Energy-saving self-heat-insulation ceramsite building block and its manufacturing method and forming mould

A production method and block technology, applied in the direction of ceramic molding machines, manufacturing tools, ceramic products, etc., can solve the problems of large cutting tools and cutting machine equipment, fine dust environmental pollution, serious problems, etc., to achieve easy and fast mass cutting, Cost reduction, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] An energy-saving self-insulating ceramsite block, its components mainly include ceramsite, cement, fly ash, water, fiber, and foaming agent; the weight ratios of the components are: ceramsite 45.7%, cement 28.6% , fly ash 15.7%, water 4%, fiber 0.92%, foaming agent 4%; and the volume of the ceramsite component ≥ 80% of the volume of the entire block.

[0064] The composition also includes a water reducing agent, a waterproofing agent and a catalyst, and their weight ratios are respectively: 0.43%, 0.2% and 0.43%.

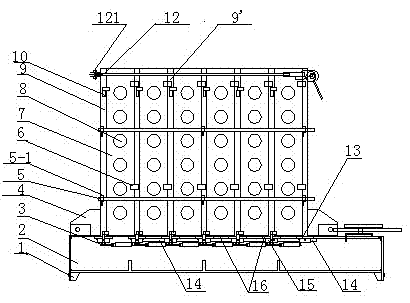

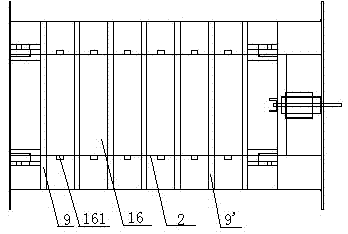

[0065] The left and right sides of the energy-saving self-insulating ceramsite block are provided with a core hole 8 that communicates with both sides.

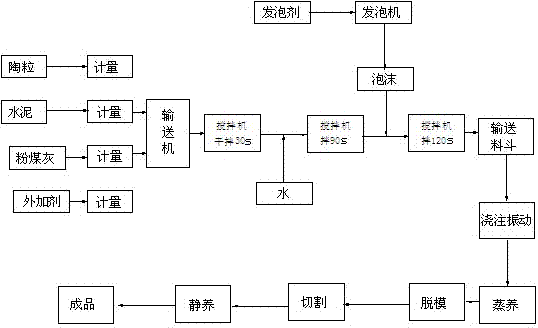

[0066] The production method that adopts is: it comprises the following steps:

[0067] 1) Material selection and measurement:

[0068] According to the requirement that the bulk density of the block product is 700kg / m3, first weigh 320 kg of ceramsite of grade 400 (ceramsite bulk density 400kg / m3), so tha...

Embodiment 2

[0092] The energy-saving self-insulating ceramsite block of Example 2 and its production method and forming mold are basically the same as those of Example 1, the difference is the material ratio of the self-insulating ceramsite block and the selection of materials in step 1) of the production method, In the measurement, the measurement of raw materials is changed according to the ratio of materials.

[0093] Embodiment 2 is 700kg / m by the bulk density of building block product Requirement, at first weigh 255 kg of ceramsite of 300 grades (ceramsite bulk density 300kg / m ), make the volume of ceramsite account for 85% of block volume;

[0094] The ratio of each component is: ceramsite 36.4%, cement 25%, fly ash 28%, fiber 0.5%, water 5%, foaming agent 4%, water reducing agent 0.3%, catalyst 0.2%, waterproofing agent 0.1 %.

[0095] Then according to the weight ratio, cement: 175 kg, accounting for 25%; fly ash: 196 kg, accounting for 28%; fiber: 3.5 kg, accounting for 0.5%; wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com