Patents

Literature

338results about How to "Efficient preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

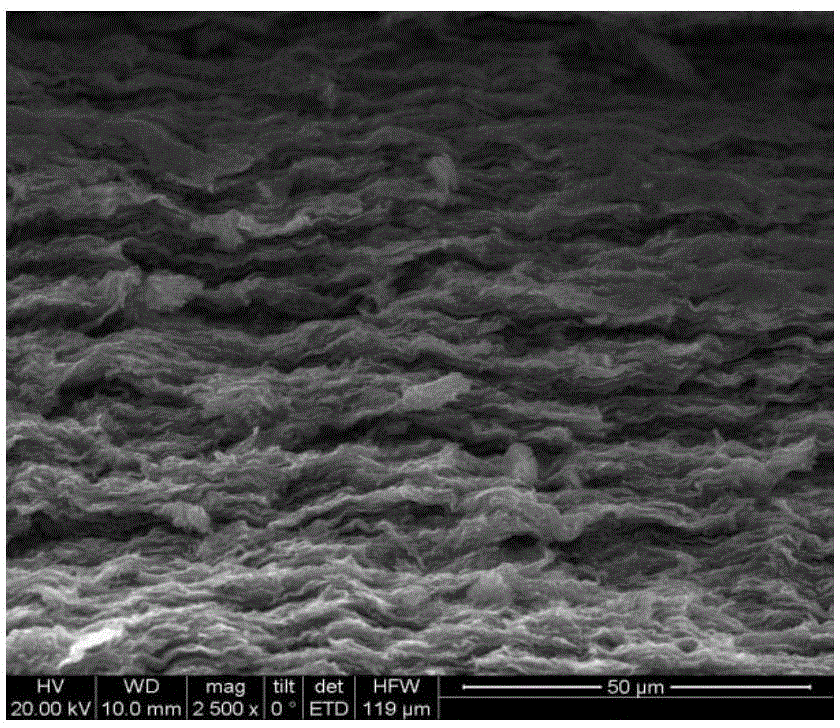

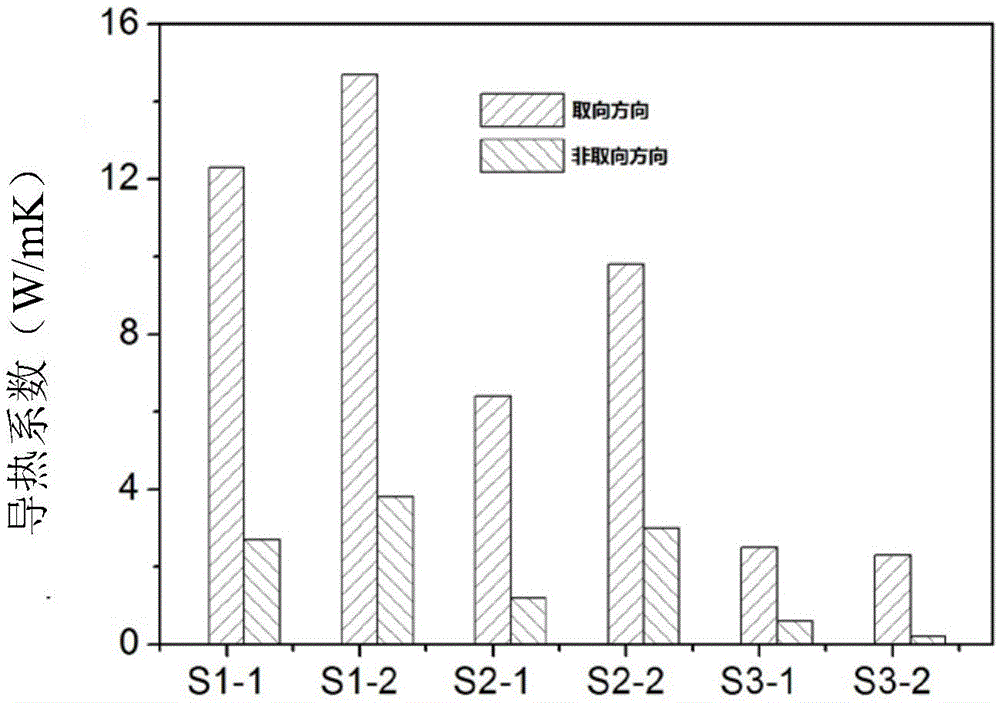

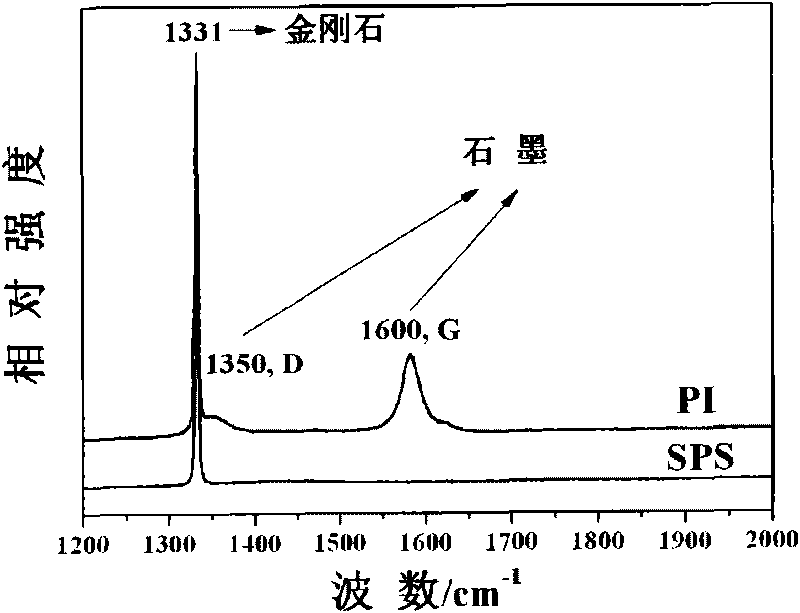

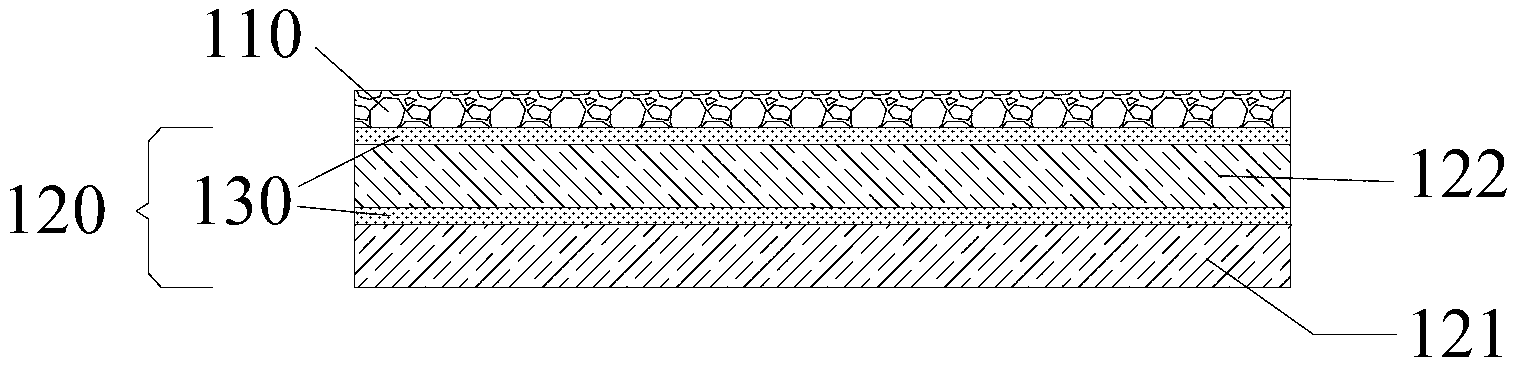

Oriented graphene/polymer composite system, and preparation method and application thereof

InactiveCN105176086AGood electrical conductivityEfficient deliveryNon-macromolecular adhesive additivesHeat-exchange elementsGraphitePolymer composites

An oriented graphene / polymer composite system, and a preparation method and an application thereof are provided. The composite system includes an oriented network component at least including graphene and a substrate component compounded with the oriented network component, wherein at least a part of graphene is arranged according to set orientation; the composite system at least has a heat conductivity coefficient in the set direction higher than heat conductivity coefficients in other directions. The preparation method includes the steps: the oriented network component is subjected to orientation treatment, at least a part of graphene is arranged according to the set orientation, and thus an oriented network is formed; and the substrate component at least containing a polymer is taken to be compounded with the oriented network component, and thus the composite system is formed. The composite system has high heat conductivity and high electrical conductive characteristic, can efficiently transfer heat in a needed direction when in use, has the characteristics of being simple, high in efficiency and the like, is suitable for scale production, and has broad application prospects in high-efficiency heat conductivity and heat dissipation.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

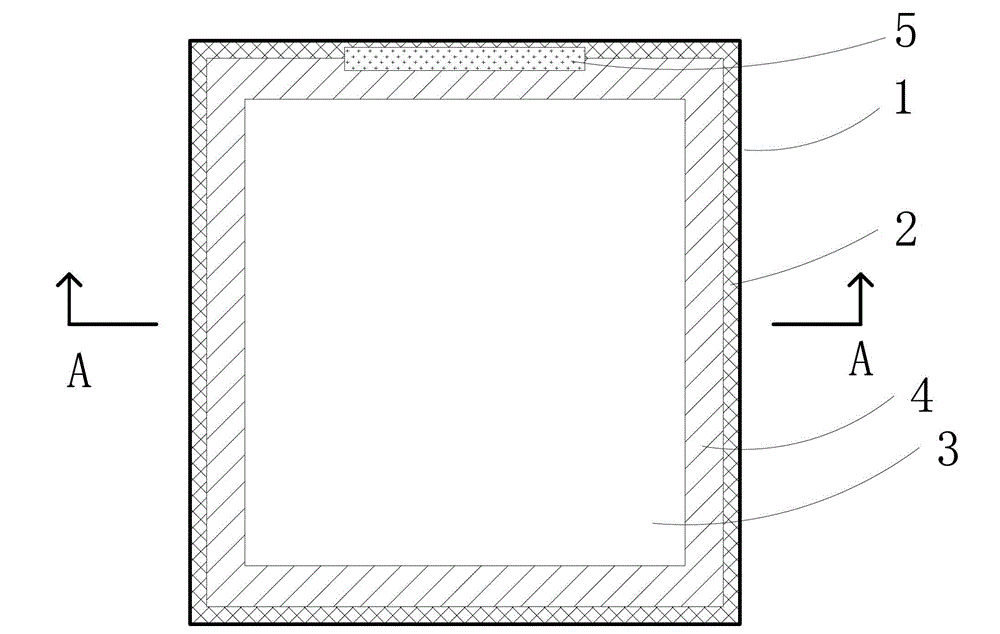

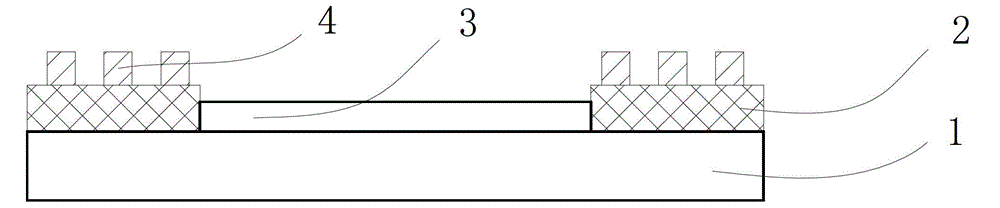

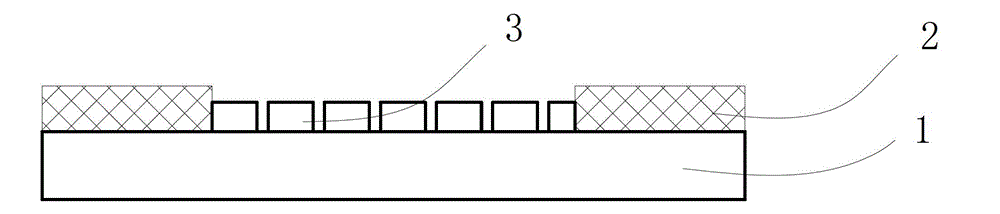

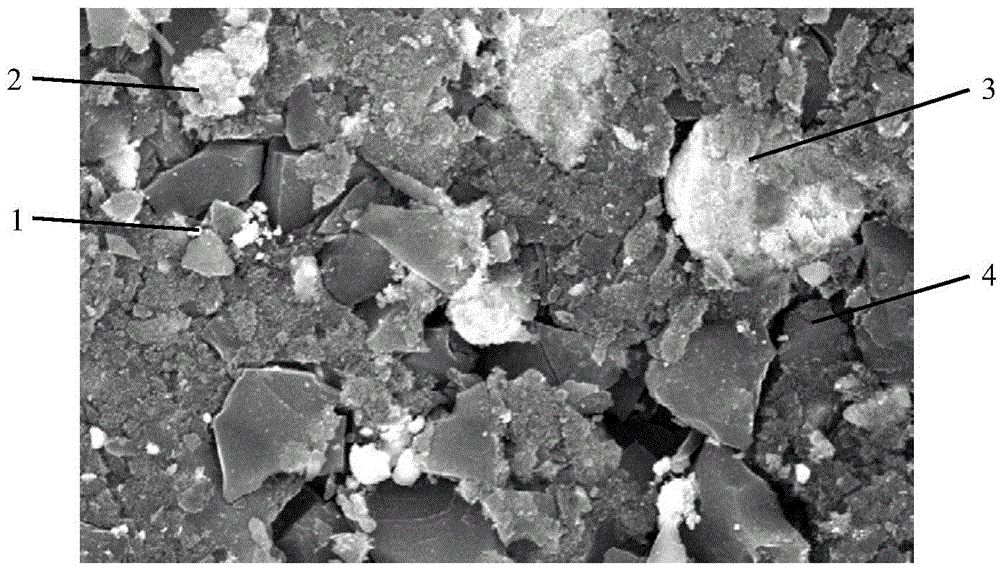

Monolithic capacitive touch screen and preparation method thereof

ActiveCN102880369AHigh light transmittanceImprove uniformityInput/output processes for data processingTransmittancePrinting ink

The invention relates to a monolithic capacitive touch screen and a preparation method thereof. The monolithic capacitive touch screen comprises a monolithic substrate (1), a non-window printing ink area (2), a window touch area (3) and a lead area (4), wherein the non-window printing ink area (2) is arranged around on the monolithic substrate (1), and encloses the window touch area (3); the lead area (4) is arranged on the non-window printing ink area (2); and an electrode material of the window touch area (3) is a graphene transparent conductive thin film. According to the preparation method for the touch screen, tampered glass can be favorably manufactured, the strength maintenance capability and stability of the tempered glass are improved, and in addition, the light transmittance and impedance uniformity of a sensing electrode of the touch area can be remarkably improved; and a yellow light preparation process is eliminated, and only laser direct writing etching or a metal mask and reactive ion etching are adopted, so that a manufacturing process is convenient, quick and high in efficiency.

Owner:WUXI GRAPHENE FILM +1

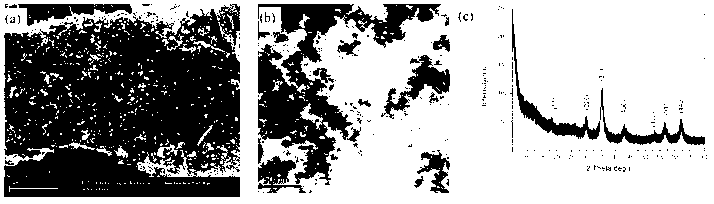

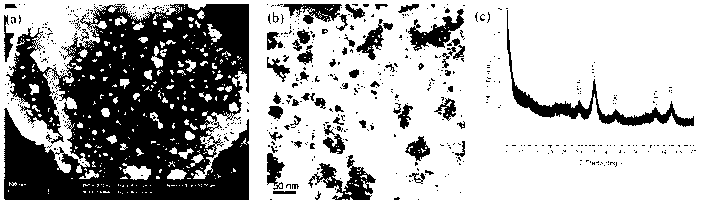

Preparation method of spinel-type magnetic MFe2O4/graphene composite material

InactiveCN102745675AHigh purityImprove bindingIron oxides/hydroxidesZinc oxides/hydroxidesNitrogen gasSolvent

The invention discloses a preparation method of a spinel-type magnetic MFe2O4 / graphene composite material. The preparation method utilizes a water-soluble metal M<2+> salt and a Fe<3+> salt as precursors and graphite oxide as a matrix and comprises the following steps of carrying out ultrasonic dispersion of graphite oxide in ethanol or water as a solvent to obtain a graphene oxide dispersion, adding a M<2+> salt and Fe<3+> salt-containing aqueous solution having a M<2+> / Fe<3+> mole ratio of 1: 2 into the graphene oxide dispersion, fully stirring to obtain a mixed solution, adjusting a pH value of the mixed solution to a value more than 10 by an alkali liquor, adding a reducing agent into the mixed solution, stirring at a temperature of 80 to 150 DEG C for a reaction lasting for 4 to 10 hours, after the reaction is finished, carrying out separation, washing, drying and grinding, and carrying out calcination of the grinded powder at a temperature of 300 DEG C in a nitrogen or argon atmosphere for 2 to 10 hours. Magnetic MFe2O4 nano particles of the spinel-type magnetic MFe2O4 / graphene composite material have high loading capacity, stable structures, good uniformity, good dispersibility and strong adhesion with graphene. The spinel-type magnetic MFe2O4 / graphene composite material can be widely used in the fields of magnetic targeting materials and other related function materials.

Owner:HEFEI UNIV OF TECH

Method for preparing aqueous solution of single-layer grapheme oxide

The invention relates to a method for preparing aqueous solution of single-layer grapheme oxide. The method is characterized by comprising the following steps of: 1, partially stripping the dried grapheme oxide in advance through microwave irradiation; and 2, adding the grapheme oxide which is partially stripped into deionized water and then adding a dispersing agent, stirring, performing oscillation or ultrasonic treatment to prepare the aqueous solution of single-layer grapheme oxide, wherein the microwave output power of the microwave irradiation is continuously adjustable and is 100 to 1,500 watts; the dispersing agent is KOH, NaOH, K2CO3, Na2CO3, NH4HCO3, (NH4)2CO3 or ammonia water; and the dispersing agent is prepared into 1 M of aqueous solution before use and the mass percentage of the ammonia water is 38 percent. The preparation method provided by the invention is low in energy consumption and is an environmentally-friendly and high-efficiency preparation method; the area of the grapheme oxide can be controlled; and the preparation time is less than 10 minutes.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

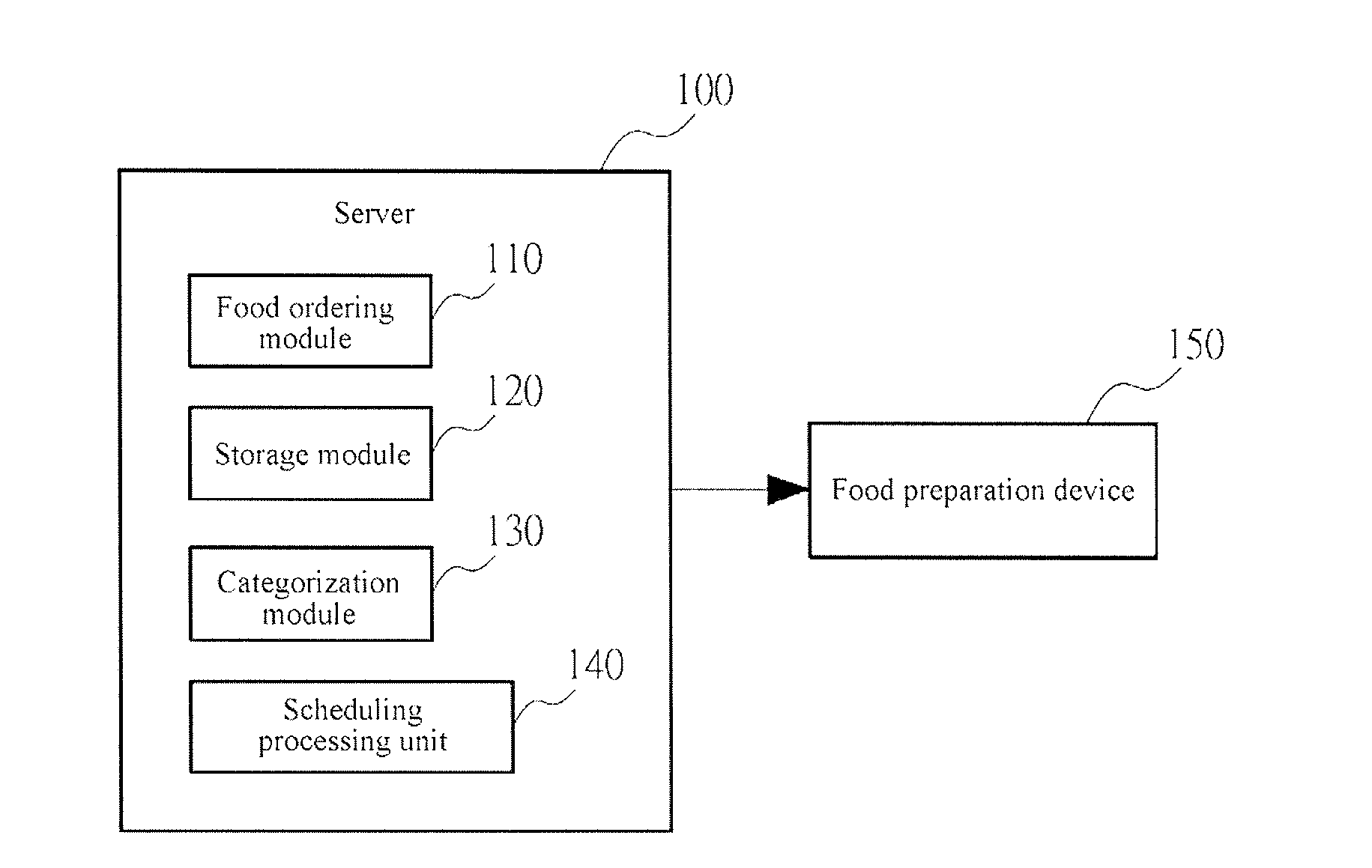

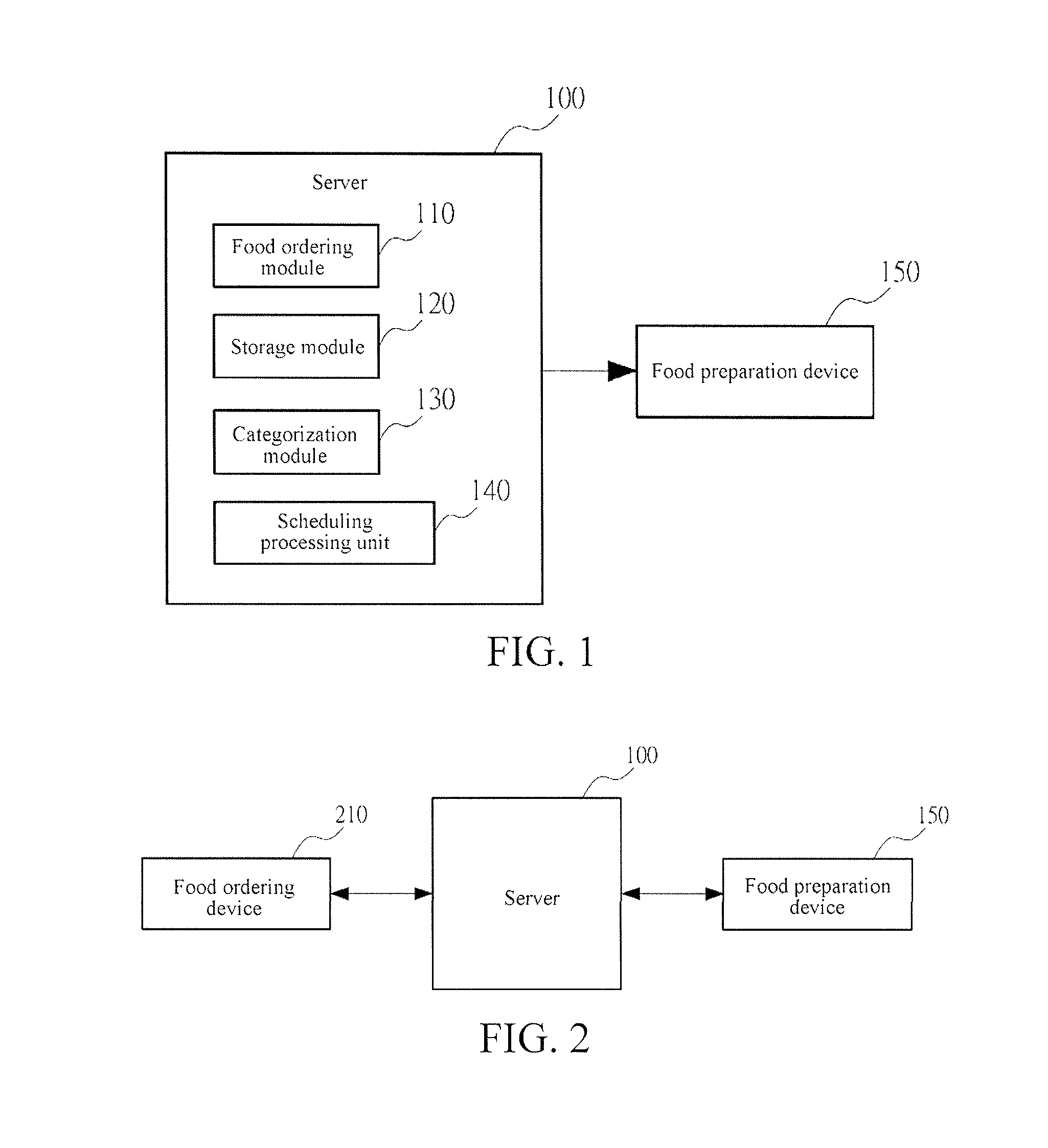

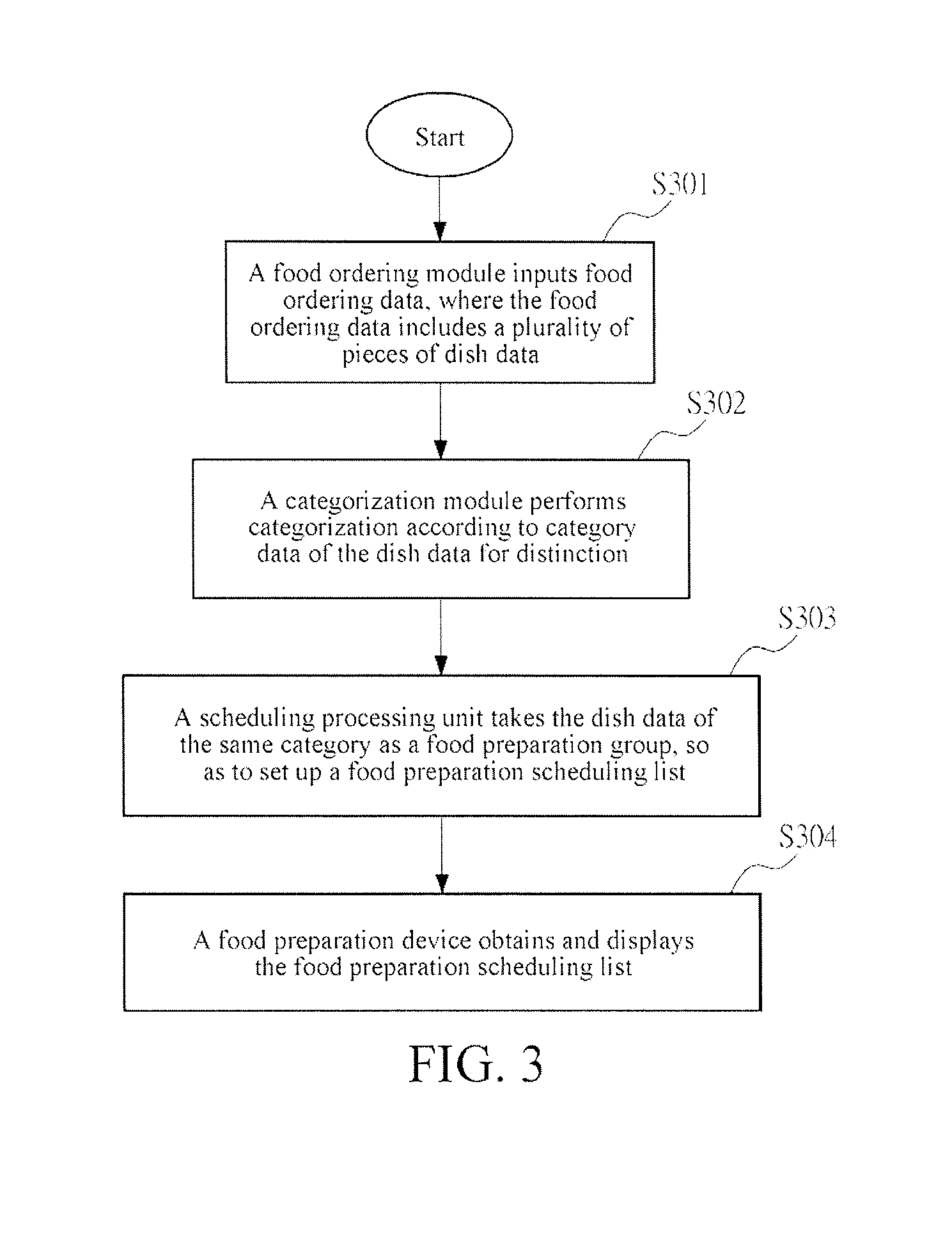

Restaurant food preparation scheduling management system and method

InactiveUS20160026958A1Ensure qualityImprove production efficiencyResourcesComputer moduleComputer science

A restaurant food preparation scheduling management system and method are provided. The system comprises: a food ordering module, used to input food ordering data, where the food ordering data includes a plurality of pieces of dish data; a storage module, used to record category data of the dish data; a categorization module, connected to the storage module and the food ordering module, and used to categorize the dish data in the food ordering data into categories according to the category data; a scheduling processing unit, used to take the dish data of the same category as a food preparation group according to the category data of the dish data, so as to set up a food preparation scheduling list; and a food preparation device, to which the food preparation scheduling list is transmitted, used to display the food preparation scheduling list.

Owner:NAT KAOHSIUNG UNIV OF SCI & TECH

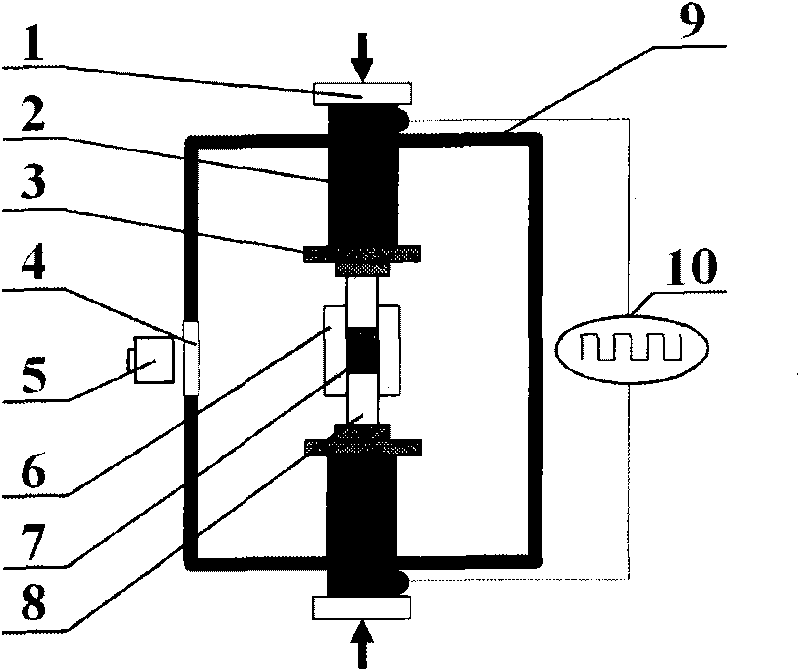

Preparation method of high-performance diamond reinforced Al-matrix electronic packaging composite material

ActiveCN101728279AHigh densityImprove thermal conductivitySemiconductor/solid-state device manufacturingSingle crystalVolumetric Mass Density

The invention relates to a preparation method of a high-performance diamond reinforced Al-matrix electronic packaging composite material, belonging to the field of metal-matrix composite materials. The preparation method is characterized by comprising the following steps: adding alloy elements into a pure Al matrix to prepare elemental mixed powder or Al alloy powder; uniformly mixing the elemental mixed powder or the Al alloy powder and diamond single crystal grains according to the volume percentage ratio of 75:25-40:60; adding the mixture into a graphite mold for carrying out spark plasma sintering, wherein the mixture is added at the heating speed of 50-100 DEG C / min until the sintering temperature is 580-800 DEG C and the sintering pressure is 30-40MPa; keeping the temperature and the pressure for 5-20min; and obtaining the high-performance diamond reinforced Al-matrix electronic packaging composite material after the sintering process finishes. The alloy elements comprise B, Si, Cr, Ti, Nb, Ag, Cu and the like. The material of the invention has the characteristics that the heat conductivity reaches 430W / m.K, the heat expansion coefficient is 6.40ppm / K, the compressive strength is 331MPa, and the density is only 3.13g / cm<3>. The invention effectively solves the problem of graphitization of single crystal diamond grains in the preparation process of the material, and has simple preparation processes and high production efficiency.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

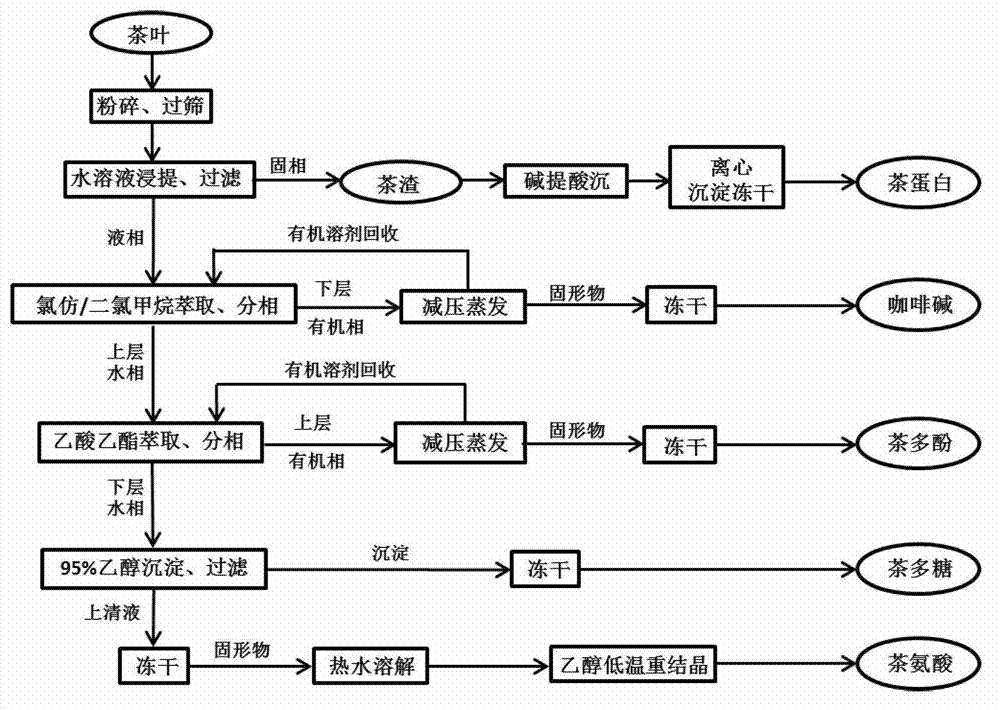

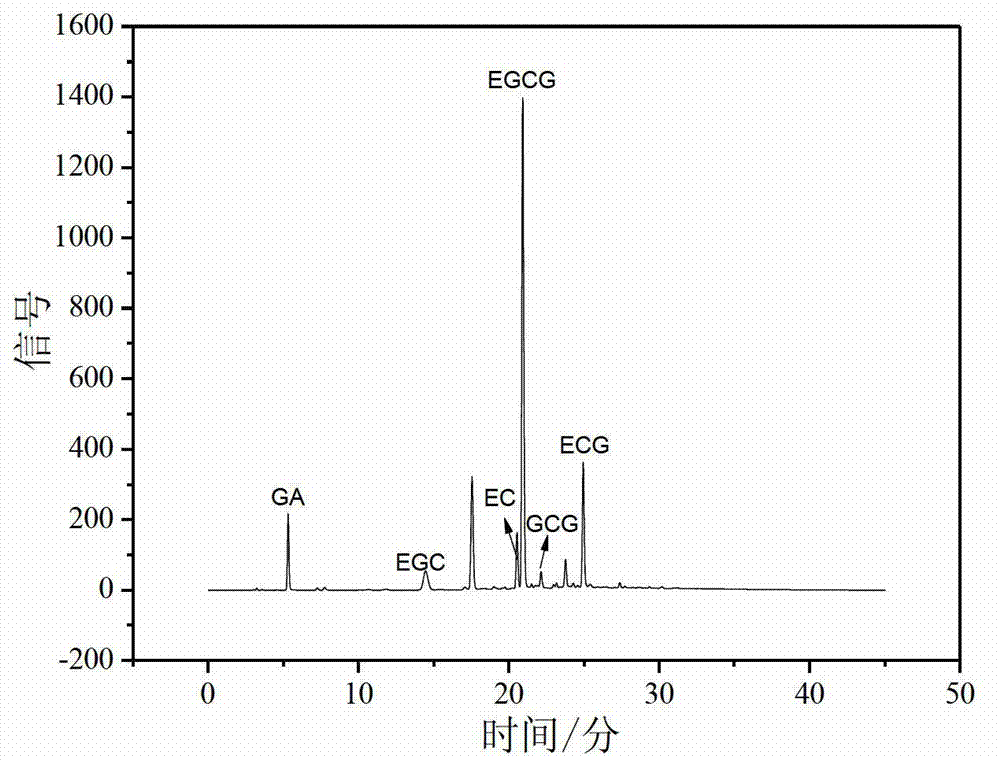

Method for comprehensively extracting effective ingredients in tea

ActiveCN103242314ALow costAvoid pollutionCarboxylic acid amide separation/purificationPeptide preparation methodsAdditive ingredientTheanine

The invention relates to a method for comprehensively extracting effective ingredients in tea. The method comprises the following steps of: with a faintly acidic water solution as a main extraction solvent and a certain amount of organic solvent as an auxiliary extraction solvent, carrying out step-by-step extraction on water extracts to obtain four effective ingredients, namely tea polyphenol, caffeine, tea polysaccharide and theanine; and meanwhile, extracting tea protein from tea residues by using an alkali dissolution and acid deposition method. According to the method, as water is used as the main solvent, the cost is low, the reactions are mild and active ingredients are favorably preserved; as a certain amount of organic solvent is used as the auxiliary extraction solvent, the problems of overhigh cost and product pollution caused by use of a large amount of organic solvents are solved; meanwhile, five effective ingredients, namely the tea polyphenol, the tea polysaccharide, the caffeine, the theanine and the tea protein are extracted, and therefore high extraction rate, high purity and high utilization rate of tea are achieved; the solvents are recycled in the extraction process, so that the preparation cost is reduced; and no alkali and acid waste liquor is discharged in the overall process, and therefore the method is environment-friendly. The overall preparation flow is high in efficiency and low in cost, and therefore the method has a favorable application value.

Owner:TIANJIN UNIV

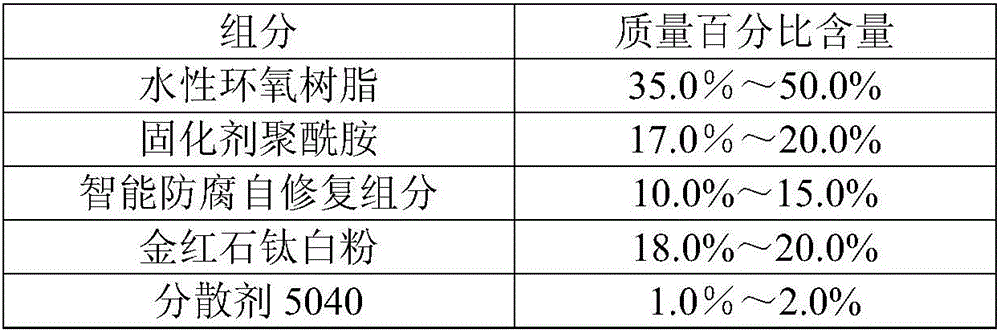

Intelligent anticorrosive and self-repairing coating and preparation method thereof

InactiveCN106433409AWith intelligent corrosion self-healing functionAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxyResin matrix

The invention discloses an intelligent anticorrosive and self-repairing coating and a preparation method thereof. The intelligent anticorrosive and self-repairing coating is prepared from the following components: waterborne epoxy resin, a curing agent polyamide, an intelligent anticorrosive and self-repairing component, rutile titanium dioxide, a dispersant 5040, a thickening agent SN-636 and a flatting agent BYK333. The preparation method comprises the following steps: firstly, carrying out in-suit polymerization on urea, a formaldehyde solution, resorcinol and ammonium chloride in a Chinese tallow kernel oil emulsification solution; after carrying out repeated filtering, washing, drying and crushing, obtaining core-shell-structured microcapsules with Chinese tallow kernel oil covered by urea formaldehyde resinand taking the core-shell-structured microcapsules as the intelligent anticorrosive and self-repairing component; and uniformly doping the intelligent anticorrosive and self-repairing component into a waterborne epoxy resin matrix, and spraying or brushing or spin-coating on a metal matrix to obtain the coating. The intelligent self-repairing coating disclosed by the invention has a good saline resisting performance, high adhesion, a good flash-rust resisting effect, a high anticorrosive capability and a long service life; and a preparation process is simple, the price is low and the raw materials are green and environment-friendly.

Owner:GUANGXI UNIV

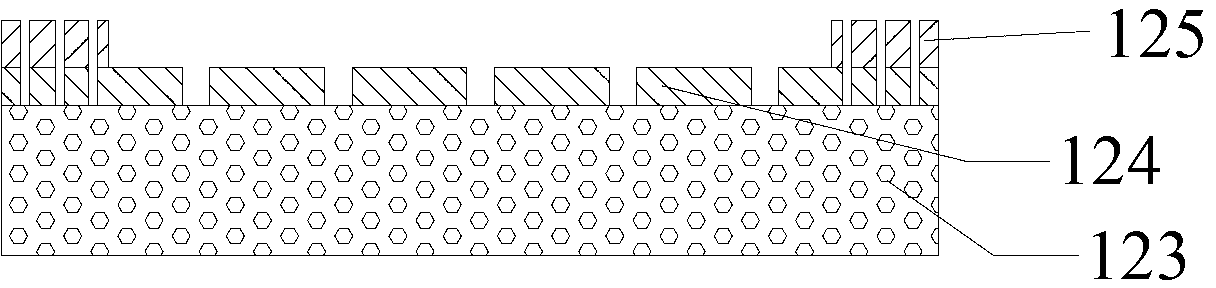

Multi-point touch grapheme capacitive touch screen and production method thereof

InactiveCN103235671AImprove performanceTo achieve the purpose of multi-touchInput/output processes for data processingCvd grapheneCapacitance

The invention relates to a grapheme capacitive touch screen, wherein a transparent conductive film of the touch screen is formed by two layers of grapheme films with different pattern directions in an attachment mode. The grapheme capacitive touch screen achieves a multi-point touch function; remarkably reduces production cost of the touch screen; avoids damage caused by polyethylene terephthalate (PET) base material bending during processing; and eliminates the complex and high-cost yellow light manufacturing process, and is fast, convenient and efficient in the production process due to the fact that only laser direct writing etching or metal mask and reactive ion etching is adopted in the forming process of sensing electrode patterns in a window touch area.

Owner:无锡力合光电石墨烯应用研发中心有限公司 +1

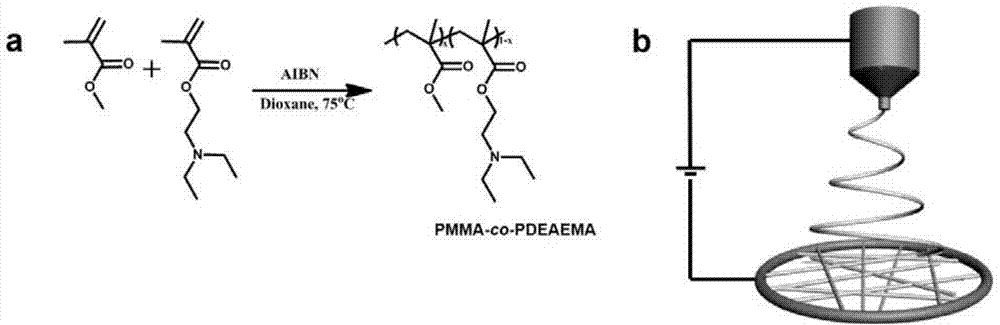

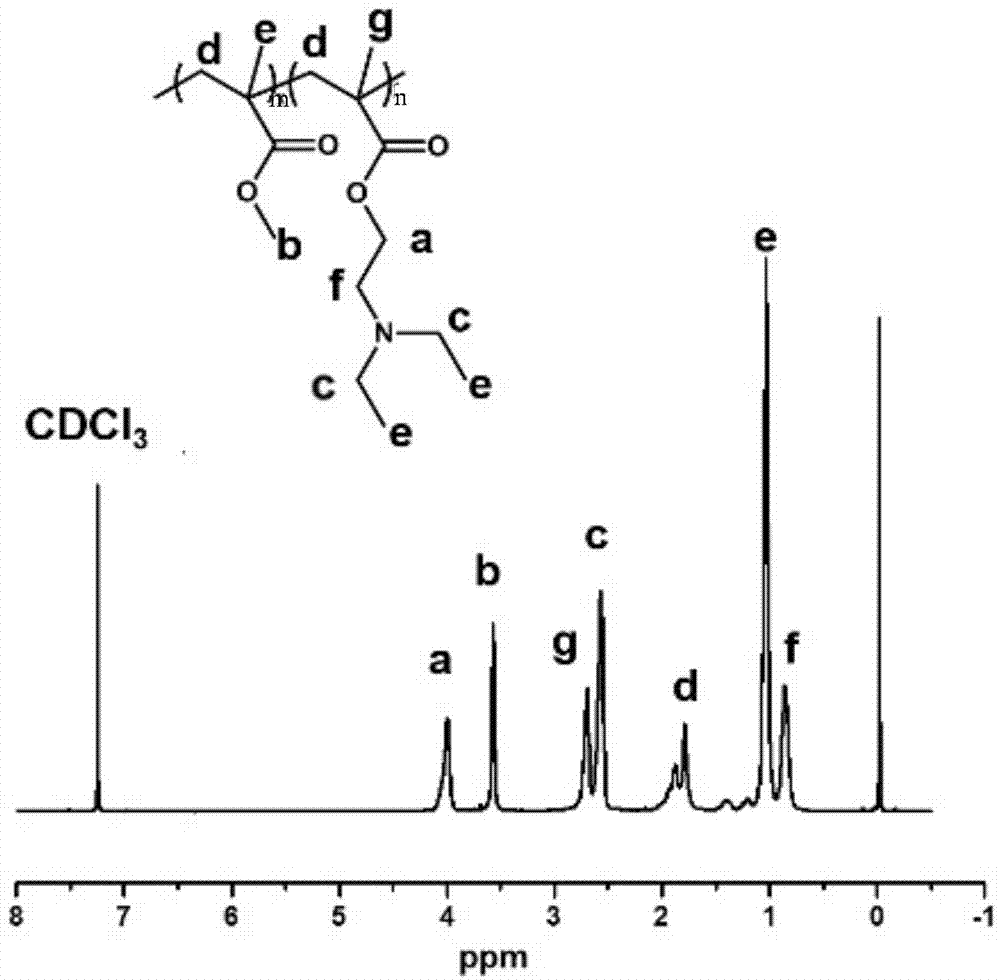

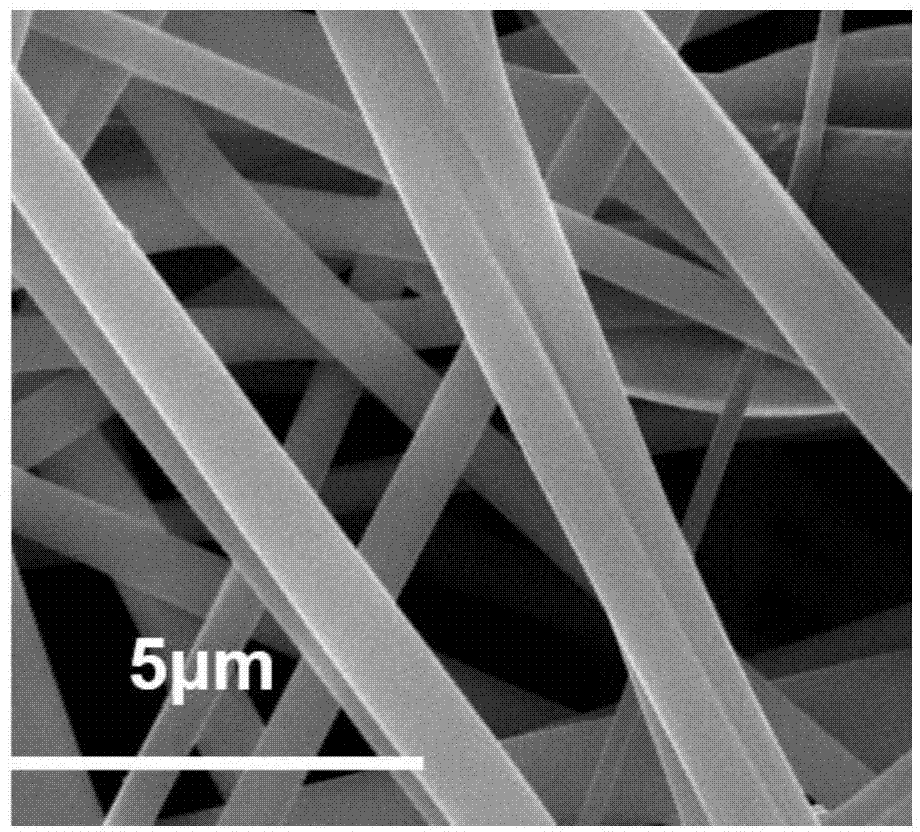

Oil water separation nanofiber membrane with CO2 stimulus response as well as preparation method and application thereof

ActiveCN104841293ALipophilic and hydrophobicSimple and fast operationSemi-permeable membranesLiquid separationPolymethyl methacrylateNanofiber

The invention discloses an oil water separation nanofiber membrane with CO2 stimulus response as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing a random copolymer and a solvent to obtain spinning solution, wherein the random copolymer is polymethyl methacrylate-2-Diethylaminoethyl Methacrylate; (2) performing electrostatic spinning on the spinning solution to obtain nanofibers, and interweaving and arranging the nanofibers to obtain the nanofiber membrane. The oil water separation nanofiber membrane is applied to oil water separation. The nanofiber membrane prepared by utilizing an electrostatic spinning technology has a CO2 stimulus response function, can selectively perform oil water separation, is low in cost, simple and convenient to operate, clean and environment-friendly, and has better separation effects for various oil-water mixed systems.

Owner:TSINGHUA UNIV

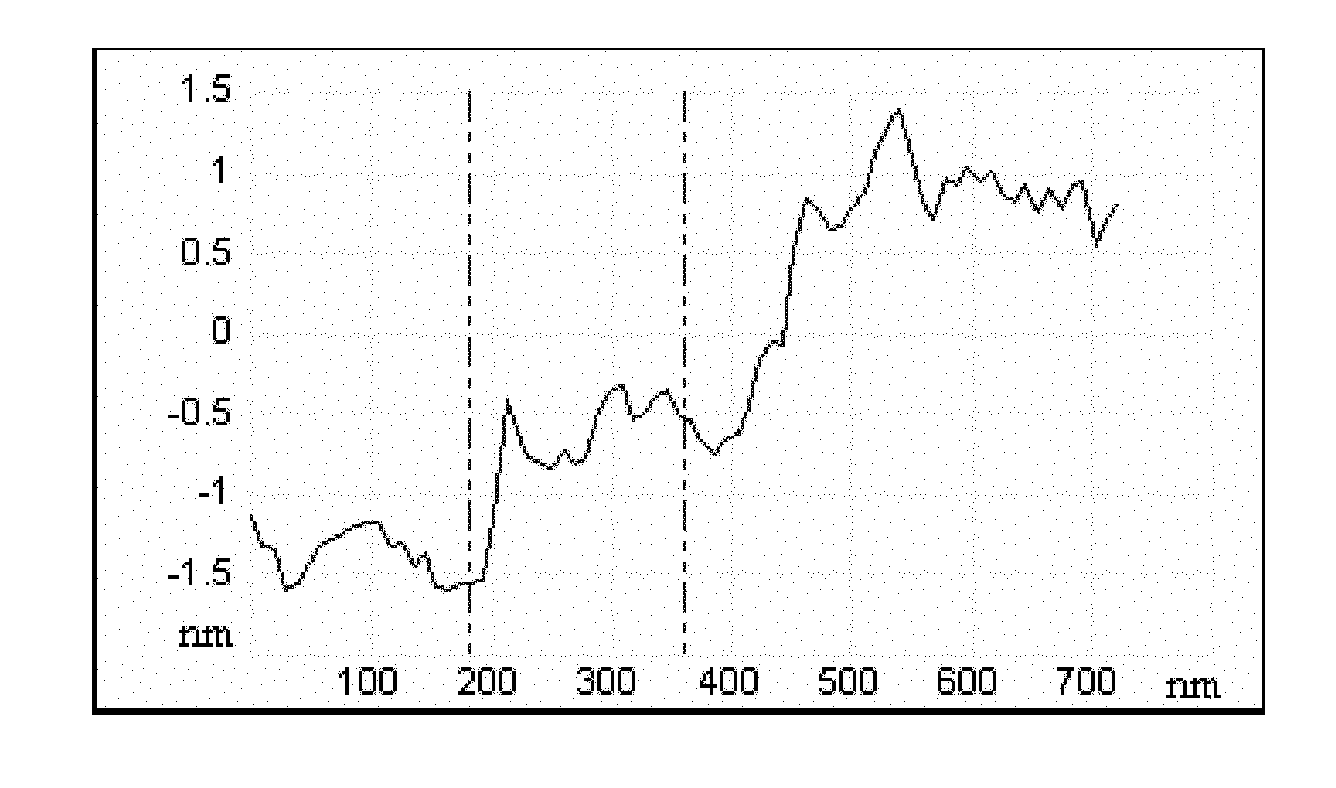

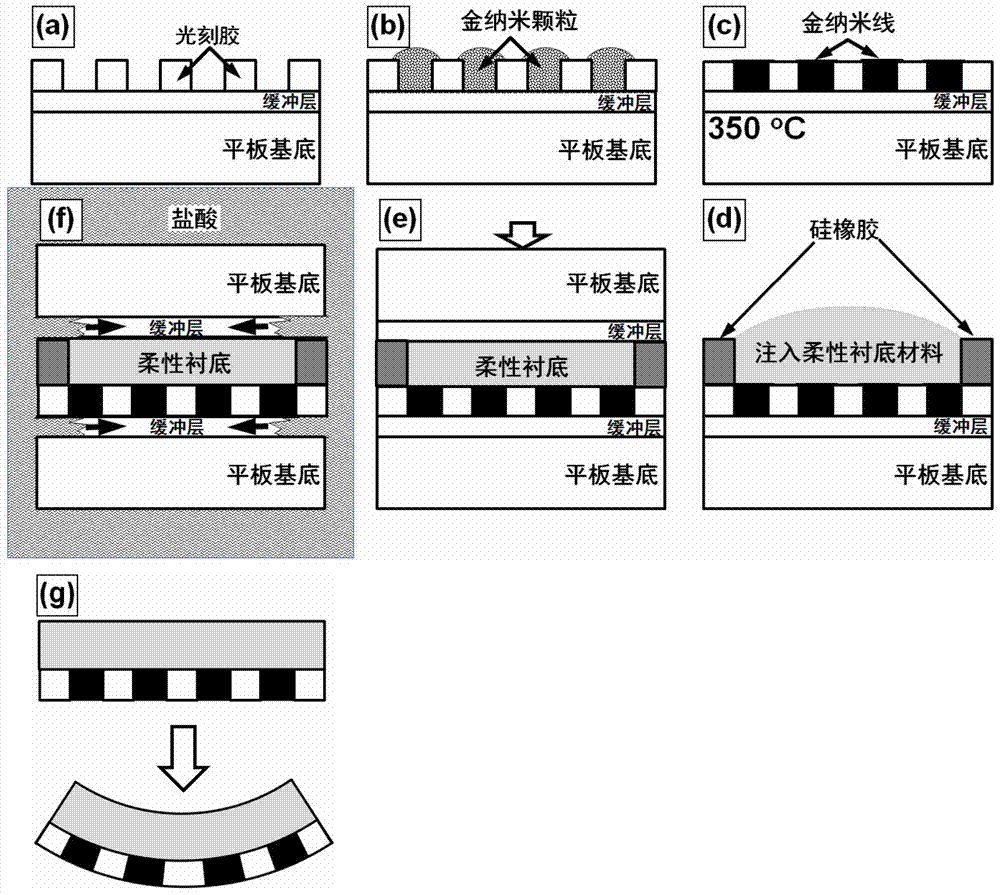

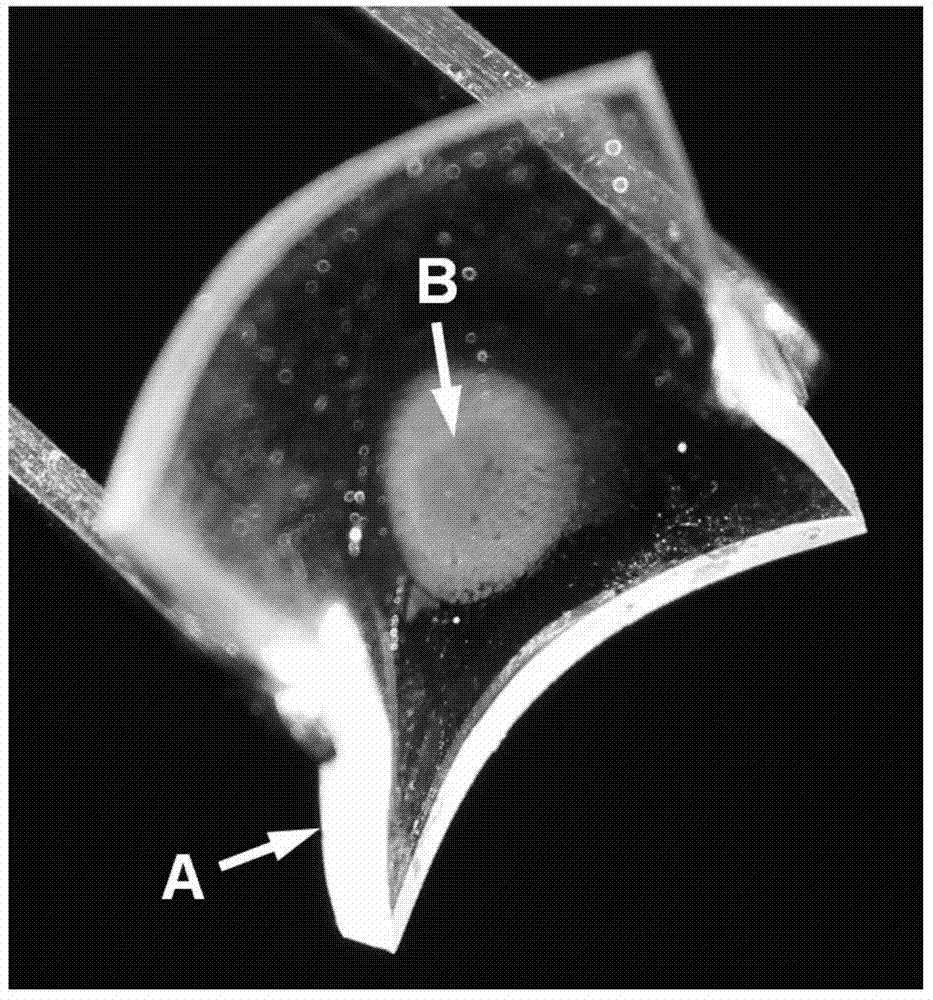

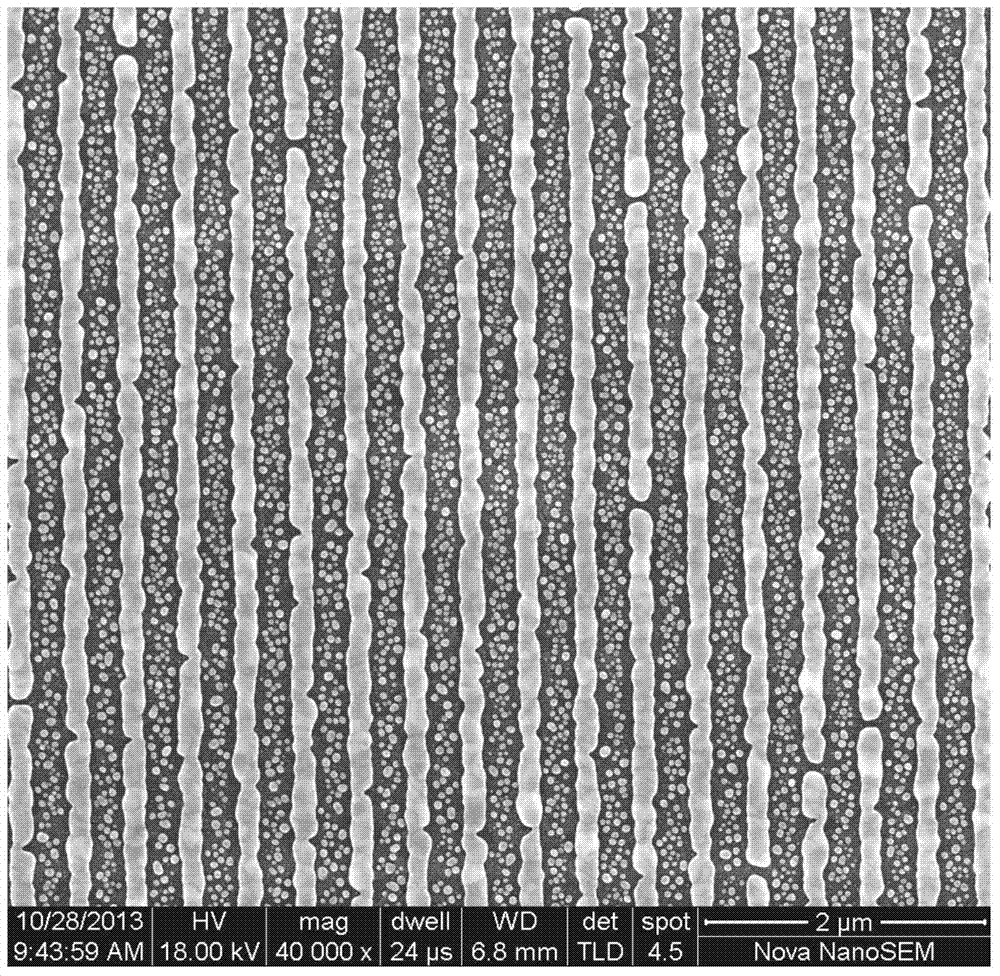

Preparation method of flexible metal photonic crystal

ActiveCN103698846AEasy to prepareEfficient preparation processNanoopticsOptical waveguide light guidePhotonicsNanoparticle

The invention discloses a preparation method of flexible metal photonic crystal and belongs to the technical field of nano photonic materials and devices. The method comprises the steps of preparing a photoresist nano grating structure on a buffer layer of a buffer layer substrate, dissolving and spin-coating gold nanoparticle colloid on the surface of grating and limiting the coating gold nanoparticle colloid in a groove of the grating, performing heating processing, so as to ensure that organic ligand on gold surface is sublimed and gold nanoparticle is fused, so as to form metal photonic crystal, coating flexible substrate liquid mixed with curing agent on the metal photonic crystal, covering another buffer layer substrate, heating the metal photonic crystal to perform cross-linking polymerization, putting the metal photonic crystal into a hydrochloric acid solution or a sulfuric acid solution, so as to sufficiently dissolve the buffer layer, and cleaning obtained samples through distilled water. The method has important direct application value for developing stress and deformation sensors and novel flexible optoelectronic devices.

Owner:BEIJING UNIV OF TECH

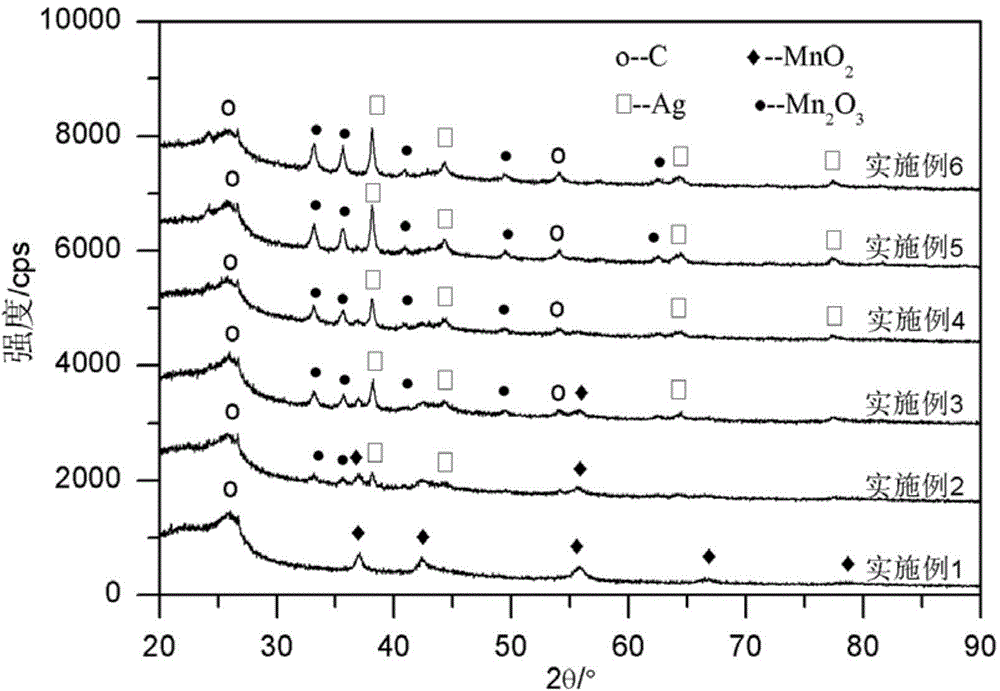

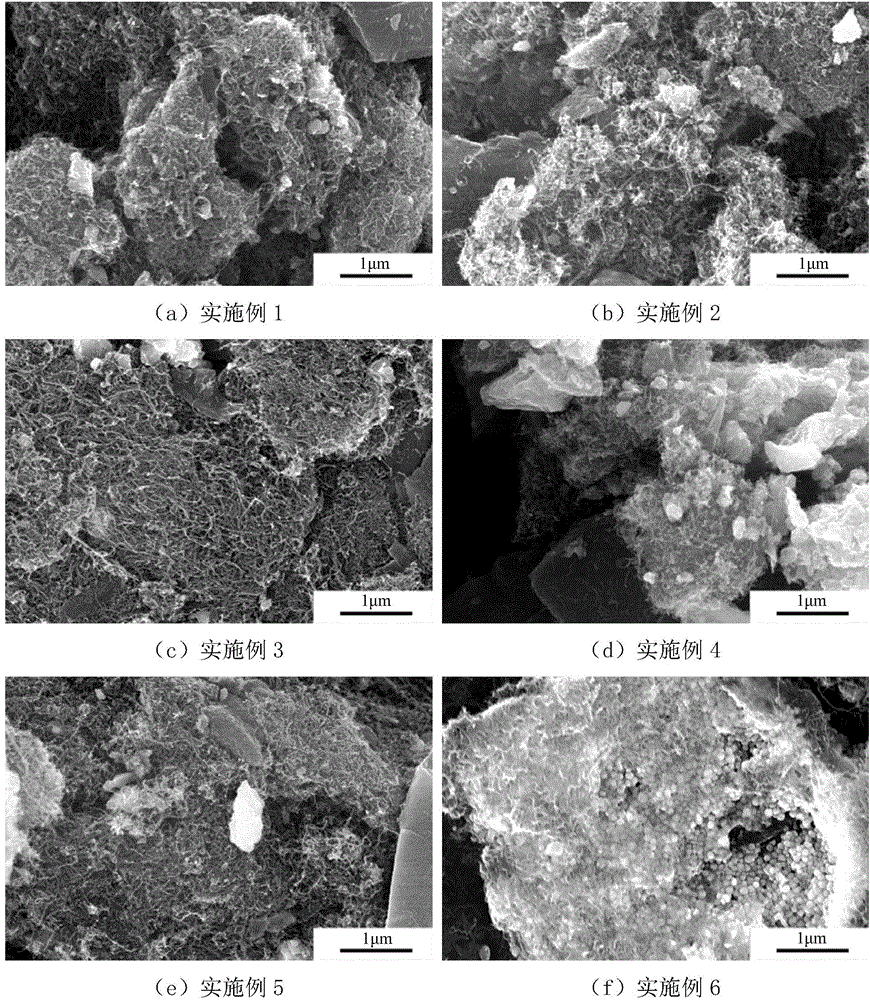

Nano-composite air electrode catalyst for zinc-air battery and preparation method of nano-composite air electrode catalyst

InactiveCN104900890AImprove wettabilityImprove oxygen reduction performanceCell electrodesCarbon nanotubeThree-phase

The invention relates to a nano-composite air electrode catalyst for a zinc-air battery and a preparation method of the nano-composite catalyst, belonging to the technical field of zinc-air batteries. The nano-composite catalyst is composed of manganese dioxide, nano-silver, a carbon nano tube and a carbon material in the mass ratio of (0-0.5) to (0-0.5) to 1 to (1.75-2.75), wherein the mass of manganese dioxide and the mass of nano-silver cannot be zero at the same time. Due to the addition of nanometer materials such as nano-silver and the carbon nano tube, the wettability of the nano-composite catalyst is improved, and the reduction reaction of oxygen in a three-phase boundary formed by electrolyte, catalyst material and oxygen is facilitated; meanwhile, the composite catalyst formed by manganese dioxide and nano-silver has oxygen reduction effect higher than that of a single catalyst. The nano-composite catalyst adopts the preparation technology comprising the steps of pretreatment, granulation, ultrasonic dispersion and ball-milling treatment, the operation is simple and efficient, and the application prospect is good.

Owner:TSINGHUA UNIV

Film-forming solution, and preparation method and application thereof

InactiveCN103666254AImprove EdibilityImprove securityMeat/fish preservation by coatingFruits/vegetable preservation by coatingAqueous ethanolMoisture resistance

The invention provides a film-forming solution. The film-forming solution is characterized by comprising the following components: 5-30wt% of alcohol-soluble protein, 1-5wt% of nano TiO2 particles, 0.1-3wt% of gelatinizing agent, 0.05-3wt% of coagulant aid, 0.1-3wt% of plasticizer, and the balance of ethanol water of which the volume ratio is 45-65%. The invention also provides a method for preparing the film-forming solution. Furthermore, the invention also provides application of the film-forming solution as a food preservation film. According to the film-forming solution provided by the invention, not only are the edibility, the safety and the stability of the preservation film improved due to the alcohol-soluble protein, but also the preservation film is degradable and free of pollution to the environment. The nano TiO2 particles are contained, so that the film-forming solution has unique barrier property and mechanical property after a film is formed, and has an antibacterial effect. In addition, the preparation method of the film-forming solution provided by the invention is simple in process, and low in cost. The preservation film not only is good in moisture resistance, but also does not become tacky after being moistened, is degradable, green and environment-friendly, can well keep the quality of the food, and prolongs the shelf life after being formed on the food surface.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method for anode material of red phosphorous cladding carbon nano tube composite ion battery

InactiveCN105098154AThe ratio is easy to controlSimple preparation processCell electrodesHigh ratePhosphate

The invention belongs to the field of a nano functional material and a new energy source, and relates to a preparation method for an anode material of a red phosphorous cladding carbon nano tube composite ion battery. The preparation method comprises the following steps of: mixing pretreated red phosphorous powder and a carbon nano tube according to a certain quality proportion; preparing to a uniform serous liquid with an appropriate amount of a grinding agent and transferring the uniform serous liquid to a ball grinding tank; carrying out anaerobic wet high-energy ball grinding, and thereby obtaining the anode material of the red phosphate cladding carbon nano tube ion battery, wherein effective ball grinding time is 2 to 6 hours. The core of the invention is that the simple and high-efficiency anaerobic wet high-energy ball grinding is adopted to further prepare the anode material of the red phosphate cladding carbon nano tube ion battery; red phosphate is uniformly coated on the surface of the carbon nano tube, a particular conductive network in the composite material is built by means of the carbon nano tube, the contact area of the red phosphate and the carbon nano tube is increased, and thus, the anode material of the composite ion battery has the advantages of high specific capacity, high rate performance and stable circularity; and moreover, the process is simple, the preparation quantity is large, and industrial production is easy to achieve.

Owner:TIANJIN POLYTECHNIC UNIV

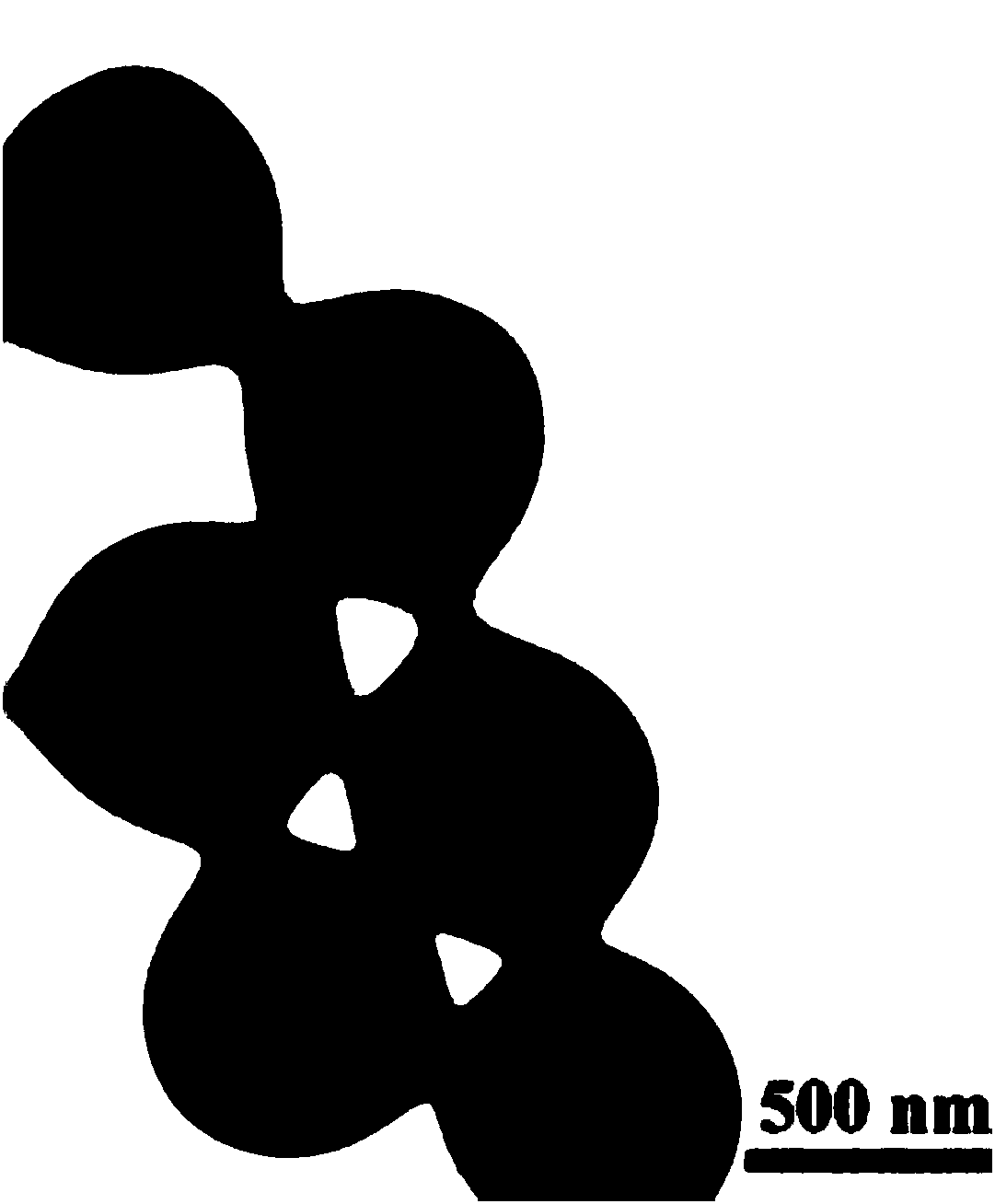

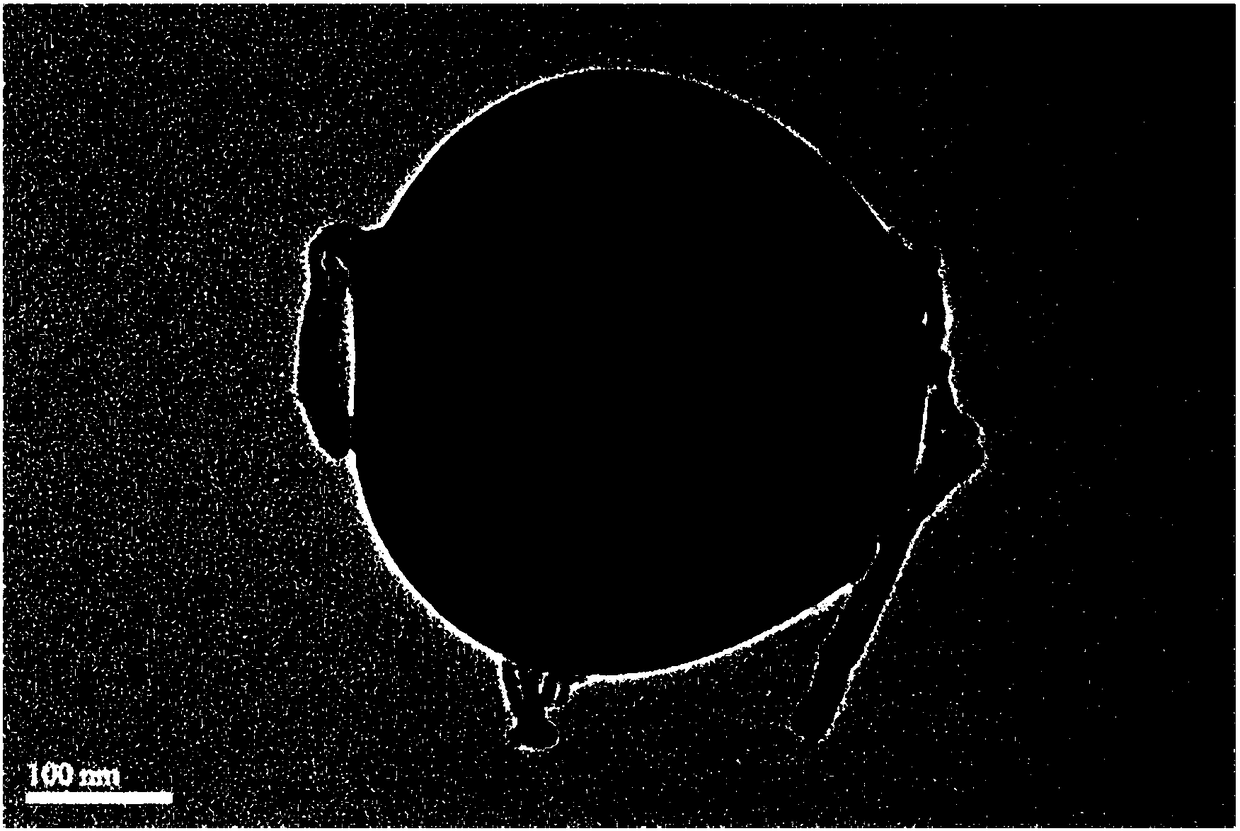

Composite particle with multiple core-shell structures and preparation method thereof

ActiveCN108543505AReduce reunionImprove toughnessMicroballoon preparationMicrocapsule preparationSilica nanoparticlesFunctional modification

The invention discloses a composite particle with multiple core-shell structures. The composite particle uses inorganic silica nanoparticles as a core, uses an organic acrylate polymer as a middle layer, and uses a carbon nanotube adsorption layer as a shell. The invention also discloses a preparation method for the composite particle, first nano-silica is synthesized through a Stober method, thenthe surface of nano-silica is coated with an acrylate polymer layer based on a dispersion polymerization method, and an initiator that can be subjected to hydrolytic ionization is used to achieve coating of the nano silica surface with the polymer and charge modification in one step, then further carbon nanotubes are adsorbed through electrostatic self-assembly. The invention provides the composite particle with multiple core-shell structures and the preparation method thereof, the preparation process is green and efficient, and does not need complicated functional modification, and the prepared composite particle has excellent overall performance.

Owner:CGN JUNER NEW MATERIALS +1

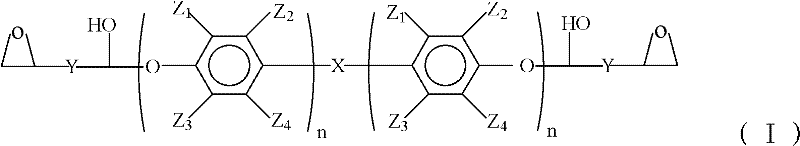

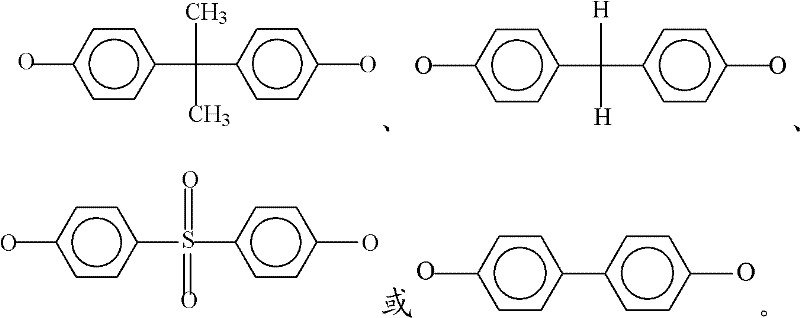

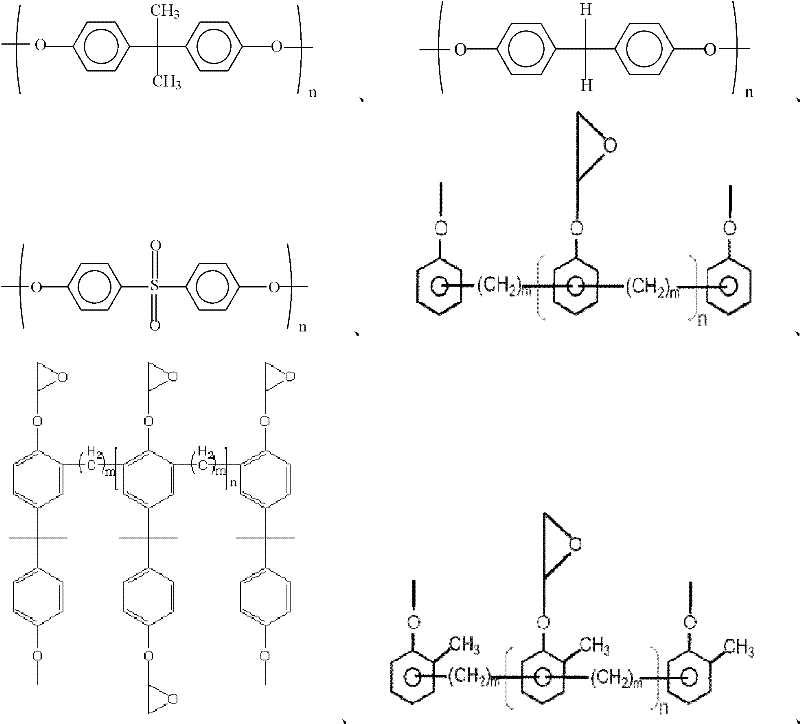

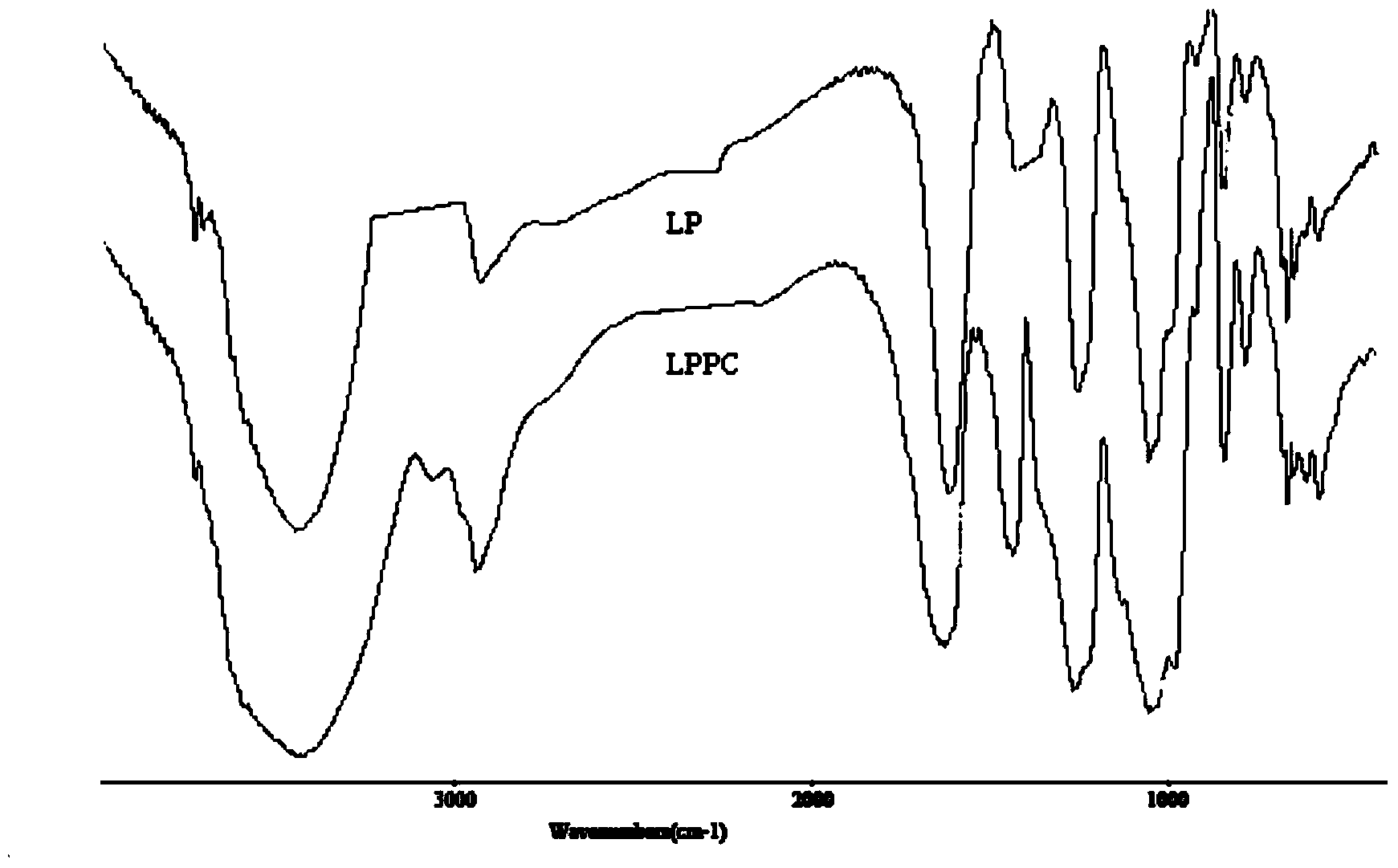

Epoxy modified polyphenylene ether resin, resin composition and its application

ActiveCN102516530AReduce investment in environmental protectionAvoid damagePrinted circuit aspectsCircuit susbtrate materialsEpoxySolvent

The invention provides an epoxy modified polyphenylene ether resin, the epoxy modified polyphenylene ether resin possesses a structural unit shown in a formula (I), and a preparation method comprises the following steps 100 parts of solid polyphenylene ether resin adds a polymerization reaction solvent for dissolving into a liquid polyphenylene ether resin solution, and then 5-60 parts of epoxy resin and 0.001-5 parts of a catalyst are added in the solution, stirred and mixed at the temperature of 80-140 DEG C for 1- 3 hours to obtain a pre-polymerization solution. The invention also discloses a resin composition containing the epoxy modified polyphenylene ethesr resin, and an application in preparation of printed circuit board. The epoxy modified polyphenylene ether resin composition has the advantages of excellent glass fiber cloth impregnation, simple preparation process, high efficiency, environmental protection and high product purity controllability; can be used for making a laminated material and a copper clad pressure plate, possess excellent heat resistance and dielectric properties, and is in favor of signal transmission of high frequency circuit board.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

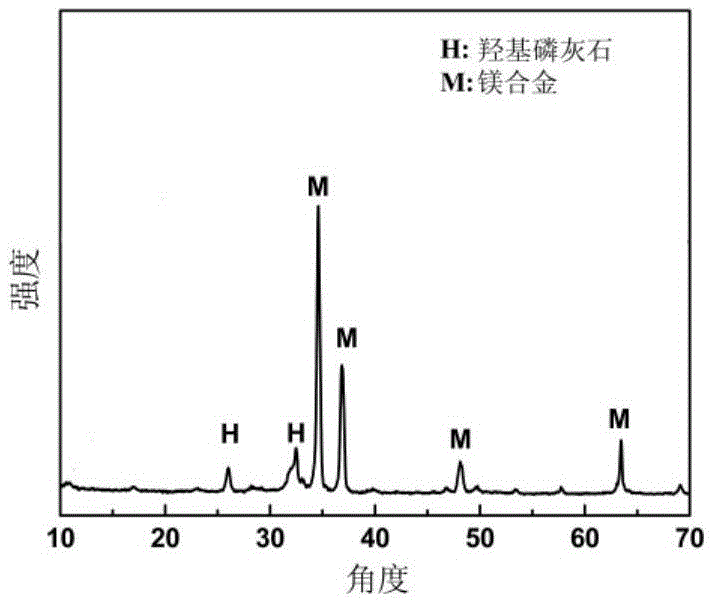

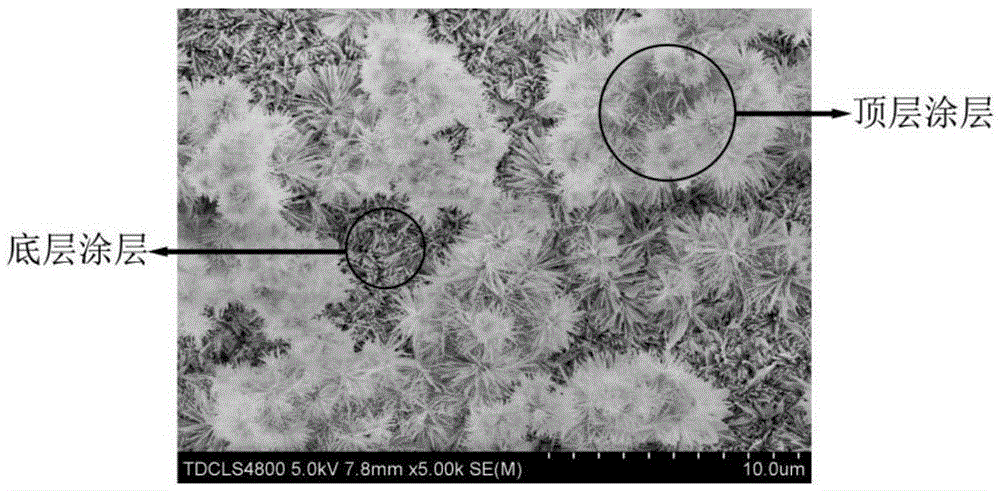

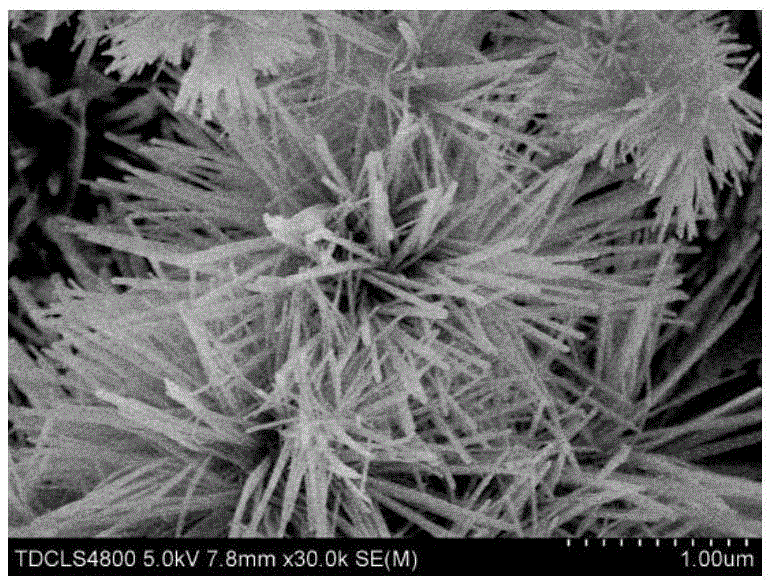

Two-layer crystal whisker-shaped fluorine-doped hydroxyapatite coating on magnesium alloy and microwave preparation method thereof

InactiveCN105457099APromote growthRapid in situ synthesisCoatingsProsthesisBi layerHydroxyapatite coating

The invention discloses a two-layer crystal whisker-shaped fluorine-doped hydroxyapatite coating on magnesium alloy and a microwave preparation method thereof, and belongs to the technical field of degradable magnesium alloy implantation materials. The fluorine-doped hydroxyapatite coating is of a two-layer structure. The length and diameter of the bottom-layer fluorine-doped hydroxyapatite crystal whisker is 0.5-0.8 micrometer and 50-70 nm respectively. The length and diameter of the top-layer fluorine-doped hydroxyapatite crystal whisker is 1.0-2.0 micrometers and 30-50 nm respectively. The microwave preparation method mainly comprises the steps that a conversion coating solution containing Ca2+, PO43- and F- is prepared, and magnesium alloy subjected to alkali treatment is placed in the conversion coating solution and subjected to microwave heating for 10-30 min. The microwave preparation method is applicable to magnesium alloy of any shapes and sizes, the technology is simple, energy is remarkably saved, and the application and popularization value is huge.

Owner:TIANJIN UNIV

Austenitic stainless steel composite resinite manufacture method

InactiveCN104846389AExtended service lifeImprove composite effectMetallic material coating processesElectrophoresisNanopore

The invention belongs to the technical field of metal surface processing treatment and specifically relates to an austenitic stainless steel composite resinite integrated manufacture method. The nanometer processing technology is adopted to enable the surface of austenitic stainless steel to form nanopores, and then, a resin composition is injected into the nanopores effectively to enable the austenitic stainless steel and the resin composition to be composited efficiently to form an integrated body. The manufacture method is good in composition performance, good in stretchability, long in service life of the binding site and resistant to acid and alkali; the formed austenitic stainless steel piece can be subjected to follow-up processes of sandblasting and wire drawing, highlight, PVD colouring and electrophoresis and the like; fraction defective of the products can be reduced; processing procedure is reduced; product development efficiency and product additional valves are improved; and various procedure development cost of the product is reduced.

Owner:深圳市澜博旺纳米科技有限公司

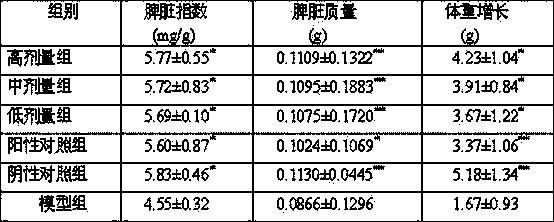

Preparation method and application of low-molecular porphyra haitanensis polyferose compound

ActiveCN103864950AImprove solubilityWide applicabilityOrganic active ingredientsBlood disorderCombinatorial chemistryIron chloride

The invention provides a preparation method and application of a low-molecular porphyra haitanensis polyferose compound. The method is characterized in that low-molecular porphyran is used as a raw material and degraded by redox reaction to obtain low-molecular-weight porphyran with the molecular weight being less than 10000Da; and the polyferose compound synthesized by heating the porphyran and ferric chloride together can be dissolved well and exist stably under a physiological pH condition, and also shows a good effect in the iron-deficiency anemia mouse model experiment. The preparation method has the advantages of being simple and convenient in operation, stable in preparation process, low in preparation cost, etc.; and the preparation method also shows wide applicability to raw materials, namely, any polysaccharide with a proper molecular weight range is applicable to the preparation method.

Owner:HUZHOU TEACHERS COLLEGE

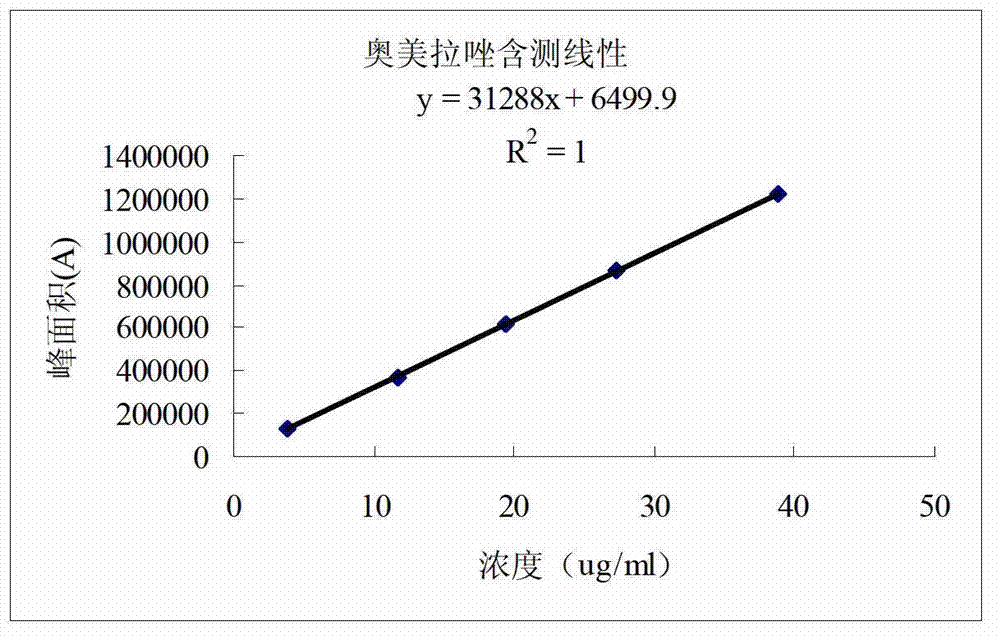

Compound omeprazole capsule and preparation method and detection method thereof

InactiveCN102949410ASimple preparation processEfficient preparation processOrganic active ingredientsChemical analysis using titrationSodium bicarbonateReflux

The invention provides a compound omeprazole capsule, a preparation method and a detection method thereof. The capsule is prepared from the following components in accordance with parts by weight: 200 parts of omeprazole, 1100 parts of sodium bicarbonate and a right amount of magnesium stearate and talcum powder or 40 parts of omeprazole, 1100 parts of sodium bicarbonate and a right amount of magnesium stearate and talcum powder. According to the compound omeprazole capsule, the preparation method and the detection method aiming at the defects of the prior art, the preparation process of the compound omeprazole capsule is optimized, so that the compound omeprazole capsule has obvious curative effects on treating diseases such as peptic ulcers, gastroesophageal reflux diseases and the like which are caused by hyperchlorhydria, and a systemic, integral and effective component identification and content determination method is established, so that the quality of the compound omeprazole capsule can be effectively controlled, thereby guaranteeing the clinic curative effects of the compound omeprazole capsule.

Owner:GUIZHOU XINBANG PHARMACEUTICAL CO LTD

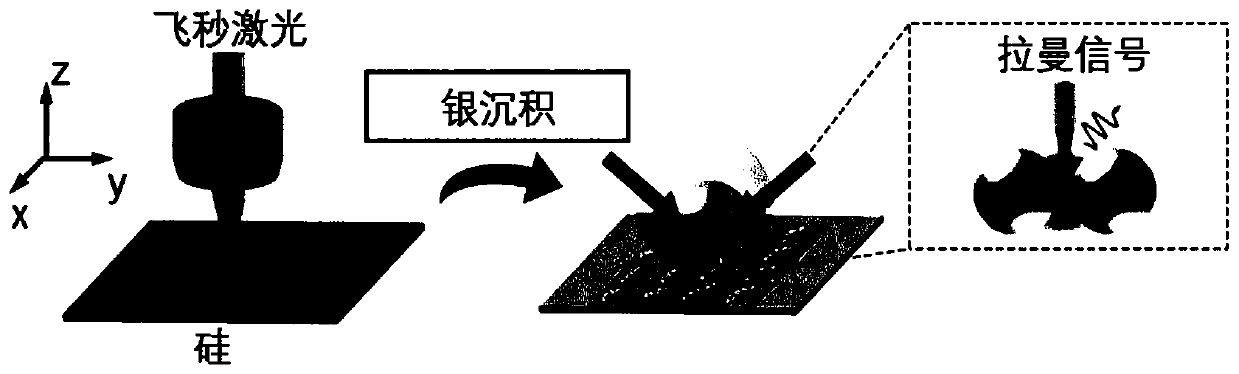

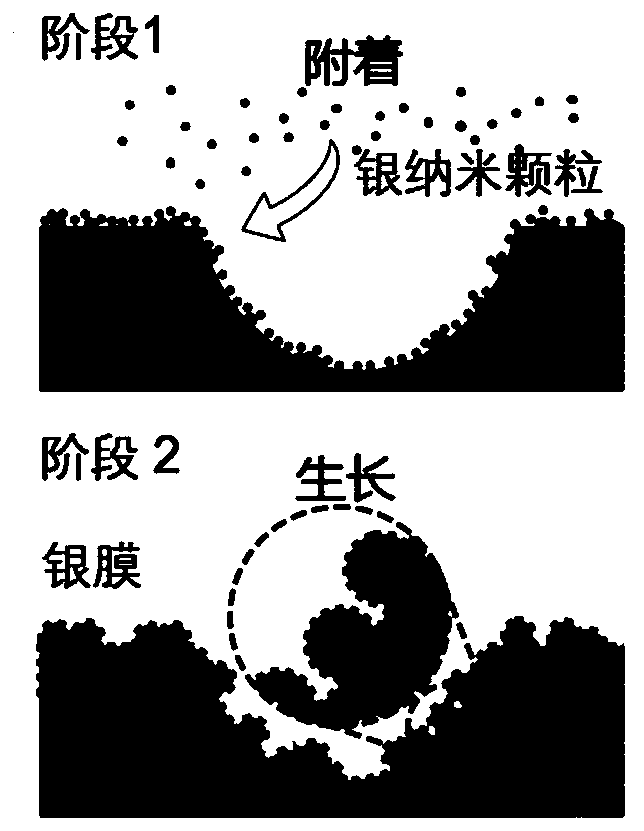

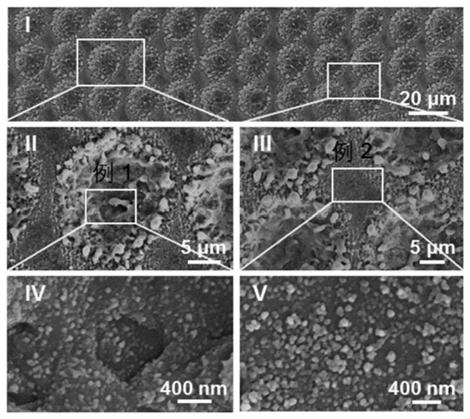

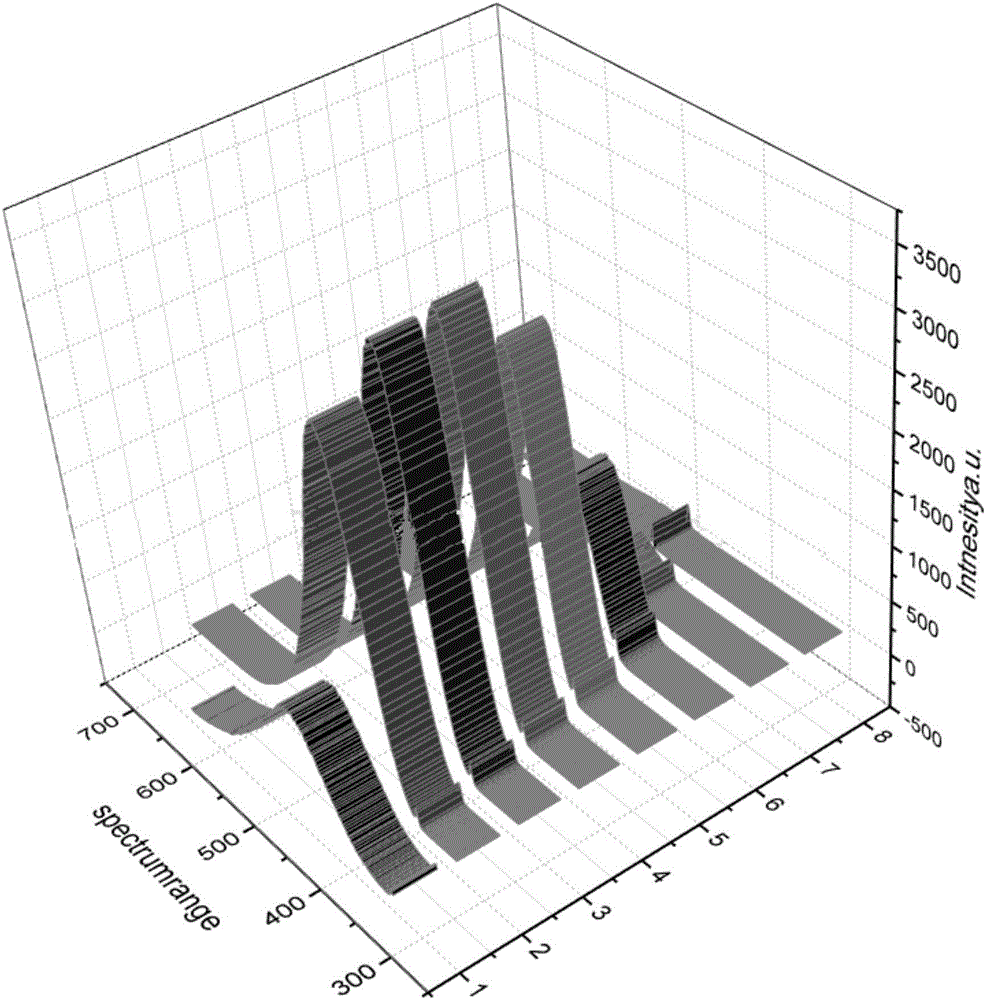

Preparation method of surface-enhanced Raman substrate with layered micro/nano structure

ActiveCN111175284AImprove wettabilityEconomics of preparation processFinal product manufactureRaman scatteringMicro nanoPesticide residue

The invention provides a preparation method of a surface-enhanced Raman substrate with a layered micro / nano structure, which comprises the following steps: irradiating the surface of a silicon or silicon dioxide substrate by using nanosecond to femtosecond laser pulses to form a micro-pit array; cleaning and drying the substrate on which the micro-pit array is formed; and depositing and forming asilver film in the micro-pit array area of the substrate. According to the method, the MA-SERS with the layered micro / nano structure can be prepared through laser treatment from nanosecond to femtosecond and magnetron sputtering; the prepared MA-SERS has good wettability, the contact angle is about 150 degrees, Meanwhile, the enhancement factor of surface enhanced Raman scattering can reach 1.3 *10 < 7 > and is sufficient to detect the molecular level; the preparation process is economical and efficient; the prepared MA-SERS has a wide application prospect in detection of biological medicines, pesticide residues and an ultralow-concentration solution polluted by the environment.

Owner:SOUTHWEAT UNIV OF SCI & TECH

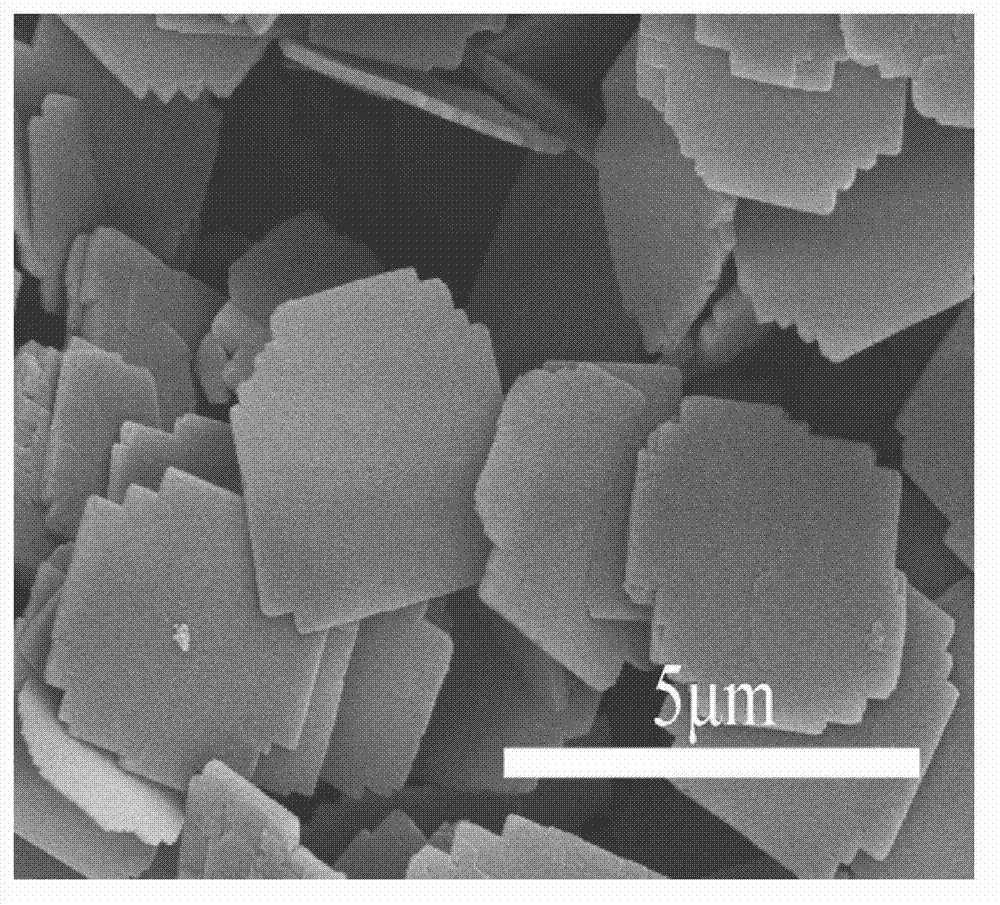

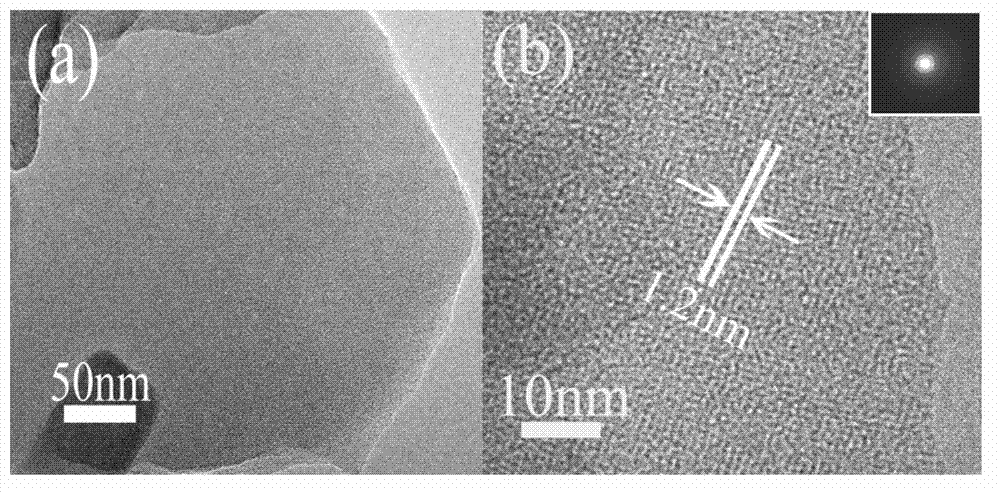

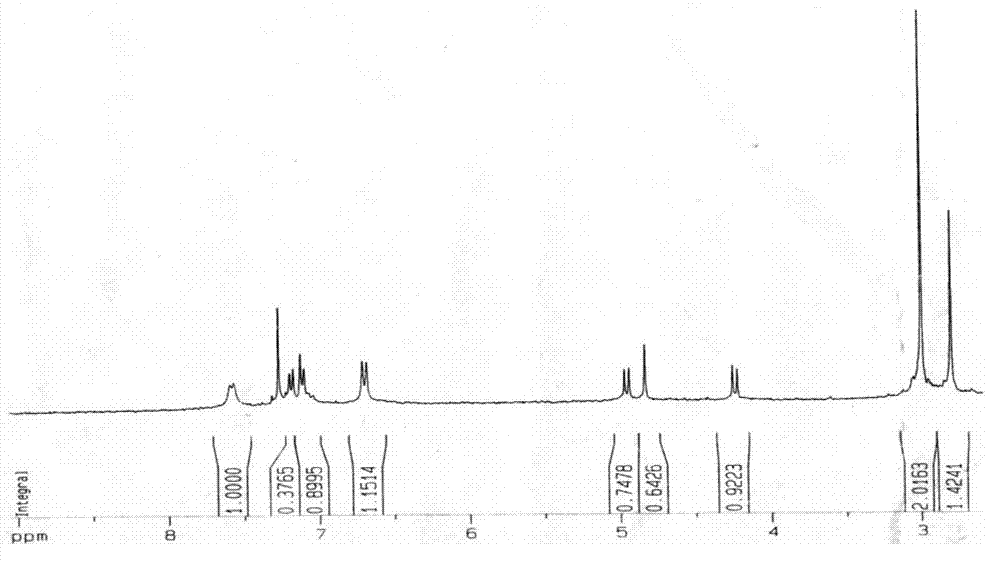

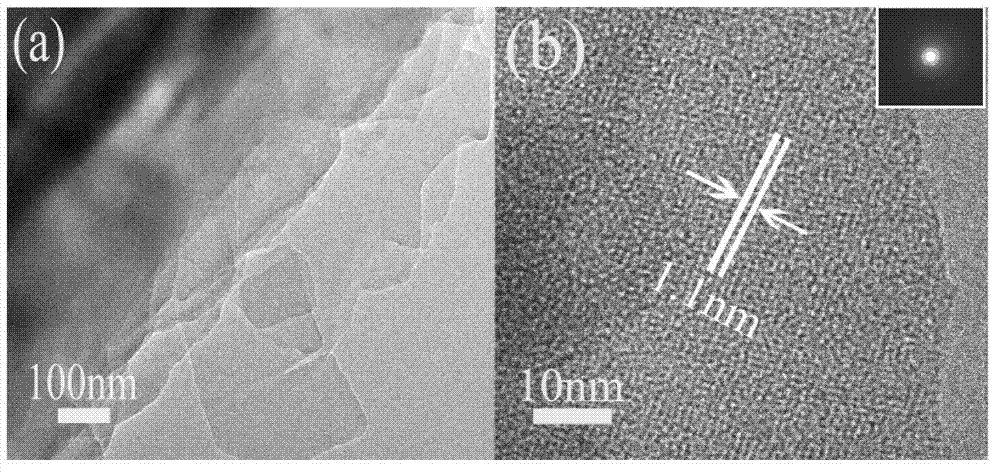

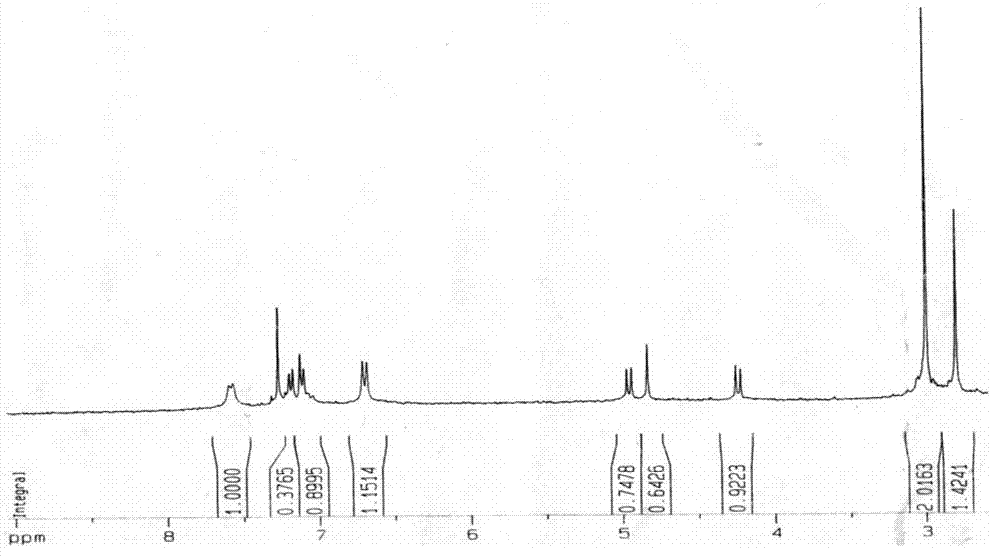

Fullerene derivative micron sheet and preparation method thereof

ActiveCN103242217APromote commercial applicationEasy to operateOrganic chemistryCleansers skinPolymer science

The invention discloses a fullerene derivative micron sheet and a preparation method thereof. The micron sheet is composed of a fullerene C60 derivative, wherein the fullerene C60 derivative is sheet N-methyl-2-[4-dimethylamino]phenyl-3,4-fulleropyrrolidine which has a sheet length in the range from 2 microns to 4 microns, a sheet height in the range from 1 microns to 3 microns and a sheet thickness in the range from 70nm to 80 nm, and is in a single crystalline structure. The method comprises the steps of: mixing the toluene solution of N-methyl-2-[4-dimethylamino]phenyl-3,4-fulleropyrrolidine having the concentration in the range from 0.75 g / L to 2.0 g / L with the isopropanol solution of hexadecyl trimethyl ammonium bromide having the concentration from 3 mmol / L to 7 mmol / L, and then stirring for at least 20 min, thus obtaining mixed solution, wherein the volume ratio of the toluene solution of N-methyl-2-[4-dimethylamino]phenyl-3,4-fulleropyrrolidine to the isopropanol solution of hexadecyl trimethyl ammonium bromide is 1: (1-6); and finally, alternately performing solid-liquid separation and washing treatment on the mixed solution, thereby obtaining the fullerene derivative micron sheet. The fullerene derivative micron sheet can be widely applied to the fields of cleanser, catalyst, hydrophobic material and the like.

Owner:HUANGSHAN UNIV

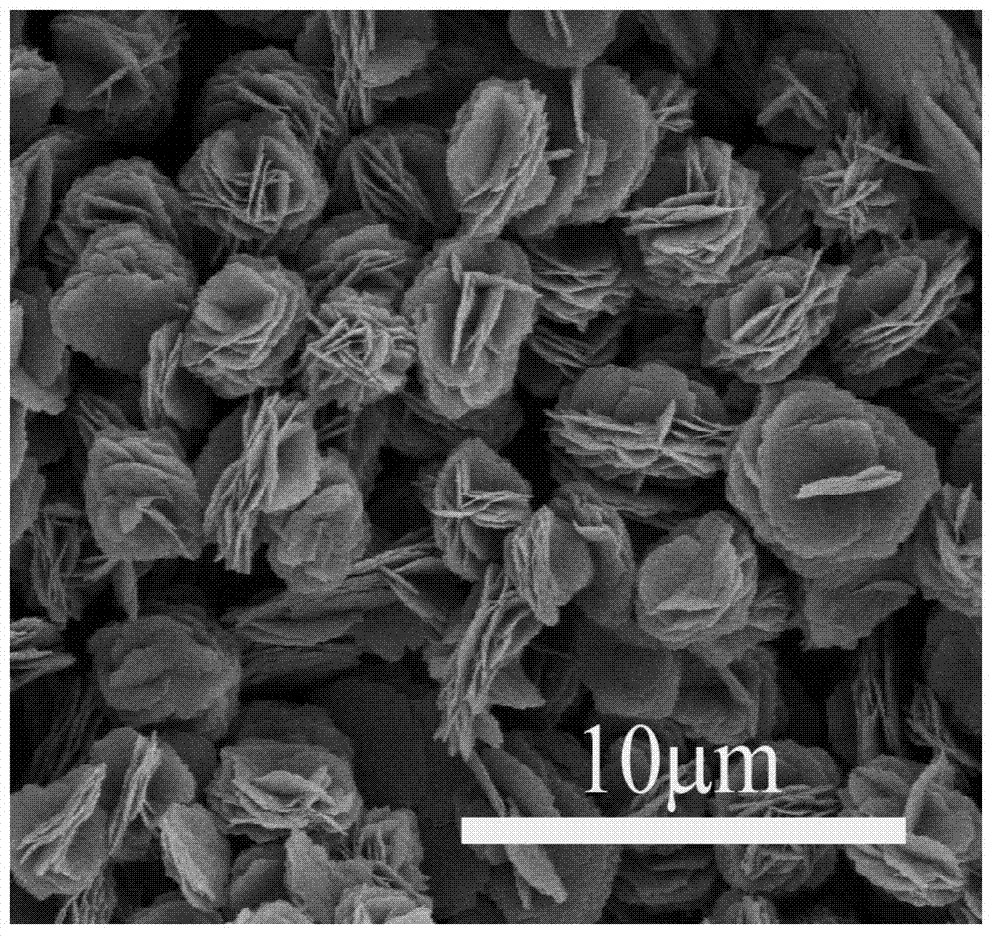

Fullerene derivative micrometer flower and preparation method thereof

InactiveCN103319397ALarge specific surface areaSimple preparation processOrganic chemistryMicrometerAmmonium bromide

The invention discloses a fullerene derivative micrometer flower and a preparation method thereof. The micrometer flower is formed by a fullerene C60 derivative, and particularly is formed by the fullerene C60 derivative N-methyl-2-[4-dimethylamino] phenyl-3,4-fulleropyrrolidine which is shaped like a spherical flower, and the spherical flower is formed by mutually crossed and standing micrometer fragments having a fragment length of 3-5[mu]m, a fragment height of 1-3[mu]m, and a fragment thickness of 20-30 [mu]m, and is of a single crystalline state structure. The method comprises the following steps: a carbon tetrachloride solution of the N-methyl-2-[4-dimethylamino] phenyl-3,4-fulleropyrrolidine and an isopropanol solution of hexadecyl trimethyl ammonium bromide are mixed and stirred to obtain a mixed liquor, wherein the volume ratio of the carbon tetrachloride solution of the N-methyl-2-[4-dimethylamino] phenyl-3,4-fulleropyrrolidine and the isopropanol solution of hexadecyl trimethyl ammonium bromide is 1:1-6. The mixed liquor is treated by alternative solid-liquid separating and washing and then the fullerene derivative micrometer flower is obtained. The fullerene derivative micrometer flower can be widely used in the field of cleaning agents, catalyst and hydrophobic materials and the like.

Owner:HUANGSHAN UNIV

Preparation method of water-soluble carbon dot and application of water-soluble carbon dot in microbial fermentation

InactiveCN106676139ASimple preparation processEfficient preparation processMaterial nanotechnologyMicroorganism based processesQuantum yieldNew energy

The invention discloses a preparation method of a water-soluble carbon dot and application of the water-soluble carbon dot in microbial fermentation, belonging to the technical field of new energy and new materials. According to the preparation method, river crab shell waste is as the raw material, and the acquired carbon dot fluorescence quantum yield can achieve 35% through a simple thermal cracking process. The prepared water-soluble fluorescence carbon dot has biocompatibility, and has an obvious acceleration effect on the fermentation of pneumonia klebsiella pneumonia, the yield of 1,3-propylene glycol can be improved by 30%. Furthermore, the water-soluble fluorescence carbon dot is applied to the standing fermentation of the acetobacter xylinum, the product bacteria cellulose yield can be improved by 75%. The water-soluble fluorescence carbon dot is applied to the microbial fermentation for the first time, and an obvious promotion effect is achieved, and a new growth factor is provided for the microbial fermentation.

Owner:DALIAN UNIV OF TECH

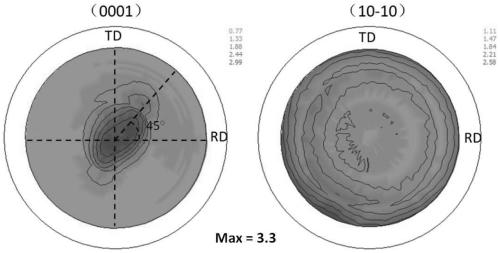

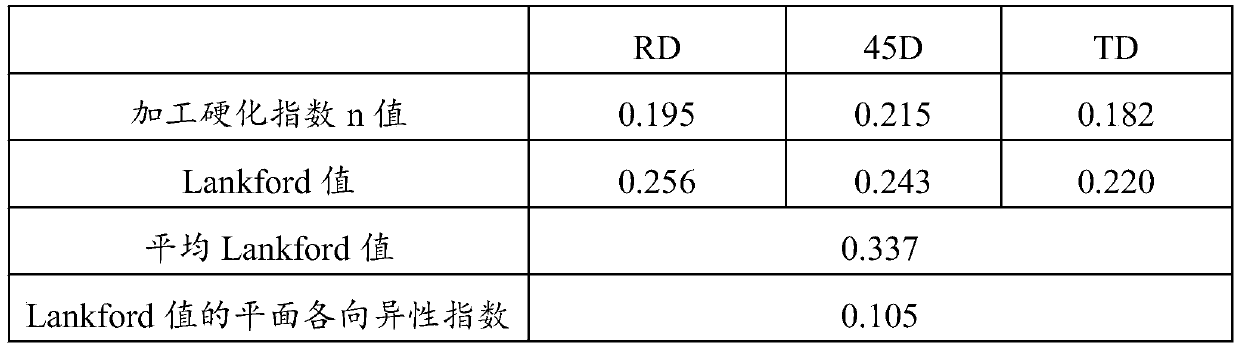

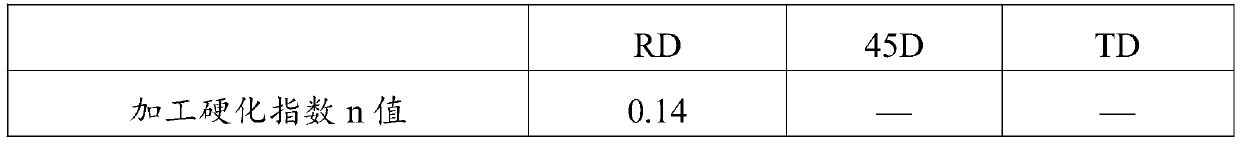

Microalloyed magnesium alloy sheet with high formability and preparation method thereof

The invention discloses a microalloyed magnesium alloy sheet with high formability and a preparation method thereof, and belongs to the nonferrous metal material and machining field, which solves theproblem of poor room temperature plasticity existing in magnesium alloy sheets. The microalloyed magnesium alloy sheet with high formability comprises, by mass percent, 0.5-1.0% of zinc, 0.3-0.6% of ytterbium, 0.2-0.4% of zirconium, and the balance magnesium and inevitable impurity elements. A weak base surface texture is showed through the sheet formed by synchronous cross rolling, the elongations in the rolling direction, 45-degree rolling direction and transverse direction are about 30%, the erishen value is 8.11 mm, and the room temperature formability is good. The key preparative techniques comprise smelting, casting, rolling and annealing, and has the advantages of being efficient, rapid, low in cost, high in operability, good in process stability, capable of realizing batch production easily, energy-saving and environment-friendly.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

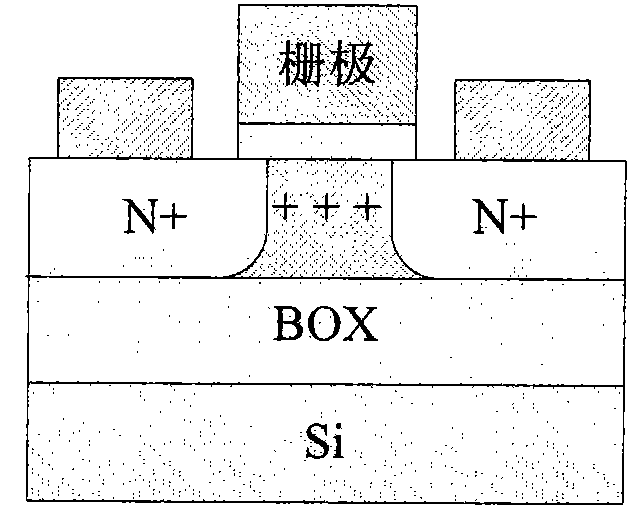

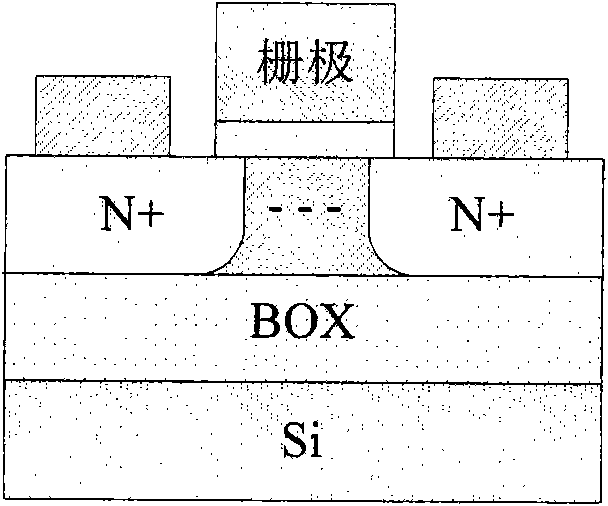

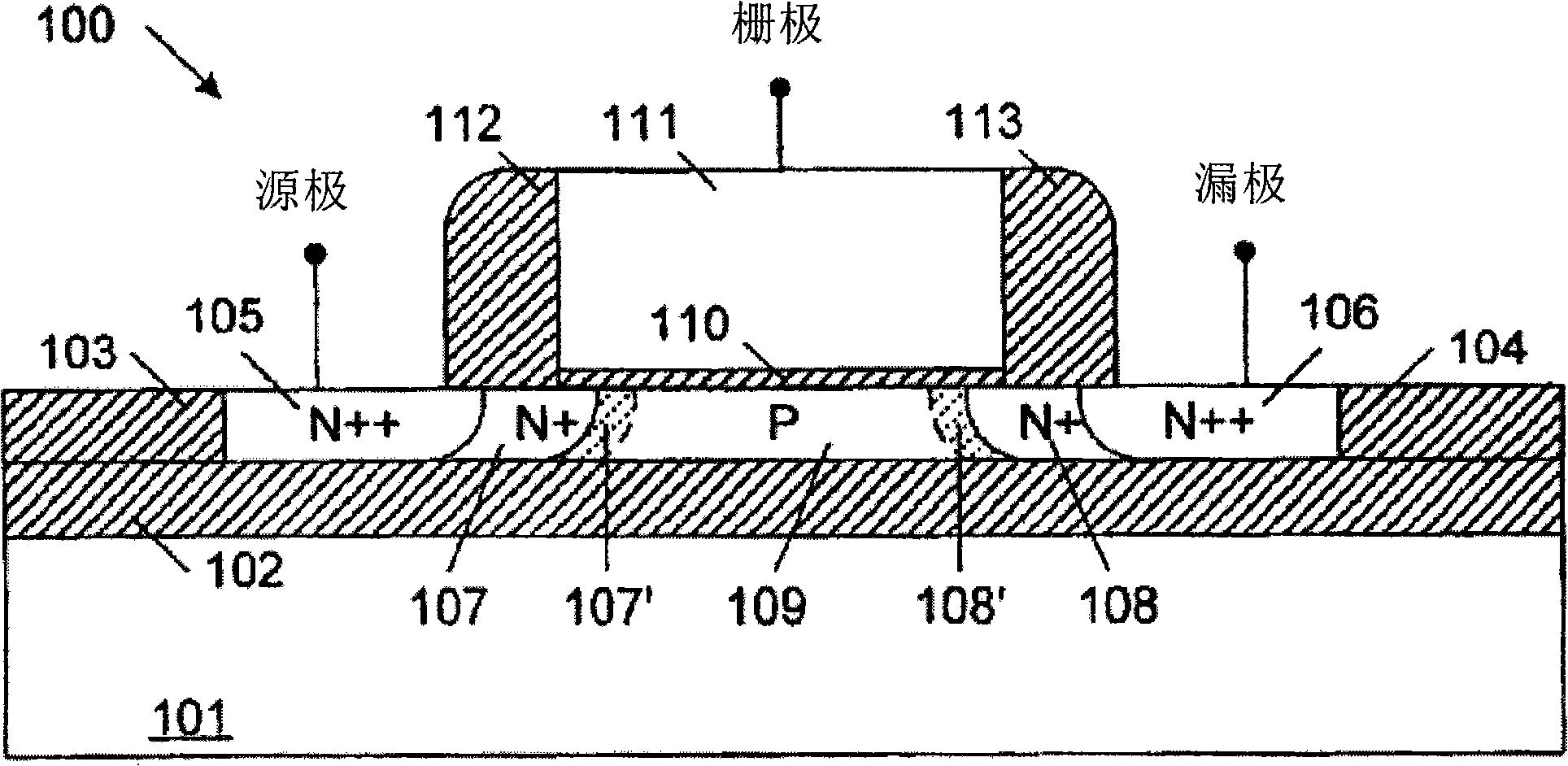

Floating body cell structure of dynamic random access memory and manufacturing technology thereof

InactiveCN101771051ASmall unit areaImprove reliabilityTransistorSolid-state devicesStatic random-access memoryManufacturing technology

The invention discloses a floating body cell structure of a dynamic random access memory and manufacturing technology thereof. The structure comprises an N type semiconductor area on a buried oxide layer (BOX), a P type semiconductor area on the N type semiconductor area and a gate area on the P type semiconductor area. Electric isolation areas are arranged around the P type semiconductor area and the N type semiconductor area. In the invention, isolated floating body gate diodes are employed as the storage nodes. Through tunneling among bands, the state that holes are accumulated in the floating body is defined as the first storage state. Through forward bias of PN junctions, the state that the holes are transmitted from the floating body or the electrons are injected into the floating body is defied as the second storage state. The two states lead to difference of the forward turn-on voltage of the floating body gate diodes (P+ / N+) and can be sensed through the current intensity. The gate diode (P+ / N+) floating body cell of the memory has high efficiency, low power consumption and high density and has the advantages of simple manufacturing technology, high integration density, low cost, high reliability, etc.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

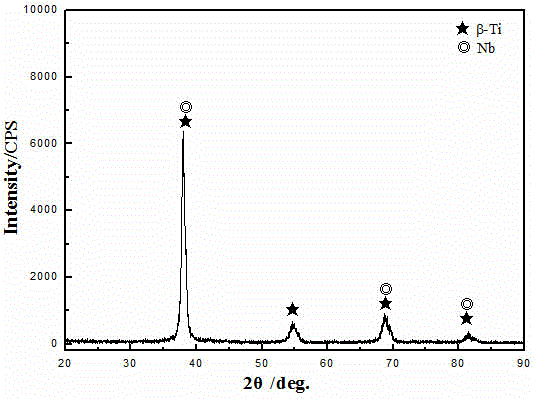

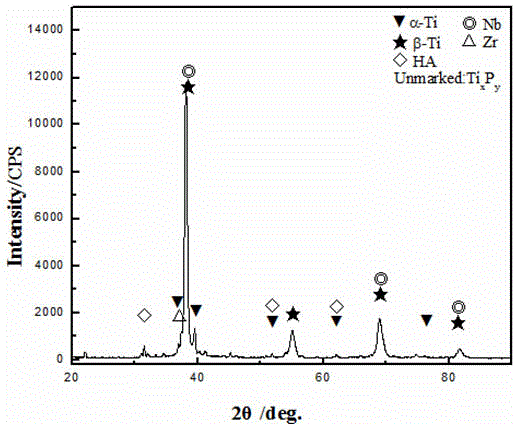

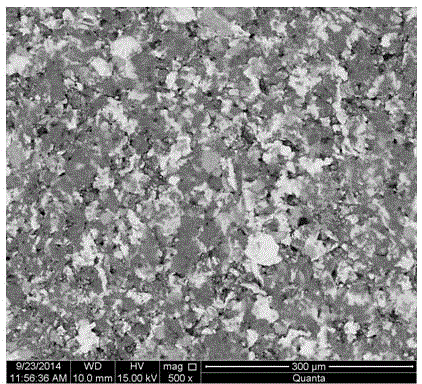

Preparation method of titanium-niobium-zirconium-based hydroxyapatite biological composite material

The invention discloses a preparation method of a titanium-niobium-zirconium-based hydroxyapatite biological composite material and belongs to the field of biomaterial preparation. The composite material of the invention employs titanium-niobium-zirconium alloy as a matrix, and hydroxyapatite as a bio-ceramic; and the weight of hydroxyapatite is 10-25% of that of the titanium alloy. The preparation process is as follows: filling a hydroxyapatite powder and a titanium alloy powder into a mill pot, sealing by alcohol, vacuumizing to 20-30Pa, milling for 6-8 h and drying in a vacuum oven; filling the dry powder into a graphite mold for cold forming; and finally carrying out spark plasma sintering with the sintering temperature at 1100 DEG C-1200 DEG C, first heating to 1000 DEG C by heating rate of in 100 DEG C / min, then heating to the sintering temperature by 25-50 DEG C / min and insulating for 6-10min with the pressure of 50-60MPa. The prepared biological composite material has elastic modulus of 25.4-45GPa, and has good mechanical properties and biocompatibility. The method of the invention is simple in process and low in production cost.

Owner:KUNMING UNIV OF SCI & TECH

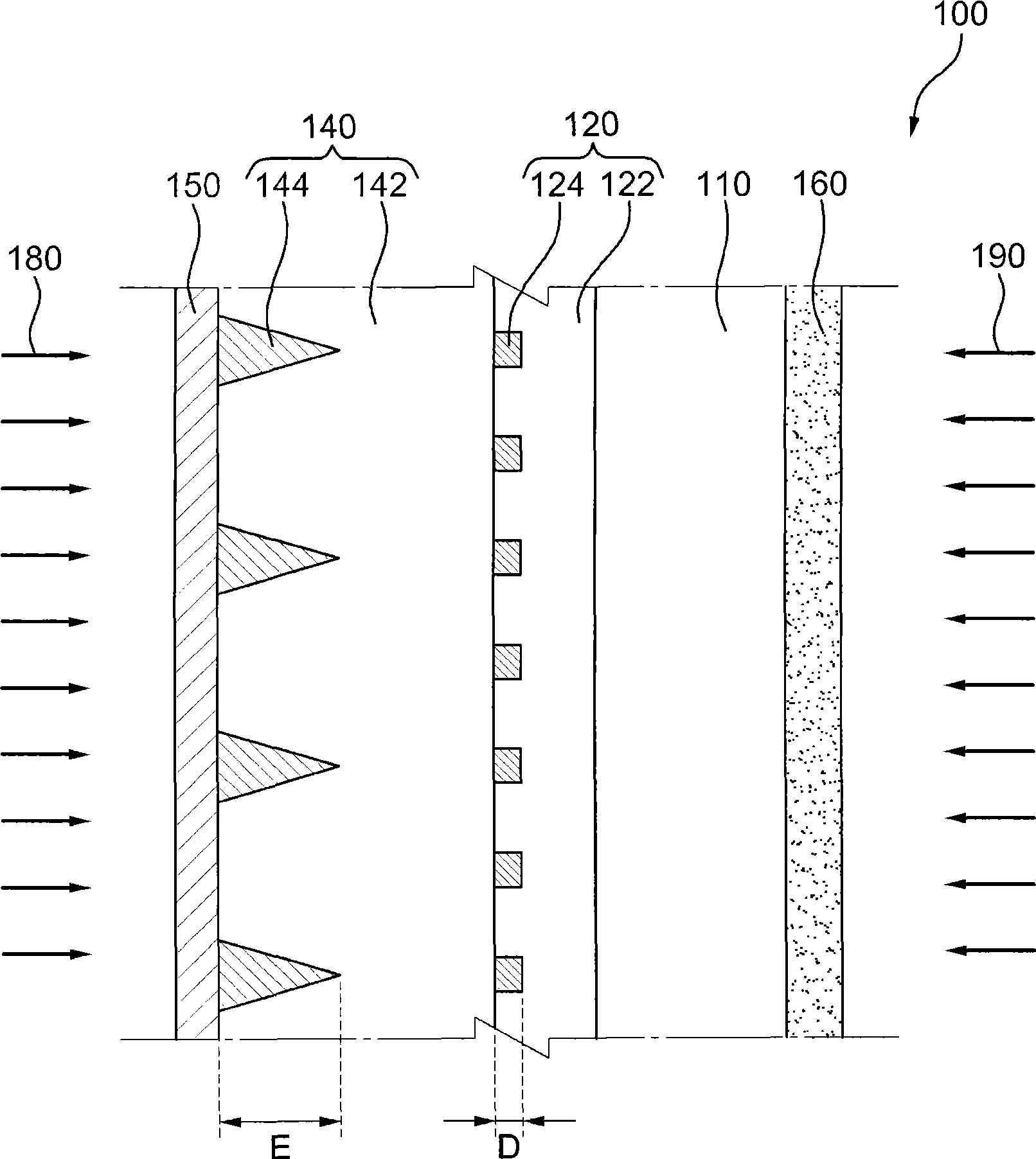

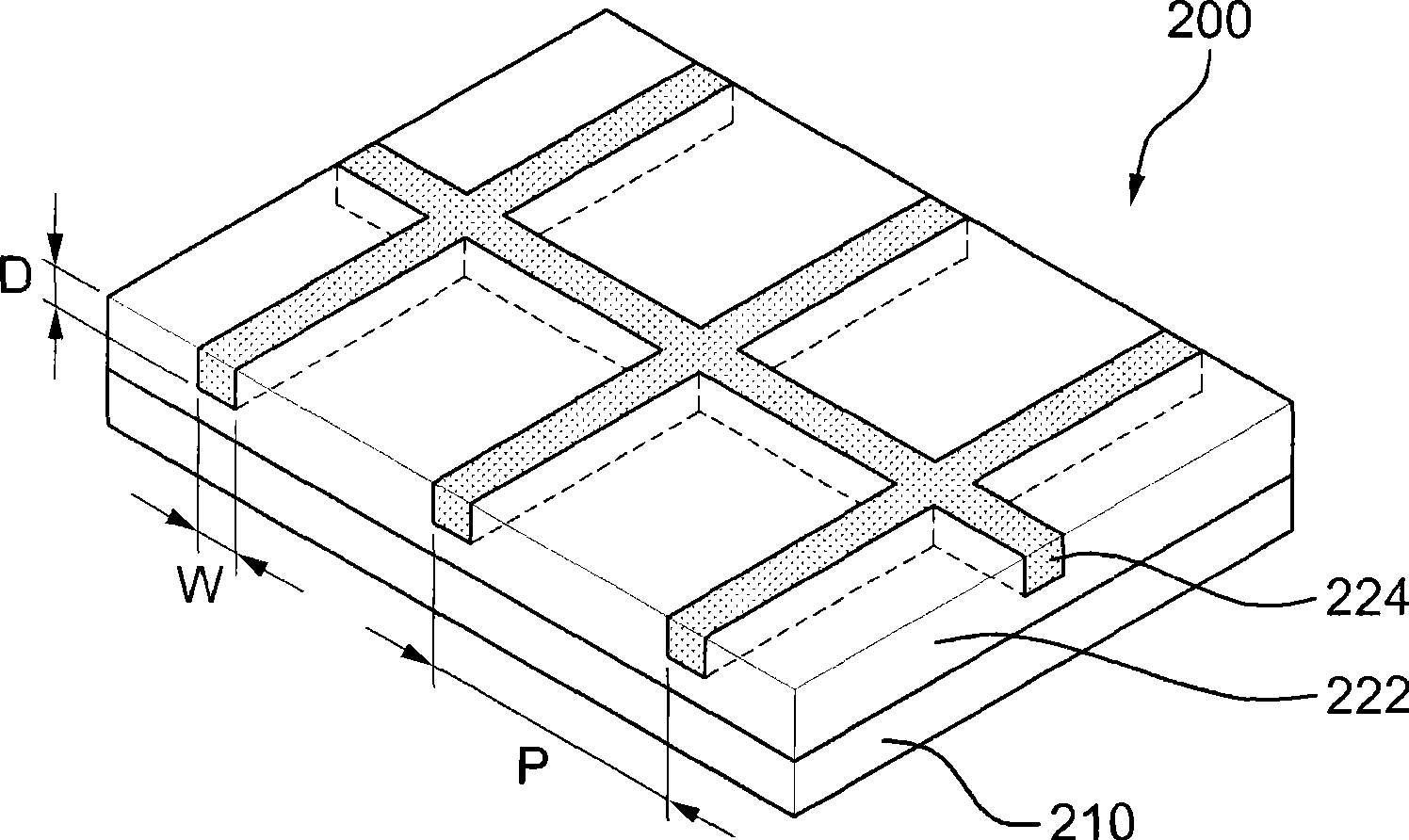

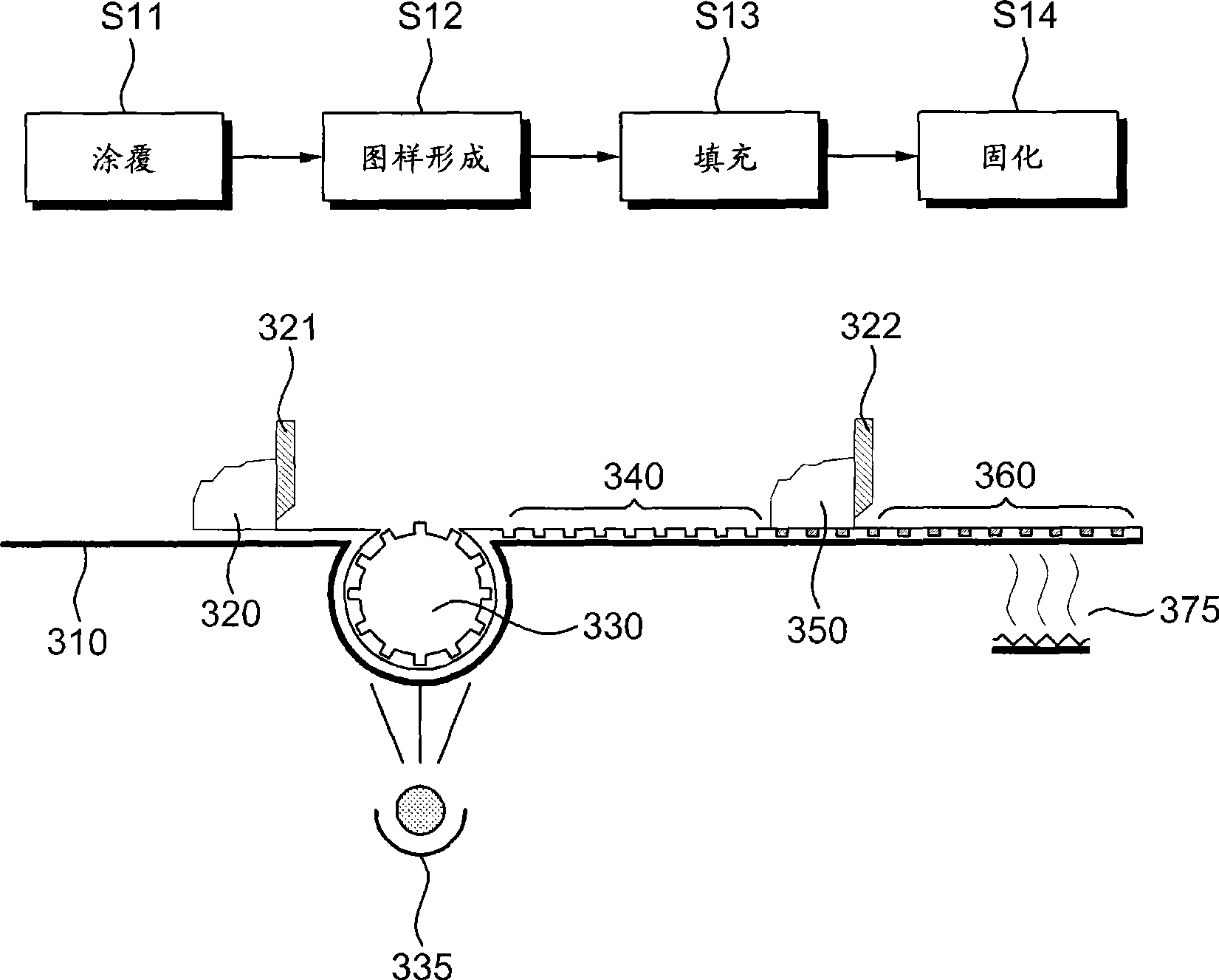

Electromagnetic shielding film for display device, filter having the same, and method of fabricating the same

InactiveCN101441290ARaise the ratioExcellent electromagnetic wave blocking abilityMagnetic/electric field screeningLayered productsDisplay deviceConductive materials

An electromagnetic shielding film for a display device includes a transparent, resinous first base, an intaglio pattern formed on at least one side of the first base, and an electromagnetic shielding pattern containing a conductive material with which the intaglio pattern is filled. A method of fabricating an electromagnetic shielding film for a display device, includes the steps of coating a first curable resin on one surface of a transparent backing, forming an intaglio pattern on the first curable resin using a patterning roll and curing the first curable resin, filling the intaglio pattern with a second curable resin containing a conductive material, and curing the second curable resin.

Owner:SAMSUNG CORNING CO LTD

Green and environment-friendly fertility fertilizer and production method thereof

InactiveCN104177199ATo make up for a certain nutrient deficiencyMake up for the shortcomings of excessFertilizer mixturesNutrient deficiencyPotassium

The invention relates to a green and environment-friendly fertility fertilizer capable of thoroughly improving soil, activating and repairing soil, protecting soil from fertilizer damage, completely restoring the soil, resisting fertilizer damage and preventing pollution, enduringly and strongly activating soil, completely getting rid of soil hardening, enriching vegan nutrition and continuously increasing both production and income. By adopting the methods of conditioning of soil and physiological regulation of crops, synthesis of biological nutrition and recombination of (mother) nutrient components, inorganic and organic combination and the addition of (sub-element) microelement supplements, the green and environment-friendly fertility fertilizer is scientific, targeted and flexible and makes up for the shortcomings that the modern fertilizer has nutrient deficiency or excess easily caused by the fixed ratio of nutrients. The green and environment-friendly fertility fertilizer has the advantages that nitrogen is supplemented if nitrogen is deficient, phosphorus is supplemented if phosphorus is deficient, potassium is supplemented if potassium is deficient, elements are supplemented if elements are deficient, the fertilizer damage is effectively inhibited, the properties of soil are improved, the fertility of soil is improved, the deterioration of soil and environmental pollution are avoided, and thus the green and environment-friendly fertility fertilizer is named as'fertility fertilizer and fertilizer in fertilizer' and is extremely perfect.

Owner:南光日 +2

Herbal tea and its preparation technology

InactiveCN103053759AGood effectFunctional conditioningTea substituesMedicinal herbsActive ingredient

The invention relates to a herbal tea. The raw medicines of the herbal tea comprise 2-4 parts by weight of honeysuckle flower, 5-11 parts by weight of Lycium Chinense, 1-3 parts by weight of chrysanthemum, 12-24 parts by weight of haw, 15-25 parts by weight of Fructus Gardeniae, 6-12 parts by weight of Myosotis sylvatica, 2-6 parts by weight of Folium Isatidis, 8-12 parts by weight of dried orange peel, 20-40 parts by weight of rock sugar and 7-13 parts by weight of red date. The herbal tea has the efficacies of liver calming, eyesight improving, heat clearing, diuresis inducing, blood cooling, detoxifying, fire purging, vexation eliminating, body fluid production promoting, thirst quenching, beauty treating and face nourishing, can effectively treat and alleviate symptoms comprising flushed face and congested eyes, pharyngoxerosis and hoarseness, large-area furuncle, redness and swelling, heat pains, oral erosion, toothache and gum swelling, fretful insomnia, epistaxis bleeding, red tongue and yellow tongue coating, oliguria and dry stool, hot perspiration and the like, and has the characteristics of coolness without coldness, and spleen and lung warming when the internal heat decrease is realized.

Owner:洛阳本草生物制药股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com