Patents

Literature

368 results about "Hydroxyapatite composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing hydroxyapatite composite and biocompatible material

A method for preparing a hydroxyapatite composite is disclosed. This method comprises alternately soaking a matrix which has been made hydrophilic at least on its surface, in a calcium ion aqueous solution containing calcium ions and substantially free of phosphate ions and in a phosphate ion aqueous solution containing phosphate ions and substantially free of calcium ions to securely form hydroxyapatite at least on the surface of the matrix. Also disclosed is a biocompatible material composed of the hydroxyapatite composite obtained by the method.

Owner:NOF CORP +1

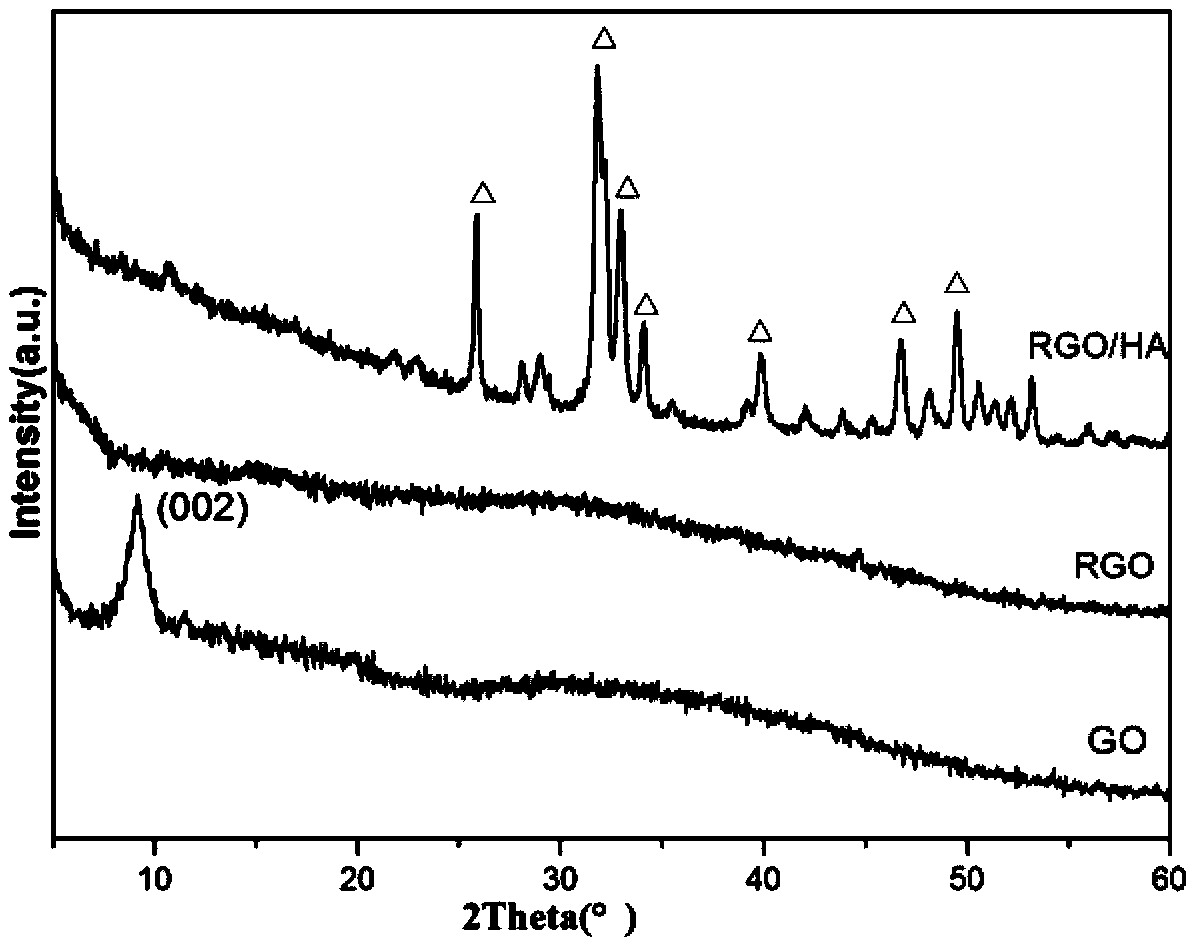

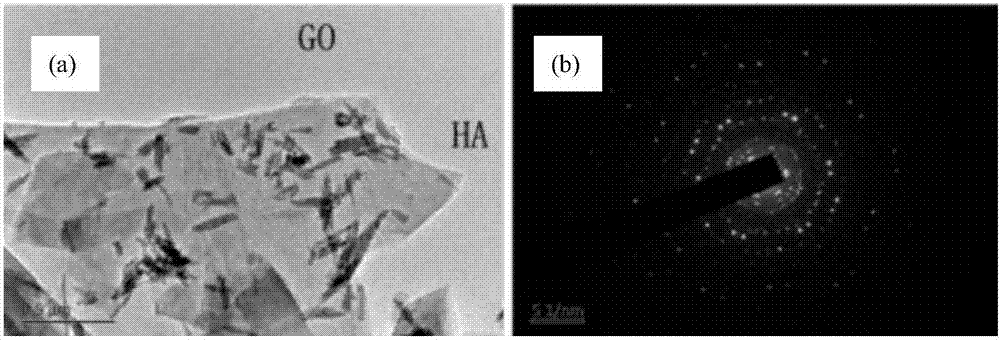

Preparation method of grapheme/hydroxyapatite composite material

InactiveCN103420364AGood biocompatibilityHigh activityCarbon compoundsPhosphorus compoundsApatitePhosphate ion

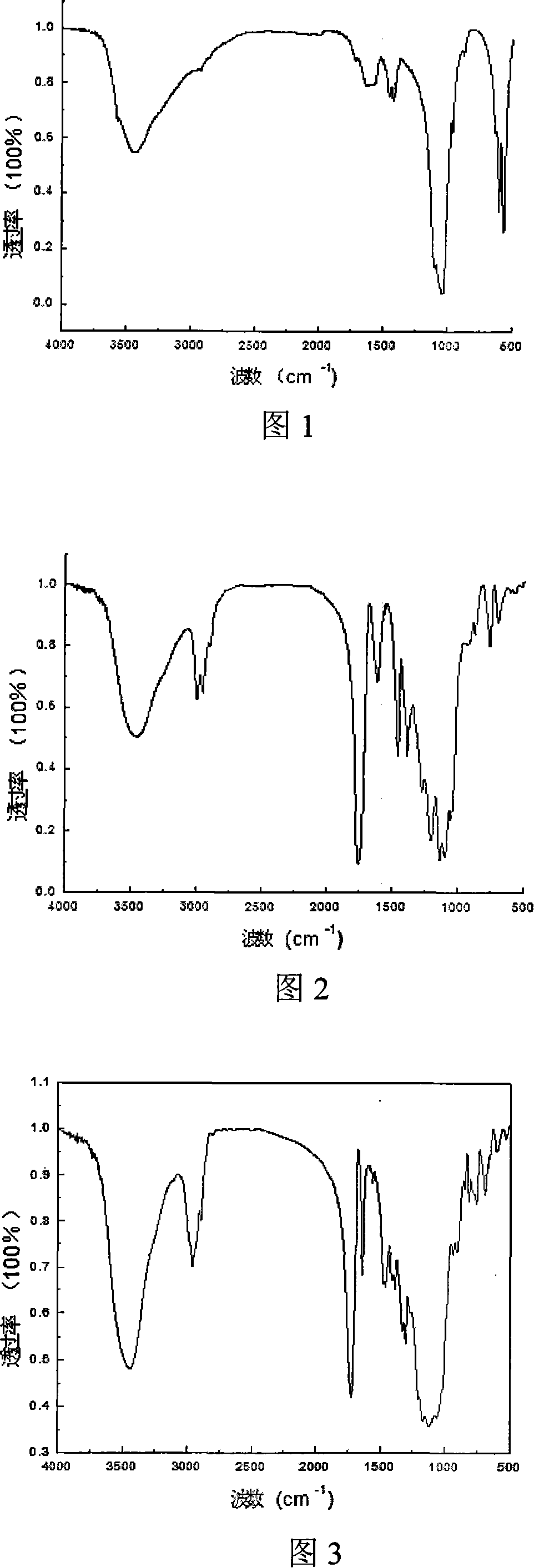

A preparation method of a grapheme / hydroxyapatite composite material comprises the following steps: uniformly mixing oxidized grapheme with the concentration of 0.5-5 mg / ml and a solution or a turbid liquid with the calcium ion concentration of 0.01-3.0 mol / L to obtain a first mixed solution; adding a solution I with the phosphate anion concentration of 0.01-2.0 mol / L to the first mixed solution according to the molar ratio of calcium to phosphorus is (1.5-2.0) to 1, and uniformly mixing the solution I and the first mixed solution under the action of magnetic mixing; adjusting the pH to be 8-14 through a pH adjusting agent to obtain a second mixed solution; transferring the second mixed solution to a reaction kettle; carrying out hydro-thermal treatment for 1-12 hours at the temperature of 160-240 DEG C; cooling the second mixed solution until the temperature of the second mixed solution is the room temperature; cleaning, freezing and drying to obtain the grapheme / hydroxyapatite composite material. The preparation method is environment-friendly, simple and beneficial to large-scale production. The prepared grapheme / hydroxyapatite composite material has the advantages of good mechanical property as well as high electrical conductivity, adsorbability, biocompatibility and osteogenic activity.

Owner:SOUTHWEST JIAOTONG UNIV

Biomimetic Hydroxyapatite Composite Materials and Methods for the Preparation Thereof

Owner:RUTGERS THE STATE UNIV

Silk fibrin and hydroxyapatite compound material and preparation process thereof

The invention discloses a silk hydroxyapatite composite stock and making method, which is characterized by the following: taking the hydroxyapatite and silk protein as base; taking the degelatinized cultivated silk or cloth as reinforcement; solidifying HA power in more homogeneous solution rapidly by adapting solution blending-freezing gel method; elevating temperature above the glass transition temperature of silk solution; adding low-molecular-weight effumable organic reagent to rearrange the silk protein molecule in the freezing solution; gelifing to fix HA powder; formatting pore of certain structure after detaching the water and organic reagent by heating; forming silk hydroxyapatite composite stock with multipore. The invention qualifies good dynamical property, cellular compatibility and right degradation speed to satisfy the need of cell cultivation bracket as bone injuring renovation, medicine control releasing and bone tissue engineering stock with broad prospect.

Owner:SUZHOU UNIV

Collagen/hydroxyapatite composite artificial bone and preparation method thereof

InactiveCN106620869AImprove toughnessNothing producedTissue regenerationProsthesisOrthopedics surgeryFreeze-drying

The invention relates to a collagen / hydroxyapatite composite artificial bone and a preparation method thereof. The artificial bone comprises type I collagen, hydroxyapatite and poly-p-dioxanone. The preparation method disclosed by the invention comprises the following steps: adding the type I collagen in a solvent to prepare a collagen solution, adding an appropriate amount of the hydroxyapatite and performing uniform stirring; placing the mixed slurry in a mold, performing pre-freezing, performing freeze-dried forming, and crushing the freeze-dried forming porous material to obtain blended powder; dissolving the poly-p-dioxanone in tetrafluoroacetic acid to prepare a solution, adding the blended powder in proportion, performing uniform stirring and performing cold press forming; and washing the formed pre-product with water, and drying the washed pre-product to obtain collagen / hydroxyapatite composite artificial bone. The preparation method disclosed by the invention is simple and low in the production cost. The collagen / hydroxyapatite composite artificial bone has compressive strength of 75-90MPa and favorable toughness, so that the collagen / hydroxyapatite composite artificial bone can meet requirements for bone filling and partial replacement in orthopedic surgery.

Owner:WUHAN YIJIABAO BIOMATERIAL CO LTD

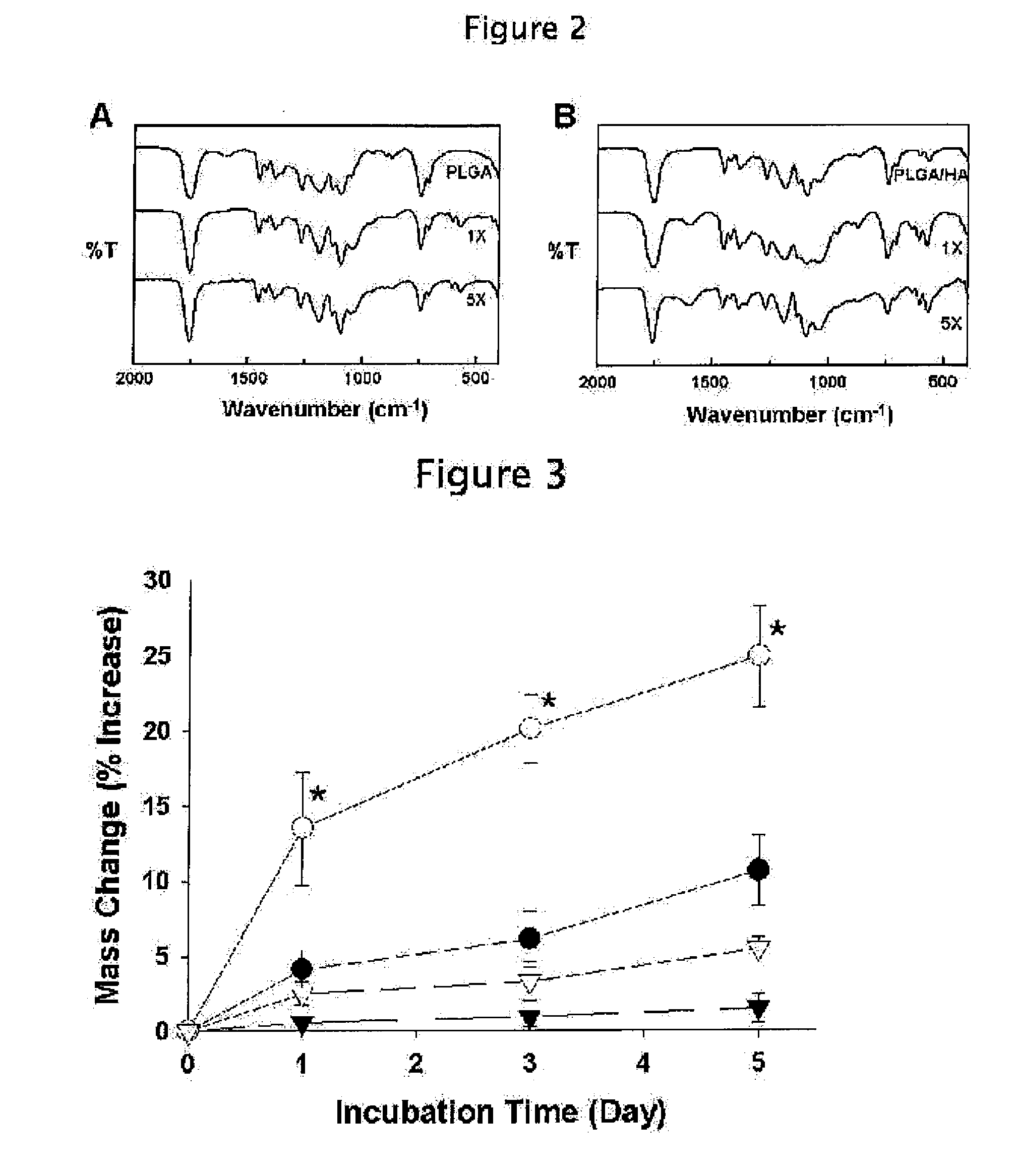

Method for preparing bioactive poly(lactic-co-glycolic acid)/collagen/hydroxyapatite composite fiber membrane for bone repair

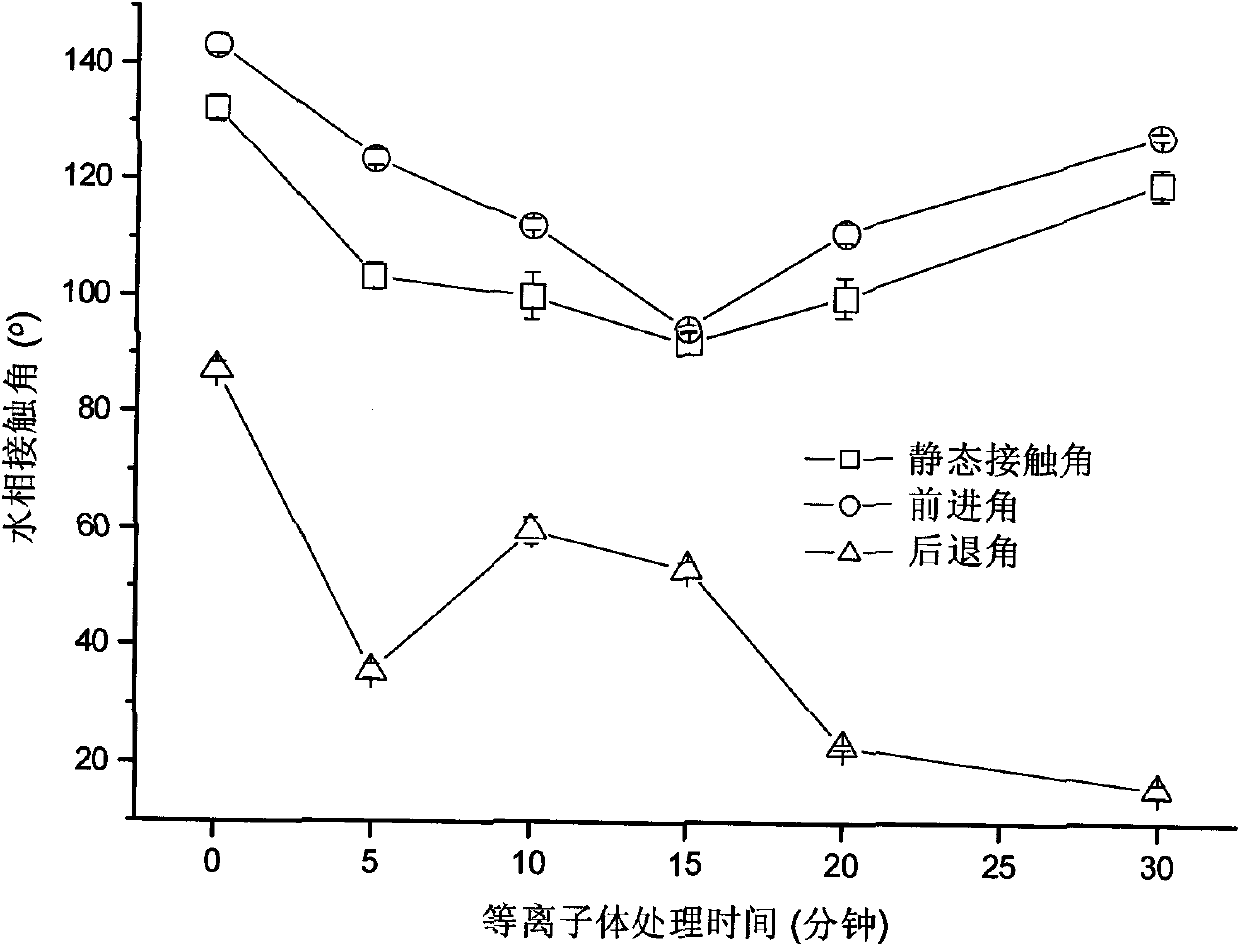

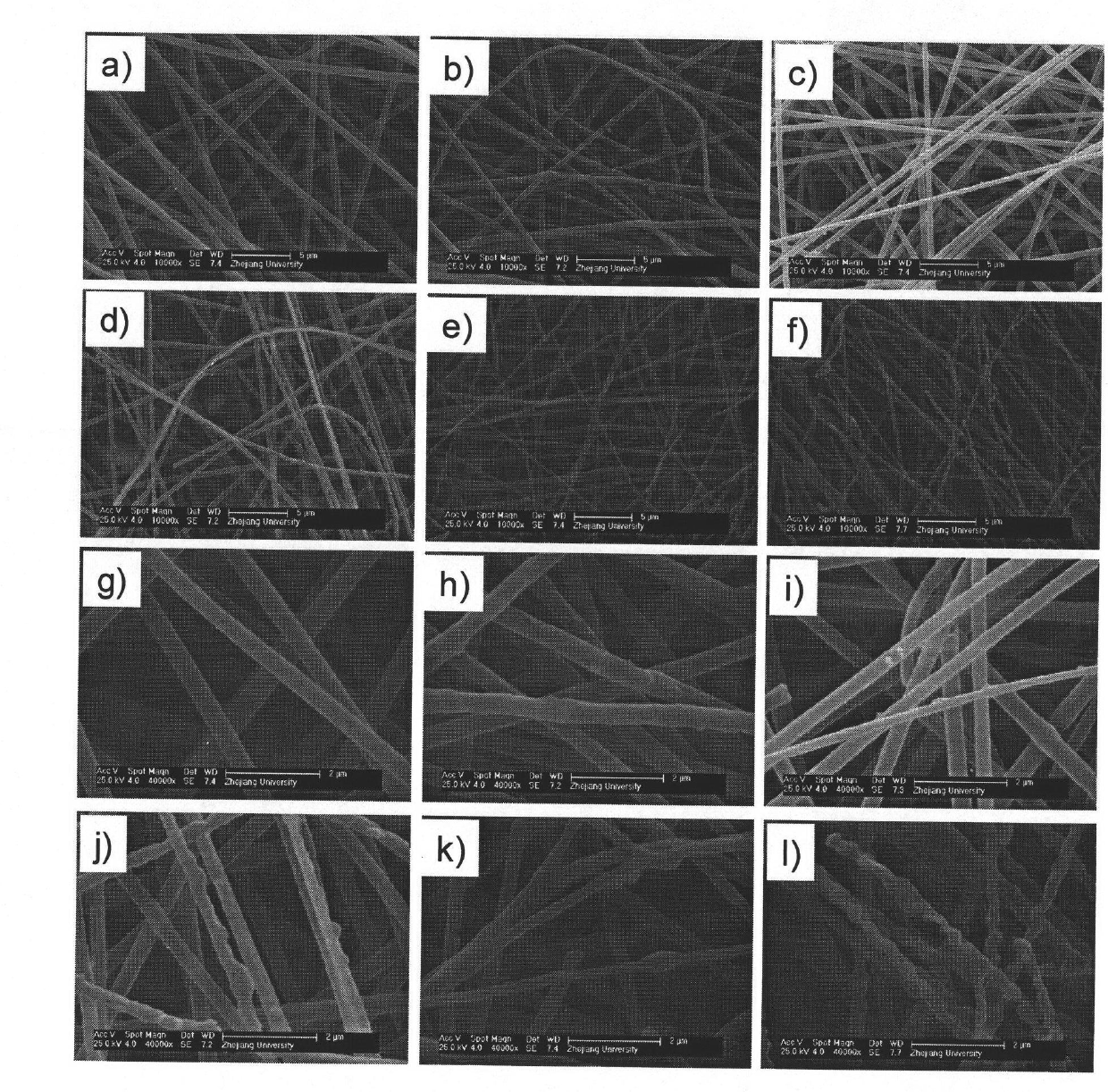

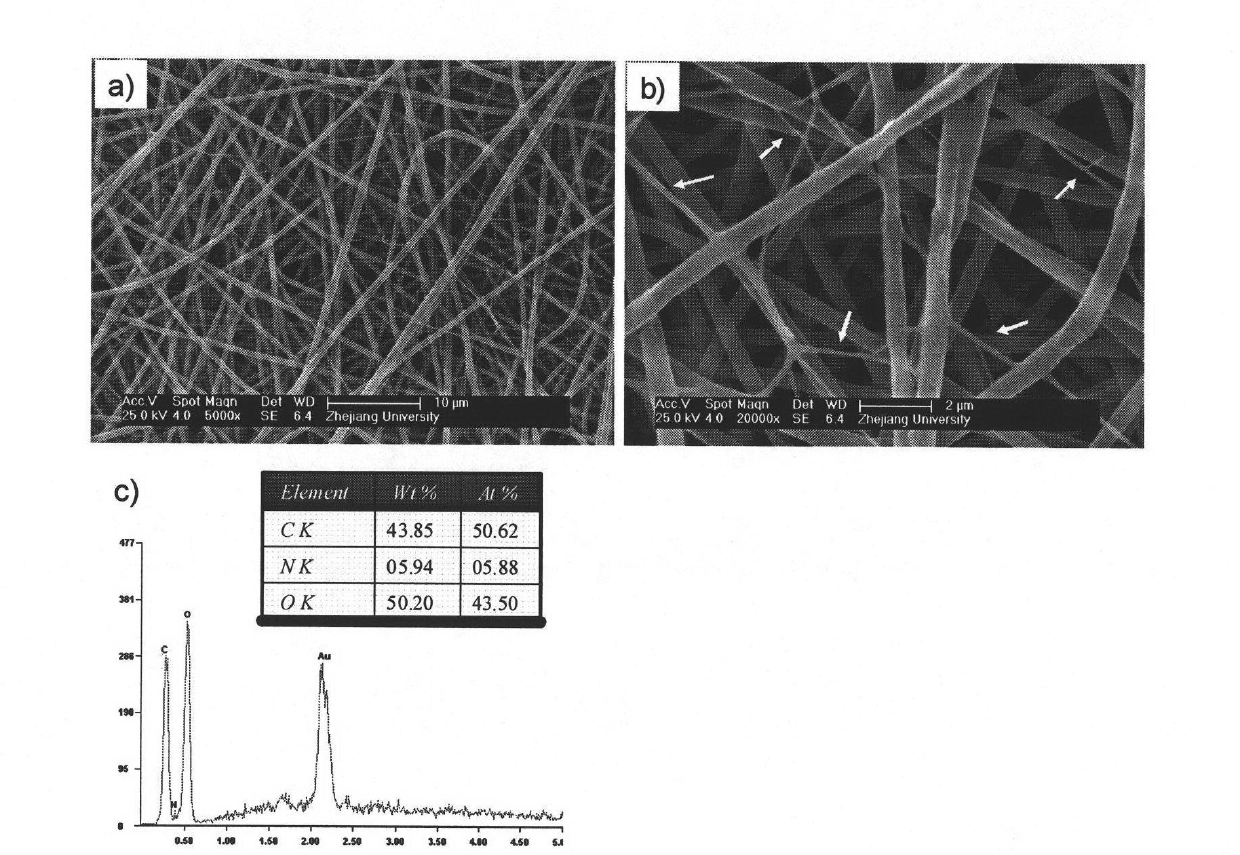

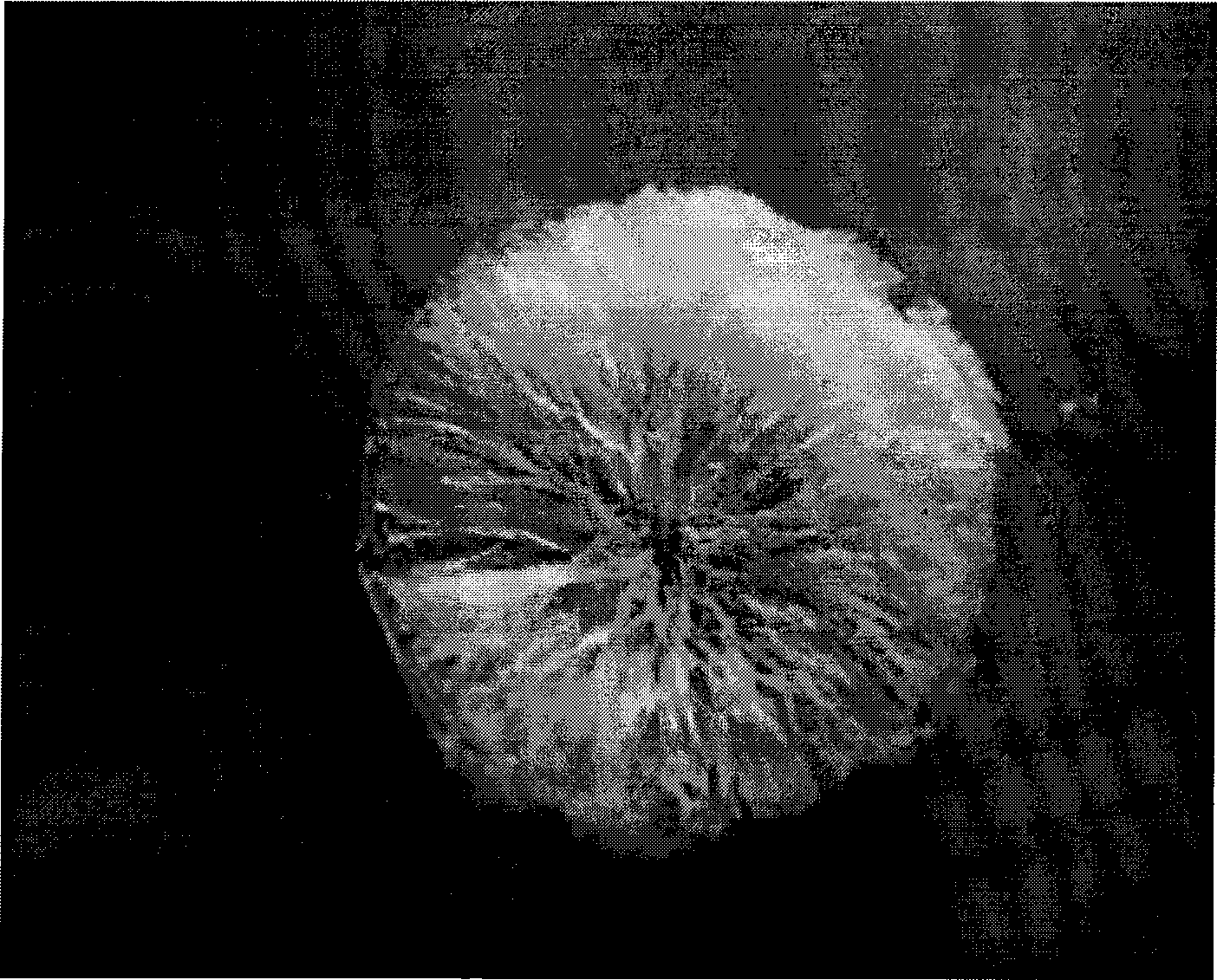

The invention discloses a method for preparing a bioactive poly (lactic-co-glycolic acid) / collagen / hydroxyapatite composite fiber membrane for bone repair. The method comprises the following steps of: treating a poly (lactic-co-glycolic acid) electrospun nanofiber membrane by using plasma, coating collagen, and immersing the poly (lactic-co-glycolic acid) electrospun nanofiber membrane into a simulated human physiologic body fluid to mineralize to obtain the poly (lactic-co-glycolic acid) / collagen / hydroxyapatite composite fiber membrane. The preparation method of the invention has the advantages of simpleness, high speed and wide material sources. By adopting the method of plasma treatment and coating, the highly-bionic nanofiber composite membrane is prepared by the steps of introducing collagen with osteocyte epimatrix into the poly (lactic-co-glycolic acid) electrospun nanofiber membrane and depositing active hydroxyapatite onto the fiber membrane, thereby obtaining. The composite fiber membrane has the advantages of favorable combination properties and convenient operation, can effectively promote the capabilities of adherence, growth and calcification osteogenesis of osteoblasts and stem cells, and is hopeful to become an ideal active bracket for bone repair.

Owner:无锡贝迪生物工程股份有限公司

Method for preparing composite bone repair stent material containing chitosan and hydroxylapatite

The invention discloses a method for preparing chitosan and hydroxyapatite composite bone support materials, which comprises the following steps: a precursor solvent of hydroxyapatite is prepared, and mixed solvents of chitosan and hydroxyapatite are prepared and placed still for defoaming; mixed solvents are evenly applied on the surface of a mould, and placed in alkalescence concreting liquid at room temperature to be concreted into a membrane; then the mixed solvents are injected into the mould, and the mould is put into the alkalescence concreting liquid again; after concretion and demoulding, gel compounded by the chitosan and the hydroxyapatite is obtained, and distilled water is used for washing the gel to neutrality; and only predry, re-freezing and desiccation in vacuum are needed. The support materials have the advantages of three-dimension sequence, good mechanical properties and high porosity, thus promoting the absorption and the growth of cells. The hydroxyapatite granules are evenly distributed in the chitosan kinetosome and can keep the continuous, stable and adagio release of calcium ions and phosphor ions in hydroxyapatite from chitosan kinetosome during the bone repairing process, thus avoiding burst release.

Owner:ZHEJIANG UNIV

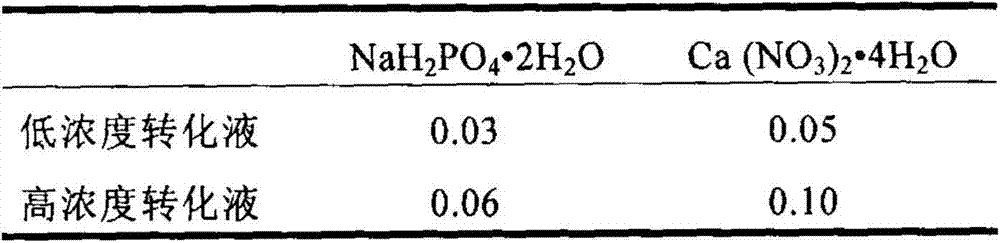

Preparation method of hydroxyapatite/polylactic acid composite coating on surface of medical magnesium alloy

InactiveCN103933611AHigh strengthReduce corrosion ratePretreated surfacesMetallic material coating processesAcid etchingCalcium nitrate tetrahydrate

The invention relates to a preparation method of a hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy, which comprises the following steps of polishing a magnesium alloy basal body to remove an oxidation layer on the surface; carrying out acid etching pretreatment and neutralizing treatment on the magnesium alloy basal body; preparing transfer solution from sodium dihydrogen phosphate dihydrate and calcium nitrate terahydrate; preparing a biomimetic calcium-phosphate coating; dissolving polylactic acid in a chloroform solvent to prepare polylactic acid solution; immersing the prepared magnesium alloy / hydroxyapatite composite material in the polylactic acid solution, and coating the polylactic acid coating on the surface of the magnesium alloy / hydroxyapatite composite material by adopting the solution dip-coating method; and putting the magnesium alloy material for 2-3 days till chloroform in the polylactic acid solution is completely volatilized, thereby obtaining the composite material of which the surface of magnesium alloy is wrapped with the hydroxyapatite / polylactic acid composite coating. Compared with the prior art, the preparation method of the hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy overcomes the disadvantages of the single coating, and therefore, the corrosion resistance and the biocompatibility of magnesium alloy are obviously increased.

Owner:TONGJI UNIV

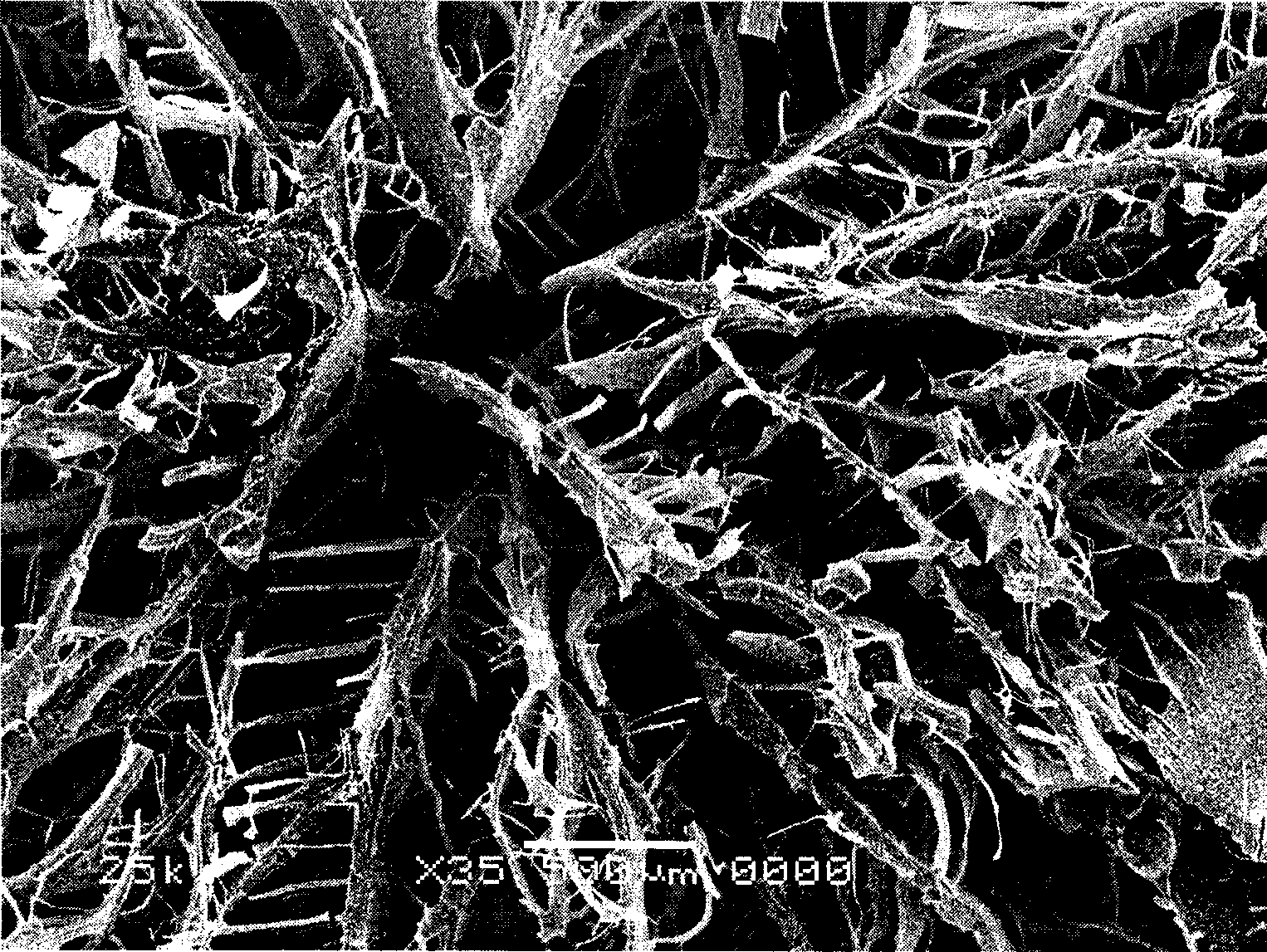

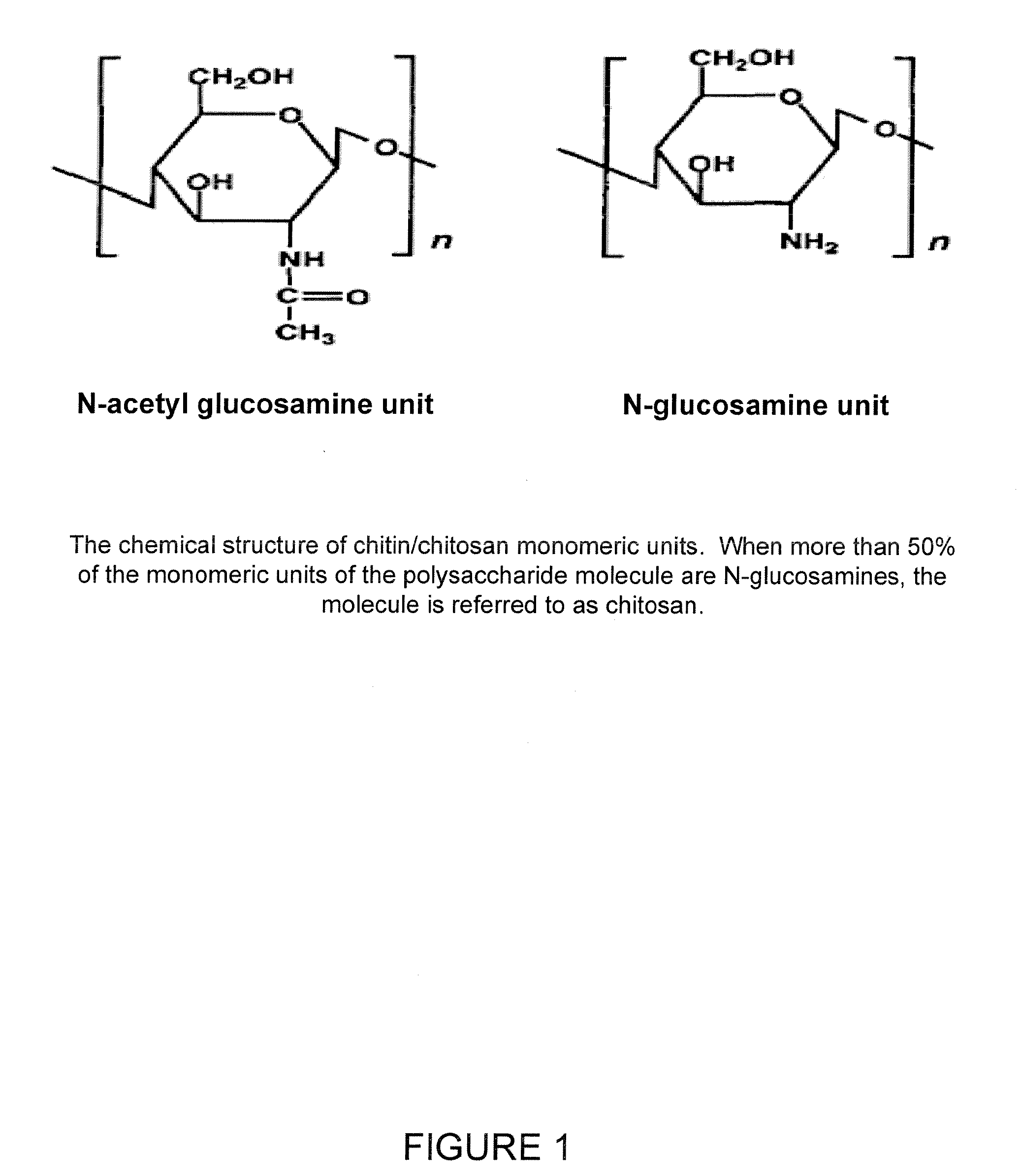

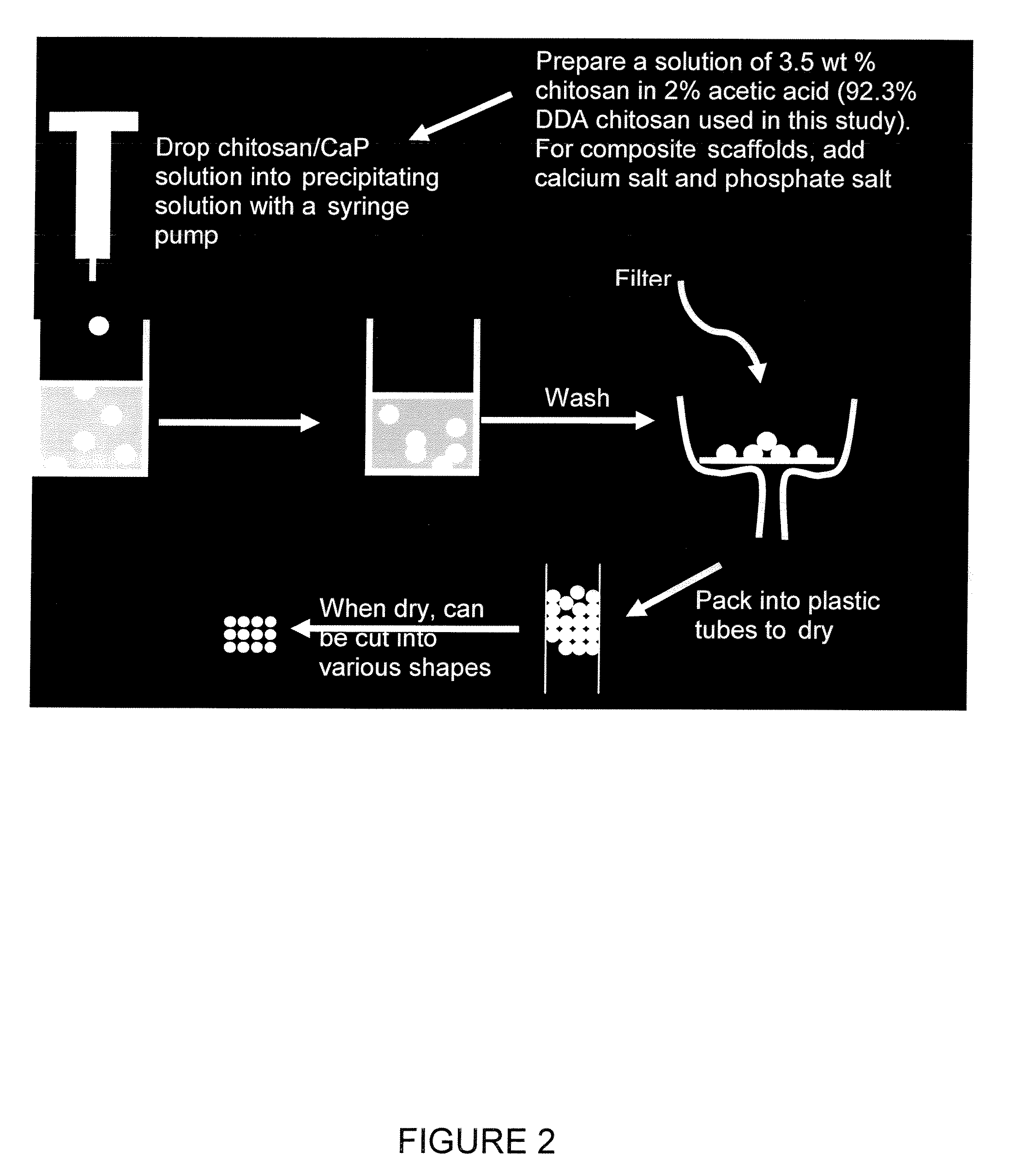

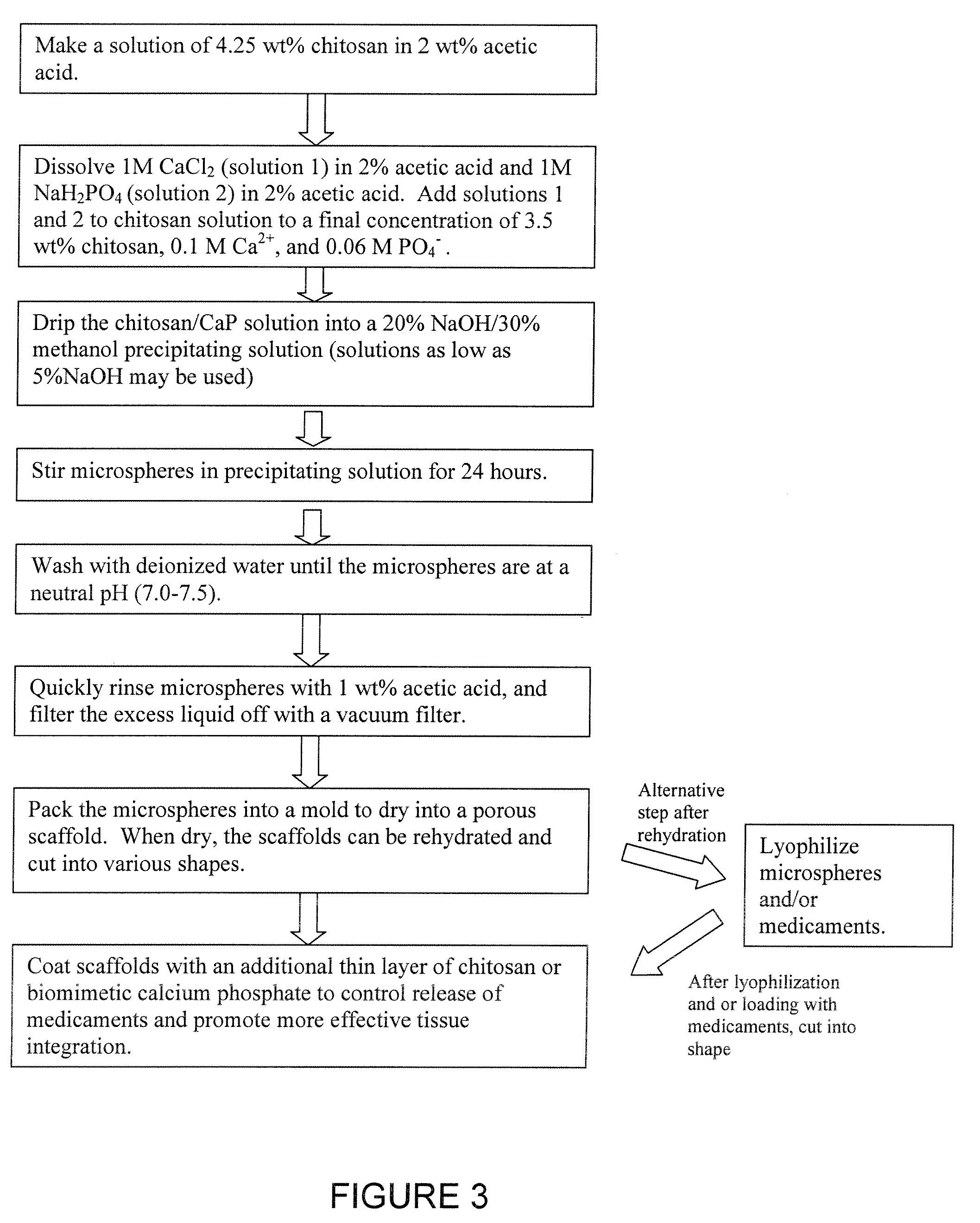

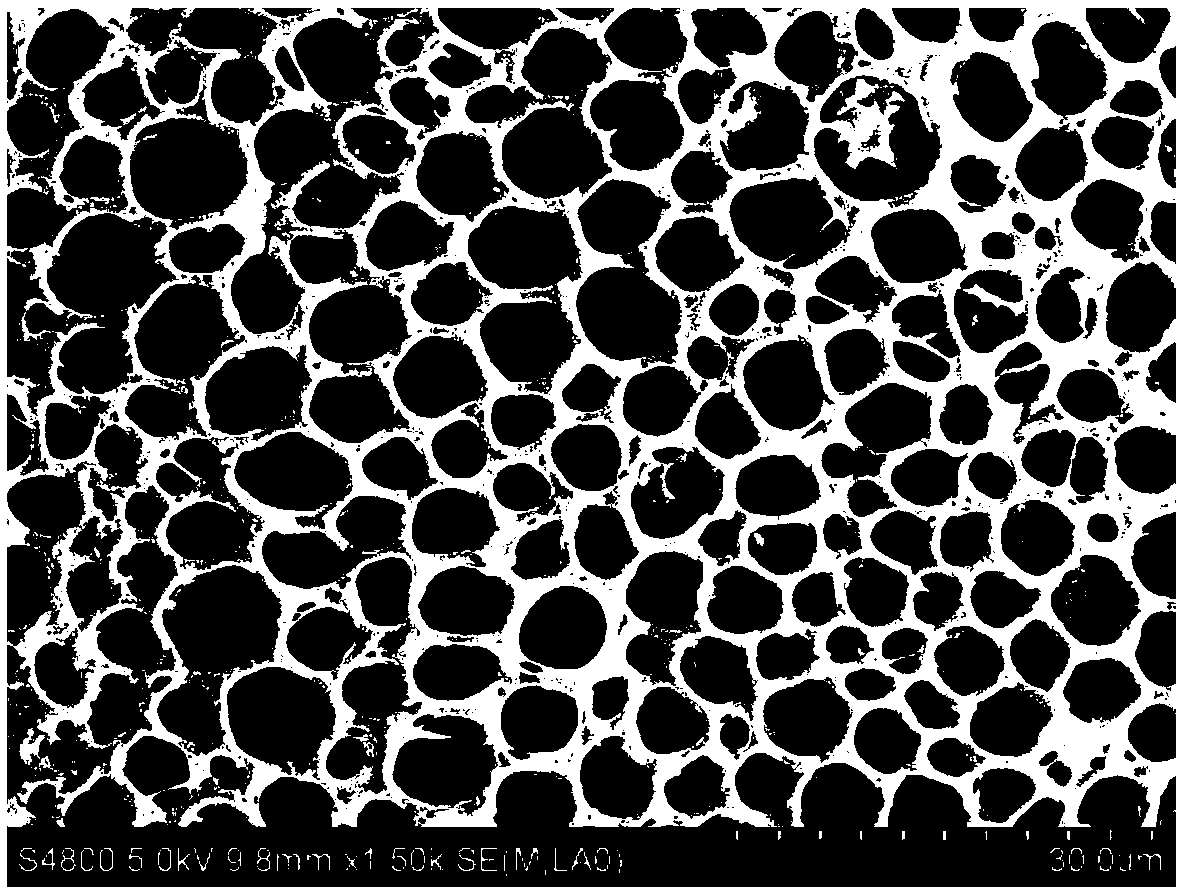

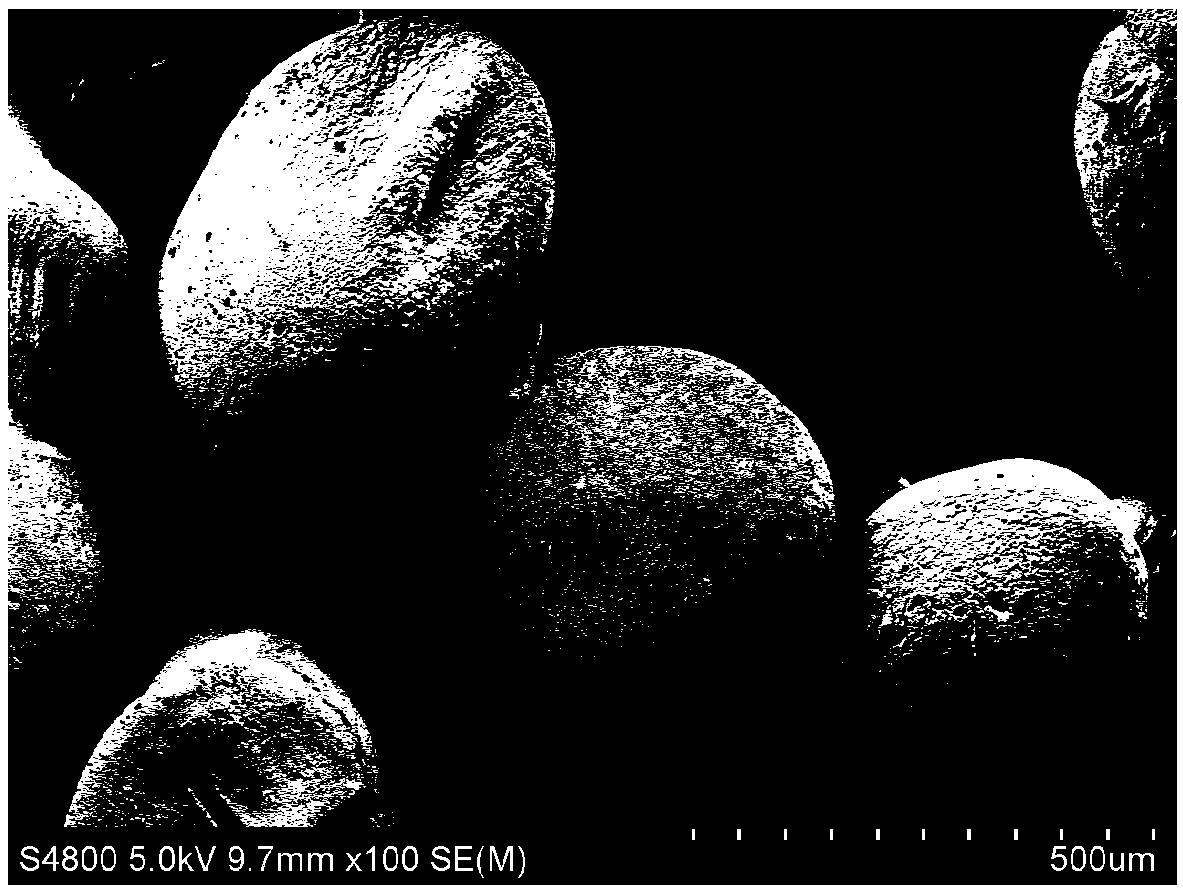

Chitosan/nanocrystalline hydroxyapatite composite microsphere-based scaffolds

InactiveUS20070254007A1High strengthReduce moisture contentBiocideOrganic active ingredientsMicrosphereOsteoblast

A composite chitosan / nano-hydroxyapatite microsphere-based material used for bone-grafting and delivery of therapeutic agents. The composite material may be produced using co-precipitation methods. The composite material may be used to form scaffolds with significantly greater surface area and surface roughness than scaffolds composed of only chitosan. Composite scaffolds exhibit less swelling and greater toughness and flexibility than scaffolds fabricated by other techniques. Composite scaffolds also exhibit greater osteoblast proliferation. Composite scaffolds also may contain therapeutic agents or medicaments, and may be lyophilized.

Owner:BUMGARDNER JOEL D +5

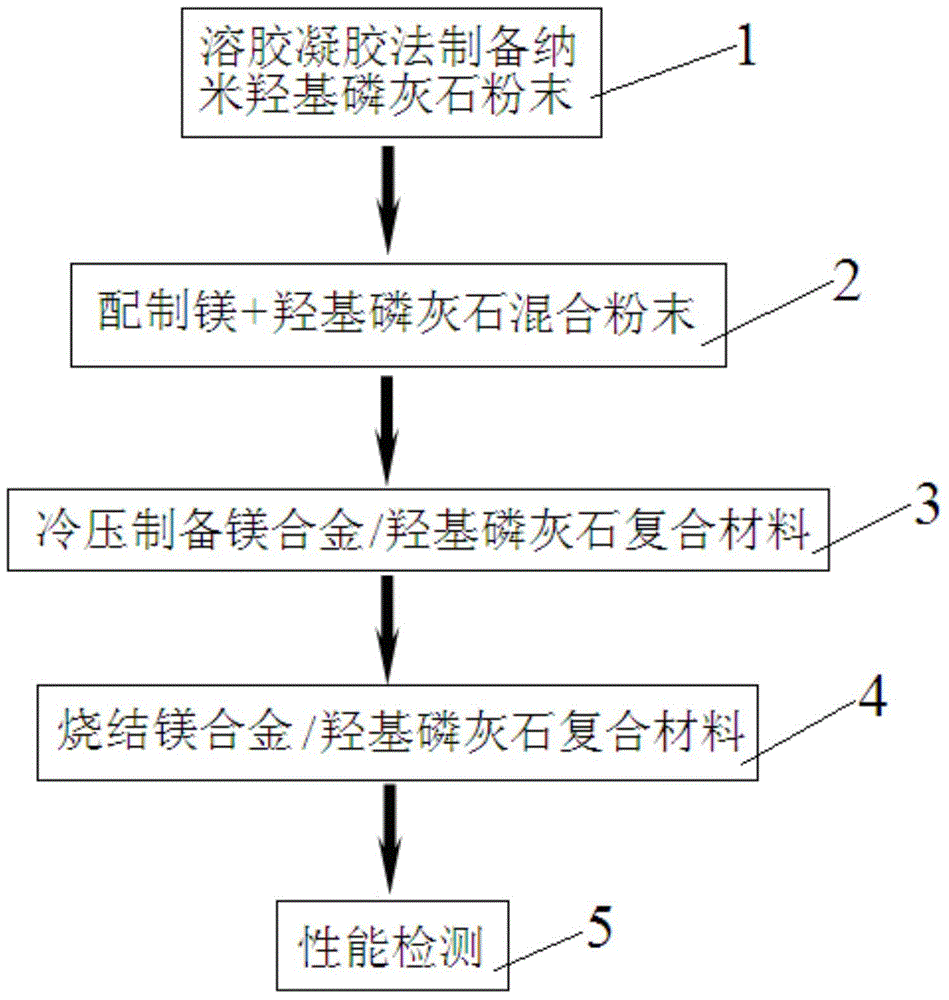

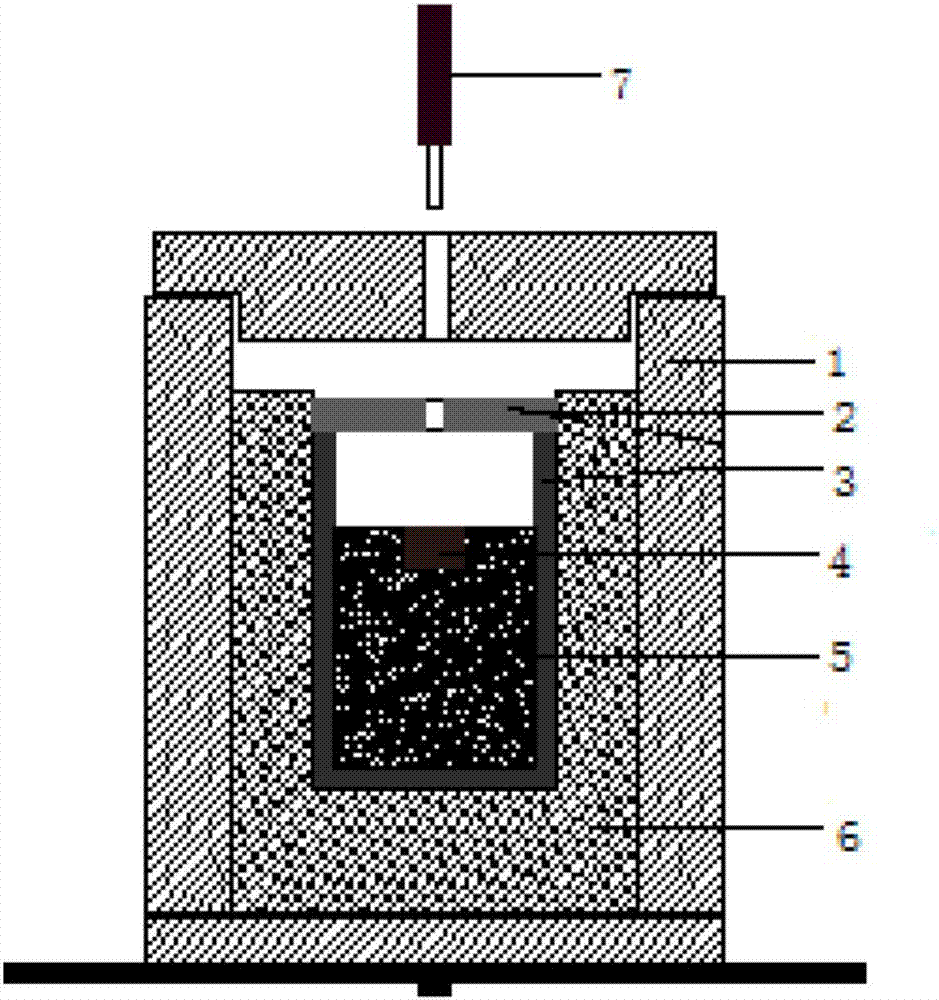

Preparation method of magnesium alloy/hydroxyapatite composite

InactiveCN103599561ADegradability adjustableDegradative regulationSurgical adhesivesProsthesisSolubilityCardiovascular stent

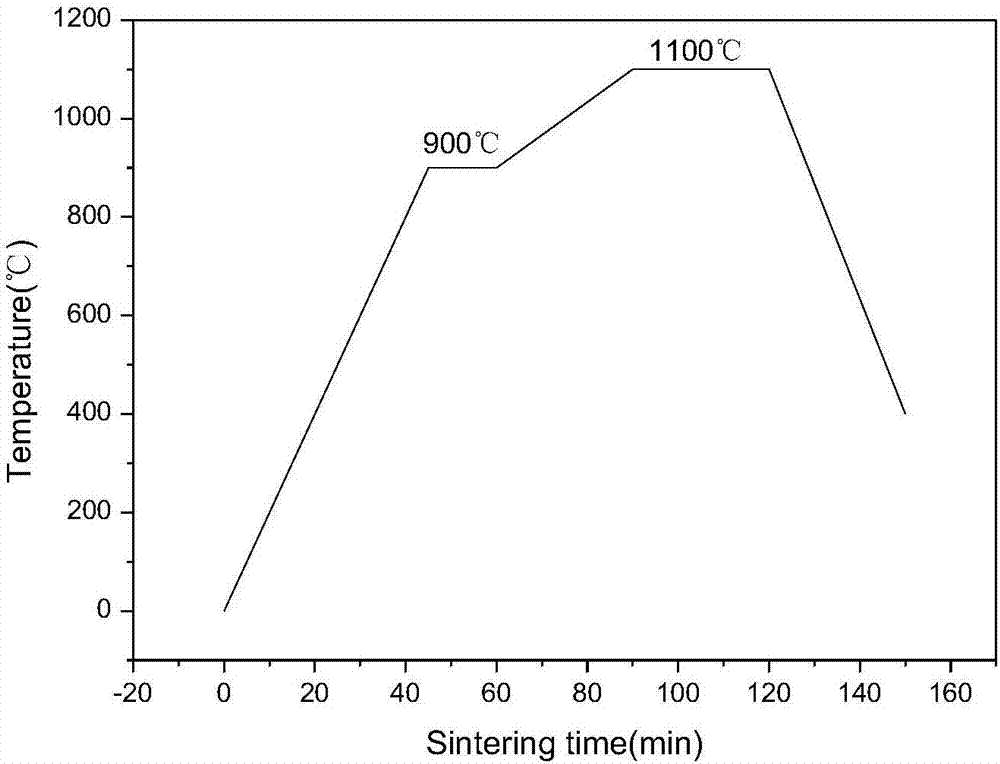

The invention relates to a preparation method of a magnesium alloy / hydroxyapatite composite, which comprises the steps of firstly preparing nano hydroxyapatite powder by a sol-gel process, and then uniformly mixing the magnesium powder with the nano hydroxyapatite powder; putting the mixture into a mould and performing cold pressing; putting the cold-pressing formed sample into a vacuum heat treatment furnace for sintering to obtain the magnesium alloy / hydroxyapatite composite. Compared with the prior art, in the method provided by the invention, the magnesium alloy is used as a metal matrix, the hydroxyapatite with the same chemical composition as the human skeleton and having low solubility in the human body environment is used as a reinforcing body, and the method aims at preparing a magnesium alloy / calcium phosphate composite biomedical material by use of a powder metallurgical process; the material is mainly applied to clinical medicine as a degradable endosteal fixing material, a porous bone repair material, a dental implantation material, an oral repair material, a cardiovascular stent and the like, and has broad prospects in terms of bone tissue defect repair.

Owner:TONGJI UNIV

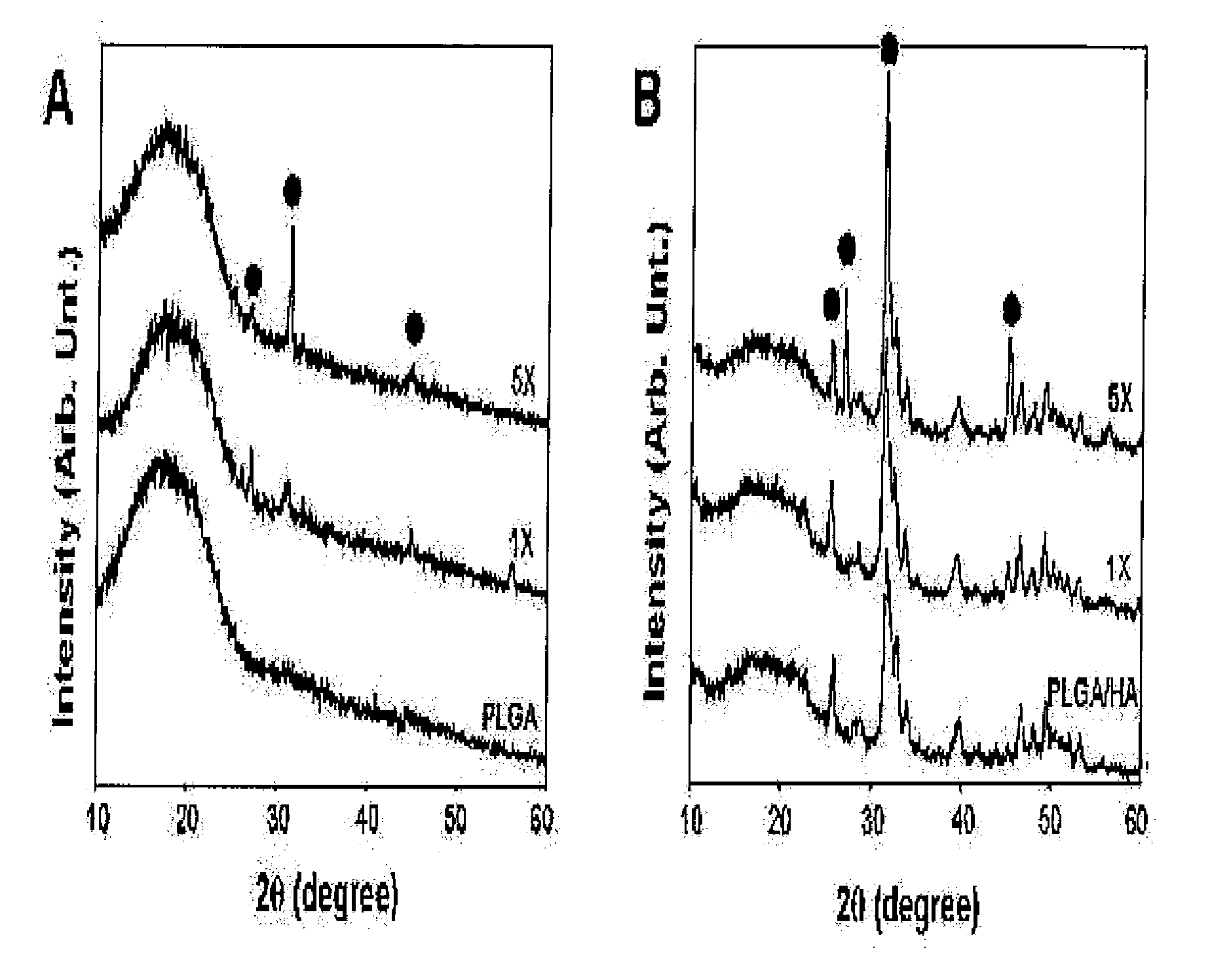

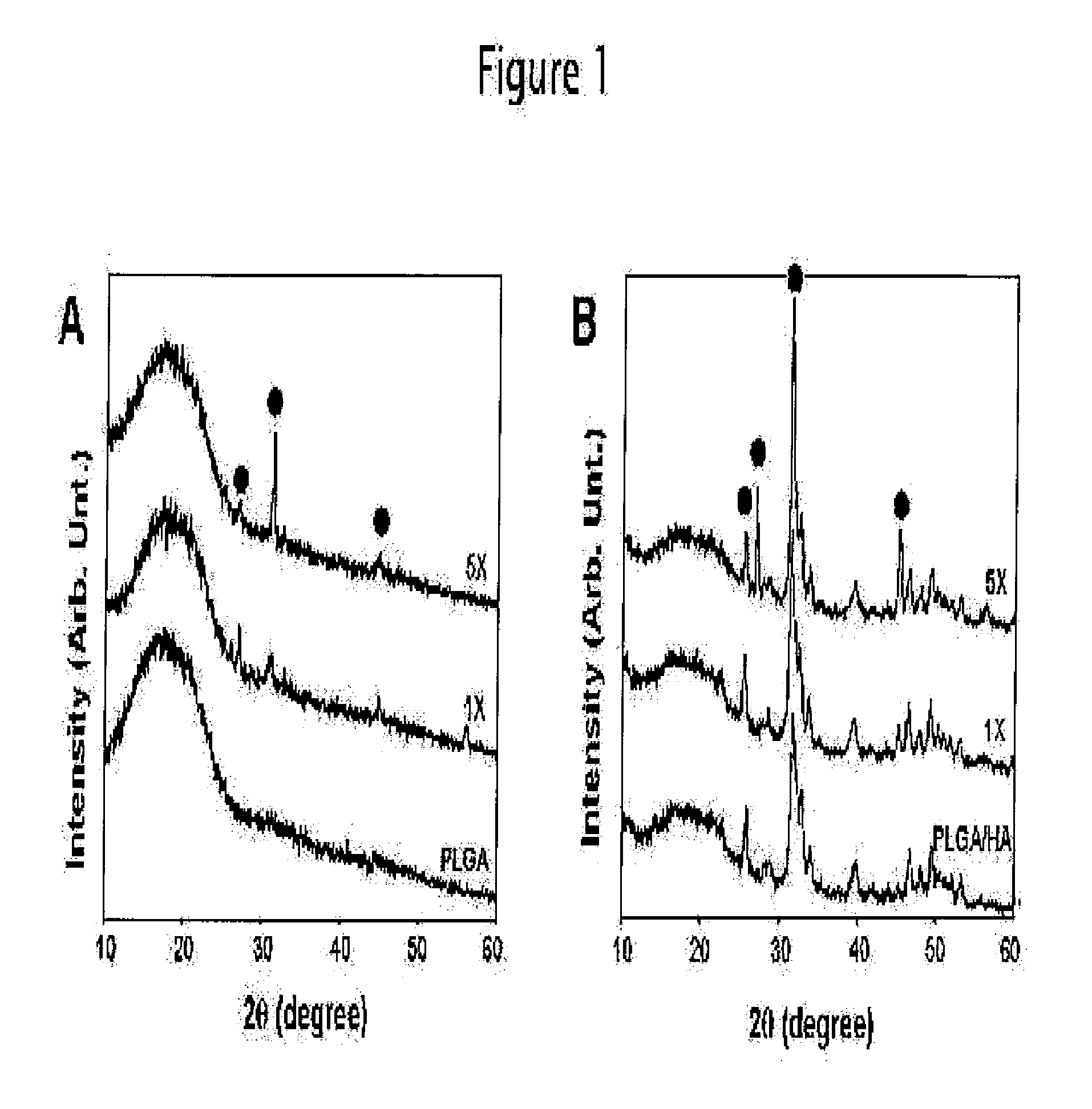

PLGA/Hydroxyapatite Composite Biomaterial and Method of Making the Same

InactiveUS20090048358A1Fastly and highly and uniformly coatedGood at propagatingCosmetic preparationsImpression capsDiseaseApatite

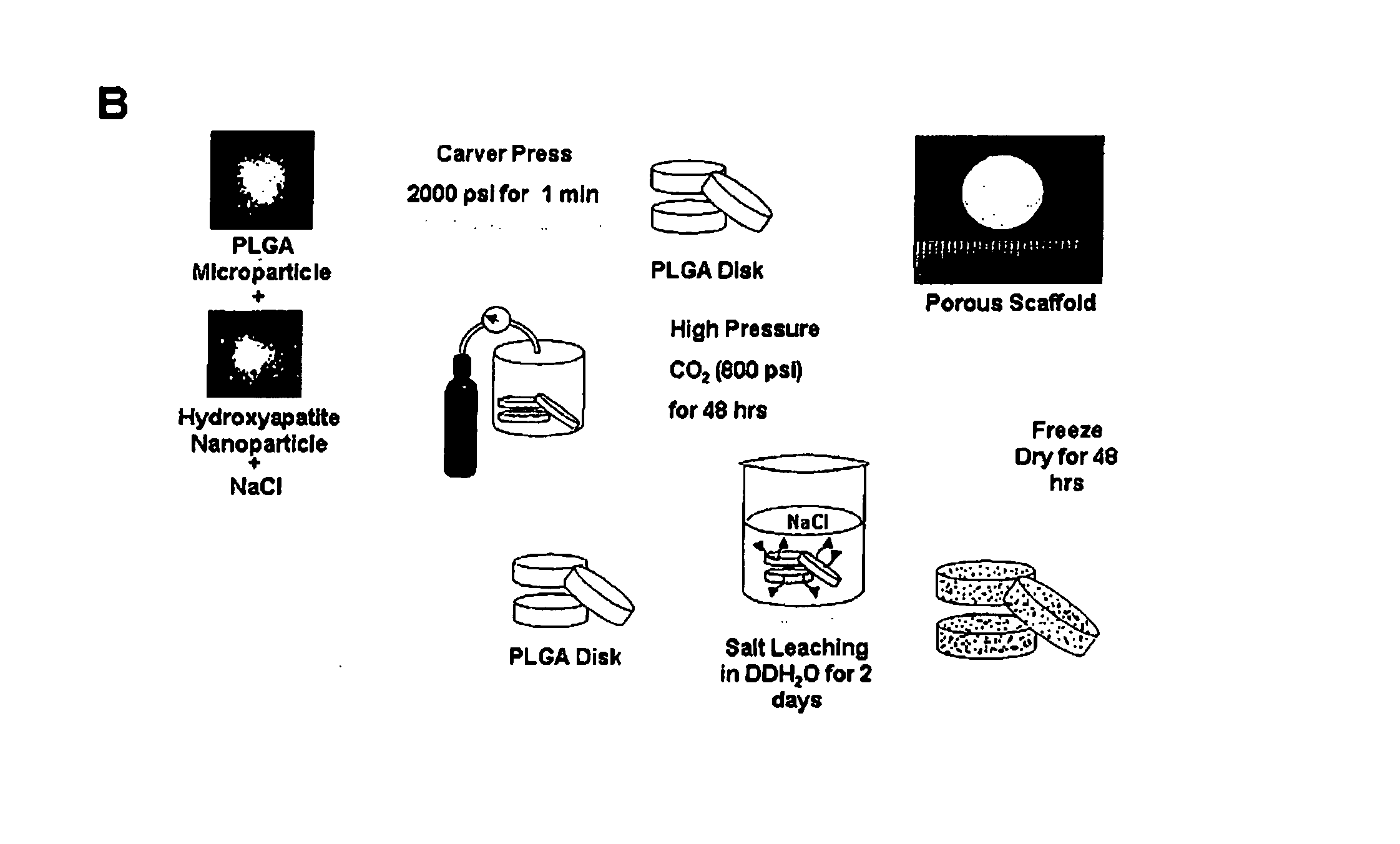

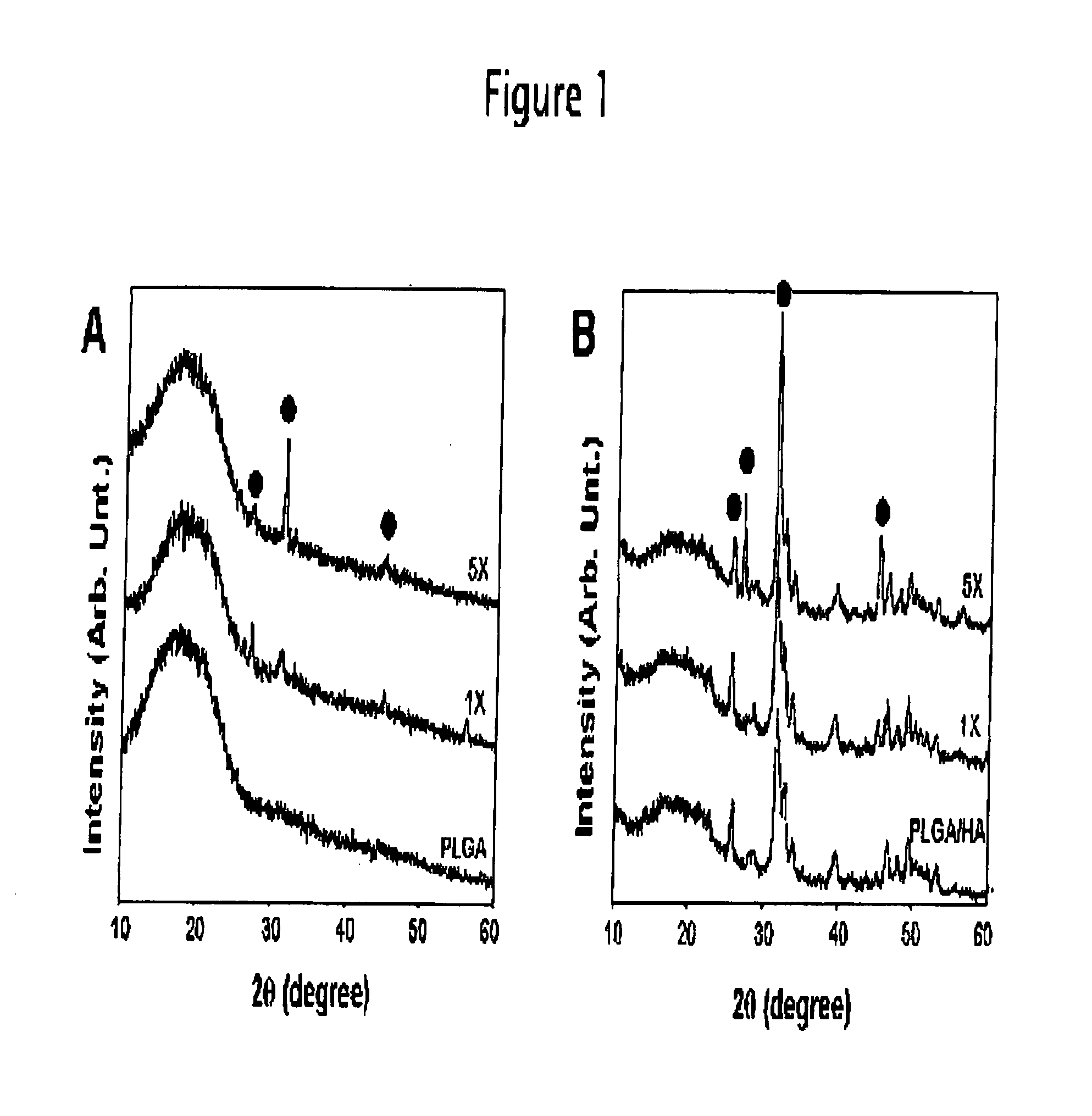

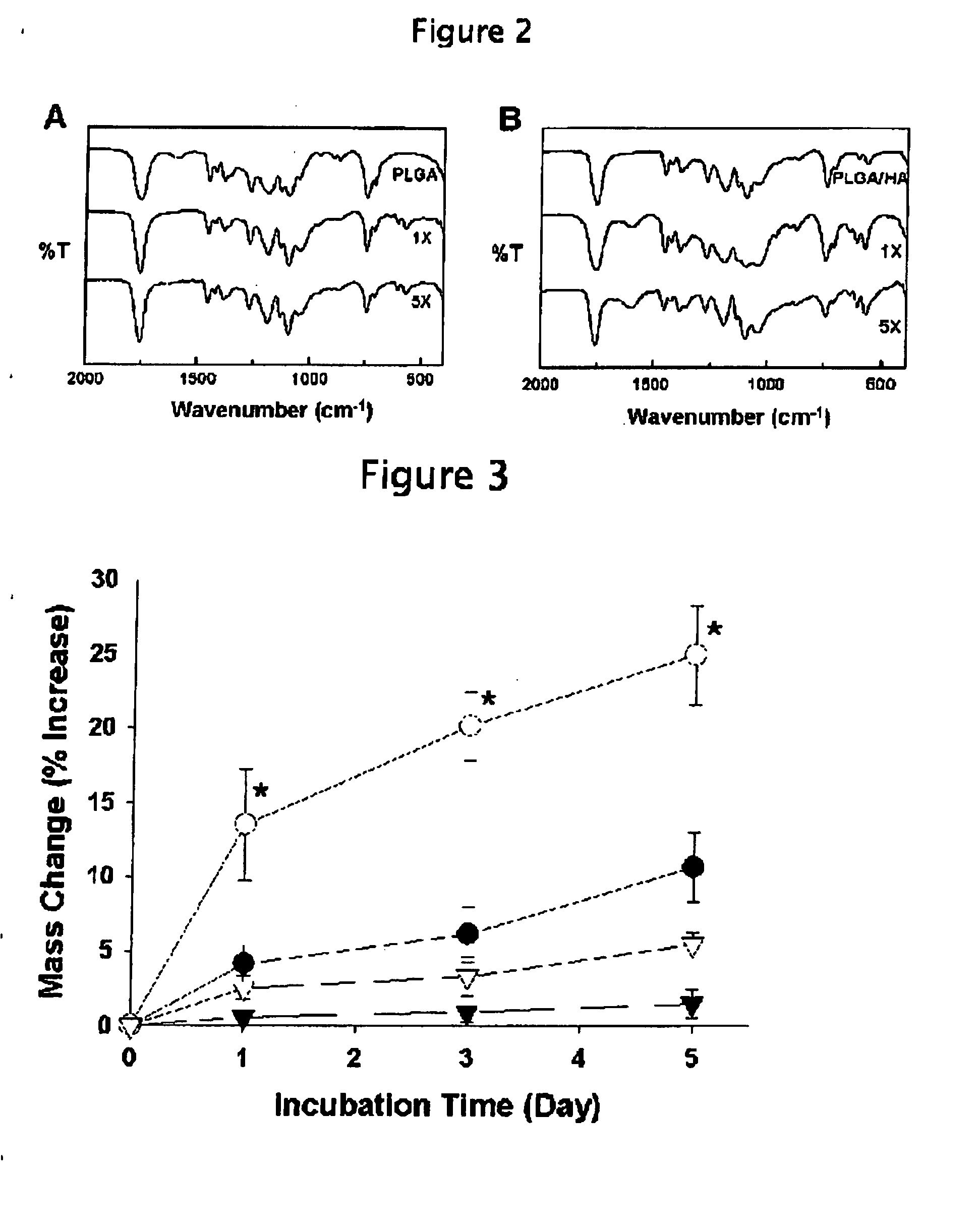

Tissue engineering is a growing field where new materials are being developed for implantation into the body. One important area involves bone graft materials to replace areas of bone lost to trauma or disease. Traditionally, graft material may be harvested from the bone of the individual receiving the graft material. However, this requires an additional surgery and additional recovery. Bone also may be taken from others, or even cadavers, but this introduces biocompatibility problems as well as the risk of disease transfer. Ideally, a biocompatible material is sought that will act as a filler with appropriate mechanical strength, encourage bone healing, and degrade to allow new bone ingrowth without the risk of disease transfer. The present invention is a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and nano-sized hydroxyapatite particles exposed on its surface using a gas foaming particle leaching (GF / PL) method. A further embodiment of this invention involves coating this PLGA / hydroxyapatite biomaterial with an adherent, fast, uniform coating of a mineral such as apatite. The PLGA polymer portion of the composite provides sufficient mechanical strength to replace bone and is degradable over time to allow new bone tissue ingrowth. The incorporated hydroxyapatite particles increase the composite material's osteogenic properties by providing sites for tissue attachment and propagation. Finally, a uniform coating of mineral apatite on the surface of this novel biomaterial composite further enhances its osteogenic qualities.

Owner:NANO ORTHOPEDICS

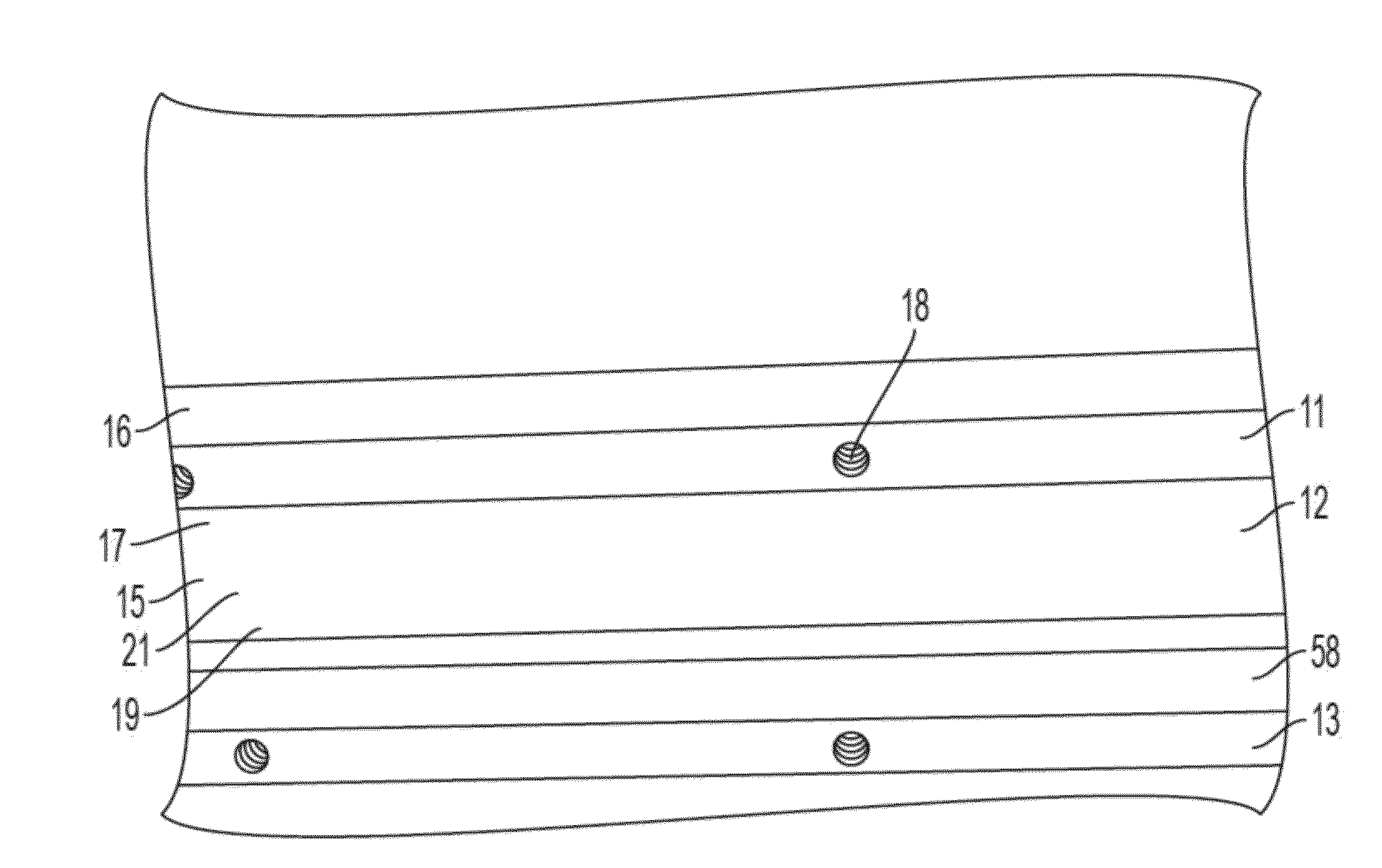

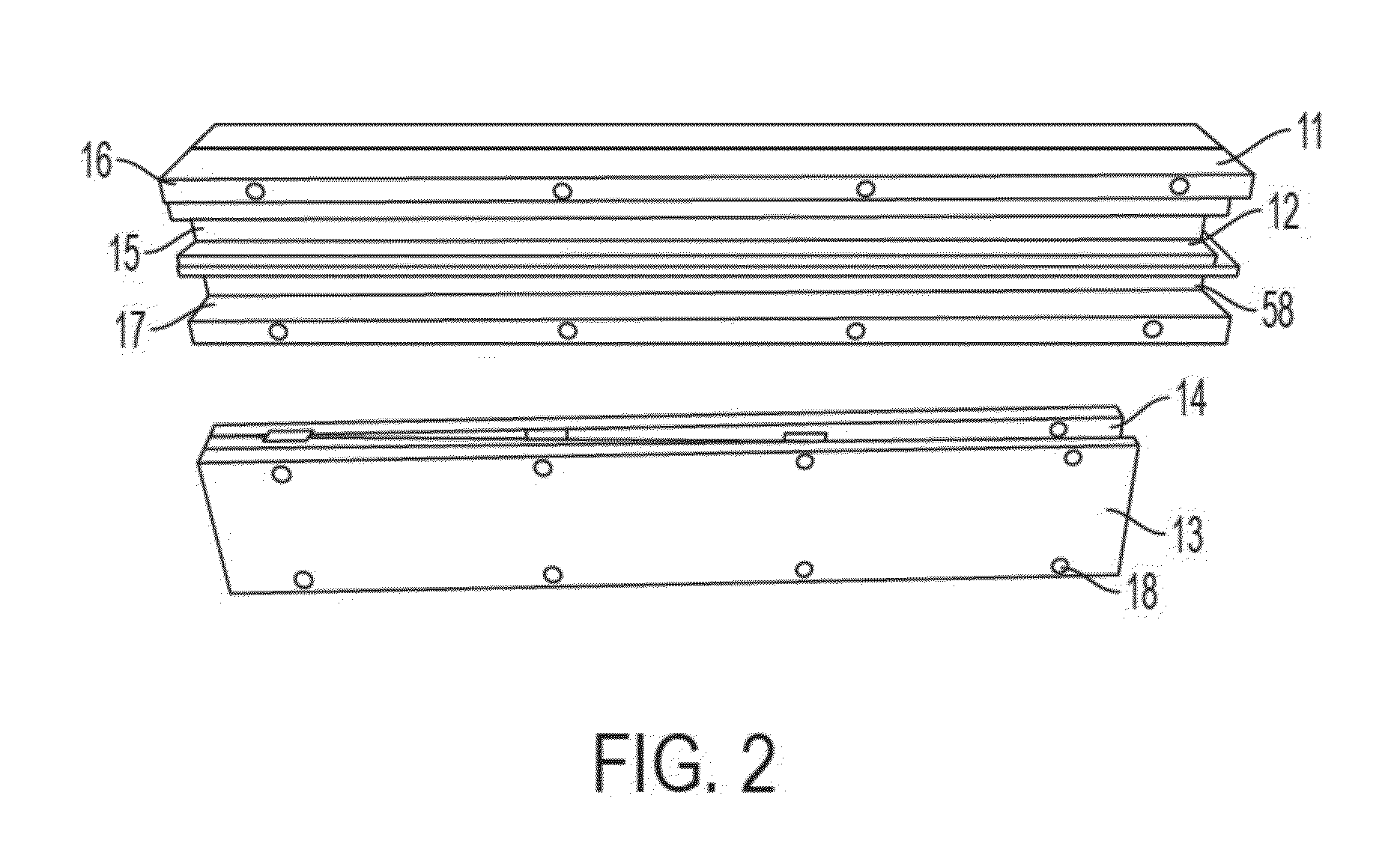

Plga/ha hydroxyapatite composite bone grafts and method of making

InactiveUS20130218291A1Fastly and highly and uniformly coatedGood at propagatingImpression capsBone implantGlycolic acidBioceramic

The present invention involves tissue engineering constructs made from a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and bioceramic particles exposed on its surface using a gas foaming particle leaching (GF / PL) method and infused with collagen. Methods and apparatus for of forming scaffolds are also disclosed.

Owner:THIERRY GIORNO

PLGA/hydroxyapatite composite biomaterial and method of making the same

InactiveUS20080065228A1Fastly and highly and uniformly coatedGood at propagatingCosmetic preparationsBone implantApatiteBiocompatibility Testing

Tissue engineering is a growing field where new materials are being developed for implantation into the body. One important area involves bone graft materials to replace areas of bone lost to trauma or disease. Traditionally, graft material may be harvested from the bone of the individual receiving the graft material. However, this requires an additional surgery and additional recovery. Bone also may be taken from others, or even cadavers, but this introduces biocompatibility problems as well as the risk of disease transfer. Ideally, a biocompatible material is sought that will act as a filler with appropriate mechanical strength, encourage bone healing, and degrade to allow new bone ingrowth without the risk of disease transfer. The present invention is a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and nano-sized hydroxyapatite particles exposed on its surface using a gas foaming particle leaching (GF / PL) method. A further embodiment of this invention involves coating this PLGA / hydroxyapatite biomaterial with an adherent, fast, uniform coating of a mineral such as apatite. The PLGA polymer portion of the composite provides sufficient mechanical strength to replace bone and is degradable over time to allow new bone tissue ingrowth. The incorporated hydroxyapatite particles increase the composite material's osteogenic properties by providing sites for tissue attachment and propagation. Finally, a uniform coating of mineral apatite on the surface of this novel biomaterial composite further enhances its osteogenic qualities.

Owner:NANO ORTHOPEDICS

Production method of attapulgite loaded hydroxyapatite composite defluorination filter bulb

ActiveCN102502907AHigh fluoride removal capacityHigh yieldWater/sewage treatment by ion-exchangeWater/sewage treatment by sorptionSolubilityPhosphoric acid

The invention discloses a production method of an attapulgite loaded hydroxyapatite composite defluorination filter bulb, which comprises the following steps: preparing attapulgite loaded hydroxyapatite powder from industrial-grade calcium hydroxide, phosphoric acid, acetic acid and attapulgite as raw materials, regulating the solubility of calcium hydroxide using acetic acid, and controlling calcium-phosphorus ratio and pH value of the solution so as to ensure the purity and the defluorination capacity of the products; and fabricating the attapulgite loaded hydroxyapatite powder into pelletsof diameters 0.5-1.5mm, and drying and molding the pellets at a temperature ranging from 350 to 450 DEG C so as to obtain attapulgite loaded hydroxyapatite composite defluorination filter bulb. The composition of attapulgite and hydroxyapatite reduces cost, is helpful for pellet formation, and enhances defluorination of hydroxyapatite. The method of the invention uses cheap and easily-accessible raw materials, high capacity of defluorination filter bulbs, long service life and small fluent water resistance, , and is simple in preparation, easy for control and regeneration, and easy for large-scale industrial production and promotion.

Owner:JIANGSU YONGGUAN WATER & WASTERWATER EQUIP CO LTD +1

Method for preparing hydroxyapatite composite and biocompatible material

InactiveUS20020127262A1Rapid and efficient formationImprove adhesion strengthPharmaceutical containersPharmaceutical delivery mechanismPhosphate ionApatite

Owner:NOF CORP

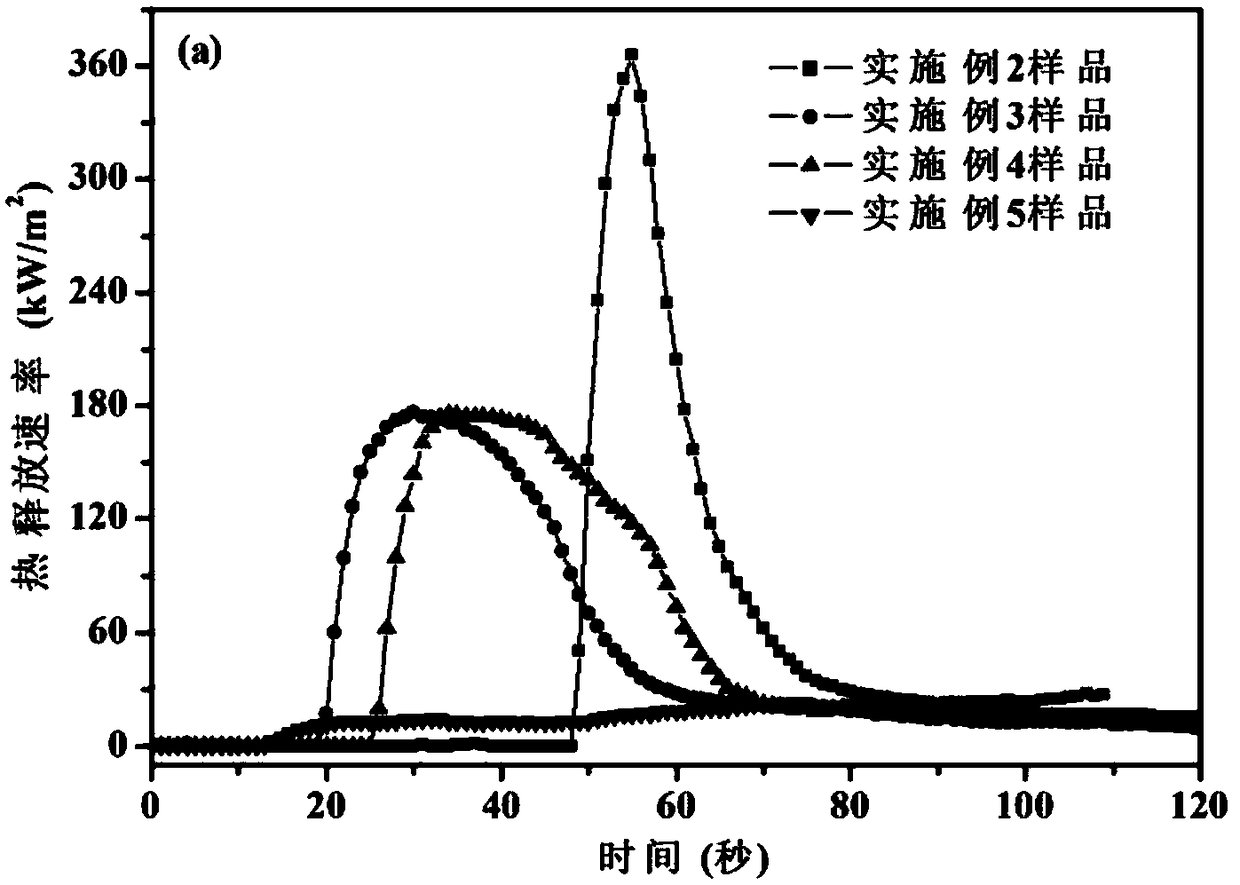

Bone repair material allowing injection of multi-pore structure and preparation method of bone repair material

ActiveCN108744060AOvercome structureOvercoming some of the problemsPharmaceutical delivery mechanismTissue regenerationTissue repairApatite

The invention provides a bone repair material allowing injection of a multi-pore structure and a preparation method of the bone repair material. The bone repair material comprises powder, a curing solution A and a curing solution B, wherein the powder is hydroxyapatite composite polylactic acid-glycolic acid copolymer porous microspheres, the curing solution A is a collagen solution, the curing solution B is a dopamine-hyaluronic acid aqueous solution, the powder is dispersed in the curing solution A and then uniformly mixed with the curing solution B, the pH value is adjusted to 7.5-8.5, thehydroxyapatite composite polylactic acid-glycolic acid copolymer porous microspheres and collagen are distributed in a 3D network structure of dopamine-hyaluronic acid copolymer hydrogel. The bone repair material has the multi-pore structure suitable for cell growth, can increase the tightness of combination of the bone repair material and autogenous bone and is expected to be applied to fields oftissue repair such as skin filling and beauty through adjustment of the composition proportion.

Owner:SICHUAN UNIV

Flame-retardant microcrystalline cellulose/hydroxyapatite composite aerogel and preparation method thereof

ActiveCN108238595AGood dispersionEvenly dispersedPhosphorus compoundsColloidal chemistry detailsCross-linkFreeze-drying

The invention provides flame-retardant microcrystalline cellulose / hydroxyapatite composite aerogel and a preparation method thereof, relating to the fields of composite aerogel and a preparation method thereof. The preparation method comprises the steps of firstly synthesizing hydroxyapatite nanorods by virtue of a hydrothermal method, dispersing the hydroxyapatite nanorods into deionized water soas to prepare hydroxyapatite dispersion liquid, preparing a microcrystalline cellulose solution by taking a sodium hydroxide / urea water solution as a solvent and epoxy chloropropane as a cross-linking agent, finally, preparing flame-retardant microcrystalline cellulose / hydroxyapatite composite aerogel with a honeycomb structure by virtue of the cooperation of a solution blending method and a vacuum freeze drying method, wherein the hydroxyapatite nanorods with the diameters of 1nm-100nm and the lengths of 10nm-300nm are uniformly dispersed into a microcrystalline cellulose matrix. The prepared composite aerogel has obvious flame retardant effect and smoke release inhibition effect, the safety of aerogel in the fire is remarkably improved, and the adopted microcrystalline cellulose and hydroxyapatite have excellent biocompatibility and environmental friendliness.

Owner:HEFEI UNIV

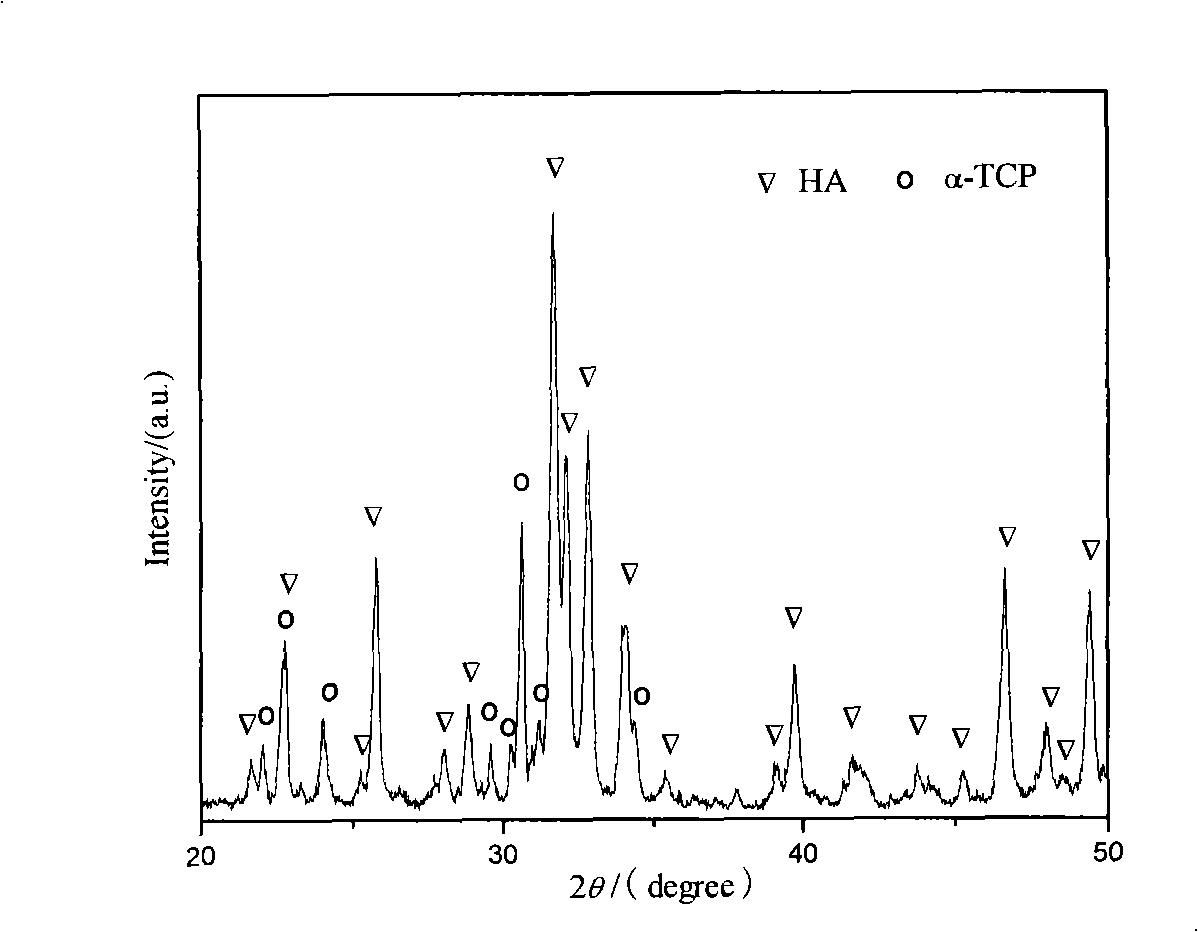

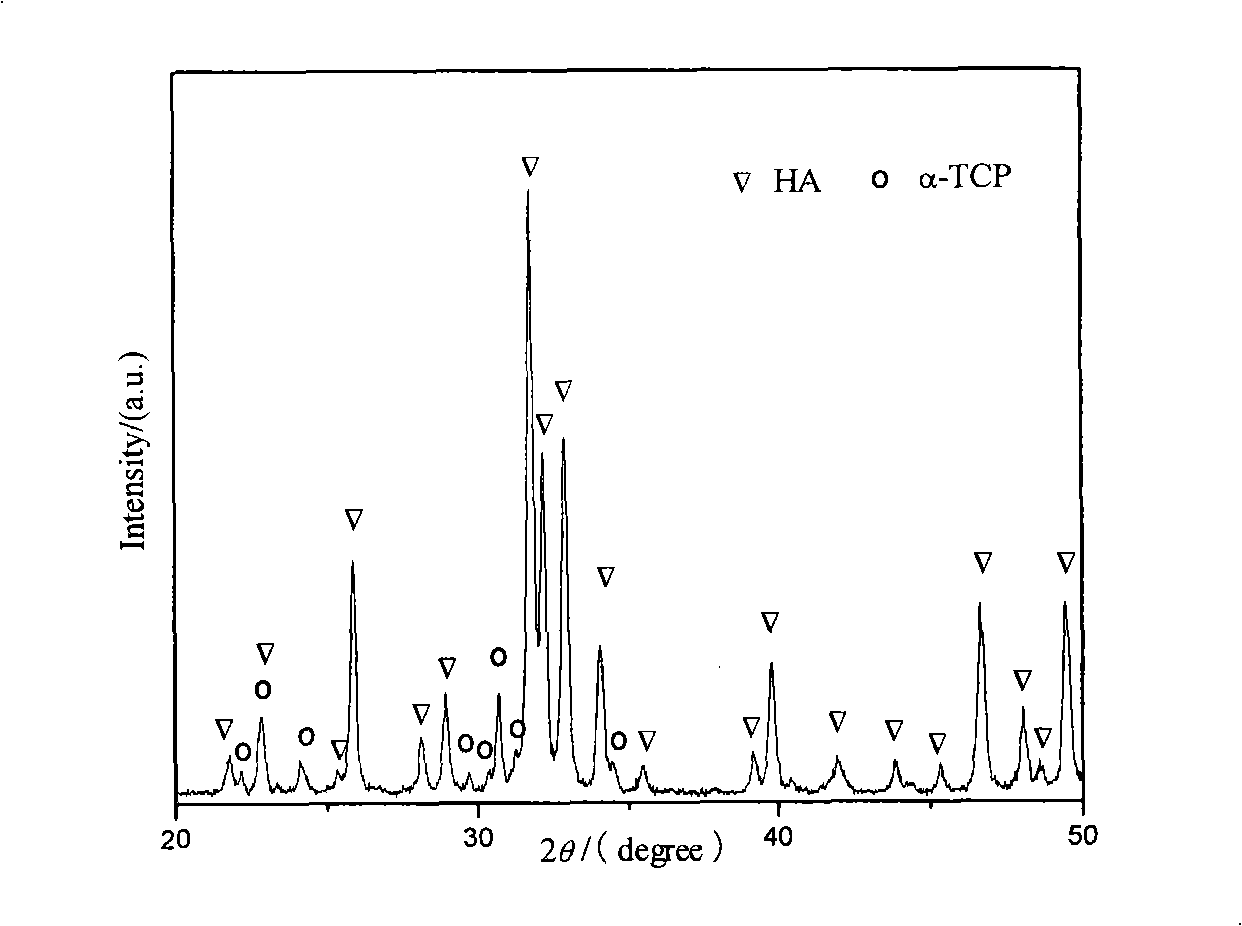

Method for preparing calcium phosphate composite powder

InactiveCN101254910AEffective control ingredientsSimple processPhosphorus compoundsProsthesisCalcium biphosphateMaterials preparation

A method for preparing composite calcium phosphate powder belongs to the field of medicinal material preparation. The powder is hydroxyapatite composite powder, Alpha-calcium phosphate / hydroxyapatite, or Alpha-calcium phosphate / Beta-calcium phosphate / hydroxyapatite composite powder, has a mole ratio of Ca / P higher than 1.500, lower than or equal to 1.667. The preparation process includes the following steps: mixing calcium source solution and phosphorus source solution at a Ca / P mole ratio of 1.500, stirring at the room temperature and aging for 1-48 hours; adjusting the pH value to 7.0-12.0 to obtain calcium phosphate precursor suspension; adding calcium source solution until the Ca / P ratio is higher than 1.500-1.667; continuously aging for 1-48 hours to obtain the complex phase calcium phosphate or the hydroxyapatite precursor; heat-treating at a temperature of 1,000 DEG C for 1-24 hours; cooling in the furnace; and grinding to obtain the powder. The method has the advantages of high processing controllability, environment friendliness and low cost.

Owner:BEIJING UNIV OF CHEM TECH

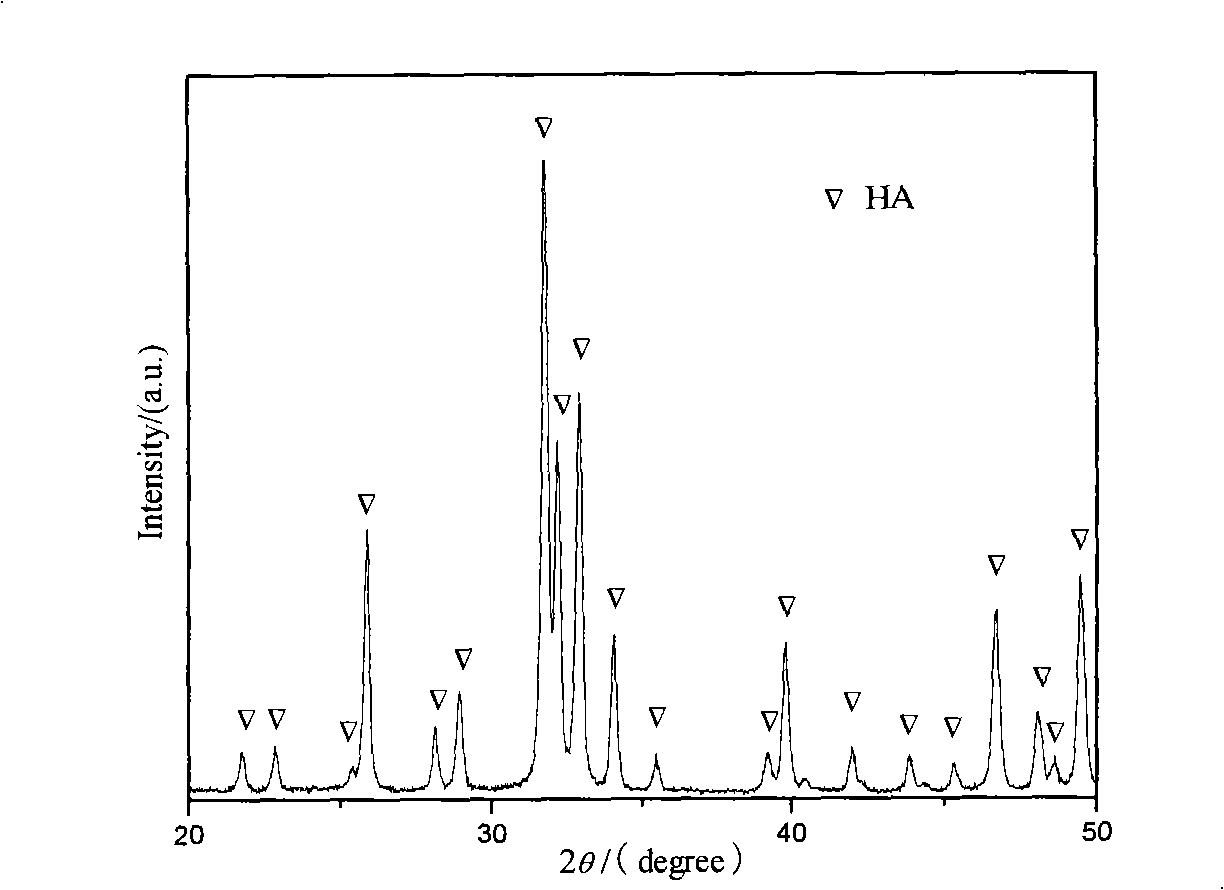

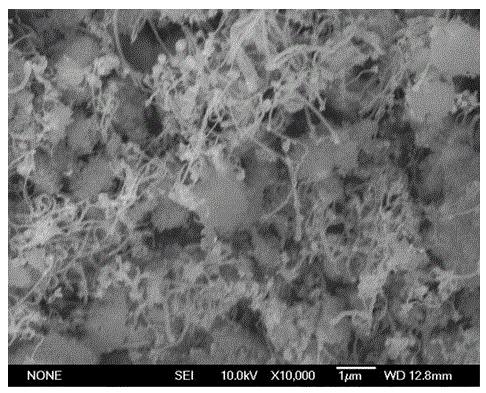

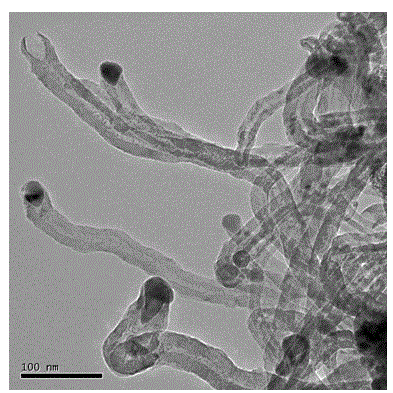

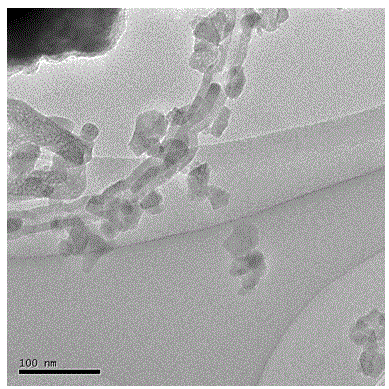

Preparation method of carbon nanotube reinforced hydroxyapatite composite material

The invention discloses a preparation method of a carbon nanotube reinforced hydroxyapatite composite material, relating to a composite material for prosthesis materials. According to the preparation method, a carbon nanotube is synthesized in hydroxyapatite powder, the carbon nanotube is subjected to surface modification by using hydroxyapatite, and the carbon nanotube reinforced hydroxyapatite composite material is further prepared. The preparation method comprises the following steps of: firstly preparing carbon nanotube-hydroxyapatite powder from nickel carbonate and the hydroxyapatite powder, then preparing hydroxyapatite-modified carbon nanotube-hydroxyapatite powder, and finally preparing the carbon nanotube reinforced hydroxyapatite composite material. The preparation method disclosed by the invention overcomes the defects that the carbon nanotube is difficult to disperse in a hydroxyapatite matrix, the wettability and the interfacial strength between the carbon nanotube and the hydroxyapatite matrix are low, the hydroxyapatite powder of which the surface is loaded with the carbon nanotube is difficult to form and the biocompatibility of the composite material is poorer in the prior art.

Owner:HEBEI UNIV OF TECH

Polyvinyl alcohol/sodium alginate/hydroxyapatite composite fiber membrane as well as preparation method and application of polyvinyl alcohol/sodium alginate/hydroxyapatite composite fiber membrane

ActiveCN106729928AEasy reunionImprove damage repairNon-adhesive dressingsAbsorbent padsFiberPolyvinyl alcohol

Owner:WUHAN UNIV OF TECH

Preparation method of graphene/hydroxyapatite composite ceramic material

InactiveCN106986625AImprove brittlenessWell mixedImpression capsDentistry preparationsSide effectBiocompatibility Testing

The invention discloses a preparation method of a graphene / hydroxyapatite composite ceramic material. To be specific, graphene oxide, used as a reinforcement phase, is added to hydroxyapatite which is prepared by a chemical precipitation method and then is subjected to microwave sintering to obtain the graphene / hydroxyapatite composite ceramic material. The preparation method mainly solves the problems that conventional hydroxyapatite material preparation process is complex, low in production efficiency, high in production cost and incapable of meeting gradually improved living requirements of people and the like. The preparation method has the advantages of short production cycle, simple technique, no waste of raw materials, and easiness in building a full-automatic production line. By the preparation method, the graphene / hydroxyapatite composite ceramic material with good wear resistance, zero toxic and side effect, high toughness and good biocompatibility is obtained.

Owner:SHANDONG NORMAL UNIV

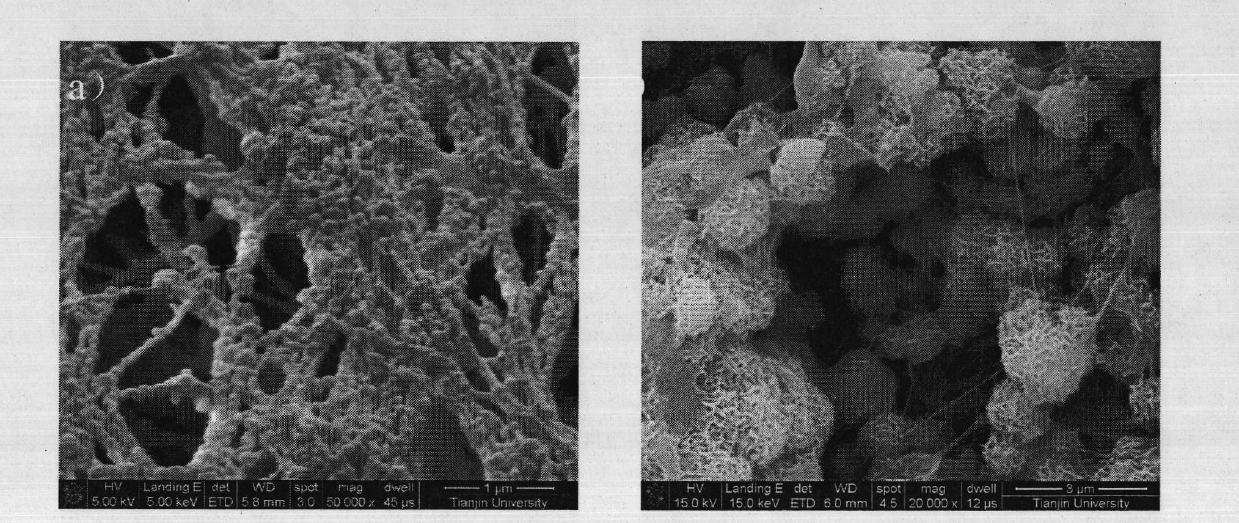

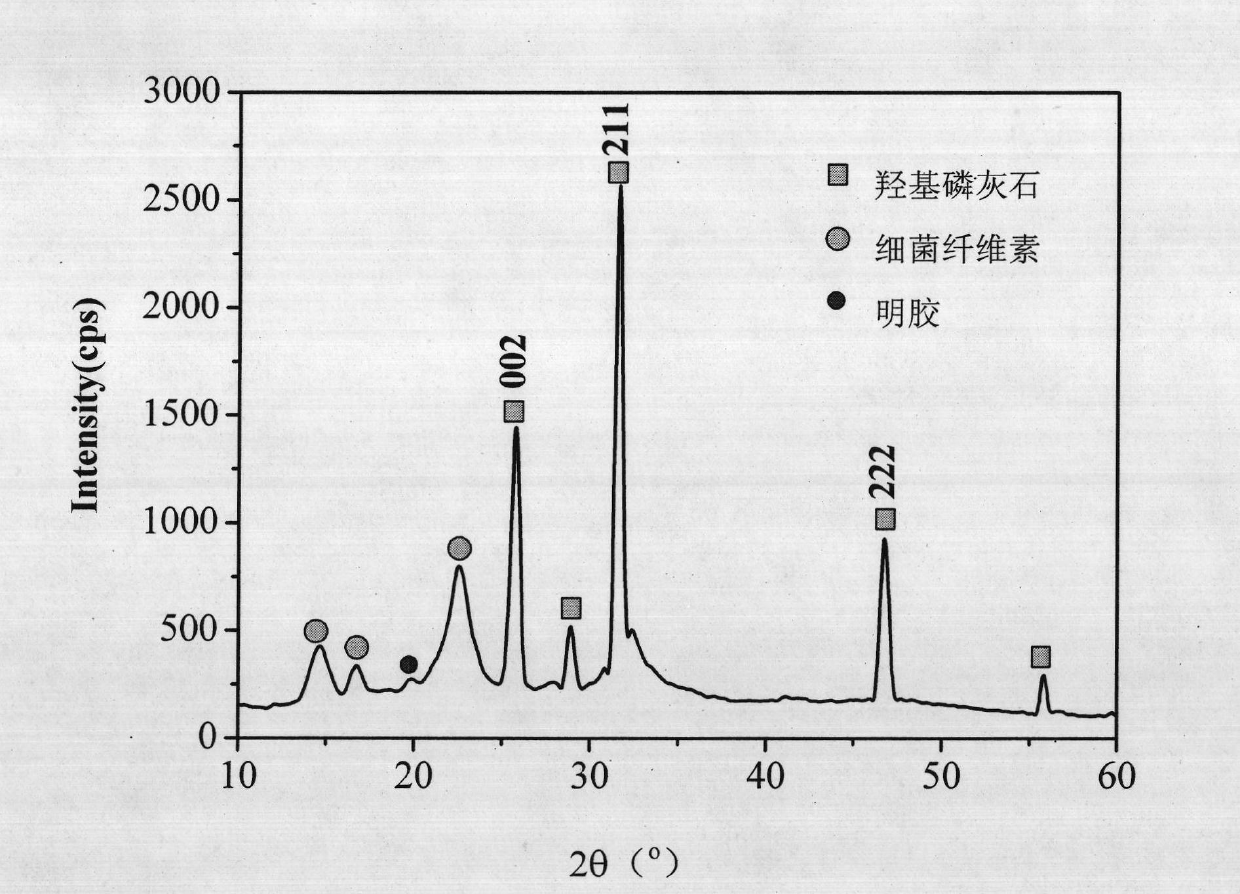

Bacteria cellulose/gelatin/hydroxyapatite composite material and preparation method thereof

InactiveCN101947335ASolve the problem of low mechanical propertiesPromote growthProsthesisFiberSimulated body fluid

The invention relates to a bacteria cellulose / gelatin / hydroxyapatite composite material and a preparation method thereof. The composite material contains the raw materials of bacteria cellulose gel sheeting, gelatin, procyanidin, CaCl2 and simulated body fluid, and the mass ratio of the bacteria cellulose gel sheeting, the gelatin, the procyanidin and the CaCl2 is 100-200:1-5:4-6:6-10. The preparation method comprises the steps of: firstly crosslinking the gelatin by using the procyanidin as crosslinking agent so that the gelatin is coated on the fiber surface of the bacteria cellulose to prepare a bacteria cellulose / gelatin composite material, and the bacteria cellulose / gelatin / hydroxyapatite composite material is further prepared by adopting biomimetic mineralization method. The composite material according to the invention has excellent mechanical properties, unique three-dimensional nano-network structure and more structural and componential similarity to bionics, and meets the demand of the engineering material for cartilage tissues of human body. The composite material according to the invention has the advantages of safe and nontoxic reagents adopted, low cost and simple preparation technology.

Owner:TIANJIN UNIV

Collagen/hydroxyapatite composite scaffold, and process for the production thereof

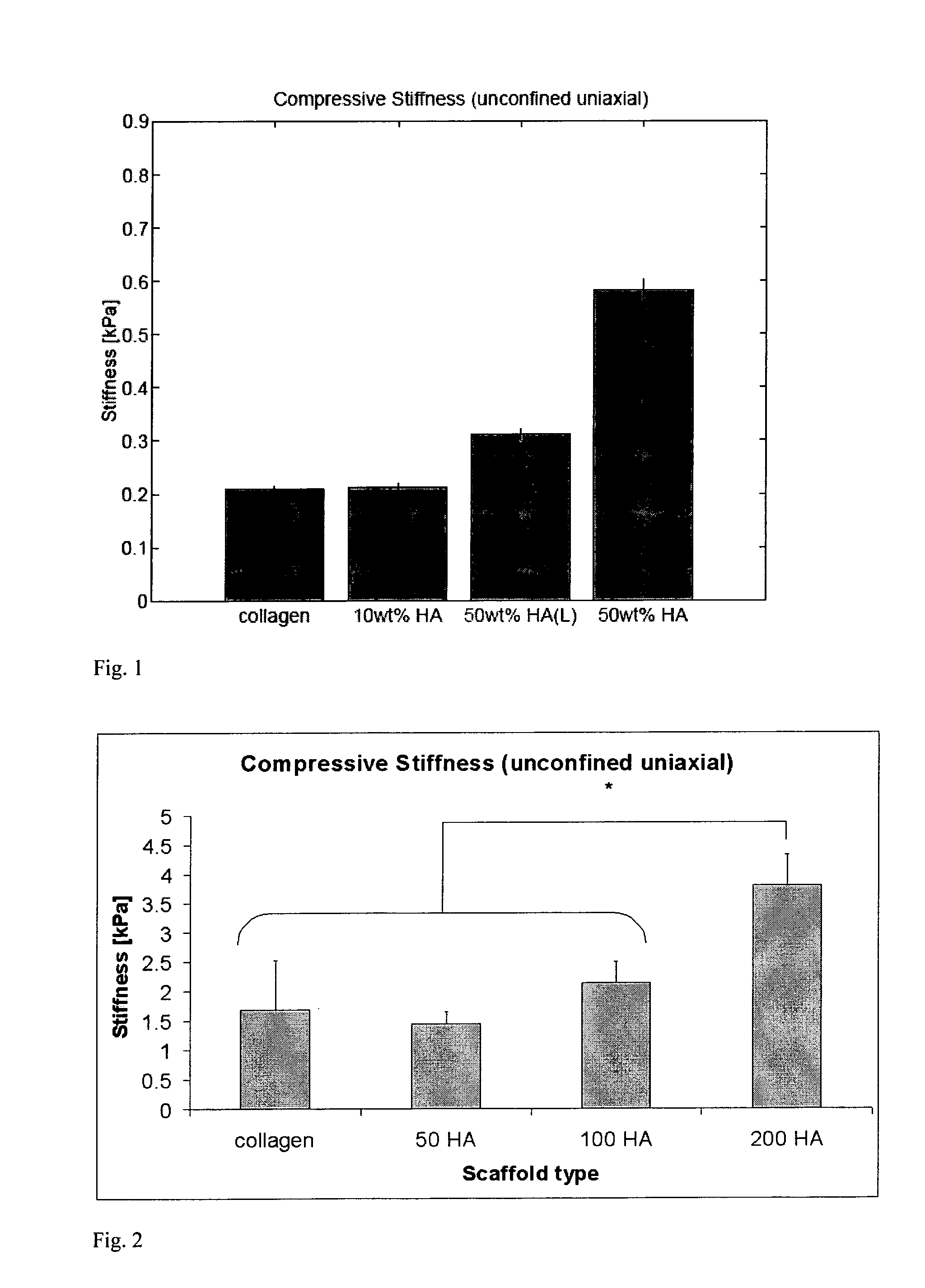

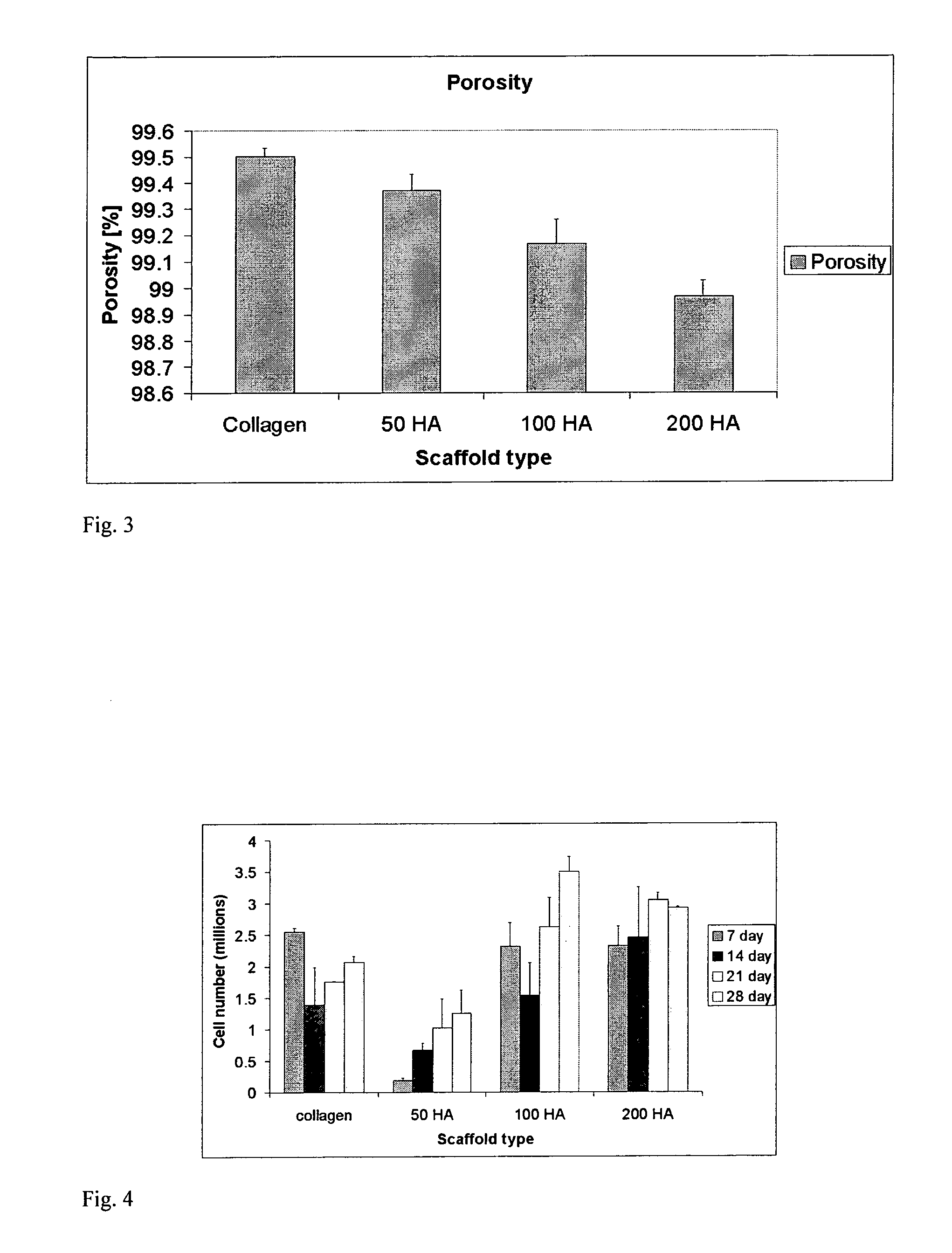

ActiveUS20100158976A1Good biocompatibilityPromotes cell adhesionPowder deliveryPeptide/protein ingredientsCompressive stiffnessCross-link

A process for producing a collagen / hydroxyapatite (HA) composite scaffold comprises the steps of forming a homogenous suspension of collagen and HA in an acidic solution, lyophilising the suspension until a desired final freezing temperature is reached to produce the composite scaffold, and optionally cross-linking the composite scaffold, wherein the ratio of HA to collagen is at least 1:10 (w / w). Also provided is a collagen / hydroxyapatite (HA) composite scaffold comprising a homogenous distribution of hydroxyapatite within a porous, crosslinked, collagen matrix, wherein the ratio of HA to collagen is at least 1:10 (w / w). Suitably, the composite scaffold has a porosity of at least 99% (v / v), and a compressive stiffness of at least 0.3 KPa. Composite scaffolds of the invention may be used to provide osteoconductive bone implants and tissue engineering implants.

Owner:ROYAL COLLEGE OF SURGEONS & IRELAND

Method of preparing compound osseous tissue renovating material interconsistency agent of polylactic acid/hydroxyapatite

The invention relates to a method for preparing an inclusive agent of a polylactic acid or hydroxyapatite composite bone tissue restoring material, which comprises the following steps: getting processed hydroxyapatite by refluxing hydroxyapatite in the alcohol solution with surface modifier as the coupler for 12-48 hours; dissolving polylactic acid macromole monomer with terminal ethenyl and the processed hydroxyapatite in the organic solvent with initiating agent; protecting with nitrogen; extracting after extracting and drying the reactor; separating and purifying no-grafted polylactic acid macromole monomer; extracting the remainder; drying; getting the inclusive agent. The inclusive agent has the wide application, the low cost, the simple method, the mild synthesis condition, the strong utility and the easy industry production, which provides the boundary interaction of the organic or inorganic phase in polylactic acid or hydroxyapatite composite bone tissue restoring material, and improves the ergology property of bone tissue restoring material.

Owner:JINAN UNIVERSITY

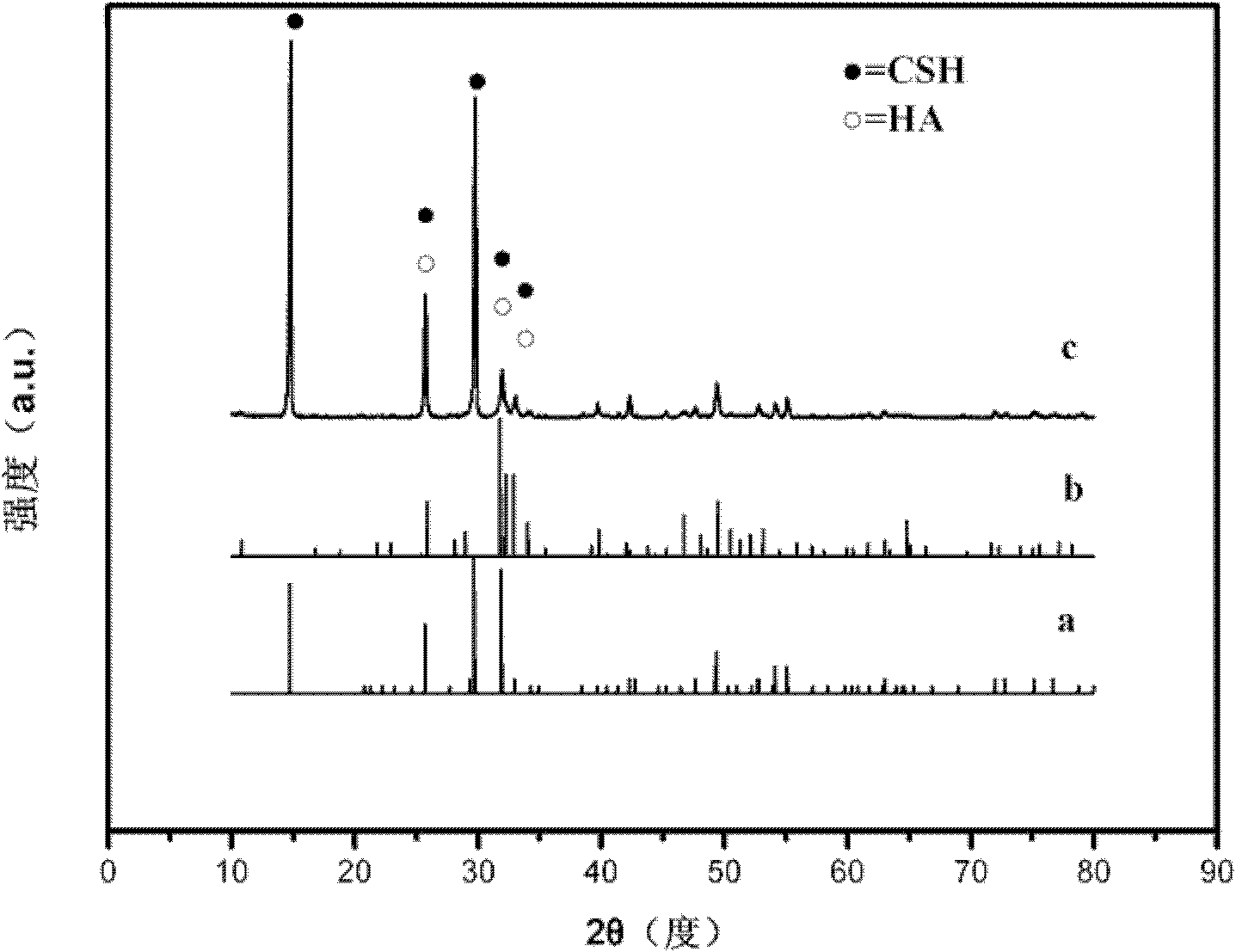

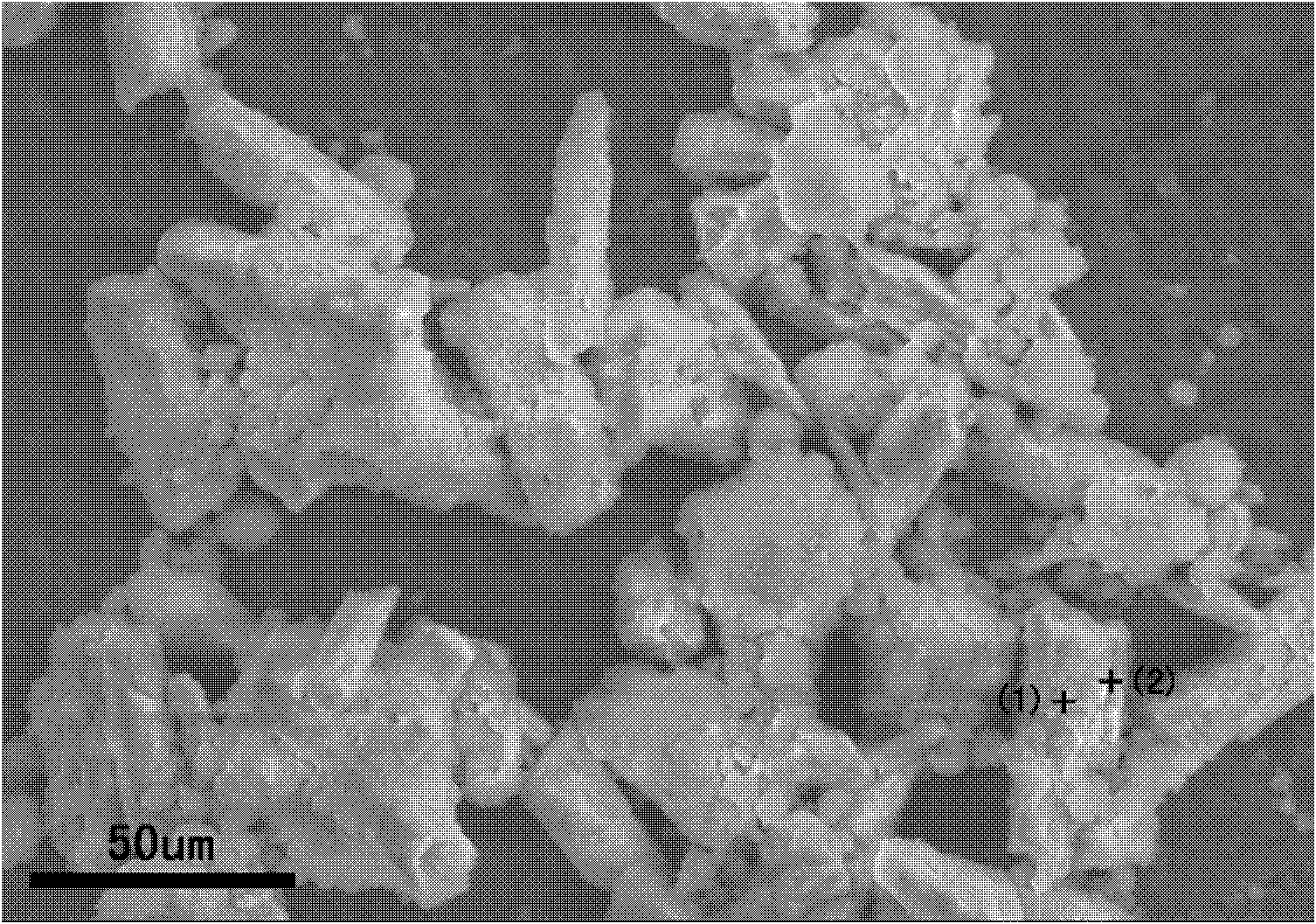

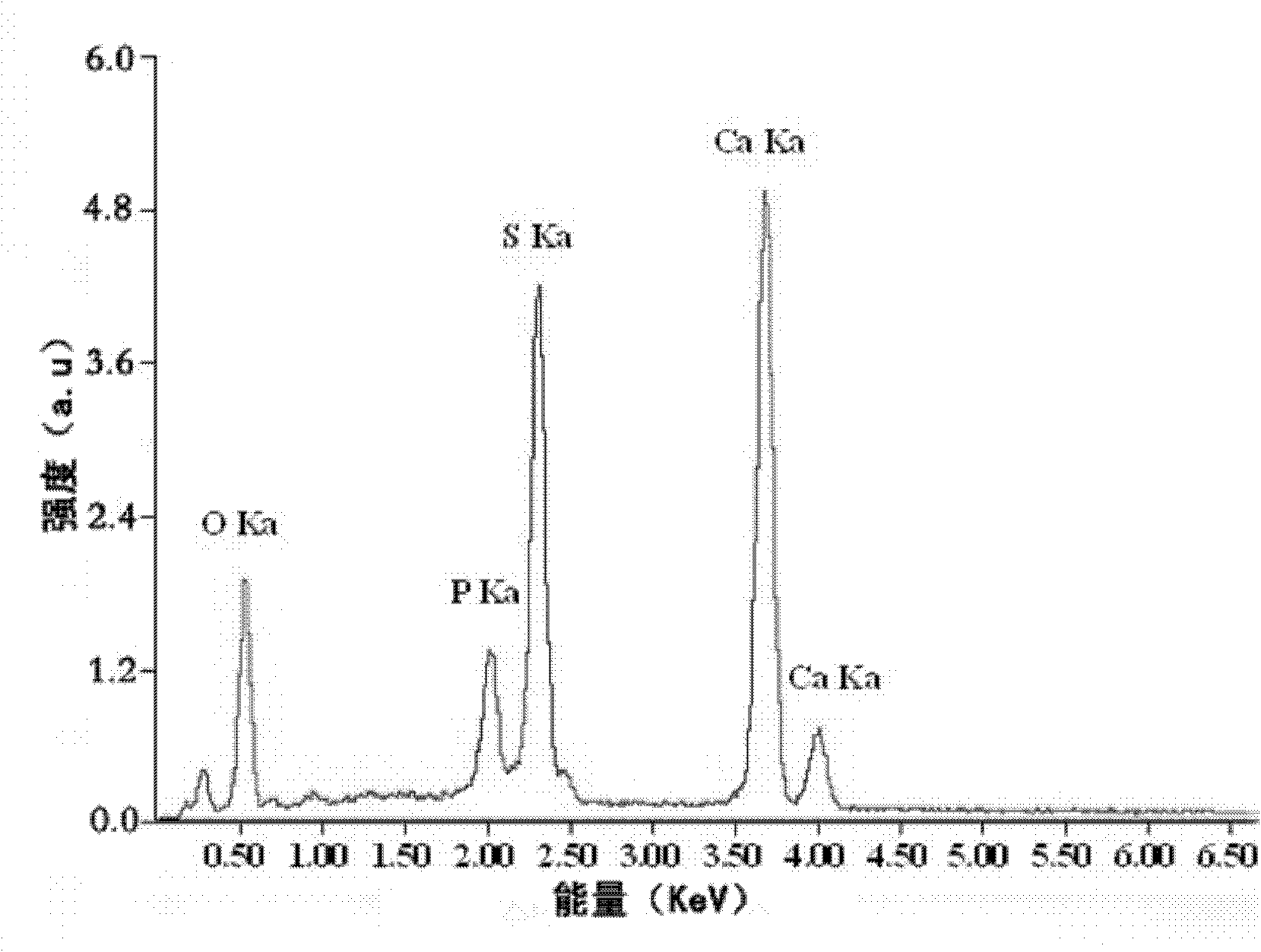

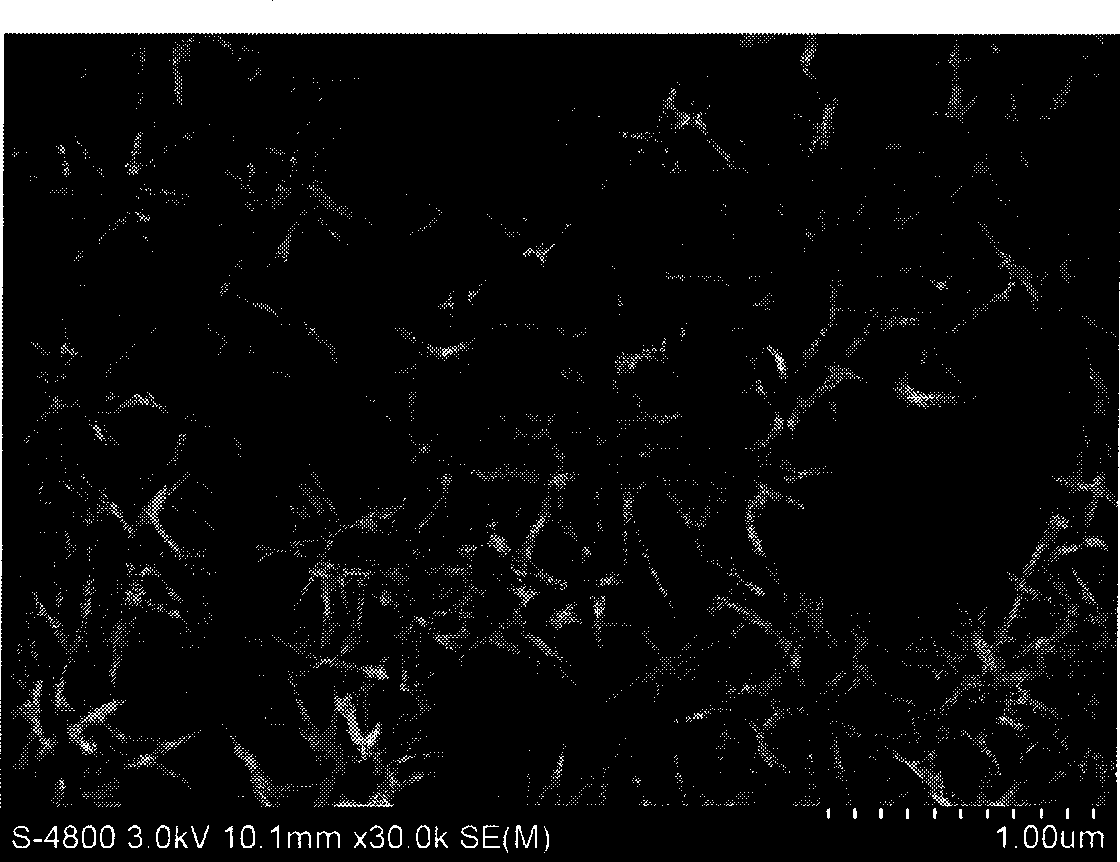

Alpha-calcium sulfate hemihydrate/hydroxyapatite composite granule with nuclear shell structure and preparation thereof

InactiveCN102488920AAdjust the degradation characteristicsEasy to prepareProsthesisInorganic saltsApatite

The invention discloses an alpha-calcium sulfate hemihydrate / hydroxyapatite composite granule with a nuclear shell structure and preparation thereof. The composite granule has a microstructure in which the hydroxyapatite wraps the alpha-calcium sulfate hemihydrate. The preparation method comprises the steps of: using deionized water as a solvent, dissolving a proper dosage of organic crystal modifier and inorganic salt crystal modifier, adding calcium sulfate dehydrate and hydroxyapatite, and performing hydrothermal synthesis under certain technical parameters. According to the invention, the alpha-calcium sulfate hemihydrate and the hydroxyapatite are compounded in the microstructure so as to adjust the quick consolidation defect of pure alpha-calcium sulfate hemihydrate to improve the injection performance thereof, and a microstructure with a controllable wrapping degree can be formed to adjust and control the biodegradation performance thereof, so that the composite granule has a brilliant clinical application prospect.

Owner:ZHEJIANG UNIV

Hydroxyapatite nano-complex particle, preparation and uses thereof

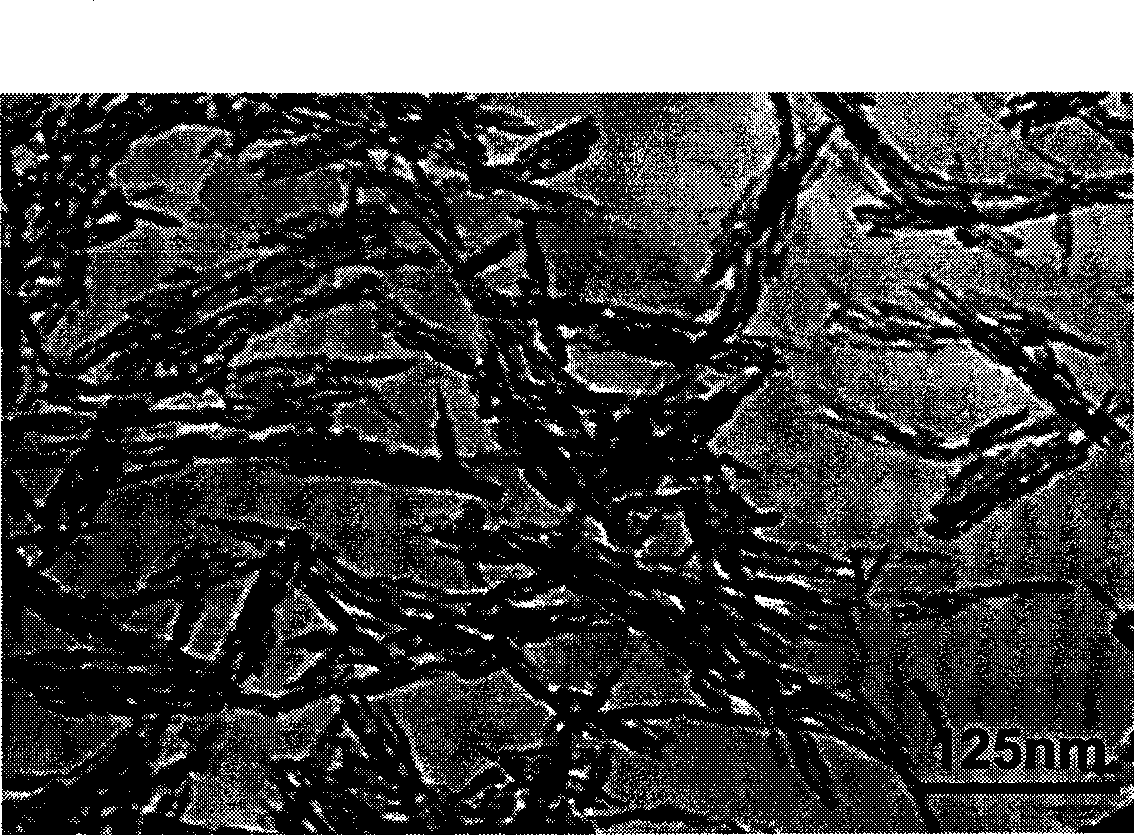

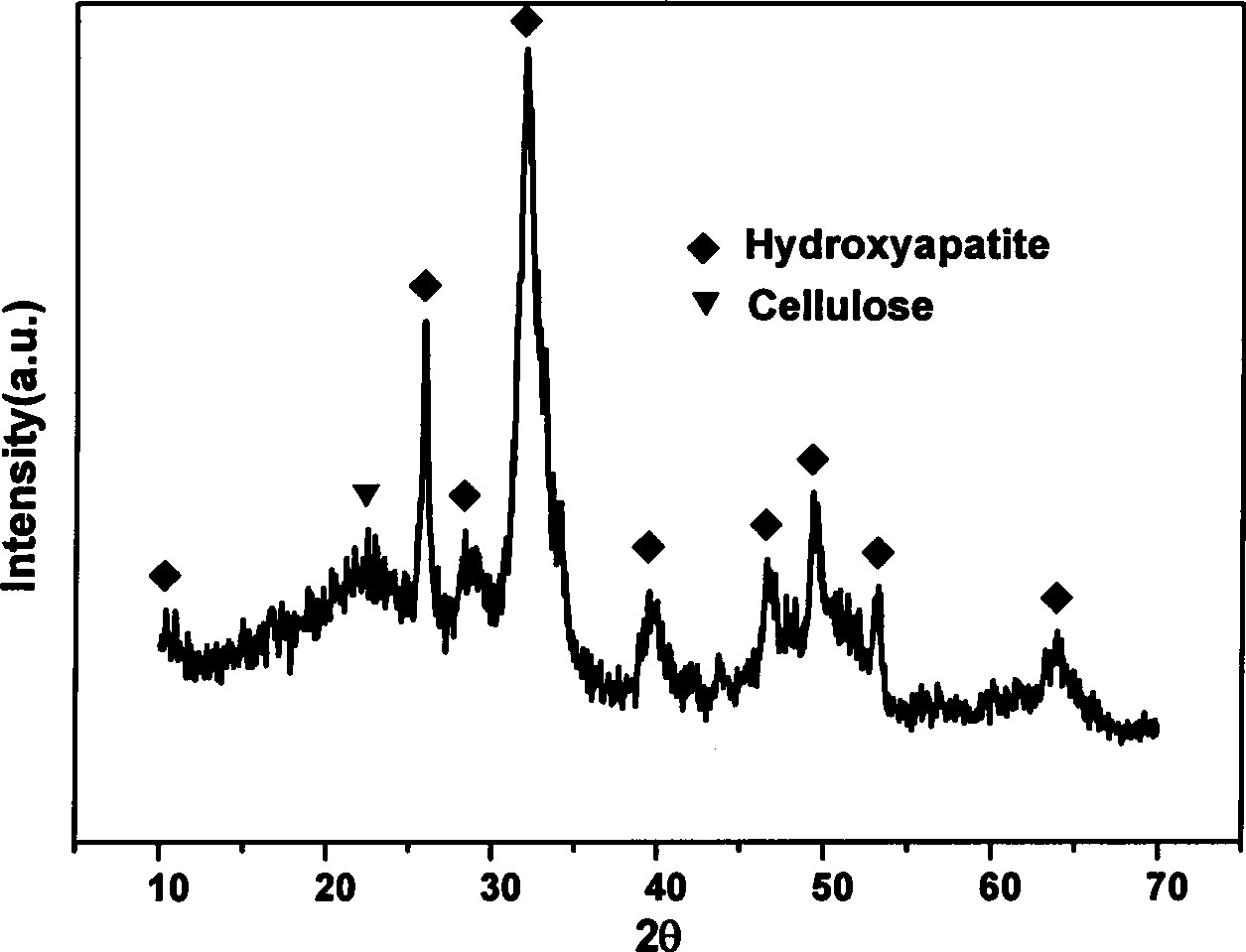

InactiveCN101508429AGood dispersion in aqueous mediumStable dispersed stateInorganic non-active ingredientsFluorescence/phosphorescenceCelluloseDispersity

The invention relates to hydroxyapatite composite nanoparticles, which comprise hydroxyapatite of which mass friction is 95 to 99.5 percent and cellulose with the mass friction of between 0.5 and 5 percent, wherein the appearance of the hydroxyapatite composite nanoparticles is a needle of which the length is between 50 and 310 nanometers and the width is between 3 and 30 nanometers. A method for preparing the hydroxyapatite composite nanoparticles comprises the following technological steps: (1) taking a metallic soluble salt aqueous solution or an ammonium salt aqueous solution as a solvent to dissolve the cellulose at a temperature of between 60 and 100 DEG C; (2) adding a calcium salt aqueous solution and a phosphate aqueous solution into a cellulose-salt solution after the cellulose-salt solution prepared in the step (1) is cooled to the room temperature, controlling the mol ratio of Ca to P of a reaction system is 1.2-2.0:1, subsequently adjusting the pH value of the reaction system, stopping stirring when the pH value is stably between 10 and 12, and keeping the obtained solution stand and performing aging for at least 48 hours; and (3) collecting and drying products. The composite particles have stable dispersity in an aqueous-phase medium, and can be taken as a fluorescent molecular carrier.

Owner:SICHUAN UNIV

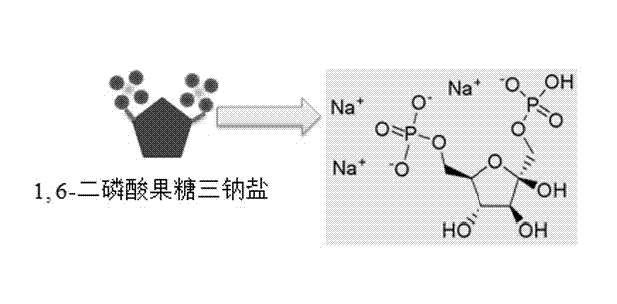

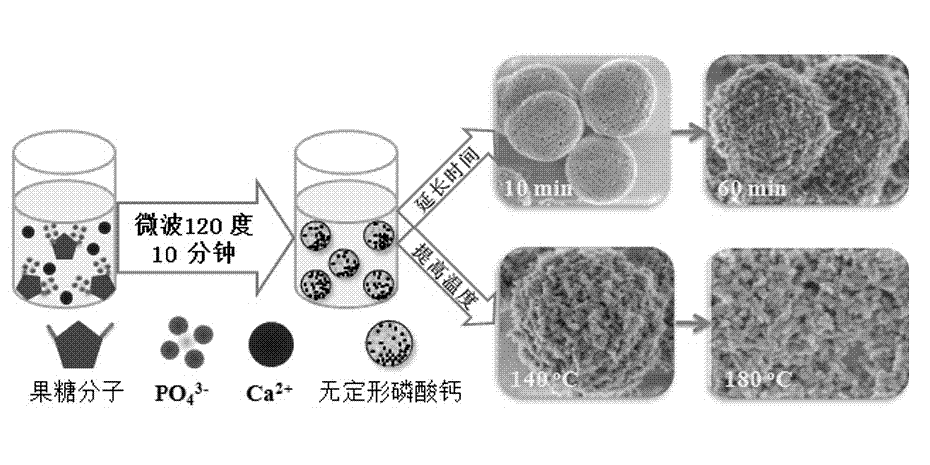

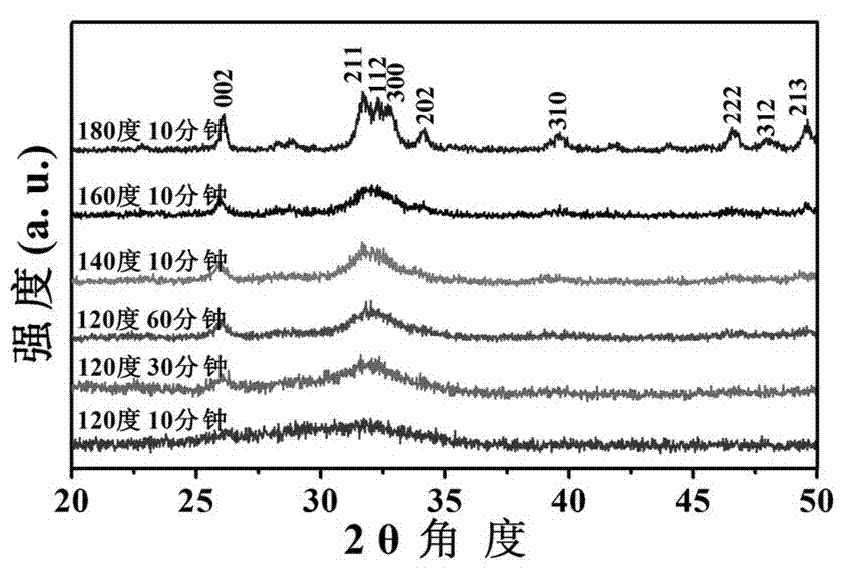

Calcium phosphate nano-structures and preparation method thereof

ActiveCN102897734APromote degradationShape is easy to controlMaterial nanotechnologyPhosphorus compoundsNanostructureNanorod

The invention relates to calcium phosphate nano-structures and a preparation method thereof. According to the method, water-soluble calcium salt serving as a calcium source and phosphorous biomolecules serving as as a phosphor source are prepared into a calcium phosphate nano-structure powder through a microwave assisted hydrothermal reaction, wherein the phosphorous biomolecules are phosphofructose or fructose diphosphate. The three different nanostructures, namely amorphous calcium phosphate porous nano-spheres, hydroxyapatite nano-rods and amorphous calcium phosphate / hydroxyapatite composite nano-spheres, prepared by the preparation method can be widely applied to biomedicine, tissue engineering and other fields.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

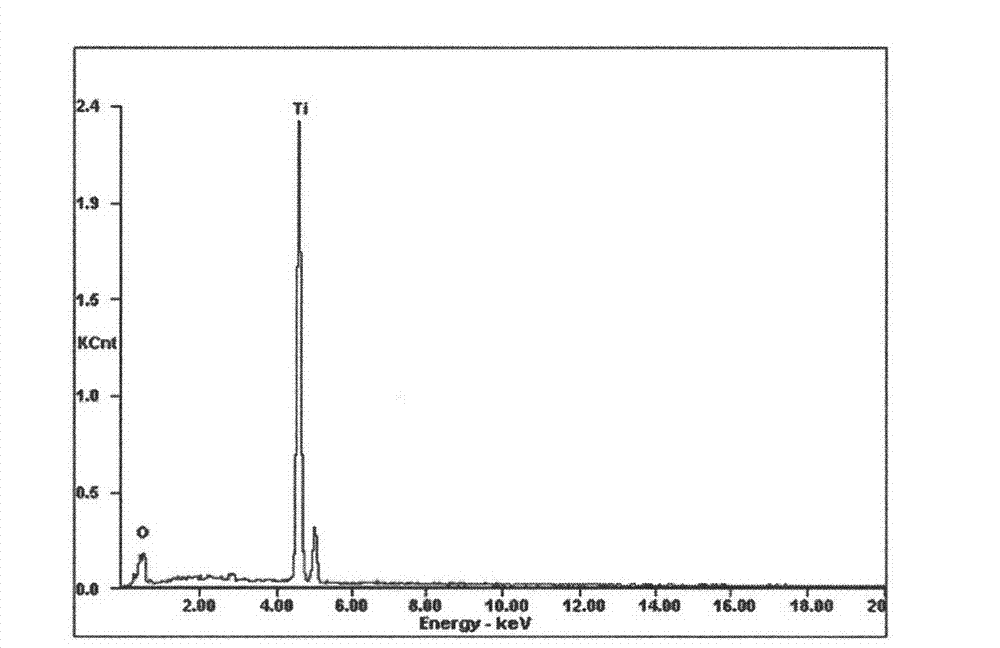

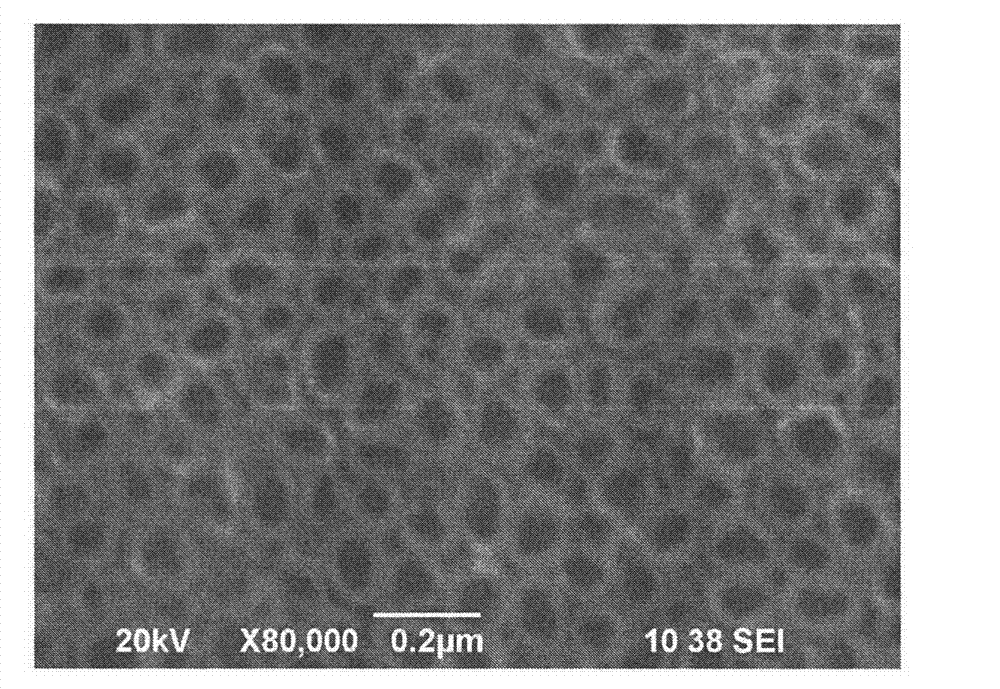

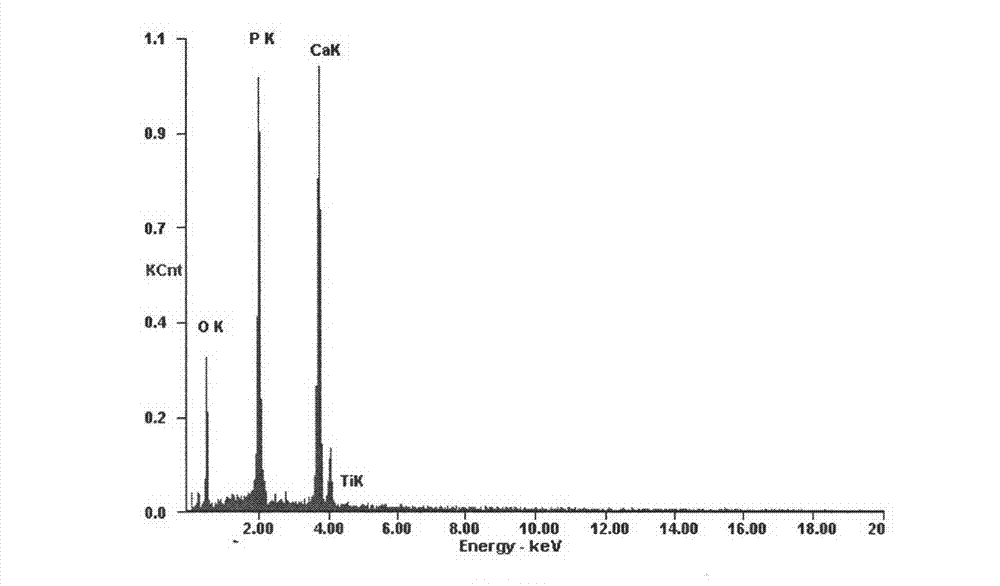

Method for surface modification of dental implant

InactiveCN103361702AEvenly distributedUniform pore sizeImpression capsSurface reaction electrolytic coatingBiocompatibility TestingDrug biological activity

The invention mainly discloses a method for surface modification of a metal titanium dental implant. A titanium dioxide / hydroxyapatite composite coating with biocompatibility and biological activity is prepared on the surface of the dental implant by using a multi-electrode method; and the technology is suitable for modifying most of medical metal surfaces. The method mainly comprises the following steps of: (1) ultrasonically cleaning a mechanical face threaded titanium dental implant through ultrapure water, acetone and absolute ethyl alcohol and then drying; (2) uniformly arranging and distributing a titanium dioxide nanotube array with consistent aperture size on an anodic oxide layer of the implant as a buffer layer by using the multi-electrode method; (3) electrodepositing the hydroxyapatite coating in a calcium phosphate electric deposition solution by using the multi-electrode method to prepare the prepared hydroxyapatite coating which is uniformly distributed and has high purity and better biological activity; and (4) processing the material obtained by the process through high-temperature vacuum sintering. The titanium dioxide / hydroxyapatite composite coating prepared by the steps has better bonding strength and superior biological activity, so that the dental implant subjected to surface modification has a broader and longer-range application prospect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Biomimetic hydroxyapatite composite materials and methods for the preparation thereof

Owner:WARSAW ORTHOPEDIC INC

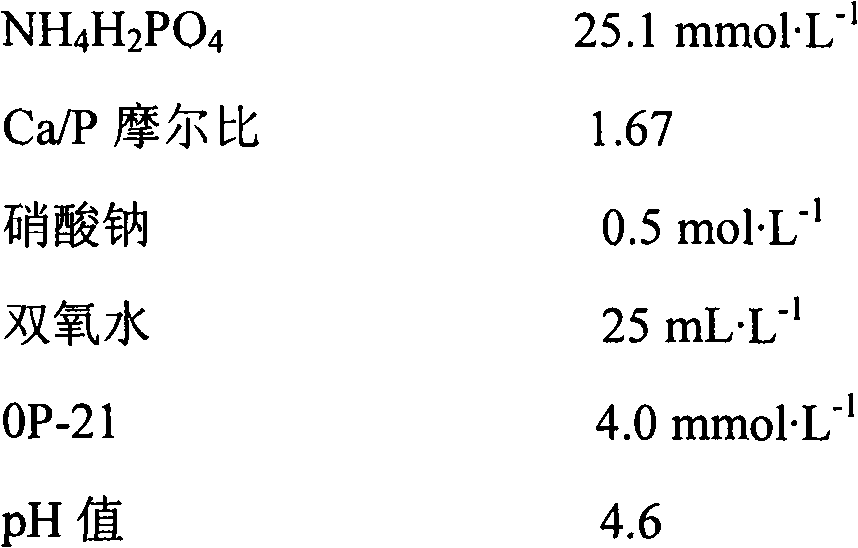

Electrodeposition preparation method for biomedical titanium base hydroxyapatite composite material

InactiveCN103014801ASimple operation processEasy to controlElectrolytic inorganic material coatingSupporting electrolyteApatite

The present invention discloses a preparation method for electrodeposition of a hydroxyapatite coating on the surface of titanium or a titanium alloy. The method comprises: adopting a pretreated titanium substrate or a pretreated titanium alloy substrate as a cathode, adopting a platinum-plated titanium mesh as an anode, heating an electroplating solution to a constant temperature of 40-80 DEG C, and adopting a constant current manner or a constant potential manner under a magnetic stirring condition to carry out electrodeposition, wherein a current density is 1.0-50.0 mA.cm<-2>, a deposition potential is 1.0-10.0 V, the electroplating solution comprises 20.2-80.0 mmol.L<-1> of Ca<2+> and 10.0-50.0 mmol.L<-1> of H2PO4<->, a Ca / P molar ratio is 1.6-2.0, a supporting electrolyte concentration is 0.1-1.0 mol.L<-1>, and the pH value is 4.2-5.0. According to the present invention, the hydroxyapatite coating prepared through electrodeposition by using the constant current manner or the constant potential manner has characteristics of fine crystal, smooth surface, strong bonding force with the substrate, good biological activity and mechanical property. The preparation method for the titanium base hydroxyapatite composite material has characteristics of mild reaction condition, avoidance of influence on material biological activity by a high temperature treatment, simple process, and low equipment investment, wherein a series of problems caused by expensive equipment and complex operation of the existing method are overcome with the preparation method.

Owner:TIANJIN XUANZHEN BIOMEDICAL TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com