Method of dyeing fabric by using dye

A dyeing method and fabric technology, applied in the field of fabric dyeing and fabric dyeing, can solve the problems of lengthy process, increased process steps, and hard fabric feel, and achieve the effects of simple process process, uniform dyeing and soft feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

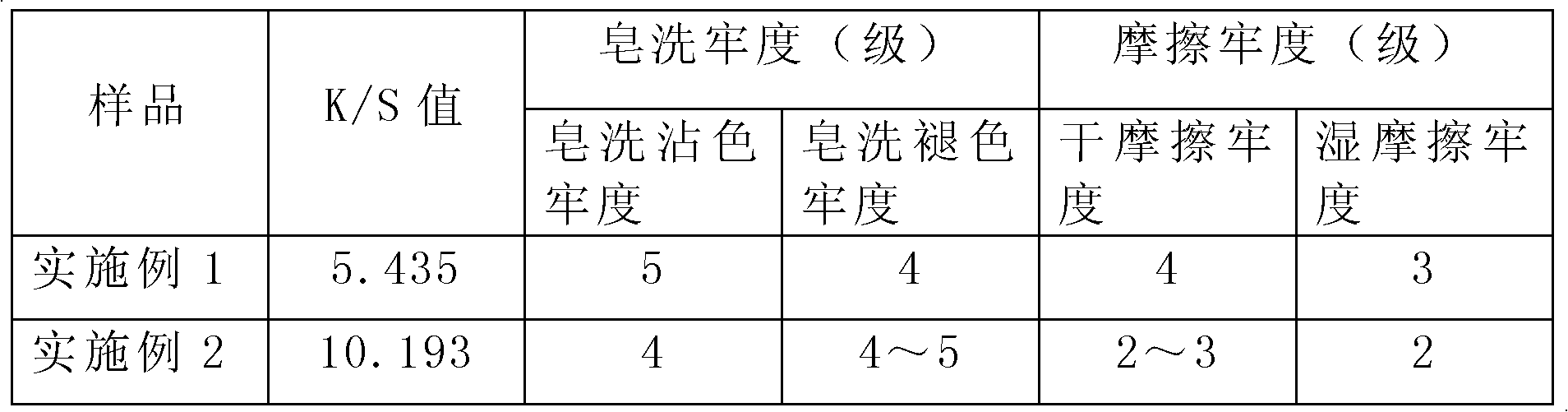

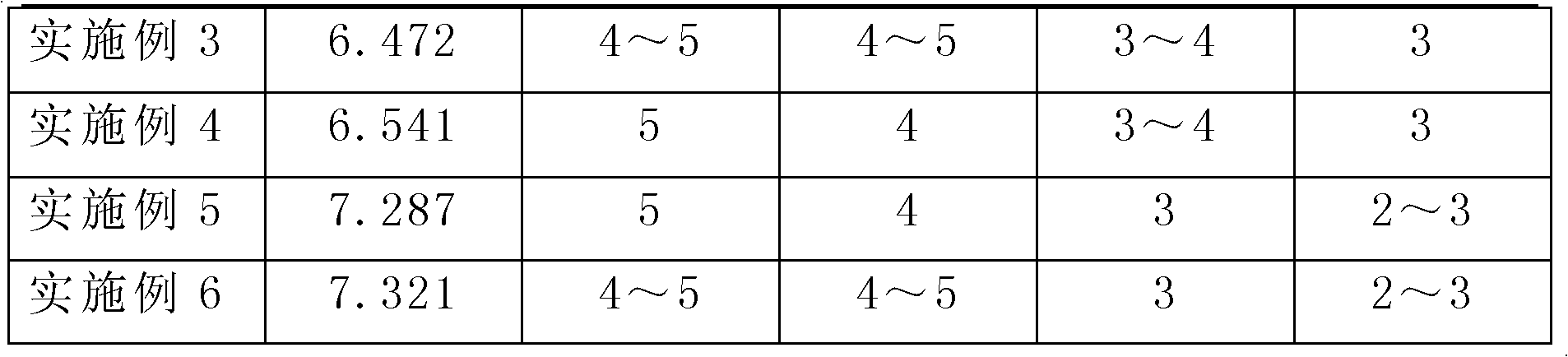

Examples

Embodiment 1

[0029] Select pure cotton woven bleached fabric as pre-dyed fabric, desizing, scouring and bleaching it to remove a large amount of impurities such as oil agent and cotton shell, and then subjecting it to hair removal enzyme mercerizing treatment. Mix the dye color agent, cationic modifier, leveling agent, dispersant, alkaline reagent, wet rubbing fastness improving agent PG and water together to prepare a dye liquor. The mass concentration of each component is:

[0030] Dye color agent: 30g / L; cationic modifier: 25g / L; leveling agent: 3g / L; dispersant: 3g / L; alkaline reagent: 5g / L; wet rubbing fastness improver PG: 10g / L L. The dye color agent used is reactive dye color agent, the cationic modifier is epoxypropyl triethyl ammonium chloride and glycidyl trimethyl ammonium chloride, the leveling agent is Pingping plus O, and the alkaline reagent is Sodium carbonate.

[0031]Then immerse the treated pure cotton woven bleached cloth in the prepared dye solution to control the b...

Embodiment 2

[0033] Select pure cotton woven bleached fabric as pre-dyed fabric, desizing, scouring and bleaching it to remove a large amount of impurities such as oil agent and cotton shell, and then subjecting it to hair removal enzyme mercerizing treatment. Mix the dye color agent, cationic modifier, leveling agent, dispersant, wet rubbing fastness improving agent PG and water together to prepare a dye liquor, and the mass concentration of each component is:

[0034] Dye color agent: 10g / L; cationic modifier: 12g / L; leveling agent: 1g / L; dispersant: 1g / L; wet rubbing fastness improver PG: 6g / L. The dye toner used is a reactive dye toner, the cationic modifier is a chlorotriazine type quaternary ammonium compound, and the leveling agent is an octylphenol polyoxyethylene ether and a phenylethylphenol polyoxyethylene ether.

[0035] Then immerse the treated pure cotton woven bleached cloth in the prepared dye solution to control the liquor ratio to 1:5, keep the initial dyeing temperature ...

Embodiment 3

[0037] Select pure cotton woven bleached fabric as pre-dyed fabric, desizing, scouring and bleaching it to remove a large amount of impurities such as oil agent and cotton shell, and then subjecting it to hair removal enzyme mercerizing treatment. Mix the dye color agent, cationic modifier, leveling agent, dispersant, alkaline reagent, wet rubbing fastness improver HT-TMS and water together to prepare a dye liquor. The mass concentration of each component is:

[0038] Dye color agent: 50g / L; cationic modifier: 35g / L; leveling agent: 5g / L; dispersant: 5g / L; alkaline reagent: 10g / L; wet rubbing fastness improver HT-TMS: 15g / L. The dye color agent used is a natural dye color agent, the cationic modifier is polyamide epichlorohydrin, chlorotriazine type quaternary ammonium compound, and the leveling agent is octylphenol polyoxyethylene ether and phenylethylphenol polyoxyethylene ether. Vinyl ether, the alkaline reagent is potassium bicarbonate.

[0039] Then immerse the treated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com