Drilling method and drilling machine

A drilling method and drilling machine technology, which are applied in the directions of drilling/drilling equipment, boring/drilling, drilling tool accessories, etc., can solve the problem of inability to accurately control the depth control drilling accuracy of printed circuit boards, Increase the production cycle and production cost of printed circuit boards to achieve the effect of reducing waiting time, reducing manpower and material resources, and reducing production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

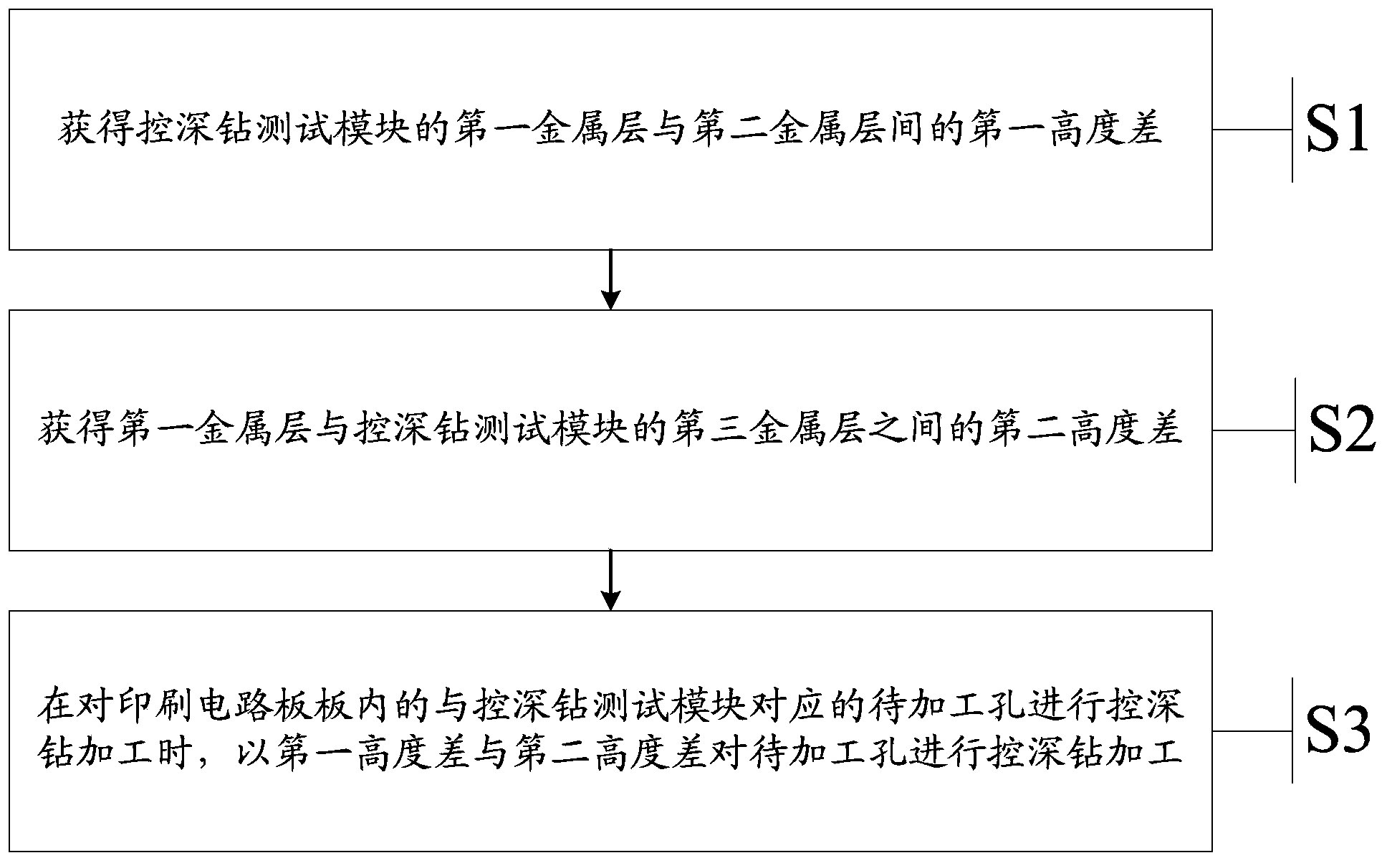

[0031] The embodiment of the present invention provides a drilling method and a drilling machine, which solves the problem of increasing the production cycle and production cost of printed circuit boards in the prior art, as well as the inability to accurately control the depth-controlled drilling of each printed circuit board. Technical issues of drilling accuracy.

[0032] The technical solution in the embodiment of the present invention is to solve the above-mentioned technical problems of increasing the production cycle and production cost of the printed circuit board and the inability to accurately control the drilling accuracy of the depth-controlled drilling of each printed circuit board. The general idea is as follows:

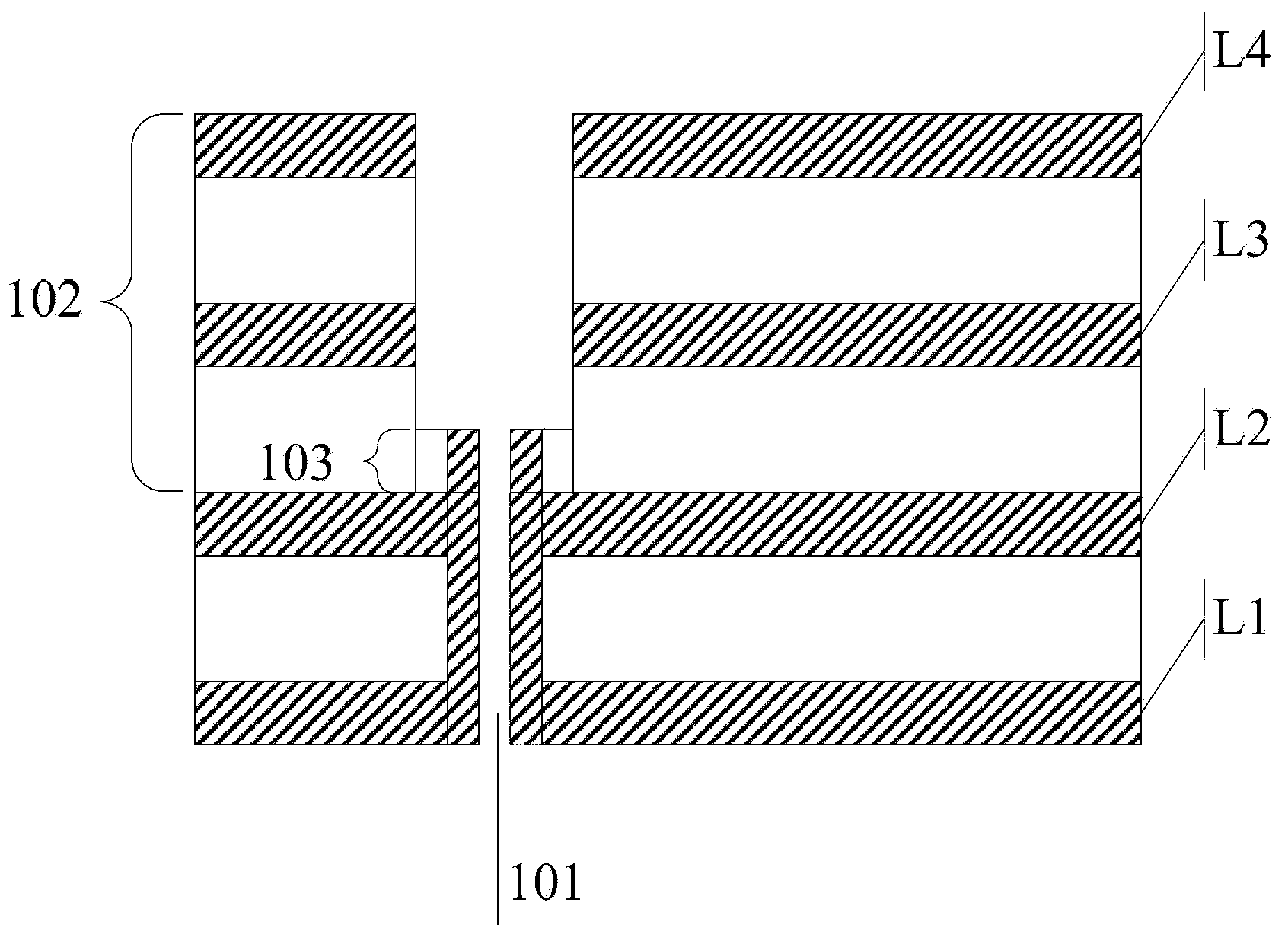

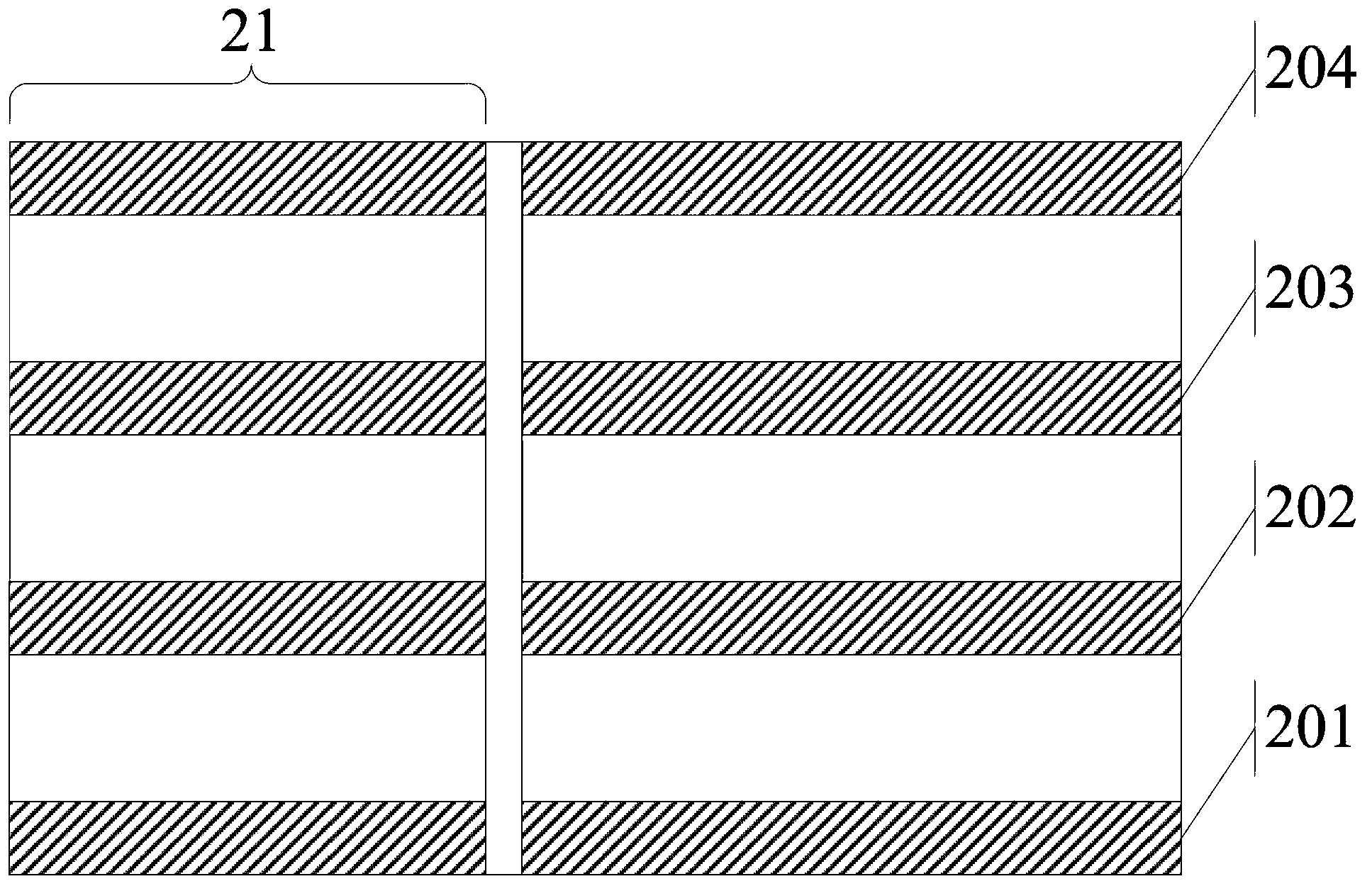

[0033] First, the first height difference between the first metal layer and the second metal layer of the controlled depth drilling test module is obtained, wherein the first metal layer and the second metal layer are respectively connected to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com