Re-processing method of leaking and drilling back board

A heavy processing and backplane technology, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of unsatisfactory drilling quality, uneven thickness of aluminum plate, and low detection accuracy of electric shock circuit, so as to improve enterprise economy Benefits, high control depth accuracy and the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

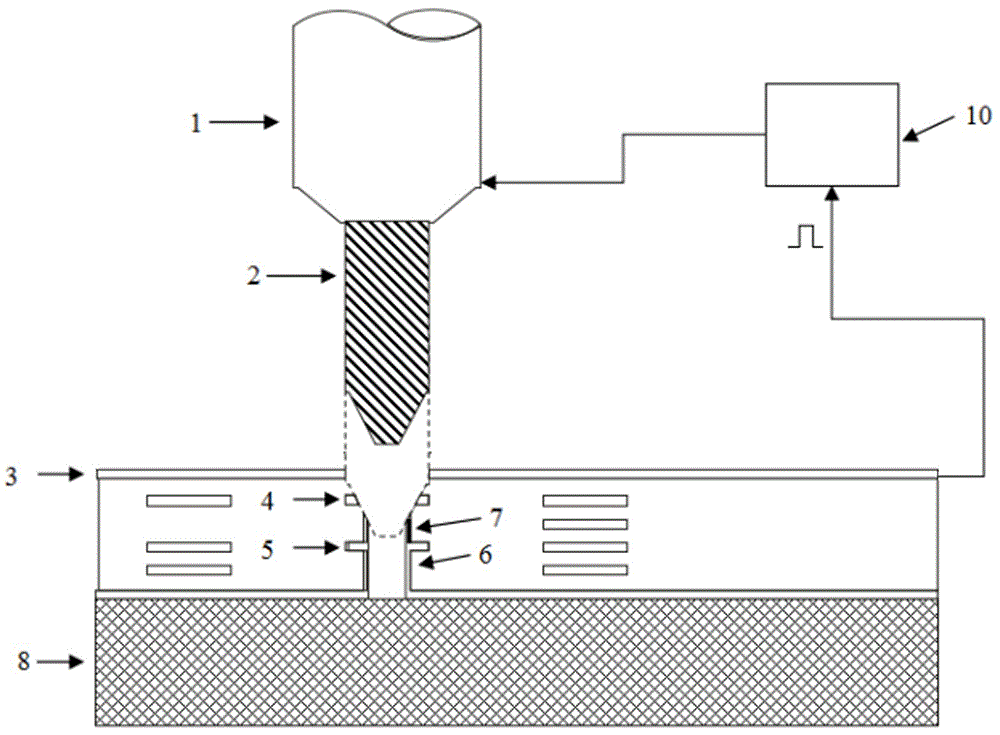

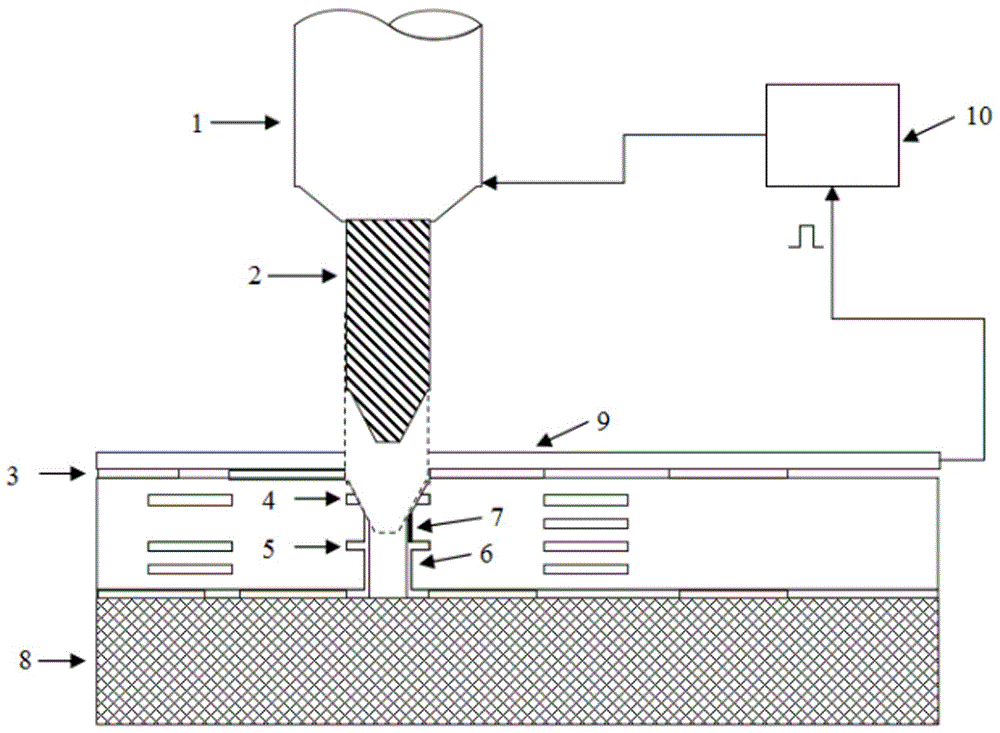

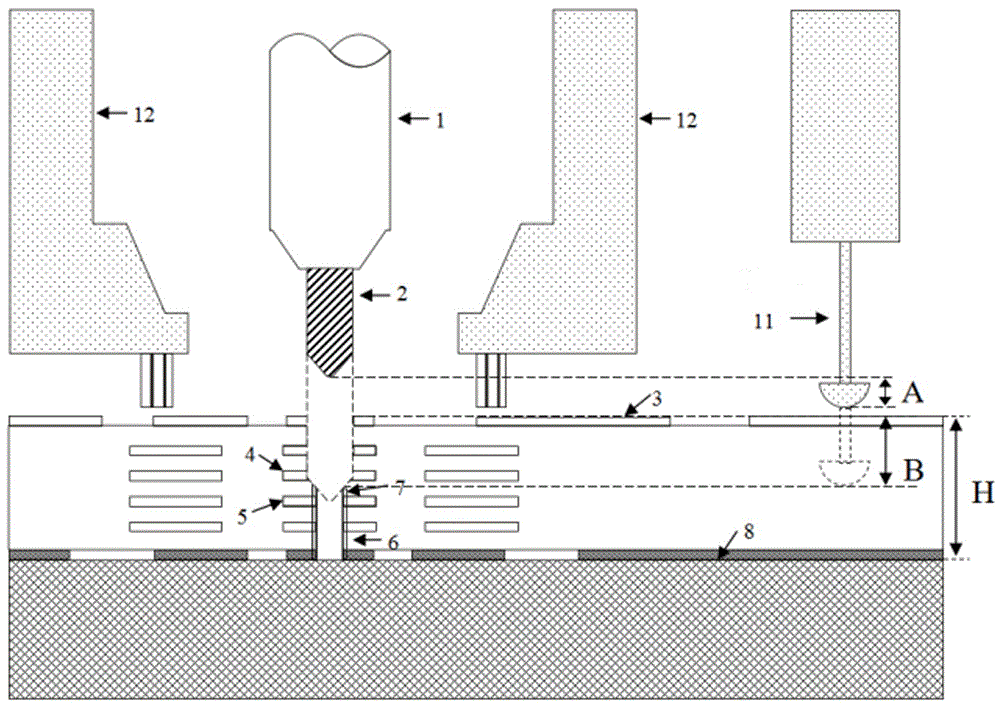

[0025] see image 3 , in the embodiment of the present invention, a method for reprocessing the missing drilling backboard, after the back drilling process of the PCB board, especially after the outer layer pattern is etched, the contact conductive circuit technology is no longer used to control the deep drilling process, but Using height difference compensation and direct contact measurement technology to carry out high-precision control depth supplementary drilling to make the back drilling of missed drilling. The specific steps are as follows.

[0026] Step 1: After the outer layer AOI test, or E-Test test, or after the outer layer pattern etching, the manual inspection of the back plate found missing drilling, and compiled the back drilling program data and set the drilling depth for the corresponding missing back drilling holes;

[0027] Step 2: By measuring the length of the drill bit 2 and the length of the optical ruler sensor detector 11, and synchronously correcting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com