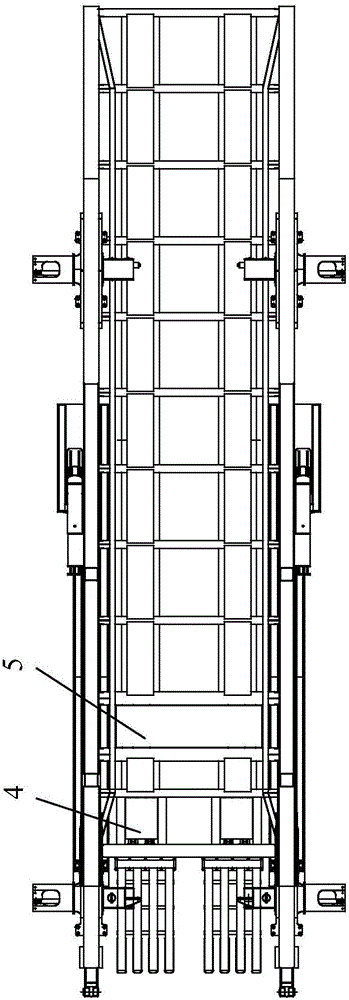

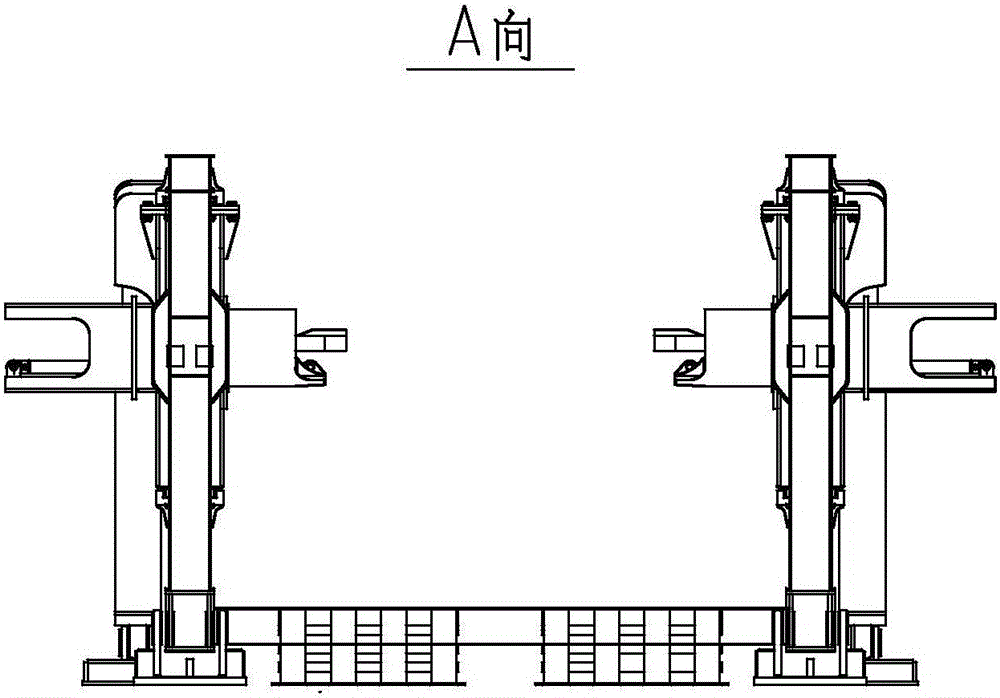

Hydraulic car dumper

ActiveCN104692150ATo achieve the purpose of unloadingLoading/unloadingEngineeringMechanical engineering

The invention discloses a hydraulic car dumper, and aims to achieve unloading operation of bulk grains of containers, particularly unloading operation of double-20-feet containers, and also achieve unloading of bulk grain tracks. According to the technical scheme, the hydraulic car dumper comprises a turning platform, two groups of tail part baffle arm mechanisms, two group of end part safety pin mechanisms, a frame jacking mechanism and a platform turning mechanism, wherein one end of the turning platform is hinged with a base; the tail part baffle arm mechanisms are symmetrically arranged at the tail part of the turning platform; the end part safety pin mechanisms are symmetrically arranged at the end part of the turning platform; the platform turning mechanism consists of two cylinders which are respectively hinged with the turning platform and the base; through telescopic movement of the cylinders, turning of the turning platform relative to hinging points of the turning platform and the base can be achieved; the frame jacking mechanism consists of a jacking cylinder and a platform structure; one end of the jacking cylinder is hinged with the turning platform; the other end of the jacking cylinder is connected with the platform structure; through movement of the jacking cylinder, the jacking action of the platform can be achieved.

Owner:SHANGHAI PORT MACHINERY HEAVY IND +1

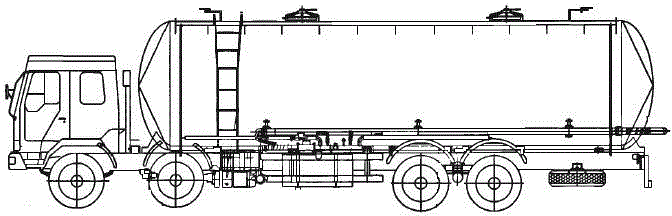

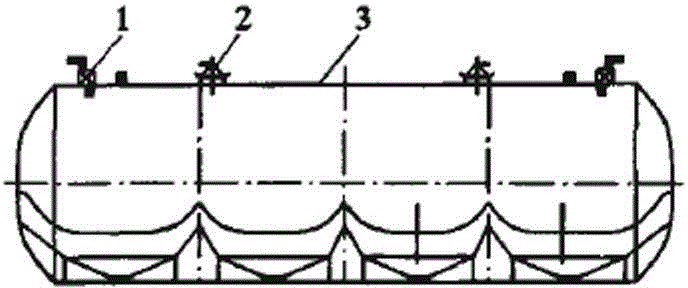

Transport vehicle for powdered and granular materials

The invention relates to vehicles suitable for freight or transporting and packing or containing of special goods or objects, in particular to a transport vehicle for powdered and granular materials. The transport vehicle for powdered and granular materials comprises a sealed cylindrical tank, a power take off system, an intake pipeline and a discharge pipeline. An elliptical tank cover is disposed on one side of the tank. An exhaust valve is disposed on the tank. Compressed air with certain pressure is utilized to enable flow combined by the powdered and granular materials and the air to be discharged under the action of pressure difference between the interior and the exterior of the tank. Compared with other same type transport vehicles, the transport vehicle for powdered and granular materials is reliable in structure, convenient to operate and maintain, and is evidently better in terms of transport efficiency, operation efficiency and residual rate of materials.

Owner:SHAANXI ALLIANCE LOGISTICS

Railway hopper car discharging device and railway hopper car

PendingCN112429021ASimple and flexible controlEasy to controlHopper carsMechanical engineeringFlux control

Owner:CRRC TAIYUAN CO LTD

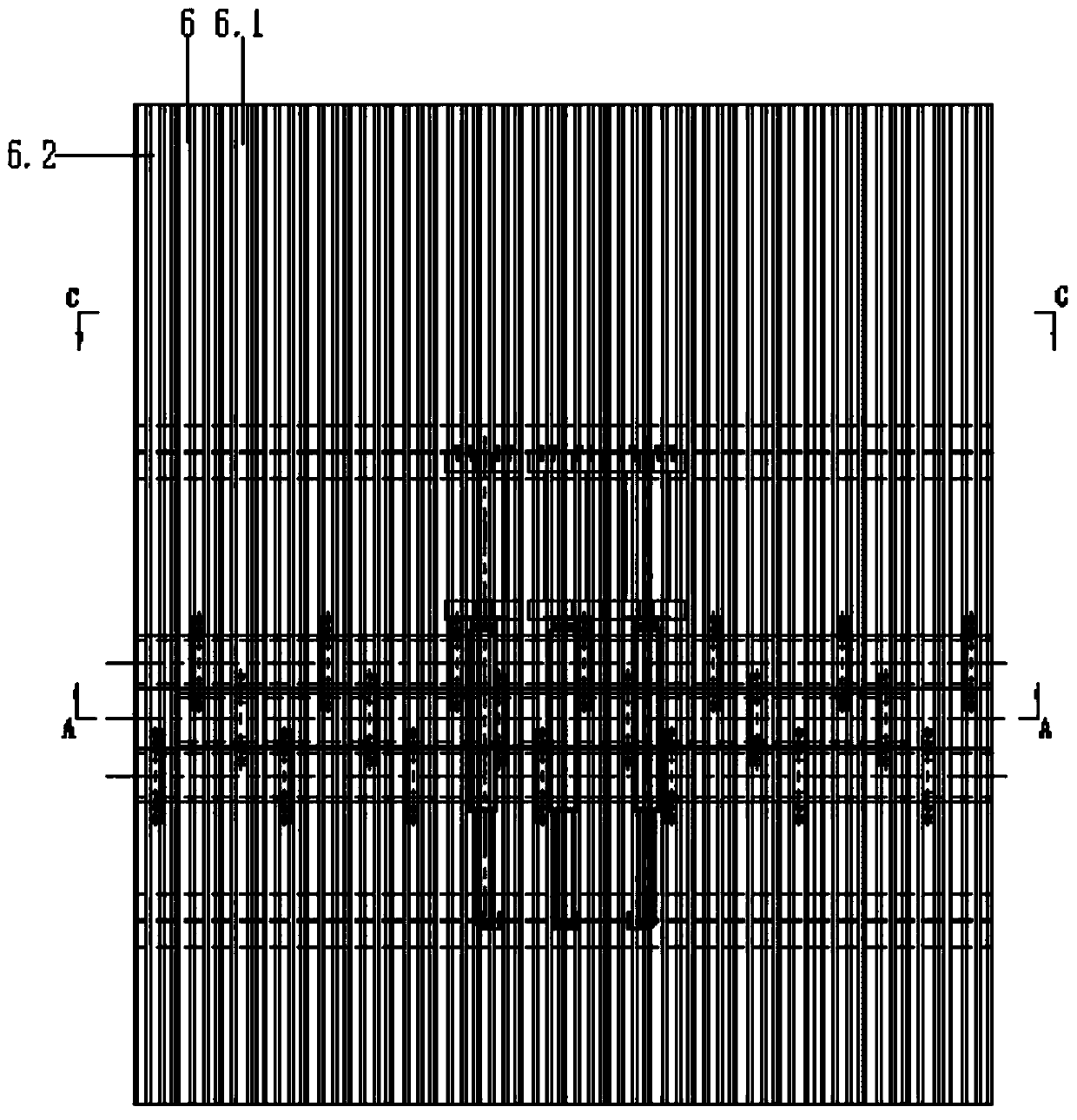

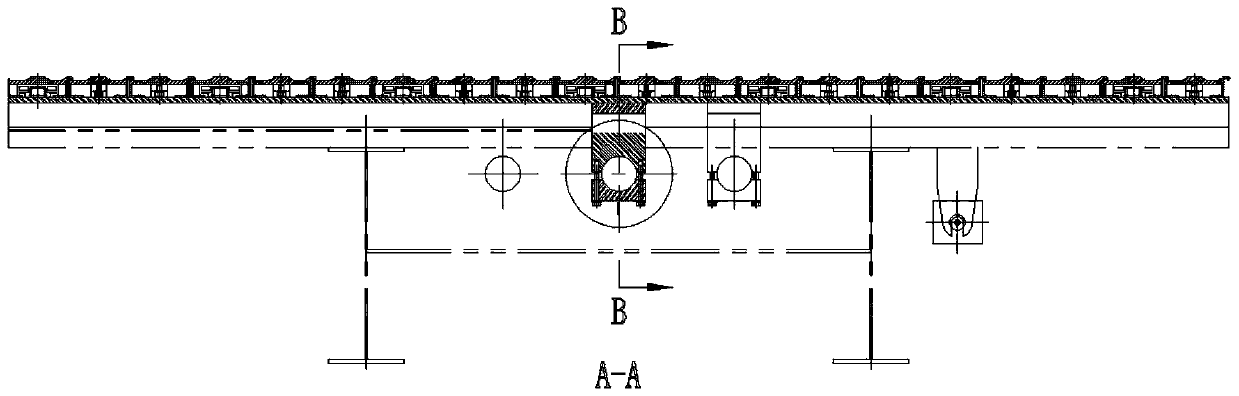

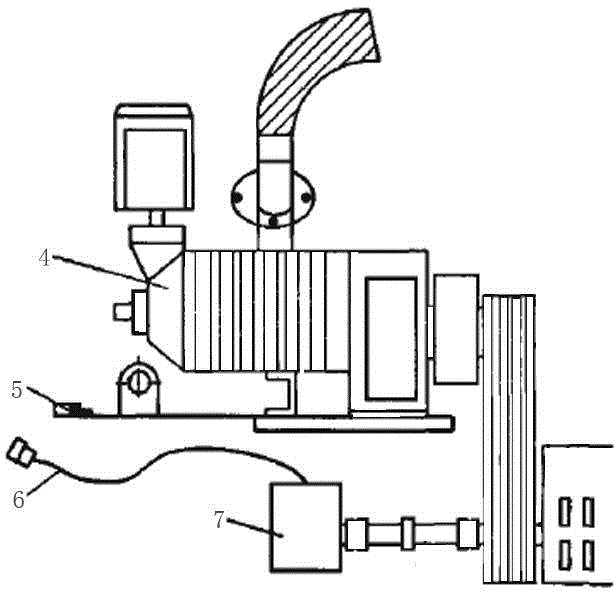

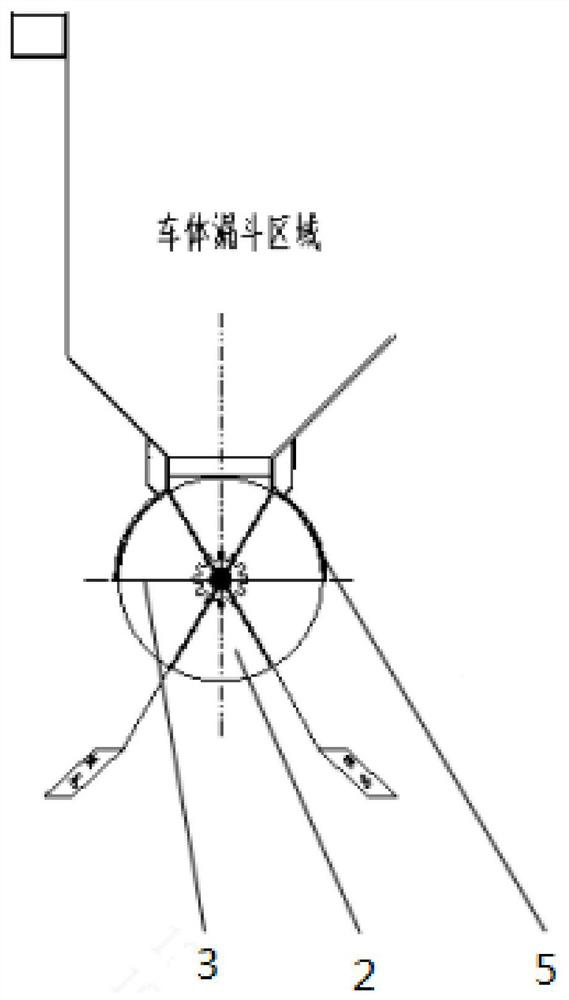

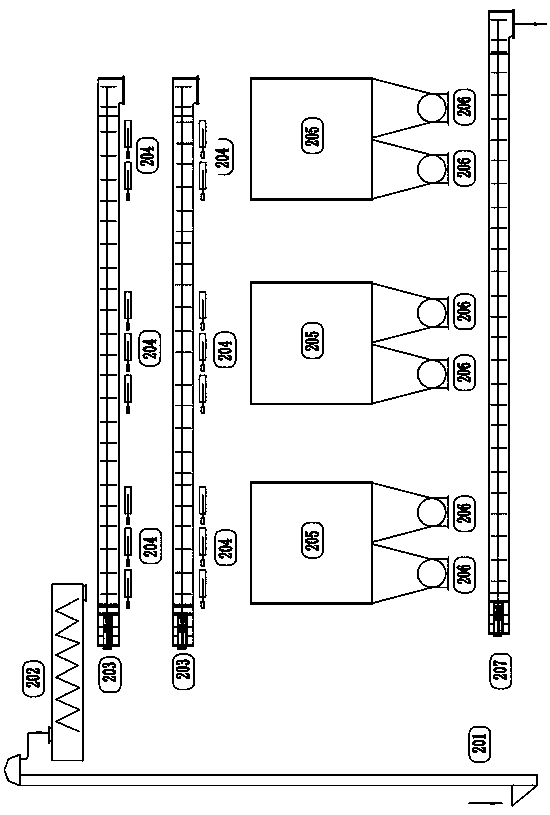

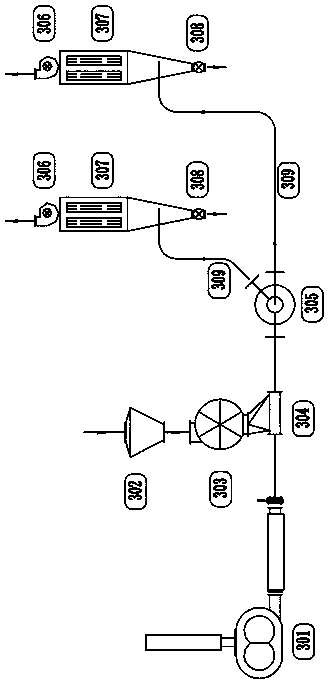

Rice husk cleaning, warehousing and conveying production line

PendingCN109626014AEasy to cleanImprove working environmentBulk conveyorsMagnetic separationProduction lineHusk

A rice husk cleaning, warehousing and conveying production line comprises a cleaning classification work section, a storage work section and a wind power conveying work section, all of which are sequentially arranged. The cleaning classification work section comprises a double-screw feeder, a first elevator, a permanent magnetic drum, a double-barrel rotation screen and a light impurity gatheringscrew conveyor. The storage work section comprises a second elevator, a both-way screw conveyor, a bin feeding scraper conveyor, a pneumatic gate valve, a rice husk bin, a bin bottom screw conveyor and a bin discharging scraper conveyor. The wind power conveying work section comprises positive-pressure conveying equipment or negative-pressure conveying equipment, and a feeding port of the positive-pressure conveying equipment or negative-pressure conveying equipment is connected with a discharging port of the bin discharging scraper conveyor. The rice husk cleaning, warehousing and conveying production line is complete in function, and the three major functions of rice husk cleaning, storing and wind power conveying can be finished. The rice husk cleaning, warehousing and conveying production line can be used for comprehensive rice husk cleaning, moulding is avoided in the storage process, bridging / arching of rice husks in the bin is not likely to happen, bin discharging is more reliable, positive-pressure and negative-pressure wind power conveying is adopted according to the conveying distance, stability and reliability are achieved, and energy saving and environment friendlinessare achieved.

Owner:三门峡高新机械有限公司

PVC pipe unloading device based on waste material production

InactiveCN111168751ATo achieve the purpose of unloadingEasy to useMetal working apparatusHydraulic cylinderWaste material

The invention discloses a PVC pipe unloading device based on waste material production. The PVC pipe unloading device based on waste material production comprises a base, wherein a rotating rod is movably mounted at the upper end of the base through a bearing, an unloading rack is fixedly arranged at the upper end of the rotating rod, a plurality of rollers are movably mounted at the lower end inthe unloading rack through the bearing, a hydraulic cylinder is movably mounted on one side of the rotating rod at the upper end of the base through a hinge pin, a telescopic rod end of the hydrauliccylinder is movably connected to the unloading rack through the hinge pin, a mounting plate is arranged on the side, close to the hydraulic cylinder, of the base, and mounting parts are separately arranged at two ends of the side, far away from the base, of the mounting plate. By placing a PVC pipe at the upper end of the unloading rack, the PVC pipe is driven by starting a transmission mechanismto move under assist of the rollers. When the PVC pipe moves to a corresponding position to be cut, the unloading rack is driven by starting the hydraulic cylinder to transfer the PVC pipe on the inner side of the unloading rack to the inner side of a PVC pipe mounting rack, so that a purpose of unloading the PVC pipe is further achieved.

Owner:江苏万隆管业有限公司

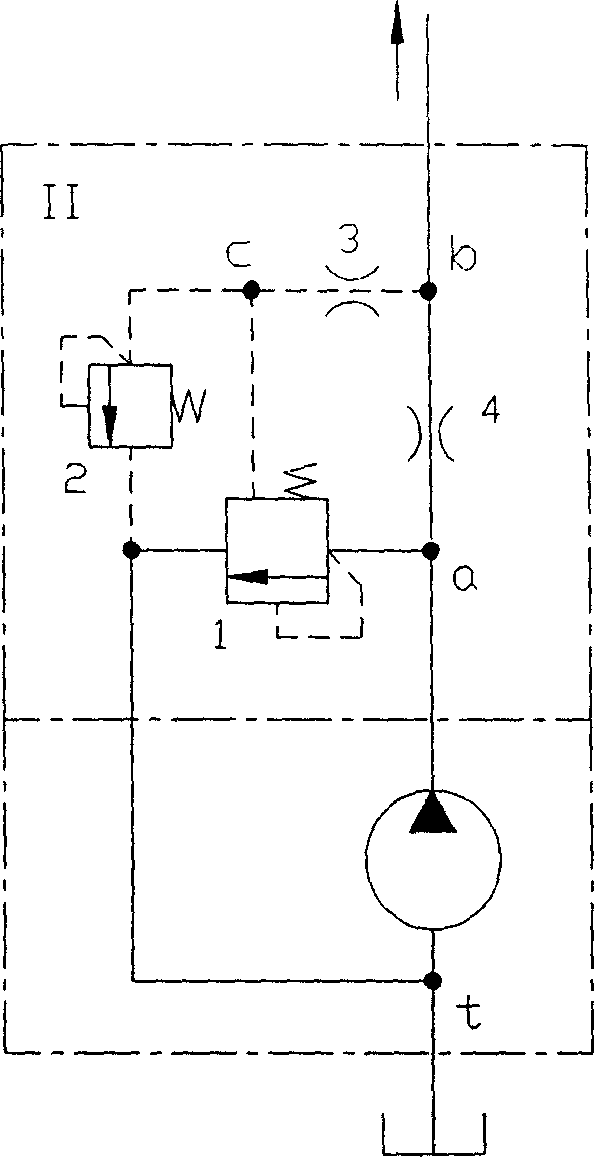

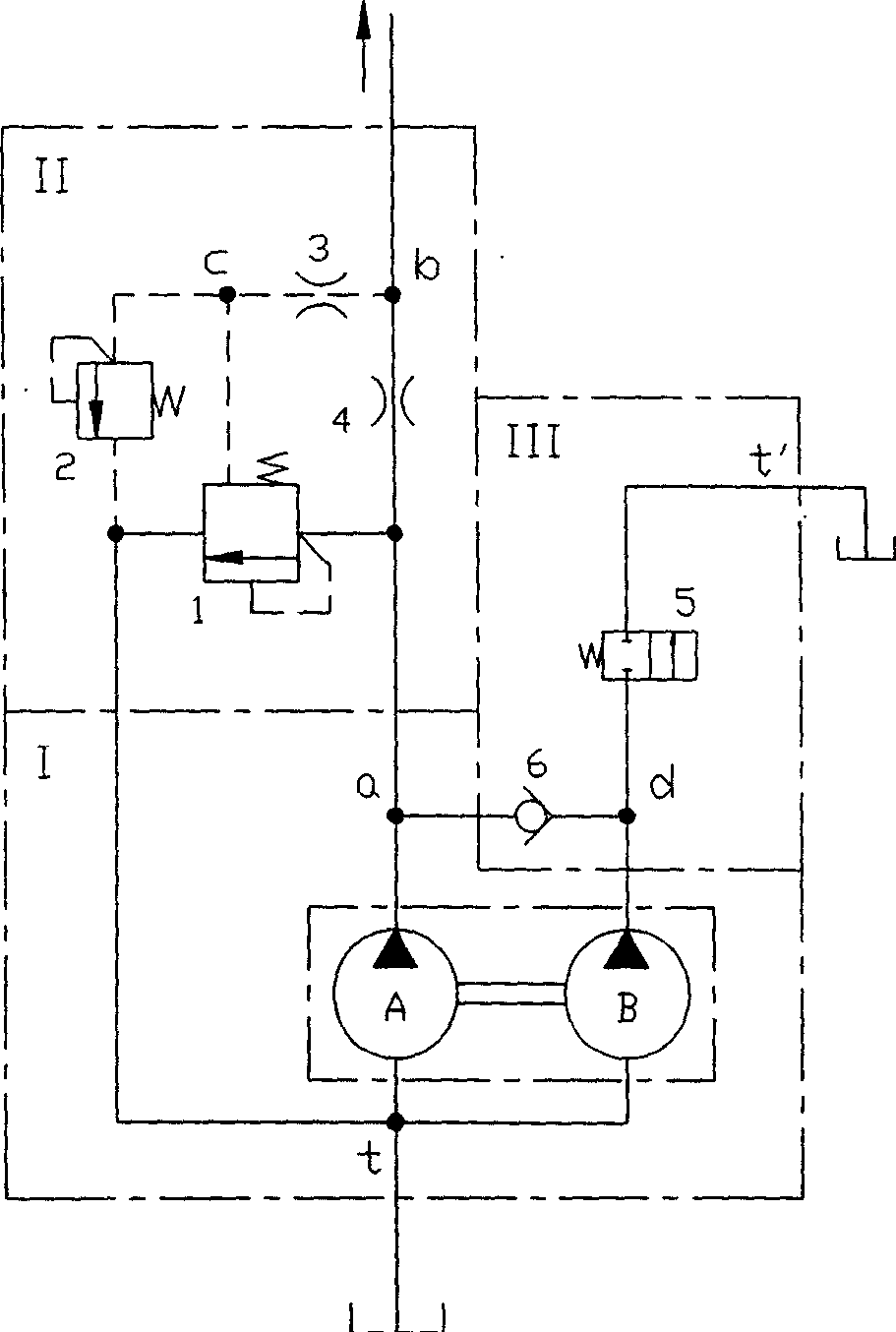

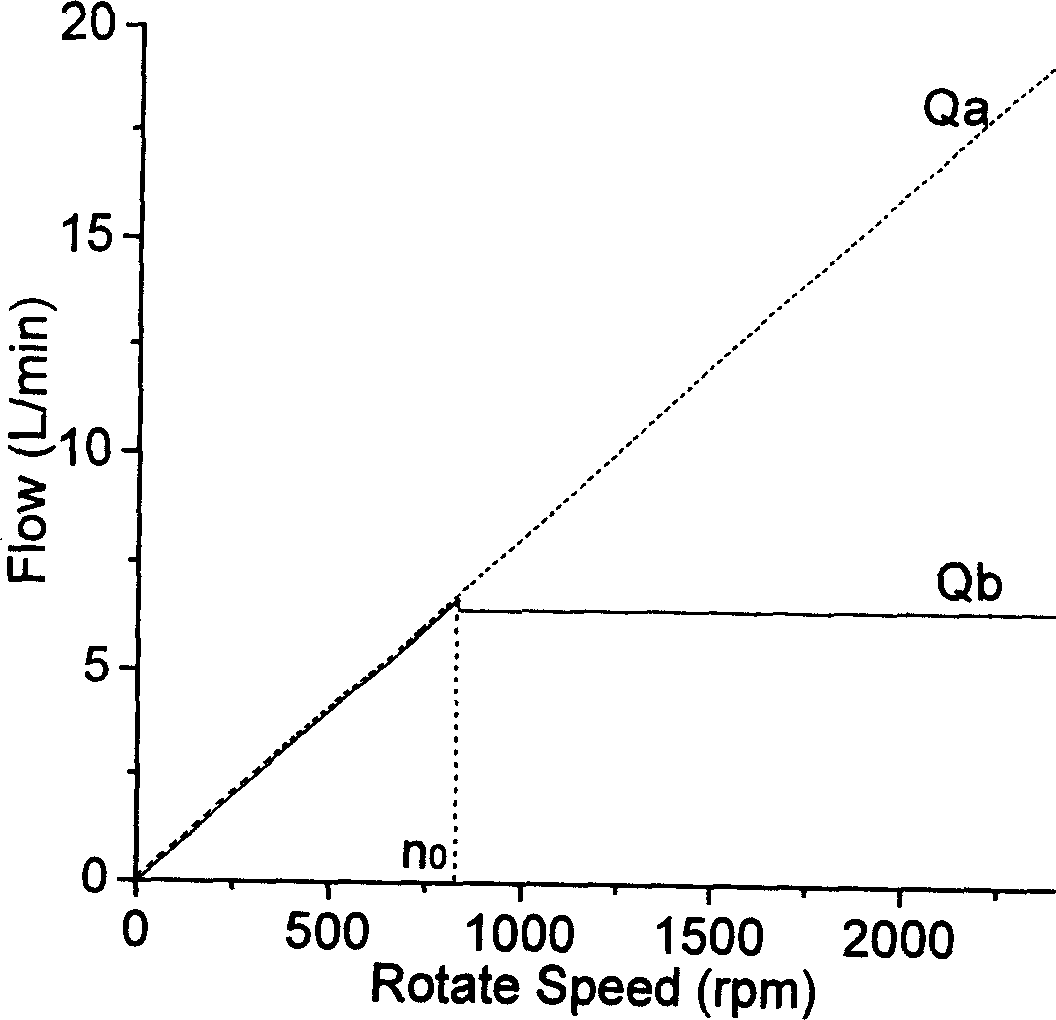

Duplex type hydraulic powered steering pump for automobile

InactiveCN1727242AReduce power lossTo achieve the purpose of unloadingSteering linkagesAutomatic steering controlControl signalControl manner

A double-type hydraulic power steering pump for car is composed of double blade pump unit, flow and pressure limiting control valve group and convergent control valve group. It features that according to the rotation speed of engine and the speed of car, the output oil of secondary pump unit is controlled to individually be returned at high speed, so decreasing the flow of the flow and pressure limiting control valve group and in turn the energy consumption.

Owner:ZHEJIANG UNIV

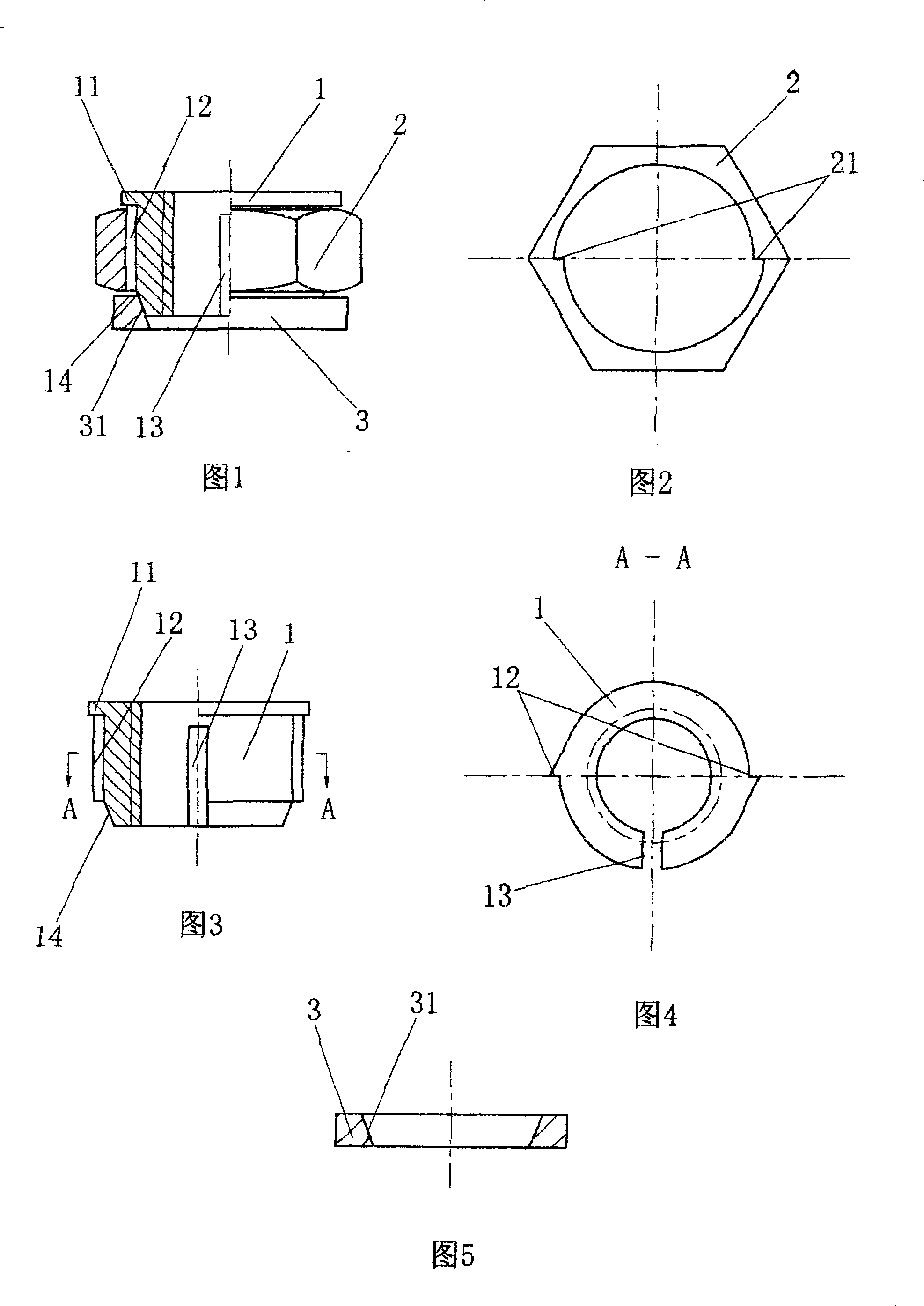

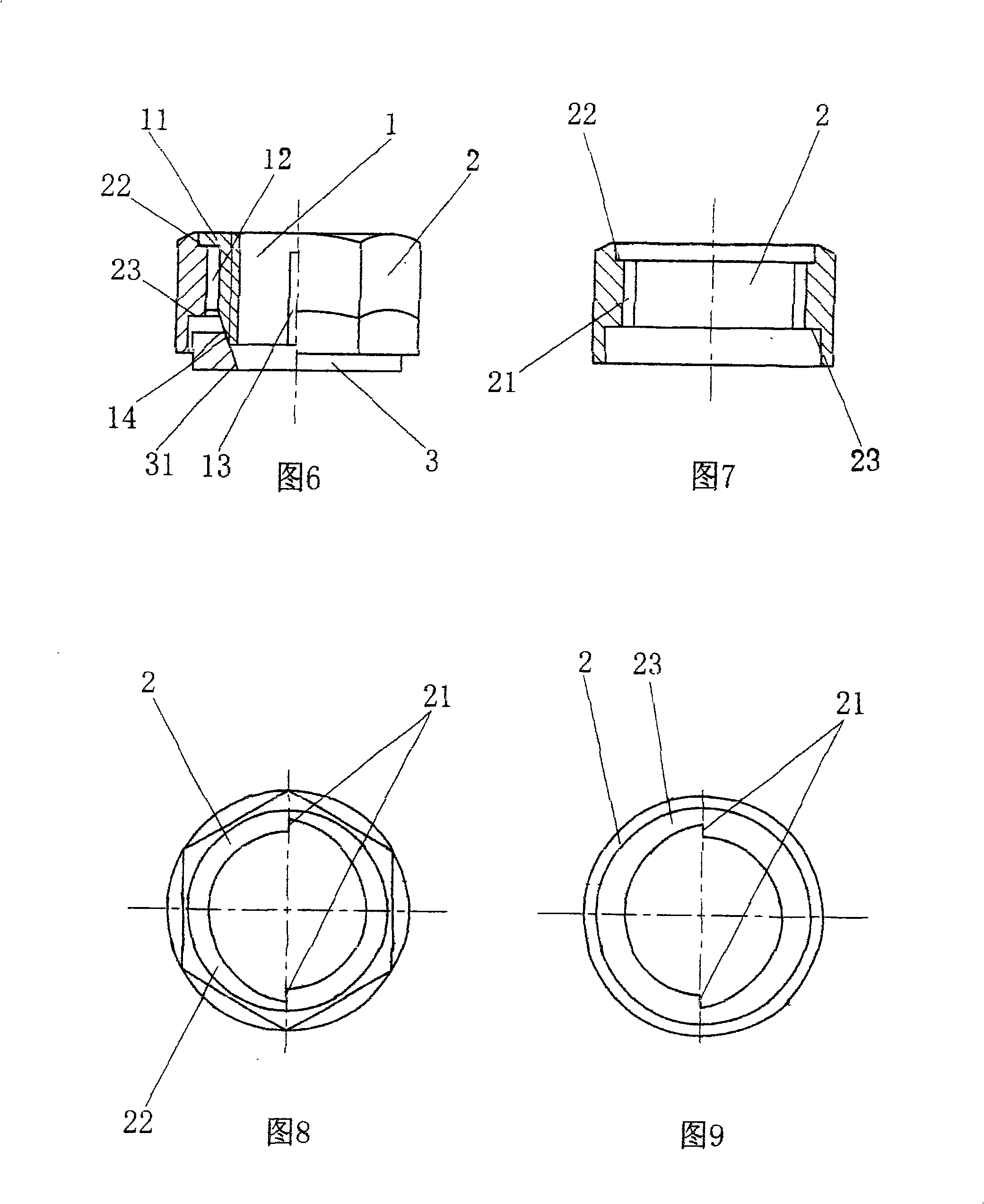

Compound nut

The invention relates to a fastening piece, in particular to a compound nut. The compound nut comprises a nut body and a outer sleeve, wherein, a penetrated internal thread is arranged on the nut body, a circular bead is arranged on the external diameter of the upper end of the nut body, the external diameter of the circular bead is larger than the internal diameter of the outer sleeve, a ratchet mechanism forming one-way meshing is arranged at the matching position between the nut body and the outer sleeve, and the ratchet mechanism is composed of one or more ratchet wheels arranged on the external diameter of the nut body and one or more ratchet wheels which are arranged on the internal diameter of the outer sleeve. The compound nut has the functions of fastening, anti-loosing and anti-unloading, and has the advantages of simple structure and strong practicability.

Owner:招远金王仪表科技有限公司

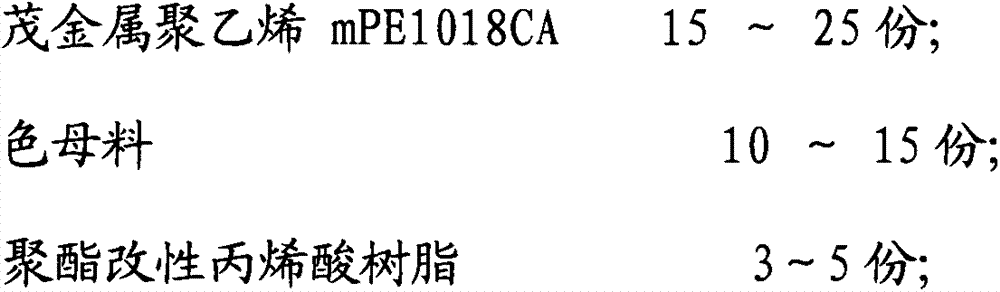

HDPE (High-Density Polyethylene) steel belt reinforced spiral corrugated pipe and production process thereof

InactiveCN107345016AImprove low temperature toughnessImprove rigidityTubular articlesPolyesterPolymer science

The invention relates to an HDPE (High-Density Polyethylene) steel belt reinforced spiral corrugated pipe and a production process thereof. The HDPE steel belt reinforced spiral corrugated pipe is prepared from the following raw materials in parts by weight: 50 to 70 parts of HDPE, 20 to 28 parts of high-modulus PP (Polypropylene), 4 to 7 parts of attapulgite, 25 to 30 parts of HDPE stiffened master batch, 26 to 29 parts of HDPE toughened master batch, 5 to 8 parts of polyester modified acrylic resin, 2 to 4 parts of siloxane modified acrylic resin, 4 to 7 parts of ABS (Acrylonitrile-Butadiene-Styrene) high glue powder, 1 to 4 parts of acrylic impact modifier ACR and 5 to 8 parts of color master batch. A mining HDPE double-wall corrugated composite pipe made by the production process has high low-temperature toughness, high rigidity, high ring stiffness and high creep resistance, and is not be deformed by gravity in a long-term use process, thus prolonging the service life of a product; the HDPE steel belt reinforced spiral corrugated pipe can be popularized on a large scale.

Owner:江苏桓通环境科技有限公司

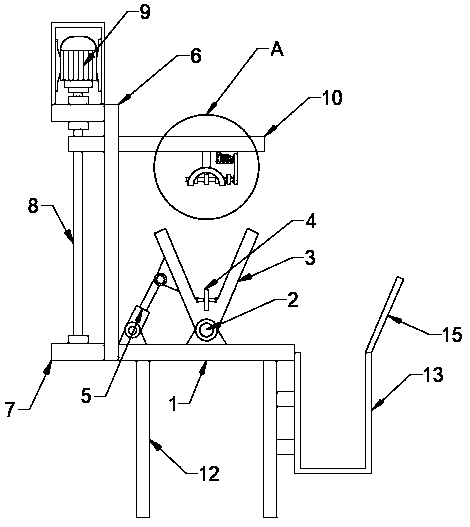

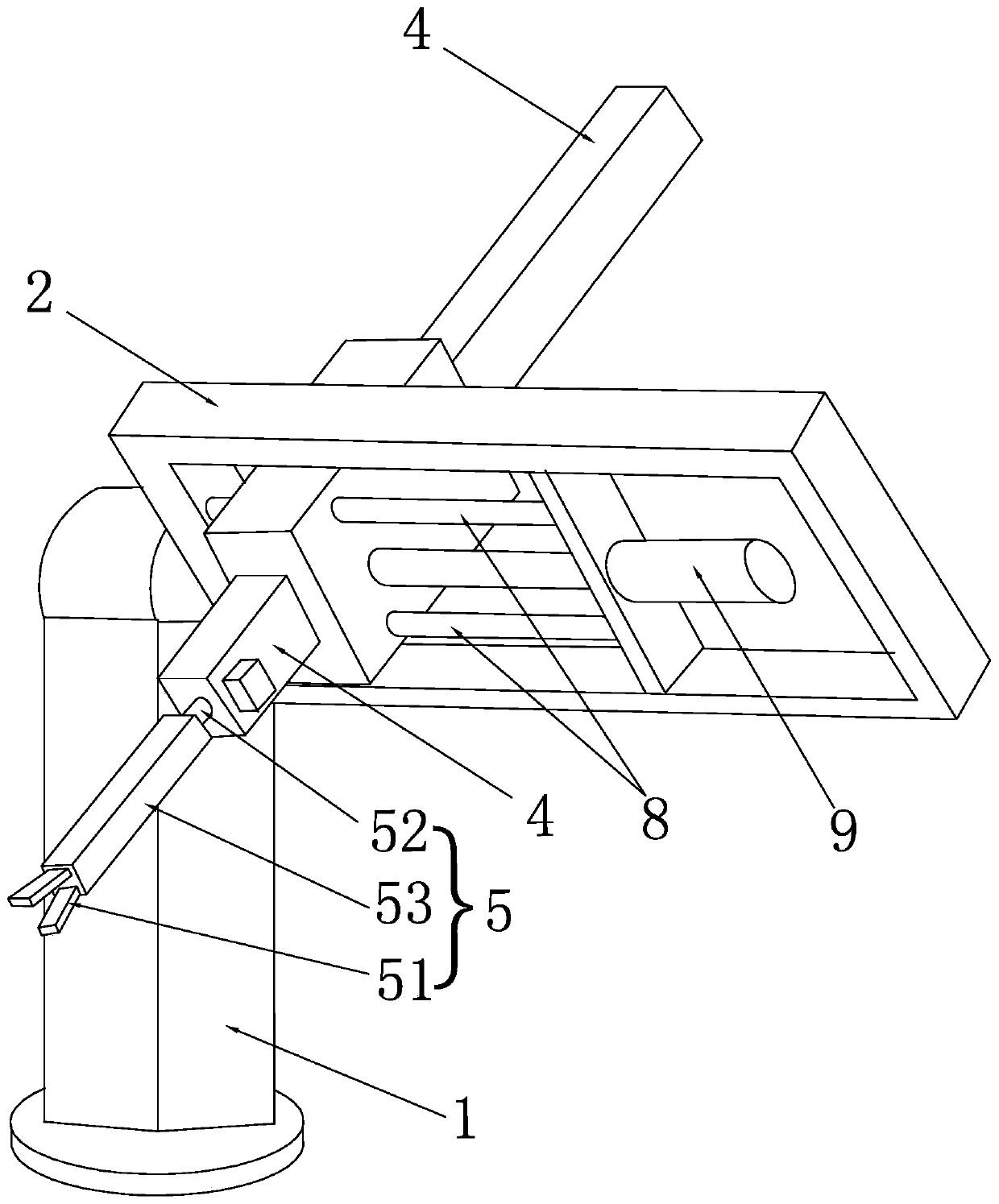

In-mold material taking oblique arm type mechanical arm

PendingCN110355959ALow structural requirementsTo achieve the purpose of unloadingEngineeringManipulator

The invention discloses an in-mold material taking oblique arm type mechanical arm. The mechanical arm comprises a support, a turnover table, and a clamping jaw assembly; the turnover table is provided with a rotating shaft, the turnover table can turn over around the rotating shaft relative to the support, the turnover table is provided with a swing arm capable of moving in the parallel directionof the rotating shaft, the swing arm can move in the length direction of the swing arm, the clamping jaw assembly is arranged at one end of the swing arm, the clamping jaw assembly can clamp / loosen the material, the mechanical arm can directly stretch into an injection mold through the clamping jaw assembly to take away materials, and retreats through the swing arm to leave the interior of the injection mold, through the turnover motion of the turnover table and the extending action of the swing arm, the material is transferred to the discharging area, the clamping jaw assembly loosens the materials, the discharging aim is achieved, and in the whole process, the mechanical arm can finish operation at a time, and is rapid and precise, small in occupied size, high in discharging efficiencyand poor in structural need for a mold.

Owner:广东力德诺电子科技有限公司

PE (Polyethylene) composite spiral corrugated pipe and processing method thereof

InactiveCN107345043AImprove low temperature toughnessImprove rigidityFlexible pipesTubular articlesToughnessSizing

The invention relates to a PE (Polyethylene) composite spiral corrugated pipe and a processing method thereof. The PE composite spiral corrugated pipe comprises a pipe extruded material outer layer and a pipe extruded material inner layer. The processing method comprises the steps of mixing raw materials, extruding through an extruder, extruding through an extruding die head, sizing, cooling, drawing a pipe, cutting and piling on a frame. The PE composite spiral corrugated pipe made by the processing process has high low-temperature toughness, high rigidity, high ring stiffness and high creep resistance, and is not be deformed by gravity in a long-term use process, thus prolonging the service life of a product; the PE composite spiral corrugated pipe can be popularized on a large scale.

Owner:江苏桓通环境科技有限公司

Power distribution cabinet device

ActiveCN111564772AEasy to pull out drawerEasy to operateSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsStructural engineeringElectrical and Electronics engineering

The embodiment of the invention discloses a power distribution cabinet device. The cabinet comprises a cabinet body, a plurality of bearing plates are arranged in the cabinet body at equal intervals;a part placing drawer is connected to the bearing plate; the end, close to the cabinet body, of the part containing drawer is provided with a force unloading protection assembly used for weakening impact and preventing parts from being damaged. The device is provided with the force unloading protection assembly; when an external force acts on the drawer, the drawer is pushed and drives a sliding force unloading table to slide along the clamping sliding strips, and preliminary force unloading is realized; meanwhile, a pressure relief supporting block is attached to the cabinet body and extrudesthe ejection spring, force unloading is realized further, at the moment, the pressure relief supporting block pushes a rubber pressure relief plate to slide through a connecting rod; by arranging thepush spring, the push force is fully released, so that the situation that parts are damaged due to collision between the drawer and the cabinet body is avoided; and when a user needs to pull out thedrawer, the push spring can reset to push the drawer to slide out, so that the user can pull out the drawer very conveniently, the protection performance is higher, and operation is convenient.

Owner:GUANGDONG POWER GRID CO LTD +1

Winding device

PendingCN107954256ASimple structureEasy to rewind and unloadFilament handlingMechanical engineeringOperational maintenance

Owner:WISDRI ENG & RES INC LTD

Cutting platform

PendingCN108453399ARealize the purpose of automatic unloading and setting outGuaranteed smoothnessLaser beam welding apparatusMetallic materialsEngineering

The invention provides a cutting platform. The cutting platform comprises a first area platform and a second area platform, wherein the second area platform can be opened and closed; the first area platform is provided with hollow structures in the shapes matched with the pre-cutting shapes of samples so that the cut samples placed on the first area platform can be dropped from the corresponding hollow structures; and the second area platform is arranged in front of the first area platform, and the second area platform is used for tilting and unloading the blank samples on the second area platform when the second area platform is in an opened state, and storing the blank samples when the second area platform is in a closed state so as to convey the blank samples to the first area platform.According to the cutting platform, the second area platform achieves the purposes of automatic sample unloading and sample storage, so that the problem of dangers caused by manual operation is avoided; the first area platform is provided with the hollow structures in the shapes matched with the pre-cutting shapes of the samples so that the samples can be conveniently collected; and the surface ofthe first area platform is flat, a non-metal material is adopted as a surface lining board so that the blank samples can be prevented from being scratched, and the smoothness of the surfaces of the samples is guaranteed.

Owner:天津泰格瑞祥仪器设备有限公司

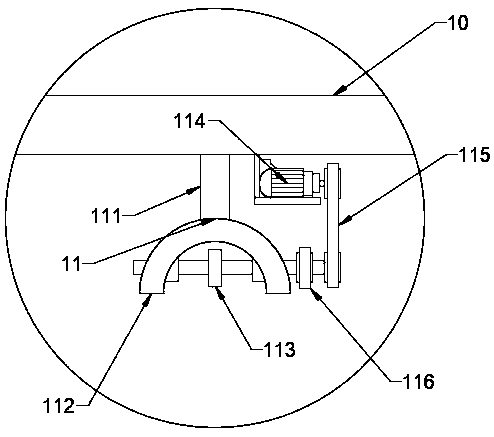

Disc unloading mechanism of dual take-up machine

The invention discloses a disc unloading mechanism of a dual take-up machine. The disc unloading mechanism comprises a first disc unloading mechanism and a second disc unloading mechanism which are arranged on the front side and the rear side and adopt the same structure, each disc unloading mechanism comprises an end cover, a pressure spring, a shaft, a machine frame, a hollow shaft, a big rotary disc, a push plate, a bracket, a membrane cylinder, a hinge chain, a lever and a pressing wheel, wherein the hollow shaft is mounted on the machine frame; the big rotary disc is mounted at the right end of the hollow shaft; the shaft is arranged in the hollow shaft; the push plate is arranged on the right side of the hollow shaft and fixedly connected with the shaft; the left end of the shaft is located out of the hollow shaft; the end cover is mounted at the left end part of the shaft; the pressure spring is arranged between the end cover and the hollow shaft; the membrane cylinder is fixedly mounted at the lower part of the machine frame through the bracket; the membrane cylinder is located below the hollow shaft; the hinge chain is fixedly connected onto a piston rod of the membrane cylinder; one end of the lever is connected with the hinge chain; the other end of the lever is connected with the pressing wheel; and the middle part of the lever is connected with the bracket and can rotate around the bracket. The disc unloading mechanism of the dual take-up machine has a compact structure, is convenient and quick to use, is smooth for unloading the disc, and has high in production efficiency.

Owner:THE NORTHWEST MACHINE

A hydraulic dumper

Owner:SHANGHAI PORT MACHINERY HEAVY IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com