Power station unit multi-steam-source shaft seal steam/gas supply system and control method

A power station unit and shaft seal technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of aggravated shaft system vibration, large shaft locking, etc., and achieves easy operation, high degree of automation, and flexible and simple control methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

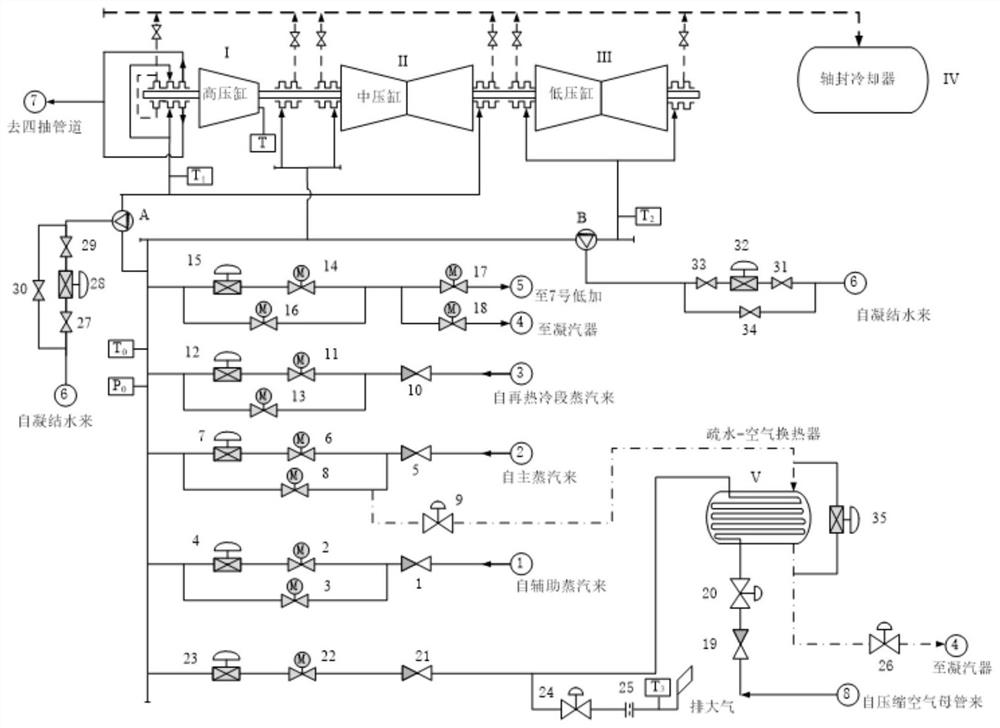

[0043] Such as figure 1 As shown, a conventional thermal power unit includes a high-pressure cylinder I, a medium-pressure cylinder II and a low-pressure cylinder III. During the operation of the unit, it is necessary to form a seal where the rotor passes through the cylinder. The present invention is provided with three external steam supply sources. One way of steam from the auxiliary steam enters the shaft seal steam supply main pipe through the check valve 1, electric valve 2, and regulating valve 4. To ensure the reliability of the system, this pipeline is equipped with a parallel bypass electric valve 3; the second road is independent The steam enters the shaft seal steam supply main pipe through the check valve 2 5, the electric valve 6, and the regulating valve 7. In order to ensure the reliability of the system, a parallel bypass electric valve 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com