Patents

Literature

78 results about "CUTEr" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CUTEr (Constrained and Unconstrained Testing Environment, revisited) is an open source testing environment for optimization and linear algebra solvers. CUTEr provides a collection of test problems along with a set of tools to help developers design, compare, and improve new and existing test problem solvers.

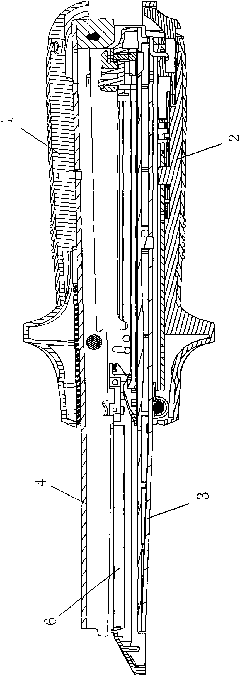

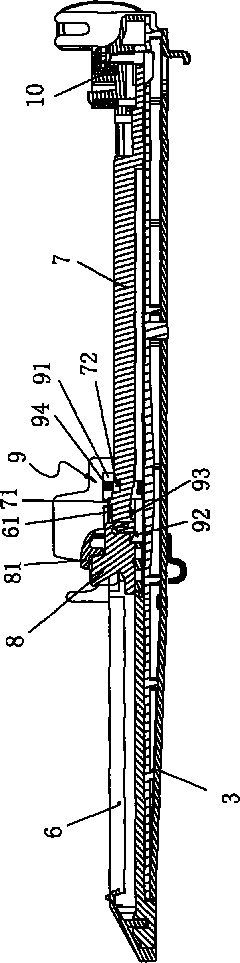

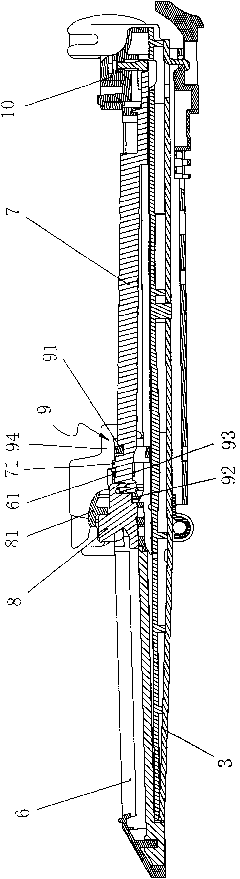

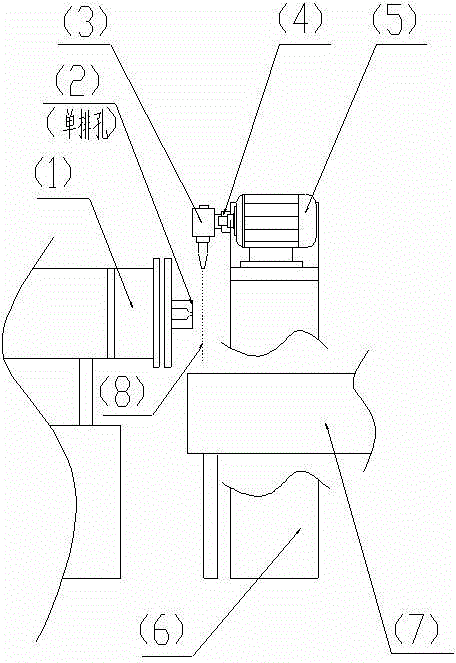

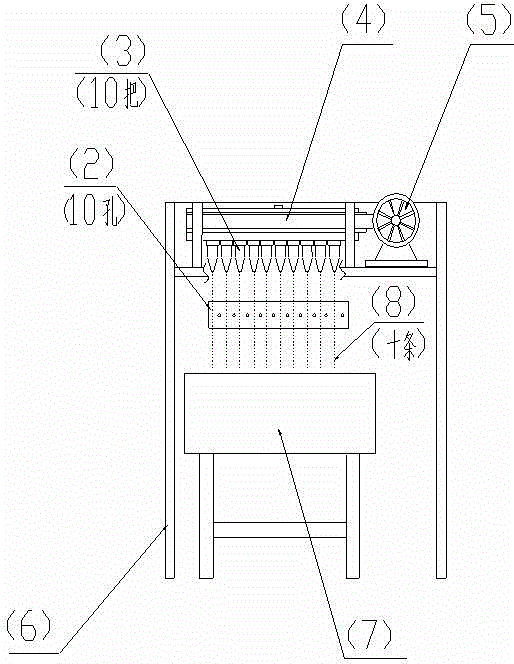

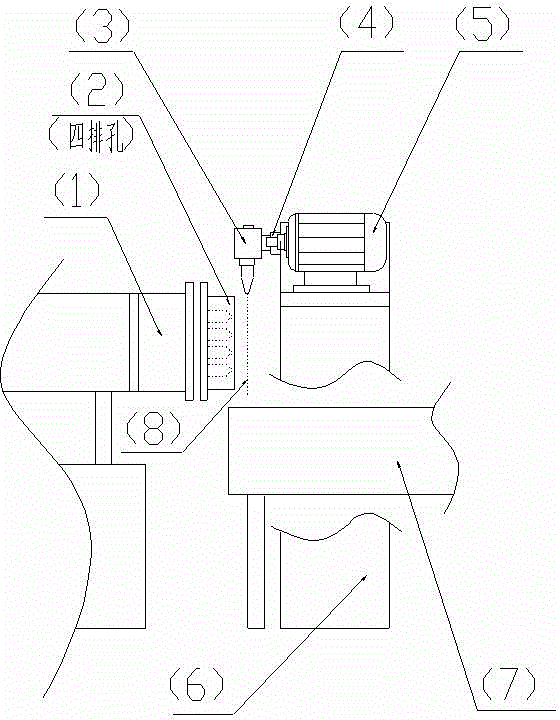

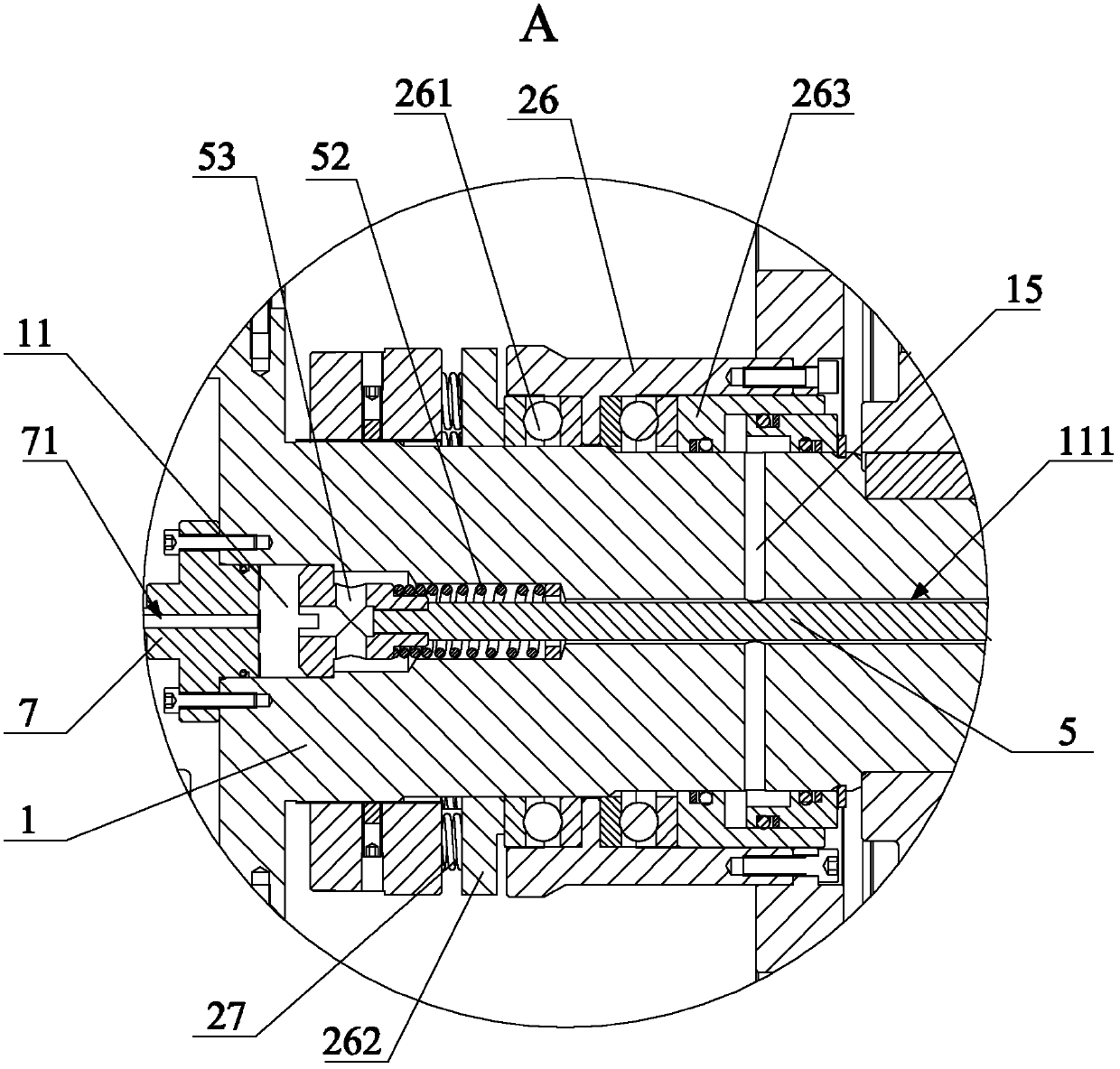

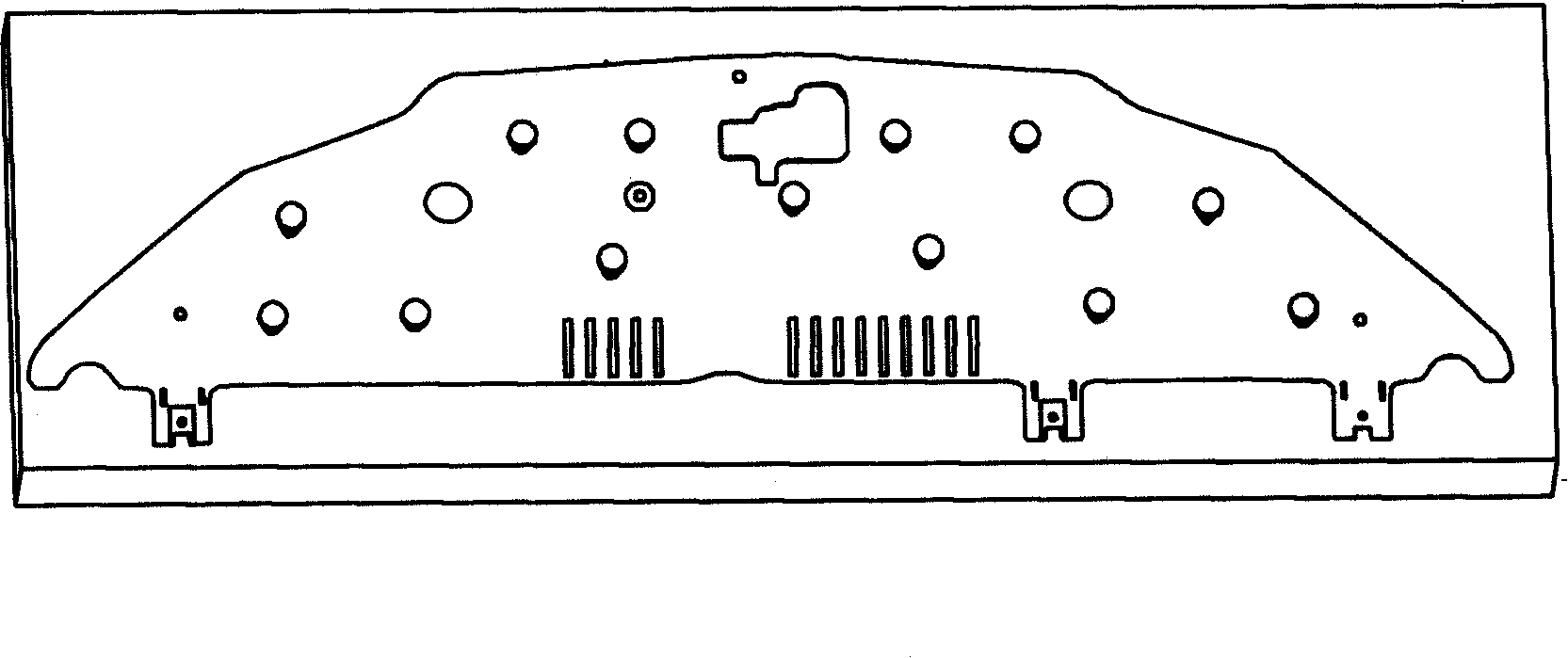

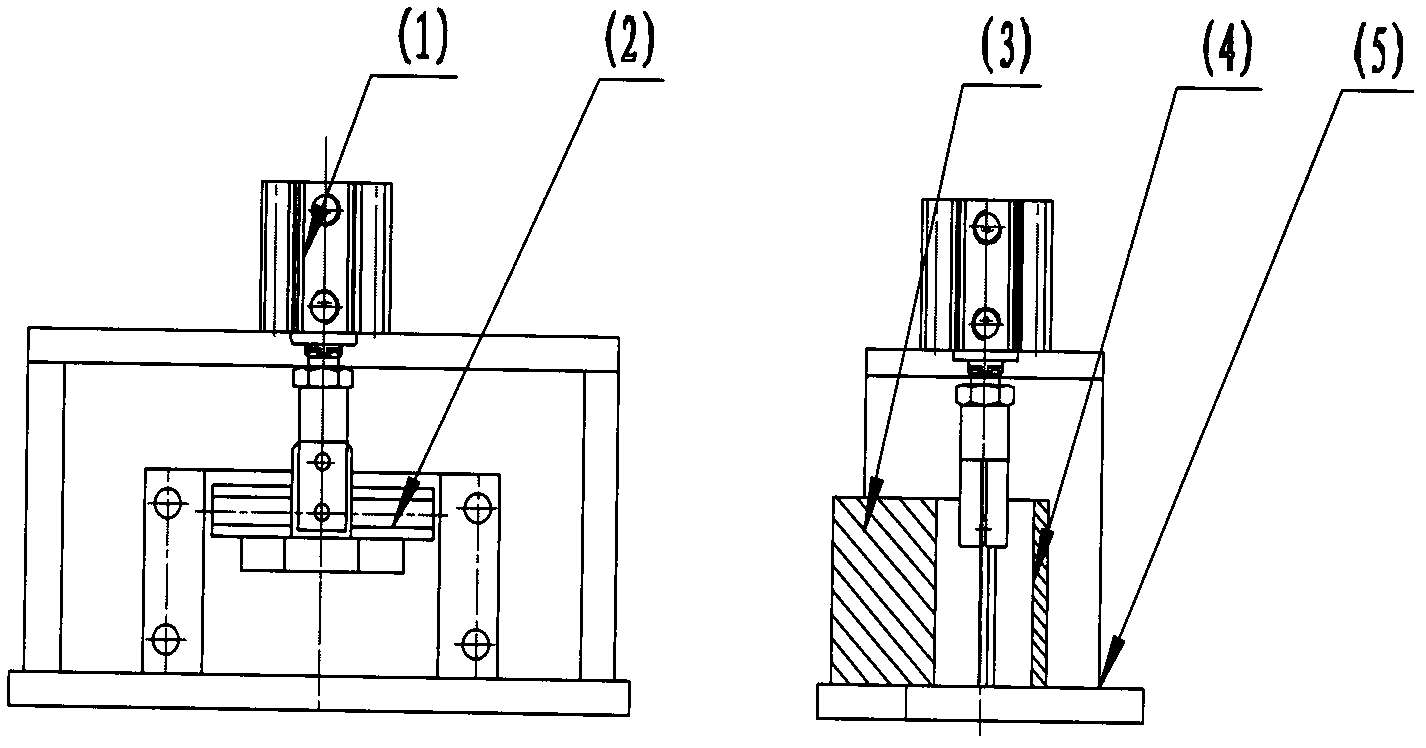

Safety device of linear cutting anastomat for surgery

ActiveCN101797174AAvoid misuseHigh insurance factorIncision instrumentsSurgical staplesElastic componentEngineering

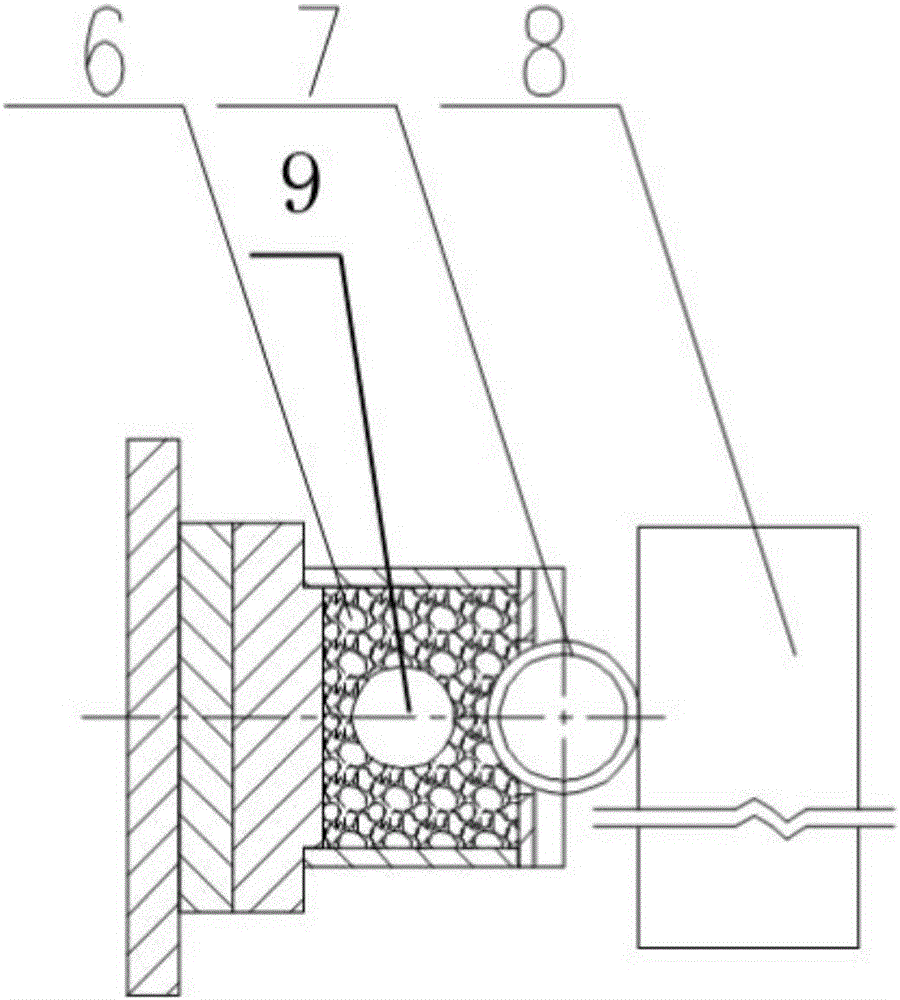

The invention discloses a safety device of a linear cutting anastomat for surgery. The safety device is provided with a nail box arm (3); the front part of the nail box arm is provided with a nail box (6), while the rear part is provided with a push cutter rod (7) capable of pushing a cuter (8) to move forward along a nail box cutting slot (62); the nail box arm is provided with a safety mechanism (9), and the safety mechanism is provided with a first elastic component (93) for elastically supporting the front part of the push cutter rod (7) and a safety block protrusion (94) downwards extending into an upper edge slot (72) of the supported push cutter rod; the cuter (8) forwards extends into the cutting slot (62) of the nail box (6); the supported front part of the push cutter rod is upwards acted on a safety bolt (61) which is blocked at the rear port of the nail box cutting slot and can be pushed forwards to support the rear end of the nail box; and the safety mechanism is also provided with a second elastic component (92) which is blocked at the front lower part of the supported push cutter rod and can be pressed down by the nail box. The safety device has the advantages of high safety factor, easy operation and simple structure, and can effectively avoid error operation of instruments.

Owner:瑞奇外科器械(北京)有限公司

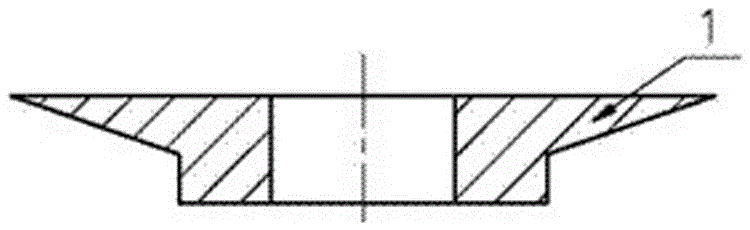

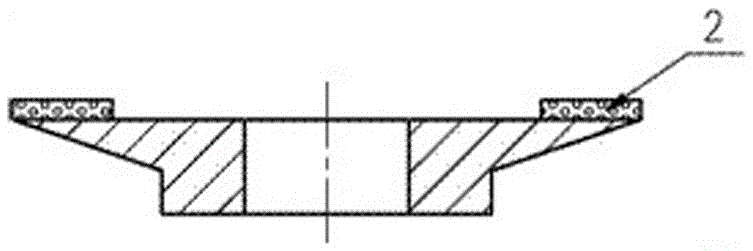

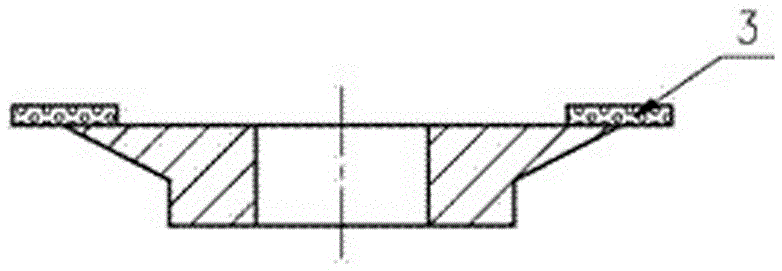

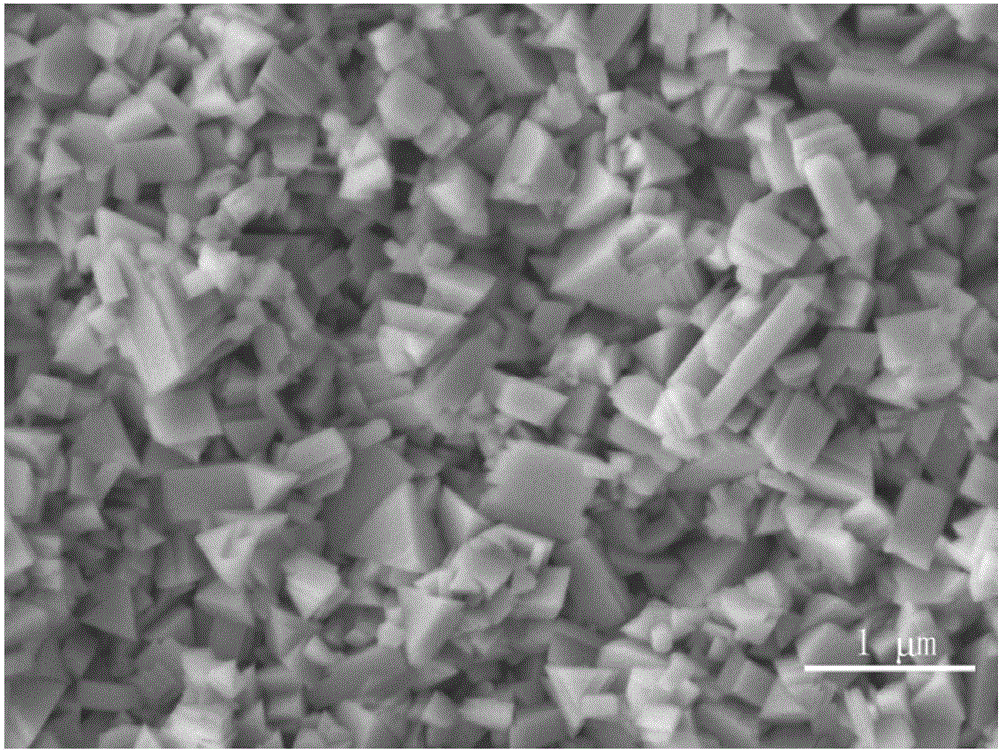

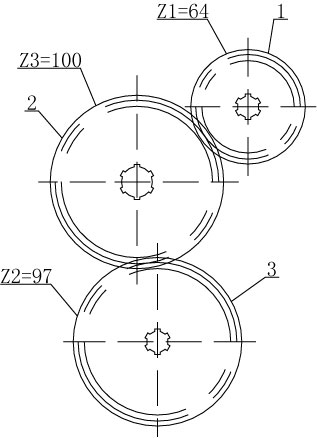

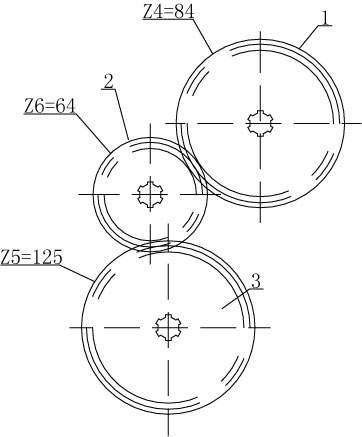

Manufacturing method of hub type electroplated ultrathin diamond abrasive cutting wheel

ActiveCN106637359AReduce stressStress reliever for low micro stressElectrolytic coatingsChemical platingGrinding wheel

The invention discloses a manufacturing method of a hub type electroplated ultrathin diamond abrasive cutting wheel. The method comprises the steps that a high-precision aluminum alloy matrix is subjected to chemical plating treatment and placed into an electroplating solution containing diamond abrasive materials, the evenly-suspended diamond abrasive materials are wrapped by a plating layer during reduction of a cathode of anode nickel ions under the effect of a direct current electric field, and a composite plating layer with the needed thickness is formed after uniform codeposition is kept for a certain period of time; and the hub type electroplated ultrathin diamond abrasive cutting wheel with the blade thickness of 0.010-0.150 mm is manufactured through the plating layer surface precise grinding, external circle grinding and blade reverse face microcorrosion treating processes. By the adoption of the phosphorous nickel aminosulfonate electroplating solution, by means of the hardness increasing effect of a hardening agent and the microstress effect of a stress removing agent, a low-stress high-hardness novel nickel-based binding agent is obtained, a blade of a cuter of the hub type electroplated ultrathin diamond abrasive cutting wheel has extremely low stress and high strength, and the problem that the cutter of the abrasive wheel is broken due to stress deformation or too low strength in practical application is avoided.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

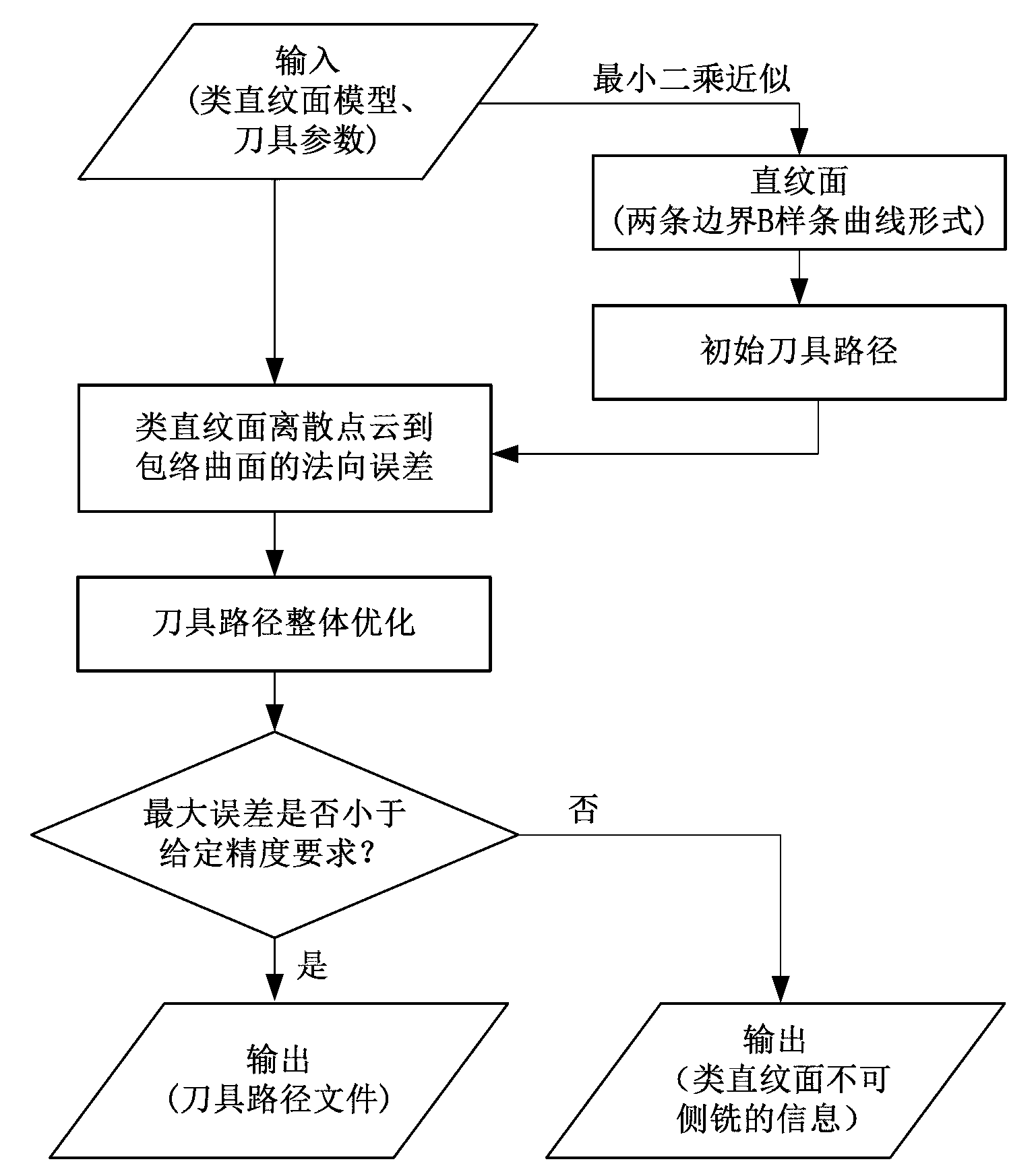

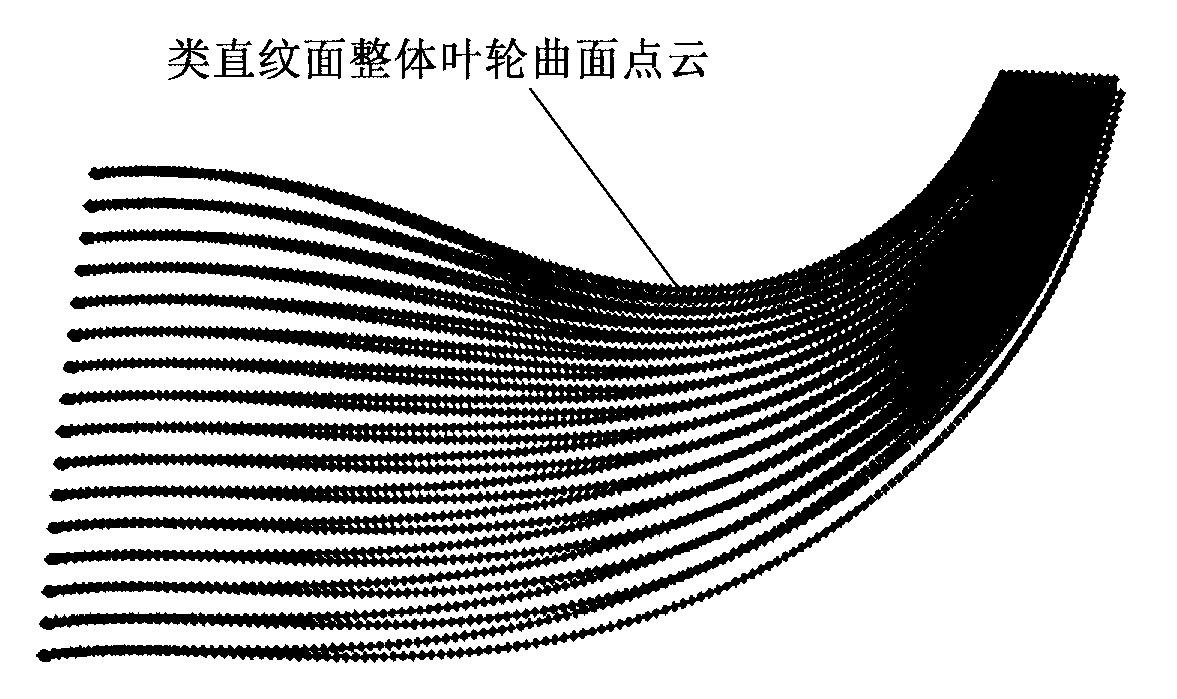

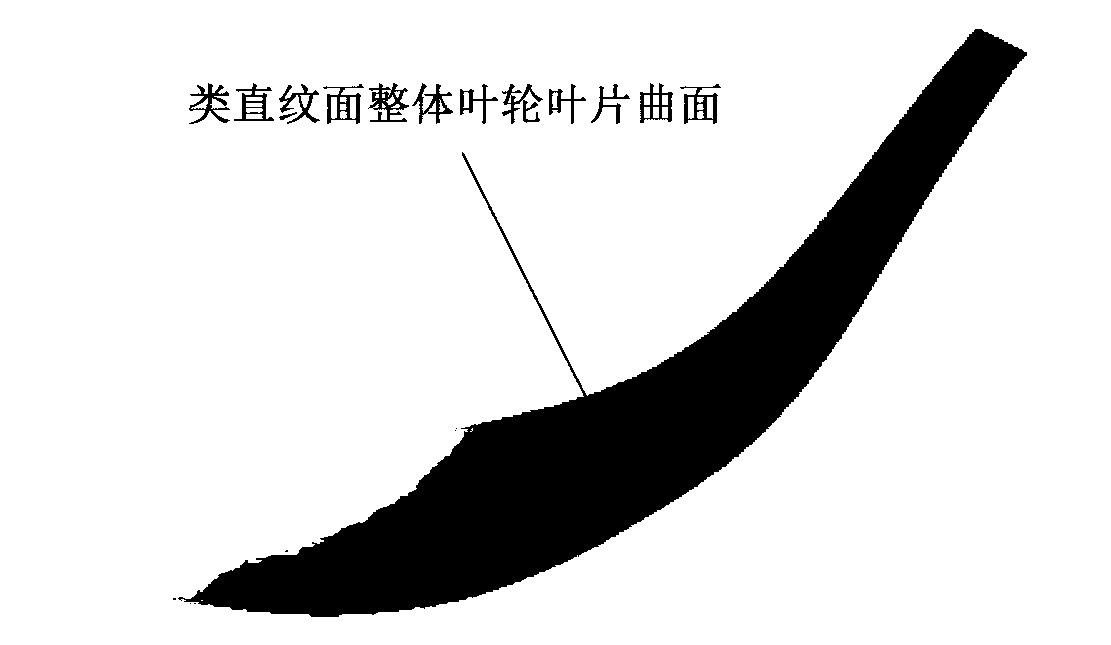

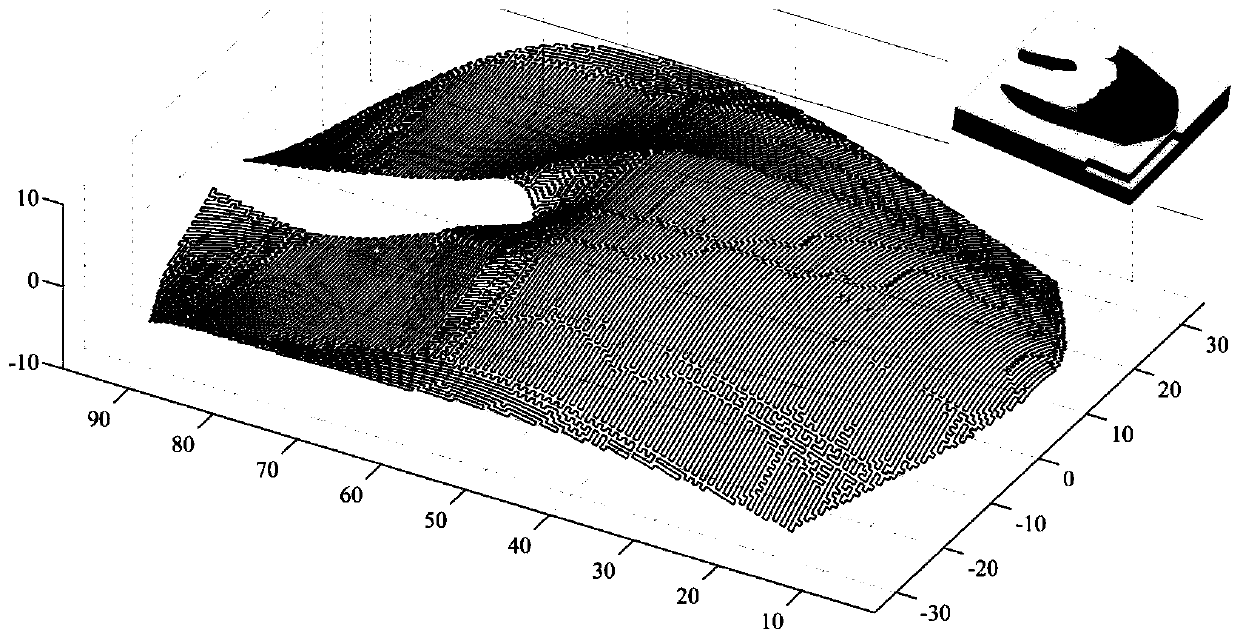

Side milling processing method of resembled ruled surface integral wheel curved surfaces

ActiveCN102794488AImprove computing efficiencyOvercomes the problem of being only applicable to straight-grained bladesMilling equipment detailsEngineeringProcessing accuracy

The invention relates to a side milling processing method of resembled ruled surface integral wheel curved surfaces. The method comprises the following steps that: firstly, similar ruled surfaces is acquired according to the resembled ruled surface integral wheel curved surfaces, and a resembled ruled surface is expressed by adopting two border triple B splines; then position and gesture of dispersed cutters are acquired through a polarization and according to approximate ruled surfaces and cutter parameters, and an initial cutter path is obtained through B spline interpolation; then the distance between the resembled ruled surface and a cutter enveloping surface is calculated, a cuter path integral optimization model following error evaluation criterions is established, the maximum optimized geometrical error is compared with a predetermined processing accuracy, and whether the resembled ruled surface meets processing accuracy requirements after being performed with side milling is judged; and at last, if the maximum optimized geometrical error is smaller than the predetermined processing accuracy, an optimal cutter path is generated, and a cutter path document is output. The side milling processing method of resembled ruled surface integral wheel curved surfaces overcomes the problem that the existing side milling processing method is only suitable for ruled surface blades, and expands application range of side milling process.

Owner:SHANGHAI JIAO TONG UNIV

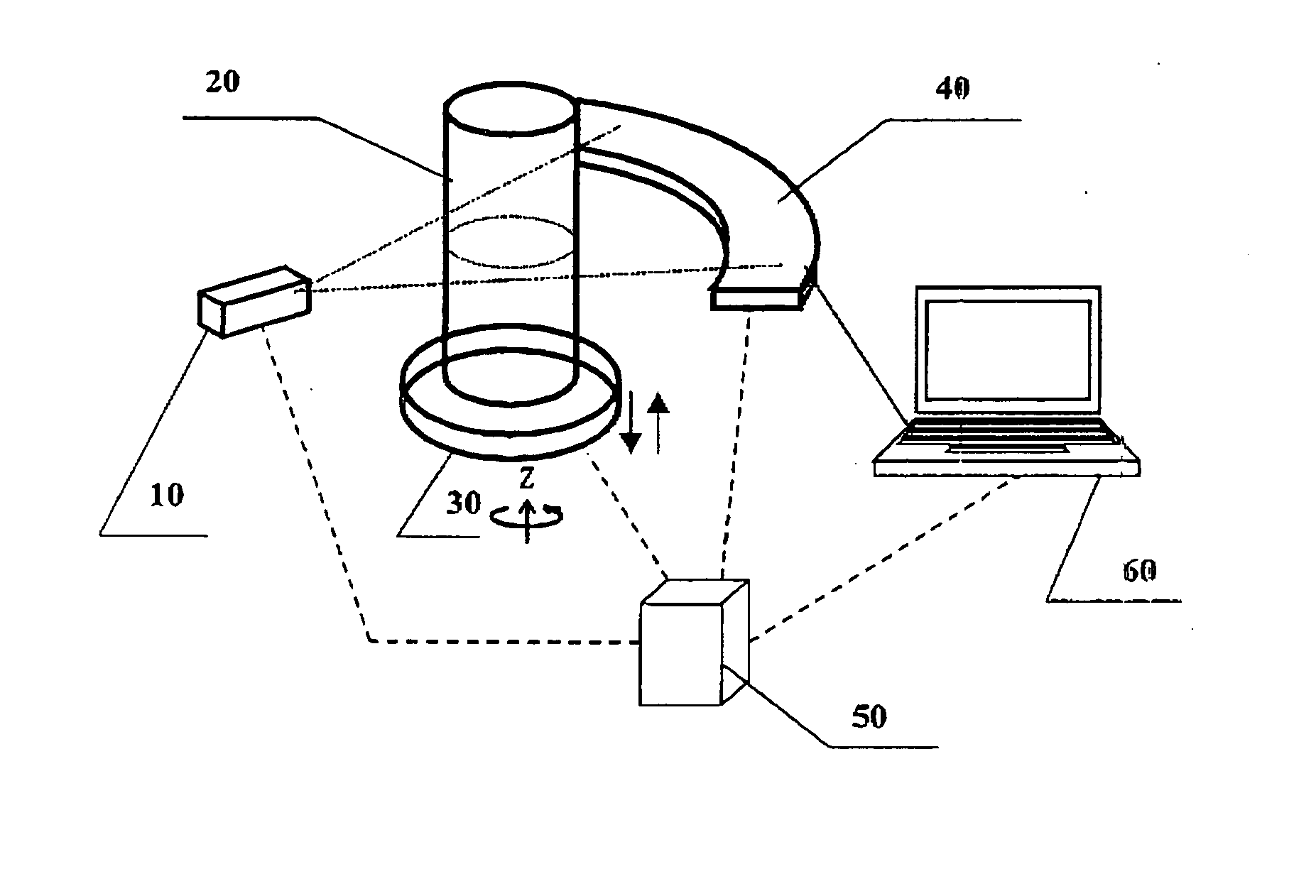

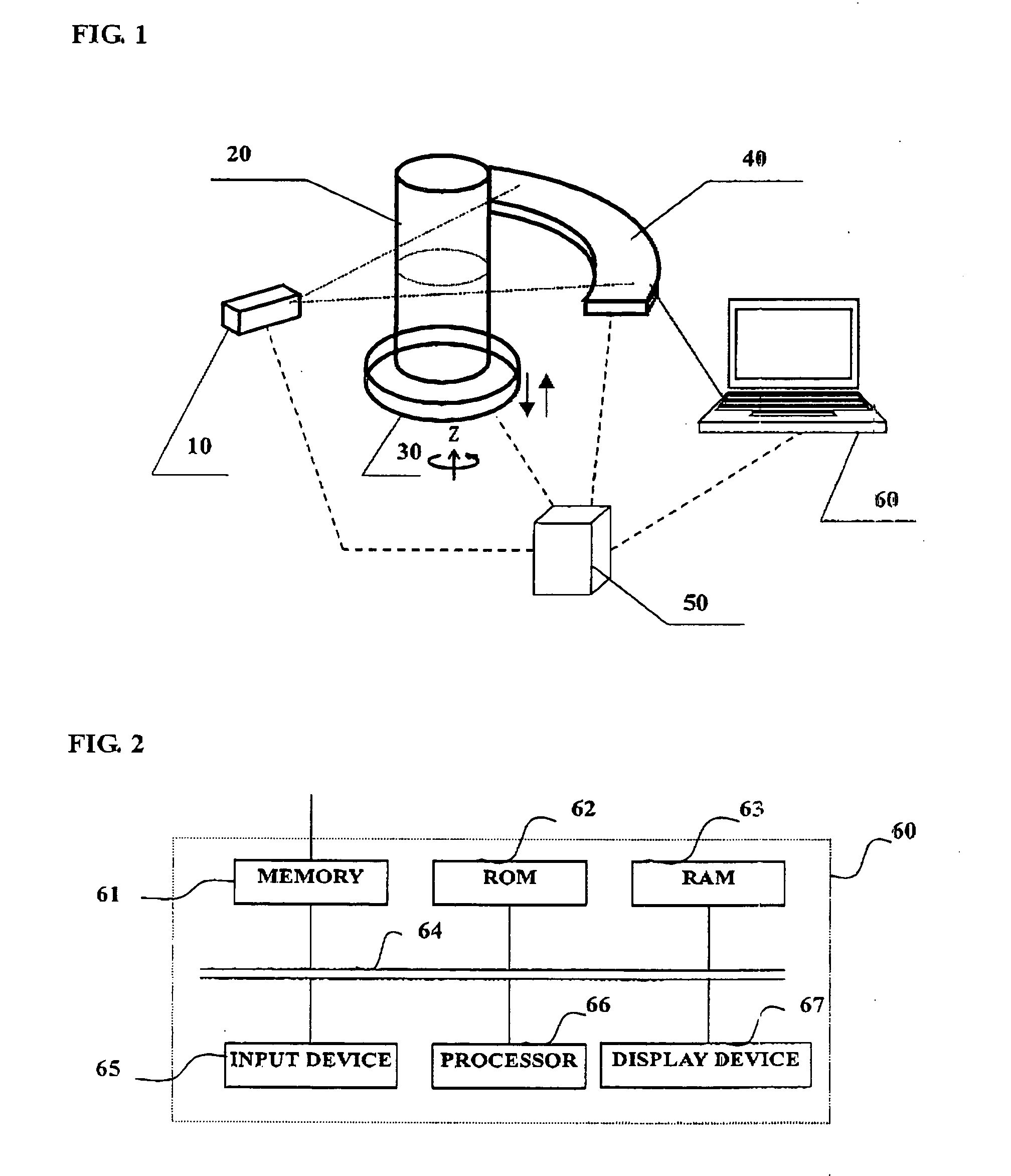

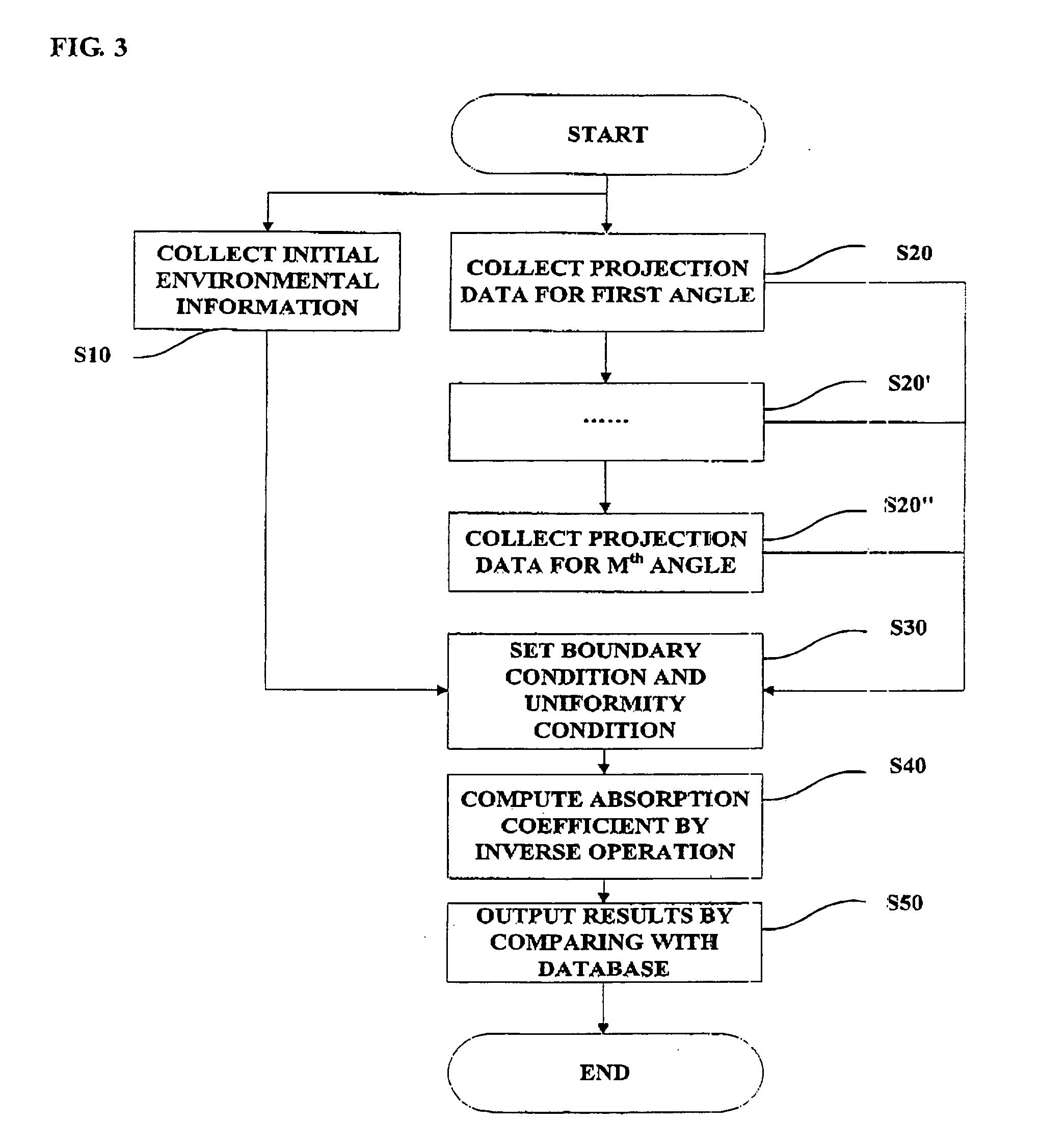

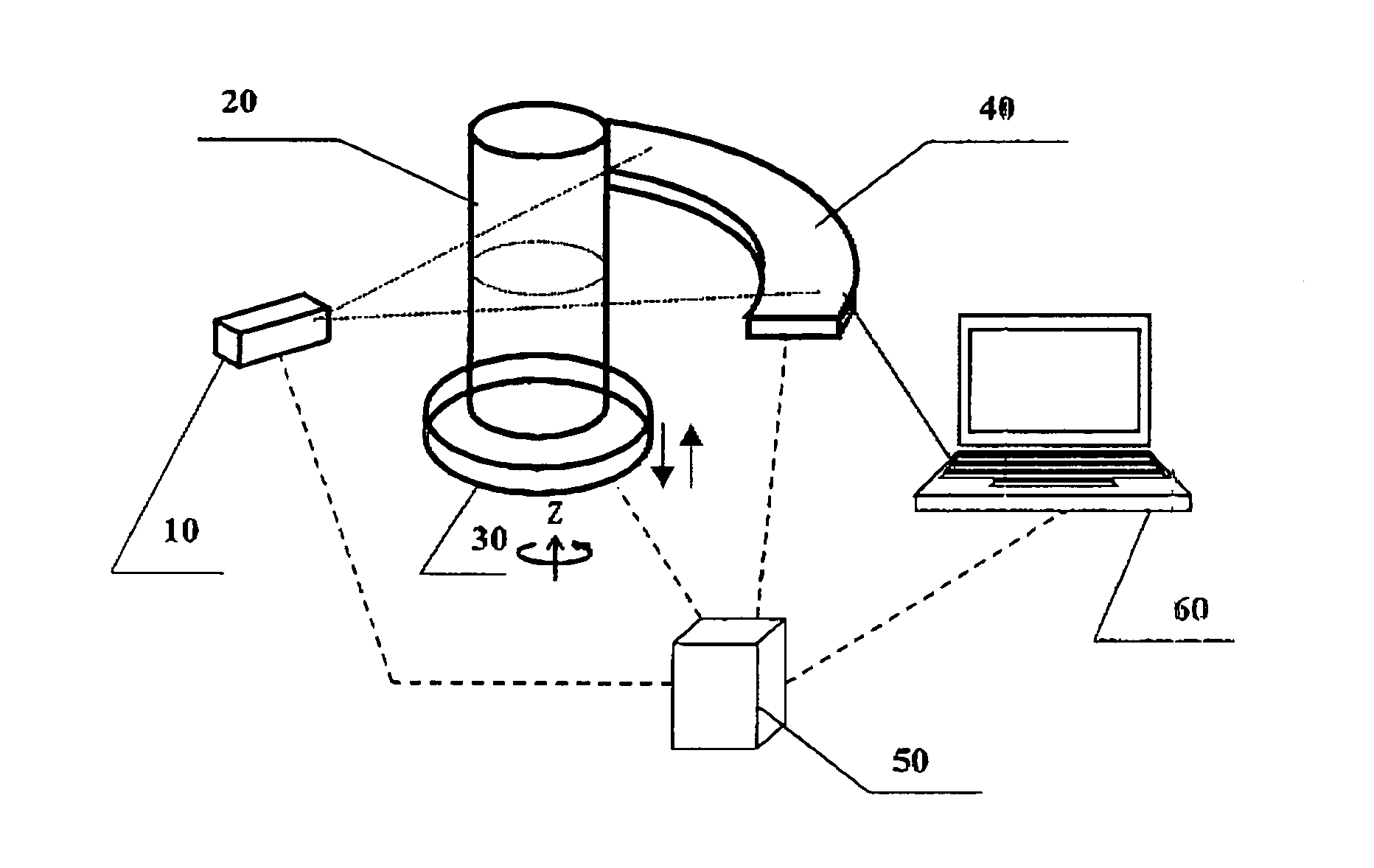

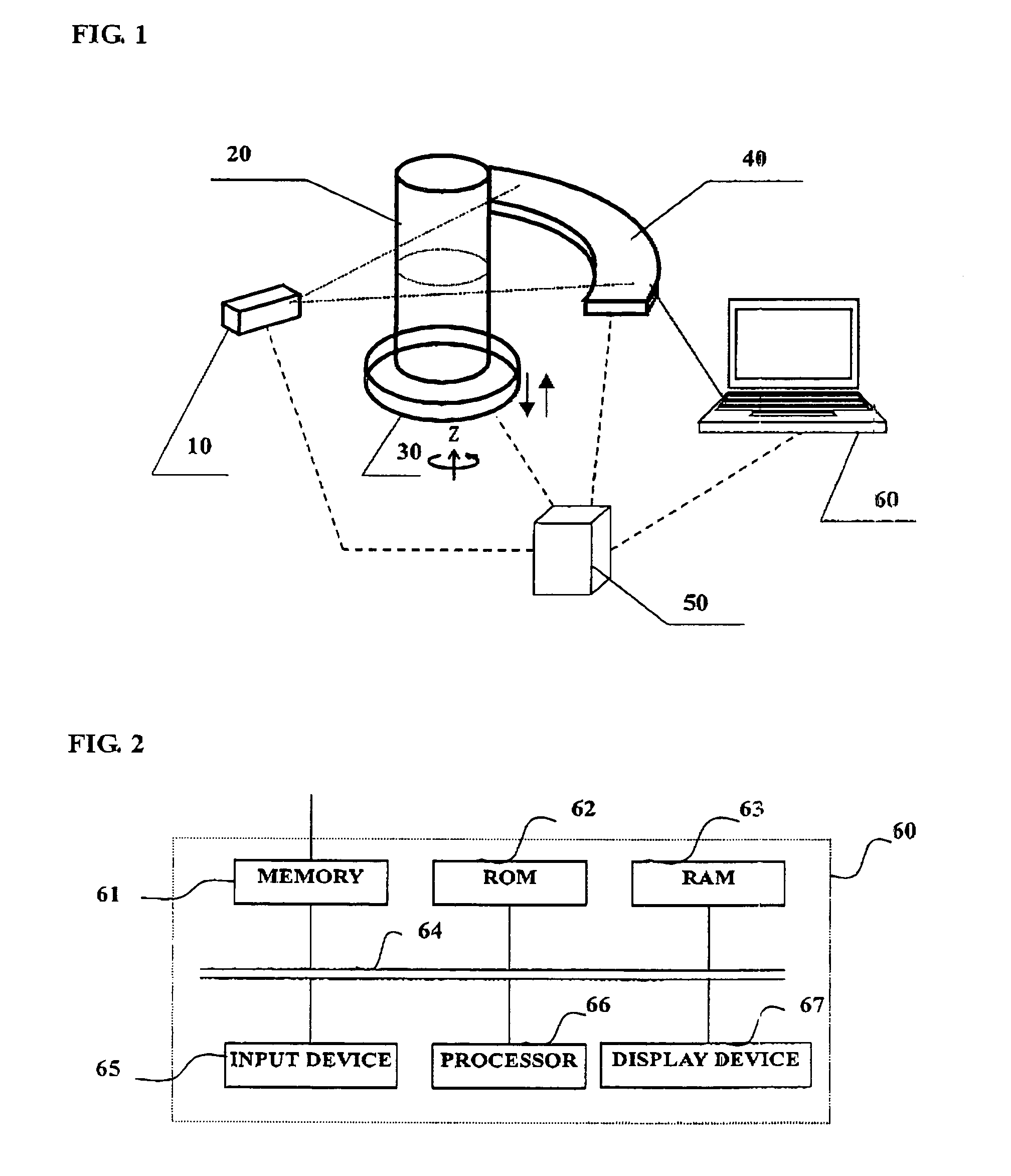

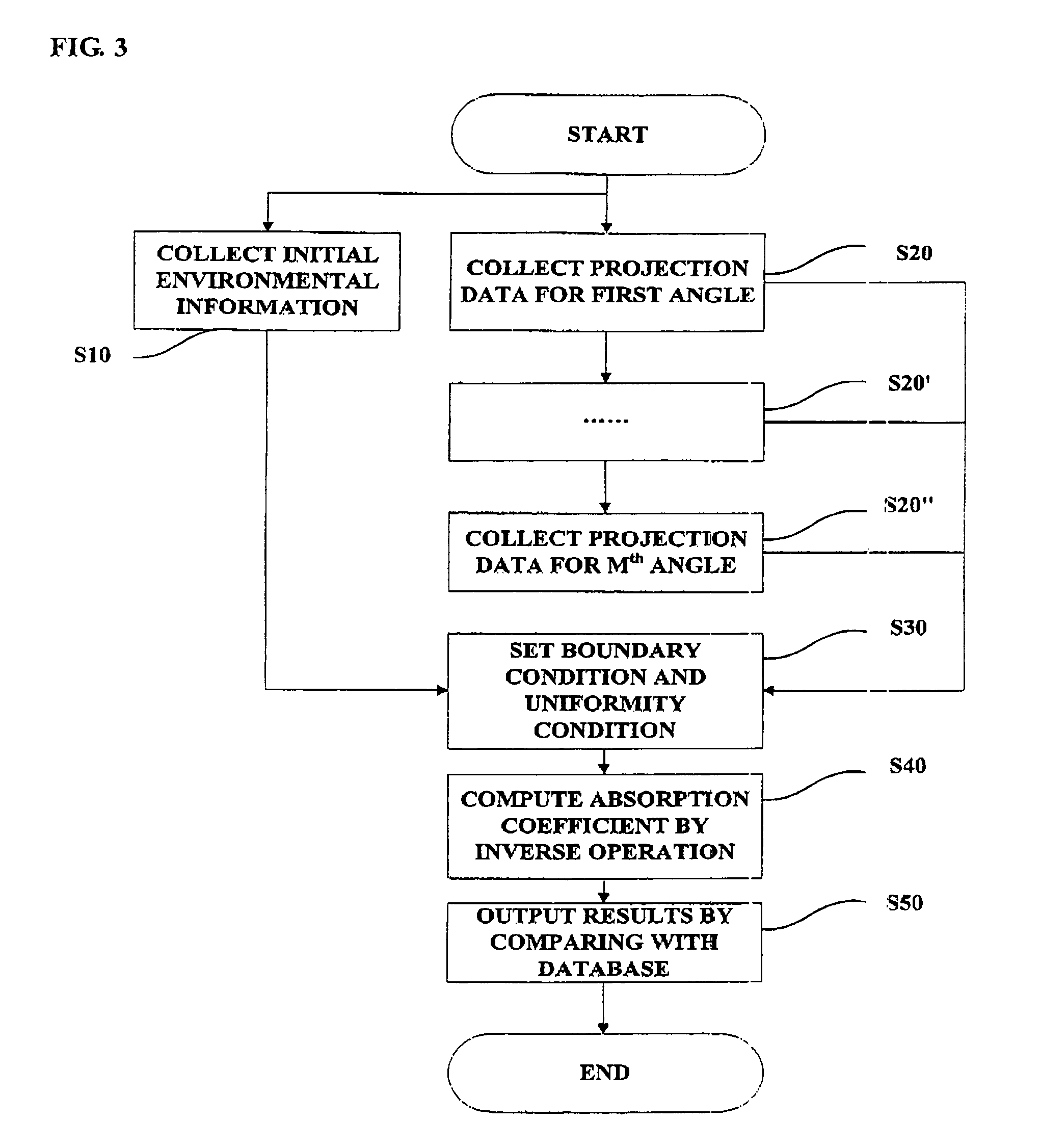

Method and device for security-inspection of liquid articles with radiations

ActiveUS20080056443A1Quick checkTaking small areaUsing wave/particle radiation meansMaterial analysis by transmitting radiationRelevant informationAnti jamming

Disclosed is a method and a device for security-inspection of liquid articles with radiations, which relate to the field of radiation inspection technology. The method comprises steps of acquiring original environment information, emitting radiation beams to transmit the liquid articles, receiving the radiation beams transmitted through the liquid articles to form multi-angle projection data, computing a radiation absorption coefficient of the liquid articles to be detected by inverse operation of the multi-angle projection data, based on the initial environmental information and the uniformity of the liquid articles, and comparing the radiation absorption coefficients with the preset data to get the relevant information of the liquid articles. Comparing with the prior art, the present invention is not subjected to affection of cuter package of the liquid article, and is advantageous of high anti-jamming high accuracy, high safety and reliability, low cost and small size.

Owner:NUCTECH CO LTD +1

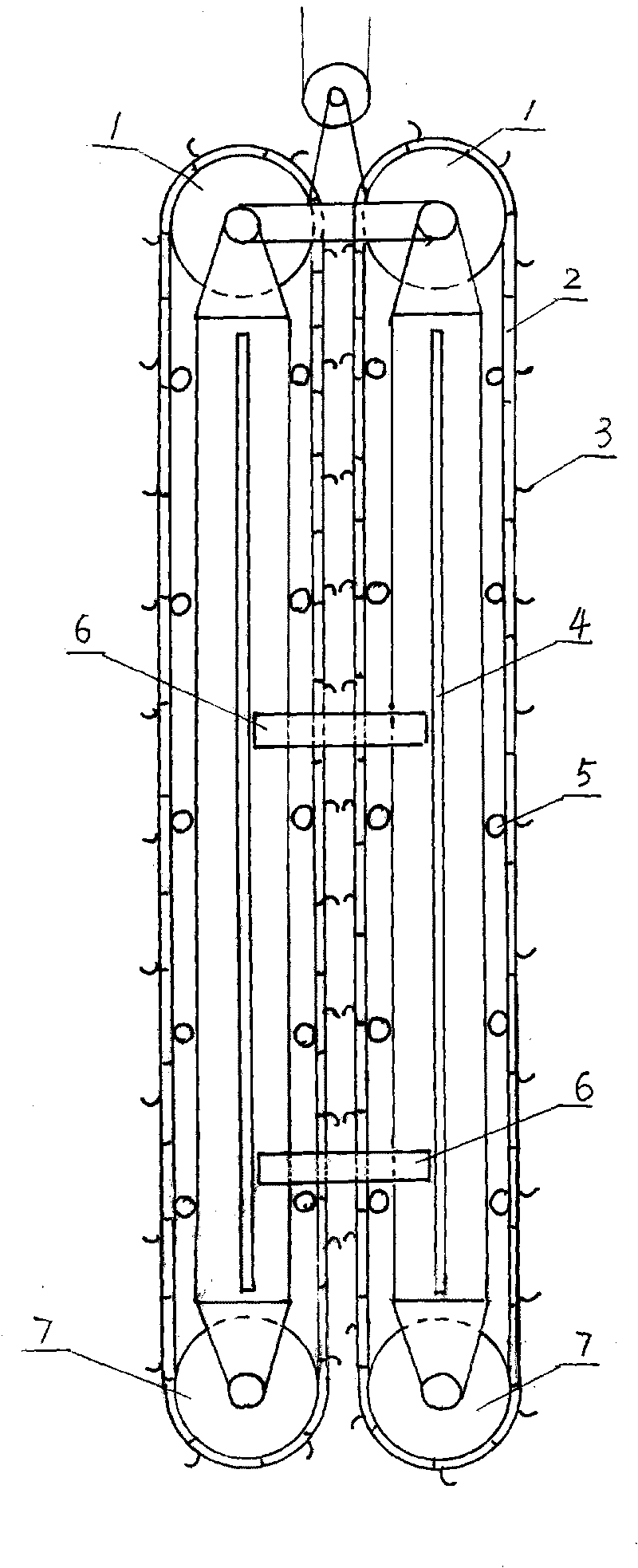

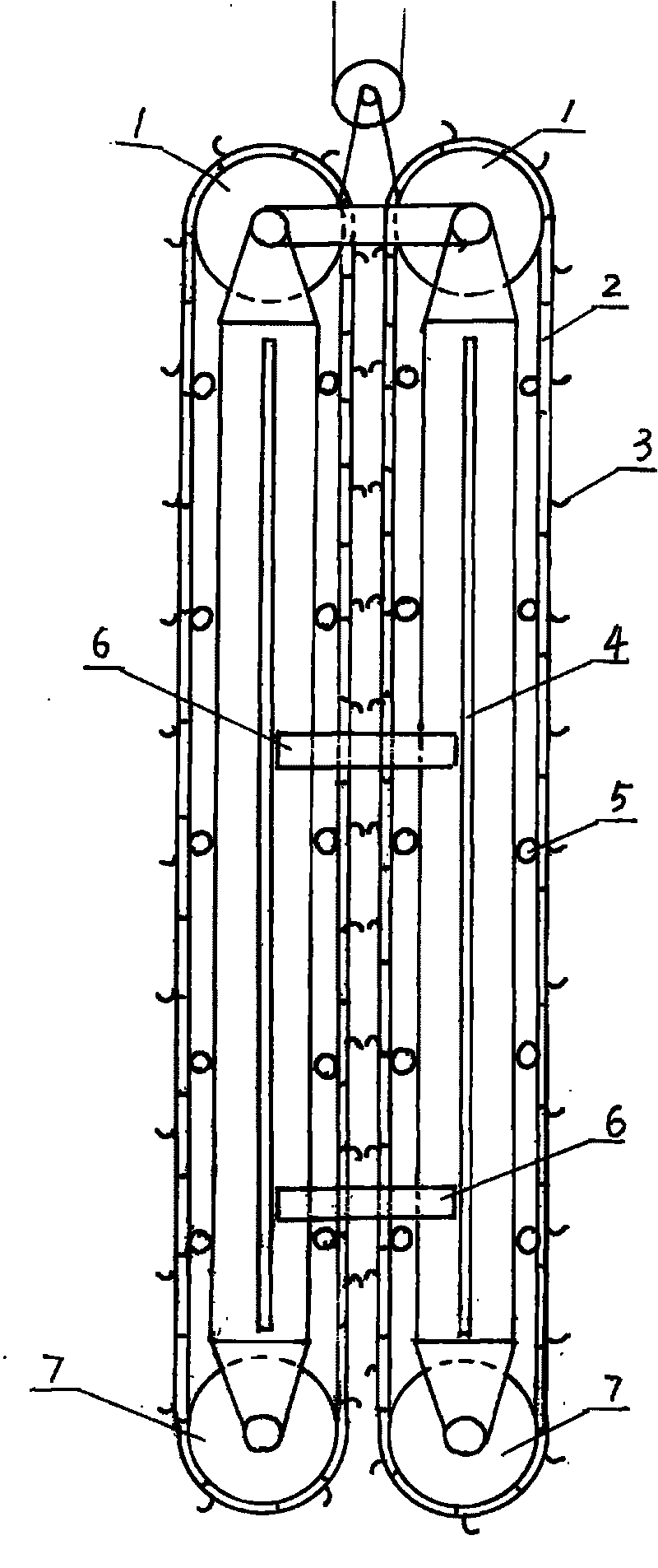

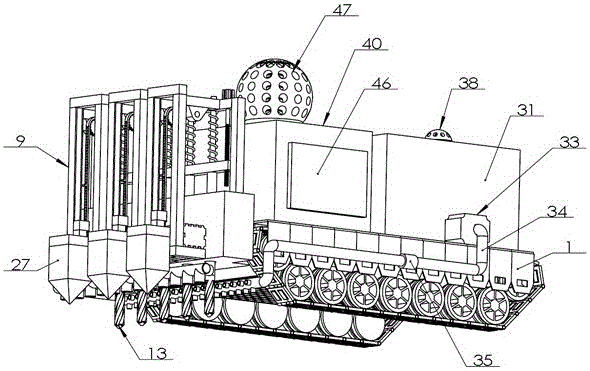

Double-chain saw slotting machine

The invention relates to a double-chain saw slotting machine, which comprises a connecting plate 6, two hydraulic motors 1, chains 2, an unearthing digging cutter 3, four tracks 4 and a limit wheel 5. The connecting plate is used for connecting two chain saws; each hydraulic motor serving as power drives each chain 2 respectively; the chain is provided with the unearthing digging cuter 3; every two tracks are positioned on both sides of each chain raw respectively and used for guiding the slotting machine; and the limit wheel 5 limits deviation of the chains. The double-chain saw slotting machine is a special tool for building diaphragm walls.

Owner:NANTONG JINHONG STEEL STRUCTURE PROJECT

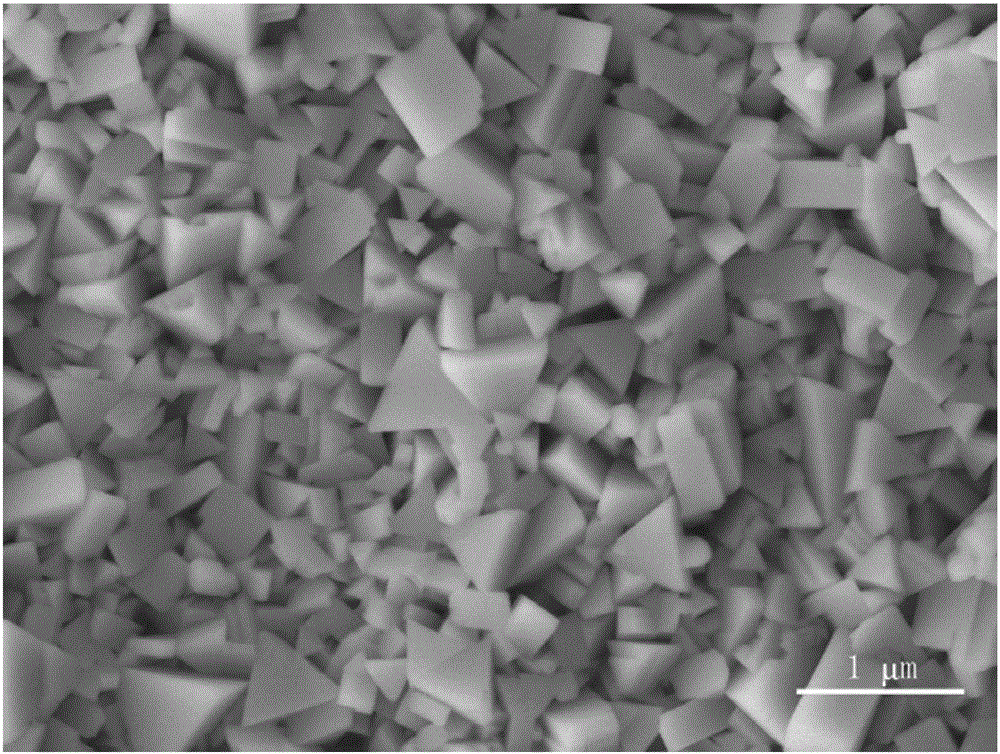

Sintering method for ultrafine hard alloy

ActiveCN106513670AChanges in developmental morphologySolve the problem of not fully developingAlloyNon oxidative

The invention relates to a sintering method for an ultrafine hard alloy. The sintering method comprises the steps that firstly, WC powder, bonding phase powder, a forming agent and an inhibitor are prepared into a press blank; secondly, the forming agent is removed from the press blank in the non-oxidative environment; and thirdly, two-step sintering is conducted on the press blank. In the first step, the temperature is increased to 1,450 DEG C-1,500 DEG C at the temperature rise rate of 10-20 DEG C / min under the vacuum condition, and then heat preservation is conducted; and in the second step, the temperature is reduced to 1,390 DEG C-1,410 DEG C at the cooling rate of 10-15 DEG / min, heat preservation sintering is conducted in the inert atmosphere, and then cooling is conducted. By the adoption of the method, the bending strength and hardness of the ultrafine hard alloy are not reduced but the breaking tenacity of the ultrafine hard alloy is greatly improved; good comprehensive mechanical performance is obtained, the phenomenon of tipping of a small-diameter mini milling cuter is reduced, the performance stability of products can be better improved, and the service life of the products can be better prolonged.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

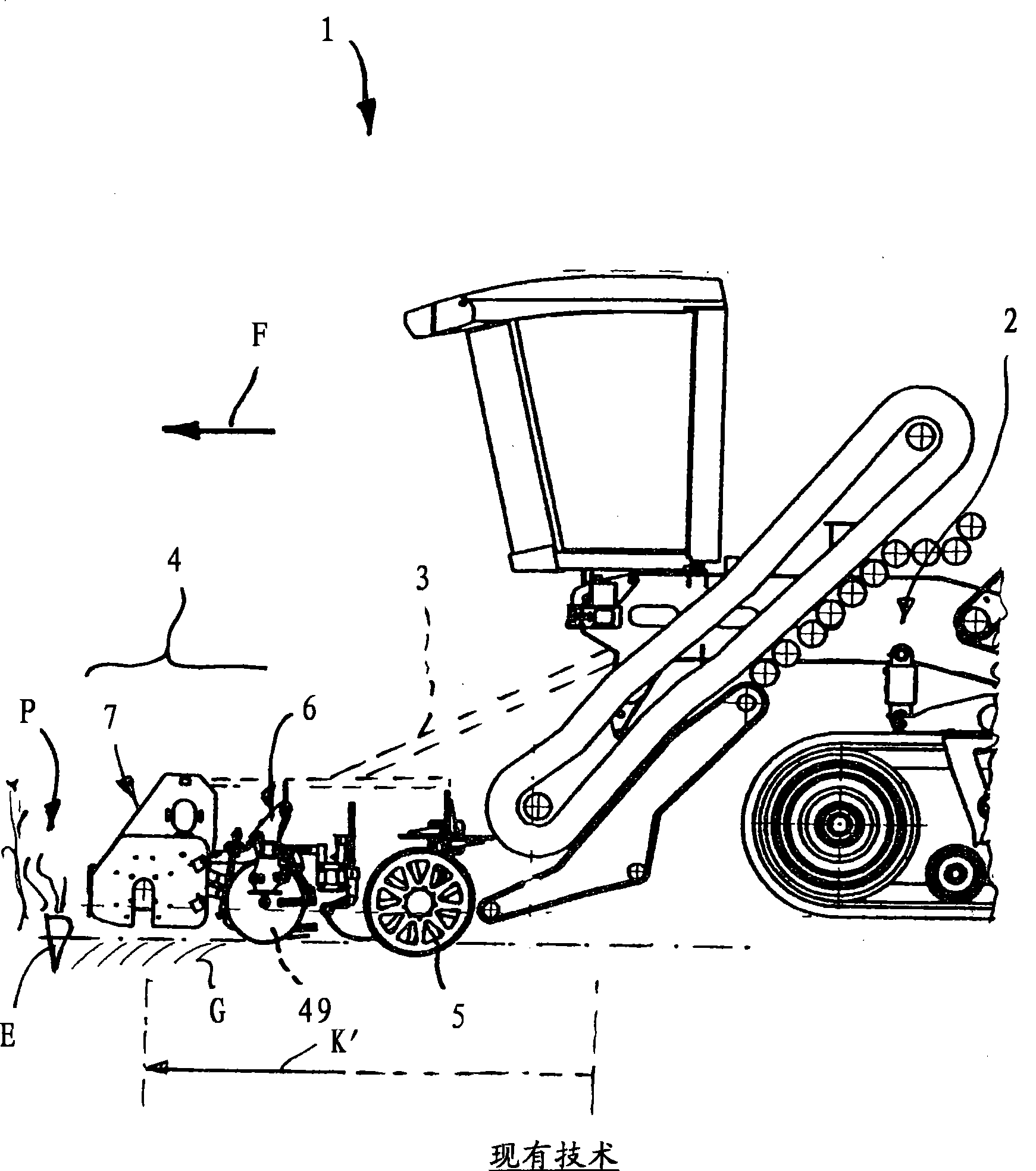

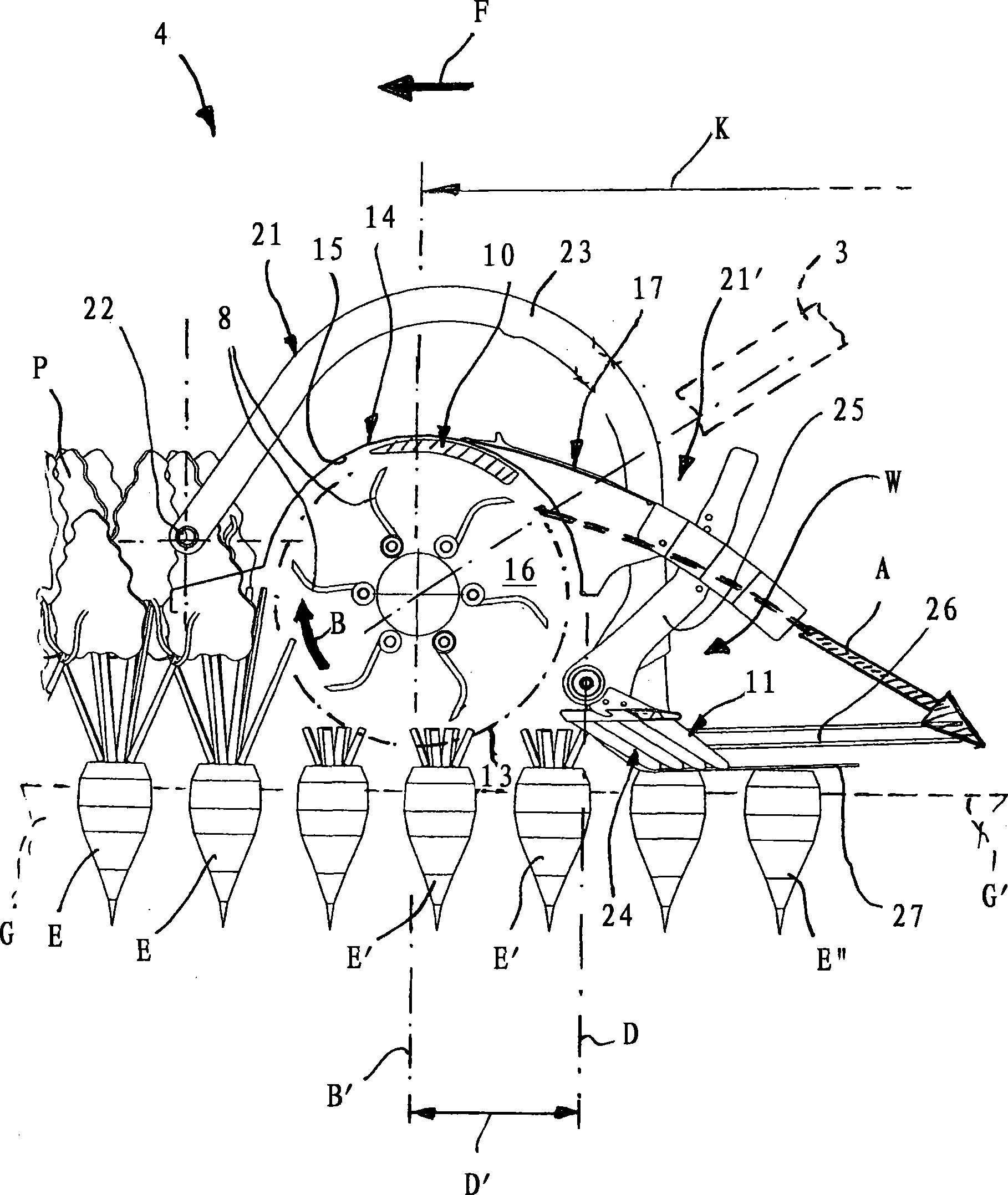

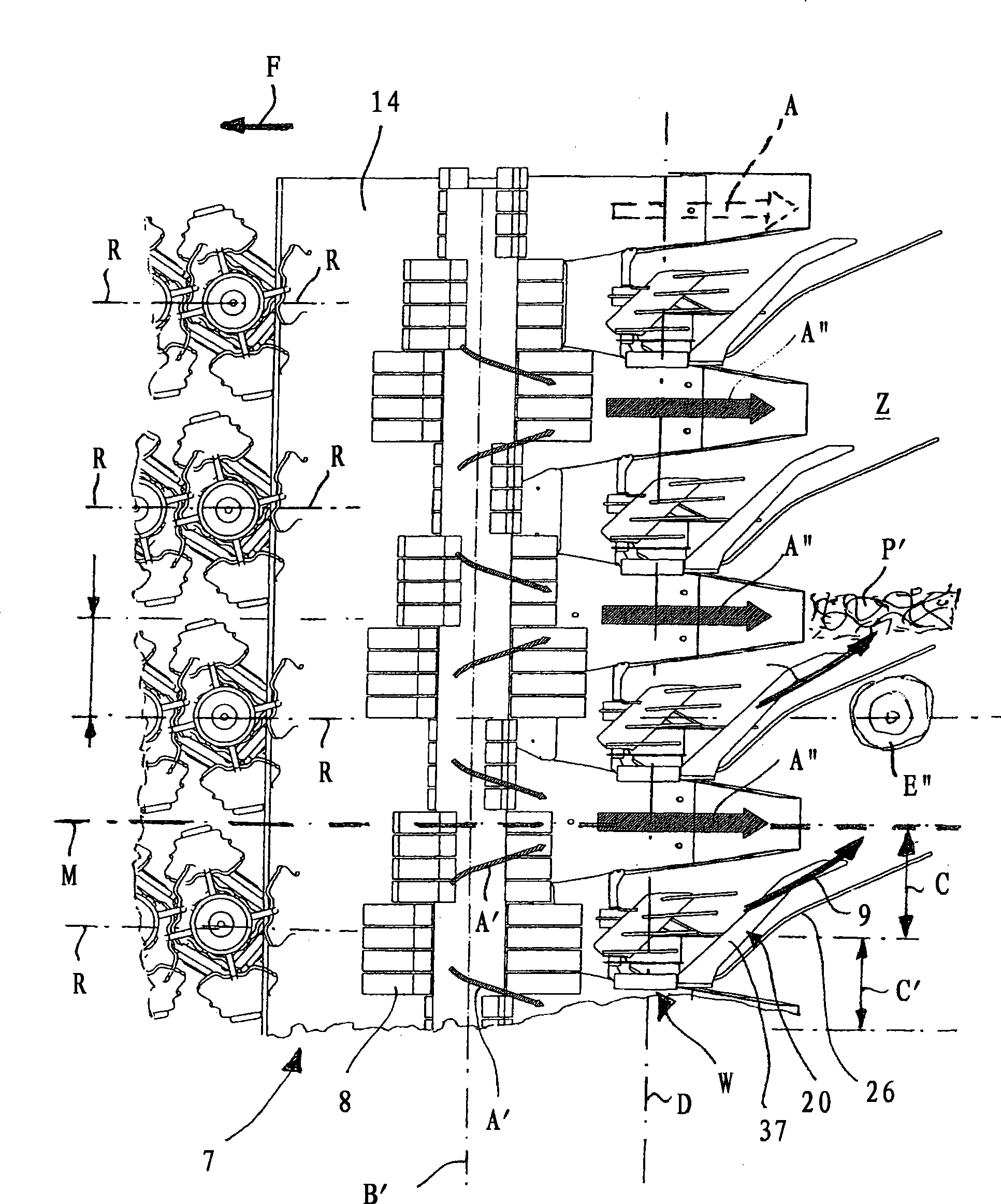

Turnip harvesting machine

InactiveCN101411263AImprove productivityAvoid additional pollutionLiftersTopping machinesPlant PartCUTEr

The invention relates to a beet harvester applied to sugar beet or crops of the like, comprising leaf cutter set between a plurality of lines of corps for removing beet leaves, green plants and the plant parts of the like, wherein a second tool in form of at least one top cuter of the assembly of the likes is set behind the cutting element of the lead cutter along the traveling direction. The present invention assigns that the plant part obtained by the lead cutter construct a transportation flow almost moving to the back of at least one placed at the rear part.

Owner:GRIMME LANDMASCHFAB

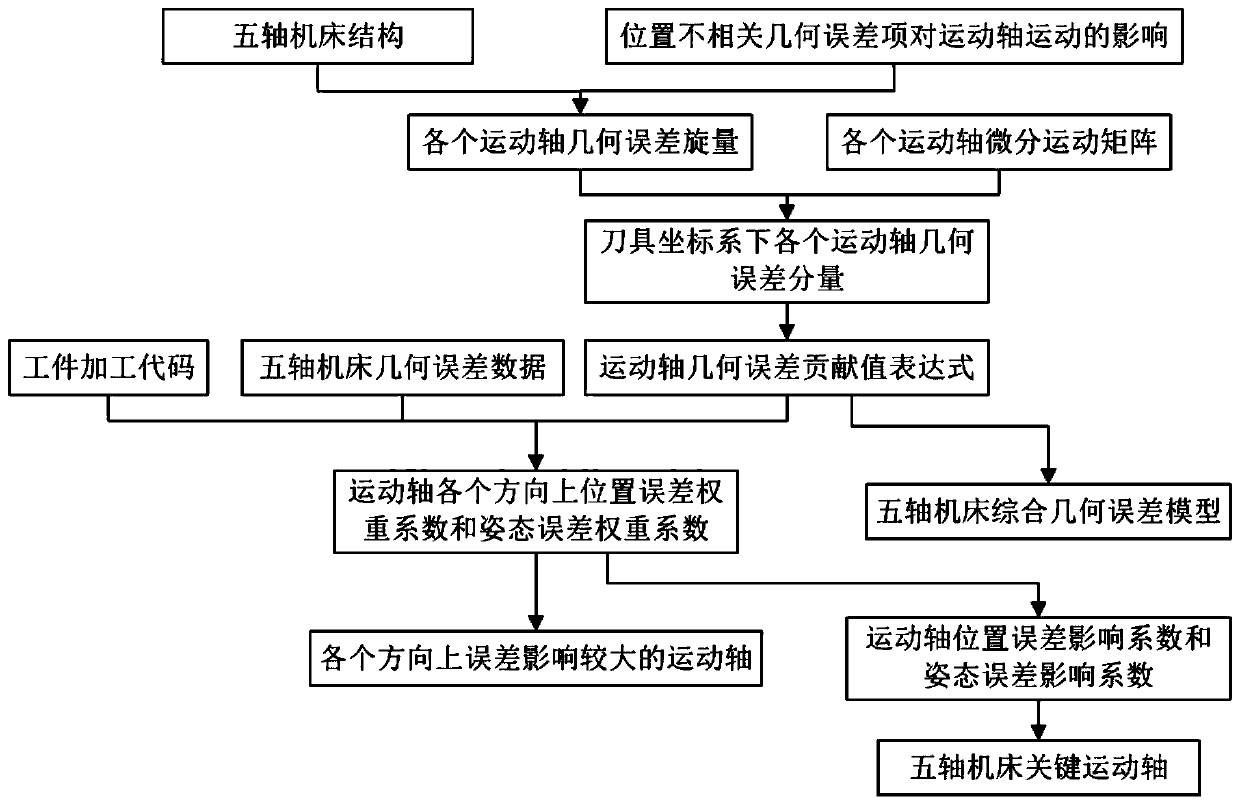

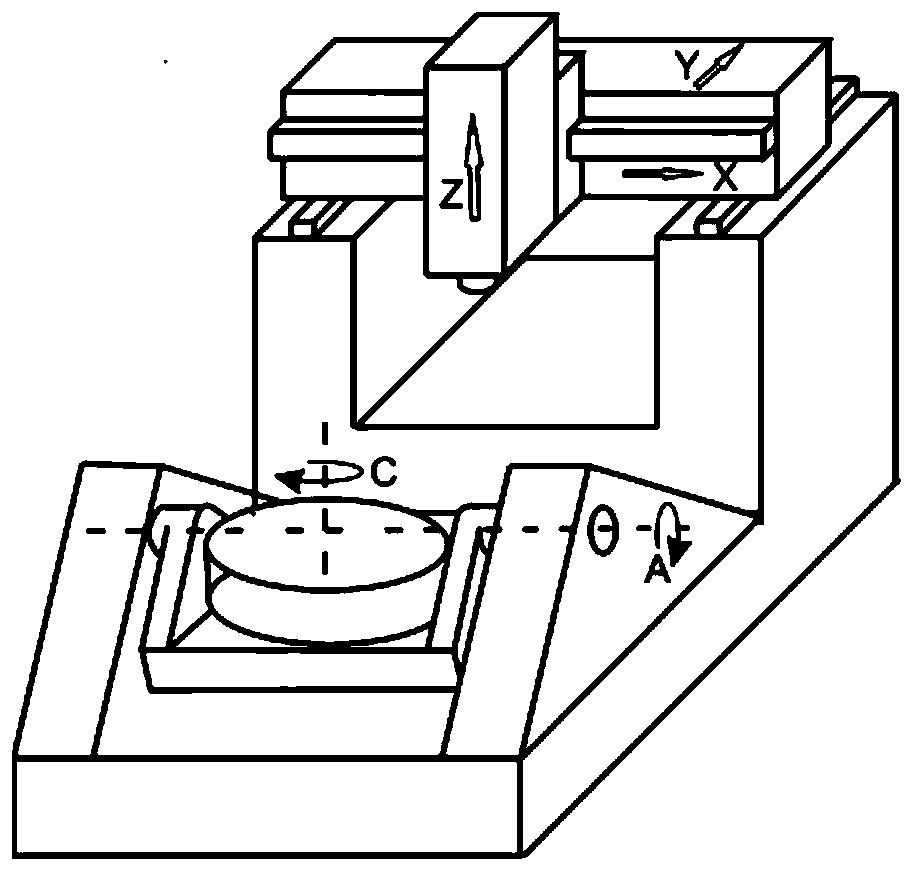

Calculation and influence evaluation method of geometric error contribution value of motion axis of five-axis machine tool

ActiveCN109765848AReduce compensation costsProgramme controlComputer controlGeometric errorRotational axis

The invention discloses a calculation and influence evaluation method of a geometric error contribution value of a motion axis of a five-axis machine tool. The method comprises steps of S1, setting astructural parameter q of each motion axis according to a five-axis machine tool structure; S2, acquiring geometric error spins of three translation axes and three rotary axes; S3, calculating and obtaining a geometric error component of each motion axis in a cutter coordinate system; S4, building a motion axis error matrix in a cutter coordinate system, and obtaining a geometric error contribution value of each motion axis; S5, adding geometric error contribution values of all motion axes of the five-axis machine tool so as to obtain a comprehensive cutter position error and a cuter gesture error of the five-axis machine tool; S6, evaluating influence of errors of the motion axes on the five-axis machine tool in all directions, and selecting a motion axis with high influence in each direction of the five-axis machine tool; and S7, calculating a position error influence coefficient and a gesture error influence coefficient of the motion axis, evaluating influence of the motion axes onprocessing accuracy of the five-axis machine tool, and selecting a key motion axis of the five-axis machine tool.

Owner:SOUTHWEST JIAOTONG UNIV

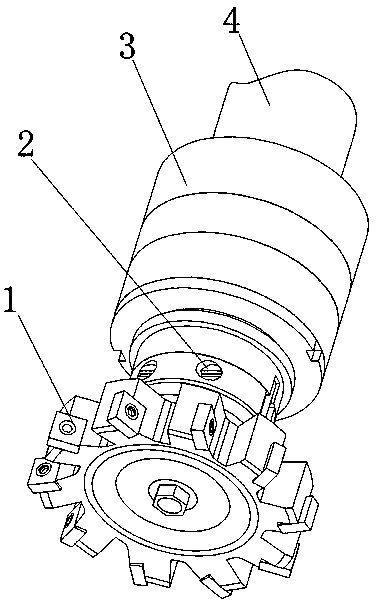

Milling device suitable for high-speed plane finish milling

InactiveCN104191005AAvoid shockImprove cutting stabilityMilling equipment detailsDisc millMilling cutter

The invention discloses a milling device suitable for high-speed plane finish milling. The milling device suitable for high-speed plane finish milling comprises a milling cutter plate, an adjustable vibration milling device and an online dynamic balance device, wherein the adjustable vibration milling device is mounted at the joint between a cutter handle and the milling cutter plate; the rear part of the online dynamic balance device is connected with a main shaft system of a milling machine; the front end of the online dynamic balance device is connected with the adjustable vibration milling device. By virtue of vibrators of the adjustable vibration milling device, feedback regulation is performed; an electric control hydraulic multi-way valve is used for controlling oil feeding amounts of different oil channels when the online dynamic balance device detects an unbalanced amount so as to achieve the dynamic balance during milling of a disc mill cuter, so that the purpose of high-speed and stable milling of the milling machine can be achieved; the stability during high-speed milling is ensured; the service life of a blade is prolonged.

Owner:HUNAN UNIV

Processing method of complicated curve surface of fragile material

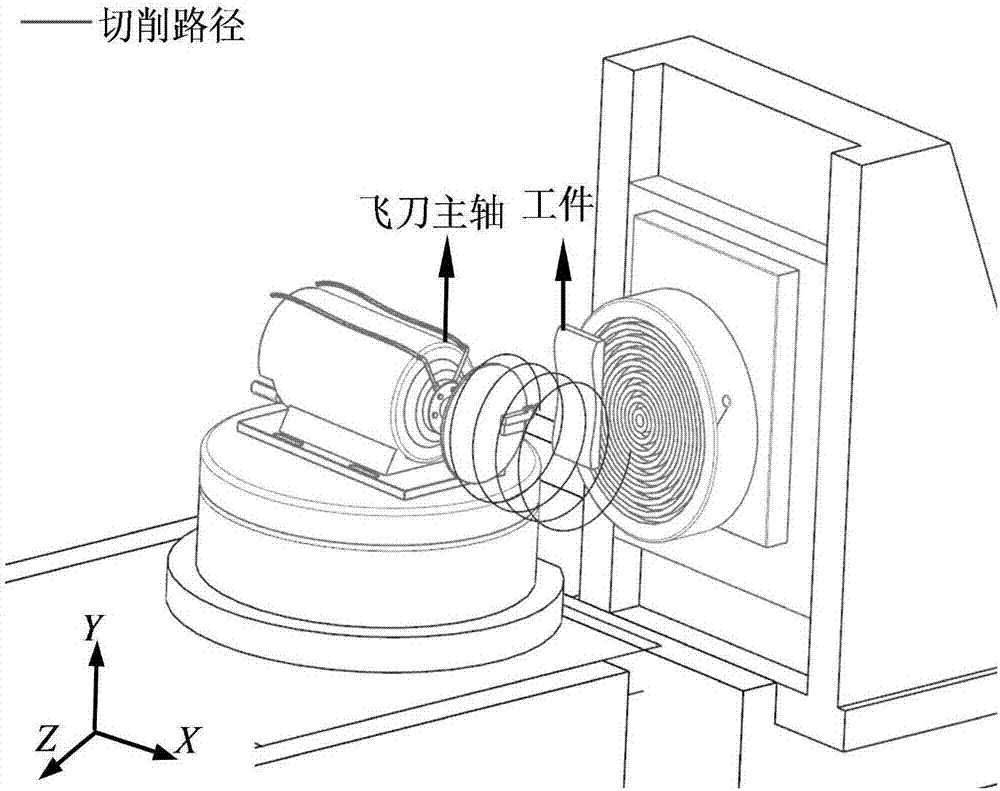

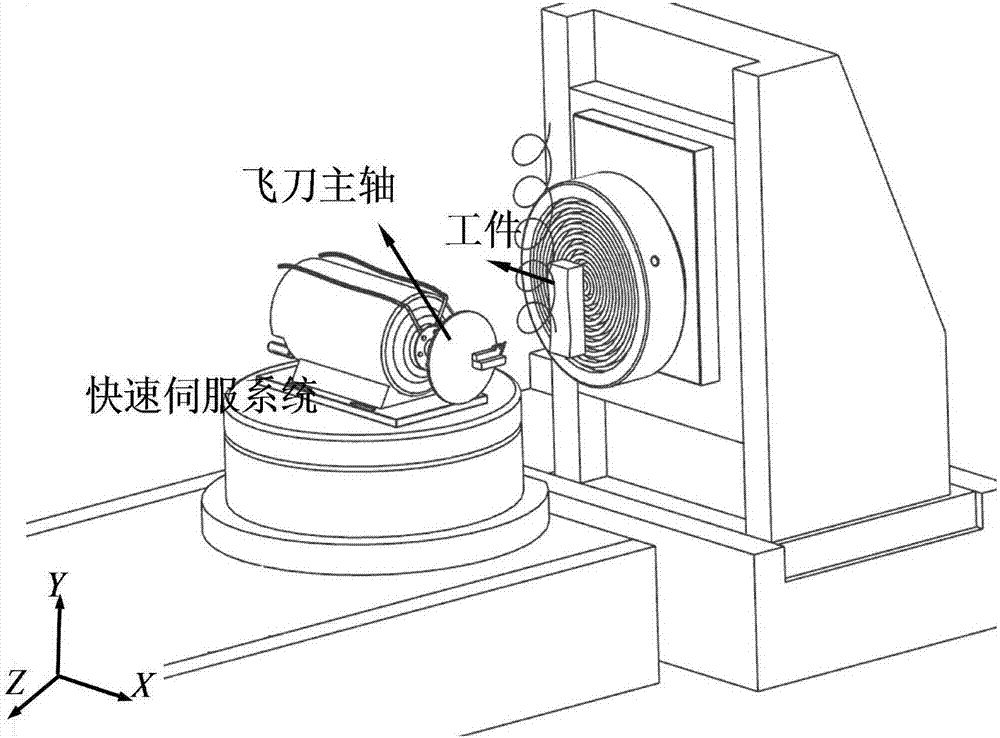

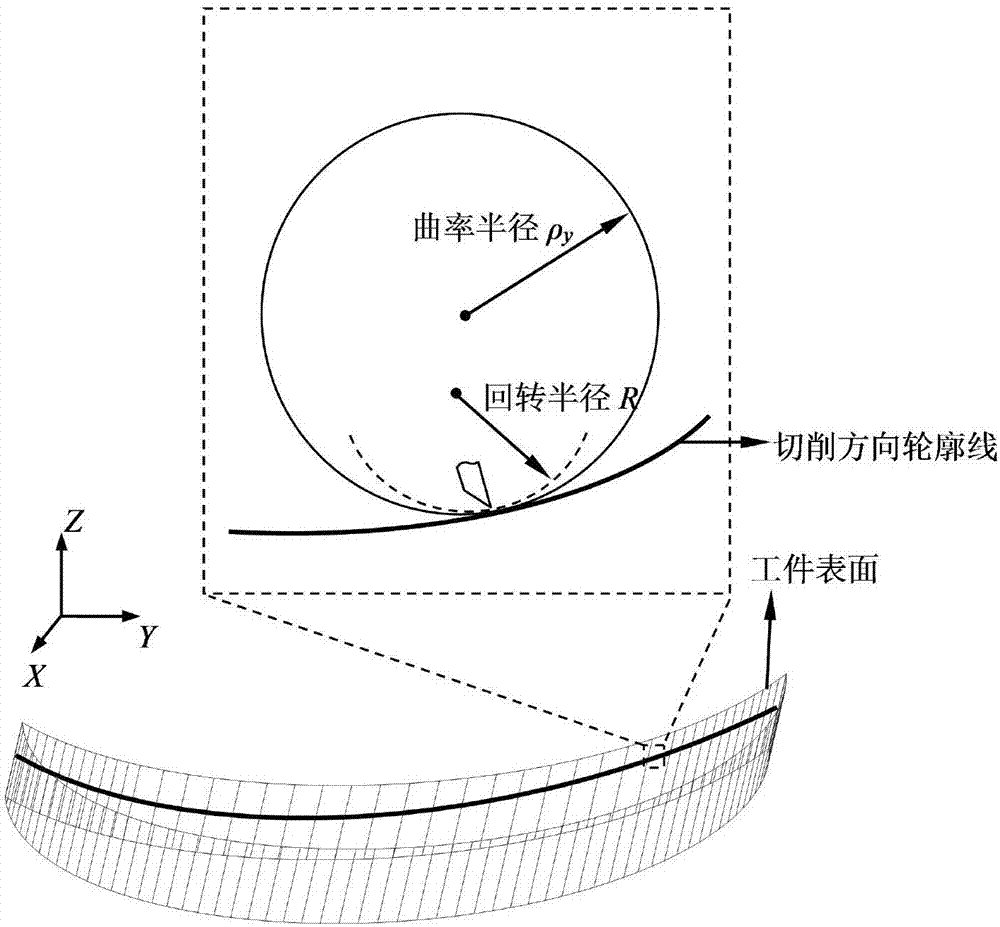

ActiveCN107116707AIncrease the frequency of intermittent cuttingReduced single-cut removalWorking accessoriesFine working devicesEngineeringMachining process

The invention relates to a processing method of a complicated curve surface of a fragile material. The processing method comprises the steps that according to the shape of a surface to be processed, an appropriate fly cutter spindle turning radius and an appropriate milling feeding direction, and a fly cuter turning spindle can be selected to be parallel to the milling feeding direction or perpendicular to the milling feeding direction; according to the processing process characteristics and the cutting characteristics of a material, appropriate cutting parameters and appropriate cutting tool geometric parameters are design so as to guarantee that the removal amount of the material in single-pass cutting is controlled within a plastic removal rang; based on the cutting parameters and the cutting tool geometric parameters, a processing path of fly cutter cutting and milling feeding is generated, and path compensation is conducted before processing, and after compensation, the contour of a cutting tool traverses the path to form a processed surface; a workpiece to be processed is mounted on a spindle of an ultra-precision machine tool, and a fly cutter is perpendicularly mounted on an ultra-precision milling shaft; and the workpiece is processed.

Owner:TIANJIN UNIV

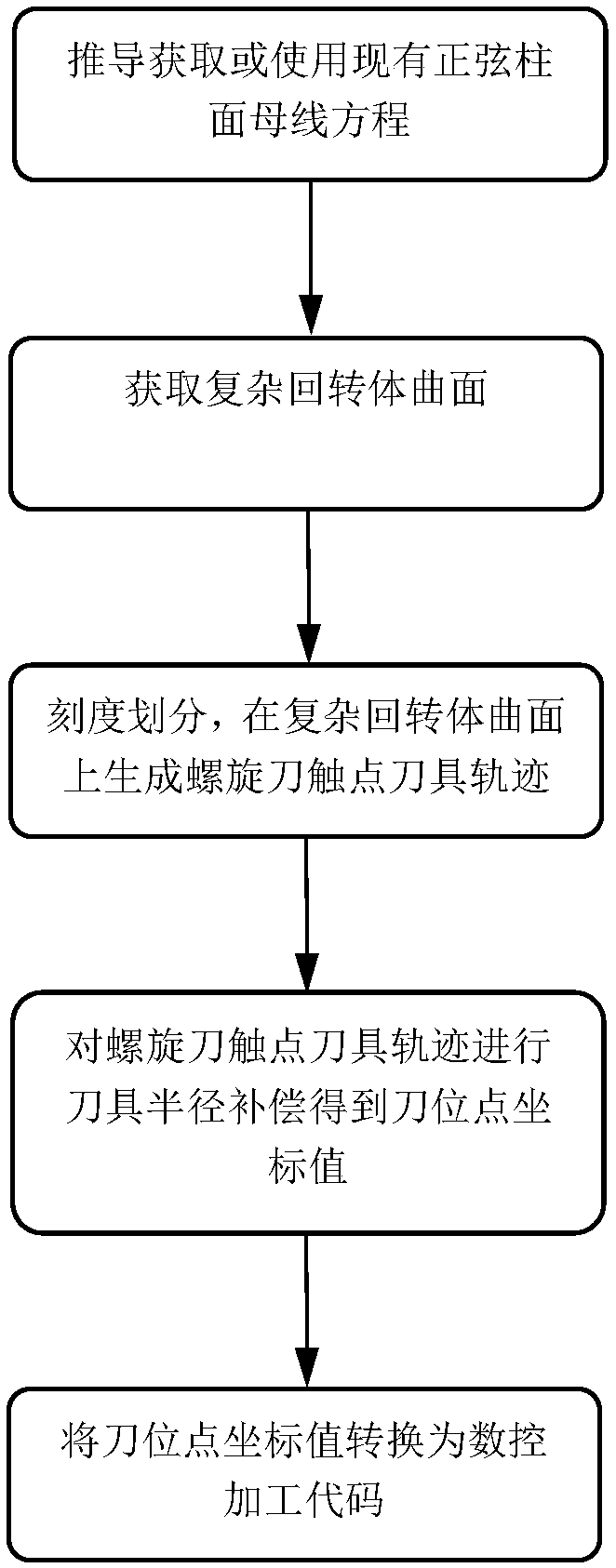

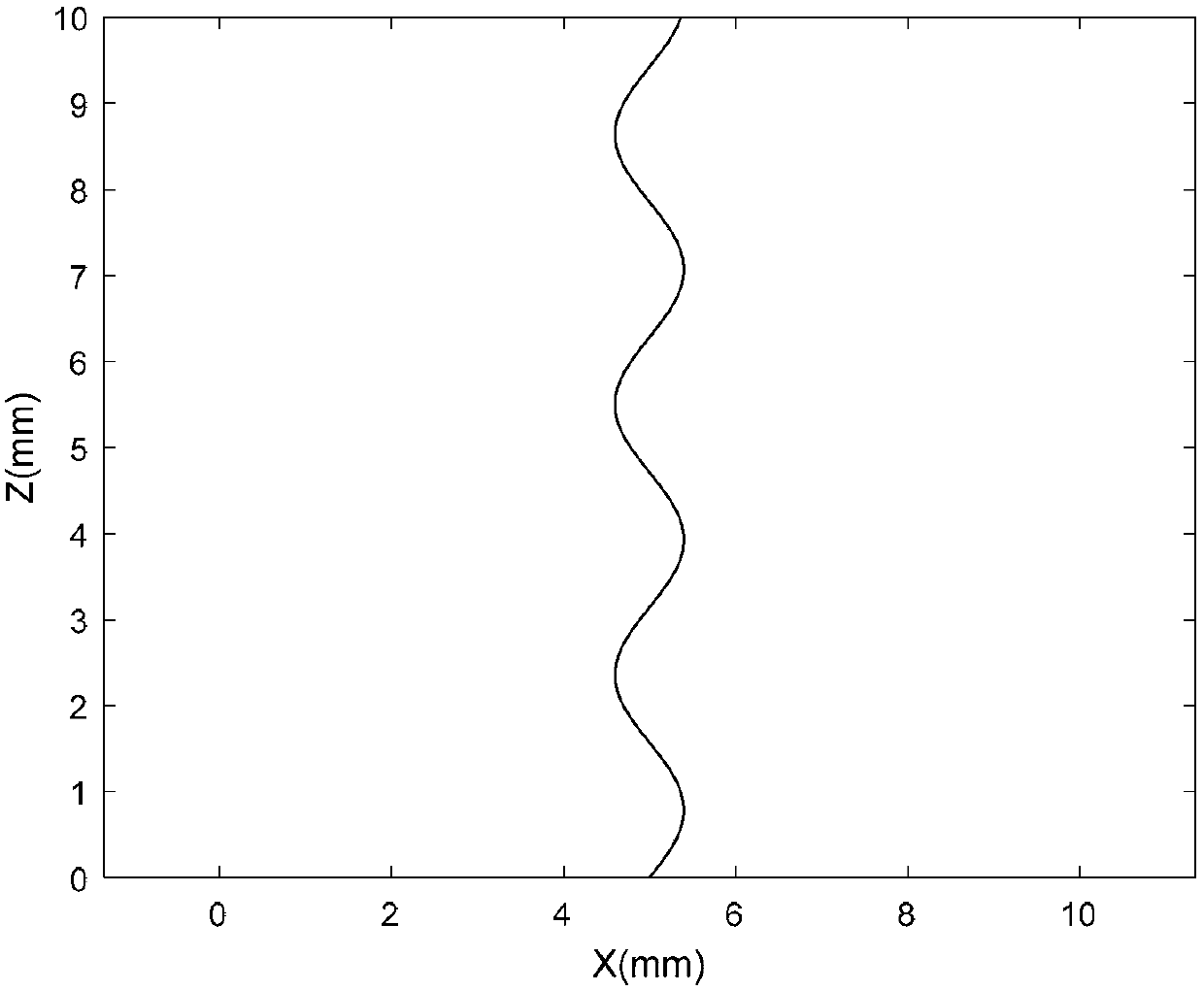

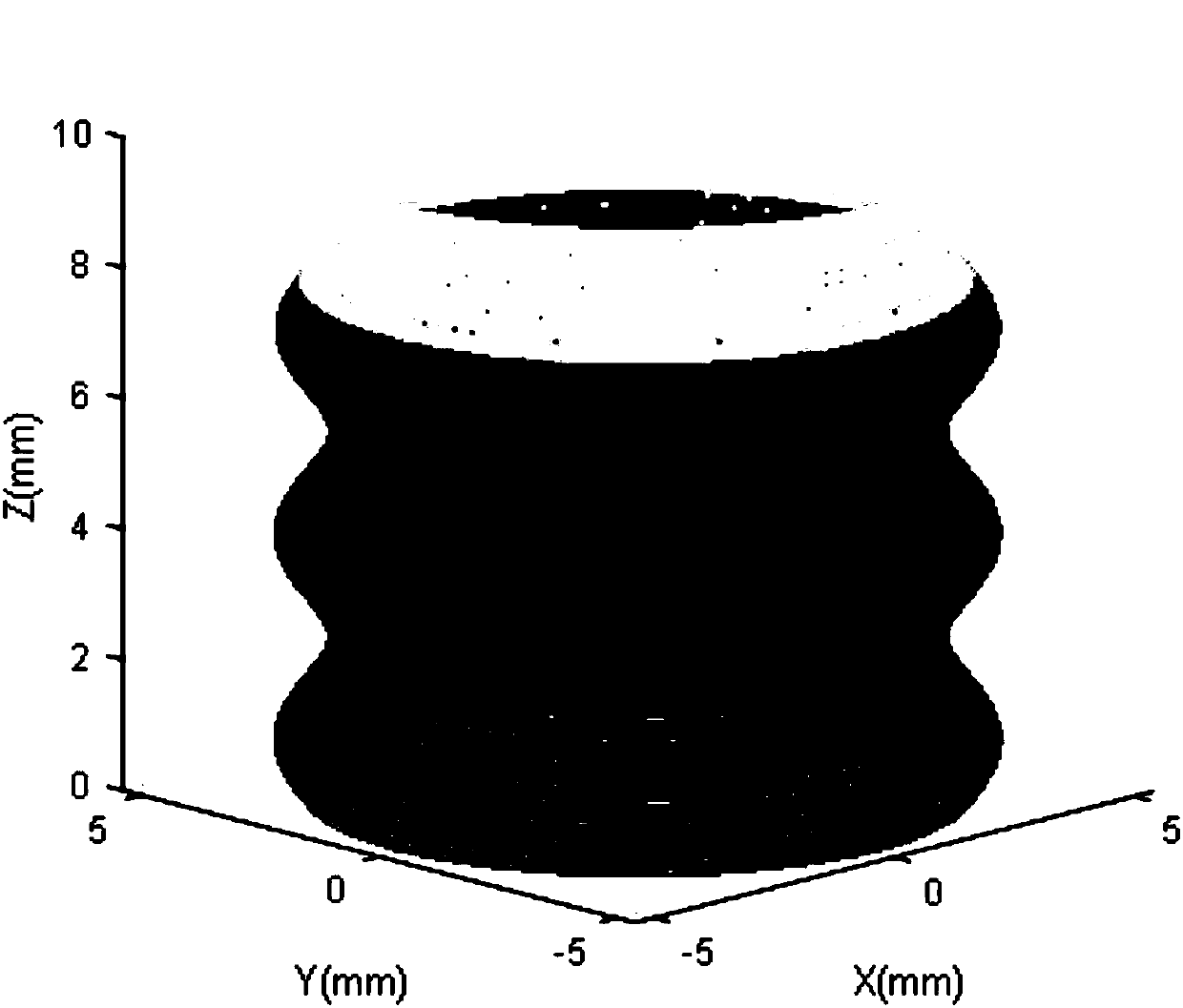

Sinusoidal cylindrical surface ultraprecise turning helical cutter path generating method

The invention relates to a sinusoidal cylindrical surface ultraprecise turning helical cutter path generating method, and belongs to the technical field of mechanical numerical control processing. AnZ axis is subjected to scale division; a sinusoidal cylindrical surface generatrix equation is obtained through derivation or the existing sinusoidal cylindrical surface generatrix equation is used; the sinusoidal cylindrical surface is subjected to radial part number division, so that the sinusoidal cylindrical surface generatrix is subjected to part number division around the axial line in the radial direction and rotates for a circle for obtaining the sinusoidal cylindrical surface; the sinusoidal cylindrical surface is subjected to screw pitch scale division in the radial direction; meanwhile, the screw pitch is subjected to cutter contact point track scale division; a helical cutter contact point cutter path is generated on the sinusoidal cylindrical surface according to the derived cuter contact path generation expression; the cutter radius r and a cutter radius compensating expression are selected; the helical cutter contact point cutter path is subjected to radius compensationto obtain the cutter location point coordinate value; the cutter location point coordinate value is converted into actual numerical control processing NC code. The method has the advantages that the processing efficiency of the sinusoidal cylindrical surface is favorably improved; the processing precision of the sinusoidal cylindrical surface is effectively improved.

Owner:JILIN UNIV

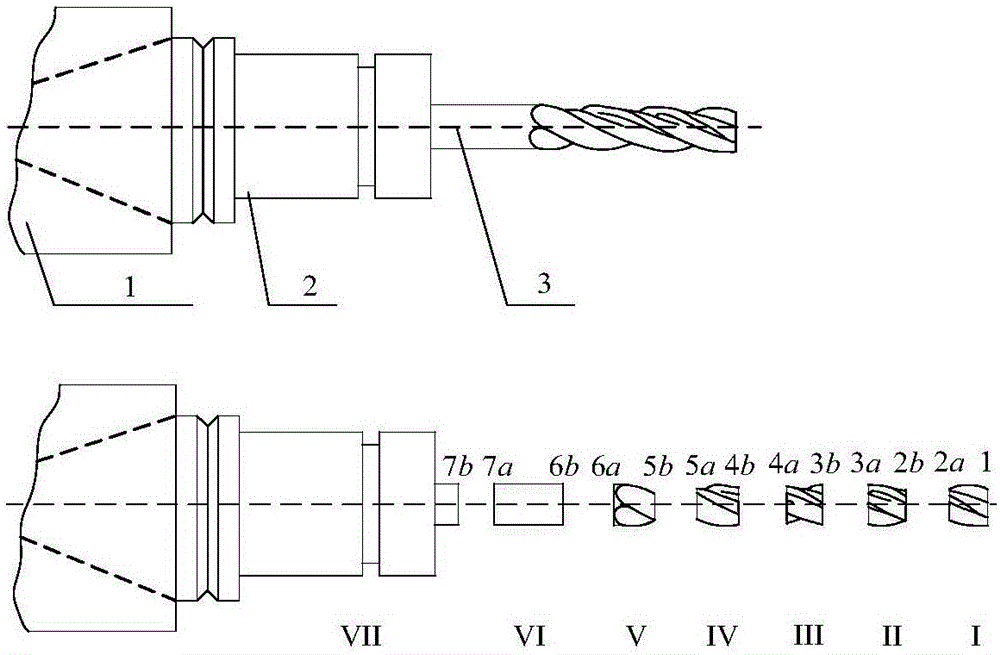

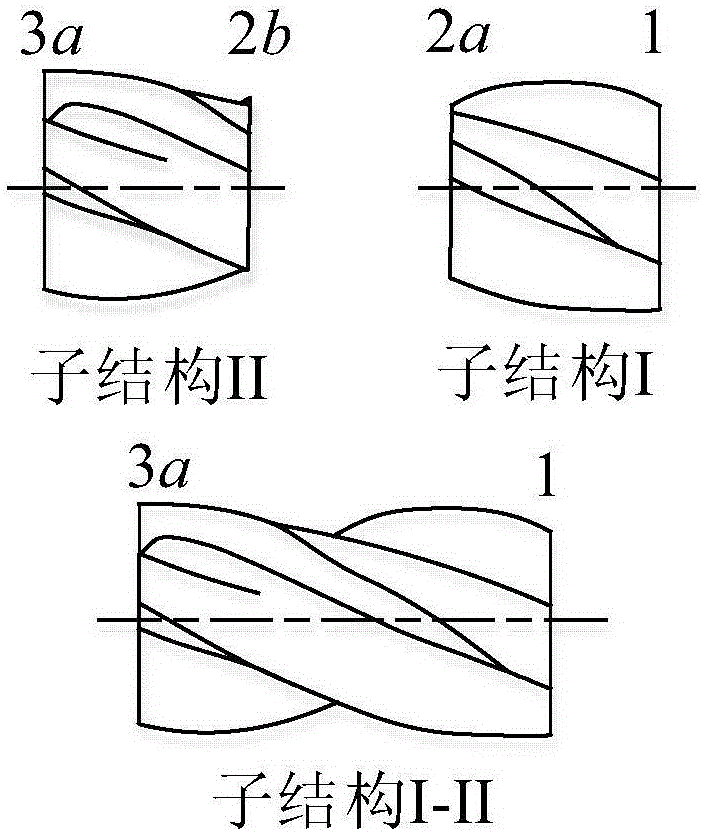

Cutter tip frequency-response function predicting method based on accurate milling cutter modeling

InactiveCN105058166AImprove forecast accuracyMeasurement/indication equipmentsMetal working apparatusMilling cutterEngineering

The invention discloses a cutter tip frequency-response function predicting method based on accurate milling cutter modeling. The method includes the steps of dividing a machine tool, a main shaft, a cutter handle and a milling cutter into the machine tool, the main shaft, the cutter handle, a first cutter rod body, a second cutter rod body, a milling cutter transition section and cutter teeth, dividing the milling cuter into a symmetrical milling cutter part and an asymmetrical milling cutter part according to actual conditions considering the actual milling cutter modeling, calculating the cross sectional inertia moment of each part of the milling cutter in detail with the two-blade milling cutter body and the four-blade milling cutter body as examples, and putting forward a universal modeling method of the milling cutter transition section so that the prediction accuracy of a cutter tip frequency-response function can be improved. The purpose of accurately predicting the cutter tip frequency-response function during accurate milling cutter modeling is achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for manufacturing marble cutter bit and matrix material adopted for same

The invention discloses a method for manufacturing a marble cutter bit and a matrix material adopted for the method for the manufacturing the marble cuter bit. The matrix material of a diamond section in the marble cutter bit mainly comprises Cu-Zn-Sn alloy powder, Cu powder and Cu-Co-Fe alloy powder. The content of the low-melting-point metal component Sn and the content of low-melting-point metal component Zn in the matrix material are low, and the sintering temperature is high and can reach 820 DEG C and 860 DEG C. In the welding stage, the matrix material can be adaptive to the brazing technology, the cutter bit does not expand and is free of burning loss deformation and low in welding cost in the welding process, and the cutter bit has the cost competitive advantage and is broad in market prospect. Tests show that the bending strength of the marble cutter bit manufactured with the method ranges from 1000 Mpa to 1400 Mpa, and the hardness of the marble cutter bit manufactured with the method ranges from 80 HRB to 95 HRB; tests with a bridge cutting testing machine show that the power consumption ranges from 6 KW to 7 KW, the service life of the marble cutter bit can be 20 to 24 m<2> / mm, and compared with an exiting marble cutter bit, the marble cutter bit manufactured with the method has the advantages that the power consumption is lower and the service life is longer.

Owner:泉州众志金刚石工具有限公司

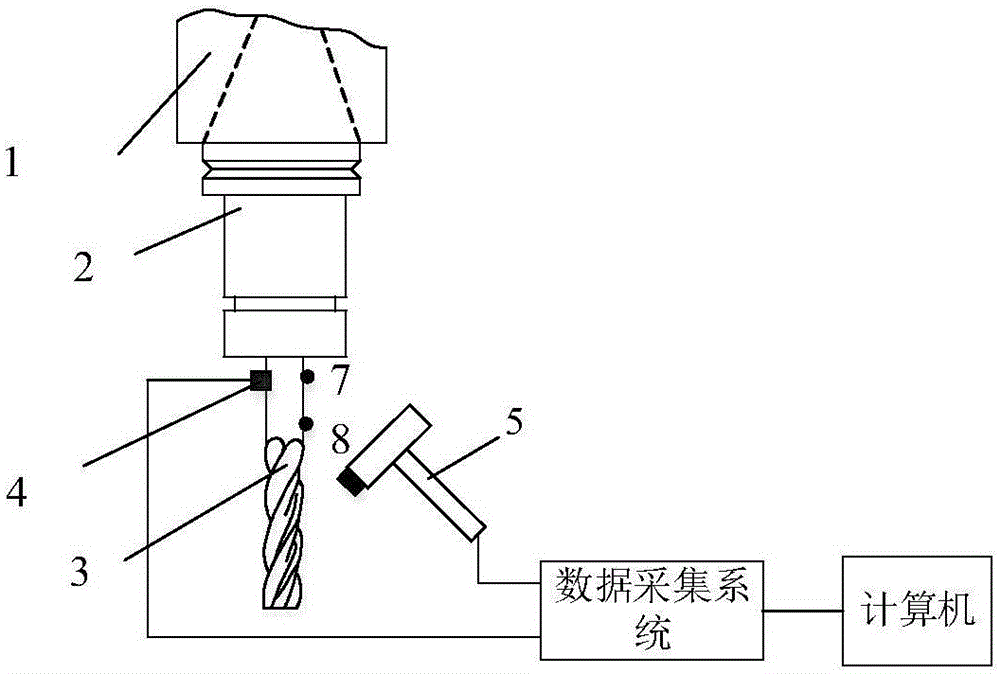

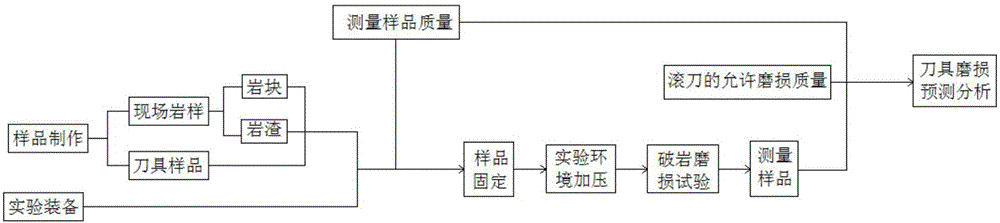

Prediction method of abrasiveness of tunnel boring machine TBM cuter

InactiveCN106248515AReduce maintenance and replacement costsInvestigating abrasion/wear resistanceTest sampleEngineering

The invention discloses a prediction method of abrasiveness of a tunnel boring machine TBM cuter. The prediction method comprises the following steps: producing a test sample, measuring the sample, simulating a scene environment, simulating a cutter rock breaking abrasion process, and predicting the abrasiveness of a cutter according to experimental results. The abrasiveness of the cutter is predicated by using the method and combining with the actual situation on site, so that the on-site cutter use amount can be effectively predicted so as to predict the use cost of the cutter, and the cutter suitable for the ground construction of the section can be selected according to the on-site geologic situation.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

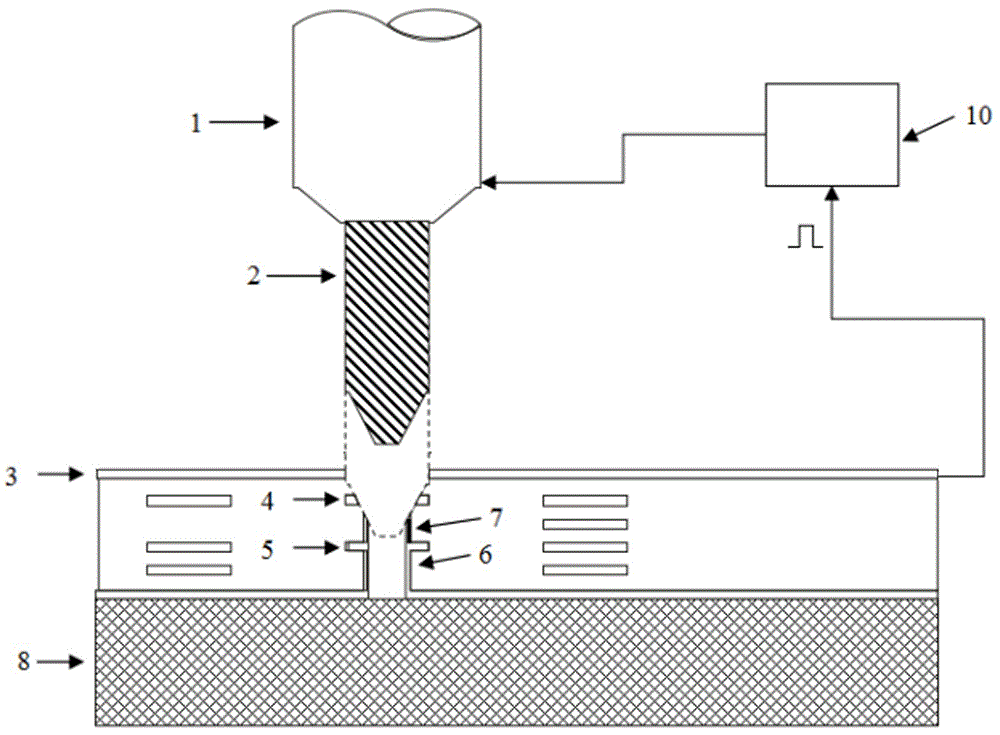

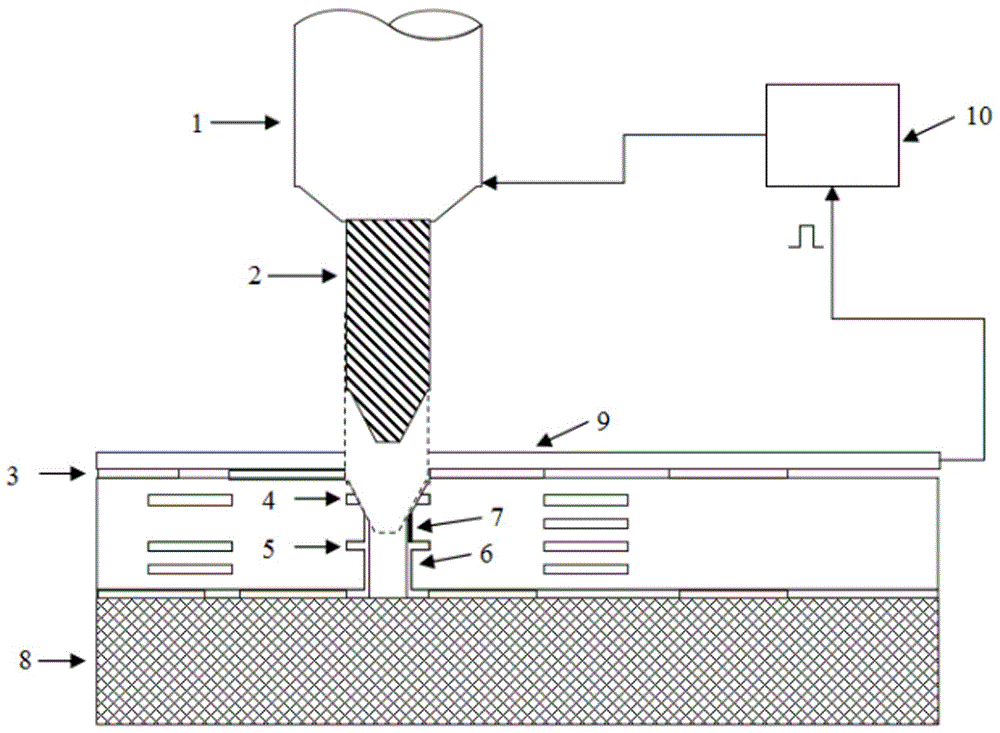

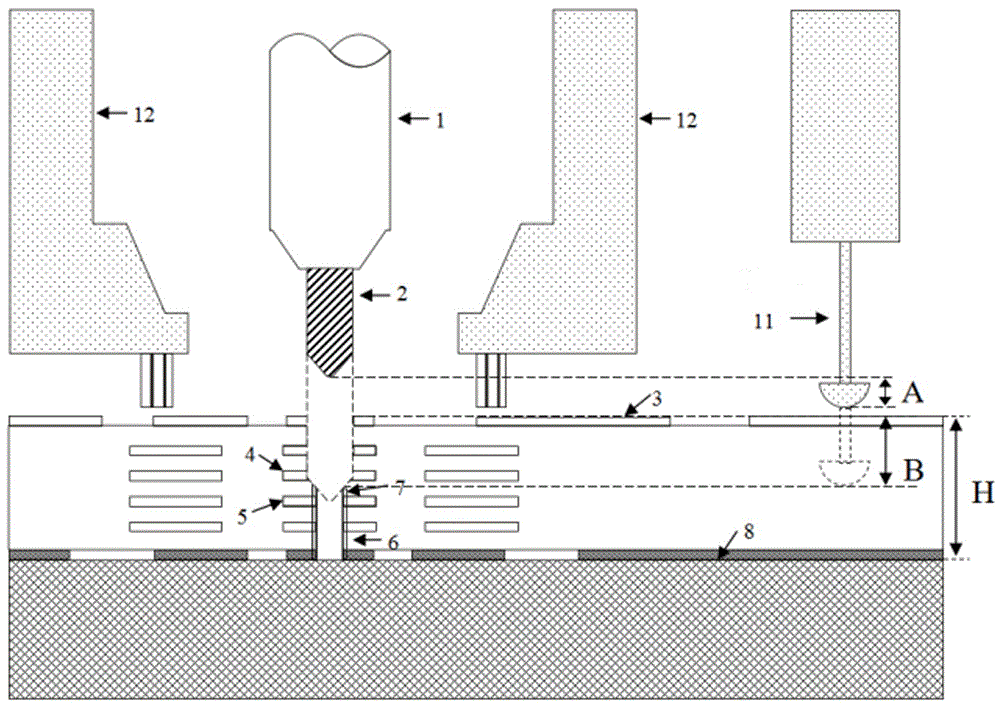

Re-processing method of leaking and drilling back board

PendingCN106851989AHigh precisionImprove production yieldPrinted circuit manufacturePrinted circuit boardCUTEr

The invention discloses a re-processing method of a leaking and drilling back board. The method comprises the following steps of drilling the back board of a PCB (printed circuit board) to obtain a back board; performing inspection to discover the back board drilling missing; compiling the back drilling supplementation program data by aiming at the corresponding drilling missing back drilling hole; setting the drilling depth; measuring the drilling cuter length and the detector length; performing synchronous correction on the drilling cuter length and the detector length; automatically compensating the difference value A of the drilling cuter length and the detector length after the drilling cutter length and the detector length are corrected; obtaining the height H of a table top of a machine table in contact with a detector through the independent work and descending of the detector to contact the table top of a machine table; resetting the detector; descending a drilling cutter at the uniform speed to reach the height H0, wherein the calculation mode of the H0 is shown as a formula that H0=H-A-B; the H0 is the height during the equipment processing; the H is the height of the table top of the machine table in contact with the machine table; the A is the difference value of the drilling cuter and the detector; the B is the drilling depth set by the back board; performing cutter withdrawal and resetting on the drilling cutter to complete the back board drilling missing complementary drilling. The re-processing of the drilling missing back drilling hole show very high depth control precision and product qualification rate.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY +1

Water jet cutter dicing machine device

The invention belongs to the technical field of rubber and plastic extrusion and granulation, and particularly relates to a water jet cutter dicing machine device. The device comprises a water jet cuter cutting head, a sliding track, a sliding track bracket, a variable-frequency adjustable-speed electromotor, a high-pressure water flow divider, a high-pressure water inlet joint, a high-pressure water pump, a water purifier and the like, wherein the water jet cutter cutting head, the sliding track, the variable-frequency adjustable-speed electromotor, the high-pressure water inlet joint and the high-pressure water flow divider and the like are arranged on a rack, or arranged on a reserved screw or bracket of an extruding machine. A clearance between a waterline of high-pressure water flowing from the water jet cutter cutting head and a discharge die orifice of an extruding machine is 0-2mm, and can be randomly adjusted according to the shape requirement of products. Through the high-speed reciprocating movement of the water jet cutter cutting head, materials of the discharge die orifice of the extruding machine are cut into different shapes of particles. The device is simple to operate, and energy-saving and protects the environment, is low in cost, excellent in performance, free from generation of waste, as well as capable of cutting any materials cooled to be at a solid state; the device can be matched with any extruding machine, and the performances of original equipment can be improved.

Owner:李振华

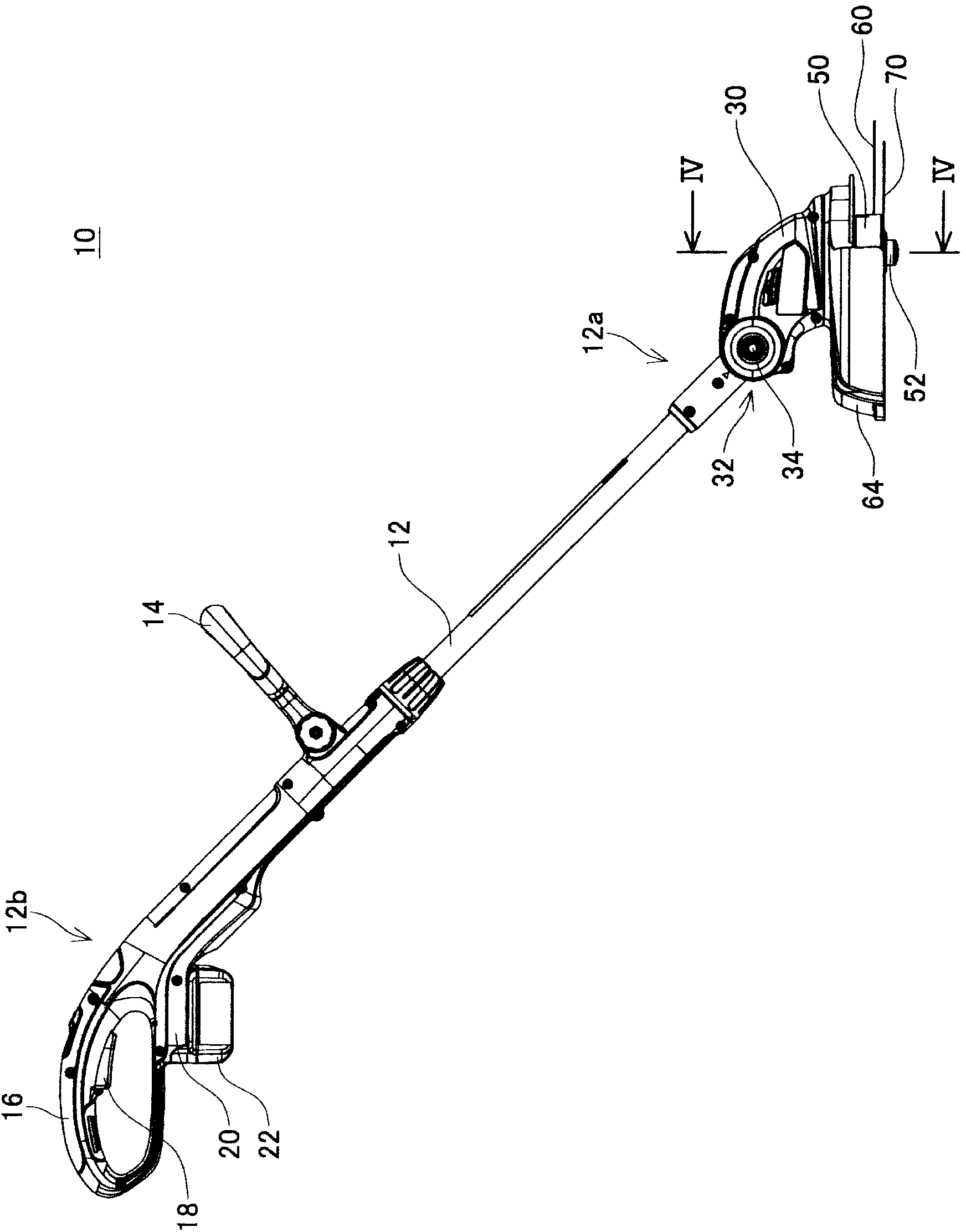

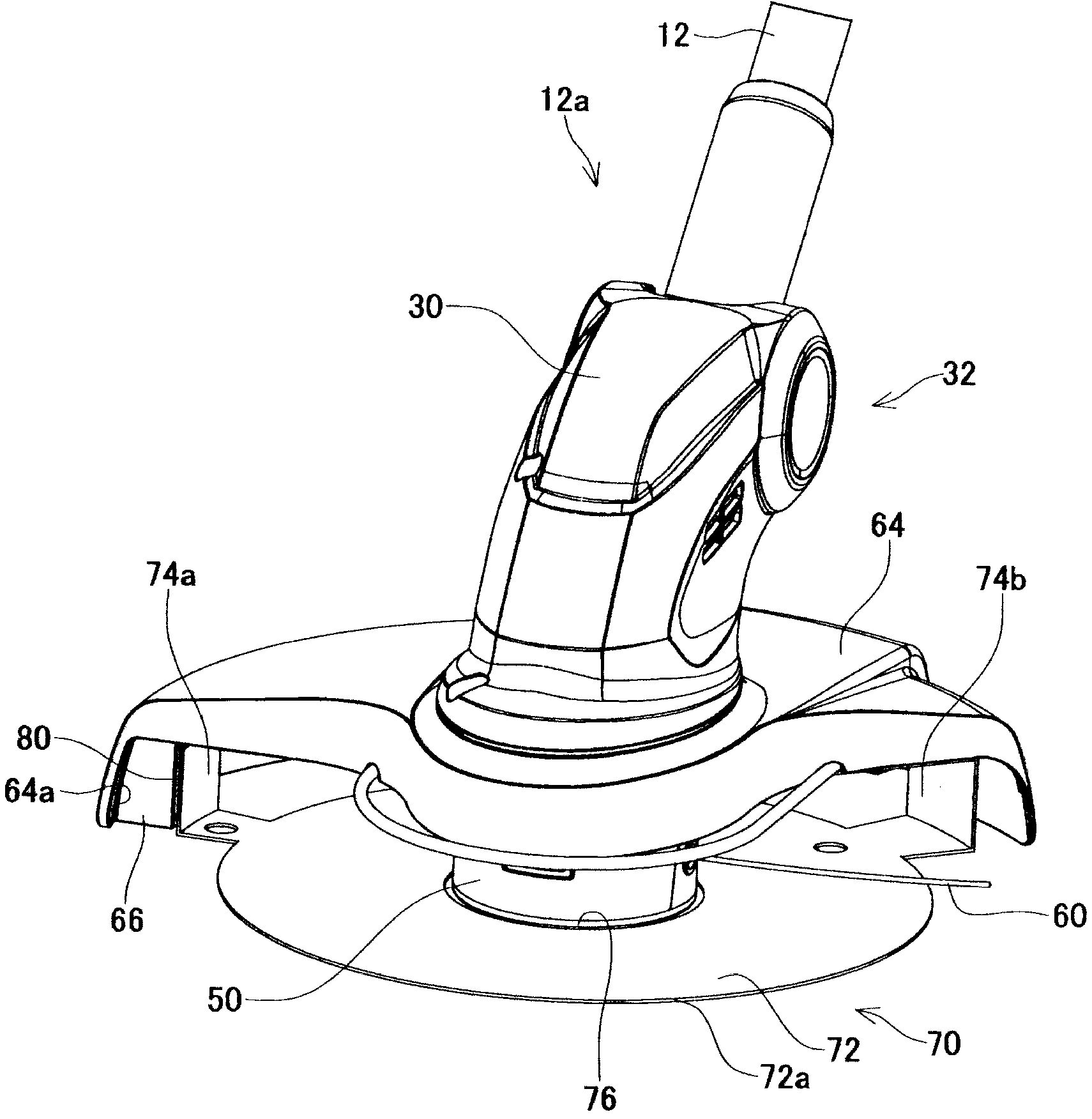

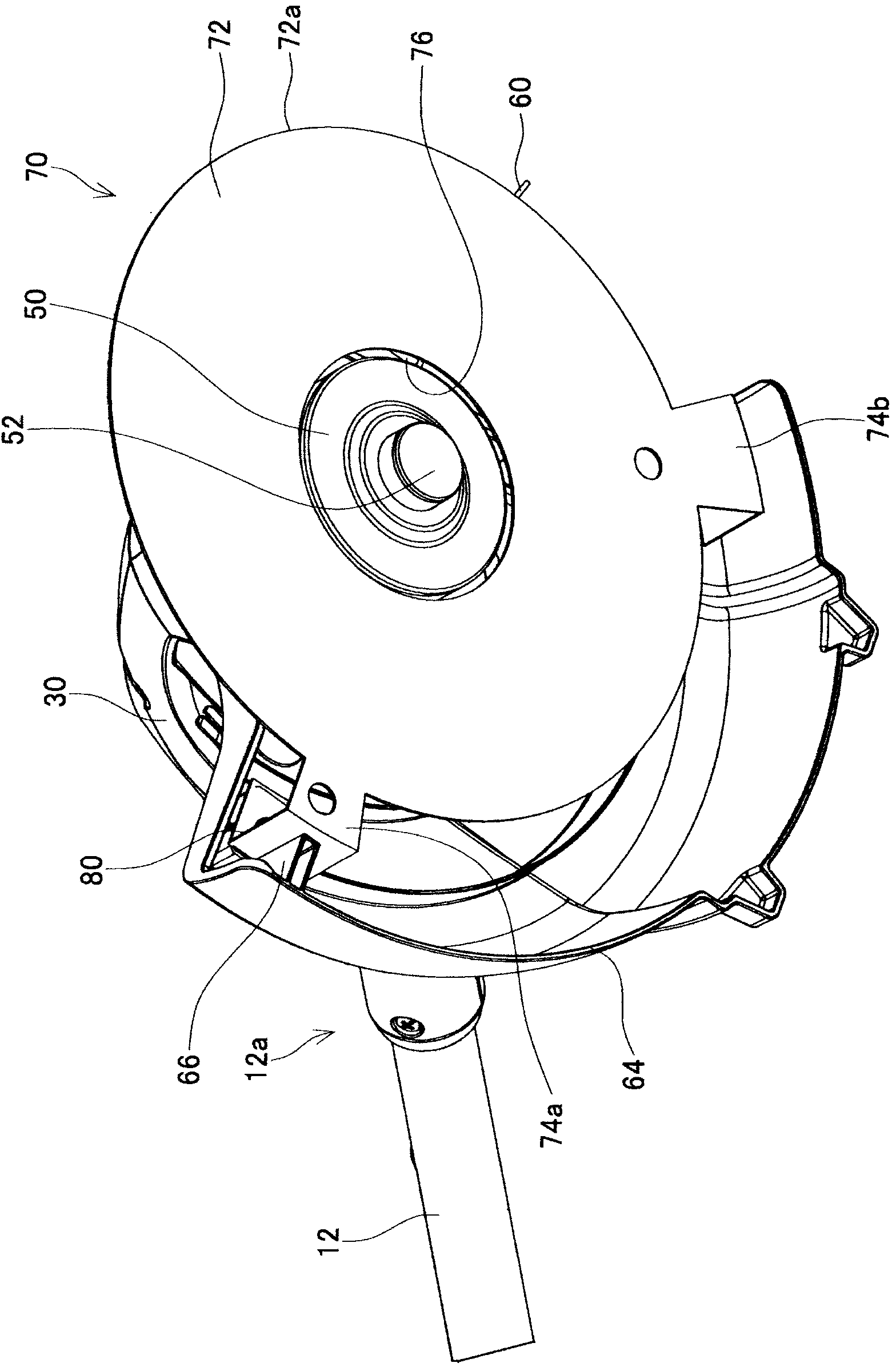

Brush cutter

Owner:MAKITA CORP

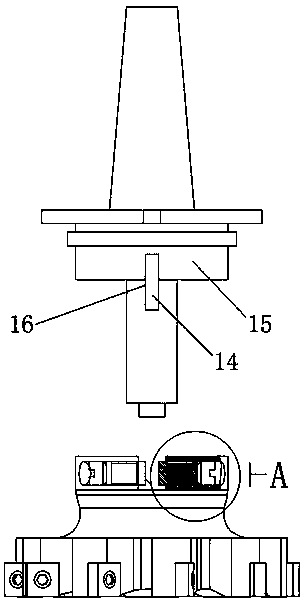

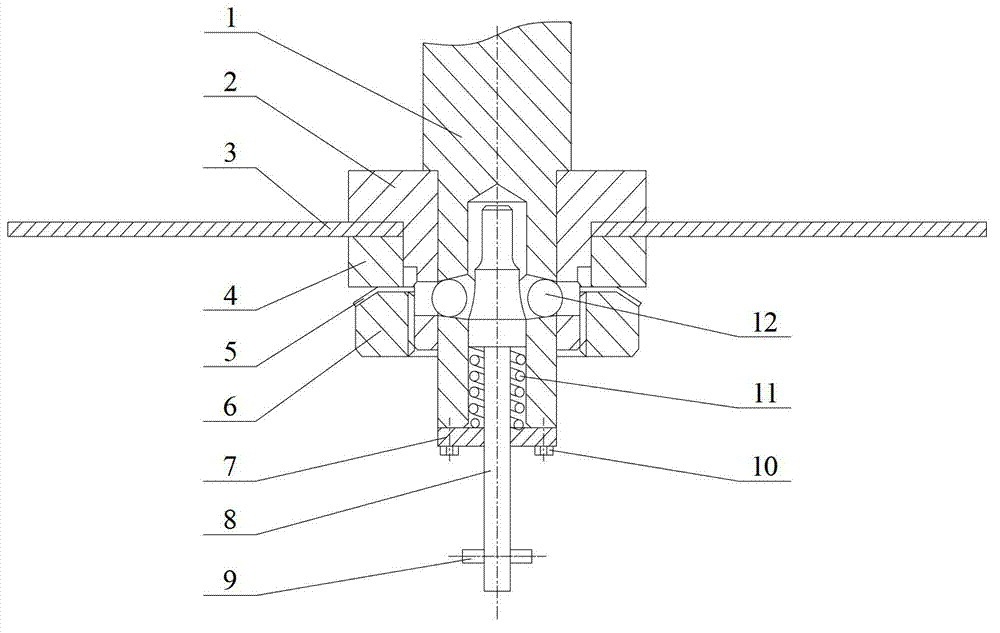

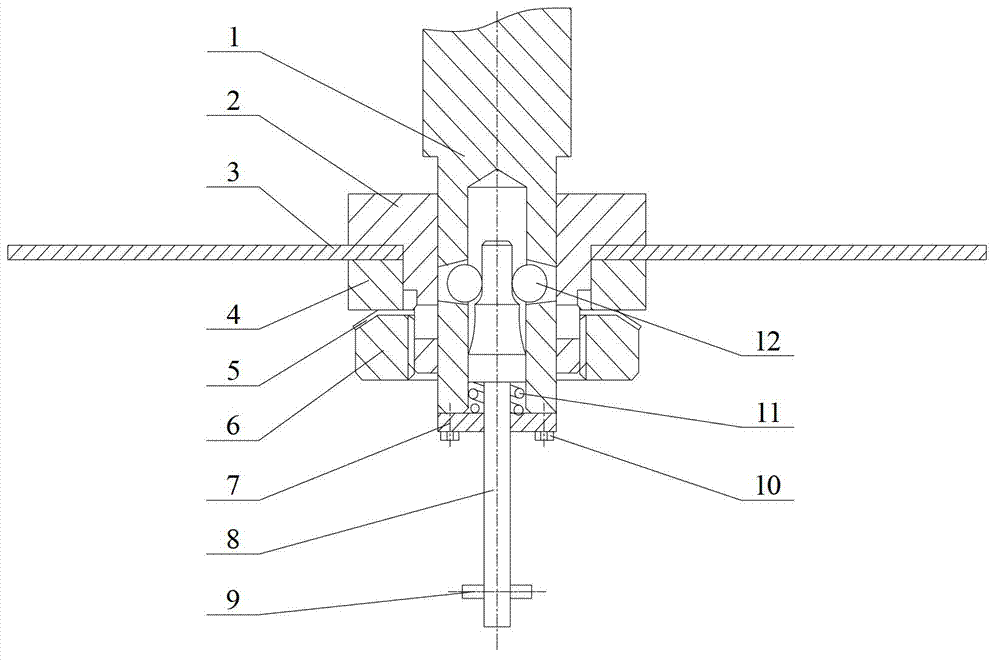

Milling cutter replacement device

ActiveCN102848004AQuick changeReduce entryMilling cuttersPositioning apparatusMilling cutterSteel ball

The invention discloses a milling cutter replacement device. A first through hole is arranged along a circumferential direction on a milling cutter shaft (1). A second through hole corresponding to the first through hole is arranged on a milling cutter seat (2) used for fixing a milling cutter. A steel ball (12) is arranged in the first through hole. A compression rod (8) capable of moving up and down is arranged in the milling cutter shaft (1). When the compression rod (8) moves up to a first position, the steel ball (12) is stuck in the first through hole and the second through hole, such that the milling cutter seat (2) is fixed with the milling cutter shaft (1). When the compression rod (8) moves down to a second position, the steel ball (12) departs from the second through hole, such that the milling cutter seat (2) can slip off from the milling cutter shaft (1), and milling cuter rapid replacement is realized. The device has a simple structure. With the device, remote replacement can be carried out by a manipulator in a hot chamber, such that the chances for stuffs to enter the hot chamber are minimized. Therefore, radiation hazard is reduced, and working efficiency is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

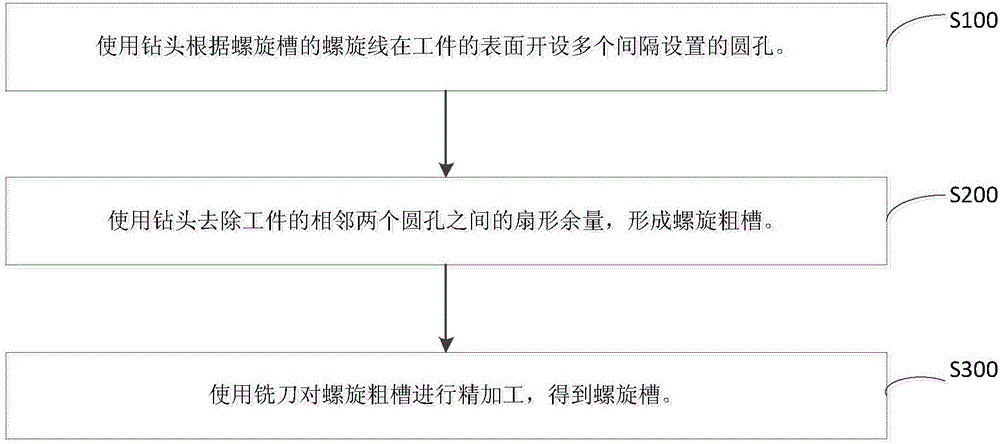

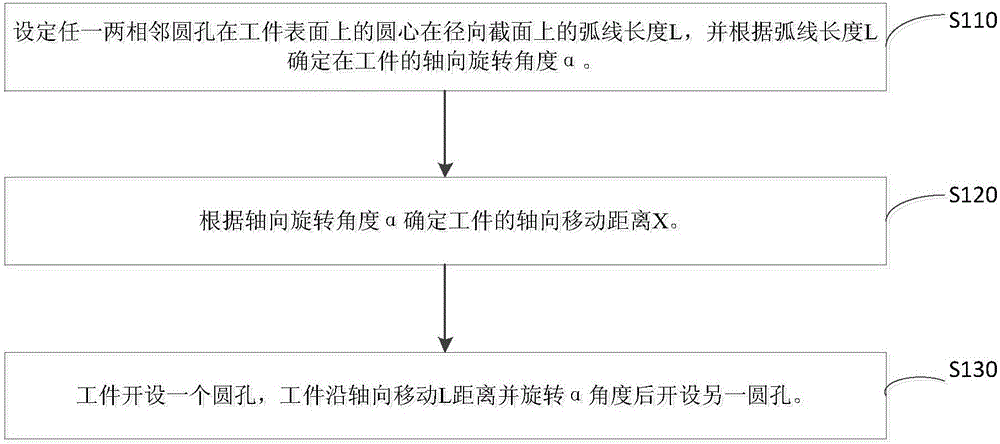

Method for machining spiral groove

The invention discloses a method for machining a spiral groove. The method includes the following steps that (1) a plurality of round holes arranged at intervals are formed in the surface of a workpiece by means of a drill according to the spiral line of the spiral groove; (2) the sector allowance between every two adjacent round holes of the workpiece is removed by means of the drill, so that a rough spiral groove is formed; (3) finish machining is conducted on the rough spiral groove by means of a milling cutter, so that the spiral groove is obtained. After most allowance is removed by means of the drill, the milling cutter is used for finish machining. The speed of the drill for machining the round holes to remove the allowance is higher than that of the milling cutter for grinding the allowance, and thus the machining speed can be increased. Besides, most allowance of the spiral groove is removed in the machining process of the rough spiral groove, and thus machining can be conducted through the milling cuter at a high speed and the machining speed of the spiral groove is further increased. The portion ground by the milling cutter is small, and therefore the abrasion loss is small, the machined spiral groove is protected against a slotting phenomenon, and the requirement for the roughness can be met. Polishing and repairing are not needed, so that the number of working procedures is reduced, and the machining speed is further increased.

Owner:AVIC POWER ZHUZHOU AVIATION PARTS MFG

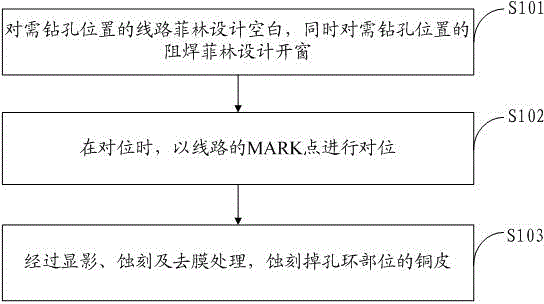

Method for improving cutter breaking condition in hole drilling process of thick copper plate

The invention discloses a method for improving cutter breaking condition in the hole drilling process of a thick copper plate. The method comprises the steps that A, a circuit film of the position where holes need to be drilled is designed to be blank, and meanwhile a solder resist film of the position where holes need to be drilled is designed to be windowed; B, during counterpoint, MARK points of lines are used for conducting counterpoint; C, through treatment of developing, etching and film removing, copper sheets at pore ring positions are etched. According to the method for improving the cutter breaking condition in the hole drilling process of the thick copper plate, the film for manufacturing a circuit is redesigned, the position where the holes need to be drilled is designed to be blank, meanwhile, the solder resist film of the position where the holes needs to be drilled is designed to be windowed, after counterpoint and exposure, the copper sheets at the pore ring positions are etched, the overall hardness of plates is lowered, so that subsequent hole drilling is conducted conveniently, and the phenomenon of cuter breaking is reduced. According to the method, only the circuit film and the solder resist film need to be designed, the production cycle is greatly shortened, and the production efficiency is improved.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

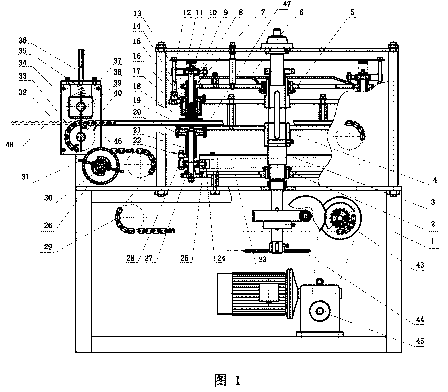

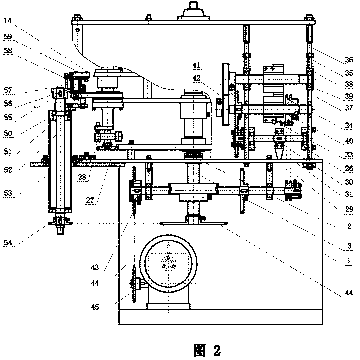

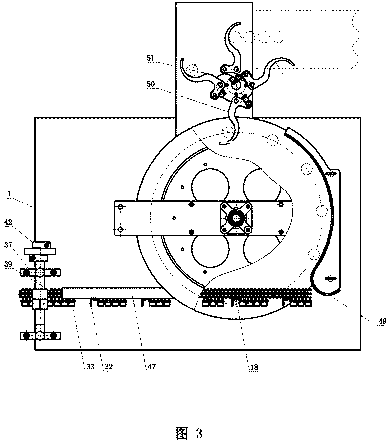

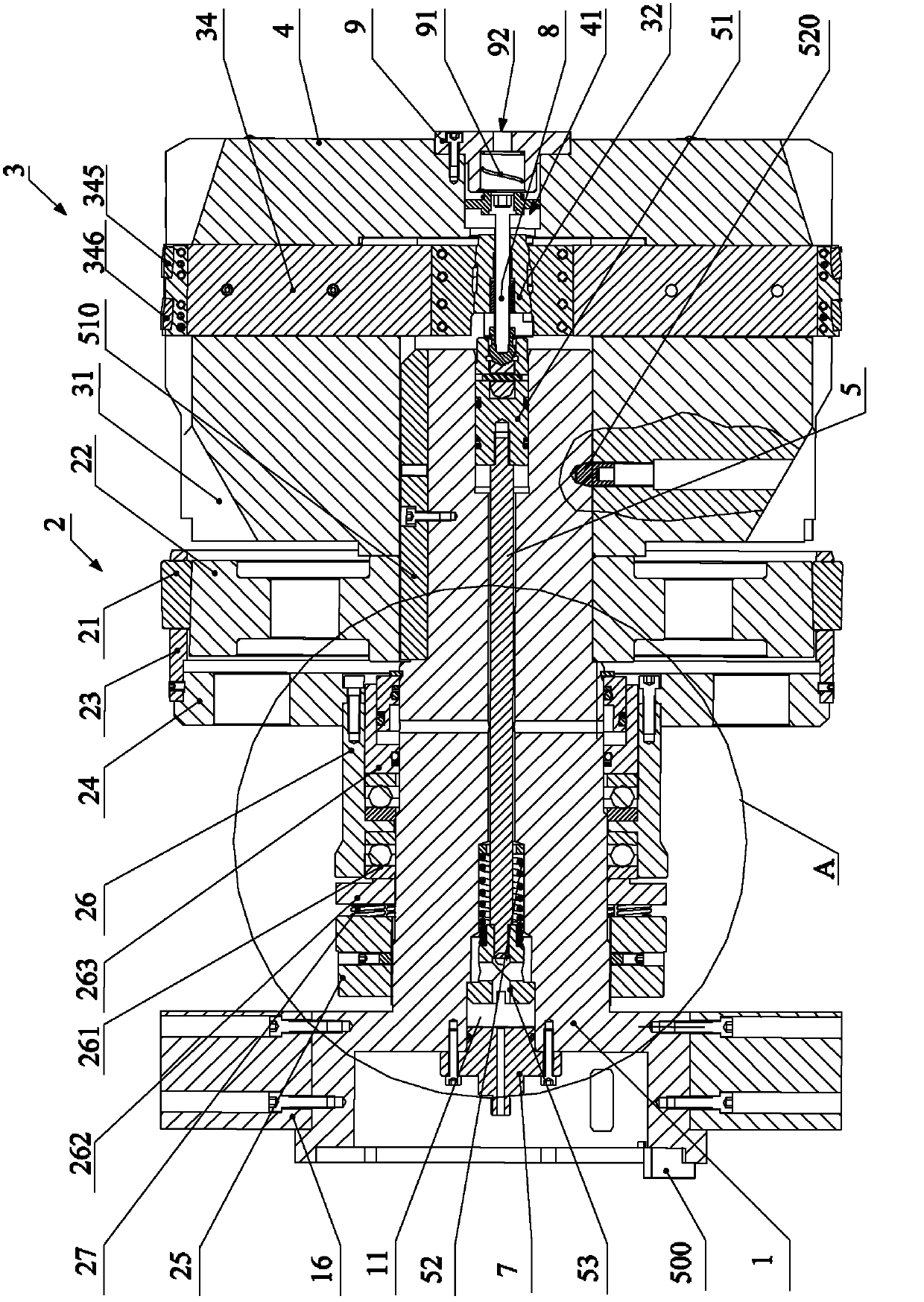

Automatic sugar coiling machine

ActiveCN103238719ARealize clamping positioningGuaranteed stabilityConfectionerySweetmeatsPulp and paper industryRotating disc

The invention discloses an automatic sugar coiling machine. The automatic sugar coiling machine comprises a frame; a cuter, a conveying belt, a central rotating disc and a shifting piece are arranged on the frame; a plurality of sets of coiling devices and sugar pressing devices which are in one-to-one correspondence are arranged on the surface of the central rotating disc; a sugar coiling pin is arranged in each coiling device; each sugar coiling pin can axially slide along the axis of the corresponding coiling device; an extruding tray is arranged in each sugar pressing device; each extruding tray can axially slide along the axis of the corresponding sugar pressing device; a sugar coiling sun gear rotating disc is fixedly arranged above the central rotating disc; a jacking sun gear rotating disc is fixedly arranged below the central rotating disc; the sugar coiling sun gear rotating disc is in mesh transmission with the coiling devices; and the jacking sun gear rotating disc is in mesh transmission with the sugar pressing devices. The automatic sugar coiling machine can automatically coil sugar sticks, and is high in production efficiency and good in product quality.

Owner:JIANGSU FLYING DRAGON FOOD MACHINERY

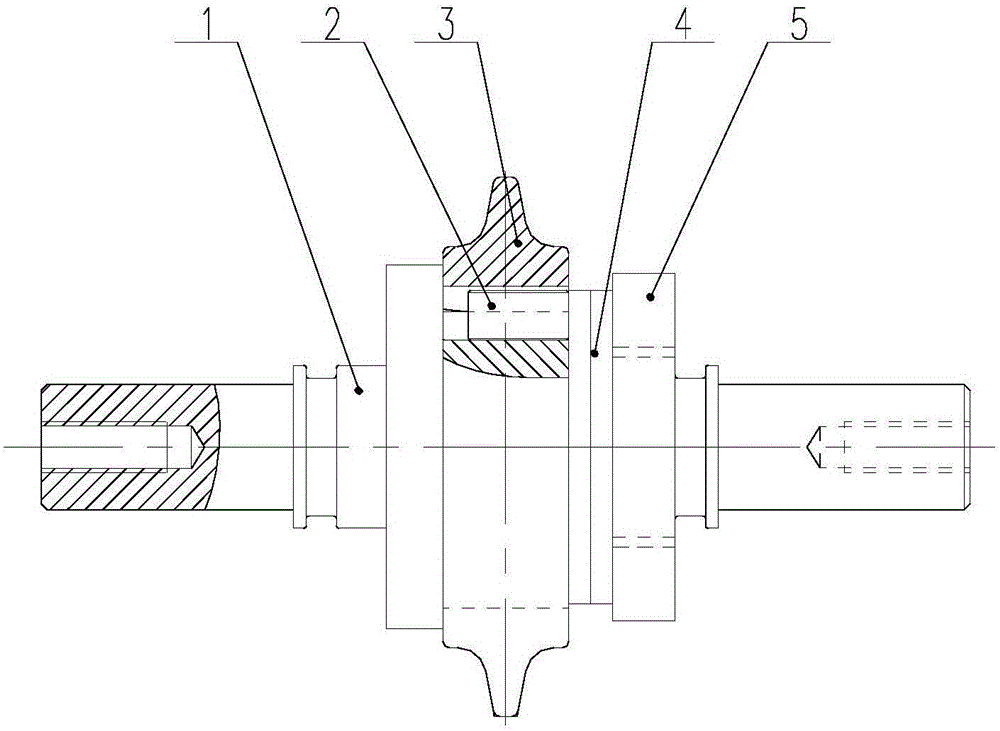

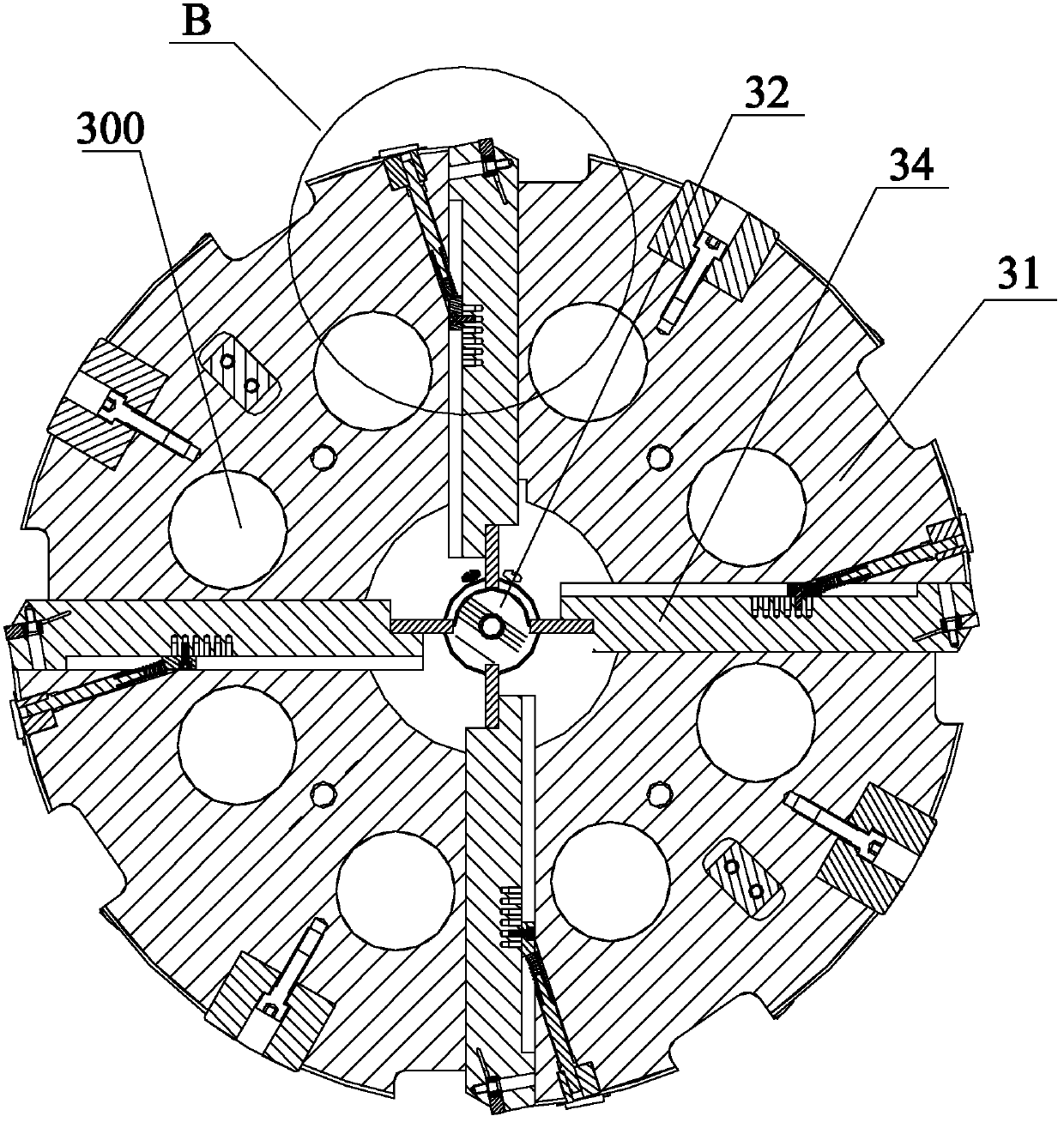

Combined cutter for skiving and rolling

InactiveCN102601617ASmall moment of inertiaImprove job stabilityTurning toolsOther manufacturing equipments/toolsDrive shaftMoment of inertia

The invention provides a combined cutter for skiving and rolling. The combined cutter comprises a driving shaft (1) and a rolling part (2) and a skiving part (3) which are installed on the driving shaft (1); the driving shaft (1) can drive the rolling part (2) and the skiving part (3) to turn; and a central hole (11) is formed in the center of the driving shaft (1). By virtue of the technical scheme provided by the invention, the turning inertia of the combined cuter for skiving and rolling is reduced and the stability and reliability of the combined cutter in work are improved. As a result, a whole roller cage is good in ductility and a roller groove is high in wear resistance to increase the strength of adjusting screw rods of an assembly base of a skiving knife holder, avoid cracking of the adjusting screw rods and guarantee the continuity and reliability of the skiving and rolling operation. Meanwhile, the combined cutter is simple in connecting and installing structures, and capable of effectively reducing weight and turning inertia of the skiving cutter, reducing manufacturing difficulty and improving production efficiency.

Owner:SANY HEAVY IND CO LTD (CN)

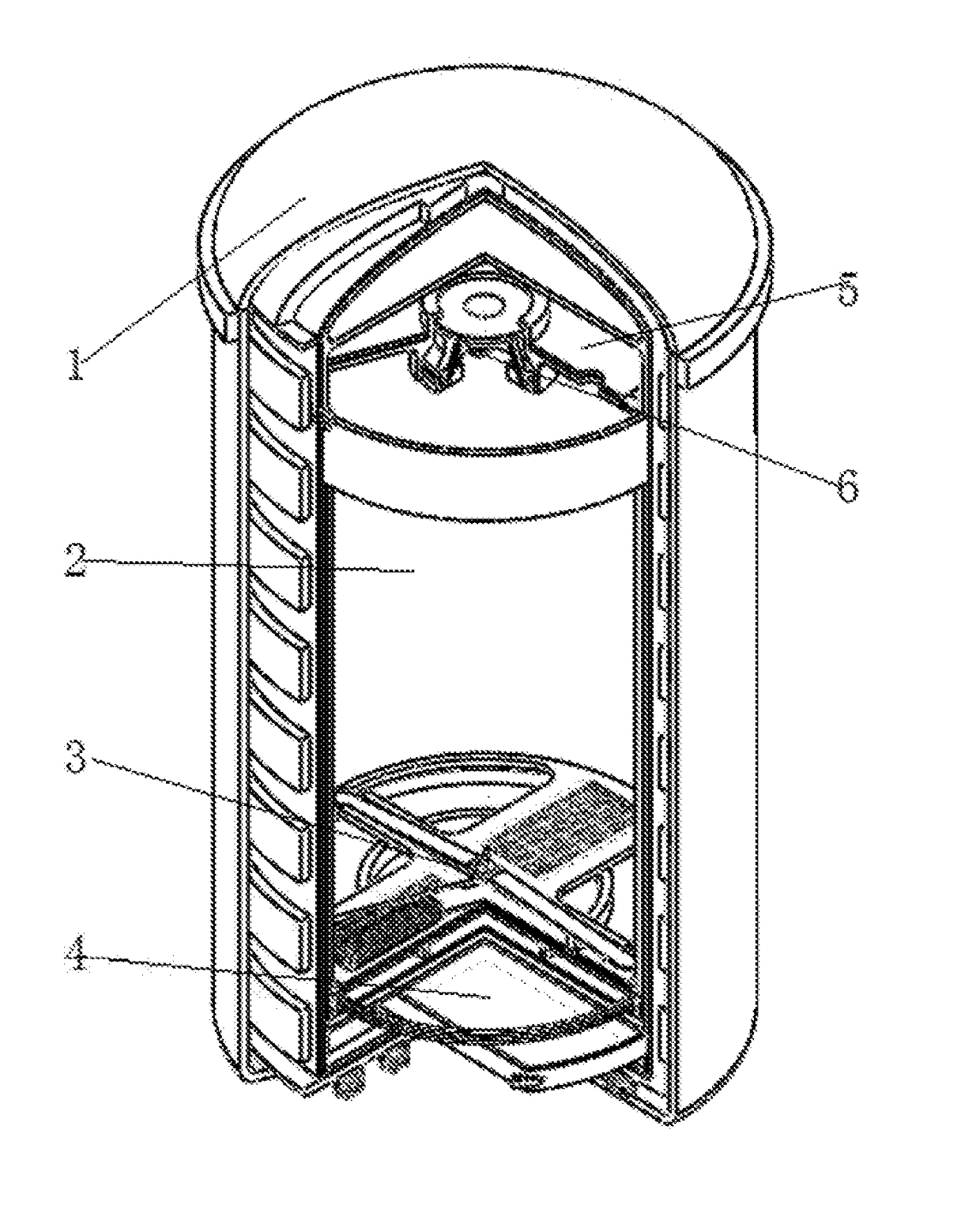

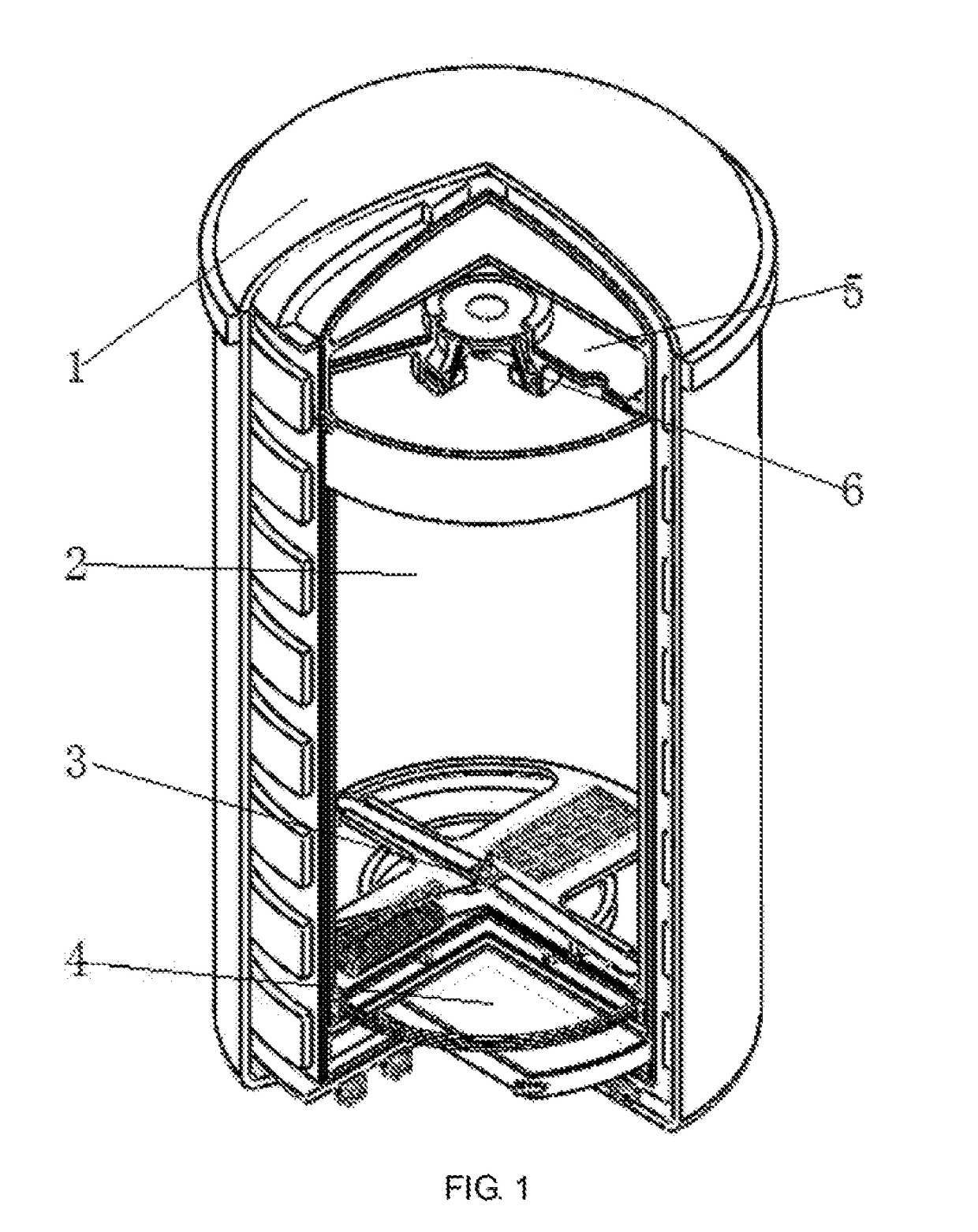

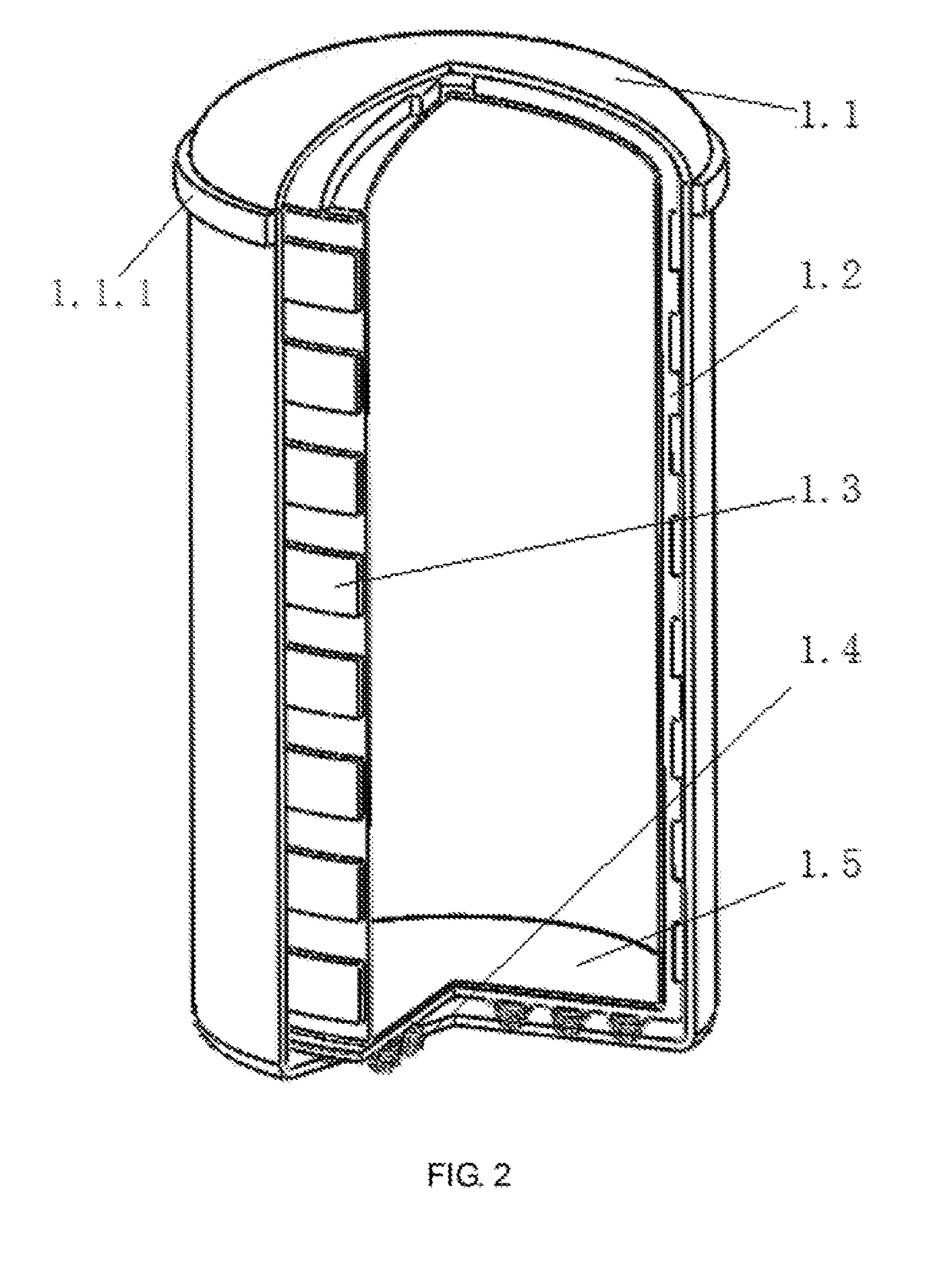

Safe and stabilized storage equipment for geochemistry research

InactiveUS20170210538A1Avoid environmental pollutionOvercome shortageDomestic cooling apparatusLighting and heating apparatusChemical storageChemical products

The invention is a safe and stabilized storage equipment for geochemistry research belonging to the chemical storage field. The container comprises an cuter sleeve, a main body of the liquid storage, a stabilizer storage mechanism, a main body pedestal, an Main body inner lid mechanism and a Neutralizer storage release mechanism. It is mostly used for storing high-precision chemicals: maintain the chemical properties of the chemicals during storage and transport, and automatically and quickly neutralize them in case of emergency to avoid chemical leakage and environment pollution. The storage process is safe and reliable, which has benefited the storage and transport of industrial hazardous chemicals, laboratory reagents, petrochemical and coal chemical products to a certain extent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

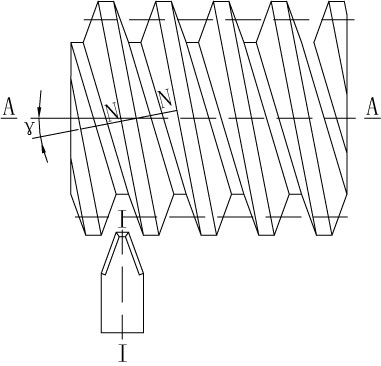

Method for machining normal straight profile cylindrical worm by using horizontal lathe

ActiveCN101920362ASolve the problem that cannot be processed by horizontal latheGet out of controlWormsSpiral lineOblique line

The invention provides a method for machining a normal straight profile cylindrical worm by using a horizontal lathe, relating to the method of machining the normal straight profile cylindrical worm. The invention aims to solve the problem that the normal straight profile cylindrical worm can not be machined on the horizontal lathe. The method comprises the following steps: 1, changing the toothnumber of a gear set in the change gear box of the horizontal lathe to achieve the change of screw pitches; 2, adopting a rotating cutter bar (4) to machine the normal straight profile cylindrical worm; and 3, firstly enabling a plane of a blade to be parallel to a normal plane of a spiral line, then leading the plane of the blade to rotate around the own axial center (I-I) of the cuter bar by a lead angle (gamma), and at the same time, ensuring the front blade to be in parallel with an oblique line (N-N), thereby ensuring that a tooth shape on a normal profile of a worm is trapezoid. The method is used for machining the normal straight profile cylindrical worm.

Owner:HARBIN TURBINE +1

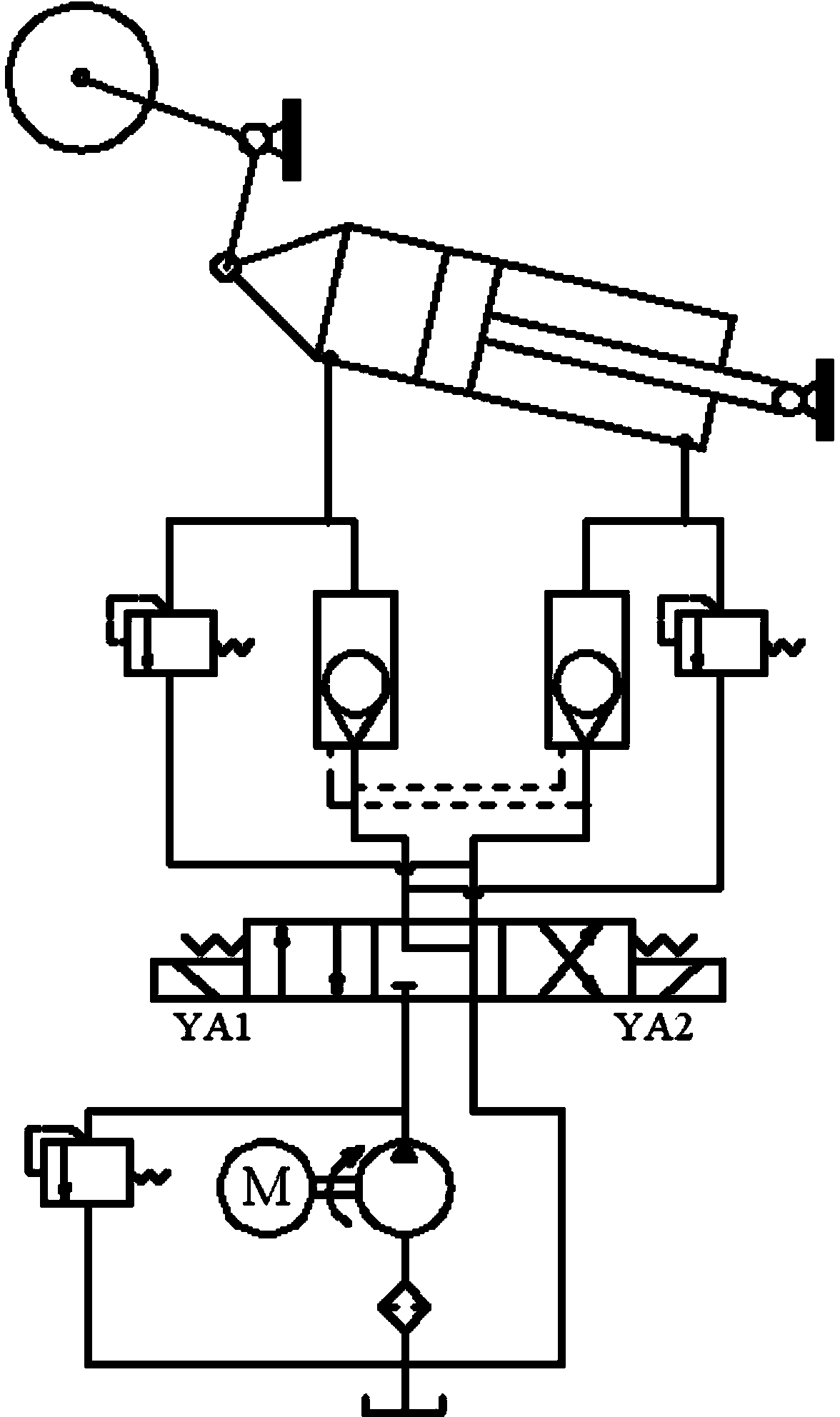

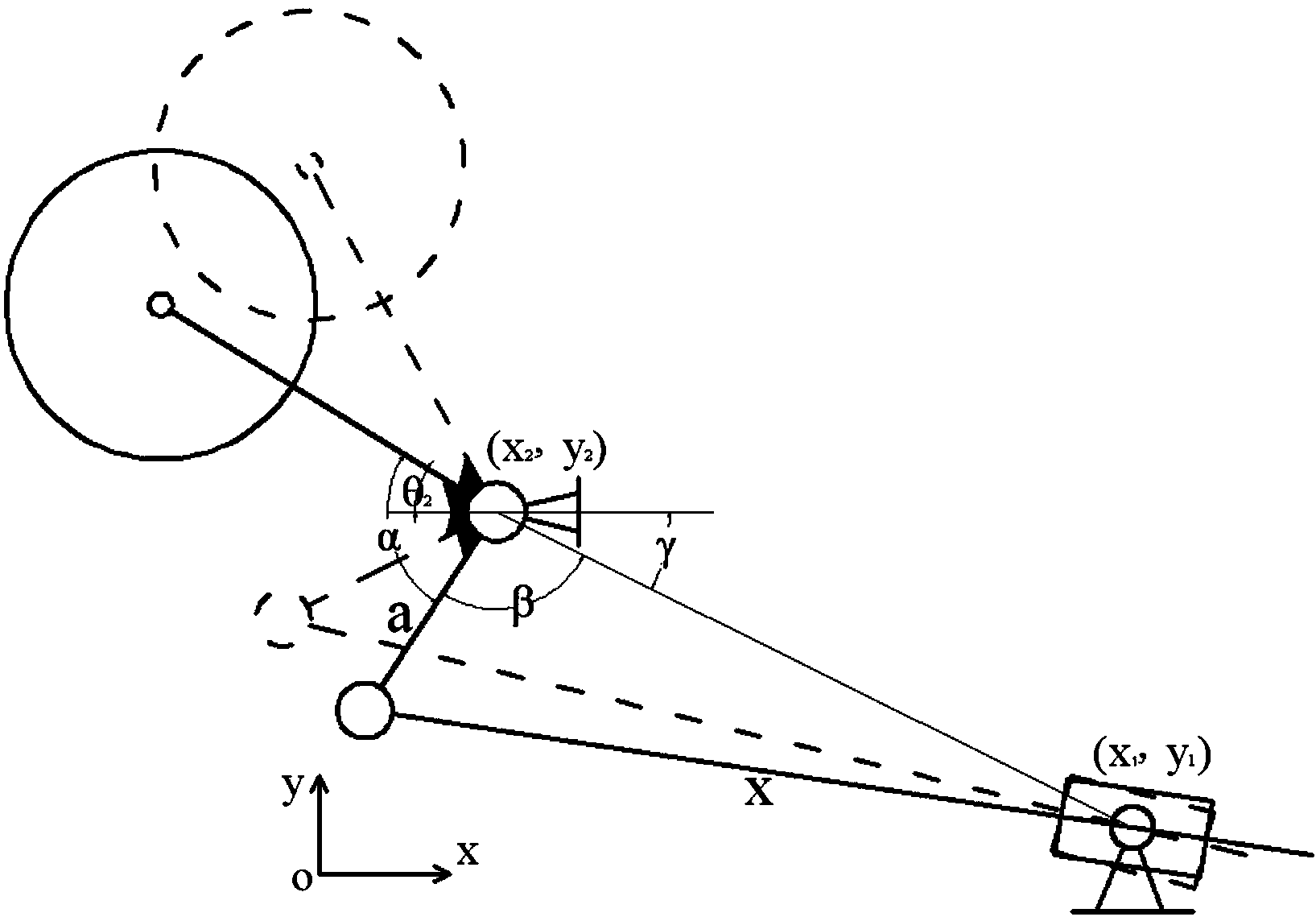

Posture positioning method of coal cutter in memory cutting process

InactiveCN103776418AReduce in quantityGuaranteed to workAngle measurementHydraulic cylinderEngineering

The invention discloses a posture positioning method of a coal cutter in a memory cutting process. The posture positioning method of the coal cutter in a memory cutting process comprises the following steps: reading a tilt angle sensor in a body of the coal cutter so as to obtain a tilt angle theta 1 of the body of the coal cutter; reading the action time of electromagnetic valves corresponding to left and right height adjusting oil cylinders, which is recorded in a machine-mounted programmable controller, further calculating the oil intake quantity of a hydraulic cylinder, then acquiring the tilt angles theta 2 and theta 3 of left and right rocker arms relative to the body of the coal cuter by the existing geometrical relationship, and positioning the posture of the coal cutter in the memory cutting process. According to the posture positioning method disclosed by the invention, the tilt angles theta 2 and theta 3 of the left and right rocker arms of the coal cutter can be obtained by an indirect method, so that the posture of the coal cutter can be positioned without installing tilt angle sensors of the left and right rocker arms; not only is the number of sensors reduced, a plurality of data volumes are not required to be collected in the memory cutting process, and the data analysis time is shortened, but also the tilt angle sensor is effectively prevented from being damaged by external knock to lead to inaccurate positioning, and the normal operation of the coal cutter is ensured.

Owner:CHINA UNIV OF MINING & TECH

Car first template exemplar shaping method

InactiveCN101190499AImprove support strengthImprove deformationOther manufacturing equipments/toolsHand PlateThin hands

The invention provides an automobile hand plate sample forming method. The invention is characterized in that the invention comprises the steps of a. blank is obtained firstly to form a workpiece which is processed in order to form the back surface of the sample; b. a plurality of formed T-shaped round piles are bonded in a processing forming area; the T-shaped round pipe vertical end is bonded with the forming area of roughcast; the upper end surface of a horizontal part is corresponding to the back surface of the roughcast; c. the residual area of process forming is filled with gypsum which is levelly scraped; d. the frontage of the roughcast is processed after the gypsum is formed; e. the T-shaped round pile and the gypsum are removed. The invention bonds the T-shaped round pile to the back surface in the processing area of the workpiece by utilizing melted AB glue, thus improving bonding performance, fills and scraps the gypsum and then processes the frontage after forming; when the frontage is processed, because of the firm supporting of the T-shaped round pile, when the hand plate roughcast vibrates as subject to a cuter, the invention improves the supporting strength of the plate and effectively improves the deformation and cracking phenomenon appearing in the processing process of thin hand pate caused when the gypsum is loosened as subject to force.

Owner:BYD CO LTD

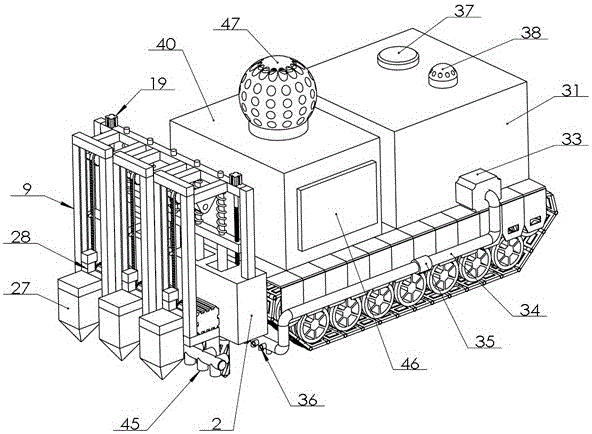

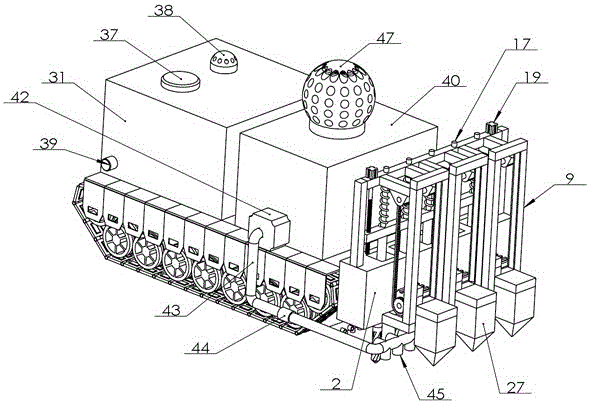

Floor crushing machine

The invention relates to a floor crushing machine which comprises a crawler-type chassis, a front frame, a speed-regulating motor placement hole, a milling cutter through hole, a vertical beam, a cross beam, a sliding rod through hole, a screw through hole, a frame, a seat bearing, a sliding groove, a speed-regulating motor, a milling cuter, a connecting rod, a connecting beam, a threaded hole, a sliding rod, a spring, a stepping motor, a screw, a motor, a driving chain wheel, a chain, a driven chain wheel, a shaft, a clamping claw, a heavy hammer, a connecting block, a roller, a water tank, a water outlet, a water pump, a water pipe, a water pipe control valve, a spray nozzle, a water inlet, an air inlet, a residue discharging port, a dust removing box, a dust inlet, an exhausting motor, an air pipe, an air pipe control valve, a dust suction opening, an airtight door and an air outlet. The floor crushing machine is reliable in structure, the labor intensity of constructors can be reduced, the working efficiency of removing old cement floors or tile floors is improved, and the body health of the constructors can be guaranteed.

Owner:嘉兴久珥科技有限公司

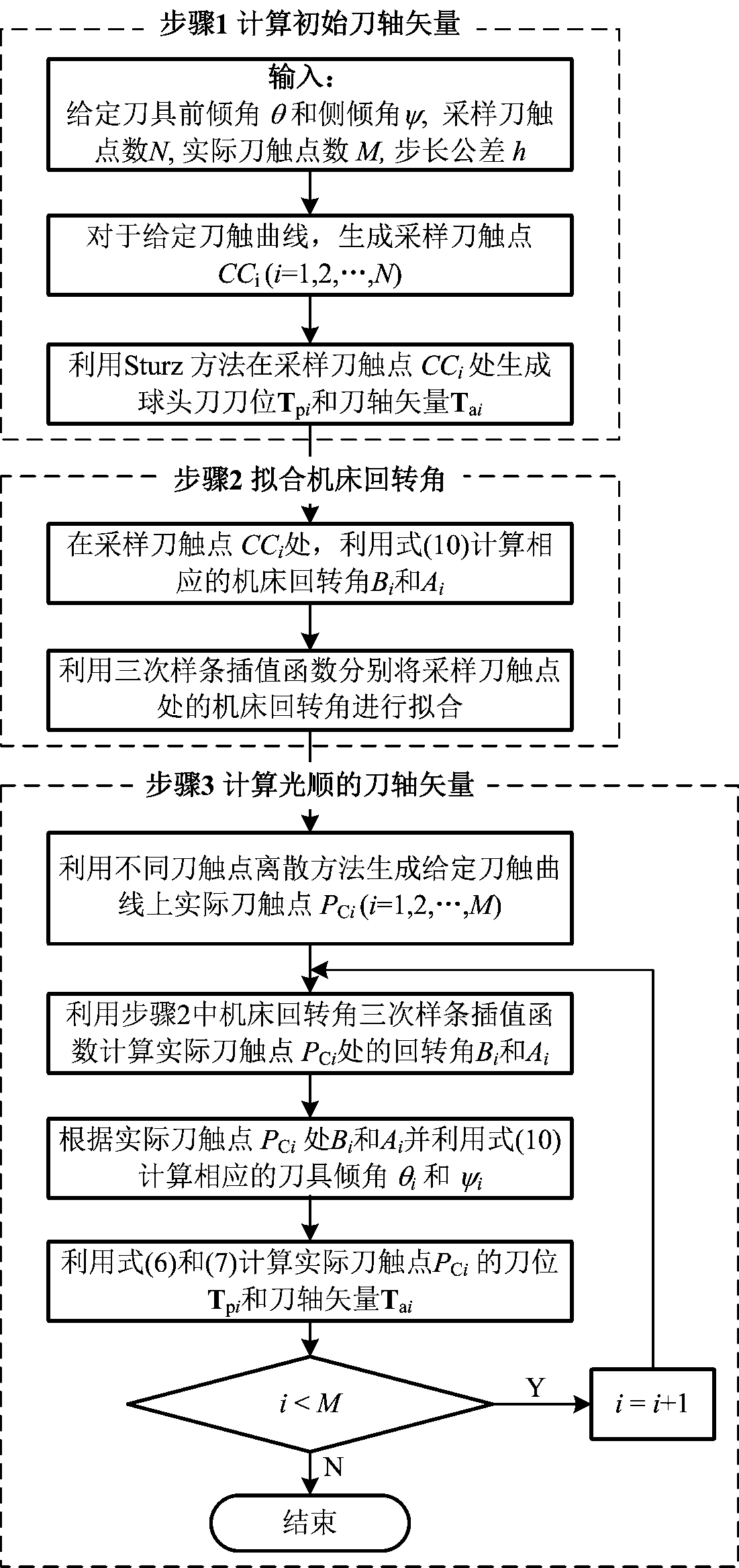

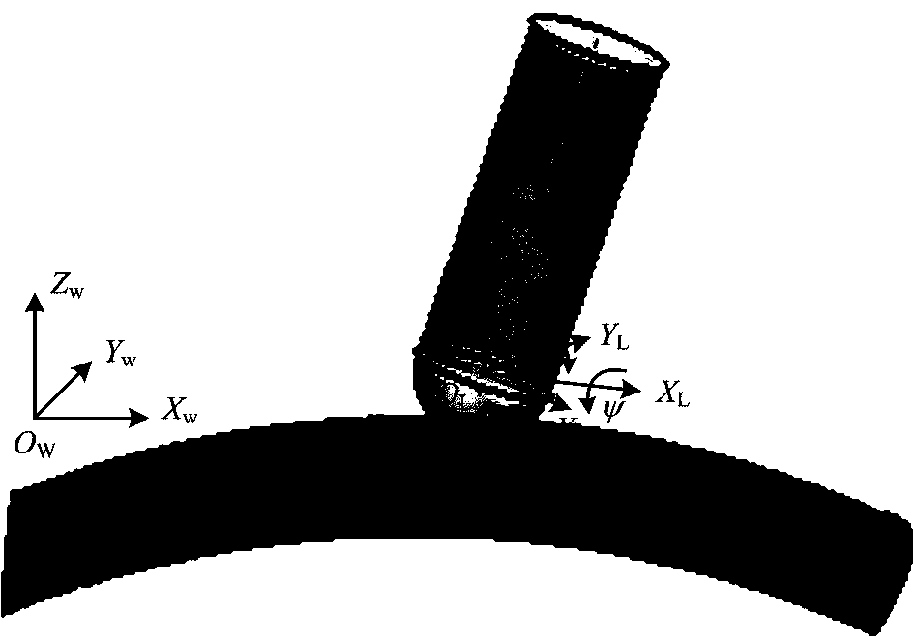

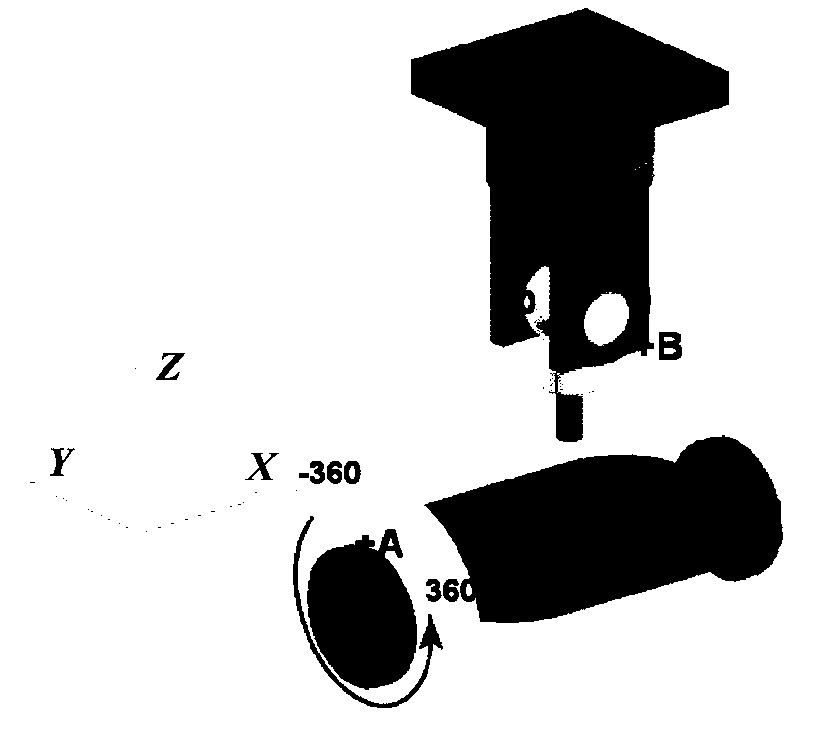

Ball-head cuter processing shaft vector smoothing method based on BA type five-axis numerically-controlled machine tool

ActiveCN107045328AAvoid mutationAvoid bad luckProgramme controlComputer controlNumerical controlDrive shaft

The invention discloses a ball-head cuter processing shaft vector smoothing method based on a BA type five-axis numerically-controlled machine tool. The method comprises: a relation equation between a ball-head cuter shaft vector and a cutter spacing design variable is established; a motion transformational equation between the ball-head cuter shaft vector and drive shafts B and A of a five-axis numerically-controlled machine tool is established; a relation equation between a ball-head cuter spacing design variable and drive shafts B and A of the five-axis numerically-controlled machine tool is established; a design variable, an objective function and a constraint condition of ball-head cuter shaft vector smoothing are determined and a BA-type-five-axis-numerically-controlled-machine-tool-based ball-head cuter processing shaft vector smoothing mathematical model is established; and a solution method of the shaft vector smoothing mathematical model is determined. With the method disclosed by the invention, the rapid change of the drive shaft of the machine tool can be avoided and thus the drive shaft of the machine tool can work smoothly and stably, so that the angular velocity and the angular acceleration speed of the drive shaft of the machine tool can be reduced and thus the processing quality and the processing efficiency of the curved surface can be improved. The method has the high practical application value.

Owner:SHANDONG UNIV OF TECH

Method and device for security-inspection of liquid articles with radiations

ActiveUS7634055B2Taking small areaImprove accuracyUsing wave/particle radiation meansMaterial analysis by transmitting radiationRelevant informationAnti jamming

Owner:NUCTECH CO LTD +1

Cutting machine special for plastic welding rods

InactiveCN103128774AExtended service lifeFast cutting speedMetal working apparatusFailure rateAviation

Plastic materials, as typical and novel materials, are widely used in building, medical care, aviation and other fields, plastic products are well popular among consumers due to the fact that the plastic products have the characteristics of being energy-saving, environment-friendly, fashionable and attractive, the plastic products are greatly supported in national policies and develop irresistibly during next few years, restoration techniques of the plastic products quickly develop, competition in the industry of plastic welding rods for plastic restoration is fierce nowadays, how to reduce production cost and improve product competition becomes a core problem which each enterprise has to face, a cutting machine special for the plastic welding rods is developed and specially aims at plastic, and the cutting machine has good reputation among the consumers due to the facts that equipment price is low, the structure is compact, cutting faces are smooth, no scraps are produced in cutting, a cutting speed is high, the reject rate is low and energy is saved. In the market nowadays, the cutting machine special for the plastic welding rods is mainly a fly-cutter cutting machine or a cam rotary cutting machine, wherein the fly-cuter machine cannot be easily accepted in the market due to the facts that equipment cost is high and cost in later maintenance is high and is only used in a small range; and the cam rotary cutting machine is complicated in equipment structure, high is equipment energy consumption, high in maintenance cost, and high in failure rate, and cannot carry out simultaneous cutting for several welding rods. Based on the preceding conditions, the cutting machine special for the plastic welding rods are designed and developed.

Owner:ZHANGJIAGANG BEIER MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com