120 steel grade drill pipe and manufacturing process method thereof

A manufacturing process and drill pipe technology, which is applied in the field of petroleum drilling engineering and mechanical processing, can solve the problems of small diameter of the inner hole of the male joint, small flow cross section, brittle fracture, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

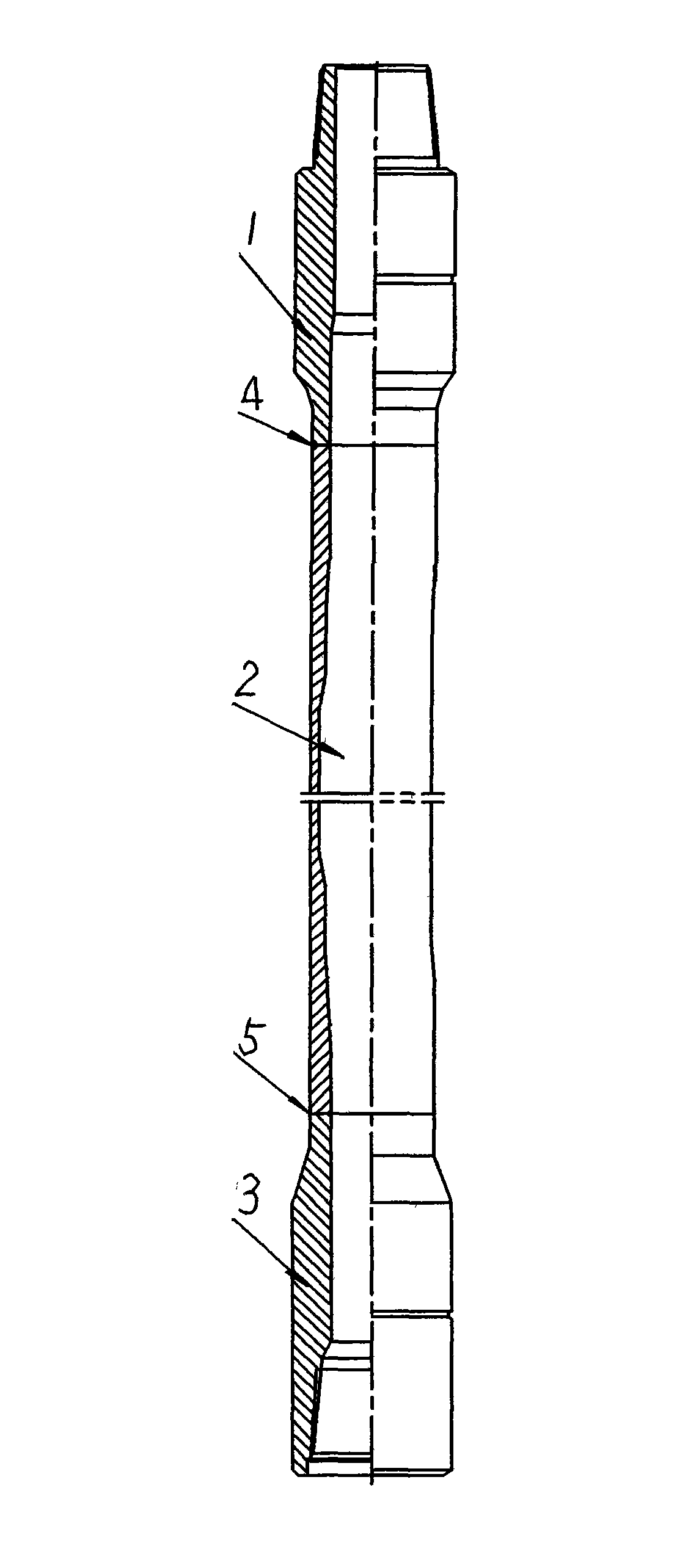

[0010] Describe below in conjunction with accompanying drawing.

[0011] As shown in the figure, the 120 steel grade drill pipe provided by the present invention is composed of a male joint 1, a drill pipe body 2 and a female joint 3. In the figure, the labels "4" and "5" are respectively the male joint 1 and the female joint 3 The weld seam that is butt welded with the drill pipe 2. The components and the overall manufacturing process of the drill pipe are as described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com