Dried tofu pressing-cutting and packaging device

A technology of dried tofu and packaging table, which is applied in the directions of packaging, packaged food, transportation and packaging, etc., can solve the problems of easy breeding of bacteria, uneven shape of dried tofu, and easy to stain dried tofu.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail through specific embodiments below.

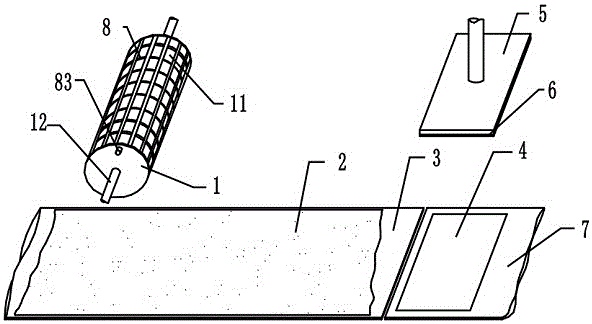

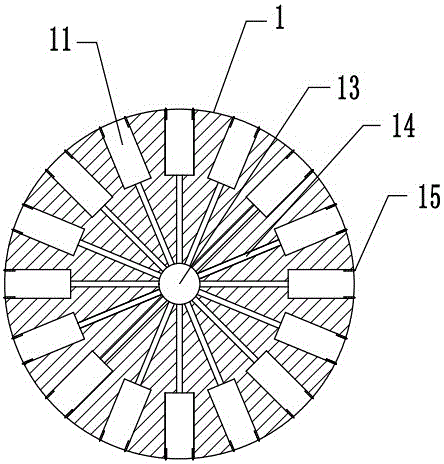

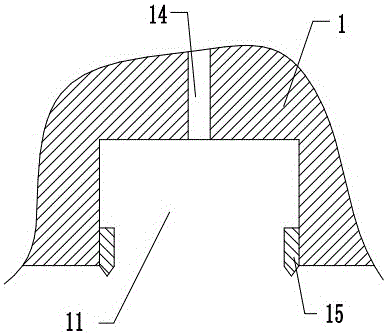

[0028] The reference signs in the accompanying drawings of the description include: forming roller 1, dried bean curd bar 2, conveying belt 3, lower packaging film 4, laminating machine 5, upper packaging film 6, packaging table 7, partition 8, strip groove 11 , Hollow shaft 12, air channel 13, air pipe 14, pressure cutting blade 15, hot pressing strip 51, arc inner groove 52, serrated edge 81, rotating shaft 82, steering shaft 83, limit block 84.

[0029] Such as figure 1 Shown: bean curd bar 2 is placed on the conveyor belt 3, and the conveyor belt is close to the packaging platform 7, and the packaging film 4 is placed on the packaging platform 7; Pressing and shearing dried tofu, one end of the forming roller 1 is inserted into a sleeve and connected with a steering shaft 83; the hollow shaft 12 of the forming roller 1 is provided with an air passage 13, and the two ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com