Intelligent unloading system, multi-silo tank container and multi-silo tank car

A multi-silo, intelligent technology, applied in the direction of loading/unloading, transportation and packaging, etc., can solve the problem of low unloading efficiency of tanks or tank trucks, achieve the effect of convenient unloading, reduce labor intensity, and improve unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

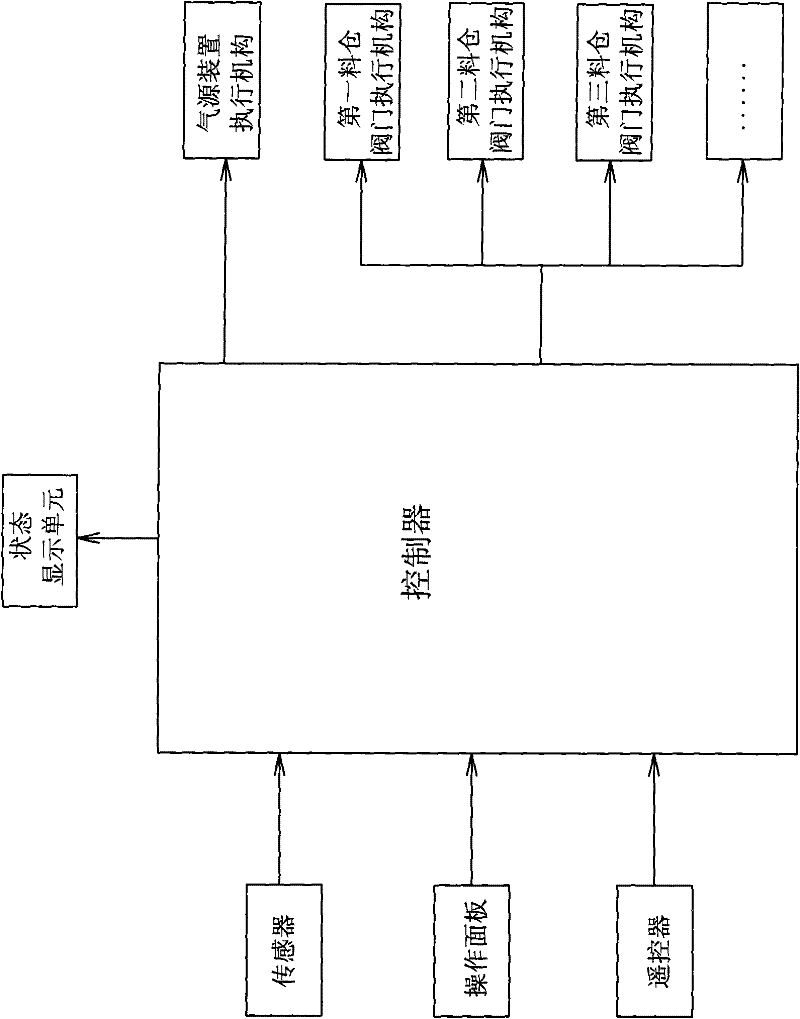

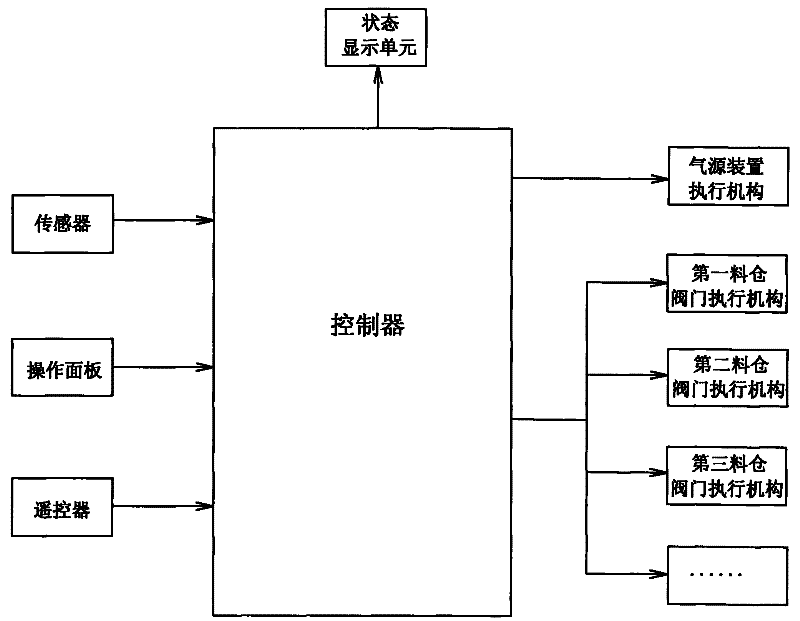

[0018] Such as figure 1 As shown, the intelligent unloading system of the present invention is used for a multi-storage tank container or a multi-storage tank car with multiple silos. A multi-silo tank or a multi-silo tank car includes a plurality of silos separated by partitions. There are through holes on the partitions so that two adjacent silos are connected to each other. The through holes can be set at the top of the partitions. , so that the materials in adjacent silos can be avoided from mixing through this through hole. The discharge system of each silo has a discharge valve. There is an air compressor on the tank, which can also be other air source devices. The air compressor is used to continuously inflate and pressurize the tank. Since the various silos in the tank are connected to each other, the pressure of each silo is the same. . If there is no gas source device in the tank, an external gas source can also be used to inflate and pressurize the tank.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com