Preparation method of titanium-niobium-zirconium-based hydroxyapatite biological composite material

A titanium-niobium-zirconium-based hydroxyapatite and composite material technology, applied in medical science, prostheses, etc., can solve the problems of poor elastic modulus, easy peeling off of the coating, long-term biological stability, low compressive strength, etc., and achieve elasticity Low modulus, short sintering time and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

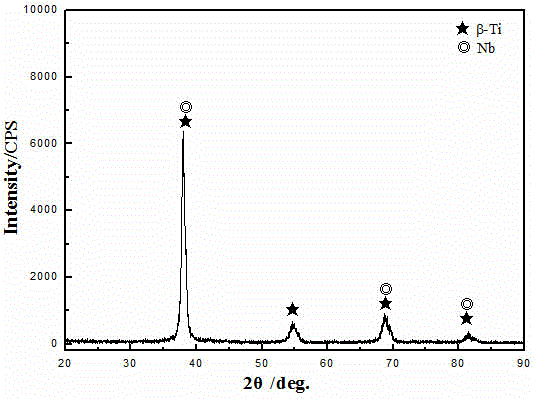

[0022] (1) According to the mass percentage (wt%) of Ti 65%, Nb 30%, and Zr 5%, respectively weigh Ti, Nb, and Zr metal powders with a purity of 99.5%, 99.95%, and 99% and a particle size of 45 μm ;Put the powder into a ball mill jar for mechanical alloying. During the ball milling process, the ball milling medium is stainless steel balls, the ball-to-material ratio is 3:1, sealed with alcohol and then vacuumed to 30Pa, and then ball milled for 7 hours, the obtained metal mixed powder is still placed in alcohol for later use.

[0023] (2) According to 15% of the mass of the mixed metal powder obtained in step (1), weigh the hydroxyapatite powder with a purity of 97% and a particle size of 100nm, add it to the mixed metal powder for ball milling, seal it with alcohol and pump it. Vacuum at 20 Pa, mix for 1.5 h, and then dry in a vacuum oven at 40°C to obtain a mixed powder.

[0024] (3) Put the mixed powder obtained in step (2) into a graphite mold, then put it into a spark pl...

Embodiment 2

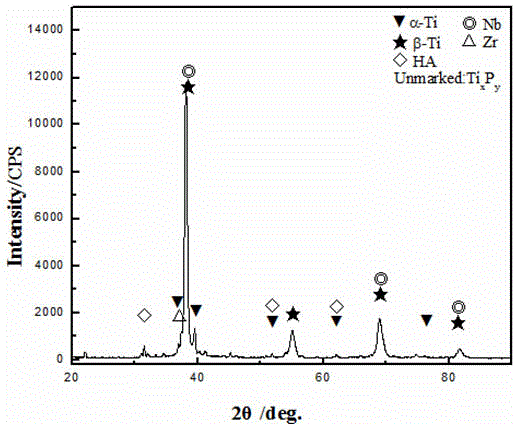

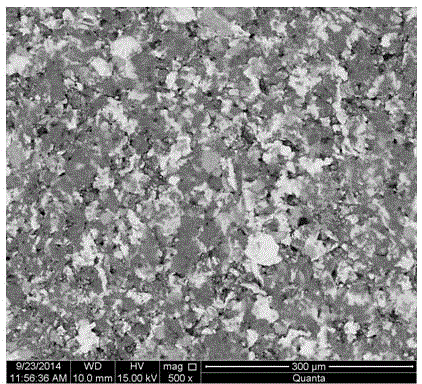

[0027] (1) According to the mass percentage (wt%) of T60%, Nb 34%, and Zr 6%, respectively weigh Ti, Nb, and Zr metal powders with a purity of 99.5%, 99.95%, and 99%, and a particle size of 25 μm; The powder is put into a ball mill jar for mechanical alloying. During the ball milling process, the ball milling medium is stainless steel balls, the ball-to-material ratio is 3:1, sealed with alcohol and then vacuumed to 30Pa, and then ball milled for 8 hours, the obtained metal mixed powder is still placed in alcohol for later use.

[0028] (2) According to 20% of the mass of the mixed metal powder obtained in step (1), weigh hydroxyapatite powder with a purity of 97% and a particle size of 10 μm, add it to the mixed metal powder for ball milling, seal it with alcohol and pump it Vacuum at 25 Pa, mix for 2 h, and then dry in a vacuum oven at 40°C to obtain a mixed powder.

[0029] (3) Put the mixed powder obtained in step (2) into a graphite mold, then put it into a spark plasma ...

Embodiment 3

[0032] (1) According to the mass percentage (wt%) of Ti 67%, Nb 29%, and Zr 4%, respectively weigh Ti, Nb, and Zr metal powders with a purity of 99.5%, 99.95%, and 99%, and a particle size of 30 μm ;Put the powder into a ball mill jar for mechanical alloying. During the ball milling process, the ball milling medium is stainless steel balls, the ball-to-material ratio is 4:1, sealed with alcohol and then vacuumed to 25Pa, and then ball milled for 6 hours, the obtained metal mixed powder is still placed in alcohol for later use.

[0033] (2) According to 10% of the mass of the mixed metal powder obtained in step (1), weigh hydroxyapatite powder with a purity of 97% and a particle size of 20nm, add it to the mixed metal powder for ball milling, seal it with alcohol and pump it Vacuum at 30Pa, mix for 1 h, and then dry in a vacuum oven at 40°C to obtain a mixed powder.

[0034] (3) Put the mixed powder obtained in step (2) into a graphite mold, then put it into a spark plasma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com