Patents

Literature

335 results about "Tube drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. This process produces high-quality tubing with precise dimensions, good surface finish, and the added strength of cold working. For this reason this process is established for many materials, mainly metalworking but also glass. Because it is so versatile, tube drawing is suitable for both large- and small-scale production. The large-scale production of glass typically uses a one step process where glass is directly drawn into a tube from a melting tank.

Method for producing quartz casing tube for optical fiber prefabricated stick

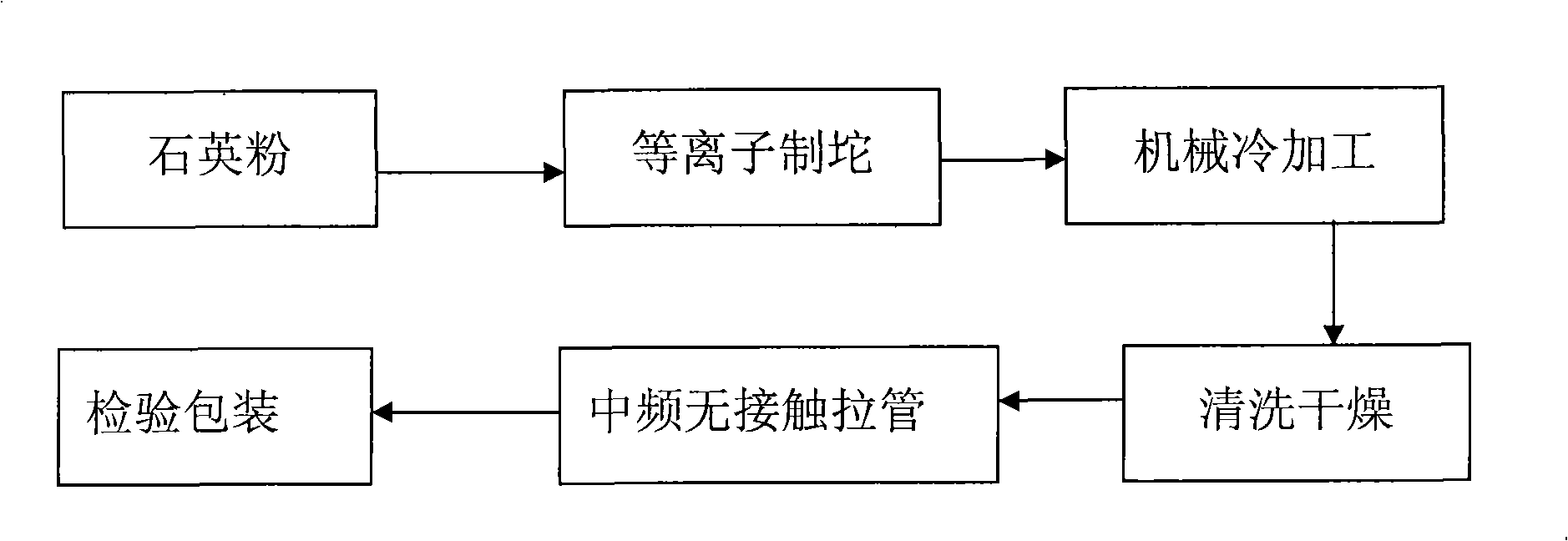

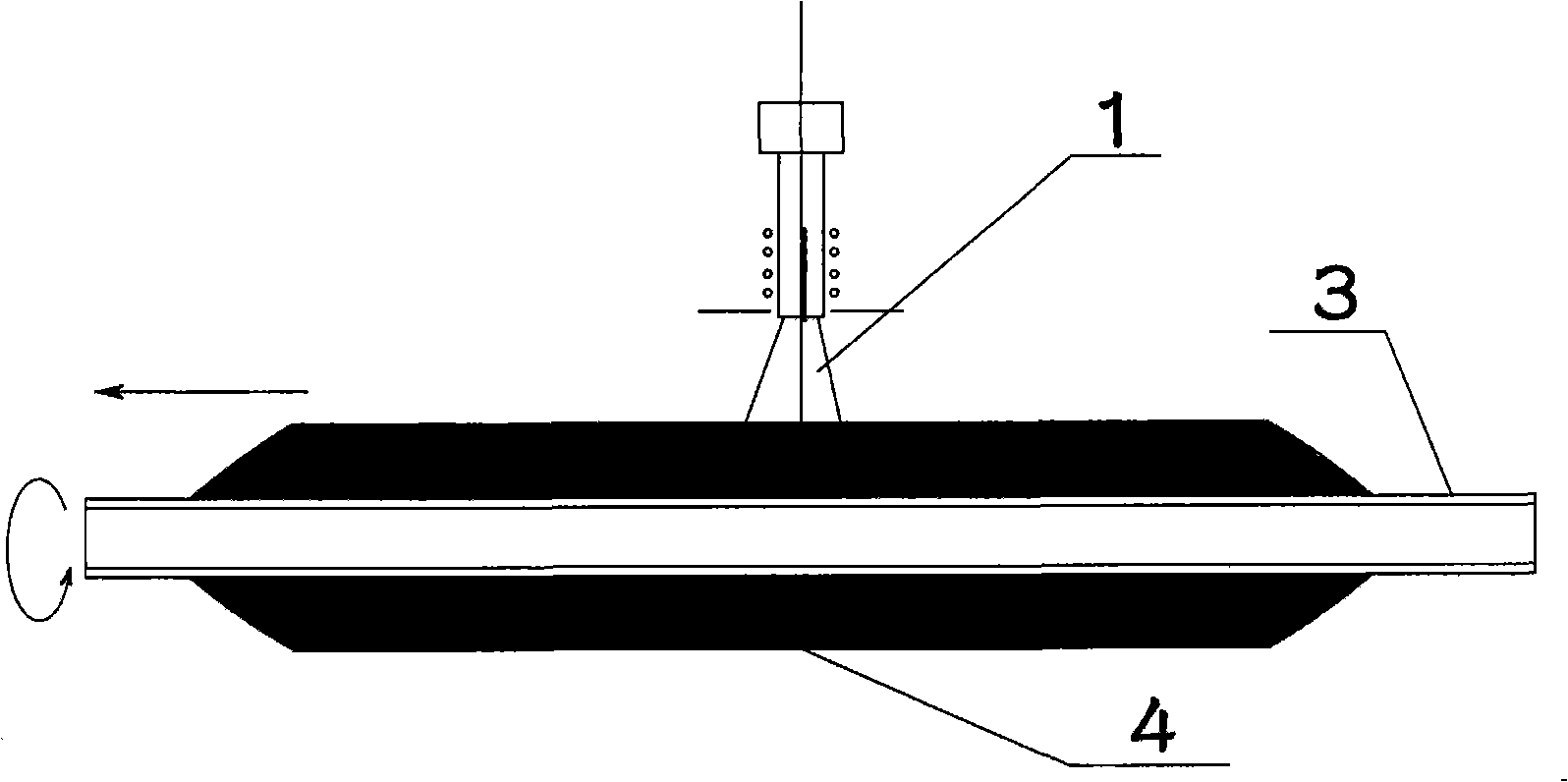

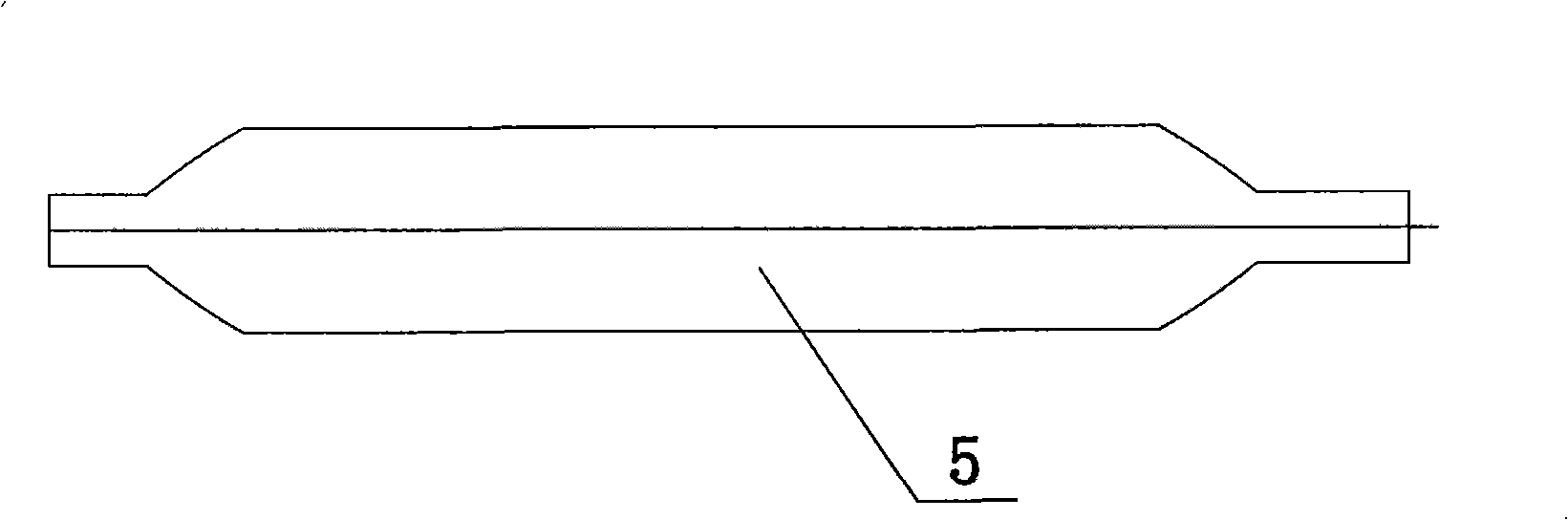

The invention discloses a method for producing a quartz sleeve for a fiber precast rod. The method comprises the following steps of: 1 weight manufacturing; 2 mechanical cold machining; 3 cleaning and drying; 4 tube drawing in a medium-frequency contactless mode; and 5 checkup and packaging, wherein, in step one, a weight is manufactured by adopting an external sedimentation mode of plasma horizontal type solid phase; in step two, an inner hole and an outer circle of the quartz weight are subject to the machining of grinding and honing by adopting a metal cutting machine tool matched with diamond and other grinding tools; in step three, the quartz weight is subject to degreasing, acidification, washing by pure water, drying and packaging for standby; in step four, the net quartz weight is hung in a medium-frequency furnace, heated up to a certain temperature, softened and deformed and drawn into the needed quartz sleeve by a tube drawing machine; and in step five, the quartz sleeve is checked and packaged. The method adopts plasma flame for heating and fully melts down raw materials in order that no bubble is in the gross quartz weight and can not introduce external impurities in order that melted quartz powder has high purity; the melted quartz powder has a characteristic of low hydroxyl group; secondary molding adopts medium frequency for heating and has no hydrogen and oxygen sources; and the final quartz sleeve has low hydroxyl content and good temperature resistance.

Owner:久智光电子材料科技有限公司

Method for producing low-hydroxy-group squartz glass tube

InactiveCN1850679ASimple processEasy to operateGlass drawing apparatusGlass forming apparatusImpurityHydroxylation

The invention is a method for producing a low-hydroxyl quartz glass tube, characterized in that it selects 60-220 mesh high-purity quartz powder containing SiO2 >=99.90%, and impurities less than 30ppm, and dopes colorizing agent in 0.1-1.0% of the weight of the high-purity quartz powder, where the colorizing agent selects at least one of the divanadium triphosphate and cobalt oxide, mixed uniformly and dried; it adds the processed raw materials into a continuous melting quartz furnace and melts them, opens the gas outlet at the furnace mouth and discharges gas impurities, feeding the melted raw materials into a drawer for making tube drawing forming and draws them into blue quartz glass tubes; feeds the blue quartz glass tubes into a de-hydroxylation furnace for de-hydroxylation and obtaining the finished products. The hydroxyl content of the blue quartz glass tubes is generally lower than 1ppm and the products have good quality, and can be applied to special industries; and the process of the invention can implement continuous quartz glass tube production, having high productivity.

Owner:单军成

Construction method for piles

InactiveCN102226341AReduce the impactLow construction noiseBulkheads/pilesEnvironment effectTube drawing

The invention discloses a construction method for piles. The method comprises the steps of positioning, pipeline sinking, rammed forming, casting molding, tube drawing forming, and the like. The method disclosed by the invention is small in construction noise, has little effect on environment, good environmental conservation capability, reliable construction quality and good pile quality; and by using the method, a multilevel expansion head can be formed.

Owner:朱建新

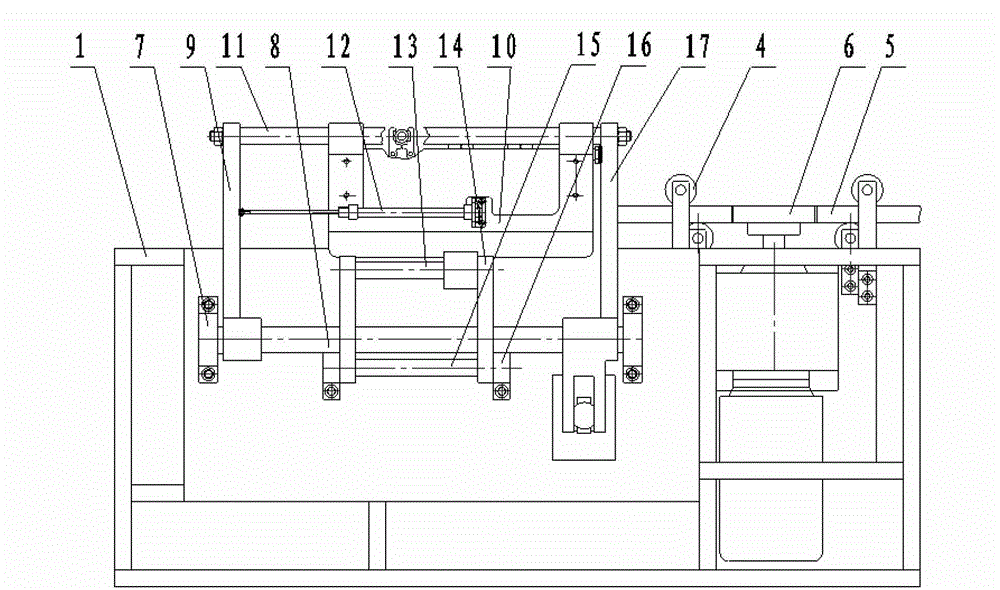

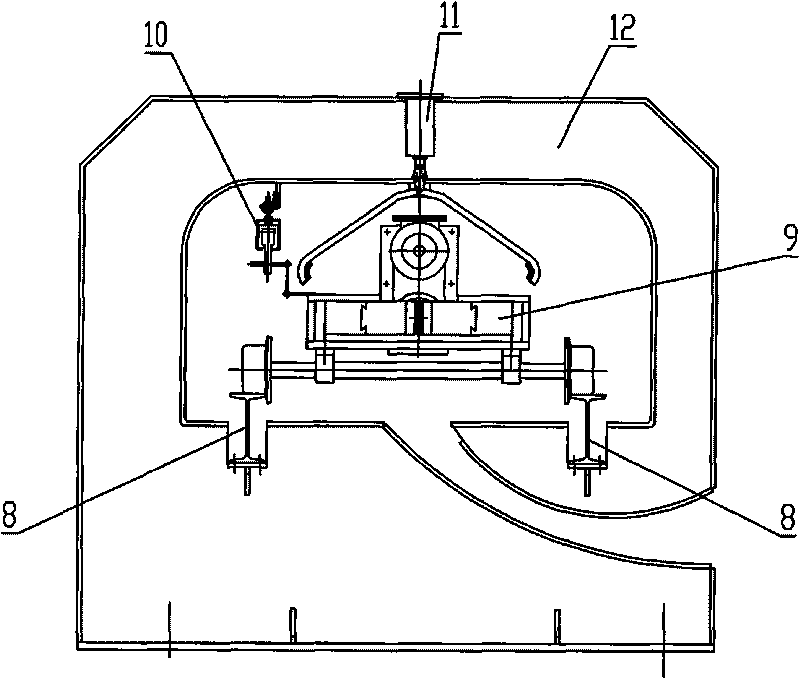

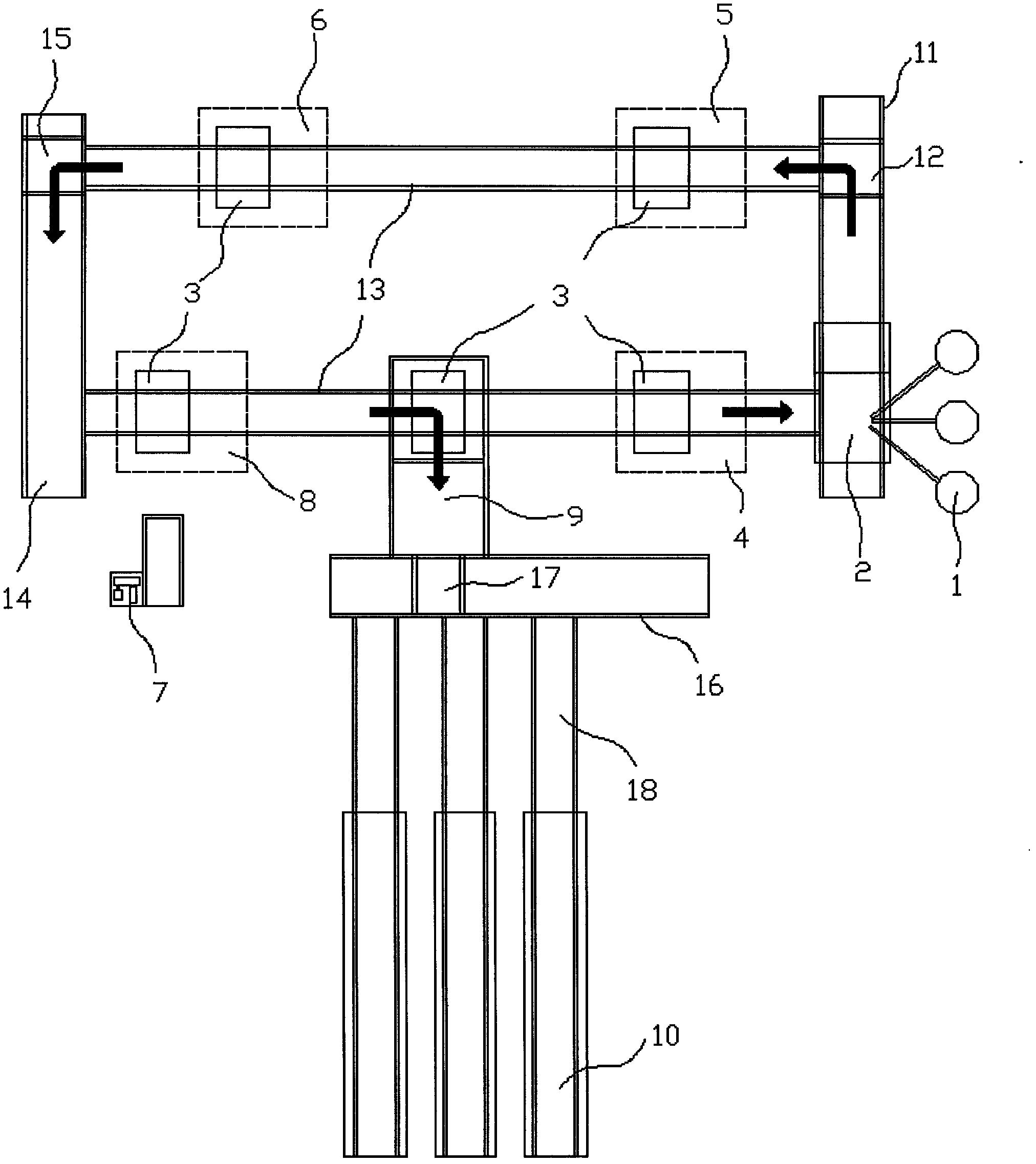

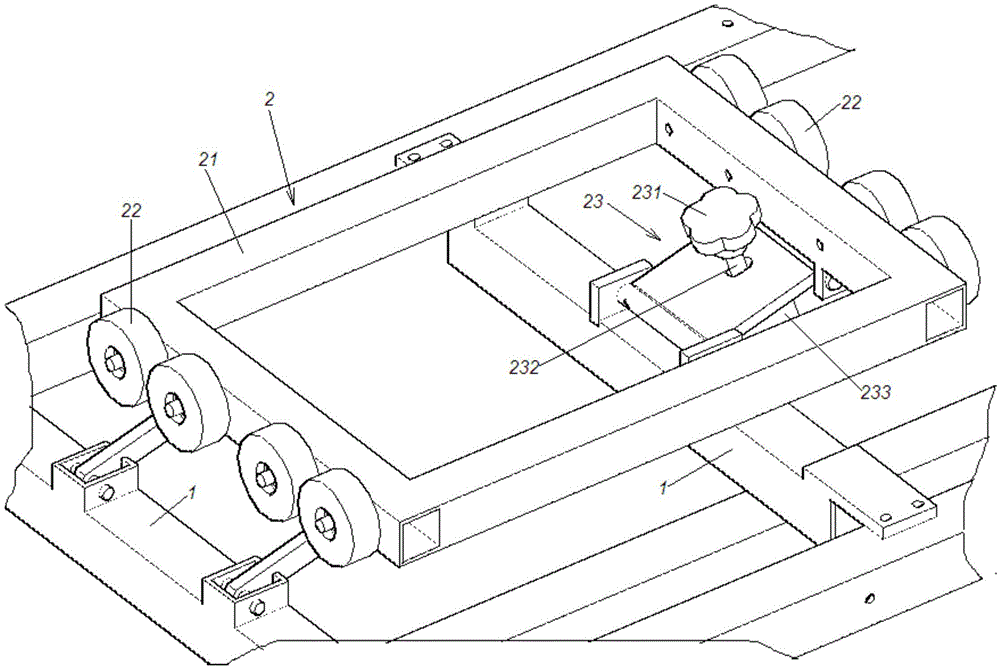

Automatic tube drawing device of doffer

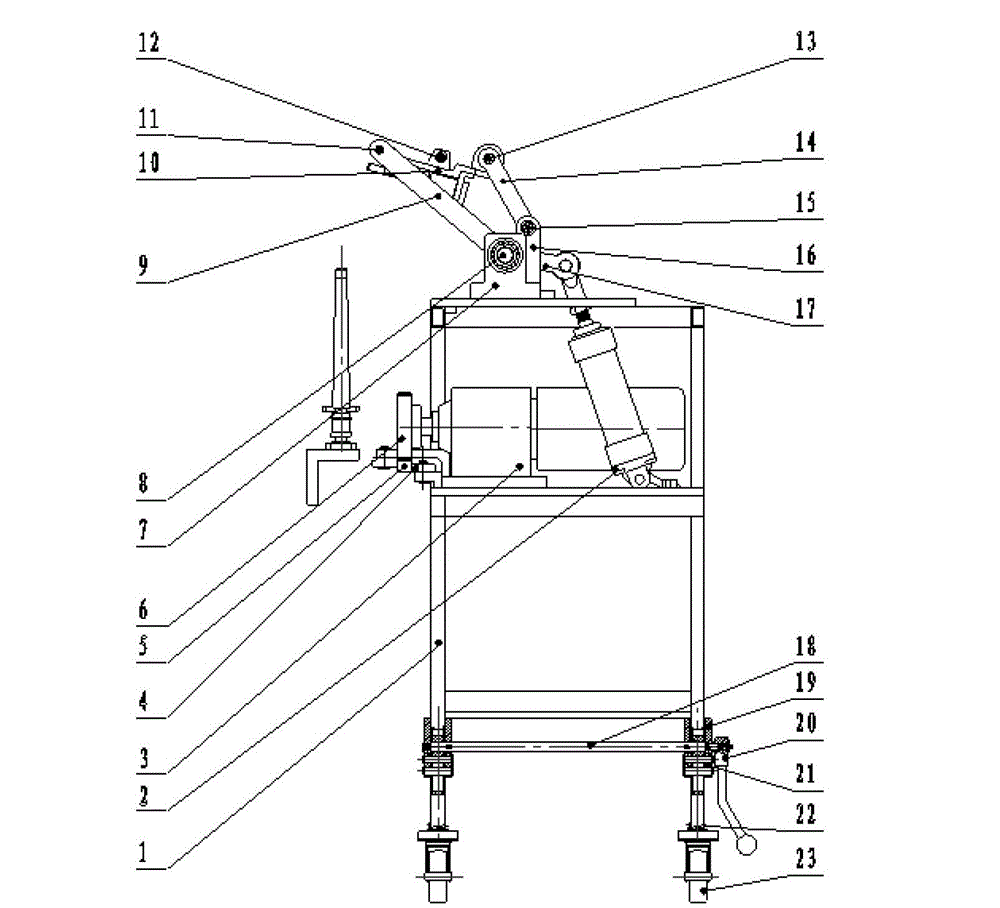

The invention belongs to the technical field of textile equipment, and relates to an automatic tube drawing device of a doffer. A main air cylinder component and a reducing motor are connected onto a doffer frame respectively; a bracket for mounting a guiding wheel is fixed on the doffer frame; a gear is meshed with racks fixed on the doffer; a driving shaft is mounted in a bearing pedestal of a driving rocker arm and is supported through a rolling bearing; a front driving rocker arm and a rear driving rocker arm are in key joint with and fixedly mounted onto the driving shaft respectively; a driving rocker arm guiding shaft is fixedly mounted in holes corresponding to the front driving rocker arm and the rear driving rocker arm; a driven rocker arm is supported through a sliding bearing mounted in a driven rocker arm bracket and is mounted on a pin shaft for a driven rocker arm in an interference fit manner; a driven rocker arm guiding shaft is mounted in a hole corresponding to the driven rocker arm; and a connecting rod is mounted on the driving rocker arm guiding shaft and the driven rocker arm guiding shaft, and performs reciprocating motion along the two guiding shafts. The automatic tube drawing device has reliable principle, simple structure, high tube drawing effective rate and friendly production environment, is safe in operation and running, and saves human resources.

Owner:QINGDAO UNIV

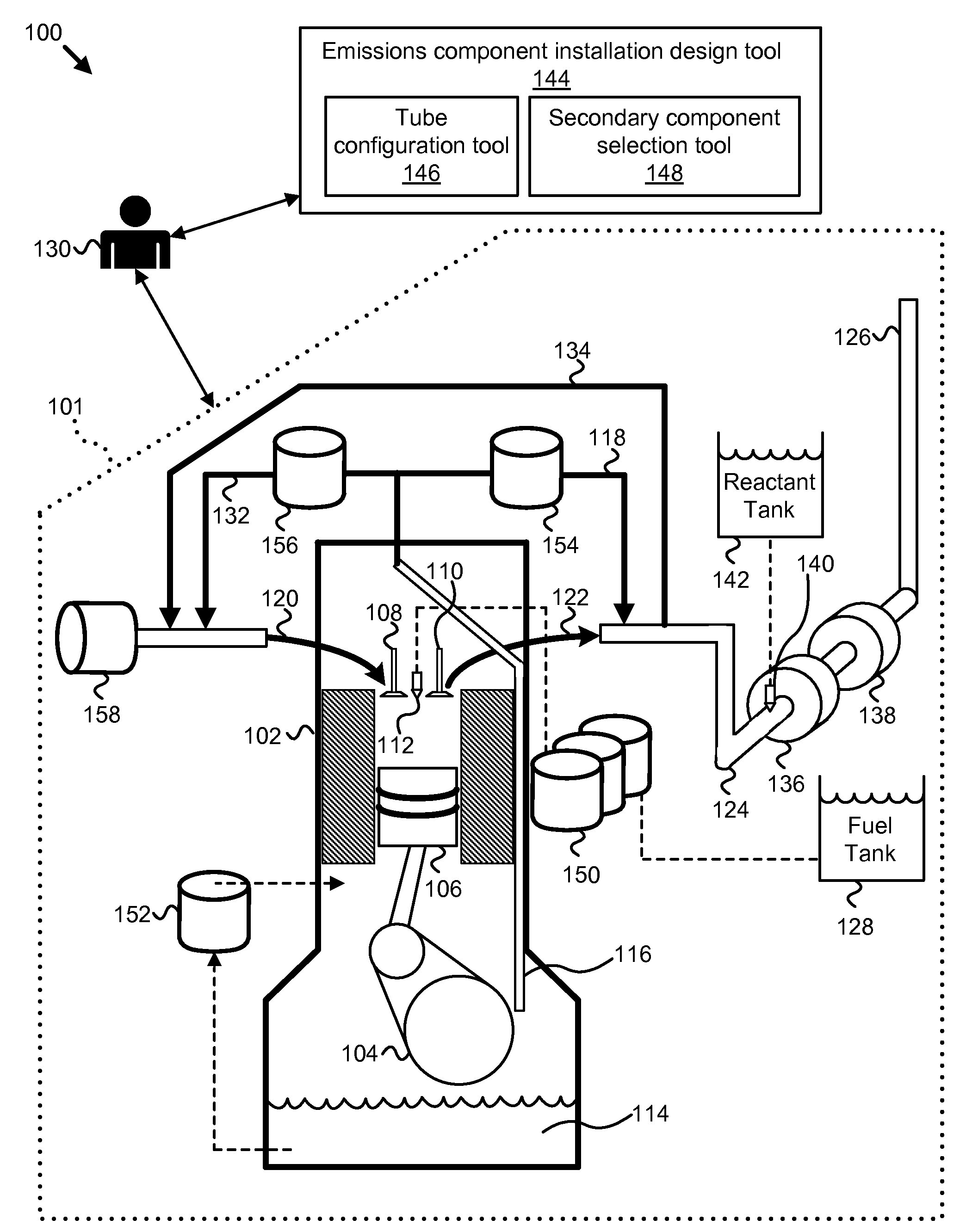

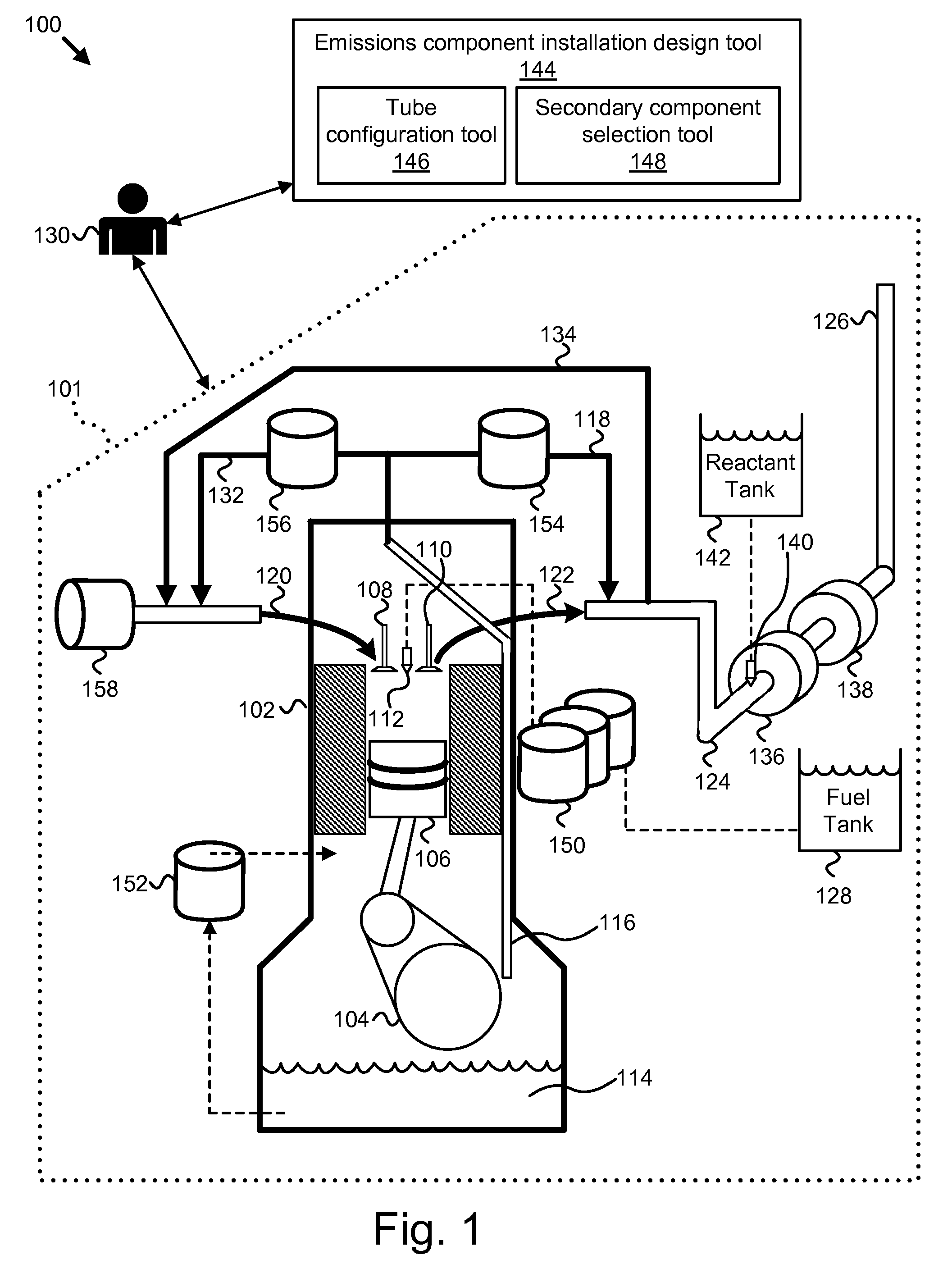

Apparatus, system, and method for rapid design of emissions component installations

ActiveUS20080156569A1Simple designExhaust apparatusShaping safety devicesCost effectivenessTube drawing

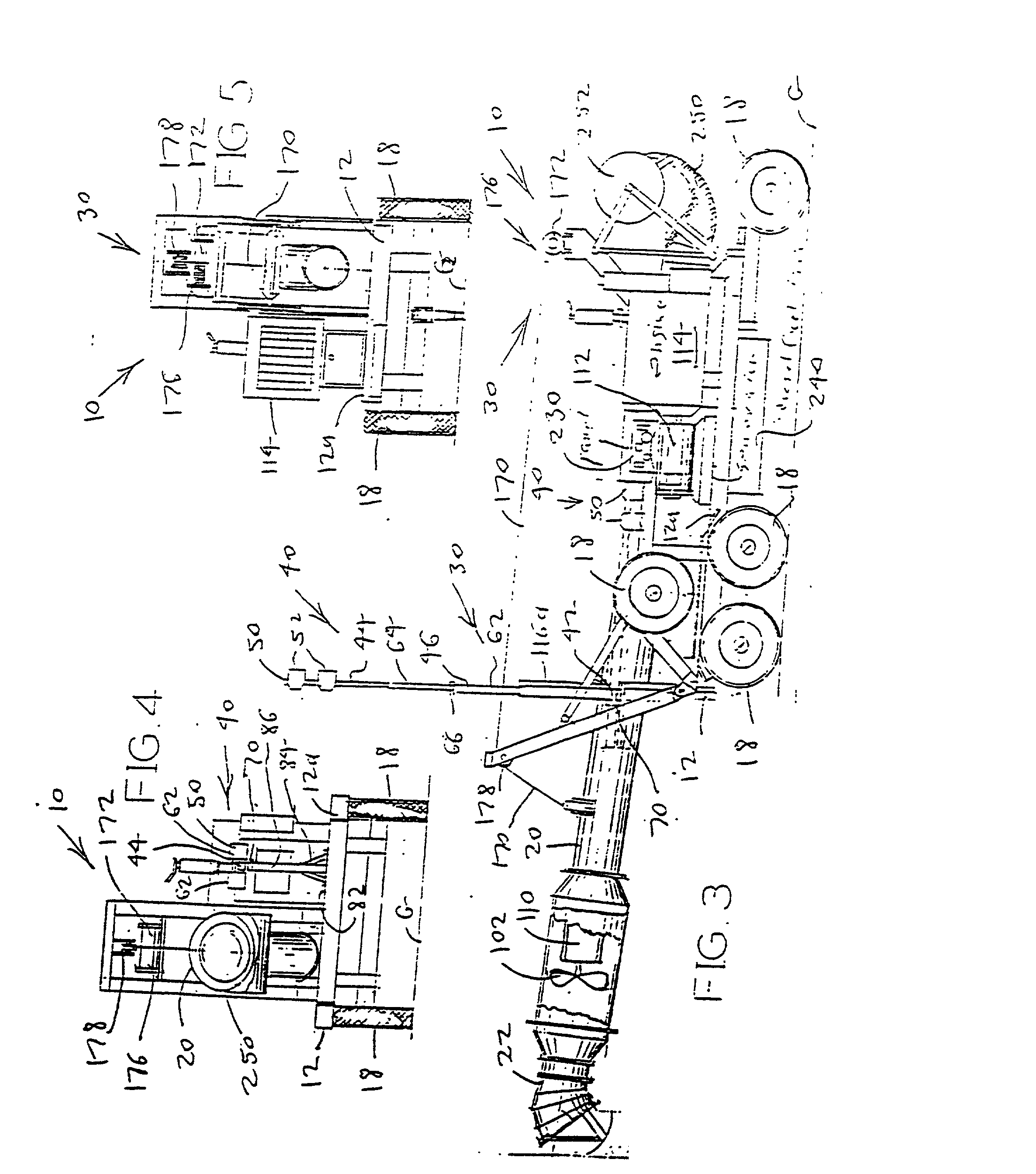

An apparatus, system, and method are disclosed for rapid design of emissions component installations. The method assists in the rapid design of emissions component installations by: interpreting a tube design input which may be an exhaust pipe with one or more aftertreatment components, calculating a final tube design and tube drawing, determining the manufacturability of the final tube design, determining the manufacturing cost of the final tube design, and displaying the drawing, manufacturability result, and manufacturing cost to a user. The method also evaluates the final tube design for portions that can be replaced with a more cost effective alternative. The method also receives the emissions reduction features of the installation from the user, and recommends secondary components to mitigate operational consequences, such as reduced fuel economy or reduced oil change intervals, of the emissions reduction features. Thus, the invention allows a user to quickly design an installation of an emissions component with an internal combustion engine into a target application.

Owner:CUMMINS FILTRATION IP INC

Manufacturing technology of transmission shaft tube

ActiveCN103591118AUniform wall thicknessImprove surface qualityShaftsManufacturing technologyTube drawing

The invention relates to a manufacturing technology of a transmission shaft tube, which is characterized by comprising the following technical steps: (1) shearing a steel rolled plate into band steel, (2) allowing the band steel to pass through a pickling tank, a cold water tank and a hot water tank sequentially and continuously, applying rust preventing oil after drying, and rolling up, (3) cold-rolling the pickled band steel with a rolling mill, and allowing the thickness of the cold-rolled band steel to be the required product thickness minus 0.05-0.10mm, (4) rolling the band steel on a welding machine, welding into a straight welding steel tube with the welding power of 70-190KW and the welding speed of 10-18m / min, (5) dogging one end of the straight welding steel tube in a dogging machine to allow the diameter of the end of the steel tube to reach the required dimension, sequentially immersing the dogged steel tube in a phosphorization pool and a saponification pool, and (6) performing secondary cold drawing on the steel tube on a chain work tube drawing bench with a short mandril to achieve the required dimension. The transmission shaft tube obtained by the technology is more uniform in wall thickness, better in surface quality and higher in product strength.

Owner:无锡苏嘉法斯特汽车零配件有限公司

Composite pile and construction method thereof

The invention discloses a composite pile and a construction method thereof. The composite pile comprises a first pile as a peripheral pile, and a second pile as a core pile, wherein the first pile is a cast-in-situ pile; a second pile is a cast-in-situ pile or a precast pile; a centre distance d between the first pile and the second pile is equal to 0; area ratio S of the second pile to the first pile is S2 / S1; length ratio L of the second pile to the first pile is L2 / L1, wherein S belongs to (0, 1), and L is more than 0.5. According to the invention, construction is convenient and reasonable; proper construction devices and construction processes are selected according to stratum conditions, site conditions, ambient environment and work amount; tube sinking and tube drawing systems can be a set of device, and also can be different independent devices; a pile is constructed integrally by a device, and also is constructed by a plurality of devices; and a plurality of devices operate in a flow line.

Owner:江苏劲桩岩土科技有限公司

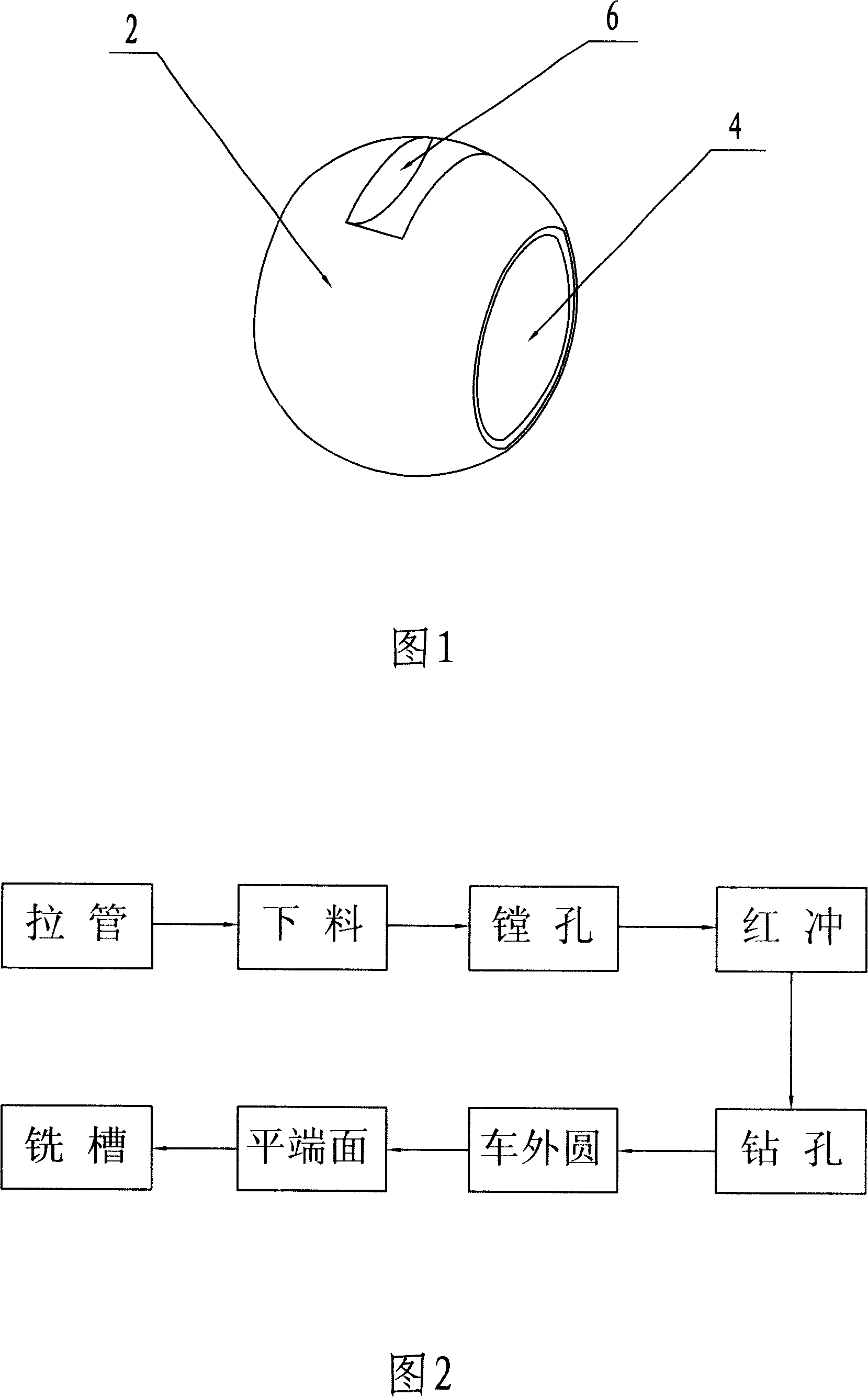

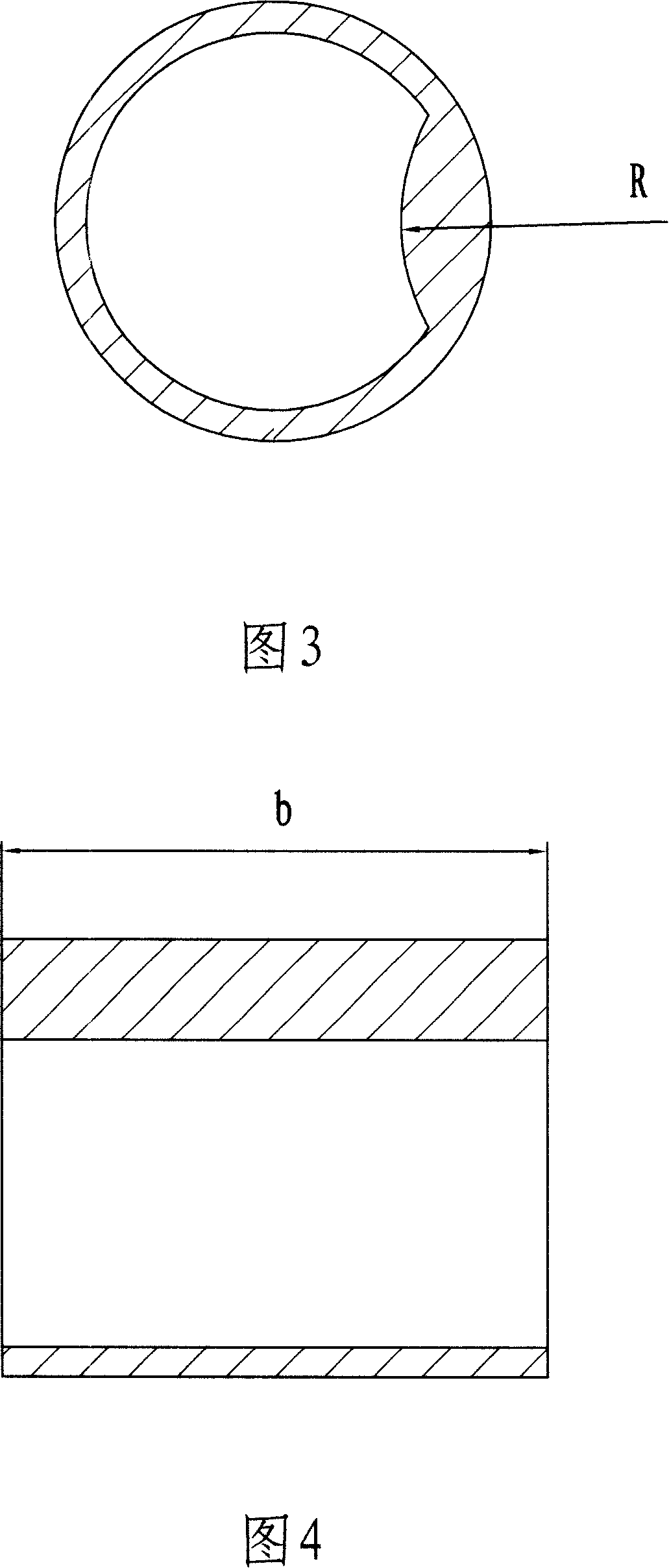

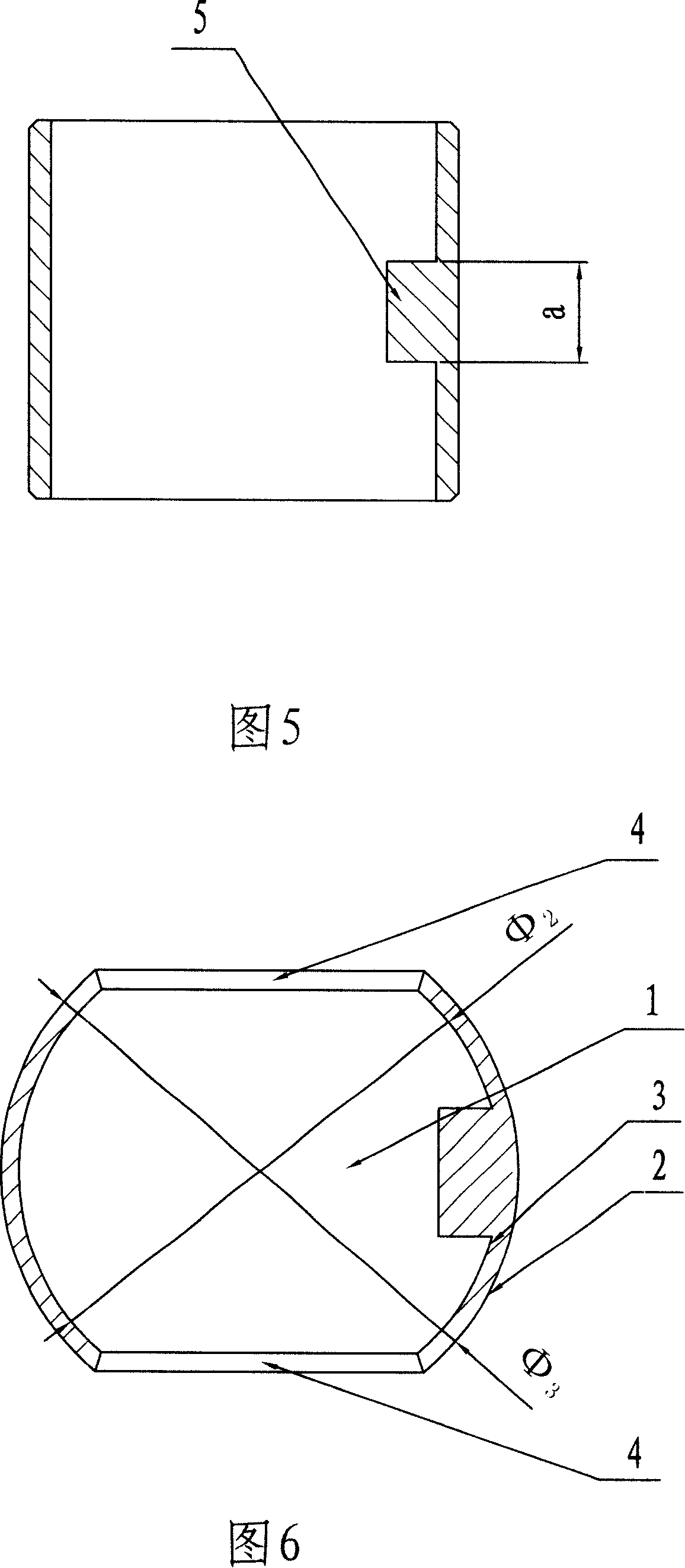

Ball valve core and fabrication technology thereof

The invention relates to a valve core of a spherical valve and a manufacturing technique thereof. The valve core of the spherical valve is manufactured through such processes as tube drawing, blanking, borizing, red punching, drilling, external cutting, end surface leveling, and slot milling; the valve core comprises a sphere body, an inner hole arranged in the center position of the sphere body and passing through the whole sphere body which is a ball shape and forms two side holes on the surface of the sphere body, and a slot arranged on the surface of the spherical surface. The center position of the inner sphere surface is provided with a circular surfaced boss, the slot is positioned at the center position of outer sphere surface corresponding to the boss. Since the sphere wall thickness is uniformity after being manufactured, the material is saved and the production cost is cut down.

Owner:金济定

Method of producing large diameter transparent quartz glass tube for semiconductor technology by continuous melting method

InactiveCN101054260AIncrease pressureImprove melting conditionsPot furnacesGlass furnace apparatusFused quartzMelting furnace

A continuous method of manufacturing large aperture transparent quartz glass tube for semiconductor technology, which is characterized in that high pure quartz sand of quartz glass material is added in a continuous melting furnace, through electric heating and fusing, fused quartz glass liquid is drew as large aperture transparent quartz glass tubes through a former, a material stage and a tube drawing machine; the high pure quartz sand added in the continuous melting furnace, before heating and fusing, preheating the high pure quartz sand 200-280 minutes to 750-850 DEG C, then heating and fusing; the upper part of the continuous melting furnace tungsten-molybdenum crucible is a preheating section, the lower part is a fusing section, the preheating treatment is processed in the preheating section; the diameter of the tungsten-molybdenum crucible is 340-360 mm, height is 1400-1600 mm; the fusing temperature in the continuous melting furnace is 2150-2250 DEG C; the diameter of the former is 244-264 mm; the current passing through the continuous melting furnace for electric heating molybdenum electrode is 215-225 A, the voltage is 19-20 V. The obtained quartz tube has wide gauge, good quality, can be fully suitable for semiconductor technical requirement.

Owner:徐胜利

Method for producing low-hydroxyl-group quartz glass tube

InactiveCN1850680ASimple processEasy to operateGlass drawing apparatusGlass forming apparatusCopper nitrateImpurity

The invention is a method for producing a low-hydroxyl quartz glass tube, characterized in that it selects 60-220 mesh high-purity quartz powder containing SiO2 >=99.90%, and impurities less than 30ppm, and dopes colorizing agent in 0.1-1.0% of the weight of the high-purity quartz powder, where the colorizing agent selects at least one of the copper nitrate, magnesia and cerium oxide, mixed uniformly and dried; it adds the processed raw materials into a continuous melting quartz furnace and melts them, opens the gas outlet at the furnace mouth and discharges gas impurities, feeding the melted raw materials into a drawer for making tube drawing forming and draws them into wine quartz glass tubes; feeds the wine quartz glass tubes into a de-hydroxylation furnace for de- hydroxylation and obtaining the finished products-red quartz glass tubes. The hydroxyl content of the red quartz glass tubes is generally lower than 1ppm and the products have good quality, and can be applied to special industries; and the process of the invention can implement continuous quartz glass tube production, having high productivity.

Owner:单军成

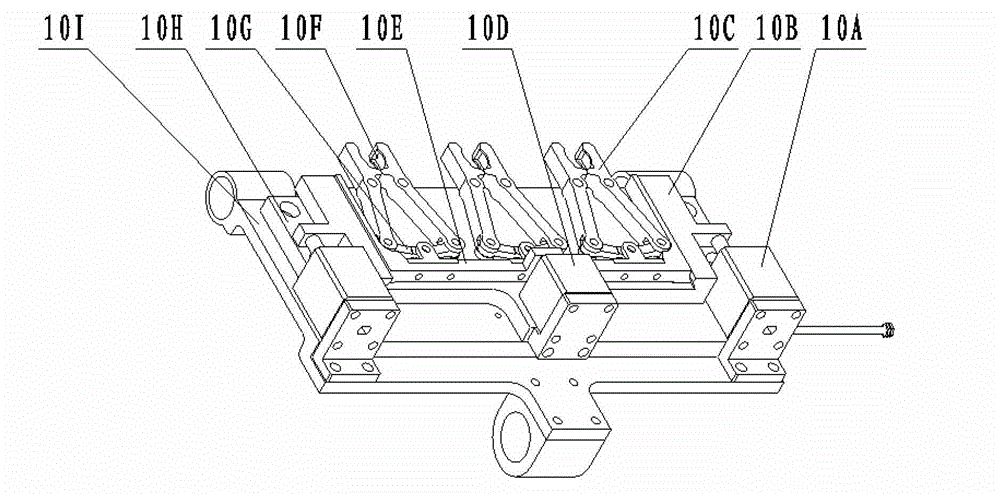

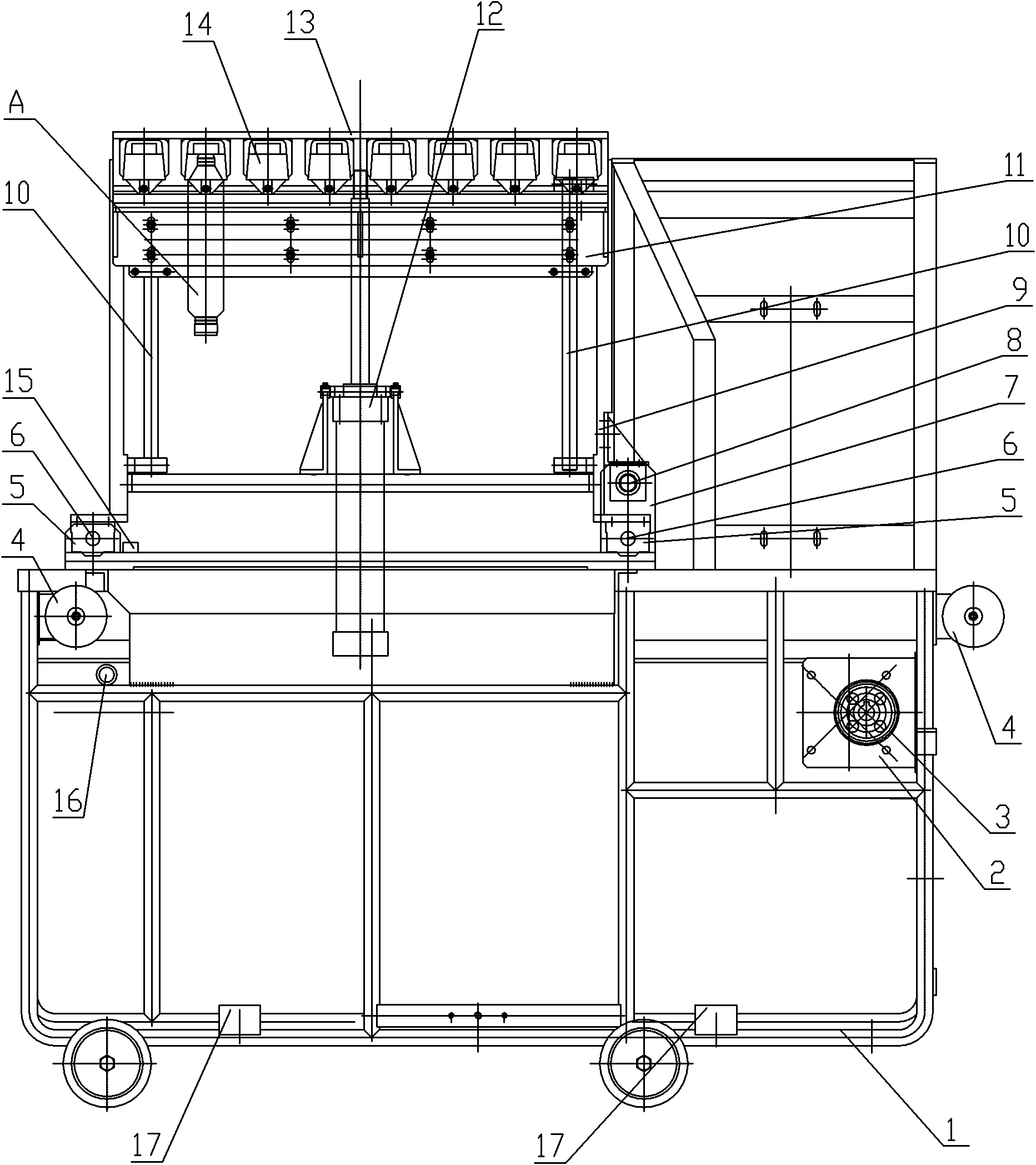

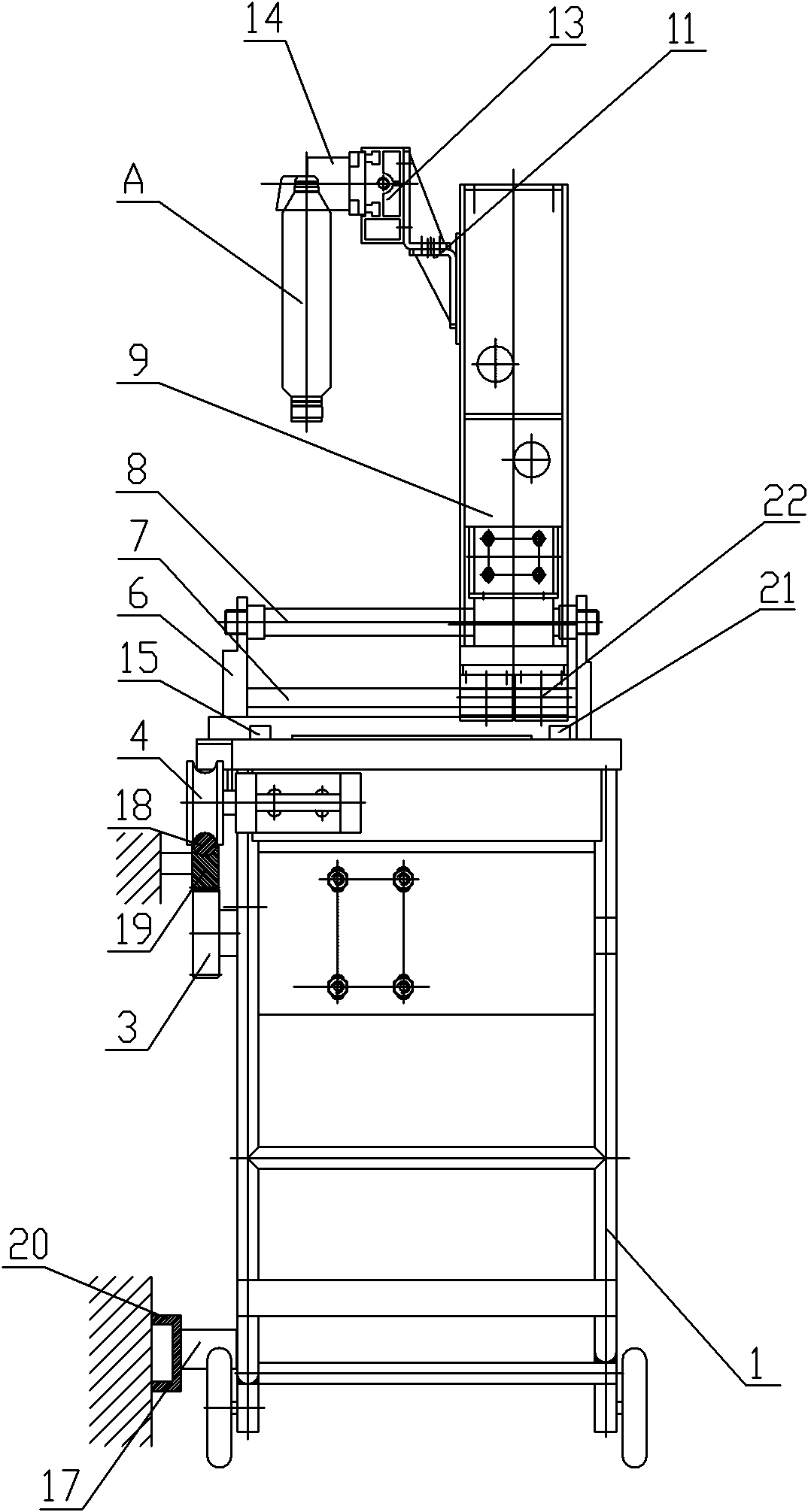

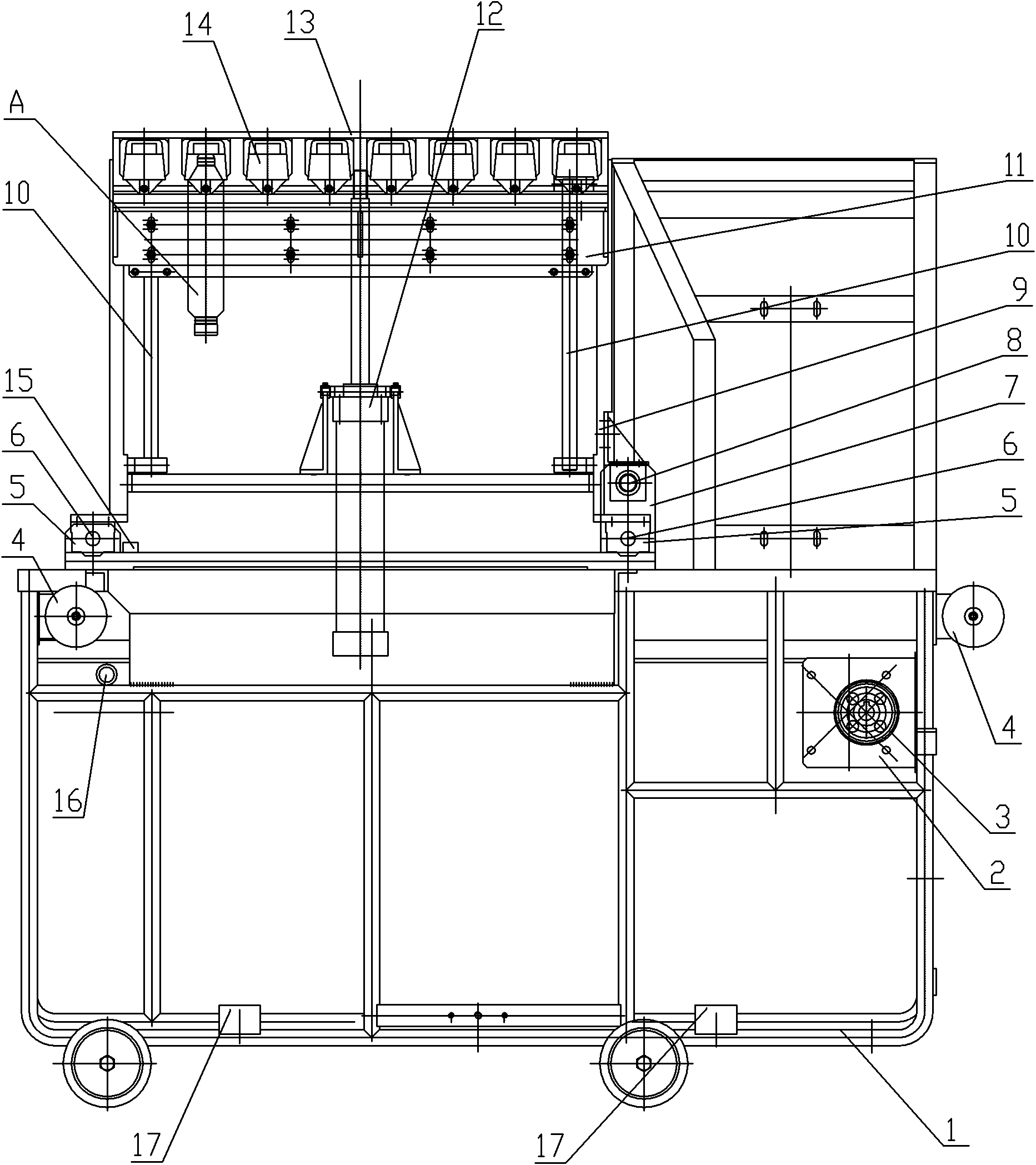

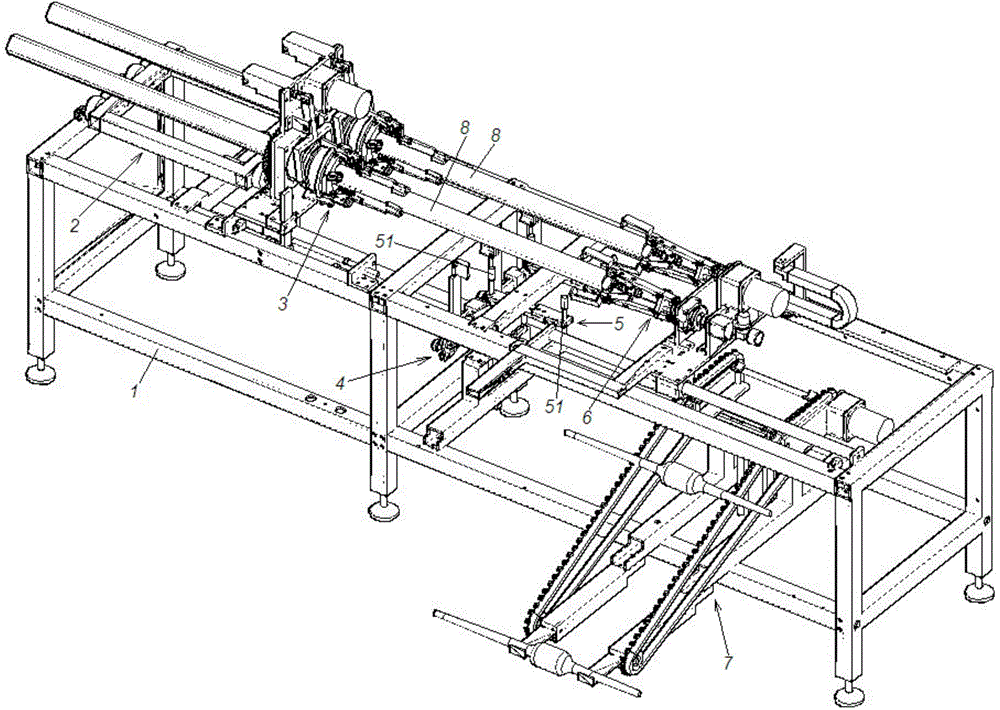

Intermittent automatic tube drawing device

The invention relates to an intermittent automatic tube drawing device which comprises a doffing trolley. The doffing trolley is arranged on a guide rail assembly and can travel, and the traveling route of the doffing trolley is parallel to the central line of a spindle of a spinning frame. The intermittent automatic tube drawing device is characterized in that the doffing trolley is provided with a traveling driving mechanism, a tube drawing mechanical arm and a control system, wherein the traveling driving mechanism is used for driving the doffing trolley to travel intermittently, the tube drawing mechanical arm is used for drawing yarn-loaded tubes on the spinning frame and collecting the yarn-loaded tubes, the control system is used for controlling the traveling driving mechanism and the tube drawing mechanical arm to act crossly, the tube drawing mechanical arm stops drawing tubes when the traveling driving mechanism drives the doffing trolley to travel, and the tube drawing mechanical arm starts to draw tubes when the traveling driving mechanism drives the doffing trolley to stop. The intermittent automatic tube drawing device has a smart structure and high automation degree, can realize automatic doffing so as to reduce labor intensity of workers, save the labor time, and improve the doffing efficiency, yarn collecting efficiency and empty tube changing efficiency, and has high action accuracy, lower production cost and low fault rate.

Owner:WUXI JIJU TEXTILE TOOLS

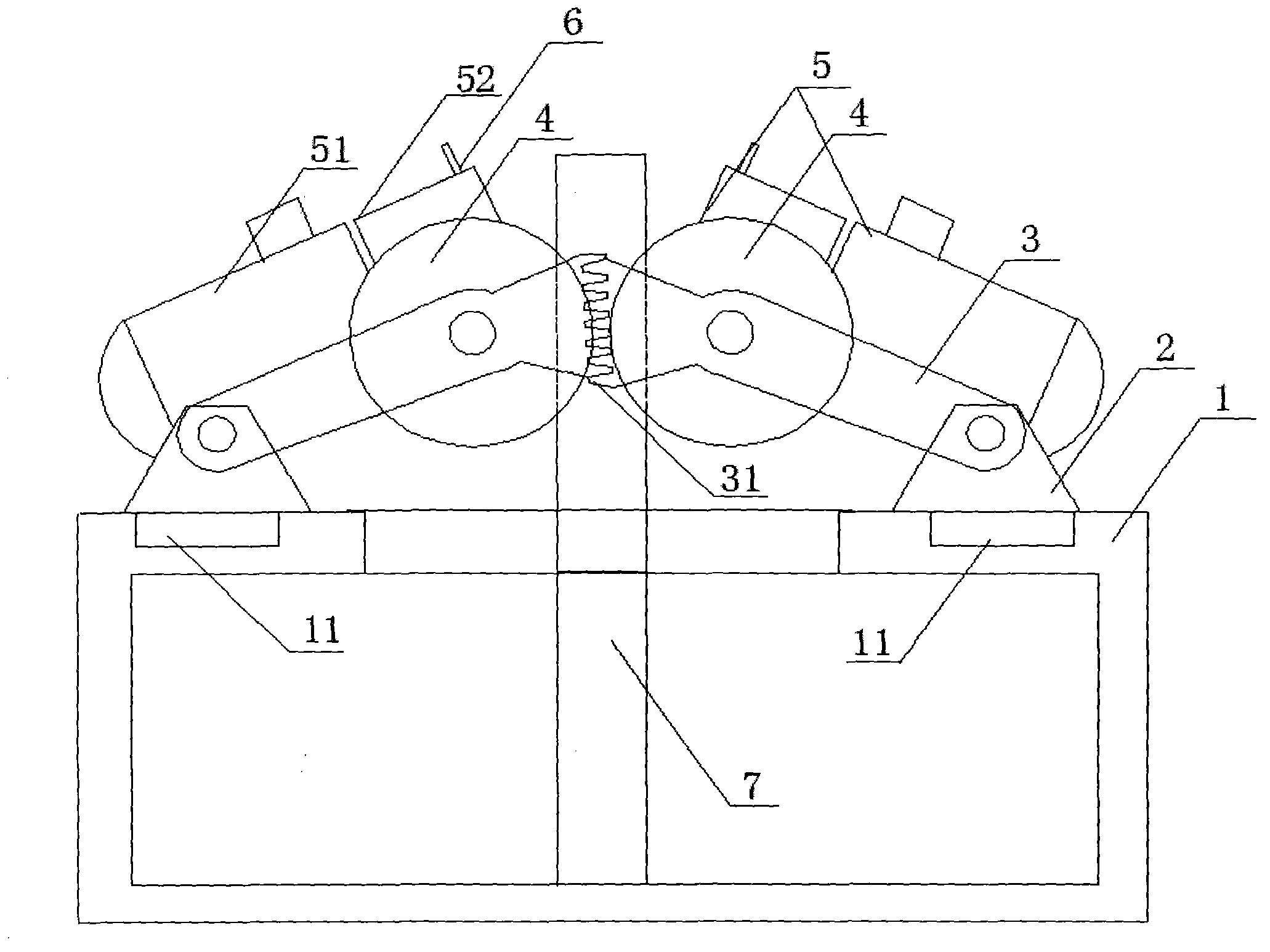

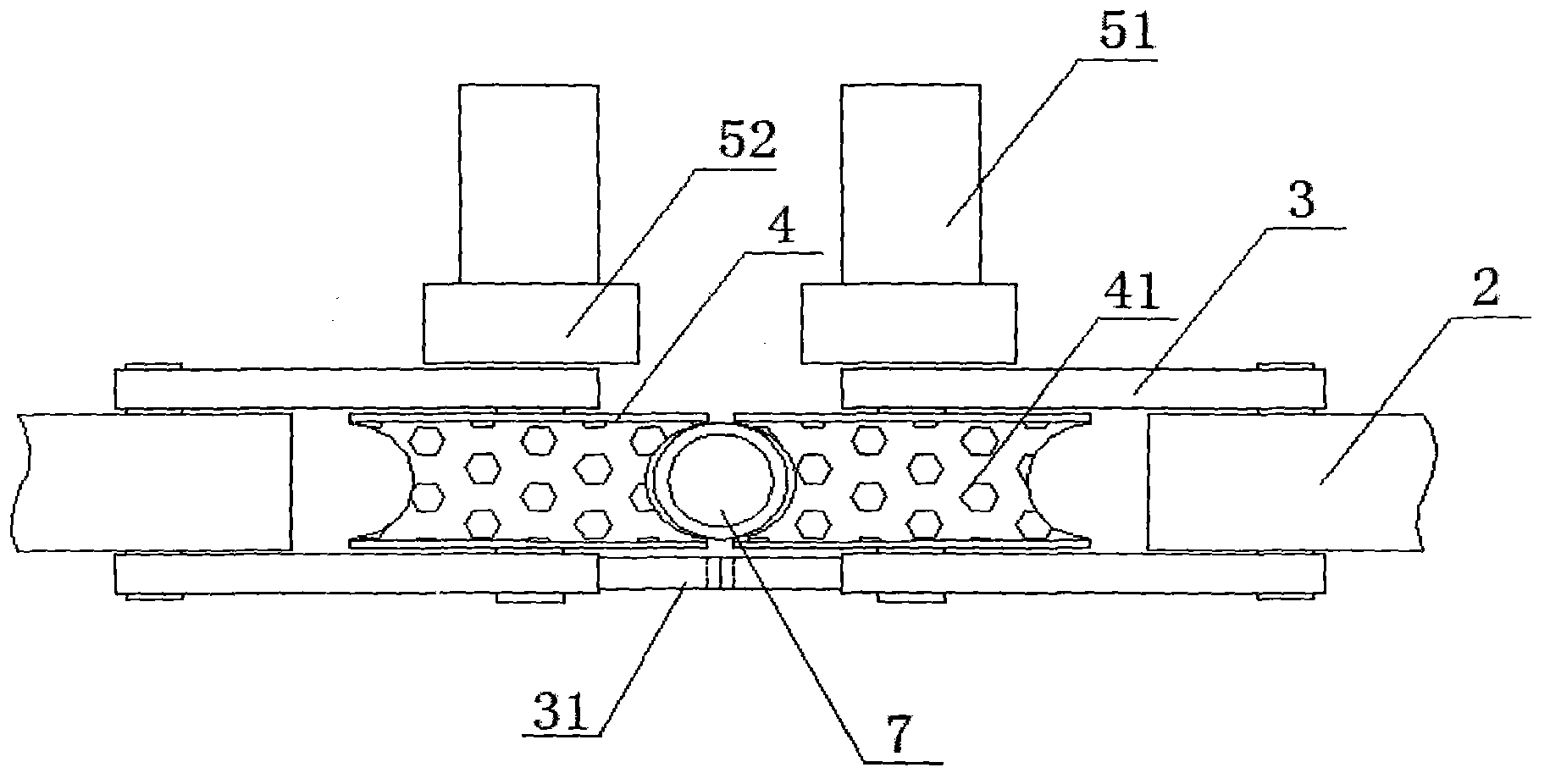

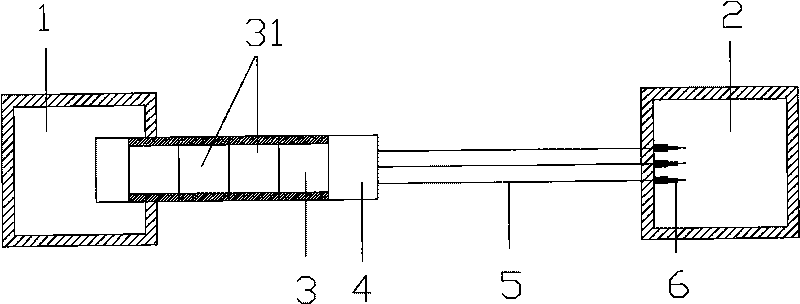

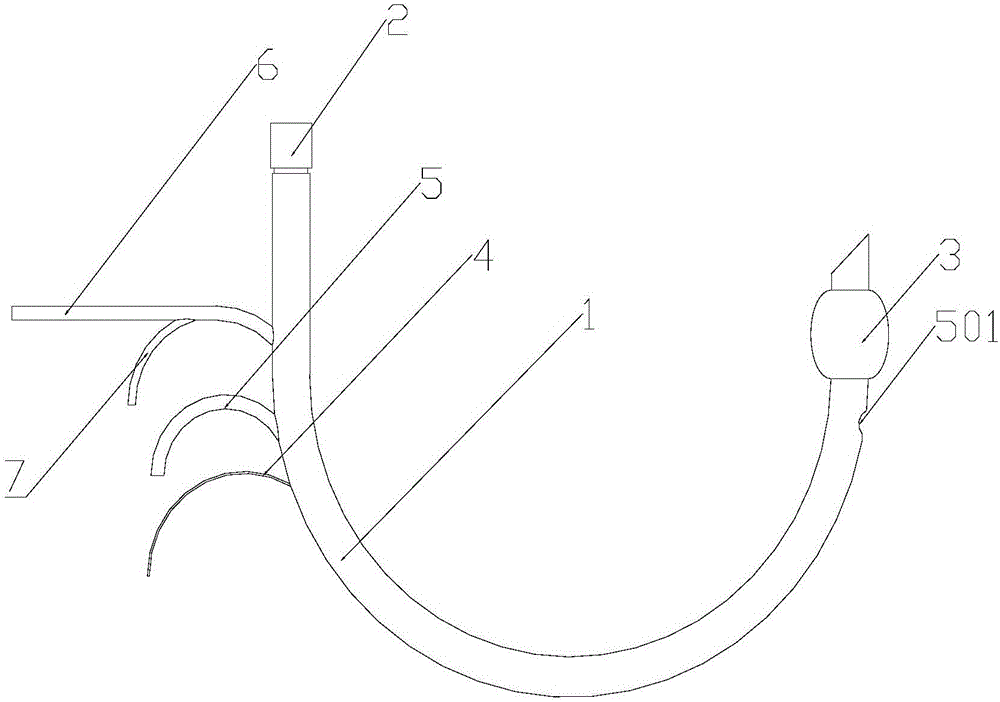

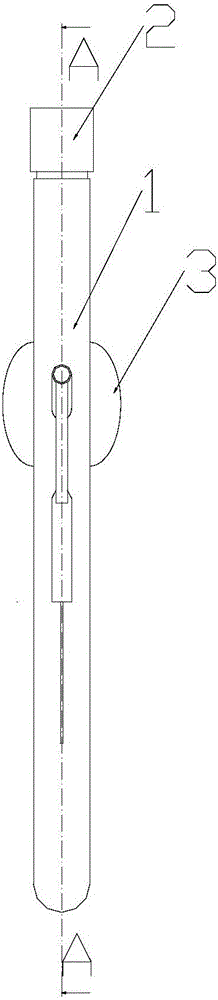

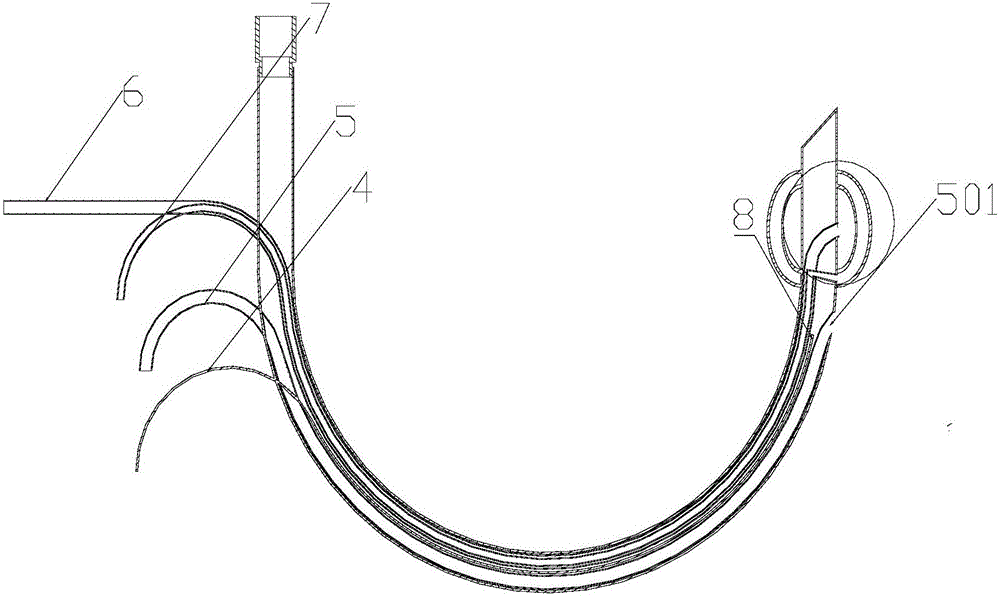

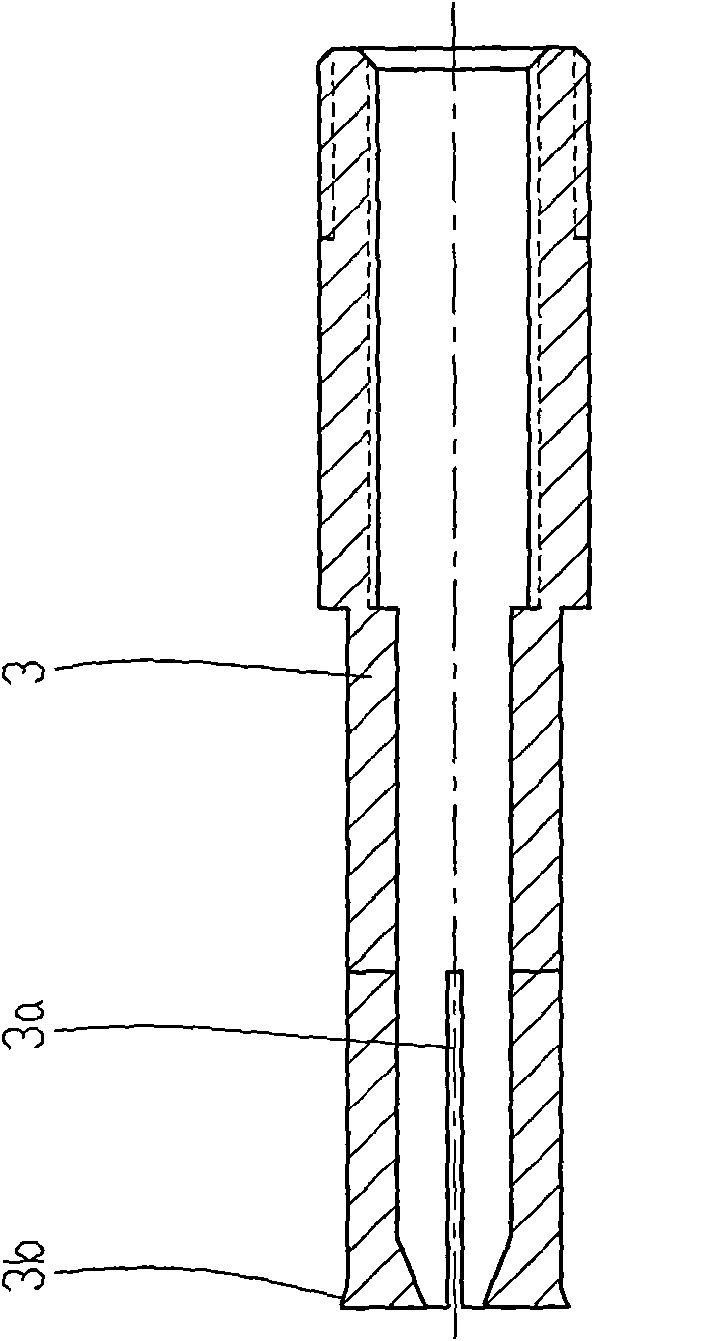

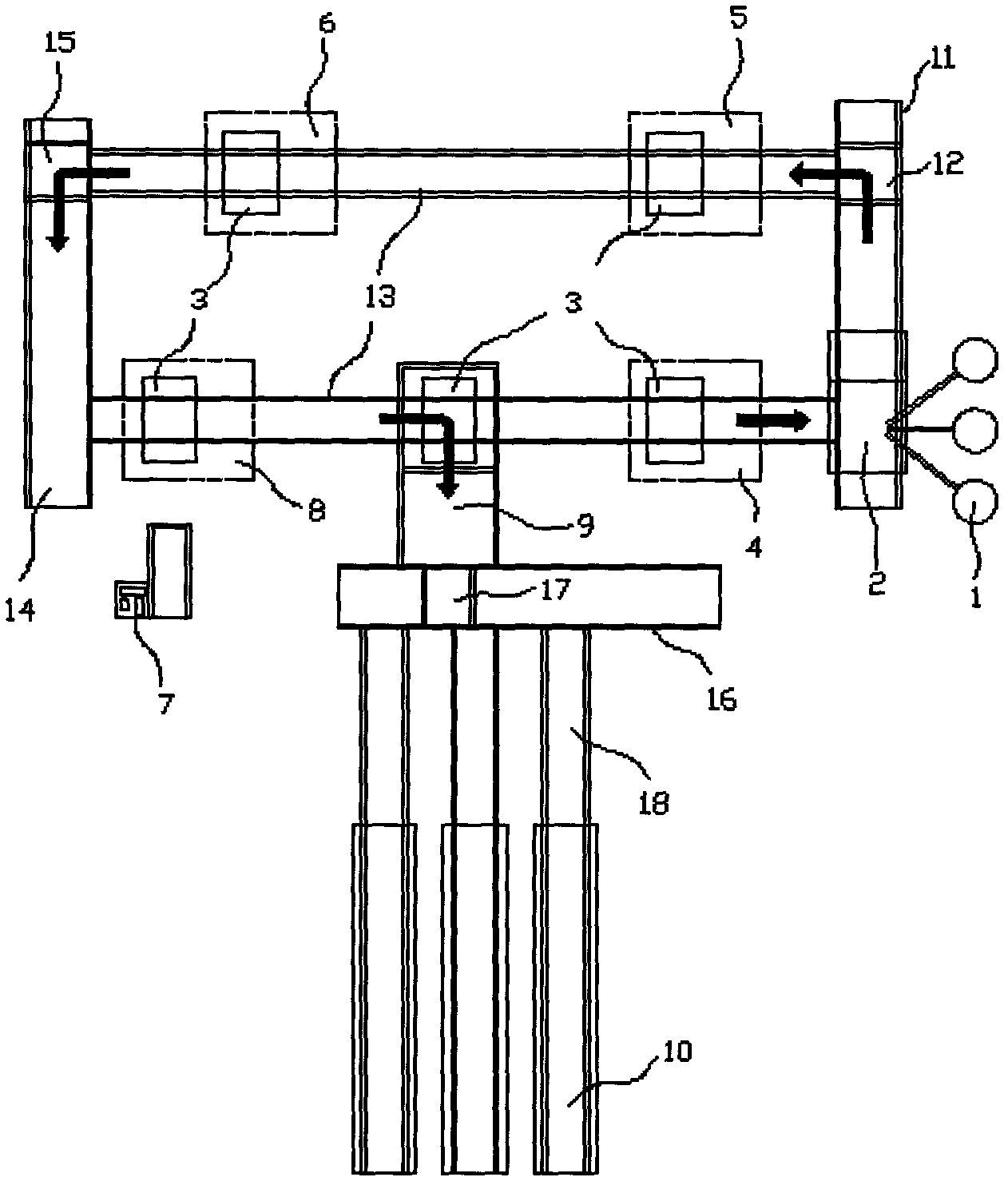

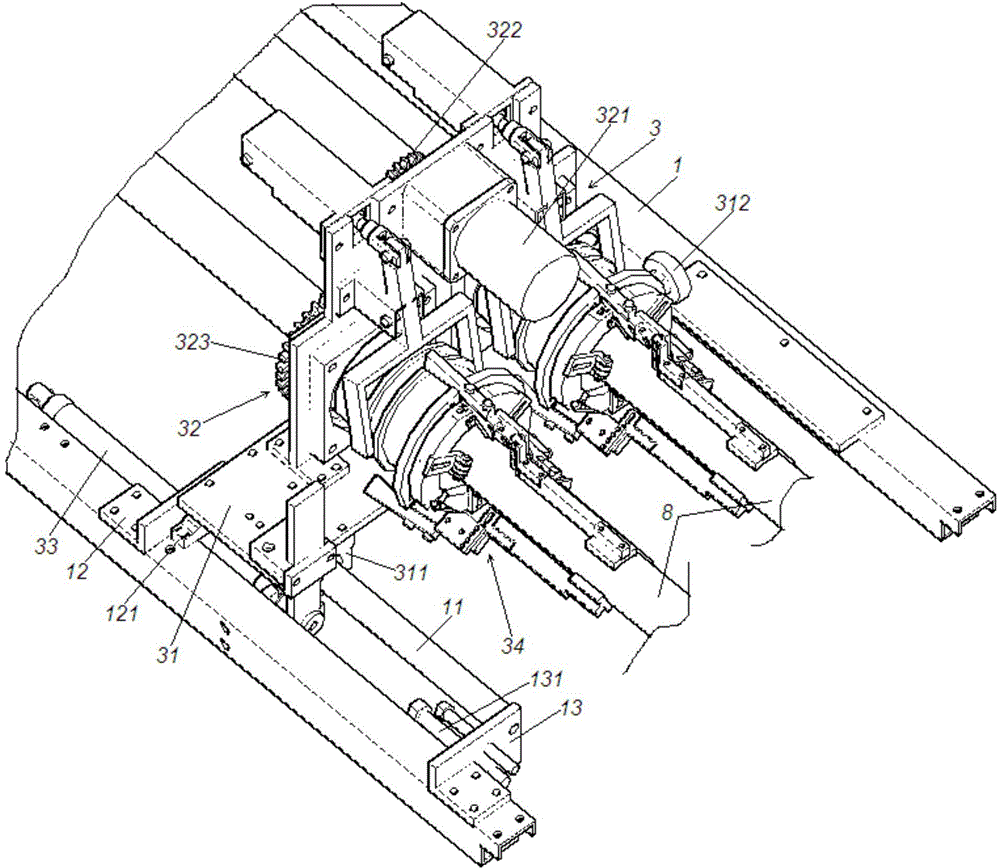

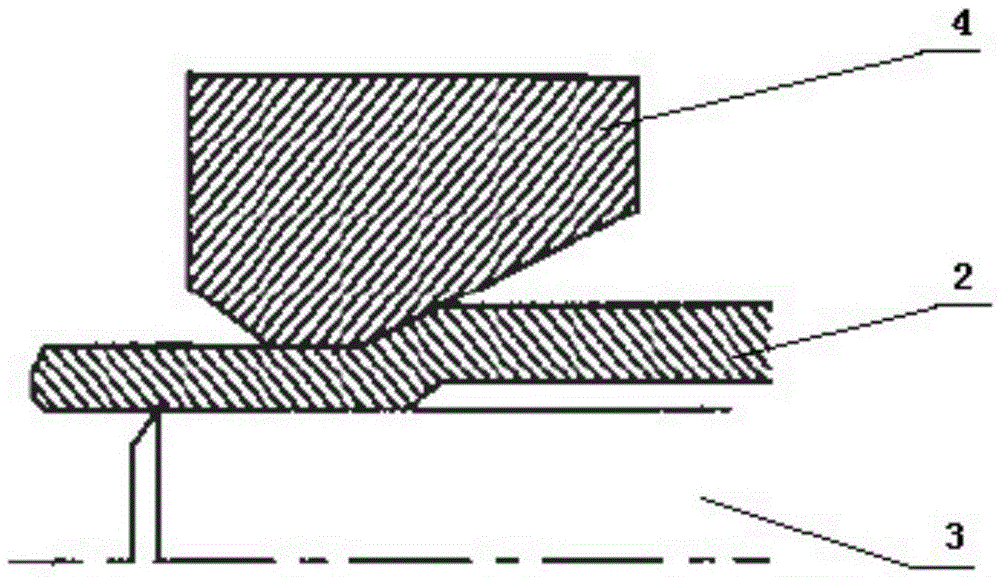

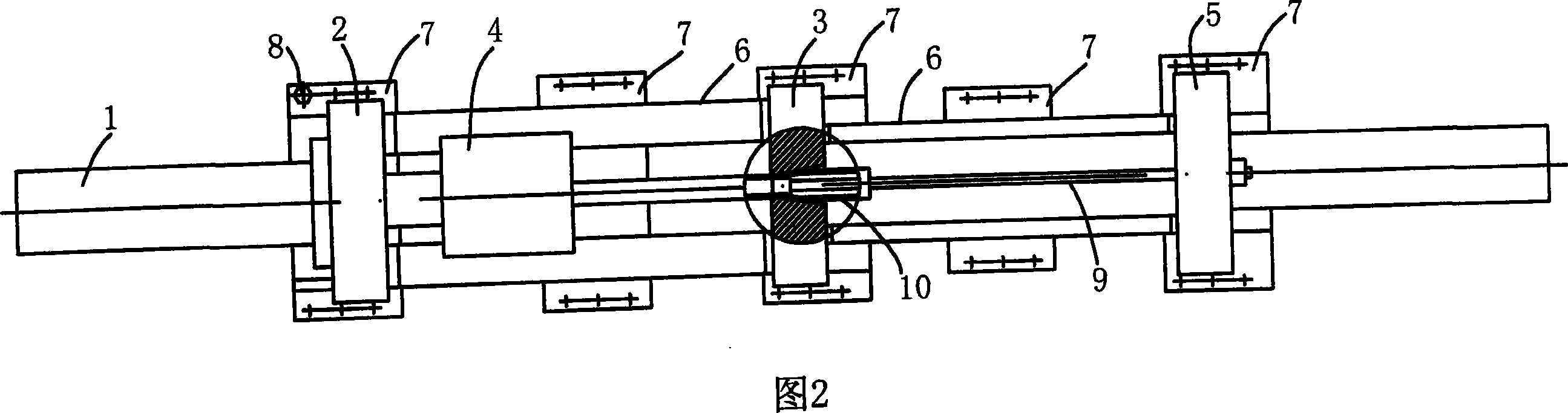

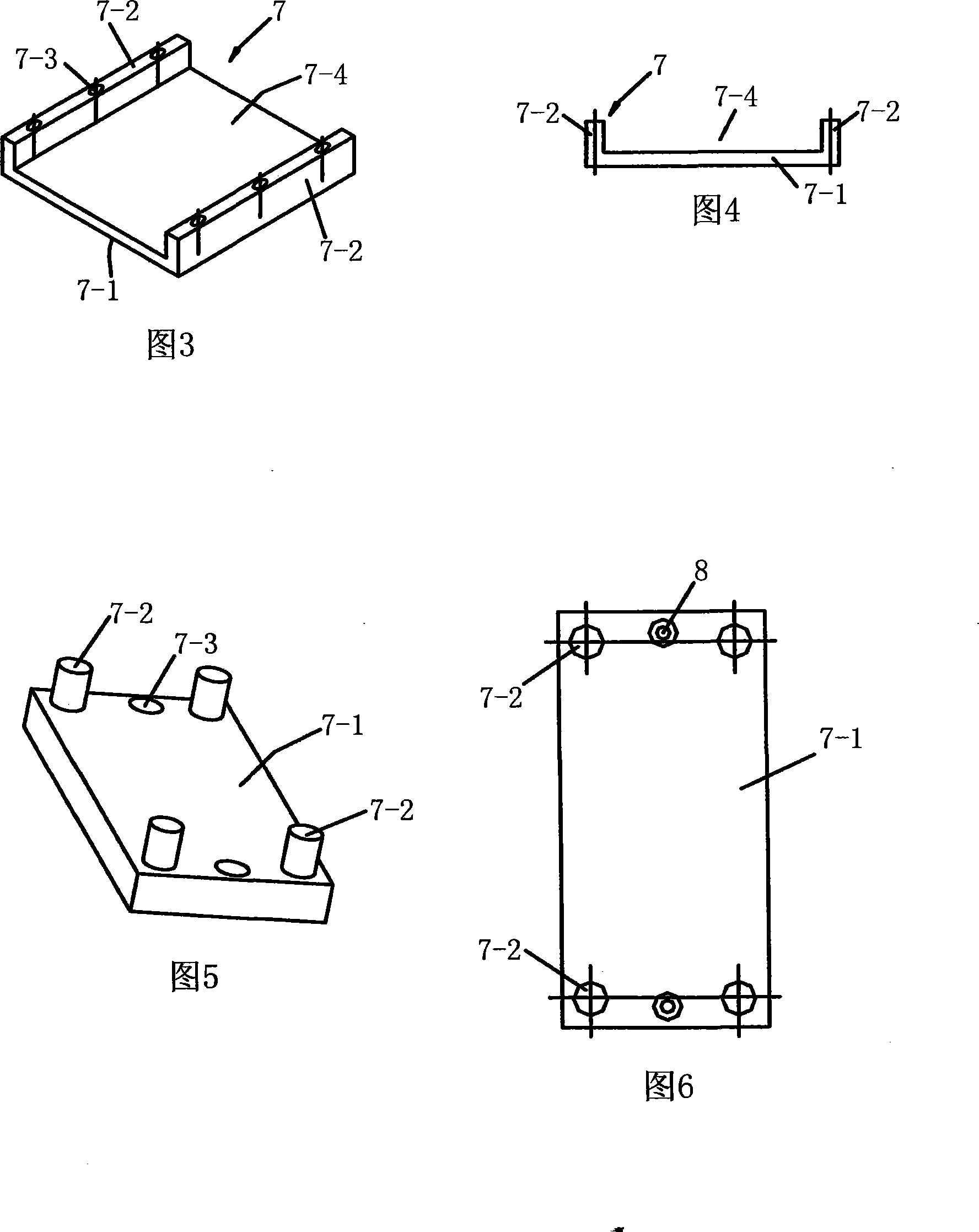

Continuous tube drawing device

InactiveCN103266610AAutomatically adjust the gapWon't hurtBulkheads/pilesTube drawingElectric machinery

The invention discloses a continuous tube drawing device. The continuous tube drawing device comprises a rack (1), support bases (2) arranged on the rack (1), idler wheels (4), power systems (5) connected with the idler wheels (4) and support arms (3), wherein one end of each support arm (3) is connected with each support base (2) through a movable shaft, and the other end of each support arm (3) is connected with each idler wheel (4) through a movable shaft. The support bases (2), the support arms (3), the idler wheels (4) and the power systems (5) are all set to be two sets and are arranged symmetrically with the rack (1). The power systems (5) comprise transmission motors (51) and speed changers (52), wherein the output shafts of the transmission motors (51) are connected with the speed changers (52), and the idler wheels (4) are arranged on the output shafts of the speed changers (52). The continuous tube drawing device is stable in power output, a tube diameter is adjusted automatically, stress borne by tube materials is adjusted automatically, the tube materials and a transmission system can not be damaged by continuous tube drawing, and using is safer and more reliable.

Owner:CHINA COAL SPECIAL DRILLING ENG

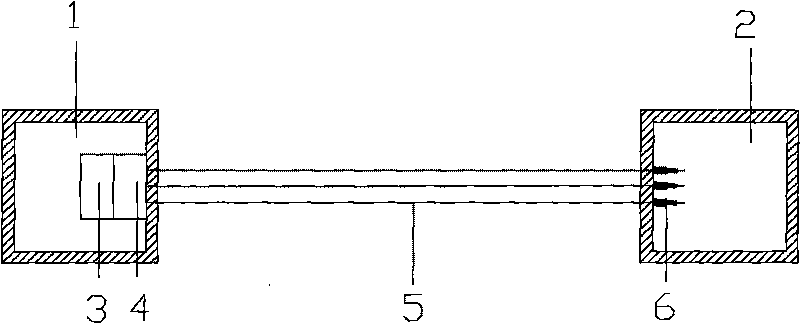

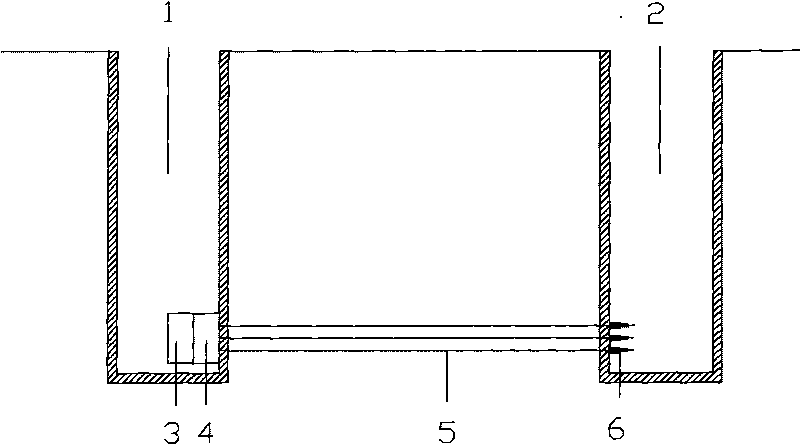

Method for slurry-water balance type pipe-pulling construction of underground pipeline

ActiveCN101701646AAdaptableReduce the number of correctionsPipe laying and repairReinforced concreteTube drawing

The invention provides a method for the slurry-water balance type pipe-pulling construction of an underground pipeline, which relates to the technical field of underground construction and aims at improving the applicability to the construction site and the construction efficiency. The method comprises the following steps: constructing a starting well and a receiving well at both ends of a pipeline design axis; then installing a horizontal pull device in the receiving well; laying a plurality of strings of coaxial bracing cables between the two working wells by using a horizontal directional drilling technology, wherein one end of each bracing cable is locked by the horizontal pull device in the receiving well, and the other end of each bracing cable is axisymmetrically fixed on the front end of an excavator head; and applying pull to the groups of bracing cables by the horizontal pull device in the receiving well when the excavator head excavates so that all pipe joints are driven into an excavating stratum by the excavator head. The method is suitable for pipelines which have various cross-sectional dimensions and are in the steel reinforced concrete structure or the steel structure.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

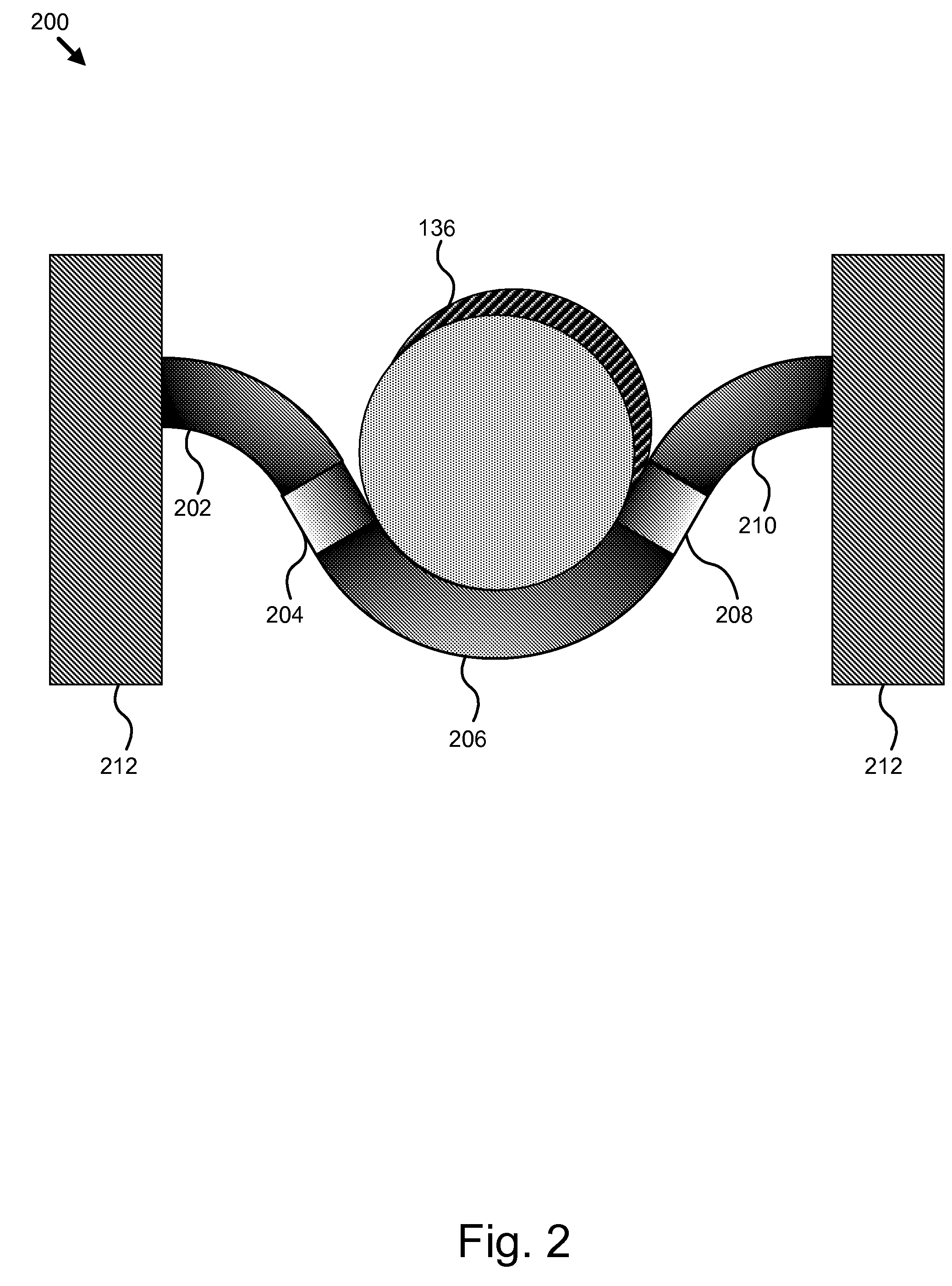

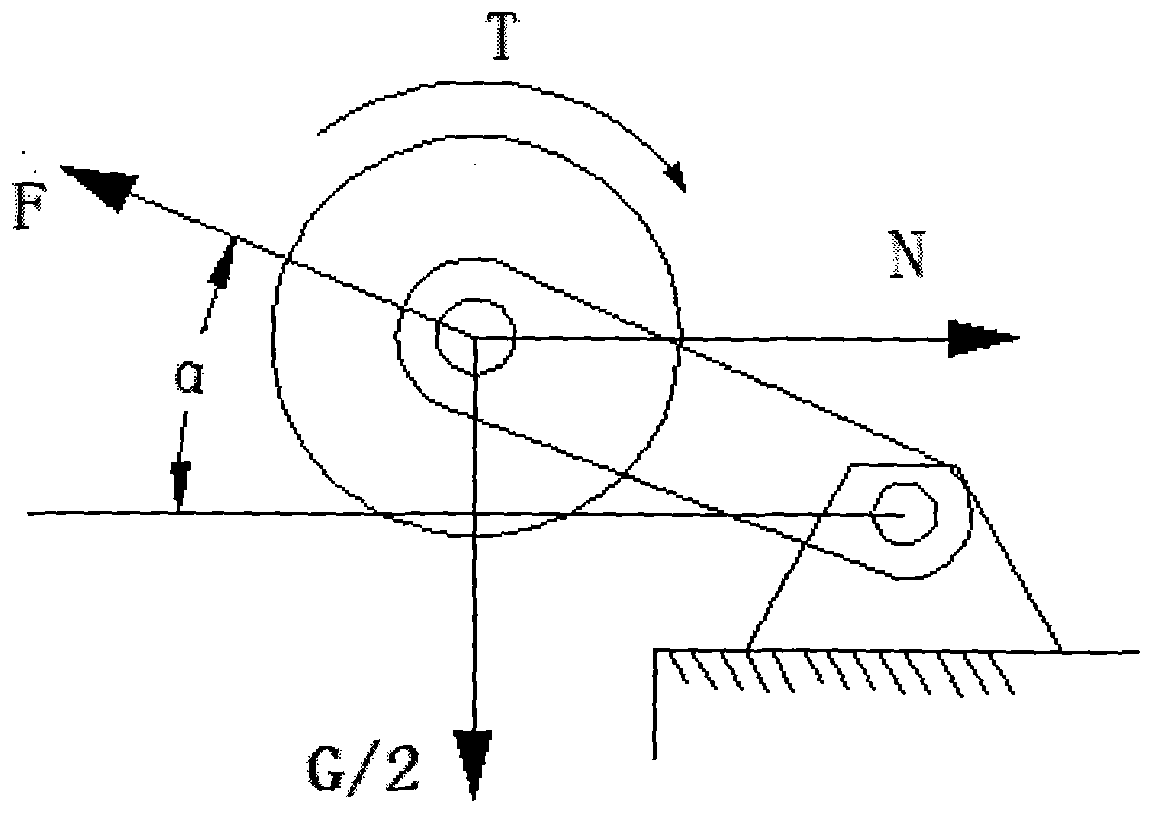

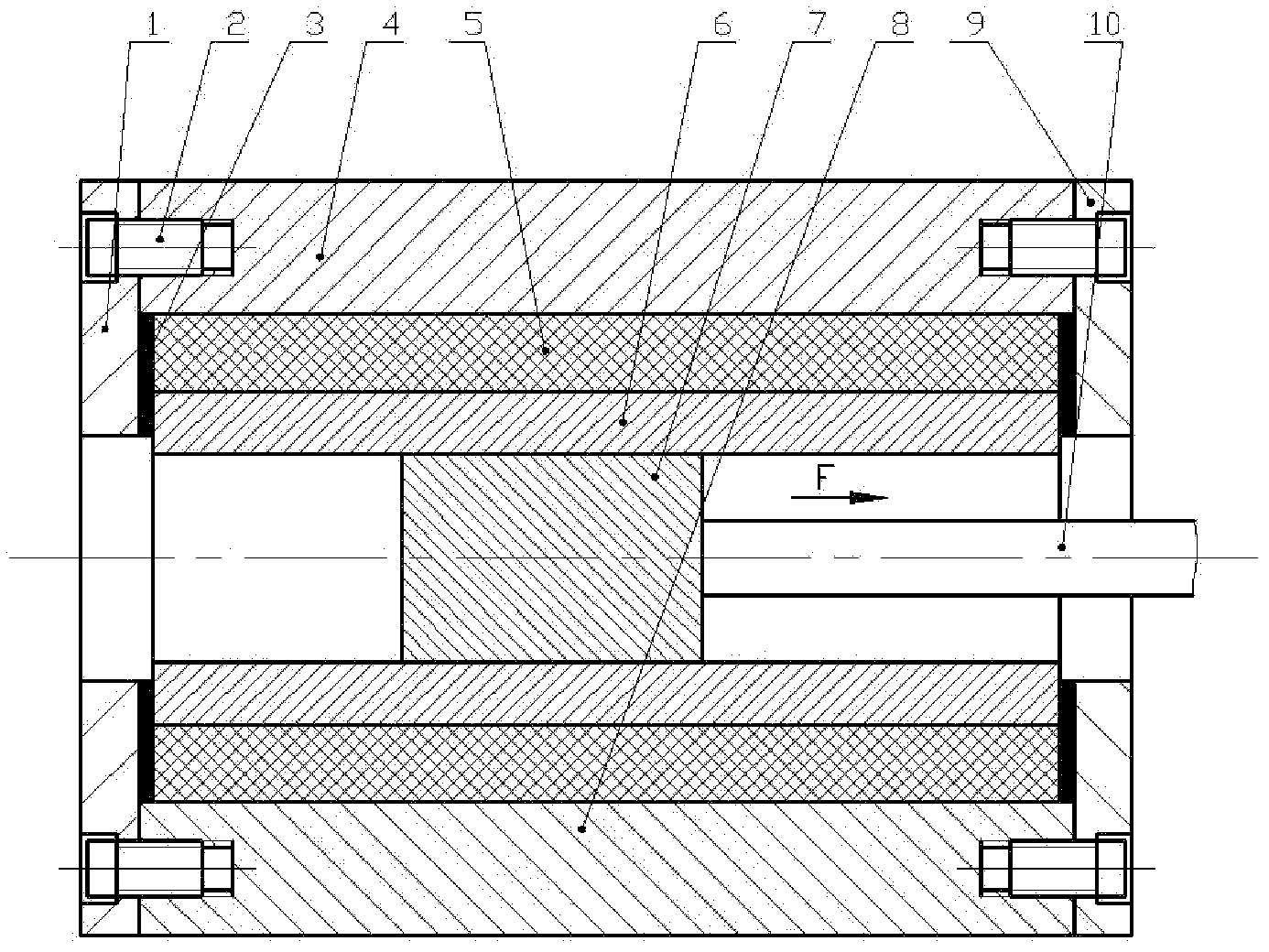

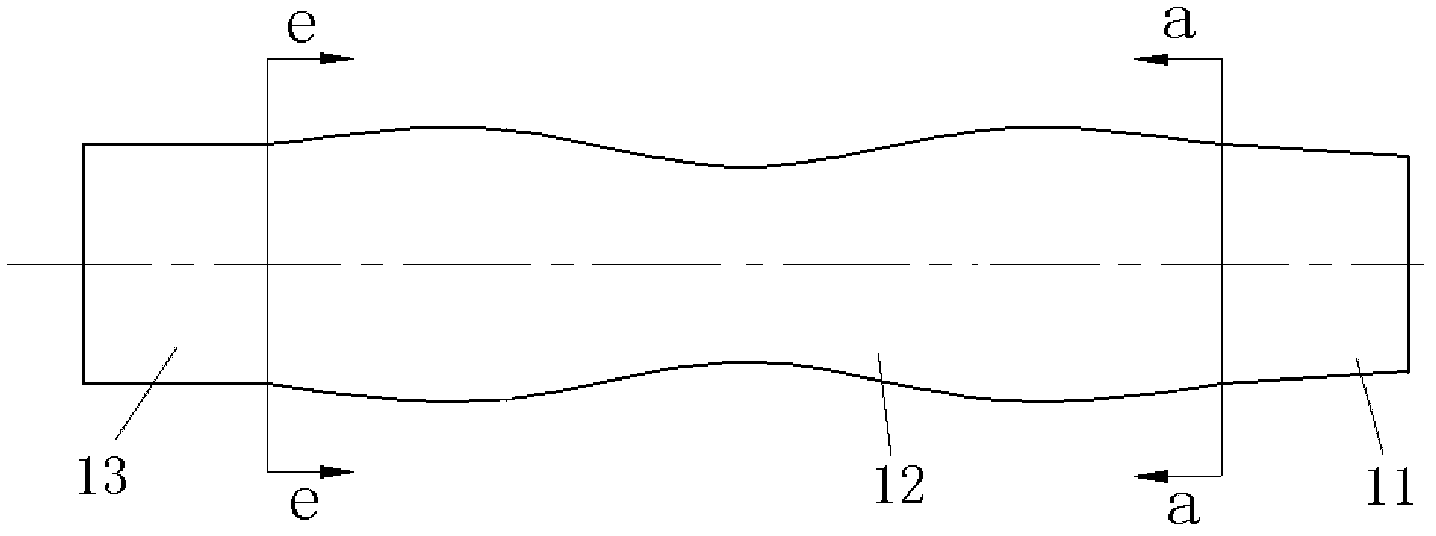

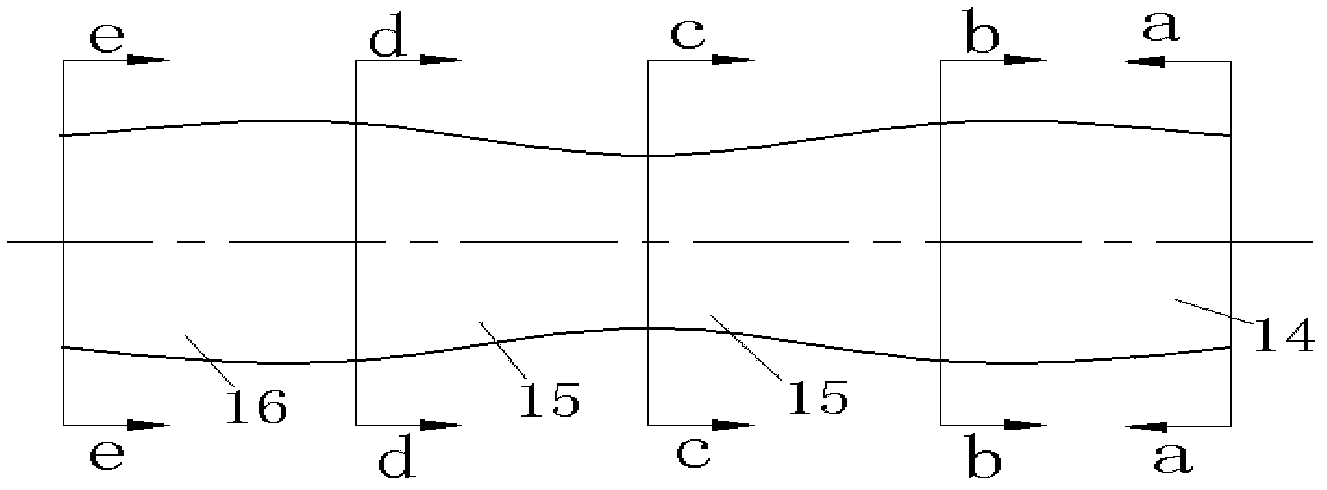

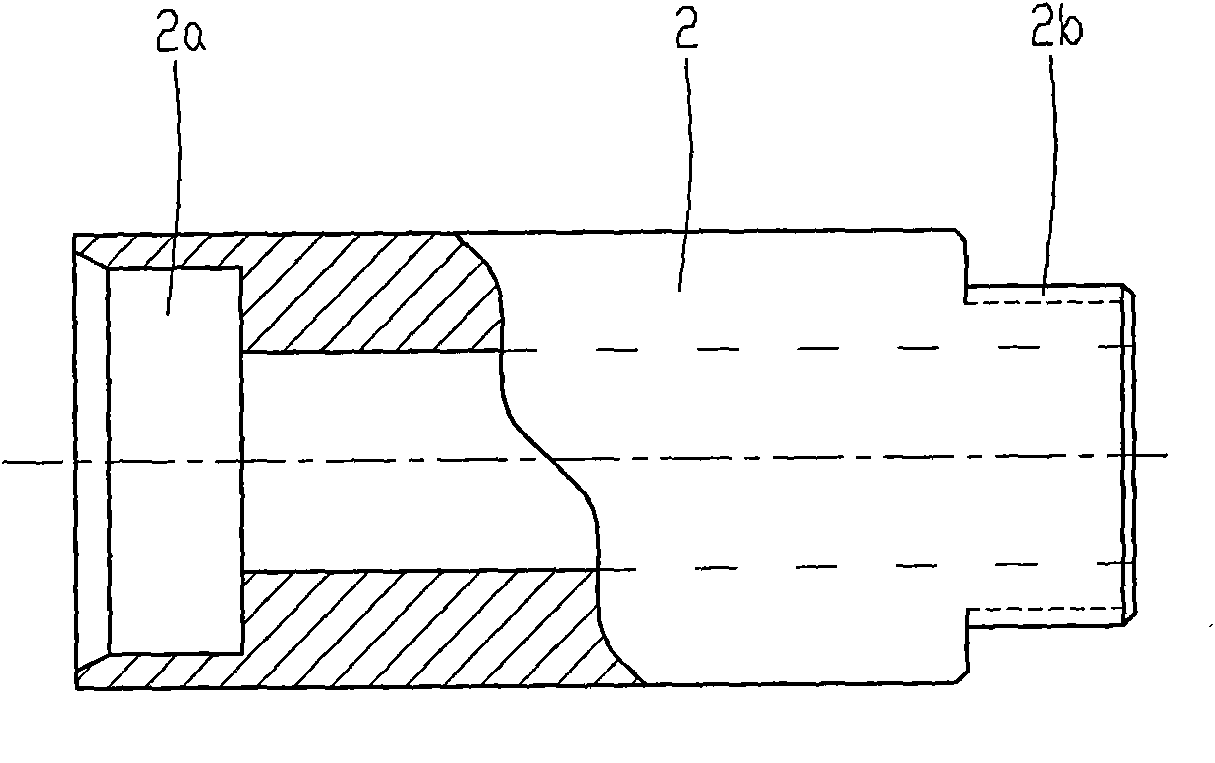

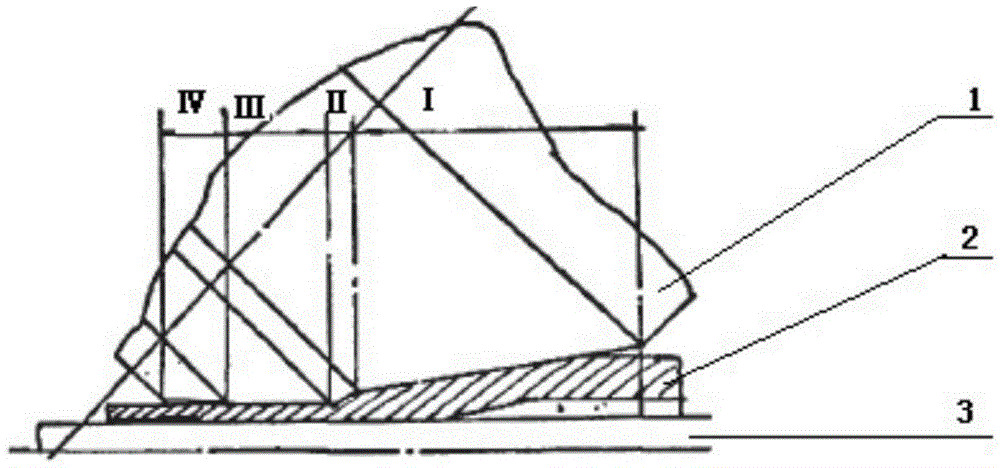

Tube drawing forming method and forming mould

InactiveCN102423770AImproved strain distributionIncrease stressDrawing diesStress distributionShear stress

The invention discloses a tube drawing forming method and forming mould. In the forming method, extrusion-bulging deformation is performed on a tube by using a drawing torsion variable-section core to realize combination of various deformation modes in a primary forming process. The tube wall of the formed tube is subjected to the extrusion-bulging of the core and is in a strong three-way compressive stress state due to the limitation of a polyurethane filling layer; at a deformation stage of circular-elliptical-circular and elliptical torsion change, the tube enters a torsion shearing deformation zone of a metal transition region; under the action of shearing stress, the internal organization of the material is subjected to rotation and shear strain to cause the orientation of a materialorganization structure, namely a new texture is formed, thereby improving deformation texture under the equivalent deformation degree. The drawing variable-section core extrusion-bulging tube deformsto achieve larger deformation degree compared with that of the conventional forming process, so that strain distribution and stress distribution in the tube are improved, the casting organization remained in the broken tube is facilitated, the form and the distribution of inclusion are changed, and the defects of the internal organization of the tube are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Dosing phlegm-absorbing temperature-measuring type trachea cannula

ActiveCN105854143AFunctional DiversificationGuarantee unimpededTracheal tubesMedical devicesIntratracheal intubationEndotracheal tube

The invention provides a dosing phlegm-absorbing temperature-measuring type trachea cannula which comprises a trachea cannula, an inflating sleeve bag, an inflating catheter, a phlegm-absorbing tube, a dosing catheter and a connection port. The inflating catheter, the phlegm-absorbing tube and the dosing catheter are arranged in the trachea cannula. The two ends of the trachea cannula are provided with the inflating sleeve bag and the connection port respectively. The phlegm-absorbing tube arranged on the dosing phlegm-absorbing temperature-measuring type trachea cannula can timely continuously or intermittently absorb a patient's secretions and sputum and the like which are gathered on the inflating sleeve bag and guarantee that the respiratory tract is smooth. Medicine liquid led in the dosing catheter is sprayed to the human trachea through a medicine spraying hole formed in an outer bag, so as to lubricate the positions of the trachea cannula and the inflating sleeve bag and alleviate cardiovascular stress response in the operation process, before tube drawing and in the tube drawing process. A temperature sensor probe can monitor the human body temperature in real time, and the functions of the trachea cannula are more diversified while mechanical ventilation is achieved and what is needed is input into the human trachea.

Owner:江苏立峰生物科技有限公司

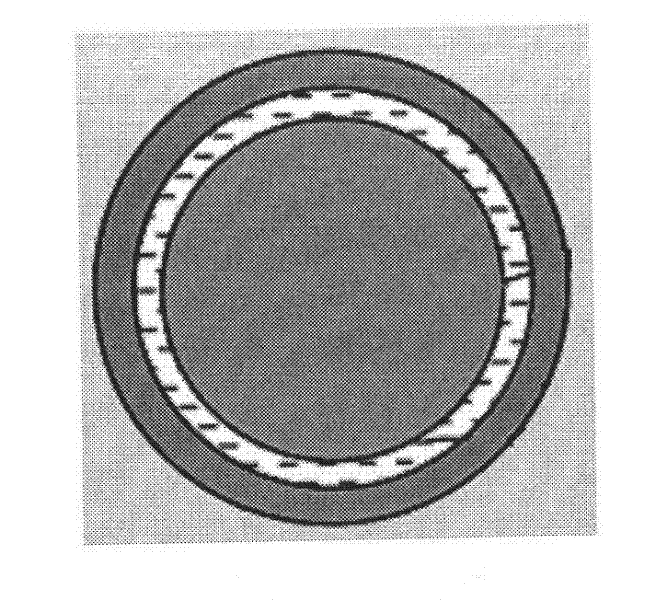

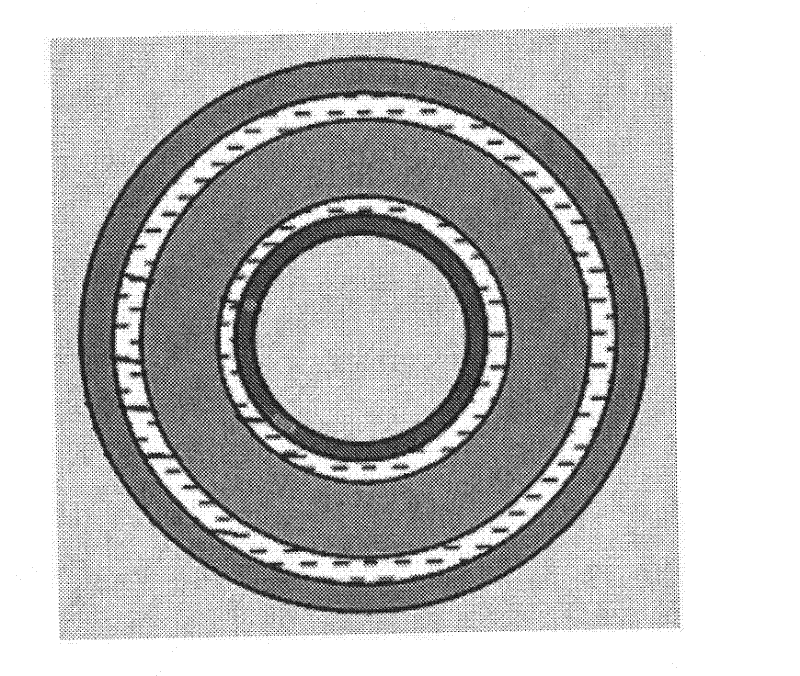

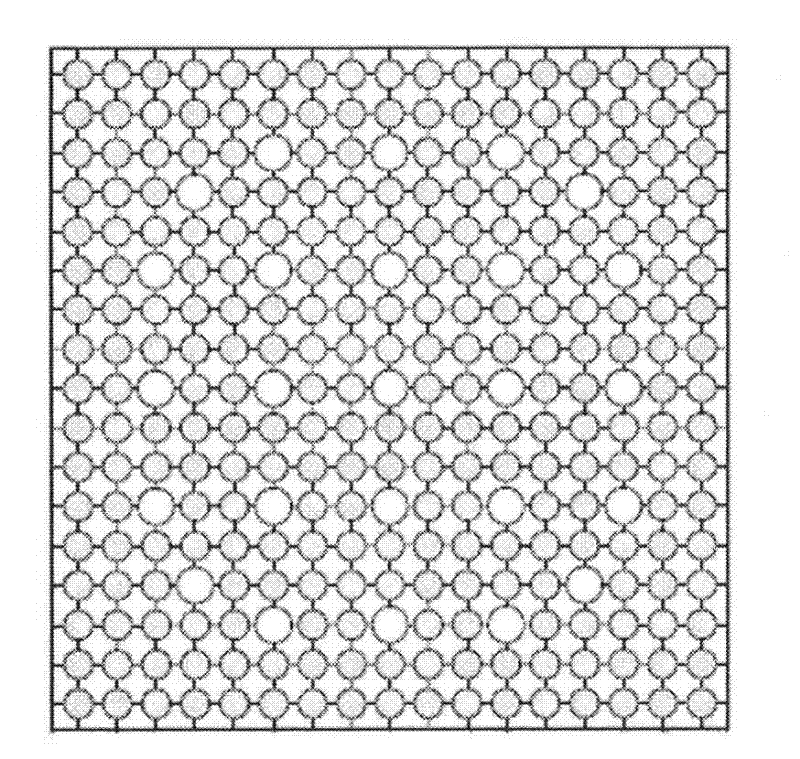

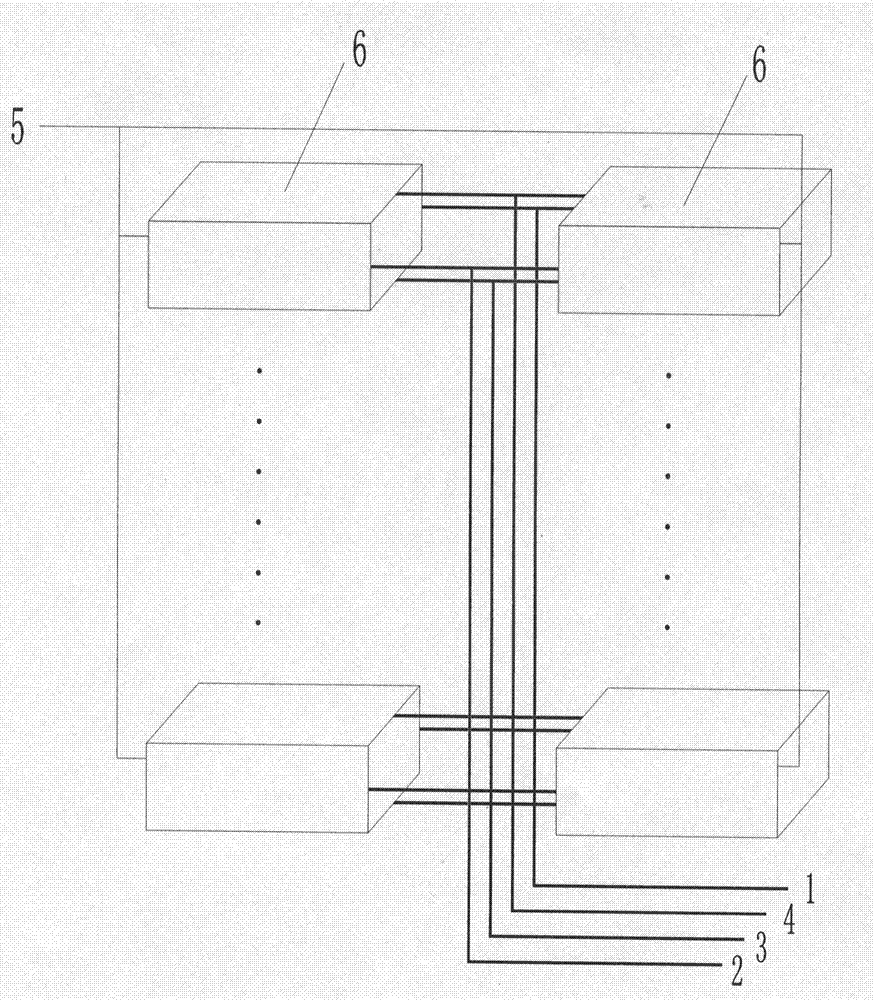

A tubular positioning grid for double-sided cooling of fuel rods in pressurized water reactors

InactiveCN102270511AEasy to assembleSupport structure is stableNuclear energy generationFuel element assembliesTube drawingGrid cell

The invention discloses a tubular positioning grid frame for double-sided cooling of fuel rods in a pressurized water reactor. The positioning grid frame is formed by welding quasi-square grid units. The convex surface of the center is in contact with the outer circle of the fuel rod to form support and positioning for the fuel rod, and the grid unit is stamped or drawn from a circular tube. The invention provides a tubular positioning grid for double-sided cooling of fuel rods of a pressurized water reactor, which has simple structure, low manufacturing process technical difficulty, better economy and better safety, and is easy to install.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

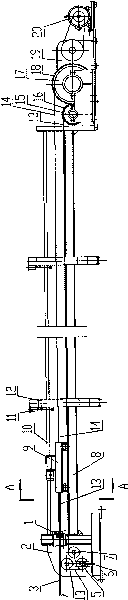

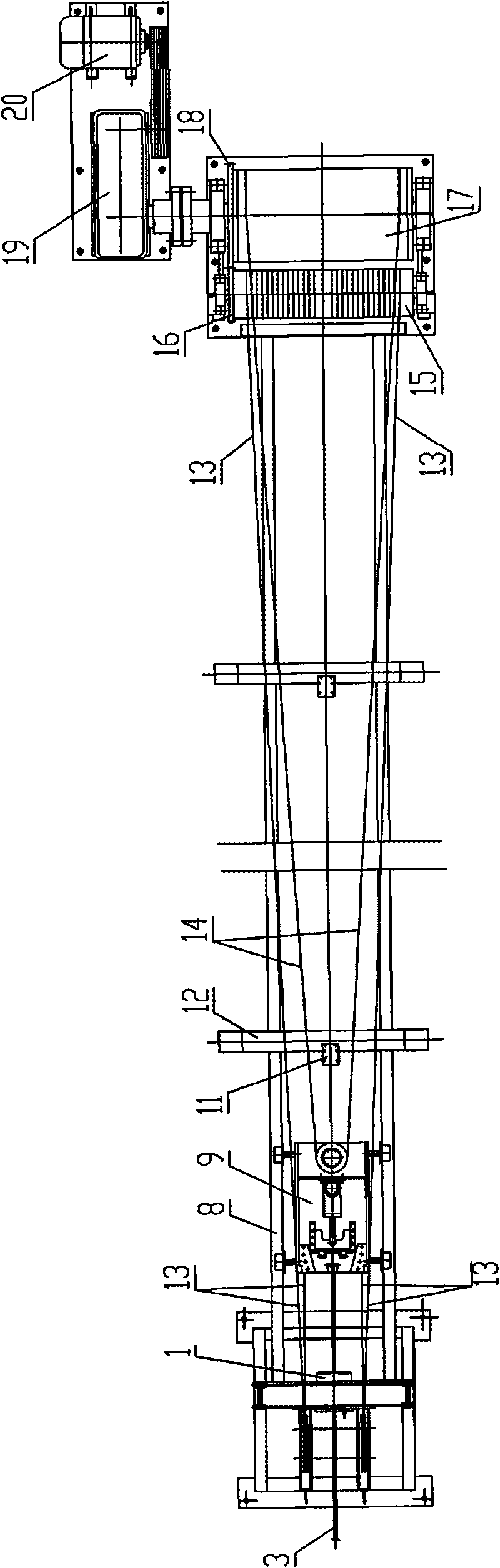

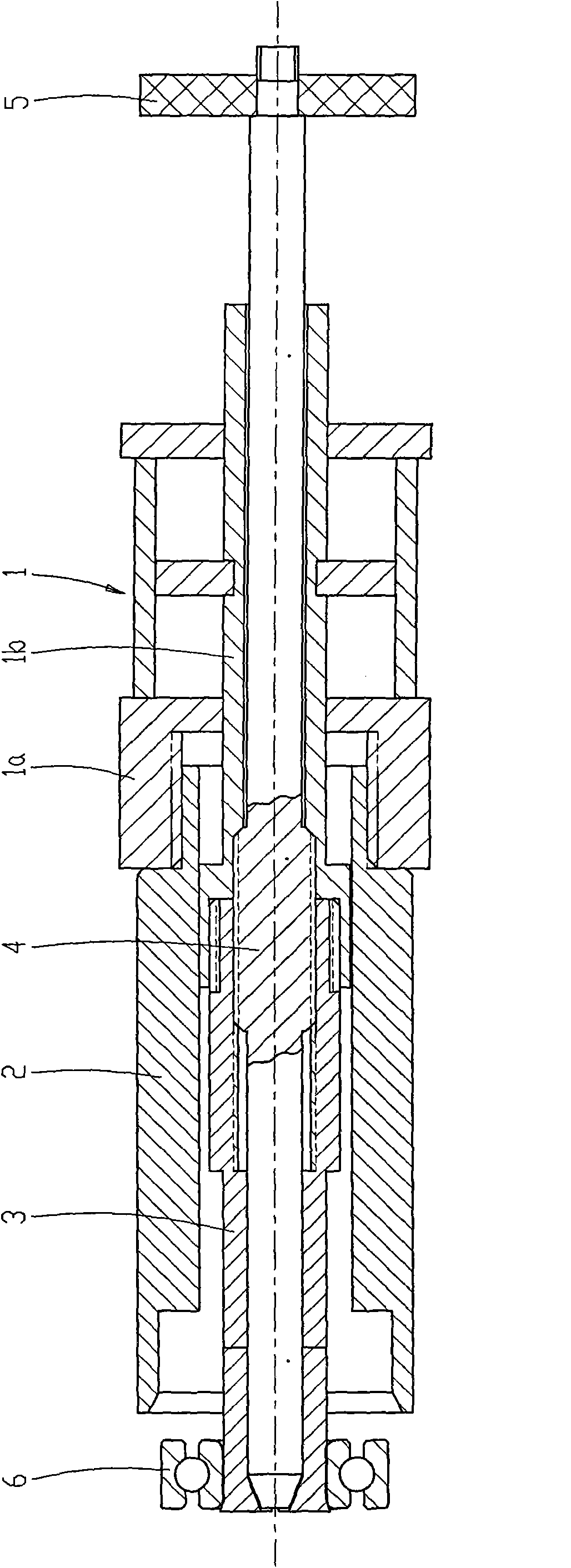

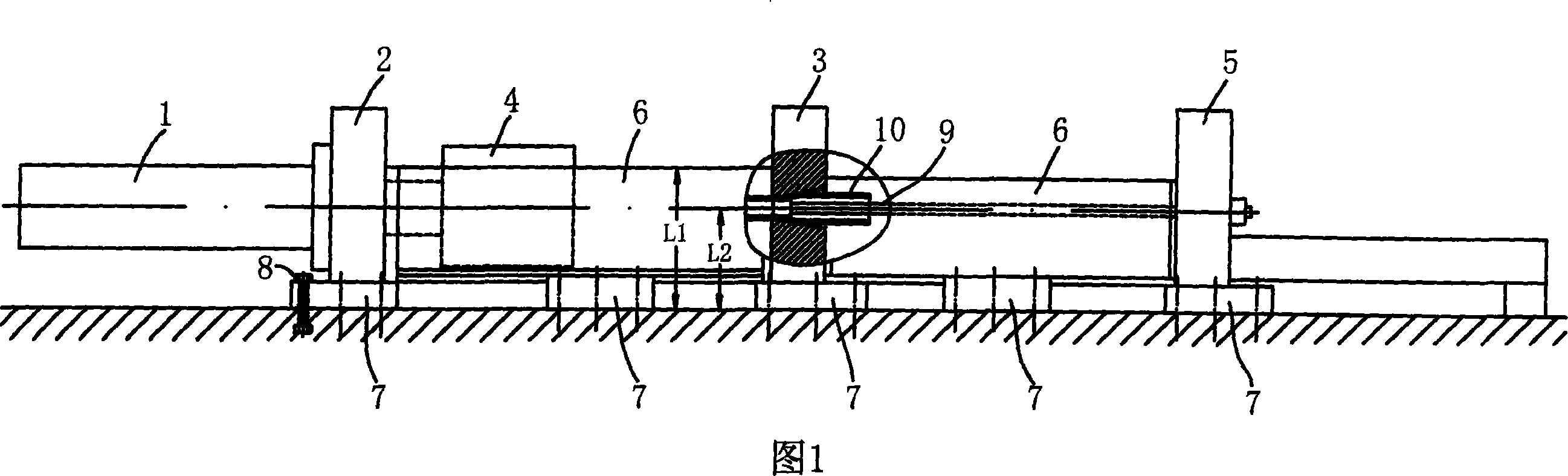

Overlength tube cold-drawing machine

ActiveCN101690956AImprove surface qualityEasy and flexible operationDrawing diesGear wheelReduction drive

The invention relates to a tube cold-drawing processing device, in particular to an overlength tube cold-drawing machine. The invention comprises a drawing die arranged on a headstock, drawing trolley capable of moving along the rail and a dragging device connected with the drawing trolley; the dragging device comprises a pulley block arranged on a headstock, a motor and a retarder connected with the motor; the rail is provided with a clamping device; the pulley block is winded with a thin steel wire rope; one end of the thin steel wire rope is connected to the back end of the drawing trolley and the other end thereof is connected to a small winding drum arranged at the front end of rail; the front end of the drawing trolley is connected to a large winding drum arranged at one side of the small winding drum by a wide steel wire rope; the small winding drum is provided with a small gear; the large winding drum is provided with a large gear meshed with the small gear; and the large gear is connected with the retarder. The invention has the beneficial effects of simple and convenient operation, small error, time-saving, labor-saving, tube material-saving, good quality of tube drawing, and high processing efficiency.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD +1

Bearing dismounting tool

InactiveCN101786225AImprove disassembly efficiencyReduce labor intensityMetal working apparatusTube drawingHand riveter

The invention discloses a bearing dismounting tool which is characterized in that: a positioning cylinder is fixed on the cylinder body of a hand riveter cylinder, the cylinder shaft of the hand riveter cylinder extends to the positioning cylinder to be fixed with one end of a pull tube, the other end of the pull tube extends out of the positioning cylinder, the tube wall of the pull tube out of the positioning cylinder is provided with 3-8 openings along axial direction and in even circumferential distribution, and the center hole of the pull tube at the end has conical closing-in structure; a mandrel penetrates through the cylinder shaft of the hand riveter cylinder and extends to the pull tube to be in threaded fit with the pull tube, the conical end of the mandrel extends to the pull tube and is matched with the closing-in structure at the center hole end part of the pull tube in shape and size. The bearing dismounting tool has simple structure, easy assembly, low cost, light weight, overcomes site limits, not only has convenient and reliable operation and movement, but also has strong generality, can effectively improve the bearing dismounting efficiency and greatly reduces the labor intensity for operators.

Owner:力帆科技(集团)股份有限公司

Automatic production line of light partition board

InactiveCN102581948ASuitable for useReduce labor intensityCeramic shaping plantsProduction lineTube drawing

The invention discloses an automatic production line of a light partition board, which comprises a burdening device, a grouting device, a wallboard forming machine, a tube filling machine, a tube drawing bench, a still kettle, a lifting machine, a travelling rail and a shuttle bus, wherein the travelling rail reaches an area where the burdening device, the grouting device, the wallboard forming machine, the tube filling machine, the tube drawing bench, the still kettle and the lifting machine are installed and is connected with the burdening device, the grouting device, the wallboard forming machine, the tube filling machine, the tube drawing bench, the still kettle and the lifting machine, and the shuttle bus walks on the travelling rail. According to the invention, the apparatuses in the procedures are connected by the travelling rail to form a wallboard production stream line for realizing mass production through a plurality of wallboard machines, so that the production line has low labor intensity, stable product stability, high production efficiency and low equipment investment, and the production line is suitable for use of enterprises with large production capacity.

Owner:蚌埠远程置业有限公司

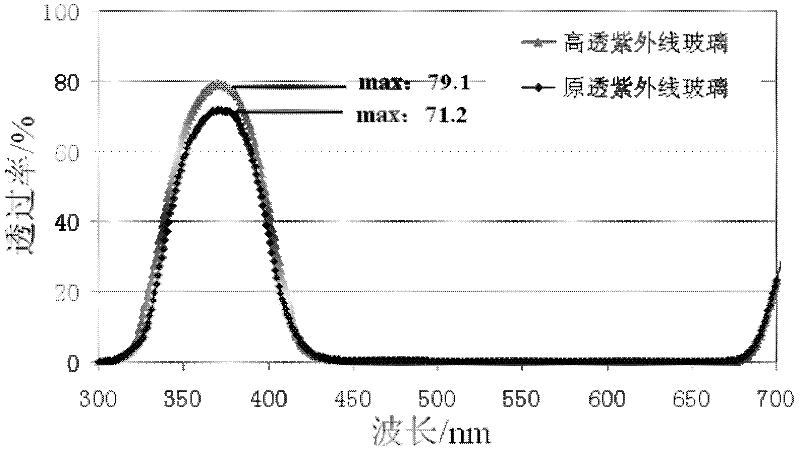

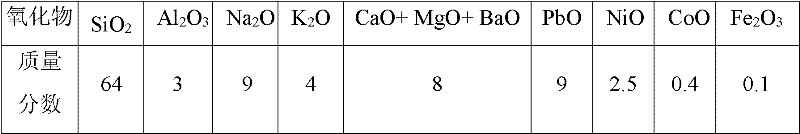

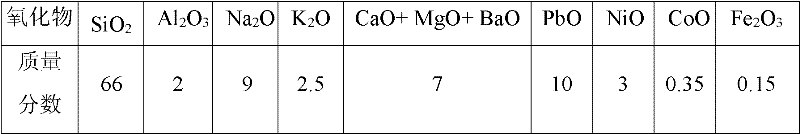

Glass with high transmissivity of ultraviolet A and preparation method for same

ActiveCN102515525AAchieve long wave transmittanceLower melting temperatureAlkaline earth metalTube drawing

The invention relates to glass with high transmissivity of ultraviolet A and a preparation method for the same. The constituents of the glass comprise, by mass fraction, 62-68% of SiO2, 2-4% of Al2O3, 6-12% of Na2O, 2-6% of K2O, 5-10% of alkaline-earth metal oxide, 7-11% of PbO, 0.1-3% of NiO, 0.1-1% of CoO and 0.1-0.2% of FeO3. The preparation method comprises the following steps of: by mass fraction, preparing glass batch according to the ratios; melting for 6-10 hours at 1400-1480 DEG C; and preparing the glass with high transmissivity of ultraviolet A by vertical or horizontal tube-drawing process. The glass disclosed by the invention can transmit ultraviolet A with a wavelength of 320-400 nm and stop the transmission of visible light; and compared with conventional ultraviolet-transmitting quartz glass, the glass disclosed by the invention is low in melting point, simple in preparation process and high in yield.

Owner:上海罗金光电科技有限公司 +1

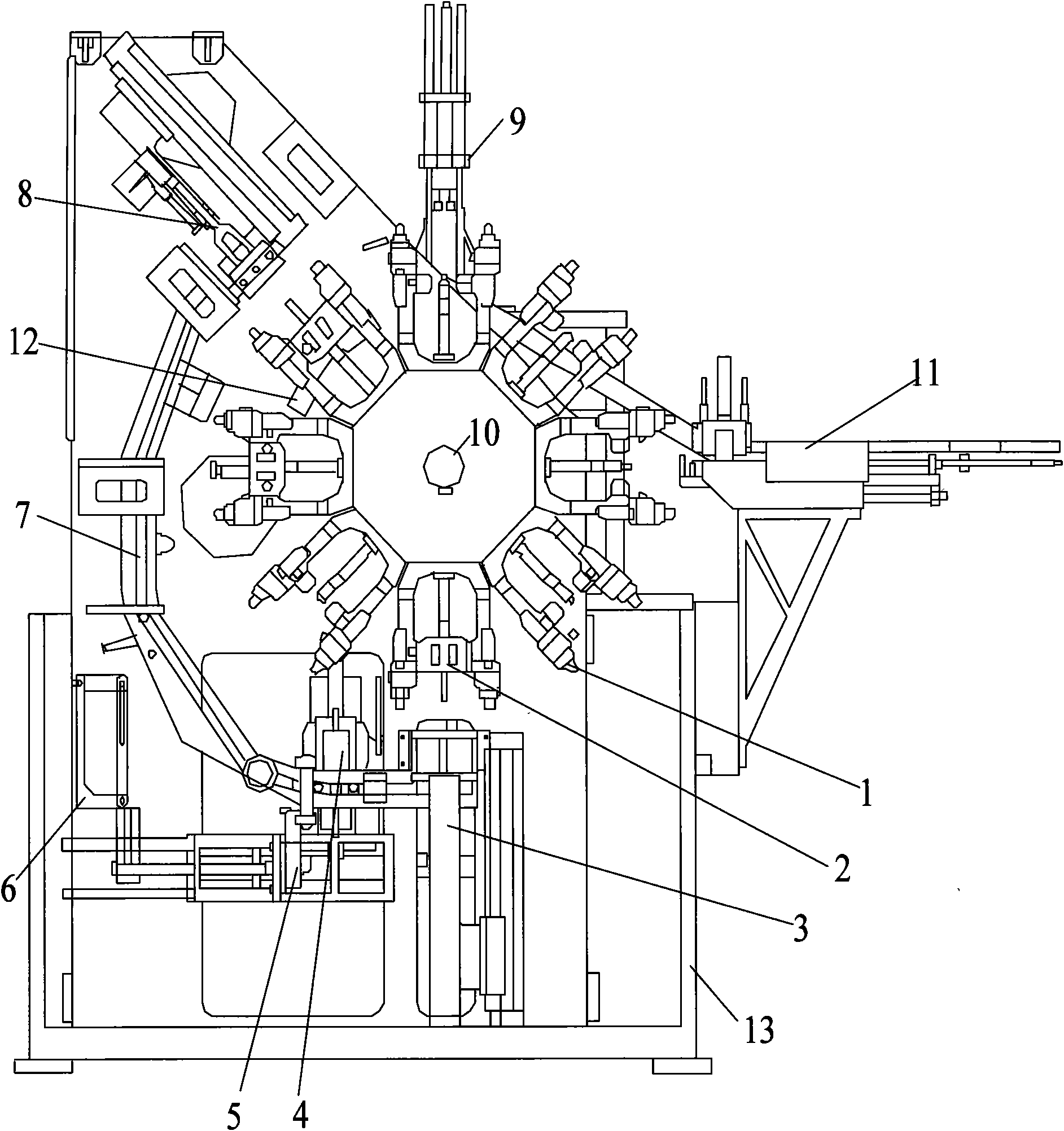

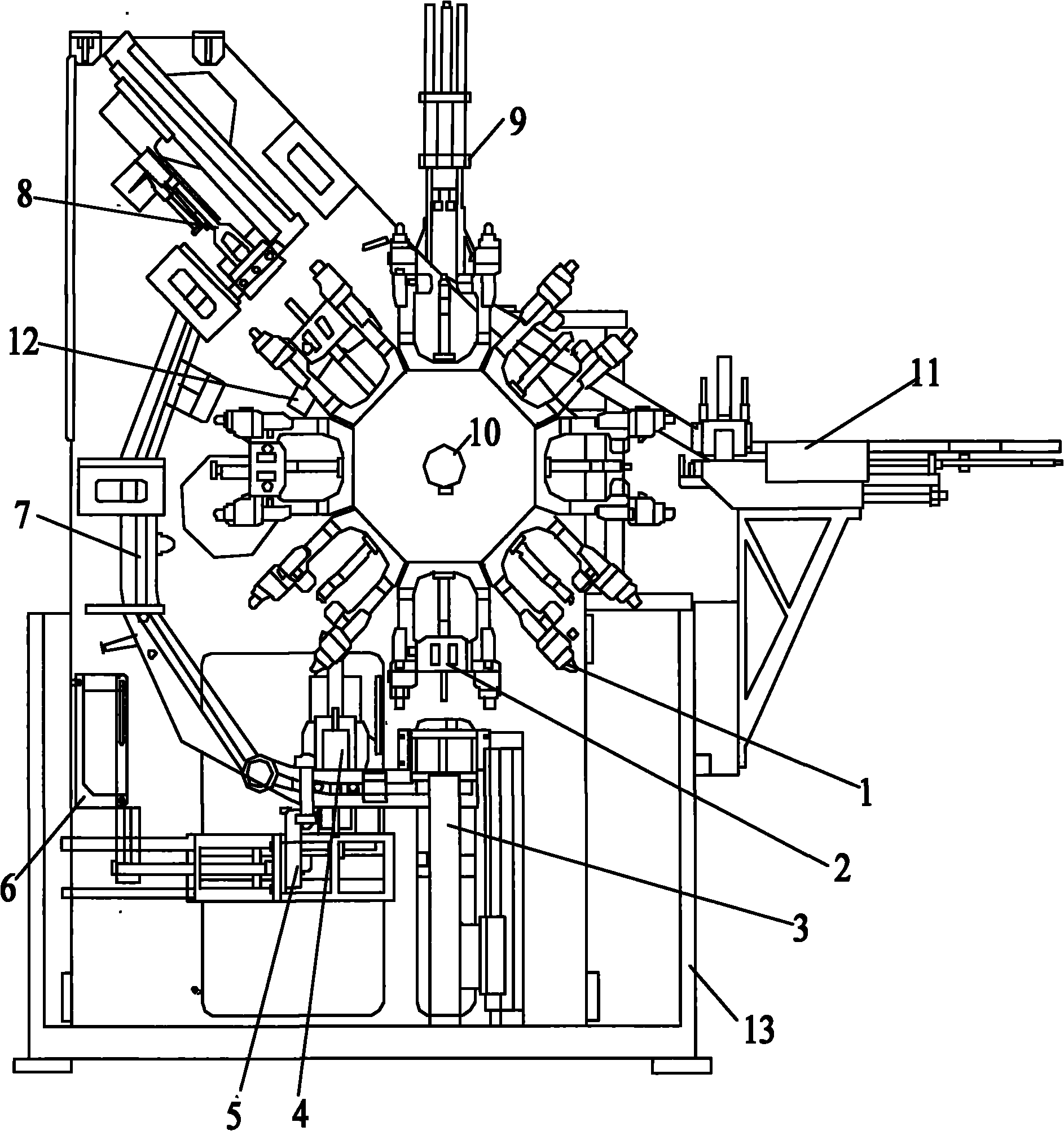

Die return type full automatic flexible tube shoulder-injecting machine

The invention discloses a die return type full automatic flexible tube shoulder-injecting machine which comprises a die holding mechanism, a female die, a die pushing mechanism, a plastic-protruding mechanism, a die sending mechanism, a buffering mechanism, a return type track, a die drawing mechanism, a tube drawing mechanism, a transmission mechanism, a tube inserting mechanism, an automatic unlocking mechanism, a frame and a cooling system, wherein the frame consists of a stand and a wall panel which is vertically erected on one side of the stand, the transmission mechanism comprises a main shaft, one end of the main shaft is fixed on the frame, a main rotating disc is arranged at the other end of the main shaft, the cooling system is mounted on the main shaft and the main rotating disc, the die holding mechanism is mounted on the main rotating disc, the tube inserting mechanism and the tube drawing mechanism are connected on the frame by a support, the die pushing mechanism is mounted on the wall panel of the frame and pushes the female die to the die closing position, the buffering mechanism is fixed on the wall panel of the frame, the plastic-protruding mechanism is fixed on the stand of the frame, the die sending mechanism, the die drawing mechanism and the return type track are mounted on the wall panel of the frame, and the automatic unlocking mechanism consists of an accessory and a stop block. The die return type full automatic flexible tube shoulder-injecting machine can improve the production efficiency.

Owner:南通市通州区三槐机械制造有限公司

Method for replacing sewage pipeline

The invention discloses a method for replacing a sewage pipeline, which does not disturb residents or destroy foundation of surrounding buildings, does not influence traffic, hardly pollutes the environment and has low construction cost. The method comprises the following steps: (1) dividing a sewage pipeline into a plurality of construction sections according to diameter differences and break points of the sewage pipeline; (2) forming a first work pit and a second work pit at two ends of each construction section; (3) putting a new pipeline in the first work pit; (4) assembling tube drawing bench equipment in the second work pit; (5) inserting tools for crushing and expanding pipelines into an old pipeline from the second work pit to crush the old pipeline; and (6) drawing a new pipeline to the position of the old pipeline by the tube drawing bench equipment.

Owner:北京万兴建筑集团有限公司

Glass tube drawing machine

InactiveCN104973756AEvenly heatedPrevent twistingGlass reforming apparatusGlass productionTube drawingEngineering

The invention discloses a glass tube drawing machine which comprises a machine frame, a flame thrower, a tube delivery mechanism and a tube drawing mechanism, wherein the tube delivery mechanism and tube drawing mechanism are arranged on the machine frame along the straight line of longitudinally arranged glass tubes, can move transversely relative to the machine frame, are used for clamping the glass tubes and driving the glass tubes to rotate, and have the same rotation direction and rotation speed; and the flame thrower is arranged on the machine frame, positioned between the tube delivery mechanism and tube drawing mechanism, and used for heating and burning out the glass tubes. The glass tubes are uniformly heated when being drawn; and the glass tube drawing machine prevents the glass tubes from twisting, improves the drawing quality of the glass tubes, and enhances the yield.

Owner:王金元

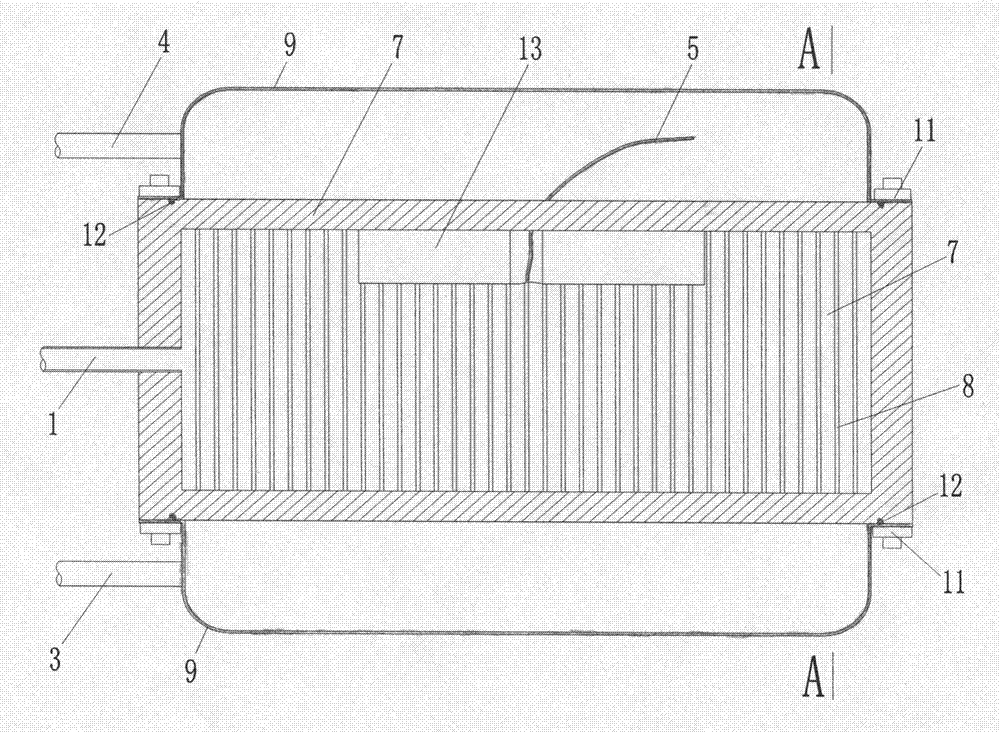

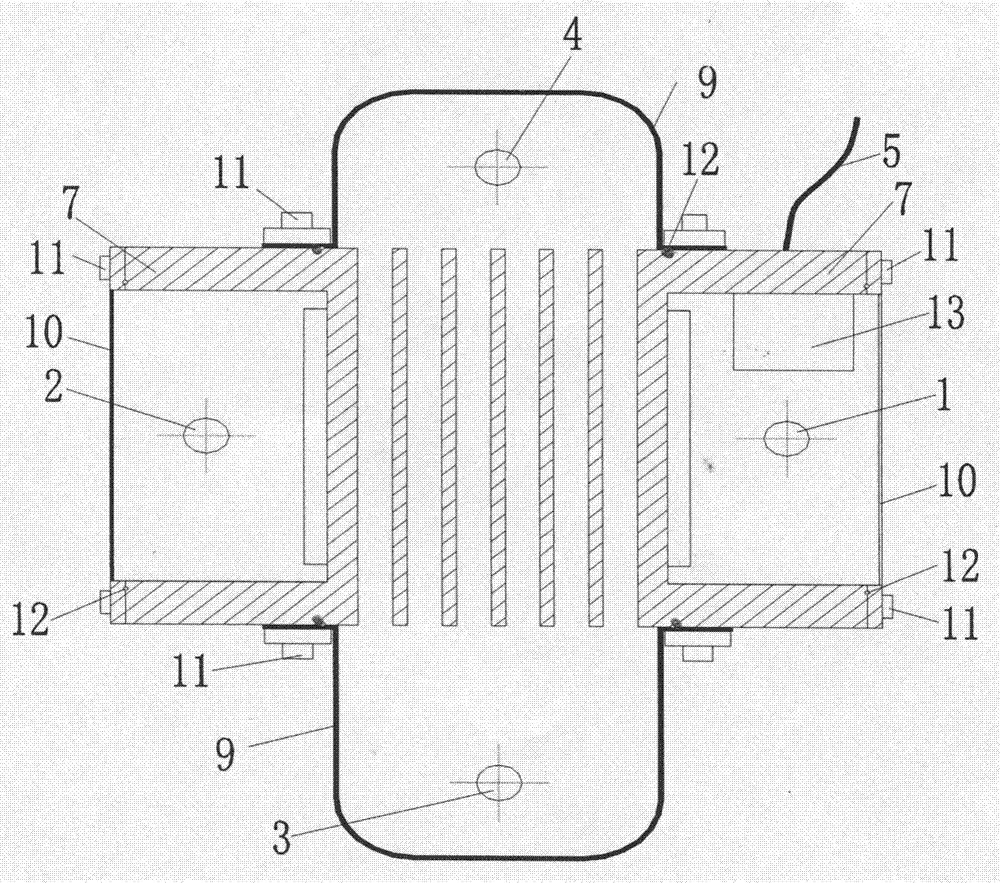

Multi-unit modularized plate type ozone generator

InactiveCN104512868AIncrease the heat exchange areaEvenly distributed waterElectrical discharge ozone preparationEngineeringHigh pressure

The invention relates to a multi-unit modularized plate type ozone generator, and belongs to the field of ozone generators. Connection manners of welding, pulling tubes, hollow studs or cold drawing and the like are adopted, ground electrodes of discharge units in a module are connected with side plates and end plates to form a whole metal structure so as to form ground electrode frames; air inlet and outlet cover plates, water inlet and outlet cover plates, a high-voltage cable and the like are mounted on the ground electrode frames so as to form ozone generator modules; the ozone generator modules are assembled through the manner of parallel connection or series connection so as to form the ozone generator satisfying users' needs; the discharge units consist of ground electrode plates, plate-shaped dielectric bodies, high-voltage electrodes and an elastic pad; air inlet and outlet covers and water inlet and outlet covers are fixed on the ground electrode frames through bolts and are sealed by O-shaped rings; the elastic pad is made of elastic materials with ozone oxidation resistance; the plate-shaped dielectric bodies can be made of glass or ceramics, and one surfaces are coated with metal films. A high-frequency high-voltage power supply is adopted.

Owner:张发鹏

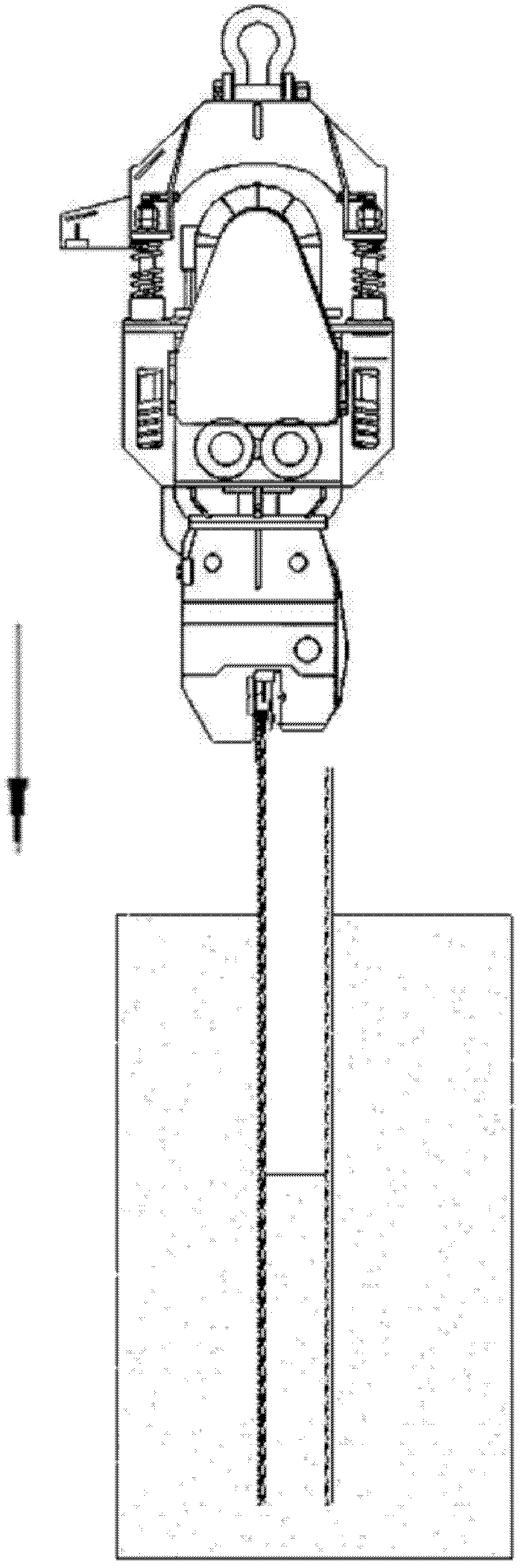

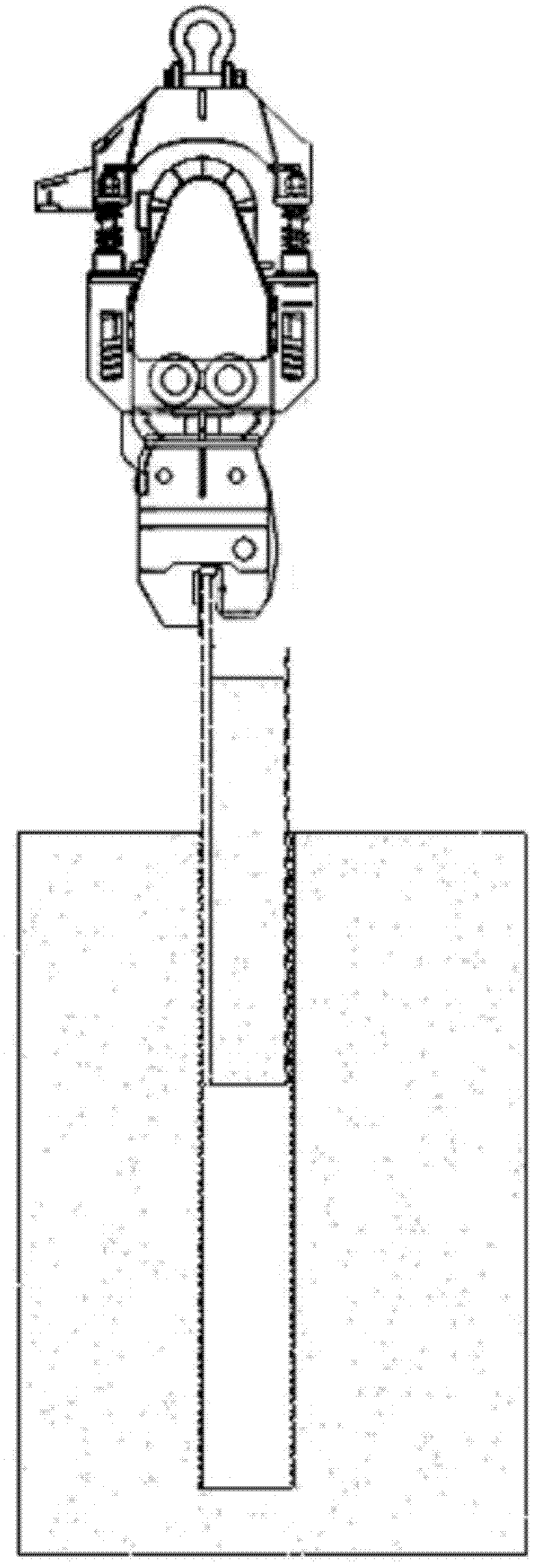

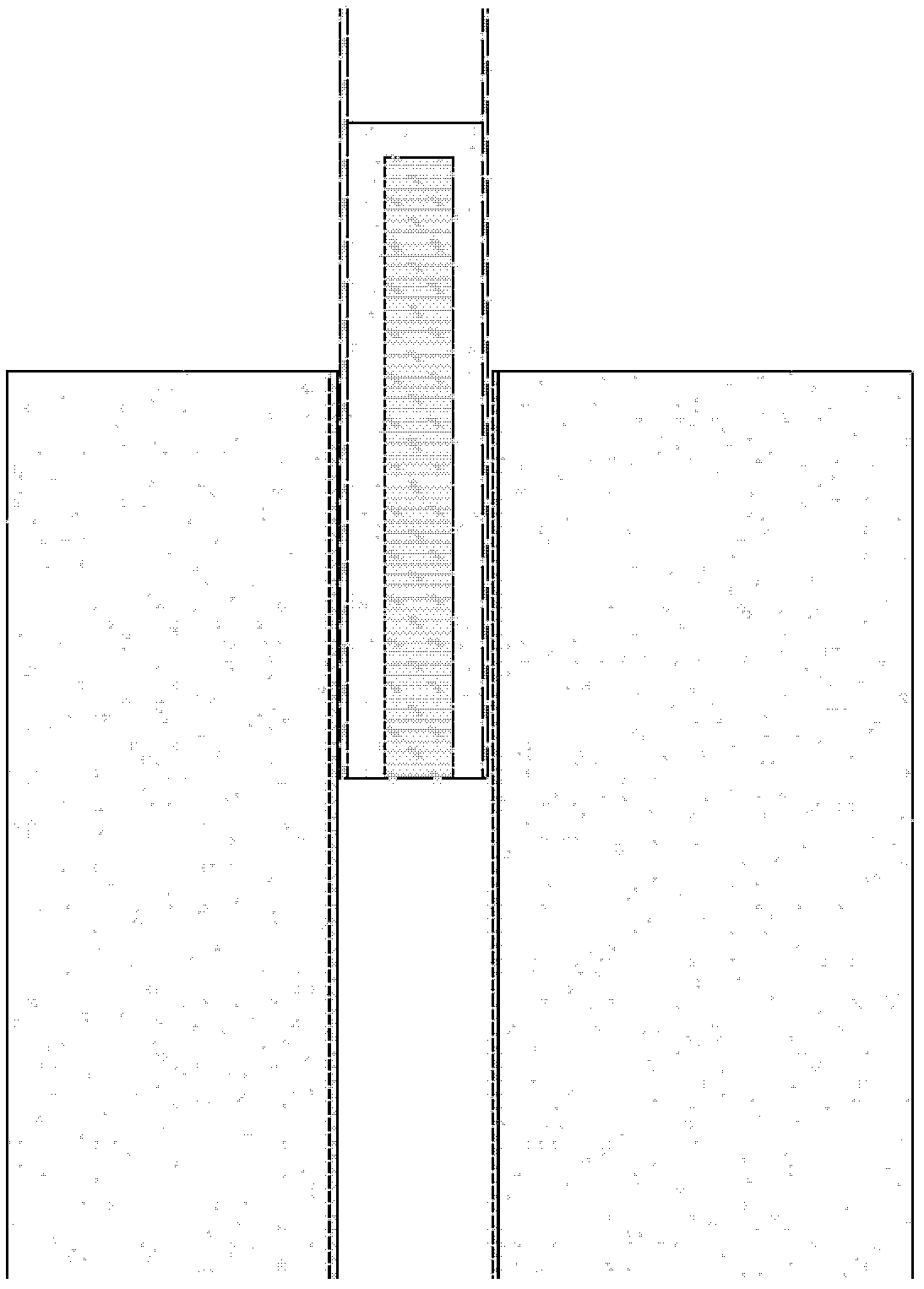

Double-tube-sinking and inner-tube-drawing bored cast-in-place pile construction method and application

The invention relates to the technical field of piling construction, and mainly relates to a double-tube-sinking and inner-tube-drawing bored cast-in-place pile construction method and application. The construction method adopts an eccentric moment-adjustable vibrating hammer, a pile gripper, inner tubes, outer tubes and a piling rack or a hoisting crane. The construction method includes steps that the inner tubes and the outer tubes are clamped by the pile gripper at first, the vibrating hammer vibrates and stops vibrating after sinking to the required depth, a pile clamping method is changed so that the pile gripper only clamps the inner tubes, a winch is started so that the vibrating hammer draws the inner tubes in a vibration-free state until the inner tubes are thoroughly drawn out, soil in the inner tubes cannot be poured out when the inner tubes are statically drawn due to effects of friction force, then the piling rack or the hoisting crane moves so that the inner tubes are separated from openings of the outer tubes, the vibrating hammer is started to vibrate, the soil in the inner tubes is continuously poured out in a vibration state until the total soil is poured out, reinforcement cages are placed in the outer tubes sunken into the soil, concrete is fully filled in the reinforcement cages, finally, the outer tubes are clamped by a fixture, the vibrating hammer is started, the outer tubes are drawn out by the aid of the vibration effect of the vibrating hammer, and simultaneously, a pile is formed. The double-tube-sinking and inner-tube-drawing bored cast-in-place pile construction method and the application have the advantages that the structure is novel, and construction efficiency is high.

Owner:SHANGHAI ZHENZHONG MACHINERY MFG

Preparation technology for medical beta type titanium alloy capillary tubes

InactiveCN105478523AImprove rolling qualityGrain refinementDrawing mandrelsTemperature control deviceFiberHigh volume manufacturing

The invention discloses a preparation technology for medical beta type titanium alloy capillary tubes. The preparation technology comprises the steps of preparing medical beta type titanium alloy ingots through the vacuum self-consuming arc melting method, carrying out forging and cogging on the titanium alloy ingots for forming round ingots, and extruding the round ingots on an extruding machine for forming tube blanks; rolling the tube blanks twice through a three-roller planetary rolling mill, and carrying out on-line induction heating on the tube blanks in the rolling process; rolling the tube blanks further through a three-roller finish tube-rolling machine, and carrying out vacuum annealing in the middle of rolling; finally, drawing the medical beta type titanium alloy tube blanks through a precision tube drawing machine for forming the finished capillary tubes; and adopting carbon fiber rods good in tensile strength, rigidity and self-lubricating property as core rods in the drawing process, and carrying out vacuum annealing in the middle of drawing. The medical beta type titanium alloy capillary tubes obtained through the preparation technology are uniform in wall thickness, smooth in surface and high in ductility; equipment is simple, production is flexible, and the cost is low. The preparation technology is especially suitable for producing the medical beta type titanium alloy capillary tubes in an industrialized and batched mode.

Owner:宝鸡市利泰有色金属有限公司

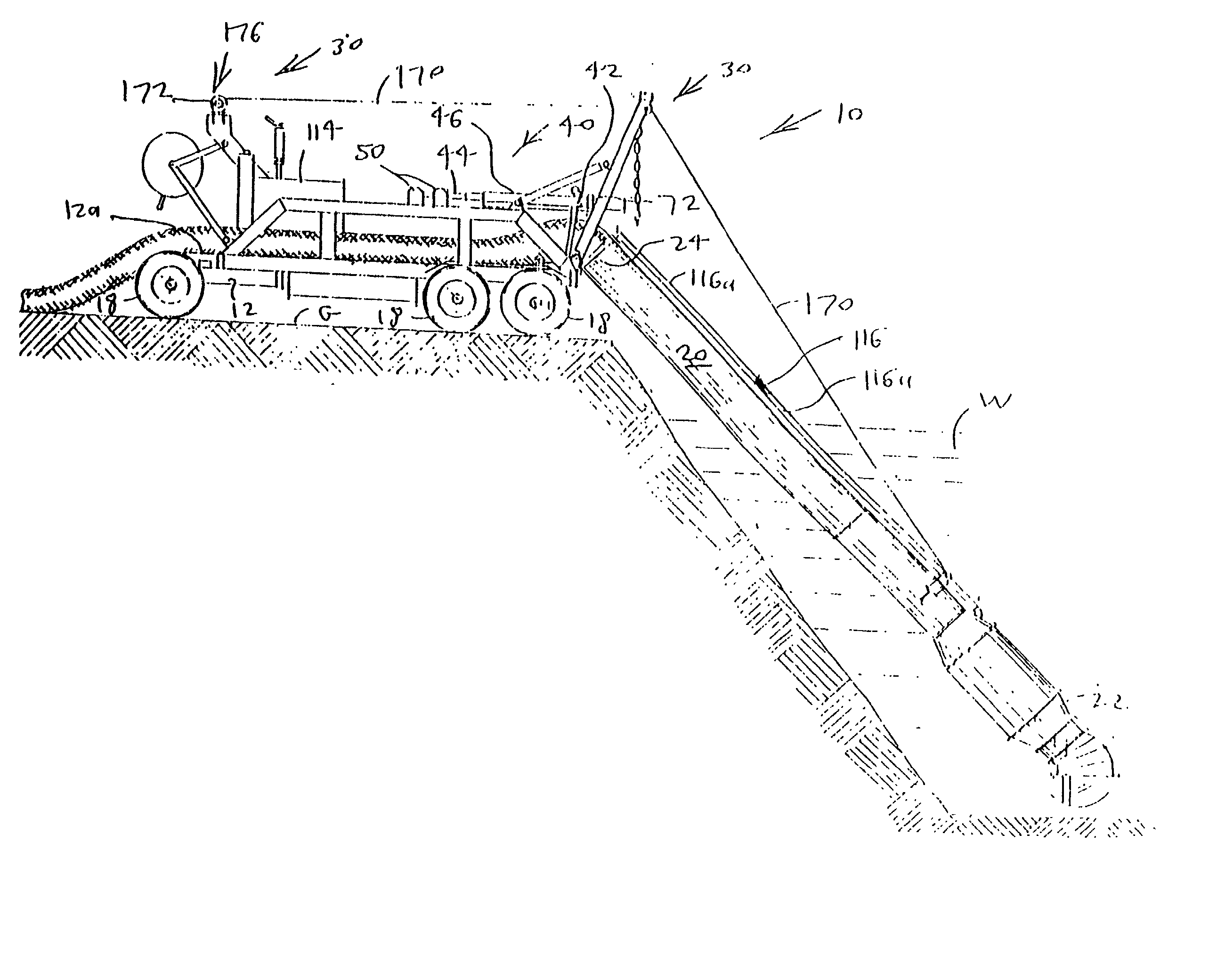

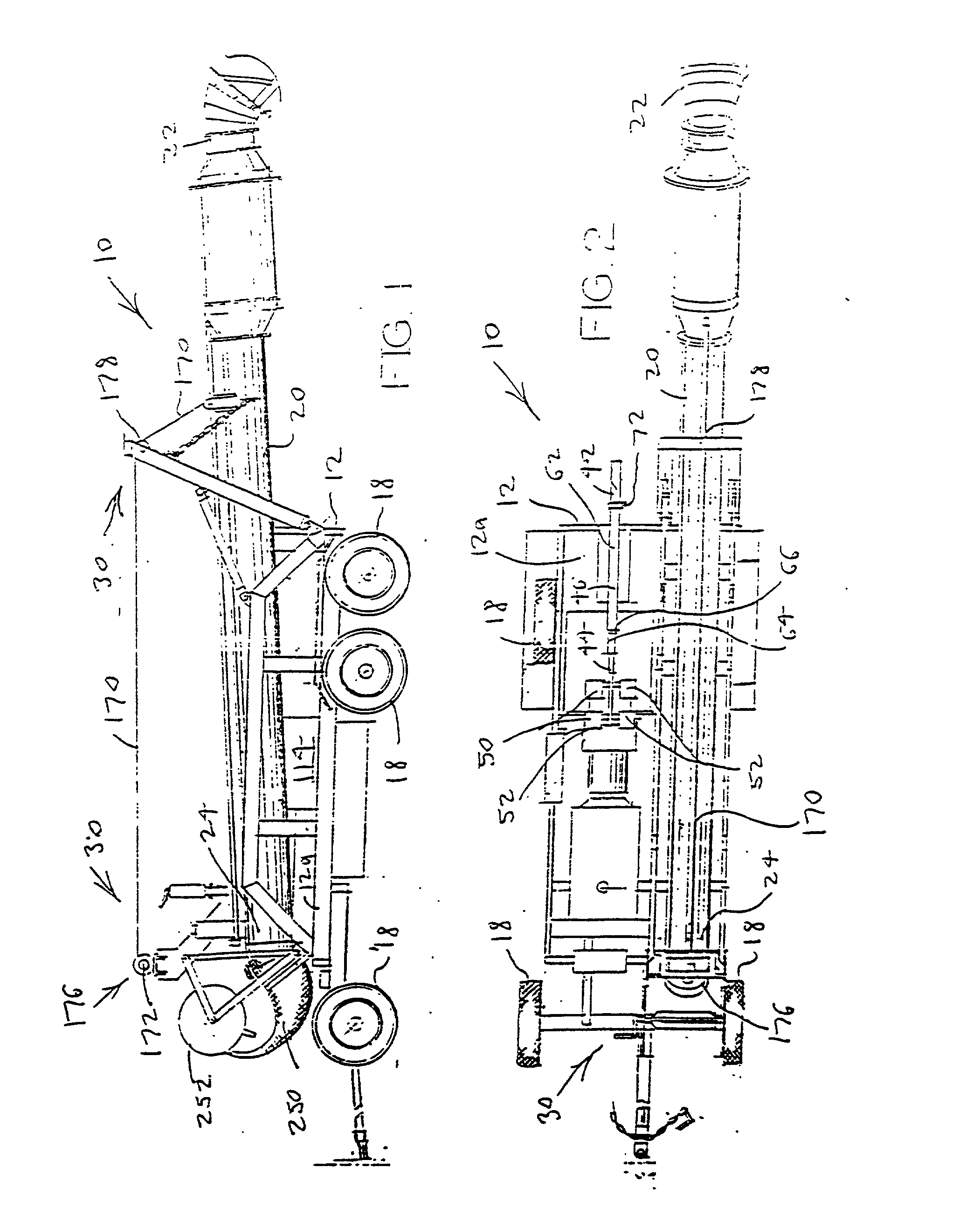

Electric pumping apparatus with extendable drawing pipe and pump light tower

A pumping apparatus for delivering water upwardly from a holding area and over a holding area bank includes an apparatus base having an apparatus base upper surface; a water drawing pipe including a pipe intake end and a pipe discharge end and being mounted to the apparatus base and extendable from the apparatus base; an impeller rotatably mounted within the drawing pipe discharge end; an impeller motor drivably connected to the impeller at the drawing pipe discharge end; impeller motor power supply structure; and a light tower having a tower mounted end mounted to the apparatus base and a tower free end including a light source structure having at least one light source for delivering light onto the apparatus base, and a tower body extending between the tower mounted end and the tower free end.

Owner:ELLER DANA J +1

Hydraulic cold drawn pipe machine

The invention discloses a hydraulic cold tube drawing bench, which comprises a main cylinder seat, a drawing die seat, a clamping dolly which is arranged between the main cylinder seat and the drawing die seat and is driven by a main cylinder, a core rod seat used for penetrating a positioning core rod, and an end which is fixedly connected with the main cylinder seat, the drawing die seat and the core rod seat sequentially on two independent section lathe beds; the main cylinder seat, the lathe bed, the drawing die seat, the lathe bed and the core rod seat are axially arranged. The invention is characterized in that: the lower parts of the main cylinder seat, the core rod seat and the lathe beds are all provided with lateral displacement limit devices containing concave positioning grooves; the concave positioning groove consists of a bottom plate and two side baffles or consists of L-shaped pieces formed by a bottom plate and side baffles and arranged symmetrically along the longitudinal axis. The lateral displacement limit devices are fixedly connected with groundwork. The invention has the advantages that: by using the simple structure, the invention effectively overcomes compression deformation of the lathe beds, and has low cost, convenient installment and low requirement for the ground which can be widely applied to metallurgical industry to reduce or expand pipe blanks.

Owner:CHANGZHOU LIAN HYDRAULIC EQUIP

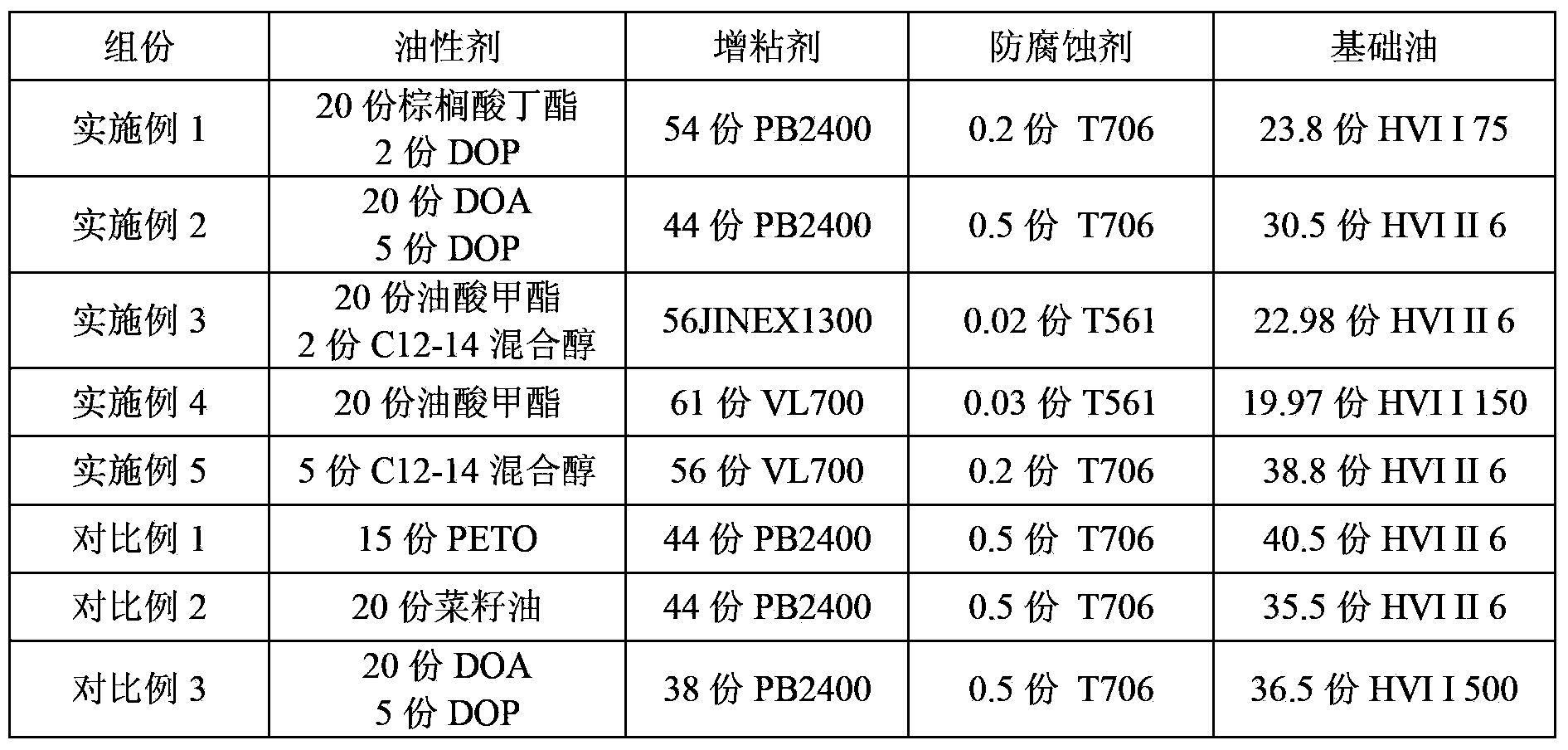

Copper tube drawing internal film oil composition and its use

ActiveCN104250576AGuaranteed lubrication effectImprove annealing cleanlinessLubricant compositionBase oilMaterials science

The invention relates to a copper tube drawing internal film oil composition and its use, and mainly solves a problem that cleaning must be carried out before annealing due to low annealing cleanness of oil products in the prior art. The composition comprises, by weight, 5-35 parts of an oiliness agent, 30-70 parts of a tackifier, 0.01-0.5 parts of an anticorrosive agent and 5-35 parts of base oil. The above technical scheme well solves the problem, and can be used for the industrial production of the copper tube drawing internal film oil composition.

Owner:CHINA PETROLEUM & CHEM CORP

Andalusite and cordierite refractory material for glass kiln and product thereof

The invention relates to an andalusite and cordierite refractory material for a glass kiln and a product thereof. The formula of the material comprises the following raw materials: 0-50% of andalusite which is 3-1mm, 15-25% of andalusite which is 1-0.088mm, 15-28% of andalusite which is smaller than 0.088mm, 0-50% of mullite which is 3-1mm, 0-50% of flint clay which is 3-1mm, 0-10% of synthetic cordierite which is smaller than 0.088mm, 1-3% of magnesia powder, 2-8% of alumina micro powder, 3-10% of silica fume, 0.01-0.1% of third generation of extra water reducer and 4-8% of extra water. The production method of the product disclosed by the invention comprises the following steps: weighing the raw materials in the ratio; preparing a green body by mixing and forming, placing the green body for 12-24 hours and demolding; conserving the green body at normal temperature for 1-3 days; drying the green body at 40-60 DEG C for 1-2 days, and sintering the green body at 1250-1380 DEG C; preparing the cast andalusite-cordierite refractory material product for the glass kiln after surface treatment and inspection. The andalusite and cordierite refractory material has good high temperature resistance, thermal shock resistance and anti-erosion function, and is applicable to application as the refractory material for the glass kiln instead of sillimanite, for example, tin bath head cover tiles of a floating glass production line, and equipment bricks of daily or special channels for the glass kiln, feeders, tube drawing machines and the like.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com