Patents

Literature

71results about "Leather edge finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing leather

ActiveCN102586497ARelieve pressureLow costLeather manufacturingPre-tanning chemical treatmentEngineering

The invention relates to the field of the manufacture of leather and provides a process for producing the leather. The production cost is reduced by changing the formula of the process. The process comprises the following steps of: preparing a crust, milling the crust, toggling, tumbling, trimming, patching, buffing, blowing dust and cleaning, spraying cations, tumbling for the second time, spraying, repairing corners, tumbling for the third time, trimming for the second time, rolling, obtaining G gloss, pressing a plate, spraying for the second time, obtaining water gloss, tumbling for the fourth time, milling for the second time, staking, tumbling for the fifth time, and spraying a handle agent.

Owner:XINGYE LEATHER TECH CO LTD

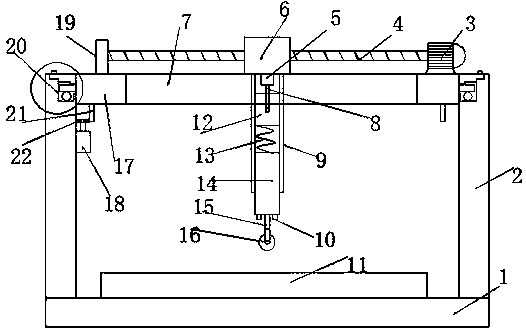

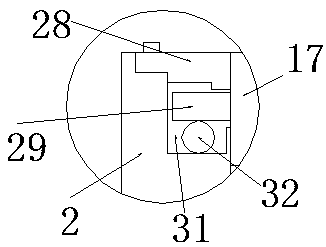

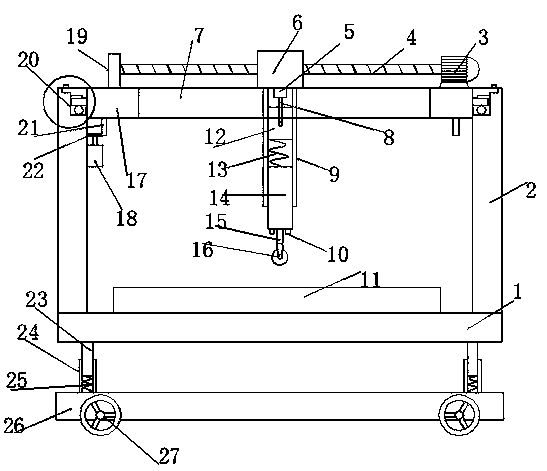

Leather wallet material processing device

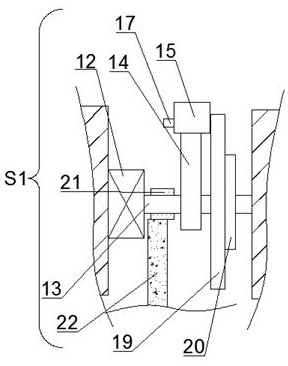

ActiveCN110172533AGuaranteed smooth grindingSimple structureEdge grinding machinesGrinding drivesEdge surfaceBristle

The invention discloses a leather wallet material processing device. The leather wallet material processing device comprises a processing box. The processing box is internally provided with a transmission cavity. A grinding threaded rod rotates to drive a grinding threaded block to move left and right. The grinding threaded block moves to drive a pressure rod to move. The moving mechanism drives the pressure rod to move up and down to adjust the position and press leather. A main motor of a transmission mechanism provides power to drive the pressure rod to move left and right and drive a grinding stone to rotate to conduct grinding on the edge of the leather. The leather wallet material processing device grinds the edge surface of the leather smooth. An auxiliary motor in a waxing mechanism provides power to drive a brush block to move left and right to conduct waxing on the surface of the leather automatically through bristles.

Owner:义乌市玉刚箱包有限公司

Suede leather production method

ActiveCN108165678AEnhance the feelImprove fullnessTanning treatmentPre-tanning chemical treatmentPhosphateTannin

The invention provides a suede leather production method. Suede leathers are obtained through performing water leaching, ash leaching, ash removal, acid leaching, tanning, uniform turning, retanning,neutralization, dyeing and degreasing and drying on leathers. The retanning process comprises the following steps: after 2% of acid-resistance acrylic acid and 0.5% of acid-resistance grease are usedfor treatment, pH is controlled as 3.0; and a chromium retanning agent is added for treatment. The neutralization process comprises the following steps: 150% of water, 2% of sodium formate and 2% of neutralization auxiliary are added; a rotating drum is rotated by 60 min; then, water washing is performed by 10 min; and the temperature is increased to 60 DEG C. The dyeing and greasing process comprises the following steps: 150% of water with a temperature of 40 DEG C, 1.5% of dicyandiamide tannin, 2% of amphoteric synthesized tannin, 4% of tannin extract and 2% of dye are added; the rotating drum is rotated by 50 min; 2% of sulfonated oil, 2% of phosphate and 5% of synthesized oil are added; the rotating drum is rotated by 50 min; 0.8% of formic acid is added; and the drum is stopped by 3 hours. The retanning, neutralization and greasing processes are improved to improve uniformity, hand feel, fullness, reading-writing effect and mercerization of the suede leathers.

Owner:NINGXIA JINHAI LEATHER IND

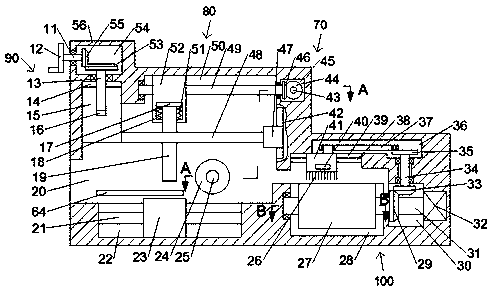

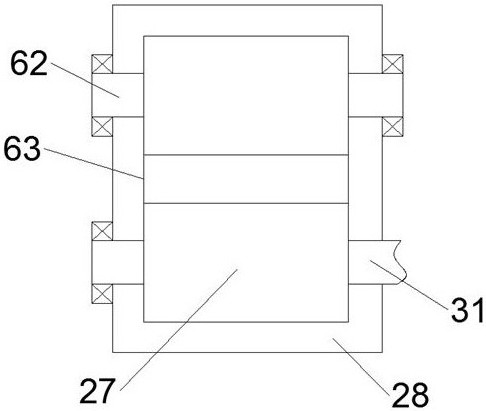

Safe and reliable leather processing edge pressing device

ActiveCN110205415AEffective protectionAvoid accidentsSkins/hides/leather/fur manufacturing apparatusLeather edge finishingEngineeringMechanical engineering

The invention discloses a safe and reliable leather processing edge pressing device. The safe and reliable leather processing edge pressing device comprises a body. An edge pressing cavity is formed in the body, a rolling device is arranged in the edge pressing cavity, a pressing roller is arranged in the rolling device, and a door opening and closing device is arranged on the right side of the edge pressing cavity. In the pressing process of the pressing roller, the door opening and closing device is synchronously closed, accidents generated in the edge pressing process of leather are avoided, a lifting device is arranged on the upper side of the rolling device, and the lifting device can drive the pressing roller to rise and fall and drive the door opening and closing device to be closed. The leather is put in a sealed environment to be subjected to edge pressing, the leather can be effectively protected in the edge pressing process, the accidents are avoided, meanwhile, the leatheris driven to move through rolling on the upper side and pressing on the lower side, and wrinkles generated by sliding caused by friction in the edge pressing process can be effectively avoided.

Owner:海宁高卓新材料股份有限公司

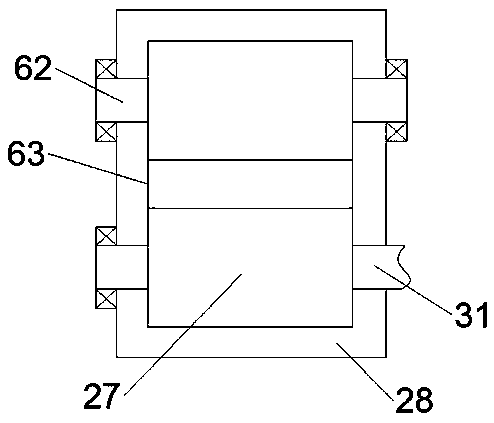

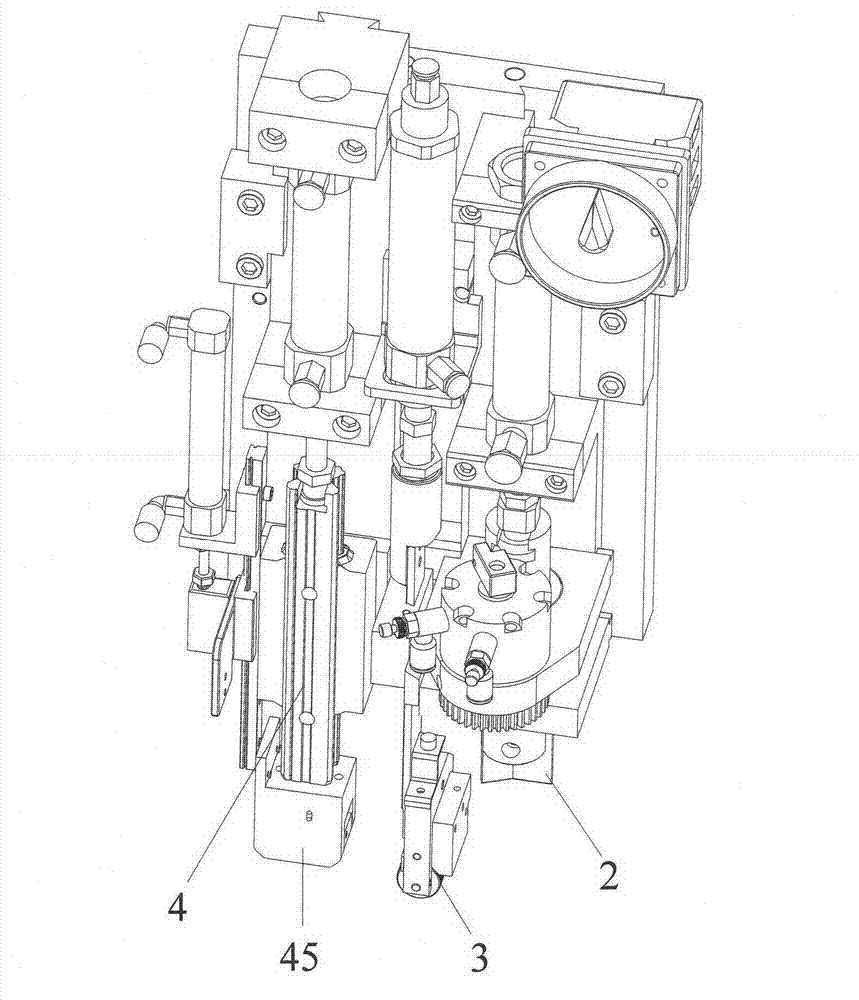

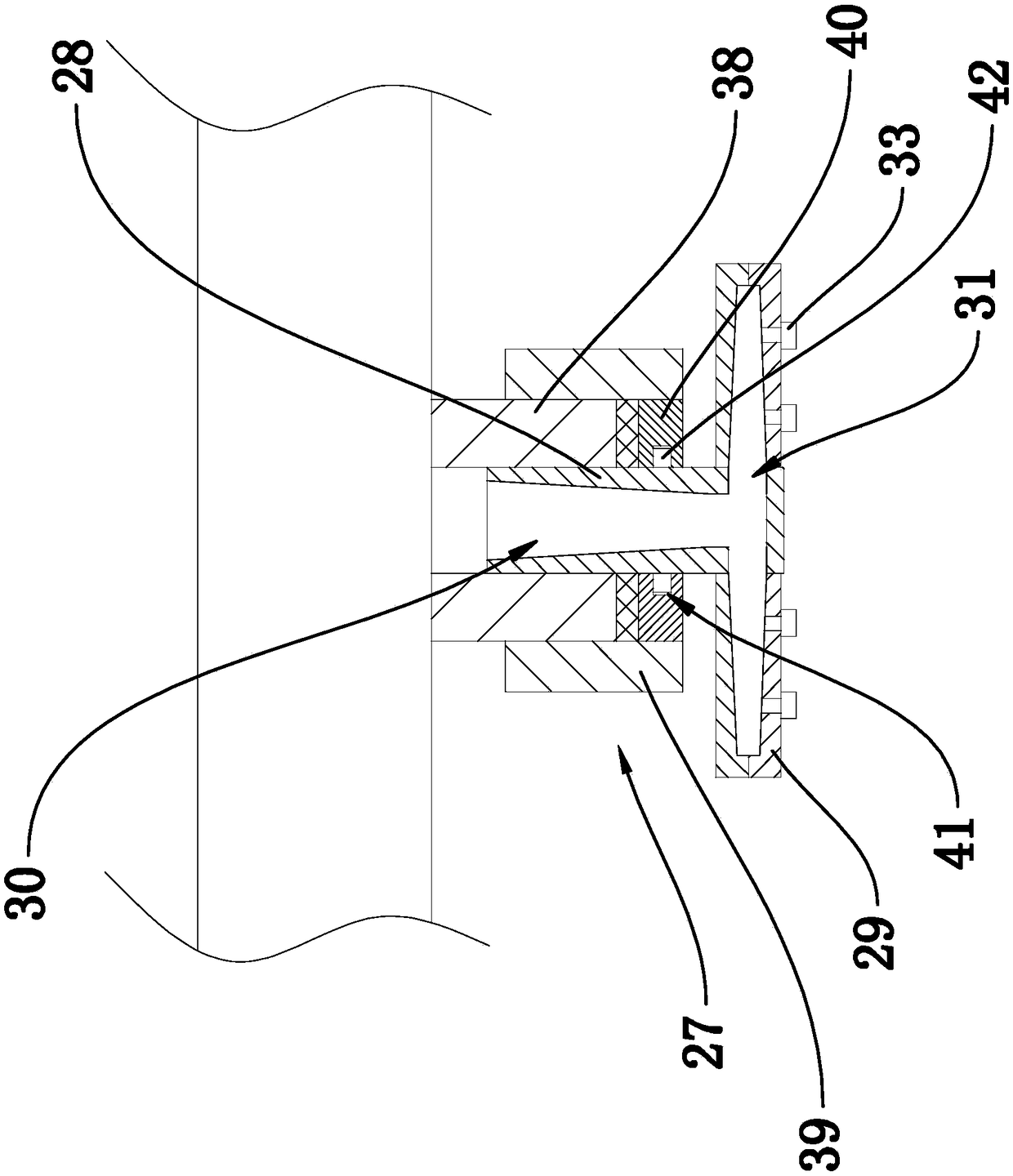

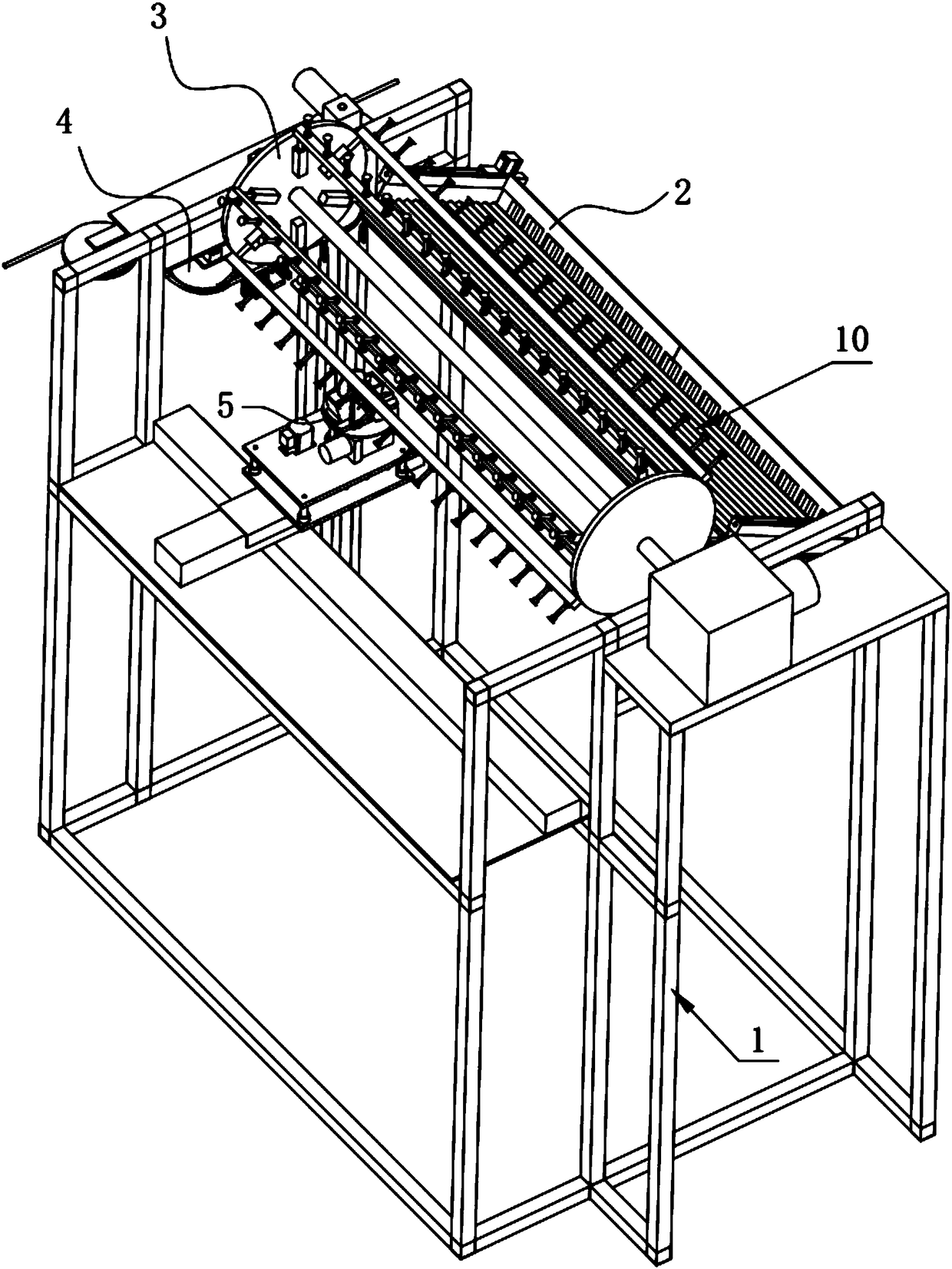

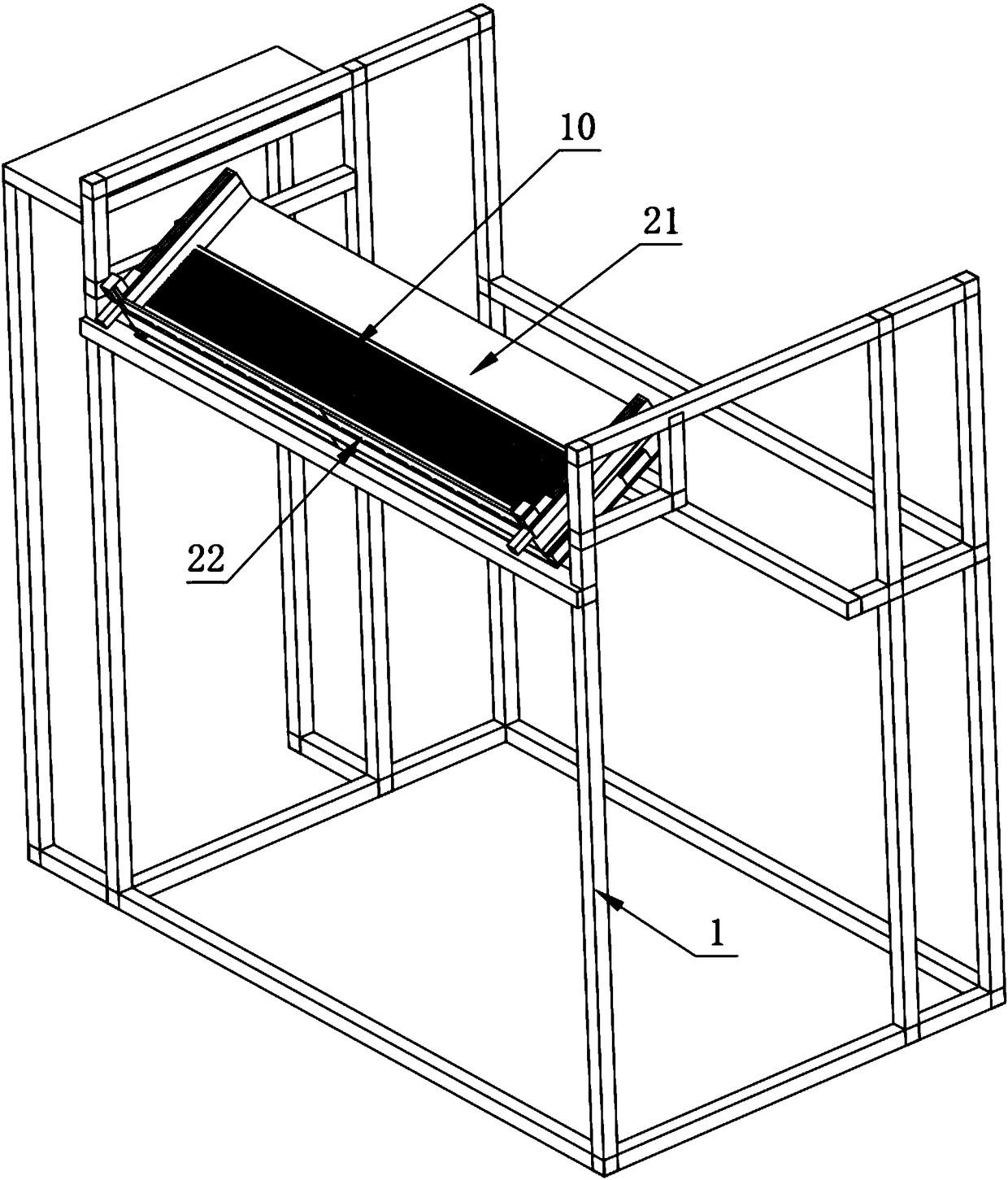

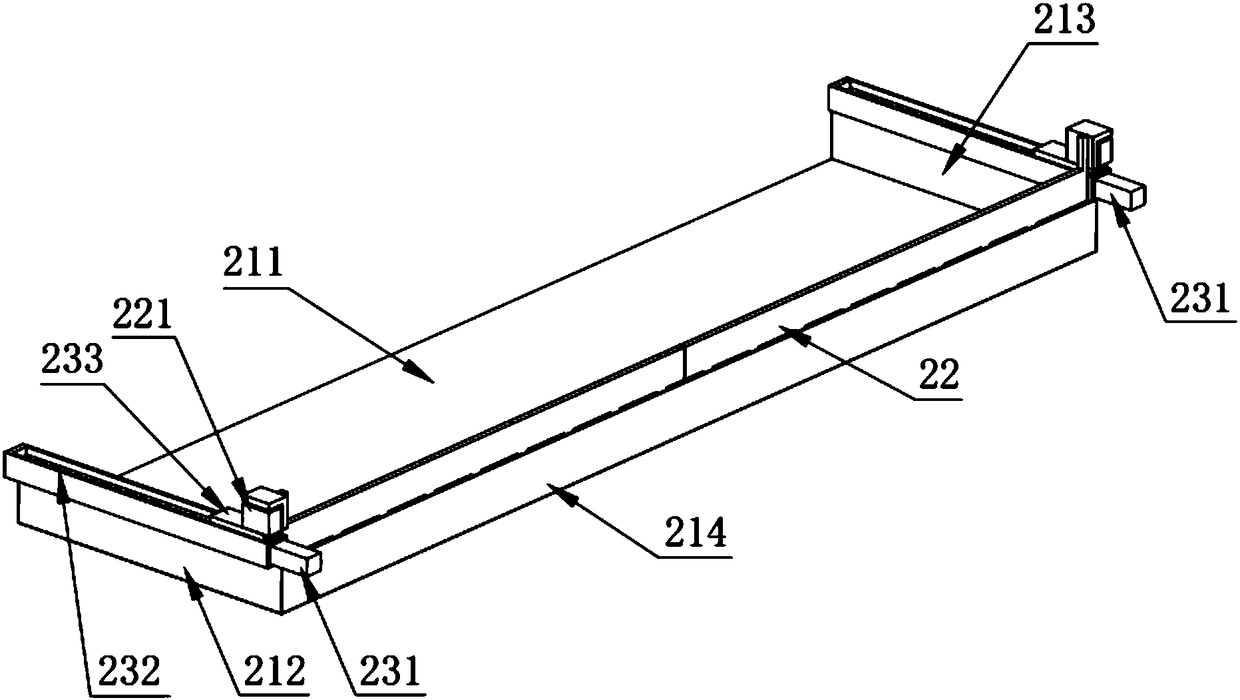

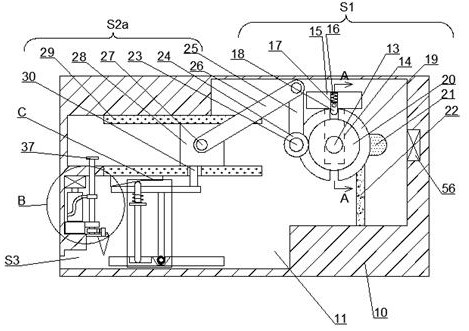

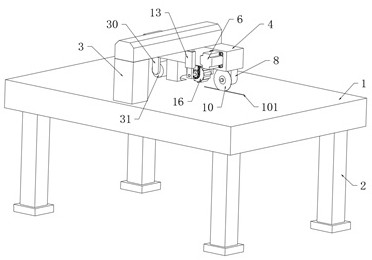

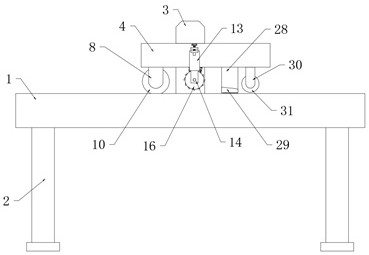

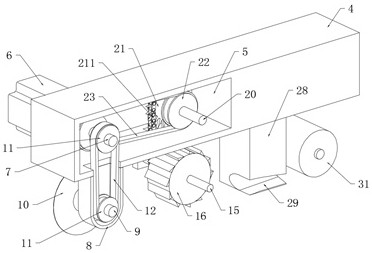

Flanging press system and flanging press method thereof

InactiveCN102808049AReduce processing timeIncrease productivityLeather edge finishingPunchingEngineering

The invention discloses a flanging press system and a flanging press method thereof. The flanging press system comprises a portal frame, a system mounting seat is arranged in the middle of the upper surface of the portal frame, a punching device, a gluing device, an edge hammering device and a paper shearing and pulling device are arranged in the front of the system mounting seat and are respectively connected onto a transmission device, a glue vat and heating elements, which are fixed above the portal frame, are arranged in the rear of the system mounting seat, the glue vat is connected to the gluing device and electrically connected with the heating elements, a fly-cutter hinge flanging device corresponding to the edge hammering device is mounted below a workbench of the portal frame, and the punching device, the gluing device, the edge hammering device, the paper shearing and pulling device, the fly-cuter hinge flanging device, the glue vat and the heating elements are controlled to be operated by a computer control device. The flanging press system is shorter in processing time and high in efficiency.

Owner:黄自斌 +1

Production method of solvent resistant leather

InactiveCN105200170AGood solvent resistanceImprove aging resistanceLeather stretching/tensioningLeather softeningPolymer sciencePolymer chemistry

The invention relates to a production method of solvent resistant leather and belongs to the technical field of leather. The production method of the solvent resistant leather comprises steps as follows: a leather crust is prepared and processed sequentially according to steps as follows: softening through vibration, toggling, filling, vacuum pumping, mending, leather buffing, soot blowing, spraying of an adhesive agent, primary roll coating, primary plate pressing, secondary roll coating, secondary plate pressing, spraying, primary spraying of polyurethane gloss oil, tertiary plate pressing, secondary spraying of the polyurethane gloss oil, roll finish and spraying of a feeling agent. The leather produced with the method not only has excellent solvent resistance, but also has good aging resistance.

Owner:FUJIAN JINJIANG ANHAI QIUXIA LEATHER CO LTD

High-performance and environment-friendly leather edge oil

The invention provides high-performance and environment-friendly leather edge oil. The oil comprises the following components including, by weight, 1-30% of N-hydroxymethyl acrylamide, 1-30% of acrylic resin, 0.5-10% of sodium alkyl benzene sulfonate, 0.1-10% of beewax, 0-10% of rosin soap, 0-5% of alcohol ether phosphomonoester, 0-3% of turpentine, 0-25% of glycerinum, 0-20% of isopropanol, 0-5%of xanthan gum and the balance solvents. The high-performance and environment-friendly leather edge oil provided by the invention has the advantages of being convenient to use, high in applicability and environmentally friendly; since a unique formula design is provided, the effect of edge hair on a section of leather can be effectively repaired in the using process, and precious leather productscan be better protected; and meanwhile, the oil does not contain components doing harm to the human body, and therefore, the oil is loved by users.

Owner:GUANGDONG FION LEATHER CO LTD

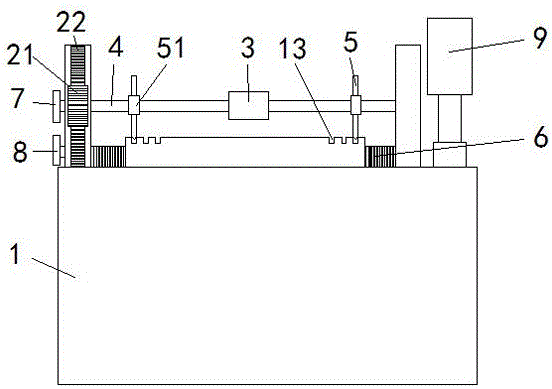

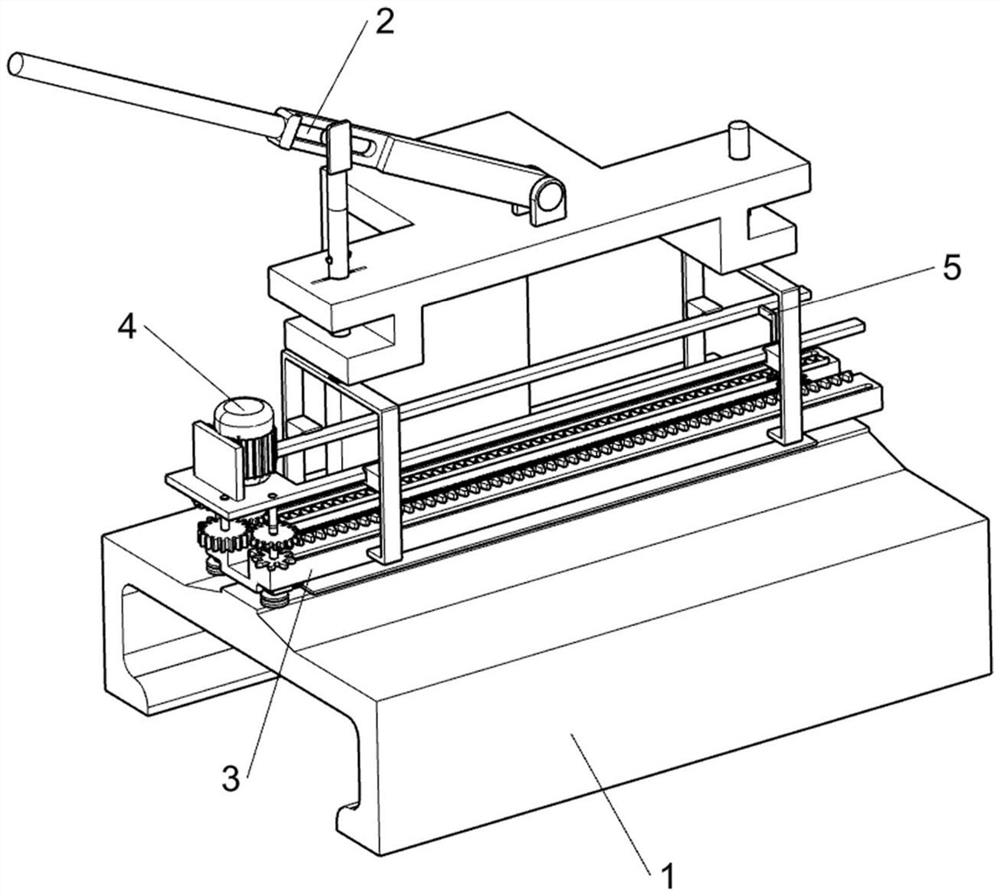

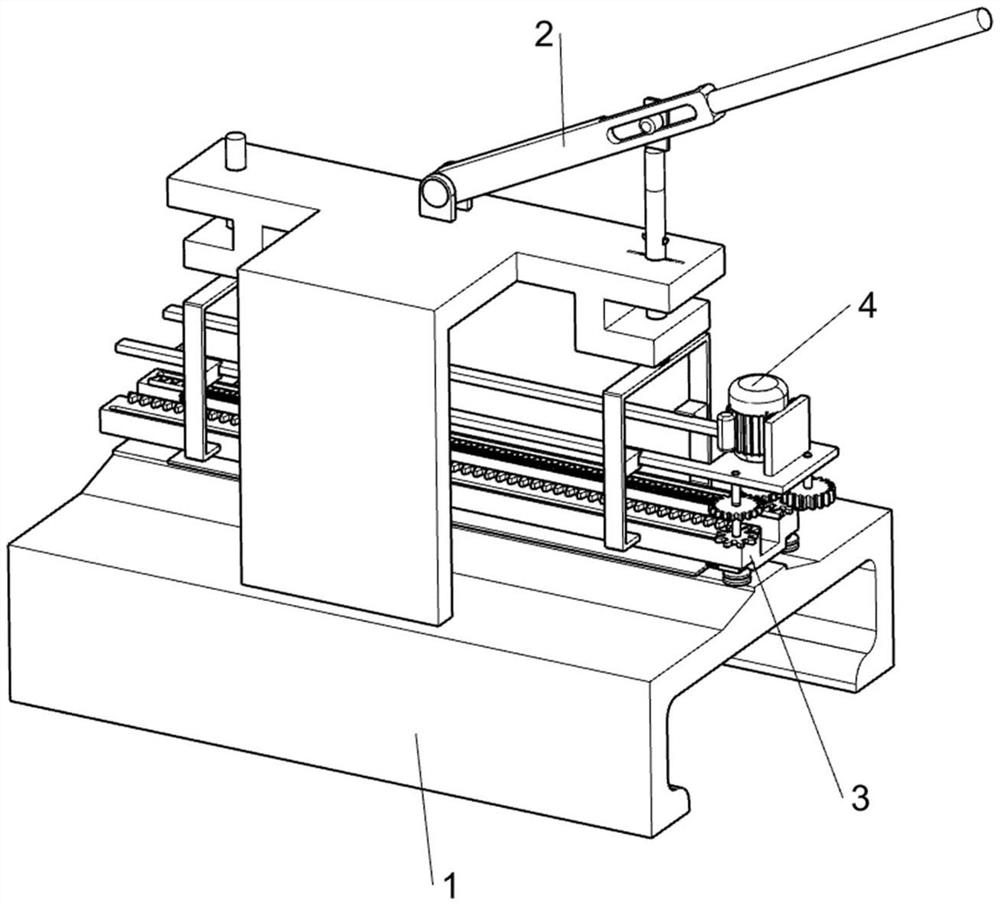

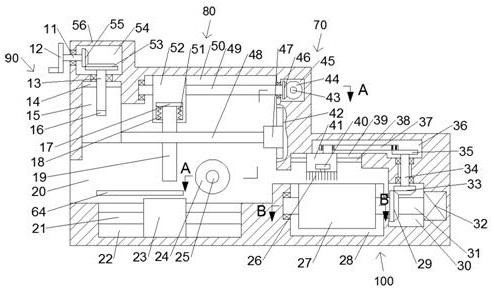

Double-cutter adjustable leather edge cutting machine

InactiveCN106755621AImprove work efficiencyImprove processing qualityLeather clicking/perforating/clickingLeather edge finishingKey pressingDrive motor

The invention discloses a double-cutter adjustable leather edge cutting machine. The machine comprises a stand, two support bases and a machining table; a driving motor is in the stand; the two support bases are arranged on two sides of the upper surface of the stand; a cutter shaft is arranged between the two support bases; two ends of the cutter shaft are rotationally connected with the support bases; a gear is arranged at the left end of the cutter shaft, and is engaged with straight racks arranged in the support bases; a transmission wheel is mounted in middle of the cutter shaft; cutters are mounted on the cutter shaft on two sides of the transmission wheel, and include cutter heads; the cutters are fixed on the cutter heads; the cutter heads are detachably connected with the cutter shaft; the machining table is mounted in middle of the upper surface of the stand between the two support bases; a touch control screen is arranged on one side of the upper surface of the stand; and the touch control screen includes a LCD display screen and four control keys. The double-cutter adjustable leather edge cutting machine is simple in overall structure, reasonable in design, high in working efficiency and liable to popularize and apply.

Owner:张明

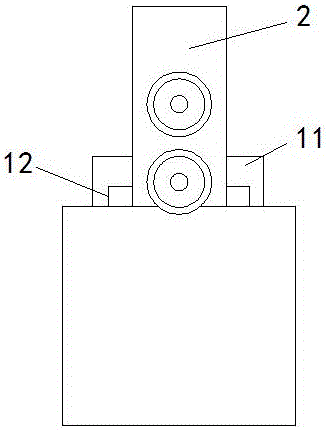

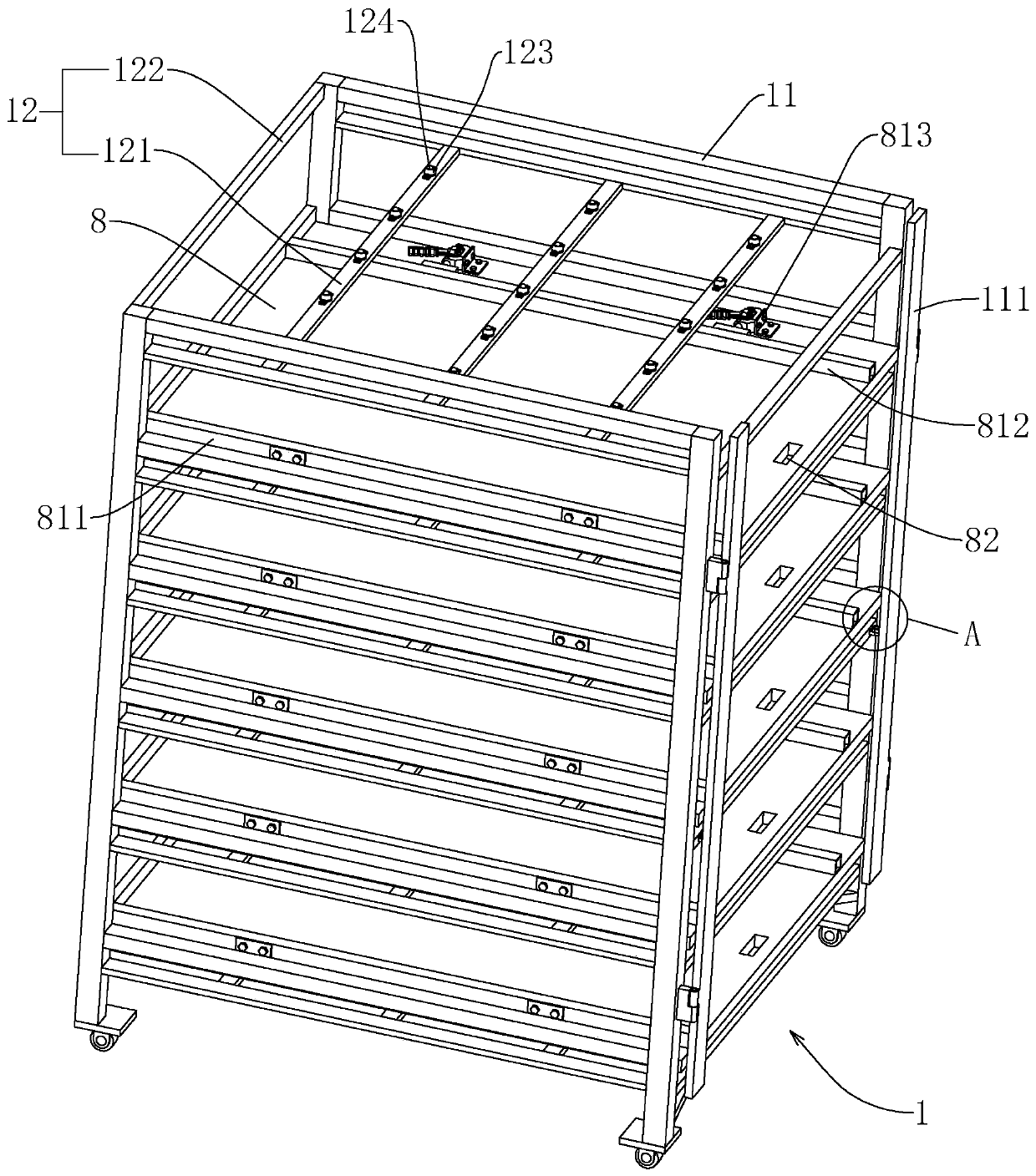

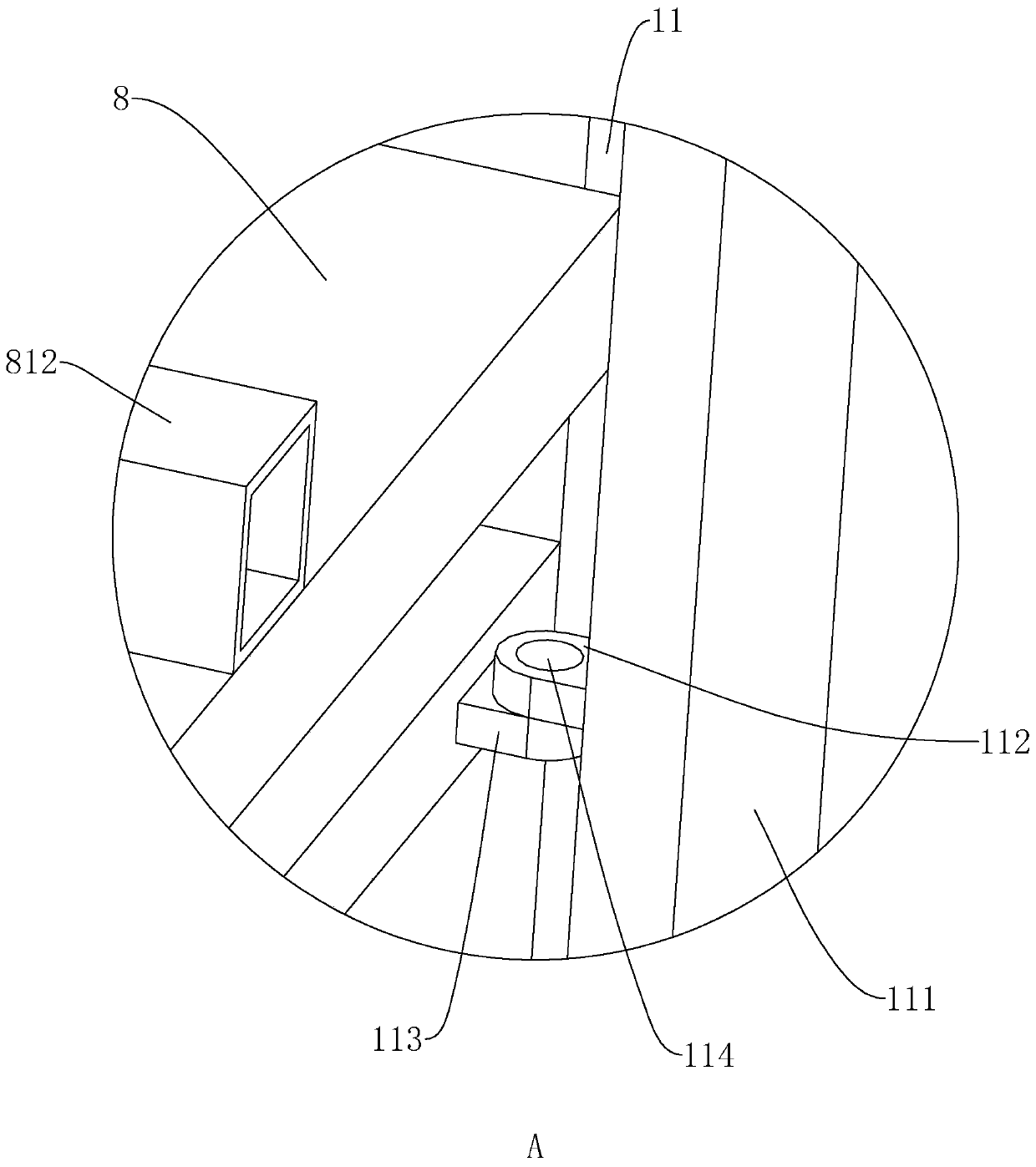

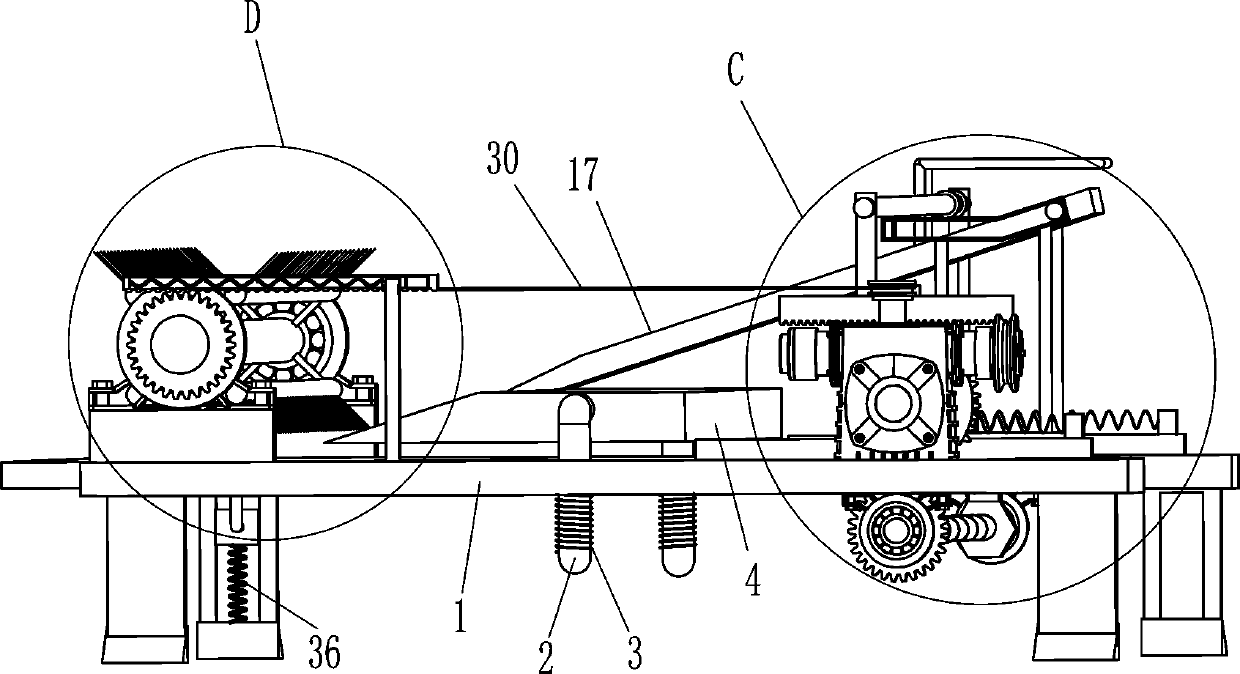

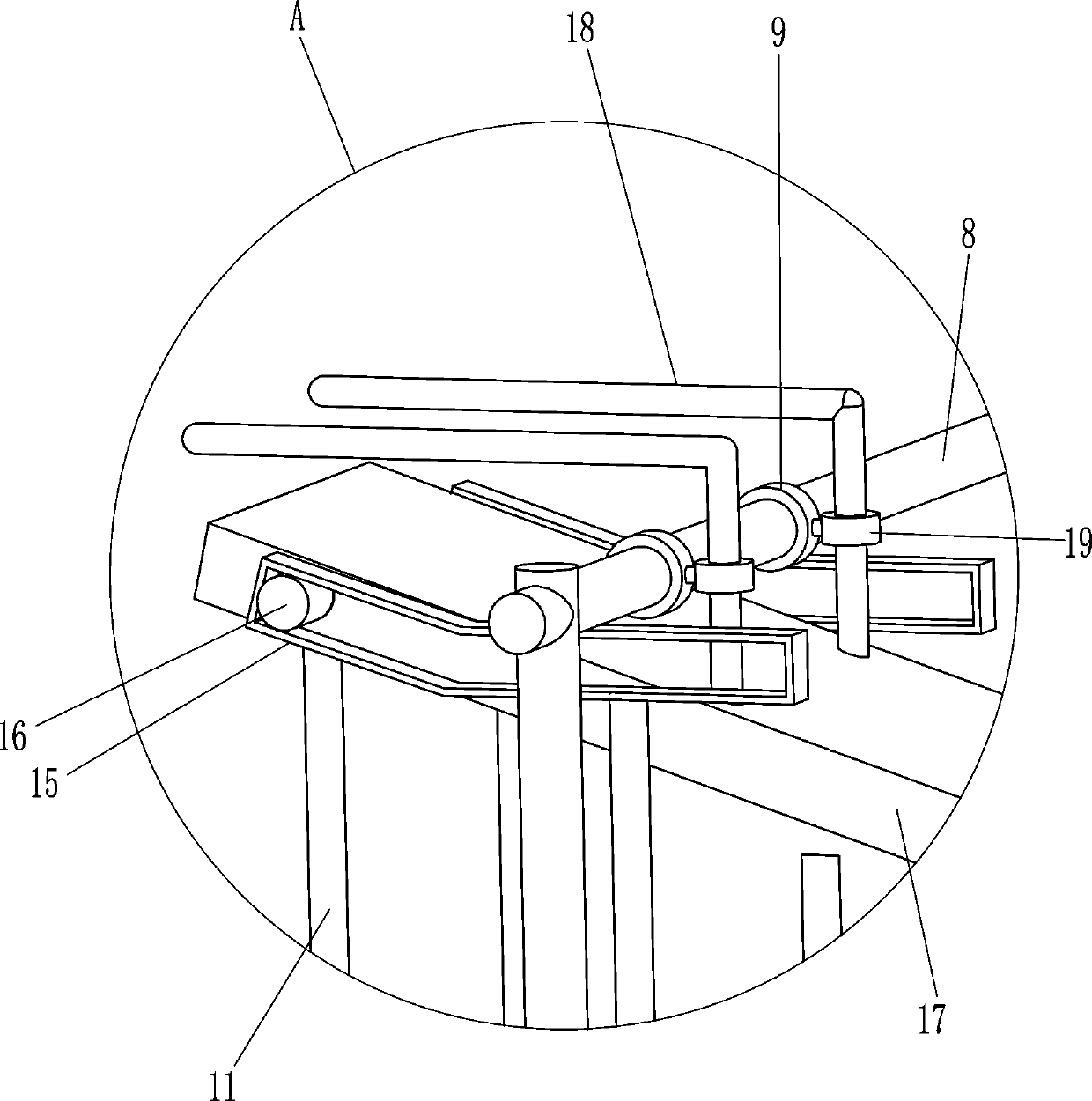

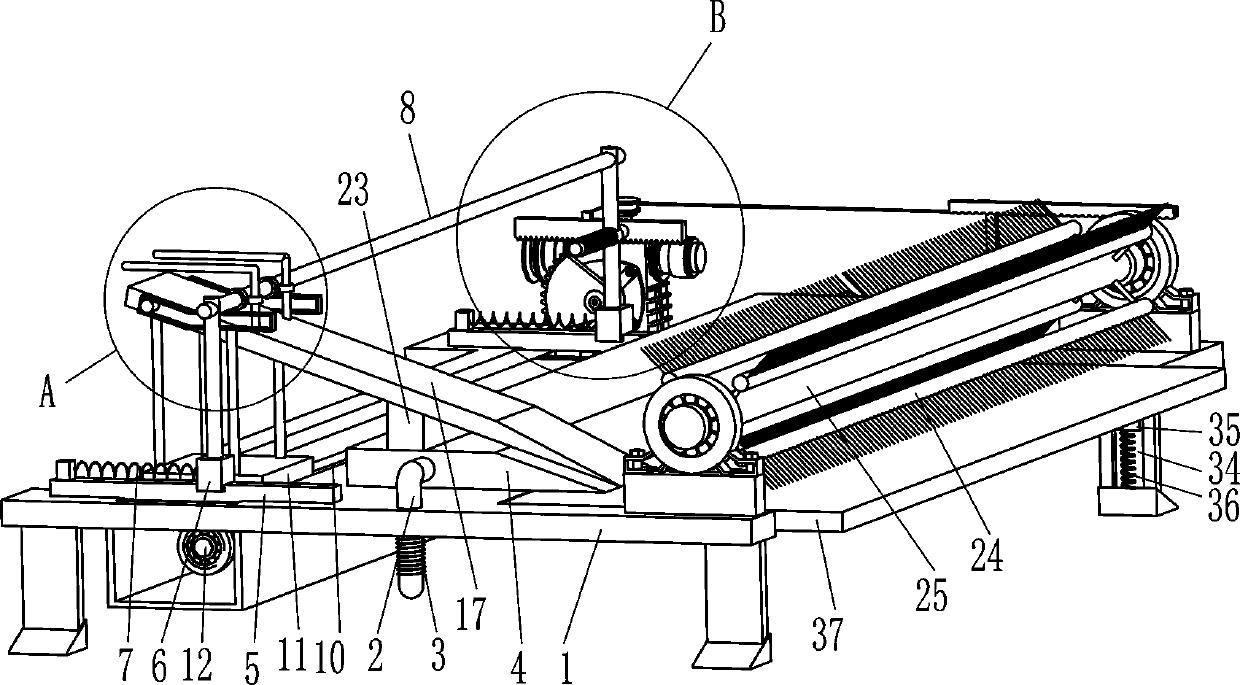

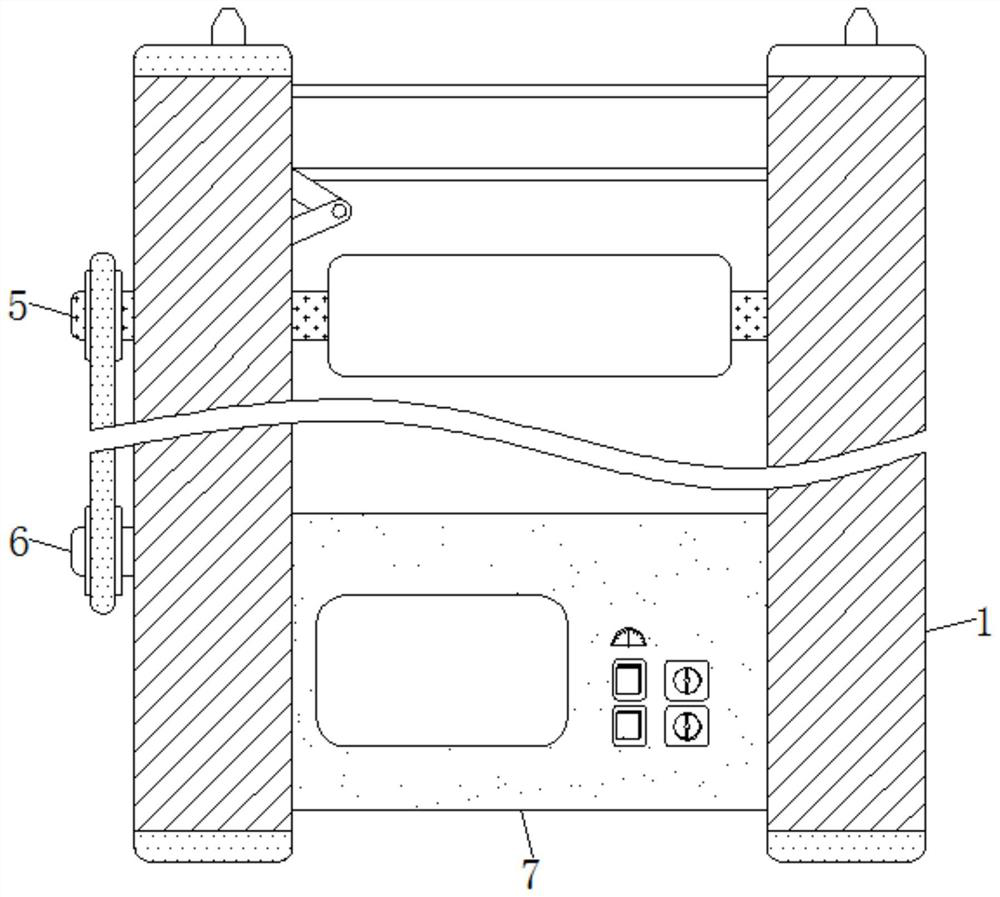

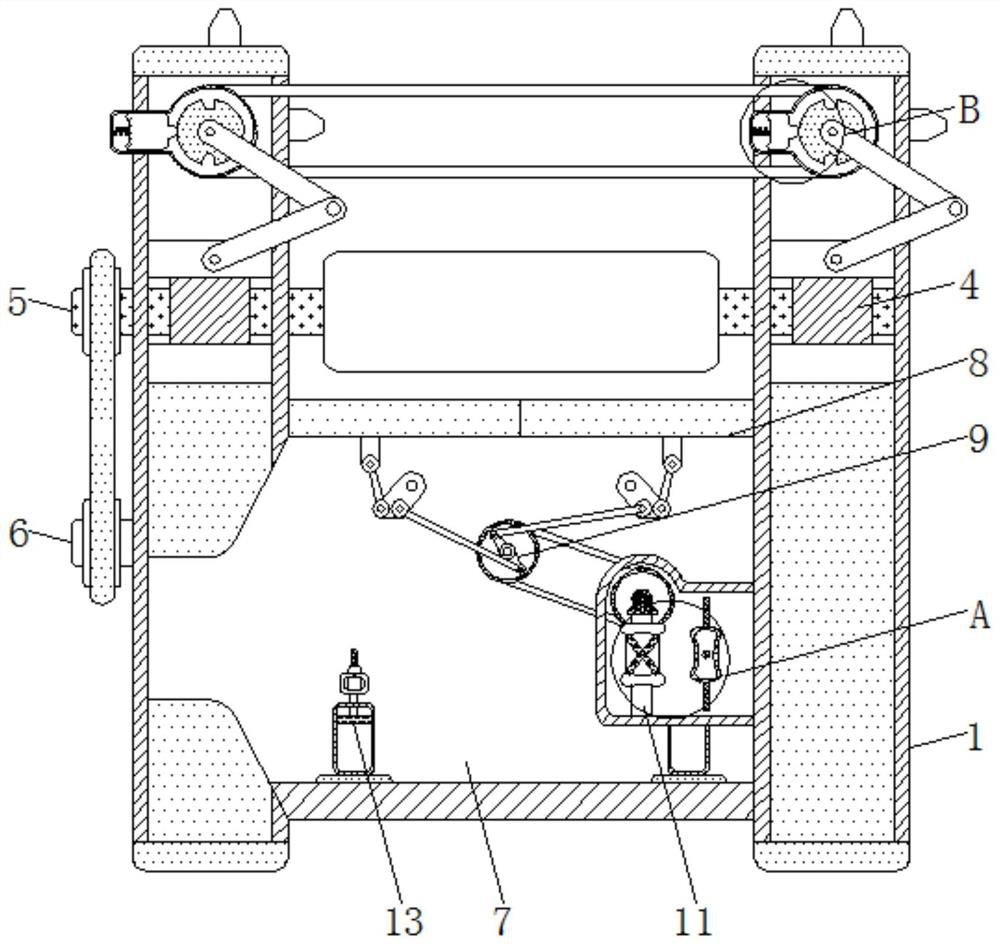

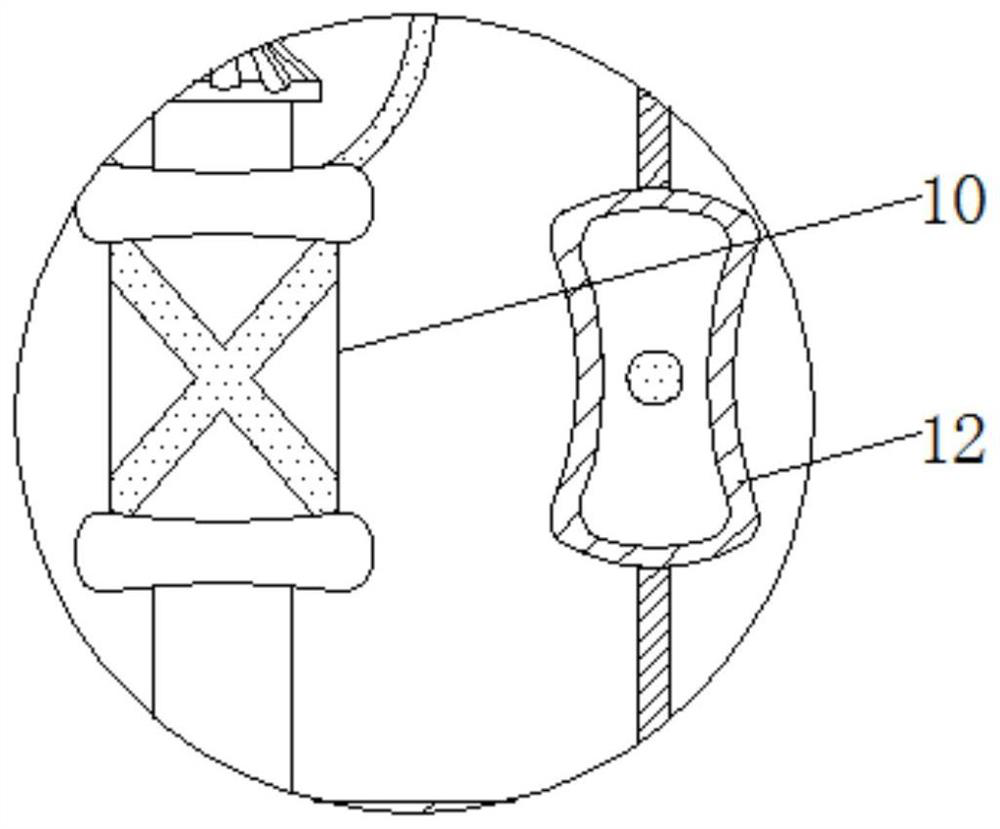

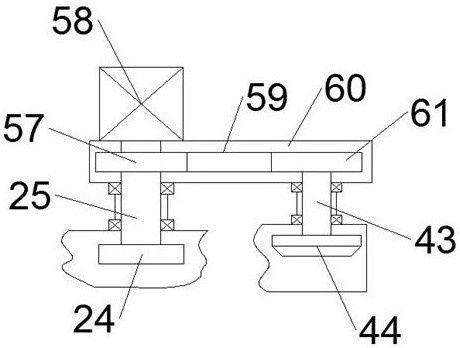

Full-automatic belt edge grinding machine

PendingCN111154925AShorten the timeImprove work efficiencySkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentStructural engineeringBelt grinding

The invention relates to the technical field of belt manufacturing and discloses a full-automatic belt edge grinding machine. The full-automatic belt edge grinding machine comprises a material frame,a fixing frame, a conveying mechanism, a material pulling mechanism, an ascending-descending mechanism, a grinding frame and an edge grinding mechanism, wherein a working plate is carried on the material frame and connected with a clamping assembly which is used for clamping a belt; the fixing frame is slideably connected with an ascending-descending frame in the vertical direction; the conveyingmechanism is used for conveying the working plate towards the side which is far away from the material frame; the material pulling mechanism is used for pulling the working plate from the material frame to the position above the conveying mechanism; the ascending-descending mechanism is used for driving the ascending-descending frame to move vertically; the grinding frame is provided with a driving assembly which is used for driving the working plate to move towards the side which is close to or far away from the fixing frame; and the edge grinding mechanism comprises an edge grinding part, avertical driving part, a first transverse driving part and a second transverse driving part, the edge grinding part is used for grinding the edge of a belt, the vertical driving part drives the edge grinding part to move vertically, and the first transverse driving part and the second transverse driving part drive the edge grinding part to move horizontally. The full-automatic belt edge grinding machine has the effects that during belt grinding, the labor intensity of workers is low, and the machining efficiency is high.

Owner:徐珏

Leather treatment technology

InactiveCN108220499AImprove processing efficiencyIncrease exposureLeather clicking/perforating/clickingTanning treatmentDepilationsEngineering

The invention provides a leather treatment technology used for solving the problem that the leather treatment efficiency is low. The leather treatment technology comprises the following steps that fixing is conducted, specifically, the two corresponding ends of leather are fixed to leather clamps, and at least two pieces of leather are fixed to each leather clamp; pre-soaking is conducted; soakingis conducted; pretreatment is conducted; depilation is conducted; swelling is conducted; dealkalizing is conducted; softening is conducted; and pickling is conducted. The leather is fixed to the leather clamps, the leather can be prevented from being rolled into a ball during rotating, the contact degree between the leather and a cleaning chemical liquid is improved, and the leather treatment efficiency is improved.

Owner:HAINING WENSHUO TECH CONSULTING CO LTD

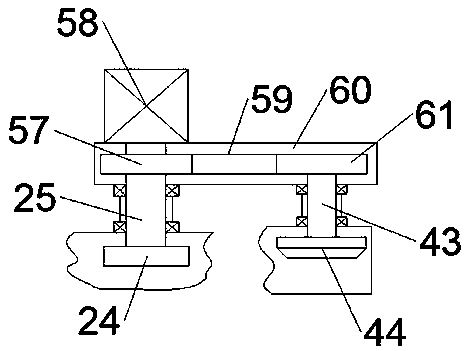

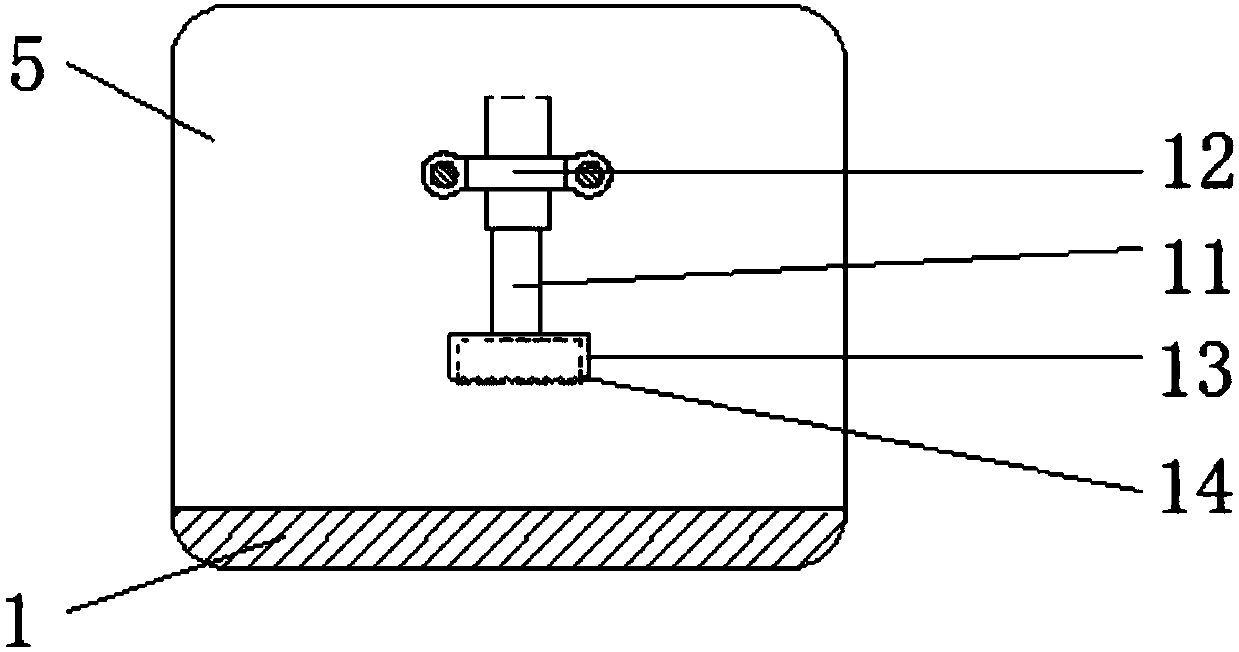

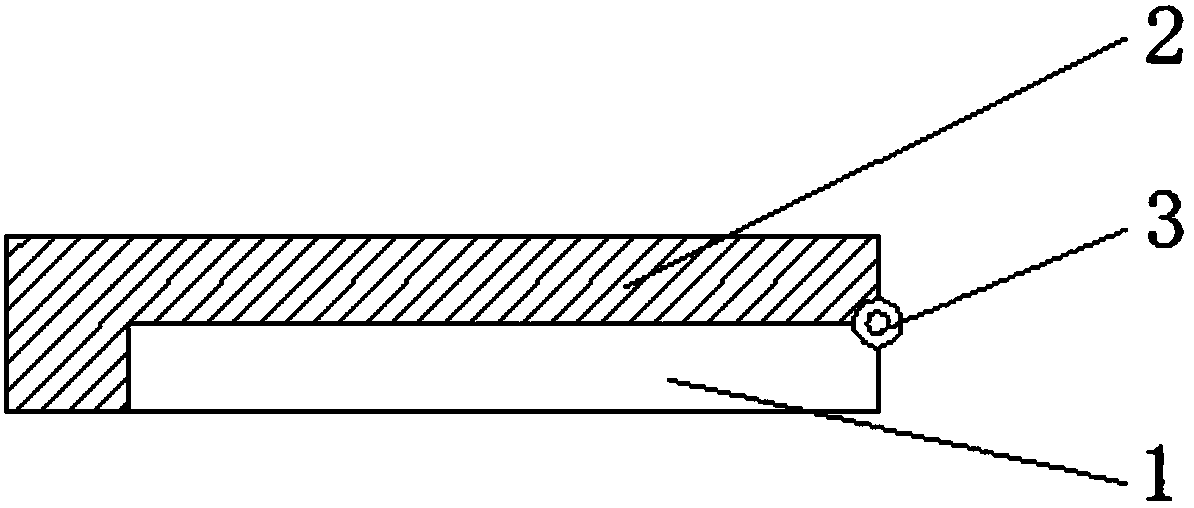

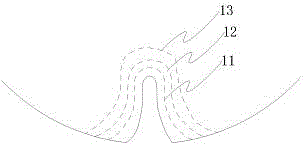

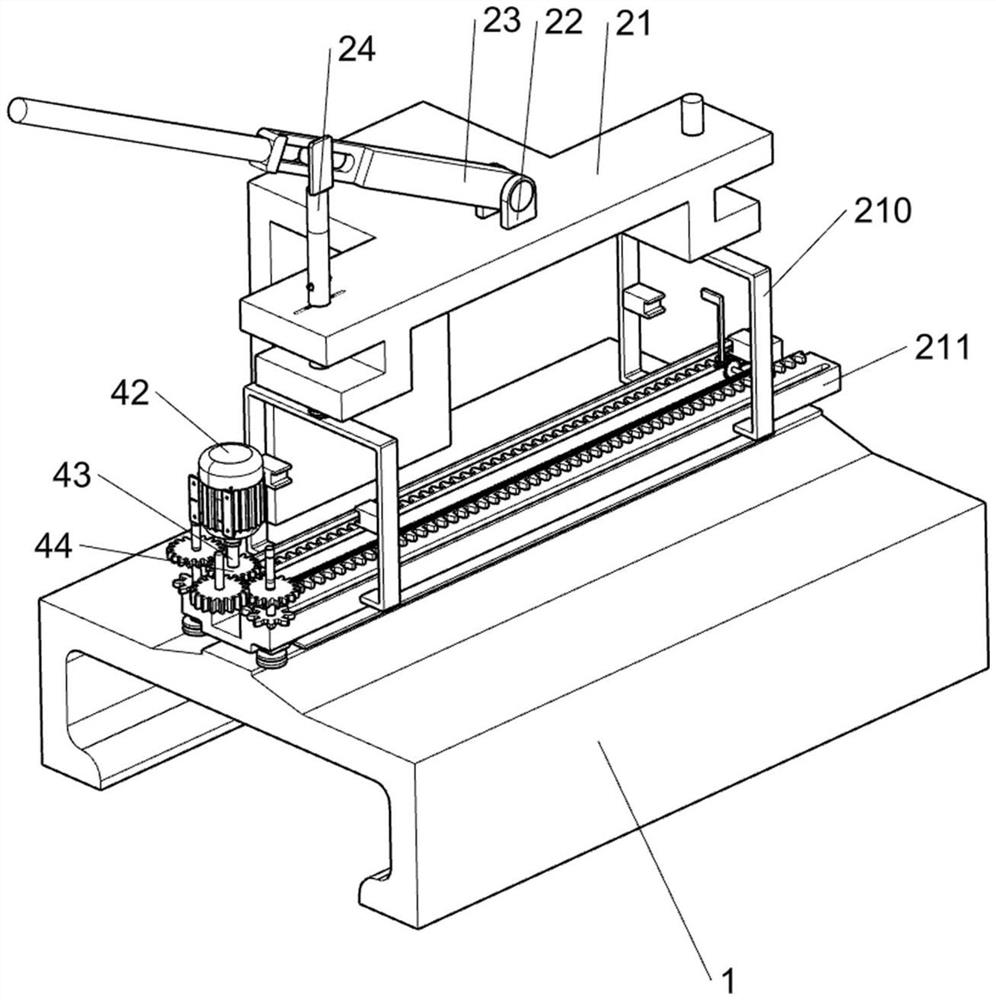

Adjustable leatherworking edge pressing device

ActiveCN109055628AEasy squeezeEasy to controlSkins/hides/leather/fur manufacturing apparatusLeather edge finishingEngineeringHorizontal transmission

The invention discloses an adjustable leatherworking edge pressing device which comprises a base. A work plate is placed in the middle of the upper end of the base, and supporting plates are symmetrically arranged on the two sides of the upper end of the base. A supporting frame is erected at the upper ends of the supporting plates, and the middle of the supporting frame is connected with a rotaryseat through a rotating mechanism. A horizontal sliding groove hole is formed in the rotating seat, and a horizontal sliding block is slidingly arranged at the upper end of the rotary seat where thehorizontal sliding groove hole is located. The horizontal sliding block is fixedly connected with the rotary seat through a horizontal transmission mechanism, and the lower end of the horizontal sliding block is connected with a pressing rod through a lifting mechanism. A pressing roll is arranged at the lower end of the pressing rod. The adjustable leatherworking edge pressing device is simple and reasonable in structure, good in buffering performance and convenient to carry; by means of cooperation of the rotating mechanism, the horizontal transmission mechanism and the lifting mechanism, the pressing roll can conveniently press leather in all the directions of the work plate, width indication can be carried out through a width indicating lamp, a worker can conveniently control the pressing position of the pressing roll, and high practicality is achieved.

Owner:温州晨曦工艺品有限公司

Pollution-free leather manufacturing technology

ActiveCN104962666APollution generationWill not polluteTanning treatmentPre-tanning chemical treatmentTime rangeWater volume

The invention discloses a pollution-free leather manufacturing technology. The pollution-free leather manufacturing technology includes the steps of leather finishing, leather soaking, preliminary tanning, secondary tanning, repeated secondary tanning, tanning finishing, dye-fixing agent adding, semi-finished product manufacturing, softening and finished product manufacturing. In the leather soaking step, the water volume for soaking naked leather accounts for 30% to 50% of the mass of the naked leather, and soaking time ranges from 20 min to 30 min. In addition, the ratios of solutions added to a drum are adjusted in proportion in the steps, and the rotation time of the drum is controlled. Thus, by the adoption of the pollution-free leather manufacturing technology, the use ratio of water to auxiliary materials is strictly controlled, all liquid is completely absorbed by leather, no sewage is drained, and no pollution is generated to the environment.

Owner:林善溪

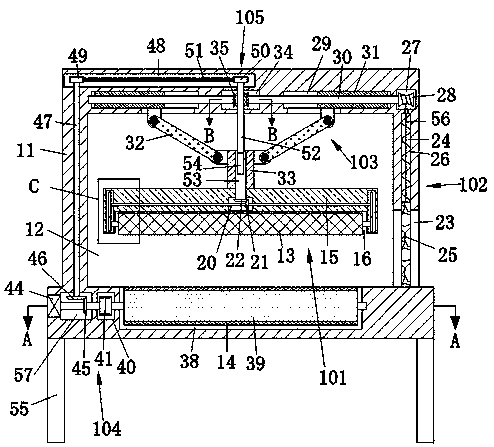

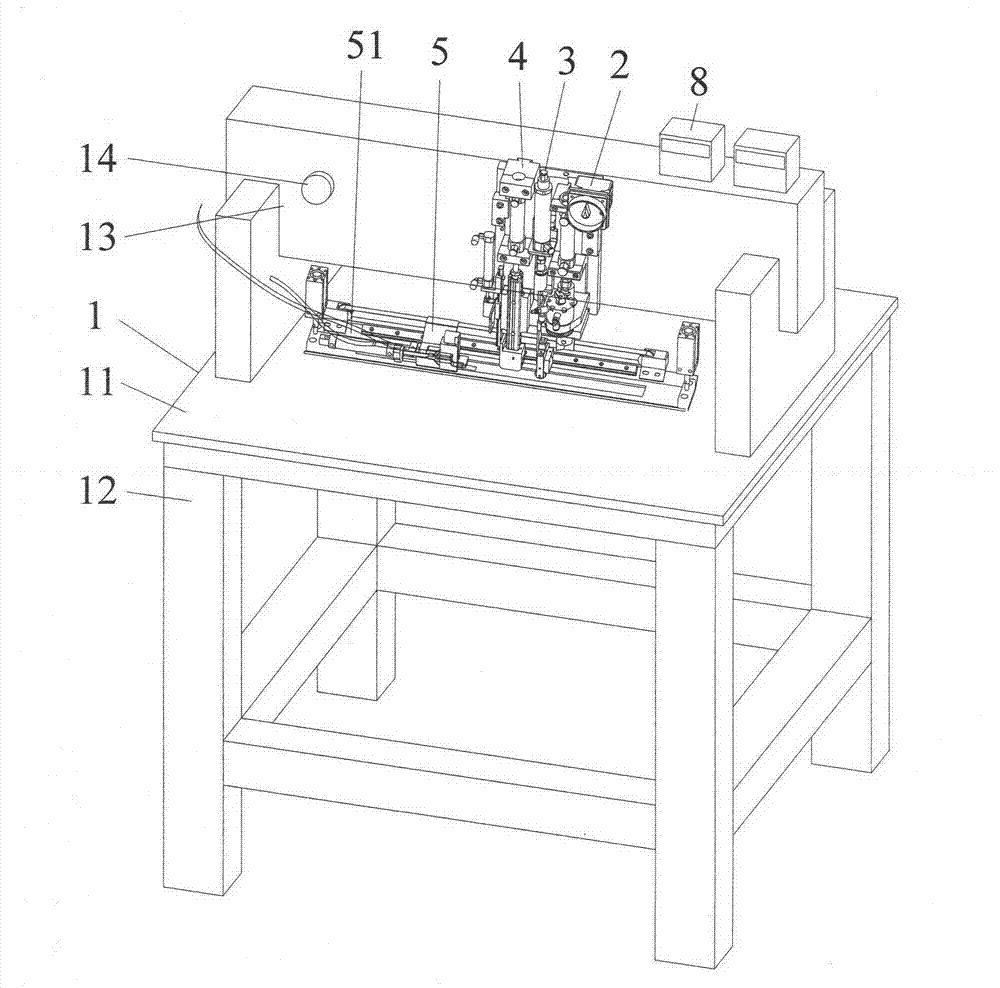

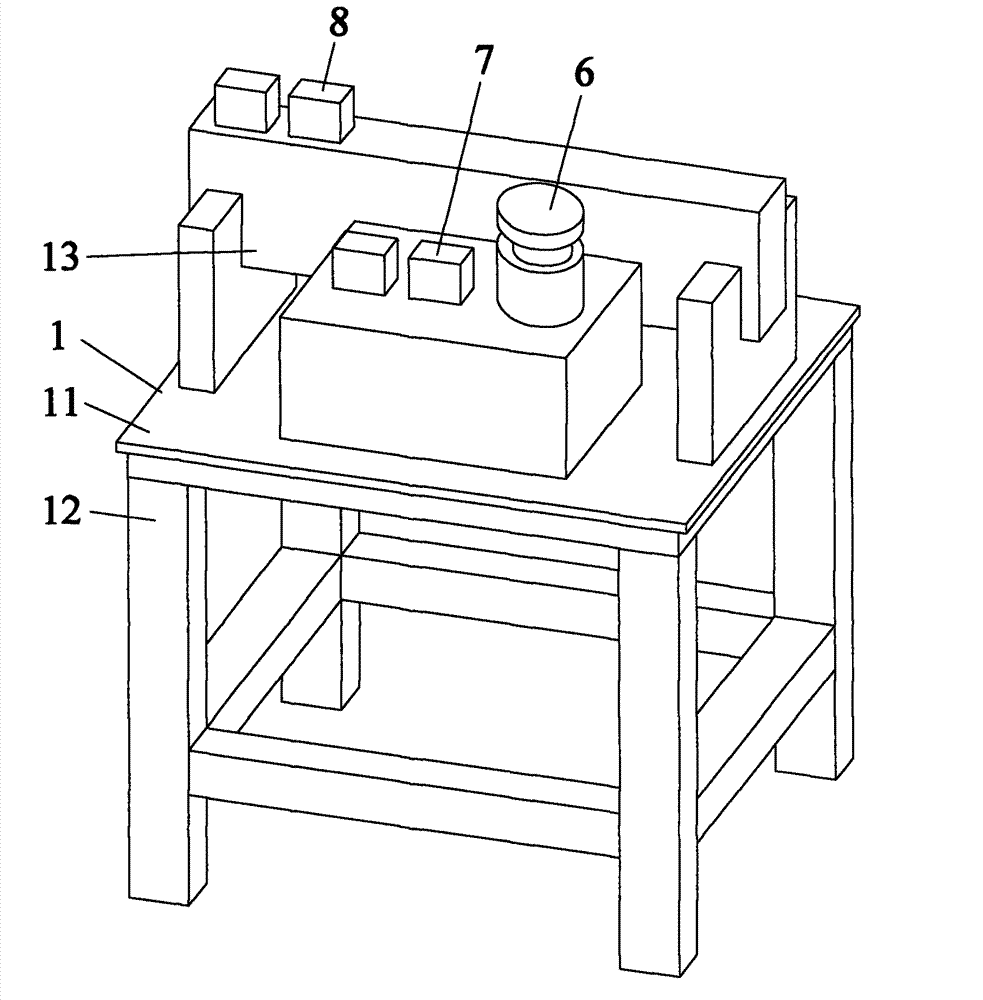

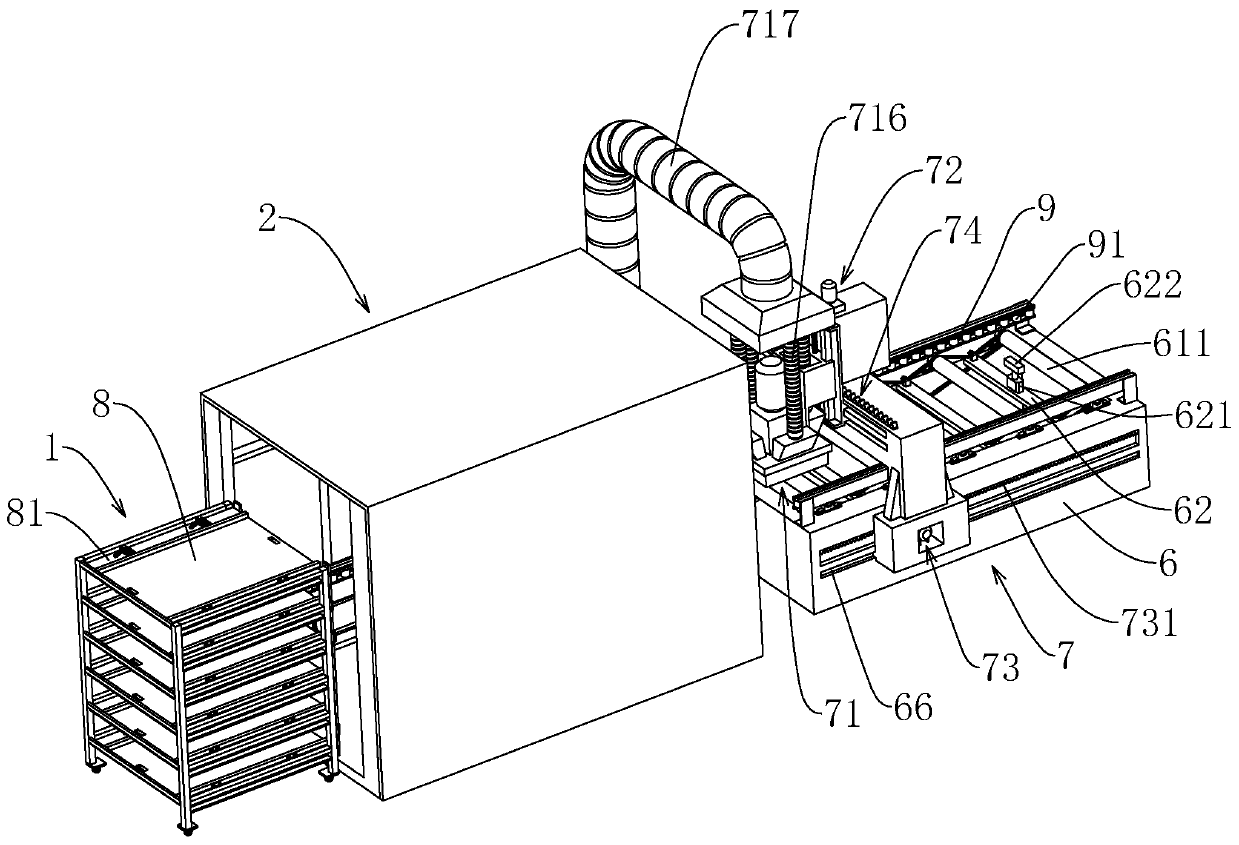

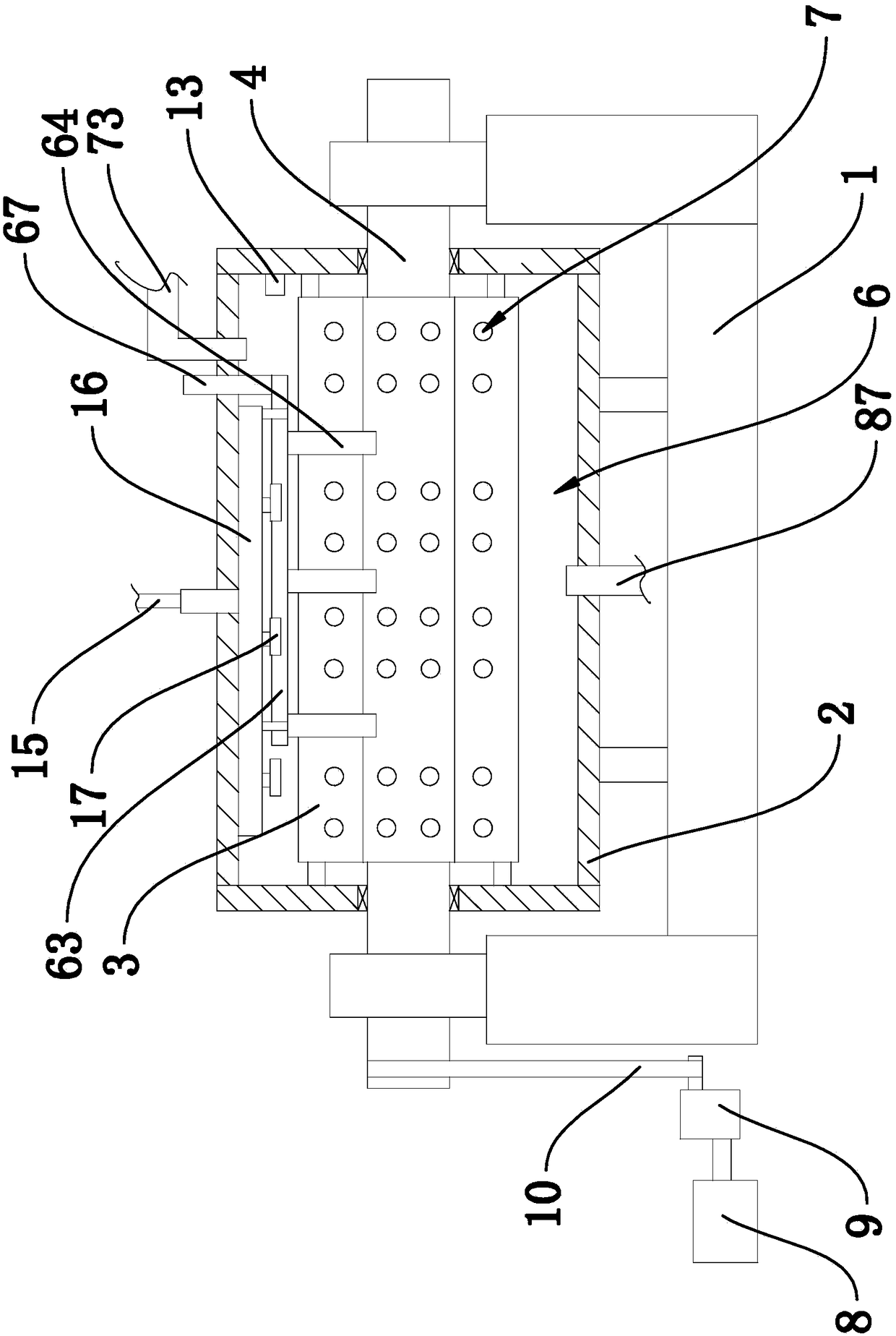

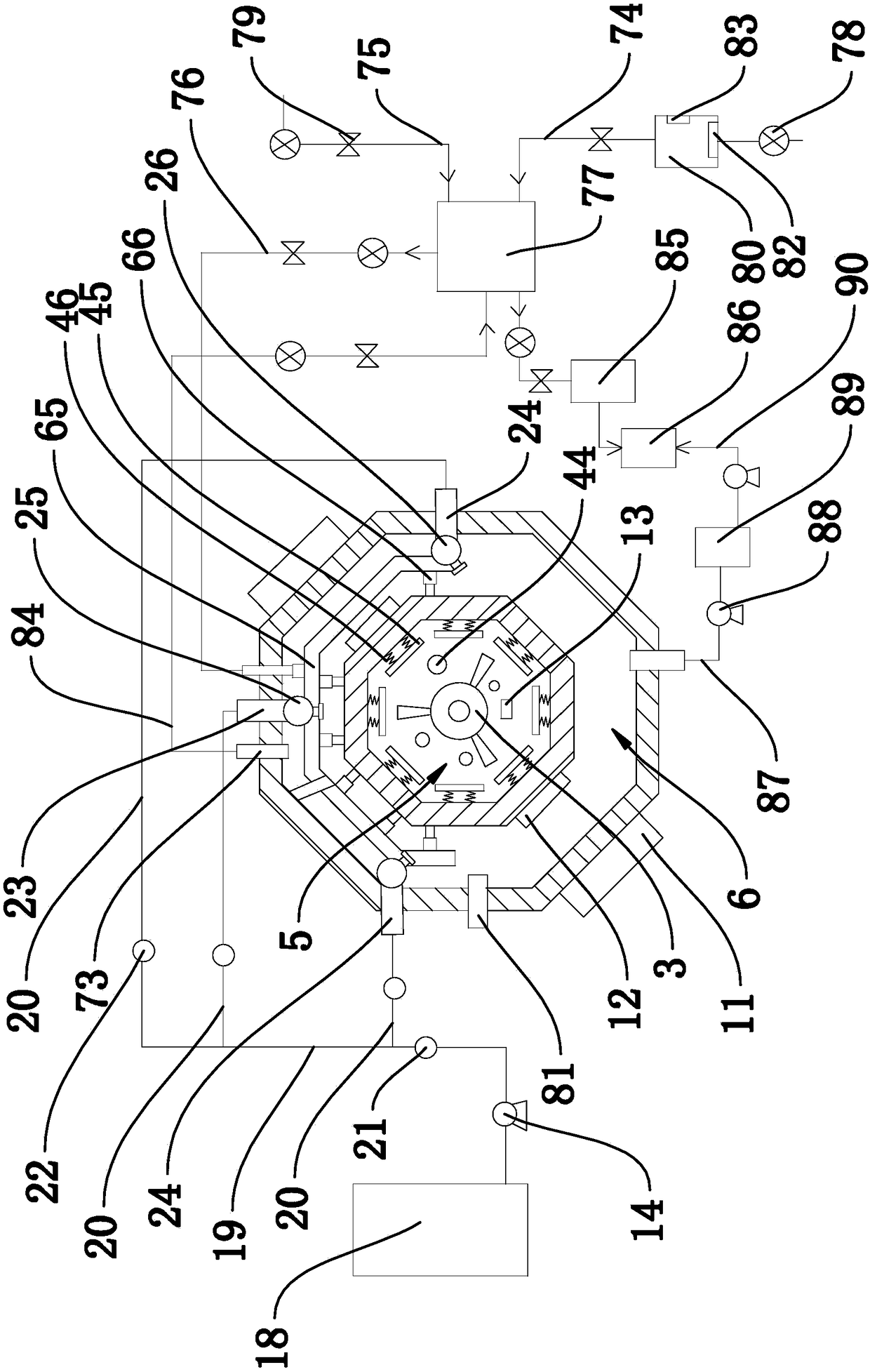

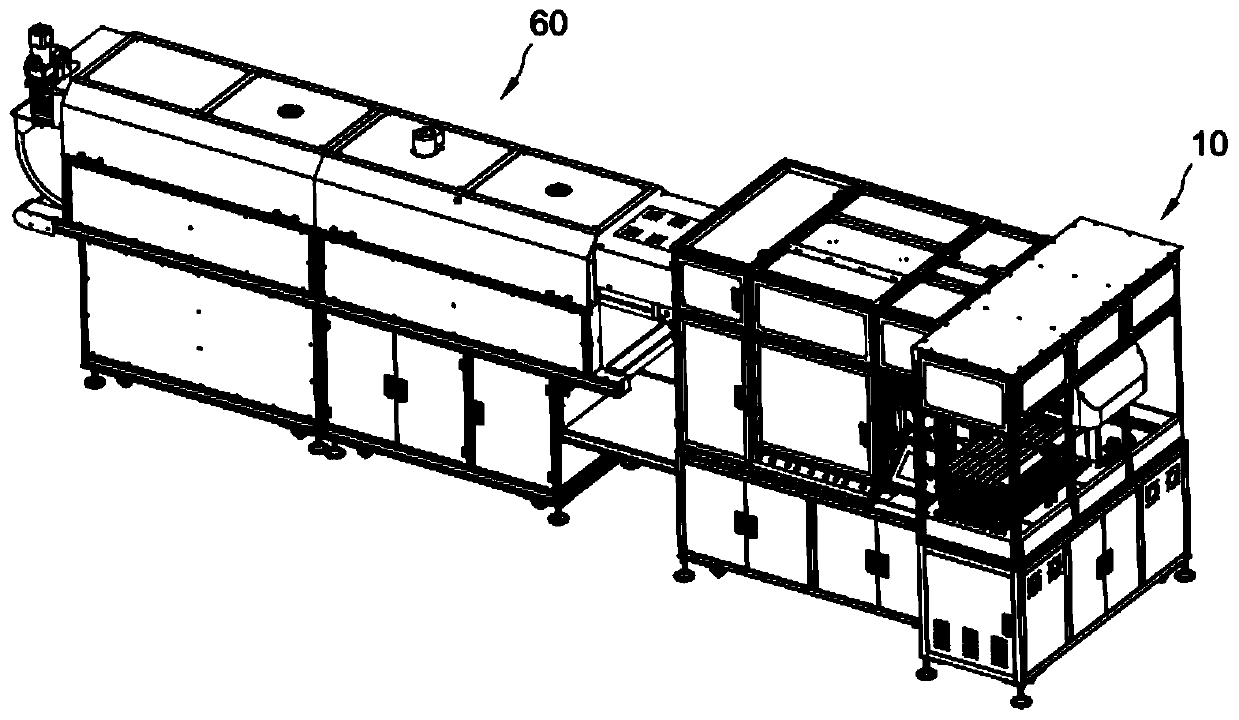

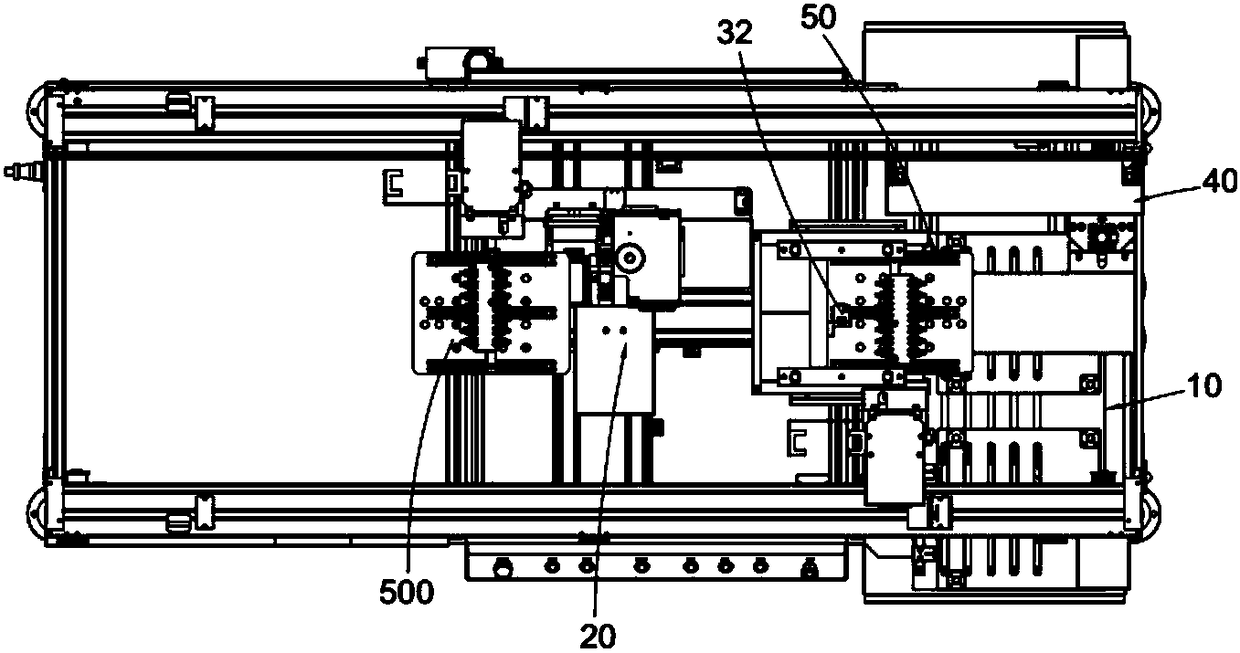

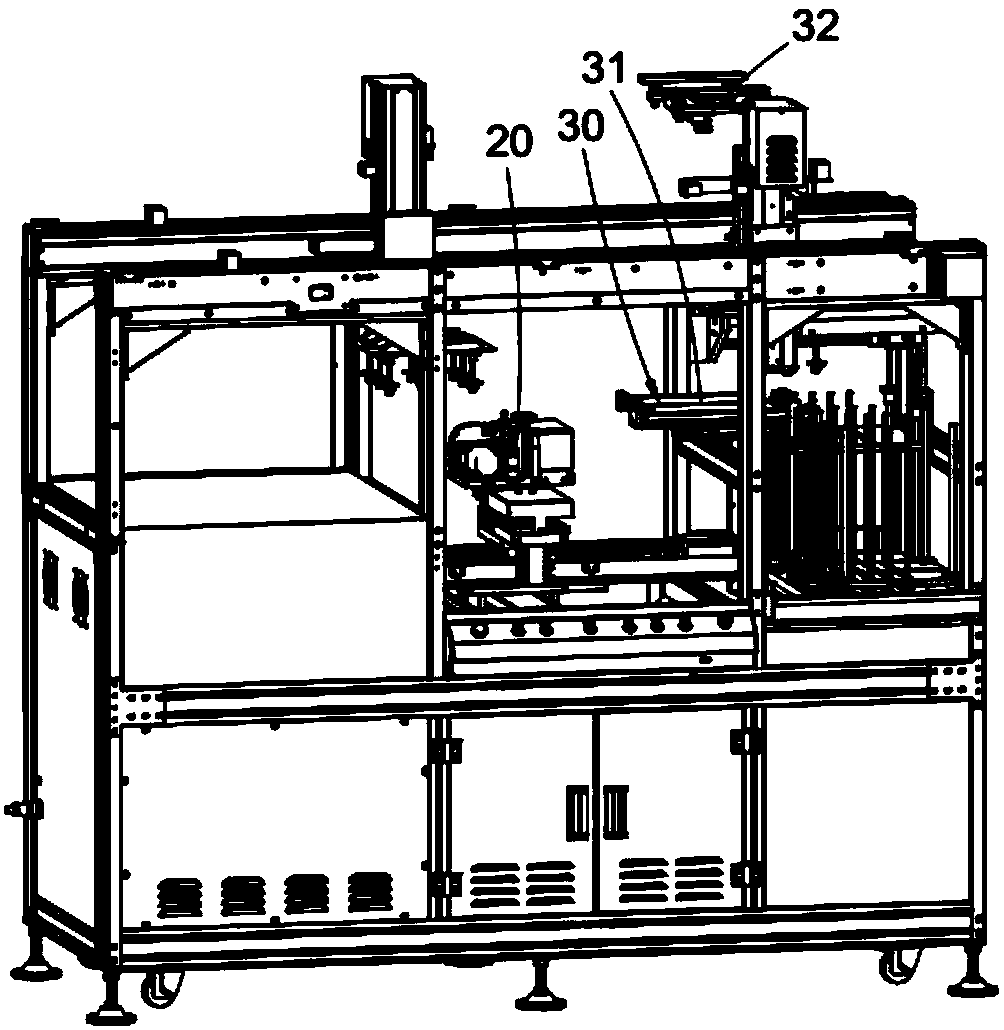

Multi-head double-arm edge oiling machine

PendingCN109957627AImprove work performanceLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a multi-head double-arm edge oiling machine which comprises a feeding mechanism, a leather positioning mechanism, an edge oiling mechanism, a drying mechanism and a leather conveying system, wherein the feeding mechanism, the leather positioning mechanism, the edge oiling mechanism and the drying mechanism are sequentially arranged, and the leather conveying system operatesback and forth among the feeding mechanism, the leather positioning mechanism, the edge oiling mechanism and the drying mechanism. The edge oiling mechanism comprises an edge oiling transverse driving device, an edge oiling longitudinal driving device arranged on the edge oiling transverse driving device, and a plurality of edge oiling modules arranged on the edge oiling longitudinal driving device. The leather conveying system is used for conveying a plurality of pieces of leather with the same quantity as the edge oiling modules from the feeding mechanism to the leather positioning mechanism at the same time, then conveying the leather to the edge oiling mechanism for edge oiling, and finally conveying the leather to the drying mechanism, and thus the edge oiling machine can process themultiple pieces of leather simultaneously, and the working capacity of the edge oiling machine is improved.

Owner:东莞市具力自动化设备科技有限公司

Automatic edge scraping device for leather wallet production

ActiveCN111187865AReduce consumptionImprove work efficiencyLeather edge finishingMechanical engineeringIndustrial engineering

The invention relates to an automatic edge scraping device, in particular to an automatic edge scraping device for leather wallet production. The invention aims to solve the technical problems so as to provide the automatic edge scraping device for leather wallet production, so that the working efficiency is improved, and meanwhile, no potential safety hazard exists. The automatic edge scraping device for leather wallet production comprises a support plate, a fixed part, a slidable leather scraping part, a cleaning part, a transmission part and the like, wherein the fixed part for pressing through a lifting manner is arranged in the middle of the top part of the support plate; and a slidable leather scraping part for scraping leather through a sliding manner is arranged on the left side ofthe top part of the support plate. According to the automatic edge scraping device for leather wallet production provided by the invention, through the cooperation of the fixed part, the slidable leather scraping part and the transmission part, the leather is firstly pressed tightly and is scraped through a scraper knife, and after the leather under the scraper knife is scraped, the scraper knifecan automatically move to the next position requiring leather scraping, so that a function on automatically scraping the leather is realized.

Owner:苏州爱柯基科技有限公司

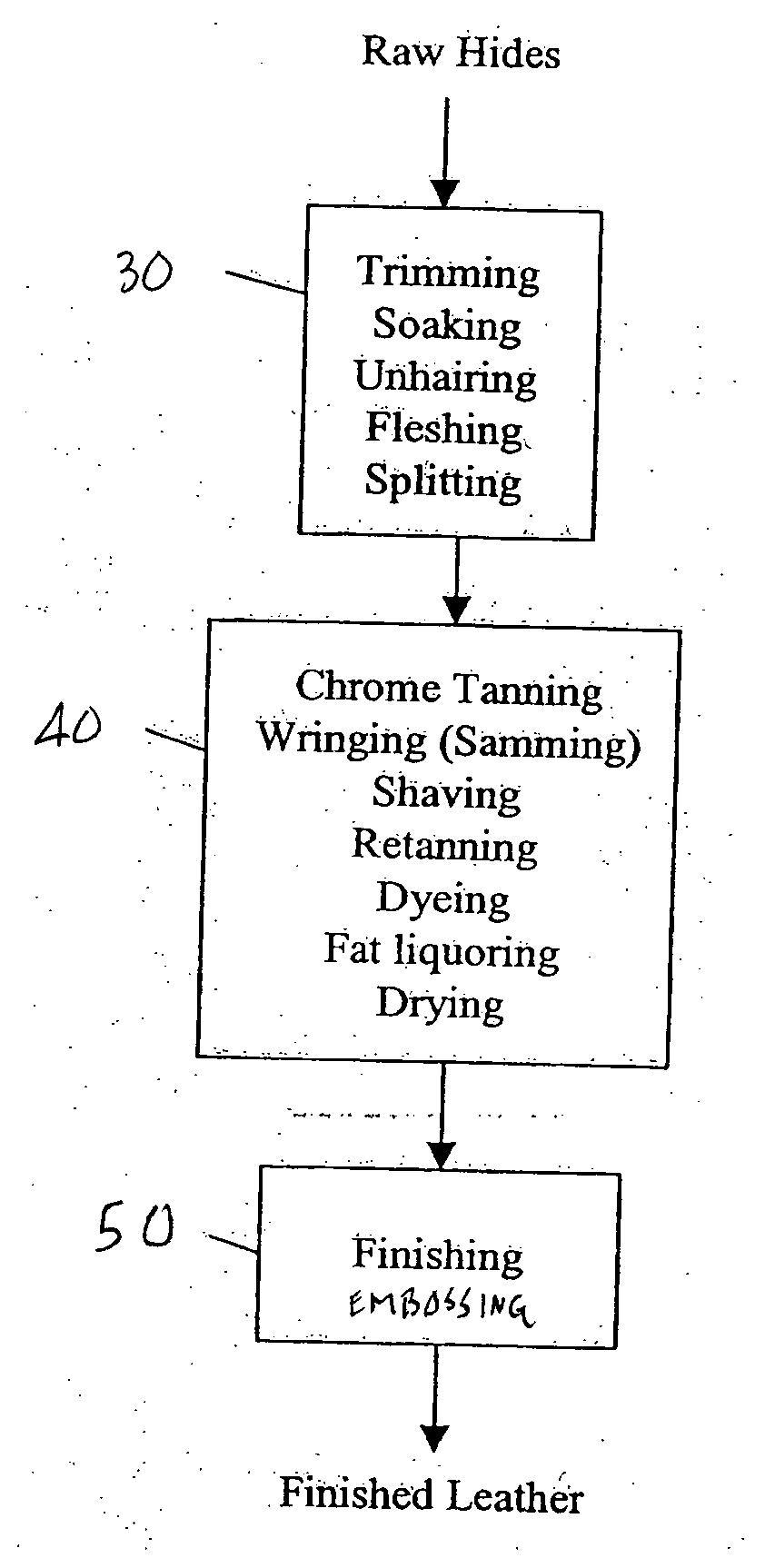

Apparatus and felt for embossing leather and artificial leather type textiles using high tension

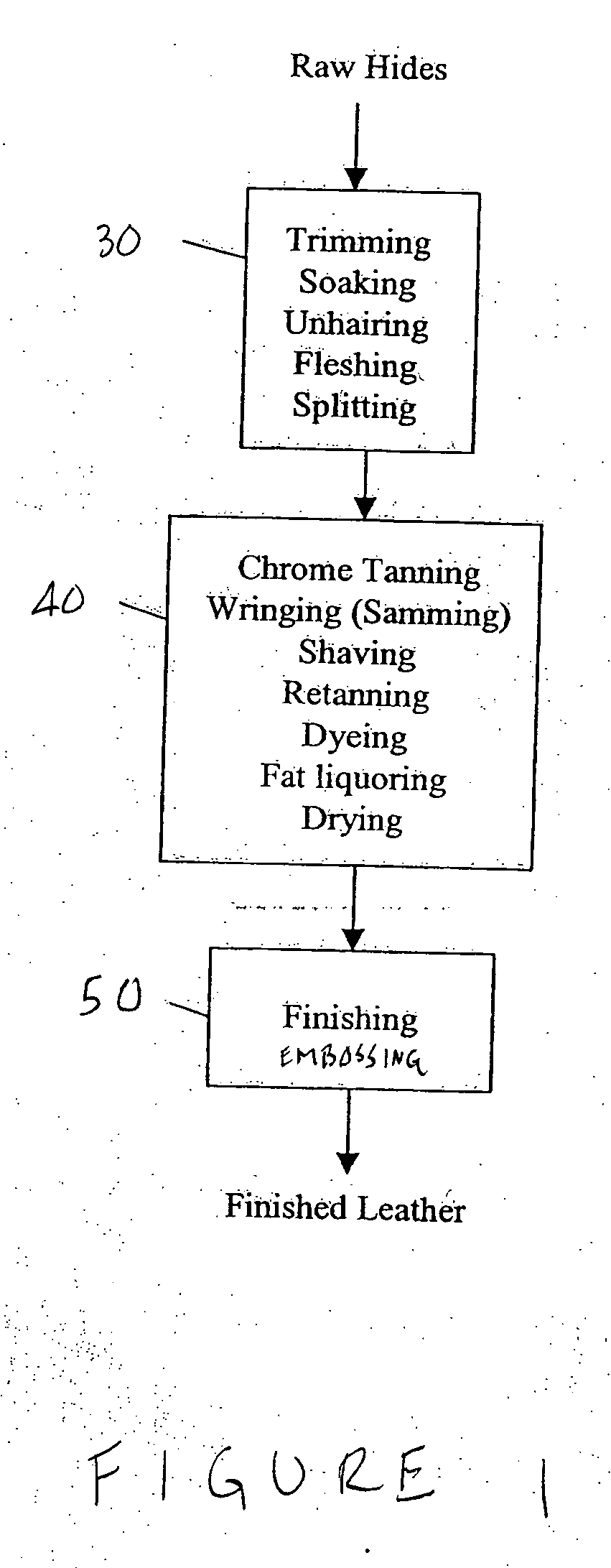

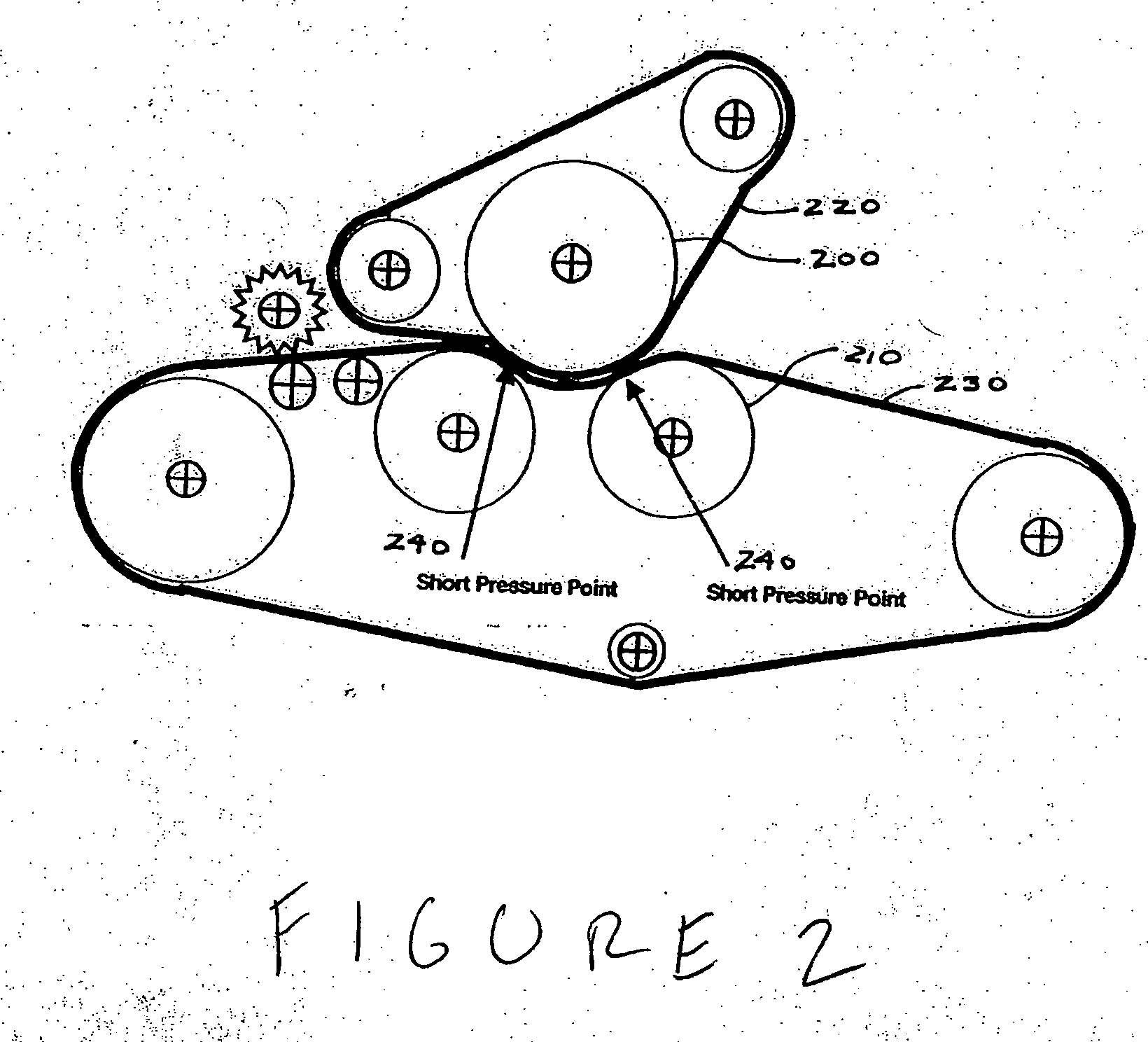

InactiveUS20050193780A1High thermalHigh chemicalLeather surface mechanical treatmentLeather edge finishingLeather industryEngineering

An embossing apparatus, similar to those used in the paper industry, for use in the leather industry to emboss leather and leather type textiles. The apparatus includes a rotating felt under tension. In a preferred embodiment, the felt wraps around a heated embossing cylinder under tension and there is no nip. In this case, the leather textile is conveyed while sandwiched between the felt and the cylinder and is thereby embossed.

Owner:ALBANY INT CORP

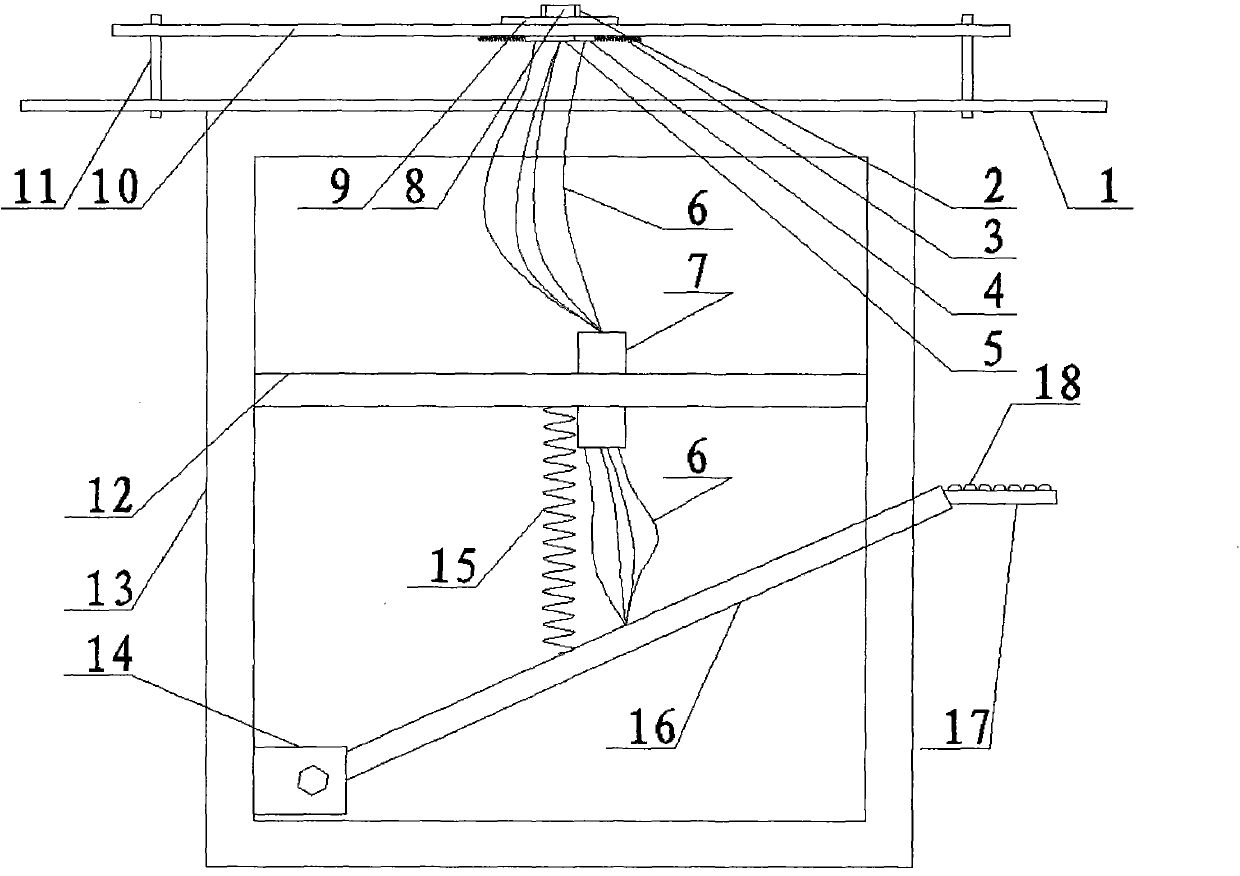

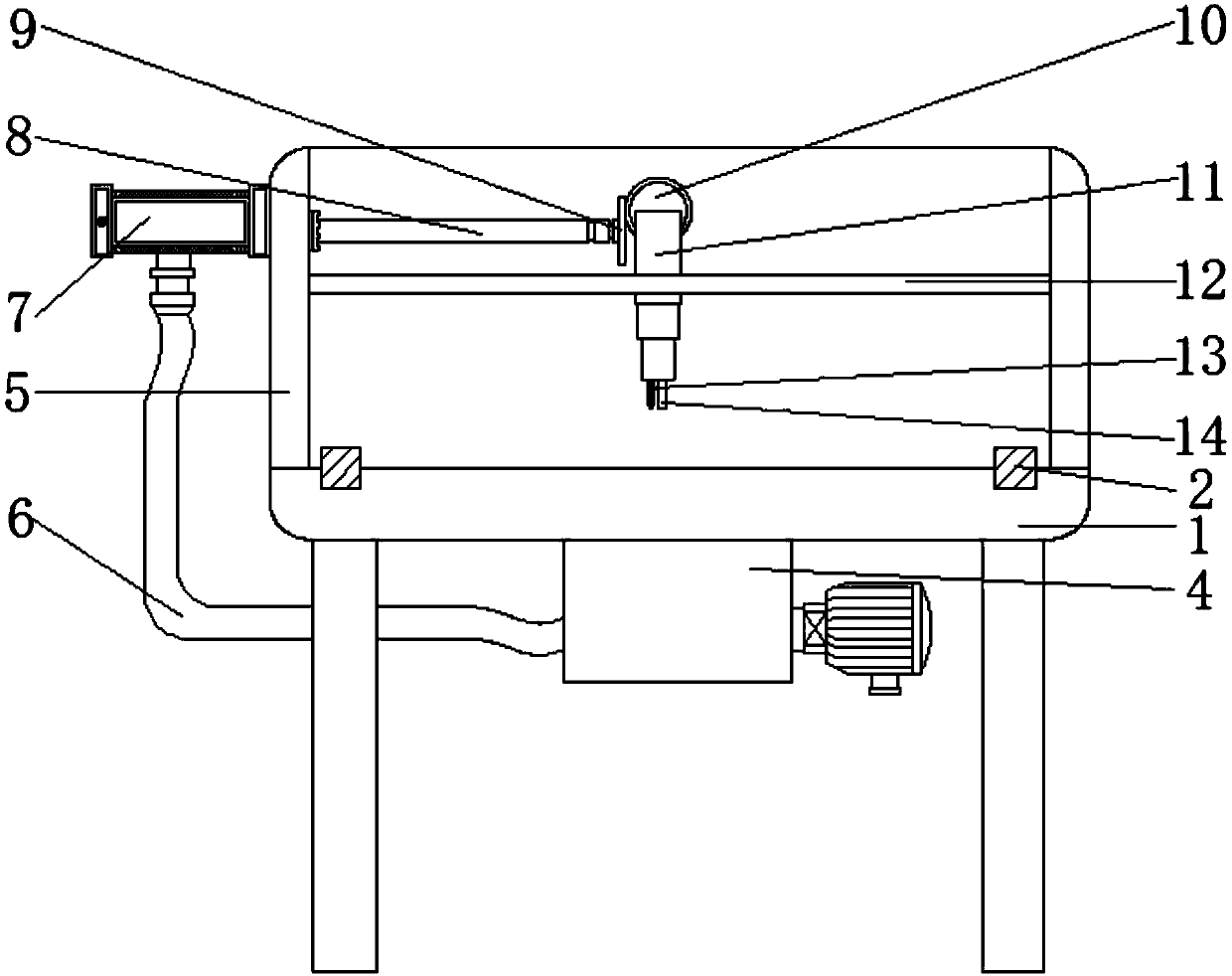

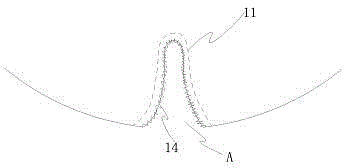

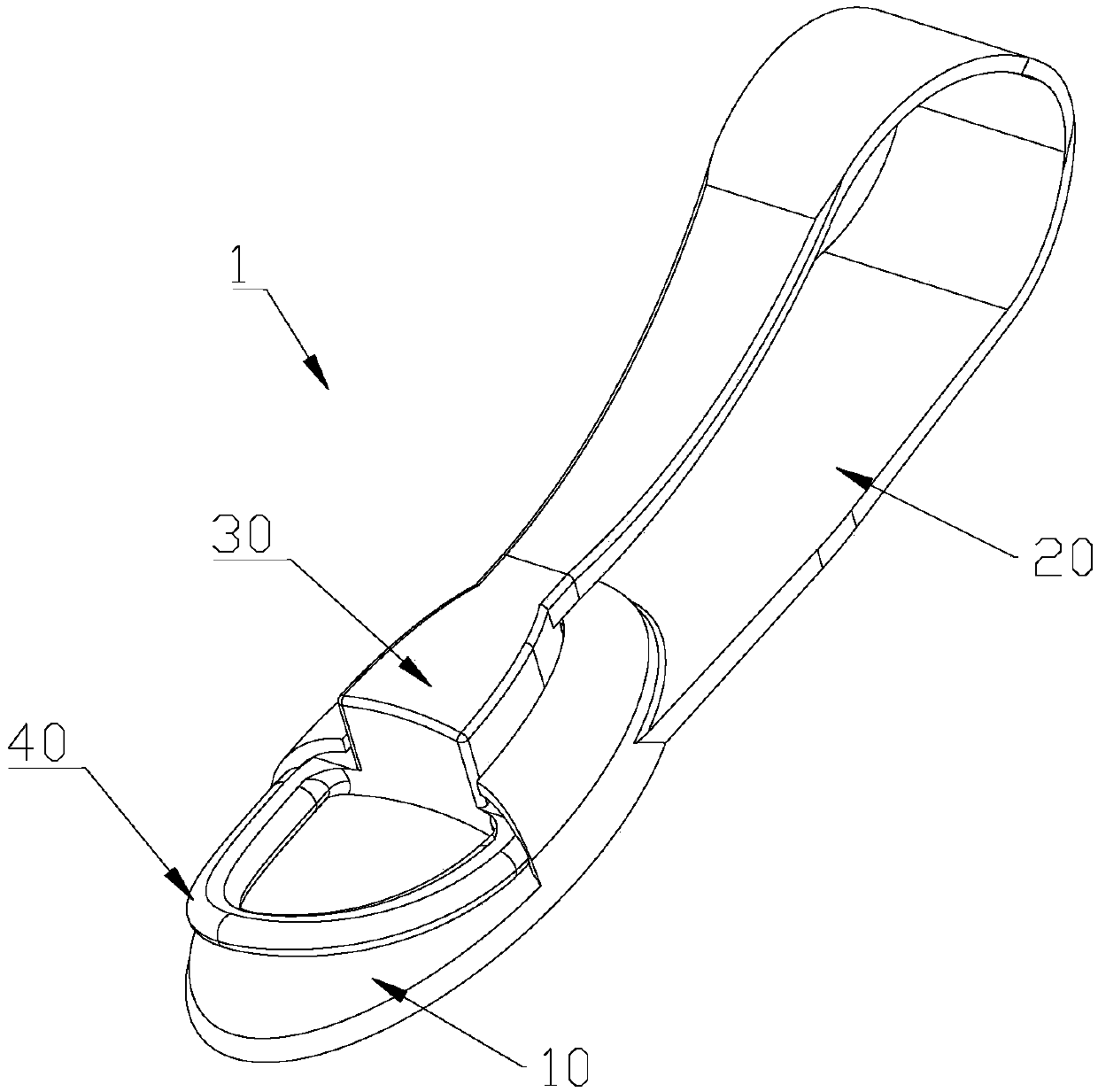

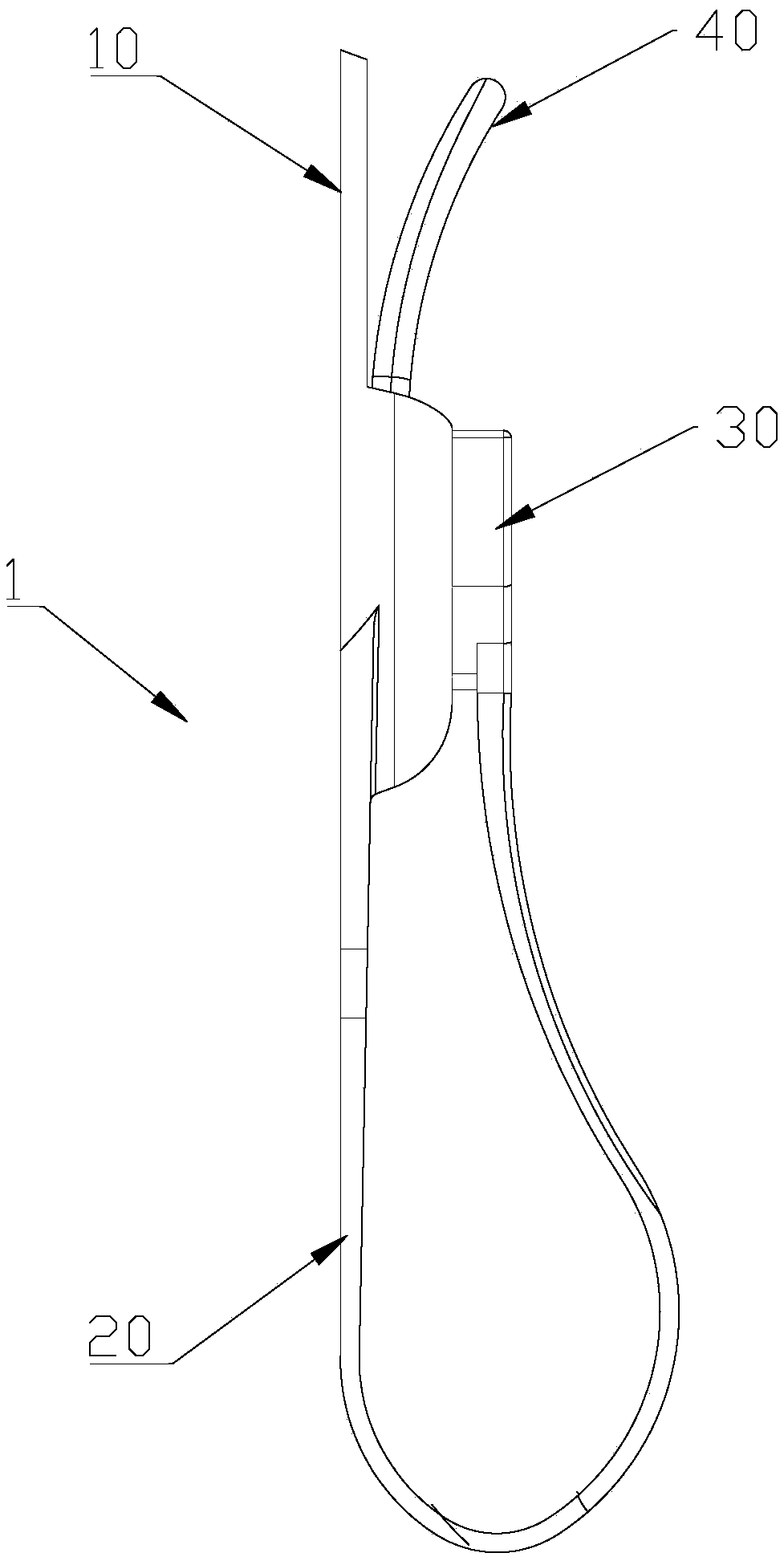

Leather product window edge folding machine

The invention discloses a leather product window edge folding machine. The leather product window edge folding machine comprises a face plate, a support leg, an edge folding assembly and a pedaling assembly, wherein the support leg is provided with a transverse pull rod; the edge folding assembly comprises a wide edge folding assembly and a narrow edge folding assembly; the wide edge folding assembly comprises a wide edge folding mold, and a wide edge folding mold hinge located under planar upper and lower molds, wherein the wide edge folding mold hinge is connected with an iron wire and a reset spring; when the iron wire is pulled down, the wide edge folding mold hinge drives the wide edge folding mold to overturn and press down for folding the edge, and when the iron wire is released, the reset spring drives the wide edge folding mold to reset; the narrow edge folding assembly comprises a narrow edge folding mold, and a narrow edge folding mold hinge located under planar upper and lower molds, wherein the narrow edge folding mold hinge is connected with another iron wire and another reset spring; when the iron wire is pulled down, the narrow edge folding mold hinge drives the narrow edge folding mold to overturn and press down for folding the edge, and when the iron wire is released, the reset spring drives the narrow edge folding mold to reset; the pedaling assembly drives the iron wire to be pulled down or released.

Owner:王良元

Leather cutting device capable of preventing edge curling

InactiveCN109797252AAvoid curlImprove efficiencyLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusHydraulic cylinderFuel tank

The invention discloses a leather cutting device capable of preventing edge curling. The leather cutting device comprises a workbench and a rack, wherein a clamping plate is installed on the surface of the workbench, an oil tank is fixed below the clamping plate, a high-pressure rubber pipe is installed on the left side of the rack, a hydraulic cylinder is connected above the high-pressure rubberpipe, the right side of the hydraulic cylinder is connected with a piston rod, and the right side of the piston rod is provided with a connecting plate; and a cutting device is fixed on the right sideof the connecting plate, the lower part of the cutting device is connected with a cutting blade and an electric iron through an electric telescopic rod, sliding rails are arranged above the two sidesof the cutting blade and the electric iron. According to the leather cutting device capable of preventing the edge curling, the hydraulic cylinder, the piston rod and the connecting plate are matched, hydraulic energy can be converted into mechanical energy, so that the piston rod is pushed to move back and forth to push the electric telescopic rod to move forwards and backwards on the sliding rails so as to carry out cutting operation on leather, and the high efficiency of cutting is guaranteed.

Owner:JIANGXI HOPU HIGH TECH COATED FABRIC CO LTD

Method for trimming cow leather

ActiveCN104531909AIntegrity guaranteedImprove integrityTanning treatmentPre-tanning chemical treatmentChemistryCoating

The invention relates to the technical field of a process for producing cow leather and provides a method for trimming the cow leather capable of maintaining the integrity of hides and increasing the yield and utilization rate of the cow leather during the production process of the cow leather. The method comprises the following steps: preparing wet blue leather, squeezing water, uniformly shaving, sewing, re-tanning, dyeing, carrying out fat liquoring, drying, finishing, coating, trimming and warehousing the finished product. In the step of sewing, the sewed position is the to-be-trimmed position of the wet blue leather, namely, by sewing with a wire, the tearing strength of the to-be-trimmed position of the wet blue leather is increased and the phenomenon of secondary damage of the to-be-trimmed position of the wet blue leather under the actions of twisting in the steps of re-tanning, dyeing, carrying out fat liquoring and finishing is avoided. The method is also applicable to the production process of pigskin and sheepskin.

Owner:XINGYE LEATHER TECH CO LTD

Processing technology of leather product

ActiveCN107338336ANo damageGood flexibility and wear resistanceLeather clicking/perforating/clickingPre-tanning chemical treatmentSurface cleaningWear resistant

The invention belongs to the technical field of leather products, and particularly relates to a processing technology of a leather product. The processing technology comprises the following specific steps of A1, skin selection; A2, first soaking; A3, meat removal; A4, secondary soaking; A5, first lime soaking; A6, hair removal; A7, secondary lime soaking; A8, skin planing; A9, surface cleaning; A10, lime removal; A11, cleaning; A12, airing; A13, first skin smoking; A14, first skin covering; A15, secondary skin smoking; A16, medicinal herb decocting; A17, liquid medicine applying; A18, secondary skin covering; A19, third skin smoking; A20, melanterite coating; A21, oil coating; A22, splitting; A23, first skin rolling; A24, third skin covering; A25, secondary skin rolling; A26, skin spreading; A27, trimming; and A28, numbering and warehousing. Under the premise that no chemical raw material is added, the prepared leather has breathable and waterproof characteristics, and is wear-resistant and tough.

Owner:汪孝凌

Leather edge cutting device capable of cutting leather with different thicknesses and avoiding dust pollution

InactiveCN111979359AAvoid pollutionIncrease diversityLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusCircular discAgricultural engineering

The invention relates to the technical field of leather, and discloses a leather edge cutting device capable of cutting leather with different thicknesses and avoiding dust pollution. The leather edgecutting device comprises two support plates, and the two support plates are consistent in specification and are symmetrically distributed by taking a center line of a negative pressure chamber as a reference. Through cooperative use of a first rotary disc, a second rotary disc, a moving block, a first gear, a hydraulic rod and a second gear, leather with different thicknesses on a roller shaft can be cut, a new edge cutting device does not need to be replaced, and the diversity of the functions of the whole device is increased; through cooperative use of a baffle, a disc and the negative pressure chamber, the negative pressure chamber is in a sealed state during edge cutting, dust generated during edge cutting is collected through negative pressure and is prevented from being sucked intothe lungs of staff to cause infection; through cooperative use of a sleeve rod and the second rotary disc, the two steps of moving of the roller shaft and moving of the baffle are linked, and therefore the linkage of the whole device is improved, and operation is simpler.

Owner:广州景铄服饰有限公司

Processing technology of belt

InactiveCN106388098AExtended service lifeHigh strengthLeather clicking/perforating/clickingFur cuttingZinc alloysEngineering

The invention discloses a processing technology of a belt, and relates to the field of leather processing. The processing technology comprises the following steps: (1) selecting and cutting leather; (2) disinfecting the leather; (3) sealing the leather; (4) drilling holes in the leather; (5) trimming edges of the leather; (6) making a belt head; and (7) mounting the belt head. The belt is made by dehydrating and sterilizing first-class pigskin, so that bacterium growth of the belt is effectively prevented and the service life of the belt is prolonged; a polyamide thread is seamed on the outer edge of the belt by a circle, so that the strength of the belt is improved and the belt is protected from becoming broken when the edge part of the belt gets worn; by covering the belt with PVC leather, the service life of the belt is prolonged, and in addition, an aesthetic effect is achieved; and by plating a layer of zinc alloy outside the belt head, cost is saved, and meanwhile, the belt head is protected from getting rusted.

Owner:ANHUI CHUANGRONG CLOTHING ACCESSORIES

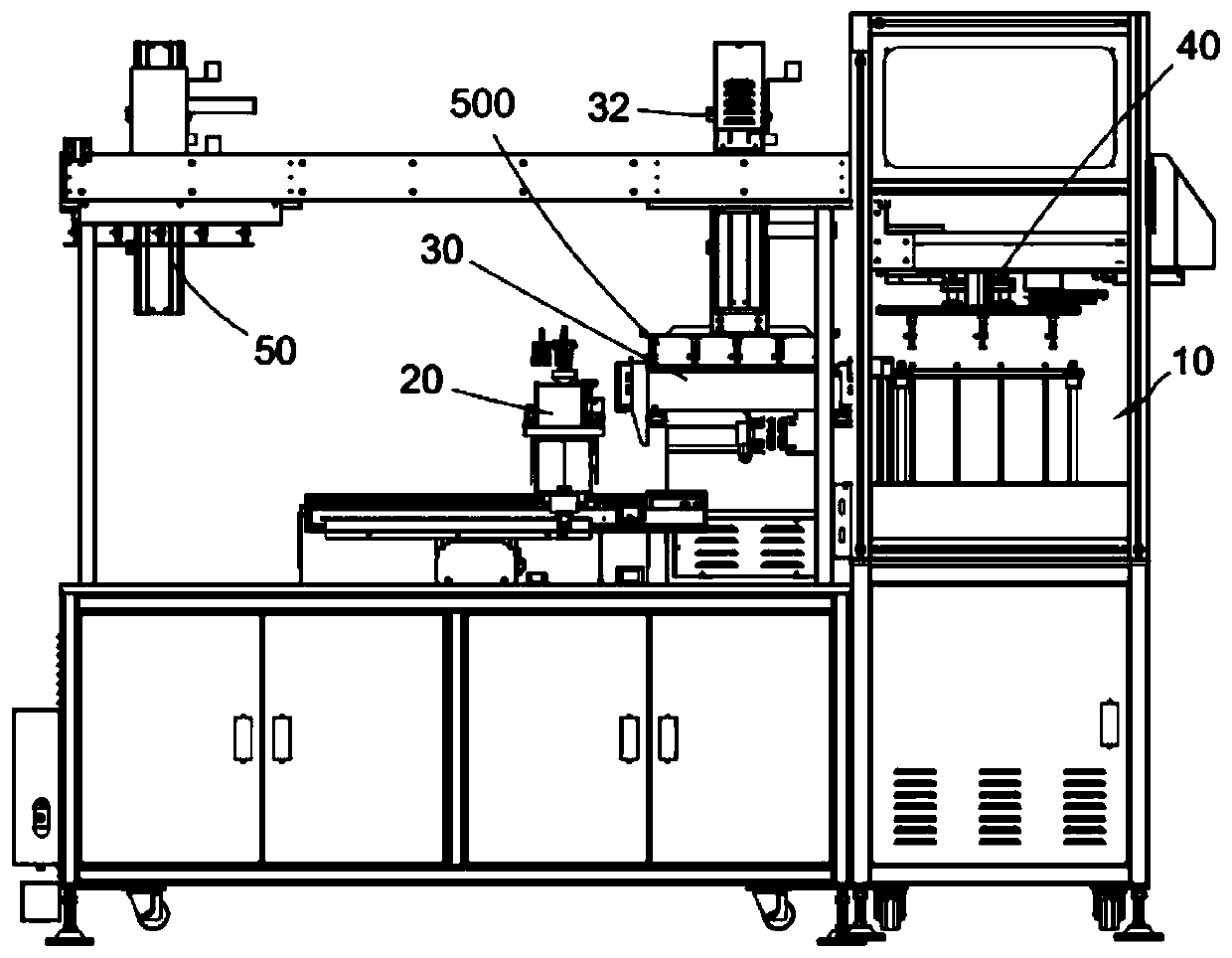

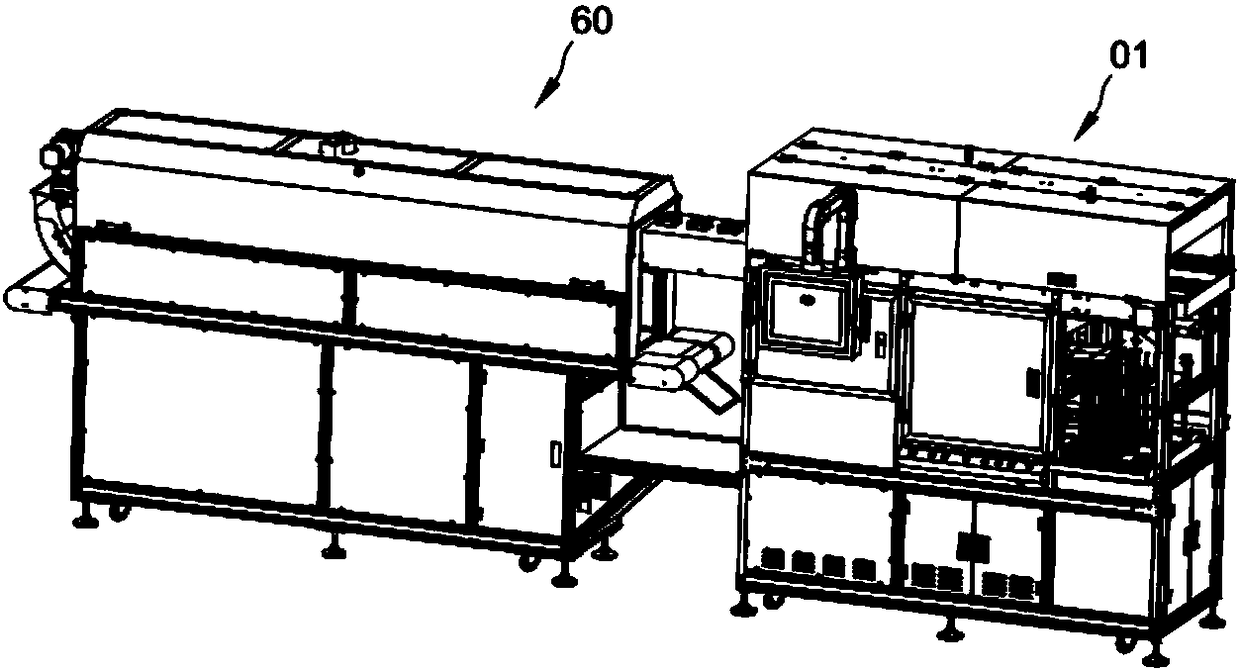

Novel automatic edge dyeing machine and edge dyeing method thereof

PendingCN108486292AImprove pass rateResponsive and efficientLeather edge finishingEngineeringMultiple layer

The invention belongs to the technical field of automatic edge dyeing machine structures, and particularly relates to a novel automatic edge dyeing machine and an edge dyeing method thereof. The automatic edge dyeing machine comprises a machine frame, wherein a feeding mechanism, a material taking mechanism, an edge dyeing mechanism and a material taking and drying mechanism are arranged on the machine frame; the feeding mechanism comprises a material containing shelf, and a material conveying mechanism is installed on the material containing shelf; the material taking mechanism comprises a rotating disc, material taking rods are arranged on the rotating disc, and material taking suction nozzles are installed on the material taking rods; the edge dyeing mechanism comprises an edge dyeing machine head; and the material taking and drying mechanism comprises steering discs, a detection device and a material taking clamp opening device, wherein clamp stringing ropes are arranged on the peripheries of the steering discs in a sleeving mode, and material taking clamps used for clamping leather materials are arranged on the clamp stringing ropes. The edge dyeing method of the novel automatic edge dyeing machine comprises the processes of feeding, material taking, edge dyeing and material taking and dying in sequence, the whole process is mechanically operated, the reaction is sensitive, and the working efficiency is high; and the strip materials are placed on the material containing shelf, and the situations such as bending are not prone to occurrence when the multiple layers of materials are overlapped, so that positioning is accurate, the later-stage uniform edge dyeing is facilitated, and the qualified rate of finished products is improved.

Owner:台州君创机械科技有限公司

Waterborne polyurethane emulsion with high solid content and preparation method thereof

The invention relates to a waterborne polyurethane emulsion with a high solid content and a preparation method thereof. The preparation method comprises the steps that firstly, a waterborne polyurethane emulsion A and a polyurethane prepolymer which are low in solid content and small in particle size are prepared respectively, the prepared waterborne polyurethane emulsion A is used for replacing water for emulsification, the polyurethane prepolymer is added into the waterborne polyurethane emulsion A which is stirred at a high speed, and the waterborne polyurethane emulsion B with a high solid content is obtained. Through mutual filling of different emulsion particle sizes, maximum accumulation is achieved, the stability of the emulsion is guaranteed, and meanwhile, the solid content of the prepared waterborne polyurethane emulsion is greater than or equal to 55%.

Owner:山西省应用化学研究所(有限公司) +1

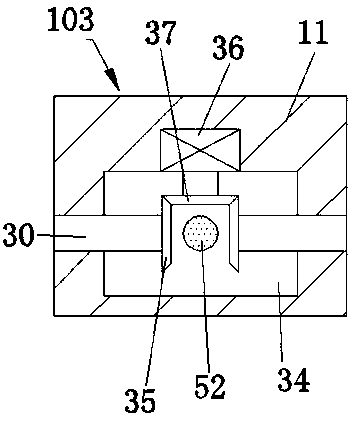

Visual two-arm edge oiling machine

A visual two-arm edge oiling machine comprises a material supply mechanism, a positioning mechanism, an edge oiling mechanism, a drying mechanism and a leather conveying system, wherein the leather conveying system reciprocates among the material supply mechanism, the positioning mechanism, the edge oiling mechanism and the drying mechanism; the positioning mechanism comprises a transparent positioning plane, a photographic device located above the positioning plane, a light source located under the positioning plane and a control system connected with the photographic device; and the controlsystem is connected with the edge oiling mechanism. Leather is photographed by the photographic device, the control system determines the travelling path of the edge oiling mechanism according to theoutlines of leather images, and thus the edge oiling mechanism can adapt to leather in various shapes efficiently and accurately.

Owner:东莞市具力自动化设备科技有限公司

Smooth edge cutting equipment for leather

InactiveCN113005239AImprove efficiencySmooth cutLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusMechanical engineeringIndustrial engineering

The invention relates to the technical field of leather production and processing, in particular to smooth edge cutting equipment for leather. The smooth edge cutting equipment for the leather comprises a rack, a main cavity is formed in the rack, intermittent action can be achieved through an ingenious mechanical structure of the equipment, and therefore the control cost of the equipment is greatly reduced, and the running reliability of the equipment is improved. Through the edge cutting device, when the edge of the leather is cut, the edge of the leather is more smoothly cut by slowly inclining a cutter and matching with an oblique feeding method, and therefore the problem that the edge is uneven is reduced, and the attractive degree is improved; and finally, materials which are cut by the edge cutting device and accumulated at the corners of the leather can be cut off from the adhesion position with the leather through a finishing device, so that the problem of the tail end adhesion of the leather is solved, the problem that additional cutting is manually carried out traditionally is solved, and the product quality and the production speed are improved.

Owner:杭州志尚服饰有限公司

A kind of leather trousers belt raw edge processor

ActiveCN106191333BLeather edge finishingLeather belt/strips manufactureCobalt nickel alloyEngineering

The invention discloses a cowhide trouser belt rough selvedge treating device. The cowhide trouser belt rough selvedge treating device comprises a magnetic scraping sheet which is an oval sheet. The thickness of the magnetic scraping sheet ranges from 1 mm to 2 mm. The magnetic scraping sheet is connected with a U-shaped handle. The handle is made of an elastic metal sheet. The tail end of the handle is connected with a magnetic body attracted to the magnetic scraping sheet. A semi-oval metal rod is arranged on the magnetic body. Emery is inlaid in the surface of the metal rod, the diameter of the metal rod ranges from 1.6 mm to 2.4 mm, and the included angle formed by the plane where the metal rod is located and the plane where the magnetic scraping sheet is located ranges from 18 degrees to 32 degrees. The metal rod is made of an iron-cobalt-nickel alloy, and the weight part ratio of iron, cobalt and nickel is 150:2:1. The magnetic scraping sheet, the handle and the magnetic body are integrally formed. According to the cowhide trouser belt rough selvedge treating device, the attraction force of the magnetic body is utilized for clamping the semi-oval metal rod and trouser belt rough selvedges, the rough selvedges are removed by the emery on the surface of the metal rod through friction in the reciprocating pulling process so that the removed rough selvedges cannot leave the shearing trace on the edge of the cowhide, and the edge of the cowhide looks uniform integrally and is more attractive.

Owner:泰州维尔雅纺织科技有限公司

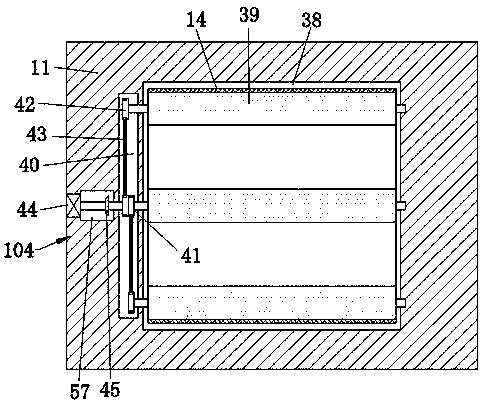

Seam pressing device for bag processing

ActiveCN113249531BImprove applicabilityImprove processing efficiencyLeather manufacturingLeather edge finishingInterior spaceEngineering

Owner:南通市通州区晓晨箱包有限公司

Novel leather manufacturing method

InactiveCN110699497AAvoid damageUniform sizeLeather surface mechanical treatmentLeather dryingProcess engineeringIndustrial engineering

Owner:蓝山县利源包装材料有限公司

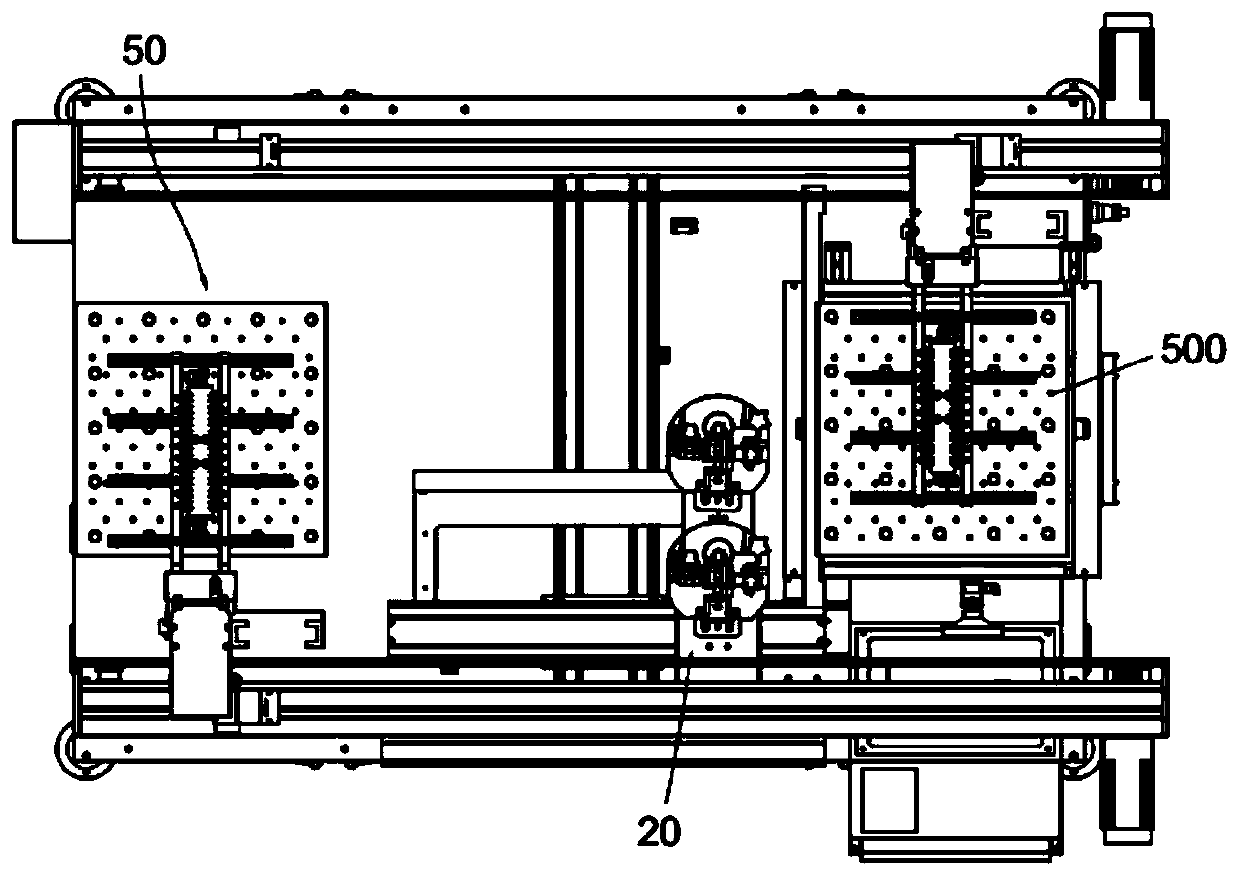

A device for trimming and grinding leather

ActiveCN112853008BEasy to polishAvoid displacementSkins/hides/leather/fur manufacturing apparatusTextile disintegration and recoveryGear wheelGrinding wheel

The present invention relates to the field of leather processing, in particular to a leather processing edge trimming and polishing device, which includes a base, a pressing mechanism, an edge trimming and polishing mechanism, a driving mechanism, etc.; The trimming and grinding mechanism is provided with a driving mechanism. Through the trimming and grinding mechanism, the two grinding wheels rotate to grind both sides of the leather. Through the action of the first rack, the two second rotating gears and their upper devices move to the right, so that the arc razor moves to the right to trim the leather. The grinding wheel rotates and moves to the right to fully polish both sides of the cut leather.

Owner:邵阳松山科技有限公司

A leather wallet material processing equipment

ActiveCN110172533BGuaranteed smooth grindingSimple structureEdge grinding machinesGrinding drivesBristleElectric machinery

The invention discloses a leather wallet material processing device. The leather wallet material processing device comprises a processing box. The processing box is internally provided with a transmission cavity. A grinding threaded rod rotates to drive a grinding threaded block to move left and right. The grinding threaded block moves to drive a pressure rod to move. The moving mechanism drives the pressure rod to move up and down to adjust the position and press leather. A main motor of a transmission mechanism provides power to drive the pressure rod to move left and right and drive a grinding stone to rotate to conduct grinding on the edge of the leather. The leather wallet material processing device grinds the edge surface of the leather smooth. An auxiliary motor in a waxing mechanism provides power to drive a brush block to move left and right to conduct waxing on the surface of the leather automatically through bristles.

Owner:义乌市玉刚箱包有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com