Drying-free dry-mixed mortar complete equipment

A complete set of equipment, dry-mixed mortar technology, applied in the direction of clay preparation equipment, mixing operation control, mixing plant, etc., can solve the problems of harmful gas emissions, large energy, etc., and achieve the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

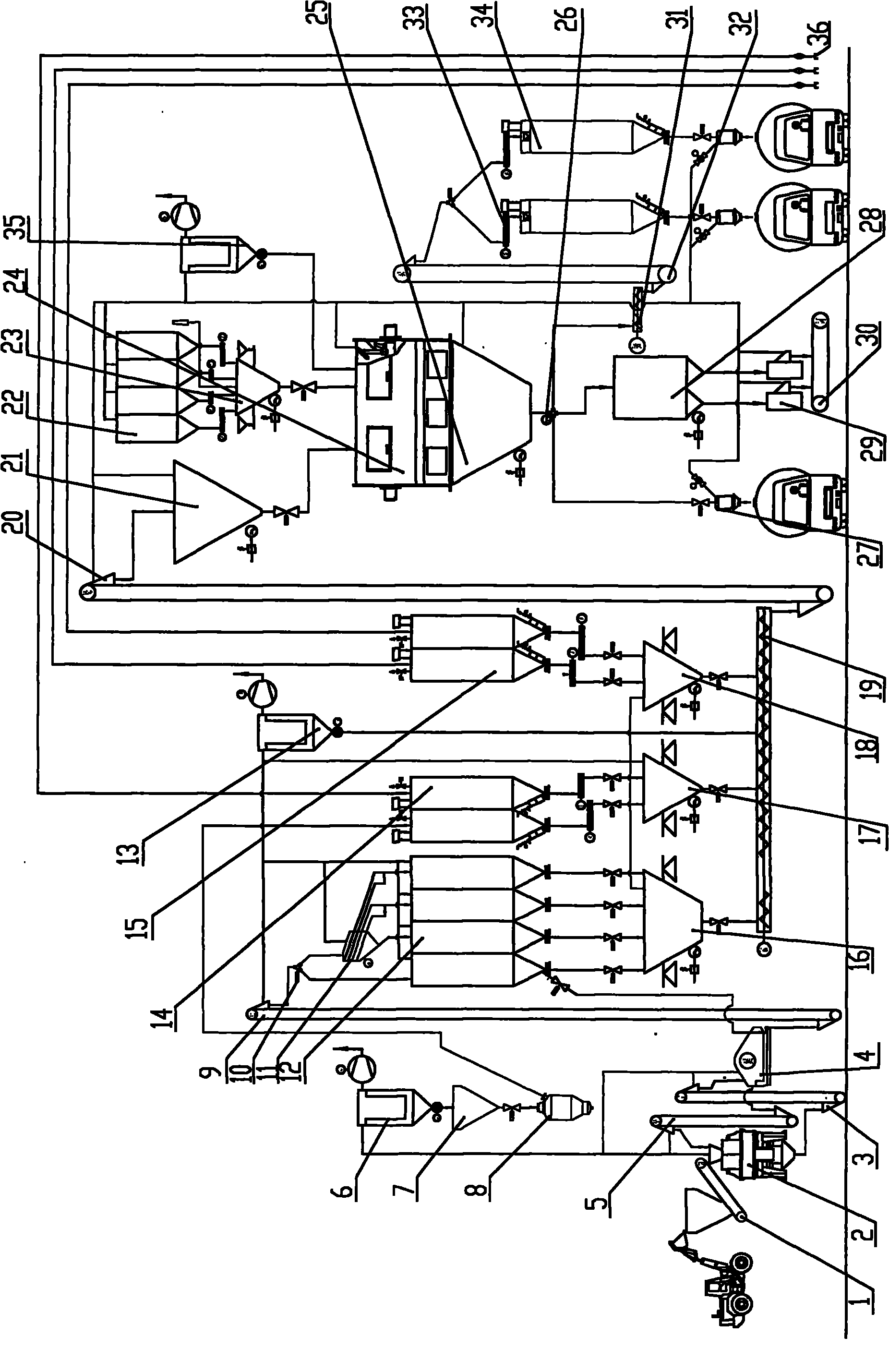

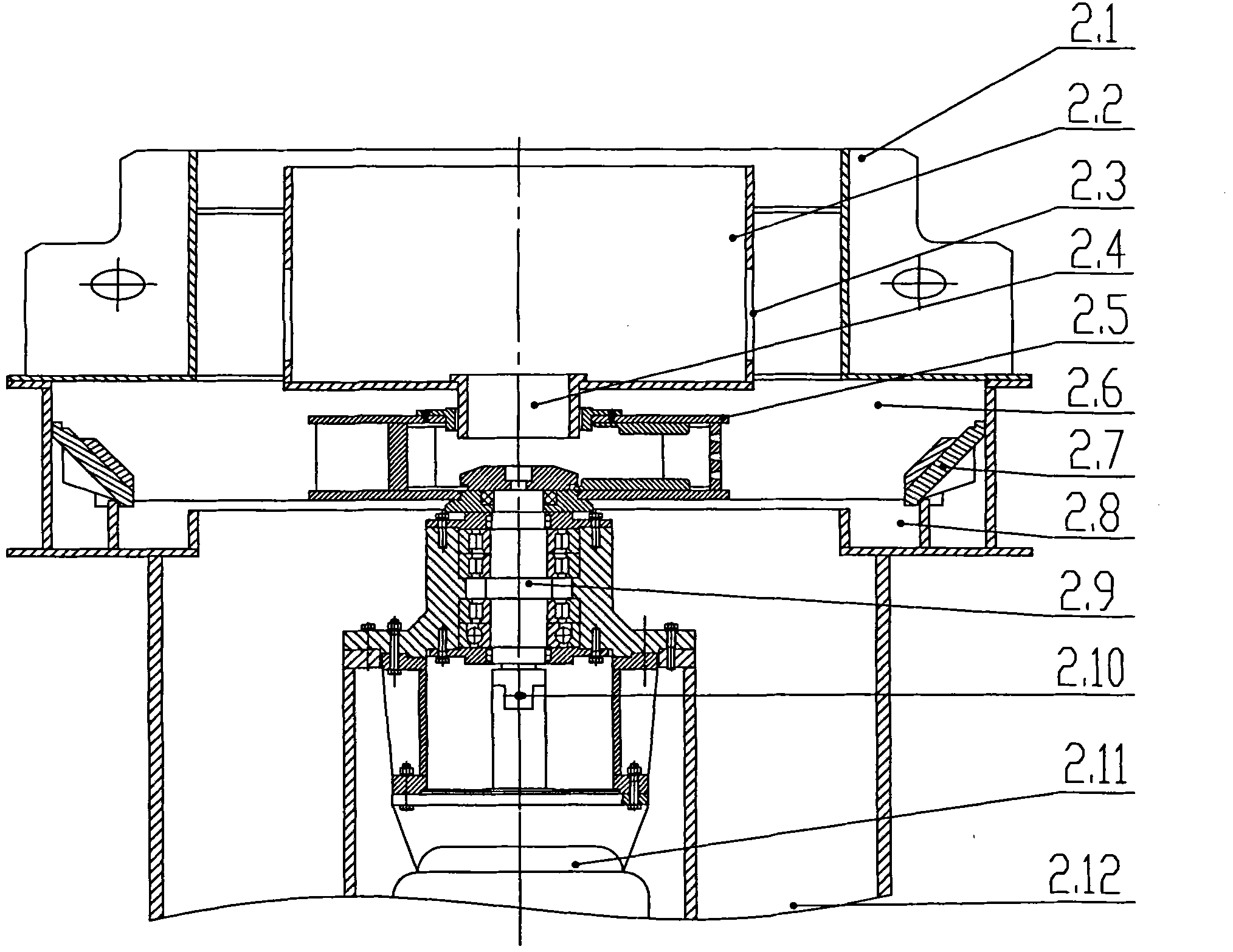

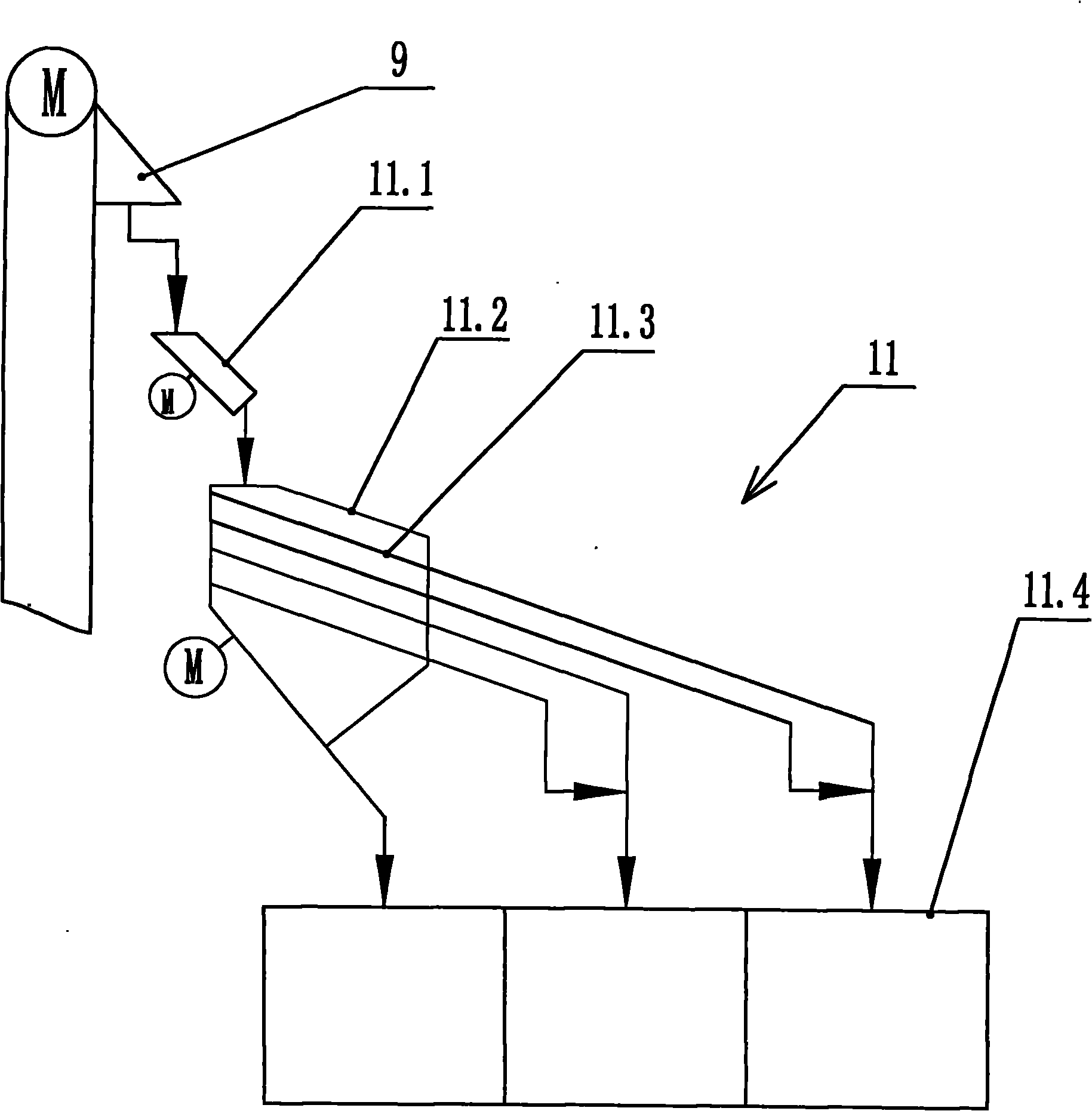

[0023] see figure 1 , figure 1 It is a schematic diagram of the overall structure of the complete set of equipment for drying-free dry-mixed mortar of the present invention. Depend on figure 1It can be seen that the dry-free dry-mixed mortar complete set of equipment of the present invention includes a feeding belt conveyor 1, a crushing sand making machine 2, a discharge bucket elevator 3, a circulating vibrating screen 4, a screening bucket elevator 9, and a three-way material distribution machine. Valve 10, vibrating screening machine 11, graded sand storage bin 12, return hopper elevator 5, stone powder dust collector 6, stone powder temporary storage bin 7, stone powder sending tank 8, stone powder adding silo 14, cement silo 15, feed transportation Pipe interface 36, sand batching metering device 16, additive batching metering device 17, cement batching metering device 18, metering material screw conveyor 19, metering hopper elevator 20, metering material intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com