Patents

Literature

339results about "Leather manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of cow skin nappa leather

ActiveCN105132596AUniform leatherImprove leather yieldLeather manufacturingTanning treatmentFiberManufacturing technology

The invention relates to the technical field of the leather manufacturing technology, and provides a production technology of cow skin nappa leather. A series of problems that due to the fact that the structure of the abdomen and the part between the ribs and the hips of the cow skin is thin and fiber is woven loosely, in the processing process, the part of the abdomen and the part between the ribs and the hips are prone to being excessively loose, the part deviation is large, and face loosening is likely to happen are solved through the production process of the cow nappa soft-face leather. The integral procedure of the technology is simple, easy to achieve, convenient to operate and practical. The grain on the abdomen and the part between the ribs and the hips is easy to open in the tan preprocessing working section of the cow skin through tanning preprocessing, retanning processing and post-tanning mechanical processing, and the whole skin body fiber is even and loose. Even and slow tanning is carried out in the tanning working section, step-by-step and multi-time even filling is carried out in the retanning working section, the whole cow skin leather is even and consistent in the manner that filling is conducted after loosening, the leather is soft but not loose, and the leather yield and the utilization rate of finished cow skin are greatly increased.

Owner:XINGYE LEATHER TECH CO LTD

Process for producing leather

ActiveCN102586497ARelieve pressureLow costLeather manufacturingPre-tanning chemical treatmentEngineering

The invention relates to the field of the manufacture of leather and provides a process for producing the leather. The production cost is reduced by changing the formula of the process. The process comprises the following steps of: preparing a crust, milling the crust, toggling, tumbling, trimming, patching, buffing, blowing dust and cleaning, spraying cations, tumbling for the second time, spraying, repairing corners, tumbling for the third time, trimming for the second time, rolling, obtaining G gloss, pressing a plate, spraying for the second time, obtaining water gloss, tumbling for the fourth time, milling for the second time, staking, tumbling for the fifth time, and spraying a handle agent.

Owner:XINGYE LEATHER TECH CO LTD

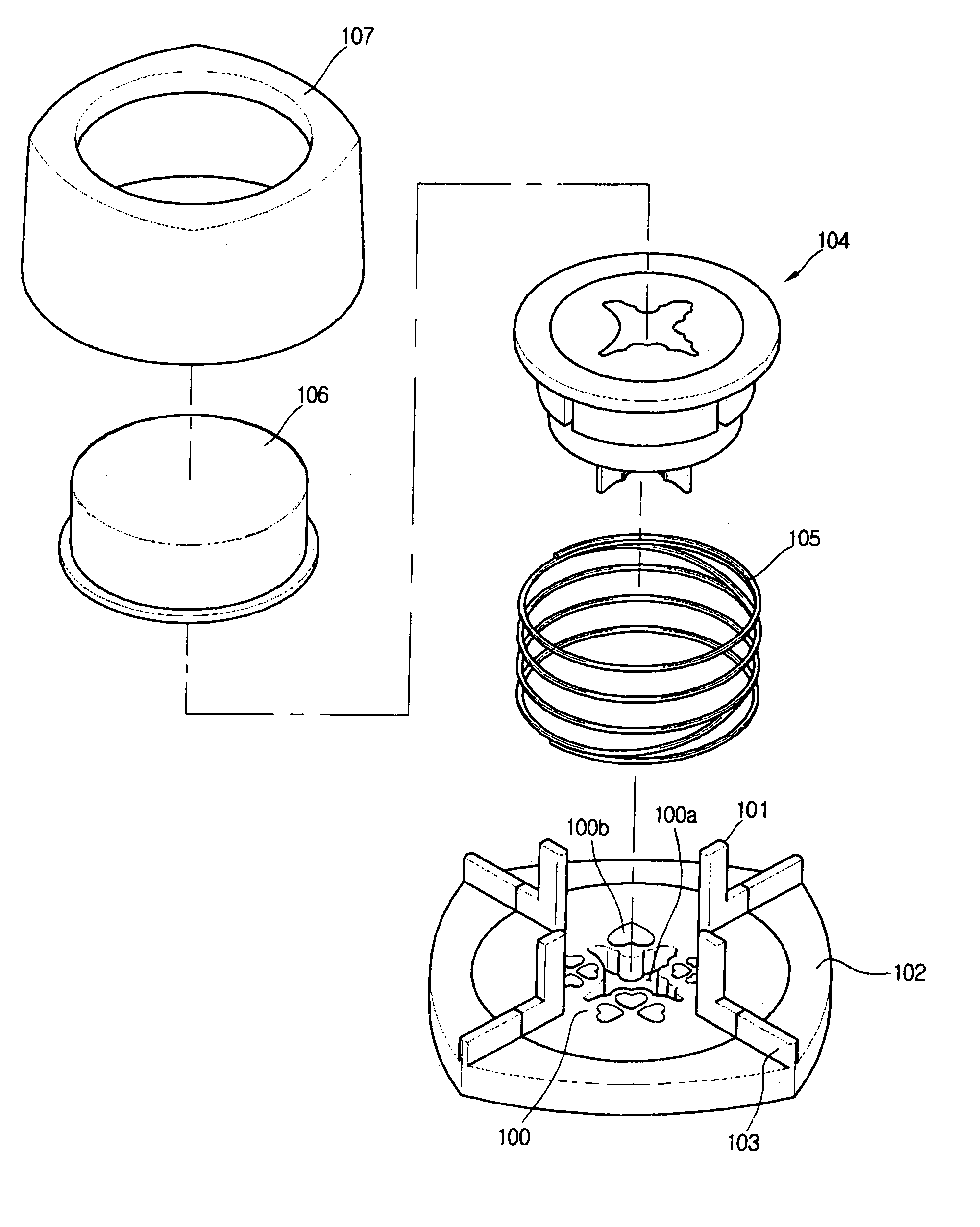

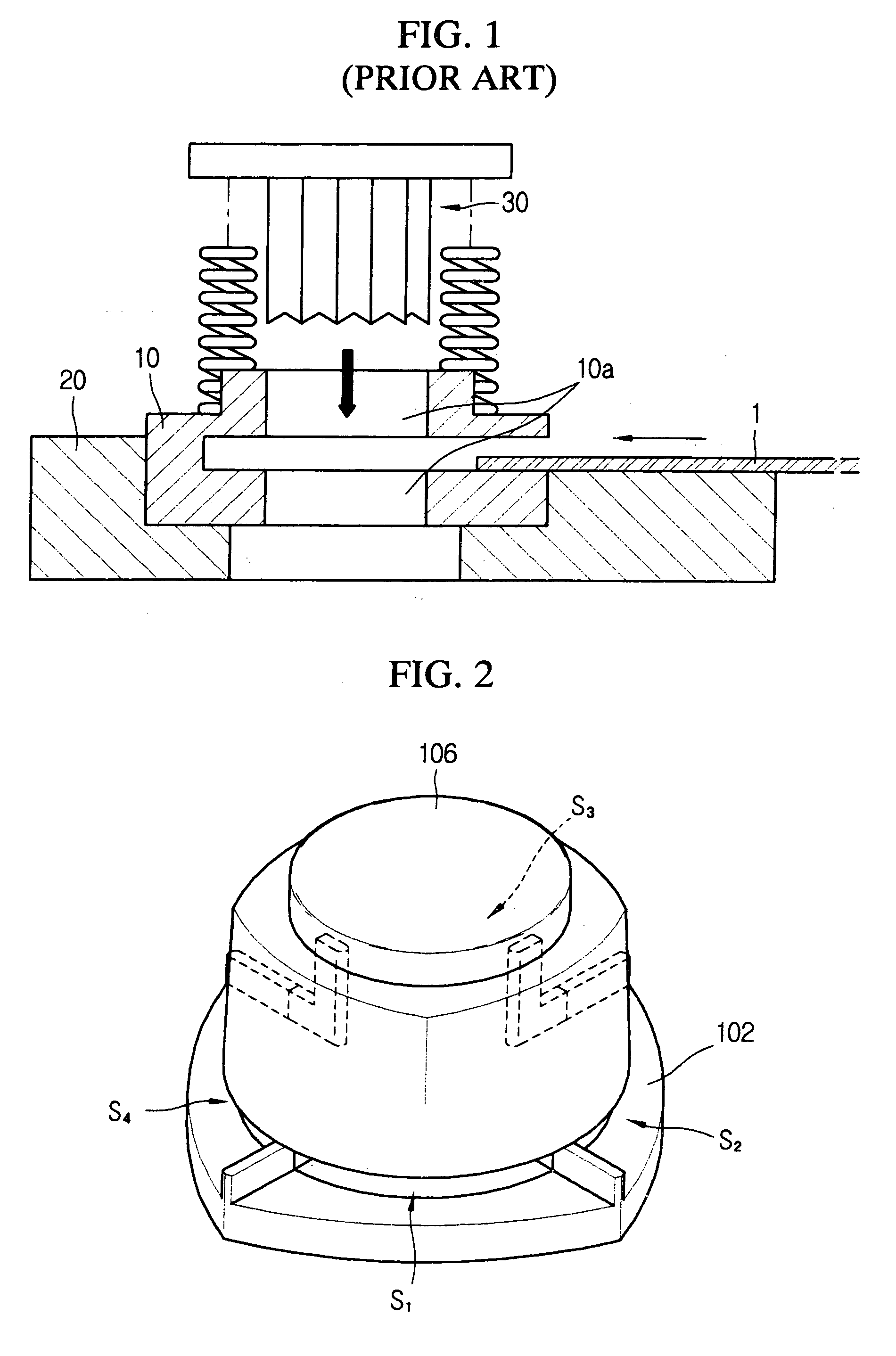

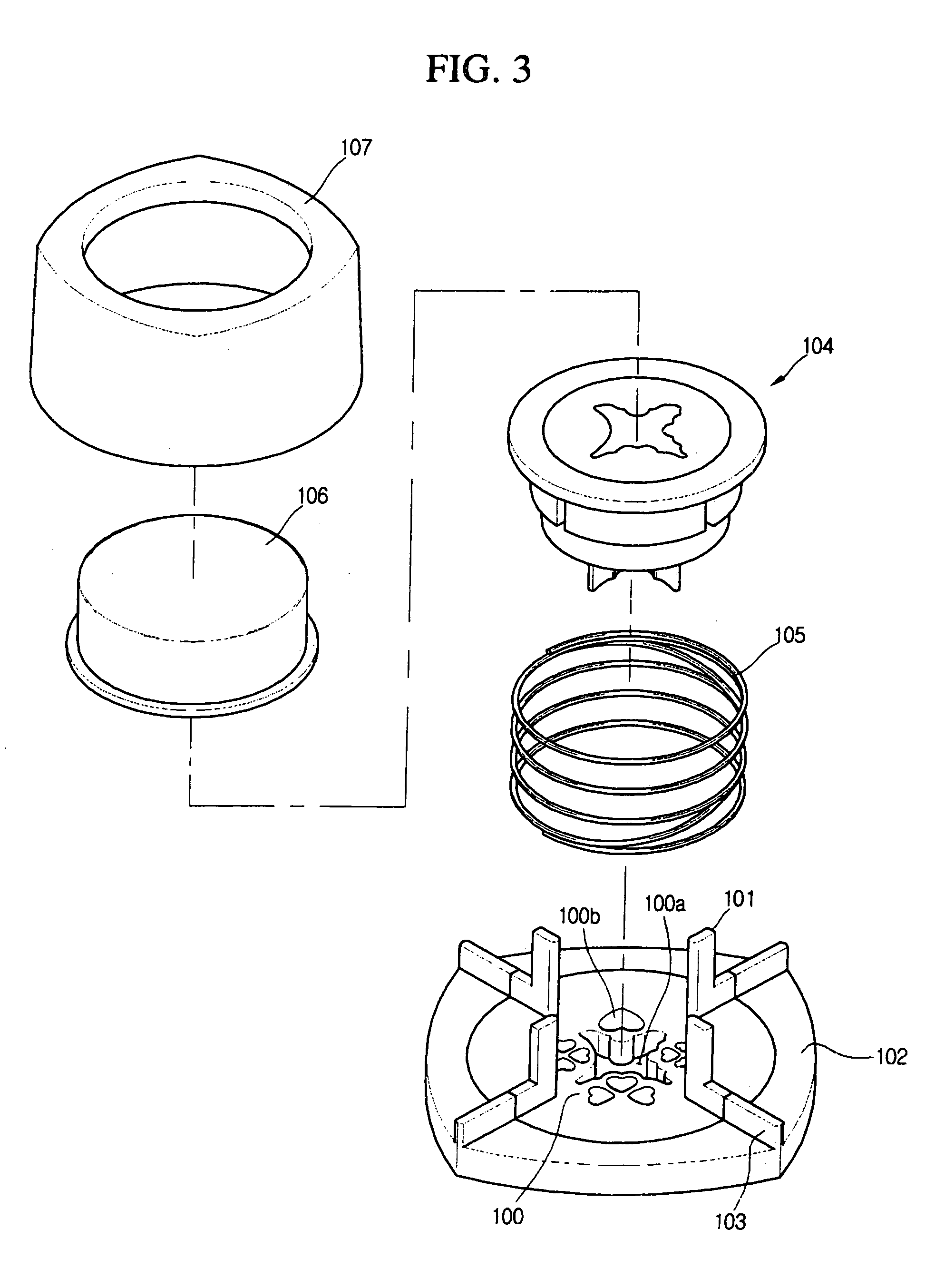

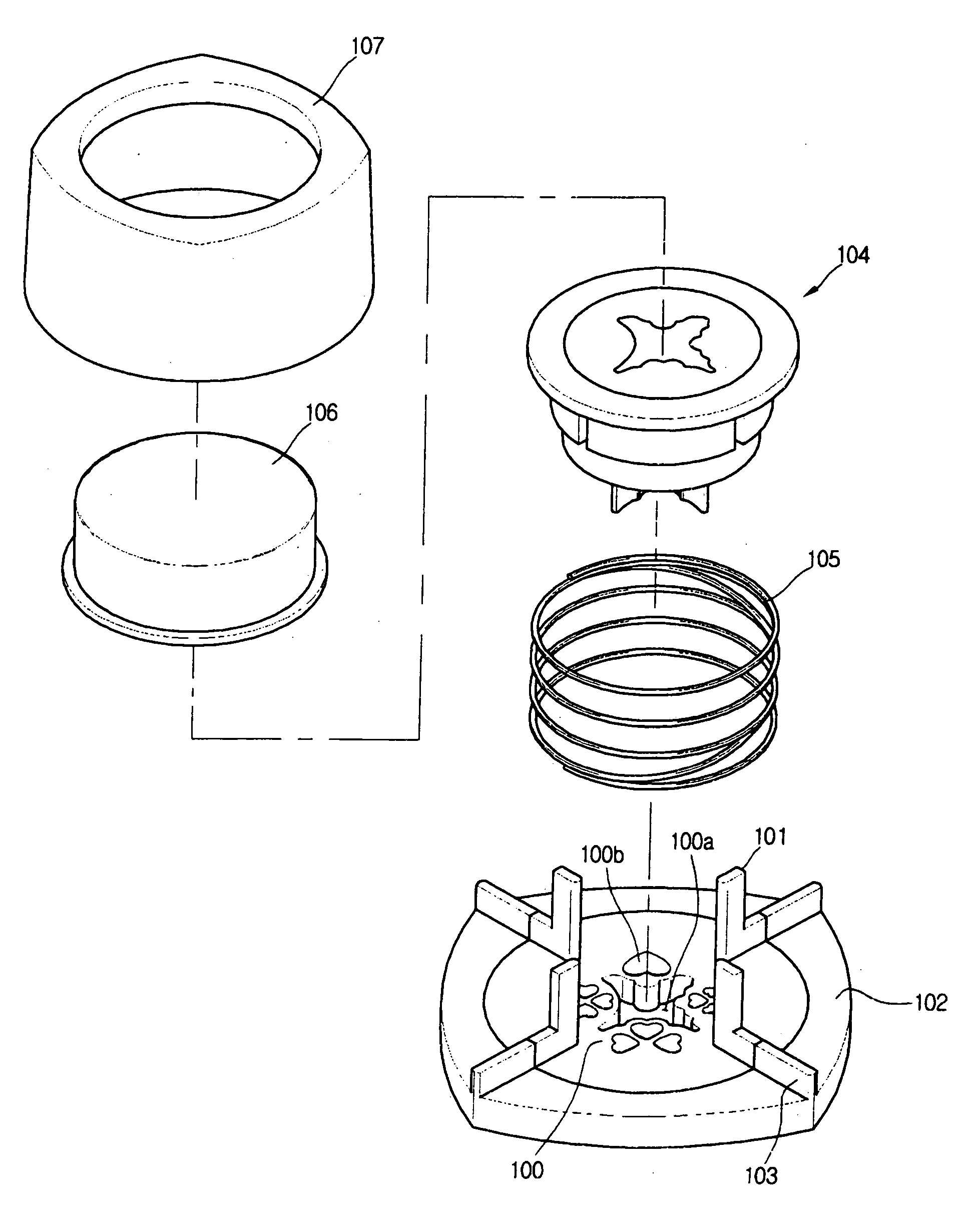

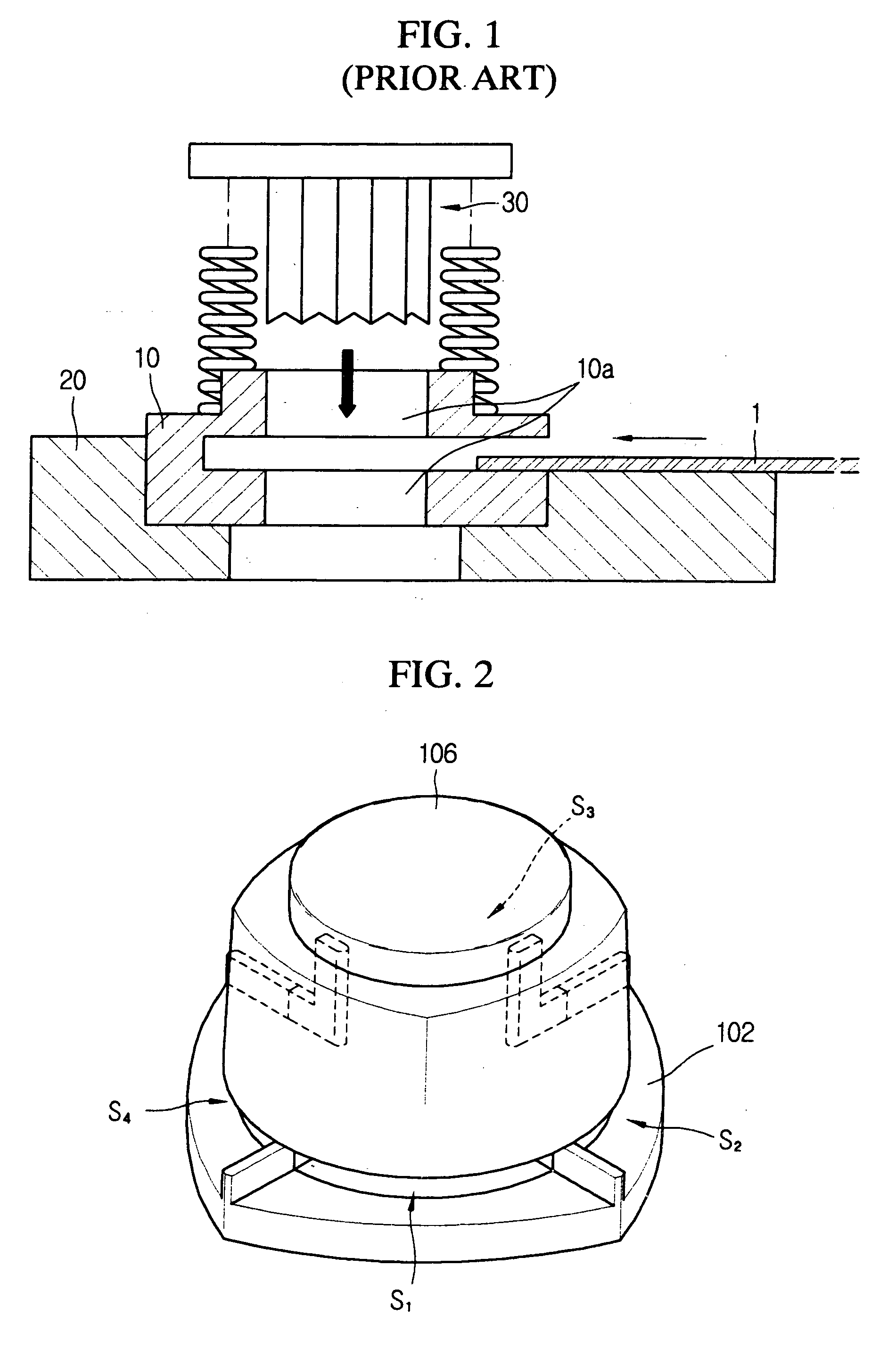

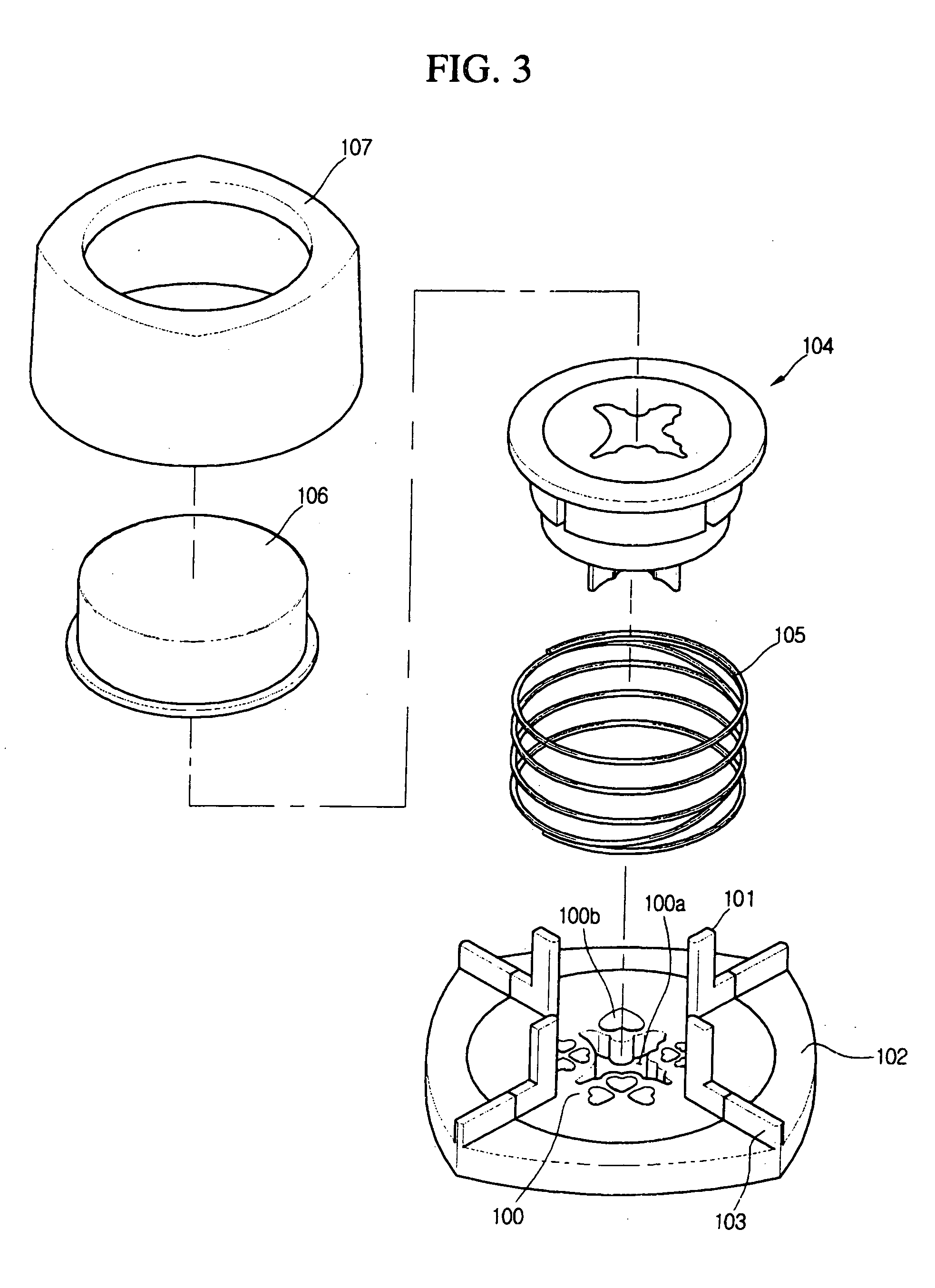

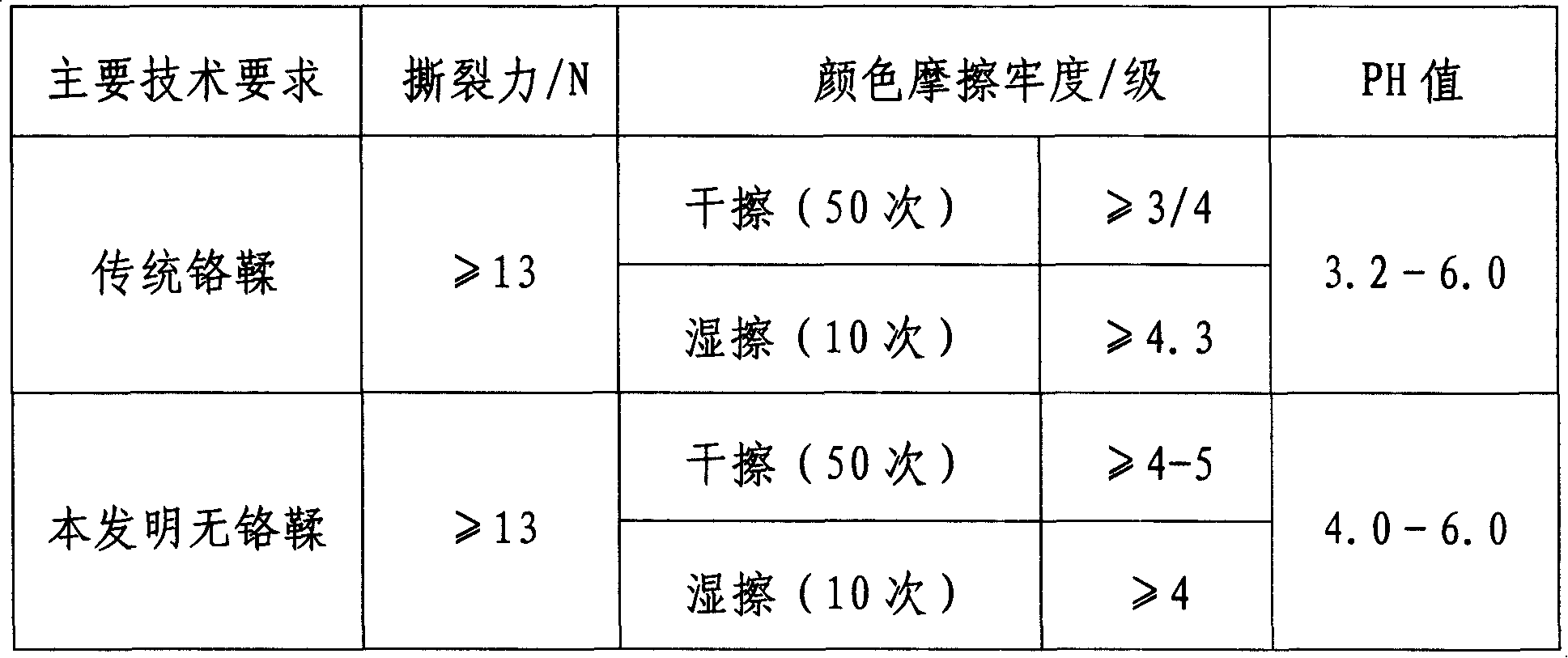

Punch capable of punching an object at four directions

InactiveUS7201101B2Simple structureEasy to useMechanical working/deformationLeather manufacturingPunch pressEngineering

A punch includes a jig having four punching regions, each punching region having a pattern hole and a concave embossment; guide columns extended upward from a border of the punching regions on the jig; a base for fixing the jig; a punching member punching and embossing the rectangular corner of a sheet member with vertically moving against the jig by guidance of the guide columns; and an elastic body to elastically bias the punching member upward.

Owner:DN CRAFT

Coating decoration method for making high-grade waxing leather from low-grade leather

ActiveCN102827966AImprove waxing effectLow toxicityLeather manufacturingLeather surface finishingLower gradeLow graded

The invention relates to the technical field of a leather coating decoration method, and provides a coating decoration method for making high-grade waxing leather from low-grade leather with the advantages that the process is simple, the operation is convenient, used solvents have low toxicity, the natural attributives of softness, ventilation and the like of real leather are maintained, and the qualification rate is high. The method mainly comprises the following steps of leather blank preparation, defect repair, baking, plate pressing, polishing, mechanical foaming, falling, toggling, top coating, beating softening and sand plate pressing.

Owner:XINGYE LEATHER TECH CO LTD

Ecofriendly bio-process for leather processing

The present invention relates to an eco-friendly beam house process for de-hairing of leather using commercially available enzymes that obviates the use of lime and other alkalis. The present invention also provides an alternate process for opening the fibers of leather using commercially available enzymes. The present invention further provides a three-step process for tanning hide or skin in a narrow pH range of from about 7.5 to about 8.5.

Owner:COUNCIL OF SCI & IND RES

Punch capable of punching an object at four directions

InactiveUS20050211036A1Simple structureEasy to useDrawing diesLeather manufacturingPunch pressEngineering

A punch capable of punching an object at four directions is disclosed. The punch includes a jig having four punching regions radially symmetrical to each other on the basis of a punching center, each punching region having a pattern hole and / or a concave embossment; guide columns extended upward from a border of the punching regions on the jig; a base for fixing the jig and giving a supply surface so that a rectangular corner of a sheet member to be punched is supplied between the adjacent guide columns; a punching member having a punch pin and / or a convex embossment corresponding to the pattern hole and / or the concave embossment, and punching and / or embossing the rectangular corner of the sheet member with vertically moving against the jig by guidance of the guide columns; and an elastic body interposed between the punching member and the jig to elastically bias the punching member upward.

Owner:DN CRAFT

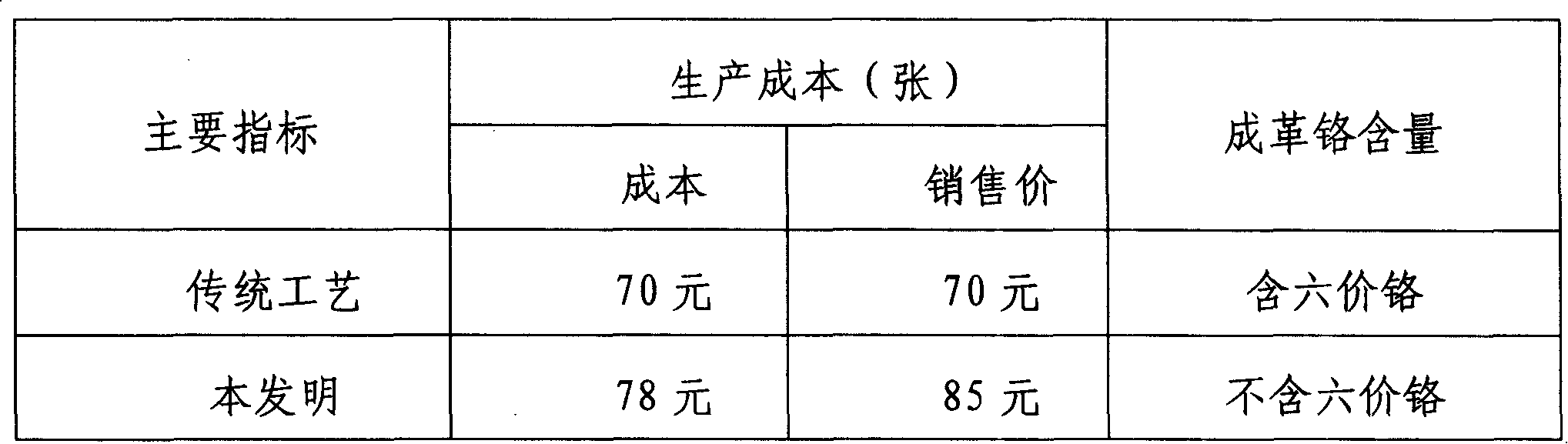

Non-chroming processing method for leather production

InactiveCN101230408AImprove heat and humidity stabilitySmooth leatherLeather manufacturingTanning treatmentOperational costsMaterial consumption

The invention relates to a chrome-free tanning method of producing the leather, which is characterized in that, the processing method includes the following steps: organizing the material, dipping in water, degreasing; dehairing by dipping in lime-sulfide, removing the lime-sulfide, rolling in saltpeter, cutting the leather, softening, dipping in acid, removing the acid, tanning, re-tanning, neutralizing, treating by fat, washing the leather by water and finally obtaining the finished product. The technique of the invention is reasonable; the leather after tanning has high muggy stability, better tolerance in acid, alkali etc. After some other treatments, the physical property, hand feeling and appearance improve a lot, and the leather becomes flat, soft, plump and elastic. The operating parameters of the corresponding technique in the production process are optimized; the technique is simplified; the material consumption for production is reduced; the production operating cost is reduced; and the product quality is increased.

Owner:湖南省怀其皮革集团制革有限公司

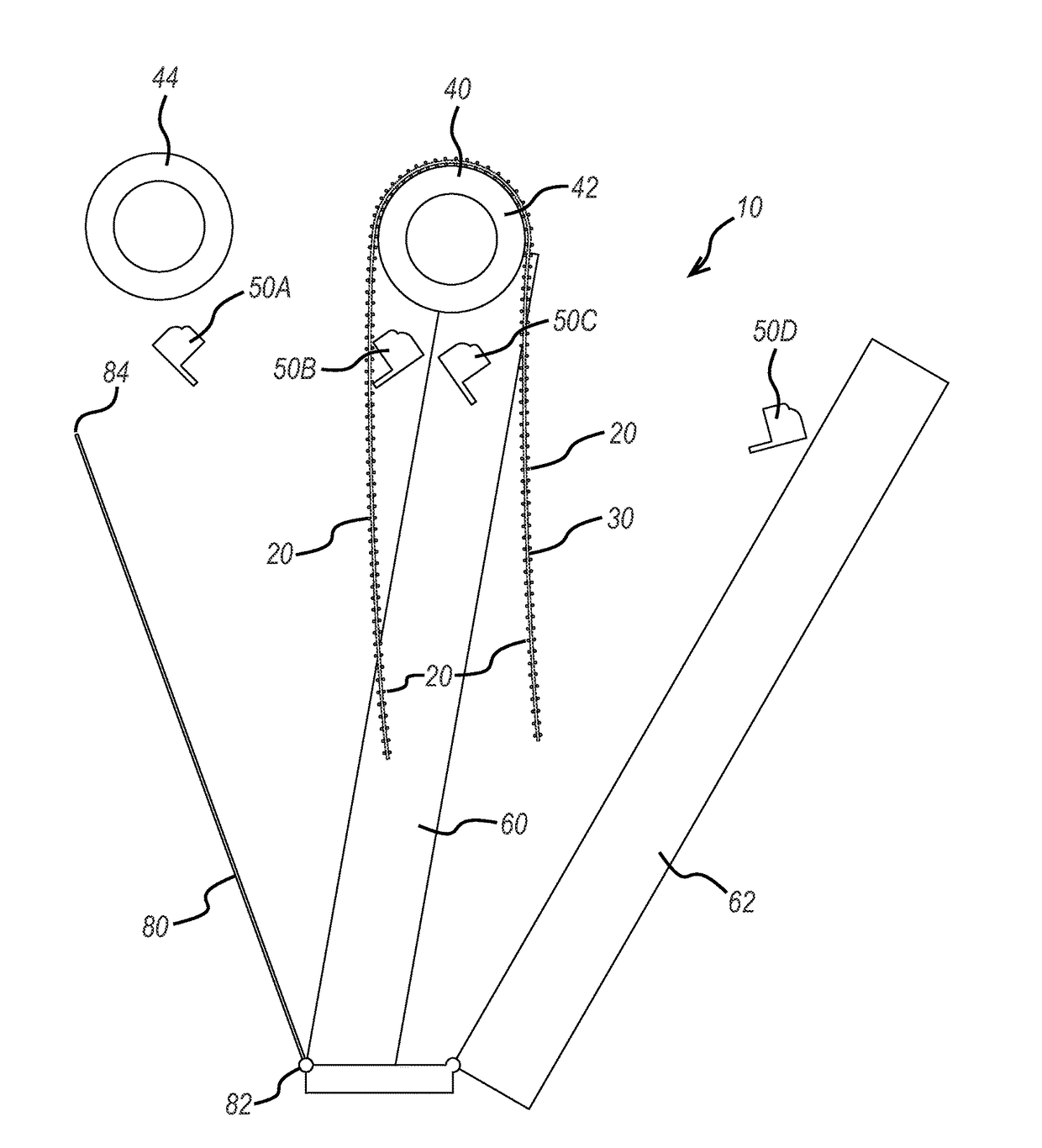

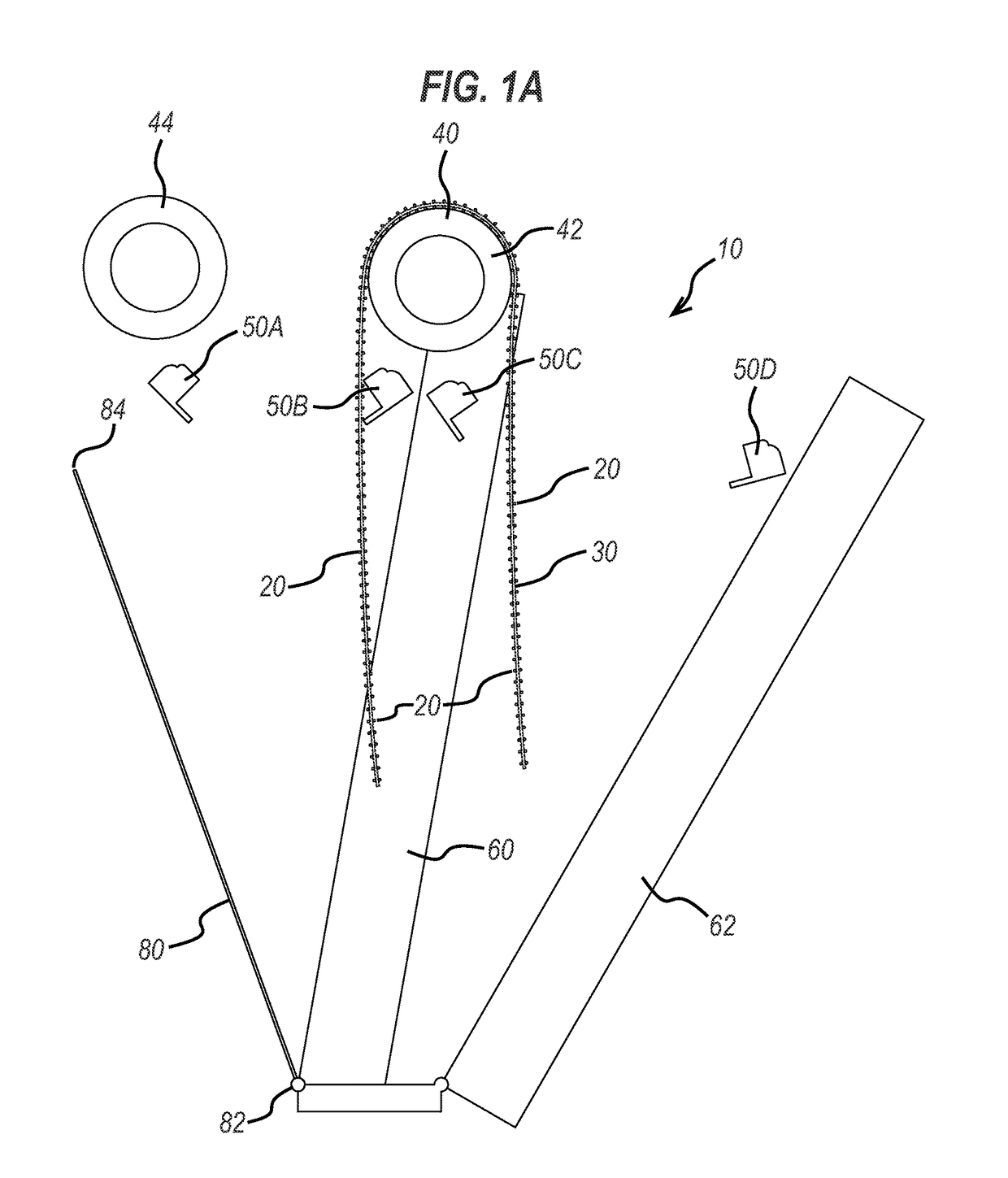

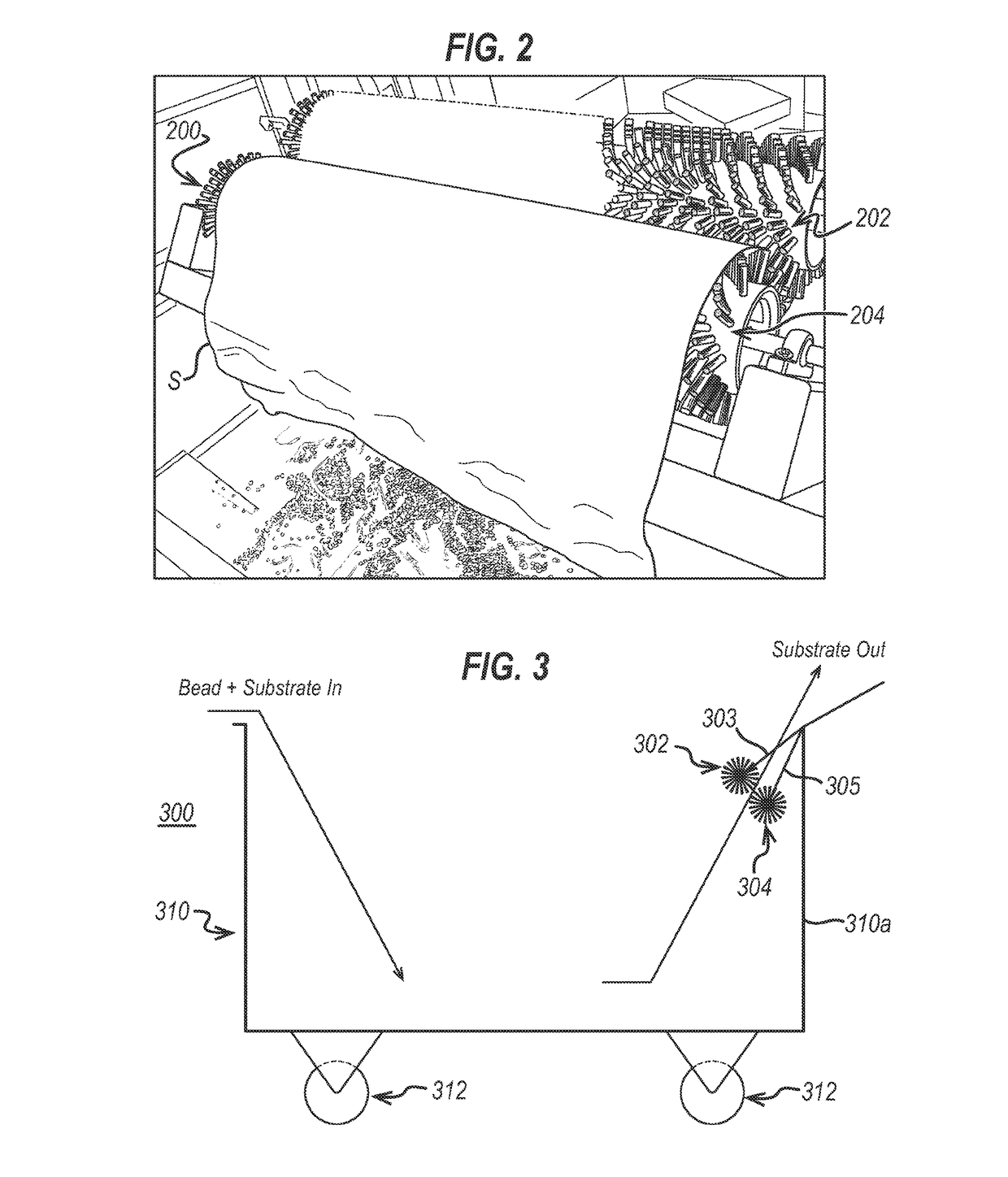

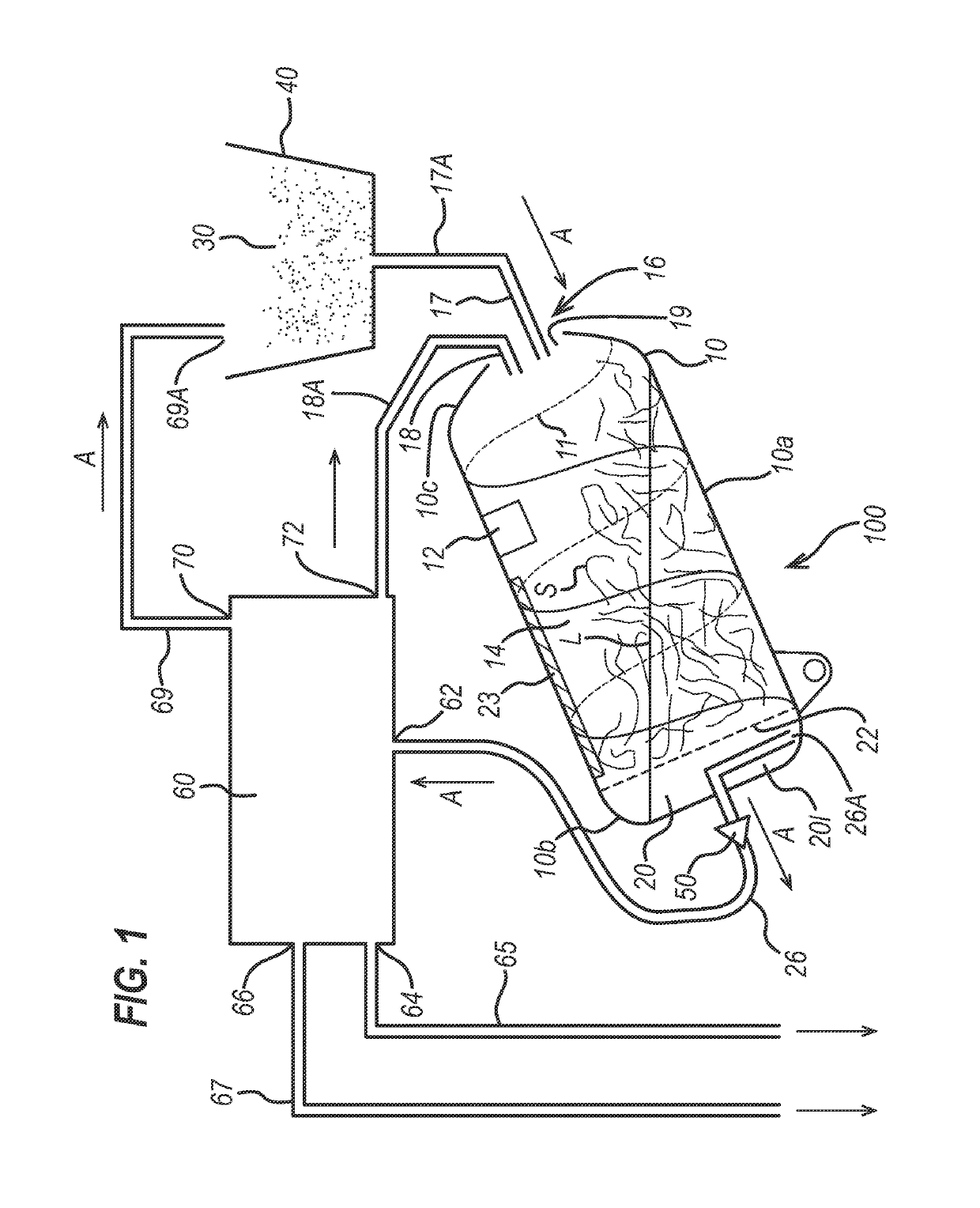

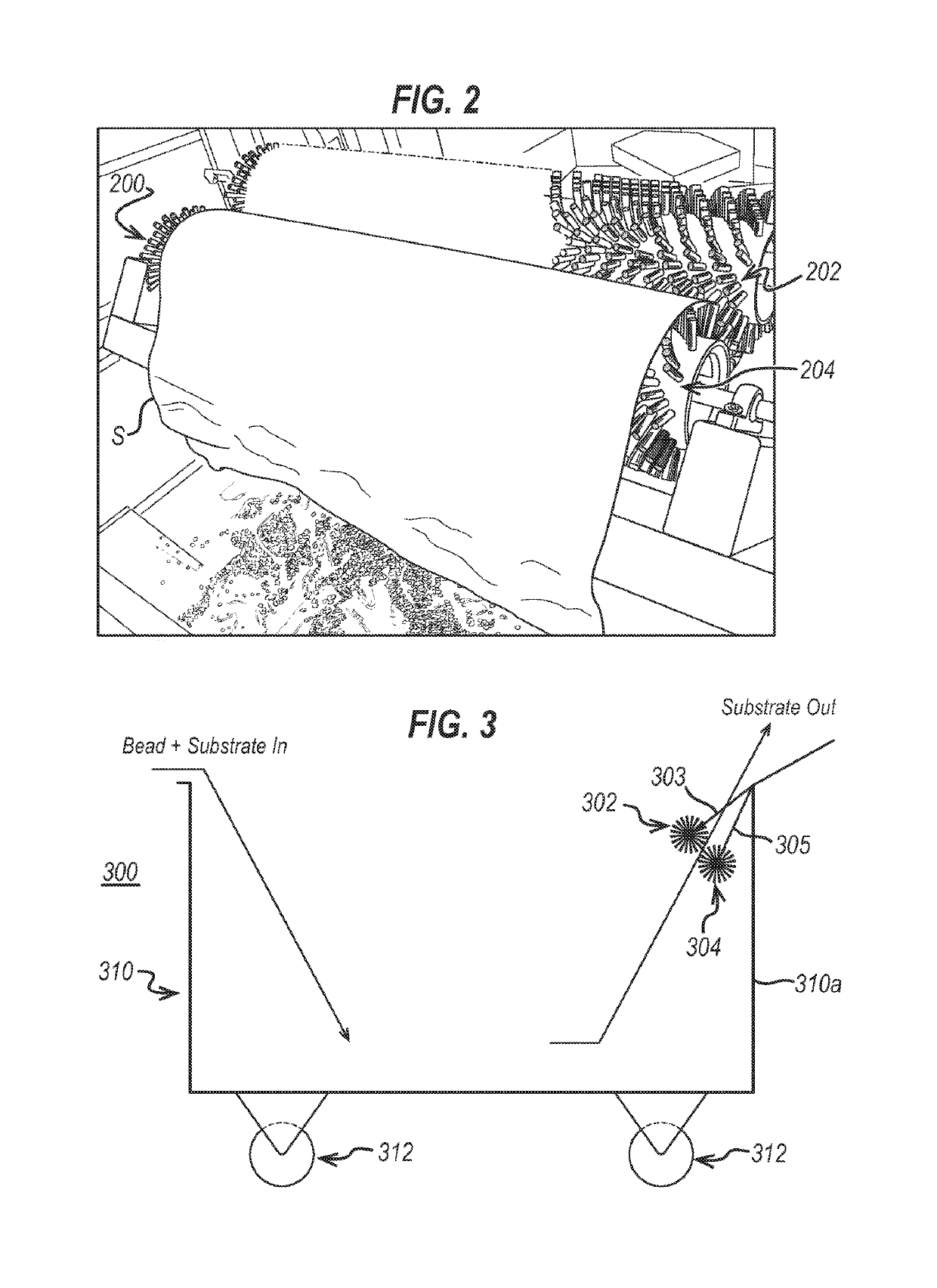

Apparatus and method for recovery of solid particulate material

InactiveUS20170247771A1Avoids and mitigates damageLeather manufacturingLeather/skins/hides/pelt chemical treatment apparatusSolid massEngineering

Apparatus for recovery of a solid particulate material from an animal skin substrate subjected to a treatment using said particulate material, comprises a support arranged to support the animal skin substrate, at least one air knife arranged to direct its output flow of air to the animal skin substrate when supported on the support, and a transport arrangement configured to move at least one of the air knife and the animal substrate relative to the other. A method of recovering solid particulate material from such an animal skin substrate is also disclosed.

Owner:XEROS LTD

Processing method of seawater-proof vamp leather

InactiveCN102168153AUniform fluffNo greasy feelingLeather manufacturingTanning treatmentChemistryComposite material

The invention relates to a processing method of leather, in particular to the processing method of full grain or light corrected vamp leather, soft vamp leather, matte vamp leather, suede vamp leather and cowhide seawater-proof vamp leather of bag leather and belt leather. The processing of the leather is completed by treatment before tanning, tanning method, resin re-tanning, stuffing and dying method, chromium fixation, and varnishing method. The leather processed by adopting the processing method of the seawater-proof vamp leather is plump and soft, the leather surface is compact and not loose, the physical and mechanical strength is in line with the requirements of the vamp leather, the seawater-proof performance is good, and the range of applications is wide.

Owner:HANGZHOU QIDA LEATHER

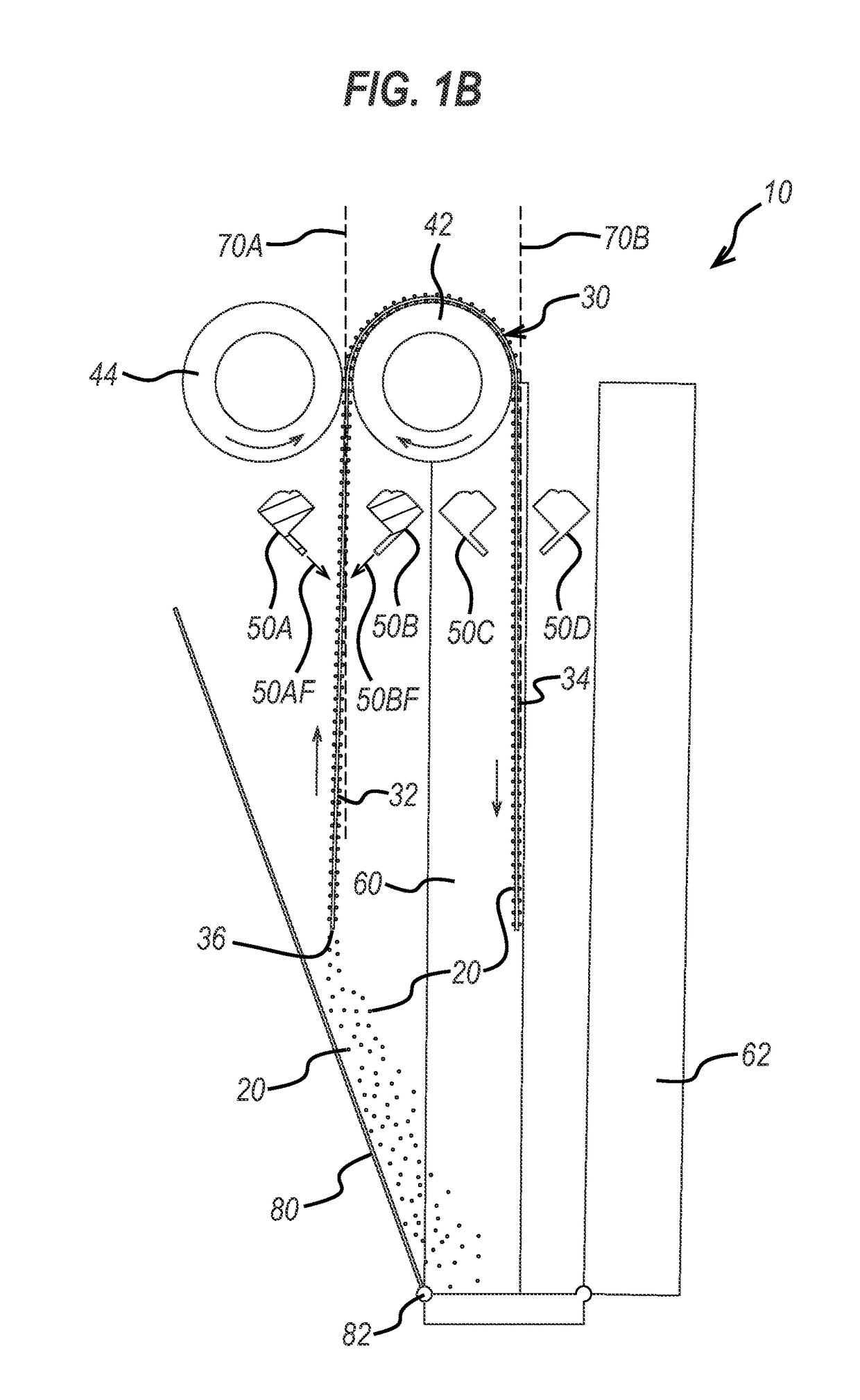

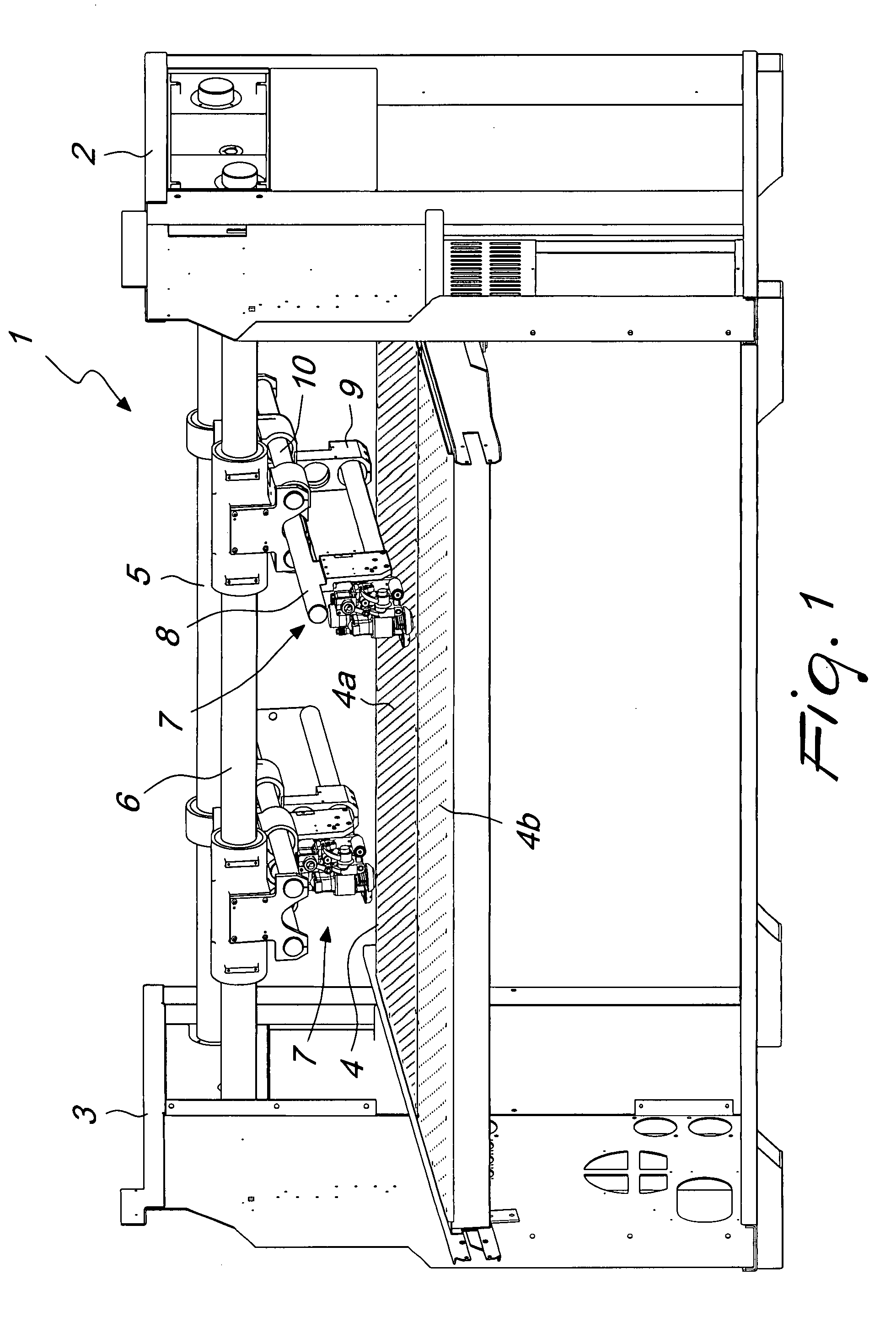

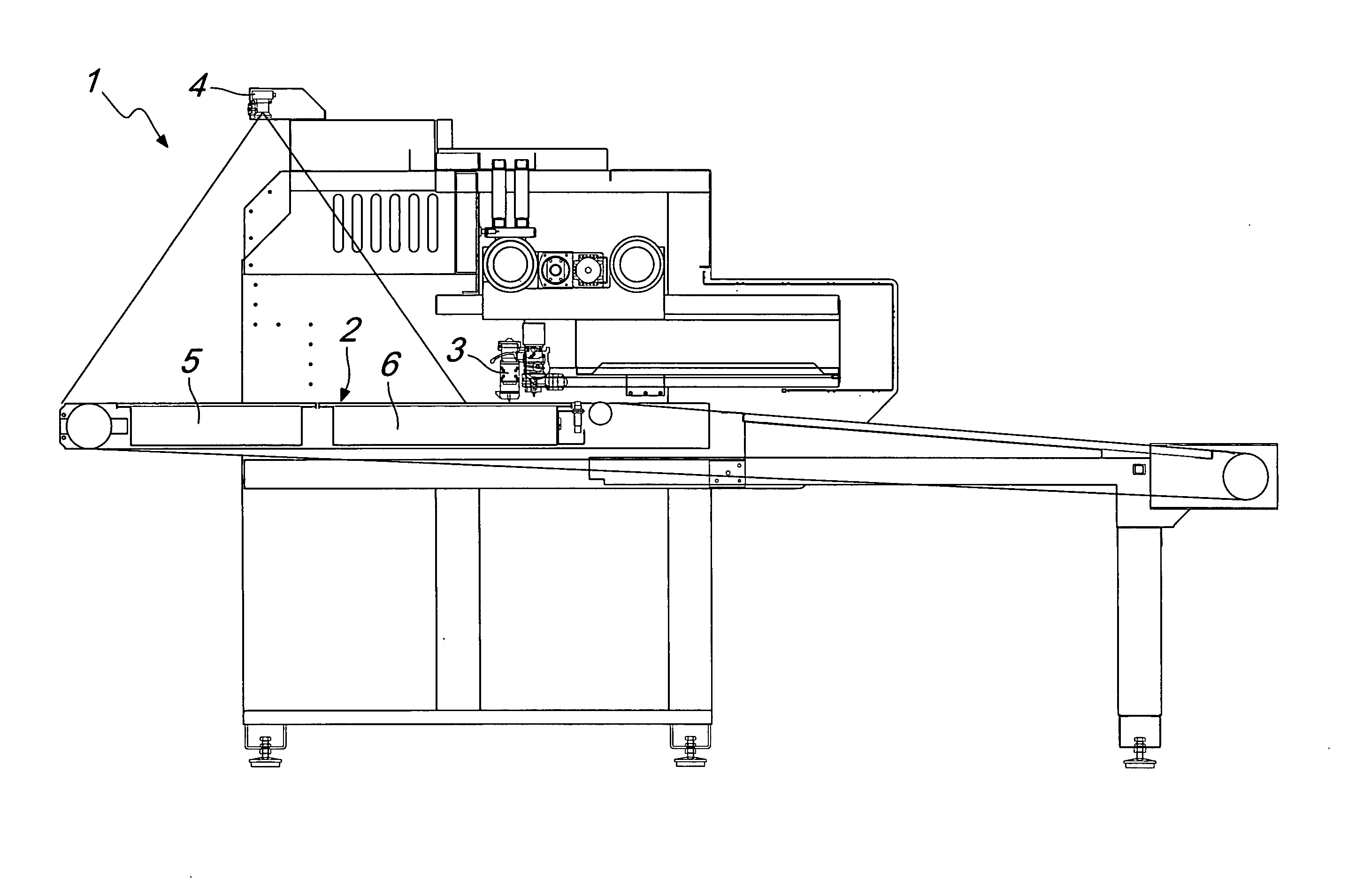

Cutting machine, particularly for leather and similar materials

ActiveUS20100043501A1Rigid enoughAdd depthLeather manufacturingLeather clicking/perforating/clickingEngineeringConveyor belt

A cutting machine, particularly for leather and similar materials, comprising a pair of shoulders which are connected by a system of guides arranged so as to lie above a conveyor belt, at least one cutting head being movable along the guide system, the movement of the cutting head in the same advancement direction as the conveyor belt and at right angles to the guide system being distributed on two or more elements, at least one of which is cantilevered.

Owner:COMELZ SPA

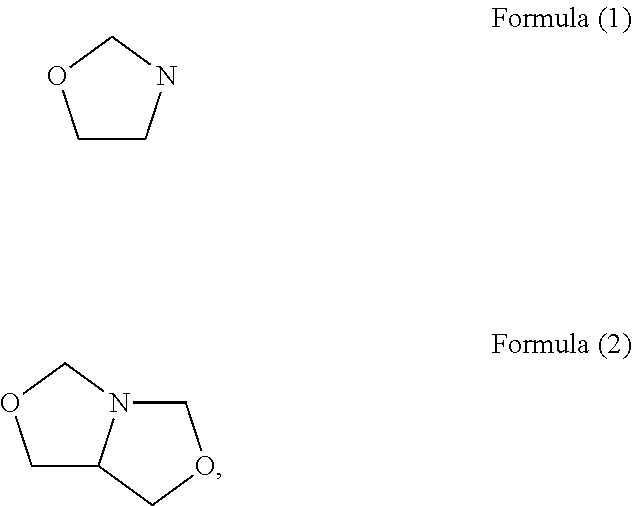

Method for treating an animal substrate

ActiveUS20170240980A1Need be addressLeather manufacturingTanning treatmentChromium freeParticulate material

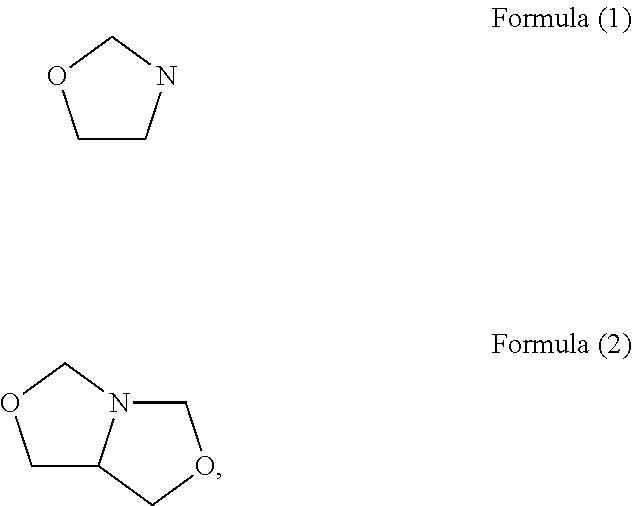

A method for tanning an animal substrate comprising the steps: i) agitating the animal substrate with a chromium-free tanning agent; and ii) agitating the animal substrate with a tanning agent having an oxazolidine group; wherein at least some of the agitation is performed in the presence of a solid particulate material having an average particle size of from 1 to 500 mm.

Owner:XEROS LTD

Anti-wet-rubbing antibacterial leather and manufacturing technique thereof

ActiveCN106148579AImprove protectionNot perishableLeather manufacturingTanning treatmentTectorial membraneAcetic acid

The invention particularly relates to anti-wet-rubbing antibacterial leather and a manufacturing technique thereof and belongs to the technical field of leather manufacturing. According to the anti-wet-rubbing antibacterial leather, a leather billet is soaked in an antibacterial solution after fat liquoring is conducted, and after drying, the surface of the leather billet is coated with a layer of protection film. The antibacterial solution comprises, by mass, 35-50 parts of honeysuckle, 20-30 parts of rhizoma smilacis glabrae, 3-8 parts of chamomile, 2-7 parts of lavender and10-20 parts of medicinal alcohol. The protection film comprises, by mass, 6-15 parts of beewax, 25-40 parts of neoprene, 1-4 parts of rosin, 12-20 parts of ethyl acetate, 0.5-1 part of nano-zinc oxide, 1-3 parts of lecithin and 0.5-2 parts of prochloraz. By soaking the leather billet into the antibacterial solution after fat liquoring is conducted and painting the layer of protection film, the leather is resistant to wet rubbing and antibacterial.

Owner:福建省永建皮革科技股份有限公司

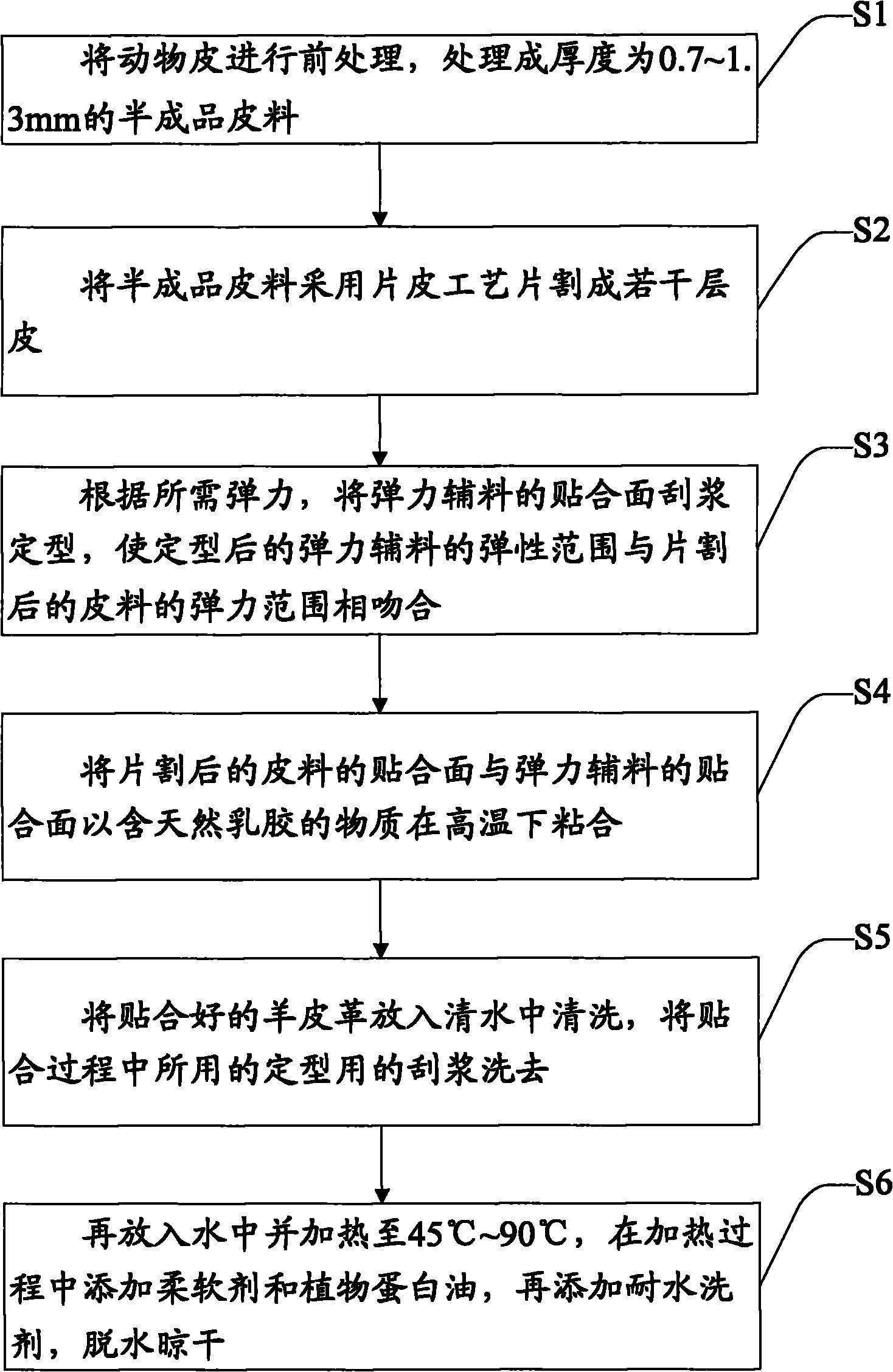

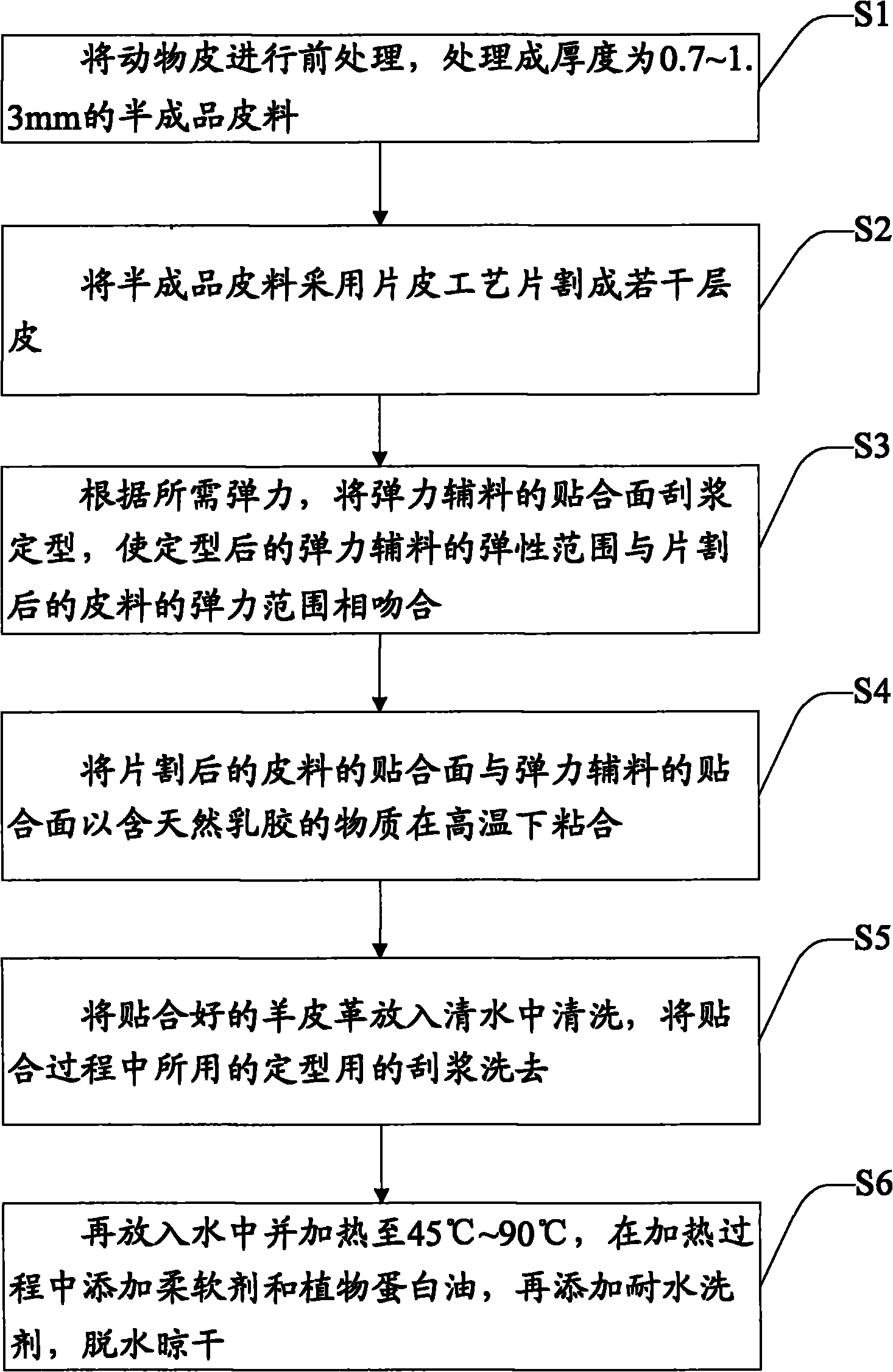

Leather material and processing method thereof

InactiveCN101956026AGive full play to the elastic propertiesIncrease elasticityLeather manufacturingComposite leathersEmulsionWork in process

The invention discloses a processing method of a leather material, comprising the following steps of: (1) pre-processing an animal skin into a semi-finished product of the leather material with the thickness of 0.7-1.3mm; (2) cutting the semi-finished product of the leather material into a plurality of layers of skins by utilizing a leather-splitting process; (3) forming scraping pulp for a binding surface of an elastic auxiliary material according to required elasticity so that the elastic range of the formed elastic auxiliary material is identical with that of the split leather material; (4) adhering the binding surface of the split leather material and the binding surface of the elastic auxiliary material at high temperature with a substance containing natural emulsion; (5) placing theadhered leather material into water for cleaning, and washing the scraping pulp for forming in the adhering process; and (6) placing into water again and heating to 45-90 DEG C, adding a softening agent and plant protein oil in the heating process, then adding a water-washing resistant agent, and dewatering and airing. The processing method of the leather material has the advantages of favorable elasticity of the obtained leather material, water-washing resistance and simple and convenient processing procedure. The invention also discloses the leather material.

Owner:谈国忠

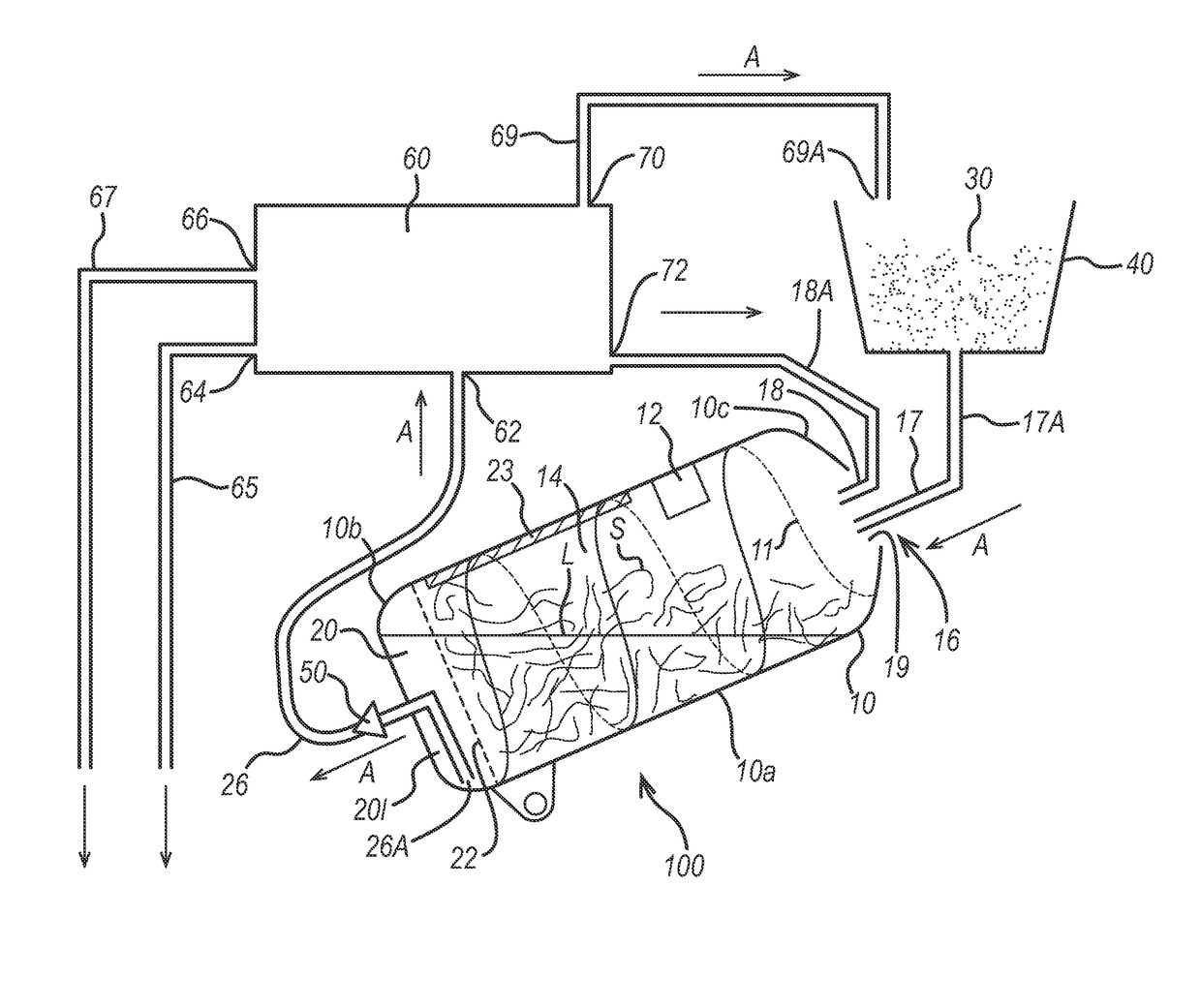

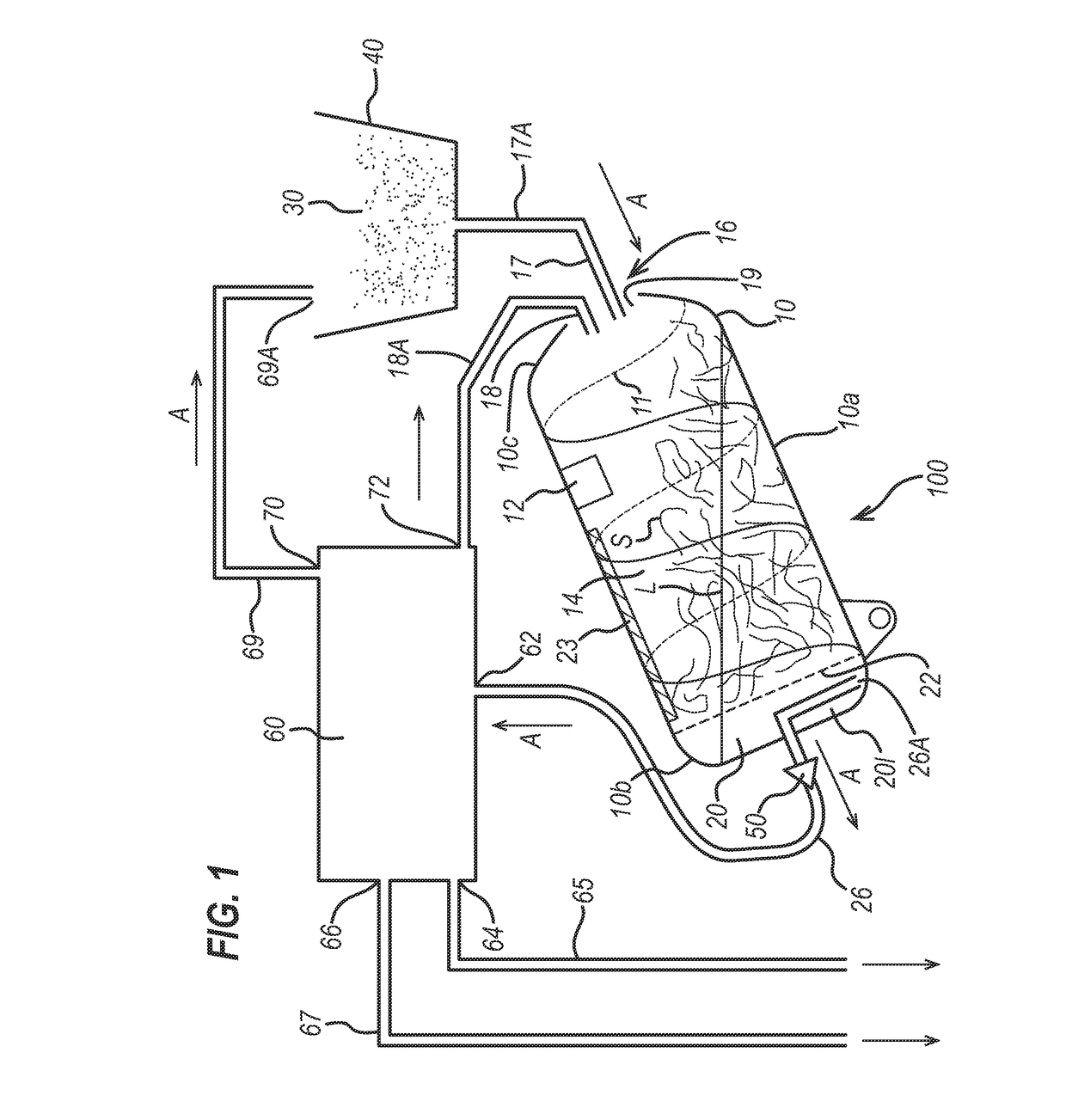

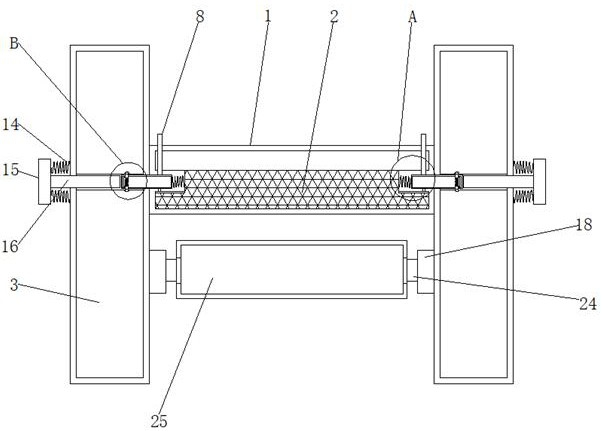

Animal skin substrate treatment apparatus and method

InactiveUS20170240981A1Extended service lifeAvoid passingLeather manufacturingTanning treatmentSolid particleEngineering

The invention relates to an improved method and apparatus for the treatment of animal skin substrates which employs a multiplicity of solid particles. There is disclosed an apparatus for treating one or more animal skin substrates with a multiplicity of solid particles and treatment liquor comprising: a rotatably mounted drum comprising an internal volume having a first portion defining a treatment volume for retaining said animal substrates and a second portion defining a collecting volume; one or more inlets for introducing solid particles and treatment liquor into said treatment volume; a partition separating said treatment volume from said collecting volume wherein said partition allows free passage of solid particles from the treatment volume to the collecting volume and prevents the passage of the substrates therethrough; a circulation path for conveying said solid particles from the collecting volume to the treatment volume; and a pumping device arranged to pump solid particles and said treatment liquor along a portion of said circulation path.

Owner:XEROS LTD

Tan sheepskin environmental protection tanning process

InactiveCN102286647AReasonable nitration processImprove product qualityLeather manufacturingTanning treatmentAgricultural engineeringEnvironmental technology

The invention discloses an environment-friendly tanning process for Tan sheepskin, which is characterized in that it adopts the following steps: 1) spraying water to return moisture; 2) beating wool; 3) soaking in water; 4) degreasing; 5) re-immersing in water; 6) degreasing again ;7) fleshing; 8) pickling; 9) tanning; 10) standing overnight; 11) water rejection; 12) brushing with fatliquoring agent; 13) standing overnight; 14) drying; 15) still damp; 16) Dry shoveling; 17) rinsing; 18) aluminum liquid brushing; 19) drying; 20) dry shoveling; 21) storage. The present invention aims at the hardening of the leather board, hair loss of needles or excessive free formaldehyde in the prior art. After analysis, it is because the traditional process of tanning the tanned surface or nitrating with formaldehyde or aldehyde and aluminum causes the leather surface of the leather board to be tanned. Unsatisfactory, high formaldehyde content and other problems. Now the skins are degreased and then pickled, tanned, brushed with fatliquoring agent, brushed with aluminum liquid, etc., so that the tanning process of Tan sheepskin is more reasonable, the product quality is greatly improved, and the use is increased.

Owner:HUASI HLDG CO LTD

Process for producing absorption styptic sponge used in operation

The production process of surgical absorbable hemostatic sponge made of animal hide incldues the following main procedures: 1. soaking animal hide chips in Ca(OH)2 aqueous solution; 2. washing expanded high material with water with pH=6.5-8, then soaking the above-mentioned material in liquid mixture of HCL and H2SO4; 3. neutralizing the soaking liquor to make its pH value be 6.5 and stirring to obtain neutral hide materia; 4. washing the neutral hide material with water and pickling to form colloidal hide material; 5. neutralizing soaking liquor and stirring; 6. cooking colloidal hide material to obtain dilute liquid gelatin; 7. vacuum adsorption and filtering to obtain pure clean dilute gelatin liquor; 8. vacuum concentration; 9. foaming under the vacuum condition; 10. using high-pressure cold air to blow said foamed gelatin liquor to obtain spongy material.

Owner:唐宝辉

Giant salamander leather production method and product thereof

ActiveCN101525672ASoft surfaceNatural textureLeather manufacturingTanning treatmentGiant salamanderSoftening

The invention provides a giant salamander leather production method and a product thereof. The technology comprises the following steps: degreasing, alkali turgescence, deashing, softening, leather mixing, re-mixing, stuffing, dyeing, drying, and the like and is characterized in the technological parameters are adopted aiming at the characteristics of giant salamander leather. The method has simple technology, natural texture and good waterproofness, air penetration and tensile resistance.

Owner:张家界金鲵生物工程股份有限公司

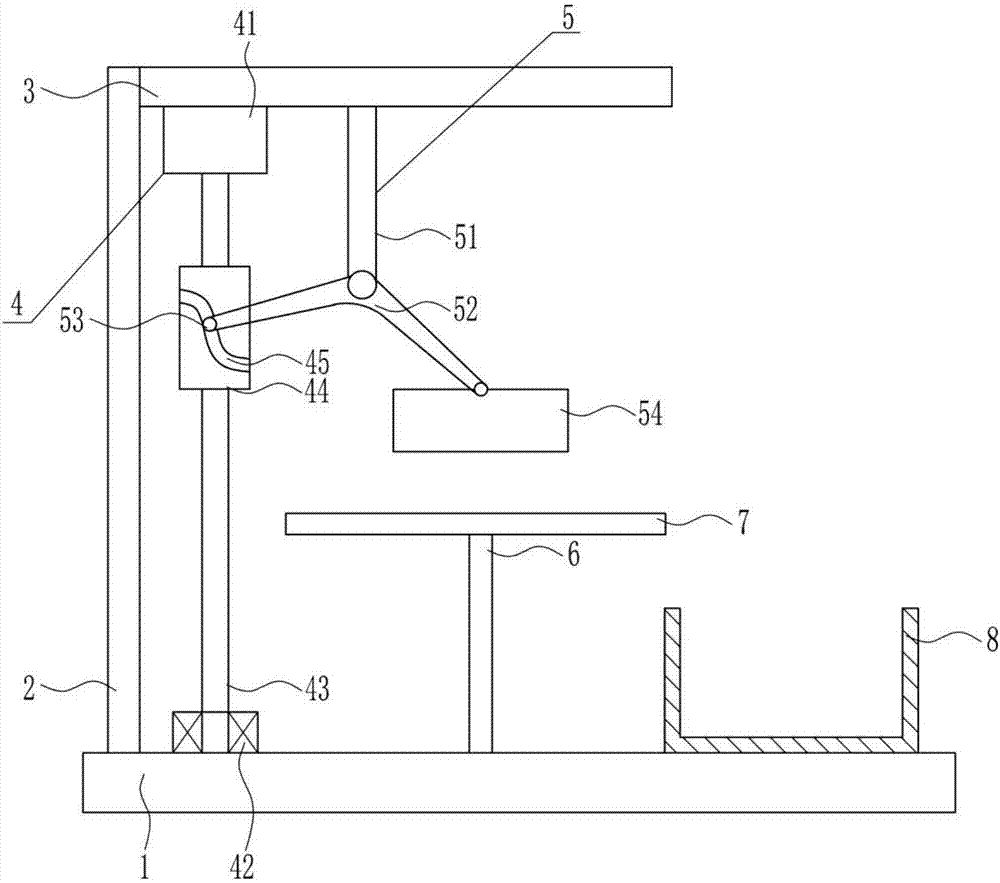

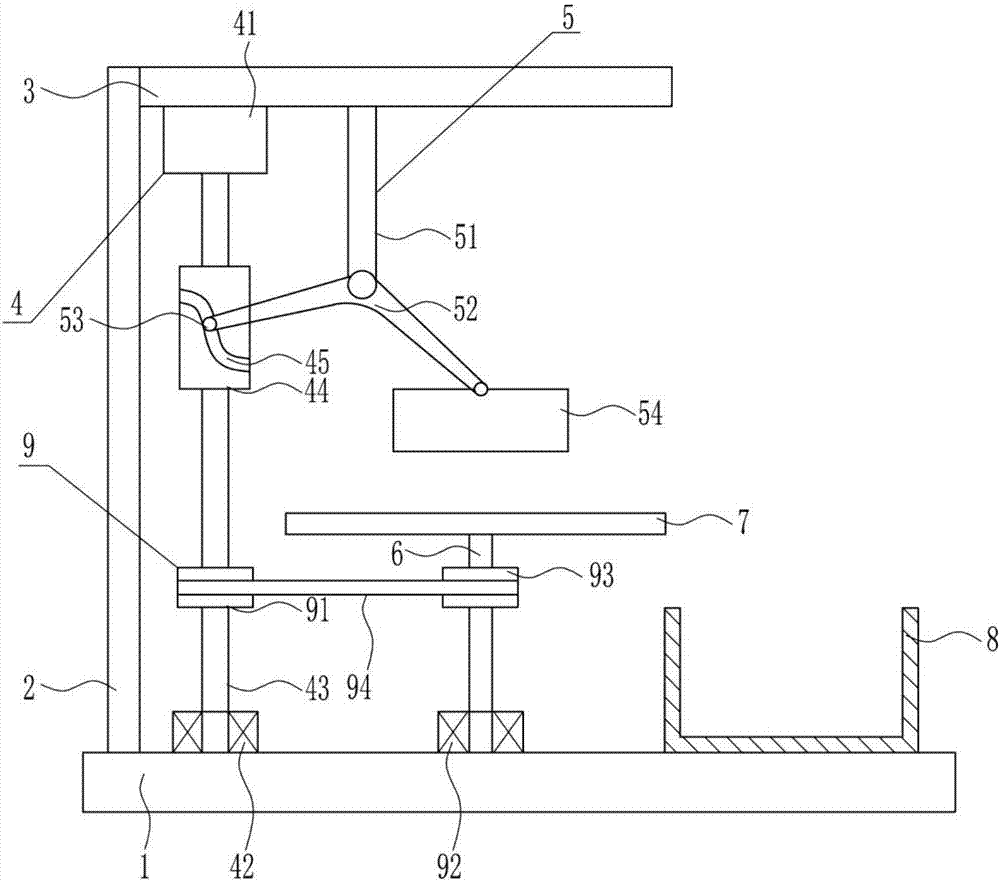

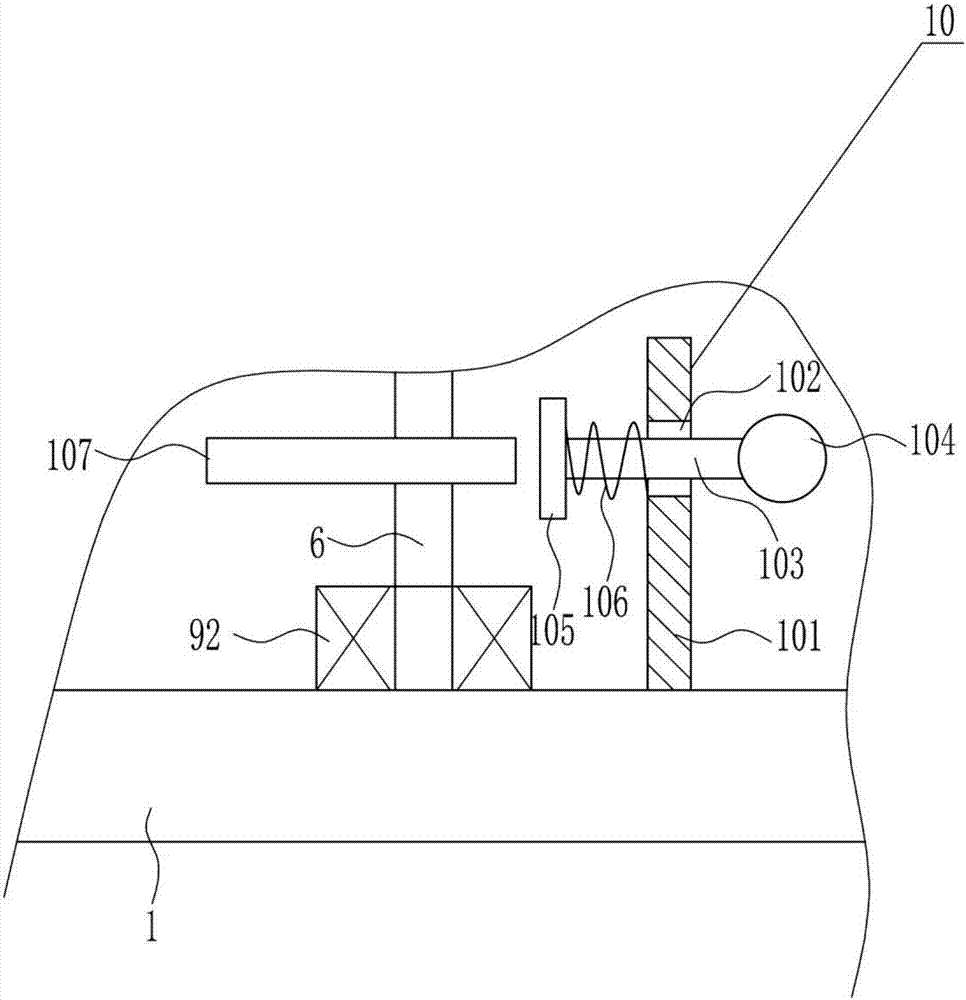

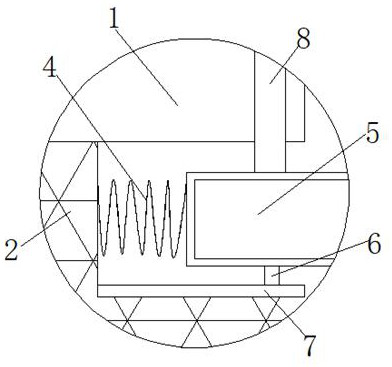

Leather product laminating device for leather product production processing

InactiveCN107460258AEven by forceImprove the pressing effectLeather manufacturingEngineeringBolt connection

The invention relates to a leather product laminating device, particularly to a leather product laminating device for leather product production processing, and provides the leather product laminating device for leather product production processing, which achieves the effects that manufacturing cost is low, operation is simple, laminated leather products are not liable to deform, and economic loss is reduced. The leather product laminating device for leather product production processing provided to solve the technical problem comprises a bottom plate, a bracket, a top plate, a driving device, a laminating device, a supporting rod, a placing plate and a collection basket, wherein the bracket, the supporting rod and the collection basket are sequentially arranged at the top of the bottom plate from left to right; the top of the right side surface of the bracket is in bolted connection with the top plate horizontally; the driving device is arranged between the top plate and the bottom plate; and the driving device is positioned on the right side of the bracket. According to the leather product laminating device, the effects that manufacturing cost is low, operation is simple, the laminated leather products are not liable to deform, and economic loss is reduced are achieved.

Owner:孙梦

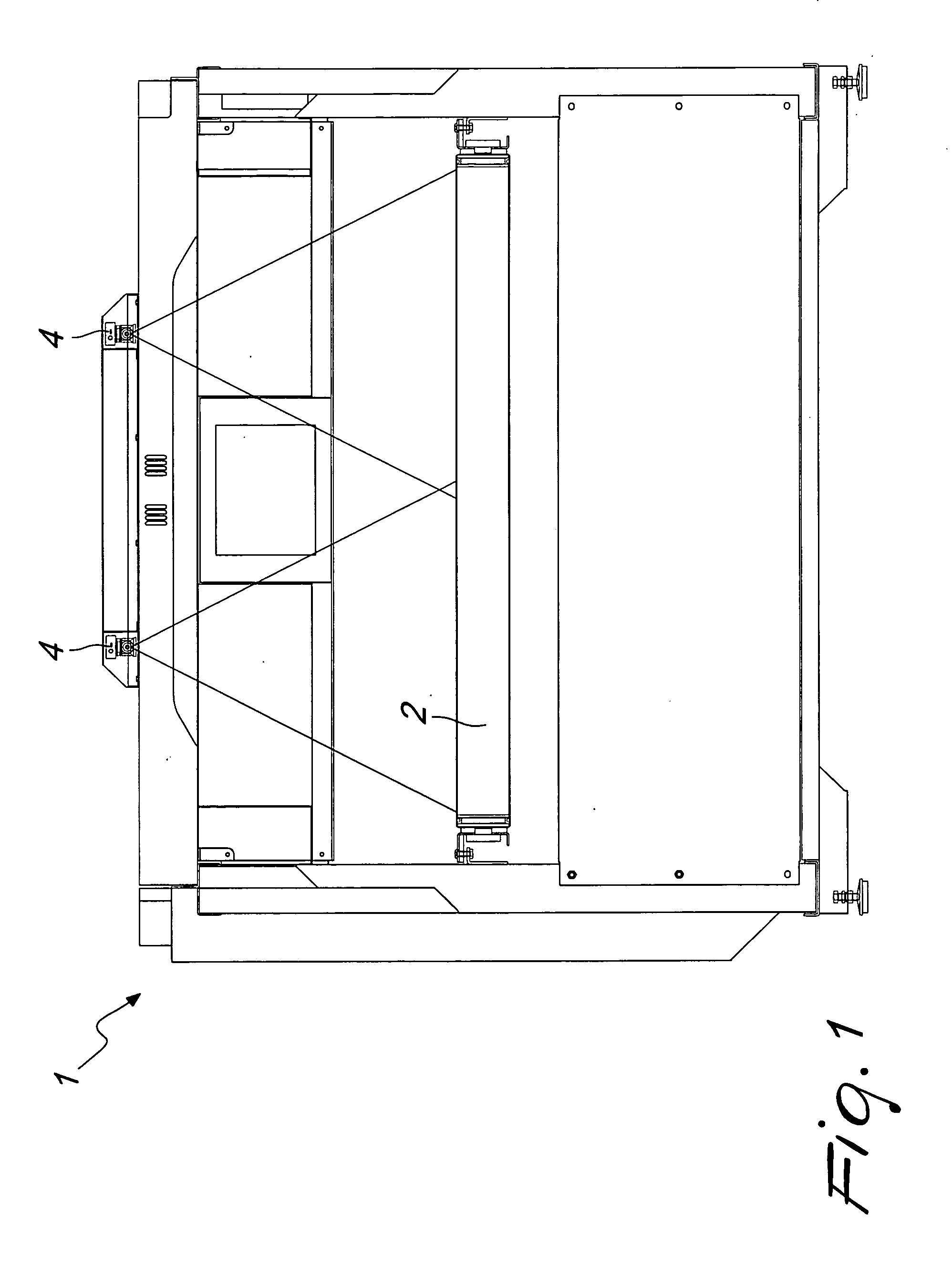

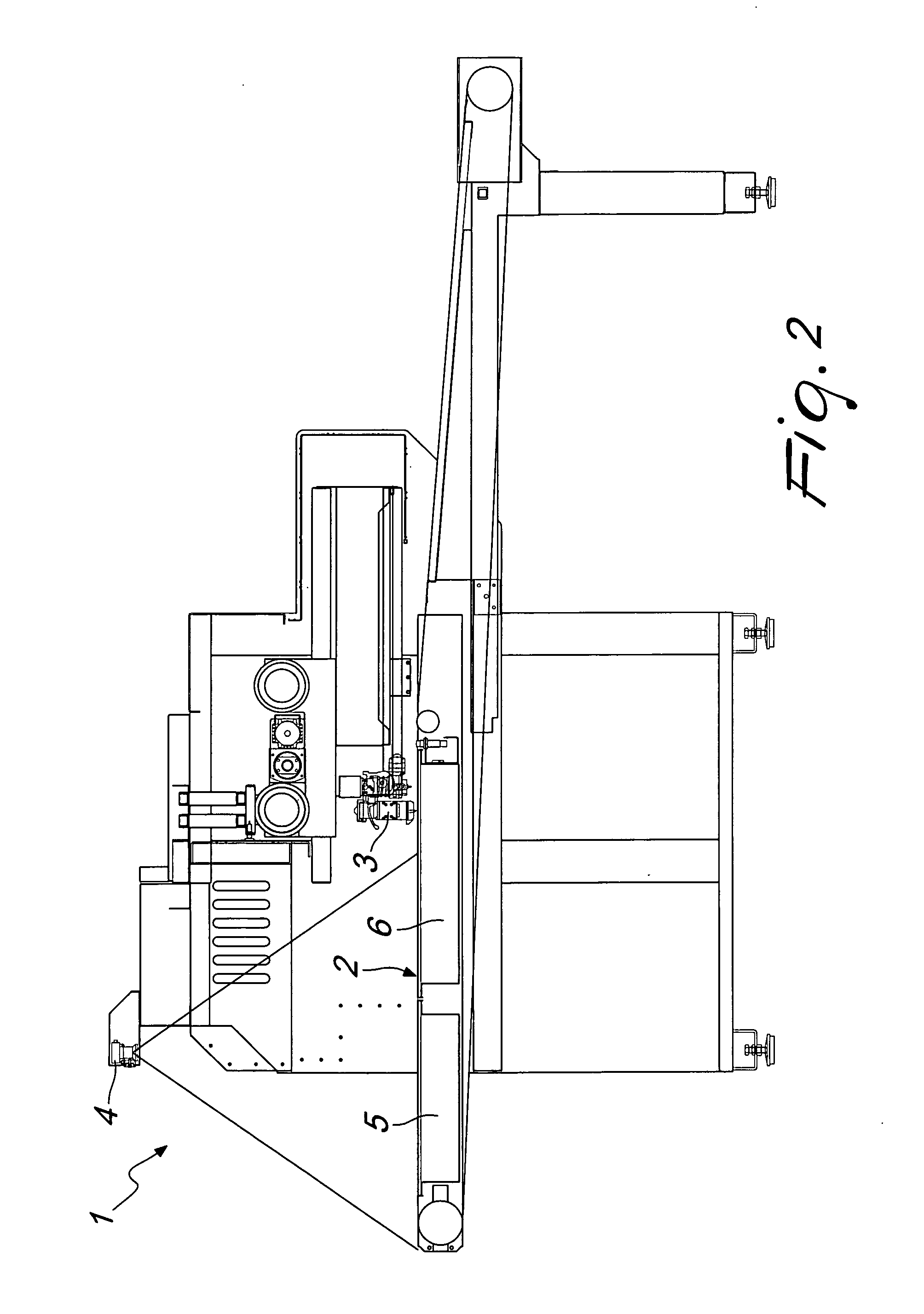

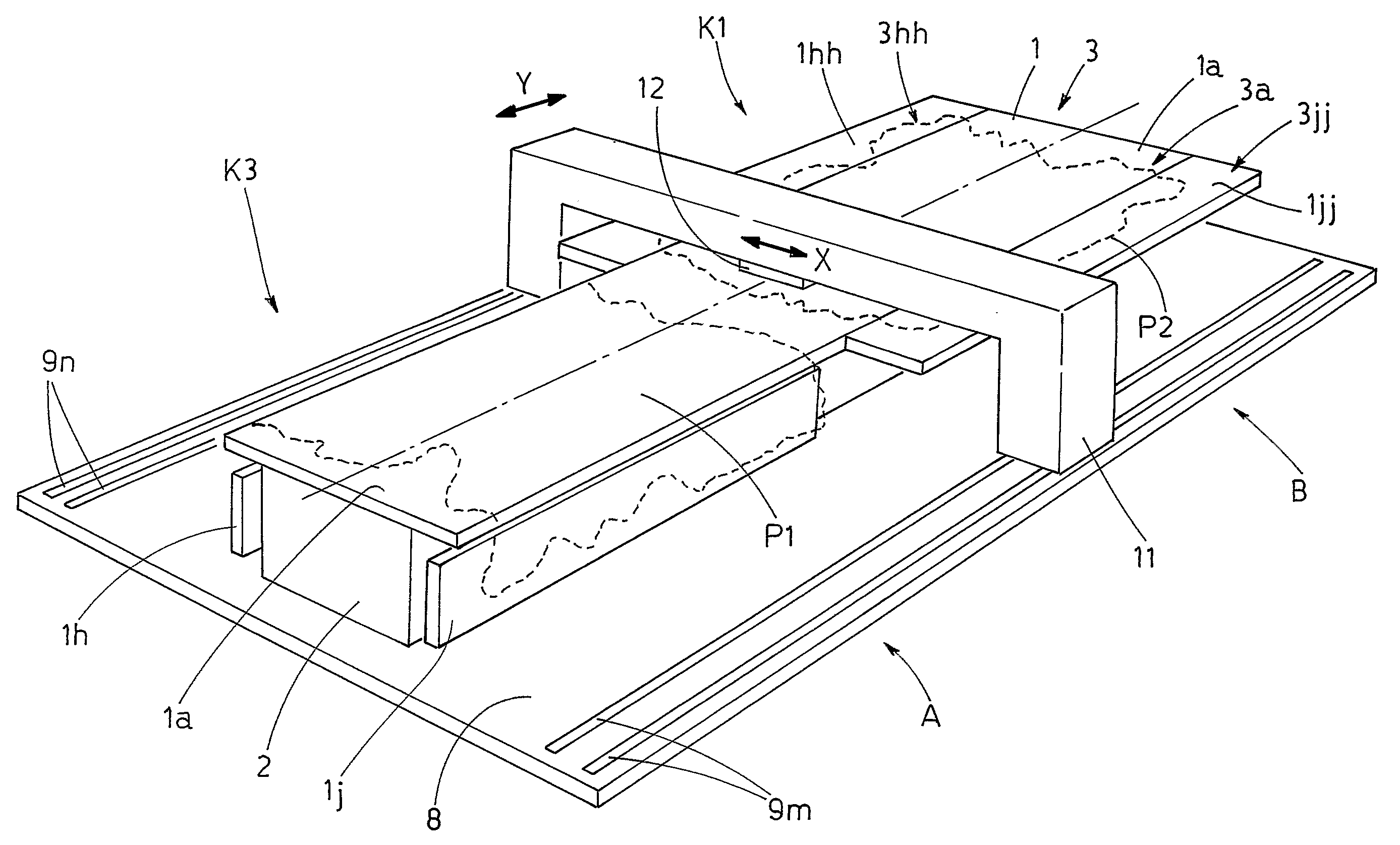

Cutting machine particulary for leather and similar materials

ActiveUS20100089103A1Advantage of productivitySimple to provideEngine sealsLeather manufacturingProviding materialConveyor belt

A cutting machine, particularly for leather and similar materials, comprising a cutting area provided with one or more cutting heads and with an area for unloading the cut parts, the areas being arranged along a conveyor belt, material detection means being provided in order to detect the position of the material before cutting it, the machine further comprising a detection area, arranged upstream of the cutting area, the material detection means being arranged in the detection area in order to detect the position of references provided on the material to be cut.

Owner:COMELZ SPA

Animal skin substrate treatment apparatus and method

InactiveUS10287642B2Maximize capacityLeather manufacturingTanning treatmentSolid particleImproved method

Owner:XEROS LTD

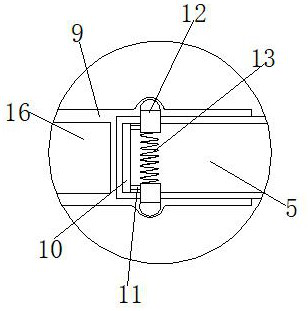

Fleshing machine for fur processing

ActiveCN111647695AEasy to cleanEasy maintenanceLeather manufacturingSkins/hides/leather/fur manufacturing apparatusStructural engineeringMechanical engineering

The invention provides a fleshing machine for fur processing, and relates to the field of fur processing. The fleshing machine for fur processing comprises a fixing column, a fleshing iron wire is fixedly installed at the bottom of the fixing column, supporting columns are arranged at the two ends of the fixing column, grooves are formed in the other two ends of the fixing column, extension springs are welded to one sides of inner cavities of the grooves, inserting rods are fixedly installed at one ends of the extension springs, first sliding rods are fixedly connected to the bottoms of the inserting rods, first sliding rails are slidably connected to the bottom ends of the first sliding rods, the bottoms of the first sliding rails are welded to the bottoms of inner cavities of the grooves, pull rods are welded to the top ends of the inserting rods, and the top ends of the pull rods penetrate through the fixing column and extends to the outer surface of the fixing column. According tothe fleshing machine for fur processing, through mutual cooperation of the devices, the whole fixing column can be detached, and therefore the fleshing iron wire can be conveniently cleaned and maintained, and the service life of the whole machine is prolonged.

Owner:谢娟

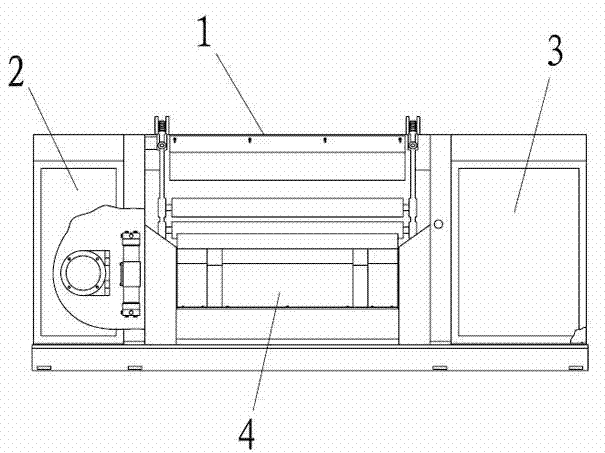

Mechanical leather splitting machine

InactiveCN102943133AEffective speed adjustmentReduce energy consumptionLeather manufacturingCouplingEngineering

The invention discloses a mechanical leather splitting machine which comprises a band-knife mechanism, a feed transporting mechanism, a knife sharpening mechanism, a drive control mechanism and a rack, wherein the feed transporting mechanism drives a compression roll, an upper bridge is arranged above the compression roll, the compression roll is pressed on a flower roll, an annular band-knife is arranged between the flower roll and a ring roll in a spaced mode, the annular band-knife is sleeved on a rim of a knife wheel, the ring roll is arranged below the annular band-knife, a rubber roll is pressed below the ring roll, and a lower machine-bracing body is arranged at the bottom of the machine; and the flower roll and the rubber roll are connected with a variable frequency motor sequentially through a universal coupling and a transmission, and grinding wheels are located on the right side of the upper bridge and arranged on the upper and lower sides of the annular band-knife. The variable frequency motor is adopted as a power device, and the rotating speed of the motor can be adjusted according to the operating state of the splitting machine, so that the power consumption can be saved, and the idling waste can be reduced; and meanwhile, through direct online knife sharpening, the efficiency of leather splitting is improved.

Owner:刘占宁

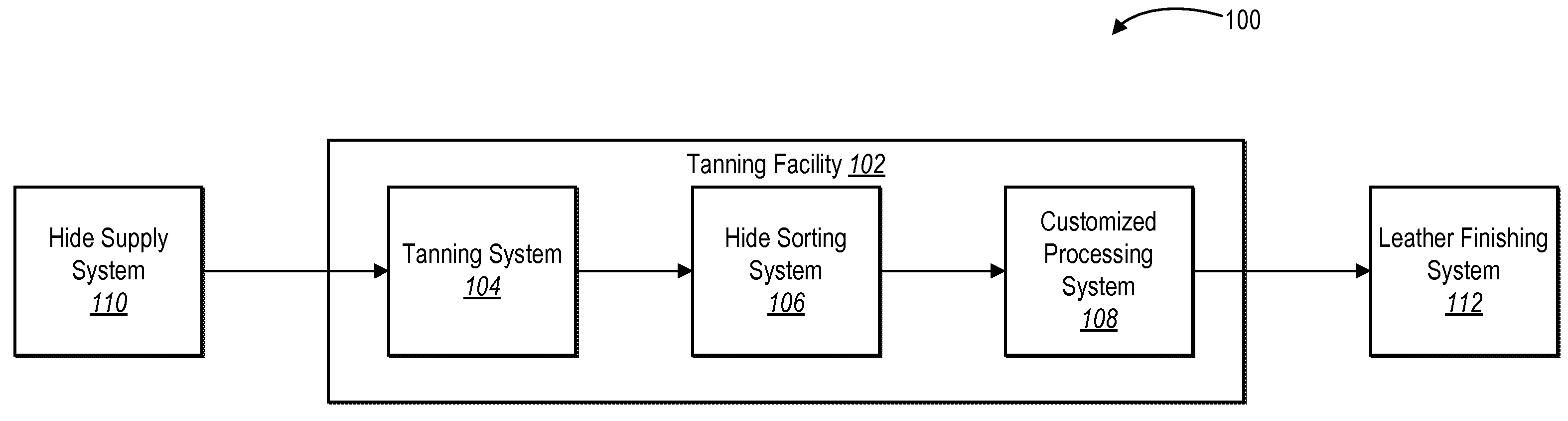

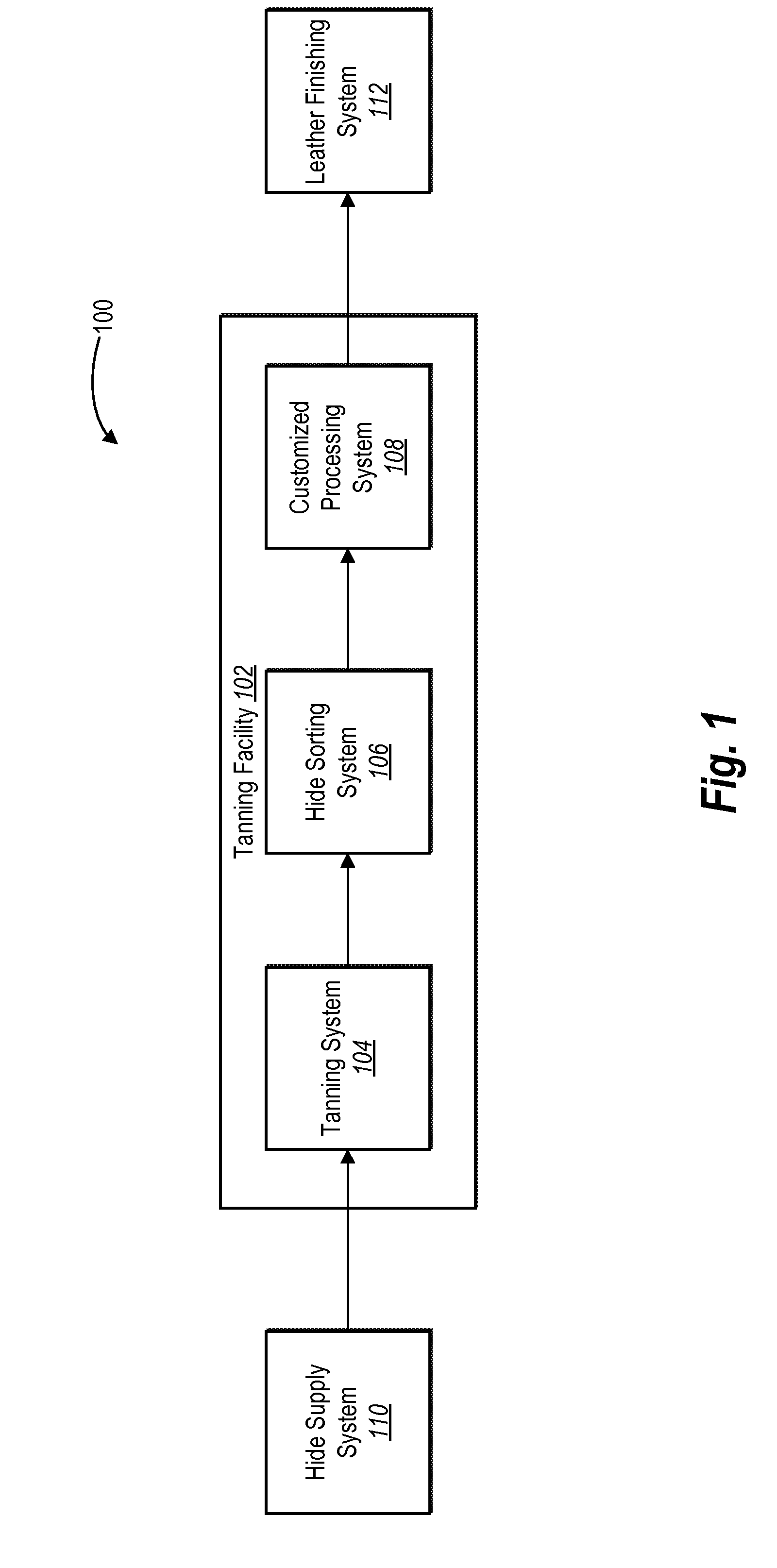

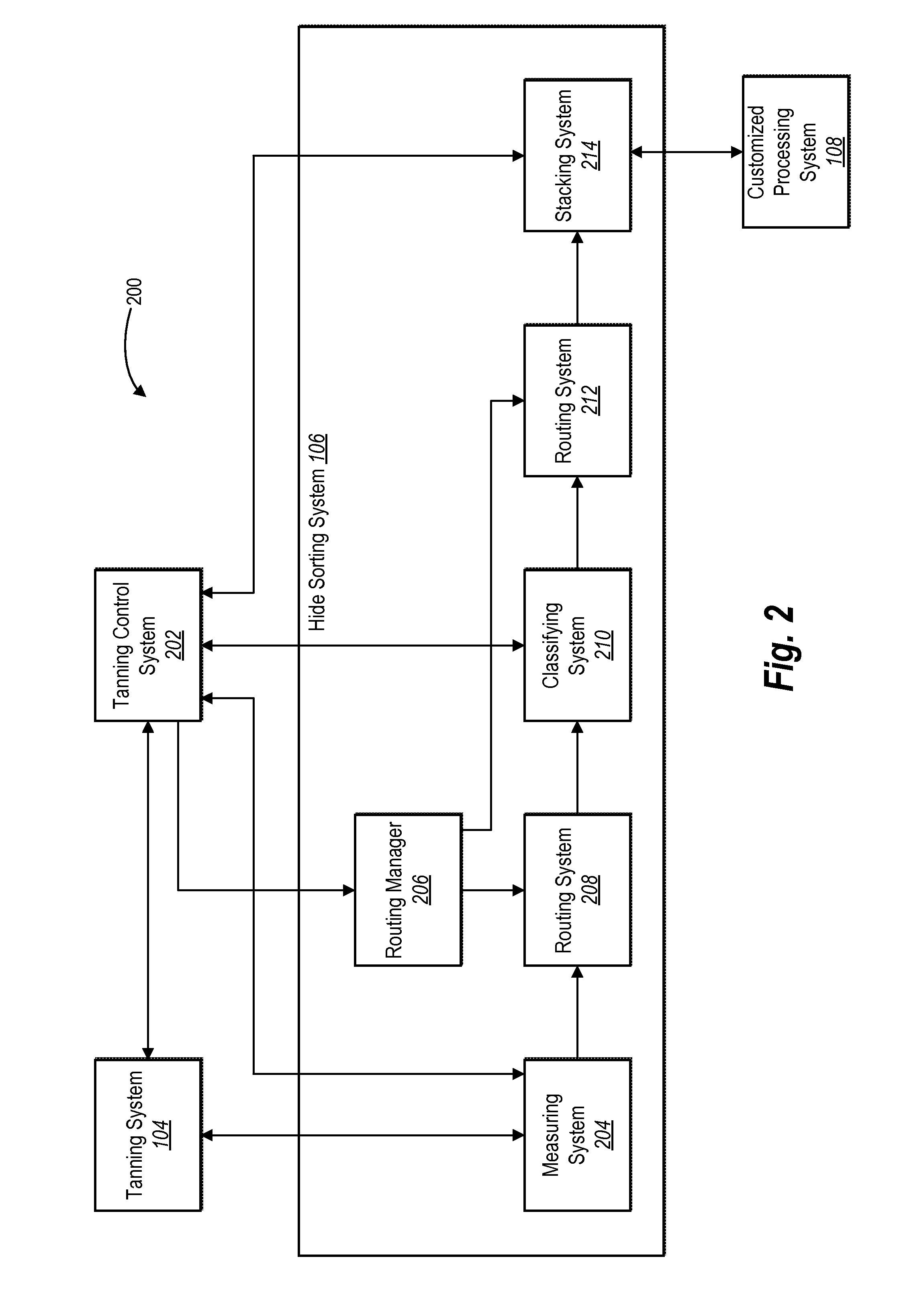

Hide sorting systems and methods

ActiveUS9530162B2Speed up the processEasy to sortLeather manufacturingTanning treatmentControl systemProcess engineering

Methods and systems for sorting hides are provided. In particular, one or more embodiments comprise a tanning control system that enhances the traceability of hides by capturing and utilizing data related to the unloading, tanning, sorting, and packaging of hides. Furthermore, one or more embodiments enable the tanning control system to improve efficiency by sorting hides based, at least in part, on data generated during prior tanning processes. Additionally, one or more embodiments facilitate the tanning control system in customizing the sorting and packaging of hides based, at least in part, on one or more hide characteristics and / or customer specifications.

Owner:NATIONAL BEEF PACKING COMPANY

Blue wet leather treatment process

ActiveCN103805722AImprove area yieldReduce dosageLeather manufacturingLeather/skins/hides/pelt chemical treatment apparatusCost savingsChemistry

The invention relates to the technical field of leather processing, and provides a blue wet leather treatment process which increases the yield of leather area, and is lower in loose side rate, uniform to dye, better in leather performance, less in use level of grease, economical, and cost-saving. The process comprises the following steps: splitting; shaving; weighing; rinsing; and retanning. The process is characterized in that at least a shaving treatment is further carried out after retanning step.

Owner:XINGYE LEATHER TECH CO LTD

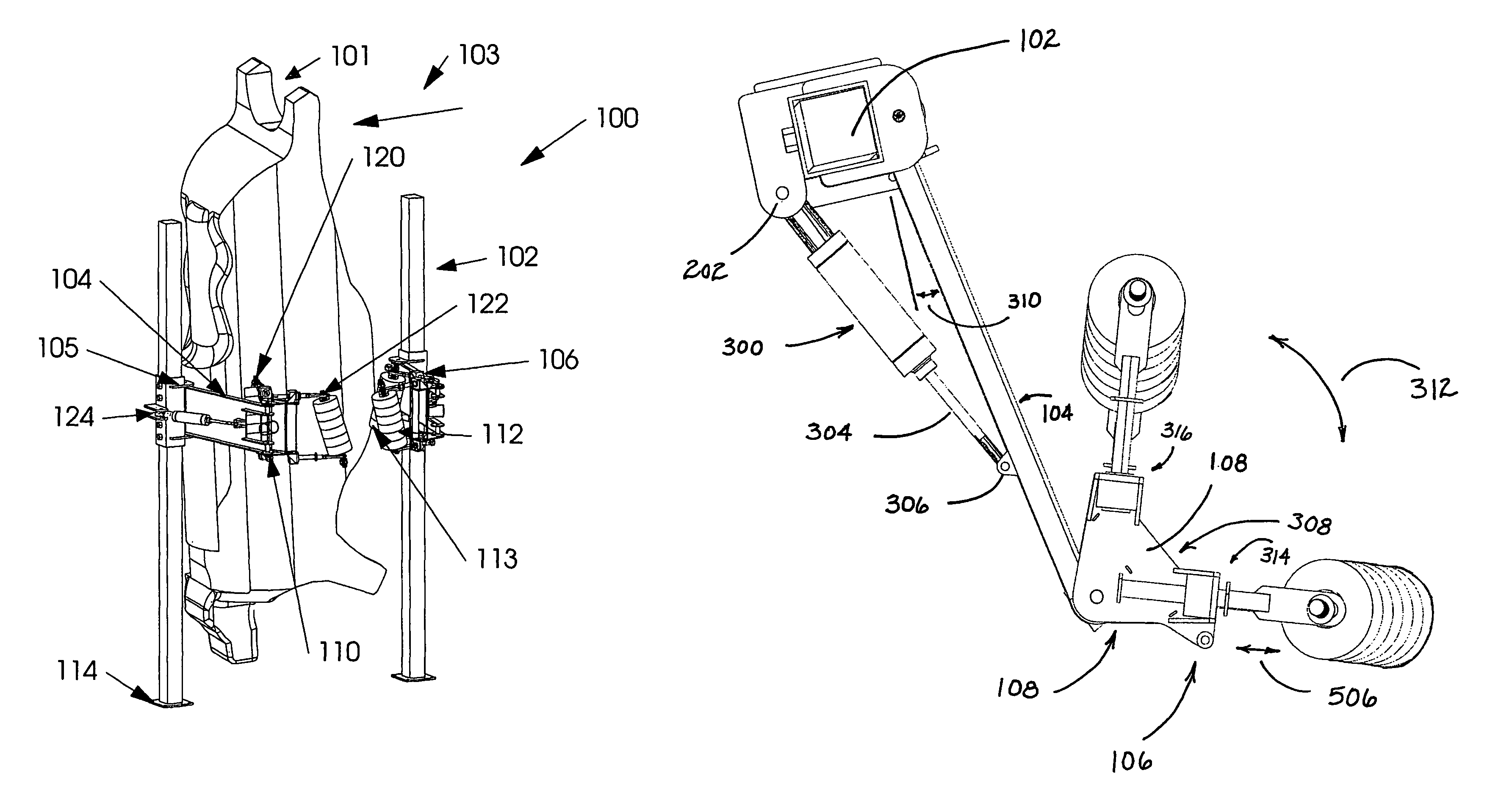

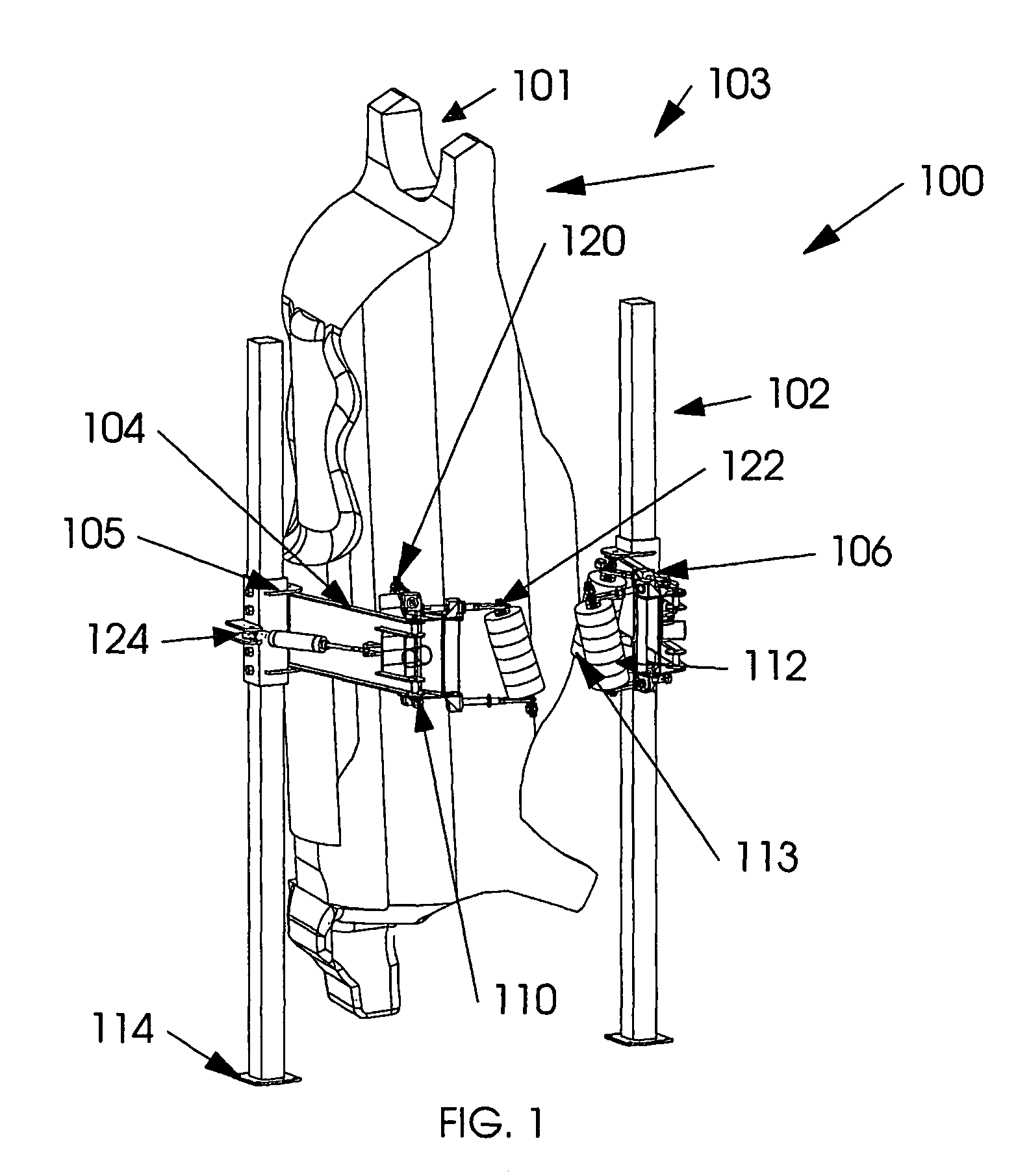

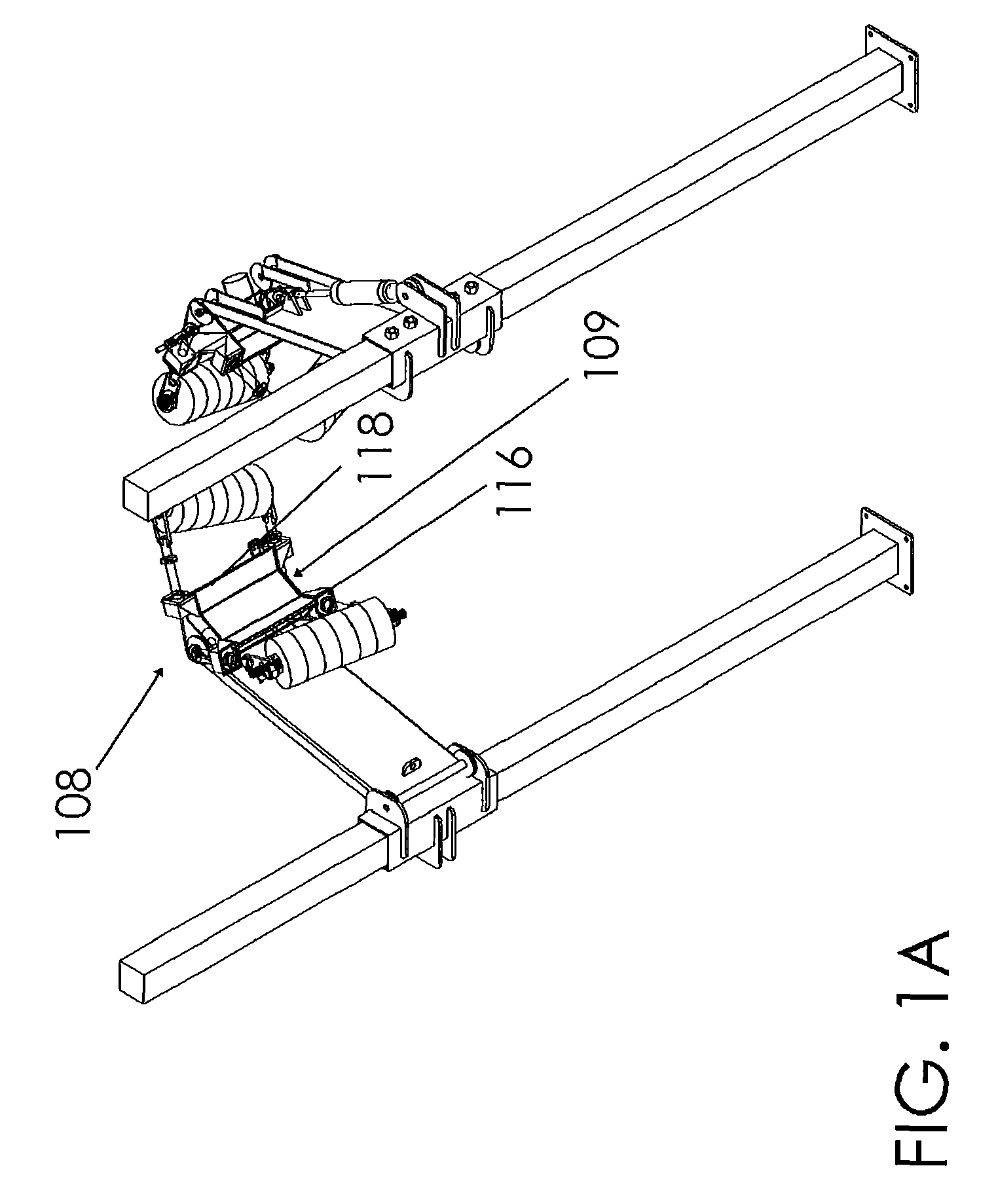

Method and apparatus for removing water from hide of cattle

InactiveUS8176652B2Solve the lack of tensionLeather manufacturingDrying solid materials with heatHydraulic cylinderHeifer calf

An apparatus and method for a water removing roller device for removing excess water from the hide of a cattle, which uses pliable urethane roller stacks that can be attached by an arm structure. The roller structure can be mounted on a hinge to an arm thereby allowing the structure to swivel. The arm can be attached to a stationery device with a hinge, which is also allowed to swivel. A tension device, for example, a spring or a hydraulic cylinder can be attached to the back of the arm and connected to the stationery device to provide enough tension on the structure to keep the rollers in contact with the cattle hide, thereby pressing out the water allowing it to run off prior the blood plasma saving section.

Owner:TYSON FRESH MEATS

Method for treating an animal substrate

A method for tanning an animal substrate comprising the steps: i) agitating the animal substrate with a chromium-free tanning agent; and ii) agitating the animal substrate with a tanning agent having an oxazolidine group; wherein at least some of the agitation is performed in the presence of a solid particulate material having an average particle size of from 1 to 500 mm.

Owner:XEROS LTD

Preparation process of bovine blue wet leather

ActiveCN109628663AGood emulsifying and moisturizing effectImprove uniformityLeather manufacturingLeather clicking/perforating/clickingHair removalSalt free

The invention relates to the technical field of leather processing and provides a preparation process of bovine blue wet leather with a large leather area, broad growth patterns, great comprehensive performance and small environmental pollution. The bovine blue wet leather prepared by the preparation process of the bovine blue wet leather is large in width, broad in pattern, compact and fine in grain surfaces, consistent in color, uniform in thickness, soft, plump and elastic in leather body and high in physical strength. Moreover, the production process flow is simple and easy to implement, and the production cost is proper; in an implementation process, recycling of wastewater, preservation and removal of hair with less ash and sulfur, ammonia-free deashing and softening, salt-free pickling chrome tanning and other clean production technologies are also adopted. The water for tanning can be saved, the pollution of tanning is obviously reduced, the pollution disposal cost is lowered,considerable benefits of energy conservation and emission reduction are provided, and the preparation process is suitable for industrial production and use. The preparation process of the bovine bluewet leather specifically comprises the following steps of batching of bovine raw material leather, soaking in water, hair removal and expansion, beef removal, splitting, ash removal and softening, pretreatment, dewatering and peeling, soaking in acid and tanning with chrome and washing with water and discharging.

Owner:XUZHOU XINGNING LEATHER CO LTD

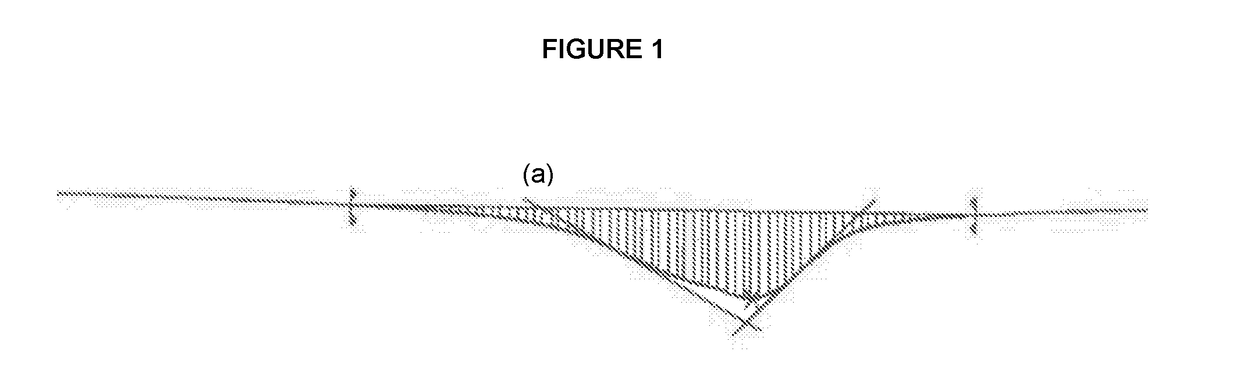

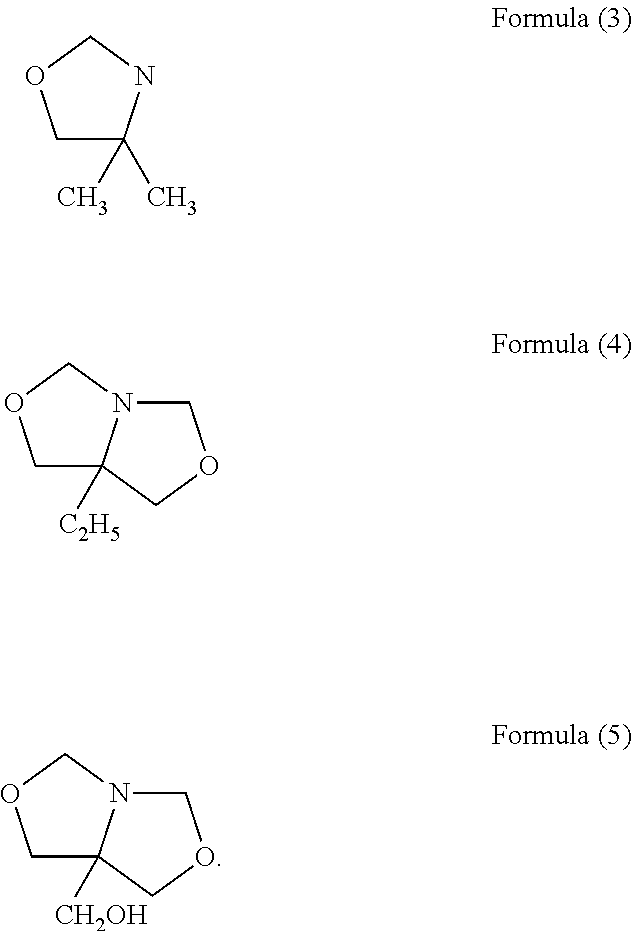

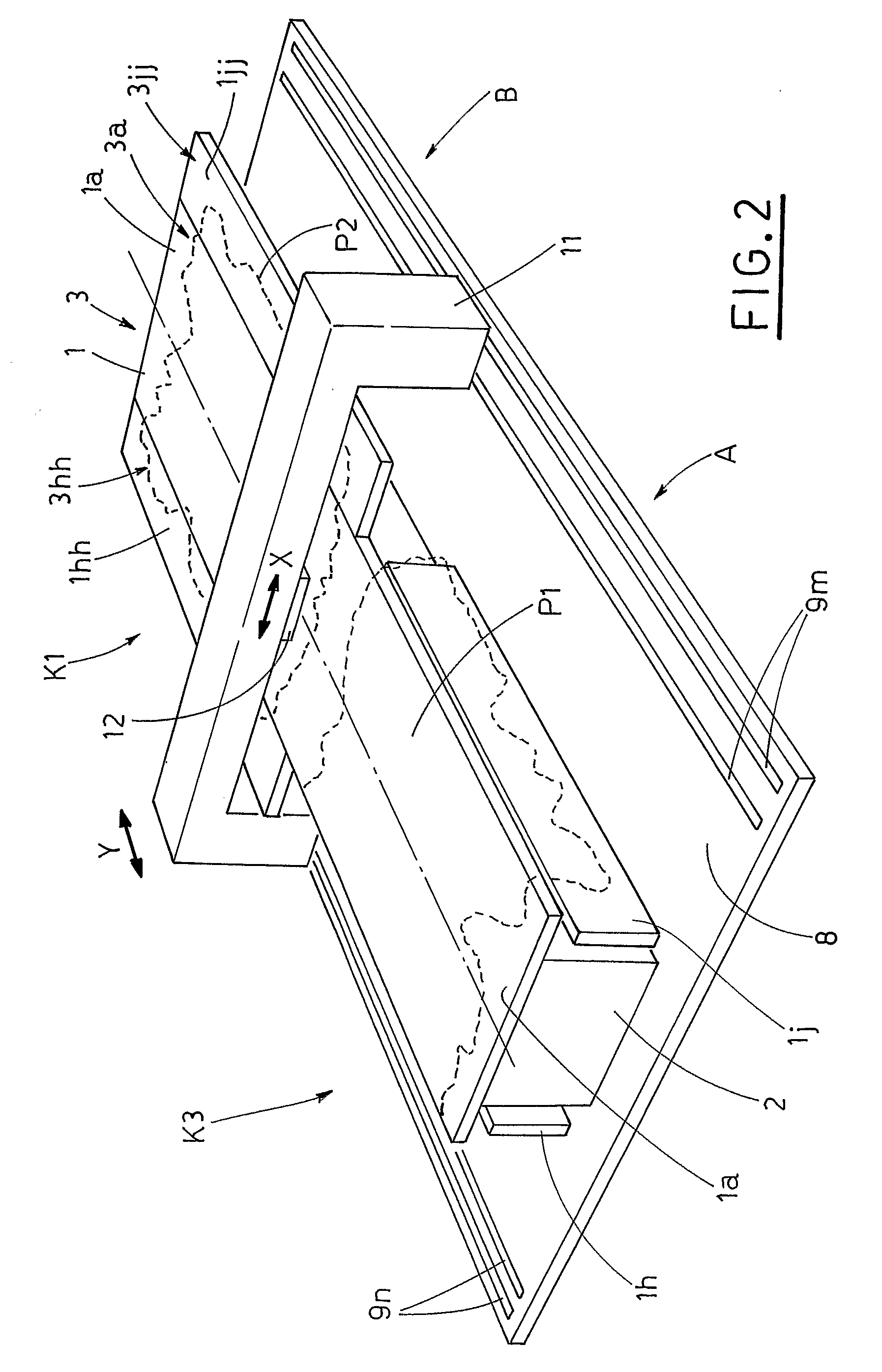

Work Table For an Automatic Machine For Cutting Leathers and the Like

ActiveUS20080149003A1Shorten the timeIncrease of machine production rateLeather clicking/perforating/clickingFur dressingMachineAutomaton

A work table for an automatic machine for cutting leathers and the like, includes a plurality of holes opening outwards and communicating with a vacuum source, to make portions of leathers to adhere to the active surface (3) of the work table (1). The work table (1) includes a central body (1a), supported by a fixed structure (2). At least one lateral portion (1h, 1j), connected to the fixed structure (2), is moved by first motion means (10h, 10j) between at least one work configuration (K1), in which its active surface (3h, 3j) is aligned with the active surface (3a) of the central body (1a), to define the active surface (3) of the work table (1), and a rest configuration (K2) of reduced dimension, in which the active surfaces (3a, 3h, 3j) of the central body (1a) and the lateral portion (1h, 1j) are arranged at an angle with respect to each other.

Owner:TESEO SPA

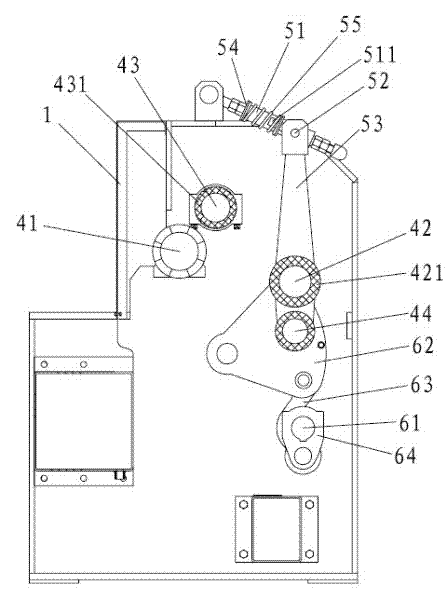

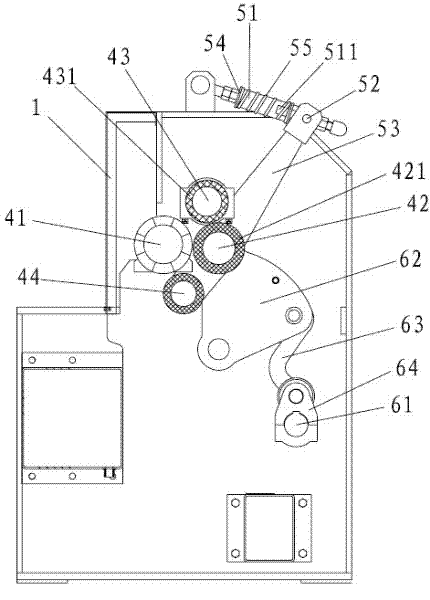

Unhairing machine

InactiveCN102399912AAvoid adverse phenomenaAvoid damageLeather manufacturingSkins/hides/leather/fur manufacturing apparatusEngineeringScrew thread

The invention relates to a peltry unhairing technology, and especially relates to an unhairing machine. The invention is realized through the following technical scheme: the unhairing machine comprises a frame, a hydraulic system arranged on one side of the frame, a regulator cubicle arranged on the other side of the frame and a transmission mechanism arranged in the middle of the frame. The transmission mechanism comprises a rotor hinged to the frame and a transport roller arranged in the frame; two ends of the transport roller are hinged to elastic compensation structures and feeding structures; the rotor comprises a rotating roller, and a left-hand screw thread-shape knife zone and a right-hand screw thread-shape knife zone, which are fixed on the rotating roller. The invention employs a physical mode to carry out unhairing on peltry, so as to avoid insufficient background technology and damage to the peltry.

Owner:HUZHOU HUAFEI MACHINERY

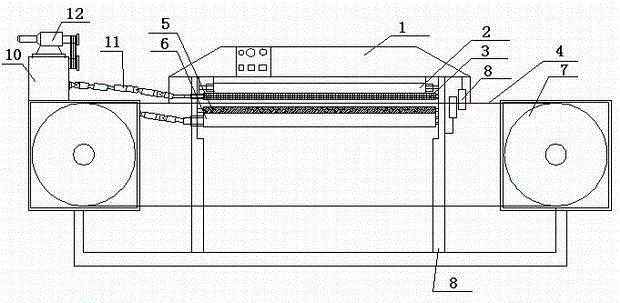

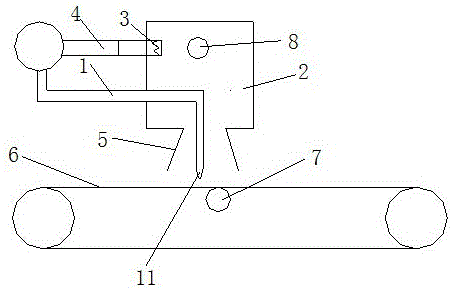

Leather dust removal machine

InactiveCN105018653AReduce labor intensitySimple structureLeather manufacturingDispersed particle filtrationWorking environmentEngineering

The invention discloses a leather dust removal machine which comprises an air injection pipeline, an air chamber, a cloth bag dust filter, a clean air outlet, a dust sucking opening, a leather conveying belt and a vibration motor, wherein the dust sucking opening is formed in the leather conveying belt, and an air injection port is formed in the center of the dust sucking opening and formed in the tail end of the air injection pipeline; the air injection pipeline is connected with the clean air outlet through an air blower, and the air chamber is arranged above the dust sucking opening; a suction fan and the cloth bag dust filter are arranged in the air chamber, and the clean air outlet is formed in the air chamber; the vibration motor used for shaking off scraps on leather is arranged under a belt of the leather conveying belt. The leather dust removal machine has the advantages of being simple in structure, clean in dust removal, high in efficiency and strong in practicality, greatly reduces the labor intensity of workers, and provides an environmental-friendly and healthy working environment for the workers.

Owner:湖州南浔新富明家私有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com