Patents

Literature

67results about How to "Obvious color difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

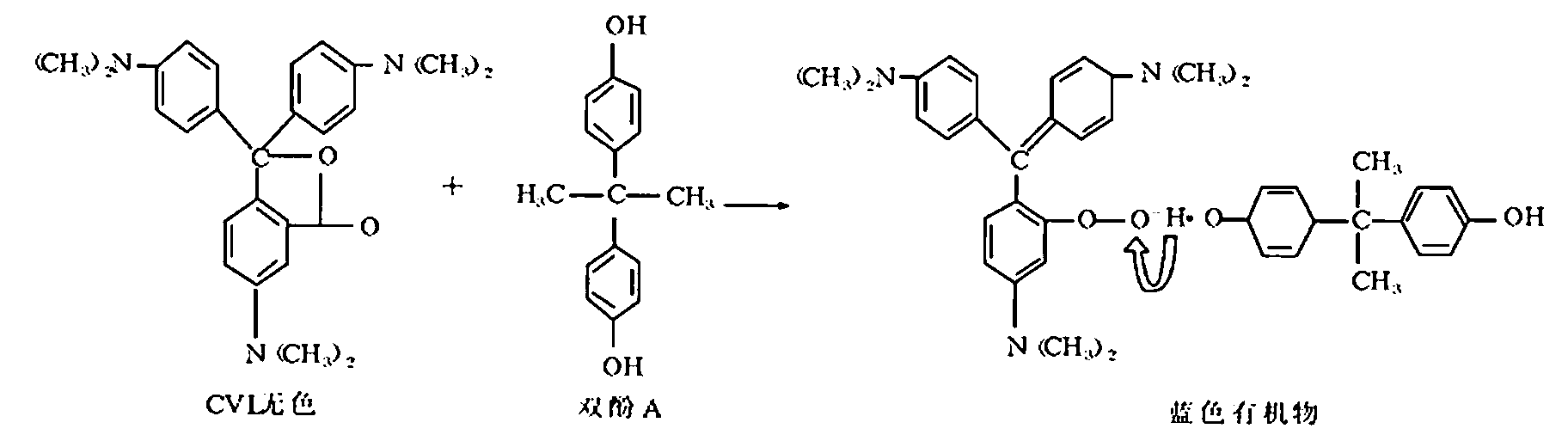

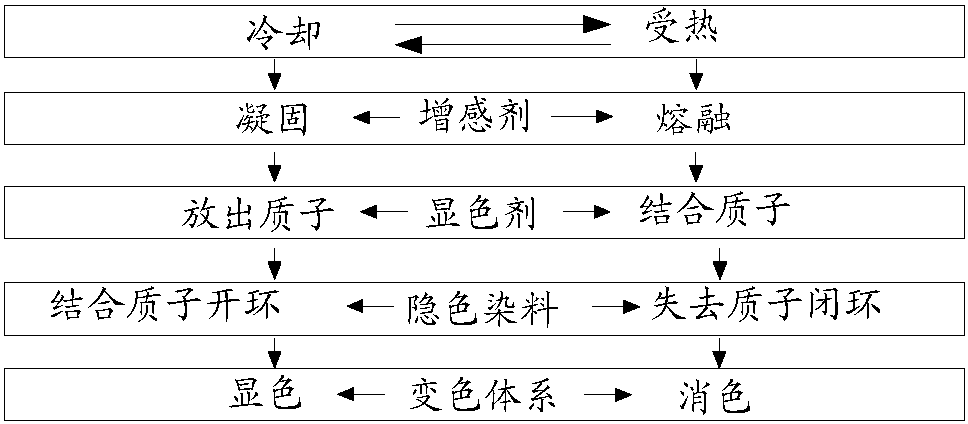

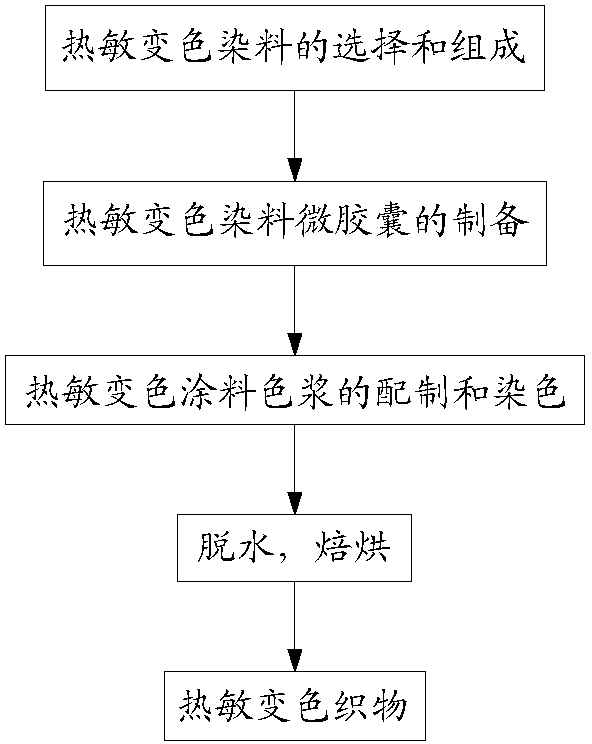

Temperature-sensitive color-changing paint dyeing technology of textile fabrics

InactiveCN103225212AObvious color differenceImprove qualityDyeing processMicroballoon preparationPolyesterFiber

Owner:FUJIAN ZHONGHE

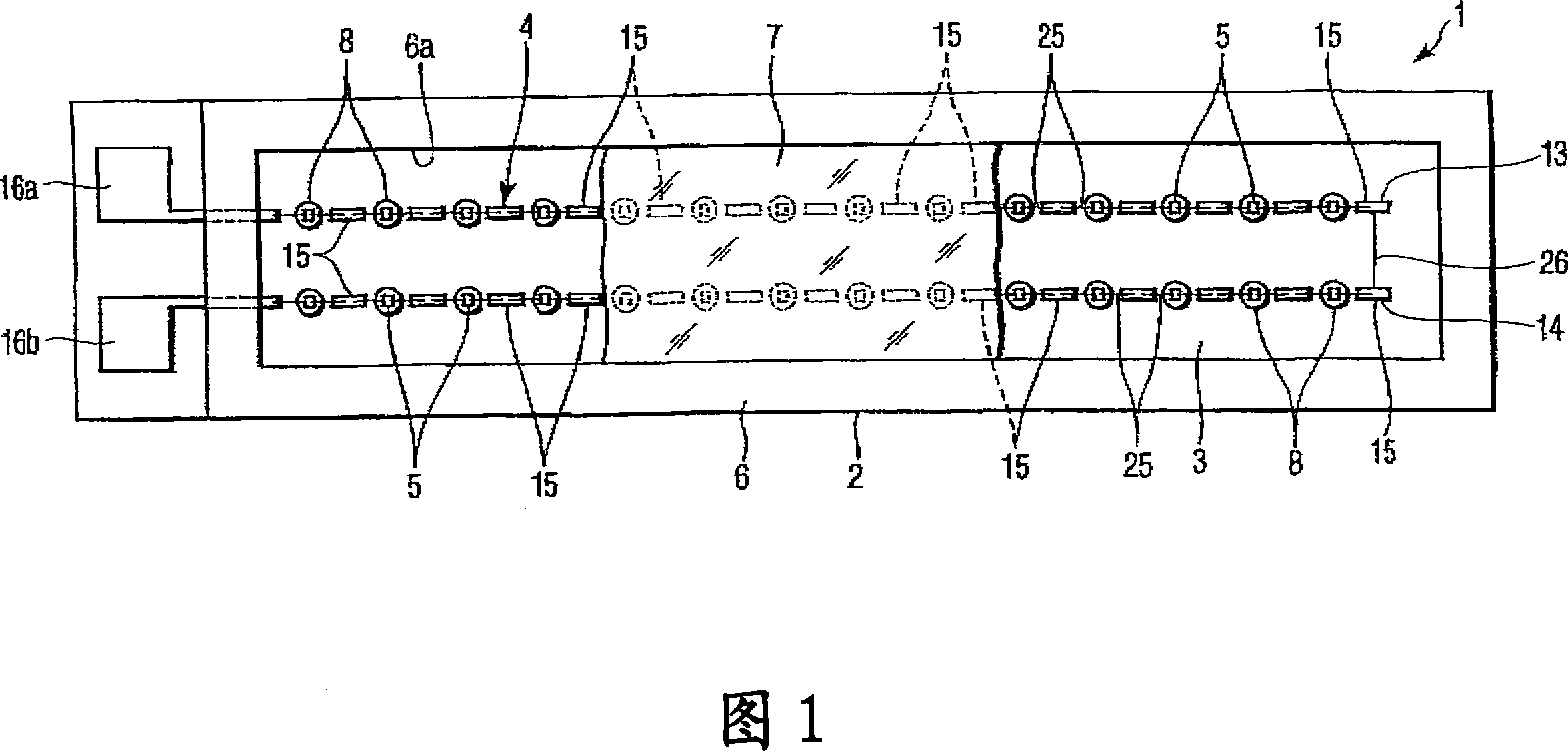

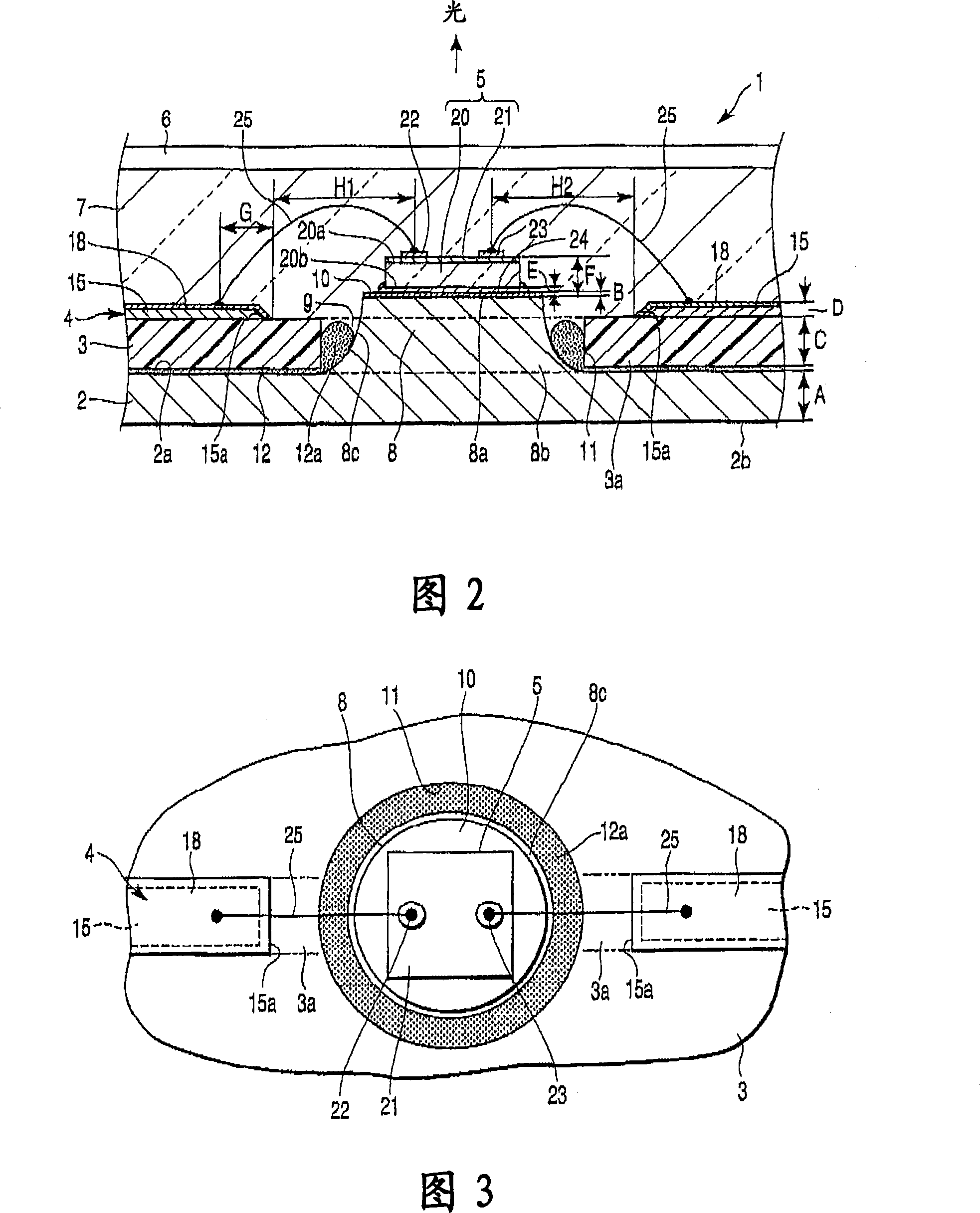

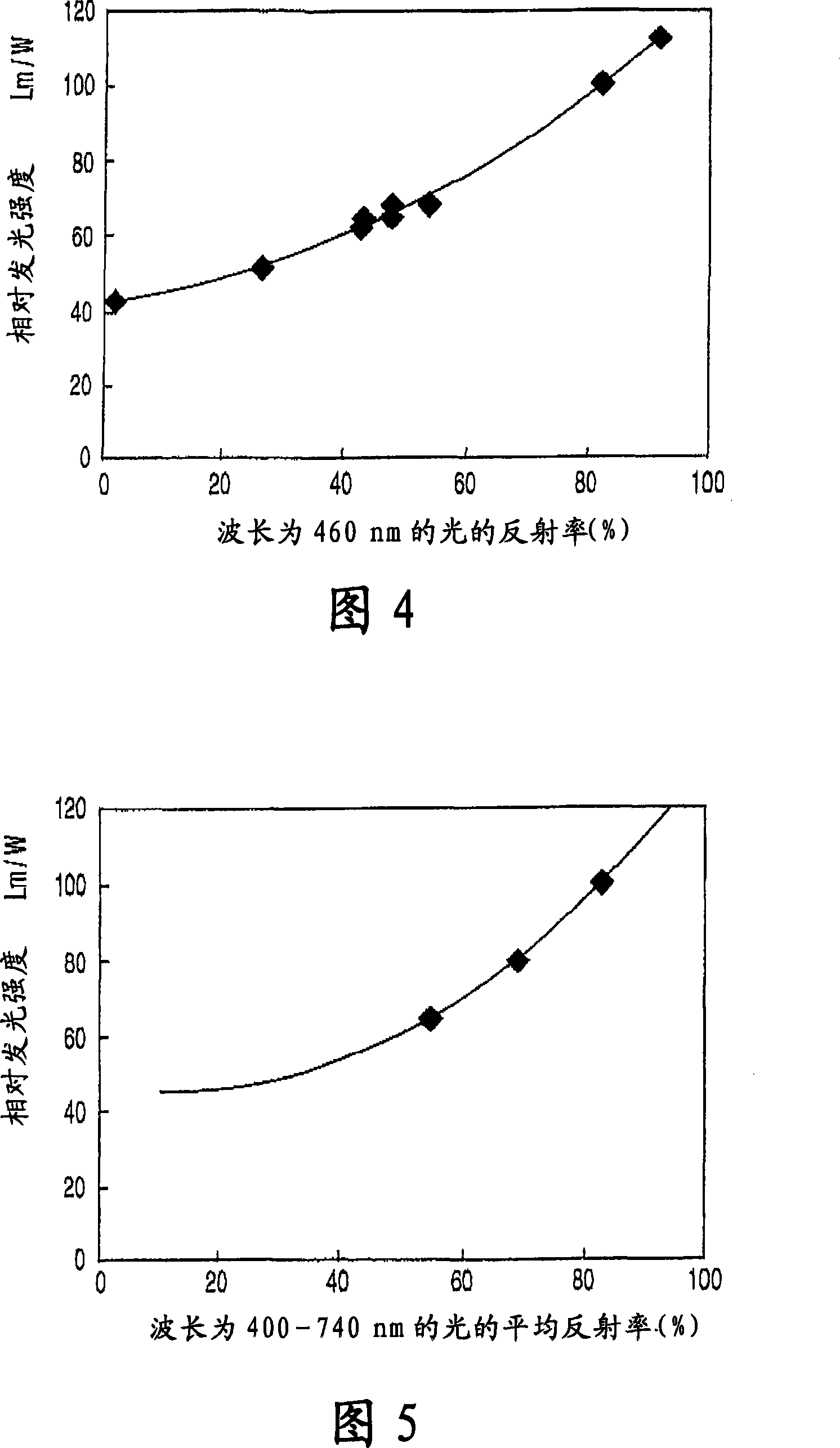

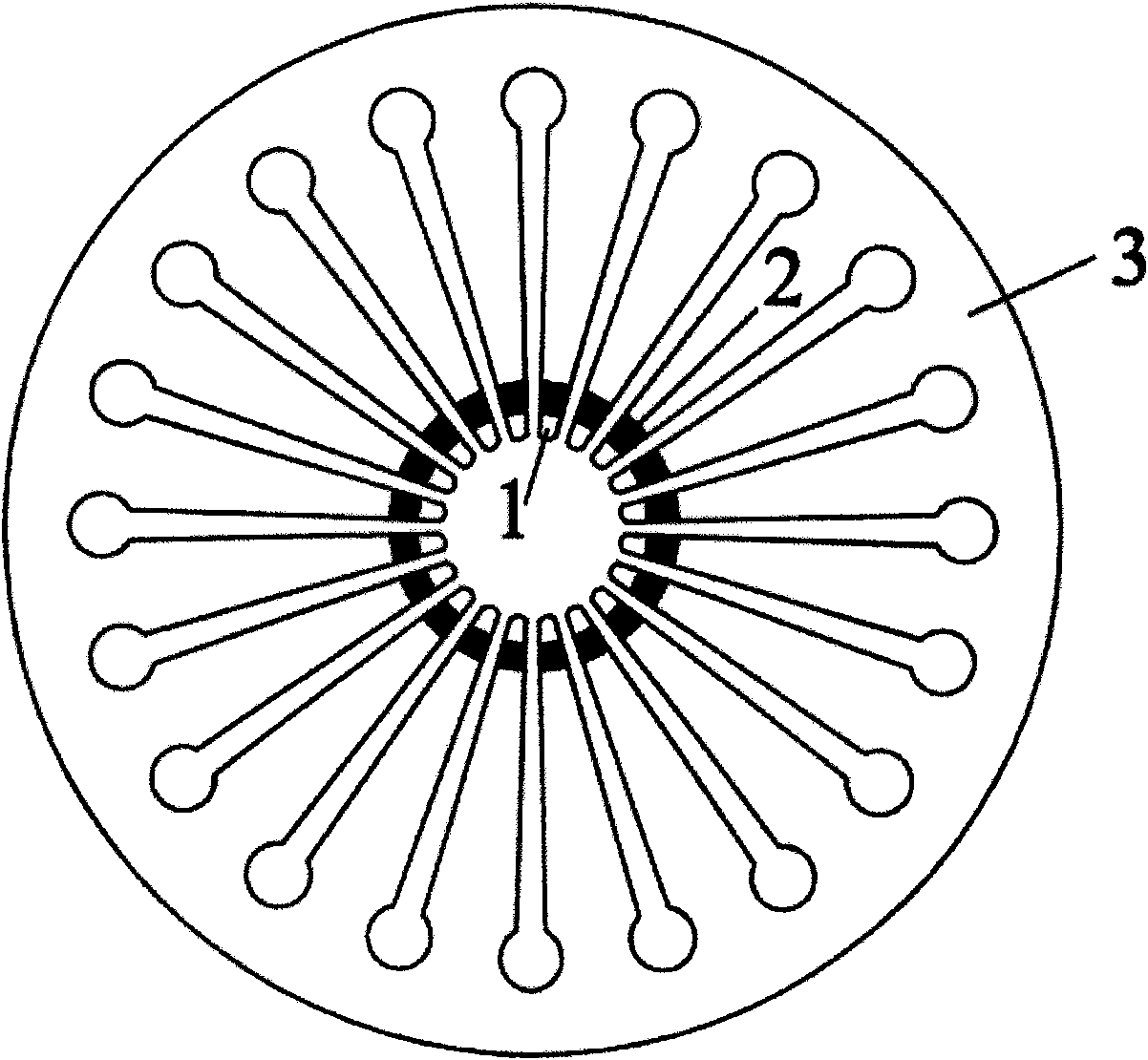

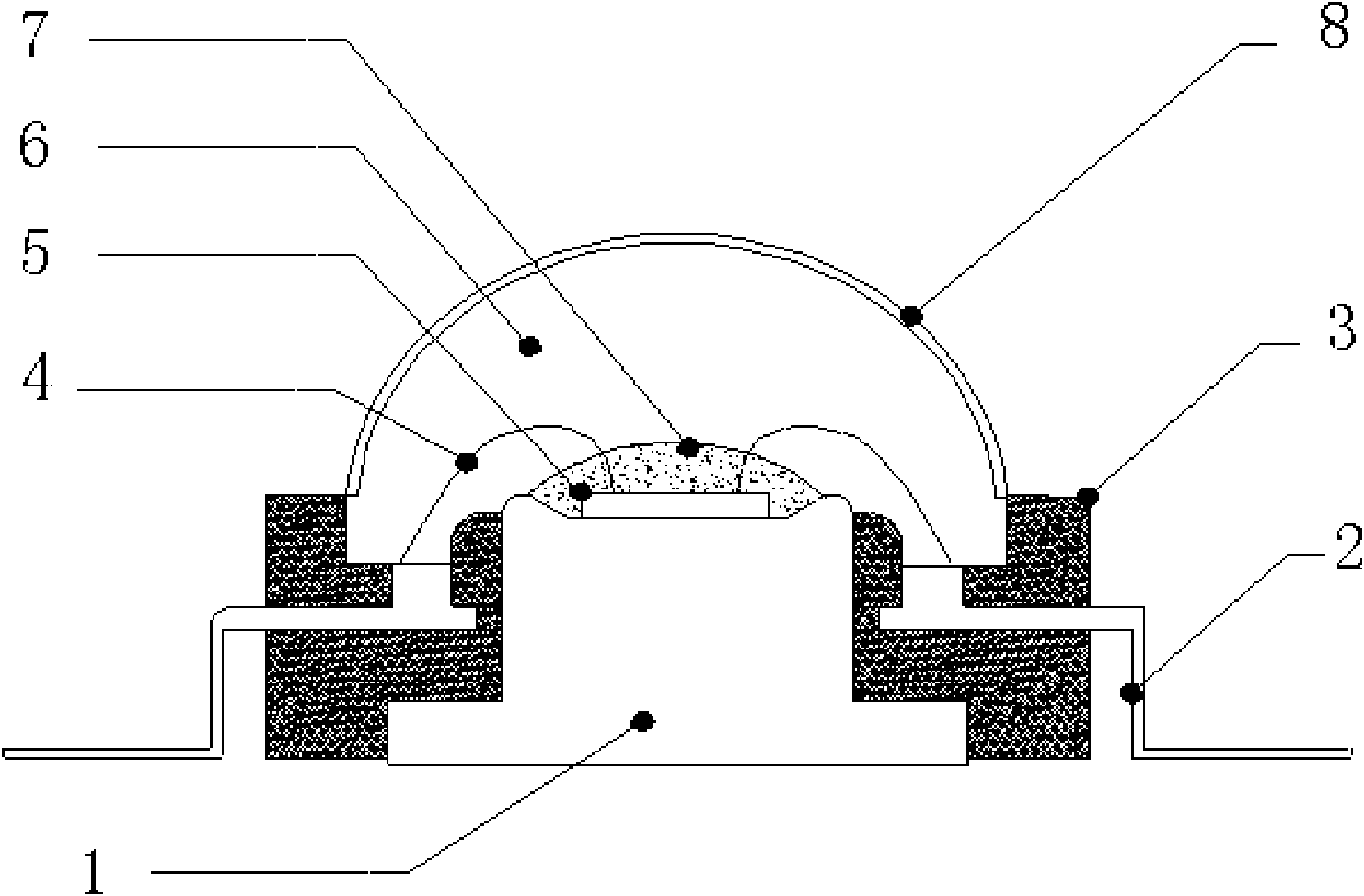

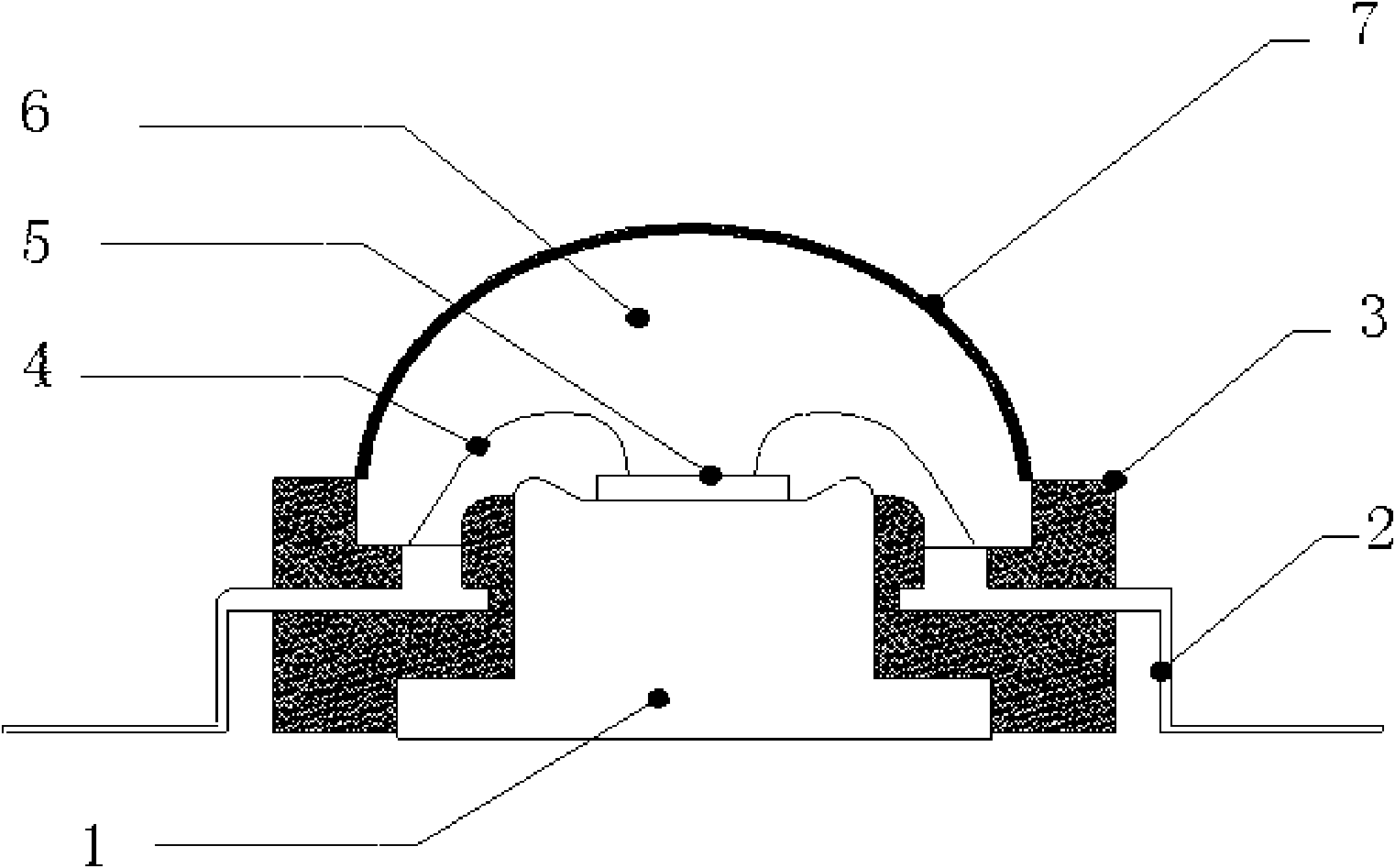

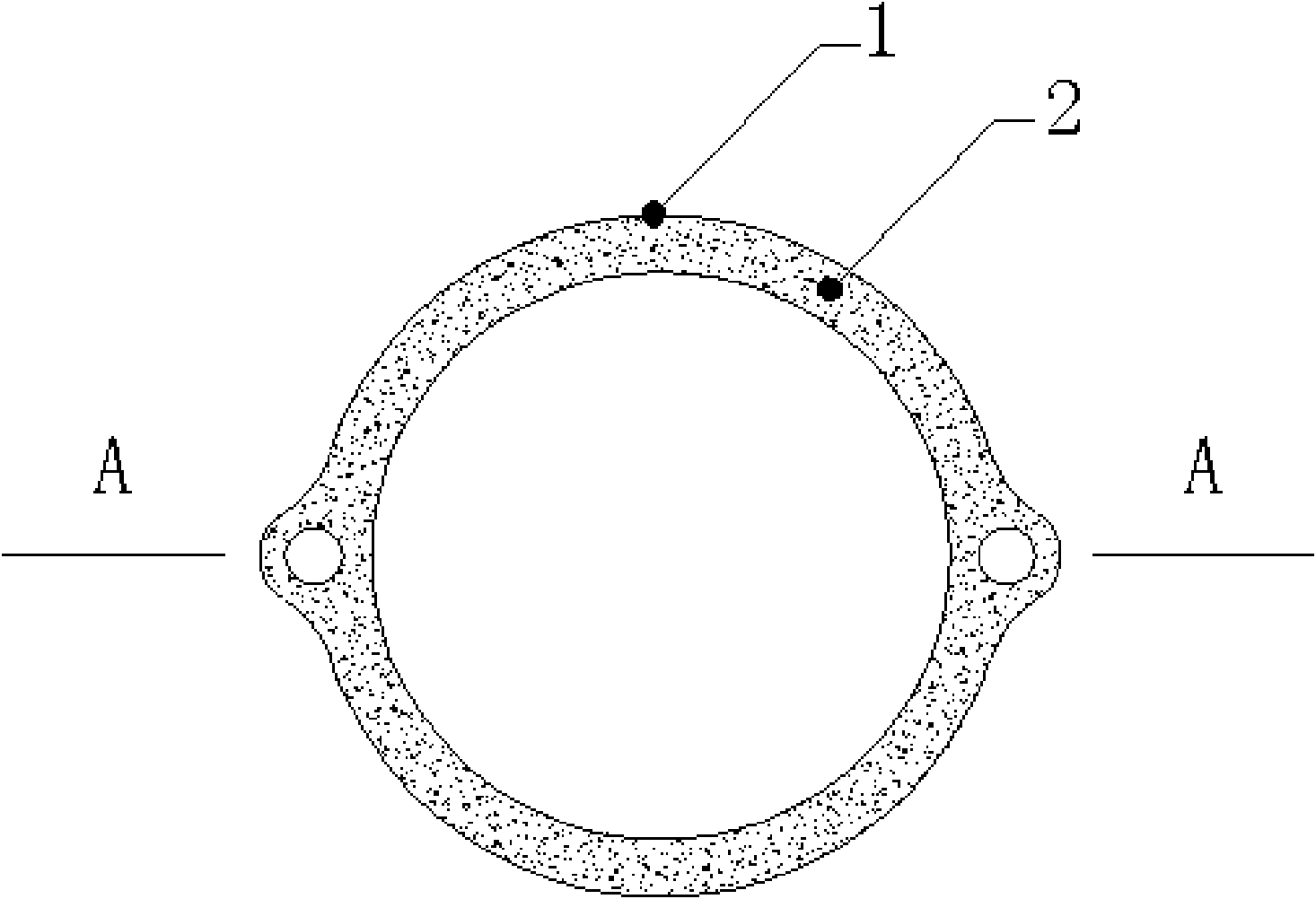

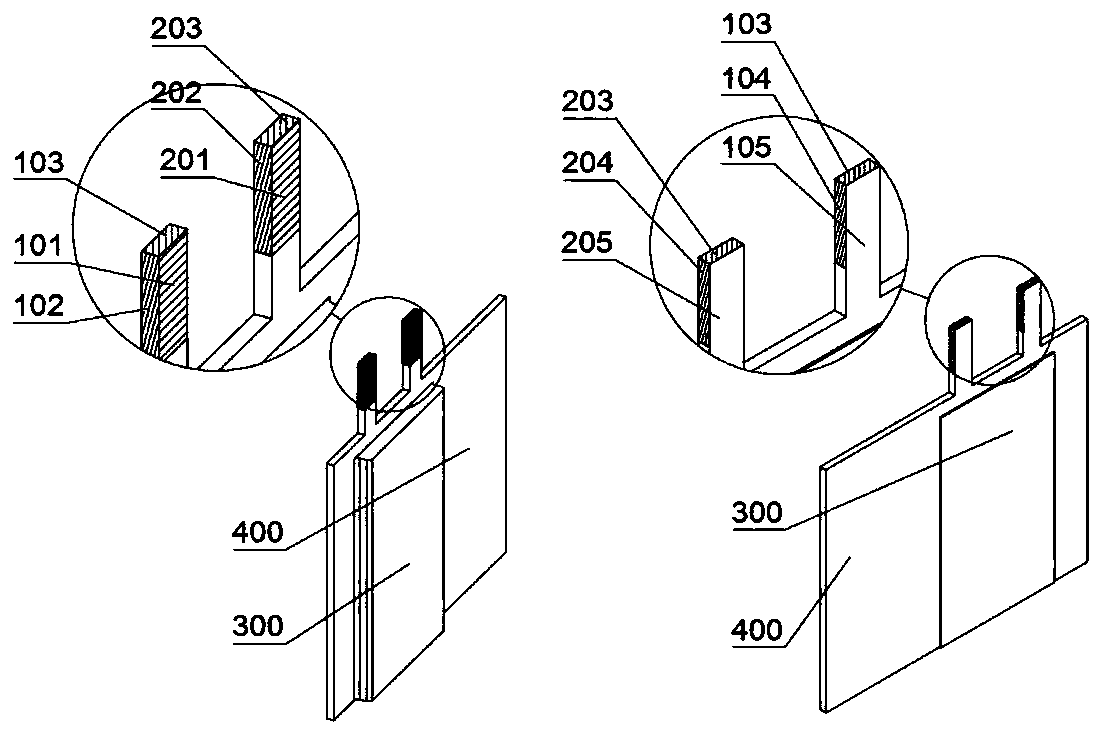

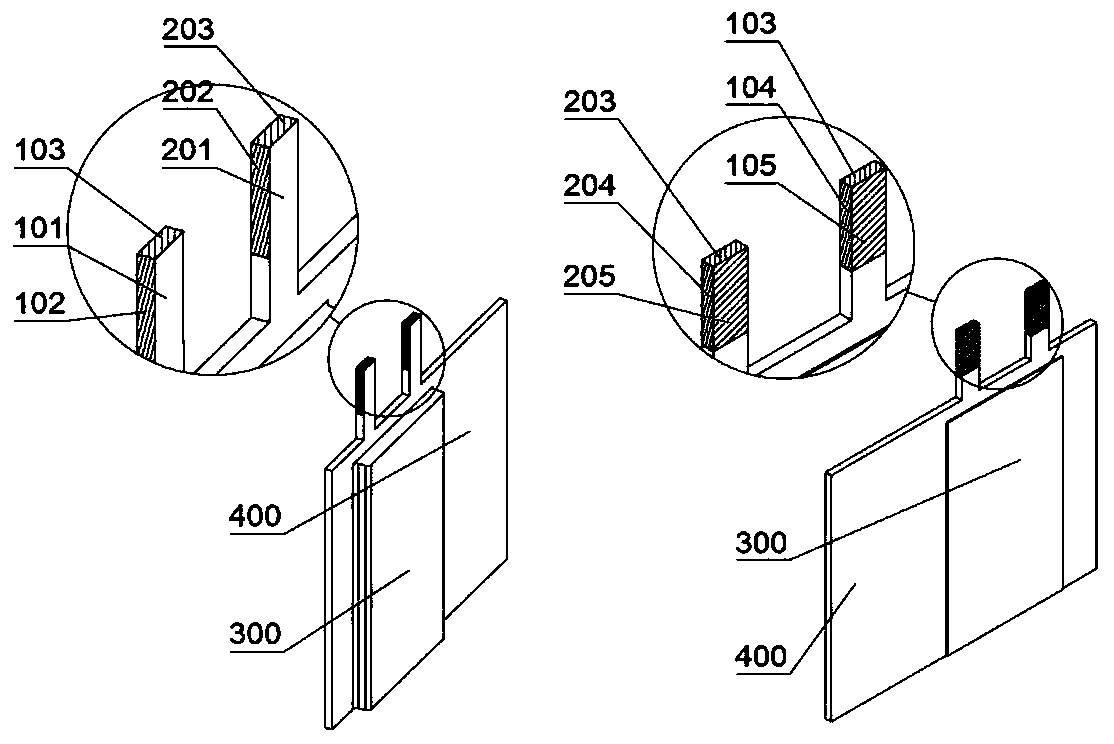

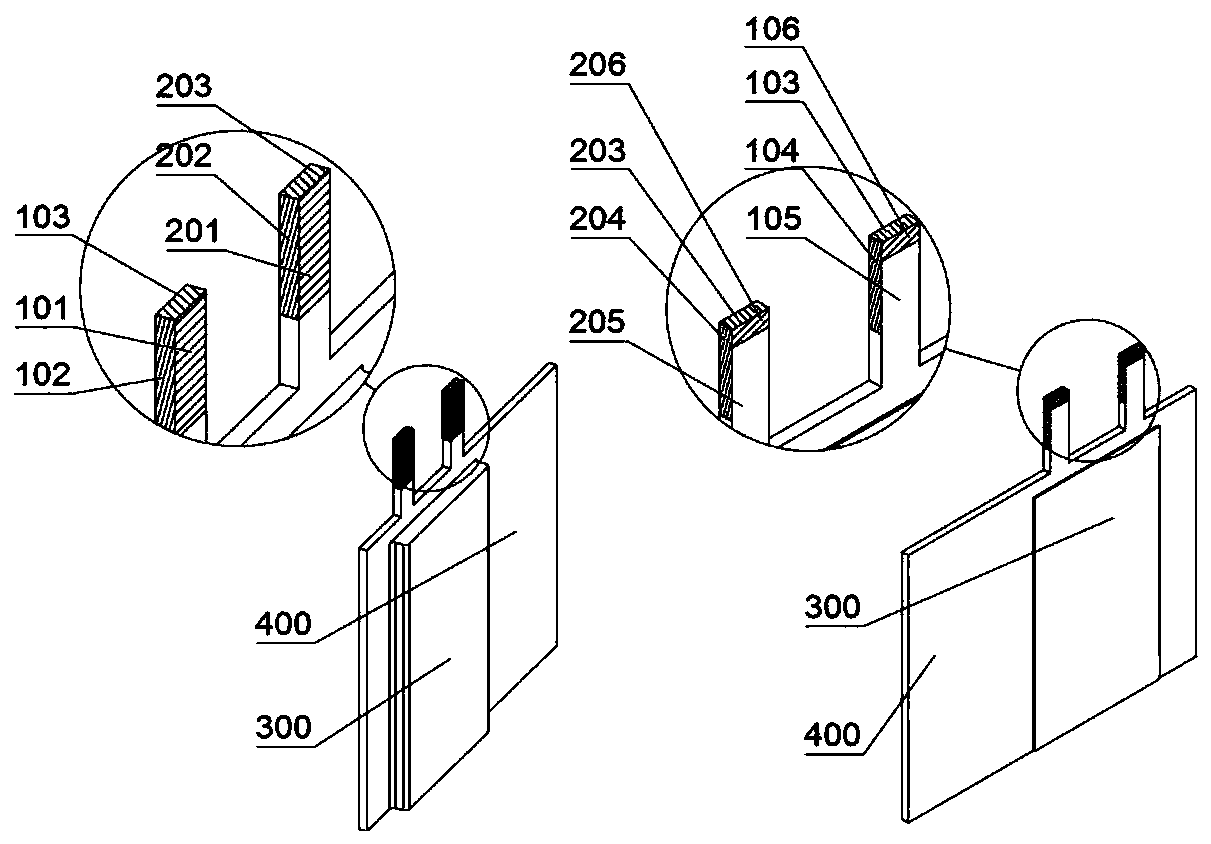

Illumination device with semiconductor light-emitting elements

InactiveCN101192601AIncrease temperatureEasy heat conductionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor

An illumination device includes a base board, an insulator, a conductor, a plurality of semiconductor light-emitting elements and a light-transmissive sealing member. The base board includes a surface and projection portions. The projection portion is formed to become gradually thicker from its end toward the surface of the base board. The insulator is formed on the surface. The conductor is formed on the insulator. The semiconductor light-emitting elements are mounted on the projection portions. The semiconductor light-emitting elements are electrically connected to the conductor via connection members. The sealing member covers the insulator, the projection portions, the semiconductor light-emitting elements and the connection members.

Owner:TOSHIBA LIGHTING & TECH CORP

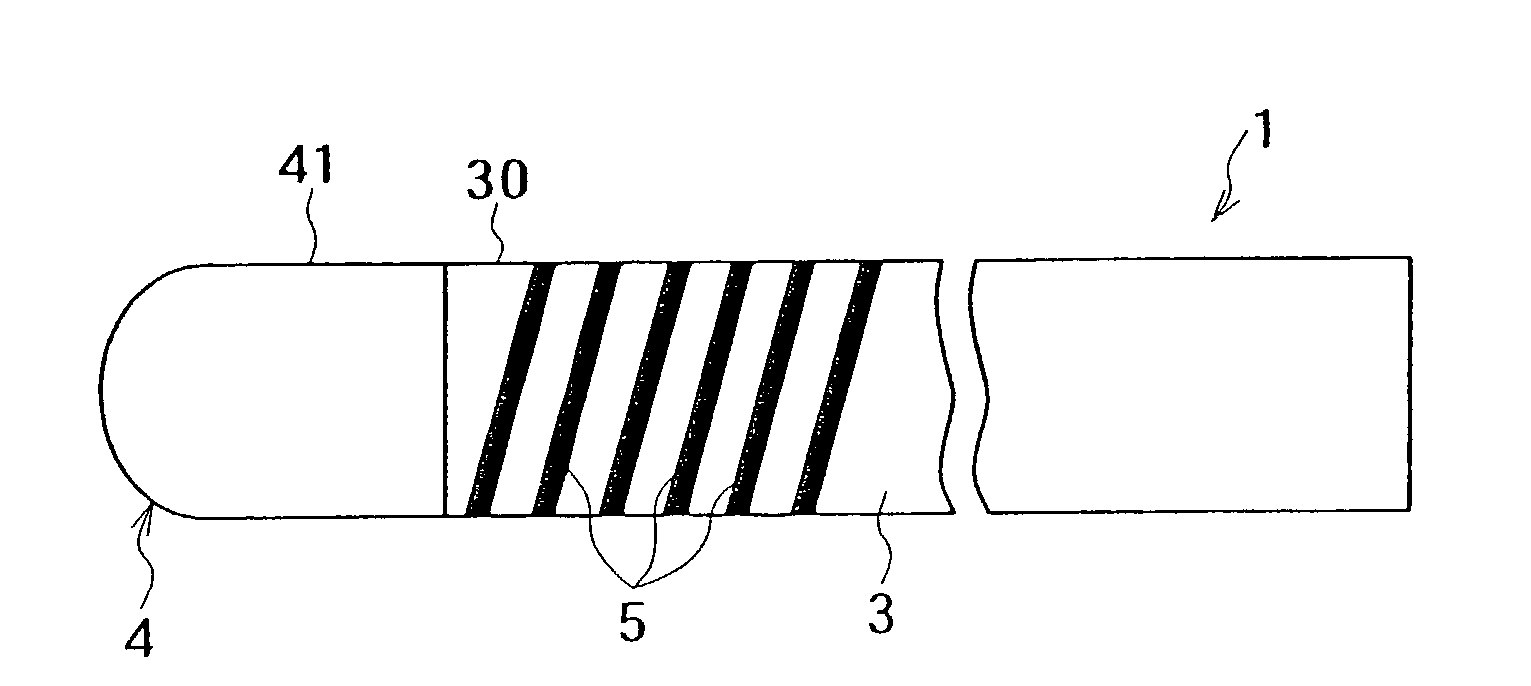

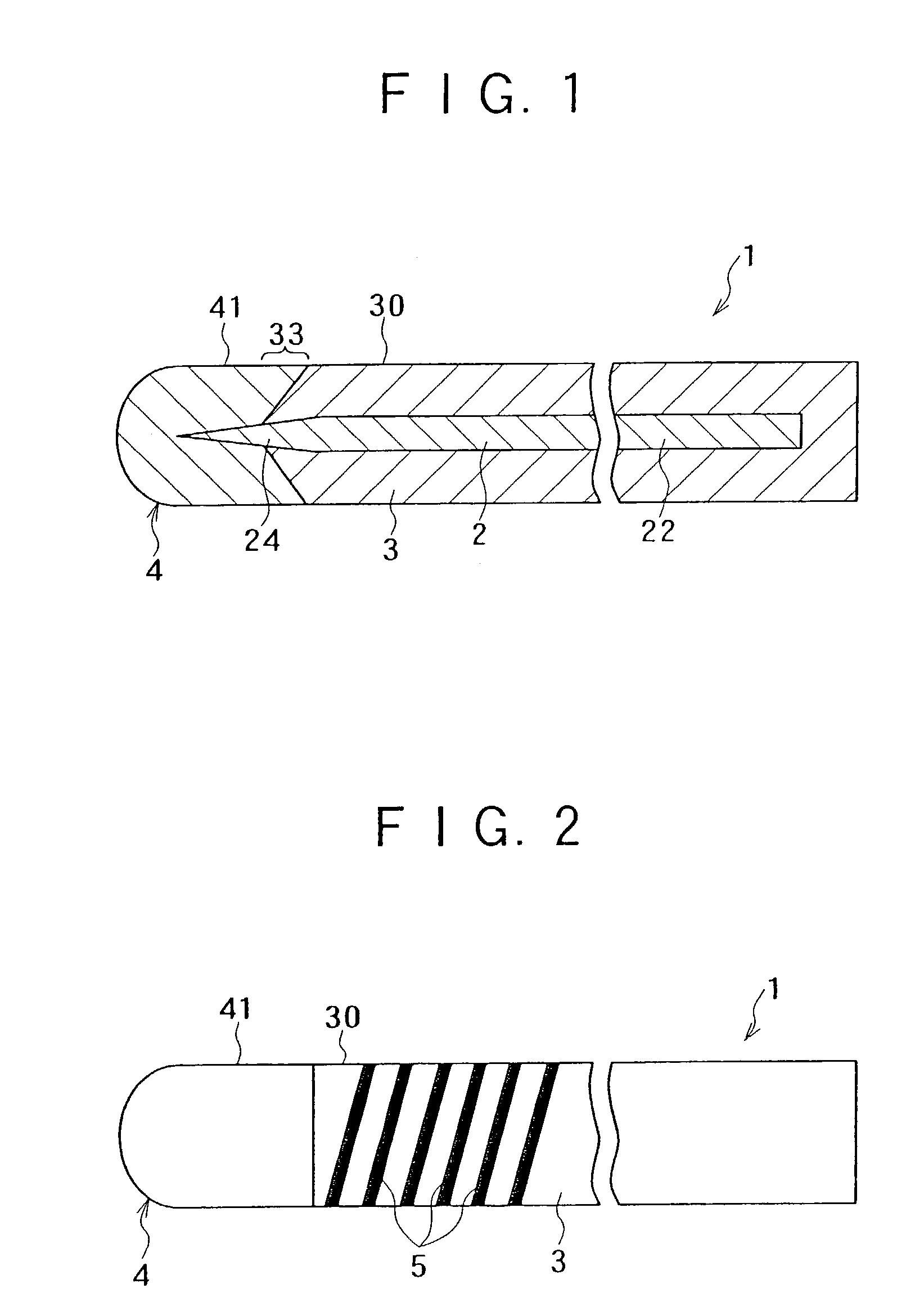

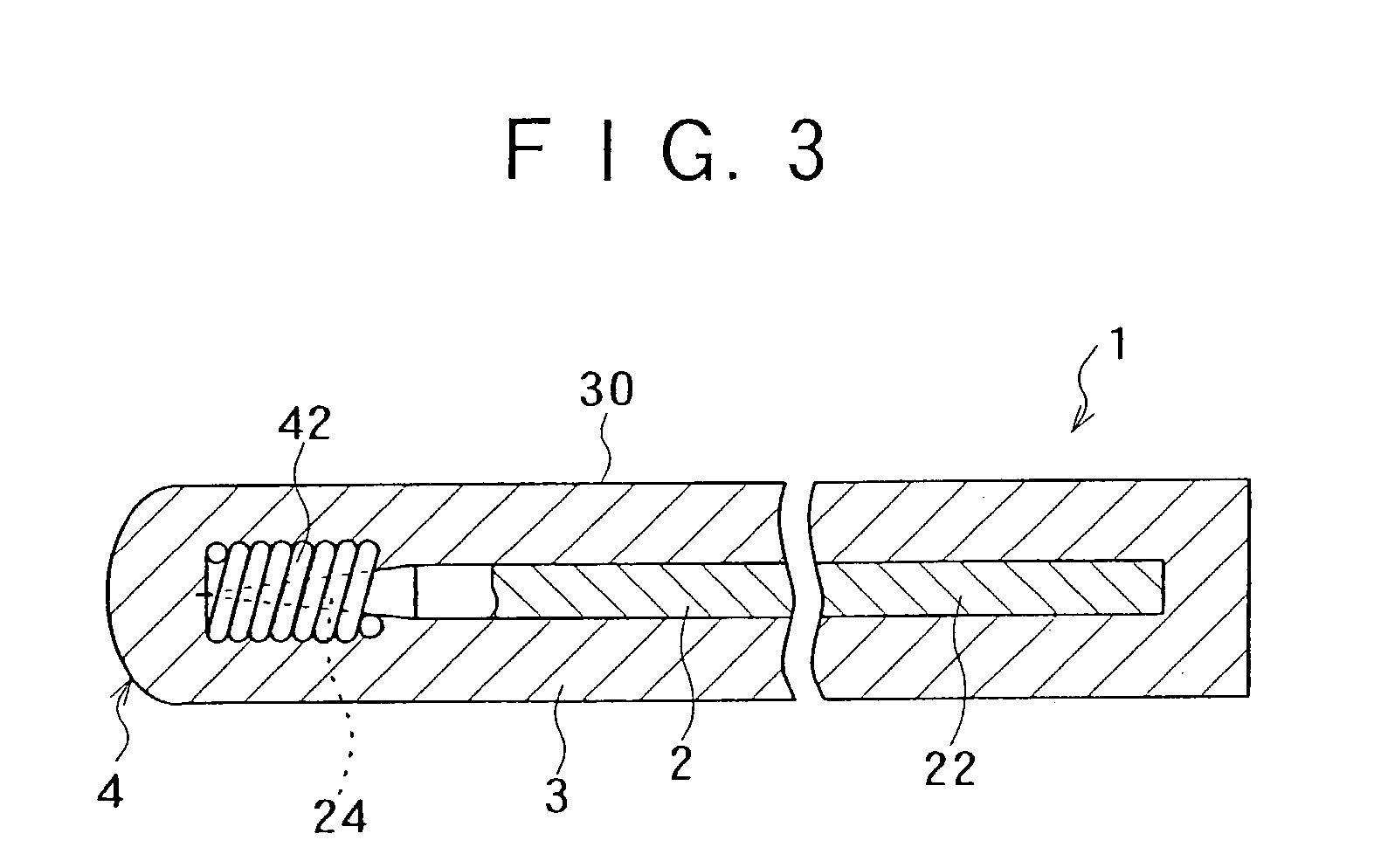

Guide wire

ActiveUS7278973B2Increase awarenessImprove visibilityGuide wiresDiagnostic recording/measuringEngineeringLaser light

A guide wire is configured to have a less lossy marker formed at a desired position and providing a relatively high degree of contrastability under X-ray fluoroscopic guidance or the like. The guide wire includes a linear core member, a resin layer covering a main body portion of the core member, and a contrasting portion covering the distal end portion of the core member. The resin layer contains a color developing agent which develops color by laser light irradiation, and a contrast agent composed of a metal oxide powder. The contrasting portion is made from a resin containing a contrast agent composed of a metal powder and has a contrasting function higher than the resin layer. A visible marker is formed on the outer surface of the resin layer through color development of the color developing agent by irradiating the surface of the resin layer with laser light.

Owner:TERUMO KK

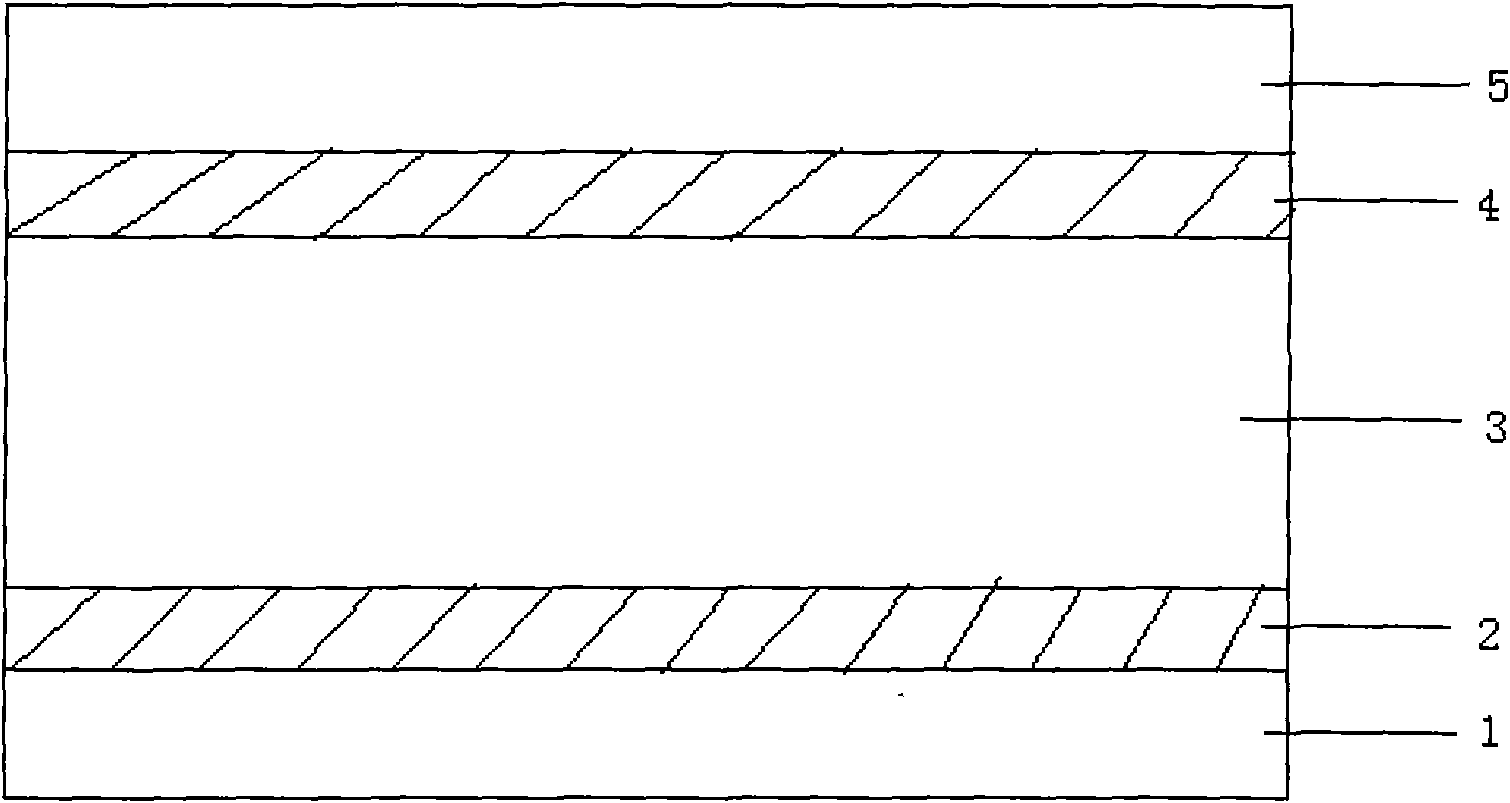

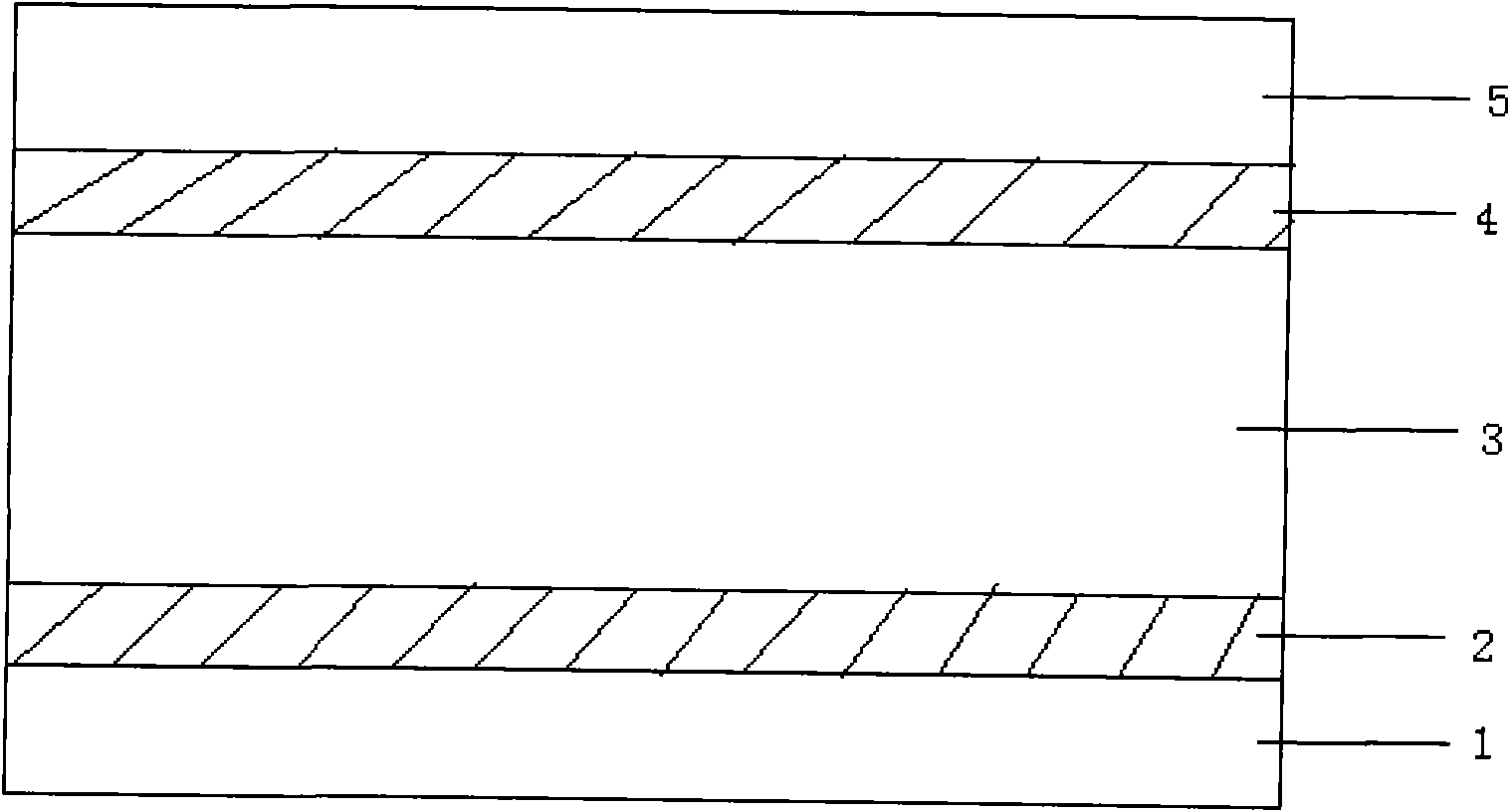

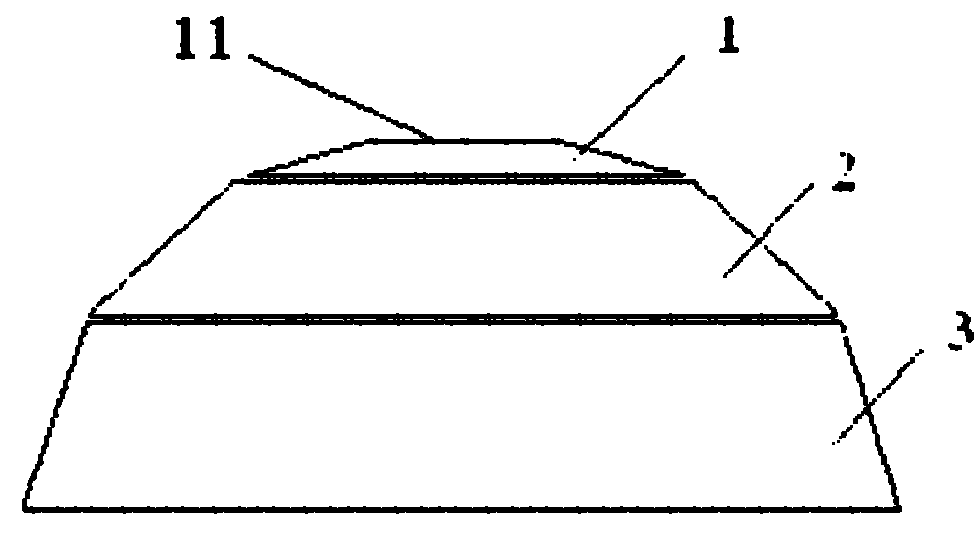

Flexible photosensitive resin plate and preparation method thereof

InactiveCN101770174AObvious color differenceImprove visual effectsPhotosensitive materials for photomechanical apparatusTectorial membraneExposure latitude

The invention relates to a flexible photosensitive resin plate, which comprises a support body (1), a bonding layer (2), a photosensitive resin layer (3), an anti-sticking layer (4) and a protective film (5) from bottom to top. The photosensitive resin layer (3) comprises at least one photochromic dye. The usage amount of the photochromic dye is 0.001-1% of the solid amount of the photosensitive layer. In the plate making process of the flexible photosensitive resin plate, the vision contrast is good, so that the operator can conveniently judge the plate making effects of patterns, characters and the like, and the plate has good exposure tolerance at the same time.

Owner:LUCKY HUAGUANG GRAPHICS

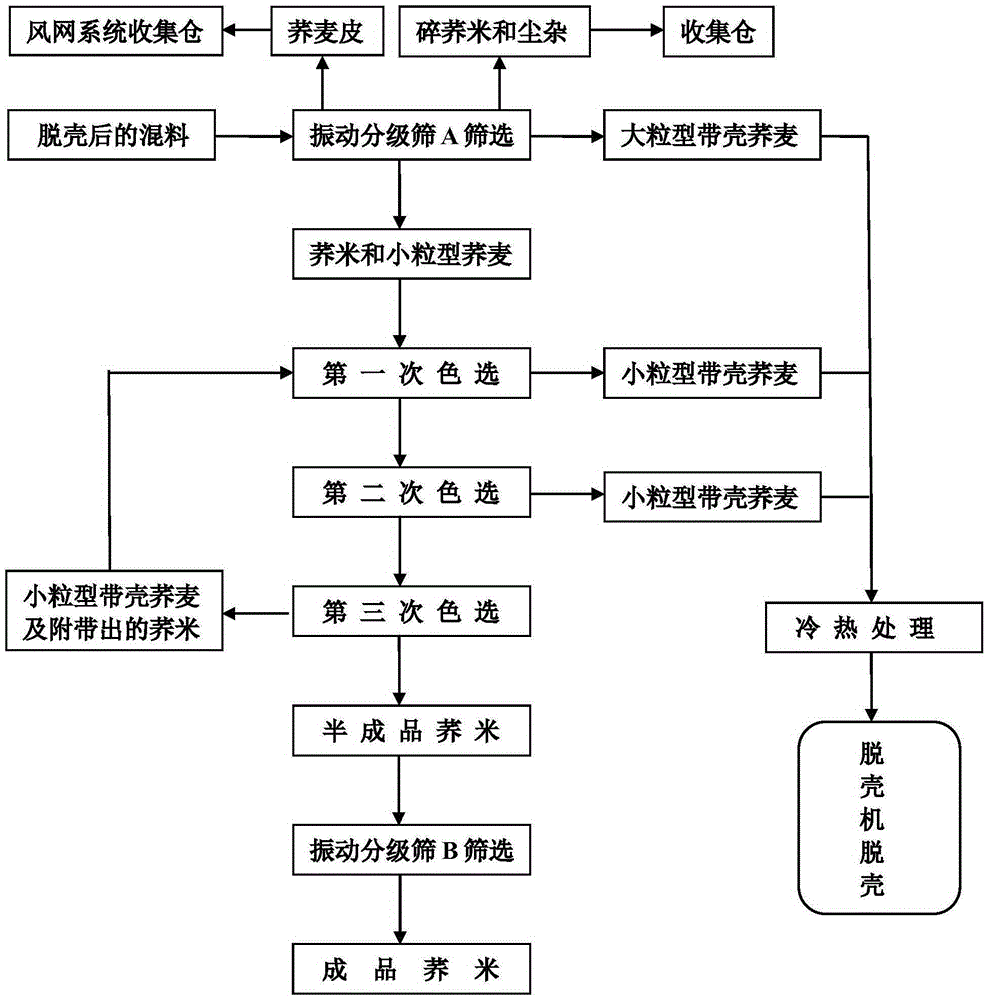

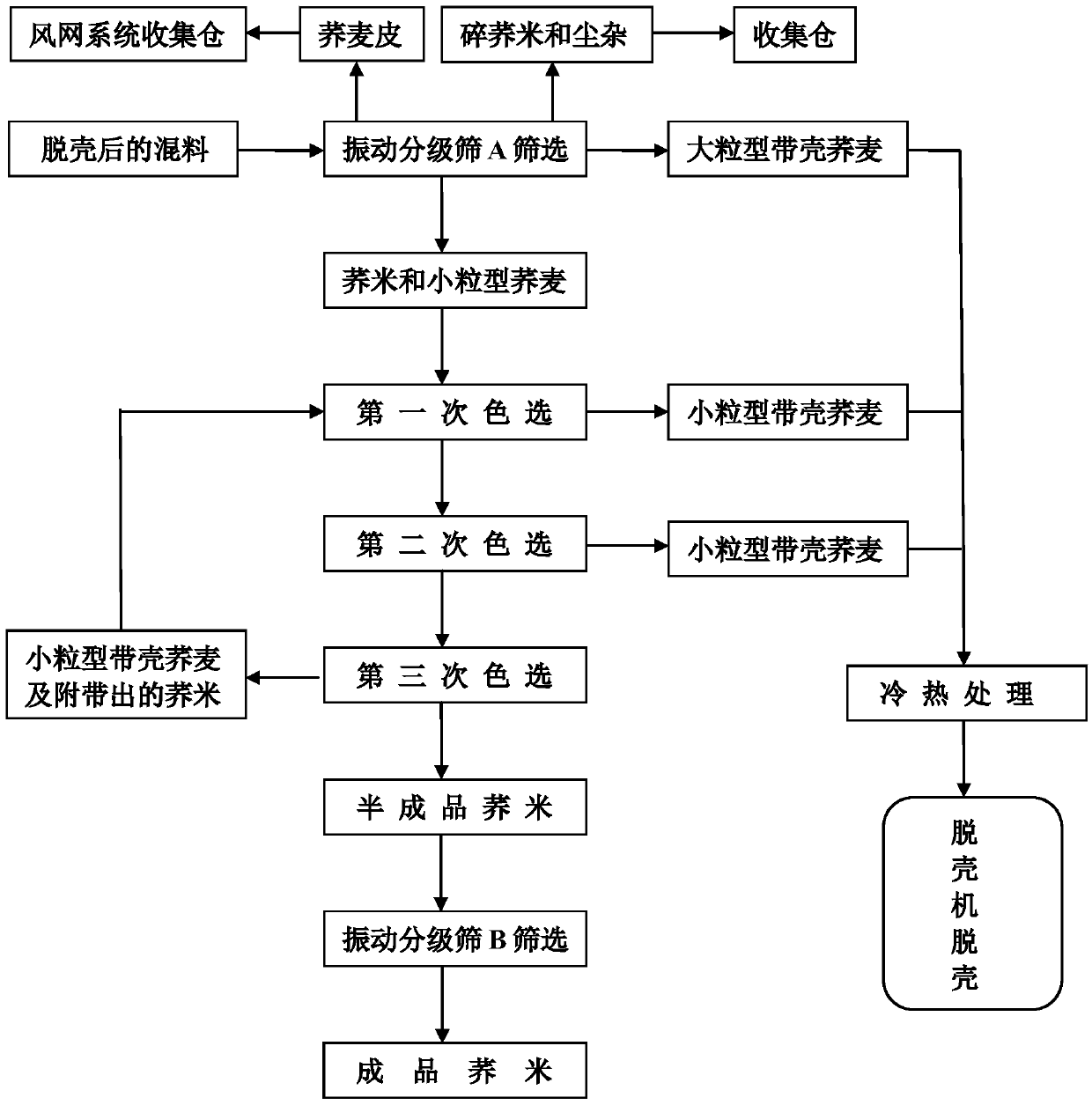

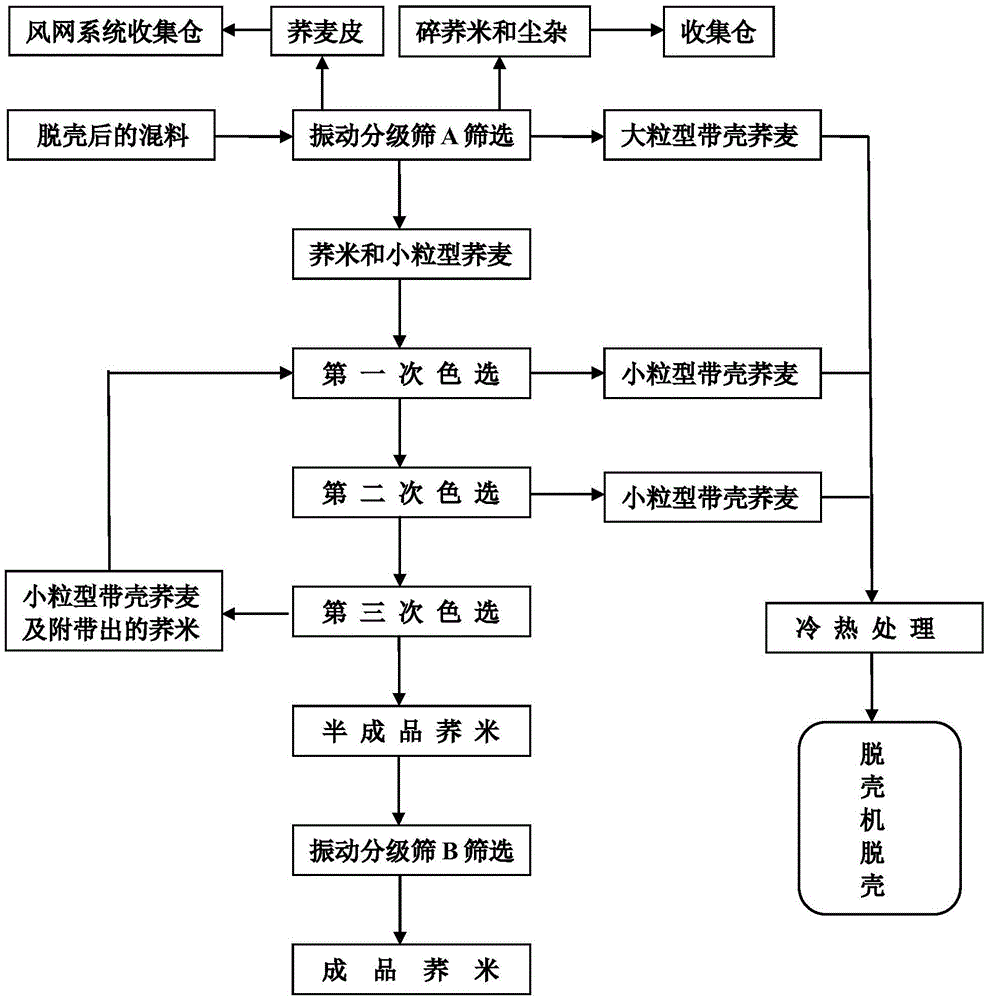

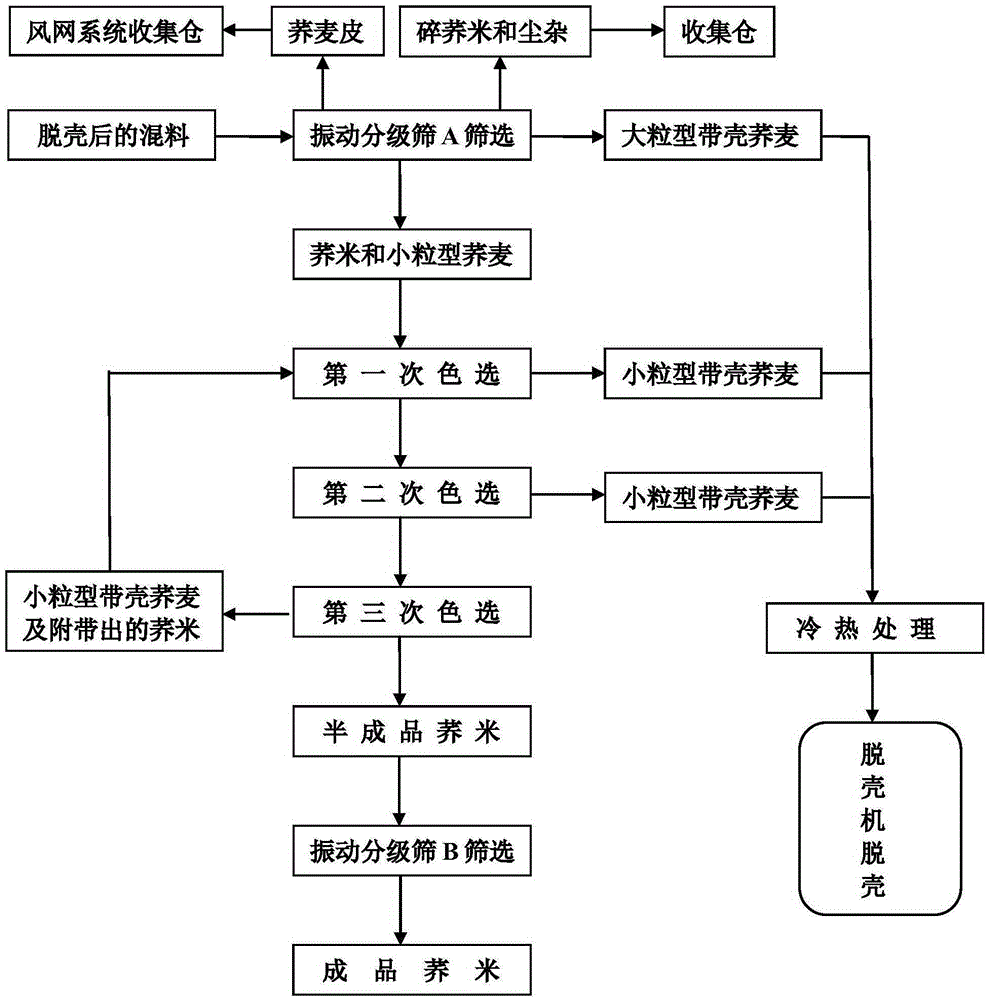

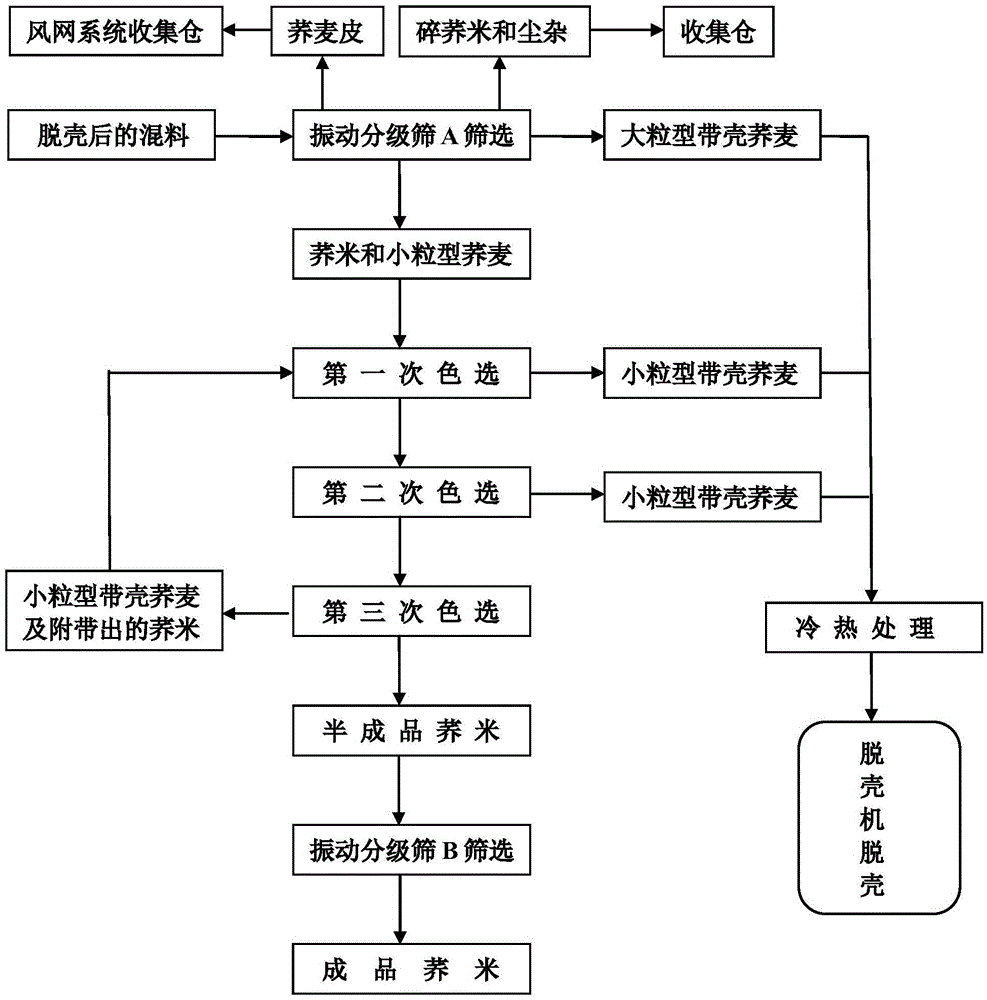

Material grain separation technology used after shelling shells during processing of buckwheat

InactiveCN105414028AFacilitate strippingSecond shelling is convenientSievingGas current separationHuskSeparation technology

The invention discloses a material grain separation technology used after shelling shells during processing of buckwheat. The technology comprises the steps that 1, after the shells of the buckwheat are separated, a mixed material containing a small part of buckwheat husks, buckwheat grains and the buckwheat with the shells is screened through a vibration grading screen at first, oversize products on lower layer screen cloth enter a color sorter through an elevator and the colors of the oversize products are sorted and separated, color sorting is conducted three times sequentially, separated semi-finished buckwheat grains are screened and graded through the vibration grading screen, and high-quality finished buckwheat grains are obtained; 2, small-grain-type buckwheat with the colors being sorted for the first time and the second time is uniformly mixed with large-grain-type buckwheat intercepted by upper layer screen cloth, wherein the small-grain-type buckwheat and the large-grain-type buckwheat are provided with the shells, and after cooling-heating treatment is conducted, the buckwheat enters a huller in batches for secondary shelling; and 3, the final material grain separation rate reaches 99.9%, the secondary shelling rate reaches 95%, the purity of the buckwheat grains can reach 99.9%, the imperfect grain mass is 1% or less, impurities account for 0.10% or less, broken grains account for 1% or less, the surface of the buckwheat is bright and clean, and the buckwheat has obvious buckwheat fragrance. The purpose of large-scale material grain separation with high quality, high efficiency and high yield is achieved for the buckwheat grains with the shells being separated.

Owner:NINGXIA JIADAO HALAL FOOD

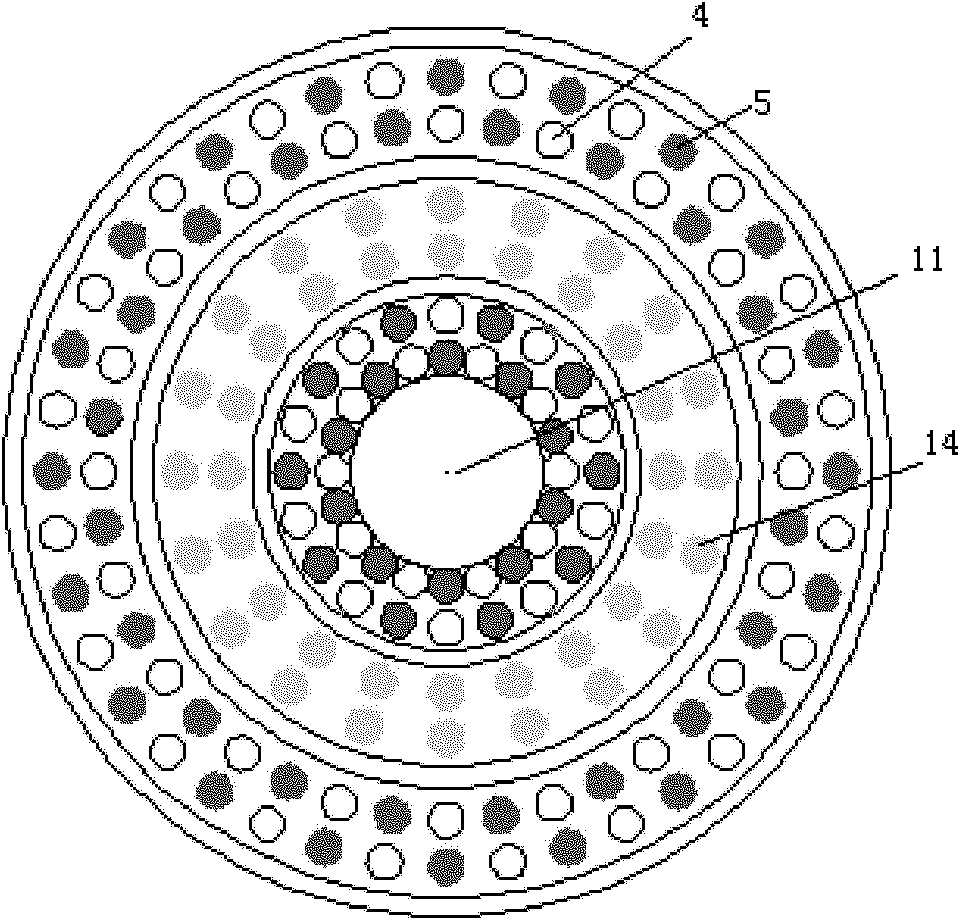

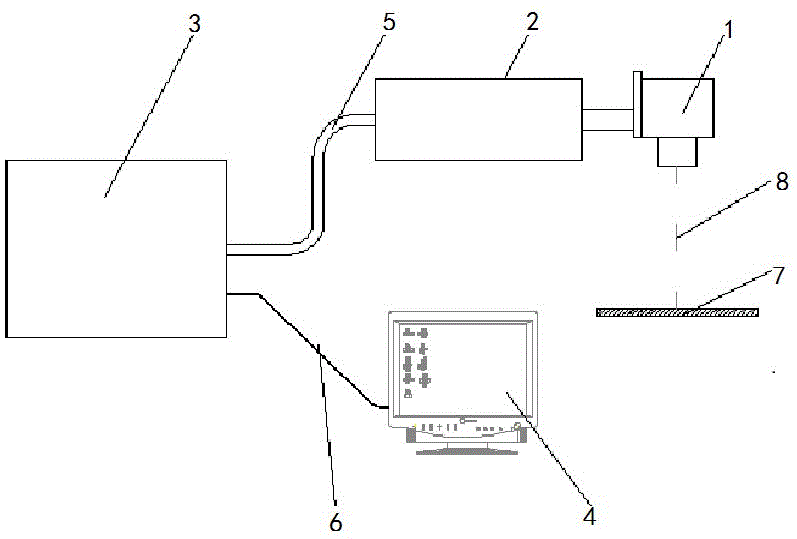

Light source for optical automatic detector

InactiveCN102033072AEasy to controlSimple structurePoint-like light sourceMaterial analysis by optical meansCamera lensLed array

The invention discloses a light source for an optical automatic detector. The light source comprises three annular LED arrays which are coaxially superposed in three layers and an intermediate through hole, wherein the three annular LED arrays are all shaped like a truncated cone, and an LED lamp is embedded at the inner lateral side of the truncated cone; two red-blue double-color annular LED arrays are respectively positioned in the top layer and the bottom layer and are used for providing high-angle and low-angle lighting; one green annular LED array is positioned in the intermediate layer and is used for providing intermediate-angle lighting; and each red-blue double-color annular LED array is divided into a red set and a blue set based on the LED color, the red set and the blue set are respectively connected with an external control device, the green annular LED array is independently connected with the external control device, and a lens is placed right above the intermediate through hole of the light source in the shooting process. By using the invention, the external control device can control the light source to select different colors of the light source in accordance with colors of circuit boards so as to achieve combined lighting effect, so that colors of tin solder images can be obviously different from those of base plate images. Besides, the light source has simple structure and is convenient to control.

Owner:SOUTH CHINA UNIV OF TECH

Sialidase detection reagent

InactiveCN1405562AImprove stabilityImprove accuracyMicrobiological testing/measurementBiological testingNeuraminateSialidase

This invention discloses a sialic acid enzyme test reagent for testing sialic acid enzyme activity in vagina secreta outside the body, containing substrate on the carrier named N-acetyl neuraminate and its salt which can be its derivant or thymolphthaleic N-acetyl neuraminate and its salt, 5-Br-4-Cl-3-indolyl-alpha-D-N-acytylneuraminate and its salt. We can diagnose the bacteriogenic vagina deseases quickly and simple by testing sialic acid enzyme to vagina searate with this sialic acid ester reagent which can be used as an independent diagnosis target with good stability, extremely excellent accuracy and simple operation (one step test).

Owner:肖洪武

Diaphragm spring and finger tip thermal processing process thereof

InactiveCN101655129AObvious color differenceReduce labor processFriction clutchesFurnace typesTemperingEngineering

The invention discloses a diaphragm spring and a finger tip thermal processing process thereof. A finger tip high-frequency region of the diaphragm spring is pale and a transition region is blue. Thefinger tip thermal processing process sequentially comprises the following procedures: quenching the diaphragm spring, high-temperature tempering, shot blasting, high-frequency quenching at a finger tip, low-temperature tempering and polishing the finger tip. During the low-temperature tempering, the diaphragm spring is placed in a mesh-belt tempering furnace, and is insulated at a temperature of185-215 DEG C for 2-2.5h under the condition of ensuring that a mesh-belt is not moved. The length of the transition region of the product obtained by thermally processing the finger tip of the diaphragm spring by the method can be distinguished whether accords with the technical requirement or not only through visual inspection by adopting the method of the invention, the product is fully detected without a special hardmeter and is marked without color, thereby reducing the labor procedure and lowering the cost.

Owner:HUBEI DAFAN AUTO PARTS

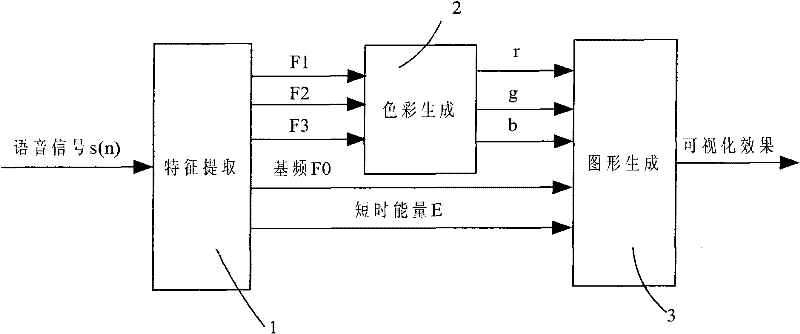

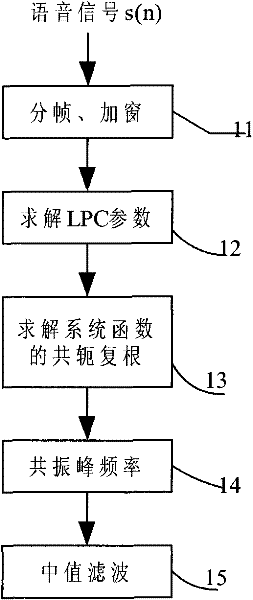

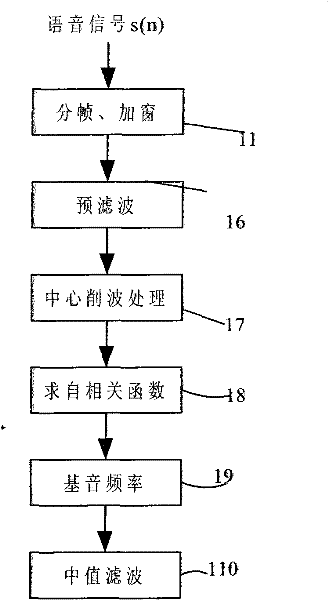

Formant-frequency-based Mandarin single final vioce visualizing method

InactiveCN102176313AObvious color differenceEasy to identifySpeech analysisSubjective perceptionFormant

The invention provides a formant-frequency-based Mandarin single final voice visualizing method. The method comprises the following steps: framing and windowing an original voice signal; extracting short-time energy, formant frequency and fundamental tone frequency of each frame of signal; correcting errors of specific values of the formant frequency and the fundamental tone frequency by adopting a median smoothing method; mapping different pronunciations into different color aspects by utilizing the formant frequency, and correcting; reflecting variation tendency of pronunciation time, energy and fundamental tone frequency in an image; and differentiating different Mandarin single final pronunciations by colors. The method is easy to implement by only extracting acoustic phonetic parameters of short-time energy, formant frequency and fundamental tone frequency of a voice signal; soft decision is introduced, each pronunciation is not subject to hard decision, but represented by different colors, and visualizing effect of different speakers on the same pronunciation is based on the principle of seeking common grounds while reserving differences, so that the decision on pronunciation more accords with subjective perception of people.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Blood smear leucocyte dye liquor and its preparing process

InactiveCN1924543AShorten dyeing timeIncrease the number ofPreparing sample for investigationOrganic dyesWhite blood cellRed blood cell

This invention relates to blood smear leucocyte dye liquid, which is composed of amine salt basic ion surface active agent, polyvinyl pyrrolidon or carbowax and regular leucocyte dye liquid with their constitution proportion as 0.0001%-0.04%,0.0125%-2.5% and 30%-75%. This invention can effectively remove the erythrocyte mixture to properly add the blood thickness to make leucocyte number add within each eye scope.

Owner:TECOM SCI CORP

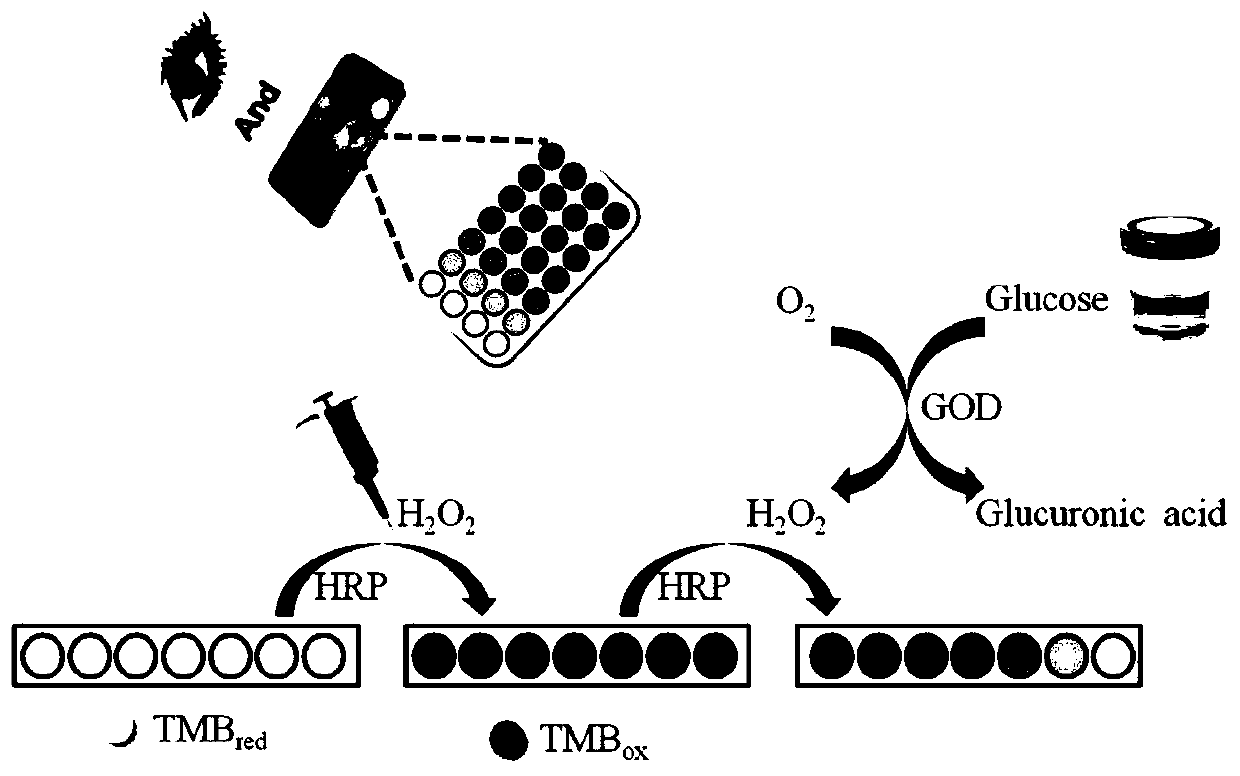

Simple urine sugar quantitative detection method and urine sugar quantitative detection kit

ActiveCN110082347AWide concentration rangeObvious color differenceMaterial analysis by observing effect on chemical indicatorPeroxidaseHorse radish peroxidase

The invention provides a simple urine sugar quantitative detection method and a urine sugar quantitative detection kit and belongs to the field of biological detection. The urine sugar quantitative detection method comprises the following steps: mixing 3, 3', 5, 5'-tetramethyl benzidine, horse radish peroxidase, hydrogen peroxide solution and glucose oxidase to obtain a blue detection solution; uniformly mixing the blue detection solution and urine to be tested to obtain a colorimetric solution; measuring intensity value of blue in the colorimetric solution; and calculating blood sugar value in the urine to be tested. The method is low in detection cost, high in accuracy and convenient and fast, does not depend on specific analytical instruments and is especially suitable for daily detection of diabetes patients at home.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

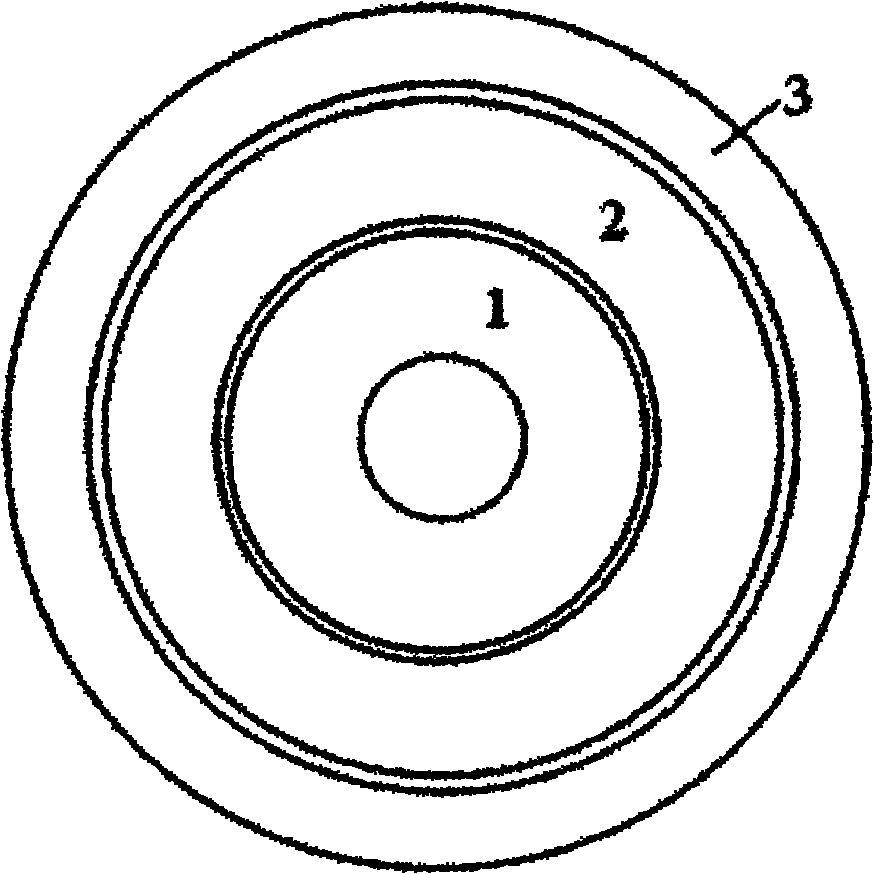

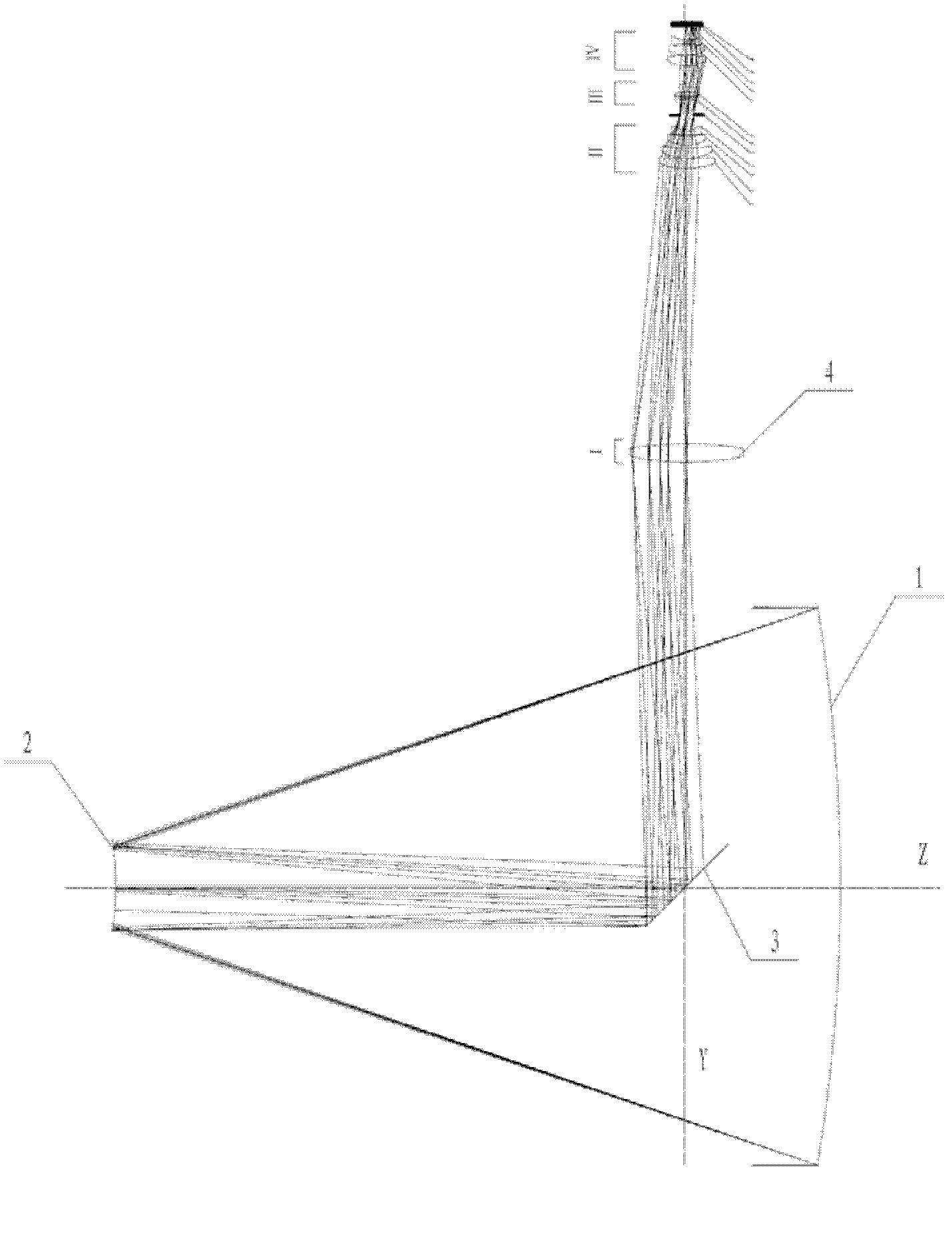

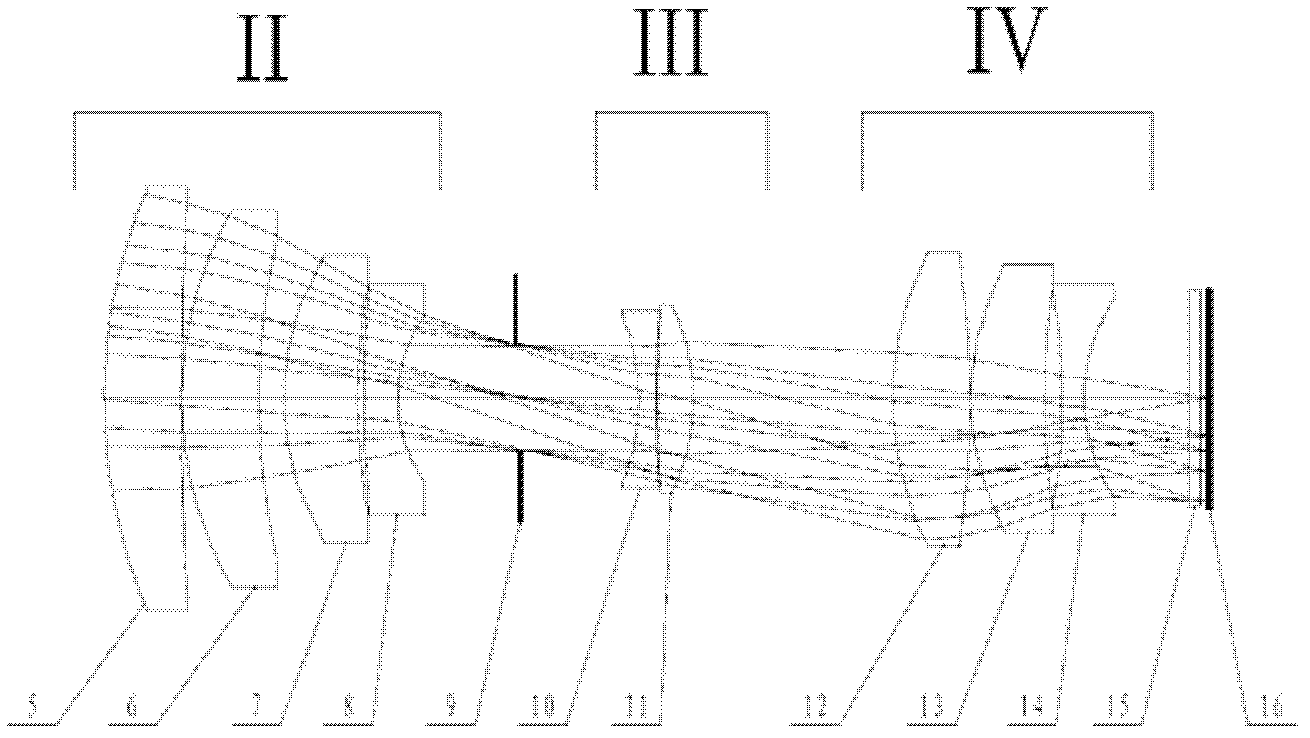

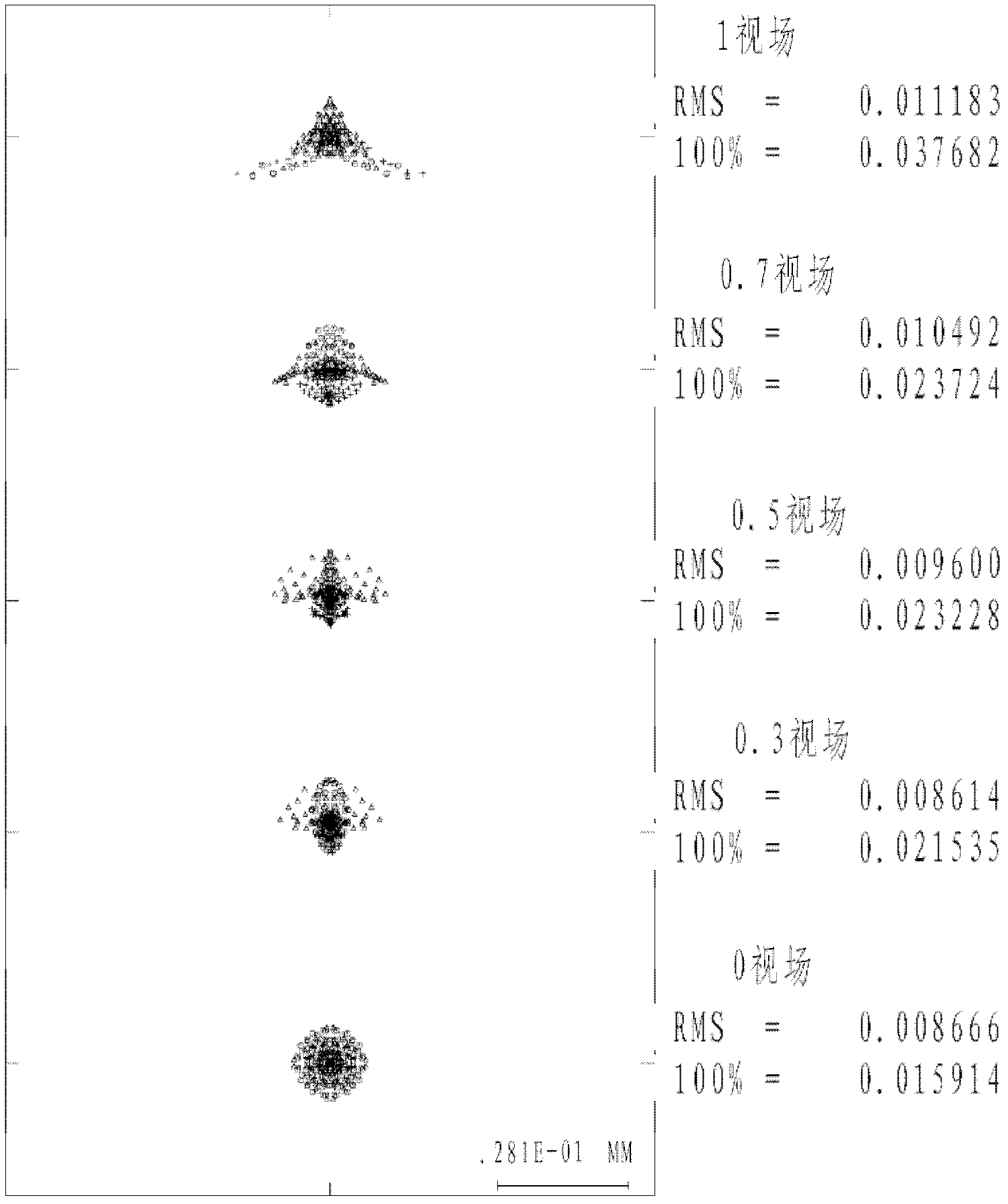

Refractive-reflective optical system with heavy caliber, large view field and small focal ratio

InactiveCN102253480AObvious color differenceRealize the purpose of small focal ratio and large field of viewTelescopesOptical pathFocal position

The invention relates to a telescope system with heavy caliber, large view field and small focal ratio. The telescope system comprises a heavy-caliber Cassegrain system at the front end, and the heavy-caliber Cassegrain system comprises a paraboloidal primary mirror (1) the caliber of which exceeds 1 meter and a hyperboloidal secondary mirror (2); by adopting an inclined plane mirror (3), the optical path is led to the horizontal optical axis Y vertical to a primary optical axis Z which comprises the primary mirror and the secondary mirror, and the plane mirror (3) is connected with a focal reducing system at the Smith-resistant focal position, wherein the focal reducing system comprises four groups of lenses, that is to say, a field lens group (I) comprising only one positive-focal-powerlens, a second lens group (II) comprising four lenses, a positive-focal-power third lens group (III) comprising two lenses, and a positive-focal-power fourth lens group (IV) comprising three lenses. Especially, a diaphragm (9) is arranged between the second lens group and the third lens group, and the diaphragm (9) and the primary mirror conjugate and can be used for dimming.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Buckwheat processing process

InactiveCN105499121AFacilitate strippingSecond shelling is convenientGrain huskingSievingMixed materialsComputer science

The invention discloses a buckwheat processing process. The buckwheat processing process comprises the following steps: screening hulled mixed materials containing a few buckwheat husks, buckwheat grains and buckwheat with husks through a vibrating classifying screen, introducing oversize materials of a lower-layer screen into a color selector to carry out color selection and separation, sequentially carrying out color selection for three times, screening and classifying separated semi-finished product buckwheat grains which are subjected to color selection for three times through the vibrating classifying screen to obtain high-quality finished product buckwheat grains; and uniformly mixing small-particle type buckwheat with husks which are subjected to color selection by the first time and by the second time with large-particle type buckwheat with husks retained on an upper-layer screen, carrying out cold-heat treatment, and introducing the buckwheat with husks into a huller in batches to carry out secondary husking. The final material-particle separating rate reaches 99.9%, the secondary husking yield is higher than 95%, the purity of the buckwheat grains can be higher than 99.9%, imperfect grain mass is less than or equal to 1%, the impurities are less than or equal to 0.10%, the broken buckwheat is less than or equal to 1%; and the processed buckwheat is bright and clean in surface, and has obvious buckwheat fragrance, so that the purpose that material-particle separation is high in quality, is high in efficiency, is high in yield and is large-scale is realized after buckwheat husking.

Owner:李秉京

Buckwheat husking technology

The invention discloses a buckwheat husking technology which comprises the steps that a mixture containing few buckwheat husks, buckwheat kernels and buckwheat with husks after husking is screened by a vibration classification screen; an oversize product of a lower layer screen mesh enters a color separator through an elevator to be subjected to color separation for three times sequentially; separated semifinished buckwheat kernels are subjected to screening classification by the vibration classification screen, and high-quality finished buckwheat kernels are obtained; and the small buckwheat with husks after the first-time color separation and the small buckwheat with husks after the second-time color separation are uniformly mixed with the large buckwheat with husks retained by an upper layer screen mesh to form a mixture, and the mixture is subjected to freezing and heating treatment, and then enters a husker in batches to be subjected to secondary husking. A final buckwheat kernel separation rate reaches 99.9%; a secondary husking rate reaches above 95%; the purity of the buckwheat kernels can reach above 99.9%; the mass of unsound kernels is less than or equal to 1%; the mass of impurities is less than or equal to 0.10%; the mass of crushed kernels is less than or equal to 1%; the buckwheat kernels have bright and clean surfaces, and obvious buckwheat fragrance; and the purpose of high-quality, high-efficiency, high-yield and scale buckwheat kernel separation after buckwheat husking is realized.

Owner:宁夏地理标志产业发展有限公司

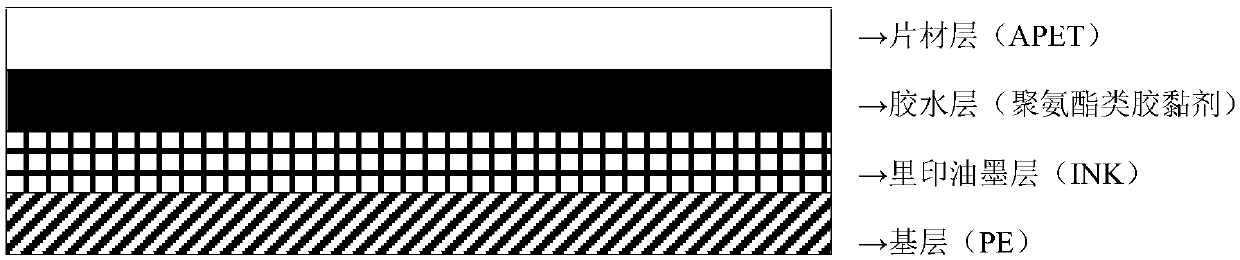

Compound colored sheet and preparation method and application thereof

InactiveCN109591413AReduce chromaHigh peel strengthFlexible coversWrappersPolyurethane adhesivePolymer science

The invention discloses a compound colored sheet and a preparation method and an application thereof. The compound colored sheet comprises a base layer, an inner printing ink layer, a glue layer and asheet layer, wherein the base layer is a transparent high molecular film; the inner printing ink layer is composed of polyurethane inner printing ink and a polyurethane printing ink curing agent in amass ratio of 10: (0.1-0.5); the glue layer is a polyurethane adhesive; and the sheet layer is a transparent high molecular sheet. According to the compound colored sheet, the color of the sheet is regulated by means of the inner printing ink layer, and the color is simple to regulate and easy to control. The sheet layer can be the transparent high molecular sheet, so that the loss of the manufacturing process can be reduced greatly. The prepared compound colored sheet is relatively small in chroma and is obviously superior to that of a color sheet prepared by a conventional method in the aspect of chroma. In addition, the peeling strength of the compound colored sheet is also relatively high and has excellent application performance.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

High polished buckwheat ratio processing process of buckwheat

The invention discloses a high polished buckwheat ratio processing process of buckwheat. The process is characterized in that unshelled mixtures containing few buckwheat husks, buckwheat and buckwheat with shells are screened through a vibration classification screen; oversize materials on a lower screen cloth are fed through a lifter into a color sorter to be subjected to color sorting and separating; the oversize materials are sequentially subjected to color selecting for three times; the separated semi-finished products of buckwheat are screened and classified through the vibration classification screen so as to obtain high-quality finished products of buckwheat; small granular buckwheat with shells, obtained from the first color sorting and the second color sorting, can be uniformly mixed with large granular buckwheat with shells, wherein the large granular buckwheat with shells is intercepted by an upper screen cloth; the mixtures are subjected to cold and heat treatment and then fed by batch into a huller to be unshelled for the second time; the final separation rate of the granules reaches 99.9%, and the secondary unshelling ratio is more than 95%; the purity of the buckwheat is 99.9% or more; the mass of unsound kernels is not greater than 1%; the impurities are not greater than 0.10%; the broken buckwheat is not greater than 1%; the buckwheat has a bright surface and is clean, and the flavor of buckwheat is obvious; the purposes of high-quality and high-efficiency granule separation of unshelled buckwheat, high output and large scale can be achieved.

Owner:宁夏地理标志产业发展有限公司

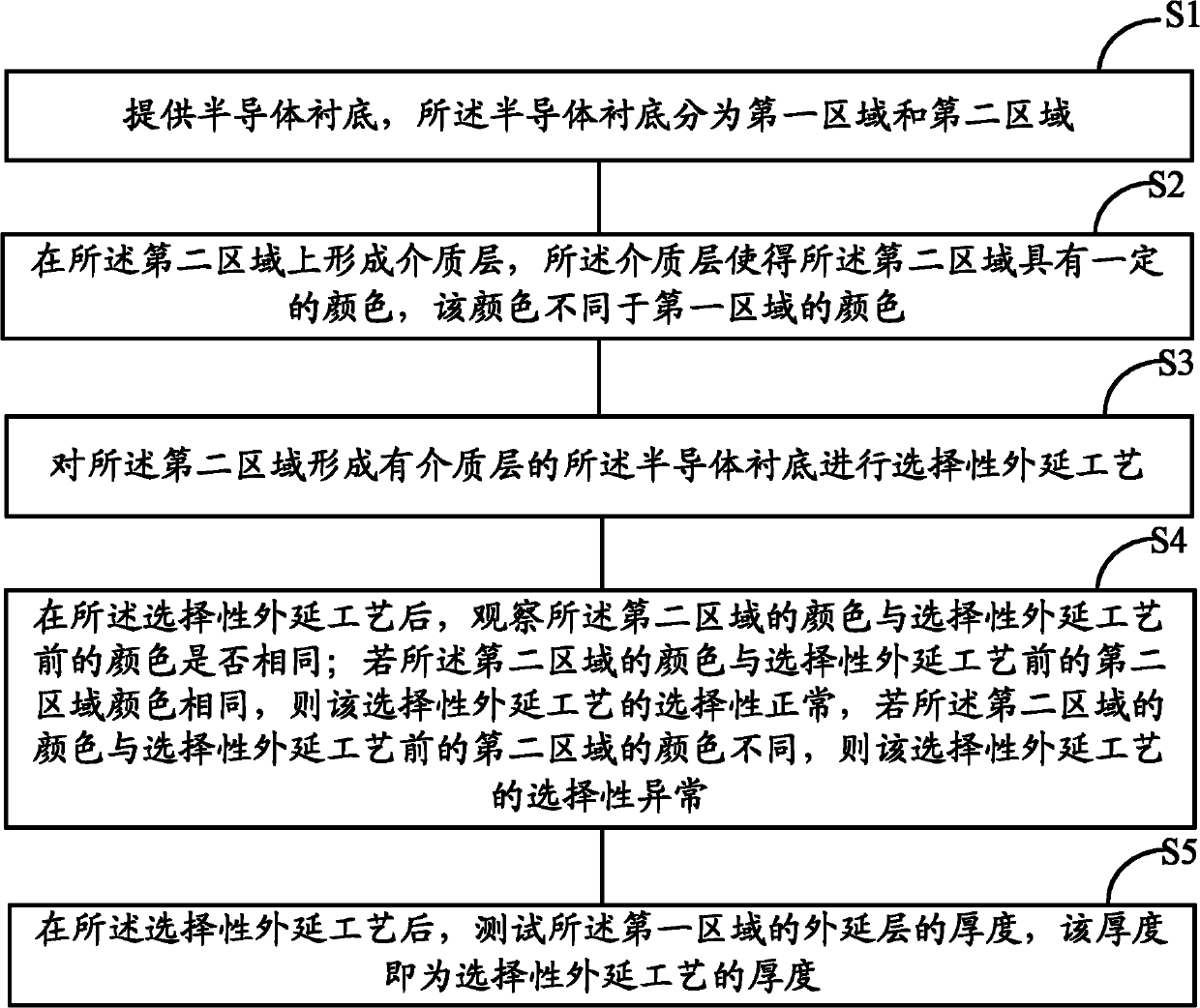

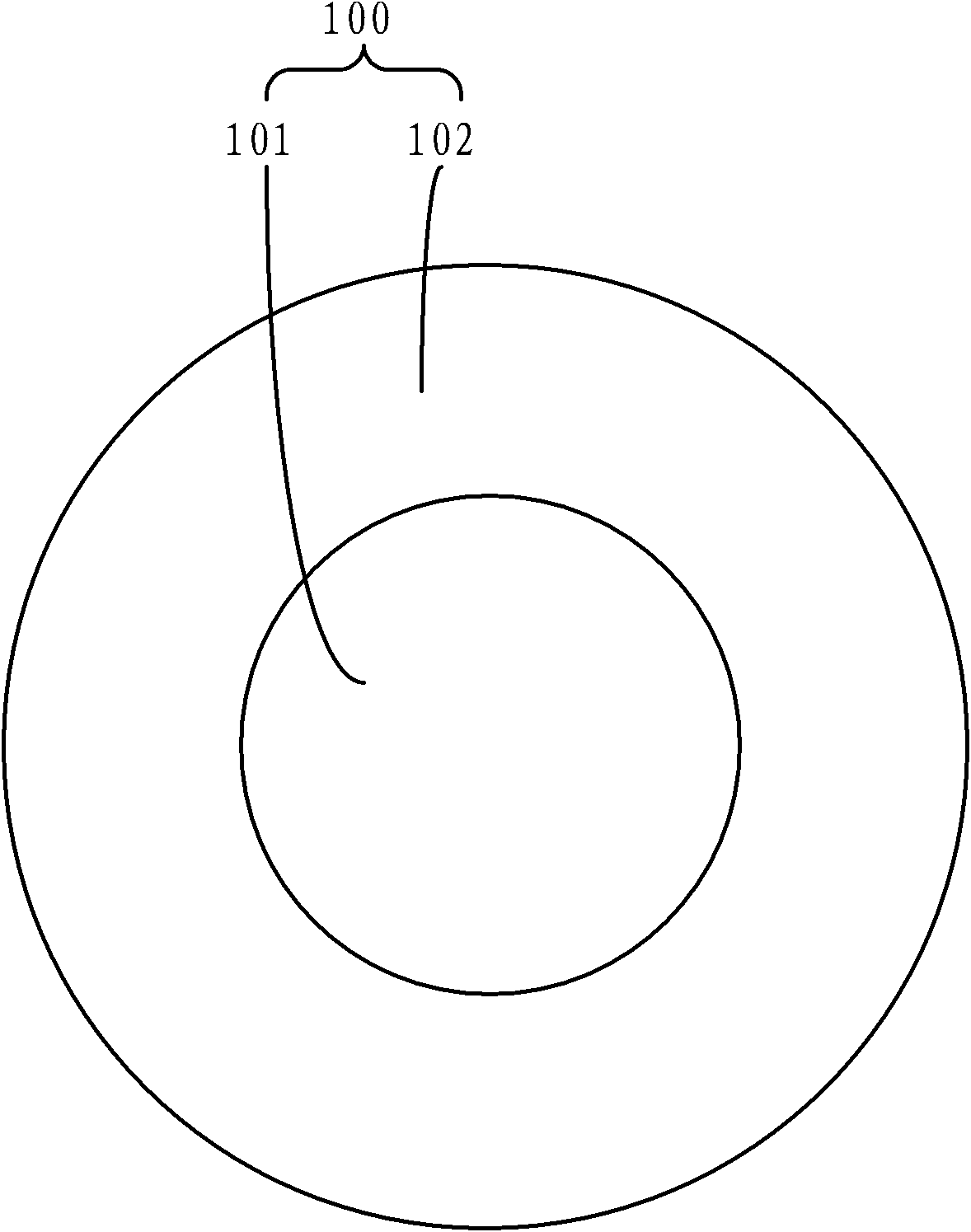

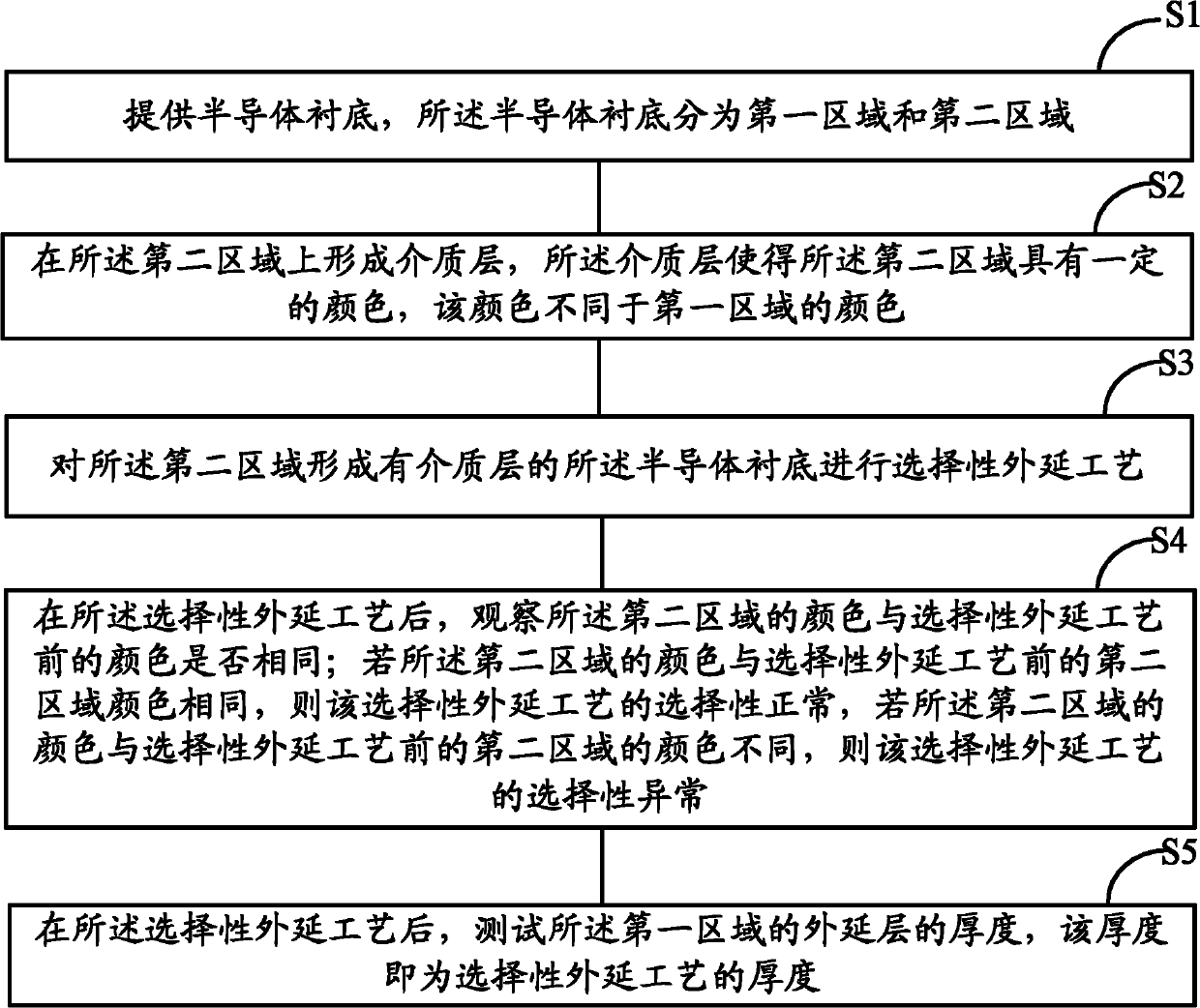

Monitoring method of selective extension process

ActiveCN102569041AReduce monitoring costsObvious color differenceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMethod testElectrical conductor

The invention provides a monitoring method of selective extension process, which comprises steps of providing a semiconductor substrate provided with a first area and a second area; forming a medium layer enabling the second area to have color different from the first area on the second area; conducting the selective extension process on the semiconductor substrate; observing whether the color of the second area is same with that before conducting the selective extension process after the selective extension process is conducted; determining selectivity of the selective extension process to be accurate if the color of the second area is same with that of the second area before conducting the selective extension process, conversely determining the selectivity of the selective extension process to be abnormal; and testing epitaxial layer thickness of the first area after the selective extension process. The testing epitaxial layer thickness is the thickness of the selective extension process. The monitoring method tests the selectivity and the thickness of the selective extension process by using the same semiconductor substrate, and reduces cost of the selective extension monitoring process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

White light lens of light-emitting diode and light-emitting diode composed of lens

InactiveCN101644406AObvious color differenceReduce carbonationPoint-like light sourceElectric circuit arrangementsSurface layerDie casting

The invention discloses a lens of a high-power light-emitting diode and a light-emitting diode composed of the lens, belonging to the technical field of photoelectric application. The white light lensof the light-emitting diode is formed by shaping the mixture of lens base material and fluorescent powder by injection-molding or die-casting or other techniques; the lens base material is any one ofpolycarbonate, polymethyl methacrylate, silica gel, Na2SiO3, CaSiO3, SiO2, Na2O-CaO-6SiO2; and the mass ratio of the lens base material and the fluorescent powder is equal to 0.1 to 1000:1. The application of the light-emitting diode of the lens lies in mixing the fluorescent powder and the lens base material and then forming instead of coating fluorescent powder resin on a chip surface layer; the fluorescent powder can be evenly distributed on the lens, the color difference of the light-emitting diode can be reduced obviously and the carbonification of heat to the fluorescent powder can be reduced.

Owner:SICHUAN JIUZHOU OPTOELECTRONIC TECH CO LTD

Buckwheat grain processing technology

ActiveCN105536913AResolve separabilityResolve gradingSievingGrain huskingMixed materialsComputer science

The invention discloses a buckwheat grain processing technology. Unshelled mixed materials containing a small part of buckwheat shells, buckwheat grains and shelled buckwheat are screened through a vibration classification screen firstly, oversize products on a lower screen enter a color selector through an elevator to be subjected to color sorting separation, three times of color sorting is sequentially carried out, separated-out semi-finished buckwheat grains are screened and classified through the vibration classification screen, and high-quality finished buckwheat grains are obtained. Small grain type shelled buckwheat obtained through the first time of color sorting and the second time of color sorting and large grain type shelled buckwheat intercepted by an upper screen are evenly mixed and subjected to cold and heat treatment to enter a huller in batches to be subjected to secondary unshelling. Finally, the material grain separation rate reaches 99.9%, the secondary unshelling rate reaches more than 95%, the purity of the buckwheat grains can reach more than 99.9%, the unsound grain mass is smaller than or equal to 1%, the proportion of impurities is smaller than or equal to 0.10%, and the proportion of broken grains is smaller than or equal to 1%. The surface is bright and clean, the obvious buckwheat fragrance is achieved, and the purposes that after buckwheat unshelling, the material grain separation quality and efficiency are high, the yield is high, and a large scale is achieved are achieved.

Owner:JILIN AGRICULTURAL UNIV +2

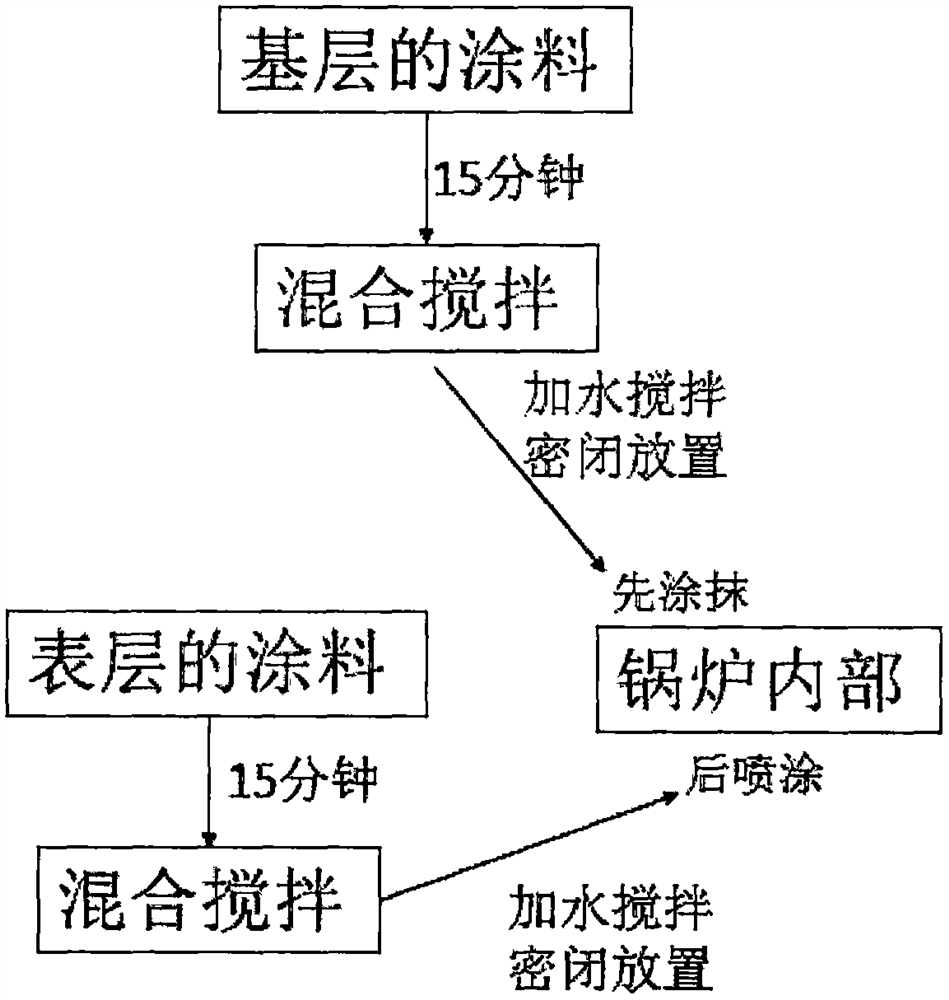

Ceramic identification coating suitable for metal substrate and preparation method thereof

The invention provides a ceramic identification coating suitable for a metal substrate and a preparation method of the ceramic identification coating. The ceramic identification coating is particularly suitable for a metal substrate in a power plant boiler. The ceramic identification coating is composed of a base layer and a surface layer. The base layer is also called as an identification layer and is white, and the thickness of the base layer is 0.10-0.15 mm; the surface layer is green, and the thickness of the surface layer is 0.10-0.15 mm; and the color difference between the surface layerand the base layer is obvious, and an identification degree is high. In the using process of the ceramic identification coating, sand blasting is not needed when the base layer part is exposed and the surface layer is re-sprayed; and after floating ash on a heating surface is blown and cleaned through high-pressure air or high-pressure water, surface layer paint can be directly sprayed to the part, where the white base layer is exposed, of the ceramic identification coating. The ceramic identification coating has the functions of resisting high-temperature corrosion, resisting dirt adhesion and coking and improving heat exchange efficiency, the service life of the substrate can be effectively prolonged, the manpower and economic cost of subsequent maintenance is remarkably reduced, and long-life-cycle protection of the heating surface is achieved.

Owner:旭贞新能源科技(上海)有限公司

Method for restoring deep scratches

InactiveCN106985795AObvious bumpy borderObvious chromatic aberrationVehicle servicing/repairingEngineeringEmery paper

The invention discloses a method for restoring deep scratches. The method comprises the steps that long strip paper is dipped with paint to fill the scratches firstly, and then the scratches are baked with a heating lamp; a thin writing brush is dipped with blended sealing water to smear the peripheries of the scratches, and then the scratches are baked with the heating lamp; then the scratches are filled with blended restoration liquid and paper strips as thick as the scratches and then baked with the heating lamp; the scratches are coated with the restoration liquid once through fingers; finally, ash scratching, grinding, polishing and waxing are carried out. The method has the advantages that the method is suitable for iron sheets, steel plates, aluminum alloy, plastic parts and other materials; the situation that the deep scratches and surrounding interfaces are different in thickness is avoided, the thickness is even, the connector of the treated scratches and an original car paint face has no obvious concave-convex boundaries or color difference, and the method is suitable for popularization; the boundary marks and color difference of the boundary of the restored scratches and the restoration surface and the original car paint face achieve the effect that distinguishing cannot be achieved with naked eyes, and the scratches are stable and cannot fall off; abrasive paper of different roughness degrees is adopted for grinding aiming at different conditions, the expected effect is achieved, and paint faces of other places cannot be damaged.

Owner:叶蔡清

Black body anti-coking ceramic identification coating layer and preparation method thereof

InactiveCN112280346AIncrease temperatureFacilitate heat exchangeAlkali metal silicate coatingsSilicic acidAluminum silicate

The invention discloses a black body anti-coking ceramic recognition coating layer and a preparation method thereof. The ceramic recognition coating layer is composed of a base layer and a surface layer, the base layer is white, and the surface layer is green; a coating for forming the base layer comprises zirconium dioxide, aluminum oxide, magnesium oxide, lithium fluosilicate, manganese powder,cerium oxide, lanthanum oxide, sodium silicate, potassium silicate, magnesium hexametaphosphate, aluminum hexametaphosphate, bentonite, clay, cured resin, modified inorganic powder and a reactive diluent; a coating for forming the surface layer comprises a ZS high-temperature-resistant far infrared radiation coating, aluminum silicate, a high-temperature binder, bentonite, clay, brown fused alumina, cordierite, a coloring agent and a dispersing agent; according to the high-temperature-resistant far infrared radiation coating, a strong radiation material contained in the high-temperature-resistant far infrared radiation coating radiates far infrared waves with extremely strong penetrating power at high temperature, so that molecules of a heated object absorb the waves to generate energy level transition, absorbed energy is uniformly heated, the heating time is shortened, and energy is fully saved.

Owner:ZHENGZHOU SANZHONG WEAR TECH

Anti-short circuit method of lithium ion battery

InactiveCN110071253AWear-resistantWith high temperature resistanceFinal product manufactureCell component detailsWear resistantSodium-ion battery

The invention discloses an anti-short circuit method of a lithium ion battery, and belongs to the technical field of lithium battery manufacturing. The method is characterized in that an insulating material covers the surface of a tab exposed outside the lithium ion battery. The insulating material is teflon, alumina ceramic, ceramic polymer or polytetrafluoroethylene. The thickness of the insulating material is 10-20 microns. The insulating material covers the surface of the tab in a spraying or pasting manner, and the process is completed before the battery is charged. The coverage range ofthe insulating material cannot exceed a tab cutting area. The insulating material used in the method has the advantages of wear resistance, high temperature resistance, corrosion resistance, insulation and easy operation: in a production process, the battery needs to be transported from one process to another process; a coating on the tab is rubbed continuously; the coating is likely to disappearif the material is not wear-resistant, and finally the purpose of insulating in the production process cannot be achieved; and the selected insulating material has relatively good wear resistance andcan ensure that the coating can play a role in the whole production process of the battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

Laser inkjet printer for engineering plastic clear identification

The invention discloses a laser inkjet printer for engineering plastic clear identification. The laser inkjet printer comprises a laser galvanometer and focus lens, a laser generator and installation cabinet thereof, a laser power supply and control system and an industrial control computer. The laser galvanometer and focus lens is arranged to the front end of the laser generator and installation cabinet thereof; the laser generator and installation cabinet thereof is connected with the laser power supply and control system through a control cabinet and laser transmission connection line; the other end of the laser power supply and control system is connected with the industrial control computer through an industrial control computer and control cabinet data transmission connection line; and a laser generator in the laser generator and installation cabinet thereof emits a 532 nm laser beam to an engineering plastic member to be marked. The laser inkjet printer suitable for direct identification printing of the engineering plastic member is clearer in effect, more obvious in color difference, convenient for automatic identification and reading of bar codes and two-dimension codes, low in cost, suitable for batch purchase of enterprises, small and flexible in machine design, and convenient for on-site installation.

Owner:SHANGHAI YINMA IDENTIFICATION TECH

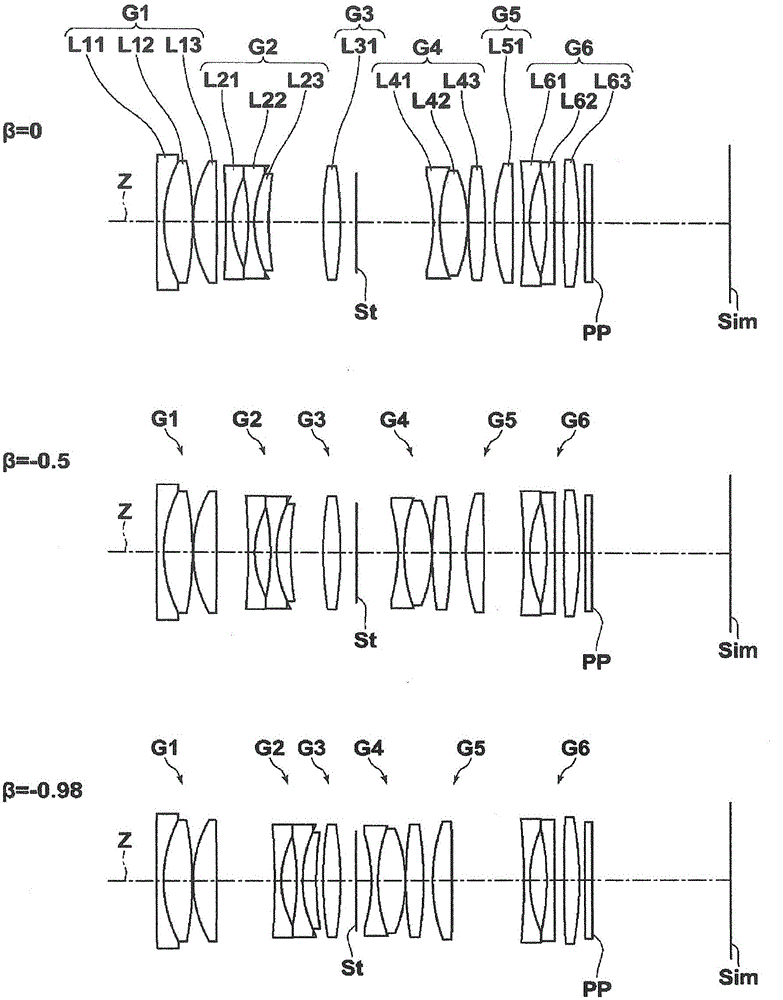

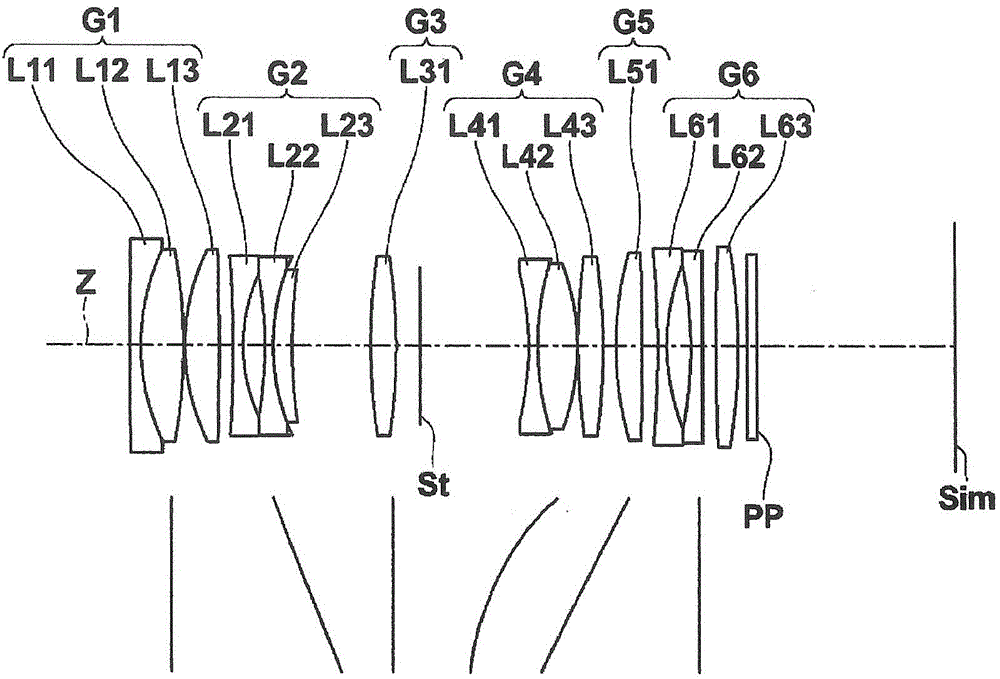

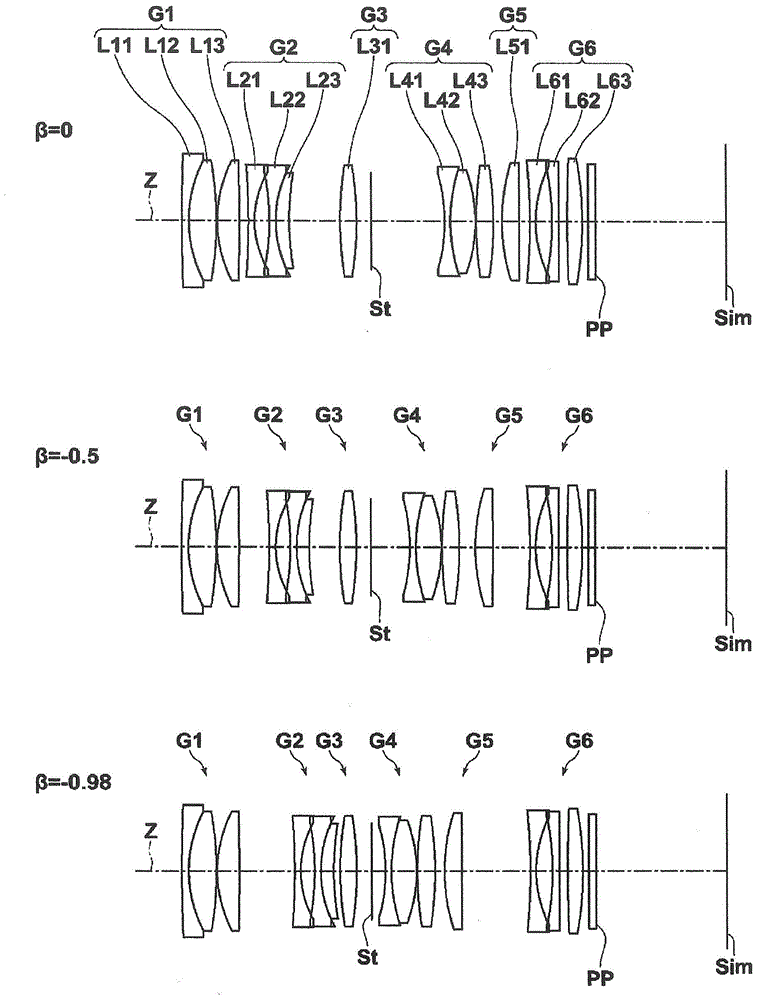

Macro Lens System And Imaging Apparatus

ActiveCN104880810AObvious color differenceImprove picture qualityOptical elementsOptical axisChromatic aberration

A macro lens system includes, in this order from an object side: a positive first lens group; a negative second lens group; a positive third lens group; a positive fourth lens group; a positive fifth lens group; and a negative sixth lens group. The first lens group is constituted by three lenses. The second lens group, the fourth lens group, and the fifth lens group are independently moved in the direction of the optical axes thereof when focusing from an object at infinity to an object at a most proximate distance.

Owner:FUJIFILM CORP +1

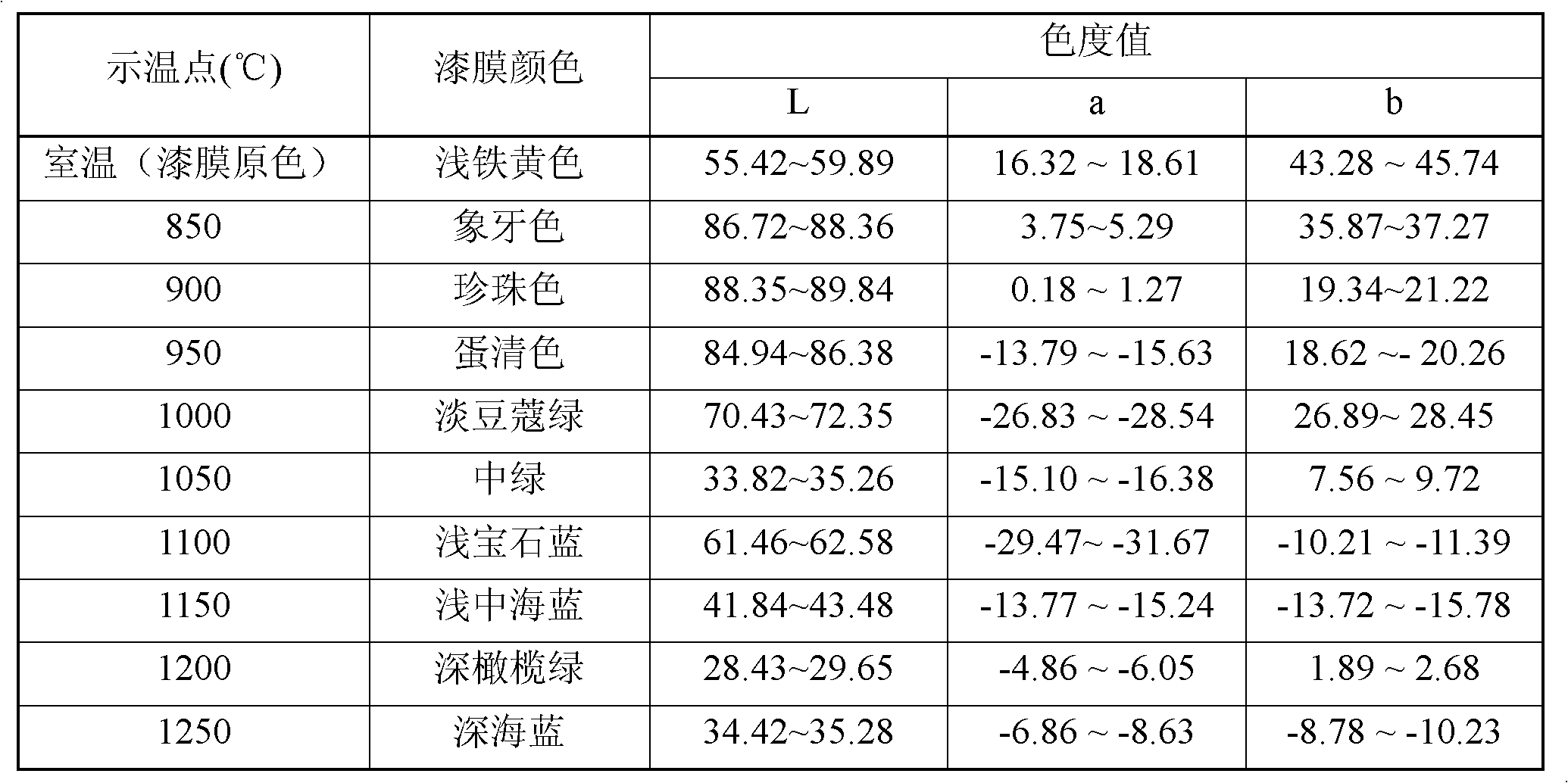

800DEG C-1250DEG C multi color-changing irreversible thermopaint

ActiveCN102492362BGood physical and mechanical propertiesSensitive to discolorationThermometers using mean/integrated valuesThermometers using physical/chemical changesAdhesiveDiluent

Owner:中昊北方涂料工业研究设计院有限公司

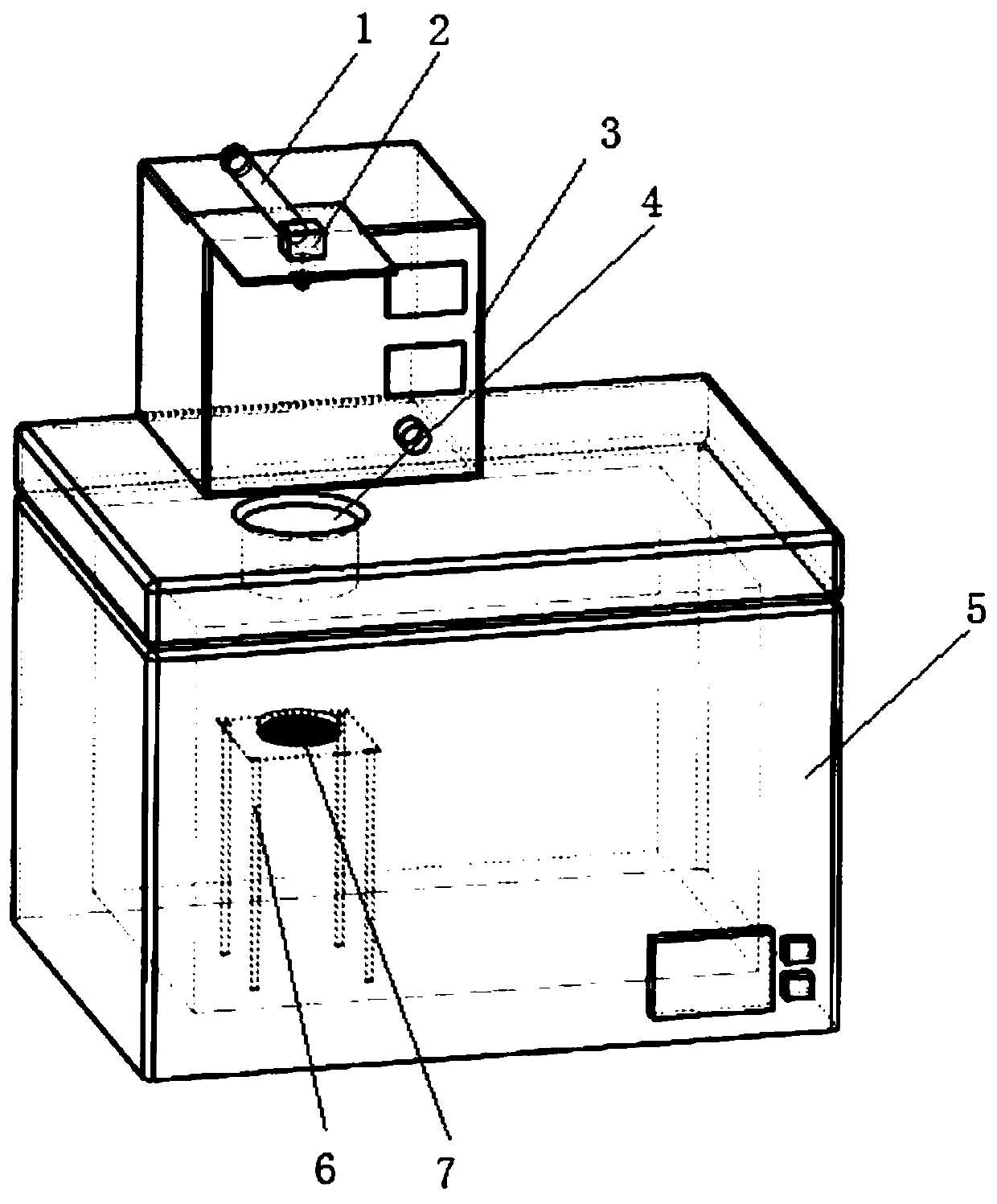

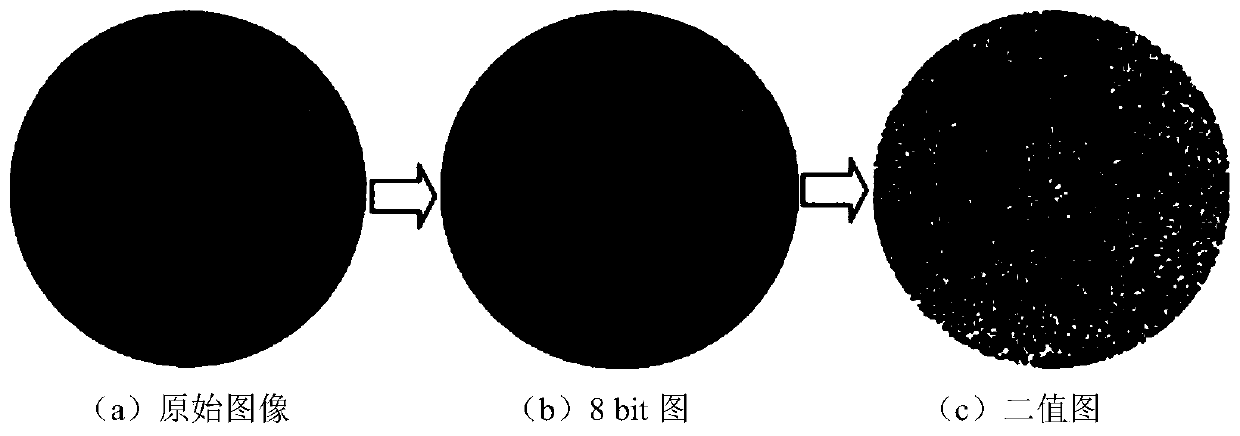

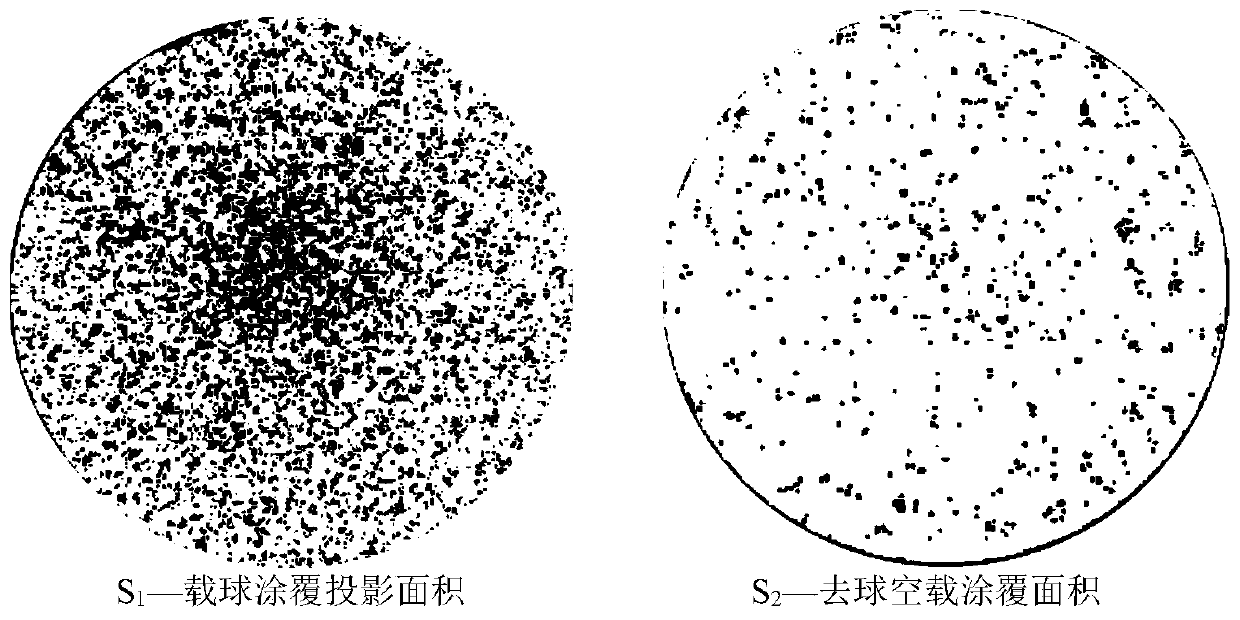

Image analysis method for spray freezing coating effect based on Image J

PendingCN110570391ASimple methodEasy to operateImage enhancementImage analysisImaging processingImaging analysis

The invention relates to an image analysis method for a spray freezing coating effect based on Image J, which comprises the following steps of: 1) a picture acquiring process, namely shooting a tray filled with inert carrier particles by using a high-definition camera, and storing the picture; shooting the no-load tray, and storing a picture; 2) an image processing process: utilizing Image J software to calculate a quantitative relation between the number of pixel points of the picture and millimeter, and setting the unit length of the picture; cutting out a to-be-processed part in the picture; dividing the colors of the pictures into 256 types, and converting the cut pictures into 8-bit pictures by utilizing Image J software; converting the 8-bit pictures into a binary image by utilizingImage J software; counting an image area ratio occupied by a black region in the binary image to obtain a projection area of spray freezing coating; and 3) a coating effect analysis process; accordingto the present invention, the spray freezing coating picture shot by the high definition camera is processed and analyzed to obtain the inert carrier particle surface coating effect, the result is reliable, accurate and objective, the operation is simple, and the implementation is easy.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

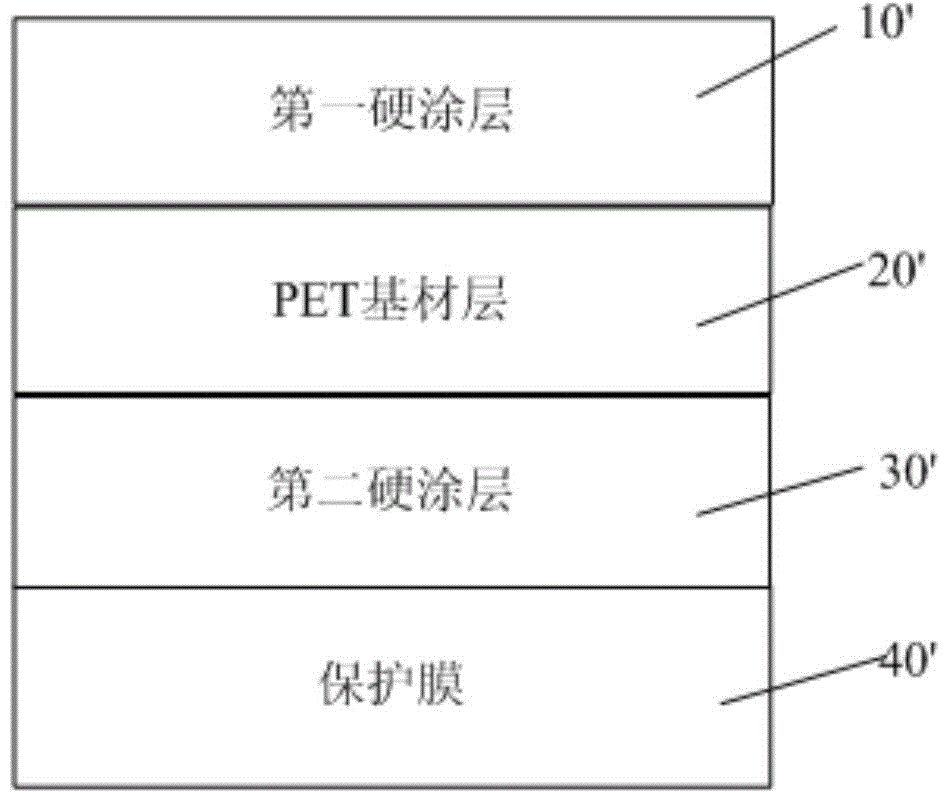

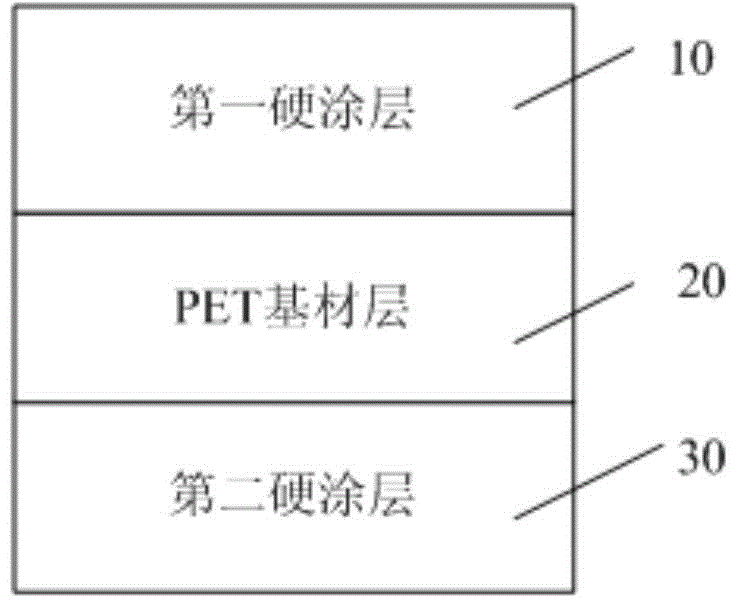

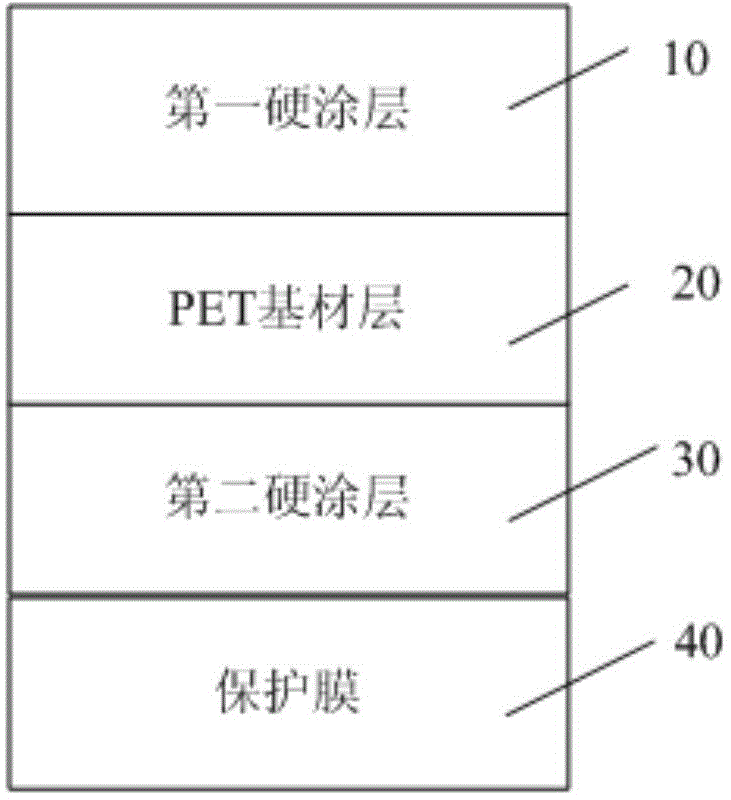

Double-face hardened film and capacitance touch screen with double-face hardened film

ActiveCN104793826AReduce thicknessReduce distortionInput/output processes for data processingCapacitanceMetallurgy

The invention provides a double-face hardened film and a capacitance touch screen with the double-face hardened film. The double-face hardened film comprises a first hard coating, a PET base material layer and a second hard coating. The PET base material layer is arranged on the surface of the first hard coating, the second hard coating is arranged on the surface, away from the first hard coating, of the PET base material layer, and the thickness of the second hard coating ranges from 1.5 micrometers to 2.5 micrometers. The thickness of the second hard coating of the double-face hardened film is small, deformation of the second hard coating at high temperature can be effectively reduced, the deformation degree of etched and baked ITO conducting layer patterns is reduced, the chromatic aberration of an etched pit and an ITO conducting layer is prevented from being obvious, stereoscopic patterns of the capacitance touch screen are effectively improved, and the requirements of clients are met.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

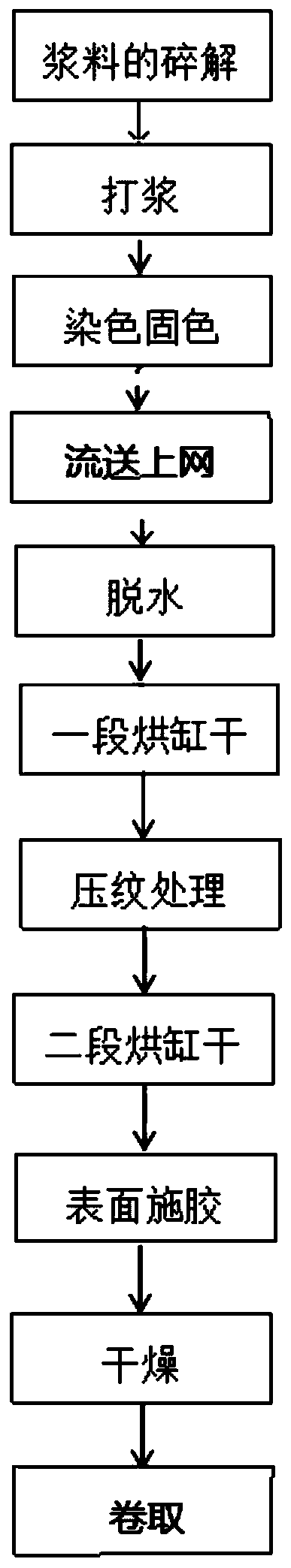

Production method of embossed double-color art paper

InactiveCN111593611AObvious color differenceMechanical working/deformationDryer sectionProcess engineeringWet strength

The invention provides a production method of embossed double-color art paper. The production method of the embossed double-color art paper comprises the following steps: (1) dyeing and fixing color:mixing paper pulp, a dye, a color fixing agent and a wet strength agent, and carrying out dyeing and color fixing; (2) drying in a first-stage drying cylinder: forming the dyed and color-fixed paper pulp on a net, squeezing and dehydrating, and drying in the first-stage drying cylinder to obtain a wet paper sheet; (3) embossing: embossing the wet paper sheet obtained by drying in the first-stage drying cylinder in a paper machine; and (4) drying in a second-stage drying cylinder: carrying out second-stage drying cylinder drying on the embossed paper sheet to obtain the embossed double-color art paper. According to the production method of the embossed double-color art paper, the defects existing in traditional off-machine embossing are overcome, and the double-color embossed art paper which can be formed only through alignment embossing after printing forms the artistic effects of color depth change and grain depth change in the paper machine at a time by controlling the dyeing and embossing process of paper sheets in the machine.

Owner:SHANDONG KAILI SPECIAL PAPER

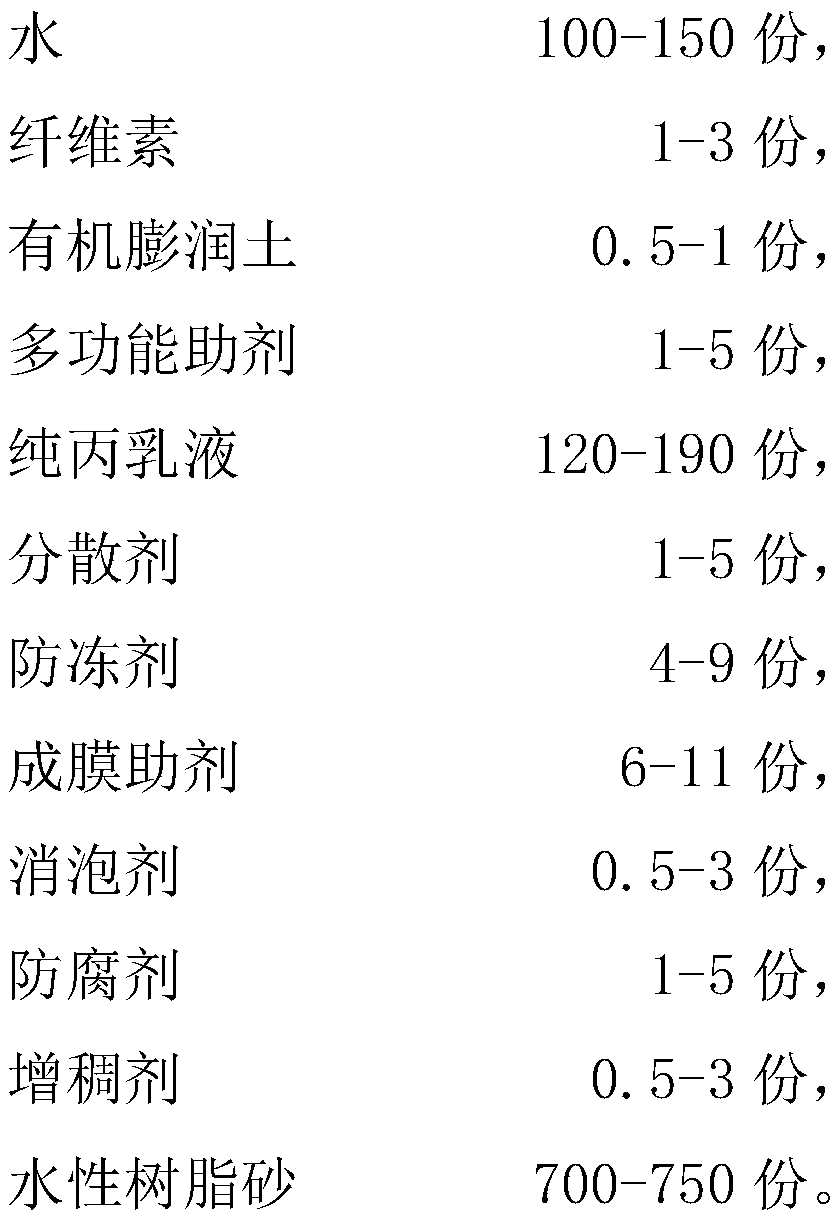

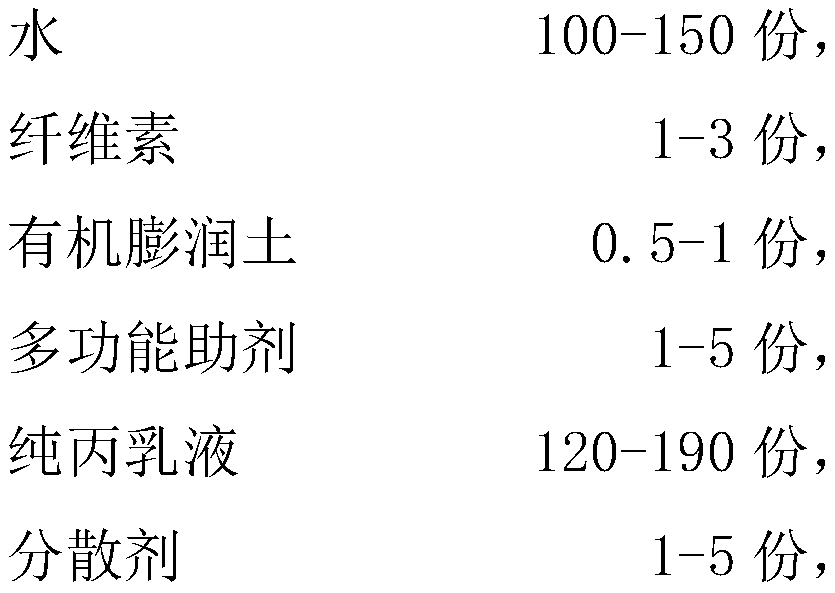

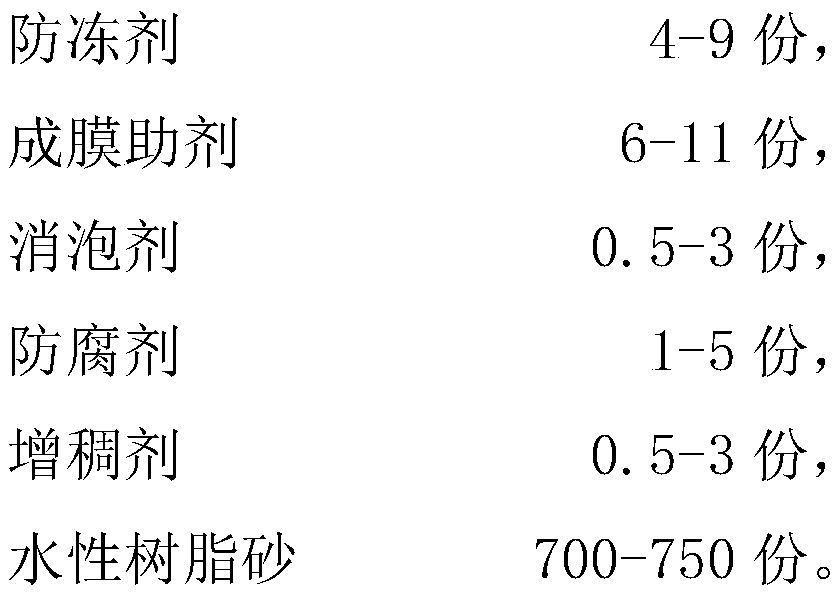

Water-based resin sand stone-like paint and preparation method thereof

The invention discloses water-based resin sand stone-like paint and a preparation method thereof, and belongs to the technical field of paint. The water-based resin sand stone-like paint comprises components as follows: water, cellulose, organobentonite, a multifunctional auxiliary, a pure acrylic emulsion, a dispersing agent, an anti-freezing agent, a coalescing agent, a defoaming agent, a corrosion remover, a thickening agent and water-based resin sand. Compared with natural color sand stone-like paint, the water-based resin sand stone-like paint has no chromatic aberration difference between batches and has excellent acid and alkali resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com