Patents

Literature

280 results about "Bulk storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

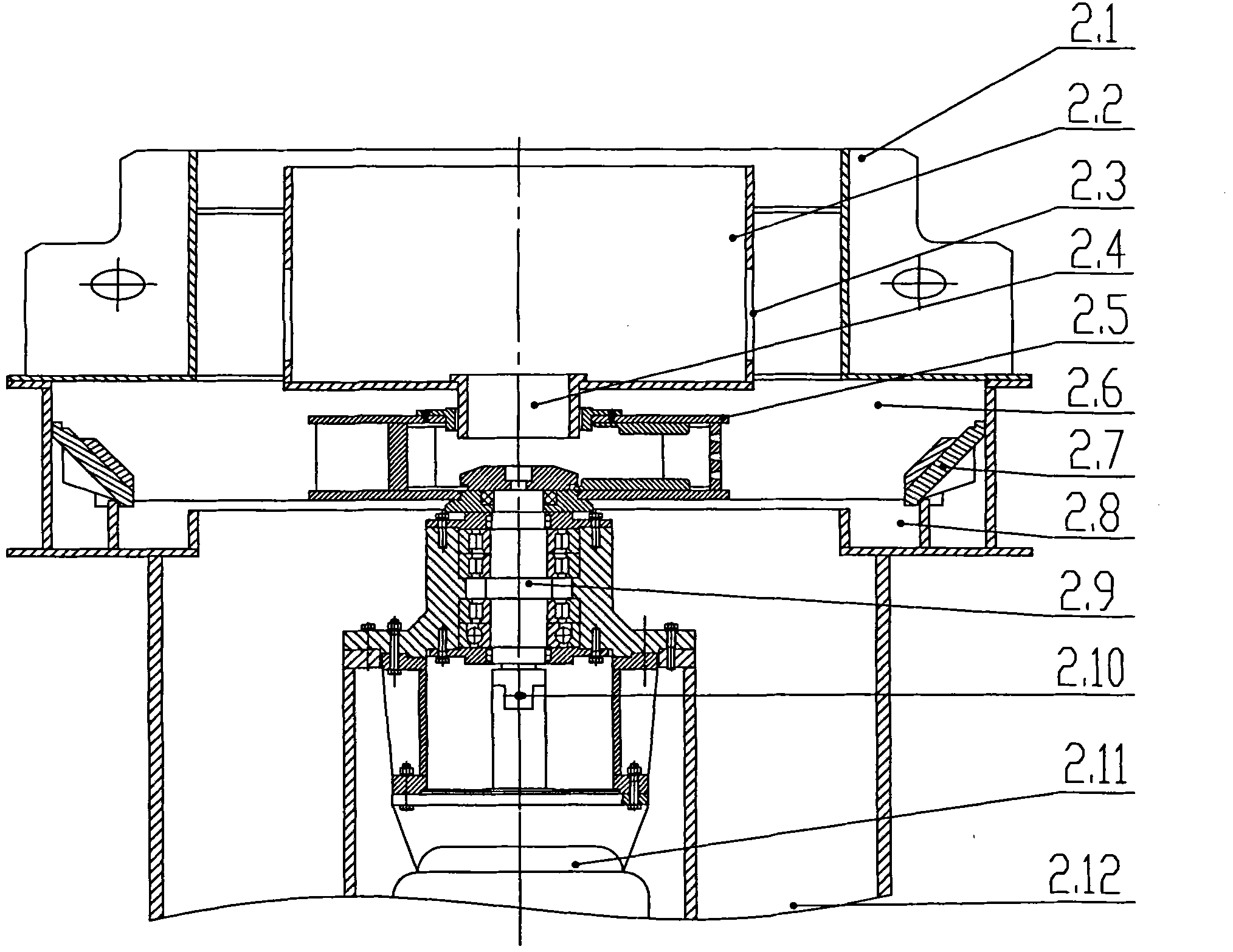

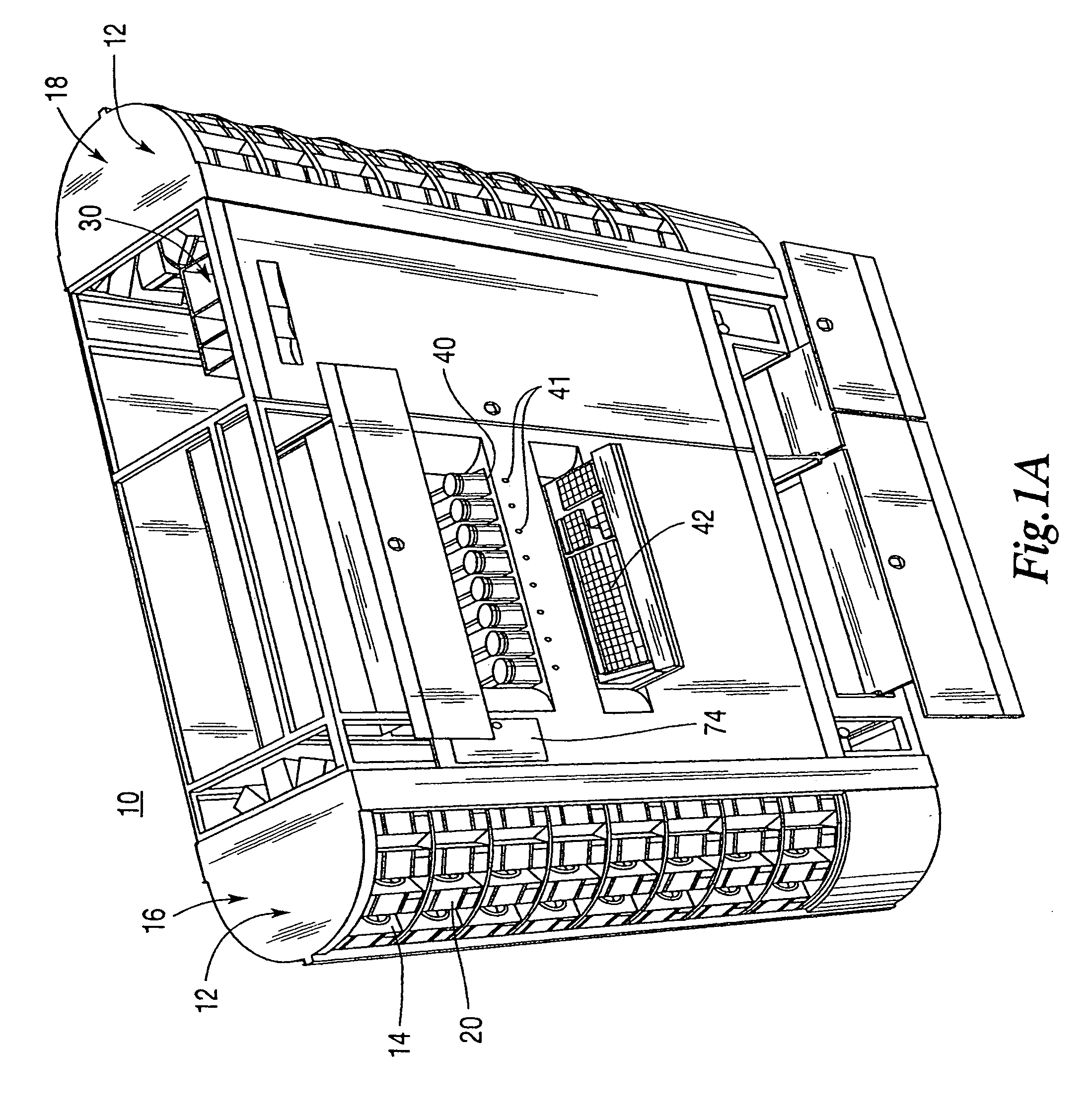

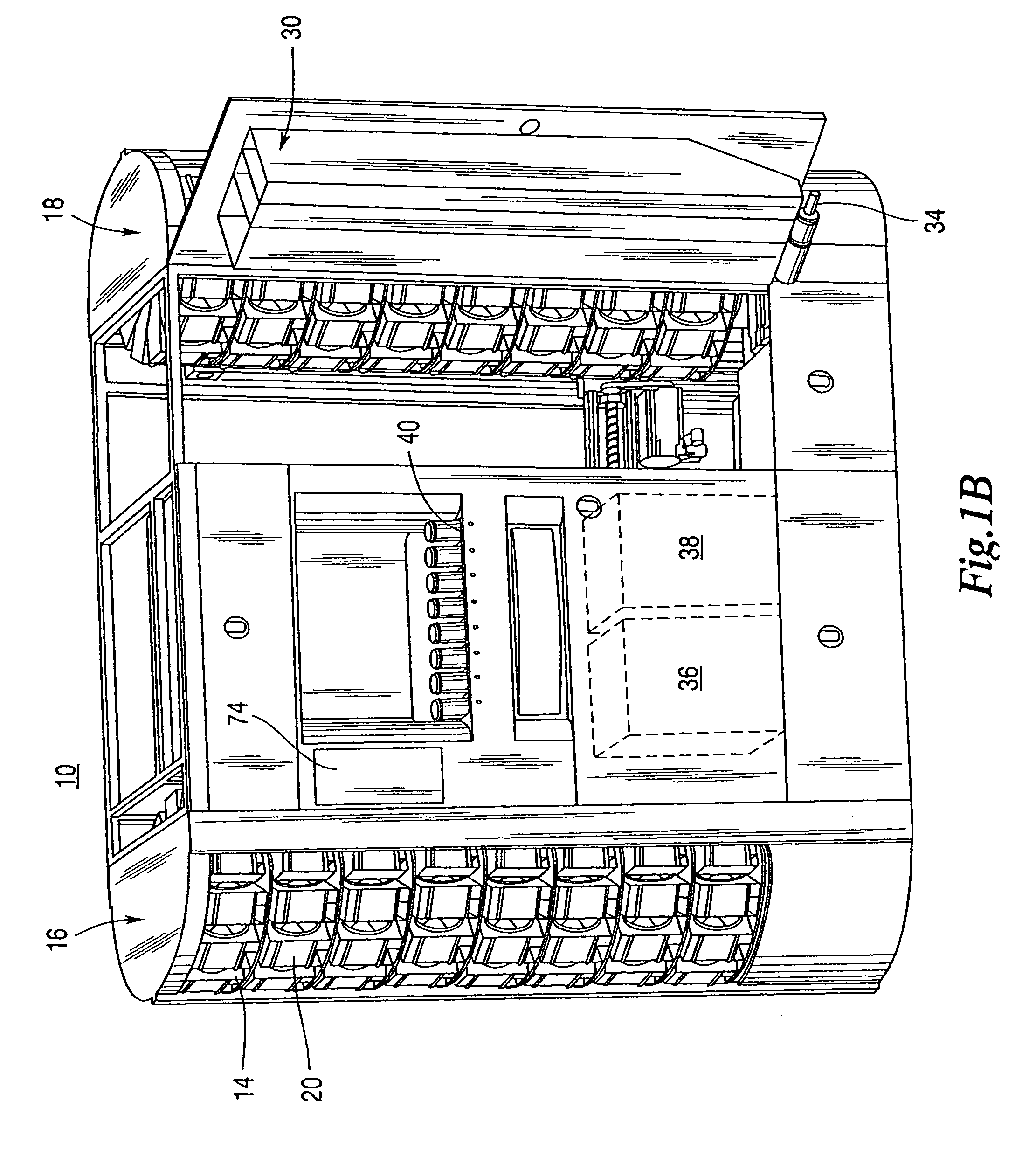

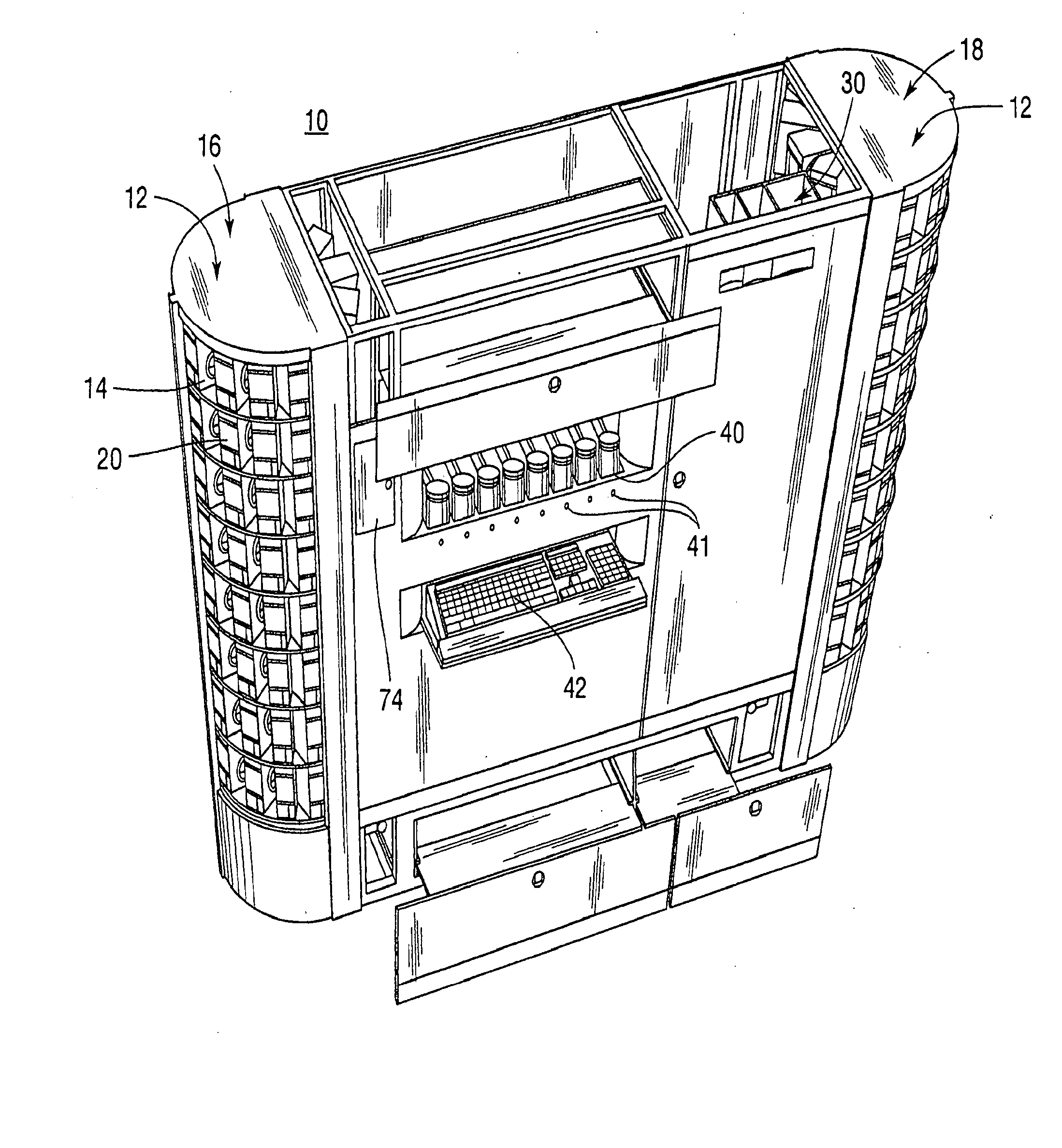

Dispensing device having a storage chamber, dispensing chamber and a feed regulator there between

A drug dispensing device is comprised of an upper hopper having an upper opening for receiving a medicament and a lower opening. A lid covers the upper opening. A lower hopper having an upper opening and a lower opening in a bottom portion thereof is provided. The upper hopper defines a bulk storage chamber and the lower hopper defines a dispensing chamber. A rotatable dispensing disc is positioned in a lower portion of the dispensing chamber for dispensing medicament from the drug dispensing device through the lower opening in the lower hopper. A regulator is situated between the bulk storage chamber and the dispensing chamber for controlling the rate at which medicament moves from the storage chamber to the dispensing chamber. The regulator may take a variety of forms. In one embodiment, the regulator includes a valve for controlling the flow of medicament from the storage chamber to the dispensing chamber. The valve may include a member responsive to the volume of medicament in the dispensing chamber for controlling the position of the valve. The valve and member may include a trap door valve and a float, a butterfly valve and a rotatable arm, a guillotine valve and a movable arm, and a conical plunger and a wing extending from the base of the plunger. In another embodiment, the regulator may include a rotatable member having an opening therein. The rotatable member may include a cylindrical wall having an opening in a portion thereof, a plate having an opening therein, a cup shaped member defining an opening and a pair of rotatable members which together define at least one opening therein. The regulator may be configured such that the rate at which medicament moves from the storage chamber to the dispensing chamber is never zero. Further, agitating members may be provided which extend toward the upper hopper. Methods of operation are also disclosed.

Owner:PARATA SYST

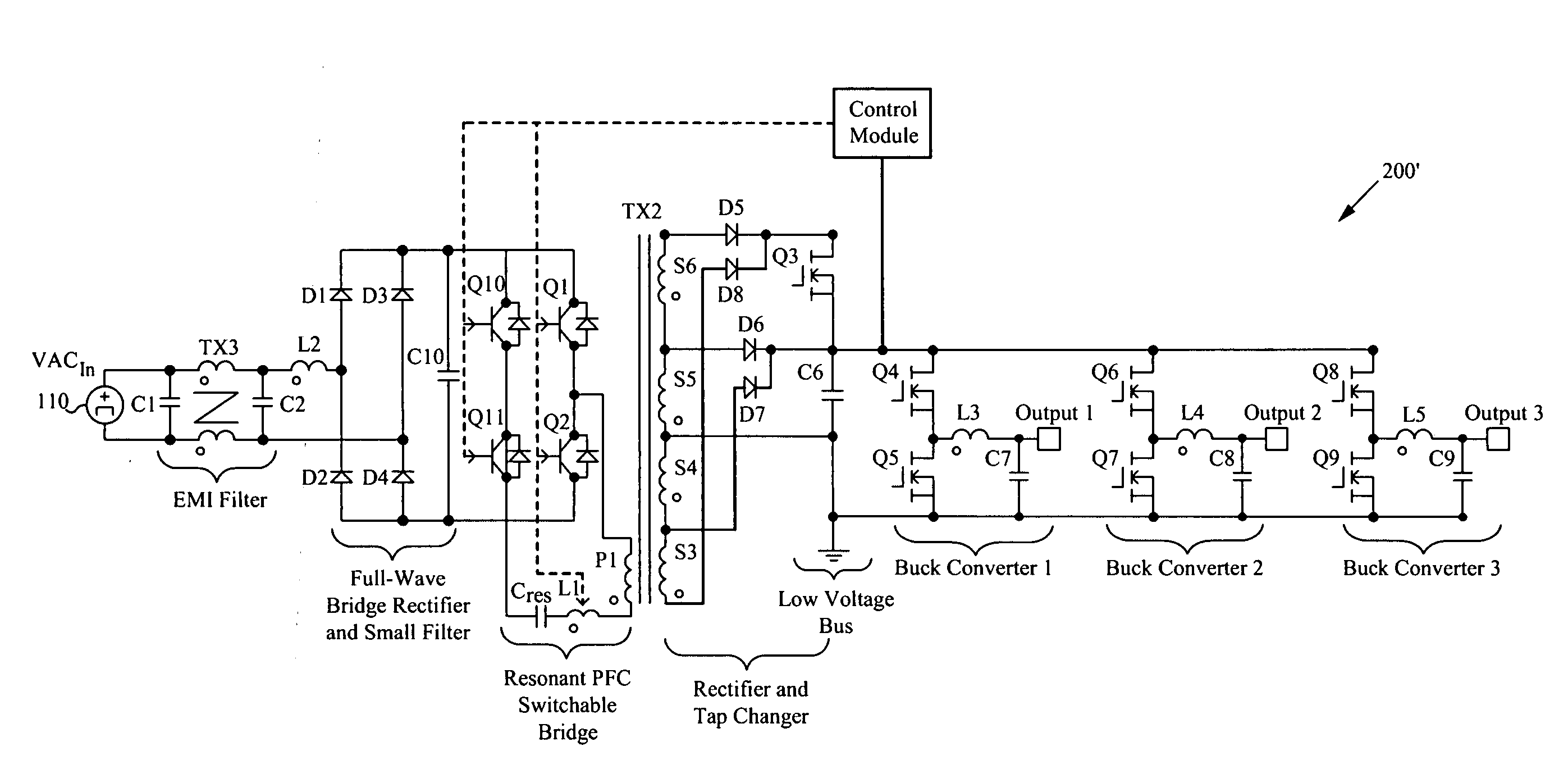

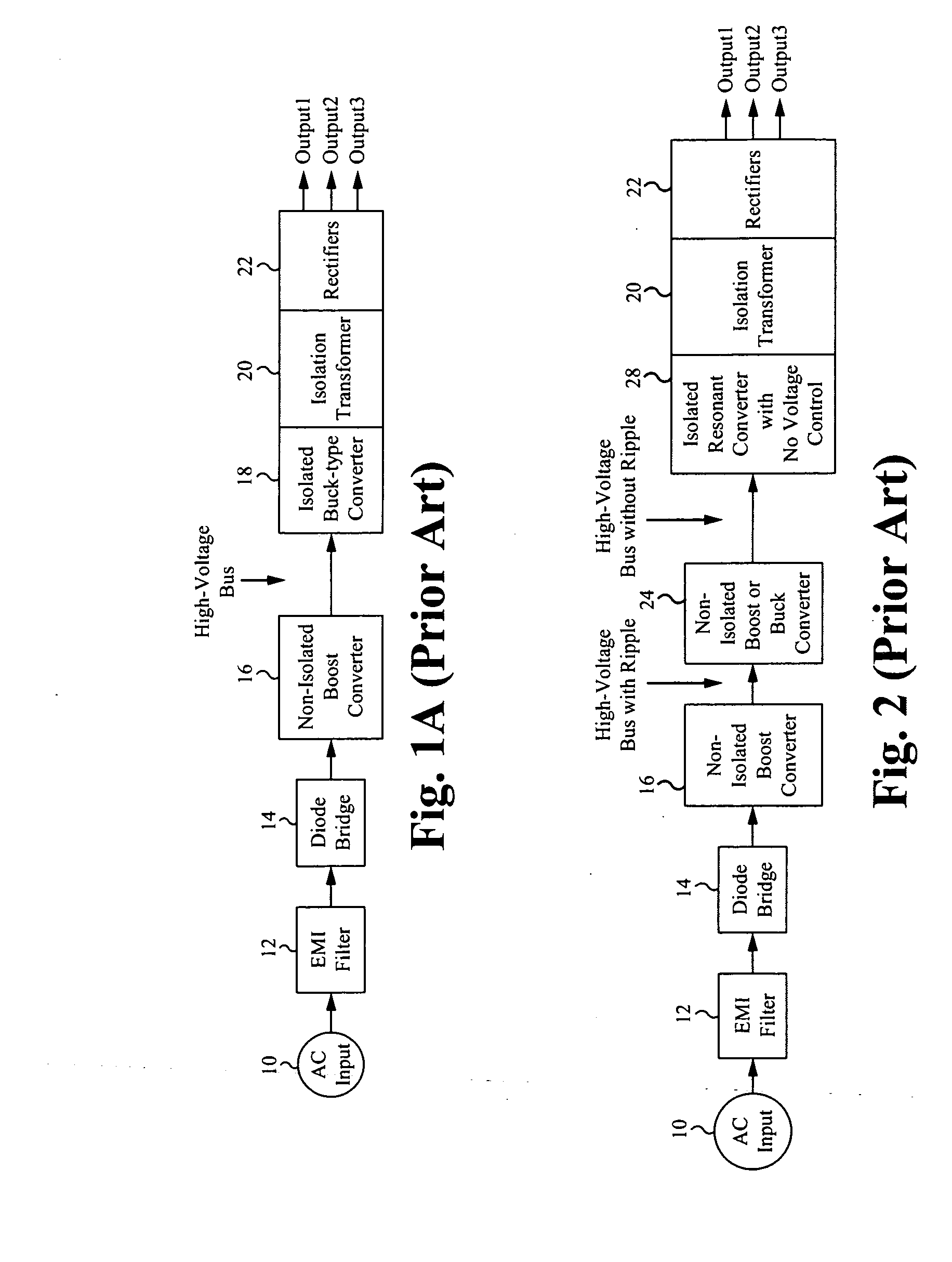

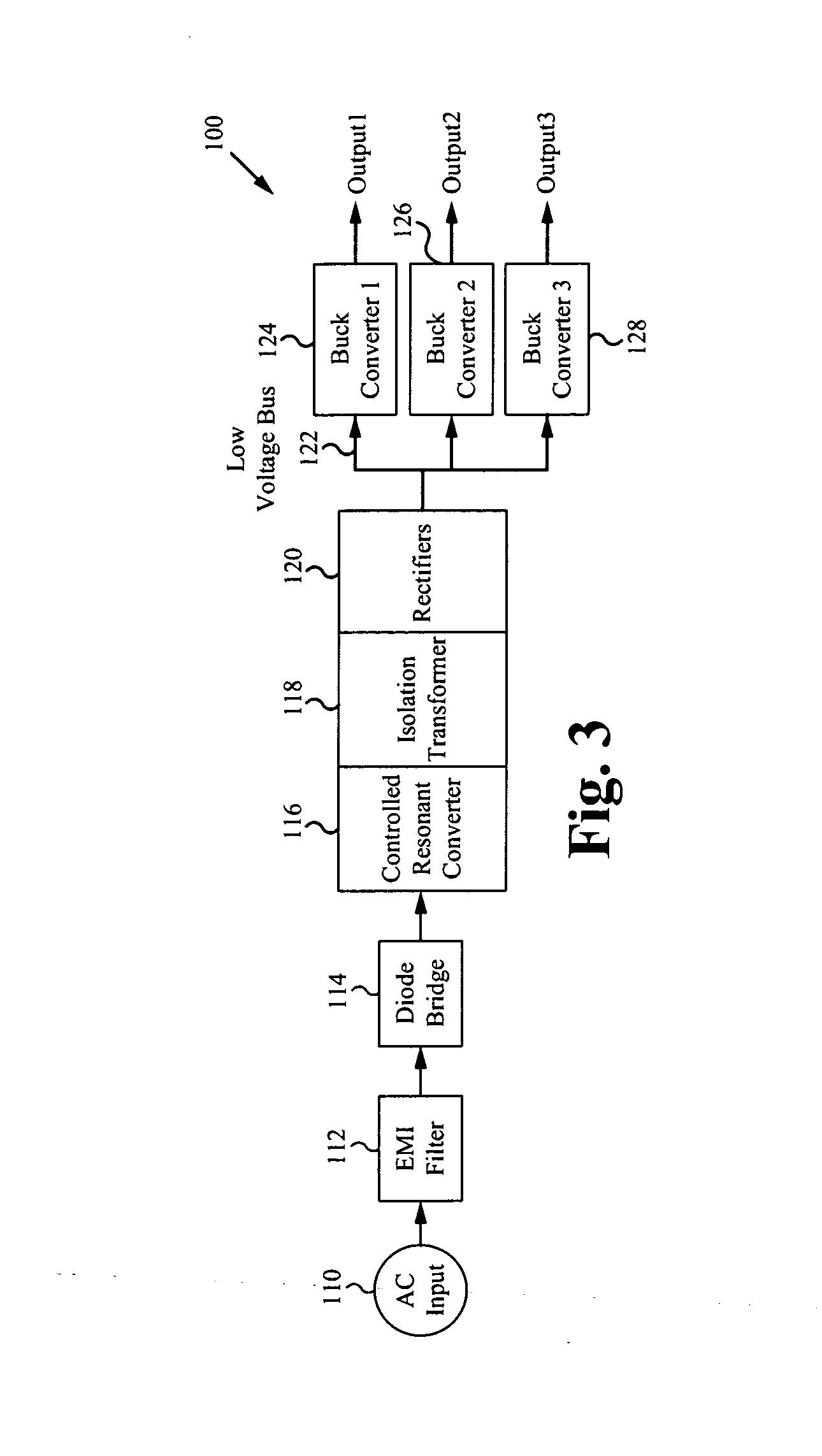

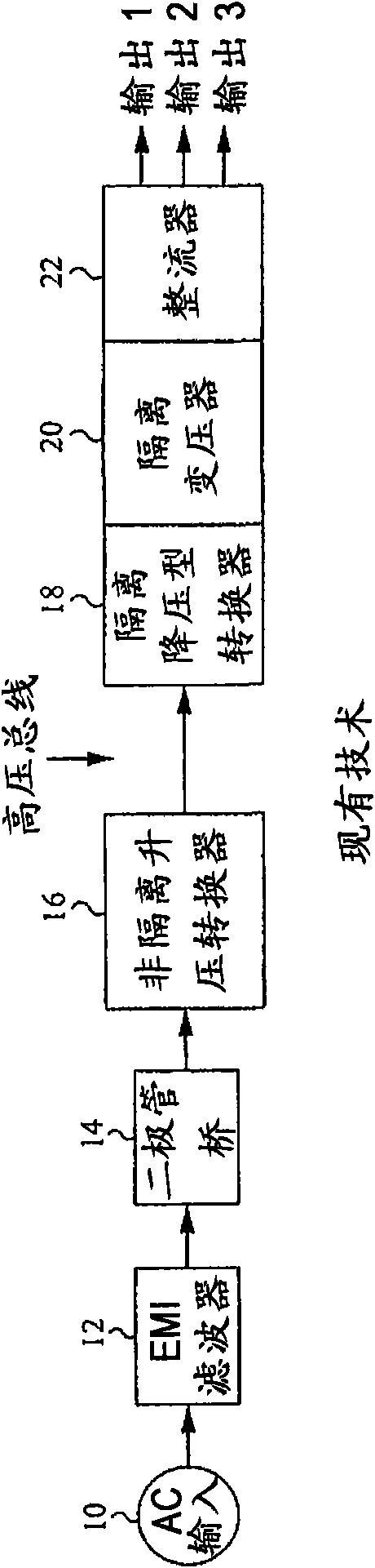

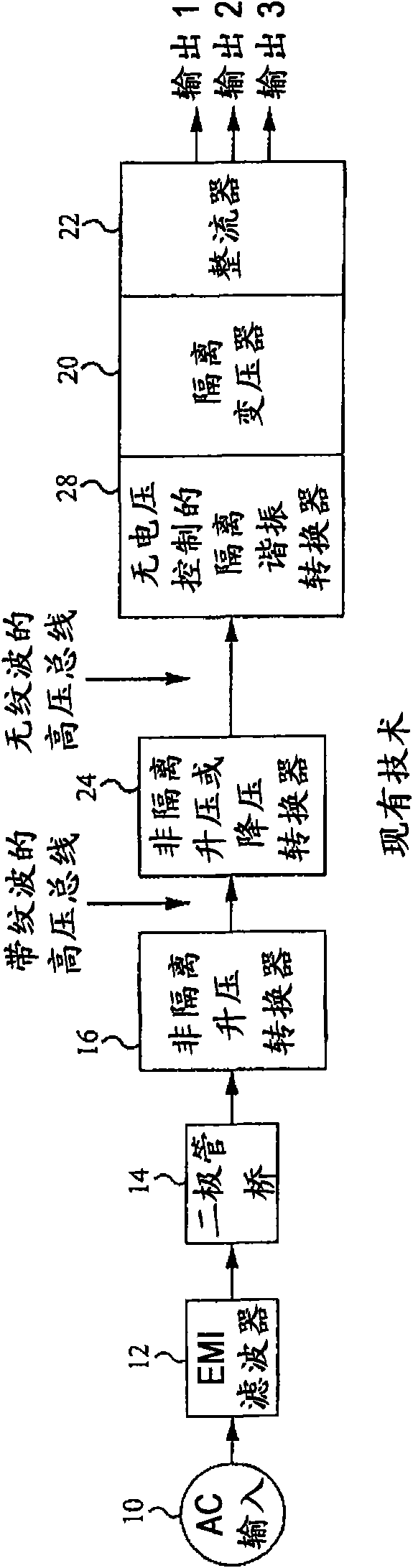

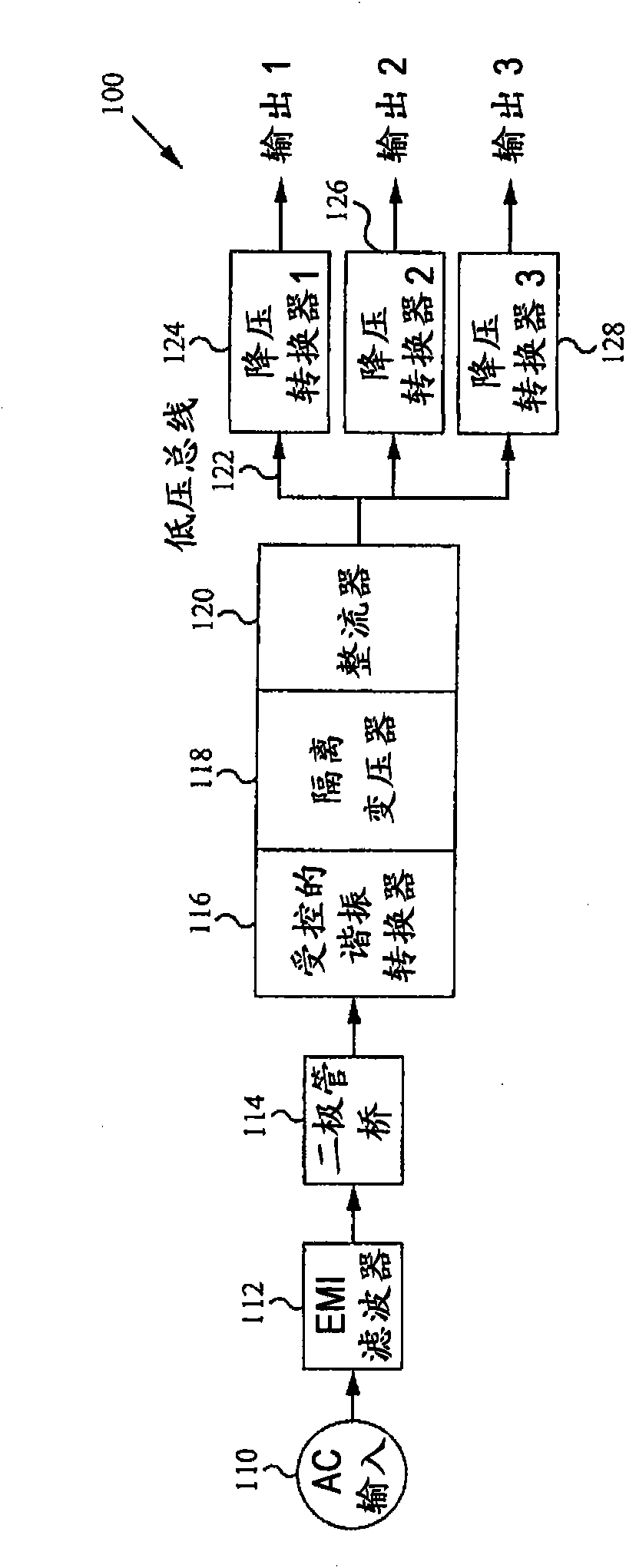

Resonant power factor correction converter

ActiveUS20090290385A1Increase pressureBurdenAc-dc conversion without reversalEfficient power electronics conversionMass storageSingle stage

An AC-to-DC power converter configured to provide power factor correction and a single isolated low-voltage output. The power converter includes a single-stage resonant power converter including an isolation transformer, a resonant tank, a rectifier, and a bulk storage capacitor coupled to an output of the isolation transformer. In typical applications, at least one non-isolated power converter is coupled to the output of the single-stage isolated power factor correction converter.

Owner:MYPAQ HLDG LTD

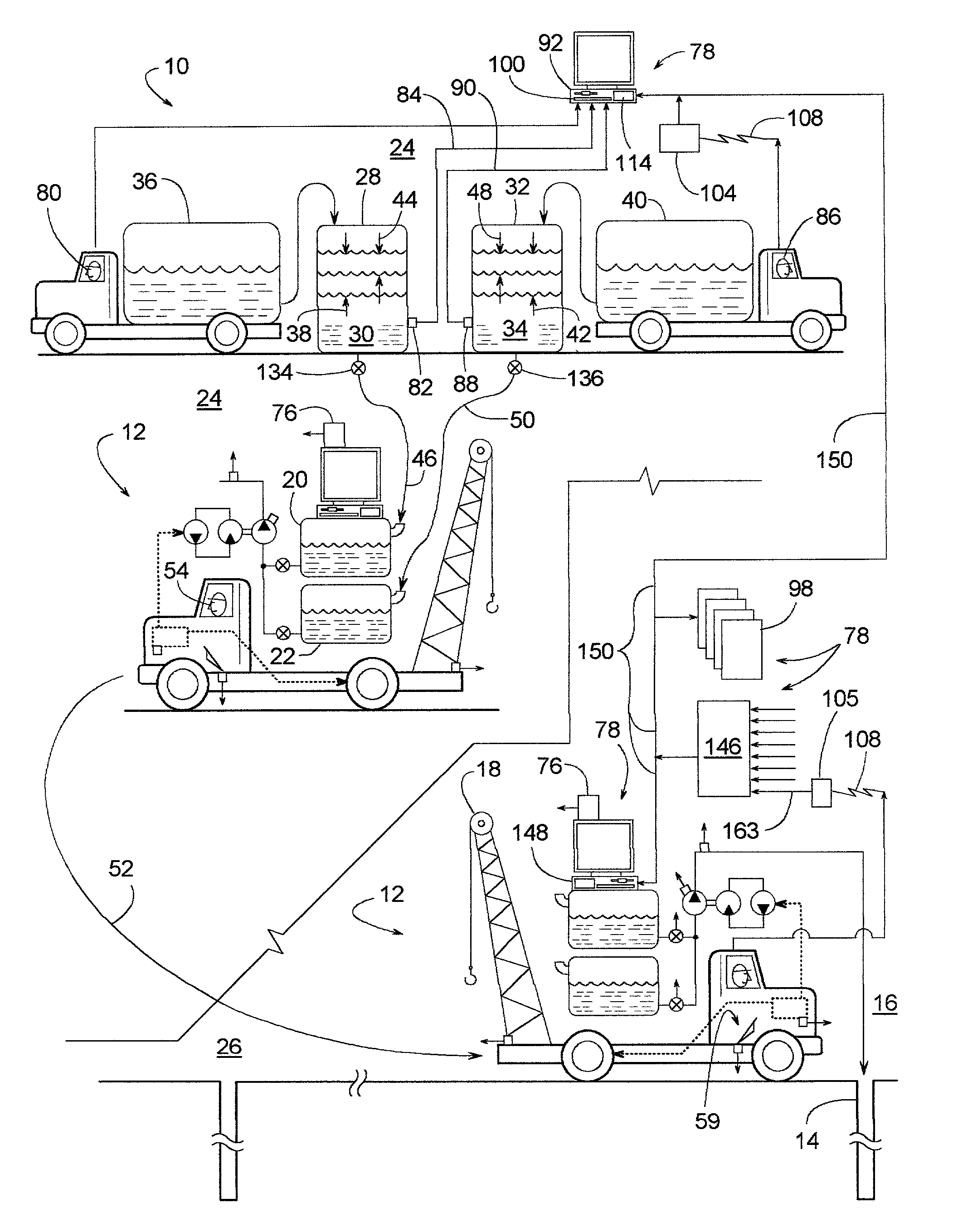

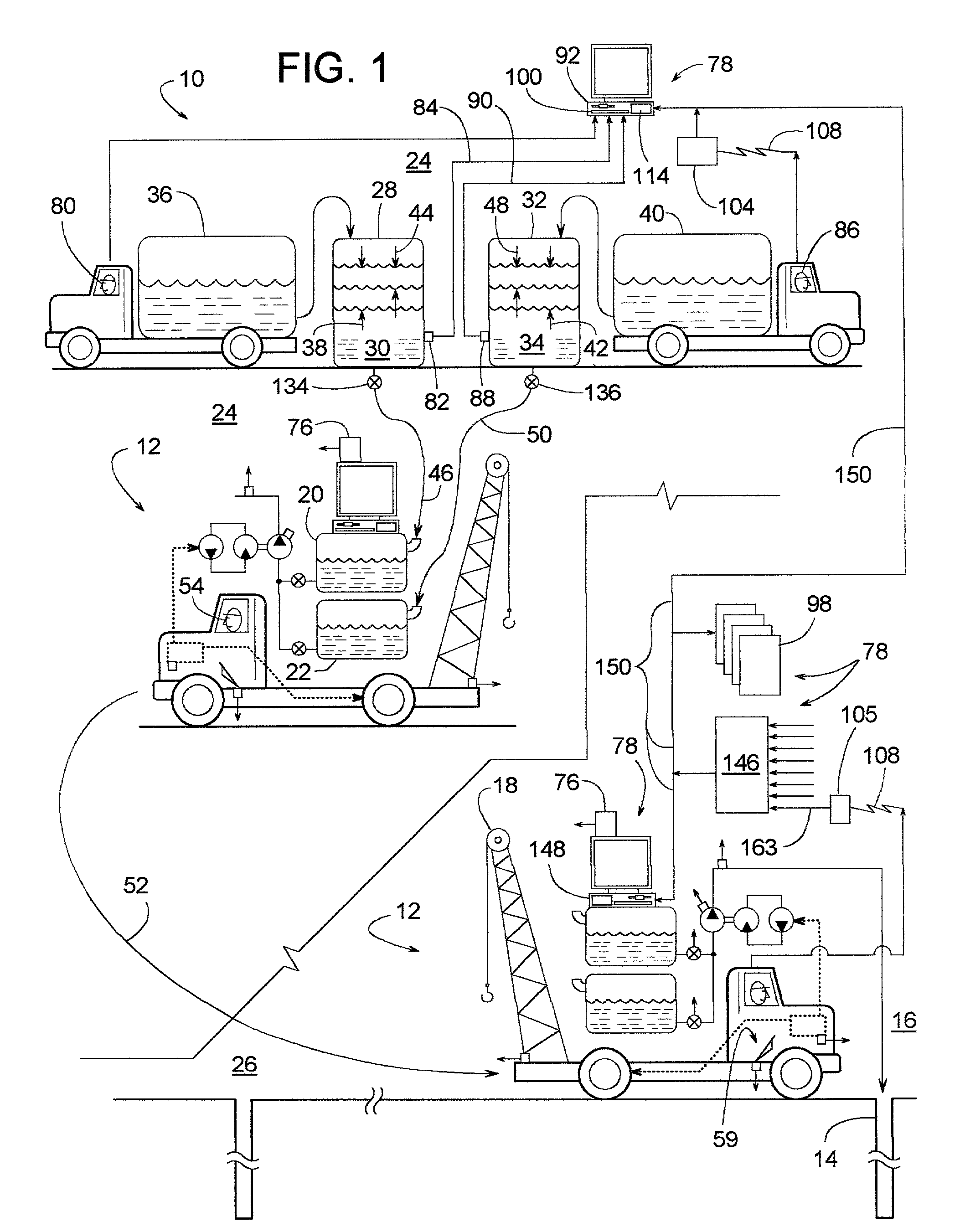

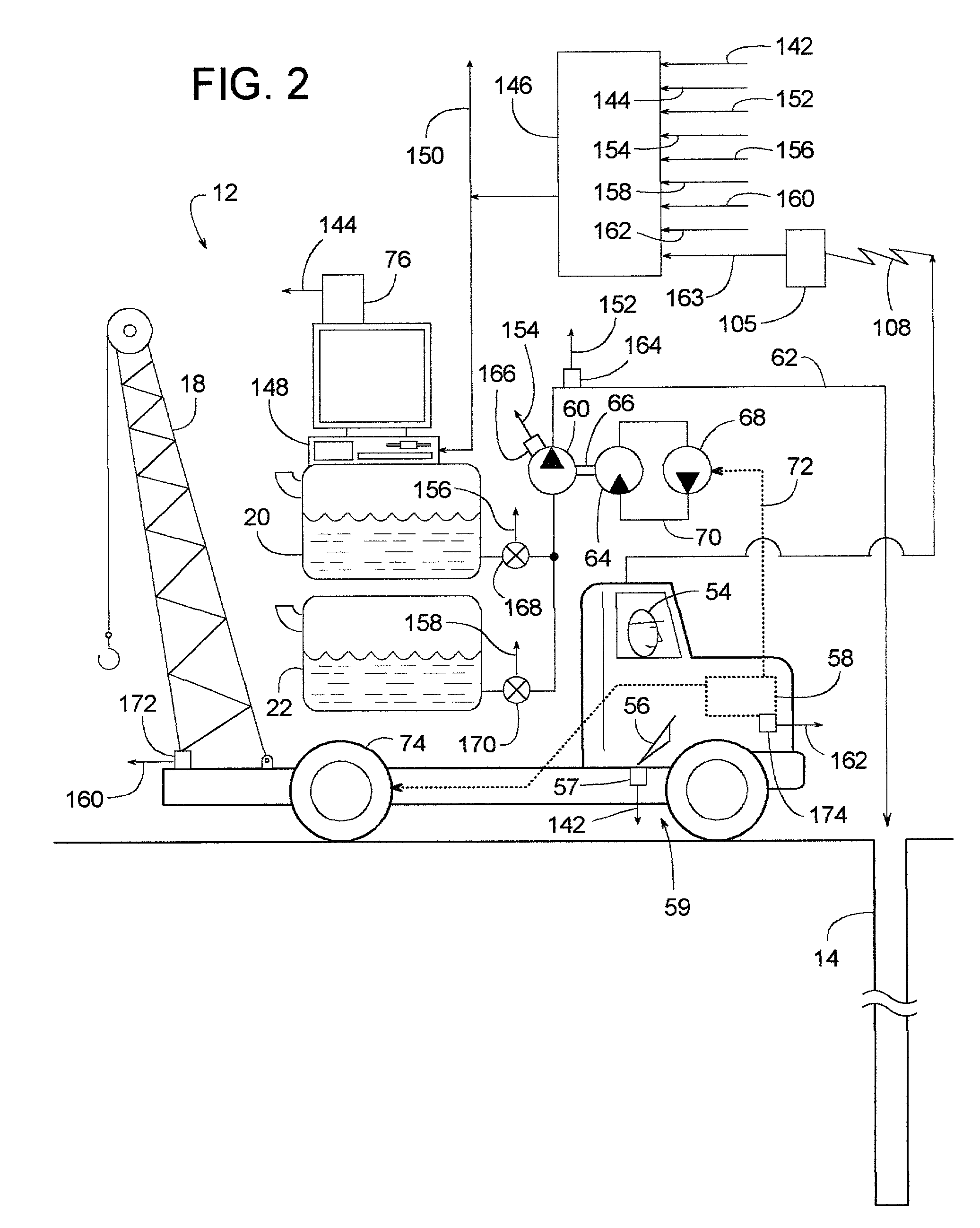

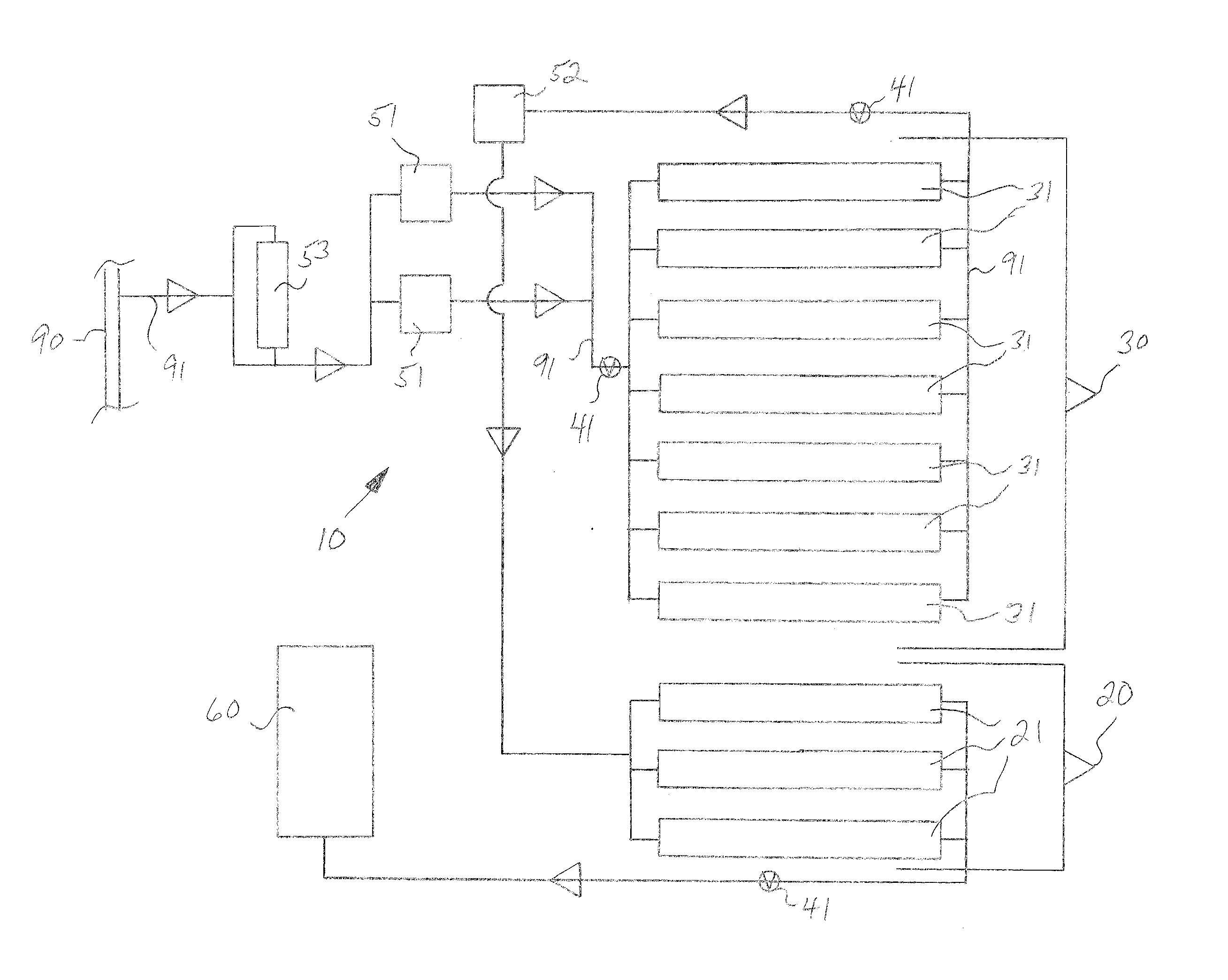

Servicing system for wells

ActiveUS7006009B2Minimize operator errorError minimizationRegistering/indicating working of vehiclesCleaning apparatusMass storageTransducer

A well servicing system includes a computer-based system that monitors pumping or other service operations at a well site and monitors deliveries and withdrawals of chemicals at a bulk storage station. A GPS device or other location identifier provides a location value that identifies the location of the service vehicle. A GPS reading is triggered by actuation of the vehicle's parking brake, and the location value is recorded in association with a process-related transducer value. The transducer value is based on the service vehicle performing some type of service operation either at the well site or at the bulk storage station.

Owner:KEY ENERGY SERVICES

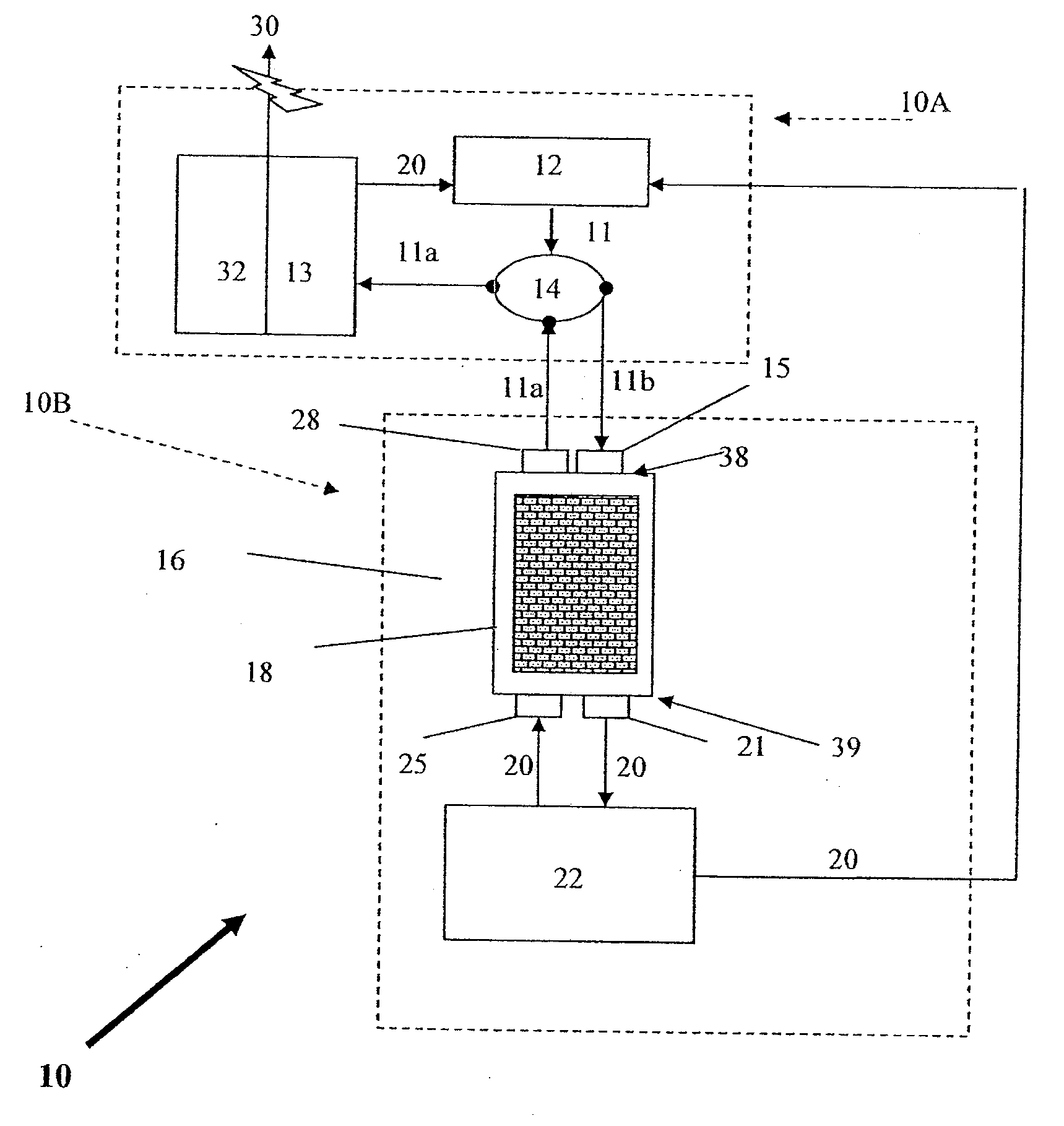

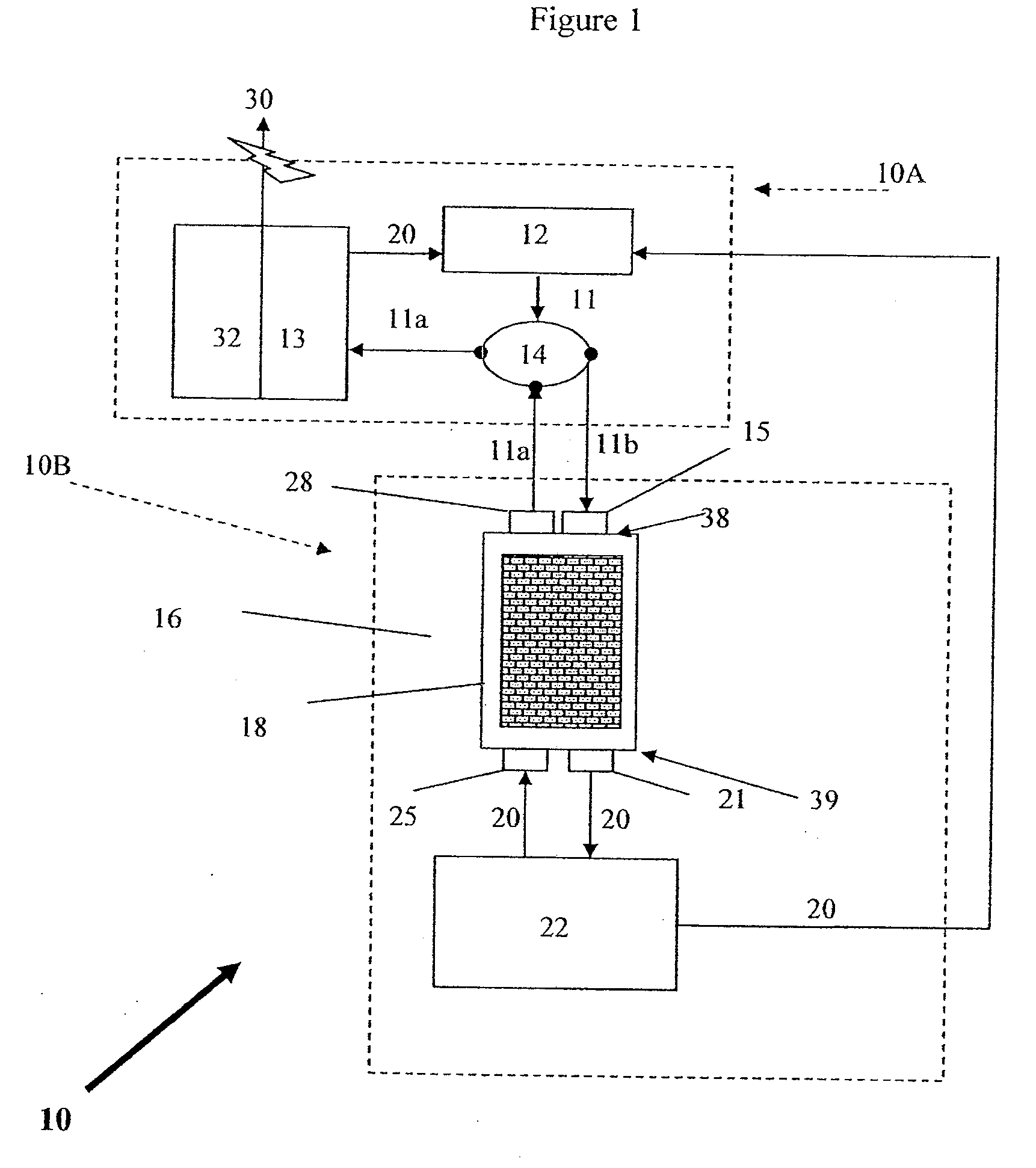

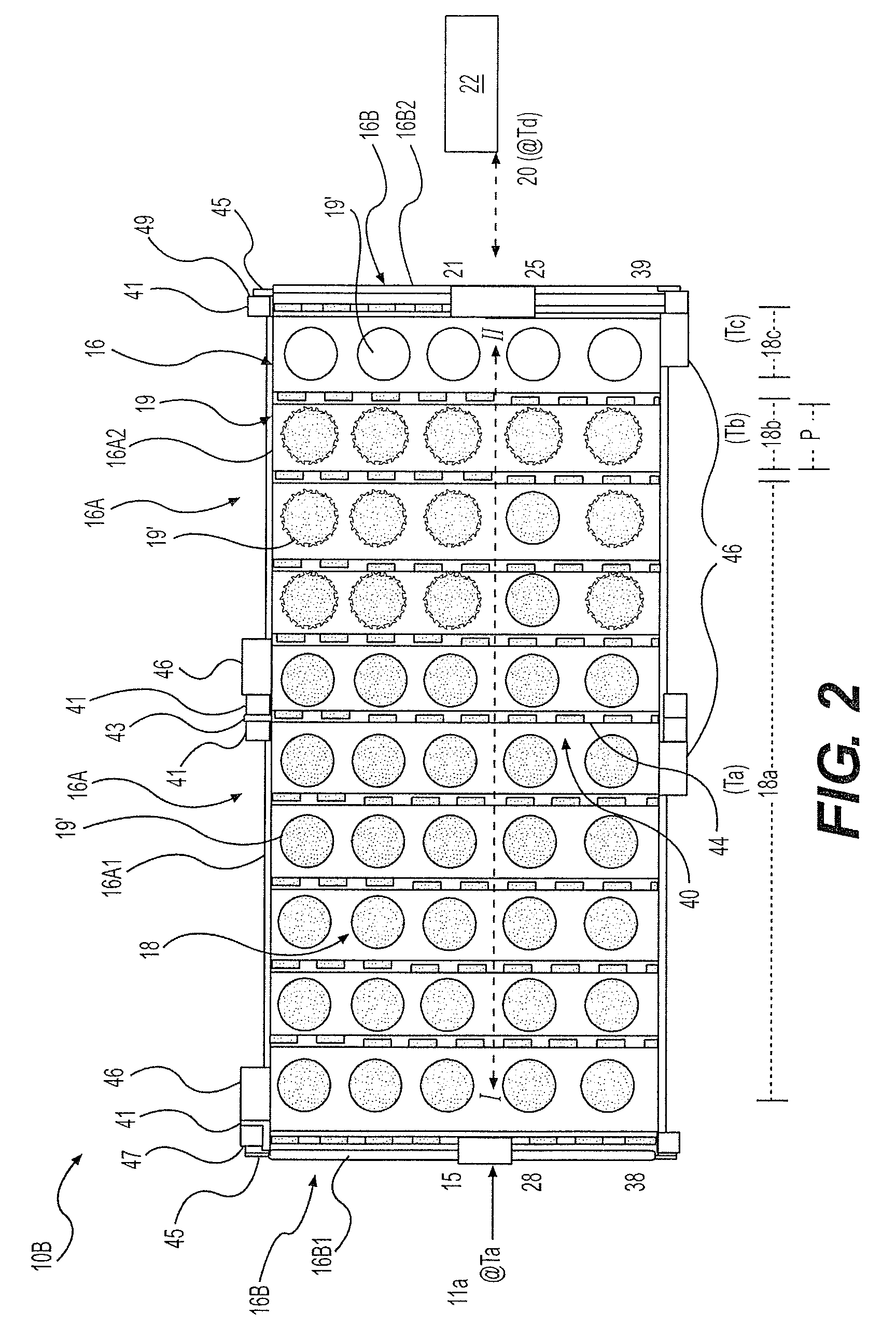

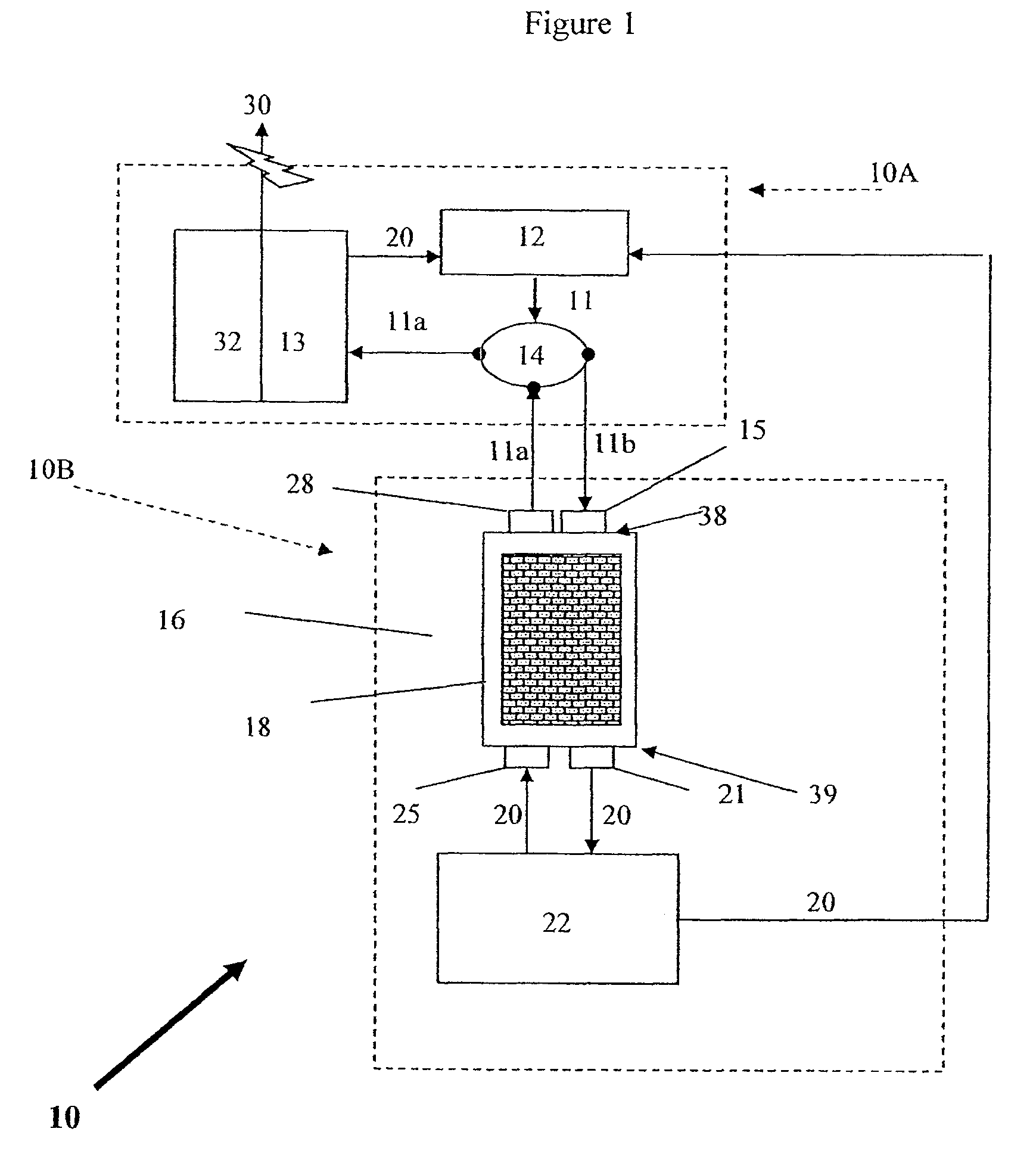

Apparatus and method for storing heat energy

ActiveUS20090178409A1Simple designLess-expensive to implementSolar heat devicesHeat storage plantsStored energyWorking fluid

Method and apparatus for storing heat in industrial systems where large sources of stored energy are called upon to meet a work load, storing the heat content of a hot working fluid by using the hot working fluid as a heat transfer fluid in vapor form and depositing its heat content on a heat storage medium and then removing the cooled and condensed liquid phase of that heat transfer fluid, and when hot working fluid again is needed, the liquid heat transfer fluid is returned to the heated storage medium and is reheated as it passes through the hot storage medium and then is returned to the working system to be used as a hot working fluid.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

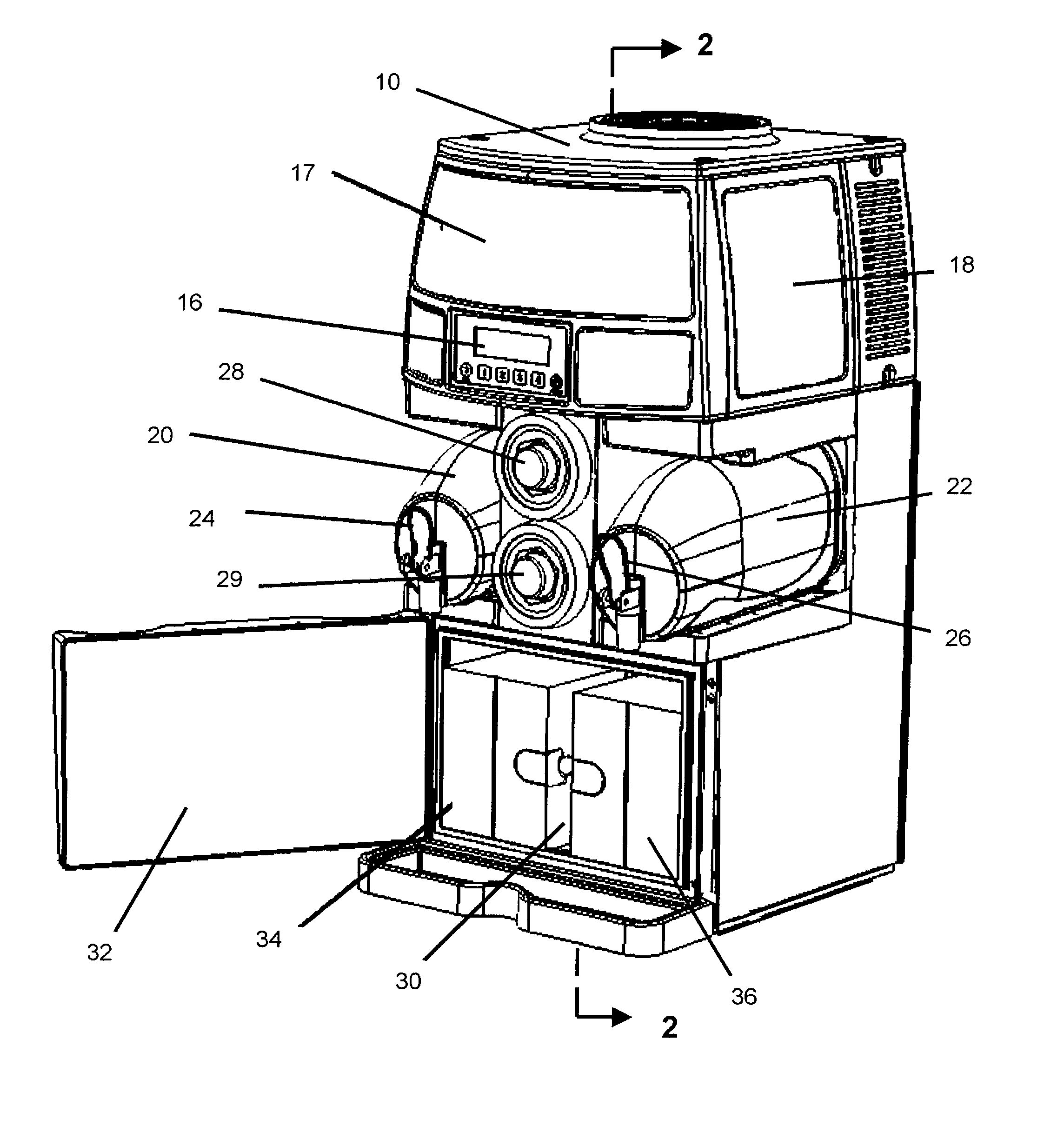

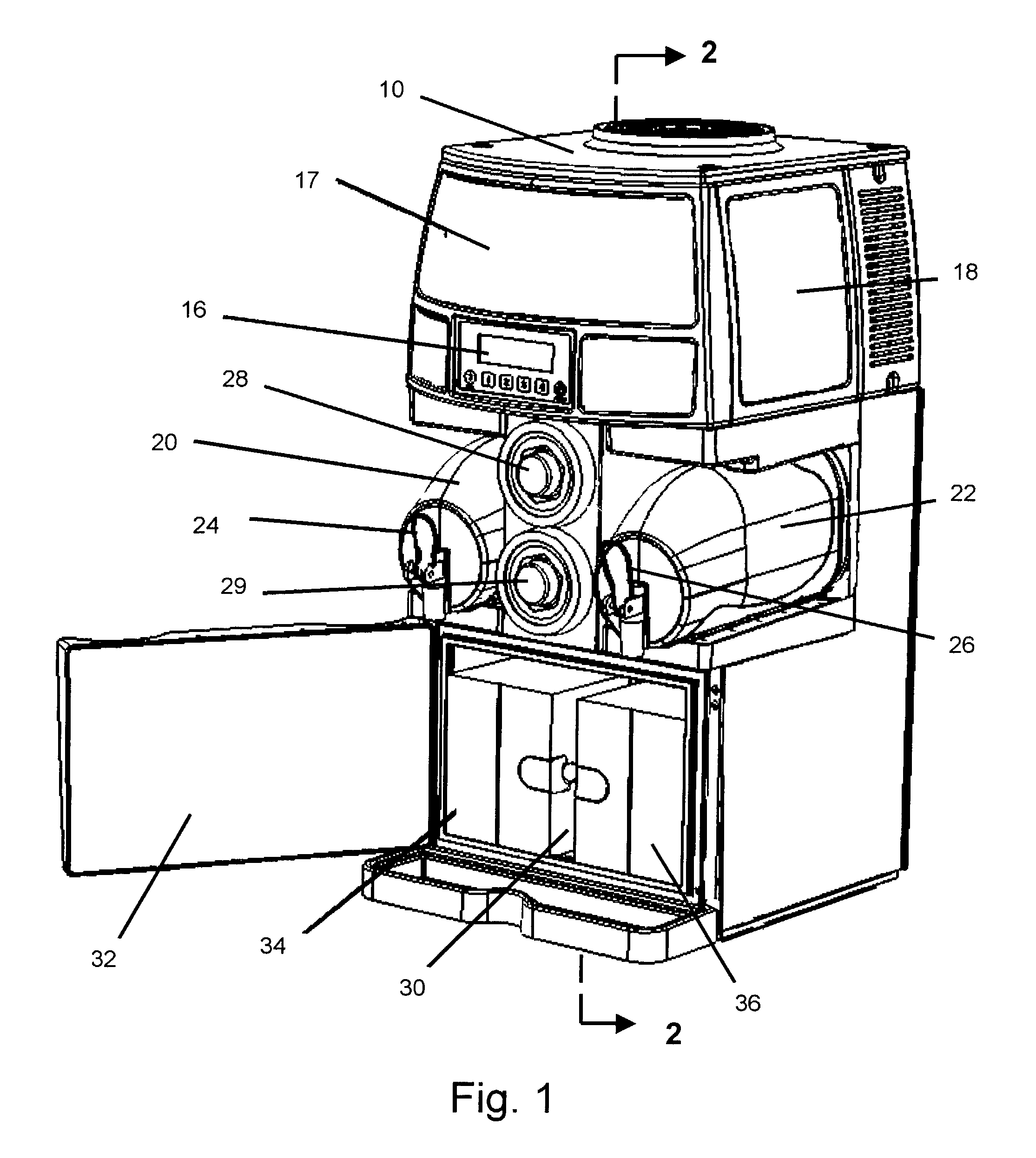

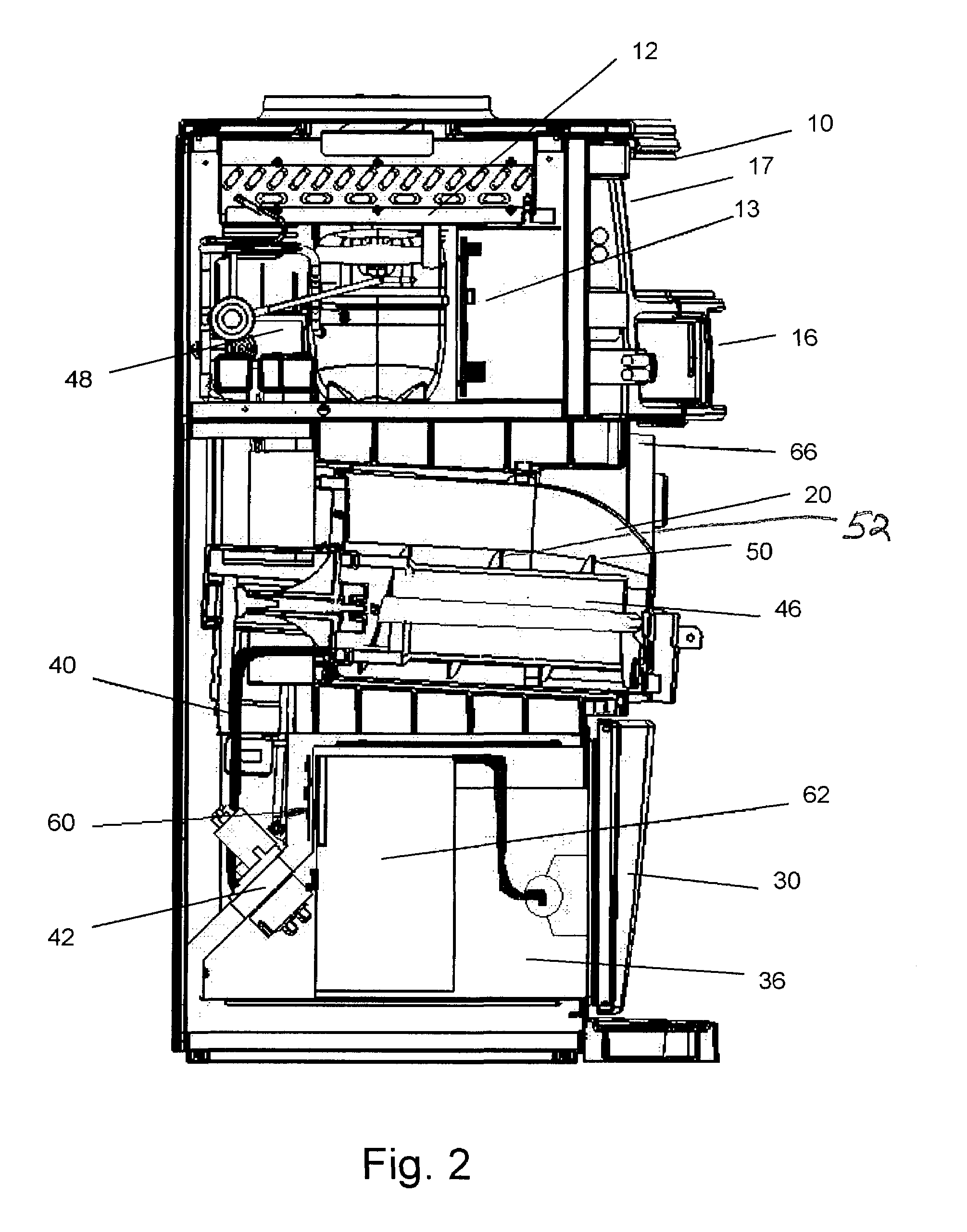

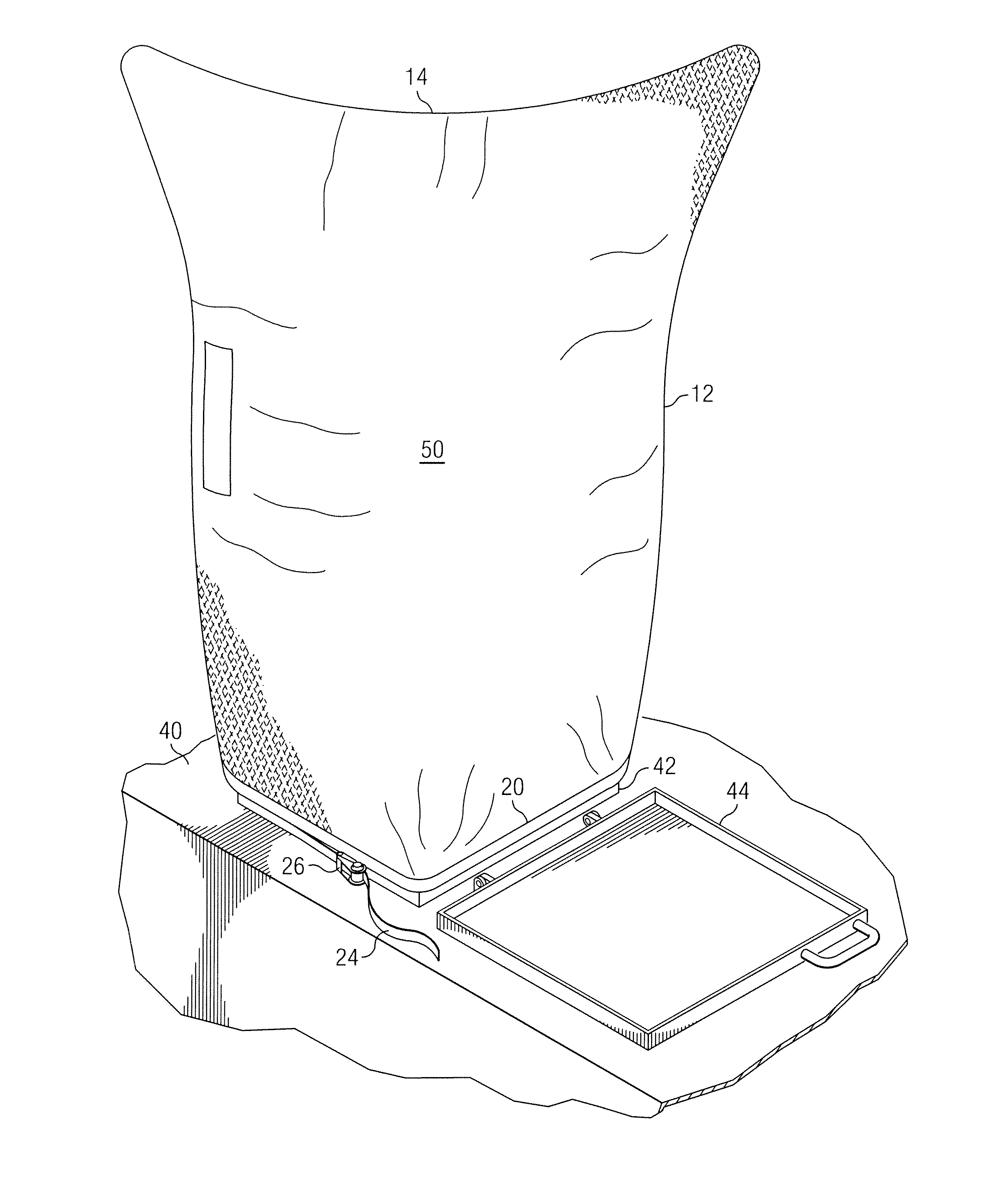

Method and apparatus to control a beverage or dessert dispenser

InactiveUS6990391B1Improve performanceReduce usageDigital data processing detailsFrozen sweetsMass storageTransceiver

A liquid or semi-frozen liquid beverage or dispenser apparatus which includes a storage compartment for a bulk storage container and which includes a controller to control operations of the apparatus. The apparatus includes a transceiver module on the dispenser, wherein transceiver module includes a memory and a RF transceiver. A replaceable bulk storage container includes a box transponder whereby a wireless communication link is established between the box transponder and the transceiver module when the bulk storage container is within the storage compartment.

Owner:KANPAK

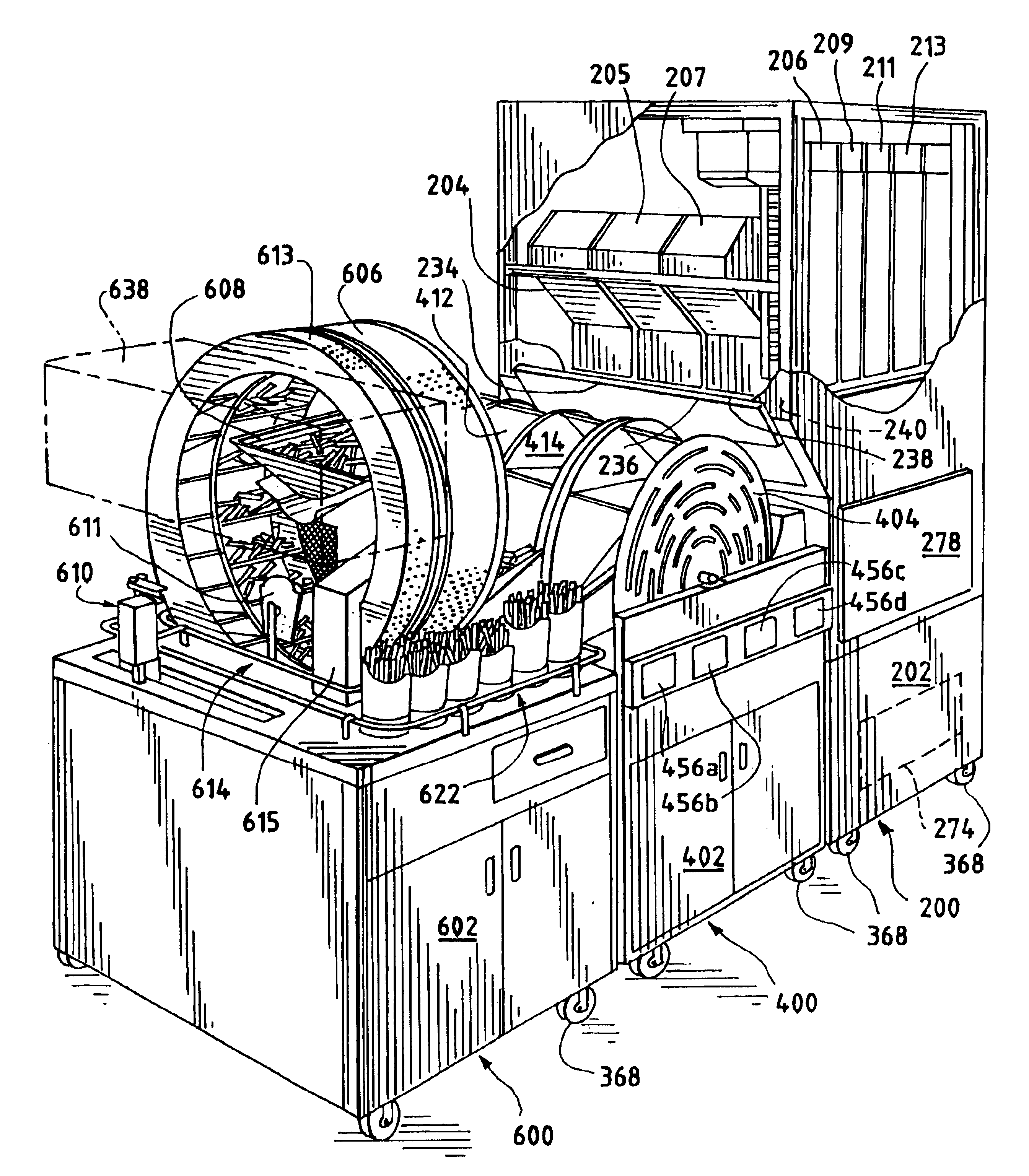

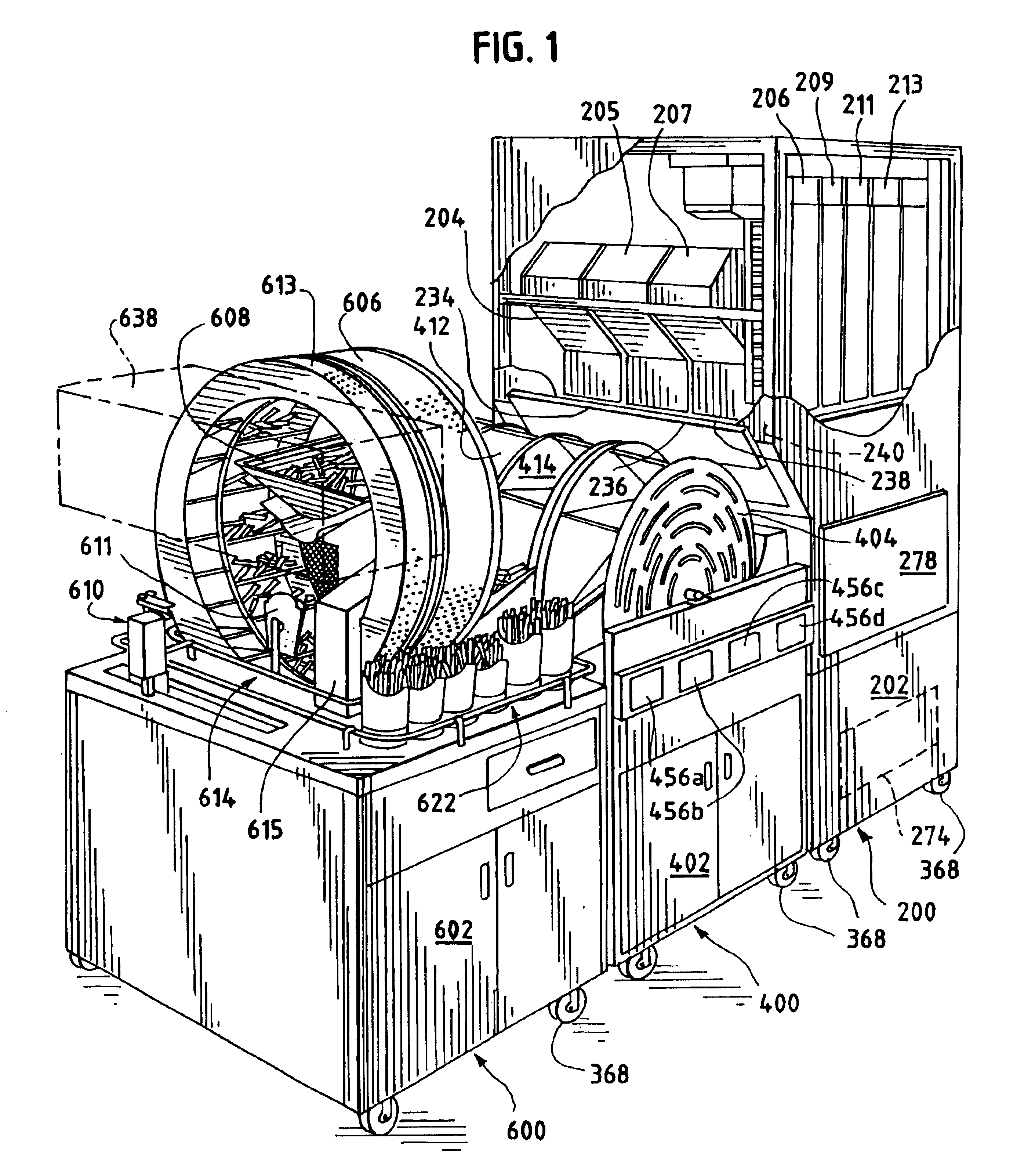

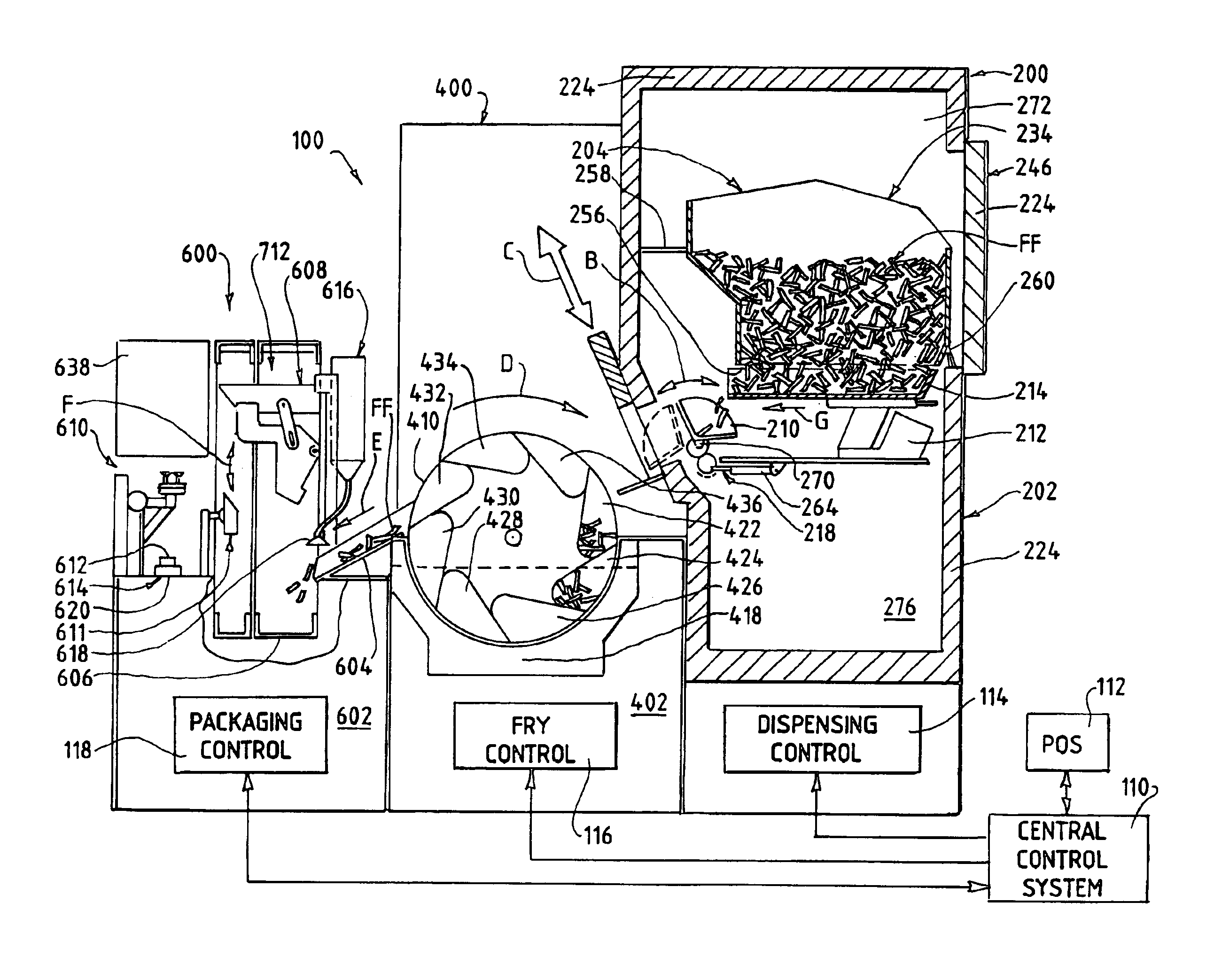

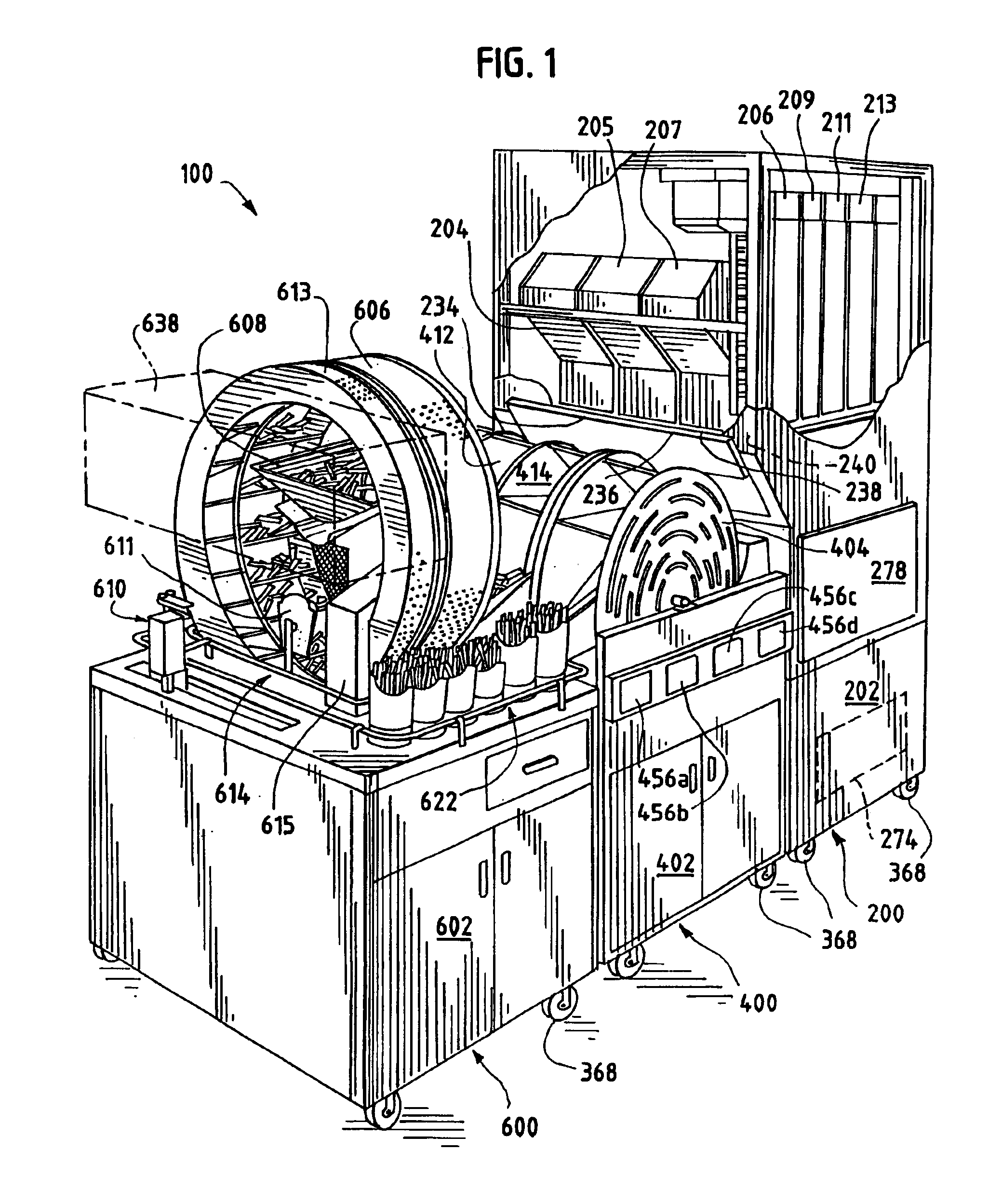

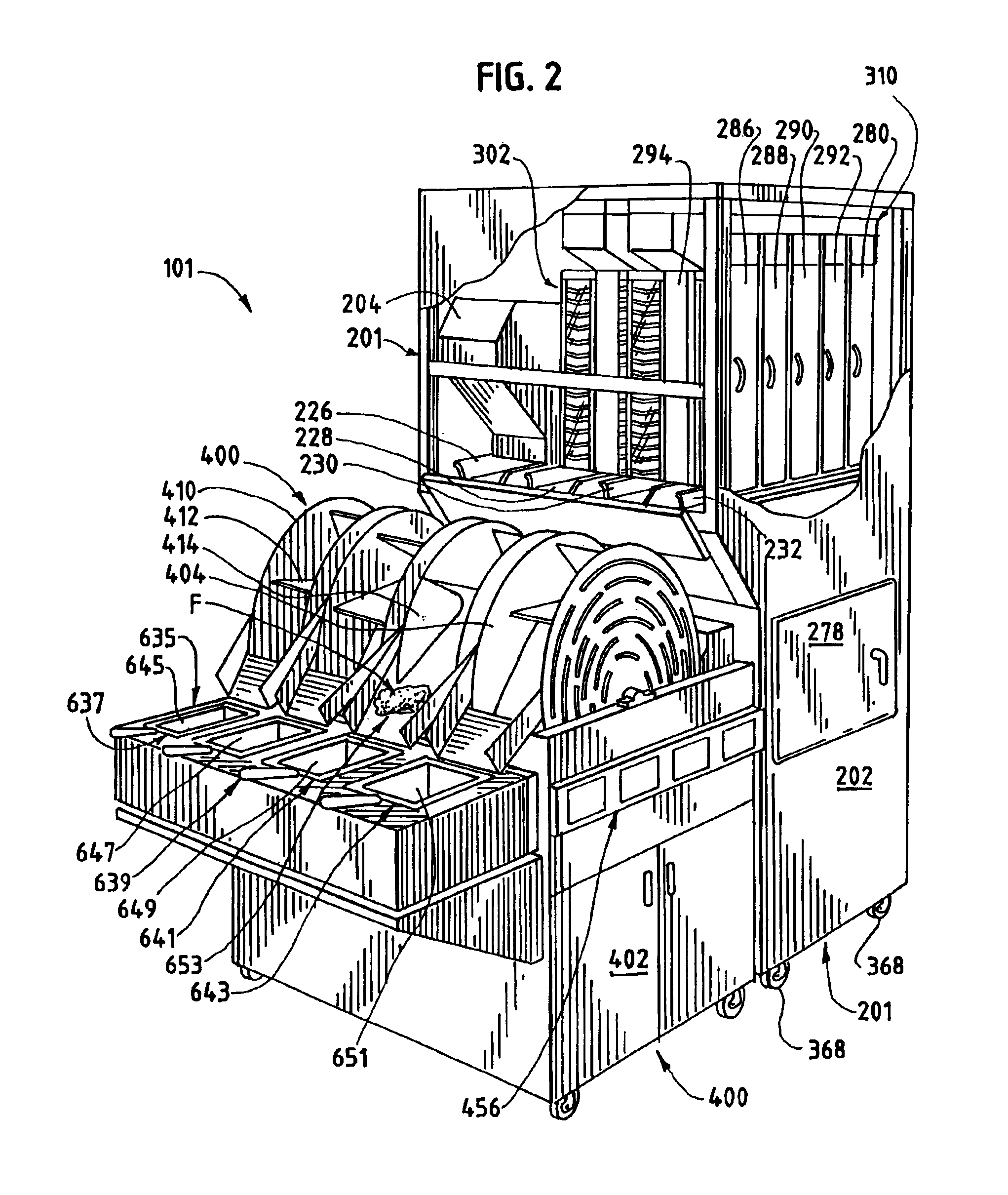

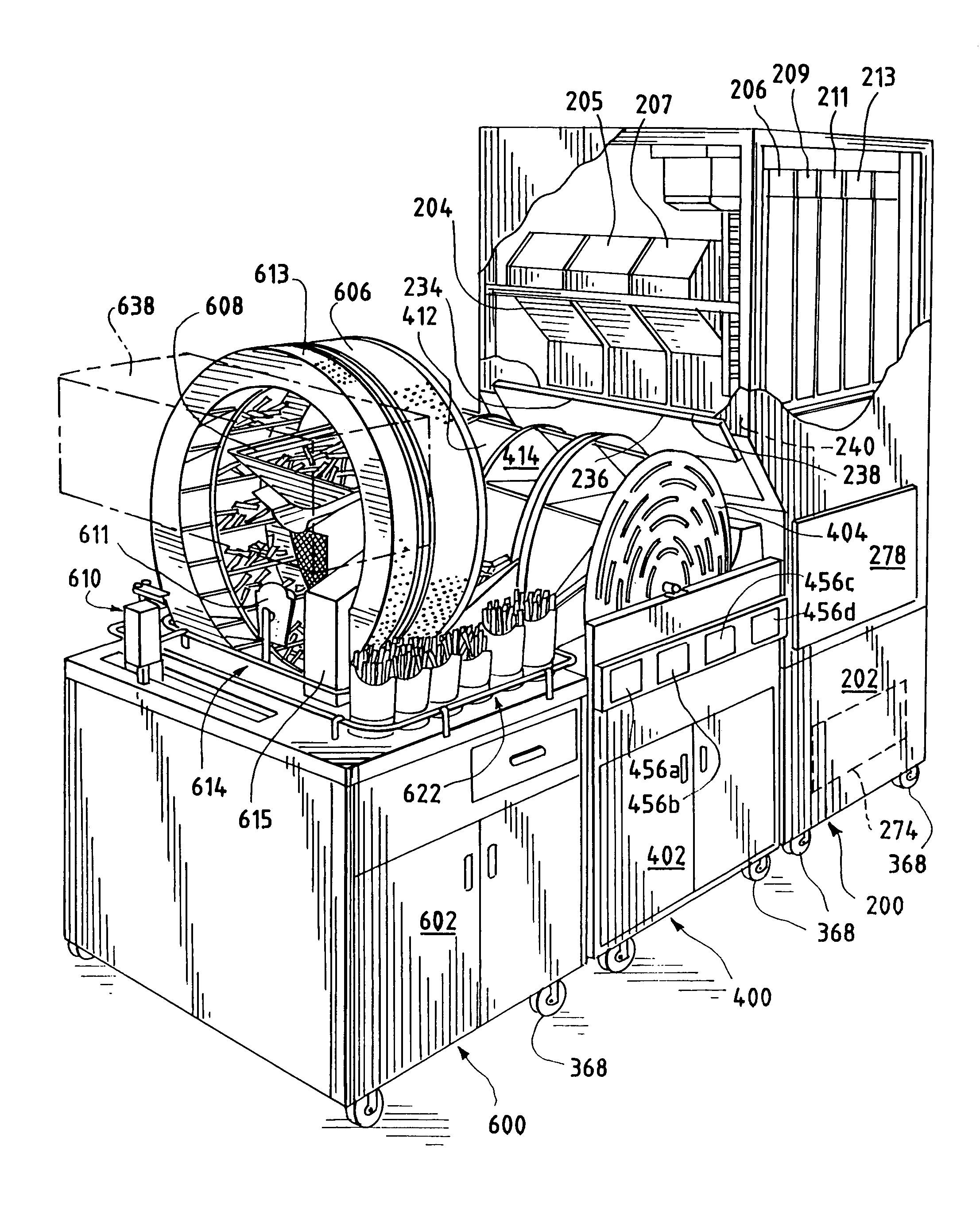

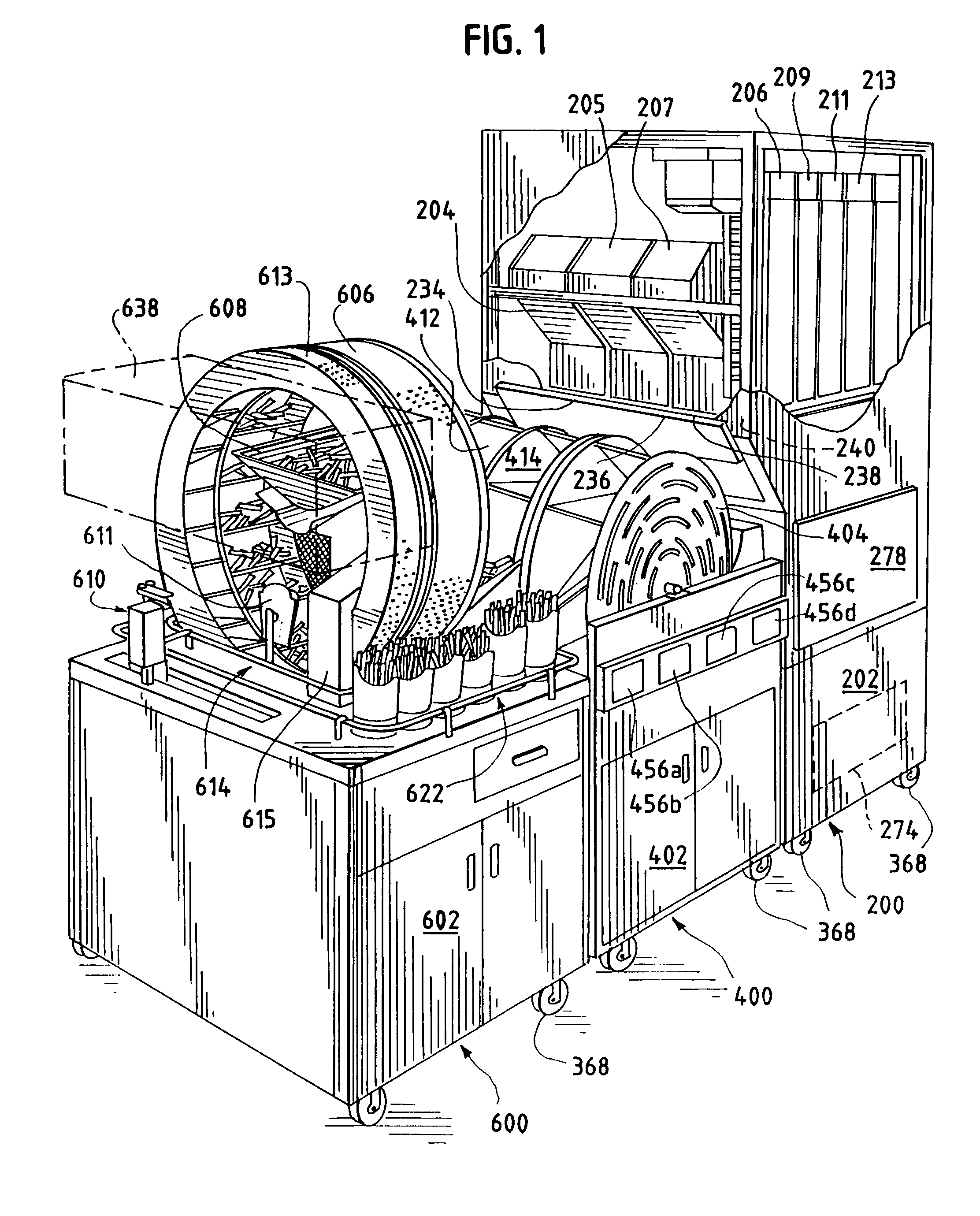

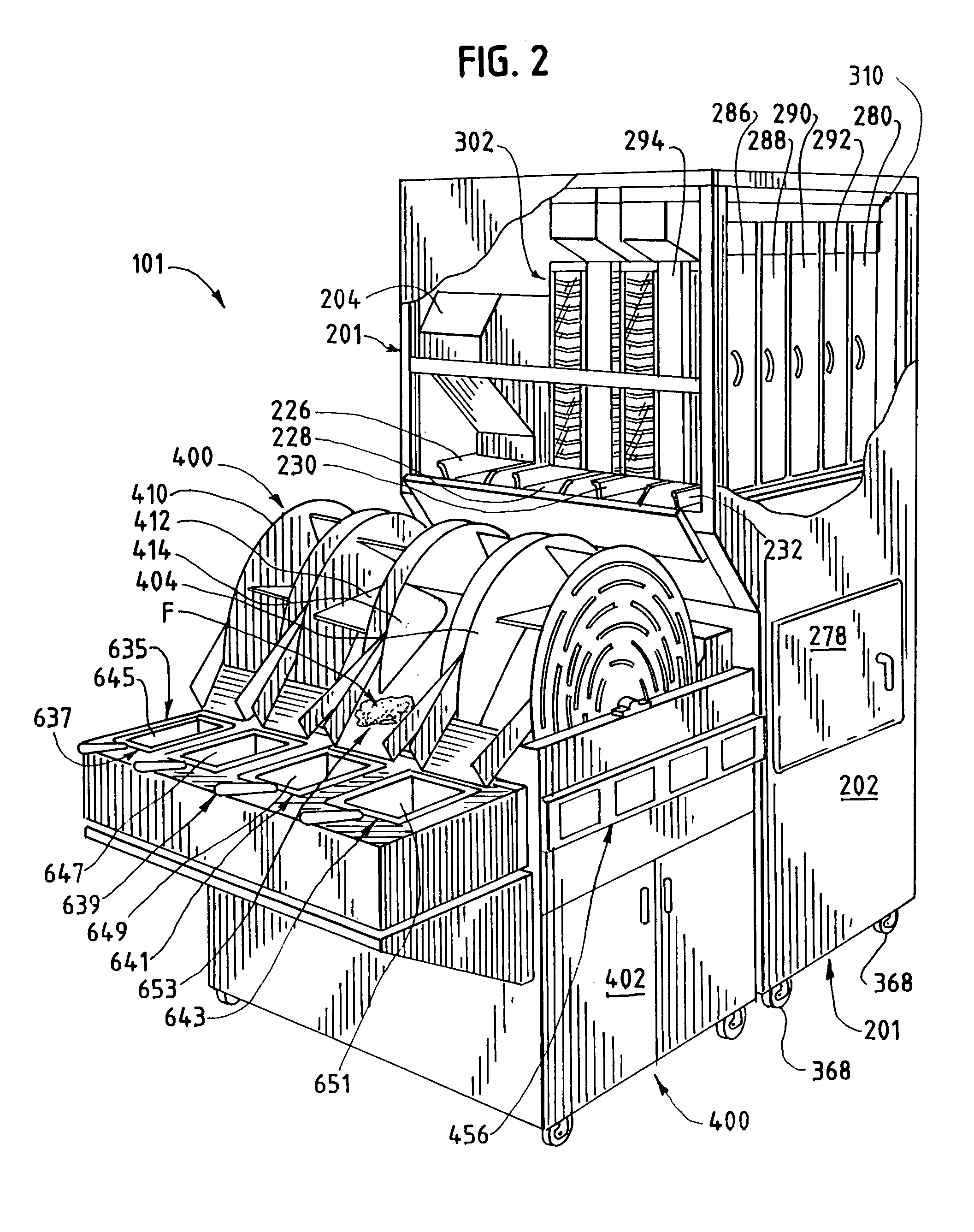

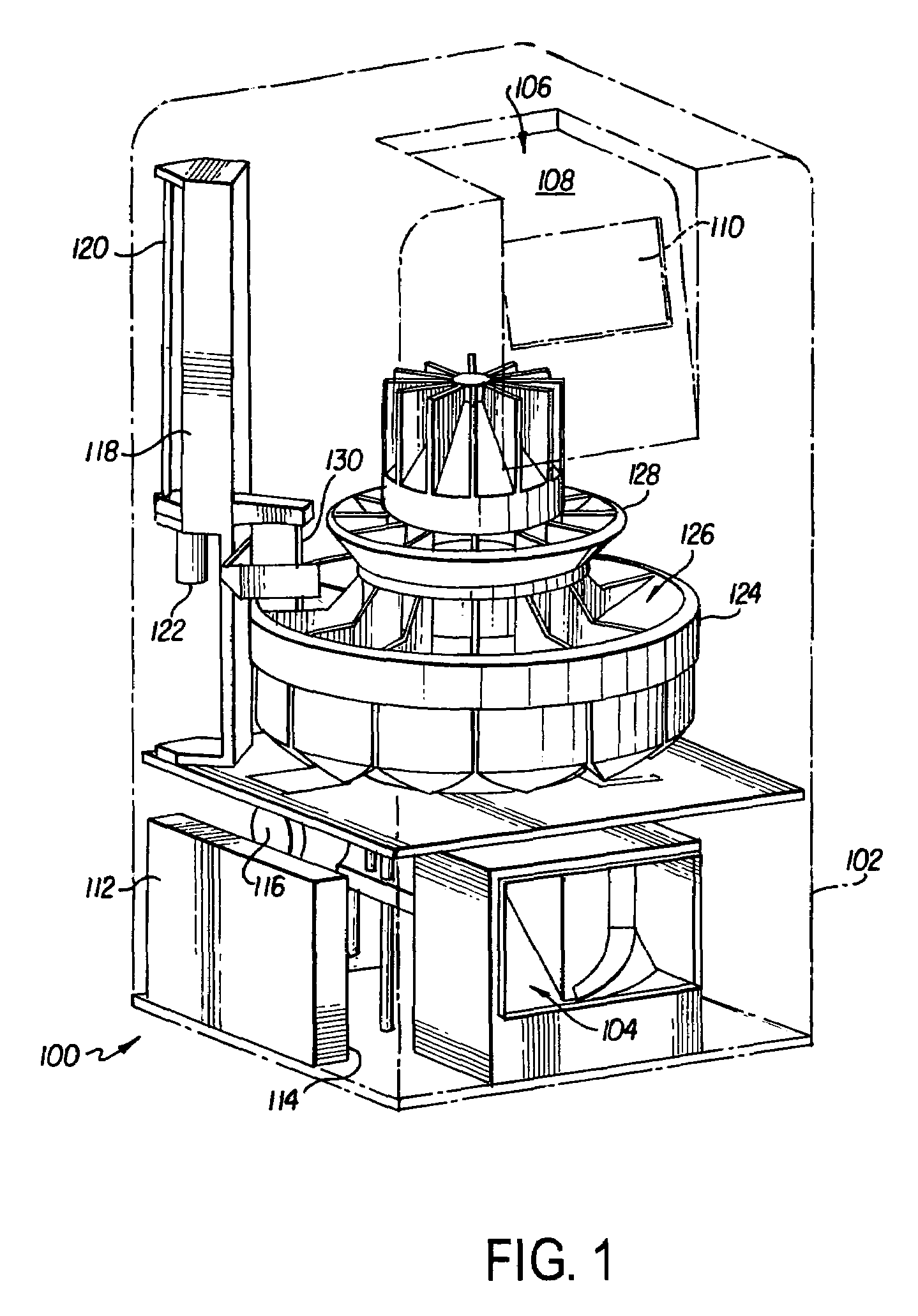

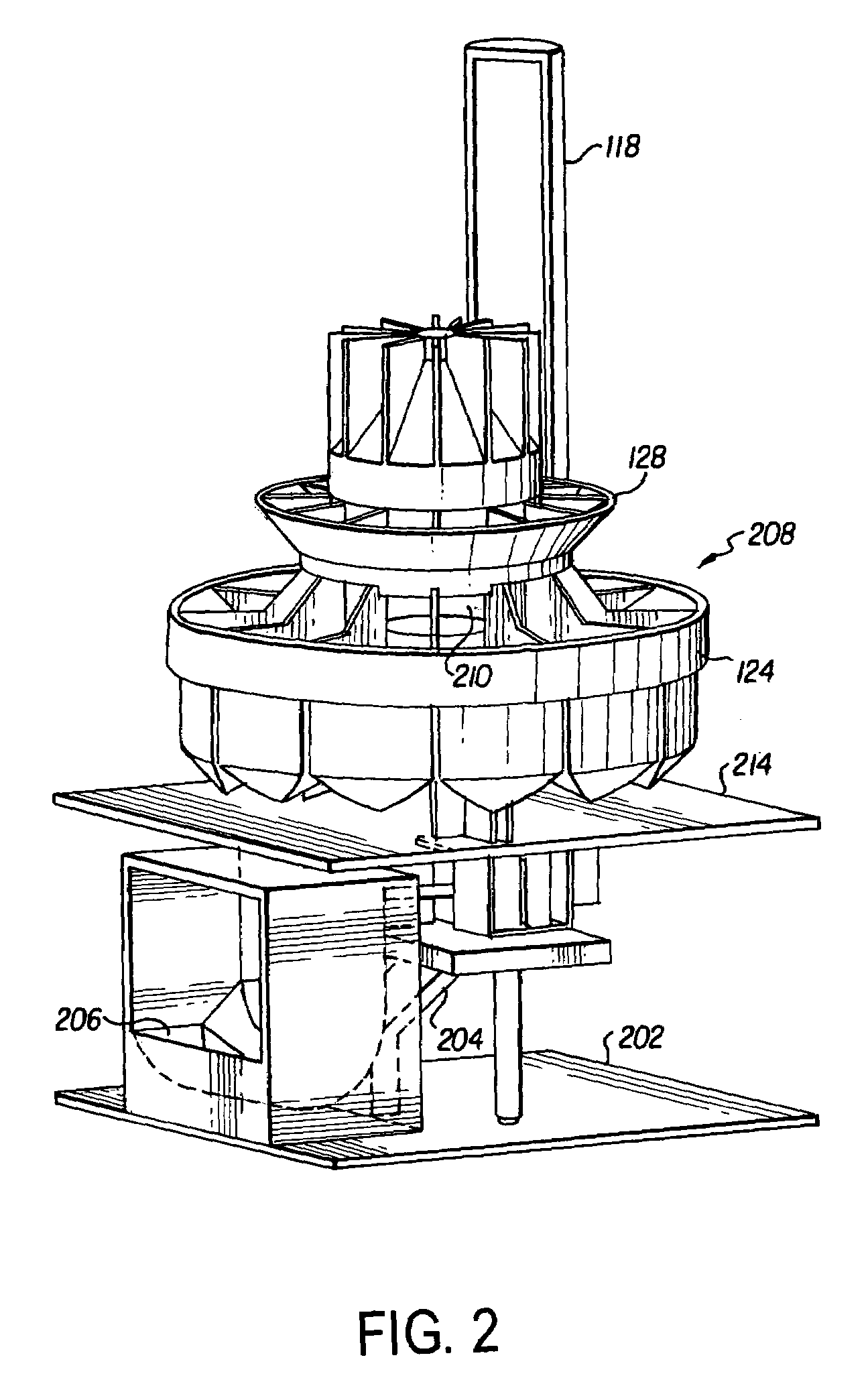

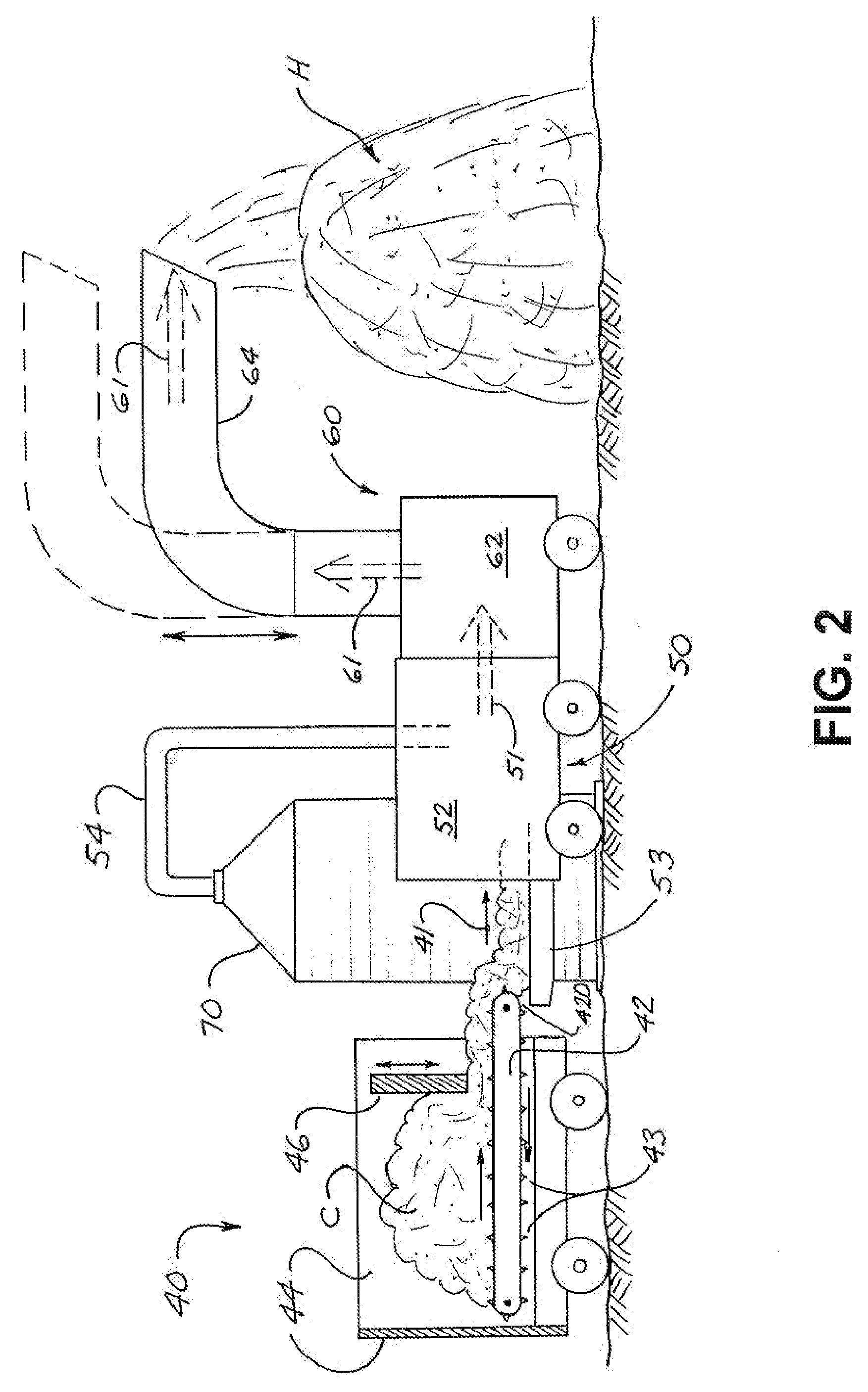

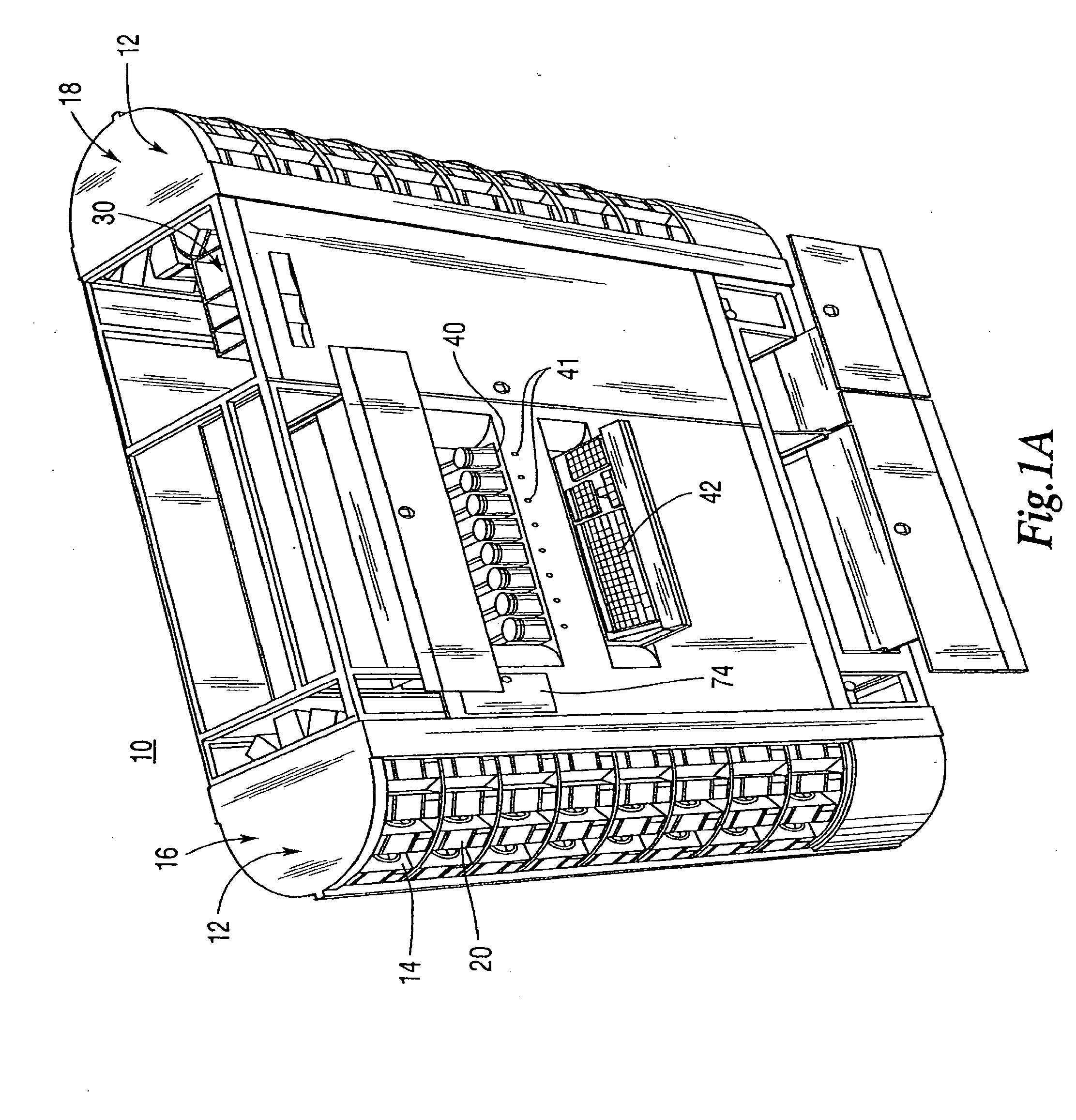

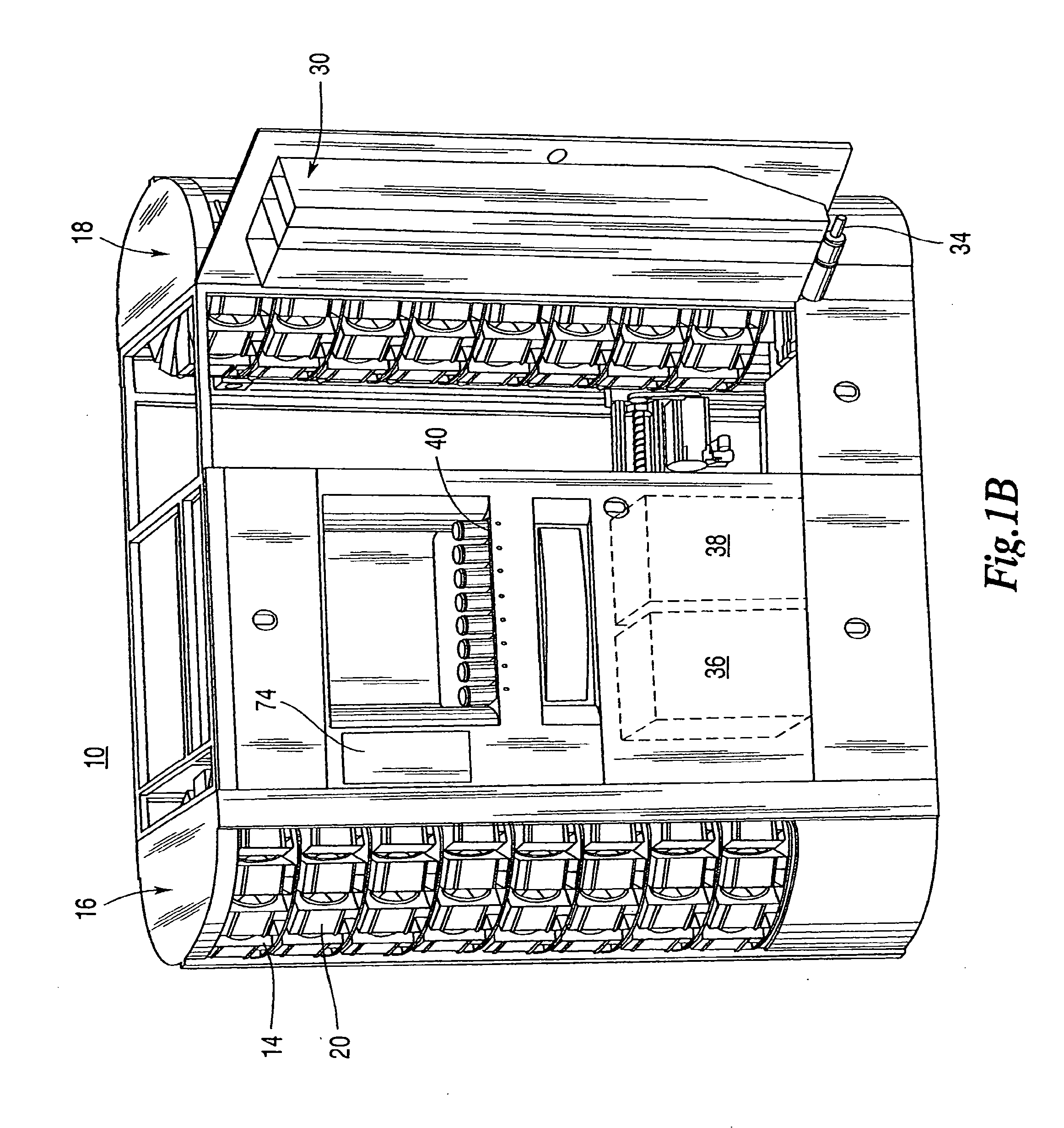

Automated food frying device and method

An automated food processing system and method is provided that allows food to be dispensed, fried and packaged in a suitable container, which may be an individual portion-sized container. In one embodiment, the system includes separate automated modules for dispensing, frying and packaging the food.In one embodiment, an automated dispensing device dispenses a predetermined portion of food from a bulk storage container or food dispensing magazine. Food is dispensed from the automated dispensing device to an automated fry device that can include at least one circular fry wheel having a plurality of food containing compartments. After the food is fried it is dispensed from the fry device to an automated packaging device. The automated packaging device dispenses food to a container that may be an individual portion-sized container that is retrieved, erected and held into position for filling by an automated container handling system. After a food container is filled, a conveyor system transports the filled container to a suitable pick-up location.

Owner:RESTAURANT TECH

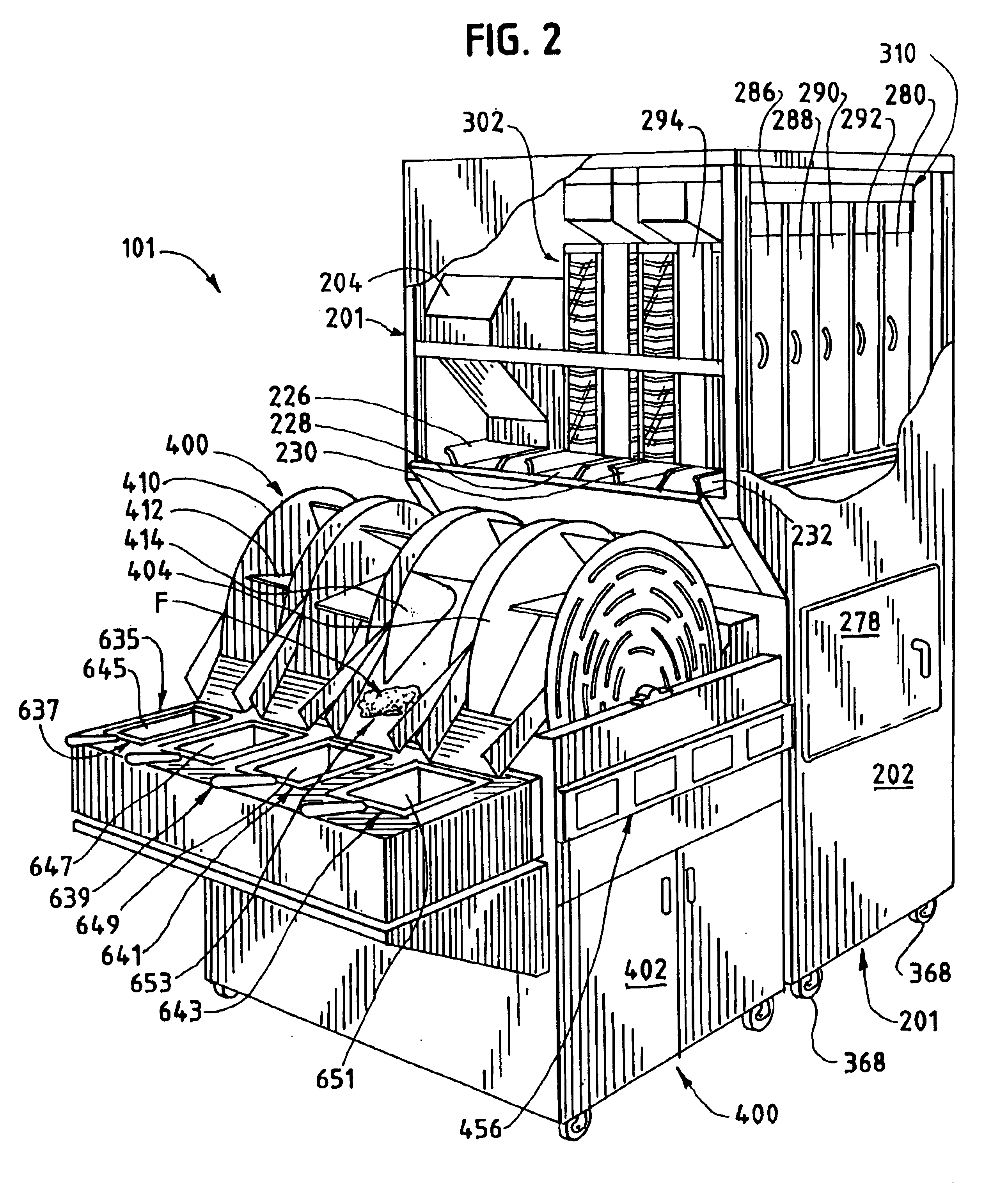

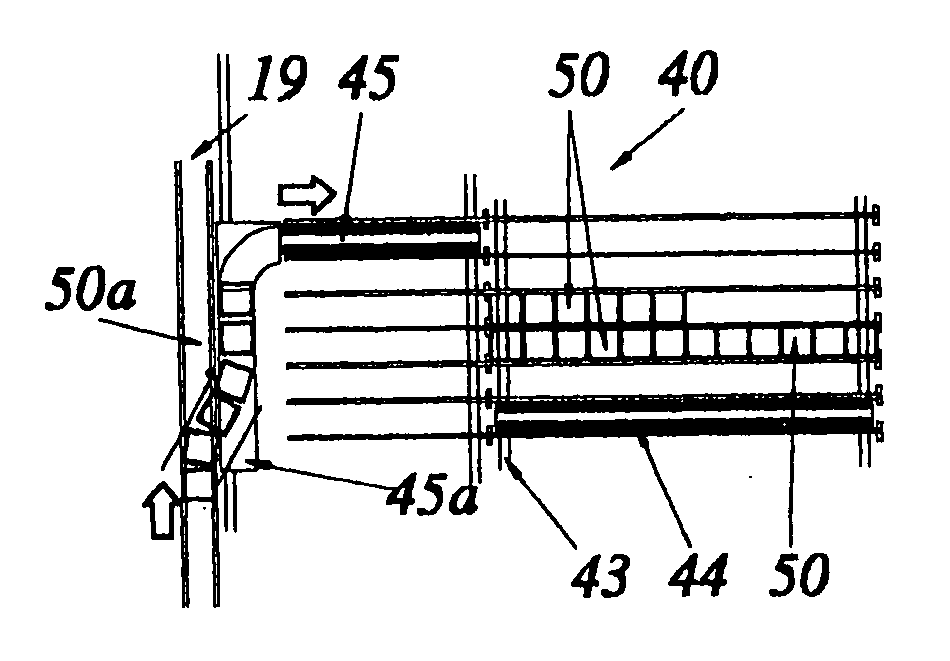

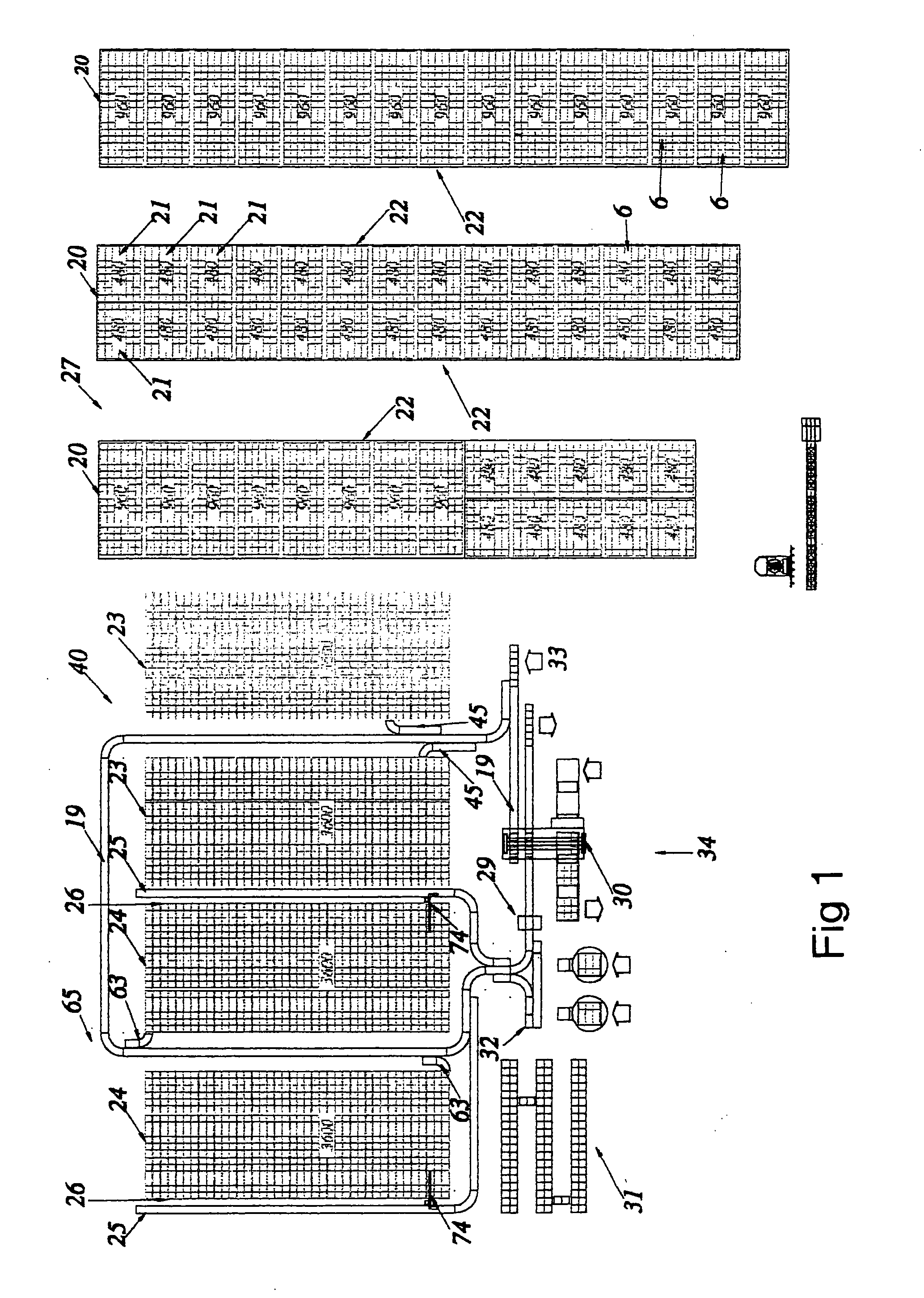

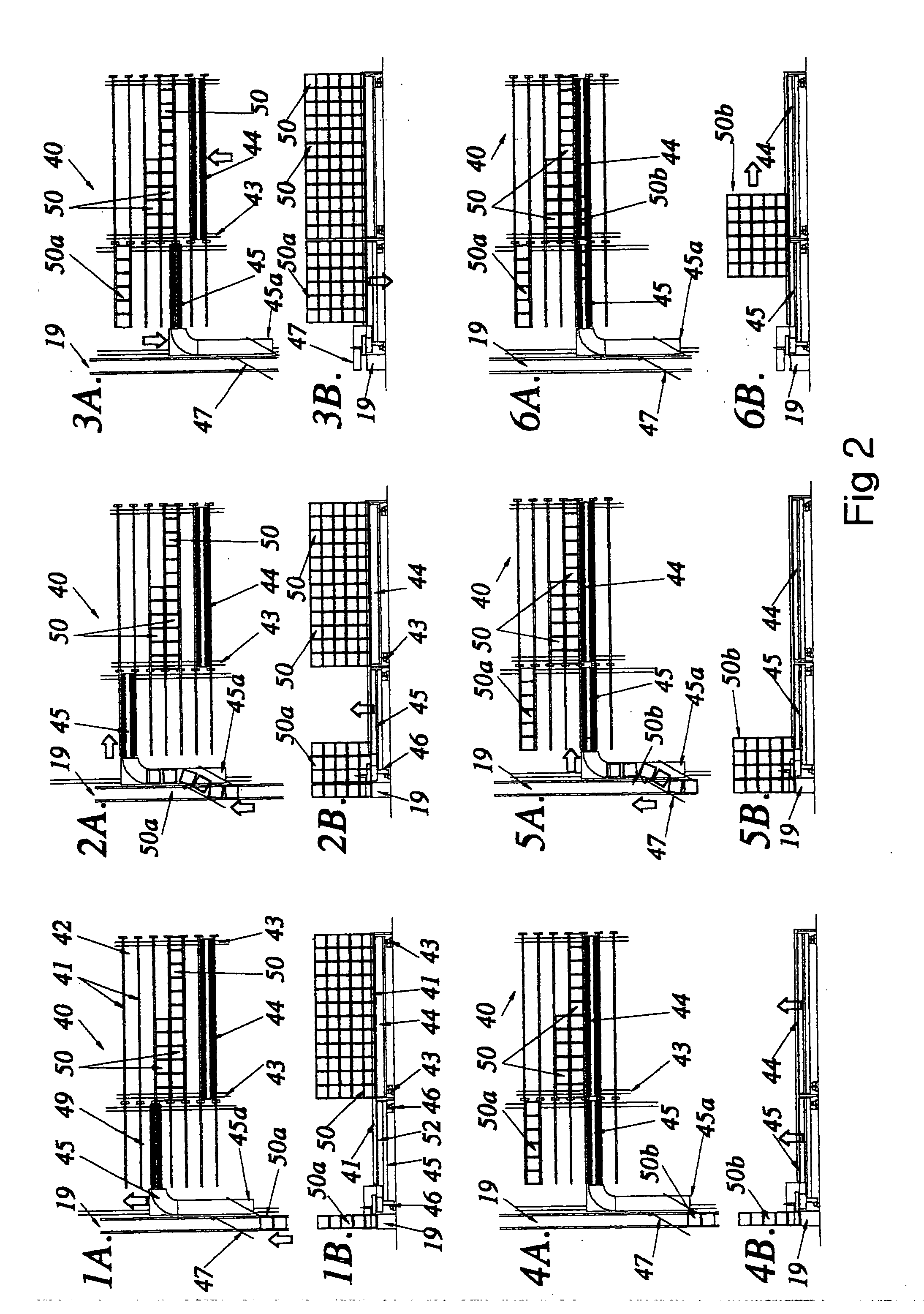

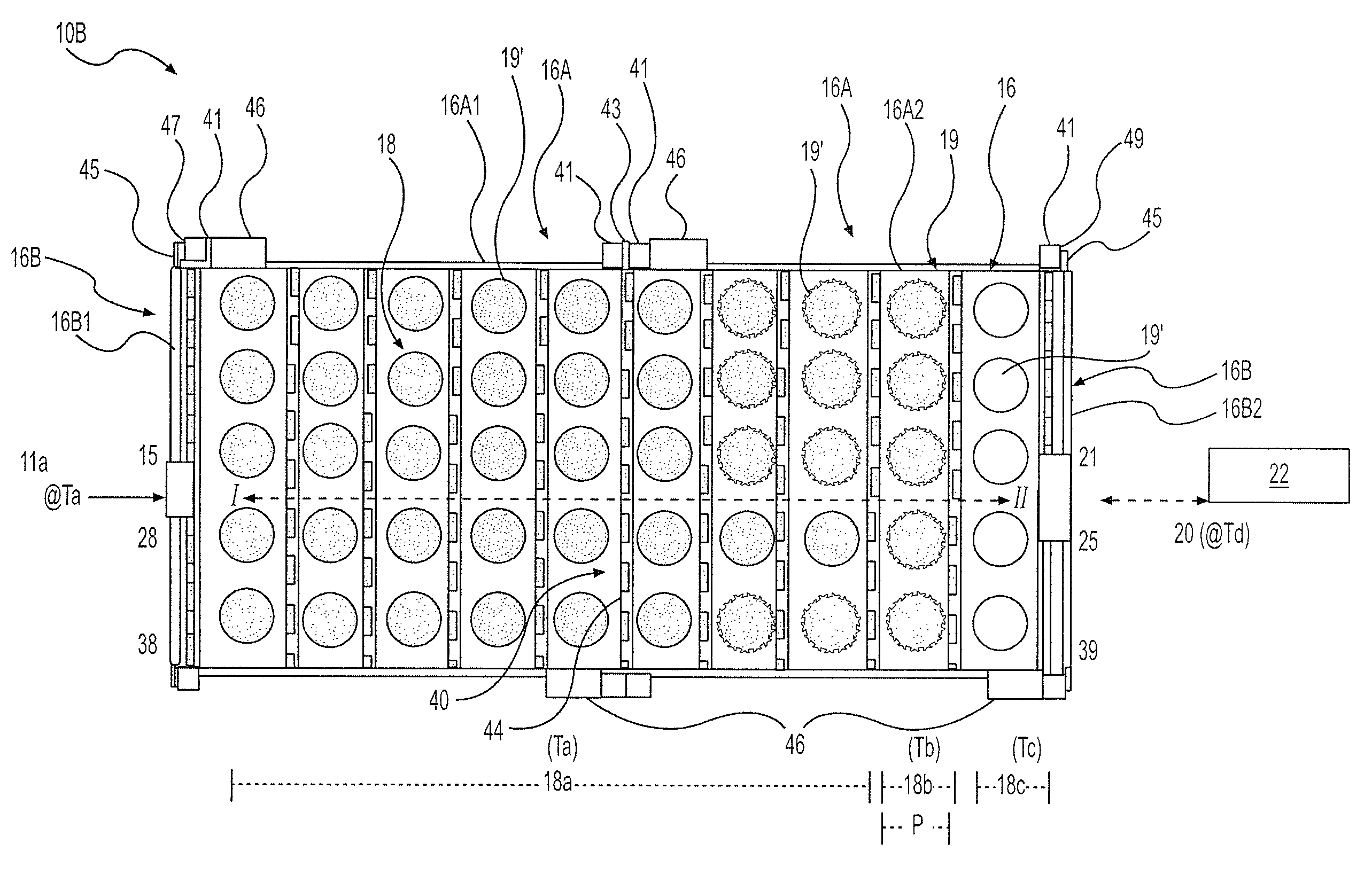

Method and apparatus for container storage and container retrieval

InactiveUS20080025833A1Space minimizationDigital data processing detailsPackagingComputer control systemMass storage

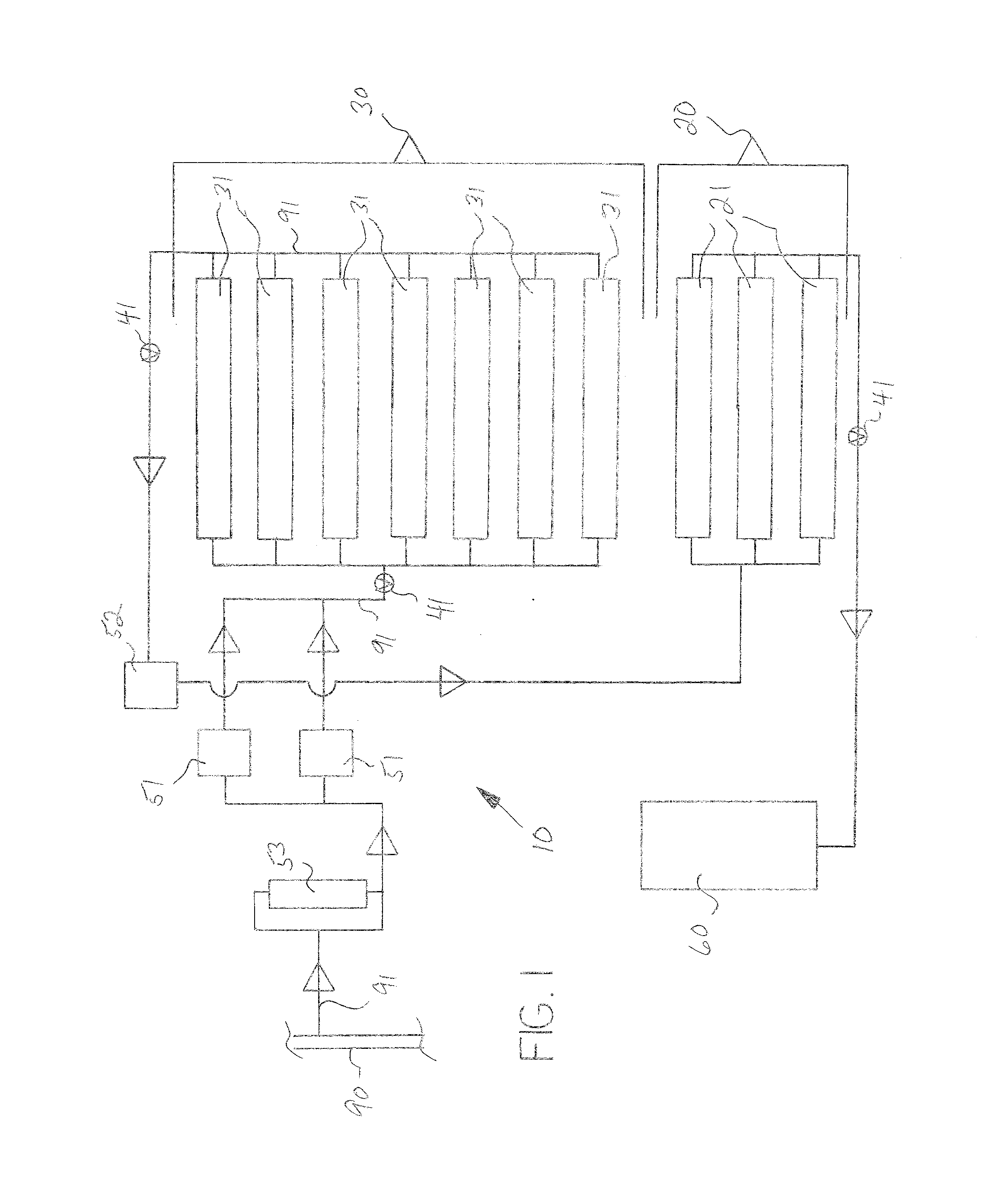

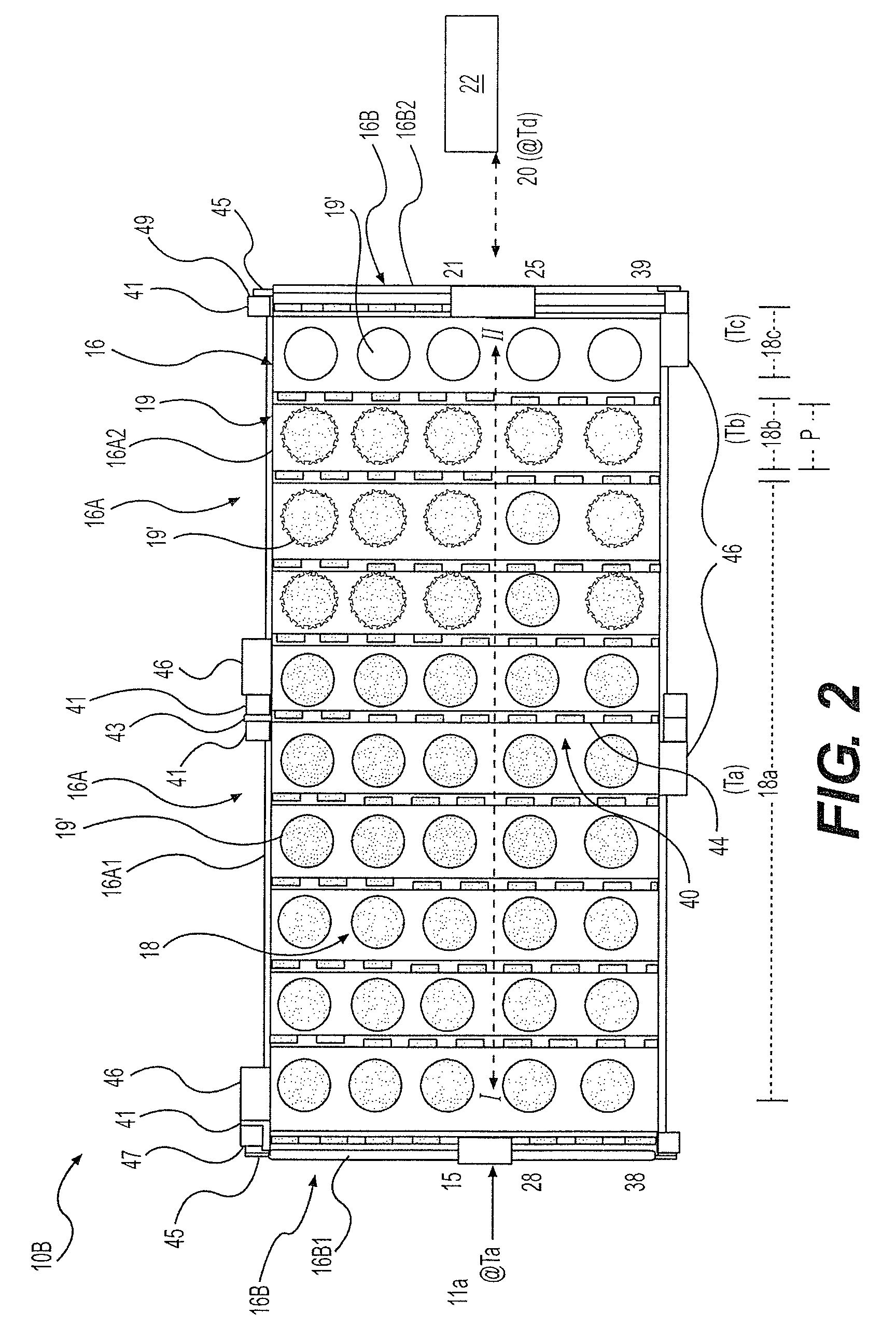

Apparatus for use in a storage and retrieval system for product held in containers is provided. The apparatus includes multiple, parallel spaced-apart support members (41) defining a plurality of rows (20), each adapted to support a base of a plurality of containers thereby forming a container store. One or more conveying means (44) is engageable with containers in a row (20) to transport the containers longitudinally within that row, the conveying means (44) movable transverse and below the rows. One or more loading means (45) is movable transverse to the rows (20) along an end of the rows to enable loading of one or more containers into a selected row. A computer control system automatically controls operation of the loading means and conveying means. The loading means (45) may include a transfer conveyor (49) extending beneath at least a portion of said rows and moveable transverse to said rows below said rows. Product may be stored in a bulk storage zone (27) in which containers of product are stored in frames (50), an intermediate storage zone (40) and a low storage zone (65). A first automated retrieval system retrieves selected stacks of containers from the intermediate storage zone (40), and a second automated retrieval system retrieves individual containers, partial stacks or stacks of containers from the low storage zone (65). Product orders are collated at a collation zone (34) and a conveying means (19) is in communication with each zone for delivering product between zones. Methods of storage and retrieval are also claimed.

Owner:BAKVERTISI

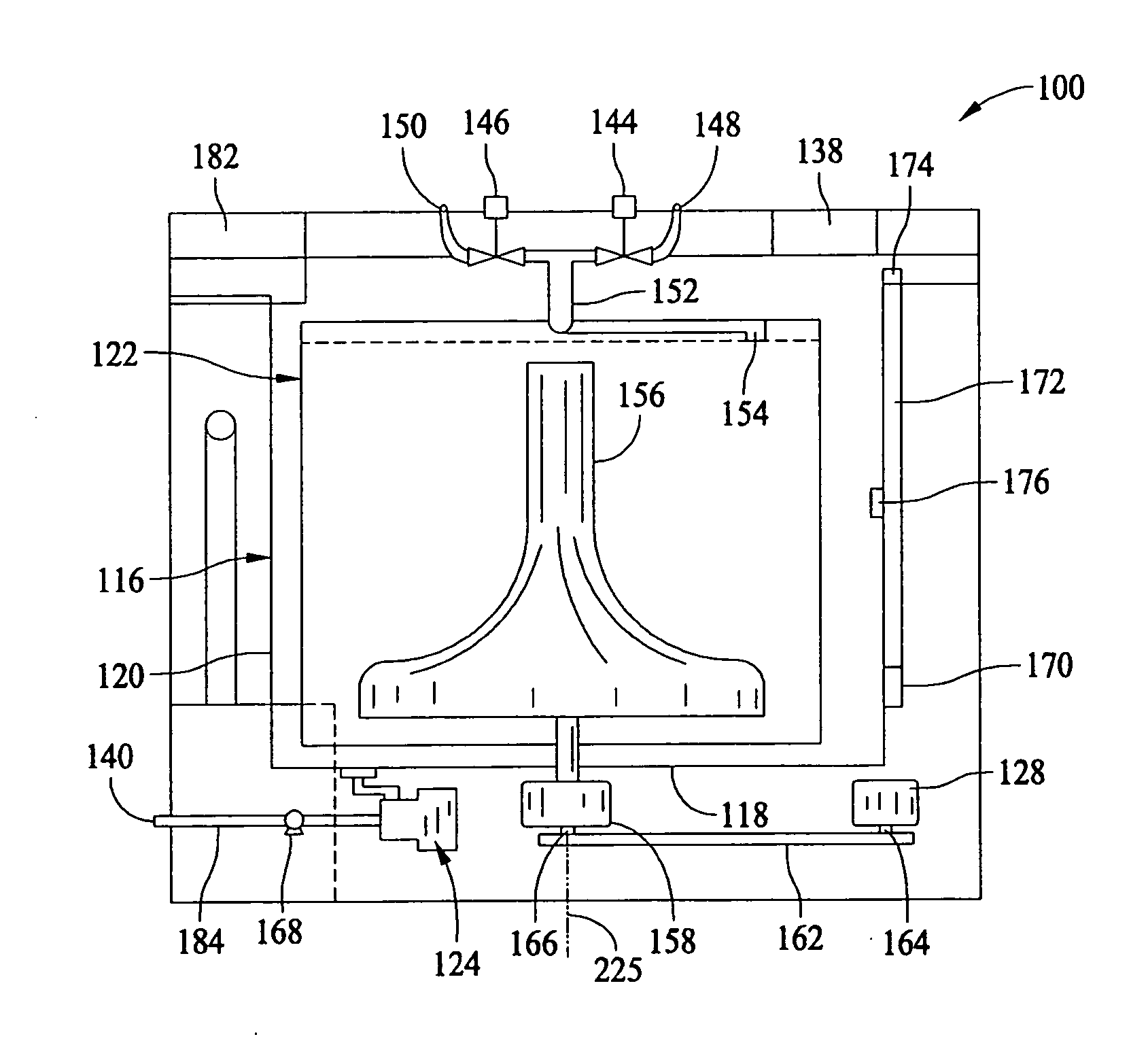

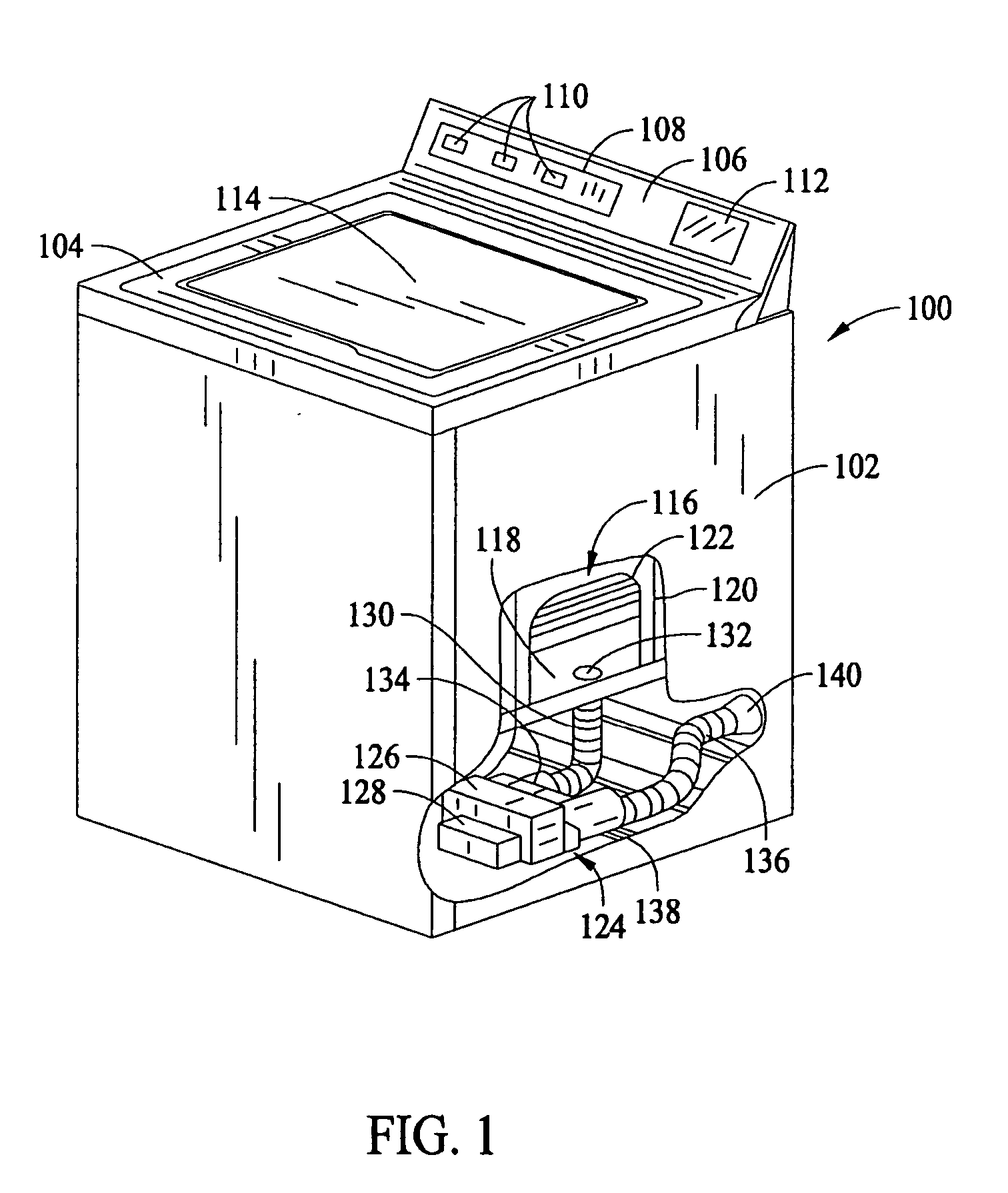

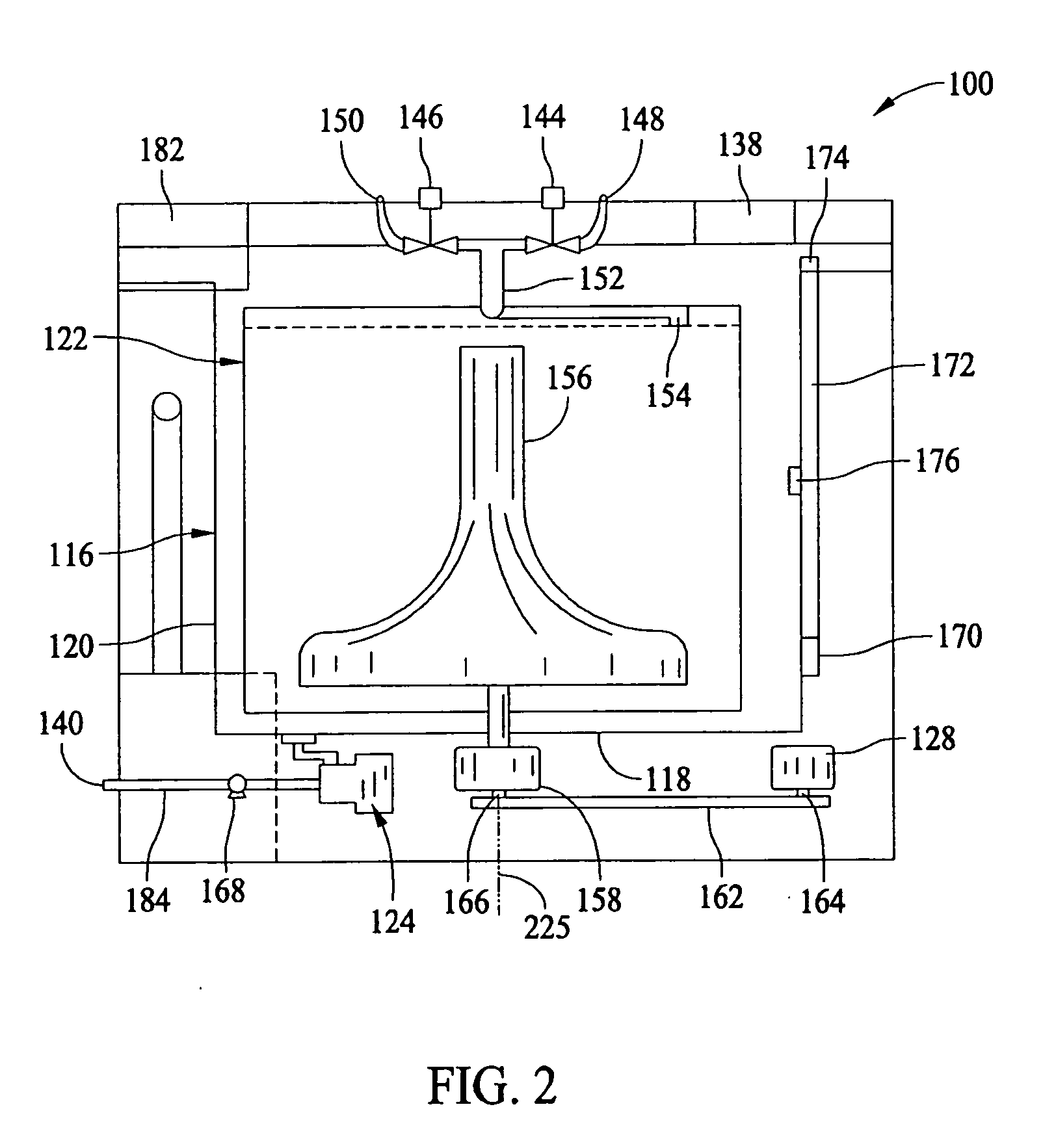

Bulk dispensing system for washing machine

ActiveUS20070261177A1Other washing machinesControl devices for washing apparatusEngineeringHolding tank

A bulk dispensing system for a washing machine is provided. The bulk dispensing system includes at least one bulk storage tank mounted within the washing machine. A tube provides fluid communication between the at least one bulk storage tank and a tub mounted within a cabinet of the washing machine. A pump is operatively coupled to the tube and configured to move fluid from within the at least one bulk storage tank into the tub through the tube. A controller is operatively coupled to the pump and configured to control an amount of fluid moved into the tub.

Owner:HAIER US APPLIANCE SOLUTIONS INC

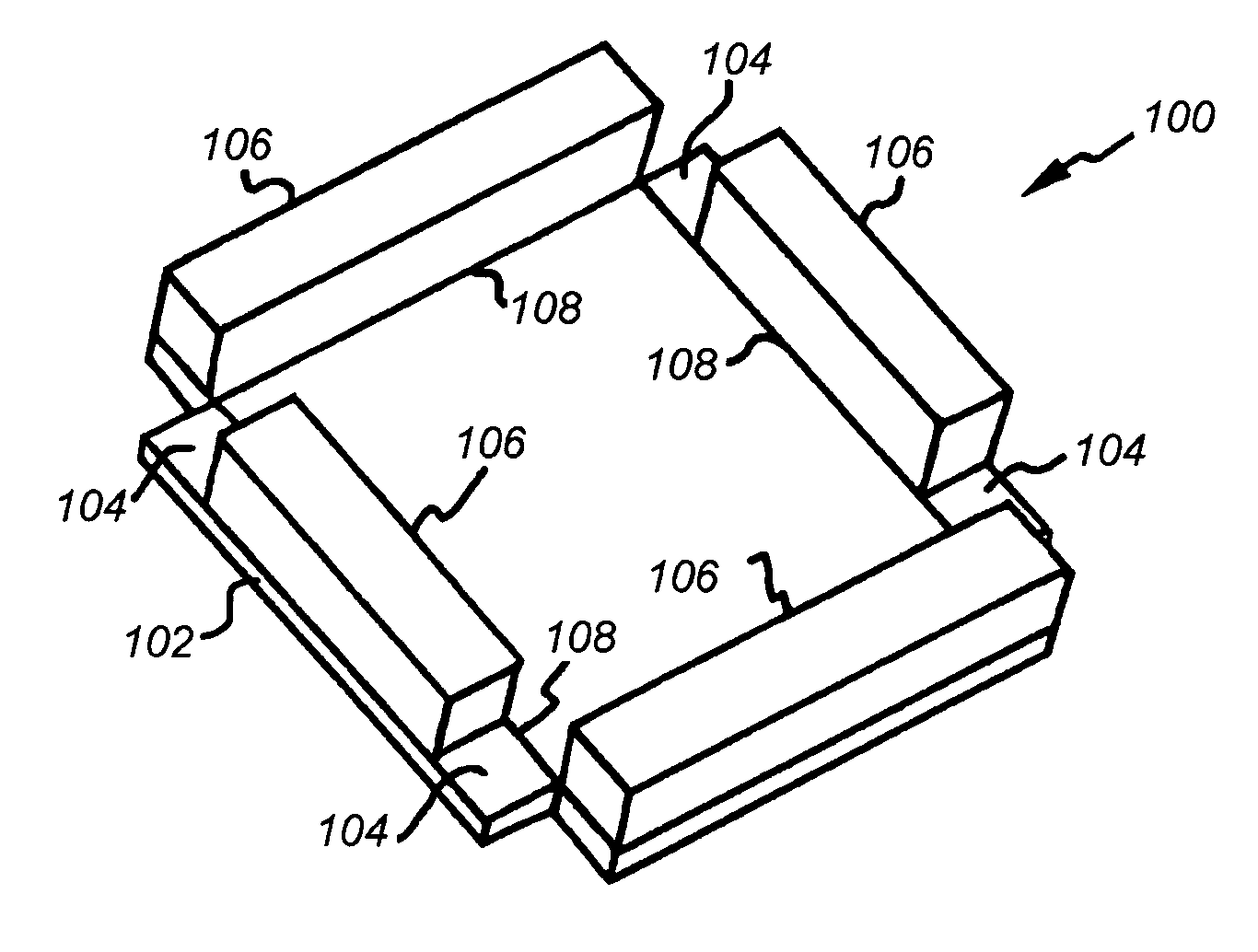

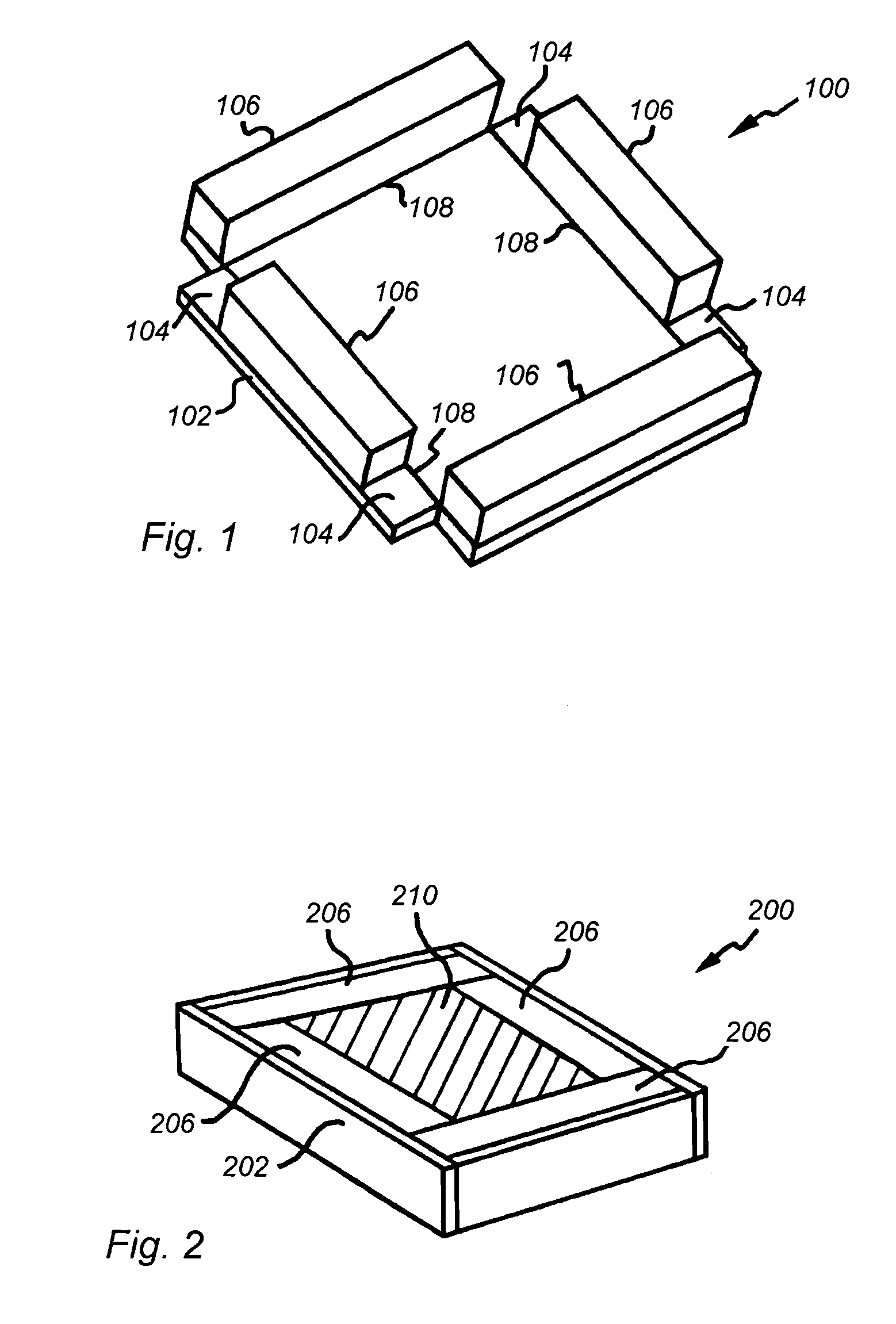

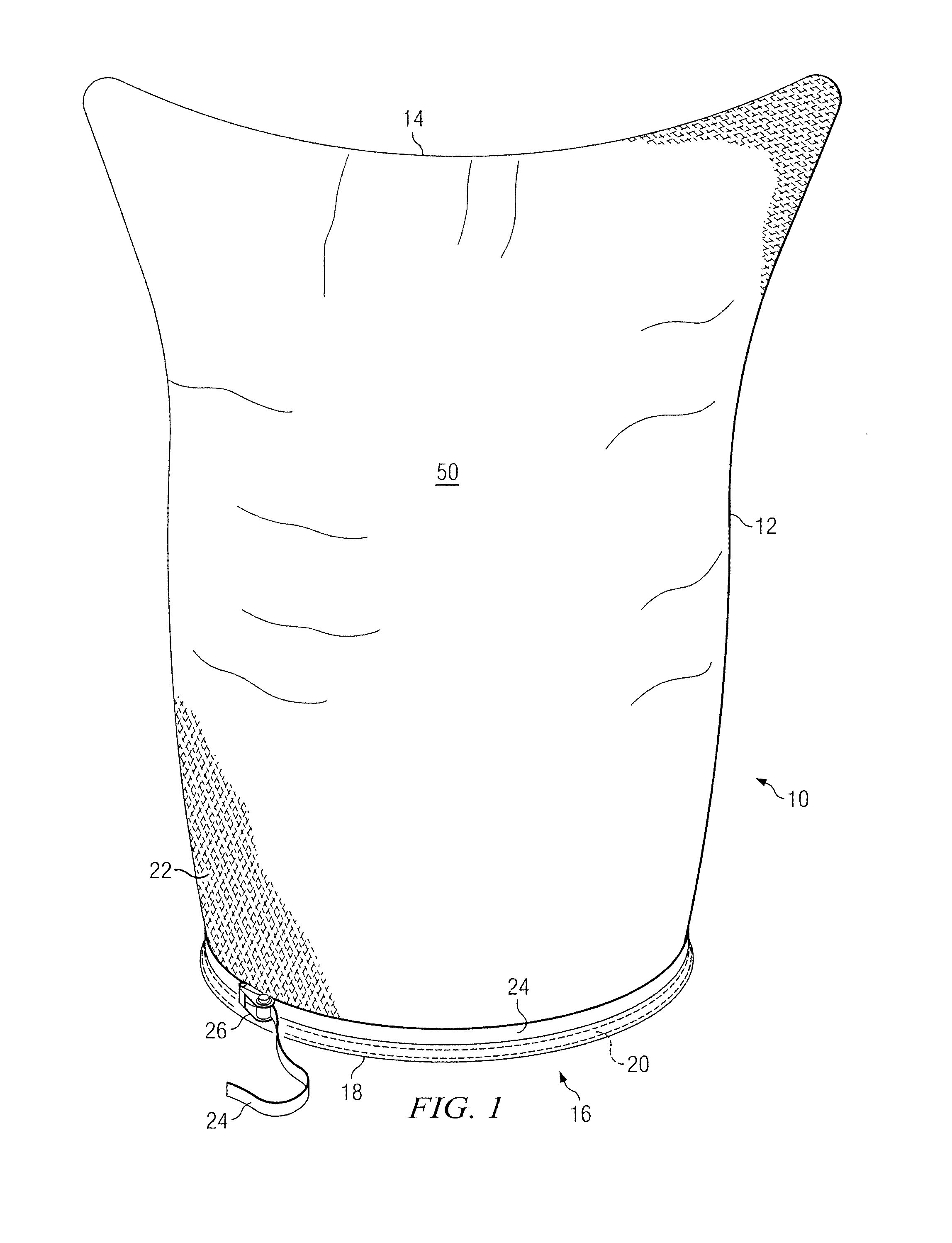

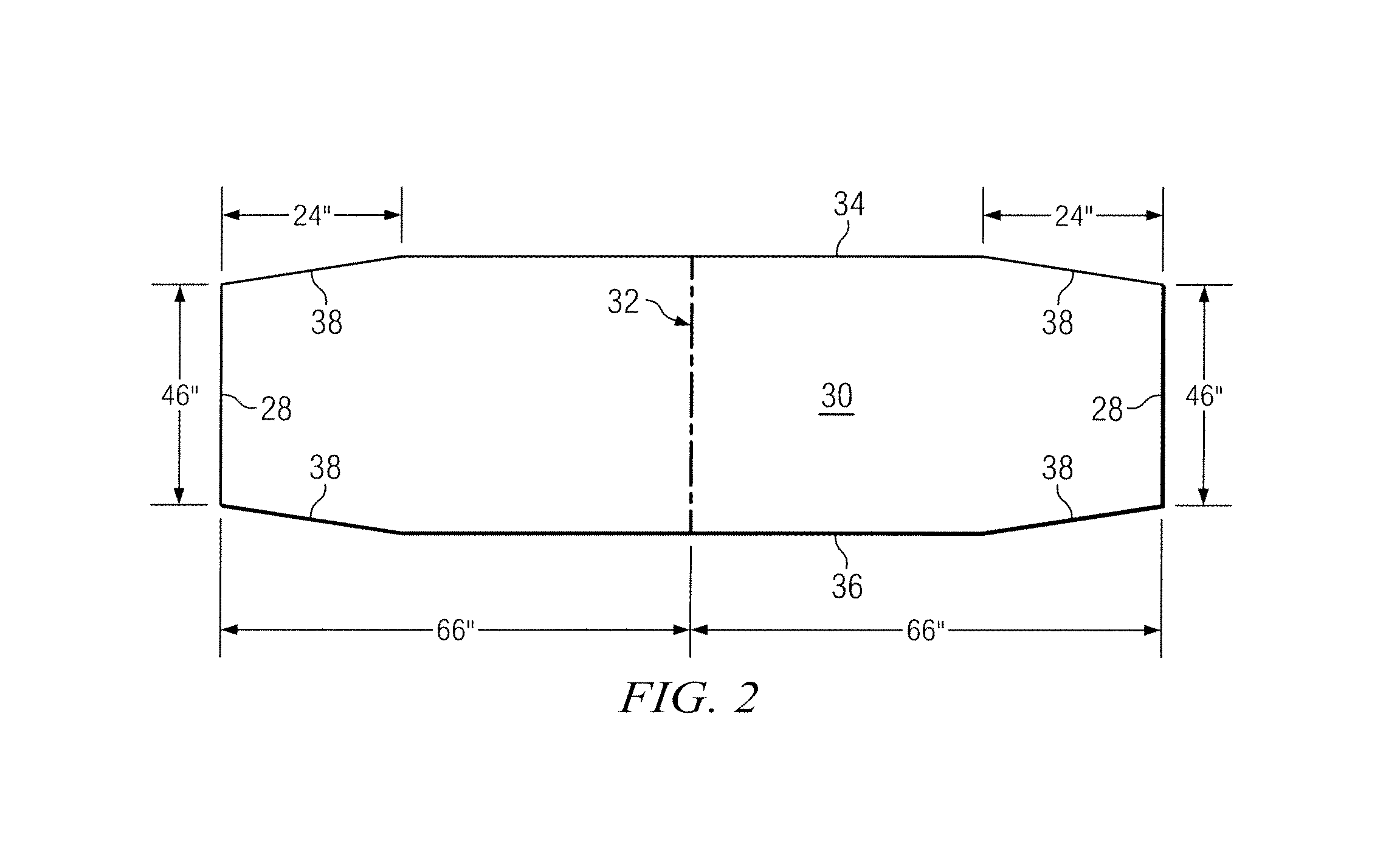

Hinged foam assembly for mattress manufacturing

ActiveUS7165282B2More convenient bulk storageStuffed mattressesSpring mattressesMass storageBulk storage

Edge rails for a mattress core are combined with an upholstery layer to provide a pre-assembled work piece that provides a perimeter about a mattress core. The edge rails, which may be foam, may be attached to the upholstery layer with hinges that permit each edge rail to rotate relative to the upholstery layer between an unassembled, flat position and an assembled, upright position. In the unassembled position, the work piece may present a relatively flat profile for more convenient bulk storage. In the assembled position, the edge rails are positioned to closely surround a mattress core of suitable size.

Owner:DREAMWELL

Resonant power factor correction converter

ActiveCN101588135ALoss does not change significantlyAc-dc conversion without reversalEfficient power electronics conversionSingle stageDistribution transformer

An AC-to-DC power converter configured to provide power factor correction and a single isolated low-voltage output. The power converter includes a single-stage resonant power converter including an isolation transformer, a resonant tank, a rectifier, and a bulk storage capacitor coupled to an output of the isolation transformer. In typical applications, at least one non-isolated power converter is coupled to the output of the single-stage isolated power factor correction converter.

Owner:MYPAQ HLDG LTD

Automated device and method for packaging food

InactiveUS6871676B2Solid materialPackaging under special atmospheric conditionsMass storageEngineering

An automated food processing system and method is provided that allows food to be dispensed, fried and packaged in a suitable container, which may be an individual portion-sized container. In one embodiment, the system includes separate automated modules for dispensing, frying and packaging the food.In one embodiment, an automated dispensing device dispenser a predetermined portion of food from a bulk storage container or food dispensing magazine. Food is dispensed from the automated dispensing device to an automated fry device that can include at least one circular fry wheel having a plurality of food containing compartments. After the food is fried it is dispensed from the fry device to an automated packaging device. The automated packaging device dispenses food to a container that may be an individual portion-sized container that is retrieved, erected and held into position for filling by an automated container handling system. After a food container is filled, a conveyor system transports the filled container to a suitable pick-up location.

Owner:RESTAURANT TECH

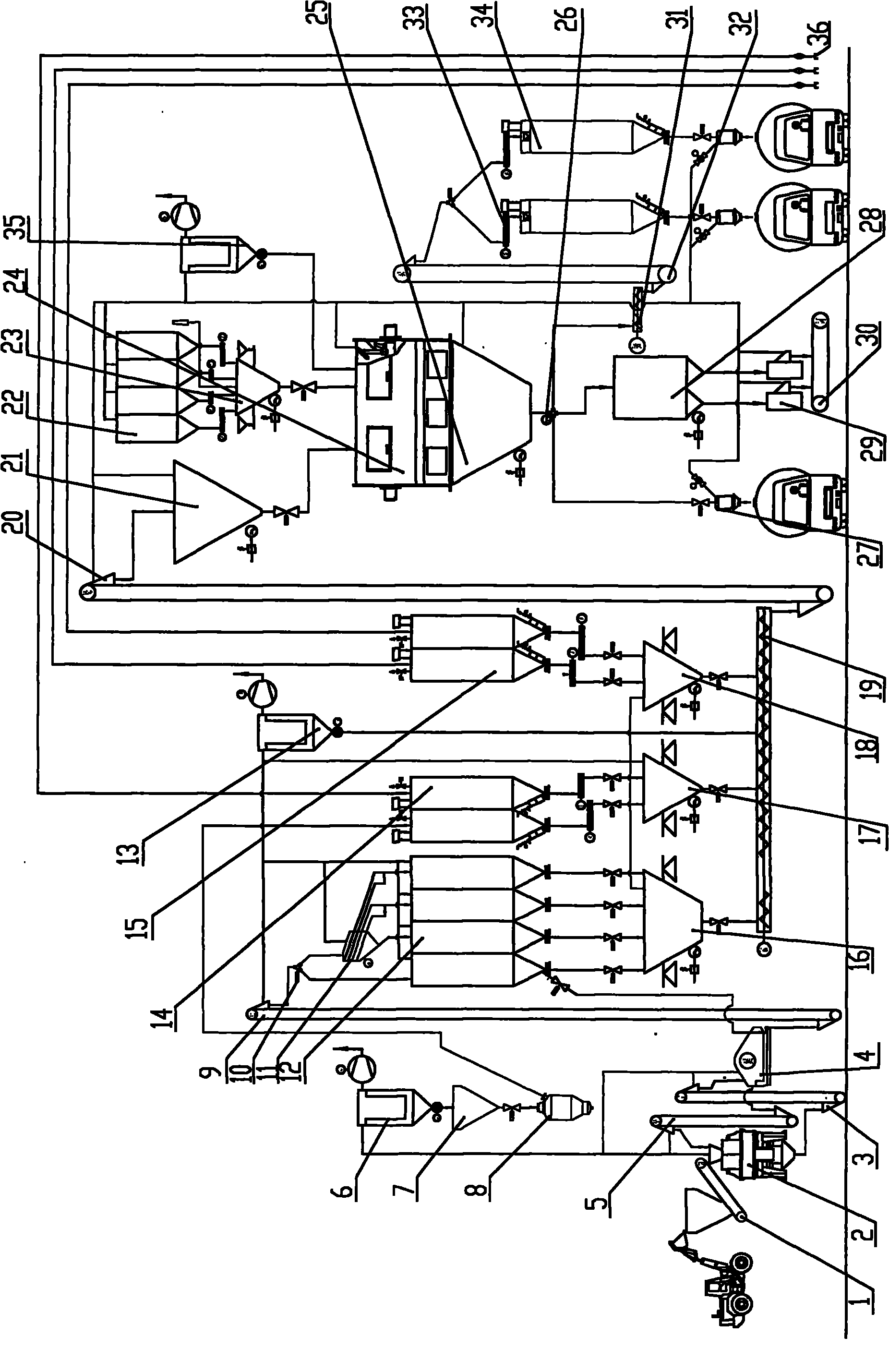

Drying-free dry-mixed mortar complete equipment

The invention relates to drying-free dry-mixed mortar complete equipment, comprising a charging belt conveyor (1), a crusher sand making machine (2), a discharging bucket elevator (3), a circulating vibration screen (4), a screening bucket elevator (9), a vibrating screen classifier (11), a classified sand warehouse (12), a return bucket elevator (5), a stone powder dust collector (6), a stone powder temporary storage bin (12), a stone powder delivery tank (8), a stone powder additive bin (14), a cement bin (15), a sand dispensing and metering device (16), an additive dispensing and metering device (17), a cement dispensing and metering device (18), a metering material spiral conveyer (19), a metering material bucket elevator (20), a metering material intermediate transition bin (21), an additive storage silo (22), an accurate dispensing and metering device (23), a mixer (24), a finished product material transition bin (25), a bulk head (27), a wrapping finished product bin (28), a sack filler (29), a package belt conveyer (30), a finished product material storage spiral conveyer (31), a finished product material storage bucket elevator (32), a dissociation-proof transport unloading device (33) and a finished product material bulk storage silo (34). The invention can omit drying and realizes drying-free effect.

Owner:WUXI JIANGJIA CONSTR MACHINERY

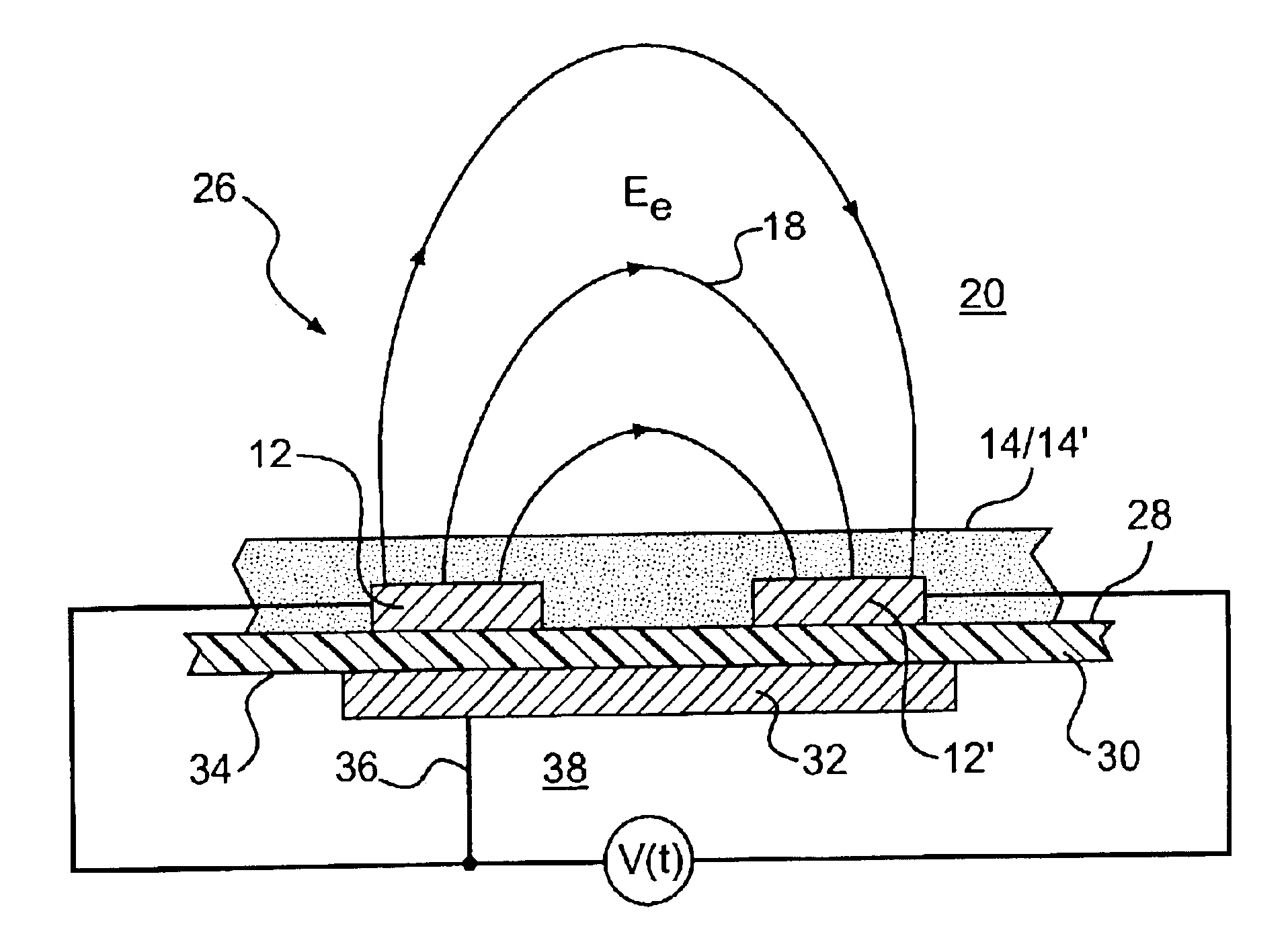

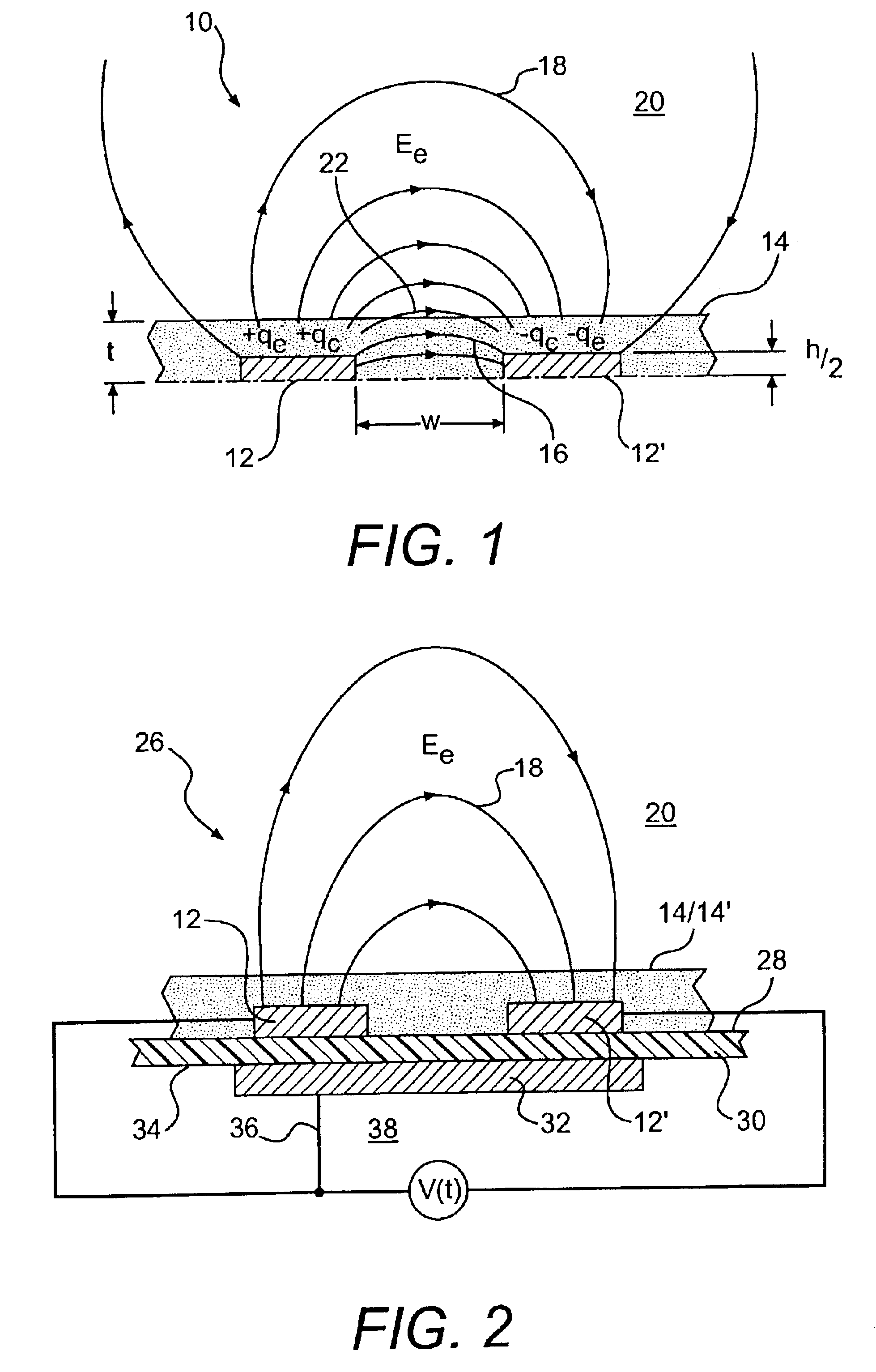

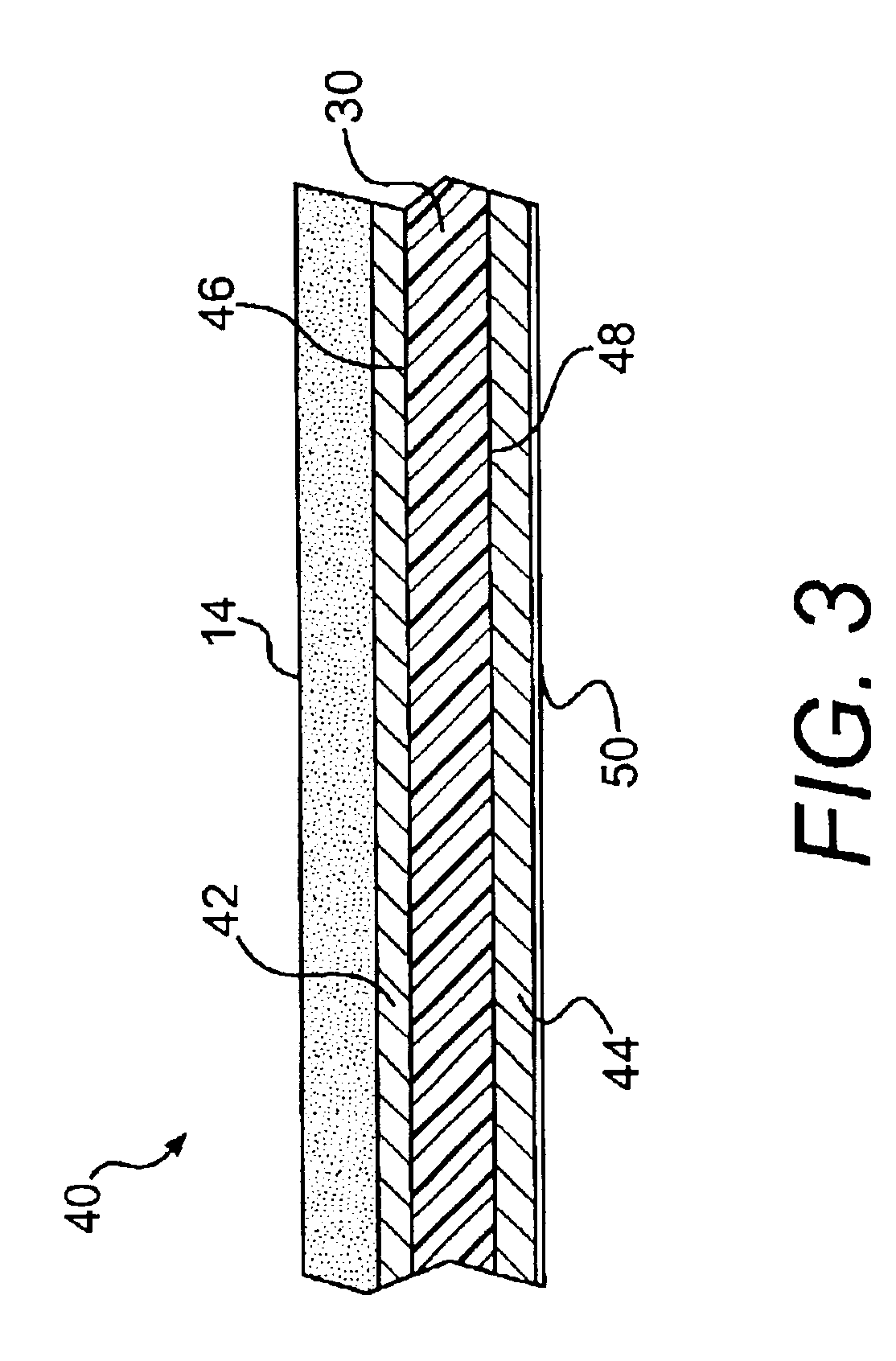

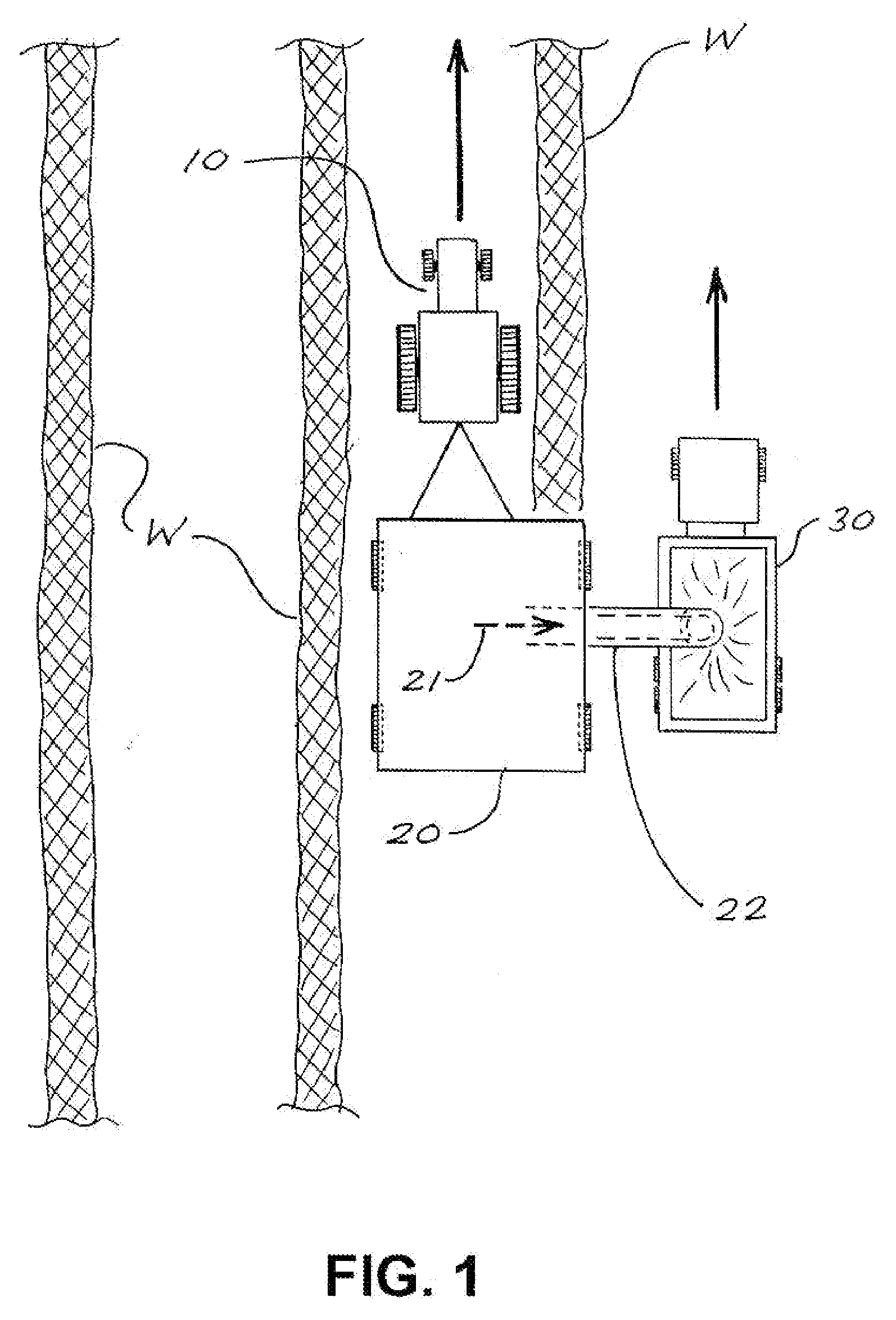

Planar capacitive transducer

InactiveUS6842018B2Increase and decrease surface free energyIncrease moisture contentResistance/reactance/impedenceUsing mechanical meansDesorptionMoisture absorption

A transducer comprising at least one planar capacitor with a thin coverlayer of material selected to maximize electric field coupling between cooperating capacitor electrodes within a region external to a principal surface of the coverlayer. Preferred coverlayer materials have low values of moisture absorption, surface free energy, permittivity, dielectric dissipation, and electrical conductance. According to one embodiment of the invention, a driven shield further enhances electric field coupling over and in a region external to the principal surface. The transducer also can promote a physical change in specific adsorbates and materials and simultaneously detect and measure an effect of the induced change. Applications for the transducer of the invention include the measurement of the moisture content of grain and bulk stored commodities, humidity, a dew point temperature, the onset of condensation and rates of adsorption and desorption.

Owner:MCINTOSH ROBERT B

Compressed Natural Gas Storage and Dispensing System

ActiveUS20140202585A1Reduce flow rateLow horse powerGas handling applicationsGas handling/storage effectsMass storageCompressed natural gas

A compressed natural gas storage and dispensing system having bulk storage tanks in fluid communication with a natural gas supply source; a primary compressor delivering the natural gas to the bulk storage tanks; dispensing storage tanks in fluid communication with the bulk storage tanks and in fluid communication with fuel dispensers; a secondary compressor delivering the natural gas to the dispensing storage tanks from the bulk storage tanks; wherein when the pressure within the dispensing storage tanks falls below a predetermined minimum pressure, natural gas is delivered from the bulk storage tanks to the dispensing storage tanks, and wherein when the pressure in the bulk storage tanks falls below a predetermined minimum pressure, natural gas is delivered from the supply source to the bulk storage tanks.

Owner:HOLYSTONE USA INC

Automated food processing system and method

An automated food processing system and method is provided that allows food to be dispensed, fried and packaged in a suitable container, which may be an individual portion-sized container. In one embodiment, the system includes separate automated modules for dispensing, frying and packaging the food. In one embodiment, an automated dispensing device dispenses a predetermined portion of food from a bulk storage container or food dispensing magazine. Food is dispensed from the automated dispensing device to an automated fry device that can include at least one circular fry wheel having a plurality of food containing compartments. After the food is fried it is dispensed from the fry device to an automated packaging device. The automated packaging device dispenses food to a container that may be an individual portion-sized container that is retrieved, erected and held into position for filling by an automated container handling system. After a food container is filled, a conveyor system transports the filled container to a suitable pick-up location.

Owner:RESTAURANT TECH

System and method for interactive items dispenser

A networked items dispenser is disclosed. The device includes a housing having a bulk storage bin for storing items, a temporary storage bin for receiving the items, and a dispensing receptacle for receiving the items from the temporary storage bin. A communications network interface is provided for entering programming instructions. A programmable internal memory device is also included for storing a schedule for dispensing the items, such that the schedule can be automatically adjusted according to a hierarchy of dispensing rules.

Owner:UNIVERSITY OF ROCHESTER

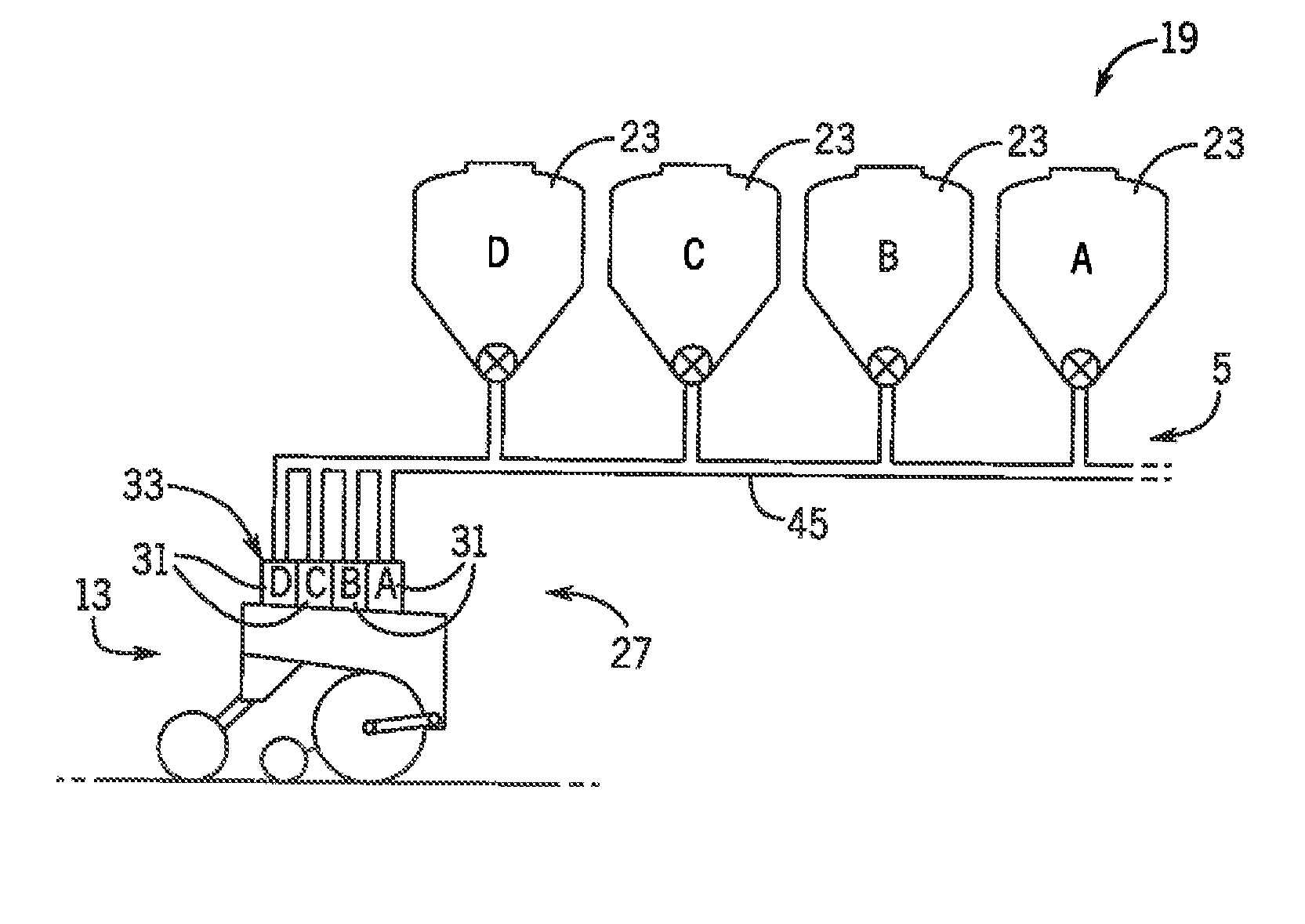

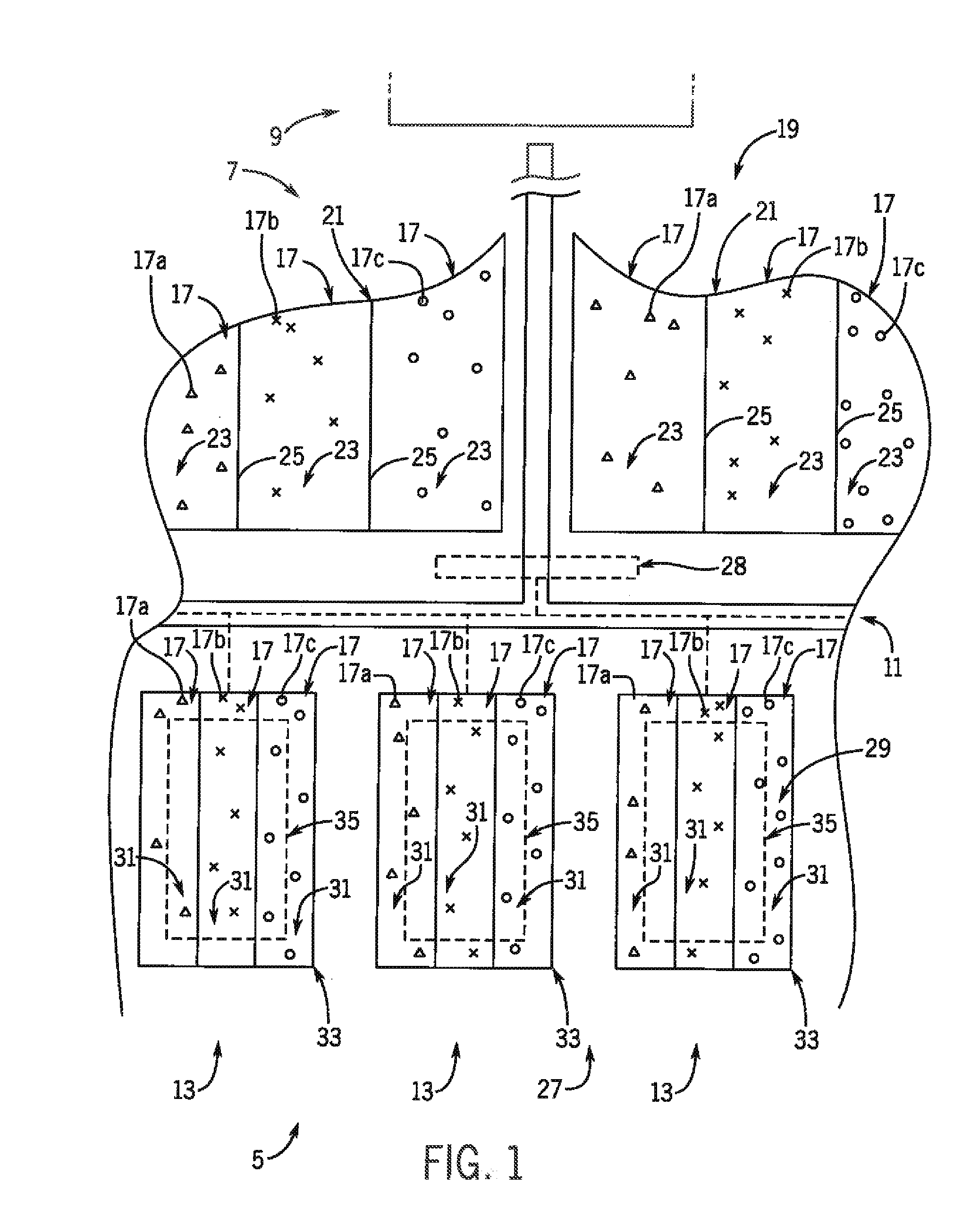

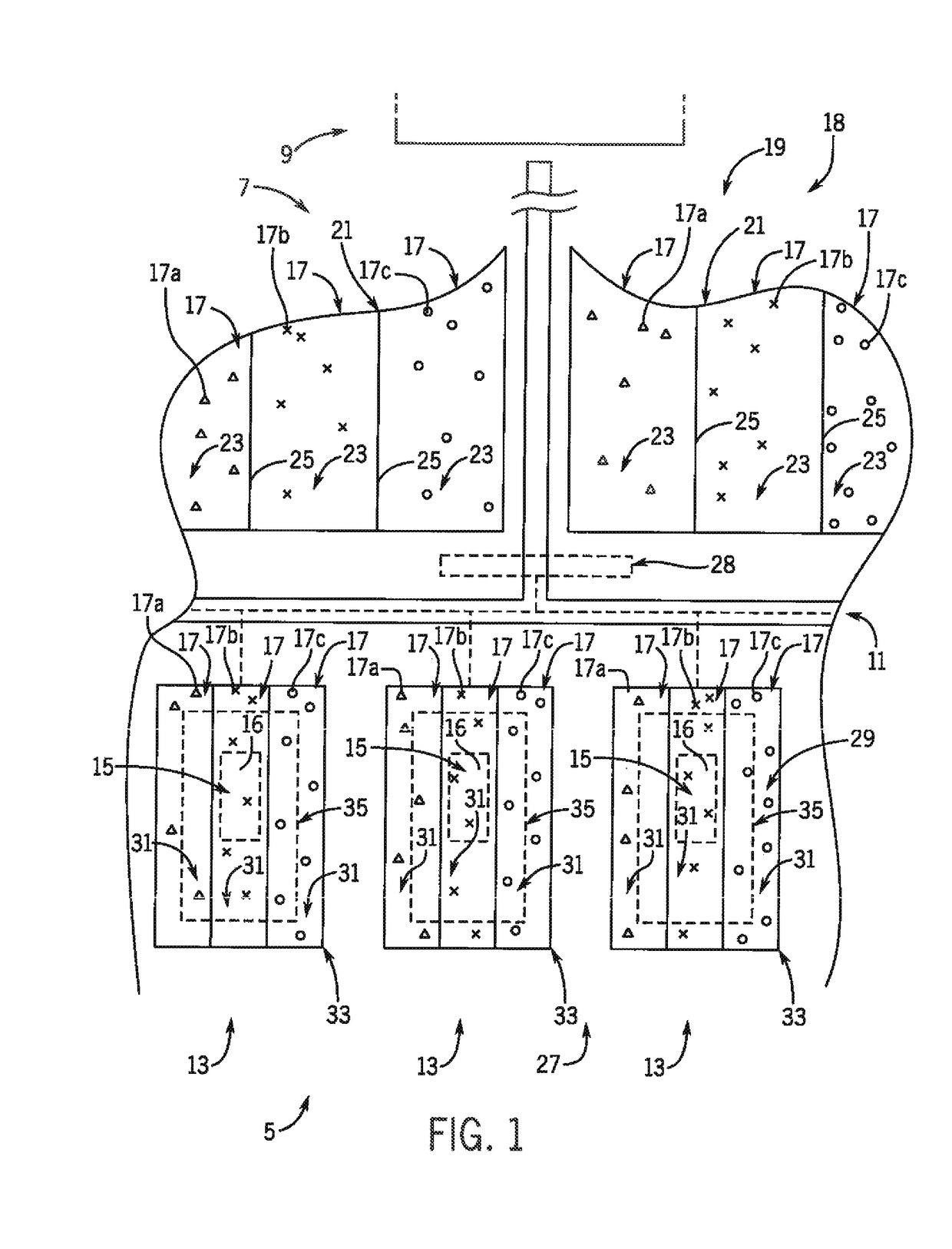

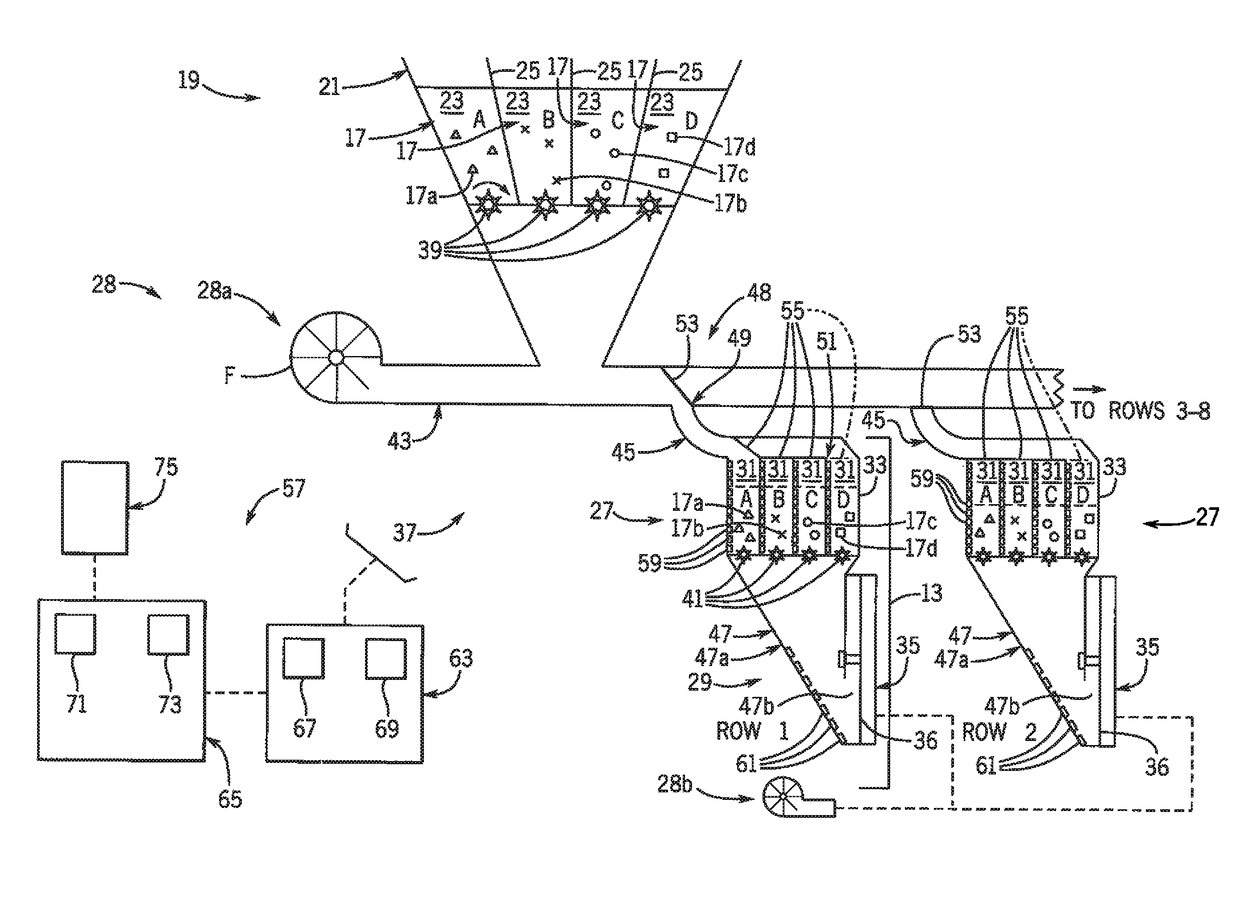

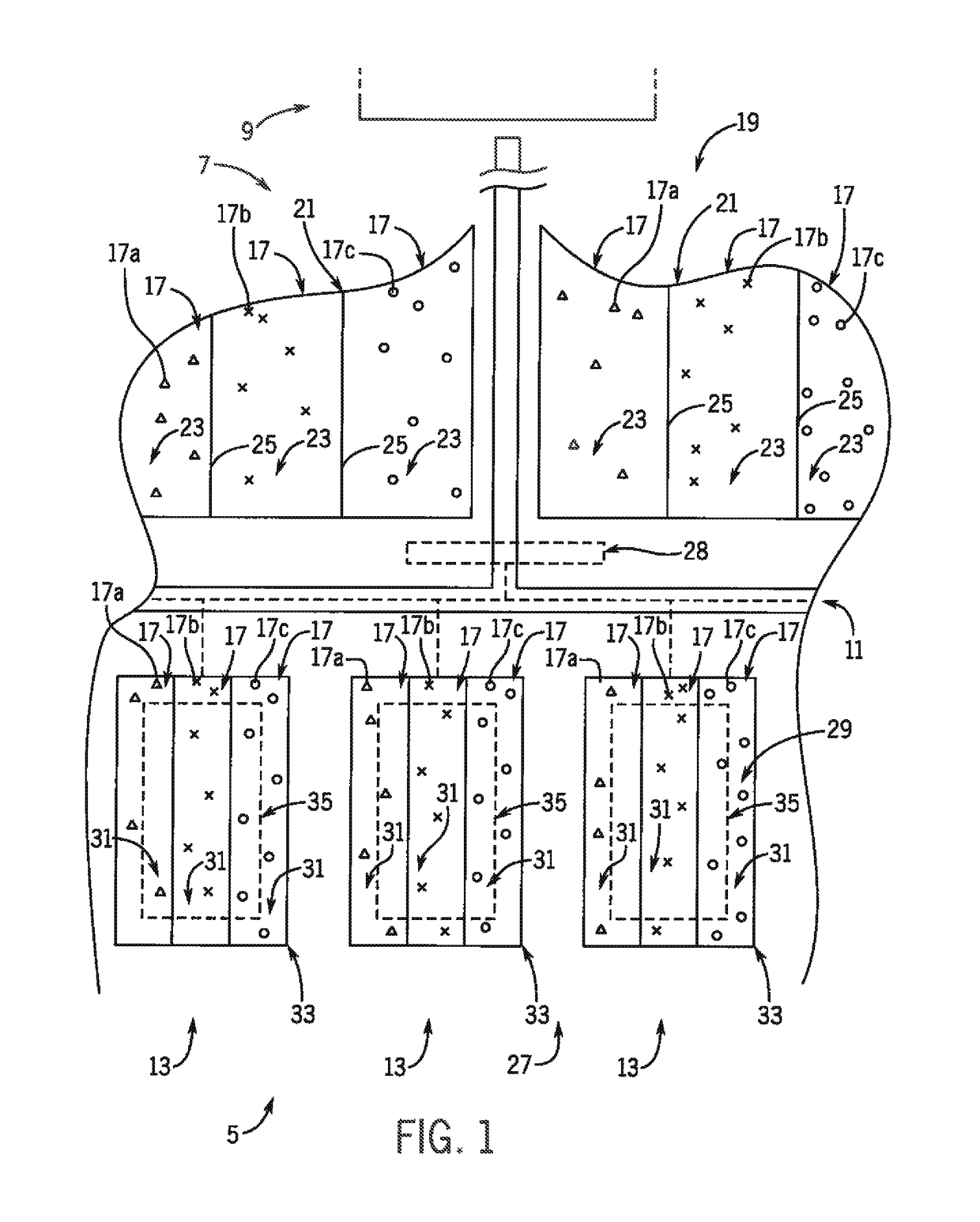

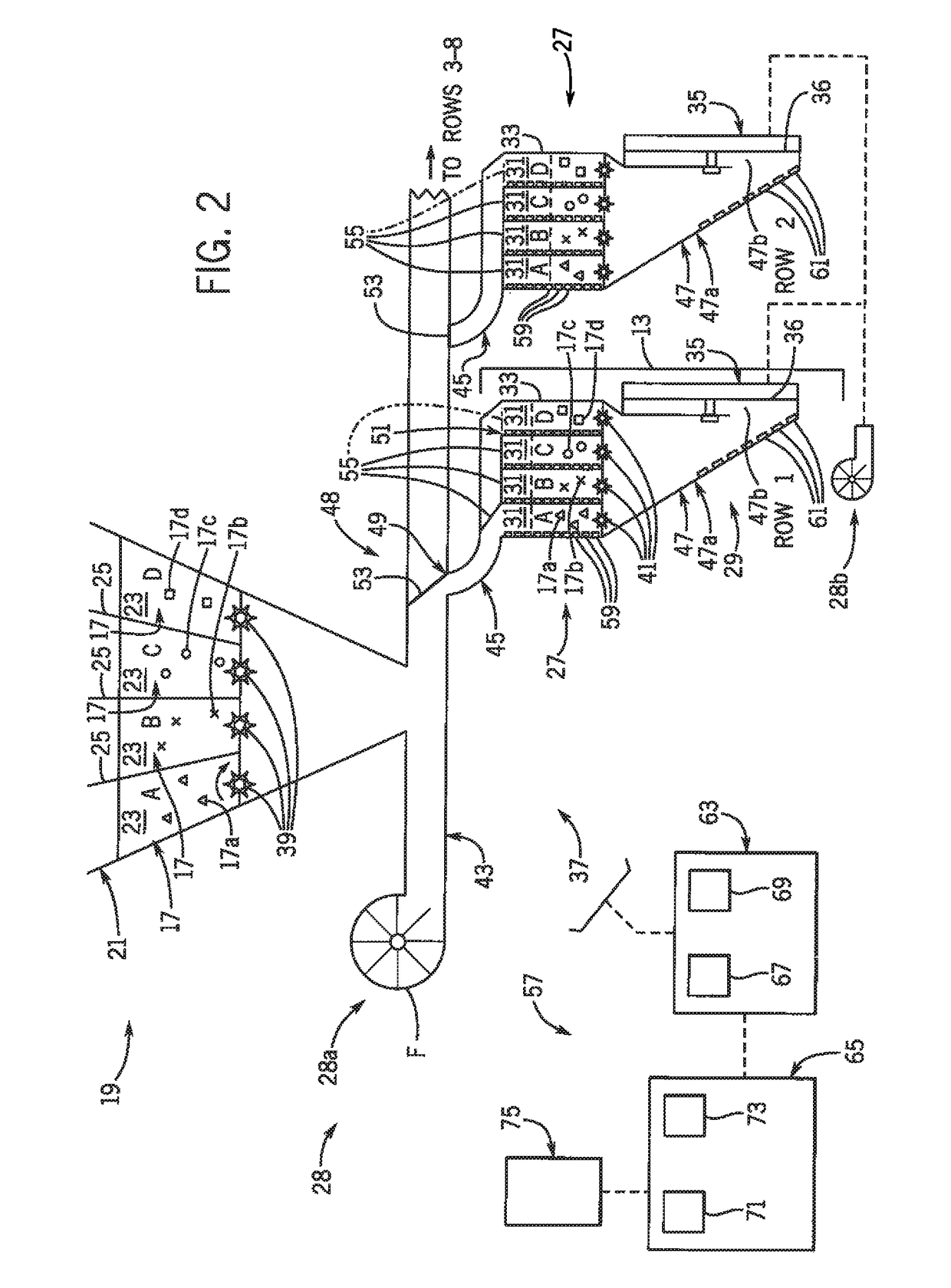

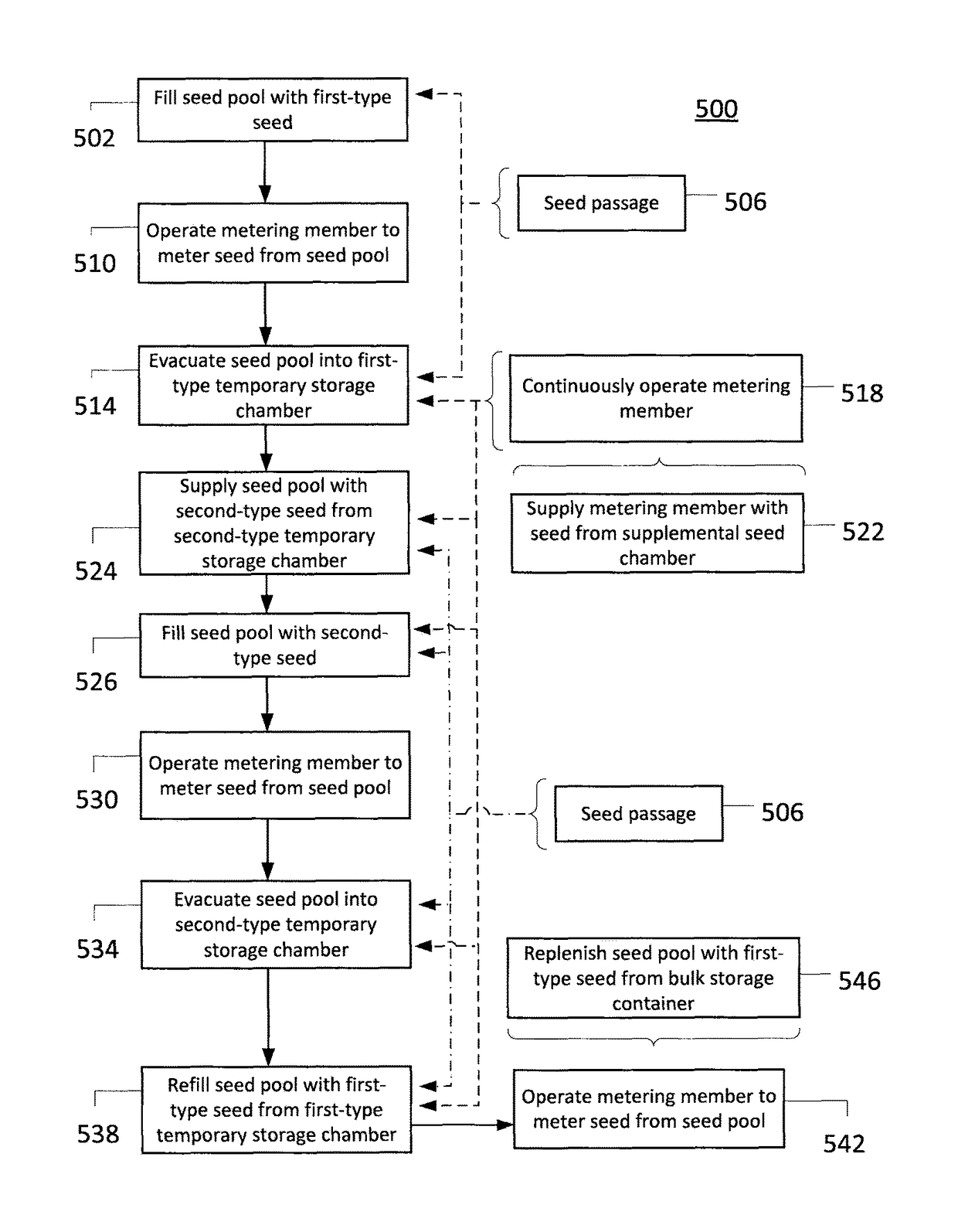

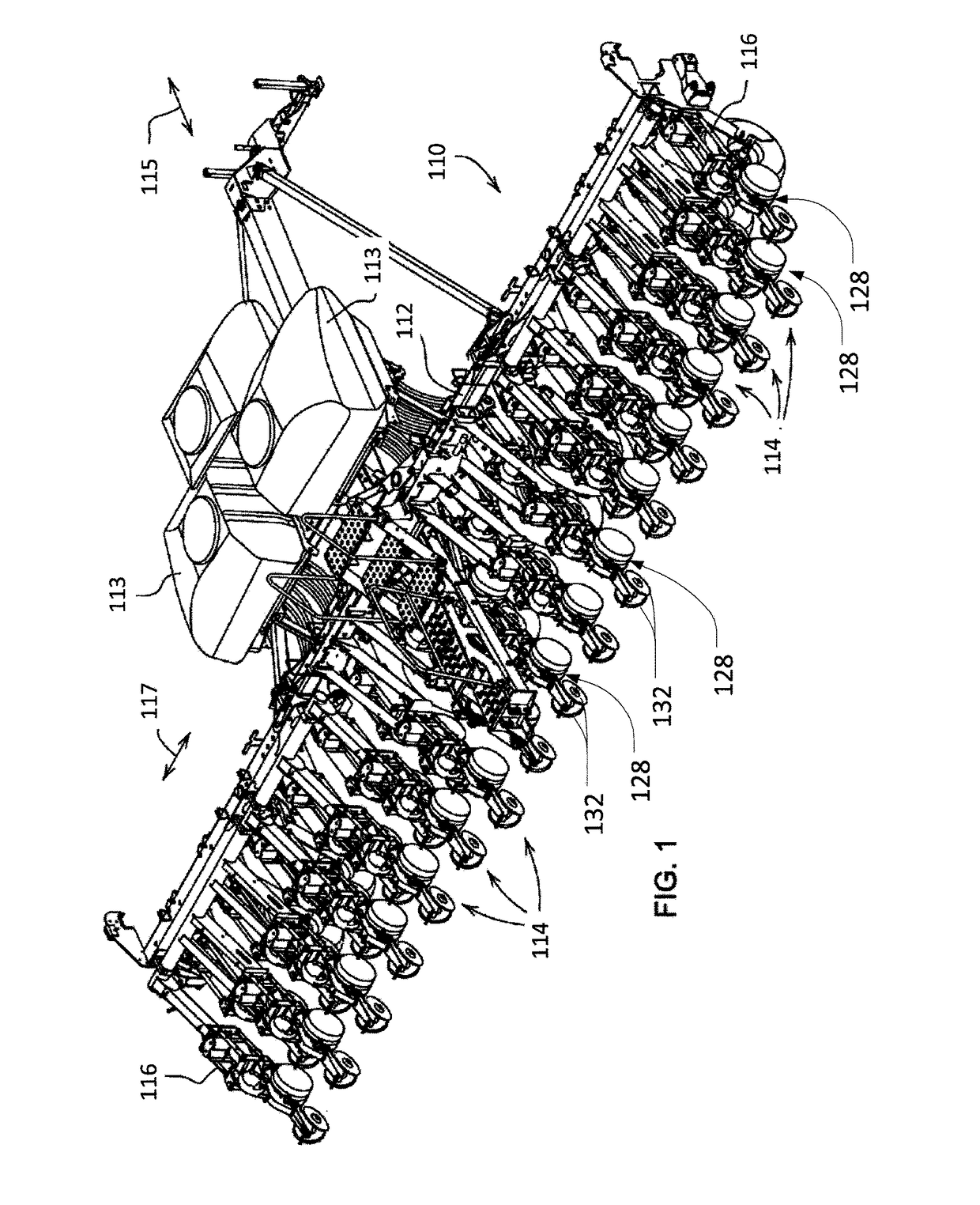

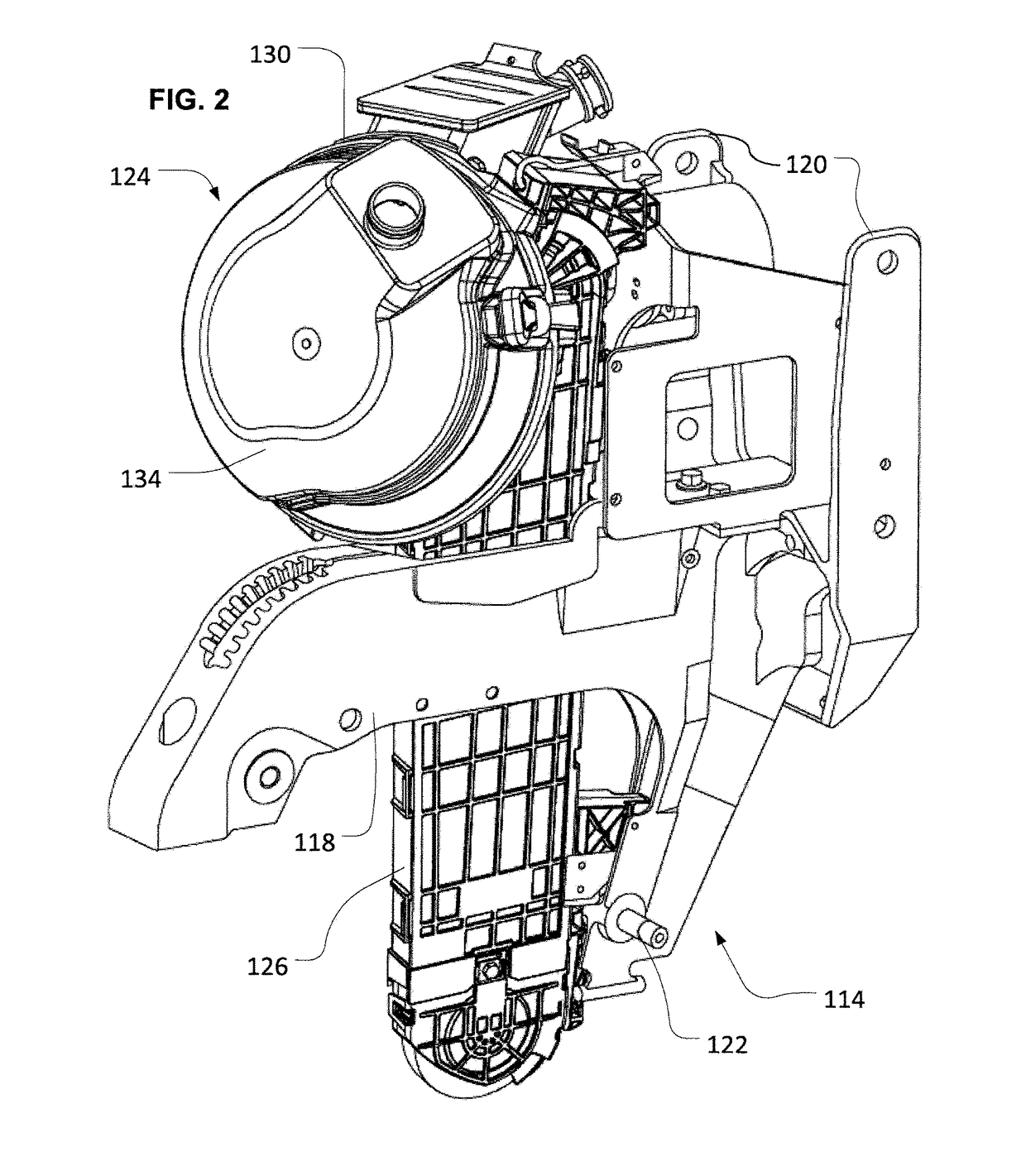

Multiple Seed-Type Planting System With On-Row Selective Delivery

ActiveUS20150223391A1Significant period of timeFully chargedFertilising methodsPotato plantersCropping systemEngineering

A system for planting multiple types of seed and automatically switching between the varieties during planting in a single planting pass of a planting session of row-crop or other planting of an agricultural field. The system may include a bulk storage system, an on-row storage system, and a charging system that selectively delivers seeds of different varieties from the bulk storage system to the on-row storage system. The system may include a seed metering system that can be controlled at each of multiple row units to selectively plant different types or varieties of seed based on seed type or variety zones agricultural field, which may correspond to field characteristics defined in a seed variety prescription map.

Owner:BLUE LEAF I P INC

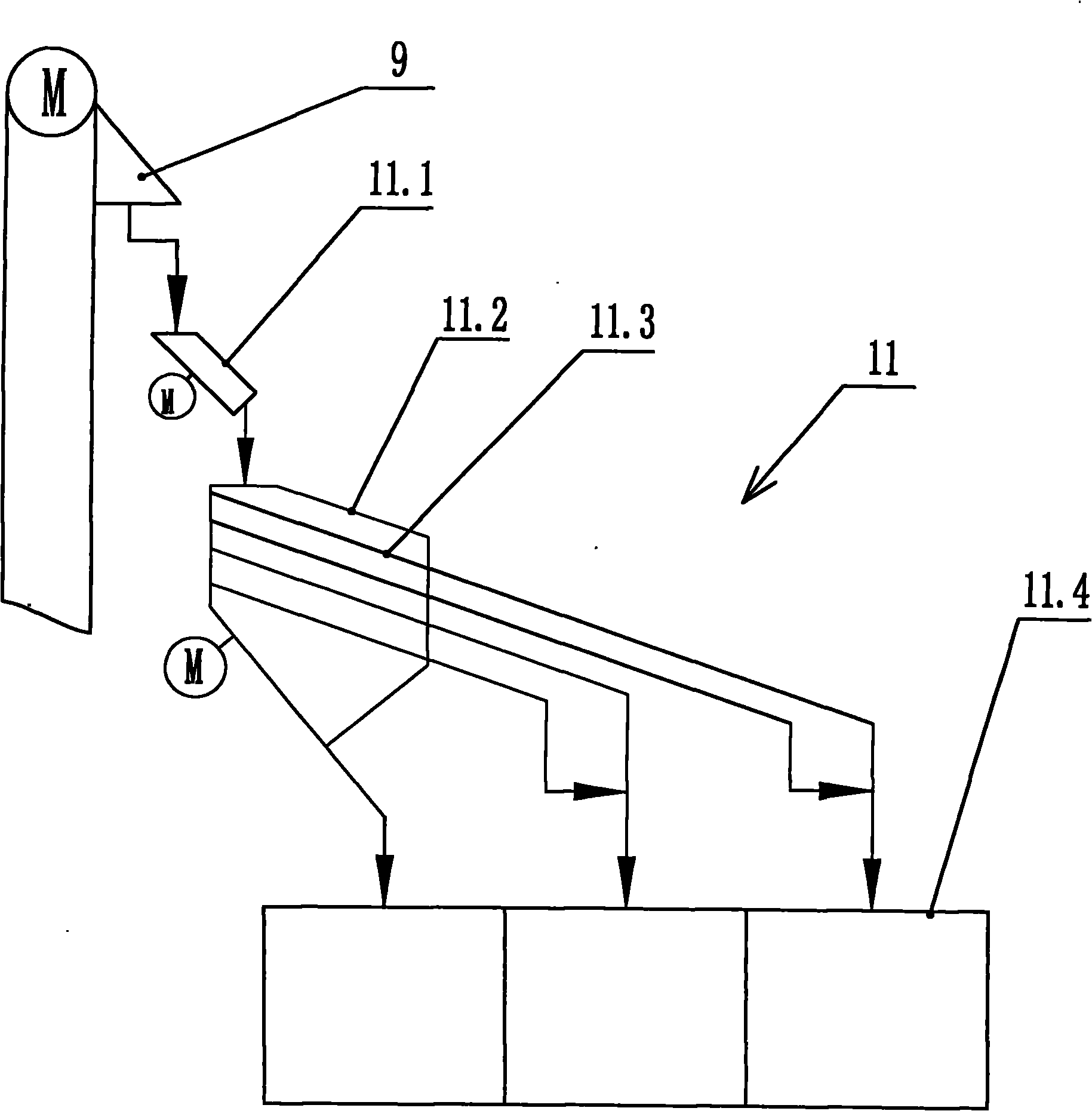

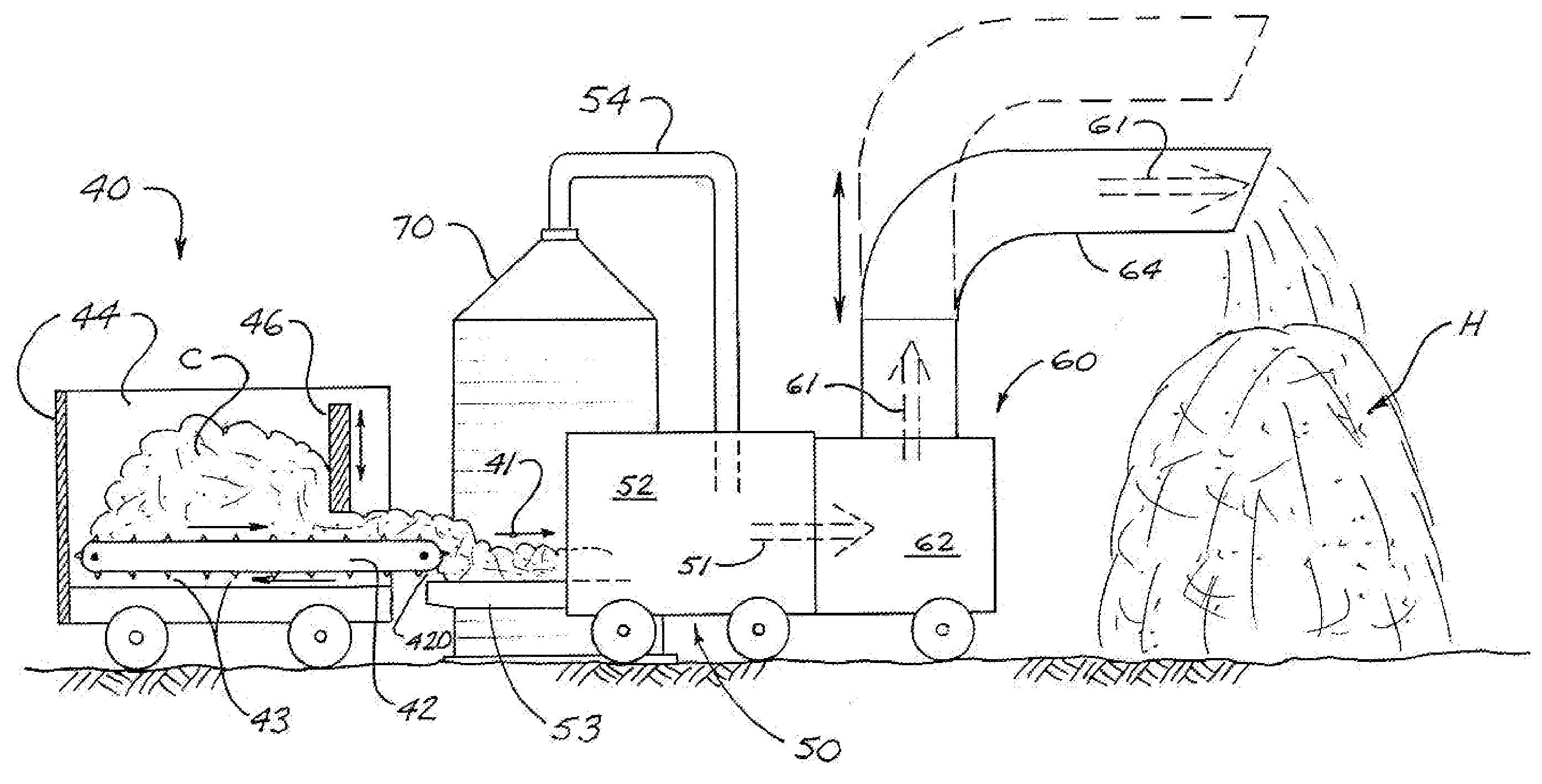

Crop processing method and apparatus

InactiveUS20090017885A1Easy constructionLower requirementHarvestersThreshersMass storageGrain storage

In a method for processing swathed crops, the entire cut crop is picked from the field and transported to a processing facility located away from the field. The processing facility has a threshing apparatus which separates grain from the cut crop, leaving a crop residue comprising plant stalks, chaff, and other constituents of the cut crop. The separated grain is conveyed from the threshing apparatus to a grain storage bin or directly to a transport truck for delivery to a grain terminal. The processing facility also includes crop residue handling means for conveying crop residue to a bulk storage pile, to a baling machine, or to some other selected location. The method makes field baling operations unnecessary, thus expediting the total removal of the crop from the field.

Owner:HALLS FLOYD W

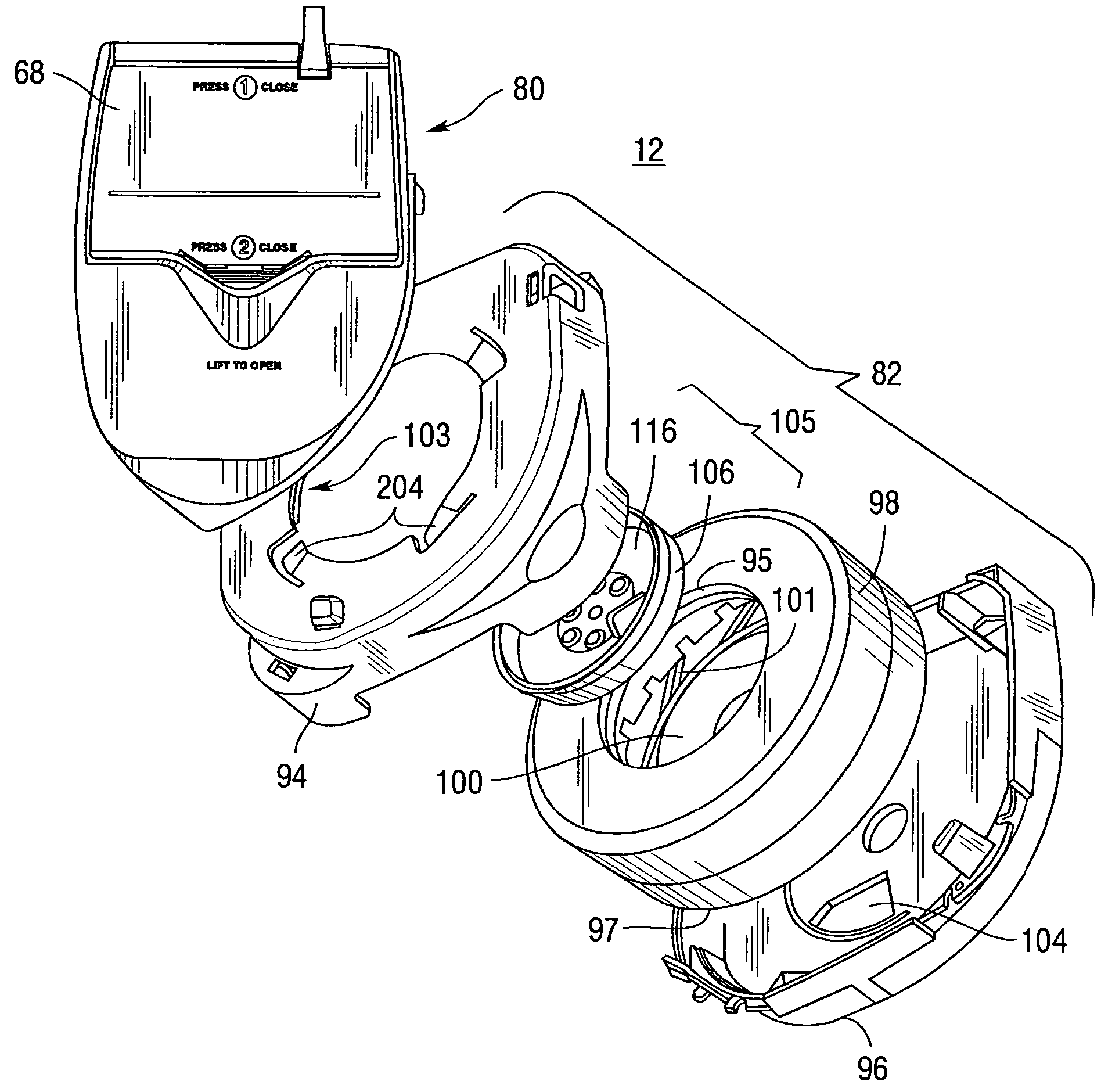

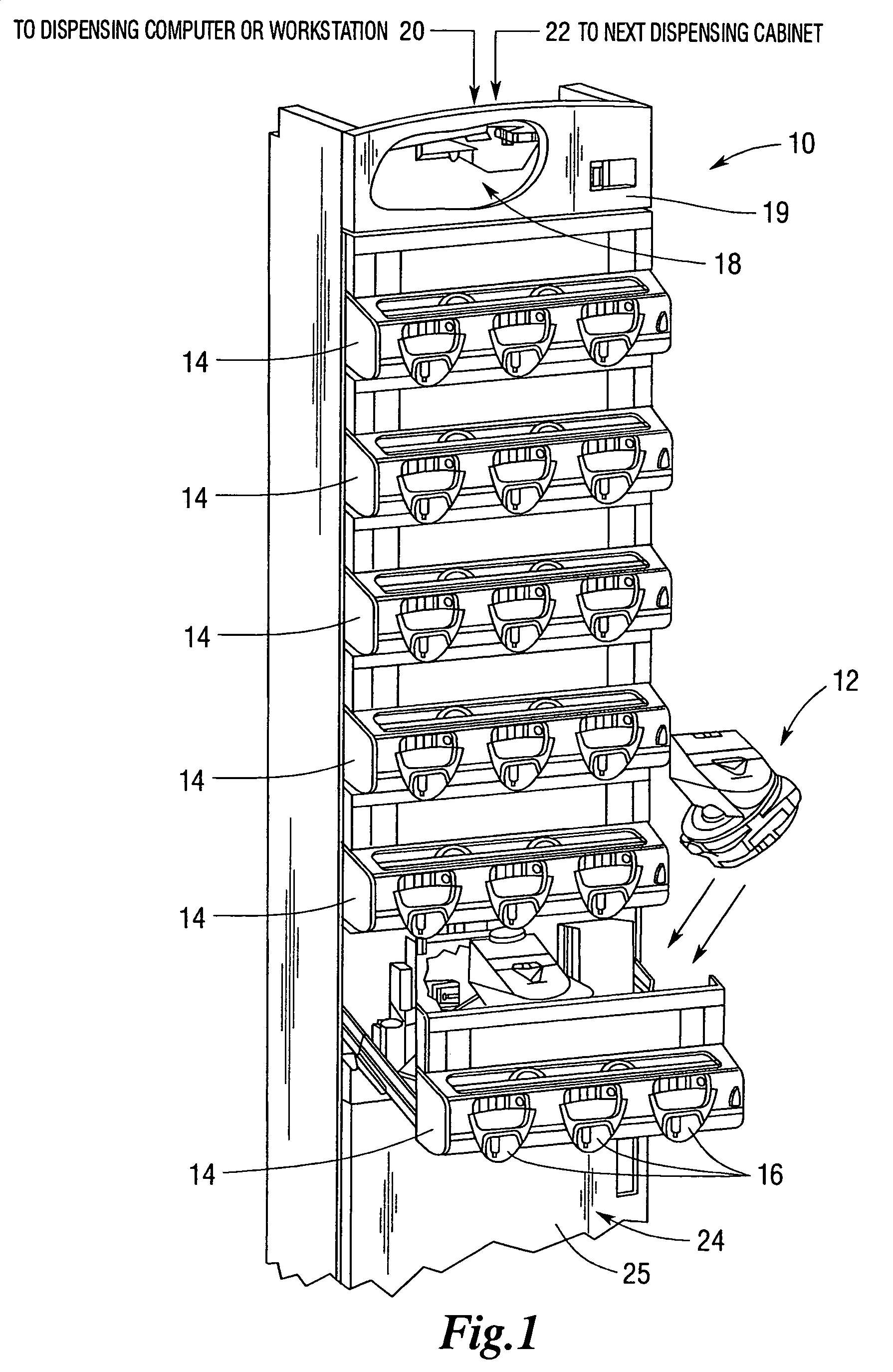

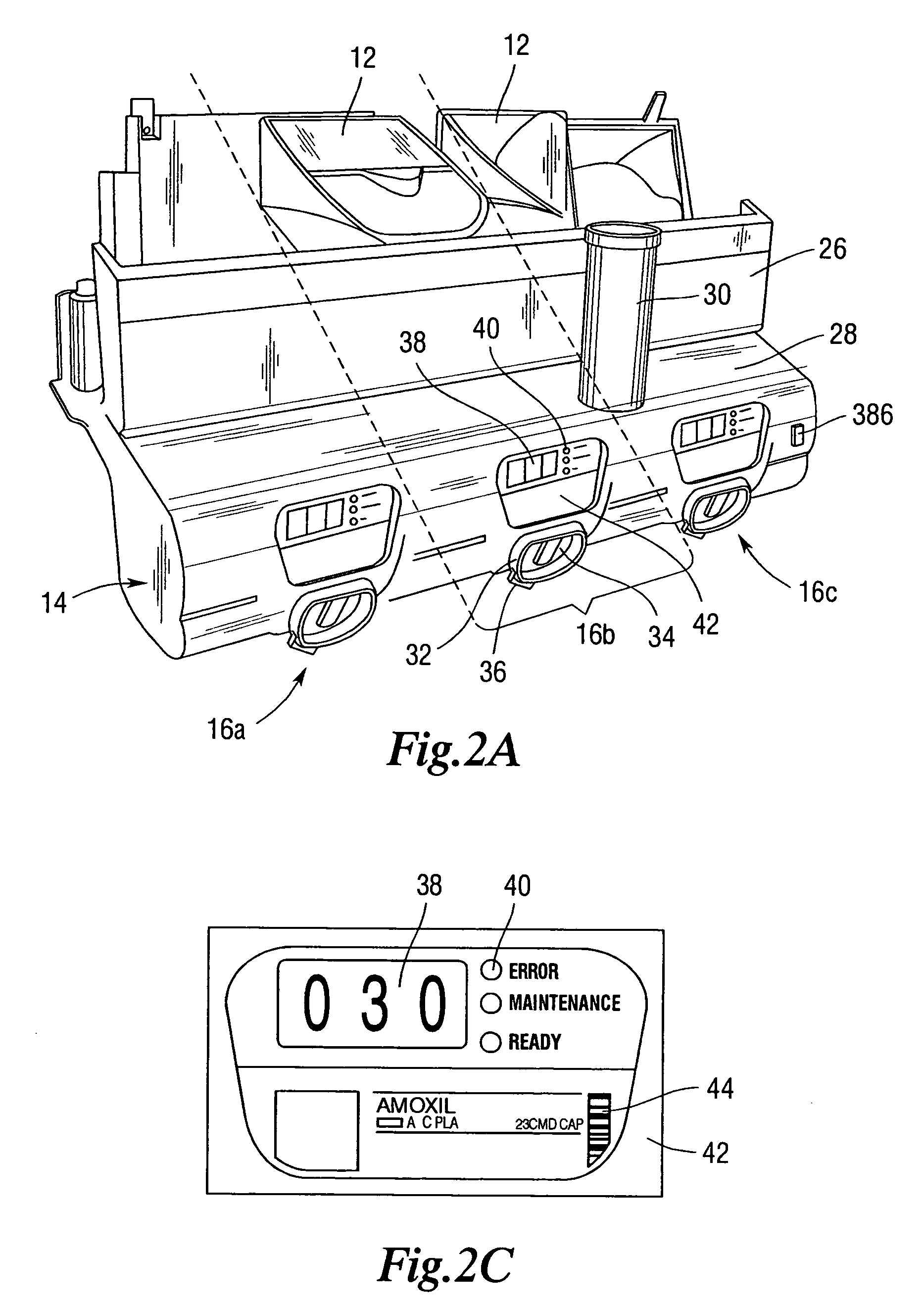

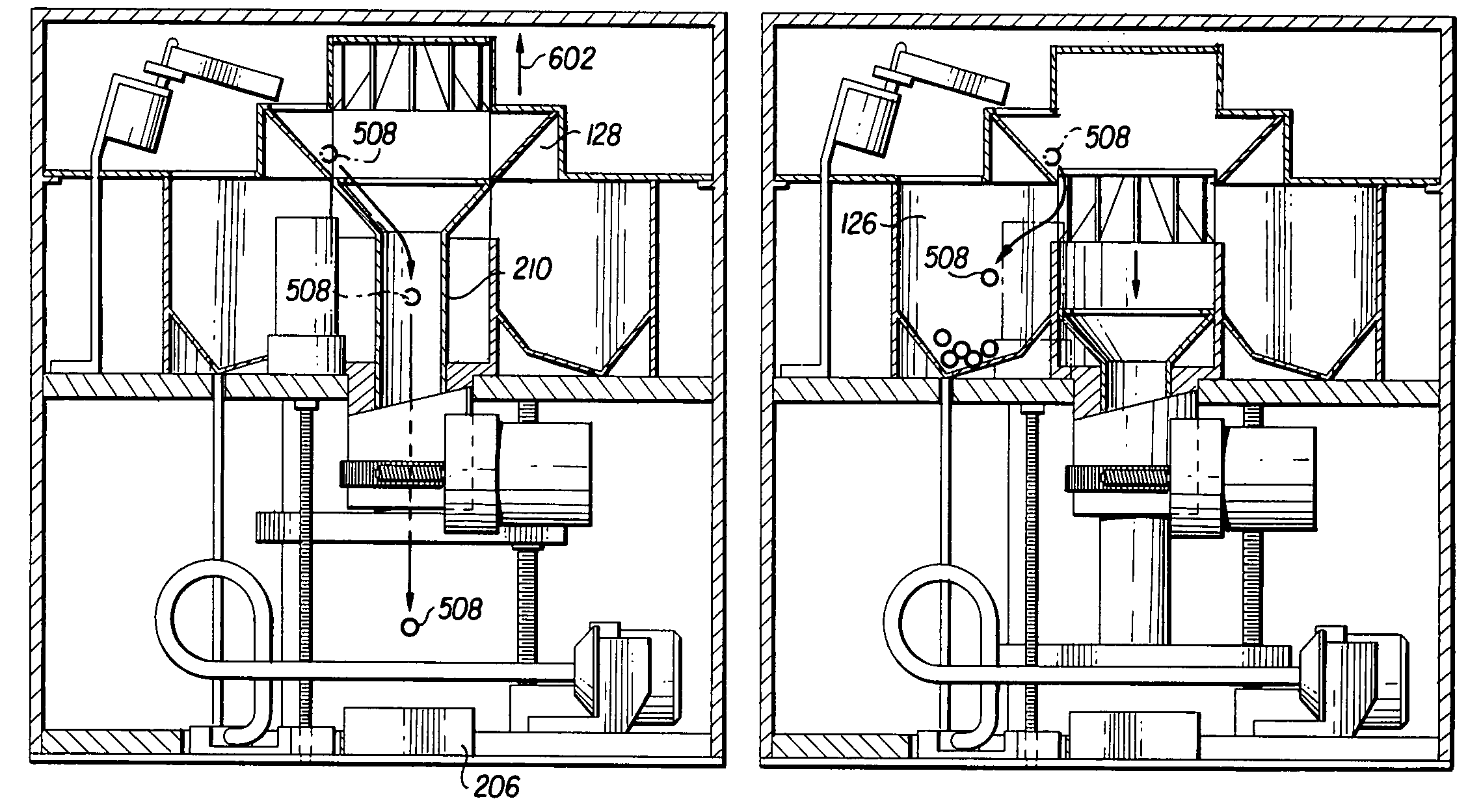

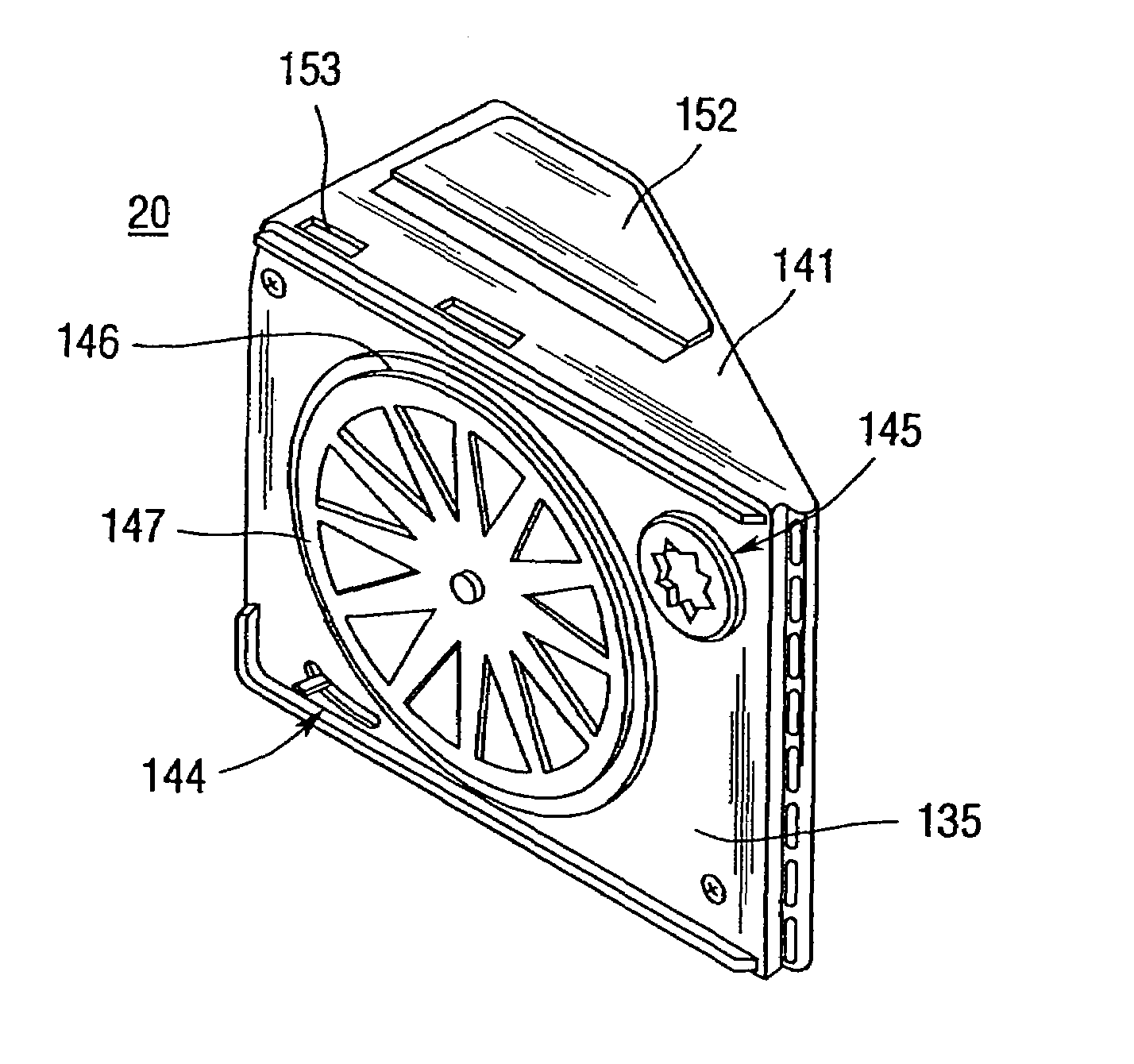

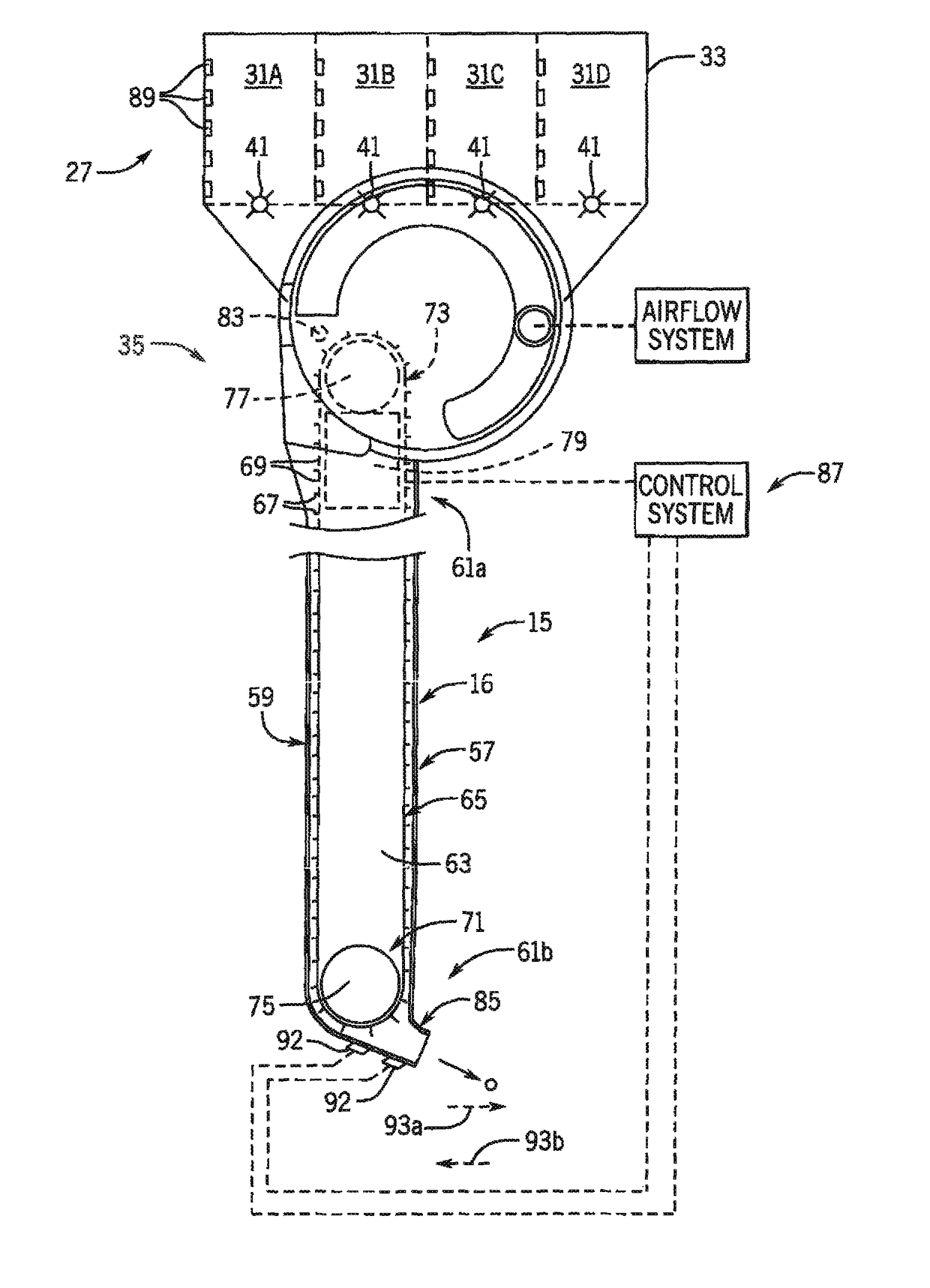

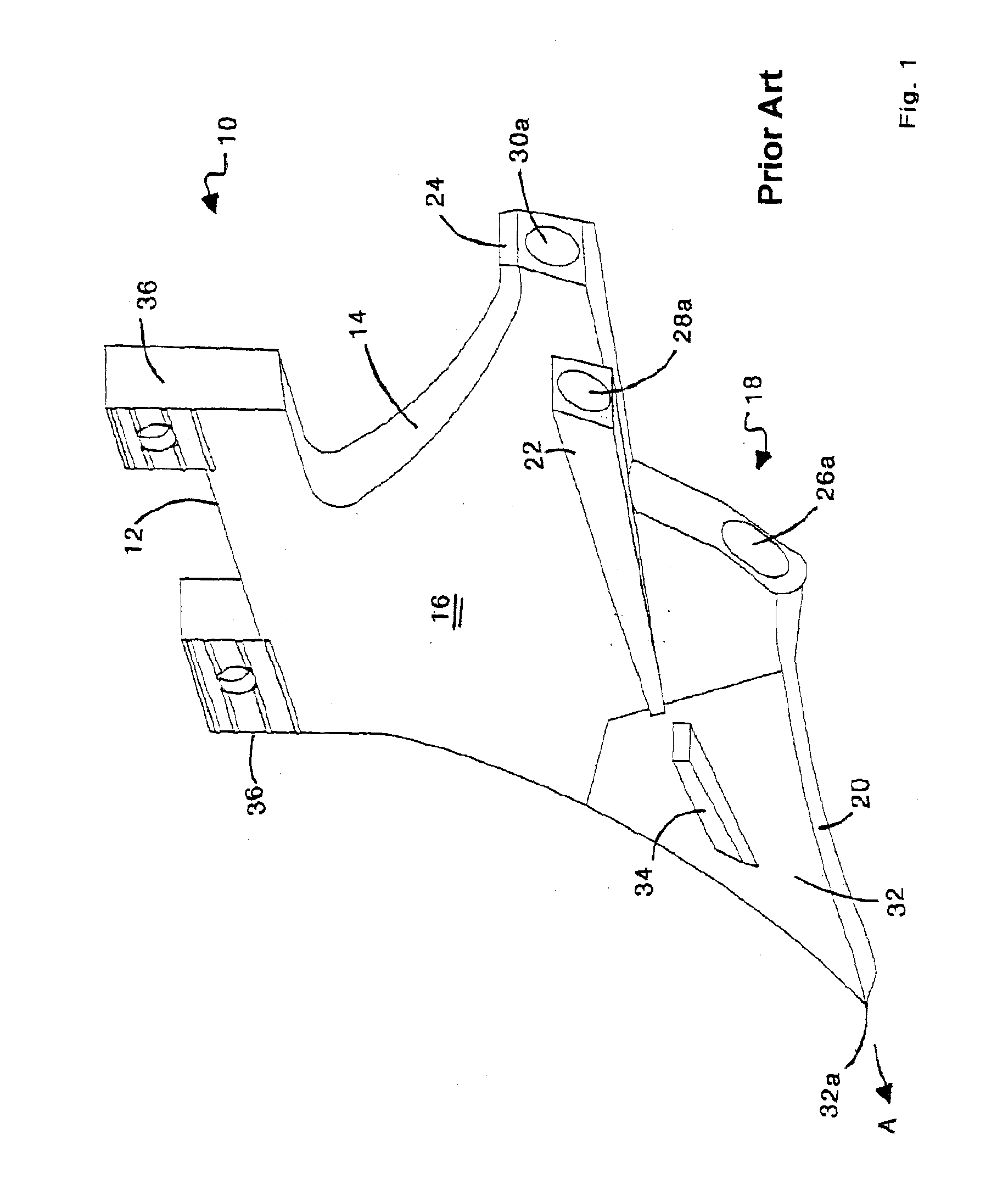

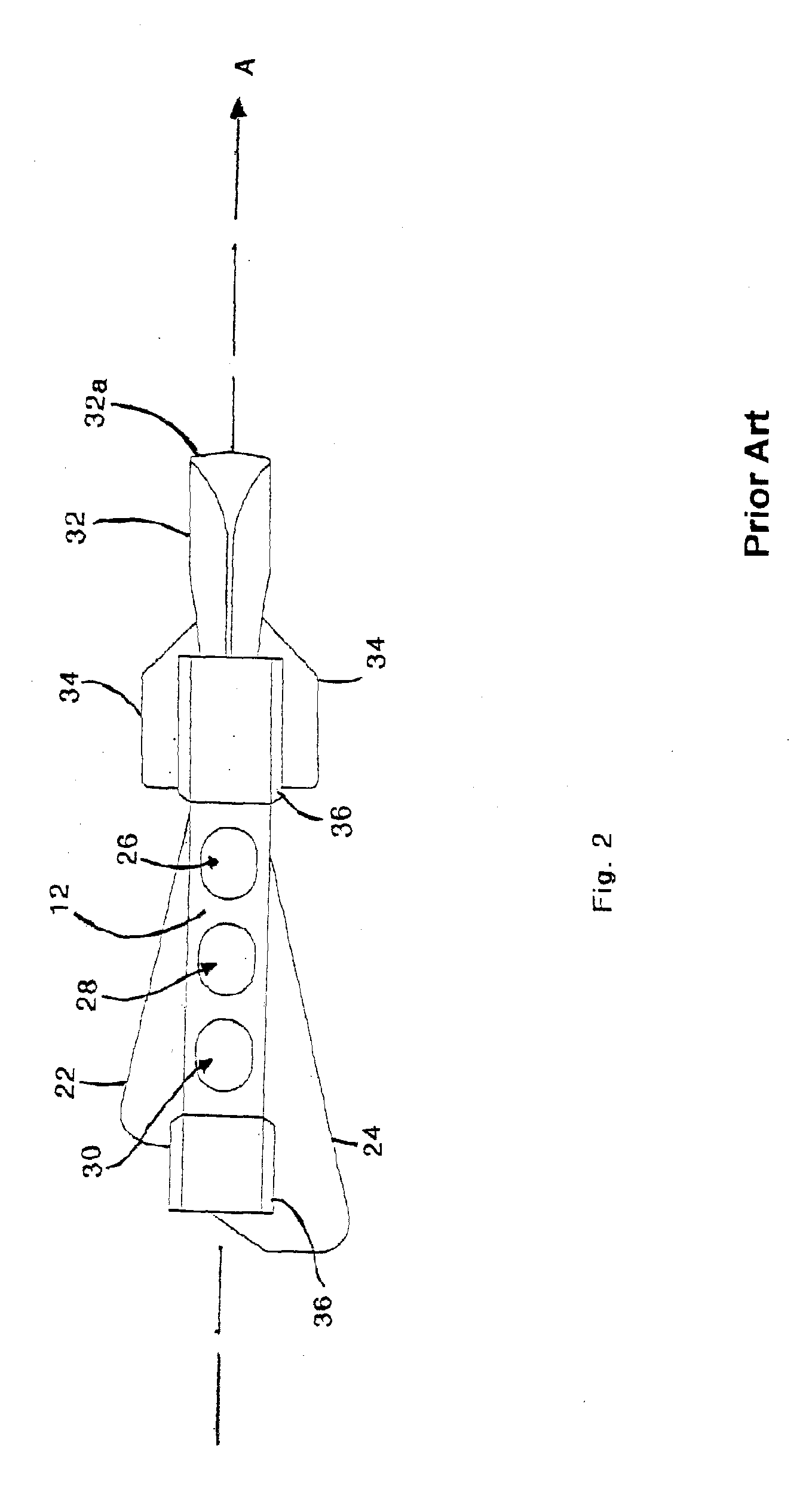

Vacuum pill dispensing cassette and counting machine

ActiveUS7303094B2Reduce air turbulenceQuieter operationCoin-freed apparatus detailsOral administration deviceMass storageEngineering

A medication storing and dispensing cassette is comprised of a housing defining at least a portion of a bulk storage chamber for storing a medication, defining at least a portion of a pick-up area, and defining at least a portion of a discharge chute sized to temporarily store a quantity of the medication. A divider wall is positioned between the bulk storage chamber and the pick-up area. A gate is positioned to control an exit end of the discharge chute. A rotatable conveying wheel having openings proximate to the periphery thereof is positioned such that a portion of the wheel is in communication with the pick-up area while another portion of the wheel is adjacent to an entrance end of the discharge chute. A calibration arm is positioned adjacent the openings of the rotatable wheel. A baffle is positioned to block those openings in that portion of the rotatable wheel adjacent to the discharge chute. An air agitation system is provided so that pills may be moved from the bulk storage chamber to the pick-up area. Methods are also disclosed in which air agitation is used to move pills from the bulk storage chamber to the pick-up area, for automatically setting the position of the calibration arm and for automatically learning the setting for the calibration arm for an unclassified medication. A counter is also disclosed for use with the cassette. The counter is comprised of a loader for receiving a cassette, a sensor for sensing whether a cassette is in the loader, means for moving the loader into an operative position, a vacuum unit for applying a vacuum to the cassette, a drive unit for driving a driven portion of the cassette and a counter for counting medication within a portion of the cassette. Methods of operating the counter are also disclosed.

Owner:MCKESSON AUTOMATION SYST

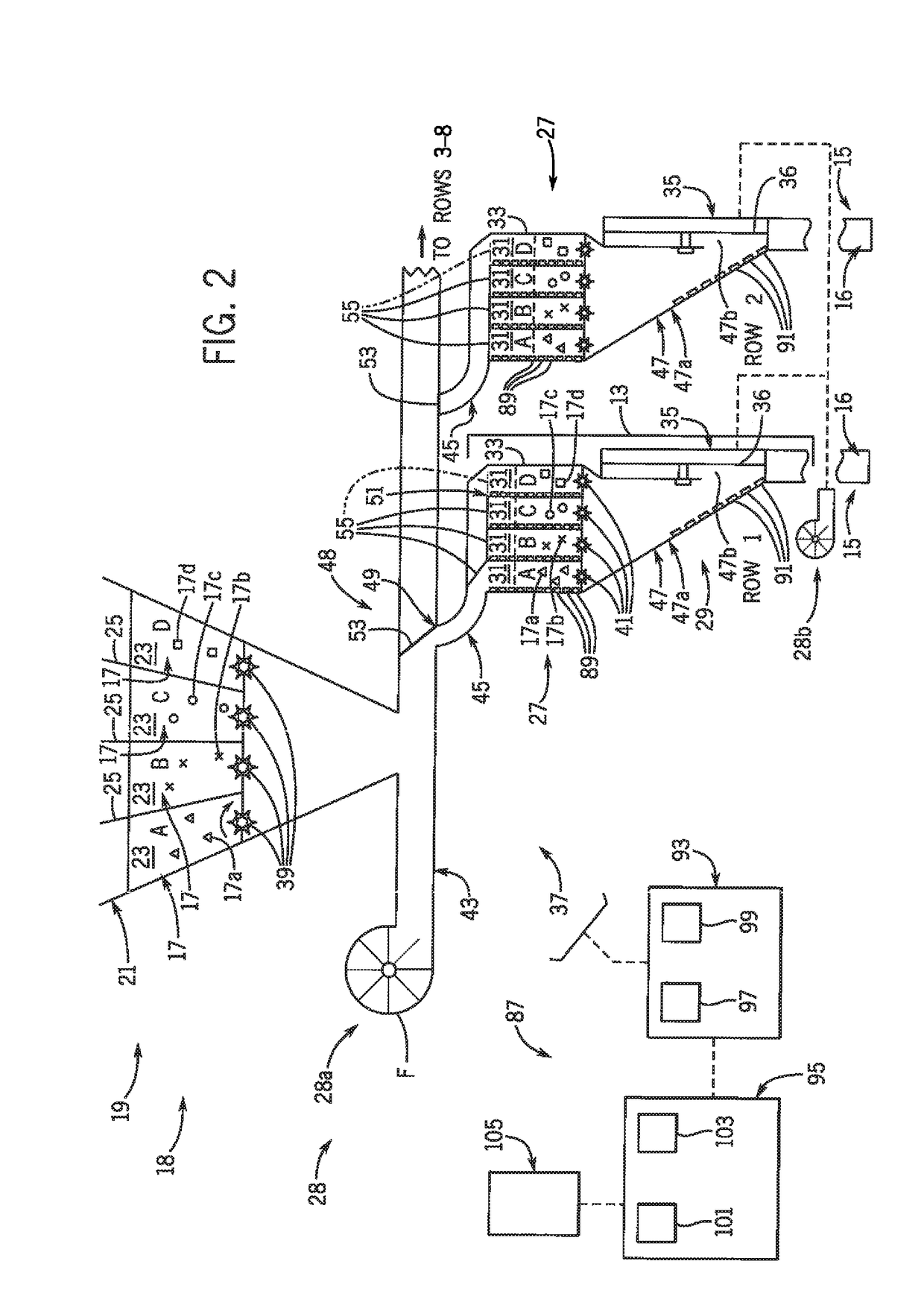

Multiple seed-type planting system with seed delivery speed control

ActiveUS9936625B2Mitigate seed bounceFertilising methodsSeed depositing seeder partsSpeed control systemControl system

A system for planting multiple types of seed and automatically switching between the varieties during planting in a single planting pass of a planting session of row-crop planting of an agricultural field while controlling seed delivery speed to mitigate seed bounce and / or provide desired seed spacing distances. The system may include a bulk storage system, an on-row storage system, and a charging system that selectively delivers seeds of different varieties from the bulk storage system to the on-row storage system and a seed delivery speed control system that regulates seed delivery speed.

Owner:BLUE LEAF I P INC

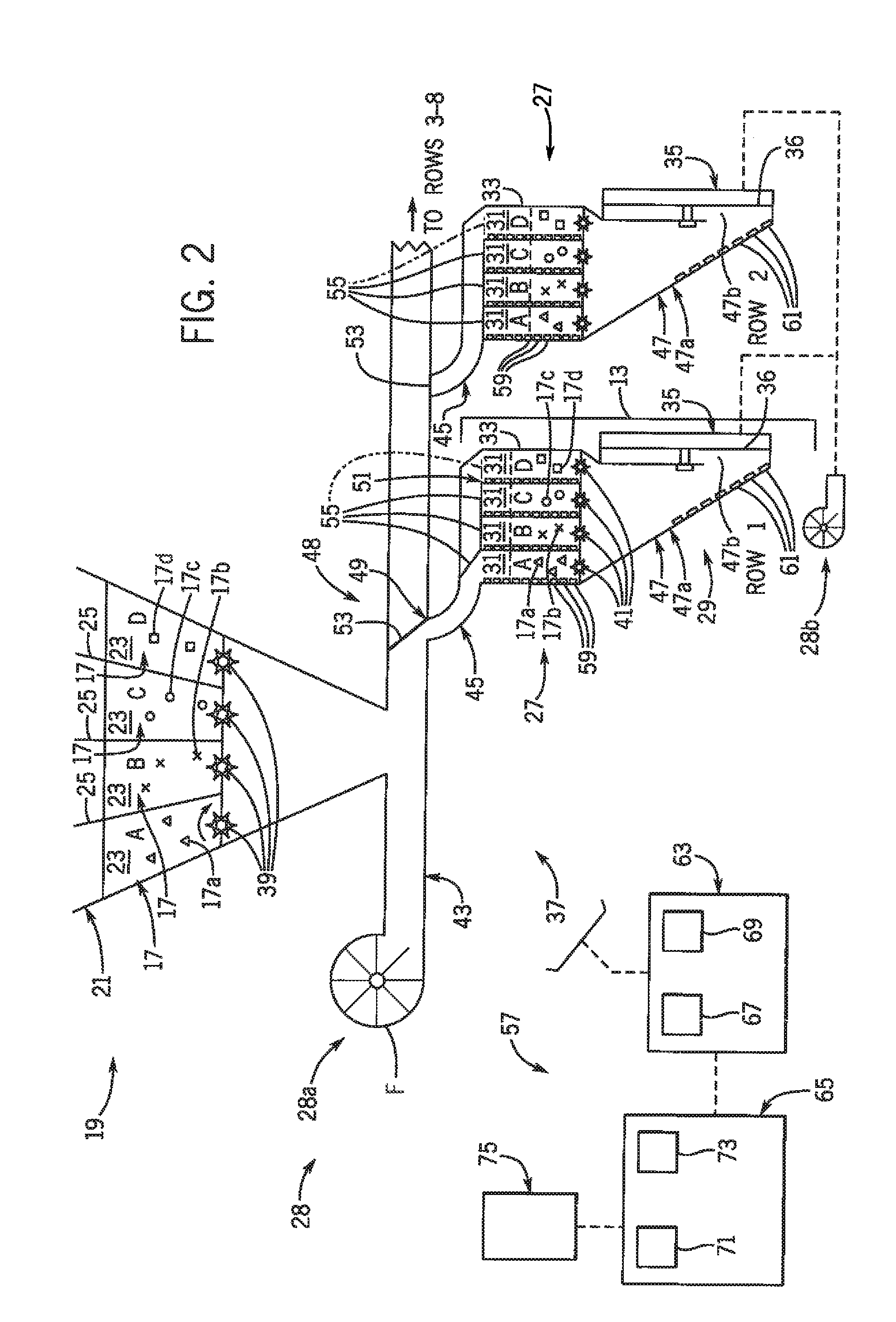

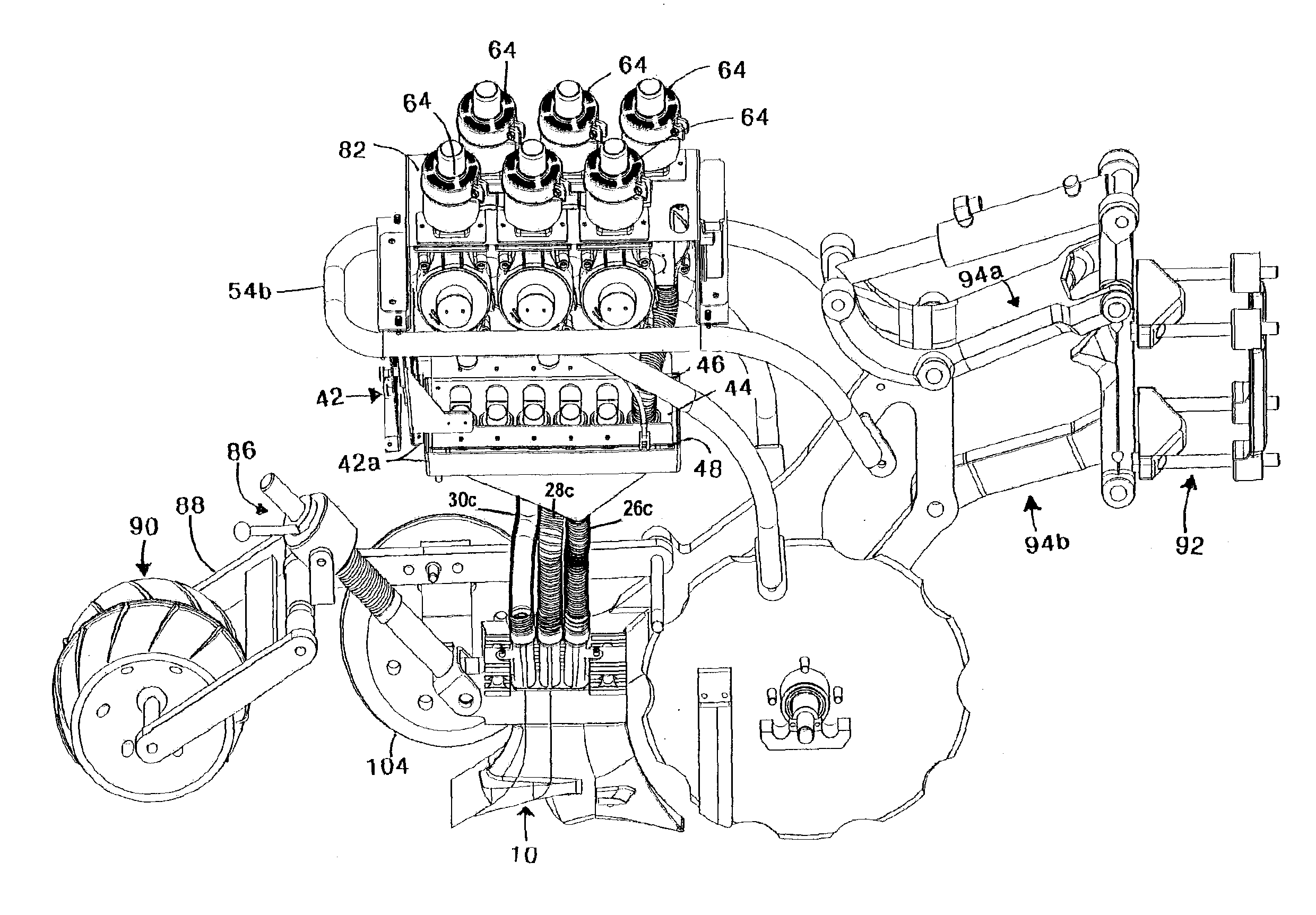

A system for variable-ratio blending of multiple agricultural products for delivery via a ported opener

ActiveUS20160113191A1Maximize efficiencyReduce wasteInstruments for road network navigationAnalogue computers for trafficMass storageEngineering

A system to meter multiple agricultural products according to an independently prescribed rate for each in a variable-ratio blend of the agricultural products from a single opener in a plurality of such systems and openers across an applicator such as a drill. Bulk storage compartments associated with the applicator deliver multiple agricultural products to metering assemblies mounted in clusters or pods across the applicator. The agricultural products are fed from the metering assemblies, via a flow re-director, into a manifold, and then into a corresponding single opener having conduits to transport the agricultural product into the soil. Controllers independently regulate metering by the metering assemblies. The flow re-director and manifold provide blending of combinations of the agricultural products for each opener according to a field prescription.

Owner:CLEAN SEED AGRI TECH

Apparatus and method for storing heat energy

ActiveUS8544275B2Simple designMore robustSolar heat devicesHeat storage plantsStored energyWorking fluid

Method and apparatus for storing heat in industrial systems where large sources of stored energy are called upon to meet a work load, storing the heat content of a hot working fluid by using the hot working fluid as a heat transfer fluid in vapor form and depositing its heat content on a heat storage medium and then removing the cooled and condensed liquid phase of that heat transfer fluid, and when hot working fluid again is needed, the liquid heat transfer fluid is returned to the heated storage medium and is reheated as it passes through the hot storage medium and then is returned to the working system to be used as a hot working fluid.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Multiple seed-type planting system with charging system

ActiveUS9603298B2Significant period of timeFully chargedFertilising methodsBroadcast seedersCropping systemEngineering

A system for planting multiple types of seed and automatically switching between the varieties during planting in a single planting pass of a planting session of row-crop or other planting of an agricultural field. The system may include a bulk storage system, an on-row storage system, and a charging system that selectively delivers seeds of different varieties from the bulk storage system to the on-row storage system. The system may include a seed metering system that can be controlled at each of multiple row units to selectively plant different types or varieties of seed based on seed type or variety zones agricultural field, which may correspond to field characteristics defined in a seed variety prescription map.

Owner:BLUE LEAF I P INC

Seed valve and planting method for multiple seed types

Owner:DEERE & CO

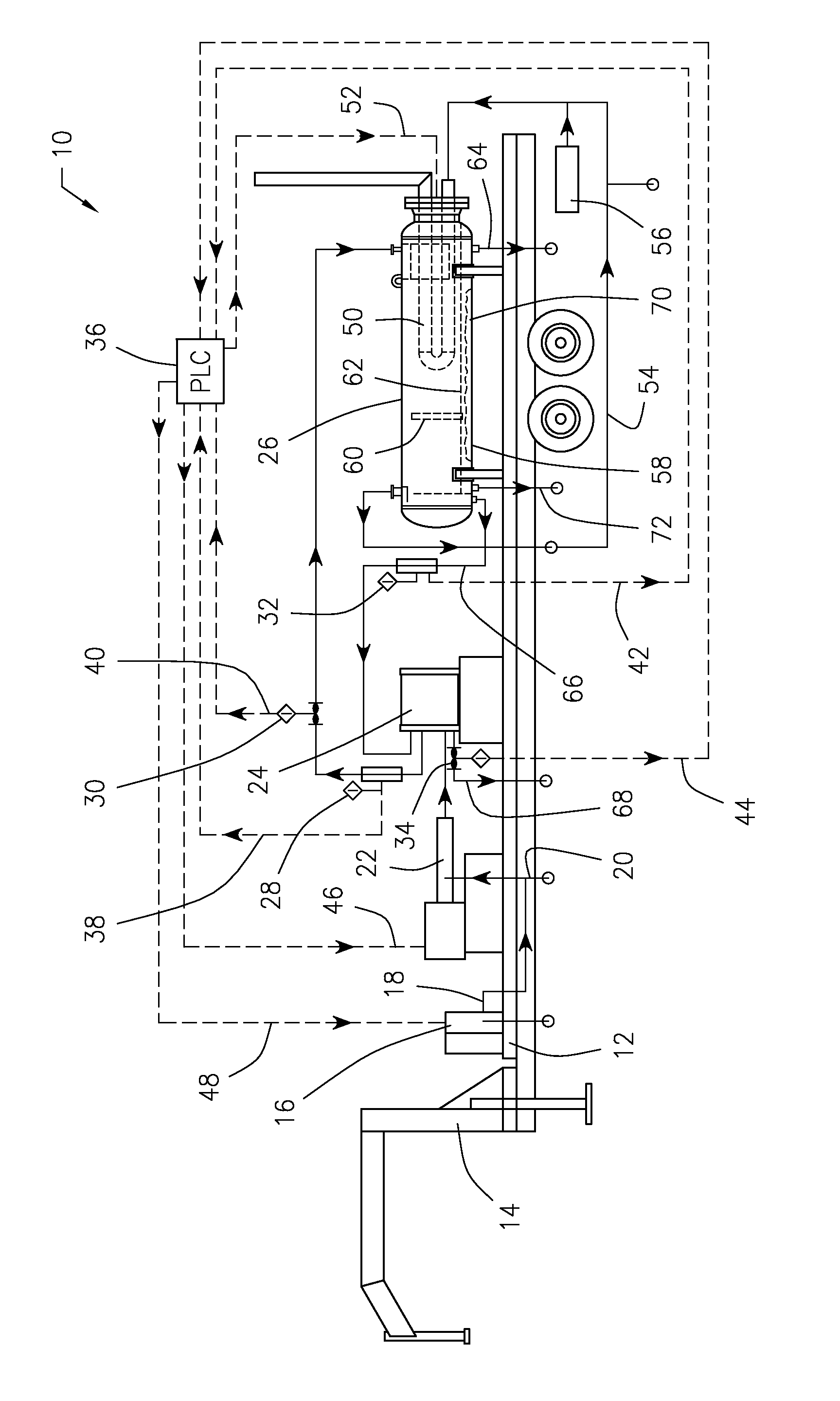

Local produced oil dehydrator

ActiveUS9157035B1Avoid necessityEasy to relocateDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDemulsifierSediment

A portable, semi-portable, or permanent system for removing BS&W from crude oil at the local production or bulk storage site. A demulsifier is added to the crude as it enters a low shear pump which pumps the mixture through a plate and frame type heat exchanger where the incoming crude is preheated using outgoing heated and dehydrated crude. Then the incoming crude enters an oil-water separator where it is further heated by a secondary heater within the separator and passes through a special coalescing section. Water and basic sediment separate from the crude are discharged from the bottom of the separator. The heated dehydrated crude exits the separator, flows back through the heat exchanger where it is cooled as it preheats incoming crude, and then is pumped to clean oil storage. BS&W and flow monitors on the incoming crude and outgoing crude are used to control operation of the system.

Owner:BREAKTHROUGH ENGENUITY LLC +1

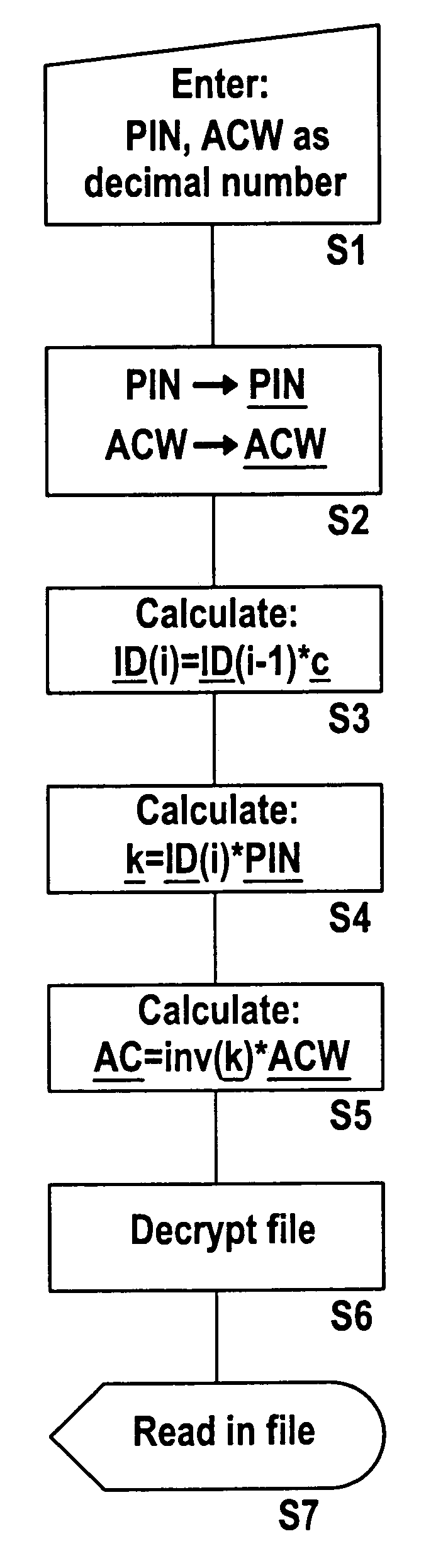

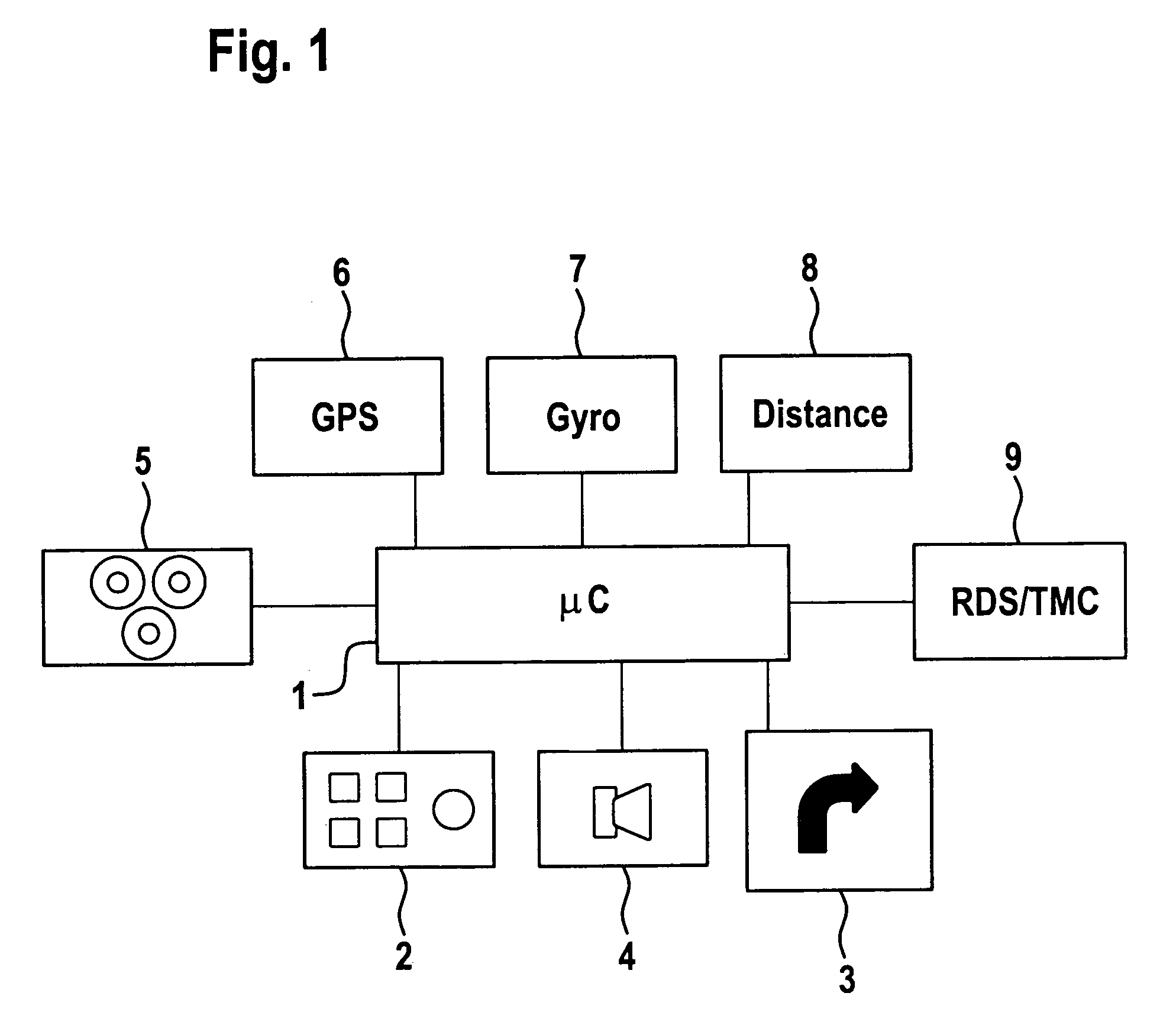

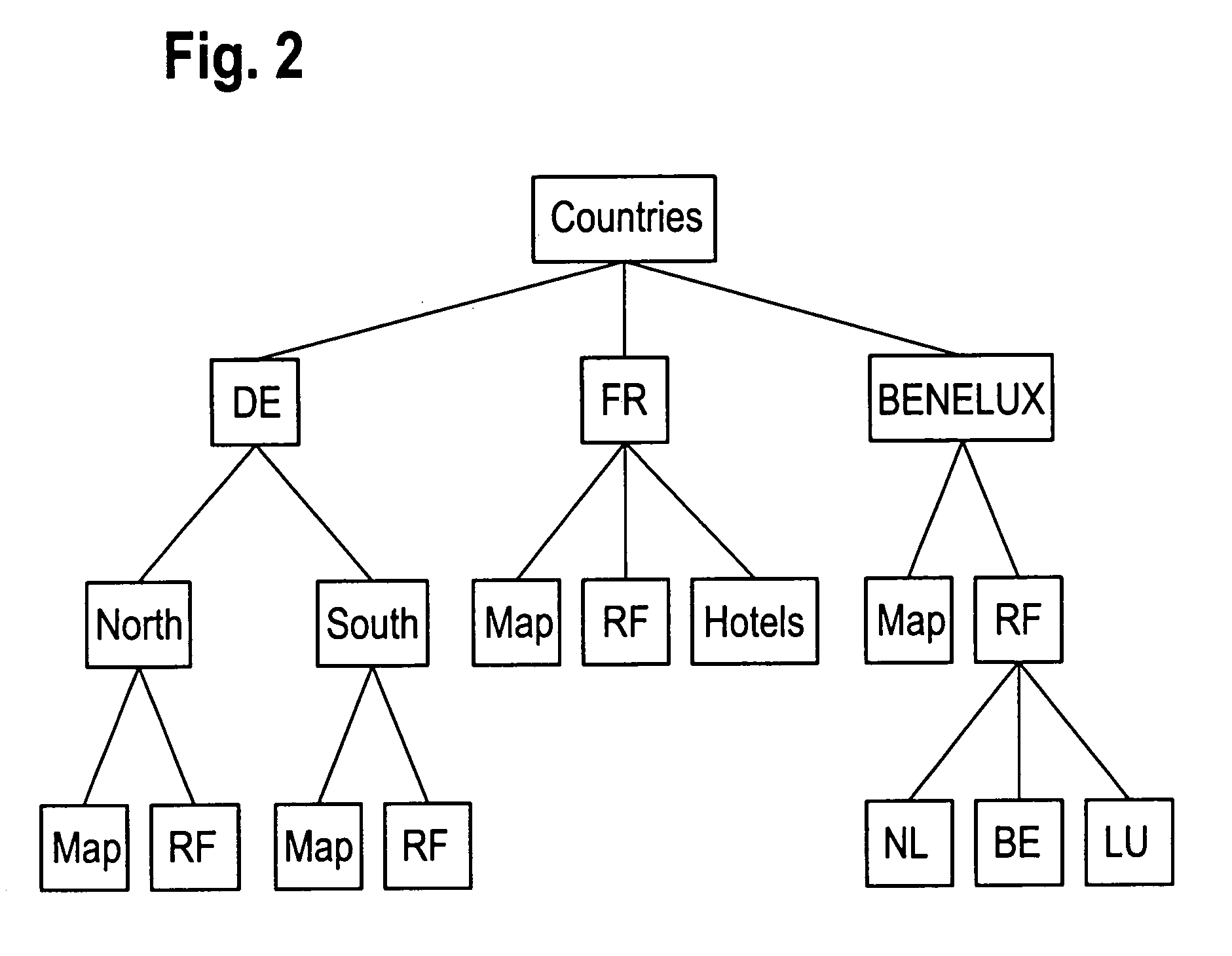

Motor vehicle navigation system having a protected storage medium

InactiveUS7185369B2Improve protectionUnauthorized useInstruments for road network navigationDigital data processing detailsMass storageMobile vehicle

The invention specifies a navigation or multimedia system in which a check is carried out to determine whether a user of files, such as roadmap data, is authorized to use these files. To this end, the navigation system has means for checking authorized use of files on the bulk storage medium on which the files are stored. The files are stored in encrypted form, in particular. In accordance with an inventive method for enabling the use rights on a file, provision is made for the user to enter a first and a second scrambled code (PIN and ACW) into the navigation system first. These codes are converted into vectors. A device identifier ID of the navigation system and the first scrambled code PIN are first used to calculate a key k. The key k and the second scrambled code ACW are used to calculate an access authorization identifier AC, which is compared with the access authorization identifiers for the files stored on the storage medium. If these identifiers match, the associated file is decrypted and enabled for use by the navigation system.

Owner:MANNESMANN VDO AG

A low temperature storage agent

InactiveCN102268240AHigh heat of solutionLarge volume heat storage densityHeat-exchange elementsFruits/vegetable preservation by freezing/coolingCold chainVolumetric Mass Density

The invention provides a low-temperature cold storage agent, which includes NaCl, NH4Cl, guar gum and water. The weight percentages of the above components are as follows: NaCl: 15%; NH4Cl: 8%; guar gum: 1%; water : 76%. When the low-temperature storage agent is prepared, first provide a container and a stirring rod, put 76% water in the container by weight; then put 15% NaCl and 8% NH4Cl in the water, and then slowly add 1% guar gum is stirred with a stirring bar at the same time until it is evenly stirred; the phase transition temperature of the low-temperature cold storage agent is -25° C., and the latent heat value is 275 (J / g). The invention has a wide application range, large heat of dissolution, high volume heat storage density, and is roughly neutral, and has the characteristics of low cost, non-toxic, harmless, green and environmentally friendly, and can prevent ice release, and is especially suitable as food and biological medicines. And cold storage agent for cold storage during cold chain transportation of vaccines.

Owner:GUANGZHOU SAINENG REFRIGERATION TECH

Vacuum pill dispensing cassette and counting machine

InactiveUS20080017661A1Lower requirementReduce air turbulenceRacksCoin-freed apparatus detailsEngineeringDispensing medications

Methods are disclosed for storing and dispensing medications. A medication storing and dispensing cassette is comprised of a housing defining at least a portion of a bulk storage chamber for storing a medication, defining at least a portion of a pick-up area, and defining at least a portion of a discharge chute sized to temporarily store a quantity of the medication. A divider wall is positioned between the bulk storage chamber and the pick-up area. A gate is positioned to control an exit end of the discharge chute. A rotatable conveying wheel having openings proximate to the periphery thereof is positioned such that a portion of the wheel is in communication with the pick-up area while another portion of the wheel is adjacent to an entrance end of the discharge chute. A calibration arm is positioned adjacent the openings of the rotatable wheel. A baffle is positioned to block those openings in that portion of the rotatable wheel adjacent to the discharge chute. An air agitation system is provided so that pills may be moved from the bulk storage chamber to the pick-up area. In one embodiment, air agitation is used to move pills from the bulk storage chamber to the pick-up area, for automatically setting the position of the calibration arm and for automatically learning the setting for the calibration arm for an unclassified medication.

Owner:MCKESSON AUTOMATION SYST

Dust Screen and Method for Dry Bulk Storage Units

Owner:MATSON INC

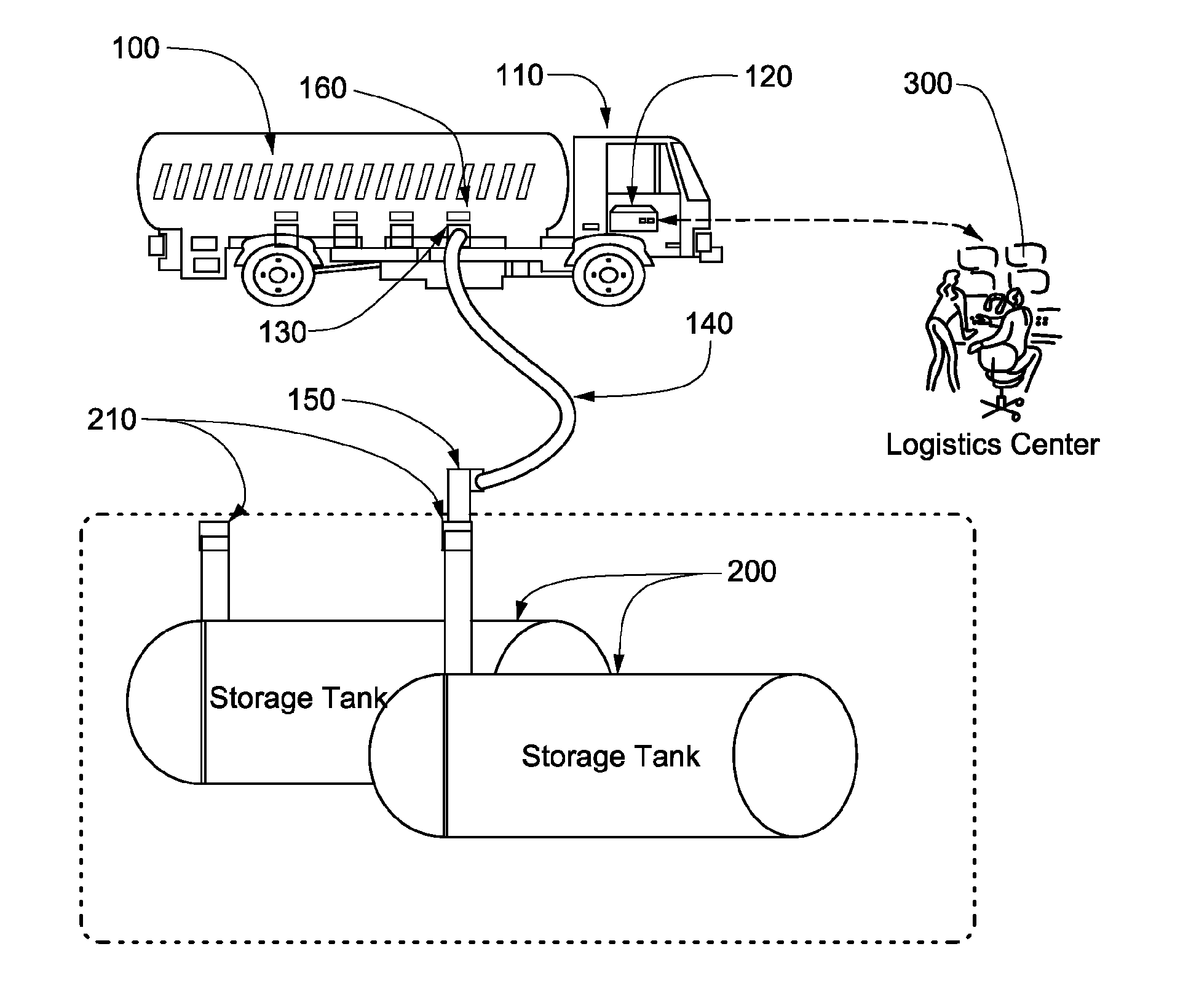

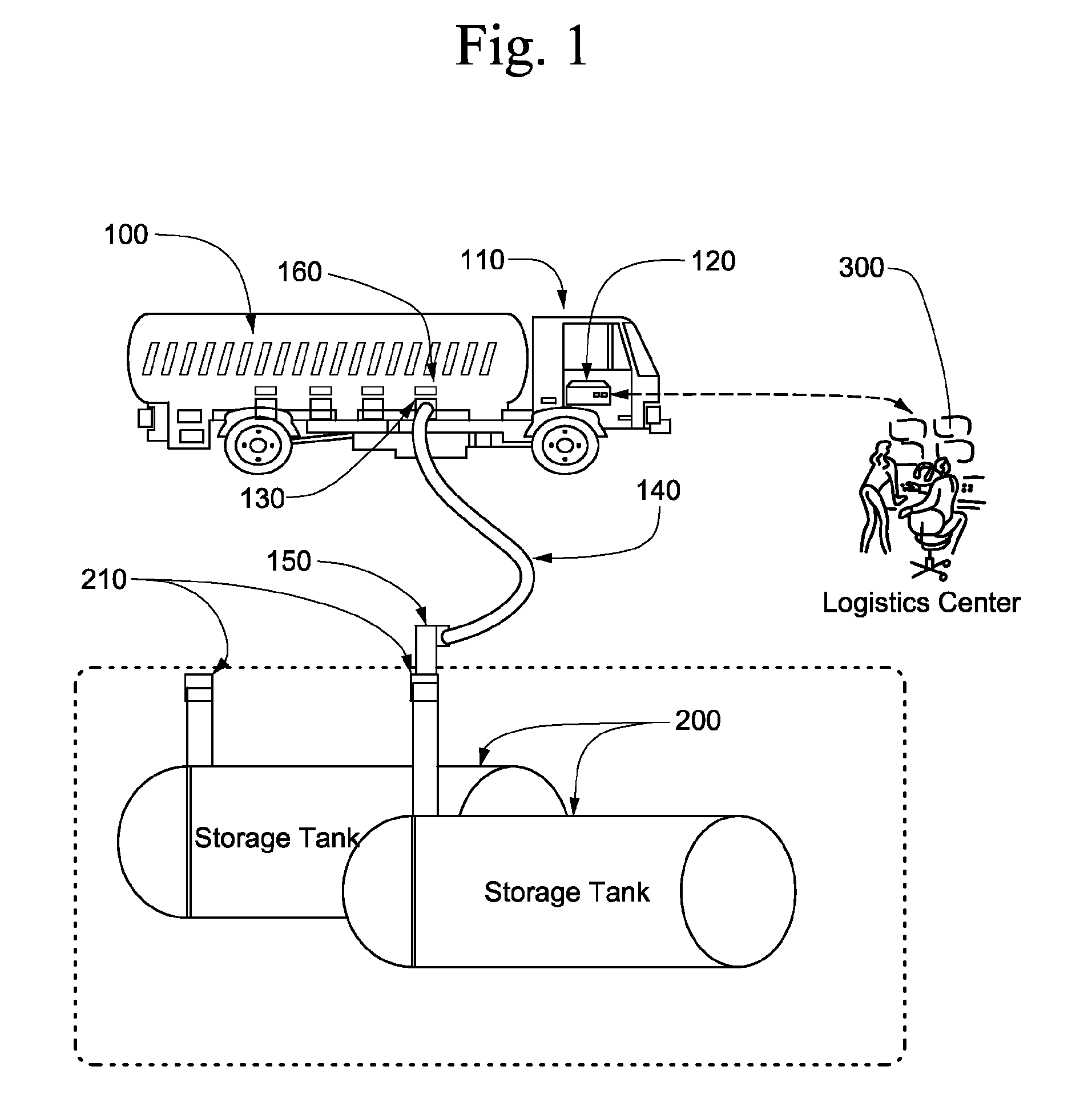

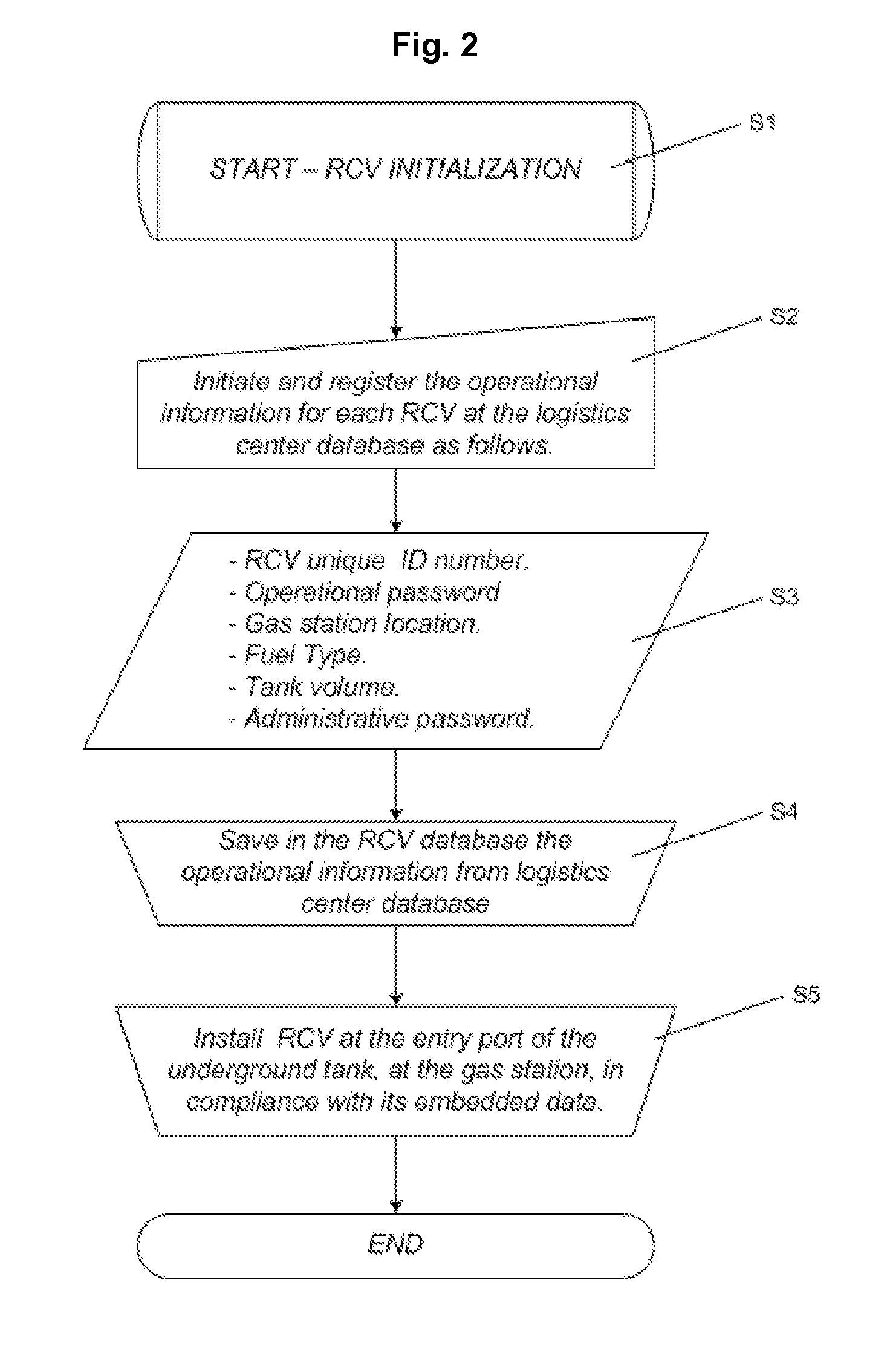

Securing product storage tanks against unauthorized delivery

ActiveUS20140316589A1Eliminating post factum investigationMinimized in sizeLiquid transferring devicesRatio controlRemote controlBiological activation

A system prevents unauthorized delivery of product to a bulk storage tank, allows authorized delivery, and controls the flow of product at a product entry port of the tank. A remote controlled valve includes a disk flap that is displaceable between an opened position and a closed position, and a disk displacement assembly including a motor coupled with the disk flap. The disk displacement assembly includes a lock feature that locks the disk flap in the opened position and the closed position. A controller is cooperable with the disk displacement assembly and controls activation of the motor. The disk displacement assembly includes a spring transmission assembly interposed between the motor and an axle of the disk flap. The spring transmission assembly permits displacement of the motor when the disk flap is blocked in the opened position or the closed position.

Owner:KNAPPCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com