Patents

Literature

280 results about "Deep drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

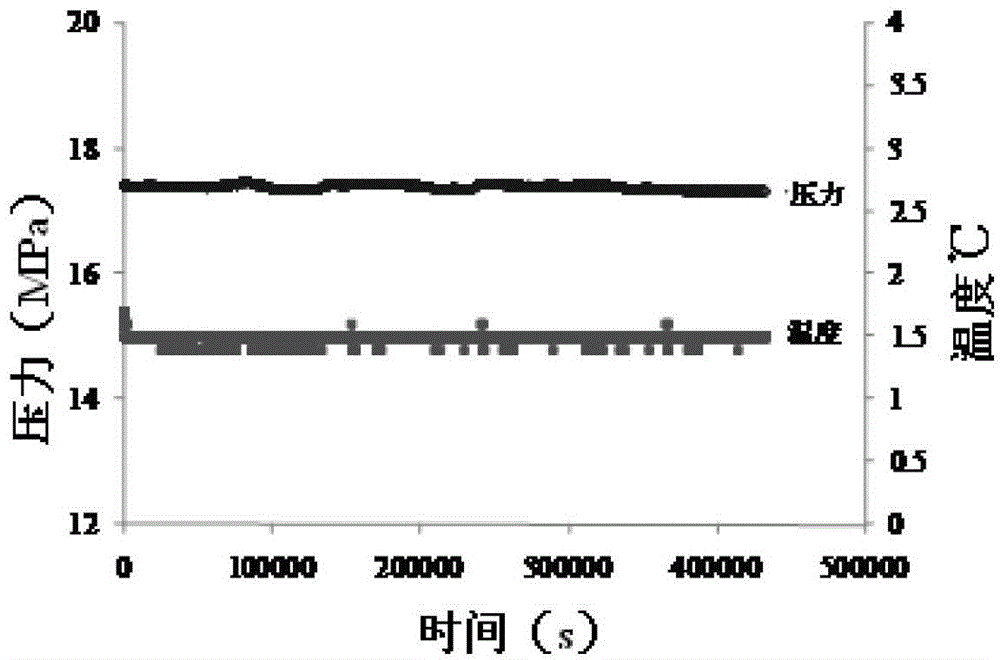

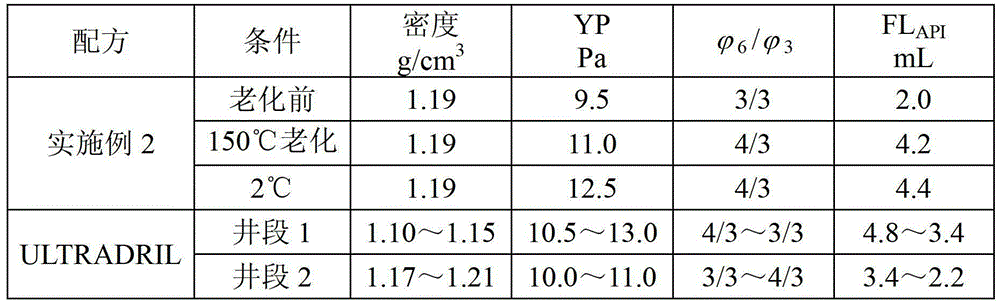

Strong-inhibition water-base drilling fluid

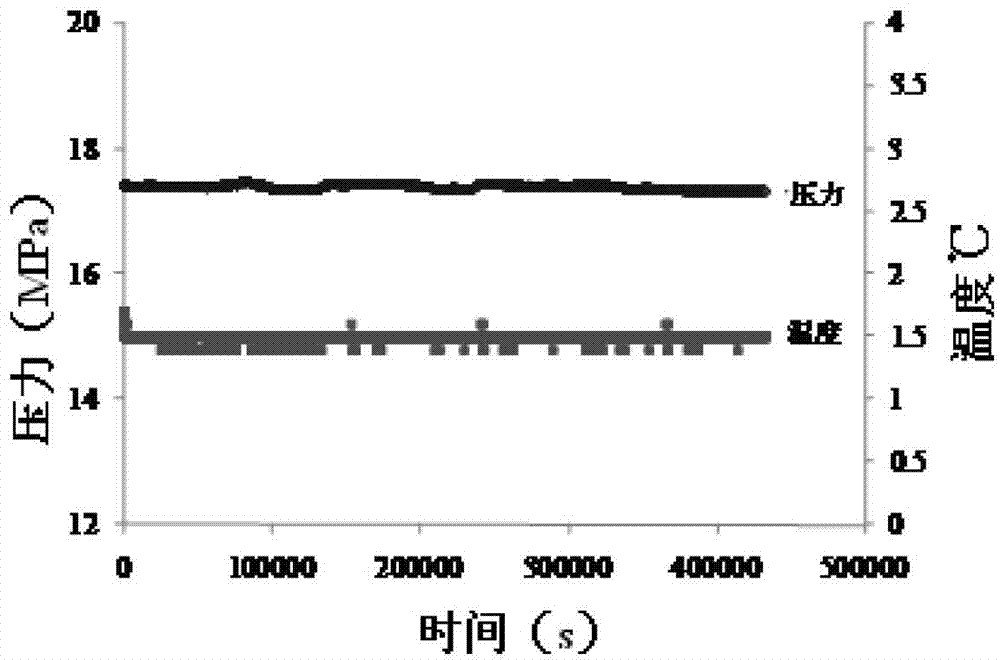

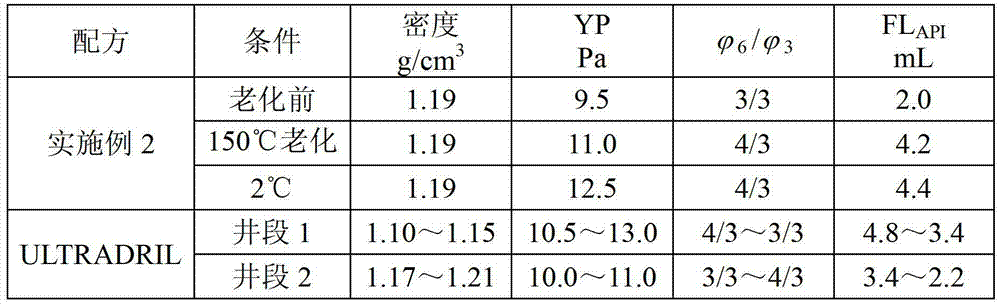

The invention discloses a strong-inhibition water-base drilling fluid which comprises the following components in parts by mass: 100 parts of water, 0.2-4 parts of polyamine inhibitor, 0.1-1 part of coating inhibitor, 10-25 parts of hydrate inhibitor, 0.1-1 part of tackifier, 0.5-5 parts of fluid loss agent and 0.5-3 parts of liquid lubricant. The polyamine inhibitor is an amino polymer polymerized from polyether diamine and epoxy alkane; and the mol ratio of the polyether diamine to the epoxy alkane is 1-10:1-20. The drilling fluid disclosed by the invention can effectively inhibit wellbore instability of deepwater shallow strata, and has equivalent inhibition capability to an oil-base drilling fluid. The drilling fluid disclosed by the invention can solve the problem of generation of hydrate in deepwater drilling, and is applicable to 3000m-deep drilling operation. The drilling fluid disclosed by the invention has favorable low temperature-high temperature stability, and is applicable to a deepwater large-temperature-difference environment (2-150 DEG C).

Owner:CHINA NAT OFFSHORE OIL CORP +1

Strong-inhibition water-base drilling fluid

The invention discloses a strong-inhibition water-base drilling fluid which comprises the following components in parts by mass: 100 parts of water, 0.2-4 parts of polyamine inhibitor, 0.1-1 part of coating inhibitor, 10-25 parts of hydrate inhibitor, 0.1-1 part of tackifier, 0.5-5 parts of fluid loss agent and 0.5-3 parts of liquid lubricant. The polyamine inhibitor is an amino polymer polymerized from polyether diamine and epoxy alkane; and the mol ratio of the polyether diamine to the epoxy alkane is 1-10:1-20. The drilling fluid disclosed by the invention can effectively inhibit wellbore instability of deepwater shallow strata, and has equivalent inhibition capability to an oil-base drilling fluid. The drilling fluid disclosed by the invention can solve the problem of generation of hydrate in deepwater drilling, and is applicable to 3000m-deep drilling operation. The drilling fluid disclosed by the invention has favorable low temperature-high temperature stability, and is applicable to a deepwater large-temperature-difference environment (2-150 DEG C).

Owner:CHINA NAT OFFSHORE OIL CORP +1

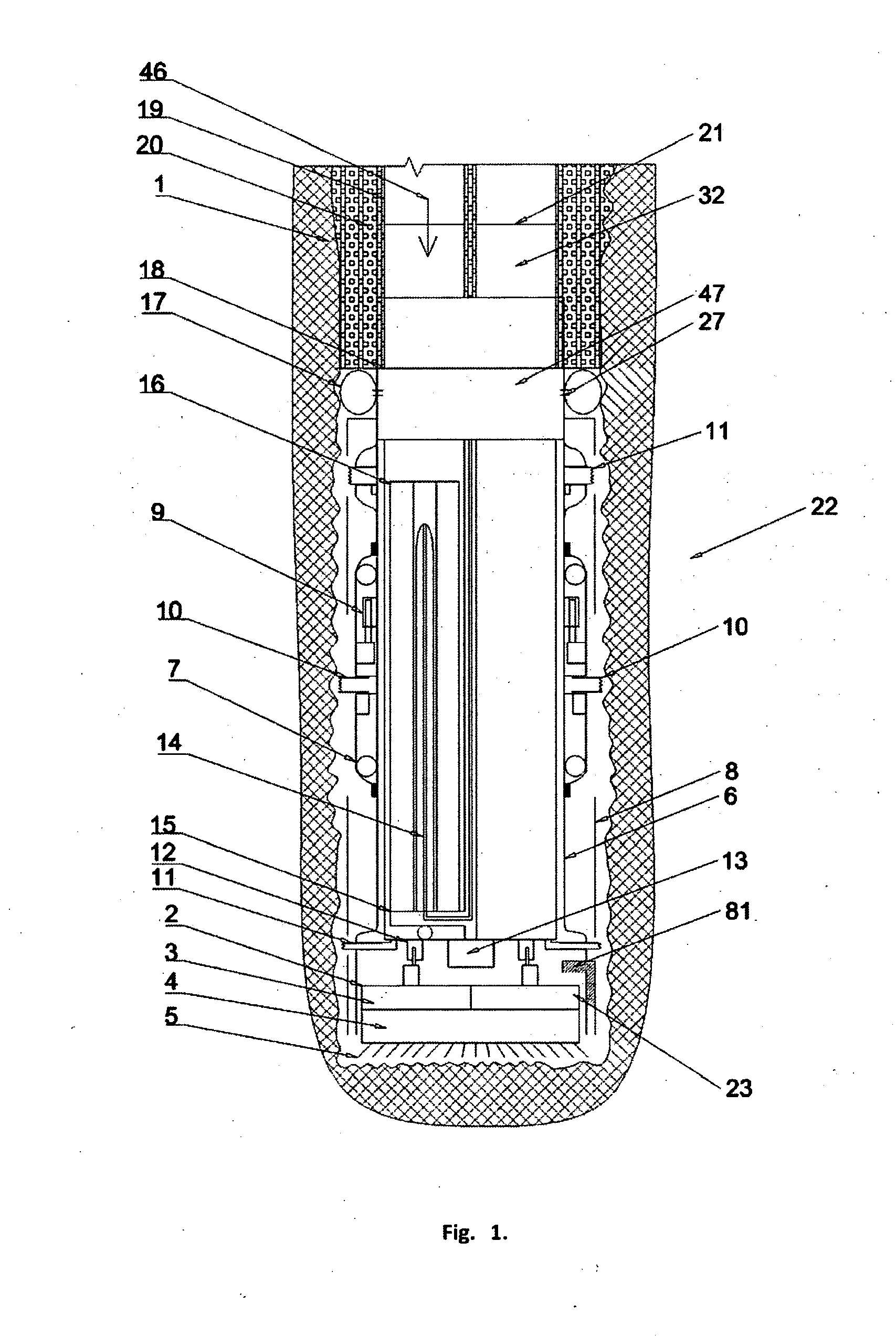

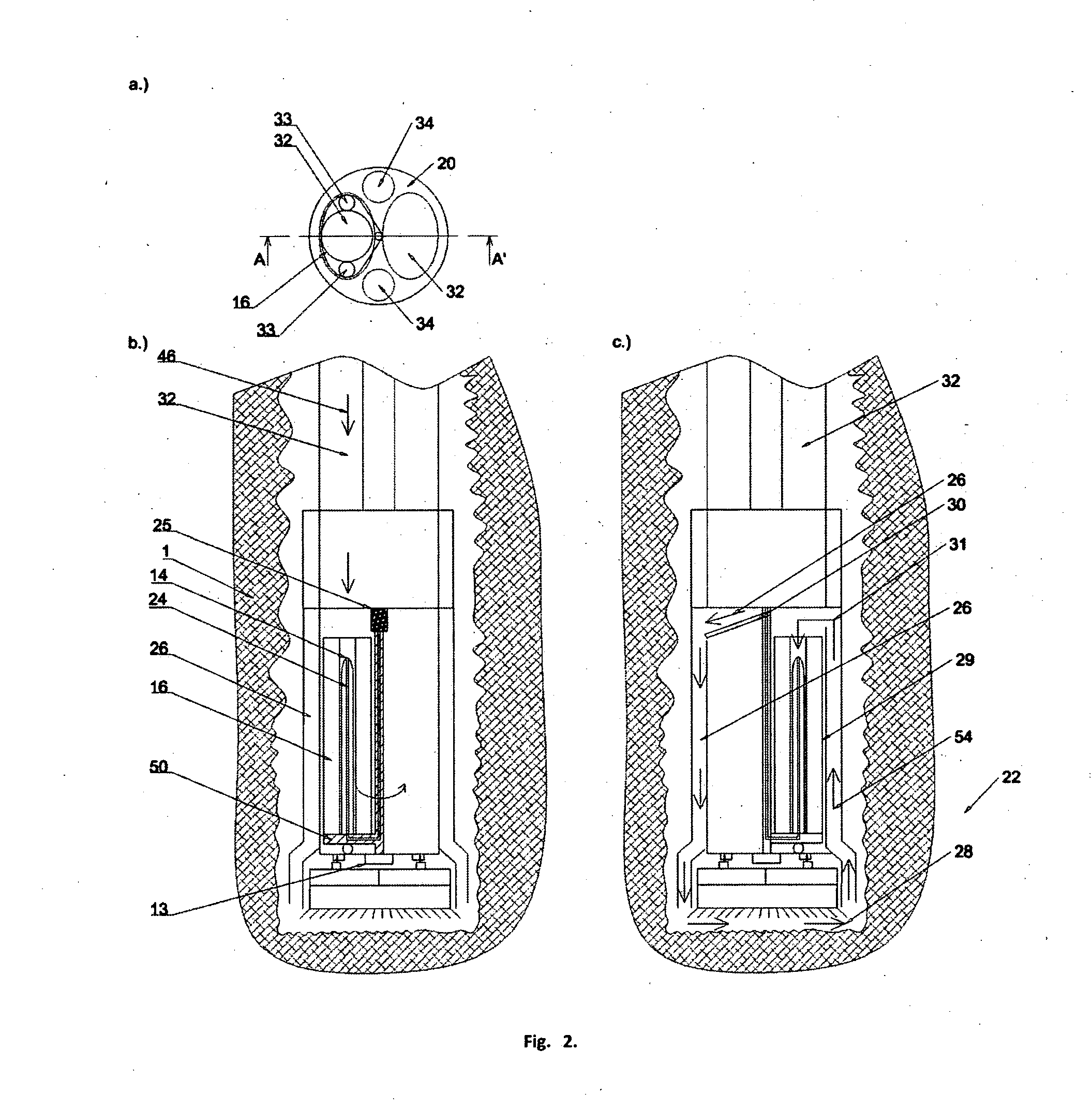

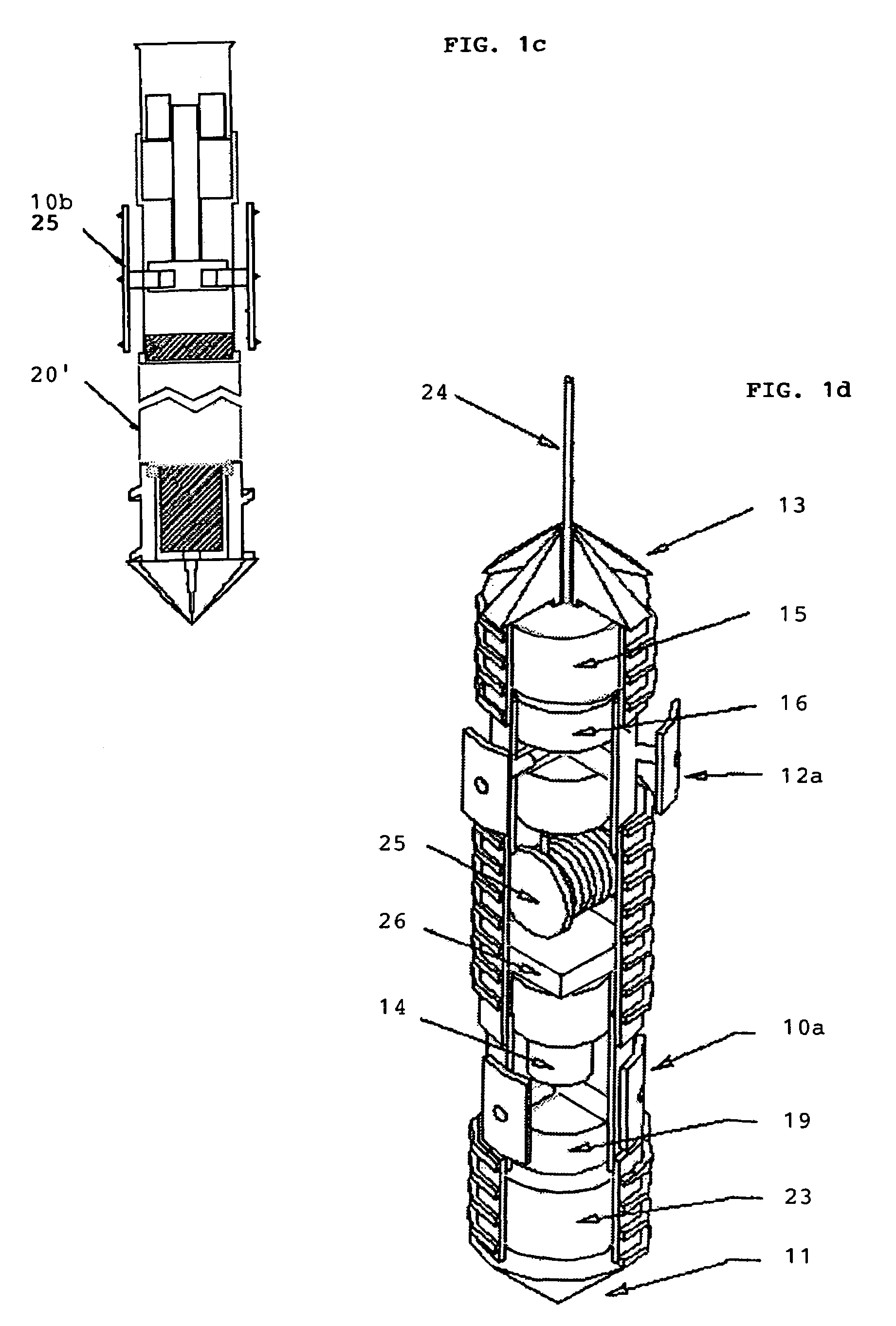

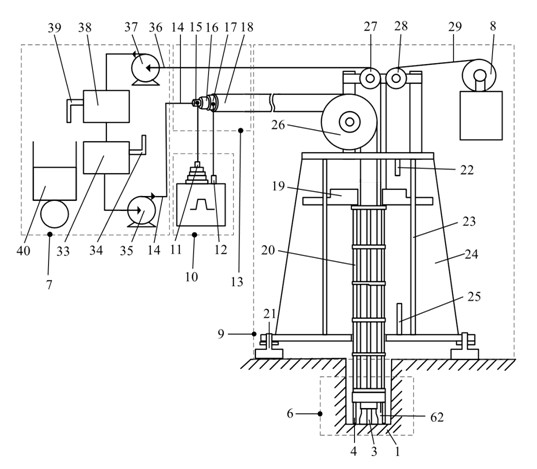

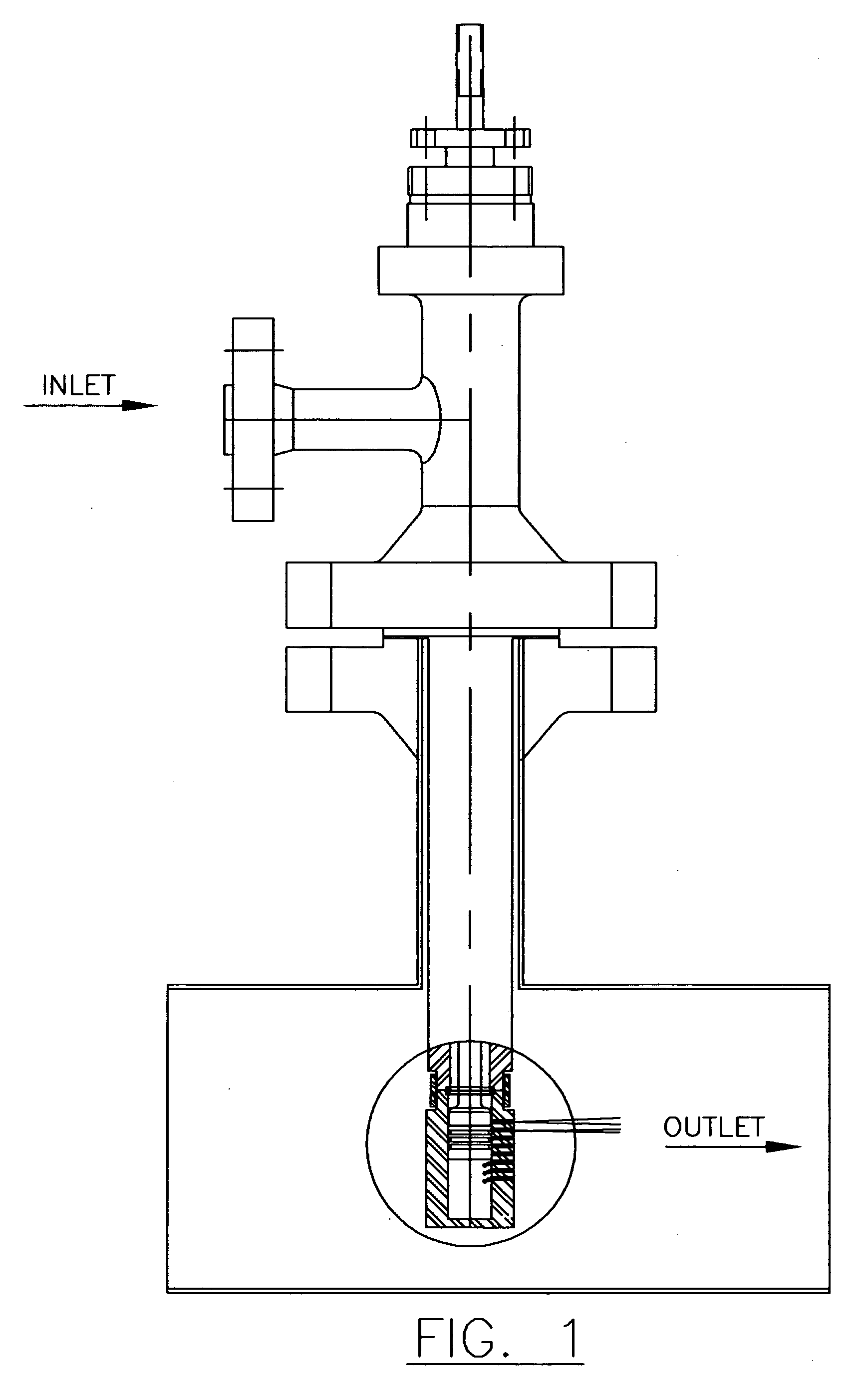

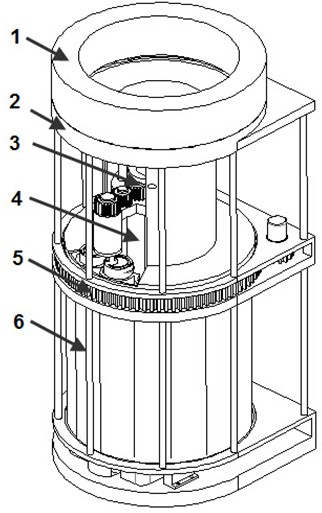

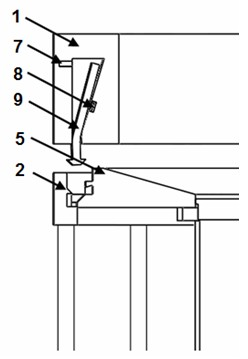

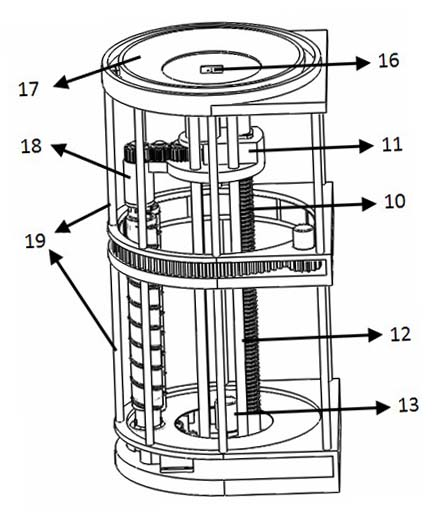

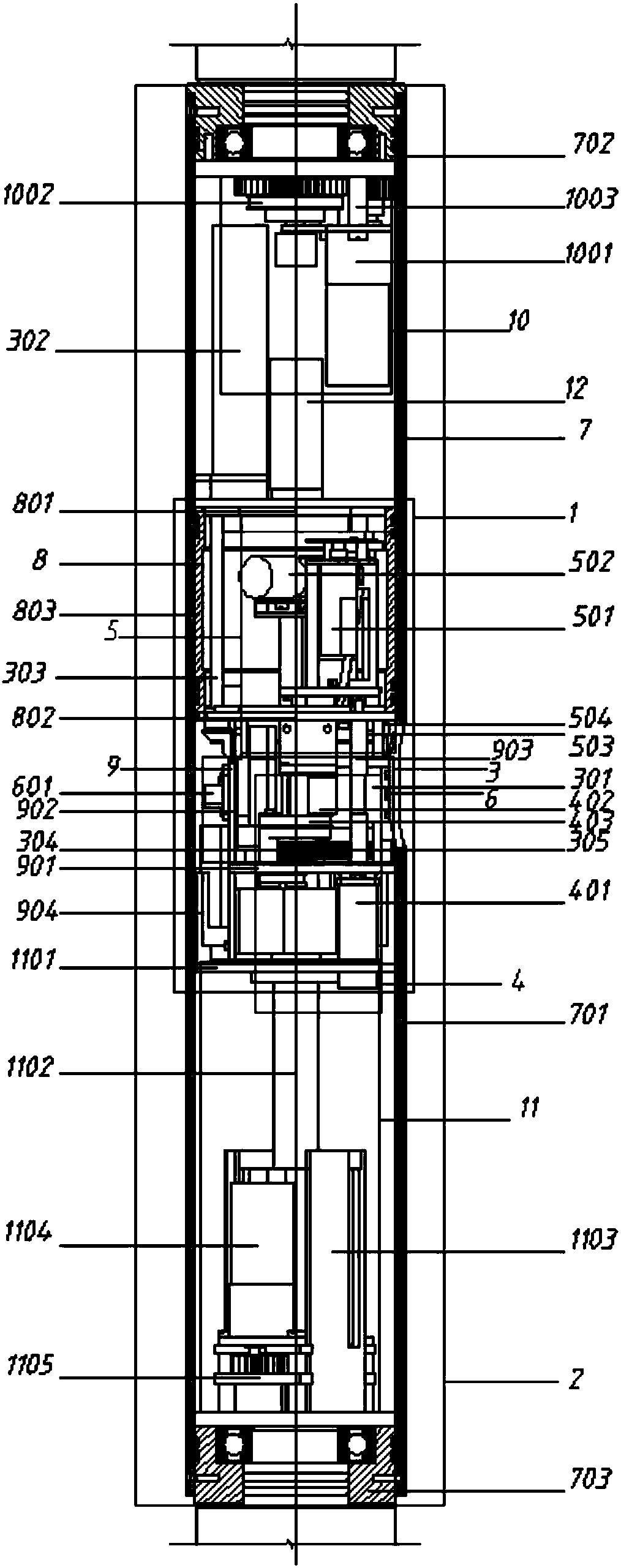

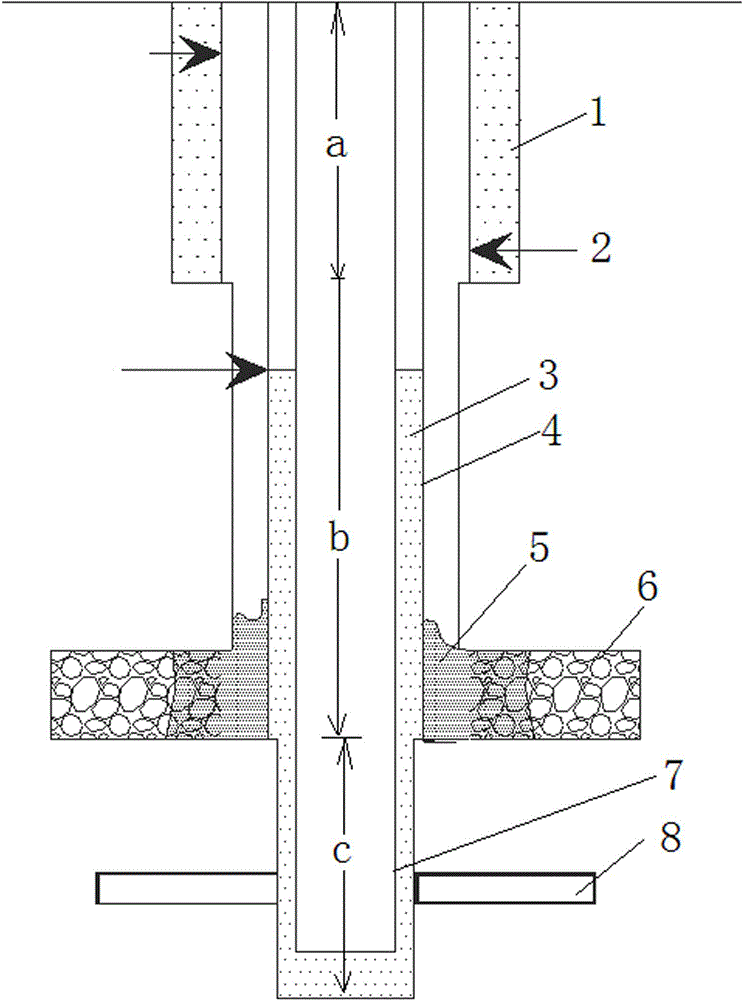

Device for performing deep drillings and method of performing deep drillings

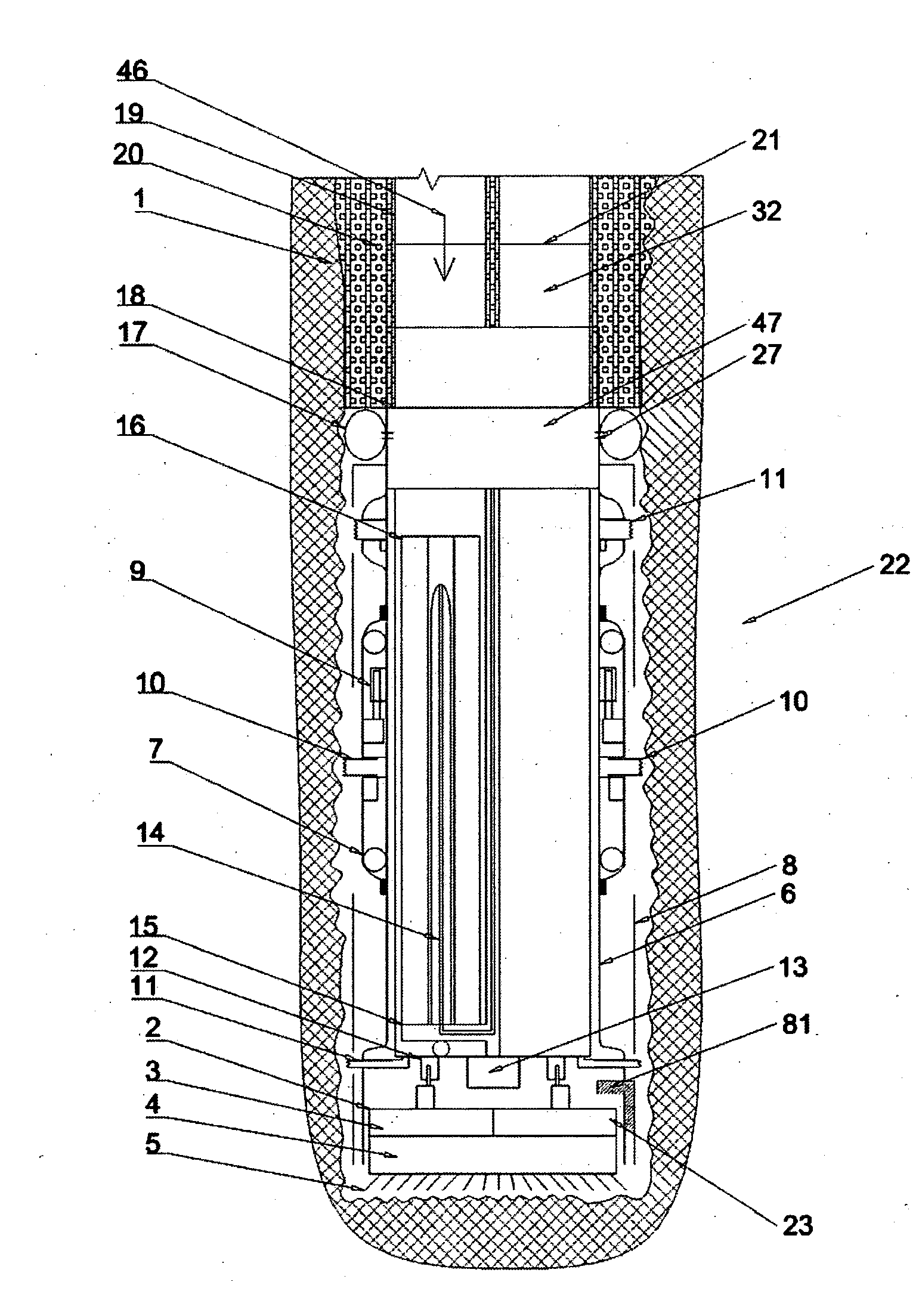

InactiveUS20110290563A1Improve equipment efficiencyRobotic multi-functional underground drilling platform can beDrilling rodsThermal drillingTransport infrastructureWater channel

Device for performing deep drillings, especially geothermal, may include a surface base, a borehole in a geological formation, filled with fluid, and a robotic multi-functional underground drilling platform, which contains especially a block (2) for crushing rock (1), a block for continuous formation of casing profile, a block of casing as transfer and transport infrastructure, a block (16) of transport container, a control and communication block (39), an energy block (4), a block of operating transport containers, and a block of removing and loading rock (1) from the place of crushing. The block (2) for rock crushing may be interconnected with block of removing and loading rock (1) from the place of crushing by means of water channels, ensuring removal of the crushed rock 107. The block of removing and loading rock (1) from the place of crushing may be interconnected with block (16) of transport container by means of water channels. The block of casing as transfer and transport infrastructure may be connected to block of continuous forming the casing profile by means of moving formworks.

Owner:GA DRILLING AS

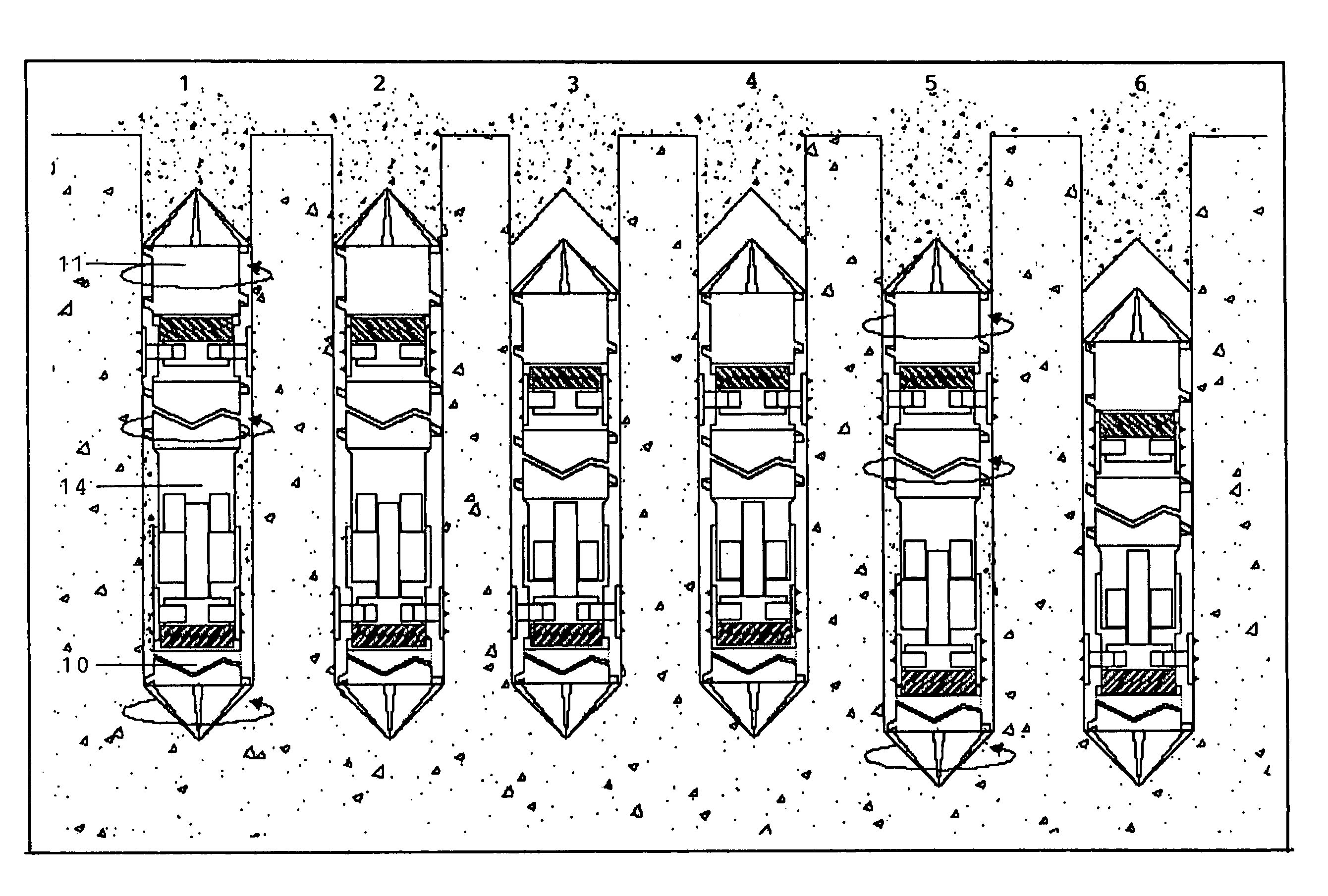

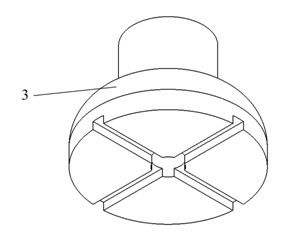

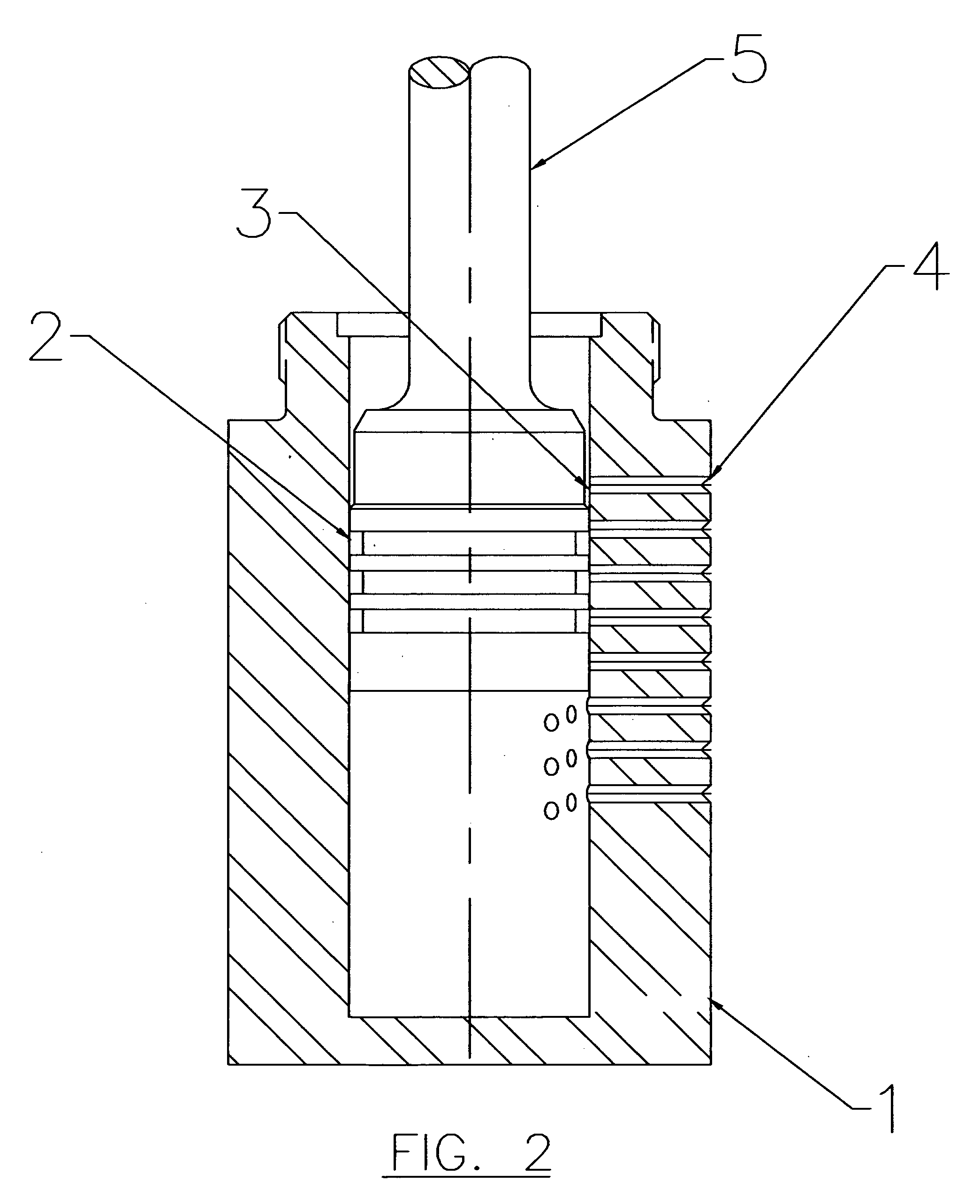

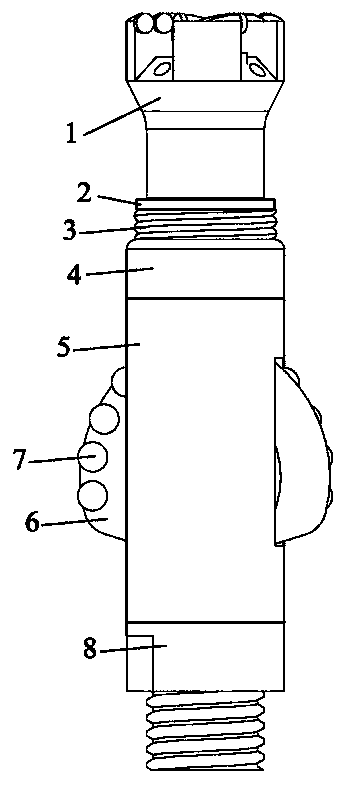

Self-propelled instrumented deep drilling system

InactiveUS7055625B1Improve mobilityEnergy self-sufficientDrilling rodsBorehole drivesOn boardAxial thrust

An autonomous subsurface drilling device has spaced-apart forward and rearward “feet” sections coupled to an axial thruster mechanism between them to operate using an inchworm method of mobility. In one embodiment, forward and rearward drill sections are carried on forward and rearward “feet” sections for drilling into material in the borehole in both forward and rearward directions, to allow the device to maneuver in any direction underground. In another embodiment, a front drill section has a drill head for cutting into the borehole and conveying cuttings through a center spine tube to an on-board depository for the cuttings. The feet sections of the device employ a foot scroll drive unit to provide radial thrust and synchronous motion to the feet for gripping the borehole wall. The axial thrust mechanism has a tandem set of thrusters in which the second thruster is used to provide the thrust needed for drilling, but not walking. A steering mechanism composed of concentric inner and outer eccentric rings provided with the rearward feet section allow small corrections in both direction and magnitude to the drilling direction as drilling commences.

Owner:HONEYBEE ROBOTICS

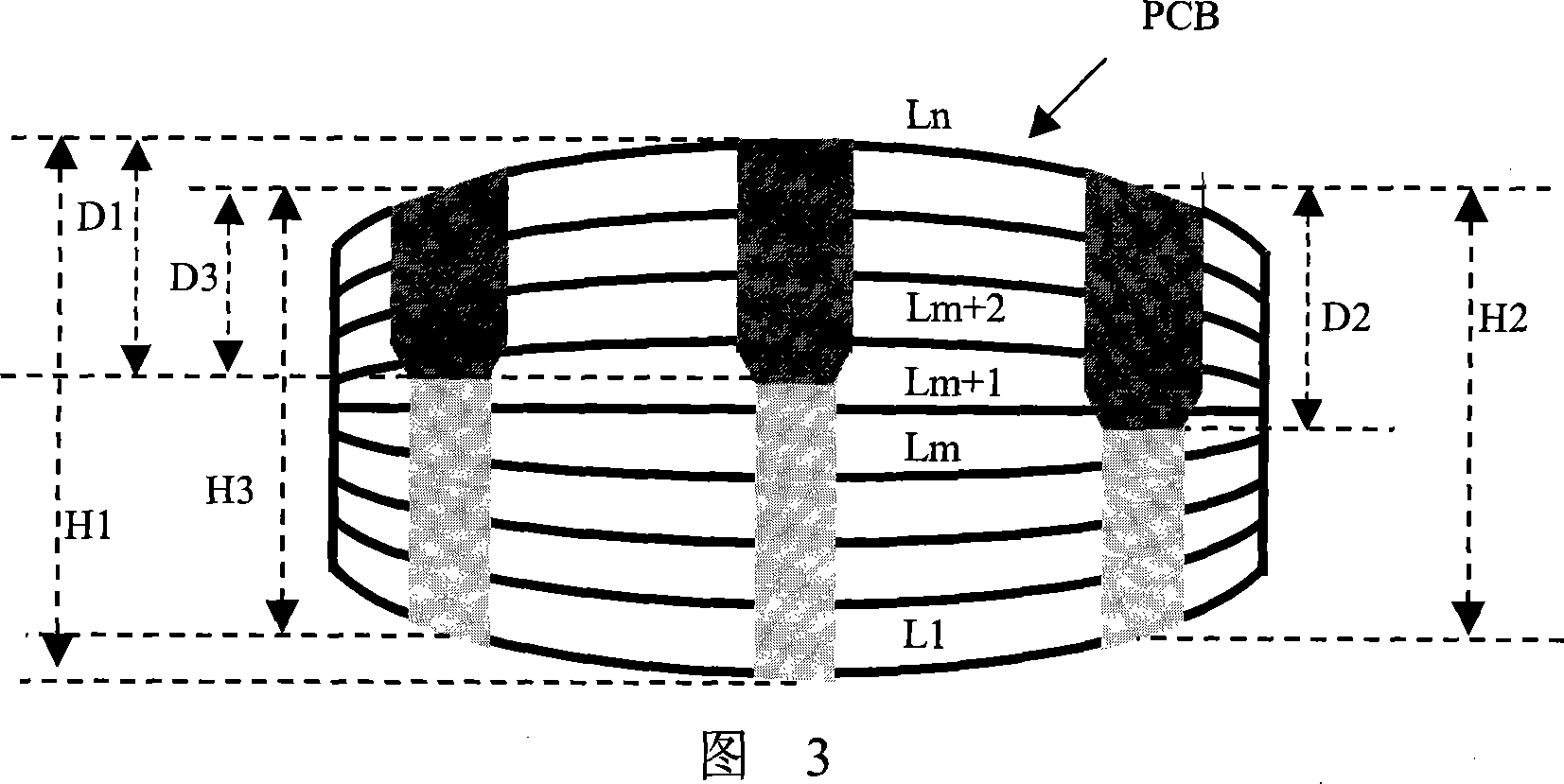

Method for drilling deep hole and PCB product obtained by same method

InactiveCN1787726AControl drilling depthReduce the impactConductive material mechanical removalEngineeringControl software

This invention discloses a new method for deep drilling and PCB products got from it, which sets the platform control loop on the POWER layer in the board and begins computing the designed depth from the place contacting the POWER by the drilling pin or drills the test holes of Z1,Z2 and Z3 on the necessary drilled regions of the upper surface, the upper target layer and the lower target layer then adds G87, G88 and G89 functional instructions on the control software of the platform to detect the depth values of Z1 and Z2 and judges the drilled depth value based on their positions, finally the platform adds a compensation value of a drill point to the depth of (Z2+Z3) / 2 to drill.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

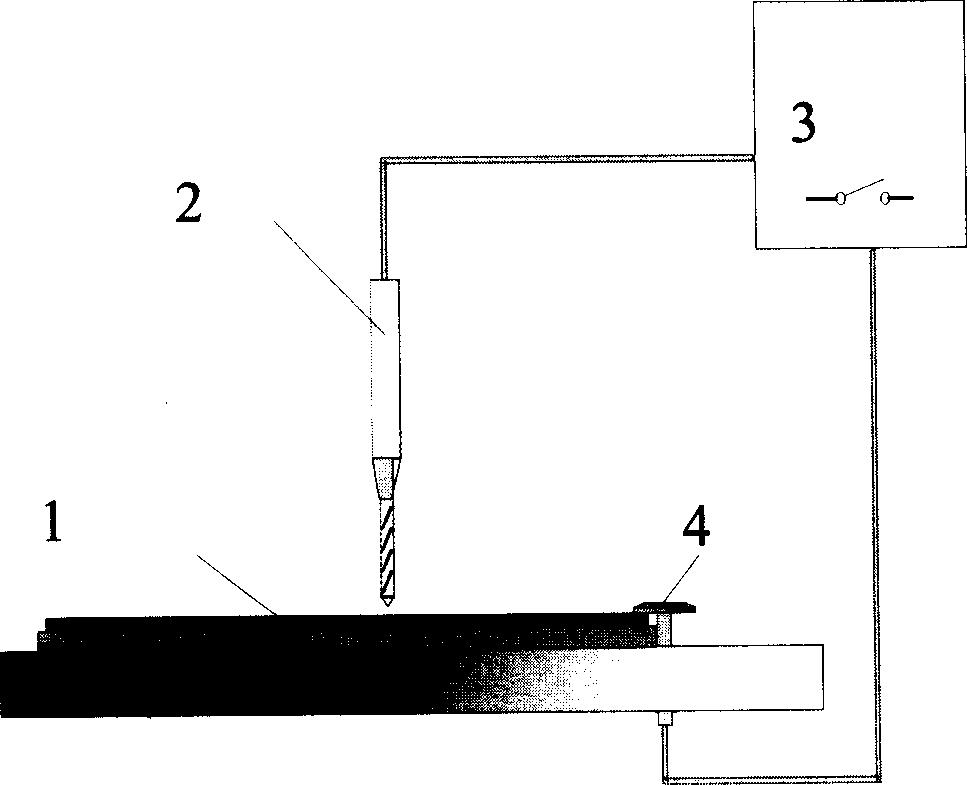

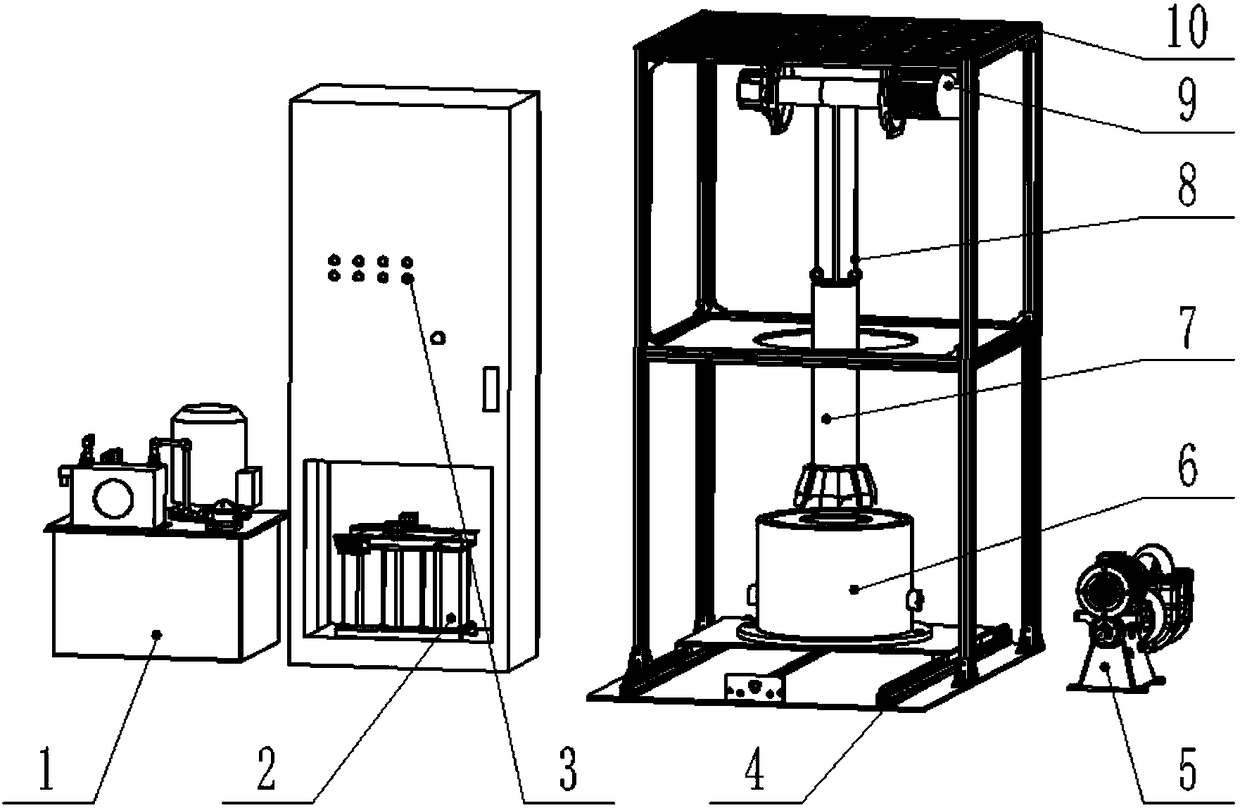

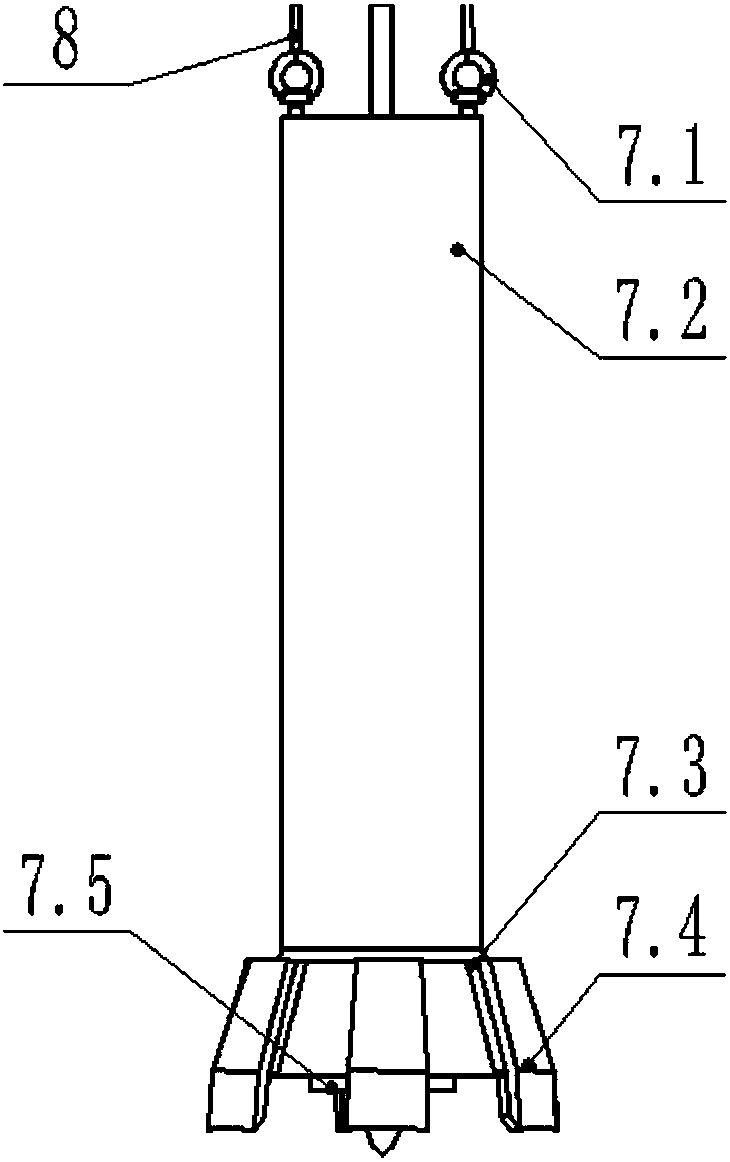

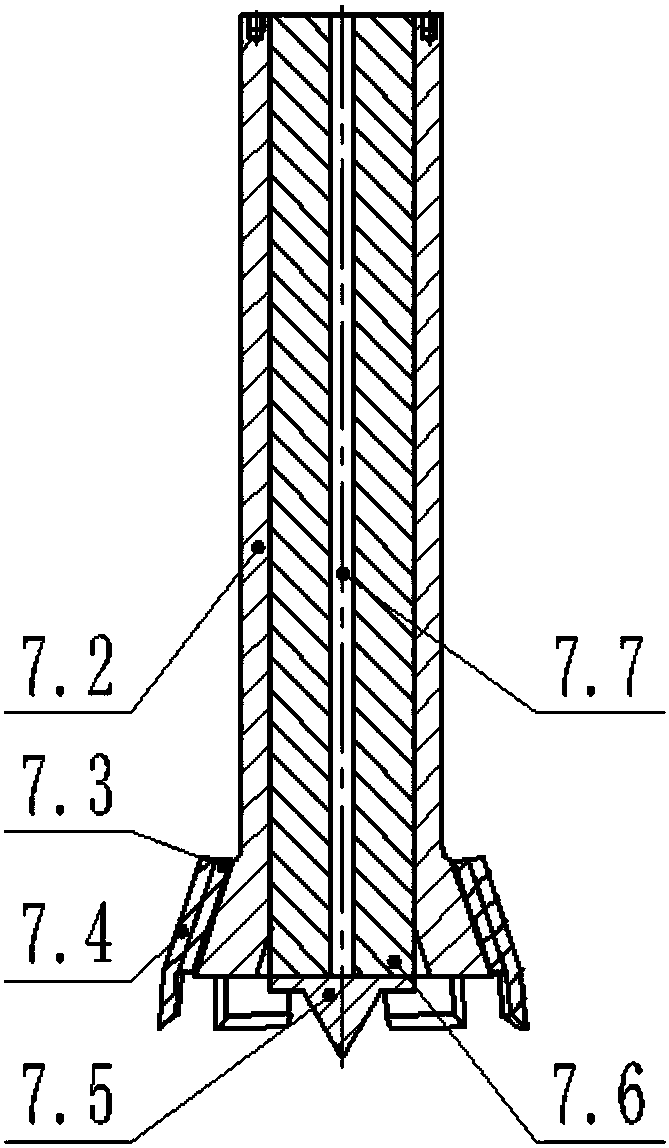

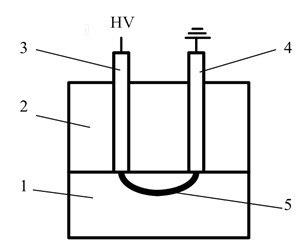

Electric pulse rock-breaking dill bit and experimental facility thereof

ActiveCN108222838AImprove energy efficiencyImprove drilling qualityMachine part testingDrill bitsLow voltageElectrical impulse

The invention discloses an electric pulse rock-breaking dill bit and an experimental facility thereof. The electric pulse rock-breaking experimental facility comprises a confining pressure pumping station, a pulsed power supply, a PLC control device, a confining pressure cylinder horizontal-moving device, a water inlet and outlet pump, a confining pressure cylinder assembly, a high-pressure electric pulse rock-breaking drill bit body, and the like. The high-voltage pulsed power supply is used for transmitting high-voltage pulse electricity from a high voltage electrode to a low voltage electrode through a cable, the high-voltage pulse electricity meeting certain conditions breaks through rocks firstly to generate a discharge channel, a plasma channel expands when heated, when the pressureexceeds the stress intensity of the rocks, and the rocks are broken and the high-voltage pulse discharge drilling is realized. The high-pressure electric pulse rock-breaking experimental facility cansimulate the high voltage environment of deep drilling in the earth, electric pulse drilling experiments carried out on high temperature and high pressure deep wells and ultra-deep wells are more close to actual drilling environments, experimental studies on the geometrical shape, distribution, spacing and electrode materials of electrodes of high-voltage electric pulse rock-breaking drill bit inthe deep wells and the ultra-deep wells can be realized, and the high-voltage pulse discharge drilling has broad development prospects.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

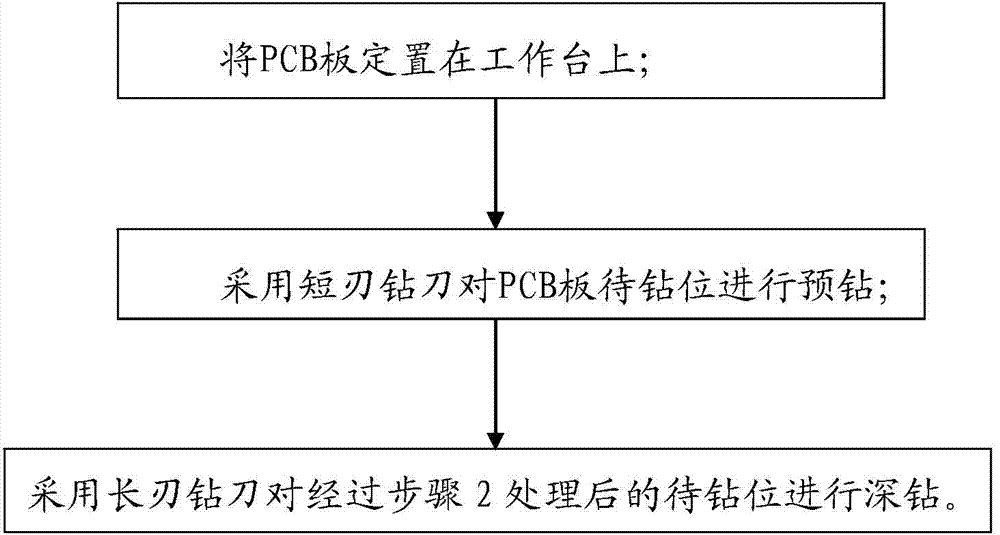

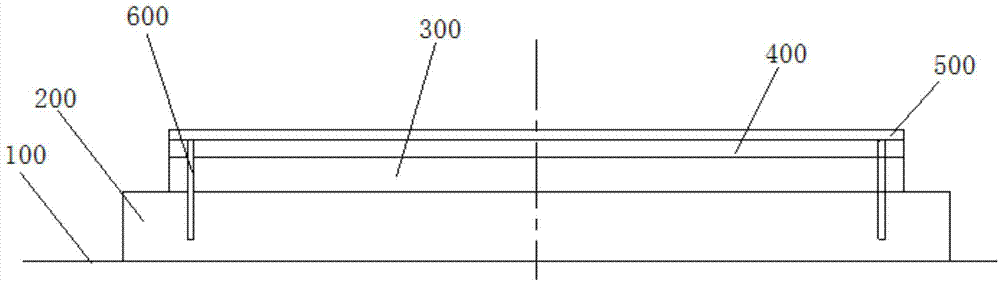

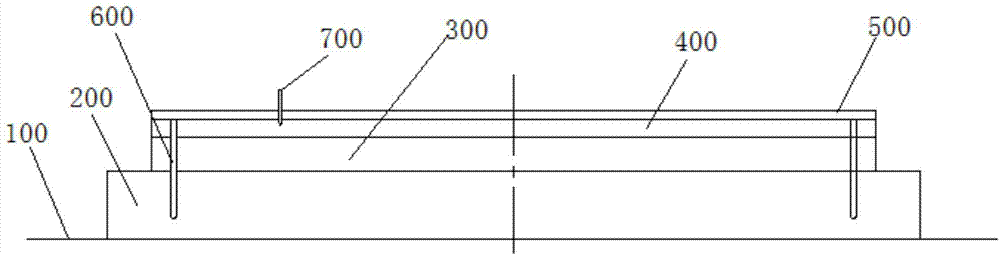

Drilling method for achieving PCB high hole-site precision

ActiveCN103786189AImprove rigidityAvoid the influence of hole position accuracyPrinted circuit manufactureMetal working apparatusHole drilling methodDeep drilling

The invention discloses a drilling method for achieving PCB high hole-site precision. The method comprises the following steps that firstly, a PCB is fixed on a workbench, secondly, the position to be drilled on the PCB is pre-drilled through a short-blade drilling tool, and thirdly, the position, to be drilled, processed in the second step is deep drilled through a long-blade drilling tool. The operation is easy and convenient and cost is low. The PCB is fixed in the first step, so that the PCB does not move during the drilling process, and the drilling precision cannot be affected. The position to be drilled on the PCB is pre-drilled through the short-blade drilling tool in the second step, and the rigidity of the short-blade drilling tool is better relative to the long-blade drilling tool, so that in the moment that the short-blade drilling tool makes contact with a PCB surface, the short-blade drilling tool is not prone to sliding. The position, to be drilled, processed in the second step is deep drilled through the long-blade drilling tool, the lateral sliding of the long-blade drilling tool during the drilling process is reduced, and therefore the drilling alignment of the long-blade drilling tool during the deep drilling process is guaranteed, and the drilled hole site can meet the requirement for the PCB high hole-site precision.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

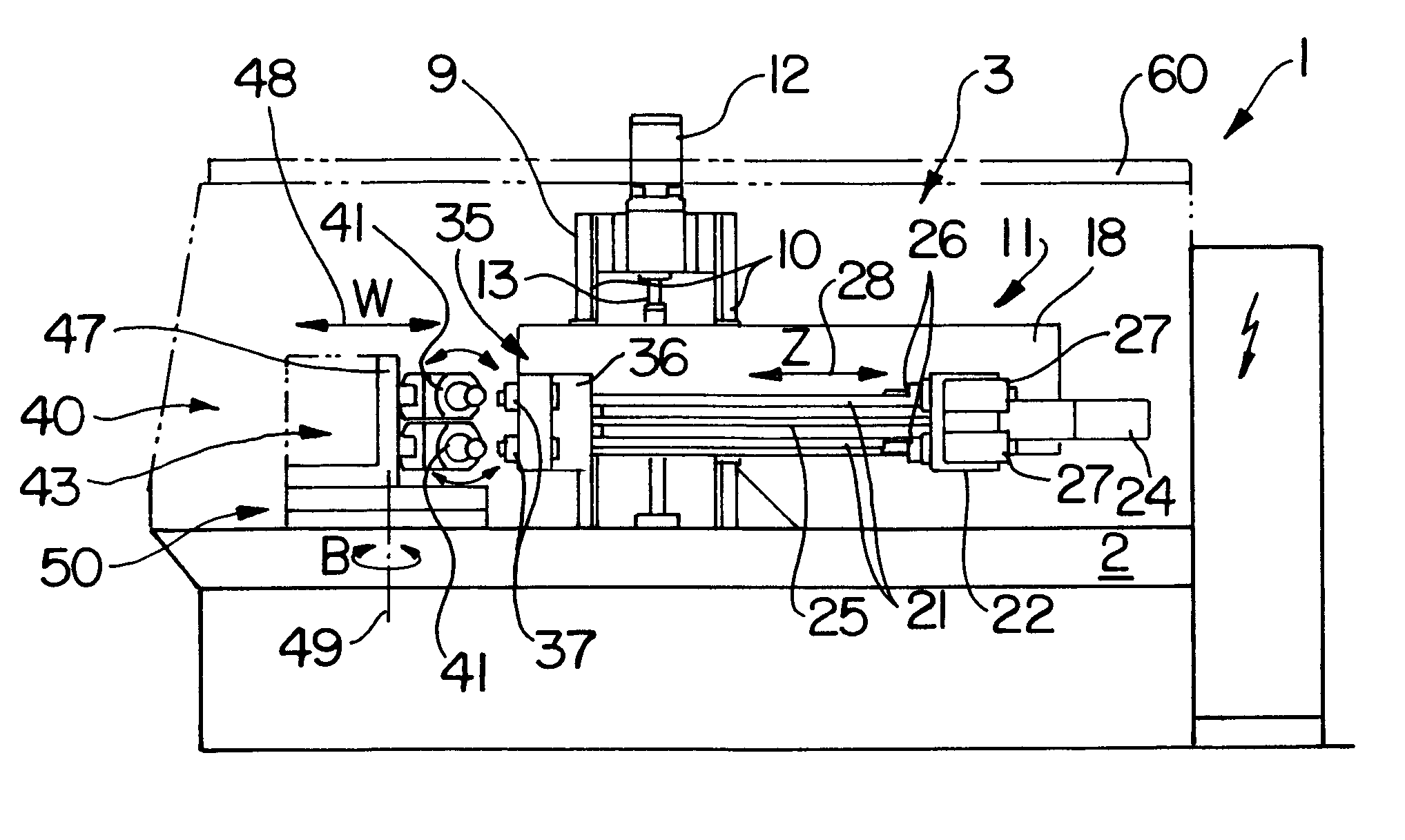

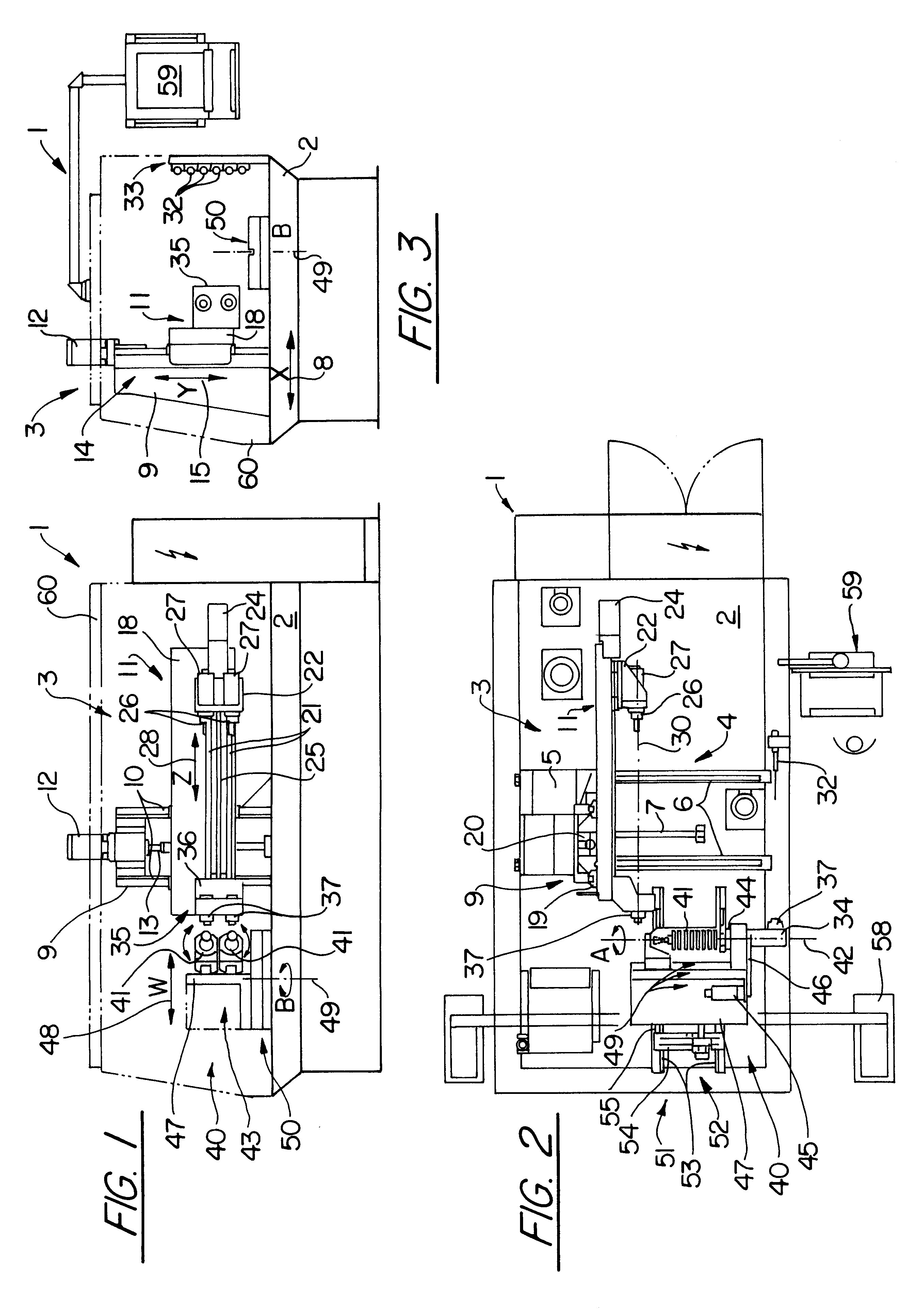

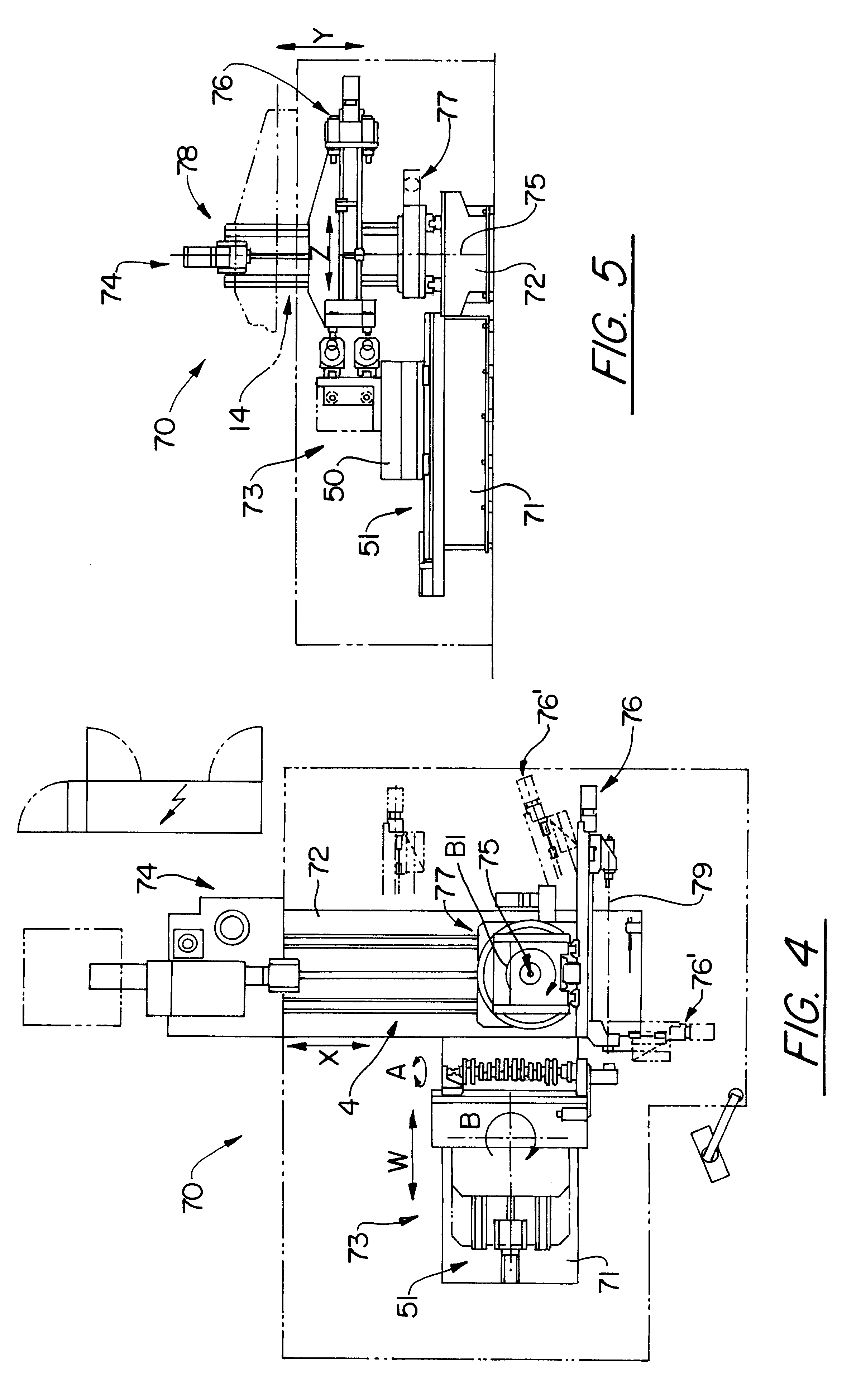

Deep drilling device

InactiveUS6287245B1Improve productivityLarge movementAutomatic control devicesRevolution surface grinding machinesEngineeringMechanical engineering

A deep drilling device suitable for drilling in workpieces, particularly crankshafts, holes at different positions and / or in different orientations relative to a work longitudinal axis, has a deep drilling unit and a work holding unit cooperating therewith. The deep drilling unit permits parallel displacements of the deep drilling tools in a horizontal X direction and a vertical Y direction, as well as a tool feed parallel to the spindle axis. The tool holding device receives one or more crankshafts in such a way that their longitudinal axis is horizontally oriented and permits a rotation about the longitudinal axis and a swivelling of the workpieces about a vertical rotary axis. As a result both different tilt angles of the holes relative to the work longitudinal axis and also different positions of the holes relative to the circumference of the workpieces can be obtained.

Owner:TBT TIEFBOHRTECHN

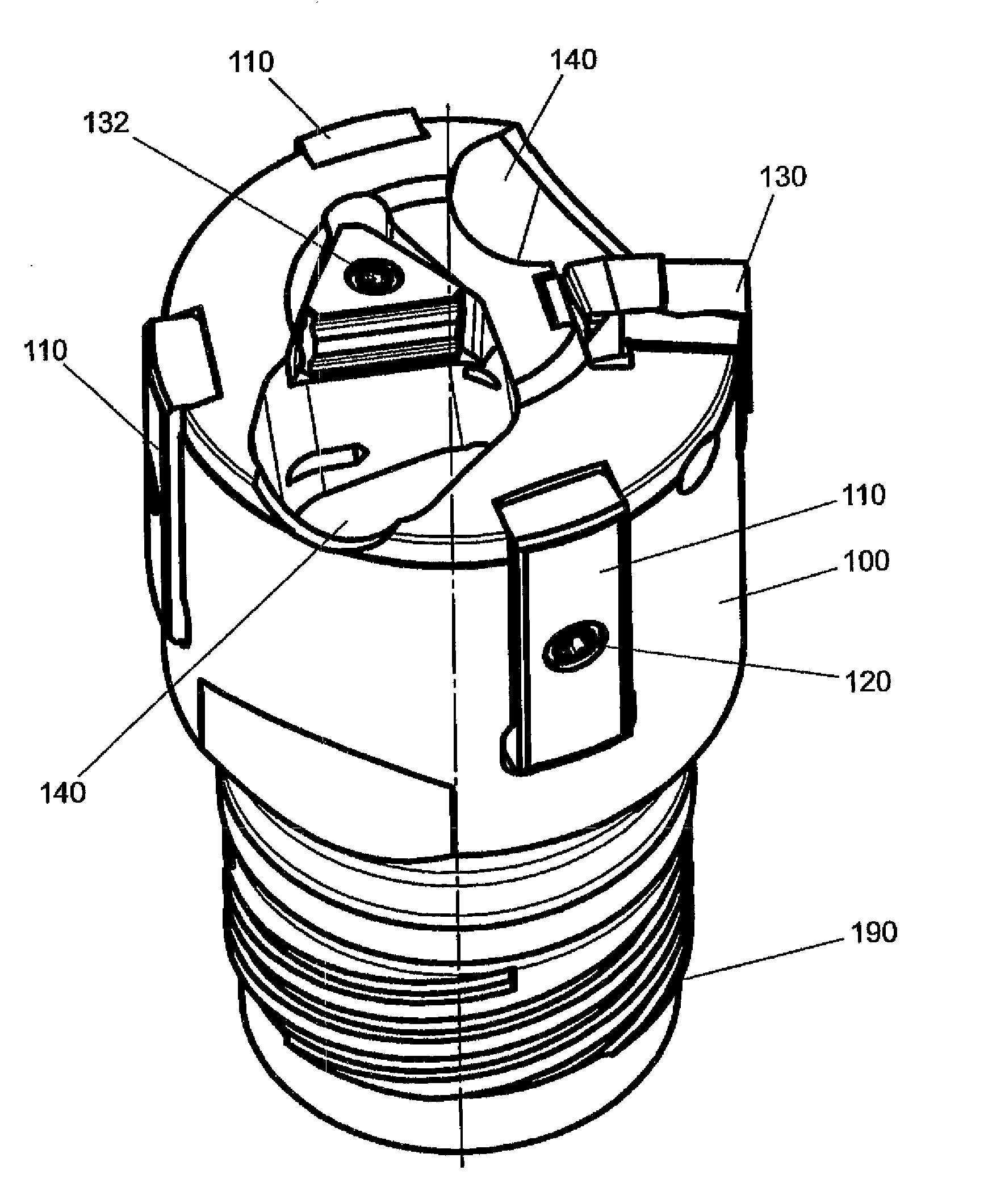

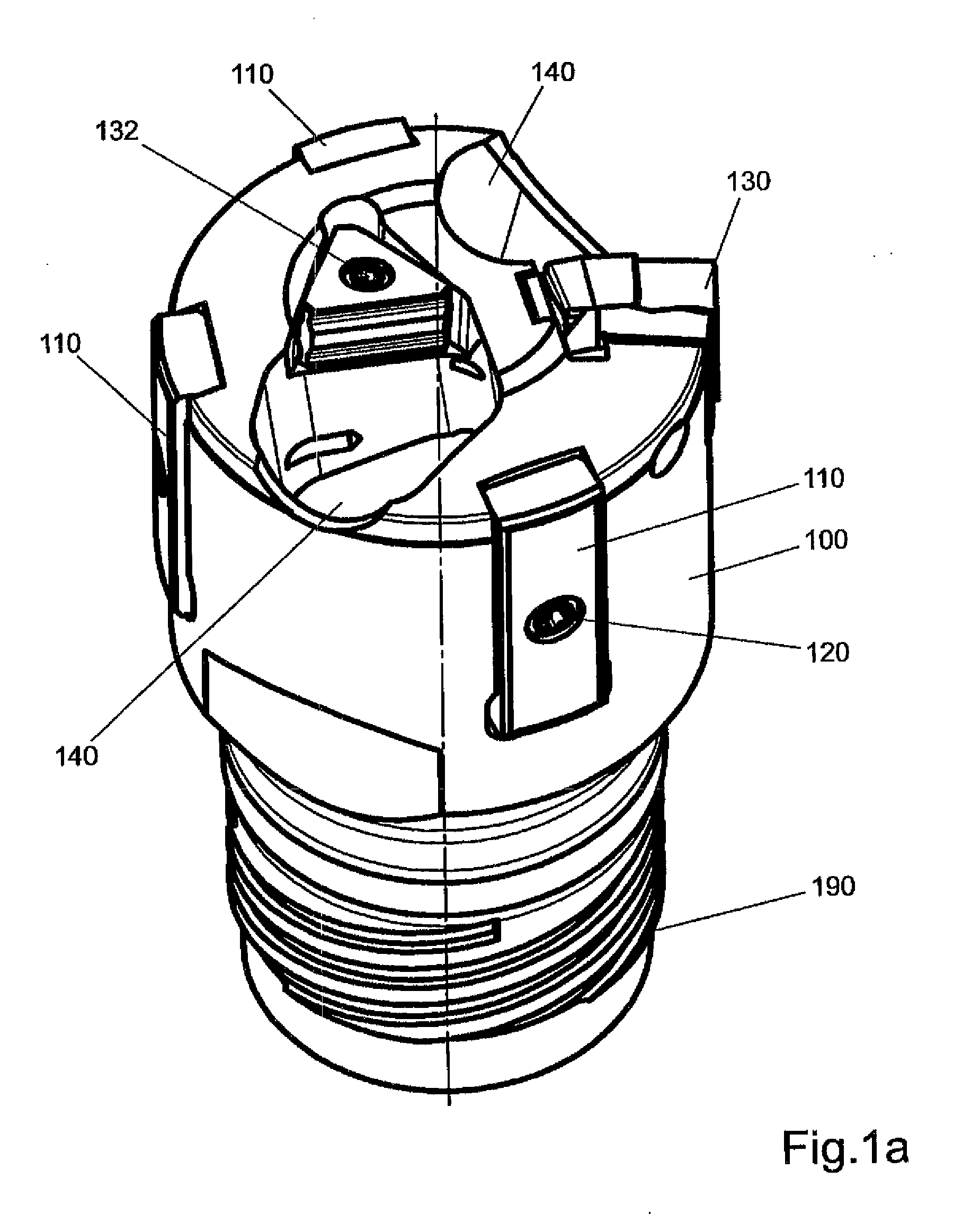

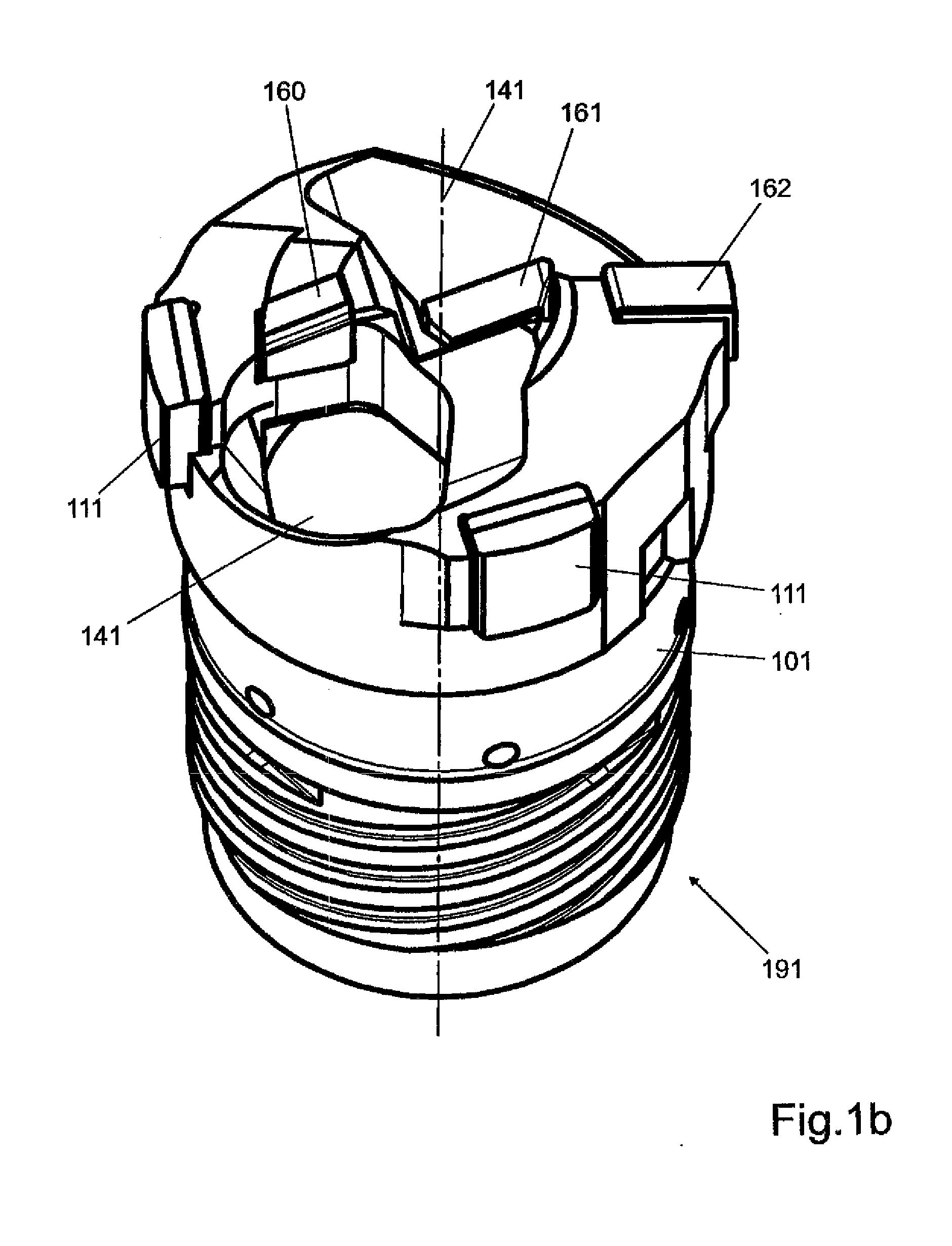

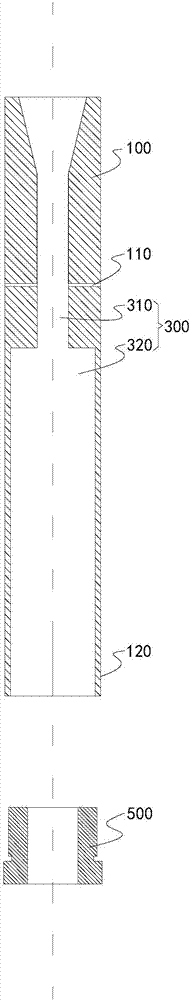

Guide pad

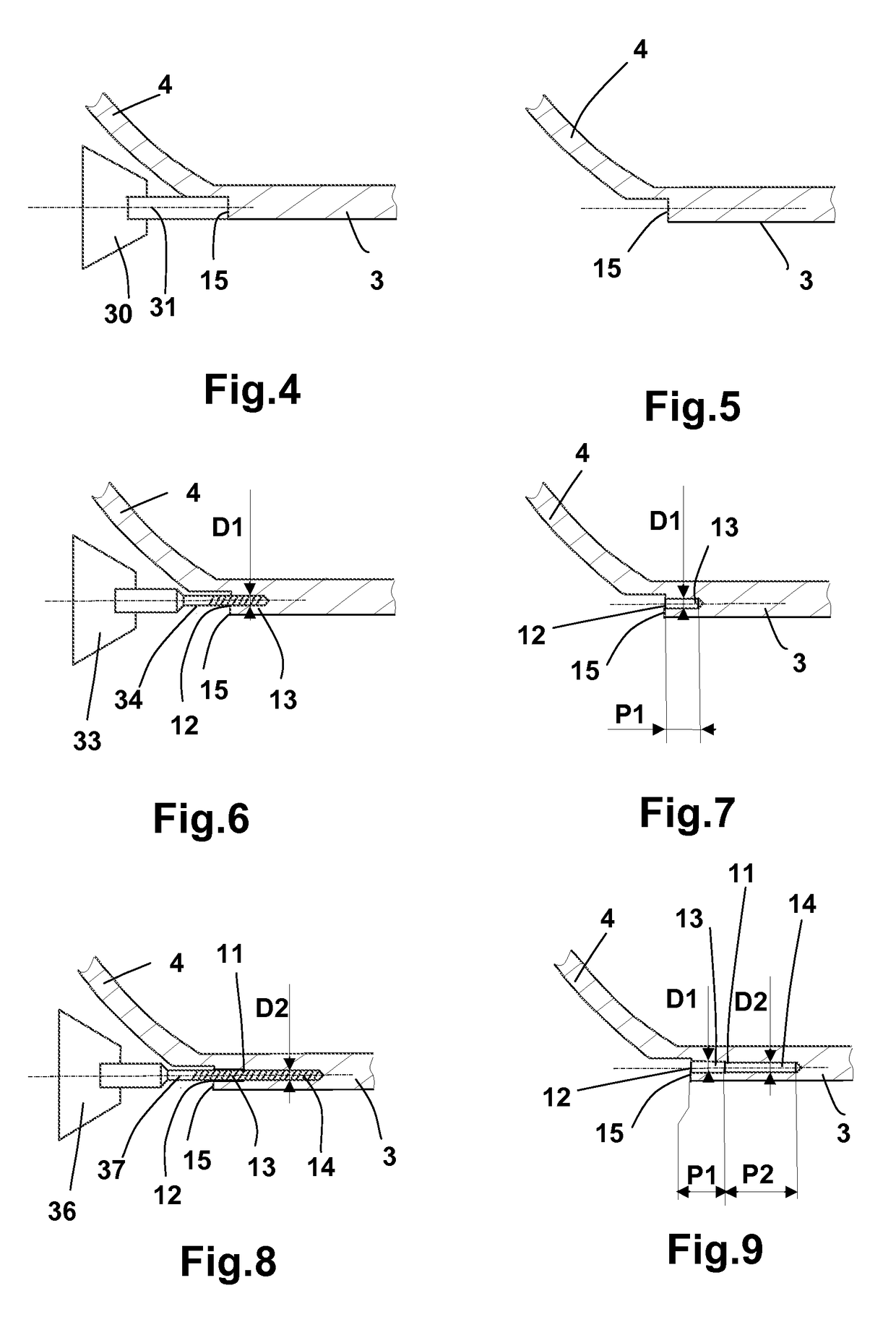

ActiveUS20130051944A1Convenient ArrangementAchieve improvementDrilling/boring measurement devicesThread cutting machinesEngineeringMechanical engineering

A guide gib (500) for a deep drilling tool of a substantially rectangular shape with a longitudinal direction (L) and a width (B) and with at least one sliding surface (540) is characterized in that at least one lubricating groove, preferably a plurality of lubricating grooves (501, 502), is / are arranged at least in the region of a contact zone of the sliding surface.

Owner:BOTEK PRAEZISIONSBOHRTECHNIK GMBH

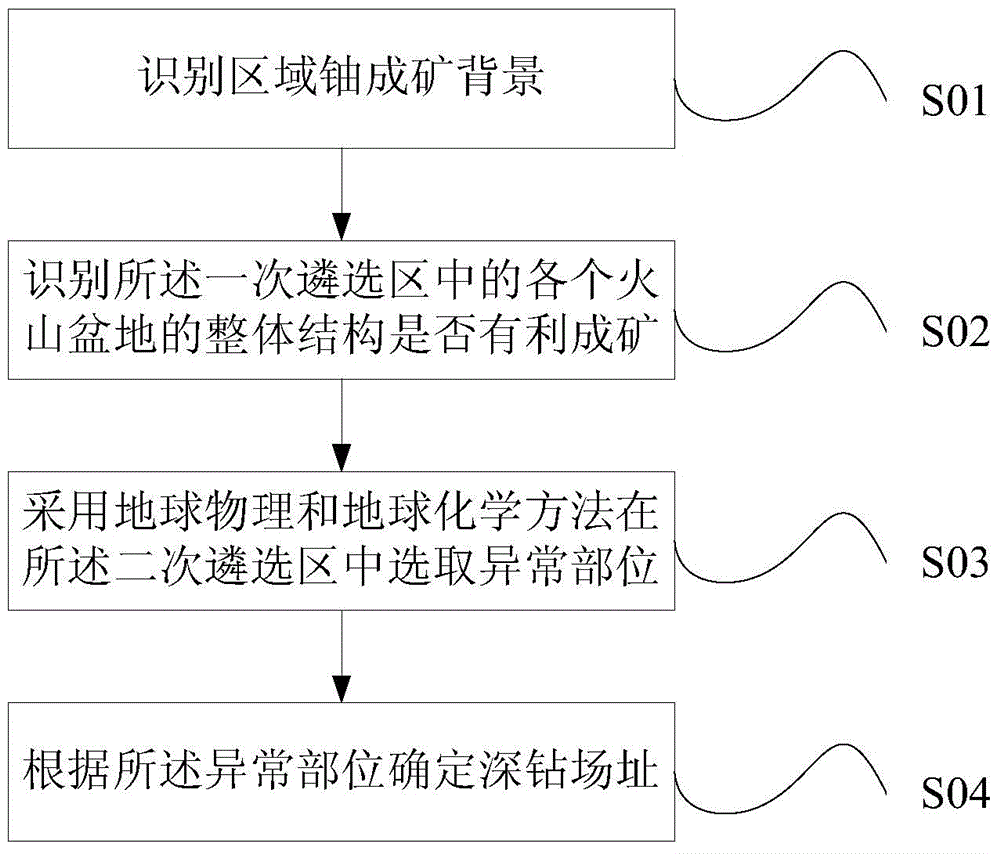

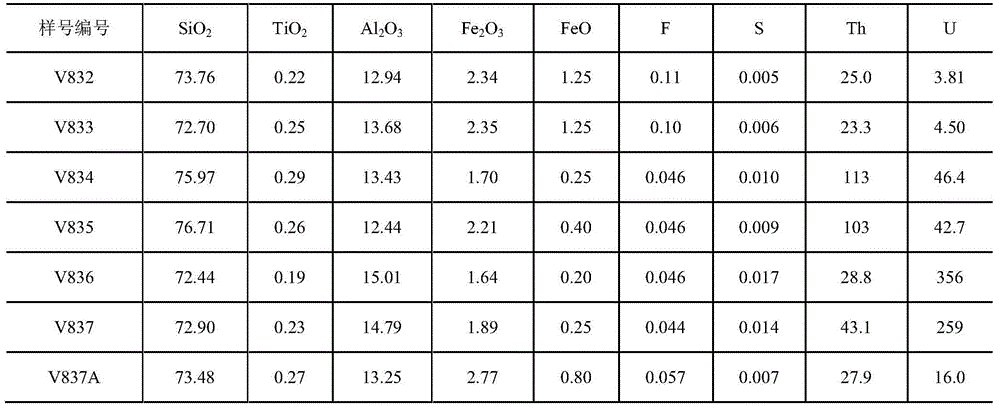

Scientific deep drilling site selection method of volcanic type uranium ore field

ActiveCN105549113ASmooth surveySuccessful research workGeological measurementsAbnormal positionsUranium mineralization

The invention discloses a scientific deep drilling site selection method of a volcanic type uranium ore field. The method includes following steps: S01: recognizing an area uranium mineralization background, and screening an area with good uranium mineralization background as a primary selection area via the recognition of the area uranium mineralization background; S02: recognizing whether the overall structure of each volcanic basin in the primary selection area is good for mineralization, and recognizing at least one volcanic basin whose overall structure is good for mineralization in the primary selection area as a secondary selection area; S03: selecting abnormal positions in the secondary selection area by employing geophysical and geochemical methods; and S04: determining the deep drilling site according to the abnormal positions. According to the selection method, the range is gradually reduced from large to small, the deep drilling site is determined, the process is clear, the implementation is convenient, and the deep drilling construction of the deep drilling site determined by the method can strongly guarantee smooth operation of uranium ore exploration and research work.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

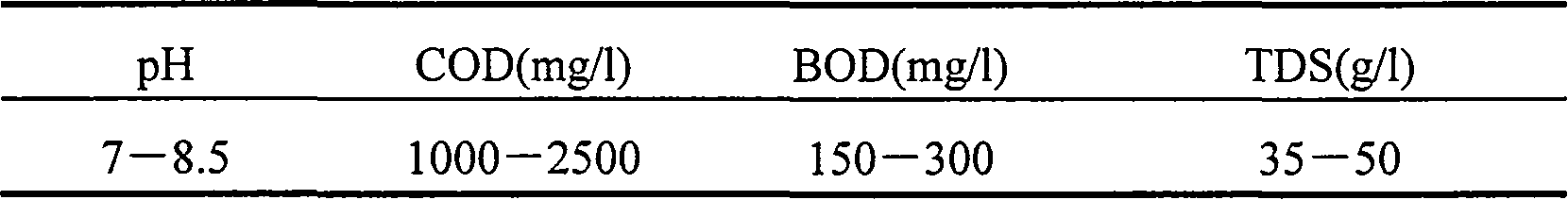

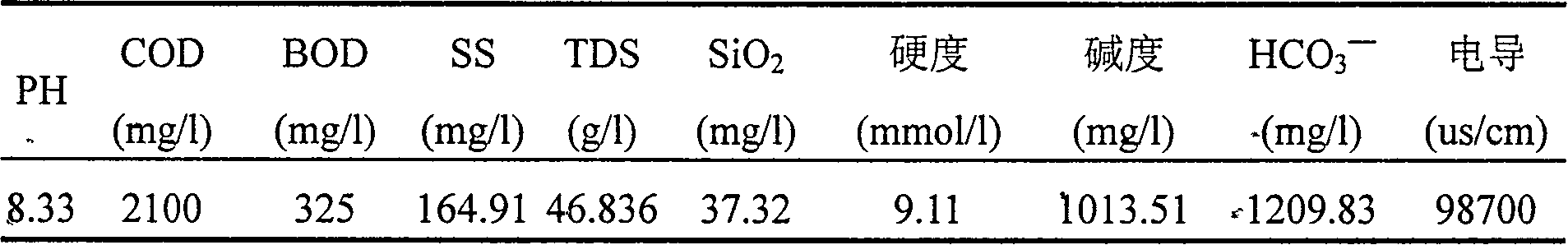

Technique for treating sewage of high well and deep drilling well

ActiveCN101190822AReduce the impactLow running costMultistage water/sewage treatmentWater/sewage treatment by neutralisationWell drillingDisposal Technique

The invention relates to a treating technique used in sewage of high well and deep bore well, which employs the treating technique that focuses on coagulating sedimentation, first stage oxidation, biological treatment and second stage oxidation and assisted by the deep treating technique of solid-liquid separation, acid-base adjustment and second stage oxidation. After going through the treatment with the treating technique provided by the invention for the sewage of high well and deep bore well, the well water can reach national sewage discharge standard (GB8378-1996). The treating technique provided by the invention can not only reduce the influence of waste discharge on environment, but also save operation cost.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

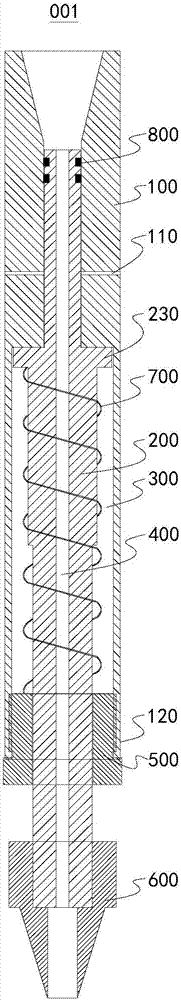

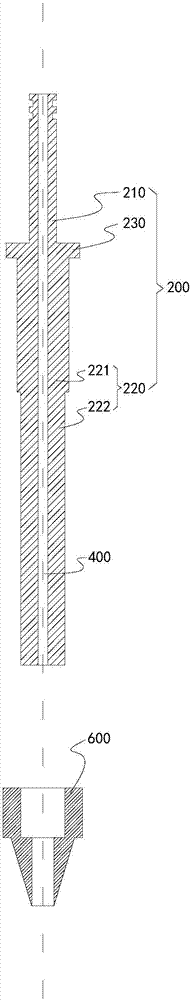

Well drilling rod and pulse plasma drilling machine system

InactiveCN102678044AAvoid problems such as collapseSimple structureDrilling rodsDrilling casingsWell drillingHigh pressure

The invention discloses a well drilling rod and a pulse plasma drilling machine system. The well drilling rod comprises at least one well drilling rod unit, wherein each well drilling rod unit comprises at least two open-close type support rings and a connecting rod; two adjacent support rings are fixedly connected through one connecting rod; the well drilling rod units are connected in sequence; and two adjacent support rings of two adjacent well drilling units are fixedly connected. The well drilling machine system comprises a well drilling mechanism comprising the well drilling rod, a high-pressure pulse power supply, a high-pressure low-wave impedance coaxial water cable, a water circulating device and a drill bit electrode for discharging towards rock stone, so that the drill bit electrode can be always contacted with the rock stone and keep drilling vertically downwards, and the problems of collapse of a water pipe and a cable and the like occurring during deep drilling in the conventional plasma drilling machine are avoided simultaneously; and moreover, the length of the well drilling rod is adjusted by increasing or decreasing the well drilling rod units, so that well drilling of different depths can be realized.

Owner:ZHEJIANG UNIV

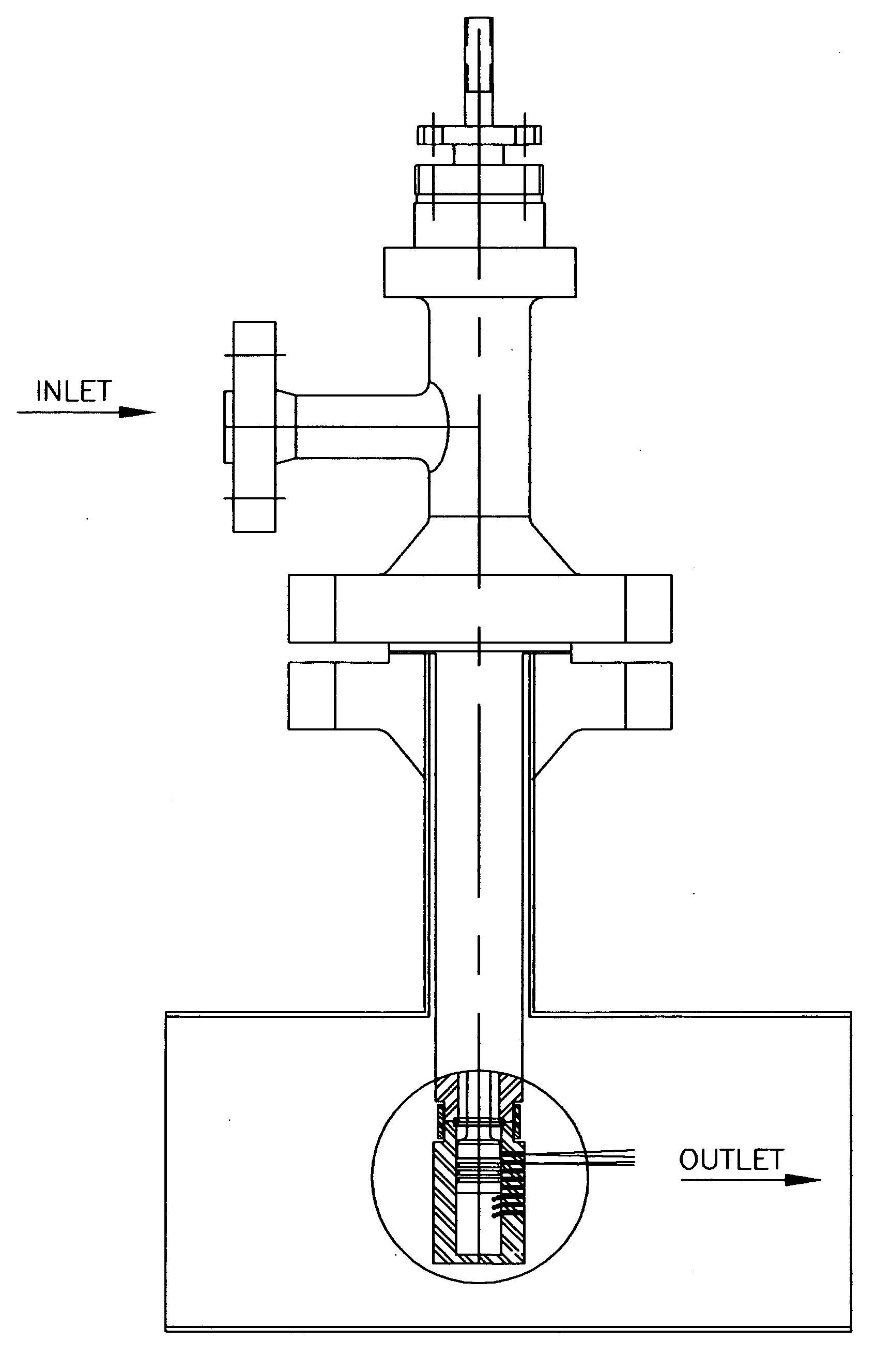

One piece liquid injection spray cylinder/nozzle

A one piece spray cylinder / nozzle, with integrally machined nozzles, for use on a high pressure and temperature, probe style, variable nozzle, gas and steam coolers. The nozzle holes can be made by deep drilling techniques such as laser, gun drilling and others methods that produce a hole, with a diameter to depth ratio of less than 1:3. No separately machined nozzles are used. On the outlet end of the nozzle (on the outside of the cylinder only), there are surface machining treatments to produce small, controllable liquid droplets that vaporize quickly into the gas or vapor stream. The spray cylinder bore can be coated, lined or hard faced to resist the ware of the piston rings sliding in it without adding stresses to the spray cylinder body at braze and weld joints. The flow and patterns and valve characteristics can be modified.

Owner:BAUER CHARLES GUSTAV

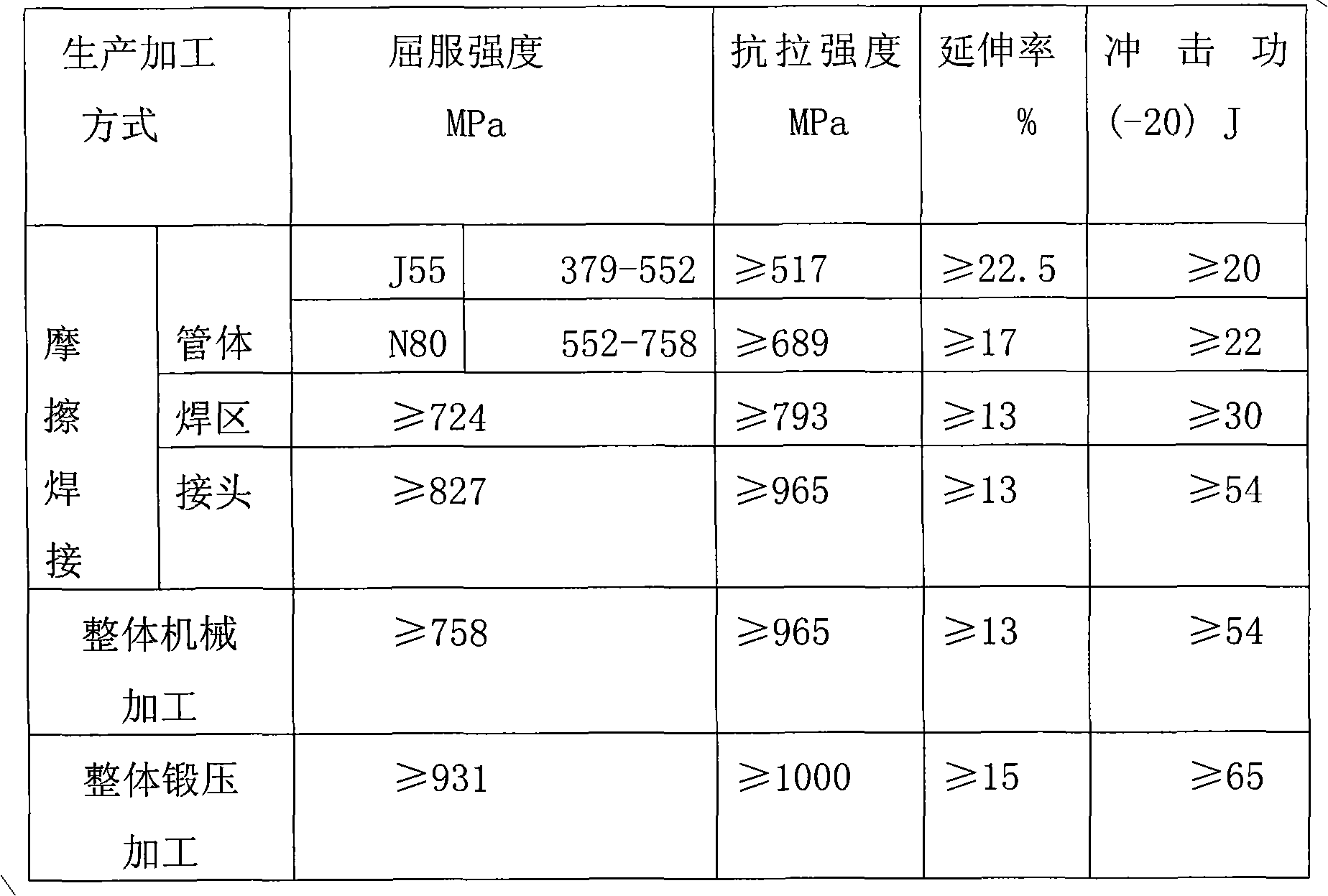

120 steel grade drill pipe and manufacturing process method thereof

InactiveCN101581200AImprove mechanical propertiesHigh strengthDrilling rodsSolid state diffusion coatingButt weldingChemical composition

The invention relates to a 120 steel grade drill pipe and a manufacturing process method thereof. A pipe body of the 120 steel grade drill pipe is made of 27CrMnMo, and subs are made of AISI4137HM, wherein the subs comprise the following chemical compositions by mass percentage: less than or equal to 0.40 percent of C, less than or equal to 0.015 percent of S, less than or equal to 0.010 percent of P, less than or equal to 0.009 percent of N, and less than or equal to 0.005 percent of B, sizes of the pin and box subs are the same as that of a G105 drilling tool, and mechanical properties respectively comprise that: the yield strength is between 130 and 150Ksi, the elongation rate is more than or equal to 17 percent, the brinell hardness HB is between 290 and 330, the longitudinal ballistic work is 80J, the transverse ballistic work is 60J, and the contraction of cross-section area is more than or equal to 45 percent. The manufacturing process method for the drill pipe comprises the steps such as pipe body manufacturing, sub manufacturing, butt welding and the other processes. The 120 steel grade drill pipe has excellent mechanical properties, is suitable for deep drilling with a depth between 4,000 and 5,000m, is favorable for the hydraulic drilling effect during the drilling due to the enlargement of inner holes of the stubs, can full play the function of a high-power drilling pump, and improve mechanical drilling rate; and the manufacturing process method has the advantages of easy implementation, practicability, reliability and excellent effect.

Owner:盘锦辽河油田派普钻具制造有限公司

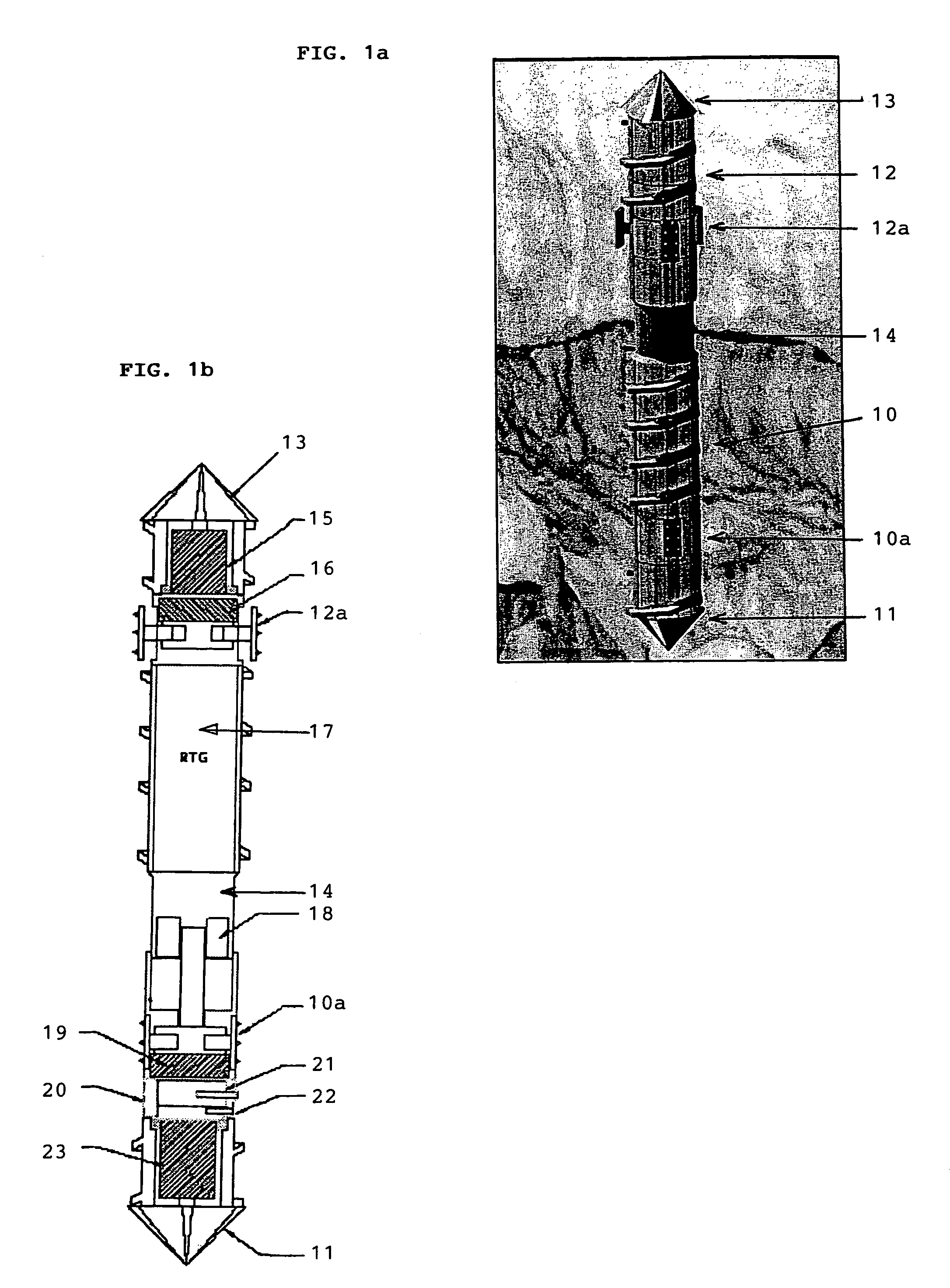

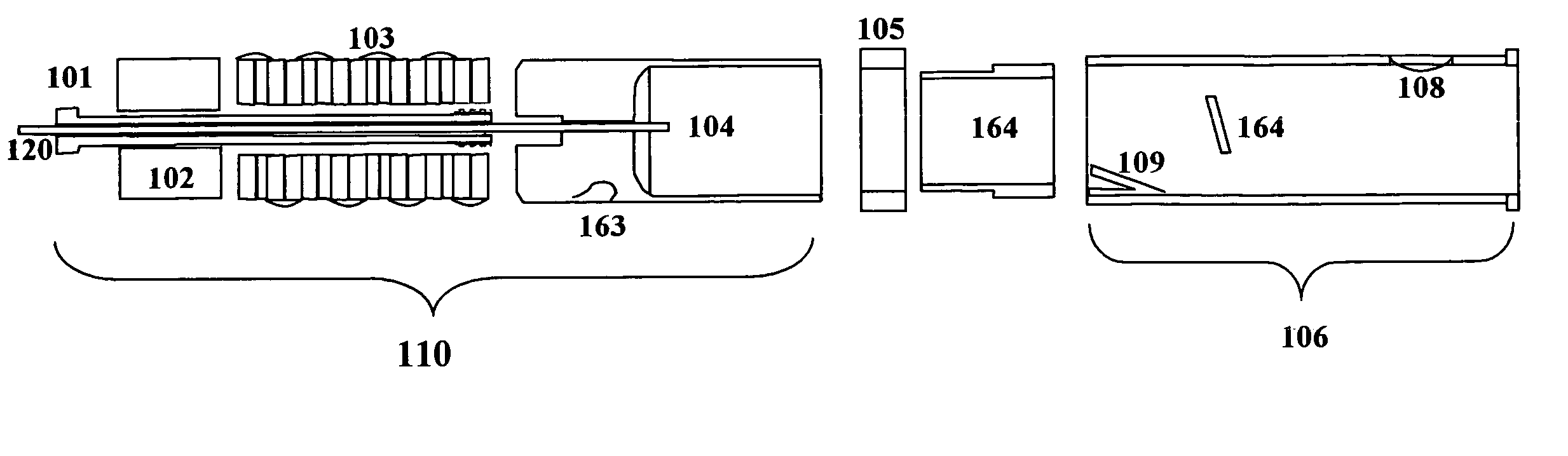

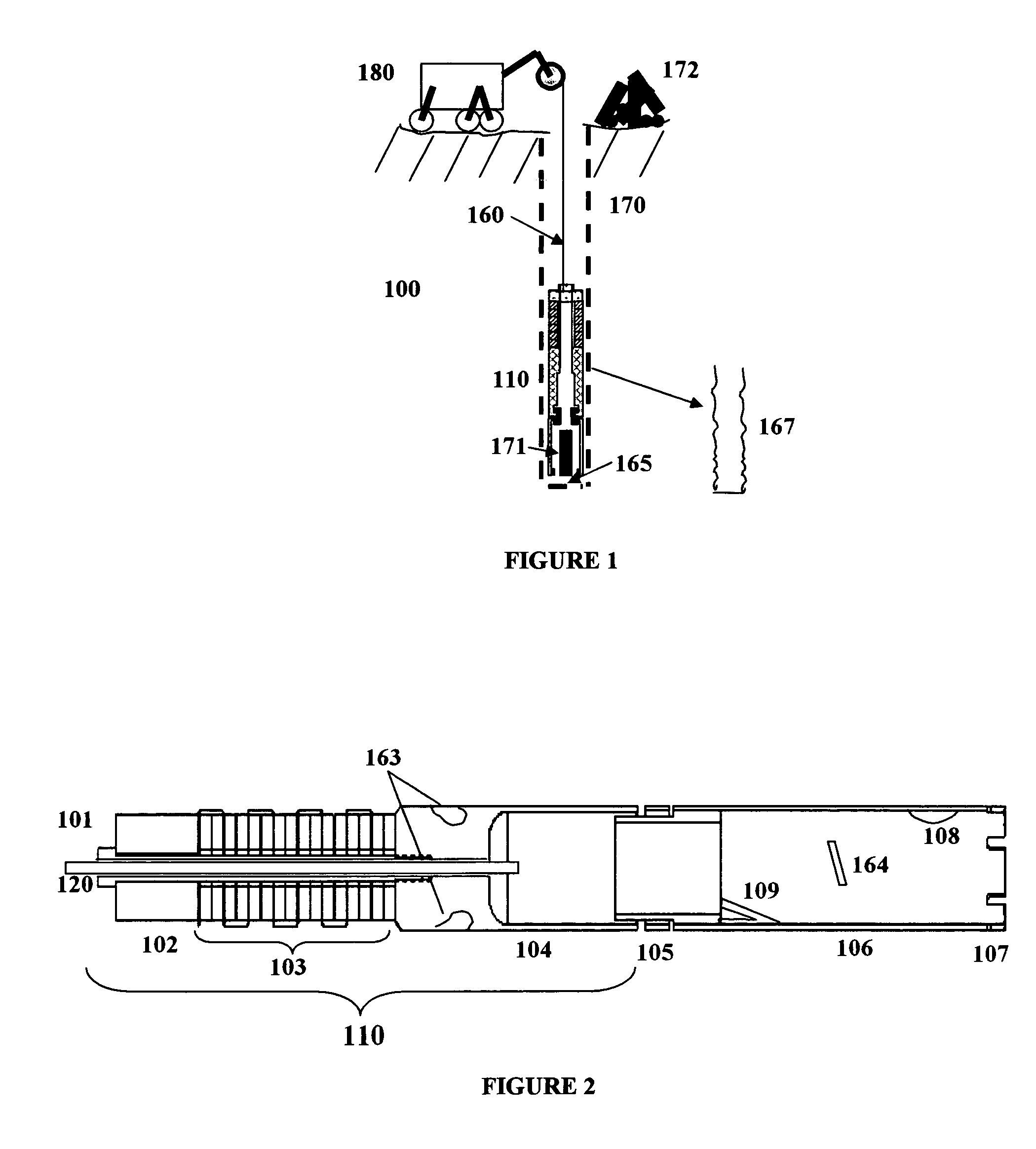

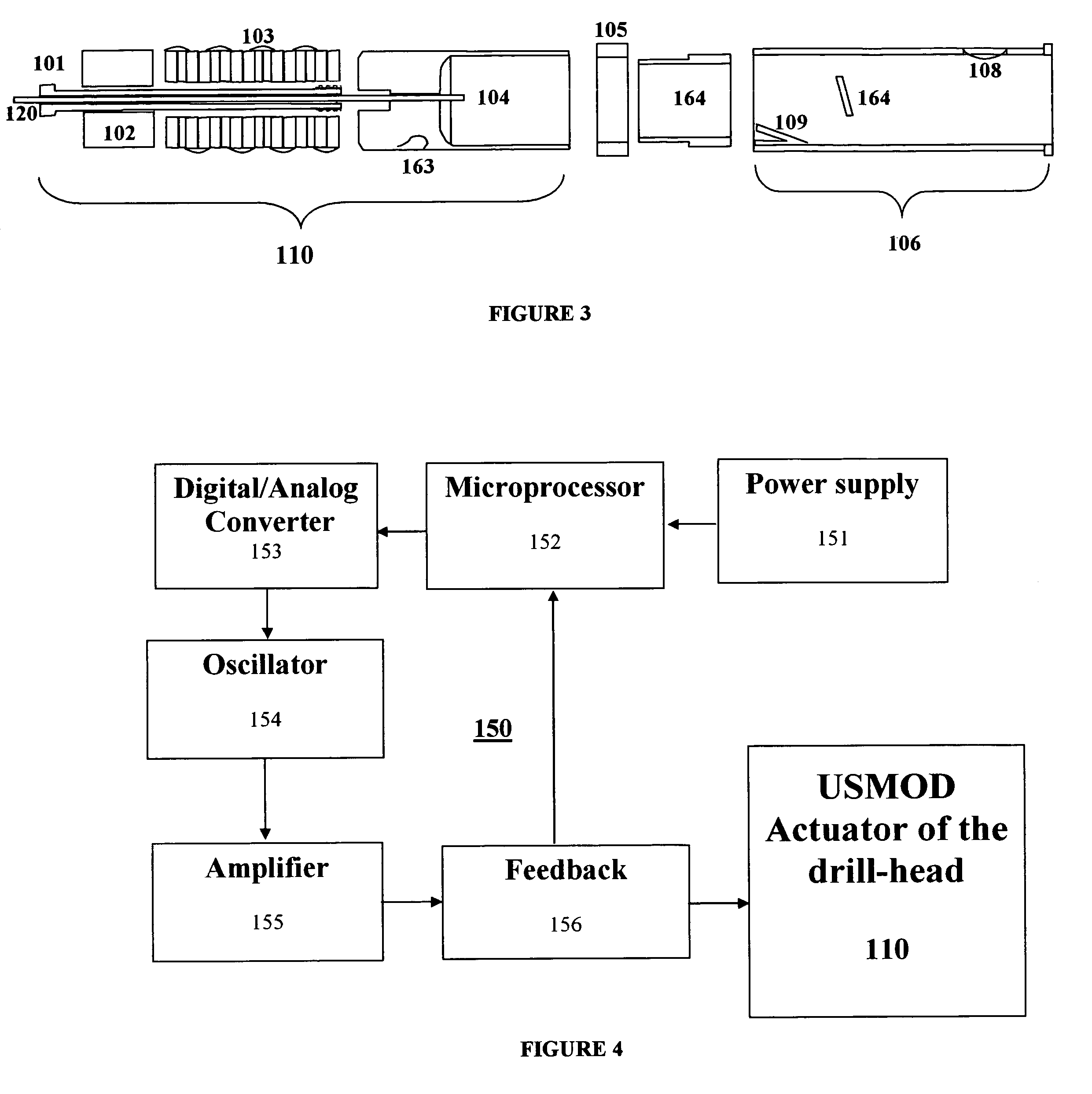

Ultrasonic/sonic mechanism of deep drilling (USMOD)

The present invention provides an ultrasonic and sonic mechanism of deep drilling (USMOD) that is driven by a vibrating actuator and operates in a similar manner to the gopher with regards to drilling debris removal. The actuator induces vibration in the form of a hammering actuation. The mechanism consists of a penetration bit with a diameter that is the same or larger than the actuator. The embodiment of the invention that is disclosed herein emulates a gopher. This ultrasonic gopher is lowered down into the produced borehole, cores the medium, breaks and holds the core, and finally extracts and deploys the core.A USMOD device consists of power drive and a drill-head. The power driver generates ultrasonic pulses to activate the USMOD mechanism and it allows optimized use of power by duty cycling the signal. The drill-head consists of an actuator, free mass and a penetration bit. The actuator consists of a vibration source and a horn that amplifies the amplitude of the vibration. The horn has a cylindrical cross-section to produce a drill-head that has cylindrical configuration and eliminate undesirable trapping of extracted soil and powdered cuttings. A cavity inside the tubular-shape horn provides space for packaging miniature instrumentation and sensors. The actuator activates an integrated free-mass that hammers the penetration bit, where the free-mass operates as a transformer to lower the vibration frequency to produce the hammering action. In one implementation of the USMOD it is designed to contain a trap for collection of upward traveling dust, debris and powdered cuttings.

Owner:BAR COHEN YOSEPH +4

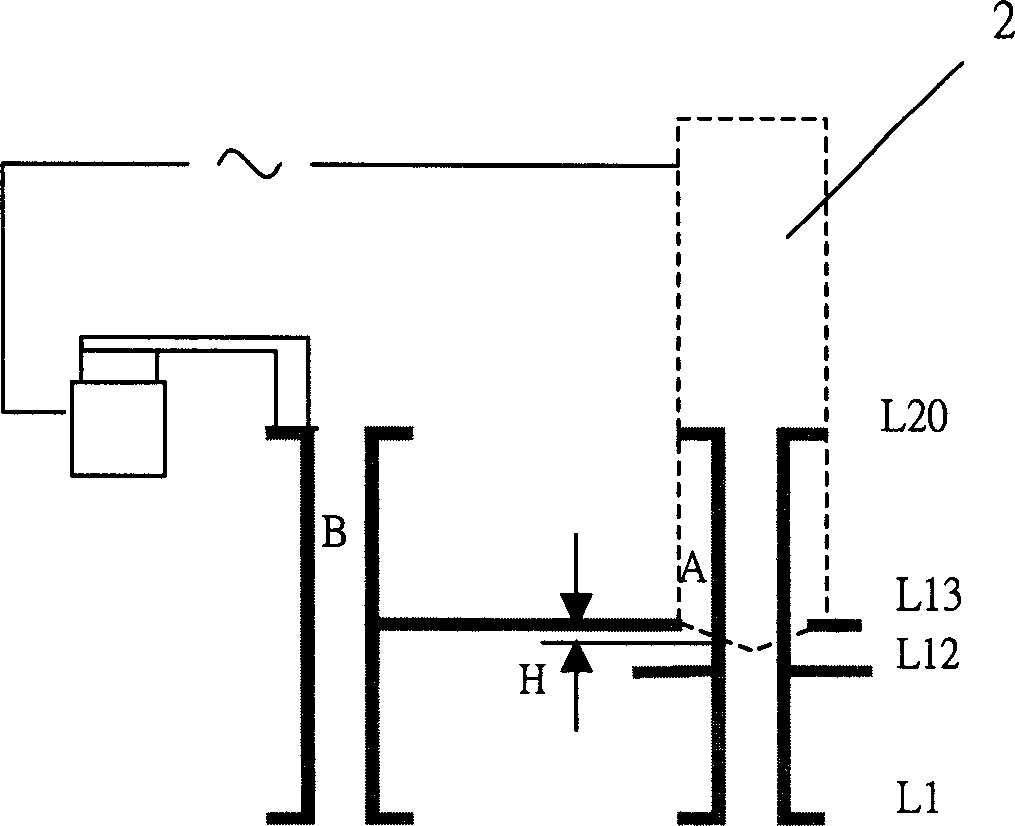

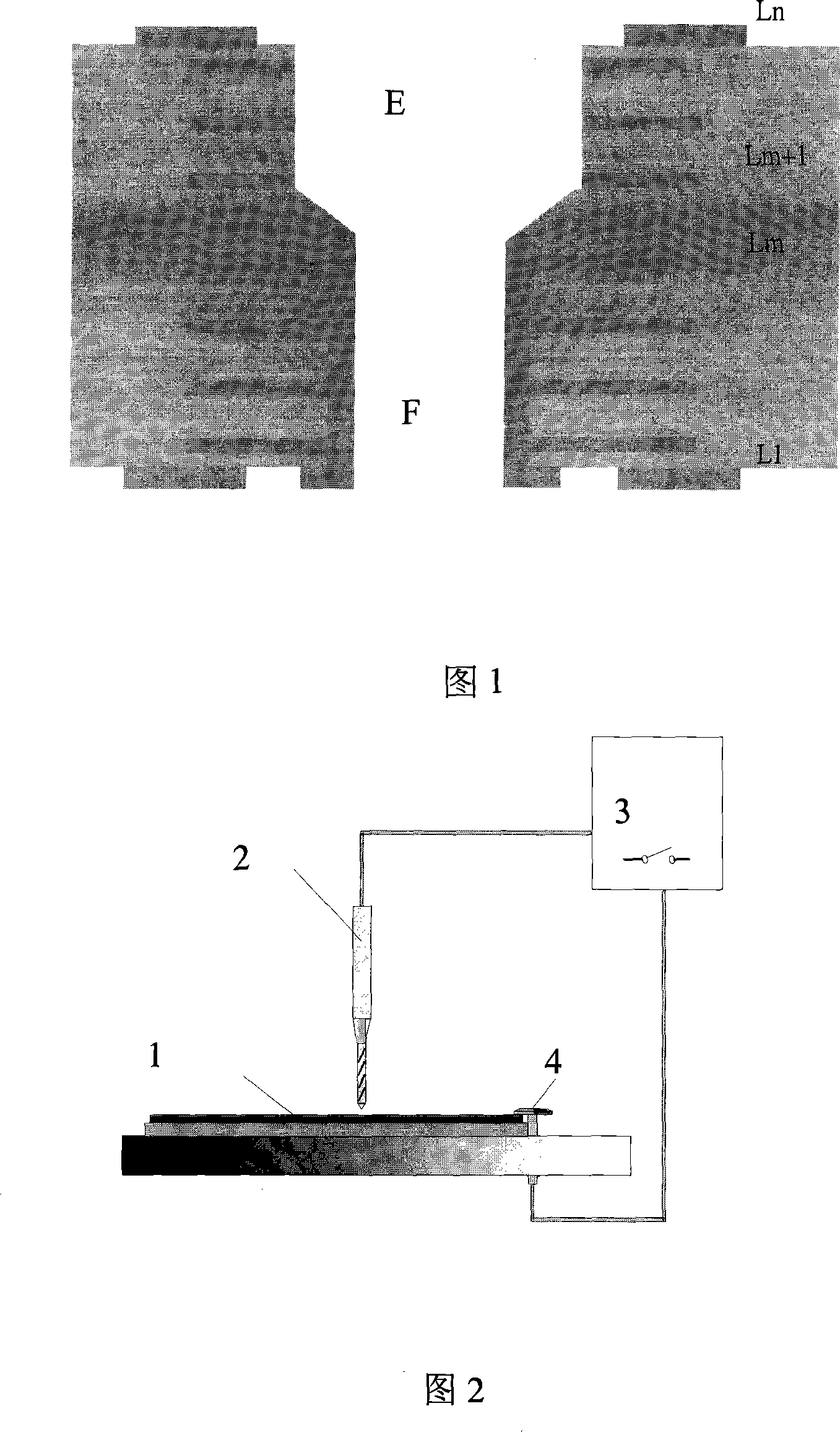

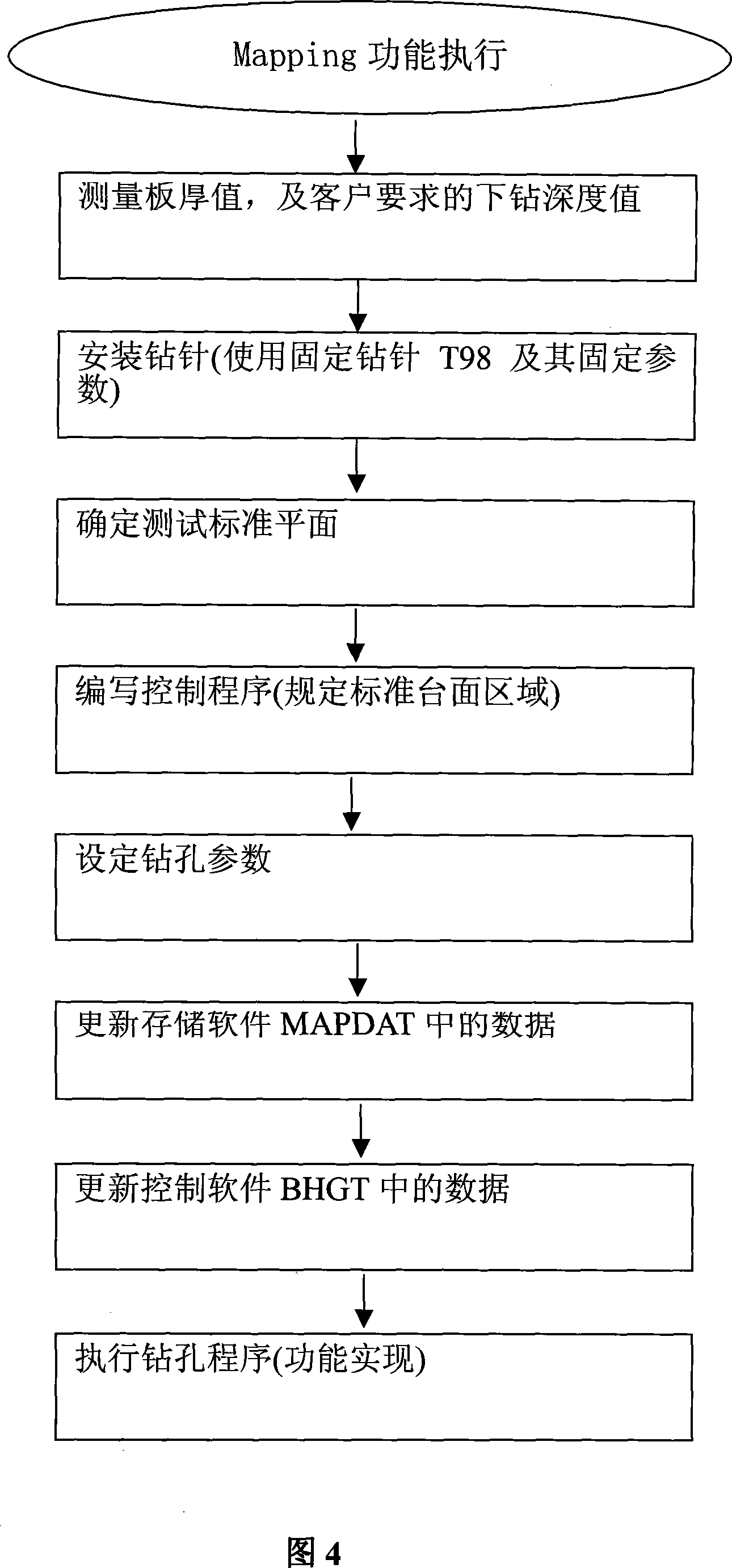

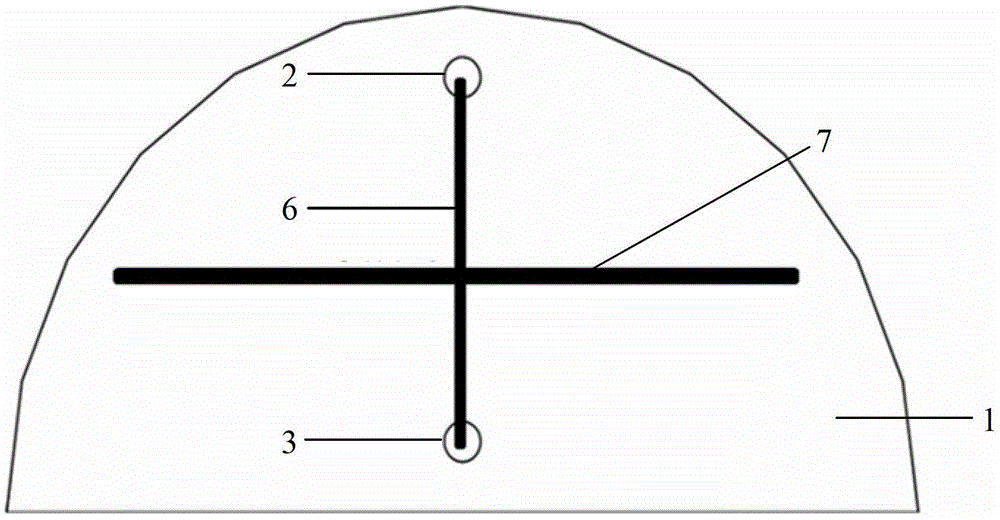

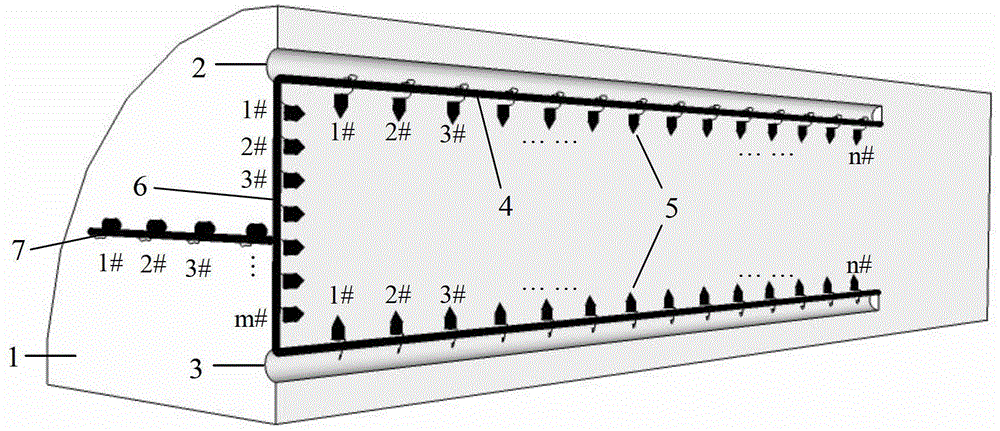

Method for deep drilling print circuit board

ActiveCN101094562AHigh control precisionEffects of reduced precisionConductive material mechanical removalStandard planeEngineering

The method comprises: setting the plane contacting with the PCB as a standard plane; recording the actual location height Hn of each point on PCB, and saving it into the storage software of the machine; selecting a target layer, setting a standard drilling depth D1 and standard plate thickness H1; the drilling depths of other points are Dn=D1*Hn / H1+ compensation value; according to the drilling depth Dn of each points, re-setting the parameters in the drilling program, and renewing each parameter in the storage software in machine; finally, according to Dn value, modifying the program-controlled instruction.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

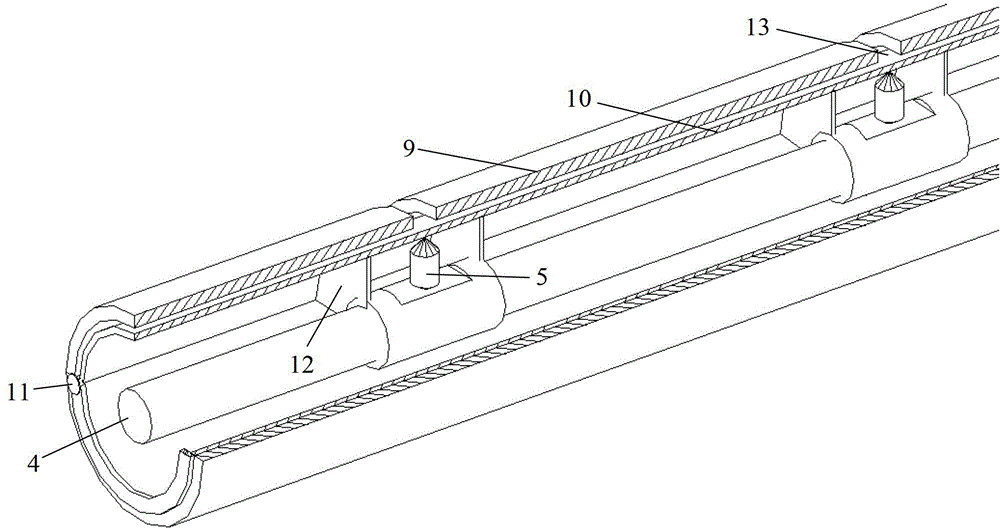

Electrode transmission device for high-resolution three-dimensional (3D) CT (computerized tomography) imaging in underground engineering

ActiveCN102749653ASolve deliverySolve the problem of fast couplingElectric/magnetic detectionAcoustic wave reradiationCouplingTomography

The invention discloses an electrode transmission device for high-resolution three-dimensional (3D) CT (computerized tomography) imaging in underground engineering. The device comprises an external sleeve, a rotary internal sleeve, a plurality of telescopic electrodes and a structure, wherein the external sleeve is provided with a conductive adhesive loading groove for loading the conductive adhesive; the rotary internal sleeve comprises a rotational sleeve, a space communicating the conductive adhesive loading groove the with the inside of the sleeve can be formed after the sleeve is rotated, a handle is arranged at the outer end of the sleeve, and a multi-core cable penetrates inside the internal rotary sleeve; each telescopic electrodes includes a housing, an electrode is arranged inside the housing and connected with the multi-core cable, and the telescopic electrode is further of a structure capable of ejecting the electrode out of the housing; the electrode is propped against the internal wall of the internal rotary sleeve before use; and the plurality of the telescopic electrodes are arranged inside the rotary sleeve and in one-to-one correspondence with the conductive adhesive loading groove. The device solves the problem related to transmission and rapid coupling of an electrode system in deep drilling and facilitates the advanced forecast work for the underground engineering in complex geological conditions.

Owner:SHANDONG UNIV

Lunar soil deep drilling sample recycling mechanism

ActiveCN102359346ALarge sampling rangeEasy to recycleDrilling rodsConstructionsLunar soilDeep drilling

Owner:ZHEJIANG UNIV

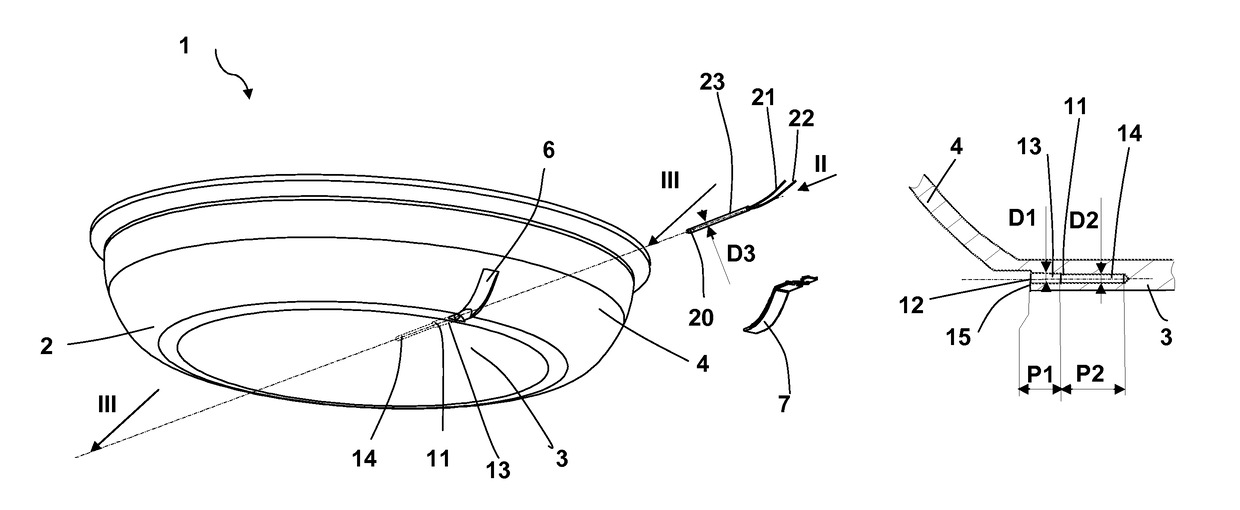

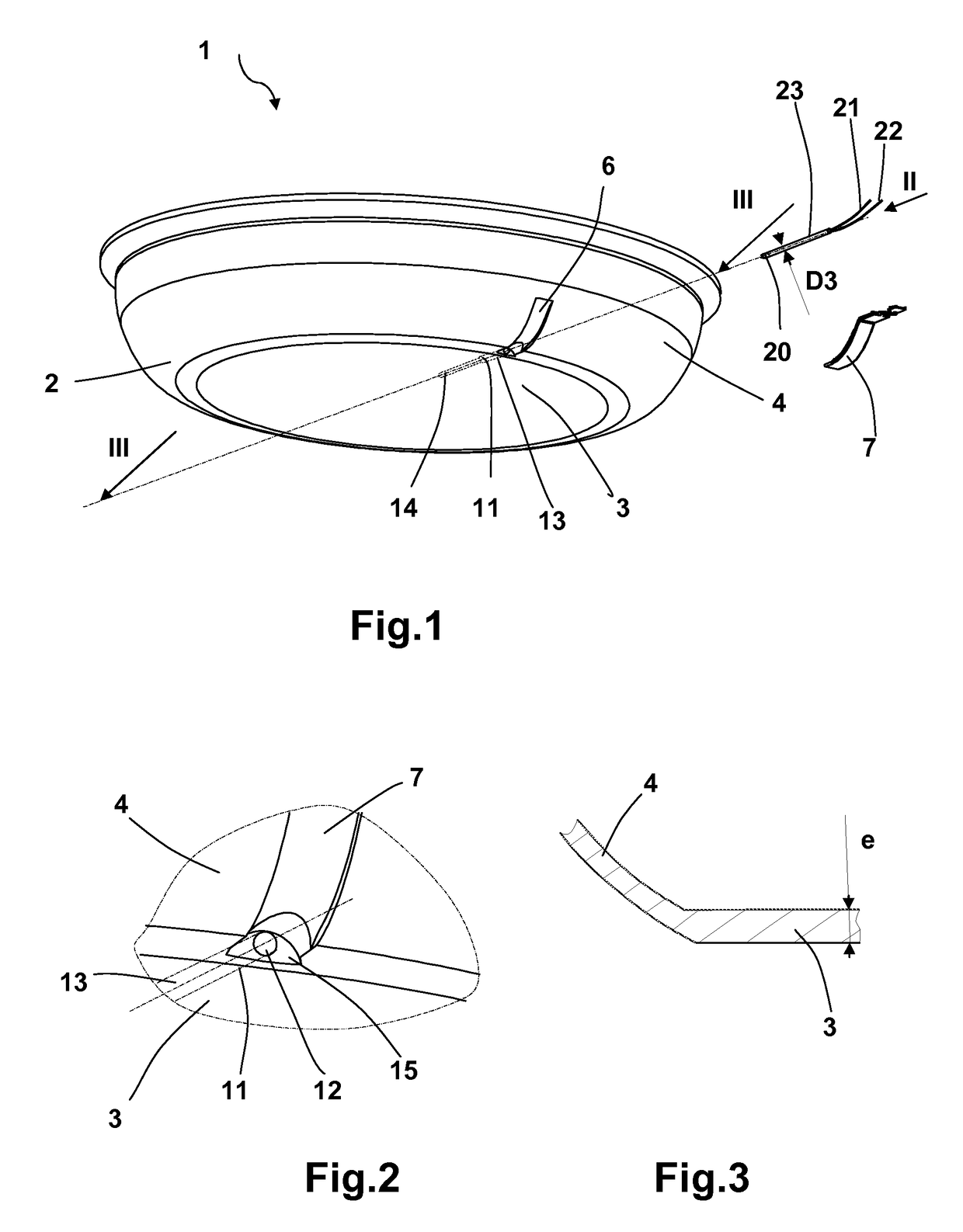

Biodegradable lubricating composition and use thereof in a drilling fluid, in particular for very deep reservoirs

ActiveUS20120283151A1Promote degradationCost advantageLiquid carbonaceous fuelsAdditivesWell drillingOil phase

The present disclosure relates to a biodegradable lubricant composition, notably intended to be incorporated as an oil phase with high lubricating power in a drilling fluid or mud. This composition may be in a drilling fluid or as a fluid for fracture of underground formations. These muds or fluids contained in the composition of the present disclosure are particularly suitable for very deep drillings, offshore in deep water and / or sidetracked drillings or with a long shift.

Owner:TOTAL MARKETING SERVICES SA

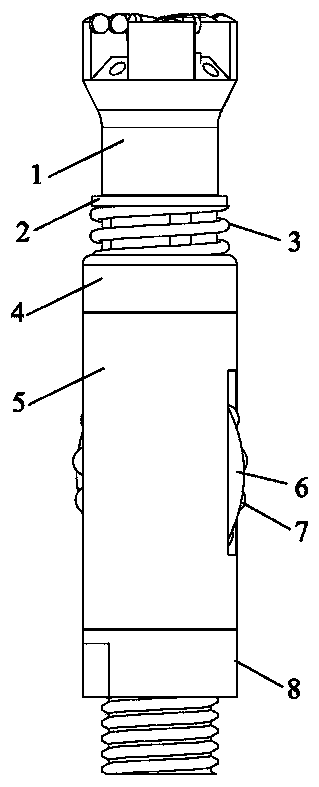

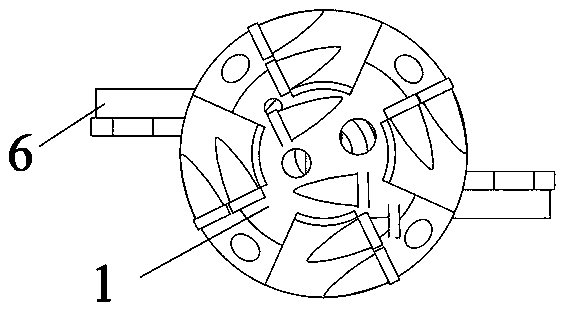

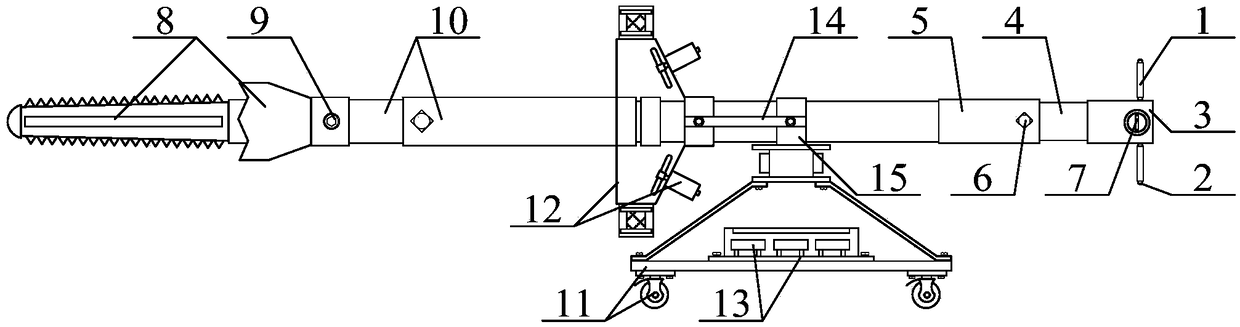

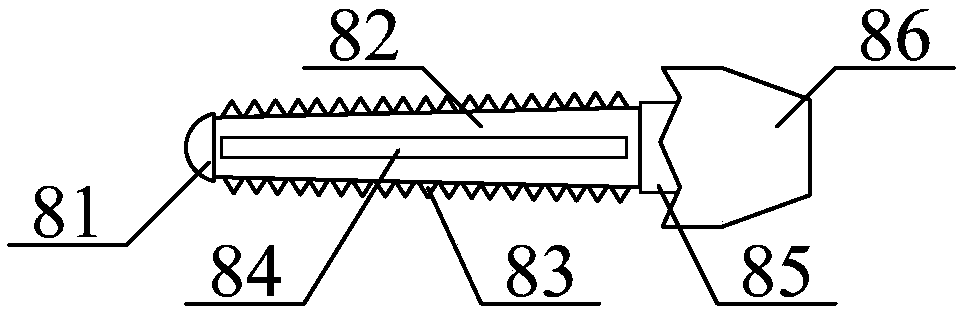

Pipe-following drilling reaming device for gas extraction holes in soft broken coal bed

The invention relates to a pipe-following drilling reaming device for gas extraction holes in a soft broken coal bed to effectively solve the problems that the deep drilling of the gas extraction holes in the soft broken coal bed is difficult to perform and the hole forming effect is poor. The technical scheme for solving the problems is as follows: a drill bit and a drill bit connecting piece are connected together; the drill bit connecting piece is arranged in a casing; a top cap is arranged at the upper end of the casing; a spring is arranged on the drill bit connecting piece in a sleeved mode, and the upper and lower ends of the spring are fixed by a gasket and the top cap respectively; a reaming cutter opening-closing component is arranged in the casing and consists of a pair of scrapers, a mandrel and a cutter pipe; the scrapers are arranged in scraper slots in the casing, and one end of each scraper is connected with the cutter pipe through the mandrel to form a fixed rotary structure; diamond compacts are embedded in the scrapers along the outer boundaries of the scrapers from top to bottom; and the lower end of the cutter pipe and the lower end of the casing are connected with a drill rod connecting piece respectively, and the lower end of the drill rod connecting piece is connected with a drill rod. The pipe-following drilling reaming device disclosed by the invention effectively improves the construction speed of the gas extraction holes, and is an innovation of drilling deices for the gas extraction holes in the soft broken coal bed.

Owner:HENAN POLYTECHNIC UNIV

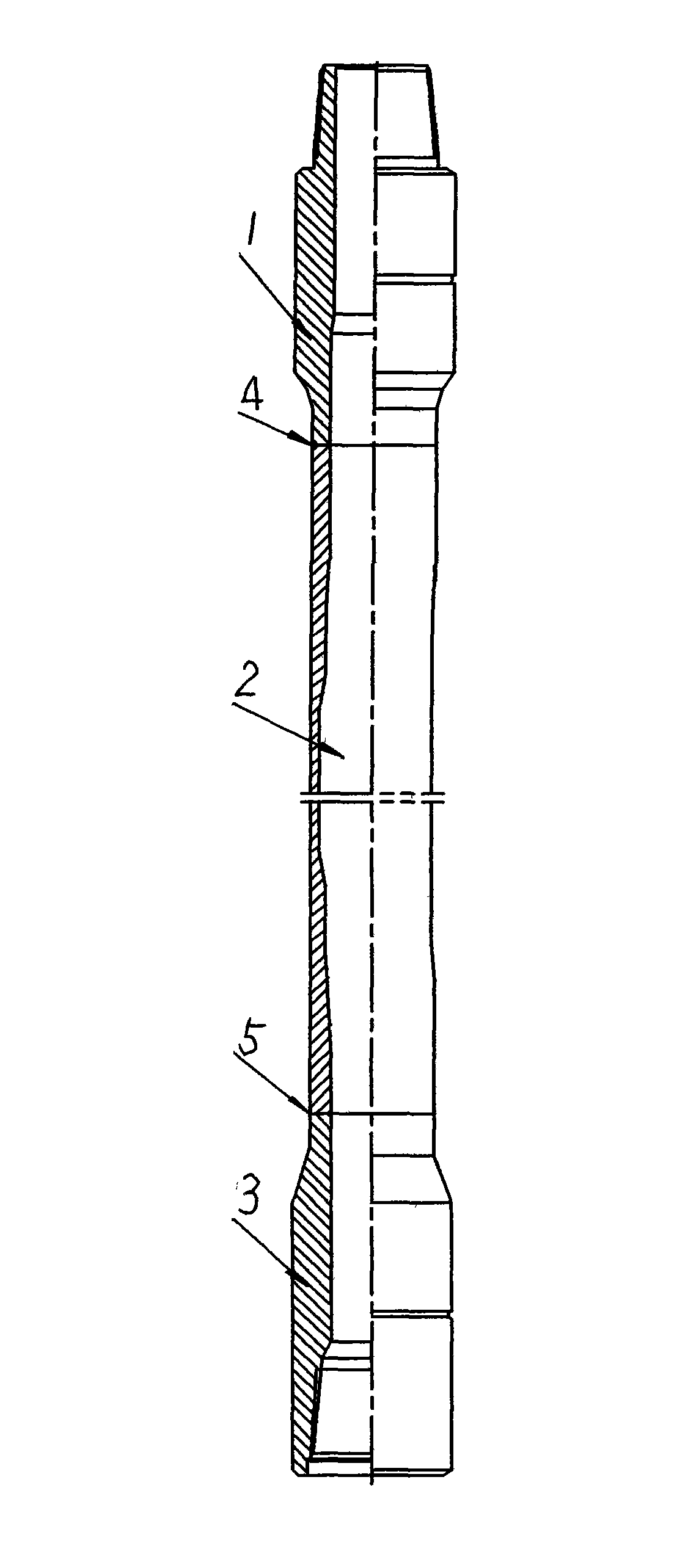

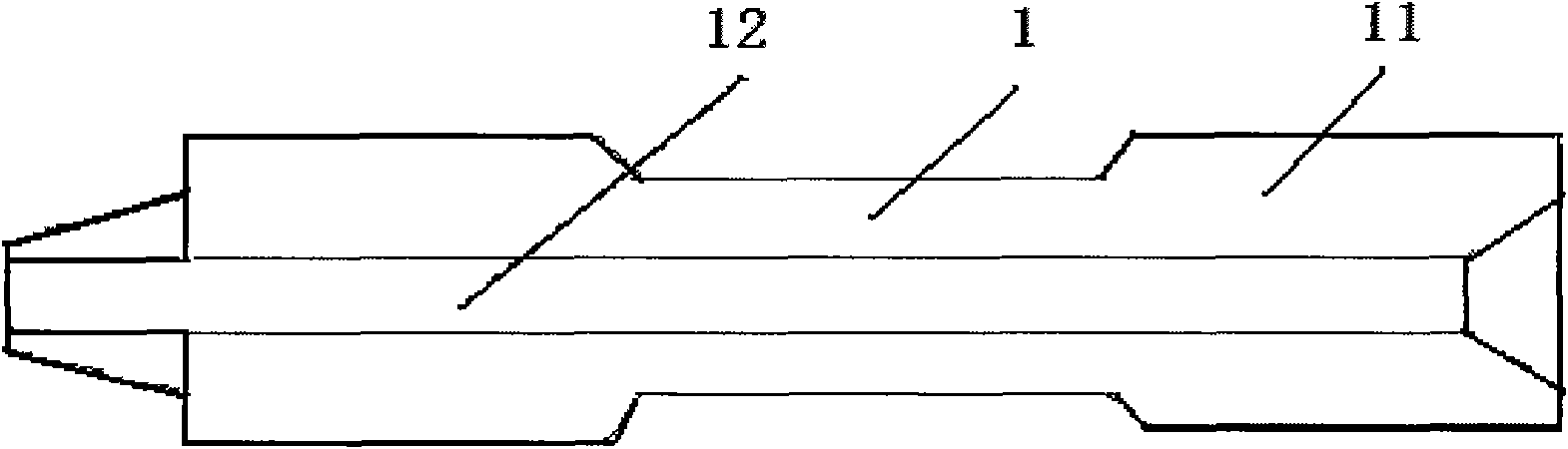

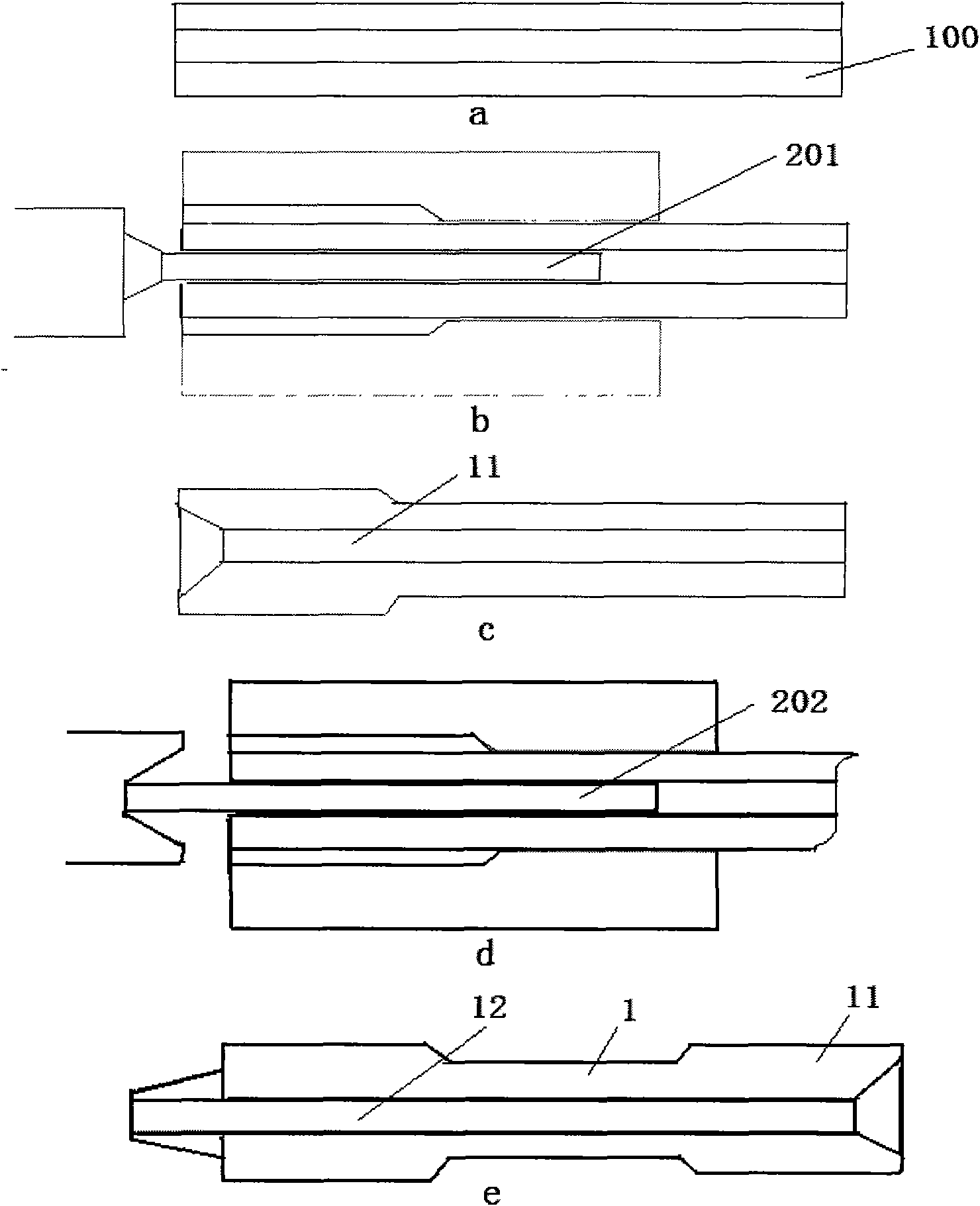

Integrally-weighted drilling rod and production and processing method thereof

InactiveCN101614112AIdeal connectorIdeal strengthDrilling rodsMetal-working apparatusIntermediate frequencyWell drilling

The invention discloses an integrally-weighted drilling rod and a production and processing method thereof. The integrally-weighted drilling rod comprises a pipe body, and a box end and a pin end arranged at two ends of the pipe body, and is characterized in that the pipe body, the box end and the pin end are formed integrally by adopting chrome molybdenum alloy steel seamless steel pipes. The method for producing and processing the integrally-weighted drilling rod by using the chrome molybdenum alloy steel seamless steel pipes comprises the steps of raw material inspection, processing and forming, subsequent processing and sorting and is characterized in that the step of the processing and forming adopts a tube upset process and comprises the following process steps: performing intermediate frequency heating on two ends of a steel pipe, performing upsetting and extrusion on respective ends respectively by using a box tool die and a pin tool die so as to form the box end and the pin end; and performing tempering heat treatment on the box end and the pin end of the steel pipe after the upsetting respectively. The integrally upsetting weighted drilling rod has the characteristics of high finished product strength, deep drilling depth, long service life, low processing cost, and more reutilization times.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

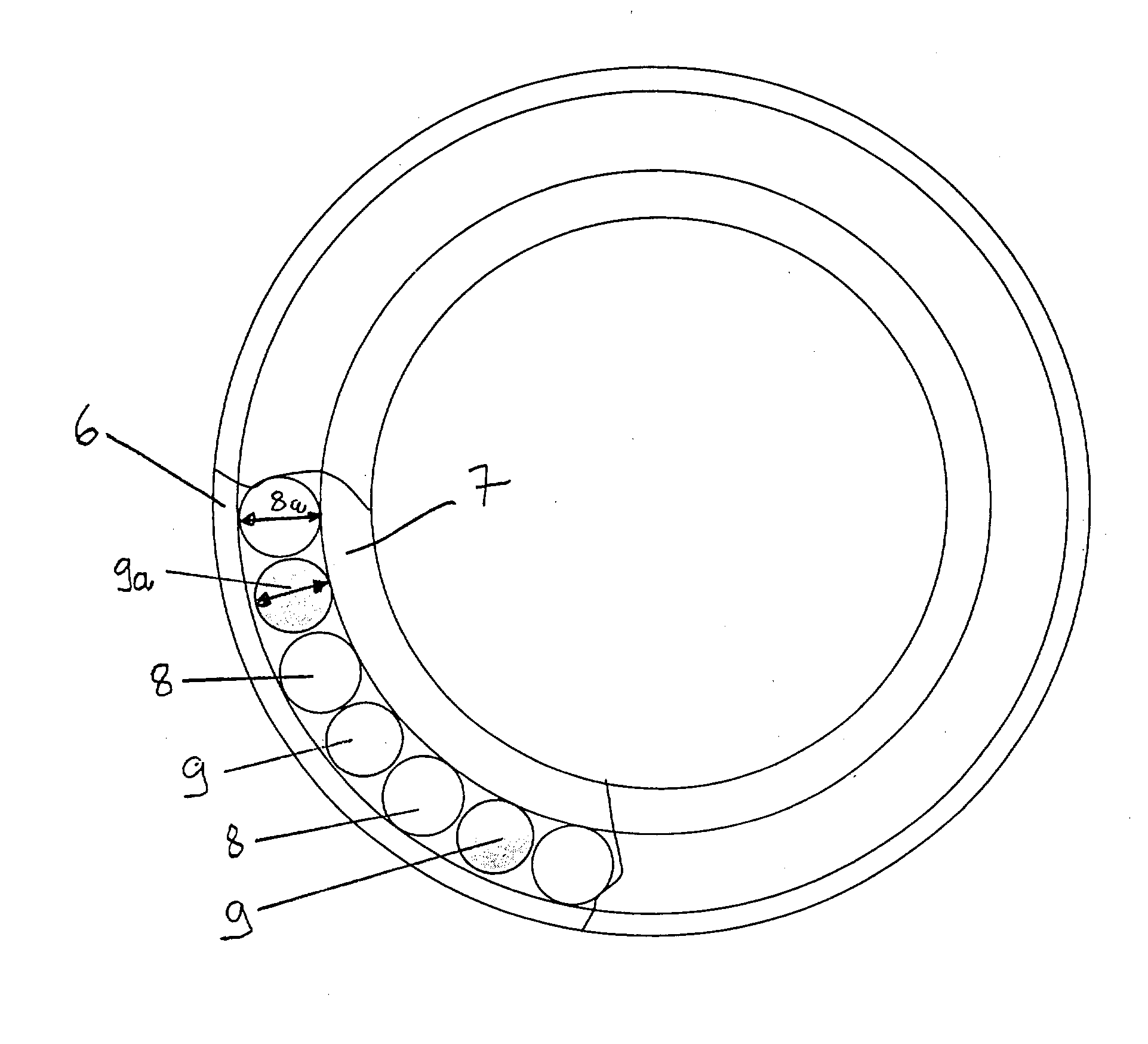

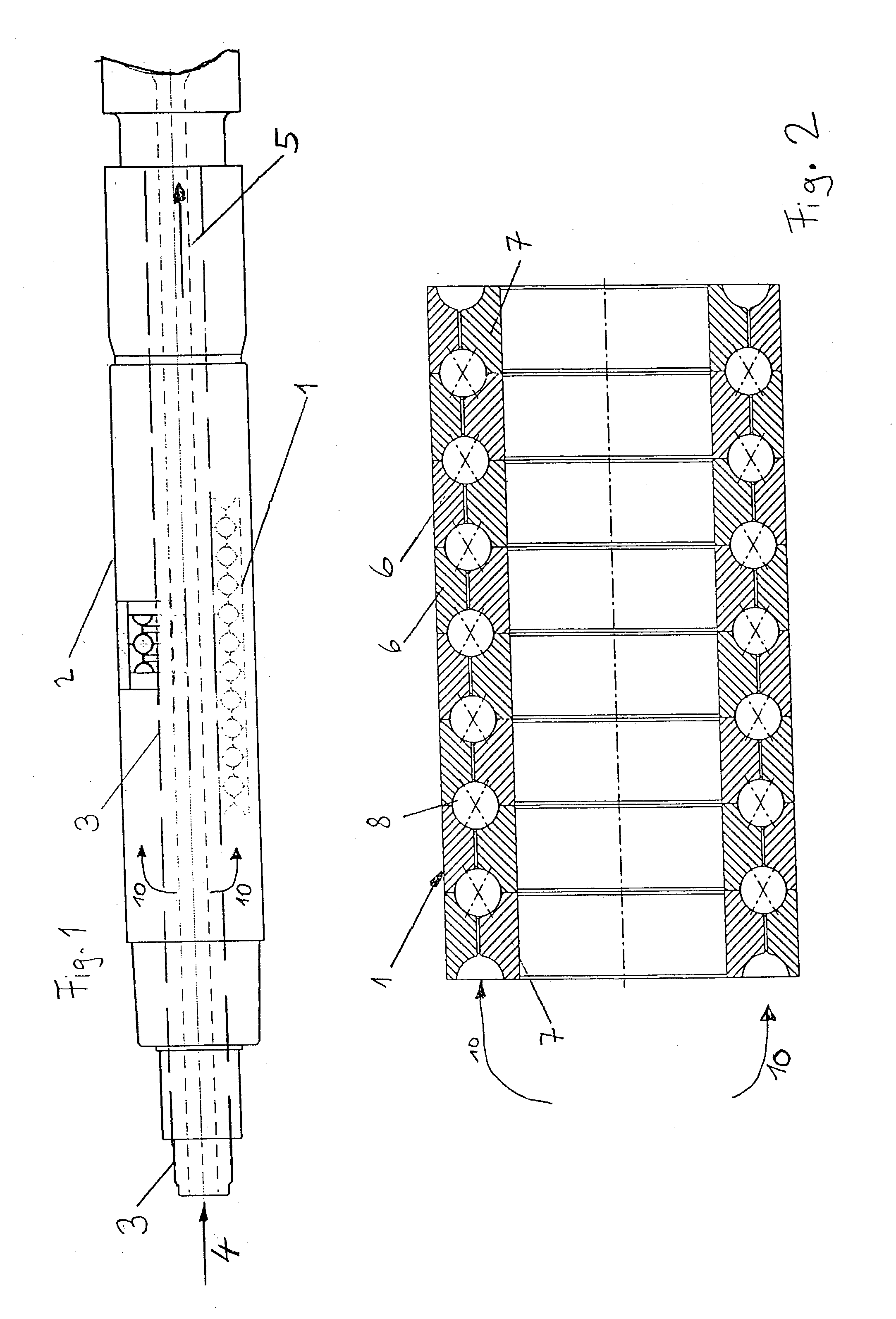

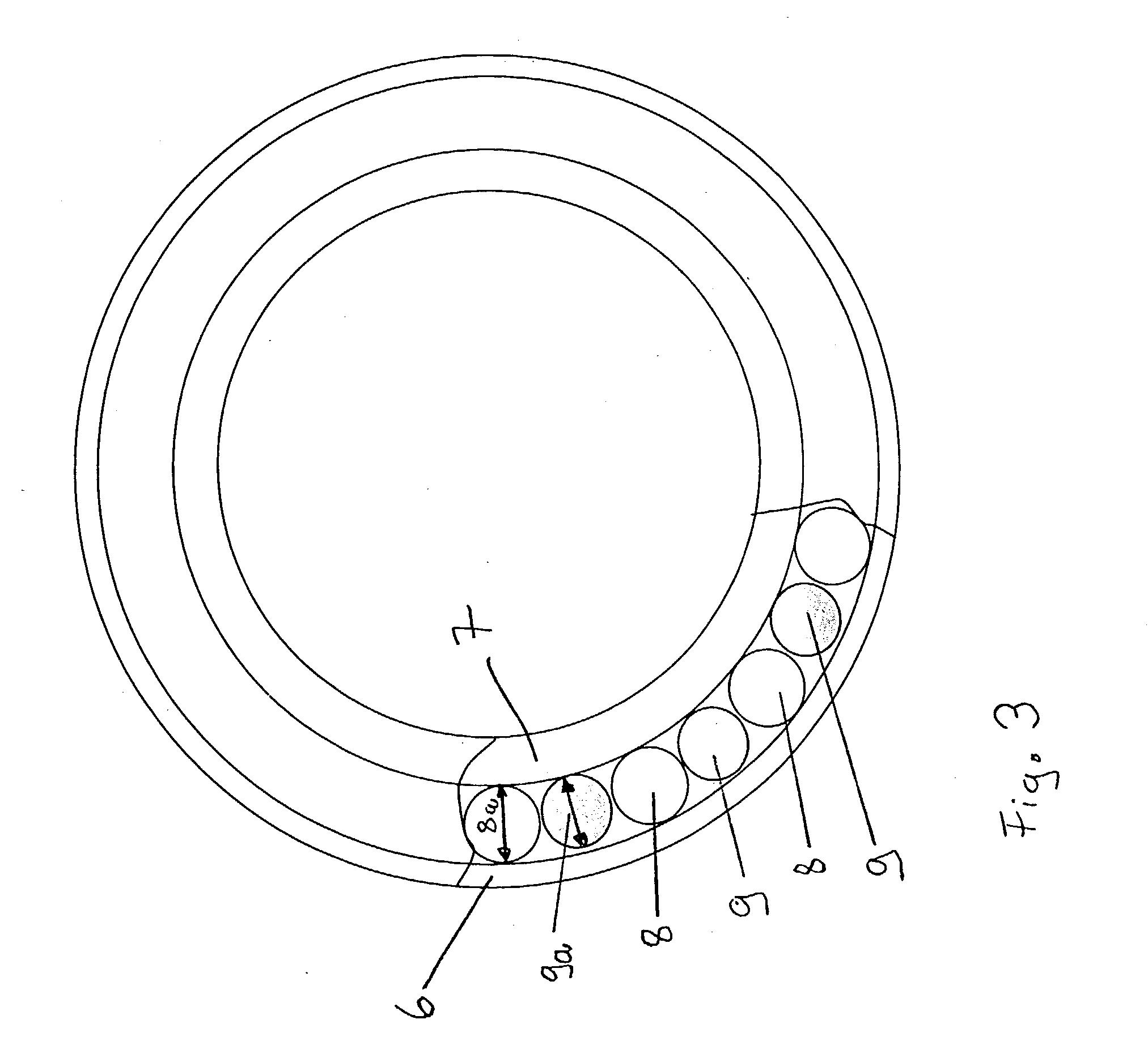

Roller bearing in a deep-drilling apparatus

A ball-bearing unit for a bearing of a deep-drilling apparatus having bearing races made from steel with balls disposed therebetween. Contaminated drilling medium passes into the space between the bearing races. Load-bearing balls made from ceramic alternate with separating balls of smaller diameter made from steel between the bearing races to extend significantly the service life of the ball-bearing unit.

Owner:SCHAEFFLER KG

Device for measuring three-dimensional ground stress of deep rock

The invention discloses a device for measuring three-dimensional ground stress of deep rock. A main detection part comprises an annular groove cutting device, a rock surface grinding device, a gluingand strain gage stripping device and a strain gage pasting device, all the parts are connected to a mobile rack and a sealing assembly through screws, and a turning device is located above an inner sealing sleeve and fixed on an upper end sleeve through screws; an air heater and a main power motor are located above the inner sealing sleeve and fixed on an upper machine base plate through screws; the strain gage pasting device is distributed in a thin wall coring bit of the annular groove cutting device; a longitudinal movement mechanism is located at the bottom of the main detection part and fixed on the lower end through screws; the inner sealing sleeve is connected with a lower machine base plate through a longitudinal connection plate and a longitudinal connection rod; the lower machinebase plate is connected with a longitudinal movement push rod base through a longitudinal connection sleeve; the longitudinal movement push rod base is connected with the longitudinal movement mechanism through a longitudinal movement push rod sleeve. The device is simple in structure, higher in compressive strength and suitable for conditions of deeper drilling tests and has a better waterproofeffect, and the testing precision is improved.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

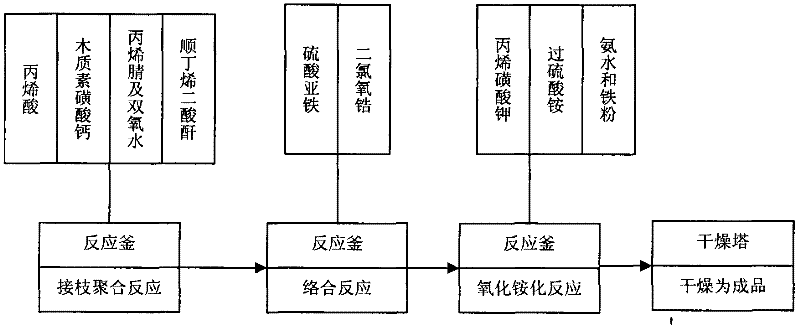

High temperature resistant and compound salt resistant viscosity reduction agent for drilling fluid and preparation method thereof

InactiveCN102391436AImprove heat resistanceImprove salt resistanceDrilling compositionHigh densityViscosity

The invention discloses a high temperature resistant and compound salt resistant viscosity reduction agent for a drilling fluid and a preparation method thereof. Modified lignin and an acrylic monomer are subjected to copolymerization, sulfonation, oxidation and complexation reactions to obtain a product. In a high temperature deep drilling process, the colloidal stability of the high-density andhigh-solid drilling fluid can be obviously improved, the rheology of the drilling fluid is improved, the used amount is few, the cost is low, the duration for the drilling fluid is long, the maintenance workload is few, and the viscosity reduction agent is innoxious and non-polluting, and can be innoxiously decomposed in an natural environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

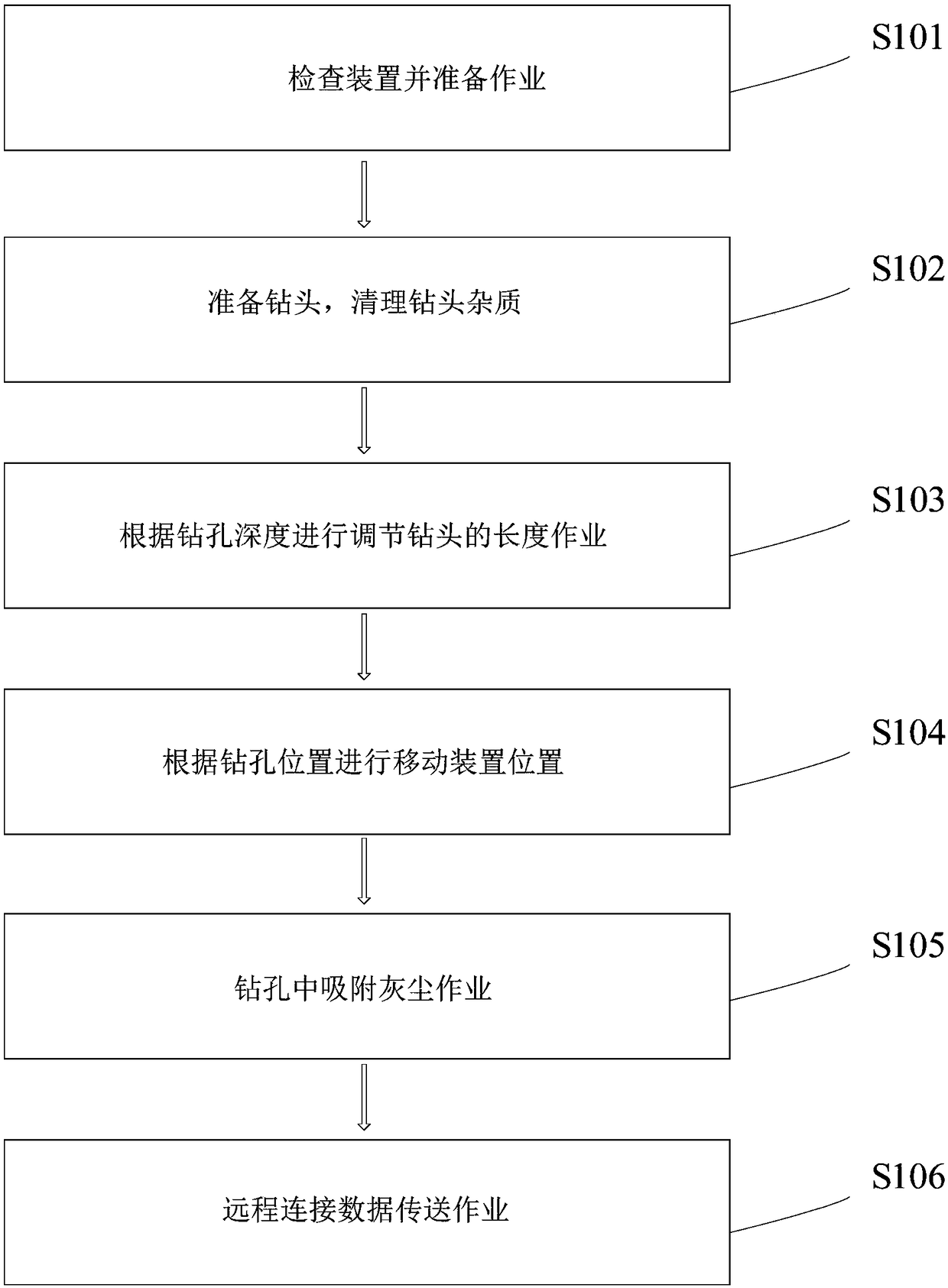

While-drilling testing method and device for coal seam gas parameters

ActiveCN109403865AImprove protectionAvoiding the Problem of Damage to Tapered BitsEarth drilling toolsSurveySlagRemote data transmission

The invention provides a while-drilling testing method and device for coal seam gas parameters. The while-drilling testingdevice comprises a hand-holdingsleeve, a hand-holdingrod, a connecting casing,a butting shaft, a connecting pipe, fastening bolts, a strip-shaped port iron pin, a removable hard coal seam assisted drilling bit structure, fixed hexagon socket bolts, a drilling extension rod structure with the adjustable length, an auxiliary moving supporting transport frame, a during-drilling dust auxiliary adsorptionsplash-preventing shield structure, a heat dissipating shield structure capable of conducting remote data transmission, a connecting plate and a fixing casing. According to thewhile-drilling testing method and device for the coal seam gas parameters, drilling teeth, a flow-guiding groove, a connection liner pipe and a drill bit body are arranged, coal slag produced during drilling through a cone-shaped bit can be discharged in time through the flow-guiding groove, and the problem of drilled hole blocking is avoided; through the drilling teeth, good auxiliary drilling work can be achieved, and influence of a hard coal seam on deep drilling is avoided; and final reaming operation can be conducted through the drill bit body, and it is ensured that drilling work is conducted smoothly.

Owner:NORTH CHINA INST OF SCI & TECH

Dry-hole pressure relief valve and hydraulic fracturing crustal stress testing device

PendingCN107238458ASimple structureEasy to operateForce transducersStructural engineeringHydraulic fracturing

The invention discloses a dry-hole pressure relief valve and a hydraulic fracturing crustal stress testing device, and relates to the technical field of rock mass engineering testing. A valve core of the dry-hole pressure relief valve is inserted in a valve cavity from the insertion end of a valve body, and one end of the valve core extends out of the insertion end; a plurality of pressure relief holes are formed in the end, away from the insertion end, of the valve body, the valve core is provided with a blocking part which can block the valve cavity, and the insertion end of the valve body is provided with a limit nut for limiting the length of the part, extending out of the valve body, of the valve core; the part, located between the blocking part and the limit nut, of the valve core is sleeved with a load-bearing spring; the dry-hole pressure relief valve is simple in structure and convenient to operate, and can effectively relieve pressure in a packer. A high-pressure pump of the hydraulic fracturing crustal stress testing device is communicated with the top end of a drilling hole, the bottom end of the drilling hole is communicated with the dry-hole pressure relief value, the end, extending out of the insertion end, of the valve core is communicated with a switching valve, and the switching valve is communicated with the packer. Through the adoption of the hydraulic fracturing crustal stress testing device, crustal stress tests can be conducted under the conditions of deep drilling holes and dry holes by using a hydraulic fracturing method, and the tests are stable.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Casing drilling technique for over-goaf

ActiveCN104405281ADrilling achievedAchieve rotationSealing/packingDrilling machines and methodsBedrockEarth surface

The invention relates to a coalbed methane mining technology, aims at solving the problem of drilling fluid loss of a goaf in coalbed methane extracting and deep drilling processes, and provides a casing drilling technique for an over-goaf. The casing drilling technique comprises the following steps: driving a first collaring head to drill through a finished drill-hole which is 10m below a weathered bedrock by virtue of a drill stem; arranging a casing on a surface layer of the next open pore to the bottom, and carrying out well cementation with cement; adding cement and returning to the earth surface; driving a second collaring head to drill into a coal seam floor of the goaf by virtue of a casing instead of the drill stem, reserving the casing into a pit shaft as an intermediate casing after second collaring is ended, and carrying out well cementation on the position between the intermediate casing and the borehole wall of the goaf; further driving a third collaring head to drill into a finished drill-hole which is 30m below the next group of coal seam floors by virtue of the drill stem. According to the casing drilling technique, a ground casing drilling technique for preventing leakage loss is adopted, when a drill drills into the coal goaf, heavy leakage loss caused by the goaf is lowered by taking the casing as a liner tube; second casing drilling or multiple casing drilling is carried out; drilling of finishing drilling by taking the next group of coal as a target layer through the goaf is achieved.

Owner:山西蓝焰煤层气集团有限责任公司

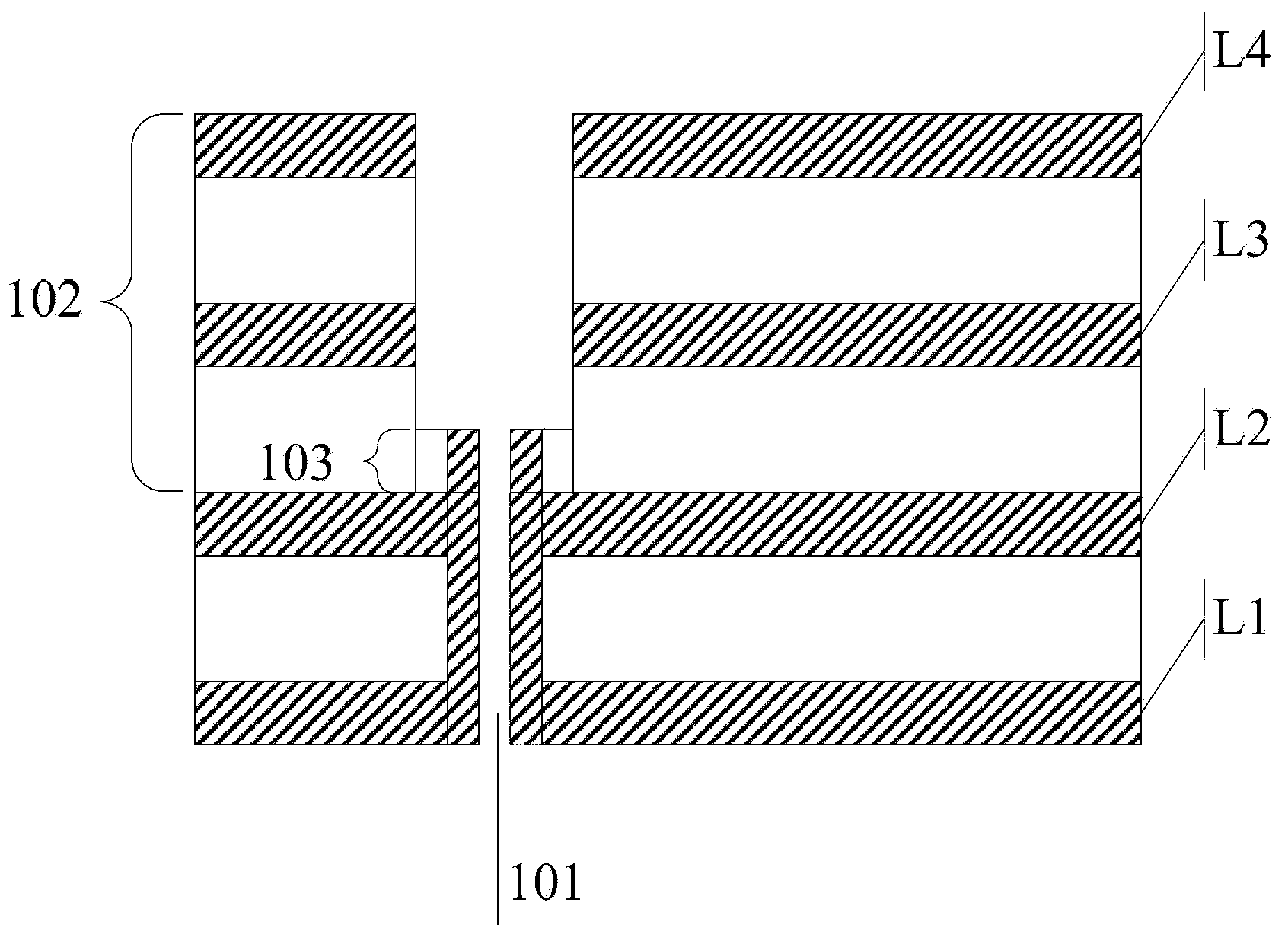

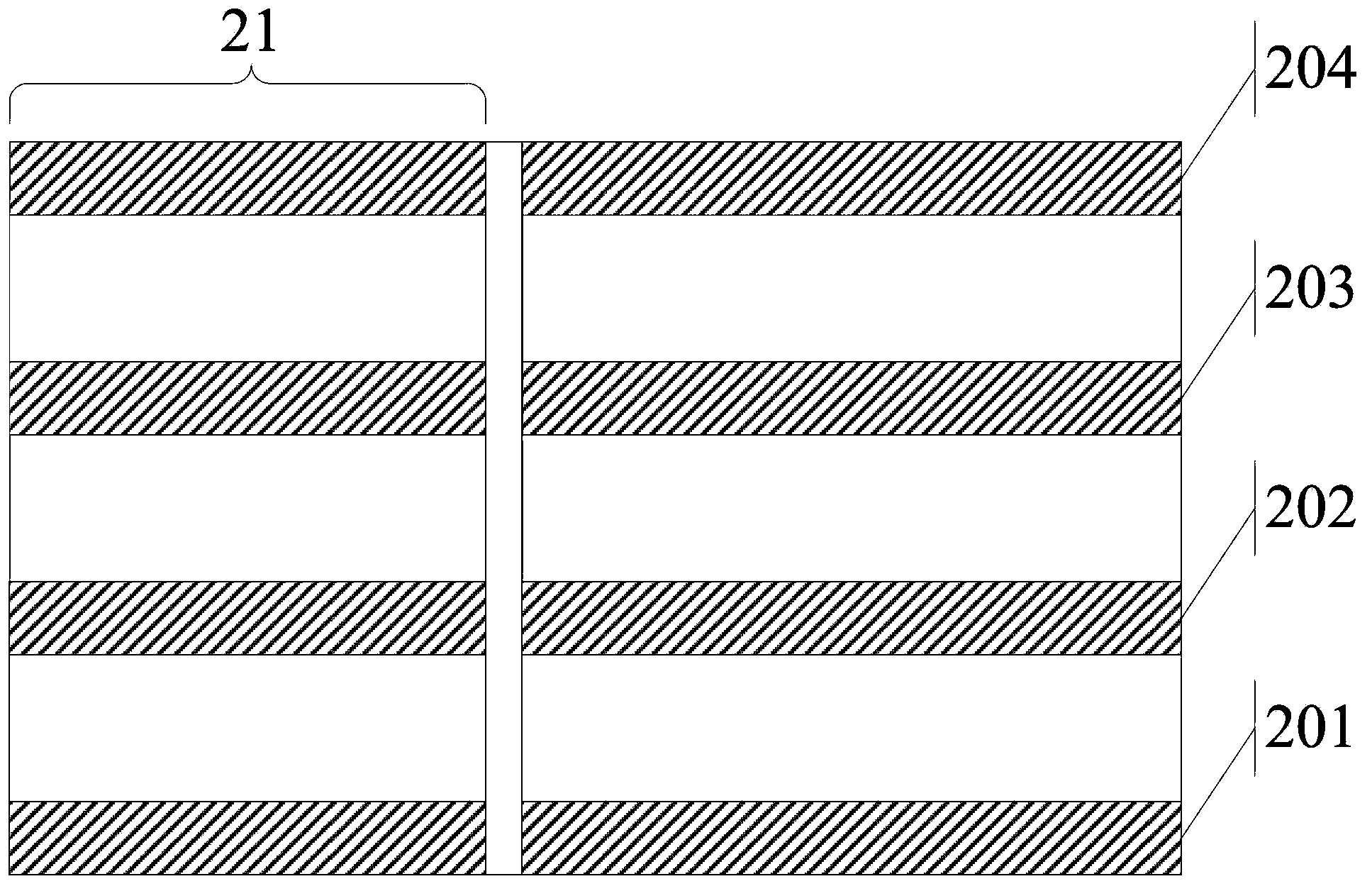

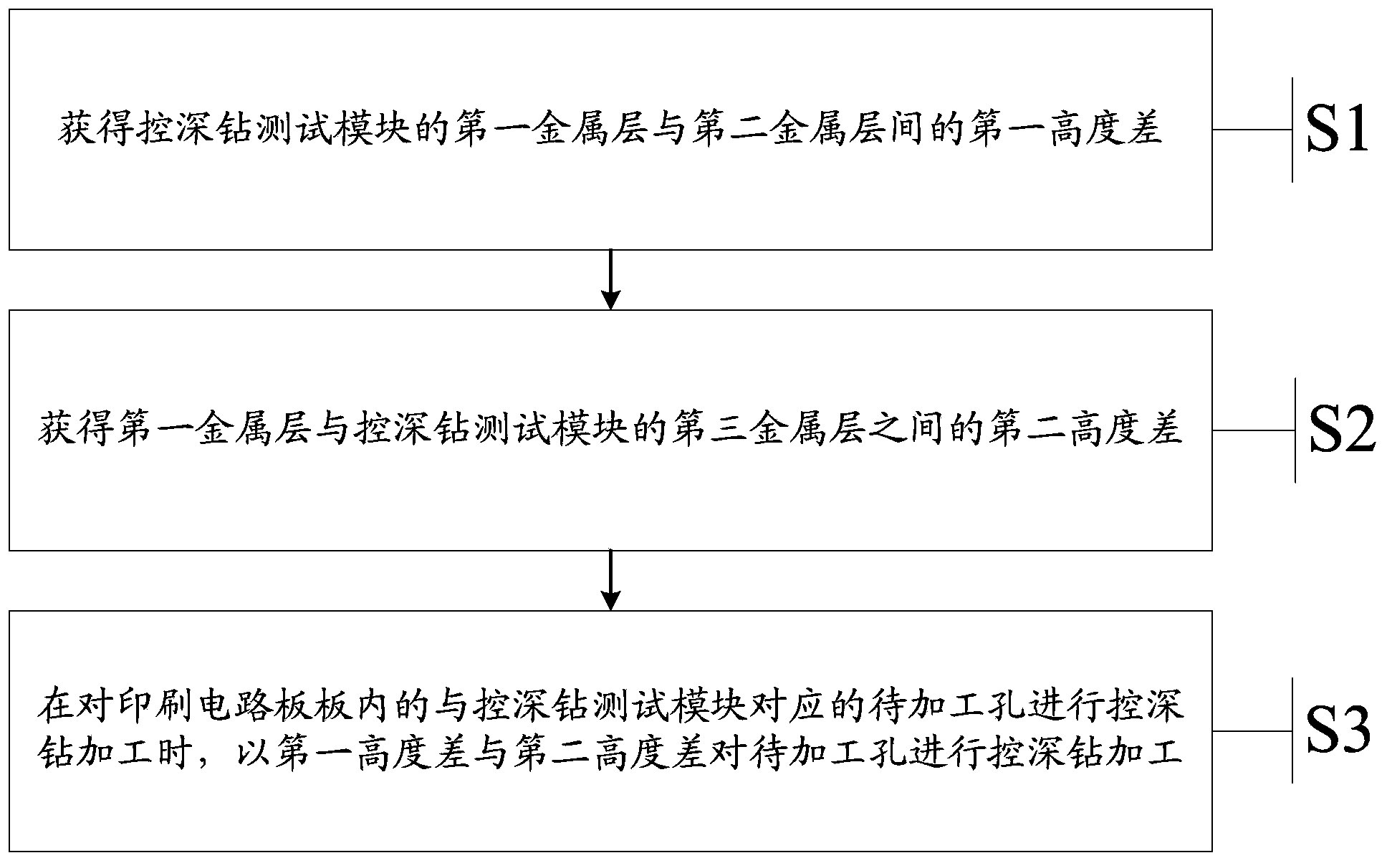

Drilling method and drilling machine

InactiveCN104227060AShorten the production cycleSave manpower and material resourcesMeasurement/indication equipmentsWorkpiecesSurface layerComputer module

The invention discloses a drilling method and a drilling machine. The drilling method is applied to the drilling machine, and includes acquiring first height difference between first metal layers and second metal layers of deep drilling control testing modules; acquiring second height difference between the first metal layers and third metal layers of the deep drilling control testing modules; performing deep drilling control machining on to-be-machined holes according to the first height difference and the second height difference when deep drilling control machining is about to be performed on the to-be-machined holes in printed circuit boards. The first metal layers and the second metal layers respectively correspond to first circuit layers and second circuit layers of the printed circuit boards, the first circuit layers are surface-layer circuits of the printed circuit boards, and the second circuit layers are circuit layers which are required to be drilled out when the printed circuit boards are drilled. The third metal layers correspond to third circuit layers of the printed circuit boards, and the third circuit layers are circuit layers which are not allowed to be drilled out when the printed circuit boards are drilled. The to-be-machined holes in the printed circuit boards correspond to the deep drilling control testing modules.

Owner:PEKING UNIV FOUNDER GRP CO LTD +3

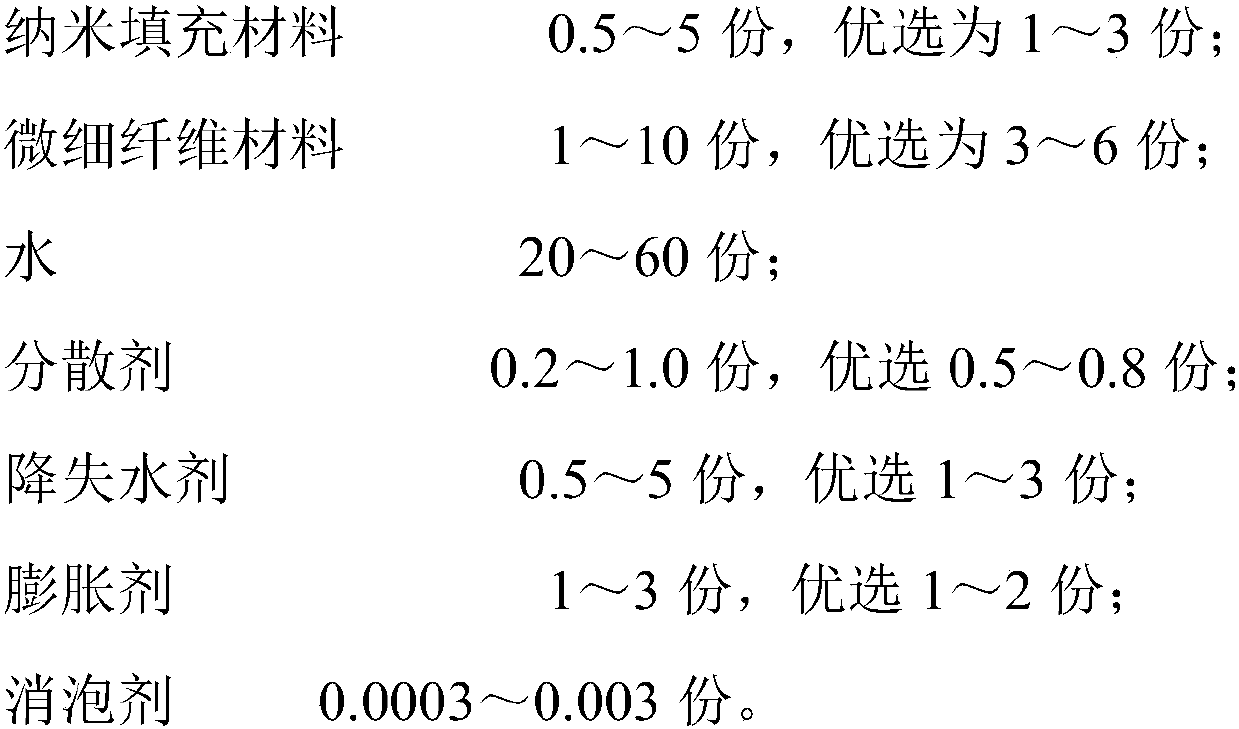

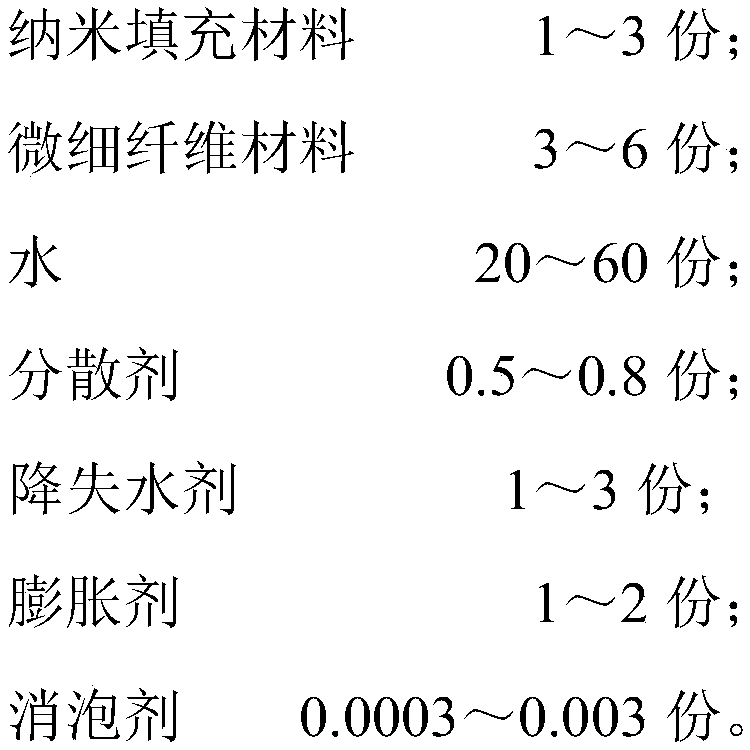

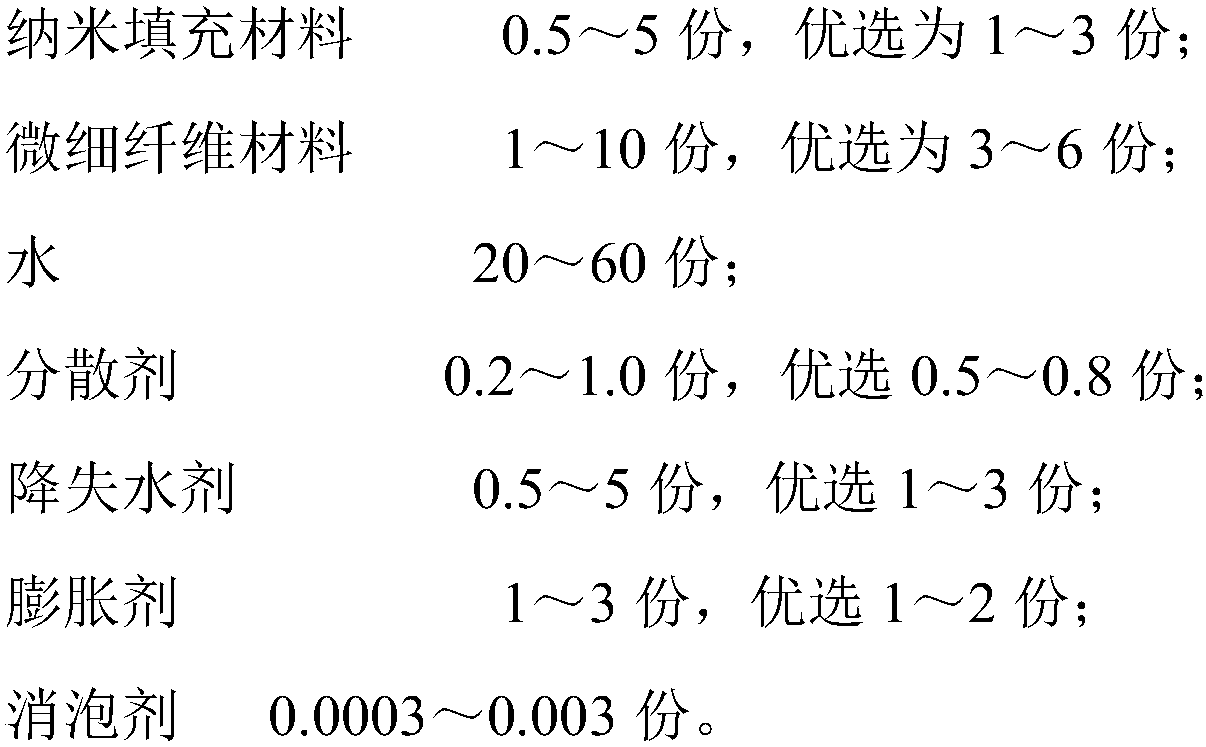

Plugging agent with high bearing strength for deep drilling and preparation method thereof

InactiveCN109868125AHigh compressive strengthImprove flexural strengthDrilling compositionFiberFlexural strength

The invention relates to a plugging agent with high bearing strength for deep drilling and a preparation method thereof, belonging to the field of ultra-deep petroleum drilling engineering. The plugging agent with high bearing strength for deep drilling comprises cement, a cement additive, a nanometer filling material, a micro-fine fiber material and water; on the basis of 100 parts by weight of the cement, the content of the nanometer filling material is 0.5 to 5 parts by weight, preferably 1 to 3 parts by weight; the content of the micro-fine fiber material is 1 to 10 parts by weight, preferably 3 to 6 parts by weight; and the content of the water is 20 to 60 parts by weight. According to the invention, the plugging agent with high bearing strength can greatly improve compressive strength and flexural strength of a plugging slurry, and has significant plugging effect. The plugging agent provided by the invention is applicable to plugging lateral cracks, malignant leakage caused by broken rock strata and long open hole segments of multi-pressure series of strata; cementation performance between the plugging agent and a leakage channel wall and the impact crushing resistance of formed cement stone are improved; and the construction requirements of plugging for long open hole segments and plugging under high strength of 30 MPa or above can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com