Patents

Literature

211results about How to "Good rubbing fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

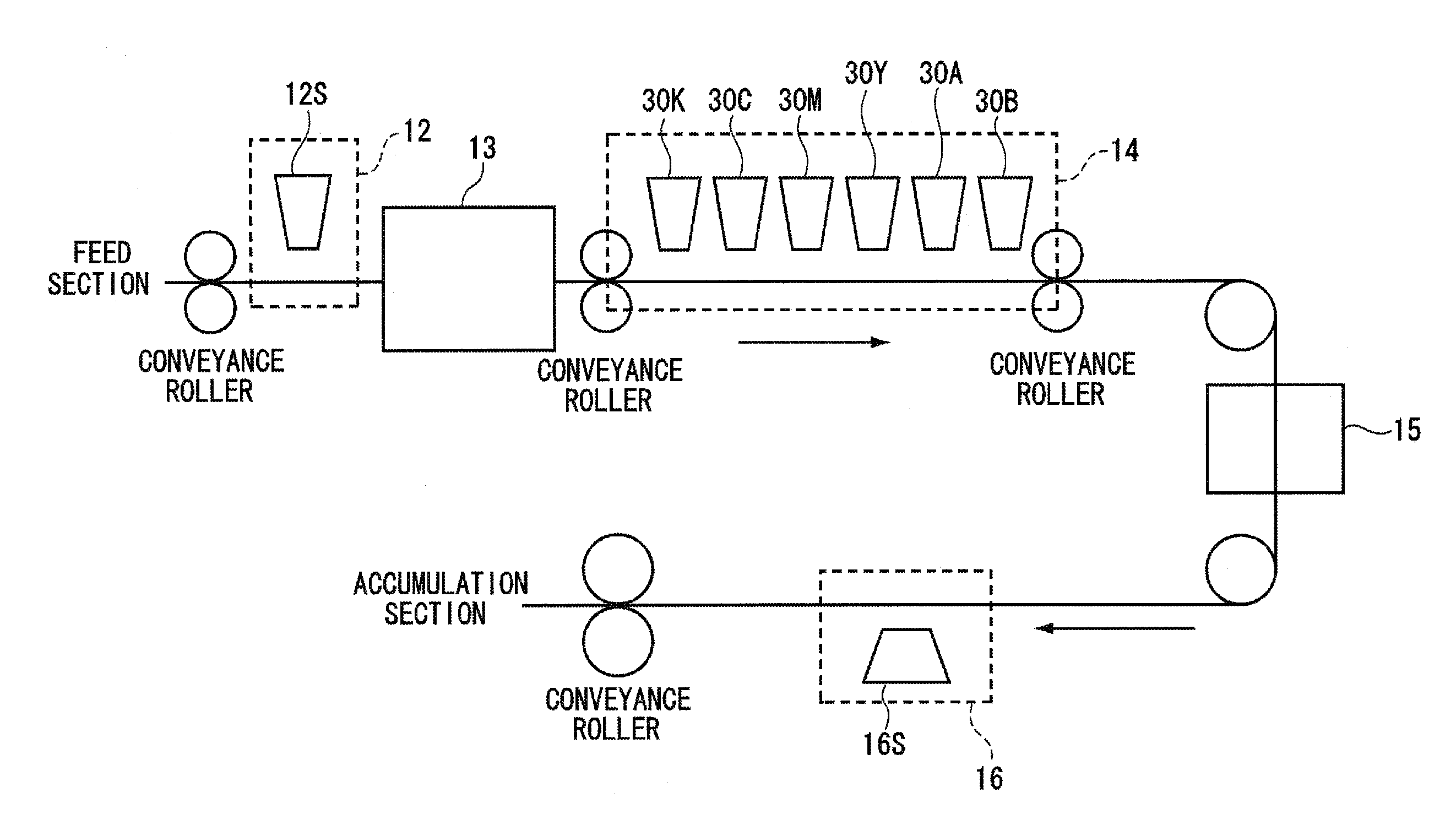

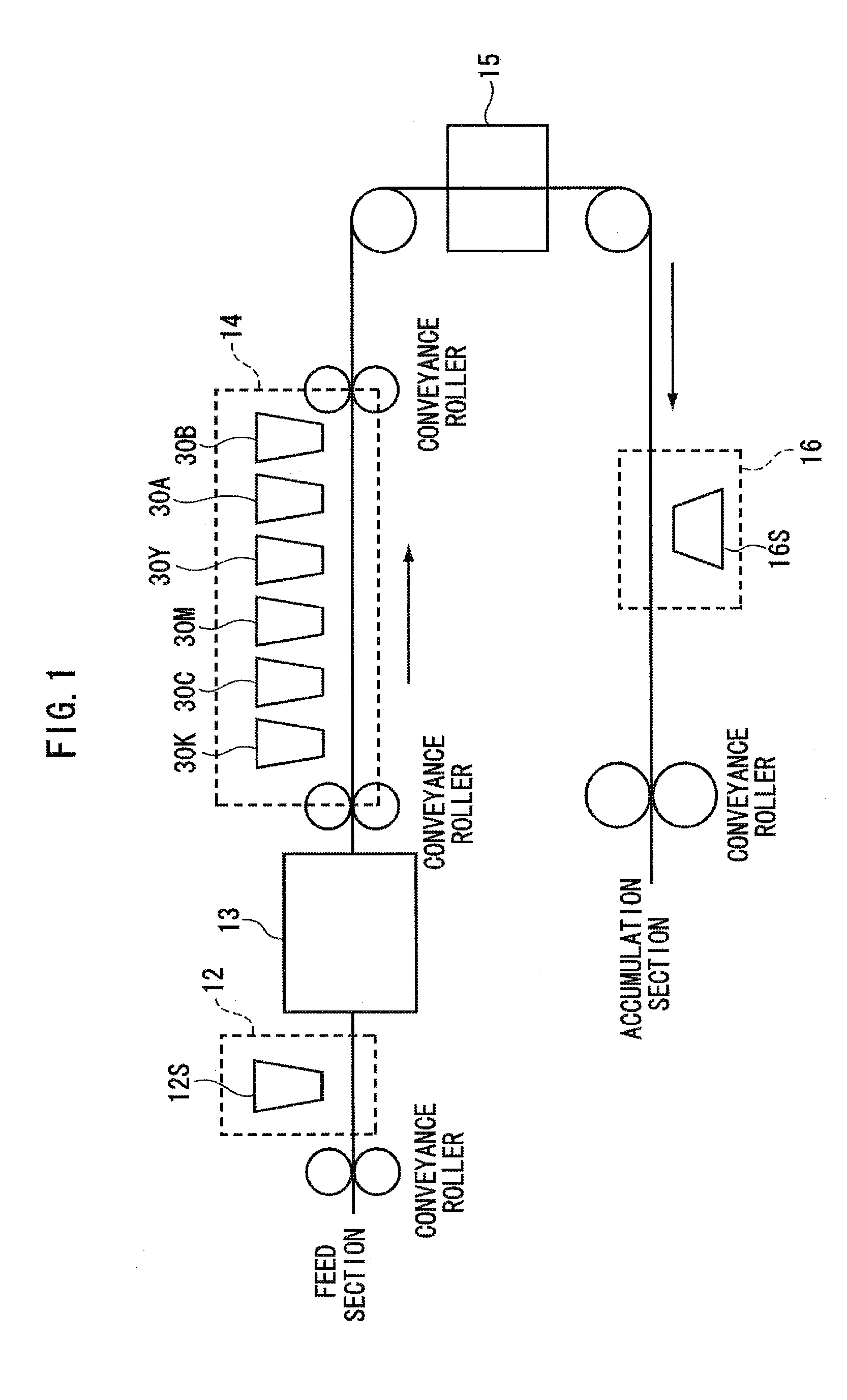

Digital ink jet fabric-treating process

The present invention is digital ink jet fabric treating process, and belongs to the field of textile science and technology. The fabric pre-treating process for digital ink jetting and printing with water thinned pigment ink is suitable for fabric of cotton, hemp, silk, Dacron, polyester and cotton blend, acrylic fiber, etc.; and the treated fabric may be ink jetting printed with water thinned pigment ink in one digital ink jetting printer. After printing and proper heat treatment, may be produced printed product with clear pattern, bright color, and high fastness to resist water washing, friction and sunlight.

Owner:JIANGNAN UNIV

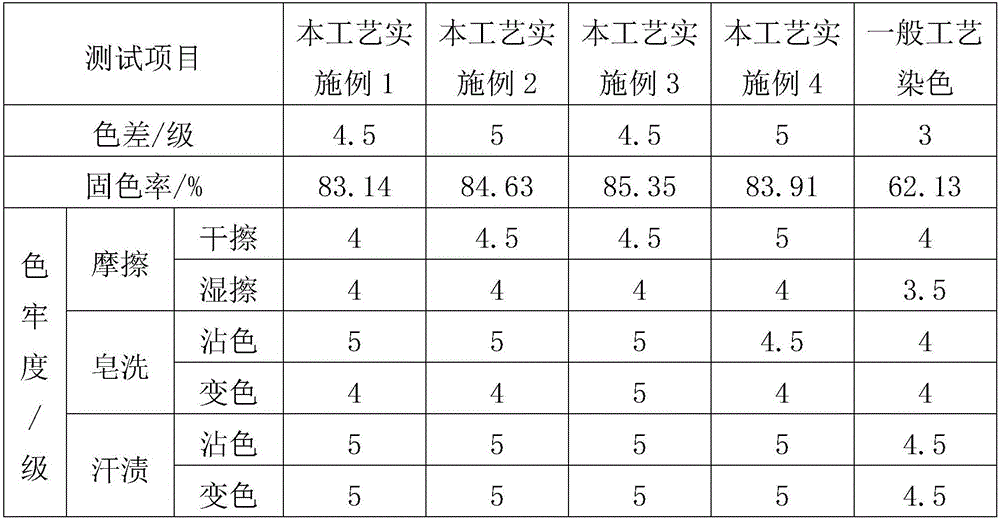

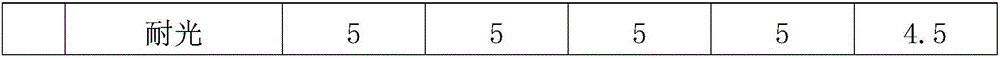

Method of dyeing fabric by using dye

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

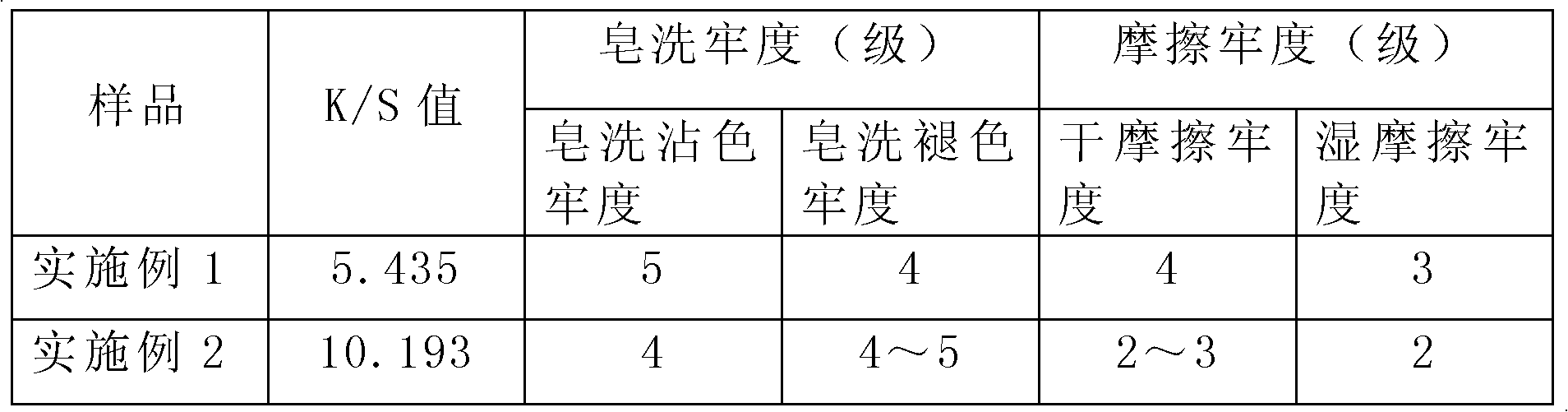

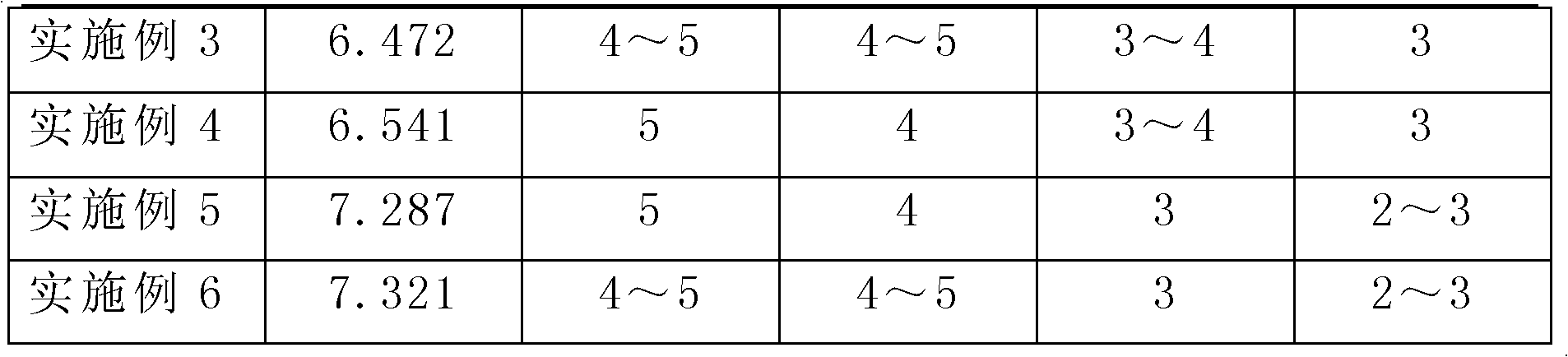

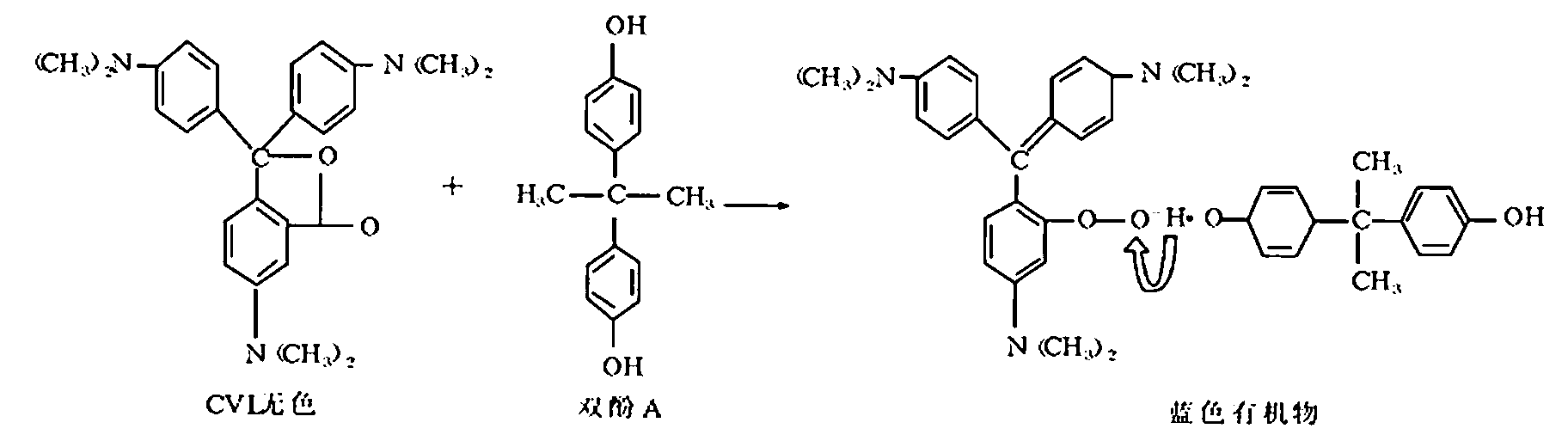

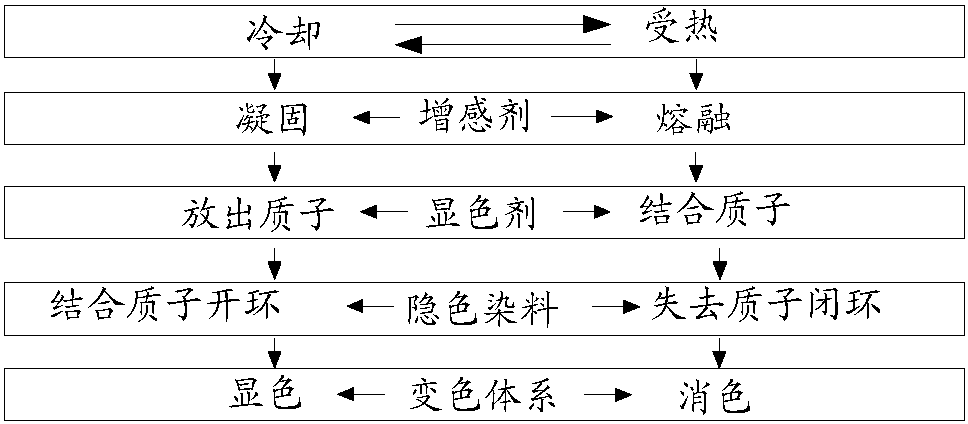

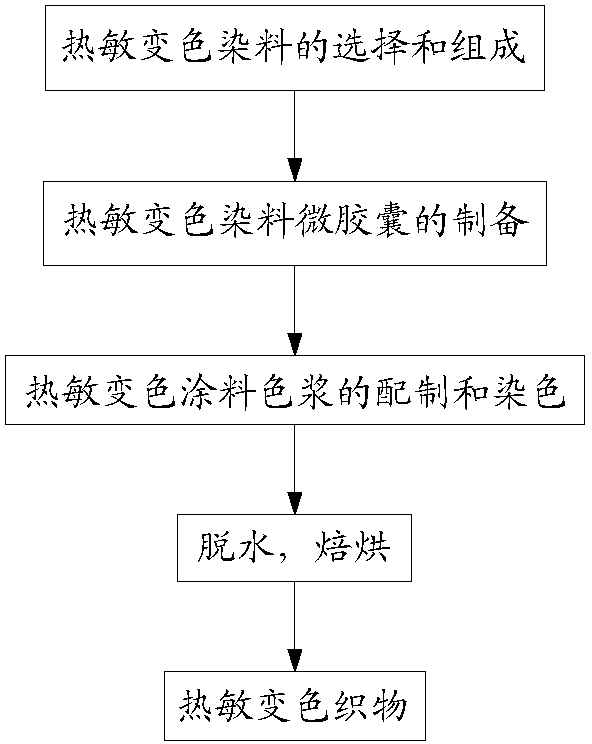

Temperature-sensitive color-changing paint dyeing technology of textile fabrics

InactiveCN103225212AObvious color differenceImprove qualityDyeing processMicroballoon preparationPolyesterFiber

Owner:FUJIAN ZHONGHE

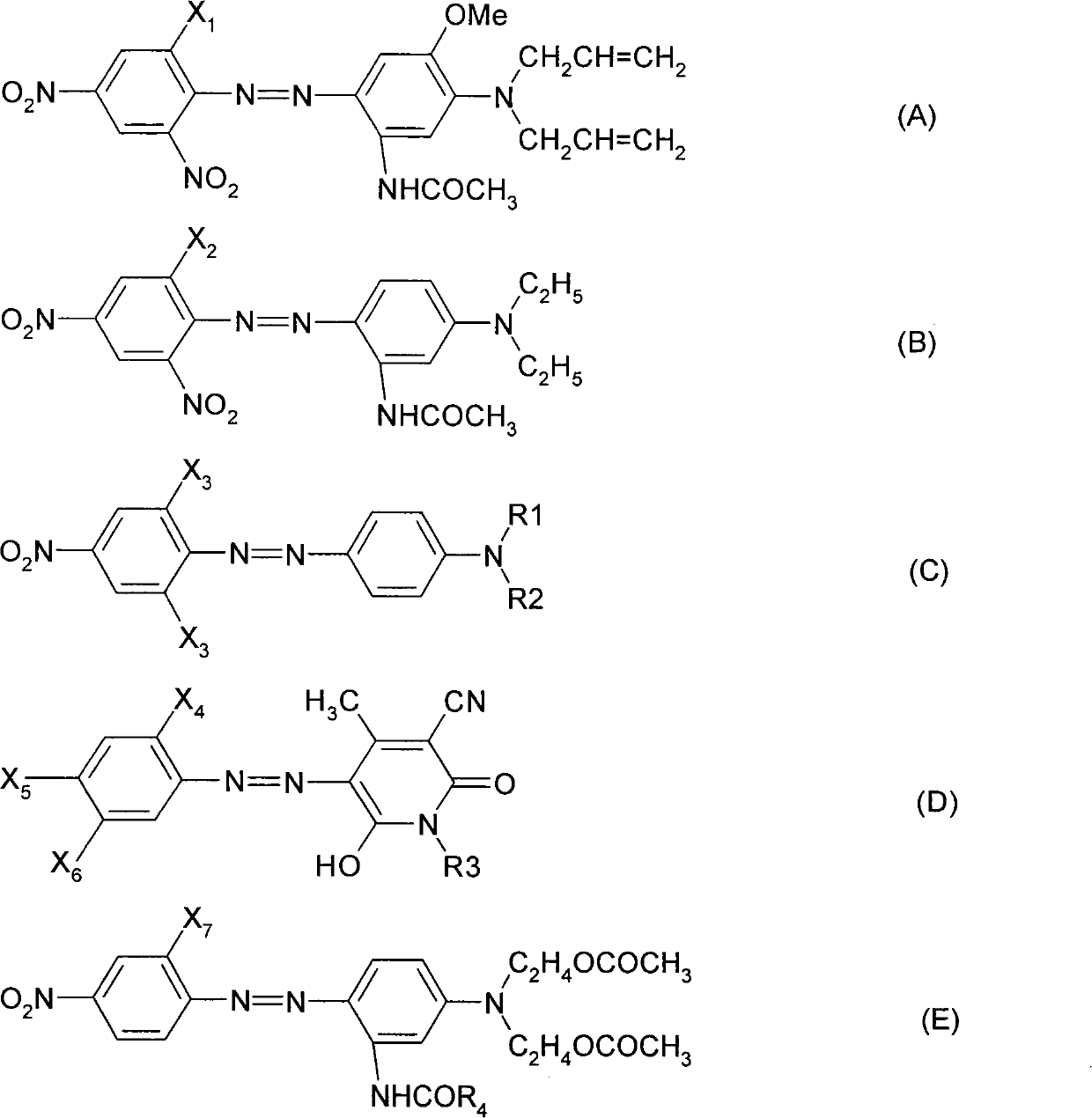

Environment-friendly dark blue and black series compound disperse dye and production method thereof

InactiveCN101792615AHigh coloring rateExcellent promotion rateOrganic dyesDyeing processDisperse dyePerspiration

A dark blue and black series disperse dye compound is formed by compounding three or four of a monomeric dye A, a monomeric dye B, a monomeric dye C, a monomeric dye D or a monomeric dye E, wherein the mass percents of the monomeric dye A, the monomeric dye B, monomeric dye C, the monomeric dye D and the monomeric dye E are respectively 18-45%, 15-50%, 0-50%, 0-20% and 0-45%. When the commercial disperse dye produced by the disperse dye compound of the invention is used for dying hydrophobic polyester fibers, polyurethane fibers, polyamide fibers, acetate fibers and the like, the dark blue or black dyed fabrics with beautiful color shade, good dispersibility, high upgrading force and excellent sun proofness, washability, friction resistance, perspiration resistance and the like can be obtained by adjusting the ratio of different dyes.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

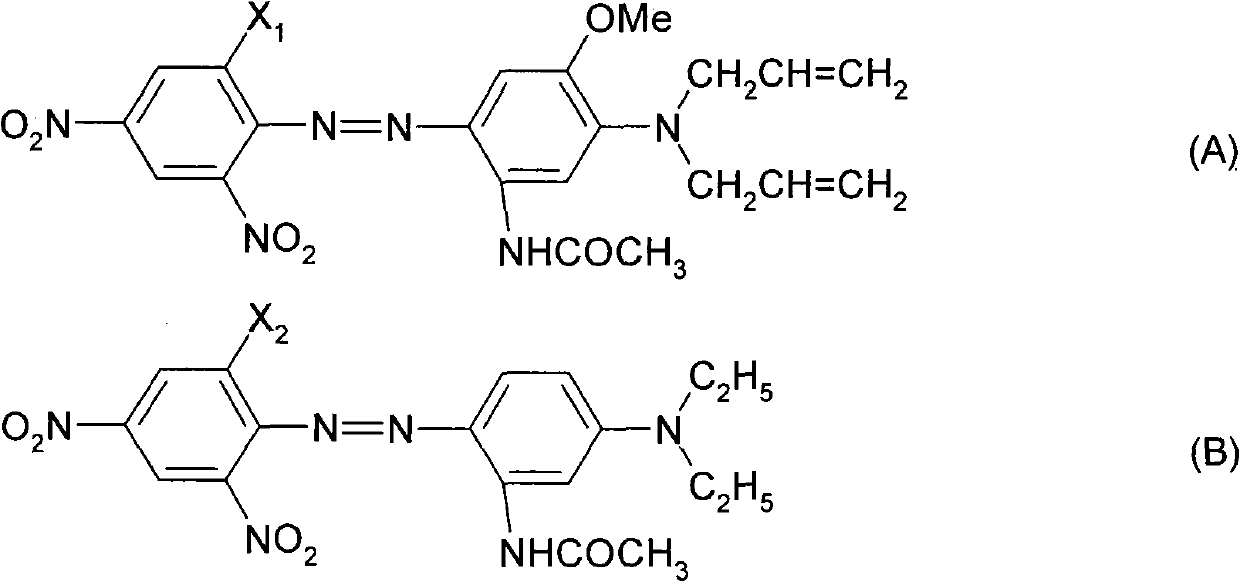

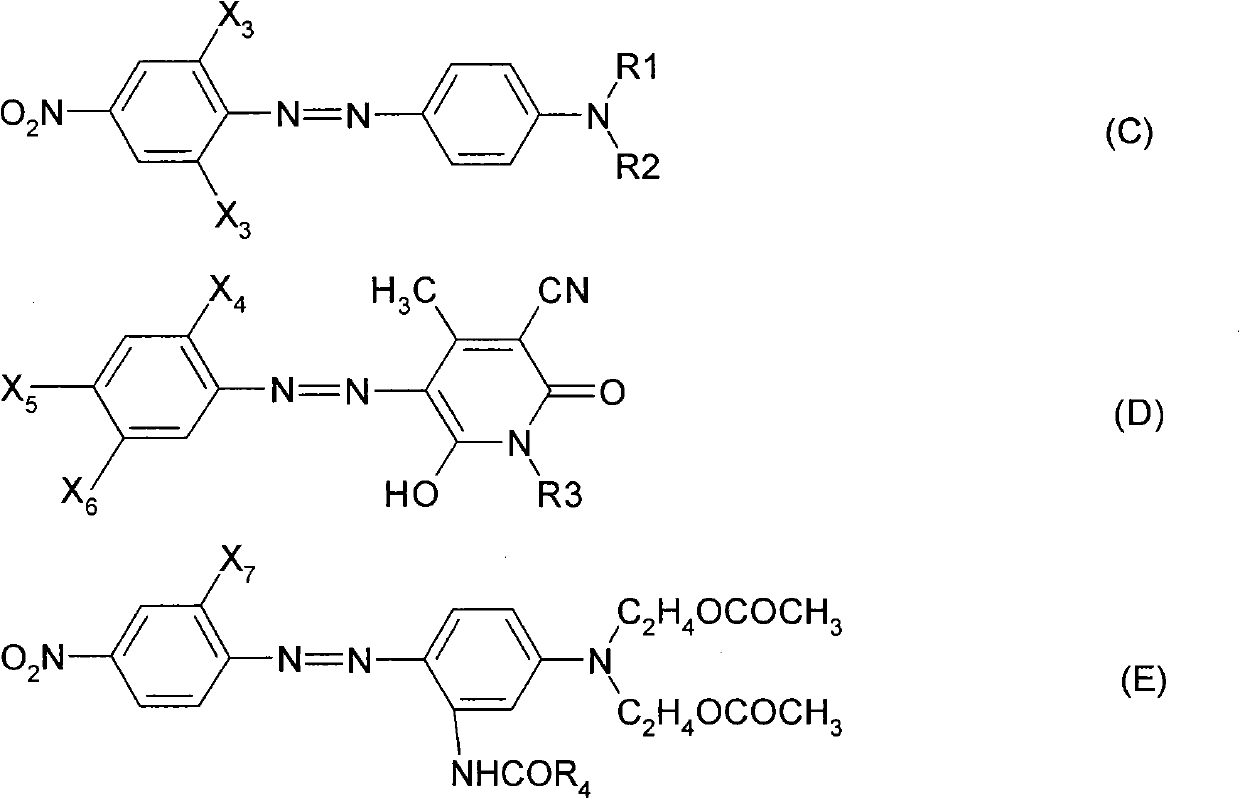

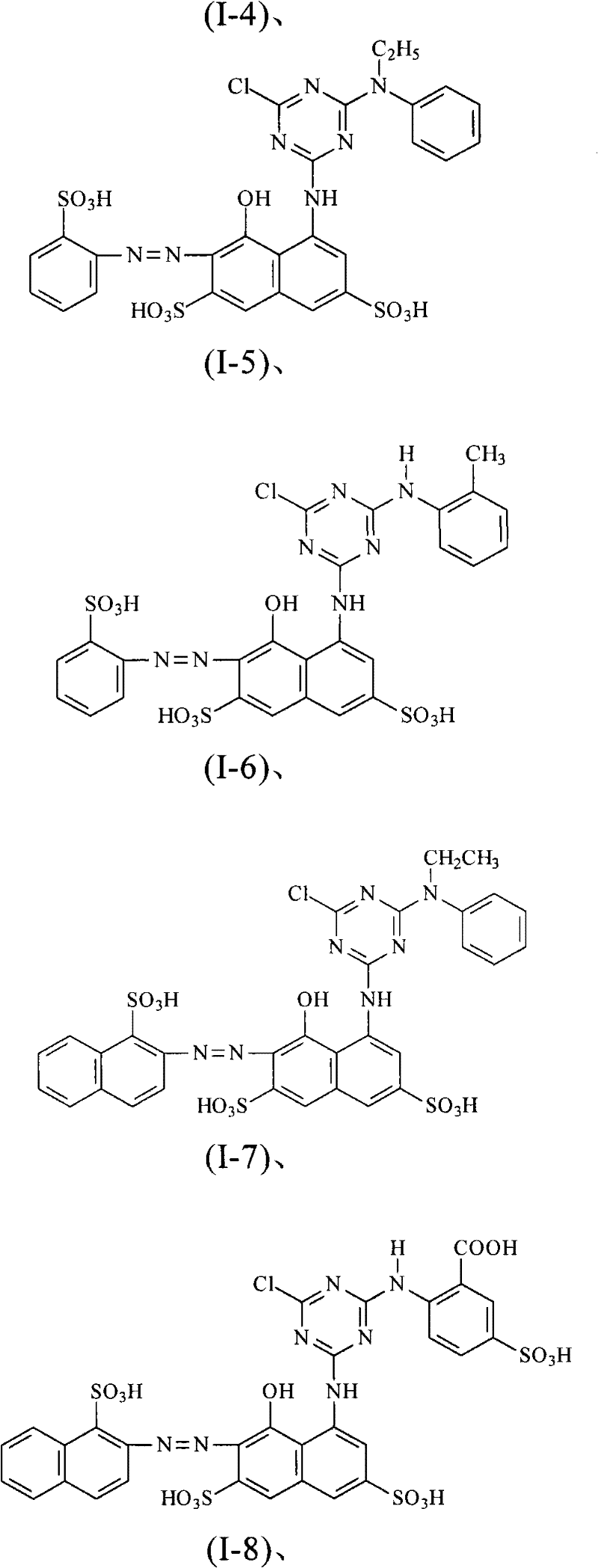

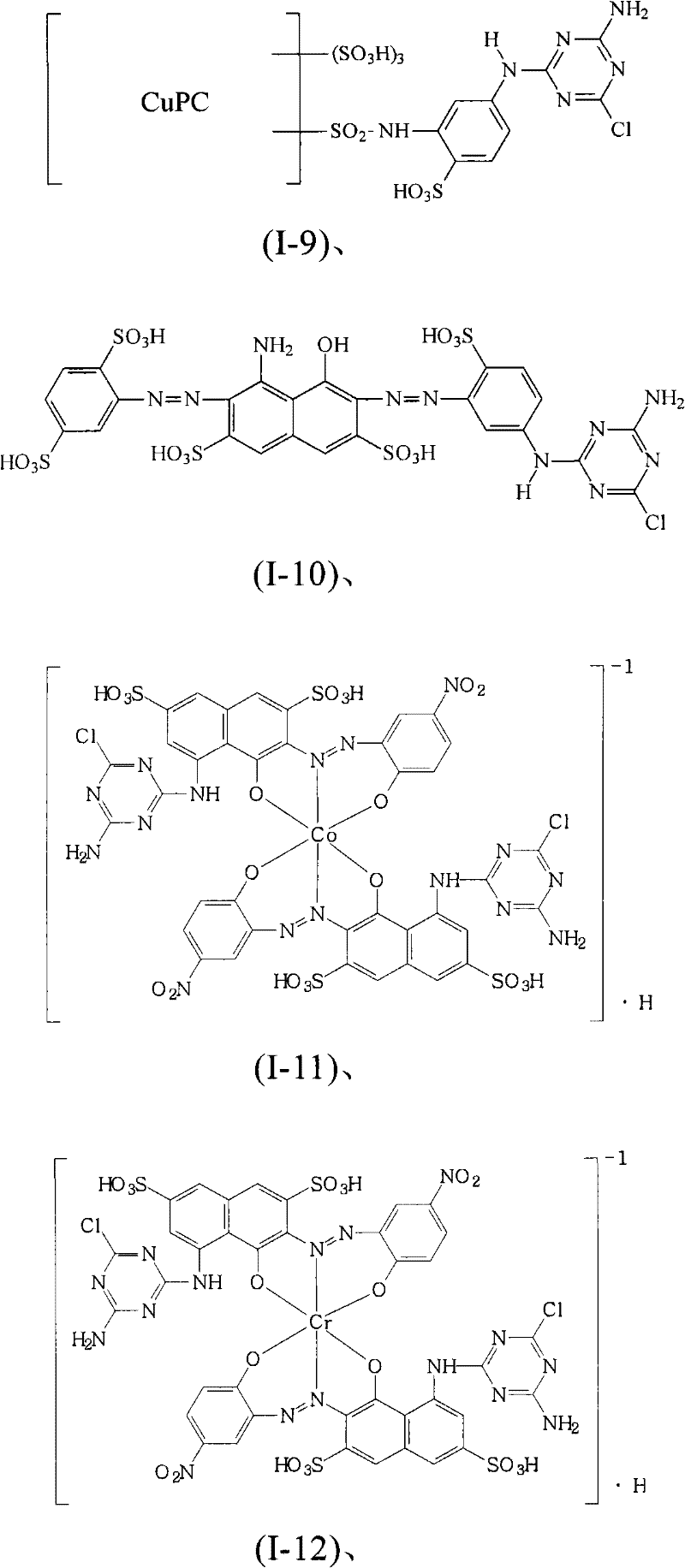

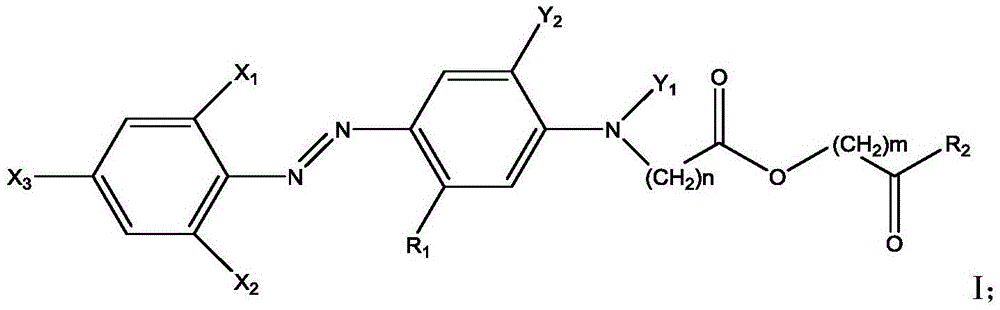

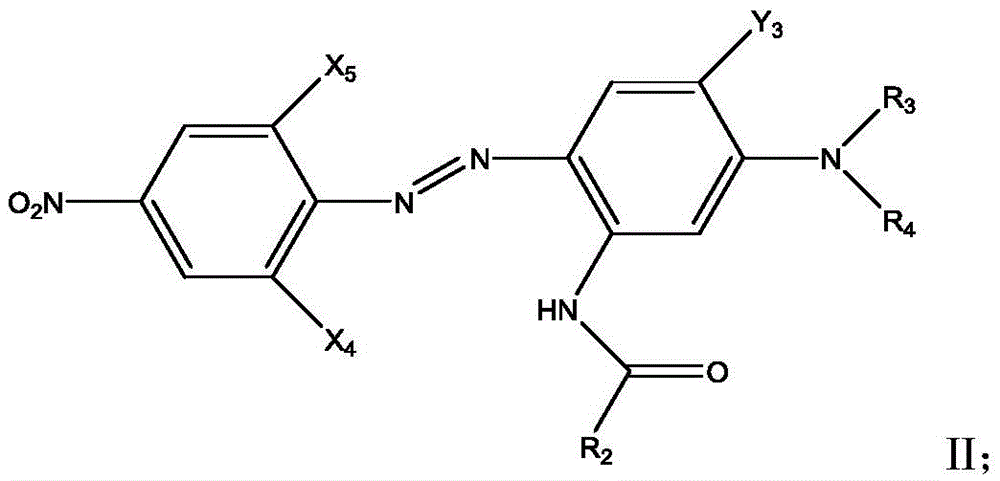

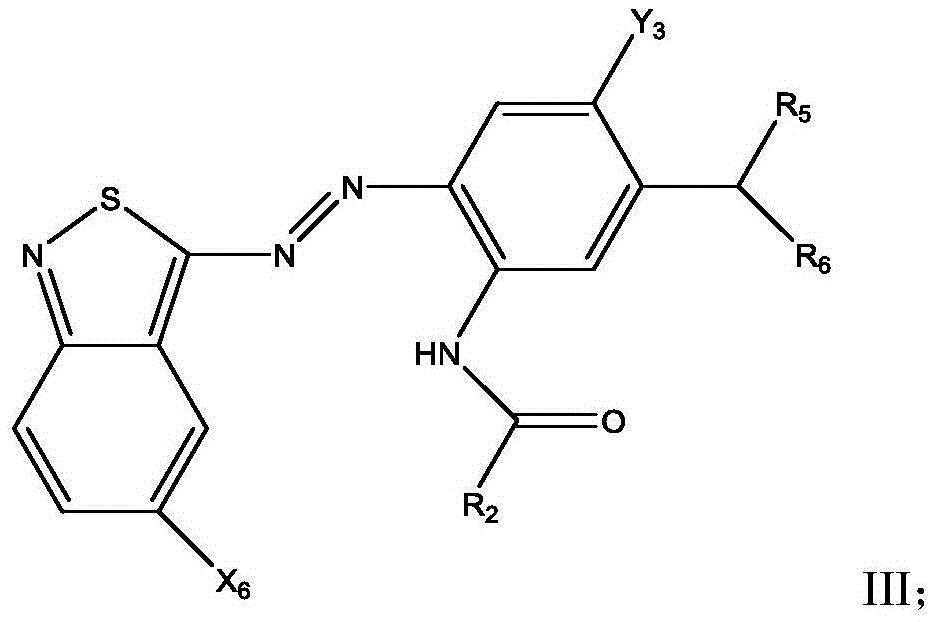

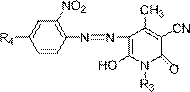

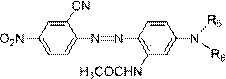

High-fastness blue-to-black disperse dye composition and dye product

InactiveCN104559316AGood thermal migration resistanceImprove washing fastnessOrganic dyesDisperse dyeRubbing

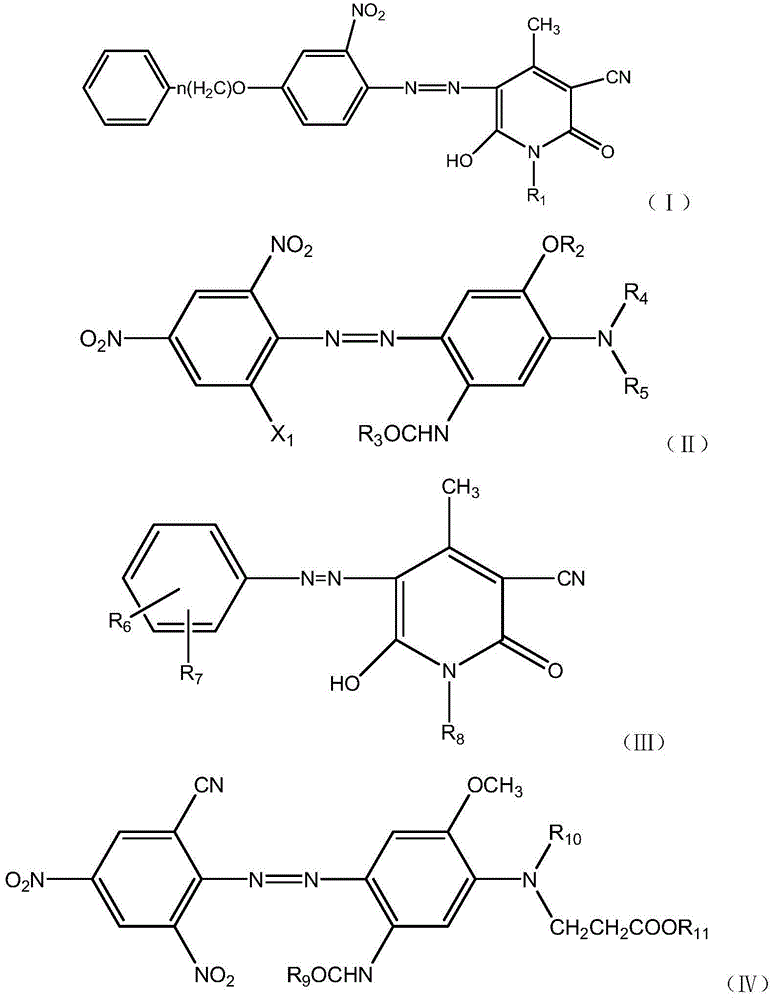

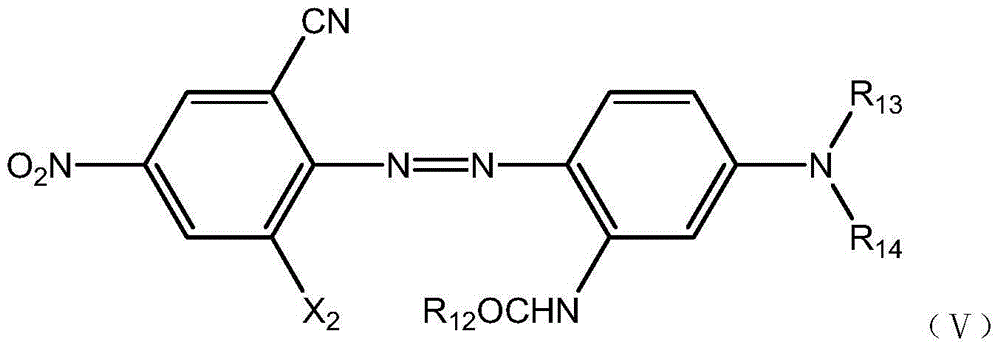

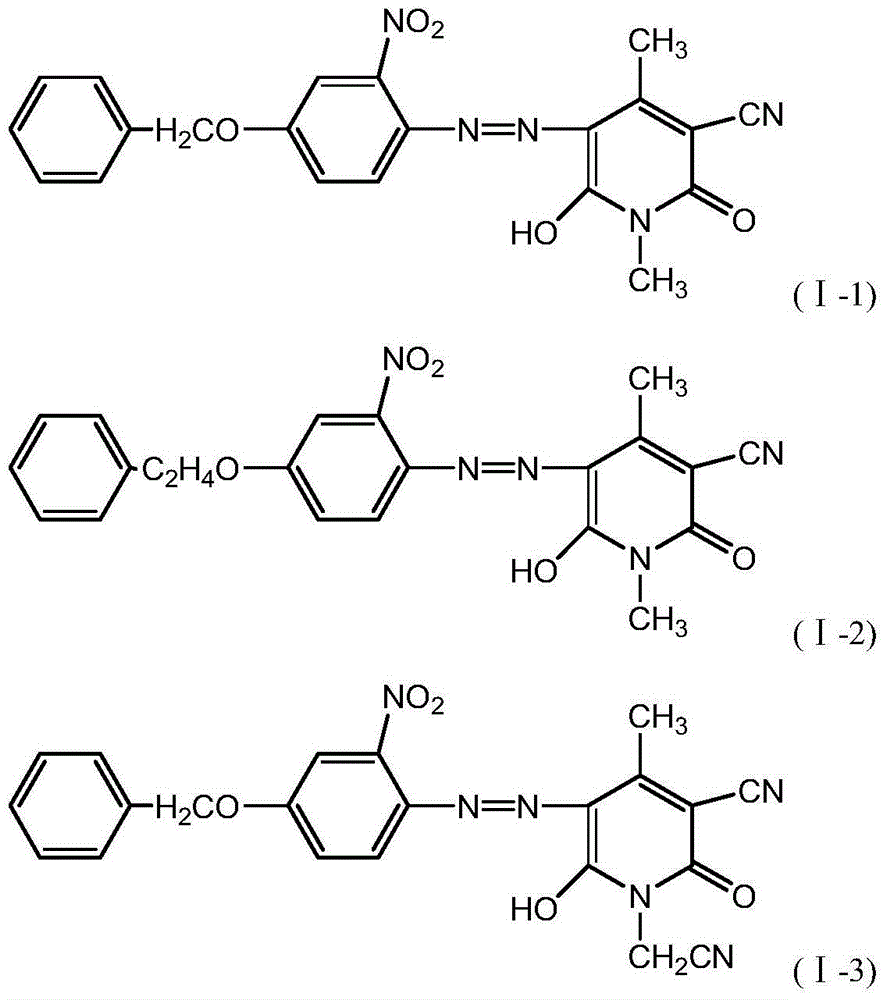

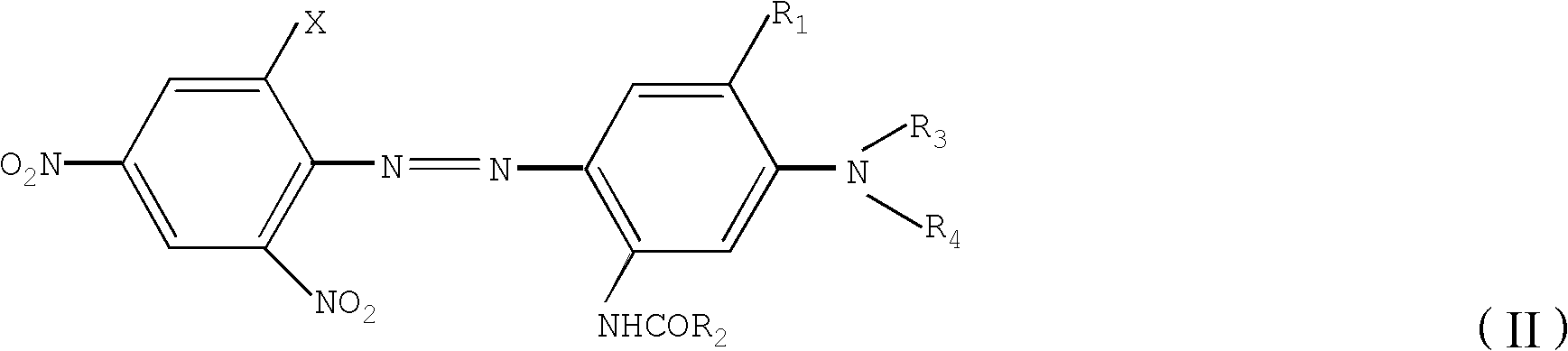

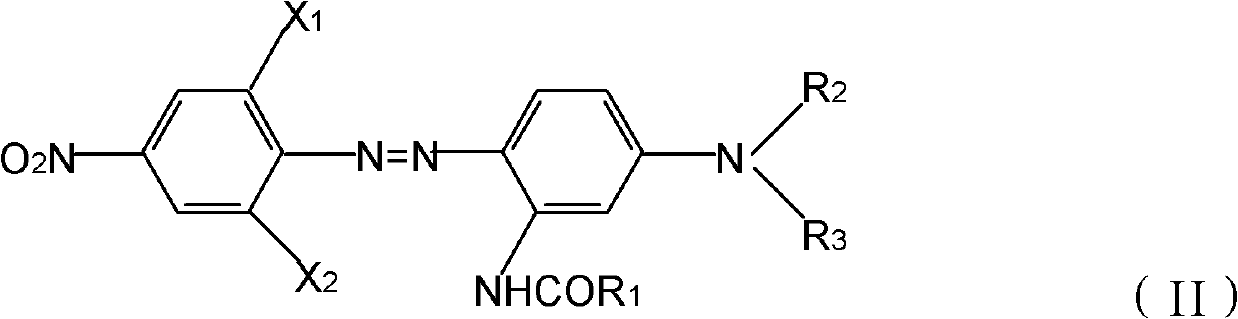

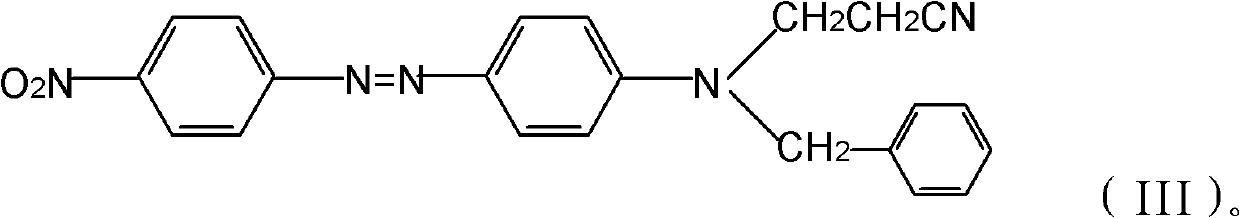

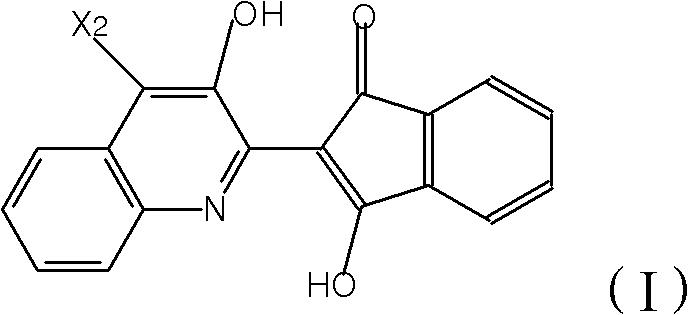

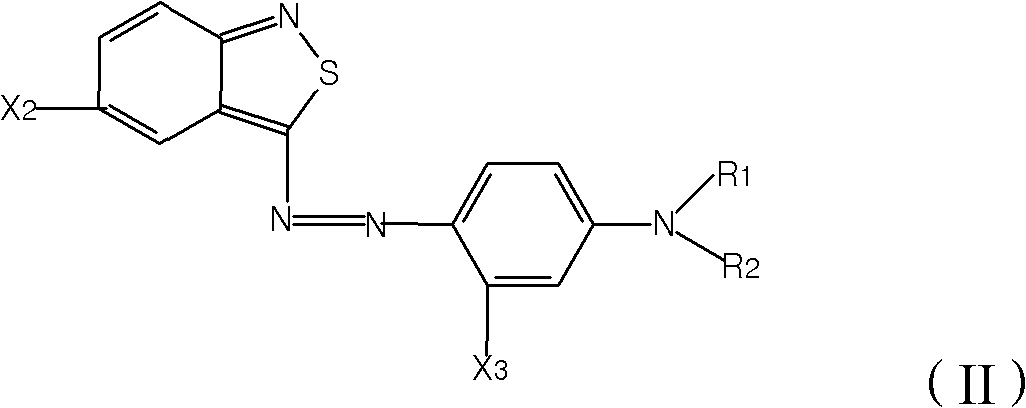

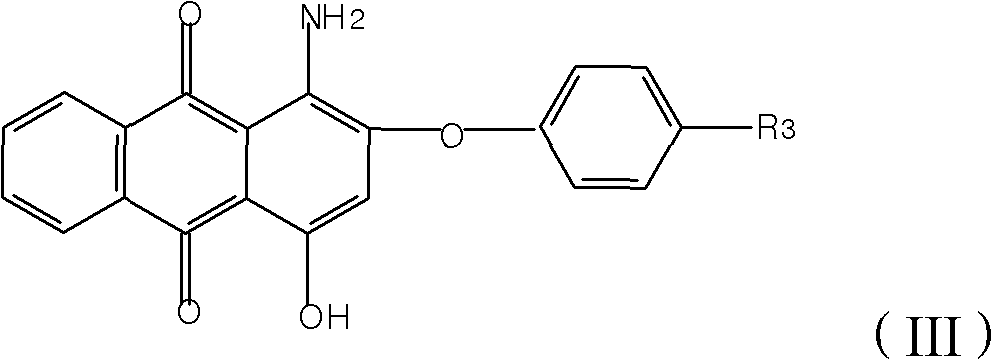

The invention relates to a disperse blue-to-black dye composition and dye product. The composition is mainly composed of a component A, a component B, a component C, a component D and a component E, wherein the component A is selected from one or more of compounds disclosed as Formula (I), the component B is selected from one or more of compounds disclosed as Formula (II), the component C is selected from one or more of compounds disclosed as Formula (III), the component D is selected from one or more of compounds disclosed as Formula (IV), and the component E is selected from one or more of compounds disclosed as Formula (V). The dye product is mainly composed of the composition and assistants. When being used for hydrophobic fiber material dyeing and after-finishing, the dye product has excellent fastness to washing and fastness to rubbing, and is very suitable for printing and dyeing of high-grade textiles.

Owner:ZHEJIANG LONGSHENG GROUP

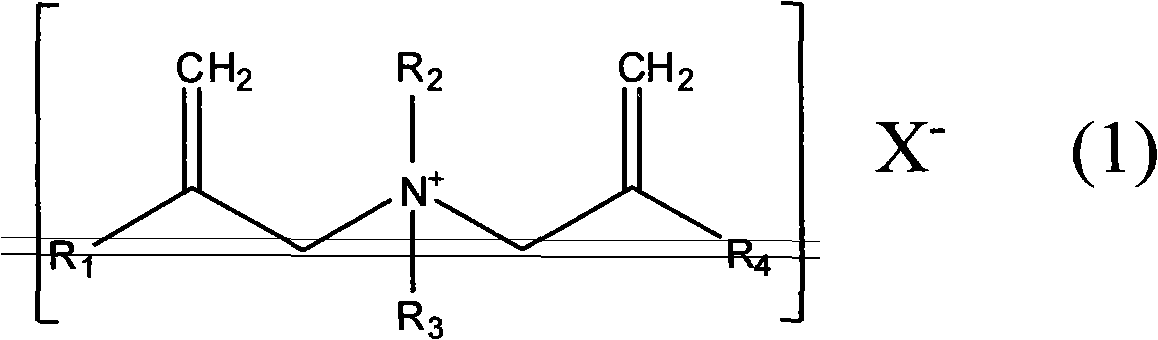

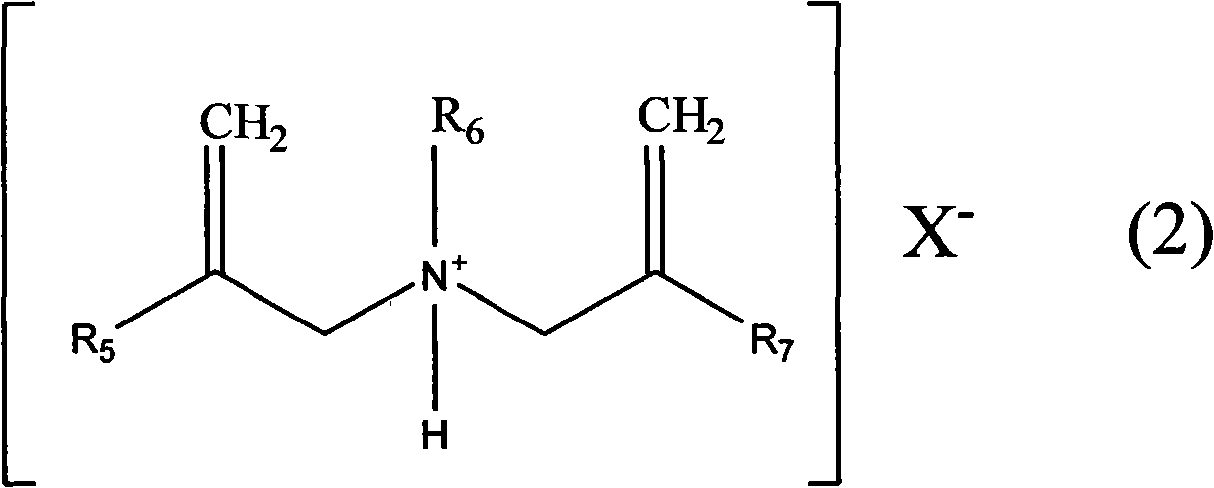

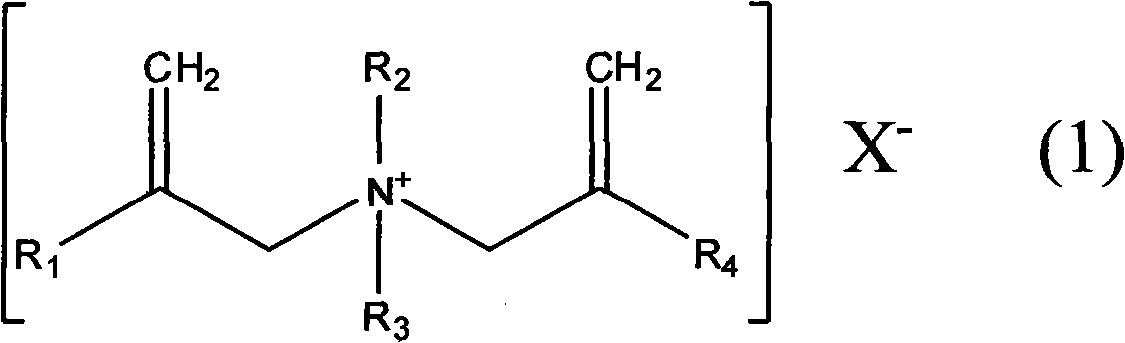

Soap-free color-fixing agent emulsion and preparation method thereof

InactiveCN101781857AGood rubbing fastnessEasy to fix colorDyeing processWater dispersiblePolymer science

The invention relates to a soap-free color-fixing agent emulsion and a preparation method thereof, which belongs to the field of textile chemistry. The emulsion is prepared mainly through the reaction of polymeric monomers, a dispersion stabilizer, cation-carrying monomers, crosslinking monomers, an initiator and deionized water. The soap-free color-fixing agent emulsion is a copolymer emulsion which is prepared by taking water-dispersible oligomer of the copolymerization of diallyl ammonium salt and hydrophobic monomers as the dispersion stabilizer, taking cationic diallyl ammonium and the like as comonomers, adding functional crosslinking monomers and performing soap-free emulsion polymerization under the action of a free radical initiator. The soap-free emulsion contains no conventional small-molecule emulsifier, and the emulsion has the advantages of excellent film-forming property, high cationic charge density, good color-fixing synergetic effect and capability of effectively promoting the color-fixing effect of fabrics.

Owner:洪桂焕

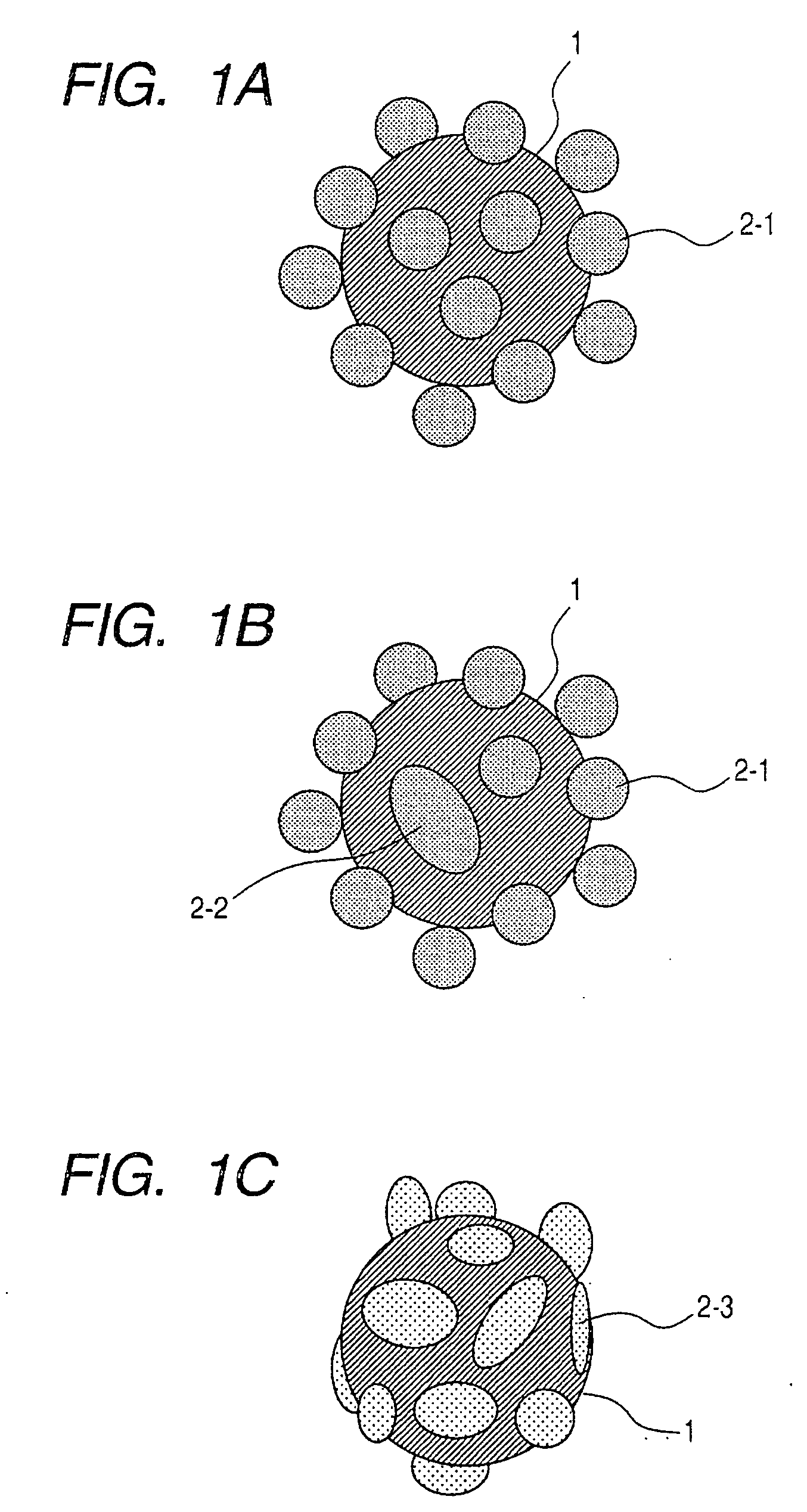

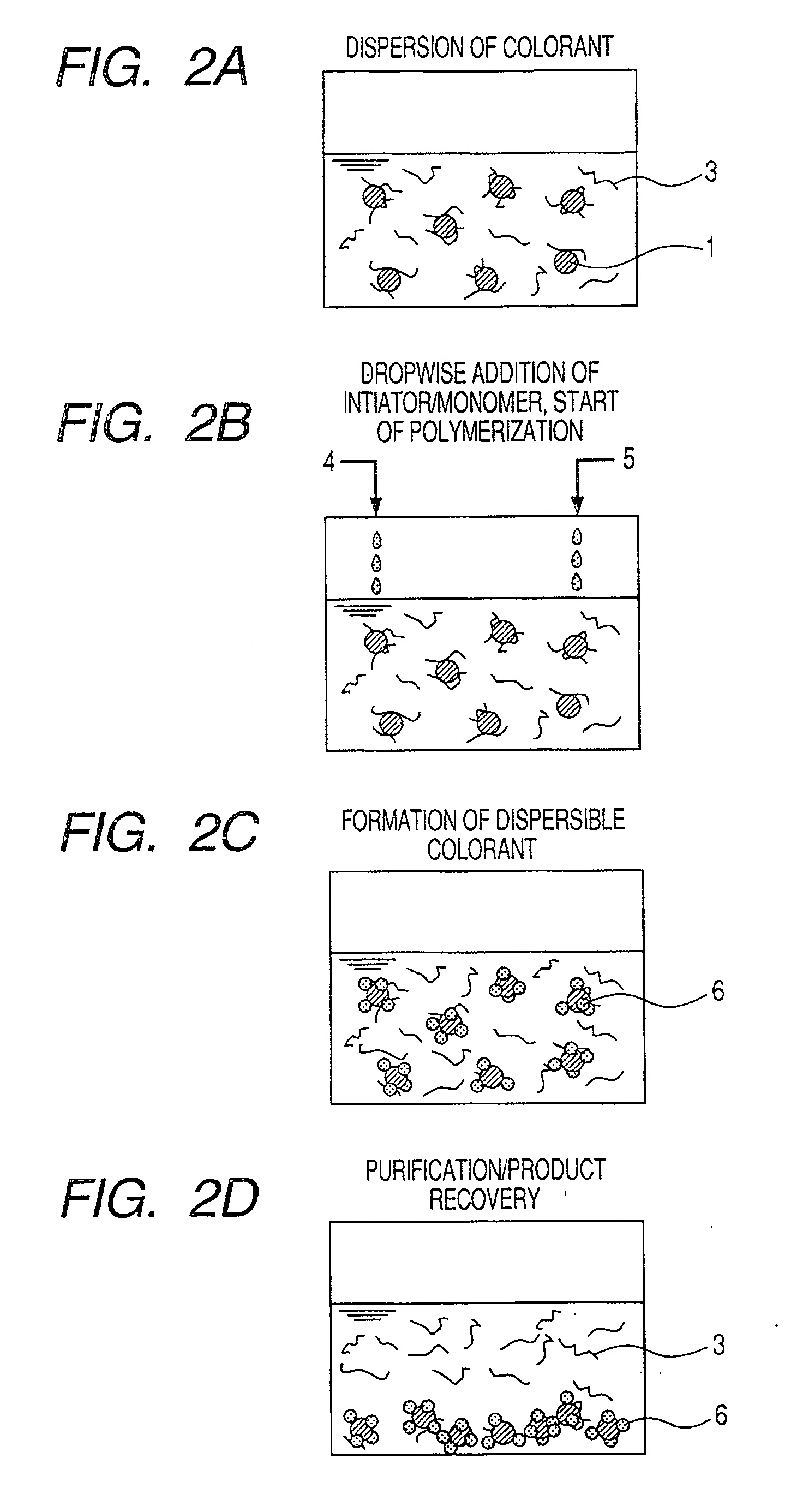

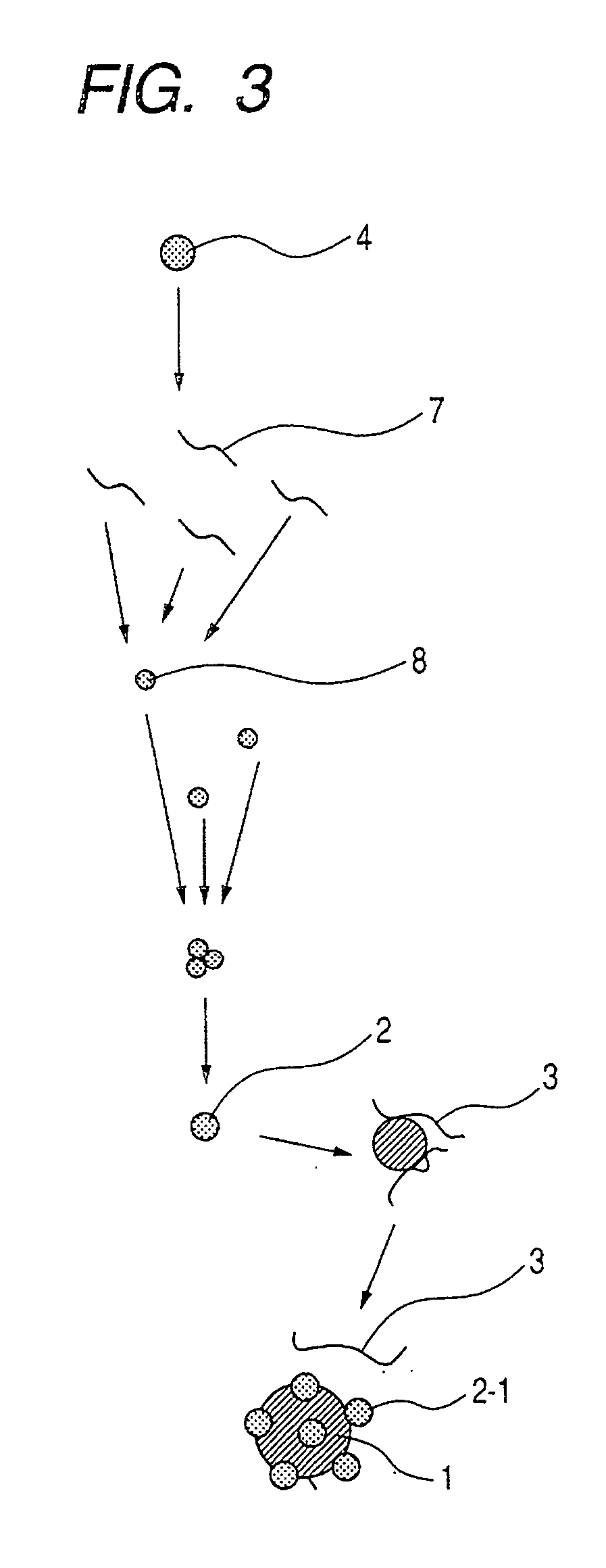

Dispersible colorant, method of producing same, aqueous ink using same, ink tank, ink jet recording apparatus, ink jet recording method, and ink jet recorded image

A dispersible colorant is provided which comprises a colorant and a chargeable resin pseudo fine particle of a size smaller than the size of the colorant being fixed or fused to the colorant, wherein the colorant itself has a surface charge. Thereby, it becomes possible to process a surface of the colorant while exploiting both the characteristic of a resin adhered and fixed to the surface of the colorant and the characteristic of the surface of the colorant, so that it is possible to provide a dispersible colorant that has sufficiently high dispersibility and a simple and easy method of producing the colorant, by use of a colorant that is essentially water-insoluble.

Owner:CANON KK

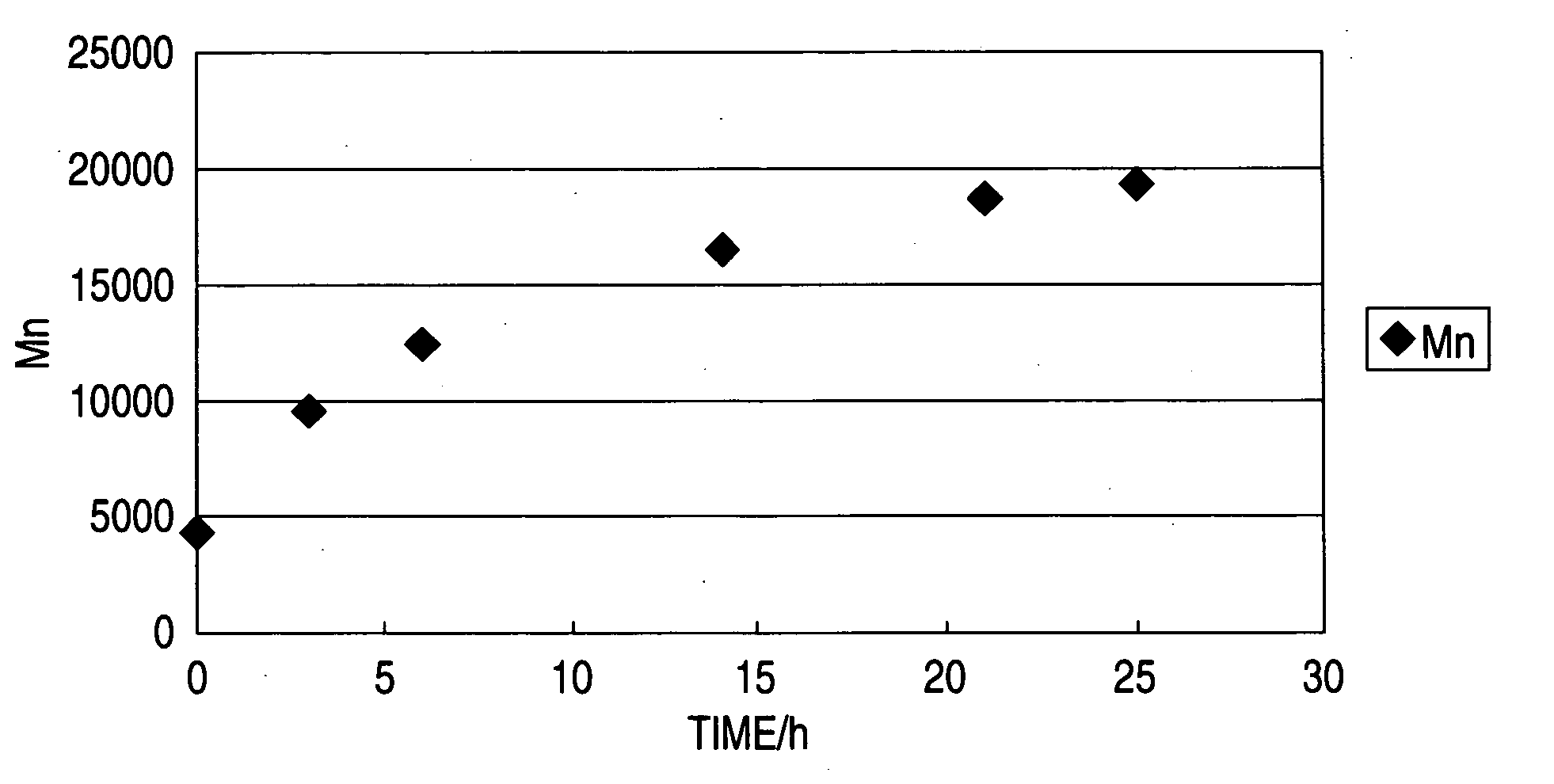

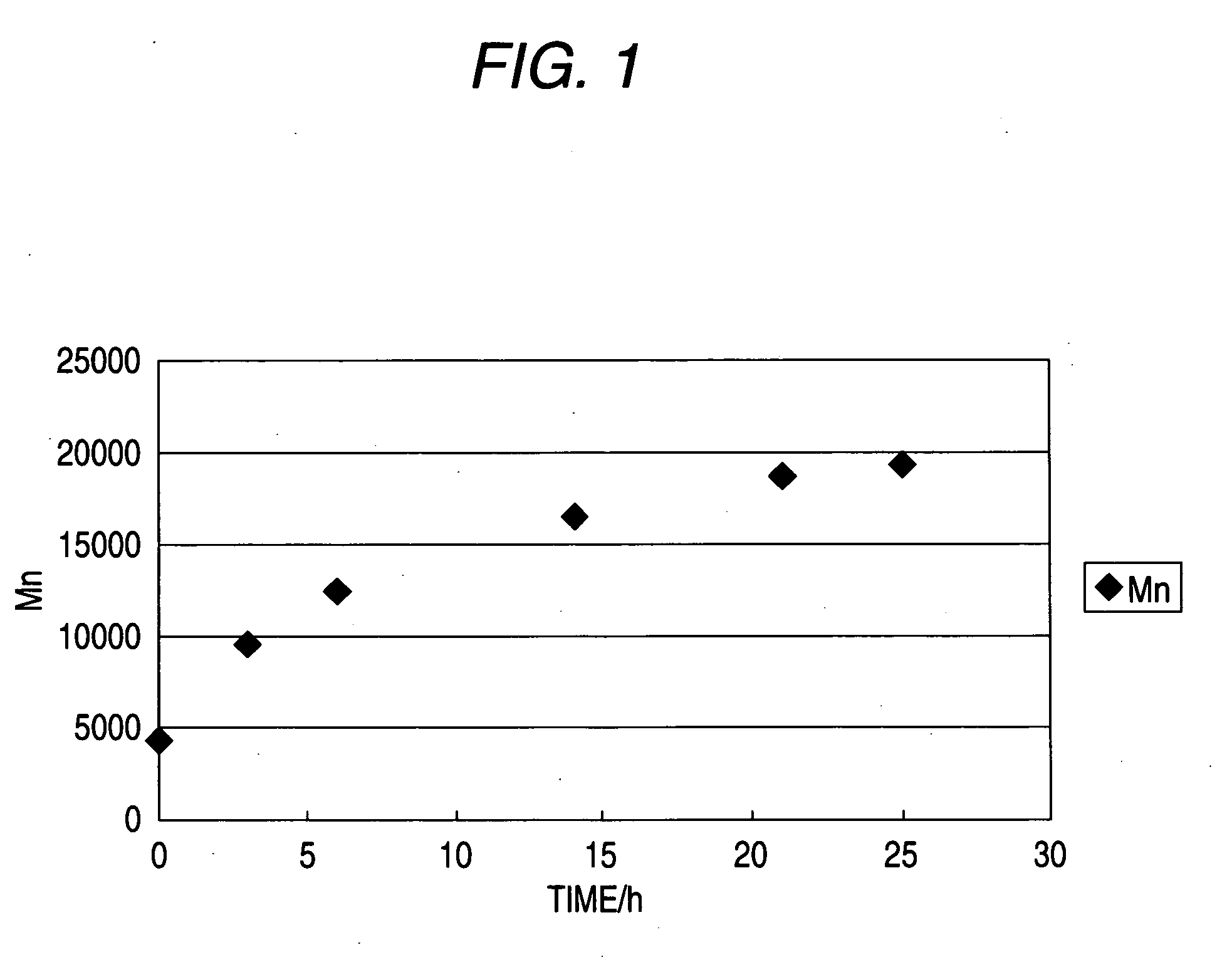

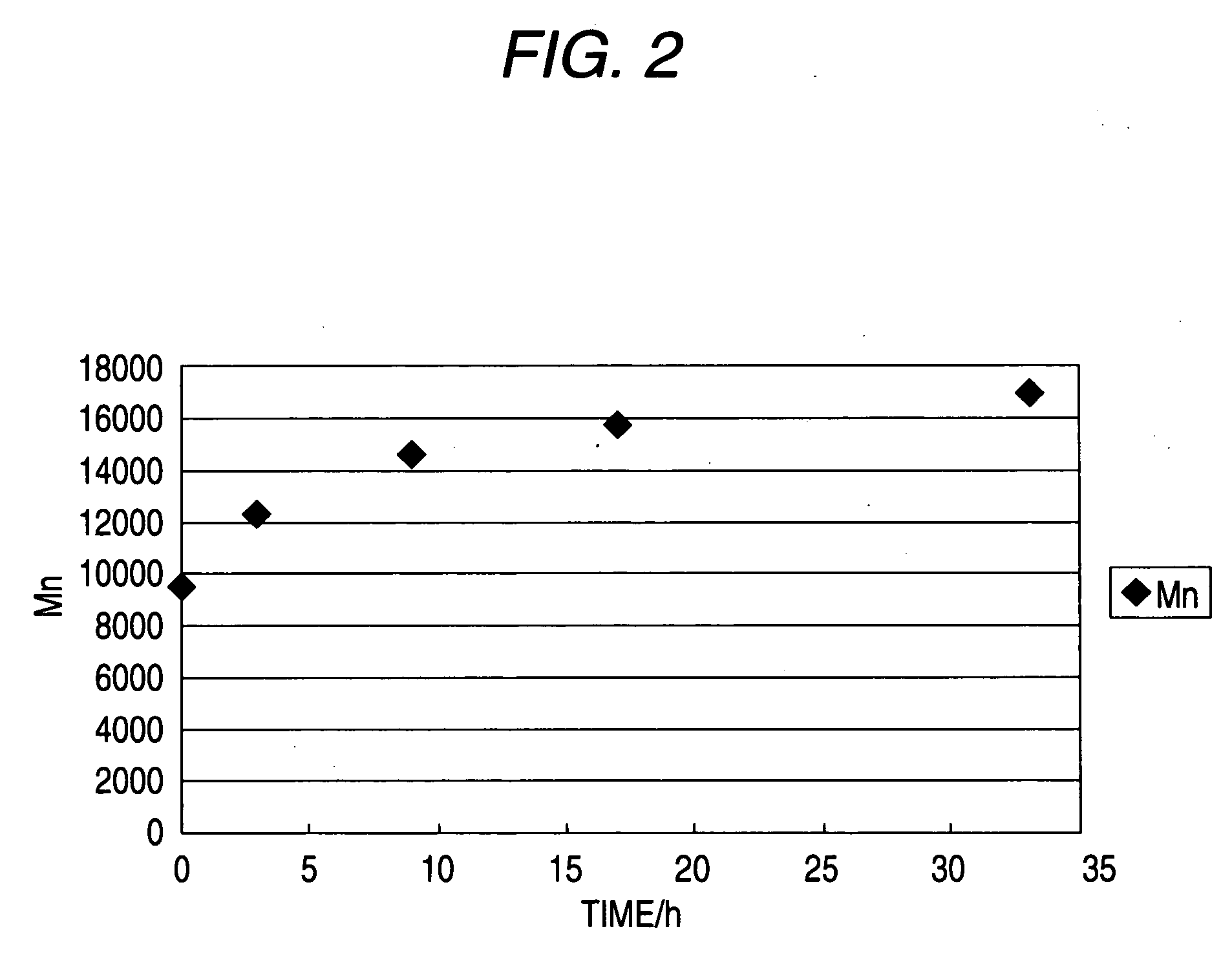

Polyvinyl alcohol based block copolymer and pigment dispersion aqueous liquid using the same and recording liquid

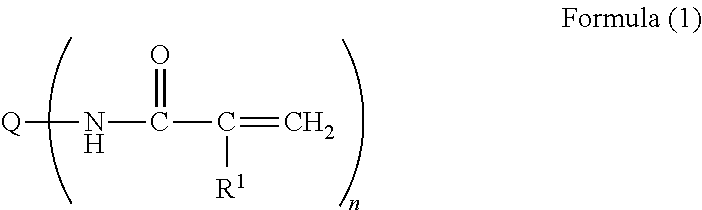

ActiveUS20060089423A1Improve dispersion stabilityGood rubbing fastnessDuplicating/marking methodsInksPolymer sciencePolyvinyl alcohol

A recording liquid capable of giving a printed matter which is high in printing density, is suppressed in blur, has high printing quality, and has good fastness of a recorded matter including light fastness, water fastness and the like and having a low viscosity, good discharge properties and excellent storage stability. The invention is concerned with a polyvinyl alcohol based block copolymer represented by the following general formula (1), a pigment dispersion aqueous liquid containing this polyvinyl alcohol based block copolymer and a pigment in an aqueous medium, and a recording liquid containing this pigment dispersion aqueous liquid. wherein A, B, X1, X2, X3, X4, m1, and m2 have the same meanings as defined in the specification.

Owner:MITSUBISHI CHEM CORP

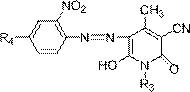

High-fastness black and blue disperse dye composite

ActiveCN102002259AImprove dye uptakeBright shadeOrganic dyesDyeing processDisperse dyePolymer science

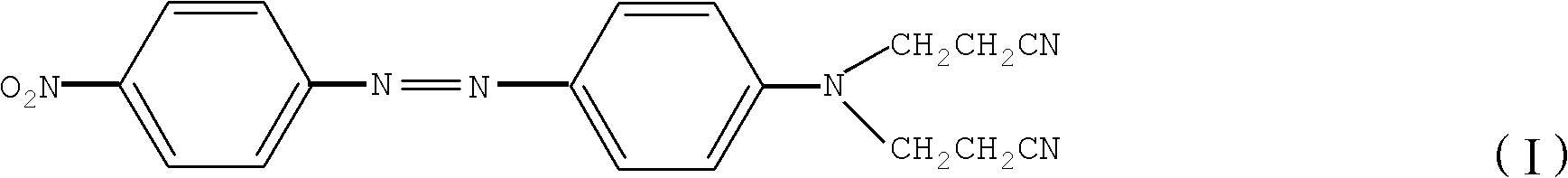

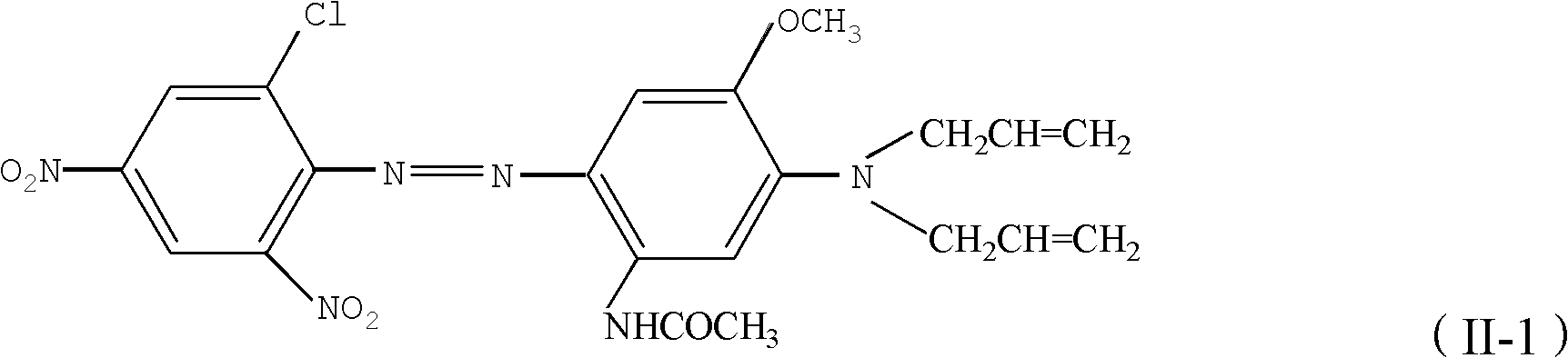

The invention discloses a high-fastness black and blue disperse dye composite, which comprises the following components in percentage by weight: 7 to 42 percent of component A, 45 to 90 percent of component B and 3 to 13 percent of aids, wherein the component A is a compound shown by a formula (I), and the component B is one or more of compounds shown by a formula (II). The high-fastness black and blue disperse dye composite provided by the invention has excellent levelling property, beautiful and bright color light, strong deep dyeing property, high color yield and excellent fastness such as sublimation resistance fastness, washing resistance fastness, friction resistance fastness and the like, and particularly by the addition of the component A, the sublimation fastness of the black and blue disperse dye composite is improved obviously.

Owner:ZHEJIANG RUNTU

Environment-friendly type composite disperse green dye composition and dye

InactiveCN105038314AGood compatibilityIncrease coverageOrganic dyesDyeing processRubbingPhotochemistry

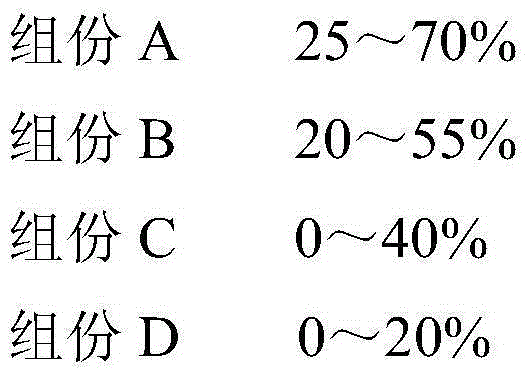

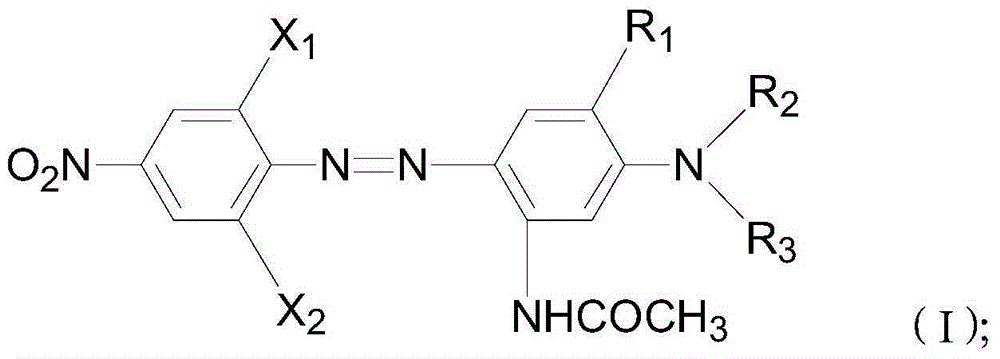

The invention discloses an environment-friendly type composite disperse green dye composition and a dye. The environment-friendly type composite disperse green dye composition comprises the following components in mass fraction: 25-70% of one or more components A with structures as shown in formula (I), 20-55% of one or more components B with structures as shown in formula (II), 0-40% of one or more components C with structures as shown in formula (III) and 0-20% of one or more components D with structures as shown in formula (IV). The disperse green dye prepared from the disperse green dye composition disclosed by the invention is high in lifting power, good in deep dyeing property and excellent in light fastness, fastness to rubbing, fastness to sublimation and the like. The dye is suitable for dyeing and printing of dacron and blended fabrics thereof, and is an economical and environment-friendly disperse green dye with high washing fastness.

Owner:ZHEJIANG DIBANG CHEM

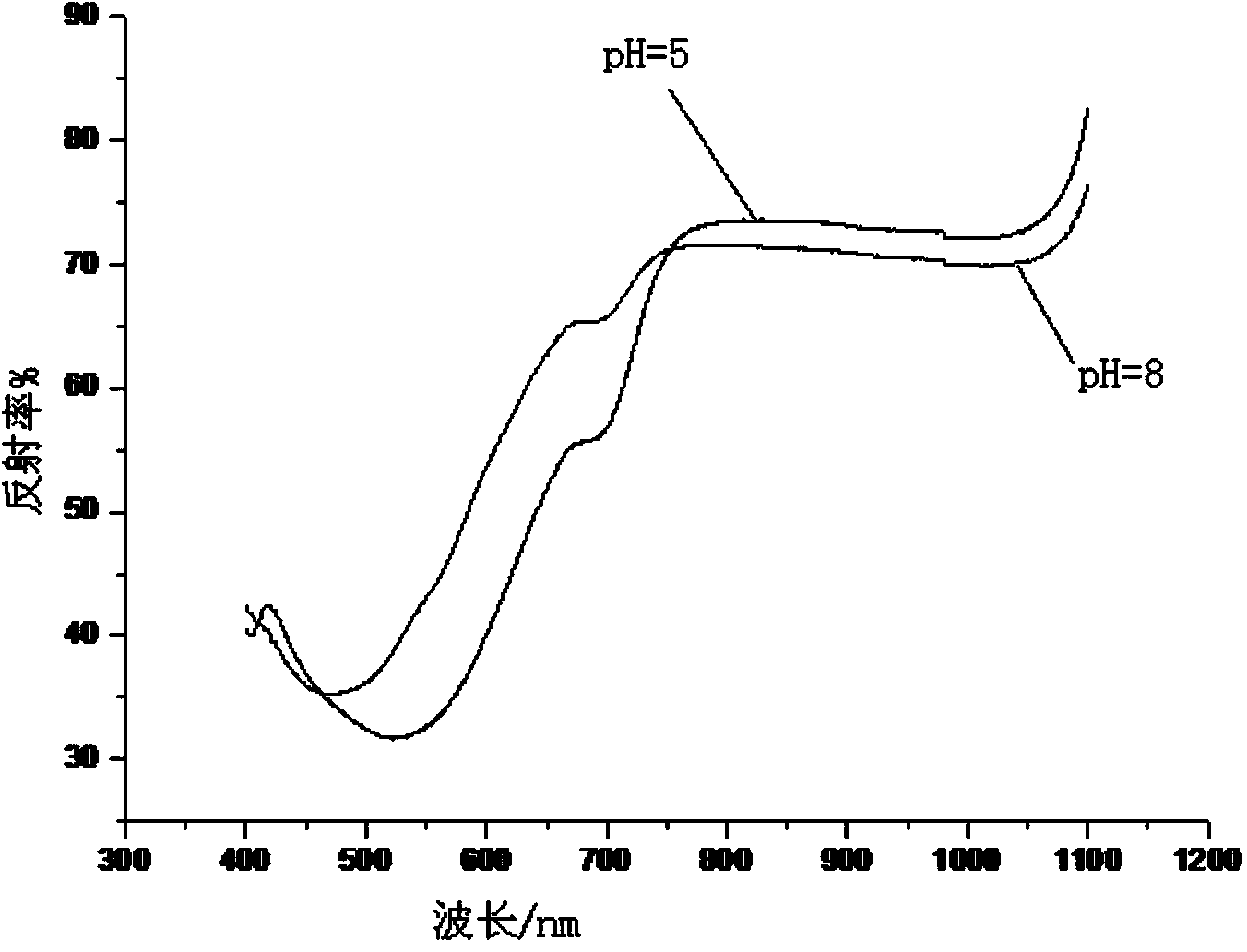

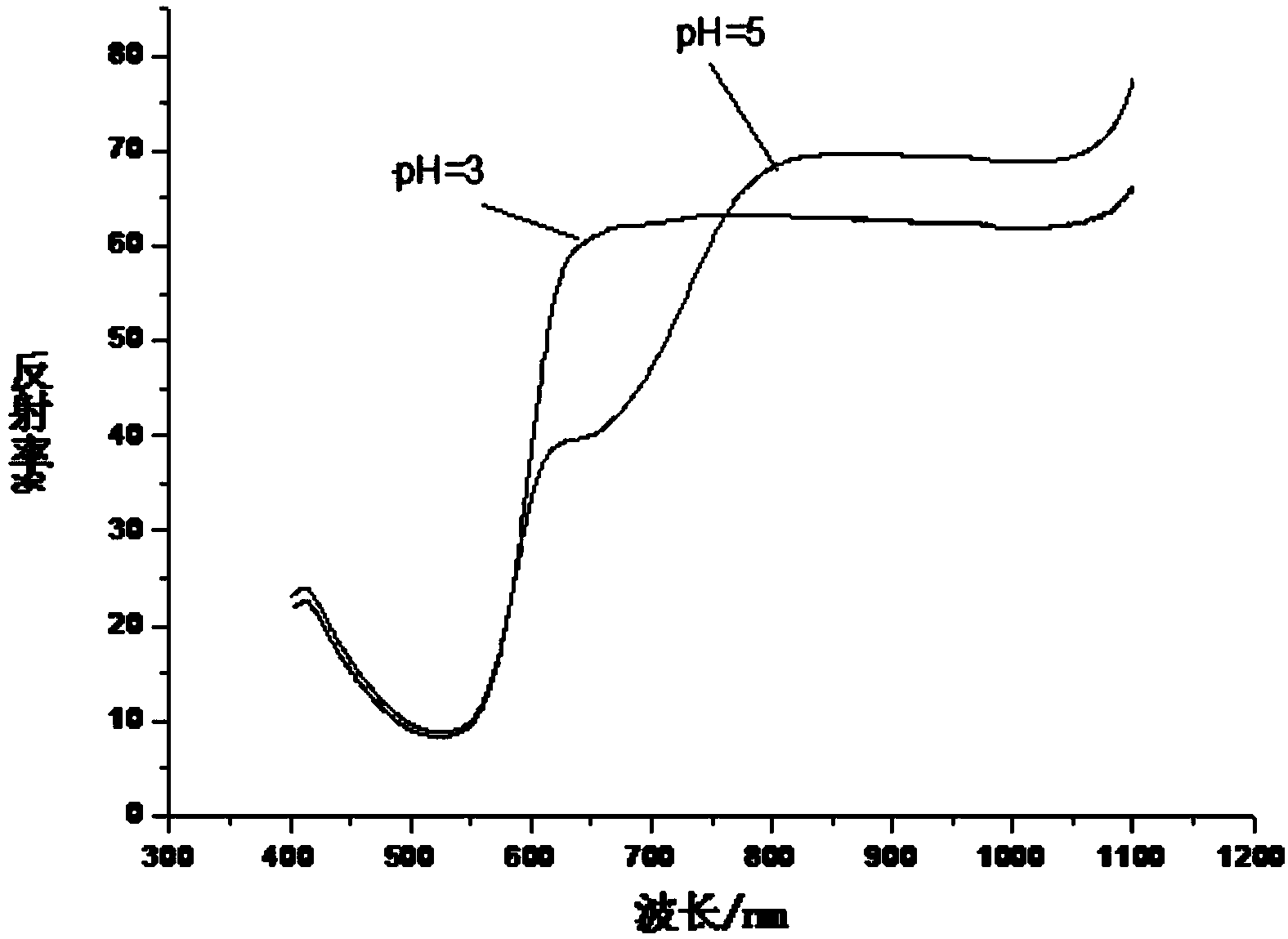

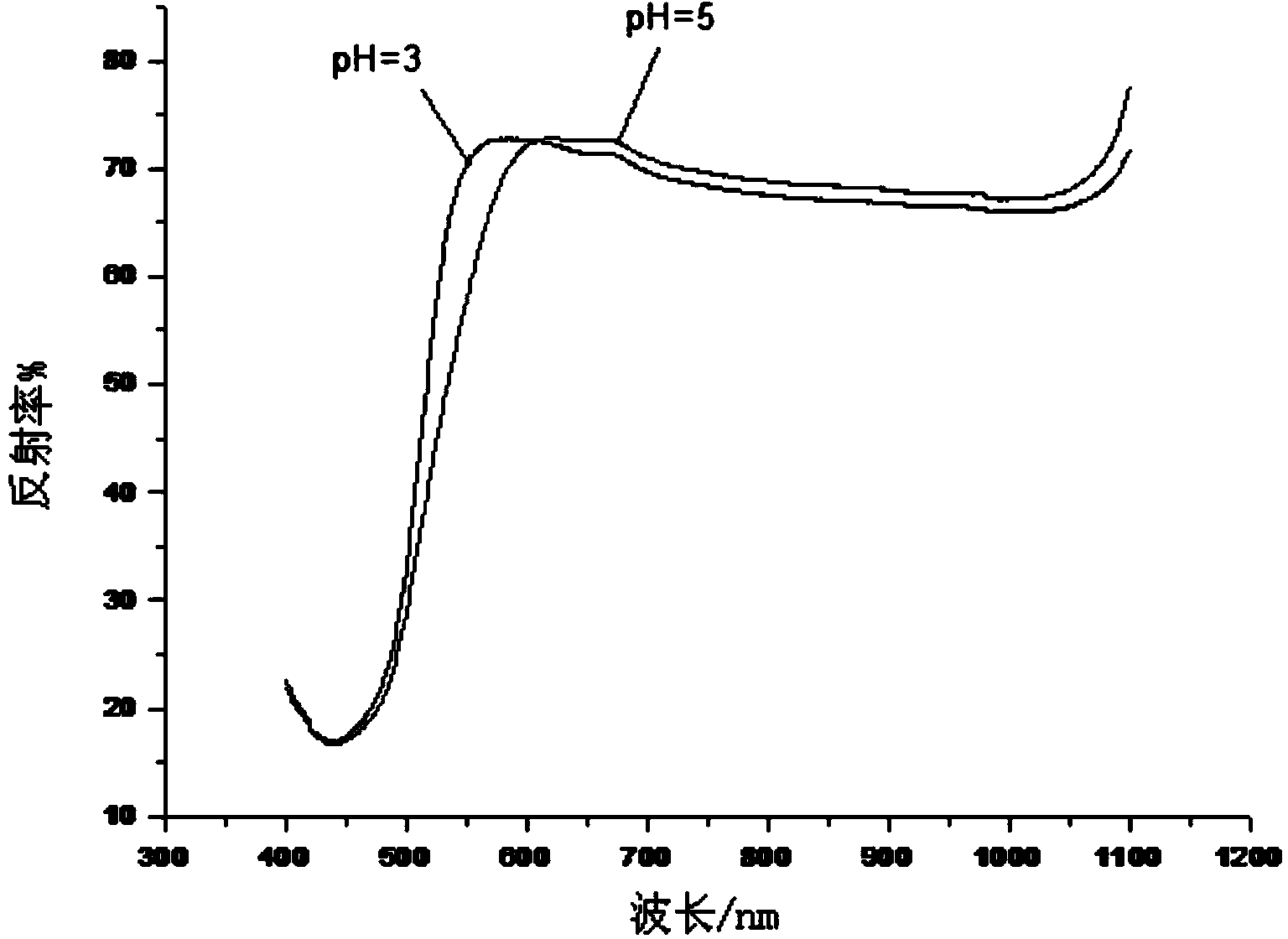

Preparation method of pH color-changing fabric

The invention relates to a preparation method of a pH color-changing fabric. The preparation method comprises steps as follows: (1), a dye solution is prepared by pH indicator dye and distilled water, then, a required amount of the dye solution is accurately measured and diluted, and a dye bath is obtained; (2), a bleached cotton fabric wetted in water is drained and then immersed in the dye bath for dyeing, a water bath constant-temperature oscillator is used for dyeing the dyeing cotton fabric, the fabric is dyed at 40 DEG C, the fabric is kept warm for 30 minutes after the temperature reaches 90 DEG C, then the cotton fabric is cooled to the normal temperature, the cotton fabric is washed in water, washed with soap and then dried after dyeing is finished, and the dyed cotton fabric is obtained; (3), the dyed cotton fabric is immersed into a pH buffer solution, and the pH color-changing fabric is obtained. According to the preparation method, the preparation process is simple and convenient, the cost is low, the wet color fastness and the crockfastness are good, the obtained pH color-changing fabric can be used for preparing a fabric pH sensor and the like, and the preparation method has a broad prospect.

Owner:DONGHUA UNIV

Polyester-cotton disperse dye, and reactive dye one-bath process dyeing method

ActiveCN106245368AHigh color fixing rateAvoid hydrolysisDry-cleaning apparatus for textilesDyeing processDisperse dyePh buffering

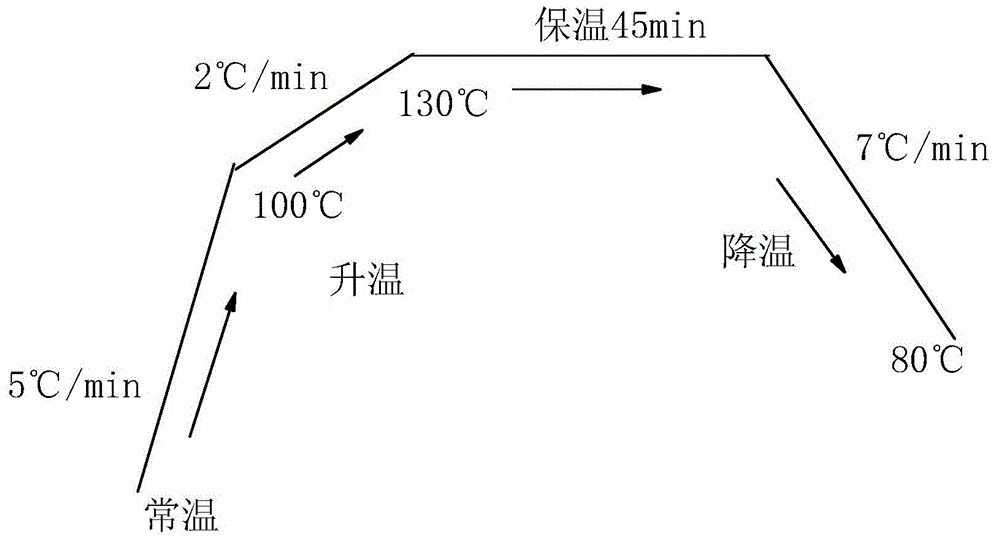

The invention discloses a polyester-cotton disperse dye, and a reactive dye one-bath process dyeing method. The reactive dye one-bath process dyeing method comprise following steps: a dyeing solution is prepared at normal temperature; pH value of the dyeing solution is adjusted to 4 to 6; polyester-cotton fabric is immersed; the temperature is increased to 95 to 105 DEG C at a rate of 2 to 3 DEG C / min, and then is increased to 130 to 150 DEG C at a rate of 1 to 2 DEG C / min; suction filtration of the dyeing solution and isolation of disperse dye microcapsules are carried out, and continuous dyeing is carried out for 15 to 25min; the temperature is reduced to 85 to 95 DEG C at a rate of 1.5 to 2.5 DEG C / min; and primary water washing, soaping, afterwashing, and drying are carried out. The dyeing solution comprise, 0.5 to 1.5%owf of a reactive dye, 30 to 40g / L of anhydrous sodium sulfate, 1.5 to 3.5g / L of a pH buffering agent, 0.5 to 5%owf of disperse dye microcapsule, and 0.1 to 3g / L of a dyeing auxiliary. The reactive dye one-bath process dyeing method is simple; period is short; fixation rate is high; and levelling properties are excellent.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology

ActiveCN106245352AImprove adsorption capacityImprove dyeing uniformityDyeing processMicroballoon preparationDisperse dyeOrganic solvent

The invention discloses a polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology. The technology comprises the steps of: S1, polyester dyeing: dipping a to-be-dyed polyester-cotton fabric in a dye solution containing microcapsule disperse dye, conducting heat preservation at 65-75DEG C, then performing heat preservation at 110-130DEG C, and carrying out cooling to 30-40DEG C, using chitosan to serve as the carrier of the disperse dye, and then conducting crosslinking curing; S2. cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, carrying out stirring reaction, then adding a reactive dye, performing heat preservation at 55-65DEG C, adding an organic solvent, conducting heat preservation at 70-90DEG C, then adding organic amine and sodium carbonate, and performing heat preservation at 60-100DEG C; and S3, aftertreatment: performing cooling to room temperature, and then carrying out primary washing, soaping and after-washing. The polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology provided by the invention has the advantages of simple process, little pollution, wide dye applicability, uniform coloring, high color fixation rate and good level-dyeing properties.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Digital ink jet fabric-treating process

The present invention is digital ink jet fabric treating process, and belongs to the field of textile science and technology. The fabric pre-treating process for digital ink jetting and printing with water thinned pigment ink is suitable for fabric of cotton, hemp, silk, Dacron, polyester and cotton blend, acrylic fiber, etc.; and the treated fabric may be ink jetting printed with water thinned pigment ink in one digital ink jetting printer. After printing and proper heat treatment, may be produced printed product with clear pattern, bright color, and high fastness to resist water washing, friction and sunlight.

Owner:JIANGNAN UNIV

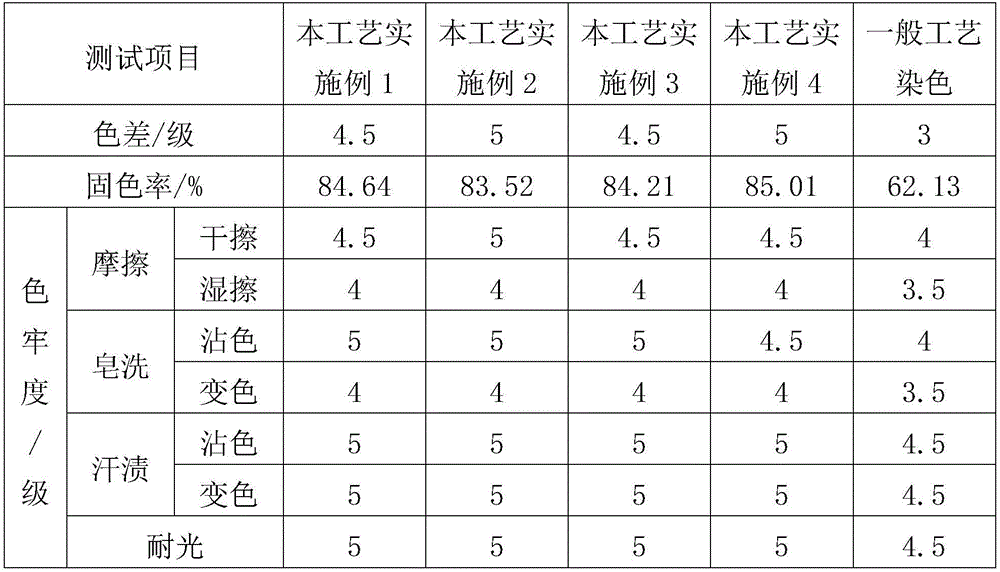

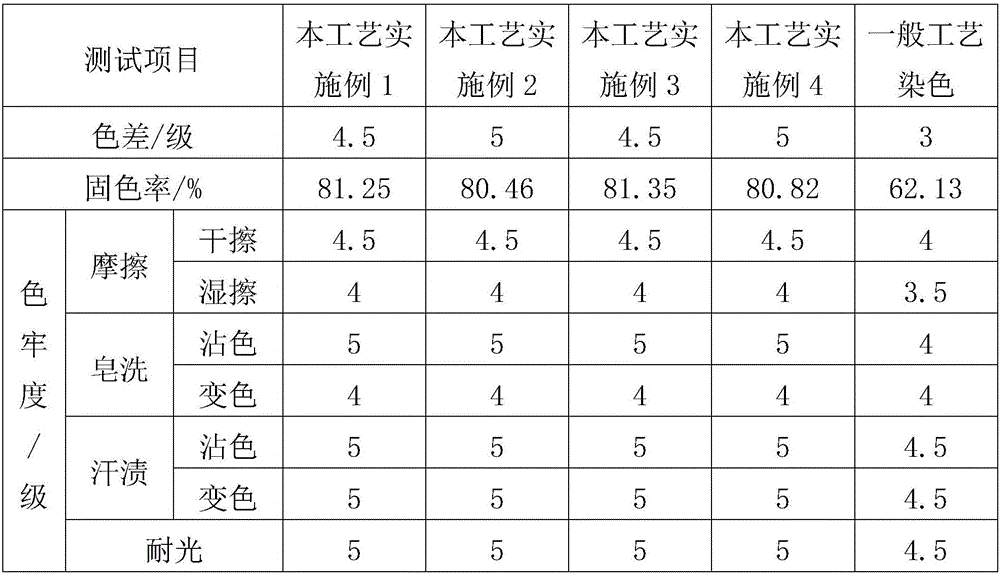

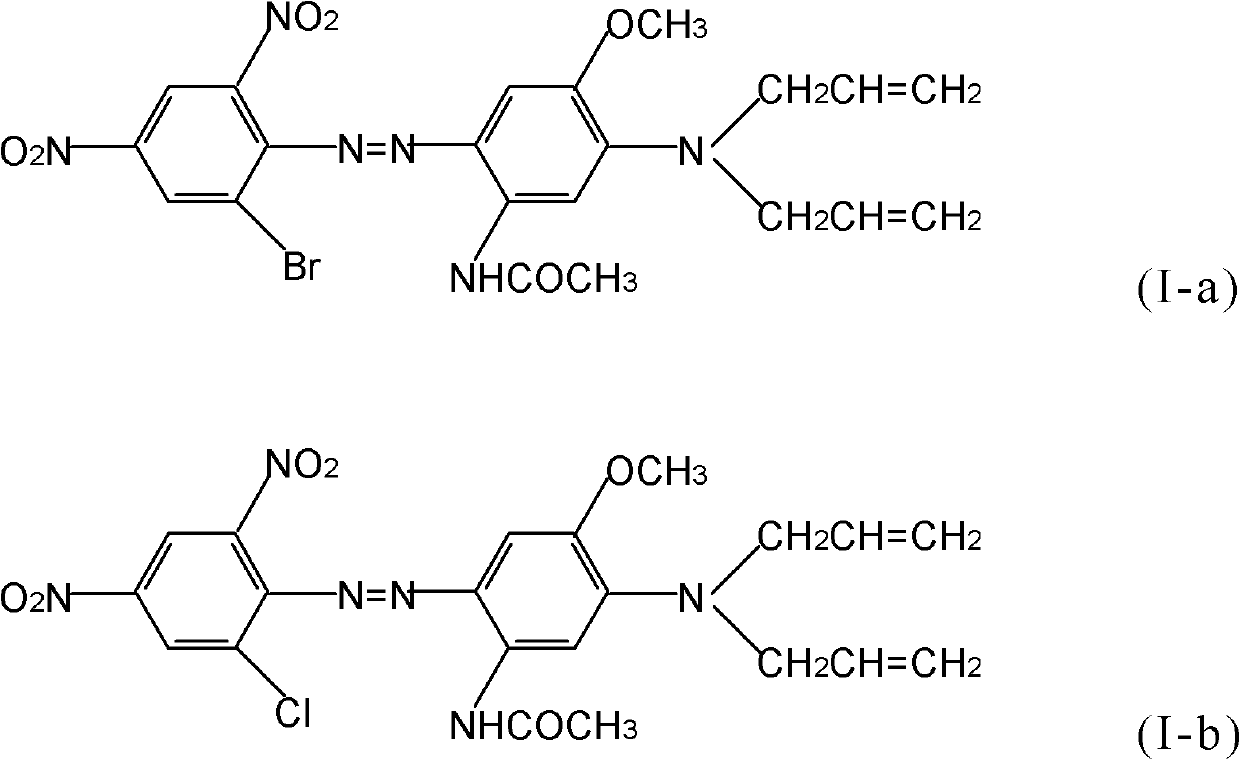

Composite dye composition, composite disperse dye and preparation method thereof

The invention relates to a composite dye composition, composite disperse dye and a preparation method thereof. The composite dye composition is composed of compounds as shown in a formula (I-a), a formula (I-b), a formula (II) and a formula (III). The composite disperse dye prepared from the composite dye composition has good comprehensive fastness property and high lifting force, and is suitable for dyeing and printing terylene and blend fabrics.

Owner:ZHEJIANG RUNTU

Process for dyeing silk interwoven jacquard fabric

ActiveCN104018369AShorten process timeIncrease productivityDyeing processColour fastnessPolymer science

The invention discloses a process for dyeing a silk interwoven jacquard fabric, belonging to the field of silk interwoven jacquard fabric dyeing technology. The process comprises the steps of dye fixing, primary washing, soaping, secondary washing and cylinder discharge and drying, wherein in the dye fixing step, the pretreated silk interwoven jacquard fabric is put into an active dye solution and dyed by adopting a jig dyeing method at 80-85 DEG C for 60-200 minutes; the active dye solution is obtained by mixing 1-5% owf of lanasol dye, 1-5% owf of HE type dye, 20-50g / L of anhydrous sodium sulphate, 5-20g / L of sodium carbonate and water. The process disclosed by the invention can be used for realizing bath dyeing when silk fibers and cellulose fibers in the silk interwoven jacquard fabric are dyed with different colors respectively, the color fastness of the obtained silk interwoven jacquard fabric with the double-color effect can reach the two-bath dyeing fastness, meanwhile, energy is saved, emission is reduced, and the process time is obviously shortened.

Owner:ZIBO DARANFANG SILK GRP

Disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric

ActiveCN106223076APreserve surface hydrophilic propertiesGood dyeing rateDyeing processDisperse dyePre treatment

The invention discloses a disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric. The method comprises the following steps: S1, pretreatment: padding a polyester cotton fabric to be dyed in a finishing liquid, conducting two dipping and two rolling, pre-drying at 60-80 DEG C, baking at 120-140 DEG C, washing with cold water and drying; S2, polyester dyeing: immersing the polyester in a disperse dye, insulating at 65-75 C, and insulating at 110-130 DEG C; S3, cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, stirring for reaction, adding a reactive dye, insulating at 70-80 DEG C, adding a dyeing auxiliary, insulating, adding soda ash, and insulating at 60-100 DEG C; and S4, posttreatment: conducting an initial washing, soaping and post washing. The disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric has the advantages of simple process, easy industrial implementation, wide dye application, uniform coloration, high fixation rate and good levelness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

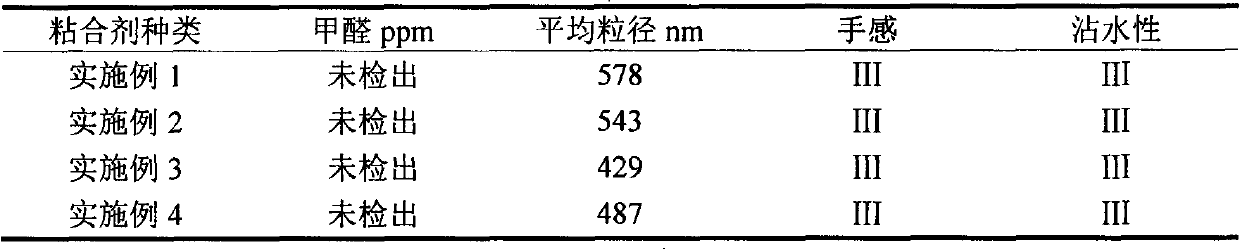

Environment-friendly emulsion modified acrylate pigment dyeing adhesive and manufacturing method thereof

ActiveCN102633954AGood rubbing fastnessExcellent wash fastnessDyeing processGraft polymer adhesivesEnvironmental resistanceEmulsion

The invention relates to an environment-friendly emulsion modified acrylate pigment dyeing adhesive and a manufacturing method of the environment-friendly emulsion modified acrylate pigment dyeing adhesive. Through improvement of additive order and relavent process parameters of materials such as a combination of methyl methacrylate, methyl acrylate, ethyl acrylate, glycidyl acrylate and acrylic acid, linear block polyether octodecane amino ternary polymerization modified silicon oil, emulsifier and the like, the environment-friendly emulsion modified acrylate pigment dyeing adhesive and the manufacturing method aim at solving the long-term technical problems that fabric feels hard, crockfastness is poor, rubbing fastness is low, hardness of dyed fabric is higher, adhesive force is low and environment is polluted, so as to realize the beneficial technical effects of good crockfastness, high rubbing fastness, soft feeling on dyed fabric, good hydrophily of the dyed fabric, better adhesive force and environment-friendly production process.

Owner:JIANGSU GOLDEN AUTUMN ELASTIC FABRICS

Ultraviolet ray color-changing printing fabric preparation method

ActiveCN101307573AOvercome hand feeling problemsOvercome problems such as free formaldehydeDyeing processFiberAdhesive

The invention discloses a method for preparing ultraviolet color-changing printed fabrics. The prescription by weight percentage of fabric printing color paste is: X percent of ultraviolet color-changing dye, 60 percent of natural modified paste material with the lid containing rate of 10 percent, 0.5 percent of glacial acetic acid, 3 percent of urea, and the balance being water, wherein the mixture ratio of X percent of the ultraviolet color-changing dye in percentage by weight is: 0.2 percent of cationic violet 5BLH, 0.4-0.9 percent of cationic yellow X-10GFF, and 0.1-0.2 percent of cationic red X-5GN. A fabric printing process comprises the following procedures of taking a fabric, printing the fabric, steaming the fabric, washing the fabric, drying the fabric and obtaining a finished product. The parameters of a steaming process are as follows: the temperature of heating with superheated steam is 125 DEG C, and the heating time is 30 min. The method overcomes the problems of hand feeling, free formaldehyde, etc. caused by applying adhesive to prepare ultraviolet color-changing printed fabrics in the prior art, has simple-convenient process and low cost, does not change the prior style of fibers, and is excellent in wet fastness and rubbing fastness. Tests show that: the fabric is environmentally friendly and safe, does not contain 23 carcinogenic aromatic amines or heavy metal ions harmful to human body, and is broad in market prospects.

Owner:HANGZHOU WENSLI SILK DIGITAL PRINTING CO LTD

Reactive printing dye and application of liquid composition thereof

ActiveCN102329523AImprove performanceGood light fastnessOrganic dyesDyeing processCellulose fiberMirabilite

The invention relates to a reactive printing dye composition, which comprises: (a) at least one reactive dye; (b) organic buffer; and (c) mirabilite or dispersing agent. The reactive printing dye composition is suitable for fabric dyeing, such as fabrics made with cellulose fibers and other mixed fibers, including cotton, fiber, silk, rayon, wool, blended fibers and the like. In addition, the reactive printing dye composition has good characteristics of high pH stability, good storage stability, improved recession of the dyeing intensity of the dye and the like. Moreover, the invention also provides a liquid reactive printing dye composition.

Owner:ETHICAL INT WAREHOUSING TRADING SHANGHAI

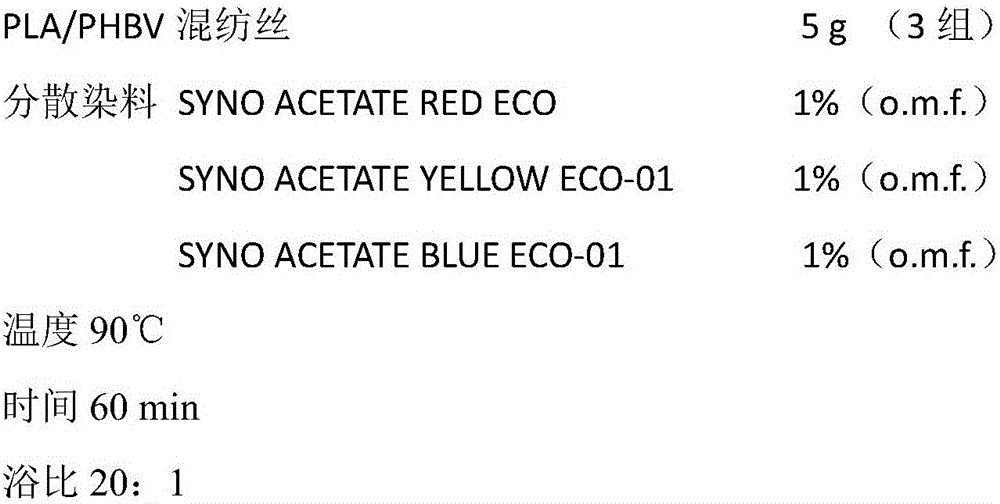

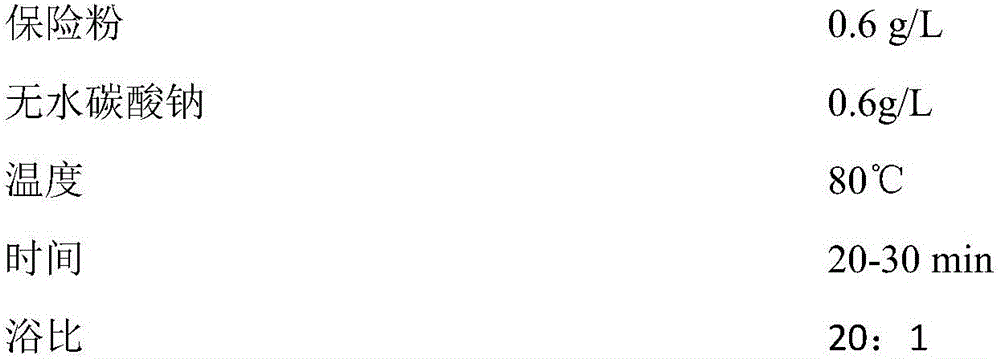

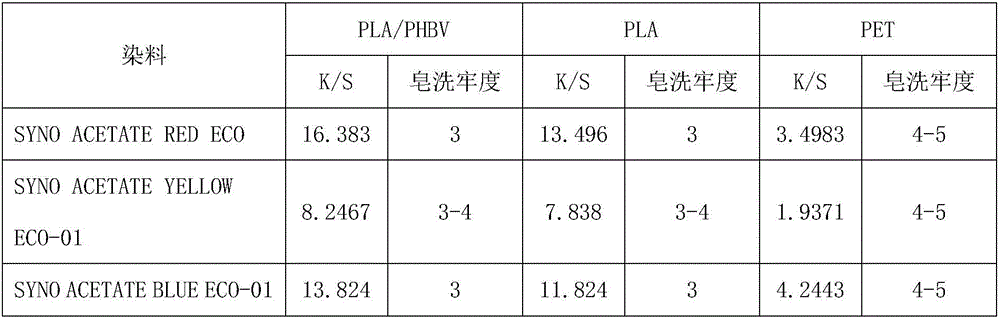

Low-temperature dyeing method of PLA/PHBV blended yarn

A low-temperature dyeing method of PLA / PHBV blended yarn comprises steps of: wetting the PLA / PHBV blended yarn into deionized water of 60-90 degrees centigrade, cleaning for 15-30min; taking disperse dye of 0.5%-2% of the weight of the blended yarn, dissolving the disperse dye into the deionized water to form a dye liquor, putting the blended yarn into the dye liquor, dyeing as per a bath ratio of 20-30:1, firstly heating up the dye liquor to 65-75 degrees centigrade by 2-4 degrees centigrade / min, heating up to 90-100 degrees centigrade by 1-2 degrees centigrade / min, maintaining the temperature for 40-60min; then cooling down to 50 degrees centigrade by 3-5 degrees centigrade / min, and taking out the blended yarn; reduction clearing the blended yarn, wherein the reduction clearing solution comprises 0.5-1g / L of sodium hydrosulfite and 0.5-1g / L of anhydrous sodium carbonate; the temperature of the reduction clearing solution is 75-90 degrees centigrade; the bath ratio is 20-30:1; and the reduction clearing duration is 20-30min. The low-temperature dyeing method of PLA / PHBV blended yarn solves the low-temperature dyeing problem of the PLA / PHBV blended yarn; the method saves energy and reduces production cost, and it has the advantages of deep dye color, uniform dyeing effect, washing fastness, and good crockfastness.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE +1

High-fastness disperse dye composition as well as preparation method and application thereof

InactiveCN105602283AGood color fixation rateGood level dyeingOrganic dyesDyeing processDisperse dyePerspiration

The invention relates to high-fastness disperse dye composition as well as a preparation method and an application thereof. The high-fastness disperse dye composition comprises two compounds with two different structures in formula I, two compounds with two different structures in formula II, a compound shown in the formula III and a compound shown in the formula IV. The preparation method comprises steps as follows: the compounds shown in the formulas I, II, III and IV are mixed uniformly with an auxiliary, ground and subjected to spray drying, and the high-fastness disperse dye composition is obtained. The high-fastness disperse dye composition is applied to dyeing of hydrophobic fibers or fiber blended fabric. The high-fastness disperse dye composition has good fixation, leveling property, washing fastness, rub fastness, perspiration fastness, sublimation fastness and build-up property and also has very good light fastness, and the preparation method is simple in process, low in cost and has good application prospect.

Owner:俞杏英

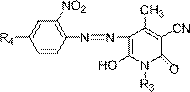

High washing fastness dispersed dark blue dye composition

ActiveCN103421347AImprove washing fastnessHigh coloring rateOrganic dyesDyeing processDisperse yellowMaterials science

The invention relates to a dye composition, in particular to a high washing fastness dispersed dark blue dye composition. The high washing fastness dispersed dark blue dye composition is composed of 35 % to 50 % of dispersed red, 20 % to 40 % of dispersed golden yellow, 10 % to 30 % of dispersed purple and 10 % to 30 % of dispersed yellow in a mixing mode, and the balance auxiliaries. The dispersed red is the combination of one or more kinds of compounds shown in a formula (1); the dispersed golden yellow is the combination of one or more kinds of compounds shown in a formula (2); the dispersed purple is the combination of one or more kinds of compounds shown in a formula (3), and the dispersed yellow is the combination of one or more kinds of compounds shown in a formula (4); when the high washing fastness dispersed dark blue dye composition is used for dyeing of spandex fabrics, the dyeing effect is good, the color fastness is good, and the quality of the spandex fabrics can be greatly improved.

Owner:HANGZHOU FLARIANT SPECIALTY

Method for preparing nano-titanium dioxide modified color fixing agent emulsion

ActiveCN104744642AImprove performanceImproves UV resistanceDyeing processEmulsionEmulsion polymerization

The invention relates to a method for preparing nano-titanium dioxide modified color fixing agent emulsion and aims to overcome the defect that color fixing emulsion is poor in ultraviolet resistance. According to the method, the nano-titanium dioxide modified color fixing agent emulsion is prepared from modified nano-titanium dioxide dispersion liquid, a cationic monomer, an organic silicon monomer, an emulsifier, an initiator and deionized water in a nuclear-shell emulsion polymerization mode. The method is simple and convenient in process, simple to control and stable in polymerization system, and by adjusting the proportions of monomer components of a core layer and a shell layer, nano-titanium dioxide, the cationic monomer and the organic silicon monomer are differently distributed, and thus a purpose of modifying the color fixing agent emulsion is achieved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

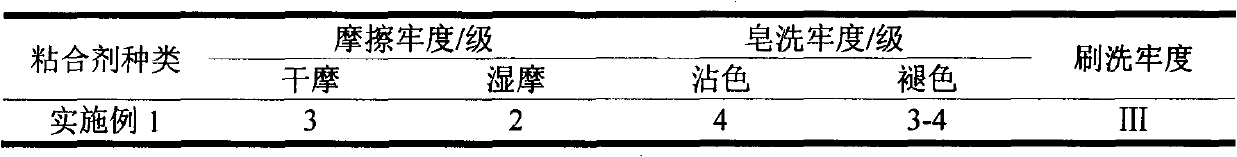

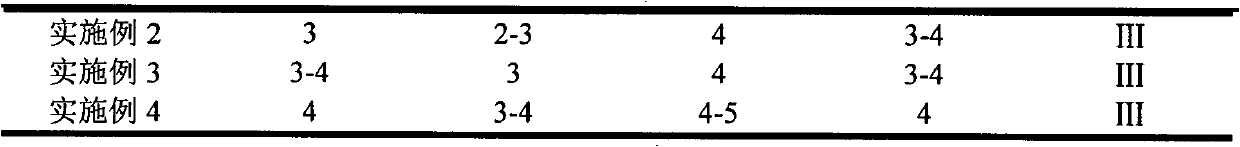

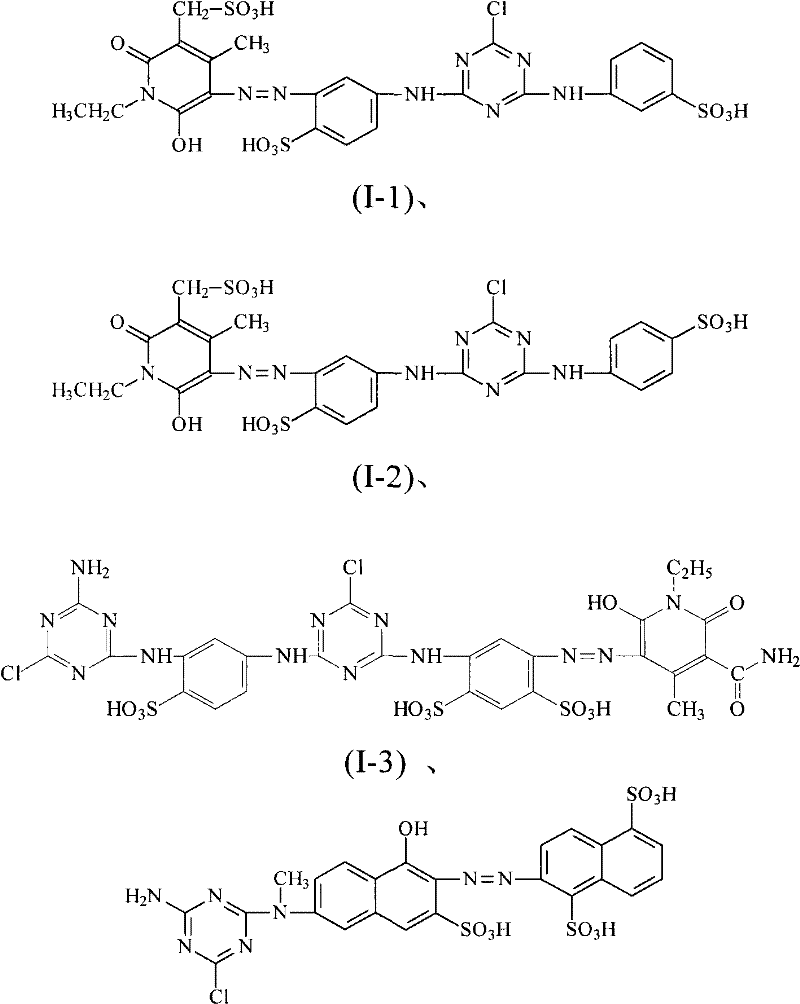

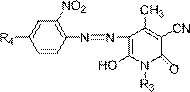

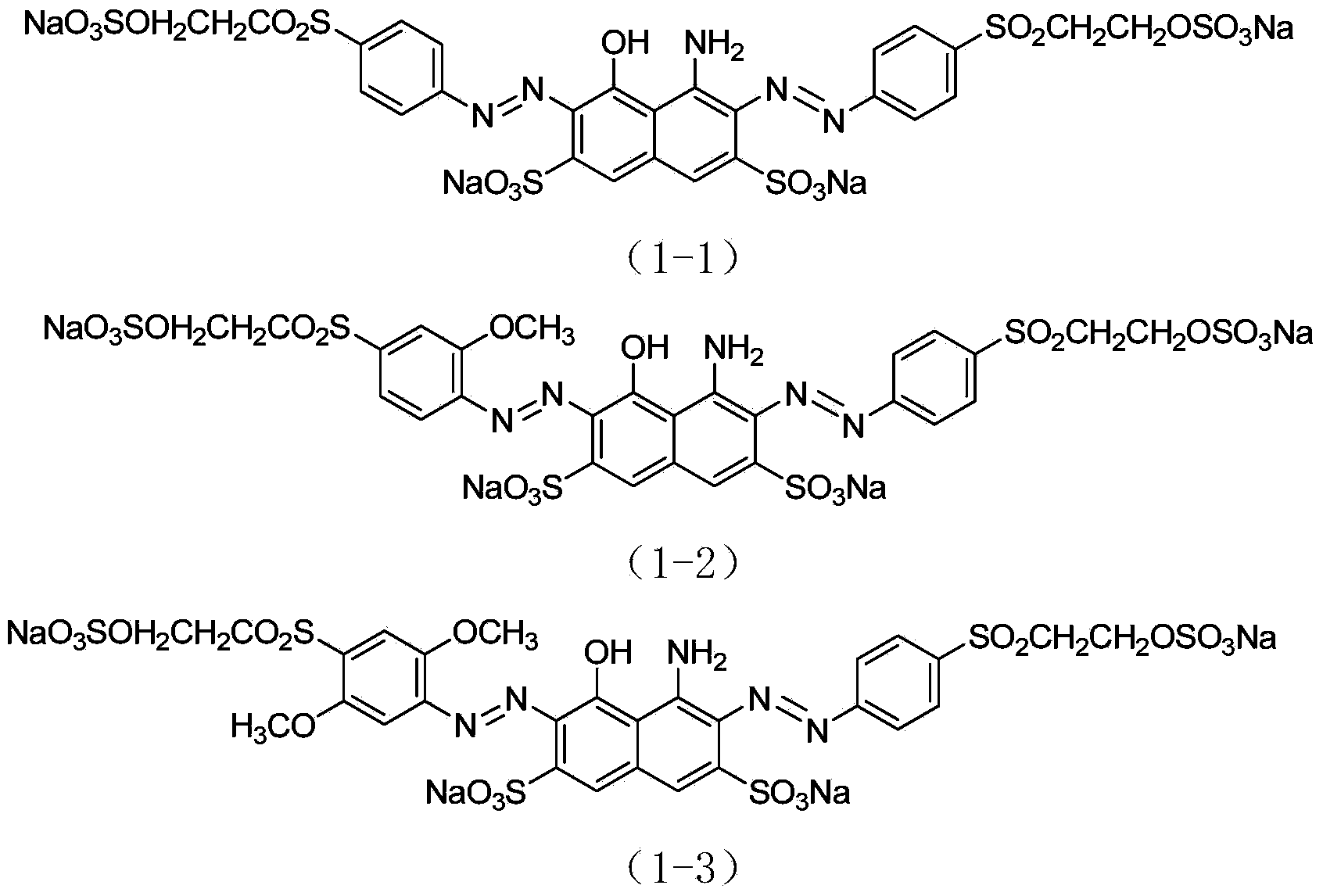

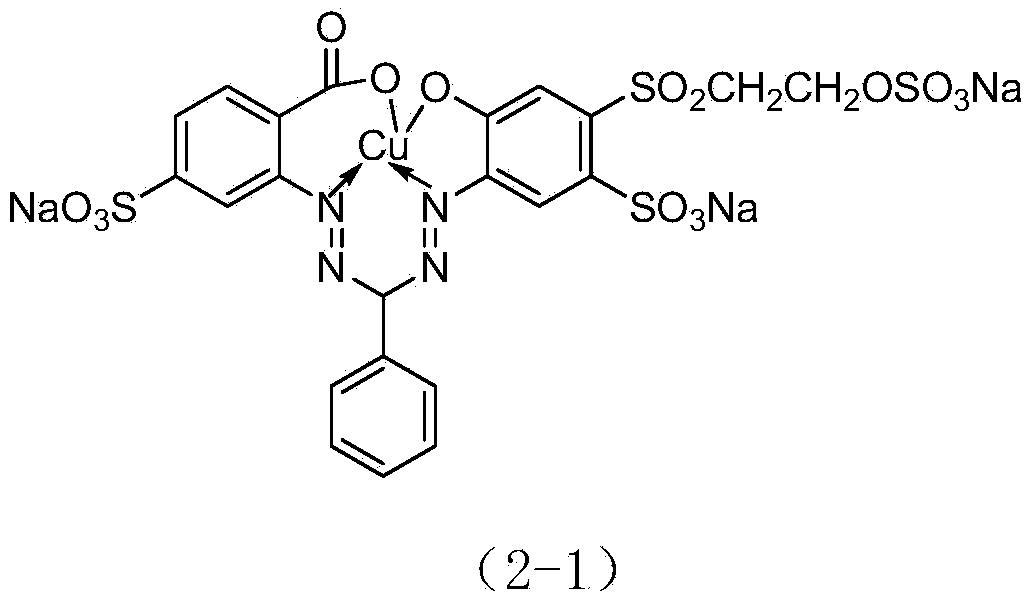

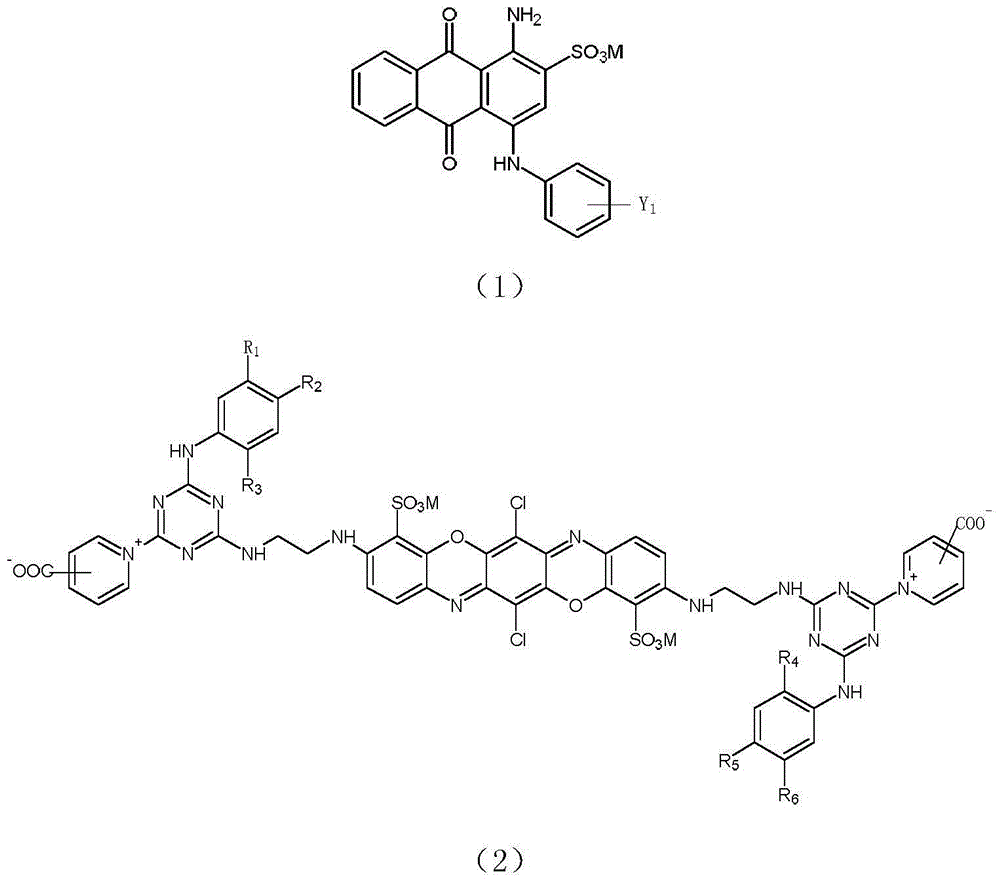

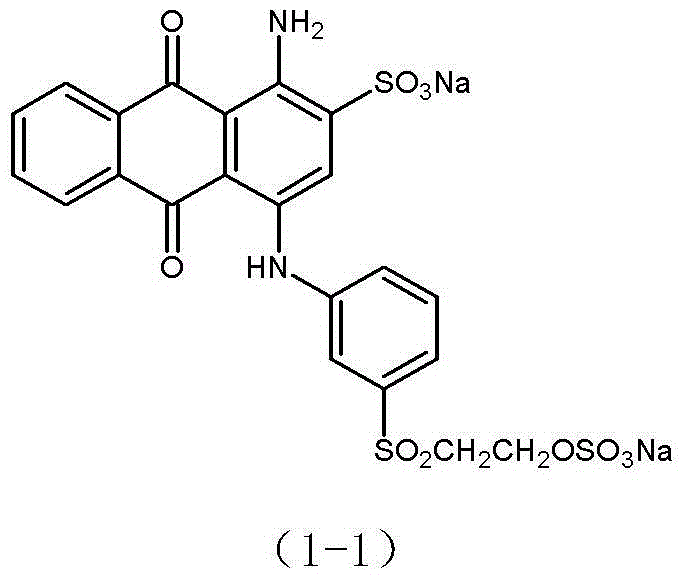

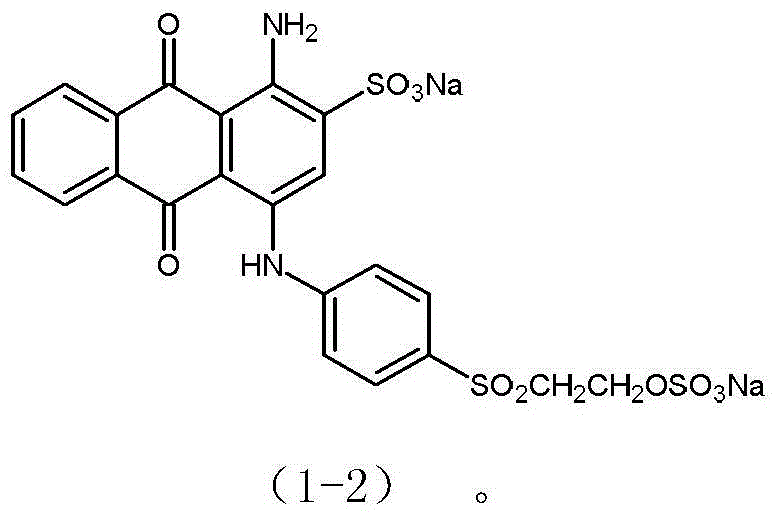

Composite reactive blue dye and application thereof

The invention relates to the field of dyes and particularly relates to a composite reactive blue dye and an application thereof. The composite reactive blue dye comprises the following dyes by weight percentage for composition: 1-50% of dye as shown in formula (1), 5-99% of dye as shown in formula (2), 0-50% of dye as shown in formula (3) and 0-50% of dye as shown in formula (4) and the balance of additives. The composite reactive blue dye provided by the invention has good dischargeability and resistance, can be used in printing and can be used for not only direct printing, but also resist printing and discharge printing; furthermore, discharge printing and resist printing processes are simple and the effects are good. The composite reactive blue dye provided by the invention has various excellent fastness, in particular to wet fastness and rubbing fastness. Secondly, the composite reactive blue dye has the advantages of low price, simplicity in use, good economic benefits, great stability and compatibility and can greatly reduce the defective rate.

Owner:ZHEJIANG YIDE CHEM

Ink composition, ink set, and image forming method

InactiveUS20130050331A1High temporal stabilityGood rubbing fastnessDuplicating/marking methodsInksSolubilityDouble bond

Disclosed is an ink composition including: (1) a pigment; (2) a polymerization initiator having a content of 2% by mass or more with respect to a total amount of the composition and having a solubility with respect to pure water at 25° C. of 5 to 8 g / l; (3) a compound A that is at least one selected from the group consisting of dimethylacrylamide, diethylacrylamide, N-isopropylacrylamide, dimethylacetamide, N-ethylpyrrolidone, 1-cyclohexyl-2-pyrrolidone, 1-(2-hydroxyethyl)-2-pyrrolidone, 1,3-dimethyl-2-imidazolidinone, tetramethylurea and gamma-valerolactone; (4) a polymerizable compound having two or more ethylenically unsaturated double bonds; and (5) water having a content of 50% by mass or more with respect to the total amount of the composition.

Owner:FUJIFILM CORP

Composite active blue dye

ActiveCN104448927AGood alkali resistanceGood level dyeingOrganic dyesDyeing processDyeingBlue green color

The invention belongs to the field of dyes and relates to an active dye composite product suitable for dyeing cellulose fibers or cellulose-containing fibers and particularly relates to a composite active blue dye. The composite active blue dye is prepared by compounding 10-90 parts by weight of a dye A represented by a formula (1), 10-90 parts by weight of a dye B represented by a formula (2) and 0-100 parts by weight of an additive. By the composite active blue dye, the medium-temperature coloring can be performed on the cellulose fibers, during the dyeing, the advantages of alkali resistance, good leveling, good even-dyeing property, good synchronization and color reproducibility and difficulty in uneven dyeing are achieved, and the colored fibers have not only a unique brilliant blue-green color and but also very good light fastness, rubbing fastness, water-washing fastness, sweat fastness and the like. The composite active blue dye can exhibit good application performance and fills the defects of commercially available other active brilliant blue.

Owner:ZHEJIANG YIDE CHEM

Disperse grey dye composition

The present invention discloses a disperse grey dye composition, which consists of the components in percentage by weight: 15-25% of component A, 25-50% of component B and 30-50% of component C, wherein the component A is one or more compounds shown in formula (I) and the component C is one or more compounds shown in formula (III). The disperse grey dye composition provided by the invention has extremely excellent compatibility and high dyeing rate, is mainly used for the dyeing of polyester fibers, has excellent fastness to light, fastness to rubbing, fastness to sublimation and the like when being used for dyeing polyester fiber fabrics, especially has very good sublimation fastness, can dye in a wide pH range and has little pollution.

Owner:ZHEJIANG RUNTU

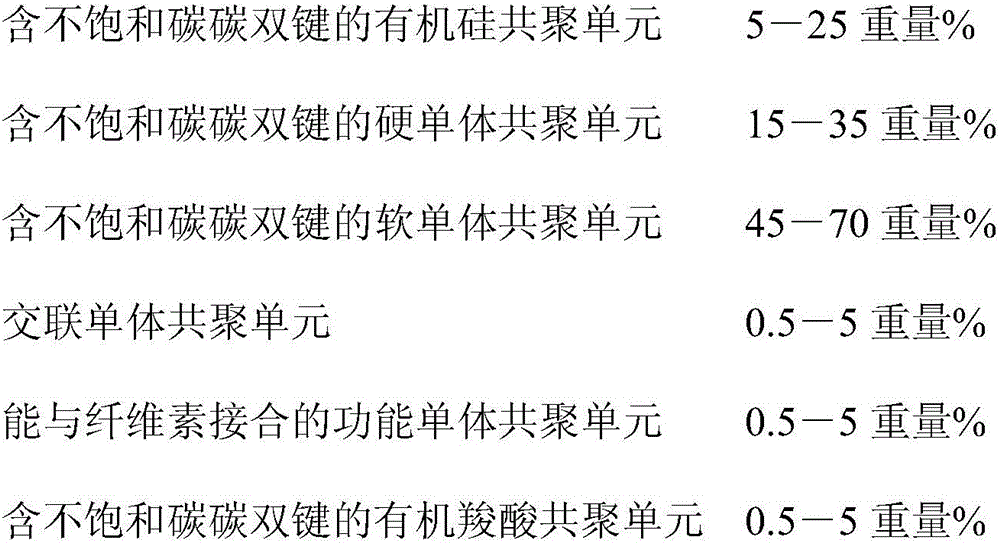

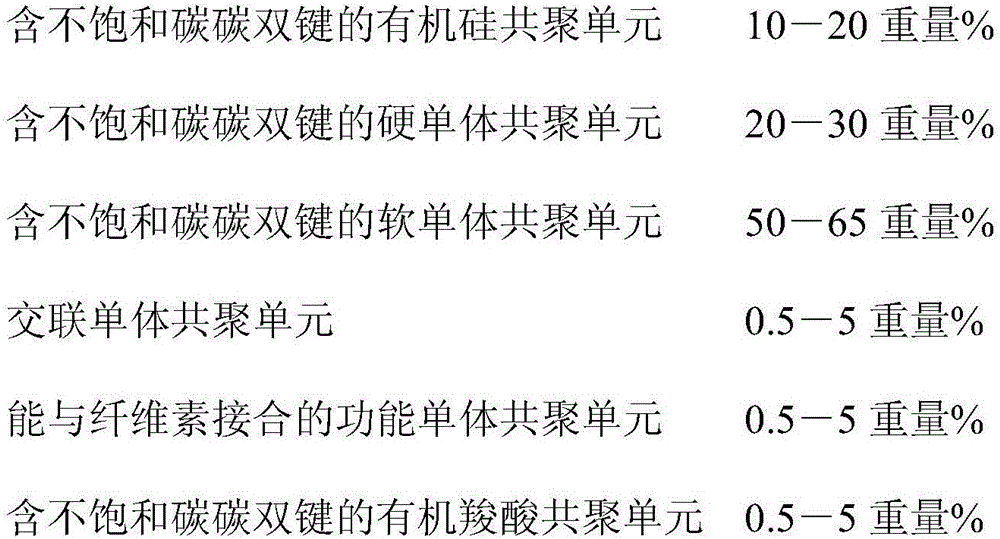

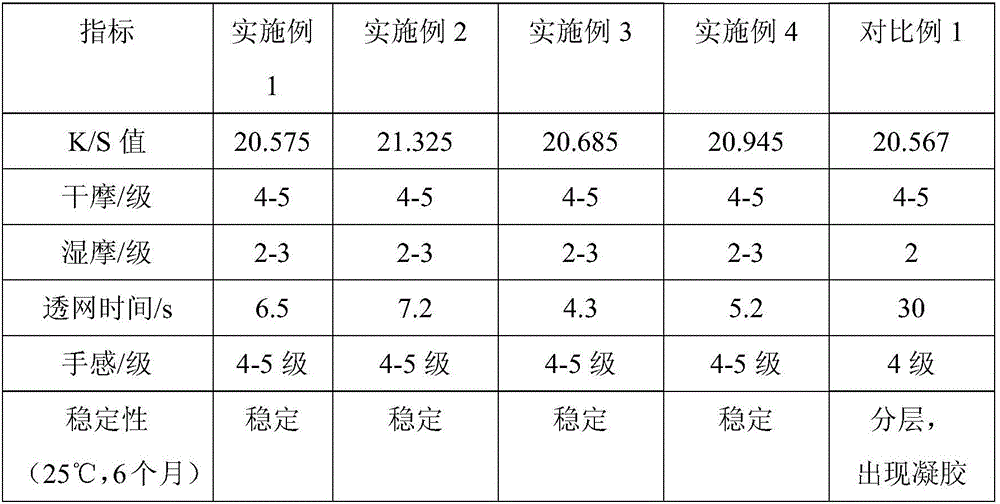

Imitated activated pigment printing adhesive copolymer and preparation method thereof

The invention discloses an imitated activated pigment printing adhesive copolymer and a preparation method thereof. The copolymer is prepared from 5-25 wt% of organosilicone copolymerization units containing unsaturated carbon-carbon double bonds, 15-35 wt% of hard monomer copolymerization units containing unsaturated carbon-carbon double bonds, 45-70 wt% of soft monomer copolymerization units containing unsaturated carbon-carbon double bonds, 0.5-5 wt% of crosslinking monomer copolymerization units, 0.5-5 wt% of functional monomer copolymerization units capable of being bonded with cellulose and 0.5-5 wt% of organic carboxylic acid copolymerization units containing unsaturated carbon-carbon double bonds based on the total weight of the imitated activated pigment printing adhesive copolymer. The adhesive product is not likely to be hydrolyzed and good in stability, has excellent crockfastness and hand feeling and achieves an imitated activated pigment printing effect.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

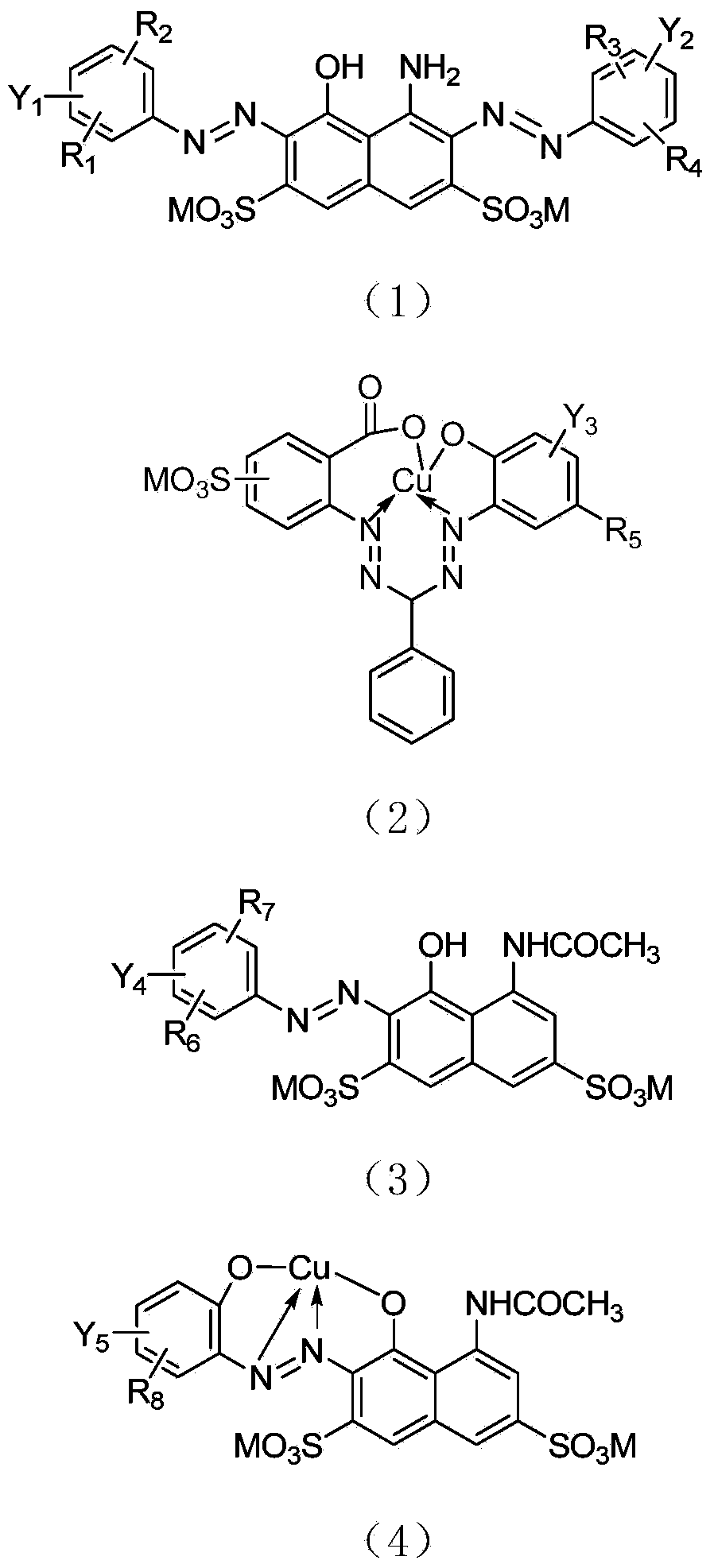

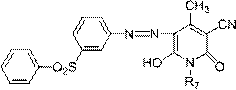

High washing fastness dispersed yellow and brown dye composition

The invention relates to a high washing fastness dispersed yellow and brown dye composition. The high washing fastness dispersed yellow and brown dye composition aims at overcoming the defects that a dye composition is poor in color fastness in the prior art. The high washing fastness dispersed yellow and brown dye composition is composed of, by weight, 20 % to 40 % of dispersed orange, 25 % to 50 % of dispersed golden yellow, 10 % to 20 % of dispersed red dye and 10 % to 20 % of dispersed yellow in a mixing mode, and the balances auxiliaries. The dispersed orange is the combination of one or more compounds shown in a formula (1); the dispersed golden yellow is the combination of one or more compounds shown in a formula (2); the dispersed red dye is the combination of one or more compounds shown in a formula (3); the dispersed yellow is the combination of one or more compounds shown in a formula (4); R7 in the formula (4) is -CH3 or -CH2CH3. When the high washing fastness dispersed yellow and brown dye composition is used for dyeing of spandex fabrics, the dyeing effect is good, the color fastness is good, and the quality of the spandex fabrics can be greatly improved.

Owner:HANGZHOU FLARIANT SPECIALTY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com