Patents

Literature

112results about How to "Efficient heat conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High heat-conducting thin graphene-based composite material, as well as preparation method and application thereof

InactiveCN103122075AGood thermal conductivityExcellent MechanicsHeat-exchange elementsCvd grapheneElectrospinning

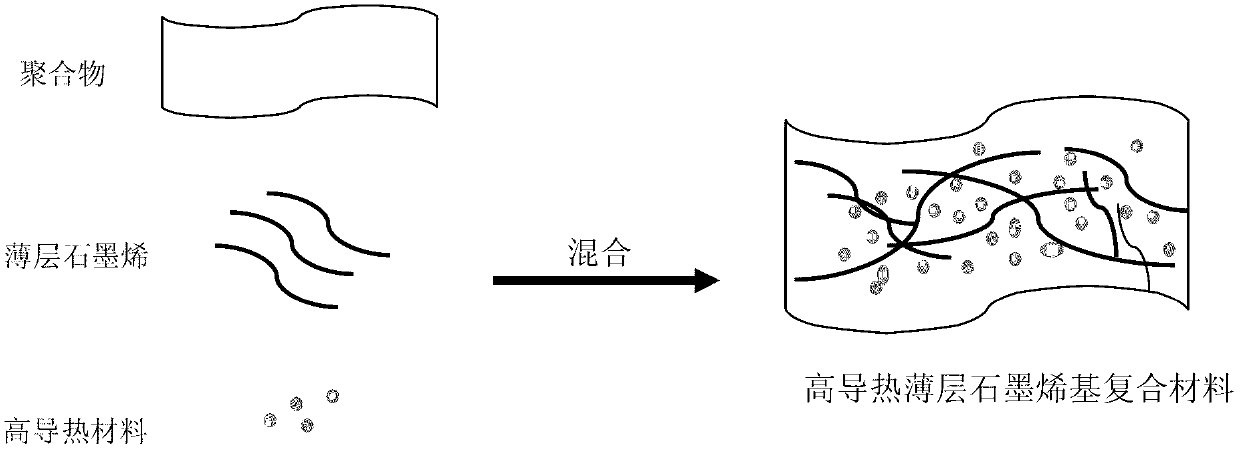

The invention discloses a high heat-conducting thin graphene-based composite material, as well as a preparation method and an application thereof. The composite material comprises a base body component and a packing component, wherein the base body component and the packing component respectively include thin graphene, polymer and / or polymer monomer and a high heat-conducting material; the preparation method comprises a step of compounding the base body component with the packing component; the compounding method comprises fusing, ball-milling, solution blending, electrostatic spinning, solution spinning, melt-spinning, extruding by double screws, mixing by an open mill or powder metallurgy. The polymer, the thin graphene, the traditional high heat-conducting material and the like are compounded by a simple process, so as to form the product with excellent heat conducting property, and good mechanical and electrical properties. Therefore, the process is easy to perform and control, and cost is low; and the obtained product has a wide application prospect in the aspects such as efficient heat conduction and radiation.

Owner:苏州格瑞丰纳米科技有限公司

Oriented graphene/polymer composite system, and preparation method and application thereof

InactiveCN105176086AGood electrical conductivityEfficient deliveryNon-macromolecular adhesive additivesHeat-exchange elementsGraphitePolymer composites

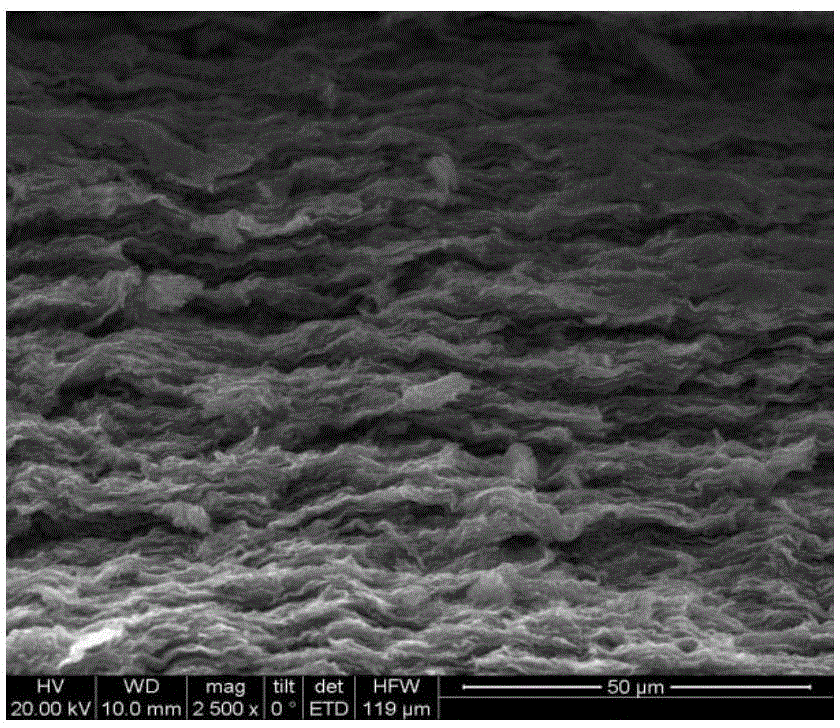

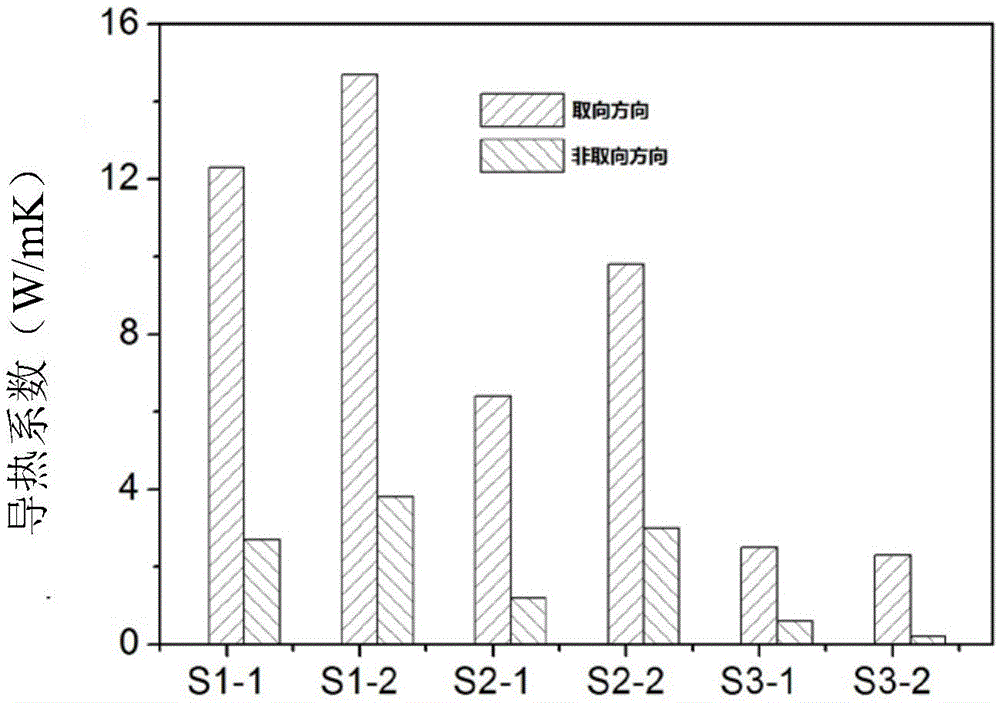

An oriented graphene / polymer composite system, and a preparation method and an application thereof are provided. The composite system includes an oriented network component at least including graphene and a substrate component compounded with the oriented network component, wherein at least a part of graphene is arranged according to set orientation; the composite system at least has a heat conductivity coefficient in the set direction higher than heat conductivity coefficients in other directions. The preparation method includes the steps: the oriented network component is subjected to orientation treatment, at least a part of graphene is arranged according to the set orientation, and thus an oriented network is formed; and the substrate component at least containing a polymer is taken to be compounded with the oriented network component, and thus the composite system is formed. The composite system has high heat conductivity and high electrical conductive characteristic, can efficiently transfer heat in a needed direction when in use, has the characteristics of being simple, high in efficiency and the like, is suitable for scale production, and has broad application prospects in high-efficiency heat conductivity and heat dissipation.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

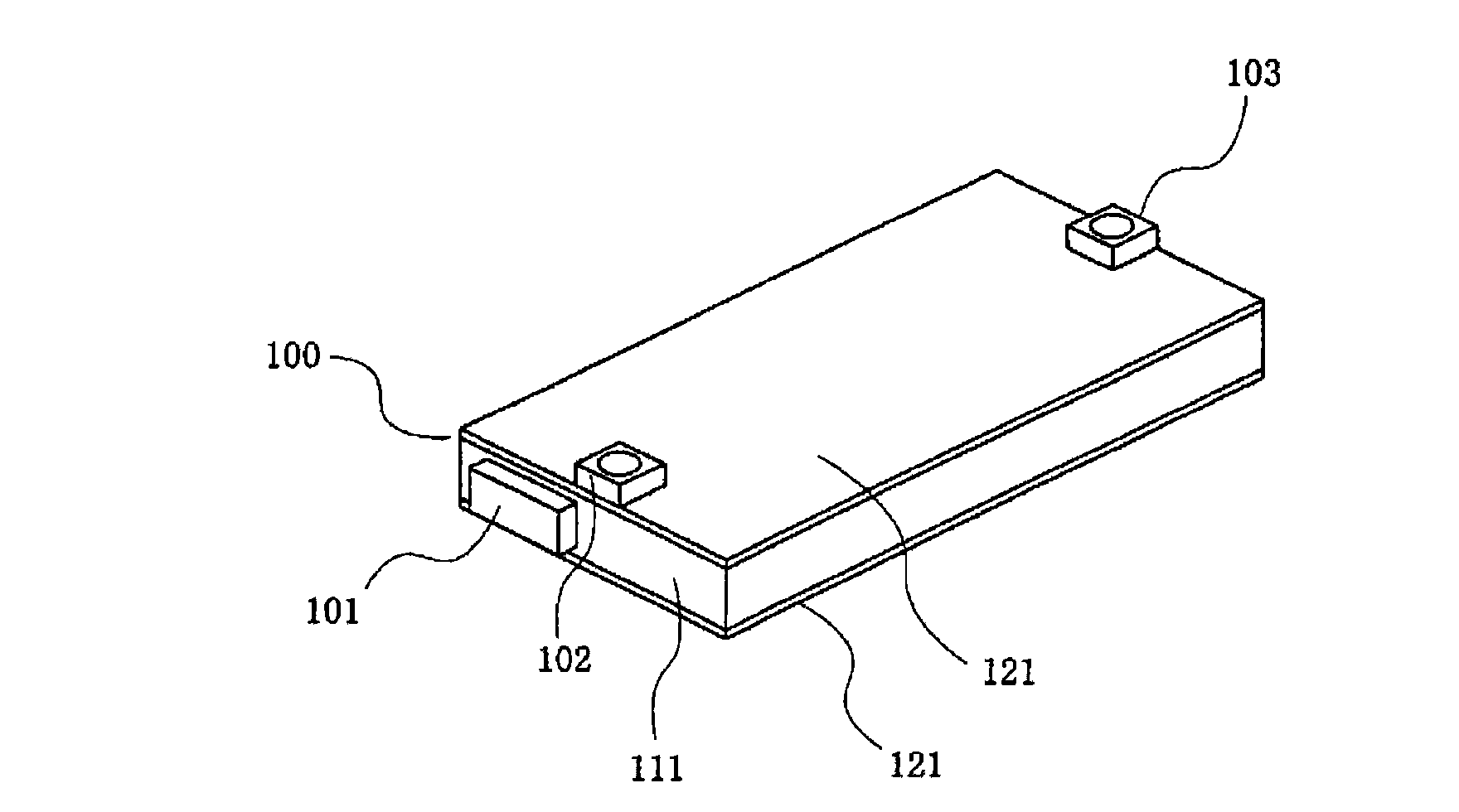

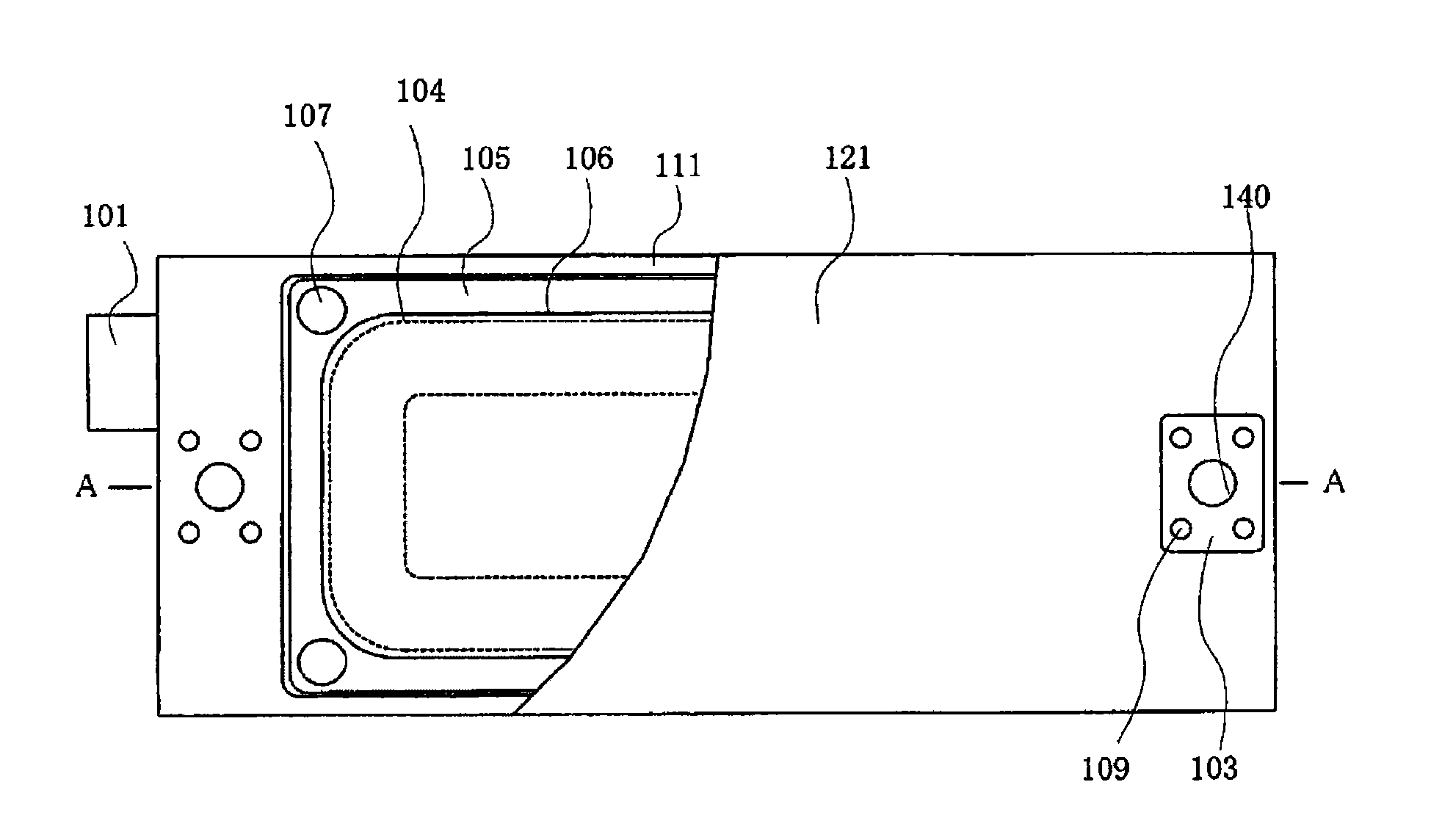

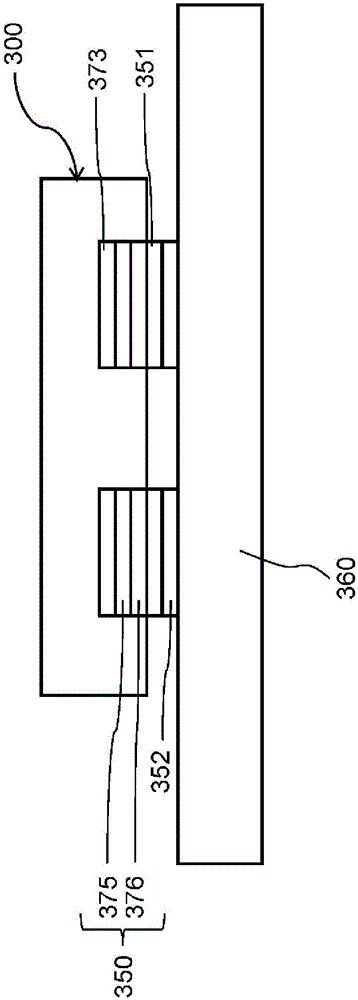

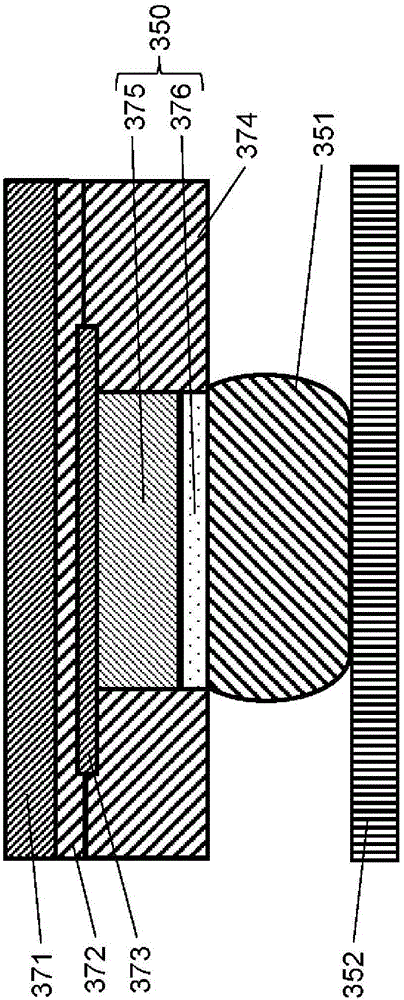

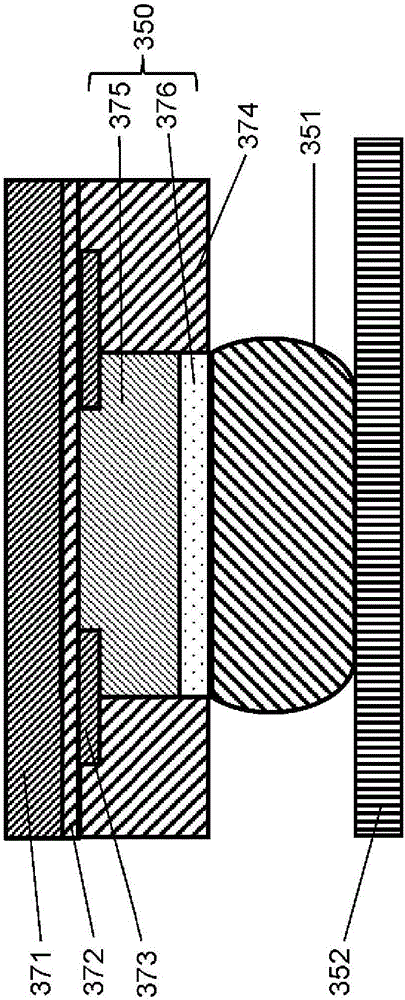

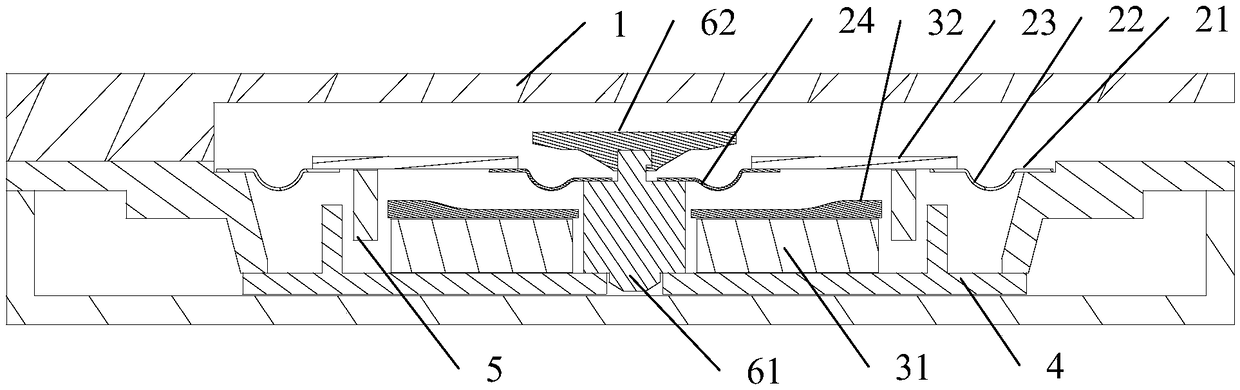

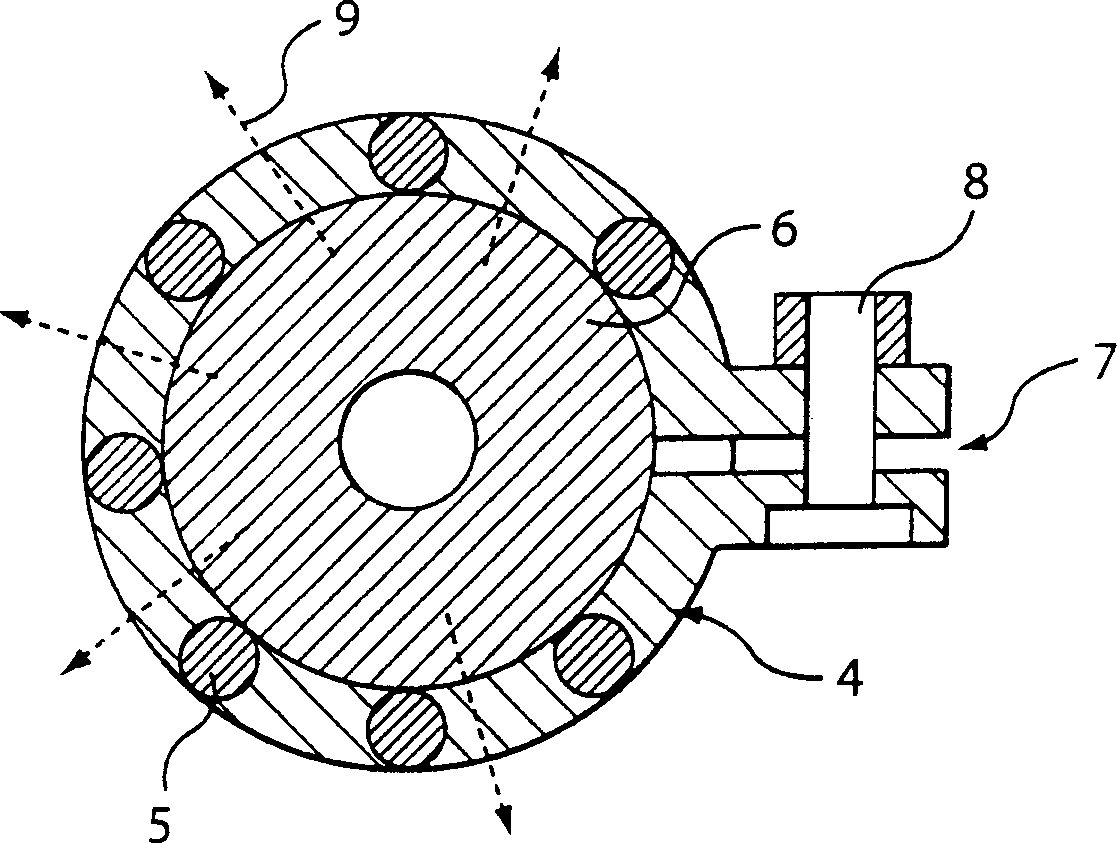

Canned linear motor armature and canned linear motor

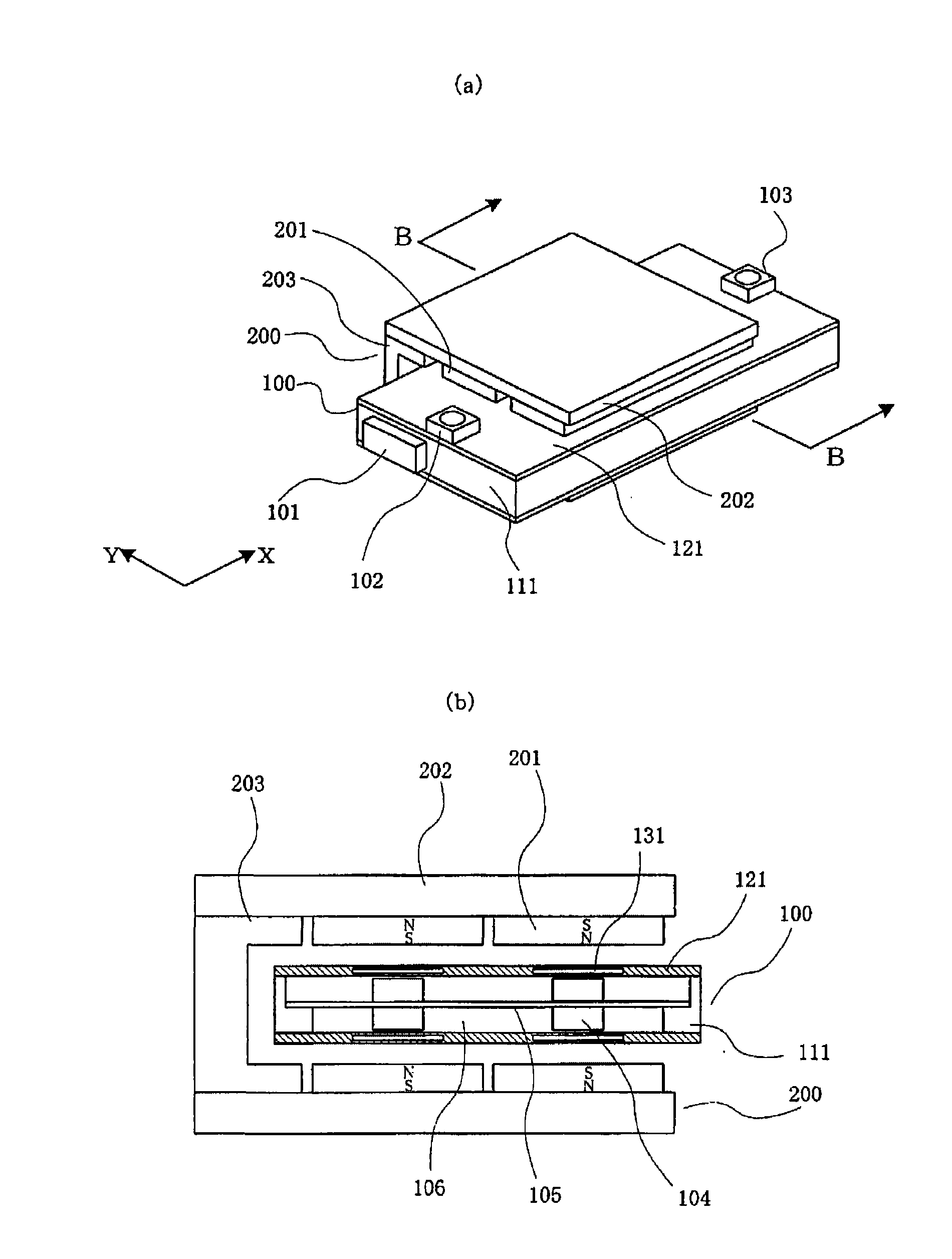

InactiveCN101657956AEliminate insulation resistance reductionReduce temperature riseMagnetic circuitCooling/ventillation arrangementBrake forcePressure increase

A canned linear motor armature and a canned linear motor of water cooling type are provided. The insulation reliability of a canned linear motor armature is improved. The temperature rises of both the linear motor surface and the armature winding are reduced. Even if the coolant pressure increases, the can neither breaks nor deforms. The weight of the armature is lightened. The viscosity braking force is reduced. In the canned linear motor armature, the armature winding (104) is surrounded with a picture-frame-shaped case (111), both the openings of the case (111) are closed with flat can (121), and coolant passages (131) are provided inside the can (121) and on the top surface of the coil side of the armature winding (104).

Owner:YASKAWA DENKI KK

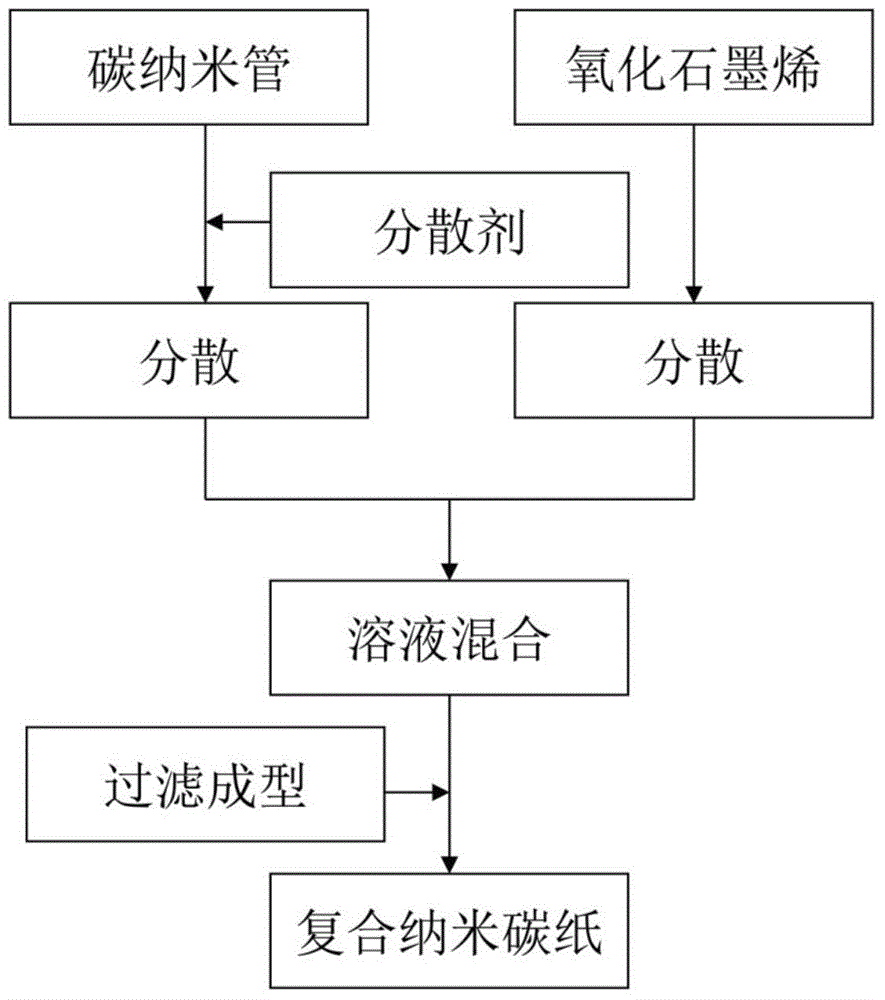

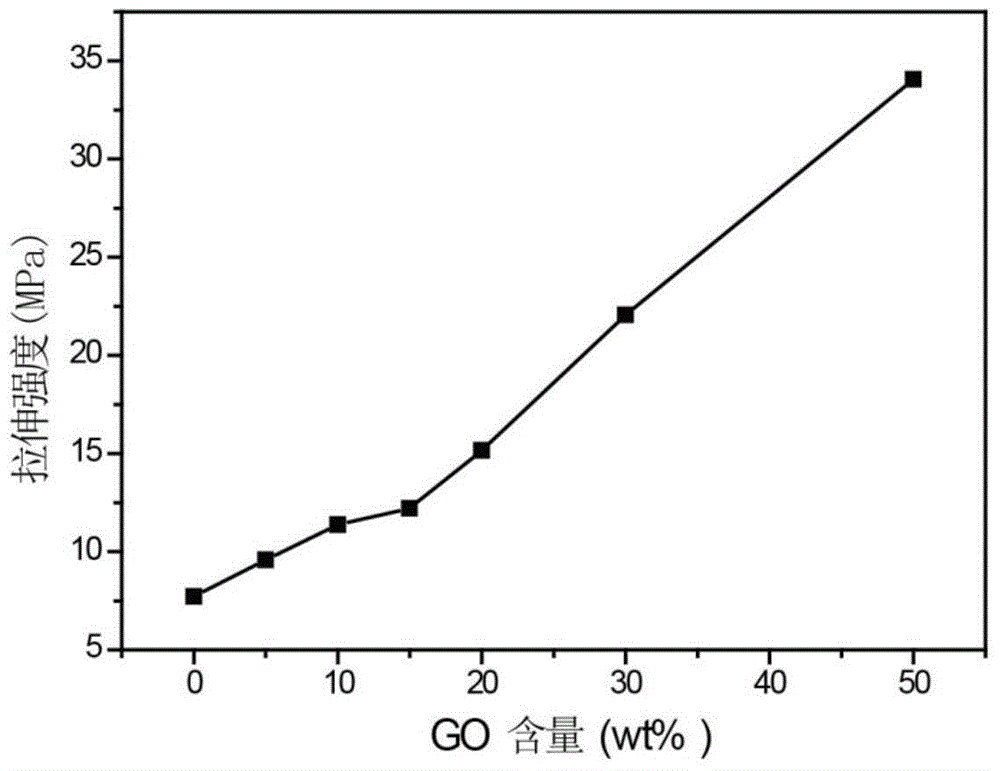

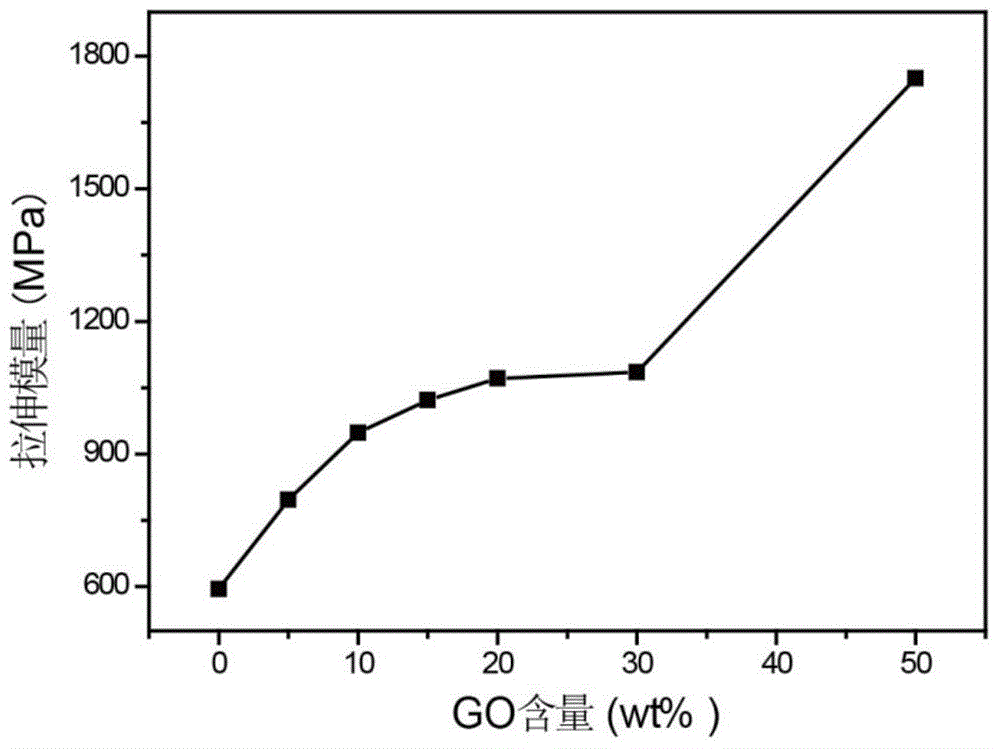

Graphene oxide reinforced composite carbon nanopaper and production method thereof

ActiveCN104627977ARegulated contentSolve the problem of poor mechanical strength of paperCarbon nanotubeNanostructured carbon

The invention discloses a graphene oxide reinforced composite carbon nanopaper and a production method thereof. The above carbon paper includes: a carbon nanotube substrate including a skeleton network mainly formed by carbon nanotubes; and at least an enhanced network for connecting the carbon nanotubes in the skeleton network, wherein the enhanced network is mainly formed by graphene oxide dispersed in the skeleton network. The production method comprises the following steps: uniformly mixing a carbon nanotube dispersion with a graphite oxide graphene dispersion filtering to form a film, and peeling the formed film from a substrate filter film in order to obtain a target product. The composite carbon nanopaper has greatly improved mechanical properties, has no apparent loss of the excellent electrical conductivity or thermal conductivity, fully solves the problem of poor mechanical strength of present carbon tube nanopaper, and has the characteristics of electrical conduction, thermal conduction, light weight, flexibility and high efficiency. The production method has the advantages of simplicity, easy operation, good controllability, low cost and wide application prospect.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

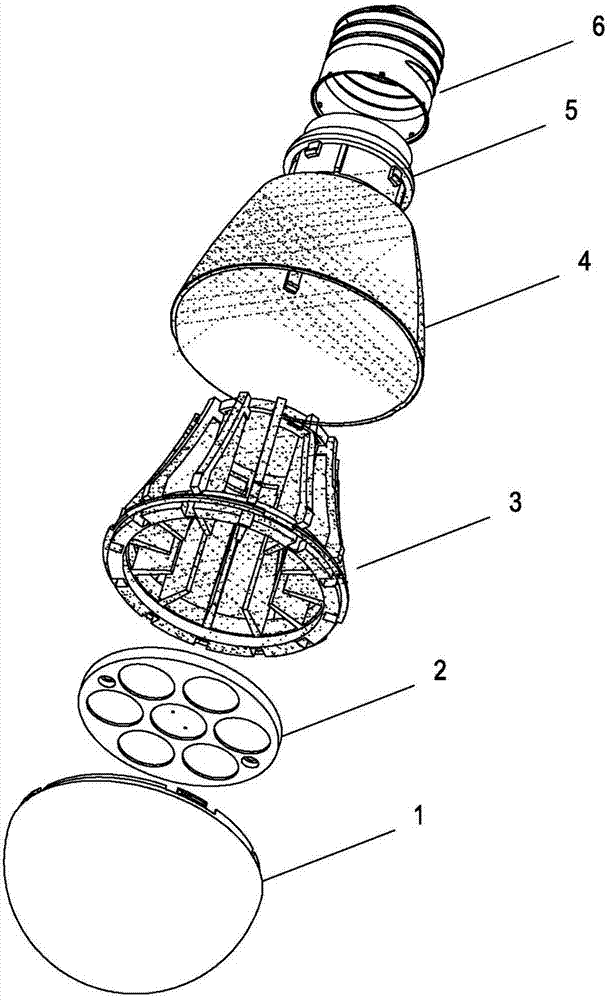

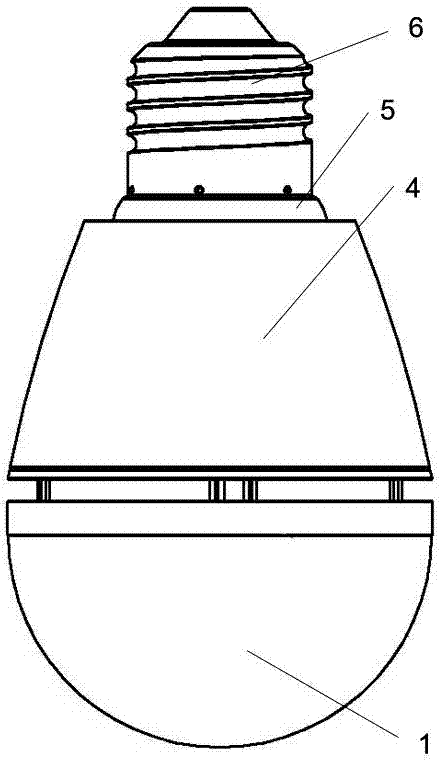

Graphene plastic casing light-emitting diode (LED) bulb lamp and production method thereof

InactiveCN103244837AEfficient heat conductionEfficient heat dissipationPoint-like light sourceLighting heating/cooling arrangementsEngineeringGraphene

The invention provides a graphene plastic casing light-emitting diode (LED) bulb lamp and a production method thereof and belongs to the field of LED illumination. At present, an LED bulb lamp is provided with a metal casing and has the problem of a potential safety hazard that the temperature on the surface of an LED lamp body is high so as to cause electric shock easily. The graphene plastic casing LED bulb lamp comprises a lamp holder, a driving power supply, a light source base, an LED light source, a casing and a light transmitting bulb casing and is characterized in that the casing is a fireproof plastic casing with the inner surface coated by a graphene material. The production method of the graphene plastic casing LED bulb lamp includes: step one, preparing parts of each component; step two, coating the graphene material on the inner surface of the casing; step three, solidifying the graphene material on the casing in the step two; step four, assembling the parts of each component in sequence; and step five, detecting and debugging. The graphene plastic casing LED bulb lamp and the production method of the graphene plastic casing LED bulb lamp have the advantage that high thermal conductivity performance of graphene is applied to the plastic casing of the LED bulb lamp and the light source base, the defect that an existing high-power bulb lamp solves the problem of heat dissipation through increasing of volume and weigh of a metal casing or a metal radiating support is overcome, and the LED bulb lamp is simple in structure, good in radiating effect, long in service life and convenient in popularization and application.

Owner:ZHEJIANG MANELUX LIGHTING

High-power LED (light-emitting diode) light source packaging structure manufactured by graphene and production process thereof

InactiveCN102412352ASolution volumeSolve the weight problemSemiconductor devicesElectricityEngineering

The invention discloses a high-power LED (light-emitting diode) light source packaging structure manufactured by graphene and production process thereof, and relates to high-power LED light source packaging. At present, the area and weight of a baseplate are added to accelerate heat dissipation for a high-power LED, the light source volume of the whole high-power LED is increased, weight is increased, LED light source cost is improved, and meanwhile the advantages such as, portability and the like of the LED are lost, thereby being difficult to apply. The high-power LED light source packaging structure provided by the invention comprises a baseplate which is fixedly connected with at least one chip and electrically connected with the chip, and the high-power LED light source packaging structure is characterized in that a single layer graphene material is covered on at least one of the upper surface and lower surface of the baseplate; the baseplate surface in a chip loaded region uses single layer flake graphene as a heat conduction, radiating material, the physical characteristic of the graphene is fully utilized, the heat energy generated by the chip when the high-power LED light source is conducted so as to diffuse; and under the condition of not increasing the light source weight and volume, the operating temperature of the chip is obviously improved.

Owner:杭州创元光电科技有限公司

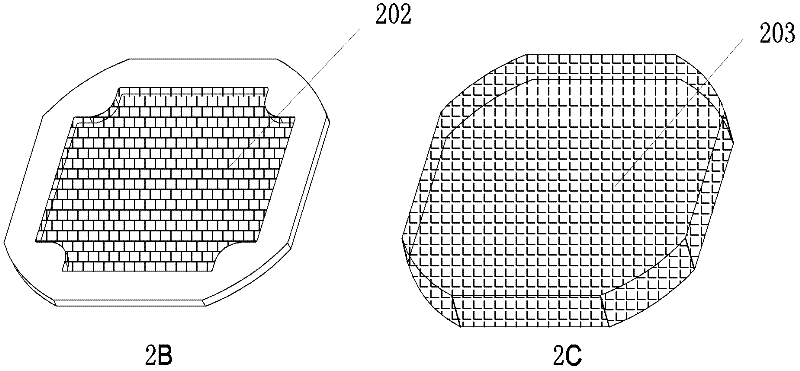

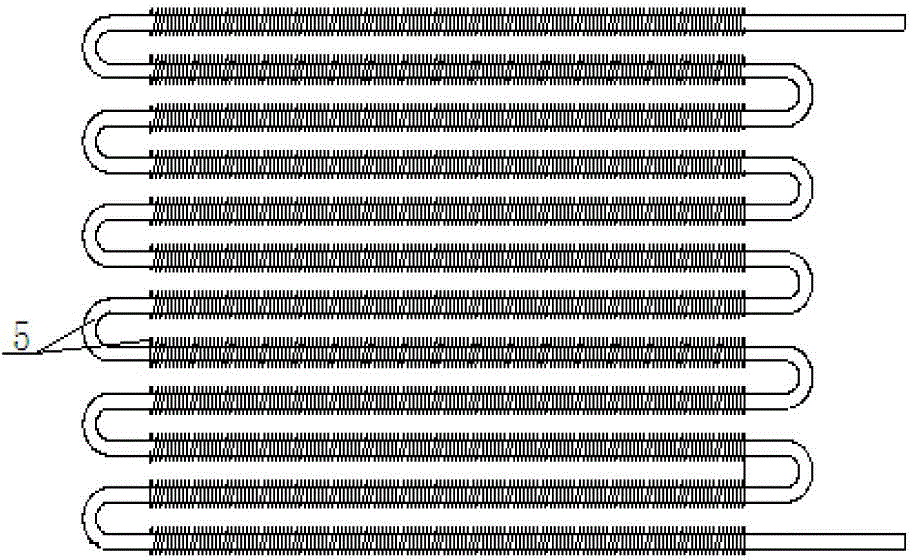

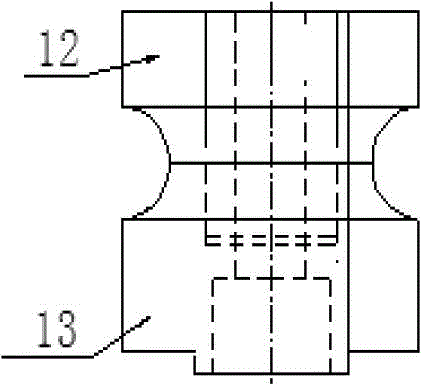

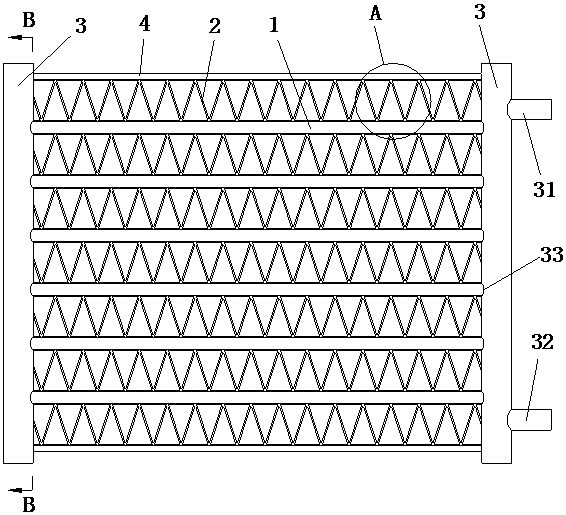

Boiler energy-saving device, and method and tool for manufacturing S-shaped fin heat exchange tube of boiler energy-saving device

ActiveCN104390504AEfficient heat conductionReduce manufacturing costShaping toolsTubular elementsThermodynamicsStraight tube

The invention discloses a boiler energy-saving device, and a method and a tool for manufacturing an S-shaped fin heat exchange tube of the boiler energy-saving device. The boiler energy-saving device mainly comprises a box body and an S-shaped heat exchange tube which is arranged in the box body; the S-shaped fin heat exchange tube is of an integrated structure and is manufactured by bending a whole tube. The method for manufacturing the S-shaped fin heat exchange tube comprises the following steps: (1) welding a plurality of tubes into a whole tube, in which the total length of the tubes is not smaller than that of the S-shaped heat exchange tube; (2) marking lines according to the length and the number of straight tube sections of the S-shaped heat exchange tube and marking relative positions of all straight tube sections and elbow joints; (3) welding a spiral fin on the outer wall of each straight tube section; (4) bending each part corresponding to the elbow joint on the straight tube of the step (3) one by one to form an elbow joint. The tool of the method is one set of mold which is combined by an upper half part and a lower half part; the mold is matched with a tube bending machine for bending and manufacturing the heat exchange tube; the heat exchange tube is manufactured by bending one whole tube; the S-shaped heat exchange tube is formed by welding the spiral fin with high-frequency resistance; the efficient heat conduction is ensured; by virtue of the manufacturing method and the tool, the manufacturing cost is lowered.

Owner:SHIFANG TONGJIA MACHINERY

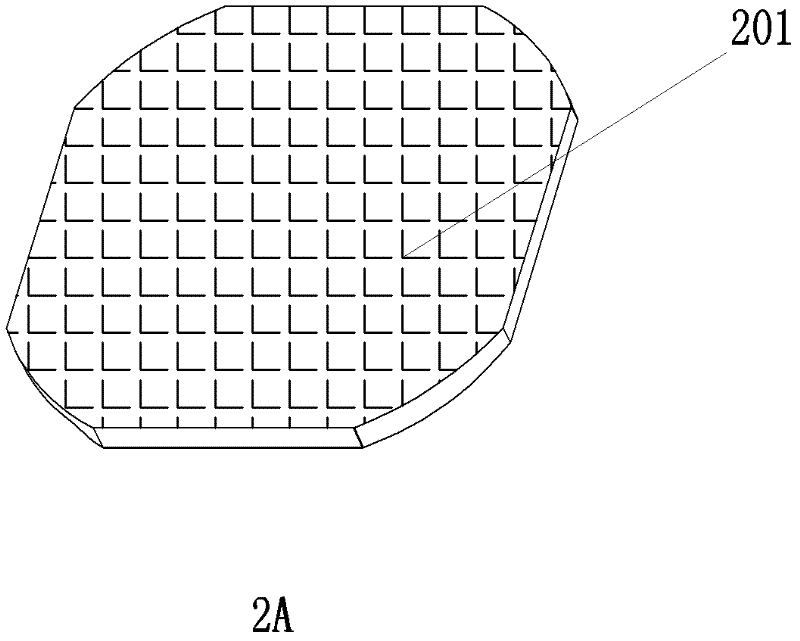

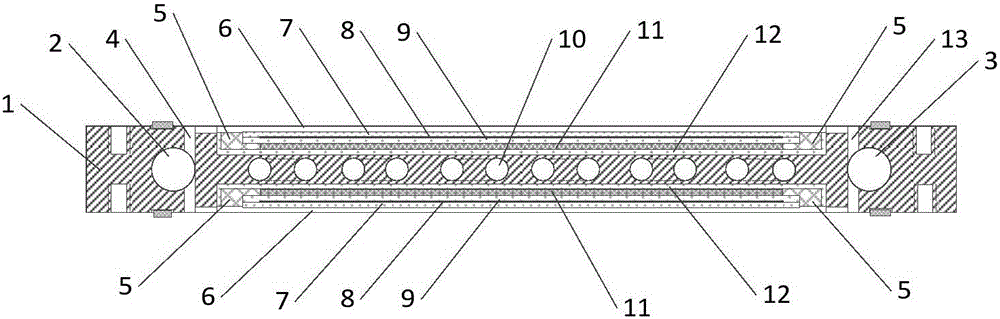

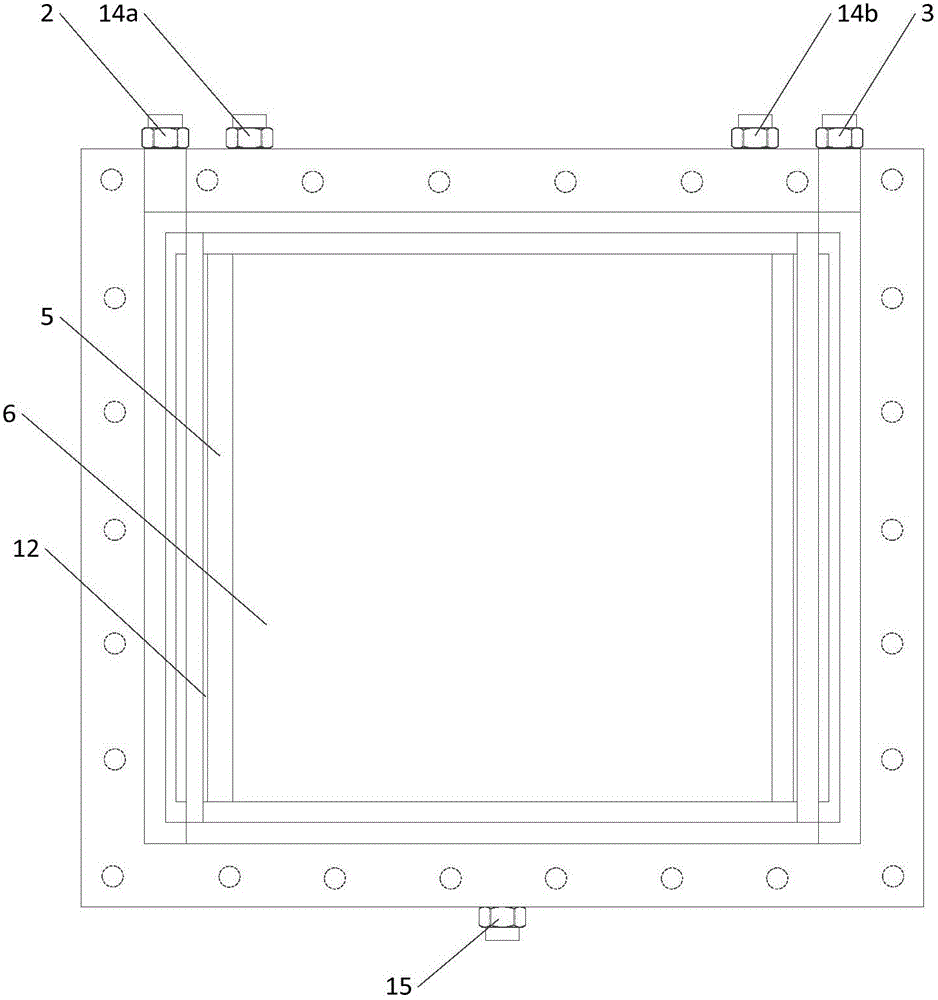

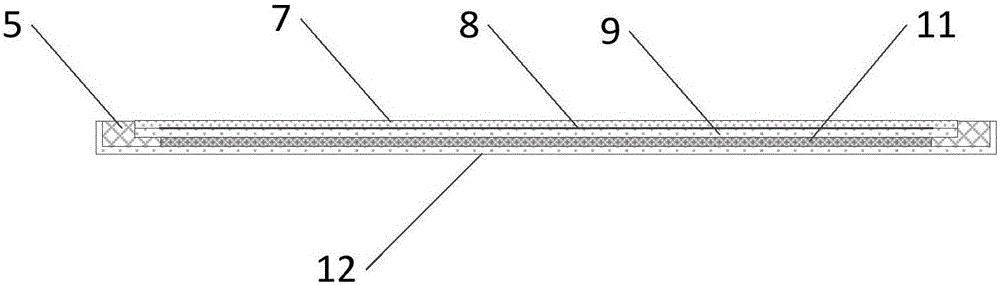

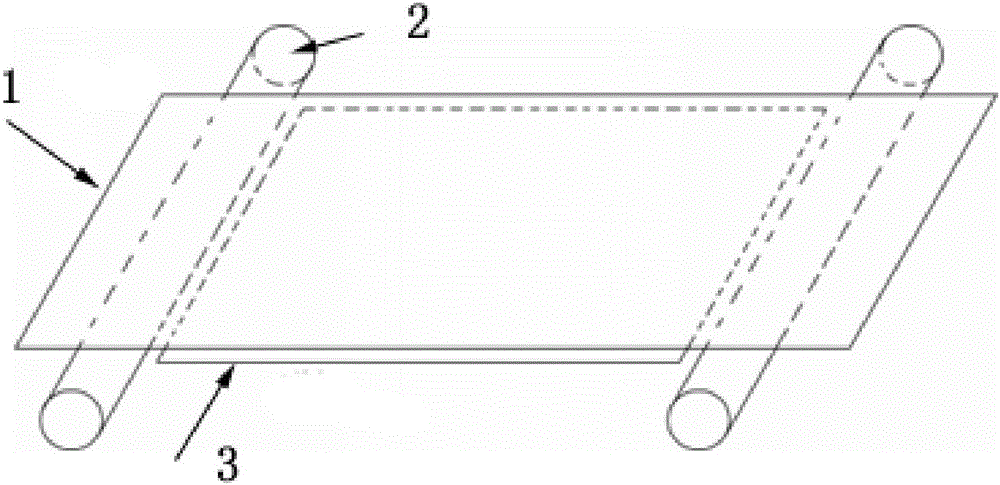

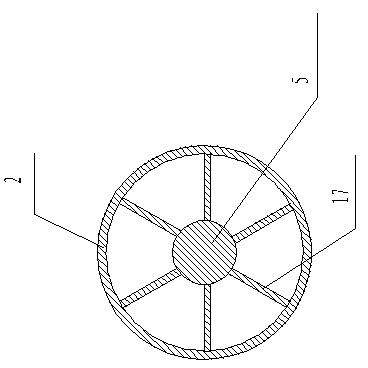

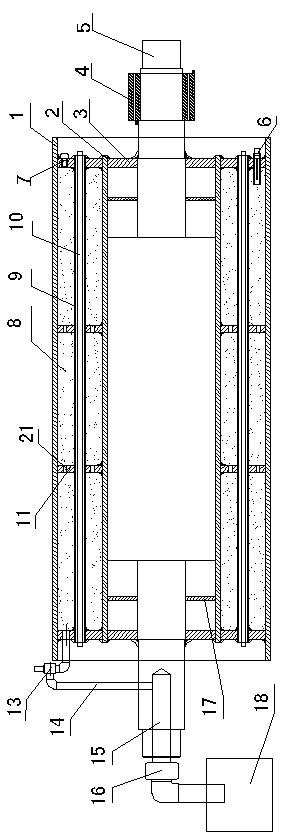

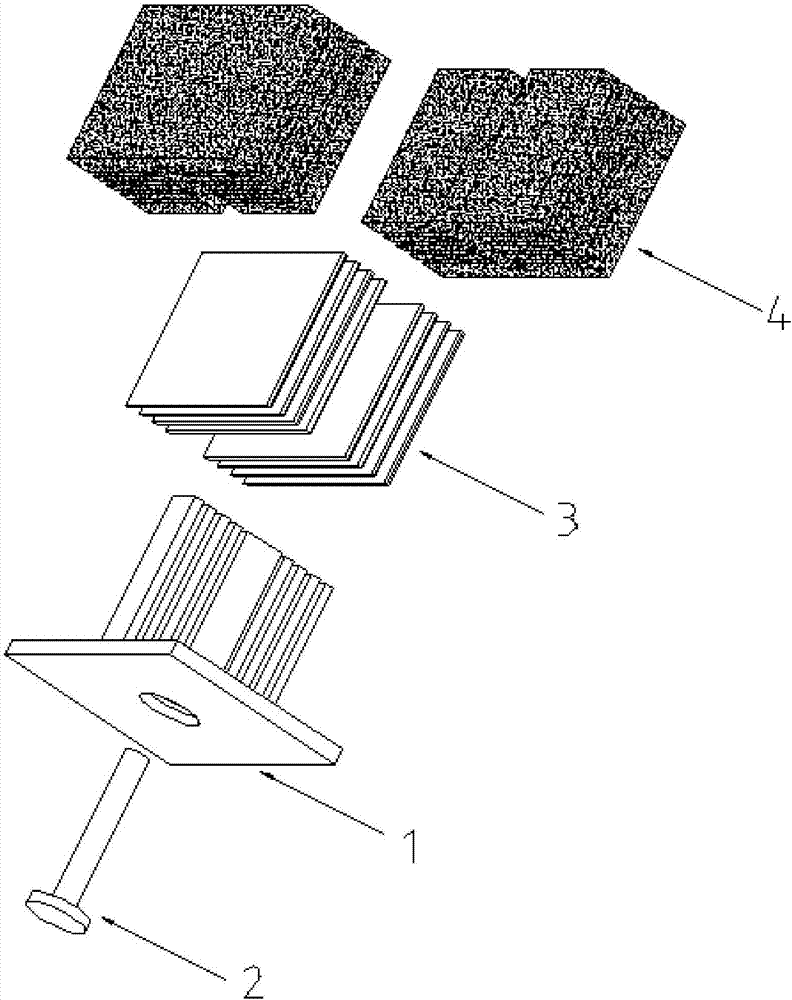

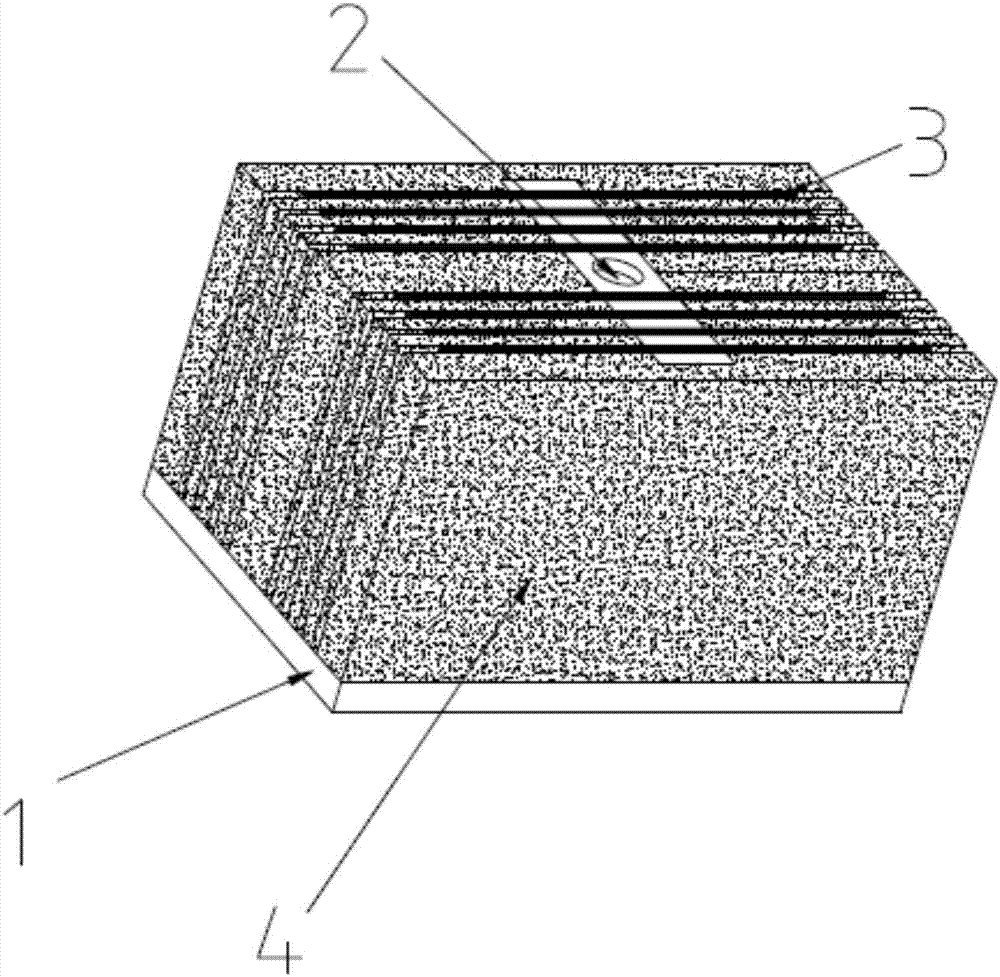

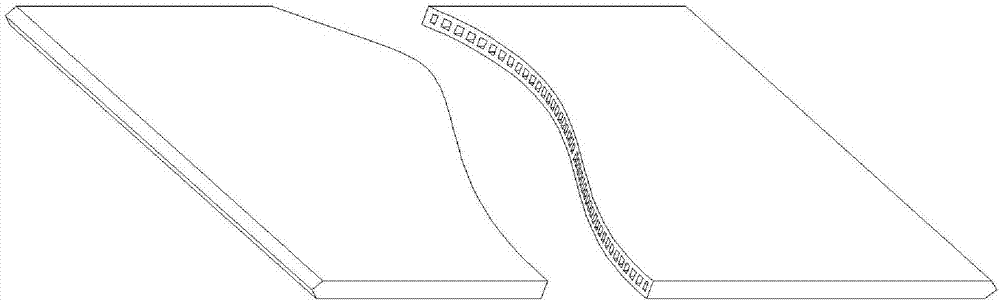

Dielectric barrier discharge plate, basic unit components of plate type ozonator and ozonator module

ActiveCN105692562AGood condition adjustmentEfficient productionElectrical discharge ozone preparationHeat conductingEngineering

The invention discloses a dielectric barrier discharge plate which comprises a plate body. An oxygen inlet, an oxygen outlet, a corresponding oxygen channel and a corresponding ozone channel are formed in the plate body. A cooling channel, a corresponding cooling water inlet and a corresponding cooling water outlet are further formed in the middle of the plate body. The upper face and the lower face of the cooling channel are each provided with a high voltage assembly. Each high voltage assembly comprises a groove-shaped ceramic vessel, and a square rubber gasket, a composite plate electrode and a heat conducting silica gel pad are arranged in a groove of each ceramic vessel, wherein the composite plate electrode and the heat conducting silica gel pad are arranged in the rubber gasket from top to bottom in an overlapped mode. The invention further discloses a plate type ozonator module with at least one set of basic unit components and a large plate type ozonator unit formed by at least one set of plate type ozonator modules.

Owner:北京天择昌宁环境技术股份有限公司

Method for preparing graphene base membrane product

ActiveCN106167693AImprove thermal conductivityImprove bindingHeat-exchange elementsSlurryVolumetric Mass Density

The invention discloses a method for preparing a graphene base membrane product. The method comprises the following steps: (1) preparing slurry; (2) coating the slurry in a magnetic field. The invention provides the method for preparing the graphene base membrane product, and a high-efficiency heat-conduction graphene heat-conduction membrane can be prepared by using the method. The graphene base membrane product prepared by using the method is prepared by preparing slurry from specific graphene, a heat-conductive additive, an adhesion additive, a binding agent and a solvent, and by coating and drying the slurry under the action of the magnetic field. Compared with a graphene heat-conduction membrane prepared by using a conventional method, the graphene base membrane product prepared by using the method is good in heat conduction property, and the cooling amplitude is about 4.9 DEG C. After the slurry is coated and dried under the action of the magnetic field, the density of a membrane layer of a membrane product prepared by using the method is improved, that is, the density is improved by about 30-50%. The heat-conduction membrane prepared by using the method is good in binding force, not easy to drop off and excellent in water resistance. The method disclosed by the invention is simple in process step, easy to operate and achieve, gentle in preparation condition and easy to control.

Owner:成都市科愿科技有限公司

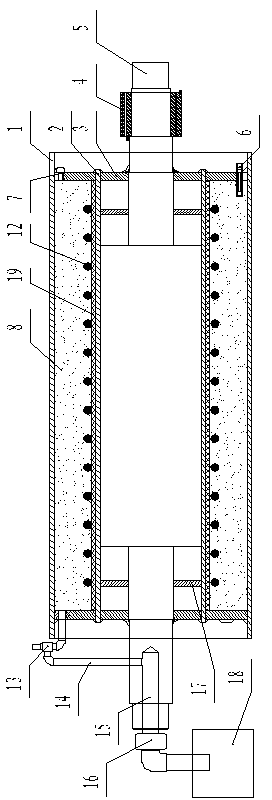

Conduction oil internal circulation type heating roller

InactiveCN103234273AEfficient heat conductionReduce energy consumptionHeater elementsStorage heatersThermodynamicsEngineering

The invention relates to a heating roller, solve the technical problems that the heating mode adopted by a conventional heating roller is high in energy consumption and poor in heating effect, and provides a conduction oil internal circulation type heating roller which comprises an outer cylinder body, end disks welded at two ends of the outer cylinder body hermetically, and left and right support shafts at two ends of the outer cylinder body. The conduction oil internal circulation type heating roller is characterized in that an inner cylinder body coaxial with the outer cylinder body is arranged in the outer cylinder body; two ends of the inner cylinder body are welded with the end disks; a conduction oil cavity is formed between the outer cylinder body and the inner cylinder body; the conduction oil cavity is filled with conduction oil; a conduction oil injection hole is formed at one of the two end disks at two ends of the outer cylinder body; a heating device is arranged in the conduction oil cylinder, and is connected with conductive slip rings on the support shafts through a lead wire. The conduction oil internal circulation type heating roller has the advantages that the heat conduction is efficient, the energy consumption is reduced, and the service life of the heating roller is prolonged greatly.

Owner:WEIHAI FENGTAI NEW MATERIAL SCI & TECH

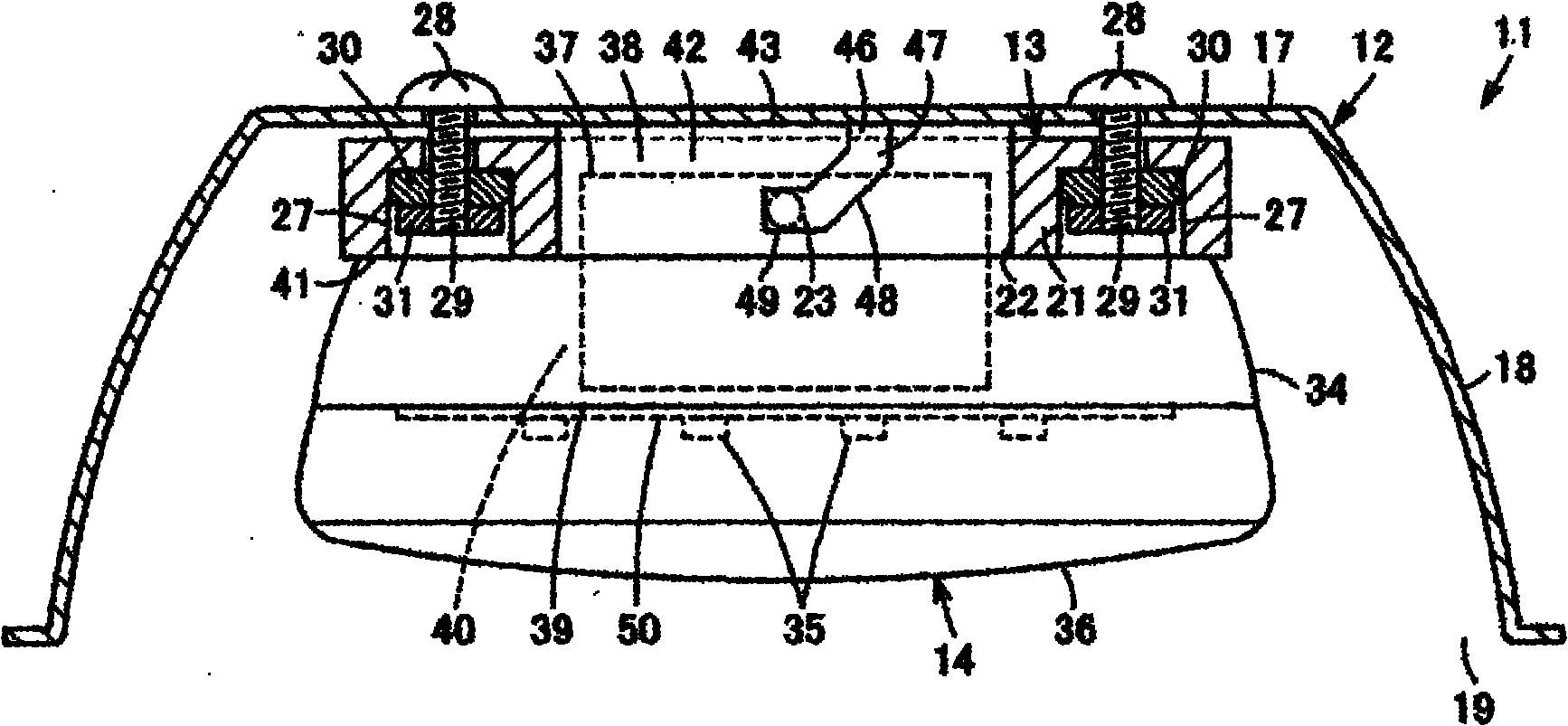

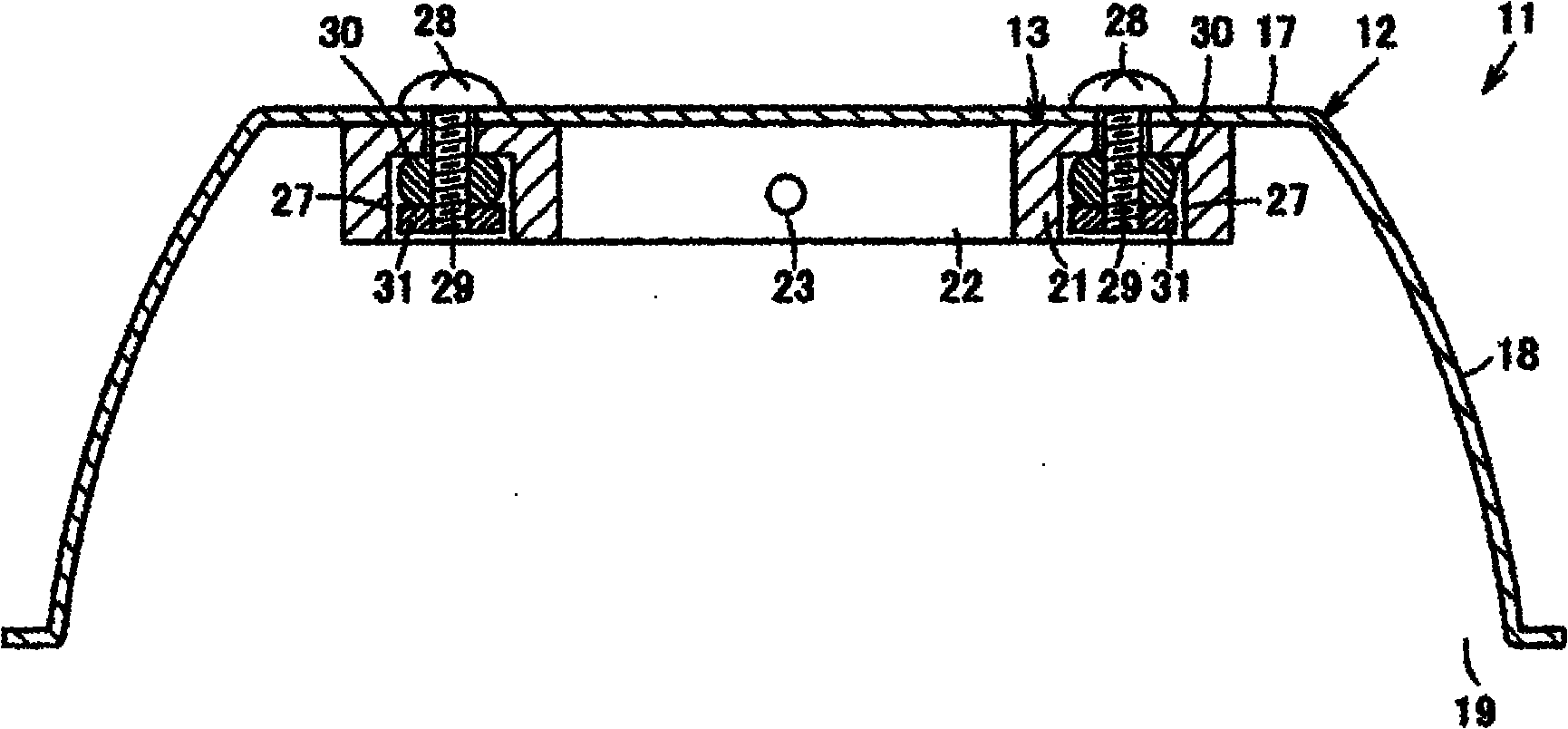

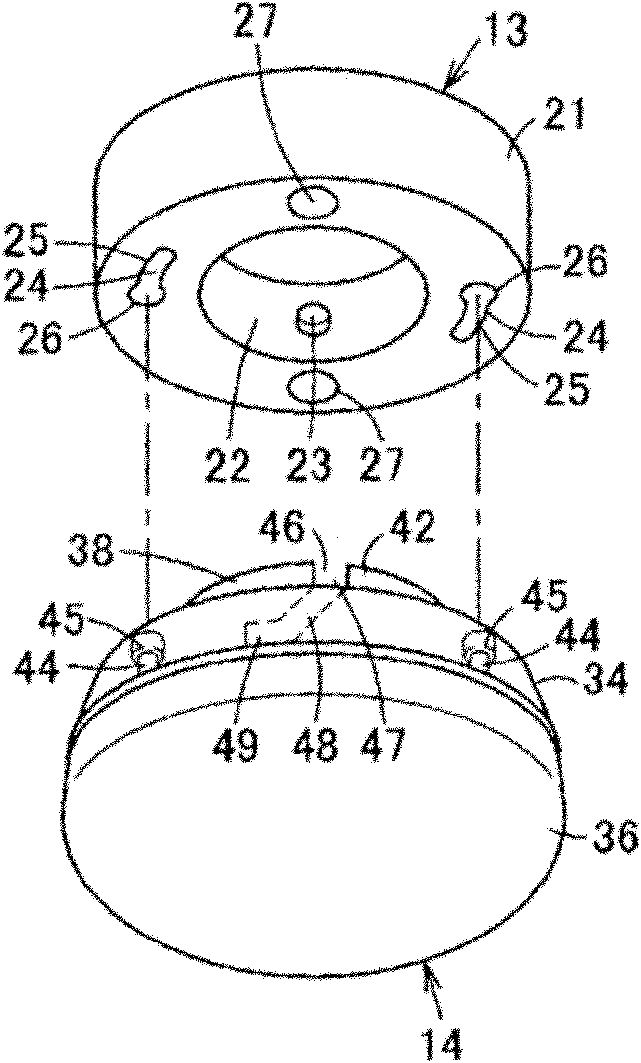

Lighting device

ActiveCN102149962AEfficient heat dissipationClose contactCoupling device connectionsPoint-like light sourceLight equipmentBiomedical engineering

A lighting device (11) capable of efficiently dissipating heat of a lamp device (14) mounted to a socket device (13). When the lamp device (14) is mounted to the socket device (13), a fitting section (38) of the lamp device (14) makes contact with a device body (12) and, at the same time, an elastic body (30) presses the fitting section (38) to the device body (12) in such a manner that the fitting section (38) is in close contact with the device body (12). Heat created by lighting of an LED (35) of the lamp device (14) is transferred from the fitting section (38) to the device body (12). Thus, the heat of the lamp device (14) is efficiently dissipated.

Owner:TOSHIBA LIGHTING & TECH CORP

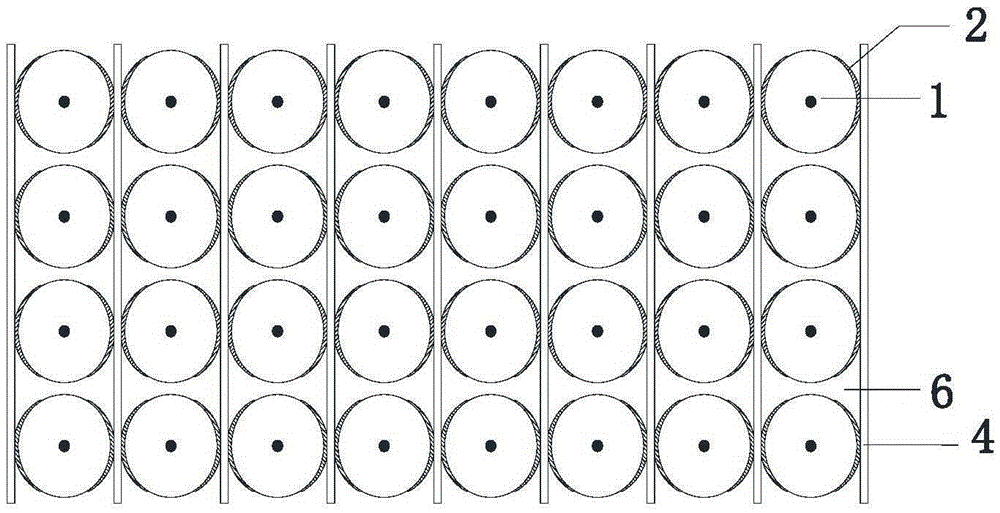

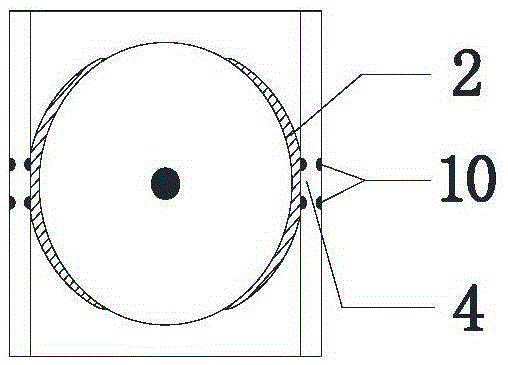

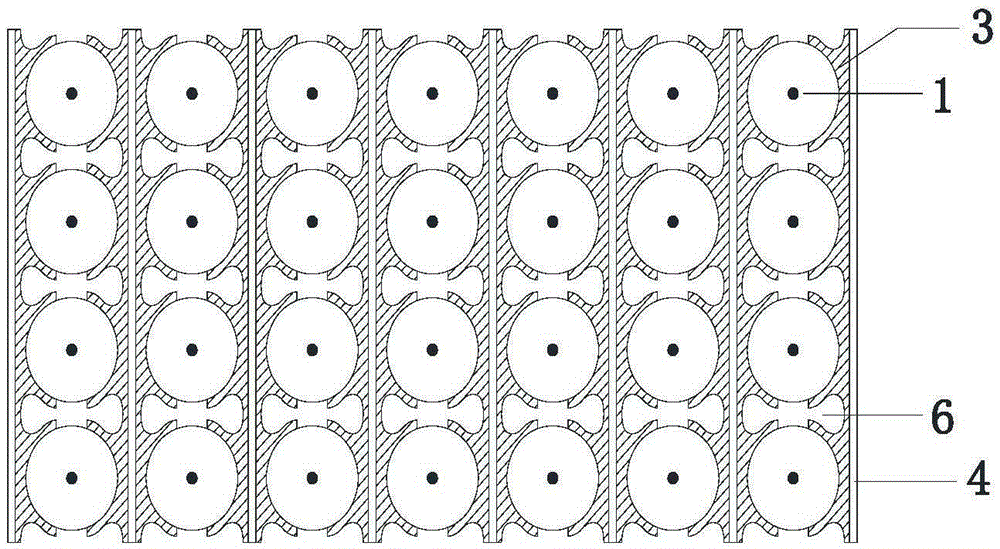

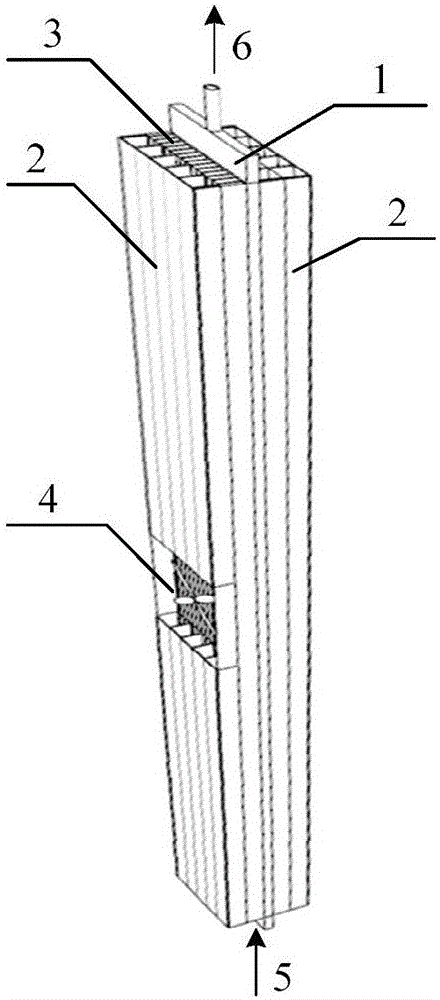

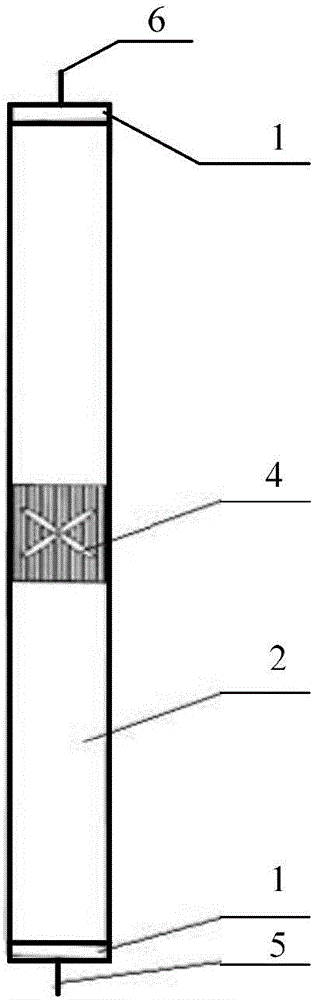

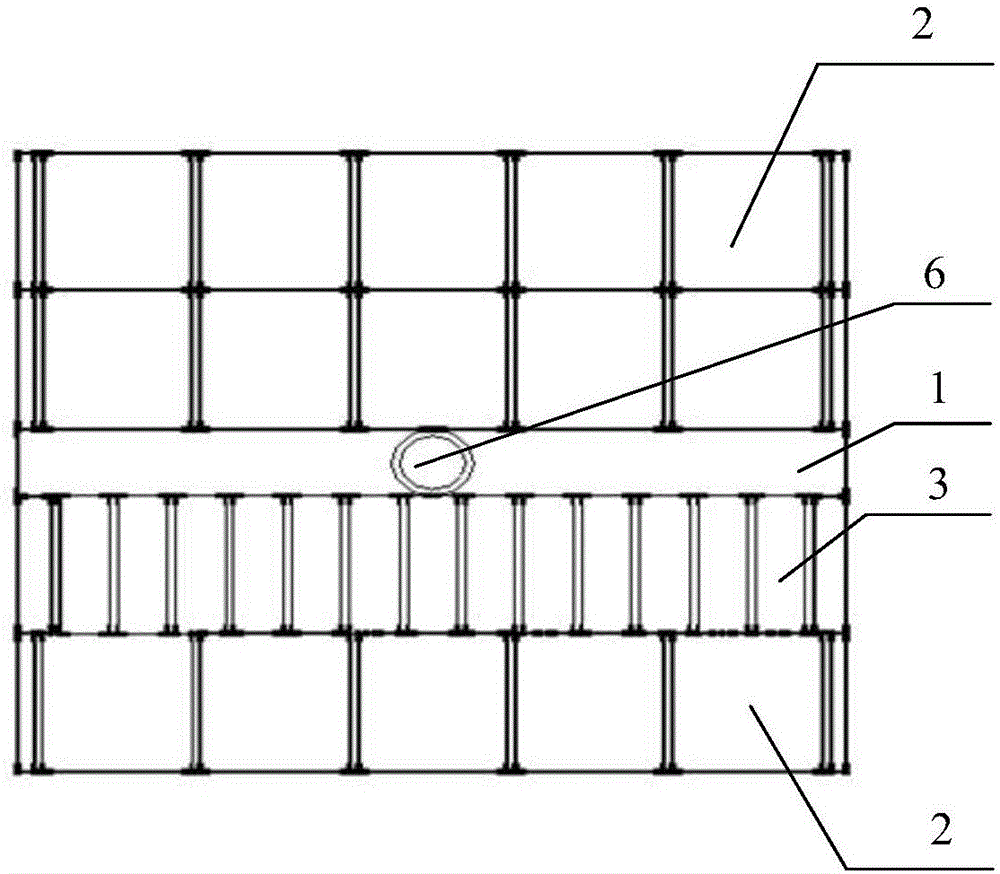

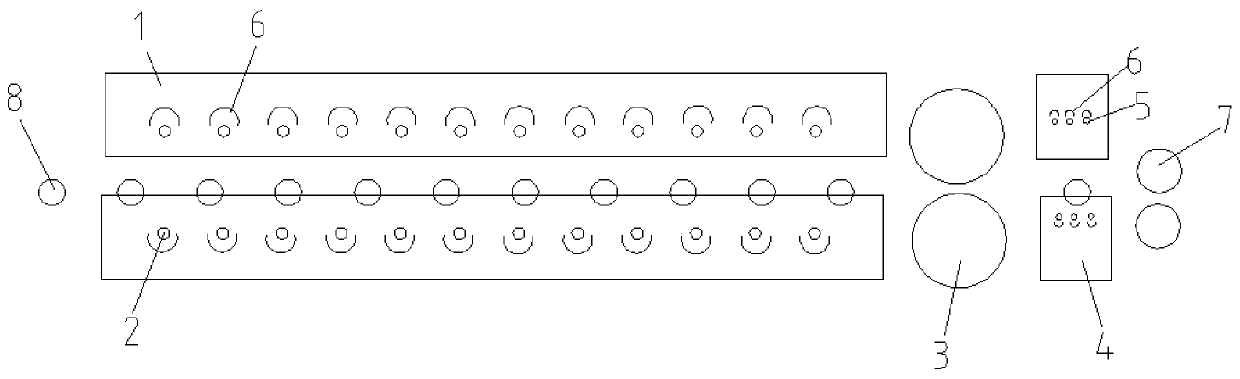

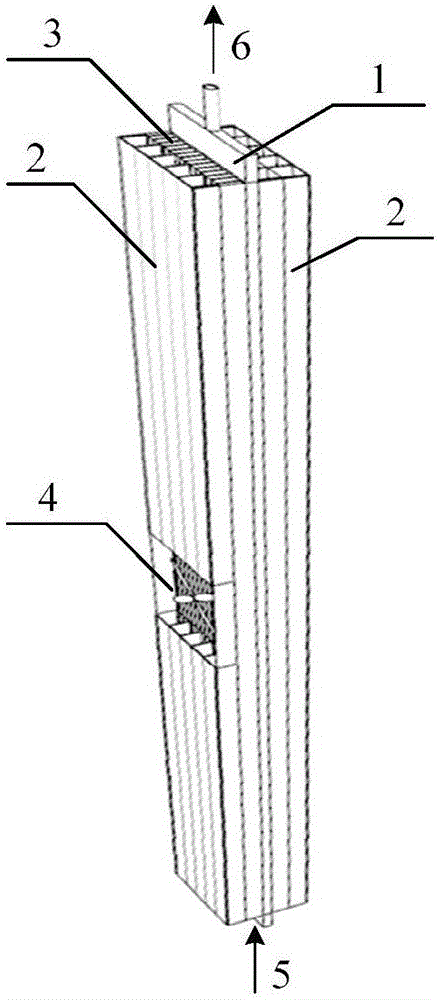

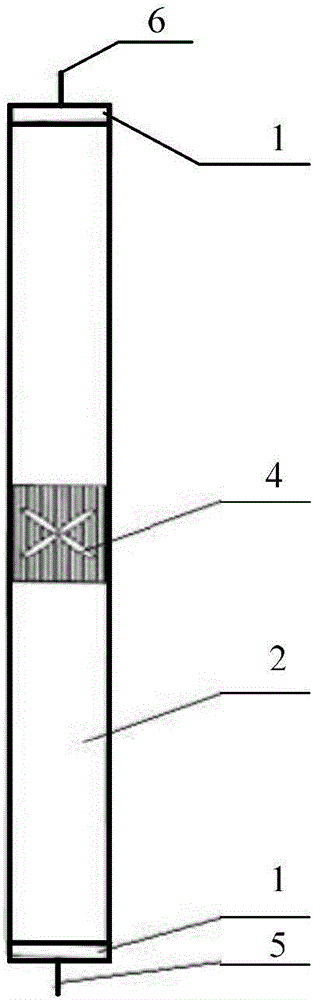

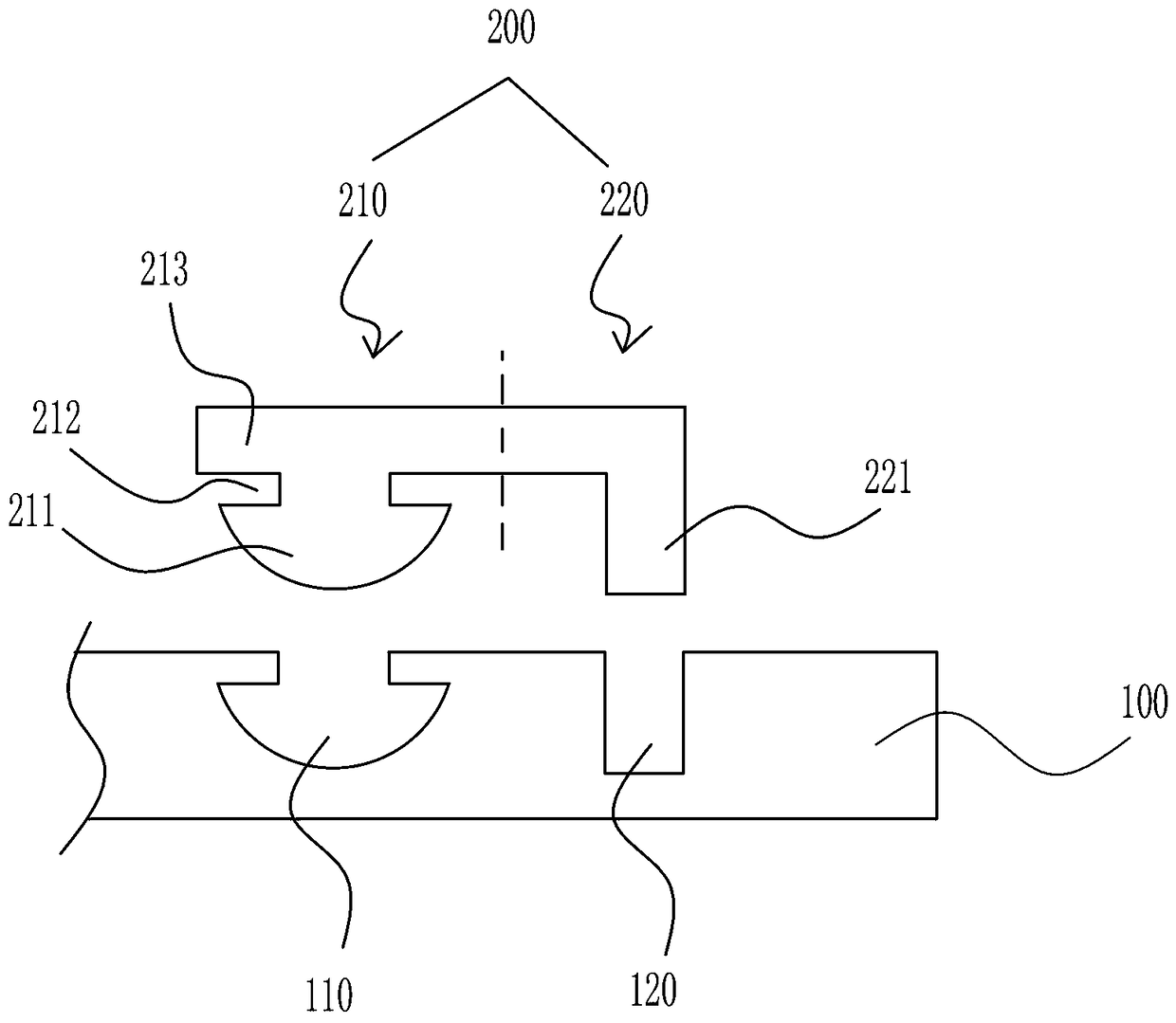

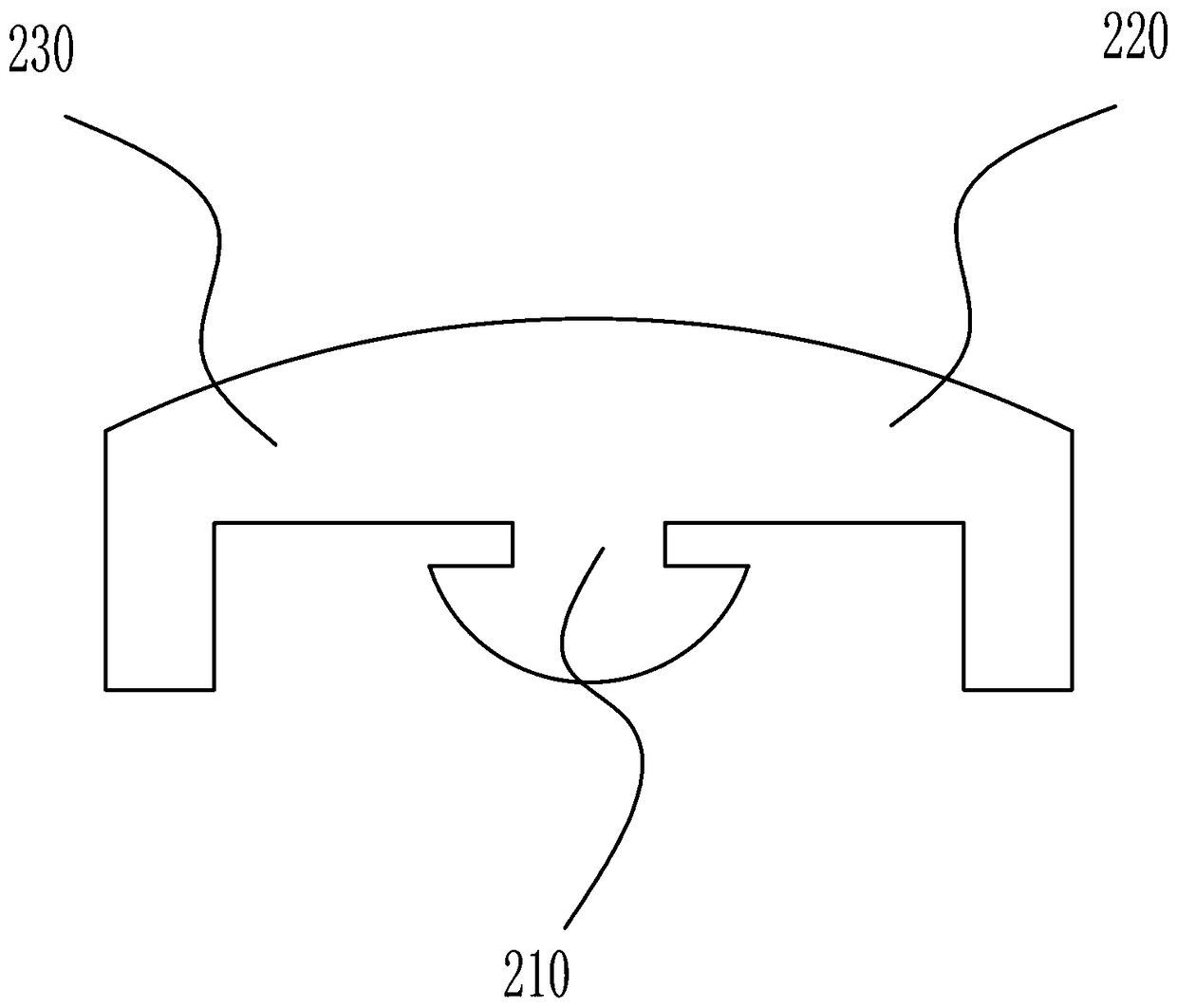

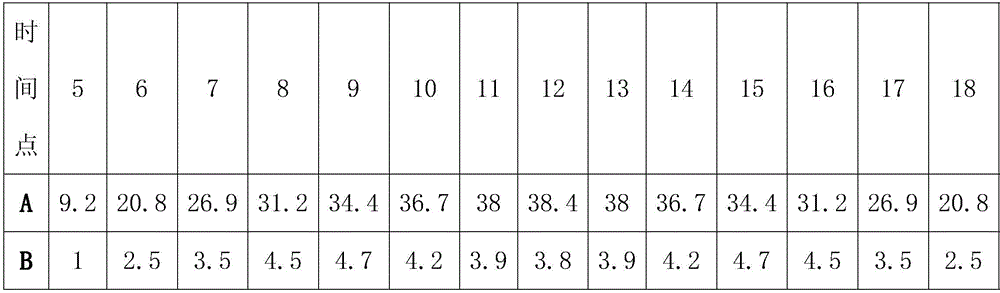

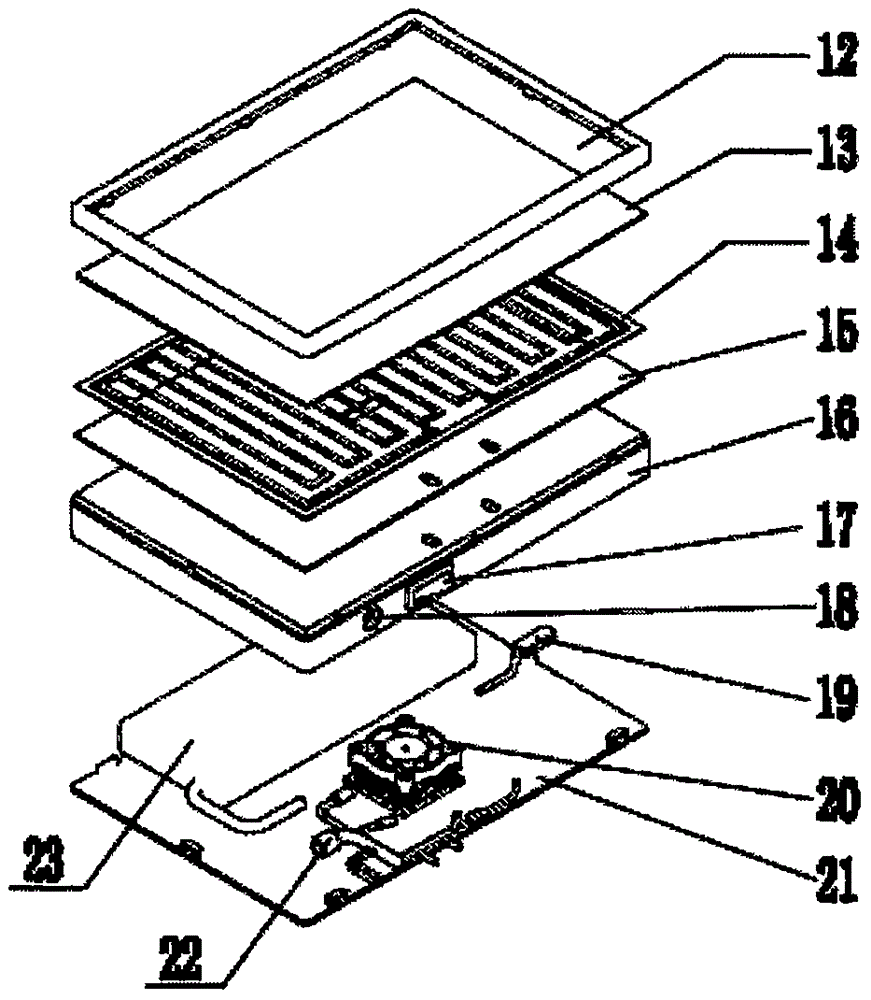

Heat management system and method of cylindrical battery pack

The invention relates to a heat management system and method of a cylindrical battery pack. The heat management system of the cylindrical battery pack comprises an anomalous heat-conducting plate, a micro-heat tube array plate and a heat source. When dissipating heat, the planar structure of the plate surface of the anomalous heat-conducting plate is stuck with an evaporation section of the micro-heat tube array plate, and the evaporation section of the micro-heat tube array plate after absorbing the heat energy of the cylindrical battery pack delivered by the anomalous heat-conducting plate is subjected to a heat tube effect, and then heat exchange with the outside is carried out by the condensing section of the micro-heat tube array plate; when pre-heating, a heat source is arranged at the evaporation section of the micro-hot tube array plate, the planar structure of the plate surface of the anomalous heat-conducting plate is stuck with the condensing section of the micro-heat tube array plate, the evaporation section of the micro-heat tube array plate after absorbing the heat energy of the heat source is subjected to the heat tube effect, then the heat is discharged through the condensing section of the micro-heat tube array plate and then the heat is conducted to the cylindrical battery pack through the anomalous heat-conducting plate. The heat management system integrates a heat dissipation function and a heating function, guarantees uniform temperature of the cylindrical battery pack, is high in heat conduction efficiency, compact in volume and light in weight, and improves the heat exchange efficiency and effect.

Owner:赵耀华

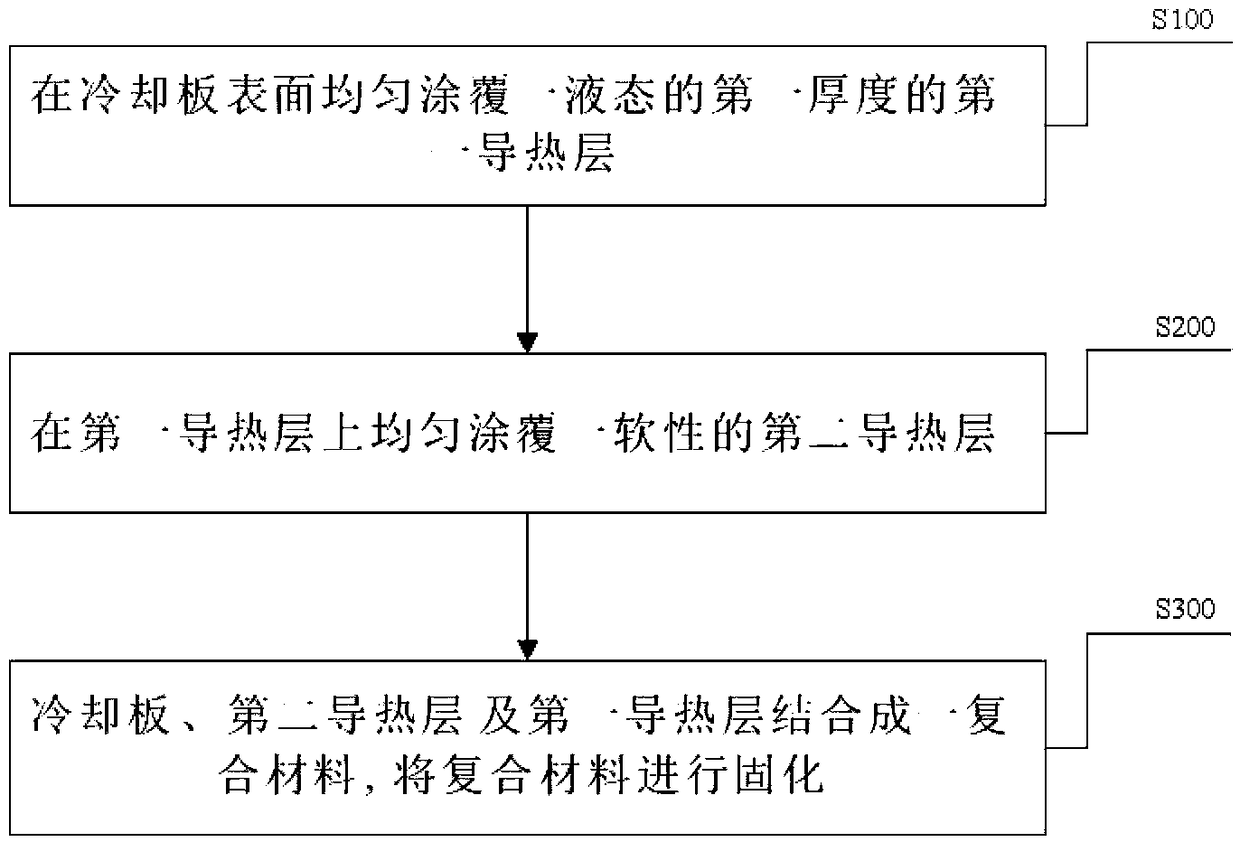

Manufacturing method of composite heat dissipation material

InactiveCN108258364AEfficient heat conductionAchieve fixationSecondary cellsWear resistantHeat conducting

The invention discloses a manufacturing method of a composite heat dissipation material. The manufacturing method specifically comprises the following steps: uniformly coating the surface of a coolingplate with a liquid first heat conducting layer of the first thickness; uniformly coating the first heat conducting layer with a soft second heat conducting layer; combining the cooling plate, the second heat conducting layer and the first second heat conducting layer into the composite heat dissipation material; curing the composite heat dissipation material. The manufacturing method disclosed by the invention has the benefits that the composite heat dissipation material is formed on the surface of the cooling plate by relying on the first high-hardness and high-mechanical strength wear-resistant first heat conducting layer and the second low-hardness flexible second heat conducting layer, the fixation, the wear resistance and the efficient heat conductivity of the composite heat dissipation material are realized, and the insulation reliability is improved.

Owner:东莞优邦材料科技股份有限公司

Low-temperature heating radiator

ActiveCN106323042ARealize energy-saving heatingSolve the problem of enhanced heat transferHeat exhanger finsStationary conduit assembliesMetallic materialsEngineering

The invention relates to a low-temperature heating radiator which comprises one or more sets of plate like heat transportation devices and one or more parallel channel type fin heat exchange structures combined with the plate like heat transportation devices. Each plate like heat transportation device is of a plate like structure formed by extruding metal materials, wherein two or more micro pipes arranged side by side are arranged in the plate like structure, and heat exchange transfer is carried out in the micro pipes through flowing media. Each parallel channel type fin heat exchange structure is attached to the plate surface of the corresponding plate like heat transportation device and provided with a plurality of air convection channels arranged side by side and comprises a parallel channel type sparse fin heat exchange structure. Heat exchange is enhanced by means of the plate like heat transportation devices of the special structures, and the parallel channel type fin heat exchange structures are attached to the plate surfaces of the corresponding plate like heat transportation devices correspondingly, so that natural air convection heat exchange and forced air convection heat exchange can be carried out as needed, the heat exchange efficiency is improved, an effective heating function is achieved, the low-temperature heating radiator has the advantages of being low in temperature, capable of saving energy, low in cost and free of maintenance, and meanwhile precision management and energy saving can be achieved.

Owner:CHANGZHOU HETONG PURUN ENERGY TECH CO LTD

Semiconductor device and semiconductor module

InactiveCN106233454AReduce the number of piecesReduced loading areaTransistorCharge equalisation circuitMOSFETElectricity

The purpose of this invention is to reduce the number of components mounted on a printed circuit board and the area taken up by said components. This MOSFET semiconductor device, in which a transistor is formed from a plurality of semiconductor layers formed inside a semiconductor substrate, has a source electrode, a gate electrode, a drain electrode, and a gate-insulating film and is characterized by the provision of the following: an insulating film formed on a first principal surface of the semiconductor substrate; a resistive film that is formed on said insulating film and is electrically connected to the drain electrode; and an ohmic electrode that is formed on the resistive film and serves as a surface-mount terminal. This design makes it possible to reduce the number of components mounted on a printed circuit board, reduce the area taken up by said components, and convey heat generated in the resistive film to the printed-circuit-board side, preventing a MOSFET from malfunctioning due to heat.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

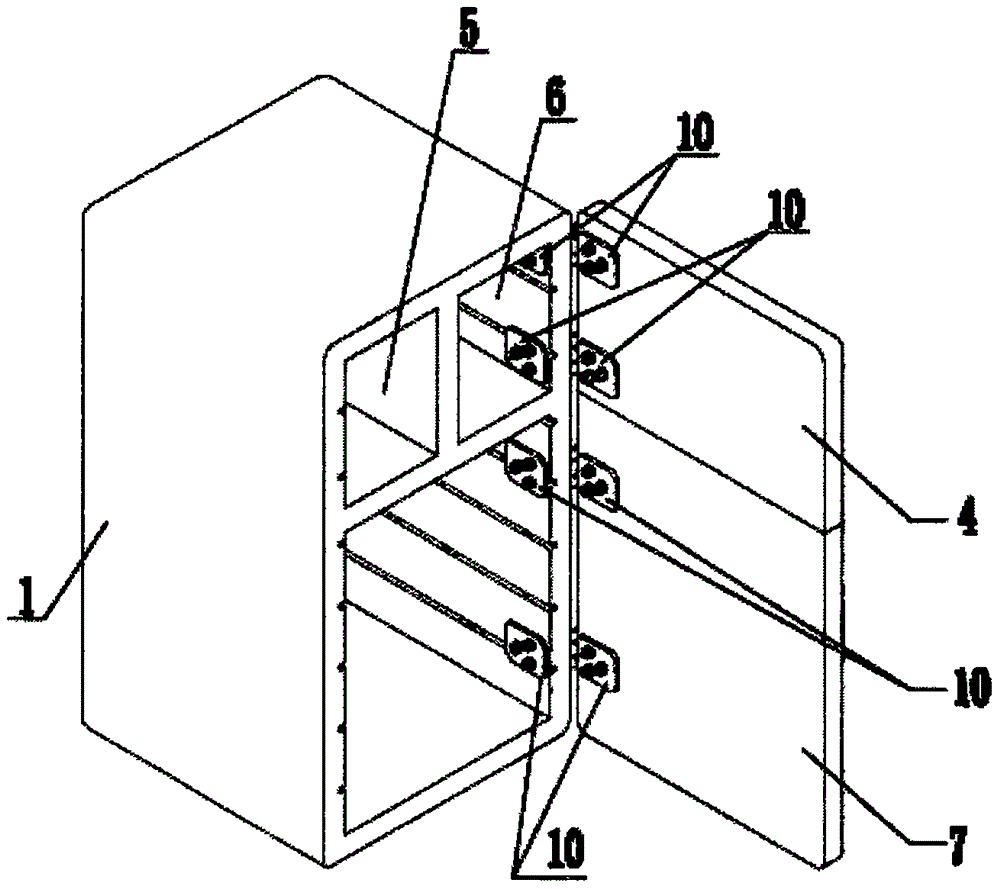

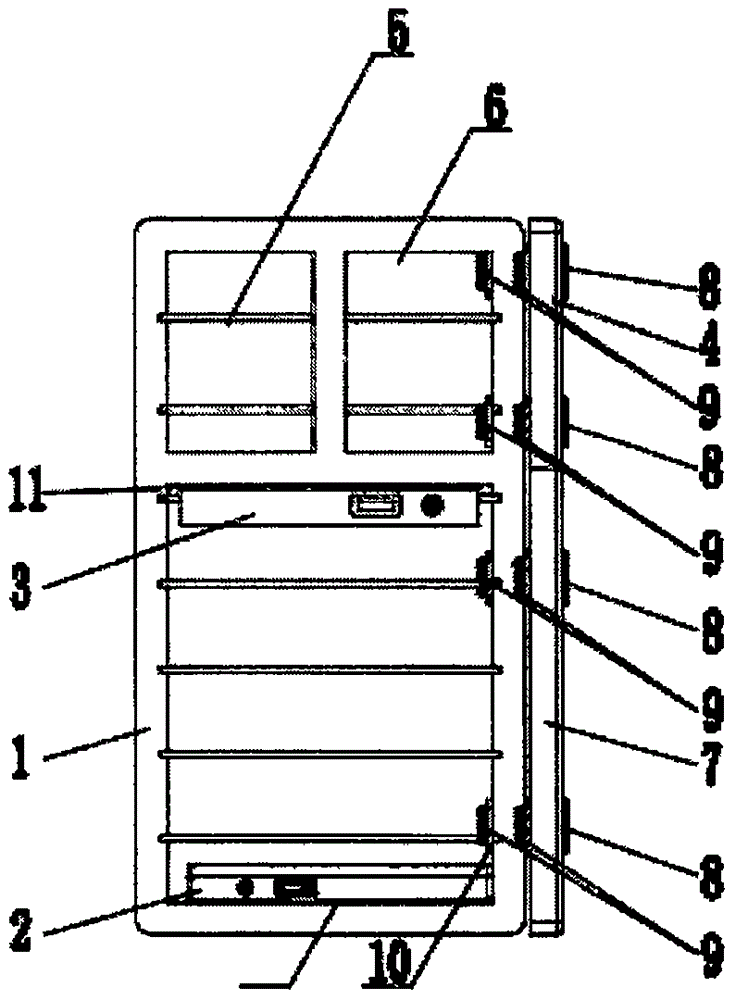

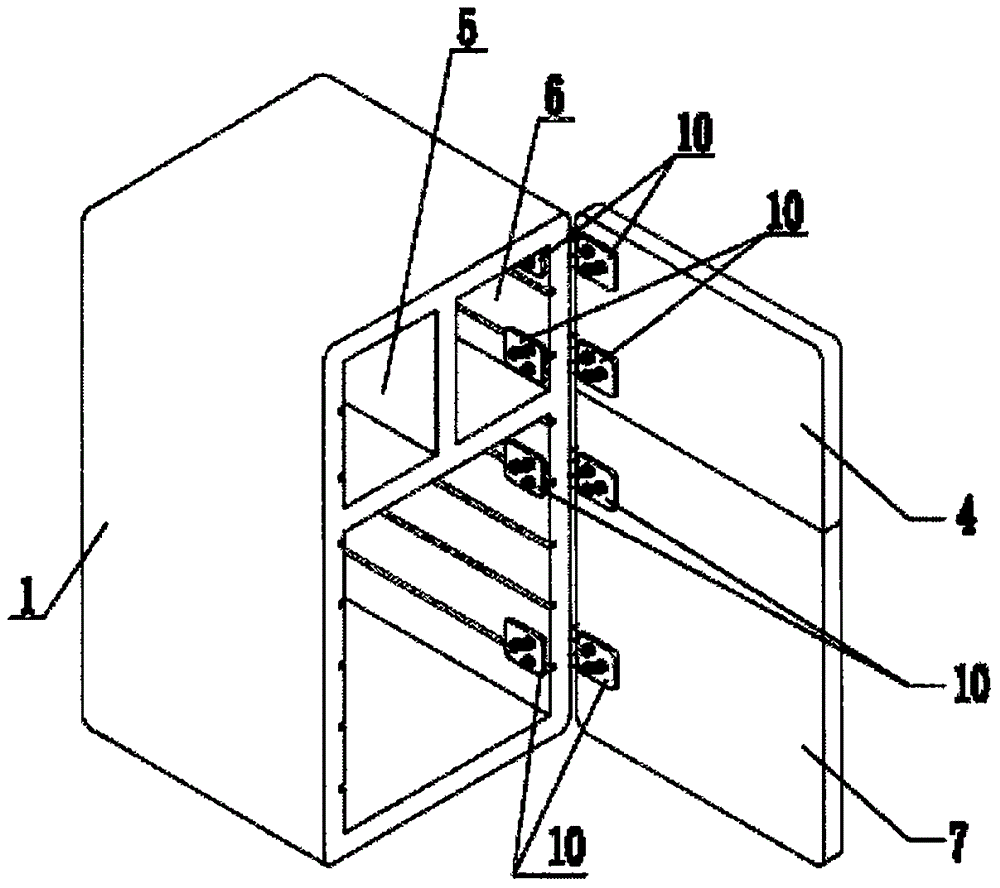

External circulation heating distribution box

ActiveCN106335711AReasonable structureGuaranteed freshnessContainers for heating foodPackaging foodstuffsTemperature controlFixed frame

The invention provides an external circulation heating distribution box. The external circulation heating distribution box comprises a heat preservation box body, a heating system, an external circulation air exchange system, an upper door, an upper left storage chamber, an upper right storage chamber, a lower door and a lower storage chamber. The heating system comprises an aluminum plate fixing frame, an aluminum plate, a heating film, a heat isolation pad, an outer shell, a heating switch, a charging port, a temperature control switch, an exhaust fan I, an outer shell bottom plate, a cable and a battery. The external circulation air exchange system is arranged above the lower storage chamber and comprises a dustproof cover, an exhaust fan II, a fan cover, a USB cable and an exhaust fan II power supply. The technical problems that distribution boxes in the prior art are unreasonable in temperature structure, non-uniform in heating, insufficient in battery capacity and unlikely to guarantee the temperature and mouthfeel of food in the long-distance long-time distribution process are solved, and the external circulation heating distribution box achieves the technical effects of being reasonable in structure and uniform in heating and enabling distributed objects to keep fresh and good mouthfeel.

Owner:北京外麦王科技有限公司

Dry laminated glass production equipment and method for producing laminated glass

The invention relates to dry laminated glass production equipment and a method for producing laminated glass. The production equipment comprises a roller furnace, an exhaust pressure roller, an edge sealing compensation furnace and an edge sealing roller which are sequentially arranged; the roller furnace includes a roller furnace body and a roller heating pipe, and the roller heating pipe is a medium wave radiation pipe; the edge sealing compensation furnace includes a compensation furnace body and compensation heating pipes located in the compensation furnace body; the compensation heating pipes are shortwave radiation pipes. By the technical scheme, the problem about film suffocation is solved, production of the laminated glass by the roller pressing process is realized and is not affected by glass thickness and glass type, and defects of the vacuum pumping production is avoided.

Owner:天津南玻节能玻璃有限公司 +1

Sounder

ActiveCN108810770AGood heat conductionAvoid Voice Coil BreakageElectrical transducersLoudspeakersEngineeringWire breakage

The invention provides a sounder which comprises a shell, a vibration system accommodated in the shell and a magnetic circuit system matched with the vibration system together. The vibration system comprises a vibration diaphragm and a voice coil combined on the vibration diaphragm; the vibration diaphragm divides an inner cavity of the shell into a front cavity and a rear cavity; the vibration diaphragm is provided with a hollow-out part; the sounder further comprises a heat dissipation part fixed at the rear cavity; the heat dissipation part extends to the front cavity by the hollow-out part; and the vibration diaphragm further comprises a connection part connected with the heat dissipation part. According to the sounder provided by the embodiment of the invention, by arranging the heatdissipation part, efficient heat conduction can be carried out between the front and rear sound cavities, so that heat of the rear cavity is rapidly conducted to the front cavity by the heat dissipation part, problems of wire breakage, wire dispersion and the like of the voice coil, which are caused by heat accumulation in the rear cavity, can be avoided, and the service life of the sounder is prolonged.

Owner:GOERTEK INC

Cool quick-drying hydrophilic polyester fiber and preparation method thereof

InactiveCN107012531AAtmospheric dyeabilityPromote absorptionElectroconductive/antistatic filament manufactureArtificial thread manufacturing machinesBreaking strengthPolyester

The invention relates to the technical field of differential chemical fiber, and provides a cool quick-drying hydrophilic polyester fiber and a processing method thereof, which aims at solving the problem of poor moisture absorbing property and poor heat absorbing property in the existing polyester fiber with cool characteristic. The cool quick-drying hydrophilic polyester fiber has the advantages that the cross section is in a cross shape; the break strength is 2.8 to 4.0cN / dtex, and the elongation at break is 18 to 30%; jade powder and perlite powder are contained; the moisture absorbing property is good, the water and steam conveying property is excellent, the heat can be quickly conducted and absorbed, the anti-ultraviolet property is realized, and the trace element and amino acid are contained.

Owner:绍兴喜能纺织科技有限公司

Wavy fin type heat exchanger and manufacturing method thereof

InactiveCN106247821AElimination of finless areasImprove heat transfer effectStationary conduit assembliesHeat exhanger sealing arrangementPulp and paper industryUltimate tensile strength

The invention discloses a heat exchanger and a manufacturing method thereof. The heat exchanger comprises a plurality of flat tubes, a plurality of groups of fins, and at least two liquid collection cavities, wherein the flat tubes and the fins are sequentially arranged at intervals; the flat tubes and the fins are bonded through a first adhesive layer; a plurality of sequentially arranged slot holes are formed in the side walls of the liquid collection cavities; the two ends of the flat tubes are inserted into the corresponding slot holes; the end parts of the flat tubes and the slot holes are bonded and sealed through a second adhesive layer; or the liquid collection cavities are formed through stacking the ends of the flat tubes; and the ends of every two adjacent flat tubes are bonded and sealed through the second adhesive layer. According to the heat exchanger, a stable and firm bonding effect is achieved between the flat tubes and the fins, and between the flat tubes and the liquid collection cavities, the sealing strength between the flat tubes and the liquid collection cavities is fully guaranteed, and the heat exchange performance of the heat exchanger can be greatly improved.

Owner:谢彦君

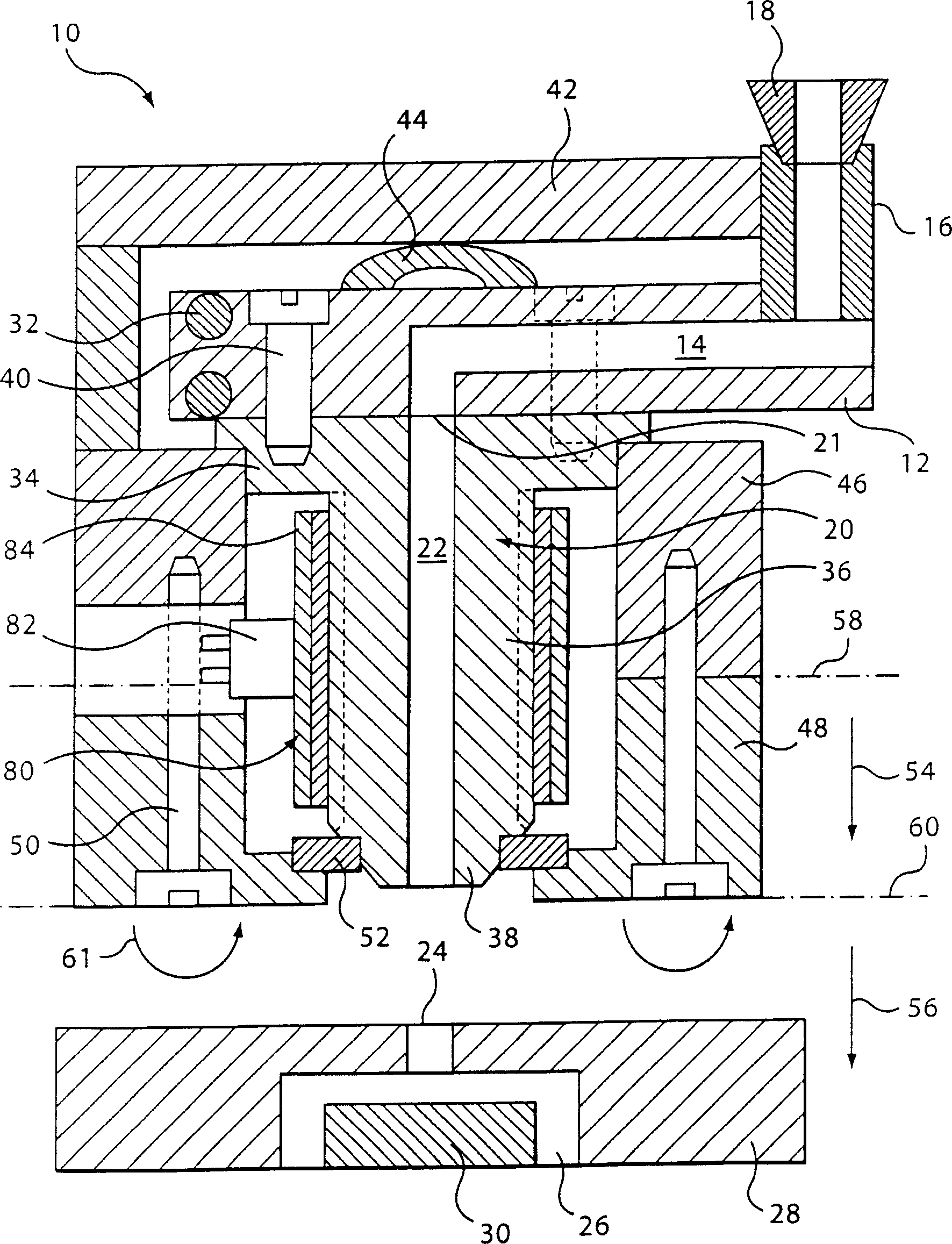

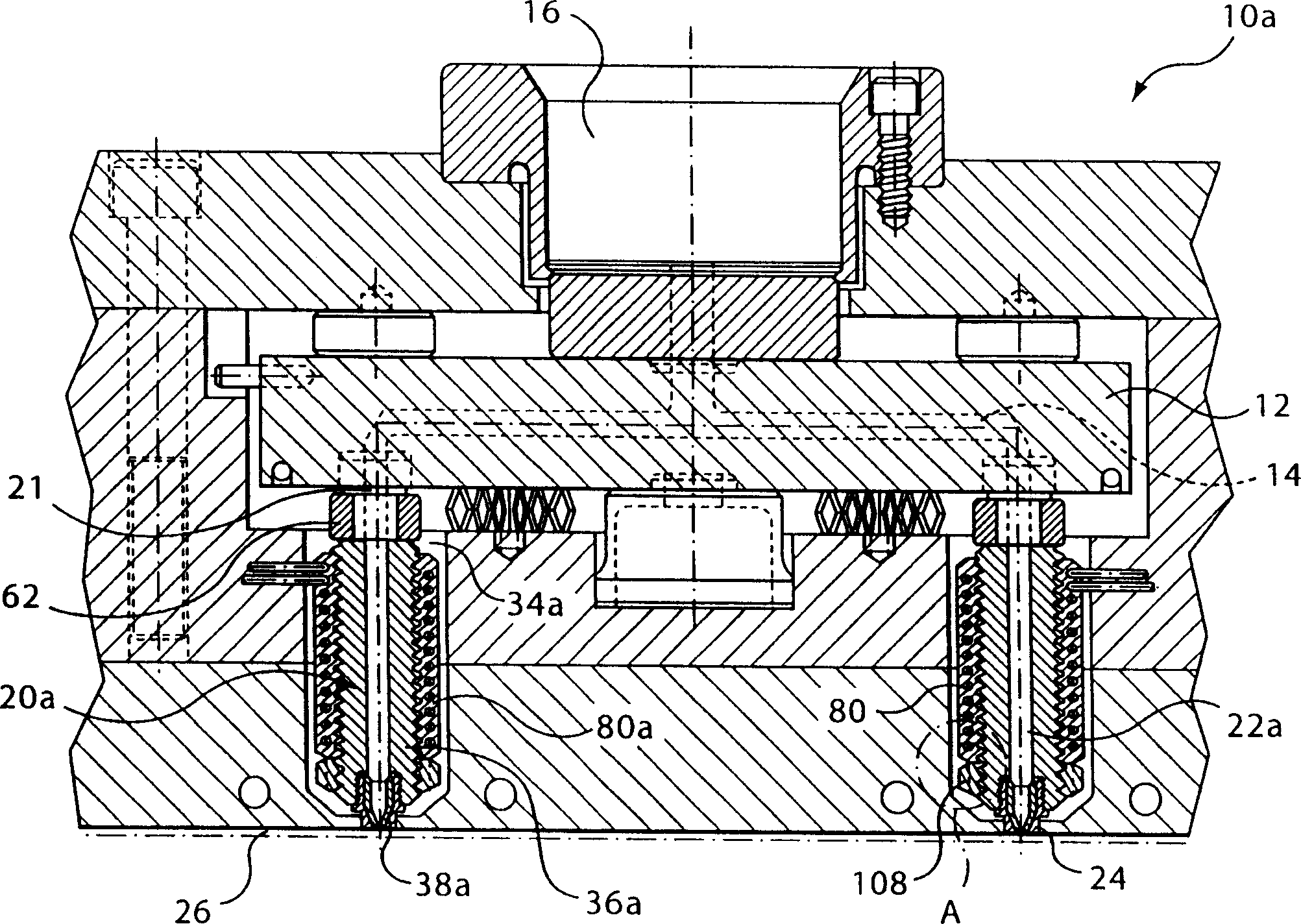

Threaded removable heater for a hot runner nozzle

A heater assembly for an injection molding apparatus comprises a heater sleeve having a threaded inner surface for engaging a threaded outer surface of a nozzle body of a nozzle or a threaded surface of a mold manifold. A clamping element such as a lock nut or a spring is provided adjacent the heater sleeve. The lock nut and / or the spring abuts the heater sleeve to force the threaded inner surface of the heater sleeve into contact with the threaded outer surface of the nozzle body. By using threads to clamp the heater to the nozzle the amount of heat transferred to the nozzle remains within an optimum range independent to the temperature of the heater.

Owner:MOLD MASTERS 2007

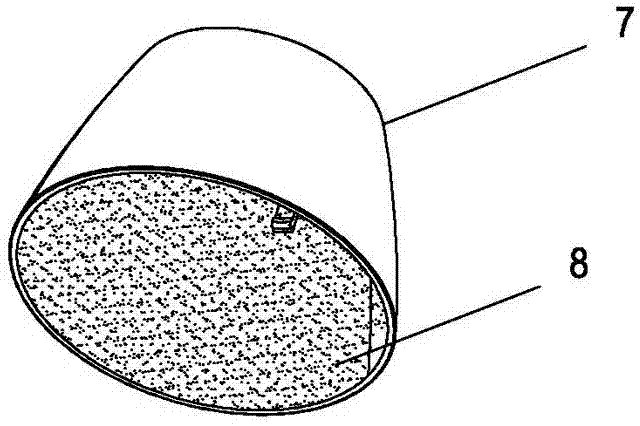

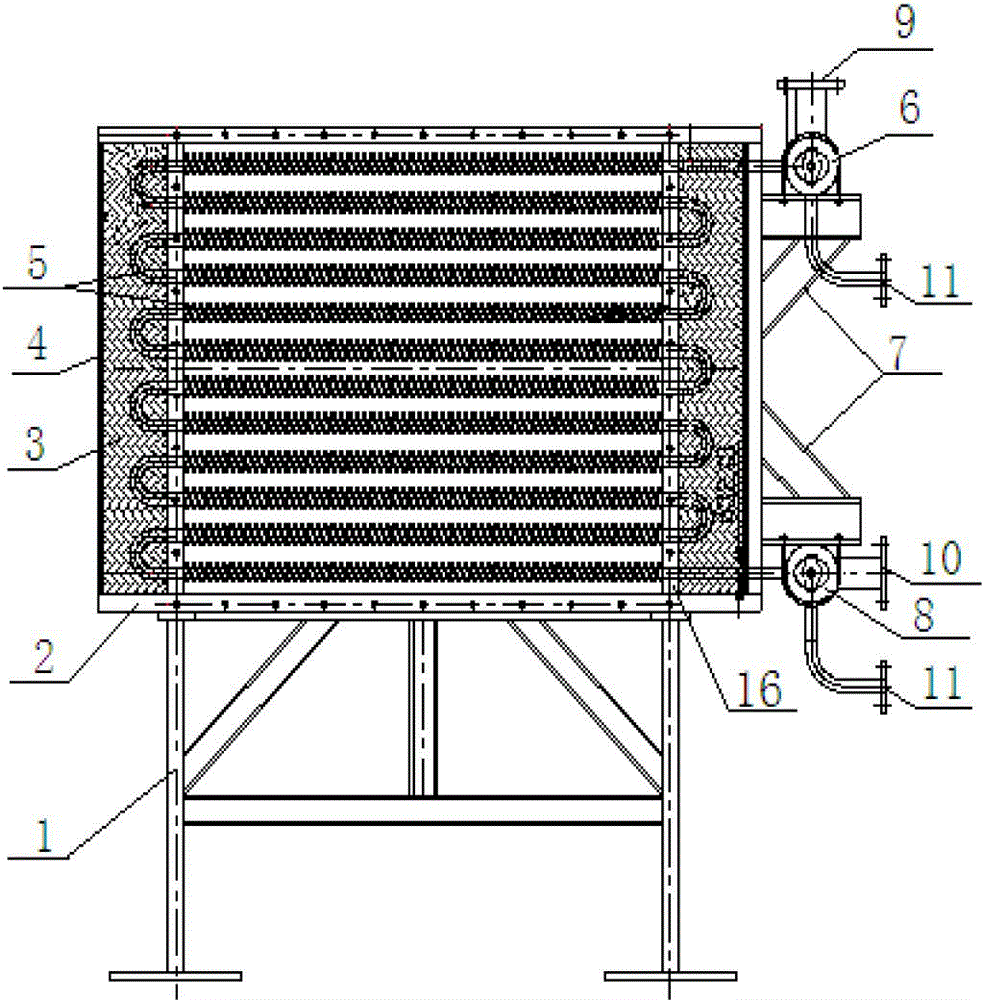

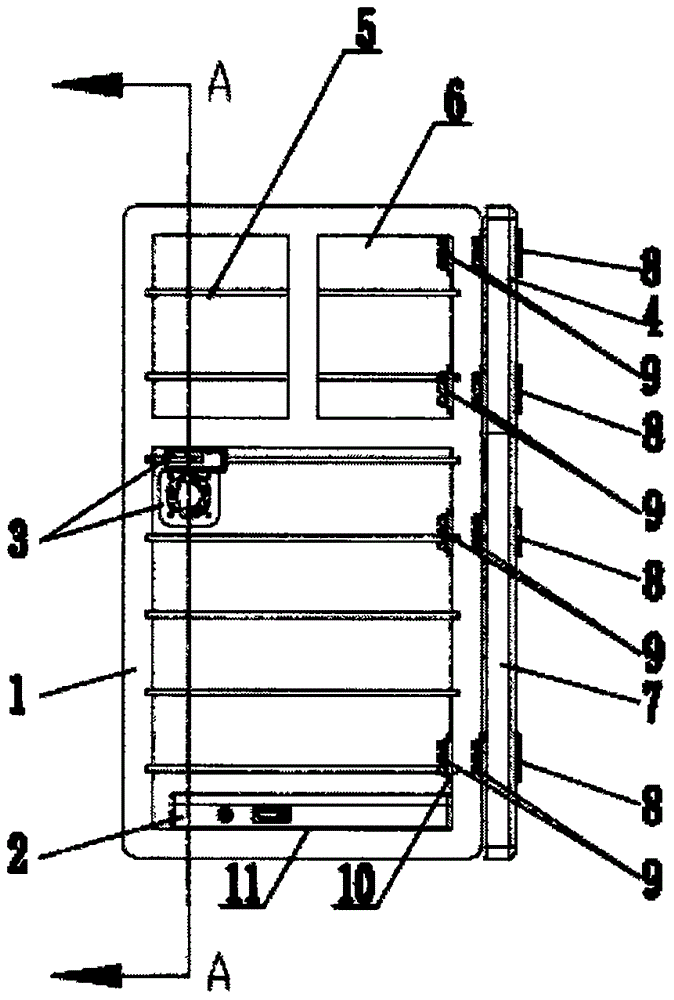

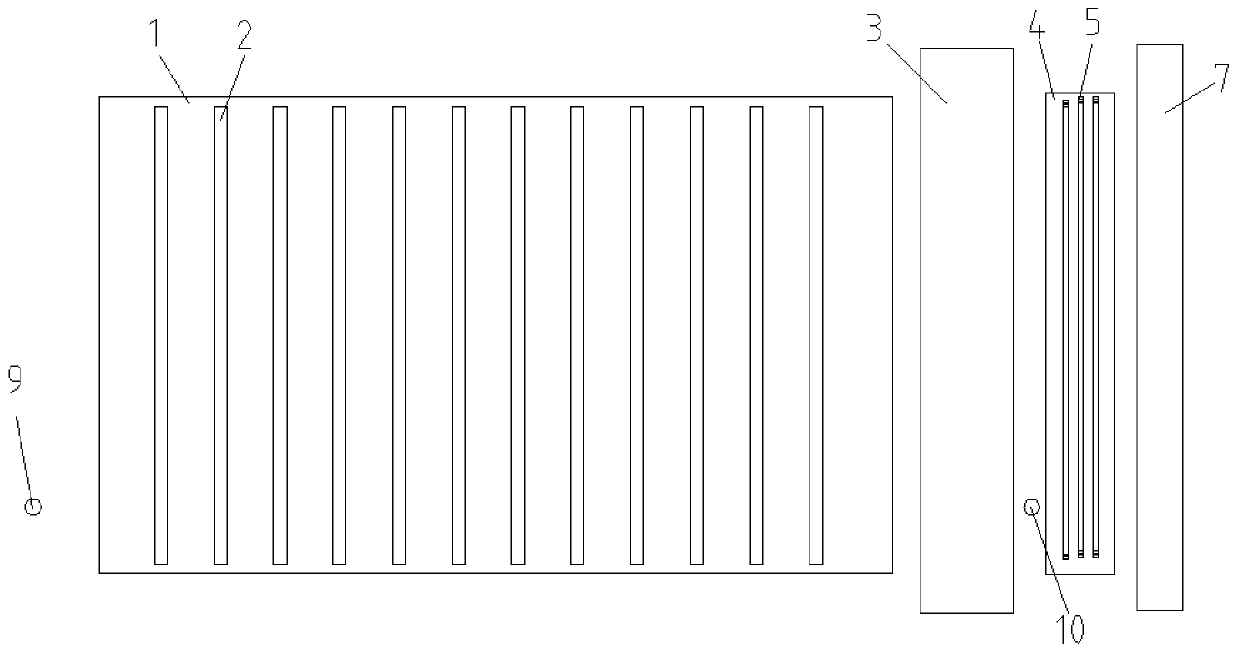

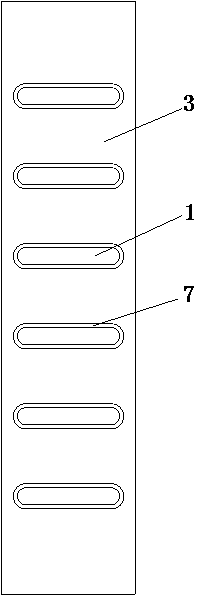

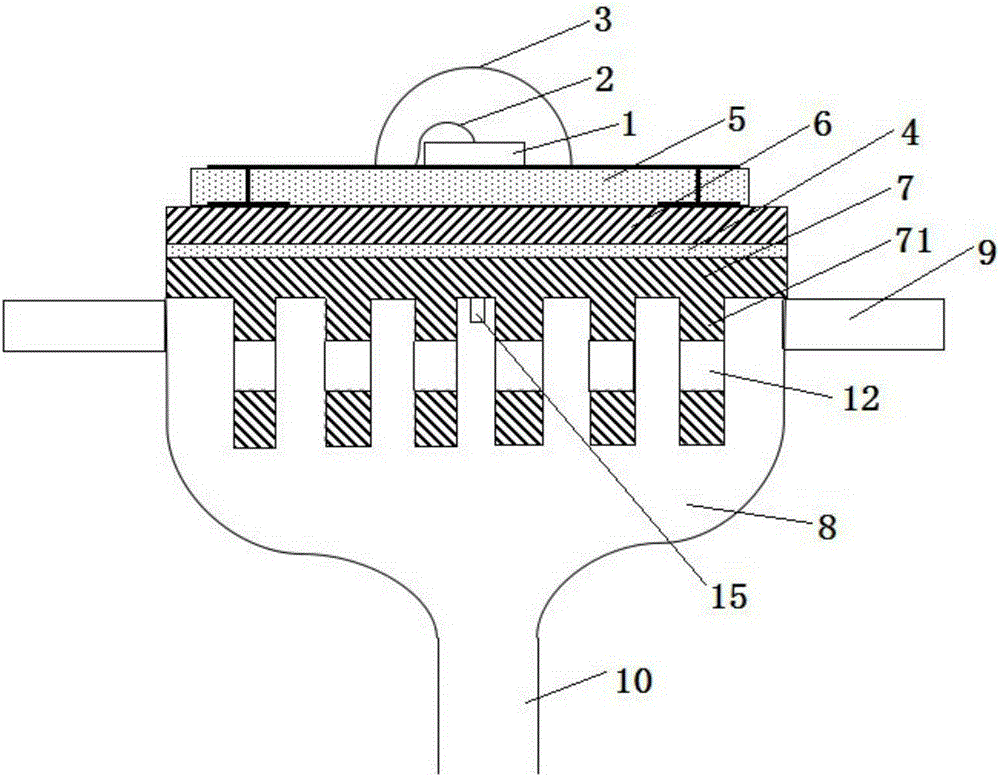

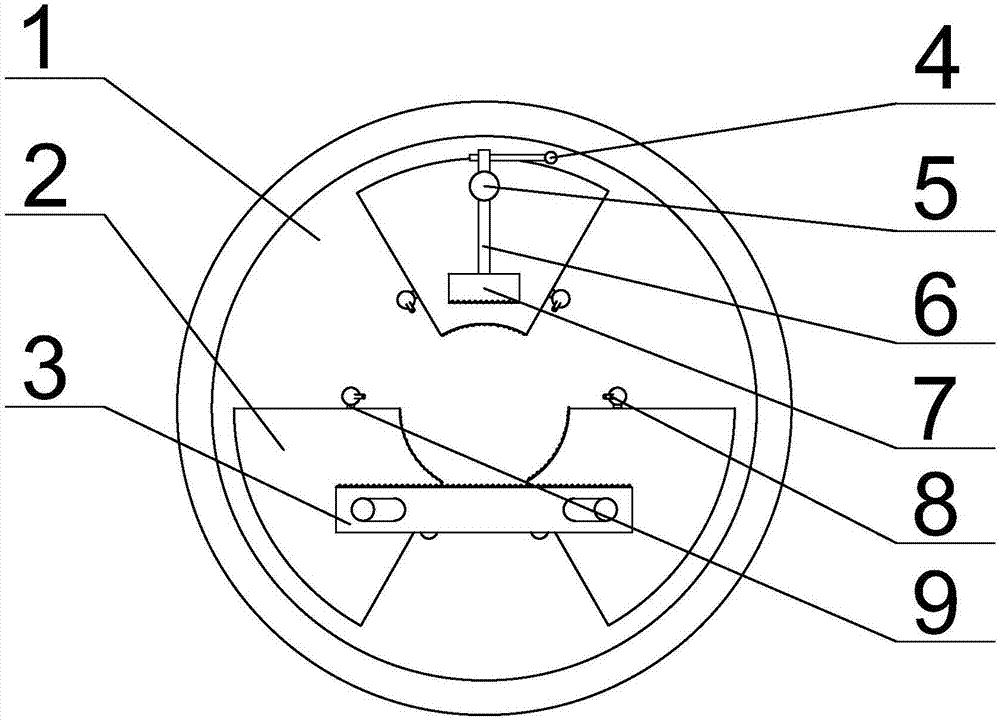

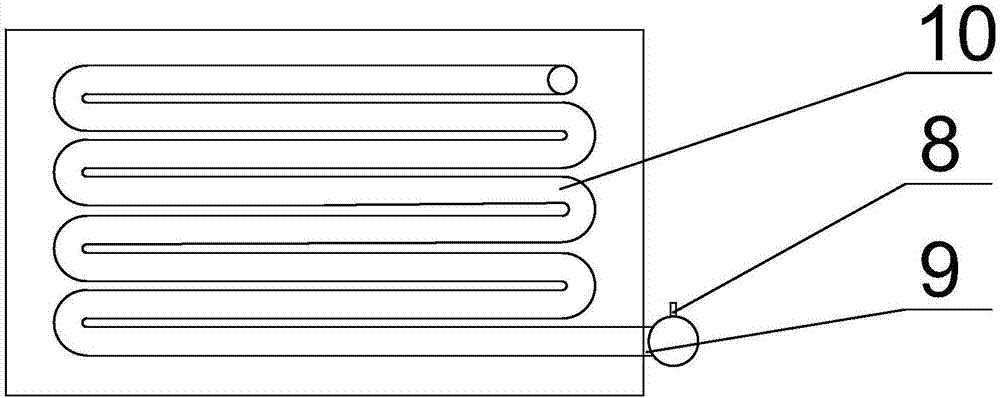

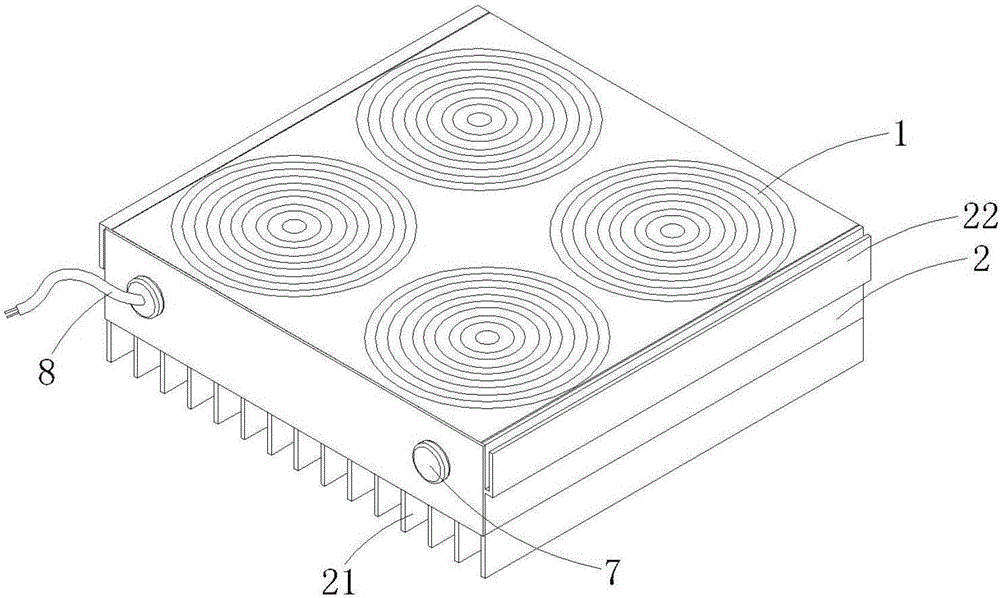

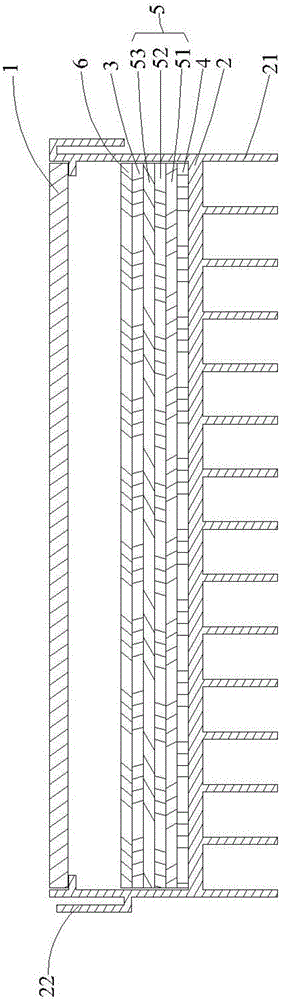

LED lamp with water-circulating heat dissipation function

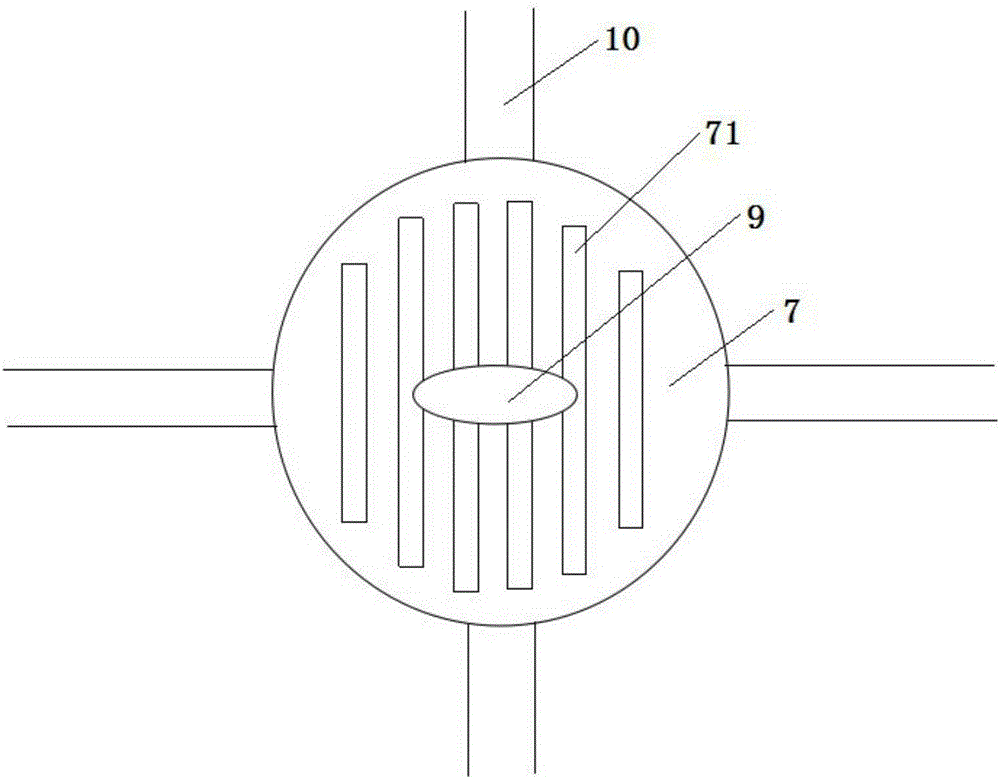

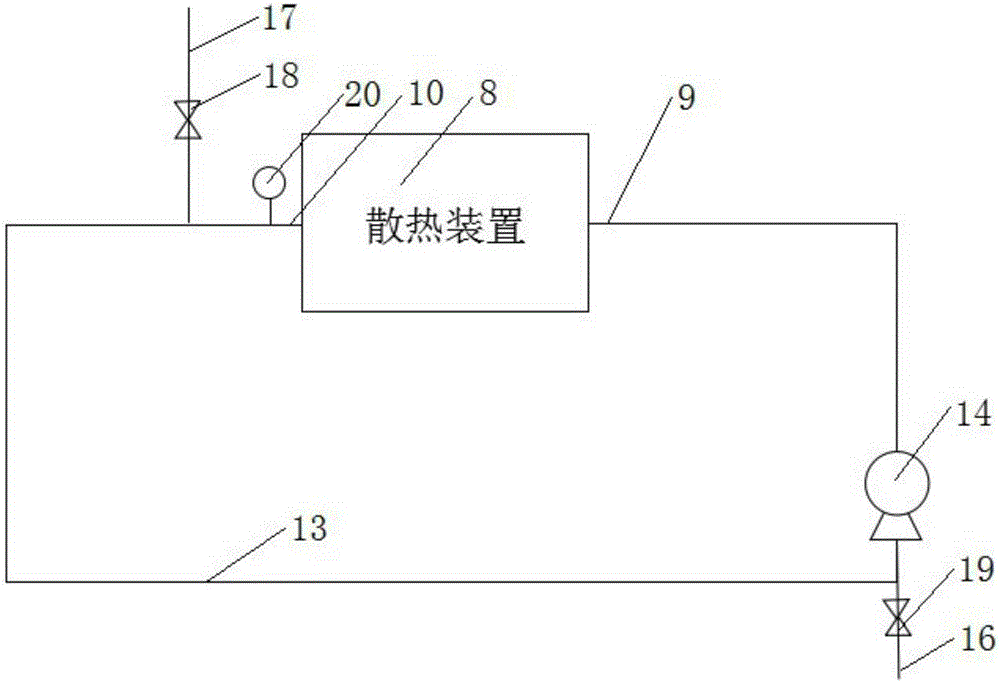

ActiveCN105221970AImprove heat absorption efficiencyEven heat absorptionPoint-like light sourceLighting heating/cooling arrangementsHeat sinkEngineering

The invention discloses an LED lamp with a water-circulating heat dissipation function. The LED lamp comprises an LED wafer (1), a connecting wire (2), a lens (3), an LED wafer substrate (5), a system circuit board (6) and a heat dissipation fin (7), wherein a heat dissipation device (8) used for heat dissipation is arranged below the heat dissipation fin (7); the water inlet (9) of the heat dissipation device (8) is positioned under the heat dissipation device (8); and two or more water outlets (10) are arranged the heat dissipation device (8) and uniformly distributed on the side surface of the heat dissipation device (8). The LED lamp has the beneficial effects that the water inlet is arranged under the heat dissipation device and the water outlets are arranged on the side surface of the heat dissipation device, and water flows in from below and flows out from the surroundings, so that water flow of relative low temperature is formed from the middle to both sides of the heat dissipation fin, heat on the heat dissipation fin is brought away, uniform heat absorption of the water flow is achieved, heat absorption efficiency of the water flow is improved, and all regions of the heat dissipation fin can keep the same and stable temperature.

Owner:JIANGSU TIWIN OPTO ELECTRONICS TECH

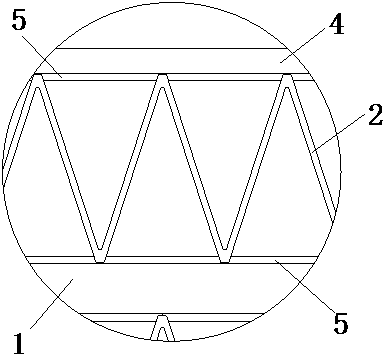

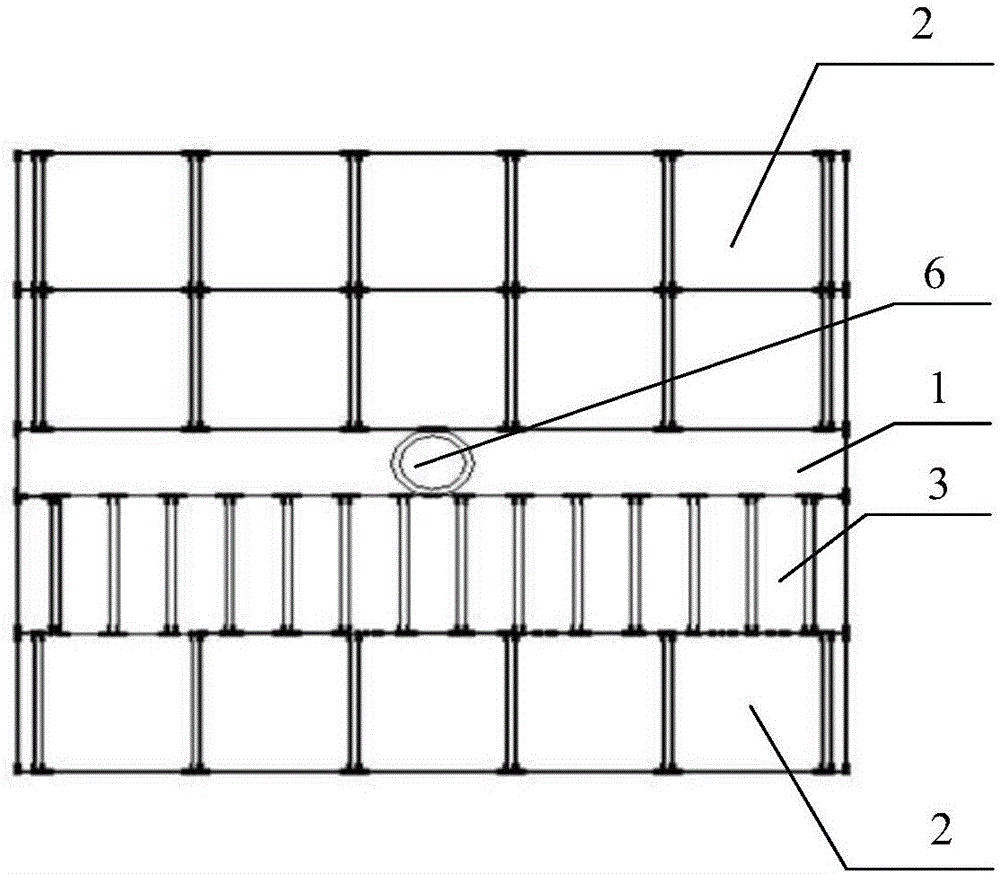

Novel hybrid-driven energy-saving air conditioning terminal

InactiveCN106369674ASolve the problem of enhanced heat transferRealize heatingLighting and heating apparatusSpace heating and ventilation detailsMetallic materialsEngineering

The invention relates to a novel hybrid-driven energy-saving air conditioning terminal which comprises more than one group of plate-shaped heat transport devices and more than one parallel channel type fin heat-exchange structure combined with the plate-shaped heat transport devices, wherein the plate-shaped heat transport devices adopt plate-shaped structures that are formed by extruding a metal material, more than two micro-tubes are arranged side by side in each plate-shaped structure, and heat exchange and transport are performed through a flowing medium in the micro-tubes; the parallel channel type fin heat-exchange structures are combined with plate surfaces of the plate-shaped heat transport devices; each parallel channel type fin heat-exchange structure is provided with a plurality of air convection channels which are arranged side by side in the length direction of the corresponding plate-shaped heat transport device in sequence; and each parallel channel type fin heat-exchange structure comprises a parallel channel type sparse fin heat-exchange structure and a parallel channel type dense fin heat-exchange structure. According to the novel hybrid-driven energy-saving air conditioning terminal, heat exchange is enhanced by the plate-shaped heat transport devices with the specific structures, and natural air convection heat exchange and forced air convection heat exchange can be performed as needed through the parallel channel type fin heat-exchange structures combined with the plate surfaces of the plate-shaped heat transport devices, so that the heat exchange efficiency is improved, effective heating, refrigeration and dehumidification functions are realized, the novel hybrid-driven energy-saving air conditioning terminal has the advantages of low cost and zero maintenance, and fine management and energy saving can be realized.

Owner:赵耀华

Water-cooled fixture of grinding machine

ActiveCN107457700AEfficient heat conductionGrinding work supportsGrinding/polishing safety devicesSpray nozzleEngineering

The invention relates to a fixture, in particular to a water-cooled fixture of a grinding machine. The water-cooled fixture of the grinding machine comprises a fixture bottom plate, a plurality of claws, fixing blocks, clamping blocks, screws, clamping columns, tightening arms and a water-cooling device, wherein the claws are arranged on the upper end surface of the fixture bottom plate and are slidably connected with the fixture bottom plate; tracks of the claws which are slidably connected with the fixture bottom plate are intersected in the center of the upper end surface of the fixture bottom plate; two ends of each fixing block are slidably connected with the upper end surfaces of the two corresponding claws separately; the clamping columns are arranged on the upper end surfaces of the claws; the screws penetrates through the clamping columns and are in threaded connection with the clamping columns; each tightening arm is arranged at one end of the corresponding screw; each clamping block is arranged at the other end of the corresponding screw; the water-cooling device comprises a nozzle, an output head and a water-cooling loop; and the water-cooling loop is arranged in the claws and comprises a pressure pump and a cooling tube. The water-cooled fixture of the grinding machine has the beneficial effects of capability of clamping and positioning different workpieces, simplicity in operation, high reliability and the like.

Owner:湖州铭灏机械有限公司

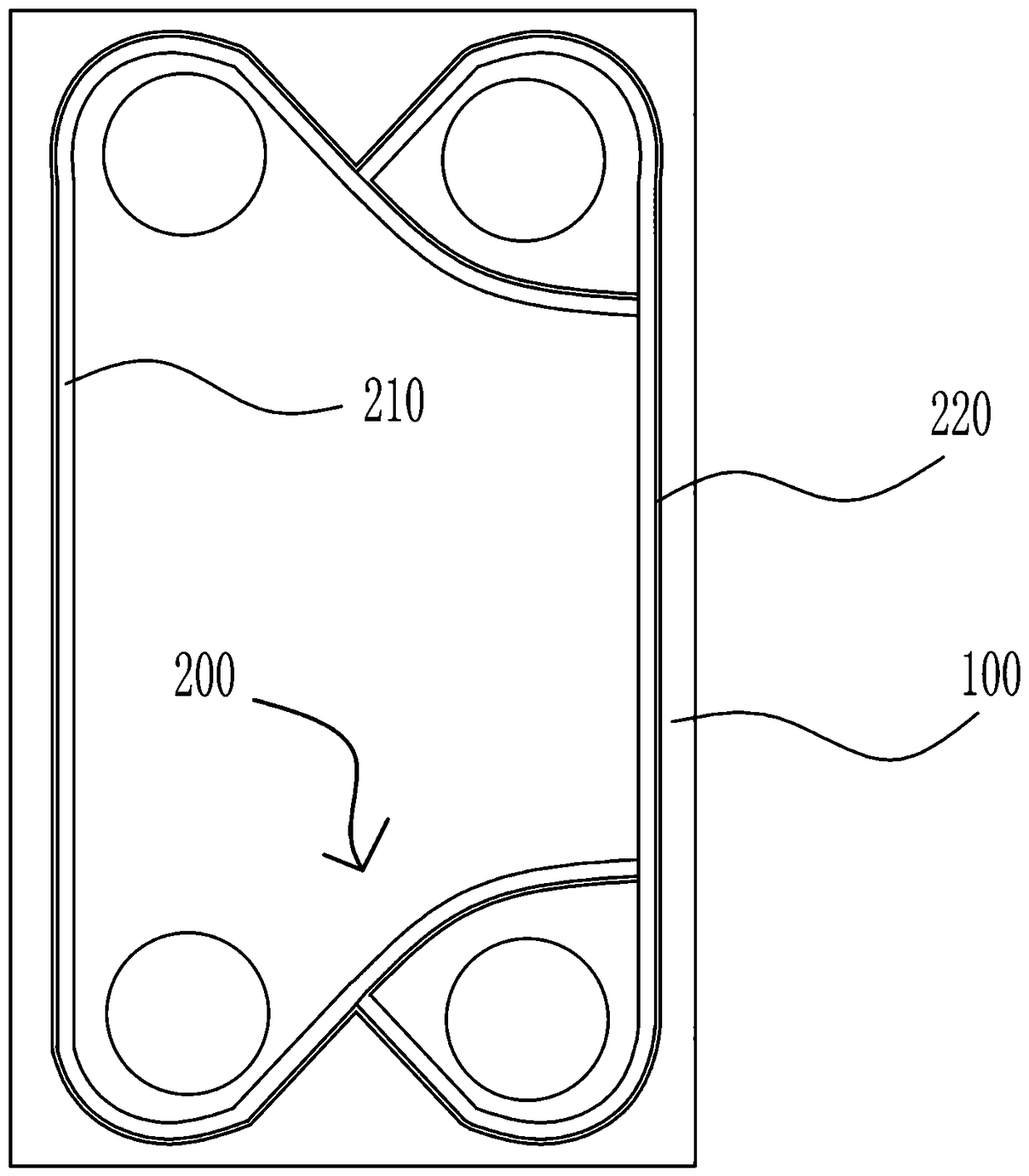

Plate type heat exchanger with good sealing property

PendingCN109141095AImprove rigidityIncrease tightnessHeat exhanger sealing arrangementHeat exchanger fasteningPlate heat exchangerButt joint

The invention relates to the technical field of plate type heat exchangers, and discloses a plate type heat exchanger with a good sealing property. The plate type heat exchanger includes a plurality of heat exchanging plate pieces alternately flipped and stacked with each other and sealing gaskets located between every adjacent heat exchanging plate pieces, each sealing gasket comprises a first sealing part and a second sealing part which is located on one side of the first sealing part and integrally formed with the first sealing part, and each first sealing part comprises an embedded arc-shaped bottom, a clamping groove part and a flow stopping top from bottom to top; and one sides of the second sealing parts are in butt joint with one sides of the flow stopping tops and formed integrally, the other sides, opposite to the flow stopping tops, of the second sealing parts are downwardly provided with flanges, and each heat exchanging plate piece is provided with an embedded arc-shaped groove matched with the correspondingly first sealing part and a positioning sealing groove matched with the correspondingly flange. According to the plate type heat exchanger with the good sealing property, installation is simple, the tightness between the heat exchanging plate pieces is good, the sealing gaskets are easier to suffer stress evenly, and sealing is firm.

Owner:ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

Solar energy and temperature difference power generation device

InactiveCN106329999AReduce conductionConduction helpsPhotovoltaicsGenerators/motorsHeat conductingTemperature difference

A solar photoelectric module sequentially comprises a gallium arsenide solar cell, a first quick heat conducting device, a temperature difference power generation unit, a second quick heat conducting device and a radiator from top to bottom. A solar energy and temperature difference power generation device comprises a radiator, an insulating layer and a solar power generation panel, the insulating layer is arranged on the surface of the radiator, and at least one temperature difference power generation chip is arranged between the insulating layer and the solar power generation panel. According to the solar energy and temperature difference power generation device, one or more temperature difference power generation chips not only can be fixed between the solar power generation panel and the surface of the radiator in a module mode, but also can be fixed in an integrated mode to form a modularization device and especially can be freely combined through U-shaped slots formed in the two sides of the radiator; the solar energy and temperature difference power generation device not only is suitable for large-batch industrialized production, but also is high in power generation efficiency, stable in performance and good in market prospect.

Owner:ZHEJIANG GEMCORE TECH

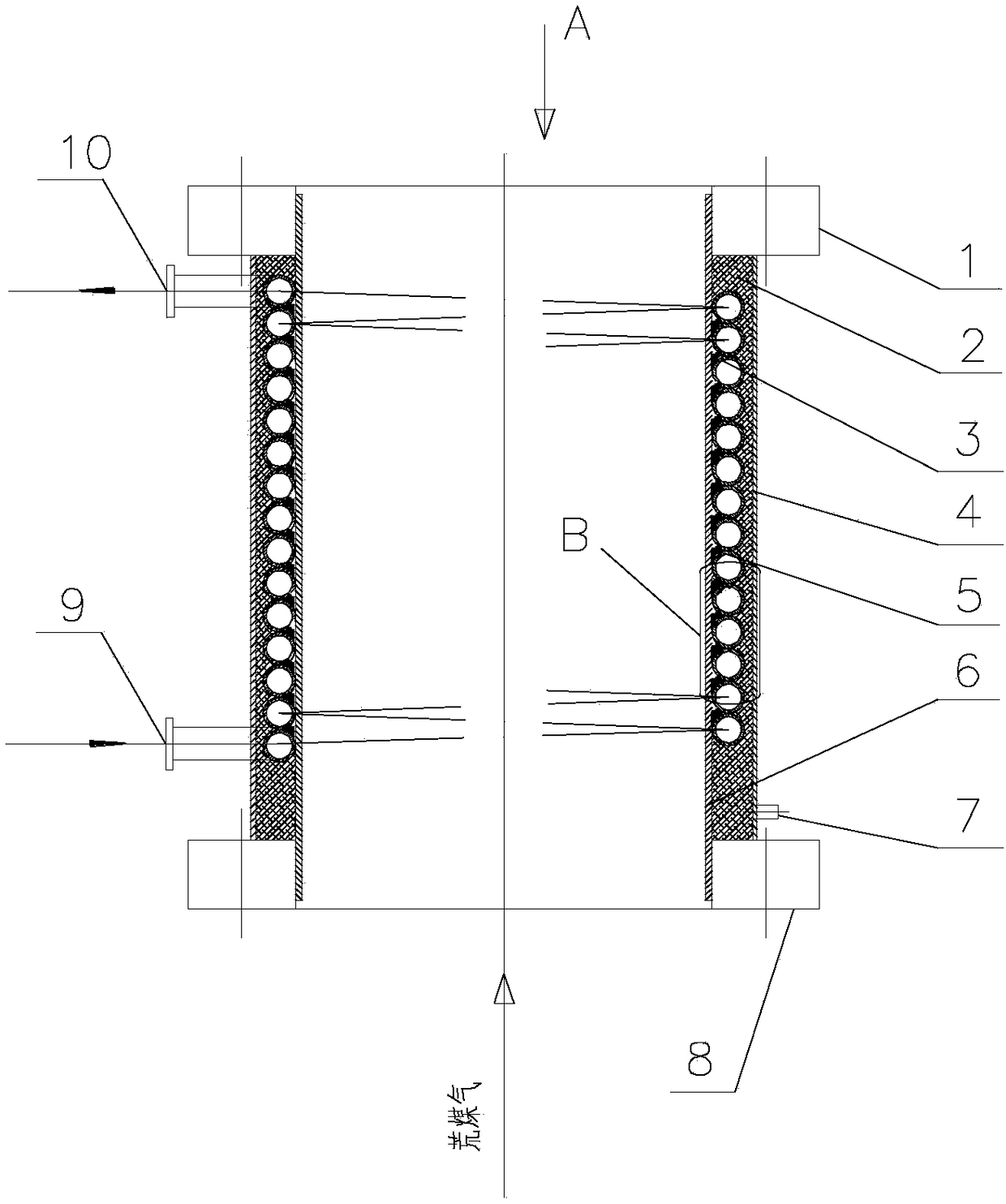

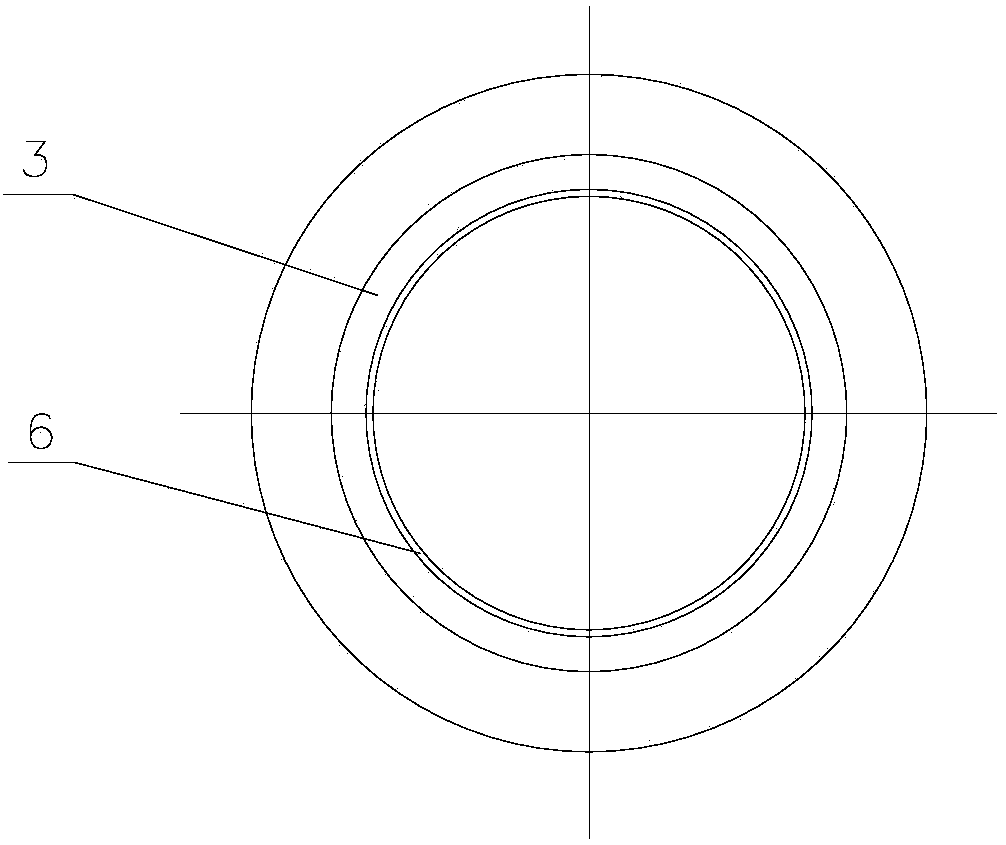

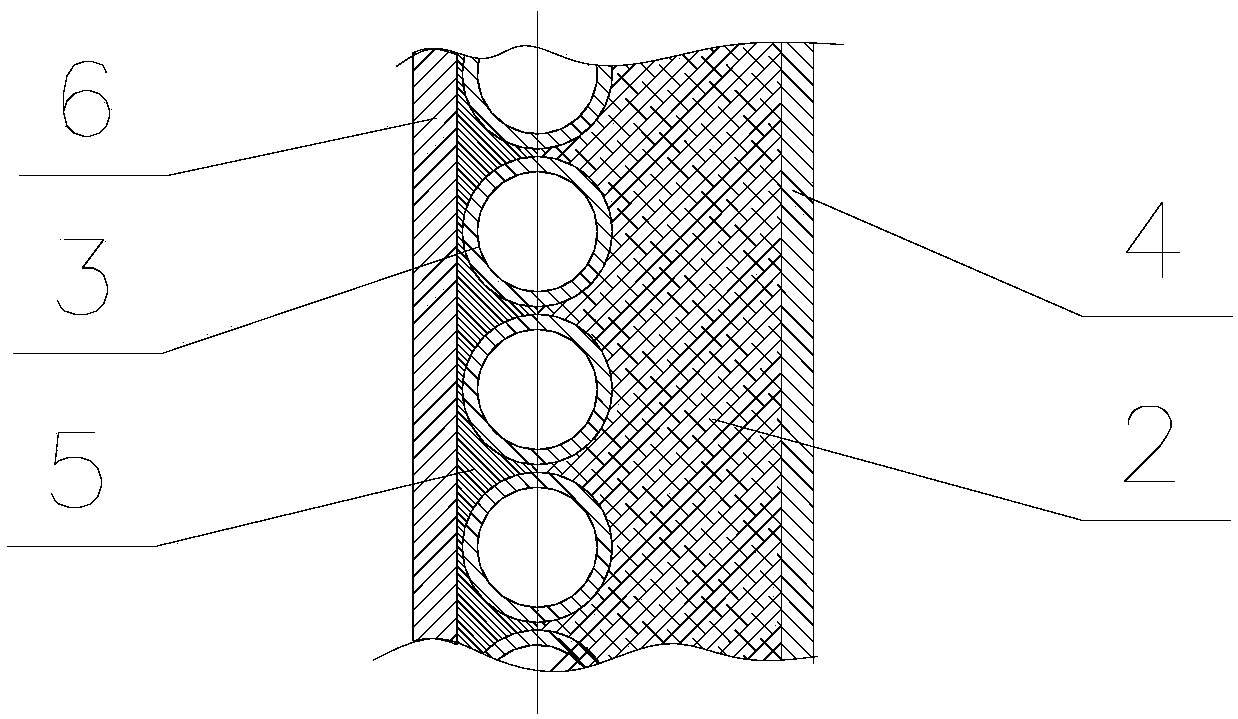

Spiral coil conduction type raw coke oven gas waste heat recovery equipment

PendingCN108467737AImprove securityFacilitate production operation managementEnergy inputIndirect heat exchangersWaste heat recovery unitTar

The invention discloses spiral coil conduction type raw coke oven gas waste heat recovery equipment. The spiral pipe conduction type raw coke oven gas waste heat recovery equipment comprises an ascending pipe inner barrel, an ascending pipe outer barrel and a heat transfer coil, wherein connecting flanges are arranged at the upper end and the lower end of the ascending pipe inner barrel and the ascending pipe outer barrel, the heat transfer coil is spirally wound on the outer side of the ascending pipe inner barrel, a heat transfer base plate is arranged between the heat transfer coil and theascending pipe inner barrel, the inner wall of the heat transfer base plate is tightly fitted with the outer wall of the ascending pipe inner barrel, the shape of the outer wall of the heat transfer base plate is matched with that of the heat transfer coil spirally wound on the heat transfer base plate, an insulating layer fills between the heat transfer coil and the ascending pipe outer barrel, and a vent nozzle is arranged at the bottom of the ascending pipe outer barrel. Compared with the prior art, the spiral coil conduction type raw coke oven gas waste heat recovery equipment has the beneficial effects that the heat transfer condition between the heat transfer coil and the ascending pipe inner barrel is improved, and the recovery rate of the heat of the raw coke oven gas is increased;the phenomenon that the tar in the raw coke oven gas is condensed on the cold wall is avoided; and the manufacturing cost of the waste heat recovery equipment is reduced.

Owner:樊晓光

Temperature equalization plate and foam metal compounded radiator

PendingCN107202509AReduce volumeSimple structureIndirect heat exchangersHeat exchange apparatusAluminiumManufacturing engineering

The invention relates to a temperature equalization plate and foam metal compounded radiator. An aluminum bottom plate, a copper column heat pipe, temperature equalization plates and foam metal are included. Integration of the aluminum bottom plate is achieved through the forging process, surface nickel plating is conducted, and welding is easy; and a through hole is formed in the aluminum bottom plate, the copper column heat pipe is embedded, and the embedment manner is welding or riveting. The temperature equalization plates are copper temperature equalization plates or aluminum temperature equalization plates. The aluminum bottom plate and the temperature equalization plates are welded into a whole. The temperature equalization plates are arrayed in radiating square column cracks in the upper surface of the aluminum bottom plate in an even distribution manner. The width of each radiating square column crack is the same as the thickness of each temperature equalization plate. Radiating square columns and the temperature equalization plates are in tight fit or are welded to be integrated. The foam metal is foam copper or foam aluminum, and the foam metal and the temperature equalization plates are attached through a welding process.

Owner:LAIDE ELECTRONICS WUXI CITY

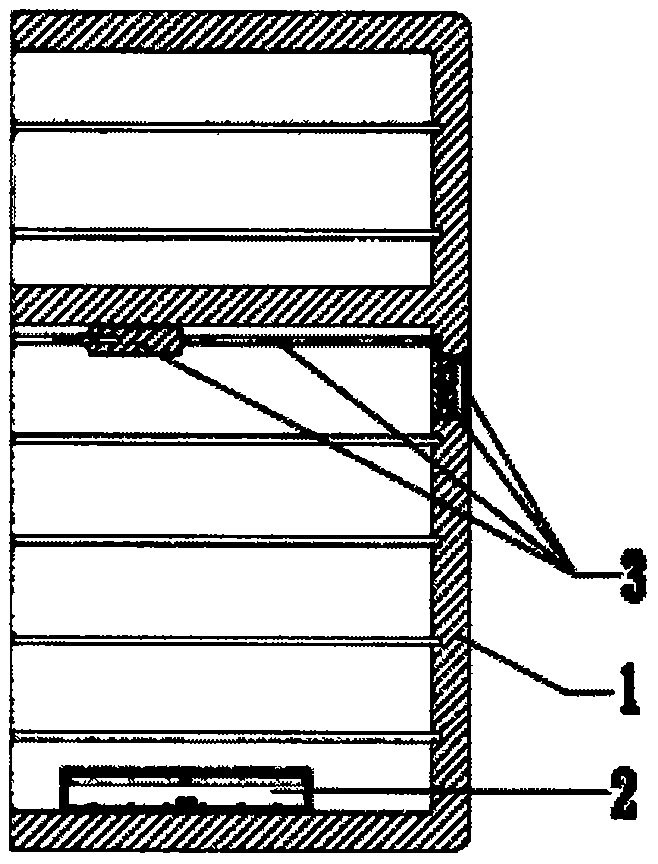

Inner circulation heating distribution box

ActiveCN106241067AReasonable structureHeating evenlyContainers for heating foodContainers preventing decayTime distributionHeating system

The invention provides an inner circulation heating distribution box. The inner circulation heating distribution box comprises a heat preservation box body, an inner circulation heating system, an inner circulation dehumidifying system, an upper layer door, an upper layer left storage chamber, an upper layer right storage chamber, a lower layer door and a lower layer storage chamber; the inner circulation heating system is arranged below the lower layer storage chamber, the inner circulation dehumidifying system is arranged above the lower layer storage chamber and comprises a rectangular top plate, a rectangular frame, a dehumidifying device, an exhaust fan II, a cable II, an exhaust fan II power source, a charging port II and an exhaust fan II switch. The technical problems that in the prior art, the distribution box is unreasonable in structure and not even in heating, the battery capacity is not enough, and in the remote long-time distribution process, the temperature and the taste of food can be difficultly ensured are solved. The technical effects that the distribution box is reasonable in structure and uniform in heating, and distributed objects are fresh and good in taste are achieved.

Owner:北京外麦王科技有限公司

SPC lock catch floor structure facilitating heat conduction of floor heating and installation technology thereof

ActiveCN113123554AClosely connectedImprove structural stabilityFlooring insulationsRenewable energy source integrationStructural engineeringMechanical engineering

Owner:ZHEJIANG CHANGXING SENDA BAMBOO & WOOD PRODCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com