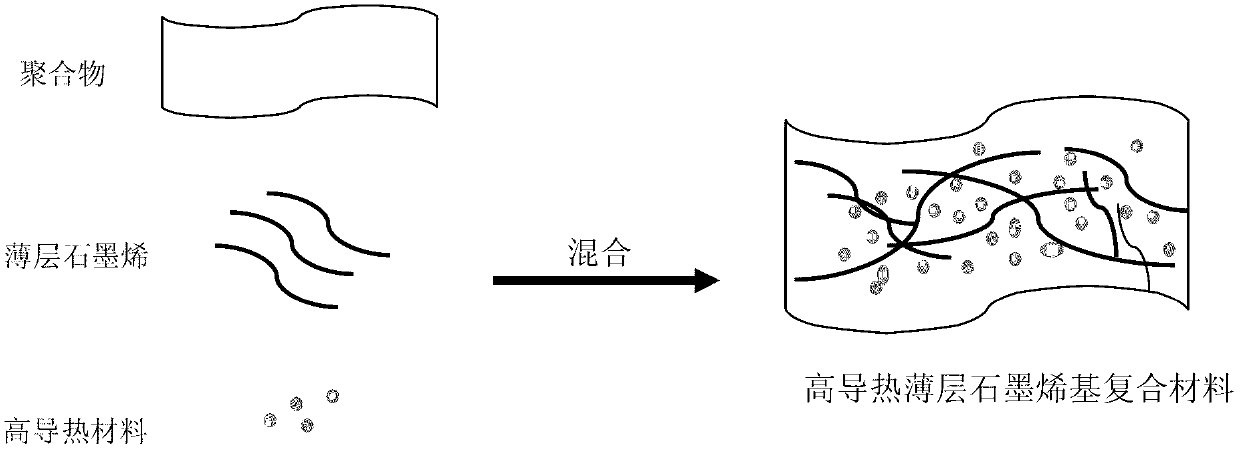

High heat-conducting thin graphene-based composite material, as well as preparation method and application thereof

A technology of thin-layer graphene and composite materials, applied in the field of material science, can solve the problems of unsatisfactory performance, large amount of addition, high cost, etc., and achieve the effects of low cost, good mechanics, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of graphene / graphite / acrylic resin thermally conductive composite

[0026] 1) Take 1g of thin-layer graphene, add it to 28g of acrylic resin, stir it mechanically for 15 minutes, add 5g of graphite flakes and continue mechanical stirring for 45 minutes to obtain a thermally conductive compound, process the compound into a film, and form a thermally conductive adhesive , thermal conductivity greater than 1.5w / mK.

[0027] 2) Take 1.5g thin-layer graphene, add it to 25g acrylic acid resin, stir mechanically for 15 minutes, add 13.5g graphite sheet and continue stirring for 45 minutes to obtain a thermally conductive resin compound, and process the compound into a film , forming a thermally conductive adhesive with a thermal conductivity of 2W / mK.

Embodiment 2

[0028] Example 2 Preparation of graphene / magnesia / silicone rubber thermally conductive compound

[0029] 1) Add 0.5g thin-layer graphene to 50g silicone rubber, add 9.5g magnesium oxide powder after mechanical stirring for 15 minutes, continue mechanical stirring for 45 minutes, then add 10g curing agent, and cure at 70°C for 12 hours to obtain a thermally conductive compound things. The compound is processed into a thermal pad with a thermal conductivity greater than 3W / mK

[0030] 2) Add 1g of thin-layer graphene to 45g of silicone rubber, stir mechanically for 15 minutes, add 9g of magnesium oxide powder, continue stirring for 45 minutes, then add 9g of curing agent, and cure at 70°C for 12 hours to obtain a thermally conductive silicone rubber compound . The compound is processed into a thermal pad with a thermal conductivity greater than 3.5W / mK.

Embodiment 3

[0031] Embodiment 3 Graphene / aluminum oxide / epoxy resin thermally conductive compound

[0032] 1) Add 1.5g of thin-layer graphene to 50g of epoxy resin, stir mechanically for 15 minutes, add 8.5g of alumina, continue stirring for 45 minutes, add 50g of curing agent, and cure for 12 hours to obtain an epoxy resin thermally conductive compound . The compound is processed into a block, and the thermal conductivity is greater than 1.5W / mK

[0033] 2) Add 1g of thin-layer graphene to 60g of epoxy resin, stir mechanically for 15 minutes, add 9g of alumina, continue stirring for 45 minutes, add 60g of curing agent, and cure for 12 hours to obtain an epoxy resin thermally conductive compound. The compound is processed into a block, and the thermal conductivity is greater than 1.2W / mK.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com