Microgravity environment-based spray cooling loop device

A spray cooling and microgravity technology, which is applied in cooling/ventilation/heating transformation, transportation and packaging, space navigation equipment, etc., to achieve the effect of occupying a small space, simple structure and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The spray cooling circuit device based on the microgravity environment of the present invention will be described in detail below with reference to the accompanying drawings.

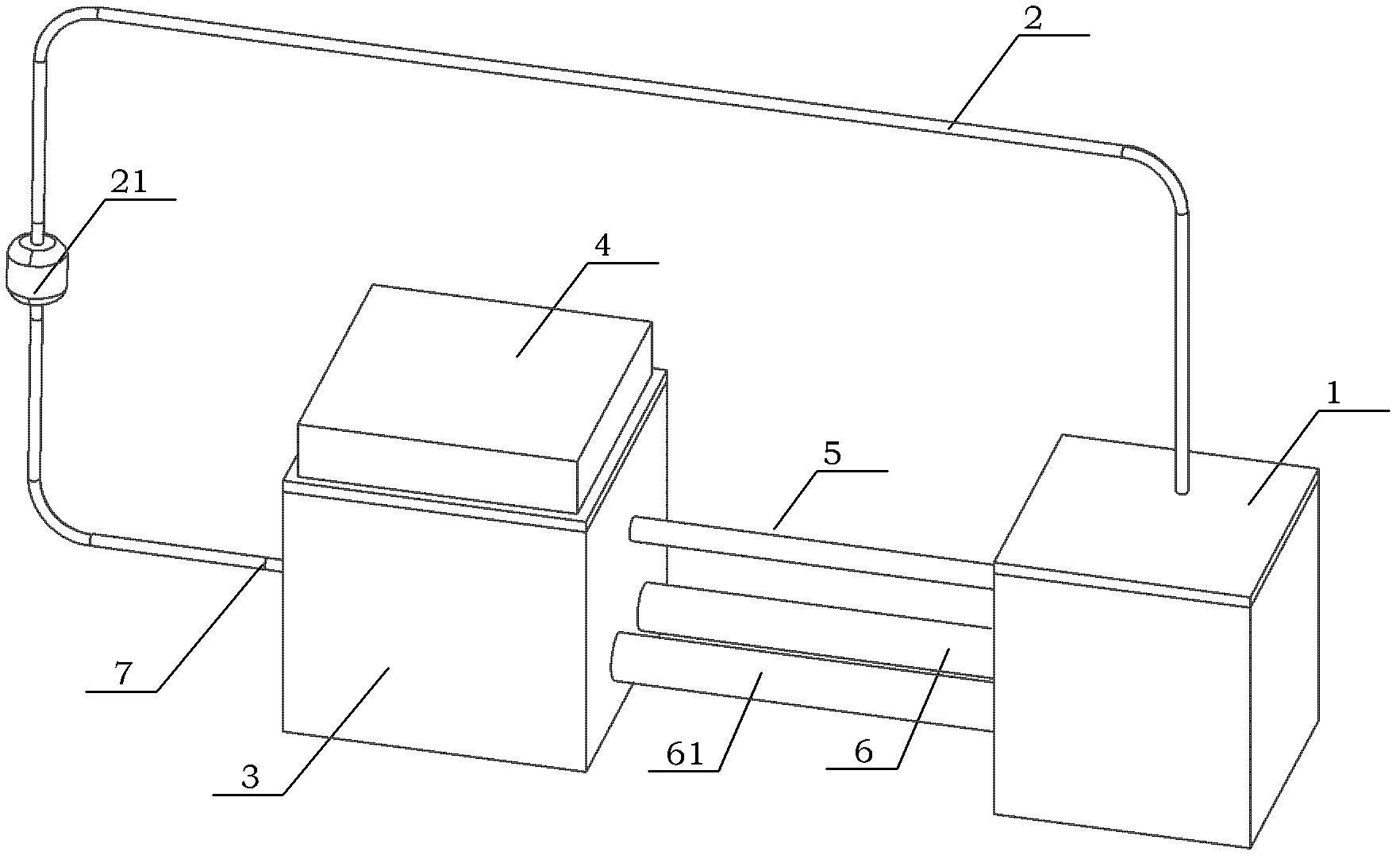

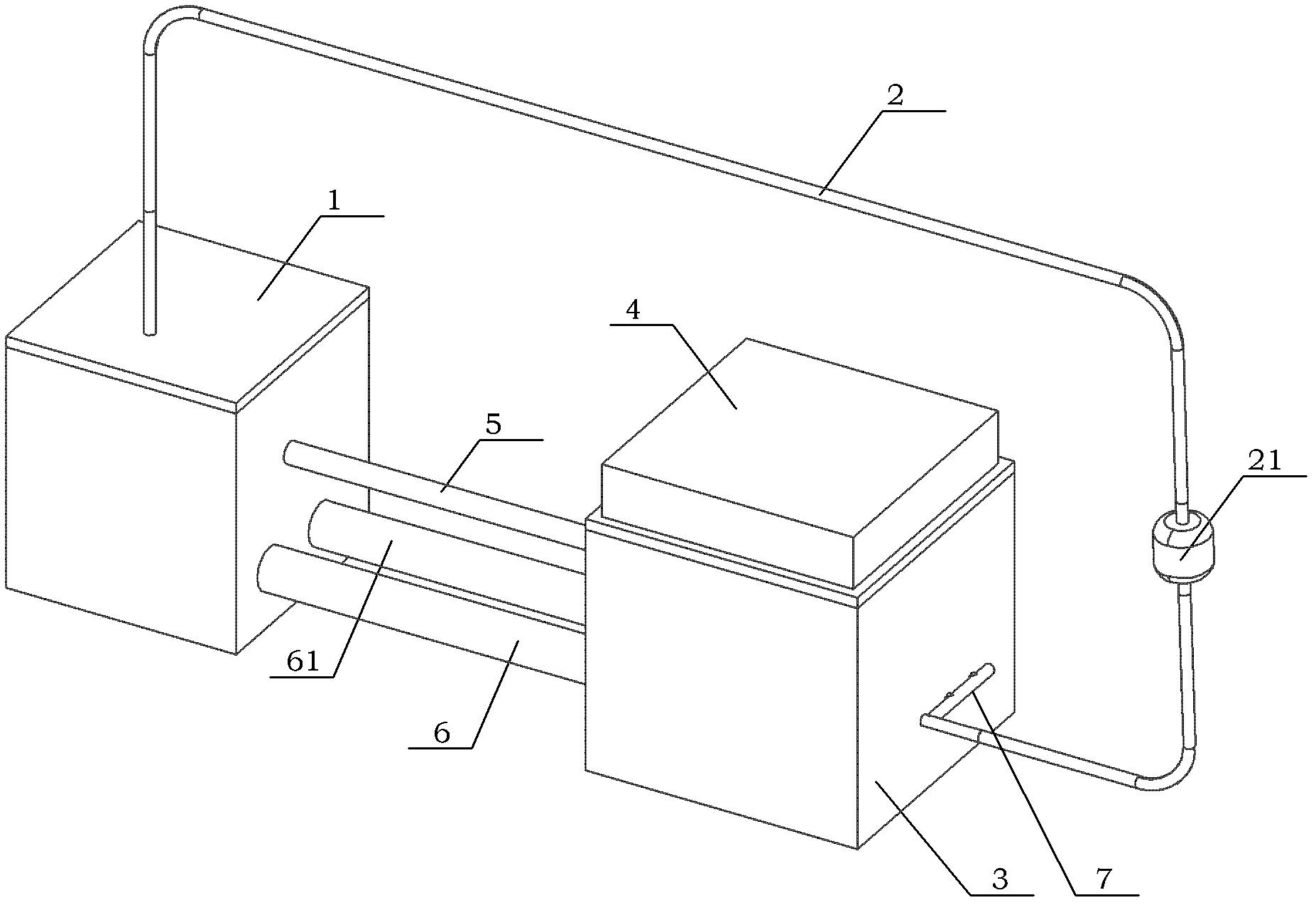

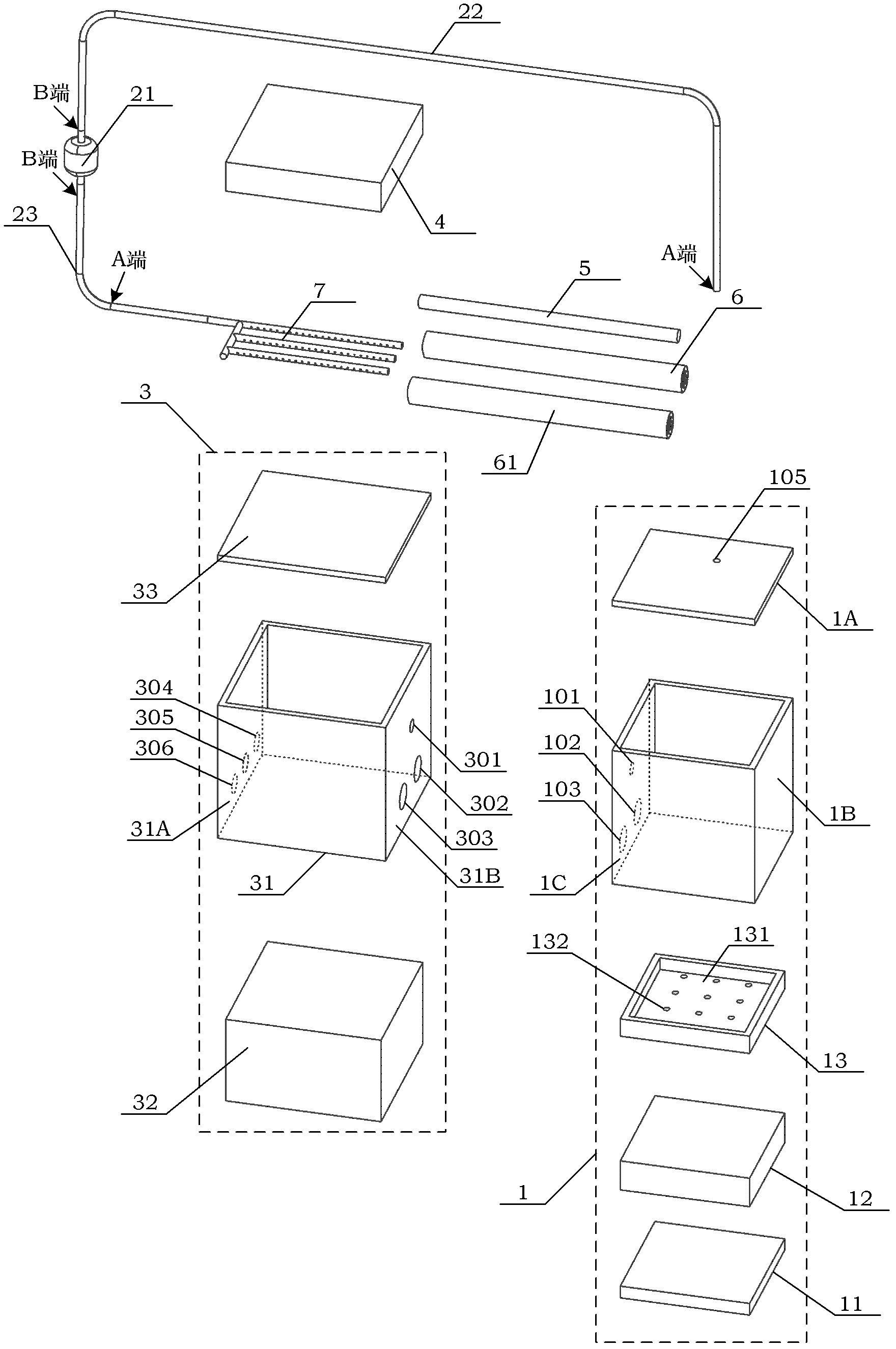

[0040] see figure 1 , Figure 1A , Figure 1B As shown, the spray cooling circuit device based on the microgravity environment of the present invention includes a spray assembly 1, a hydraulic drive pipeline 2, a liquid storage assembly 3, a heat sink 4, a steam collection pipeline 5, a liquid collection first pipeline 6, a liquid The second collection pipe 61 and the liquid collector 7 are arrayed holes; the structure of the first liquid collection pipe 6 is the same as that of the second liquid collection pipe 61 .

[0041] (1) Spray assembly 1

[0042] see figure 1 , Figure 1A , Figure 1B , image 3 , Figure 5 As shown, the spray assembly 1 in the present invention includes a spray chamber 1B, a spray chamber cover plate 1A, a heat source 11 , a first capillary core 12 and an atomiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com