Patents

Literature

576results about How to "No shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy emulsion modified quick repair mortar for concrete roads and bridges and preparation method for mortar

The invention discloses epoxy emulsion modified quick repair mortar for concrete roads and bridges and a preparation method for the mortar, and belongs to the technical field of chemical construction materials. The prepared epoxy emulsion modified quick repair mortar for the concrete roads and bridges is good in construction performance, high in early strength and stable in later strength, does not shrink, and can be formed by selecting a proper formula according to different engineering requirements; the early strength is increased quickly, the repair speed is high, the traffic can be openedin 4 hours, the 4H compressive strength is more than 25MPa, and the 4H breaking strength is more than 3.5MPa; and the mortar is highly bonded to an old concrete base layer, and the positive pulling bonding strength in 28 days is more than 2.5MPa; and the mortar is good in freezing resistance and impermeability. The mortar mainly solves the problems of long traffic opening time, low bonding strength with the old concrete base material, poor durability and the like of the conventional quick repair mortar for the concrete roads and bridges.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Wet-lay flame barrier

InactiveUS20060068675A1Increase speedExtension of timeDomestic upholsteryLayered productsFiberGlass fiber

Nonwoven wet-lay flame barrier of the invention comprises a blend of water dispersible fibers, that are inherently fire resistant and nonshrinking to direct flame, along with water dispersible fibers extruded from polymers made with halogenated monomers and optionally including fiberglass and wood pulp, being together thermally bonded with a binder resin in a wet-lay manufacturing process to provide a relatively thin, but dense, durable flame barrier with excellent tensile, and durability properties in the end use application. The wet-lay flame barrier of this invention also allows for the manufacture of open flame resistant composite articles, while also permitting the continued use of conventional non-flame retardant dress cover fabrics, conventional non-flame retardant fiberfills and conventional non-flame retardant polyurethane foams.

Owner:HANDERMANN ALAN C +3

High adhesiveness silicone gel for embedding precision electron component

InactiveCN102516775AImprove liquiditySelf defoamingOther chemical processesAdhesivesCross-linkSilicone Gels

The invention relates to silicone gel and specifically provides a high adhesiveness silicone gel for embedding a precision electron component. The silicone gel comprises a component A and a component B that have similar viscosity and are in transparent fluid shape. The component A mainly comprises vinyl silicone oil and catalyst; the component B mainly comprises vinyl silicone oil, cross-linking agent and inhibitor; an accessory employs a diluent or an adhesion agent or a mixture of the two; the accessory is arranged in the component A or the component B or both of the two; and the component A and the component B are independently packaged and mixed in a ratio of 1:0.8-1.2 for usage. The invention has advantages of good fluidity, property of automatic deaeration and simple operation. The component A and the component B are independently packaged, and the two components will not gelatinize after mixing, so as to gain a long operating time; the mixture can solidify rapidly once heated, and the solidification time can be controlled freely by temperature and inhibitor amount; and the silicone gel is in semi-solidification state after solidification, has good adhesiveness and sealing performance on many base materials and has excellent hot-cold alternate resistance.

Owner:TANGSHAN SANYOU SILICON IND

No-shrinkage grouting filler with adjustable performance

The present invention belongs to the field of building material, and is especially one kind of no-shrinkage grouting filler with adjustable performance. The no-shrinkage grouting filler is hydraulic mixture comprising Portland cement and fly ash or silica fume as cementing material, quartzite, water reducing agent, expanding agent, water loss reducing agent, early settling preventing agent and early contract preventing agent. It has high flowability, no settling, no weeping, micro plastic expansion, no shrinkage, no cracking, adjustable performance, and no plastic settling and other excellent performance, and may be applied widely in installing large precise equipment, large area leveling, emergency repair engineering, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Tail sealing grease for shield tunneller

The invention discloses a sealing grease for a shield tail of a shield tunneller, which comprises by weight the following components: basic oil 17.5-19 portions, thickener 8-15 portions, waterproof sealing material 58-65 portions, lubricant 1.5-3 portions, antioxidant 1-2 portions, anti-rust agent 0.5-1.5 portions, and tackifier 4-6 portions. The invention is of low cost, strong adhesion, good sealing performance, good pumping effect, environmental friendliness, good lubrication and steadiness, is resistant to aging and oxidation, free from separation and dry contracting during the quality warranty period of the product.

Owner:刘延鹏

Wallpaper water-based paint, preparation method thereof and wallpaper

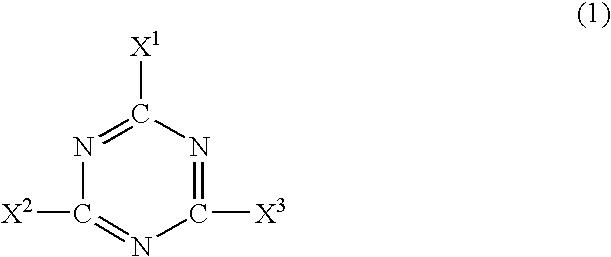

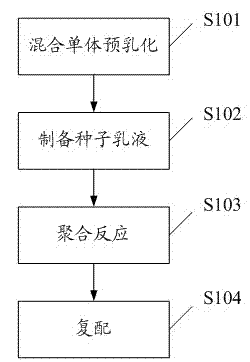

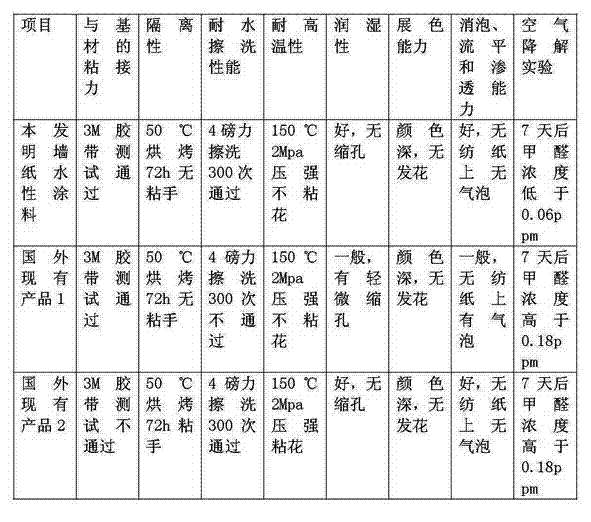

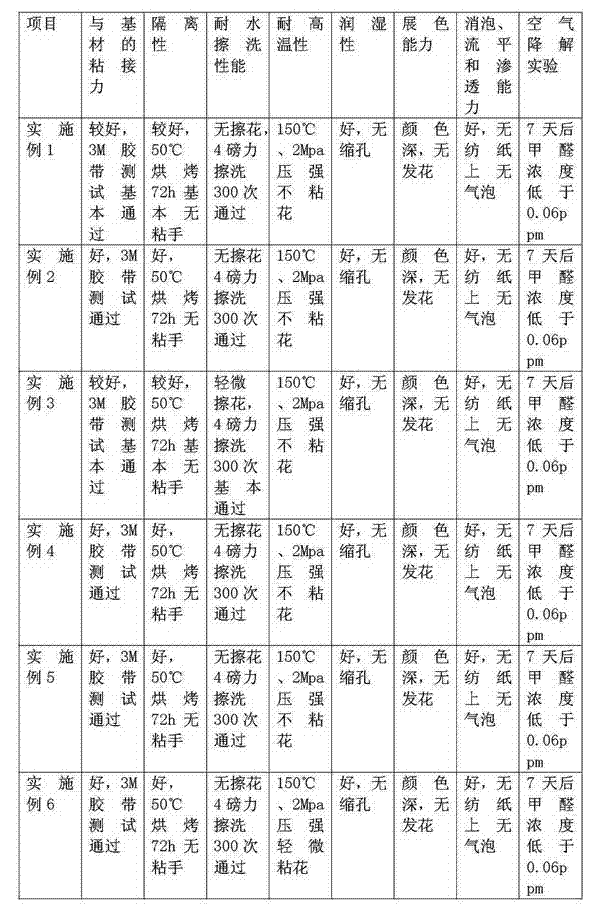

The invention discloses wallpaper water-based paint. The wallpaper water-based pain is water-based acrylate emulsion with solid content being 20-40% and the water-based acrylate emulsion is mainly made from a (methyl) acrylate monomer, a functional polymerizable monomer, an emulsifier, a photocatalyst, an initiator and deionized water through an emulsion polymerization method and a sol-gel method. Accordingly, the invention also discloses a method for preparing the wallpaper water-based paint and wallpaper made by adopting the wallpaper water-based paint. The wallpaper water-based paint is obviously improved in wallpaper substrate adaptability, the wallpaper water-based paint has good adhesive force, isolation, wettability and colour developing capability and is resistant to scrubbing and high temperature, defoaming is realized and the hole shrinkage phenomenon of a substrate is avoided; meanwhile, the wallpaper water-based paint also has light degradation property and can purify indoor air.

Owner:佛山市三水灏诚合成树脂有限公司

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Quick setting and rapid hardening non-shrinkage anti-disturbance self-compacting concrete and preparation method thereof

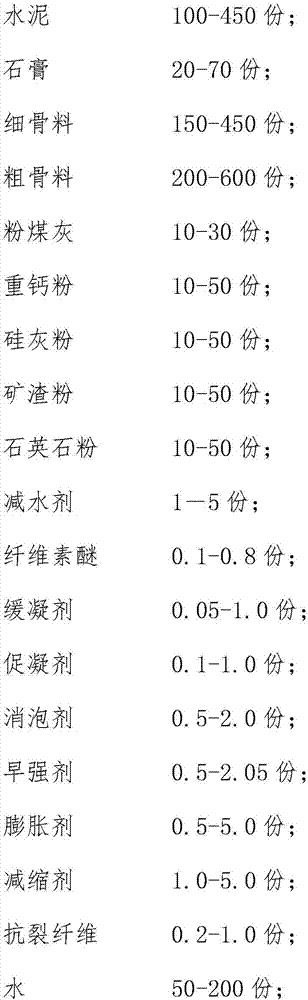

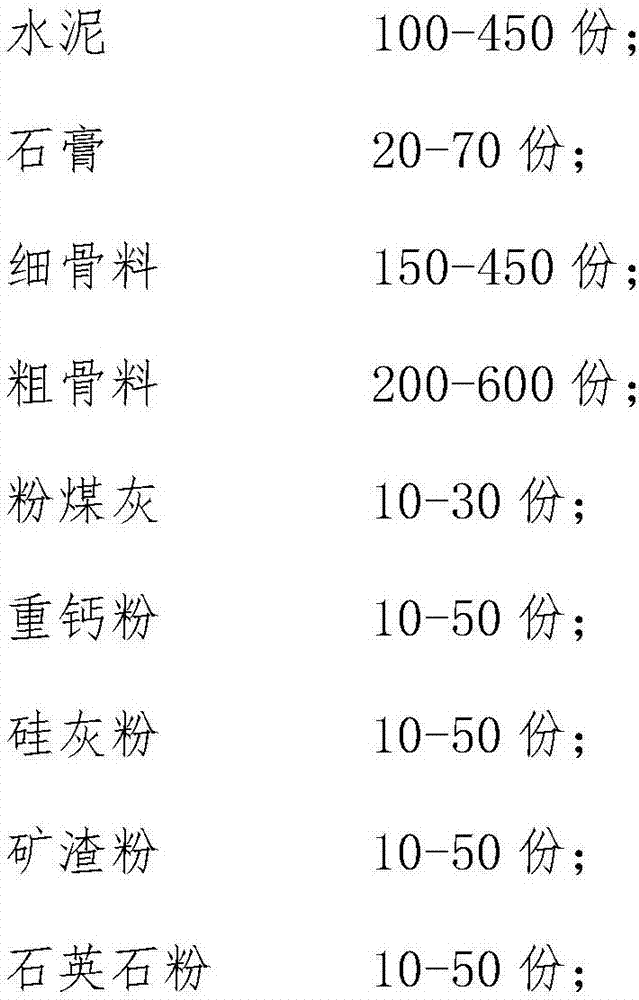

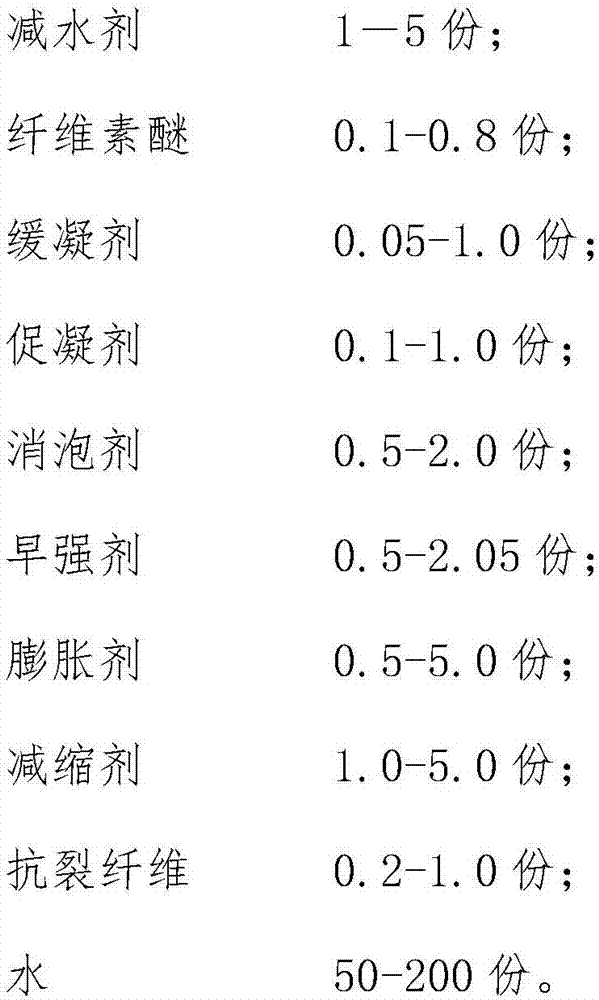

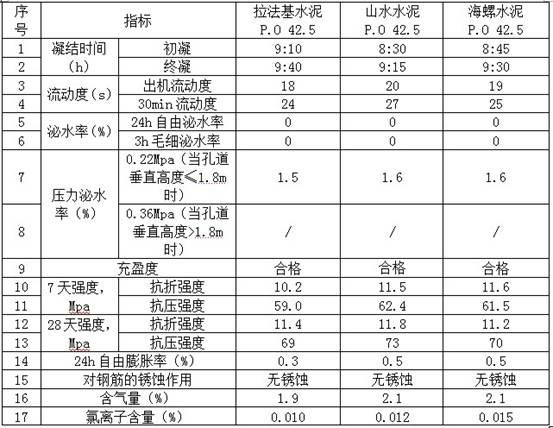

The invention relates to quick setting and rapid hardening non-shrinkage anti-disturbance self-compacting concrete and a preparation method thereof. Raw materials contain the following ingredient (by weight): 100-450 parts of cement, 20-70 parts of gypsum, 150-450 parts of fine aggregate, 200-600 parts of crude aggregate, 10-30 parts of fly ash, 10-50 parts of heavy calcium powder, 10-50 parts of silica fume, 10-50 parts of slag powder, 10-50 parts of quartz powder, 1-5 parts of a water reducer, 0.1-0.8 part of cellulose ether, 0.05-1.0 part of a retarder, 0.1-1.0 part of a coagulation accelerator, 0.5-2.0 parts of an antifoaming agent, 0.5-2.05 parts of an early strength agent, 0.5-5.0 parts of an expanding agent, 1.0-5.0 parts of a shrinkage reducing agent, 0.2-1.0 part of anti-crack fiber, and 50-200 parts of water. Through an optimum mixture ratio and by the use of a polycarboxylate superplasticizer, the early strength agent and other additives, properties such as early strength, disturbance rejection, crack resistance, durability, self-compaction and the like of concrete are greatly enhanced, and disadvantages of low early strength, long time interval of initial set and final set and the like of common concrete are solved.

Owner:张彬

Concrete pipeline mud-jacking agent and preparation method

The invention belongs to the field of building materials, and particularly relates to a concrete pipeline mud-jacking agent and a preparation method thereof. The invention adopts the technical scheme that the concrete pipeline mud-jacking agent comprises the following components in percentage by weight: 0.5 to 2 percent of efficient water reducing agent, 0.1 to 0.5 percent of stabilizer, 1 to 5 percent of early expansion agent, 35 to 55 percent of medium and later expansion agent, 0.1 to 1 percent of retarder, 0.2 to 1 percent of rust inhibitor, 0.05 to 0.1 percent of air entraining agent and 50 to 60 percent of mineral admixture. The concrete pipeline mud-jacking agent has the advantages of wide raw material source, good mobility, high strength, no bleeding or layering, good durability, ageing resistance, low chlorine ion content, no corrosion to steel bars, firmness, high filling property, one-time mud-jacking construction, capability of making slurry in a pipeline compact and pore-free, no shrinkage, no rust corrosion of prestressed steel bars, and firm adhesion with concrete.

Owner:济南鲁新新型建材股份有限公司

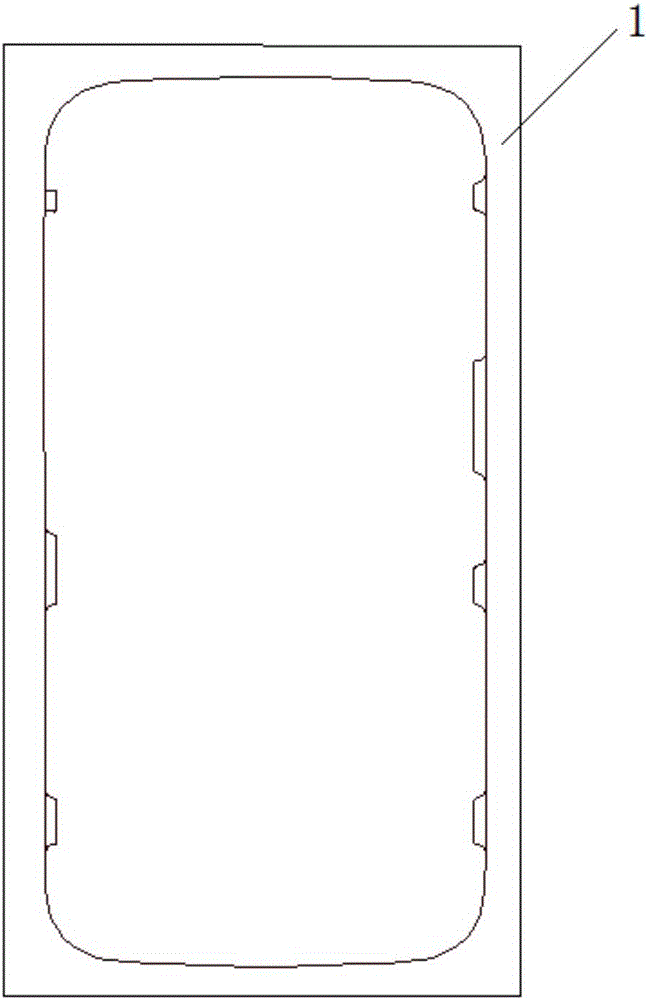

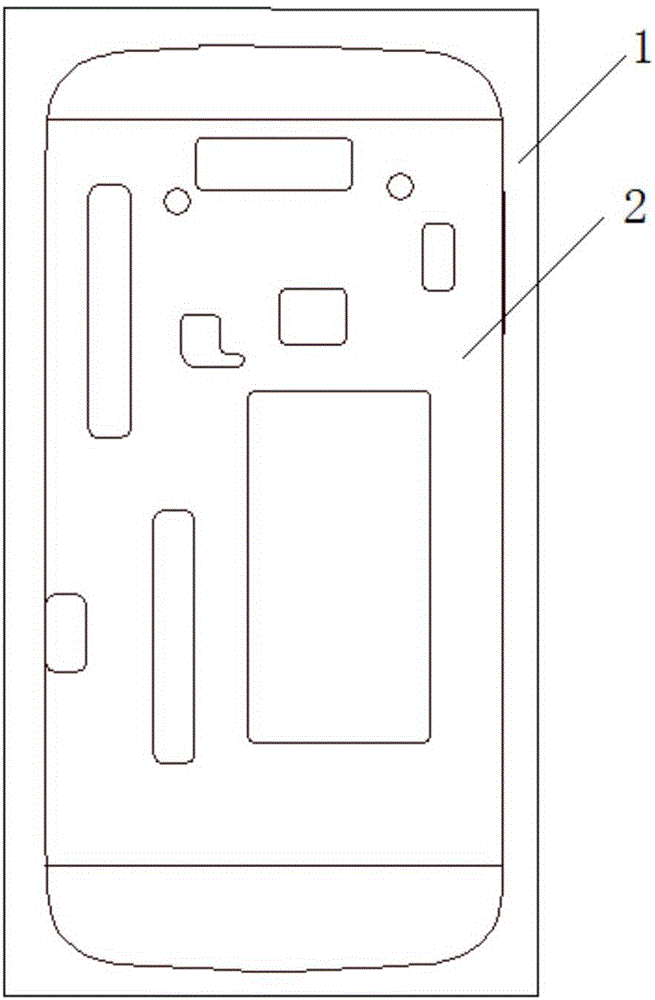

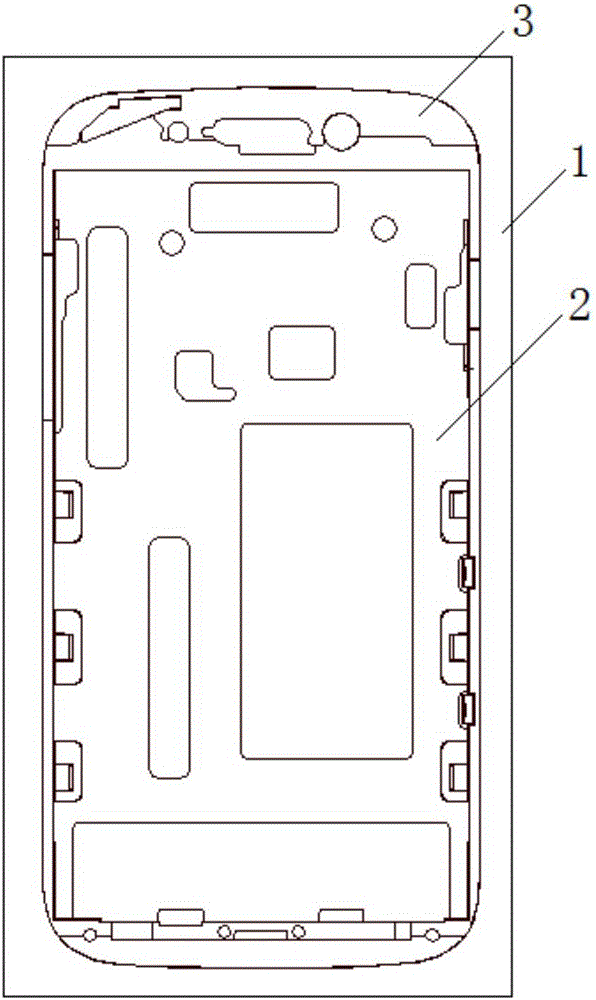

Manufacturing method of mobile phone middle frame

InactiveCN106435686AAvoid corrosion onlyReduce the amount of processingAnodisationDomestic articlesPressure castingMachining

The invention discloses a manufacturing method of a mobile phone middle frame. The manufacturing method comprises the following steps: S1, preparing a stainless steel rim; S2, putting the stainless steel rim into a pressure casting die, then adding smelted aluminum alloy liquid into the pressure casting die for pressure casting to form an aluminum alloy middle plate, and integrally forming an aluminum alloy-stainless steel middle frame from the aluminum alloy middle plate and the stainless steel rim; S3, covering the aluminum alloy middle plate with protective rubber capable of resisting corrosion of acidic liquid and alkaline liquid, putting the aluminum alloy-stainless steel middle frame into microhole treatment liquid for corrosion to form micro holes, and then removing the protective rubber; S4, forming a plastic structural member on the aluminum alloy-stainless steel middle frame through injection molding; and S5, performing post machining treatment on the aluminum alloy middle frame. The manufacturing method can avoid the problem that only the aluminum alloy is corroded, but the stainless steel cannot be corroded due to different activities of metals in the manufacturing process. According to the method, the machining amount of the whole structure of the middle frame can be reduced, the appearance effect is good, and the yield is high.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Method for preparing ceramic material by process steps of powder green body dipping and precursor cracking

The invention provides a method for preparing a ceramic material by process steps of powder green body dipping and precursor cracking. The method comprises the following steps: (1) preparing ceramic powder into a required green body by using a conventional method; (2) drying the green body for 1-30 hours at the drying temperature of 80-150 DEG C to obtain a porous green body; (3) dipping the porous green body into a liquid ceramic precursor for 1 hour or more in vacuum or at a certain pressure; (4) placing the porous green body with the ceramic precursor in an airtight high-pressure kettle, introducing inert gas, raising the temperature to 60-300 DEG C at the pressure of 0.1-30 MPa, and then performing heat insulation for 10-55 hours so that the precursors in the holes of the powder green body are crosslinked and cured; and (5) placing the green body with the cured ceramic precursor in a high temperature furnace, protecting with nitrogen, heating to 1200-1400 DEG C, and then performing heat insulation for 50-70 minutes, so that the cured precursor is cracked and converted into ceramic. The method has the advantages of high production efficiency, high yield and low production cost, and can be used for preparing various ceramic materials such as silicon carbide, silicon nitride, silicon oxide, boron nitride, boron carbide, alumina, aluminium nitride, zirconia and the like.

Owner:NAT UNIV OF DEFENSE TECH

Early-strength type gypsum-based thick-layer leveling mortar

The invention discloses early-strength type gypsum-based thick-layer leveling mortar. The early-strength type gypsum-based thick-layer leveling mortar is prepared from the following components in percent by mass: 10-40% of gypsum, 0-10% of hydraulic cementitious material, 0-5% of excitant, 40-80.75% of filler and 0.25-5% of additive, wherein the additive is prepared from the following components in percent by mass: 0-3% of redispersible latex powder, 0.05-0.5% of super plasticizer, 0-0.2% of water-retaining agent, 0.05-0.2% of retarder, 0-0.1% of segregation-resistant agent and 0.01-0.2% of defoaming agent. All the components are mixed uniformly according to the mass percents and are packaged into bags. The early-strength type gypsum-based thick-layer leveling mortar disclosed by the invention has the advantages of early strength, no shrinkage, wear resistance, water resistance, good constructability, segregation and bleeding resistance, low cost and no harmful chemical substances.

Owner:江苏兆佳建材科技有限公司

Red-green dry-pasting glue and preparation technique thereof

A red and green dry adhesive consists of a component A and B. The component A comprises epoxy resin, coupling agent, reactive diluents, inorganic filling, and red acid organic ointment. The component B comprises organic modified amine curing agent, coupling agent, inorganic filling, accelerant, thickener, reactive diluents and green organic ointment. The component A is mixed with the component B to become white. The invention overcomes the disadvantages of the present dry adhesive (used for direct adhesion) such as low intensity, weak weatherproof performance, and inconvenience for construction, etc. The red and green dry adhesive of the invention which is special for direct adhesion has the advantages of high strength, good weatherproof performance and convenient construction. The invention discloses a preparation method of the red and green dry adhesive at the same time.

Owner:JIANGSU DALISHI YUNSHI NURSING MATERIAL CO LTD

Early-strength type cement-based thick-layer leveling mortar and use method

The invention discloses early-strength type cement-based thick-layer leveling mortar and a use method. The early-strength type cement-based thick-layer leveling mortar is prepared from the following components in percent by mass: 10-20% of cement, 3-6% of reinforcing agent, 0-5% of excitant, 65.1-86.86% of filler and 0.14-3.9% of additive, wherein the additive is prepared from the following components in percent by mass: 0-3% of redispersible latex powder, 0.03-0.5% of super plasticizer, 0-0.2% of water-retaining agent, 0-0.1% of retarder, 0-0.1% of segregation-resistant agent and 0.01-0.2% ofdefoaming agent. The use method comprises the steps of: uniformly mixing all the components according to the mass percents, packaging into bags and using by adding water according to a water-to-material ratio of 14-18%. The early-strength type cement-based thick-layer leveling mortar disclosed by the invention has the advantages of early strength, no shrinkage, wear resistance, water resistance,good constructability, segregation and bleeding resistance, low cost and no harmful chemical substances.

Owner:江苏兆佳建材科技有限公司

Rapid hardening high-strength grouting material

InactiveCN101913840ASolve the problem of degraded perfusion qualityWith antifreeze functionSolid waste managementAnti freezingLithium carbonate

The invention discloses a rapid hardening high-strength grouting material, which consists of the following components in percentage by weight: 40 to 55 percent of fast hardening sulphoaluminate cement, 40 to 55 percent of quartz sand, 1 to 5 percent of silicon micro-powder, 2 to 5 percent of high-calcium powder, 0.6 to 1.0 percent of FDN water reducer, 1 to 3 percent of anhydrite powder, 0.02 to 0.14 percent of lithium carbonate, and 0.2 to 1.4 percent of sodium chloride. The components are uniformly mixed, and stirred with water in a water / cement ratio of 0.14-0.18, and the grouting material can be used after uniform stirring. The grouting material is suitable for low-temperature construction, and has the characteristics of early strength, high strength, good flowing performance, no shrinkage, good anti-freezing effect and the like.

Owner:刘茂平

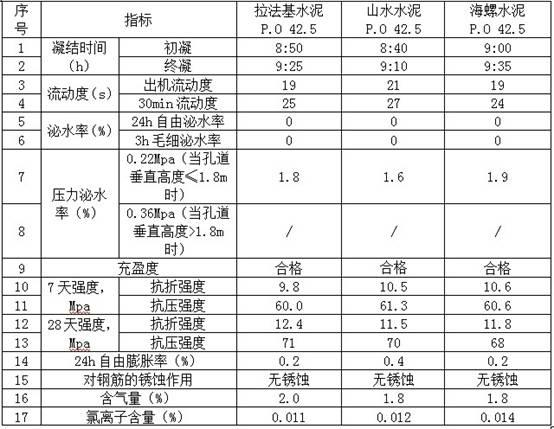

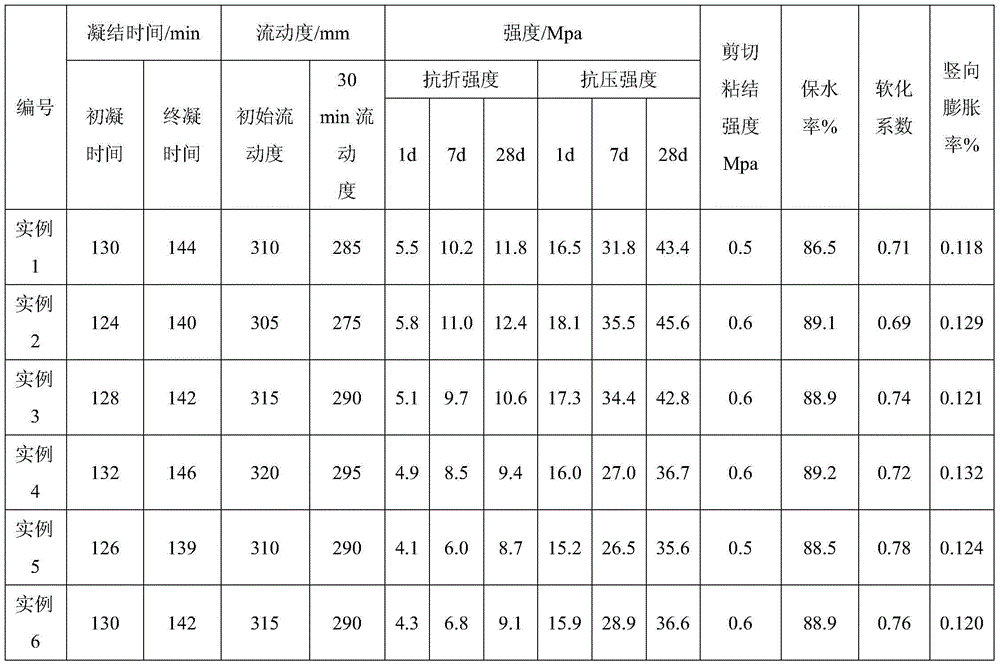

Early-strength type cement-based grouting material and using method thereof

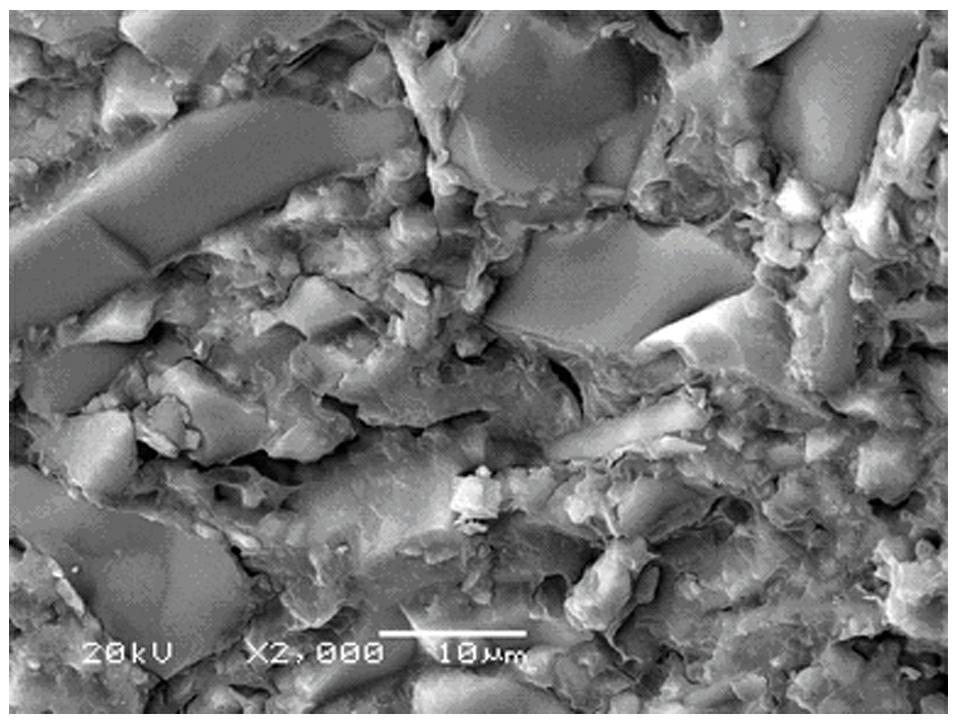

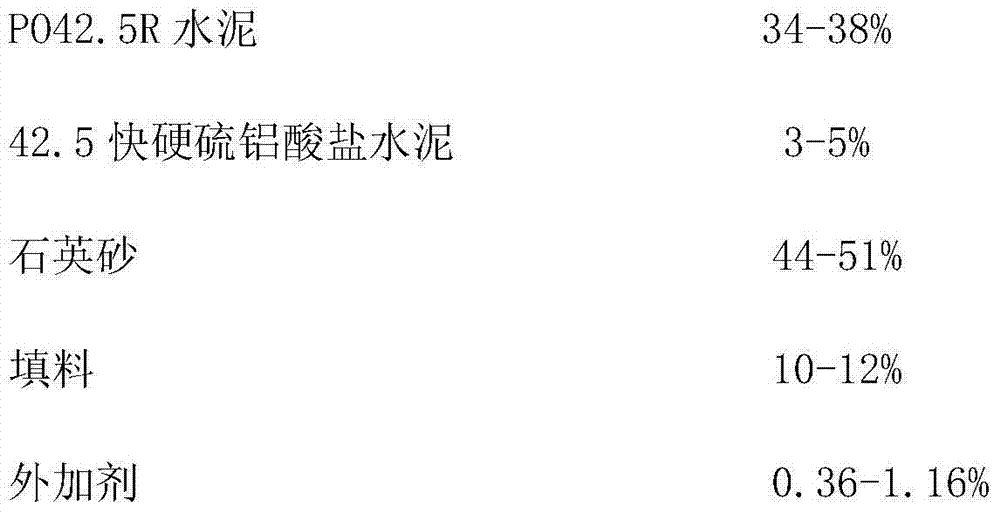

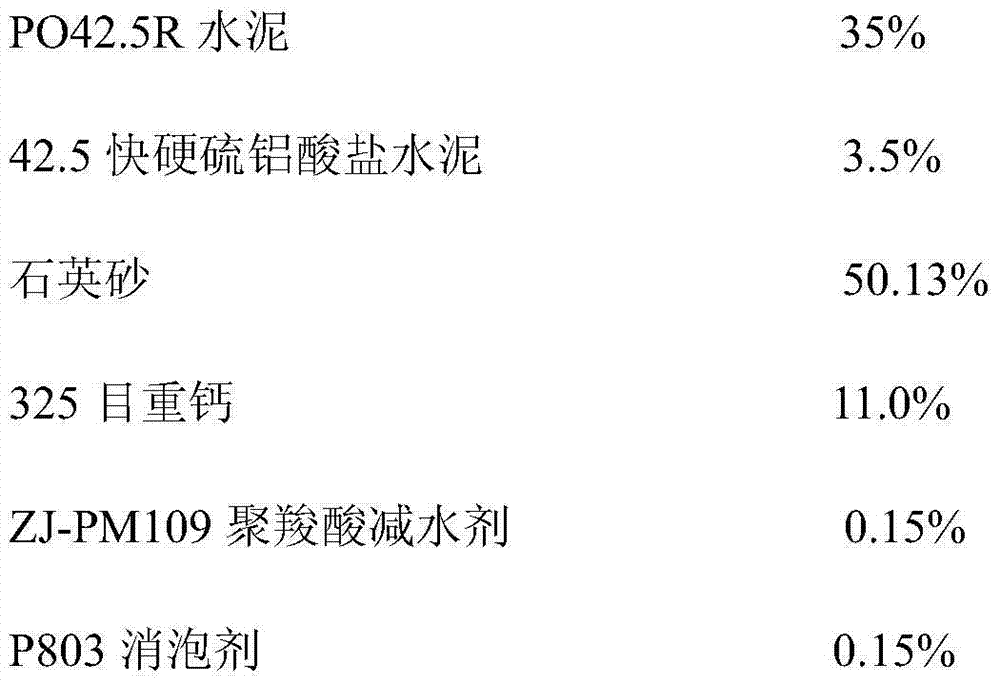

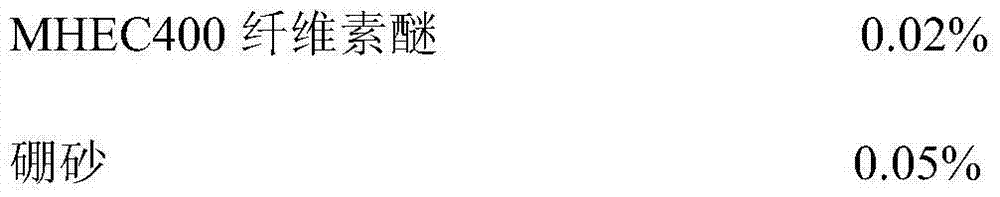

The invention discloses an early-strength type cement-based grouting material and a using method of the grouting material. The grouting material comprises the following components by mass percent: 34-38% of PO 42.5R cement, 3-5% of 42.5 early-strength sulphoaluminate cement, 44-51% of quartz sand, 10-12% of filler and 0.36-1.16% of additive, wherein the additive comprises a water reducing agent, a water-retaining agent, a retarder and a defoaming agent, and the mixing amounts of the water reducing agent, the water-retaining agent, the retarder and the defoaming agent are respectively 0.15-0.30%, 0.015-0.025%, 0.05-0.15% and 0.15-0.33%. The using method comprises the steps of evenly mixing the components according to the mass percent, packaging into bags, and adding water into the grouting material according to the ratio of 0.15: 1 between water and material for use. The early-strength type cement-based grouting material has the advantages of being early in strength, high in strength, free from shrinkage, high in fluidity, low in cost and free from harmful chemical substances.

Owner:江苏兆佳建材科技有限公司

Phosphogypsum based high flow state grouting material

InactiveCN104628349ARealize resource utilizationImprove water resistanceSolid waste managementMass ratioResource utilization

The invention discloses a phosphogypsum based high flow state grouting material. The phosphogypsum based high flow state grouting material is composed of the following components in parts by weight: 50-70 parts of phosphorus based semi-hydrated gypsum, 20-40 parts of coal ash, 8-12 parts of compound activator, 6-10 parts of gypsum whisker, 0.05-0.15 part of retarder, 0.2-0.6 part of water reducing agent, 0.04-0.08 part of water retaining agent and 0.02-0.06 part of water repellent. Wherein, the phosphorus based semi-hydrated gypsum is phosphorus based high-strength gypsum or a mixture of the phosphorus based high-strength gypsum and phosphorus based building gypsum with a mass ratio of 4:1 to 5:1. The grouting material is prepared from the phosphogypsum in the invention to achieve the resource utilization of the phosphogypsum, and is green and environmentally friendly. The coal ash is used as a mineral admixture, and acetylene sludge and cement are used as an alkali activator to reduce the cost and well improve the water resistance and durability of the grouting material, and the gypsum whisker is used for modifying the grouting material to improve the breaking strength of the grouting material.

Owner:WUHAN UNIV OF TECH

Macromolecule composite metal healant and preparation and use method

The invention discloses a macromolecule composite metal healant containing two components which are separately prepared and are used together. The invention also discloses preparation and use methods of the macromolecule composite metal healant. The macromolecule composite metal healant has the following advantages: 1, the material after being cured has high strength and can be used for various mechanical reprocessing; 2, the macromolecule composite metal healant has high combination strength with metal and composite materials; the macromolecule composite metal healant has wide application range, and is suitable for repairing and reproducing various metal materials with defects; the macromolecule composite metal healant has the characteristics of resisting against abrasion, aging, high temperature, oil, weak acid-base media and the like; 5, no micromolecule is volatilized during the curing period, and the solid has no shrink. The preparation process disclosed by the invention is simple and easy to implement and is favorable for scale production.

Owner:CHENGDU YUEDING TECH

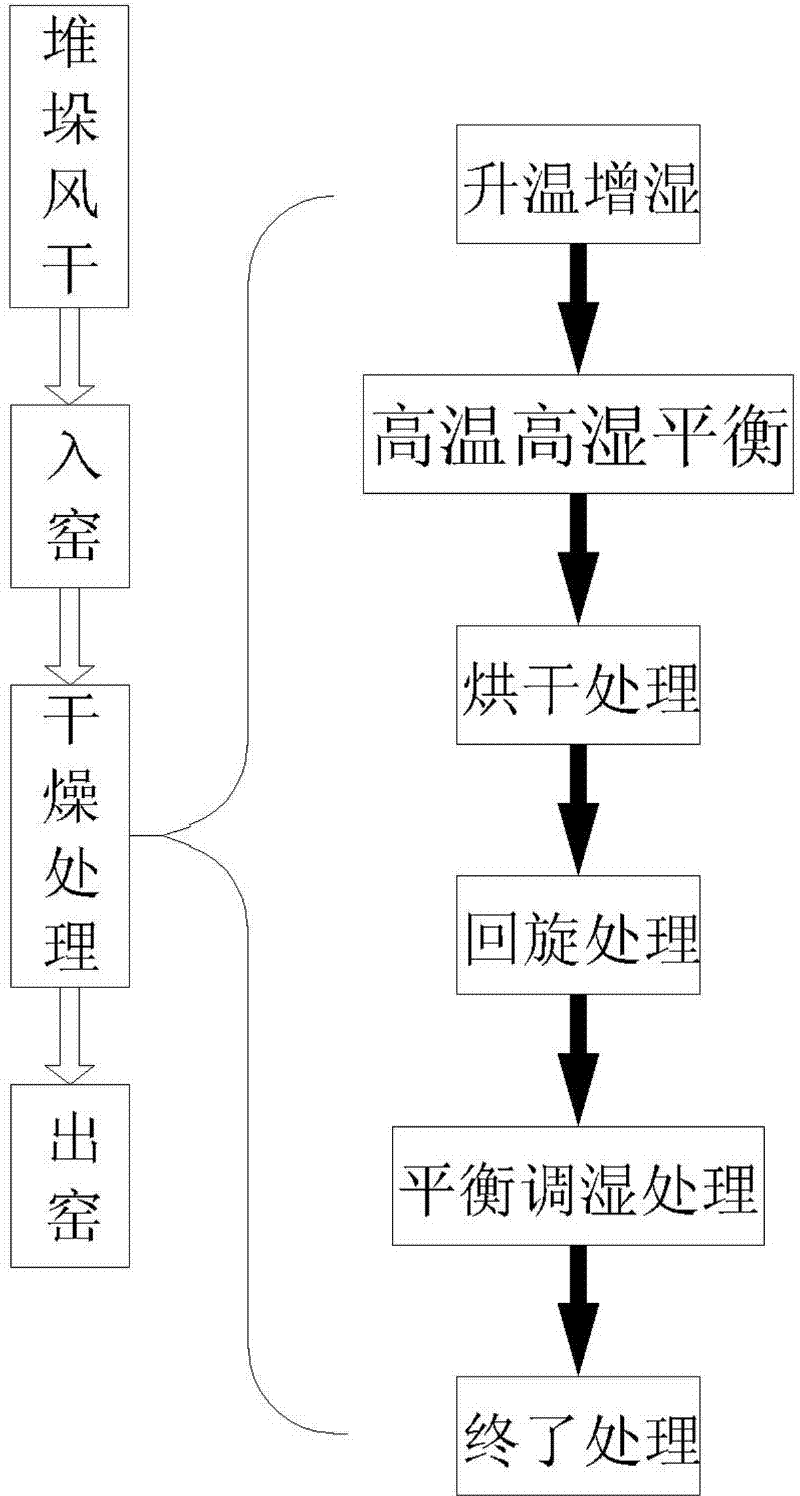

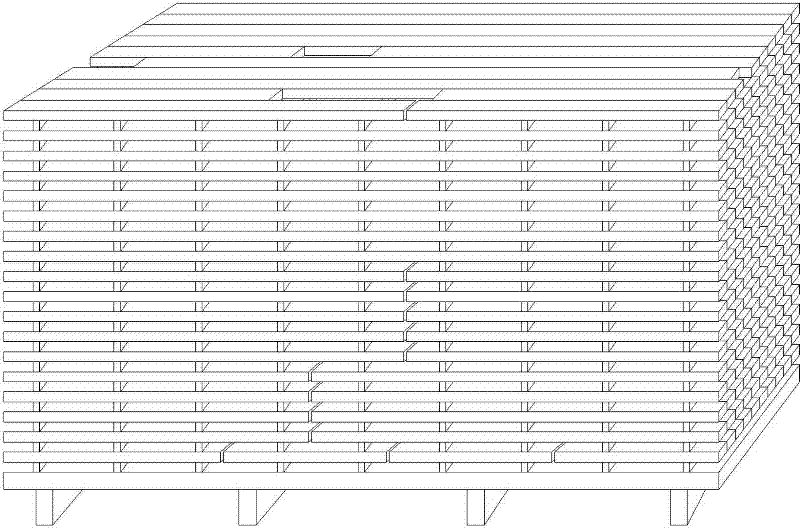

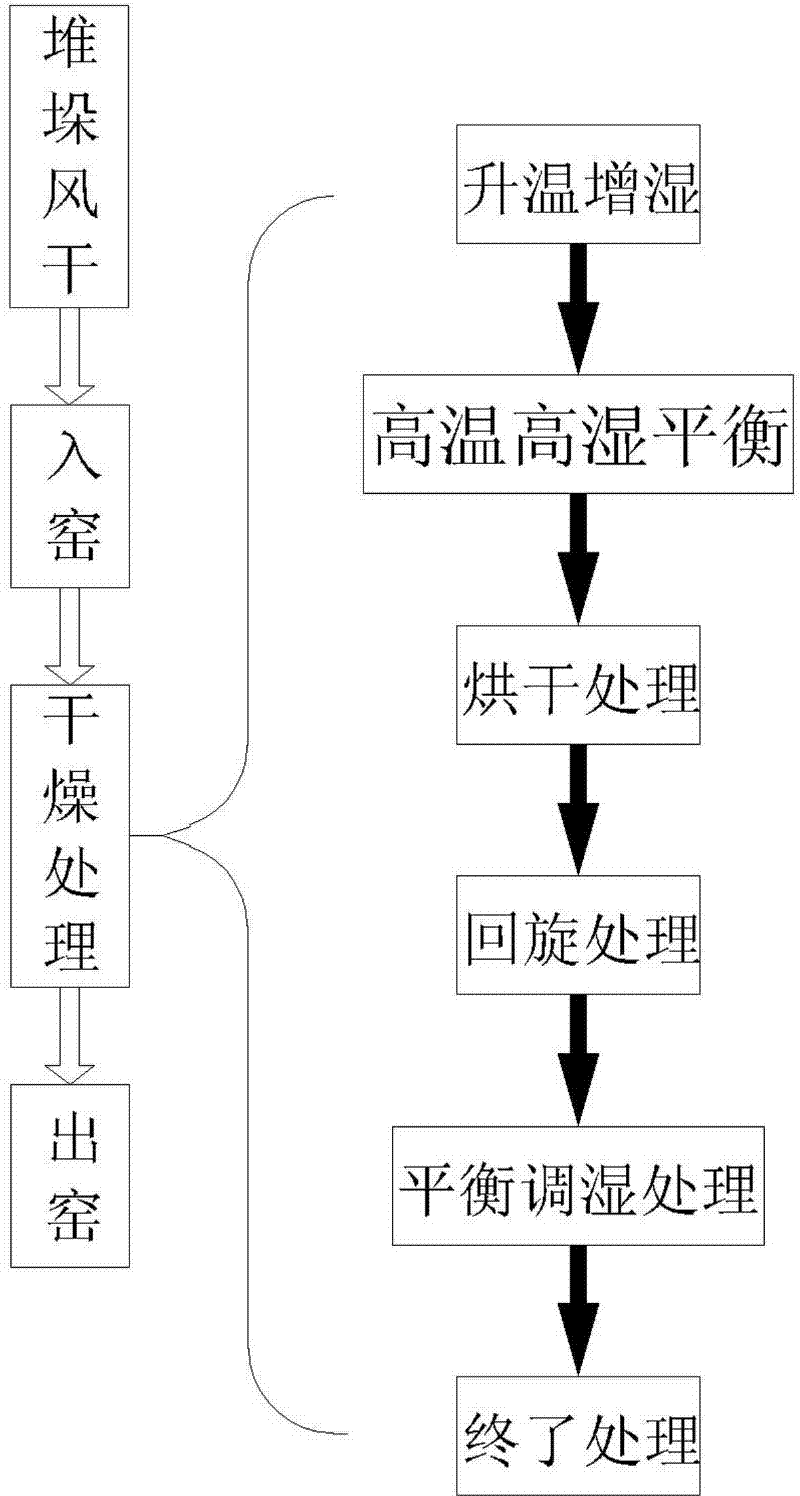

Rotary drying method for timbers

The invention provides a rotary drying method for timbers. The method comprises the following steps of: stacking the timbers and airing the timbers till the water content is about 30 percent; stacking the aired timbers, putting the timbers in a timber drying kiln, preheating, raising the temperature, humidifying, preserving heat and moisture, drying and dehydrating, finally treating and carrying out balanced humidification and rotary treatment many times. The method has the keys that a drying medium in a kiln is kept to form rotary vortex, and the water content of the timbers is not reduced in one step and is kept in rotary decline; by the rotary method, the internal stress of the timbers is dispelled in time, drying stress and surface hardening are eliminated, plasticizing deformation is prevented in the drying stage of the timbers, the defects of air shrinking, bending, deforming, cracking and the like are not caused, the degradation loss of the timbers is reduced to be below 6 percent, the drying period is shortened by about 20 percent, energy can be saved by about 15 percent, and limited timber resources are utilized more effectively; and the method has strong universality, is suitable for various different timbers, and can be widely applied to drying kilns with high automation degree.

Owner:GUANGDONG YIHUA TIMBER IND

Glass fiber reinforcement cement board and production method thereof

InactiveCN101386509AGuaranteed StrengthGuaranteed lifeSolid waste managementCeramicwareExpanded clay aggregateCement board

The invention relates to a building material and a method for preparing the same, in particular to a glass fiber reinforced cement board and a method for preparing the same. The glass fiber reinforced cement board comprises the following components in weight portion: 100 portions of Portland cement, 13.6 to 15 portions of high alumina cement, 3.1 to 3.4 portions of fly ash, 5.7 to 6.3 percent of plaster stone powder, 120 to 132 portions of ceramsite, 6.5 to 7.1 percent of foaming agent, 74.5 to 81.3 percent of dispersing agent, 53 to 58.7 portions of pure water and 3.6 to 4 portions of plastic-coated glass fiber grid cloth. The preparation method sequentially comprises the following steps: mixing weighed-up solid materials, adding weighed-up liquid materials in the previous step, cavity forming, roll extruding, vibration, cutting and curing. The invention has the advantages that: the glass fiber reinforced cement board has advantages of light volume weight, high strength, low dry shrinkage wet swelling coefficient, no after expansion and shrinkage, corrosion resistance, sound insulation, heat insulation, fire resistance and non-combustion; the preparation method has the characteristics of scientific and reasonable method, continuous production, high efficiency and low cost, flat board surface, convenient in-site mounting and the like; the glass fiber reinforced cement board is good in water resistance, and particularly applied to the finishing of internal and external walls and ceilings of various buildings in wet environments; moreover, the glass fiber reinforced cement board and a method for preparing the same have the advantages of ensuring the strength and service life of cement due to the adoption of the plastic-coated anti-alkali glass fiber grid cloth, along with reasonable blending ratio and reduced alkalinity.

Owner:YINGCHUANG BUILDING TECH SHANGHAI CO LTD

Antiseptic fixing liquid composition for cadaver sample and preparation method thereof

InactiveCN101473812ANatural colorTissue flexibilityDead animal preservationChemistryLiquid composition

The invention discloses an antiseptic stationary liquid composition for corpse specimen, mainly comprising a metal complexing agent, a protein corsslinking agent, an osmoregulation agent and a food-grade antiseptic / mildew inhibitor and water; the metal complexing agent is ethylenediamine tetracetic acid disodium salt or ethylene glycol diethyl ether ethylenediamine tetracetic acid, the protein corsslinking agent is glyoxal, malonaldehyde, succinaldehyde or glutaraldehyde, the osmoregulation agent is a mixture, according to any proportion, of more than two substances selected from potassium nitrate, sodium nitrate, potassium chloride and sodium chloride, the food-grade antiseptic / mildew inhibitor is sodium dehydroacetate, sodium diacetate or potassium sorbate. The inventive composition is dedicated to antisepsis and fixing perfusion for animal or human corpses and has the advantages of strong antiseptic performance, good fixing performance and excellent safety without formaldehyde and toxicity. The invention also provides a method for preparing the antiseptic stationary liquid composition for corpse specimen.

Owner:WENZHOU MEDICAL UNIV

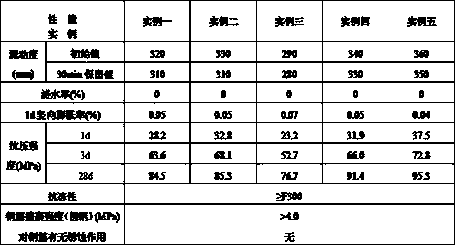

Preparation and construction method of epoxy grouting material for track filling and secondary grouting

The invention relates to preparation and a construction method of a grouting material (referred to as RE-GD) for track filling and secondary grouting. The RE-GD comprises three components, A, B and C. The component A is a modified epoxy resin mixing system, which comprises modified epoxy resin, an active diluent, a toughening agent, an antioxidant, a leveling agent, a defoaming agent and a coupling agent. The component B is a curing agent. The component C is a filler. The high-strength precise non-contraction epoxy resin grouting material for tracking provided by the invention has the advantages of high adhesion to a cement base and a steel base, high strength, good toughness, no expansion, extremely low contraction rate and small amount of dense porosity; excellent properties of polymer material enables the material with characteristics, unmatched by other materials, in corrosion resistance and weatherability performance, and can satisfy usage in different climate environment. The material provided by the invention has long cycle of usage and a general service life of up to 30 years, and can be used as a substitute or be applied to environment and position, which CA mortar or cement base grouting material can not be applied to.

Owner:BEIJING ALLIED RONGDA CONSTR MATERIAL

Phosphogypsum-based outdoor landscape material for 3D (three-dimensional) printing

ActiveCN106495630AReduce raw material lossCost controlAdditive manufacturing apparatusOxidePollution

The invention discloses a phosphogypsum-based outdoor landscape material for 3D (three-dimensional) printing. 70-85 parts of phosphorus gypsum, 3-8 parts of coagulation accelerators, 2-4 parts of cement, 0.01-0.03 part of graphene oxide and 0.5-2 parts of nano-silicon dioxide are mixed to obtain composite powder, a roller is pushed to a modeling platform, a layer is uniformly paved, the thickness of the layer is smaller than 0.075mm, a printing head sprays 8-20 adhesive curing composite powder, a color ink-jet printing head selectively jets two pigments on paved powder, and the modeling platform repeatedly reduces layer by layer until phosphogypsum-based outdoor landscapes are finished. The prepared phosphogypsum-based outdoor landscape material is a green building material, wide in source, low in cost, easy to obtain, low in toxic and side effect, good in water resistance and prepared in a 3D printing manner and has functions of removing odor, resisting pollution, purifying air and the like, mechanical machining or any molds are omitted, 28d strength is larger than 20Mpa, and a softening coefficient is larger than 0.85.

Owner:HUBEI UNIV OF TECH

High-performance shrinkage-free cement-based grouting material prepared by manufactured sand and preparation method of cement-based grouting material

The invention relates to a high-performance shrinkage-free cement-based grouting material prepared by manufactured sand, which comprises the following raw materials by weight percentage: 50-60% of manufactured sand, 30-40% of ordinary portland cement, 3-6% of fly ash, 1-5% of slag powder, 0.02-0.04% of fiber, 0.1-0.14% of heavy material and 3-5% of light material. A preparation method of the cement-based grouting material comprises the following steps of manufactured sand treatment: selecting sand within three gradation ranges produced by a dry sand manufacturing system for standby, proportionally compounding and mixing components in the light material and the heavy material to obtain a mixture A, and proportionally mixing the manufactured sand, the ordinary portland cement, the fly ash, the slag powder, the fiber and the mixture A to obtain the cement-based grouting material. The cement-based grouting material has the advantages of low cost, good flowability, high uniformity, plastic micro-expansion without shrinkage, early strength, high strength and the like.

Owner:经纬建材有限公司

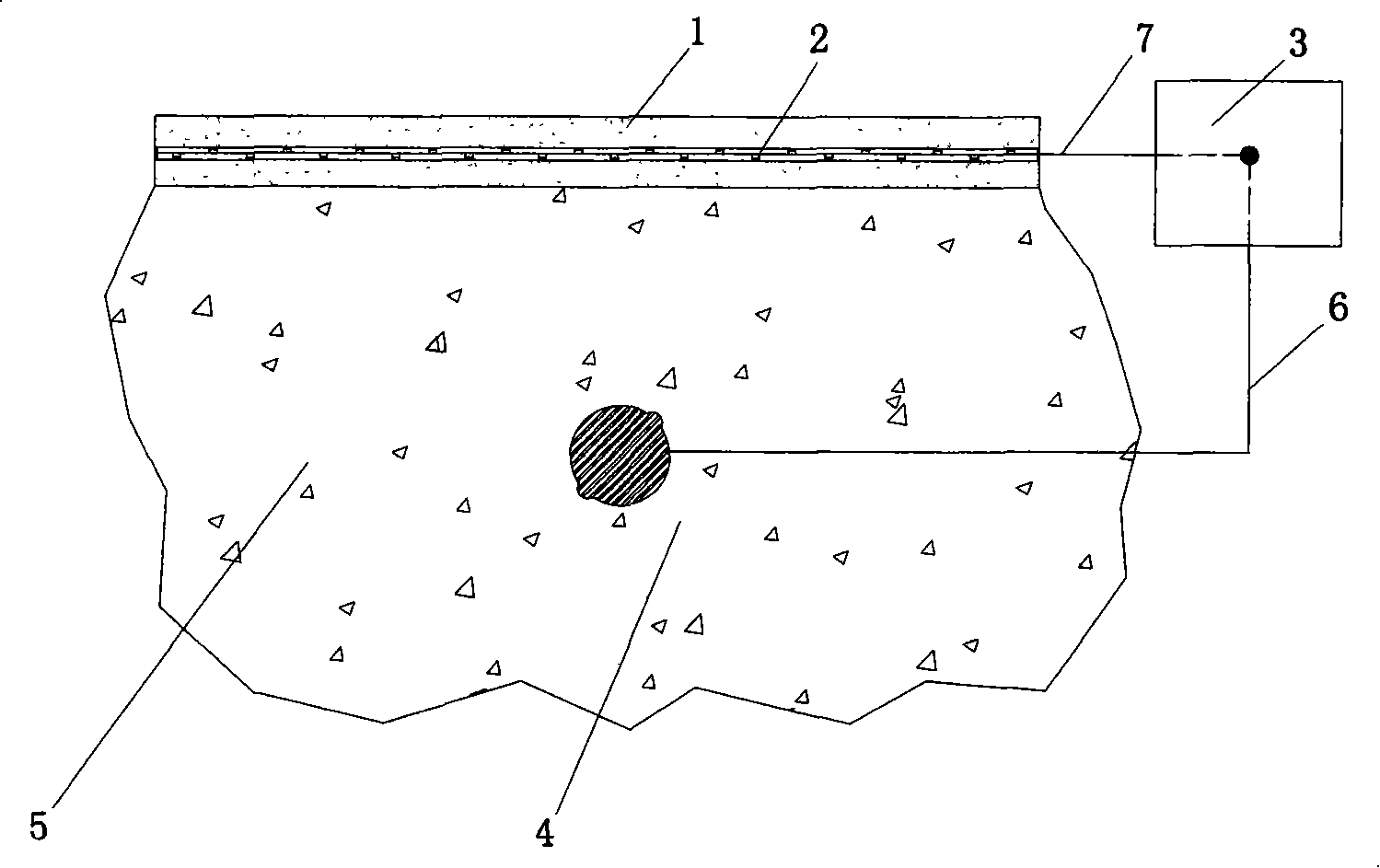

Steel reinforced concrete sacrificial anode cathodic protection devices in atmospheric environment and method thereof

The invention relates to a protection device for sacrificial anodes and sacrificial cathodes in reinforced concrete structures in the atmospheric environment; wherein, the reticular sacrificial anodes are electrically connected with steel bars in concrete to form a protection system for the sacrificial anodes and sacrificial cathodes; the protection device is characterized in that the sacrificial anode is embedded in active mortar which is laid on the surface of the reinforced concrete; the sacrificial anode adopts pure zinc or zinc alloy; the active mortar consists of Portland cement, aggregates, water, synthetic fibers and active additives, and the water-cement ratio is 0.35 to 0.55:1 and the cement-sand ratio is 0.3 to 0.6:1; the active additives are lithium bromide or lithium nitrate with the mixing amount of 0.05 to 0.50g / cm <3>; the synthetic fibers are selected from polypropylene fiber, polyethylene fiber, cellulose and / or glass fiber with the mixing amount of 0.05 to 0.5 percent; the protection device also comprises a protection method; the protection device saves human and material resource and has low price and service life as long as 20 years; the active mortar does not shrink or crack and is lower in resistivity, high in intensity and stable in the open circuit potential of the sacrificial anode.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

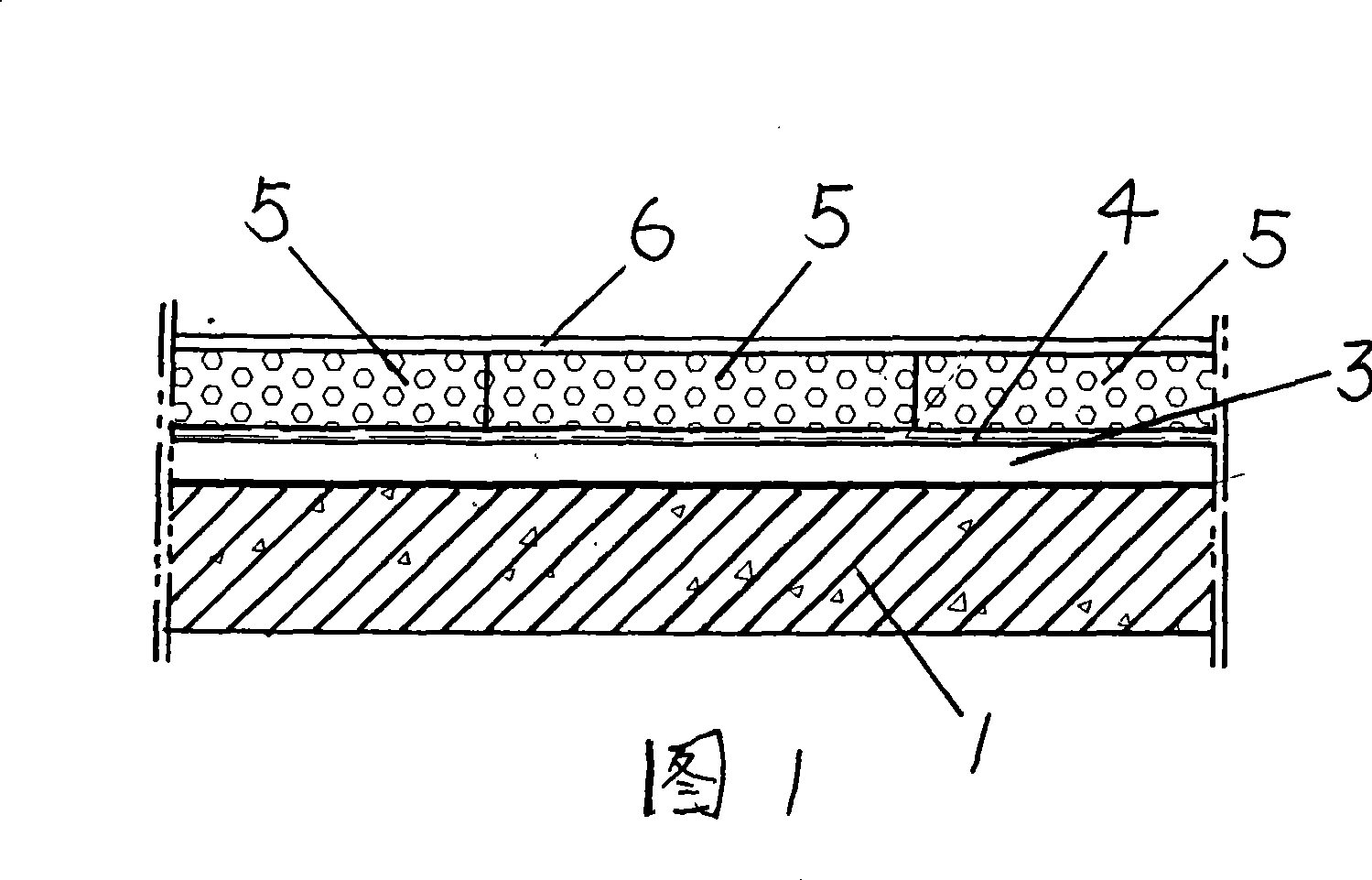

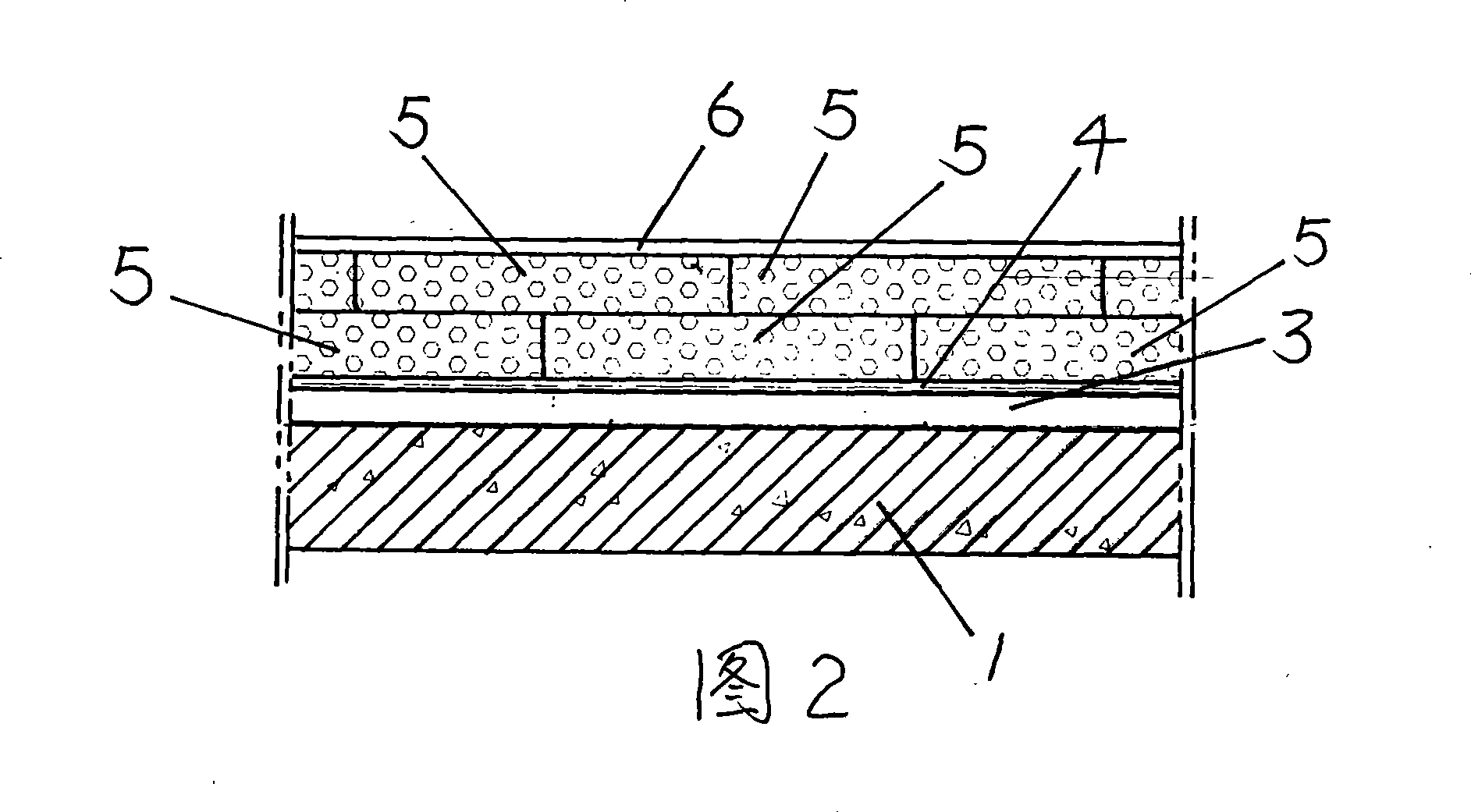

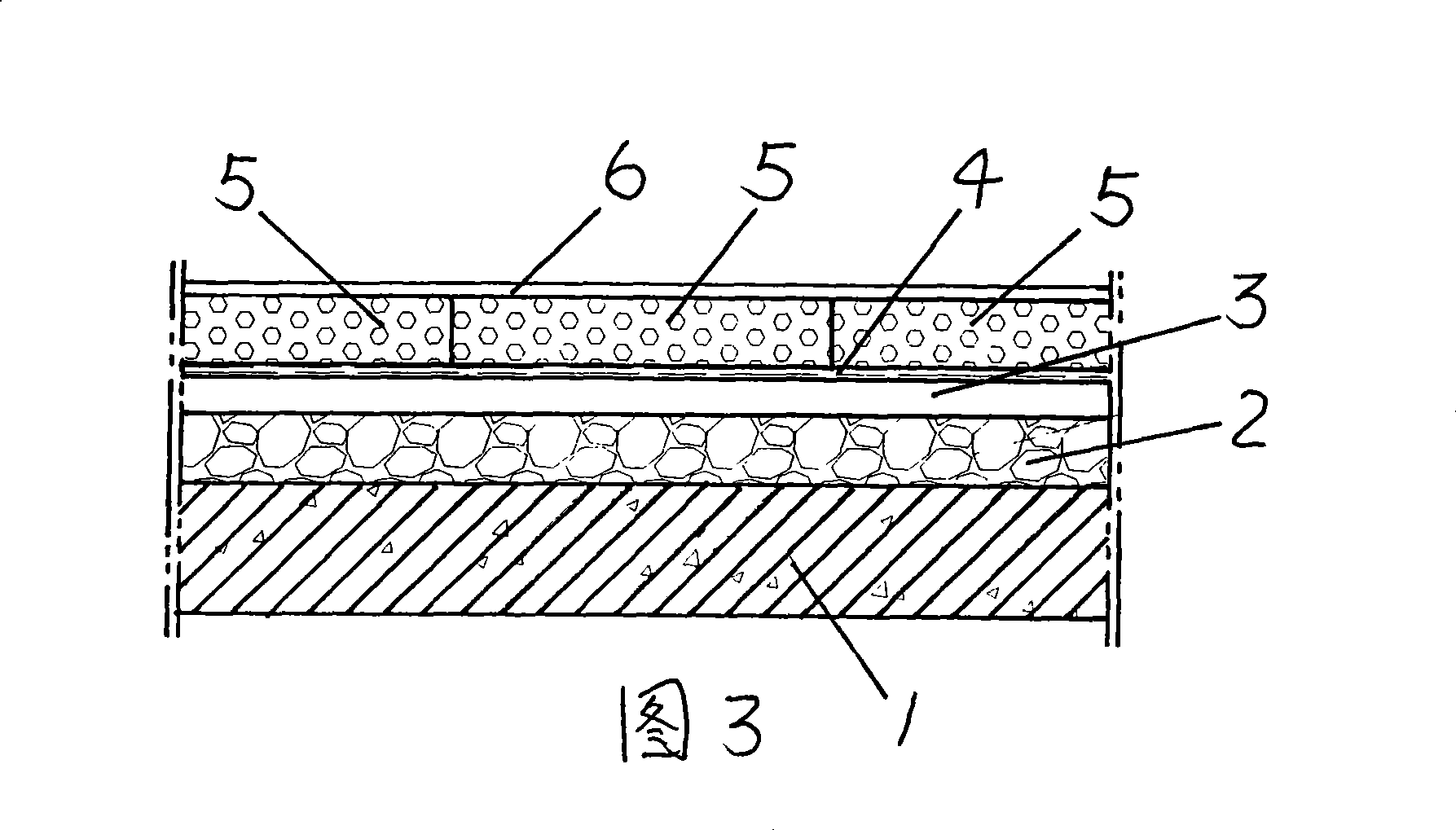

Construction method of thermal insulation buildings roof of foam glass

InactiveCN101363265ASimple daily maintenanceNo shrinkageRoof improvementClimate change adaptationThermal insulationUltraviolet

The invention relates to the technical field of building construction, in particular to construction method which is applicable to sloping roofs, tile roofs, flat roofs, elevated overhead roofs, planted roofs of buildings and basement roof with heat preservation and thermal insulation requirements. The construction method comprises the following steps: a leveling layer is cast on a building roof, the leveling layer is successively provided with a waterproof layer and a thermal insulation panel, a protective layer is cast on the thermal insulation panel which is a foam glass thermal insulation panel. The construction method fully utilizes the characteristics of the foam glass thermal insulation panel namely heat preservation, thermal insulation, incombustibility, water resistance, corrosion prevention, aging resistance, long service life, wide application temperature range, linear expansion coefficient of the panel similar to the concrete materials, etc. By laying the foam glass thermal insulation panel on the waterproof layer of the building roof, the influence of the atmosphere, temperature difference and ultraviolet radiation on the waterproof layer is greatly reduced, thus protecting the waterproof layer from aging, prolonging the service life of the waterproof layer, improving the thermal insulation performance of the building roof, saving the valuable energy sources, changing the waste material into useful material, and reducing the environmental pollution.

Owner:上海永丽节能墙体材料有限公司

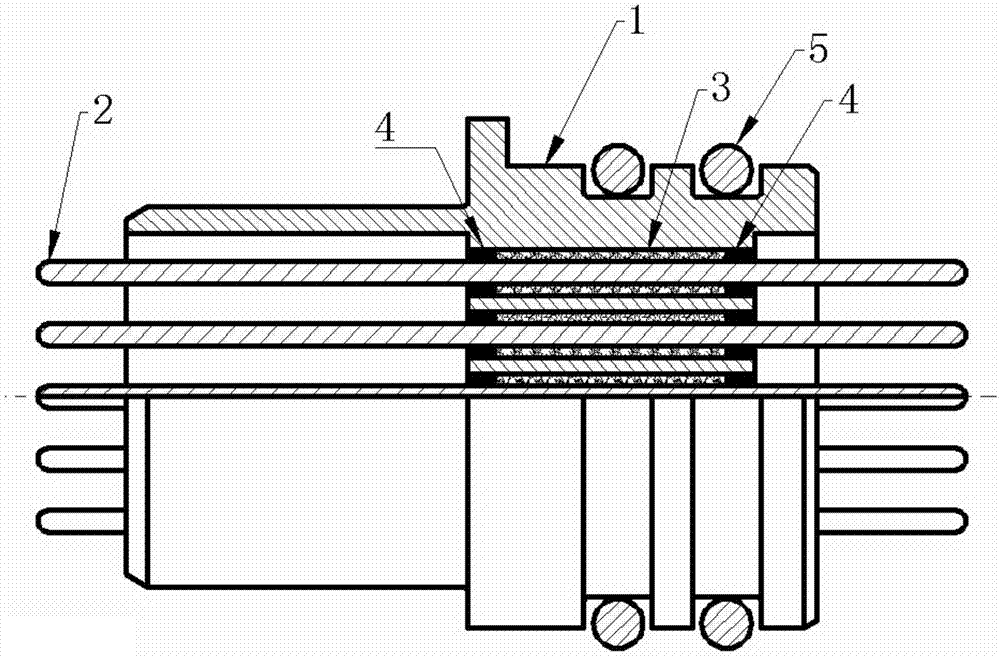

Slender hole glass-sealing multi-pin electrical connector and preparation method of slender hole glass-sealing multi-pin electrical connector

ActiveCN105449420AConsistent sizeGood shape and size consistencyContact member cases/bases manufactureSecuring/insulating coupling contact membersElectrical conductorEngineering

The invention discloses a slender hole glass-sealing multi-pin electrical connector and a preparation method of the slender hole glass-sealing multi-pin electrical connector. The slender hole glass-sealing multi-pin electrical connector comprises a metal housing, wherein a plurality of sealing holes are axially formed in the metal housing; conductor pins are assembled in the sealing holes; glass insulators are clamped between the conductor pins and the sealing hole walls of the metal housing; and epoxy curing layers are sealed at two ends in each sealing hole of the metal housing. The glass insulators are fabricated by a vitreous molten high-pressure tubing technology; sintering is carried out by a mesh-belt high-temperature sintering furnace; fractional potting and curing are carried out in grooves in two ends of the sealing holes of the electrical connector by a high-temperature resistant high-insulation epoxy adhesive, so as to form a compact protection layer; and the glass insulators are prevented from being polluted by external impurities. By the slender glass insulators, glass tubes are consistent in size, smooth in surface and good in boundary dimension; the problems of shrinkage and internal bubbles after a plurality of glass beads are superposed are solved; and two ends are sealed through the epoxy curing layers, so that high air-tightness, high loading capacity and high insulating property are achieved.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

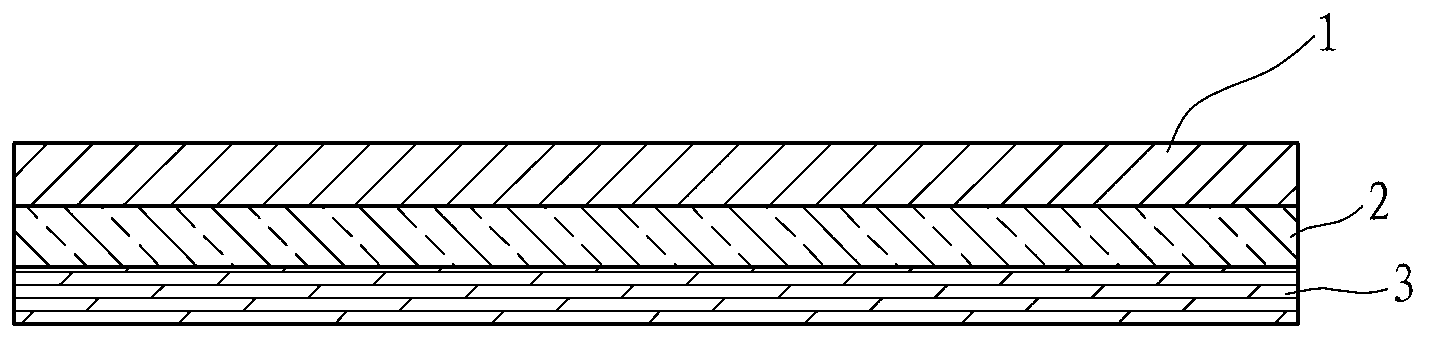

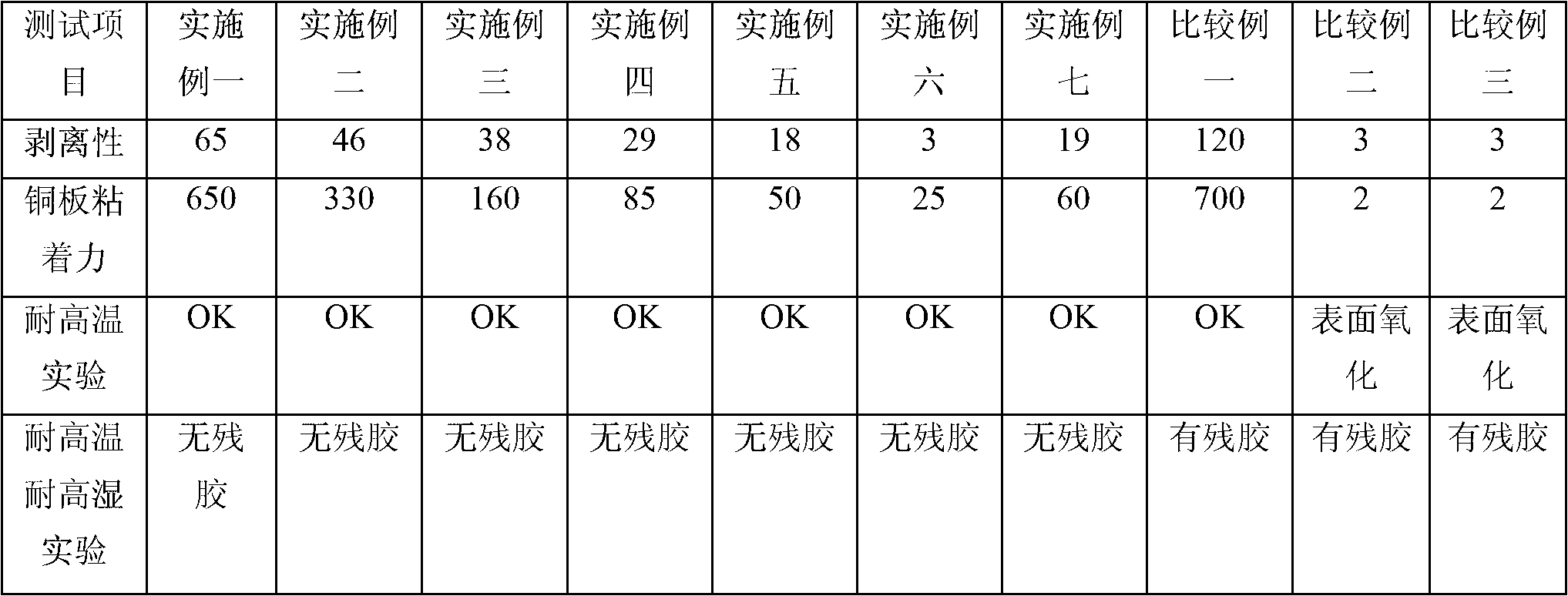

High-temperature resistant protecting film of electronic circuit board

ActiveCN103009734ANo shrinkageNo warpingFilm/foil adhesivesSynthetic resin layered productsHybrid typeTectorial membrane

The invention relates to a high-temperature resistant protecting film of an electronic circuit board. The high-temperature resistant protecting film comprises a base material layer and an adhesive layer coated on the base material layer. The high-temperature resistant protecting film is characterized in that the adhesive layer is composed of the following components in parts by weight: 100 parts of mixed type organic silicon raw rubber, 0.1-5 parts of polydimethylsiloxane and 0.1-5 parts of Pt catalyzer. Compared with the prior art, according to the high-temperature resistant protecting film, the mixed type organic silicon raw rubber is adopted so that the protecting film can be automatically wetted and pasted on the surface of a pasted object, the protecting film can not contract or raise after being pasted for more than 200 hours at the high temperature of 250 DEG C, and the surface of the pasted object does not have oxidation, pollution or residual adhesive.

Owner:NINGBO SOKEN CHEM

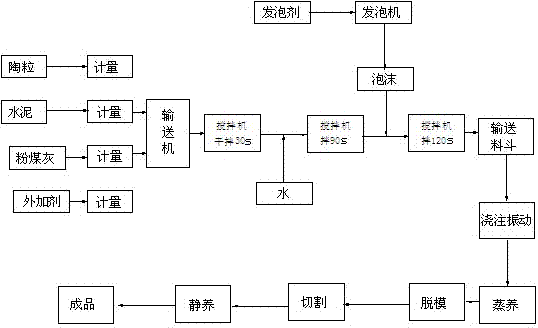

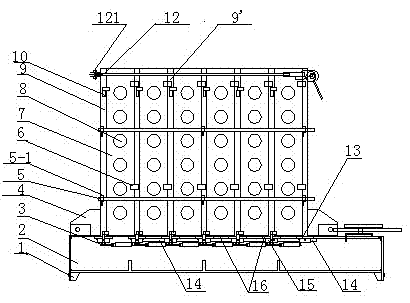

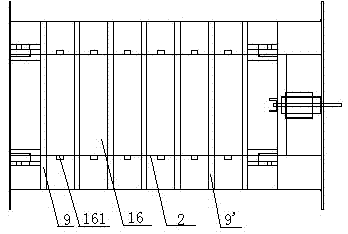

Energy-saving self-heat-insulation ceramsite building block and its manufacturing method and forming mould

ActiveCN102503522ALow water absorptionGood energy saving effectCeramic shaping apparatusCeramicwareCorrosion resistantEarthquake resistant

The invention relates to an energy-saving self-heat-insulation ceramsite building block and its manufacturing method and forming mould. The energy-saving self-heat-insulation ceramsite building block is made of, by weight, 35-50% of ceramsite, 20-29% of cement, 15-30% of coal ash, 0.5-1% of fibers, 2-5% of foaming agent, 0.3-0.5% of water reducing agent, 0.1-0.3% of waterproof agent and 0.2-0.5% of catalyst, wherein the volume of the ceramsite accounts for more than 80% of that of the whole building block. The manufacturing method of the building block includes steps of material selecting, metering, stirring, pouring, vibrating, steaming, tube drawing for demoulding, cutting forming and stacking for rest. The forming mould of the building block can be used for once forming of multiple medium-sized rectangular ceramsite building blocks, and each building block can be conveniently cut into standard small ceramsite building blocks. The energy-saving self-heat-insulation ceramsite building block is high in ceramsite content and has the advantages of light weight, warm retention, heat insulation, sound insulation, sound adsorption, low water adsorption, fire resistance, freezing resistance, quake proofing, corrosion resistance and the like.

Owner:NINGBO PINGHAI BUILDING MATERIALS

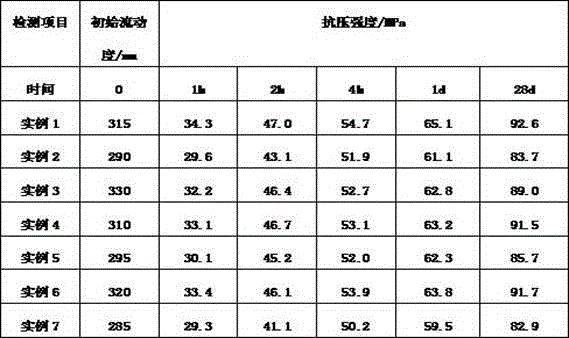

Super early-strength mortar

The invention discloses super early-strength mortar. The key point of the technical scheme is that the super early-strength mortar is prepared from the following components in percentage by weight: 40-50% of an inorganic bond material, 1-3% of an enhancer, 45-55% of aggregates, 0.3-1.5% of an early-strength agent, 0.05-0.4% of a retarder, 0.1-0.5% of a water reducer and 0.03-0.15% of anti-cracking fibers. The invention provides the super early-strength mortar which does not bleed or shrink and is high in liquidity; in addition, the 1h compressive strength can reach 30MPa and the long-term strength is not decreased.

Owner:苏州大乘环保新材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com