Oriented graphene/polymer composite system, and preparation method and application thereof

A graphene and polymer technology, used in non-polymer organic compound adhesives, chemical instruments and methods, adhesive additives, etc., can solve the problems of inability to meet thermal conductivity, inability to form composite materials, and large additions. Achieve the effect of high electrical conductivity, efficient heat, and efficient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Further, the preparation method of a kind of oriented graphene / polymer composite system of the present invention can comprise:

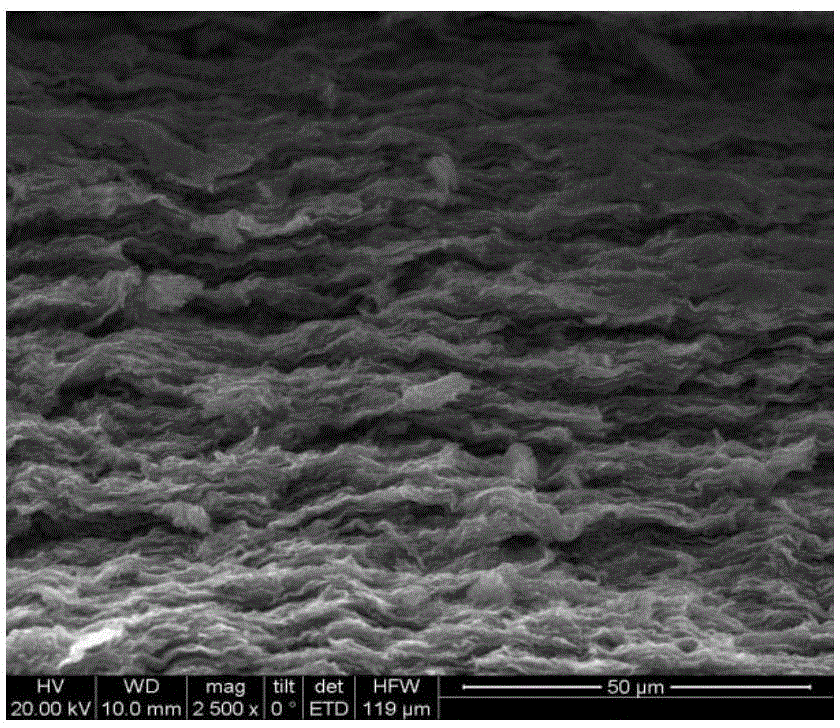

[0045] Taking the orientation network component containing at least graphene and performing orientation treatment, so that at least part of the graphene is arranged according to the set orientation to form an orientation network,

[0046] And, the matrix component containing at least polymer is combined with the oriented network component to form the oriented graphene / polymer composite system.

[0047] refer to figure 1 Shown is a typical preparation process of oriented graphene / polymer composite system.

[0048] Wherein, the manner of the orientation treatment can at least be selected from but not limited to ball milling, spin coating, solution blending, layer-by-layer self-assembly, electrospinning, solution spinning, melt spinning, twin-screw extrusion, vacuum assisted forming , vacuum filtration, filtration, etc. in one or several ways. ...

Embodiment 1

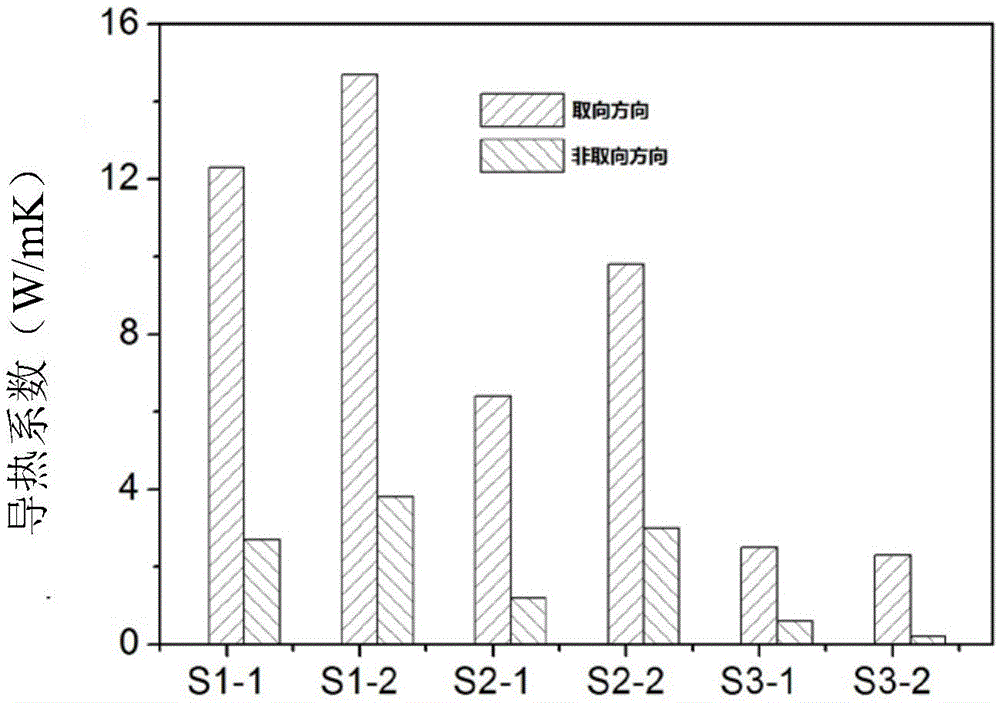

[0051] Example 1 Preparation of oriented graphene / copper / silicone rubber composite with high thermal conductivity

[0052] 1-1) Add 1g of graphene and 0.5g of copper powder to 250ml of DMF, mix evenly at room temperature, let it stand at room temperature for 48 hours, then let it stand at 80°C for 24 hours, then add silicone rubber dropwise, and solidify at 80°C when saturated After 12 hours, a thermally conductive composite material can be obtained, which can be processed into a thermally conductive pad.

[0053] ) Add 1g of graphene to 250ml of DMF, mix evenly at room temperature, let stand at room temperature for 48 hours, then let stand at 80°C for 24 hours, then add 20g of silicone rubber and 2g of aluminum powder, mix evenly at room temperature, mechanically stir for 15 Minutes, then dropwise add silicone rubber, and cure at 80°C for 12 hours at saturation to obtain a thermally conductive composite material. The compound is processed into a thermal pad.

[0054] ...

Embodiment 2

[0056] Example 2 Preparation of Oriented Graphene / Epoxy Resin Thermally Conductive Composite

[0057] 2-1) Take 1g of graphene and add it to 250ml of NMP, mix evenly at room temperature, filter at room temperature, and then stand at 80°C for 24 hours to form an aligned graphene network. Add 25g of curing agent to 20g of epoxy resin and mechanically stir for 15 minutes, then let it stand in vacuum for 1 hour, then add it dropwise into the oriented graphene network, and cure it at 80°C for 24 hours when it is saturated, to obtain a thermally conductive composite material. It can be processed into thermal conductive resin.

[0058] ) Take 1g of graphene and add it to 250ml of NMP, mix evenly at room temperature, filter at room temperature, and then stand at 80°C for 24 hours to form an aligned graphene network. Take another 1g of graphite and add it to 20g of epoxy resin, stir mechanically for 15 minutes, add 25g of curing agent, continue to stir for 45 minutes, leave it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com