A method for preparing high-conductivity garnet-type electrolyte sheet at low temperature

A garnet-type, high-conductivity technology, applied in the direction of electrolytes, circuits, electrical components, etc., can solve the problems of difficult control of solid electrolyte components, volatilization of lithium components, etc., to facilitate large-scale production, low synthesis temperature, and high conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Weigh lithium hydroxide, lanthanum hydroxide, zirconium oxide, germanium oxide, and tantalum pentoxide according to the stoichiometric ratio, and add lithium hydroxide to the ball mill tank with an excess of 10wt.%, and add an appropriate amount of isopropanol to ball mill for 10 hours , Dry at 75°C for 12h.

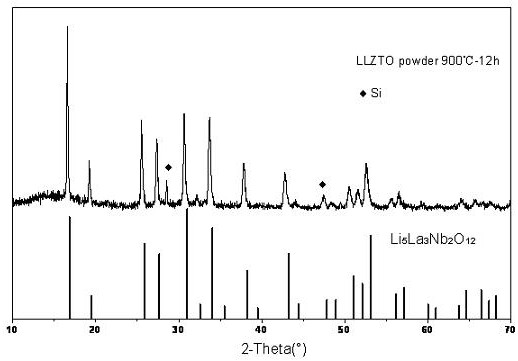

[0022] 2. Calcining the obtained powder at 900° C. for 10 h to prepare solid electrolyte powder.

[0023] 3. Ball mill the burnt powder again, dry it at 75°C, and press it into tablets under isostatic pressure at 300MPa. The solid electrolyte sheet is placed on a high-purity corundum ceramic plate covered with solid electrolyte powder, and the electrolyte sheet is buried with the electrolyte powder. Cover with an arc-shaped crucible, heat up to 1150°C at 5°C / min for sintering, and hold for 10 hours to prepare the required Li 6.6 La 3 Zr 1.4 Ta 0.4 Ge 0.2 o 12 Solid Electrolyte Sheet.

[0024] 4. Use 400-mesh SiC sand to polish the solid electrolyte shee...

Embodiment 2

[0026] 1. Weigh lithium carbonate, lanthanum oxide, zirconium oxide, tungsten oxide, and tantalum pentoxide according to the stoichiometric ratio, wherein the excess lithium is 15wt.%, and add an appropriate amount of alumina at the same time, and add the above raw materials into the ball mill tank, Add an appropriate amount of n-butanol to ball mill for 12 hours, and dry at 80°C for 12 hours.

[0027] 2. Calcining the obtained powder at 900° C. for 12 hours to prepare solid electrolyte powder.

[0028] 3. Ball mill the burnt powder again, dry it at 80°C, press isostatically at 200MPa to form a tablet. The solid electrolyte sheet is placed on a high-purity corundum ceramic plate covered with solid electrolyte powder, and the electrolyte sheet is buried with the electrolyte powder. Cover with an arc-shaped crucible, heat up to 1200°C at 3°C / min for sintering, and hold for 10 hours to prepare the required Li 6.4 La 3 Zr 1.4 Ta 0.5 W 0.1 o 12 Solid Electrolyte Sheet.

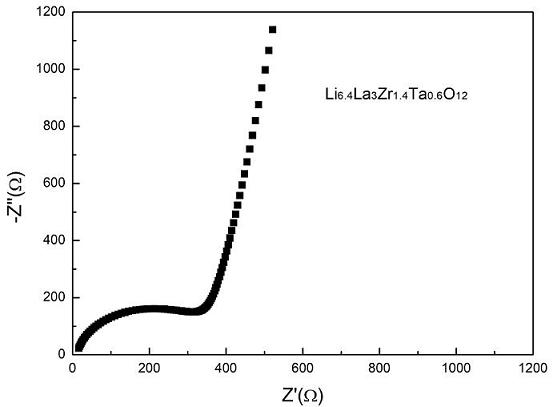

[0...

Embodiment 3

[0031] 1. Weigh lithium carbonate, lanthanum nitrate, zirconium oxide nitrate, germanium oxide, tantalum pentoxide, and tungsten oxide according to the stoichiometric ratio, among which lithium hydroxide is in excess of 10wt.%. , Dry at 55°C for 12h.

[0032] 2. Calcinate the obtained powder at 850°C for 10 hours.

[0033] 3. Ball-mill the burnt powder again, dry it at 55°C, press isostatically at 200MPa to form a tablet. The solid electrolyte sheet is placed on a high-purity corundum ceramic plate covered with solid electrolyte powder, and the electrolyte sheet is buried with the electrolyte powder. Cover with an arc-shaped crucible, heat up to 1050°C at 5°C / min for sintering, and hold for 10 hours to prepare the required Li 6.6 La 3 Zr 1.4 Ta 0.3 W 0.1 Ge 0.2 o 12 Solid Electrolyte Sheet.

[0034] 4. Use 1500-mesh SiC sand solid electrolyte sheet to polish and silver-plate it, and test its electrochemical impedance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com