Patents

Literature

937results about How to "Improve unloading efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

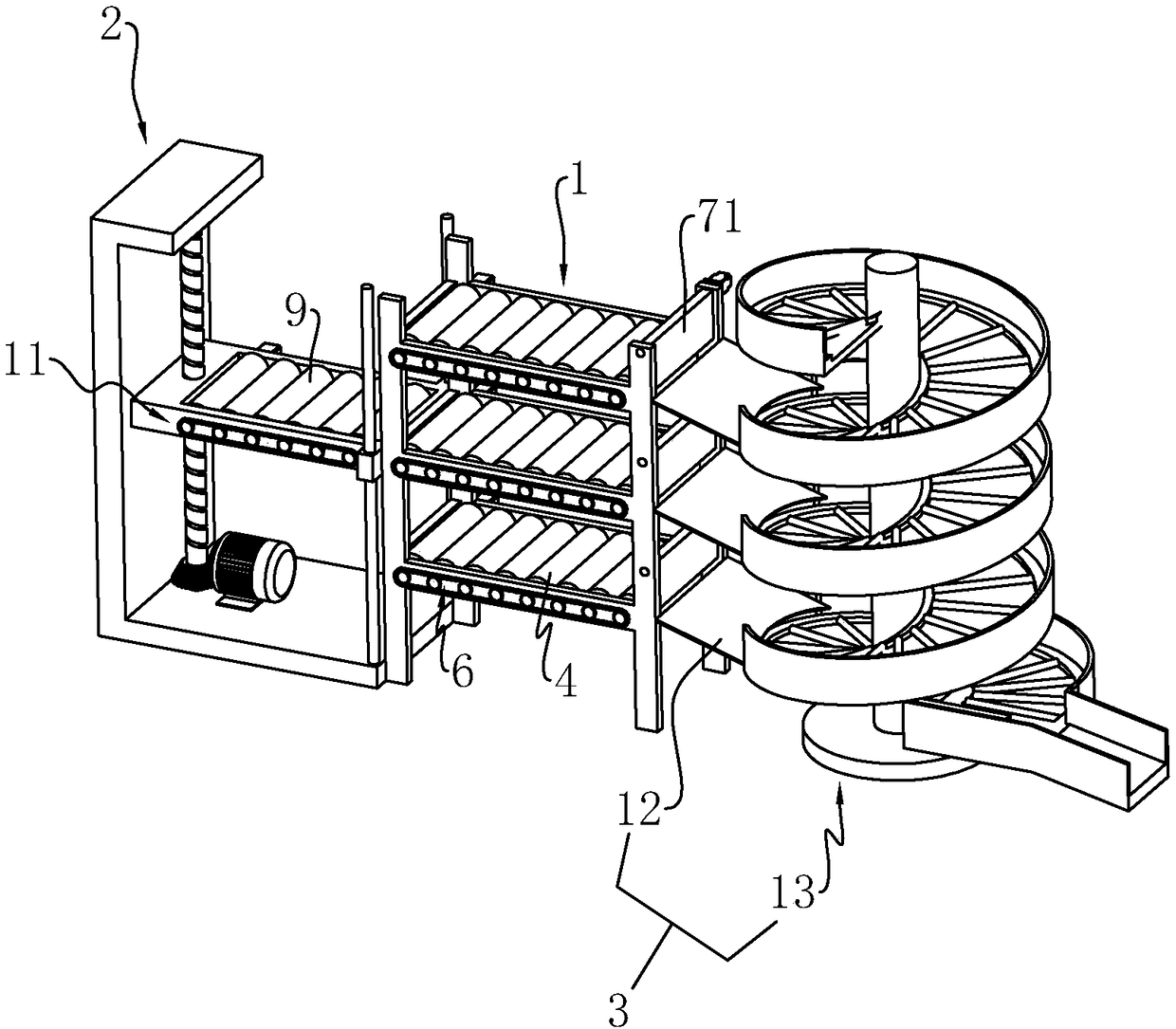

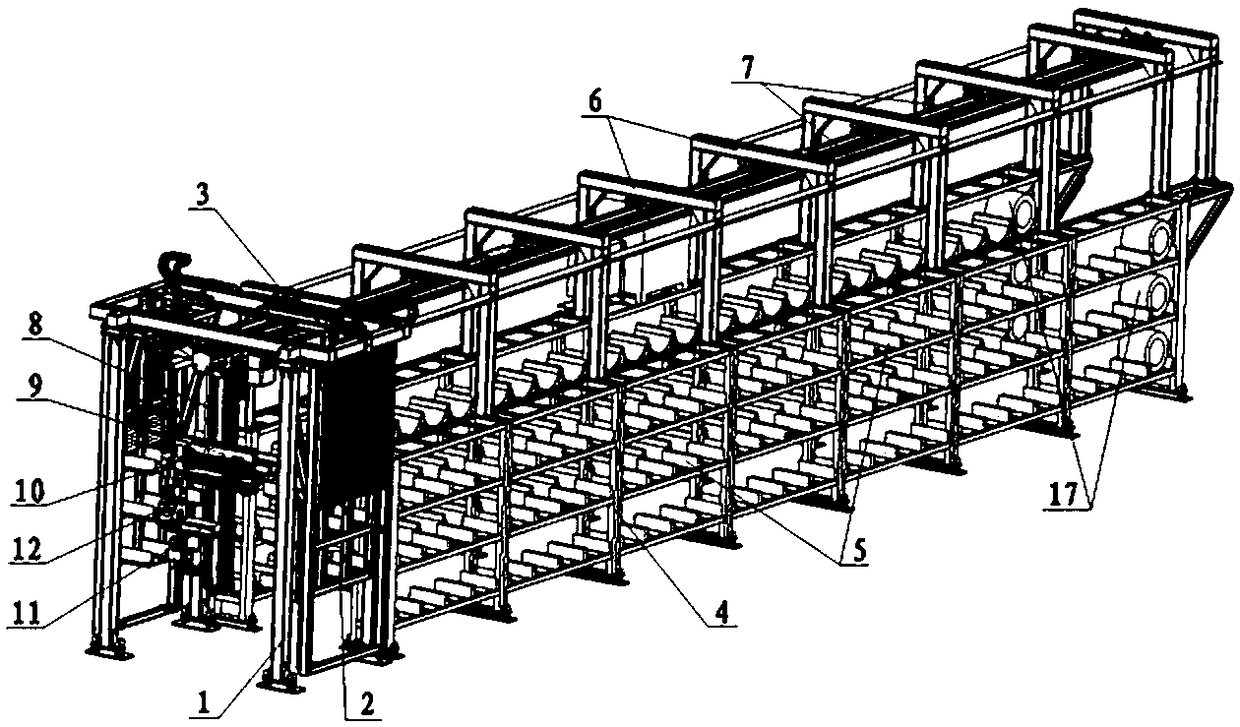

Warehouse goods storage device

InactiveCN108545389ARealize fully automatic loading and unloadingImprove loading and unloading efficiencyStorage devicesChutesLogistics managementEngineering

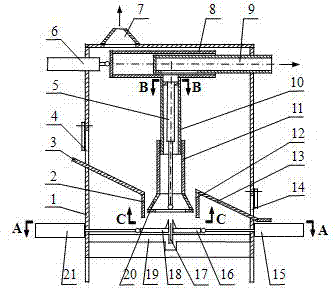

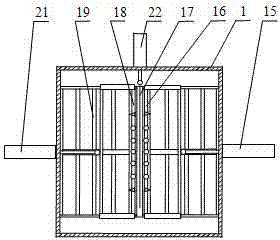

The invention discloses a warehouse goods storage device and relates to the field of warehouse storage logistics. The warehouse goods storage device comprises a storage rack main body which at least comprises two placing layers, wherein a goods inlet and a goods outlet are separately formed in two sides of each placing layer; the warehouse goods storage device also comprises a goods upper rack mechanism and a goods lower rack mechanism; the goods upper rack mechanism comprises a base, a placing table, a first driving assembly and a second driving assembly, and a third driving assemblies and barrier parts are arranged on the placing layers; the goods lower rack mechanism comprises a lower slideway and a bearing rack, the bearing rack comprises a central rod and a spiral slideway which is spirally arranged around the central rod from top to bottom, and a goods delivery port is formed in the lower end of the spiral slideway. The warehouse goods storage device provided by the invention isstable to work, convenient to operate and high in degree of automation, can improve the goods loading and unloading efficiency and reduce the labor intensity greatly, and meets the modern logistics development tendency.

Owner:上海诺尔国际物流有限公司

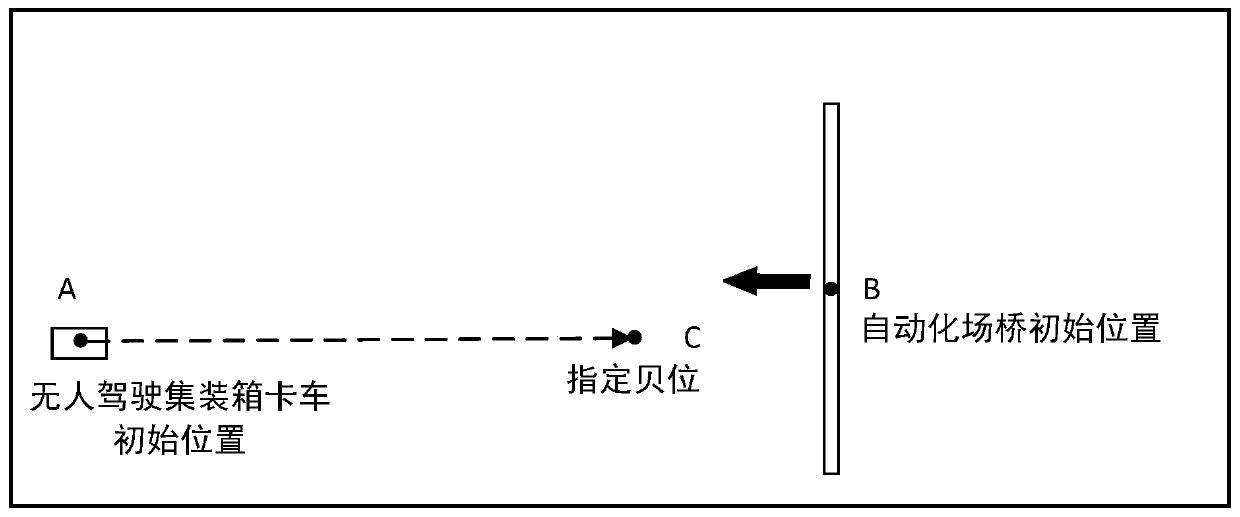

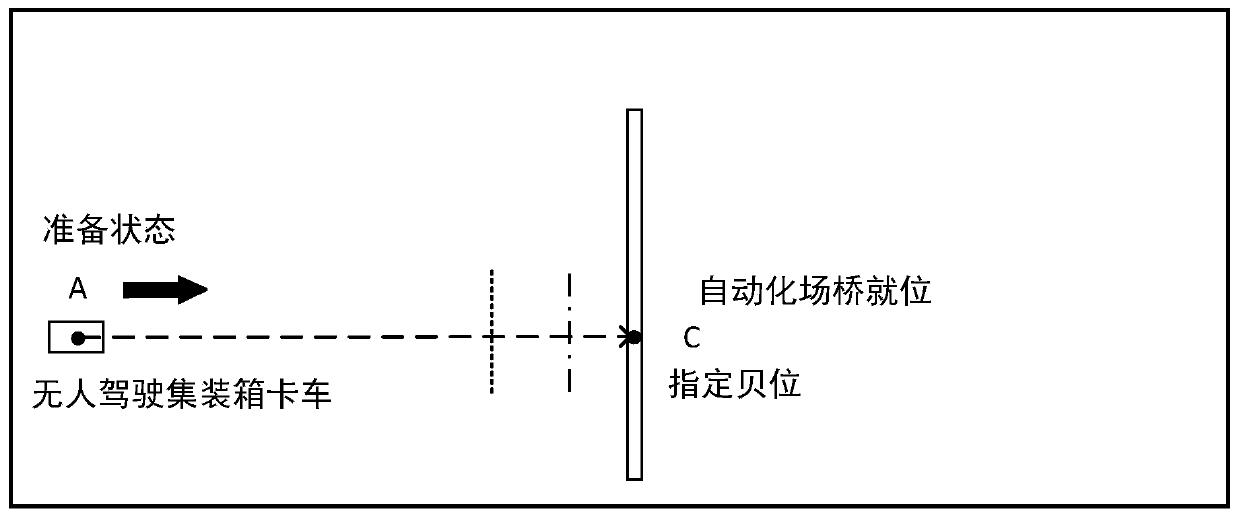

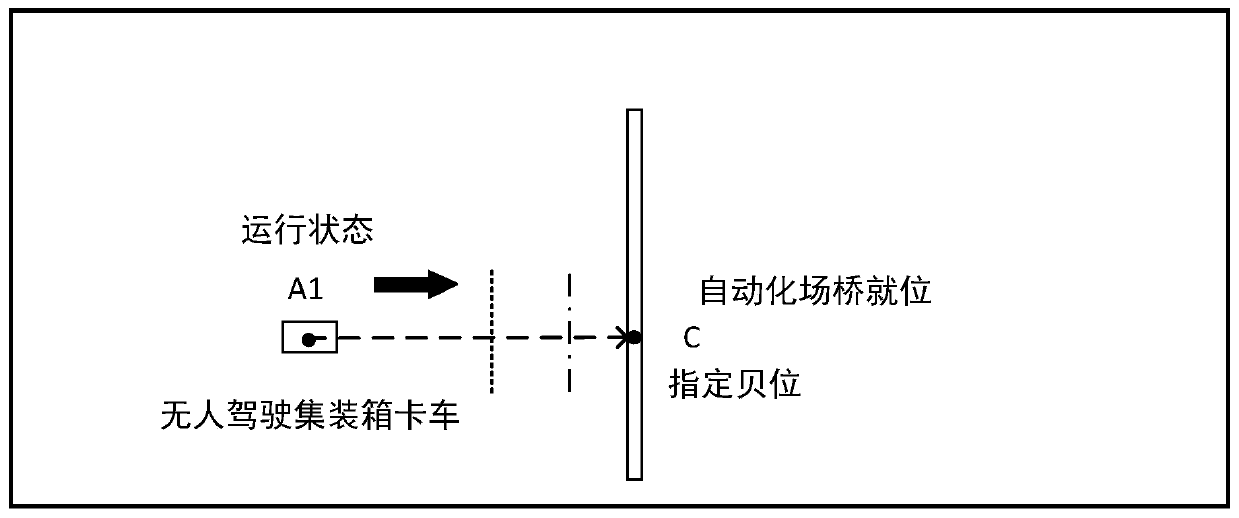

High-precision positioning parking method for unmanned container truck relative to automatic field bridge

ActiveCN109828577AStepper Parking PreciseAccurate parkingPosition/course control in two dimensionsRadarFinite-state machine

The invention relates to a high-precision positioning parking method for an unmanned container truck relative to an automatic field bridge. The method comprises the steps of: employing laser radar anda visual sensor to regulate a relative location interval between an unmanned container truck and an automatic field bridge in a range within 10m; through the automatic field bridge trailing locationdetection information, correcting a mutual position between the unmanned container truck and the automatic field bridge, and according to the relative location information, employing a location finite-state machine and a stepping parking controller to achieve the high-precision location of unmanned container truck field bridge operation. The high-precision positioning parking method for an unmanned container truck relative to an automatic field bridge solves the problem of the GPS / Beidou location errors when the unmanned container truck is operated in a storage yard, can achieve relative high-accuracy position of the unmanned container truck relative to the automatic field bridge, can reduce the number of times of position posture adjustment of the unmanned container truck, can achieve accurate parking and can improve the efficiency of encasement and unloading between the automatic field bridge and the container truck.

Owner:北京主线科技有限公司

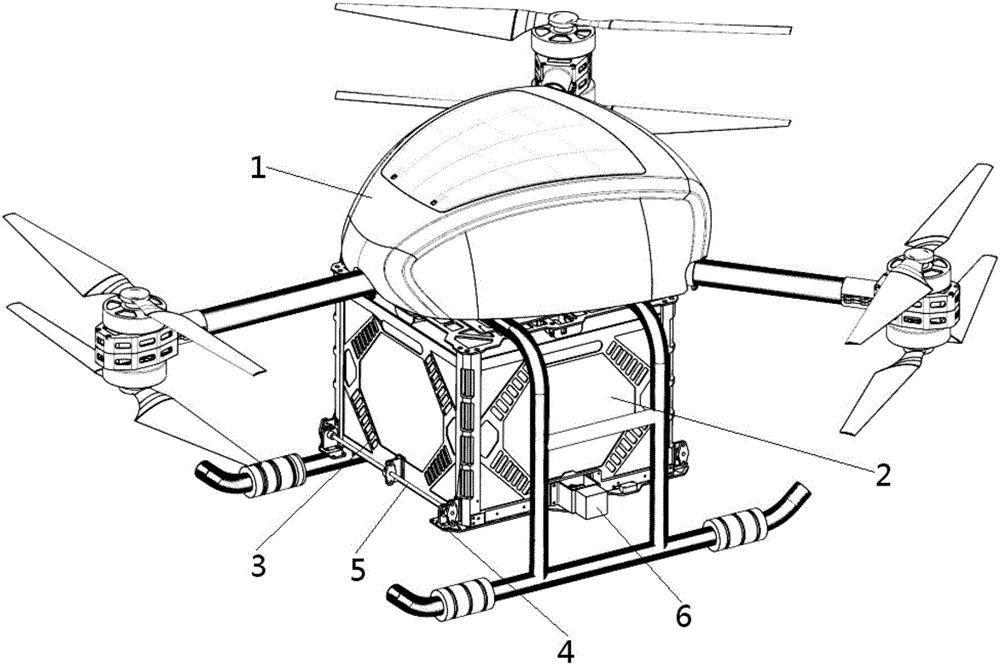

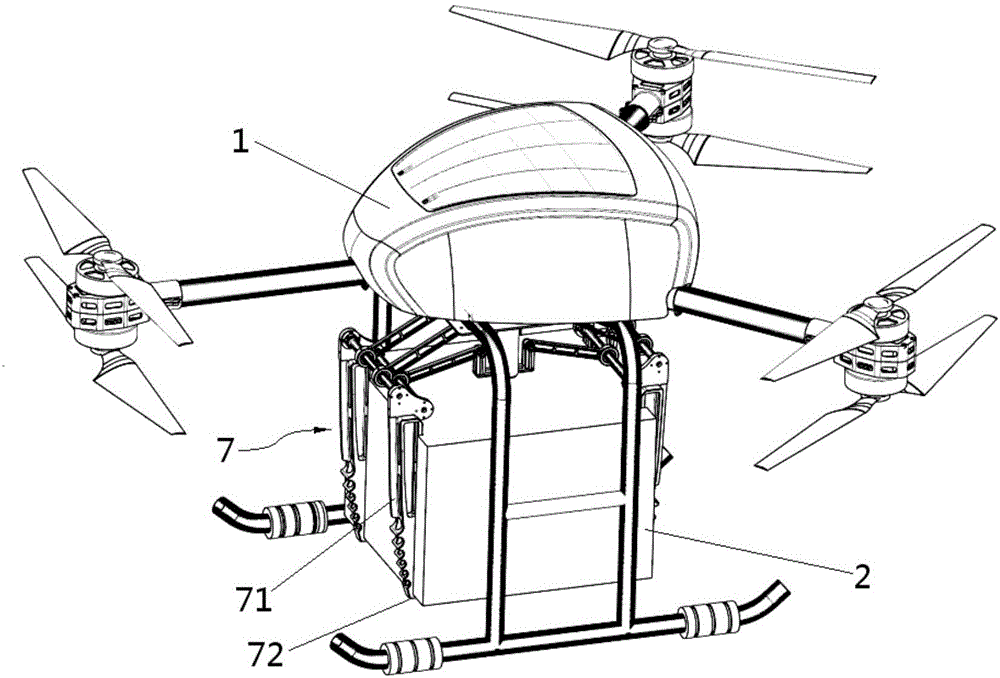

Cargo transportation method based on unmanned aerial vehicle

InactiveCN106809393AAvoid waiting timeImprove unloading efficiency and reliabilityAircraft componentsLaunching weaponsAutomotive engineeringAerospace engineering

The invention relates to a cargo transportation method based on an unmanned aerial vehicle. A flight control system used for controlling flight posture, a first detection component used for detecting the flight position and a carrying component used for carrying a cargo (2) are arranged on the unmanned aerial vehicle. The cargo transportation method comprises the following steps that a first detection component detects the flight position of the unmanned aerial vehicle (1) and sends a signal to the flight control system; the flight control system receives a detection signal of the first detection component and judges whether the unmanned aerial vehicle (1) reaches the preset unloading position or not; if the preset cargo loading position is reached, a cargo unloading instruction is sent out to control the loading component to perform automatic cargo unloading. The cargo transportation method of the unmanned aerial vehicle has the advantages that the unmanned aerial vehicle can realize the independent automatic cargo loading without landing on the ground; the labor cooperation is not needed; the waiting after the unmanned aerial vehicle reaches the cargo unloading position and the misoperation in the cargo unloading process can be avoided, so that the cargo unloading efficiency and the reliability of the unmanned aerial vehicle are improved; the cargo unloading cost is reduced.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

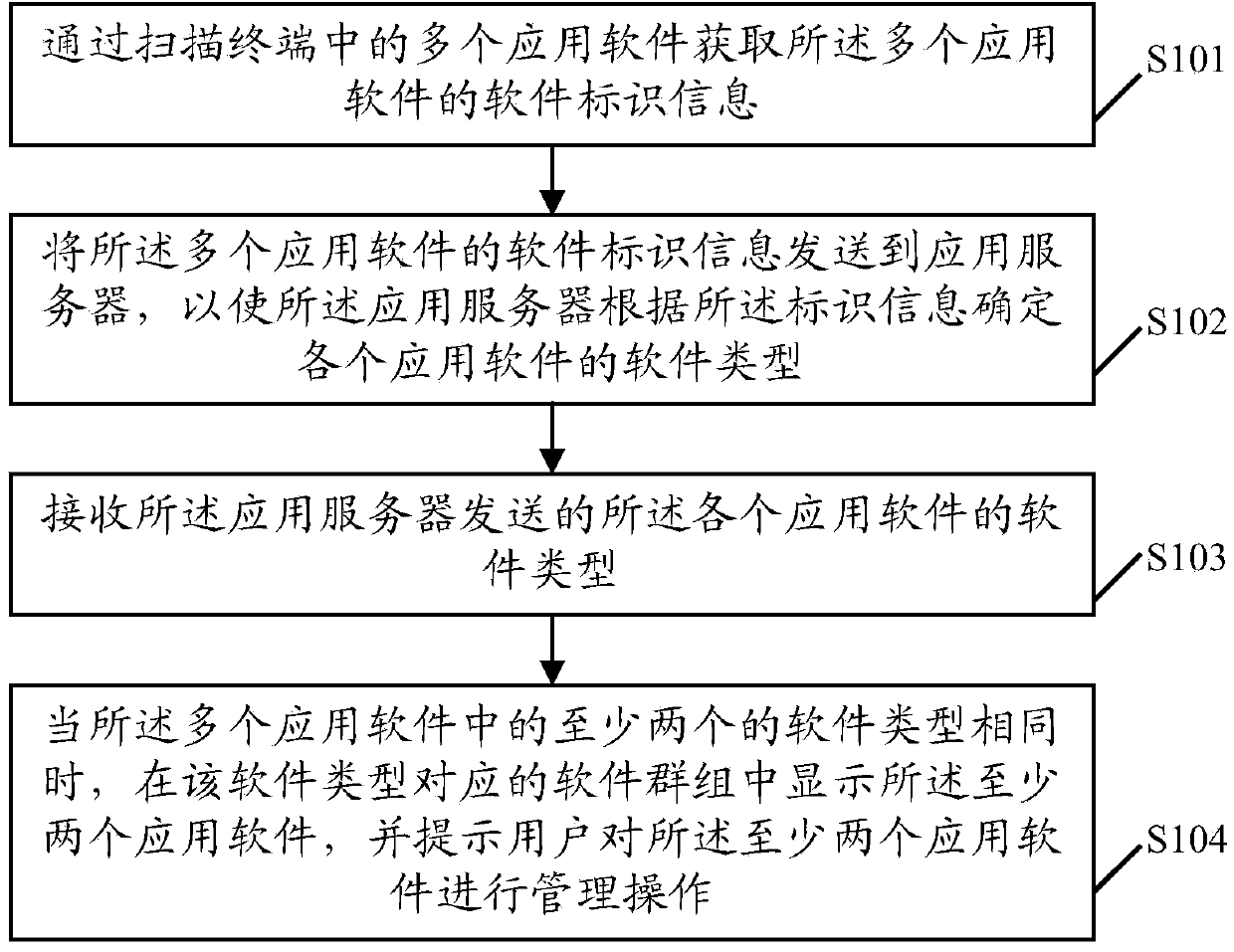

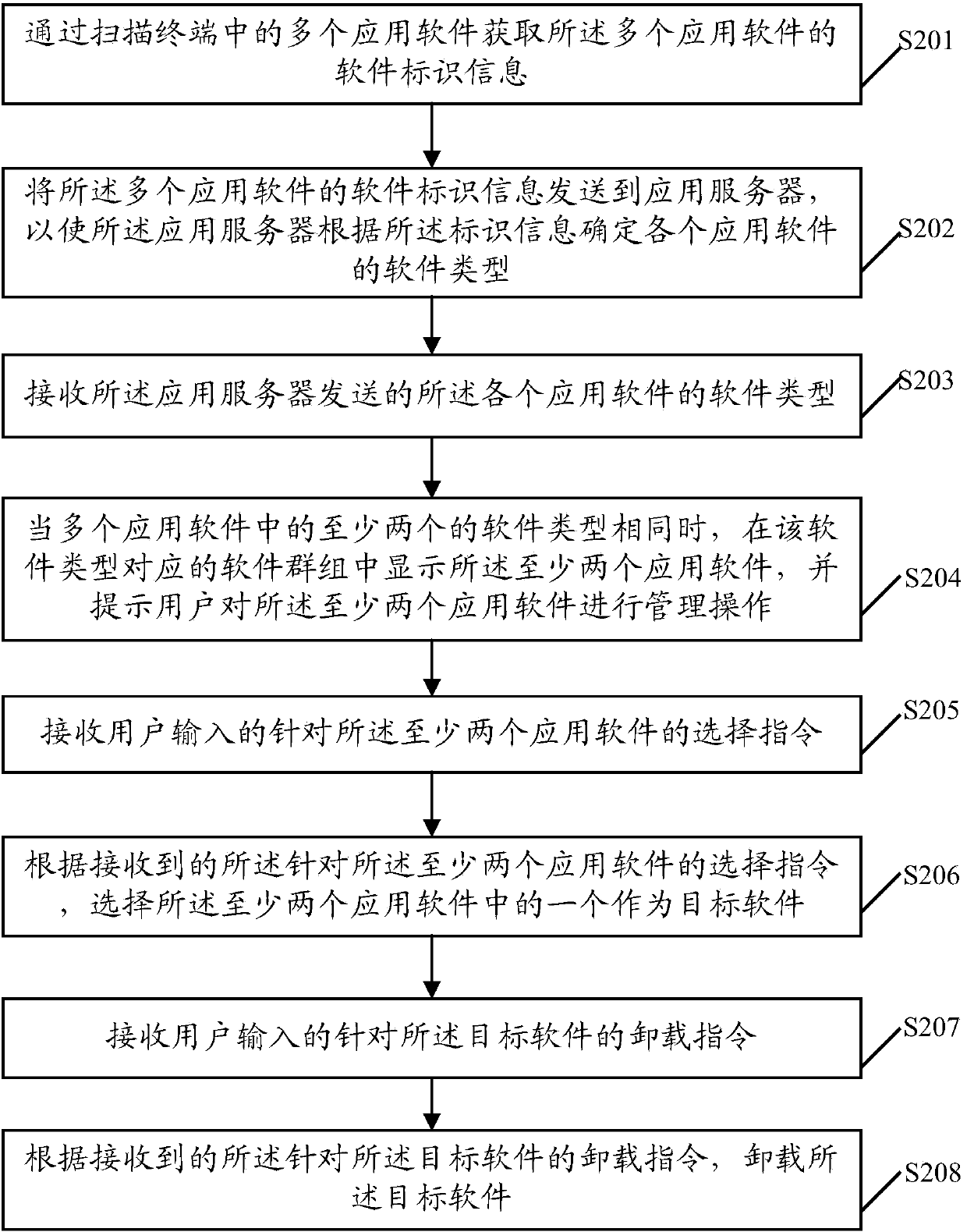

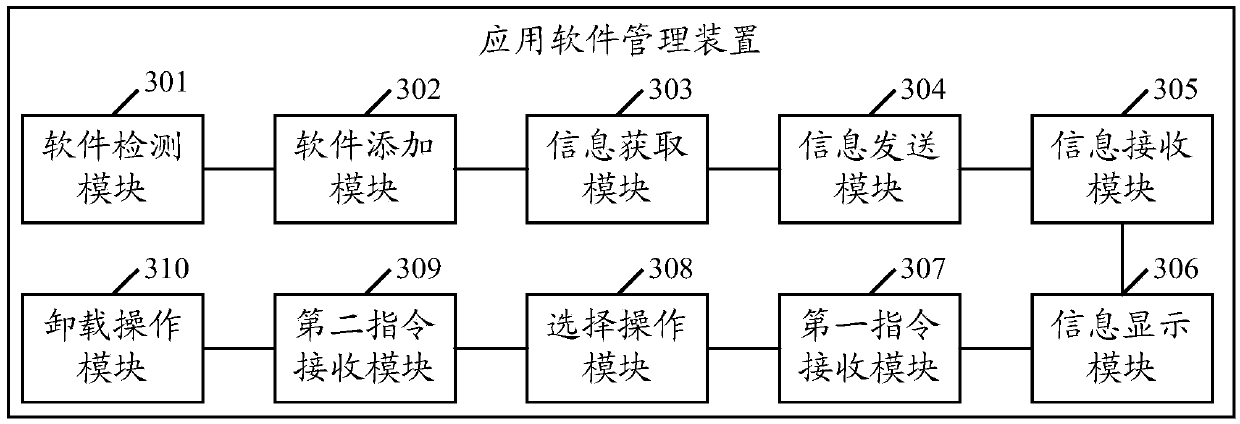

Management method and management device for pieces of application software and terminal

InactiveCN104216740ASave storage spaceImprove unloading efficiencyProgram loading/initiatingApplication serverSoftware engineering

The embodiment of the invention discloses a management method for pieces of application software. The method comprises the following steps that software identification information of a plurality of pieces of application software are obtained through scanning a plurality of pieces of application software in a terminal; the software identification information of a plurality of pieces of application software are sent to an application server, so that the application server determines the software type of each piece of application software according to the identification information; the software type of each piece of application software sent by the application server is received; when at least two software types of the software in a plurality of pieces of application software are identical, the at least two pieces of application software are displayed in a software group corresponding to the software types, and in addition, a user is reminded of carrying management and operation on the at least two pieces of application software. The embodiment of the invention also discloses a management device for the pieces of application software and a terminal. By adopting the method, the device and the terminal provided by the embodiment of the invention, the uninstalling efficiency of the similar software is improved, and the software storage space is saved.

Owner:BEIJING KINGSOFT INTERNET SECURITY SOFTWARE CO LTD

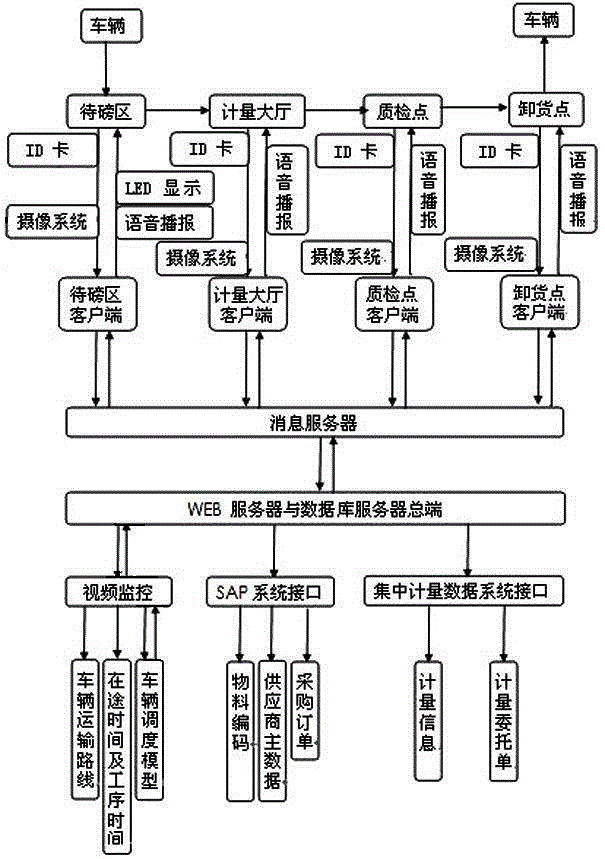

Novel logistics management and control system

InactiveCN104537511AImprove unloading efficiencyImprove logistics speedLogisticsVideo monitoringLogistics management

The invention belongs to a logistics management system, and particularly relates to a novel logistics management and control system. The novel logistics management and control system comprises a vehicle-mounted monitoring device, a logistics transportation and distribution working area and a monitoring and command working area, wherein the vehicle-mounted monitoring device comprises car identification marks of IC cards and ID cards, the logistics transportation and distribution working area is provided with a monitoring workstation, the monitoring workstation comprises a to-be-weighed area client side, a metering hall client side, a quality testing point client side and an unloading point client site, the monitoring and command working area is provided with a message server, a WEB server and a database server general end, communication between the WEB server and the database server general end is forwarded and received by the message server, and the WEB server and the database server general end are connected with video monitoring equipment and a vehicle scheduling model and are provided with interfaces connected with an SAP system and a centralized metric data system. The novel logistics management and control system can dynamically manage and control vehicle logistics, improves the logistics speed, improves the factory entering and unloading efficiency of vehicles, and reduces transportation expenses.

Owner:ANYANG IRON & STEEL

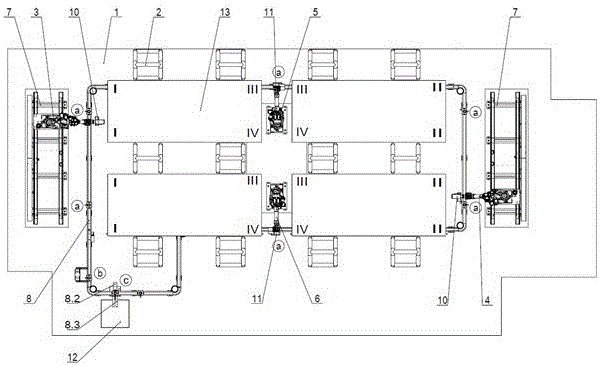

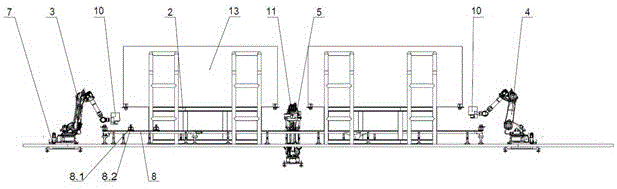

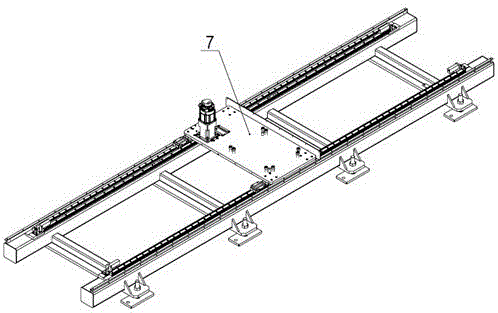

Automatic disassembling and assembling system for container spin lock

The invention discloses an automatic disassembling and assembling system for a container spin lock. The system is arranged on a transfer platform of a shore crane and comprises a container parking and containing platform, an industrial robot, robot walking mechanisms and a clamp; the container parking and containing platform is arranged on the transfer platform of the shore crane; the robot walking mechanisms are arranged at the two ends of the transfer platform; the industrial robot is installed on the robot walking mechanisms; and the clamp is installed at the tail end of the industrial robot. The automatic disassembling and assembling system is low in cost, high in automation degree, accurate and efficient.

Owner:NANJING SCIYON AUTOMATION GRP

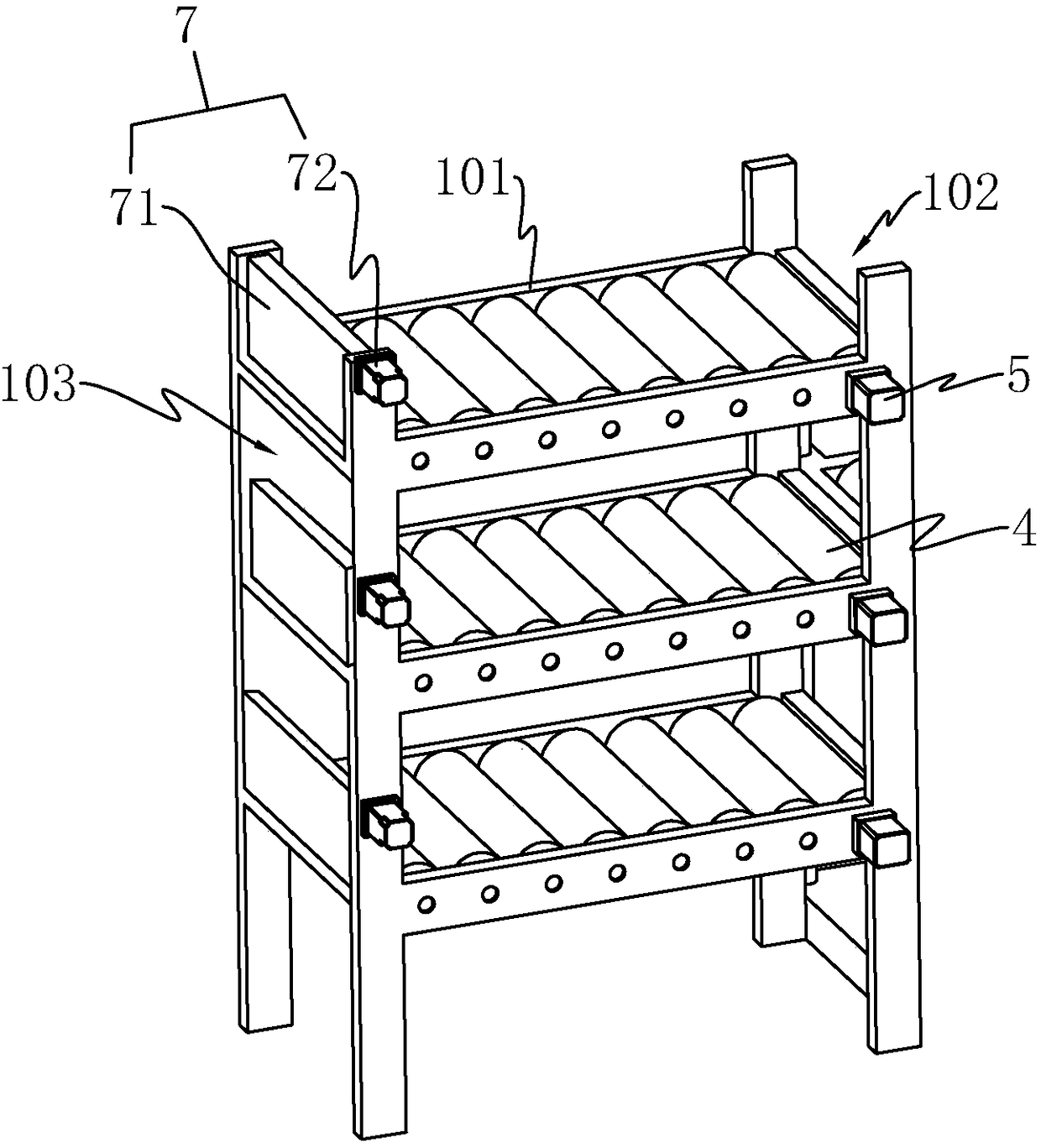

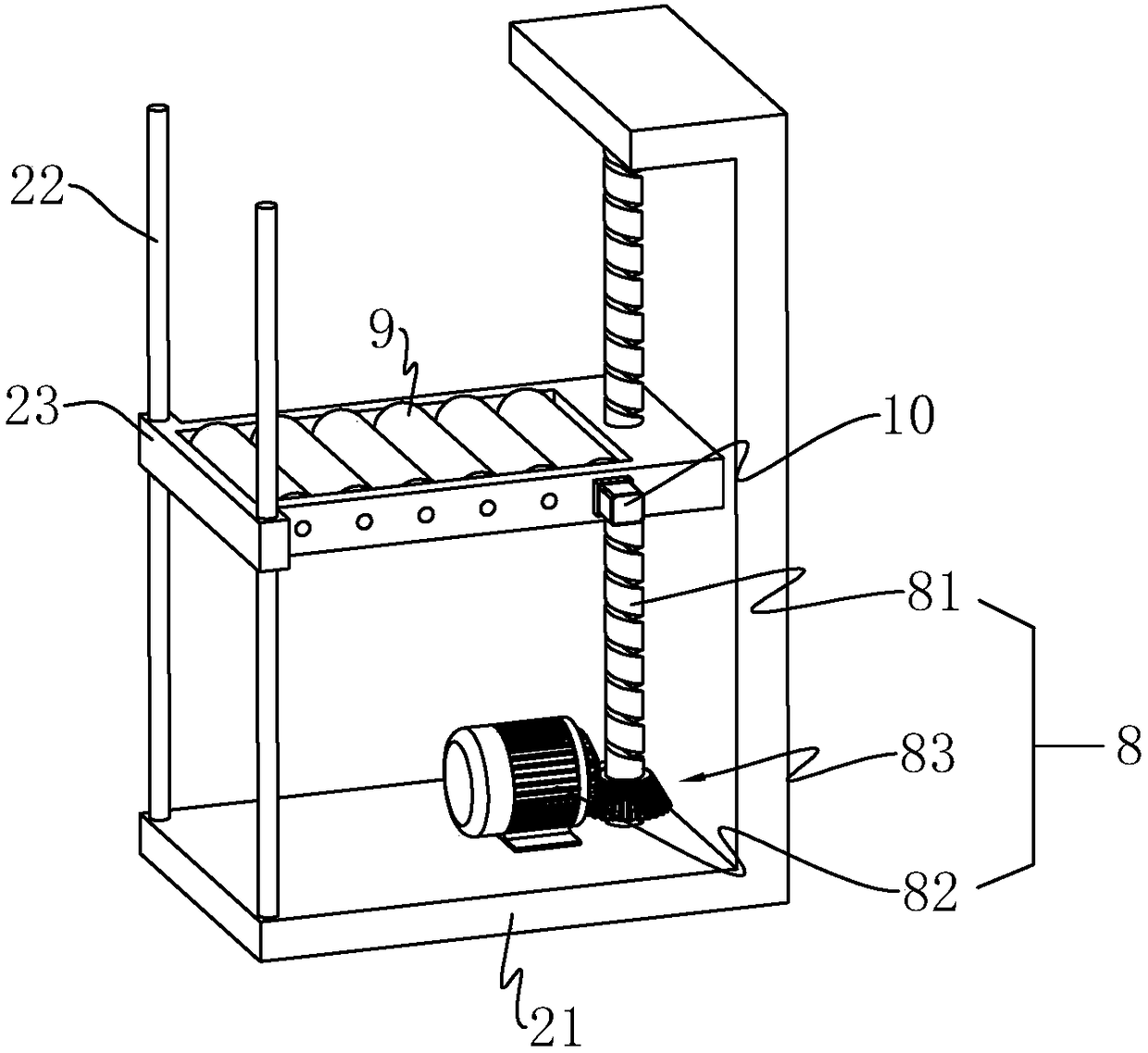

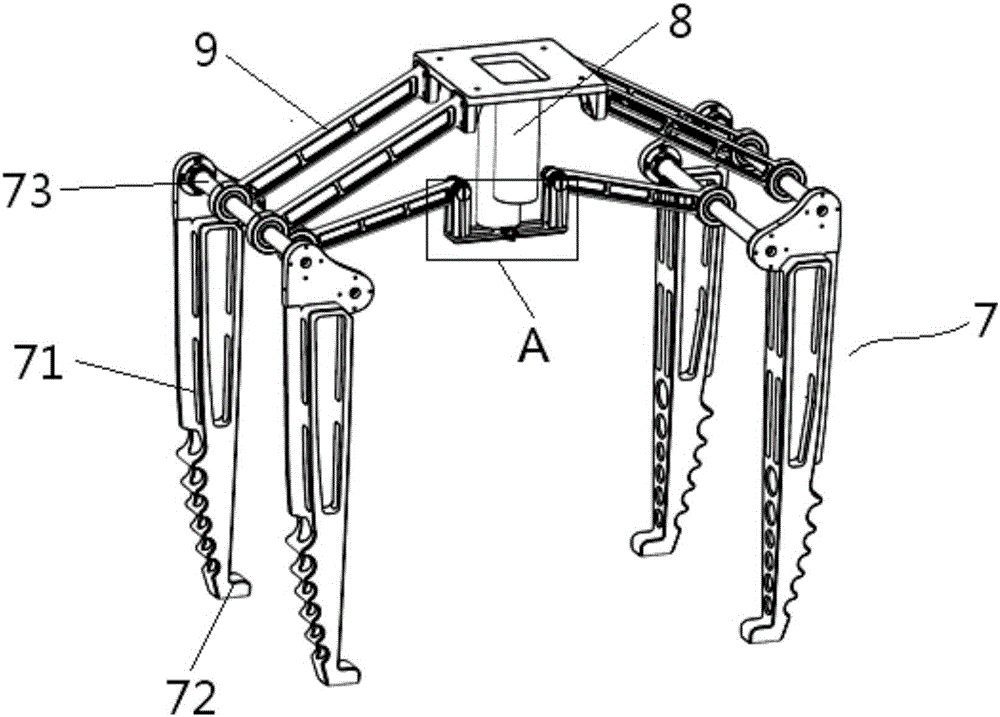

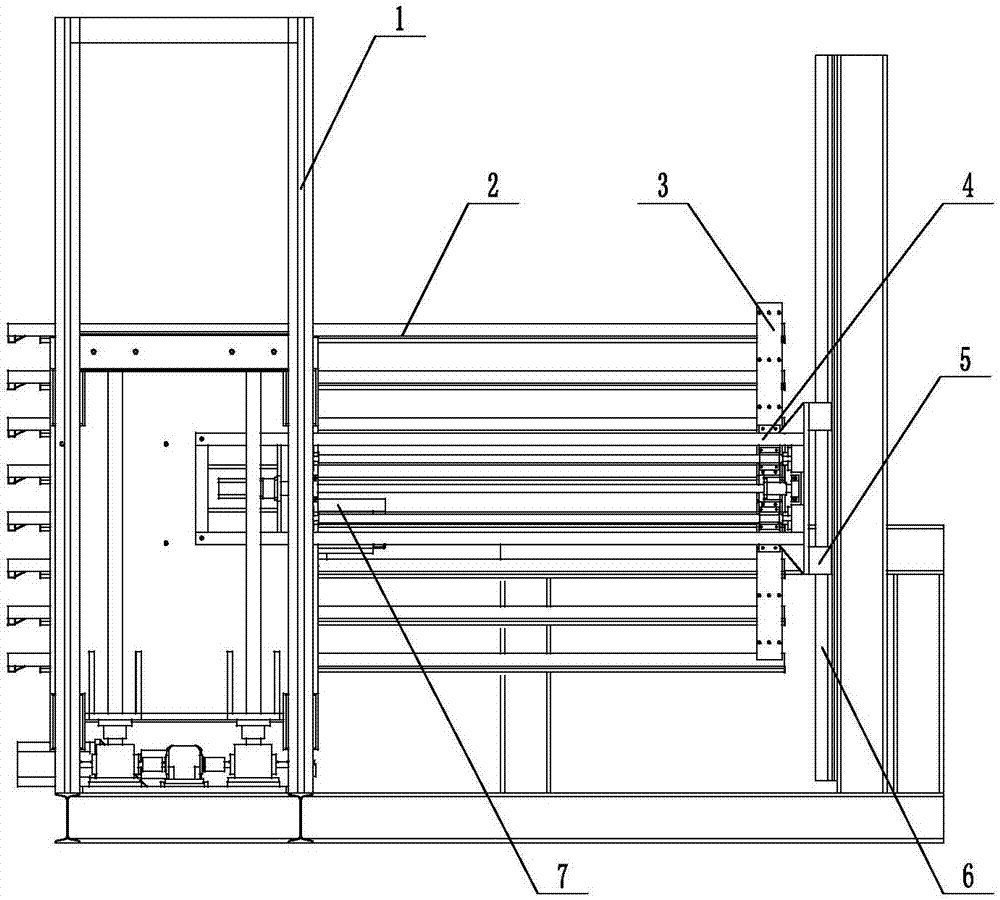

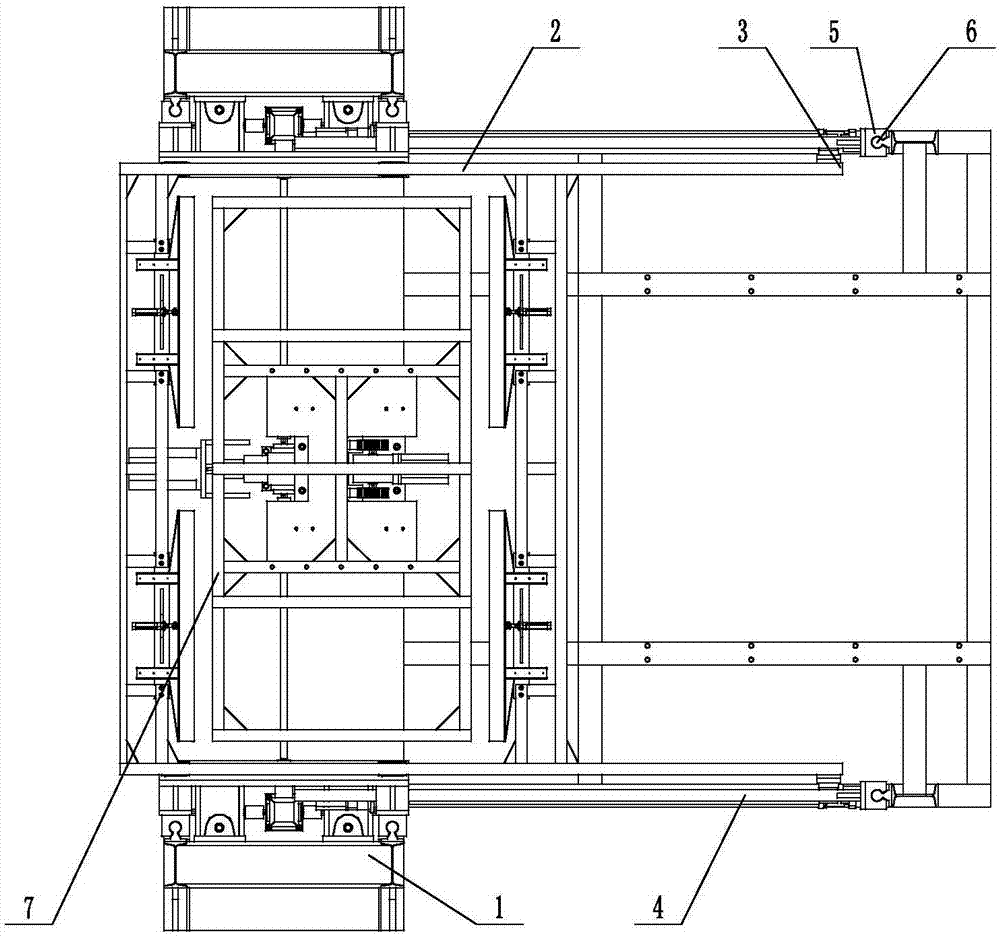

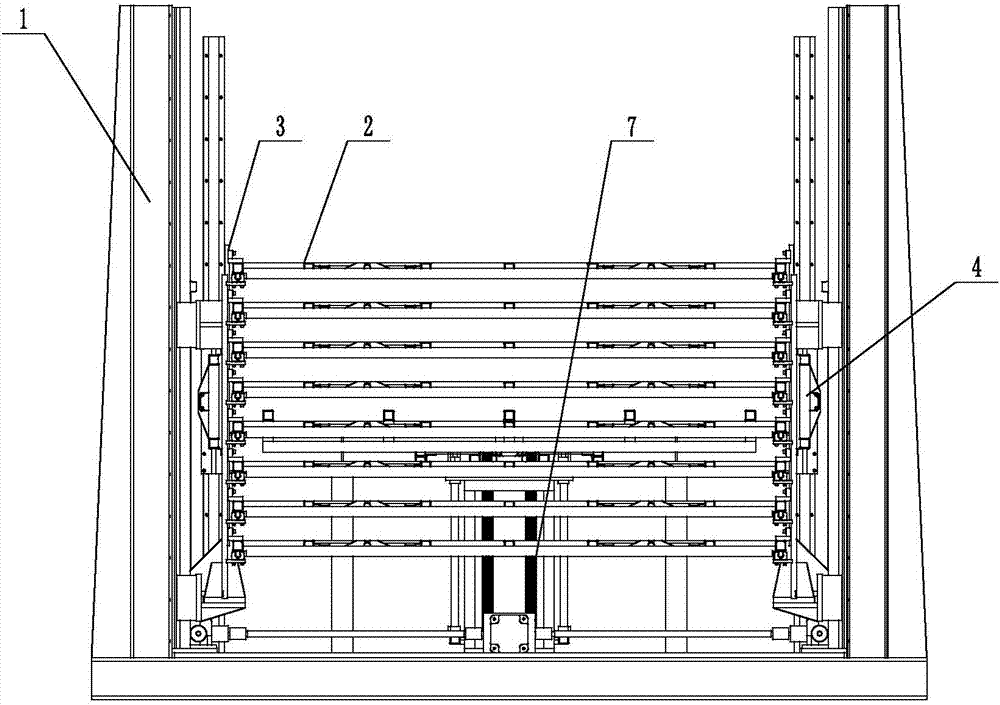

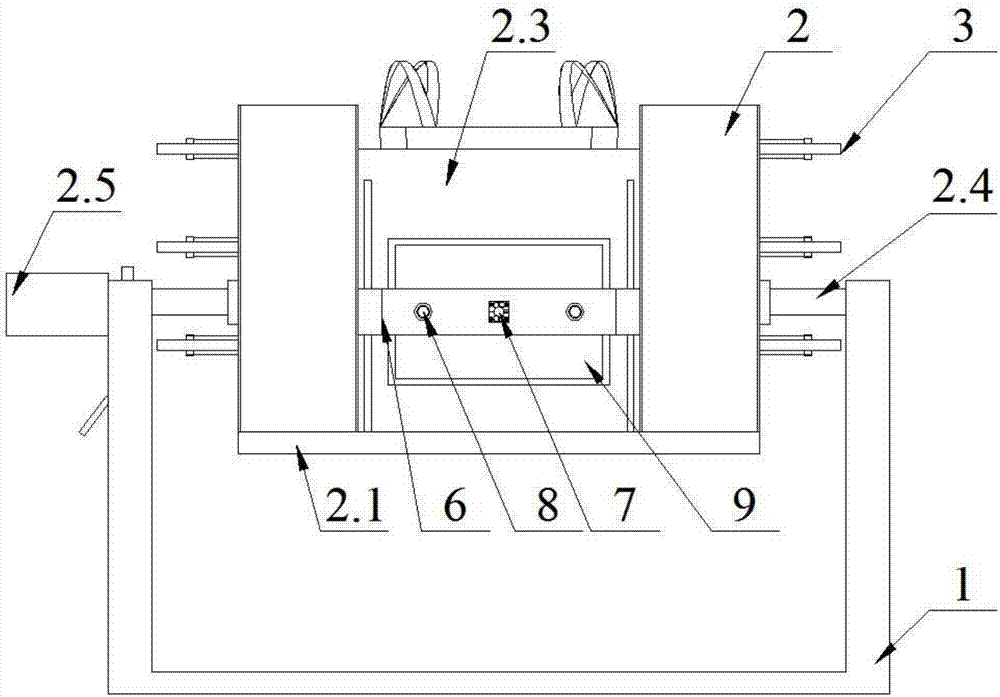

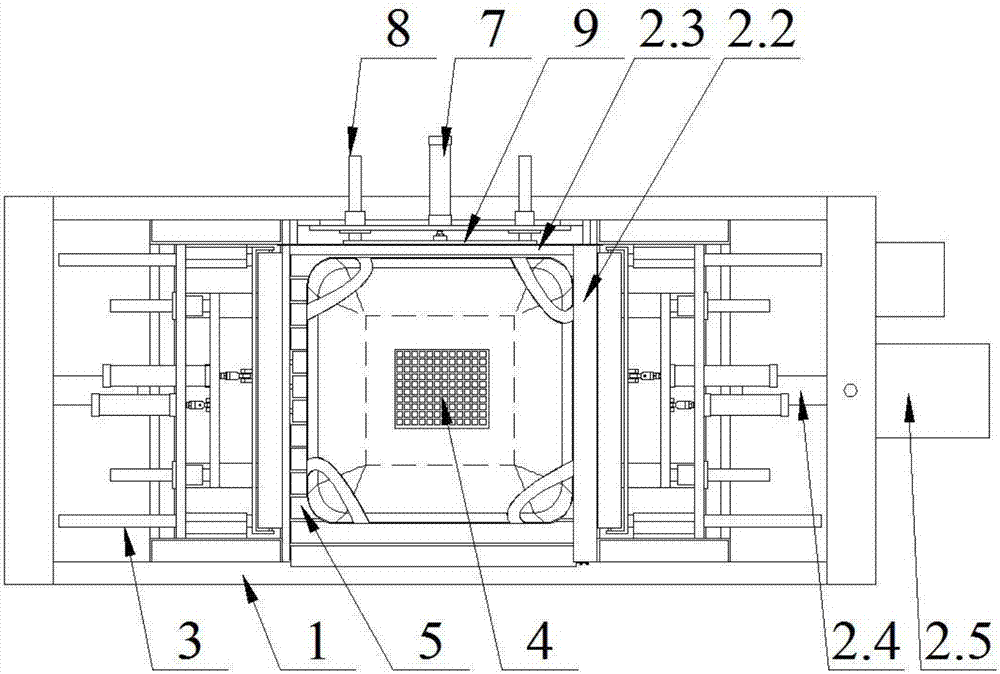

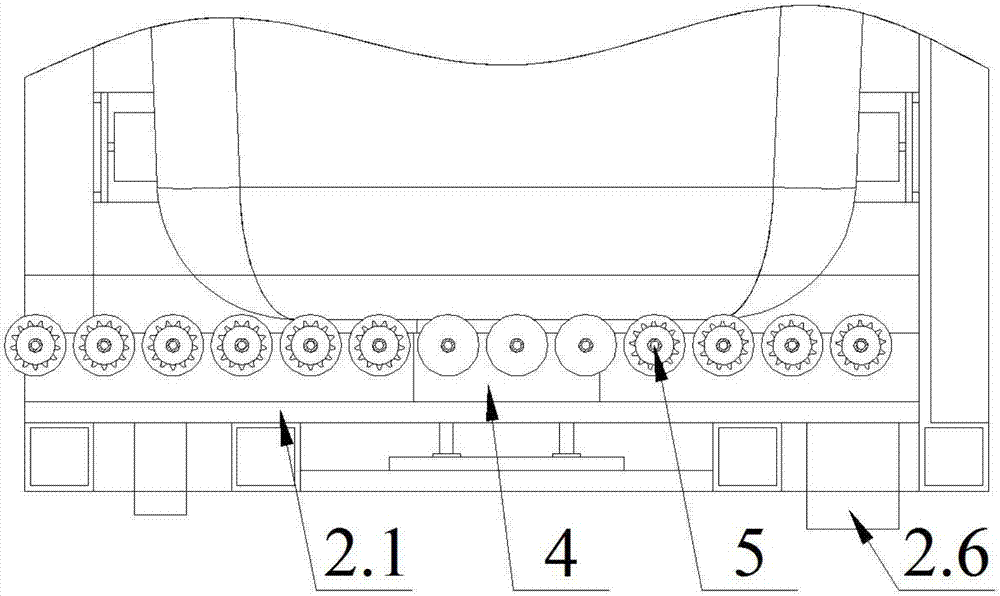

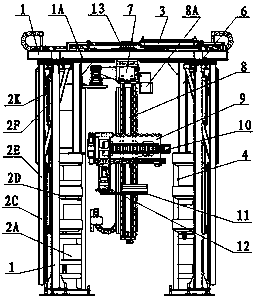

Wood board loading and unloading lifting assembly

ActiveCN107139280AHigh degree of automationReduce manpower consumptionPlywood pressesLaminationEngineeringMechanical engineering

The invention discloses a wood board loading and unloading lifting assembly which comprises a lifting mechanism (1), a jacking mechanism (7), a push mechanism (4) and a plurality of bearing and connecting mechanisms (2). The wood board loading and unloading lifting assembly has the advantages that working efficiency is high, energy consumption is reduced, manpower is saved, conveying precision is high, and a hot press can conduct hot pressing on the two faces simultaneously.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

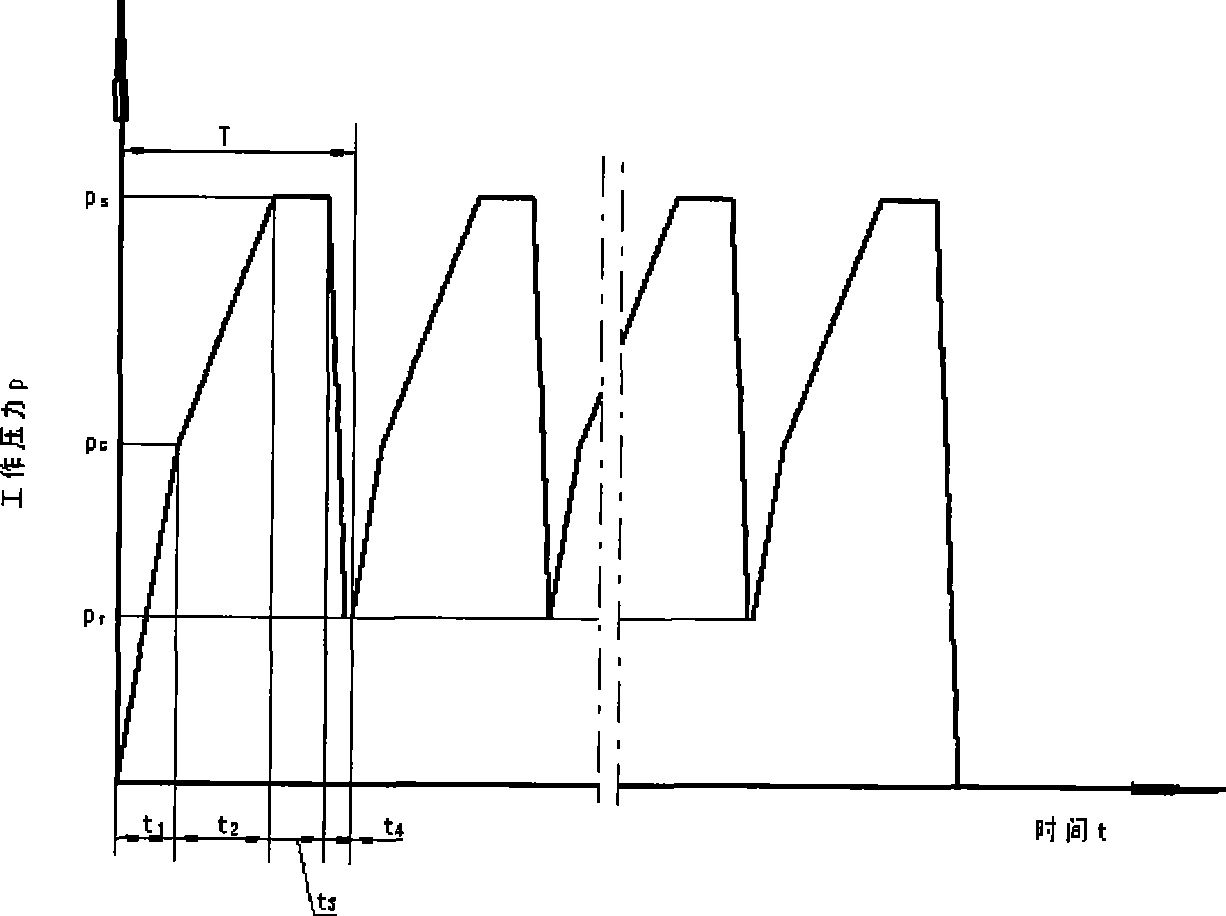

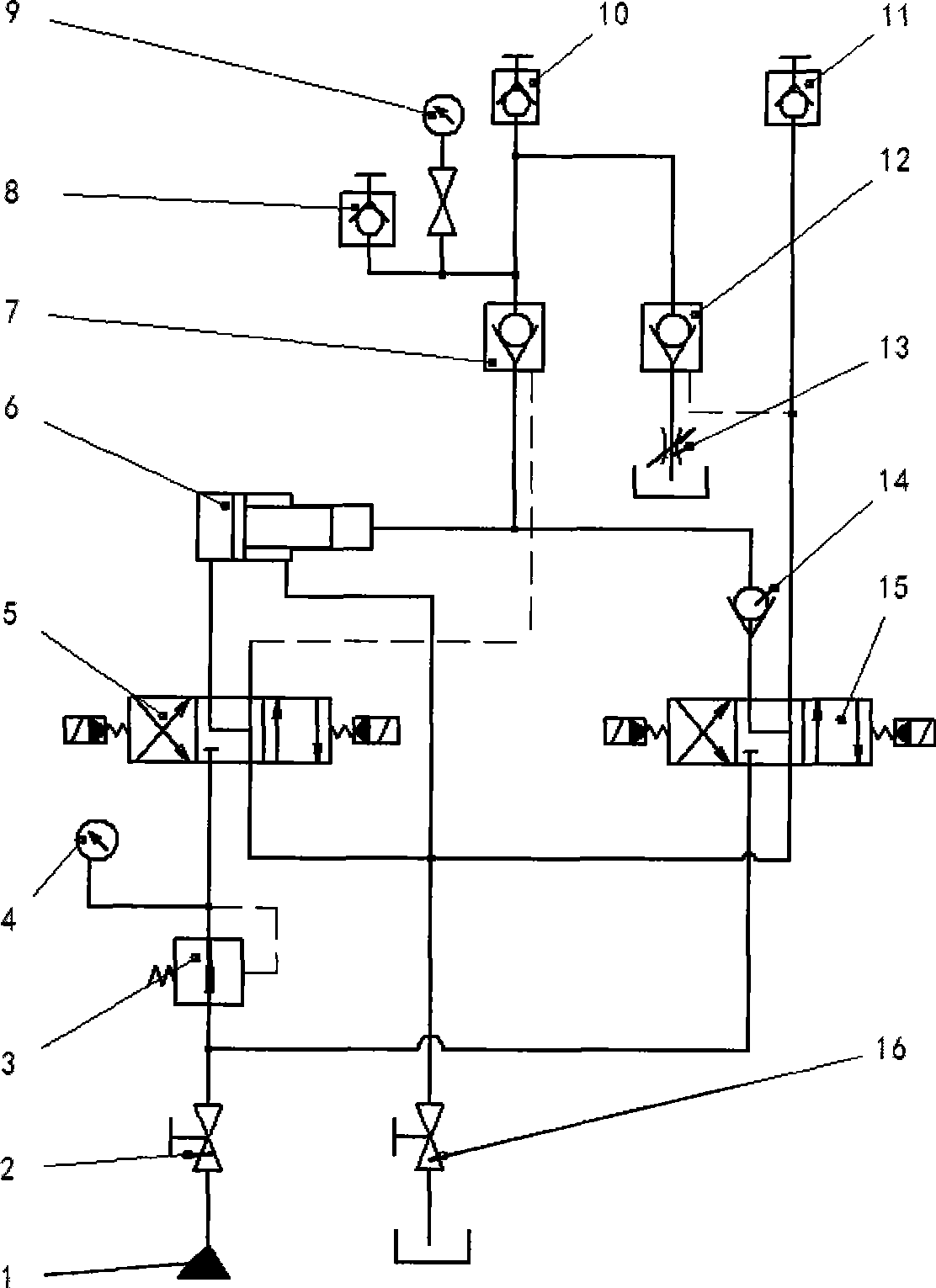

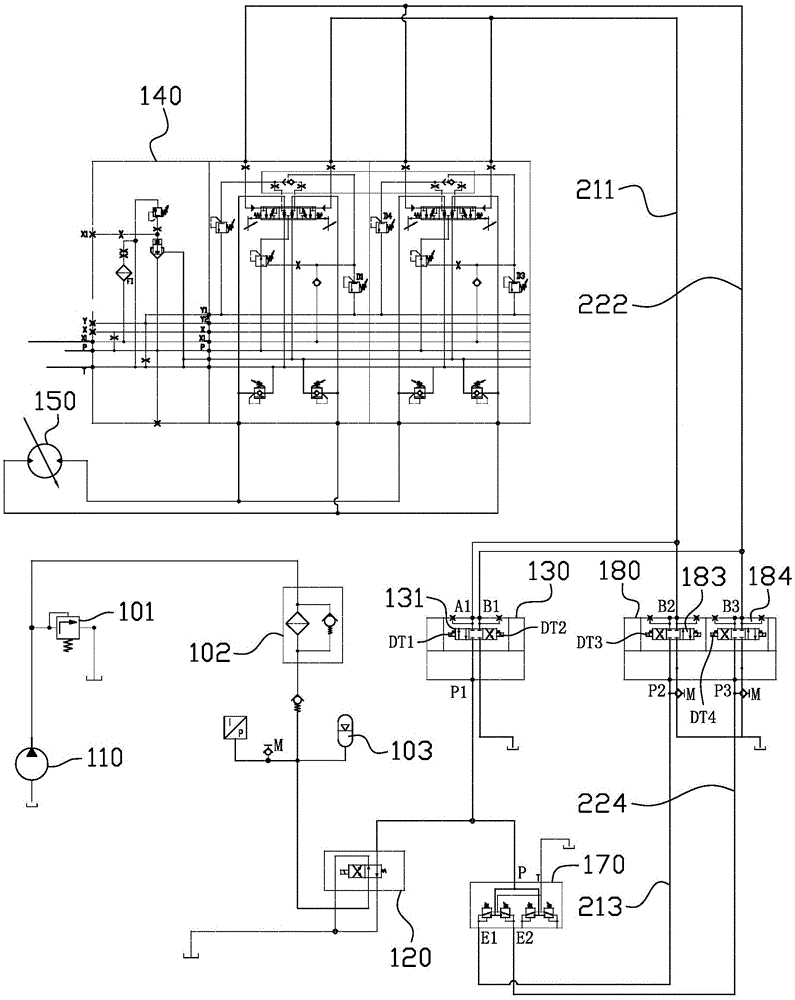

Ultra-high pressure high flow supercharging and unloading system

InactiveCN101451922AAchieving supercharged loadingImprove unloading efficiencyServomotor componentsStructural/machines measurementUltra high pressureElectro hydraulic

The invention relates to a superhigh pressure large-traffic pressurizing and unloading system, belonging to a superhigh rapid-loading, unloading hydraulic control system for delivery and type tests of a hydraulic support. The invention mainly solves difficult technical problems about low efficiency of pressurizing loading and unloading in current internal-loading hydraulic support test bench, and about frequency failures caused by large impact on hydraulic elements of the system. The technical proposal employed by the invention is as below: the superhigh pressure large-traffic pressurizing and unloading system includes a hydraulic source, a stop valve and a pressure cylinder, wherein the system further includes a pressure reducing valve, electro-hydraulic reversing valves, a pilot operated check valve, a throttle valve and a check valve, an primary pressure opening of the pressure reducing valve is connected with the hydraulic source via the stop valve, a secondary pressure opening of the pressure reducing valve is connected with an liquid inlet P of the electro-hydraulic reversing valve; an A opening of the electro-hydraulic reversing valve is connected with a low pressure chamber of the pressure cylinder, a low pressure rod chamber of the pressure cylinder, an O opening of the electro-hydraulic reversing valve and an O opening of another electro-hydraulic reversing valve are connected with a liquid supply tank via the stop valve.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

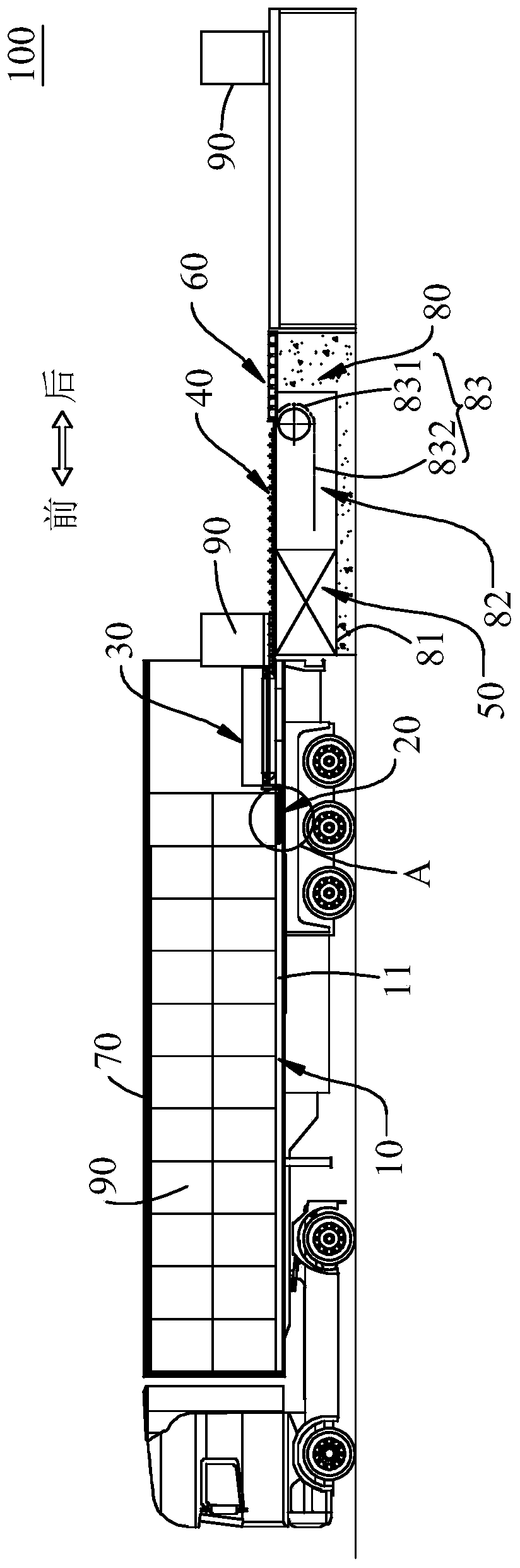

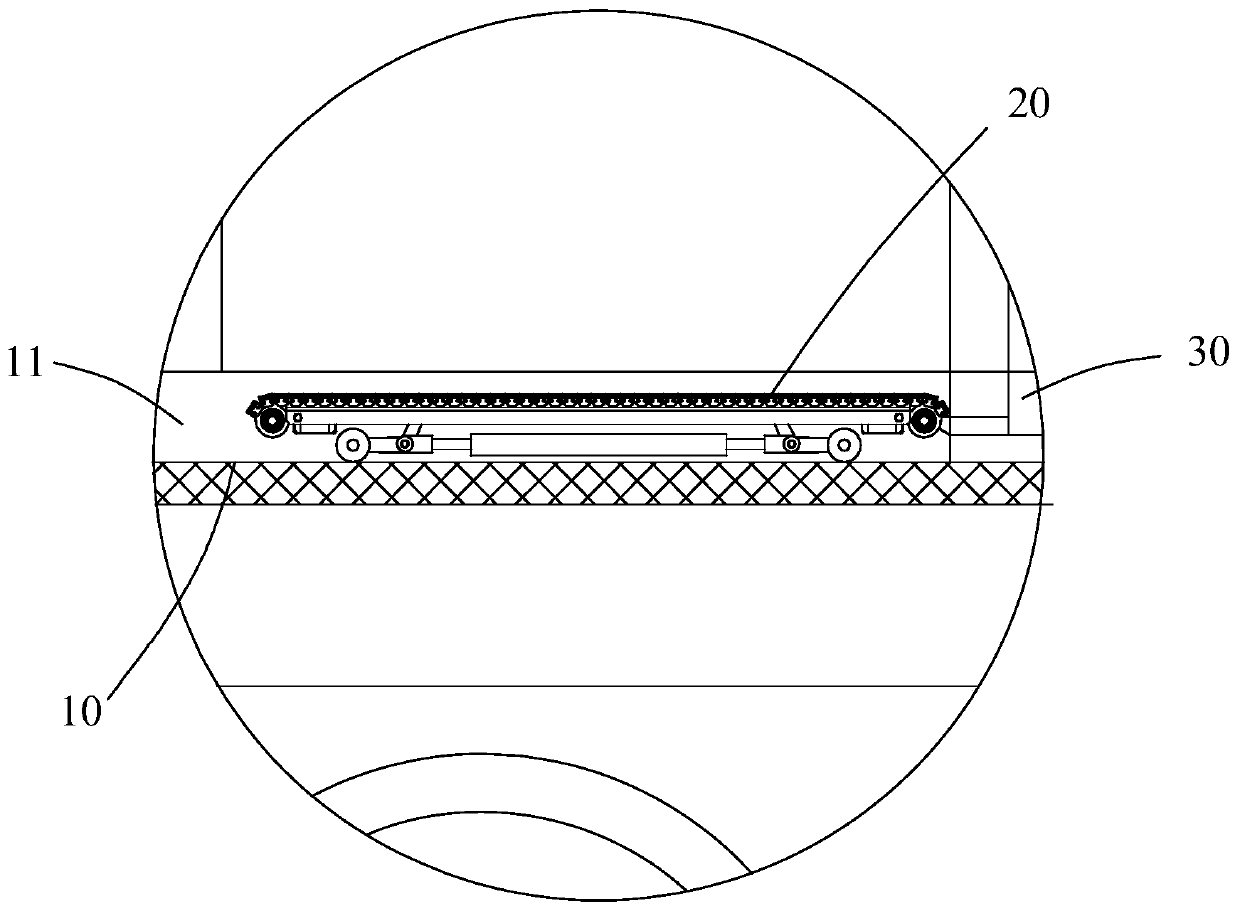

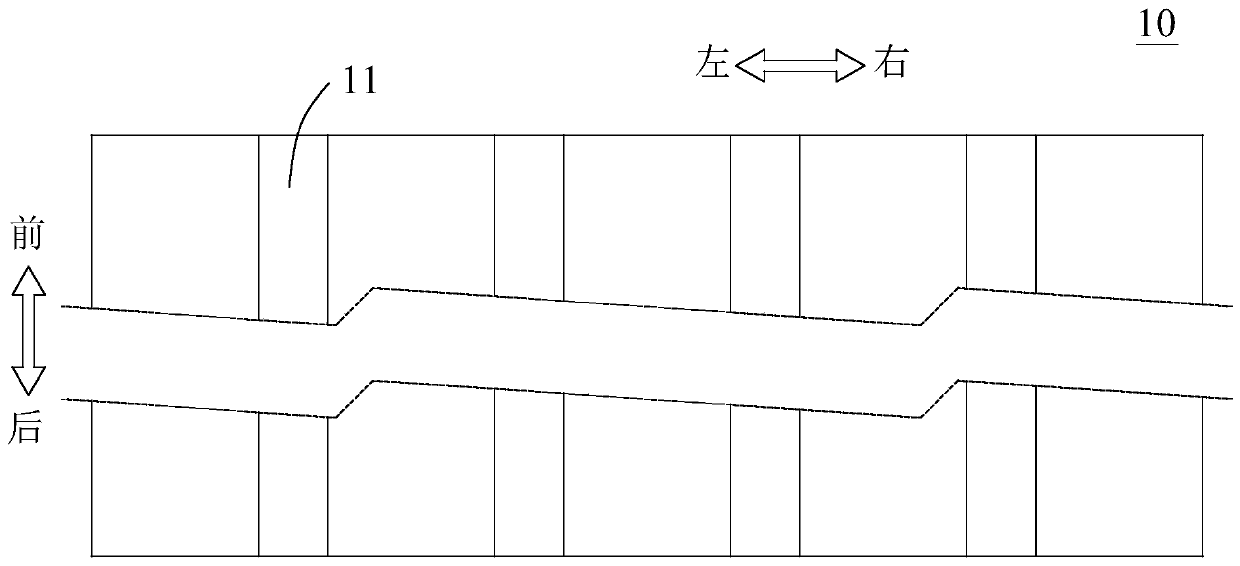

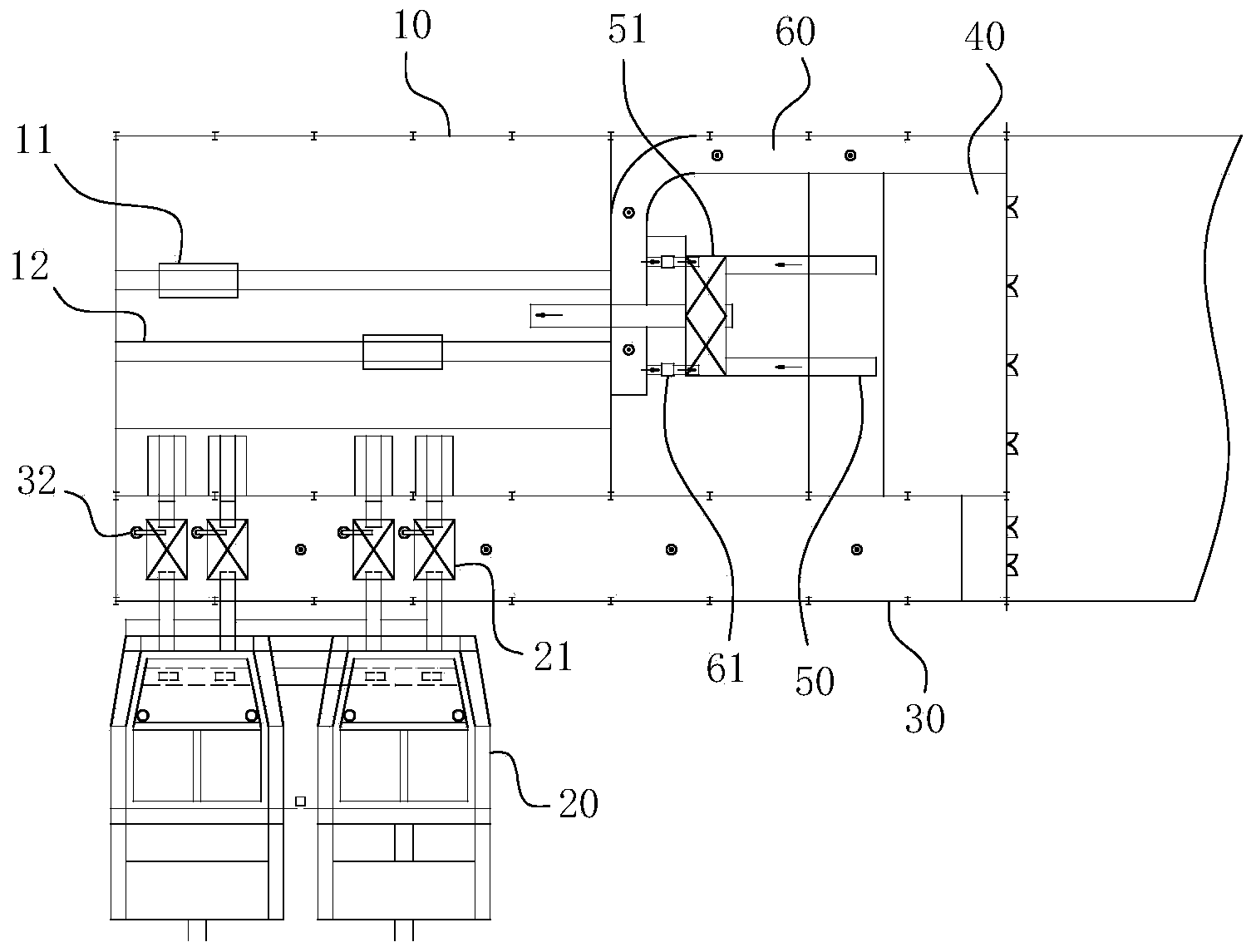

Automatic loading and unloading system, automatic loading method and automatic unloading method

PendingCN111573316ARealize automatic loadingImprove loading efficiencyLoading/unloadingLogistics managementTruck

The invention relates to an automatic loading and unloading system, an automatic loading method and an automatic unloading method, and belongs to the technical field of logistics systems. The automatic loading and unloading system involves a cargo bearing plate, submerged transferring devices, a traction loading and unloading operation device and a flexible conveying line, wherein the cargo bearing plate is used for being laid on a bottom plate of a truck carriage, the traction loading and unloading operation device is located between the submerged transferring devices and the flexible conveying line, the traction loading and unloading operation device is connected with the submerged transferring devices and the front end of the flexible conveying line, the traction loading and unloading operation device can drag the submerged transferring devices and the flexible conveying line to move in the front-back direction, and the submerged transferring devices, the traction loading and unloading operation device and the flexible conveying line can achieve cargo transferring. According to the automatic loading and unloading system, automatic loading and unloading on cargo can be achieved,labor and time are saved, and the logistics cost is reduced.

Owner:JIANGSU GUANCHAO LOGISTICS TECH CO LTD

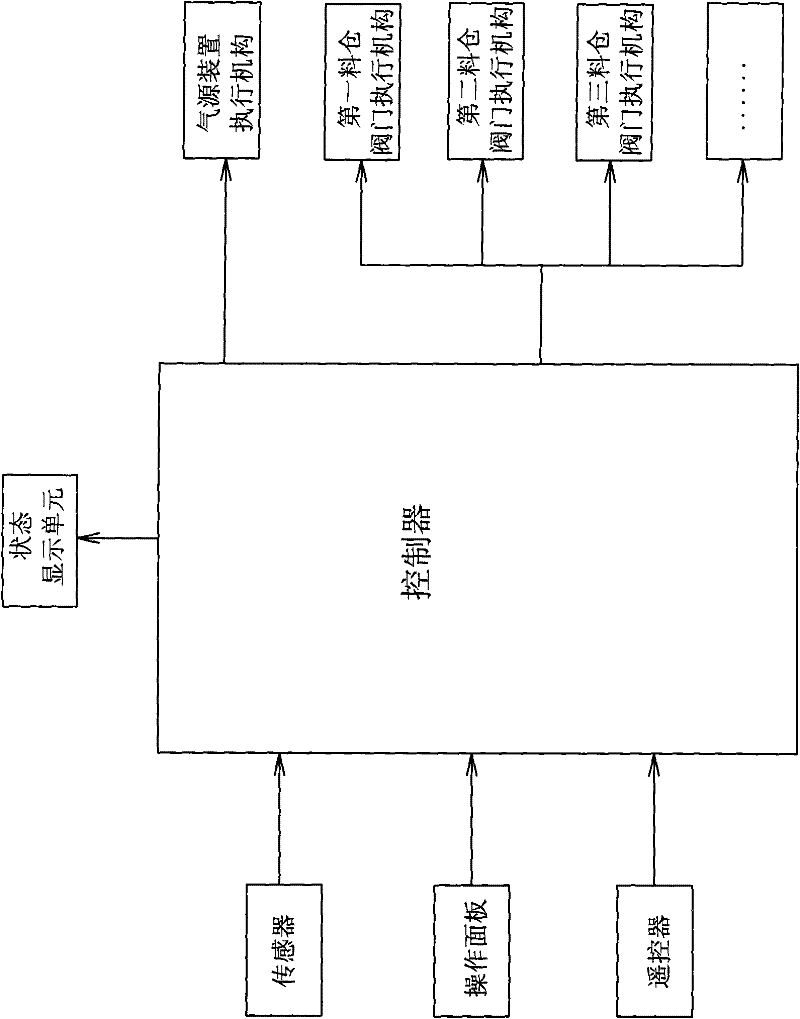

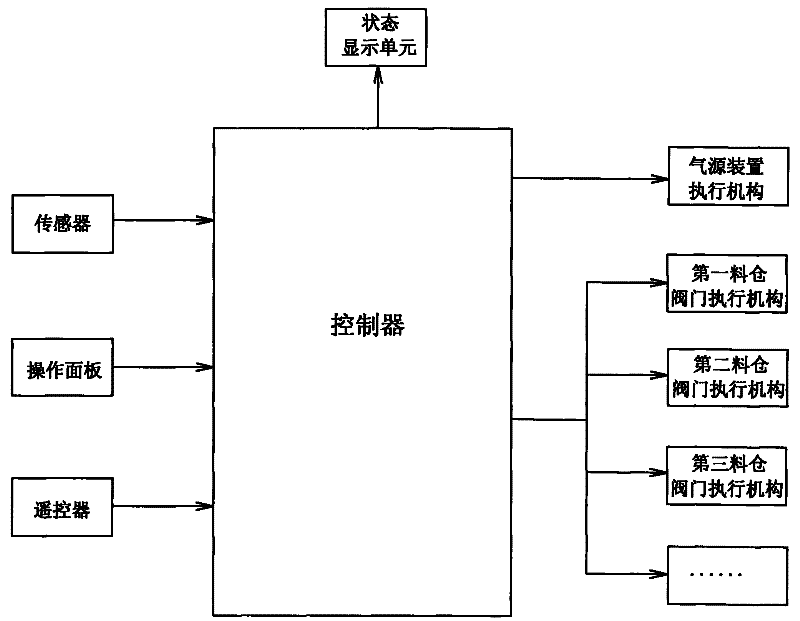

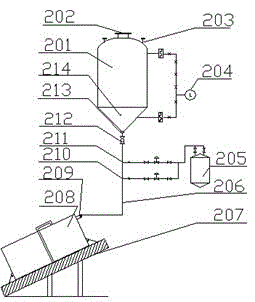

Intelligent unloading system, multi-silo tank container and multi-silo tank car

ActiveCN102234027AReduce labor intensityImprove unloading efficiencyLoading/unloadingControl signalValve actuator

The invention discloses an intelligent unloading system, a multi-silo tank container and a multi-silo tank car. The intelligent unloading system comprises a sensor which is arranged in a tank body and is used for timely acquiring a pressure signal in the tank body, multiple valve actuators which are respectively connected with multiple unloading valves of multiple silos and are used for opening or closing the unloading valves, a controller and an input unit, wherein the controller is used for receiving the pressure signal input by the sensor, comparing a pressure value with multiple opening pressure set values and multiple closing pressure set values in the controller and then controlling multiple actuators to sequentially open and close the unloading valves of all the silos according to the comparison result, thus all the silos sequentially unload; and the input unit is connected with the controller and is used for inputting a control signal to the controller. By adopting the intelligent unloading system disclosed by the invention, the labour intensity can be greatly reduced, and the unloading efficiency can be improved. A tank container or tank car provided with the intelligent unloading system disclosed by the invention is convenient and rapid to unload.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

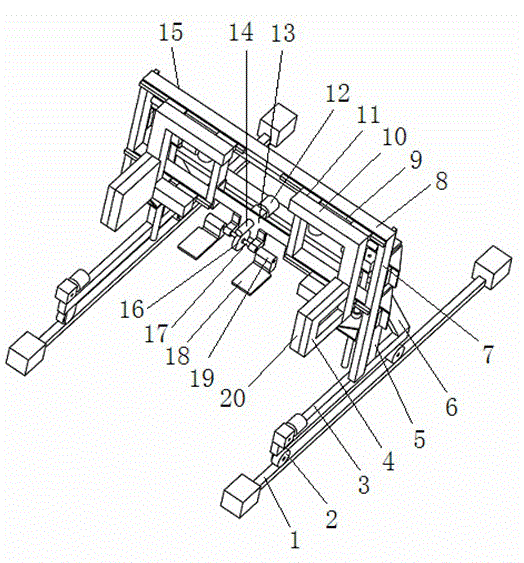

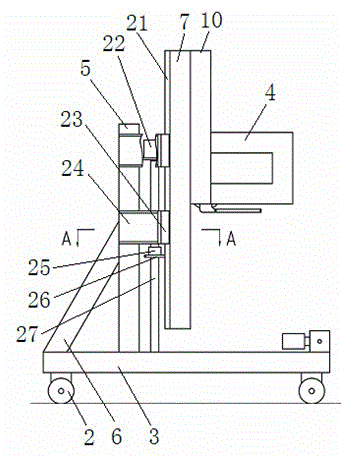

Fully-automatic unloader

The invention provides a fully-automatic unloader which comprises a stand with mobile wheels. The fully-automatic unloader is characterized in that a lifting portal frame is arranged on the stand, a cross beam on the top of the lifting portal frame is provided with a telescopic clip, and a supporter is arranged on a cross beam at the middle part of the lifting portal frame. The supporter can be conveniently used for clipping goods through the lifting portal fame and the telescopic clip on the lifting portal frame and conveying the goods to a storehouse with the movement of the stand, therefore the goods can be automatically unloaded, are effectively from being damaged through matching of the clip and the supporter; and meanwhile, input of manpower resources and fixed assets such as a forklift is reduced, the labor intensity is greatly lowered, the unloading efficiency is increased, and the fully-automatic unloading is realized.

Owner:KUNMING DINGCHENG TECH

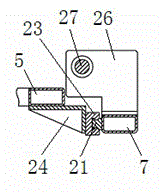

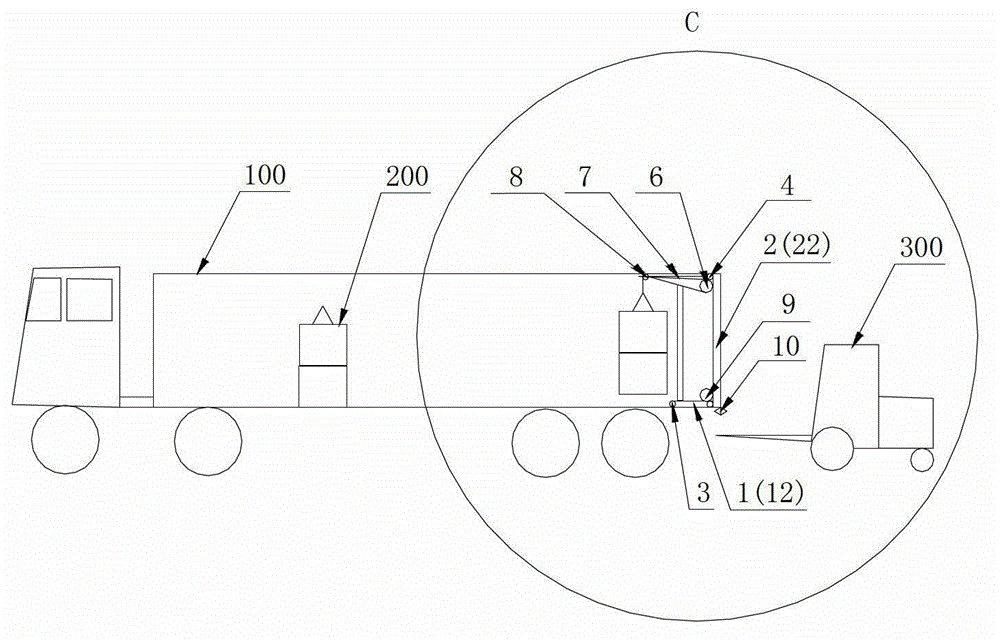

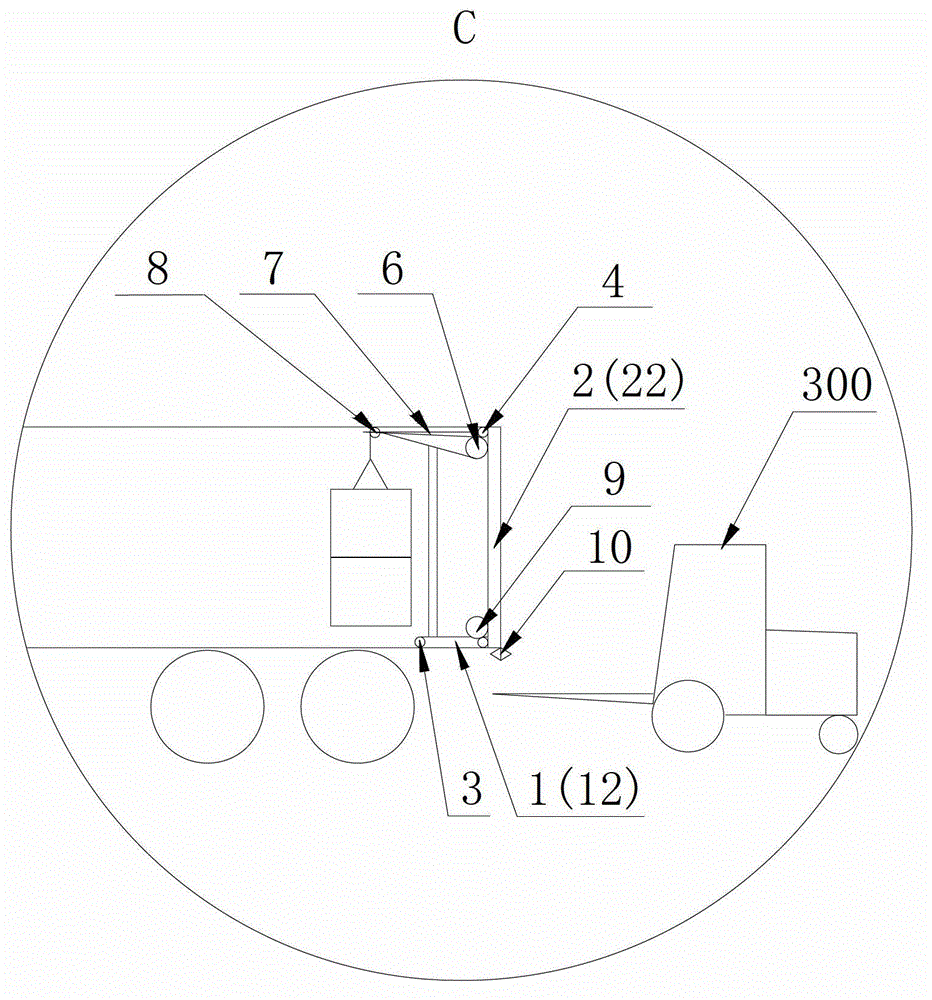

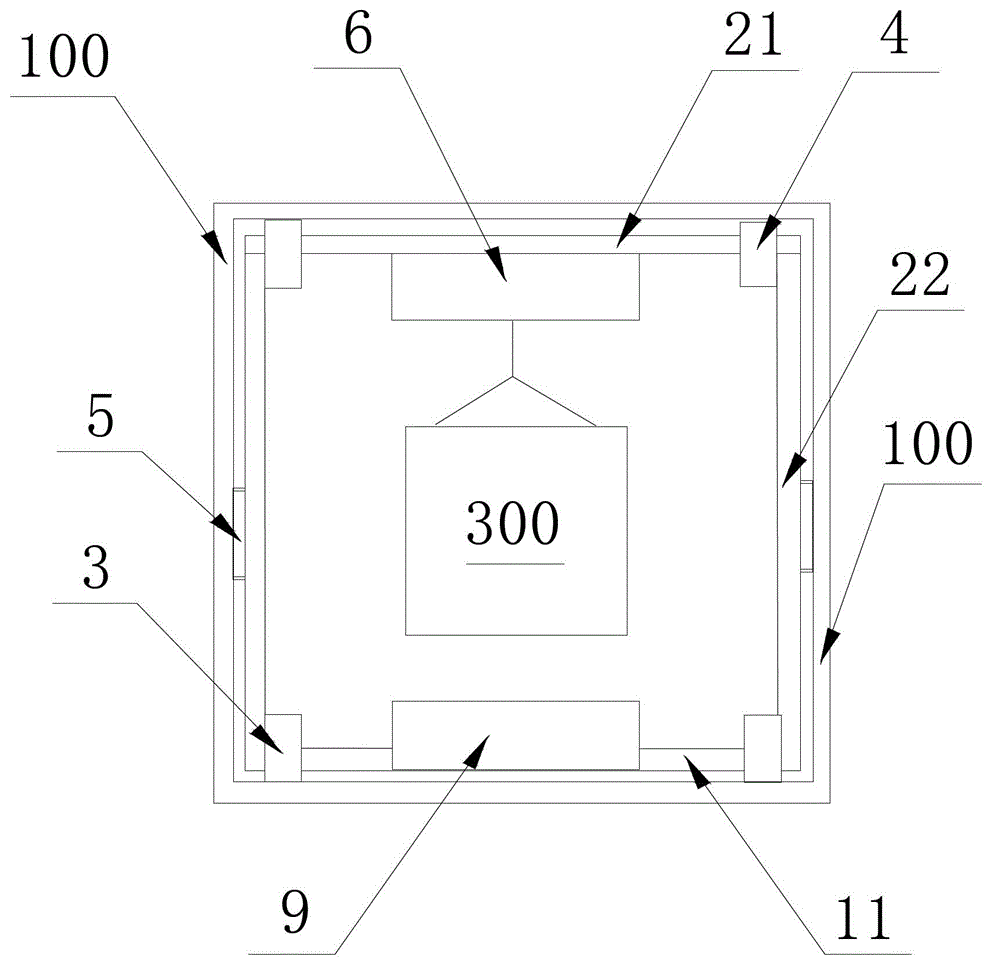

Container unloading device

ActiveCN103935925AEliminate potential safety hazardsSmall unloading areaPortable liftingTrolley cranesEngineeringMechanical engineering

The invention discloses a container unloading device. The device comprises a travelling mechanism, a travel actuating mechanism and a hoisting mechanism, wherein the travelling mechanism is arranged in a container and can move in the container, the travel actuating mechanism is used for at least moving the container unloading device to the tail part of the container from the inside of the container, and the hoisting mechanism is arranged on the traveling mechanism and used for hoisting cargo (200) loaded in the container. The container unloading device can be used for moving a starch ton bag and the like loaded in the container to the tail part of the container from the inside of the container, and the starch ton bag can be further moved out of the container from the tail part of the container by ways such as a forwarder forklift (300), therefore, the use of a boarding bridge is avoided, potential risk is eliminated, and the area of required unloading site is small; moreover, the container unloading device is applicable for container unloading under conditions of no landing platform and poor site, site area is saved, and unloading efficiency can be greatly improved.

Owner:COFCO FOOD SCI & TECH WUHAN CO LTD

Automatic cheese discharging machine

InactiveCN103789952AEasy to installFast and convenient cage loadingTextile treatment machine partsDischarge efficiencyYarn

The invention discloses an automatic cheese discharging machine which comprises a base. A fixing support is vertically arranged on the base, an overturning support capable of overturning around the fixing support is hinged to the fixing support, a driving device is installed on the overturning support, one side of the bottom of the overturning support is vertically connected with an overturning base, a yarn bobbin fixing seat is connected onto the overturning base through a rotary disk, the rotary disk is driven to rotate by the driving motor, at least two locking parts for fixing the yarn bobbin are arranged on the yarn bobbin fixing seat, the yarn bobbin comprises a yarn bobbin base and multiple inserting rods arranged on the yarn bobbin base, and the driving device and a driving motor are electrically connected with an electronic control cabinet. The bobbin installation is convenient and quick, and the operation is safe. In addition, the automatic cheese discharging machine is high in automation degree and cheese discharging efficiency, and a large amount of human resources are saved.

Owner:WUXI DANGKOU TONGHE TEXTILE MACHINERY PLANT

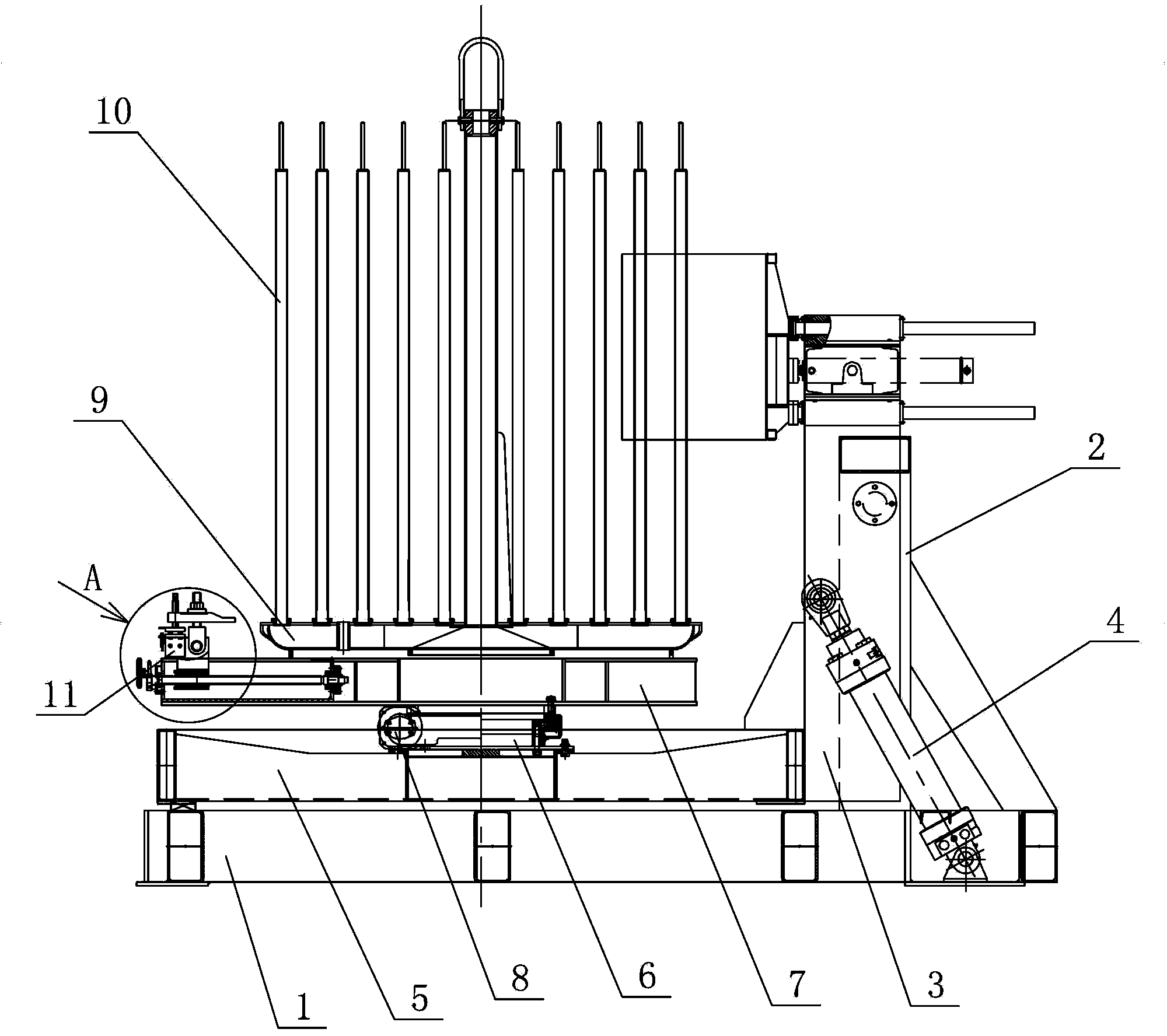

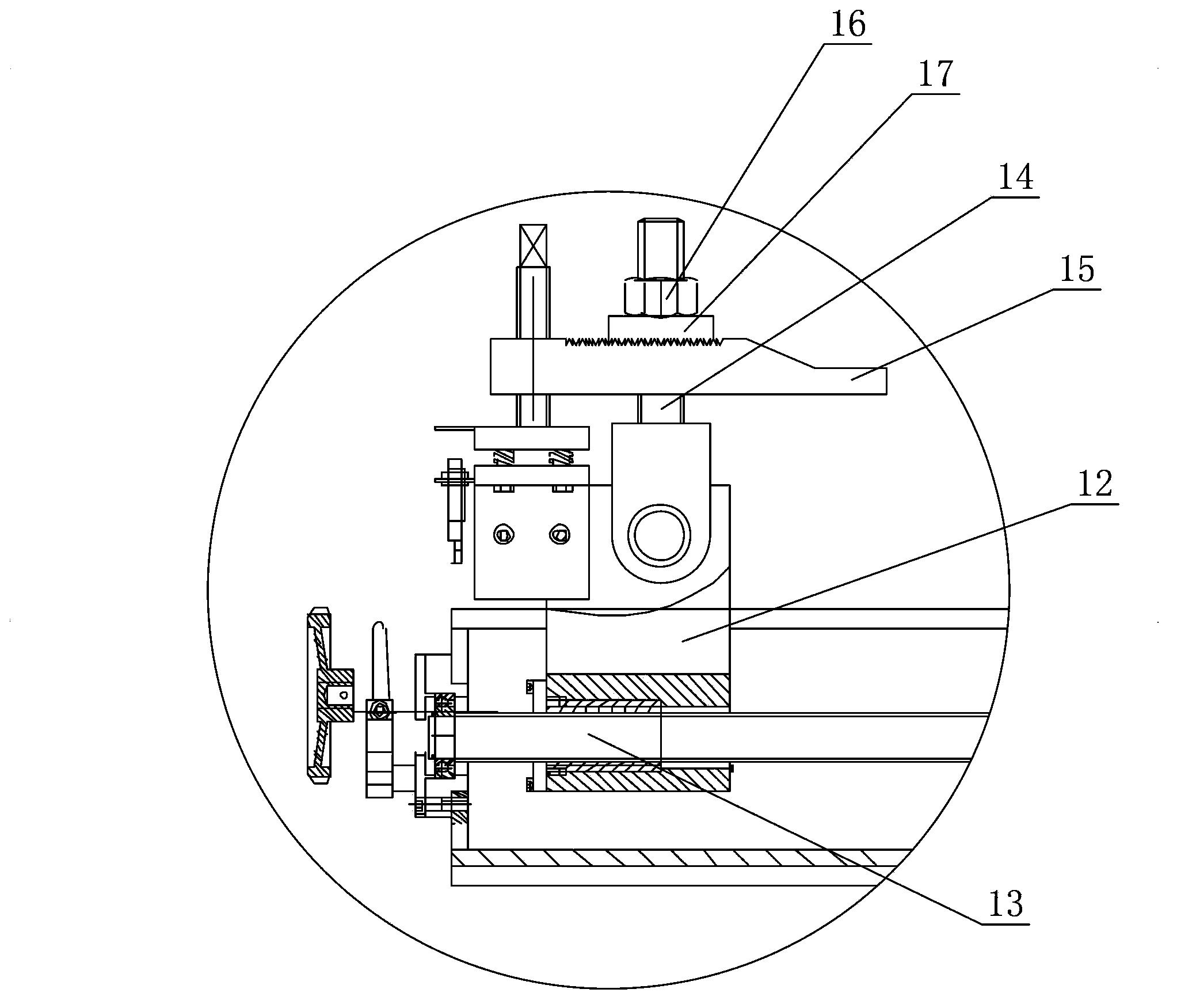

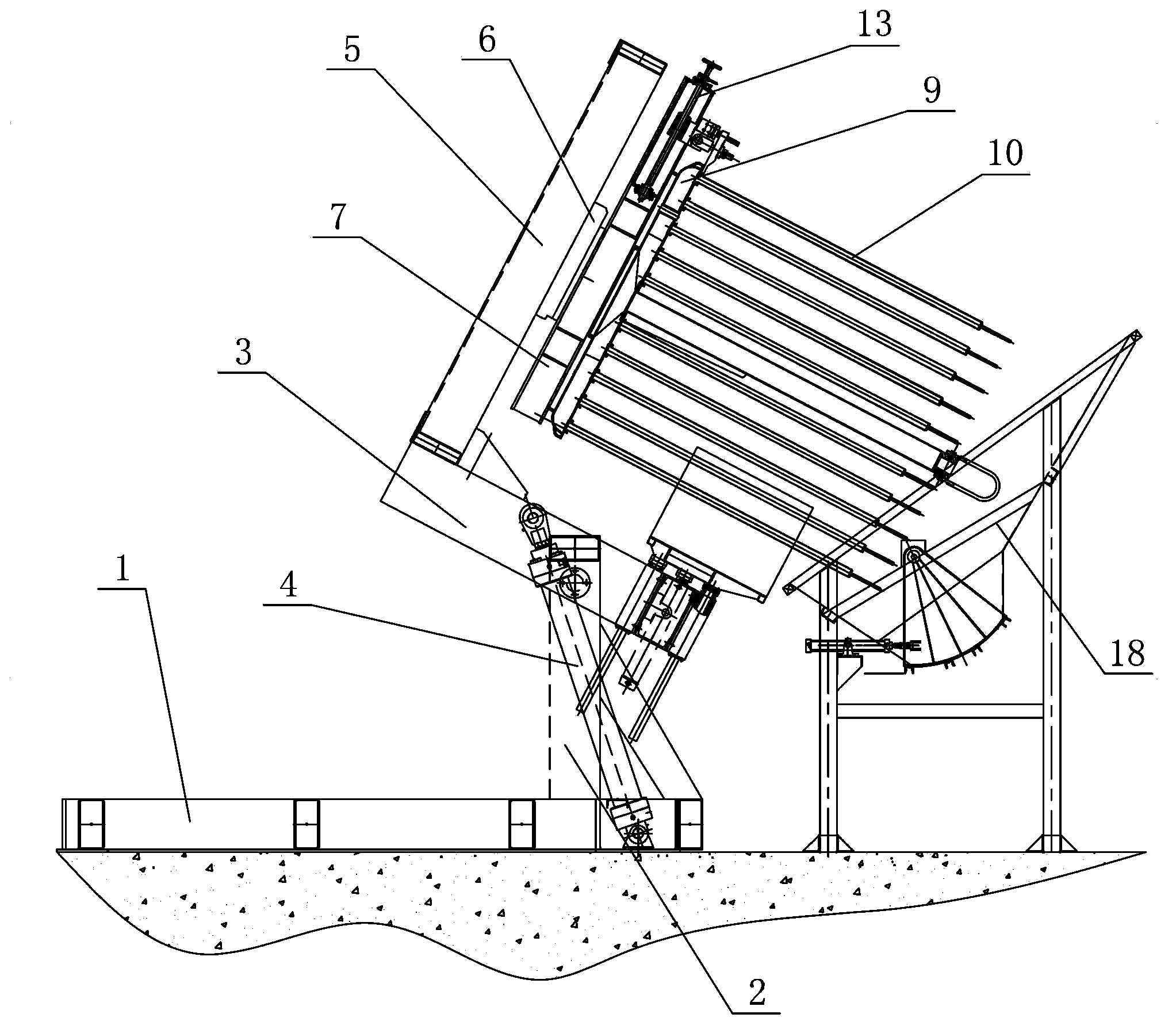

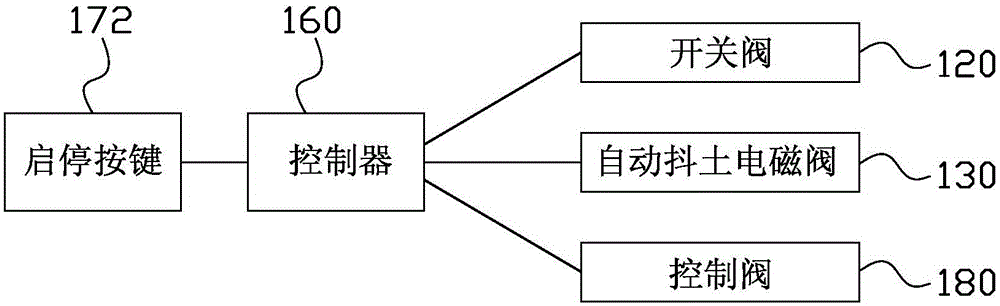

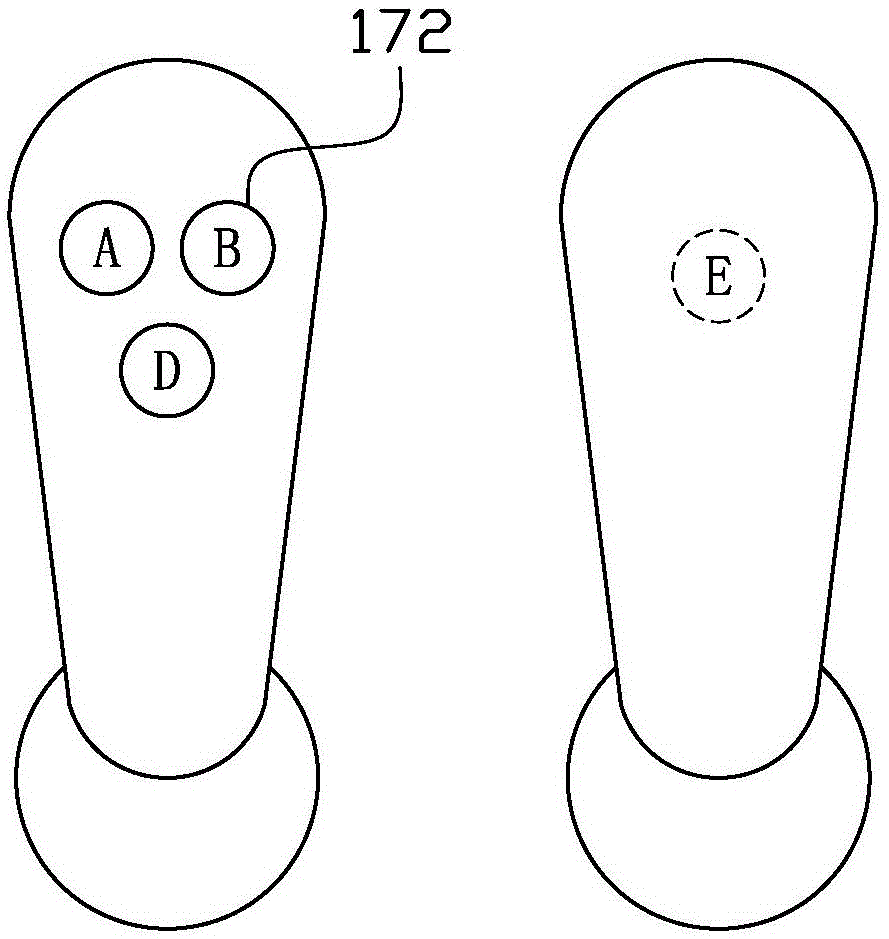

Control system having automatic earth shaking function and rotary drilling rig

ActiveCN105041732AReduce workloadAvoid damageServomotor componentsServomotorsElectricitySolenoid valve

The invention relates to a control system having an automatic earth shaking function. The control system comprises a pilot pump, a main valve, a power head motor, an automatic earth shaking solenoid valve, and a controller; and the main valve and the power head motor are connected. An oil inlet of the automatic earth shaking solenoid valve is connected with the pilot pump; a first working port is connected with one end of the main valve by a first oil way; and a second working port is connected with the other end of the main valve by a second oil way. The automatic earth shaking solenoid valve contains a first electromagnet and a second electromagnet; the controller is connected with the first electromagnet and the second electromagnet electrically; and the controller controls the first electromagnet and the second electromagnet lose power repeatedly and alternately according to preset time intervals during the automatic earth shaking process. When the first electromagnet gets power, the oil inlet of the automatic earth shaking solenoid valve is in conduction with the first working port; and when the second electromagnet gets power, the oil inlet of the automatic earth shaking solenoid valve is in conduction with the second working port. According to the control system, the earth unloading efficiency is improved and the working load of the operators can be effectively reduced.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

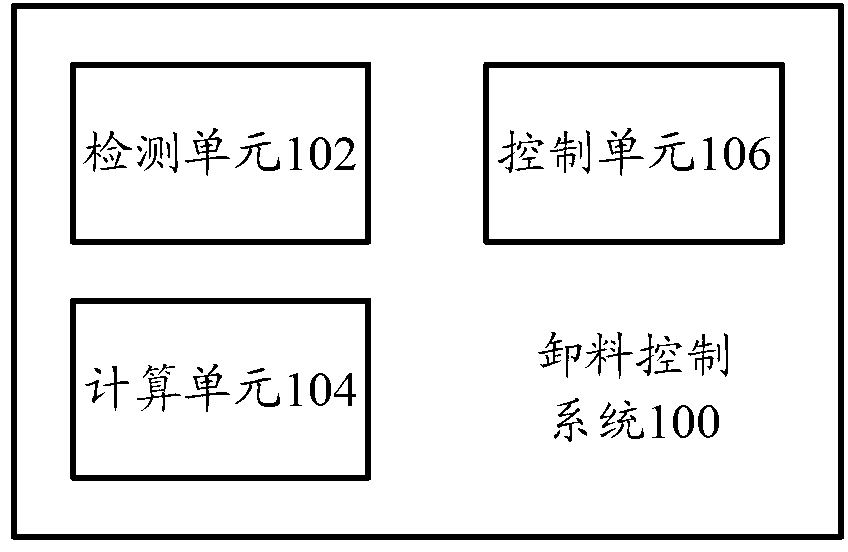

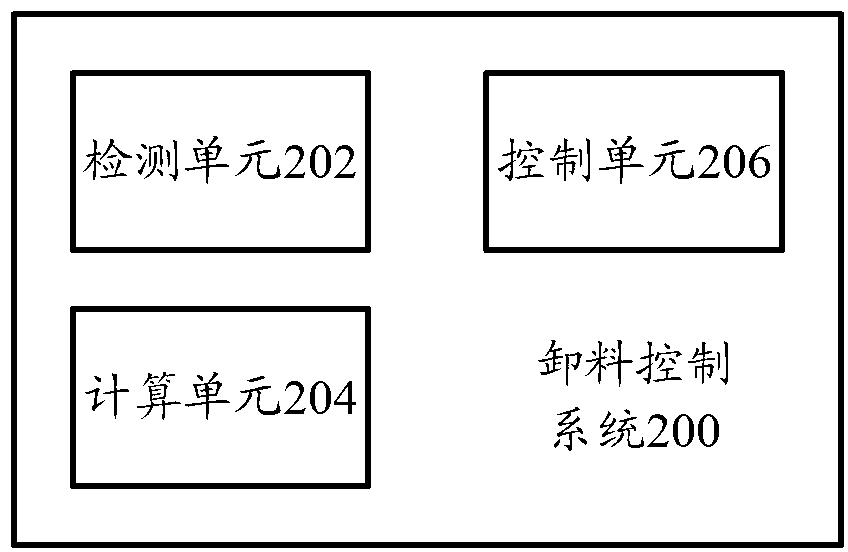

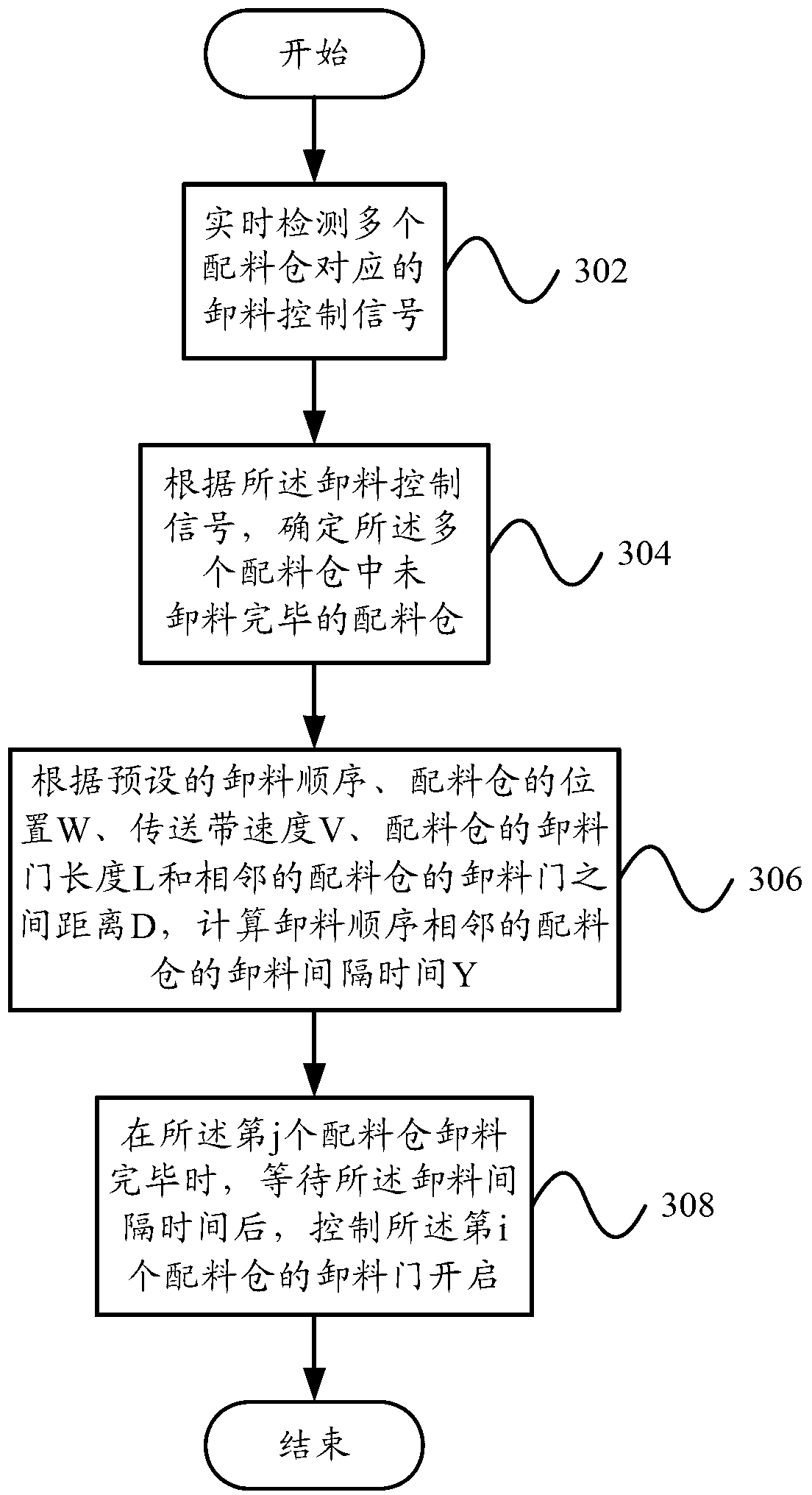

Discharging control system and discharging control method

ActiveCN103009485AAvoid scatterImprove the mixing effectDischarging apparatusProgramme control in sequence/logic controllersDischarge efficiencyControl system

The invention provides a discharging control system. The discharging control system comprises a detecting unit, a calculating unit and a control unit, wherein the detecting unit is used for determining incompletely-discharged stock bin in stock bins, the calculating unit is used for calculating the discharging interval time Y of the matched stock bins with adjacent discharging orders according to the discharging order, the positions W of the stock bins, the speed V of a conveying belt, the lengths L of discharging doors and the distance D between the adjacent discharging doors, the position Wn of the nth stock bin is equal to n which is progressively increased along the motion direction of the conveying belt, wherein Yj=(Wi-Wj+1)*X+(Wi-Wj)*J, X=L / V, J=D / V, the discharging orders of the ith stock bin and the jth stock bin are adjacent, and the ith stock bin is used for discharging after the jth stock bin is used for discharging. When the jth stock bin is used for discharging, the control unit can control the opening of the discharging doors of the ith stock bin after waiting for the waiting time Yj. The invention also provides a discharging control method. According to the technical scheme of the discharging control system, different aggregates can be prevented from being piled on the conveying belt in the discharging process so as to avoid the scattering of the aggregates. Moreover, the discharging time can be shortened, and the discharging efficiency and the aggregate mixing effect are enhanced.

Owner:SANY HEAVY IND CO LTD (CN)

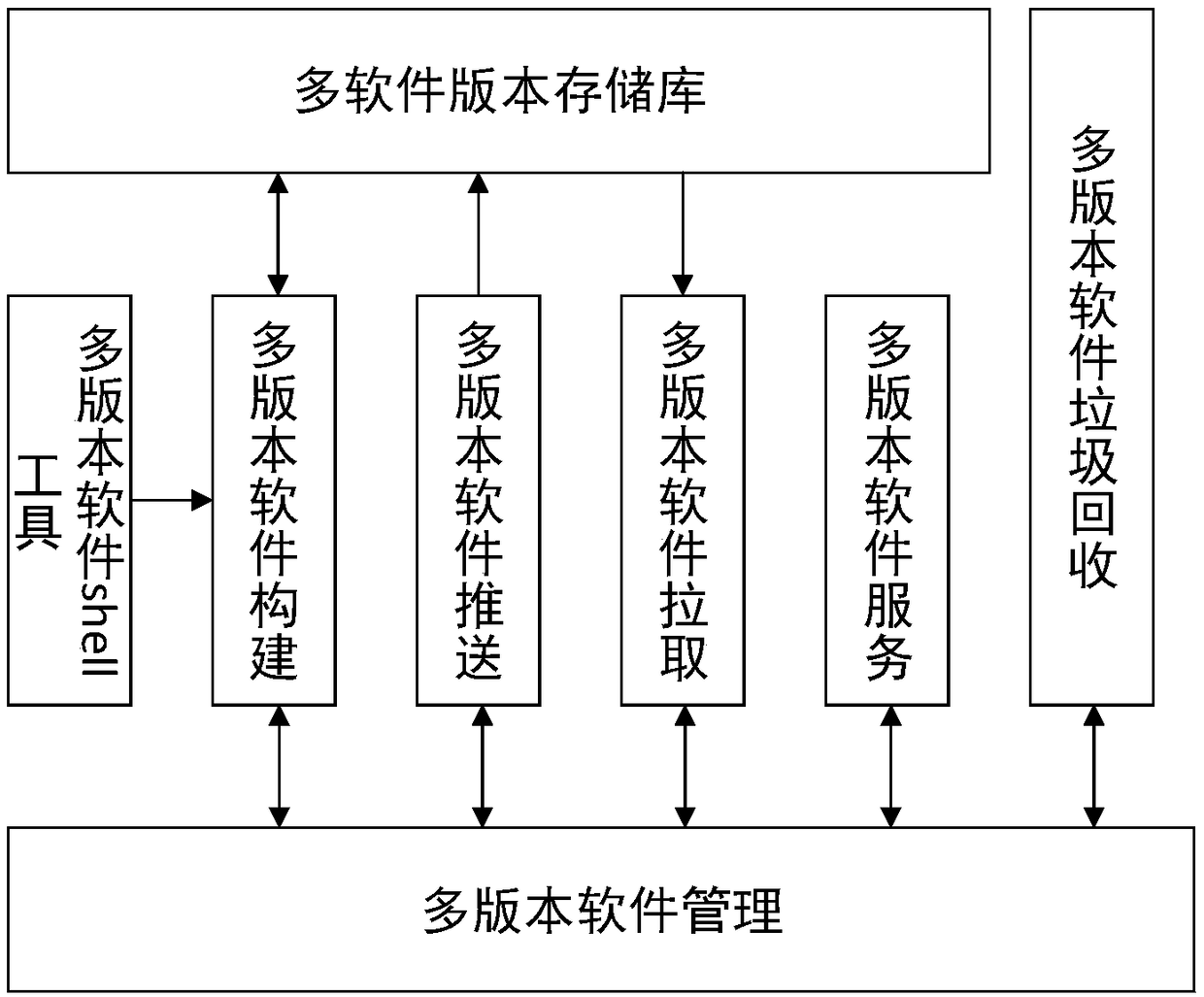

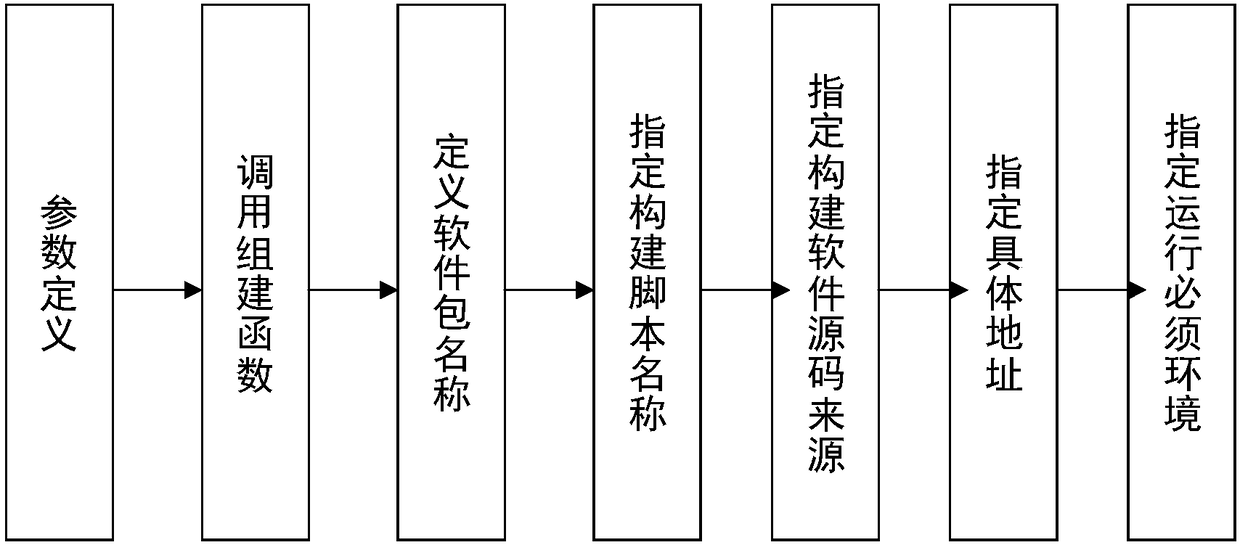

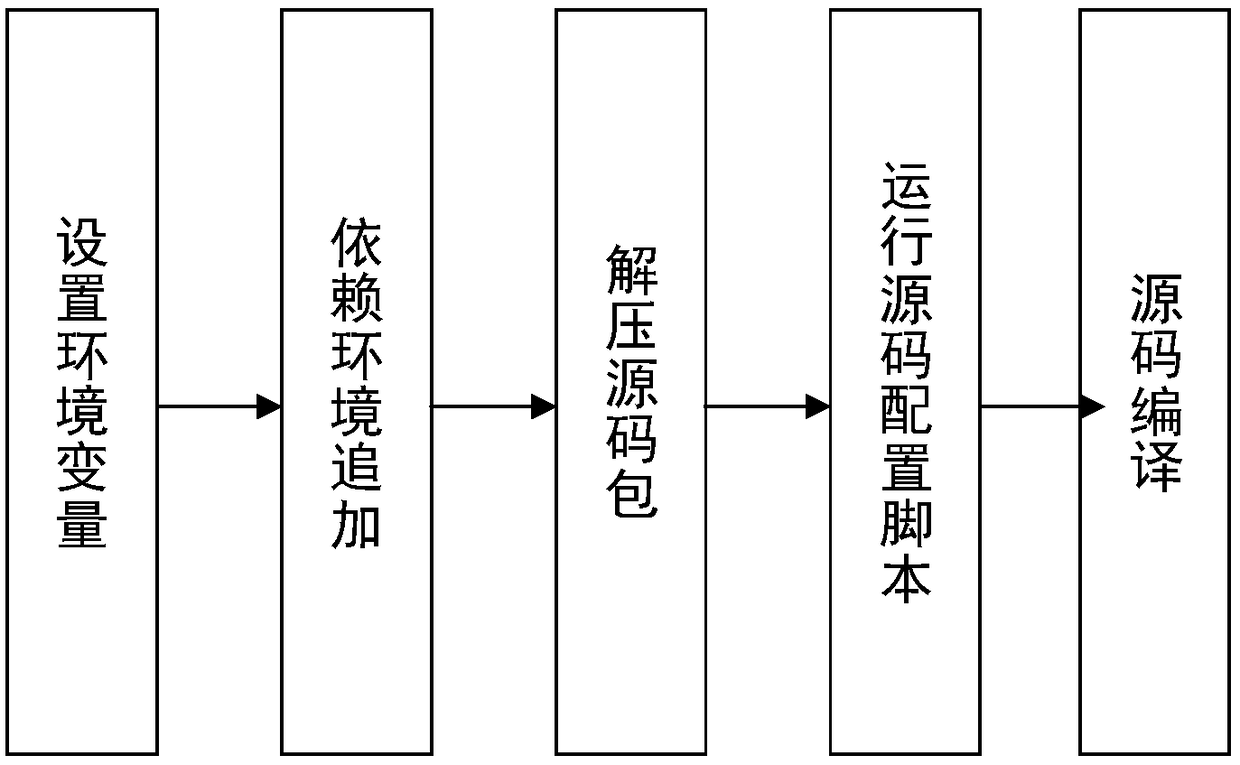

Method of complete function-based multi-version software management on Phytium platform

ActiveCN108595186AImprove efficiencyImprove installation efficiencyTransmissionSoftware deploymentApproaches of managementState of art

The invention discloses a method of complete function-based multi-version software management on a Phytium platform. The method comprises the steps of: S1, carrying out construction of software packages on the basis of a complete function; and S2, generating corresponding hash values according to different construction environments of all the software packages, and using the hash values to mark the corresponding software packages. Compared with the prior art, the method has the advantages that the generated packages do not depend on existing software of an operating system, dependency does notexist among the packages, coexistence of multiple versions of software without a conflict can be allowed, and installation, upgrading and uninstallation of a user on software of a version needed thereby are facilitated.

Owner:KYLIN CORP

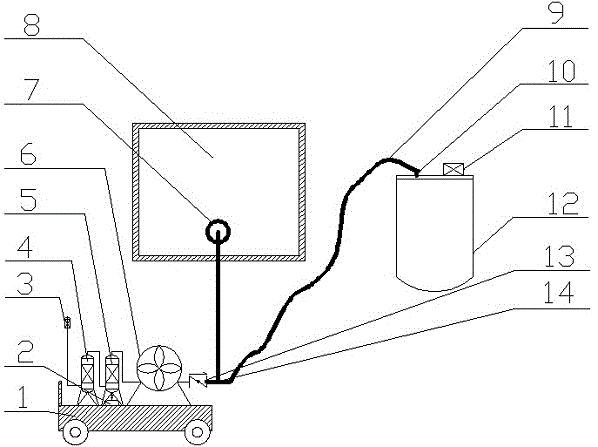

Bag moving machine with full-automatic bag breaking and discharging functions

The invention relates to a bag moving machine with full-automatic bag breaking and discharging functions. According to the technical scheme, a transverse air pipe (9) is horizontally fixed to the upper portion of the right side of a dustproof closed cover (1), the closed end of the transverse air pipe (9) is movably installed into a transverse sleeve (8), the upper end of a longitudinal inner pipe (10) is perpendicularly fixed to the lower surface of the transverse sleeve (8), the longitudinal inner pipe (10) is movably sleeved with a longitudinal outer pipe (11), an internal air absorbing cover (20) is installed at the lower end of the longitudinal outer pipe (11), the working end of a piston rod of a longitudinal motion air cylinder (5) is hinged to the center of an opening of the internal air absorbing cover (20), a bag breaking tool rack (19) is arranged on the lower portion of the dustproof closed cover (1), a bag cutting tool (17) is arranged in the middle of the bag breaking tool rack (19) in the front and back direction, and a left bag breaking tool (18) and a right bag breaking tool (16) are correspondingly installed at the left side and the right side of the bag cutting tool (17). The bag moving mechanism has the advantages of being small in size, good in dust suppression effect, high in discharging efficiency, small in labor intensity, high in automation degree and suitable for bag breaking and discharging for powdery materials.

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

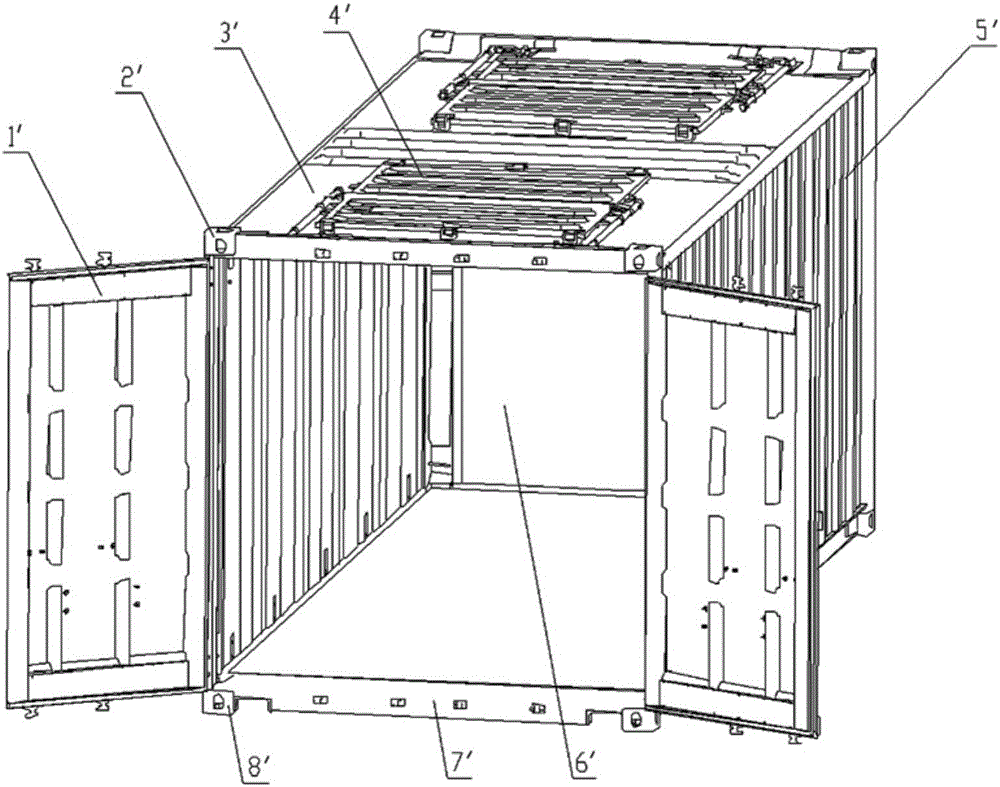

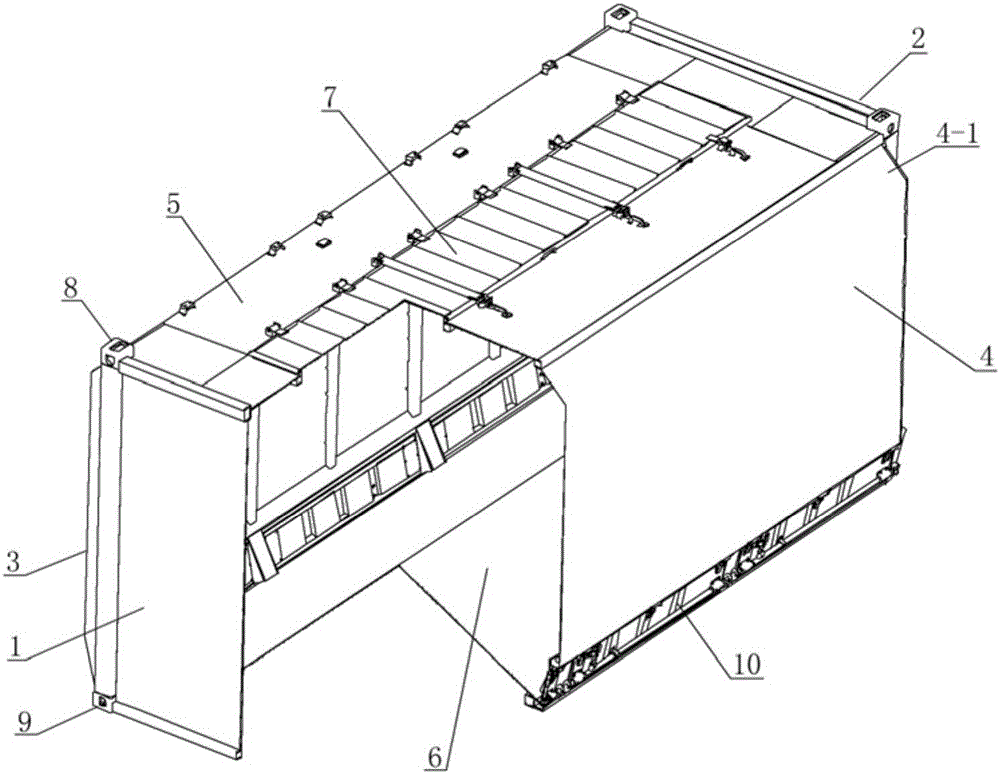

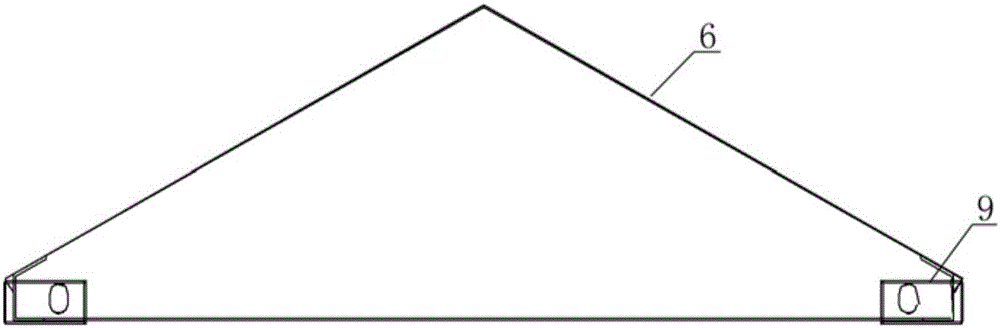

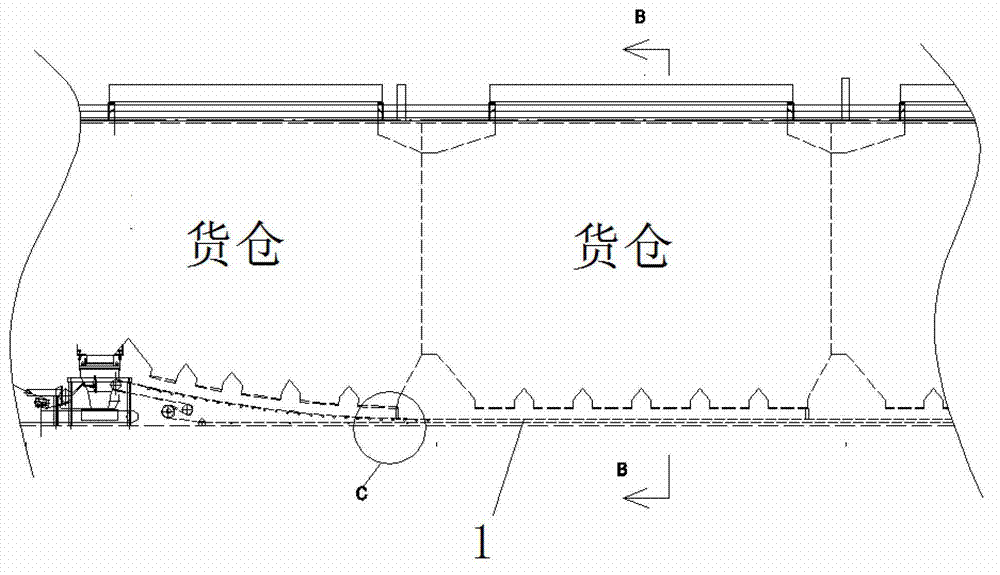

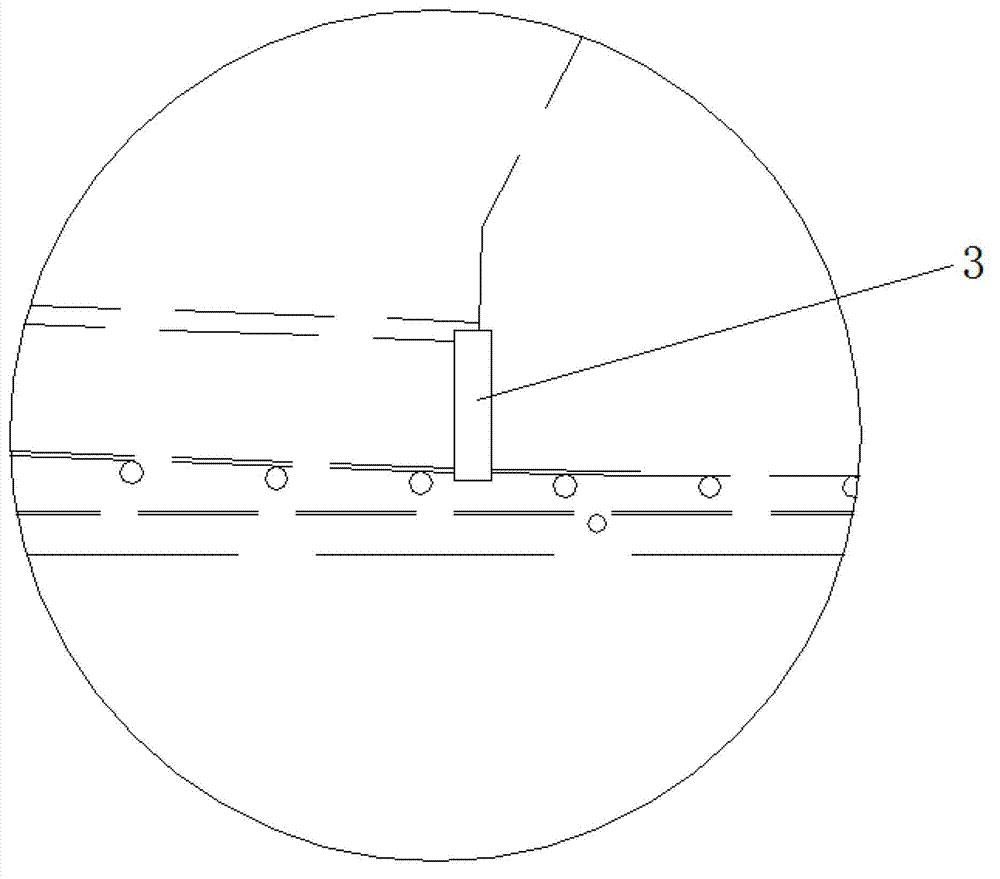

Wide-body bulk transport container and transport vehicle

The invention discloses a wide-body bulk transport container and a transport vehicle. The wide-body bulk transport container comprises a front end wall (1), a back end wall (2), a left side wall (3), a right side wall (4), a box top (5) provided with a loading port cover (7), a chassis (6), a top angle piece (8) and a bottom angle piece (9), and is characterized in that a floor of the chassis (6) is reversely V-shaped on the cross section; and the left side wall (3) and the right side wall (4) are wide-body structures with widths exceeding the outer sides of the top angle piece (8) and the bottom angle piece (9), and are respectively provided with bottom side doors (10) for unloading. The side walls of the container adopt the wide-body structures, so that the space in the limit is effectively used, the volume can be increased by 5-20%, the loading capacity of the transport container is improved, the vehicle transport capacity is fully used, and the comprehensive benefit is high; and moreover, the transport container adopts an inclined chassis form and a bottom side door unloading form, can realize automatic goods unloading without needing any equipment, has no residues, improves the efficiency, and reduces the cost.

Owner:CRRC QIQIHAR ROLLING CO LTD

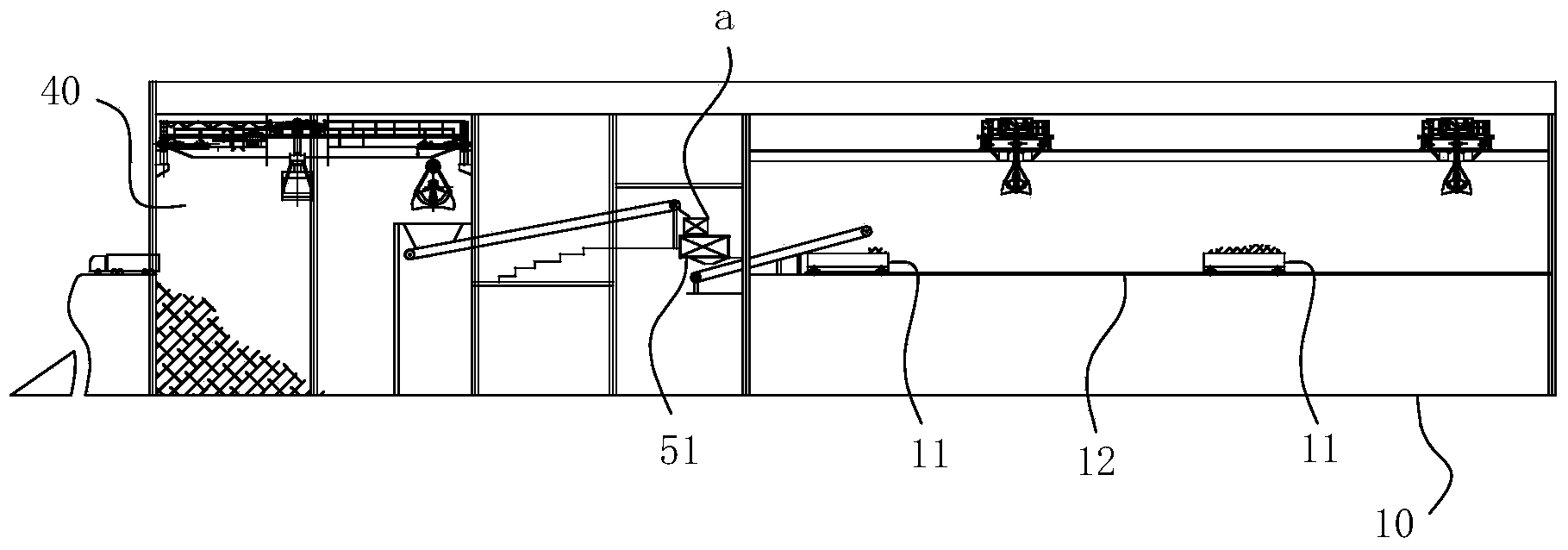

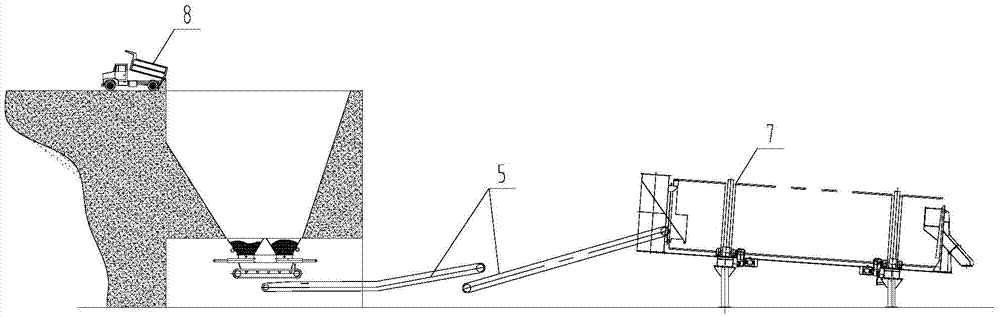

Self-unloading bulk cargo transport ship and unloading method thereof

InactiveCN103204227ASimple structureEasy to operateCargo handling apparatusPassenger handling apparatusBulk cargoConveyor belt

The invention relates to a self-unloading bulk cargo transport ship. The self-unloading bulk cargo transport ship comprises a plurality of marine cranes which are arranged above a deck, and a cargo hold grab bucket is arranged at the end of each of the marine cranes; deck hoppers which are in one-to-one correspondence to the marine cranes are arranged on the deck of a ship body and positioned on a starboard, and a longitudinal conveyor belt is arranged below the deck hoppers along the longitudinal direction of the ship body and positioned above cargo holds; a first discharge outlet is arranged on the tail portion of the longitudinal conveyor belt and corresponds to a horizontal conveyor belt, and the horizontal conveyor belt is arranged along the horizontal direction of the ship body and communicates the deck starboard and a deck larboard; a second discharge outlet is arranged on the tail portion of the horizontal conveyor belt and corresponds to an inclined conveyor belt, and the inclined conveyor belt is upwards inclined along a deck of the larboard; and a third discharge outlet is arranged at the tail end of the inclined conveyor belt and corresponds to an unloading arm of a gantry crane, the unloading arm can telescope, slew and luff, and a fourth discharge outlet is arranged at the tail end of the unloading arm.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

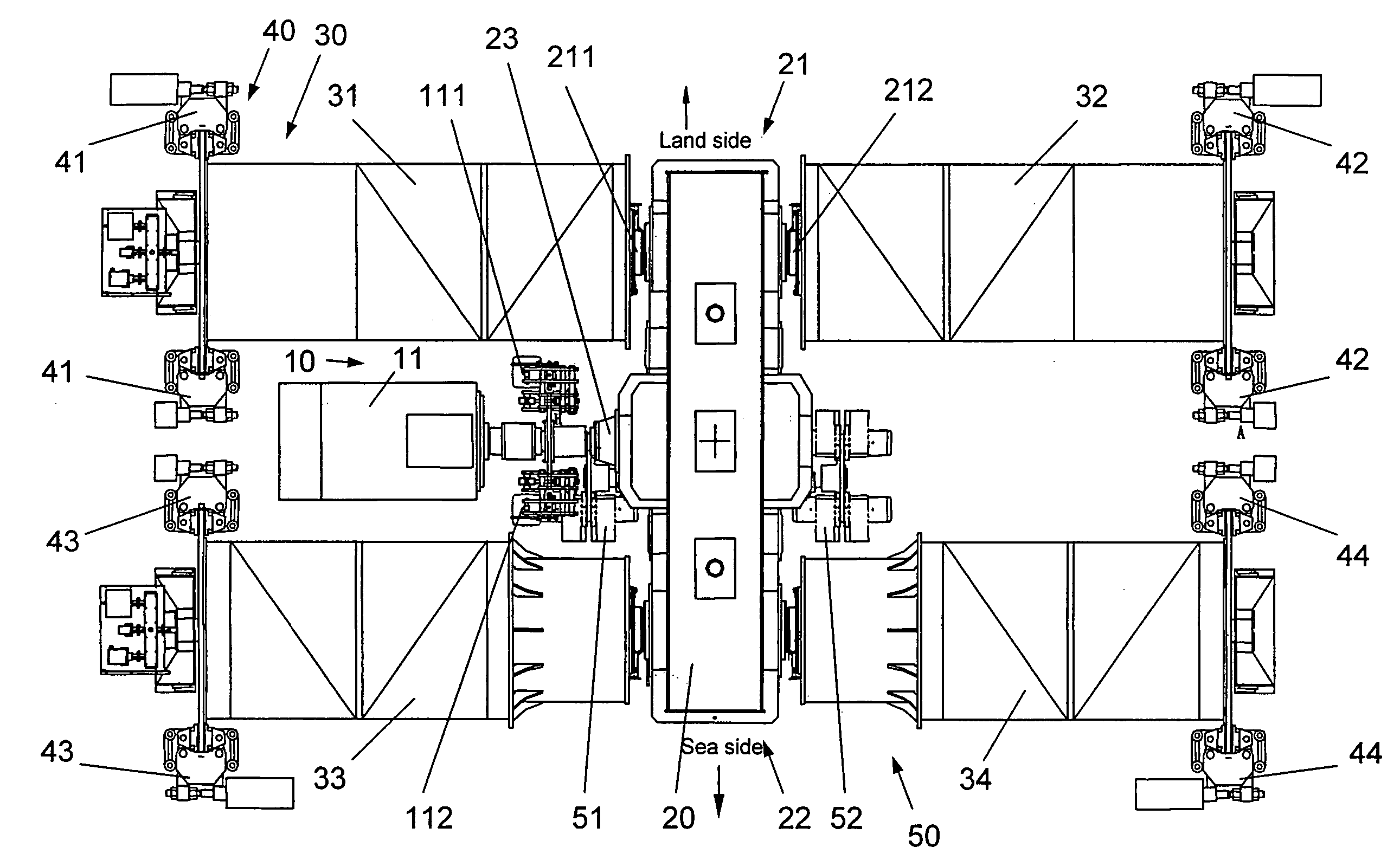

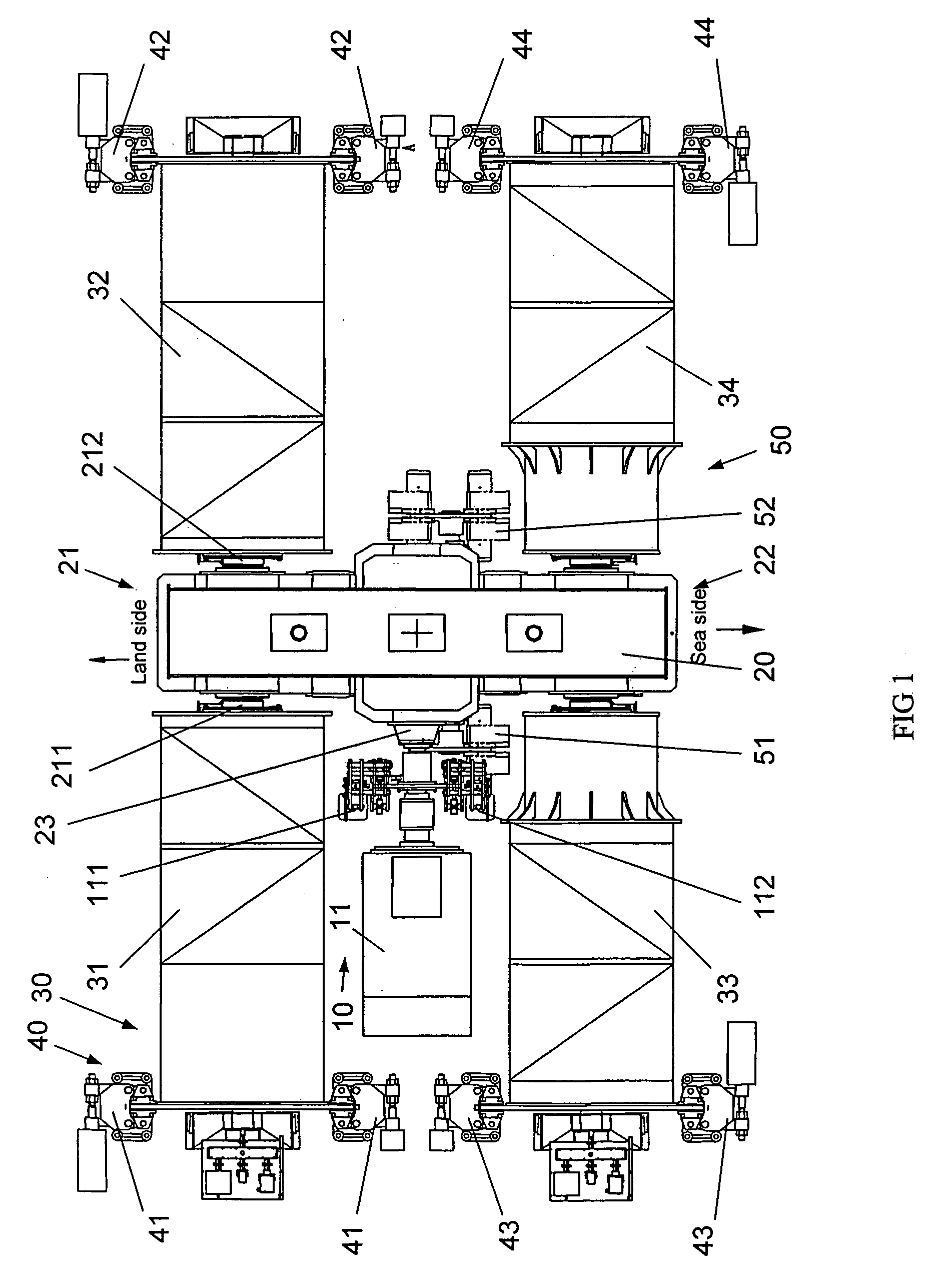

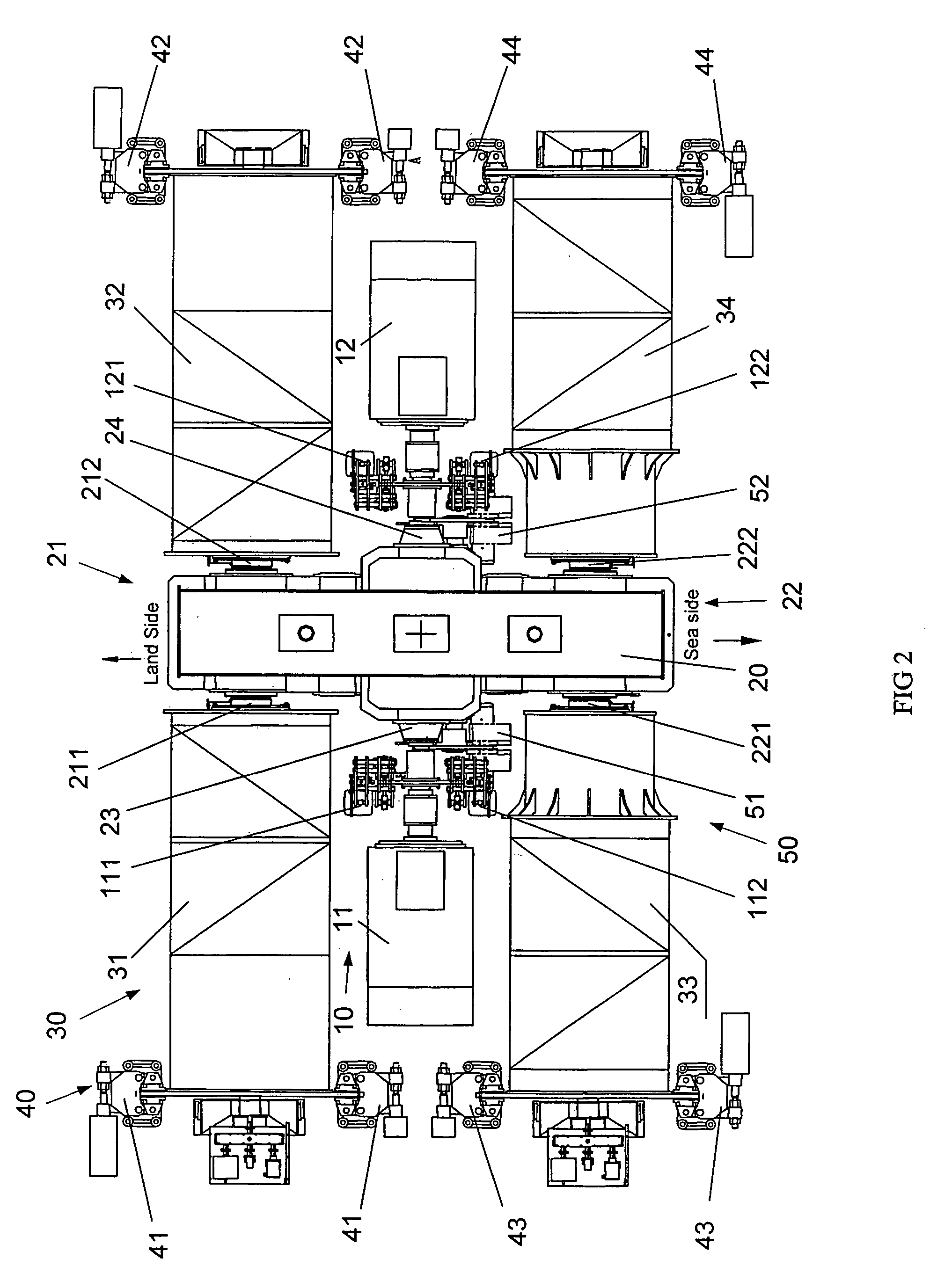

Lifting machinery of four reel differential type for two 40 feet container shore crane

InactiveUS20060240933A1Improve unloading efficiencyImprove efficiencyGearingTravelling cranesLow speedReduction drive

The invention relates to a lifting machinery of four reel differential type for two 40 feet container shore crane comprising: motors, reductors, high speed brakes, reels and reel brakes; wherein at least one motor is provided; the reductor connected at the motor output end is a planetary differential reductor having a plurality of high speed input shafts, low speed output shafts and the differential project shafts; the high speed input shaft connects to the motor output shaft, at least one high speed brake is provided on the high speed input shaft; four two-project rope reels are connected to the four low speed output shaft; at least one reel brake is provided to each reel; and a differential shaft brake consisting of at least two differential shaft brakes provided on two differential project shaft is also included; the revolution of the two differential project shaft of the planetary differential reductor is controlled by the two differential shaft brakes so that power of the planetary differential reductor may be distributed, and both the synchronous operation of two hanger tool or the separate operation of a single hanger tool can be carried out. The present invention meets the loading and unloading requirement and increases the loading and unloading efficiency of the container crane by more than 60%.

Owner:SHANGHAI ZHENHUA HEAVY IND

Full-automatic crushed material unloading device and method

ActiveCN107324072AImprove unloading efficiencyEasy to collect and process manuallyBottle emptyingGrain treatmentsEngineeringHanging basket

The invention relates to the technical field of ton bag unloading device structures, in particular to a full-automatic crushed material unloading device and method. The device comprises a rack and an overturn hanging basket. The overturn hanging basket is of a frame structure rotatably connected to the rack through a rotary shaft and is provided with at least one opening used for enabling ton bags to enter, and a gaseous disk used for adsorbing and fixing the ton bags is arranged at the bottom of the overturn hanging basket; a plurality of extruding units arranged on the peripheries of the ton bags correspondingly and capable of applying transverse extruding and pushing acting force to the ton bags are arranged on the inner side of the overturn hanging basket; and the multiple extruding units are vertically arranged at intervals along the ton bags. According to the full-automatic crushed material unloading device and method, the structure is simple, operation is convenient, ton bag materials can be quickly poured through grading unloading and extruding crushing, the ton bags can be conveniently and quickly collected by using a movable plate and a purging structure, damage to the ton bags cannot be caused, working procedures for manual operation are reduced, and the device and method have extremely large popularization value.

Owner:HUBEI UNIV OF TECH

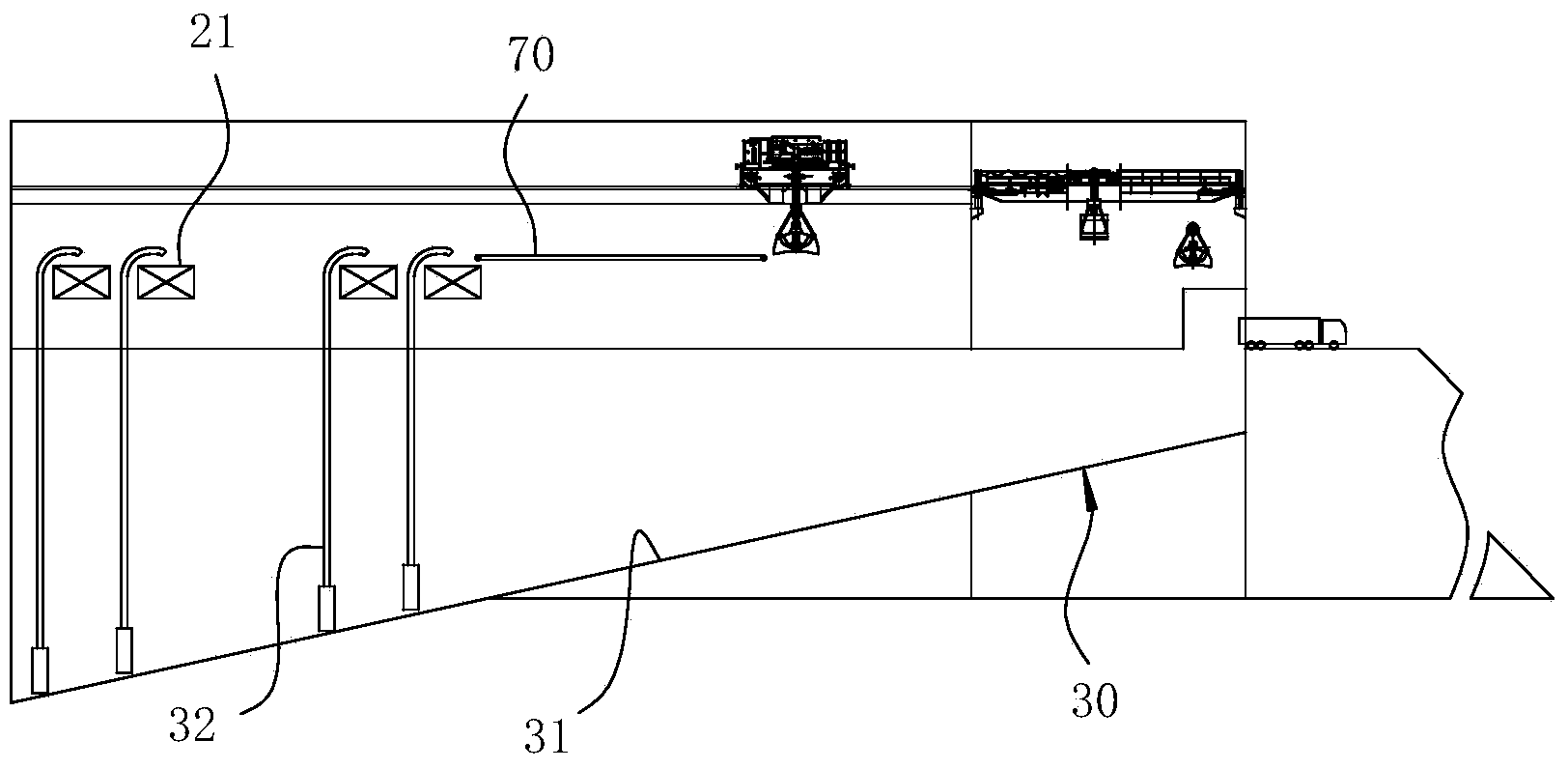

Mixed waste disposal system

InactiveCN103759273AReduce moisture contentHigh calorific valueSolid waste disposalIncinerator apparatusMixed wasteMunicipal solid waste

The invention belongs to the field of municipal solid waste disposal and particularly relates to mixed waste disposal system. The mixed waste disposal system at least comprises a waste pile-up unit used for waste pile-up fermentation and a waste incineration unit used for waste incineration. The mixed waste disposal system further comprises a sludge storage disposal pool, a material sliding ramp used for conveying materials is arranged in the sludge storage disposal pool, and the material sliding ramp is in the shape of an inclined face or a step-shaped structure becoming lower gradually. A sludge feeding end is arranged at the higher end of the material sliding ramp, and the lower end of the material sliding ramp forms a sludge discharging end. The time for sludge to flow from the sludge feeding end to the sludge discharging end along the material sliding ramp is longer than or equal to the number of days for the sludge to undergo set pile-up and warm-up fermentation and aerobic reaction. Both the waste pile-up unit and the discharging end of the sludge storage disposal pool are communicated with the feeding end of the waste incineration unit. Due to the simple and practical structure, mixed incineration disposal effect on municipal sludge and household waste can be achieved efficiently.

Owner:南京溧水石湫机场科技工业园开发有限公司

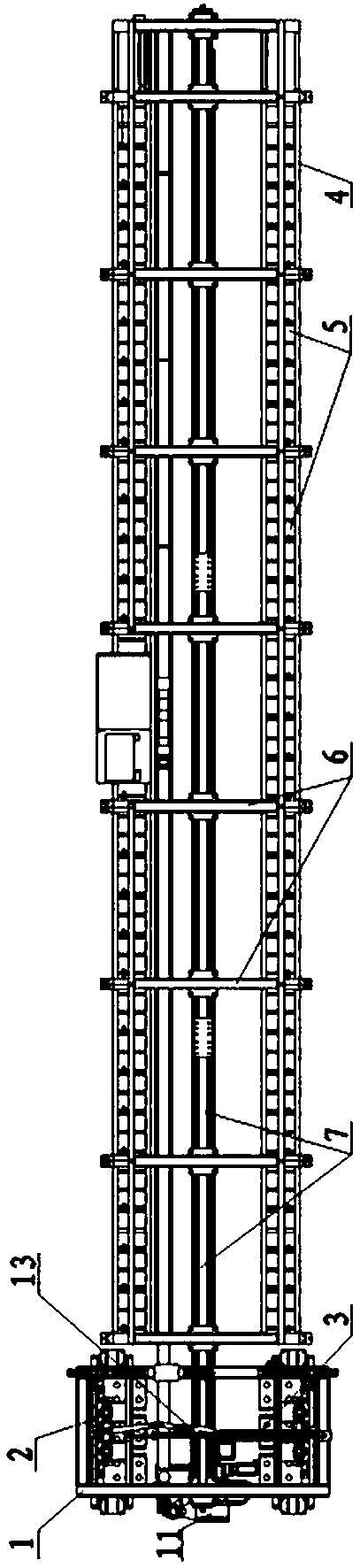

Intelligent yarn discharging and rectangular coordinate robot automatic yarn supplementing system

ActiveCN108190646AImprove efficiencyReduce labor intensityFilament handlingYarnRectangular coordinates

The invention discloses an intelligent yarn discharging and rectangular coordinate robot automatic yarn supplementing system. According to the system, yarn discharging mechanisms are perpendicularly arranged on one side or two sides of a yarn discharging support, the two ends of a yarn discharging horizontal-driving device are fixedly connected or are hinged to the yarn discharging support and theyarn discharging mechanisms so as to drive the yarn discharging mechanisms to horizontally move, each yarn discharging mechanism is provided with a plurality of yarn discharging brackets and a firstperpendicular linear driving device, wherein the yarn discharging brackets are perpendicular to the yarn discharging mechanism, and the first perpendicular linear driving device drives the yarn discharging brackets to vertically move; a yarn storage rack is fixedly provided with a plurality of yarn storage grooves in the direction perpendicular to the moving direction of the yarn discharging mechanisms; yarn supplementing supports are fixedly arranged on the ground or the yarn storage rack along the X axis; an X-axis cross beam is fixedly arranged on the yarn supplementing supports along the Xaxis; one end of a Z-axis vertical shaft is in perpendicular sliding driving connection with the X-axis cross beam; a Y-axis longitudinal beam is in sliding driving connection with a Z-axis guide rail; an A-axis mounting base is in perpendicular sliding driving connection with the Y-axis longitudinal beam; and a clamp rotating driving device is fixedly arranged on the A-axis mounting base and isperpendicularly and fixedly connected to the driving end of the clamp rotating driving device. The system has the advantages that the automation degree is high, the yarn discharging and supplementingefficiency is high, and a yarn roll is not liable to deform.

Owner:云南柔控科技有限公司 +1

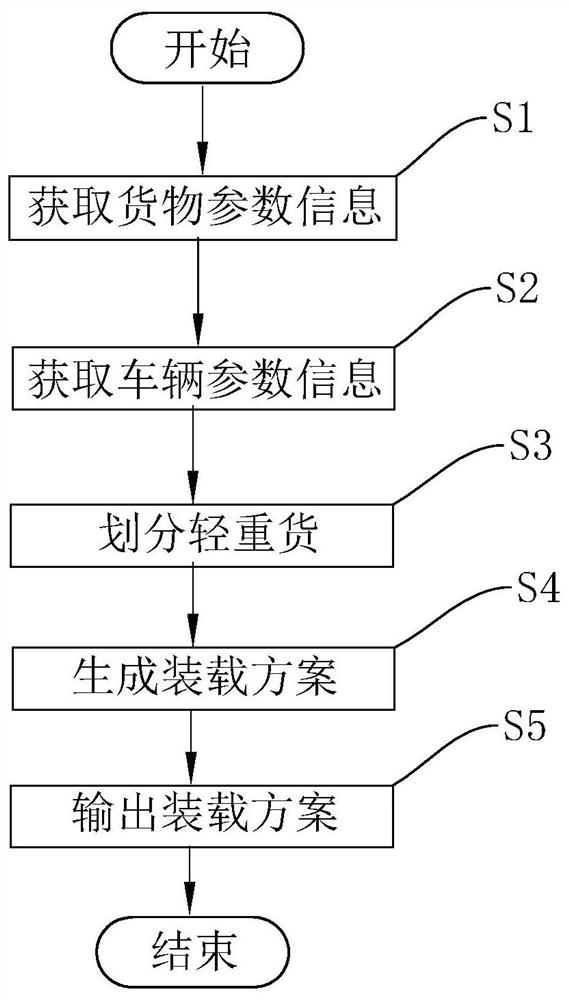

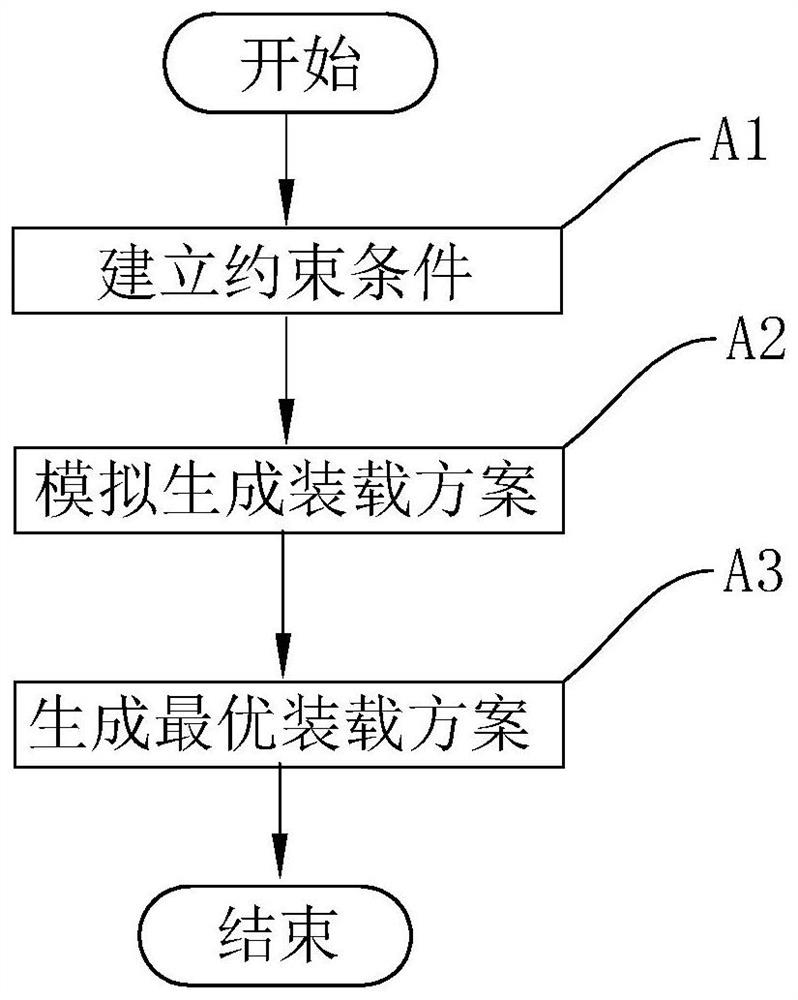

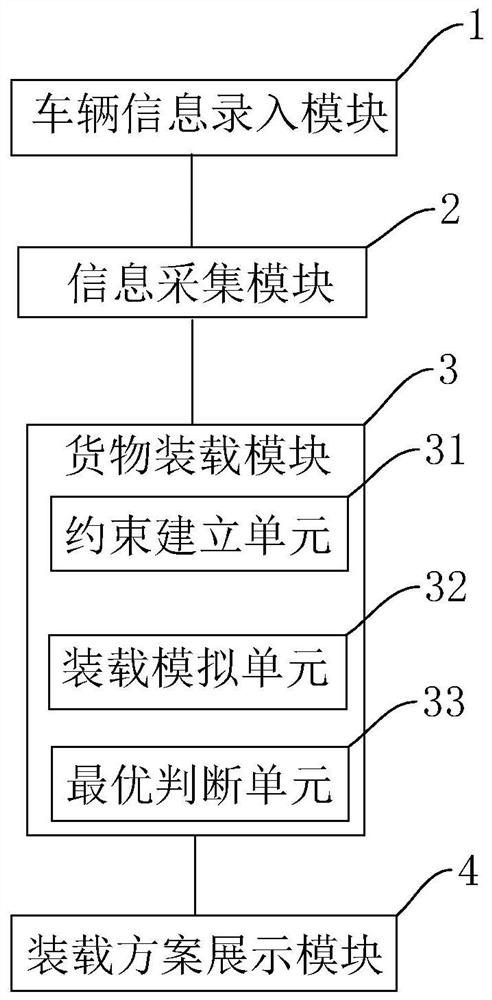

Vehicle loading method and system for cargo loading

PendingCN111768151AFast loadingImprove loading efficiencyResourcesLogisticsLogistics managementTransport engineering

The invention relates to a vehicle loading method and system for cargo loading. The method comprises the following steps: S1, obtaining cargo parameter information, specifically, measuring the weightand size information of cargos, and collecting and summarizing the information of the cargos on a logistics order to generate the cargo parameter information of the cargos; s2, obtaining vehicle parameter information: inputting the vehicle parameter information of a vehicle waiting for transporting goods, wherein the vehicle parameter information comprises container size information, license plateinformation, load information, insurance information and transportation type information of the vehicle; s3, light and heavy goods division: dividing the goods into light goods and heavy goods according to the goods parameter information and the light and heavy goods standards, and classifying the light and heavy goods into the goods parameter information; s4, generating a loading scheme: performing simulated arrangement on the heavy goods and the light goods according to a preset loading model to generate an optimal loading scheme; and s5, outputting a loading scheme. The cargo loading efficiency and the space utilization rate of the cargo box are improved.

Owner:战马物流(苏州)有限公司

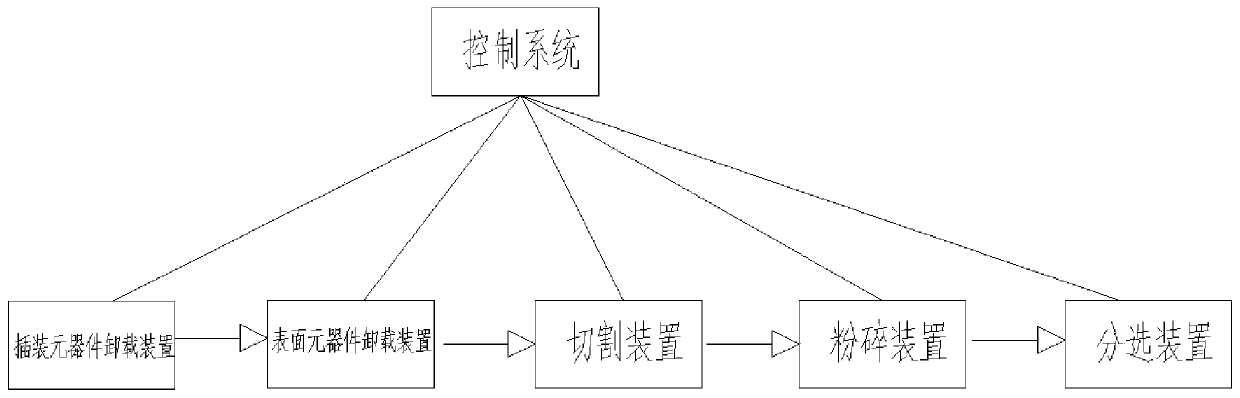

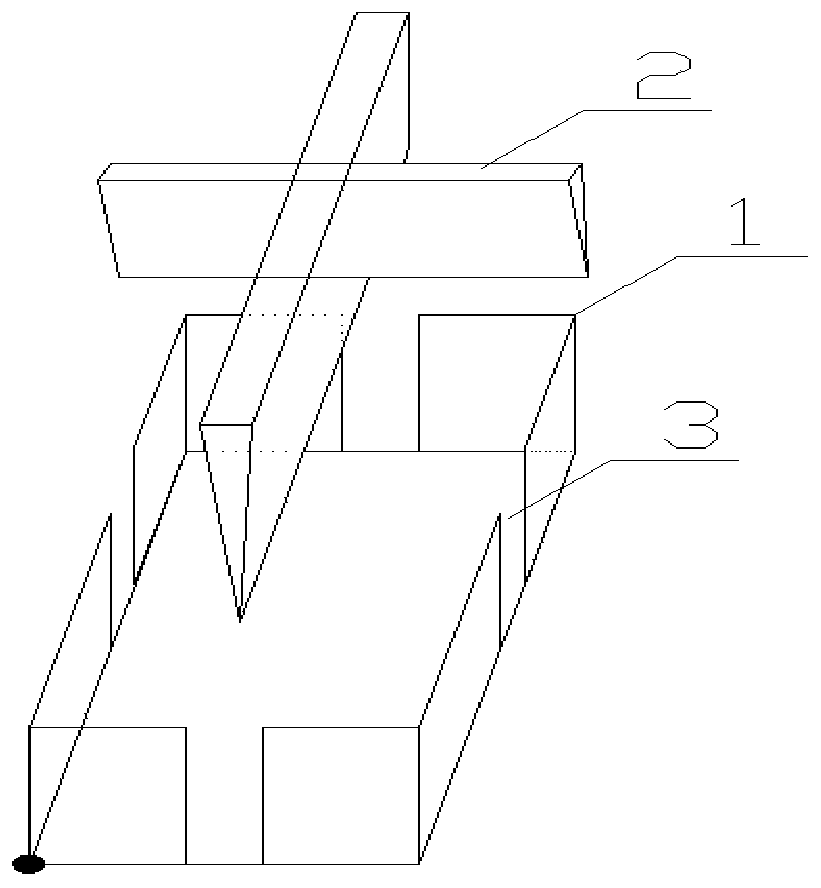

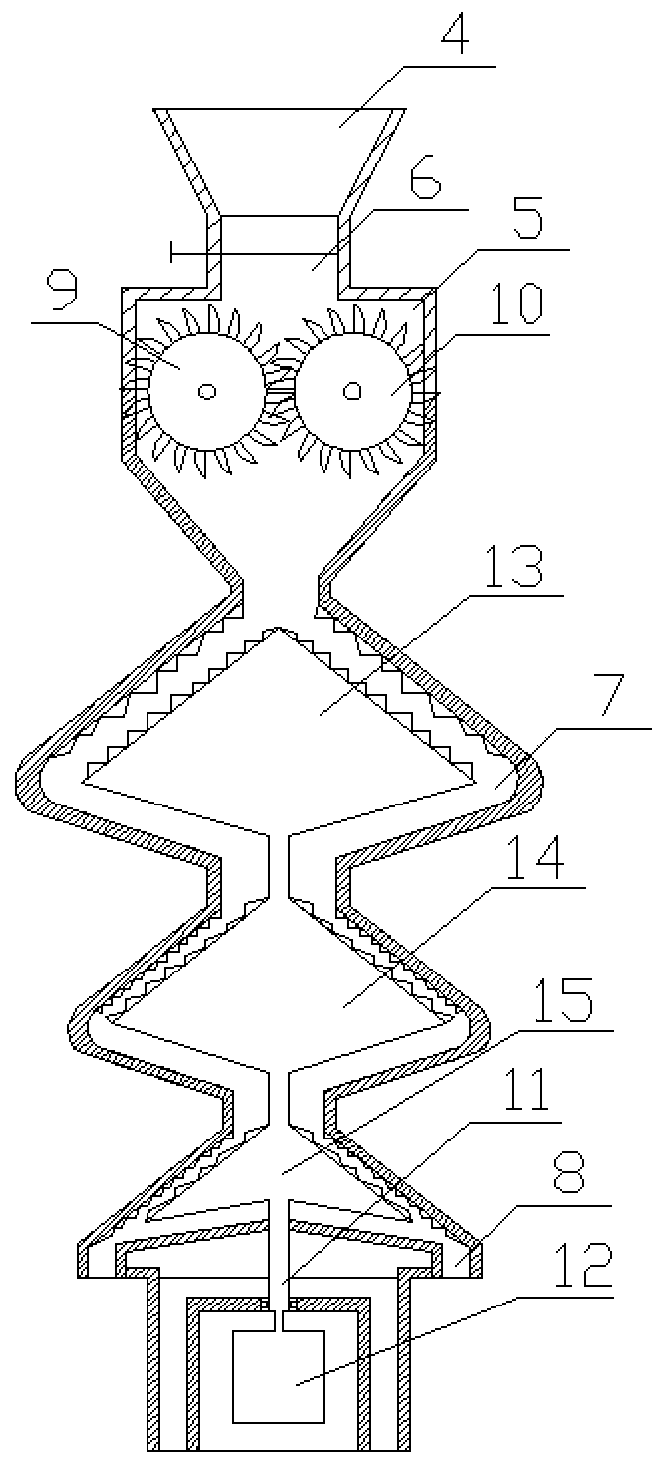

Waste circuit board recovery device

InactiveCN109865735APrecise UninstallImprove unloading efficiencySolid waste disposalControl devices for conveyorsThree levelControl system

The invention discloses a waste circuit board recovery device. The waste circuit board recovery device comprises a circuit board conveying device, a plug-in mounting component unloading device, a surface component unloading device, a cutting device, a smashing device, a sorting device and a control system. The circuit board conveying device comprises a clamping mechanism and a conveying interval adjusting mechanism, and the smashing device comprises a feeding hopper, a coarse crushing device, a feeding pipe, a grinding device and a discharging pipe. The waste circuit board recovery device canbe applied to waste circuit boards with different sizes, the application range is wide, finer and more uniform circuit board particles are obtained through coarse crushing and three-level grinding, then classification collection is carried out, the recovery rate is high, more environmental protection and high efficiency are achieved, and industrial recovery of the waste circuit boards can be achieved.

Owner:张雨璠

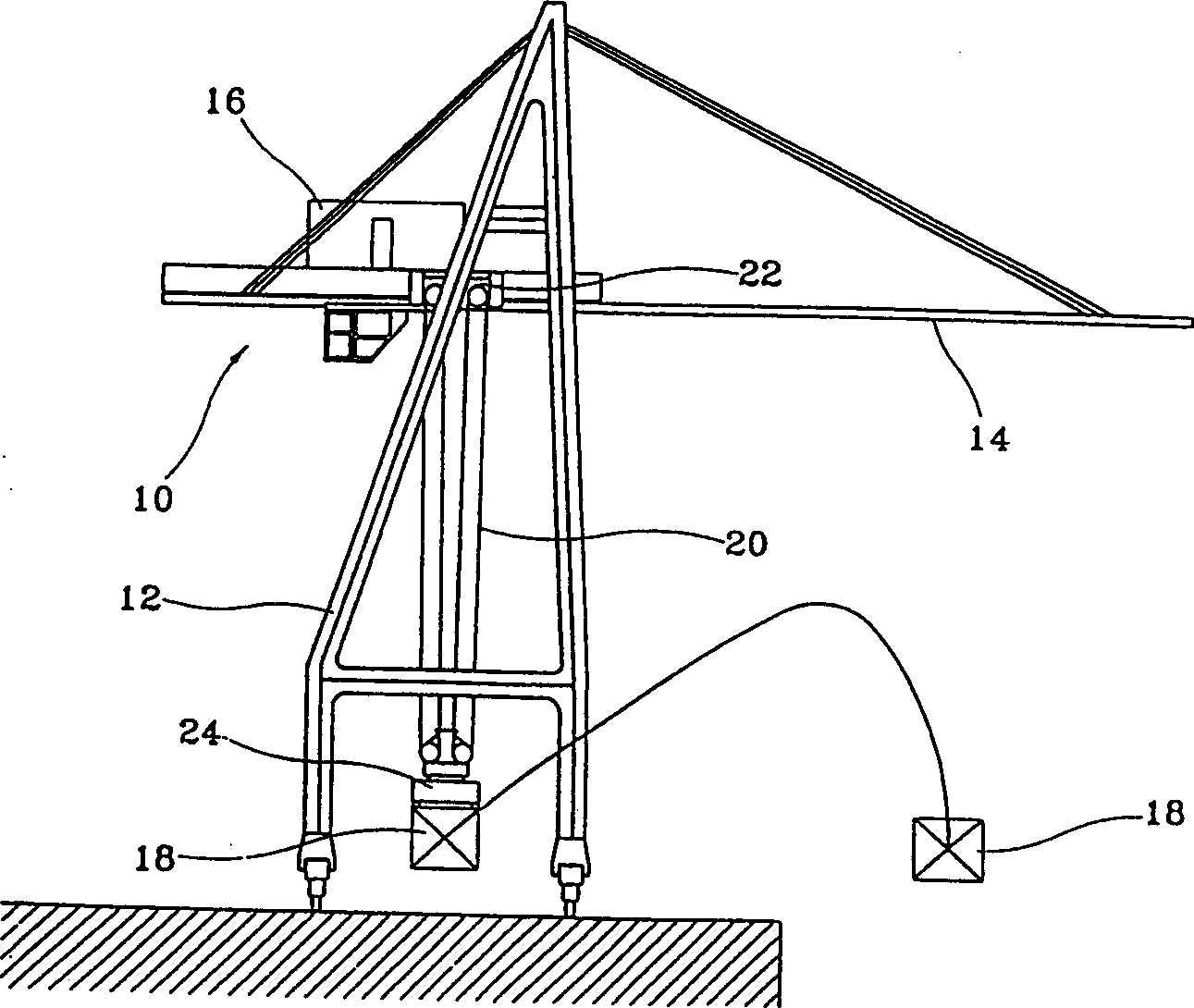

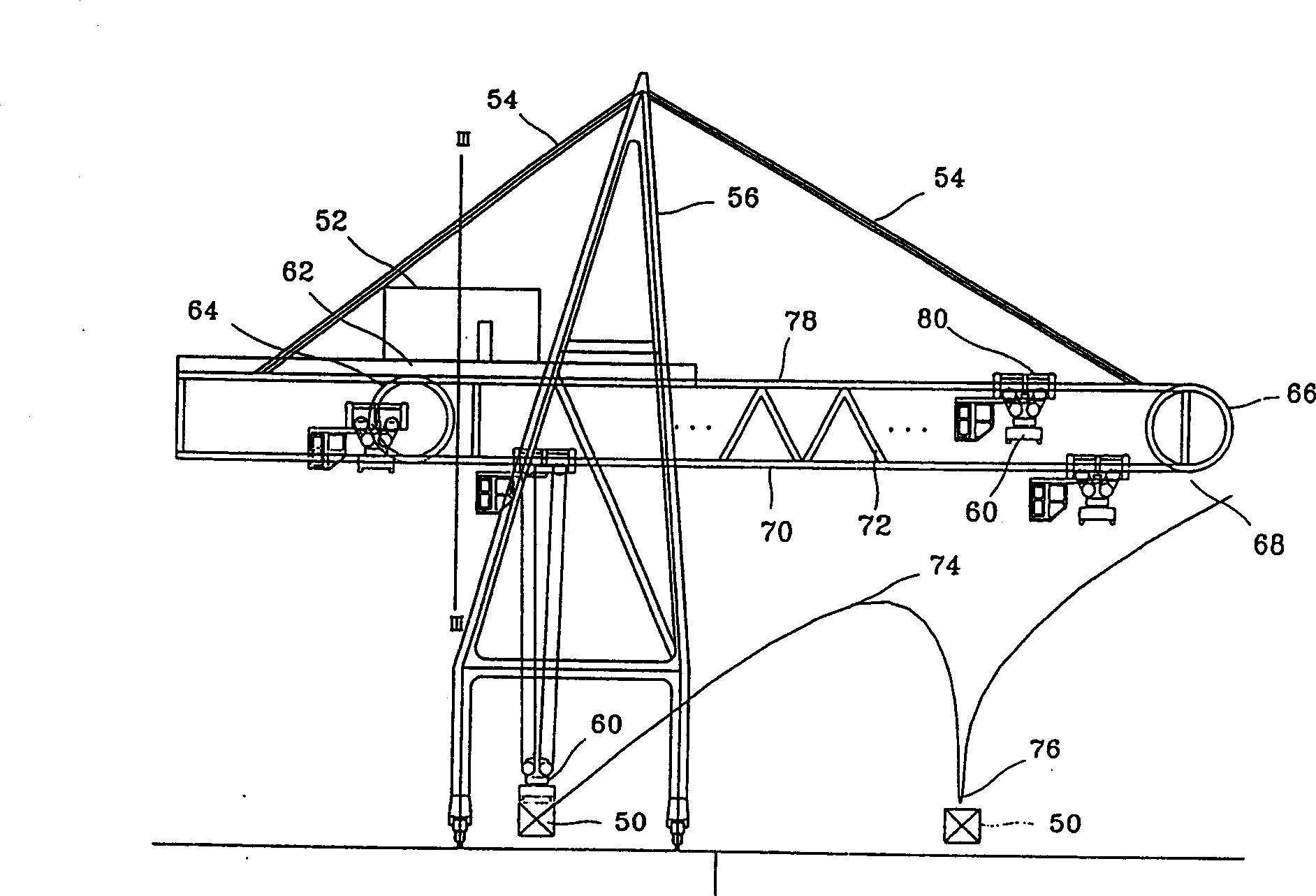

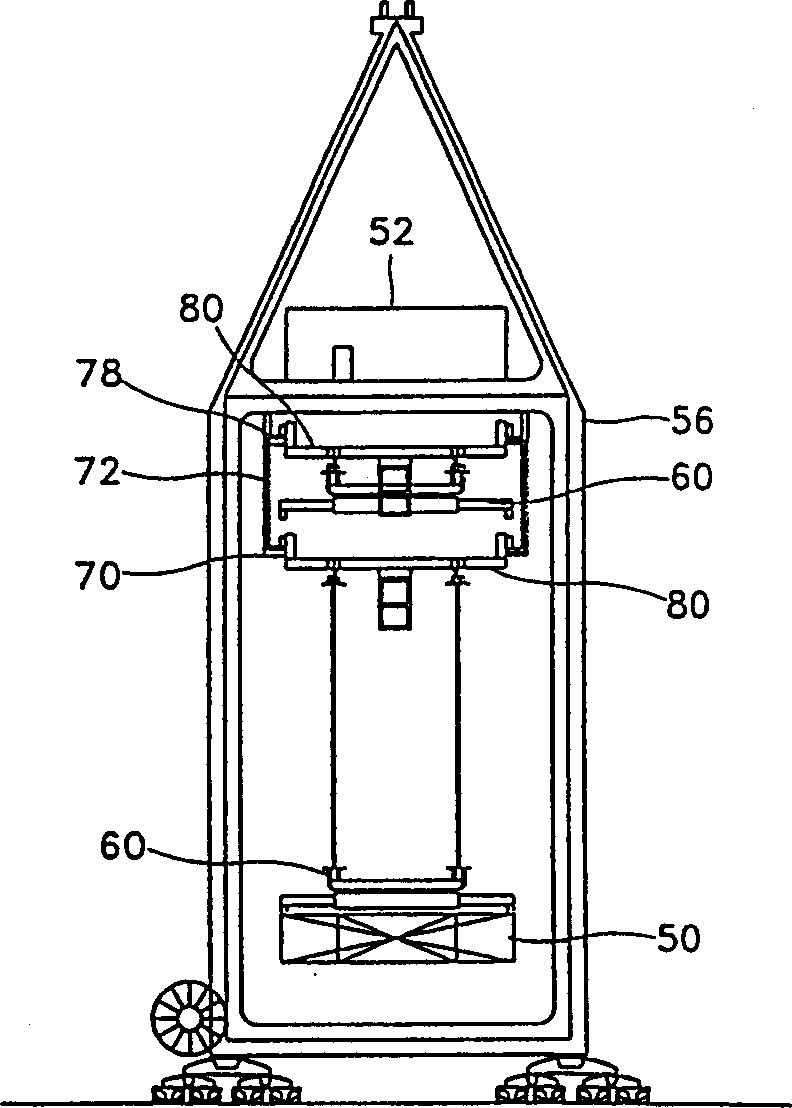

Gantray crane having circulating trolleys

InactiveCN1337918AFast transferImprove unloading efficiencyTrolley cranesLoad-engaging elementsGantry craneEngineering

A Gantry crane having circulating trolleys (102), including a movable main tower pillar (56), a circulating boom, at least one trolley (102), at least one spreader (60), two hoists (106, 108), and a hook (116). The circulating boom is installed on the main tower pillar (56). The trolley (102) is installed to be capable of circulating along the circulating boom (100). The spreader (60) can be attached to and detached from the lower surface of the trolley (102), is combined with the trolley (102) when the trolley (102) moves, and is separated from the trolley (102) and descends to pick up a container (50). Two hoists (106, 108) are installed to be capable of moving along the circulating boom (100), each having a hoist motor (110) and a hoist wheel (112). The hook (116) is connected to the hoist motor (110), and combined with the spreader (104) by descending while vertically passing through the trolley (102) and is separated from the spreader (104) by ascending, so that the hook (116) descends with the spreader (104) combined with the hook (116) in order to pick up a container (150).

Owner:CREA-TECH

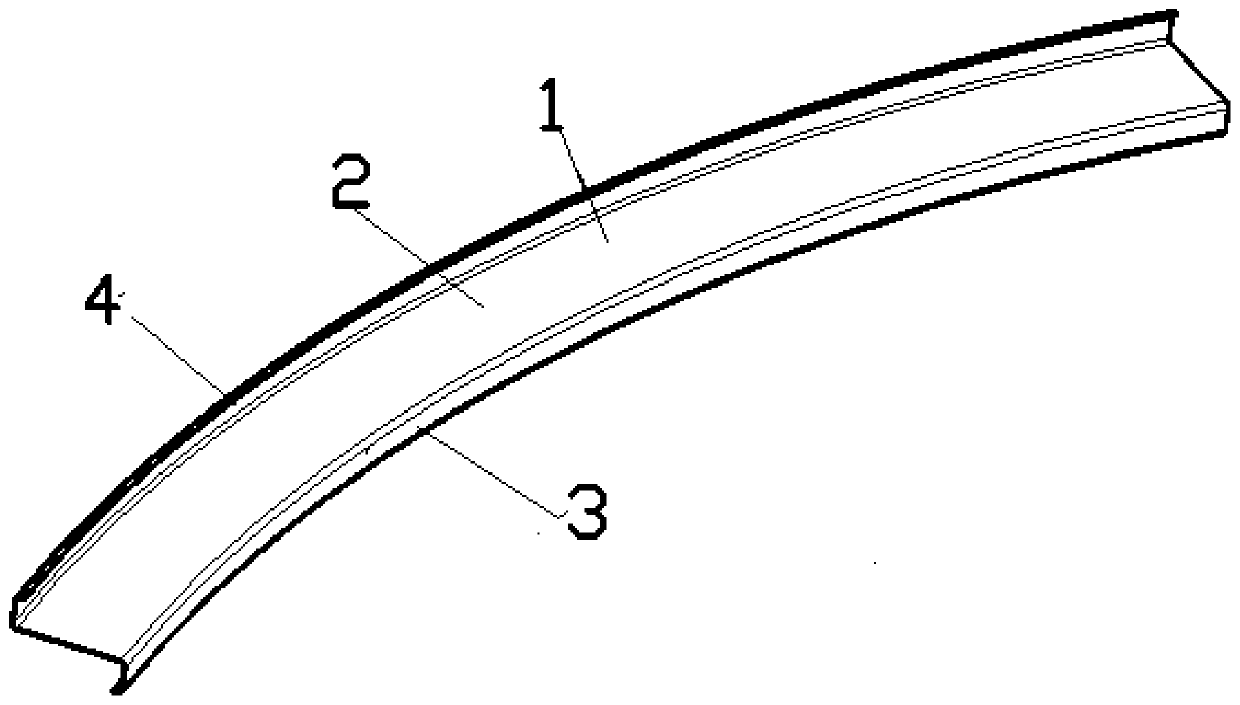

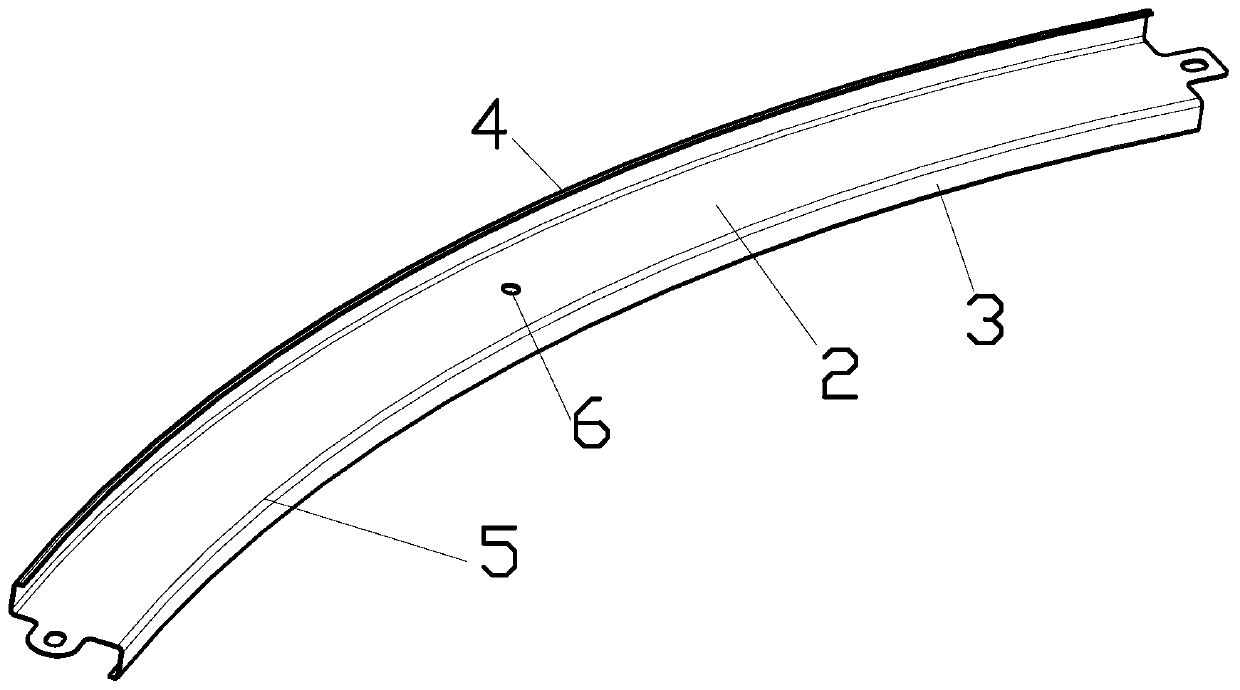

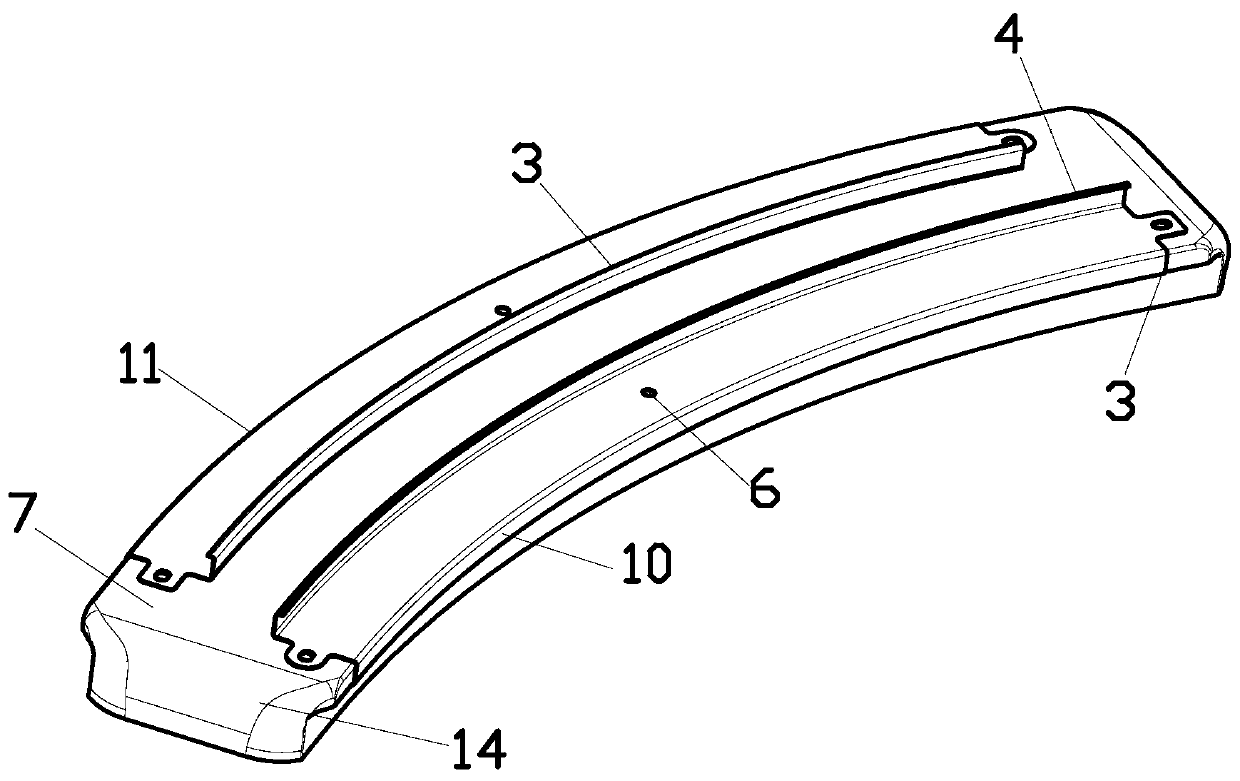

Rubber forming method and die for sheet metal frame parts with different-direction flanges

ActiveCN111229914AReduce in quantityImprove forming efficiencyShaping toolsEngineeringMechanical engineering

The invention discloses a rubber forming method and die for sheet metal frame parts with different-direction flanges. A model of the sheet metal frame parts comprises an equal-curvature arc-shaped webplate, the first flange and the second flange, wherein the first flange and the second flange are symmetrical; and the forming die comprises a carcass and a cover plate matched with the carcass, thecarcass comprises two forming stations, the first forming station matched with the first flange is arranged on the inner side of the carcass, the second forming station matched with the second flangeis arranged on the outer side of the carcass, an arc-shaped avoiding groove is formed in the inner surface of the cover plate, an expanded sheet of the first sheet metal frame part is placed on the first forming station of the carcass for positioning, an expanded sheet of the second sheet metal frame part is placed on the second forming station of the carcass for positioning, first rubber formingis performed, then the first sheet metal frame part is turned over and placed on the second forming station of the carcass, the second sheet metal frame part is turned over and placed on the first forming station of the carcass, and second rubber forming is performed.

Owner:XIAN AIRCRAFT IND GROUP

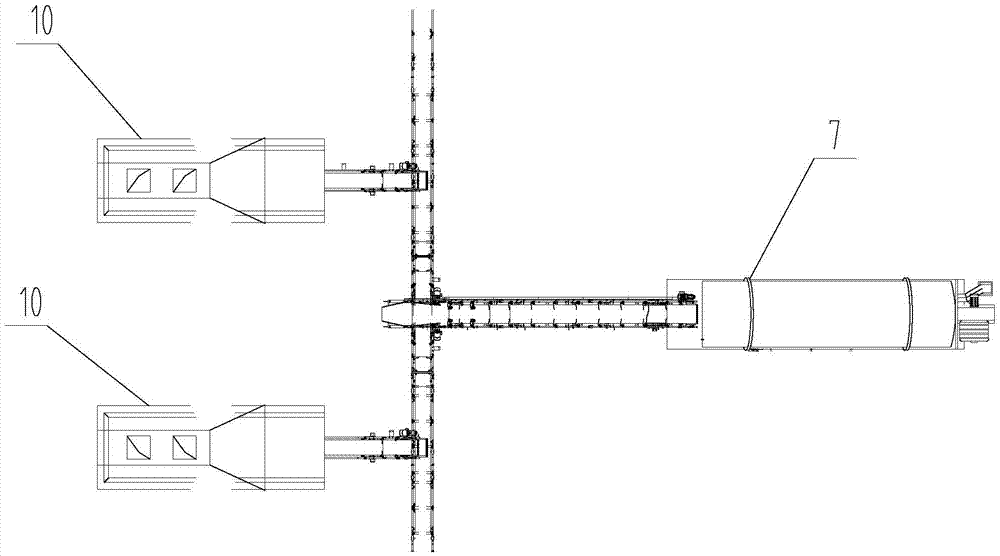

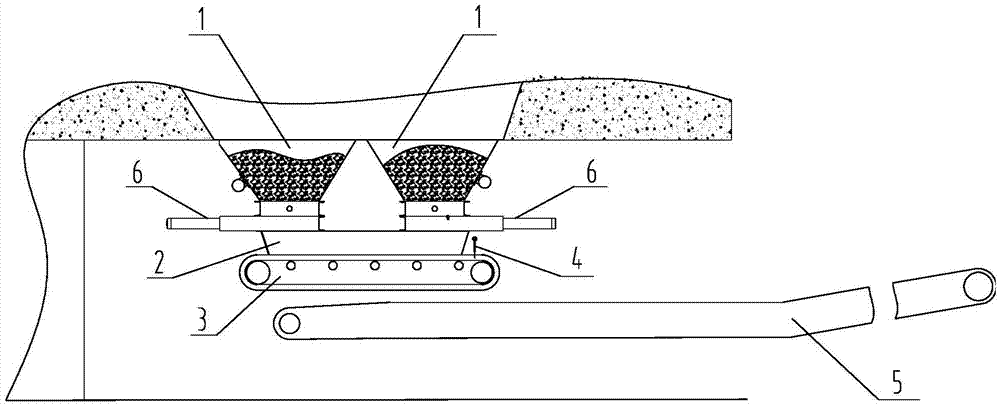

Mixing station and automatic feeding device thereof

InactiveCN105438848ATimely control of unloadingImprove work efficiencyConveyorsRoads maintainenceContinuous flowEngineering

The invention discloses an automatic feeding device. According to the automatic feeding device, a belt feeder is arranged below storage bins; a material flow detecting device is arranged at a discharging hole of the belt feeder or at the outlet of a discharge hopper; during material supply, the discharging hole of one or a plurality of storage bins is opened, a material flows to the belt feeder via the discharge hopper, the belt feeder is used for metering the material and supplying the material to a material collecting conveyer, and finally the material is conveyed to a target position by the material collecting conveyer; during a material supply process, the material flow detecting device is used for detecting the material at the discharging hole of the belt feeder in time; when the material flow detecting device detects continuous flow cutoff, a controller is used for controlling the discharging hole of another storage bin to be opened for discharging the material. Besides, the invention also discloses a mixing station comprising the automatic feeding device.

Owner:HUNAN SANY ROAD MACHINERY

Self-adaption gripper type discharge device and discharge method

ActiveCN107285055AImprove efficiencyIncrease unloading rateBottle emptyingLoading/unloadingSelf adaptiveEngineering

The invention relates to the technical field of ton bag discharge device structures, in particular to a self-adaption gripper type discharge device and a discharge method. The self-adaption gripper type discharge device comprises a rack, wherein the rack is provided with an overturning frame which is used for containing ton bags, and the overturning frame is of a frame structure which can be rotationally hinged to the rack and is provided with at least one opening. The self-adaption gripper type discharge device further comprises a fixing device which is used for fixing the ton bags, wherein the fixing device comprises a ton bag side wall fixing device and a ton bag bottom fixing device, the ton bag side fixing device comprises a plurality of pairs of opposite side suction cups which are arranged on the inner side of the overturning frame, and the ton bag bottom fixing device comprises a plurality of pairs of gripper devices which are arranged on the two sides of the bottom of the overturning frame and used for clamping the bottoms of the ton bags. The self-adaption gripper type discharge device is simple in structure, convenient to operate and capable of discharging materials in the ton bags completely and rapidly, the ton bags cannot be damaged, collection and recirculation of the ton bags are facilitated, the discharging difficulty is greatly lowered, and great popularization value is achieved.

Owner:HUBEI UNIV OF TECH

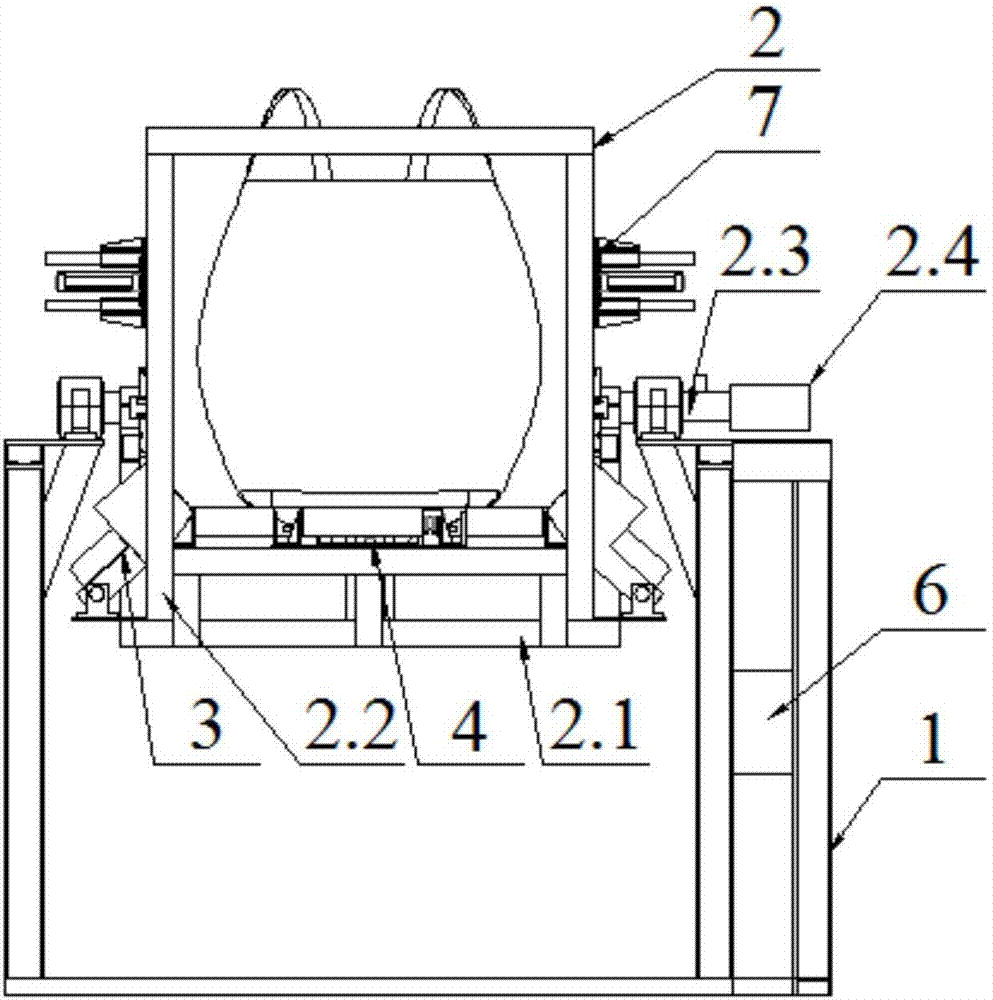

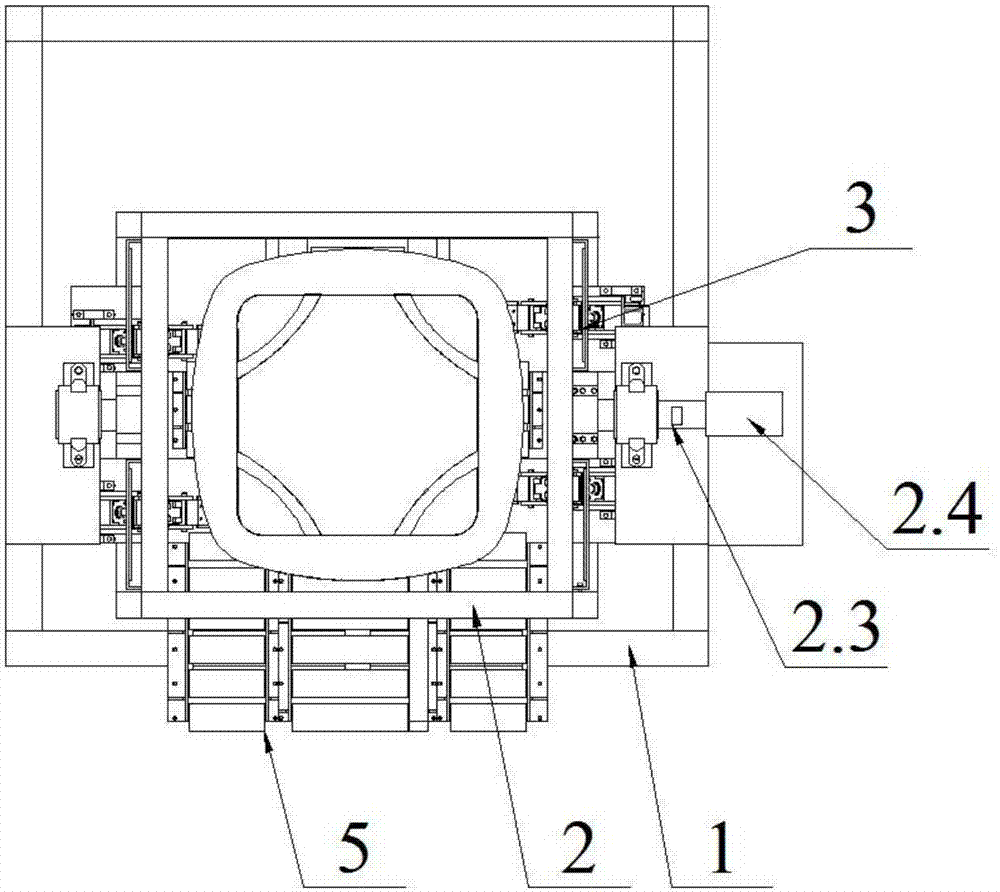

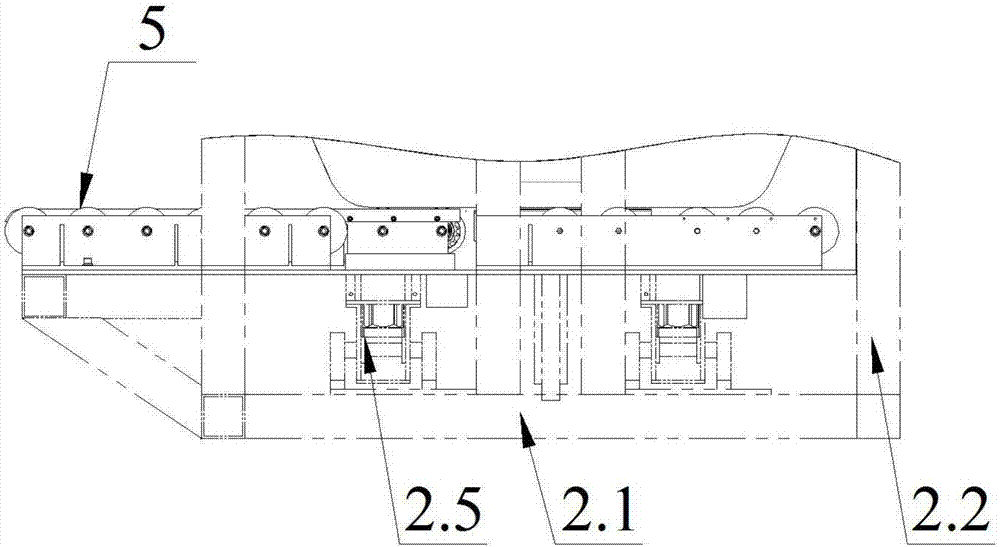

Container polyvinyl chloride powder logistics system

InactiveCN105564672AImprove shipping efficiencyReduce consumptionSolid materialBulk conveyorsLogistics managementPolyvinyl chloride

The invention discloses a container polyvinyl chloride powder logistics system which comprises three links. Firstly, the filling link is conducted, wherein polyvinyl chloride powder from a packing bin enters a filling device, a container is filled with the polyvinyl chloride powder through the filling device, and dust generated in the filling process is removed through a dust removing device of the container; secondly, the transfer link is conducted, wherein after filling of the container is completed, the container is transported to a railway container delivery place through a plate trailer and then loaded on a train through a railway container assembly table so as to be delivered, and the container is conveyed to a user field through the plate trailer afterwards; and finally the user field unloading link is conducted, wherein the powder in the container in the user field is directly conveyed to enter a user bin through an unloading device, after unloading is completed, a draught fan is stopped, and unloading is over. By means of the container polyvinyl chloride powder logistics system, consuming of a large number of outer packages is reduced, the reshipment cost of robot stacking and manual work / forklifts is reduced, pollution and product losses caused by transporting and unpacking of small-bag packages of products are avoided, the processes of the container polyvinyl chloride powder logistics system are shortened into three processes, production cost is reduced, and the logistics delivery efficiency of polyvinyl chloride is improved.

Owner:XINJIANG TIANYE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com