Multiple boride metal ceramic based on high-entropy alloy adhesion agent and preparation method thereof

A high-entropy alloy and cermet technology, which is applied in the field of multi-component boride cermet and its preparation, can solve the problems of insufficient strength and toughness, affecting the service life, and limiting the use range, so as to improve the interface wettability and refine the crystallinity. The effect of grain, hardness and toughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

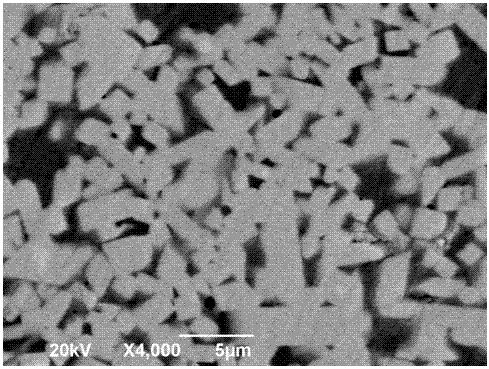

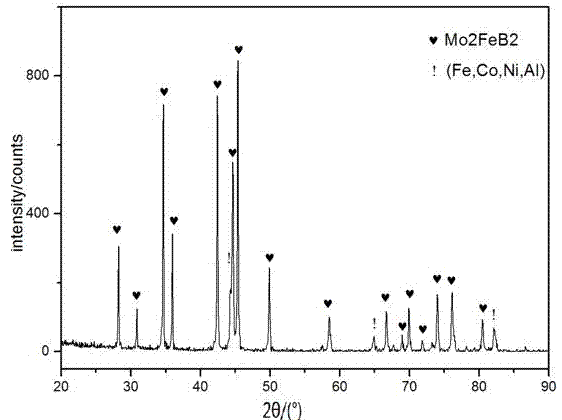

[0038] Weigh 65g Mo respectively 2 FeB 2Powder, 35g of high-entropy alloy binder phase raw material powder, wherein the high-entropy alloy binder phase raw material powder is iron powder, nickel powder, cobalt powder and aluminum powder, according to the molar ratio of iron, cobalt, nickel and aluminum elements 1:1:1 : 1 preparation. Put the above raw materials together into a ball mill for wet grinding and dispersing, the ball milling speed is 30 rpm, the grinding time is 24 hours, the grinding ball adopts WC-8wt%Co cemented carbide balls with a diameter of φ10mm, and the ball-to-material ratio is 8: 1. The wet grinding medium is anhydrous acetone. The ground mixed slurry was sieved to take out the grinding spheres, and the mixed slurry was separated by precipitation and dried at 80°C for 4 hours to obtain a mixed material. Add paraffin wax as a molding agent according to 3wt% of the weight of the mixture, mix evenly, then granulate and dry to obtain mixed pellets with goo...

Embodiment 2

[0040] Weigh 40g Mo respectively 2 FeB 2 Powder, 40gW 2 FeB 2 powder and 20g of high-entropy alloy binder phase raw material powder, wherein the high-entropy alloy binder phase raw material powder is titanium-iron alloy powder, chromium-nickel alloy powder, iron powder, copper powder and vanadium powder, according to iron, cobalt, nickel, chromium, titanium , Copper, vanadium element molar ratio 1:1:1:1:1:1:1:1:1 preparation. Put the above raw materials together into a ball mill for wet grinding and dispersion, the ball milling speed is 30 rpm, and the grinding time is 48 hours. The grinding ball adopts WC-8wt%Co cemented carbide balls with a diameter of φ10mm, and the ball-to-material ratio is 8: 1. The wet grinding medium is absolute ethanol. The ground mixed slurry was sieved to take out the grinding spheres, and the mixed slurry was separated by precipitation and dried at 80°C for 4 hours to obtain a mixed material. Add polyethylene glycol as a molding agent according...

Embodiment 3

[0042] Weigh 450g Mo respectively 2 NiB 2 Powder, 450gW 2 NiB 2 powder and 30g high-entropy alloy binder phase raw material powder, wherein the high-entropy alloy binder phase raw material powder is iron powder, nickel powder, zirconium powder, molybdenum powder and manganese powder, according to the molar ratio of iron, nickel, zirconium, molybdenum and manganese 1:1:1:1:1 formulation. Put the above raw materials together into a ball mill for wet grinding and dispersion, the ball milling speed is 26r / min, the grinding time is 10 hours, the grinding balls are WC-8wt%Co cemented carbide balls with a diameter of φ10mm, and the ball-to-material ratio is 10:1 , the wet grinding medium is methanol. The ground mixed slurry was sieved to take out the grinding spheres, and the mixed slurry was separated by precipitation and dried at 80°C for 4 hours to obtain a mixed material. Add SD glue as a forming agent according to 2wt% of the weight of the mixture, mix evenly, then granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com