Improved structure of fiberboard production line modulated glue four-way valve

A production line and fiberboard technology, which is applied in the field of improved structure of the four-way valve of the fiberboard production line. The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

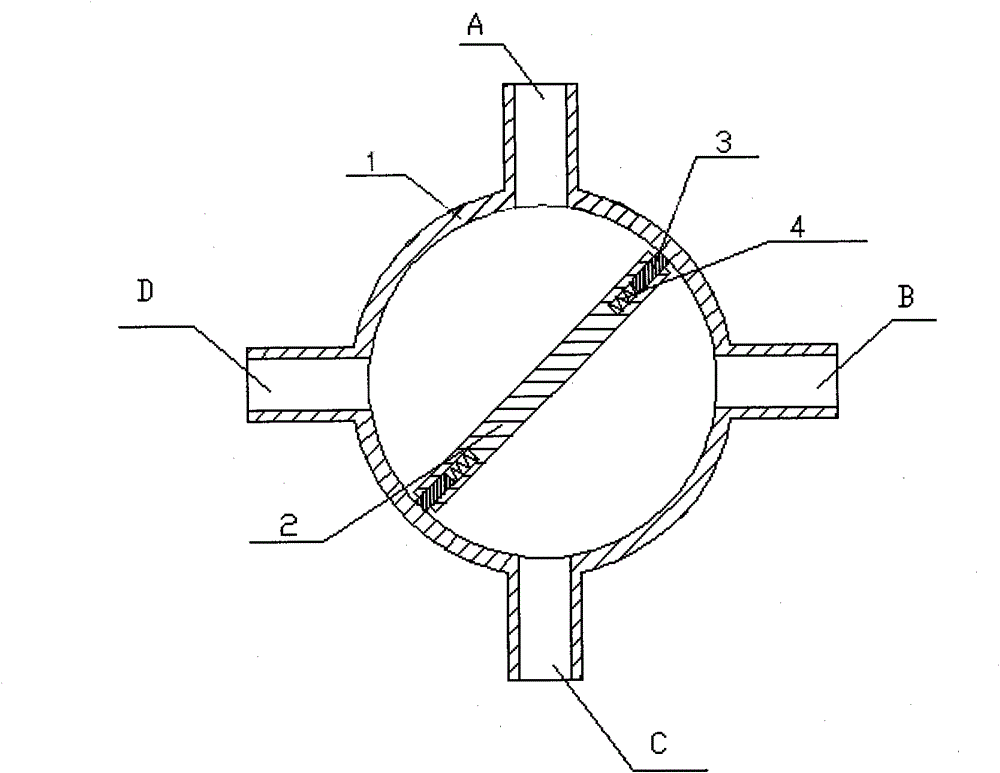

[0018] image 3 It is a schematic diagram of the principle of a structure provided by the present invention, Figure 4 It is a partial enlarged view of the connection position between the valve core and the movable valve plate in Embodiment 1. refer to image 3 , 4 As shown, an improved structure of a fiberboard production line glue-adjusting four-way valve includes a valve body 1, a valve core 2, and through holes A-D arranged in the valve body. The valve core 2 is slotted towards the two ends of the valve body 1, and the groove A movable valve plate 3 is installed inside, and a spring leaf 4 is installed between the bottom of the groove and the movable valve plate.

[0019] In this way, when the valve core is in normal operation, the movable valve plate is always close to the inner wall of the valve to ensure the minimum clearance, and when debris passes, the spring is compressed, and the movable valve plate slides inward to ensure the passage of debris.

Embodiment 2

[0021] Figure 5 It is a schematic diagram of the principle of another structure provided by the present invention. refer to Figure 5 As shown, an improved structure of a glue-adjusting four-way valve for a fiberboard production line includes a valve body, a valve core, and a through hole arranged in the valve body. The end of the valve core facing the valve body is provided with a movable valve plate. The movable valve The sheet is a plastic sheet. Because the plastic sheet has a certain degree of elasticity, the movable valve sheet of the valve core is finally close to the inner wall of the valve body during normal operation to ensure the minimum gap, and when debris passes through, the plastic sheet is deformed to ensure the passage of debris.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com