All-component wide-distribution organic polyaldehyde tanning agent and preparation method thereof

A technology with multiple aldehyde groups and wide distribution, which is applied in the field of preparation of leather and fur tanning agents, can solve the problems of narrow molecular weight distribution, poor tanning performance, and affecting the comprehensive performance of leather, and achieve wide molecular weight distribution, improved tanning degree, and good cross-fertilization The effect of co-tanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

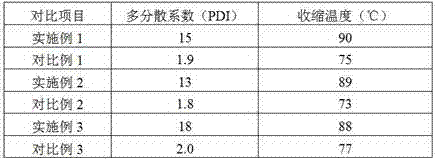

Embodiment 1

[0027] In parts by weight, 10 parts of sodium alginate and 10 parts of sodium periodate were added to 500 parts of water, the temperature of the system was controlled at 30°C, the pH was 9.5, and the aldehyde was stirred for 2 h in the dark to obtain a full-component, wide-distributed aldehyde Polysaccharide solution; add 12 parts of sodium bisulfite to the above solution, continue stirring and reacting for 10 min, reduce the iodine-containing compound to simple iodine, separate and recover solid iodine by filtration, heat-treat the filtrate at 100 °C for 1.5 h, and make the residual The iodine is evaporated in the form of vapor and absorbed and recovered with NaOH solution, and finally a polyaldehyde-based organic tanning agent with full components and wide distribution is obtained;

[0028] The weight-average molecular weight of the tanning agent is 18065 g / mol, the polydispersity coefficient is 15, and the aldehyde group content is 8.5 mmol / g;

[0029] In the drum, add 500%...

Embodiment 2

[0034] In parts by weight, 10 parts of taradin and 8 parts of sodium periodate were added to 200 parts of water, the temperature of the system was controlled at 20 ° C, the pH was 7.5, and the aldehyde was stirred for 4 h in the dark to obtain a full-component, wide-distributed aldehyde Polysaccharide solution; add 10 parts of sodium bisulfite to the above solution, continue stirring and reacting for 10 min, reduce the iodine-containing compound to simple iodine, separate and recover solid iodine by filtration, and heat-treat the filtrate at 95 °C for 1.5 h to make the residual The iodine is evaporated in the form of vapor and absorbed and recovered with NaOH solution, and finally a polyaldehyde-based organic tanning agent with full components and wide distribution is obtained;

[0035] The weight-average molecular weight of the tanning agent is 14870 g / mol, the polydispersity coefficient is 13, and the aldehyde group content is 8.0 mmol / g;

[0036] In the drum, add 500% water...

Embodiment 3

[0041] In parts by weight, 10 parts of sodium carboxymethylcellulose and 12 parts of sodium periodate were added to 400 parts of water, the temperature of the system was controlled at 10 °C, the pH was 9.5, and the mixture was stirred for 6 h in the dark to obtain the complete components, broad Aldehydated polysaccharide solution distributed; add 14 parts of sodium bisulfite to the above solution, continue stirring and reacting for 10 min, reduce the iodine-containing compound to simple iodine, separate and recover solid iodine by filtration, and heat-treat the filtrate at 100 °C for 2.0 h , the residual iodine is evaporated in the form of vapor and absorbed and recovered with NaOH solution, and finally a full-component, wide-distributed polyaldehyde-based organic tanning agent is obtained;

[0042] The weight-average molecular weight of the tanning agent is 4000 g / mol, the polydispersity coefficient is 18, and the aldehyde group content is 9.0 mmol / g;

[0043] Put the pickled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com