Patents

Literature

745 results about "Nichrome" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nichrome (NiCr, nickel-chrome, chrome-nickel, etc.) is any of various alloys of nickel, chromium, and often iron (and possibly other elements). The most common usage is as resistance wire, although they are also used in some dental restorations (fillings) and in a few other applications.

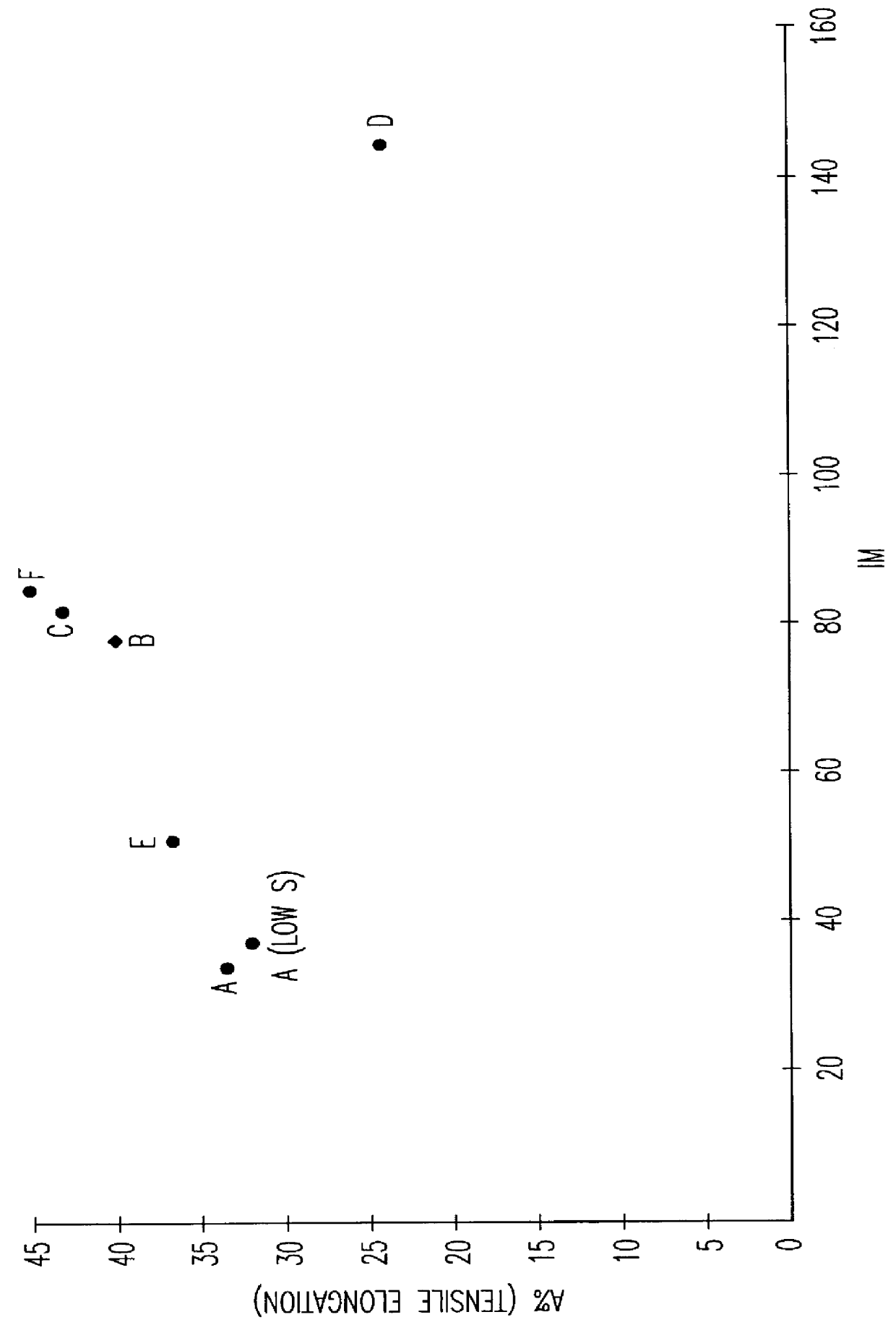

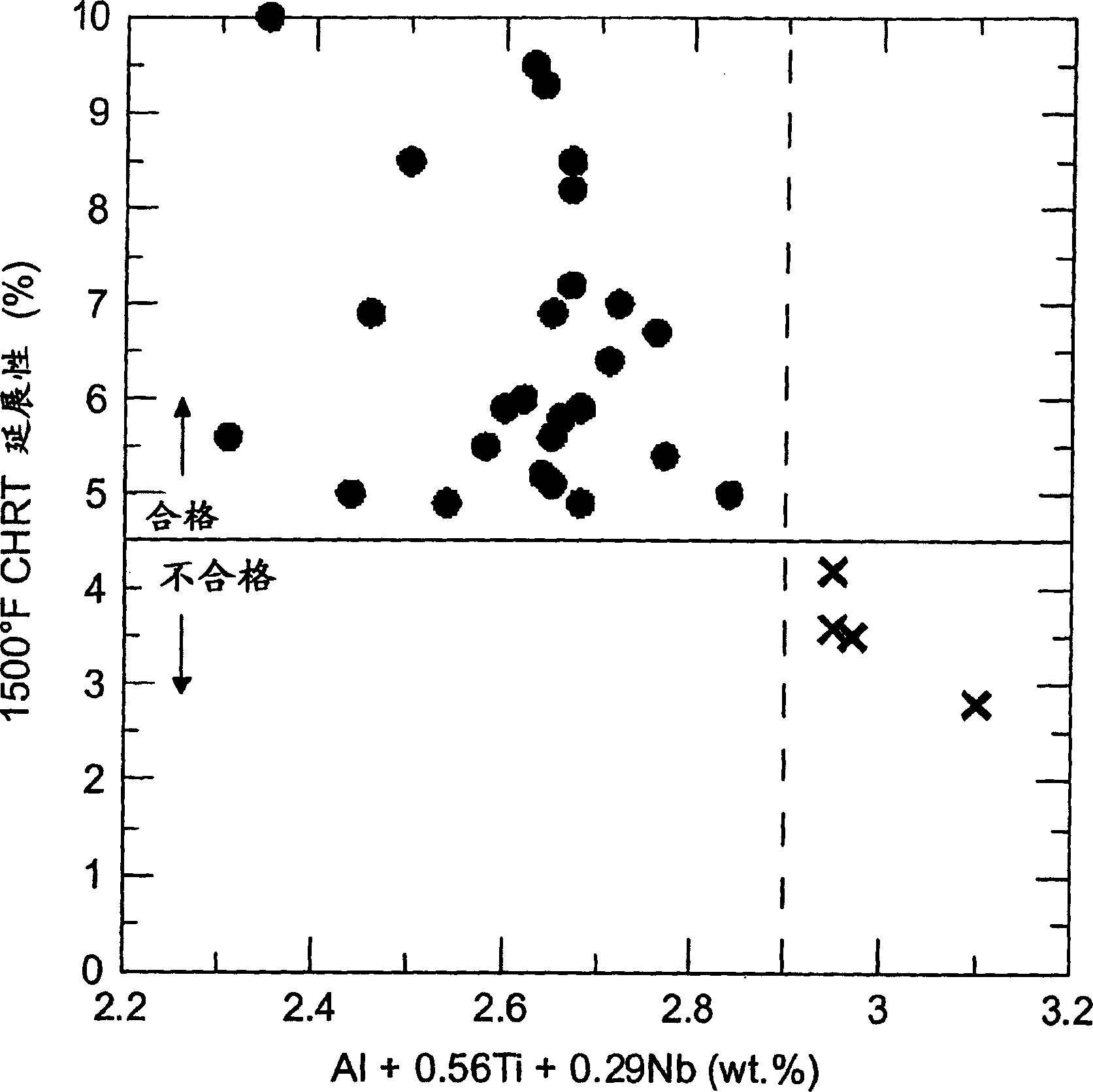

Austenoferritic stainless steel having a very low nickel content and a high tensile elongation

InactiveUS6096441ALow nickel contentImproved general propertyHeat treatment process controlElectric furnaceSulfurManganese

An austenoferritic stainless steel with high tensile elongation includes iron and the following elements in the indicated weight amounts based on total weight: carbon<0.04% 0.4%<silicon<1.2% 2%<manganese<4% 0.1%<nickel<1% 18%<chromium<22% 0.05%<copper<4% sulfur<0.03% phosphorus<0.1% 0.1%<nitrogen<0.3% molybdenum<3% the steel having a two-phase structure of austenite and ferrite and comprising between 30% and 70% of austenite, wherein Creq=Cr %+Mo %+1.5 Si % Nieq=Ni %+0.33 Cu %+0.5 Mn %+30 C %+30 N % and Creq / Nieq is from 2.3 to 2.75, and wherein IM=551-805(C+N)%-8.52 Si %-8.57 Mn %-12.51 Cr %-36 Ni %-34.5 Cu %-14 Mo %, IM being from 40 to 115.

Owner:UGITECH

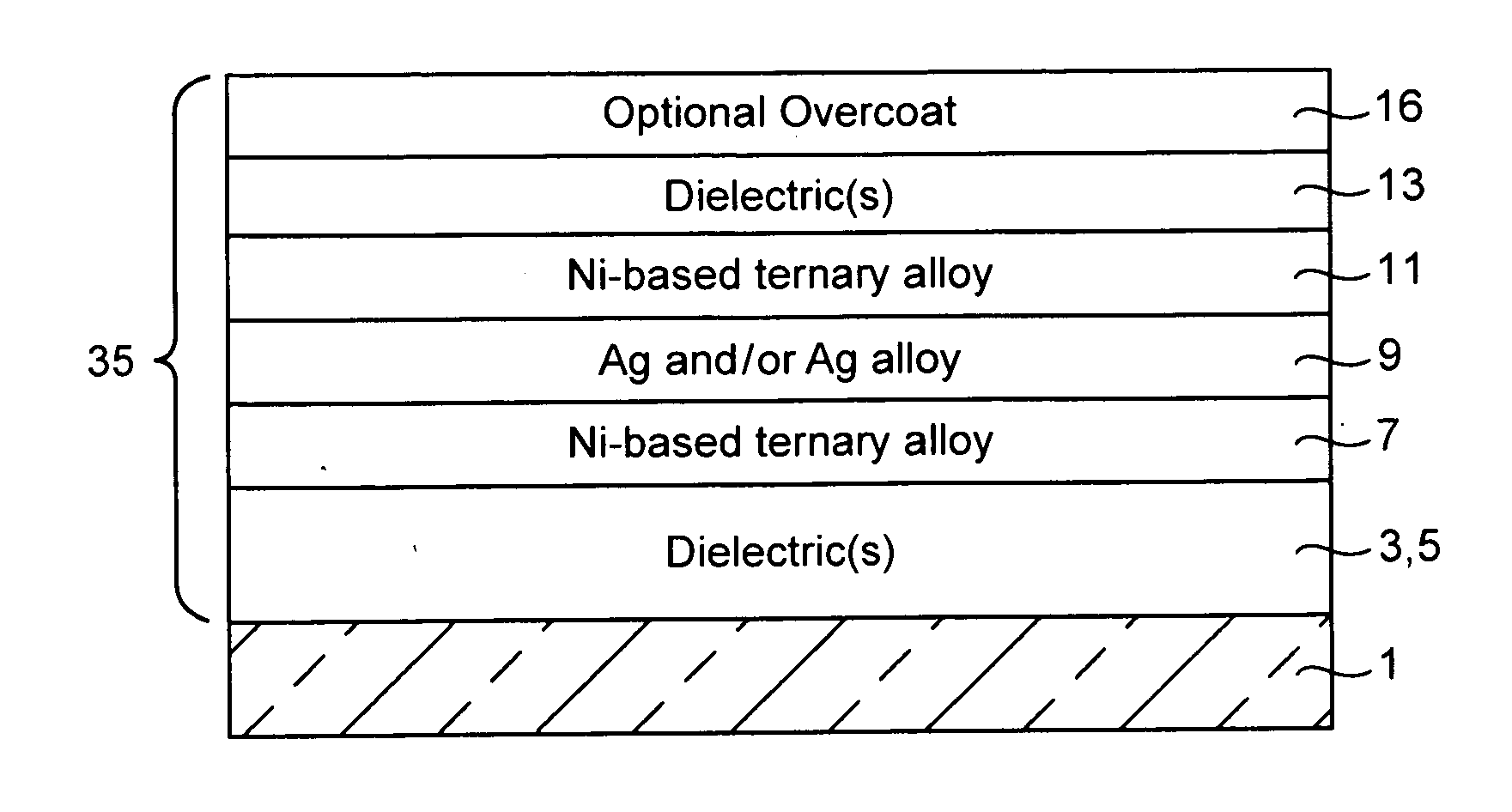

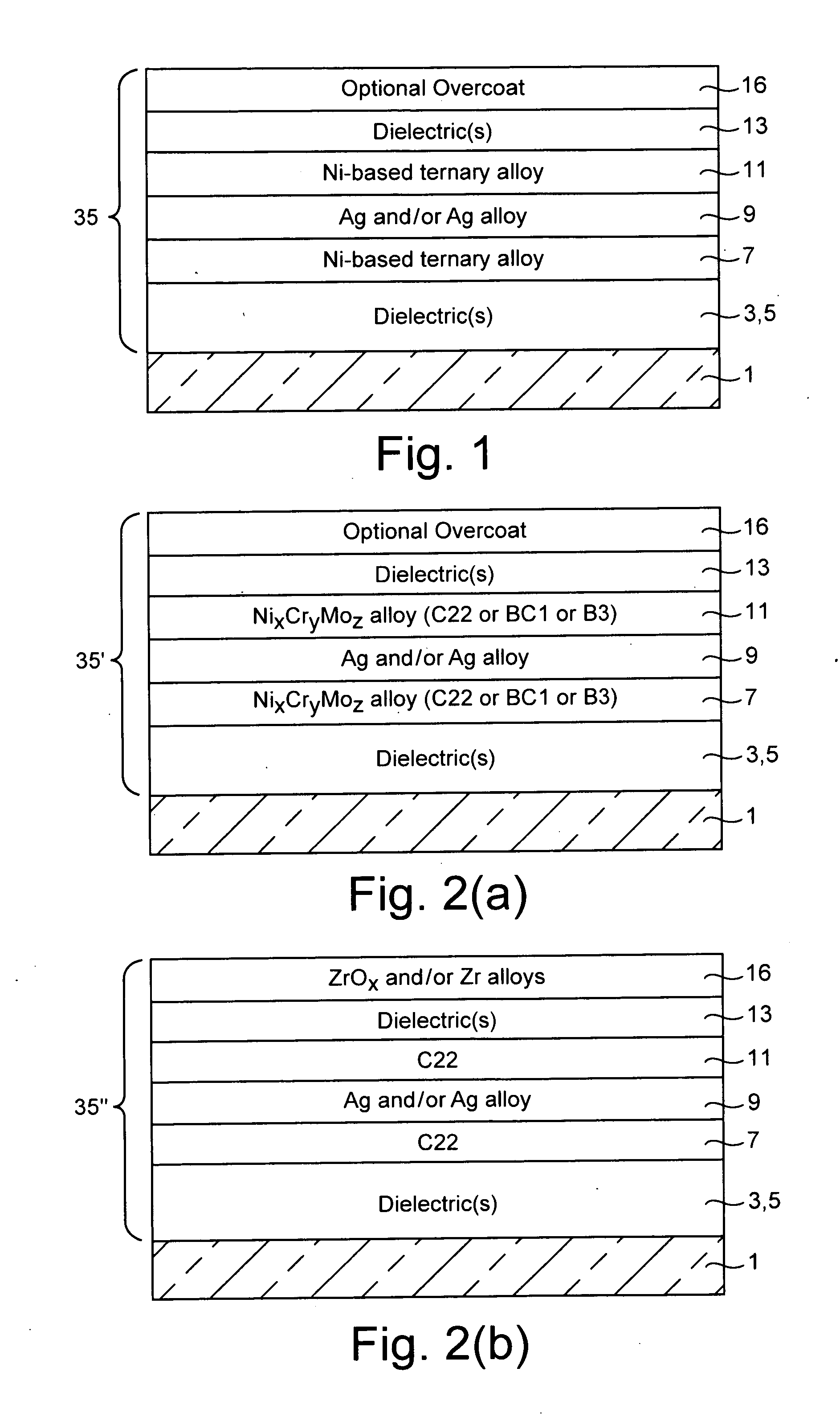

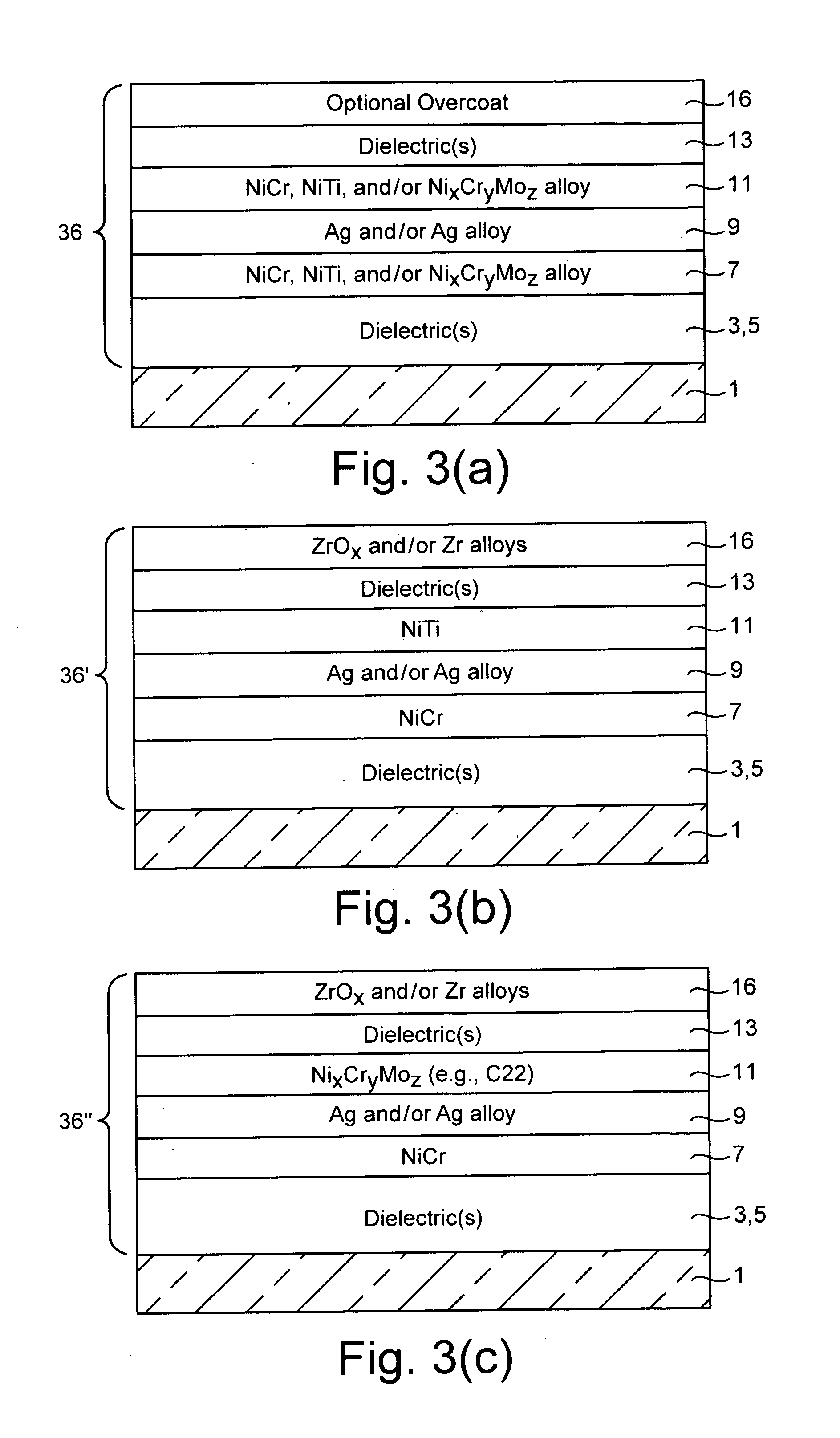

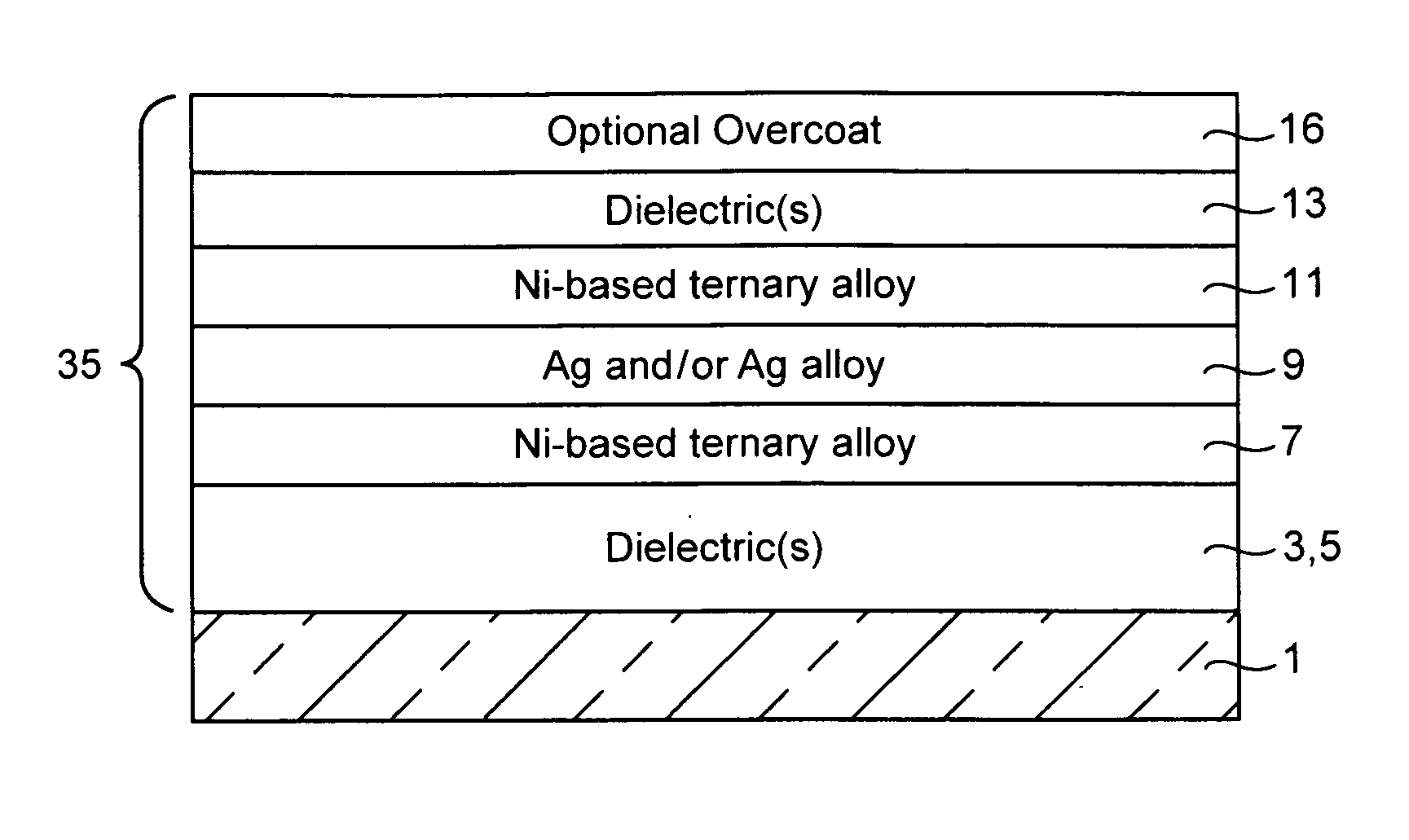

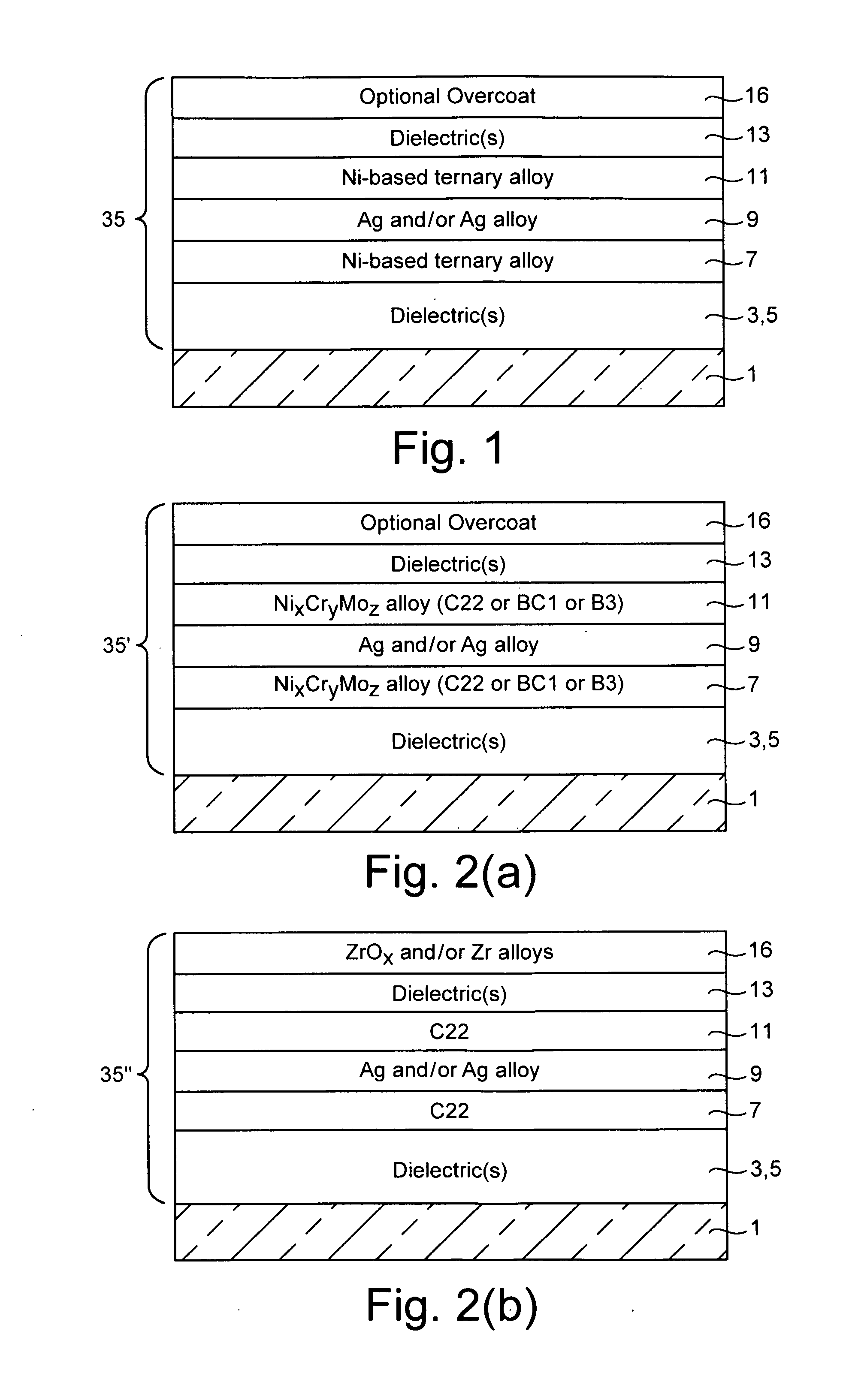

Barrier layers comprising Ni-inclusive ternary alloys, coated articles including barrier layers, and methods of making the same

ActiveUS20120225317A1Reduce sheet resistanceImprove transmittanceVacuum evaporation coatingSputtering coatingMaterials scienceChromium

Certain example embodiments relate to Ni-inclusive ternary alloy being provided as a barrier layer for protecting an IR reflecting layer comprising silver or the like. The provision of a barrier layer comprising nickel, chromium, and / or molybdenum and / or oxides thereof may improve corrosion resistance, as well as chemical and mechanical durability. In certain examples, more than one barrier layer may be used on at least one side of the layer comprising silver. In still further examples, a NixCryMoz-based layer may be used as the functional layer, rather than or in addition to as a barrier layer, in a coating.

Owner:GUARDIAN GLASS LLC

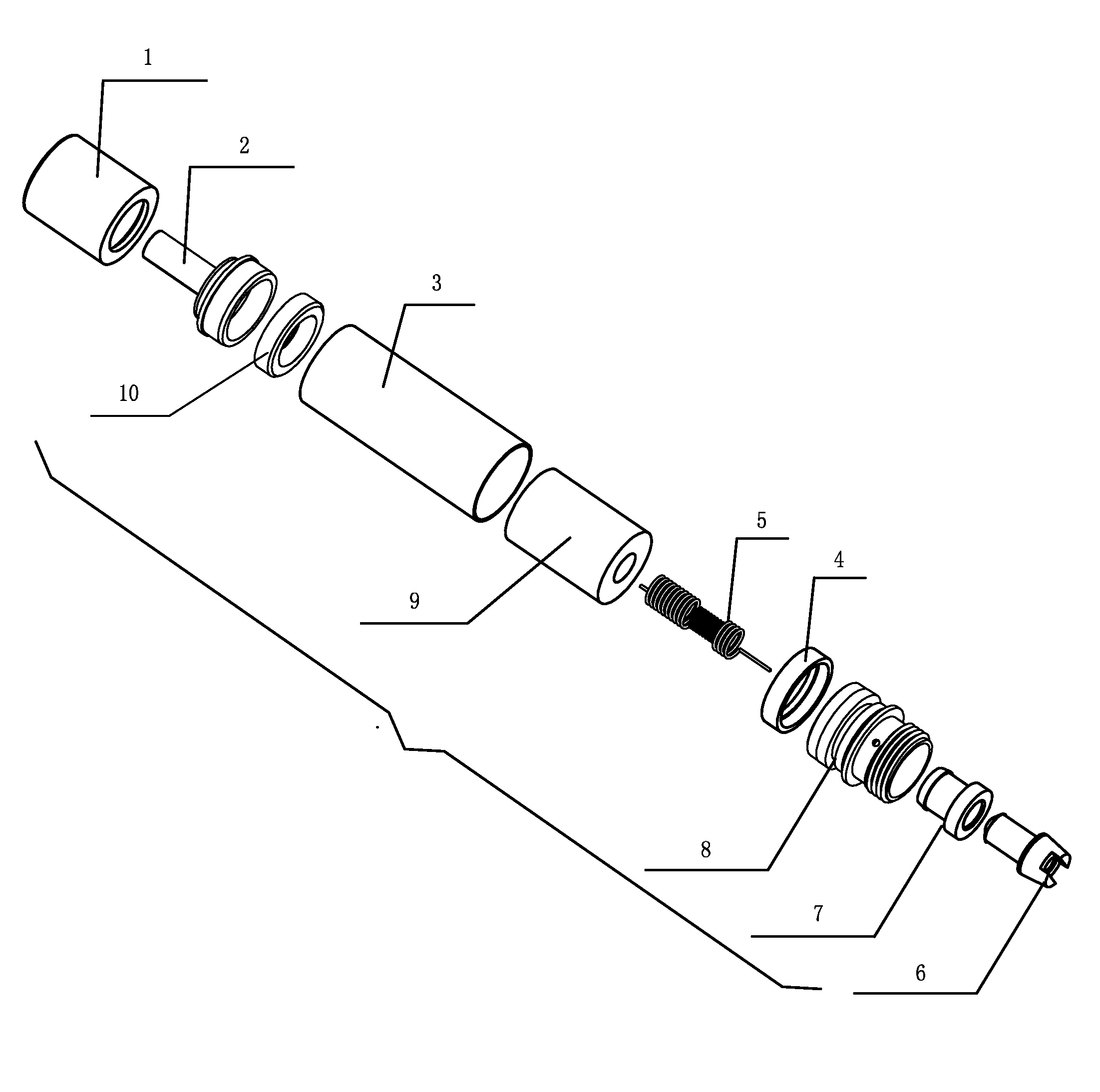

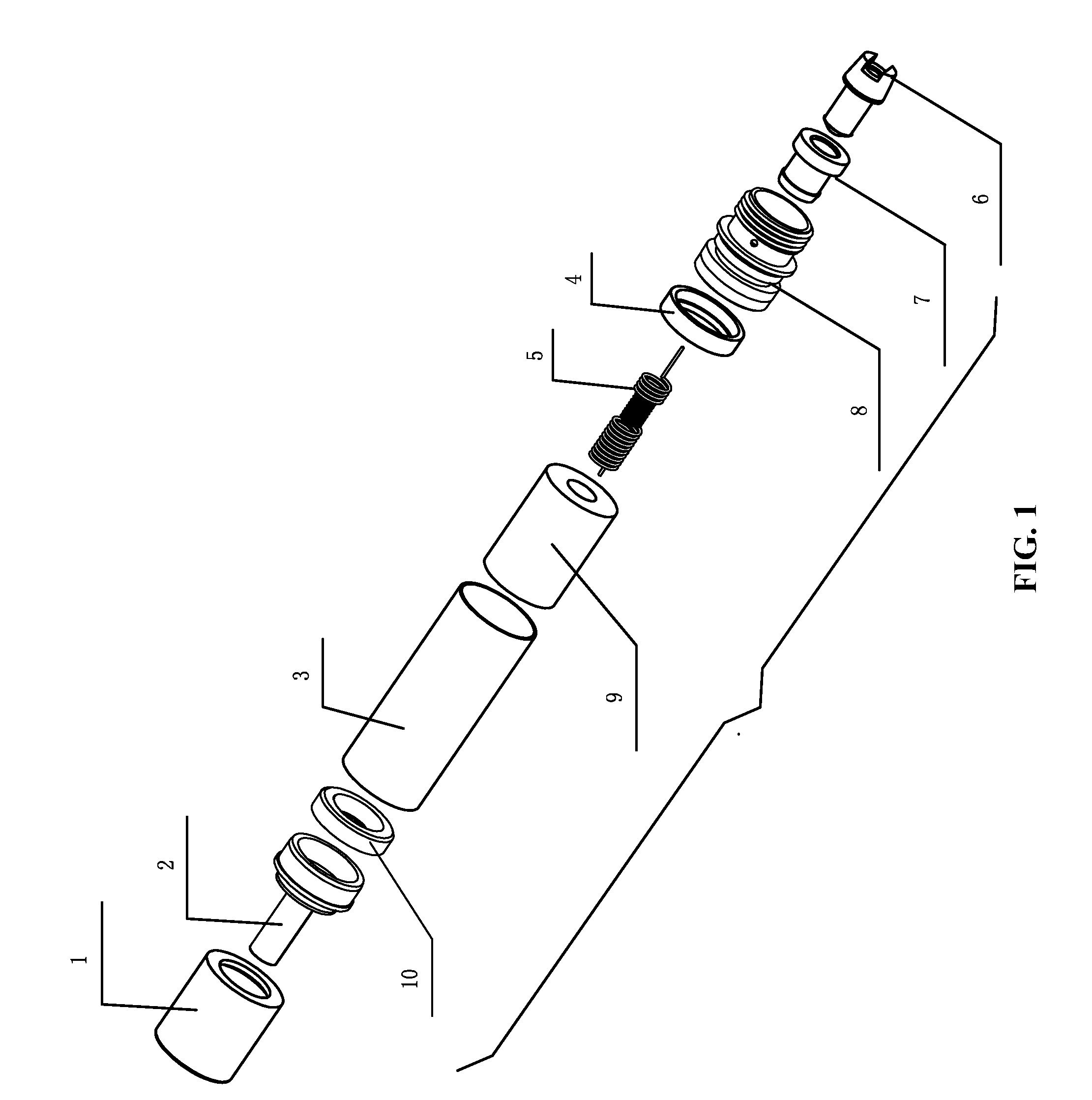

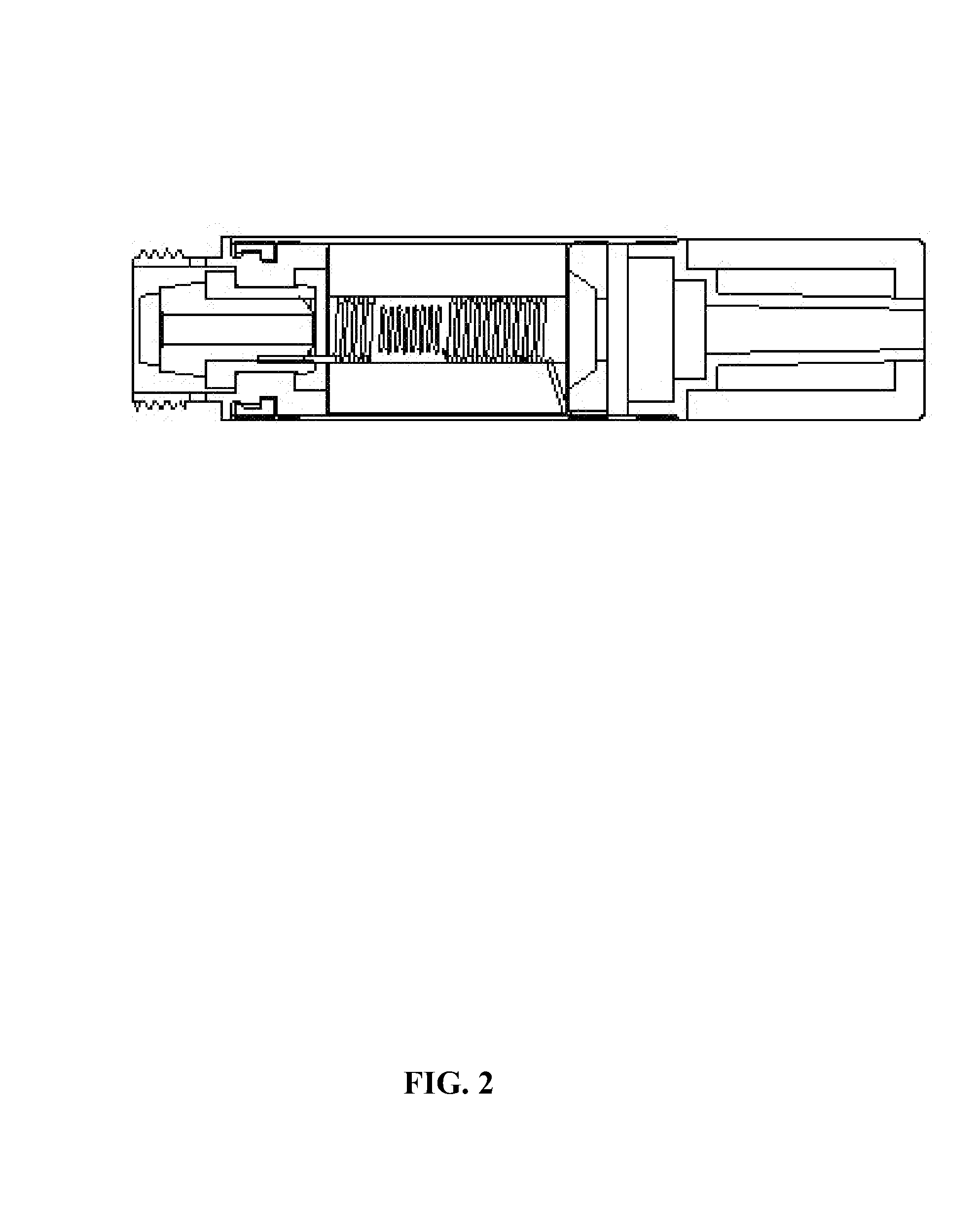

Electronic cigarette

ActiveUS20150013700A1Improve cooling effectEasy to useTobacco pipesTobacco devicesEngineeringElectronic cigarette

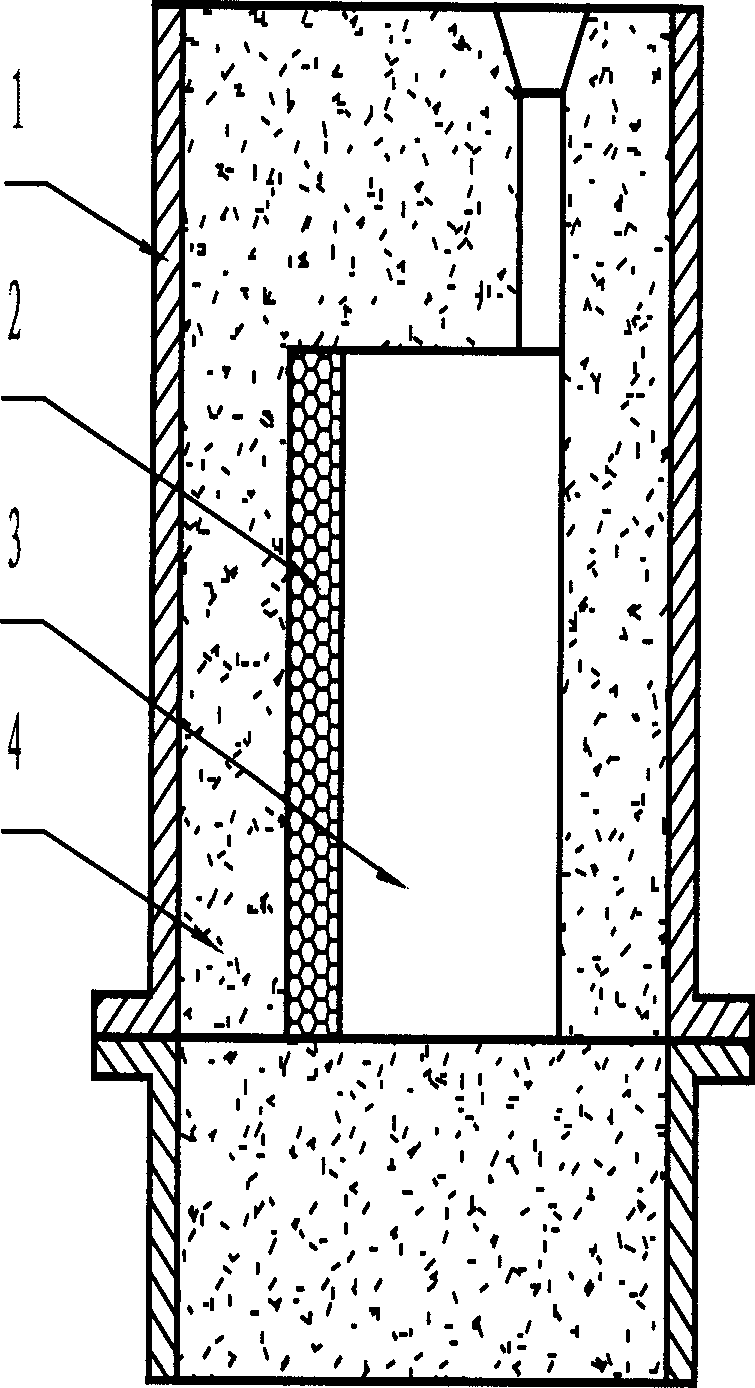

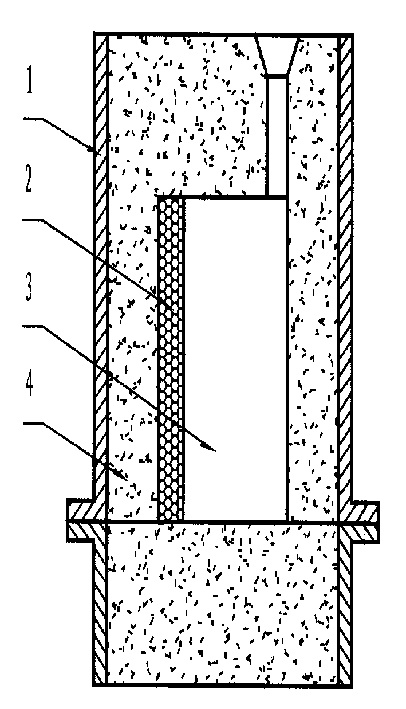

An electronic cigarette including a mouthpiece, a bracket for the mouthpiece, an atomization pole including a threaded copper ring, a silicate ring, a heating wire, a joint, an insulating ring, a filter cotton, and a fluid stop ring. The mouthpiece is made of silica gel and is connected with the atomization pole via the bracket. The heating wire is electrically welded using nickel-chrome as a material. The heating wire is spiral. One end of the threaded copper ring is connected with the joint. The insulating ring is disposed between the thread ring and the joint. The silicate ring is disposed between the filter cotton and the threaded copper ring. The fluid stop ring is disposed between the bracket and the heating wire for preventing the leakage of fluid.

Owner:LIU TUANFANG

Wear resistant low friction coating composition, coated components, and method for coating thereof

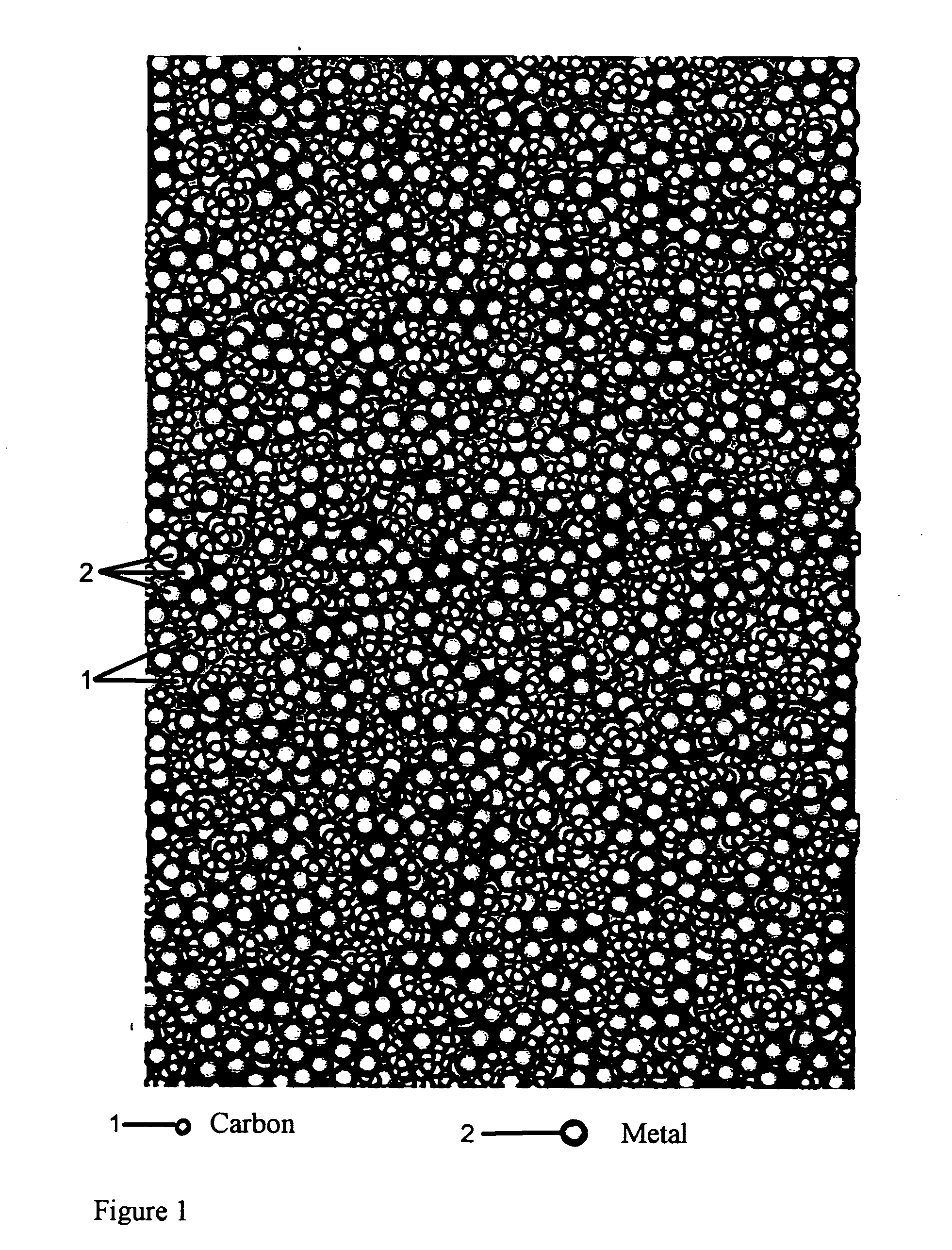

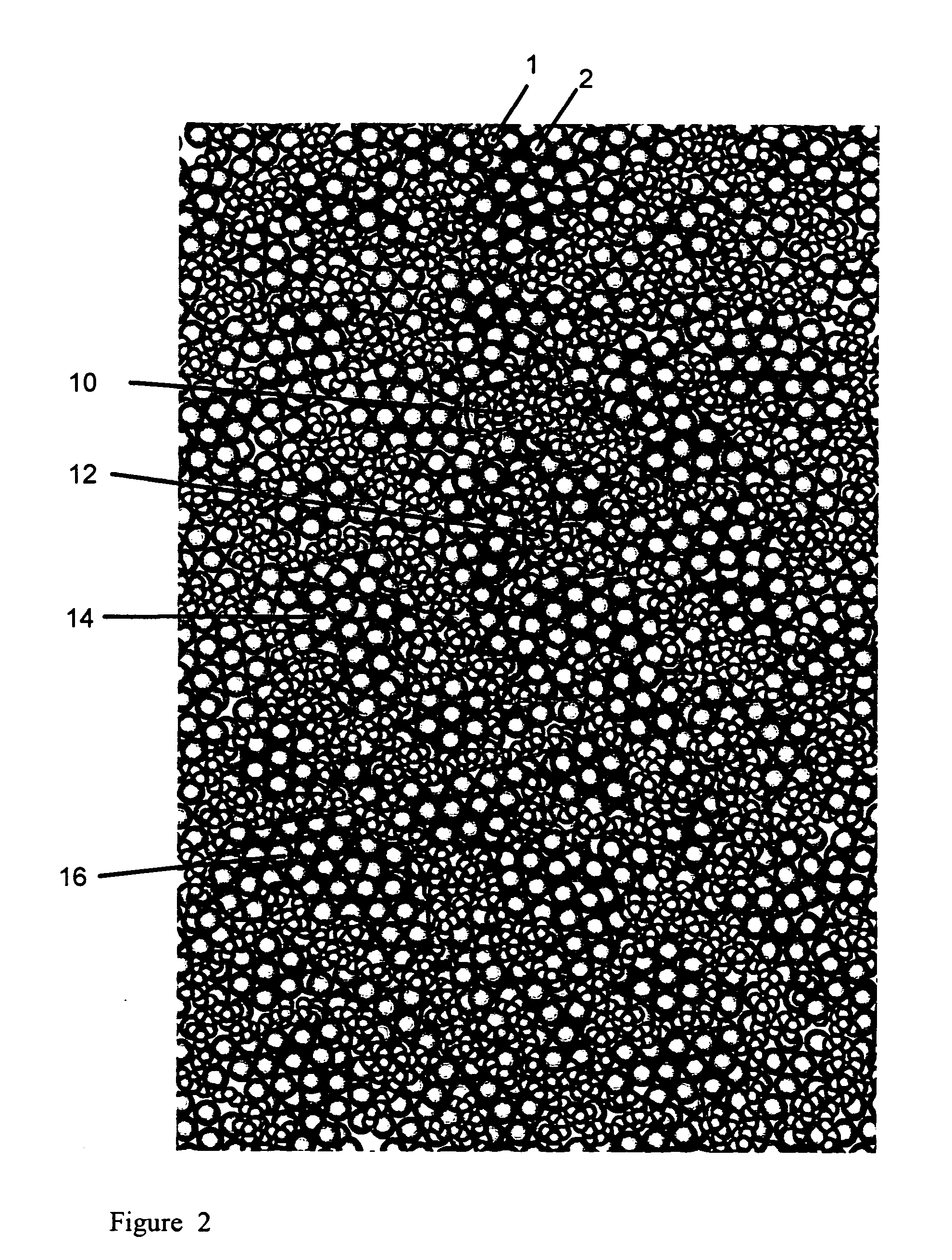

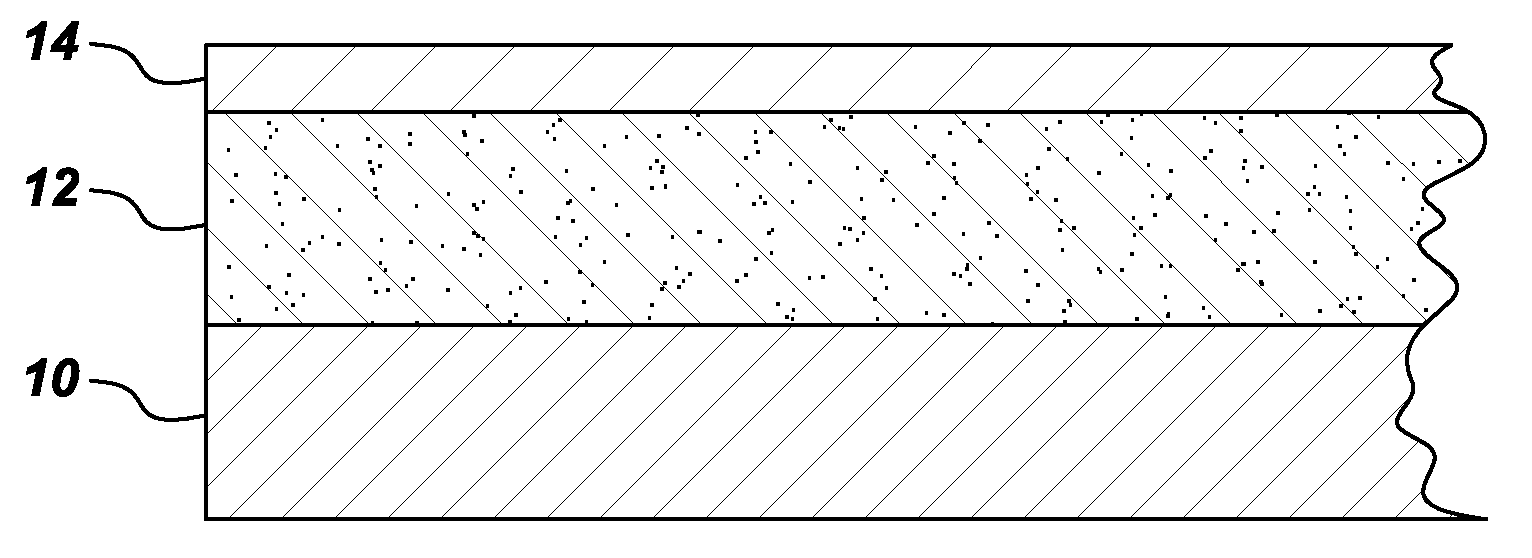

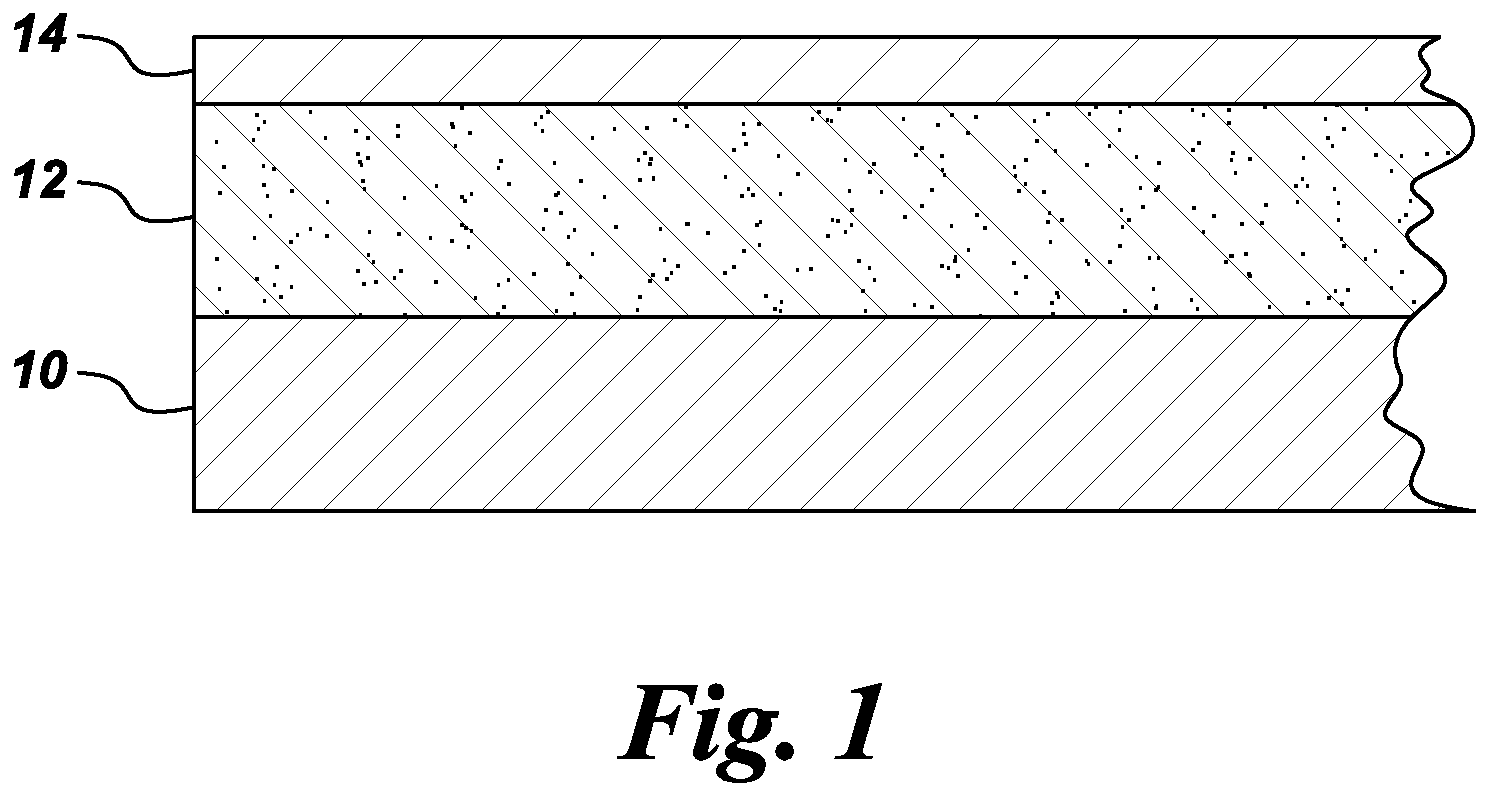

A composition for coating sliding or rolling or fretting or impacting members is formed by preparing a composite powder of TiB2 and BN, with a TiB2 to BN ratio ranging from 1:7 to 20:1, and a metallic matrix selected from the group consisting of nickel, chromium, iron, cobalt, aluminum, tungsten, carbon and alloys thereof.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

Barrier layers comprising NI-inclusive alloys and/or other metallic alloys, double barrier layers, coated articles including double barrier layers, and methods of making the same

InactiveUS20120225304A1Reduce sheet resistanceImprove transmittanceLight protection screensGlass/slag layered productsDouble barrierMetallic Nickel

Certain example embodiments relate to Ni-inclusive ternary alloy being provided as a barrier layer for protecting an IR reflecting layer comprising silver or the like. The provision of a barrier layer comprising nickel, chromium, and / or molybdenum and / or oxides thereof may improve corrosion resistance, as well as chemical and mechanical durability. In certain examples, more than one barrier layer may be used on at least one side of the layer comprising silver. In still further examples, a NixCryMoz-based layer may be used as the functional layer, rather than or in addition to as a barrier layer, in a coating.

Owner:GUARDIAN GLASS LLC

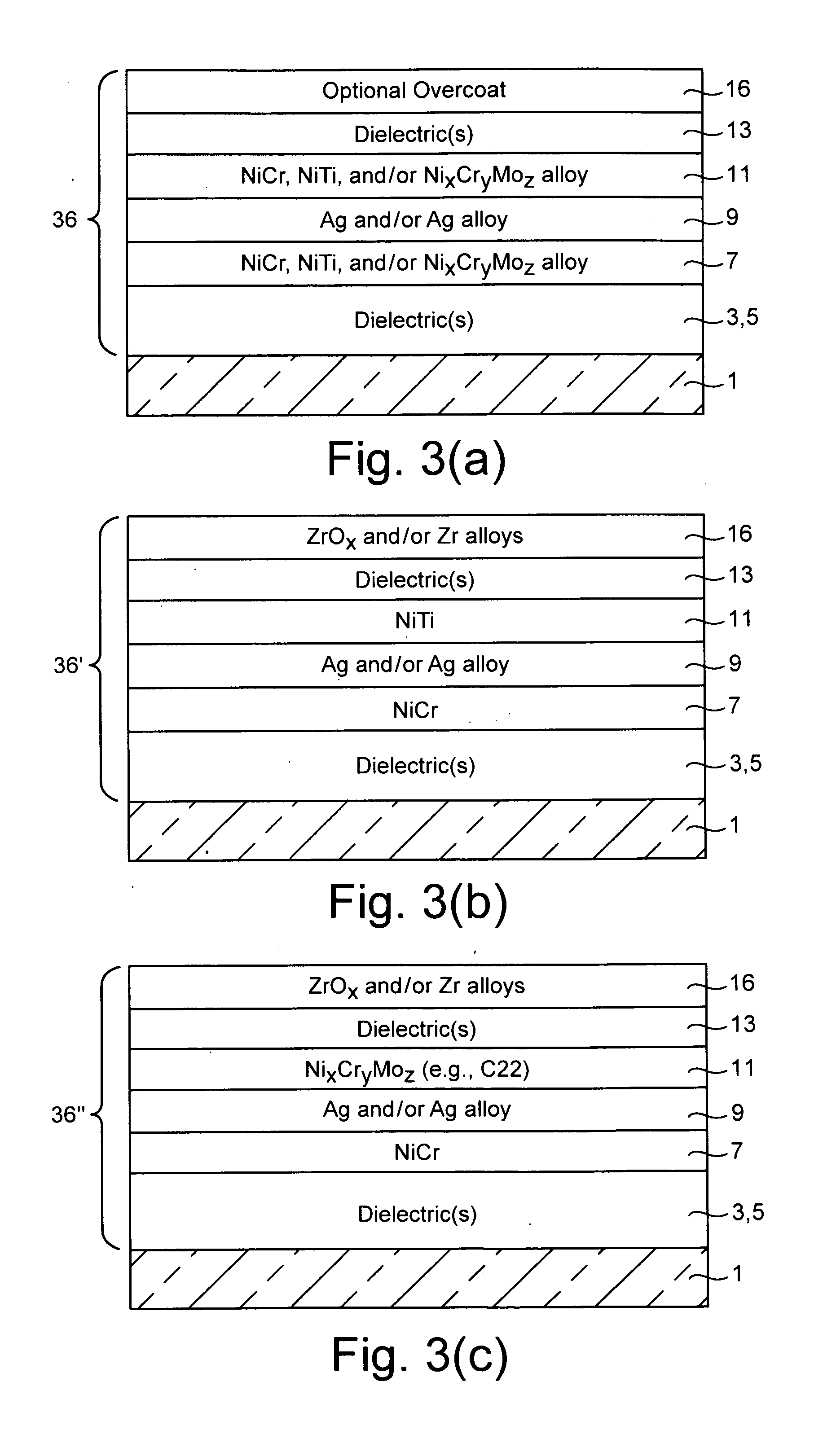

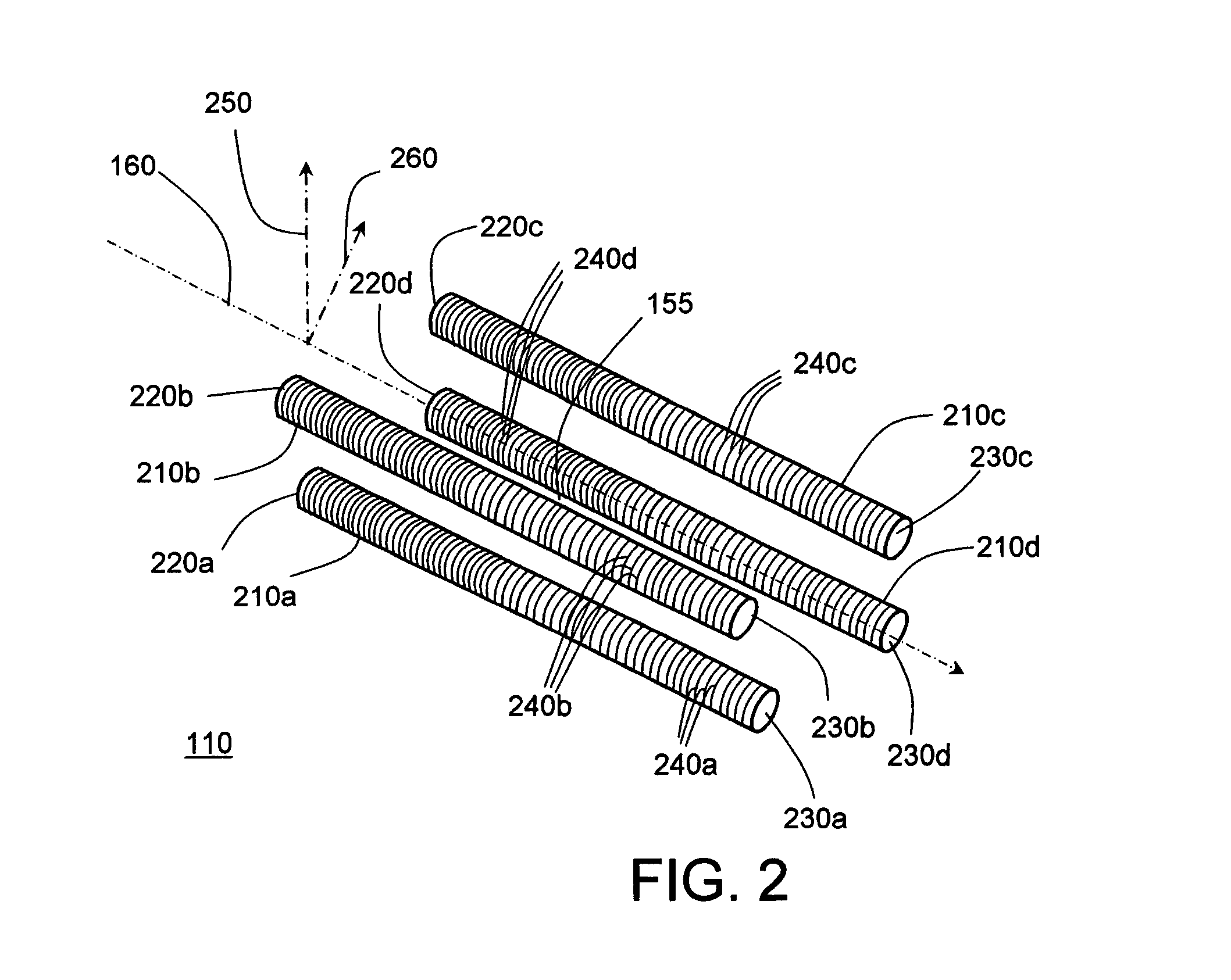

Generation of combination of RF and axial DC electric fields in an RF-only multipole

InactiveUS7067802B1Reduce usageParticle separator tubesIsotope separationRf fieldElectrical resistance and conductance

An RF-only multipole includes a spiral resistive path formed around each multipole rod body. RF voltages are applied to the rod body and resistive path, and DC voltages are applied to the resistive path, to create a radially confining RF field and an axial DC field that assists in propelling ions through the multipole interior along the longitudinal axis thereof. In one implementation, the resistive path takes the form of a wire of resistive material, such as nichrome, which is laid down in the groove defined between threads formed on the rod body. The RF-only multipole of the invention avoids the need to use auxiliary rods or similar supplemental structures to generate the axial DC field.

Owner:THERMO FINNIGAN

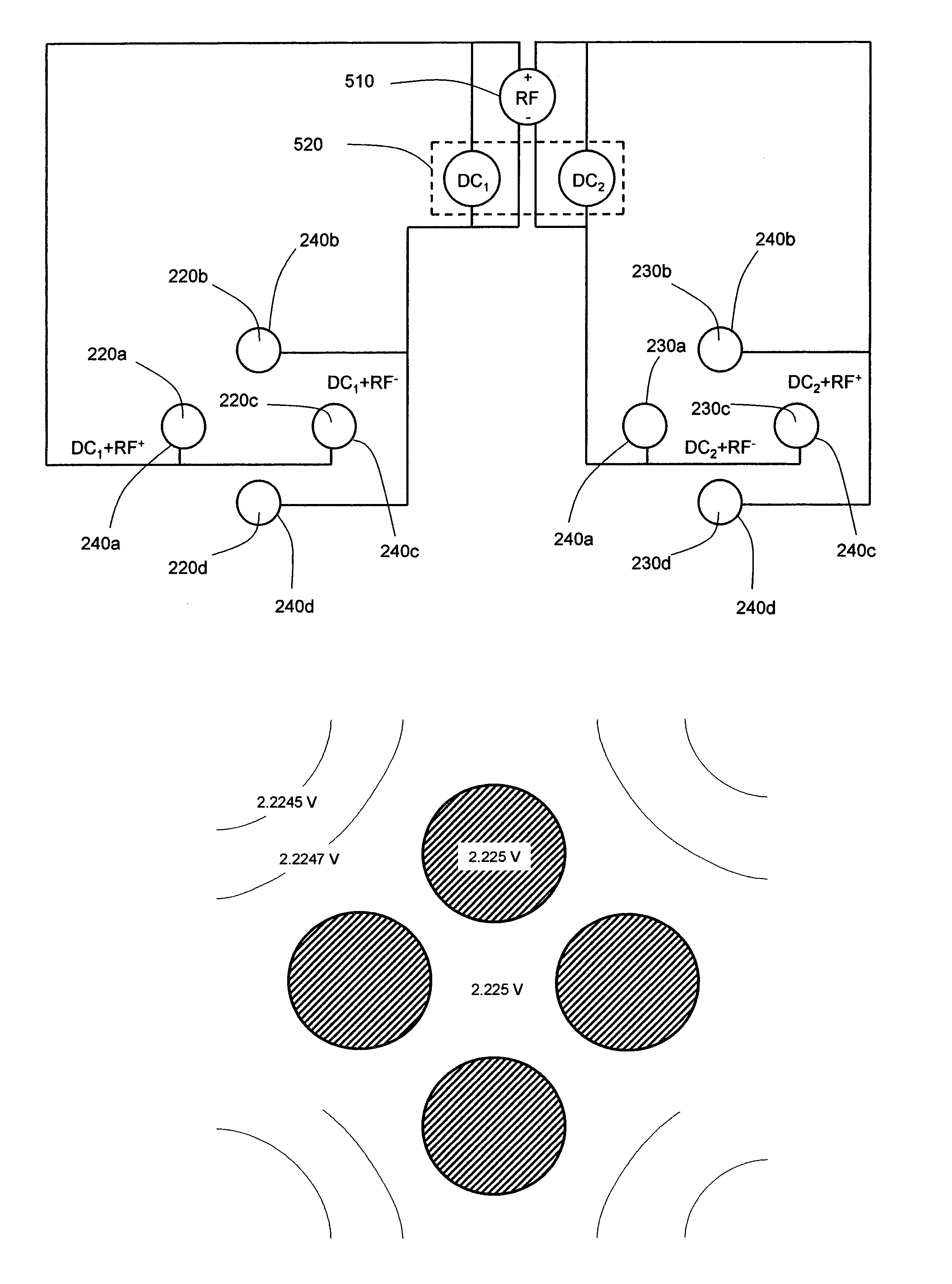

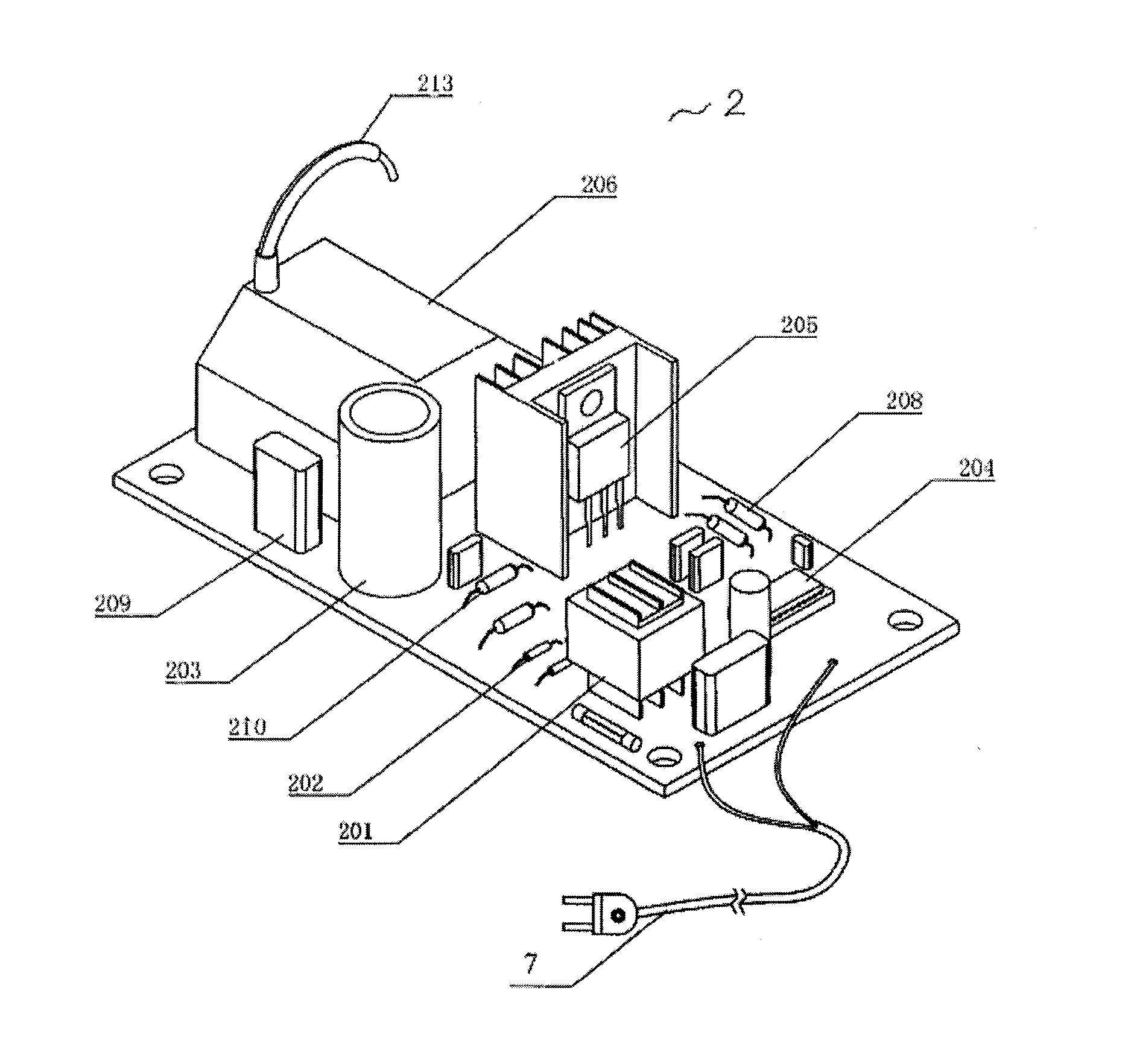

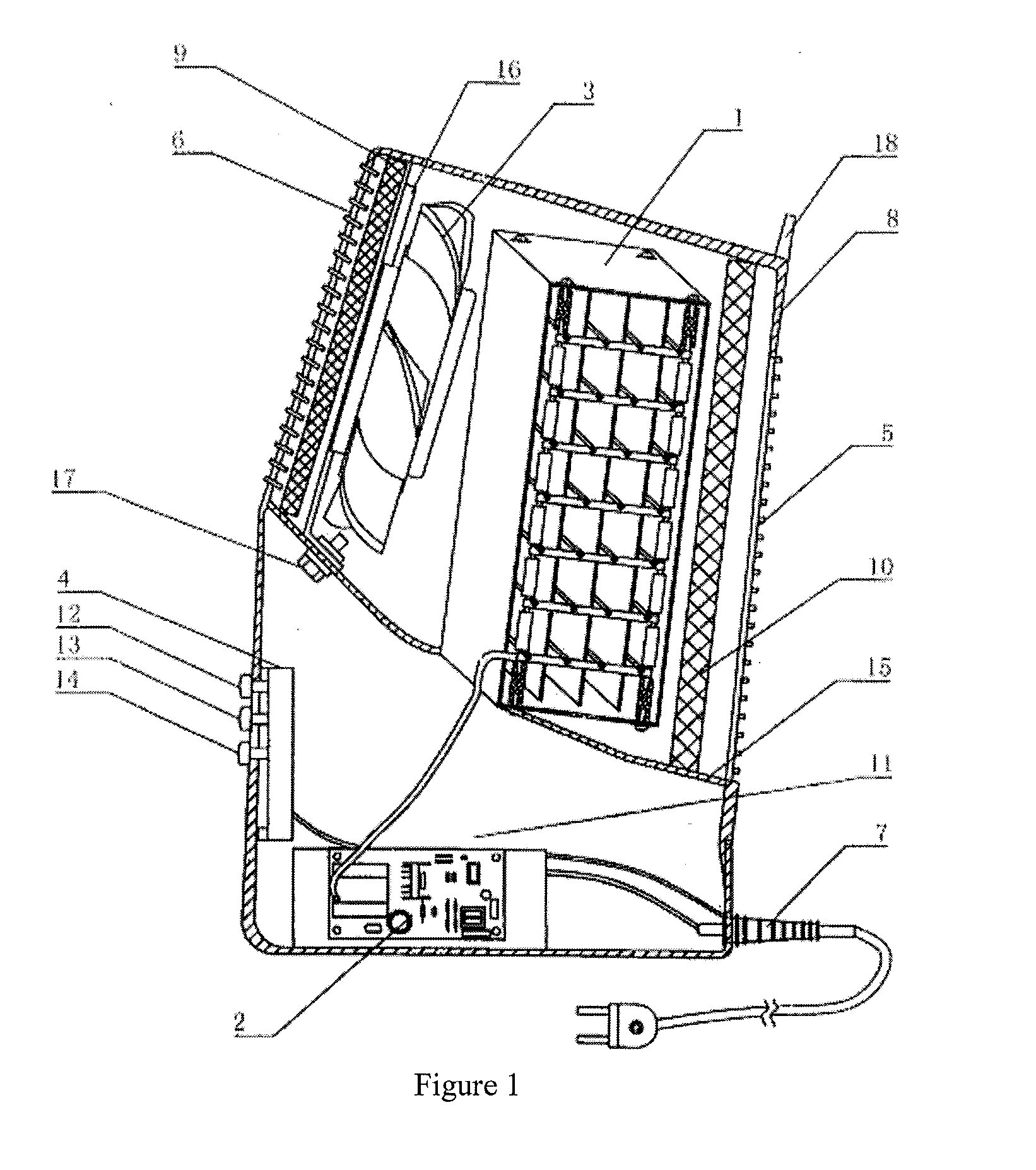

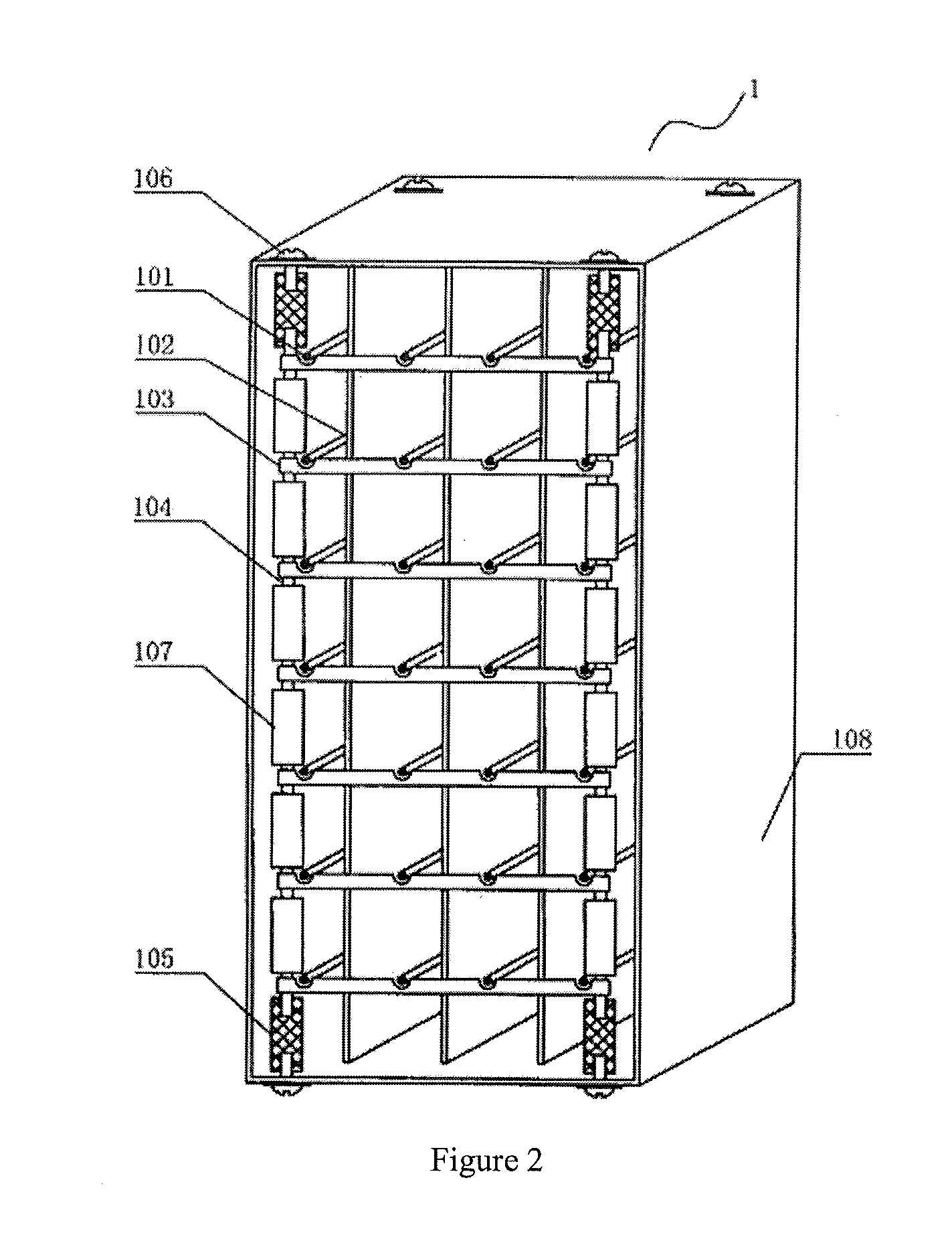

Plasma sterilizing-purifying device and method for air sterilizing and purifying

ActiveUS20120269677A1Improve reliabilityEasy to useMechanical apparatusLighting and heating apparatusVoltage pulseNickel chromium alloy

The present invention belongs to the technical field of air sterilizing and purification and in particular relates to a plasma air sterilizing and purifying device and an air sterilizing and purifying method. The plasma air sterilizing and purifying device comprises a plasma reactor, a pulse power supply, a fan component, a control device, a power adaptor, and a housing case, wherein the reactor is provided with positive electrodes formed by several nickel-chromium alloy wires or nickel-chromium alloy belts, and the two ends of each positive electrodes are fixed in the corresponding grooves on the micro-discharge preventive conductor rail; and a pulse power supply has a digital control circuit with an oscillator, an error amplifier and a PWM comparator inside which converts signals into a digital control current to control the width of the high-voltage pulse.

Owner:ZHEJIANG TIANQING ENVIRONMENTAL PROTECTION TECH CO LTD

Compound high speed steel roll and its making process

InactiveCN1846887AImprove efficiencySimple production processFurnace typesRollsChemical compositionHigh intensity

The present invention discloses compound high speed steel roll and its making process. The compound high speed steel roll consists of roll body and roll core compounded through central casting. The roll body is made of high speed steel comprising chemically C 1.8-2.8 (in wt%, same as below), Mo 4.0-8.0, V 3.0-7.0, Nb 1.5-4.0, Cr 6.0-12.0, RE 0.1-0.25, Ti 0.15-0.40, N 0.08-0.20, K 0.06-0.18, Si<2.0, Mn<2.0, S<0.05 and P<0.05, except Fe and inevitable impurity. The roll core is made of high strength nodular cast iron comprising chemically C 3.2-3.6 (in wt%, same as below), Si 1.8-2.4, Mn 0.4-0.8, Ni 0.3-1.2, Cr 0.3-0.8, Mo 0.2-0.5, Mg 0.03-0.08, RE 0.05-0.14, P<0.08 and S<0.03, except Fe and inevitable impurity. The compound high speed steel roll has high wear resistance, simple making process and high production efficiency.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

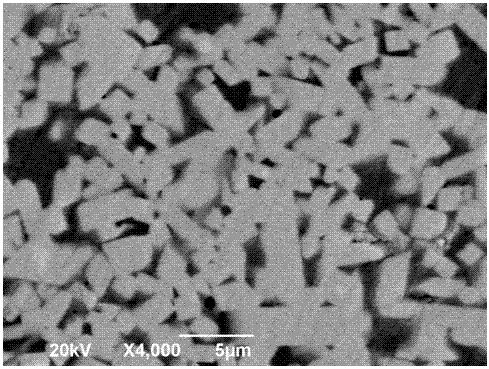

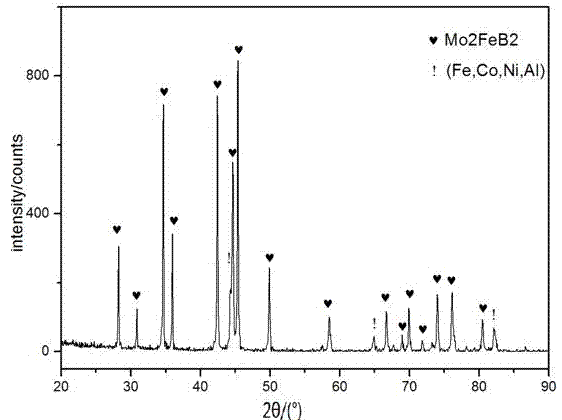

Multiple boride metal ceramic based on high-entropy alloy adhesion agent and preparation method thereof

InactiveCN102787267AImprove mechanical propertiesOvercoming the defect of a single principal element in the binder phaseBorideHigh entropy alloys

The invention discloses a multiple boride metal ceramic based on a high-entropy alloy adhesion agent and a preparation method thereof. According to the boride metal ceramic, high-entropy alloy serves as an adhesion phase, multiple boride serves as a hard phase, the high-entropy alloy adhesion phase is composed of at least four of iron, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum and manganese, and the content mole ratio of each element is between 5% and 35%. The multiple boride hard phase comprises W2M1B2 or / and Mo2M2B2, wherein M1 and M2 are at least one of Fe, Ni, Co and Cr. The preparation method of the multiple boride metal ceramic based on the high-entropy alloy adhesion agent comprises the steps of ball-milling mixing, forming and low-pressure sintering.

Owner:SICHUAN UNIV

Solder alloy, use of the solder alloy and method for processing, particularly repairing, workpieces, particularly gas turbine components

InactiveUS20070175546A1High strengthHigh melting pointWelding/cutting media/materialsSoldering mediaRheniumNiobium

A solder alloy and a multi-component soldering system, to the use of the same, and to a method for repairing gas turbine components are described herein. The solder alloy based on nickel includes the following elements: nickel (Ni), chromium (Cr), cobalt (Co), molybdenum (Mo), aluminum (Al), tantalum (Ta), niobium (Nb), yttrium (Y), hafnium (Hf), palladium (Pd), boron (B) and silicon (Si). The multi-component soldering system includes the solder alloy and additionally at least one additive material. The additive materials include the following elements: nickel (Ni), chromium (Cr), cobalt (Co), molybdenum (Mo), aluminum (Al), tantalum (Ta), titanium (Ti), rhenium (Re), iron (Fe), niobium (Nb), yttrium (Y), hafnium (Hf), palladium (Pd), carbon (C), zirconium (Zr), boron (B) and silicon (Si). A specific mixing of solder alloy and additive materials produces a multi-component soldering system that may be specifically adapted to the material of the component to be repaired, the mixture ratio of solder alloy and additive materials being freely selectable. The repair method is based on high-temperature diffusion soldering using the solder alloy hereof or the multi-component soldering system hereof.

Owner:MTU AERO ENGINES GMBH

Etchant and replenishment solution therefor, and etching method and method for producing wiring board using the

ActiveUS20050109734A1Suppress too much dissolutionExcessive dissolutionDecorative surface effectsPrinted circuit aspectsDissolutionMetallic Nickel

An etchant of the present invention includes an aqueous solution containing hydrochloric acid, nitric acid, and a cupric ion source. An etching method of the present invention includes bringing the etchant into contact with at least one metal selected from nickel, chromium, nickel-chromium alloys, and palladium. Another etching method of the present invention includes bringing a first etchant that includes an aqueous solution containing at least the following components A to C (A. hydrochloric acid; B. at least one compound selected from the following (a) to (c): (a) compounds with 7 or less carbon atoms, containing a sulfur atom(s) and at least one group selected from an amino group, an imino group, a carboxyl group, a carbonyl group, and a hydroxyl group; (b) thiazole; and (c) thiazole compounds; and C. a surfactant) into contact with a surface of the metal, and then bringing a second solution that includes an aqueous solution containing hydrochloric acid, nitric acid, and a cupric ion source into contact with the surface of the metal. According to the etchant and the etching methods of the present invention, it is possible to etch at least one metal selected from nickel, chromium, nickel-chromium alloys, and palladium quickly and suppress excessive dissolution of copper.

Owner:MEC CO LTD

Nickel-chromium-cobalt-molybdenum heat resisting alloy and pipe manufacturing process thereof

The invention provides a nickel-chromium-cobalt-molybdenum heat resisting alloy and a pipe manufacturing process thereof and belongs to the technical field of the heat-resisting alloys. The alloy comprises the following chemical components in percentage by weight: 21-23% of Cr, 0.05%-0.07% of C, less than or equal to 0.3% of Mn, 11-13% of Co, 6.0-9.0% of Mo, 0.3-0.5% of Ti, 0.8-1.3% of Al, 0.1-1.0% of W, 0.002-0.005% of B, 0.03-0.15% of Zr, 0.2-0.6% of Nb+V and 0.01-0.05% of Nb, less than or equal to 0.15% of Cu, less than 0.008% of P, less than 0.002% of S, less than or equal to 0.015% of N, 0.005-0.02% of Mg, less than or equal to 0.01% of Ca, less than or equal to 0.01% of As, less than or equal to 0.07% of Pb, less than or equal to 0.001% of Bi and the balance of nickel and inevitable impurity elements. The nickel-chromium-cobalt-molybdenum heat resisting alloy has the advantages that the room-temperature mechanical properties, the high-temperature mechanical properties, the low cycle fatigue properties and the durability of a large-diameter thick-wall boiler pipe produced from the nickel-chromium-cobalt-molybdenum heat resisting alloy are all over ASME standard requirements and the technical requirements of CCA617 alloys; the formulation of HAZ liquation cracks and stress relaxation cracks is greatly reduced, and the HAZ long term rupture strength and the tenacity after long term aging both are excellent.

Owner:CENT IRON & STEEL RES INST

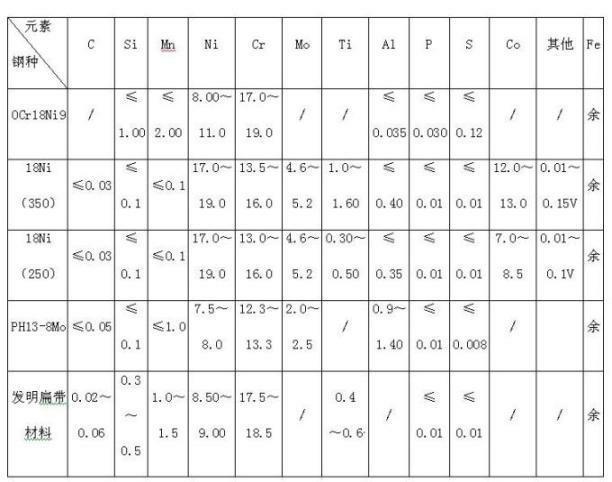

Martensite stainless steel and preparation method for flat strip of martensite stainless steel

ActiveCN102251191AHigh strengthHigh hardnessIncreasing energy efficiencySolution treatmentMartensitic stainless steel

The invention discloses martensite stainless steel and preparation method for flat strips of martensite stainless steel. The martensite stainless steel comprises following chemical components by weight percentage: C 0.02 to 0.06%, Si 0.3 to 0.5%, Mn 1.0 to 1.5%, Ni 8.5 to 9.0%, Cr 17.5 to 18.5%, Ti 0.4 to 0.6%, P no more than 0.009% and S no more than 0.009%, with the balance being Fe. The preparation method for flat strips of the martensite stainless steel comprises the following steps: a) weighing above-mentioned chemical components at desired weight percentage; b) carrying out vacuum induction melting; c) carrying out casting to obtain remelt electrode bars; d) carrying out electroslag remelting to obtain steel ingots; e) forging steel ingots into billets; f) processing billets into round strips; g) carrying out solid solution treatment; h) drawing treated blanks into wires; i) preparing flat strips. According to the invention, equivalents of nickel and chromium are strictly controlled, the ratio of C to Ti and alloy elements are optimized, EVR smelting is carried out and such alloying elements as C, Si, Mn and Ti are added, thereby enabling formation of a metastable austenite structure; a predeformed phase-changed martensite wire material is obtained by wire drawing; and the ultra high strength deformed flat strips of martensite stainless steel are obtained by flat strip rolling.

Owner:CHONGQING MATERIALS RES INST

Ni-Cr-Fe alloy and its production process

InactiveCN1847440ASave resourcesOptimize the smelting processBlast furnace detailsRecycling and recovery technologiesGranularityManganese

The present invention is Ni-Cr-Fe alloy and its production process. The Ni-Cr-Fe alloy contains Ni 1.5-6.0 wt%, Cr 3.0-21.0 wt%, Si 0.6-2.0 wt% and Mn 0.3-0.8 wt%, except Fe, and can meet the requirement for use as material smelting stainless steel. The production process includes the following steps: producing Ni-Cr agglomerate with industrial Ni-Cr waste, Ni-Cr ore powder of granularity smaller than 10 mm, flux, coke and water and through pelletizing, sintering and sieving; and smelting with the Ni-Cr agglomerate, Ni-Cr ore of granularity greater than 10 mm, flux and coke in a blast furnace. The present invention has sang in resource and environment friendship.

Owner:DONGDA CASTING WUJIANG

Composite roll for centrifugally casting high-chromium cast iron and a preparation method thereof

The invention relates to a composite roll for centrifugally casting high-chromium cast iron and a preparation method thereof, belonging to the technical field of the steel rolling. The composite roll comprises a roll external layer and a roll core. The chemical components of the materials of the roll external layer in terms of the percentage by weight are as below: 25-28 of alloy scrap iron of a high-nickel-chromium infinite chilled iron roll, 28-30 of carbon ferrochrome, 1.5-2.5 of mid-carbon ferromanganese, 2.5-3.5 of ferroboron, 0.5-0.8 of silicon-calcium-barium alloy, 0.2-0.4 of aluminum, 0.3-0.5 of ferrotitanium, 0.2-0.4 of rare earth ferrosilicon, 0.10-0.15 of zinc, 0.15-0.18 of magnesium and the balance of low-carbon waste steel sheet. The roll core is high-strength alloy cast iron or low-alloy ductile cast iron. The roll external layer and the roll core are formed through centrifugal composite casting. The roll has low production cost, contains a small number of impurities and has high degree of purity; the hardenability, the mechanical performance and the thermal fatigue of the roll can be improved; and the roll has long service life and low production cost.

Owner:江苏环立板带轧辊有限公司

Casinghead gas corrosion resistant pumping rod steel and manufacturing method thereof

InactiveCN101440461AImproved corrosion cracking performanceGood plasticityTemperature control deviceFurnace typesNiobiumManganese

The invention provides steel for a pumping rod resisting casinghead gas corrosion and a manufacture method thereof. The steel comprises the following chemical compositions by mass percentage: 0.05 to 0.25 percent of carbon, 0.50 to 2.00 percent of silicon, 1.10 to 2.50 percent of manganese, 0.02 to 0.50 percent of molybdenum, 0.02 to 0.50 percent of nickel, 0.50 to 1.50 percent of chromium, 0.01 to 0.10 percent of vanadium, 0.005 to 0.050 percent of aluminum, 0.02 to 0.10 percent of niobium, 0.05 to 0.50 percent of copper, 0.01 to 0.10 percent of titanium, less than or equal to 0.015 percent of sulphur, less than or equal to 0.020 percent of phosphorus, and the balance being ferrum. The method is to manufacture a pumping rod wire through a design of adding the niobium and other trace alloy elements and corresponding compositions into steel, and controlled rolling and controlled cooling organization control technology. The pumping rod manufactured by the wire has excellent oilwell medium corrosion resistance, proper strength, excellent plastic tenacity and excellent welding performance, thereby improving the service life and reliability of the pumping rod, and improving the whole stability of pumping equipment, and further solving the problem that the prior pumping rod has repeated stress failure caused by endurance of complex casinghead gas corrosion.

Owner:BAOSHAN IRON & STEEL CO LTD +1

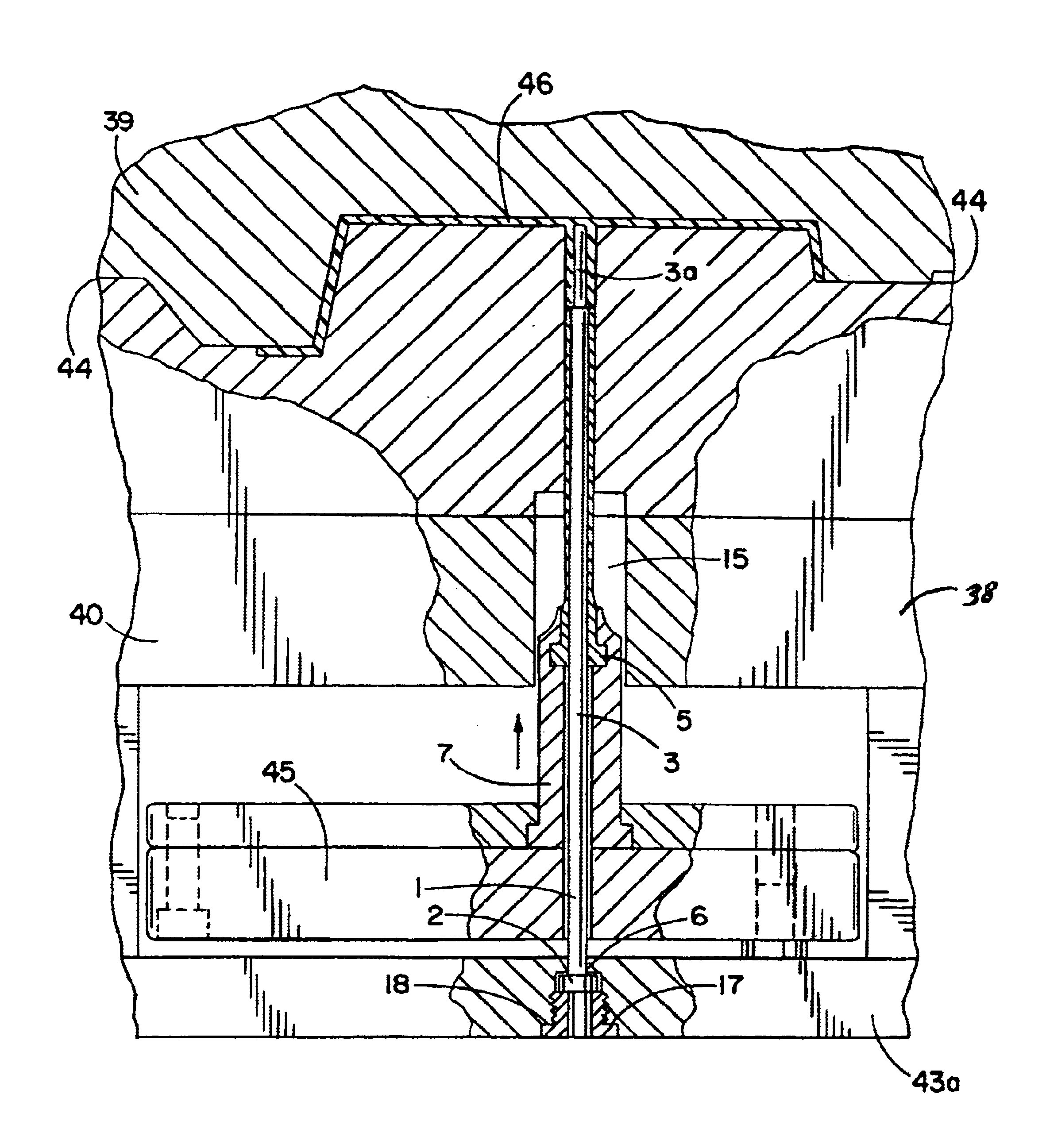

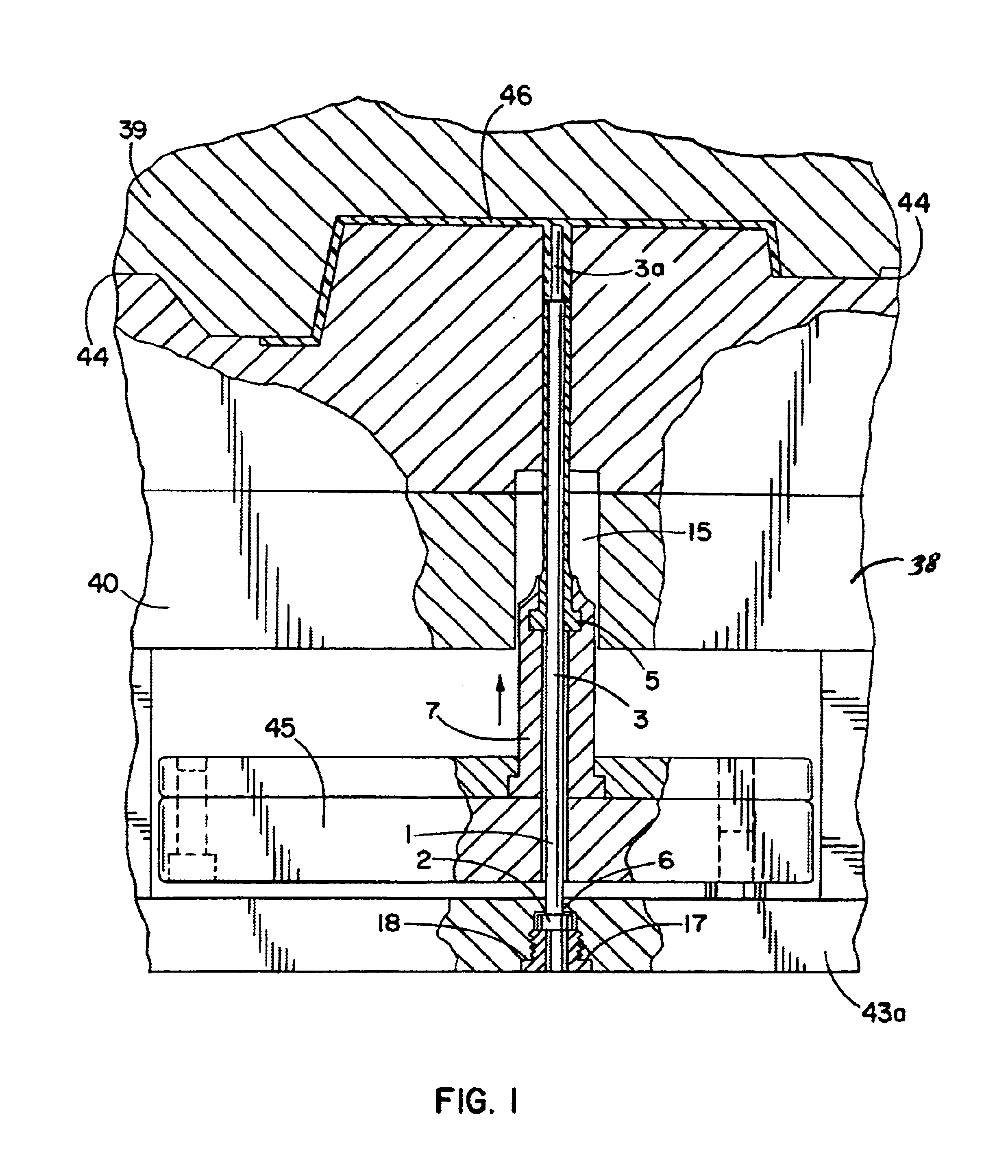

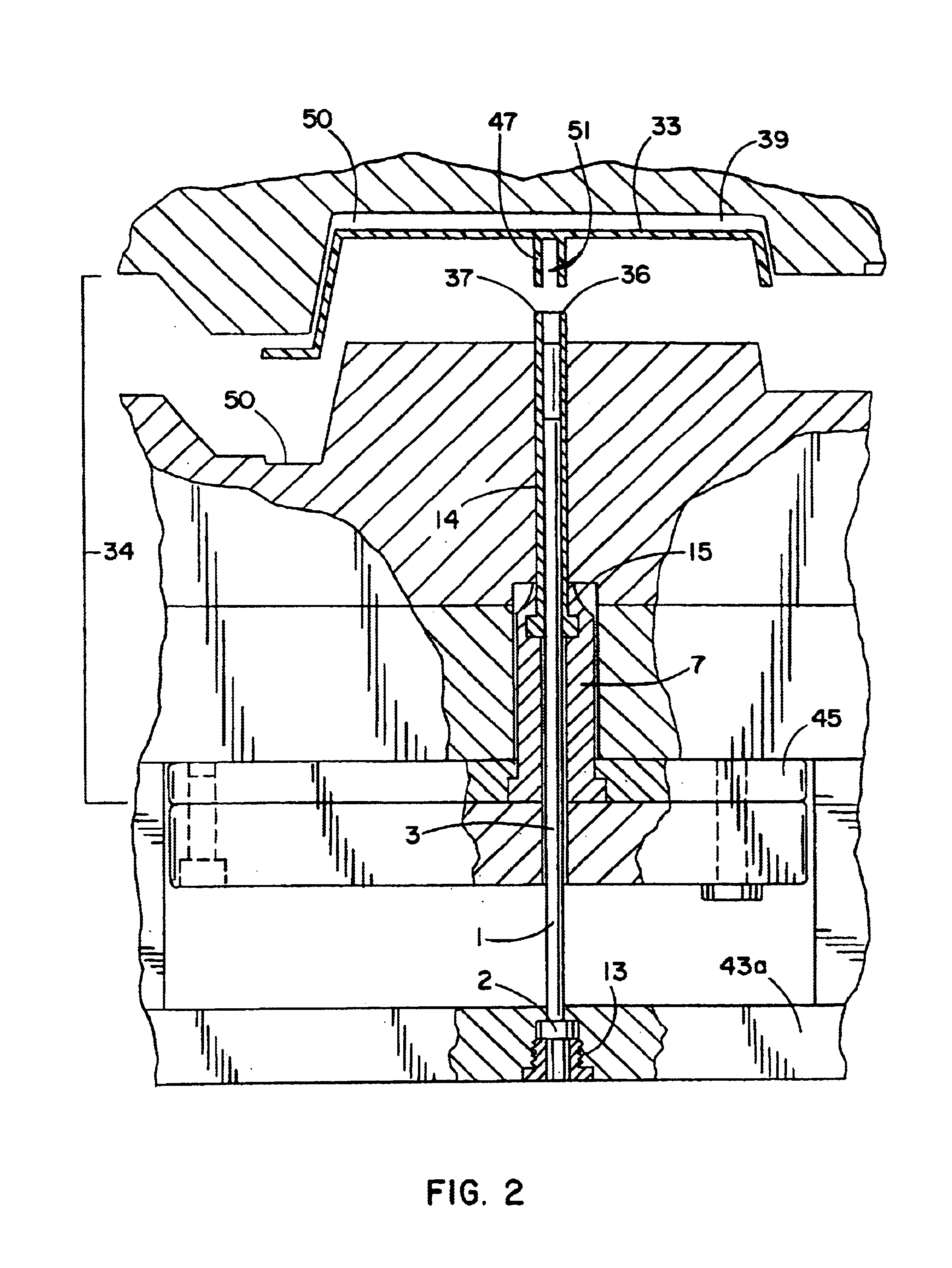

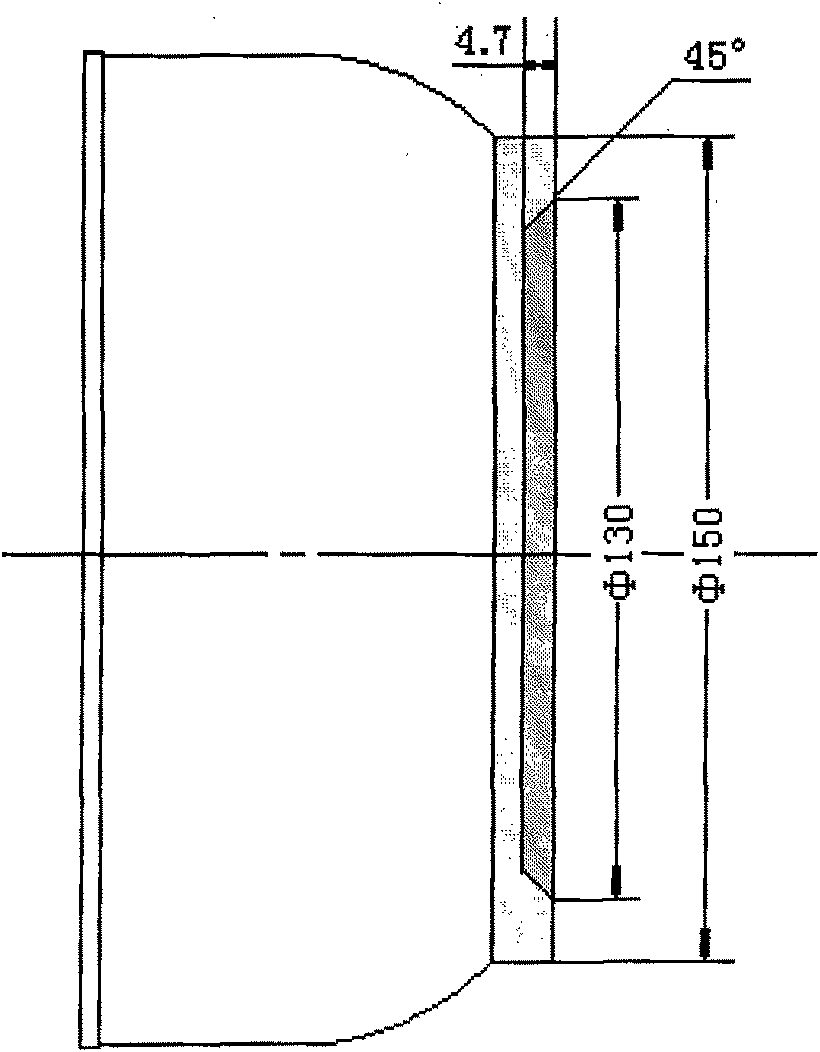

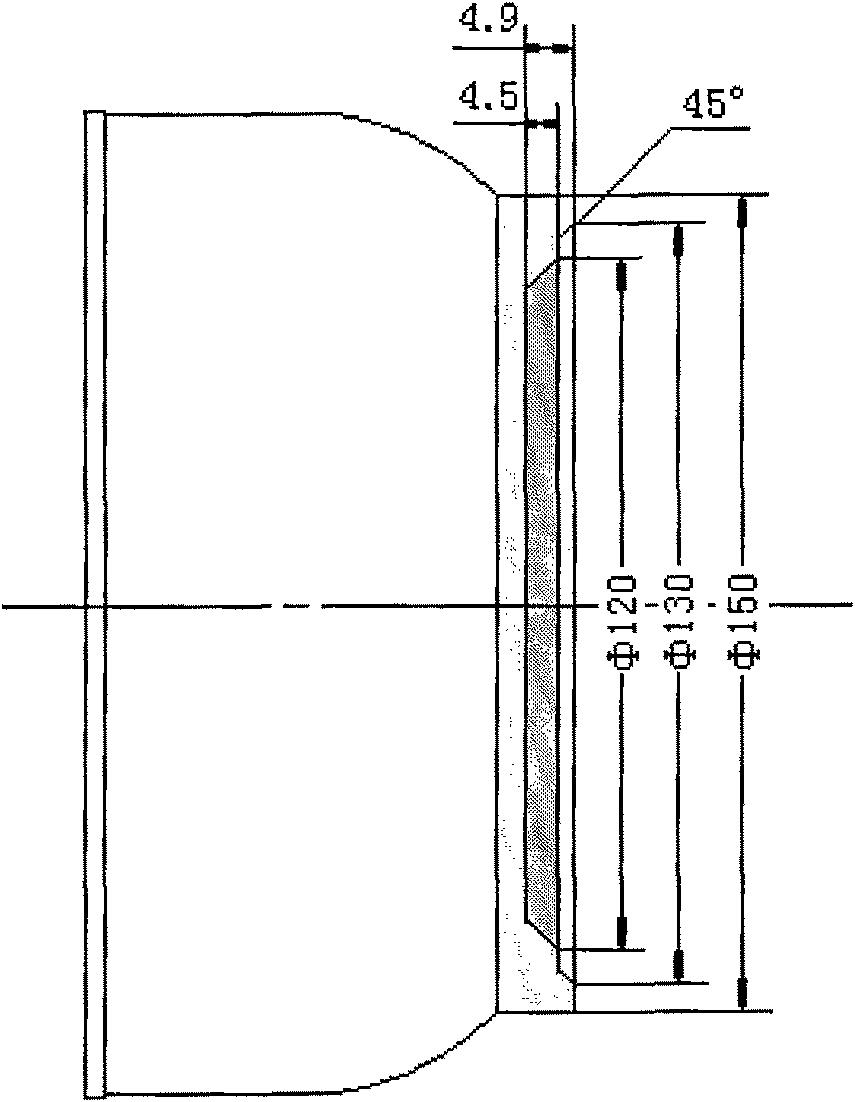

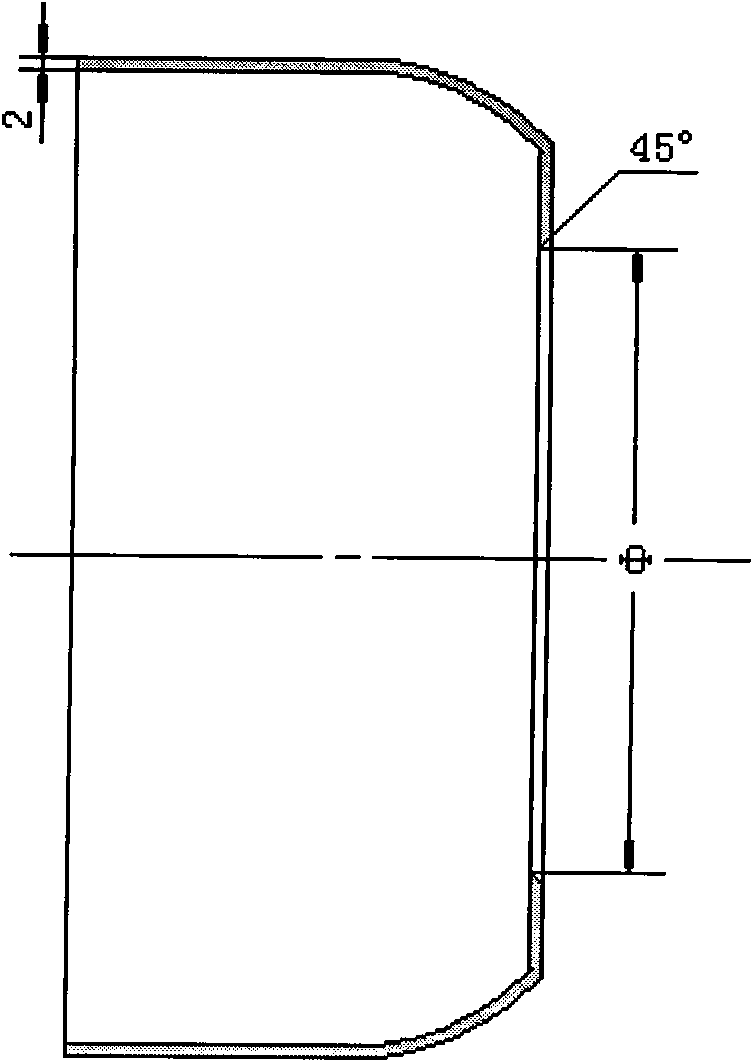

Ejector sleeve for molding a raised aperture in a molded article

The present invention includes an improved ejector sleeve (5) having thinner side-walls than prior sleeves. The sleeves generally include a ring (31) for mounting the sleeve, a central bore (42) for receiving a core pin (1), a tube portion extending from the ring to a tube end portion. The side-walls defining the tube end portion have a thickness of less than forty thousandths, and preferably thirty thousandths of an inch. Preferably, the coated ejector sleeve is provided in which a thin, lubricous coating of nickel, chromium or alloys of chromium or nickel is applied to at least a portion of the sleeve. The coating is applied in thickness of less than 0.0001 inch which improves the wear characteristics of the pins and sleeves as well as allowing the coated pins and sleeves to be stocked and used as nominal thickness parts.

Owner:PROGRESSIVE COMPONENTS INT CORP

High-boron high-speed steel roller material and smelting process thereof

ActiveCN102994692AHigh yieldEasy to useProcess efficiency improvementElectric furnaceMetallic aluminumSilicon alloy

The invention provides a high-boron high-speed steel roller material and a smelting process thereof. The smelting process of the high-boron high-speed steel roller material comprises the following steps: firstly, adopting Q235 waste steel, ferrotungsten, ferromolybdenum, ferrovanadium, high carbon ferro-chrome, metal copper, metal aluminum, calcium-silicon alloy, rare earth ferrosilicon magnesium alloy, ferrocolumbium, ferroboron, ferrosilicon, vanadium-nitrogen alloy, zirconium ferrosilicon and ferrotitanium as materials for smelting low-alloy high-speed molten steel in an electric furnace; then, adding the ferrovanadium and part of ferroboron to carry out alloying in a discharging process; finally, adding part of ferroboron and composite modificator in a casting ladle, adding the vanadium-nitrogen alloy, the zirconium ferrosilicon, the ferrosilicon and part of ferroboron in the casting process. The obtained casting piece has a little alloy elements, excellent abrasive resistance and good thermal fatigue resistance. When the high-boron high-speed steel roller material is used as a roller, the service life is prolonged by more than six times relative to a high nickel-chrome infinite cast-iron roller, and prolonged by 20% relative to a high-vanadium high-speed steel roller. Moreover, the roller is safe to use and reliable.

Owner:YUNNAN HEAVY EQUIP MFG GRP

Stainless steel high temperature oxidation resistance paint and application thereof

InactiveCN101265372ANo lossPrevent oxidationLiquid surface applicatorsAnti-corrosive paintsNichromeRoom temperature

The invention relates to the technology field of an antioxidation coating, in particular to a stainless steel high-temperature oxidation-resistant coating and the application thereof, and solves the problems in the prior stainless steel oxidation-resistant coating such as complex production process, high cost, low protection temperature, narrow painting temperature range and so on. The stainless steel high temperature oxidation-resistant coating is prepared with organic powdered ore in an amount of 30 to 50 parts; an inorganic binder in an amount of 50 to 70 parts; a suspending agent in an amount of 0.1 to 1 part; and water in an amount of 200 parts. The stainless steel high temperature oxidation-resistant coating is applicable to oxidation protection / decarburization when semi-finished nickel chromium stainless steel products are heated for 0.5 to 30 hours at the temperature of 800 DEG C to 1500 DEG C, and is sprayed or coated on stainless steel surfaces within the range from room temperature to 500 DEG C. The coating thickness ranges from 50 Mu m to 300 Mu m. The coating formed at the high temperature forms a vitreous dense coating during high-temperature processing of a stainless steel basal body, and prevents oxygen from spreading on the surface of the stainless steel basal body, thus resisting oxidation, alleviating depletion and decarburization of microelements on stainless steel surfaces, and improving the rolling quality of the surface of the base body. The raw materials used for preparing the coating are cheap, and the coating is friendly to the environment. The preparation process is simple. The high-temperature oxidation and melting loss of various semi-finished nickel chromium stainless steel products is reduced by more than 90 percent, and the output and the yield of good plate blanks can be improved.

Owner:SHANXI XIHUI TECH

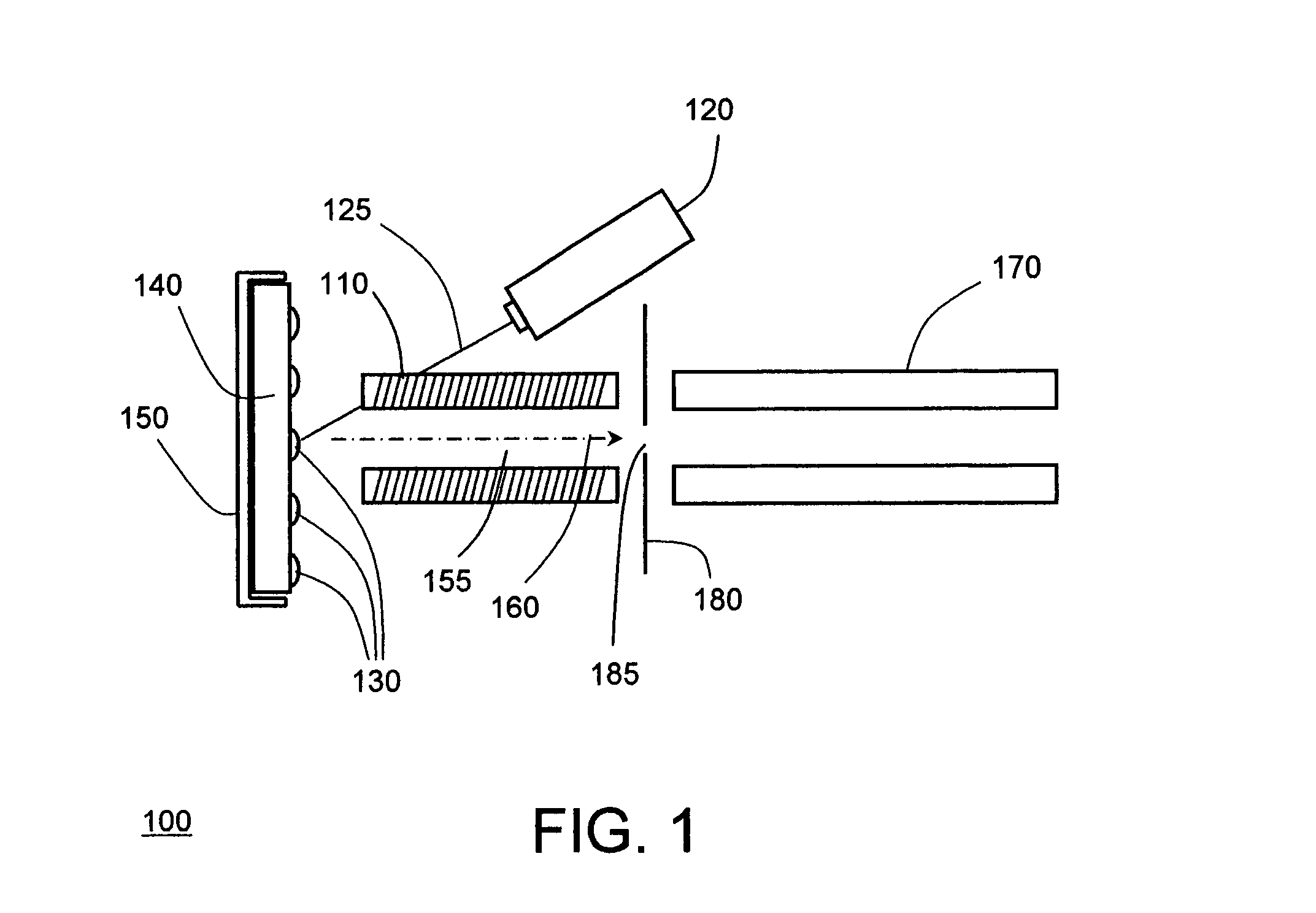

Method for thermal spraying of composite bottom layer of aluminum pan of electromagnetic oven

InactiveCN101880850AWide range of choicesImprove product qualityCooking-vessel materialsDomestic stoves or rangesThermal sprayingThermal printing

The invention discloses a method for thermal spraying of a composite bottom layer of an aluminum pan of an electromagnetic oven, which is used in the manufacturing industry of food cookers and is as shown by a drawing appended to the abstract. A magnetic composite layer with a certain thickness is formed by using an automatic spraying method, designing the joint of a coating and the pan bottom into a concave mosaic structure and spraying a magnetic material (pure iron, iron alloy or 430 stainless steel) to the bottom of the aluminum pan so as to meet the operating requirements of the electromagnetic oven. According to the requirements of a product, one or more material (copper, stainless steel, aluminum, nickel, chromium or ceramic) coatings with different thicknesses or functions can be sprayed to realize aesthetic property, practicability and functionality of the electromagnetic oven pan to ensure that the pans for the electromagnetic oven become various middle-grade and high-grade series products.

Owner:慈溪光华金属复合材料有限公司

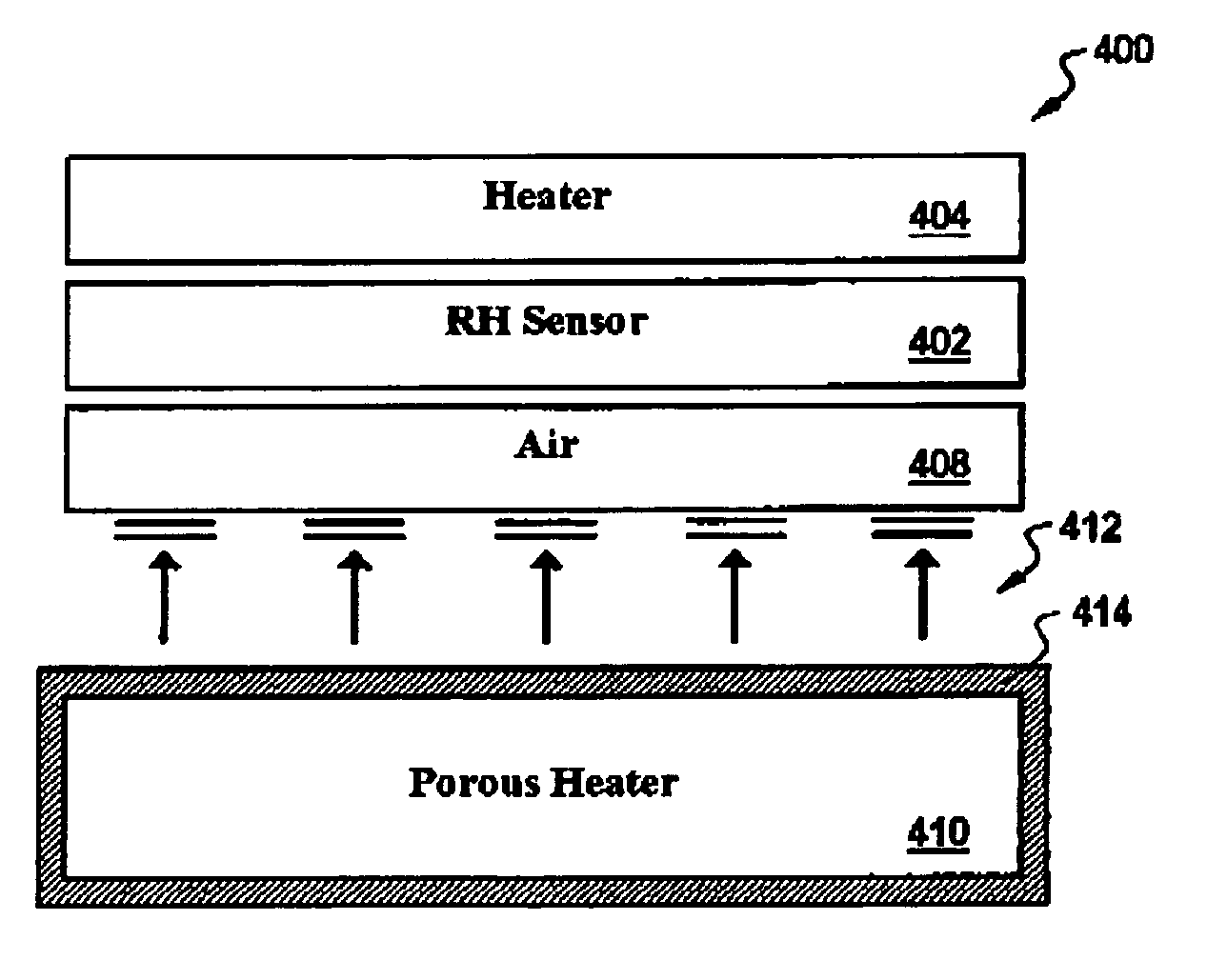

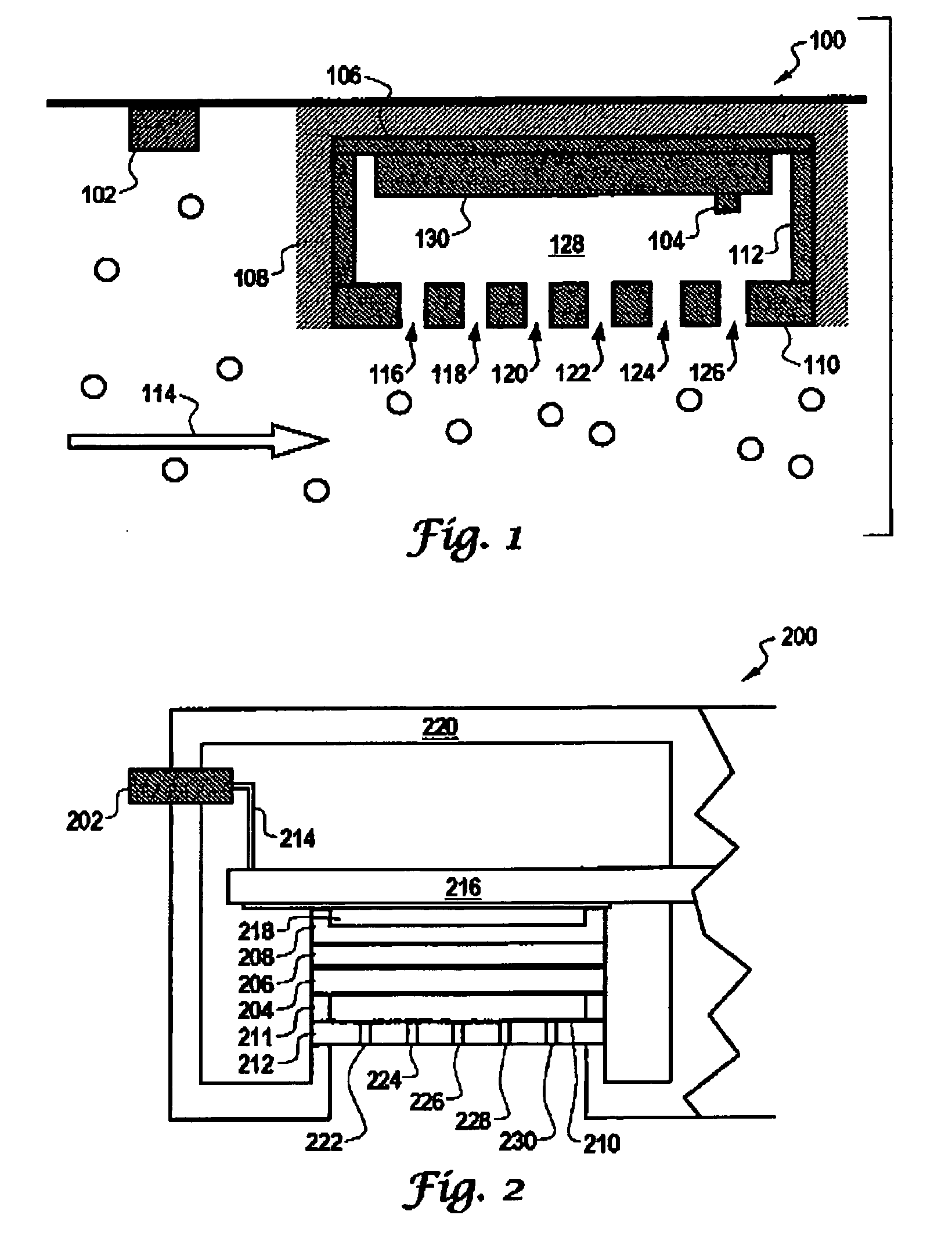

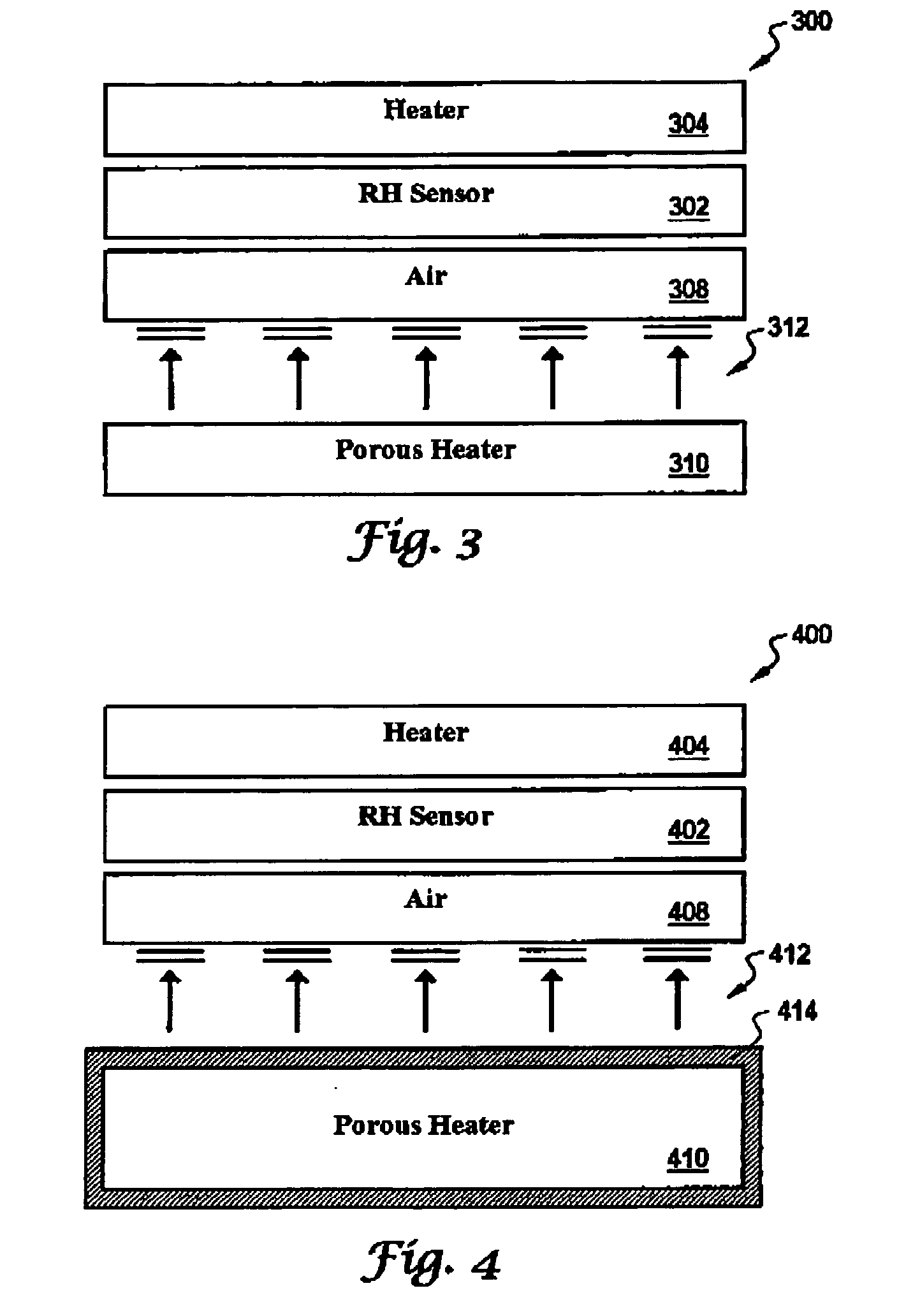

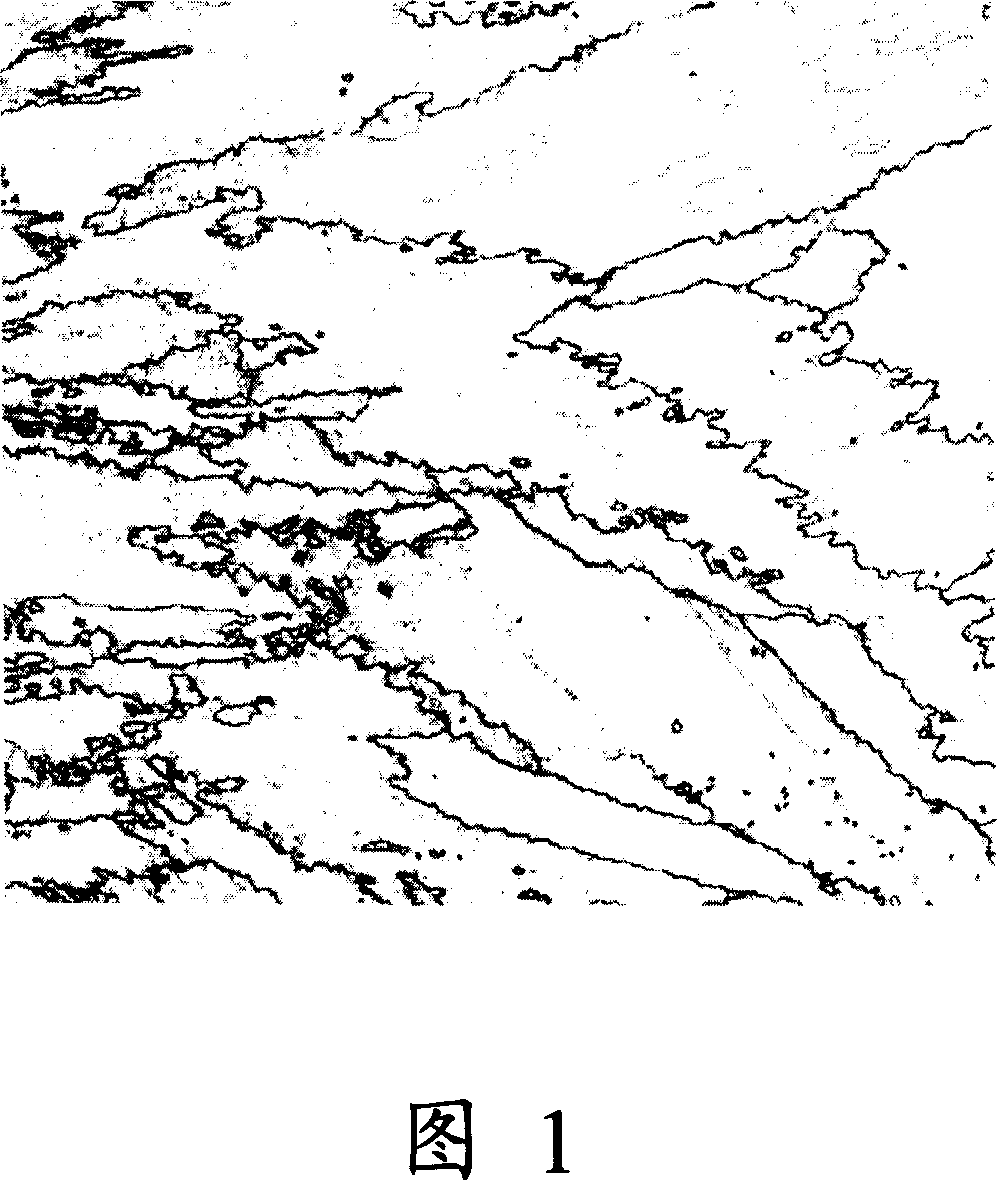

Relative humidity sensor enclosed with formed heating element

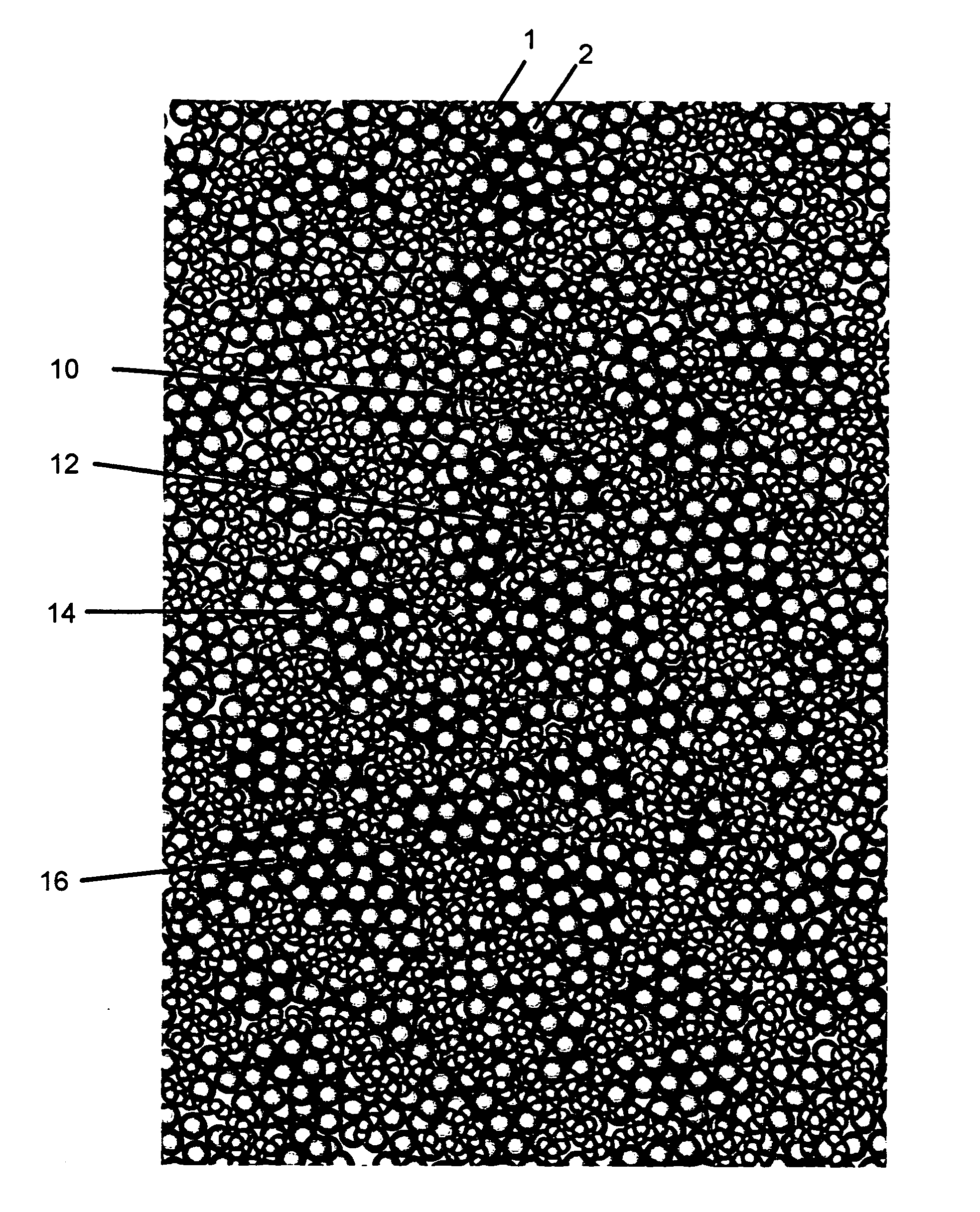

InactiveUS20060201247A1Lower the volumeSmall sizeMaterial moisture contentUsing mechanical meansElectrical resistance and conductanceChromium nickel

Sensor systems and methods are disclosed herein. A relative humidity sensor is generally associated one or more porous heating elements. A porous resistive material surrounds the relative humidity sensor. Additionally, one or more flat heating elements can be bonded to a base of the relative humidity sensor to conduct heat and insure uniform heating about the relative humidity sensor. The porous heating elements can be configured to permit humid air to pass through the porous heating elements. Also, the porous heating element(s) can be assembled slightly offset from a surface of the relative humidity sensor so that air that is saturated with water vapor passes through and is heated by the porous heating element in order to evaporate water droplets associated with the water vapor and thereby reduce relative humidity to a measurable level. The porous resistive material can be configured from a material such as, for example, tantalum or nichrome. The porous resistive material can also be configured in a sheet arranged in a woven pattern.

Owner:HONEYWELL INT INC

Welding alloy and articles for use in welding, weldments and method for producing weldments

Nickel, chromium, iron alloys and methods for producing weld overlays and weldments formed therefrom. In percent by weight, the alloy comprises about 28.5% to 31.0% chromium; about 0 to 16% iron, preferably 7.0% to 10.5% iron; less than about 1.0% manganese, preferably 0.05% to 0.35% manganese about 2.1% to 4.0% niobium and tantalum, preferably 2.1% to 3.5% niobium and tantalum, and more preferably 2.2% to 2.8% niobium and tantalum; 0 to 7.0% molybdenum, preferably 1.0% to 6.5% Molybdenum, and more preferably 3.0% to 5.0% molybdenum; less than 0.50% silicon, preferably 0.05% to 0.30% silicon; 0.01% to 0.35% titanium; 0 to 0.25% aluminum; less than 1.0% copper less than 1.0% tungsten; less than 0.5% cobalt; less than about 0.10% zirconium; less than about 0.01% sulfur; less than 0.01% boron, preferably less than 0.0015% boron, and more preferably low less than 0.03% carbon; less than about 0.02% phosphorus; 0.002% to 0.015% magnesium and calcium; and the balance nickel and incidental impurities. The method includes the steps of forming an electrode from the alloy composition described above and melting the electrode to form a weld overlay. Preferred weldments made from the alloys and methods include alloy matrices in the form of nuclear reactor tube sheets.

Owner:HUNTINGTON ALLOYS INC +1

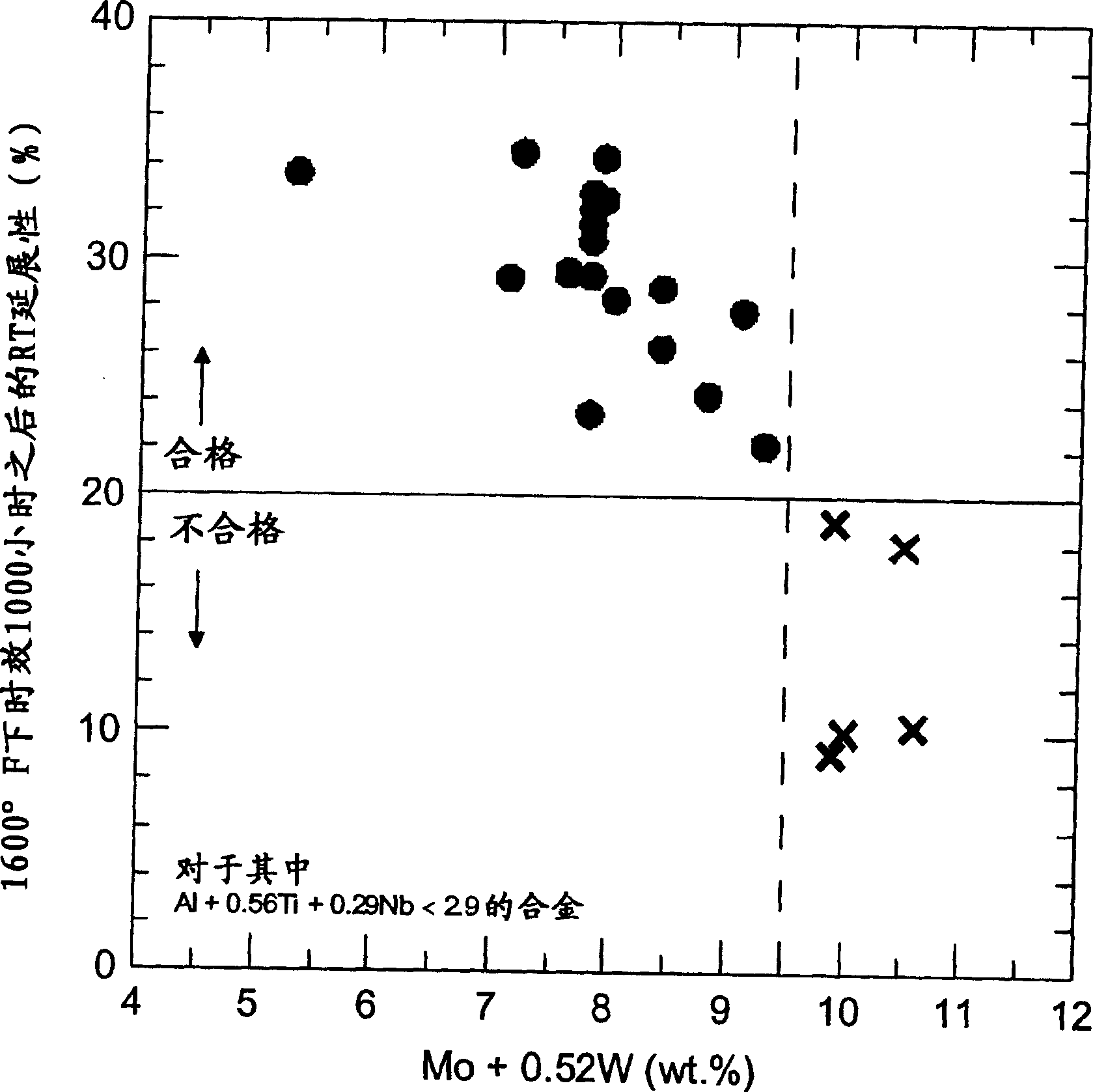

Ni-Cr-Co alloy for advanced gas turbine engines

Owner:HAYNES INTERNATIONAL

Technology for producing wear-resisting compound material

The production process for forming high-alloy wear-resisting layer composite material on the surface of carbon steel or alloy steel includes the following steps: firstly, selecting and using 40-80 % of alloy powder which is formed from Cr, Mo, W, V, Ti, Ni, Co, Mn, B and C and whose grain size is 0.005-0.8 mm or selecting and using sintered hard alloy granules whose grain size is 0.4-0.8 mm and 20-60 % of nichrome alloy powder whose grain size is 0.05-0.1 mm, mixing adhesive and alloy powder and stirring them to obtain the alloy powder coating material, then applying the alloy powder coating material on the side surface of casting mould, and third step pouring and forming to form alloy layer with compact structure, and the combination of alloy layer and self-body is good.

Owner:陈振华 +2

Low-radiation coated glass capable of being toughened off line and production method thereof

ActiveCN102615877AGood heat insulationDo not destroyGlass/slag layered productsMetal layered productsNichromeMetallic Nickel

The invention discloses low-radiation coated glass capable of being toughened off line, which comprises a glass substrate. A silicon nitride Si3O4 layer, a metal nickel-chromium NiCr layer, a metal silver Ag layer, a metal nickel-chromium NiCr layer and a silicon nitride Si3O4 layer are sequentially arranged on the glass substrate. A production method of the low-radiation coated glass capable of being toughened off line comprises the steps of respectively setting the basic vacuum and the linear speed of dual-end offline high-vacuum magnetron sputtering coating equipment to be 10<3> Pa and 2.5m / minute, and the sequentially sputtering the silicon nitride Si3O4 layer, the metal nickel-chromium NiCr layer, the metal silver Ag layer, the metal nickel-chromium NiCr layer and the silicon nitride Si3O4 layer on the glass substrate. On the premise that the low radiance and the low heat transfer performance of the coating are realized, the low-radiation coated glass capable of being toughened off line has the advantage that the deep processing such as heat treatment at different places of the glass can be realized.

Owner:JIANGSU AOLAN ARCHITECTURE GLASS

High-alloy metals reinforced by diamond-like framework and method for making the same

InactiveUS20060005900A1Improve corrosion resistanceImprove thermal stabilityVacuum evaporation coatingSputtering coatingDiamond-like carbonAlloy

A new class of high-alloy metals is invented. The metals possess an amorphous, nano crystalline, or combined amorphous-nano-crystalline structure and are reinforced, stabilized and hardened with a framework formed by predominantly sp3-bonded carbon, also known-as diamond like carbon. Optionally, other alloying nonmetallic elements selected from the group of Si, B, O, N may additionally stabilize the structure. The disclosed high-alloy metals comprise a metallic matrix which may include iron, nickel, chromium, refractory, and various other metals. These materials are very stable, and do not suffer a structural degradation up to relatively high temperatures. The disclosed high-alloy metals have the properties of high hardness, corrosion and wear resistance, and low friction. They have a wide range of applications as protective coatings on a wide variety of materials in various industries. They may be further applied as magnetic and electronic devices, such as field emission cathodes. Some of these alloys possess high emissivity, and their electrical conductivity may be varied in a relatively wide range.

Owner:DORFMAN BENJAMIN R

Protective coatings which provide erosion resistance, and related articles and methods

A coating composition is described, having a first coating layer which includes a nickel-chromium matrix in which metal carbide particles are dispersed; and a hard, dense second coating layer disposed over the first coating layer. The second coating layer is formed from a metal nitride-type material, and has an average roughness of less than about 80 micro-inches (Ra). Related articles and processes are also disclosed.

Owner:GENERAL ELECTRIC CO

Nickel-picotite type infrared radiation ceramic powdered material for thermal spraying and preparation method

InactiveCN1762893AShort manufacturing processProcess parameters are easy to controlThermal sprayingAdhesive

The Ni-Cr spinel type infrared radiation powder material is prepared by using Cr2O3 and NiO with stable high performance as main components and TiO2, Nb2O5, TiN and TiB2, or Fe2O3 and MnO2, or SiO2 and ZrO2 as supplementary material, and through the steps of mixing powdered solid materials, adding adhesive and water to compound slurry, spray drying to form aggregate powder, and final plasma nodulizing or sintering to densify. The Ni-Cr spinel type infrared radiation powder material has heat radiation factor as high as 0.89-0.93, and may be molten and sprayed via plasma spraying, oxygen-acetylene flame spraying or fuel gas expansion spraying to surface of base body to form firm mechanically combined coating, which has controllable thickness, chemical performance stable in 500-700 deg.c, high heat shock resistance and low heat radiation factor attenuation in long term use.

Owner:WUHAN UNIV OF TECH

High-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and coating and preparing method of coating

ActiveCN105463359AImprove solid solution strengtheningPlay a reinforcing roleMolten spray coatingChromium carbideTurbine blade

The invention discloses high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and a high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide coating prepared through the composite powder. The composite powder comprises, by weight percentage, 65-85% of Cr3C2, 10-25% of NiCr, 1-5% of Nb and 1-5% of Ta. The coating is prepared in the manner that the composite powder is subjected to hypersonic flame spraying or high-enthalpy plasma spraying or is subjected to hypersonic flame spraying or high-enthalpy plasma spraying, and then the high-enthalpy plasma remelting technology is combined. The coating is greatly improved in the aspects of microhardness, combing strength, corrosion resistance and cavitation resistance. Meanwhile, the production cost is low, the preparing method is reliable in technology, performance is stable, and the coating is suitable for being applied to the fields such as hydraulic machine flow passage components, compressor screws and turbine blades on a large scale.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

High-temperature alloy base self-lubricating composite material and surface pattern treatment method thereof

InactiveCN101078072AExtended service lifeReduce coefficient of frictionBearing componentsLaser beam welding apparatusSurface patternSuperalloy

A kind of high temperature alloy group self-lubricating compound material and the method to pattern surface of it. The components and the mass percent of them are as following: Ni: 28.8-56.8%, Fe: 10.0-30.0%, Cr: 7.2-14.2%, W: 5.0- 15.0%, C: 3.0-6.0%, Si: 0.8%-1.2%, MoS2: 5.0%-15.0%. The method to pattern it' s surface contains the following steps: The surface of the nickel chromium alloy group self-lubricating compound material sample after being hot pressed and mould will be polished. A gammaray laser will be used to corrase micropore on the surface, the focus of the focusing lens will be adjusted to 40-60mm, the facula diameter at the focus is 0.15- 0.20mm, the impulse duration will be adjusted to 450-500ns, the laser bean will process micropore according to ring shape from outside to inside. The surface after being corrased and polished will be lubricated by daubing the fat of solid layered dry lubricant. The alloy group material not only owns high mechanical strength but also owns high temperature self-lubricating ability. The coefficient of friction can be decreased, the application life can be prolonged, and low attrition abrasion in wide temperature range can also be realized by patterning the surface.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com