Method for preparing calcium phosphate composite powder

A composite powder, calcium phosphate technology, applied in phosphorus compounds, chemical instruments and methods, medical science and other directions, to achieve the effects of easy realization, process environmental protection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

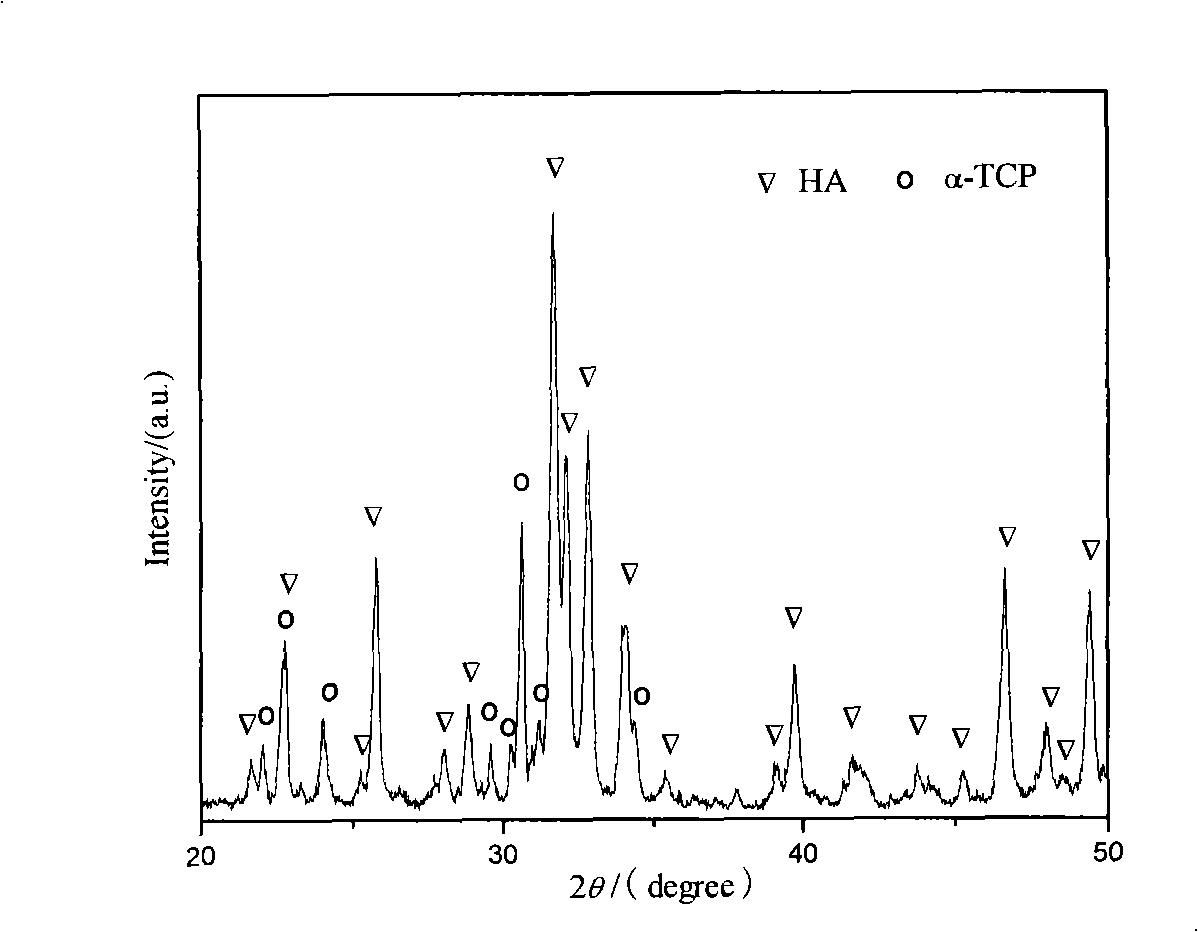

[0027] 7.0845g Ca(NO 3 ) 2 Dissolve in 50mL of deionized water, and add 50mL of (NH 4 ) 2 HPO 4 solution, make the calcium-phosphorus molar ratio in the system be 1.500, react at room temperature, maintain the pH value of the system at 11.0 with ammonia water, stir for 24 hours, and age for 24 hours to obtain a reaction product mixed solution, and then add Ca(NO 3 ) 2 solution, so that the Ca / P molar ratio of the system reaches 1.600. After stirring evenly, age for another 24 hours, filter, wash and dry. Then calcined at 900°C for 2 hours, lowered to room temperature with the furnace, and after grinding, a multiphase α-calcium phosphate / hydroxyapatite powder with a Ca / P molar ratio of 1.600 can be obtained. The XRD spectrum and SEM photos of the product are as follows figure 1 and Figure 5 .

Embodiment 2

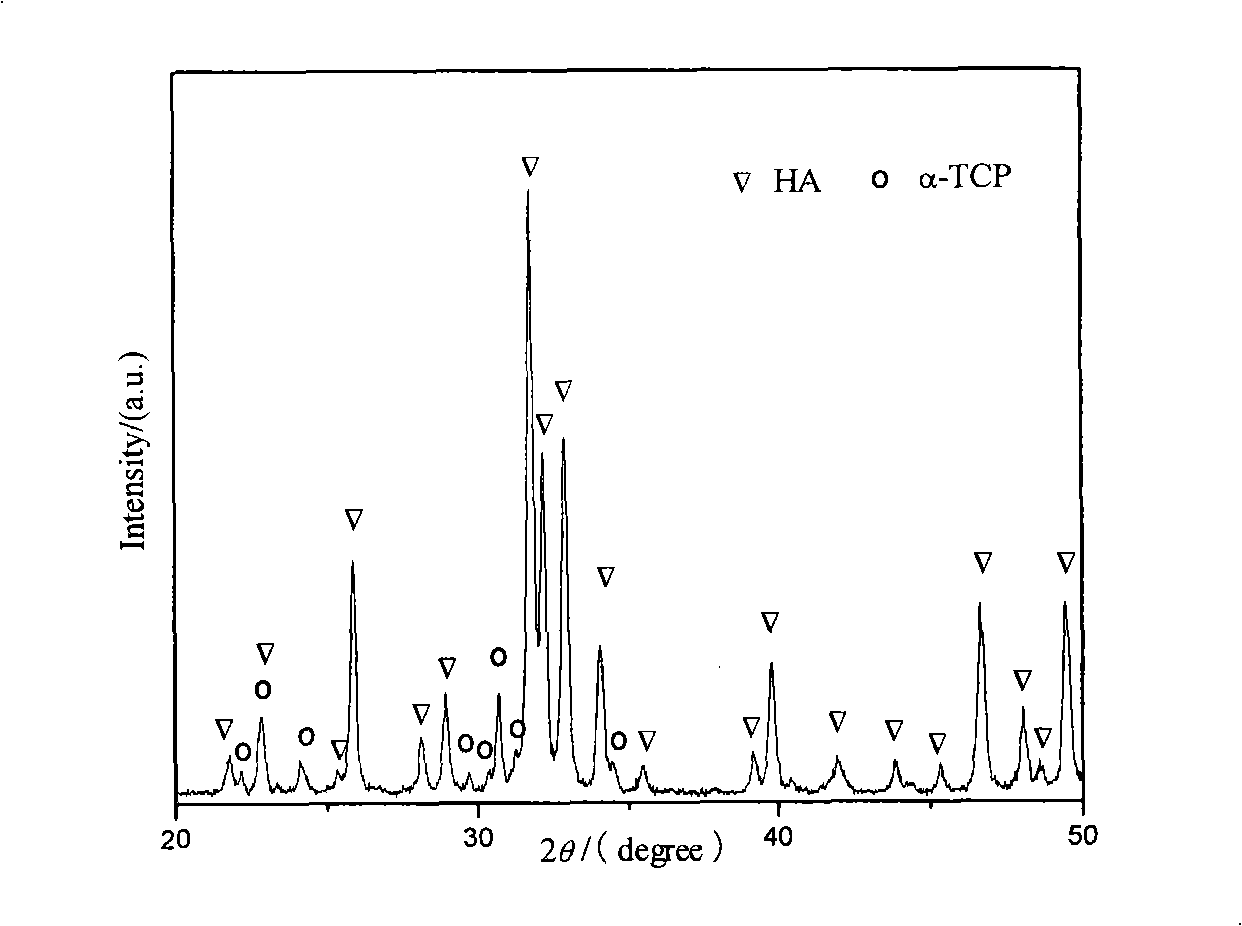

[0029] 7.0845g Ca(NO 3 ) 2 Dissolve in 50mL of deionized water, and add 50mL of (NH 4 ) 2 HPO 4 solution, make the calcium-phosphorus molar ratio in the system be 1.500, react at room temperature, maintain the pH value of the system at 11.0 with ammonia water, stir for 24 hours, and age for 24 hours to obtain a reaction product mixed solution, and then add Ca(NO 3 ) 2 solution, so that the Ca / P molar ratio of the system reaches 1.636. After stirring evenly, age for another 24 hours, filter, wash and dry. Then calcined at 900°C for 2 hours, lowered to room temperature with the furnace, and after grinding, a multiphase α-calcium phosphate / hydroxyapatite powder with a Ca / P molar ratio of 1.636 can be obtained. The XRD spectrum and SEM photos of the product are as follows figure 2 and Figure 6 .

Embodiment 3

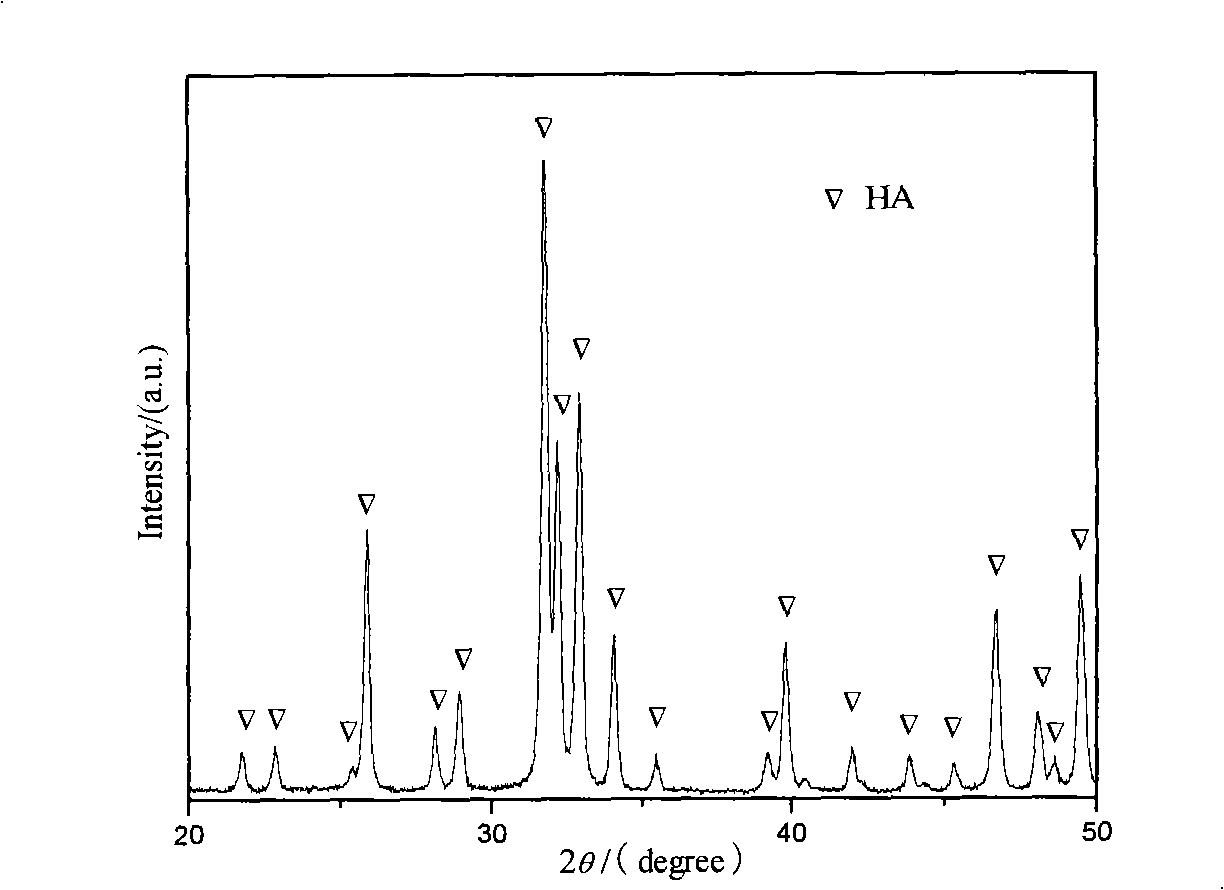

[0031] 7.0845g of Ca(NO 3 ) 2 Dissolve in 50mL deionized water, and add 50mL (NH 4 ) 2 HPO 4 solution, make the calcium-phosphorus molar ratio in the system be 1.500, react at room temperature, maintain the pH value of the system at 11.0 with ammonia water, stir for 24 hours, and age for 24 hours to obtain a reaction product mixed solution, and then add Ca(NO 3 ) 2 solution, so that the Ca / P molar ratio of the system reaches 1.667. After stirring evenly, age for another 24 hours, filter, wash and dry. Then calcined at 900°C for 2 hours, then lowered to room temperature with the furnace, and after grinding, a hydroxyapatite powder with a Ca / P molar ratio of 1.667 can be obtained. The XRD spectrum and SEM photos of the product are as follows image 3 and Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com