Patents

Literature

145results about How to "Increase shrinkage temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dual-purpose modification process for native breed sheepskin leather

InactiveCN102839236AHas softnessIncrease shrinkage temperatureTanning treatmentPre-tanning chemical treatmentExtensibilityWork in process

The invention discloses a dual-purpose modification process for native breed sheepskin leather. The process sequentially comprises the following steps of processing native breed sheepskin semi-finished products: (1) classifying skin; (2) returning water; (3) soaking; (4) softening; (5) pickling; (6) performing chromium aluminum tanning; (7) performing tanning post-processing; (8) performing chrome retanning; (9) performing chrome retanning before dyeing; and (10) dyeing. According to the dual purpose modification process, commercially available native breed semi-finished skin (namely white skin) is processed, and the native breed semi-finished skin is tanned by increasing aldehyde aluminum tanning particularly, so that the extensibility of the native breed sheepskin can be effectively improved, the problem of dyeing defects is solved, and the uniformity in the post dyeing is ensured. The dual purpose modification process is matched with other steps and appropriate additives, and each additive is added according to reasonable additive amount, so that the final products have good handfeeling, high tearing resistance and high fullness, and the quality of the native breed sheepskin leather is greatly improved.

Owner:桐乡市雄鹰皮草股份有限公司

Processing method of leather semi-finished product

InactiveCN102517407AIncrease elasticityImprove breathabilityTanning treatmentPre-tanning chemical treatmentIndustrial waste waterEconomic benefits

The invention relates to a processing method of a leather semi-finished product. The method comprises the steps of pre-soaking, main soaking, liming, washing, pre-deliming, deliming, softening, pickling, tanning and the like. By adjusting the processing technology and adopting proper auxiliaries, the method provided by the invention can reduce the chromium content in a chromium solution, remove barilla in lime pelt, eliminate scurf, and improve the elasticity, air permeability and smooth grain side of the leather. According to the invention, preparation is made for the tanning operation, the contraction temperature of leather can be increased, the heat / humidity resistance stability is high, and thus the leather is soft and full and has excellent corrosion resistance. The leather processing method provided by the invention uses a relatively small amount of water, generates little industrial waste water, is favorable for environmental protection, and has a relatively short technologicalperiod, low power consumption, low cost and relatively good economic benefits.

Owner:郑州科信化工有限公司

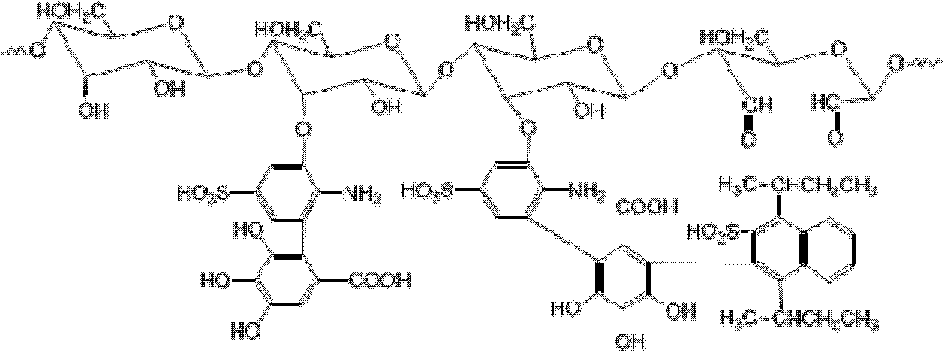

Method for preparing modified starch tanning agent

InactiveCN102020719AImprove absorption rateIncrease shrinkage temperatureTanning treatmentHigh absorptionGallic acid ester

The invention discloses a method for preparing a modified starch tanning agent, comprising the following steps of: firstly, degrading corn starch; in the presence of HRP (Horse Radish Peroxidase) / hydrogen peroxide (H2O2), grafting and modifying the degraded starch with sulfanilic acid, gallic acid and nekal; and then oxidizing the grafted starch with periodic acid. The invention has the innovation points that a nekal structure unit is introduced in the starch structure so as to improve the permeation wetting function of the modified starch tanning agent; the gallic acid structure unit is introduced to improve the tanning properties of the modified starch tanning agent, the sulfanilic acid is introduced to increase the dispersivity of the modified starch tanning agent, and dialdehyde action is used for improving the tanning properties of the modified starch tanning agent. The preparation method of the invention is peculiar and practical, and the obtained tanning agent is an environmentally-friendly leather tanning agent and is suitable for primary tanning and retanning. The shrinkage temperature (Ts) of pickled leather after primary tanning can be improved to 75-80 DEG C; and the retanned product has the advantages of wash resistance, high absorption rate on dyes and fatting agents and the like, is soft and plump.

Owner:SHAANXI UNIV OF SCI & TECH

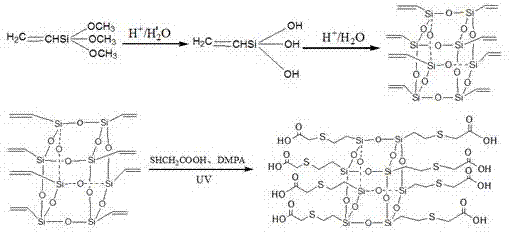

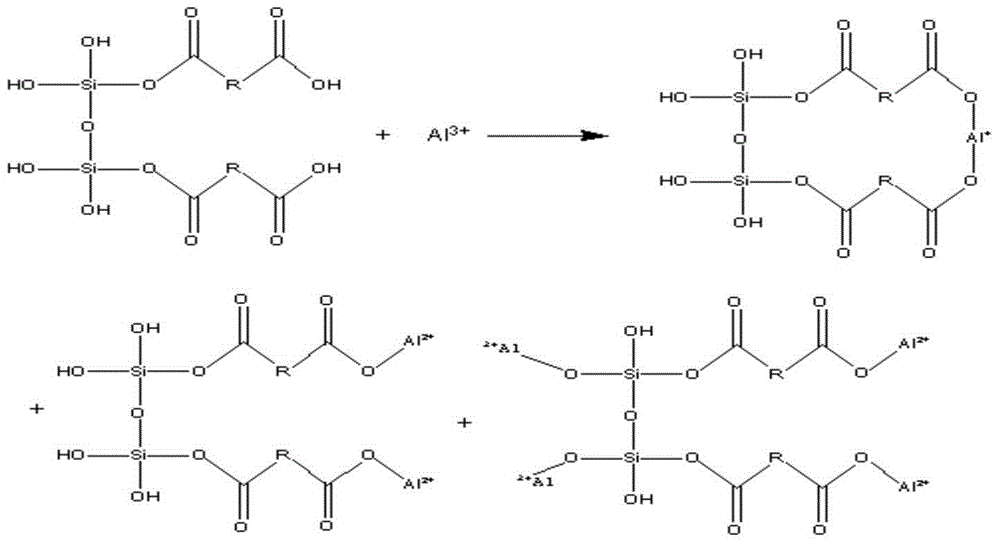

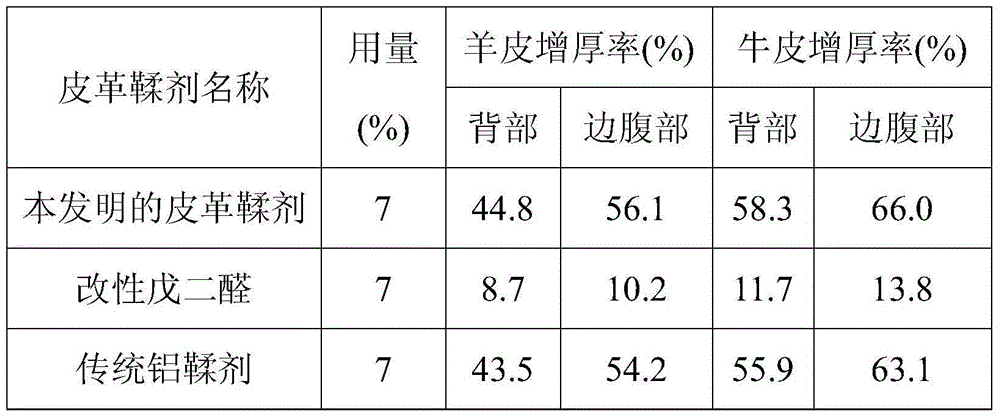

Water-soluble octacarboxyl silsesquioxane tanning agent prepared by mercaptan-alkene click chemistry process and method thereof

ActiveCN107345261AGood shrinkage temperatureIncrease shrinkage temperatureTanning treatmentSilanesClick chemistry

The invention relates to a water-soluble octacarboxyl silsesquioxane tanning agent prepared by mercaptan-alkene click chemistry process and a method thereof. The method comprises the following steps: firstly preparing octavinyl-polyhedral oligomeric silsesquioxane by using vinyl trimethoxy silane through a hydrolysis condensation method, then reacting octavinyl-polyhedral oligomeric silsesquioxane with mercaptoacetic acid under the condition with photoinitiators and irradiation of ultraviolet lamps to obtain the water-soluble octacarboxyl silsesquioxane tanning agent. The water-soluble octacarboxyl silsesquioxane tanning agent is high in yield and high in purity; the reaction process is easy to control and operate; the reaction time is short; the tanning agent has a certain tanning effect; when the tanning agent cooperating with 2% chromium powder is applied to a tanning process of pickled goat skin, the shrinkage temperature of the tanned crust leather is increased by 35 DEG C; the thickening rate reaches about 67%.

Owner:广州麦吉高分子新材料科技有限公司

Production technology for improving smoothness and fineness of grain surface of leather

ActiveCN108977593AImprove grainImprove grain flatnessTanning treatmentPre-tanning chemical treatmentTanninFineness

The invention relates to a technical field of tanning chemistry and engineering, and provides a production technology for improving the smoothness and fineness of the grain surface of leather. According to the production technology, the grain surface of the cow leather obtained through the production technology is smooth, fine, tiny in pores, attractive, elegant, high in product grade, good in physical and mechanical properties, soft and comfortable in hand feeling and good in resilience, and in addition, the production technology is simple and easy to realize, appropriate in production cost and suitable for mass production and use. The production technology for improving the smoothness and fineness of the grain surface of the leather sequentially comprises the following steps of carryingout splitting on limed hide, carrying out deliming, softening and pickling, carrying out tanning, carrying out wringing and shaving, carrying out softening, carrying out retannin, carrying out neutralizing, carrying out filling, carrying out greasing, carrying out overdyeing and carrying out post treatment, wherein the tanning process adopts an aluminum-contained multi-metal tanning agent and a chrome tanning agent for co-tanning, the retanning process adopts a liquid betel nut tannin extract, an aldehyde tanning agent, an amphoteric synthetic tanning agent and the aluminum-contained multi-metal tanning agent for retanning, and the filling process adopts a micromolecular acrylic resin retanning agent, a phenolic condensation compound, a naphthalene sulfonic acid condensation compound, a synthetic greasing agent, sulfonated natural oil and a plant tannin extract for filling.

Owner:XINGYE LEATHER TECH CO LTD

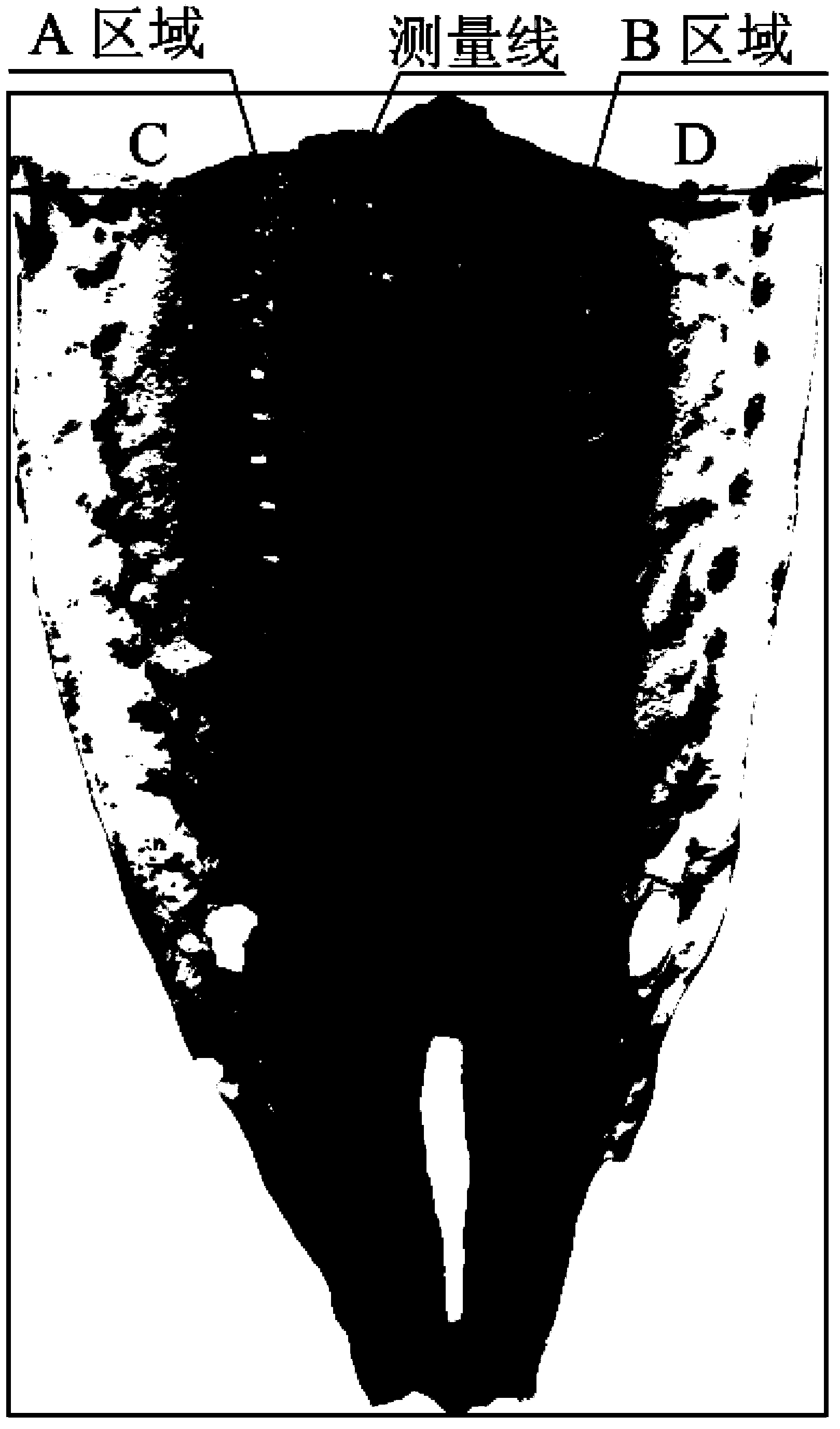

Environment-friendly leather-producing process by using sturgeon skins

InactiveCN103436643AFeel goodFine grainTanning treatmentPre-tanning chemical treatmentSturgeonSolvent degreasing

The invention relates to a leather-producing process, and specifically relates to an environment-friendly leather-producing process by using waste sturgeon skins in a food processing process of artificially cultured sturgeons. The leather-producing process comprises the following steps of 1) group batching the sturgeon skins; 2) washing; 3) soaking; 4) liming; 5) washing; 6) deliming; 7) bating; 8) washing; 9) pickling; 10) neutralizing; 11) oxidation bleaching; 12) reduction bleaching; 13) washing; 14) dealkalizing; 15) washing: washing the dealkalized sturgeon skins with water; 16) repeat pickling; 17) tanning; 18) re-tanning; 19) drying; 20) trimming; 21) buffing; 22) solvent degreasing; 23), spin-drying; 24), drying; 25), rewetting; 26), re-tanning; 27), dyeing; 28) drying; 29) buffing; 30) finishing: spraying a coating agent on the buffed leather to obtain sturgeon leather. The sturgeon leather produced by the process has the advantages of softness, fullness, non-harsh handfeel and fine grains. The process is environment-friendly.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for manufacturing environment-friendly ecological tanned lamb skin

ActiveCN104673943APollution hasReduce pollutionTanning treatmentPre-tanning chemical treatmentBiotechnologyBiochemical engineering

The invention discloses a method for manufacturing environment-friendly ecological tanned lamb skin. The method comprises the following steps: firstly, soaking a raw material lamb skin into water, adding degreasant and sodium carbonate in the soaking process, and removing hair and meat in the water soaking process; putting the lamb skin in water, adding degreasant and sodium carbonate for soaking and removing fat, and removing meat for the second time; putting into water for the second time to soften the lamb skin and removing fur and meat; pickling and softening, and taking out the skin and standing still for two days; tanning, taking out and standing still for two days; performing primary treatment, putting into water, adding syntans, a fatting agent and formic acid, soaking, taking out, standing for one day, performing oxidation washing and reduction bleaching, and finally finishing, thus obtaining a product. When tanned lamb skin is manufactured by using the method, environment pollution can be reduced and relevant maintenance expense for wastewater treatment and the like can be reduced, so that the production cost can be reduced and moreover the manufactured product is excellent in property.

Owner:济源澳吉尔商贸有限公司

Preparation method of modified Chinese gall tanning extract environmentally-friendly leather tanning agent

The invention relates to a preparation method of a modified Chinese gall tanning extract environmentally-friendly leather tanning agent. Graft modification is performed on a Chinese gall tanning extract with p-hydroxy benzenyl sulfonate sodium and nekal under the catalytic action of horseradish peroxidase / H2O2 so as to obtain the environmentally-friendly leather tanning agent. The nekal is introduced into the leather tanning agent, so that the dissolubility of the Chinese gall tanning extract and the penetrability of the Chinese gall tanning extract in a leather fiber can be improved remarkably; and the p-hydroxy benzenyl sulfonate sodium is introduced, so that the tanning effect of the Chinese gall tanning extract can be enhanced. When the modified Chinese gall tanning extract related bythe invention is applied to major tanning, the shrinkage temperature can be raised to be 70 and 75 DEG C and leather thickening effect is remarkable; when the Chinese gall tanning extract is applied to retanning, the Chinese gall tanning extract has high seepage velocity, the leather body of finished leather is full, has moderate elasticity and fine grain surface, and incision fibers have high dispersibility and light colors; and the product is beneficial to the realization of environmentally-friendly leather production and plays a positive role in reducing pollution caused by leather tanning.

Owner:南通安广美术图案设计有限公司

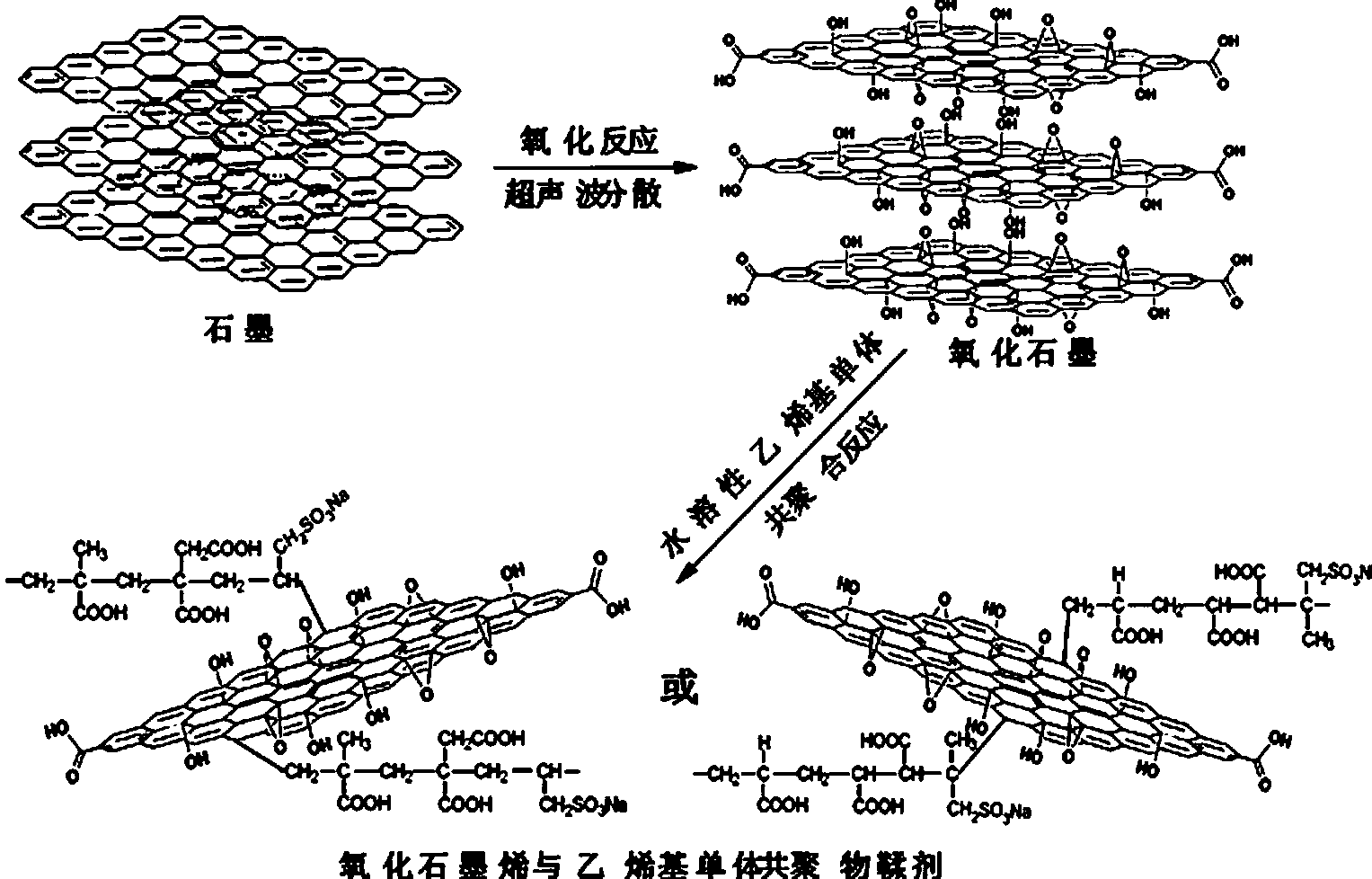

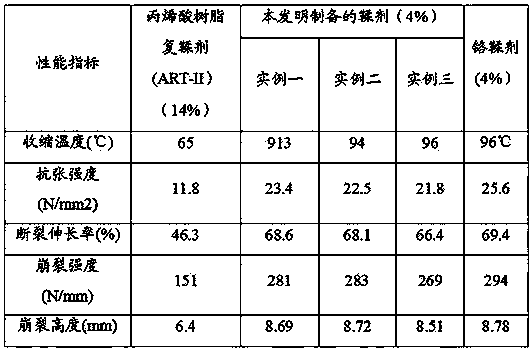

Oxidized graphene and water-soluble vinyl monomer copolymerized leather tanning agent and preparation method thereof

The invention discloses an oxidized graphene and water-soluble vinyl monomer copolymerized leather tanning agent. The leather tanning agent is prepared from the following raw materials in parts by weight: 20-30 parts of oxidized graphene nanosheet dispersion liquid, 0.5-1 part of an oxidizing agent, 60-80 parts of a monomer mixed solution, and 20-30 parts of an initiator. The invention further discloses a preparation method of the oxidized graphene and water-soluble vinyl monomer copolymerized leather tanning agent. The preparation method adopts the water-solution free radical polymerization reaction to implement the free radical copolymerization reaction for double bonds in the oxidized graphene structure and the water-soluble vinyl monomer, so that the obtained copolymer both comprises the oxidized graphene nanosheet and the water-based vinyl structural unit; furthermore, the size of the oxidized graphene nanosheet can be reduced and the distribution can be more uniform, and the tanning agent can generate the chemical bond function and the nanometer size effect after the tanning agent permeates the leather collagenous fibers, so as to obtain the tanning effect on the leather fibers; the tanning agent can serve as the leather tanning agent separately.

Owner:苏州盛泽科技创业园发展有限公司

Transparent leather and preparation method thereof

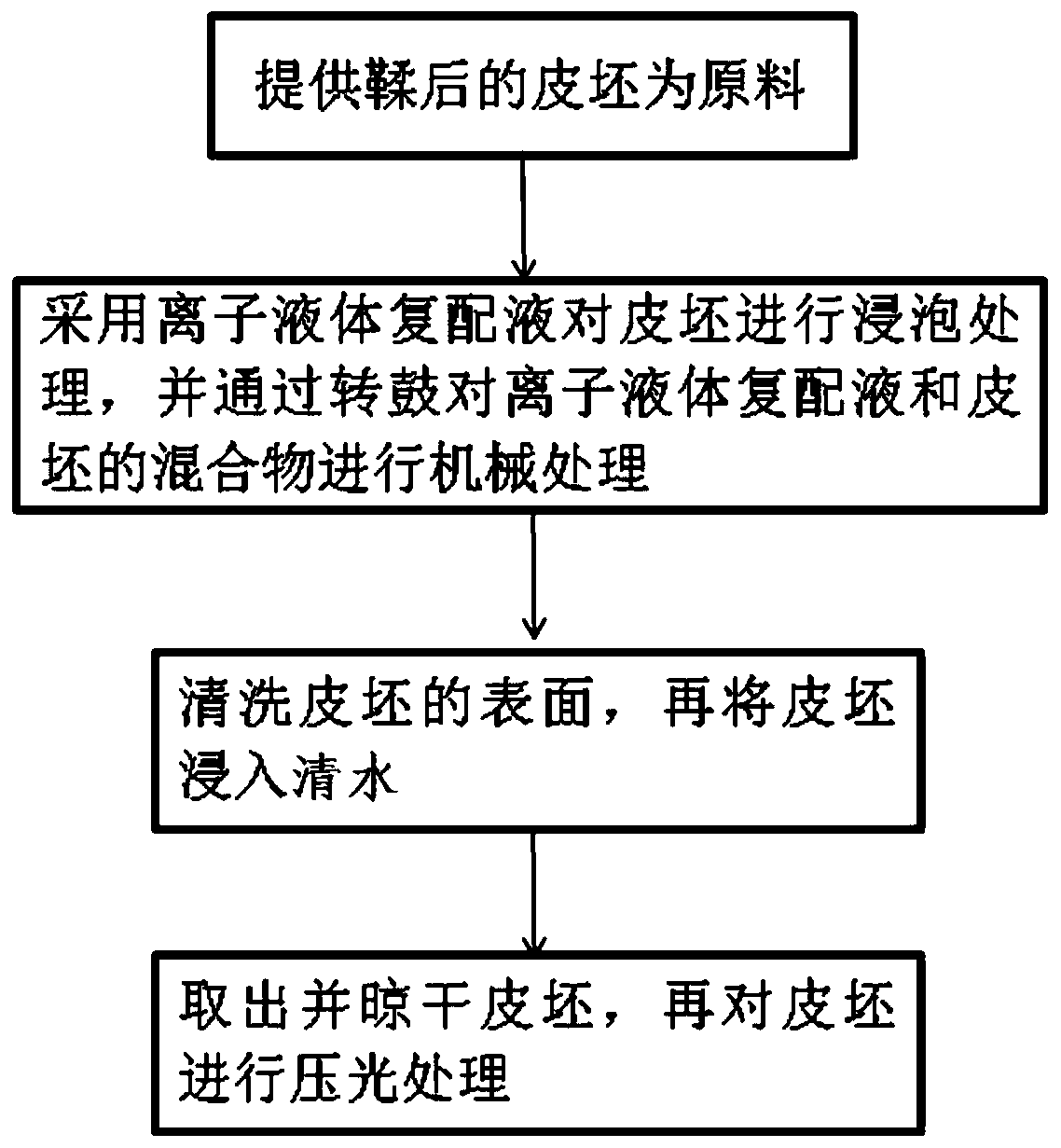

ActiveCN110184398AIncrease shrinkage temperatureKeep natural propertiesLeather/skins/hides/pelt chemical treatment apparatusLeather surface mechanical treatmentIonic liquidRaw material

The invention relates to transparent leather, wherein transparency of the transparent leather is 46-74%, the shrinkage temperature is 90-110 DEG C, and the thickness is 0.4-1.4 mm. The invention further provides a preparation method of the transparent leather. The preparation method comprises the following steps: providing a tanned leather blank as a raw material; carrying out immersion treatmenton the leather blank by adopting an ionic liquid compound liquid, and carrying out mechanical treatment on the mixture of the ionic liquid compound liquid and the leather blank through a rotary drum;cleaning the surface of the leather blank, and then soaking the leather blank into clear water; and taking out the leather blank, airing the leather blank, and then carrying out calendering treatmenton the leather blank.

Owner:浙江通天星集团股份有限公司

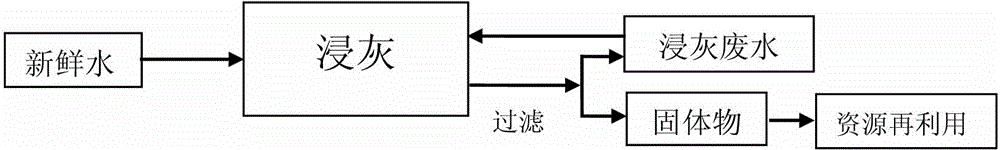

Ashless (or less-ash) liming unhairing process by recycling waste lime liquor indefinitely

ActiveCN102534055AEliminate serious pollution problemsPromote expansionPre-tanning chemical treatmentEnvironmental engineeringEnvironmental protection

The invention provides an ashless (or less-ash) liming unhairing process by recycling waste lime liquor indefinitely, which is characterized in that all waste liquor can be recycled indefinitely, and a liming effect is better than that in a conventional process. Use quantity of lime and other liming materials is greatly reduced, 50%-100% of lime is saved, and 40%-60% of other relevant materials are saved.

Owner:宝斯卡(商丘)化工有限公司

Tanning method by using improved-structure chromium-free retanning agent

InactiveCN104561396AAvoid pollutionIncrease shrinkage temperatureTanning treatmentChromium freeAfter treatment

The invention relates to a tanning method by using an improved-structure chromium-free retanning agent, belonging to the technical field of leather treatment. In order to overcome the defects of severe chromium pollution, low shrinkage temperature and low setting point in the retanning process, the invention provides a tanning method by using an improved-structure chromium-free retanning agent. The method comprises the following steps: adding shaving leather into a rotating drum, adding 100-150 wt% of water, regulating the temperature to 25-30 DEG C, adding 1.5-2.0 wt% of coordination polymerization inhibitor, and rotating for 10-30 minutes; regulating the pH value of the bath to at most 3.5, and rotating for 60-90 minutes; adding 1.0-2.0 wt% of tanning-assisting tannin, and rotating for 90-120 minutes; adding a non-chromium metal composite tanning agent and 0.2-0.4 wt% of alkali extractor to perform alkali extraction; and heating to 38-40 DEG C to perform treatment, and carrying out after-treatment to obtain the finished leather product. The tanning agent has the advantages of high setting point and high shrinkage temperature; and the method effectively controls the total chromium content in the wastewater and sludge.

Owner:海宁瑞星皮革有限公司

Ecological bating method

This invention provides an ecological tanning method. The method comprises: pre-tanning with aldehyde tanning agent, tanning with tetrahydroxymethyl phosphonium salt, and then adding collagen to enhance the bonding of the tanning agents. The method utilizes the reaction among aldehyde tanning agent, tetrahydroxymethyl phosphonium salt and collagen to enhance the bonding of the tanning agents as well as increase the shinkage temperature. Besides, the addition of collagen can improve the comprehensive properties of leather and reduce the aldehyde content in leather. The method can be used to replace chrome tannage, thus can avoid the harm of chrome salt to human body and environment.

Owner:XUZHOU XINGNING LEATHER CO LTD

Tanning method for tanning sheepskin clothing leather by hyperbranched polymer-aluminum salt tanning agent

InactiveCN103060490AIncrease shrinkage temperatureHas a tanning effectTanning treatmentPre-tanning chemical treatmentPolymer scienceMeth-

The invention relates to a tanning method for tanning sheepskin clothing leather by a hyperbranched polymer-aluminum salt tanning agent. Current chrome free tanning agents cannot completely replace chrome tanning agents for realizing better anti-hydrothermal stability of leather. The tanning method provided by the invention comprises the following steps of: pre-treating; pickling; tanning; degreasing; retanning; neutralizing; filling; oiling and drying acidic leather. The preparation method of the hyperbranched polymer-aluminum salt tanning agent used in the tanning process comprises the following steps of: mixing diethanol amine and methyl acrylate, and adding methanol to obtain an AB2 type monomer; carrying out reaction of the AB2 type monomer with trimethylolpropane, and adding para-toluenesulfonic acid for temperature rising reaction to prepare hydroxyl-terminated hyperbranched polymer; carrying out reaction of the hydroxyl-terminated hyperbranched polymer with maleic anhydride, adding para-toluenesulfonic acid to prepare an intermediate of an aqueous liquor of the hydroxyl-terminated hyperbranched polymer, and mixing and reacting the intermediate aqueous liquor with analytically pure analytically pure at normal temperature to obtain the hyperbranched polymer-aluminum salt tanning agent. The method provided by the invention is higher in shrinkage temperature and can replace the conventional chrome tanning method, so that chrome tanning pollution is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

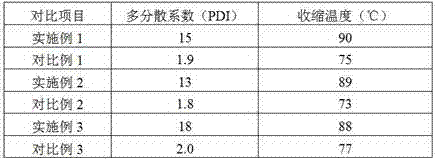

All-component wide-distribution organic polyaldehyde tanning agent and preparation method thereof

ActiveCN107217116AExcellent tanning performanceDoes not reduce tannabilityTanning treatmentPre-tanning chemical treatmentIodideIodine

The invention relates to an all-component wide-distribution organic polyaldehyde tanning agent and a preparation method thereof. The preparation method is characterized in that firstly, periodate is utilized to perform hydroformylation on polysaccharide and derivatives thereof under a proper condition, so as to retain all components of hydroformylated polysaccharide; secondly, an inorganic reducing agent is utilized to efficiently convert an iodine-containing compound into solid molecular iodine, and the solid molecular iodine is filtered and recycled; and finally, the hydroformylation product filtrate is subjected to heat treatment, so that the residual iodide is separated out in the form of steam, further absorbed by a NaOH solution and recycled, and the all-component wide-distribution organic polyaldehyde tanning agent is obtained. According to the all-component wide-distribution organic polyaldehyde tanning agent and the preparation method thereof, the technical problems that the conventional hydroformylated polysaccharide tanning agent is too narrow in molecular weight distribution and poor in tanning property, or contains the iodine-containing compound and affects the overall performance of leather after tanning are solved; besides, the prepared tanning agent retains all components of hydroformylated polysaccharide, the molecular weight distribution is wide, the shrinkage temperature of leather / fur after tannage can reach 85-90 DEG C, and the treated leather is pure white, full and soft.

Owner:SICHUAN UNIV +1

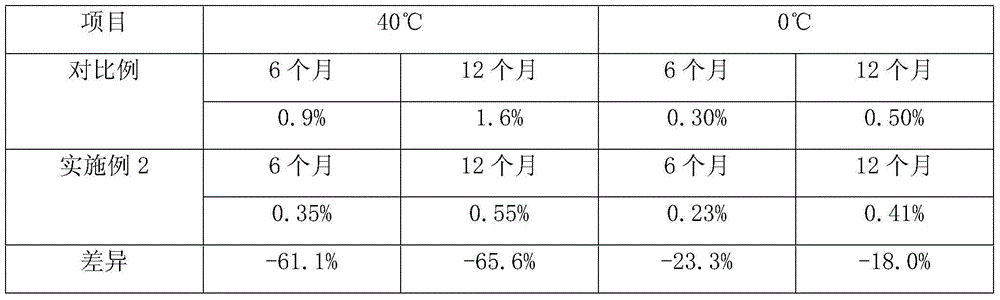

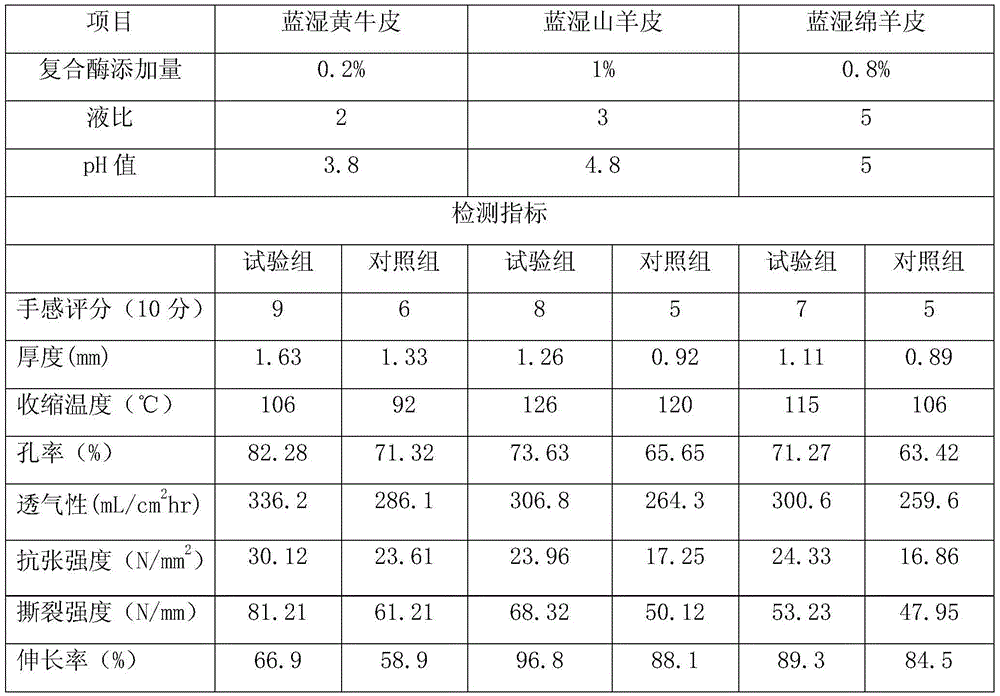

Leather softening compound enzyme with acid proteases and method for preparing leather softening compound enzyme

InactiveCN105524906AEnsure food safetyIncrease profitHydrolasesPre-tanning chemical treatmentPorosityAntioxidant

The invention discloses a leather softening compound enzyme with acid proteases and a method for preparing the leather softening compound enzyme. The leather softening compound enzyme and the method have the advantages that the leather softening compound enzyme is mainly made of the high-activity acid proteases with abundant plant proteases and microorganism proteases, mould culture, acid lipase, non-ionic surfactants, plant extract, antioxidants, protective agents, activators and the like are scientifically compounded, accordingly, the compound enzyme is provided with complete enzyme systems, is stable in activity and high in efficacy, permeability and degreasing capacity and can act mildly and moderately, the hand feel and physical and mechanical properties of crust leather can be obviously improved, the bare weight of the crust leather can be obviously increased, and the shrinkage temperatures of the crust leather of raw hide of wet-blue leather of different animals can be increased by 9-14 DEG C; the porosity of the crust leather can be improved by 7.85-10.96%; the breathability of the crust leather can be improved by 41.0-50.1 mL / cm<2>hr; the tensile strength of the crust leather can be improved by 6.51-7.47 N / mm<2>; the tear strength of the crust leather can be improved by 5.28-20 N / mm; the elongation of the crust leather can be improved by 4.8-8.7%; the quality of products can be greatly improved, and the production cost can be reduced.

Owner:湖南新鸿鹰生物工程有限公司

Method for producing transparent leather based on organic tanning agent

ActiveCN112322806AIncrease shrinkage temperatureGood chemical resistanceTanning treatmentLeather surface finishingPolyolPulp and paper industry

A method for producing transparent leather based on an organic tanning agent is characterized by comprising the steps of firstly, using the organic tanning agent in a rotary drum for tanning deashed and softened bare leather, wherein the tanning liquid ratio is 60-100%, the temperature is 25-40 DEG C, and the total rotating time is 4-8 h; after tanning is completed, completely discharging tanningwaste liquid, adding water accounting for 100% of the mass of the deashed and softened bare leather and a proper amount of polyhydric alcohol, and conducting rotating for 2-6 hours at the temperatureof 25-35 DEG C; then adding acid substances in two times, conducting rotating for 0.5-2 h after each time of adding, and adjusting the pH value of the bath lotion to 3.5-4.5; and finally, conducting toggle drying on the leather subjected to the above operation until the moisture content is lower than 20%, thereby completing the production of the transparent leather. According to the transparent leather production method, the organic tanning agent is used in the production process, the shrinkage temperature, chemical resistance and microbial degradation resistance of the leather can be improved, meanwhile, the obtained transparent leather retains the natural color, the operation process in the production process is simple, and the used chemical materials are wide in source, small in toxic and side effect and high in practicability.

Owner:SICHUAN UNIV +1

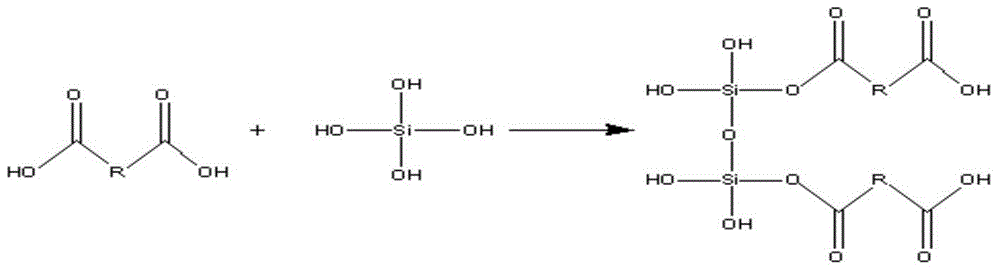

Chromium-free tanning agent and preparation method thereof

ActiveCN103980304AIncrease shrinkage temperatureFine and firm grainSilicon organic compoundsTanning treatmentSolventOrganic acid

Disclosed is a preparation method of a chromium-free tanning agent. The preparation method includes following steps: adding a mixed solution into a solution and carrying out an acidification reaction with stirring to prepare a silicic acid solution, wherein the mixed solution contains a silicon-containing compound and a solvent and the solution is a mixture of an inorganic acid, an organic acid and a solvent, dissolving an aluminium-containing compound and adding the aluminium-containing compound to the prepared silicic acid solution, carrying out a spray drying process to obtain a white powdery chromium-free tanning agent product and drying and preserving the product. The tanning agent is free of harmful substances such as hexavalent chromium, formaldehyde and the like, is excellent in environmental-friendly performance, is substantially harmless to human body, is simple and convenient in production process, is low in cost and is suitable for large-scale production. [0]

Owner:SHAANXI UNIV OF SCI & TECH

Leather tanning method

InactiveCN106755630AStrong TanningReduce the position differenceTanning treatmentPre-tanning chemical treatmentHair removalSodium acetate

The invention provides a leather tanning method. The method comprises the steps of a, pretreatment before tanning, dry animal skin is subject to soaking, meat removal, degreasing, hair removal, splitting and acid maceration, and raw hide is obtained; b, tannin extract tanning, wherein the raw hide is put into a rotary drum, and water and a plant tanning agent are added for plant tanning; c, aluminum tanning, wherein leather is put into the rotary drum, tanning liquid is added, and after tanning, baking soda and sodium acetate are used for neutralizing; d, aftertreatment, wherein through the above steps, finished leather is manufactured. A plant tanning agent and aluminum tanning agent composite tanning method is used for replacing a chromium metal tanning agent for tanning, and on the basis of keeping the tanning effect, the harm of chromium salt to the environment and the human body is removed.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Ecological environment-friendly vegetable tanning yellow cattle upper leather production process

ActiveCN109628659AMeet the requirementsEasy to fixTanning treatmentPre-tanning chemical treatmentCross-linkOrganic solvent

The invention relates to the technical field of leather manufacturing, and provides an ecological environment-friendly vegetable tanning yellow cattle upper leather production process. According to the ecological environment-friendly vegetable tanning yellow cattle upper leather production process, an organic pre-tanning agent is used for pretreating softened leather, the tanning agent based on avegetable tanning agent is used for tanning, wherein the vegetable tanning agent is mainly a condensed vegetable tanning agent, and then an aldehyde tanning agent is combined for retanning; the vegetable tanning agent, collagen, the aldehyde tanning agent can form cross-linking to produce a vegetable-aldehyde synergistic tanning effect, the fixation effect of the vegetable tanning agent is improved to improve the absorptivity of the vegetable tanning agent, the washing resistance, organic agent resistance performance and shrinkage temperature of the obtained green leather are improved, and thedistribution of vegetable tanning agent on each layer of green leather is more uniform; and the green leather has fine grain size, good compactness, good softness, good fullness and good elasticity,and accords with the characteristics of upper leather products.

Owner:XINGYE LEATHER TECH CO LTD

Preparation method of starch and sulfomethyl phenol graft copolymer leather synthesis tanning agent

InactiveCN102241781AImprove applicabilityIncrease shrinkage temperatureTanning treatmentFermentationSodium bicarbonateHigh absorption

The invention relates to a preparation method of starch and sulfomethyl phenol graft copolymer leather synthesis tanning agent, the method comprises the following steps: reacting sodium bisulfite with sodium sulfite and formaldehyde, to prepare sodium hydroxymethanesulphonate, then performing a sulfomethylation of hydroxymethyl sulfonate and phenol under the alkaline condition, to prepare a sulfomethyl phenol solution, finally, mixing the sulphur methyland phenol solution with enzymatic degradated starch, regulating the pH value of the solution by sodium bicarbonate, performing a graft copolymerization reaction of starch and sulphur methyland phenol under the catalytic effect of horseradish peroxidase, to obtain the starch graft copolymer leather synthesis tanning agent. The obtained product has the advantages of moderate relative molecular mass, good permeability and high absorption, and is a high-molecular tanning agent with no pollution and green performance. The preparation method of the present invention has an unique synthesizing preparation technology, the shrinkage temperature can reach at 78 DEG C when the obtained synthesis tanning agent is taken as a main tanning agent, the thickening rate of the leather can reach at 28% when the obtained synthesis tanning agent is used for retanning, thereby the leather possesses soft handfeel. The agent can be used as the leather tanning agent with green environmental protection performance.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of high-performance carbon nanotube modified chrome tanning agent

InactiveCN101880735AImprove the coordination effectLarge amount of bindingTanning treatmentCarbon nanotubeGlucose polymers

The invention provides a preparation method of high-performance carbon nanotube modified chrome tanning agent, which comprises the following steps of: after mixing a carbon nanotube with an acid solution, and ultrasonically processing the mixture to prepare a suspension; then, heating, condensing, refluxing, repeatedly washing and centrifugally separating until the pH value becomes neutral; subsequently, after dissolving dichromate in water, slowly adding sulfuric acid and the treated carbon nanotube; ultrasonically processing to prepare a stable suspension; taking glucose and adding water to dissolve the glucose; dropwise adding the water solution of glucose into the suspension containing dichromate while stirring so as to produce a carbon nanotube modified chrome tanning liquid in-situ; and finally, settling and placing for long time. The chrome tanning agent enhances the bonding force of chrome, increases the quality and the properties of leather, is friendly to environment, reduces pollution and decreases resource waste.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing semi-chrome tanning addition agent through waste chrome shavings and application method of semi-chrome tanning addition agent

ActiveCN107988443ARealize rational utilizationEco-friendly tanningTanning treatmentPhosphonium saltAcid hydrolysis

The invention relates to the technical field of tanning waste source utilization and provides a method for preparing a semi-chrome tanning addition agent through waste chrome shavings and an application method of the semi-chrome tanning addition agent. Waste chrome shaving resources can be effectively converted into the semi-chrome tanning addition agent so as to be reused in the leather production and preparation processes, and the dual economic benefits of environment-friendly tanning and reduction of tanning cost are achieved. According to the method for preparing the semi-chrome tanning addition agent through the waste chrome shavings, collagen hydrolysate liquor is obtained through acid hydrolysis of the waste chrome shavings and then modified through unsaturated dicarboxylic acid andtetrakis hydroxymethyl phosphonium salt, the semi-chrome tanning addition agent is obtained, carboxyl functional groups of collagens in the semi-chrome tanning addition agent are increased, the jointpoints of proteins in the obtained semi-chrome tanning addition agent and a chrome tanning agent are increased, thus, combination and absorption of leather treated through the obtained semi-chrome tanning addition agent and the chrome tanning agent are promoted, meanwhile, the obtained semi-chrome tanning addition agent has certain tanning performance and filling property, the crust leather contraction temperature can be increased, and the fullness, elasticity and grain surface flatness of crust leather are improved.

Owner:XINGYE LEATHER TECH CO LTD

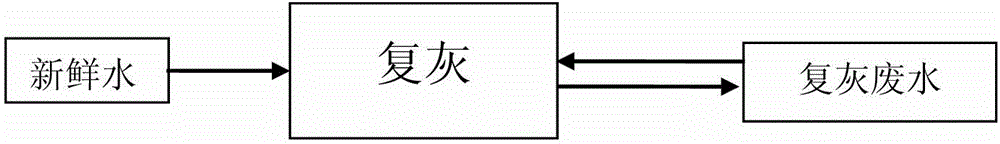

Leather making process for retanning by indefinitely recycling waste liquid

InactiveCN101985668AEliminate serious pollution problems caused by emissionsImprove firmnessTanning treatmentPulp and paper industryChromium

The invention provides a leather making process for retanning by indefinitely recycling waste liquid. The process is characterized by greatly reducing the using amount of chromium powder and other retanning materials by 40 to 60 percent, and realizing indefinite recycling of all waste liquids, and the retanning effect is better than that of the conventional process.

Owner:张壮斗

Preparation method of formaldehyde-free leather synthetic tanning agent

InactiveCN101781392AImprove tanning effectEasy to fillTanning treatmentSodium bicarbonateEnzymatic synthesis

The invention relates to a preparation method of a formaldehyde-free leather synthetic tanning agent by enzymatic synthesis. Firstly, p-hydroxybenzoic acid and poly hexanediol are reacted to produce ester, then p-hydroxybenzoic acid macrogol ester, p-hydroxybenzaldehyde and sodium phenolsulfonate are dissolved in deionized water, the pH value of the system is adjusted with a sodium bicarbonate solution, and finally copolymerization is carried out under the catalytic action of horseradish peroxidase (HRP) to obtain the formaldehyde-free leather synthetic tanning agent. Through ester producing reaction and combined polymerization, aldehyde group, carboxyl and phenolic hydroxyl which have tanning effect on leather collagen fibers and polyethylene glycol branched chains, sulfo group and the like which have the functions of penetration, lubrication and filling are introduced into the product structure, and the obtained product has moderate relative molecular weight, good permeability and high absorption rate, and is a pollution-free polymer tanning agent with green performance.

Owner:SHAANXI UNIV OF SCI & TECH

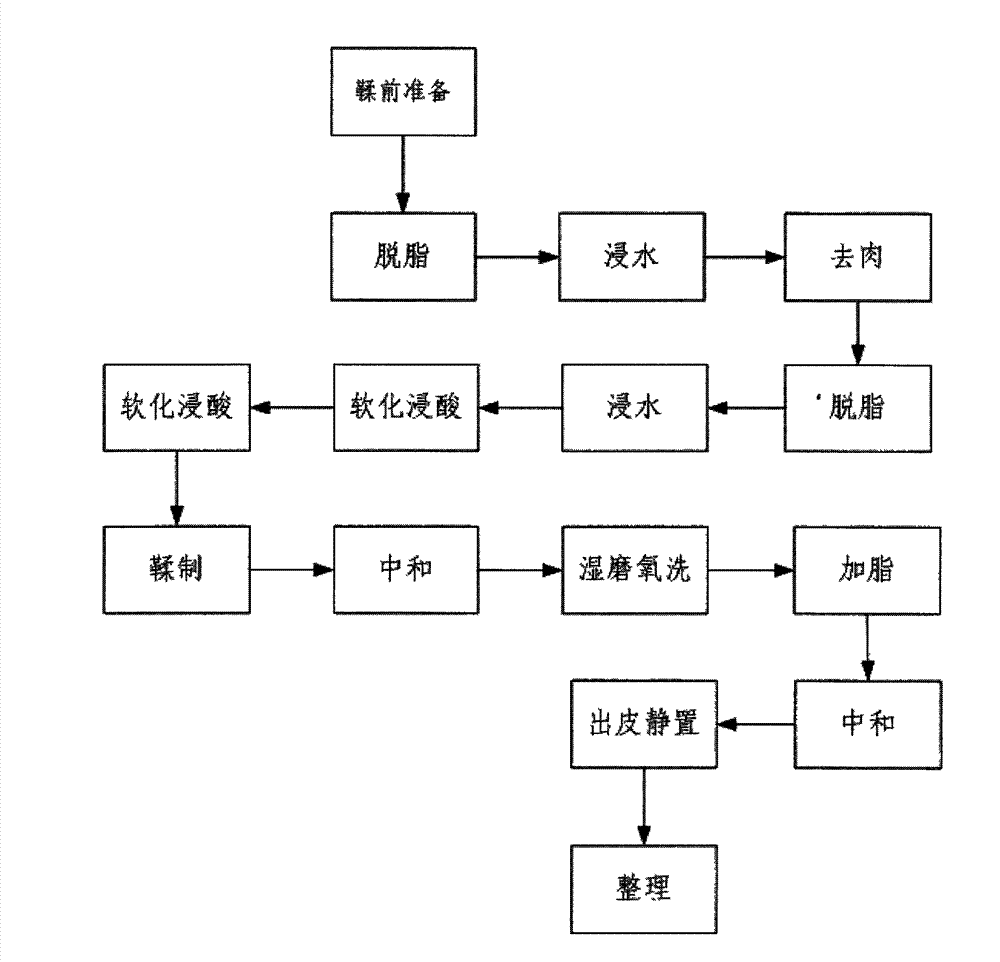

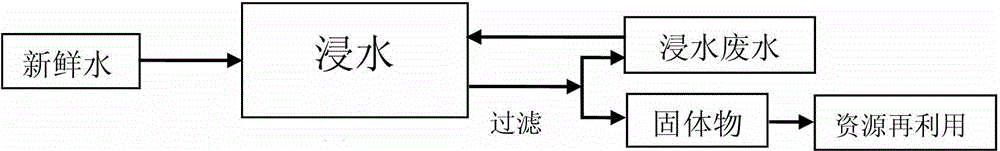

Cleaner production method of ecological tanning of Tan sheep skin

InactiveCN102827963AImprove antioxidant capacityImprove anti-corrosion performanceTanning treatmentPre-tanning chemical treatmentSheep skinOxygen

The invention discloses a cleaner production method of ecological tanning of Tan sheep skin, comprising the steps of preparation prior to tanning, degreasing, soaking in water, fleshing, degreasing, soaking in water, softening and pickling, tanning, neutralizing, wet grinding and oxidizing washing, fat liquoring, neutralizing, outputting skin and standing and clearing up. The softening and pickling comprises the following steps: edible salt, formic acid and water are mixed to obtain first mixed solution; fur fatting agent and softening enzyme are added into the first mixed solution and mixed uniformly to obtain softened pickling solution and the softened pickling solution is heated to 48 DEG C; a Tan sheep skin is put in the softened pickling solution in a drum, softening enzyme is added into the softened pickling solution again, the drum rotates continuously for 6 hours and the softened pickling solution is filtered. The tanning comprises the following steps: the filtered softened pickling solution is put again in the drum in which the Tan sheep skin is put, formic acid solution and sulfuric acid solution are added into the filtered softened pickling solution and the drum is rotated; edible salt, formic acid, white tanning agent and water are mixed to obtain second mixed solution and the drum is rotated continuously; sodium formate, bicarb and soda ash are added for alkali adjustment; then the tanning of the Tan sheep skin is finished.

Owner:宁夏西部皮草有限公司

Preparation method of green and environmental protection tanning agent

InactiveCN105506198AIncrease shrinkage temperatureEasy to detanTanning treatmentLeather impregnationHydrogenAlcohol

The invention discloses a preparation method of a green and environmental protection tanning agent, comprising the following steps: weighing starch, deionized water, sodium hydrogen sulfite, CMC, SDS, silicone oil, op-10, sulfur alcohol and NaOH solution, adding the starch, the deionized water A, sodium hydrogen sulfite, CMC, SDS, the silicone oil, op-10, sulfur alcohol and the NaOH solution to a flask, heating to 50-60 DEG C while stirring, then adding hydrogen peroxide A, heating to 94-98 DEG C after constant temperature stirring for reaction, then cooling to 75-85 DEG C, adding HCL and then dropwise adding an initiator and a monomer, and cooling to room temperature after constant temperature stirring for reaction, thus obtaining the green and environmental protection tanning agent. The green and environmental protection tanning agent prepared according to the method disclosed by the invention can effectively improve the water resistance and shrinking temperature of leather, and de-tanning is not easy to cause.

Owner:SHAANXI UNIV OF SCI & TECH

Leather manufacturing method achieving three-waste discharge reduction

InactiveCN105779667ADoes not affect executionQuality is not affectedTanning treatmentPre-tanning chemical treatmentWastewater reusePollution

The invention provides a leather manufacturing method achieving three-waste discharge reduction. The leather manufacturing method can comprehensively achieve reduction of three-waste discharge in the leather manufacturing process. Through wastewater reuse, solids are inhibited from decomposing or dissolving and are recycled; and exhaust emission is reduced through reduction of volatilization of wastewater, the solids and chemical materials. The leather manufacturing method is specially characterized in that soaking, liming, reliming, lime removal and softening, pickling chrome tannage, degreasing, retanning, neutralizing and dyeing are conducted independently, water is saved by over 70%, and energy is saved by over 20%; emission of solid waste is reduced by over 70%; the chemical materials are saved by 15% to 100%, and pollution to air due to volatilization of the chemical materials is reduced; and by the adoption of the method, the quality of leather can be improved remarkably.

Owner:张壮斗

Method for tanning pigskin first layer shoe lining leather by utilizing non-chromium metal compound tanning agent

InactiveCN101717832AMeets hexavalent chromiumFulfil requirementsLeather manufacturingTanning treatmentSludgePollution

The invention relates to a method for tanning pigskin first layer shoe lining leather by utilizing a non-chromium metal compound tanning agent. The method comprises an oil adding step and a tanning step. In the tanning step, an LTA-100 metal (without chromium) compound tanning agent, non-chromium tanning chaperones D6, an auxiliary tanning agent GM-40 and the like are adopted. The method is characterized in that the leather shrinkage temperature in industrial production can reach more than 90 DEG C, which conforms to the shoe-making manufacture requirement; the hexavalent chromium and total chromium detection requirement of the environment identification product can be met; the method has no phosphorus pollution and no formaldehyde release; the tannery sludge can be directly burned; a post-tanning process and the material do not need special adjustment, and the integrity property is good when compared with the traditional leather-making process. The invention meets the limit requirement on the hexavalent chromium and total chromium content of the environment identification product, has high shrinkage temperature, and provides a new path for shoe-making enterprises to produce high-grade environment-protection shoe lining leather.

Owner:WENZHOU UNIVERSITY

Preparing method for modifying organophosphorus tanning agent through compound containing amidogen and carboxyl functional groups simultaneously

ActiveCN105154598AEasy to crackImprove burst strengthTanning treatmentBursting strengthReaction temperature

The invention belongs to the field of leather chemicals, and particularly relates to a preparing method for modifying an organophosphorus tanning agent through a compound containing amidogen and carboxyl functional groups simultaneously. The method includes the following steps: 1 molar of organophosphorus tanning agent is added into a reaction vessel; 0.5 molar to 3 molars of compound containing the amidogen and carboxyl functional groups simultaneously is weighed to be dissolved with water, and the solution is slowly added into the reaction vessel; the reaction temperature is set to range from 35 DEG C to 50 DEG C, and a reaction is made; the pH is adjusted to range from about 4.0 to about 7.0, and the reaction is continuously carried out; and after the reaction is finished, the modified organophosphorus tanning agent is obtained. Compared with an unmodified organophosphorus tanning agent, the crack strength of retannage leather is improved by 20 N / mm to 30 N / mm, the bursting strength is improved by 50 N / mm to 70 N / mm, the cracking height is improved by 1.5 mm to 3 mm, and the bursting height is improved by 3 mm to 5 mm. The finished leather fullness is better; and compared with the unmodified organophosphorus tanning agent, and the thickness of the retannage leather is improved by 5% to 10%.

Owner:阳信瑞丰集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com