Continuous tube drawing device

A technology of extubation machine and frame, which is used in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of inconvenient transportation or manual handling, long construction interval, poor stability and safety, etc., to achieve convenient transportation or Manual handling, reduced working time interval, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

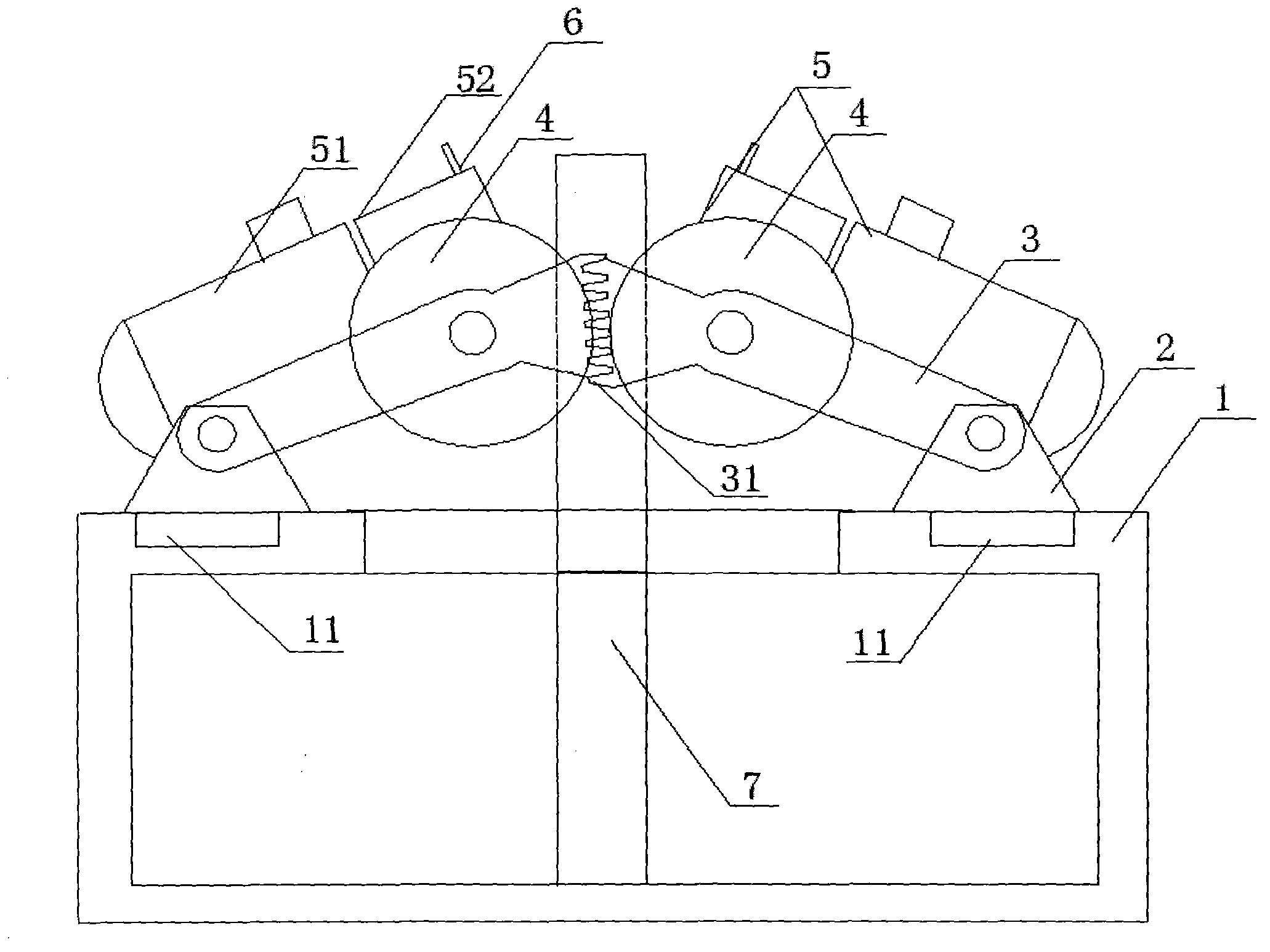

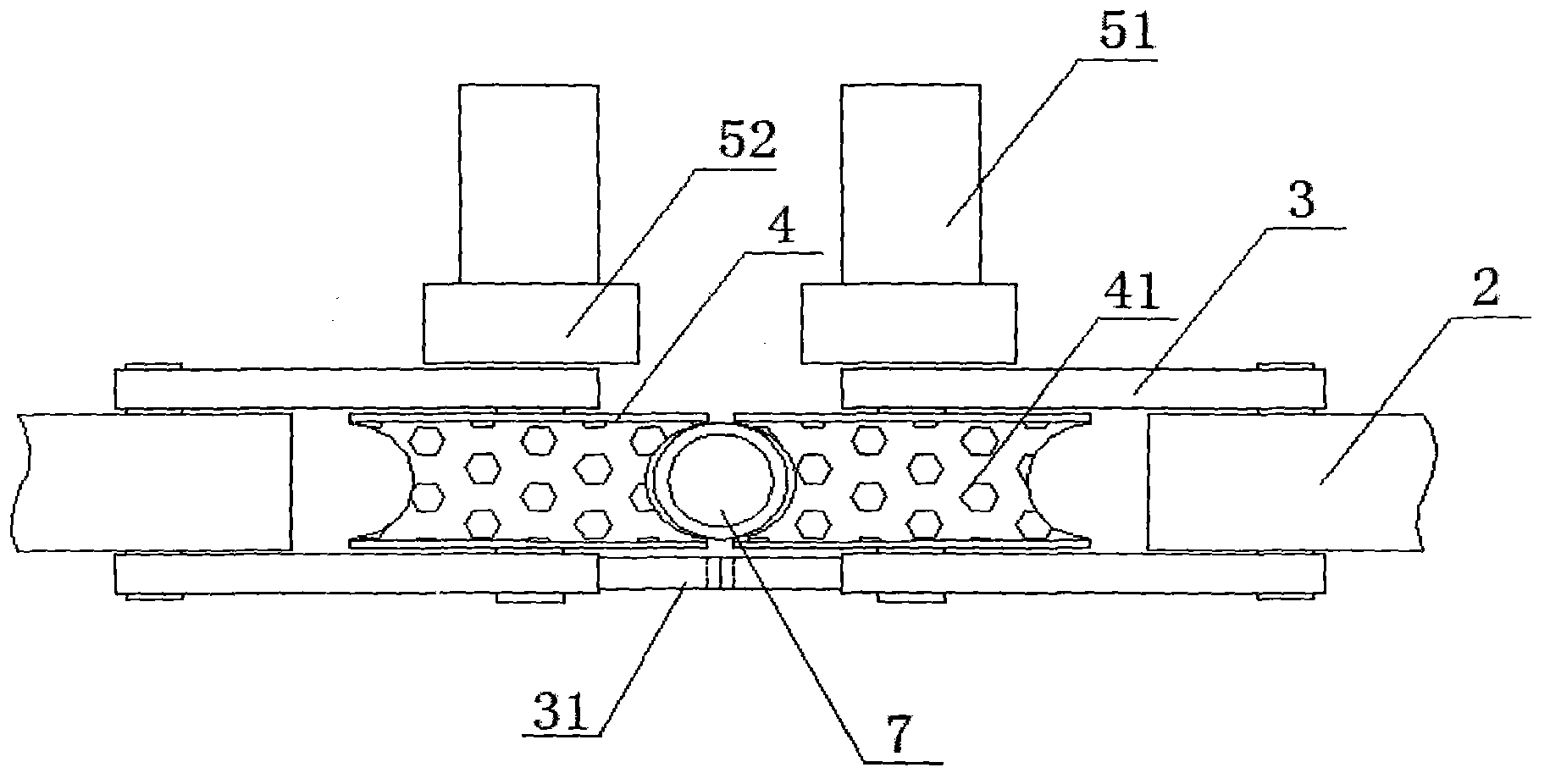

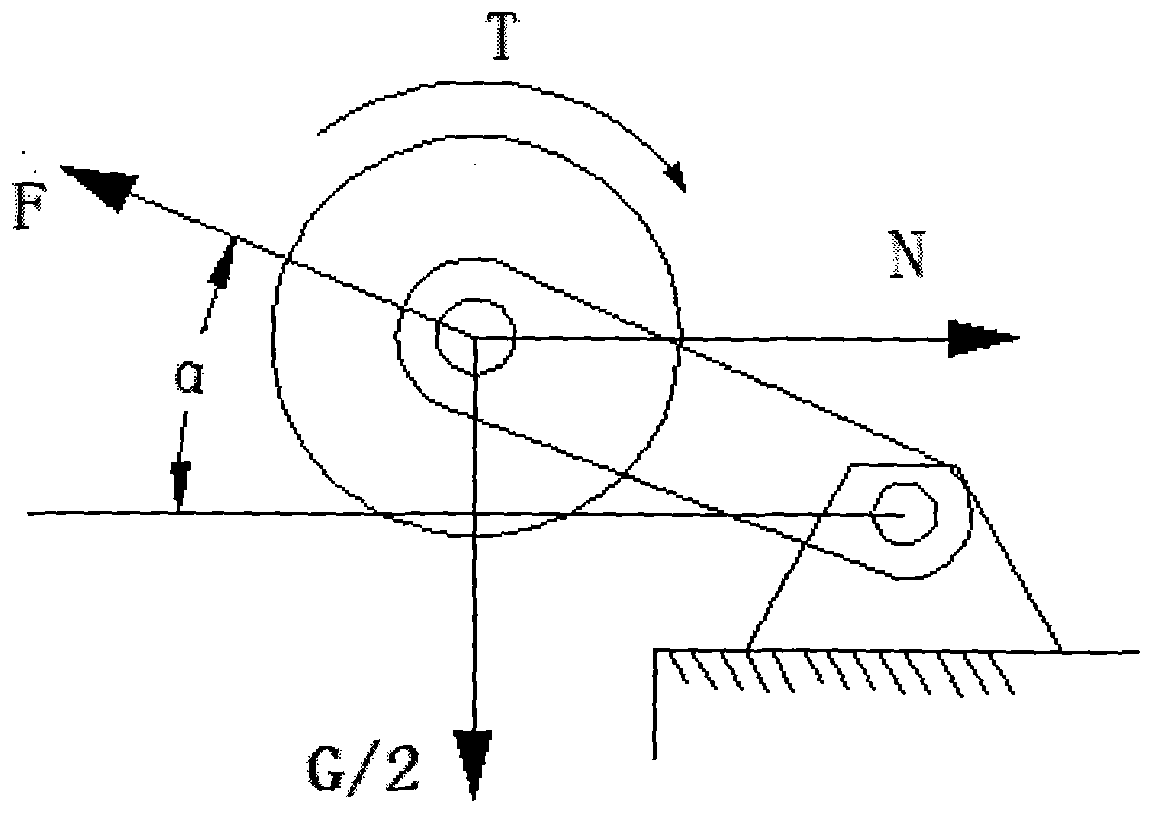

[0019] Such as figure 1 , 2 The shown continuous extubation machine includes a frame 1, a bracket seat 2 installed on the frame 1, a roller 4, one end is connected with the bracket seat 2 through a movable shaft, and the other end is connected with the roller 4 through a movable shaft. Arm 3, the power system 5 that is connected with roller 4; Described support seat 2, support arm 3, roller 4, power system 5 are provided with two groups, are installed symmetrically with frame 1; Described power system 5 comprises transmission motor 51 and speed changer 52, wherein the transmission motor 51 output shaft is connected to the transmission 52, and the roller 4 is installed on the transmission 52 output shaft.

[0020] Further, the structure of the roller 4 adopts an "I" shape, and small protrusions 41 are evenly distributed on the inner surface of the roller 4 .

[0021] Further, claws 31 are provided at the mounting roller 4 of the bracket arm 3 , and two groups of claws 31 inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com