Railway hopper car discharging device and railway hopper car

A technology of unloading device and hopper car, applied in the direction of hopper car, railway car body parts, transportation passenger car, etc. Control flexible and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

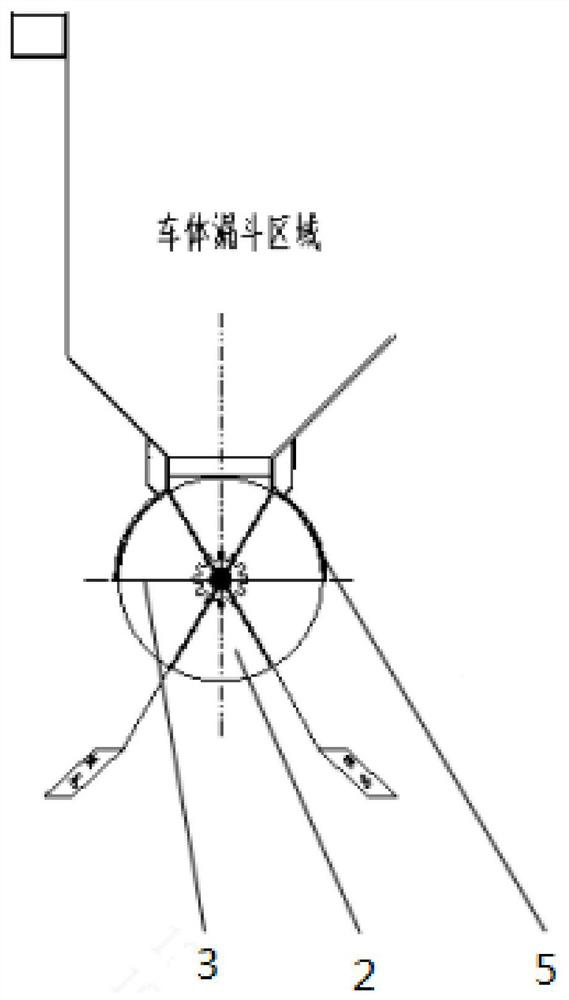

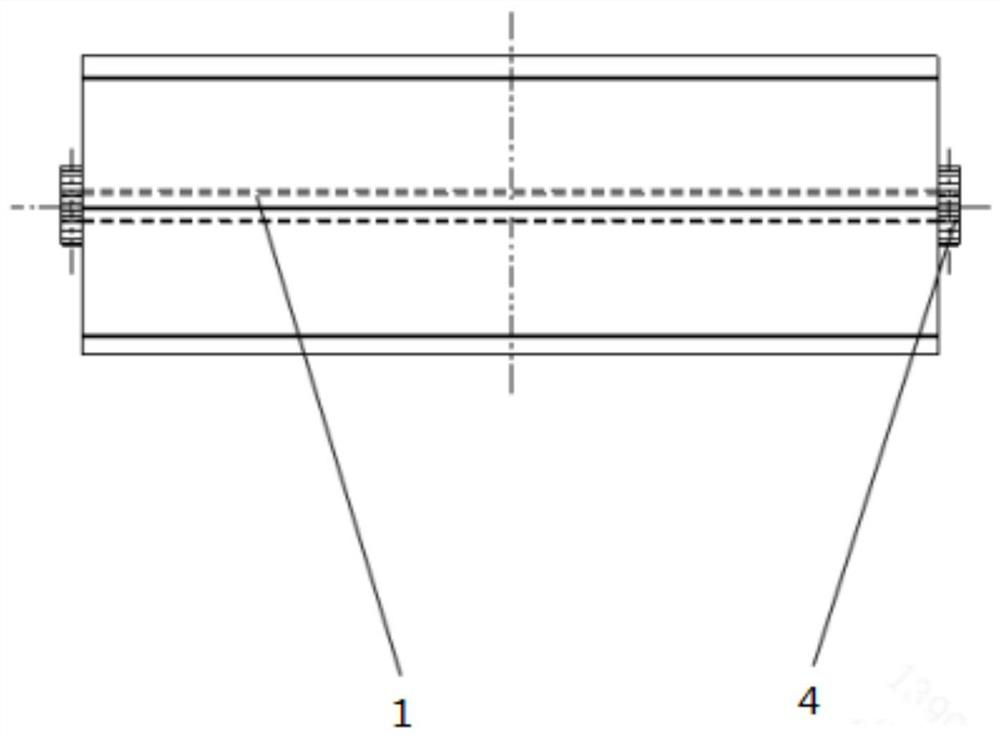

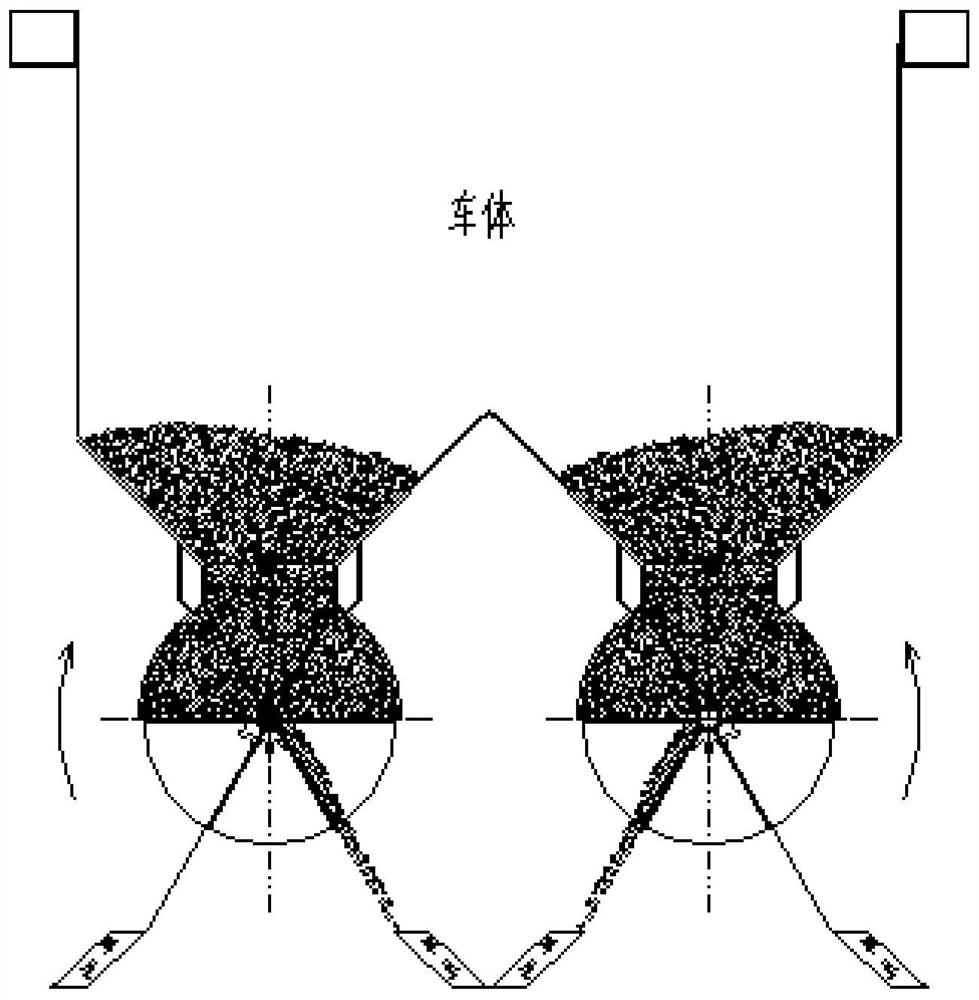

[0073] Such as Figure 1 to Figure 3 Shown, a kind of railway hopper car unloading device comprises:

[0074] The central tube 1 is arranged below the discharge port of the railway hopper car;

[0075] Two baffles 2 are respectively arranged at both ends of the central cylinder 1;

[0076] A plurality of partitions 3 are arranged on the outer periphery of the central cylinder 1 along the radial direction of the central cylinder 1, and the two ends of the partitions 3 are respectively connected with the two baffles 2, so that two adjacent partitions 3 and two The baffle plate 2 forms a collecting tank with an open top;

[0077] The transmission structure 4 is arranged on at least one end of the central cylinder 1, and the transmission mechanism is used to cooperate with the driving mechanism.

[0078] In this embodiment, the baffle 2 is disc-shaped.

[0079] In this embodiment, arc-shaped outer baffles 5 are arranged symmetrically on both sides of the discharge port, and th...

Embodiment 2

[0092] Such as Figure 4 As shown, the difference between the railway hopper car unloading device in the present embodiment and the railway hopper car unloading device in Embodiment 1 is:

[0093] In this embodiment, a cover plate 6 is provided on the top of the collecting tank, and the cover plates 6 are arranged on the collecting tank at intervals, so that one of the two adjacent collecting tanks is open and the other is closed.

[0094] In this embodiment, the cover plate 6 is in the shape of an arc, and the cover plate 6 matches the circumferential curve of the baffle plate 2 .

[0095] Specifically, the cover plate 6 is fixed on the top of the collecting tank, and the adjacent collecting tank of the collecting tank containing the material is closed by the cover plate 6. When the collecting tank rotates around the central cylinder 1, the adjacent collecting tank The groove seals the discharge port by the cover plate 6, which can also prevent material leakage and splashing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com